Philips AZ-7386 Service Manual

MABEL PLATFORM 3A/4A – PB2

THIS MANUAL IS VALID FROM FACTORY CHANGE CODE KT02 ONWARDS

Technical specification ......................................................1-1

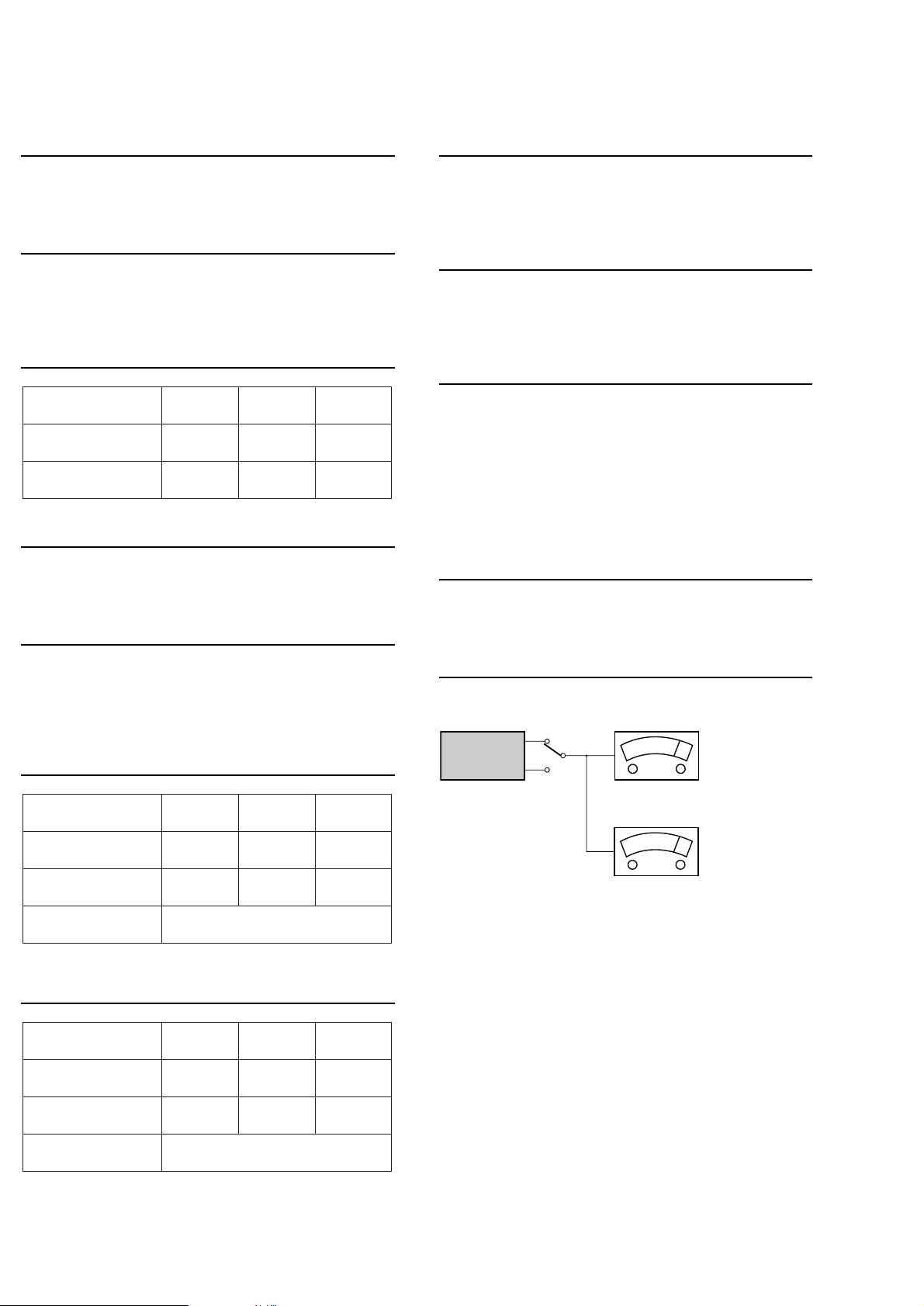

Connections and controls..................................................1-2

Feature overview...............................................................1-2

Accessories .......................................................................1-3

Safety warnings.................................................................1-4

Service hints

Repair positions ............................................................2-1

Service tools..................................................................2-1

Training material ...........................................................2-1

ESD protection equipment............................................2-1

Handling chip components............................................2-2

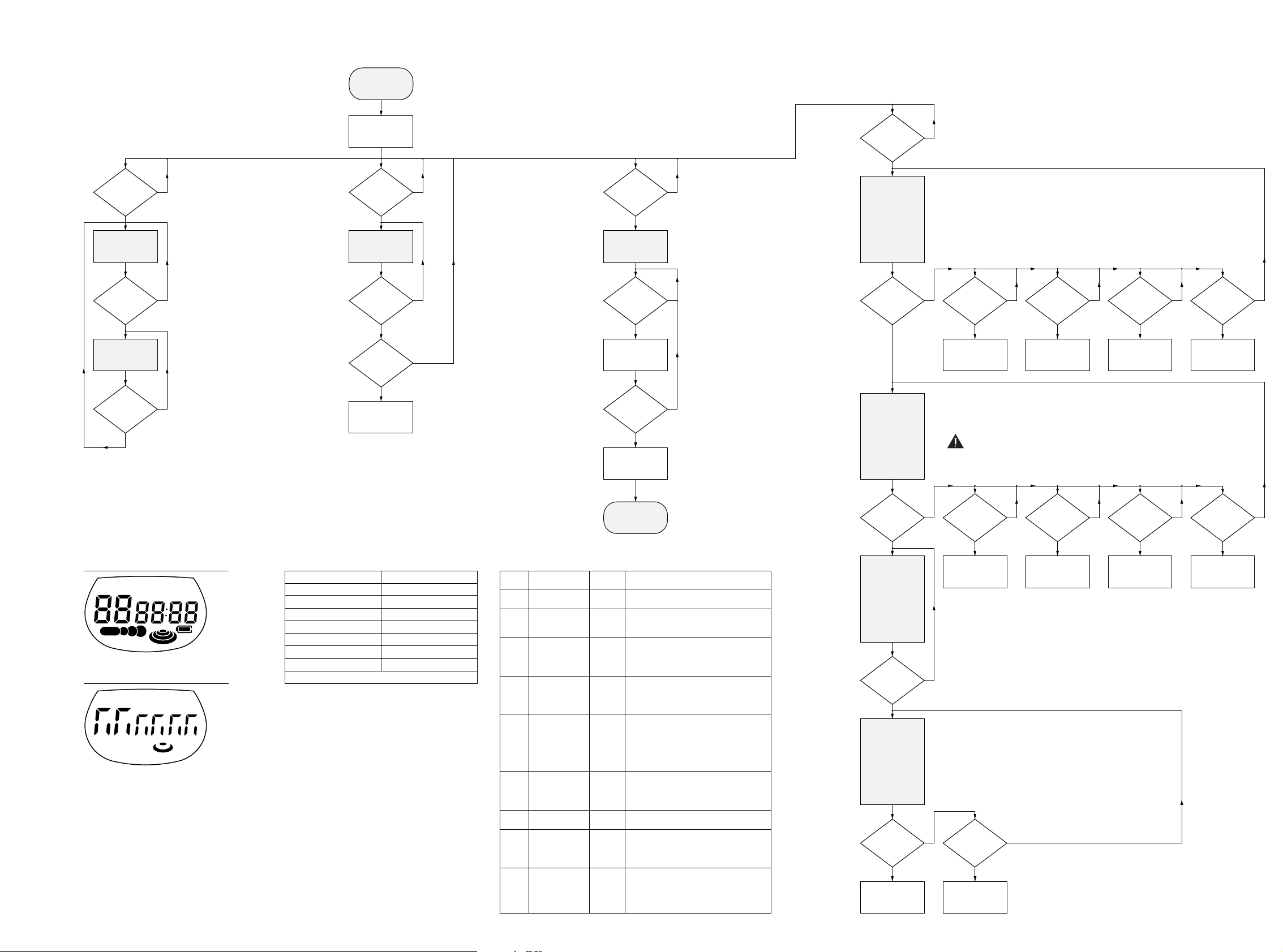

Service test program .................................................3-1...3-2

Blockdiagram.....................................................................3-3

Start-up procedure.............................................................3-4

Pinning of ICs............................................................3-5...3-9

Circuit diagrams

Supply/Servodriver part.................................................4-1

Signal processing part...................................................4-2

Membrane assembly 4822 360 10363..........................4-3

Control part ...................................................................4-4

Audio part......................................................................4-5

Printed circuit board

Copperside view............................................................4-6

Componentside view.....................................................4-7

Exploded view...........................................................5-1...5-2

Mechanical partslist...........................................................6-1

Electrical partslist ......................................................6-1...6-3

CS 46 510

© 4822 725 26021

Published by PW 9813 Service Audio Printed in The Netherlands Subject to modification

Portable compact disc player

CLASS 1

LASER PRODUCT

AZ7381

AZ7382

AZ7383

AZ7384

AZ7385

AZ7386

AZ7387

AZ7481

AZ7482

AZ7483

all versions

TABLE OF CONTENTS

©

Copyright 1997 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

MODE

P

R

O

G

R

E

P

E

A

TA

L

L

R

E

P

E

A

TA

L

L

1-1

CS 46 511

TECHNICAL SPECIFICATION

General

Dimensions (WxHxD) : 128x28x136.5mm

Weight without batteries : 225g

Power supply modes

DC-in socket : 4.5-5.5V

Primary batteries (2xLR6) : 1.55-3.6V

Rechargable batteries : 1.55-3.6V

Battery lifetime

Battery empty detection

Battery weak level : 2.1V nom. ±150mV

Battery empty level : 1.6V nom. +100/-50mV

Charge circuit

Charge current : 200mA nom. ±20%

Charge time for 80% AY3361 : 4.0hrs nom.

Max. charge time (µP controlled) : 5.0hrs nom.

Temperature protection : none

Current consumption (DC-in=4.5V, excl. illumination)

Current consumption (Batt. supply=2.25V, excl. illumin.)

Shock resistance (ESA off)

+X/-X direction : ≥2.5g

+Y/-Y direction : ≥2.5g

+Z/-Z direction : ≥2.0g

Shock resistance by use of car base (ESA off)

+X/-X direction : ≥6g

+Y/-Y direction : ≥6g

+Z/-Z direction : ≥6g

Headphone out (measured with 16Ω load, ESA & DBB off)

Output power (THD=10%) : 2x12mW (+1/-3dB)

Frequency response (1mW) : 100Hz-20kHz within 6dB

S/N ratio (unwght) : >80dB (83dB typ.)

S/N ratio (A-wght) : >82dB (85dB typ.)

THD+N (1kHz, 1mW) : <1% (0.2% typ.)

Channel crosstalk (1kHz, no load): <-24dB (-44dB typ.)

Channel unbalance (-40dB) : <5dB

Volume attenuation (1kHz) : >60dB

Laser

Output power : <5mW (3mW typ.)

Wavelength : 780nm

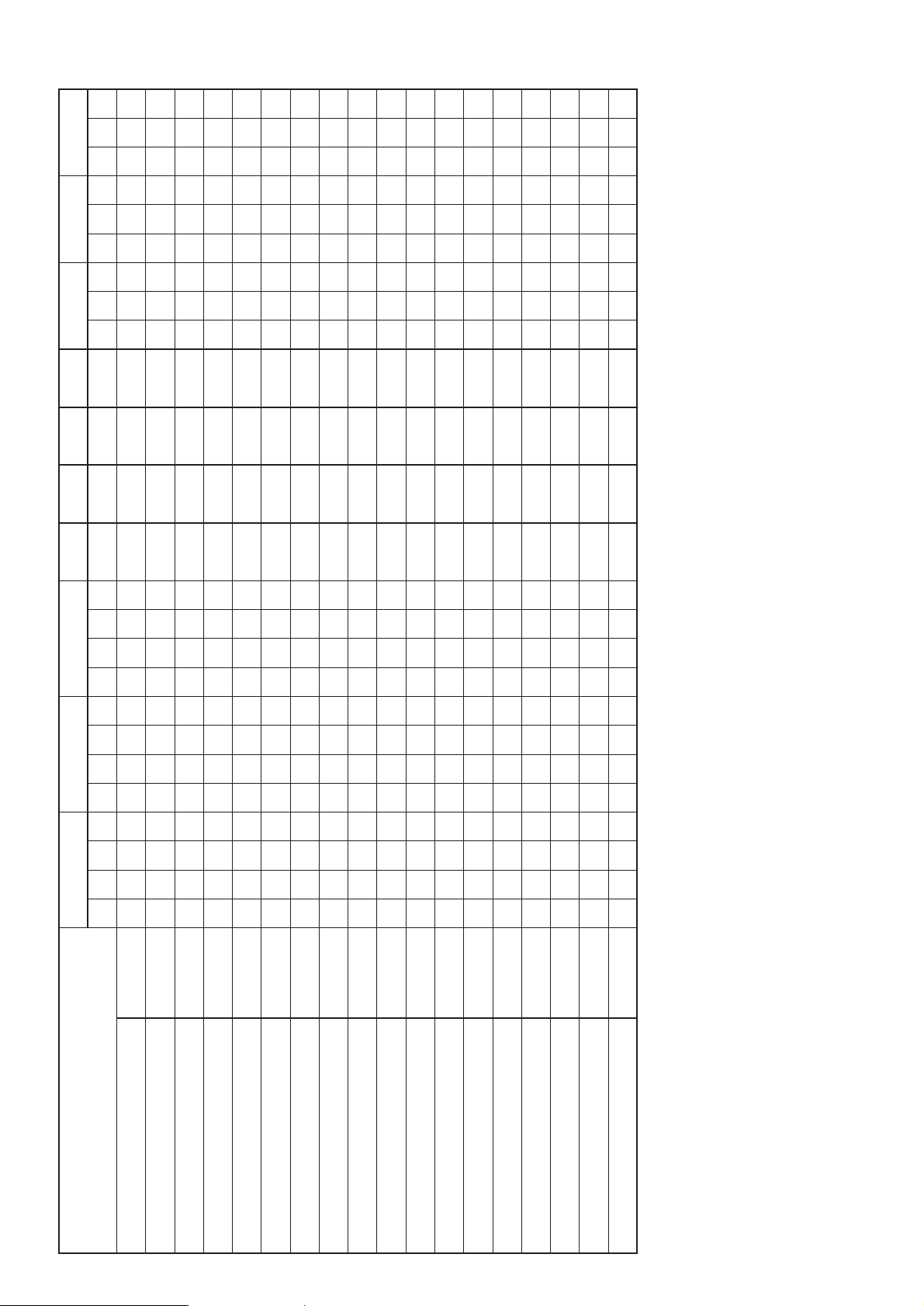

Measurement setup

Use Audio Signal disc SBC429 4822 397 30184

L

R

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

S/N and distortion meter

e.g. Sound Technology ST1700B

NOITAREPOFFOASENOMSPNOASE

edom-yalP.pytAm561– .pytAm561

edom-pmuJ.pytAm054– .pytAm054

yb-dnatS

)egrahcer.lcxe(

.pytAm4.0

NOITAREPOFFOASENOMSPNOASE

edom-yalP.pytAm541– .pytAm561

edom-pmuJ.pytAm054– .pytAm054

yb-dnatS

)egrahcer.lcxe(

.pytAm51

EPYTYRETTABFFOASENOMSPNOASE

seirettabyramirP

)6RLx2(

.pytsrh21– .pytsrh21

1633YAkcap-uccA

)hAm007,dCiN(

.pytsrh4– .pytsrh4

DISPLAY................

shows the different playing modes, tracks and times

§ ...........................skips and searches forward

∞ ...........................skips and searches backward

VOLUME................adjusts the volume level at the headphone socket

RESUME/HOLD ....activates the RESUME function and/or HOLD function (locking all buttons)

MODE 00................selects the different playing modes: SHUFFLE™SHUFFLE REPEAT ALL™REPEAT™REPEAT

ALL™SCAN™off

PROG P.................stores tracks in a program and reviews the program

DBB .......................Dynamic Bass Boost: enhances the bass response,

DBB 1™DBB 2™DBB 3™off

Press this button for more than 3 seconds to switch off/on acoustic feedback.

STOP 9..................stops CD play, deletes various settings, switches off the CD player and activates charging.

OPEN.....................opens the lid of the CD player

2; ..........................starts and pauses CD play

ESA........................Electronic Shock Absorption is the buffer memory for uninterrupted sound

EARPHONE p .......Earphone socket (3.5mm)

4.5 V DC................Socket for external power supply

Battery compartment to insert batteries

1-2

CS 46 512

CONNECTIONS AND CONTROLS

4.5 V DC

TYPEPLATE

OPEN

DBB

MODE

DISPLAY

PROGRAM

ESA

PLAY / PAUSE

STOP

NEXT

PREVIOUS

EARPHONE JACK

VOLUME

HOLD / RESUME

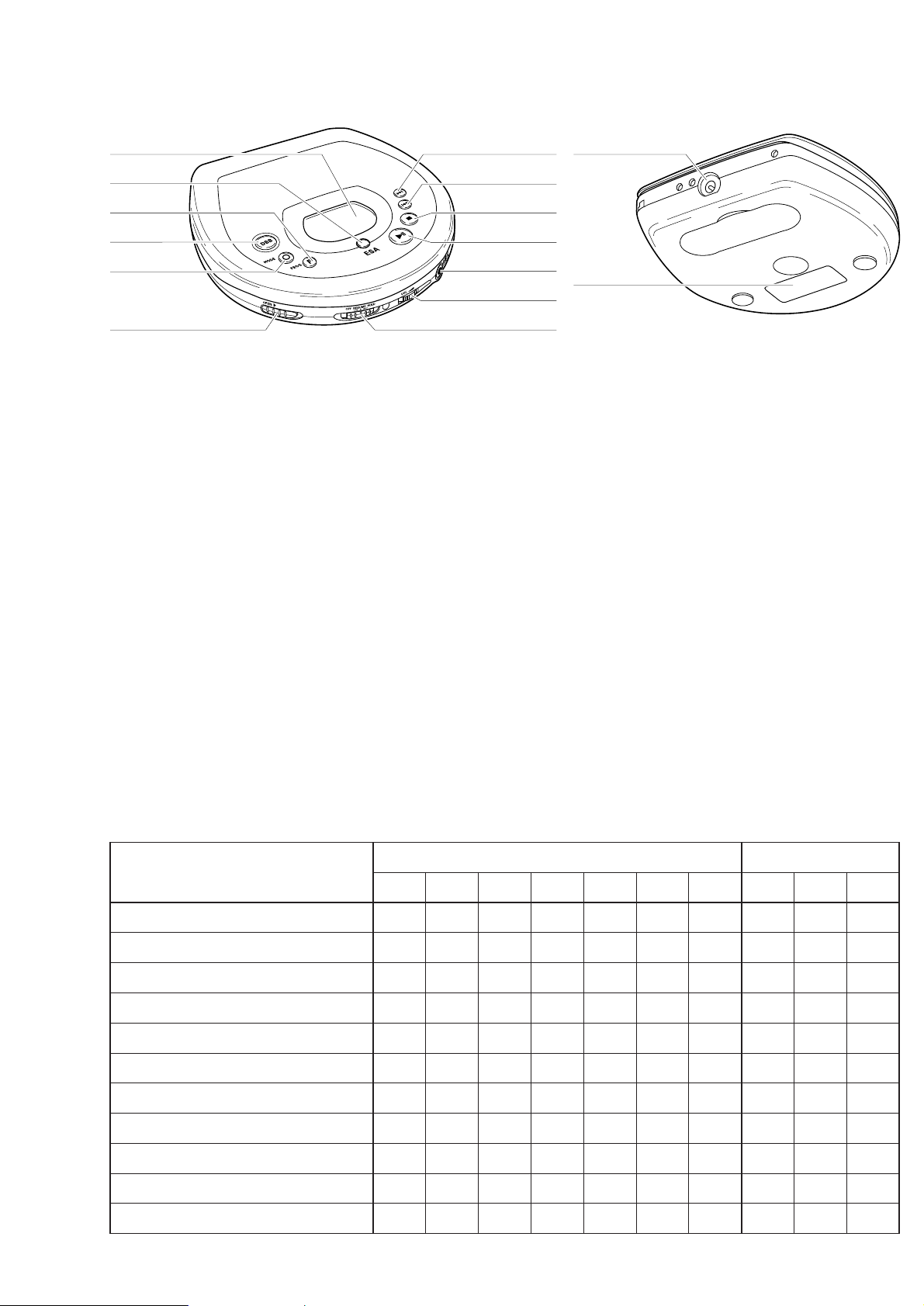

ELBATROP-DCFOSERUTAEF

A4,A3LEBAMYLIMAF

A3MROFTALPA4MROFTALP

1837ZA2837ZA3837ZA4837ZA5837ZA6837ZA7837ZA1847ZA2847ZA3847ZA

)ASE(NOITPROSBAKCOHSCINORTCELE

.ces21.ces21.ces21.ces21.ces21.ces21.ces21.ces52.ces52.ces52

)MSP(EDOMEVASREWOP

––––––––––

NOITCNUFEMUSER/DLOH

0 / 00/ 00/ 00/ 00/ 00/ 00/ 00/ 00/ 00/ 0

SEGATSBBD

3333333333

KCABDEEFCITSUOCA

0000000000

YROMEMMARGORP

99999999999999999999

HMiN/dCiNNOITCNUFEGRAHCER

0 –/ 0 –/ 0 –/ 0 –/ 0 –/ 0 –/ 0 –/ 0 –/ 0 –/ 0 –/

DERAPERPXOBYRETTABLANRETXE

––––––––––

NOITANIMULLIDCL

––––––––––

DERAPERPLORTNOCETOMERDROC

––––––––––

TUPTUOLATIGID/ENIL

–/––/––/––/––/––/––/––/––/––/–

FEATURE OVERVIEW

1-3

CS 46 513

ELBATROP-DCROFSEIROSSECCA

A4,A3LEBAMYLIMAF

1837ZA2837ZA3837ZA4837ZA5837ZA6837ZA7837ZA1847ZA2847ZA3847ZA

00/10/41/71/00/50/11/41/10/50/11/71/71/71/71/71/00/50/41/00/50/41/00/01/71/

A00/0613YA ROTPADACD/CA752019122284X X XXX

20/0613YA ROTPADACD/CA944019122284X X

A50/0613YA ROTPADACD/CA762019122284XX XX

A01/0613YA ROTPADACD/CA643019122284 X

A21/0613YA ROTPADACD/CA824019122284XXXX XX

A73/0613YA ROTPADACD/CA281019122284 X XXXXX X

00/3623YA HCUOP567010062284 OOOOOOOOOOOO OOOOOOOXXXOOO

00/1633YA dCiNKCAPYRETTAB516018312284 OOOOXXXXXXXO OOOOOOOXXX O

00/1053YA ETTESSACROTPADARAC950017932284 OOO OOOOXXX OOOOOOOO

73/1053YA ETTESSACROTPADARAC890017932284 O XXXXX O

00/5453YA RETREVNOCCD/CDRAC330019122284 OOO OOOOXXX OOOOOOOO

73/5453YA RETREVNOCCD/CDRAC381019122284 O XXXXX O

00/4763YA ENOHPRAE248012422284 XXX XX XXXX XXX XX

V00/4763YA ENOHPRAE458012422284X XXX

73/2863YA ENOHPDAEH448012422284 X XXXXX X

00/0683YA XOBREKAEPSEVITCA315015442284 OOO OOOOOOO OOOOOOOO

71/0683YA XOBREKAEPSEVITCA415015442284 O OOOOO O

4643YA mm5.3(DROCIFIH → )gulp-L,hcnic188110232284 OOOOOOOOOOOO OOOOXXXXXXOOO

X....supplied with the set, O....optional available

ACCESSORIES

1-4

CS 46 514

© WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

f ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

d WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß Sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

ñ WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

i AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

©

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

i

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

ñ

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

s Varning !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

∂ Advarsel !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

ß Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

f

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

ESD

SAFETY

d

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

f

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

CLASS 1

LASER PRODUCT

©

DANGER: Invisible laser radiation when open.

©

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

AVOID DIRECT EXPOSURE TO BEAM.

©

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1MΩ) 4822 320 11307

extendible cable (2m, 2MΩ, to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2MΩ, to connect table mat to connection box) 4822 320 11306

earth cable (1MΩ, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

SAFETY WARNINGS

2-1

CS 46 515

SERVICE HINTS

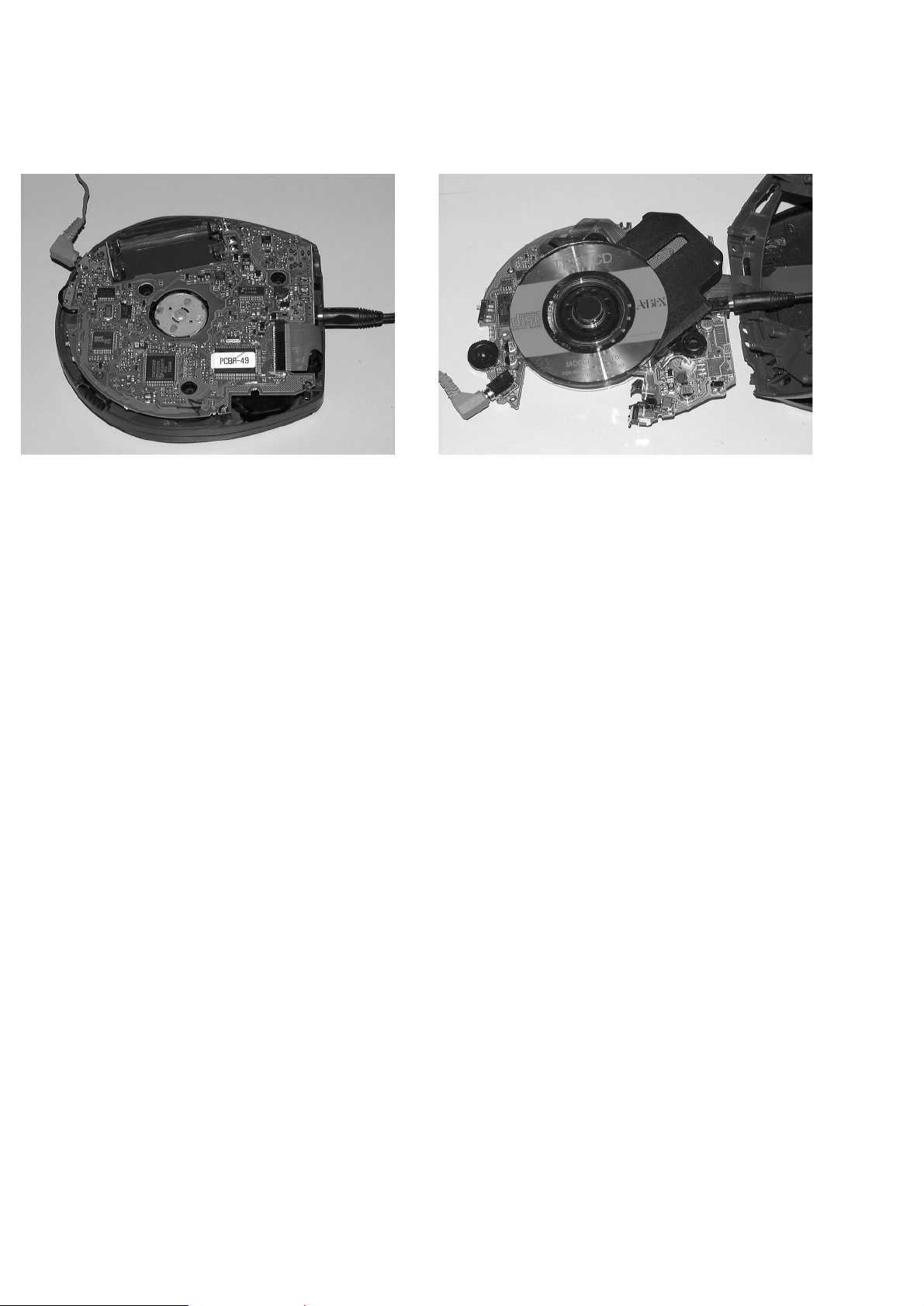

REPAIR POSITION COPPERSIDE

To get access to the copperside of the

printed circuit board proceed as follows:

1. Remove the bottom screws (6x)

2. Lift the bottom-cabinet

3. Supply the unit via external DC-socket

4. Take care of door switch during measurement or enter

service test program, radial test

To get access to the componentside of the

printed circuit board proceed as follows:

1. Remove the bottom screws (6x)

2. Open the CD-door

3. Lift the top-cabinet and put it backwards on the table

4. Remove the bottom and supply the unit via the external

DC-socket as shown in the picture above

5. Close the door-switch (i.e. adhesive tape) or enter

service test program, radial test

SERVICE TOOLS

Audio signal disc SBC429 4822 397 30184

Playability test disc SBC444 4822 397 30245

Test disc 5 (disc without errors) + Test disc 5A (disc with dropout errors,

black spots and fingerprints) SBC426/SBC426A 4822 397 30096

TRAINING MATERIAL

Portable CD 1994 – Principles of Electronic Shock Absorption System ESA,

Key components 1994, Remote control system 4822 725 24941

Portable CD 1996 – Key components 1996, Battery charging, DC/DC-converter 4822 725 24986

Portable CD 1998 – Key components 1998, Power Save Mode PSM 4822 725 26017

(available from April 1998 onwards)

ESD PROTECTION EQUIPMENT

Anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

Anti-static wristband 4822 395 10223

Connection box (3 press stud connections, 1MΩ) 4822 320 11307

Extendible cable (2m, 2MΩ, to connect wristband to connection box) 4822 320 11305

Connecting cable (3m, 2MΩ, to connect table mat to connection box) 4822 320 11306

Earth cable (1MΩ, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

Wristband tester 4822 344 13999

REPAIR POSITION COMPONENTSIDE

The unit is now in a proper working position and can be turned in all directions necessary to get access for measurements.

2-2

CS 46 516

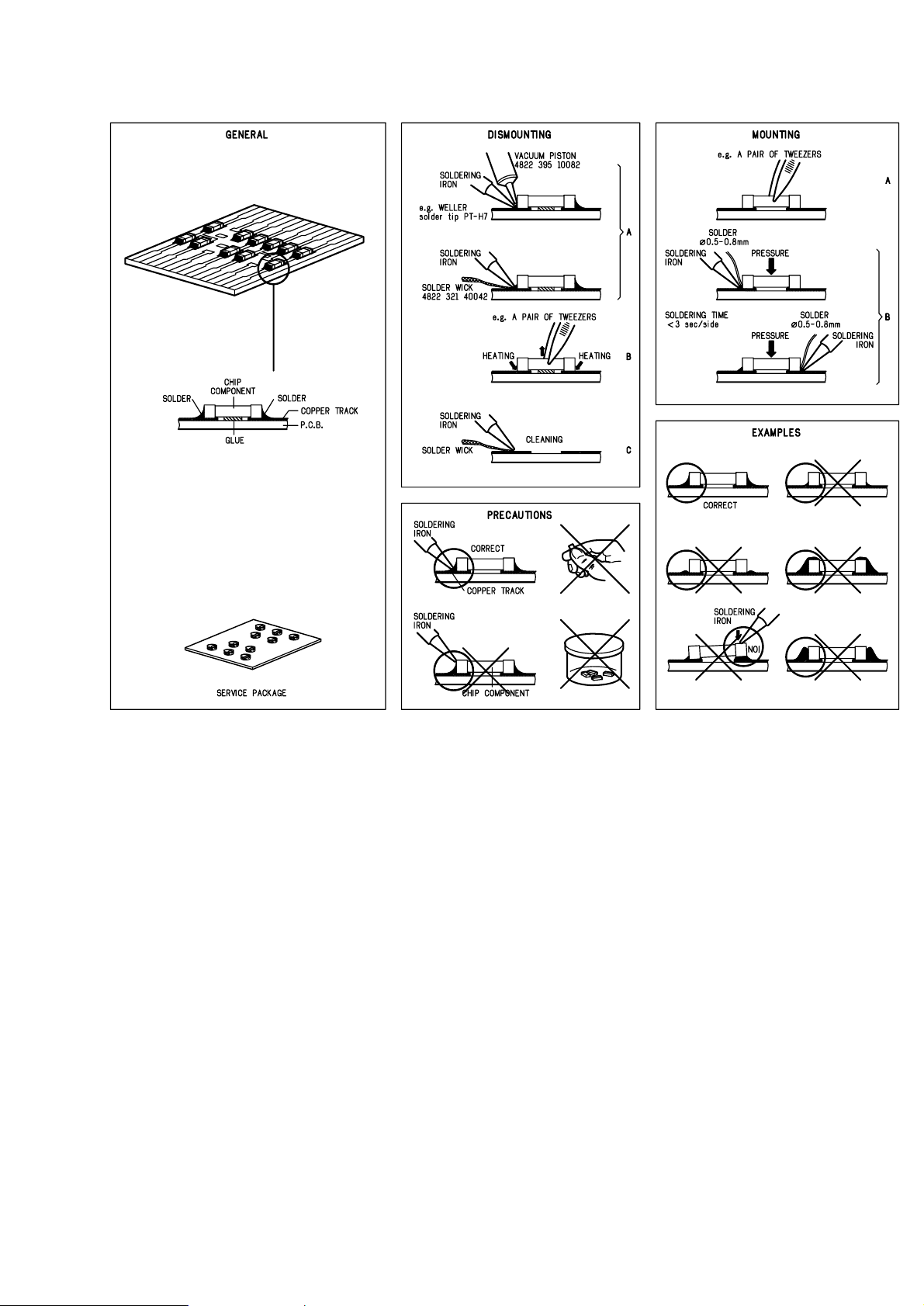

HANDLING CHIP COMPONENTS

SERVICE TEST PROGRAM

1. PRELIMINARY SETUP

• To enter the service test program hold the keys “MODE” and

“STOP” depressed while turning POWER ON (i.e. connecting

the AC/DC adaptor or inserting batteries).

• The display shows the software version of the built-in

microprocessor (i.e. “S-19”). Versions are counted from “00”

onwards; that means the higher the number the newer the

software.

• The program is now in the main menu – various tests can be

entered by pressing the corresponding buttons (see flow chart

on next page or detailed description of test programs below).

• To exit the service test program disconnect the set from the

power source.

2. DISPLAY TEST

Purpose: Check functionality of display and display driver.

• To enter the display test start service test program and press

the “NEXT” button.

• The display shows test pattern1. All segments are activated for

finding open circuits (see flow chart on next page).

• To jump to the next pattern press the “NEXT” button.

• The display shows test pattern2. All alternate pins (2, 4, ...) are

activated for finding short circuits (see flow chart on next page).

• To jump back to test pattern1 press the “NEXT” button, to exit

the display test and return to the main menu press the “STOP”

button.

3. KEY TEST

Purpose: Check operation of keys.

• To enter the key test start service test program and press the

“MODE” button.

• The display shows “--”.

• Hold key depressed and check corresponding key code on the

display. Key codes can be found in table1 (see flow chart on

next page).

• To exit the key test and return to the main menu press the

“STOP” button.

4. PLAYBACK TEST WITH ERROR ANALYSIS

Purpose: Analyse errors that occur during playback and search

for intermittent failures.

• To enter the playback test start service test program and press

the “DBB” button. Note that the playback test can only be

entered if the CD-door is closed.

• The set now reads the TOC and switches to stand-by.

• Press the “PLAY” button to start the error analysis.

As long as the playback is free of errors the display shows track

and time information like in normal play-mode.

In case of an error a corresponding error code will be displayed.

The meaning of this error code can be found in table2 (see flow

chart on next page).

Note: Errors can either be

“fatal”

or

“non fatal”

. Fatal errors

always stop the playback, non fatal errors only cause a

short interruption of the music. Fatal errors are displayed

as long as the set is connected to the power source, non

fatal errors are displayed until a new error occurs or a

button is pressed.

• To stop the playback test disconnect the set from the power

source.

5. SERVO TEST

Purpose: Check door switch and inner switch, movement of

slide and acceleration of discmotor.

• To enter the servo test start service test program and press the

“PLAY” button.

• The display shows “Sxy”.

“x” indicates state of door switch;

“y” indicates state of inner switch.

x,y

= “0” means switch is closed; “1” means switch is open.

• To move slide outside hold the “NEXT” button depressed.

• To move slide inside hold the “PREV” button depressed.

• To accelerate the discmotor clockwise hold the “MODE” button

depressed.

• To accelerate the discmotor counter-clockwise hold the

“PROG” button depressed.

• To enter the focus test press the “PLAY” button, to exit the

servo test and return to the main menu press the “STOP”

button.

6. FOCUS TEST

Purpose: Check movement of lens and operation of focus servo.

• The focus servo loop is switched on and the set starts

searching the focus (“focus ramping”). As soon as the focus

has been found the focus servo loop is closed and the state of

the focus is monitored continuously.

If the focus is OK the display shows “ F”, else “-F”.

• When the disc is turned manually “focus noise” is audible.

• To move slide outside hold the “NEXT” button depressed.

• To move slide inside hold the “PREV” button depressed.

• To accelerate the discmotor clockwise hold the “MODE” button

depressed.

• To accelerate the discmotor counter-clockwise hold the

“PROG” button depressed.

• In case the focus is OK the discmotor test can be entered by

pressing the “PLAY” button, to exit the focus test and return to

the main menu press the “STOP” button.

7. DISCMOTOR TEST

Purpose: Check speed regulation of discmotor.

• The speed regulation is switched on and the discmotor starts

rotating. If the speed reaches 75% of the nom. speed the

display shows “ d”, else “-d”.

• In parallel also the state of the focus is monitored continuously

(display “ F” or “-F”).

• In case the disc speed is OK and the focus is OK the radial test

can be entered by pressing the “PLAY” button, to exit the

discmotor test and return to the main menu press the “STOP”

button.

8. RADIAL TEST

Purpose: Check if radial loop locks and an audio signal is

audible at the headphone output.

• The radial servo loop is switched on, mute is released and the

audio signal is audible. If the system is on track the display

shows “ r”, else “-r”.

• In parallel also the disc speed (display “ d” or “-d”) and the

state of the focus (display “ F” or “-F”) are monitored

continuously.

Note: In case of radial errors the audio output is muted and

muting is not released automatically when the systems

recovers from the error. “-r” remains on the display.

To open mute again press the “NEXT” or “PREV” button.

• To jump 10 tracks outside press the “NEXT” button.

• To jump 10 tracks inside press the “PREV” button.

• To exit the radial test and return to the main menu press the

“STOP” button, to exit the service test program disconnect the

set from the power source.

Important remark:

In radial test mode data to the DRAM is written at 1.2 times the

nominal speed, and read from the DRAM at nominal speed.

Because writing is done faster than reading the DRAM gets full

after a certain time.

In normal play mode the system would now wait until the DRAM

is partly emptied again, jump backwards and resume filling at the

last written position. However, in radial test mode the jumps

would disturb measurements on the radial servo loop.

Therefore this function has been disabled and filling restarts

immediately from the current position of the pick-up unit. As a

result “jumps” are audible during playback.

3-1

CS 46 517

3-23-2

CS 46 518

table1 – key test

DISPLAY OF SET

3

5

6

2

7

8

1

KEYS OF SET

PLAY

NEXT

PREVIOUS

ESA/ESP

MODE

PROGRAM

DBB

Press “STOP” on the CD-player to exit the key test.

PRELIMINARY

SETUP

EXIT

SERVICE TEST

PROGRAM

Display shows

software-version

(e.g. “S-

19”)

DISPLA Y TEST 1

display shows

test pattern1

DISPLA Y TEST 2

display shows

test pattern2

KEY TEST

Display shows

“--”

To enter service test program hold “MODE” & “STOP”-button

depressed, while turning POWER ON.

Door switch is ignored → CD-door can be opened.

“STOP”-button pressed in any step returns to main menu.

Remark: Playback test can only

be entered if CD-door

is closed!

CUE-MODE

Track servo jumps

16 tracks forward

“NEXT”

pressed?

“MODE”

pressed?

any button

depressed?

“STOP”

button?

“DBB”

pressed?

“PLAY”

pressed?

“PLAY”

pressed?

Error during

playback?

“PLAY”

pressed and

focus OK?

“PLAY”

and focus OK

and speed

OK?

“NEXT”

pressed?

REVIEW-MODE

Track servo jumps

16 tracks backw.

Fatal error?

Display shows

error-code

(see table2)

PLAYBACK

TEST

Slide moves

outside

Slide moves

inside until inner

switch is activated

“NEXT”

depressed?

“NEXT”

pressed?

“NEXT”

pressed?

“PREV”

depressed?

“MODE”

depressed?

“PROG”

depressed?

Stop playback

check display

according to table1

MAIN MENU

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y Y

N

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

Y

N

Y

N

Y

N

Y

Y

N

CODE

E 1000

E 1001

E 1002

E 1003

E 1004

E 1005

E 1006

E 1008

E 1020

ERROR

focus error

radial error

sledge in error

sledge out error

DRAM filling

error

jump error

subcode error

turntable motor

error

focus search

error

TYPE

non fatal

non fatal

non fatal

non fatal

non fatal

non fatal

non fatal

fatal

fatal

CAUSE

Focus point lost for at least 3ms.

CD7 indicates offtrack while radial

tracking is switched on.

The slide did not reach it´s inner pos.

(inner switch of CDM doesn´t close)

within approx. 6 seconds.

The slide did not come out of it´s inner

pos. (inner switch of CDM is open)

within approx. 250ms.

The DRAM controller was not able to

connect two consecutive audio frames.

The microcontroller had to perform a

direct audio connection that produces

audible clicks.

The offtrack values of CD7 don´t

decrease properly when jumping tracks,

the jump destination could not be found.

No valid subcode for approx. 230ms.

During start-up, the disc speed did not

reach 75% of the nom. speed within

approx. 6 seconds.

The focus point could not be found

within approx.

10 seconds (no valid TOC info), resp.

30 seconds (valid TOC info).

table2 – playback error analysis

Disc motor turns

clockwise

(accelerate)

Disc motor turns

counter-clockwise

(brake)

Slide moves

outside

Slide moves

inside

“NEXT”

pressed?

“PREV”

pressed?

“MODE”

pressed?

“PROG”

pressed?

N

Y

N

Y

N

Y

N

Y

Disc motor turns

clockwise

(accelerate)

Disc motor turns

counter-clockwise

(brake)

ATTENTION: FROM THIS TEST ONWARDS THE

LASER IS SWITCHED ON !!

→ AVOID DIRECT EXPOSURE TO BEAM !!

ATTENTION: JUMPS ARE AUDIBLE DURING PLAYBACK

(read remark on previous page) !!

RESUME

SHUFFLE REPEATALL

SCAN

PROG

2

3

DBB

1

REPEATALL

SCAN

test pattern1

test pattern2

“PREV”

pressed?

RADIAL TEST

• On track status

“ r” = on track

“-r” = not on track

• Disc speed status

“ d” = speed OK

“-d” = speed error

• Focus status

“ F” = focus OK

“-F” = focus error

DISC MOT. TEST

• Disc speed status

“ d” = speed OK

“-d” = speed error

• Focus status

“ F” = focus OK

“-F” = focus error

FOCUS TEST

• Focus status

“ F” = focus OK

“-F” = focus error

Note: If focus has

been lost, focus

start-up procedure

is entered (ramping).

SERV O TEST

Display shows:

“S

xy”

• State of switches

x = door switch

y = inner switch

“0” = closed

“1” = open

FLOW CHART

Loading...

Loading...