Page 1

ChungHwa Picture tubes ,Ltd

OE Business Unit

P D P

Service Menu

Polished by After Service Section

APP Dept. Product Planning Division

First Edition Copyright : Ver_001.

All Rights Reversed

0

Page 2

Content :

0. Safety measures / Attention…………………….…………………………………

1. Summary …………………………………………………

2. Introduction to PDP circuit boards………………….……………………………

2.1 VIF board ………………………………………………………………………

2.1.1 VIF basic framework………………………………………………………

2.1.2 Photos of VIF Board……………………………………………………….

2.1.3 Pin assignments of connectors ……………………………………………..

2.1.4 VIF (Video interface)……………………………………………………….

2.1.5 System Block diagram………………………………………………………

2.1.6 Some Waveforms…………………………………………………………….

2.2 DIF board ………………………………………………………………………

2.2.1 DIF 2.95 board……………………………………..………………………

2.2.2 Equipments…………………………………………………………………

2.2.3 Simple electric circuit test………………………….………………………

2.2.4 Advanced electric circuit test………………………………………………

2.2.5 IC100 - IC106 :main signal waveform measuring….………………………

2.2.6 Waveform …………………………………………………………………

2.3 POWER board …………………………………………………………………

2.3.1 Introduction ………………………………………….……………………

2.3.2 The output power………………………………………..…………………

2.3.3 pin assignments of connectors…………………………………………….

2.3.4. Troubleshooting…………………………………………………………..

2.4 X-Sustainer board ………………………………………………..……………

2.4.1 X-Sustainer board’s pin alignments ………………………………………

2.4.2 X-side function explanation :………………………………………………

2.5 Y-Sustainer board ………………………………………………………………

2.5.1 Y-Sustainer board’s pin alignments…………………………………………

2.5.2 Y-side function explanation…………………………………………………

3. PDP repairing flow-chart …………………………………………………………

3.1 Main flow-chart………………………………………………………………

3.2 No picture repairing flow-chart………………………………………………

3.3 X sustainer malfunction repairing flow-chart…………………………………

3.4 Y sustainer malfunction repairing flow-chart…………………………………

4. Generally common defective checking and testing…………………………………

4.1 Phenomenon 1 : Dark screen and flickering…………………………………..

4.2 Phenomenon 2 : 170v limit current……………………………………………

1

Page 3

4.3 Some phenomenon of failure PCB boards……………………………………..

5. Debug / Inspection…………………………………………………………………….

5.1 Debug………………………………………………………………………….

5.2 Inspection………………………………………………………………………

6. Common use of BOM lists …………………………………………………………

7. Repair record: …………………………………………………………………………

2

Page 4

0. Safety measures and Attentions:

1. Observation and measures carefully:

When in repair service , should pay attention to these safety measures and the description

Of the service menu.。

2.Preparation:

The preparation for repair in a defective PDP is necessary , ex:stable working table , repair

Tools , measuring equipments , replace parts………etc。

3.Pay attention to electrical shock:

Because the PDP is using the AC power source , and the power board contents high voltage ,

so to preventing the high voltage shock is necessary . Such as , using a isolated transformer ,

plastic glove , charged components should be discharged first . The high voltage is supplied

to inferior components , so when repair the PDP should pay more attentions.

4.Using the specified components:

Some components provide fire-resist and endure high-voltage. So when replace these parts

, should use the same characteristic components. So when replace a component should according

to the BOM form for a assigned component.

5.Stable the components and recovery the wiring :

Some components are using isolated sleeve or adhesive tape to isolate from the electric

board . Moreover the interior wiring should be arranged again to prevent the interference

from given out heat components and high voltage components .So after repairing , should

recover the same layout of the PDP.

6.Integrity of the electric circuit :

Use the specified components to replace the defective parts . Under any circumstance,do

not try to modified the electric circuit .

7.Safety check after repairing:

After repairing , should check the screws and the wiring condition .Checking the quality

of repairing components . The insulation test of the metal component , power cord to make

sure the safety of repairing.

3

Page 5

1 . Summary :

N

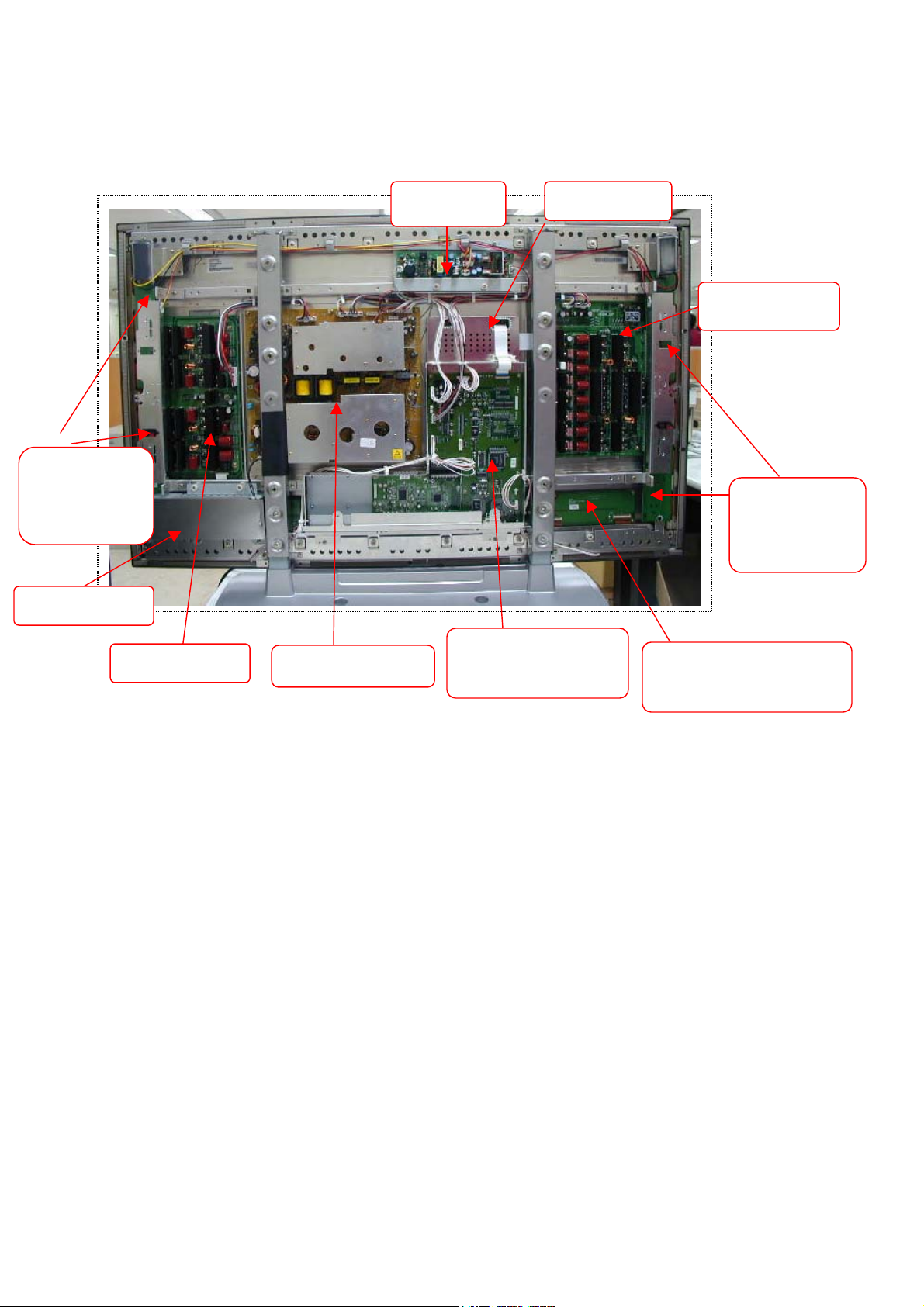

1.1 Photos of disassembly:

ote.3

Fig. 1 Fig. 2

1.2 Procedure:

1.First put on the PDP on a stable working table and power off the PDP which is going to repair ,

then using a screwdriver to unfasten the screws which fasten the back cover .

2.Befor taking apart as Fig.1 shown , after taking apart as Fig. 2 shown .

3.The screws of back cover:

a. pan-headed screw M4 *13 pcs。

b. screw TB-12 *18 pcs。

c. stand screw M5-16 * 4pcs。

1.3 Note:

2.After taking apart , put the screws at a safe place to avoid losing

1.Make sure that the power is off before taking apart .

3.Taking apart and installing the back cover , be careful not to pull out the switch of AC power

switch .(Fig.3)

Fig.3

4

Page 6

1.4 Introduction to PDP circuit board:

d

)

)

1.4.1The introduction of circuit board at Back board:

Y-Extension

board (upper

and lower

AC Line Filter

Y-SUSTAINER

1.4.2 Explanation:(Function / Characteristic)

POWER SUPPLY

Audio Board

VIF(PC Module &

Video Module)

DIF Boar

X-SUSTAINER

X-Extension

board (upper

and lower

W-Extension board (left

and right)

a. POWER:(1).Input Voltage (AC 110V〜240V、47HZ〜63HZ),Max. range 90V〜265V.

(2).Providing electrical power to all the PCB.

b. VIF:Transfer S-video , Video , PC(D-sub& DVI) , HDTV signal to digital signal to the DIF

board.

c. DIF:Dealing with the digital signal for output to panel.

d. X-Sustainer / Y-Sustainer:(1).Receiving the signal from DIF.

(2). Output scanning waveform.

e. X / Y-Extension board: Receive signal from X / Y sustainer , output horizontal scanning waveform

to the panel.

f. W-Extension board: Receive signal from DIF , output the vertical scanning waveform , addressing

data.

g. Audio Board:Amplifying the audio signal to the internal or external speakers of which select.

h. AC Line Filter:AC power line filter。

5

Page 7

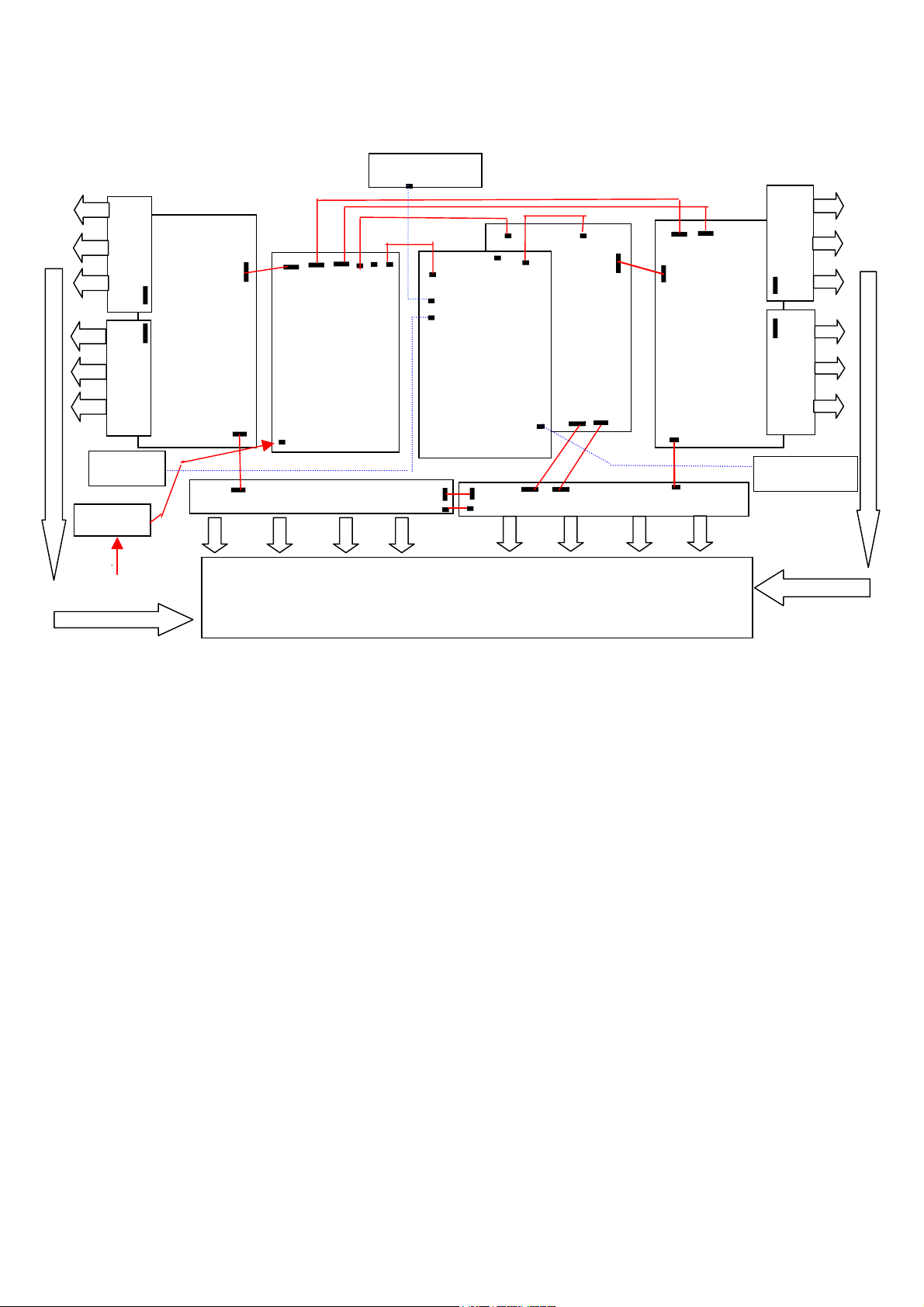

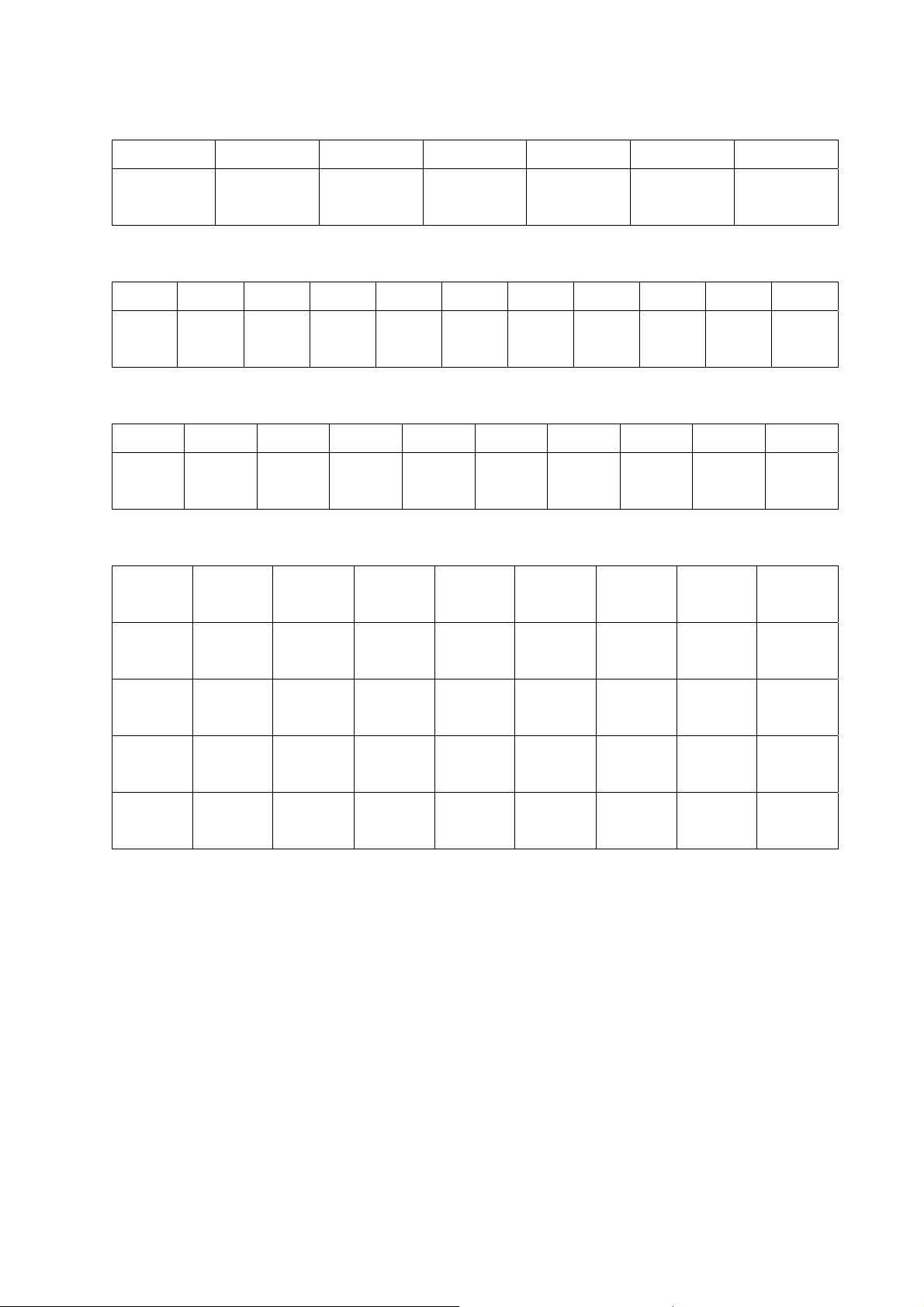

1.4.3. PDP 46” block diagram:

pp

W

d

W

Y

Lower

Uppe

Y-

PY

r

Y- S us t ai n er

-

PY PX1 PX2 PW

Key PAD

AC Filter

AC 90~240 V

Panel

POWER

-Board

Audio-AMP

J17

J12

Power CN1

J15 J16 CV1

DIF

V I F

DW1 DW2

J11

DW1 DW2

DX1

-Boar

PX1 PX2

DX1

X-Sustainer

X-U

er

X-Lower

Front Receiver

1.4.4 Function:

a. The input voltage AC 90 ~ 240 through line filter to the power board , after main switch is on

then power board generate 5 volts to VIF board. The VIF board after receiving 5 volts then

from CN connector send signal(5 volts) to power board .Power board generates 5 volts to DIF

and VIF .When VIF receives the 5 volts ,then generates 5 volts to power board through CN

connector(pin1 ,pin6) , and it means that DIF has received 5 volts already.

b. When power on(key-pad or receiver),the VIF send VCC_ON signal to power to start Vcc and

Vf voltage through CN connector(pin2).

c. The VIF sends HV_ON signal to power board to start high voltage Vs , Vxg , Vw through CN

connector(pin4).

d. At the same time the signal from VIF to DIF for signal processing , then through X / Y / W

board to start the screen.

6

Page 8

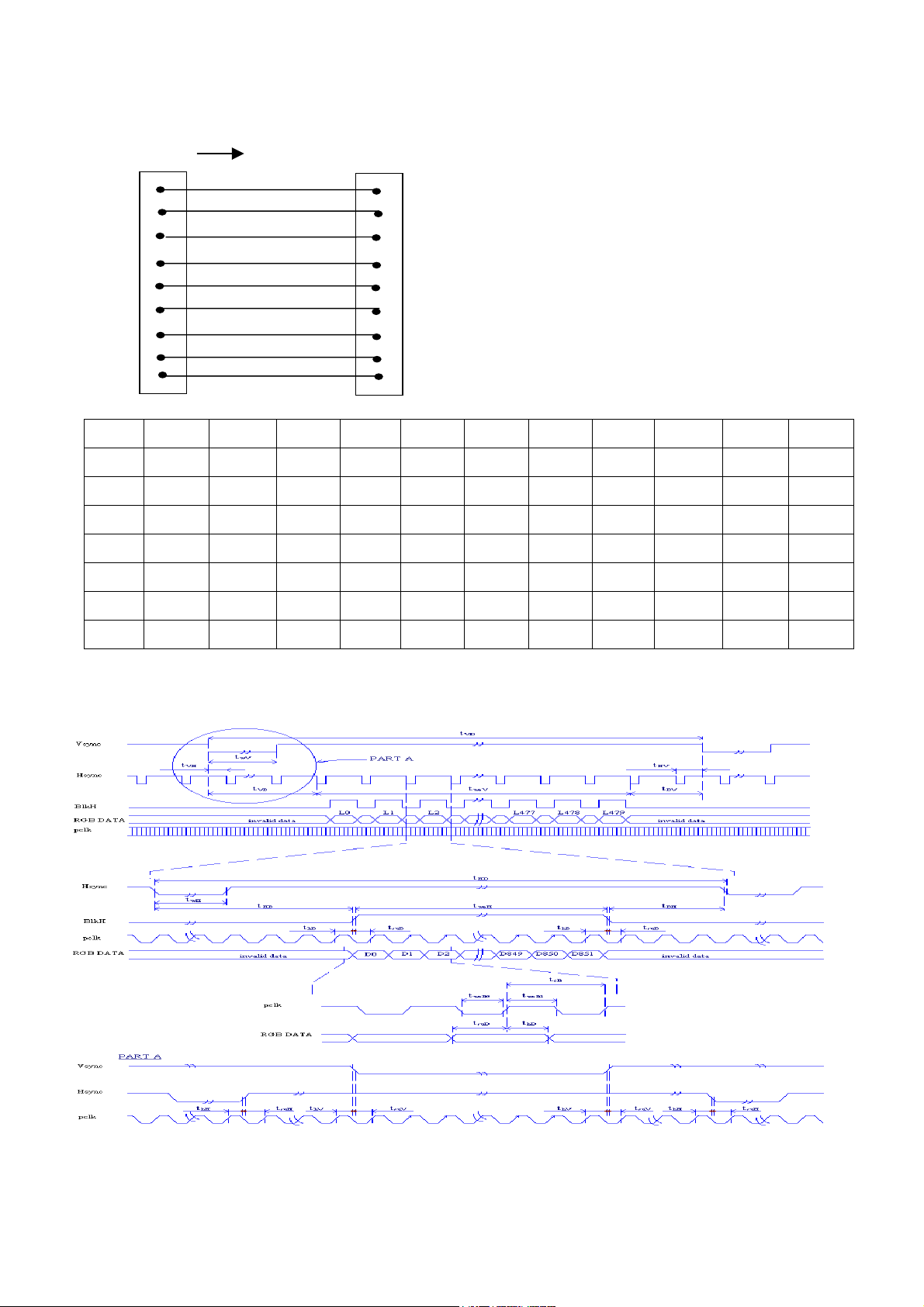

1.4.5 The waveform of connector:

a. CN1-V CN1-D:

8bit R [7:0]

8bit G [7:0]

8bit B [7:0]

clock

Hsync

Vsync

Blank (Blank H)

I*2C

a-1. PIN assignment :

PIN No.

Output

1 2 3 4 5 6 7 8 9 10 11

CLK0 CKL1 Gnd BLK Gnd VD Gnd HD Gnd Gnd B7

12 13 14 15 16 17 18 19 20 21 22 23

B6 B5 B4 Gnd B3 B2 B1 B0 Gnd G7 G6 G5

24 25 26 27 28 29 30 31 32 33 34 35

G4 Gnd G3 G2 G1 G0 Gnd R7 R6 R5 R4 Gnd

36 37 38 39 40 41 42 43 44 45

R3 R2 R1 R0 Gnd None TP66 none

Sda/TP5 Scl/TP2

a-2. Signal explanation:

7

Page 9

b. DX1 to DXS:

b-1 PIN assignment :

PIN No.

Output

1 2 3 4 5 6 7 8 9 10

Gnd

XDD2/TP1

40

XDD1/TP1

39

Gnd

XP2L/TP1

38

XG2L/TP1

37

XG3L/TP1

36

XG1L/TP1

35

Gnd

XG1H/TP

134

11 12 13 14 15 16 17 18 19 20 21

XSU/TP133 XAEL/TP1

52

XEAH/TP

151

Gnd

XELL/TB1

50

XEFH/TP1

49

Gnd

XNEL/TP1

48

XNEH/TP

147

Gnd

XCLK/TP1

46

22 23 24 25 26 27 28 29 30

Gnd

XSI2/TP14

5

Gnd

XLE/TB144 XSTB/TP1

42

XTSC/TP1

41

Gnd

XSI1/TP14

3

Gnd

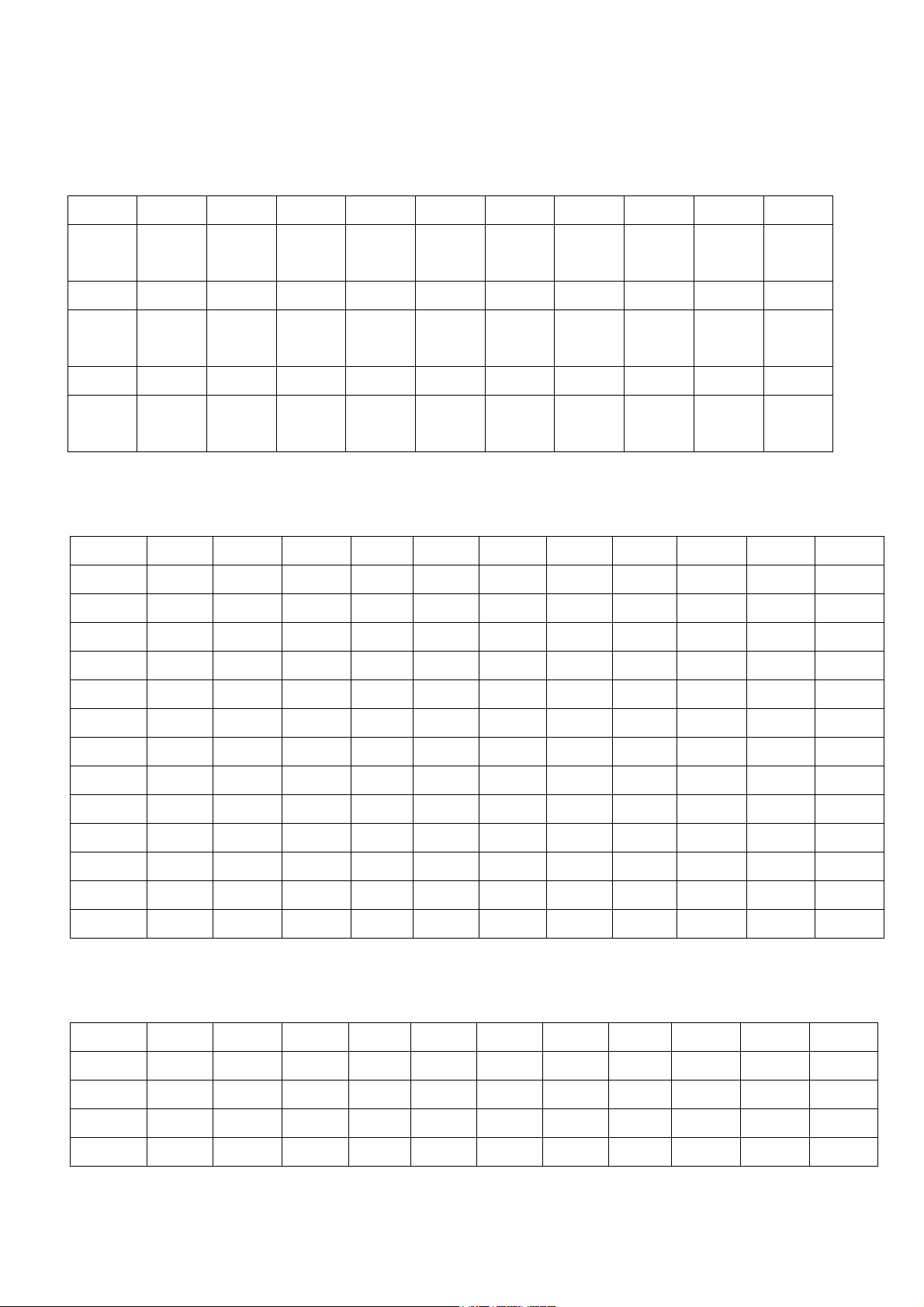

c. DW1 to DW1(DIF to W board)

Signal:DDR(27.0)、DDG(27.0)、DDB(27.0)、DLE(2.0)、DBL(2.0)、DBH(2.0)、DHZ(2.0)。

PIN No.

Output

1 2 3 4 5 6 7 8 9 10 11

GED YSC2A YSC1A GED YEELA YEEHA GED YEFLA YEFHA GED YCA2B

12 13 14 15 16 17 18 19 20 21 22 23

YSC1B GED YNELB YNEHB GED YEFLB YEFHB GED DDB27 DDG27 DDR27 GED

24 25 26 27 28 29 30 31 32 33 34 35

DDB26 DDG26 DDR26 GED DDB25 DDG25 DDR25 GED DDB24 DDG24 DDR24 GED

36 37 38 39 40 41 42 43 44 45 46 47

DDB23 DDG23 DDR23 GED DDB22 DDG22 DDR22 GED DDB21 DDG21 DDR21 GED

48 49 50 51 52 53 54 55 56 57 58 59

DDB20 DDG20 DDR20 GED DDB19 DDG19 DDR19 GED DDB18 DDG18 DDR18 GED

60 61 62 63 64 65 66 67 68 69 70 71

DDB17 DDG17 DDR17 GED DDB16 DDG16 DDR16 GED DHZ2 DBH2 DBL2 DLE2

72 73 74 75 76 77 78 79 80

GED RAKa GED RAKb GED V50 V50 V50 V50

d. DW2 to DW2 (DIF to W board)

signal:DDR(27.0)、DDG(27.0)、DDB(27.0)、DLE(2.0)、DBL(2.0)、DBH(2.0)、DHZ(2.0)。

PIN N.

Output

1 2 3 4 5 6 7 8 9 10 11

V50 V50 V50 GED DDB15 DDG15 DDR15 DDB14 GED DDG14 DDR14

12 13 14 15 16 17 18 19 20 21 22 23

DDB13 DDG13 GED DDR13 DDB12 DDG12 DDR12 GED DDB11 DDG11 DDR11 DDB10

24 25 26 27 28 29 30 31 32 33 34 35

8

Page 10

GED DDG10 DDR10 DDB9 DDG9 GED DDR9 DDB8 DDG8 DDR8 GED DHZ1

36 37 38 39 40 41 42 43 44 45 46 47

DBH1 GED DBL1 DLE1 GED GAKa GED DHZ0 DBH0 GED DBL0 DLE0

48 49 50 51 52 53 54 55 56 57 58 59

GED GAKb GED DDB7 DDG7 DDR7 DDB6 GED DDG6 DDR6 DDB5 DDG5

60 61 62 63 64 65 66 67 68 69 70 71

GED DDR5 DDB4 DDG4 DDR4 GED DDB3 DDG3 DDR3 DDB2 GED DDG2

72 73 74 75 76 77 78 79 80

DDR2 DDB1 DDG1 GED DDR1 DDB0 DDG0 DDR0 GED

e. W-COF to Y-Sustainer:

PIN No

Output

PIN No

Output

1 2 3 4 5 6 7 8 9 10

LGED YSC2A YSC1A LGND YNELA YNEHA LGND YEFLA YEFHA LGND

11 12 13 14 15 16 17 18 19 20

LGND YSC2B YSC1B LGND YNELA YNEHA LGND YEFLB YEFHB LGND

9

Page 11

3

4.

1

3.

3

8.

1

3.

6

21.

0

1.

5

4.

4.5

6

0.

5

4.

0.6

5

4.

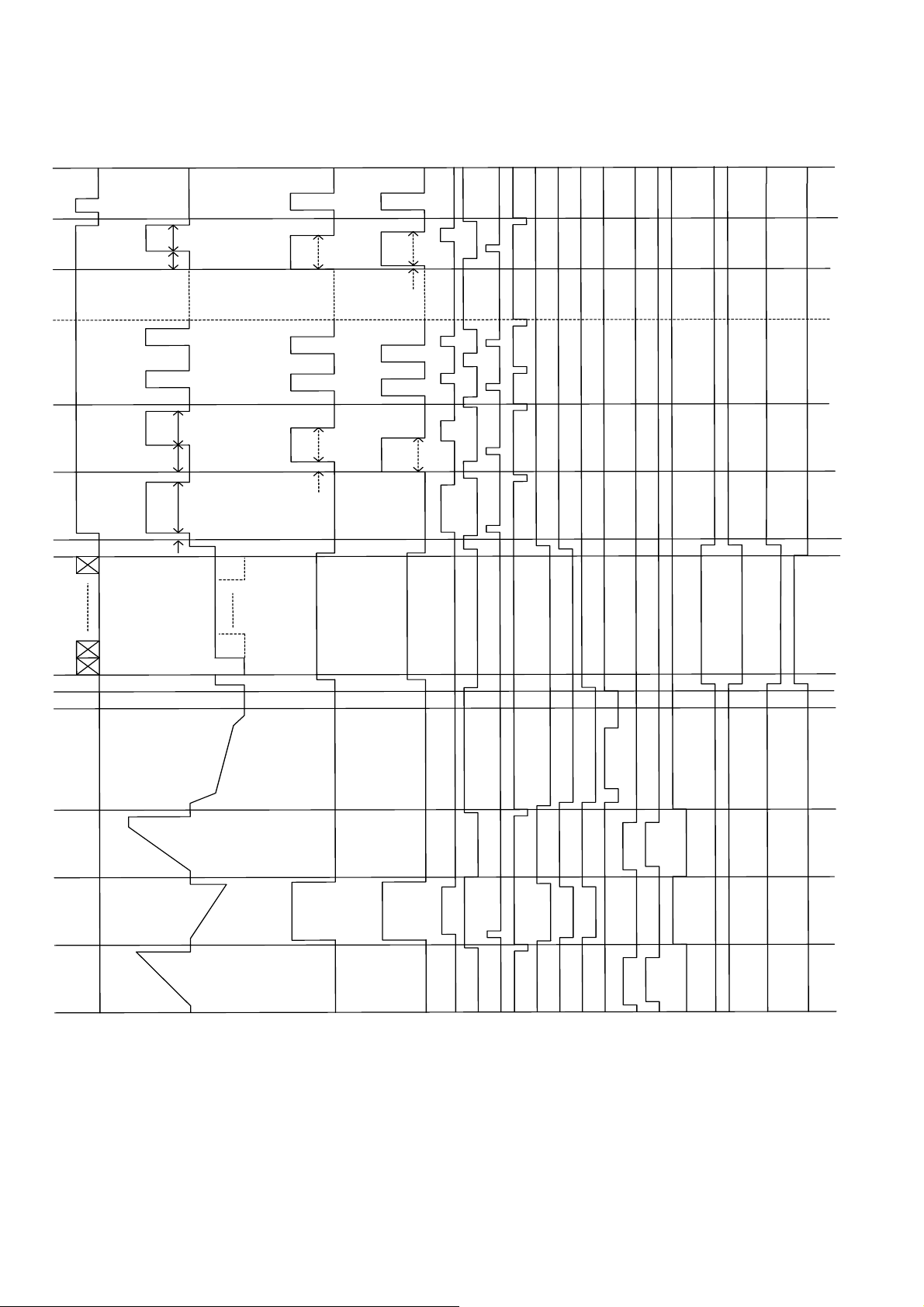

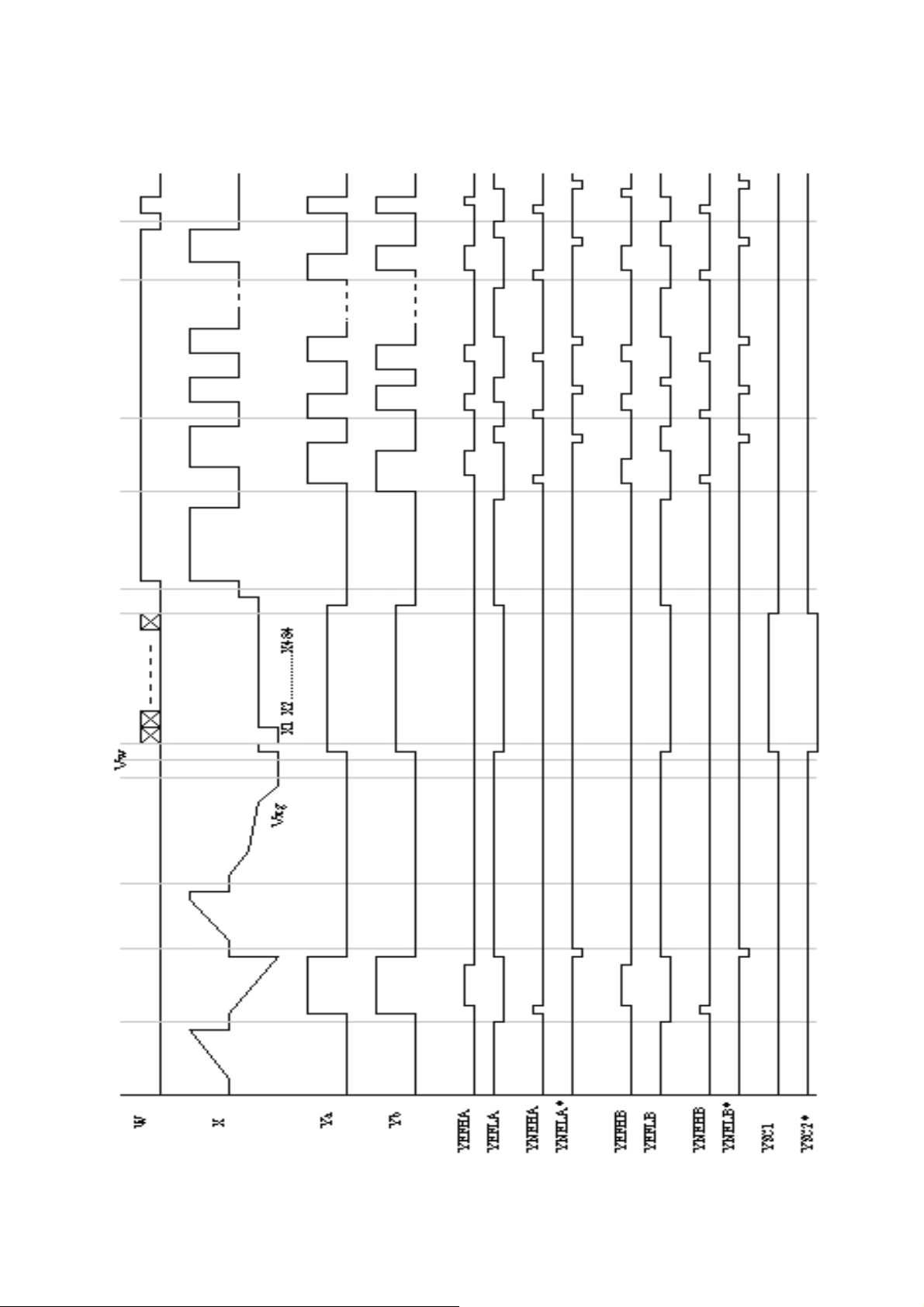

I,1 I,2 ............... I,484

Xv

X484

圖 4. 2

X1 X2 ...................

g

W

Y

Ya

Yb

XVDD

LOG2

XSI1

XLE

XSI2

XCLK

XTSC

XSTB

10

Page 12

3

4.

1

3.

3

8.

1

3.

6

21.

0

1.

4.5

4.5

0.6

4.5

0.6

4.5

X484

X1 X2 ...................

I,1 I,2 ............... I,484

g

Xv

W

Y

*

Yb

Ya

XLFH

XEFL

XNEL

XG1H

XNEH

XG1L*

XG2L

*

XP2L

*

XS

H

U

XAE

XAEL

XDD1

XDD2*

XTSC

圖 4. 1

XSTB

11

Page 13

12

Page 14

f. Power signal:Power to Y-Sustainer (PY):

PIN No.

Symbol Vcc-G Vcc Vf-G Vf Vw Vw-G Vs-G None Vs

Output 5V 5V 15v 15v 65V 65V 170V None 170v

g. Power signal : Power to X-Sustainer (PX1):

PIN No. 1 2 3 4 5 6 7

Symbol Vf-G Vf Vw Vw-G Vs-G None Vs

Output 15v 15v 65V 65V 170V None 170v

h. Power signal:Power to X-Sustainer (PX2):

PIN No. 1 2 3 4 5

Symbol Vxg None Vxg-G Vcc Vcc

Output -160V None 15v 15v 65V

1 2 3 4 5 6 7 8 9

2.1 VIF Board:

Summary:

General digital video signals include Vsync、Hsync、R(8Bit)、G(8Bit)、B(8Bit) and Data

Enable(Blank);the VIF of PDP is making for processing these digital signal.

Because PDP belonging a high end product , so its application should include the functions of

monitor(analog VGA , digital DVI signal input). And for consumer’s sake , the VIF should have the

functions of video , like audio , composite , s-video , component signal processing.

Below is the explanation of VIF system:

The role of VIF:

UHF/VHF TV

Cable TV

HDTV

VTR

DVD Player

PC

Home Video Game

DIFVIF

13

Page 15

Currently the video signal sources are video cassette recorder , DVD player , CATV , RF tuner , VGA

card(PC). In order that all the video signal sources can be displayed on PDP , so we need a interface to

transfer these signals to a specified signals for PDP to display , and this is the function of VIF(Video

Interface).

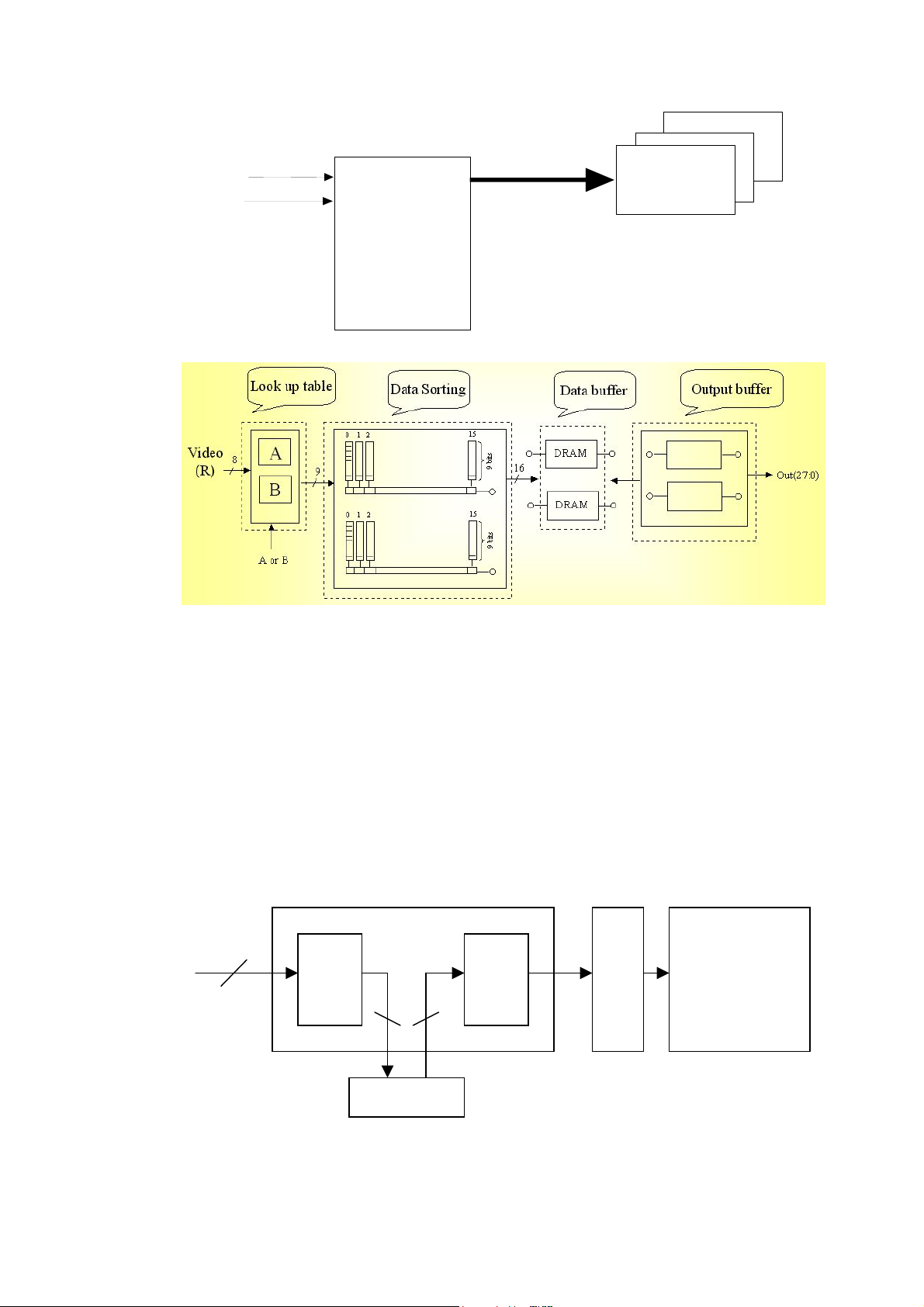

2.1.1 Basic framework of VIF board

For dealing with the signals of CVBS , S-video and Component, it requires a video decoder IC .

And the output of video decoder will input to a de-interlace chip IC for a stable image quality .

Because the TV system uses interlace scanning , it causes flickers on the screen . To improve this

situation so we use a de-interlace chip IC . The ADC(Analog to Digital Converter) IC converts

the analog RGB signal to digital RGB signal. The TMDS(

decoder IC transmits digital RGB signal. All the output of ICs’ signal send to scalar IC. The

relationship is shown as below , and make a brief explanation of the system.

Transition Minimized Differential Signaling)

D-SUB

ADC

Converter

Scalar

Chip

Out to DIF

DVI

TMDS

Receiver

Y/Cb/Cr

De_

Interlace

S-Video

Composite

Video

Decoder

Micro_

Controller

a. ADC Converter:AD9888 KS

RGB graphics signals. Its 205 MSPS encode rate capability and full-power analog bandwidth of

500 MHz supports resolutions up to UXGA(1600 x1200 @ 75 Hz).

The AD9888 is a complete 8 bit , 205 MSPS monolithic analog interface optimized for capturing

b. TMDS Receiver: SIL153BCT100

The Sil153BCT100 receiver uses PanelLink Digital technology to support high resolution displays up

to SXGA(25MHz~112MHz) . The Sil153B receiver supports up to true color panels (24 bit/pixel,

16.7M colors) in 1 or 2 pixels/clock mode. In addition , the receiver data output is time staggered to

14

Page 16

reduce ground bounce that affects EMI.

c. VIDEO Decoder:SAA7118E

The SAA7118E decoder is a ADC too , but it can deal with the ordinary TV signals. The

SAA7118E can input Composite (fig.A)、S-video (fig.B)、Component (fig.C) and its outputs

Are digital Y(Luminance) , C(Chromacity) signals. And also can adjust brightness , contrast ,

Saturation , hue .

Fig.A : Composite 信號 for COLOR BAR

Fig.B-1 YY ssiiggnnaall ooff SS--vviiddeeoo

15

Page 17

g

g

g

g

d

d

i

FFi

..BB--22CCssi

i

nnaallooffSS--vvi

i

o

eeo

FFiigg..CC--11 YY--ssiiggnnaall ooff CCoommppoonneenntt

FFiigg..CC--22 CCbb--ssiiggnnaall ooff CCoommppoonneenntt

16

Page 18

d. De-interlace:SIL504CM208

FFiigg..CC--33 CCrr--ssiiggnnaall ooff CCoommppoonneenntt

The Sil504 transfer interlacing signals to progressive signals. The advantage of progressive

signals is that the scanning rate doubling to let the screen more stable and non-flickering. Besides, the

sources of input may have 24 0r 30 or 25 frames per sec, so the de-interlaced chip shall tell from the

differences and processing the signals. The basic principle of de-interlaced IC is combined the odd and

even fields to a frame , and the processing needs a memory IC(SDRAM) to store these signals for

processing . For the improving the quality of image sake , more and more TVs or DVD players all

have the functions of progressive scanning.

e. Image Processor chip:PW171-20U(system on chip)

◎ Scaling function :

The Image scalars provide high quality up and down image scaling . For the applications of VIF , the

input signals could be VGA , SVGA , XGA formats , and its output fixed at 852 x 480 @60 HZ . For

example , SVGA format:800 x 600 @75Hz , first scaling down : Horizontal 800Î640、Vertical

600Î480 , 75 frames / sec after frame rate conversion become 60 frames per sec. Then scaling up

640Î852 , to accomplish the scaling function.

◎ Micro Processor Function :

This chip includes microprocessor(on-chip 80x86) ; selectable function and I/O interface control .

With 3 groups of 8-bit programmable I/O , 1 group of RS-232 communication port , IR

decoder ,timer and a PWM generator

17

Page 19

◎ OSD Function :

3

o/Video

S-VideoY/Cb/Cr

Video Decoder

Switc

V

The on-screen-display(OSD) can be used for startup screens , menus , and scribble functions.

2.1.2 Photos of VIF Board :

a. Video Module:

Audi

b 2nd PC Module:

D Y/C SEP

To VIF Main Board

Audio

To VIF Main Board

h

PC OUT

H B G R

PC Audio IN

18

Page 20

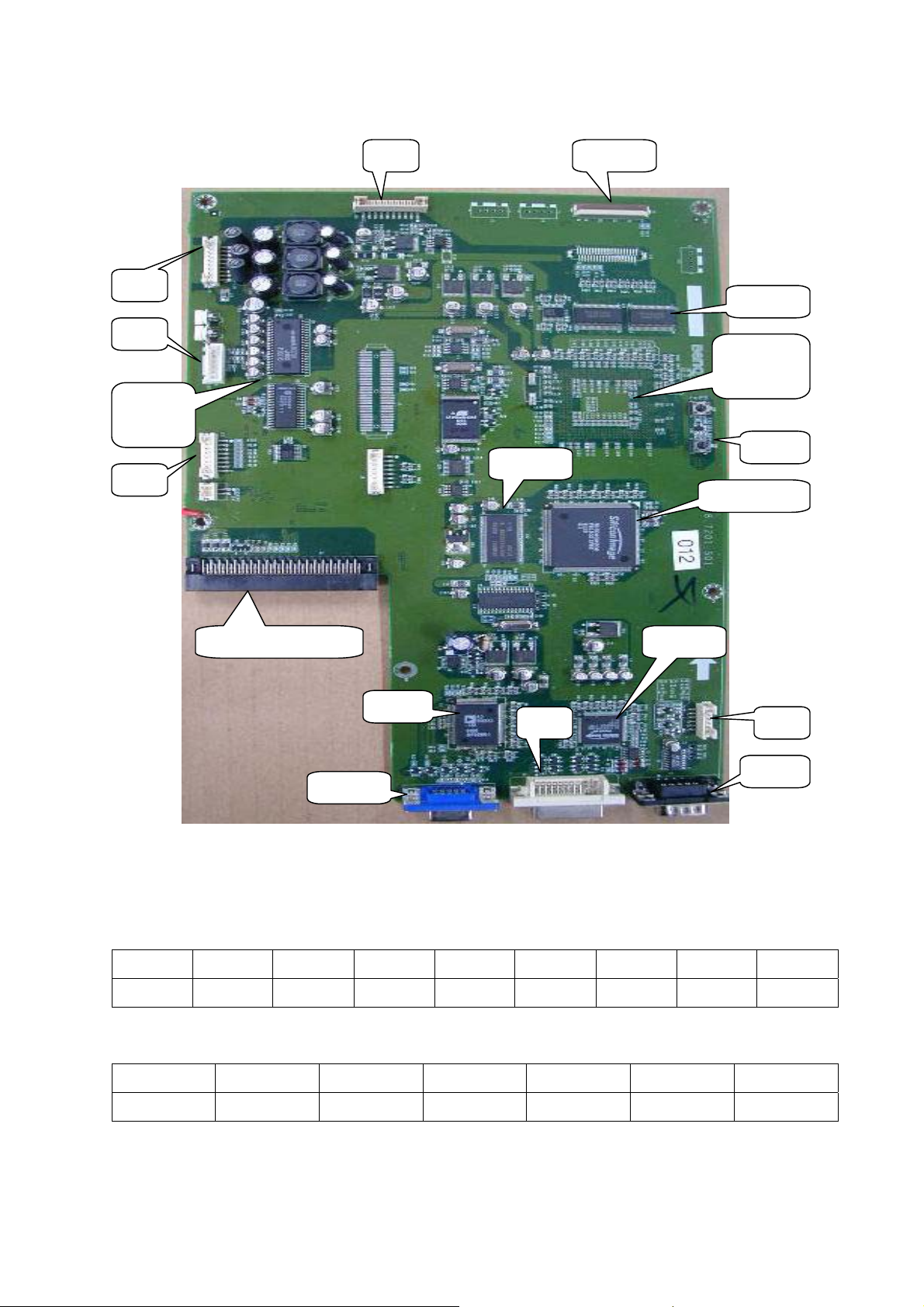

c. VIF Main Board:

J16

To DIF

J15

SDRAM

J17

Image

Processor

Tone

Control

Reset

SDRAM

J12

De_interlace

To Video/PC Module TMDS

ADC

D-SUB

DVI

2.1.3 Pin assignments of connectors :

a. J12 : Key Pad Signal

NO

ITEM Power Right Left Up Down Menu Input Gnd

b. J11 : Receiver/Indicator Signal

1 2 3 4 5 6 7 8

J11

RS232

NO

ITEM NC Red LED Green LED Gnd Ir_Rcv +5V

1 2 3 4 5 6

19

Page 21

c. J17 : Audio Signal

NO 1 2 3 4 5 6

ITEM Mute L_Out L_Gnd R_Out R_Gnd

SPK

Int/Ext

d. J16 : Power –Control Signal

NO 1 2 3 4 5 6 7 8 9 10

+5V

ITEM

LV ON NC HV ON NC Gnd Fault Pwloss Fan Gnd

Standby

e. J15 : Power –Supply Voltage

NO 1 2 3 4 5 6 7 8 9

ITEM

+9V

Audio

+9V

Audio

GND GND

+5V

VCC

+5V

GND GND

VCC

f. J9:Output – Out to DIF

1/

SCL

2/

SDA

3/

NC

4/

NC

5/

Status

6/

GND

7/

R-00

8/

R-01

+5V

Standby

9/

R-02

10/

R-03

19/

G-02

28/

B-01

37/

GND

11/

GND

20/

G-03

29/

B-02

38/

H-sync

12/

R-04

21/

GND

30/

B-03

39/

GND

13/

R-05

22/

G-04

31/

GND

40/

V-sync

14/

R-06

23/

G-05

32/

B-04

41/

GND

15/

R-07

24/

G-06

33/

B-05

42/

Blanking

16/

GND

25/

G-07

34/

B-06

43/

GND

17/

G-00

26/

GND

35/

B-07

44/

PixelCLK

18/

G-01

27/

B-00

36/

GND

45/

GND

2.1.4 VIF (Video interface) :

a. When main switch is ON , the power board generates Vsby 5 volts to VIF board. The IC of

microprocessor become standby status waiting for a startup signal from key-pad or receiver.

b. When a startup signal is detected then microprocessor sending a ON signal to the power board

through CN connector , and the power board begins generating all voltage to PCB board(Vs ,

Vxg , Vw , Vf , Vdd , Vcc , 9volts) . At the same time VIF will generate background light and

OSD menu as select .After searching a input source , then will display on the PDP screen , if

there are audio signals , it will amplify and send to speakers through audio board.

c. If there are abnormal signals are detected(such as over voltage , over current , low voltage ..) , the

power board will send abnormal detective signal to shut down all the system.

20

Page 22

2.1.5 System Block diagram :

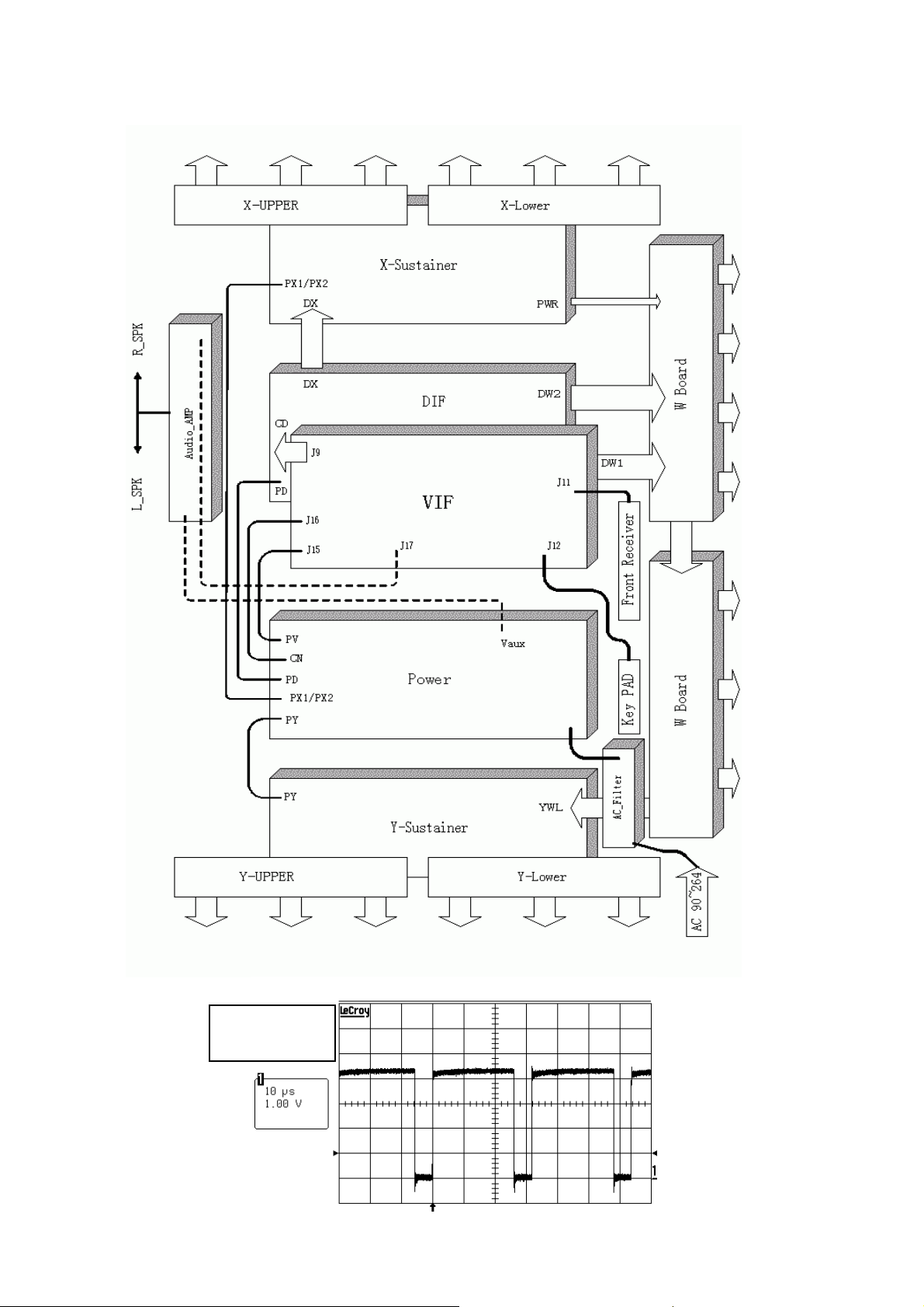

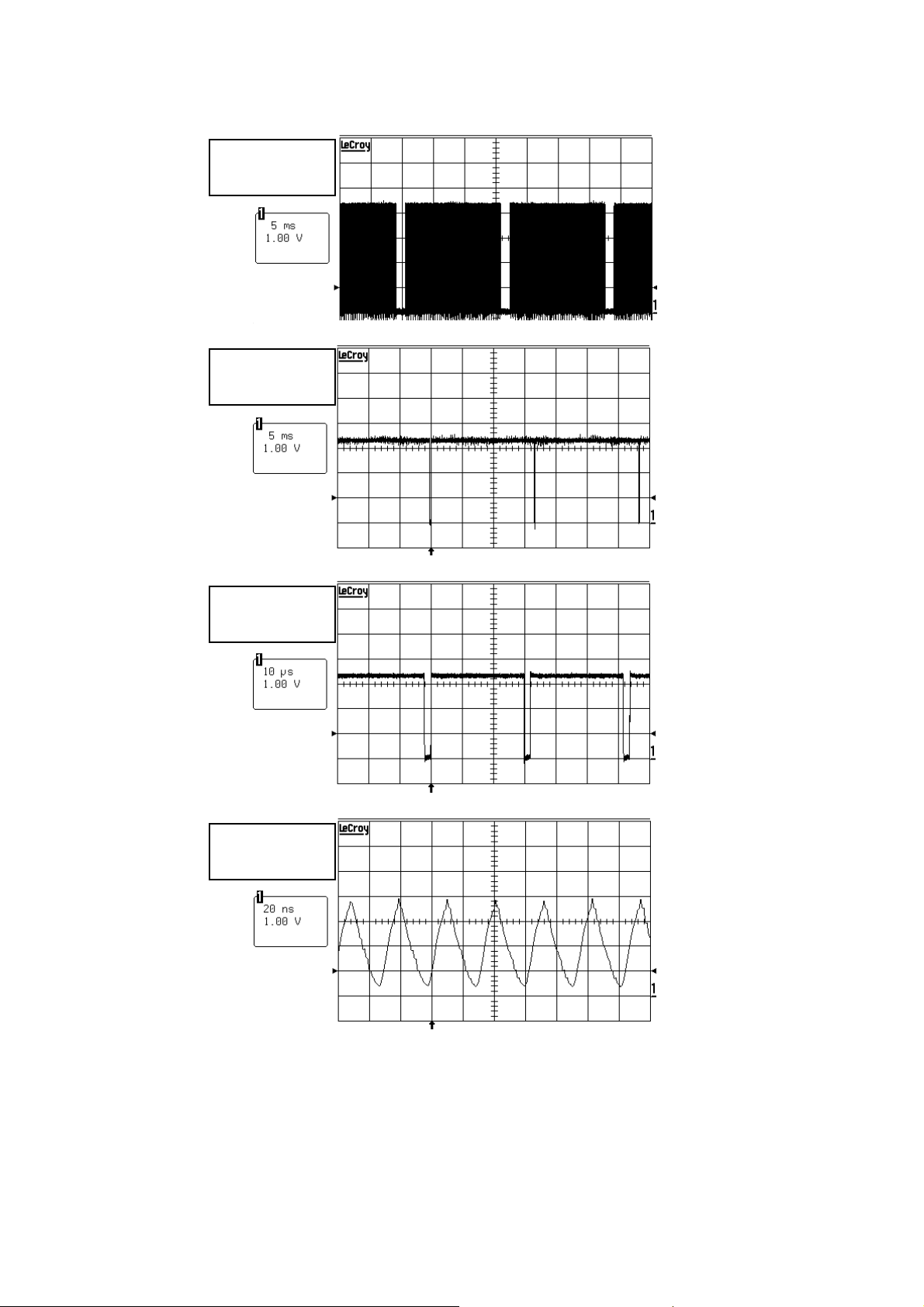

2.1.6 Some Waveforms:

J9_42 TP155

Blanking

21

Page 23

J9_42 TP155

Blanking

J9_40 TP154

Vsync

J9_38 TP152

Hsync

J9_44 TP156

PixelClock

22

Page 24

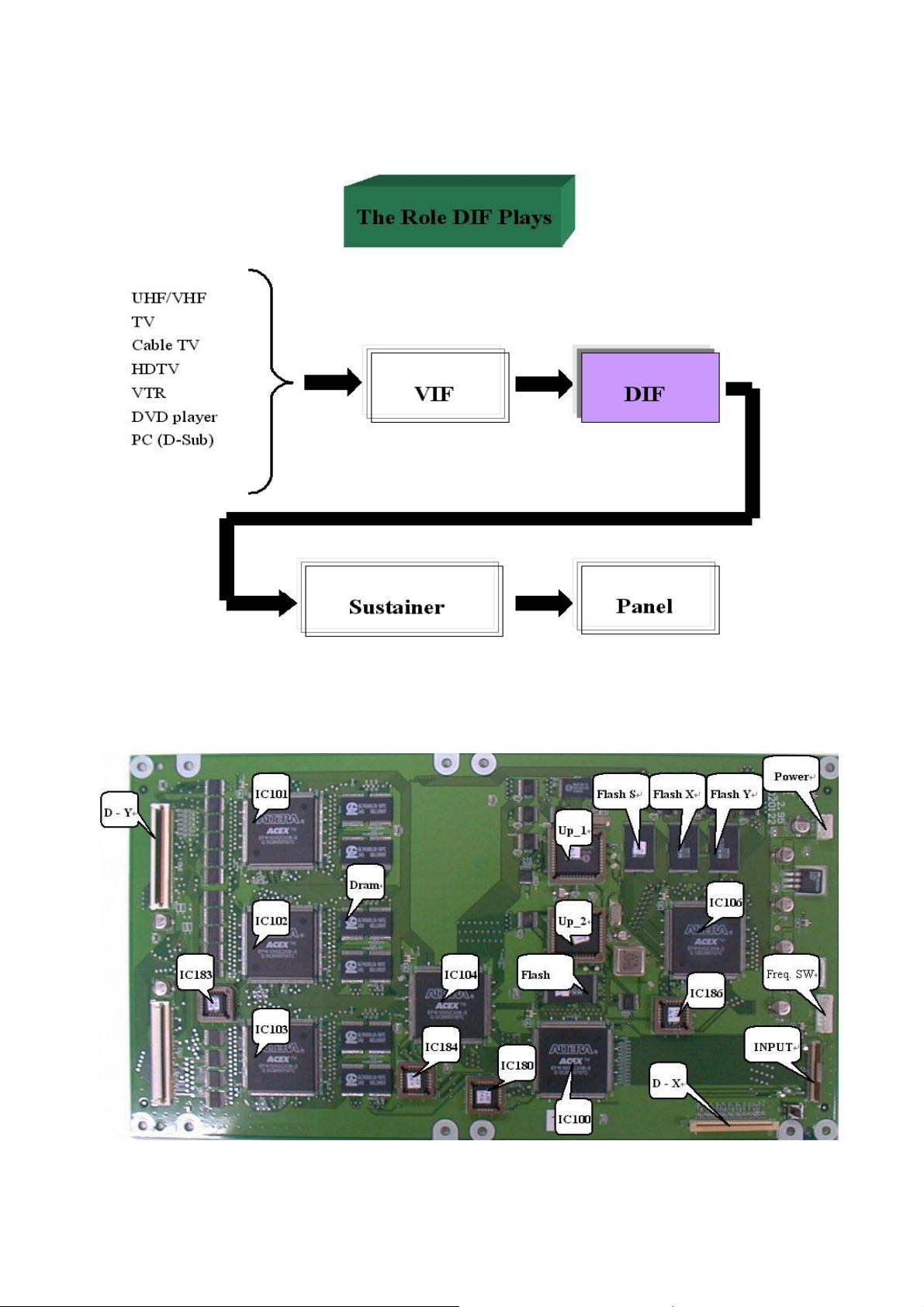

2.2. DIF board:

2.2.1 DIF 2.95 board:

DIF 2.95 board :

Fig. 1 The role of DIF board

Fig.2 The photo of a DIF board

23

Page 25

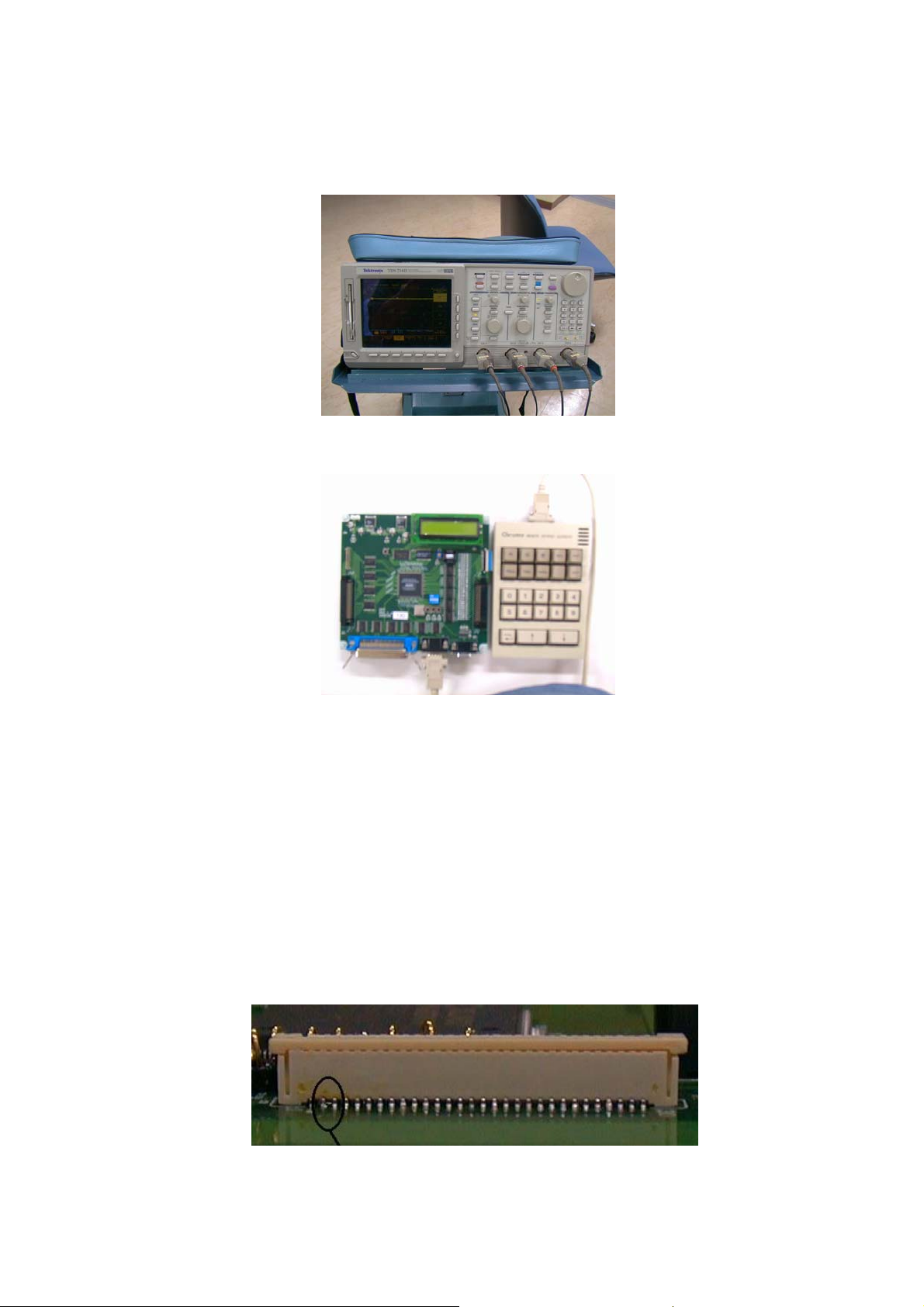

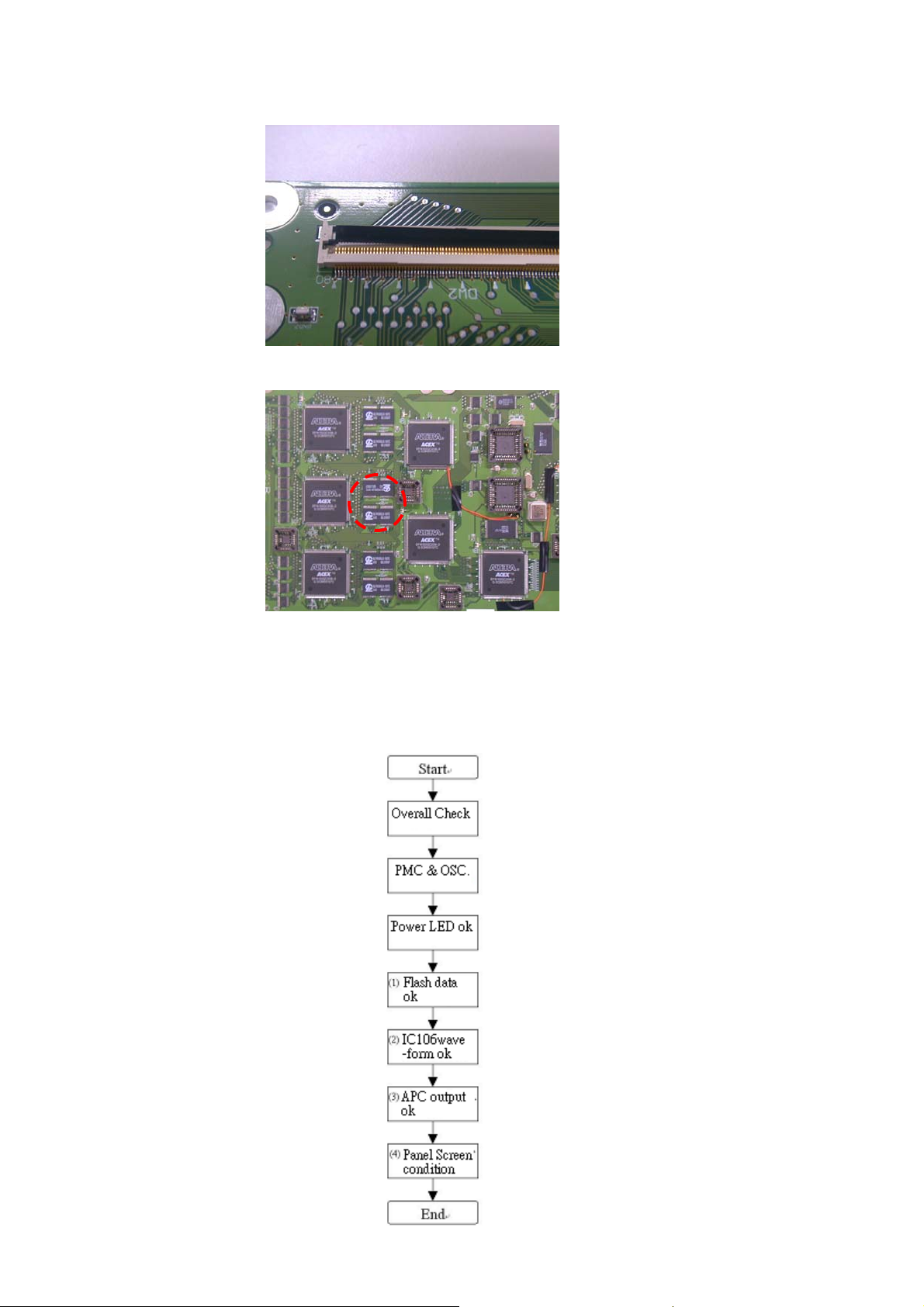

2.2.2 Equipments:

a. Power : 5V 3A power supply * 1

b Tools:

b-1 Oscilloscope

b-2 PMC

Fig. 3 Oscilloscope with 4 channels

b-3 45 pin FFC connector * 1

b-4 Multi-meter * 1

c. Test flow

c-1 Overall check:

To inspect the DIF board whether broken board occurred , components broken or short

circuit…. etc .

Ex:

(1)

Fig.4 PMC * 1

Fig. 5 Connector short circuit

24

Page 26

(2)

Fig.5 D to W connector broken

(3)

c-2 Power test:

Make sure that the power is normal without any short circuit happening.

2.2.3 Simple electric circuit test:

Checking all functions of the board is normal.

Test flow as Fig.7 shown.

Fig.6 Wrong DRAM

Fig.7 Test flow

25

Page 27

** LED : When DIF power on , the LED light on means that the FPGA download OK , at this time the

p

current will be about 1.3A .

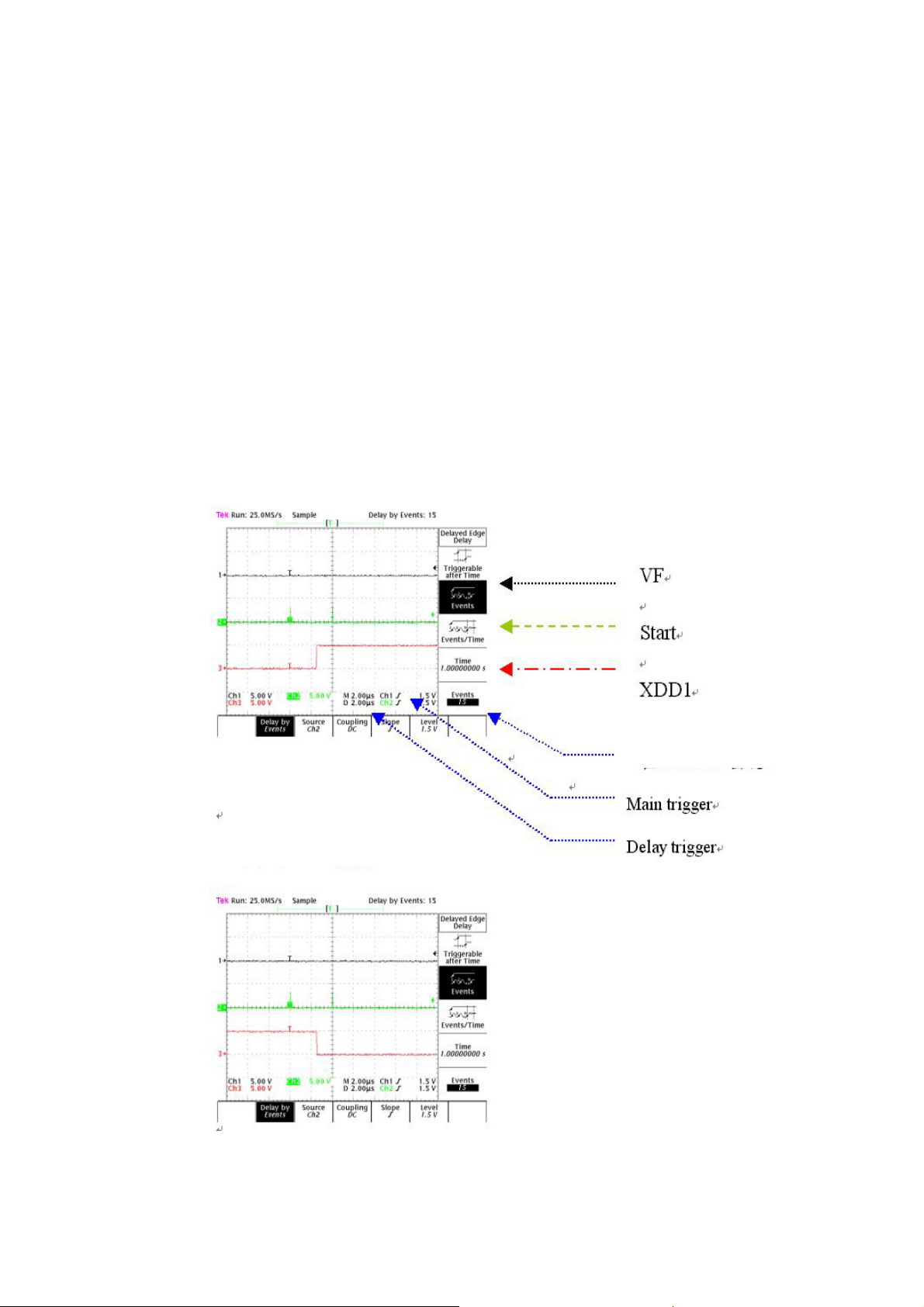

a. Waveform testing :

a-1 Make sure that the waveforms of S , X , Y are normal . Repeat reading the data from IC to

make sure the downloading data is normal.

a-2 The Waveform of IC106 : If the waveforms of S , X , Y are normal. Then we can check

the functions of controlling waveforms of IC106.

a-3 Next procedure is going to check the waveform of V、Start、Wp、Wn、SF0~SF3、Esq.

Check Vf , Vf is signal after processing from V. SF0~SF3 , Esq is the setting time and

ending time of the sub-field .

a-4 Check the output of X and Y :

As Fig. 8 shown. Confirm that the waveform is normal.

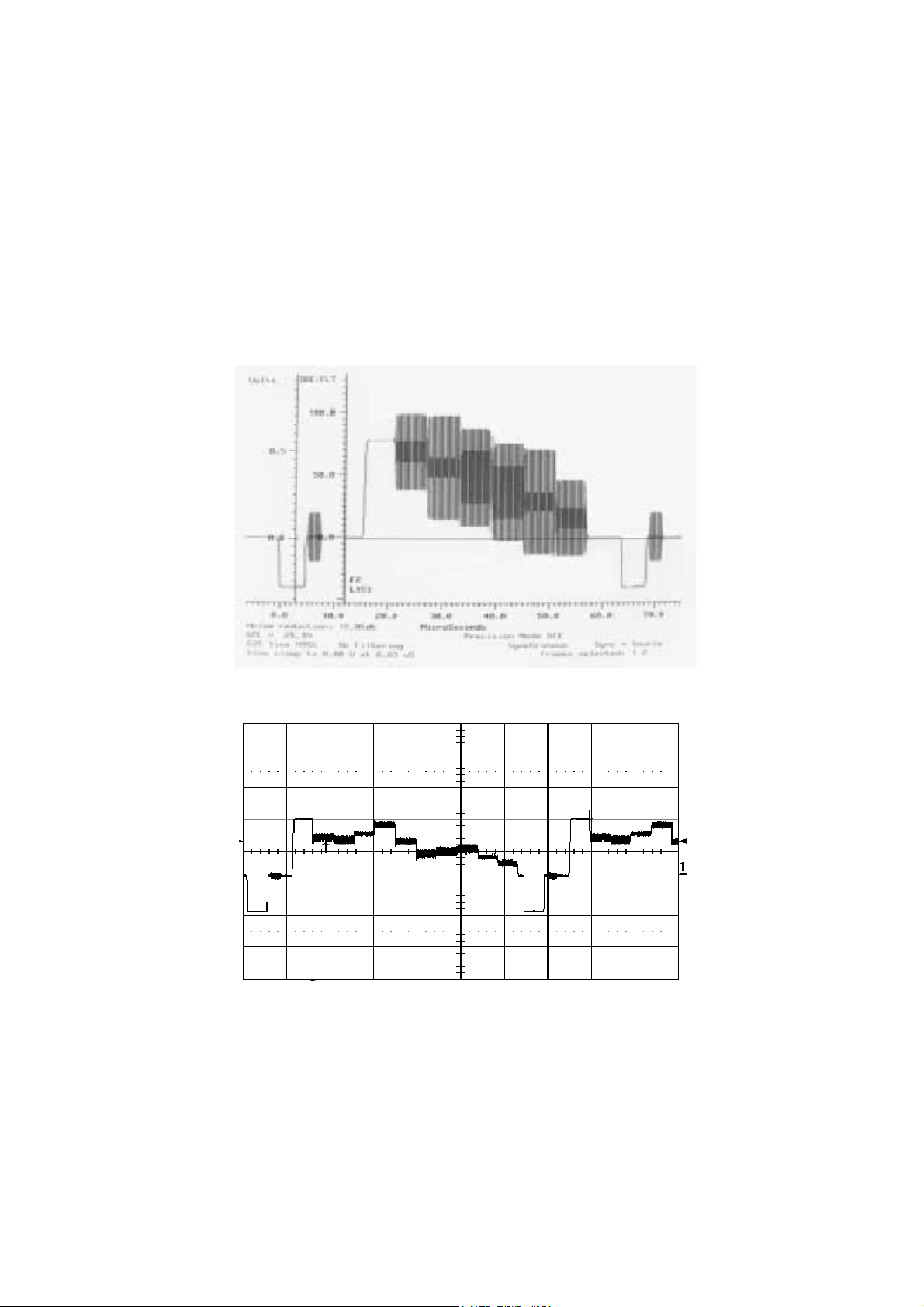

X : DD1 Waveform

X : DD2 Waveform

Event =15 ,means that

ulse shown at block15

Fig.8 X : DD1 and DD2 output waveform

26

Page 28

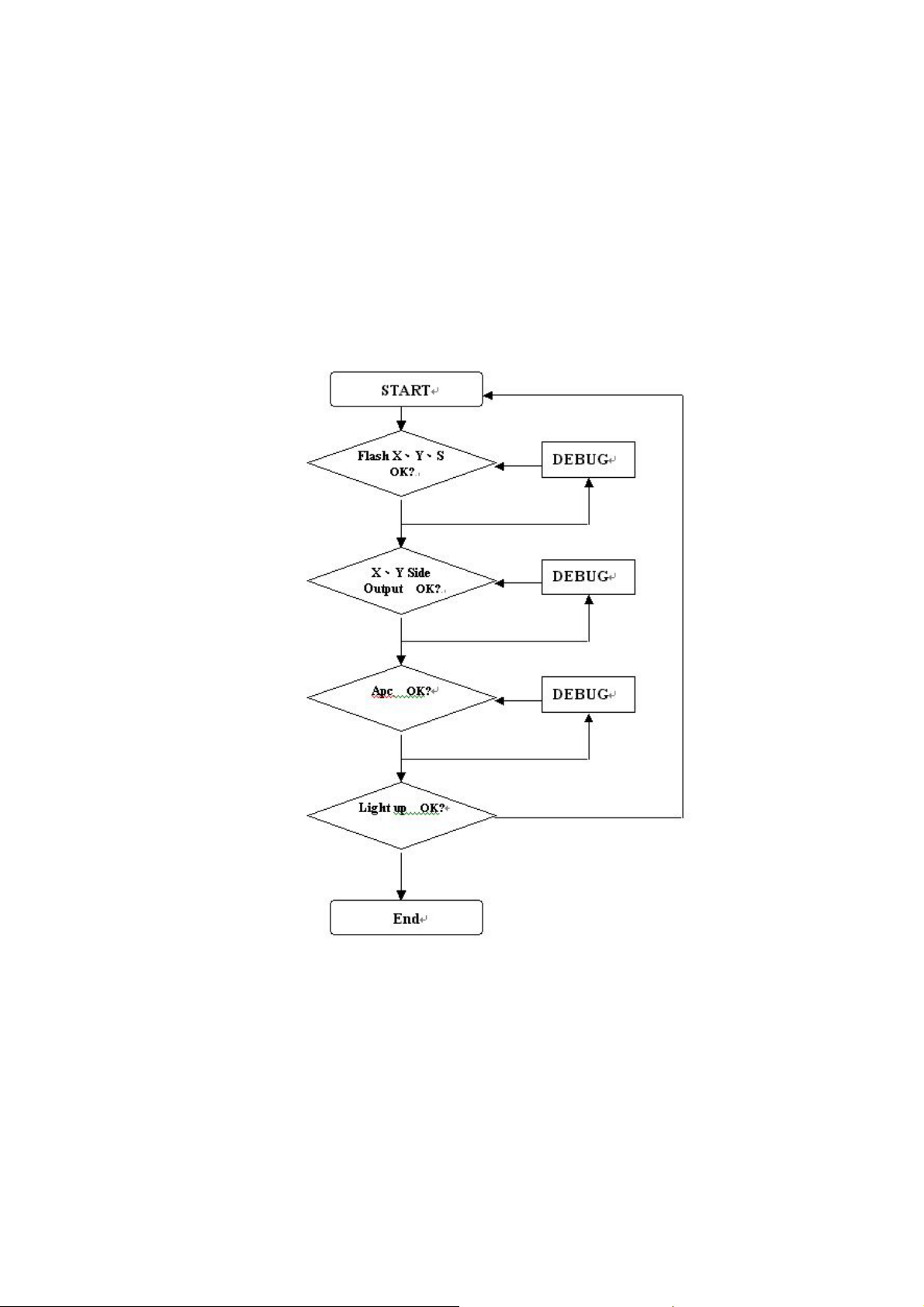

b. Checking the function of APC:

b-1 The data of Adat are normal. Compared with look up table(LUT).

b-2 Checking the power of WAPC , Check the signal of SM and SF0 to make sure the power

WAPC functions OK.

b-3 Check the screen of PDP :

From the screen to check the functions of DIF’s performance is good or not.

c The debug flow chart as Fig.9 shown.

Fig.9 The debug flow chart

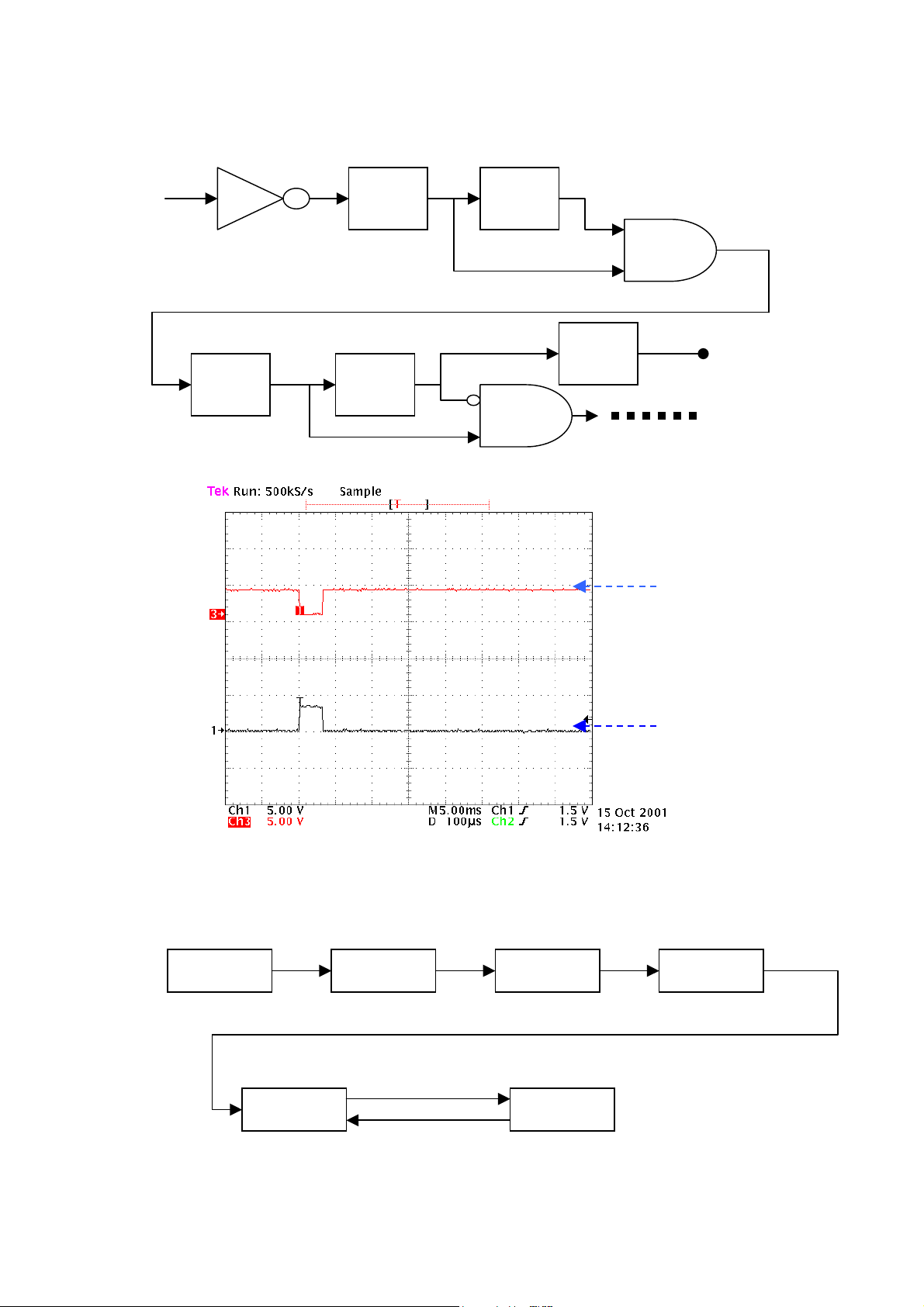

2.2.4 Advanced testing and checking:

The DIF board has three major functions.

a. Image signal process:

a-1 Purpose: To check the functions of image signal process are correct.

As Fig.10 shown ,

27

Page 29

data

buffe

age

source

a

ce

compute

deo

r

vi

Antenna

r

RAM

im

interf

Fig.10 Image signal process

a-2 As Fig.11 Shown , the image signals separated into R , G , B for processing.

Fig.11 Image signal process

a-3 Here we check the input / output signals is correct or not. Compared with the output

and input waveforms of Rx7-Rx0 , Gx7-Gx0 , Bx7-Bx0 are the same or not , and check

the waveforms of Vx , Hx , Blkx , BlkVx , Clkx are normal or not .

a-4 For IC101-103 , IC106 is passing a Wp signal to IC101-103 , as fig.11 image signal

process , IC101-IC103 output signals to panel , so the buffer and extension board ,

connector are checking points too.

a-5 Image process

EX : IC101 –> PANEL Output

IC101

LUT

7-9

8-9

Driver IC

Panel

In IC101 , There are 7 blocks for processing , from system trigging to output signal.

DRAM

28

Page 30

For example ,the process of VF signal as below shown:

V

The real waveform is as below , the length is 60μS.

VF

V

Fig.12 Real waveform

Ex : IC100 –> IC106

μ-com

VF

SRAM IC104 IC100 PMC

IC106

29

Page 31

Ex : Dividing panel into 30*28 , store the data into SRAM.

IC104 not only calculate the block sum , scan sum , total sum but also deal with the

Pattern A , pattern B , pattern judgment of the pattern check. The value of calculation

will be sent to up1 for operation . In the checking of buffer , we only compare the

waveforms between input and output.

b. Waveform controlling :

SRAM

b-1 Purpose : To check the waveform of X , Y is normal or not.

These parts of functions are accomplished by IC 106 to control the sustainer of

Fig.13 Driving signal (Sub-fielb period T Sfi)

X and Y. The controlling waveform is stored in IC170 and IC171 , that’s FlashX

and FlahY , the waveform is as Fig.13 shown.

30

Page 32

b-2 List of signal input

R Red Data Pixel_Red Data

G Green Data Pixel_Green Data

B Blue Data Pixel_Blue Data

CLK Clock dot clock

HD H_sync Horizontal synchronous

VD V_sync Vertical synchronous

BLK Blank blanking-invalid data period

EN Enable display enable

31

Page 33

b-3 Timing spec. – see with video signal input time chart

b-4 Sub-field:

Start End

The real information is:

1-SF 2-SF 3-SF 4-SF 5-SF 6-SF 7-SF 8SF 9-SF

SF0

SF1

SF1

SF2

c. Auto Power Control (APC):

c-1 Purpose : To check the functions of APC are normal or not.

The functions of APC are important to panel ; it may cause power failure or even

panel broken . The processing is as Fig.14 shown:

Fig.14 APC block diagram

32

Page 34

c-2 When signal data send to APC , the Calculate Display Ratio begins to calculate the ratio

of pattern .After checking and calculating pattern(A ,B , C) , the numbers of pattern , then

sending the data of display and switching count to the window memory .

Fig.15 Pattern A , Pattern B , Pattern C (CPT thousand-birds’ pattern)

c-3 The APC is performing mathematical calculations , by reducing the sustain frequency and

closing some sub-fields to accomplish. There is reference for judgment , as Fig.16 and Fig.17

shown . The parameters has been tested by experiments to determine , so if the parameters of

APC are not the optimal parameter , it may cause panel broken , scan IC burned , power supply

failure.

Fig.16 The curve of APC

33

Page 35

Fig.17 The limit of power vs. sustain frequency

c-4 The debug flow chart is as Fig.18 shown.

Fig.18 APC debug flow chart

34

Page 36

c-5 According to the past experiences , most of the errors of APC happened at SRAM and

buffer IC , so these parts will be the checking points.

2.2.5 IC100 - IC106 : Main signals measurement

Purpose : To check the action of FPGA from IC100 to IC106

The waveform is shown as below.

a. Take the Wp waveform as examples:

2. Observe

ch2 signal

1. Trigger

ch3 signal

a-1 Explanation of waveform :

1. Trigger

ch1 signals

2. Observe

ch2 signals

3. trigger

level

4.ch2 waveform

The scanning waveforms look correctly.

35

Page 37

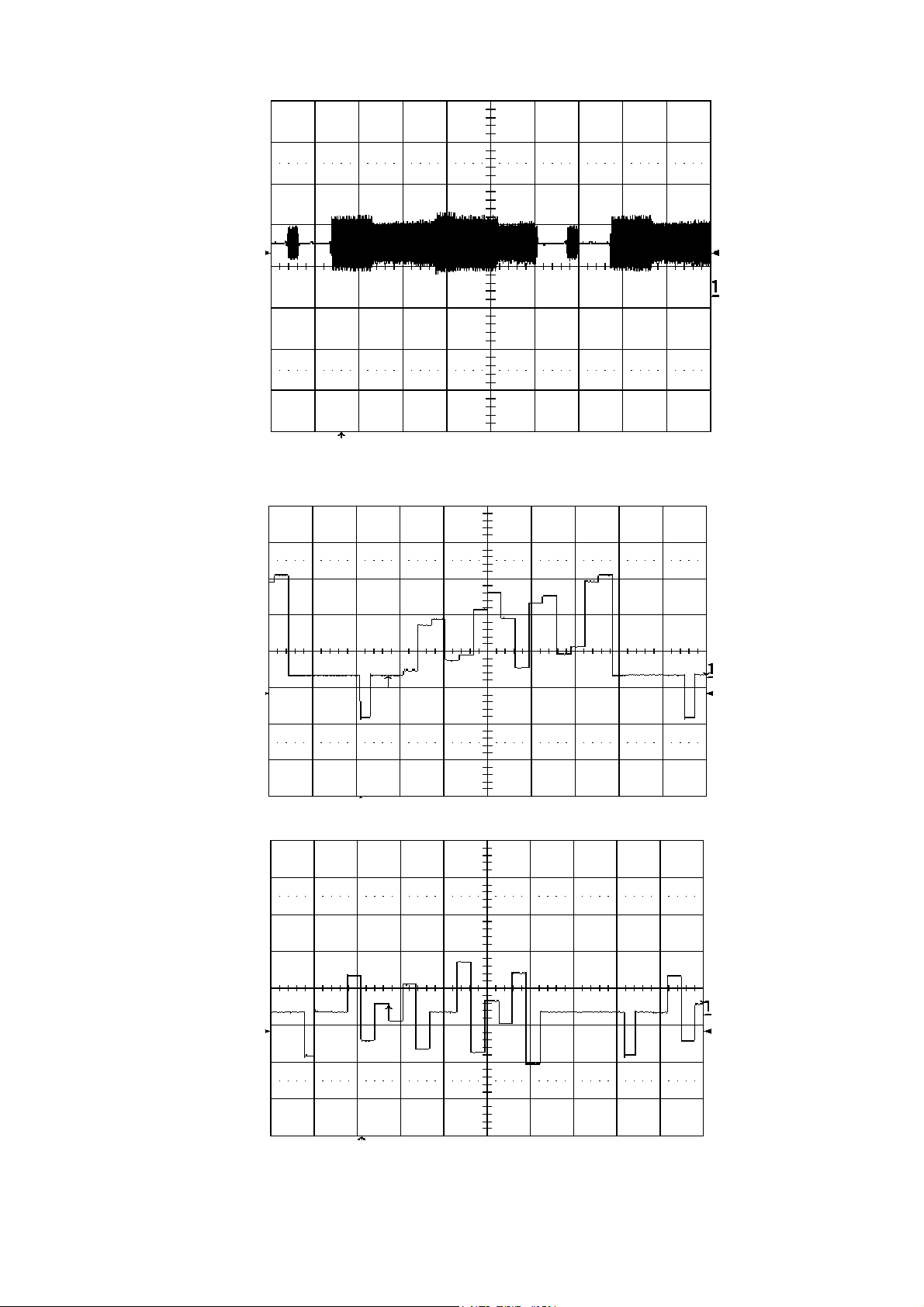

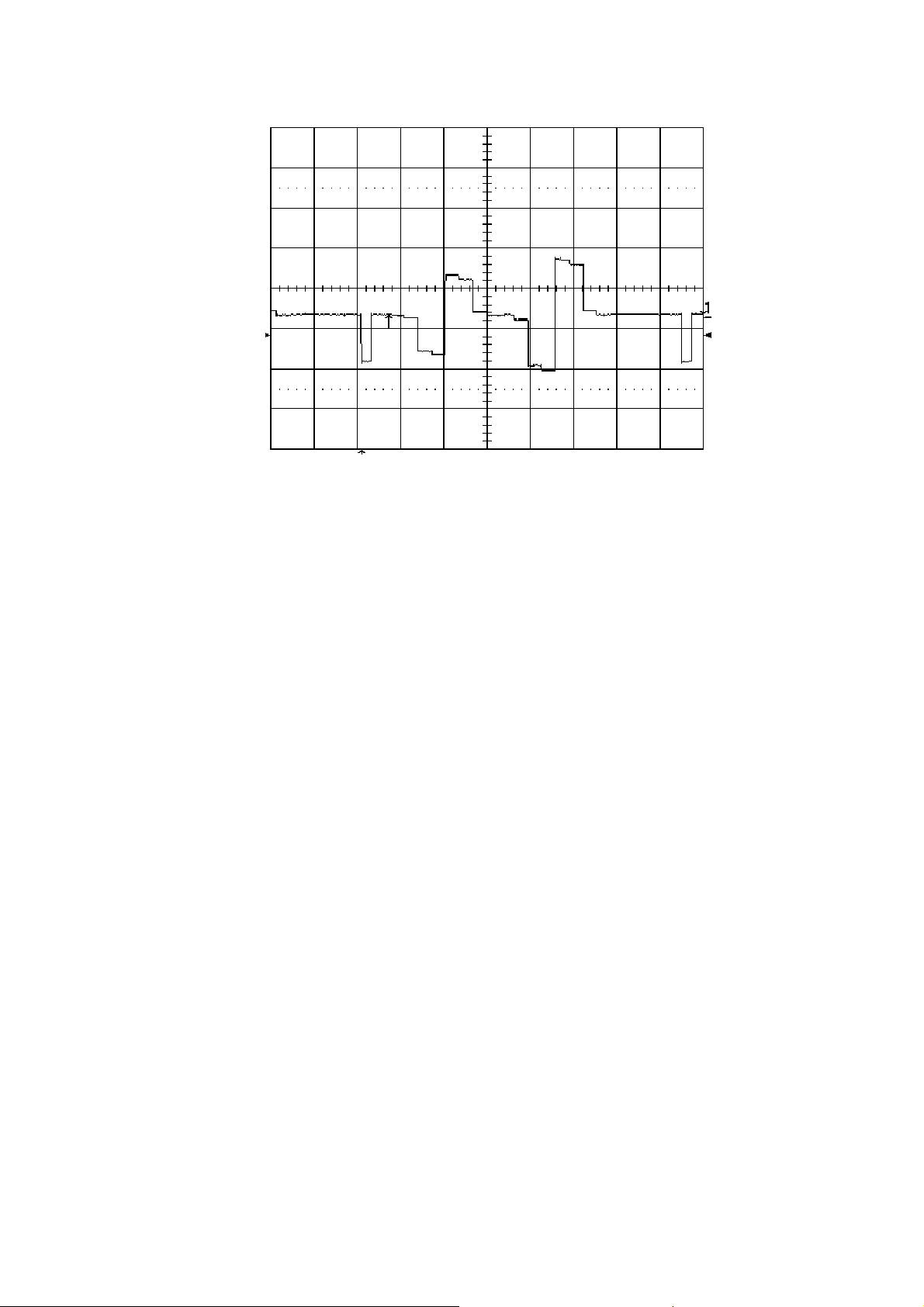

b. The controlling waveforms of IC106 are checking below signals(CH3 trigger V signals):

V、Start、Wp、Wn、SF0~SF3、Esq

Test Pattern=Random

Main

signal

1

Singal

Name

V

P41(V

Remark

)

D

Make sure the DIF input signal of V signal is correct , and is the

trigger signals.

2

Wp

TP121

(Wp)

36

Page 38

3

Wn

TP123

(Wn)

4

5

SF0

SF1

TP126

(SF0)

TP127

(SF1)

37

Page 39

6

SF2

TP128

(SF2)

7

8

SF3

Esq

TP129

(SF3)

TP125

(ESQ)

38

Page 40

c. Checking the outputs of X and Y sustainer board

Make sure the waveform of X/Y are correct , the reference waveforms as below

( CH3 trigger V signals)

Test Pattern=random

IC106_Signal List

X

-side

1

Signal

Name

XSI1

Pin No

TP143

2

XTSC

TP141

39

Page 41

3

XSTB

TP142

4

5

XLE

XSI2

TP144

TP145

40

Page 42

6

XCLK

TP146

7

8

XNEH

XNEL

TP147

TP148

41

Page 43

9

XEFH

TP149

10

11

XEFL

XAEH

TP150

TP151

42

Page 44

12

XAEL

TP152

13

14

XSU

XG1H

TP133

TP134

43

Page 45

15

XG1L

TP135

16

17

XG3L

XG2L

TP136

TP137

44

Page 46

18

XP2L

TP138

19

20

XDD1

XDD2

TP139

TP140

45

Page 47

Y

-side

1

YSC2A J7-PIN2

YSC1A J7-PIN3

2

YNELA J7-PIN5

3

46

Page 48

YNEHA J7-PIN6

4

YEFLA J7-PIN8

5

6

YEFHA

J7-PIN9

47

Page 49

YSC2B J7-PIN11

7

YSC1B J7-PIN12

8

YNELB J7-PIN14

9

48

Page 50

YNEHB J7-PIN15

10

YEFLB J7-PIN17

11

YEFHB

12

J7-PIN18

49

Page 51

d. The function of APC checking, reference waveform as below (Aclk is trigger signals,Adata is

checking signals)

Test Pattern=Pattern A

Pin

Signal Name

Adata&

1

Aclk

No

TP21

&

TP24

( Complete thousands_birds )

Checking point

1-a

50

Page 52

1-b

1-c

2 SM&W

P

TP130

&

TP121

51

Page 53

e. IC100

Make sure the waveforms of IC100 is normal or not.(CH1 trigger V signal)

IC100_Signal List

Test Pattern=Pattern A ( Complete thousands_birds )

1

Singal

Name

Rx7-

Rx0

Pin No

P7-14

Remark

2 Gx7-Gx0

P15-19、

24-26

52

Page 54

3 Bx7

P27-31、

26-38

4 Vx P39

5 Hx P40

53

Page 55

6 BLKx P41

7 CLK 321 P46

8 CLK 324 P47

54

Page 56

9 R7-R0

P111-116、

119-120、

P122、

10 G7-G0

P135-136、

11 B7

125-128、

131-133

139-144

55

Page 57

12 HD P148

13 VD P149

14 BLK c P150

56

Page 58

f. IC101

Make sure the waveforms of IC101 is normal or not.(CH1 trigger V signal)

IC101_Signal List

Test Pattern=Pattern A ( Complete thousands_birds )

Singal

Name

RAD27 P7

1

Pin No Checking point

RACLKa P45

2

RACLKb P46

3

57

Page 59

SF0-SF3 P53-56 Same as (a)

4

5

6

7

WN P57 Same as (a)

WP P58 Same as (a)

BLHR P60

58

Page 60

VFR P62

8

HPR P63

9

10

VPR P64

59

Page 61

11

Rx7 P75

12

13

SM P86

RMBD0 P87

60

Page 62

RMBOE P111

14

RMBWE P112

15

RMBCS1 P113

16

61

Page 63

RMBRS P115

17

RMBA0 P116

18

RMAD0 P132

19

62

Page 64

RMAOE P158

20

RMAWE P159

21

RMACS1 P160

22

63

Page 65

RMARS P162

23

RMAA0 P174

24

25

RFI8 P192

64

Page 66

26

Vx P205

27

BLKx P207

g. IC104

Make sure the waveforms of IC104 is normal or not.(CH1 trigger V signal)

IC104_Signal List

Test Pattern=Pattern A

Singal

Name

( Complete thousands_birds )

Pin No

65

Page 67

1

EW P144

2 CLK324 P183

h. gamma flash and up2

The gamma functions can check with VIF , select the low , medium , high color temperature to see the

changes.

66

Page 68

2.3 POWER Board:

2.3.1 Introduction:

VXG

VF VCCVS

VSB

VW

Explanation :

Input voltage is from AC100V to 240V , frequency 47HZ~63HZ is available.

The maximum input AC voltage range is from 90V to 265V .

2.3.2 Output Power rating :

Voltage Adjustment

Danger ! High Voltage

VAU

Name Peak load

Vsb 5V 0.4A

Vdd 5V 2.0A

Ccc 5V 3.0A

Vau 9V 1.7A

Vfan 12V 0.5A

Vf 15V 0.6A

Vs 170V 290W 50A

Vw 65V 80W 6A

Vxg -160V 0.1A 1A

Vaux 310~380V 65W

Output Max Load

2.3.3 pin assignments of connectors

67

Page 69

a. Connector ; AC IN

Pin-No Name Voltage

1 AC 100~240V AC

2

3 AC 100~240V AC

b. Connector ; PD

Pin-No Name Voltage REMARK

1 Vcc 5V

2 Vcc 5V

3 VccG ( Vcc GND ) LV Ground

4 VccG ( Vcc GND ) LV Ground

c. Connector ; PX1

Pin-No Name Voltage REMARK

1 Vs 175V

2 NC

3 VsG Vs GND HV Ground

4 VwG Vw GND HV Ground

5 Vw 65V

6 Vf 15V

7 VfG (Vf GND) HV Ground

d. Connector ; PX2

Pin-No Name Voltage REMARK

1 Vcc 5V

2 VccG ( Vcc GND ) LV Ground

3 VxgG ( Vxg GND ) HV Ground

4 NC

5 Vxg -160V

e. Connector ; PY

Pin-No Name Voltage REMARK

1 Vs 175V

2 NC

3 VsG (Vs GND) HV Ground

4 VwG (Vw GND) HV Ground

68

Page 70

5 Vw 65V

6 Vf 15V

7 VfG (Vf GND) LV Ground

8 Vcc 5V

9 VccG (Vcc VGND) LV Ground

f. Connector ; Vaux

Pin-No Name Voltage

1 Vaux DC( + ) 300~380V ( primary)

2

3

VauxG DC( 一 )

Vaux G ( primary )

g. Connector ; PW

Pin-No Name Voltage REMARK

1 Vw 65V

2 Vw 65V

3 NC

4 VwG ( Vw GND) HV Ground

5 VwG (Vw GND) HV Ground

6 Vcc 5V

7 VccG (Vcc GND) LV Ground

h. Connector ; PV

Pin-No Name Voltage REMARK

1 Vau 9V

2 Vau 9V

3 VauG VIF GND VIF Ground

4 VauG VIF GND VIF Ground

5 Vdd 5V

6 Vdd 5V

7 VddG VIF GND VIF Ground

8 VsbG VIF GND VIF Ground

9 Vsb 5V 0.4A

i. Connector ; OH

Pin-No Name Voltage REMARK

1 OH Dry Contact

2 COM OH GND Connect to VccG

69

Page 71

j. Connector ; FAN1 FAN2

Pin-No Name Voltage REMARK

1 Vfan 12V

2 Fan_STS Fan Status

3 VfanG 12V GND FAN Ground

k. Connector ; CN

Pin-No Name Voltage REMARK

1 Vsb +5V Input Signal Voltage

2 VCC__ON 0V/OPEN Input Signal (O.C.)

3 Reserved

4 HV_ON 0V/OPEN Input Signal (O.C.)

5 Reserved

6 Vsb GND VGND VIF Ground

7 FLT 0V/OPEN Output Signal (O.C.)

8 PWRLOSS 0V/OPEN Output Signal (O.C.)

9 FAN _OK 0V/OPEN Output Signal (O.C.)

10 Vsb GND Vsb GND VIF Ground

2.3.4. Troubleshooting

a. Plug out CN connector but no Vsb voltage : Replace IC101 0254(TNY264P).

b. Vaux not enough 300~380 voltage : Replace IC001 FA5332 ; Q003 K2698 ; Q004 K2698 ;

R028 100Ω ; R030 100Ω.

c. Vcc , Vdd no 5 voltages : Replace IC201 M51995 ; Q201 K2717 ; R201 0.22Ω

3W.

d. Vw no 65 voltage : Replace IC301 M51995 ; Q301 K2717 ; R301 0.18Ω 3W.

e. Vs no 175 voltage : Replace IC501 M51995 ; Q501 K2607 ; Q502 K2607 ;

R511 0.22Ω 3W ; R512 0.22Ω 3W.

f.Vxg no –165 voltage : Replace Q703 K2638 ( Under Vs is normal )

g. The adjustment of all voltage : VR

5V…..…….1A…….….VR151 5V……..…5A…….…...VR253

15V…..…0.5A…..……VR251 9V……...1.7A…………VR252

65V……..1.7A………..VR351 175V……...2.5A…………VR551

160V…….0.1A……….VR751

70

Page 72

2.4 X-Sustainer board:

2.4.1 X-Sustainer board’s pin alignment :

a. Input Vlotage

Name Input Voltage Current(mA) Remark

Vcc 5 240

Vf 15

Vs 170 1.2A Normal 1.0~1.5A

Vxg -160 40

Vw 65 40

Vs 170 1.2A Normal 1.0~1.5A

Vxg -160 40

Vw 65 40

b. Photo of X sustainer :

J7:(VXDD-VXG)70

J3: W-side

70(全白)

R407: J7 VR

Normal 40~150mA

J6:(VXE-GND)60V

R417: J6 VR

J1:X-side

PX2:VXG,VCC input

J302:X-side

PX1:VF,VW,VS input

J301:X-side

output

c. Input signals: DIF-X sustainer 30 lead 5V TTL signal

71

Page 73

d. Output signal :

d-1 Output to PDP

Above figure shows the waveform from X and Y extension board(TP301~TP308)

; Green line is the X-side output and Red line is the Y-side output.

d-2 Output to W-extension board :

Vw 65V DC

2.4.2 X-side function explanation :

Low voltage and High voltage

There are two kinds of low voltages : 5V and 15V . They are used to provide the input

signals of driving waveform .

5V signal : Providing the power of ICs . The TC4426 and IR2113S(Driver IC) are for

driving MOS FET. IC :MC74244 and HCPL-M611 , provide signals to scan IC.

So the 5V of X sustainer includes the power of driver IC and input signals and DC

5V adapter.

15V signal : Providing the power of TC4426 and IR2113S , the input signals of 5V

switching to 15V to drive the signal of MOS. So we can check the 15V

only at the output of driver IC and the input of MOSFET(VG).

65 Voltage : The voltage of Vxe(Vw) at X-side is 65 voltage .There are two groups of

circuit: one generates 65V to get the waveform of NAMARI , the other

provide 65V for COF of W-side .

The 65V of Vysc of Y-side generates 35V at the address period of bulk-side.

High voltage:170V and -160V belong PDP high drive voltage.

170 Voltage: The control signals of EFH , EFL , NEH , NEL , XSU (170V)are generated

by the MOSFET after MOSFET got a control signal from GATE pin.

72

Page 74

Resister : 820Ω / 3W x 6 pcs . For generating the positive exponential

waveform.

High-speed diode: C16T40F; D104 , D106 , D204 , D206 , D123 , D124

, D125 , D126 , D127….. etc。

-160 Voltage : Using for generating two negative exponential waveforms , the control

signals of XG1L , XG2L , XP2L , XG3L to drive –160V let the MOSFET

to generate waveforms.

Resister : 390Ω / 3W , 820Ω / 3W . For generating the negative

exponential waveforms.

2.5 Y-Sustainer board:

2.5.1Y-Sustainer pin alignments :

a.Input voltage ::

Name Input Voltage(VDC) Current(mA) Remark

Vcc 5 240

Vf 15 70(Full white) Normal 40~150Ma

Vs 170 1.2A Normal 1.0~1.5A

Vysc 65 8

Vw 65 40

b. Photo of Y sustainer :

J301:Y-side output

to Y- upper

extension board

J1:Y-side input

voltage :Vcc , Vf ,

Vs , Vysc ,Vw

R417: VR

J302: Y-side

output to Y- lower

extension board

J3:W-side 20PIN

signals input

73

Page 75

c. Input signals : DIF-Y sustainer 20 lead 5V TTL signa

d.Output signal :

d-1 Output to PDP

C414:40

V 輸出接

Above figure shows the waveform from X and Y extension board(TP301~TP308)

; Green line is the X-side output and Red line is the Y-side output.

2.5.2 Y-side function explanation :

The driving methods are the same of X and Y . The 5V signals from DIF board through

IR2113 and TC4426 transfer to 15 V to drive MOSFET to generate waveforms.

There are two kinds of low voltages : 5V and 15V . They are used to provide the input

Signals of driving waveform .

5V signal : Providing the power of ICs . The IR2113S(Driver IC) are for driving the

MOS FET of Y-side.

15V signal : Providing the power of TC4426 and IR2113S , the input signals of 5V

switching to 15V to drive the signal of MOS. So we can check the 15V

only at the output of driver IC and the input of MOSFET(VG).

65 Voltage :The 65V of Vysc of Y-side generates 35V at the address period of bulk-side.

170 Voltage: The control signals of EFH , EFL , NEH , NEL , XSU (170V)are generated

by the MOSFET after MOSFET got a control signal from GATE pin.

High-speed diode: C16T40F; D104AB , D106AB , D204AB , D206AB

74

Page 76

3. PDP repairing flow-chart

Q

N

N

N

N

k

3.1 Main flow-chart :

on-warranty

Repair

CPT responsibility

Defective PDP

Judgment

Can not repair

Customer responsibility

Can repair

Repair ?

Warranty ?

What’s wrong

on-warranty

ot repair

Panel screen

defect

Replace Module

Power failure

Disassemble and

Check

Replace PCB

Adjustment

A Test

Repair Center

ext flow

chart

Signal failure

Disassemble and

Chec

Check debug

flow chart

Customer

75

Page 77

3.2 Debug Flow chart : 1 No screen

N

N

N

N

N

N N N N N

N

N

Plug out connector

PV/ CN , Check

CN connector= 5

volts(1+ , 6 - ) ?

Y

Power OK ?

Y

PDP switch ON ?

Y

Stand-By Red light OK

N

AC inlet Fuse burned ?

Open back cover

Power board Fuse burned ?

Y

Replace Fuse

CFM Power cord OK

Turn on power switch

Y

Replace Fuse

Y

Y

Replace VIF board

Replace power board

Plug out PX1,PX2,PY one by

one to check X /Y board OK?

Check the signals from

DIF to X,Y,W board ?

Check CN connector= 5 volts(1+ , 6 - ) ?

Y

Voltage = 4.9V ~5.3V ?

Y

Check PD connector= 5 volts(1+ , 4 - ) ,Power on

to check voltage = 4.9V~5.3V ?

Y

PD voltage from 5V drops to 0V ?

Y

Plug out the PY,PX1,PX2 one by one and

After power on can not start PD voltage ?

Y

Adj. VR151 make

Voltage = 4.9V ~5.3V

Adj. VR253 make

Voltage = 4.9V ~5.3V

Y

Replace DIF board

76

Page 78

3.3 X sustainer malfunction repairing flow-chart

77

Page 79

78

Page 80

79

Page 81

80

Page 82

81

Page 83

3.4 Y sustainer malfunction repairing flow-chart

82

Page 84

83

Page 85

84

Page 86

85

Page 87

4. Common defect debug:

4.1 Screen dark and flickering :

a. Phenomenon :

b. explanation :

b-1 At first figure shown , the second “namari” waveform is dropped under 170 volts , but the

first “ namari “ waveform is normal . It is related to the sequences of switching operations:

AEH , AEL , XSU .

b-2 Checking above waveforms , found that the waveform of XSU from MOSFET is abnormal.

b-3 As the second figure shown , blue curve is the control signal from the input of XSU driver

86

Page 88

IC , green curve is output of 15V driving MOSFET , we have seen that the voltage had

dropped causing the second “namari” waveform don’t work.

b-4 Correction : Replace the IR2113S DRIVER IC .

4.2 170v Limit current

a. Phenomenon :

The voltage can not adjust to 170V .Checking all the input signals are normal , driving Ics

normal , but the MOSFET Q123 has no output , it maybe the failure from XEFH circuits.

b. Explanation :

b-1 The voltage can not adjust above 170 volts , but the negative waveform is normal after

applying the –160 voltage.

b-2 It should be wrong with the sustain pulse generator circuits , from the outputs of MOS ,

found that the Q123 had no output by the IC121 controlling .

b-3 There is signal from driver IC IR2113 , but no Vsg.

b-4 Shut down the power , measuring the D/S pin of Q123 through multi-meter the resister

is only 22 ohms , normal is open , so it was breakdown .(type MOSFET IRFP460A)

b-5 Replace a new MOSFET Q123 ,then OK.

4.3 Some phenomenon of failure PCB boards :

a. DIF: Noise on the screen , no screen。

b. VIF: Missing color , poor color steps , no sound , no screen (OSD OK)

c. POWER: No screen , PCB no power.

d. X-Sustainer: No screen , Color not enough , Screen flickering , When connect to PMC ,

Can not change pattern.

e. Y-Sustainer: Screen dark , but video OK

(DIF+VIF+POW+X-Sus = “screen dark” means DIF+VIF+POW+X-Sus OK)

f. Audio Bard: No sound , power input : DC :300〜380V

g. X-sustainer : No screen .

h. Y-Sustainer : Screen dark .

i. X-extension board abnormal :

dark screen

Bright screen

Bright screen

87

Page 89

j.Y-extension board abnormal:

dark screen Bright screen

5. Debug / Inspection :

5.1 Debug :

5.1.1 X-sustainer board:

a. According to the X-sustainer board debug flow chart , applied the electrical power to check

the condition is normal or not.

b. Using multi-meter to check the J6 connector DC output(Gnd-VXE) is 60 volts or not, if not

then adjust the VR147 to 60 volts.

c. Using multi-meter to check the J7 connector DC output(VXG-VXDD) is 70 volts or not, if not

then adjust the VR407 to 70 volts.

d. Check the screen is normal or not; Change pattern to full white and thousands_birds to check

the power is normal or not.

e. After screen lighting for 5 minutes, Check the heat-sink of the MOSFET at the X-sustainer board

, the temperature should be around 50 degree C.

5.1.2 Y-sustainer board:

a. According to the Y-sustainer board debug flow chart , applied the electrical power to check

the condition is normal or not.

b. Using multi-meter to check the J5 connector DC output(VYSC-GND) is 40 volts or not, if not

then adjust the VR147 to 40 volts.

c. Check the screen is normal or not; Change pattern to full white and thousands_birds to check

the power is normal or not.

d. After screen lighting for 5 minutes, Check the heat-sink of the MOSFET at the X-sustainer board

, the temperature should be around 50 degree C.

5.2 Inspection :

PDP SET inspection items after finishing repair :

Item Classified Inspection item Method Remark

1

2

Appearance Back cover screw shortage Eye view

Appearance Screen Filter scratch Eye view

3

4

5

6

7

Appearance Terminal loosing Eye view

Reliability voltage / frequency variation POWER SUPPLY

Reliability Hi-pot test Hi-pot tester

Reliability AC-INLET hi-pot test Hi-pot tester

Screen Position /Width Eye view

88

Page 90

8

Screen H/V resolution / saturation Eye view

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Screen H/V stability Eye view

Screen Hue / Color Eye view

OSD AUDIO-Mute/ Balance Eye view/remote

OSD INPUT-PC1 / HDTV / AV1 / AV2 Eye view/remote

OSD VIDEO-Color Temp / Gamma Eye view/remote

OSD VIDEO-Brightness / Contrast Eye view/remote

OSD FUNCTION-Information / Default Eye view/remote

OSD DISPLAY-Aspect Ratio / Zoom Eye view/remote

Signal/terminal Factory default / key-pad function Eye view

Signal/terminal PC TIMING/ TUNNER Eye view

Signal/terminal D-sub / DVI Eye view

Signal/terminal AV / S-video Eye view

Signal/terminal VIDEO / Component / PC AUDIO Eye view

Signal/terminal D-SUB/ DVI-I / RS-232 Eye view

characteristic

characteristic

White balance(△x) / (△y) / (△Y) / contrast

Power consumption Power meter

CA-100

89

Page 91

6.BOM list:

6.1 PDP PCB board BOM list :

NO. Item no. Description/specification Remark

1 4359011400 X-SCAN SU ASSY PCB 46"WVGA V00

2 4359021400 X-EXT. U ASSY PCB 46"WVGA V00

3 4359041400 X-EXT. L ASSY PCB 46"WVGA V00

4 4359111400 Y-BULK SU ASSY PCB 46"WVGA V00

5 4359121400 Y-EXT. U ASSY PCB 46"WVGA V00

6 4359141400 Y-EXT. L ASSY PCB 46"WVGA V00

7 4359211400 W-EXT. L ASSY PCB 46"WVGA V00

8 4359221400 W-EXT. R ASSY PCB 46"WVGA V00

9 4359301400 DIF ASSY PCB 46"WVGA V00

10 4322500001 FFC CABLE X-DIF 30L 46"WV-V00

11 4322500002 FFC CABLE Y-WEL 20L 46"WV-V00

12 4322500003 FFC CABLE DIF-WER

13 4322500004 FFC CABLE WEL-WER

14 4313514001 POWER SUPPLY MPF7701

15 4359401401 ASSY PCB PC1 V00

16 4359401402 ASSY PCB PC2 V00

17 4359491401 ASSY PCB VIDEO PW2.5-VD

18 4359441401 ASSY PCB AUDIO

19 4359421401 ASSY PCB REMOTE FRONT PAD

20 4359431101 ASSY PCB KEY PAD

21 4359411401 LINE FILTER ASSY PCB

6.2 BOM: DIF

NO Item No. Part No Assignment Remark

1 4322000007 MC74ACT541DTR2 IC8-IC21 buffer

2 4322403004 FF038OSA1-2000 J3&J5 Connector

3 4322401001 52610-3090 J7 Connector

4 4322403002 FH12-45S-0.5SV J8 Connector

6.3 BOM :Video Module

90

Page 92

NO Item No. Part No Assignment Remark

1 UPD64083GF-3BA 4322090012 U3C

2 49US/20PF/40/+-30ppm 4321500010 Y1B(24.576MHz)

3

4 H354LAI8113 4323201001 FIL1C FIL2C

5 LM1117MPX-2.5V 4322100006 U1C

6 LM1117MPX-3.3V 4322100004 U2C

7 NJM2244M 4322090013 U2D

8 NJM2267M 4322090014 U1D

9 MMBT3904 4321490001

10 MMBT3906 4321490002 Q1C Q3C Q4C Q5C Q7C Q8C Q10C Q12C Q15C

11 SAA7118E/V1 4322200001 U1B

12 49US/20PF/40/+-30ppm 4321500005 Y1C(20MHz)

13 RJ-1078 white stand 4322404004 JP4A

14 RJ-1086 red stand 4322404005 JP3A

15 RJ-1086 yellow stand 4322404006 JP1A

Q1A Q1B Q1D Q2A Q2C Q2D Q3A Q4A Q5A Q6A

Q6C Q7A Q8A Q9A Q9C Q11C Q13C Q14C

16 JY-5042 4322404003 JP2A

6.4 BOM : VIF Main Board

91

Page 93

NO Item No. Part No Assignment Remark

1 MMBT3904 4321490001 Q3 Q7 Q15 Q8 Q10 Q12

2 MMBT3906 4321490002 Q6

3 49USM/20PF/40/+-30ppm 4321500009 Y2,Y3(16.257MHz)

4 49USM/20PF/40/+-30ppm 4321500005 Y1(20MHz)

5 74LCX16374MEAX 4322000013 U22,U24

6 74LCX244MTCX 4322000014 U21,U23

7 74VHC123AMTCX 4322000015 U6

8 NC7SZ126P5X 4322000016 U7 U8

9 74LVX273MTCX 4322000017 U25

10 AD9888KS-140 S-128 4322005005 U3

11 NM24C02M8X 4322007022 U1

12 NM24C16M8X 4322007023 U18

13 SII504CM208 4322090007 U11

14 HY57V64322CT-7 4322800003 U12

15 LM1117-1.8V 4322100005 U13

16 LM1117DTX-3.3 4322100004 U10 U29 U4 U28 U4001 U5 U27

17 LM317M

18 AT49BV8192AT-12TC 4322007024 U15

19 ICS501

20 NJM2700G SOP40 4322090011 U32

21 PIC16C63A-20 4322090010 U33

22 PW171-20U 4322090009 U19

23 LT1381A

24 SII153BCT100 4322090006 U9

25 TEA6320T/V1 4322090008 U31

26 V6300L 4322090003 U20

U16 U17

U30

U2

6.5 BOM:POWER SUPPLY

92

Page 94

NO Item No. Part No Assignment Remark

1 IC 0254 IC 101 TNY264P

2 IC FA5332 IC 001

3 IC M51995 IC 201

4 IC M51995 IC 501

5 2SK 2698 Q003

6 2SK 2717 Q201

7 2SK 2607 Q502

8 2SK 2638 Q703

9 2SK 2607 Q501

10 2SK 2717 Q301

11 0.22-3W R201

12 0.18-3W R301

13 0.22-3W R511

14 0.22-3W R512

15 10-5W R004

16 10-5W R005

17 10-5W R070

18 10-5W R551

19 10-5W R552

20 10-5W R553

21 0.18-3W R024

22 0.183W R025

23 0.18-3W R026

24 PQ30RV11 IC252

25 PQ30RV31 IC253

26 PQ12RD11 IC151

27 TA76431S IC551

28 PC123FY8 PC004………… PC502

29 ICP-N15 ICP201

30 PC017 PC254……… PC735

31 600V.10A YG912S6 D017 D018

6.6 BOM:X sustainer board

93

Page 95

NO Item No. Part No Assignment Remark

1 IR2113S 4322005002 IC121A

2 IR2113S 4322005002 IC121B

3 IR2113S 4322005002 IC231

4 IR2113S 4322005002 IC241

5 TC4426 4321405004 IC101A

6 TC4426 4321405004 IC101B

7 TC4426 4321405004 IC141

8 TC4426 4321405004 IC151

9 TC4426 4321405004 IC171

10 TC4426 4321405004 IC181

11 TC4426 4321405004 IC201A

12 TC4426 4321405004 IC201B

13 HCPL-M611 4322004001 PC31

14 HCPL-M611 4322004001 PC32

15 HCPL-M611 4322004001 PC33

16 HCPL-M611 4322004001 PC34

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

17 HCPL-M611 4322004001 PC35

18 HCPL-M611 4322004001 PC36

19 DC-302R 4322100002 P451

20 HC244 4322003002 IC21

21 HC244 4322003002 IC41

22 2SC2482 4321400002 Q402

23 2SC2482 4321400002 Q403 65V

24 2SC2482 4321400002 Q404 65V

25 2SC2482 4321400002 Q412 65V

26 2SC2482 4321400002 Q413 65V

27 2SC2482 4321400002 Q414 65V

28 2SC4161N 4321400001 Q401 65V

29 2SC4161N 4321400001 Q411 65V

30 2SJ449 4321404001 Q101A 170V

31 2SJ449 4321404001 Q101B 170V

32 2SJ449 4321404001 Q102A 170V

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

65V 元件

33 2SJ449 4321404001 Q102B 170V

34 2SJ449 4321404001 Q151 170V

35 2SJ449 4321404001 Q171 170V

36 2SJ449 4321404001 Q201A 170V

94

Page 96

37 2SJ449 4321404001 Q201B 170V

38 2SJ449 4321404001 Q202A 170V

39 2SJ449 4321404001 Q202B 170V

40 2SK2508 4321405002 Q103A 170V

41 2SK2508 4321405002 Q103B 170V

42 2SK2508 4321405002 Q203A 170V

43 2SK2508 4321405002 Q203B 170V

44 2SK2508 4321405002 Q231 170V

45 2SK2508 4321405002 Q232 170V

46 2SK2508 4321405002 Q234 170V

47 2SK2508 4321405002 Q241 170V

48 CON64-2 4322402001 J301 170V

49 CON64-2 4322402001 J302 170V

50 IRFP460A 4321405004 Q121A 170V

51 IRFP460A 4321405004 Q121B 170V

52 IRFP460A 4321405004 Q122A 170V

53 IRFP460A 4321405004 Q122B 170V

54 IRFP460A 4321405004 Q123A 170V

55 IRFP460A 4321405004 Q123B 170V

56 IRFP460A 4321405004 Q124A 170V

57 IRFP460A 4321405004 Q124B 170V

58 2SK2543 4321405003 Q141 -160V

59 2SK2543 4321405003 Q142 -160V

60 2SK2543 4321405003 Q152 -160V

61 2SK2543 4321405003 Q172 -160V

62 2SK2543 4321405003 Q181 -160V

63 390,3W 4321405003 R148A -160V

64 390,3W 4321405003 R149A -160V

65 820,3W 4320882401 R148B -160V

66 820,3W 4320882401 R149B -160V

67 820,3W 4320882401 R246A -160V

68 820,3W 4320882401 R246B -160V

69 820,3W 4320882401 R247A -160V

70 820,3W 4320882401 R248B -160V

71 820,3W 4320882401 R249A -160V

72 820,3W 4320882401 R248B -160V

95

Page 97

73 39,2W 4320839301 R158 -160V

74 39,2W 4320839301 R159 -160V

75 4.7K,3W 4320839301 R188 -160V

76 4.7K,3W 4320847501 R189 -160V

77 27,1/2W 4320827301 R157 -160V

6.7 BOM:Y sustainer board

NO Item No. Part No Assignment Remark

1 IR2113S 4322005002 IC121A

2 IR2113S 4322005002 IC121B

3 IR2113S 4322005002 IC231

4 IR2113S 4322005002 IC241

5 TC4426 4321405004 IC101A

6 TC4426 4321405004 IC101B

7 TC4426 4321405004 IC141

8 TC4426 4321405004 IC151

9 TC4426 4321405004 IC171

10 TC4426 4321405004 IC181

11 TC4426 IC201A

12 TC4426 4321405004 IC201B

13 2SC2482 4321400002 Q402 65V

14 2SC2482 4321400002 Q403 65V

4321405004

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

Low Volts

15 2SC2482 4321400002 Q404 65V

16 2SC2482 4321400002 Q412 65V

17 2SC2482 4321400002 Q413 65V

18 2SC2482 4321400002 Q414 65V

19 2SC4161N 4321400001 Q401 65V

20 2SC4161N 4321400001 Q411 65V

21 2SJ449 4321404001 Q101A 170V

22 2SJ449 4321404001 Q101B 170V

23 2SJ449 4321404001 Q102A 170V

24 2SJ449 4321404001 Q102B 170V

25 2SJ449 4321404001 Q151 170V

26 2SJ449 4321404001 Q171 170V

27 2SJ449 4321404001 Q201A 170V

28 2SJ449 4321404001 Q201B 170V

29 2SJ449 4321404001 Q202A 170V

96

Page 98

30 2SK2508 4321405002 Q103A 170V

31 2SK2508 4321405002 Q103B 170V

32 2SK2508 4321405002 Q203A 170V

33 2SK2508 4321405002 Q203B 170V

34 2SK2508 4321405002 Q231 170V

35 2SK2508 4321405002 Q232 170V

36 2SK2508 4321405002 Q234 170V

37 2SK2508 4321405002 Q241 170V

38 CON64-2 4322402001 J301 170V

39 CON64-2 4322402001 J302 170V

40 IRFP460A 4321405004 Q121A 170V

41 IRFP460A 4321405004 Q121B 170V

42 IRFP460A 4321405004 Q122A 170V

43 IRFP460A 4321405004 Q122B 170V

44 IRFP460A 4321405004 Q123A 170V

45 IRFP460A 4321405004 Q123B 170V

46 IRFP460A 4321405004 Q124A 170V

47 IRFP460A 4321405004 Q124B 170V

97

Page 99

7.Repair record:

7.1 Record sheet:

Item Repair

date

Defective

description

Repair condition Replace parts Finished

date

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Signature

15

16

17

18

19

20

21

22

23

24

98

Loading...

Loading...