Page 1

PRODUCT FAMILY FOCUS ESP

Technical specification ......................................................1-1

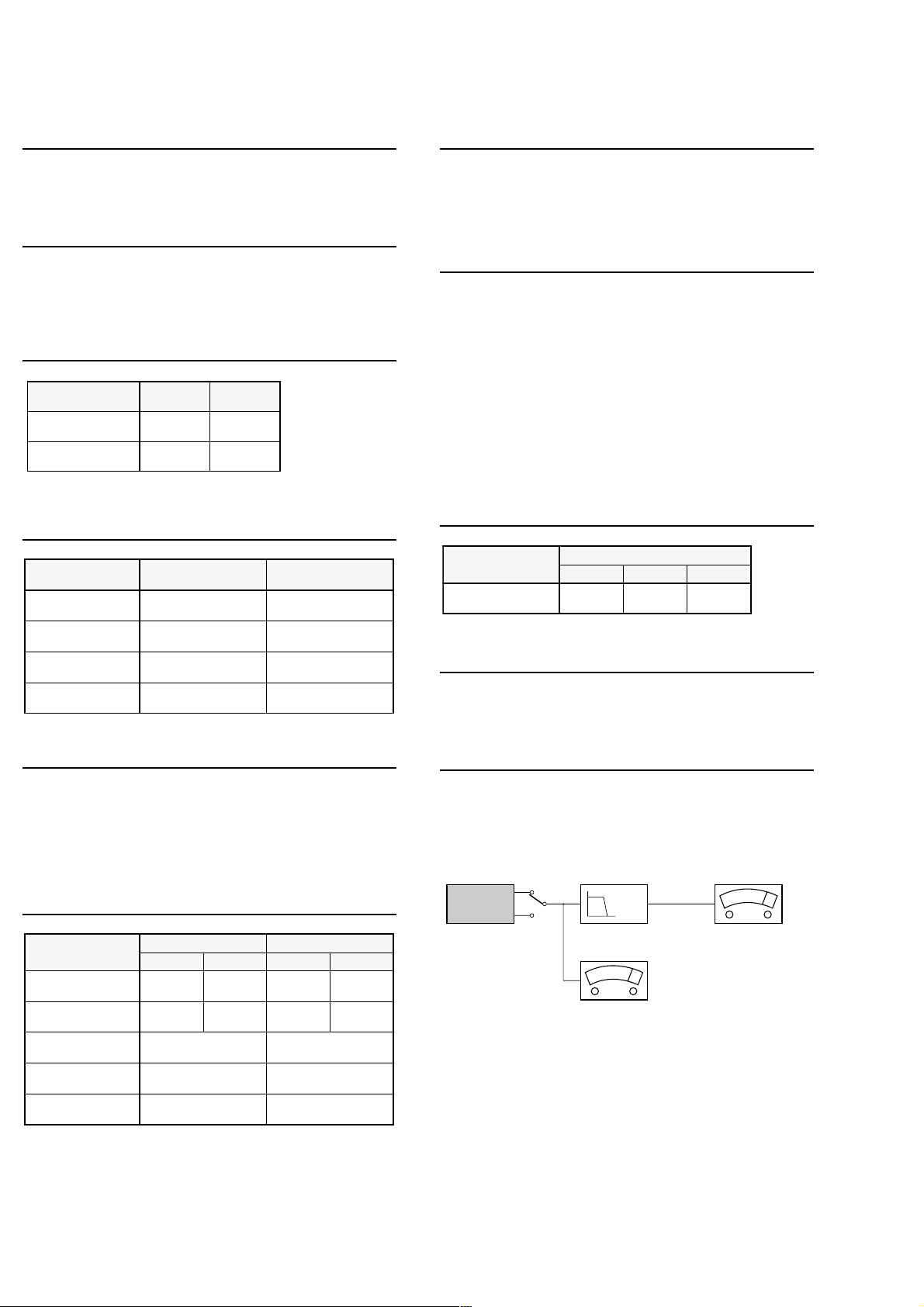

Connections and controls..................................................1-2

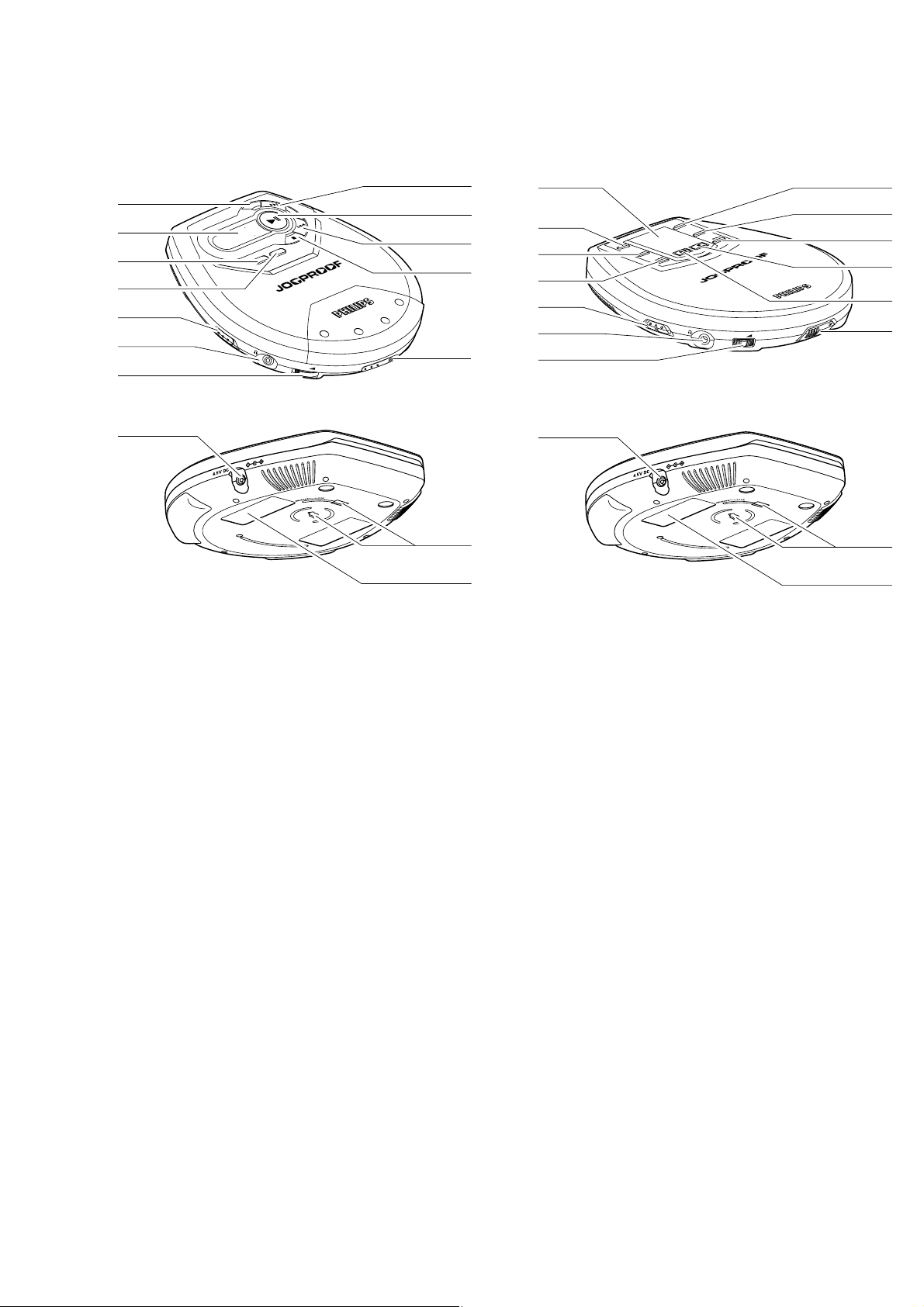

Features ............................................................................1-3

Accessories.......................................................................1-3

Safety & Warnings.............................................................1-4

Service hints

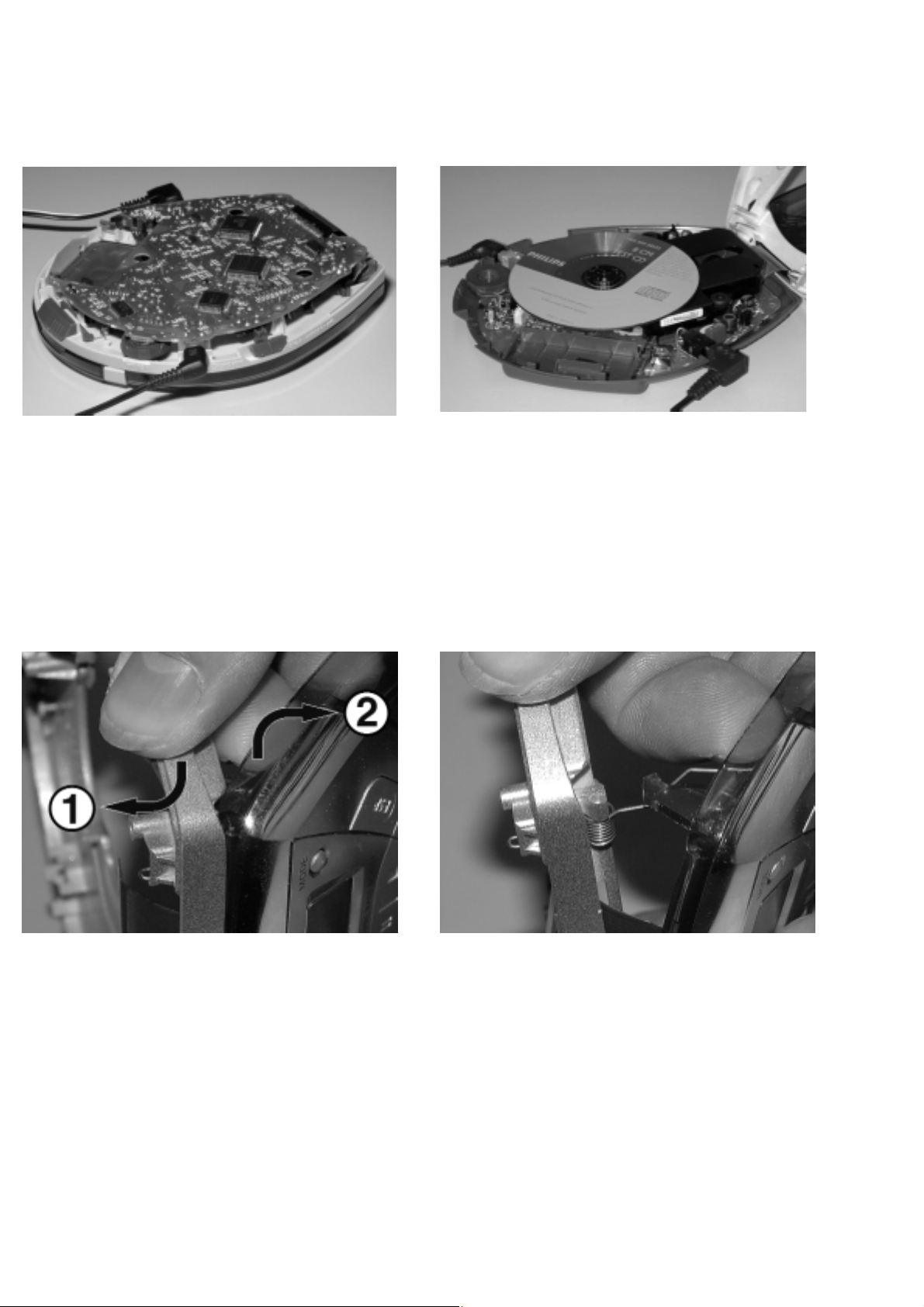

Repair positions ............................................................2-1

Dismantling CD-door.....................................................2-1

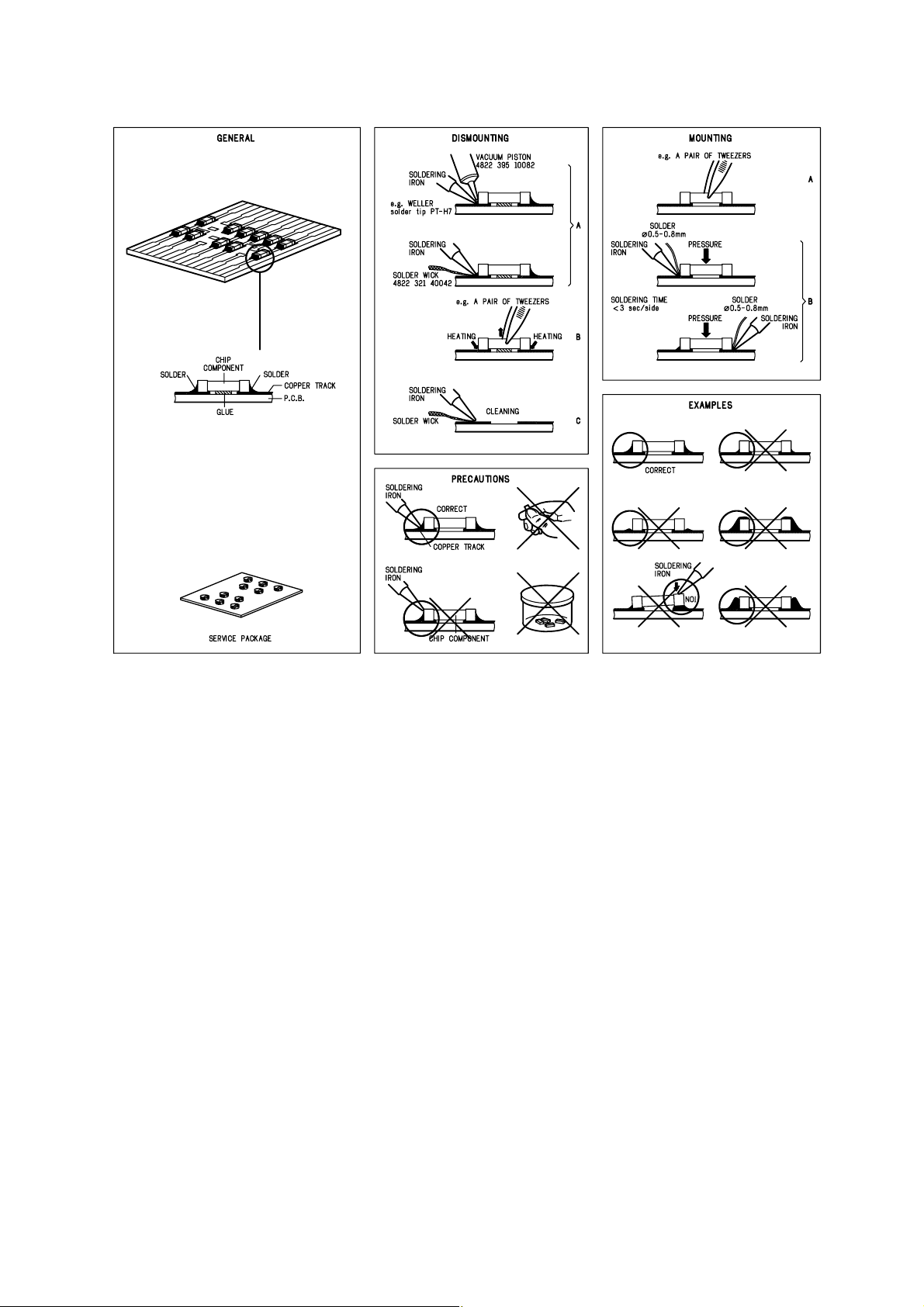

Handling chip components............................................2-2

Service tools..................................................................2-2

Pin description of ICs ................................................3-1...3-3

Start-up procedure.............................................................3-4

Service Test Program................................................3-5...3-6

Blockdiagram.....................................................................3-7

Circuit diagrams

CD part..........................................................................4-1

Control / Supply partpart...............................................4-2

Audio part......................................................................4-3

PCB layout diagram

Componentside view.....................................................4-4

Copperside view............................................................4-5

Exploded view ...................................................................5-1

Mechanical partslist...........................................................5-1

Electrical partslist ......................................................6-1...6-4

© 3140 785 22870

Published by YT 0150 Service Audio Printed in The Netherlands Subject to modification

Portable compact disc player

AX 2100

AX 2101

AX 2102

AX 5100

AX 5101

AX 5102

AX 5103

AX 5104

AX 5111

AX 5112

AX 5113

AX 5114

AX 5115

AX 5116

AX 5117

AX 5118

AX 7101

AX 7104

AX 7113

all versions

TABLE OF CONTENTS

©

Copyright 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

CLASS 1

LASER PRODUCT

Page 2

1-1

General

Dimensions (WxHxD) : 129x26x140mm

Weight without batteries : 220g

Power supply modes

DC-in socket : 2.5-6.0V

Primary batteries (2xLR6) : 1.7-3.6V

Rechargable batteries (AY3362) : 1.7-3.6V

Battery lifetime

Battery level detection

Charge section (not on all versions)

Charge current : 250mA ±10%

Charge time for 80% AY3362 : 4.0h nom.

Charge time for 100% AY3362 : 6.0h nom.

Max. charge time (µP controlled) : 7h

Temperature protection : 50°C ±5°C

Current consumption CDDA-playback

Shock resistance

+X/-X direction : ≥2.5g

+Y/-Y direction : ≥2.5g

+Z/-Z direction : ≥2.0g

Headphone out (measured with 16Ω load, DBB/ESP off)

Output power (THD=10%)

/17 version only : 2x12mW (+1/-3dB)

all other versions : 2x6mW (+1/-3dB)

Frequency response (1mW) : 100Hz-20kHz within 6dB

S/N ratio (unwght) : ≥80dB (83dB typ.)

S/N ratio (A-wght) : ≥82dB (85dB typ.)

THD+N (1kHz, 1mW) : ≤1% (0.2% typ.)

Channel crosstalk (1kHz, no load): ≤-24dB (-44dB typ.)

Channel unbalance (-40dB) : ≤5dB

Volume attenuation (1kHz) : ≥60dB

Dynamic Bass Boost DBB

Laser

Output power : <5mW (3mW typ.)

Wavelength : 780nm

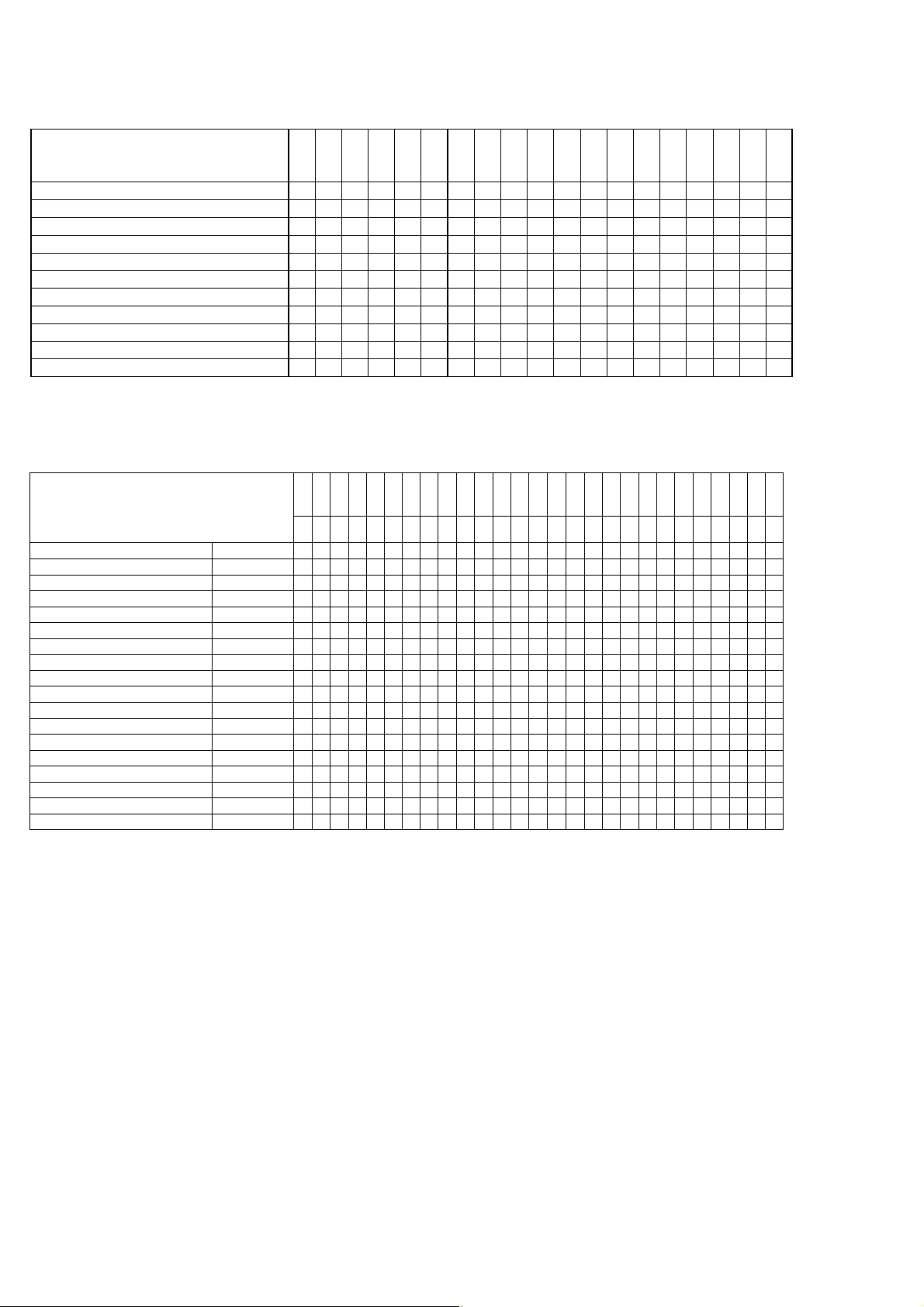

Measurement setup

Use Audio Signal disc SBC429 4822 397 30184

TECHNICAL SPECIFICATION

Power Save

EPYTYRETTAB

seirettabyramirP

6RLx2

seirettabelbagrahceR

)hAm0021(2633YA

OPSE N

ON

25 hours22 hours

10 hours9 hours

LEVELNOITCETED seirettabyramirP seirettabelbagrahceR

ytpmeyrettaB

1kaewyrettaB

2kaewyrettaB

3kaewyrettaB

V8.1

Vm05-/001+

V9.0

±

V6.0

±

V3.0

±

+levelytpmeyrettab

Vm001

+levelytpmeyrettab

Vm001

+levelytpmeyrettab

Vm001

V7.0

±

V5.0

±

V3.0

±

EGATSBBD

V8.1

Vm05-/001+

+levelytpmeyrettab

Vm001

+levelytpmeyrettab

Vm001

+levelytpmeyrettab

Vm001

1BBD Bd8+ ± Bd2 Bd0 ± Bd2 Bd0 ± Bd2

zHk36 zHk1 zHk01

esnopserycneuqerF

EDOMNOITAREPO

edom-yalP.pytAm001.pytAm001.pytAm021.pytAm021

edom-pmuJ.pytAm022.pytAm022.pytAm003.pytAm003

edom-egrahC.pytAm004a/n

gnithgilkcaB

)lanoitidda(

yb-dnatS

)egrahcer.lcxe(

FFOPSE NOPSE FFOPSE NOPSE

)V5.4(YLPPUSNI-CD )V52.2(YLPPUS.TTAB

.pytAm05.pytAm05

.pytAm0305

Use Audio Signal Disc SBC429 4822 397 30184 (replaces test disc 3)

L.P.F. = 13

µ

.pytA

th

order filter 4822 395 30204

DUT

L

R

Low pass filter 22kHz

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

S/N and distortion meter

e.g. Sound Technology ST1700B

Page 3

1-2

CONNECTIONS AND CONTROLS

AX21.. & AX51..

1 OPEN 2..............opens the CD lid

2 9 ......................stops CD play, clears a program or switches the

player off

3 ∞ .....................skips and searches CD tracks backwards

4 2; ....................switches the player on, starts or pauses CD play

5 § .....................skips and searches CD tracks forwards

6 DBB.................switches the bass enhancement on and off. This

button also switches acoustic feedback (the

beep) on/off when it is pressed for more than 2

seconds

7 ........................display

8 PROGRAM......programs tracks and reviews the program

9 MODE..............selects the different playing possibilities:

SHUFFLE,

SHUFFLE REPEAT ALL, REPEAT, REPEAT ALL and

SCAN

0 RESUME.........stores the last position of a CD track played

HOLD ..............locks all buttons

OFF.................switches RESUME and HOLD off

! LINE OUT/p ....3.5 mm headphone socket, socket to connect the

player to another audio input of an additional

appliance, remote control socket (not on all

versions)

@ VOL E ..........adjusts the volume

# 4.5V DC...........socket for external power supply

$ ........................belt clip holder

% ........................typeplate

AX71..

1 OPEN 2..............opens the CD lid

2 2; ....................switches the player on, starts or pauses CD play

3 9 ......................stops CD play, clears a program or switches the

player off

4 § .....................skips and searches CD tracks forwards

5 ESP .................ELECTRONIC SKIP PROTECTION ensures

continues CD playback regardless of vibrations

and shocks

6 MODE..............selects the different playing possibilities:

SHUFFLE,

SHUFFLE REPEAT ALL, REPEAT, REPEAT ALL and

SCAN

7 ........................display

8 PROGRAM......programs tracks and reviews the program

9 BASS...............switches the bass enhancement on and off. This

button also switches acoustic feedback (the

beep) on/off when it is pressed for more than 2

seconds

0 ∞ .....................skips and searches CD tracks backwards

! RESUME.........stores the last position of a CD track played

HOLD ..............locks all buttons

OFF.................switches RESUME and HOLD off

@ LINE OUT/p ....3.5 mm headphone socket, socket to connect the

player to another audio input of an additional

appliance, remote control socket (not on all

versions)

# VOL E ..........adjusts the volume

$ 4.5V DC...........socket for external power supply

% ........................belt clip holder

^ ........................typeplate

For more information of operation instruction

please visit Philips Audio internet site :

http://www.audio.philips.com

6

7

8

9

0

!

@

#

O

F

F

•

R

E

S

U

M

E

•

H

O

L

D

5

B

B

D

K

C

A

R

T

E

D

O

M

E

OD

M

ST

IGITA

D

IC BA

AM

L DYN

O

SS BO

CD REWRITABLE COMPATIBLE

V

O

L

.

0

N

E

P

O

AM

GR

PRO

L

I

N

E

O

U

T/

4

3

2

1

8

9

0

!

@

#

E

D

O

M

P

S

E

T

S

O

O

B

S

E

L

S

B

A

I

B

T

A

P

C

I

M

M

O

A

C

N

M

A

R

G

O

R

P

O

F

F

•

R

E

S

U

M

E

Y

E

D

L

B

L

A

T

A

I

T

R

I

G

W

I

E

D

R

D

C

S

S

A

B

•

H

O

L

D

L

I

N

E

O

U

T

/

V

.

O

L

N

E

P

O

$

$

%

67

5

4

3

2

1

%

^

Page 4

1-3

FEATURES

FEATURES OF CD-PORTABLE

PRODUCT FAMILY FOCUS ESP

CD-RW COMPA TIBILITY

ELECTRONIC SKIP PROTECTION

ESP DRAM SIZE [Mbit]

HOLD / RESUME FUNCTION

DBB STAGES

ACOUSTIC FEEDBACK

PROGRAM MEMORY

RECHARGE NiCd / NiMH

BELT-CLIP

CORD REMOTE CONTROL

LINE / OPT. DIGITAL OUTPUT

ACCESSORIES

AX2100

●

12s

16

●/●

1

●

30

--/--

●

--

--/--

AX2101

●

12s

16

●/●

1

●

30

--/--

●

--

--/--

AX2102

●

12s

16

●/●

1

●

30

●/●

●

--

--/--

AX5100

●

45s

45s

16

●/●

●/●

1

●

30

--/-- --/--

--/--

●

--

--/--

--/--

AX5101

●

45s

16

16

●/●

1

●

30

●/●

●

--

--/--

AX5102

●

45s

●/●

1

●

30

●

--

--/--

AX5103

●

45s

16

16

●/●

1

●

30

30

●/●

●

--

--/--

AX5104

●

●

45s

16

●/●

1

●

●

30

--/--

●

●

●

--/--

AX5111

●

45s

16

●/●

1

1

●

30

●/●

●

--

--

--/--

AX5112

AX5113

●

45s

16

●/●

1

●

30

--/--

●

--

--/--

AX5114

●

45s

16

●/●

1

●

30

--/--

●

●

--/--

AX5115

●

45s

16

●/●

1

●

30

--/--

●

--

--/--

AX5116

●

45s

16

●/●

1

●

30

--/--

●

--

--/--

AX5117

●

45s

16

●/●

1

●

30

--/--

●

--

--/--

AX5118

●

●

100s

45s

32

16

●/●

●/●

1

●

●

30

30

--/--

--/--

●

●

●●

--/--

--/--

AX7101

●

100s

32

●/●

1

1

●

30

●/●

●

●●

--/--

AX7104

AX7113

●

100s

32

●/●

1

●

30

--/--

●

--/--

ACCESSORIES FOR CD-PORTABLE

PRODUCT FAMILY FOCUS ESP

AY3170/00 AC/DC Adaptor

AY3170/02 AC/DC Adaptor

AY3170/05 AC/DC Adaptor

AY3170/10 AC/DC Adaptor

AY3170/12 AC/DC Adaptor

AY3170/17 AC/DC Adaptor

AY3266/00 Pouch

AY3362/00 Rechargable Batt. NiMH

AY3464 HiFi Cord

AY3501/00 Car Adaptor Cassette

AY3545/00 Car DC/DC Converter

AY3545/17 Car DC/DC Converter

AY3768/00 Cord Remote Control

HE205/77 Headphone

HE205/77s Headphone

HL351/77 Headphone

HL351/77s Headphone

BELT-CLIP

X...supplied with the set, O...optional available

(Neoprene)

(3.5mm L-plug→cinch)

(S-plug)

(S-plug)

4822 219 10617

4822 219 10676

4822 219 10672

4822 219 10681

4822 219 10671

4822 219 10616

3140 113 10360

3103 308 84120

4822 320 11881

4822 397 10059

4822 219 10033

3140 118 32970

3140 118 50980

9082 100 00615

9082 100 00616

9082 100 00639

9082 100 00641

3103 304 70250

AX2100

AX2101

AX2002

/00

/00c

/00c

O

X

X

OOOO OOOOOOO

OOOO OOOOOOO

OOOO OOOO O

OOOO OOOO O

X

XOXXX

AX5100

AX5101

/05

/00

/00c

X

XX

XXX

XXX

X

AX5103

AX5102

/11

/00

/01

X

X

X

X

X

X

XXXXXXX

/10

XX

X

X

X

X

XX

XXX

AX5104

/05

/00c

O

X

O

OOOOOO

OO

X

XXXXX

AX5113

AX5112

AX5111

/17

/17

OO OOOOOO O

OO OOOOOO O

OOOOOOOOO

OO OO

AX5114

AX5116

AX5115

/00

/17

/17

/17

/17

X

O

XXXX X

XXXX X

X

X

X

X

X

XXXXXXXXXXXXX

X

AX5118

AX5117

/17

/17

X

AX7101

AX7104

/17

/00

X

O

O

X

OOOO

OO

O

O

X

XXX

X

AX7113

/17

Page 5

1-4

SAFETY & WARNINGS

© WARNING

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically.

When repairing, make sure that you are connected with the

same potential as the mass of the set via a wristband with

resistance. Keep components and tools at this potential.

f ATTENTION

Tous les IC et beaucoup d´autres semi-conducteurs sont

sensibles aux décharges statiques (ESD). Leur longévite

pourrait être considérablement écourtée par le fait qu´aucune

précaution nést prise à leur manipulation.

Lors de réparations, s´assurer de bien être relié au même

potentiel que la masse de l´appareil et enfileer le bracelet

serti d´une résistance de sécurité.

Veiller à ce que les composants ainsi que les outils que l´on

utilise soient également à ce potentiel.

©

AVAILABLE ESD PROTECTION EQUIPMENT :

anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

anti-static wristband 4822 395 10223

connection box (3 press stud connections, 1MΩ) 4822 320 11307

extendible cable (2m, 2MΩ, to connect wristband to connection box) 4822 320 11305

connecting cable (3m, 2MΩ, to connect table mat to connection box) 4822 320 11306

earth cable (1MΩ, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

wristband tester 4822 344 13999

ESD

d WARNUNG

Alle ICs und viele andere Halbleiter sind empfindlich

gegenüber elektrostatischen Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kann die

Lebensdauer drastisch reduzieren.

Sorgen Sie dafür, daß Sie im Reparaturfall über ein Puls-

armband mit Widerstand mit dem Massepotential des

Gerätes verbunden sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls auf diesem

Potential.

ñ WAARSCHUWING

Alle IC´s en vele andere halfgeleiders zijn gevoelig voor

electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de levensduur

drastisch doen vermindern. Zorg ervoor dat u tijdens reparatie

via een polsband met weerstand verbonden bent met hetzelfde

potentiaal als de massa van het apparaat.

Houd componenten en hulpmiddelen ook op ditzelfde potentiaal.

i AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili alle scariche

statiche (ESD).

La loro longevità potrebbe essere fortemente ridatta in caso di

non osservazione della più grande cauzione alla loro

manipolazione. Durante le riparationi occorre quindi essere

collegato allo stesso potenziale che quello della massa

delápparecchio tramite un braccialetto a resistenza.

Assicurarsi che i componenti e anche gli utensili con quali si

lavora siano anche a questo potenziale.

©

Safety regulations require that the set be restored to its

original condition and that parts which are identical with

those specified be used.

Safety components are marked by the symbol

f

Les normes de sécurité exigent que l`appareil soit remis

à l`état d`origine et que soient utilisées les pièces de

rechange identiques à celles spécifiées.

Les composants de sécurité sont marqués

©

DANGER: Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

s Varning !

Osynlig laserstrålning när apparaten är öppnad och

spärren är urkopplad. Betrakta ej strålen.

SAFETY

d

Bei jeder Reparatur sind die geltenden Sicherheitsvor-

schriften zu beachten. Der Originalzustand des Gerätes

darf nicht verändert werden. Für Reparaturen sind Original-

ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol markiert.

CLASS 1

LASER PRODUCT

∂ Advarsel !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere

er ude af funktion. Undgå udsaettelse for stråling.

ñ

Veiligheidsbepalingen vereisen, dat het apparaat in zijn

oorspronkeliijke toestand wordt teruggebracht en dat

onderdelen, identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

i

Le norme di sicurezza estigono che l´apparecchio venga

rimesso nelle condizioni originali e che siano utilizzati i

pezzi di ricambiago identici a quelli specificati.

Componenty di sicurezza sono marcati con

ß Varoitus !

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen !

©

After servicing and before returning the set to customer

perform a leakage current measurement test from all

exposed metal parts to earth ground, to assure no

shock hazard exists.

The leakage current must not exceed 0.5mA.

f

"Pour votre sécurite, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 6

2-1

SERVICE HINTS

REPAIR POSITION COPPERSIDE

To get access to the copperside of the

printed board assembly proceed as follows:

1. Remove the bottom screws (6x)

2. Lift the bottom-cabinet

3. Supply the unit via external DC-socket

4. Take care that the door switch is closed during

measurements

To get access to the componentside of the

printed board assembly proceed as follows:

1. Remove the bottom screws (6x)

2. Open the CD-door

3. Lift the top-cabinet and put it backwards on the table

4. Supply the unit via the external DC-socket

5. Take care that the door switch is closed during

measurements

REPAIR POSITION COMPONENTSIDE

DISMANTLING THE CD-DOOR

To dismantle the CD-door proceed as follows:

1. Dismantle bottom and printed board/drive assembly

2. Disconnect membrane keyboard

(flex-foil connector on copperside of printed board)

3. Bend the cabinet leftwards downwards 1,

while bending the CD-door rightwards upwards 2

The procedure appears to be tricky at first, but force

needs to be applied with thumb and middle finger only.

It’s just like snapping one’s fingers.

Remark: Don’t worry about applied force - both parts have a

solid design. However, do not use screwdrivers or

tools like that. Sharp edges could damage hinge or

cabinet part.

Page 7

HANDLING CHIP COMPONENTS

SERVICE TOOLS

Audio signal disc SBC429 4822 397 30184

Playability test disc SBC444 4822 397 30245

Test disc 5 (disc without errors) + Test disc 5A (disc with dropout errors,

black spots and fingerprints) SBC426/SBC426A 4822 397 30096

ESD PROTECTION EQUIPMENT

Anti-static table mat large 1200x650x1.25mm 4822 466 10953

small 600x650x1.25mm 4822 466 10958

Anti-static wristband 4822 395 10223

Connection box (3 press stud connections, 1Mø) 4822 320 11307

Extendible cable (2m, 2Mø, to connect wristband to connection box) 4822 320 11305

Connecting cable (3m, 2Mø, to connect table mat to connection box) 4822 320 11306

Earth cable (1Mø, to connect any product to mat or to connection box) 4822 320 11308

KIT ESD3 (combining all 6 prior products - small table mat) 4822 310 10671

Wristband tester 4822 344 13999

2-2

Page 8

PIN DESCRIPTION OF INTEGRATED CIRCUITS

TZA1024 – HF-PREAMPLIFIER AND LASER SUPPLY CIRCUIT

Pin Name Direction Description

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 LD HF-preamp →CD-drive current output to laser diode

2 VCCL +2.6V laser supply voltage

3 CFIL → HF-preamp external filter capacitor

4 MON CD-drive → HF-preamp laser monitor diode input

5 DIN CD-drive → HF-preamp central diode input

6 GND GND ground

7 PWRON CD10 → HF-preamp power-on select input

8 CMFB +2.6V / 2 common mode feedback voltage input

9 RFFB → HF-preamp external RF feedback resistor

10 RFEQO HF-preamp → RF amplifier output

11 CDRW CD10 → HF-preamp gain select input for CDDA/CDRW

12 EQSEL CD10 → HF-preamp equalizer/speed select input

13 VCC2 +2.6V supply voltage

14 RGADJ GND external laser supply gain adjust resistor

SC111259FTA – SERVO DRIVER & POWER MANAGEMENT IC

Pin Name Direction Description

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 SLEEP µP → servo driver sleep input

2 WAKW µP → servo driver wake input

3 VR +VR reference voltage input (motor driver)

4 ERR4 CD10 → servo driver control signal input (slide error signal)

5 CF4 → servo driver phase correction capacitor connect (CH4)

6 CF3 → servo driver phase correction capacitor connect (CH3)

7 ERR3 CD10 → servo driver control signal input (radial error signal)

8 ERR2 CD10/µP → servo driver control signal input (disc speed error signal)

9 CF2 → servo driver phase correction capacitor connect (CH2)

10 CF1 → servo driver phase correction capacitor connect (CH1)

11 ERR1 CD10 → servo driver control signal input (focus error signal)

12 OUT1A servo driver → CD-drive positive drive output (CH1)

13 PGND1 GND H-bridge driver ground

14 OUT1B servo driver → CD-drive negative drive output (CH1)

15 VIN12 +A CH1 and CH2 H-bridge driver supply voltage

16 OUT2B servo driver → CD-drive negative drive output (CH2)

17 PGND2 GND H-bridge driver ground

18 OUT2A servo driver → CD-drive positive drive output (CH2)

19 OUT3A servo driver → CD-drive positive drive output (CH3)

20 PGND2 GND H-bridge driver ground

21 OUT3B servo driver → CD-drive negative drive output (CH3)

22 VIN34 +A CH3 and CH4 H-bridge driver supply voltage

23 OUT4B servo driver → CD-drive negative drive output (CH4)

24 PGND4 GND H-bridge driver ground

25 OUT4A servo driver → CD-drive positive drive output (CH4)

26 VG +VG charge pump output

27 C2H → servo driver charge pump capacitor connect

28 C1H → servo driver charge pump capacitor connect

29 C1L → servo driver charge pump capacitor connect

30 C2L → servo driver charge pump capacitor connect

31 VIN battery → servo driver battery supply voltage

32 RSTB servo driver → reset block output

33 CHGSW servo driver → charge circuit transistor drive output for battery charger

34 RS charge circuit → servo driver OpAmp non-inverting input for battery charger

35 INM2 → servo driver error amplifier inverting input

36 RF2 → servo driver error amplifier output

37 DCIN +DC DC power supply from AC/DC adaptor

38 VDET servo driver → DCIN over voltage and VIN low voltage detect output

39 VREF servo driver → Voltage reference circuit output

40 DTC → servo driver max. duty control voltage input for power management

41 VOUT servo driver → DC/DC converter PWM output for power management

42 VC → servo driver power management power supply

43 CGND GND internal ground

44 RF1 servo driver → OpAmp output for power management

45 INM1 → servo driver OpAmp inverting input for power management

46 CLK → servo driver clock input

47 OE µP → servo driver output enable for motor drivers

48 CHGON µP → servo driver charge enable for battery charger

3-1

Page 9

SAA7324 – DECODER, DIGITAL SERVO IC AND D/A-CONVERTER CD10 (low voltage version)

Pin Name Direction Description

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 HFREF → CD10 comparator common mode input

2 HFIN → CD10 comparator signal input

3 ISLICE CD10 → current feedback from data slicer

4 VSSA1 GND analog ground 1

5 VDDA1 +2.6V analog supply voltage 1

6 IREF CD10 → reference current output pin

7 VRIN CD10 → reference voltage for servo ADC’s

8 D1 CD-drive →CD10 unipolar current input (central diode signal input)

9 D2 CD-drive →CD10 unipolar current input (central diode signal input)

10 D3 CD-drive →CD10 unipolar current input (central diode signal input)

11 D4 CD-drive →CD10 unipolar current input (central diode signal input)

12 R1 CD-drive →CD10 unipolar current input (satellite diode signal input)

13 R2 CD-drive →CD10 unipolar current input (satellite diode signal input)

14 VSSA2 GND analog ground 2

15 CROUT CD10 →X-TAL crystal/resonator output

16 CRIN X-TAL → CD10 crystal/resonator input

17 VDDA2 +2.6V analog supply voltage 2

18 LN CD10 → DAC left channel differential output - negative

19 LP CD10 → DAC left channel differential output - positive

20 VNEG GND DAC negative reference input

21 VPOS +2.6V DAC positive reference input

22 RN CD10 → DAC right channel differential output - negative

23 RP CD10 → DAC right channel differential output - positive

24 SELPLL CD10 → selects whether internal clock multiplier PLL is used

25 TEST1 GND test control input 1; this pin should be tied low

26 CL16 CD10 → DSP 16.9344 MHz system clock output

27 DATA CD10 → NPC or CD10 → DSP serial data output (3-state)

28 WCLK CD10 → NPC or CD10 → DSP word clock output (3-state)

29 SCLK CD10 → NPC or CD10 → DSP serial bit clock output (3-state)

30 EF CD10 →NPC C2 error flag output (3-state)

31 TEST2 GND test control input 2; this pin should be tied low

32 KILL CD10 → kill output (programmable; open-drain)

33 VSSD1 GND digital ground 2

34 V2/V3 CD10 → NPC versatile I/O: input versatile pin 2 or output versatile pin 3 (open-drain)

35 WCLI NPC → CD10 or DSP → CD10 word clock input (for data loopback to DAC)

36 SDI NPC → CD10 or DSP → CD10 serial data input (for data loopback to DAC)

37 SCLI NPC → CD10 or DSP → CD10 serial bit clock input (for data loopback to DAC)

38 RESETn µP → CD10 power-on reset input (active low)

39 SDA µP ↔ CD10 microcontroller interface data I/O line (open-drain output)

40 SCL µP → CD10 microcontroller interface clock line input

41 RAB µP → CD10 microcontroller interface R/W and load control line input (4-wire bus mode)

42 SILD µP → CD10 microcontroller interface R/W and load control line input (4-wire bus mode)

43 STATUS CD10 → servo interrupt request line/decoder status register output (open-drain)

44 TEST3 GND test control input 3; this pin should be tied low

45 RCK → CD10 subcode clock input

46 SUB CD10 → P-to-W subcode bits output (3-state)

47 SFSY CD10 → µP subcode frame sync output (3-state)

48 SBSY CD10 → NPC subcode block sync output (3-state)

49 CL11/4 CD10 → DSP 11.2896 MHz or 4.2336 MHz (for microcontroller) clock output

50 VSSD2 GND digital ground 3

51 DOBM CD10 → bi-phase mark output (externally buffered; 3-state)

52 VDDD1P +2.6V digital supply voltage 2 for periphery

53 CFLG CD10 → correction flag output (open-drain)

54 RA CD10 → servo driver radial actuator output

55 FO CD10 → servo driver focus actuator output

56 SL CD10 → servo driver slide control output

57 VDDD2C +2.6V digital supply voltage 3 for core

58 VSSD3 GND digital ground 4

59 MOTO1 CD10 →servo driver motor output 1; versatile (3-state)

60 MOTO2 CD10 → motor output 2; versatile (3-state)

61 V4 CD10 → HF-preamp versatile output pin 4

62 V5 CD10 → HF-preamp versatile output pin 5

63 V1 innerswitch → CD10 versatile input pin 1

64 LDON CD10 → HF-preamp laser drive on output (open-drain)

3-2

Page 10

SM5907AF – COMPRESSION-TYPE ANTI-SHOCK MEMORY CONTROLLER NPC

Pin Name Direction Description

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

1 VDD2 +2.6V supply voltage

2 UC1 NPC ↔ µP interface extension I/O line 1

3 UC2 NPC ↔ µP interface extension I/O line 2

4 UC3 NPC ↔ µP interface extension I/O line 3

5 UC4 NPC ↔ µP interface extension I/O line 4

6 UC5 NPC ↔ µP interface extension I/O line 5

7 NACS3 NPC → DRAM DRAM2 CAS control

8 TEST2 +2.6V test pin

9 CLK CD10 → NPC 16.9344MHz clock input

10 VSS GND ground

11 YSRDATA CD10 → NPC audio serial data input

12 YLRCK CD10 → NPC audio serial L/R clock input

13 YSCK CD10 → NPC audio serial bit clock input

14 ZSCK NPC → CD10 audio serial bit clock output

15 ZLRCK NPC → CD10 audio serial L/R clock output

16 ZSRDATA NPC → CD10 audio serial data output

17 YFLAG CD10 → NPC signal processor IC RAM overflow flag

18 YFCLK GND crystal-controlled frame clock input

19 YBLKCK CD10 → NPC subcode block clock signal output

20 RESET µP → NPC system reset input (active low)

21 ZSENSE NPC → µP interface status output

22 VDD1 +2.6V supply voltage

23 YDMUTE → NPC forced mute input

24 YMLD µP → NPC µP interface latch clock input

25 YMDATA µP → NPC µP interface serial data input

26 YMCLK µP → NPC µP interface shift clock input

27 A10/NCAS2 NPC → DRAM DRAM OE control output (active low)

28 CAS NPC → DRAM DRAM CAS control output (active low)

29 D2 NPC ↔DRAM DRAM data input/output 2

30 D3 NPC ↔DRAM DRAM data input/output 3

31 D0 NPC ↔DRAM DRAM data input/output 0

32 D1 NPC ↔DRAM DRAM data input/output 1

33 WE NPC → DRAM DRAM WE control output (active low)

34 RAS NPC → DRAM DRAM RAS control output (active low)

35 A9 NPC → DRAM DRAM address output 9

36 A8 NPC → DRAM DRAM address output 8

37 A7 NPC → DRAM DRAM address output 7

38 A6 NPC → DRAM DRAM address output 6

39 A5 NPC → DRAM DRAM address output 5

40 A4 NPC → DRAM DRAM address output 4

41 A0 NPC → DRAM DRAM address output 0

42 A1 NPC → DRAM DRAM address output 1

43 A2 NPC → DRAM DRAM address output 2

44 A3 NPC → DRAM DRAM address output 3

3-3

Page 11

3-4

START-UP PROCEDURE – FLOW CHART

PLAY

pressed ?

µP sends

command to CD10:

“move slide inside”

µP accelerates

disc motor for

~200ms

inner switch

closed within

~6s ?

µP sends

command to CD10:

“move slide outside”

µP sends

commands to CD10:

“slide servo off”

µP sends

commands to CD10:

“laser on”

“focus servo on”

µP resets

CD10 and NPC

PORES=L

NPC_RESET=L

µP outputs servo

signal for disc motor

(DM_PWM 50% duty)

µP switches

servo driver on

(via S_MUTE)

µP initializes

CD10 and NPC

with default

parameter/settings

inner switch

open within

~0.25s ?

Start-up procedure for ext.DC supply,

no accu inserted, hold-switch in off pos.,

ESP on, resume-mode off, CD-door closed.

µP switches

headphone amplifier

on (via LF_POW)

N

N

N

Y

TOC

found within

~30s ?

N

Y

Y

Y

POWER OFF

(stand-by)

focus found

during ramping

cycle ?

µP accelerates

disc to nom. speed

DC/DC converter

is switched on

(via WAKE)

Y

N

µP calculates

ramping offset and

sends play-params

to CD10

jump

ok ?

µP initializes

radial servo loop

(~330ms)

µP releases

muting

(via MUTE)

µP sends command

to CD10: “jump

10 tracks inside”

Y

Y

subcode

ok ?

N

N

Y

Y

N

PLAY-MODE

N

N

display shows

“no d1SC”

start-up stopped

display shows

“nF d1SC”

start-up stopped

disc at nom.

speed within

~10s ?

N

focus

stability test

ok ?

µP sends new focus

parameters to CD10

(switch to higher

focus sensitivity)

switch back to

normal focus

sensitivity

Y

already

looped through

all (4) focus

sensitivities

?

re-initialize CD10

and restart focus

search procedure

N

Y

Y

re-initialize CD10

and restart focus

search procedure

N

focus found

during ramping

cycle ?

subcode

error handler

radial

error handler

N

µP sends new focus

parameters to CD10

(switch to higher

focus sensitivity)

Y

already

looped through

all (4) focus

sensitivities

?

Y

focus found

during ramping

cycle ?

focus found

during ramping

cycle ?

START-UP PROCEDURE - FLOW CHART

Page 12

3-5

SERVICE TEST PROGRAM

1. PRELIMINARY SETUP

• To enter the service test program disconnect the AC/DC adaptor

and remove batteries, open the CD-door and hold the buttons

“PLAY” & “PREV” depressed while turning power on (i.e.

connecting the AC/DC adaptor).

• The display shows the software version of the built-in µP

(i.e. “S-26”). Versions are counted from “ 00” onwards; that

means the higher the number the newer the software.

• The program is now in the main menu – various tests can be

entered by pressing the corresponding buttons (see flow chart on

next page or detailed description of available tests below).

• To exit the service test program press the “STOP“ button or

disconnect the set from the power source.

2. DISPLAY TEST

Purpose: Check functionality of display and display driver.

• To enter the display test start the service test program and press

the “NEXT” button.

• The display shows test pattern1. All segments are activated for

finding open circuits (see flow chart on next page).

• To jump to the next pattern press the “NEXT” button.

• The display shows test pattern2. All alternate pins (2, 4, ...) are

activated for finding short circuits (see flow chart on next page).

• To jump back to test pattern1 press the “NEXT” button, to exit the

display test and return to the main menu press the “STOP” button.

3. KEY TEST

Purpose: Check operation of keys and cord remote control.

• To enter the key test start the service test program and press the

“MODE” button.

• The display shows “--”.

• Hold key depressed and check corresponding key code on the

display. Key codes can be found in table1 (see flow chart on next

page).

• To exit the key test and return to the main menu press the “STOP”

button.

4. PLAYBACK TEST WITH ERROR ANALYSIS

Purpose: Analyze errors that occur during playback and search for

intermittent failures.

• To enter the playback test start the service test program and press

the “BASS” button.

• To start the error analysis press the “PLAY” button. Note that the

playback test can only be entered if the CD-door is closed.

• The set will read the TOC and start playback.

As long as the playback is free of errors the display shows track and

time information like in normal play-mode. In case of errors

corresponding error codes will be displayed. The meaning of these

error codes can be found in table2 (see flow chart on next page).

Note:

Errors can either be

“fatal”

or

“non fatal”

. Fatal errors always

stop the playback, non fatal errors only cause a short

interruption of the music. Fatal errors are displayed as long

as the set is connected to the power source, non fatal errors

are displayed until a new error occurs or a button is pressed.

• To stop the playback test disconnect the set from the power

source.

5. SERVO TEST

Purpose:

Check door switch, inner switch of CD-drive, movement

of slide and acceleration of discmotor.

• To enter the servo test start the service test program and press

the “PLAY” button.

xy

• The display shows “Cd

”.

“x” indicates state of door switch;

“y” indicates state of inner switch.

x,y

= “0” means switch is closed; “1” means switch is open.

• To move slide outside hold the “NEXT” button depressed.

• To move slide inside hold the “PREV” button depressed.

• To accelerate the discmotor clockwise hold the “MODE” button

depressed.

• To accelerate the discmotor counter-clockwise hold the “PROG”

button depressed.

• To enter the focus test press the “PLAY” button, to exit the servo

test and return to the main menu press the “STOP” button.

6. FOCUS TEST

Purpose: Check movement of lens and operation of focus servo for

CDDA and CDRW discs.

Since the CDRW reflects much less light than an ordinary CDDA, the gain

of the HF-amplifier stage and the sensitivity of the ADC inside the

Decoder&Digital Servo IC “CD10” must be adapted accordingly.

The gain is switched via the CDRW input of the HF-preamplifier.

The ADC-sensitivity is set via software parameters (sent from µP to

“CD10”). In total, there are 4 sensitivity modes available: 1 for CDDA and

3 for CDRW. The modes are listed in table3 (see next page).

In normal play-mode, the correct focus sensitivity is choosen

automatically during start-up (see “Start-up procedure” on previous page).

In the service test program, the sensitivity can be choosen manually in

order to allow individual measurements in several modes.

• The focus servo loop is switched on and the set starts searching

the focus (“focus ramping”). As soon as the focus has been found

the focus servo loop is closed and the state of the focus is

monitored continuously.

x

• If the focus is OK the display shows “ F

”, else “-Fx”.

“x” indicates the sensitivity mode. Details can be found in table3

(see flow chart on next page).

• To toggle between sensitivity modes press the “BASS” button.

• To move slide outside hold the “NEXT” button depressed.

• To move slide inside hold the “PREV” button depressed.

• To accelerate the discmotor clockwise hold the “MODE” button

depressed.

• To accelerate the discmotor counter-clockwise hold the “PROG”

button depressed.

• In case the focus is OK the discmotor test can be entered by

pressing the “PLAY” button, to exit the focus test and return to the

main menu press the “STOP” button.

7. DISCMOTOR TEST

Purpose: Check speed regulation of discmotor.

• The speed regulation is switched on and the discmotor starts

rotating. If the speed reaches 75% of the nom. speed the display

shows “ d”, else “-d”.

• In parallel also the state of the focus is monitored continuously

(display “ F

x

” or “-Fx”).

• In case the disc speed is OK and the focus is OK the radial test

can be entered by pressing the “PLAY” button, to exit the

discmotor test and return to the main menu press the “STOP”

button.

8. RADIAL TEST

Purpose: Check if radial loop locks and an audio signal is audible

at the headphone output.

• The radial servo loop is switched on, mute is released and the

audio signal is audible. If the system is on track the display shows

“ r”, else “-r”.

• In parallel also the disc speed (display “ d” or “-d

of the focus (display “ F

x

” or “-Fx”) are monitored continuously.

”) and

the

state

Note: In case of radial errors the audio output is muted and muting

is not released automatically when the systems recovers from the

error. “-r” remains on the display.

To open mute again press the “NEXT” or “PREV” button.

• To jump 16 tracks outside press the “NEXT” button.

• To jump 16 tracks inside press the “PREV” button.

• To exit the radial test and return to the main menu press the

“STOP” button, to exit the service test program disconnect the set

from the power source.

Important remark:

In radial test mode data to the DRAM is written at 1.2 times the

nominal speed, and read from the DRAM at nominal speed.

Because writing is done faster than reading the DRAM gets full after

a certain time.

In normal play mode the system would now wait until the DRAM is

partly emptied again, jump backwards and resume filling at the last

written position. However, in radial test mode the jumps would

disturb measurements on the radial servo loop.

Therefore this function has been disabled and filling restarts

immediately from the current position of the pick-up unit. As a result

“jumps” are audible during playback.

Page 13

3-63-6

SERVICE TEST PROGRAM – FLOW CHART

“NEXT”

pressed?

DISPLAY TEST 1

display shows

test pattern 1

“NEXT”

pressed?

DISPLAY TEST 2

display shows

test pattern 2

“NEXT”

pressed?

N

Y

N

Y

N

Y

test pattern 1 (all segments activated)

PRELIMINARY

SETUP

Display shows

software-version

(e.g. “S-

“MODE”

pressed?

KEY TEST

Display shows

“--”

key on

cd-player

depressed?

Display shows

keycode

(see table1)

To enter the service test program

1. Disconnect the AC/DC adaptor and remove batteries

2. Open the CD-door

3. Hold “PLAY” & “PREV” buttons depressed

4. Connect the AC/DC adaptor or insert batteries

26”)

N

Y

key on

N

remote control

depressed?

YY

Display shows

keycode + “rc”

(see table1)

MAIN MENU

Remark: Playback test can only

be entered if CD-door

is closed!

N

“DBB”

pressed?

Y

PLAYBACK

TEST

Error during

playback?

Y

Display shows

error-code

(see table2)

Fatal error?

Y

Stop playback

N

("BASS" for AX71xx)

N

N

CD TEST

SERVO

Display shows:

• State of switches

x = door switch

y = inner switch

“0” = closed

“1” = open

FOCUS TEST

• Focus status

“ F

“-F

x = focus sensitivity

Note: If focus has

been lost, focus

start-up procedure

is entered (ramping).

“PLAY”

pressed?

Y

TEST

xy”

“Cd

“PLAY”

pressed?

Y

x” = focus OK

x” = focus error

(see table3)

N

“NEXT”

N

depressed?

Y

Slide moves

outside

ATTENTION: FROM THIS TEST ONWARDS THE

LASER IS SWITCHED ON !!

→ AVOID DIRECT EXPOSURE TO BEAM !!

N

“PREV”

depressed?

Y

Slide moves

inside

("BASS" for AX71xx)

N

depressed?

Disc motor turns

(accelerate)

“MODE”

Y

clockwise

N

depressed?

Disc motor turns

counter-clockwise

“PROG”

Y

(brake)

N

DBB

program

resume

shuffle

DBB

shuffle holdrepeatall

holdrepeatall

test pattern 2 (alternate segments activated)

AX21..

AX51..

AX71..

table1 – key test

DISPLAY SET

KEYS OF SET

DBB (or BASS)

PROGRAM

MODE

PLAY

NEXT

PREVIOUS

ESP

1

2

3

5

6

7

8

KEYS OF CORD REMOTE CONTROL

STOP

PLAY

NEXT

PREVIOUS

4 rc

5 rc

6 rc

7 rc

Press “STOP” on the CD-player to exit the key test.

table2 – playback error analysis

CODE

1000

1001

1002

1003

1004

1005

1006

1008

1009

1020

ERROR

focus error

radial error

sledge in error

sledge out error

DRAM filling

error

jump error

subcode error

turntable motor

error

audio error

(error flag)

focus search

error

TYPE

F=Fatal error

W=Warning

CAUSE

Focus point lost for at least 3ms.

W

W

The radial servo was offtrack for a

certain amount of time.

The slide did not reach it´s inner pos.

W

(inner switch of CD-drive does not close)

within approx. 6s.

The slide did not come out of it´s inner

W

pos. (inner switch of CD-drive is open)

within approx. 250ms.

The DRAM controller was not able to

W

connect two consecutive audio frames.

The microcontroller had to perform a

direct audio connection that produces

audible clicks.

The offtrack values do not decrease

W

properly when jumping tracks, the jump

destination could not be found.

No valid subcode for approx. 230ms.

During start-up, the disc speed did not

F

reach 75% of the nom. speed within

approx. 6 seconds.

Uncorrectable audio error (EF error flag

W

from CD-Decoder).

The focus point could not be found

F

within approx. 10s (no valid TOC info),

resp. 30s (valid TOC info).

EXIT

SERVICE TEST

PROGRAM

table3 – focus sensitivity

DISPLAY

-F 01

-F 02

-F 03

-F 04

ESP-FLAG

off

on

on

on

FOCUS SENSITIVITY

Normal focus sensitivity for CDDA

Low focus sensitivity for

high-reflective CD-RW

Medium focus sensitivity for

normal-reflective CD-RW

High focus sensitivity for

low-reflective CD-RW

“PLAY”

pressed and

focus OK?

Y

DISC MOT. TEST

• Disc speed status

“ d” = speed OK

“-d” = speed error

• Focus status

x” = focus OK

“ F

x” = focus error

“-F

x = focus sensitivity

(see table3)

“PLAY”

and focus OK

and speed

OK?

Y

RADIAL TEST

• On track status

“ r” = on track

“-r” = not on track

• Disc speed status

“ d” = speed OK

“-d” = speed error

• Focus status

x” = focus OK

“ F

x” = focus error

“-F

x = focus sensitivity

“NEXT”

depressed?

Y

CUE-MODE

Track servo jumps

16 tracks forwards

N

pressed?

Toggle focus

sensitivity

(see table 3)

N

N

depressed?

REVIEW-MODE

Track servo jumps

16 tracks backw.

“DBB”

Y

“PREV”

Y

N

N

“NEXT”

depressed?

Y

Slide moves

outside

N

“PREV”

depressed?

Y

Slide moves

inside

N

depressed?

Disc motor turns

(accelerate)

“MODE”

Y

clockwise

N

depressed?

Disc motor turns

counter-clockwise

“PROG”

Y

(brake)

N

Page 14

3-7 3-7

BLOCKDIAGRAM

LCD

+

Keyboard

(Membrane)

+2.6V

From / To

RC - socket

+2.6V

Only for AX71xx - ESP100

+2.6V

DA23 (LN)

CD-Drive

D1-4, R1-2

+2.6V

TZA1024

LD

Laser Power Control

HF Amplifier

Track±,

Focus±,

SL±,

DM±

RC

TMP86CH21

RC

Circuit

16MBit

DRAM

uP

+

+

HF

LCD Driver

+2.6V

16MBit

PWRON,

EQSEL,

CDRW

SL / FO / RA

From/To

Supply &

Charging

Circuit

Digital Servo Processor &

CD Decoder (w/ DAC)

From/To

Servo & Power

Management

CD10

SAA7324H

+2.6V

DRAM

+2.6V

SM5907AF

Memory Controller

From

uP

Battery

or

ACCU

DC-IN

Socket

DC/DC

Converter

&

Charging

Circuit

From/To

uP

SC111259FTA

Servo Driver

+

Power Management

From/To

uP

LP

LN

&

RP

RN

&

+2.6V

Mute &

Beep

Control

Mute

Beep

+2.6V

From / To

RC Circuit

Volume

R

TDA1308

L

Headphone

Amplifier

Headphone / RC

Socket

TC75W51FU

DBB

Page 15

4-14-1

CIRCUIT DIAGRAM - CD PART

1830 B1

1840 E5

2800 A1

2801 B2

2802 B5

2803 C4

2804 C5

2805 C2

2830 D1

2831 E2

3802 B2

2837 E4

2832 E3

2833 E3

2834 E3

2835 E3

2836 E3

1

2838 E4

2839 E4

2840 E5

2841 E5

2

2842 E5

2843 C4

2844 C4

2845 C4

2846 B5

2847 B5

2848 B5

2849 C5

2850 A9

2851 A9

2857 F5

2852 A9

2858 F6

2853 A10

2854 A10

2859 F7 3844 D4

2855 A10

2860 F7

2856 D10

2861 B7

34567

2886 D13

2862 B9

2880 E11

2881 H13

2882 G14 3850 C5

2885 C13

2887 C14

2888 F7

2889 H12

2890 B4

2891 C4

2892 C15

2893 C11

3800 A1

3801 B1

3803 B4

3804 A5

3805 B4

3806 C4

3807 C5

3808 C3

3809 B1

3830 C1

3831 C2

3832 C2

3833 C2

3834 C2

3835 E2

3836 E2

3837 D3

3838 D3

3839 D3

3840 D3

3841 D4

3842 D4

3846 E4

3847 C4

3848 C4

3849 B5

3851 B5

CD-PART

7800

2u2

2801

4n7

F849

3802

H

56K

2805

3832

68K

1,8V

2,5V

0,8V

0,2V

0,7V

2,4V

0V

100n

5K6

3833

1

2

3

4

5

6

7

TZA1024

LD

VCCL

CFIL

MON

DIN

GND

PWRON

5K6

3831

5K6

3834

3835

27K

5K6

Vgap

3836

27K

2831

H

V/I

V/I

1x

4x

2x

0,2V

H

180p

3837

33K

2832

H

0V

7801

BC847BW

3838

33K

330p

2833

H

3808

220K

3839

33K

180p

2834

H

RGADJ

RFEQO

+2.6V

3840

33K

2835

180p

VCC2

EQSEL

CDRW

RFFB

CMFB

H

180p

2836

H

14

0V

13

2,5V

12

0V

11

0V

10

1,4V

9

0,8V

8

1,3V

3847

33R

180p

H

3841

10K

3842

10K

3843

10K

3844

10K

3845

10K

3846

10K

3875

4K7

X

3876

X

2891

2843

2837

2890

H

3804

+2.6V

47R

22u

2802

3K3

3803

2844

220p

3805

4K7

H

3806

2838

H

100n

H

3K3

220p

2803

2839

H

3848

33K

2845

47n

F851

H

100n

220p

2846

1n

2804

2840

H

220p

3849

47u

H

2841

H

1K

3807

+2.6V

220p

470R

3874

27p

2842

220p

2847

2848

F844

22n

3850

22K

1M

F854

1840

*

CSTCC

8.46MHz /

33.86MHz

A

3867

22R

3851

1

1,2V

1K

1

2

1,2V

3

1,2V

4

10n

2849

0V

H

5

2,5V

6

1,2V

7

1,3V

8

1,3V

9

1,3V

10

1,3V

11

1,3V

12

1,3V

13

1,3V

14

15

1,3V

16

1,2V

3868

100n

2857

4p7

4K7

22p

22u

LDON

HFREF

HFIN

ISLICE

VSSA1

VDDA1

IREF

VRIN

D1

D2

D3

D4

R1

R2

VSSA2

CROUT

CRIN

VDDA2

22R

F852

64

2,4V

V1

VREF GEN.

ADC

TIMING

LN18LP

17

2,6V

F855

INNERSWITCH

from CONTROL / SUPPLY-PART

63

62

0V

2,6V

V5

VERSATILE

INTERFACE

FRONT

END

BITSTREAM DAC

19

1.3V

1.3V

2858

1n5

F856

LP

LN

60

61

0V

0,4V

V4

MOTO2

MOTOR

CONTROL

DIG.

PLL

EFM

DEMOD

CONTROL

FUNCTION

PRE-

PROCESSING

VNEG20VPOS

21

0V

2.5V

2888

100n

2859

47u

A

3869

+2.6V

to AUDIO-PART

+2.6V

3852

2861

1u

57

58

59

0,4V

2,6V

0V

VSSD3

MOTO1

VDDD2C

ADDR

SRAM

AUDIO

PROCESSOR

SELPLL

RN22RP

47R

24

23

2.5V

1.3V

1.3V

2860

*

*

1n5

3878

3877

F858

F857

RP

RN

+Audio

Item 3877 ... only for 8.46MHz

*

Item 3878 ... only for 33.86MHz

10R

56

1,3V

SL

TEST1

25

0V

E_KILL

STAGES

A

B

from/to

CD-drive

1830

16

15

14

C

13

12

11

10

9

8

7

D

6

5

4

3

2

1

E

FMN

F830

F831

F832

F833

F834

F835

F836

F837

F838

F841

F842

F839

F840

F843

F848

3800

+2.6V

4R7

2800

F850

H

15K

3801

10

9

3809

Track+

Focus+

FocusTrack-

H

3830

10R

2830

+2.6V

22u

H

H

F

G

H

A ... only for ESP100

X ... component only provided (not in use)

3852 A7

3853 A8

3854 A9

3856 A9

1,2V

FO

OUTPUT

CL16

5800

KILL

55

ERROR

CORR.

SER. DATA

INTERFACE

26

8

1,4V

RA

DATA

3871

54

27

3857 A10

3858 A10

3859 A10

3860 C10

3861 C10

15

13

14

+VR

F846

53

0V

CFLG

INTERF.

PEAK

DET.

WCLK

28

3872

F847

+2.6V

3853

2,6V

VDDD1P

EBU

SCLK

3873

52

29

3862 C10

3863 C10

3864 C10

3865 F9

3867 F5

3854

2K2

3855

2K2

3856

2K2

10R

2862

1u

51

0V

DOEMEF

VSSD2

SUBCODE

MICROCONTROLLER

SER. DATA

LOOPBACK

INTERF.

VERSAT.

KILL

INTERF.

TEST2

30

F845

3868 F6

3869 G7

3871 F8

3872 F8

3873 F8

9

3n3

2850

50

49

0V

0V

CL11|4

SBSY

SFSY

SUB

PROCESSOR

RCK

TEST3

STATUS

SILD

RAB

SCL

INTERFACE

SDA

RESETn

SCLI

SDI

WCLI

V2|V3

VSSD1

KILL

31

32

2,6V

2851

3865

3K3

3n3

7830

SAA7324

48

0V

47

1,5V

46

0V

45

2,1V

44

0V

43

0V

42

2,0V

41

0.3V

40

1.9V

39

1,8V

38

2.6V

37

1,3V

36

1,0V

35

1,3V

34

0,1V

33

0V

3

3880 D11

3874 C5

3881 E113843 D4

3875 B4

3882 G12 F837 D1

3876 C4

3883 G123845 E4

3877 F7

3878 F7

3884 G13

3885 H13

3886 H14

3887 G14

3888 G15

3889 G14

3890 D14

3909 E11

5800 F8

7800 A23855 A9

7801 C3

7830 B9

7880 D11

7881 C11

7882 H14

7883 C14

10 11

to CONTROL / SUPPLY-PART

10K

3863

DM

Sledge

Focus

Radial

3n3

1n5

2855

MCU_XIN

SFSY

10K

3864

10K

SILD

RAB

from/to CONTROL / SUPPLY-PART

SCL

SDA

+2.6V

2856

PORES

33n

D

16,9MHz

F860

NCAS3

2880

D

3880

100n

22R

*

*

*

*

3909

3881

D

D

D

D

2852

3857

2K2

3858

2K2

3859

2K2

1n5

3n3

2854

2853

+2.6V

10K

3862

3860

10K

3861

F859

5

7

6

Item 3881 ... only for ESP12

*

*

Item 3909 ... only for ESP100

F835 C1

F830 C1

F836 D1

F831 C1

F832 C1

F833 C1

F838 D1

F834 C1

F839 D1

12 13 14

{A1,A2,A3,A4,A5,A6,A7,A8,A9,A10,D0,D1,D2,D3,A0,RAS,WE,CAS}

A9

D1

D0

CAS

D

25

26

GND | GND

DRAM_16/4 BIT

VCC | I/01

7881

1

2893

33n

7880

SM5907

1

2,6V

2

2,5V

3

2,5V

2,5V

5

2,5V

6

0V

7

0,6V

8

2,6V

9

1,3V

10

0V

11

1,3V

22

23

24

21

A9 | NC

OE | OE

I/04 | I/04

I/03 | I/03

CAS | CAS

WE | RAS

I/02 | WE

RAS | A9

345

D3

0V

1,3V

WE

3882

0V

1,3V

RAS

2889

NC | NC

6

0V

1,3V

D

A0A1A2A3

10p

I/01 | I/02

2

D2

12 13 14 15 16 17 18 19

F845 F9

F840 E1

F846 B8

F841 D1

F847 G8

F842 D1

F843 E1

F848 A1

F844 C5

F849 A2

A7A6A5

18

9

A7 | A8

A0 | A0

A0

0V

0,9V

3884

16

17

A6 | A7

A5 | A6

A1 | A1

A2 | A2

101112

A2

A1

A6A5A4

0V

0,1V

+2.6V

A4

15

A4 | A5

A3 | A3

A3

D

14

GND | A4

VCC | VCC

13

2885

D

0V

0V

3885

10K

A8

19

A8 | NC

16 MBit | 4 MBit

A10 | NC

8

A10

0V

1,3V

3883

F850 B1

F851 B4

F852 B6

F854 C5

F855 G6

D

D

DRAM_16/4 BIT

A

7883

2887

33n

100n

F863

3890

22R

22u

2886

D

0V

0V

20 21 22

0V

2,6V

F861

2881

D

A9A8A7

A

100n

26

1

+2.6V

F856 G6

F857 G7

F858 F7

F859 D10

F860 E11

D0

D1

25

I/04 | I/04

GND | GND

I/01 | I/02

VCC | I/01

345

2

RAS

2,4V

34353637383944041424344

0V

0V

2882

D

3886

0V

10K

23

24

I/03 | I/03

I/02 | WE

WE

D3

3887

100n

F861 G14

F862 F14

F863 C13

F864 F14

NCAS3

22

OE | OE

CAS | CAS

WE | RAS

RAS | A9

RAS

33

2,5V

32

1,2V

31

1,3V0V

30

1,2V

29

1,2V

CAS

28

2,5V

A10

27

2,4V

26

2,0V

25

1,8V

24

2,7V

23

0V

D

22R

1,8V

7882

BC847BW

D

A9D2A8

21

A9 | NC

NC | NC

6

WE

D1

D0

D3

D2

F862

F864

3889

1K

+2.6V

15

A5

A4

A7

A6

14

15

16

17

18

19

A7 | A8

A6 | A7

A4 | A5

A5 | A6

A8 | NC

16 MBit | 4 MBit

A10 | NC

A0 | A0

A1 | A1

A2 | A2

9

101112

A0

A1

SCL

SDA

+2.6V

3888

100K

YMLD

NPC_RESET

A3 | A3

13

A

2892

A3

A2

8

A10

X

A

B

C

D

E

F

G

H

1

234

5

6

7891011

12

13 14 15

Page 16

4-2 4-2

CIRCUIT DIAGRAM - CONTROL/SUPPLY PART

1250 H4

1402 B15

1251 A2

2250 A6

1252 D1

2251 A2

2252 B6

1400 B10

2253 B6 3294 G4

1401 B14

2254 B6

2255 C7

2256 C7

2257 C8

2259 D7

2261 D1

2262 D4

2263 E8

2264 E7

2265 F4

2266 F8

2267 F4

2268 F8

2269 G4

2272 G5

2273 G6

2275 F8

2276 F8

2277 E8

2278 D8

2279 E8

2401 G12

1234

CONTROL / SUPPLY-PART

A

B

F251

C

D

2261

100n

DC JACK

F250

E

TEMP.

F426

3284

X

3285

+2.6V

C

150K

C

3286

F

G

H

I

TEMP

R....only for Cord R/C

C....only for charging version

X....component only provided (not in use)

%....tolerance 1%

1252

ESD

F253

t

10K

F252

6252

4,4V

SB140

F261

6257

SB140

7255

BC868

3271

C

2R7

ACCU_IN DETECTION

3280

470K

1251

630mA

391

2251

1u

5,0V

3251

270R

7252

C

+A

4,5V

7259

0V

4,3V

3259

220K

C

BC857BW

3282

470K

0V

3283

470K

C

C

X

3253

100R

+2.6V

3281

47K

2,6V

7260

BC847BW

5,0V

4,8V

BC369

3258

100K

C

3,8V

0V

C

0V

F254

*

3270

2R7

Item 3270: 0 ohm for non-charging version

*

+A

3279

C

2M2

C

4,0V

L ... only for DA23L

LN ... only for DA23LN

3298

680R

C

ACCU

2402 E10

2403 E10

2404 E10

2405 G12

2700 H14

C

X

BATT_LEVEL

+VG

RESET

2701 I14

2702 I15

3202 D5

3250 B7

3251 C22258 D5

2262

100p

3294

470K

3252 C6

3253 C3

3254 C5

3256 C7

7256

SC111259FTA

36

3,4V

3266

35

0,4V

10K

34

0V

C

3293

33

0V

330R

32

2,6V

31

4,4V

30

1,2V

2265

29

1,4V

100n

28

2267

27

7,4V

100n

F429

26

8,4V

2269

25

100n

2,2V

F257

1250

B-ZR

3261

10K

RF2

INM2

RS

CHGSW

RSTB

VIN

C2L

C1L

C1H

C2H

VG

OUT4A

11

1

37

VG

24

SL+

3257 D6

3258 D2

3259 D2

3260 D6

3261 C4

5

+DC

3254

47K

+1.25V

3297

4K7

2,6V

38

39

4,8V

DCIN

VDET

BANDGAP

REF.

DCIN

DCIN

DETECT

RESET

VC

VIN

SAW

CHARGE PUMP

VG

MOTOR

VC

DRIVER

OUT4B

PGND4

22

23

0V

2,2V

F258

INNERSWITCH

2345

SL-

from/to CD-drive

3403 B15

3404 B14

3405 C14

3406 C14

3250

680R

5251

10u

2256

100u

2264

220p

2263

220p

2266

220p

2268

220p

3407 E10

3408 E10

3409 E10

3410 G12

3411 F15

2257

4u7

2278

1u

2279

C

Focus

to CD-PART

F255

F256

+2.6V

F428

Radial

2277

100n

3292

10K

1u

2275

Sledge

3412 D15

3413 E15

3414 A15

3419 C153289 F8

+A

3910

10K

10n

+2.6V

+A

DM

3290

5K6

3291

100K

3269

10K

3268

3289

2276

100n

X

3703 I15

3421 B14

3422 E10

3704 I15

3700 H15

3705 H15

3701 H14

3706 I14

3702 H15

3707 I14

9

DC_IN

S_MUTE

F263

+VR

10K

5K6

C

SLEEP

16

# Item 3407 ... 150K ohm for ESP100

# Item 3409 ... 15k ohm for ESP45 & 12

WAKE

# Item 3422 ... 15K ohm ONLY for ESP45 & 12

3708 H15

5251 B7

3709 I14

6252 C2

3710 I14

6257 E2

3910 F8

6400 A13

5250 B6

7250 B7

S2

S1

S0

C3

C2

C1

C0

+2.6V

3408

#

12K

3407

150K

F436

#

#

3409

3422

15K

5K6

F437

S_MUTE

SLEEP

5K6 ohm for ESP100

7251 C6

7252 C2

7255 E2

7256 D4

7259 H2

10 11

F407

F438

F400

1400

22

23

24

ESD

+AVDD

C0C1C2

Key1

7400

49

SEG2

1,3V

50

SEG1

1,3V

51

SEG0

1,3V

52

COM3

1,3V

53

COM2

1,3V

54

COM1

1,3V

55

COM0

1,3V

2402

56

V3

2,6V

100n

2403

57

V2

1,7V

100n

58

V1

0,9V

2404

59

C1

0,7V

100n

60

C0

1,5V

61

P30

DV0

1,3V

PD03

62

P31

1,5V

TC3

PD04

63

P32

2,6V

TC4

PD06

64

P33

0V

TC6

F425

RC

MUTE

BEEP

to AUDIO-PART

3279 H2

3280 H2

3281 H3

3282 H2

3283 I2

3284 E1

3285 F1

3286 F1

3288 B7

3266 E4 F254 E2

3268 E8

3269 E8

3270 E2

3271 E1

3295 D6

3290 G8

3297 D5

3291 D8

3298 E3

3292 D8

3293 E4 F403 C13

3400 A14

3401 B14

678

46

40uH

23

2253

22n

4,4V

7251

BC368

3257

220K

3260

1M

1,6V

45

RF1

CGHSW

SAW

GEN2

OSC

OE

RST

VR

ERR2

CF2

CH2

DRIVER

PGND2

16

0V

12

Track-

to 1830 CD-PART

5250

1

BC337-40

2260

100p

3295

270K

0,6V

46

INM1

CONTROL

SAW

VIN12

15

1,8V

Track+

3288

10R

2252

330p

X

SAW

GEN

SAW

VG

VC

VIN12

2273

1u

7250

3256

2K7

2259

10n

0V

47

CLK

OE

OE

VR

ERR1

CH1

MOTORMOTOR

DRIVER

VIN12

14

4,4V

X

2,5V

2,6V

2255

1u

2,6V

0V

CHGON

OE

SLEEP

1

0V

WAKE

2

4,4V

VR

3

1,3V

ERR4

4

1,3V

CF4

5

1,3V 2,6V

CF3

6

1,3V

ERR3

7

1,3V

ERR2

8

1,5V

CF2

9

RST

1,3V

CF1

10

1,3V

ERR1

11

0V

OUT1A

12

2,2V

OUT1B

PGND1

13

0V

2,3V

Focus-

Focus+

3255

47K

X

3202

40

1,2V

VREF

VC

VC

VC

RST

OE

VR

ERR4

CF4

CH4

VIN34

21

4,4V

2272

1u

to CD-part

DM+

RST

6

DM-

X

F262

22K

1u

2258

41

0,2V

DTC

RF2

INM2

DTC

RF1

INM1

VIN34

OUT3B

20

2,3V

F260

F259

SAW

VG

VC

2250

4u7

2254

4n7

3252

0V

330R

0,3V

2,6V

42

44

43 48

VC

VOUT

CGND

VIN

RS

CONSTANT VOLTAGE

CURRENT & BATTERY

CHARGE CIRCUIT

VIN

VC

VOUT

DC/DC

CONVERTER

SAW

OE

VR

RST

ERR3

CF3 CF1

VIN34

CH3

PGND3

19

0V

VG

VC

OUT2A18OUT2B

OUT3A

1,2V

2,2V

+A

17

MOTOR

DRIVER

7702 H14

7260 H33402 B14

F250 E1

7400 C102260 D6

F251 B1

7401 A14

F252 A1

7700 H15

F253 E1

7701 I15

F411

F409

20

21

S3

48 47 46 45 44

1,3V

SEG3

LCD VOLTAGE

VSS

123

0V

{C0,C1,C2,C3,S0,S1,S2,S3,S4,S5,S6,S7,S8,S9,S10,S11,S12,S13,Key1,Key2,S_MUTE,SLEEP,DC_IN}

F410F408

F412

17

18

19

C3

S13

S12

S4

S5

1,3V

1,3V

SEG5

SEG4

LCD - DRIVER

BOOSTER CIRCUIT

P3

XIN

XOUT

1,0V

1,1V

+2.6V

MCU_XIN

F413

16

S11

S6

1,3V

SEG6

TEST

4

0V

3410

10R

F255 A8

F256 B8

F257 H43418 C15

F258 H5

F415

F414

14

15

S10

S7

1,3V

SEG7

S9

S8

F260 H5

F262 C5

F263 D9

12

F417 F419

F418

F416

12

13

10

11

S7S6S5S4S3

S8

S9

S10

1,3V

1,3V

1,3V

P76

P75

P77

SEG9

SEG8

SEG10

LCD - DRIVER

TMP86C829

F400 B11

F401 C13

F402 B13

F404 B14

4,4V

BAS316

F421

F420

8

9

S11

1,3V

P74

SEG11

I/O PORT P7

F405 C15

F406 C15

F407 B11

F408 B112400 F15

F409 B11

13 14 15

6400

F422

7

S2S1S0

S12

1,3V

P73

SEG12

6

F423

S13

P72

F402

F424

5

F401

1,3V

SEG13

4

P71

4,3V

Key2

3637383940414243

0V

SEG14

3

F410 B11

F411 B11

F412 B11

F413 B12

F414 B12

3400

100K

F427

2

ESD

F403

2,7V

P70

SEG15

7430

BC847BW

3430

1M

7401

BC857BW

1

0V

P57

SEG16

F415 B12

F416 B12

F417 B12

F418 B12

F419 B12

3404

1K

F404

2,6V

P56

SEG17

I/O PORT P5

LCD - DRIVERLCD - DRIVER

2430

3405

333435

TMP86CH21

ROM RAM

8-BIT-CPU

8 BIT A/D Converter

ADC INPUT I/O PORT P6P2P2

XTIN

P21

VDD

5 111213141516

2,6V

2,6V

F434

F433

2401

2u2

ACCU

STOP

RESET

P22

XTOUT

96

8

7

0V

2,6V

100n

2405

DC_IN

RESET

ECIN

P60

P20

INT5

P61

ECNT

P62

0V

1,5V

2,6V

F432

3,2V

10

I/O PORT P1

INT0

P64

STOP2

P65

P63

BATT_LEVEL

STOP3

1,4V

1,4V

1,8V

F431

+AVDD

*

R

1,4V

3709

R

2701

330K

1n

3707

+2.6V

2M2

TEMP

{TEMP,ACCU,BATT_LEVEL,CHG_DET,RESET,WAKE,DM_PWM}

Item 3701... 0 ohm for Non RC version

*

*

F420 B13

F421 B13

F422 B13

F423 B133255 C5

F424 B13

1u

Only for Ver.1

MCU-314011051321

3421

220K

1401

ESD

3406

1K

2,6V

P55

SEG18

P54

SEG19

P53

SEG20

P52

SEG21

P51

SEG22

P50

SEG23

P17

SEG24

SCK

P16

SEG25