Philips C500 Service Manual

15” CRT Colour Monitor C500

Service

Service

Service

105E69/05(Samsumg)

Service Manual

HORIZONTAL FREQUENCIES

30-54Khz

TABLE OF CONTENTS

Description Page Description Page

1.0 IMPORTANT SAFETY NOTICE .........................1

2.0 SPECICATION.......................................................2

2.1 CRT DESCRIPTION ................................................. 2

2.2 INTERFACE SIGNALS................................................ 2

2.3 PRESET TIMING.......................................................4

2.4 BRIGHTNESS AND CONTRAST .................................. 4

2.5 POWER CORD .........................................................5

2.6 SIGNAL CABLE......................................................... 5

2.7 INTERNAL CONNECTORS .......................................... 6

2.8 POWER REQUIREMENTS .......................................... 6

2.9 VISUAL CHARACTERISTICS ...................................... 7

2.10 LUMINANCE UNIFORMITY .......................................13

2.11 FUNCTIONAL PERFORMANCE .................................13

2.12 ENVIRONMENT REQUIREMENTS ............................. 13

2.13 RELIABILITY REQUIREMENTS ................................. 14

2.14 WHITE BALANCE ...................................................14

2.15 LUMINANCE UNIFORMITY .......................................15

2.16 FOCUS ................................................................. 15

2.17 IMAGE STABILITY (JITTER) .....................................15

2.18 WARM-UP TIME .................................................... 15

3.0 INTRODUCTION..................................................16

4.0 MECHANICAL INSTRUCTION ...........................17

5.0 ALIGNMENT........................................................22

5.1 B+ VOLTAGE, G1, H. POSITION ADJUSTMENT ........22

5.2 WHITE BALANCE ADJUSTMENT .............................. 22

5.3 FOCUS ADJUSTMENT............................................. 22

5.4 PRESET TIMING ADJUSTMENT................................ 22

6.0 CIRCUIT DESCRIPTION .................................... 23

6.1 GENERAL DESCRIPTION:....................................... 23

6.2

RECTIFIER AND FILTER CKT ........................... 26

6.3

FLYBACK AND PWM CKT ................................. 26

6.4

SNUBBER CKT .................................................. 27

6.5

SYNCHRONIZED CKT....................................... 27

6.6

SYNC RPOCESSOR.......................................... 28

6.7

HOR. PROCESSOR & VERT. PRE-AMP........... 28

6.8

VERTICAL OUTPUT .......................................... 29

6.9

HORIZONTAL DRIVER CIRCUIT....................... 29

6.10

HORIZONTAL OUTPUT STAGE ........................ 29

6.11

FLYBACK TRANSFORMER............................... 29

6.12

VIDEO PRE. AMP............................................... 29

6.13

VIDEO AMPLIFIER............................................. 30

6.14

DIGIT CONTROL ............................................... 30

7.0 REPAIR FLOW CHART...................................... 31

7.1 TROUBLE SHOOTING............................................. 31

7.2

MONITOR CHECK FLOW CHART............................. 32

8.0 DC/AC WAVEFORM MEASUREMENT.............. 35

9.0

PCB LAYOUT ..................................................... 37

9.1 MAIN PCB............................................................ 37

9.2

VIDEO PCB........................................................ 38

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION :USE A SEPARATE ISOLATION TRANSFORMET FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Published by BCU Monitor Printed in Taiwan Copyright reserved Subject to modification M July 15,2004 GB 8639 000 15714

1

1.0 Important Safety Notice

Proper service and repair is important to the safe, reliable operation of all Philips Consumer

Electronics Company** Equipment. The service procedures recommended by Philips and described

in these service manual are effective methods of performing service operations. Some of these

service operations require the use of tools specially designed for the purpose. The special tools

should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be

carefully read in order minimize the risk of personal injury to service personnel. The possibility exists

that improper service methods may damage the equipment. It is also important to understand that

these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Philips could not possibly know, evaluate

and advise the service trade of all conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such broad

evaluation. Accordingly, a servicer who uses a service procedure or procedure or tool which is not

recommended by Philips must first satisfy himself thoroughly that neither his safety nor the safe

operation of the equipment will be jeopardized by the service method selected.

**Hereafter therouhout this manual, Philips Consumer Electronics Company will be referred to as

Philips.

WARNING

Critical components having special safety characteristics are identified with a by the Ref. No. in the

parts list and enclosed within a broken line*

(where several critical components are grouped in one area) along with the safety symbol on the

schematics or exploded views.

Use of substitute replacement parts which do not have the same specified safety characteristics may

create shock, fire, or other hazards.

Under no circumstances should the original design be nodified or altered without written permission

for Philips. Philips assumer no liability, express or implied, arising out of any unauthorized

modification of design.

Servicer assumes all liability.

*Broken Line

FOR PRODUCTS CONTAINING LASER:

DANGER- Invisible laser radiation when open.

AVOLD DIRECT EXPOSURE TO BEAM.

CAUTION- Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

CAUTION- The use of optical instruments with this product will increase eye hazard.

2

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY ORIGINAL

MANUFACTURER’S REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART

NUMBERS IN THE PARTS LIST SECTION OF THIS SERVICE MANUAL.

2.0 Specication

2.1 CRT Description

This display unit shall employ a CRT complying with the following specification:

Size: 15 inches diagonal

Deflection angle: 90 degrees diagonal

Electron gun: In-line type

Focusing method: Electrostatic

Focus lens: Bipotential

Convergence method: Magnetic

Surround type: Black matrix

Array: Dot trios

Trio spacing: 0.28 mm dot pitch

Phosphor type: P22 or equivalent

Phosphor persistence: Medium-short

Light transmission: 57% approx.

Anti reflection: Anti-glare treatment

(45÷65 gloss)

2.2 Interface Signals

This color display shall have an analog video interface and shall be capable to operate with multiple

horizontal and vertical frequencies. Moreover it shall be capable to support compatible DDC1and

DDC2B signals.

2.2.1 Sync Input

Separate, composite TTL compatible

Polarity Positive or negative

2.2.2 Interface Frequency

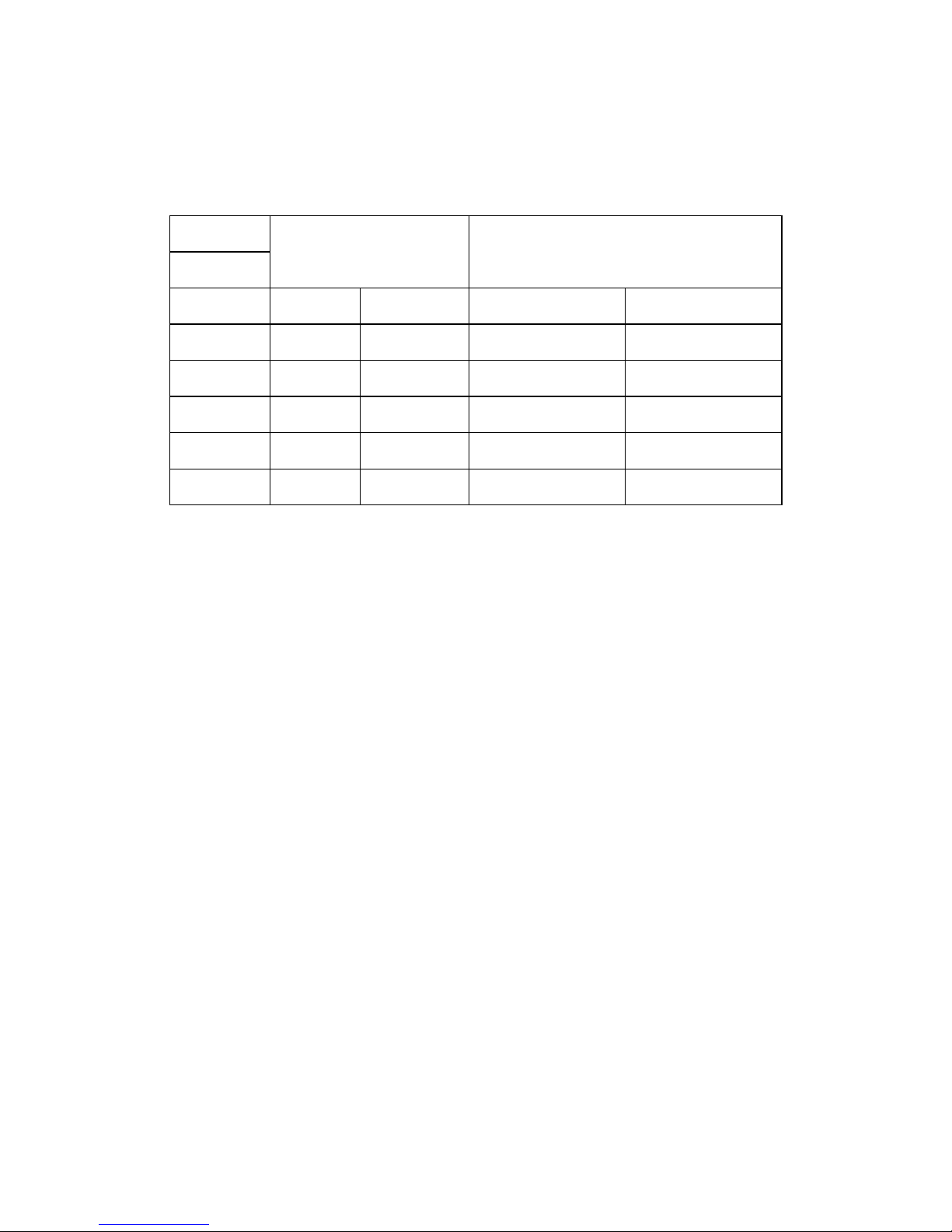

Table 1:Interface Frequency

3

Horizontal line frequency

(KHZ)±500HZ

Vertical frame frequency

(HZ)±3HZ

31.649 59.94

46.875 75

48.363 60

53.674 85.061

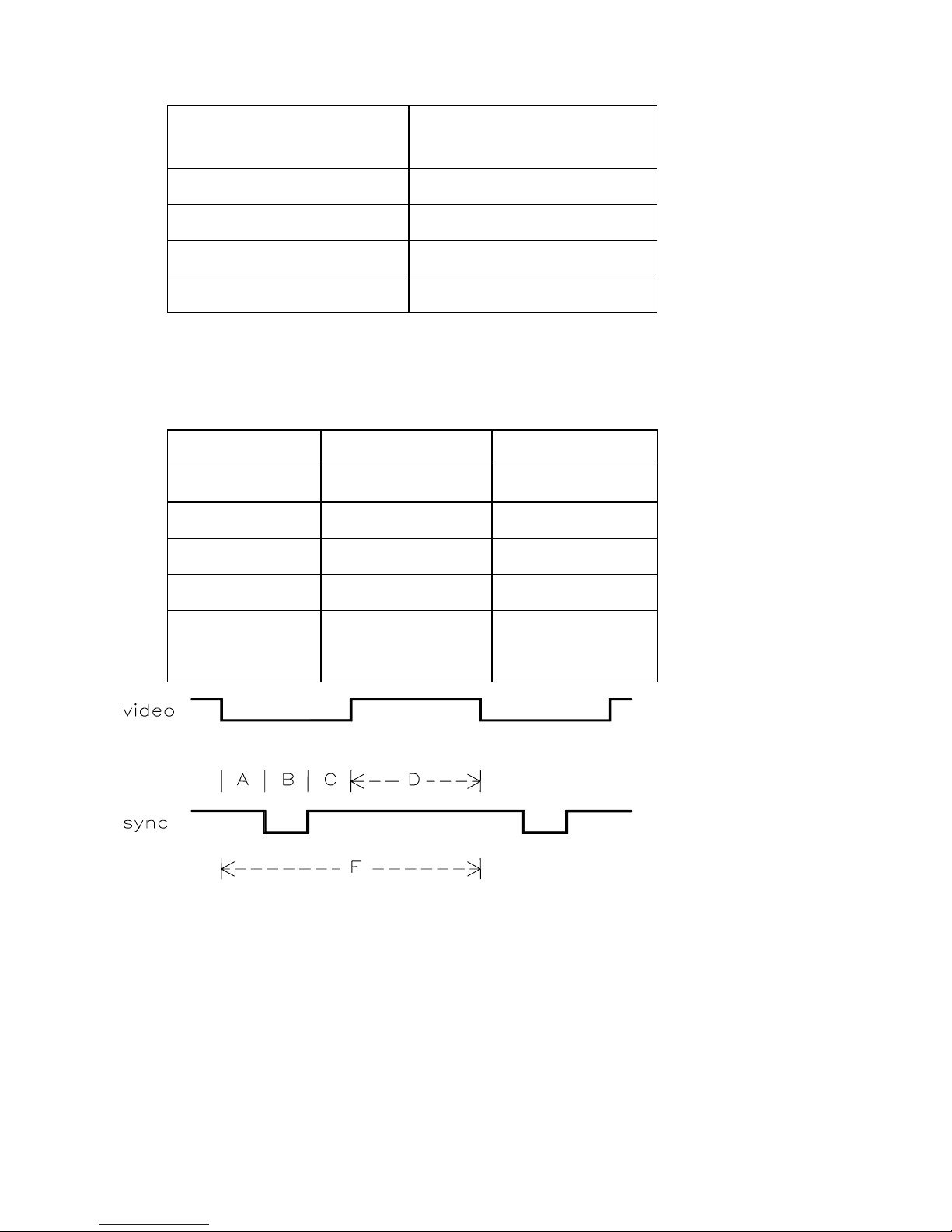

2.2.3 Input Timing Limits

The monitor will accept all timings within the limits of table 2

Table 2: Input Timings Limits

Parameter Horizontal Vertical

Frequency (30 to 54) KHz (50 to 120)Hz

Blanking

≥2.5µs ≥0.4ms

Back Porch

≥1.0µs ≥0.1ms

Front Porch

≤back Porch ≤Back Porch

Sync Pulse

≥0.7µs

<0.3ms

>0.03ms

4

2.3 Preset Timing

M454 U-P Default Timing

Table 3

sweep F D C B A

MODE H Pixes

V Lines

Fd(MHz)

Polar(H/V)

Fh(KHz)

Fv(Hz)

Th(us)

Tv(ms)

Td(us)

Td(ms)

Tb(us)

Tb(ms)

Tp(us)

Tp(ms)

Tf(us)

Tf(ms)

d: dot d: display b: backporch p: pulse f: front

1

VGA60 640

480

25.175

N/N

31.469

59.94

31.777

16.683

25.422

15.253

1.907

1.049

3.813

0.064

0.635

0.317

2

VESA75 800

600

49.5

P/P

46.875

75

21.333

13.333

16.162

12.8

3.232

0.448

1.616

0.064

0.323

0.021

3

VESA60 1024

768

65

N/N

48.363

60

20.677

16.667

15.754

15.88

2.462

0.6

2.092

0.124

0.369

0.063

4

VESA85 800

600

56.25

P/P

53.674

85.061

18.631

11.756

14.222

11.179

2.702

0.503

1.138

0.056

0.569

0.018

2.4 Brightness and Contrast

Definitions:

Active area This zone can be lighted when the background color is changed from

black to any other color. Its dimensions, in terms of timing correspond to

the "active area "times described in table 3

Raster area Under certain conditions (see table 4) this zone must be visible when no video input is

applied. Width and height of the raster area must be larger than the corresponding

dimensions of the active area.

Border Comprising any area of the screen outside the raster area.

Brightness This control is mainly intended as a raster luminance adjustment.

Contrast This control shall vary the gain of the video amplifier, thus adjusting the contrast

of the displayed images, and shall not have any visible effect on the raster luminance.

Both controls shall not affect the border. Inside this zone the raster shall be always under the minimum

perceptible level and no evidence of retracing(images or distortion)shall be visible on the screen at any

5

setting of the luminance controls. The user controls shall operate as described on table 4. This check

must be performed under a diffused illumination of 10 lux and on 48k mode (Horizontal frequency).

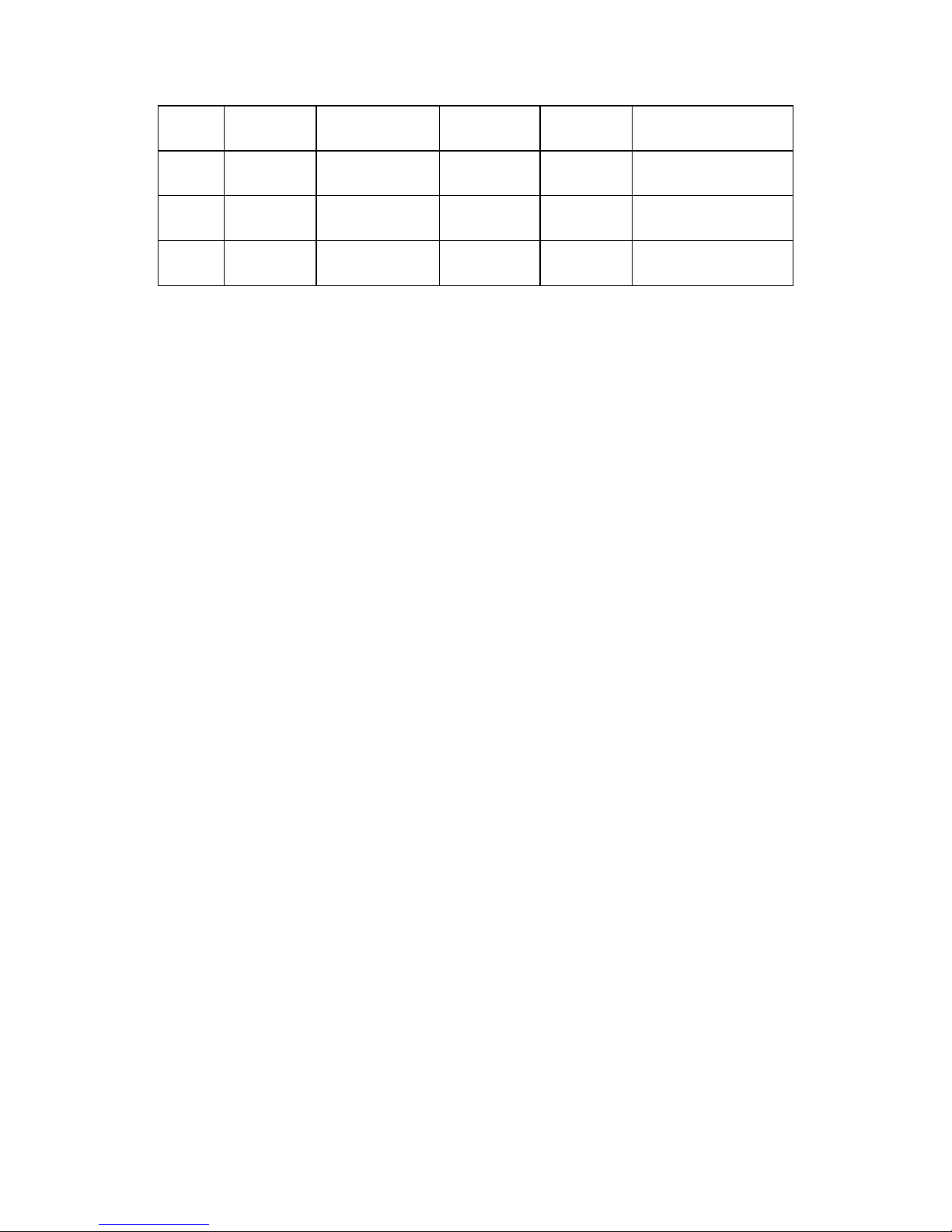

Table 4

Patterns Setting of user Controls Luminance Limits

Brightness Contrast Raster Area White Area

A Min Any Not Visible *

A Max Min 0.3 ~ 3.0 FL *

B Max Max * 60 FL<=

C Max Max *

>27FL

B Min Max Not Visible Visible

B Min Min Not Visible Not Visible

Legend:

*Don't Care

A Black screen @0 mV video level.

B 2″ x 2 ″white box, @700mV video level.

C Full white screen, 100% of the data area @700mV video level

.

Power inlet

Power shall be applied to the display device through a standard three wire receptacle NEMA

A/5261 or equivalent.

2.5 Power cord

The power cord supplied with the monitor must conform to the International Standards described

on part 8.0 and shall have physical and electrical characteristics such that to comply with any other

specification item. The power cord shall be of removable type.

2.6 Signal cable

Signals shall be applied to the display device through a shielded cable, which must be intended as

part of monitor. This cable shall be of a suitable type in order to comply with any specific item, and

shall be terminated in a 15 pin D-Shell male connector type AMP 211350-1 or equivalent, with pin

assignment as follows:

15 pin mini D-sub

1 Red video input

2 Green video input

3 Blue video input

6

4 Identify output

5 Ground

6 Red video ground

7 Green video input

8 Blue video ground

9 Not connected

10 Logic ground

11 Identify output

12 SDA (DDC1 or DDC2B)

13 Horizontal sync.

14 Vertical sync. (VCLK)

15 SCL (DDC2B)

2.7 Internal connectors

All internal connectors for the interconnection of sub assemblies must be distinct in their physical

characteristics or polarization so as to prevent any misconnection which may cause permanent

damage to the display.

2.8 Power Requirements

The display device shall maintain the specified performances in the range described below:

Frequency: 50/60Hz ± 3Hz

Voltage: 90 to 264 Vac RMS

The following consumption requirements shall be met:

Power consumption: 75W for MPRII & VLMF Yoke

70W for NORMAL Yoke

Current consumption: 1.2 Aac RMS

Note:

Current and power consumption are the maximum values allowed in the voltage ranges describe

above.

2.8.1 Power Management

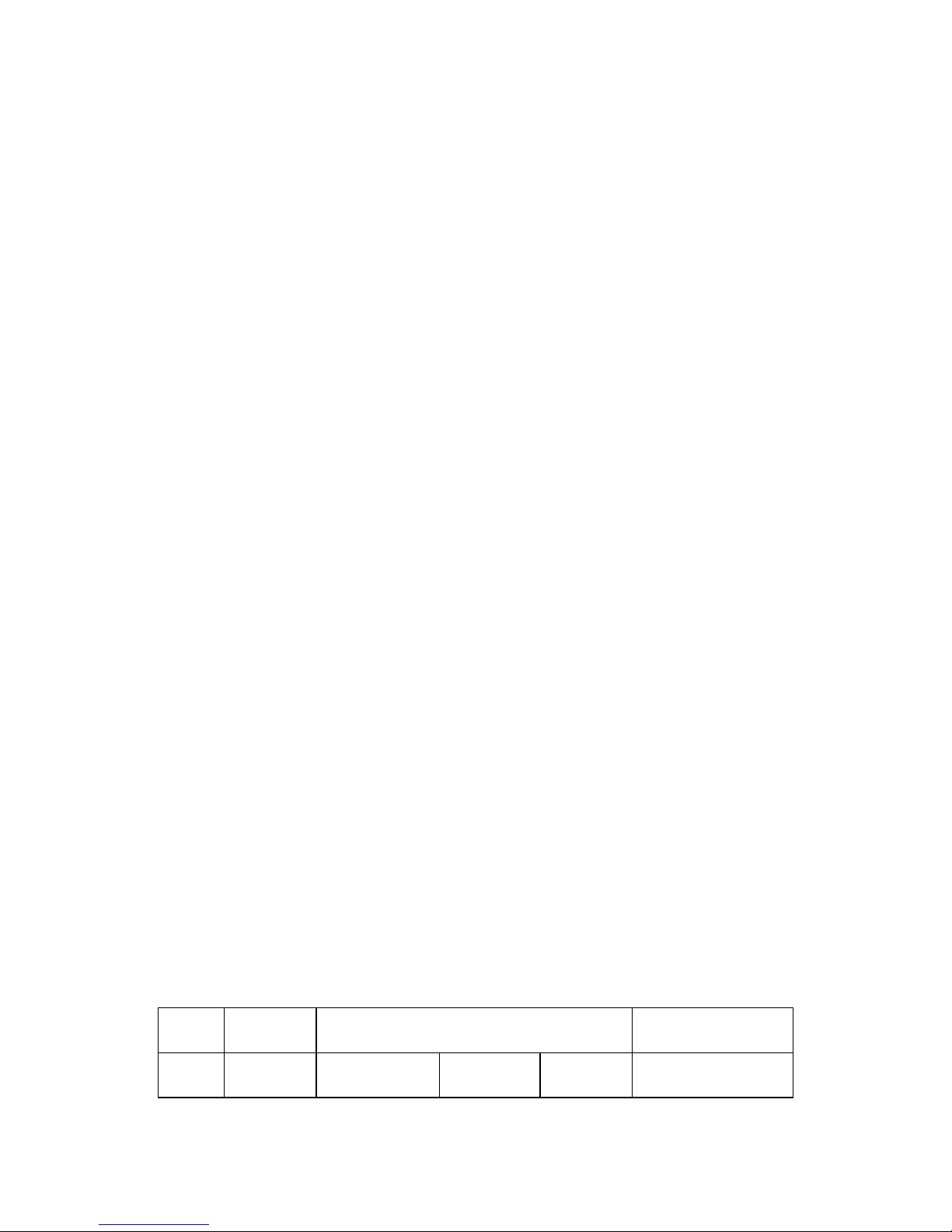

Table 5: Power Management

NO STATE STATE POWER SAVING

HORIZONTAL VERTICA VIDEO

7

1 ON PLUSES PLUSES ACTIVE NONE

2 STAND-BY NO PLUSES PLUSES BLANKED

<15W@90~240VAC

3 SUSPEND PLUSES NO PLUSES BLANKED

<15W@90~240VAC

4 OFF NO PLUSES NO PLUSES BLANKED

<5W@90~240VAC

The states of power saving function shall be display by LED indication.

2.9 Visual Characteristics

All factory preset resolutions must guarantee the right display dimension and centering. Other

resolutions can be adjusted correctly with the external controls as per section 2.5.

In all resolution must be possible to adjust the monitor in full screen (overscan mode) by external

controls. The viewing eye angle while performing any dimensional measurement is parallel to the axis

of the picture tube.

2.9.1 Test Conditions

Resolution: any of preset modes

Input level: 700 mV

Pattern: crosshatch after setting full white pattern with

20FL luminance.(Except otherwise indicated)

Brightness control: cutoff position

Contrast control: position after setting full white pattern with 20FL luminance.

Unless otherwise specified, the display shall meet the requirements of this section under any

combination of the following operating ranges:

Image duty cycle: 10% to 90%

Input power: As per section 3.1

Operating temperature: As per section 6.2

Humidity: As per section 6.2

Magnetic field: Horizontal=0 Gauss

Vertical=0.4 Gauss

2.9.2 Display Dimensions

The dimensions of the data area for all presetting mode listed in part 2.3.1,measured along the

8

horizontal and vertical axes of the screen, shall be as follows:

Horizontal=270 ± 4mm

Vertical=203± 4mm

The external control ranges of the data area, shall be as follows:

Maximum horizontal size: overscan the screen

Minimum horizontal size: ≤255mm

Maximum vertical size: overscan the screen

Minimum vertical size: ≤183mm

2.9.3 Picture Size Variation

The change in display size shall be less than 3mm in width or 2mm in height at full white

pattern.(250x188mm

2

)

Brightness change from 5FL to 25FL

Temperature change in 25°C ±10°C

2.9.4 Display Centering

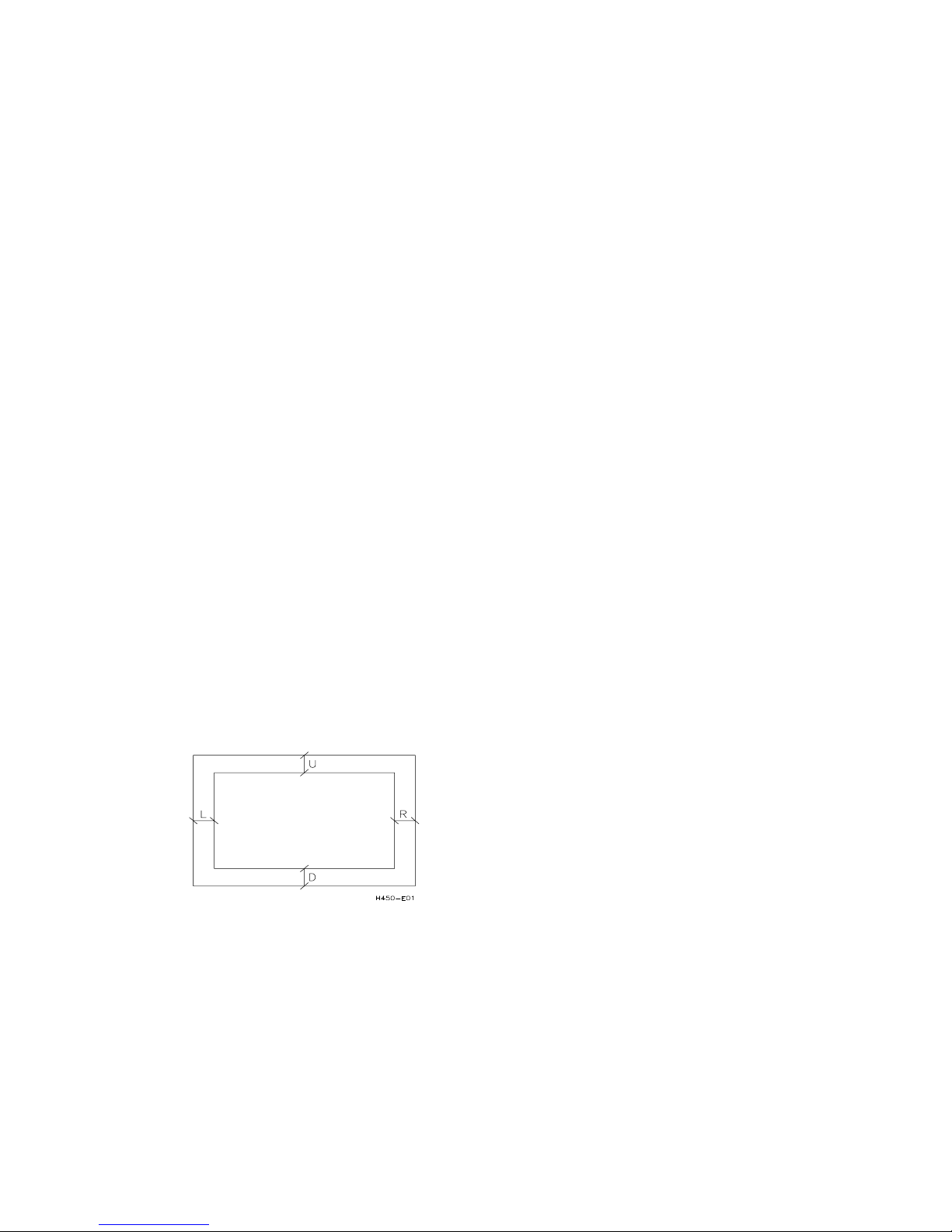

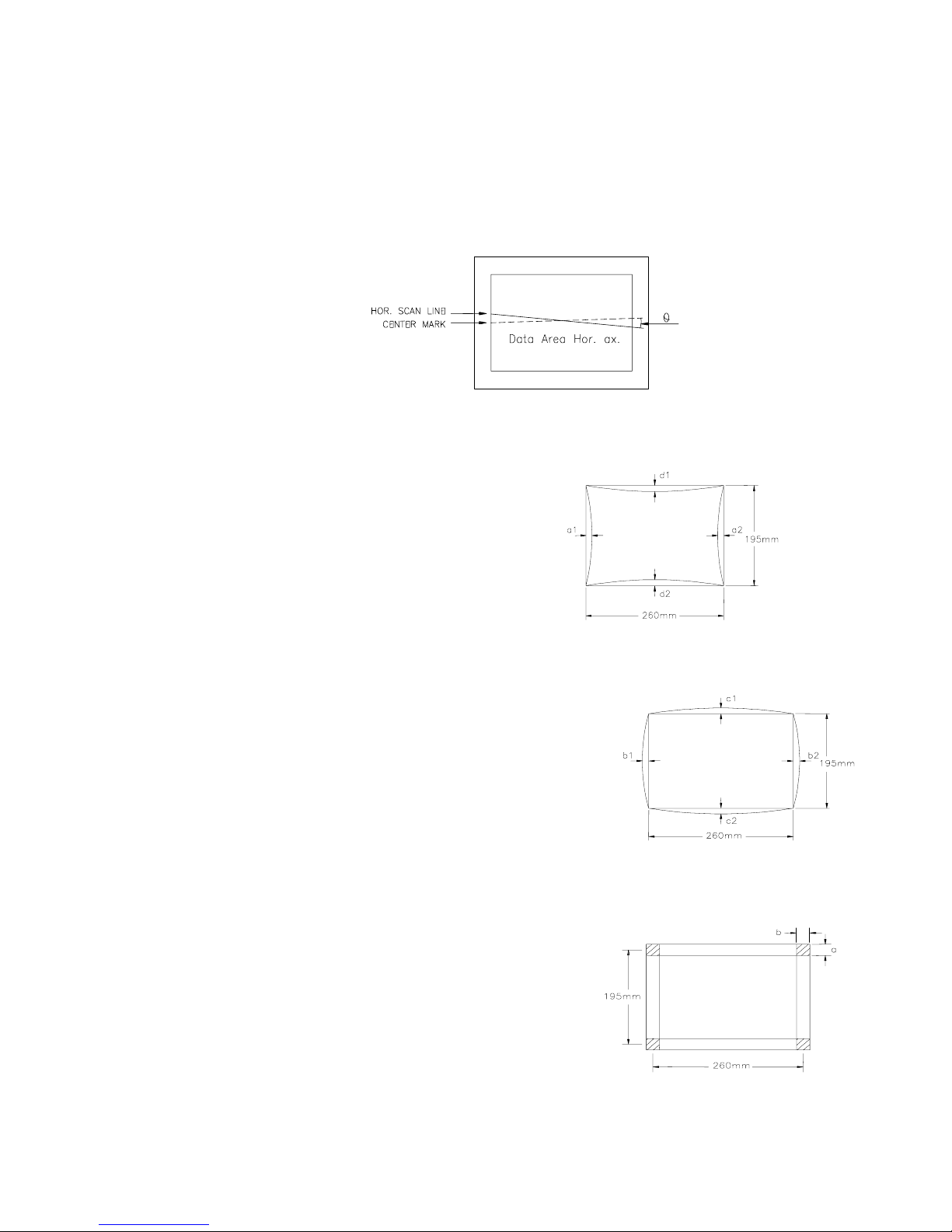

Figure 9. Describes the pattern for this test. Basically a single pixel white line around the perimeter

of the data area composes it, with marks for the horizontal ad vertical axes. The background is

black.

The maximum variation of the display centering shall be such that the following relationship shall be

met:

a | L - R | ≤ 3mm | U - D | ≤3mm

Figure 9: Display Centering

The external control ranges of display position for all modes listed in part 2.3.1 shall be as follows:

Horizontal position: total control range≥ 40mm

Vertical position: total control range≥ 25mm

9

2.9.5 Tilt

The maximum variation of the display rotation (tilt) shall be such that the following relationship shall

be met:

θ≤0.5 degree

2.9.6 Geometric Distortions

1. Pincushion

Pincushion(top) d1≤1.5mm

Pincushion(bottom) d2≤1.5mm

Pincushion(leftside) a1≤1.5mm

Pincushion(rightside) a2≤1.5mm

"S" distortion ≤0.5mm

2. Barrel

barrel(top) c1≤1.5mm

barrel(bottom) c2≤1.5mm

barrel(leftside) b1≤1.0mm

barrel(rightside) b2≤1.0mm

3. Trapezoid & Parallelogram distortion

a≤2.0mm

b≤2.5mm

10

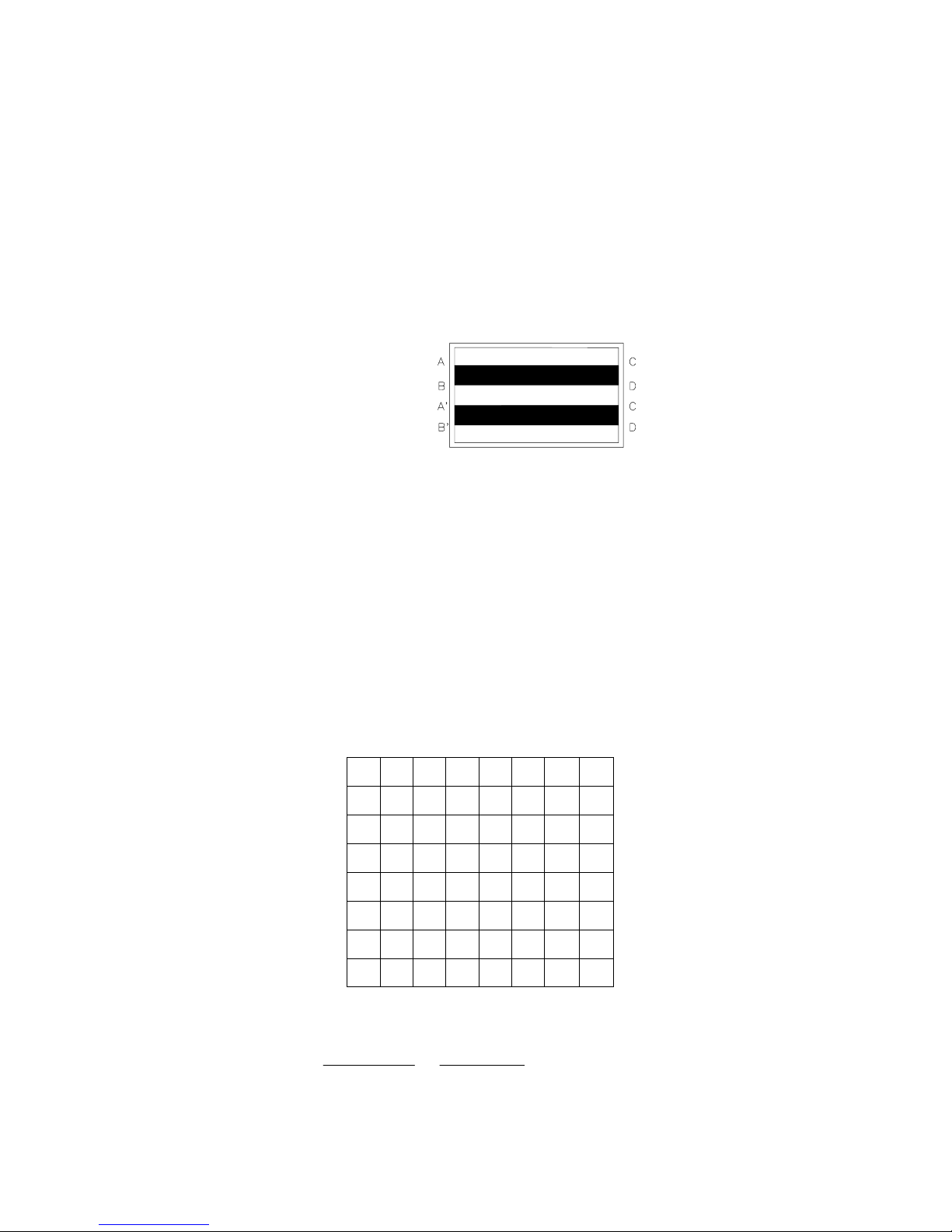

2.9.7 Geometric Distortion By Luminance

The test pattern is composed of two white areas and a black area, the three areas are equivalents.

The input signal level is 700 mV with brightness control at cut-off and contrast control at

maximum(see Figure 12).

The distortion introduced by dynamic High Voltage variation, due to different brightness level on the

screen, are admitted with following limits:

|AC - BD| or |A'C'-B' D'|≤2.0mm

Figure 12

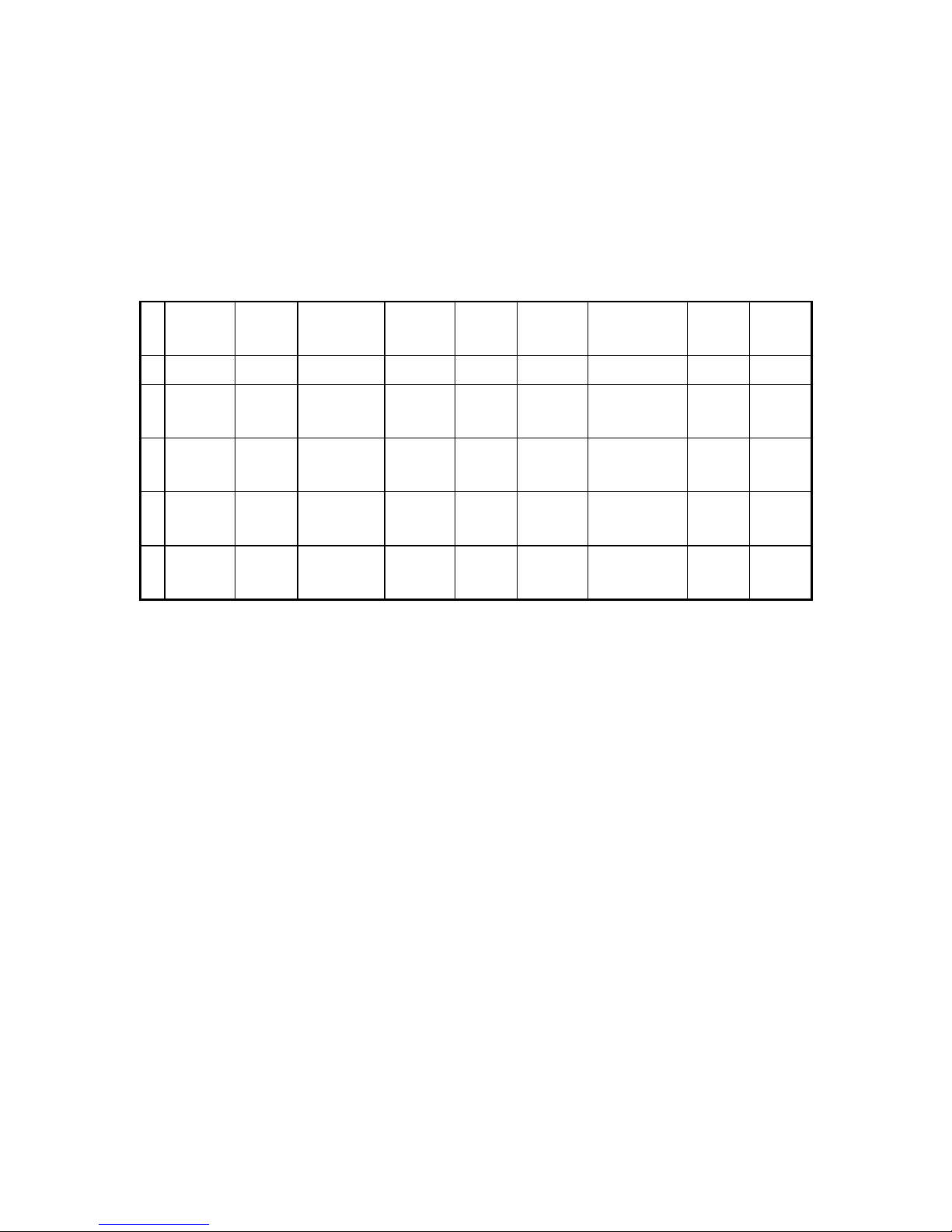

2.9.8 Linearity

The linearity of an image displayed on the CRT must meet the following requirements, with

reference to figure 13 for both X and Y axis.

The measured value of linearity shall be less than 6% when calculated using all lattices and shall be

less than 4% when calculated using adjacent lattices.

X1 X2 X3 X4 X5 X6 X7 X8

Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

mi

n

max

minmax

mi

n

max

minmax

YY

YY

OR

X

XXX+

−

+

−

11

Figure 13:Linearity

Where: X max and X min are belong to the set Xi,i=1......8

X max, X min, be Calculated Same Line

Y max, Y min, be Calculated Same Row

Y max and Y min are belong to the set Yi,i=1....8

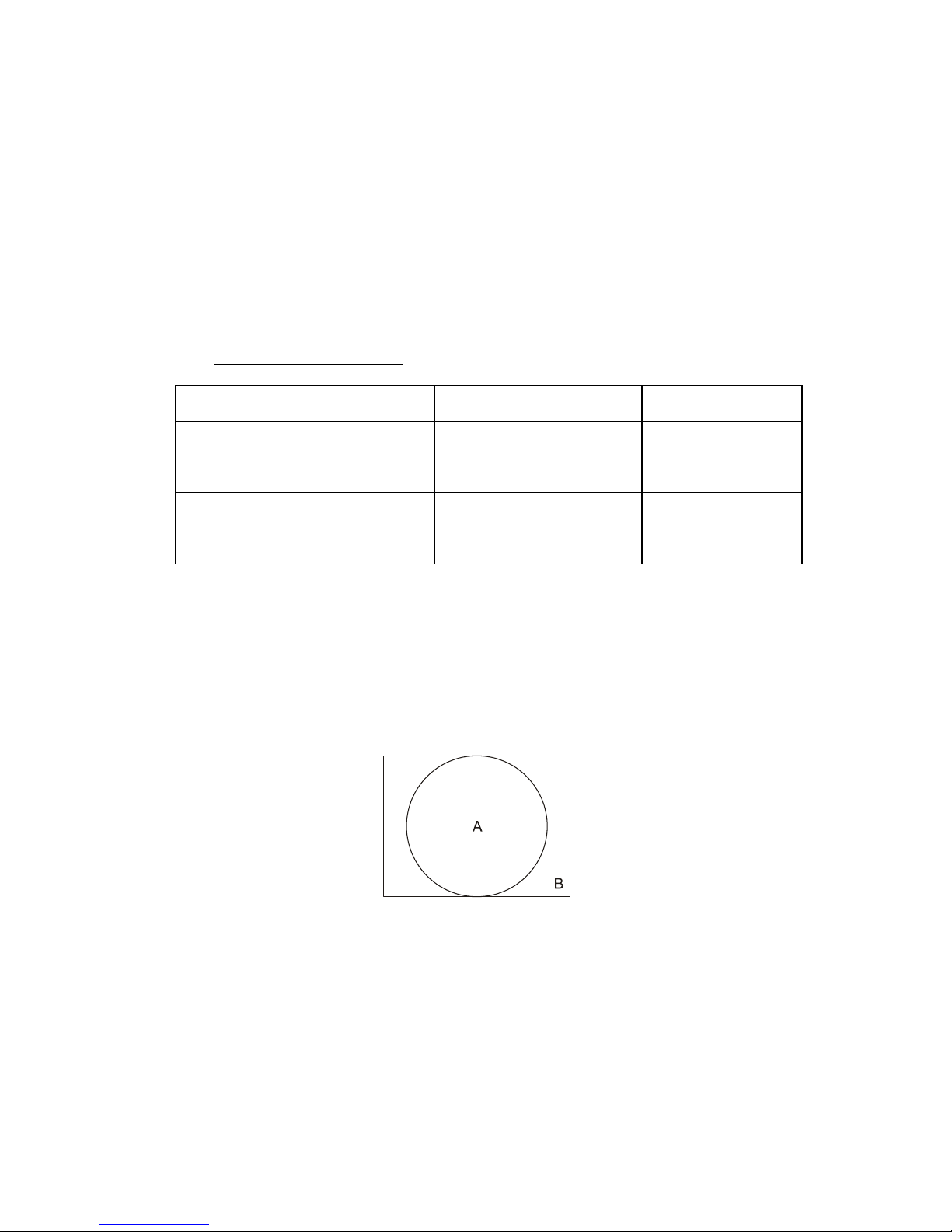

2.9.9 Misconvergence

The display must conform to all the following requirements:

Maximum convergence error.

Area Horizental Direction Vert. Direction

A

Center field of 203mm diameter

0.30mm 0.30mm

B

Square field of 270 x 203 mm

0.40mm 0.40mm

Table 6 : Misconvergence

The maximum convergence error shall be measured for a white spot or line, and represents the

maximum distance between the energy centers of any two primary colors. The central area is

defined as the area within a circle centered on the CRT faceplate having a diameter equal to the

display vertical dimension.

Figure 14

2.9.10 Image Stability (Jitter)

Not perceivable Jitter will be present on the display, when displaying a cross-hatch pattern, at a

distance of 500 mm from the screen. In any case it is not admitted a measured Jitter value greater

than one dot (both on X axis or on Y axis).

12

2.9.11 White Color Adjustment

The chromaticity coordinates of the white color shall be verified with standard full white screen

@700 mV input level with brightness control at cut-off and contrast control adjusted to 25FL nits of

luminance on the center of the screen. The 1931 CIE chromaticity diagram (x, y) coordinates for the

screen center shall be:

x = 0.283± 0.030

y = 0.297± 0.030

2.9.12 White Color Uniformity

With a standard full white screen as described in section 4.11, the color coordinates measured at

any point of the screen shall be:

x = Xref ± 0.030

y = Yref ± 0.030

2.9.13 White Color Tracking

Contrast Control Tracking Error

After performing the standard setting as described in section 4.11, the contrast control shall be

moved within 30FL (max) and 7FL (min) of screen luminance or to the mechanical stop if the lower

limit cannot be reached. The white color coordinates in the center of the CRT when displaying the

standard pattern at all the allowed setting of the contrast control shall be:

x = Xref ± 0.035

y = Yref ± 0.035

Brightness Control Tracking Error

The initial setting shall be as follows:

Pattern: white raster

Input level: 700mV

Brightness control: maximum

Contrast control: adjust to 100 nit of screen luminance in the center of the CRT

The brightness control shall be moved within 30FL (max) and 7FL (min) of screen luminance or to

the mechanical stop if the these limits cannot be reached. The white color coordinates in the center

of the CRT at all the allowed settings of the brightness control shall be:

x = Xref ± 0.035

y = Yref ± 0.035

13

2.10 Luminance Uniformity

The variation in average display luminance between any area(with dimension approximate 2 cm of

diameter)on standard flat white screen, must be less than 35% of the luminance of the brightest

area with brightness control at cut-off and contrast control adjusted to 80 nits of luminance on the

center of screen.

2.10.1 Focus

When external contrast control is adjusted for 20±1FL light output with a flat white field pattern, then

switch to a character pattern filled with "H" characters, the characters shall be readable and

distinguishable.

2.10.2 Moire

While displaying a white raster, no Moire effect shall be visible at any luminance setting 15FL.

2.10.3 Purity

Conspicuous miss-landing shall not be visible within display area. at distance of 60cm from CRT

surface at 20FL white luminance.

2.11 Functional Performance

2.11.1 Acoustical noise:

The acoustical noise shall be less than 50dB when operating in normal condition, mode change or

power on/off.

2.11.2 Turn off:

Set unit at 20FL of full white screen, then turn off unit, image should disappear smoothly, no

persistent spot and flash.

2.11.3 High voltage discharge:

The arcing due to monitor high voltage discharge shall not cause any damage to devices connected

to the monitor.

2.11.4 Tapping test:

No objectionable intermittence or noise occur while tapping top, left right, rear side of enclosure by

a rubber hammer.

2.12 Environment Requirements

2.12.1 Non-adjusting operation

25℃ ± 10℃

2.12.2 Operating

Temperature 0°C to +40°C

14

Relative Humidity 10% to 90%

Altitude Sea level to 8,000ft

2.12.3 Storage of shipment

Temperature -20°C to + 60°C

Relative Humidity 10% to 90%

Altitude Sea level to 40,000ft

2.12.4 TEST PROCEDURUE:

• Put in temperature chamber under 60°C Time: 24 hours

• Back to room temperature Time: 4 hours

• Put in temperature chamber under -20°C Time: 24 hours

• Back to room temperature Time: 4 hours

• The process repeat 2 times.

2.13 Reliability Requirements

2.13.1 Mean Time Before Failure ( MTBF )

30,000 hours with 90% confidence level.(CRT less)

2.13.2 Reference Document

MIL-STD-105D

MIL-HDBK-217E

2.13.3 Electro-Static Discharge ( ESD )

Contact discharge:

Apply 6KV,the set must be auto-recovery

Apply 4KV,the display pattern doesn’t appear noise

Air discharge:

Apply 8KV,be disallow components damage or EEPROM data loss

Apply 6KV,the display pattern does not appear noise.

2.14 White Balance

Set the external BRIGHTNESS at the point that raster just cut off, adjust CONTRAST over the range

from 5F-L to 20F-L, or reversed, with full-intensity reverse pattern, the color coordinate, measured by

MINOLTA TV-COLOR ANALYZER-II (TV-2130), shall be within the limitation listed below:

x=0.283

0.03

y=0.297

0.03 (At 5 F-L and 20 F-L)

15

2.15 Luminance Uniformity

The variation in average display luminance between any area(with dimension approximate 2 cm of

diameter)on standard flat white screen, must be less than 35% of the luminance of the brightest area

with brightness control at cut-off and contrast control adjusted to 80 nits of luminance on the center of

screen.

2.16 Focus

When external contrast control is adjusted for 15+/-1FL light output with a flat white field pattern, then

switch to a character pattern filled with "H" characters, the characters shall be readable and disting

uishable.

2.17 Image Stability (Jitter)

Not perceivable Jitter will be present on the display, when displaying a cross-hatch pattern, at a

distance of 500 mm from the screen. In any case it is not admitted a measured Jitter value greater

than one dot (both on X axis or on Y axis).

2.18 Warm-Up Time

The warm-up time shall be 20 minutes maximum. At the end of the warm-up period, no adjustment or

service shall be necessary to cause the display to meet the requirements contained herein. After a

warm-up time of 1 minute, the display shall produce a usable image. Repetitive power ON/OFF

cycles must be possible with a minimum switch-off time of about 4s.

16

3.0 INTRODUCTION

This document is related to a 15" CRT color monitor MC500 to be used with various kinds of graphic

adapters, including IBMVGA, VESAVGA, ERGOVGA, SVGA, UVGA and XGA modes. It is intended

as a mutisync monitor type based on microprocessor unit, capable to support all the video standards.

This monitor, simply adjusting image size and centering by means of the user controls gathered on

the front panel, can support other graphic standards. The monitor is used with 30KHZ to 54KHZ

frequency in horizontal sweep while vertical refresh rate is from 50HZ to 120HZ.

Moreover it offers Power Management and DDC1 and DDC2B features according to VESA

recommendations.

17

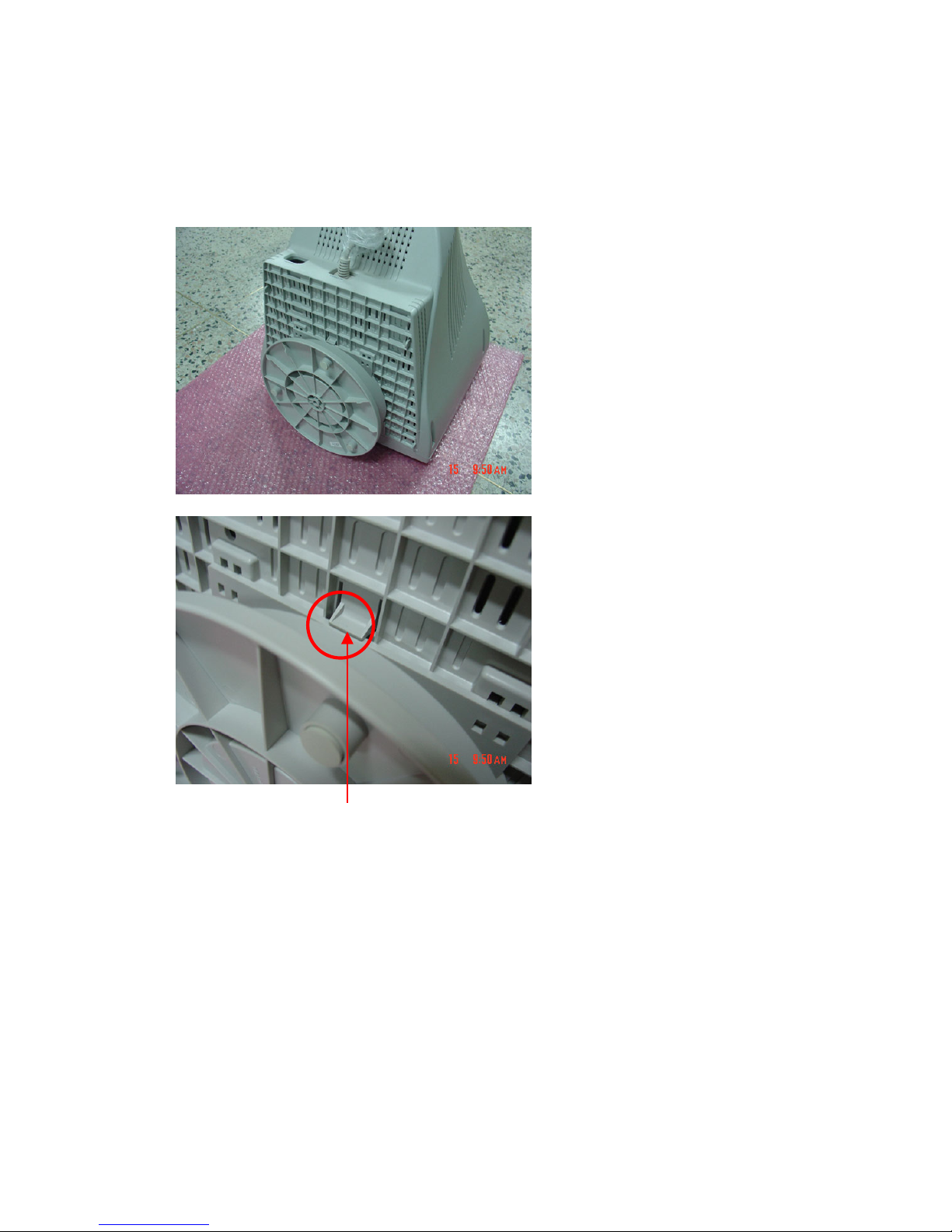

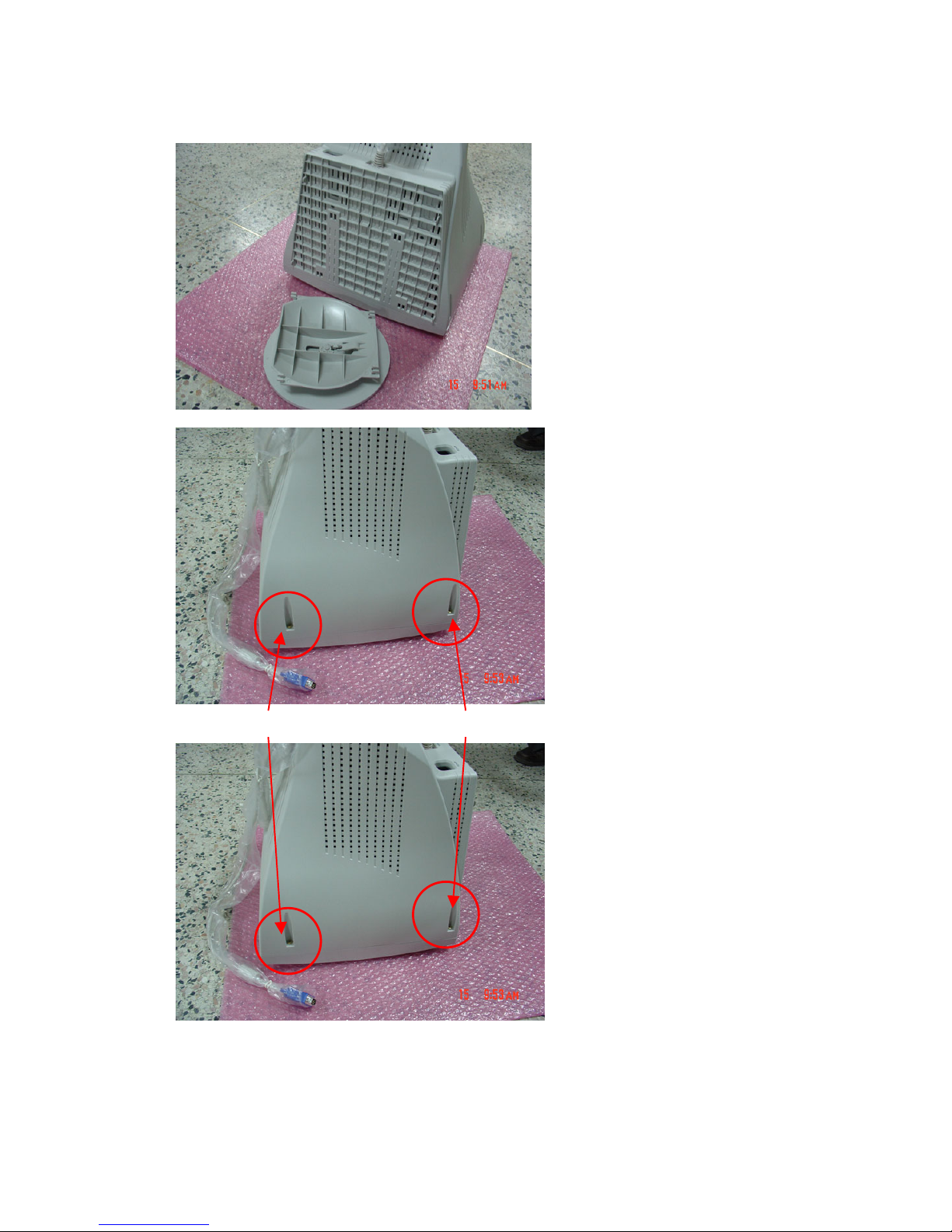

4.0 MECHANICAL INSTRUCTION

Remove base

Push the hook to remove base.

18

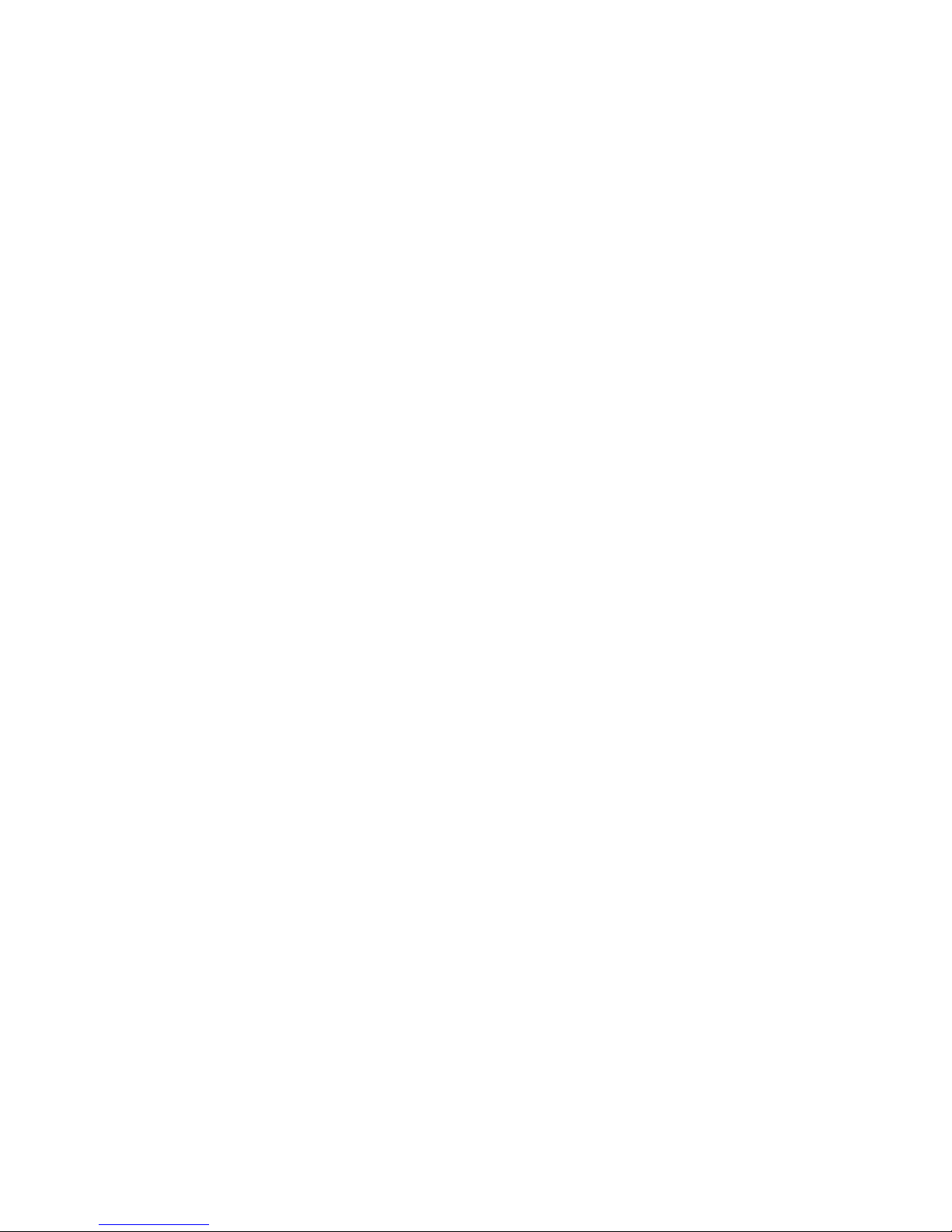

Remove 4 screws between bezel and back cover.

19

Remove back cover

Remove 4 screws to remove guild L & R

20

Remove 4 screws to remove bezel

21

22

5.0 ALIGNMENT

Warm up the monitor for at least 30 minutes before adjustment.

• Set the front of CRT to the east.

• Turn all VR set to center position.

5.1 B+ Voltage, G1, H. Position Adjustment

Use front control key adjust the display size about 270mm, adjust VR501 let the voltage of FBT

PIN3 cathode is 130±0.3V. (Timing is 48k 1024x768.Pattern is full white.)

5.2 White Balance Adjustment

• EXT. BRIGHTNESS and EXT. CONTRAST set MAX.

1. Input timing 48k 1024x768 without pattern adjust G2 VR (mounting on F.B.T) so that the

brightness of back raster to become 0.5± 0.1 FL.

2. Adjust Brightness to cut-off (Raster), then adjust VR801 let the brightness is 45 ± 1FL

(2” pattern).

3. Adjust Bri & Cont. to max, then adjust VR802 let the brightness is 29 ± 1FL (Full white).

4. All the value must be check repeatedly.

5.3 Focus Adjustment

1. EXT. BRIGHTNESS move to cut off point. Use EXT.CONTRAST set the brightness to

25FL.

2. Adjust Focus VR (mounting on F.B.T), to get best focus.

5.4 Preset Timing Adjustment

(Short P102 or press recall key when power on)

1. Input each PRESET MODE timing, and use front control key adjust the display to the

normal position and size, and wait for 2 seconds.

2. Switch to next timing repeat 1 process. Unitl every PRESET MODE timing have been

adjusted

Loading...

Loading...