Philips BDP-7100 Service Manual

BLU-RAY DISC PLAYER

BDP7100/12

Contents Page Contents Page

1 Technical Specifications 2

Location PCB Drawing 3

2 Safety Precautions 4

Servicing Precautions 6

ESD Precautions 7

Handing optical pick-up 8

Lead-Free Requirement 9

3 Disassembly Instructions 10

4 Trouble Shooting 16

5 Firmware Upgrading 35

6 Block and Wiring Diagram 37

Block Diagram 37

Wiring Diagram 38

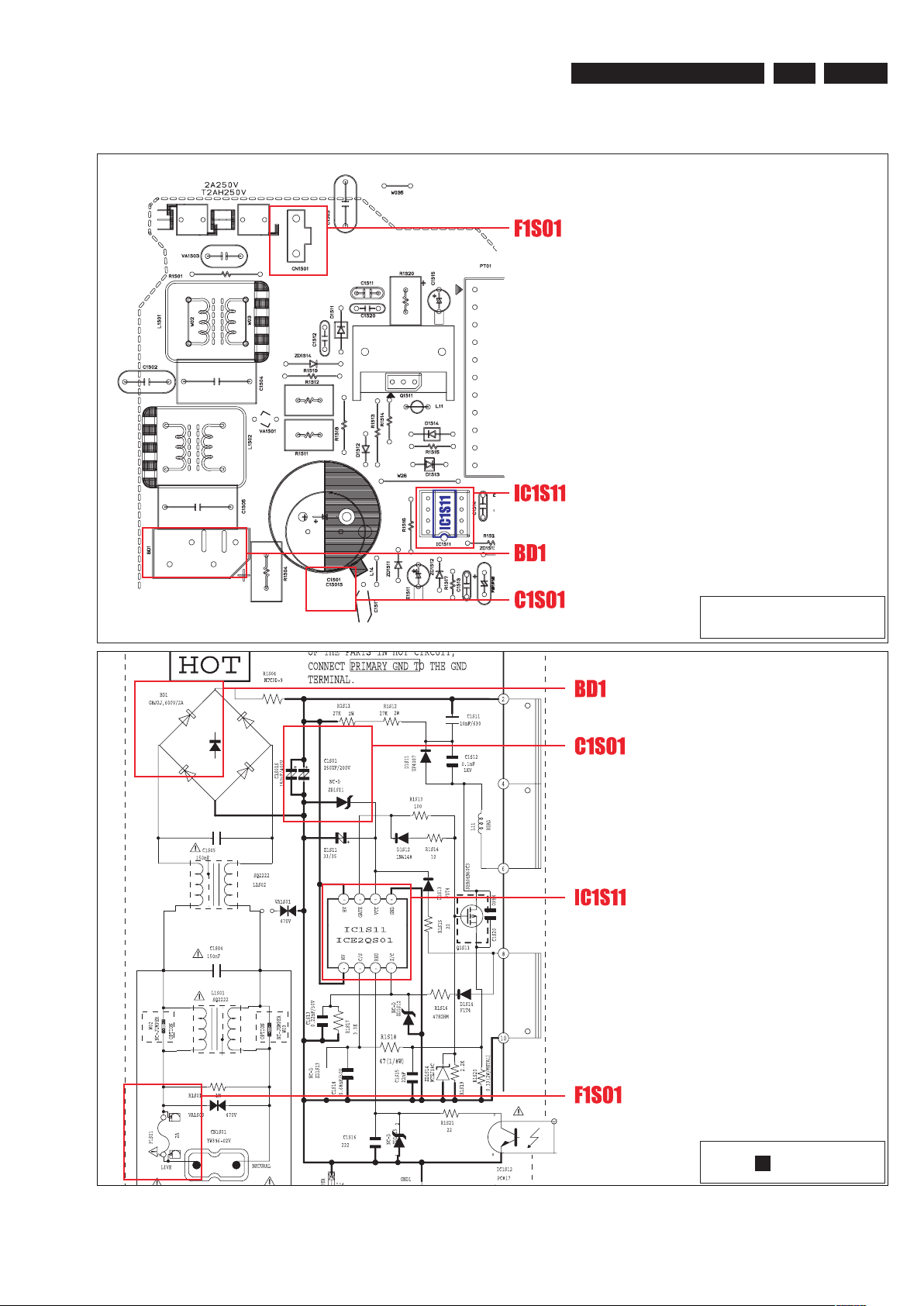

7 Circuit Diagrams and PCB Layouts 39

S.M.P.S (S.M.P.S PCB) 39

SMP8634 DDR SDRAM (Main PCB) 40

SMP8634 Flash Memory (Main PCB) 41

Nand Flash, Controller (Main PCB) 42

SMP8634 Power, Decoupling (Main PCB) 43

Sil9134 HDMI (Main PCB) 44

HDMI-CEC (Main PCB) 45

Ethernet contol (Main PCB) 46

Audio (Main PCB) 47

7 Circuit Diagrams and PCB Layouts 48

SMP8634 GPIO Control, JTAG,

Debug (Main PCB) 48

MM1757 Analog Video Out (Main PCB) 49

PATA Control (Main PCB) 50

Power (Main PCB) 51

PCI, ETC (Main PCB) 52

Front Interface (Main PCB) 53

Front (Front PCB) 54

Power Key (Power Key PCB) 55

7 PCB Layouts 56

Main PCB Component Side-1 56

Main PCB Component Side-2 57

Main PCB Conductor Side-2 58

S.M.P.S PCB Component Side 59

S.M.P.S PCB Conductor Side 60

Front PCB Component Side and

Conductor Side 61

Power Key PCB Component Side and

Conductor Side 62

8 Exploded View and Service Parts List 63

Cabinet Assembly 63

Service Parts List 64

9 Directions for Use 65

10 Revision List 67

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by KC-TE 0740 V&MA Printed in he Netherlands Subject to modification EN 3139 785 32971

Version 1.1

EN 2

3139 785 32970

1.

Technical Specifications

1. Technical Specification

1.1 General

Mains voltage : 220V ~ 230V

Mains frequency : 50Hz

Power consumption : 29 W

Standby Power consumption : < 1.1W

1.2 Dimensions and Weight

Height of feet : 2mm

Apparatus tray closed : WxDxH: 430 x 319 x

79mm

Apparatus tray open : WxDxH: 430 x 445 x

79mm

Weight without packaging : 4.3kg

Weight with packaging : 7.4kg

1.3 Optical Drive reading speed

BD (Blu-ray Disc) : 4.917 m/s

DVD : 3.49 – 4.06 m/s

CD 12cm : 4.8 – 5.6 m/s

CD 8cm : 4.8 – 5.6 m/s

1.4 Region codes

BD (Blu-ray Disc) : B

DVD : 2

1.5 Playable Disc types

1.8.1 Component Video:

Outpuy Impedance : 75 Ω

SNR : > -60dB on all output

Bandwidth Y : 5.7MHz ± 3dB (480i)

11.6MHz ± 3dB (480p)

26.1MHz ± 1dB

(720p/1080i)

Bandwidth PbPr : 2.9MHz ± 3dB (480i)

5.8MHz ± 3dB (480p)

13MHz ± 1dB

(720p/1080i)

Supports: : BD: 1080i, 720p, 480p,

480i

DVD : 480p, 480i

1.8.2 Composite Video (CVBS):

Output Impedance : 75Ω

SNR Luminance : > -65dB

SNR Chrominance AM : > -59dB

SNR Chrominance PM : > -49dB

Bandwidth Luminance : 4.2MHz ± 1dB

Supports: : BD: 480i / DVD: 480i

1.8.3 S-Video:

Output Impedance : 75Ω

SNR Y : > -65dB

SNR C AM : > -59dB

SNR C PM : > -49dB

Bandwidth Y : 4.2MHz ± 1dB

Supports: : BD: 480i / DVD: 480i

BD-ROM : BD-ROM ver2.0, BD RE2.0 and 3.0, BD Rv1.0, v2.0

DVD : DVD Video, DVD-R/RW

(4.7GB)

CD : Audio CD, CD-RW, CD-R

1.6 Audio Output:

2-Channel analog : Left / Right

5.1 Channel : Front L/R, Rear L/R,

Center, Subwoofer

HDMI : PCM multi-channel audio,

bitstream audio, PCM

audio

Digital audio output : Optical/Coaxial (S/PDIF)

1.7 Video Output:

Component video: Y : 1Vpp 75Ω load

Pb : 0.7Vpp 75Ω load

Pr : 0.7Vpp 75Ω load

Composite video : 1Vpp 75Ω load

S-Video: Luminance : 1Vpp 75Ω load

Chrominance : 0.3Vpp 75Ω load

HDMI : 480p, 720p, 1080i, 1080p

1.8 Video Performance

1.9 Audio Performance

Output voltage : 2Vrms ± 5%

Channel unbalance (1kHz) : < 0.1dB

Crosstalk 1kHz : < -110dB

Crosstalk 20Hz-20kHz : < -95dB

Frequency response

20Hz-20kHz : ± 0.1dB max.

Signal to noise ratio

(unweighted) : > 115dB

Dynamic range 1kHz : > 95dB

Distortion and noise 1kHz : < -90dB

Distortion and noise

20Hz-20kHz : < -90dB

Intermodulation distortion : < -80dB

Mute : < -100dB

Outband attenuation (above

25kHz) : > 50dB

1.10 Laser Output Power & Wavelength

1.10.1 Blu-Ray Disc

Output power : 0.35mW (single),

0.7mW (Dual)

Wavelength : 405nm

1.10.2 DVD

Output power : 0.8mW

Wavelength : 650nm

1.10.3 CD

Output power : 0.3mW

Wavelength : 780nm

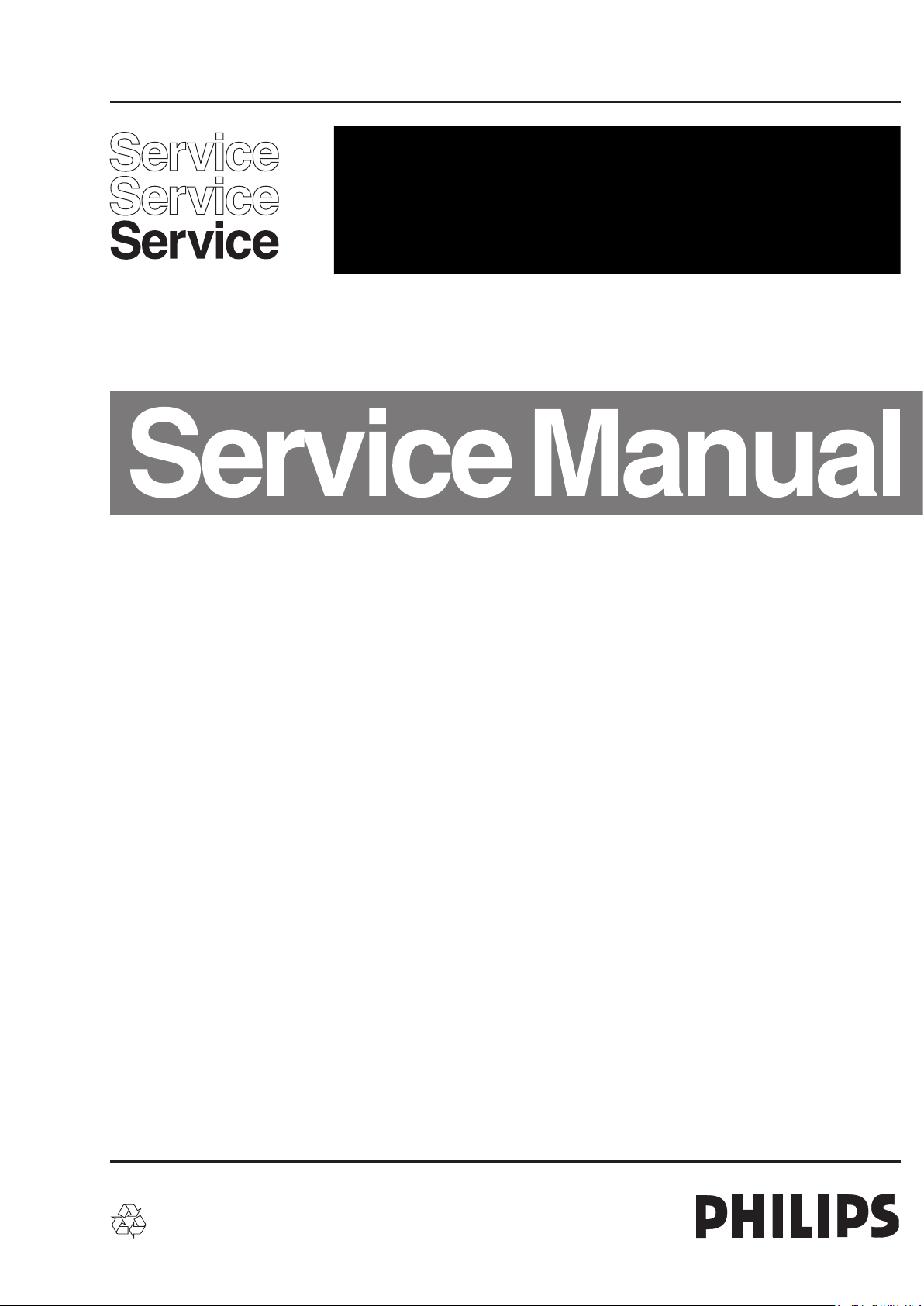

MAIN PCB

S.M.P.S PCB

BDP LOADER ASSY

1.11 PCB Location

Location PCB Drawing

3139 785 32970

1.

EN 3

EN 4

3139 785 32970

2.

Precautions

Fig. 1-1 AC Leakage Test

Fig. 1-2 Insulation Resistance Test

2. Precautions

2-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire

instrument, including, but not limited to, the

following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1) Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2) When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in

place all protective devices, including, but not

limited to, nonmetallic control knobs, insulating

fish papers, adjustment and compartment covers/

shields, and isolation resistor/capacitor networks.

Do not operate this instrument or permit it to be

operated without all protective devices correctly

installed and functioning.

(2) Be sure that there are no cabinet openings

through which adults or children might be able

to insert their fingers and contact a hazardous

voltage. Such openings include, but are not limited

to, excessively wide cabinet ventilation slots, and

an improperly fitted and/or incorrectly secured

cabinet back cover.

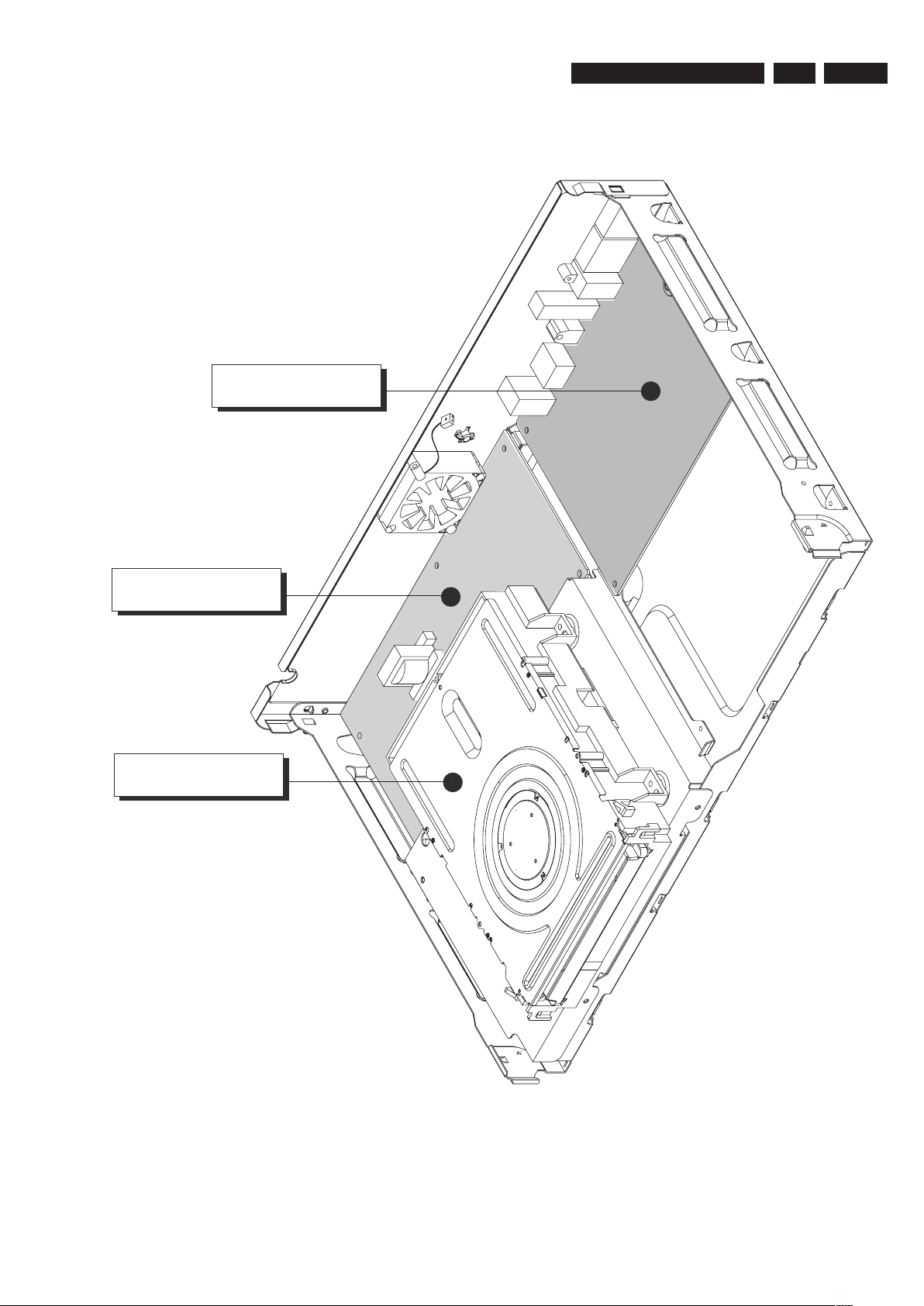

(3) Leakage Current Hot Check-With the

instrument completely reassembled, plug the

AC line cord directly into a 230V(220V ~ 240V)

AC outlet. (Do not use an isolation transformer

during this test.) Use a leakage current tester

or a metering system that complies with

American National Standardsp institute (ANSI)

C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1270 (40.7). With

the instrument’s AC switch first in the ON position

and then in the OFF position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinets,

screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer

an electrical return path to the chassis. Any current

measured must not exceed 0.5mA. Reverse

the instrument power cord plug in the outlet and

repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to the

customer

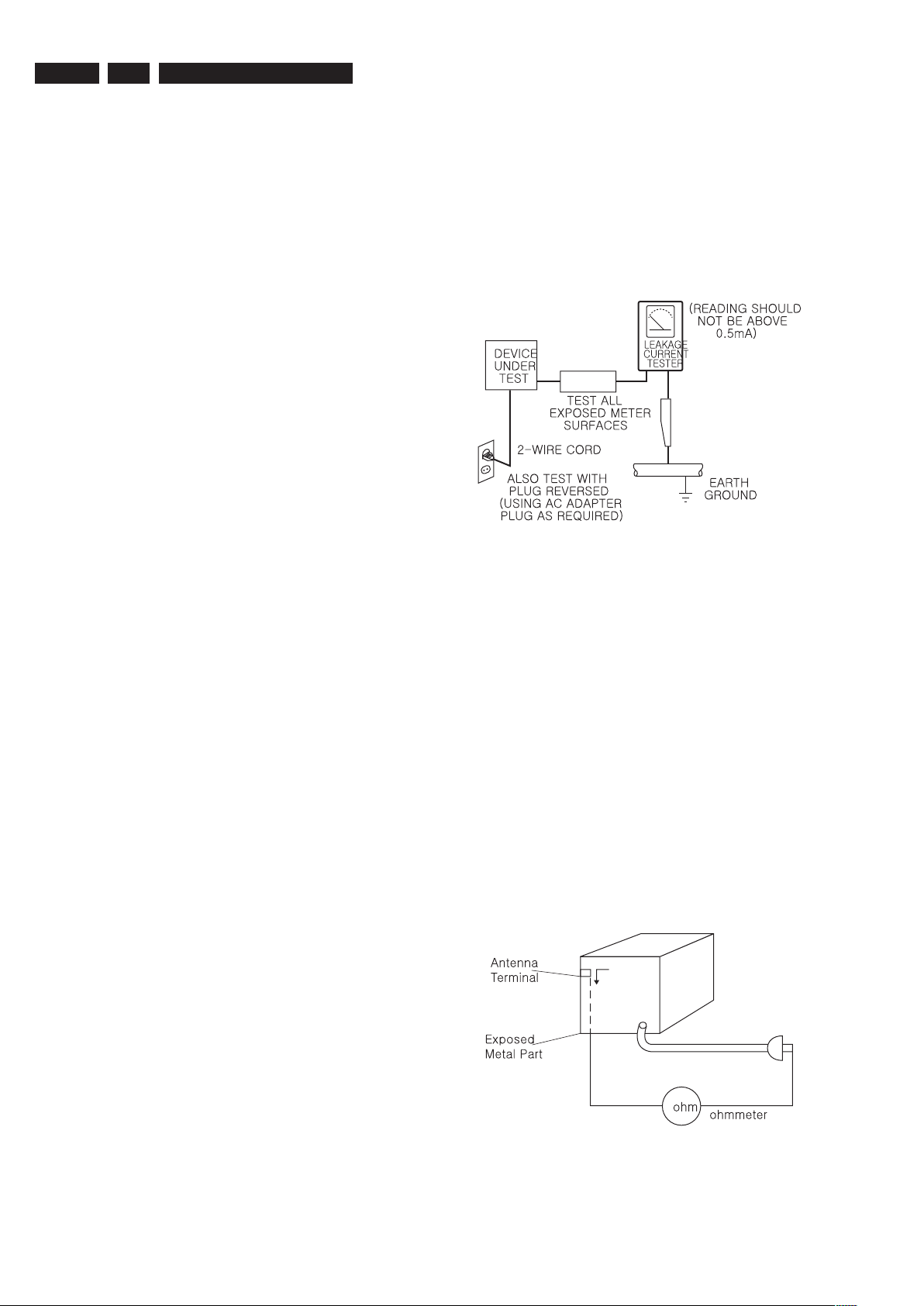

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug.

(2) Turn on the power switch of the instrument.

(3) Measure the resistance with an ohmmeter

between the jumpered AC plug and all exposed

metallic cabinet parts on the instrument, such as

screwheads, antenna, control shafts, handle brackets,

etc. When an exposed metallic part has a return path

to the chassis, the reading should be between 1 and

5.2 megohm. When there is no return path to the

chassis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibility of

a shock hazard, and the instrument must be repaired

and rechecked before it is returned to the customer.

See Fig. 1-2.

.

Precautions

Precautions

3139 785 32970

2.

EN 5

2) Read and comply with all caution and safety

related notes on or inside the cabinet, or on the

chassis.

3) Design Alteration Warning-Do not alter or add

to the mechanical or electrical design of this

instrument.

Design alterations and additions, including but not

limited to, circuit modifications and the addition of

items such as auxiliary audio output connections,

might alter the safety characteristics of this

instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts

(be sure that leads and components do not touch

thermally hot parts), (3) the AC supply, (4) high

voltage, and (5) antenna wiring. Always inspect in

all areas for pinched, out-of-place, or frayed wiring,

Do not change spacing between a component and

the printed-circuit board. Check the AC power cord

for damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by shading, an ( )or a ( )on schematics

and parts lists. Use of a substitute replacement

that does not have the same safety characteristics

as the recommended replacement part might

create shock, fire and/or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

EN 6

3139 785 32970

2.

Precautions

2-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.Note : If

unforseen circumstances create conflict between the

following servicing precautions and any of the safety

precautions, always follow the safety precautions.

Remember: Safety First.

2-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC powercord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic ca pacitor

in the instrument.

b. Do not defeat any plug/socket B+ voltage

interlocks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and/or

any of its electrical assemblies unless all solidstate device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting

the test instrument positive lead. Alwaysremove

the test instrument ground lead last.

(4) An insulation tube or tape is sometimes used

and some components are raised above the

printed wiring board for safety. The internal wiring

is sometimes clamped to prevent contact with

heating components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been

installed correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades

of the attachment plug and accessible conductive

parts.

2-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive parts

(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal

panels,input terminals, earphone jacks, etc.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed

on the cabinet, chassis or components. When

servicing, follow the printed or indicated service

precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength. When

replacing components, use components which

have the same ratings. Components identified

by shading, by ( ) or by ( ) in the circuit diagram

are important for safety or for the characteristics

of the unit. Always replace them with the exact

replacement components.

2-3 ESD Precautions

Electrostatically Sensitive Devices (ESD)

Precautions

3139 785 32970

2.

EN 7

Some semiconductor (solid state) devices can be

dam-agedeasily by static electricity.Such components

commonly are called Electrostatically Sensitive

Devices(ESD). Examples of typical ESD devices are

integrated circuits and some field-effect transistors

and semiconductor chip components. Thefollowing

techniques should be used to help reducethe

incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body

by touching a known earth ground. Alternatively,

obtain and wear a commercially available

discharging wrist strap device, which should be

removed for potential shock reasons prior to

applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a

conductive surface such as aluminum foil, to

prevent electrostatic charge buildup or exposure

of the assembly.

CAUTION : Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling

unpackaged replacement ESD devices.

(Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static

electricity sufficient to damage an ESD device).

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges

sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESD devices.

(6) Do not remove a replacement ESD device from

its protective package until immediately before

your are ready to install it.(Most replacement

ESD devices are packaged with leads electrically

shorted together by conductive foam, aluminum foil

or comparable conductive materials).

(7) Immediately before removing the protective

materials from the leads of a replacement ESD

device, touch the protective material to the chassis

or circuit assembly into which the device will be

installed.

EN 8

3139 785 32970

2.

Precautions

Fig.1-3

2-4 Handling the optical pick-up

The laser diode in the optical pick up may suffer

electrostatic breakdown because of potential static

electricity from clothing and your body.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The

black sheet used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

(3) Place your hands on the conductive sheet (This

gives them the same ground as the sheet.)

(4) Remove the optical pick up block

(5) Perform work on top of the conductive sheet. Be

careful not to let your clothes or any other static

sources to touch the unit.

Be sure to put on a wrist strap grounded to the

sheet.

Be sure to lay a conductive sheet made of copper

etc. Which is grounded to the table.

(6) Short the short terminal on the PCB, which is

inside the Pick-Up ASS’Y, before replacing the

Pick- Up. (The short terminal is shorted when the

Pick- Up Ass’y is being lifted or moved.)

(7) After replacing the Pick-up, open the short terminal

on the PCB.

Precautions

3139 785 32970

2.

EN 9

2.5 Lead Free Requirement

Information about Lead-free produced sets

Philips CE is starting production of lead-free sets from

1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1 Jan 2005 onwards,

according next rules.

Example S/N:

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is

the week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

• Special information for BGA-ICs:

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of

• On our website www.atyourservice.ce.Philips.com you

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in Philips-

You will find this and more technical information within

For additional questions please contact your local repair-helpdesk.

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for de-soldering

always use the lead-free temperature profile, in case of

doubt)

- lead free BGA-ICs will be delivered in so-called ‘drypackaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening, dependent

of MSL-level seen on indicator-label in the bag, the

BGA-IC possibly still has to be baked dry. (MSL=Moisture

Sensitivity Level). This will be communicated via AYSwebsite.

2004), containing leaded solder-alloy and components,

all needed spare-parts will be available till the end of the

service-period. For repair of such sets nothing changes.

find more information to:

sets

the “magazine”, chapter “workshop news”.

Important note: In fact also products of year 2004 must be treated in this way as long as

you avoid mixing solder-alloys (leaded/ lead-free). So best to always use SAC305 and the

higher temperatures belong to this.

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

• Use only adequate solder tools applicable for lead-free

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

• Mix of lead-free solder alloy / parts with leaded solder

• Use only original spare-parts listed in the Service-

order code 0622 149 00106. If lead-free solder-pate

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste within

workshops should be avoided because paste is not easy

to store and to handle.

solder alloy. The solder tool must be able

360°C – 380°C is reached and stabilized at the solder

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400°C otherwise

wear-out of tips will rise drastically and flux-fluid will be

destroyed. To avoid wear-out of tips switch off un-used

equipment, or reduce heat.

alloy / parts is poss ble but PHILIPS recommends

strongly to avoid mixed solder alloy types (leaded and

lead-free).

If one cannot avoid or does not know whether product is

lead-free, clean carefully the solder-joint from old solder

alloy and re-solder with new solder alloy (SAC305).

Manuals. Not listed standard-material (commodities) has

to be purchased at external companies.

EN 10

3139 785 32970

3.

Disassembly Instructions

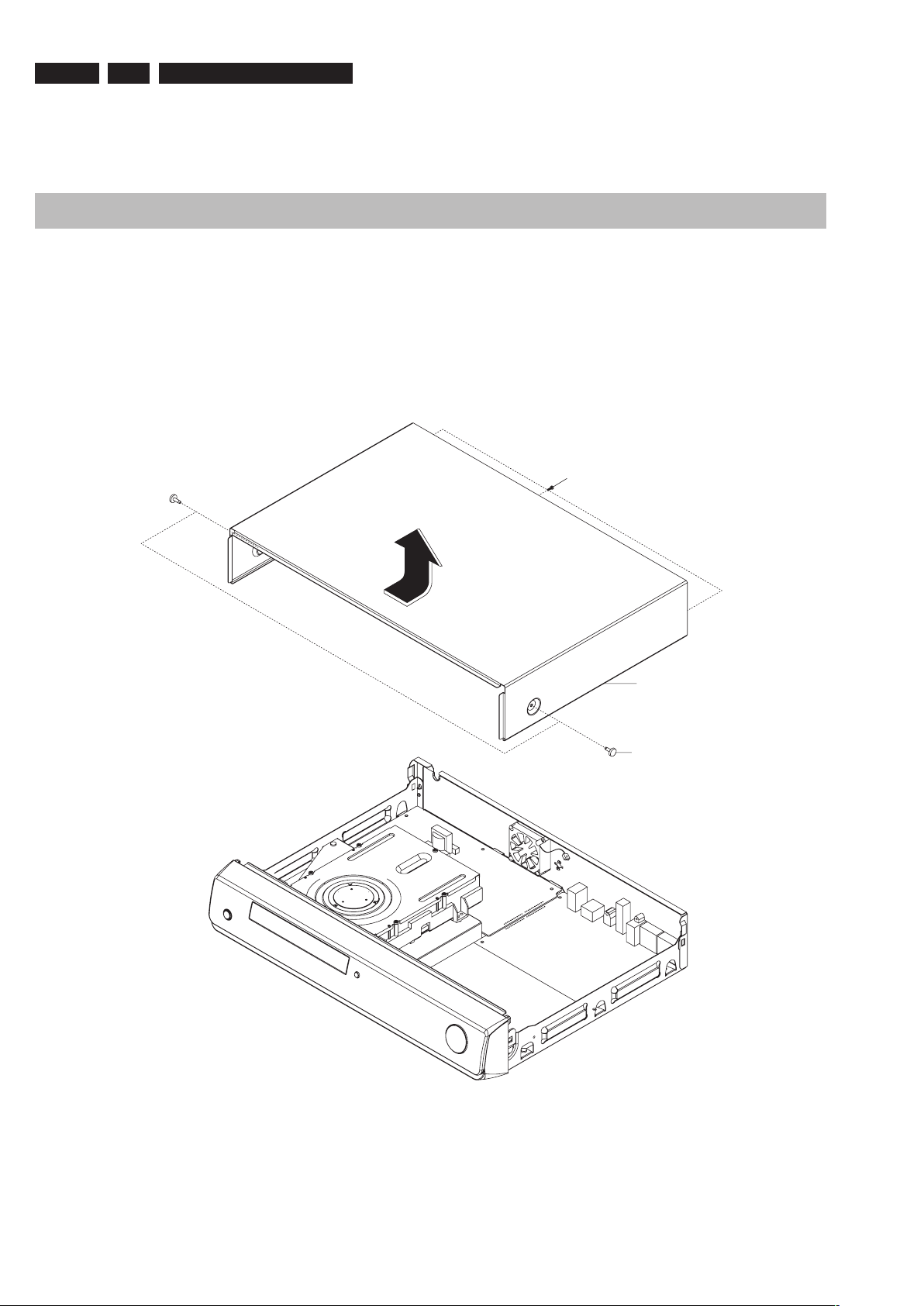

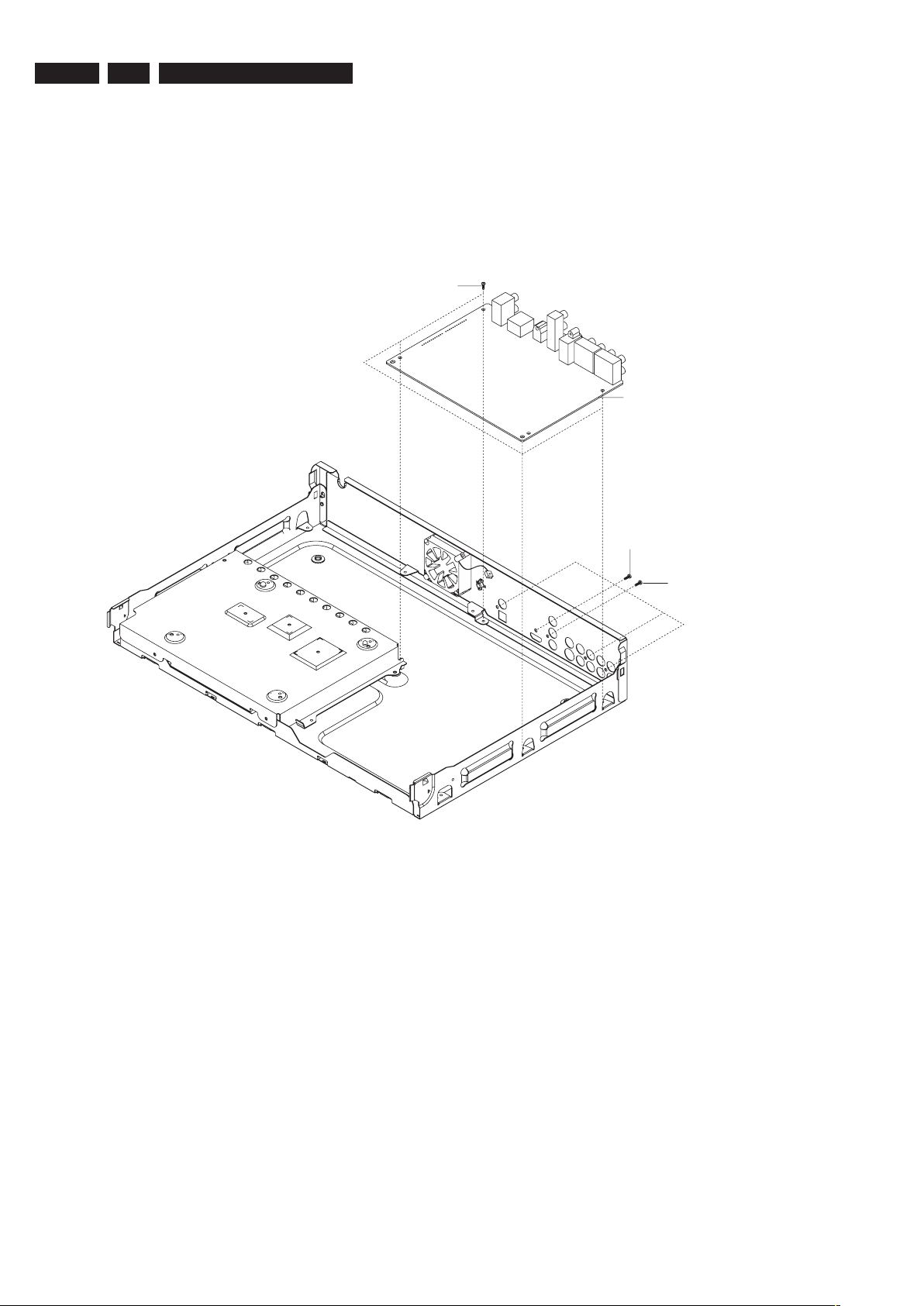

Fig. 3-1 Top Cabinet Removal

3 SCREWS

(3X10 B)

TOP CABINET

2 SCREWS

(3X8 B)

2

3

1

3. Disassembly and Reassembly

Cabinet and PCB

CAUTION : Connector Must be removed with care

3-1 Top Cabinet Removal

1) Remove 5 Screws 1 2.

2) Lift up the Top Cabinet 3 in direction of arrow.

Disassembly Instructions

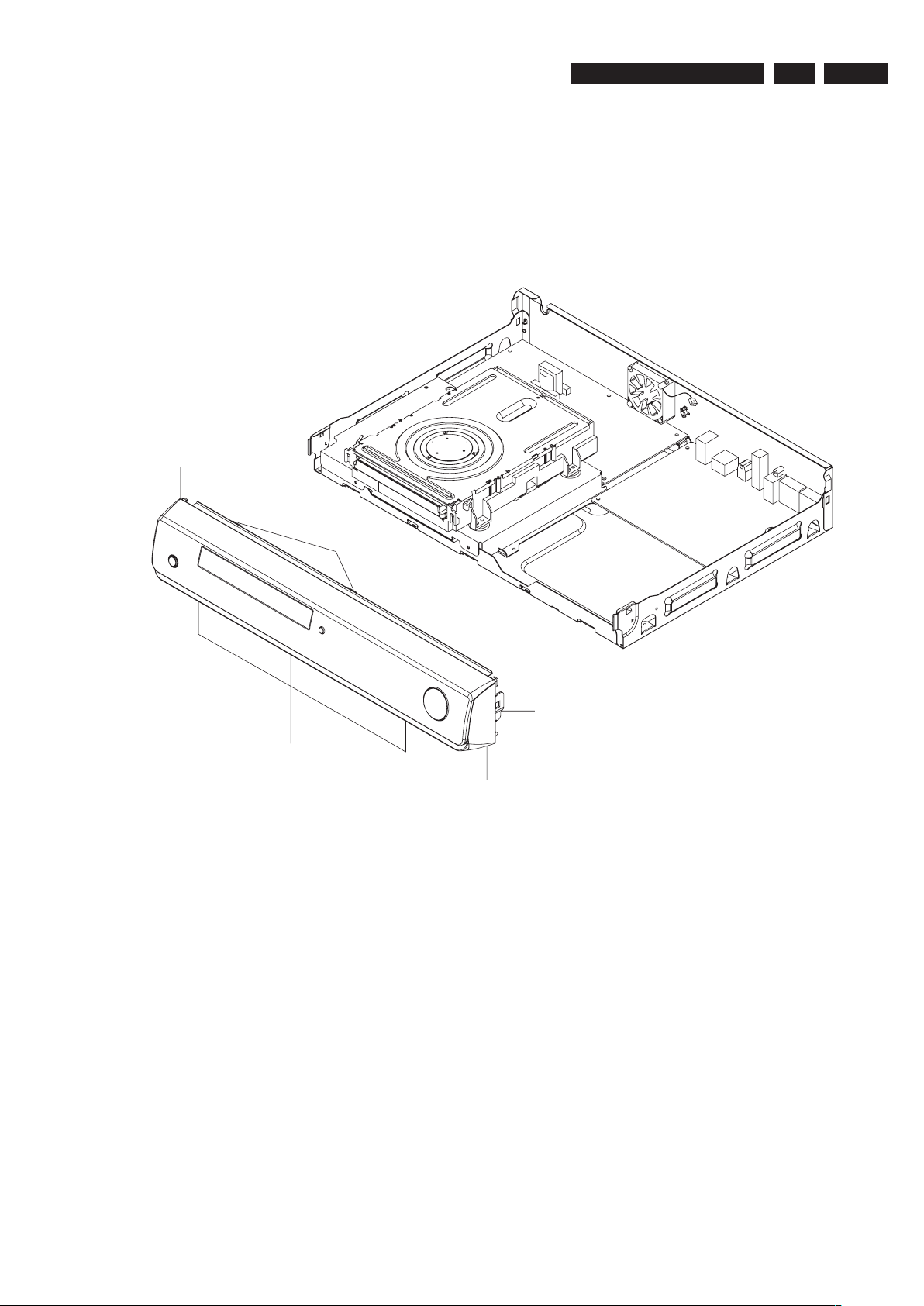

Fig. 3-2 Ass’y Front-Cabinet Removal

1 HOOK

ASS’Y FRONT-CABINET

2 HOOKS

3 HOOKS

1 HOOK

1

4

3

2

5

3-2 Ass’y Front-Cabinet Removal

1) Release 7 Hooks 1, 2, 3, 4 and Ass’y Front-Cabinet 5.

3139 785 32970

3.

EN 11

EN 12

3139 785 32970

3.

Disassembly Instructions

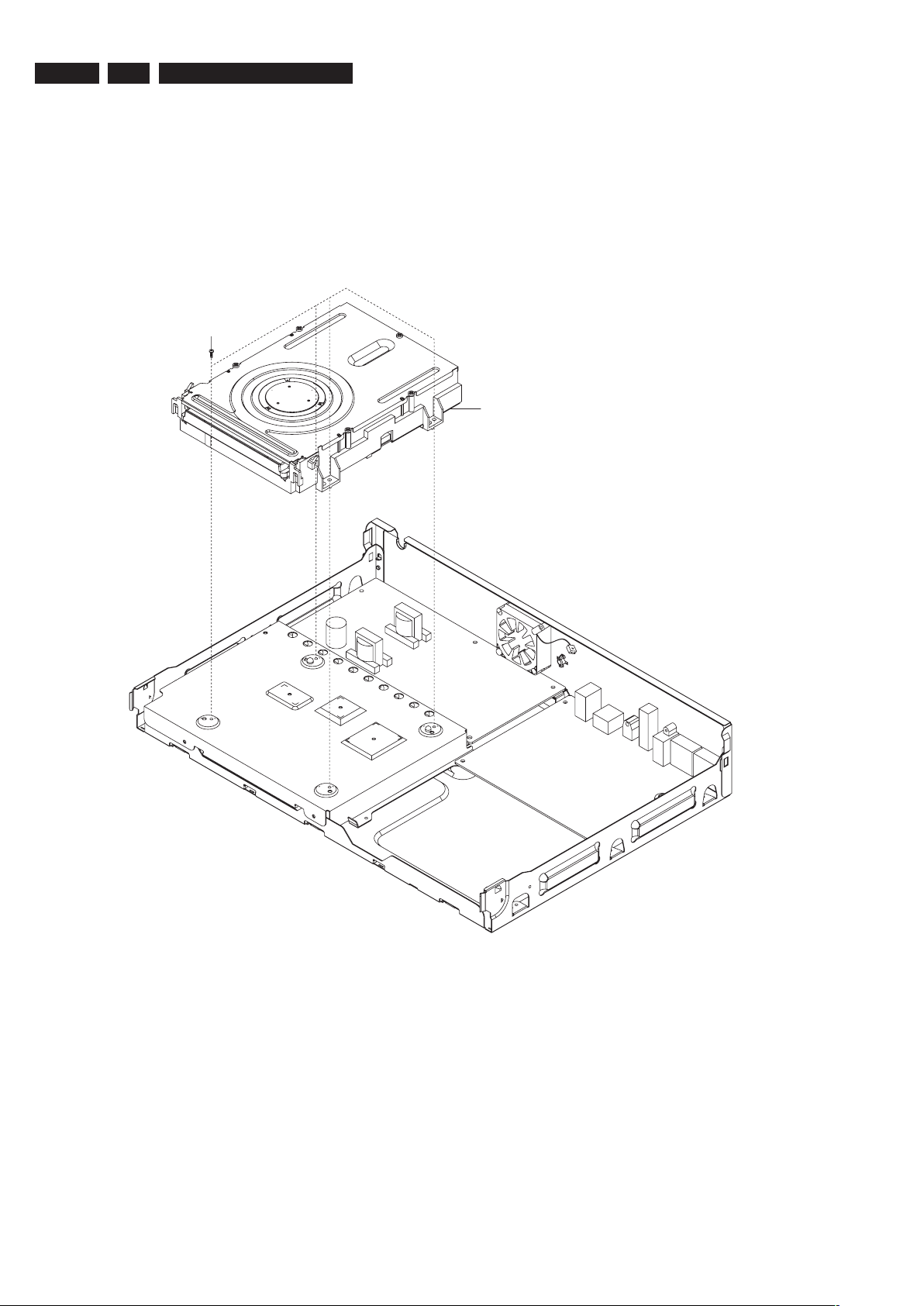

Fig. 3-3 Ass’y Deck Removal

4 SCREWS

(3X10 W)

ASS’Y DECK

1

2

3-3 Ass’y Deck Removal

1) Remove 4 Screws 1 from the Ass’y Deck 2 and lift it up.

Disassembly Instructions

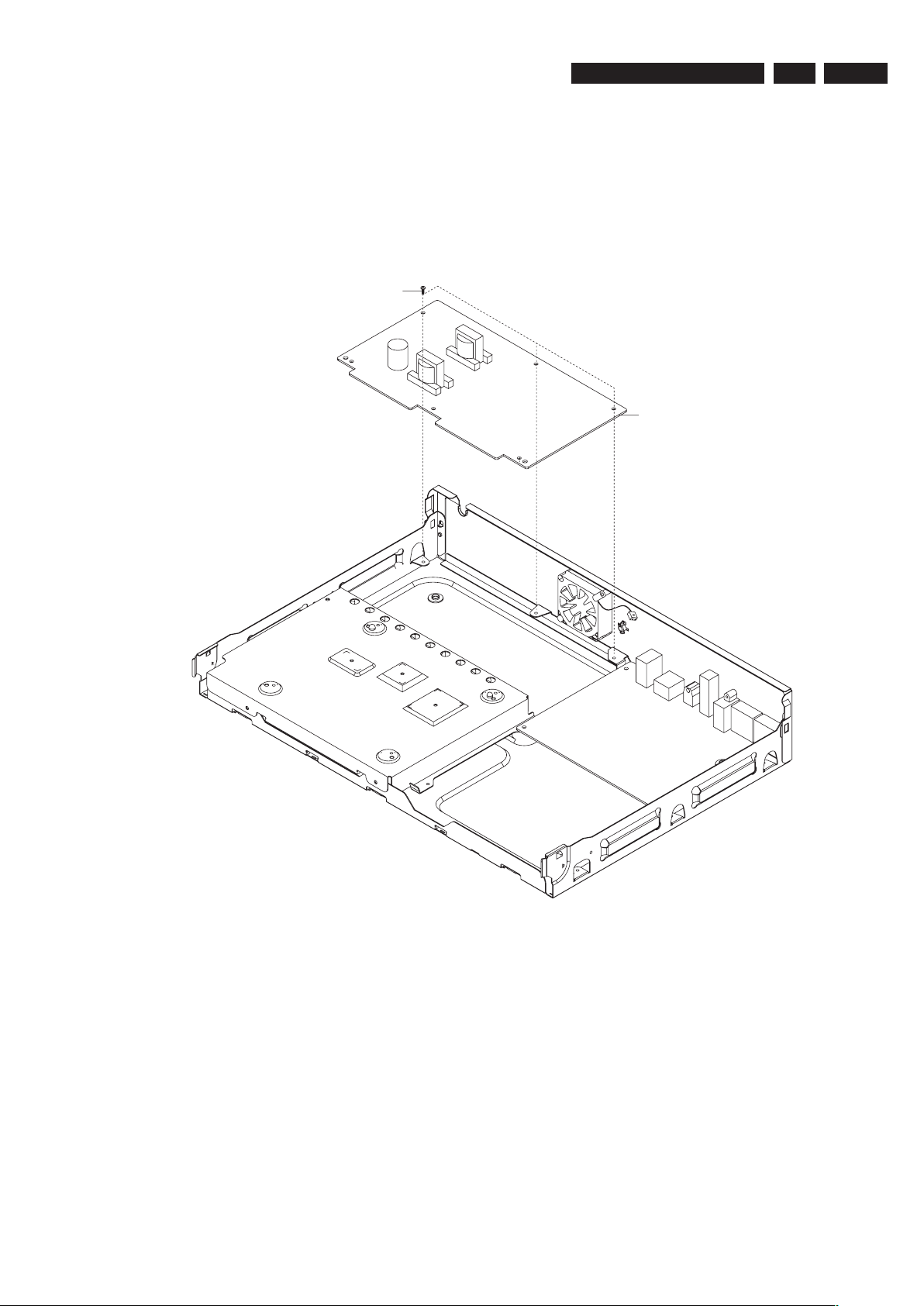

Fig. 3-4 S.M.P.S PCB Removal

6 SCREWS

(3X8 W)

S.M.P.S PCB

1

2

3-4 S.M.P.S PCB Removal

1) Remove 3 Screws 1, from the S.M.P.S PCB 2 and lift it up.

3139 785 32970

3.

EN 13

EN 14

3139 785 32970

3.

Disassembly Instructions

Fig. 3-5 Main PCB Removal

MAIN PCB

1 SCREW

(3X6 B)

4 SCREWS

(3X6 W)

5 SCREWS

(3X10 B)

1

4

2

3

3-5 Main PCB Removal

1) Remove 10 Screws 1, 2, 3 from the Main PCB 4 and lift it up.

Disassembly Instructions

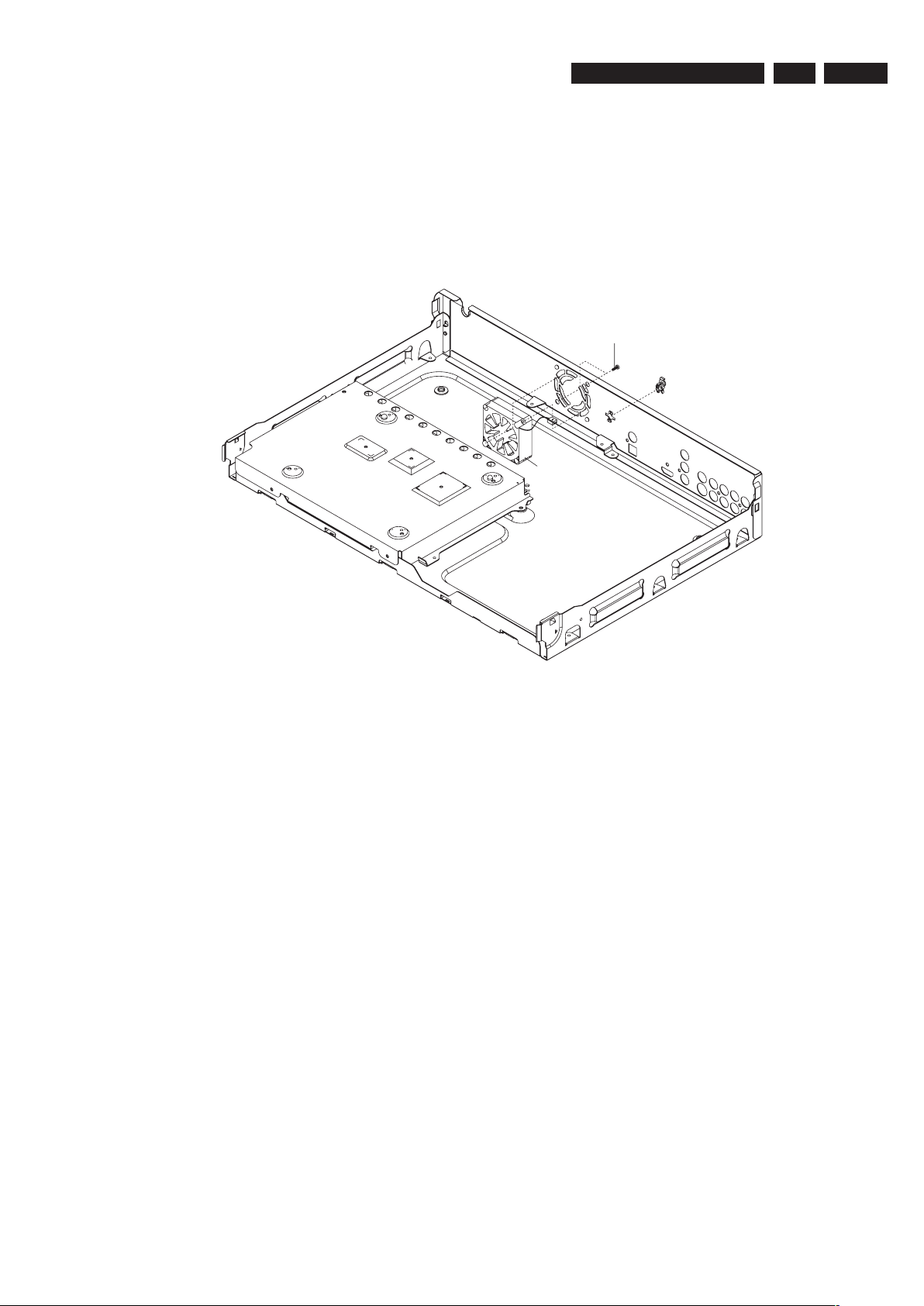

Fig. 3-6 FAN Removal

2 SCREWS

(5X14 S)

FAN

1

2

3-6 FAN Removal

1) Remove 2 Screws 1 from the Fan 2 and lift it up.

3139 785 32970

3.

EN 15

EN 16

3139 785 32970

4.

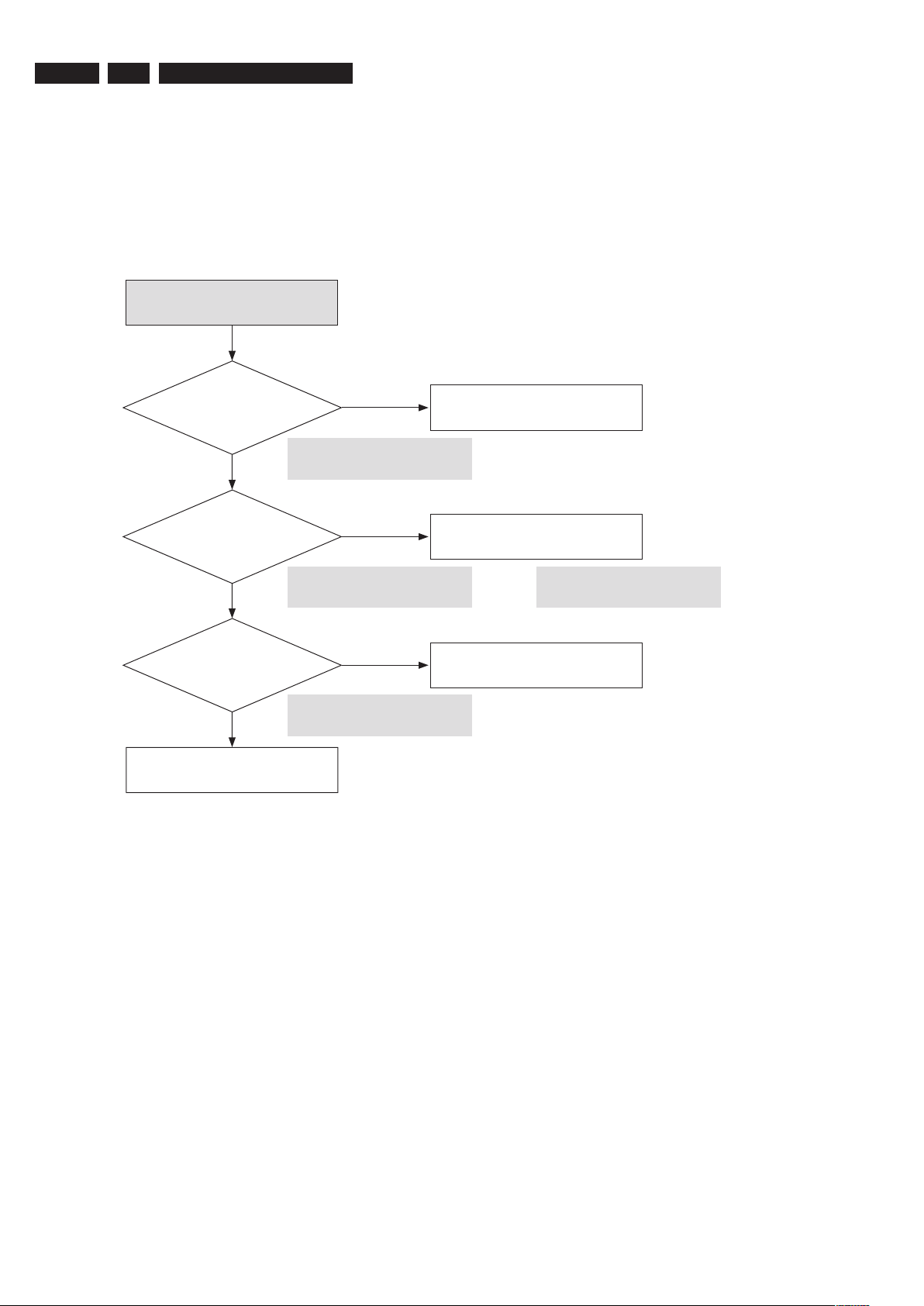

Trouble Shooting

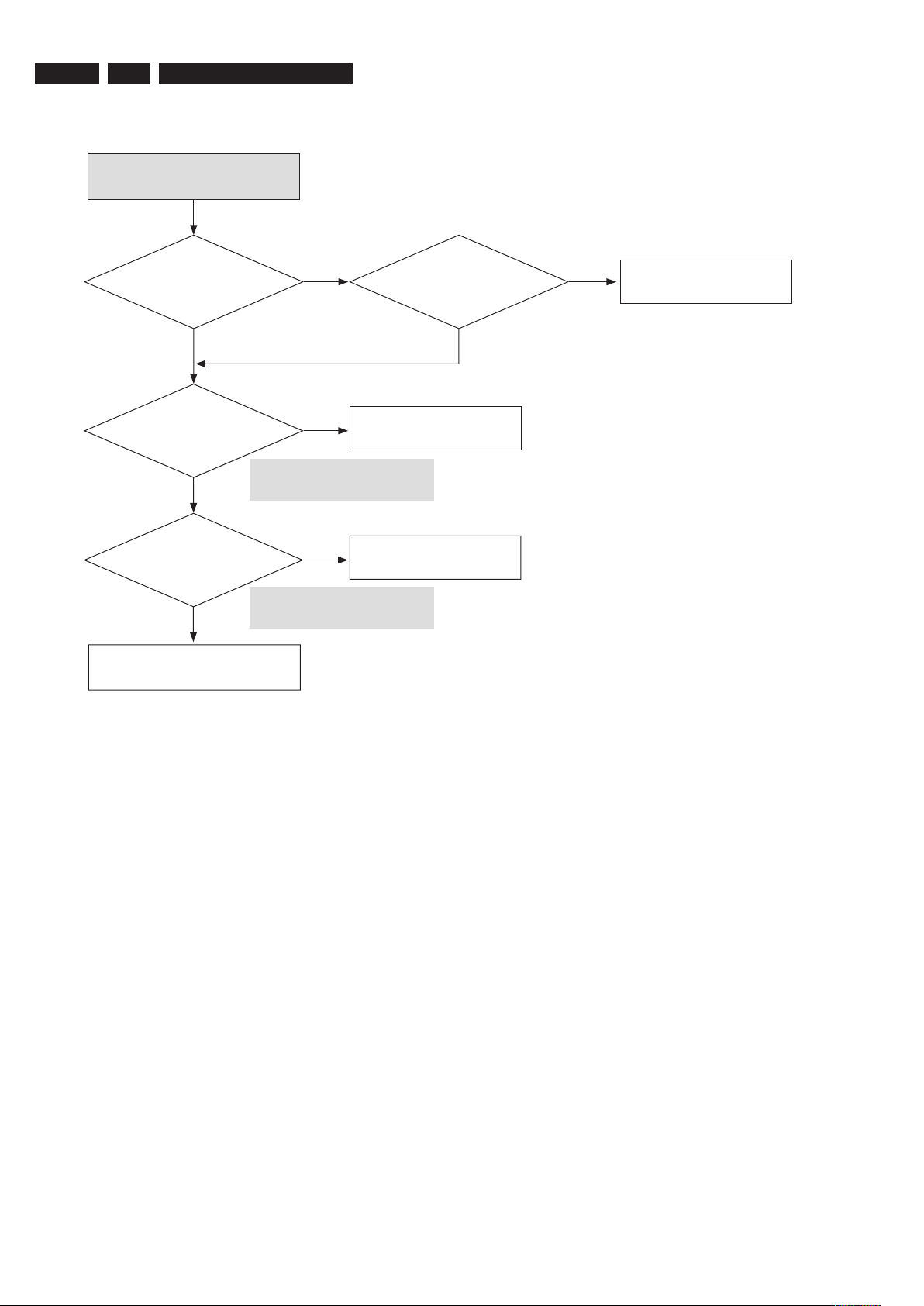

NO Power Detected

(Stand by LED OFF)

F1S01 is normal?

C1S01

voltage

is normal voltage?

Switching

operation

of IC1S11 is normal?

Change the SMPS PCB

Change fuse

Change BD1

Change IC1S11

No

Yes

No

No

Yes

Yes

Refer to Fig. 4-1

Refer to Fig. 4-1 Refer to Fig. 4-1

Refer to Fig. 4-1

4 Trouble Shooting

Trouble Shooting

Fig. 4-1

Refer to S.M.P.S. PCB

COMPONENT SIDE

Refer to 1 (Circuit Diagrams)

3139 785 32970

4.

EN 17

EN 18

3139 785 32970

4.

Trouble Shooting

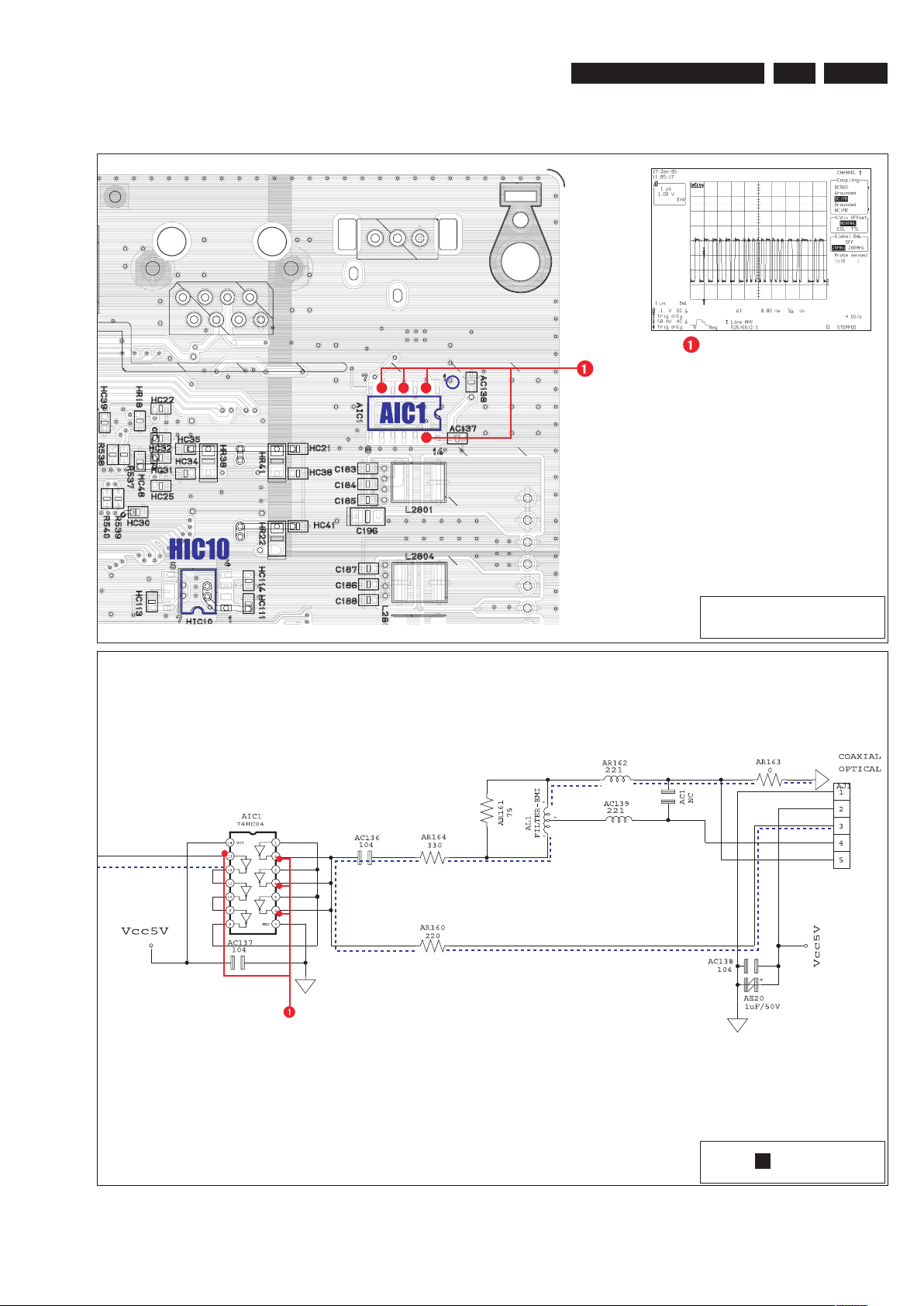

There’s no Digital Audio Out

Check

Current Digital Audio

Setting is PCM.

Set to Bitstream

No

Yes

Check

the A/V Receiver can

Decode Current

Bit-Steam

No

Yes

Check

Digital Audio Data

at AIC 1 (Pin 2,4,6)

No

Yes

Check AIC1 soldering or

replace AIC1

Digital Audio cable error

Check the

Audio Data at AIC1

(Pin 13)

No

Yes

Replace the Main PCB

Refer to Fig. 4-2

Refer to Fig. 4-2

Trouble Shooting

Fig. 4-2

DIGITAL AUDIO DATA

AIC1 (Pin2,4,6,13)

Refer to Main PCB

CONDUCTOR SIDE

Refer to 9 (Circuit Diagrams)

3139 785 32970

4.

EN 19

EN 20

3139 785 32970

4.

Trouble Shooting

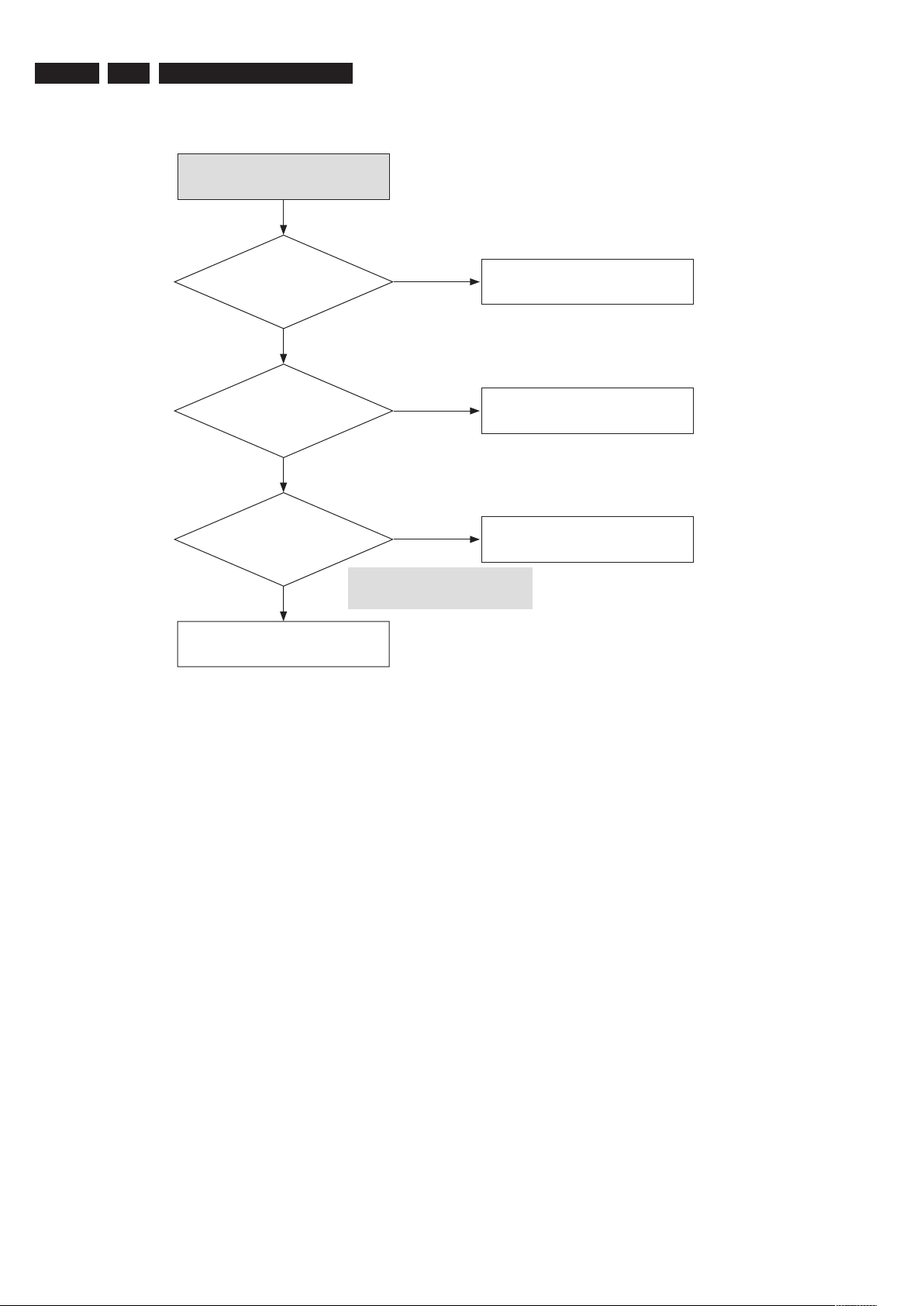

There is no Audio Output

Check

the Audio

signal at PIN 13,14,15,16

of AIC2

Check

the Audio

signal at pin1,2,37~48 of

AIC2

Check

the Audio

signal at AIC4,5,6,7

Audio cable error

Replace the main PCB

Check AIC2 soldering or replace

AIC2

Check AIC4~7 soldering of

peripheral devices

No

Yes

No

No

Yes

Yes

Refer to Fig. 4-3

Trouble Shooting

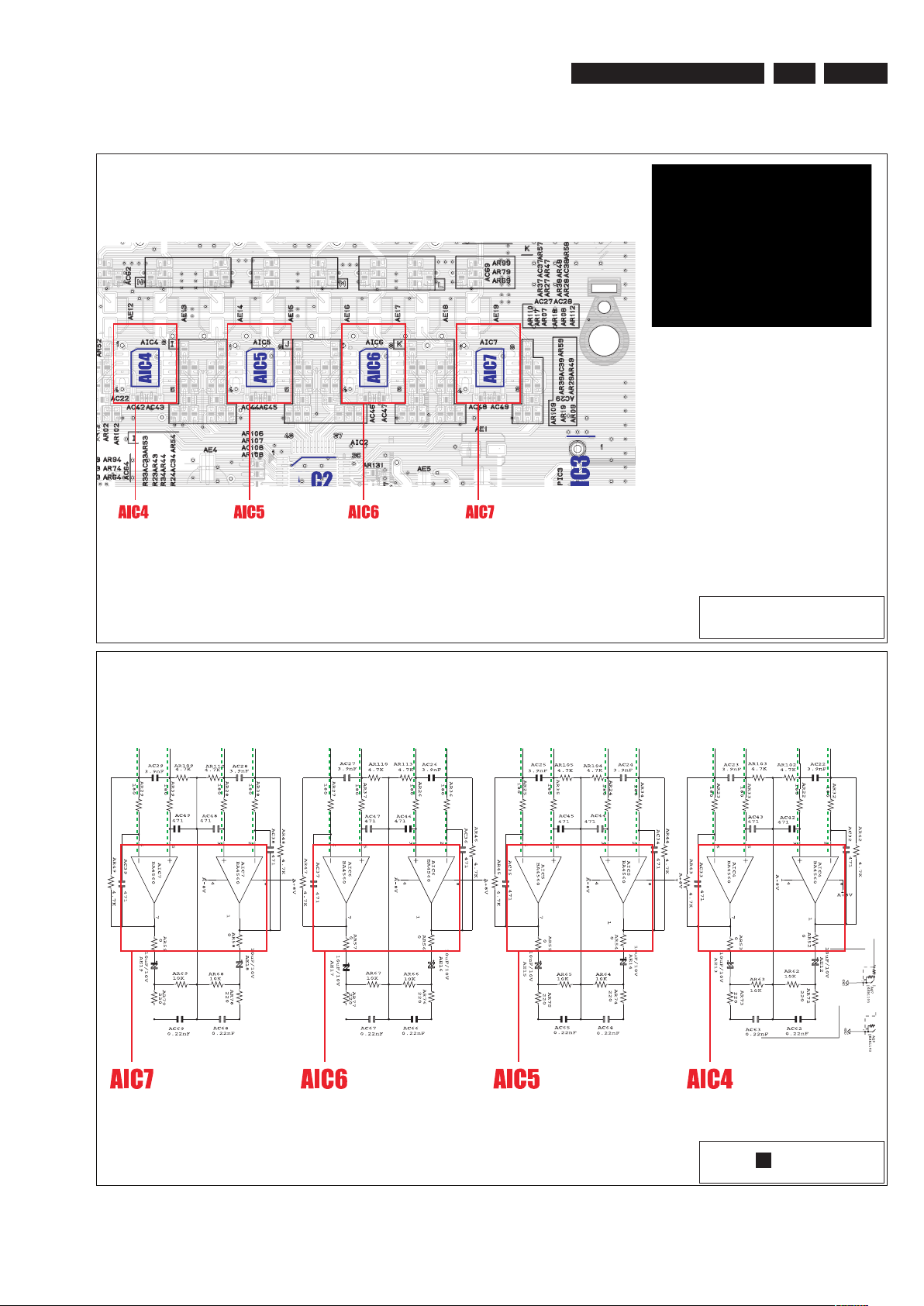

Fig. 4-3

ANALOG AUDIO DATA(AIC4,5,6,7)

Refer to Main PCB

COMPONENT SIDE-2

Refer to 9 (Circuit Diagrams)

3139 785 32970

4.

EN 21

Loading...

Loading...