Page 1

CD Stereo Radio Recorder

AZ1570

AZ1575

all versions

TABLE OF CONTENTS

chapter

Handling chip components and safety 1 - 1

Technical Specification & Service Tools 2 - 1

Service Measurement 2 - 2

Connections & Controls

Instructions for use

Disassembly Diagram 4 - 1

CD Service Test Program 4 - 2 to 4 - 3

Block Diagram

Wiring Diagram 6 - 1

AF BOARD

circuit diagram

layout diagram

TUNER BOARD

circuit diagram

layout diagram

CONTROL BOARD

circuit diagram

layout diagram

..................................................

................................................

.................................................

...................................................

........................................

.............................................................

...........................................................

.......................................................

.......................................................

.......................................................

.......................................................

.......................................................

.......................................................

.............................

..........................

3 - 1

3 - 2 to 3 - 6

5 - 1

7 - 1

7 - 2

8 - 1

8 - 2

9 - 1

9 - 2

chapter

FEATURE BOARD

circuit diagram

layout diagram

POWER BOARD

circuit & layout diagram

KEYBOARD

circuit & layout diagram

RECORDER BOARD

circuit diagram

layout diagram

CD MODULE

layout diagram

circuit diagram

EXPLODED VIEWS DIAGRAM

cabinet

tape deck

Mechanical partslist 15 - 2 to 15 - 3

Electrical partslist

.......................................................

.......................................................

..........................................

..........................................

......................................................

......................................................

......................................................

......................................................

..............................................................

......................................................

...............................................

...............................................

10 - 1

10 - 2

11 - 1

12 - 1

13 - 1

13 - 2

14 - 1

14 - 2

15 - 1, 15 - 4

15 - 2 to 15 - 3

16 - 1 to 16 - 6

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

be used.

C

Copyright 1995 Philips Consumer Electroncis B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

Printed in The Netherlands Copyright reserved Subject to modification

PCS 104 626

CLASS 1

LASER PRODUCT

GB

3140 785 22500Published by SS 0038 Service Audio

Page 2

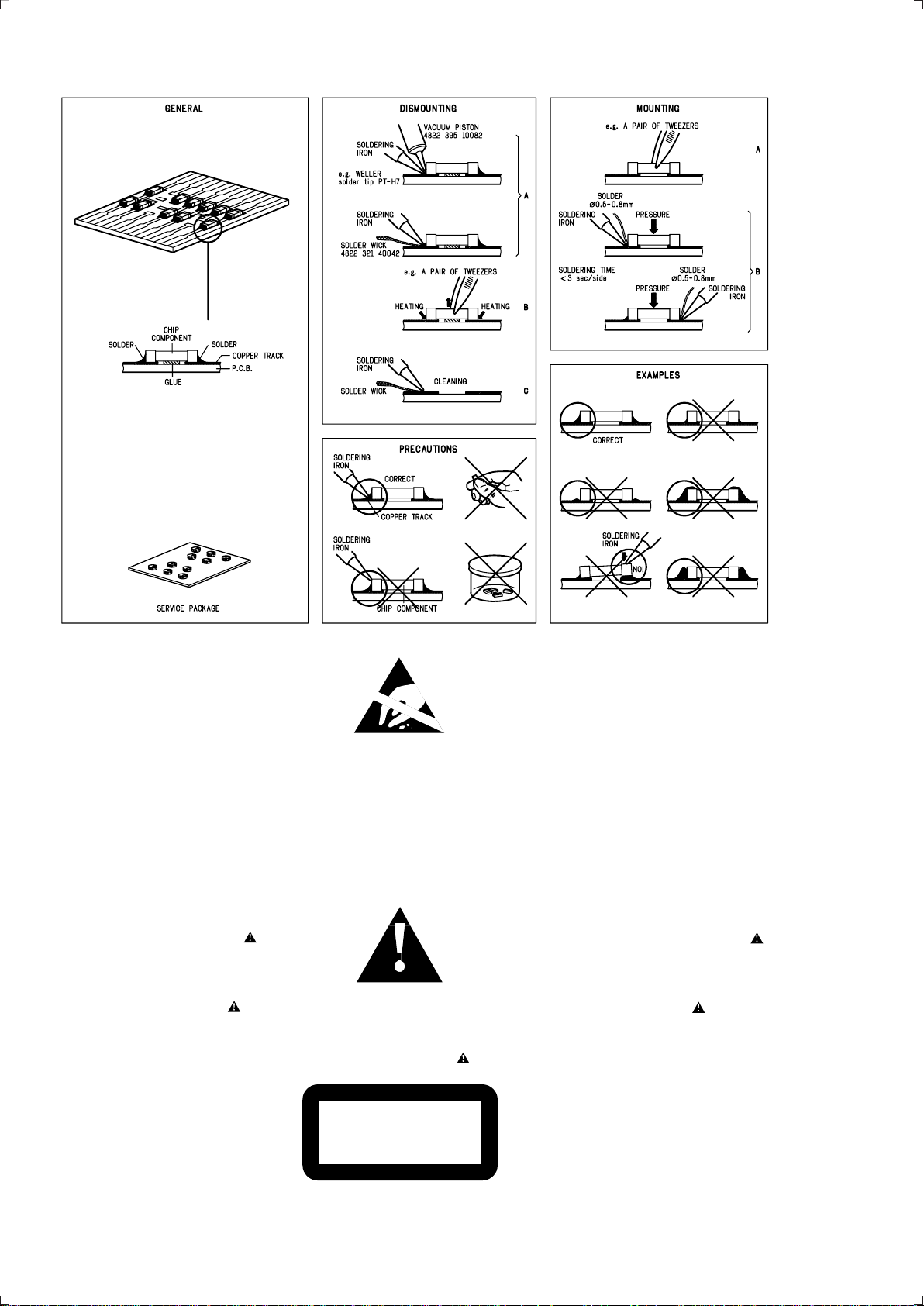

HANDLING CHIP COMPONENTS

1-1

© WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

f ATTENTION

Tous les IC et beaucoup d ´autres semi-conducteurs sont

sensibles aux d écharges statiques (ESD). Leur long évite

pourrait être consid érablement écourt ée par le fait qu ´aucune

précaution n ést prise à leur manipulation.

Lors de r éparations, s ´assurer de bien être reli é au m ême

potentiel que la masse de l ´appareil et enfileer le bracelet

serti d ´une r ésistance de s écurit é.

Veiller à ce que les composants ainsi que les outils que l ´on

utilise soient également à ce potentiel.

©

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

f

Les normes de s écurit é exigent que l`appareil soit remis

à l`état d`origine et que soient utilis ées les pi èces de

rechange identiques à celles sp écifiées.

Les composants de s écurit é sont marqu és

d WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegen über elektrostatischen Entladungen (ESD).

Unsorgf ältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie daf ür, daß Sie im Reparaturfall über ein Pulsarmband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

d

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten. Der Originalzustand des Ger ätes

darf nicht ver ändert werden. F ür Reparaturen sind Originalersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

ESD

SAFETY

ñ WAARSCHUWING

Alle IC ´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparat ie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal .

i AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scar iche

statiche (ESD).

La loro longevit à potrebbe essere fortemente ridatta in caso di

non osservazione della pi ù grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

ñ

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepas t.

De Veiligheidsonderdelen zijn aangeduid met het symbool

i

Le norme di sicurezza estigono che l ´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

©

DANGER : Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

s Varning !

Osynlig laserstr ålning n är apparaten är öppnad och

spärren är urkopplad. Betrakta ej str ålen.

∂ Advarsel !

Usynlig laserstr åling ved åbning n år sikkerhedsafbrydere

er ude af funktion. Undg å udsaettelse for str åling.

PCS 104 437

CLASS 1

LASER PRODUCT

ß Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alt tiina

näkymättömälle laseris äteilylle. Älä katso s äteeseen !

©

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

f

"Pour votre s écurite, ces documents doivent être utilis és par

des sp écialistes agr éés, seuls habilit és à réparer votre

appareil en panne".

Page 3

TECHNICAL SPECIFICATIONS

2-1

GENERAL

Mains voltage -/00/14 : 230 V

-/01/11/16 : 120 / 230 V

-/05/10 : 240 V

-/13 : 220V

-/17 : 120 V

Mains frequency -/00/05/10/14 : 50 Hz

-/01/11/16 : 50 / 60 Hz

-/13/17 : 60 Hz

Battery mains : 9 V (R20 x 6)

remote : 3 V (R6 x 2)

Power consumption : 35 W

Dimension (W x H x D) : 505 x 163 x 245 mm

Weight : 4.5 Kg

AMPLIFIER

Output power mains : 2 x 1.6 W

battery : 2 x 1.6 W

Speaker impedance : 2 x 4 ohm

: 2 x 8 ohm

Frequency response : 100 Hz - 10 kHz (±3dB)

TUNER - FM SECTION

Tuning range : 87.5 - 108 MHz

-/14 : 65.81 MHz - 74 MHz

IF frequency : 10.7 MHz ± 0.03 MHz

Sensitivity : 18 dB at 26dB S/N

Selectivity : 55 dB at 300kHz

IF rejection : 90 dB

Image rejection : 40 dB

TUNER - AM SECTION

Tuning range MW : 531 - 1602 kHz

-/17 : 530 - 1700 kHz

LW : 153 - 279 kHz

Sensitivity MW : 2000 µV/m at 26dB S/N

LW : 4500 µV/m at 26dB S/N

Selectivity MW : 23 dB

LW : 29 dB

IF rejection MW : 60 dB

LW : 60 dB

Image rejection MW : 37 dB

LW : 38 dB

AUDIO CASSETTE RECORDER

Number of tracks : 1 stereo

Tape speed : 4.76 cm/sec ± 3%

Wow & flutter : < 0.48 JIS UWTD

Fast wind/rewind C60 : < 110 sec.

Frequency response P/B : 125 - 6300 Hz

S/N ratio :

≥ 45 dB

COMPACT DISC

Frequency response : 100 Hz - 10 kHz

S/N ratio : 60 dB

Channel difference 1 kHz : 2 dB

Channel crosstalk 1 kHz : 40 dB

Laser wavelength : 780 ± 20 nm

Laser light power : < 0.3 mW

SERVICE TOOLS

TORX T10 screwdriver with shaftlength 150mm.........................................4822 395 50423

TORX screwdriver set SBC 163...............................................................4822 295 50145

Audio signal disc SBC 429........

Playability test disc SBC 444...................................................................4822 397 30245

Test disc 5 (disc without errors ) +

Test disc 5A (disc with dropout errors, black spots and fingerprints)

SBC 426/426A.....................................................................4822 397 30096

Burn in test disc (65 min. 1kHz signal at -30 dB level without “pause”)

Universal test cassette Fe SBC 420

..............................................................4822 397 30184

.....4822 397 30155

........................................................4822 397 30071

AVAILABLE ESD PROTECTION EQUIPMENT

anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1MΩ) 4822 320 11307

extendible cable (2m, 2MΩ, to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2MΩ, to connect table mat to connection box) 4822 320 11306

earth cable (1MΩ, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

PCS 104 627

Page 4

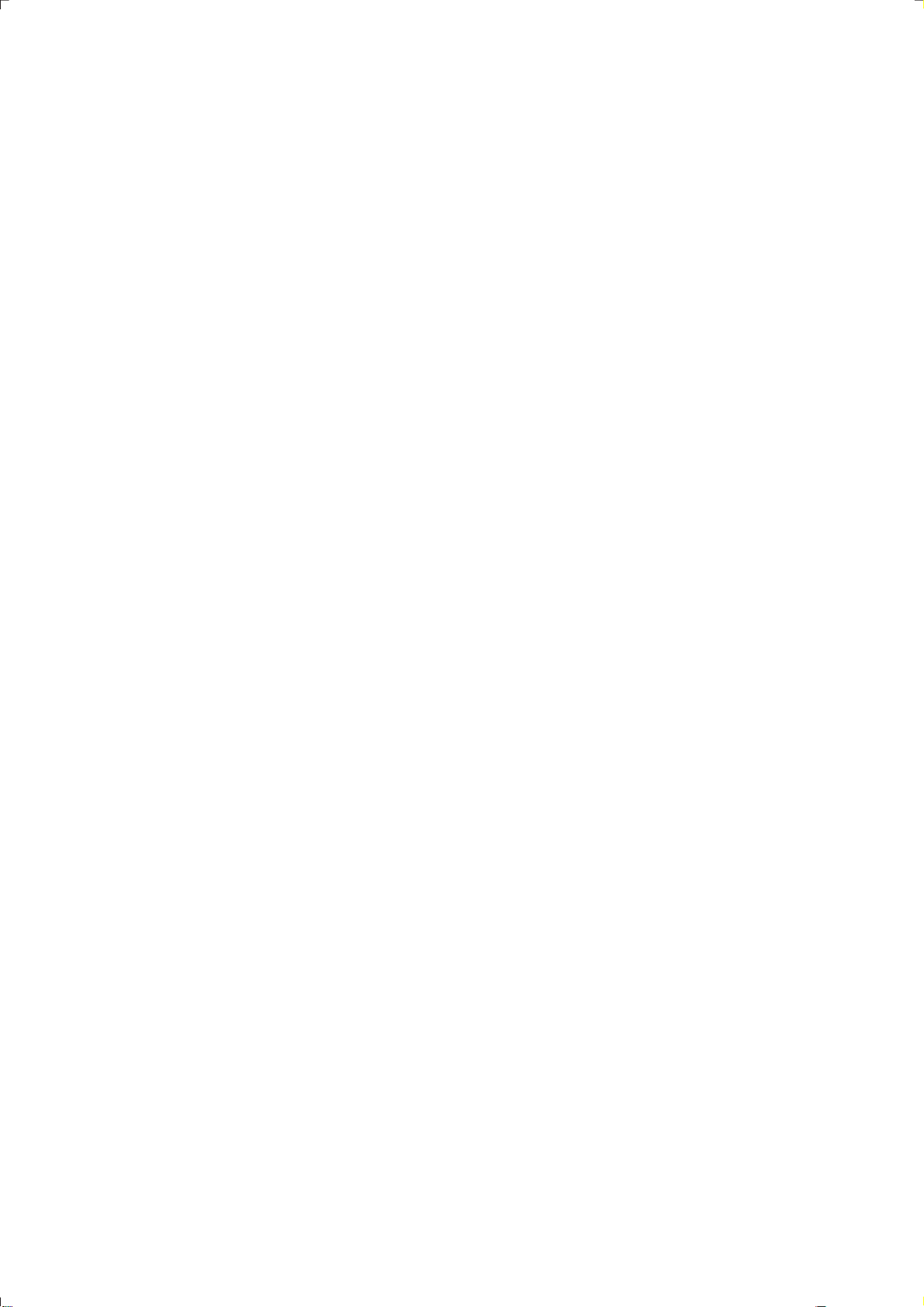

CONNECTIONS AND CONTROLS

3-1

remote control

% Display – shows the status of the set

^ REMOTE SENSOR – infrared sensor for

TOP AND FRONT PANELS

1 DIGITAL EQUALIZER – selects volume or the

tuner station (down, up)

BACK PANEL

& BAND – selects waveband

* TUNER PRESET 4, 3 – selects a preset

various frequency for adjustment: volume,

bass, mid and high frequencies

2 VOLUME/SOUND CONTROL CENTER –

( p – 3.5 mm headphone socket

adjusts the volume level and digital equalizer

settings

3 DIGITAL DBB (Dynamic Bass Boost) –

to the local mains voltage. Disconnect the

mains lead first if this selector has to be reset.

) Telescopic aerial – improves FM reception

¡ Voltage selector (not all versions) – to be set

enhances the bass

enhanced stereo effect

4 INCREDIBLE SURROUND – creates a super-

™ AC MAINS – inlet for mains cord

CD/ TUNER/ TAPE and also

switches the set off

5 POWER slider – selects the sound source for

£ Battery door

stations

radio station

REMOTE CONTROL

1 VOLUME 3,4 – adjusts volume level

2 PRESET 3,4 – (up, down) selects a preset

tape

PLAY 1 – starts playback

SEARCH 5, 6 – fast winds/rewinds the

RECORD 0 – starts recording

OPEN•STOP /9– stops the tape;

4 SHUFFLE – to play CD tracks in random order

3 TUNING ∞, § – (down, up) tunes to radio

compartment

– opens the cassette

PAUSE ; – interrupts recording or playback

6 CASSETTE RECORDER keys:

entire CD

5 REPEAT – repeats a track/ CD programme/

6 2; – starts CD playback/ interrupts CD

playback

7 ¡, ™ – skips to the beginning of a current

programme

track/ previous/ subsequent track

8 STOP 9 – stops CD playback or erases a CD

9 SEARCH 5, 6 – searches backwards or

play

running low

programme

7 OPEN•CLOSE – opens/ closes the CD door

8 STOP 9 – stops CD playback or erase a CD

9 PLAY•PAUSE 2; – starts or interrupts CD

0 BATT LOW – indicates when battery power is

the programme;

! PROG – CD: programmes tracks and reviews

forwards within a track/CD

Tuner: programmes preset radio

stations

previous/ subsequent track

track;

- skips to the beginning of a current track/

TUNER: - (down, up) tunes to radio stations;

CD: - searches back and forward within a

@ SHUFFLE – plays CD tracks in random order

# SEARCH ∞, §

entire CD

$ REPEAT – repeats a track / CD programme /

7

6

2345

1

T

I

R

W

E

R

D

CD SYNCRO

C

E

M

U

185

VOLUME

PRESET

2

E

L

B

I

O

S

E

L

AT

C

N

P

E

RDING

P

M

O

O

C

E

T RECO

L

B

A

STRA

L

O

V

R

E

T

N

E

C

L

O

R

T

N

O

C

D

N

U

O

S

T

E

S

E

R

P

R

E

N

U

T

R

E

D

R

O

C

5

E

7

R

E

5

T

1

T

E

S

Z

S

A

A

C

IO

D

A

R

D

C

U

A

•P

Y

A

L

P

P

O

T

S

D

N

A

B

TE

R

O

REM

SENSO

R

E

T

N

E

L

C

VO

L

E

O

L

G

R

F

O

F

T

R

U

P

N

H

O

S

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

M

F

F

M

U

A

H

T

W

S

W

L

BA

LO

E

S

G

O

R

P

D

IGIT

U

AL EQ

IG

D

LIZER

A

U

T

L

A

IT

R

E

N

INCREDIBLE SURROUND

*

^&

#$ %

@

!

(

3

TUNING

4

7

REPEAT

SEARCH

ontrol

C

STOP

emote

SEARCH

9

R

igital

D

Remote Control is only

for AZ1575.

¡

™

MAINS ~

£

SHUFFLE

6

)

890

PCS 104 628

Page 5

INSTRUCTIONS FOR USE

R

E

Y

PRO

D

C

O

L

O

E

R

T

L

A

B

R

T

A

S

T

I

O

R

R

C

W

N

E

Y

R

S

R

D

D

E

C

D

C

R

O

C

5

E

6

R

E

5

T

1

T

E

S

Z

S

A

A

C

O

I

D

A

R

D

C

E

M

U

L

O

V

SE

U

A

•P

Y

LA

P

R

E

P

T

O

N

ST

E

C

L

O

R

T

N

O

C

D

N

U

O

S

S

R

D

D

E

C

D

C

R

O

C

5

E

6

R

E

5

T

1

T

E

S

Z

S

A

A

C

O

I

D

A

R

D

C

N

U

O

S

E

T

M

A

B

U

L

O

V

SE

AU

•P

LAY

P

R

E

P

T

O

N

ST

E

C

L

O

R

T

N

O

C

D

N

U

O

S

and a number from

VOL

¥¥¥¥¥¥¥

+

3-2

¥

—

0

L

O

V

TUNER or TA PE.

SWITCHING ON AND OFF

TAPE/OFF position and the keys on the tape deck are

• Adjust the POWER slider to the desired sound source: CD,

• The set is switched off when the POWER slider is in the

the set's memory.

released.

– The volume, sound settings and tuner presets will be retained in

6 x D-cells - R20 - UM4

Turn the VOLUME/ SOUND CONTROL CENTER control

clockwise to increase or anti-clockwise to decrease volume on

the set (or press VOLUME 3 or 4 on the remote control).

To adjust the bass, mid and high frequency levels, press DIGITAL

EQUALIZER once or more until the desired option is displayed.

While the option is shown, turn the VOLUME/ SOUND

CONTROL CENTER control to increase or decrease

(- 5 to + 5 maximum) the desired frequency.

from 0-32.

Press DIGITAL DBB to switch dynamic bass boost on or off.

ADJUSTING VOLUME AND SOUND

1.

0-32.

™ Display shows the volume level indication

2.

™ VOLUME can also be adjusted in this way with a level range

Press INCREDIBLE SURROUND to switch the surround sound

3.

4.

™ If on, the DIGITAL DBB light goes on.

, e.g. alkaline with carbon zinc.

different types of music.

effect on or off.

™ If on, the INCREDIBLE SURROUND light goes on.

Note: The effect of INCREDIBLE SURROUND may vary with

GENERAL INFORMATION

rain, sand or excessive heat caused by heating equipment or direct

sunlight.

General maintenance

• Do not expose the set, batteries, CDs or cassettes to humidity,

not use any cleaning agents containing alcohol, ammonia, benzene

• To clean the set, use a soft, slightly dampened chamois leather. Do

MAINS

, corresponds to your local

as shown on the type plate

or abrasives as these may harm the housing.

not tilt. Make sure there is adequate ventilation to prevent the

system from overheating.

Safety information

• Place the set on a hard and flat surface so that the system does

and must not be oiled or lubricated.

• The mechanical parts of the set contain self-lubricating bearings

Whenever convenient, use the power supply if you want to

PCS 99 414

Open the battery compartment and insert six batteries, type

R-20, UM-4 or D-cells, (preferably alkaline) with the correct

polarity as indicated by the "+" and "-" symbols inside the

1.

compartment.

Remote control (supplied)

conserve battery life. Make sure you remove the plug from the

BATTERIES (OPTIONAL)

set and wall socket before inserting batteries.

Replace the compartment door, making sure the batteries are

Open the battery compartment and insert two batteries,

firmly and correctly in place. The set is now ready to operate.

type AAA, R03 or UM1 (preferably alkaline).

2.

are too weak.

– If BATT LOW lights up, battery power is running low.

– The BATT LOW indicator eventually goes out if the batteries

Only use batteries of the same type for the set.

batteries with the new ones.

time.

Do not mix battery types

– When inserting new batteries, do not try to mix old

–

Therefore:

will corrode the compartment or cause the batteries to burst.

– Incorrect use of batteries can cause electrolyte leakage and

should be disposed of properly.

Batteries contain chemical substances, so they

– Remove the batteries if the set is not to be used for a long

–

Check if the mains voltage

located on the back of the set

power supply. If it does not, consult your dealer or service

USING AC POWER

1.

centre.

If your set is equipped with a voltage selector, adjust the

selector so that it matches with the local mains.

Connect the mains lead to the wall socket and the set is now

ready for use.

To disconnect the set from the mains completely, remove the

2.

plug from the wall socket.

3.

4.

Page 6

INSTRUCTIONS FOR USE

E

E

1

5

C

A

O

D

ESET

PR

ER

N

TU

R

E

D

D

R

N

O

A

C

B

5

E

6

R

E

E

T

T

R

T

O

O

E

S

M

S

E

N

E

R

S

S

R

E

T

N

E

L

C

O

V

L

O

G

R

O

FFLE

T

U

PR

N

H

O

S

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

SE

U

Y•PA

A

G

PL

RO

P

P

O

ST

(some versions only)

3-3

O

S

E

L

C

N

E

P

O

ESET

PR

R

E

N

TU

R

E

D

D

R

N

O

C

BA

5

E

6

R

E

5

E

T

T

R

1

T

O

O

E

S

M

S

E

N

Z

E

R

S

S

A

A

C

R

O

I

E

D

T

A

N

R

E

L

C

D

O

V

C

L

O

G

R

FLE

O

F

T

U

PR

N

O

SH

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

USE

•PA

Y

G

PLA

PRO

P

O

ST

: Simultaneously, press PROG and REPEAT on

Check that the set is in the TAPE/OFF position and switched

Changing tuning grid

In North and South America the frequency step between adjacent

channels in the AM and FM band are 10 KHz and 100 KHz

respectively. In the rest of the world this step is 9 KHz and

50 KHz. Usually the frequency step has been preset in the factory

off.

for your area.

1.

2. To select 9KHz

: Repeat steps 1-3 but in step 2,

Switch the set on to TUNER and then release the controls.

To select 10KHz

simultaneously, press PROG and TUNING § on the set.

either steps of 9 or 10.

the set.

3.

•

reprogramme the preset stations.

™ When you tune to radio stations, the display shows tuning in

™ All preset stations will be affected and you may need

English

P

O

T

SE

PRE

R

E

N

TU

R

E

D

D

R

N

O

A

C

B

5

E

6

R

E

5

E

T

T

R

1

T

O

O

E

S

M

S

E

N

Z

E

R

S

S

A

A

C

R

O

I

E

D

T

A

N

R

E

L

C

D

O

V

C

L

O

G

EO

R

R

FFLE

T

RO

U

P

N

STE

O

SH

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

SE

U

A

•P

Y

G

PLA

O

PR

P

STO

STEREO is shown.

Select CD source.2.Press OPEN•CLOSE to open the CD door.

Playing a CD

™ Display: when you open the CD door.

1.

– the CD has reached the end (unless you have selected

– the CD door is opened;

Insert a CD or CD-R(W) with the printed side facing up and

press OPEN•CLOSE to close the CD door.

The total number of tracks and playing time are then shown.

Press PLAY•PAUSE 2; (on the remote control 2; ) to start

playback.

track during CD playback.

To interrupt playback press PLAY•PAUSE 2; .

Press PLAY•PAUSE 2; again to resume play.

playback is paused.

™ Display: as the CD player scans the contents of a CD.

™ Display: is shown if the CD R(W) is not finalised.

3.

P

O

R

E

D

R

O

C

5

E

6

R

E

5

T

1

T

E

S

Z

S

A

A

C

O

I

D

A

R

D

C

USE

•PA

Y

LA

P

P

O

ST

™ Display: Current track number and elapsed playing time of the

4.

T

SE

RE

P

ER

N

TU

D

N

A

B

E

T

R

O

O

S

M

E

N

E

R

S

R

E

T

N

E

L

C

O

V

L

O

G

R

FFLE

T

RO

U

P

N

O

SH

C

D

•

N

•

U

O

S

E

L

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

G

RO

P

5.

T

A

E

P

E

R

H

C

R

A

E

S

To stop CD playback, press STOP 9

™ The display freezes and the elapsed playing time flashes when

6.

Note: CD play will also stop when:

REPEAT ALL);

– you select another source: TAPE / TUNER.

if necessary until you find the desired station.

3

is shown.

or §) and release when the frequency in the display starts

running.

Select TUNER source.

Press BAND once or more to select your waveband.

Tuning to radio stations

1.

Press SEARCH ∞ or § (on the remote control, TUNING ∞

2.

3.

™ is displayed briefly and then the radio station frequency

reception. Display shows during automatic tuning.

™ The tuner automatically tunes to a station of sufficient

repeatedly until you have found optimal reception.

Repeat step

™ If an FM station is received in stereo,

4.

• To tune to a weak station, press SEARCH ∞ or § briefly and

To improve radio reception:

, the set is provided with a built-in aerial so the

, pull out the telescopic aerial.

FM

MW (AM)

telescopic aerial is not needed. Direct the aerial by turning the

Incline and turn the aerial. Reduce its length if the signal is too

• For

whole set.

strong (very close to a transmitter).

• For

Programming radio stations

You can store up to a total of 30 radio stations in the memory.

PROG flashes.

Tune to your desired station (see Tuning to radio stations).

Press PROG to activate programming.

™ Display:

1.

2.

PROG disappears, the preset number and the frequency

Press PRESET 3 or 4 once or more to allocate a number from

1 to 30 to this station.

Press PROG again to confirm the setting.

Repeat the above four steps to store other stations.

of the preset station are shown.

™ Display:

3.

4.

5.

frequency in its place.

• You can overwrite a preset station by storing another

Tuning to preset stations

Press TUNER PRESET 4 or 3 until the desired preset station is

displayed.

PCS 99 415

Page 7

INSTRUCTIONS FOR USE

T

W

S

Y

C

L

U

3-4

ER

N

U

T

R

E

D

D

R

O

AN

C

B

5

E

6

R

E

5

E

T

T

R

1

T

O

O

E

S

M

S

E

N

Z

E

R

S

S

A

A

C

R

O

I

E

D

T

A

N

R

E

L

C

D

O

V

C

L

O

G

R

FFLE

T

U

PRO

N

O

SH

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

SE

U

•PA

G

PLAY

O

PR

P

O

ST

N

O

V

D

N

U

O

S

R

E

N

TU

R

E

D

D

R

N

O

C

BA

5

E

6

R

E

5

E

T

T

R

1

T

O

O

E

S

M

S

E

N

Z

E

R

S

S

A

A

C

R

O

I

E

D

T

A

N

R

E

L

C

D

O

V

C

L

O

G

R

O

FFLE

T

PR

N

O

SHU

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

SE

U

A

•P

Y

A

G

PL

O

R

E

PR

P

T

N

STO

E

C

L

O

R

T

N

O

C

X

PROG disappears.

PROG and the selected track number. appears

) to select your desired track number.

Use the SEARCH ∞ or § on the set, (on the remote control

¡ or ™

Programming track numbers

Programme in the STOP position to select and store your CD tracks

in the desired sequence. If you like, store any track more than

Press PROG.

once. Up to 20 tracks can be stored in the memory.

1.

2.

™ Display:

Repeat steps 1-2 to select and store all desired tracks.

briefly.

number, is shown.

™ If you attempt to programme without first selecting a track

3.

To start playback of your CD programme, press

PLAY•PAUSE 2; (on the remote control 2; ).

4.

STOP 9, then PLAY•PAUSE 2;.

™ If you have selected the tracks during CD play, first press

tracks.

™ is displayed if you attempt to programme more than 20

Reviewing the programme

In the stop position or during playback, press and hold down PROG

for a while until the display shows all your stored track numbers in

sequence.

Erasing a programme

You can erase the programme by:

– pressing STOP 9 once in the STOP position;

– pressing STOP 9 twice during playback;

• The display shows briefly and

The programme is also erased by:

– pressing the CD door open;

– selecting another source: TAPE / TUNER.

T

ESE

PR

R

E

N

U

T

R

E

D

D

R

N

O

A

C

B

5

E

6

R

E

5

E

T

T

R

1

T

O

O

E

S

M

S

E

N

Z

E

R

S

S

A

A

C

R

O

I

E

D

T

A

N

R

E

L

C

D

O

V

C

L

E

O

G

R

O

FFL

T

R

U

P

N

O

SH

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

U

AM

H

T

W

S

A

LW

O

B

L

SE

U

•PA

Y

G

PLA

O

PR

P

O

ST

available cleaning CD to clean the lens before taking the set to

CD player and CD handling

• If the CD player cannot read CDs correctly, use a commonly

R

E

D

R

O

C

5

E

6

R

E

5

T

1

T

E

S

Z

S

A

A

C

O

I

D

A

R

D

C

SE

PLAY•PAU

P

O

ST

continuously

continuously in random order

repair. Other cleaning methods may destroy the lens.

condensation to cloud over on the lens of your CD player.

Playing a CD is then not possible. Do not attempt to clean the

lens but leave the set in a warm environment until the

moisture evaporates.

• The lens of the CD player should never be touched!

• Sudden changes in the surrounding temperature can cause

RESE

P

R

NE

U

T

ND

BA

E

T

R

O

O

S

M

E

N

E

R

S

R

E

T

N

E

L

C

O

V

L

O

G

R

FFLE

T

U

PRO

N

O

SH

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

F

FM

M

U

A

H

T

W

S

A

LW

O

B

L

G

O

PR

lens.

• Always keep the CD compartment closed to avoid dust on the

to cancel your play mode.

STOP 9

PCS 99 416

¡ or ™) once or repeatedly until the desired track number

appears in the display.

Selecting a different track

• Press SEARCH ∞ or § on the set, (on the remote control

or in the PAUSE position, you will need to press PLAY•PAUSE

• If you have selected a track number shortly after loading a CD

Press and hold down on SEARCH ∞ or § (on the remote

When you recognize the passage you want, release SEARCH

∞ or §.

2; (on the remote control 2; ) to start playback.

control 5 or 6).

Finding a passage within a track

1.

2.

Note:

– The CD is played at high speed and low volume.

– Normal playback continues.

only possible within a track.

During a CD programme or if SHUFFLE/ REPEAT active, searching is

Different play modes: SHUFFLE and REPEAT

You can select and change the various play modes before or during

playback. The play modes can also be combined with PROGRAM.

SHUFFLE - tracks of the entire CD/ programme are played in

random order

To select your play mode, press the SHUFFLE or REPEAT

button before or during playback until the display shows the

SHUFFLE and REPEAT ALL - to repeat the entire CD/ programme

REPEAT ALL - to repeat the entire CD/ programme

REPEAT and SHUFFLE REPEAT - plays the current (random) track

desired function.

1.

Press PLAY•PAUSE 2; (on the remote control 2; ) to start

playback if in the STOP position.

2.

To return to normal playback, press the respective SHUFFLE or

mode.

REPEAT button until the various SHUFFLE / REPEAT modes are

no longer displayed.

3.

• Playback starts immediately if you have selected a SHUFFLE

– You can also press

Page 8

INSTRUCTIONS FOR USE

T

E

R

A

M

P

ET

T

E

R

A

M

P

ES

R

P

ER

N

TU

R

E

D

D

R

N

O

A

C

B

5

E

6

R

E

5

E

T

T

R

1

T

O

O

E

S

M

S

E

N

Z

E

R

S

S

A

A

C

R

O

I

E

D

T

A

N

R

E

L

C

D

O

V

C

L

E

O

G

R

FFL

T

RO

U

P

N

O

SH

C

T

D

A

•

E

N

•

P

U

E

R

O

S

H

C

R

A

E

E

L

S

F

M

F

F

M

U

A

H

T

W

S

A

LW

O

B

L

SE

U

A

•P

Y

A

G

PL

O

PR

P

STO

3-5

E

L

B

I

G

T

N

O

S

E

I

L

A

C

D

N

P

E

R

P

M

O

O

O

C

E

C

R

E

T

L

A

B

R

T

A

S

T

I

O

R

R

C

W

N

E

Y

R

S

R

D

D

E

C

D

C

R

O

C

5

E

6

R

E

5

T

1

T

E

S

Z

S

A

A

C

O

I

D

T

A

N

R

E

C

D

C

L

O

R

T

N

O

C

D

N

U

O

S

FM

E

T

M

W

A

O

B

U

L

L

O

V

E

S

U

•PA

Y

G

LA

P

O

R

E

PR

P

T

O

N

ST

E

A AB

C

Press RECORD 0 to start recording.

beginning of the programme. It is not necessary to start the CD

player separately.

– Playing of the CD programme starts automatically from the

5.

control 5 or 6).

∞ or §.

• When you recognize the passage you want, release SEARCH

• To interrupt CD playback press PLAY•PAUSE 2; (on the

remote control 2;).

• Recording will begin from this exact point in the track when

E

L

B

T

A

S

T

I

O

R

R

C

W

N

E

Y

R

S

D

D

C

C

E

M

U

L

O

V

To select and record a particular passage within a track:

• Press and hold down on SEARCH ∞ or § (on the remote

resume recording, press PAUSE ; again.

For brief interruptions during recording, press PAUSE ;. To

To stop recording, press OPEN•STOP /9.

you press RECORD 9.

6.

7.

E

L

B

I

G

T

N

O

S

E

I

L

A

C

D

N

P

E

R

P

M

O

O

O

C

E

C

R

T

A

R

R

E

D

R

O

C

5

E

6

R

E

5

T

1

T

E

S

Z

S

A

A

C

O

I

D

T

A

N

R

E

C

D

C

L

O

R

T

N

O

C

D

N

U

O

S

FM

T

W

A

O

B

L

SE

U

Y•PA

G

PLA

O

R

R

E

P

P

T

O

N

ST

E

to open the cassette door.

/9

TAPE throughout tape operation.

Tune to the desired radio station (see Tuning to radio stations).

Press OPEN•STOP /9to open the cassette door.3.Insert a suitable tape into the cassette deck and close the

cassette door.4.Press RECORD 0 to start recording.

For brief interruptions, press PAUSE ; To resume recording,

Recording from the tuner

1.

2.

press PAUSE ; again.6.To stop recording, press OPEN•STOP /9.

5.

Tape deck maintenance

To ensure quality recording and playback of the tape deck, clean

parts A, B and C shown in the diagram below, after approx.

50 hours of operation, or on average once a month. Use a cotton

bud slightly moistened with alcohol or a special head cleaning

fluid to clean both decks.

.

/9

Open the cassette holder by pressing OPEN•STOP /9.2.Press PLAY 1 and clean the rubber pressure rollers C. 3.Press PAUSE ; and clean the magnetic heads A and also the

capstan B.4.After cleaning, press OPEN•STOP /9.

1.

cassette through once.

Cleaning of the heads can also be done by playing a cleaning

Note:

to open the cassette holder.

/9

write on a CD or attach any stickers to it.

lifting the CD. Always pick up the CD by the edge and return

the CD to its box after use to avoid scratching and dust.

• To take a CD out of its box, press the centre spindle while

Never

towards the edge using a soft, lint-free cloth. Do not use

cleaning agents as they may damage the disc.

• To clean the CD, wipe in a straight line from the centre

•

Select TAPE source.

Press OPEN•STOP

Cassette playback

Insert a recorded cassette and close the cassette door.4.Press PLAY 1 to start playback.

1.

2.

3.

™ The display shows

To interrupt playback press PAUSE ;. To resume, press this

key again.

By pressing SEARCH 5 or 6 on the set fast winding of the

tape is possible in both directions.

To stop the tape, press OPEN•STOP

5.

6.

except if PAU SE ; has been activated.

7.

• The keys are automatically released at the end of the tape,

third parties are not infringed.

METAL (IEC IV) type cassettes. For recording, use only

NORMAL type cassettes (IEC I) on which the tabs have not

been broken.

VOLUME, INCREDIBLE SURROUND, DIGITAL EQUALIZER or DBB

controls will not affect the recording in progress.

take place during the 7 seconds, when the leader tape passes

the recorder heads.

front of you and break out the left tab.

Recording on this side is no longer possible. To record over this

GENERAL INFORMATION ON RECORDING

• Recording is permissible insofar as copyright or other rights of

• This deck is not suited for recording on CHROME (IEC II) or

• The best recording level is set automatically. Altering the

• At the very beginning and end of the tape, no recording will

side again, cover the tabs with a piece of adhesive tape.

• To protect a tape from accidental erasure, have the tape in

Select CD source.

Insert a CD and if desired, programme track numbers.

Press OPEN•STOP

Insert a suitable tape into the cassette deck and close the

Synchro Start CD recording

1.

cassette door.

2.

3.

4.

PCS 99 417

Page 9

INSTRUCTIONS FOR USE

3-6

indication

CD-R(W) is blank or the disc is not finalised

CD damaged or dirty

• Use a finalised CD-R(W)

–

invalidate the guarantee.

circumstances should you try to repair the set yourself, as this will

PROBLEM

– POSSIBLE CAUSE

If a fault occurs, first check the points listed below before taking the set for repair.

If you are unable to remedy a problem by following these hints, consult your dealer or service centre.

WARNING: Do not open the set as there is a risk of electric shock. Under no

• REMEDY

SHUFFLE or PROGRAM is active

The CD skips tracks

–

• Replace or clean CD

–

No sound/power

– VOLUME not adjusted

• Adjust the VOLUME

– Headphones connected

Dust and dirt on the heads, etc.

• Switch off SHUFFLE / PROGRAM

Poor cassette sound quality

–

• Disconnect headphones

– Mains lead not securely connected

• Connect AC mains lead properly

or CHROME)

Use of incompatible cassette types (METAL

• Clean deck parts, see Maintenance

–

• Only use NORMAL (IEC I) for recording

VCR or computer

Electrical interference: set too close to TV,

Severe radio hum or noise

–

Cassette tab(s) may be broken

missing tab space.

Recording does not work

–

• Apply a piece of adhesive tape over the

Weak radio signal

• Increase the distance

Poor radio reception

optimum reception

–

• FM: Direct the FM telescopic aerial for

Remote control does not function properly

indication

Batteries exhausted

Batteries incorrectly inserted

–

CD badly scratched or dirty

–

Distance/ angle between the set too large

• Insert fresh batteries

–

• Insert the batteries correctly

–

• Reduce the distance/ angle.

Laser lens steamed up,

• Replace/ clean CD, see Maintenance

–

• Wait until lens has cleared

Environmental information

All unnecessary packaging material has been omitted. We have done our utmost to make the

packaging easy to separate into three mono-materials: cardboard (box), expandable polystyrene

(buffer), polyethylene (bags, protective foam).

Your set consists of materials which can be recycled if disassembled by a specialized

company. Please observe the local regulations regarding the disposal of packing

materials, exhausted batteries and old equipment.

PCS 99 418

Page 10

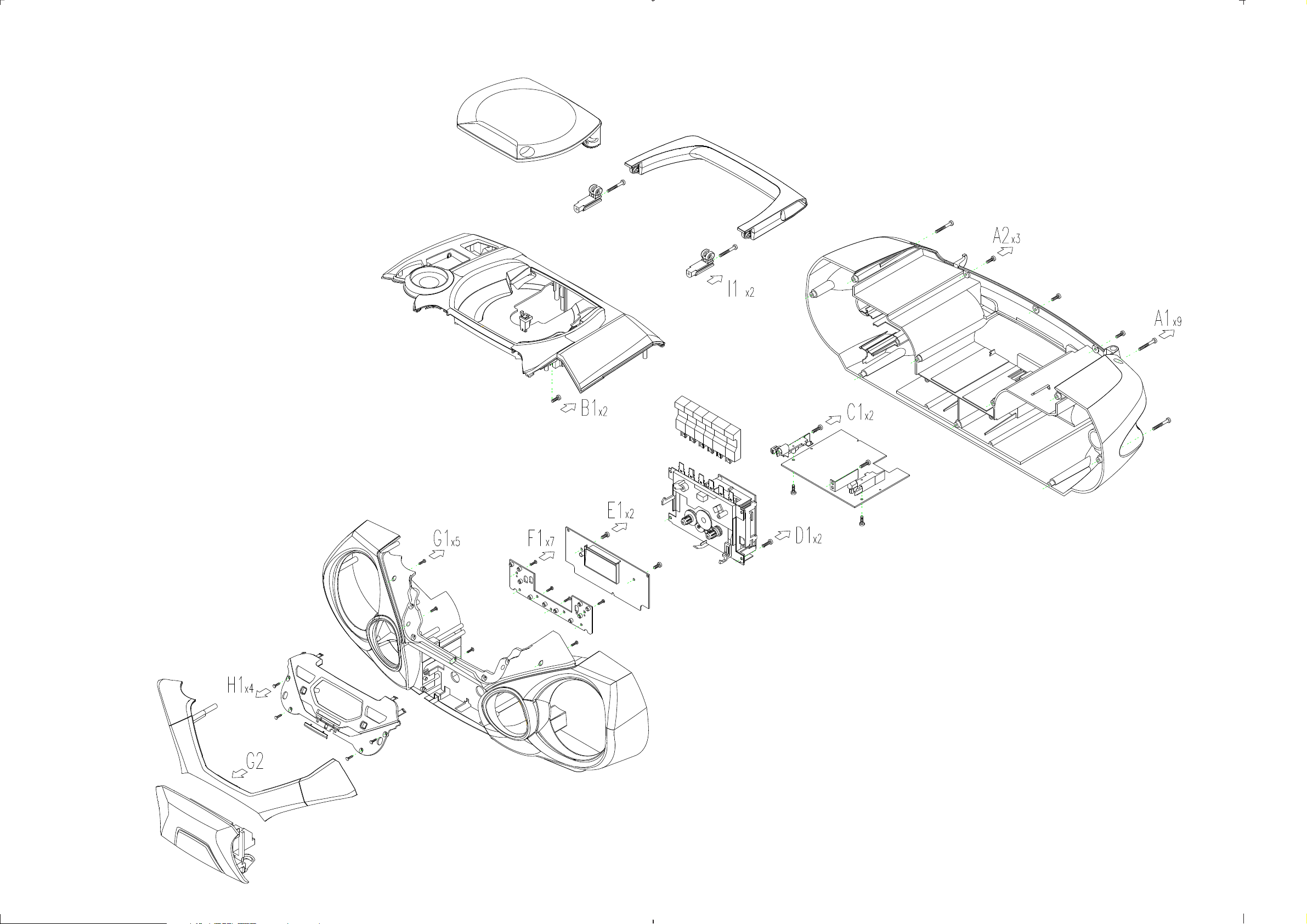

DISASSEMBLY DIAGRAM

A. To remove Front Cabinet Assembly

B. To remove Top Cabinet

C. To remove AF Board

D. To remove Tape Deck

E. To remove Control Board

F. To remove Keyboard

G. To remove Ornamental Plate

H. To remove CD Panel Front

I. To remove Handle

4-1 4-1

PCS 99 419

Page 11

CD SERVICE TESTPROGRAM

Grid switchable1) Grid switchable

- 17 MHz - - - - - - - -

4-2

4-2

STOP button pressed in any step returns

*

to begin of Service Testprogram.

To leave Service Testprogram switch mode switch

*

to off-position.

Door switch is ignored Æ CD door can be opened.

*

Volume up/down buttons function independentely

*

of the service testprogram.

+

VOL

PROG

•

STEREO

•

•

SHUFFLE

•

0

REPEAT ALL

•

•

•

•

–

fig. 1

ERROR MEANING

Err 1 No focus found

Err 2 Time out error for disc motor reach the normal speed

Err 3 Focus error during tracking initialization

Err 4 Subcode error on play mode

Err 5 Focus error on play mode

Err 6 Radial error on search mode

Err 7 Focus error

DISPLAY TEST

NEXT button

N

Display shows all

segments and flags.

see figure 1

STOP button

N

table 1

pressed?

Y

pressed?

Y

EP2PROM CLEAR

PREV button

N

pressed?

Y

Display shows

EP

E2prom clear

STOP button

N

pressed?

Y

To enter Service

Testprogramm hold

PLAY & STOP buttons

depressed while switching

CD mode on.

Display shows

version number

of the µP - software.

16

CD TEST TUNER TEST

Slide servo, Radial servo, Focus servo, Disc motor

and Laser are switched off.

Mute is switched on via decoder IC.

CD SERVO TEST

PLAY button

N

pressed?

Y

Display shows

01

SLIDE test DISC MOTOR test

N N N N N

PLAY button

pressed?

FOCUS search

Display shows

objective moves up&down

disc motor for 160ms "on"

FOCUS found?

Display shows

disc motor turns.

PLAY button

pressed?

Enter Service Play

Mode Test

Error code

display?

Display shows

e.g.

see table 1

Y Y Y Y Y

-2

FOC

Y

+2

FOC

Y

Y

01

E

outside as long as

N

N

N

NEXT button

pressed?

Slide moves

button is held

depressed.

PREV. button

pressed?

Slide moves

inside as long as

button is held

depressed.

PROG. button

pressed?

Disc motor turns

counter clockwise

as long as button

is held depressed.

(brake)

SHUFFLE button

pressed?

Disc motor turns

clockwise

as long as button

is held depressed.

(accelerate)

To enter Service

Testprogramm hold

PLAY & STOP buttons

depressed while switching

TUNER mode on.

Display shows

version number

of the µP - software.

16

DISPLAY TEST

NEXT button

N

Display shows all

segments and flags.

see figure 1

STOP button

N

pressed?

Y

pressed?

Y

IF-OFFSET CORRECTION

PLAY button

pressed?

IF - OFFSET correction

activated 2).

Y

TUNER TEST

Service preset frequencies

acc. table 3 are copied

to the RAM.

Tuner is normal working

except the PROGRAM key.

N

PROG button

(Tuner)

pressed?

Y

STOP button

pressed?

Y

N

N

SERVICE PRESET FREQUENCIES

REGION

PRESET

10 - 5.9 MHz - - 11 MHz - 279 kHz - - 17 MHz

11 - 17.9 MHz - - - - 198 kHz - - 12 - 6.2 MHz - - - - - - - 13

EUROPE EUROPE4B EUROPE2B OVERSEAS OVERSEAS3B KOREA EAST-EUROPE EAST-EUROPE USA CHINA

FM/MW/LW FM/MW/LW/SW FM/MW FM/MW FM/MW/SW FM/MW FM/MW/LW FM/MW FM/MW FM/MW/SW

/00/05/20/25 /00/05/20/25 /00 /01/21 /01/21 /13/33 /14/34 /14 /14/37 /15/35

1 87.5 MHz 87.5 MHz 87.5 MHz 87.5 MHz 87.5 MHz 87.5 MHz 65.81 MHz 65.81 MHz 87.5 MHz 87.5 MHz

2 108 MHz 108 MHz 108 MHz 108 MHz 108 MHz 108 MHz 108 Mhz 108 Mhz 108 MHz 108 MHz

3 531 kHz 531 kHz 531 kHz 531/530 KHz 531/530 KHz 531 kHz 74 MHz 74 MHz 530 kHz 531 kHz

4 1602 kHz 1602 kHz 1602 kHz 1602/1700 kHz 1602/1700 kHz 1602 kHz 87.5 MHz 87.5 MHz 1700 kHz 1602 kHz

5 558 kHz 558 kHz 558 kHz 558/560 kHz 558/560 kHz 558 kHz 531 kHz 531 kHz 560 kHz 558 kHz

6 1494 kHz 1494 kHz 1494 kHz 1494/1500 kHz 1494/1500 kHz 1494 kHz 1602 kHz 1602 kHz 1500 kHz 1494 kHz

7 153 kHz 153 kHz - - 3.9 MHz - 558 kHz 558 kHz - 5.9 MHz

8 279 kHz 279 kHz - - 12.1 MHz - 1494 kHz 1494 kHz - 17.9 MHz

9 198 kHz 198 kHz - - 4.2 MHz - 153 kHz - - 6.2 MHz

1)

10-100kHz/9-50kHz 10-100kHz/9-50kHz

table 3

PCS 99 420

STATUS MEANING

Sta 0 Silde mode

Sta 1 Silde mode

Sta 2 Silde mode

Sta 3 Silde mode

Sta 8 Play mode

NEXT button

pressed?

Display shows

00

e.g.

S R

see table 2

Y

Sta > 8 Recover mode

table 2

STOP button

pressed?

Y

N

1)

How to set frequency grid:

AM - 9 kHz / FM - 50 kHz : Hold PROGRAM KEY buttons depressed while switching MODE-switch to RADIO.

AM - 10 kHz / FM - 100 kHz : Hold PROGRAM KEY buttons depressed while switching MODE-switch to RADIO.

Selected frequency grid is stored in the EEPROM.

N

2)

In sets with 30kHz grid on FM band it may occur that the

tuned frequency is indicated wrong on the display because

of tolerances of the discriminator filter.

For that reason the testsoftware is prepared for an

automatic IF-offset correction .

Note:

This test functions only with the East European

tuner version used in /14/34 set versions.

The test was executed on every set in the production line.

In case the discriminator filter or the EEPROM has to be

exchanged the automatic IF-offset correction should also be

executed after repair.

To execute the automatic IF-offset correction proceed as follows:

* feed a strong 87.5MHz signal to the antenna

* press the PLAY button

The µP starts now several times the search mode.

If the transmitter was found at 87.5MHz the stop-frequency sent by the

radio IC is compared with the nominal frequency else the d isplay shows "00E".

When the same difference is found twice the value will be s tored as offset.

The actual used offset is shown on the display ( -3, -2, -1, 0, 1, 2, 3 ).

Page 12

4-3 4-3

Abbreviations and Pin-description of CD Ics

Abbreviations and Pin-description of CD Ics

SERVO PROCESSOR SAA7325H

SYMBOL PIN DESCRIPTION

HFREF 1 comparator common mode input

HFIN 2 comparator signal input

ISLICE 3 current feedback output from data slicer

V

SSA1

V

DDA1

I

ref

V

RIN

D1 8 unipolar current input (central diode signal input)

D2 9 unipolar current input (central diode signal input)

D3 10 unipolar current input (central diode signal input)

D4 11 unipolar current input (central diode signal input)

R1 12 unipolar current input (satellite diode signal input)

R2 13 unipolar current input (satellite diode signal input)

V

SSA2

CROUT 15 crystal/resonator output

CRIN 16 crystal/resonator input

V

DDA2

LN 18 DAC left channel differential output - negative

LP 19 DAC left channel differential output - positive

V

neg

V

pos

RN 22 DAC right channel differential output - negative

RP 23 DAC right channel differential output - positive

SELPLL 24 selects whether internal clock multiplier PLL is used

TEST1 25 test control input 1; this pin should be tied LOW

CL16 26 16.9344 MHz system clock output

DATA 27 serial d4(1)ata output (3-state)

WCLK 28 word clock output (3-state)

SCLK 29 serial bit clock output (3-state)

EF 30 C2 error flag output (3-state)

TEST2 31 test control input 2; this pin should be tied LOW

KILL 32 kill output (programmable; open-drain)

V

SSD1

V2/V3 34 versatile I/O: input versatile pin 2 or output versatile pin 3 (open-drain)

WCLI 35 word clock iutput (for data loopback to DAC)

SDI 36 serial data input (for data loopback to DAC)

SCLI 37 serial bit clock input (for data loopback to DAC)

RESET 38 power-on reset input (active LOW)

SDA 39 microcontroller interface data I/O line (open-drain output)

SCL 40 microcontroller interface clock line input

(1)

4

(1)

5

analog ground 1

analog supply voltage 1

6 reference current output pin

7 reference voltage for servo ADC's

(1)

14

17

analog ground 2

(1)

analog supply voltage 2

20 DAC negative reference input

21 DAC positive reference input

(1)

33

digital ground 2

SERVO PROCESSOR SAA7325H

SYMBOL PIN DESCRIPTION

RAB 41 microcontroller interface R/W and load control line input (4-wire bus mode)

SILD 42 microcontroller interface R/W and load control line input (4-wire bus mode)

STATUS 43 servo interrupt request line/decoder status register output (open-drain)

TEST3 44 test control input 3; this pin should be tied LOW

RCK 45 subcode clock input

SUB 46 P-to-W subcode bits output (3-state)

SFSY 47 subcode frame sync output (3-state)

SBSY 48 subcode block sync output (3-state)

CL11/4 49 11.2896 MHz or 4.2336 MHz (for microcontroller) clock output

V

SSD2

DOBM 51 bi-phase mark output (externally buffered; 3-state)

V

DDD1(P)

CFLG 53 correction flag output (open-drain)

RA 54 radial actuator output

FO 55 focus actuator output

SL 56 sledge control output

V

DDD2(C)

V

SSD3

MOTO1 59 motor output 1; versatile (3-state)

MOTO2 60 motor output 2; versatile (3-state)

V4 61 versatile output pin 4

V5 62 versatile output pin 5

V1 63 versatile intput pin 1

LDON 64 laser drive on output (open-drain)

Note : All supply pins must be connected to the same external power supply voltage.

50

52

57

58

(1)

(1)

(1)

(1)

digital ground 3

digital supply voltage 2 for periphery

digital supply voltage 3 for core

digital ground 4

PCS 99 458

Page 13

BLOCK DIAGRAM

5-1 5-1

+TUNER

ECO5/ECO6

TUNER MODULE

+A_ON +CD

CD99

CD MODULE

+B +MOTOR

R

SOUND

DBEISBUFFER

R

R

PROCESSOR

TDA7449

+TAPE

+TUNER

+CD

POWER AMP

MUTE

TA8227

Woofer

4 OHM

R

4u7

Tweeter

8 OHM

TAPE

MODULE

R

R

+MOTOR+TAPE

+CD

+TUNER

+TAPE

REGULATOR

~

+

-

~

For -/01/11 only

230V

120V

PCS 99 421

Page 14

WIRING DIAGRAM

+

LEAF DOOR SWITCH

TAPE DECK

8802

140mm

6-1 6-1

1494

FE-ST-VK-N

GND

K01

K02

K1

K2

K3

K4

K5

FE-ST-VK-N

K01

K02

+B

1493

FE-ST-VK-N

8402

AD

80mm

1491

K1

K2

K3

K4

K5

1821

EH-B

1800

CD 99 /DA11

L

+CD

GND

R

8800

280mm

GND

15

1

+A

CD-DRIVE

DA11

1823

FE-ST-VK-N

6 1

FE-ST-VK-N

SILD

SICL

DATA

GND

/PORE

DOOR_SW

1801

1824

8400

8801

180mm

140mm

MONO_ST

FE-ST-VK-N

1490

SILD

SICL

DATA

GND

/PORE

DOOR_SW

DATA

CLK

ENABLE

+TUNER

Keyboard board

LCD

Frontboard

REC_INFO

SDA/PWM

+A

J2

J1

KEY_IS

IS

DBB

KEY_EQ

GND

KEY_DBB

1492

FE-ST-VK-N

GND

SCL/Search_mute

8401

140mm

VERSION

ITEM

/00/05/10/13/14

/01/11/11H

/17

0001

RED

BLUE

BLUE

0002

ORANGE

0003

RED

BLACK

BLUE

71

ECO-MTF-MS

73

H Y R

FE-ST-VK-N

GND

+TAPE

RO

EH-S

REC_INFO

GND

+MOTOR

W

FE-ST-VK-N

1725

LI

RI

LO

8626

1702

180mm

+1

8625

180mm

LO

RO

GND

LI

+B

RI

1801

1625

L

VCC

GND

R

FE-ST-VK-N

R

+CD

GND

8101

340mm

1251

L

EH-S

GND

+A

MONO_ST

CLK

DATA

+TUNER

ENABLE

MONO_ST

Feature Board

1250

EH-S

1

GND

ENABLE

DATA

CLK

8100

340mm

1122

1121

IS

DBB

3

2

FE-ST-VK-N

GND

ENABLE

DATA

CLK

MONO_ST

FE-ST-VK-N

L

GND

R

VCC

1400FE-ST-VK-N

J1

KEY_EQ

1500

EH-S

6

7

220MM

GND

GND

+A_ON

GND

GND

MUTE

ALC

KEY_IS

4

KEY_DBB

5

8550

ECO6 Tuner

(AZ1560/AZ1565)

(AZ1570/AZ1575)

0001

0002

0003

EH-B

Supply

GND

Power Board

GND

2

1

1009

XH-B

Transformer

1015

DC

PH-B

8251

180mm

+

Battery

FE-BT-VK-N

1000

FE-ST-VK-N

J2

1550

+A

+1

+B

R

L

8500

FE-ST-VK-N

180mm

ALC

MUTE

GND

GND

+A_ON

GND

1004

1

2

3

4

5

6

7

1006

EH-B

L

R

+B

+1

+A

EH-B

+1

REC_INFO

GND

GND

SCL/Search_mute

+MOTOR

+A

SDA/PWM

AF Board

1003

EH-B

GND

Supply

REC_INFO

1007

PH-B

EH-B

+B

GND

1005

1013

400mm

8250

8803

180mm

(For AZ1565 Only)

1014

Copper foil

-

8502

8501

480mm

220mm

3.8M

8103

8104

220mm

4 OHM

80mm

Tweeter

8 OHM

2129

4u7

80mm

80mm

4 OHM 8 OHM

Tweeter

LeftRight

2130

4u7

PCS 104 629

Page 15

AF BOARD - CIRCUIT DIAGRAM

T02 C1

T07 D1

T11 D1

T15 F1

T19 G1

T03 C1

T04 C1

T06 C1

T08 D1

T09 D1

T10 D1

T12 E1

T13 F1

T14 F1

T16 F1

T17 F1

T18 G1

T20 G1

T21 H1

T22 H1

T23 D8

T24 E8

T25 C14

T26 D17

T27 E17

T29 E17

T30 F17

T31 E19

T33 E19

T34 E19

T35 I11

T37 H5

7-1

T38 H5

1000 B1

1003 D19

1004 D17

1005 E1

1006 G1

1007 E19

1013 H6

2000 B14

2001 F6

2002 C6

2003 C6

2004 D11

2005 D11

2006 D12

2007 D14

2008 E16

2009 F6

2010 D11

2011 D15

2012 D12

2013 C6

2015 C5

2016 C5

2017 F6

2018 F11

2019 F12

2020 F14

2021 F14

2022 E16

2023 F11

2024 F12

2025 F14

2026 F15

2027 G14

2031 D3

2032 E3

2033 K7

2034 K10

2035 K11

2128 E11

2036 F8

2037 D8

2038 E10

3000 B14

2129 D19

3001 B15

2130 F19

3002 G7

2131 G5 3030 K12

3003 B6

3004 F7

3005 C6

3007 D10

3008 D12

3009 D12

3014 E17

3018 F9

3015 B5

3010 D9

3011 D10

3012 E17

3019 F12

3016 E10 3041 F5

3020 F10

3017 E12

3021 G14

3022 G8

3023 H8

3024 H9

3025 I10

7-1

3026 I12

3028 J12

3029 J12

3031 K13

3032 K13

3033 L11

3034 D11

3035 F11

3036 C15

3037 G9

3038 D3

3039 E3

3040 F5

6001 B14

6002 G15

6003 G15

6008 K11

6009 K10

6010 B14

7000 B14

7001 C4

7002 D10

7004 E13

7005 F10

7006 I8

7007 I9

7008 I11

7009 J12

7010 K12

7106 B152039 F10

2021

7.61V

6002

BAS216

6003

BAS216

15

BC557B

7106

2011

470n

2026

470n

+A_ON

3001

2K2

7.33V

3036

10K

16 17 18 19 20

470u

2008

470u

2022

3012

120R

3014

120R

Item 3037 provision only

ignore

Ref Des

319801606810

2012

680p

319801606810

2024

680p

6009

319801033380

BZX79-F3V3

T26

T27

T29

T30

1004

EH-B

1

2

3

4

5

6

7

T31

T33

T34

Right

EH-B

1003

1

2

1007

PH-B

1

2

Left

2129

4u7

4u7

2130

A

B

C

D

TWEETER

WOOFER

E

WOOFER

TWEETER

F

G

H

I

J

K

L

1 2 3 4 5

6 7 8 9

10 11 12

A

B

C

D

FE-BT-VK-N

1000

1

2

3

4

5

6

7

8

9

10

11

T02

T03

T04

T06

T07

T08

T09

T10

T11

E

FE-BT-VK-N

1005

T12

1

T13

2

T14

F

G

3

4

5

6

7

1

2

3

4

EH-B

1006

T15

T16

T17

T18

T19

T20

T21

T22

H

I

J

K

+A_ON

SDA

DIGGND

SCL

+A

+1

9V

+B

Right

Mute

Left

Bass

+B

+A

REC

Rec

+1

3038

4K7

3039

4K7

2031

2032

3V

47p

3V

47p

7001

TDA7449

LIN18

LIN29

RIN17

RIN26

+6V

3015

10R

2015

470u

3.1V

VOLUM

VOLUM TREBLE BASS

SDA

SCL

0.46V

20

19

4.6V

3040

1K

3041

+A

T37

T38

2016

100u

2013

150n

6.18V

3.1V 3.1V 3.1V

2

1

16

VA

CREF

SUPPLY

TREBLEL

TREBLE BASS

I2C

BUS DECODER + LATCHES

TREBLER

DIGGND

PGND

17

18

3

3.1V

2009

150n

1K

2n2

2131

1013

EH-B

1

2

2002

5n6

2017

5n6

15

BINL

BINR

12

3.1V 3.1V

2003

330n

14

BOUTL

BOUTR

13

2001

330n

2K2 3004

22K3003

2K23005

SPKR ATT

LEFT

SPKR ATT

RIGHT

22K 3002

MUXOUTL 10

LOUT 5

ROUT 4

MUXOUTR 11

2033

470u

5.57V

2.39V

2.39V

T23

T24

3022

4R7

3023

3R3

8.89V

7006

BC337-25

2u2

2037

2u2

2036

Mute

3037

4R7

3024

3R3

7007

BC337-25

3010

2K2

3011

10K

3016

3018

2K2

3020

10K

3025

6.22V 6.23V

220R

3007

8K2

BC337-25

7002

0V

2038

2n2

8K2

BC337-25

7005

0V

2039

2n2

2034

470u

6009

0V

3034

6K8

0V

3035

6K8

+6V

BZX79-F3V3

BZX284-C3V3

2005

680p

2018

680p

T35

7008

BC327-25

6008

3033

220R

2035

47u

2004

470n

2010

47u

2128

470n

2023

47u

BC547B

7010

2.65V

470R

3029

8.26V

3008

470R

3009

220R

3017

470R

3019

220R

3026

1K

8.9V

7009

BC557B

3.26V

2012

680p

2024

680p

3030

470R

2006

2n2

2019

2n2

3028

4R7

13

14

8.99V8.26V

13 14

+A_ON

3000

12K

8.56V

2000

220u

7.54V

0.6V

0V

456

MT1

7004

TA8227P

MT2

7 8 9

10 11 12

0.2V 0.6V

7.54V

4.45V

2020

47u

Bass

3031

4K7

3032

470R

7.86V

3.94V

23

6001

BAS216

8.25V

7000

BC547B

6010

BAS216

T25

7.86V

1

9V

3.97V

2025

4m7

3021

47R

2027

100u

2007

47u

+A

47u

L

PCS 99 423

1 2 3 4 5 6 7 8 9 10 11 12

13 14 15 16 17

18 19 20

Page 16

AF BOARD - LAYOUT DIAGRAM

7-2 7-2

A

B

C

D

1000 C3 2007 E7 2023 E10 2128 F9 7007 K4 9006 G5 9017 I7

1003 A10 2008 B9 2025 C5 3037 J5 7008 J7 9007 G4 9018 K5

1004 B9 2010 E8 2026 B10 6009 J7 7009 J6 9008 G5 9021 B3

1005 C1 2011 D8 2027 D5 7000 E6 7010 K8 9009 I5 9022 E3

1006 B5 2015 I2 2033 J2 7001 F3 7106 E7 9010 G6 9023 D1

1007 B7 2016 I3 2034 J3 7002 F7 9001 D3 9011 D1 9024 E1

1013 B6 2020 D10 2035 K6 7004 D9 9003 B5 9012 H2

2000 E5 2021 C10 2036 H9 7005 G10 9004 D7 9013 E6

2004 F8 2022 C7 2037 G7 7006 J4 9005 B8 9015 D4

1 2 3 4 5 6 7 8 9 10

A

B

C

D

2001 F9 2017 G8 2131 G8 3008 F3 3017 F2 3025 L6 3034 G3 6002 E6

2002 G8 2018 G2 3000 F6 3009 E3 3018 G1 3026 K6 3035 G2 6003 E6

2003 F9 2019 E2 3001 F5 3010 G4 3019 E1 3028 J5 3036 F4 6008 K5

2005 G3 2024 D1 3002 E9 3011 G4 3020 G1 3029 J4 3038 F7 6010 F5

2006 E3 2031 F8 3003 G9 3012 B2 3021 E6 3030 K6 3039 F7 9020

2009 F9 2032 F8 3004 E9 3014 B3 3022 K6 3031 L6 3040 G9

2012 E3 2038 G4 3005 G9 3015 H9 3023 J6 3032 L3 3041 H9

2013 F9 2039 G1 3007 G3 3016 H2 3024 K6 3033 L4 6001 F5

1 2 3 4 5 6 7 8 9 10

A

B

C

D

A

B

C

D

E

F

G

H

I

J

K

E

F

G

H

I

J

K

E

F

G

H

I

J

K

E

F

G

H

I

J

K

L

M

1 2 3 4 5 6 7 8 9 10

L

M

L

M

L

M

1 2 3 4 5 6 7 8 9 10

PCS 99 424

Page 17

TUNER BOARD ECO6 - CIRCUIT DIAGRAM

8-1 8-1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

TUNER BOARD ECO6 / PORTABLE AUDIO

FM

C-PAD

A

B

C

D

E

F

G

H

I

A

B

AM FRAME AERIAL

1 2 3 4 5 6 7 8 9

1105

T102

RT-01T

T103

6103

BAV99

AM-RF

Ferrite Antenna only

blue

black

5104

MW

red

5105

LW

3106

LW=HIGH

22R

3108

2K2

P01

MW=HIGH

2111

2110

100p

3107

4M7

1.4V

0V

7104

BC337-40

0.7V

3109

P0

2K2

0.7V

0V

Frame Aerial only

4102

0R

330k

*

LW

5102 7KL

6

5

4

T105

T106

4101

0R

*

LW only

LW

7PA5103

B

6

34

2

100p

2108

1

78

2109

LW only

4K7

3125

10K

3123

3.9V

3.3V

LW=HIGH

P0

P01

2104

100p

Printed

LW only

33p

Vref

0V

7105

BC337-40

MW

78

10p

0V

1

2

3

VDDVDD

3180

2101

4109

4.1V

4.0V

BC857B

7109

0V

4.0V

10K

0R

3128

2K2

1105 A1

5123 G5

1121 F14

5130 E6

1122 E14

5131 C6

2101 A3

6103 A3

2103 C7

6105-1 B4

2104 A3

6105-2 G6

2106 B4

AM-IF1

450kHz

5111

4

47p

6

T115

C

330R

2106

*

0.7V

0V

11p

4110

LW frame

20p

0R

2107

1

HN1V02H

7

3101

33K

1

T111

1u

0V

7122

BC847C

p

6106

BAS216

6105-1

2

3102

100K

FM-OSCILLATOR

2152

3132

FM-RF

6131

1SV228

6130

1SV228

E_EU

33n

560p

T110

6105

1

2

3

HN1V02H

AM-OSCILLATOR

5123

47R

6

5122

*

0R

4104

6

2153

78

78

8

7

6

54

MW

LW

3105

220R

2155

E_EU

12p

15p

5130

T109

2V

Vref

6K8

3103

0.6V

Q-multiplier

7102

BF550

0V

5131

11p

USA

1K8

3181

33p

2159

2103

Printed

Printed

3142

VCO

100K

5

T112

2165

100n

2129

100u

1n

T128

D

3.5V

3.5V

4.5V-8V

1V-8V

3141

56K

2127

220n

330p

2126

VCC1

1.3V

0.7V

1.2V

1V

0V

0V

0V

0V

7101

2V

2

4

6

8

9

10

11

2128

10u

TEA5757H

AM DET

RIPPLE1

AM-RF

FM-RF3

RF-GND1

FM-OSC5

AM-OSC

VCC17

I-TUNE

VCO

AF-OUT

MPX-IN

2131

470n

RDS only

VCC1

6

3

6105-2

5

HN1V02H

34

LW

2

22p

18p

2120

1

p

2119

3

2

2123

1

2122

10p

390p

3n3

3134

560p

2125

*

22n

2124

22K

7124

BC847C

3176

0V

33K

0.7V

2149

0.1V

0.7V

3143

1.3V

33p

3137

15K

22K

2169

3144

2n2

1K

7103

BC857C

MPX

BUFFER AMPLIFIER

P0

MW=HIGH

0.6V

AGC

AGC

CTRL

RIPPLE

CHARGE

PUMP

LPF

0.8V

0.15V

2132

3145

to 1122

pin 2

0.8V

44

FM-IN

FM

FRONTEND

FM

OSC

MUTE

12

0.8V

470n

2133

2K2

MPX

3104

43

AM-IF

FRONTEND

VSTABA