Page 1

Blue-Ray Disc Player

BDP9600/12/51/93/98

Contents

1 Repair Scenario Matrix..................................... 1-1

2 Technical Specification and Connection Facilities

3 Laser Beam Safety Precautions.................................3-1

4 Important Safety Precautions ..........................4-1 to 4-2

5 Safety Check After Servicing .................................... 5-1

6 Safety Information General Notes & Lead Free

Requirements ............................................................6-1

7 Standard Notes For Servicing,Lead Free Requirements

& Handling Flat Pack IC ..................................7-1 to 7-4

8 Direction of Use ...............................................8-1 to 8-5

9 Cabinet Disassembly Instructions ................... 9-1 to 9-3

10 Troubleshooting ....................................................... 10-1

11 Software Version Check &Upgrad..............11-1 to 11-2

12 Repair Service Flow....................................12-1 to 12-5

13 Block Diagram ........................................................13-1

14 Wiring Diagram ...................................................... 14-1

15 Touch Key Board

©

Copyright 2010 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

...................................................2-1 to 2-2

Circuit Diagram .................................15-1

Layout Diagram ................................15-1

Page

/93/51

Page

/98

Contents

16 Output Board

Circuit Diagram .................................15-2

Layout Diagram ................................15-3

17 Power Socket and LED Board

Circuit Diagram .................................15-4

Layout Diagram ................................15-4

18 VFD Display Board

19 MCU Board

20 Decoder Board

21 Power Board

22 Exploded View......................................................16-1 to 16-2

23 Revision List .........................................................17-1

Circuit Diagram ...............................15-5

Layout Diagram ...............................15-6

Circuit Diagram ..............................15-7

Layout Diagram .............................15-8

Block Diagram ................................15-9

Layout Diagram ..............................15-10

Circuit Diagram ..............................15-11

Layout Diagram .............................15-12

Feature

Features

RDS

Voltage Selector

ECO Standby

DTS

Different

/12

Published by RY-KM 1046 AVM Printed in the Netherlands

Version 1.1

Subject to modi cation EN

3139 785 35511

Page 2

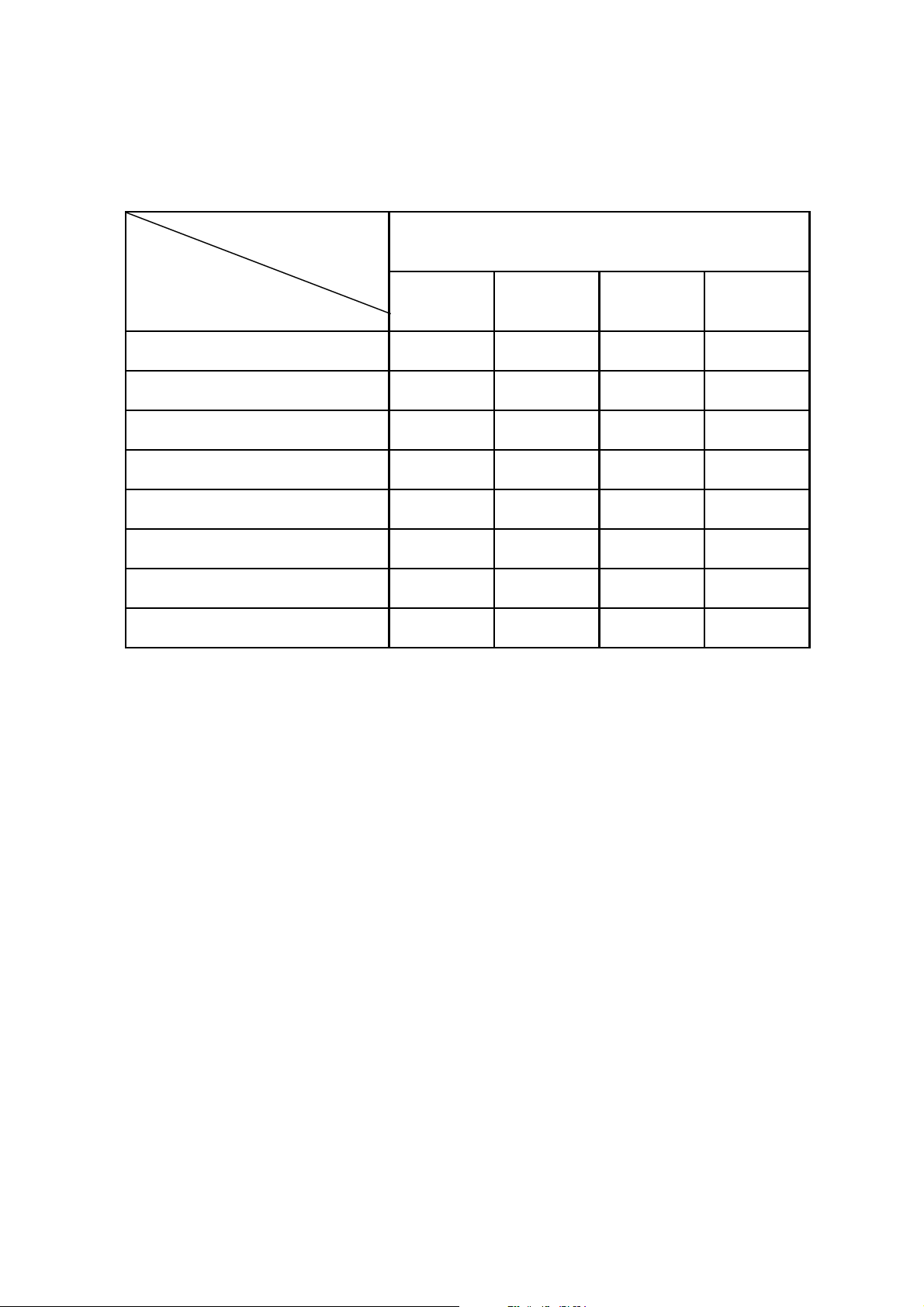

Rapir Scenario Matrix

Type Versions

BDP9600

Boards in Used /12 /51 /93 /98

Touch Key Board C C C C

Power Socket Board C C C C

VFD Display Board C C C C

MCU Board C C C C

LED Board C C C C

Power Board BD BD BD BD

Output Board BD BD BD BD

Decoder Board BD BD BD BD

*C=Component Level Repair

*BD=Board Level Replacement

1-1

Page 3

Technical Specification and Connection Facilities

1. Technical Specification and Connection Facilities

1.1 PCB Locations

Power Board

VFD Display Board

Power Socket Board

Bly-Ray Loader Driver

Output Board

LED Board

Touch Key Board

Decoder Board

WIFI Module

MCU Board

Specifications differences

Type/Versions

Specifications /12 /51 /93 /98

Voltage 230V 230V 110V-240V 110V-240V

Frequency 50Hz 50Hz 50Hz-60Hz 50Hz-60Hz

2-1

BDP9600

Page 4

Technical Specifications and Connection Facilities

1.2 General

Power supply : 110-240V, 50Hz~60Hz

Power consumption : 30W

Standby power consumption : <0.2 W

1.3 Connectivity

CD-DA(PCM)/VideoCD(MPEG-1)

Output Voltage : 2V ± 0.5dB

Signal to Noise Ratio

8QZHLJKWHG G%

$ZHLJKWHG G%

:LWK$XWRPXWH G%

2XWEDQG$WWHQXDWLRQ$ERYHN+]G%

DVD(LPCM / MPEG-2 /Dobly AC-3)

Output Voltage : 2V ± 0.5dB

6LJQDOWR1RLVH5DWLRG%

Outband Attenuation(Above25kHz) :

Digital Audio Outputs

LPCM : accordingIEC 60958-3

MPEG 1, MPEG 2, AC3 : according IEC 61937

DTS : according IEC 61937+

addendum

Coaxial & Optical output

2XWSXWVLJQDO$PSOLWXGHȍWHUPLQDWHU9SS

2XWSXWLPSHGDQFHȍ

DC Output voltageȍWHUPLQDWHU9

Video Supporting Format

Signal system : PAL/NTSC

HDMI output : 480p,576p,720p,1080i,

Video output : 480/576i,480/576p,

CVBS Output Component

Amplitude Output : 1000mVpp ± 10%

White Bar : 714mVpp ± 10%

Sync.Amplitude : 286mVpp ± 10%

S/N Luminunce G%

Chroma/Luminunce Delay(2T pulse) :

DC Level :

Video Output Component

Amplitude Output : 1000mVpp ± 10%

White Bar : 714mVpp ± 10%

Sync.Amplitude : 286mVpp ± 10%

S/N Luminunce G%

DC Level :

USB

Compatibility : USB2.0

Type of connector : Series A Connector

Class support : UMS(USB Mass Storage Class)

File System : FAT12,FAT16,FAT32

HDMI Output

Compatibility : HDMI Version 1.4

Type of connector : Type A Connector(19pins)

-50dB

1080p,1080p24

720p,1080i

20nS

1V

1V

1.4 Dimension and Weight

Set Dimension WxHxD : 435x70x260(mm)

Net Weight : 5.0kg

1.5 Laser Output Power & Wavelength

DVD

Output power : 6mW

Wavelength : 655 +10nm/-10nm

CD

Output power : 7mW

Wavelength : 790 +10nm/-20nm

1.6 Playability

Video Playback

1. Playback Media:

CD-R/CD-RW, DVD+R/+RW,

DVD-R/-RW, DVD-Video, Video

CD/SVCD, DVD+R DL, DVD-R

DL,USB flash drive

2. Compression Formats:

MPEG2, MPEG1, DivX 3.11, DivX

4.x, DivX 5.x, DivX 6.0, MPEG4

Audio Playback

1. Playback Media:

Audio CD, CD-R/RW, DVD+R DL,

DVD+R/+RW, DVD-R/-RW, MP3CD,MP3-DVD,USB flash drive,

WMA-CD

2. Compression Format:

Dolby Digital, MP3, MPEG2

Multichannel, PCM, WMA

3. MPEG1 bit rates: 64-384 kbps

and VBR

Still Picture Playback

1. Playback Media: CD-R/RW,

DVD+R DL, DVD+R/+RW, DVDR/-RW, Picture CD, USB Digital

Camera(PTP),USB flash drive

2. Picture Compression Format:

JPEG, JPEG digital camera

photos

3. Picture enhancement: Slideshow

with MP3 playback, Create

albums, Rotate, Slideshow with

music playback, Zoom

x

x

x

x

x

x

x

x

2-2

Page 5

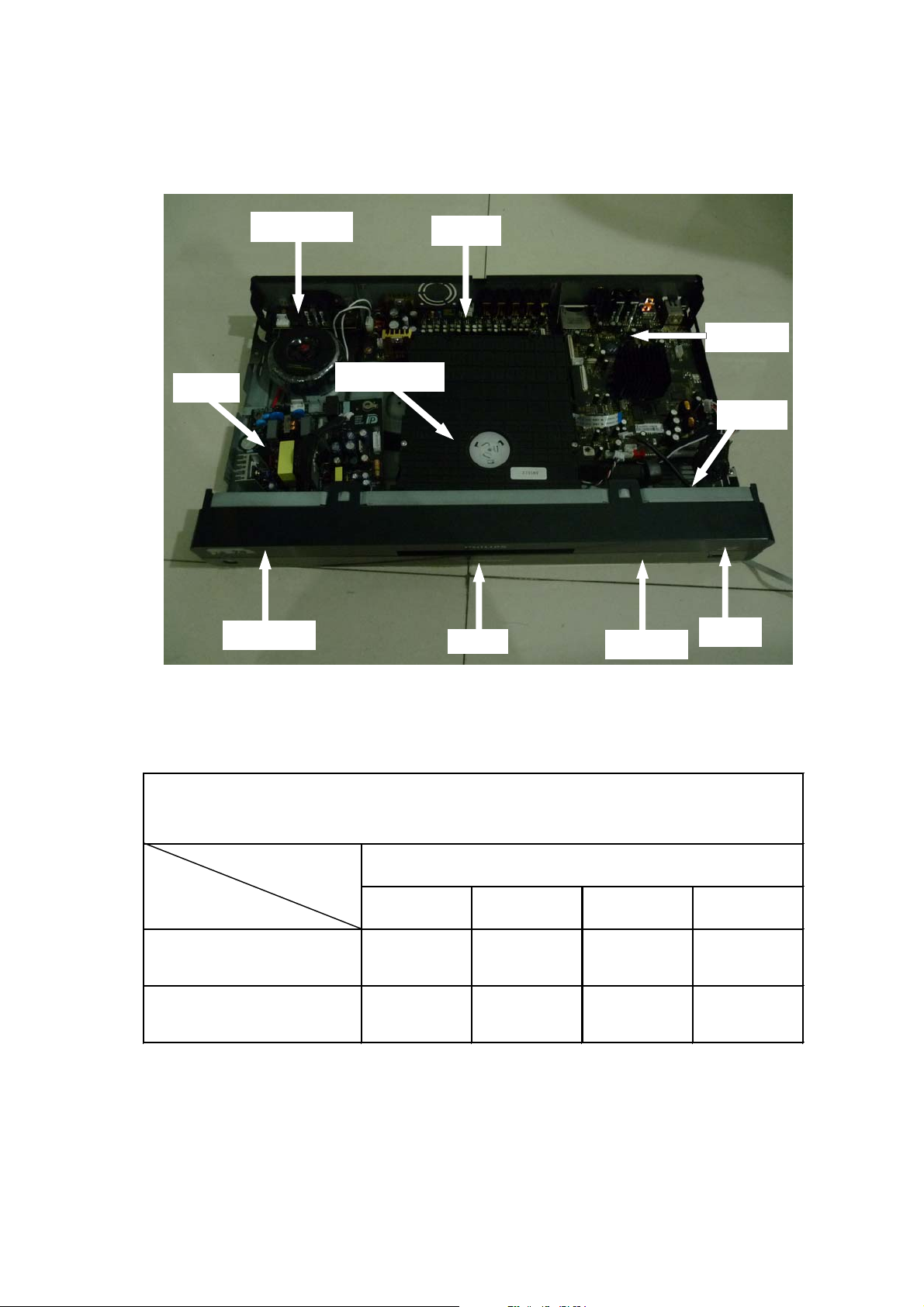

Laser Beam Safety Precautions

This Blu-Ray player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of Blu-Ray mechanism.

3-1

Page 6

Important Safety Precautions

Important

Read and understand all instructions before you use

your home theater. If damage is caused by failure to

follow instructions, the warranty does not apply.

Safety

Riskof electricshockor re!

Neverexposetheproductand

accessories to rain or water. Never place

liquid containers, such as vases, near the

product. If liquids are spilt on or into the

product, disconnect it from the power

outlet immediately. Contact Philips

Consumer Care to have the product

checked before use.

Never place the product and accessories

near naked

including direct sunlight.

Neverinsertobjectsintotheventilation

slots

or other openings on the product.

Wherethemainsplugoranappliance

coupler is used as the disconnect device,

the disconnect device shall remain readily

operable.

Disconnect the product from the power

outlet before lightning storms.

Whenyoudisconnectthepowercord,

always pull the plug, never the cable.

Riskof short circuit or

Before you connect the product to the

poweroutlet,ensurethatthepower

voltage matches the value printed on the

back or bottom of the product. Never

connec

if the voltage is different.

Risk of injury or damage to the home theater!

For wall-mountable products, use only

the supplied wall mount bracket. Secure

the wall mount to a wall that can support

the combined weight of the product

and the wall mount. Koninklijke Philips

Electronics N.V. bears no responsibility

for improper wall mounting that results in

accident,injuryordamage.

ames or other heat sources,

re!

ttheproducttothepoweroutlet

For speakers with stands, use only the

supplied stands. Secure the stands to

the speakers tightly. Place the assembled

stands on

support the combined weight of the

speaker and stand.

Never place the product or any objects

on power cords or on other electrical

equipment.

If the product is transported in

temperatures below 5°C, unpack the

product and wait u

matches room temperature before

connecting it to the power outlet.

Visible and invisible laser radiation when

open. Avoid exposure to beam.

Do not touch the disc optical lens inside

the disc compartment.

Risk of overheating!

Never install this product in a con

space. Always leave a space of at least

four inches around the product for

ventilation. Ensure curtains or other

objects never cover the ventilation slots

on the product.

Risk of contamination!

Do not mix batteries (old and new or

carbon and alkaline,

Remove batteries if they are exhausted

oriftheremotecontrolisnottobeused

for a long time.

Batteries contain chemical substances,

they should be disposed of properly.

t,levelsurfacesthatcan

ntil its temperature

etc.).

Product care

Do not insert any objects other than discs

into the disc compartment.

Donotinsertwarpedorcrackeddiscs

intothedisccompartme

Remove discs from the disc compartment

ifyouarenotusingtheproductforan

extended period of time.

Only use microfiber cloth to clean the

product.

nt.

ned

4-1

Page 7

Important Safety Precautions

Disposal of your old product and

batteries

Your product is designed and manufactured

with high quality materials and components,

which can be recycled and reused.

When this crossed-out wheeled bin symbol

is attached to a product it means that the

product is covered by the European Directive

2002/96/EC.Pleaseinformyourselfaboutthe

local separate collection system for electrical

and electronic products.

Please act according to your local rules and

do not dispose of your old products with your

normal household waste.

Corr

ect disposal of your old product helps to

prevent pote

the environment and human health.

ntial negative consequences for

Your product contains batteries covered by

the European Directive 2006/66/EC, which

cannot be disposed with normal household

waste.

Please inform yourself about the local rules

on separate collection of batteries because

correct disposal helps to prevent negative

consequences for the environmental and

human health.

4-2

Page 8

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

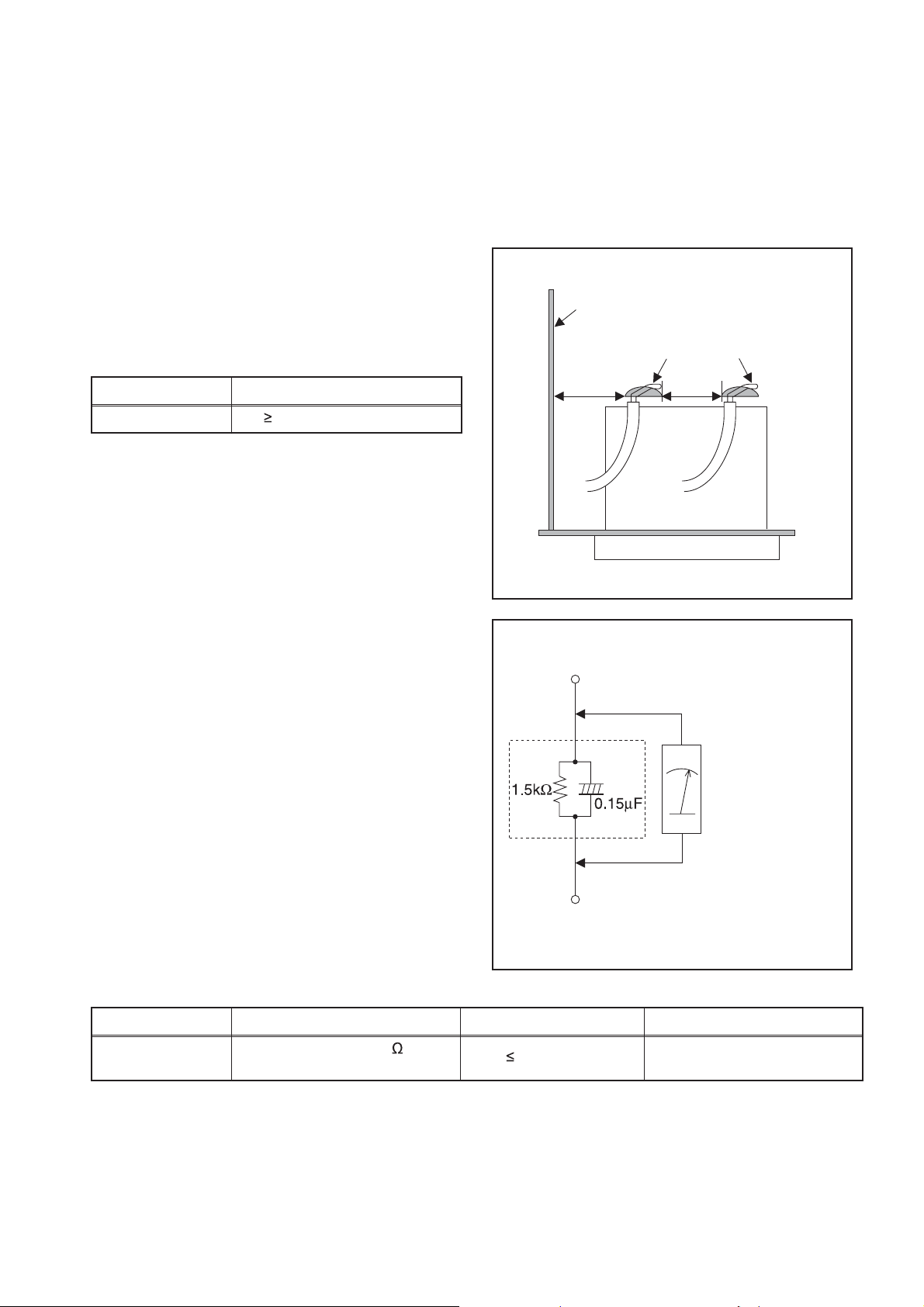

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between term

surrounding metallic parts. (See Fig. 1)

Table 1: Rating

s for selected area

inals and

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d

110V~220V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

3.2 mm (0.126 inches)

’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

than or equal to the specified value in the table

lower

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

110V~220V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

0.15 μF CAP. & 1.5 k

Connected in parallel

RES.

i

0.5 mA Peak Exposed accessible parts

5-1

Fig. 2

Page 9

Safety Information, General Notes & Lead Free Requirements

1 Safety Instructions

1.1 General Safety

Safety regulations require that during a repair:

Connect the unit to the mains via an isolation transformer.

Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

Route the wires/cables correctly

mounted cable clamps.

damage.

Check the electrical DC resistance between the mains

plug and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the ‘on’ position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4. Repair or correct unit when the resistance

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

1.2 Laser Safety

This unit employs a laser

may remove the cover, or attempt to service this device (due

to possible eye injury).

2 Warnings

2.1 General

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD,

,

during repair can reduce life drastically. Make sure that,

during repair, you are at the same potential as the mass

of the set by a wristband with resistance. Keep

components and tools at this same potential.

Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

4822 310 10671.

– Wristband tester 4822 344 13999.

Be careful during measurements in the live voltage

section. The primary side of the power supply, including

the heatsink, carries live mains voltage when you

connect the player to the mains (even when the

player is ‘off’!). It is possible to touch copper tracks and/

or components in this unshielded primary area, when

you service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A ‘lightning stroke’ and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

Never replace modules, or components, while the unit is

‘on’.

2.2 Laser

The use of optical instruments with this product, will

Only quali ed service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

Repair handling should take place as much as possible

with a disc loaded inside the player.

T

shield:

). Careless handling

Laser Device Unit

epyT

:AIGalnN(BD)

:AIGalnP(DVD)

: AIGalnP(CD)

Wavelength : 650 nm (DVD)

)DC/DCV(mn087:

405nm(BD):

Output Power : 20 mW

)gnitirwWR+DVD(

Wm8.0:

)gnidaerDVD(

Wm3.0:

)gnidaerDC/DCV(

Beam divergence : 60 degree

CLASS 1

LASER PRODUCT

1-2erugiF

Note: Use of controls or adjustments or performance of

procedure other than those speci

ed herein, may result in

A

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPENAVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO ! AVAT TAESSA OLETALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNETNICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPENAVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D’OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Figure 2-2

6-1

Page 10

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

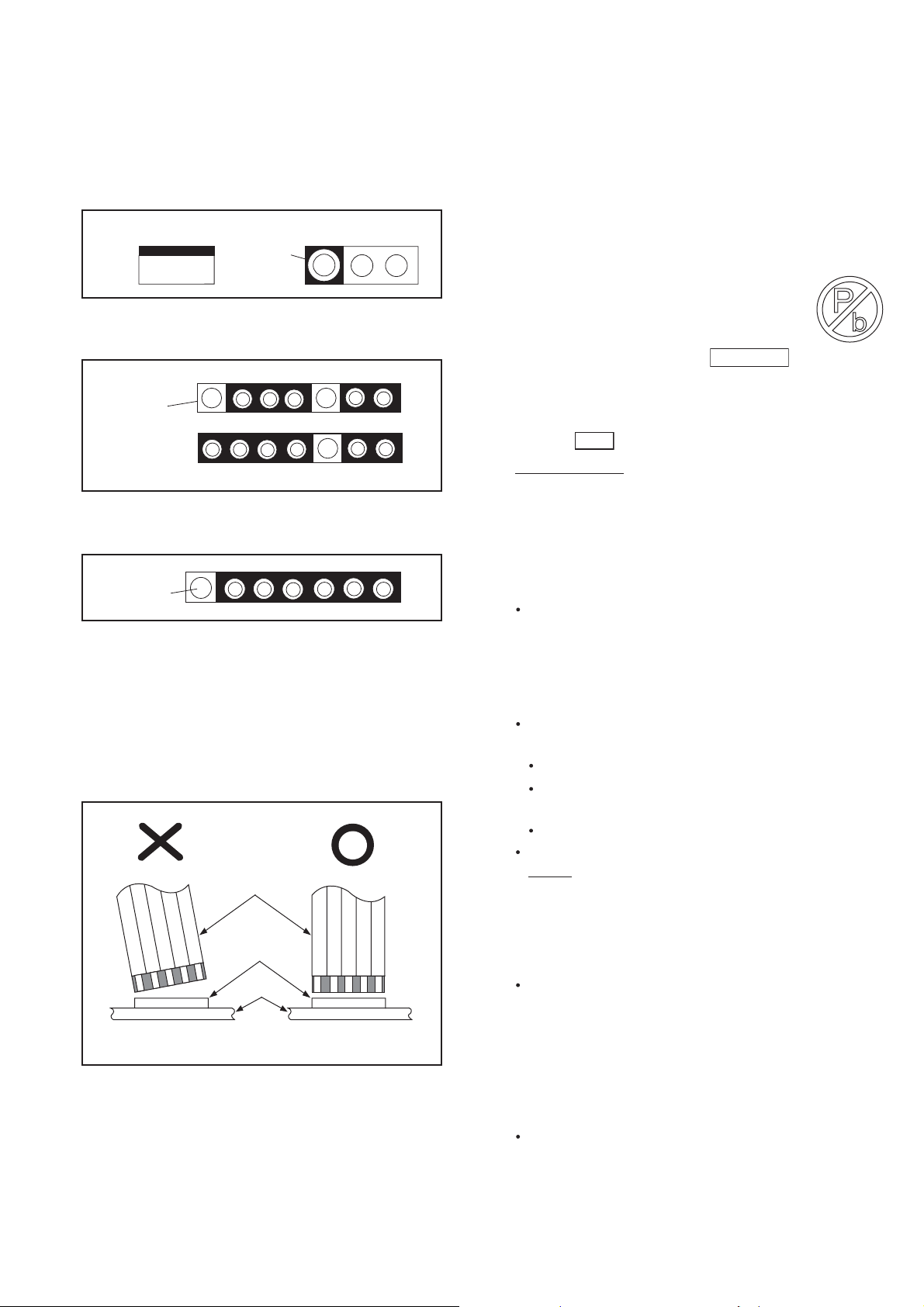

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

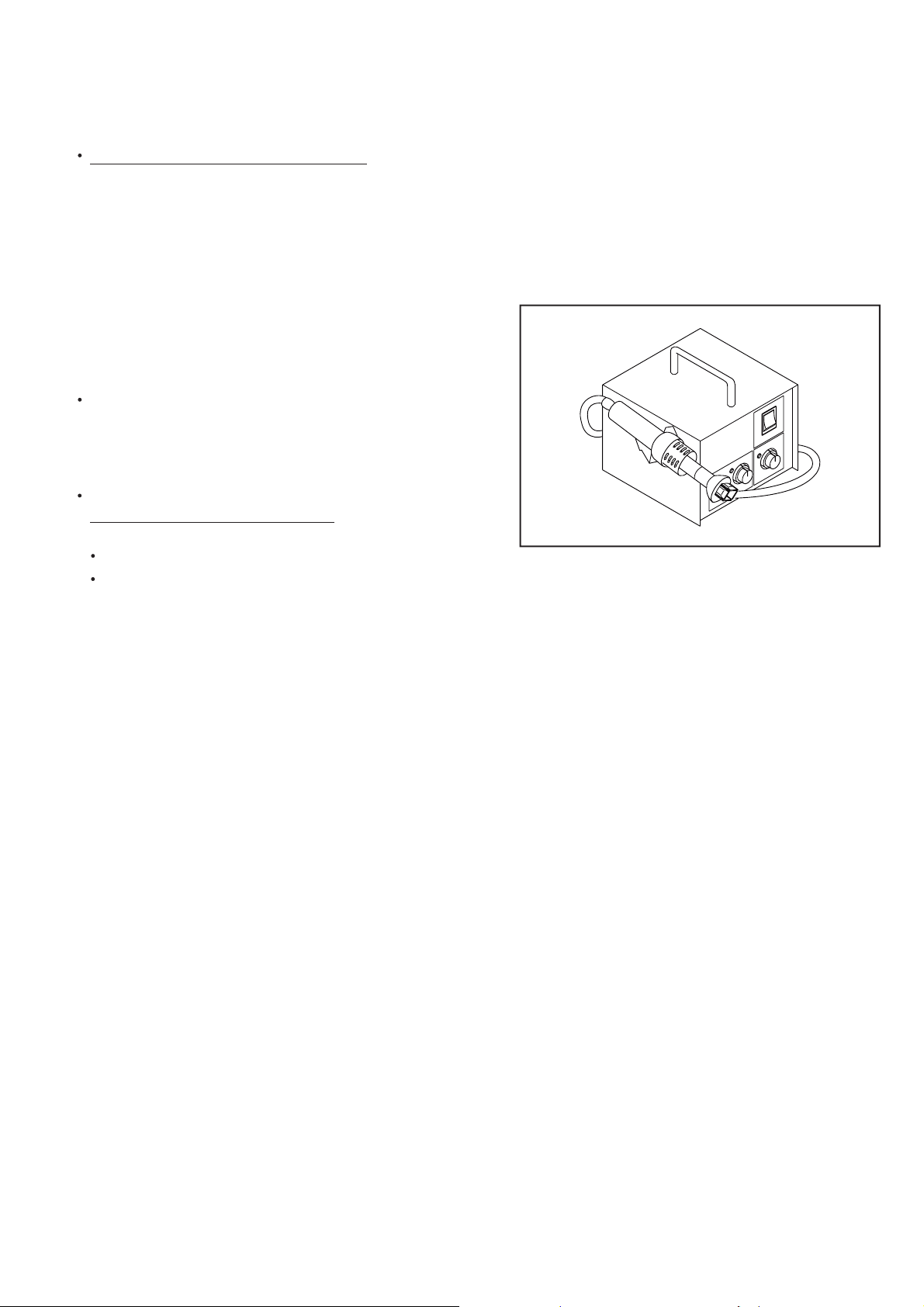

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

Information about lead-free soldering

Philips CE is producing lead-free sets from 1.1.2005

onwards.

IDENTIFICATION

Regardless of special logo (not always

indicated)

One must treat all sets from

onwards, according to the next rule:

Serial Number gives a 14-digit. Digit 5&6 shows the

YEAR, and digit 7&8 shows the WEEK.

So from onwards=from 1 Jan 2005 onwards

0501

Important note : In fact also products of year 2004

must be treated in this way as long as you avoid

mixing solder-alloys (leaded/ lead-free). So best to

always use SAC305 and the higher temperatures

belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solderpaste is required, please contact the manufacturer

of your sol

paste within workshops should be avoided because

paste is not easy to store and to handle.

Use only adequate solder tools applicable for leadfree solder alloy. The solder tool must be able

To reach at least a solder-temperature of 400°C,

To stabilize the adjusted temperature at the solder-

tip

To exchange solder-tips for different applications.

Adjust your solder tool so that a temperature around

360°C

solder joint. Heating-time of the solder-joint should

not exceed ~ 4 sec. Avoid temperatures above

400°C otherwise wear-out of tips will rise drastically

and flux-fluid will be destroyed. To avoid wear-out of

tips switch off un-used equipment, or reduce heat.

Mix of lead-free solder alloy / parts with leaded

solder alloy / parts is possible but PHILIPS

recommends strongly to avoid mixed solder alloy

types (leaded

If one cannot avoid or does not know whether

product is lead-free, clean carefully the solder-joint

from old solder alloy and re-solder with new solder

alloy (SAC305).

Use only original spare-parts listed in the ServiceManuals. Not listed standard-material (commodities)

has to be purchased at external companies.

der-equipment. In general use of solder-

- 380°C is reached and stabilized at the

and lead-free).

1 Jan 2005

7-1

Page 11

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature

profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

'dry-packaging' (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on indicatorlabel in the bag, the BGA-IC possibly still has to be

baked dry. (MSL=Moisture Sensit

will be communicated via AYS-website.

Do not re-use BGAs at all.

For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

On our website

www.atyourservice.ce.Philips.com

information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information within

the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

ivity Level). This

you find more

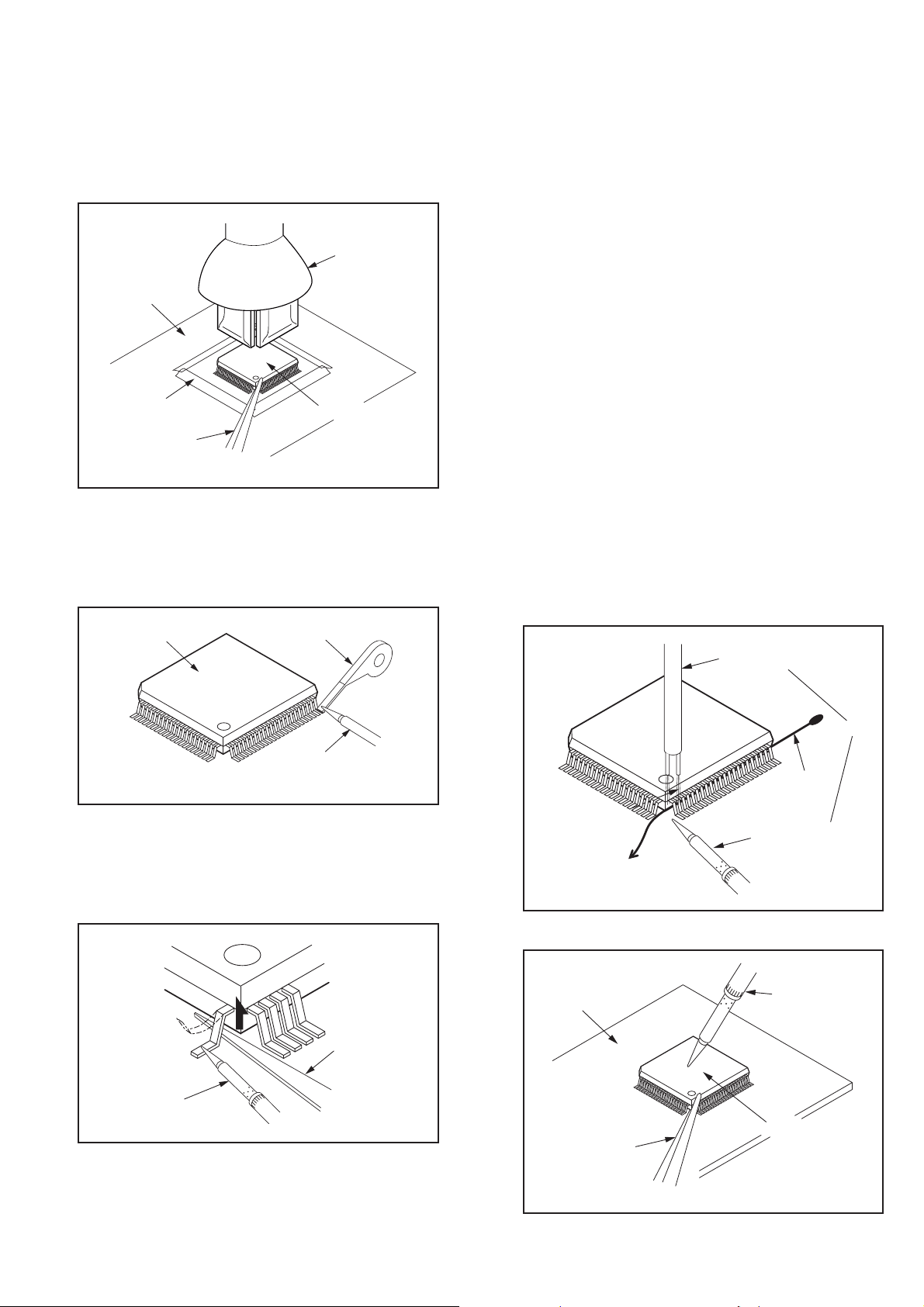

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

to the

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appr

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

opriate hot-air flat pack-IC desoldering

7-2

Page 12

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

Machine

Flat Pack-IC

Fig. S-1-2

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

With Iron Wire:

1. Using desoldering braid, remove

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or s

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be dama

flat pack-IC is fixed with glue to the

ensure that the flat pack-IC is not

the solder from

olid mounting

ged if force is applied.

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to whic

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air de

machine. (Fig. S-1-4)

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

h solder will

soldering

Sharp

Pin

Fig. S-1-4

7-3

To Solid

Mounting Point

CBA

Tweezers

Hot Air Blower

or

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

Fig. S-1-6

Page 13

Standard Notes for Servicing, Lead Free Requirements & Handling Flat Pack IC

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

” mark on the flat pack-IC indicates pin 1.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

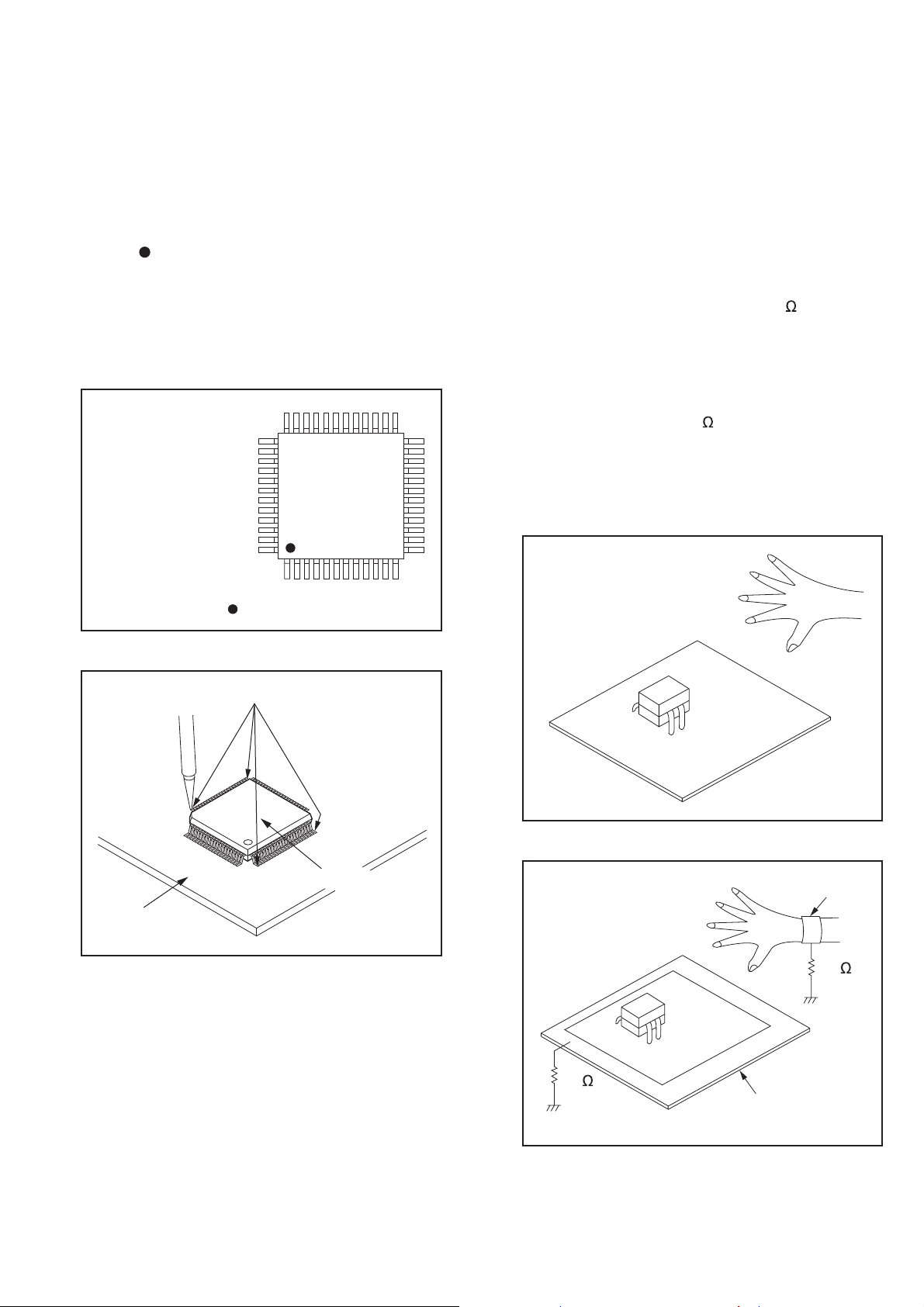

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 M ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 M

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be

with your clothing.

careful to avoid contacting semi-conductors

<Incorrect>

) on the workbench or

CBA

Presolder

Flat Pack-IC

Fig. S-1-8

<Correct>

1M

CBA

Grounding Band

1M

CBA

Conductive Sheet or

Copper Plate

7-4

Page 14

Direction of Use

j

*The following excerpt of the DFU/QSG serves as an introduction to the set.

The Complete Direction for Use can be download in different languages from

the internet site of Philips Customer care Center : www.support.philips.com

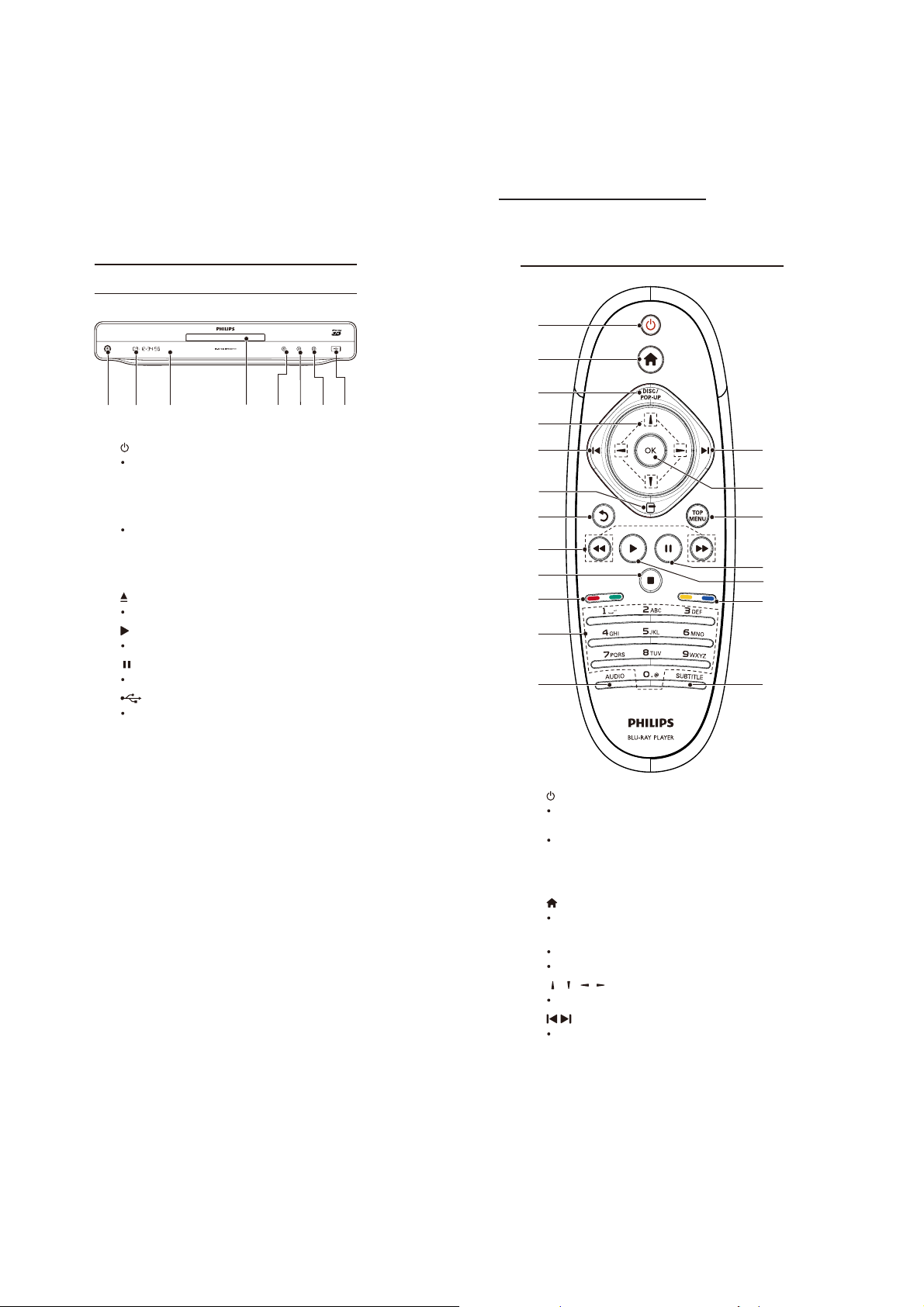

Product overview

Main unit

c

b

a

a

bDisplaypanel

cIRsensor

d Disc compartment

e

f

g

h

Turn on this player or switch to standby

mode.

Detect signals from the remote control.

Always point the remote control at the

IR sensor.

Open or close the disc compartment .

Startorresumeplay.

Pause play.

jack

Connect a USB device.

Remote control

a

b

c

g

e

d

h

f

d

e

f

g

e

q

p

h

i

o

n

j

k

l m

a

b

cDISC/POP-UP

d

e

Turn on this player or switch to standby

mode.

When EasyLink is enabled, press and

hold for at least three seconds to turn all

connected HDMI CEC compliant devices

to standby.

Accessthehomemenuofthisplayer.

BD:Accessorexitthepop-upmenu.

DVD: Access or exit the disc menu.

/ / /

Navigate through the menus.

/

Skip to the previous or next title, chapter,

or track.

8-1

Page 15

Direction of Use

Remote Control

f

g

h

i

j Color buttons

k Alphanumeric buttons

lAUDIO

m SUBTITLE

n

o

pTOPMENU

qOK

Access options for the current activity or

selection.

Return to a previous display menu.

/

Search backward or forward.

Stop play.

Press and hold to open/close the disc

compartment.

BD: Select tasks or options.

Selectanitemtoplay.

Enter values.

Enter letters via SMS style entry.

Select an audio language or channel on

adisc.

Select a subtitle language on a disc.

Start or resume play.

Pause play.

Move the paused picture forward frame

by frame .

BD: Display the top menu.

DVD: Display the title menu.

rm an entry or selection.

Con

3 Connect

Make the following connections to use this player.

Basic connections:

Video

Audio

Power

Optional connections:

Route audio to other devices

HDMI-compliant AV receiver/ampli er

Multi-channel AV ampli er/receiver

DigitalAVampli er/receiver

Analog stereo system

USB device

Wired/Wireless network

Note

Refer to the type plate at the back or bottom of the

product for identi cation and supply ratings.

Before you make or change any connections, ensure that

all the devices are disconnected from the power outlet.

Connect video/audio cables

Select the best video connection that theTV can support.

Option 1:Connect to the HDMI jack (for a

HDMI, DVI or HDCP-compliant TV).

Option 2:Connect to the component video

jacks (for a standard TV or Progressive Scan TV).

Option 3:Connect to the composite video

jack (for a standard TV).

Option 1: Connect to the HDMI jack

8-2

HDMI IN

Connect an HDMI cable (not supplied) to:

1

the

HDMI jack on this player.

the HDMI input jack on the TV.

Page 16

Direction of Use

Tip

If the TV has a DVI connector only, connect via an

HDMI/DVI adaptor. Connect an audio cable for sound

output.

If there is a blank TV screen under HDMI connection,

ontheremotecontrolpress and then press “731”

(numeric buttons) to recover picture display.

If this player connects to a TV compatible with 1080p

or 1080p/24Hz, Philips recommends HDMI category 2

cable, also known as High Speed HDMI cable, for optimal

video and audio output.

To play the digital video images of a BD-video or DVDvideo via anHDMI connection, it is necessary that both this

player and the display device(or an AV receiver/ampl

support a copyright protection system called HDCP (highbandwidth digital content protection system).

This connection provides the best picture quality.

Option 2: Connect to the component

video jacks

Y

Pb

Pr

AUDIO IN

Option 3: Connect to the composite

video jack

AUDIO IN

VIDEO IN

er)

1

Connect a composite video cable (not

supplied) to:

the

VIDEOjack on this player.

the VIDEO input jack on the TV.

2 Connect the audio cables (not supplied) to:

the

Audio LINE OUT- L/Rjacks on this

player.

the AUDIO input jacks on the TV.

Tip

ThevideoinputjackontheTVmightbelabeledasA/V

IN, VIDEO IN, COMPOSITE or BASEBAND.

1

Connect the component video cables (not

supplied) to:

the

Y Pb/Cb Pr/Crjacks on this player.

the COMPONENT VIDEO input jacks

on the TV.

2 Connect the audio cables (not supplied) to:

the

Audio LINE OUT-L/Rjacks on this

player.

the AUDIO input jacks on the TV.

Tip

The component video input jack on the TV might be

labeled as Y Pb Pr or YUV.

Route audio to other devices

You can route the audio from this player to other

devices.

Connect to an HDMI-compliant AV

receiv

HDMI IN

1 Connect an HDMI cable (not supplied) to:

the

HDMI jack on this player.

the HDMI jack input jack on the device.

8-3

Page 17

Direction of Use

Tip

The HDMI connection provides the best audio quality.

Connect to a multi-channel AV receiver/

7.1 CH AUD IO INP UT

1 Connect a coaxial cable (not supplied) to:

COAXIAL jack on this player.

the

the COAXIAL/DIGITAL input jack on

the device.

Connect to optical jack

OPTICAL

1 Connect an optical cable (not supplied) to:

the

OPTICALjackonthisplayer.

the OPTICAL/DIGITAL input jack on the

device.

Connect an analogue stereo system

AV IN

1 Connect the 7.1-channel audio cables (not

supplied) to:

7.1 CH AUDI O OUTPUT

the

jacks on

this player.

the corresponding AUDIO input jacks

on the device.

Tip

To connect 5.1-channel AV receiver/ampli er, connect

the 7.1-channel audio jacks except theSL/SR jacks.

You can optimize the speaker output (see “Adjust

settings” >[Audio]>[Speaker Setup]).

Connect to a digital A receiver

Connect to coaxial jack

COAXIAL

1

Connect the audio cables (not supplied) to:

Audio LINE OUT-L/R jacks on this

the

player.

the AUDIO input jacks on the device.

Connect a USB device

1 Connect a USB device to the

on the front panel of this player.

Note

Press , and select [Browse USB] in the menu

to access the content and play the

Connect a USB device only to the

this player.

Philips does not guarantee compatibility with all

USB devices.

les.

jack on

(USB) jack

8-4

Page 18

Connect a network

With a wired or wireless connection (see “Get

started” > “Set up a network”), you can connect

this player to:

theInternet(forsoftwareupdate/BD

Live/Net TV service).

or a home network (to access media

from a DLNA media server, e.g. PC).

Note

Internet access to Philips website for software update

maynotbeallowed,dependingontherouteryouuse

or the Internet Service Provider’s policy. Contact your

Internet Service Provider for more information.

Connect power

Caution

Riskofplayerdamage!Ensurethatthepowersupply

voltage corresponds to the voltage printed on the back

of the unit.

Before connecting the AC power cord, ensure you have

completed all other connections.

Direction of Use

es

Note

The type plate is located on the back of the player.

1 Connect the AC power cable to:

this player.

thewallsocket.

This player is ready to be set up for use.»

8-5

Page 19

Cabinet Disassembly Instructions

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[1] Aluminum decorative floor,

Machine bracket

[2] TOP Cover

[3] Machine shield

[4] DVDDoor

[5] Bly-Ray Driver

[6] Top Loader Driver

[7] Transformer

[8] Power socket board,

Decoder board,

output board,Power

board

[9] USB Terminal board

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

0x = Screw, CNxx/Jxx/CONxx = Connector

D3.5X12BA is specification of screw.

* = Unhook, Unlock, Release, Unplu

g, or Desolder

e.g. 7(01) = seven Screws

[10] Front panel

[11]Touch Key Board

VFD Display Board

[12] Transparent PMMA,Tou -

ch pad,Power button spport,LED lens

[13] USB door,Decorative Lenses,

Touch pad

2. Disassembly Method

ID/

Loc.

No.

[1]

[2]

[3]

[4]

[4]

Part

Aluminum decorative floor, Machine bracket

Machine shield

Bly-Ray Loader

Driver

Top Loader Cover

Transformer

Fig.

No.

4(01) D3x6BMTT

D1

D3

3(02) D3x8BT

4(03) D3x8BT

D5

D6

2(08) D3x5BMTT

1(04) D4x6KMTT,4x6KT

D7

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

01

Fig. D1

Note

Fig. D2

Power socket bo-

ard, Decoder boa-

[5]

rd, Output board

Power board

Touch Key board

[6]

VFD display board

7(06) D3x4BMTT

D8

18(05) D3x8BT

D11

10(07) D2.6x8BT

9-1

Page 20

Cabinet Disassembly Instructions

Fig. D3

02

08

Fig.D6

04

Fig. D4

Fig. D5

03

Fig. D7

06

05

05

05

Fig. D8

9-2

Page 21

Fig. D9

Cabinet Disassembly Instructions

Fig. D12

Fig. D10

Fig. D11

Fig. D13

07

9-3

Page 22

Troubleshooting

No power

Check the Power Cord

is connected

Y

Check whether the

Power Transfer Board has

provided voltage output—

(AC220V)

Y

Check the FUSE is ok or

not?

Y

Check whether the

PowerBoard has provided

voltage output

Y

Check the FUSE is ok or

not?

Replace a new

N

Power Transfer

Board

Replace a new

N

one

Replace a new

N

Board

Replace a new

N

one

No sound

Y

Adjust the volume

Y

Check the connect cable is

OK or NOT

Y

Check whether provide 18V

voltage for Digital Output

Board jack(J3)

Y

Check Digital output board(J2)

& decoder board(xp8)between

the flat connect wire is OK or

NOT and Re-planted

Y

Test the decoder board jack(xp8)

pin no.22#(+12vA)、23#(-12V)

has provided voltage

Y

Confirm decoder board jack(xp8)

location pin no.16#(mute) low level

N

Replace a

N

new one

Check&replace

the transformer

Replace a

N

new one

Check&replace the

N

digital output board

Check related MUTE

N

circuit decoder board

Can’t Loading

Y

Confirmed machine

tray in and out

action normal

Confirmed the disc piece

revolving movement is

whether normal

Y

Check the flat connect wire is

OK or NOT and Re-planted

Check&replace the Loader

N

Y

Y

check decoder board

location XP4 jack pin

no.3#~4# has 3.6v provide voltage

Test decoder board jack

(XP4)pin no.1#~2# impedance 0ohm

N

Test decoder board jack

(XP3) W\U\V between

wheter has12V provide

voltage

Replace a

N

new one

No display

Check the power pcb “CON1”

connection to display board

cable normal

Y

Check location CON1 in power

board has normal voltage:+5v、

-27v、VF(-12V)、S5V(5V)、

and has STB provide voltage

Y

Check location U201 in display

board pin No15#、37# has 5V

provide voltage,check 27# pin

has -30v provide voltage

Y

Use Oscillograph to checkVFD

data cable if has normal nignal or

not ,the check location is U201 pin

No 5#(VFD DATA)、8#(CLK)and

STB provide voltage

Y

replace display board IC

U201

N

Re- insert

N

replace the

power board

N

check&replace the

N

decoder board

No picture on HDMI connection

Check if the HDMI cable

is usable

Y

Check a television

change to HDMI mode

Y

Use Oscillograph to check jack

(J300)pin No 15#(HDMI_SCL)、

16#(HDM_SDA)wave if normal

check J300 cable pin No 1#、

3#、4#、6#、7#、9#、10# TX

signal normal or no

Y

Check &replaec the J300

jack

Replace a new

N

HDMI cable

Change to HD-

N

MI mode

N

Replace the

decoder board

Y

use oscillograph to check decoder

board jack(xp8)pin no.6#(MCLK)、

8#(BCK)data whether normal

Y

replace digital output board

N

replace decoder board

10-1 10-1

Page 23

Software Upgrading Procedure

1. Download the Software from Philips support

Website:

http://www.philips.com/support.

2. Copy the Software upgrade file into USB device.

A. Connect to TV and Turn on Main Unit,

Select Upgrad from USB,TV Screen Display:

Press OK on Remote Control,

TV Screen Display:

C. Software Upgrading

D. When Software Upgrading finish,TV screen

display

B. Press OK on Remote Control,

TV Screen Display:

Software Upgrade finish.

11-1

Page 24

Software Version Check

1. Select the “ ”, like below show:

2. TV Screen Display,select Version Info.

4.Press “ ” on Remote Control:

VFD display:

3. Select OK to get the Version information :

5. Press 8-5-2-0 on Remote Control,can find

Software Version:

11-2

Page 25

Repair Service Flow

How to replace the defective Blu-ray Loader

1.Remove the defective Blu-ray Loader.

2.Remove the shield cover at the top of Blu-ray Loader as shown below:

3.Assembly Blu-ray Loader to “HA1,HA2,HA3” on the top of BD Board as shown below:

4. Remove soldered joint on the ESD protection points.

The ESD protection

points on the top of board.

The ESD protection points

on the bottom of board.

Top Side

Bottom Side

HA3

HA1

HA2

Note:The ESD protection points on any one side must be soldered if

a.The Blu-ray Loader needs to be disconnected from connector HA1,HA2 and HA3 of

the BD Board.

b.The defective Blu-ray Loader is needed to be send back to supplier for failure analysis and

to support backcharging evidence.

12-1

Page 26

Repair Service Flow

BD board and Blu-ray Loader OPU matching procedure

Step1

1.Assemble loader to 8530 PCB

2.Remove laser protection point

3.Power on,Press“ ”<Home> button and input 85177 on R/C

4.Select item[5],then press<OK>,as shown below:

Step2

Insert USB device of MSC type and press<OK>button

on R/C as shown below:

12-3

Page 27

Repair Service Flow

Step3

Using Navigate buttons on R/C input the 6 digit @ Sanyo OPU

Input 1D info from left to right

Press<OK> button to save

Sanyo

12-4

Page 28

Repair Service Flow

Step4

Goto to Top manual and select

item[6]laser check press <OK>,as shown below:

Step5

Wait laser check pass to verify the

status of the assemble.

12-5

Page 29

Block Diagram

FAN

TRV412VH5

BD ROM ASA

UVWCOM

A+A-B+B-

WIFI DONGLE MODULE

VFD Display

KEY

SD(VOD)

USB

IR

UVWCOM

A+A-B+B-

WIFI DONGLE

VFD Driver

PT16312

IR

MCU

R5F21266

Display

MCU5V

IIC_MCU

CEC

AABBUVWC

LOAD+-

TRAY IN/OUT

Collimator II

TPC1391G4

Motor Driver

R2A30209SP

Ethernet

Ethernet

SMSC8710

WIFI DONGLE

VFD_BUS

DDR2

256M

SD_BUS

USB

IR

IIC_MCU

QDEO

Scalar

Kyoto 2750

IIC_QDEO

MPEG

MT8530KEFG

(Divx PlusHD)

Digital video out

Digital video in

NAND-FLASH

16G

DDRII

DDRII

DDRII

DDRII

HDMI_OUT

CEC

1G

1G

1G

1G

Buffer

FMS6363CS

ESD

REJECTOR

FAN

IIS_BUS

S/Pdif

CVBS

YUV

CEC

OPTION

OPTICAL

COAXIAL

CVBS

YUV

HDMI

12V

-12V

MPEG5V

Loader

SC5V

MPEG

Display

MCU5V

Transformer2

Transformer1

DAC

PCM1789

DAC

PCM1754

DAC

PCM1754

DAC

PCM1754

DAC

PCM1754

OP

OP

OP

OP

OP

POW318A

Regulator

4558

4558

4558

4558

4558

12V

7.1CH Audio OUT

12V

Regulator

7812

Regulator

OPTION

REL?

1 5

2

RELAY2

AC

2CHLt/Rt

-12V

Regulator

7912

4

3

Touched key

WT5700

Touch key x N

13-1 13-1

Page 30

Wiring Diagram

VFD DISPLAY BOARD

LED+

LED-

LED BOARD

GND

CLK

STB

ECO_POWER

GND

A5V

K0K1K2

MCU5V

DATA

KEY_STBY

LED_STBY

GND

GND

ANT1

K3

GND

IR

-30V

VF1

VF2

MCU5V

ECO_POWER

GND

~220V

~0V

POWER BOARD

Cable Location

No.:C103

AC220

0

AC220

D12V

+5V

+5V

GND

GND

+12V

GND

-12V

POWER SOCKET BOARD

AC21

0

AC21

D5V

GND

No.:ACC2

Cable Location

AC INPUT 100--240V/50-60HZ

POWER LINE

OUTPUT BOARD

Cable Location

No.:C102

Cable Location

No.:C100

GND

CLK

3.3V

GND

DATA

TOUCH KEY BOARD

MCU BOARD

GND

GND

D+

STB

CLK

HDMI5V

GND

MUTE

RST

CEC

SDA

SCL

14-1

LOAD+

LOADGND

TRAY+

TRAY-

VCC

D-

VCC2

D-2

D+2

GND

WIFI MODULE

HPD

DATA

GND

IR

ANT2

Cable Location

No.:C101

A+

A-B+B-

VWCDM

U

DECODER BOARD

Cable Location

NO.:W01

GND

I/O

D-12V

ADLRCK

A_MUTE

GND

GND

ADSDATA3

ADMCLK

ADSDATA4

GND

NC

GND

SDA

SCL

ADSDATA0

ACBCK

ADSDATA2

ADSDATA1

GND

GND

VCC5VNCD+12V

14-1

Page 31

Touch Key Board -- Circuit and Layout Diagram

K1

OPEN/CLOSE

K2

PLAY

K3

PAUSE

KEY1

KEY2

KEY3

C801

NC/5P

C802

NC/5P

C803

NC/5P

J801

1.0/5P

TKEY+3.3V

R801

2M

5

4

3

2

1

C804

104

TKEY+3.3V

GND

KEY_CLK

GND

KEY_DATA

C805

103

1

VDD

2

SI[0]

3

SI[1]

4

SI[3]

5

SI[8]

6

SI[10]

7

SI[11]

VSS8OUT11

IC-WT5700-S160

U801

OUT0

OUT1

OUT3

SCL

SDA

OUT8

OUT10

TKEY+3.3V

16

15

14

13

12

11

10

C806

9

10P

C807

10P

R802

R803

470

470

R804

10K

R805

47K

KEY_CLK

KEY_DATA

15-1 15-1

Page 32

Output Board -- Circuit Diagram

AOBCK

AOSDATA0

AOLRCK

A5V

L1 FB

+

CE3

CD11X/22UF16V/D4H7

A

AOBCK

AOSDATA1

AOLRCK

A5V

L3 FB

CE15

CD11X/22UF16V/D4H7

MUTE_0

+3.3VVDDA

R137 4.7R

+

CE59

CD11X/22UF16V/D4H7

L11 FB

L8 FB

L9 FB

L10 FB

A

AV6-8.4-13D

MK1

MK2

MK3

MK4

18V1

1

2

18V2

J3

3

CON2.54-3

A

R3 33

R10 33

R8 33

CB1

0.1uF

R39 33

R46 33

R55 33

CB3

+

0.1uF

A

R156

AOLRCK

AOBCK

AOSDATA4

I/O

AOMCLK

CB15

0.1uF

CB16

0.1uF

CD11X/10UF16V/D4H7

P1

9

8

7

6

5

4

3

2

1

PP1

9

9

8

8

7

7

6

6

10K

2

CB24 102/1uF

R141 NC/10K

R133 33

R134 33

R136 33

R147 33/NC

R142 33

PIN4/12

CE60

2CEN

2SUB

3SBL

3SBR

1SL

1SR

A

2

3

4

5

1

1

PCM1754

1

BCK

2

DATA

3

LRCK

4

DGND

5

NC

6

VCC

7 10

VoutL VCOM

8 9

VoutR AGND

CD11X/10UF16V/D4H7

CE9

+

+

CE11

CD11X/10UF16V/D4H7

PCM1754

1

BCK

2

DATA

3

LRCK

4

DGND

5

NC

6

VCC

7 10

VoutL VCOM

8 9

VoutR AGND

CD11X/10UF16V/D4H7

CE21

CE24

CD11X/10UF16V/D4H7

R155

Q12

2N3904

1 3

A

0.1uF

+

CB13

A

TP5

TP6

TP20

2

3

4

5

U1

16

SCK

15

FMT

14

MUTE

13

DEMP

12

TEST

11

ZEROA

U5

SCK

FMT

MUTE

DEMP

TEST

ZEROA

+

+

A5V

R161

0

13

4.7K

2

R157

10K

-9V

A_MUTE

1 2

PCM1789

1

LRCK

2

BCK

3

DIN

4

RST

5

SCKI

6

VDD

7

DGND

8

VCC1

9

VCOM

10

AGND1

11

VOUTL-

12 13

VOUTL+ VOUTR+

TP14

TP9

TP17

TP18

9

8

7

6

R0_OUT

L0_OUT

16

15

14

13

12

11

R1_OUT

L1_OUT

Q11

2N3906

D11

1N4148

U17

ADR5/ADR1/RSV

MS/ADR0/RSV

MD/SDA/DEMP

AV4-8.4-13D

PP2

9

8

7

6

C1 NC/10pF/J

R4 33

R11 33

R19 NC/33

R23 33

R26 33

R40 33

R49 33

R56 NC/33

R59 33

R62 33

MUTE_00

MC/SCL/FMT

MODE

ZERO1

ZERO2

AMUTE1

VCC2

AGND2

VOUTR-

P2

1

1

+

CE4

CD11X/10UF16V/D4H7

A

C18NC/10pF/J

+

A

R160

4.7K

A

24

23

22

21

20

19

18

17

16

15

14

6

5

4

3

2

1

2

2

3

3

4

4

5

5

AOMCLK

A_MUTE

MUTE_0

AOMCLK

A_MUTE

MUTE_1

CE17

CD11X/10UF16V/D4H7

R138 47/NC

R131 47/NC

R139 NC/0

R140 NC/0

R143 0/22K

R159 33

R158 33

R146 33

0FL

0FR

4TL

4TR

TP13

A

R1

12k

C2

-9V

120p/J

R5

8.2k

390

L0_OUT

R0_OUT

R6

C5

2200p/J

A

12k

R25

8.2k

R29

R30

390

C11

2200p/J

A

R37

12k

R42

390

R41

8.2K

L1_OUT

C19

2200p/J

AA

R61

R66

8.2K

R65

R1_OUT

C25

2200p/J

A

R166

MUTE_1

10K

2

SCL

SDA

A5V

MUTE_5

MUTE_4

R145

1789_MUTE

PIN4/12

4.7R

+

CB17

CE58

0.1uF

DAC4_R_M

DAC4_R_P

DAC4_L_P

DAC4_L_M

CD11X/22UF16V/D4H7

A

A5V

TP7

TP8

TP15

TP11

R178

10K

1789_MUTE

Q19

A_MUTE

2

2N3904

R177

4.7K

1 3

A

PP3

2

9

9

2

3

8

3

8

4

7

4

7

5

6

5

6

1

1

MUTE_5

CD11X/10UF16V/D4H7

-

CE1

U3A

2

+

1

+

3

JRC4558

R132

SOP8

220K

8 4

+9V

A

MUTE_00

A

C9

-9V

120p/J

CD11X/10UF16V/D4H7

-

U3B

CE6

6

+

7

+

5

JRC4558

R135

SOP8

220K

8 4

+9V

A

12k

390

Q13

2N3904

1 3

A

A

C15

-9V

120p/J

CD11X/10UF16V/D4H7

-

U6A

CE13

2

+

1

+

3

JRC4558

SOP8

8 4

+9V

MUTE_11

C24

-9V

120p/J

CD11X/10UF16V/D4H7

-

U6B

CE18

6

+

7

+

5

JRC4558

SOP8

8 4

+9V

A

A5V

R165

0

1

4.7K

R162

Q14

2

2N3906

MUTE_11

3

R163

10K

-9V

A_MUTE

2

1

D12

1N4148

DAC4_L_P

DAC4_L_M

R12 560

1KR14

R31 560

1KR32

R52 560

R144

220K

A

1K

R51

R67 560

R148

220K

1K

R70

R164

4.7K

A

+

CE25

CD11X/10UF16V/D4H7

+

CE35

CD11X/10UF16V/D4H7

L12 FB/600

0FL

C6

33pF/J

Q1

2

2SD2653K

1 3

L13 FB/600

0FR

C13

33pF/J

Q3

2

2SD2653K

A

1 3

A

L14 FB/600

1SL

C20

33pF/J

Q5

2

2SD2653K

A

1 3

A

L15 FB/600

1SR

C26

33pF/J

3

Q7

2

2SD2653K

A

1

A

-9V

C32

R81

100pF/J

36K

51K

R83

51K

R97

-

U13A

2

1

3K

R84

+

3

JRC4558

C44

8 4

NC

C47

390PF

R99

36K

+9V

MUTE_55

C58

A

NC

3K

R98

C60

100pF/J

A5V

CD11X/22UF16V/D4H7

A5V

CD11X/22UF16V/D4H7

MUTE_2

CD11X/10UF16V/D4H7

CE38

+

1KR89

AOBCK

AOSDATA2

AOLRCK

L2 FB

+

CE5

A

AOBCK

AOSDATA3

AOLRCK

L14 FB

+

CE16

A

10K

R171

2

47

R86

C42

R153

220K

33pF/J

Q9

2

2SD2653K

A

1 3

A

A

-9V

C62

R105

36K

100pF/J

+

CE36

CD11X/10UF16V/D4H7

CD11X/10UF16V/D4H7

CE37

+

R107

C64

NC

C65

390PF

C67

NC

3K

R114

51K

R113

R115

36K

DAC4_R_P

DAC4_R_M

3K

R108

51K

A5V

R188

0

13

R185

4.7K

Q23

2

2N3906

Q22

2

2N3904

R189

10K

1 3

A

MUTE_55

R186

10K

-9V

A_MUTE

1 2

D16

1N4148

MUTE_4

R187

4.7K

A

CD11X/10UF16V/D4H7

-

CE48

U13B

6

+

5

8 4

C68

100pF/J

A

10K

R184

47

R109

+

7

JRC4558

R154

220K

+9V

MUTE_44

Q20

2

2N3904

1 3

A

C63

33pF/J

A

Q10

2

2SD2653K

R111 1K

1 3

A

A

A5V

R183

0

13

R180

4.7K

Q21

2

2N3906

MUTE_44

R181

10K

-9V

A_MUTE

1 2

D15

1N4148

L20 FB/600

L21 FB/600

CB2

0.1uF

CB4

0.1uF

Q15

2N3904

1 3

A

R9 33

R16 33

R21 33

R43 33

R47 33

R57 33

R182

4.7K

A

R167

-9V

1

2

3

4

5

6

7 10

8

CE12

CD11X/10UF16V/D4H7

1

2

3

4

5

6

7

8

4.7K

2

R168

10K

A_MUTE

4TL

4TR

U2

PCM1754

BCK

DATA

LRCK

DGND

NC

VCC

VoutL VCOM

VoutR AGND

CD11X/10UF16V/D4H7

CE10

+

+

U7

PCM1754

BCK

DATA

LRCK

DGND

NC

VCC

VoutL VCOM

VoutR AGND

CD11X/10UF16V/D4H7

CE22

+

CD11X/10UF16V/D4H7

CE23

+

A5V

R170

0

1

Q16

2N3906

3

1 2

D13

1N4148

18V1

18V2

CON2.0-2

H24S/P1.0/DB

HEADER 24 SMD1.0 DOUBLE

SCK

FMT

MUTE

DEMP

TEST

ZEROA

SCK

FMT

MUTE

DEMP

TEST

ZEROA

MUTE_22

+3.3VVDDA

J1

16

15

14

13

12

11

9

R2_OUT

L2_OUT

16

15

14

13

12

11

10

9

R3_OUT

L3_OUT

R169

4.7K

A

C30 0.022uF/dilun

C35

1N5401

C43 0.022uF/dilun

D4

1N5401

C49

0.022uF/dilun

J2

D3

1

2

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R7 33

R17 33

R22 NC/33

R24 33

R28 33

C16NC/10pF/J

R50 33

R48 33

R58 NC/33

R60 33

R64 33

D1

1N5401

0.022uF/dilun

D2

1N5401

2200UF25V

R100 10K

R104 10K

R102 10K

R103 10K

C3 NC/10pF/J

CE41

A

AOMCLK

A_MUTE

+

CE7

CD11X/10UF16V/D4H7

A

AOMCLK

A_MUTE

MUTE_3

+

CE19

CD11X/10UF16V/D4H7

A

2200UF25V

CE26

+

A

+

C54

0.1uF/dilun

A

A

SCL

SDA

A_MUTE

I/O

VCC

SCL

SDA

AOMCLK

AOLRCK

AOBCK

AOSDATA0

AOSDATA1

AOSDATA2

AOSDATA3

AOSDATA4

I/O

A_MUTE

VCC5V

D+12V

-9V

-9V

TP31

MUTE_2

R101 22R/2W

C40

0.1uF/dilun

A

R112 22R/2W

TP29

TP30

TP10

TP16

TP12

TP19

TP21

TP22

TP23

TP24

TP25

TP26

TP27

TP28

FBL6

V

CE51

+

CD11X/220UF16V/D6H12

L2_OUT

R2_OUT

L3_OUT

R3_OUT

1

C

C

CB9

0.1uF

8.2K

R15

C7

2200p/J

R33

8.2K

C12

2200p/J

8.2K

R44

C21

2200p/J

R68

8.2K

C27

2200p/J

R176

MUTE_3

U10

32

OUTIN

CD11X/1000UF16V/D10H16

GND

CE29

1

CW7902

TO-220-UP

A

A

U12

3

OUTIN

GND

+

2

CW7809

CD11X/1000UF16V/D10H16

TO-220-UP

AA

12k

R2

R13

390

A

12k

R27

390

R34

A

12k

R38

390

R45

12k

R63

390

R69

A

10K

2

-9V

-9V

+

CB5

0.1uF

A

+9V

+9V

CB6

CE39

0.1uF

A

A5V

CB7

0.1uF

+9V

R179

CD11X/220UF16V/D6H12

C4

120p/J

2

3

A

C10

120p/J

6

5

A

C17

120p/J

2

3

C23

120p/J

6

5

A

Q17

2N3904

1 3

A

22uF

CE31

+

+

22uF

CE40

AZ1117H-ADJ

342

IN

10R/0.5W

CE53

-9V

4

CD11X/10UF16V/D4H7

-

CE2

U4A

+

1

+

JRC4558

R149

SOP8

220K

8

+9V

MUTE_22

-9V

4

CD11X/10UF16V/D4H7

-

CE8

U4B

R35 560

+

7

+

JRC4558

R150

SOP8

220K

8

+9V

A

-9V

CD11X/10UF16V/D4H7

-

U8A

CE14

R53 560

+

1

+

JRC4558

R151

SOP8

220K

8 4

+9V

A

MUTE_33

-9V

CD11X/10UF16V/D4H7

-

U8B

CE20

R71 560

+

7

+

JRC4558

R152

SOP8

220K

8 4

+9V

A

A5V

R175

0

13

4.7K

R172

Q18

2

2N3906

R173

10K

-9V

A_MUTE

1 2

D14

1N4148

+

+

+

CE32

CE33

CE28

CE27

22uF

22uF

22uF

22uF

22uF

22uF

22uF

22uF

+

CE43

+

+

CE44

CE45

CE42

U14

OUT1

OUT2

ADJ

R106

1.2K

1

SOT223

R110

2K

U11 7805

1

IN OUT1

GND

+

2

CD11X/220UF16V/D6H12

CB11

0.1uF

TO-252-3/SMD

A

A

R18 560

MUTE_33

1KR20

1KR36

1KR54

1KR72

+

CB8

0.1uF

2

2

2

2

R174

4.7K

A

C36

+

0.1uF

C52

0.1uF

+3.3VVDDA

3

Q2

2SD2653K

1 3

A

Q4

2SD2653K

1 3

A

Q6

2SD2653K

1 3

A

Q8

2SD2653K

1 3

A

C33

C41

0.1uF

0.1uF

C53

C55

0.1uF

0.1uF

+

CE49

CD11X/220UF16V/D6H12

FAN12V

A5V

+

CE54

A

L16 FB/600

2CEN

C8

33pF/J

A

L17 FB/600

2SUB

C14

33pF/J

A

L18 FB/600

3SBL

C22

33pF/J

A

L19 FB/600

3SBR

C28

33pF/J

A

C37

C34

0.1uF

0.1uF

C56

C50

0.1uF

0.1uF

FAN12V

1

J4

2

CON2.54-2

L7 FB

R79

CB12

0.1uF

A

+

CB10

CE52

0.1uF

47UF16V/D5H11

A

A

A

82R/0.5W

R76

+9V

8550,DIP

Q25

13

39R/0.5W

A5V

R73

2

47k

R78

R75

10k

6.8K

Q24

3904

A

A_MUTE

FAN_CTRL

1

J5

2

R74

4.7k

R190

CB48

22k

0.1uF

2

R77 4.7K

CON2.0-2

A

Q26

2N3904

1 3

A

15-2 15-2

Page 33

Output Board -- Layout Diagram

Page 34

Power Socket and LED Board -- Circuit and Layout Diagram

3

2

1

CN701

AC 3P

AC220-

AC220+

35-BDP9600-07A1

Power Socket Board

2

1

CN702

7.9/2P

35-BDP9600-04A1

LED Board

MLED+

3

MLED-

2

1

CN401

2.0/3P

LED401

LED-W

LED402

LED-W

C401

104

C403

104

R401

C402

104

R402

10

10

15-4 15-4

Page 35

VFD Display Board -- Circuit Diagram

VFD1

R225

NC/1K

R227

NC/1K

C203

MCU+5V

R228

NC/4K7

100u/10V

CE202

NC/104

NC/10K

CE201

100u/10V

R229

VFVF

R203

VFD1

C207 104

C231

NC/100P

A5V

R201

NC/3DG3904M

R202

NC/10K

NC/18K

Q203

8

7

6

5

4

3

2

1

CN201

2.0/8P

Q204

NC/3DG3904M

ECO_POWER

GND

MCU+5V

VF_1

VF_2

-30V

GND

A5V

+12V

NC/0

Q205

NC/3DG3904M

VFD2

R226

NC/1K

Q206

NC/3CG3906M

VF_1

C220 101

C213

104

VF_2

C221 101

A5V

Q207

NC/3DG3904M

CE204

NC/3.3u/50V

C208

104

R230

R231

NC/6V2

-30V

C204

104

MCU+5V

C209

104

DZ201

NC

NC/470

C215

104

VFD__2

CE206

4.7u/50V

R224

NC/10K

R232

NC/330

C216

104

VFD__1

C232

104

CE205

NC/3.3u/50V

VFD1

R233

0/NC

VFD_DATA

VFD_CLK

VFD_ST B

VFD201 20075-2A23

VF1

R204

2.2 1/2

C201

101

R206

470

R207

470

R208

470

VF11VF1

NC4S155S146NC7S138S129S1110S1011S912S813S714S615S516S417S3

2

S1S2S3S4S5S6S7S8S9

A5V

C205

104

10K

10K

10K

R209

R211

R210

KEY SW0

KEY SW1

KEY SW2

KEY SW3

DS-DAT

DS-CLK

DS-STB

1

2

3

4

5

6

7

8

9

10

11

S2

18

19

S10

S11

S12

S13

R212

47K

LED_MID

43

42

44

41

VSS

OSC

LED1

LED0

SW0

SW1

SW2

SW3

DO

DI

VSS

CLK

CS

K0

K1

U201

PT6312

S0/K0

K3

K2

VDD

15

12

13

14

S1

S120NC21G122G223G3

25

24

S14

G8

37

35

40

38

G136G0

VDD

LED339LED2

S3/K318S4/K419S5/K5

S1/K116S2/K2

17

21

20

S2S3S4S5S6S7S8

G4

G526G627G728G8

G334G2

S15/G6

S14/G7

S13/G8

S12/G9

S11/G10

S6

S7

22

VF231VF2

VF2

32

29

G1G2G3G4G5G6G7

33

G4

32

G5

31

30

29

28

27

VEE

26

25

S10

24

S9

23

S8

R205

C202

101

G1

G2

G3

G4

G5

G6

G7

G8

S14

S13

S12

S11

S10

S9

2.2 1/2

C206

104

-30V

R234

0/NC

VFD__ 2

KEY SW3

KEY SW0

KEY SW1

KEY SW2

VFD_DATA

VFD_CLK

VFD_ST B

LED_MID

R213 1K

R214 1K

R215 1K

R216 1K

4K7

R217

C219

KEY3

KEY0

KEY1

KEY2

GND

GND

MCU+5V

VFD_DATA

VFD_CLK

VFD_ST B

IR

KEY_STBY

LED_STBY

ECO_POWER

MCU+5V

R218

100

104

LED_MID+

LED_MID-

Q201

8050

1

2

3

4

5

6

7

8

9

10

11

12

13

14

CN202

2.0/14P

3

2

1

CN203

2.0/3P

VFD2

SW201

SW H=5.0

MCU+5V

R220

22K

KEY_STBY

C210

104

IR201

JP201 0

R222

47

3

1

2

IR VCC

+

C214

104

R223

IR

33

JP223 0

JP222 0

JP221 0

JP220 0

JP219 0

JP217 0

JP218 0

GND

VFVF

VFD__2

GND

GND

-30V

KEY SW3

JP202 0

JP203 0

JP204 0

JP207 0

JP208 0

JP209 0

JP212 0

JP205 0

JP206 0

JP210 0

JP211 0

JP213 0

JP214 0

JP215 0

JP216 0

MCU+5V

IR

LED_MID

GND

A5V

-30V

GND

A5V

KEY3

KEY0

KEY1

KEY2

MCU+5V

DS-STB

DS-CLK

DS-DAT

ECO_POWER

LED_STBY

R221

C211

CE203

100u/10V

MCU+5V

MCU+5V

R219

1K

LED201

LED RED

4K7

104

Q202

8050

15-5 15-5

VFD_CLK

VFD_DATA

VFD_STB

C230 33P

C218 33P

C217 33P

C212 104

KEY_STBY

LED_STBY

ECO_POWER

C223 104

C222 104

C224 104

KEY0

KEY1

KEY3

IR

C225 33P

C226 104

KEY2

C229 104

C228 104

C227 104

Page 36

VFD Diaplay Board -- Layout Diagram

15-6 15-6

Page 37

MCU Board -- Circuit Diagram

CEC_IN

CEC_OUT

CN103

14

13

12

11

10

9

8

7

6

5

4

3

2

1

2.0/14P

KEY SW3

C110

104

5

4

3

2

1

CN106

2.0/5P

R101

18K

C101

10P

KEY SW3

KEY SW0

KEY SW1

KEY SW2

GND

GND

MCU+5V

VFD_DATA

VFD_CLK

VFD_STB

IR

KEY_STBY

LED_STBY

ECO_POWER

KEY SW0

KEY SW1

C111

104

C118

104

USB_VC C

USB_DUSB_D+

USB_GN D

R102

KEY SW2

C135

104

C133

NC/10P

VFD_DATA

C137

100K

IR

VFD_CLK

C138

33P

R104

47K

MCU+3.3V

R109

22K

D102

IN60

D103

IN60

VFD_STB

33P

C139

L107

10uH/1A

C134

NC/10P

33P

R105

27K

IN5819

Q101

BC847B

R116

220

C140

D101

33P

CEC3.3V

CECA

R110

22K

IR_MTK

IR_MCU

KEY_STBYIRLED_STBY

C141

C142

104

104

CE102

100u/10

MCU+3.3V

L101

10uH

C103

104

CN102

2.0/4P

4

3

2

1

MCU+3.3V

MCU+3.3V

GND

MODE

RST_MCU

MCU+3.3V

R111

10K

C112

103

R106

4K7

R118

100

C144

101

MCU+3.3V

R107

22K

C129

103

R119

100

R108

22K

MCU+3.3V

C115

USB

R117

1K/220

Q102

8050

104

CE103

100u/10

JP116 0

JP115 0

JP114 0

JP104 0

JP109 0

JP105 0

JP103 0

JP106 0

JP107 0

JP108 0

JP102 0

JP101 0

MCU+3.3V

C113

104

C116

104

C104

C106

C114

104

104

104

ECO_POWER

MCU+5V MCU+3.3V

C143

104

C117

104

C136

104

L103

10uH

_5V

C105

104

DZ101

3K3/3.9V

6

1

2

3

4

5

J101

I2C_SCL

100R120

P3.5/SCL

RST_MCU1

CE101

100u/10

I2C_SDA

R121

100

1

2

3

4

5

6

7

8

P3.5/SCL

P3.7

RESET

XOUT

VSS

XIN

VCC

MODE

HPD

HPD

HPD

GND

LED_T3

GND

IR_MTK

MCU+3.3V

GND

MCU+3.3V

IR_MTK

LED_T2

LED_T1

LED_T2

LED_T3

MUTE

R122 680

29

30

31

32

P0.0

P0.1/AN6

P0.2/AN5

U101

R5F21266NFP

P4.5/INT09P1.7/INT110P3.6

11

R124 2K2

R125 100

LED_STBY

CEC_IN

CEC_OUT

ECO_POWER

KEY SW3

KEY SW0

KEY SW1

MTK_RST

R123 330

28

25

27

P0.7

P0.626P0.5

P0.4

P0.3/AN4

P3.4/SDA

P1.4/TXD0

P5.3

P3.112P5.4

P1.5/RXD0

P1.6

16

14

15

13

R126 100

KEY_STBY

JP124 0

JP125 0

JP110 0

JP111 0

JP112 0

JP121 0

JP113 0

JP120 0

JP119 0

JP118 0

JP117 0

JP122 0

JP123 0

MCU+3.3V

R132

22K

SDA_MCU

P3.3

P1.0

P1.1

VREF

P1.2

P1.3

24

23

22

21

20

19

18

17

MCU+3.3V

R130

HPD

GND

GND

MODE

GND

LED_T1

IR_MTK

GND

HDMI+5V

MTK_RST

MUTE

CECA

GND

GND

K_SW2

1K

MCU+3.3V

10K

R131

R112

22K

LED102

LED W

KEY SW2

KEY_DATA

KEY_CLK

IR_MCU

MCU+3.3V

_5V

NC/10uH

I2C_SDA

C119

R113

47

LED_T1

MAX 220PF

KEY_CLK

KEY_DATA

C107

104

L104

I2C_SCL

33P

C120

VFD_STB

33P

C124

C130

104

L102

C108

104

33P

LED103

LED W

C122

101

L105

FB

FB

L106

10uH

VFD_CLK

VFD_DATA

33P

C126

C125

LED_T2

KEY_CLK

C121