Page 1

INTEGRATED CIRCUIT

S

Control signals

µController

µProcessor

DSP or ASIC

Abstract

Philips Semiconductors family of bus controllers is detailed in this application note. PCA9564

device operation, software and hardware methodology and typical applications are discussed.

8 bits

PCA9564

SDA

SCL

AN10148

2

PCA9564 – I

C-bus controller

Jean-Marc Irazabal, PCA Technical Marketing Manager

Paul Boogaards, Sr. Field Application Engineer

Steve Blozis,

PCA International Product Manager

Supersedes data of 2004 August 11

Philips

Semiconductors

2004 November 22

1

Page 2

TABLE OF CONTENTS

OVERVIEW.......................................................................................................................................................................3

DESCRIPTION..................................................................................................................................................................... 3

APPLICATIONS................................................................................................................................................................... 3

FEATURES ......................................................................................................................................................................... 4

DEVICE PINOUT.................................................................................................................................................................5

ORDERING INFORMATION.................................................................................................................................................. 7

DATA SHEETS AND IBIS MODELS .....................................................................................................................................7

PCF8584 TECHNICAL INFORMATION.......................................................................................................................7

PCA9564 TECHNICAL INFORMATION......................................................................................................................7

BLOCK DIAGRAM............................................................................................................................................................... 7

REGISTERS DEFINITIONS ....................................................................................................................................................8

READ AND WRITE STROBES ............................................................................................................................................12

POLLING SI BIT VERSUS USING INT PIN AS INTERRUPT ..................................................................................................12

RESET.............................................................................................................................................................................. 13

INTERFACING THE PCA9564 WITH CPU AND SLAVE DEVICES – HARDWARE .................................................................13

INTERFACING THE PCA9564 WITH CPU AND SLAVE DEVICES – SOFTWARE ................................................................... 14

MASTER AND SLAVE MODES HANDLING..........................................................................................................................15

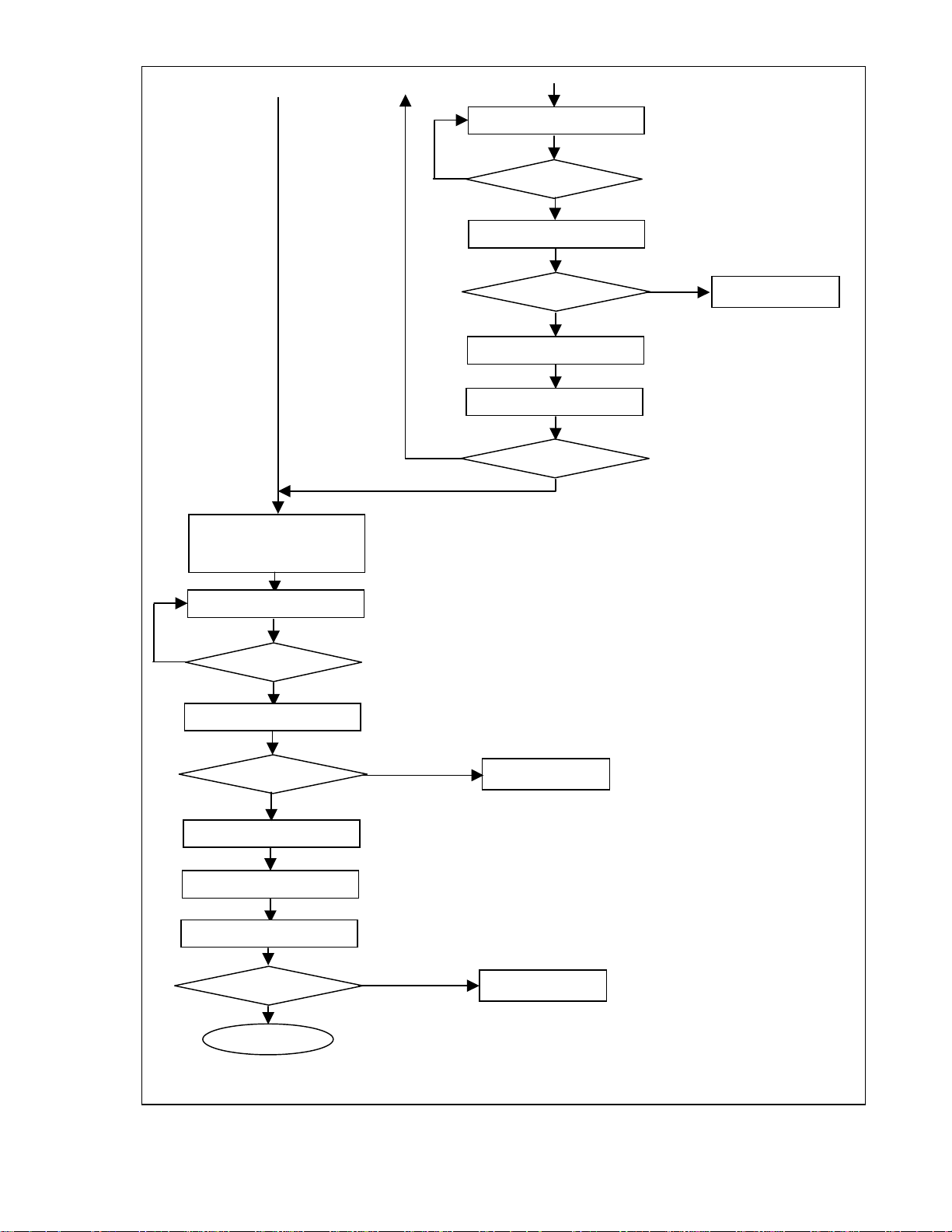

FLOWCHARTS.............................................................................................................................................................16

Initialization Sequence ...............................................................................................................................................16

Master Transmitter Mode...........................................................................................................................................17

Master Receiver Mode................................................................................................................................................19

Slave Transmitter / Receiver mode.............................................................................................................................21

Time-out – SCL Stuck Low Error...............................................................................................................................22

Bus Recovery – SDA Stuck Low Error .......................................................................................................................23

Bus error.....................................................................................................................................................................23

APPLICATIONS..............................................................................................................................................................24

TYPICAL APPLICATION USING THE 80C51 MICROCONTROLLER....................................................................................... 24

INTERFACING THE PCA9564 TO SEND/RECEIVE I2C COMMANDS OVER LONG CABLES..................................................... 24

PCA9564 EVALUATION BOARD ................................................................................................................................27

FREQUENTLY ASKED QUESTIONS.........................................................................................................................27

ADDITIONAL INFORMATION...................................................................................................................................30

REVISION HISTORY...................................................................................................................................................30

DISCLAIMERS ..................................................................................................................................................................31

2

Page 3

OVERVIEW

)

%

Description

The PCF8584 and the PCA9564 are bus controller devices performing the following functions:

- Receive data in a parallel format from a microcontroller/microprocessor, convert them to a serial format conforming

- Receive serial data from the I

The PCF8584 is an integrated circuit designed in CMOS technology that serves as an interface between most standard

parallel-bus microcontrollers/microprocessors and the serial I

functions. Communication with the I

controls all the I

communicate bi-directionally with the I

The PCA9564 is an integrated circuit designed in CMOS technology that serves as an interface between most standard

parallel-bus microcontrollers/microprocessors and the serial I

communicate bi-directionally with the I

or receiver. Communication with the I

PCA9564 controls all the I

The PCA9564 is similar to the PCF8584 but operates at lower voltages and higher I²C frequencies. Other programming

enhancements requested by design engineers have also been incorporated although the PCA9564 does not support bus

monitor “snoop” mode, General Call Address or long distance mode, as does the PCF8584.

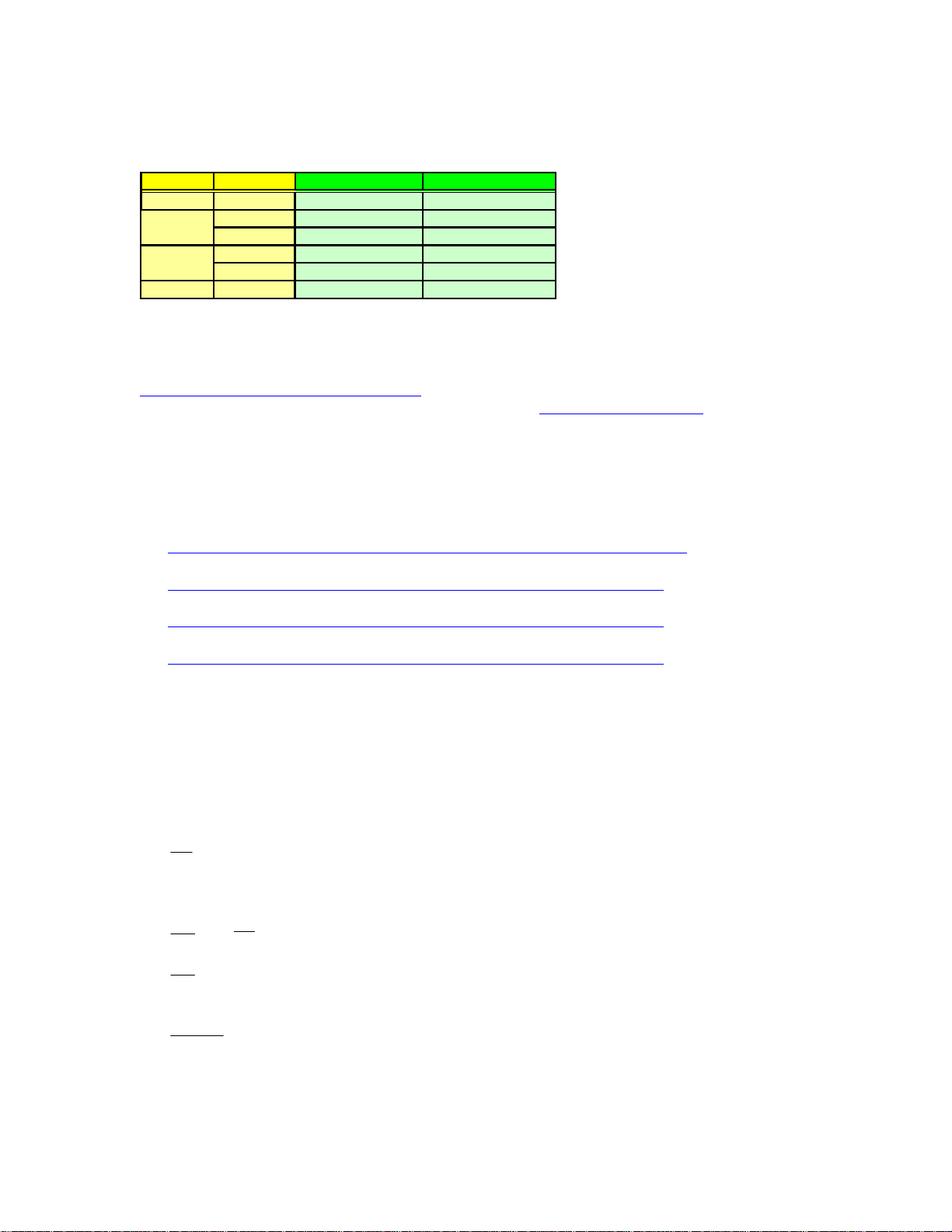

Characteristics PCF8584 PCA9564 Comments PCA9564

Voltage range 4.5 V - 5.5 V 2.3 V - 3.6 V 5 V tolerant

Maximum I

2

to the I

C protocol and send them to I2C devices located on the bus

2

C-bus, convert them to a parallel format and send them to the microcontroller /

microprocessor connected to the controllers

2

2

C -bus specific sequences, protocol, arbitration and timing. The PCF8584 allows parallel-bus systems to

2

C-bus specific transactions with no external timing element required.

2

C freq. 90 kHz 360 kHz Fast-mode I2C compatible

C-bus is carried out on a byte-wise basis using interrupt or polled handshake. It

2

C-bus.

2

C-bus. The PCA9564 can operate as a master or a slave and can be a transmitter

2

C-bus is carried out on a byte-wise basis using interrupt or polled handshake. The

2

C-bus. The PCF8584 provides both master and slave

2

C-bus allowing the 8-bit parallel bus system to

External Internal

Clock source Less expensive and more flexible

TTL (3 to 12

MHz

Parallel interface Compatible with faster processors

Slow Fast

3 MHz 50 MHz

accuracy:

±15

Snoop Mode Yes No

Long Distance Mode Yes No

While the PCF8584 supported most parallel-bus microcontrollers/microprocessors including the Intel 8049/8051,

Motorola 6800/68000 and the Zicor Z80, the PCA9564 has been designed to be very similar to the Philips standard

80C51 microcontroller I

2

C hardware so existing code, for devices such as Philips 8xC552 can be utilized with a few

modifications. There is already code written on the Philips Microcontroller website which would greatly reduce the

software development for the PCA9564. For more information, please check the following URL:

http://www.semiconductors.philips.com/markets/mms/products/microcontrollers/support/software_download/8051/index

.html

Applications

These bus controller devices can be used for a wide variety of applications:

2

I

C-bus Mastering – Some microprocessors have none or an insufficient number of I

be a way to add an I

from the processor to interface to the I

2

the I

C-bus using 2 bits of GPIO, one for the data and one for the clock, if it is the only master on the bus and needs to

2

C port to the microcontroller. The PCF8584 and PCA9564 use 8-bit I/Os and several control signals

2

C-bus in a multiple master capable environment. Any processor can “bit bang”

2

C ports and sometimes there must

3

Page 4

send only simple commands. The PCF8584 or PCA9564 is required when full multiple master compliance with the I

specification is required.

2

I

C-bus Slaving – The PCF8584 and PCA9564 can be used to interface any processor to the I

2

C-bus using 8-bit of

GPIO and some control signals.

2

I

C-bus Sniffing (PCF8584 only) – The PCF8584 provides an I

2

C-bus snoop mode that allows the microprocessor to

monitor communications on the bus without changing the structure.

2

I

C General Call Address (PCF8584 only) – The PCF8584 provides an I

2

C General Call Address mode that allows I2C

General Call Address detection (0x00) when bus controller addressed as a slave.

2

I

C Long Distance Mode (PCF8584 only) -The long-distance mode provides the possibility of longer-distance serial

communication between parallel processors via two I

2

C-bus controllers. In this mode the I2C -bus protocol is transmitted

over 4 unidirectional lines, SDA OUT, SCL IN, SDA IN and SCL IN (pins 2, 3, 4 and 5). These communication lines

should be connected to line drivers/receivers for long-distance applications. Hardware characteristics for long-distance

transmission are then given by the chosen standard. Control of data transmission is the same as in normal I

2

C -bus mode.

Features

PCA9564 Features

• Parallel-bus to I

• Both master and slave functions

• Multi-master capability

• I2C and SMBus compatible

• 2.3 V to 3.6 V operating supply voltage

• 5.5 V tolerant I/Os

• -45 ºC to 85 ºC operating temperature range

• 0 kHz to 360 kHz (400 kHz in slave mode) clock frequency

• Glitch free operation at power-up and power-down, supports hot insertion

• Manufactured in high-volume CMOS process

• ESD protection exceeds 2000 V HBM per JESD22-A114, 200 V MM per JESD22-A115 and 1000 V CDM per

JESD22-C101

• JESDEC Standard JESD78 Latch-up testing exceeds 100mA.

• Offered in 20-pin DIP (N), SO (D), TSSOP (PW) and HVQFN (BS)

PCF8584 Features

• Parallel-bus to I

• Compatible with most parallel-bus microcontrollers/microprocessors including 8049, 8051, 6800, 68000 and Z80

• Both master and slave functions

• Automatic detection and adaptation to bus interface type

• Programmable interrupt vector

• Multi-master capability

2

C-bus monitor mode

• I

2

C-bus All Call Mode

• I

• Long-distance mode (4-wire)

• 4.5 V to 5.5 V operating supply voltage

• -40 °C to +85 °C operating temperature range

• 0 kHz to 90 kHz (100 kHz in slave mode) clock frequency

• Manufactured in high-volume CMOS process

• Offered in 20-pin DIP (P) and SO (T)

2

C -bus protocol converter and interface

2

C -bus protocol converter and interface

2

C

4

Page 5

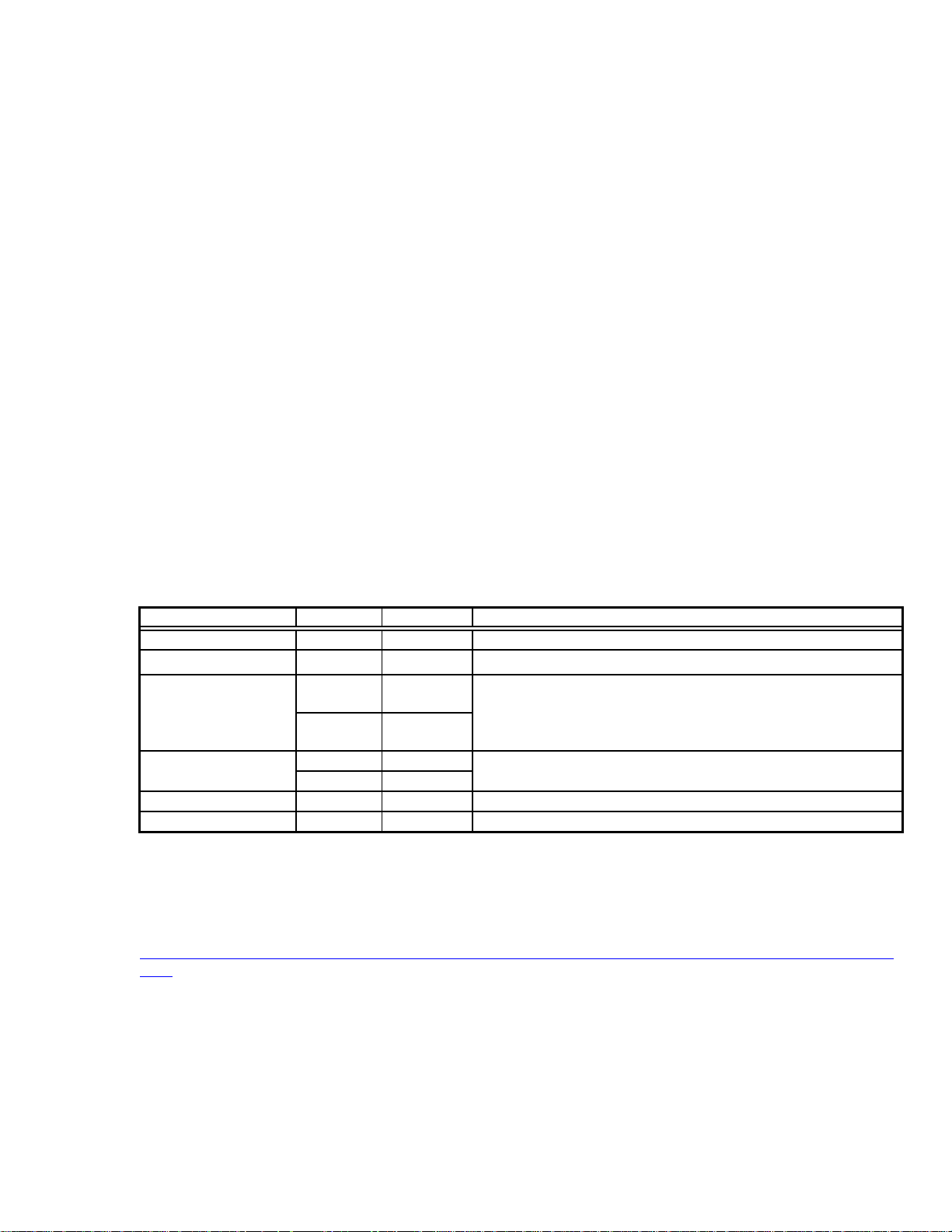

Device Pinout

PCA9564 Pinout

5

Page 6

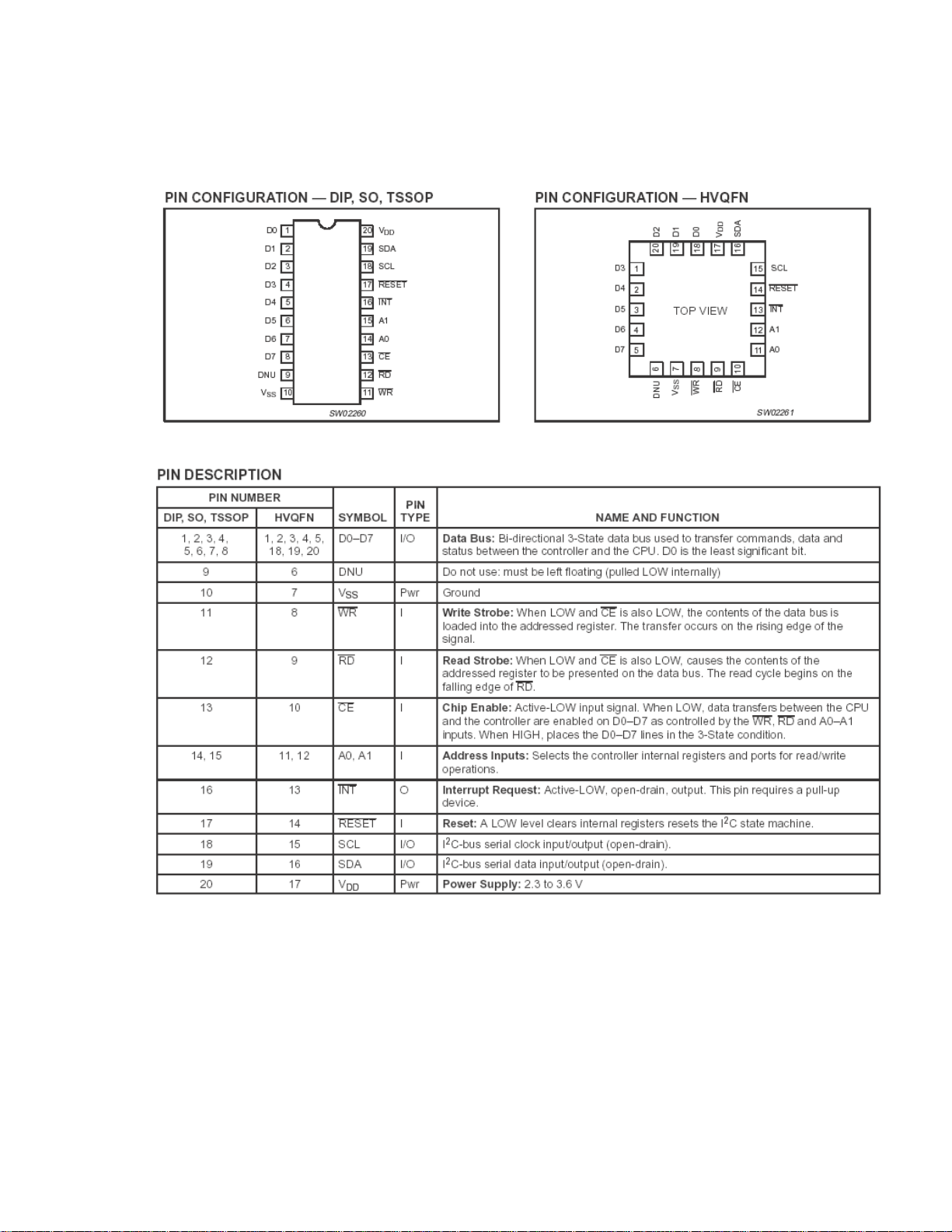

PCF8584 Pinout

6

Page 7

Ordering Information

Package Container

DIP

SO

TSSOP

HVQFN

Tube

Tube PCF8584D PCA9564D

T & R PCF8584D -T PCA9564D -T

Tube Not Available PCA9564P W

T & R Not Available PCA9564P W-T

T & R

PCF8564 PCA9564

PCF8584 PCA9564N

Not Available PCA9564B S-T

Data Sheets and IBIS Models

Data sheet of the PCF8584 and PCA9564 and IBIS model of the PCA9564 can be downloaded from

http://www.standardproducts.philips.com/i2c

PCA9564 HSPICE model is available upon request via email at I2C.Support@philips.com

There are no IBIS and HSPICE models available for the PCF8584.

PCF8584 TECHNICAL INFORMATION

PCF8584 Technical information can be found in the following Philips Application Notes.

• AN425: Interfacing the PCF8584 I

http://www.semiconductors.philips.com/acrobat/applicationnotes/IC22_AN425.pdf

• AN95068: C Routines for the PCx8584

http://www.semiconductors.philips.com/acrobat/applicationnotes/AN95068.pdf

• AN96098: Interfacing 68000 family peripherals to the XA

http://www.semiconductors.philips.com/acrobat/applicationnotes/AN96098.pdf

• AN96040: Using the 8584 with non specified timings and other frequently asked questions

http://www.semiconductors.philips.com/acrobat/applicationnotes/AN96040.pdf

2

C-bus controller to 80C51 family microcontrollers

PCA9564 TECHNICAL INFORMATION

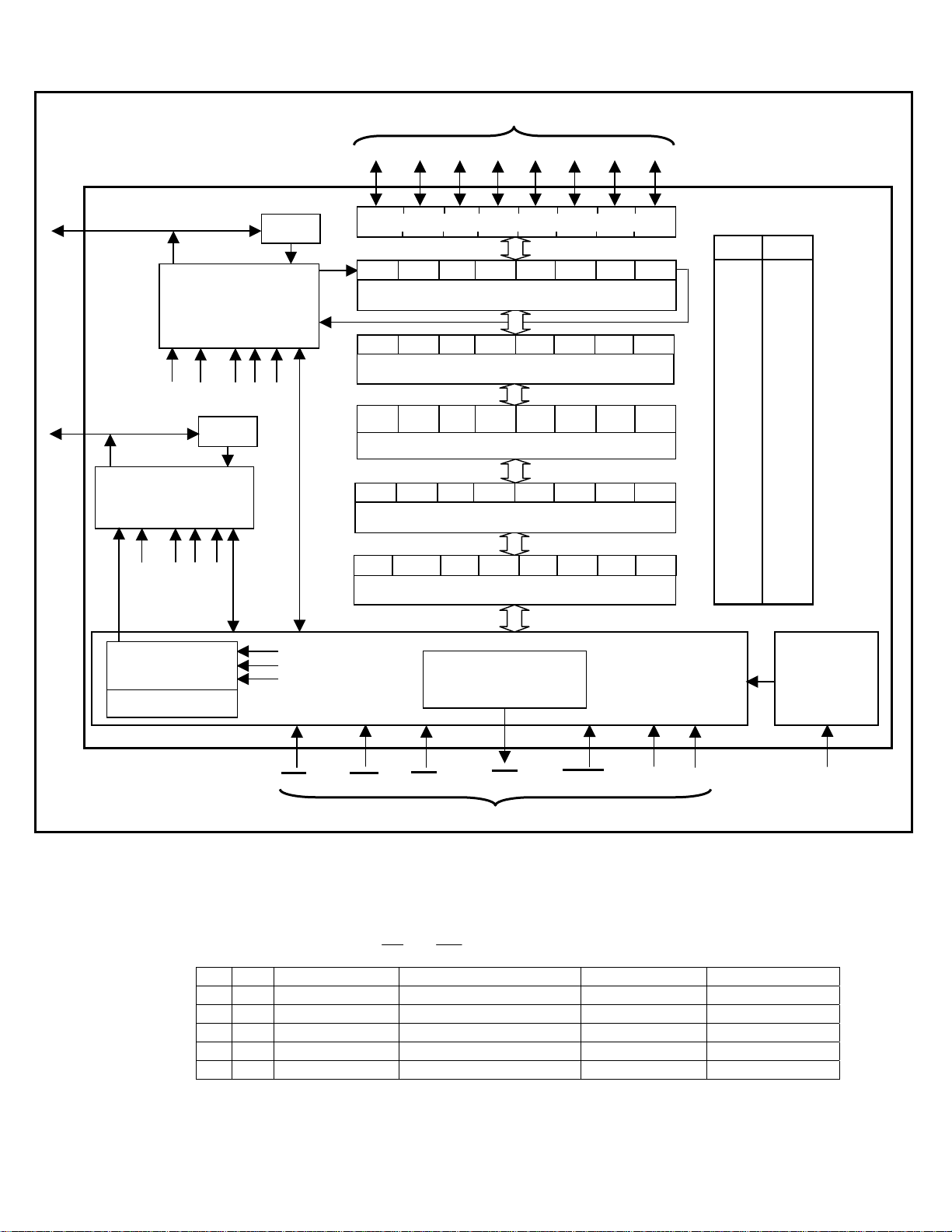

Block diagram

The block diagram of the PCA9564 is shown in Figure 1. Interfacing to the microcontroller, microprocessor or any

device able to communicate with the bus controller (“CPU” will be used from now to designate such a device) and to I

slave or master devices is done through the following pins:

•

: Active-LOW Chip Enable input signal allowing the PCA9564 to communicate with the CPU. This signal may

CE

be held low when it is the only device on the CPU address/data bus.

• D7 to D0: 8-bit bi-directional 3-statable data bus

• A1, A0: Address input pins for internal register-selection

•

and RD: Active-LOW Strobe input signals allowing writing or reading the content of the register addressed

WR

through A1 and A0 pins.

•

: Active-LOW Interrupt output indicating to the master that an event pertinent to the PCA9564 occurred on the

INT

2

C-bus or that an action requested by the CPU has been performed by the PCA9564. Nature of the event or result of

I

the requested action is available by reading the Status register (I2CSTA)

•

RESET

• SDA and SCL: Data and Clock lines of the I

Five internal registers allow the PCA9564 to be configured and data to be sent or received.

An internal 9 MHz oscillator controls I

(Standard-Mode and Fast-Mode I

: Active-LOW Reset input pin clearing the PCA9564 internal registers and resetting the I2C state machine.

2

C-bus timings and generates the I2C clock when the PCA9564 is used as a master

2

C protocol)

2

C-bus

7

2

C

Page 8

K

SDA

SCL

AA

SCL Control

STA STO SI ENSIO

CLOCK

SELECTOR

OSCILLATOR

SDA Control

STA STO SI ENSIO

Filter

Filter

CR0

CR1

CR2

CE

DATA

D7 D6 D5 D4 D3 D2

Bus Buffer

I2CDAT – Data Register – Read / Write

I2CTO – Timeout Register – Write Only

BIT7 BIT5 BIT4 BIT3 BIT2 BIT1 0

BIT6

I2CADR – Own Address – Read / Write

I2CSTA – Status Register – Read Only

AA ENSIO STA STO SI CR2 CR1 CR0

I2CCON – Control Register – Read / Write

INTERRUPT CONTROL

WR

RD

CONTROL SIGNALS

INT

D1

CONTROL BLOC

RESET

Figure 1. PCA9564 Block Diagram

D0

A1

A1 A0

0 1

0 0

1 0

0 0

1 1

A0

POWER

ON

RESET

VDD

Registers definitions

The five internal registers allow the PCA9564 to be configured and data to be sent or received. Definition of the registers

is shown in Table 1. The logic level of pins A1 and A0 determines access to a register. Read or Write operation is

determined by signals applied on pins

A1 A0 Register Name Register Function Read / Write Default Value

0 0 I2CSTA Status Register Read Only 0xF8

0 0 I2CTO Time-out Register Write Only 0xFF

0 1 I2CDAT Data Register Read / Write 0x00

1 0 I2CADR Own Address Register Read / Write 0x00

1 1 I2CCON Control Register Read / Write 0x00

RD and WR .

Table 1. Registers definition

8

Page 9

2

• I2CTO is the time-out register used to determine the maximum time that SCL is low before the I

C state machine is

reset.

Time-Out Period = I2CTO[6:0] x 113.7 µs

The MSB of I2CTO register contains the TE bit.

TE = 0 Time-out function disabled

TE = 1 Time-out function enabled

• I2CADR contains the own address of the CPU connected to the PCA9564 when the device is used in slave mode.

Content of the register is irrelevant when the PCA9564 is functioning as a master.

The seven MSB’s determine the slave address that the PCA9564 will respond to. The LSB should be programmed

with a “0”.

- A “0” in the I2CADR register corresponds to a LOW level in the I

- A “1” in the I2CADR register corresponds to a HIGH level in the I

• I2CDAT contains the byte to be transmitted on the I

In master mode, along with the data byte to be transmitted, it also includes the slave address that the master CPU

wants to send out on the I

2

C-bus: the seven MSB’s are the slave I2C address (SD[7:1] with SD7 as the MSB of the

2

C-bus or a byte that has been received from the I2C-bus.

2

C-bus

2

C-bus

address) while the LSB (SD[0]) is the Read/Write bit.

• I2CCON is the Control Register where the CPU can read from and write to.

A Write to the I2CCON register via the parallel interface automatically clears the SI bit (bit 3), which causes the

Serial Interrupt line to be de-asserted and the next clock pulse on the SCL line to be generated. Since none of the

registers should be written to via the parallel interface once the Serial Interrupt line has been de-asserted, all the

other registers that need to be modified should be written to before the content of the I2CCON register is modified

.

- Bit 7 is the AA bit: Assert Acknowledge Flag

AA = 1 An Acknowledge is sent (Low on SDA) during the Acknowledge clock pulse if:

- The “own slave address” has been received

- A data byte has been received in Master Receiver mode

- A data byte has been received in Addressed Slave Receiver mode

AA = 0 An Acknowledge is not sent (High on SDA) during the Acknowledge clock pulse if:

- The “own slave address” has been received

- A data byte has been received in Master Receiver mode

- A data byte has been received in Addressed Slave Receiver mode

Note:

1. AA bit can be used to temporarily remove the PCA9564 (and the connected CPU) by setting it to “0”.

No acknowledge will then be sent to the device accessing the PCA9564.

- Bit 6 is the ENSIO bit: Enable Serial Input Output (I

2

C-bus)

ENSIO = 1 Serial Input Output enabled – Internal oscillator enabled

ENSIO = 0 Serial Input Output disabled (Hi-Z) – Internal oscillator disabled

Notes:

1. When ENSIO = 0, the PCA9564 is in a “not addressed” slave state and will not respond if its address is

sent by a master on the I

2. When ENSIO = 1, it takes 500 µs for the internal oscillator to stabilize.

3. ENSIO bit should not be used to temporarily remove the PCA9564 form the I

2

C-bus.

2

C-bus since the I2C-bus

status is lost when ENSIO = 0. The AA flag should be used instead as explained above.

- Bit 5 is the STA bit: START command

STA = 1 START command requested – PCA9564 enters Master mode

STA = 0 START command not requested

9

Page 10

Notes:

1. START command is generated when the I

2. If the I

2

C-bus is not free at the request moment, the PCA9564 waits until a STOP command is placed on the

2

C-bus is free.

bus and then generates a START command after the bus free time between a STOP and a START

condition (t

) has elapsed.

BUF

3. If STA is set and the PCA9564 is already in a master mode (and one or more bytes have been sent or

received), the device sends a repeated START command.

- Bit 4 is the STO bit: STOP command

STO = 1 STOP command requested – Bus is free after the t

time has elapsed

BUF

STO = 0 STOP command not requested

Notes:

1. If both STA and STO are set when PCA9564 is in master mode, then a STOP command is generated on the

2

I

C-bus. PCA9564 then generates a START condition after the t

time has elapsed.

BUF

- Bit 3 is the SI bit: Serial Interrupt Flag

SI = 1 Serial Interrupt requested when ENSIO bit is set to 1

The serial interface entered one of 24 of the 25 possible states

(see I2CSTA register definition below)

Serial transfer is suspended

Low period of SCL is stretched

SI = 0 Serial Interrupt not requested

No stretching of SCL

Notes:

1. SI bit must be reset by software (by writing a “0” on that bit)

2. SI bit should never be set to “1” by the user

3. SI bit is not set to 1 when the value in I2CSTA is equal to F8

h

- Bit 2 to Bit 0 are the CR2 to CR0 bits: Clock Rate bits

CR2 CR1 CR0 Serial Clock Frequency (kHz)

0 0 0 330

0 0 1 288

0 1 0 217

0 1 1 146

1 0 0 88

Note 1

1 0 1 59

1 1 0 44

1 1 1 36

Notes:

1. The clock frequency values are approximate and may vary with temperature, supply voltage, process, and

SCL output loading. If normal mode I

2

C parameters must be strictly followed (SCL < 100 kHz), it is

recommended not to use CR[2:0] = 100 (SCL = 88 kHz) since the clock frequency might be slightly higher

than 100 kHz (109 kHz under worst case temperature, voltage, and process conditions) and use CR[2:0] =

101 (SCL = 59 kHz) instead.

2. Clock frequency values in the table are only for master mode. When PCA9564 is used in slave mode, the

device automatically synchronizes with any clock in the I

2

C-bus up to 400 kHz.

• I2CSTA contains the status code. It is a Read Only register and the 3 LSB are always “0”. 25 different codes are

possible and are shown in Table 2. Each code represents a different serial interface state. The first 24 states when

entered sets the SI bit in I2CCON Register to 1 and forces the

INT pin to go low. The 25

th

state (0xF8) does not set

the SI bit to 1 and does not generate an Interrupt because no relevant information is available and no serial interrupt

is then required.

10

Page 11

Status Code

(Hexadecimal)

1 00

2 08 - A START command has been transmitted

3 10 - A repeated START command has been transmitted

4 18

5 20

6 28

7 30

8 38

9 40

10 48

11 50

12 58

13 60

14 68

15 70

16 80

17 88

18 90

19 A0

20 A8

21 B0

22 B8

23 C0

24 C8

25 F8

Note: MT = Master Transmitter, MR = Master Receiver, SR = Slave Receiver, ST = Slave Transmitter

- Bus error due to illegal START or STOP command

- Address+W has been transmitted

- ACK has been received

- Address+W has been transmitted

- NACK has been received

- Data byte in I2CDAT has been transmitted

- ACK has been received

- Data byte in I2CDAT has been transmitted

- NACK has been received

- Arbitration lost in Address+W or Data byte

- Arbitration lost in Address+R or Data byte

- Arbitration lost in NACK bit

- Address+R has been transmitted

- ACK has been received

- Address+R has been transmitted

- NACK has been received

- Data byte has been received

- ACK has been returned

- Data has been received

- NACK has been returned

- Own Address+W has been received

- ACK has been returned

- Arbitration lost in Address+RorW as master

- Own Address+W has been received

- ACK has been returned

- Bus error, SDA stuck low

- Previously addressed with Own Address

- Data byte has been received

- ACK has been returned

- Previously addressed with Own Address

- Data byte has been received

- NACK has been returned

- Bus error, SCL stuck low

- A STOP or Repeated START command has been

detected while still addressed in SR mode

- Own Address+R has been received

- ACK has been returned

- Arbitration lost in Address+RorW as master

- Own Address+R has been received

- ACK has been returned

- Data byte in I2CDAT has been transmitted

- ACK has been received

- Data byte in I2CDAT has been transmitted

- NACK has been received

- Last data byte in I2CDAT has been transmitted (AA=0)

- ACK has been received

- Reset or STOP command

Table 2. Status Codes – I2CDAT Register

Status

MT MR SR ST

• • • •

•

•

•

•

•

• •

• •

• • • •

Mode

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

11

Page 12

Read and Write Strobes

r

t

U

Read and Write strobes are used to select the type of operation that needs to be performed on the selected register.

D[7:0]

Floating

Data from CPU

Floating

A[1:0]

Floating Address

Floating

Address

WR

RD

CE

ADDRESS LATCHED ADDRESS LATCHED

DATA WRITE

Address is latched when WRis going

low.

Data are written to the addressed registe

on the rising edge. Data must be stable a

that time.

Figure 2. Read and Write Strobes

Data available

DATA

READ

Address is latched when RD is going

low.

Data from the PCA9564 becomes

available after 17 ns max. The CP

can then read data from the PCA9564.

When

RD is going high, data bus

floating after 17 ns max.

Floating

Floating

Polling SI bit versus using INT pin as Interrupt

Interfacing and control of the I2C-bus operation can be done by either:

• Polling the SI bit by reading I2CCON Register.

- When SI is at 0, no new state has been generated or detected by the PCA9564 and SCL clock line is not held

low by the PCA9564

- When SI is at logic 1, a new state has been generated or detected by the PCA9564. SCL clock line is held low

by the PCA9564 (Clock stretching) and action by the CPU is required. To leave the “clock stretched” state, SI

bit must be reset by the CPU (write a “0”).

• Using the

- When

held low by the PCA9564

- When

by the PCA9564 (Clock stretching) and action by the CPU is required. To clear the Interrupt, SI bit must be

reset by the CPU (write a “0”).

pin as Interrupt function

INT

is High, no new state has been generated or detected by the PCA9564 and SCL clock line is not

INT

goes low, a new state has been generated or detected by the PCA9564. SCL clock line is held low

INT

12

Page 13

)

d

p

w

•

N

START

SI = 0, INT = 1

Power Up

Power Up default state

I2CCON = 0x00

CPU command

Initialization

See Figure 5. PCA9564 Initialization

PCA9564 initialized and ready to:

- Execute commands from the CPU

(START, STOP, Send/Receive Data)

- Recognize I

2

C traffic/command targeting it

Method 1:

CPU polls the SI bit (loop on I2CCON Register

Read until SI = 1

When SI = 1:

• The request from the CPU has been performed

by the PCA9564, or

• PCA9564 detected an a command targeting it

• The I2CSTA register contains new Status

•

INT

• SCL line is held low (clock stretching)

pin goes low

Method 2:

CPU waits until /INT pin goes low

When INT goes low:

• The request from the CPU has been performed by

the PCA9564, or

• PCA9564 detected an a command targeting it

• I2CSTA register updated with the new Status

• SI bit is set to 1

• SCL line is held low (clock stretching)

Important note:

SI bit is not set to 1 an

INT

in does not go Lo

when I2CSTA register is

loaded with F8

.

H

Read I2CSTA

Read I2CSTA: SI = 1 and pin INT Low

Write I2CCON Register

SI = 0

SI = 0

pin goes High

•

INT

• SCL not stretched

SI = 0 allows to clear the Interrupt condition

ote: a Write to I2CCON Register automatically clears SI bit

Figure 3. SI bit and

INT pin

Reset

An active low Reset allows to

- Clear all internal registers to their default values

- Reset the I

2

C-bus state machine

Reset pulse must be at least 100 ns long (Low state) to reset the device

Interfacing the PCA9564 with CPU and slave devices – Hardware

• Power supply: The PCA9564 is a 3.3V device and all the I/O’s are 5 V tolerant. This allows the device to interface

with 5 V CPU and 5 V I

• Interfacing with the I

SCL and SDA pins are open drain and must be connected to pull-up resistors. Pull-up resistors must be chosen to

satisfy:

- 3 mA drive capability with V

- Rise time max at 1 µs for Standard-Mode I

max capacitive load

2

C devices.

2

C devices:

at 0.4 V

OL

2

C protocol and 0.3 µs for Standard-Mode I2C protocol, for a 400 pF

13

Page 14

• Interfacing with the CPU:

- Data bus (D7 to D0), Address pins (A1 and A0), Chip Enable, Read and Write control signals (

CE , RD and

WR ), Reset pin ( RESET ) are a function of the I/O architecture of the CPU used.

-

INT is open drain and requires a pull-up resistor if the CPU pin connected to it does not have any

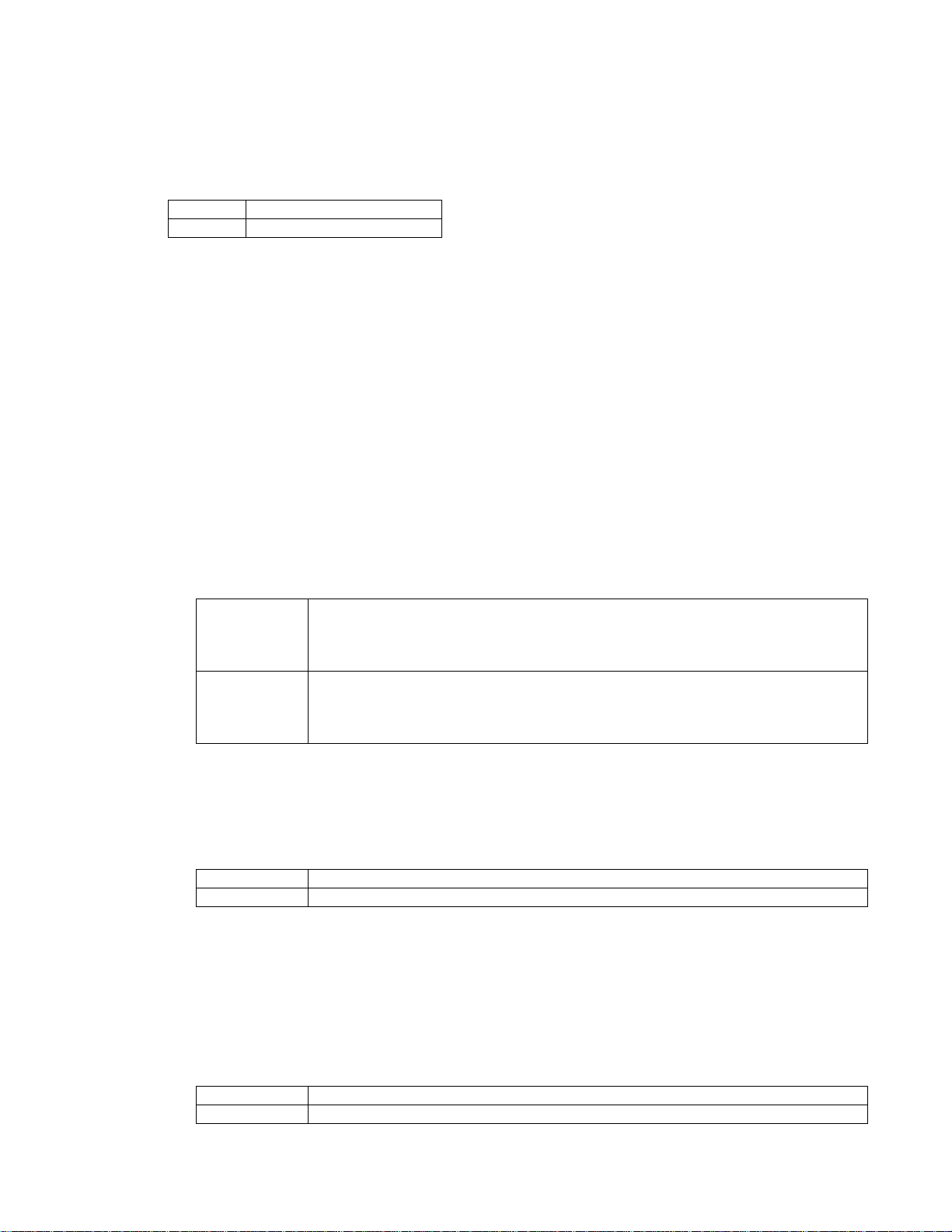

Interfacing the PCA9564 with CPU and slave devices – Software

An evaluation board with some embedded code is available at

http://www.standardproducts.philips.com/support/boards/pca9564. Block diagram is shown in Figure 4.

The evaluation board includes:

- A Philips P89LV51RA2 microcontroller

- A Philips PCA9564 interfacing with the P89LV51RA2 microcontroller

2

The I

C-bus has the following devices:

- A Philips P89LPC932 microcontroller able to be either an I

- A Philips PCF85116 I

- A Philips PCA9531 I

- A Philips PCA9554 I

2

Two I

C connectors allow connection to daughter cards with other I2C master and/or slave devices

2

C 16 kbits EEPROM

2

C 8-bit LED dimmer

2

C 8-bit GPIO collecting program selection information through 8 pushbuttons

Code can be downloaded to the 2 microcontrollers through a RS232 connector (ISP programming).

Sample code will show:

- How to create some dimming/blinking patterns using the P89LV51RA2 + PCA9564 + PCA9531 + PCF85116

- The multi-master capability of the PCA9564 using the P89LV51RA2 and the P89LPC932 as 2 masters trying to take

control of the bus at the same time.

For more information on the evaluation board and the sample code, consult Application Note AN10149 and the fllowing

link:

http://www.standardproducts.philips.com/support/boards/pca9564

2

C Connector (To Daughter Cards)

I

P89LV51Rx2

DATA

CONTROL

RS232

Connector

SP3223

Figure 4. PCA9564 evaluation block diagram

2

C slave or an I2C master

2

I

C

PCF85116

PCA9564

PCA9531

P89LPC932

INT

PCA9554

Pushbuttons for program selection

LEDs

LEDs

14

Page 15

Master and Slave modes handling

Master or Slave mode is automatically handled by the PCA9564. When the bus is idle (SDA = SCL = 1, before a

START command or after a STOP command), the PCA9564 is in:

- Active slave-receiving mode when ENSIO = 1 and AA = 1

- Passive slave-receiving mode when ENSIO = 1 and AA = 0

- Disabled mode in the bus when ENSIO = 0

From an idle situation, there are 3 possible scenarios:

1. The device (for example, µcontroller) connected to the parallel port of the PCA9564 requests a START command

(STA = 1, ENSIO = 1). The PCA9564 is then automatically configured in master mode until the device

(µcontroller) requests a STOP command and the PCA9564 sends it (then causing the I

condition) or if PCA9564 loses arbitration to another master (see scenario 3).

2. A master connected to the I

2

C-bus sends a START command, followed by the slave address of the PCA9564

(assuming the PCA9564 I2CADR register has been previously programmed with its slave address).

- If ENSIO = 1 and AA = 1, the PCA9564 is then automatically configured in active slave mode (receiver or

transmitter depending of the LSB of the I

master located in the I

2

C-bus (then causing the I2C-bus to be in an idle condition). Active slave mode means

that the PCA9564 acknowledges its I

2

C address byte) and will stay so until a STOP command is sent by the

2

C address and will either send or receive data (depending of the R/W bit

value) at the speed determined by the SCL signal.

- If ENSIO = 1 and AA = 0, the PCA9564 is then automatically configured in passive slave mode and will stay

so until a STOP command is sent by the master connected to the I

idle condition). Passive slave mode means that the PCA9564’s SIO (Serial I/O) can be temporarily released

(virtually disconnected) from the I

running and the SIO can be connected back to the bus at any time by setting the AA bit. When AA = 0, the

PCA9564 does not acknowledge its I

2

C-bus without completely disabling it, i.e. the internal oscillator is still

2

C address and will stay “quiet” until the master has sent a STOP

2

C-bus (then causing the I2C-bus to be in an

command.

- If ENSIO = 0, the PCA9564 is in disabled mode. The internal clock is disabled, the PCA9564 is virtually

disconnected from the I

3. In a multi-master configuration, both sides of the PCA9564 (parallel and I

2

C-bus and its state machine is not synchronized with what is happening on the I2C-bus.

2

C) try to take control of the bus, thus

causing the PCA9564 to start an arbitration procedure. The arbitration will end with one of the following:

- The PCA9564 enters master mode (it won the arbitration, same as scenario 1 above)

- The PCA9564 enters slave mode (it lost the arbitration and the other master addresses the PCA9564, same as

scenario 2 above)

- The PCA9564 enters master-in-waiting mode, where the PCA9564 is waiting for the other master (that won

arbitration) to complete its transaction so that it can once again try to gain control of the I

2

C-bus to be in an idle

2

C-bus.

15

Page 16

FLOWCHARTS

r

Initialization Sequence

Delay: wait a time equal to the

longest I

(Multimaster systems only)

Reset 100 ns

TIMEOUT REGISTER

I2CTO =0xFF

OWN ADDRESS

I2CADR = 0x64

ENABLE SERIAL IO

I2CCON = 0x44

Wait 500 µs

READ BACK REGISTERS

2

C message

I2CCON = 0xC4

START

END

A0 = 0

A1 = 0

A0 = 0

A1 = 1

A0 = 1

A1 = 1

A0 = 1

A1 = 1

Set own address for use as a slave

Clock Frequency set at 88 kHz

Wait for Oscillator Startup

Optional verification – allows verification of the

previous programming

At power-up, if a PCA9564 node is powered-up slightly afte

another node has already begun an I2C-bus transmission, the bus

busy condition will not have been detected. Thus, introducing this

delay will insure that this condition will not occur.

Slave receiver mode

AA = 1, ENSIO = 1, SI = 0

Figure 5. PCA9564 Initialization

16

Page 17

Master Transmitter Mode

N

N

N

N

In this flow chart, I2C clock frequency is programmed to run at 88 kHz (I2CCON Register, bits CR [2:0] = 100)

`

O

Load Slave Address + R/W bit = 0

Reset SI and STA bits in I2CCON

O

N = number of bytes to be transferred

M = number of bytes transferred = 0

Load data into I2CDAT

Reset SI bit in I2CCON

Write I2CCON = 0xC4

Continued on next page – Figure 6b

START

Write I2CCON = 0xE4

Read I2CCON

SI = 1?

YES

Read I2CSTA

I2CSTA = 0x08?

YES

into I2CDAT

Write I2CCON = 0xC4

Read I2CCON

SI = 1?

YES

Read I2CSTA

I2CSTA = 0x18?

YES

Figure 6a. Master Transmitter Mode

A0 = 1

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

O

A0 = 1

A1 = 0

A0 = 1

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

A0 = 1

A1 = 0

A0 = 1

A1 = 1

O

Generate START command

AA = 1, ENSIO = 1, STA = 1

Poll from transmission finished

FAULT HANDLER

Send Slave address + Write Command

AA = 1, ENSIO = 1

Poll from transmission finished

FAULT HANDLER

Data to be sent is loaded I2CDAT register

Send Data

AA = 1, ENSIO = 1

17

Page 18

N

N

N

N

Continued from previous page – Master Transmitter mode

Read I2CCON

A0 = 1

A1 = 1

O

SI = 1?

YES

Read I2CSTA

A0 = 0

A1 = 0

Poll from transmission finished

I2CSTA = 0x28?

YES

M = M + 1

O

FAULT HANDLER

O

N = M?

YES

Write I2CCON = 0xD4

A0 = 1

A1 = 1

Generate STOP command

AA = 1, ENSIO = 1, STO = 1

Read I2CCON

A0 = 1

A1 = 1

STO = 0?

YES

END

O

FAULT HANDLER

Slave receiver mode

AA =1, ENSIO = 1, SI = 0, Clock Frequency = 88 kHz

STO bit resets itself once the

STOP command is sent

Figure 6b. Master transmitter Mode

18

Page 19

N

N

N

N

N

Master Receiver Mode

In this flow chart, I2C clock frequency is programmed to run at 88 kHz (I2CCON Register, bits CR [2:0] = 100)

O

Load Slave Address + R/W bit = 1

Reset SI and STA bits in I2CCON

O

N = number of bytes to be transferred

M = number of bytes transferred = 0

START

Write I2CCON = 0xE4

Read I2CCON

SI = 1?

YES

Read I2CSTA

I2CSTA = 0x08?

YES

into I2CDAT

Write I2CDAT

Write I2CCON = 0xC4

Read I2CCON

SI = 1?

YES

Read I2CSTA

I2CSTA= 0x40?

YES

N = 1?

YES

A0 = 1

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

A0 = 1

A1 = 0

A0 = 1

Continued on next page – Figure 7b

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

O

Generate START command

AA = 1, ENSIO = 1, STA = 1

Poll from transmission finished

O

Send Slave address + Read Command

AA = 1, ENSIO = 1

Poll from transmission finished

O

Figure 7a. Master Receiver Mode

FAULT HANDLER

FAULT HANDLER

Reset SI bit and set AA bit in

I2CCON

Write I2CCON = 0xC4

A0 = 1

A1 = 1

Read Data

AA = 1, ENSIO = 1

19

Page 20

N

Continued from previous page – Master Receiver mode

N

N

N

N

N

Read I2CCON

O

SI = 1?

YES

Read I2CSTA

A0 = 1

A1 = 1

A0 = 0

A1 = 0

Poll from transmission finished

A0 = 1

A1 = 0

O

FAULT HANDLER

Data read from the I2C bus can be

read from I2CDAT register

I2CSTA = 0x50?

YES

Read data from I2CDAT

M = M + 1

Reset SI and AA bits in I2CCON

Write I2CCON = 0x44

A0 = 1

A1 = 1

Read I2CCON

A0 = 1

A1 = 1

O

The last byte of the transmission is not

acknowledged

AA = 0, ENSIO = 1

Read Data

M = N - 1?

YES

O

SI = 1?

YES

Read I2CSTA

A0 = 0

A1 = 0

Poll from transmission finished

I2CSTA = 0x58?

YES

Read Data from I2CDAT

A0 = 1

A1 = 0

O

FAULT HANDLER

Data read from the I2C bus can be

read from I2CDAT register

Write I2CCON = 0xD4

A0 = 1

A1 = 1

Generate STOP command

AA = 1, ENSIO = 1, STO = 1

Read I2CCON

STO = 0?

YES

END

A0 = 1

A1 = 1

O

FAULT HANDLER

Slave receiver mode

AA =1, ENSIO = 1, SI = 0, Clock Frequency = 88 kHz

STO bit resets itself once the

STOP command is sent

Figure 7b. Master Receiver Mode

20

Page 21

Slave Transmitter / Receiver mode

N

N

N

N

N

N

N

N

N

A0 = 1

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

A0 = 1

A1 = 0

O

Read Data from I2CDAT

START

Read I2CCON

SI = 1?

YES

Read I2CSTA

I2CSTA = 0x60?

YES

Reset SI bit in I2CCON

Write I2CCON = 0xC4

Read I2CCON

SI = 1?

YES

Read I2CSTA

I2CSTA

= 0x80?

YES

Data read from the bus

can be read from

I2CDAT Register

A0 = 1

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

O

Slave Receiver Mode

O

Read Data or Command from the bus

AA = 1, ENSIO = 1

O

FAULT HANDLER

I2CSTA

= 0xA0

Write I2CCON = 0xC4

END

Figure 8. Slave Receiver / Slave Transmitter Modes

Assumption: PCA9564 is in Slave Receiver Mode

I2CCON = 0xC4 (AA = 1, ENSIO = 1, Clock Frequency = 88 kHz)

Own slave address already loaded in I2CADR (see Figure 5 – PCA9564 Initialization)

Poll from transmission finished

O

?

YES

Slave Receiver Mode

AA =1, ENSIO = 1, SI = 0, Clock Frequency = 88 kHz

Slave Transmitter Mode

Send Data on the bus

AA = 1, ENSIO = 1

FAULT HANDLER

O

I2CSTA

= 0xC0?

YES

I2CSTA = 0xA8?

YES

Load I2CDAT with Data

Reset SI bit and set AA bit in

I2CCON = 0xC4

Read I2CCON

O

Read I2CSTA

O

I2CCON

SI = 1?

I2CSTA

= 0xB8?

FAULT HANDLER

YES

YES

O

A0 = 1

A1 = 0

A0 = 1

A1 = 1

A0 = 1

A1 = 1

A0 = 0

A1 = 0

21

Page 22

Time-out – SCL Stuck Low Error

Command?

)

N

p

N

N

p

N

N

N

N

N

N

N

N

PCA9564 integrates a “SCL Low” sensing feature that generates a “SCL Stuck Low” error (90H) when activated (TE bit

in I2CTO Register = 1) and the clock line stays low longer than the TimeOut Value programmed on I2CTO register.

O

YES

Count TimeOutCount

- Reset TimeOutCount

- Send START

Command (Send

LOW SDA

- I2CSTA = 0x08

-

INT = Low

- SI = 1

Read I2CSTA (08H)

START

Command

START

YES

Bus idle?

YES

Bus idle and

STOP

detected?

O

TimeOutCount >

TimeOutValue?

YES

START, STOP, Send / Receive Data

ENSIO = 1, SI = 0

STA = 1 if START Command

STO = 1 if STOP Command

O

O

- Send LOW SCL

- Send Data on SDA if Write

- Send Low on SDA if STOP

Command

- Count SCLCount

- Count TimeOutCount

O

O

SCLCount

> Half SCL

Release SCL

SCL = HIGH?

Keep counting TimeOutCount

TimeOutCount >

TimeOutValue?

Timeout on SCL

detected

SCL is stuck low

- Reset TimeOutCount

I2CSTA = 0x90

-

- INT = Low

- Set SI bit at 1

- Release SDA and SCL

Read I2CSTA (90H)

Reset PCA9564

RESET = Low

- Reset SCLCount

Figure 9. Timeout Flowchart

eriod?

YES

YES

otes:

1. Time-out feature enabled (TE=1)

2. Time-out register loaded with TimeOutValue (7 bits)

3. Valid for Master Mode

CPU Command

YES

O

- Count SCLCount

- Receive Data if Read Mode

- Receive ACK or NACK if

- Send ACK or NACK if Read

O

STOP

Command?

O

Reset TimeOutCount

Write Mode and ACK Phase

Mode and ACK Phase

SCLCount

eriod?

> SCL

YES

Command fully

YES

Send Low SCL

-

Release SDA

-

Reset SCLCount

-

- Update I2CSTA

INT = Low

-

- SI = 1

Read I2CSTA

YES

- Release SDA

- Reset TimeOutCount

- Reset SCLCount

END

O

22

Page 23

Bus Recovery – SDA Stuck Low Error

K

K

p

N

S

ow

d

d

N

N

eceiving data (byte+ACK)?

N

N

A built-in bus recovery feature allows the PCA9564 to initiate automatically a recovery attempt from a “SDA Stuck

Low” situation. If the attempt is unsuccessful, a “SDA Stuck Low” error (70

START Command

ENSIO = 1, SI = 0, STA = 1

SDA Stuck Low Detected

- Send 9 SCL Clock Pulses

- Keep PCA9564 SDA

released

The 9 clock pulses will make the hanging

device’s state machine move to the next state

after each clock pulse while the PCA9564 SDA

released (not pulled down) will cause a NAC

when the state machine will move to the AC

hase. The NACK will force the device to go

to idle mode

Generate a STOP command

If the bus recovery has been successful,

the bus is now idle (SDA = SCL = 1) an

a STOP command can be generated

SDA Stuck

O

Generate START Command

- I2CSTA = 0x70

- INT = Low

- Set SI bit at 1

- Release SDA and SCL

YES

Bus recovery has not been successful an

a “Bus Stuck Low” error needs to be

generated

Read I2CSTA (70H)

Reset PCA9564

RE

ET = L

Figure 10. Bus recovery Flowchart

) is generated.

H

ote:

1. Valid for Master Mode

CPU Command

Bus error

A “Bus Error” error (00H) is generated by the PCA9564 every time an illegal command is generated.

Command

Command = STOP

and sent right after

START?

YES

- I2CSTA = 0x00

- INT = Low

- Set SI bit at 1

- Release SDA and SCL

Figure 11. Bus error Flowchart

O

Read I2CSTA (00H)

Reset PCA9564

RESET = Low

23

Command = STOP or

START when sending or

r

YES

ote:

1. Valid for Master and Slave Modes

CPU Command

O

Valid

Command

Page 24

APPLICATIONS

Typical Application using the 80C51 microcontroller

Figure 12 shows the PCA9564 in a typical application. Interfacing is simple to realize and requires minimal external

devices.

Figure 12. PCA9564 using the 80C51

Interfacing the PCA9564 to send/receive I2C commands over long cables

Figure 13 shows an application of PCA9564 used in conjunction with Philips P82B96 Bus buffers to send I2C commands

through long cables to slave ICs.

Figure 13. PCA9564 with P82B96 for long distance application

In such I

The existing I

enclosure. When we introduce delays we need to design to ensure the necessary bus timings will still be met. See

Figure 14 for one example of the necessary timing.

2

C systems, we introduce bus propagation delays into the SCL and SDA signals.

2

C specifications do not expect bus delays because they were written for small systems inside one

24

Page 25

Figure 14. Illustrating the allowed delay time that needs to be considered

The following example shows how to calculate the longest allowed cable based on PCA9564 running at the maximum

speed of 400 kHz (nominal 330 kHz with the limits of tolerances applied). When even longer cables are needed the bus

speed must be reduced.

Two bus signal propagation delays are introduced:

1. Propagation delays caused by buffering with P82B96

2. Cable propagation delays.

Flat 4-core telephone cable makes a convenient cable for I

2

C signals. The logic signals should be separated by a ground

or supply wire so the signals across the cable might be chosen in the order Ground, SCL, 5V, SDA. The characteristic

impedance of the transmission lines will probably be in the 75-150 Ω range, and will not be equal due to their

asymmetry. The allowed pull-up resistors will be greater than the correct termination impedance, especially if the pullups are split, for symmetry, by putting half the pull-up at each end of the link. For 5V operation, the lowest resistance

allowed at each end of the cable is (5 V – 0.4 V) / 15 mA = 307 Ω and it is best to use the nearest convenient value,

316 Ω or 330 Ω. Plastic cable propagation delays are about 5 ns/m. We need to consider the “round trip” delays, meaning

the sum of SCL signal delays from master to slave then the SDA reply signal delays back to the master. So for each

meter of cable, the “round trip” signal delay will be 10 ns.

The delays associated with the P82B96 buffering include its internal logic propagation delays (about 300 ns from master

to slave, and 300 ns from slave back to master because the signals in each direction will travel through two devices) plus

“effective” propagation delays caused by bus rise and fall times if there is significant local bus capacitive loading at the

ends of the cables. Each device will cause about 200 ns delay for signals in one direction and less than 80 ns in the other

direction, the total is less than 300 ns.

Because the delays will be almost identical on the SCL and SDA lines, and PCA9564 supports “clock stretching”, about

half of the propagation delay introduced by P82B96 on the SCL wire does not need to be considered. When it delays the

rise of the SCL line at the master (PCA9564), the master will simply adjust its timings to take account of that delay.

The important delays are:

1. The effective delay of the falling edge of the SCL signal from the PCA9564 to the slave and

2. The effective delay of a rising edge of SDA information from a slave back to the PCA9564.

These are usually the longest delay times that effectively reduce the timing margins of I

2

C signals.

25

Page 26

(A falling edge generated by a slave usually has a faster fall time than the corresponding (passive) bus rise time, so the

rise time case becomes the design limit. A delay of the rising edge of the SCL is an allowed “clock stretching”.)

Consider:

1. The SCL falling edge propagation to the slave. PCA9564 drives Sx low, the low at Sx propagates to Tx with less

than 80 ns delay. Tx has powerful sinking capability and will drive the cable past the logic low threshold in about

20 ns. The low propagates to the distant P82B96 after a cable delay of 5ns/meter. The received low at Rx propagates

to Sx on the slave I

2

C-bus with about 200 ns delay. Total delay = 80 ns + 20 ns + 200 ns + 5 ns/m = 300 ns +

5 ns/m.

2. When the slave receives the SCL low it responds with an ACK pulse or data on its SDA line. Most Philips slave

parts will respond in less than 600 ns (See AN255 Appendix 7). I/O expanders and LED drivers e.g. PCA9554 or

PCA9550 respond in less than 375 ns. We need to consider the worst case where a slave outputs a “1” and the SDA

line needs to rise from a low.

The slave SDA line at Sx rises to 0.65 V and that high level at Sx propagates through P82B96 in 80 ns to release its

Tx pin. The cable at Tx will rise with a time constant that depends on any local capacitance and the pull-up resistor

in parallel with the cable’s characteristic impedance. The maximum allowed rise time is 300 ns (measured between

30% and 70% of V

) but to allow for buffer/cable delays it is necessary to design for much shorter times. It is

CC

difficult (without simulations) to accurately predict the signals on improperly terminated transmission lines but in

practice it is easy to achieve the more practical cable rise time (i.e. its 0-50% rise time) in less than 50 ns by using

minimum pull-up resistors (30 mA total sink current).

The cable delays will not exceed 5 ns/m, but don’t be surprised if, due to reflection effects, the Rx pin crosses Vcc/2

at the far end before it reaches that level at the end that generates the signal!

The signal from the cable connected at Rx propagates to Sx (connected to PCA9564) with a delay less than 200 ns.

So the total propagation delay of the SDA signal = 80 ns + 50 ns + 5 ns/m. + 200 ns = 330 ns + 5 ns/m.

The slave response delay may be measured, or taken as less than 600 ns for most Philips parts.

The delay in the rise of Sx on the SCL connection at the PCA9564 is calculated as follows:

- PCA9564 releases Sx

- Sx rises to the high threshold at Sx = 0.65 V, this high at Sx propagates to Tx after a delay about 80 ns.

- Tx releases the cable and the cable input voltage rises to half rail in typically 30 ns.

- That high at Rx propagates back to release the SCL line at Sx after a delay about 200 ns.

So the total “clock stretch” = 80 ns + 30 ns + 200 ns = 310 ns.

The total (effective) delay introduced into the data signal returning from a slave is calculated as:

Propagation delay of SCL falling edge from PCA9564 to the slave – compensating local clock stretch effect at the

PCA9564 + slave response time + delay of an SDA rising edge of data sent from a slave to PCA9564.

Effective delay (ns) = (300 ns + 5 ns/m) – 310 ns + Slave response time + (330 ns + 5 ns/m) = slave response time plus

(320 ns + 10 ns/m)

The available response time for 400 kHz operation = minimum clock low period – data set-up time = 1300 ns – 100 ns =

1200 ns.

The safety margin available to be used for introduced delays (assuming a 600 ns slave response time) = 1200 ns – 600 ns

– 320 ns – 10 ns/m = 280 ns – 10 ns/m.

This would allow a maximum cable length of 28 m, for full 400 kHz operation.

Notice that no allowance is made until now for the rise/fall times of the buses connected at Sx at the master and slave.

When these are 3.3 V buses, that permit pull-up resistors of around 1 kΩ, practical rise and fall times with say 50 pF

loading can be kept to less than 80 ns total.

That means practical cable lengths up to at least 20 m, having 200 ns propagation delay, are possible when operated with

5 V logic and slaves with delays up to 600 ns. For greater noise immunity, it is also allowable to use 12 V logic levels on

the cable but with such fast switching and unshielded the possible radiated interference also should be considered.

In practice these calculations provide quite large safety margins. For example PCA9564 does not actually use the SDA

signal until about 180 ns after the SCL rising edge while our calculations, based on the general I

2

C requirements, have

allowed 100 ns set-up time. That provides some 280 ns of additional safety margin.

And when PCA9564 is operating at its normal master speed of 330 kHz there will be an additional clock low time of

276 ns, providing another very large factor of safety. At the nominal 330 kHz a typical cable could be over 70 meters

long.

26

Page 27

PCA9564 EVALUATION BOARD

An evaluation board for the PCA9564 device has been designed and is available free of charge (while supplies last)

through your local Philips Sales office or by sending an email to: I2C.Support@philips.com.

More information can be found at the PCA9564 Evaluation Board main web page:

http://www.standardproducts.philips.com/support/boards/pca9564

FREQUENTLY ASKED QUESTIONS

1. Question: We are planning on using the PCA9564. Does this device support Hot Insertion (i.e., the SCL and SDA

pins receive a signal before power is up)?

Answer: The PCA9564 would be OK, in the sense that it should not do anything to the bus until the power-up

sequence is finished and the part is programmed to do so. There could be some drooping of the bus lines as the part

is added to the line and the SCL/SDA pin capacitance is charged.

2. Question: What happens to the PCA9564 and the PCF8584 if they are inserted to an active I

that they will not be well initialized and will not recognize that the bus is busy.

Answer: Both the PCF8584 and PCA9564 will be in an incorrect initialization state if they are inserted into a

system in the middle of an I

2

C transmission. Both devices need to see the Start condition to recognize that the bus is

busy. For that, it is a good design practice to introduce a delay at least equal to the longest I

up before starting any operation. Introducing this delay will insure that the bus controller will detect correctly the

“bus busy” condition.

3. Question: We have begun to work with the PCA9564 Parallel ↔ I2C converter in our application and we noticed

that there is no specific mention of the handling of the General Call Address in the specification. Is this device able

to process messages from the general call address as well as its specific node address (set by software)?

Answer: The PCA9564 has not been designed to respond to the General Call Address. When such a command is

generated in the bus, the PCA9564 will ignore it, will not acknowledge and no further action will be taken during

the sequence.

4. Question: The PCA9564 does not seem to include a bus monitor mode. Is it only the PCF8584 that has this

capability?

Answer: Yes, the PCF8584 can monitor the bus, but the PCA9564 cannot. This feature was not included in the

PCA9564 to make the part less complex.

5. Question: Prior to changing the design over to the PCA9564, we had planned to use the PCF8584. It was my

understanding the PCF8584 was not recommended for new designs. Is that the case?

Answer: The PCF8584 is recommended for new designs. It is usually always better to move to the newer devices

for new design since they would give the greatest life span, but since the PCA9564 doesn't have the snoop mode,

long distance mode, all call and can't work at 5 V AND the PCF8584 is currently being used in many different

segments in cumulative large volumes, the PCF8584 is not going to be obsolete for 5-10 years if then, so please feel

free to use it for your new design without worrying about EOL issues.

6. Question: How do masters know who they are (how is their address assigned)?

Answer: Masters do not have addresses unless they can also be slaves. The system architect reviews all I

devices that will operate within the system and which I

then writes firmware in C or Assembly language that includes the specific 7-digit I

2

C address each slave device will be assigned. The designer

2

C address for that master/slave

device. The firmware is loaded into the microcontroller in three possible ways:

1) Mask programmable by manufacturer (e.g., Philips Semiconductors),

2) OTP on test bench by manufacturer or done locally

3) Sent to device and stored in flash (EEPROM like memory) by manufacturer or done locally.

When the microcontroller powers up, the firmware will assign the slave address to the device (127 different

addresses are possible). If the microcontroller does not have an I

PCF8584 or PCA9564 to interface with the I

2

C-bus. The bus controllers are programmed by the microcontroller at

2

C port, it can use a bus controller device like the

start up through the 8 parallel I/O pins with the slave address in the firmware. The bus controller's slave address is

stored in the “Own Address” register in the PCF8584 and the “I2CADR” register in the PCA9564.

2

C-bus? It seems to me

2

C transmission at power

2

C slave

27

Page 28

7. Question: What happens when the master connected to the PCA9564 initiates an I

a START condition and that the SDA line is LOW because an I

2

C device downstream is holding the line (stuck

situation)? Can the PCA9564 manage this situation or does it only report a “SDA Stuck Low” status?

Answer: The PCA9564 is capable of sending out 9 clock pulses and a STOP condition on the I

2

C communication by requesting

2

C-bus (when it has

been requested to send a START condition and the SDA line is LOW). It will then look at the SDA line again and

check if the line has gone HIGH after this particular sequence. If not, it will report an error condition. If the SDA

line has gone HIGH, it will go ahead and send a START condition on the I

2

C-bus. This was designed in specifically

for the situation in which a slave is holding the SDA line low because it is stuck in a READ operation and is sending

out a LOW (zero) to the master but does not receive any further clock cycles followed by a NACK to reset itself.

8. Question: I want to know if Philips Semiconductors has an I

Answer: I don't know of any bus controller that handles 3.4 MHz. The bus controller is used to interface a

Microcontroller to the I

2

C-bus in a multiple master application since it supports all master modes. In simple systems

with only one master it would be possible to bit bang the I

2

C-bus controller for high-speed mode – 3.4 MHz?

2

C-bus using two I/O ports on the micro. This allows the

higher bus speeds assuming the slave is rated for the High-Speed mode.

9. Question: Is there a low power standby mode in the PCA9564. If yes, how?

Answer: When the SDA/SCL lines are high, the bus is idle and the PCA9564 is in active standby mode, meaning

that the digital core does not consume any current and since the SDA/SCL lines are high, there is no current also in

the I/O's. However, the device is ready to send/receive data to/from the I

There is a bit in the Control register (I2CCON Register, bit ENSIO) that enables/disables the Serial I/O (I

2

C-bus and the built-in oscillator is running.

2

C-bus)

and thus disabling the internal oscillator.

- When this bit is at 0, SDA/SCL are in high-impedance state, all signals from the SDA/SCL lines will be ignored

and the device is in a "not addressed" slave state. Internal oscillator is also deactivated. This is the low power

standby mode of the PCA9564. All the block of the devices are disabled.

- When this bit is set to 1, the part becomes fully "awake" after 500 µs, which is the required time to have the

internal oscillator up and running. The device is then ready to send/receive data to/from the I

2

C-bus.

10. Question: The standby current of the PCA9564 is specified at 0.1 µA typical, 3 µA max. What test setting is it used

to achieve such a value?

Answer: As far as the measurement conditions for testing went, 3 different setups for I

standby were tested. For

DD

all the following conditions, the ENSIO bit of the control register I2CCON must be set to "0" (which is also the

default conditions at power up or external reset).

I

standby(L1): All inputs low except for CEwhich is high, V

DD

standby(L2): All inputs low except for RDwhich is high, V

I

DD

I

standby(H): All inputs high except for NC that is internally pulled low when not connected. V

DD

Note: You cannot have

CE

and

low at the same time or the outputs are enabled and any then additional

RD

= 3.6 V

DD

= 3.6 V

DD

= 3.6 V

DD

current will be a function of your parallel port loading.

11. Question: I would like to use the PCA9564 in my design but I noticed that its power supply can be 3.6 V max.

However, I need to interface the device with a 5 V microcontroller. Do I need a 5 V↔ 3.3 V interface between the

2 devices?

Answer: No. Even though the PCA9564 is a 3.3 V device, all the I/O’s (parallel port and control signals, serial bus)

are 5 V tolerant and do not require additional device to interface with 5 V systems.

12. Question: PCA9564 has a SCL clock frequency specified at 330 kHz. Fast-mode I

2

C protocol specifies a max

frequency at 400 kHz. Why this difference?

Answer: Maximum clock frequency has been designed to be 330 kHz typical in order to include its variation

depending on the power supply, the temperature and the process. Doing that ensures not to violate the “400 kHz max

2

I

C clock frequency” specified by the protocol when the PCA9564 is in Master mode.

When PCA9564 is in Slave mode, it accepts a clock frequency up to 400 kHz from the bus master.

13. Question: Does the PCA9564 have to switch the mode between slave transmitter and master transmitter mode or

can the PCA9564 do these in a signal-operating mode?

Answer: PCA9564 takes care of that itself. From an idle situation, the device is able to recognize if it has to act as a

master or slave.

- If from an idle situation, data are sent in the parallel port from the microcontroller (data will be a START

command first), then the PCA9564 will act as a master and later on, depending on what the master wants to do

28

Page 29

(read or write), it will be a transmitter and/or receiver. Note that if the bus is not idle at that time (another master

is communicating with somebody else), the PCA9564 will tell the microcontroller that it can't take the control

of the bus so far.

- If from an idle condition, a Start command is placed by somebody in the I

2

C-bus and that the address matches

the address that the PCA9564 has on it, it will then configure itself as a slave and again, depending on what the

master outside wants to do (read or write), the PCA9564 will be either a transmitter or and/or receiver.

14. Question: The manual states that only a Reset may set the PCA9564 into a working state 0xF8 but that would

require an additional port bit in my master device for resetting the PCA9564. I would suggest to use ENSIO bit for

that purpose. Is that possible?

Answer: ENSIO bit only disables the I

2

I

C-bus) but does not reset the state machine and does not put the PCA9564 on that specific state. It's actually quite

2

C port of the PCA9564 (it cannot send / cannot respond to anything from the

dangerous not to use the Reset pin of the PCA9564 because it can go to some states (see datasheet page 14 table 6)

where only a Reset allows the device to leave this mode (or a Power down/ Power up sequence).

15. Multi-part Question: Decoupling capacitors/noise

Question15-1: Do you have any recommendation for the bypass capacitor between V

Answer 15-1: A 0.1 µF capacitor can be used and it needs to be located as close as possible from the V

Question 15-2: Is there any limitation for noise on V

line that we should be aware of? We are concerned about

DD

and VSS?

DD

pin.

DD

“false operations" or "dispersion of clock frequency" that might be caused by noise.

Answer 15-2: We have not seen any limitation induced by noise on the PCA9564 (simulation, bench,

characterization). The device has good noise immunity. The internal clock is 9 MHz (+/- 10 %) and goes through

several dividers to be used by the digital core. Special cares have been taken for the clock tree. The I

2

C max

frequency is not high (400 kHz max) and at such value, not that much noise is generated.

Question 15-3: From a noise point of view, are there any PCB rules that have to be applied to the PCA9564 and the

different signals connected to it?

Answer 15-3: There are not special cares for that device. Only rules that apply to any other digital devices must be

followed:

- No digital signals should cross each other and no other high frequency clock should cross those signals (parallel

bus, control signals, SDA, SCL)

- The parallel bus signals should be separated from the other signals (those ones can run up to 50 MHz and are

susceptible to generate higher noise levels.

- "Quiet" signals (V

, VSS) can be used to separate the control signals.

DD

16. Question: I want to use the PCA9564 as master receiver. How do I handle the ACK/NACK phases? The PCA9564

has to ACK all the received bytes except the last one where it has to NACK so it can take control of the SDA line

and generate the STOP command.

Answer: This is controlled by the bit AA in the I2CCON Register. When you write AA = 1 in the I2CCON

Register, the PCA9564 will acknowledge the received byte (ACK). When you write AA = 0 in the I2CCON

Register, the PCA9564 will not acknowledge the received byte (NACK)

17. Question: Which pins of the PCA9564 device require pull-up resistors?

Answer:

INT , SDA and SCL signals must have pull-up resistors. The data bus D[0:7], the address bus A[0:1],

CE , RD and WR signals may require pull-up resistors but it depends what you are interfacing it with. Most

microcontrollers have pull-ups in their I/O ports so pull-ups are not required. If the device controlling the PCA9564

does not have pull-ups then you will need to add them.

18. Question: We have connected the PCA9564 towards a FPGA circuit that acts as a control-unit for the PCA9564.

The FPGA sets its data bus pins in tri-state mode when reading from the data bus between the FPGA and the

PCA9564. To enable the PCA9564 to read from the data bus between the FPGA and the PCA9564, should the

CE pin be in a 0-state? What worries me is that the PCA9564 really has the ability to read from the bus when in

3-state mode.

Answer:

CE needs to be active (Low) to read from the bus. When CE is High, the PCA9564 will ignore any RD or

WR signals on the bus.

29

Page 30

ADDITIONAL INFORMATION

The latest datasheets for the Bus Controller family of products and other SMBus/I

Semiconductors website:

http://www.semiconductors.philips.com/i2c

Software tools for most of Philips’ products can be found at:

http://www.semiconductors.philips.com/i2c/support

Additionnal technical support for Bus Controller devices can be provided by e-mailing the question to:

Email: I2C.Support@philips.com

2

C products can be found at the Philips

REVISION HISTORY

Revision Date Description

_4 20041122 Application note (9397 750 14357)

Modification:

• Page 12: Figure 2 modified to correct timing errors

_3 20040802 Application note (9397 750 13934)

Modifications:

• Page 4: PCA9564 features: added DIP package

• Page 5: Modified Pin configuration and Pin information to include DIP package

• Page 15: Added “Master and Slave modes handling” paragraph

• Page 27: Added “PCA9564 Evaluation Board” paragraph

• Page 29: Added Question/Answer 14 to 18

_2 20031013 Application note (9397 750 12166).

Modifications:

• Page 4: added “I

• Page 4: PCF8584 Features: added bullet “I

• Page 10: Clock bit rates for CR2-CR0 bits (table): modified Note 1.

_1 20031003 Application note, initial version (9397 750 12149).

2

C General Call Address” paragraph

2

C-bus All Call Mode”

30

Page 31

A

Purchase of Philips I2C components conveys a license under the Philips I2C

patent to use the components in the I

conforms to the I

2

C specifications defined by Philips. This specification can

2

C system provided the system

be ordered using the code 9398 393 40011.

Disclaimers

Application information – Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

Life support – These products are not designed for use in life support appliances, devices or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips Semiconductors customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such

application.

Right to make changes – Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits,

standard cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors

assumes no responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask

work right to these products, and makes no representations or warranties that these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified.

Contact information

For additional information please visit

http://www.semiconductors.philips.com

Fax: +31 40 27 24825

For sales offices addresses send e-mail to:

sales.addresses@www.semiconductors.philips.com

©Koninklijke Philips Electronics N.V. 2004

All rights reserved. Printed in U.S.

Date of release: 11-04

Document order number: 9397 750 14357

31

Loading...

Loading...