Page 1

Wall Mount Split Units

AMW/AMC 25, 30, 45 &60

by AITONS'

AMW / AMC SERIES

Installation, Operation

And Maintenance Manual

Please read this manual before

installing and operating the unit

CONTENTS

INSTALLATION INSTRUCTIONS

! Tools / Supplies

! Safety considerations

! Selection of location

! Recommended height and length

! Installation Method

! Refrigerant piping & drainage

! Electrical wiring

OPERATING INSTRUCTIONS

! Operating tips

! Product description

! Auxiliary control

! Remote control operation

! Operating instructions

! Care and maintenance

! Trouble shooting

Page 2

INSTALLATION INSTRUCTIONS

TOOLS AND SUPPLIES

The following tools are needed

for installation.

1. Level

2. Hole Saw

3. Core bits

4. Hammer

5. Drill

6. Torque wrench

7. Adjustable wrench

8. Flat head screwdriver

9. Philips head screwdriver

10. Wire stripper

11. Measuring tape

12. Ratchet set

13. Flaring tools

14. Tube cutter

The following materials are

required:

1. Correct size copper tubing

2. Correct size drain pipe

3. Sleeve and bush

4. Vinyl tape

5. Saddle & Clamps to support

refrigerant piping

6. Power supply cable

7. Insulation material

8. Putty or similar sealant

SAFETY CONSIDERATIONS

Installation and servicing of air conditioner can be hazardous due to high refrigerant pressure

and electrical components inside the unit. Only fully trained, qualified and certified service

personnel should install, repair and service the air conditioner.

While working on the air conditioner, all precautions in the literature, tags and labels attached to

the unit and all other general safety precautions should be carefully observed. Please follow all

safety codes, wear safety glasses and work gloves. Also use quenching cloth for brazing

operations.

It is highly recommended that this manual be read completely before installing and operating the

system.

WARNING: The main power breakers to the unit , including its accessory or

parts, should be turned off before performing service or maintenance operations

on the unit. Dangerous high voltage can cause electric shock, serious personal

injury or even death.

Page 3

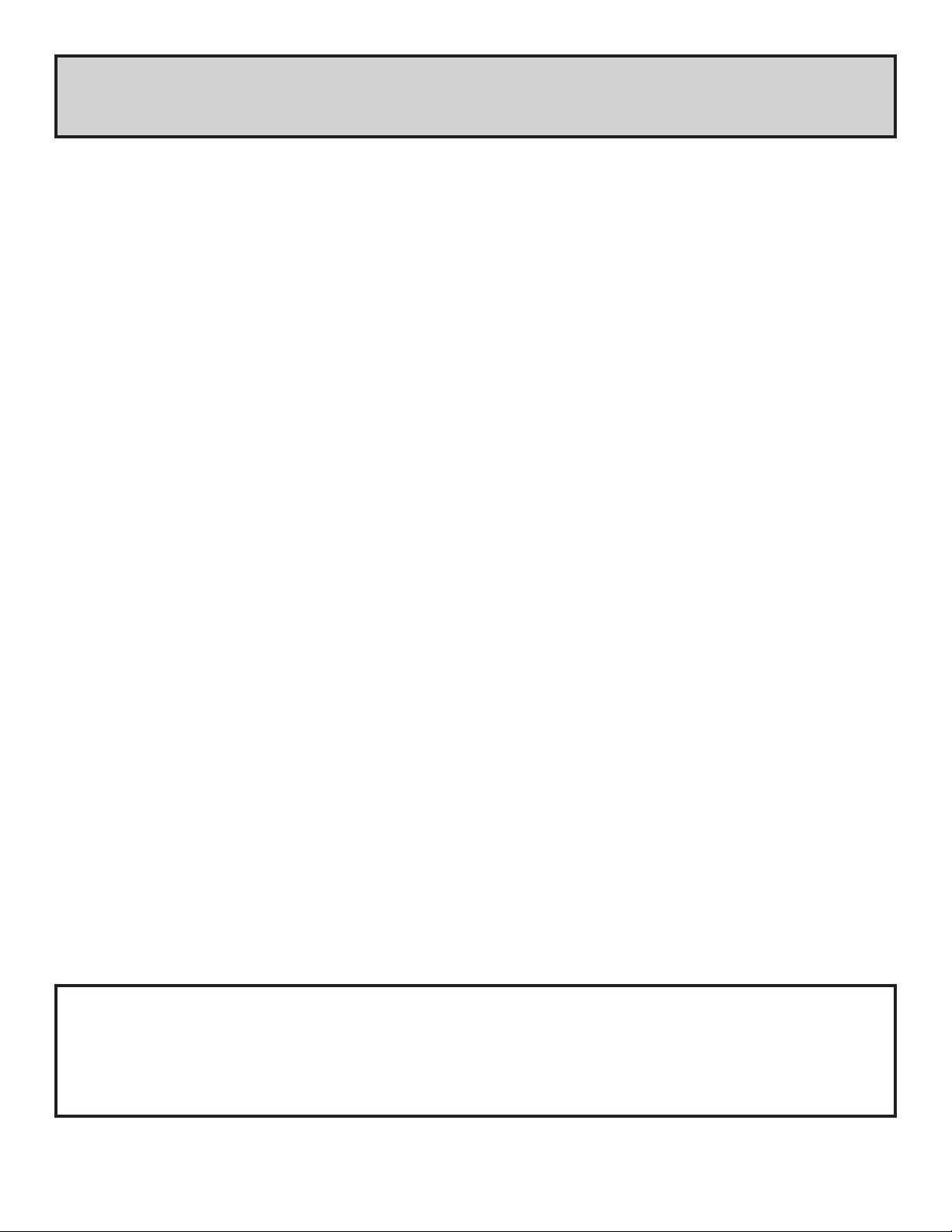

SELECTION OF LOCATION

Select a convenient location where:

INDOOR UNIT

! The cool air can reach every corner of the

area to be cooled.

! The unit is away from any direct heat

source

! Easy and short routing of the refrigerant

and drain pipes to the exterior.

! There are no flammable gas, alkaline or

acid present in the air.

! Air circulation is not obstructed, preventing

good air circulation.

! The structure where the unit is installed

should be strong enough to support the

weight of the unit and also prevent any

vibration during operation of the unit.

! Figure on the right shows the spacing to the

nearest wall.

OUTDOOR UNIT:

! The condensing unit should be located as

close as possible to the fan coil.

! The air inlet shall be located at least 4” from

the wall or other obstruction for unrestricted

airflow.

! The air outlet shall be located so as to

direct discharged warm air away from the

building. (Avoid low overhanging roofs to

avoid re-circulation of condenser discharge

air on vertical discharge models.)

! Mount the unit on a sturdy base.

! Figure on the right shows the spacing to be

provided.

Page 4

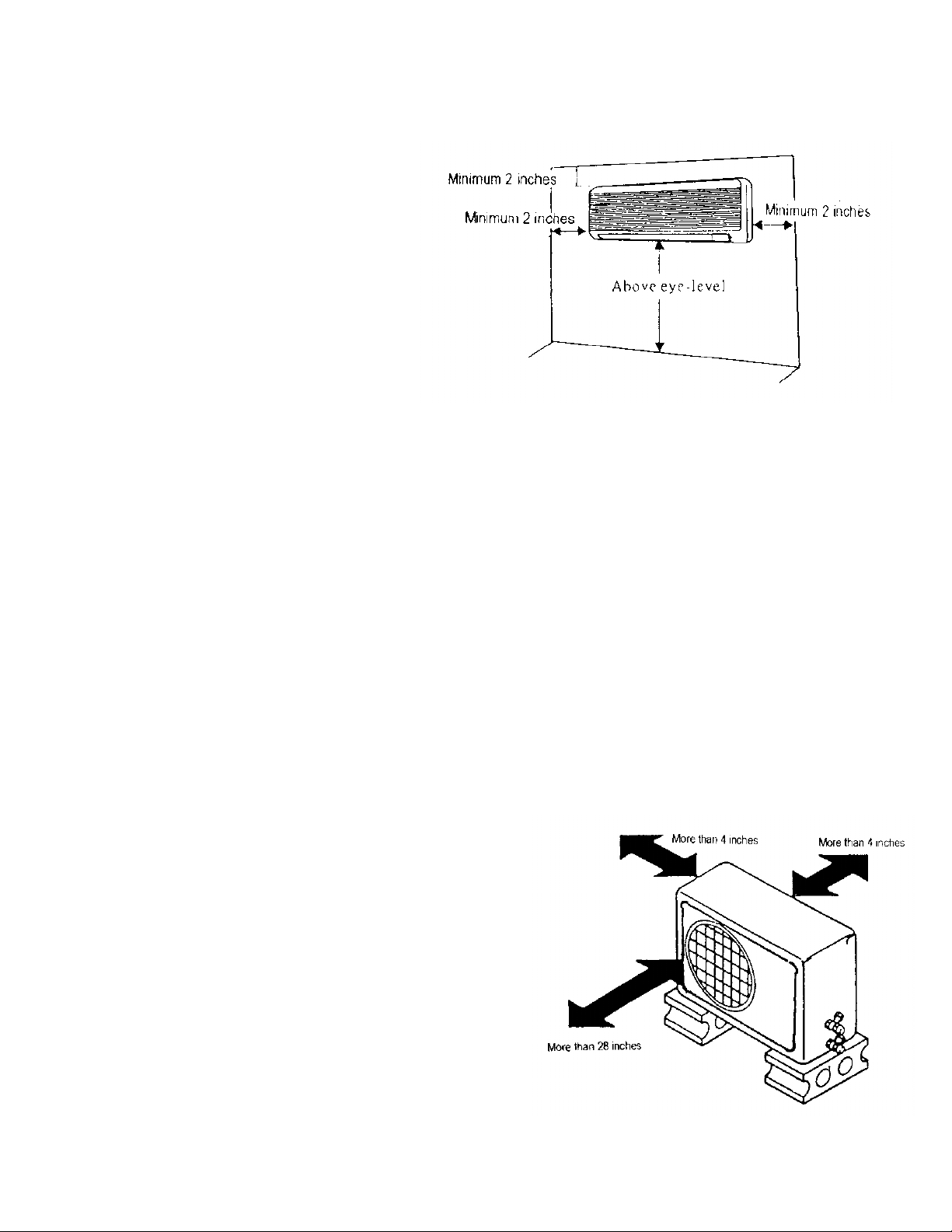

RECOMMENDED HEIGHT AND LENGTH

If the refrigerant piping is longer than the

recommended length, or if the height

difference between the indoor and outdoor

unit is greater than recommended, the

capacity will drop and the compressor could

malfunction. Select an installation location

that is within the recommended parameters.

Cooling

capacity

7,500 to

9,000

Btuh

Recommended height difference is 23 ft or less

*Evacuate refrigerant lines

An installation with a piping length of 23 ft. or less is desirable.

(1)

If this is not possible, the maximum piping length can be

extended to 50 ft. by charging the system with additional

refrigerant. However, cooling and heating capacity will be

reduced.

• Additional charge volume = (piping length - 23 ft.) x 0.2 oz.

& HEIGHT RECOMMENDED)

Add

charge

(MAXIMUM PIPING LENGTH

Piping length (feet)

Not

needed

23 50

Installation

Needed

(1)

not

recom-

mended

Notes

Unit

Piping

Diameter

1/4" and

3/8”

INSTALLATION METHOD

HOLE DRILLING: After deciding the

method your unit will be installed, a hole to

route the connecting tubes and wires to the

outdoor unit is to be drilled on the wall. The

hole must be lower than the point where the

drainpipe attaches to the drain pan of the

unit. It should also be slightly declined

towards the outside.

Piping length (feet)

Cooling

capacity

18,500 to

36,000

Btuh

Recommended height difference is 23 ft or less

*Evacuate refrigerant lines

An installation with a piping length of 33 ft. or less is desirable.

(2)

If this is not possible, the maximum piping length can be

extended to 55 ft. by charging the system with additional

refrigerant. However, cooling and heating capacity will be

reduced.

• Additional charge volume = (piping length - 33 ft.) x 0.2 oz.

Add

charge

needed

Not

33 55

Needed

(2)

Installation

not

recom-

mended

Notes

Unit

Piping

Diameter

Page 5

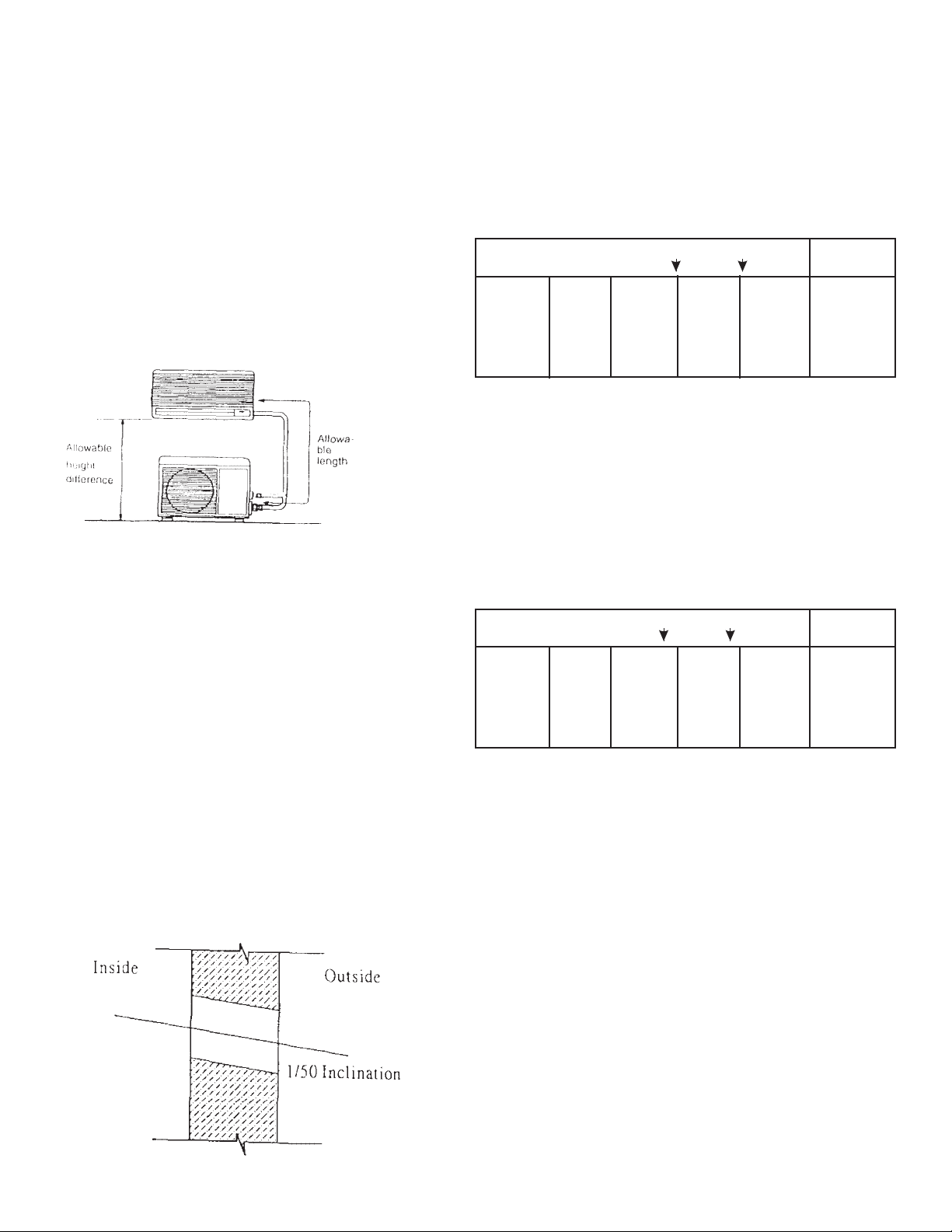

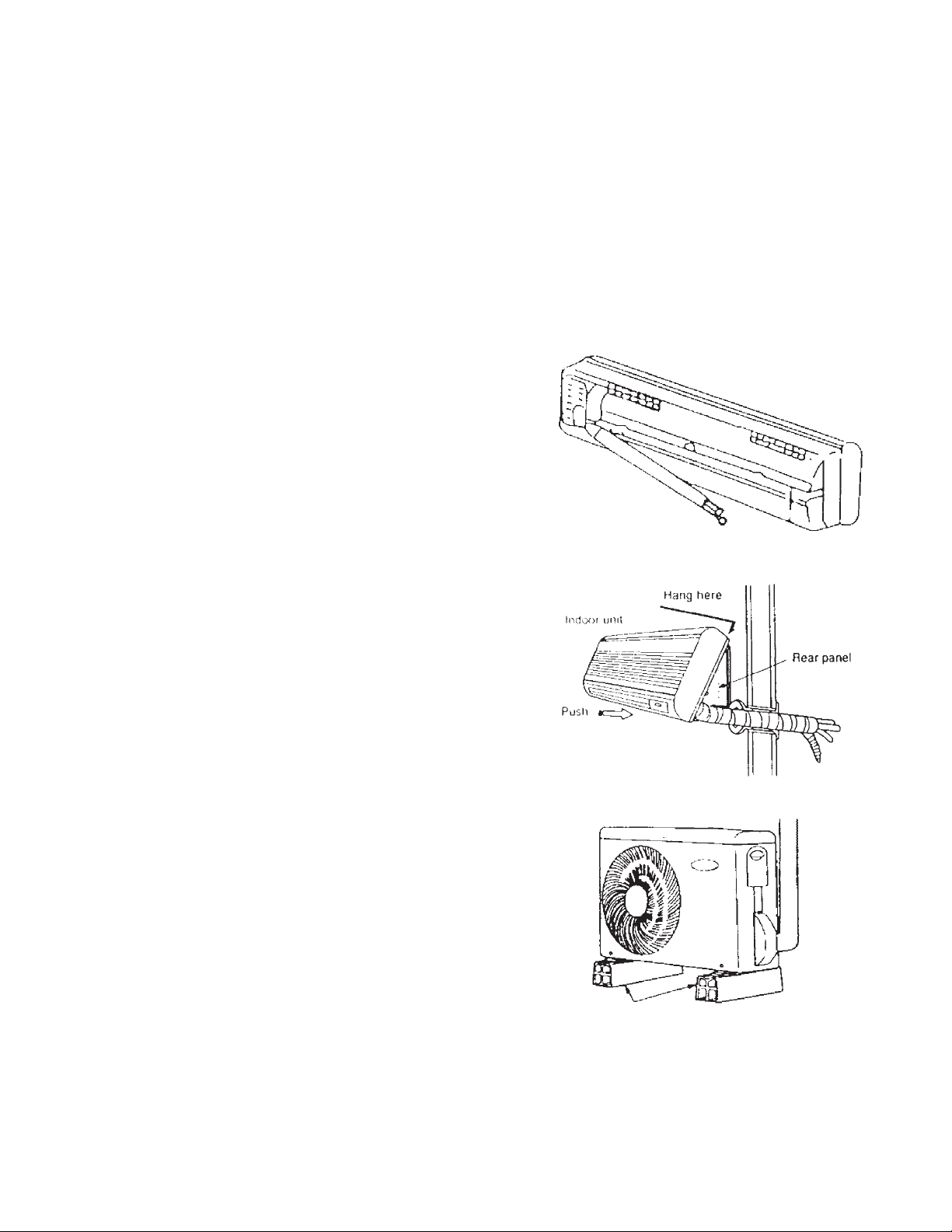

MOUNTING INSTALLATION PLATE:

The fan coil can be installed using any of the four methods described below.

Determine which is the most suitable method.

Position the installation plate on the wall

making sure that it is parallel to the ground.

This can be done by aligning the markingoff line with a thread and weight as shown

in figure on the right. This is to ensure that

the condensate water does not overflow

from the drain pan.

Mount the installation plate with the 4

screws provided. (If the unit is to be

mounted on a concrete wall, consider using

anchor bolts instead of the screws provided.

Page 6

INSTALLATION OF FAN COIL:

The extended liquid and suction pipes and drain hose are hidden inside a slot at the

back of the fan coil. This allows the hole on the wall to be either on the right or left side

of the fan coil.

RIGHT SIDE HOLE POSITION: The piping and drain hose are routed straight through

the hole.

LEFT SIDE HOLE POSITION: The

piping and drain hose run from the

right side to the left side of the unit,

hidden in the slot at the back of the

unit before routing through the hole

on the left side of the unit.

MOUNTING FAN COIL UNIT:

Hook the fan coil onto the upper

portion of the installation plate

ensuring that it sits securely on the

installation plate.

Press the lower portion of the unit

against the installation plate until the

hooks at the back of the unit are

securely engaged with the installation

plate.

MOUNTING CONDENSING UNIT:

Do not place the condensing unit

directly on the ground. It should

preferably be placed on a slightly

raised platform to prevent rain water

from splashing into it. Also ensure

that it is level. Avoid installing the unit

in places where flammable gases

may be present.

beams or blocks

If necessary, due to the placement conditions,

rubber cushions can be placed underneath the

outdoor unit.

Page 7

REFRIGERATION PIPING & DRAINAGE

PREPARATION OF PIPING

Fan coil and side discharge condensing units are equipped with flare connections. Improper flaring

and brazing may cause refrigerant to leak out of the system. Follow these instructions carefully in

preparing the refrigerant piping.

! Ensure that all piping is of the correct size.

! Measure the distance between the indoor and outdoor units' refrigerant connections, together

with all the curves necessary. Add a few inches as slack.

! Lay the piping as straight as possible on a flat surface and with a pipe cutter, cut the piping

according to the measured length.; Do not tighten the cutter excessively during cutting as this

may cause the pipe to deform. Do not use hacksaw or similar tools to cut the pipe, as it results

in metal shavings getting inside the pipe. This also makes proper flaring impossible.

! Use a reamer to remove burrs from cut edges. Hold the pipe ends upside down to prevent

metal powder from getting into the pipe.

Pipe

Reamer

Note:

As the pipe is round, cutting should be

performed on a straight section. Also,

do not apply too much force with the

blade of the pipe cutter.

Pipe cutter

Keep pipe facing downward

when removing burrs.

! For connection to flare settings, the pipe has to be flared. Remove the flare nut from the unit

and insert it onto the piping.

! Fit the pipe into the bar of the flare tool, about 0.5 mm higher than the surface of the bar.

! Center the flare punch carefully on the pipe and turn gradually to widen the pipe. Check the

finish of the flare to ensure even flaring.

! Cover the flared ends with tape to prevent dust from entering.

Handle

Flaring tool

Flaring bar

Length of periphery portion

Flare nut

L should be constant

0.635 (1/4”) only 0.952 (3/8”) and larger

Approx. 1 mm

0.5 mm

Page 8

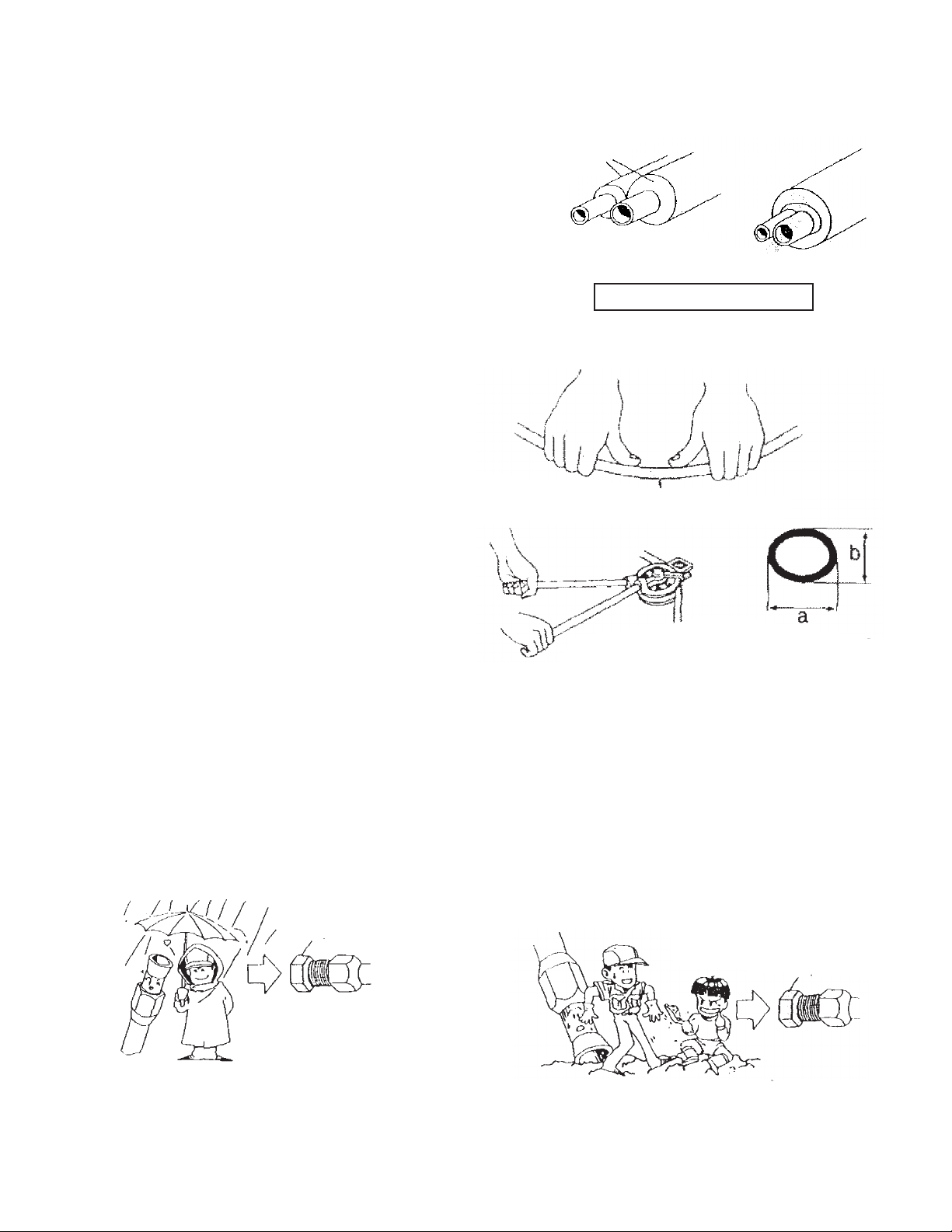

PIPING INSULATION

Liquid and suction lines must be insulated

separately. In a cooling only type air

conditioner, both pipes become cold during

operation. This can cause moisture to

condense on the surface of the pipes,

resulting in heat loss.

PRECAUTIONS WHEN BENDING

PIPES

! The air conditioner's performance

will suffer if the piping is crushed.

! Bend pipes using the pads of your

thumbs to prevent them from

collapsing (See picture on the right.)

! Use a pipe bending tool to bend pipe

wider than 1/2" in diameter.

Insulation

Narrow Pipe

Bend with pads of thumbs

Wide Pipe

Common insulation

Separate insulation is essential

Pipe bending tool

FLARE FITTING CONNECTION. There are 3 piping rules:

(a) DRY: Never allow any water to get

inside the piping.

Cap

Keep cap attached until immediately

before making piping connections.

(b) CLEAN: Never allow dirt, sand or other

foreign particles to get inside the piping.

b/a = 0.7 or more

Cap

Keep cap attached until immediately

before making piping connections.

Page 9

(c) PRECAUTIONS WHEN CONNECTING PIPES:

Connections will go more smoothly if the

large pipe is connected first, followed by the

small pipe. Hold the nipple and the flare

nut straight and lightly turn the nut two or

three turns by hand to ensure that the

threads are aligned.

Then tighten to the specified torque using a

wrench. In particular, when tightening 1/4"

diameter flare nuts, use the specified torque

wrench

Fan Coil

! Align the center of both flare fittings

and tighten the flare nut with your

hand.

! With a torque wrench tighten the

flare nut fully.

Torque wrench

First, 2 or 3 turns by hand

Nipple

Flair nut

Fix in place.

Wrench

Torque wrench

Always look at arrow on

torque wrench to

determine direction.

Condensing Units

! Align the center of the flare nut of the

liquid line to the liquid valve. Tighten

the flare nut, first with your hand and

then fully tighten with the torque

wrench.

! Align the center of the flare nut of the

gas line to the gas valve. Tighten

the flare nut with your hand. After

purging, tighten it fully with a torque

wrench and check all connections for

leaks with soap solution.

Outdoor unit

Liquid side piping

Gas side piping

Torque wrench

Page 10

AIR PURGING

This procedure is used to remove air from inside the piping connecting the indoor and outdoor units,

as well as the air inside the indoor unit. If air purging is not carried out, air will beocme mixed into the

refrigerant cycle, causing the pressure to rise to abnormally high levels, increasing power

consumption and reducing the capacity of the unit. Also, moisture in the air can cause insulation

failure in the compressor motor and deterioration of the refrigerant oil, resulting in a significant

reduction in the air conditioner life.

The procedure is as follows:

! Confirm that all piping connections

have been completed correctly.

! Connect a gauge manifold and a

vacuum pump as shown in the

diagram.

! Completely open the low-pressure

valve of the gauge manifold and

completely close the high-pressure

valve.

! Start the vacuum pump and allow it

to operate until the pressure is at 29”

of vacuum. This will take about 15

minutes or more.

! With the low-pressure valve

completely open, switch off the

vacuum pump.

! Completely open both the suction

and liquid service valves.

! Disconnect the manifold.

! Tighten the caps on the service

valves and the flange nut on the

charging port.

Narrow pipe

service valve

Wide pipe

service valve

Low pressure

valve

Gauge Manifold

High pressure

valve

Vacuum pump

Page 11

DRAIN PIPE CONNECTION

The fan coil is equipped with a drain hose. It is

tied together with the refrigerant piping. During

installation, it is important to observe the following

instructions to prevent water overflowing from the

drain pan.

! Insure that the indoor unit is level and not

tilted forwards or backwards.

! Insure that the drain hose does not rise

above the drain pan. It should be sloping

towards the hole.

! Route the drain hose through the same

hole as the refrigerant pipes.

! If the drain pipe extends horizontally a long

way, use PVC tubing to provide heat

insulation.

! Outside insert the drain hose into a PVC

drainpipe and not the other way around and

glue them together.

! Run the PVC drainpipe straight down the

wall. There should be no traps and avoid

putting the end of the pipe into water.

! Ensure that all sections of the PVC pipes

are glued securely together.

! Ensure that the entire indoor part of the

drain hose is insulated to avoid

condensation from dripping.

! Drain pipe may be required for heat pump

unit and should be connected if necessary.

Drain Pipe

• Traps

Trap

• Long Horizontal Extensions

Good

No good

The lack of a

downward

slope causes

water to build

up and

overflow the

drain pan.

Even if there is a downward slope overall,

there must not be any “double traps” formed

Gap of approximately 50 cm

Secure in place

with saddles

Good

Drain hose

Downward

Slant

Down-

ward

slant

Drain Pipe

Traps

Stiff vinyl

chloride (PVC)

tubing

Trap effect created

Flexible tube

No good

Drain water cannot

flow freely

Drainage gutterDrainage gutter

SLIME

Water leakage due to a clogged drain hose can be caused by accumulated dirt in the drain pan or by

a buildup of slime inside the drain hose.

Slime is caused by the following factors:

! Temperature : 25°C (77°F) to 30°C(86°F)

! Accumulated water

! Nutrients (components of perspiration and dust in the air)

! A combination of certain types of mold and bacteria.

To reduce the chance of clogging, it is very important to ensure that the drain hose has a downward

slant to prevent water from accumulating and a clean and a well ventilated environment.

Page 12

Outdoor unit

Holder for

connecting cable

Control board

cover

ELECTRICAL WIRING

to power supply

LOCATION OF TERMINAL BLOCK:

The terminal block on the indoor unit is located

next to the PCB. Cable access is through the

back of the unit. For the condensing unit, the

terminal block is located behind the control panel.

Holder to

power supply cord

connecting cable

WIRING CONNECTION:

! All wiring and grounding must comply with the local Electric Codes.

! See the unit nameplate for electrical rating and use correct wire size to handle the minimum

circuit ampacity required for the unit. Refer to Local Electric Codes for wire sizing.

! Always use a separate power line with circuit breaker for each air conditioner.

! Always ground the unit.

! Ensure that no wiring touches the tubing, motors or any other moving parts.

! Depending on the outdoor unit type, the number of inter-connecting wires between indoor and

outdoor unit varies. Please refer to the wiring diagram on the unit to determine the number of

wires required and correct connection.

! Finally inspect all the electrical connections, including the factory wiring to ensure that all

connections are tight.

EXTERNAL FINISHING OF PIPING

! After completing the installation of the

refrigerant piping, drain pipe and wiring,

bind them together into a bundle with tape

at 4 inches to 8 inches (100 to 200 mm)

intervals. Start from the bottom and work to

the top. Keep the drainpipe at the bottom

of the bundle.

! Do not fail to apply insulation to the joints

and wrap them with tape. If the joints are

not insulated, condensation could form on

them, resulting in water leakage.

! Use saddles to secure piping in place so

that it does not sway back and forth.

! Plug any open portions of the pass through

hole with putty to ensure that no rain or

wind can get inside.

! Finally, tidy up both the inside and outside

and the installation process is complete.

Insulation

Refrigerant Tubing

Wall cap

Putty

Inside

Putty

Inter-connecting Wiring

Insulation

Wall

Outside

Tape

Drain Pipe

Putty

Page 13

OPERATING INSTRUCTIONS

OPERATING TIPS:

Observe the following points for economical and safe operation:

! Keep the room temperature at a comfortable level. Too much cooling is unhealthy and results

in excessive consumption of electricity. A temperature setting of 75°F (24°C) is usually

sufficient during the day. During the night, set the temperature a few degrees higher as the

body temperature is reduced when a person is asleep.

! Adjust the vertical and horizontal louvers to provide uniform distribution of air in the room.

! Clean the filter at least twice a month. A clogged air filter reduces performance and increases

power consumption.

! Keep the indoor and outdoor coils clean to maintain high heat transfer capability. Periodically,

inspect the coils and call a professional serviceman to clean the coils with special cleaning

chemicals if necessary.

! Reduce heat gain through windows by stopping direct sunlight with curtains or blinds. Awnings

are also helpful by creating shade around the windows. Keep windows and doors closed

except when ventilating the room.

! It is good practice to ventilate the room occasionally to rid the room of stale air.

PRODUCT DESCRIPTION

Figure below illustrates the important components of the air conditioning unit.

Front Cover

Auxiliary controller

Indicating lamps

Vertical louver

Horizontal louver

Remote controller

Air filter

Pipe and electrical

Drain hose

Page 14

AUXILIARY CONTROL

Figure below illustrates the auxiliary control on the fan coil. This can be used to

operate / control the air conditioner when the remote controller is not available or lost.

Test

Use to operate the air conditioner under "COOL" mode. All other functions will not be

effective. The air conditioner will automatically stop operating after 30 minutes. This is

to test if the air conditioner is in working condition.

Remote

In this position, the air conditioner is controlled by the remote controller.

Auto

Use to by-pass the remote controller. The air conditioner will operate automatically

when power is supplied. The remote controller is ineffective in this position.

Red indicating lamp

Red light will be lit when electrical power is supplied to the air conditioner.

Green indicating lamp

This green lamp will be lit when the compressor starts operating. It indicates cooling

operation is in progress. It will blink if the operating temperature is abnormal.

Page 15

REMOTE CONTROL OPERATION

CONTROLS AND INDICATORS

Figure below illustrates the various controls and indicators of the LCD wireless remote

control.

MODEL: AMW 25, 30

Page 16

MODEL: AMW 45, 60

Page 17

OPERATING INSTRUCTIONS

Before operating the unit for the first time, it is necessary to install the batteries in the

remote controller.

! Batteries are located at the back of the

remote controller (Model AMW25, 30) and

at the front of the remote controller (Model

AMW45, 60).

! Open the battery holder by simultaneously

pushing downwards and inwards at the

area marked "OPEN"

! Use only "AAA" alkaline batteries

! Dispose of used batteries correctly, in a

manner not causing pollution or harm to the

environment.

OPERATING GUIDE MODEL: AMW 25, 30

! Start air conditioner. Point the remote controller at the fan coil and press ON/OFF button.

! Select the operational mode. Press either "Cool", "Dry" or "Vent" button to select the desired

mode.

! Set temperature. Press "+" or "-" button to set desired temperature.

! Select fan speed. Press "Fan" button to select desired fan speed.

! Set airflow position. Press "Vane" button to adjust airflow direction or to set vane to auto

swing.

! Set Timer. If required, press "Time" button to set timer On or Off. After pressing "Time"

button, the Time display on the LCD will start to flash. Press "+" or "-" to set the time before

flashing stops.

! Sleep mode. Select sleep mode by pressing "Time:" button until "Sleep" appears on the LCD

display. Sleep mode allows the air conditioner to raise the room temperature by up to 2°F from

set temperature while you sleep to save power.

Page 18

MODEL: AMW 45, 60

! Start air conditioner. Point the remote controller at the fan coil and press "ON/OFF" button.

! Select operation mode. Press "Mode" button to select any of the following modes: "Cool",

"Dry" or "Vent".

! Temperature setting. Press "+" or "-" button to set desired temperature.

! Select fan speed. Press "Fan control" button to select desired fan speed.

! Select airflow direction. Press "Louver control" button to set position of horizontal vane or

set it to auto swing.

! Set Timer. If desired, set timer on or off by pressing "Time Control" button, followed by "+" or

"-" button to select time before air conditioner starts or stops operating.

! Sleep mode. Press "Sleep" button to select sleep mode. A s the name suggests, it is used

during sleeping. The room temperature would be adjusted by 2°F up from set temperature to

save power.

2) FUNCTIONS

AUTO

This allows the air conditioner to operate automatically at a pre-set temperature. Cooling will be

affected when room temperature is above 82°F (28°C).

COOLING

When activated, the fan will automatically operate at high speed for 5 minutes before operating at the

set speed. During cooling if the humidity in the room is very high (RH above 80 %), condensation

may occur at the air discharge louver. It is advisable to operate the fan at high speed under this

condition.

DRYING

When activated, the air conditioner will operate on and off intermittently. The fan will automatically

operate at low speed. Fan speed, temperature settings and sleep mode will be by-passed. This

function will not operate if the room temperature is lower than 59°F (15°C).

FAN ONLY

The following speed can be selected. Low mid high auto. At auto, the fan speed will be

automatically selected by the micro-processor, depending on the difference between factory pre-set

and room temperature.

TIMER

This feature allows the air conditioner to be automatically SWITCH ON or SWITCH OFF after a predetermined time.

CLOCK

This is for setting the real time to facilitate the operation of the timer.

Page 19

CARE AND MAINTENANCE

! The air conditioner requires proper care and maintenance for efficient operation.

A periodic inspection and cleaning may be available from your dealer or

distributor. Be sure to ask about this service at the time of installation. The user

can also perform some of the care and maintenance. Please follow these

instructions.

! Be sure to disconnect the power supply before undertaking any inspection.

! Open the RETURN AIR GRILLE and remove the air filters. Clean by washing or

with a vacuum cleaner. Dry the filters before putting them back on the unit.

! Do not operate the air conditioner without the air filters in it. Remember that the

filters protect the coil from getting dirty. A dirty coil is more difficult to clean than a

dirty filter. Clean the filters at least twice a month and more if the environment is

dusty.

! CLEAN THE UNIT: Clean with a wet soft cloth. Do not wash the air conditioner.

Never use the following to clean the air conditioner.

• Hot water above 104°F (40°C).

• Volatile substances like benzene, gasoline, thinner and other solvents.

END OF SEASON:

! When the air conditioner is to stop operating for prolonged periods, for example,

at the end of the season, please follow these instructions before shut down.

Operate the unit at the following setting for 2 to 3 hours.

• Type of Operation: Cool

• Temperature setting: 86°F (30°C).

• This will dry up any residual water in the unit.

• Remove the batteries from the Remote Controller.

! Use car wax on the painted surface of the outdoor unit.

START UP: Operation after prolonged period

! Clean the unit and the filter as described above.

! Operate the FAN ONLY for half a day to remove any moisture that may have

accumulated inside the unit.

Page 20

TROUBLE SHOOTING

The following are normal and should not be treated as defects.

! Hissing sound, like flow of water from the unit. This is the sound of the

refrigerant at the expansion device, which can be heard from time to time

depending on the indoor and outdoor ambient conditions.

! The unit does not cool for a few minutes after it restarts. This is because a time

delay mechanism built into the unit prevents the compressor from starting for a

few minutes. This is to protect the compressor from breakdown.

! Smell from the supply air: The coil and filters absorb the smell from the

environment and the supply air may also have the same smell. This usually

happens in places where heavy cigarette smoke exists in the air.

BEFORE CALLING FOR SERVICE, PLEASE CHECK THE FOLLOWING:

Air conditioner does not operate:

! Check the thermostat setting to ensure that it is not set above the room

temperature.

! Check the circuit breaker.

! Check the power supply to ensure that it is not interrupted.

Cooling is insufficient:

! Check and clean the filters if necessary.

! Check that the thermostat setting is not above room temperature for cooling.

! Check that all windows and doors are closed.

! Check if there are sources of heat present in the room, like stove burners.

! Check that the fan speed is set to the HIGH setting

! If the system still does not operate or does not provide sufficient cooling, call for

a professional serviceman.

Page 21

AMW/AMC 25

Page 22

AMW/AMC 30

Page 23

AMW/AMC 45 & 60

Page 24

SERVICE NOTES

AITONS' EQUIPMENT INC.

Guelph, Ontario

www.aitons.com

e-mail: info@aitons.com

Printed in Canada 03/03

Loading...

Loading...