Philips AMC S, AMC 25, AMC 30, AMW, AMC 45 User Manual

...

Wall Mount Split Units

AMW/AMC 25, 30, 45 &60

by AITONS'

AMW / AMC SERIES

Installation, Operation

And Maintenance Manual

Please read this manual before

installing and operating the unit

CONTENTS

INSTALLATION INSTRUCTIONS

! Tools / Supplies

! Safety considerations

! Selection of location

! Recommended height and length

! Installation Method

! Refrigerant piping & drainage

! Electrical wiring

OPERATING INSTRUCTIONS

! Operating tips

! Product description

! Auxiliary control

! Remote control operation

! Operating instructions

! Care and maintenance

! Trouble shooting

INSTALLATION INSTRUCTIONS

TOOLS AND SUPPLIES

The following tools are needed

for installation.

1. Level

2. Hole Saw

3. Core bits

4. Hammer

5. Drill

6. Torque wrench

7. Adjustable wrench

8. Flat head screwdriver

9. Philips head screwdriver

10. Wire stripper

11. Measuring tape

12. Ratchet set

13. Flaring tools

14. Tube cutter

The following materials are

required:

1. Correct size copper tubing

2. Correct size drain pipe

3. Sleeve and bush

4. Vinyl tape

5. Saddle & Clamps to support

refrigerant piping

6. Power supply cable

7. Insulation material

8. Putty or similar sealant

SAFETY CONSIDERATIONS

Installation and servicing of air conditioner can be hazardous due to high refrigerant pressure

and electrical components inside the unit. Only fully trained, qualified and certified service

personnel should install, repair and service the air conditioner.

While working on the air conditioner, all precautions in the literature, tags and labels attached to

the unit and all other general safety precautions should be carefully observed. Please follow all

safety codes, wear safety glasses and work gloves. Also use quenching cloth for brazing

operations.

It is highly recommended that this manual be read completely before installing and operating the

system.

WARNING: The main power breakers to the unit , including its accessory or

parts, should be turned off before performing service or maintenance operations

on the unit. Dangerous high voltage can cause electric shock, serious personal

injury or even death.

SELECTION OF LOCATION

Select a convenient location where:

INDOOR UNIT

! The cool air can reach every corner of the

area to be cooled.

! The unit is away from any direct heat

source

! Easy and short routing of the refrigerant

and drain pipes to the exterior.

! There are no flammable gas, alkaline or

acid present in the air.

! Air circulation is not obstructed, preventing

good air circulation.

! The structure where the unit is installed

should be strong enough to support the

weight of the unit and also prevent any

vibration during operation of the unit.

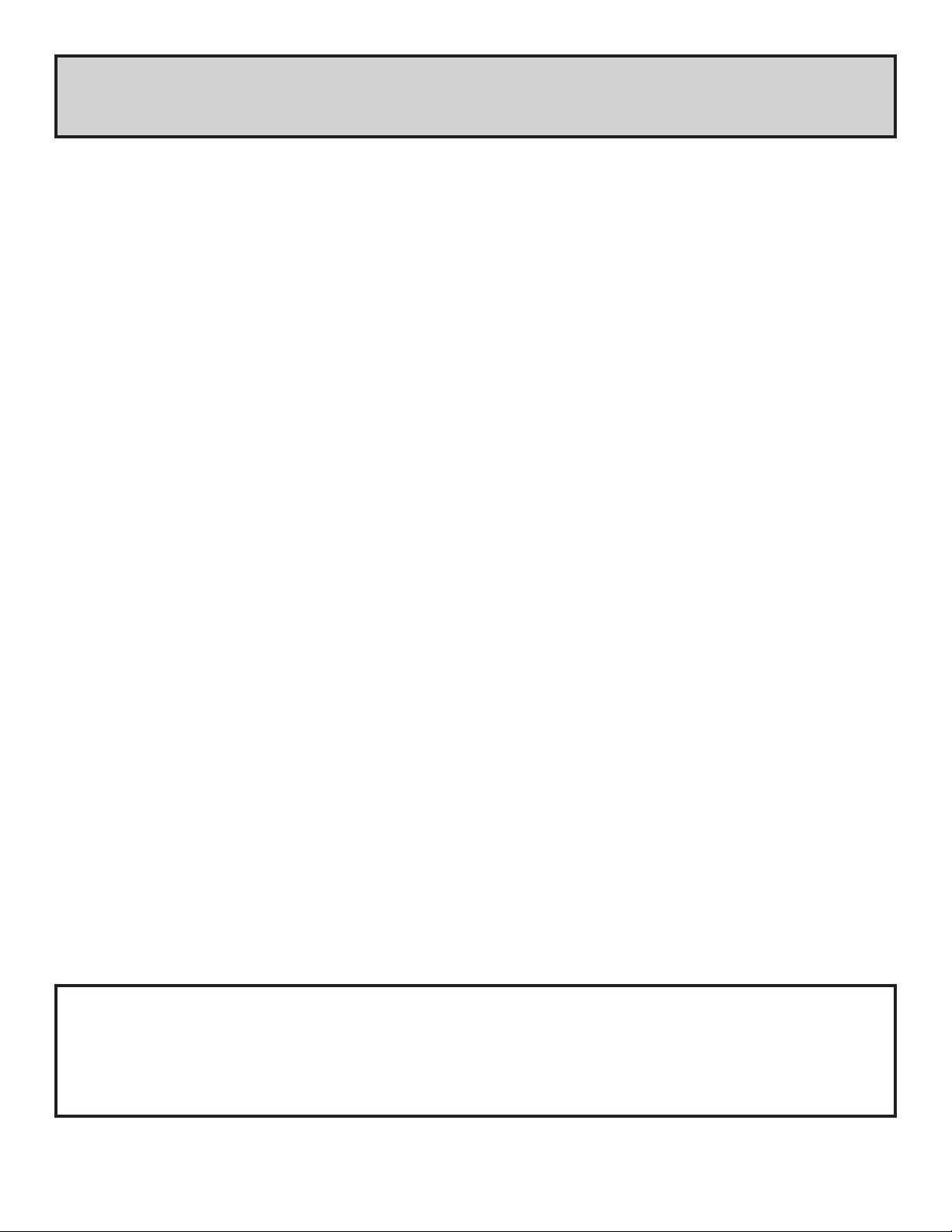

! Figure on the right shows the spacing to the

nearest wall.

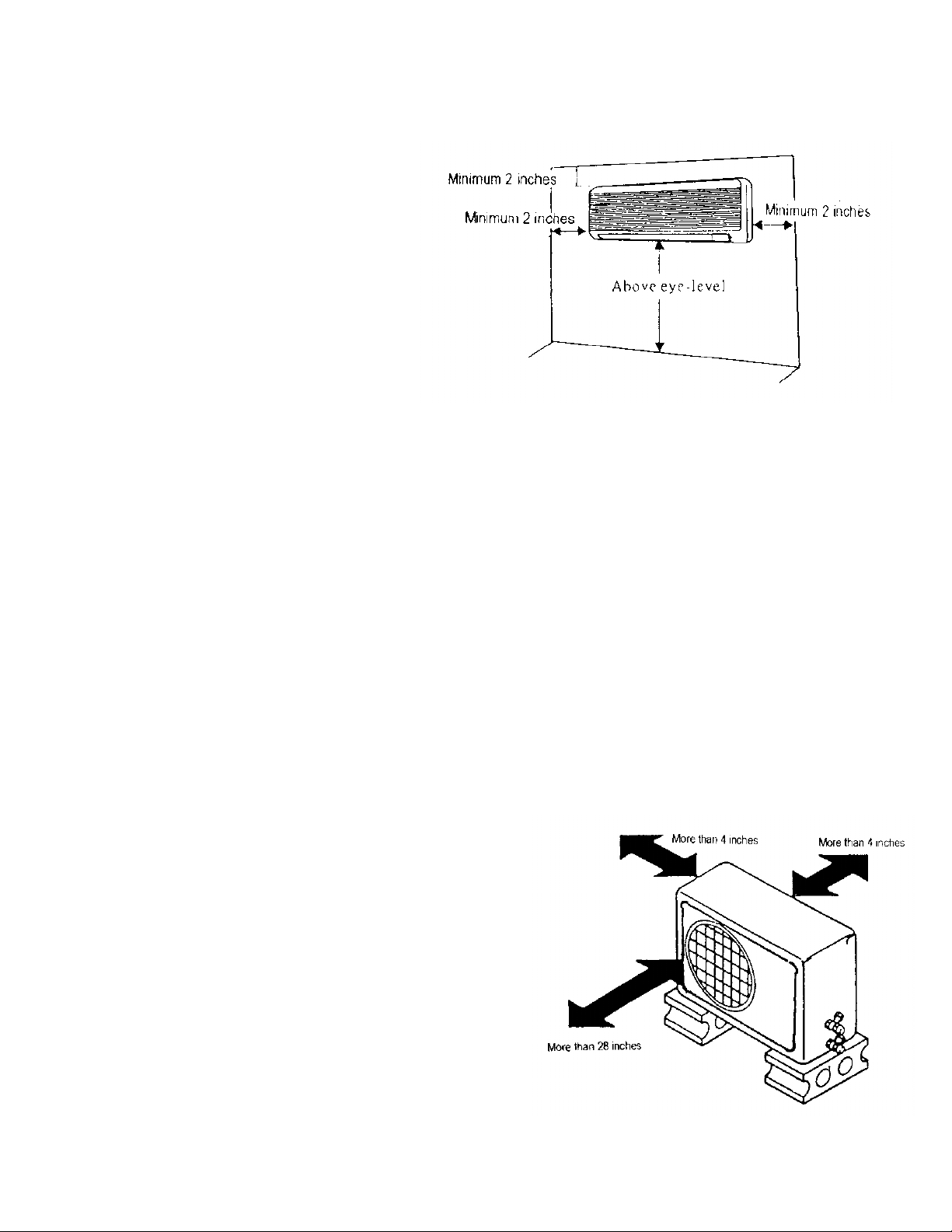

OUTDOOR UNIT:

! The condensing unit should be located as

close as possible to the fan coil.

! The air inlet shall be located at least 4” from

the wall or other obstruction for unrestricted

airflow.

! The air outlet shall be located so as to

direct discharged warm air away from the

building. (Avoid low overhanging roofs to

avoid re-circulation of condenser discharge

air on vertical discharge models.)

! Mount the unit on a sturdy base.

! Figure on the right shows the spacing to be

provided.

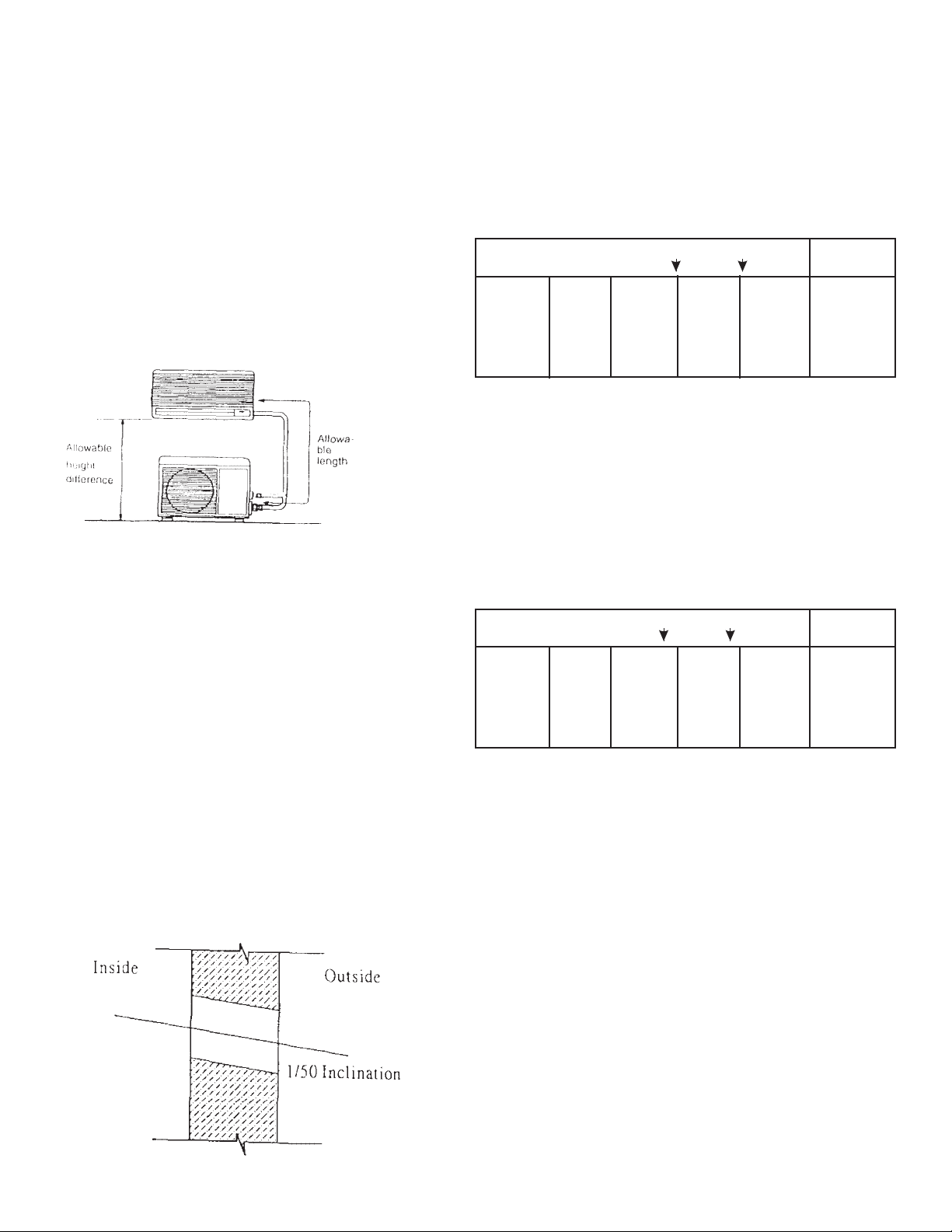

RECOMMENDED HEIGHT AND LENGTH

If the refrigerant piping is longer than the

recommended length, or if the height

difference between the indoor and outdoor

unit is greater than recommended, the

capacity will drop and the compressor could

malfunction. Select an installation location

that is within the recommended parameters.

Cooling

capacity

7,500 to

9,000

Btuh

Recommended height difference is 23 ft or less

*Evacuate refrigerant lines

An installation with a piping length of 23 ft. or less is desirable.

(1)

If this is not possible, the maximum piping length can be

extended to 50 ft. by charging the system with additional

refrigerant. However, cooling and heating capacity will be

reduced.

• Additional charge volume = (piping length - 23 ft.) x 0.2 oz.

& HEIGHT RECOMMENDED)

Add

charge

(MAXIMUM PIPING LENGTH

Piping length (feet)

Not

needed

23 50

Installation

Needed

(1)

not

recom-

mended

Notes

Unit

Piping

Diameter

1/4" and

3/8”

INSTALLATION METHOD

HOLE DRILLING: After deciding the

method your unit will be installed, a hole to

route the connecting tubes and wires to the

outdoor unit is to be drilled on the wall. The

hole must be lower than the point where the

drainpipe attaches to the drain pan of the

unit. It should also be slightly declined

towards the outside.

Piping length (feet)

Cooling

capacity

18,500 to

36,000

Btuh

Recommended height difference is 23 ft or less

*Evacuate refrigerant lines

An installation with a piping length of 33 ft. or less is desirable.

(2)

If this is not possible, the maximum piping length can be

extended to 55 ft. by charging the system with additional

refrigerant. However, cooling and heating capacity will be

reduced.

• Additional charge volume = (piping length - 33 ft.) x 0.2 oz.

Add

charge

needed

Not

33 55

Needed

(2)

Installation

not

recom-

mended

Notes

Unit

Piping

Diameter

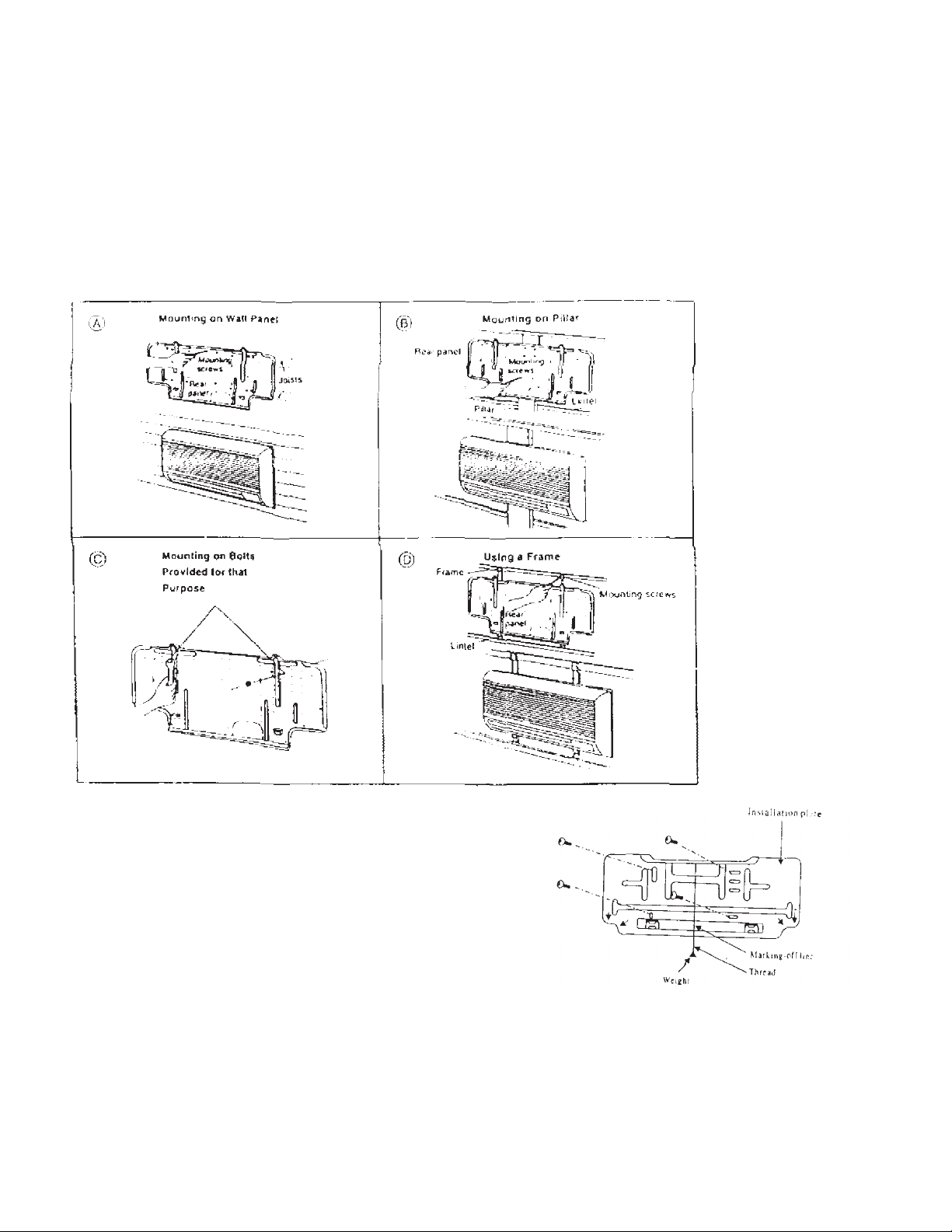

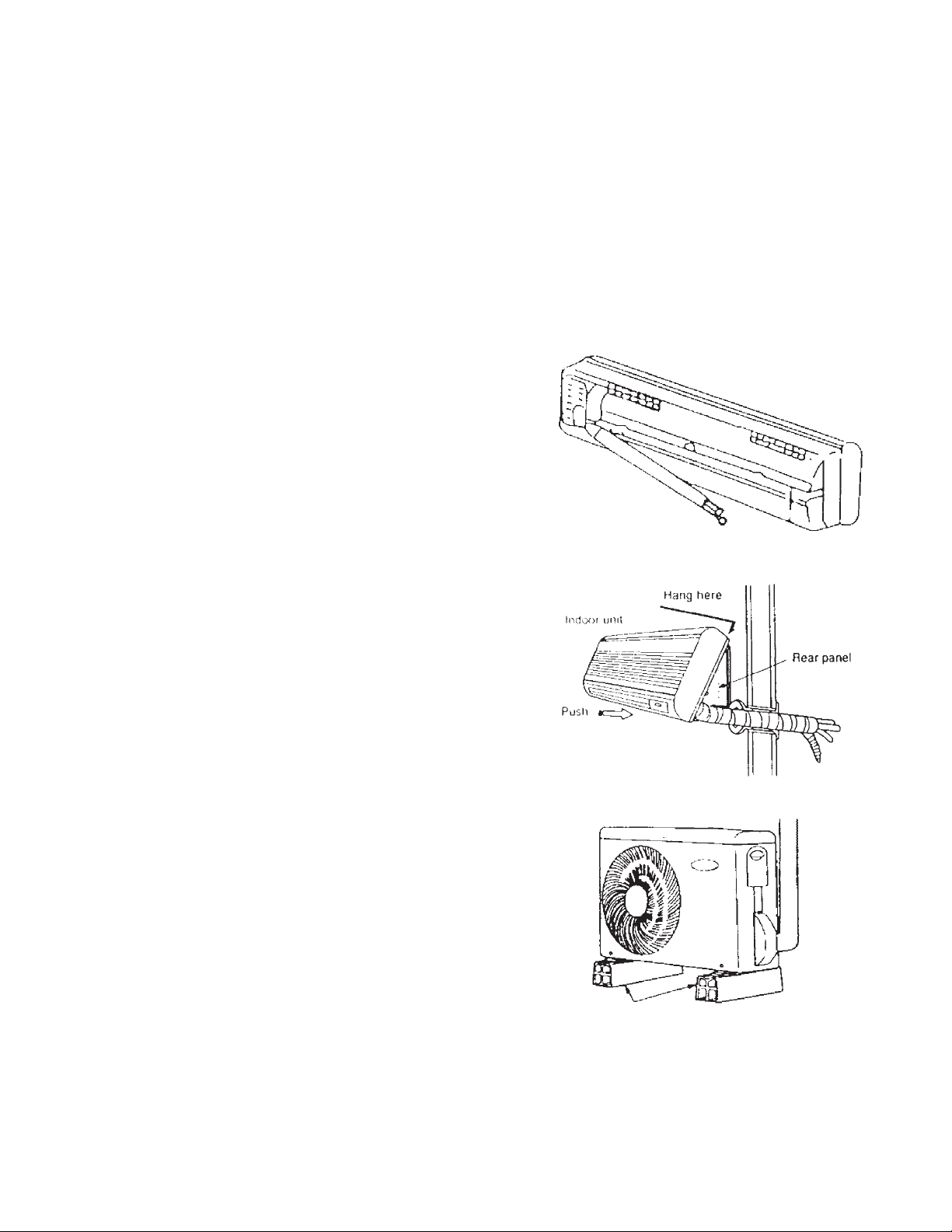

MOUNTING INSTALLATION PLATE:

The fan coil can be installed using any of the four methods described below.

Determine which is the most suitable method.

Position the installation plate on the wall

making sure that it is parallel to the ground.

This can be done by aligning the markingoff line with a thread and weight as shown

in figure on the right. This is to ensure that

the condensate water does not overflow

from the drain pan.

Mount the installation plate with the 4

screws provided. (If the unit is to be

mounted on a concrete wall, consider using

anchor bolts instead of the screws provided.

INSTALLATION OF FAN COIL:

The extended liquid and suction pipes and drain hose are hidden inside a slot at the

back of the fan coil. This allows the hole on the wall to be either on the right or left side

of the fan coil.

RIGHT SIDE HOLE POSITION: The piping and drain hose are routed straight through

the hole.

LEFT SIDE HOLE POSITION: The

piping and drain hose run from the

right side to the left side of the unit,

hidden in the slot at the back of the

unit before routing through the hole

on the left side of the unit.

MOUNTING FAN COIL UNIT:

Hook the fan coil onto the upper

portion of the installation plate

ensuring that it sits securely on the

installation plate.

Press the lower portion of the unit

against the installation plate until the

hooks at the back of the unit are

securely engaged with the installation

plate.

MOUNTING CONDENSING UNIT:

Do not place the condensing unit

directly on the ground. It should

preferably be placed on a slightly

raised platform to prevent rain water

from splashing into it. Also ensure

that it is level. Avoid installing the unit

in places where flammable gases

may be present.

beams or blocks

If necessary, due to the placement conditions,

rubber cushions can be placed underneath the

outdoor unit.

REFRIGERATION PIPING & DRAINAGE

PREPARATION OF PIPING

Fan coil and side discharge condensing units are equipped with flare connections. Improper flaring

and brazing may cause refrigerant to leak out of the system. Follow these instructions carefully in

preparing the refrigerant piping.

! Ensure that all piping is of the correct size.

! Measure the distance between the indoor and outdoor units' refrigerant connections, together

with all the curves necessary. Add a few inches as slack.

! Lay the piping as straight as possible on a flat surface and with a pipe cutter, cut the piping

according to the measured length.; Do not tighten the cutter excessively during cutting as this

may cause the pipe to deform. Do not use hacksaw or similar tools to cut the pipe, as it results

in metal shavings getting inside the pipe. This also makes proper flaring impossible.

! Use a reamer to remove burrs from cut edges. Hold the pipe ends upside down to prevent

metal powder from getting into the pipe.

Pipe

Reamer

Note:

As the pipe is round, cutting should be

performed on a straight section. Also,

do not apply too much force with the

blade of the pipe cutter.

Pipe cutter

Keep pipe facing downward

when removing burrs.

! For connection to flare settings, the pipe has to be flared. Remove the flare nut from the unit

and insert it onto the piping.

! Fit the pipe into the bar of the flare tool, about 0.5 mm higher than the surface of the bar.

! Center the flare punch carefully on the pipe and turn gradually to widen the pipe. Check the

finish of the flare to ensure even flaring.

! Cover the flared ends with tape to prevent dust from entering.

Handle

Flaring tool

Flaring bar

Length of periphery portion

Flare nut

L should be constant

0.635 (1/4”) only 0.952 (3/8”) and larger

Approx. 1 mm

0.5 mm

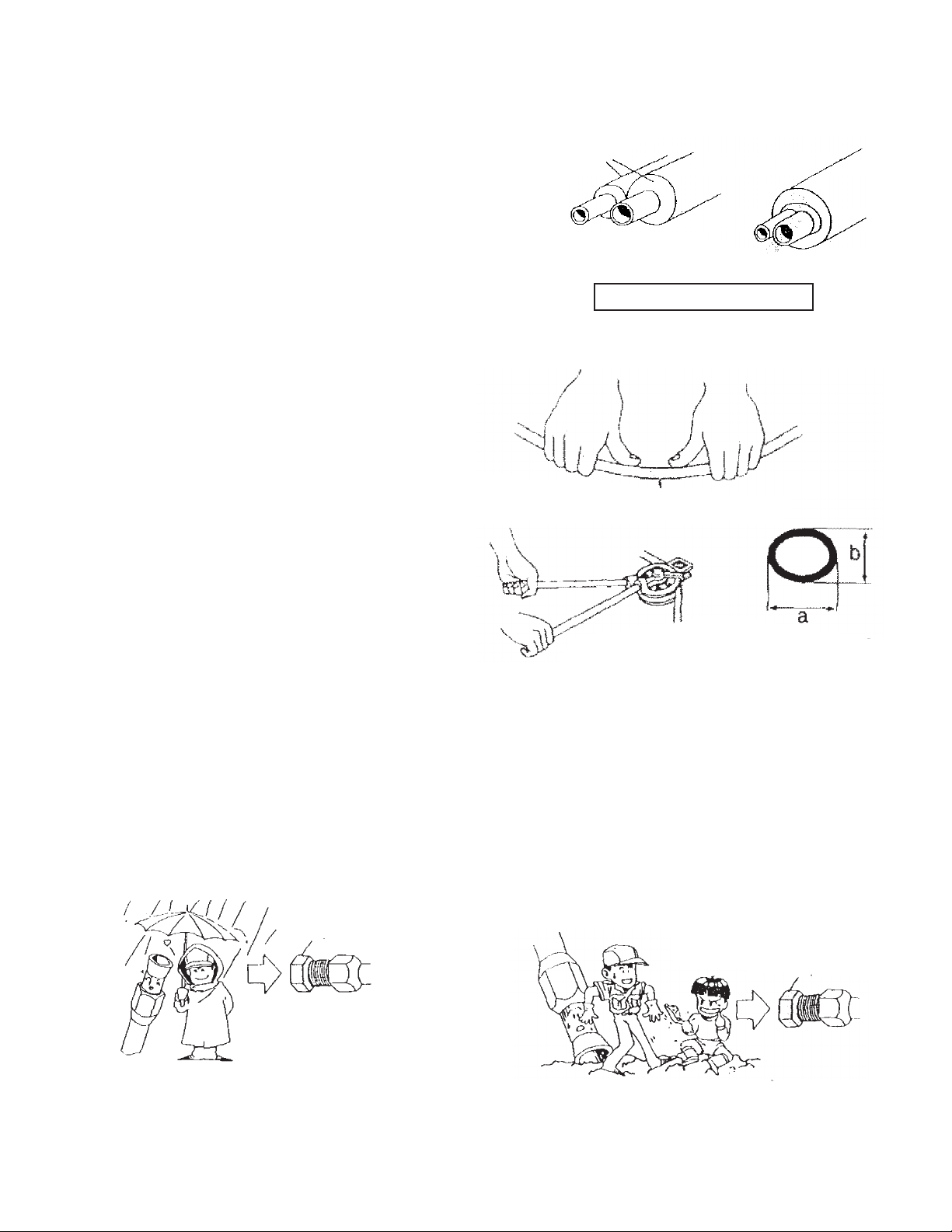

PIPING INSULATION

Liquid and suction lines must be insulated

separately. In a cooling only type air

conditioner, both pipes become cold during

operation. This can cause moisture to

condense on the surface of the pipes,

resulting in heat loss.

PRECAUTIONS WHEN BENDING

PIPES

! The air conditioner's performance

will suffer if the piping is crushed.

! Bend pipes using the pads of your

thumbs to prevent them from

collapsing (See picture on the right.)

! Use a pipe bending tool to bend pipe

wider than 1/2" in diameter.

Insulation

Narrow Pipe

Bend with pads of thumbs

Wide Pipe

Common insulation

Separate insulation is essential

Pipe bending tool

FLARE FITTING CONNECTION. There are 3 piping rules:

(a) DRY: Never allow any water to get

inside the piping.

Cap

Keep cap attached until immediately

before making piping connections.

(b) CLEAN: Never allow dirt, sand or other

foreign particles to get inside the piping.

b/a = 0.7 or more

Cap

Keep cap attached until immediately

before making piping connections.

Loading...

Loading...