Page 1

Colour Television Chassis

FM23, FM24, FM33

AA

Supplement ALIS PDP Repair Manual

Contents Page

1 Technical Specifications, Connection,

and Chassis Overview 2

2 Safety Instructions, Warnings, and Notes 3

3 Directions for Use (Not Applicable) 4

4 Mechanical Instructions 4

5 Service Modes, Error Codes, and Faultfinding 9

6 Block Diagrams, Testpoint Overview, and

Waveforms 31

(Not Applicable)

7 Circuit Diagrams and PWB layouts 33

(Not Applicable)

8 Alignments 33

9 Circuit Descriptions 34

List of Abbreviations 35

10 Spare Parts List (Not Applicable) 36

11 Revision List 36

©

Copyright 2004 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by LM 0464 Service PaCE Printed in The Netherlands Subject to modification EN 3122 785 14580

Page 2

EN 2 ALIS-PDP Suppl.1.

Technical Specifications

1. Technical Specifications

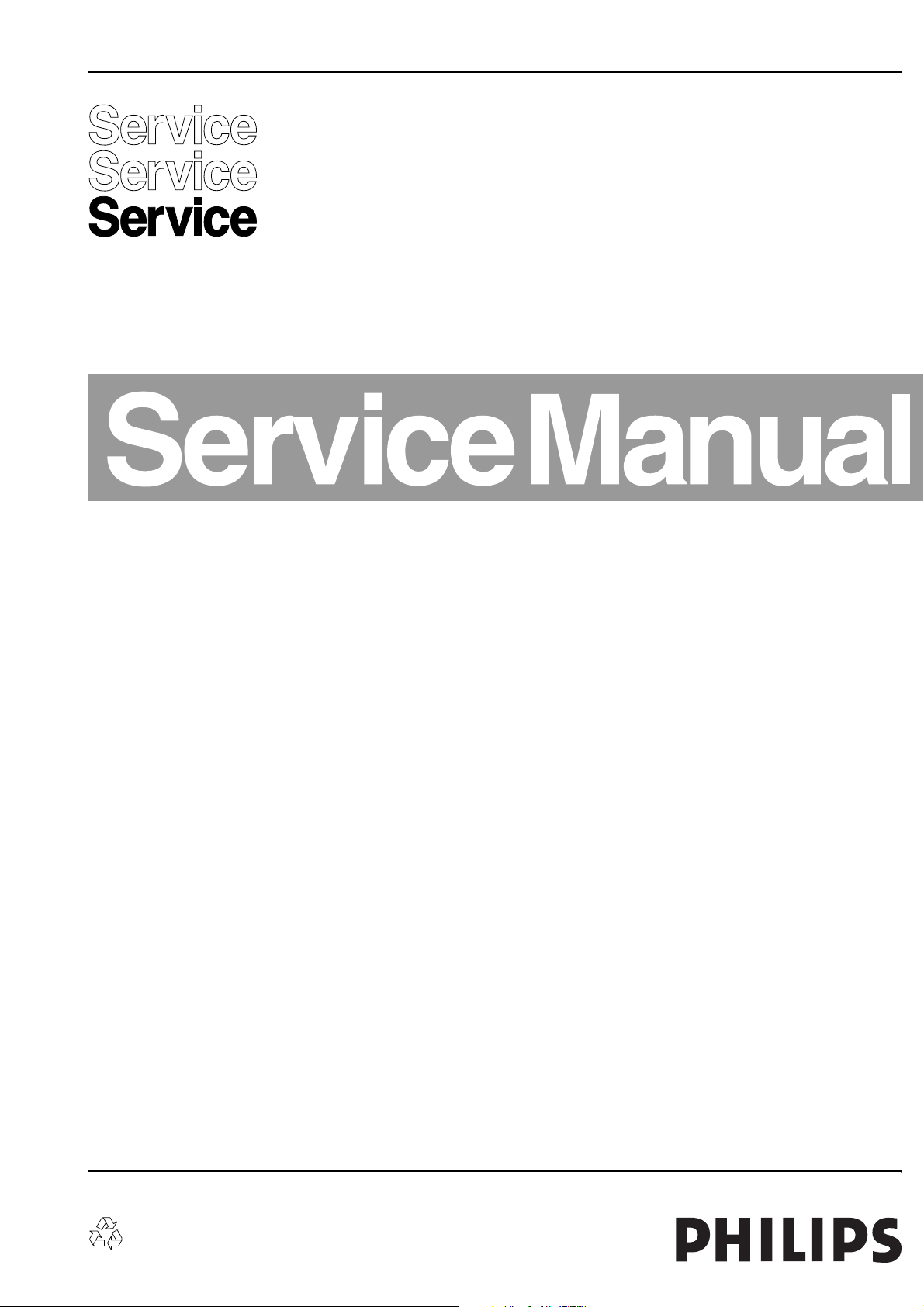

1.1 Chassis overview

Y-SUS BOARD

SCAN MODULE

ABUSL BOARD

LOGIC BOARD

ADM1 ADM2 ADM3 ADM4 ADM5 ADM6 ADM7 ADM8

Figure 1-1

PSU BOARD

X-SUS BOARD

XBB

ABUSR BOARD

ADRESS MODULE (ADM)

E_14580_001.eps

310304

Page 3

Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

EN 3ALIS-PDP Suppl. 2.

2.1 Safety instructions h

It is not allowed to operate the FTV-set without glass plate. One

function of this glass plate is to absorb Infrared Radiation.

Without this glass plate the level of Infrared Radiation produced

by the plasma display could damage your eyes.

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer ( in this particular case a

transformer of ≥ 800 VA);

– safety components, indicated by the symbol h ,

should be replaced by components identical to the

original ones;

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– Note: The wire trees should be routed correctly and

fixed with the mounted cable clamps.

– The insulation of the mains lead should be checked for

external damage.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets that have a mains isolated power supply). This

check can be done as follows:

• unplug the mains cord and connect a wire between

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ;

• switch off the TV and remove the wire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

2.2 Warnings

1. ESD w

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling during

repair can reduce life drastically. When repairing, make sure

that you are connected with the same potential as the mass of

the set by a wristband with resistance. Keep components and

tools also at this same potential.

1. Available ESD protection equipment:

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

2. Never replace modules or other components while the unit

is switched on.

3. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

1. A glass plate is positioned before the plasma display. This

glass plate can be cleaned with a slightly humid cloth. If

due to circumstances there is some dirt between the glass

plate and the plasma display panel it is recommended to do

some maintenance by a qualified service employee only.

2. Never disconnect the power display cable when the set is

operating

3. With DST no failures (error-codes) can be red, when the

set is in Service-mode.

4. If DST reacts with "error 2", there is no communication

between set and DST. Note that IR-transmitter LED is

positioned at right side of IR-receiver eye of the E-box.

Take into account that receiver-LED on DST is positioned

not in the middle but at the left side. Point corresponding

LED"s to each other. In case the amount of Infrared

produced by the screen pollutes the communication, the

set can be set in Standby-mode. Then still the errormessages can be retrieved.

2.3.1 Notes on safe handling of the plasma display

Notes to follow during service

• The work procedures shown with the Note indication are

important for ensuring the safety of the product and the

servicing work. Be sure to follow these instructions.

• Before starting the work, secure a sufficient working space.

• At all times other than when adjusting and checking the

product, be sure to turn OFF the main POWER switch and

disconnect the power cable from the power source of the

display (jig or the display itself) during servicing.

• To prevent electric shock and breakage of PC board, start

the servicing work at least 30 seconds after the main power

bas been turned off. Especially when installing and

removing the power supply PC board and the SUS PC

board in which high voltages are applied, start servicing at

least 2 minutes after the main power bas been turned off.

• While the main power is on, do not touch any parts or

circuits other than the ones specified. The high voltage

power supply block within the PDP module has a floating

ground. If any connection other than the one specified is

made between the measuring equipment and the high

voltage power supply block, it can result in electric shock or

activation of the leakage-detection circuit breaker.

• When installing the PDP module in, and removing it from

the packing carton, be sure to have at least two persons

perform the work white being careful to ensure that the

flexible printed-circuit cable of the PDP module does not

get caught by the packing carton.

• When the surface of the panel comes into contact with the

cushioning materials, be sure to confirm that there is no

foreign matter on top of the cushioning materials before the

surface of the panel comes into contact with the cushioning

materials. Failure to observe this precaution may result in,

the surface of the panel being scratched by foreign matter.

• When handling the circuit PC board, be sure to remove

static electricity from your body before handling the circuit

PC board.

• Be sure to handle the circuit PC board by holding the large

parts as the heat sink or transformer. Failure to observe

this precaution may result in the occurrence of an

abnormality in the soldered areas.

• Do not stack the circuit PC boards. Failure to observe this

precaution may result in problems resulting from scratches

on the parts, the deformation of parts, and short-circuits

due to residual electric charge.

• Routing of the wires and fixing them in position must be

done in accordance with the original routing and fixing

configuration when servicing is completed. All the wires

are routed far away from the areas that become hot (such

as the heat sink). These wires are fixed in position with the

wire clamps so that the wires do not move, thereby

ensuring that they are not damaged and their materials do

not deteriorate over long periods of time. Therefore, route

the cables and fix the cables to the original position and

states using the wire clamps.

• Perform a safety check when servicing is completed. Verify

that the peripherals of the serviced points have not

undergone any deterioration during servicing. Also verify

that the screws, parts and cables removed for servicing

purposes have all been returned to their proper locations in

accordance with the original setup

Page 4

EN 4 ALIS-PDP Suppl.3.

Directions for Use

3. Directions for Use

Not Applicable

4. Mechanical Instructions

Index of this chapter:

• Service Positions Monitor

• Rear Cover Removal

• Service Position Panels

• PDP and Glass Plate Replacement

• Re-assembly

Note: Figures below can deviate from the actual situation, due

to different set executions.

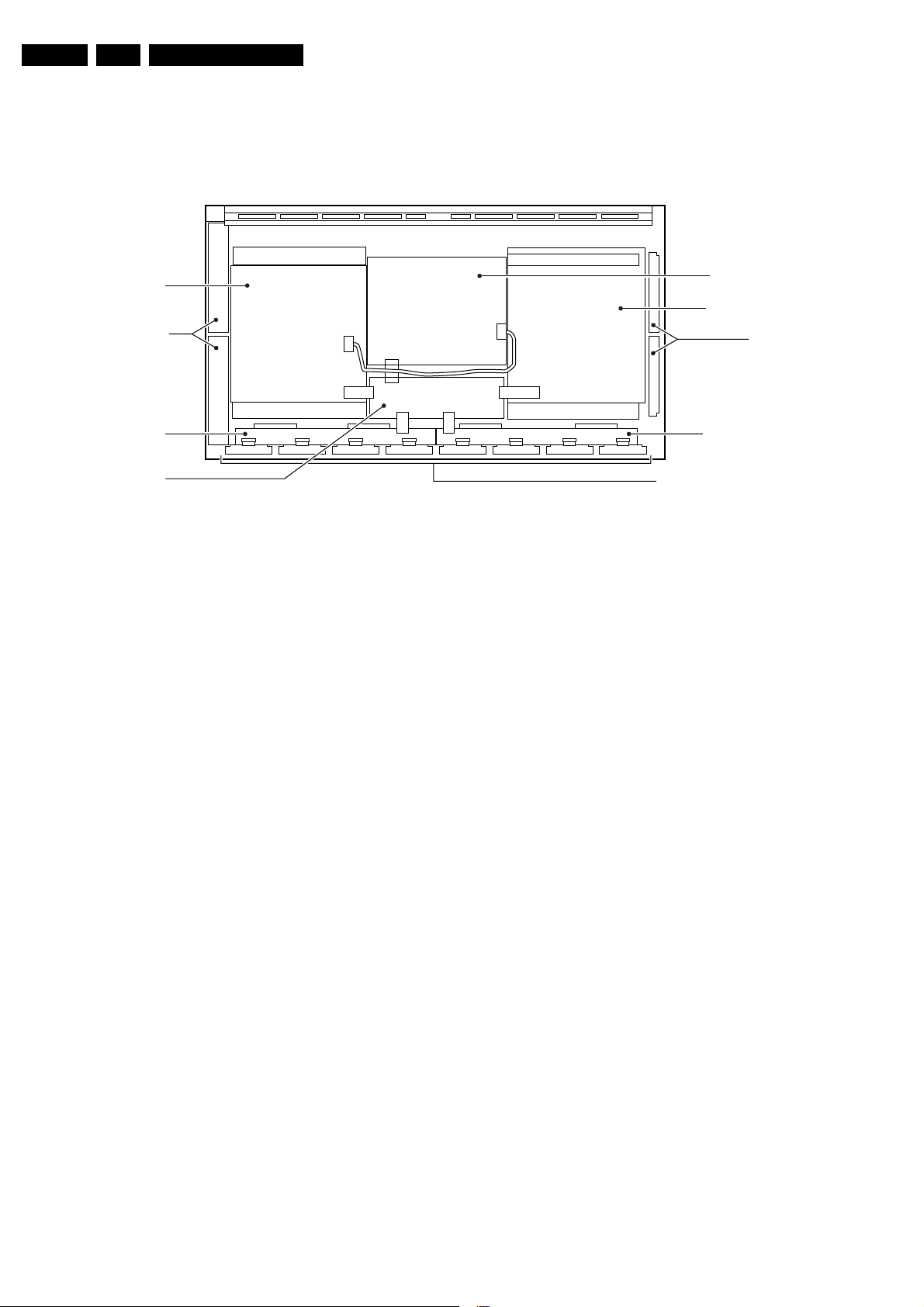

4.1 Service Positions Monitor

4.1.1 Transport Cushions

position. A better solution to access the IR-LED and/or ON/

OFF switch is to make some holes in the stands at the

position of the LED and switch. Do not make the holes to

big, as this will influence the strength of the stands.

4.1.2 Aluminium Stands

CL 36532051_001.eps

040703

E_14580_028.eps

310304

Figure 4-1 Transport cushions

First, put the monitor in its service position. Therefore,

disconnect all cables connected to the monitor and take the

monitor of the wall (or tabletop stand). Then, place the monitor

in the re-enforced transport cushions that function also as

service stand (you can order them separately under code 3122

126 40612). See figure "Transport cushions".

Notes:

• There are no special "re-enforced service stands". The

cushions used in the factory packaging are already made

of reinforced material.

• Always keep in mind that the stands are only designed to

keep the monitor in service position as long as the monitor

is being serviced. The stands are NOT designed to keep

the monitor in the upright position for more then two days.

• After the monitor is serviced, or when nobody is working on

the monitor (e.g. in the weekend), it should be removed

from the stands and laid down on a cushion or other

support system to prevent it from falling.

• Worn out stands should be replaced by new ones (monitor

will tilt to much forward).

• Never leave the monitor alone when the stands are not fully

pressed on its place.

• It is possible to move the right stand a bit to the right so that

you can access the IR-LED and ON/OFF switch, but the

monitor can then not be left alone because the stands are

NOT designed to carry the weight of the monitor in that

Figure 4-2 Aluminium stands

The aluminium stands (order code 3122 785 90480) can be

mounted with the back cover removed or still left on. So, the

stand can be used to store products or to do measurements. It

is also very suitable to perform duration tests without taking

much space, without having the risk of overheating and no risk

of products falling. The stands can be mounted and removed

quickly and easy with use of the delivered screws that can be

tightened and loosened manually without the use of tools. See

figure above.

Note: Only use the delivered screws to mount the monitor to

the stands.

Page 5

Mechanical Instructions

EN 5ALIS-PDP Suppl. 4.

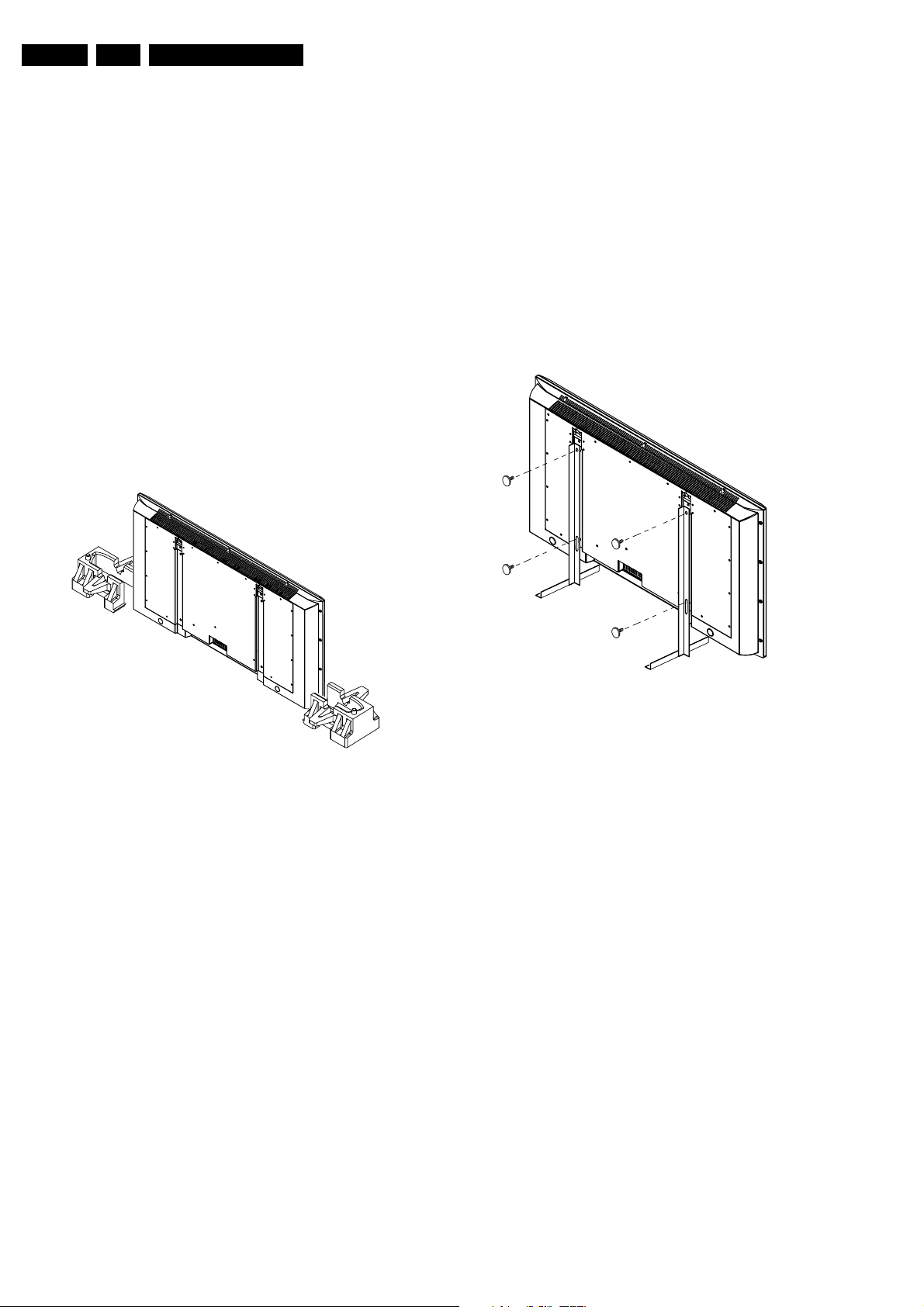

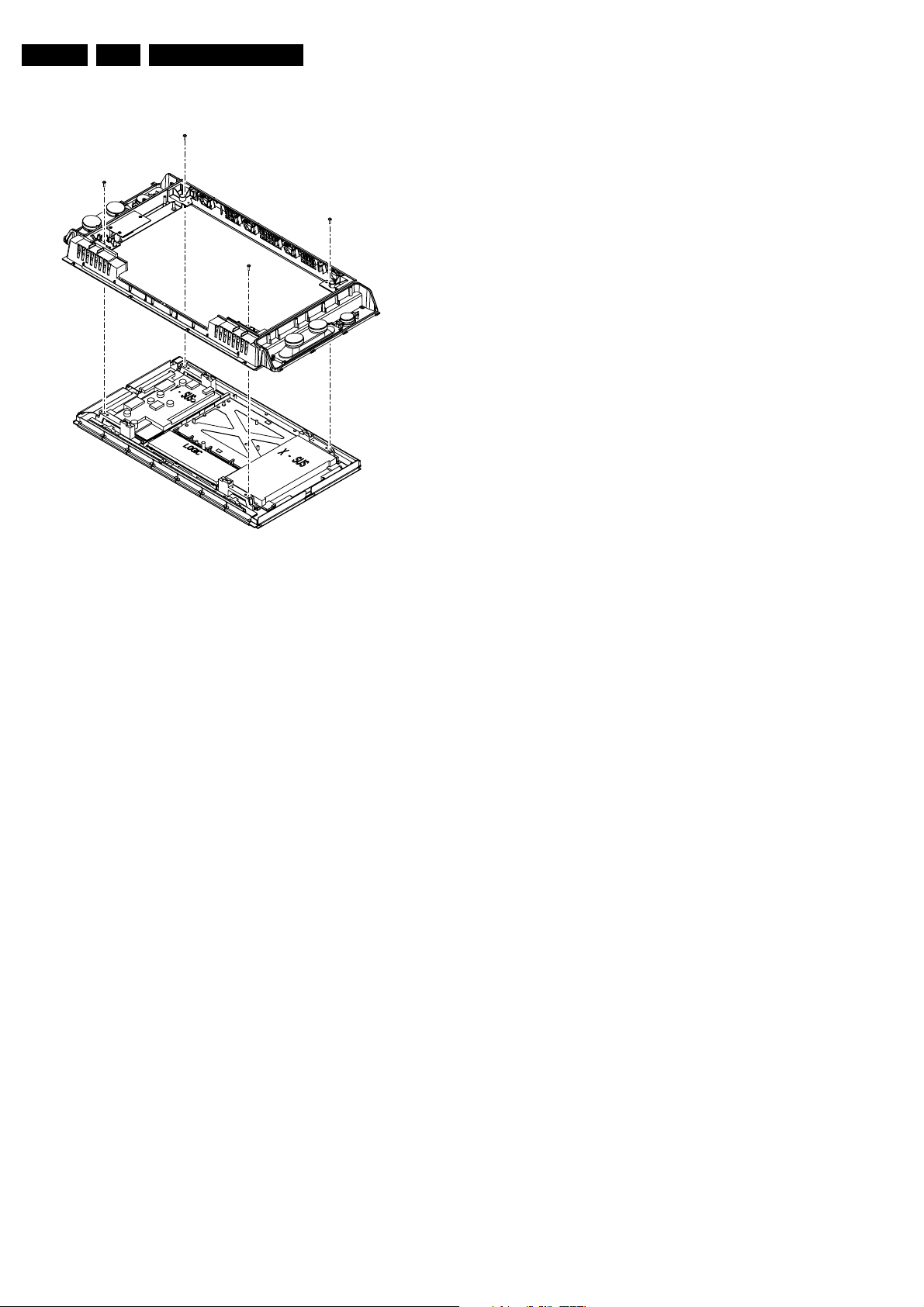

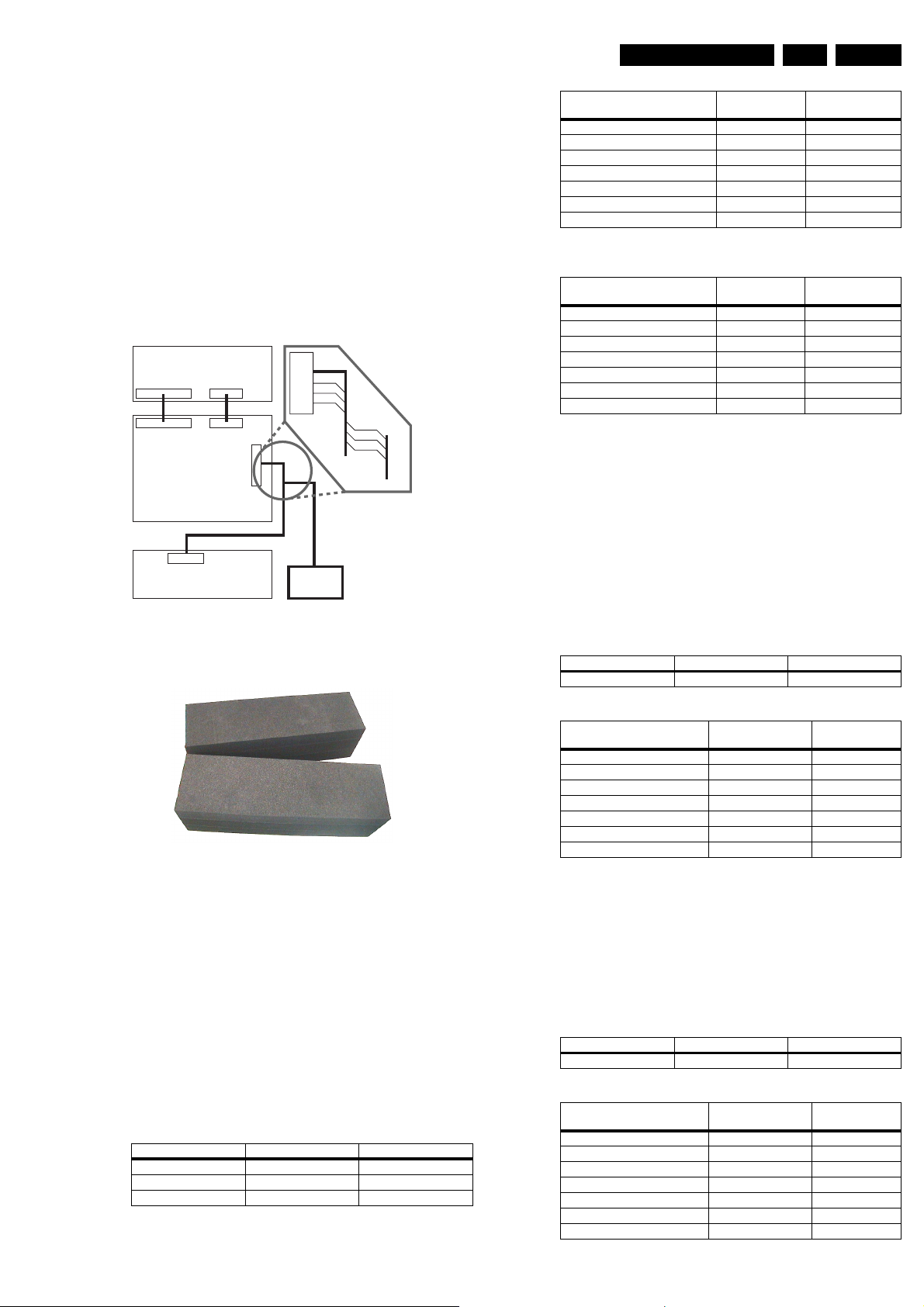

4.1.3 Foam Bars

CL 36532051_002.eps

Figure 4-3 Foam bars

The foam bars (order code 3122 785 90580) can be used for

all types and sizes of FTVs and LCD TVs and can even be used

to e.g. exchange a CRT of a normal TV. By laying the plasma

or LCD TV flat on the (ESD protective) foam bars, a stable

situation is created to perform measurements and alignments.

See figure "Foam stand".

By first placing a mirror flat on the table under the TV you can

easily see if something is happening on the screen. The bars

are also handy to replace the screen (PDP or LCD).

190603

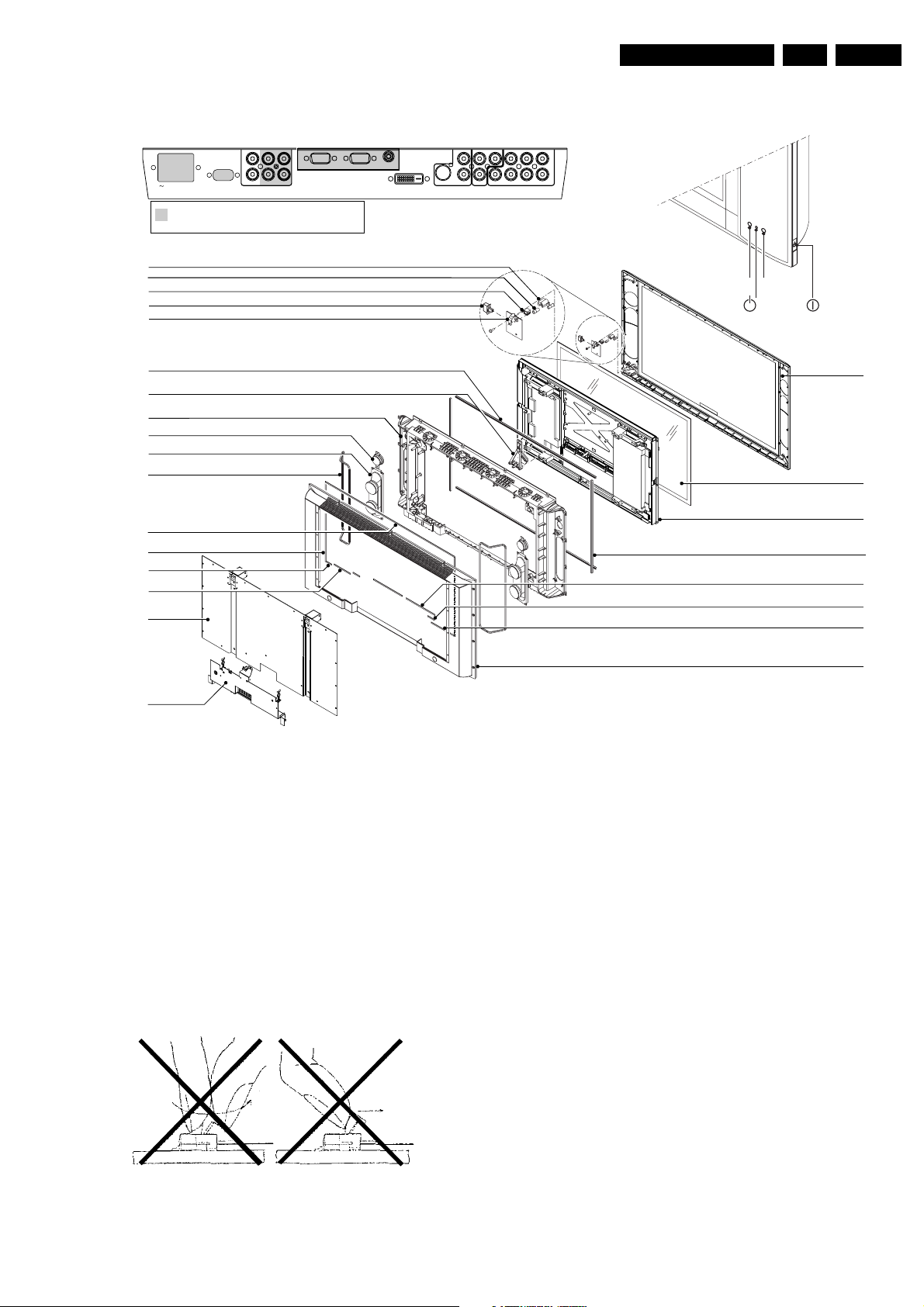

4.3 PDP and Glass Plate Replacement

Shielding frame

Front displayFoam cushion

Figure 4-5 Exchanging the glass plate

CL 16532099_046.eps

270901

4.2 Rear Cover Removal

Figure 4-4 Rear cover removal

To be able to access or measure the panels, remove the rear

cover (metal back plate):

1. Remove all fixation screws from the back plate, as

indicated in figure above (the amount of screws that need

to be removed differs from the amount in the figure above).

2. Remove the metal back plate. Make sure that wires and flat

foils are not damaged during plate removal.

CL 16532099_041.eps

250901

Exchanging the glass plate

1. Take the monitor from its service stand, and put it (face

down) on a soft surface (blanket, foam cushion or foam

stand), to make sure that you do not damage the front glass

plate.

2. Remove the metal back plate as described in paragraph

'Rear Cover Removal'.

3. Unscrew all fixation screws of the plastic back cover.

4. Lift and remove the plastic back cover.

5. If the triangular shaped cable holder at the left bottom is

present, unscrew the fixation screws of the holder at the left

bottom, see figure 'Exchange Glass Plate'.

6. Unplug the cable of the LED/Switch panel, connector 0320

7. If the ESM Filter Panel at the left bottom is present,

unscrew the fixation screws.

8. Unscrew all fixation screws of the (metallised) shielding

frame, see figure 'Exchange Glass Plate'.

9. You can now remove the (metallised) shielding frame,

together with the PDP, Audio panel, Power supply and

SCAVIO panel attached to it, see figure 'Exchange Glass

Plate'.

Note: To prevent scratches, make sure to put the shielding

frame together with the PDP on a soft surface.

10. Replace the glass plate.

Warning: make sure that the mains power is disconnected

when you remove the metal back plate.

Page 6

EN 6 ALIS-PDP Suppl.4.

Mechanical Instructions

CL 16532099_047.eps

Figure 4-6 Exchanging the PDP

To exchange the PDP panel:

1. Take out the SCAVIO panel and Power Supply panel, as

described earlier.

2. Unscrew all fixation screws of the (metallised) shielding

frame (two at the top and two at the bottom, see figure

'Exchange PDP').

3. The shielding frame can now be taken off the PDP.

4. Replace the PDP.

260901

Page 7

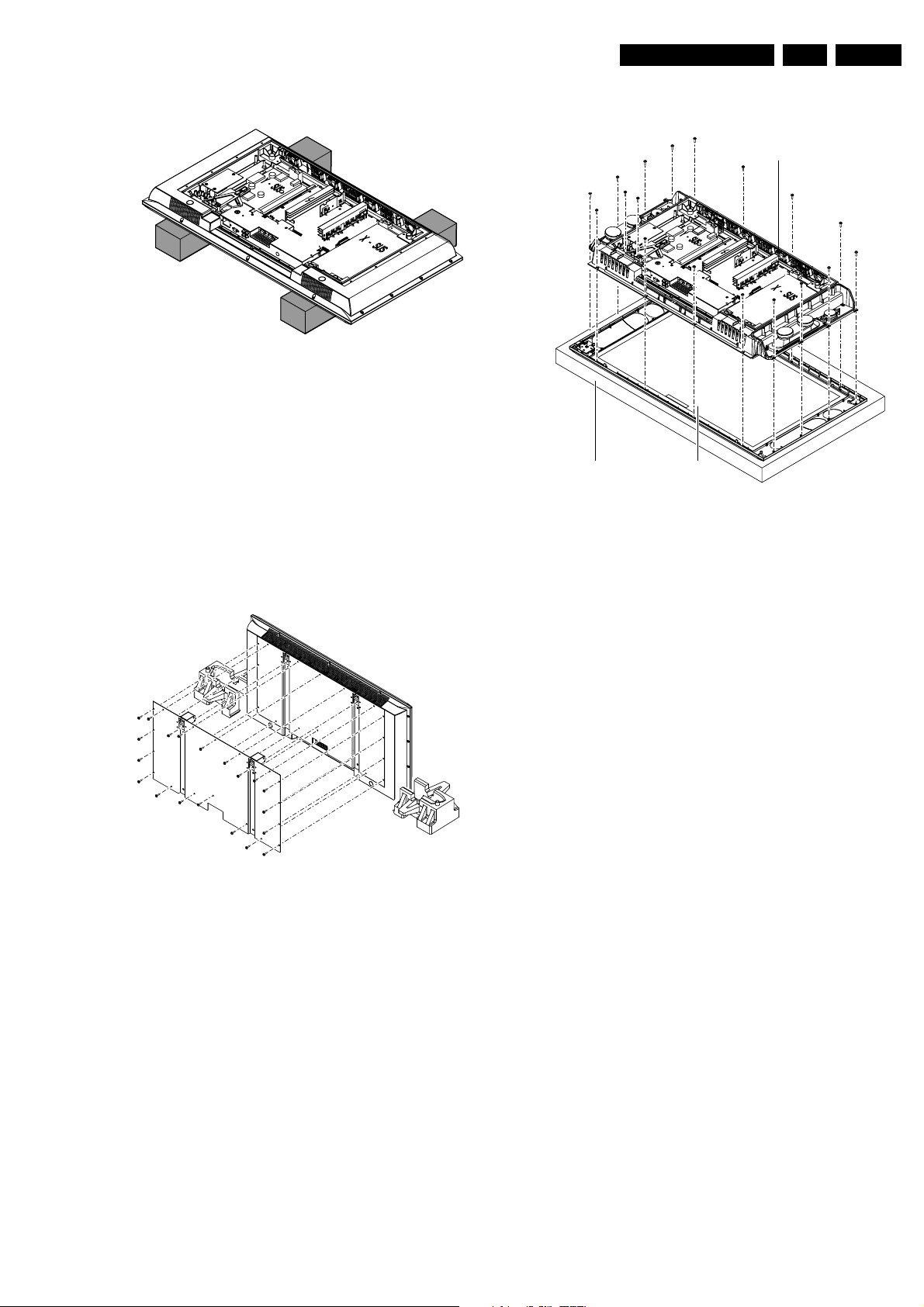

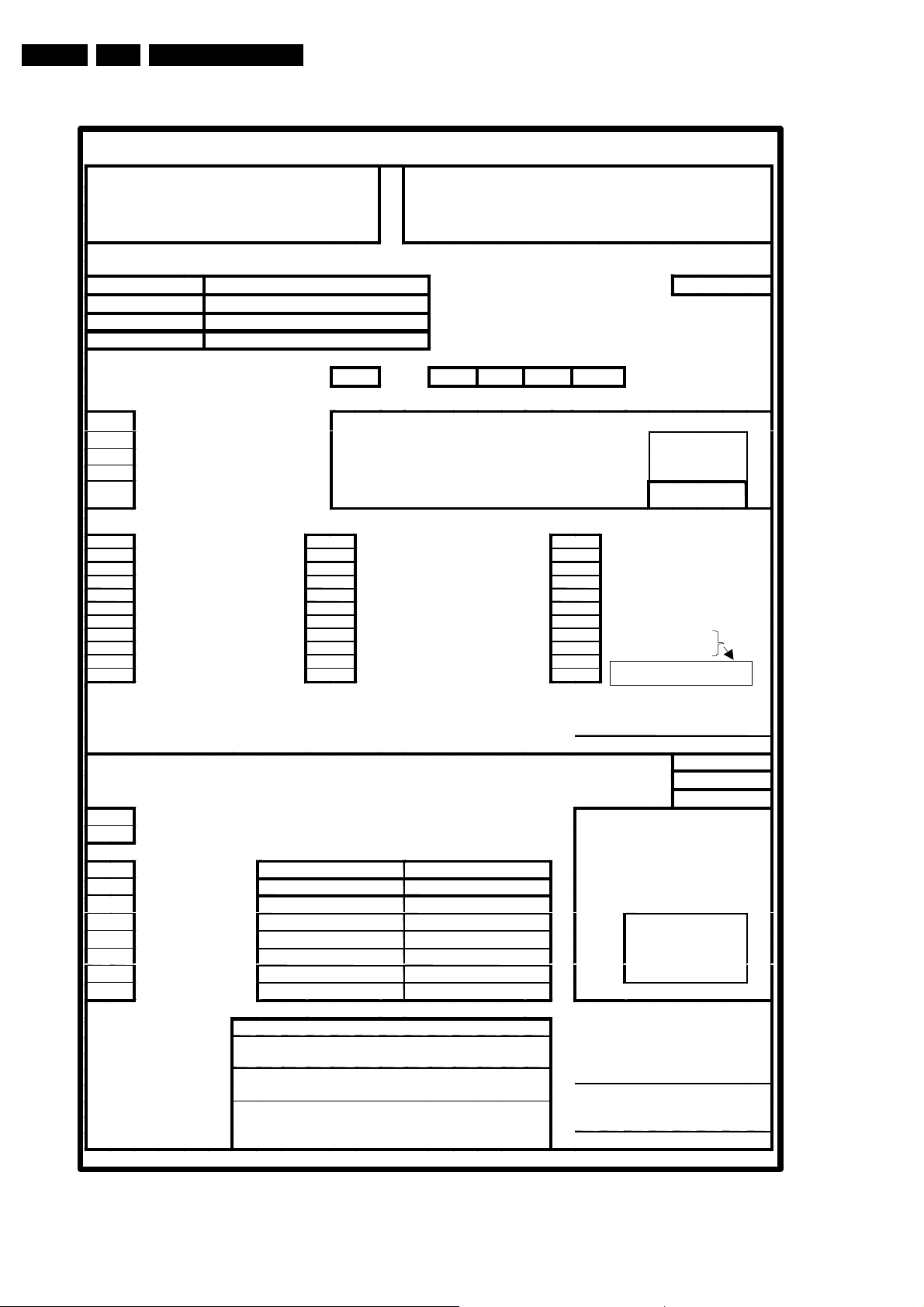

4.4 Board swap instructions for ALIS PDP

Mechanical Instructions

EN 7ALIS-PDP Suppl. 4.

AUDIO IN

L

R

MAINS

1

2

RS323

DVI-D

VGA2 VGA1

! All Functional blocks shaded grey are required for

the "Basic Configuration".

The remainder is required for the "Enhanced Configuration".

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VGA1 VGA2 RC-OUT

DVI-D

Y/C S

SVHS

AV2 AV1

L

R

AUDIOINAUDIO

IN

CVBSB/Pb/Cb

B/Pr/Cr

H

L

R

AV3

v

AUDIO

IN

IR lightsensor

Red

18

19

20

21

22

23

24

17

Figure 4-7 Exploded view

Before dismounting panels read notes below!

Caution when removing circuit board!

When removing the circuit board after the main power is turned

on/off, wait for at least one minute before starting to remove the

circuit board.

If the circuit board removal is started immediately after turning

off the main power, it can result in electric shock or damage to

the circuit due to residual electric charge.

On handling the FPC connector!

To release the lock, release it by gently flipping it with the nail

of the thumb or forefinger. Never pinch the lock lever with

fingers or hook on it (especially with a fingernail).

Doing so might damage the lock lever.

E_14580_025.eps

260304

Figure 4-8 Handling FPC connector

E_14580_002.eps

250304

4.4.1 X-SUS Circuit Board Removal / installation Procedure

Remove the circuit board following the steps below. To install

the circuit board, reverse the removal procedure.

1. Remove the fixing screws (M3 X 8) at 9 locations.

2. Release the lock of the FPC connecter (CN21) and

disconnect the signal cable.

3. Disconnect the cables from the VH connectors (CN22,

CN23).

4. Pull out the XSUS board horizontally and disconnect the

connectors (CN24, CN25).

5. Remove the X-SUS board.

Make sure that you do not touch the heat sink when removing

the Y-SUS board.

4.4.2 Y-SUS Circuit Board Removal / installation Procedure

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Remove the fixing screws (M3 X 8) at 9 locations.

2. Release the lock of the FPC connecter (CN3 1) and

disconnect the signal cable.

3. Disconnect the cables from the VH connections (CN32,

CN33).

4. Pull out the YSUS board horizontally and disconnect the

connections (CN34, CN35).

5. Remove the Y-SUS board

25

Page 8

EN 8 ALIS-PDP Suppl.4.

4.4.3 ABUS-L Circuit Board Removal / Installation Procedure

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Disconnect the connecter CN52 from the ABUS-L board.

2. Raise the lock of the FPC connectors CN53, CN54, CN55

and CN56 to release it and remove the ADM flexible board.

3. Release the lock of the FPC connecter CN51 and

disconnect the signal cable (FPC).

4. Remove the screws (M3X8) fixing the ADM at the 8

locations.

5. Remove the screws (M3x8) fixing the ABUS-L board at the

3 locations.

6. Remove the ABUS-L board.

7. When installing the ABUS L-board, put the ABUS L-board

in such position that it is locked by the tabs before fixing it

in position (at 3 locations).

4.4.4 ABUS-R Circuit Board Removal / Installation Procedure

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Disconnect the connecter CN42 on the ABUS-R board.

2. Raise the lock of the FPC connectors CN43, CN44, CN45,

CN46 to release it and disconnect the ADM flexible board.

3. Release the lock of the FPC connecter CN41 and

disconnect the signal cable (FPC).

4. Remove the screws (M3X8) fixing the ADM at the 8

locations.

5. Remove the screws (M3X8) fixing the ABUS-R board at the

3 locations.

6. Remove the ABUS-R board.

7. When installing the ABUS-R board, put the ABUS R-board

in such position that it is locked by the tabs before fixing it

in position (at 3 locations).

Mechanical Instructions

4.4.5 LOGIC Board Removal / Installation Procedure

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Disconnect the EH connecter CN6.

2. Release the lock of the FPC connectors CN2, CN3, CN4,

CN5 and disconnect the signal cable (FPC).

3. Slide the lock of the FPC connecter CN7 toward the PSU

board side, then press it down toward the front and remove

the PSU signal cable.

4. Remove the screws (M3 X 8) fixing the LOGIC board in

position at 2 locations.

5. Remove the LOGIC board.

6. When installing the LOGIC board, put the LOGIC board in

such position that it is locked by the tabs before fixing it in

position (at 3 locations.

4.4.6 PSU Board Removal / Installation Procedure

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Release the lock of the cable clamp (large).(At 4 locations)

2. Disconnect the X-SUS board connecter CN23.

3. Disconnect the Y-SUS board connecter CN33.

4. Disconnect the ABUSR board connecter CN42.

5. Disconnect the ABUSL board connecter CN52.

6. Remove the wires (4), (5) from the cable clamp (small).

7. Disconnect the LOGIC board connecter CN6.

8. Disconnect the PSU signal cable from the PSU board

connecter CN69 side.

Page 9

Repair Process and Fault Finding

5. Repair Process and Fault Finding

EN 9ALIS-PDP Suppl. 5.

Index of this chapter:

1. Process flow

2. Repair instructions

3. Faultfinding

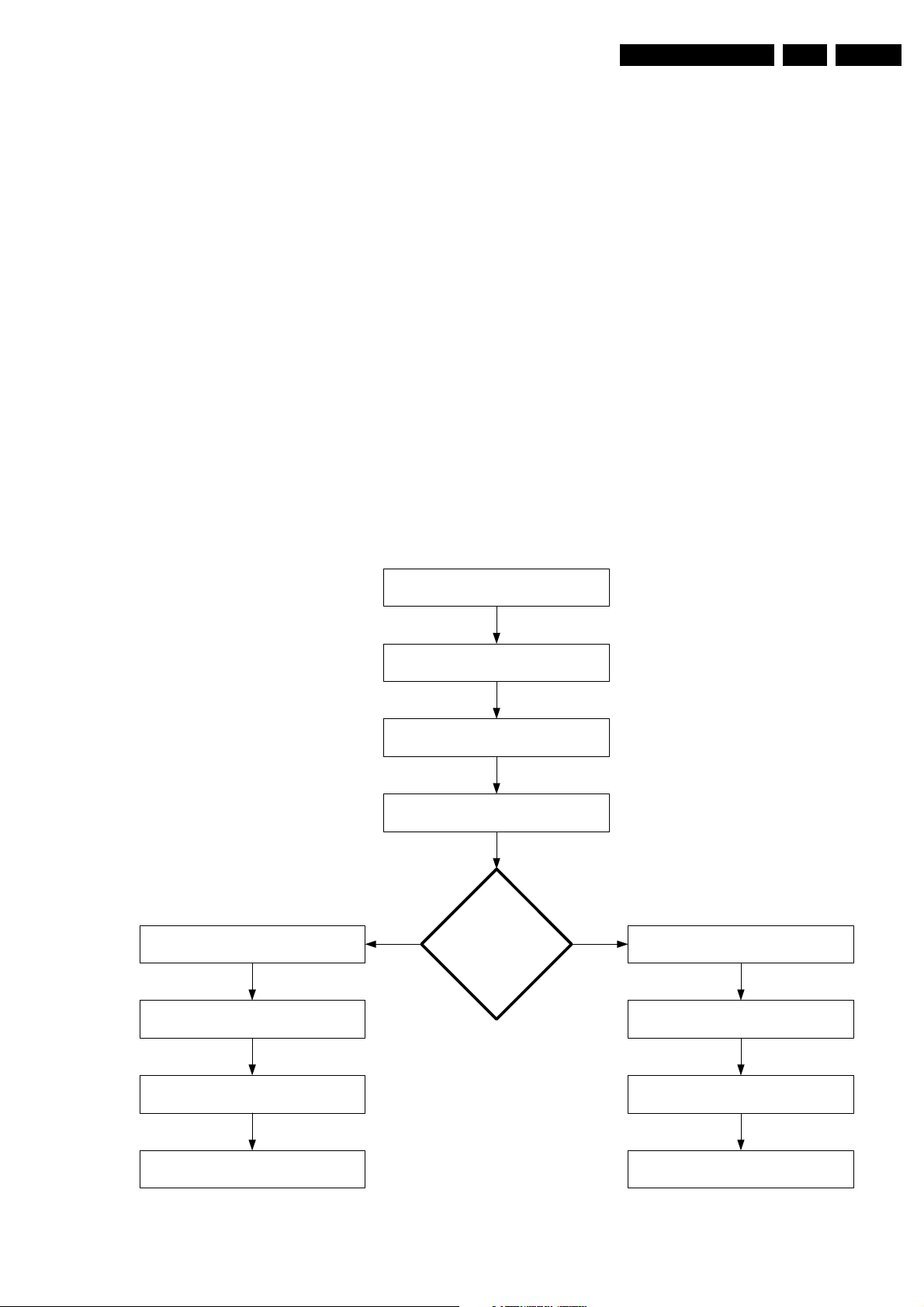

5.1 Process flow

The selected workshop receives the defect TV set and

investigates the PDP. Two possible solutions shall follow:

5.1.1 Advanced PDP exchange (actual way-of-working)

If the defect concerns one of the folowing items, the actual way

of working has to be followed:

• Glass broken

• Flex foil damaged

• Y-COM IC on flex foil is damaged

• NVM on logic board defect, no communication with

ComPair

A new PDP will be ordered at Euroservice. Euroservice issues

an RMA number and ships a refurbished PDP from its swap

(from 1st May 2003 onwards)

end user contacts dealer because his

pool in a flight case to the workshop. After receipt the workshop

sends the defect PDP, accompanied by a completely filled in

Failure Description Form (see Figure 5.1), in this flight case to

Euroservice. Euroservice makes sure the defect PDP is

repaired and afterwards added to its swap pool. The workshop

makes the TV set complete by building in the refurbished PDP.

Afterwards the TV set is sent back to the customer.

5.1.2 Customized repair

If the defect is not related to the exceptions, mentioned in 5.1.1,

the workshop orders the necessary spare parts, being boards,

at Euroservice. After receipt the workshop swaps the

concerning board and makes the TV set complete by building

in the PDP. Afterwards the TV set is sent back to the customer.

PDP flow chart

plasma TV set is defect

VIP workshop orders refurbished PDP

at Euroservice

Euroservice ships refurbished PDP from its

swap pool to VIP workshop in a flight case

VIP workshop swaps PDP's

and makes plasma TV set complete

dealer requests VIP workshop

to contact end user

VIP workshop brings home visit to end user

and swaps defect TV set with a loan set

VIP workshop analyses the PDP

of the defect plasma TV set

PDP:

YES

glass repair

or

flex c able m ach i ne

needed

??

NO

VIP workshop orders spare part(s)

being boards at Euroservice

Euroservice ships spare part(s) with

next-day-delivery to VIP workshop

VIP workshop repairs PDP on board level

and makes plasma TV set complete

VIP workshop brings plasma TV set to

end user and swaps with loan set

Figure 5-1 PDP flow chart

VIP workshop brings plasma TV set to

end user and swaps with loan set

E_14580_027.eps

250304

Page 10

EN 10 ALIS-PDP Suppl.5.

F

F

Failure Description Form for Defective Plasma Displays for Philips

Repair Process and Fault Finding

Form to be sent together with the defect

Plasma Display

actory/Service Repair Workshop

Product Data

Part No:

Serial No, display:

MRA No:

Serial No, set:

Condition Code | Symptom Code

Possible Condition Codes:

Possible Symptoms:

310 No Picture

321 Picture Too Dark

327 Only Partial Picture

350 Unstable Picture

351 Synchronisation Poblem

352 Picture Luminance Pumping [slow]

353 Picture Jitter

354 Picture Shaking

355 Flickering Picture (Luminance) [fast]

356 Flashing Picture (active-inactive)

35A Frozen Picture

Please fill in at least the yellow part

1 Constant

2 Intermittent

3 After a While

4 In a Hot Environment

5 In a Cold Environment

From:

Factory / Service Repair Workshop

Additional Failure Description

In case of 32 FTV please fill in service error codes of the monitor

35X Other Unstable Picture Problem

381 Burn-In Mark On Display (Phosphor)

382 Scratch On Display

384 Phosphor/Pixel Missing

a Non Lightning (Flickering) Cells each Color

R:. G:. B:.

b Wrong Phosphor/ For Each Color

c Non Extinguishing (Flickering) Cell:.

d High Intensity Cell Defect

e Mechanical Failure

- Due To Fujitsu Factory

A Inactive Row(s)

B Inactive Column(s)

C Various Missing Display Cells

D Picture, but non linear greyscale

E Video Stretched Over Total Height

431 Missing Color

64X Mechanical noise (accoustical sound)

F Broken Plasma Panel

G Broken flexible cabling

Date

PDP

New symptoms descriptions

ujitsu Part of Form

Recognition & Repair

Conditions (Temp., Soft, ETC ):

Normal

Under Stress

Failed Component Serial # defect

Glass Panel

X-SUS-Std

Y-SUS

Logic12

A-Bus Right

A-Bus Left

DC/DC

Other

PCB Name:

Repair Part/Location:

Corrective Action:

Preventive Action:

(not to be filled in by factory or by Service Workshop)

Æ

additional Description

Signature/Stamp Factory

Æ

Serial # replaced

Warranty?

Date

Ship to FJ?

Additional Failure Description :

Signature/Stamp Repair Center

Signature/Stamp FHP Japan

no/yes

no/yes

E_14580_026.eps

250304

Figure 5-2 Failure description form

Page 11

Repair Process and Fault Finding

EN 11ALIS-PDP Suppl. 5.

5.2 Repair instructions

5.2.1 General

All below listed Plasma Display Panels must be repaired on

board level except in case of:

• Broken glass panel

• Defective flex foil

• Defective Y-COM IC on the flex foil

The Plasma panels with these faults needs to be send back via

the central repair procedure of Euroservice.

To be able to repair the Plasma Display Panels on board level

the following repair tools are available:

9965 000 23434 Special LVDS cable

Power Supply

CN7 CN6

Logic Board

SCAVIO Customer's Interface Board

CN1

Figure 5-3 Extension cable kit ALIS PDP

3122 785 90581 Foam buffers for PDP

CN1

8

6

4

Compair

other

signals

SDA

GND

SCL

IIC

SCAVIO

E_14580_023.eps

SDA

GND

SCL

Compair

IIC

050404

Module description

X-SUS board FPF17R-XSS5002 996500017432

Y-SUS board FPF17R-YSS5003 996500017433

Logic board FPF17R-LGC5012 996500017435

A-BUS Right FPF17R-ABR5005 996500017436

A-BUS Left FPF17R-ABL5004 996500017437

Signal Cable (Logic - ABUS,SUS) FPF17R-CBL2001 996500017438

Signal Cable (XSUS-YSUS) FPF17R-CBL1001 996500017439

Factory code

number

The available modules for the Plasma Display Panel

FPF32C106128UA-62 are:

Module description

X-SUS board FPF17R-XSS5010 996500017440

Y-SUS board FPF17R-YSS5011 996500017441

Logic board FPF17R-LGC5013 996500017442

A-BUS Right FPF17R-ABR5005 996500017436

A-BUS Left FPF17R-ABL5004 996500017437

Signal Cable (Logic - ABUS,SUS) FPF17R-CBL2001 996500017438

Signal Cable (XSUS-YSUS) FPF17R-CBL1001 996500017439

Factory code

number

Remark:

1. If the LOGIC board is defective, the procedure mentioned

in chapter 5.x must be used.

5.2.3 32” H2 ALIS Plasma Display Panel

These Plasma Display Panels are used in FM23 sets with

production code:

• AG07 and higher for the sets 32FD9954/17S and

32FD9954/69S

• AG08 and higher for the sets 32FD994/69S

• AG09 and higher for the sets 32FD9944/01S

The involved Plasma Display Panels are:

Display type Service code number Production code

FPF32C106128UA-72 9322 194 11682

Service code

number

Service code

number

1

*

E_14580_024.eps

Figure 5-4 Foam buffers for PDP

The following Plasma Display Panels must be repaired on

board level:

1. 32” H1 ALIS Plasma Display Panel

2. 32” H2 ALIS Plasma Display Panel

3. 37” H2 ALIS Plasma Display Panel

4. 42” H1 ALIS Plasma Display Panel

5. 42” H2 ALIS Plasma Display Panel

5.2.2 32” H1 ALIS Plasma Display Panel

These Plasma Display Panels are used in FM23 sets with

production code AG00 up to and including AG05.

The involved Plasma Display Panels are:

Display type Service code number Production code

FPF32C106128UA-51 9322 172 11682

FPF32C106128UA-52 9322 178 04682

FPF32C106128UA-62 9322 190 61682 From AG06 0242 onwards

The available modules for the Plasma Display Panel

FPF32C106128UA-51 and -52 are:

250304

The available modules for this Plasma Display Panel are:

Module description

X-SUS board FPF17R-XSS5016 9965 000 22709

Y-SUS board FPF17R-YSS5017 9965 000 22710

Logic board FPF17R-LGC5018 9965 000 22711

A-BUS Right FPF17R-ABR5015 9965 000 22713

A-BUS Left FPF17R-ABL5014 9965 000 22712

Signal Cable (Logic - ABUS,SUS) FPF17R-CBL2001 9965 000 17438

Signal Cable (XSUS-YSUS) FPF17R-CBL1001 9965 000 17439

Factory code

number

Remark:

1. If the LOGIC board is defective, the procedure mentioned

in chapter 5.x must be used.

5.2.4 37” H2 ALIS Plasma Display Panel

These Plasma Display Panels are used in FM33 sets with

production code AG00 and onwards.

The involved Plasma Display Panels are:

Display type Service code number Production code

FPF37C128128UA-72 9322 156 44682

The available modules for these Plasma Display Panels are:

Module description

X-SUS board FPF18R-XSS5007 996500023342

Y-SUS board FPF18R-YSS5008 996500023343

Logic board FPF18R-LGC5009 996500023344

A-BUS Right FPF18R-ABL5005 996500023346

A-BUS Left FPF18R-ABR5004 996500023347

Signal Cable (Logic -ABUS,SUS) FPF18R-CBL100103 996500017431

Signal Cable (XSUS-YSUS) FPF18R-CBL100103 996500017431

Factory code

number

Service code

number

Service code

number

1

*

1

*

Page 12

EN 12 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

Module description

Signal Cable (Logic - ABUS,SUS) FPF18R-CBL200112 996500017430

Signal Cable (XSUS-YSUS) FPF18R-CBL200113 996500023345

Factory code

number

Remark:

1. If the LOGIC board is defective, the procedure mentioned

in chapter 5.x must be used.

5.2.5 42” H1 ALIS Plasma Display Panel

These Plasma Display Panels are used in FM24 sets with

production code AG00 and higher.

The involved Plasma Display Panels are:

Display type Service code number Production code

FPF42C128128UB-54 9322 185 78682

The available modules for these Plasma Display Panels are:

Module description

X-SUS board FPF16R-XSS500203 996500017423

Y-SUS board FPF16R-YSS500303 996500017424

Logic board FPF16R-LGC5006 996500017425

A-BUS Right FPF16R-ABR5005 996500017426

A-BUS Left FPF16R-ABL5004 996500017427

Signal Cable (LOGIC-XSUS) FPF16R-CBL200104 996500017428

Signal Cable (LOGIC-YSUS) FPF16R-CBL200106 996500017429

Signal Cable (LOGIC-ABUS) FPF18R-CBL200112 996500017430

Signal Cable (XSUS-YSUS) FPF18R-CBL100103 996500017431

Factory code

number

Service code

number

Service code

number

1

*

Remark:

1. If the LOGIC board is defective, the procedure mentioned

in chapter 5.x must be used.

5.2.6 42” H2 ALIS Plasma Display Panel

These Plasma Display Panels are used in FM24 sets with

production code:

• AG04 and higher for the sets 42FD9934/17S, 42FD9934/

69S, 42FD9944/01S, 42FD9944/17S, 42FD9944/69S and

420P30/00

• AG06 and higher for the sets 42FD9954/69S

The involved Plasma Display Panels are:

Display type Service code number Production code

FPF42C128128UB-72 9322 194 10682

The available modules for these Plasma Display Panels are:

Module description

X-SUS board FPF16R-XSS5008 996500022705

Y-SUS board FPF16R-YSS5009 996500022704

Logic board FPF16R-LGC500703 996500022706

A-BUS Right FPF16R-ABR5011 996500022707

A-BUS Left FPF16R-ABL5010 996500022708

Signal Cable (LOGIC-XSUS) FPF16R-CBL200104 996500017428

Signal Cable (LOGIC-YSUS) FPF16R-CBL200106 996500017429

Signal Cable (LOGIC-ABUS) FPF18R-CBL200112 996500017430

Signal Cable (XSUS-YSUS) FPF18R-CBL100103 996500017431

Factory code

number

Service code

number

1

*

Remark:

1. If the LOGIC board is defective, the procedure mentioned

in chapter 5.x must be used.

Page 13

Repair Process and Fault Finding

Problem analysis procedure PDP repair / Board swap

PDP Repair procedure Board Swap

EN 13ALIS-PDP Suppl. 5.

The entire Screen does not light.

The set is going into protection.

(PSU is OK)

Step 0

Check the 3,3V Stby on the PSU and the

Logic board

Step 1

Check if there is no short circuit on the Boards

Power Supply lines

Step 3

Check current of 5V Vcc Power Supply line,

on ABUSL, ABUSR, Y-SUS, X-SUS board.

Vertical Line / Vertical Bar? Horizontal bar?

Logic Board Exchange

procedure.

Use of ComPair

Copy data from the

defective Logic board

Check Va on ABUSL and ABUSR Board

Step 4

Step 5

Check Vs on Y-SUS and X-SUS board

SDM Y-SUS

Step 6

Check Vs on Y-SUS and X-SUS board.

X-SUS board XBB

Figure 5-5

Restore data into the new

board

Ship Out

Auto alignment procedure

E_14580_008.eps

250304

Page 14

EN 14 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

Problem Analysis Procedure the entire screen does not light.

The entire screen does not light

All the boards are connected

Connect the set to mains.

Switch the set on via vacation switch

Standby LED is on?

Set is in Standby?

Y

Check 3,3V Stby

on pin 1 CN6

Logic board

Y

Caution; do never disconnect connectors or

remove boards when the mains plug is connected.

Allow discharge of power supplies before

disconnecting connectors!

N

N

Switch vacation switch off

Check supply voltages

Vcc pin 6 Cn306

Vs pin 10 Cn323

Va pin 1 Cn323

Vcc Pin 3 Cn323

Vcc pin 7 Cn342

Vcc pin 7 Cn352

3,3V Standby is ok.

Switch on the set via RC

Disconnect CN306 Logic board

Y

Switch vacation switch on and check

3,3V Stby on PSU

N

Set is going into protection?

Y

Disconnect the mains plug.

Remove the following power connections

CN23 X-Sus

CN33 Y-Sus

CN42 ABUSR

CN52 ABUSL

1

3,3V Stby

on pin 1 Cn306

is ok?

Y

CC on Logic board

Replace Logic Board

Follow Logic board

replacement procedure

N

Defect is on PSU

board.

Standby supply repair

See PSU repair

method

E_14580_009.eps

250304

Figure 5-6

Page 15

1

X-Sus Board CN23

VCC pins 3 - 4

Vs pins 6 - 8

Va pins 1 - 4

are shorted?

N

Y-Sus Board CN33

Vcc pins 1 - 2

Vs pins 5 - 7

are shorted?

Repair Process and Fault Finding

Short-circuit check on Power Supply Lines

Check with ohmeter if following

pins are not shorted

Y

Y

Remove SDM from the following

connectors CN34 , CN35

EN 15ALIS-PDP Suppl. 5.

X-Sus board is defective

Replace X-Sus board

N

ABUSL Board

Va CN52 pins 1 - 4

Vcc CN52 pins 5 -7

are shorted?

N

Y-Sus Board CN33

Vcc pins 1 - 2

Vs pins 5 - 7

are shorted?

Y

Y

Remove ADM from the

following connectors

CN53, CN54, CN55, CN56

ABUSL Board

Va CN52 pins 1 - 4

Vcc CN52 pins 5 -7

are shorted?

N

N

SDM is defective

PDP is defective

Y-Sus board is defective.

Replace Y-Sus Board

ADM is defective

PDP is defective

ABUSL Board is defective

Y

2

PSU board has a short circuit

Replace ABUSL Board

End of analysis

E_14580_010.eps

310304

Figure 5-7

Page 16

EN 16 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

2

ABUSR Board

Va CN42 pins 1 - 4

Vcc CN42 pins 5 -7

are shorted?

N

Only the Logic board CN306 and CN307 are

connected.

Connect set to mains

Switch vacation switch on

Switch set on via RC

Short-circuit check on Power Supply Lines

Y

Remove ADM from the following connectors

CN43, CN44, CN45, CN45

ABUSR Board

Va CN42 pins 1 - 4

Vcc CN42 pins 5 -7

are shorted?

Y

N

ADM is defective

PDP is defective

ABUSR Board is defective.

Replace ABUSR board

PSU Board

Vcc 5V exists a few

seconds?

Y

Disconnect the set from AC Mains

3

N

Check if VCEGO

is High

Logic board is

defective

In step 3 the 5V Vcc will be checked by use of an external PSU.

First adjust the current output on the external PSU to 5V 0,5A

Connect external PSU to Diodes D6224 and/or D6225 on the set

Replace Logic Board

Follow Logic board replacement

procedure

Set V output to 0V

PSU (D6224 not present in FM33).

See diagram P7

End of analysiis

E_14580_011.eps

310304

Figure 5-8

Page 17

Repair Process and Fault Finding

EN 17ALIS-PDP Suppl. 5.

3

Set is disconnected from AC mains!

Connect CN42 ABUSR

Switch the PSU on

Vcc 5V OK?

I < 0,35A?

Y

Switch off the PSU

Connect CN52 ABUSL

Switch on the PSU

Vcc 5V OK?

I < 0,35A?

Y

5V Vcc check ABUSR, ABUSL, Y-Sus, X-Sus board

In the next steps the 5V Vcc power supply lines will be checked.

AExternal Power Supply is connected to D6224/D6225 5V Vcc on the set PS.

For testing each board, ramp up the External PSU from 0 to 5V.

Monitor the current!

N

N

Adjust External PSU

max. current to 2A

ABUSR board is defective.

Replace ABUSR board

Logic buffer circuit has abnormalty.

ABUSL board is defective.

Replace ABUSL Board

Logic buffer circuit has abnormalty.

Switch off the PSU

Connect CN23 X-Sus

Switch on the PSU

Vcc 5V OK?

I < 2A?

Y

Switch off the PSU

Connect CN33 Y-Sus

Switch on the PSU

Vcc 5V OK?

I < 2A?

Y

Switch off the external PSU

and disconnect.

N

X-Sus board is defective

Replace X-Sus board

DC/DC power supply circuit or control

logic cicuit has abnormality

N

Y-Sus board is defective

Replace Y-Sus board

DC/DC power supply circuit or control

logic cicuit has abnormality

Switch PSU off

Remove ADM 1 - 8

4

Figure 5-9

End of analysis

E_14580_012.eps

250304

Page 18

EN 18 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

4

Connect the set to AC Mains.

Switch on

PSU board Va 50V

exists?

N

Switch off

Disconnect connector CN42 ABUSR board

VA check on the ABUSR and ABUSL board

Va and Vs Check with internal PSU

For each step switch the set off and on via

the vacation swith and the RC

Y

ADM is defective

Panel chassis is defective

Switch on

PSU board

Va 50V exists?

N

Switch off

Disconnect connector CN52 ABUSL board

switch on

PSU board

Va 50V exists

Y

Y

ABUSR board is defective.

Replace ABUSR board.

ABUSL board is defective.

Replace ABUSL board

N

Disconnect the AC Power.

End of analysis

5

Figure 5-10

E_14580_013.eps

250304

Page 19

Repair Process and Fault Finding

Vs Check on Y-Sus & X-Sus board and SDM / XBB

EN 19ALIS-PDP Suppl. 5.

5

PSU board

Vs 80V exists?

N

Switch off

Disconnect SDM / Y-Sus board

Measure resistance of SDM power line

Between A1-A2, B1-B2, C1-C2 and D1-D2

SDM Power line is

shorted?

There is no start up of Vs switched and Va if power supply to

Remark:

X-Sus (CN23) or Y-Sus (CN33) board is diconnected.

Y

PSU Board Va block is defective.

Y

Panel chassis is defective

SDM is faulty

Switch off

End of analysis

ADM1 ADM2 ADM3 ADM4 ADM5 ADM6 ADM7 ADM8

A2

A1

B1

B2

C1

C2

D1

D2

Switch on

N

Switch off

N

PSU board Vs / Vcc

is output?

Y

SDM is faulty

Panel chassis is defective

6

Switch off

End of analysis

E_14580_014.eps

310304

Figure 5-11

Page 20

EN 20 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

Vs Check on Y-Sus & X-Sus board and SDM / XBB

6

Disconnect connection from

XBB / X-Sus board

Measure resistance of XBB line.

Between A1-B1, B1-A2, A2-B2, B2-A3, A3-B3,

B3-A4, A4-B4

There is a posibility to check the VS and Va power supply lines

via an external power supply.

External power supply connected to VS or Va power supply line

and ground, output voltage = 20V, current = 0mA or very low

current to charge the capacitors at switch on.

ADM1 ADM2 ADM3 ADM4 ADM5 ADM6 ADM7 ADM8

A1

B1

A2

B2

A3

B3

A4

B4

XBB line has short-

circuit?

N

Y-Sus board is defective.

Replace Y-Sus board

X-Sus board is defective.

replace X-Sus Board

Y

XBB is faulty

Panel chassis is defective

X-Sus board is defective

End of analysis

Figure 5-12

E_14580_015.eps

310304

Page 21

Repair Process and Fault Finding

Vertical Line / Vertical bar Problem analysis procedure

Vertical line / Vertical bar

EN 21ALIS-PDP Suppl. 5.

Logic - ABUS board signal

cable has abnormal

appearance?

N

ADM flexible has

abnormal appearance?

N

Switch on

Y

Y

Signal cable is defective.

ADM is defective

PDPs is defective

End of analysis.

One vertical line?

N

1

Tap lightly on ADM flexible

Y

heat-melted junction

Any changes?

N

Panel Adress has open circuit or

ADM IC chip is defective.

PDP is defective

Figure 5-13

Heat-melted junction is

Y

defective.

PDP is defective

Switch off

End of analysis

E_14580_016.eps

250304

Page 22

EN 22 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

1

Bar of 1/2 screen width on the

left does not light?

N

Bar of 1/2 screen width on the

right does not light?

Y

Voltage exists at

ABUSL board CN52?

N

Switch off

Disconnect CN52 from ABUSL board

Switch on

Voltage exists

at PSU board?

N

Y

Y

Y

Logic board is

defective

ABUSL board is

defective

PSU Cable is defective.

Connector has poor connection.

Logic board is defective.

Voltage exists at

ABUSR board CN42?

Y

Logic board is

defective

N

Disconnect CN42 from ABUSR board

Switch off

Switch on

N

Voltage exists

at PSU board?

Y

N

2

ABUSR board is

defective

PSU Cable is defective.

Connector has poor connection.

Logic board is defective.

Switch off

End of analysis

E_14580_017.eps

250304

Figure 5-14

Page 23

Repair Process and Fault Finding

2

EN 23ALIS-PDP Suppl. 5.

Vertical line of

different color?

Y

Exists in left 1/2

area?

Y

Switch off.

Replace ABUSL board.

Switch on

Normal?

N

Switch off

Replace Logic board

Switch on

Y

ABUSL board is

defective

N

N

Normal?

Y

LOGIC board is

defective.

N

Replace Logic ABUSL signal cable.

Switch off.

Switch on

Normal?

Y

N

Signal cable is

defective

ADM is defective

PDP is defective

3 4

Figure 5-15

Switch off

End of analysis

E_14580_018.eps

250304

Page 24

EN 24 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

3

Replace ABUSR board

4

Switch off

Switch on

Normal?

Y

ABUSR board is

defective

N

Switch off

Replace Logic board

Switch on

Normal?

N

Switch on

Replace signal Cables Logic - ABUSR

Switch on

Normal?

N

Y

Y

Logic board is

defective

Signal cable is

defective

ADM is defective.

Panel chassis is

defectiive.

Panel is defective

Panel chassis is defective

Figure 5-16

Switch off

End of analysis

E_14580_019.eps

250304

Page 25

Repair Process and Fault Finding

Horizontal bar problem analysis procedure

Horizontal bar

Switch off

Replace X-Sus board

Switch on

EN 25ALIS-PDP Suppl. 5.

Normal?

N

Switch off

Replace X-Sus board (original board)

Replace Y-Sus board

Switch on

Normal?

Y

Y

X-Sus board is defective

Y-Sus board is defective

N

Figure 5-17

PDP is defective

SDM or XBB is defective

Switch off

End of analysis

E_14580_020.eps

250304

Page 26

EN 26 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

Remark: Do not interchange boards between different PDP’s,

this can damage your PDP

Logic Board Exchange (1)

1. Copy NVM Data from defective Logic Board

1.

2.

Disconnect the LVDS Cable from the SCAVIO at

3.

Connect the service Cable (12nc 9965 000 23434) to

4.

5.

6.

Click the link in ComPair to open the Logic Board

7.

Unscrew the SCAVIO Panel

(CN0310)

the LVDS connector on the FME Logic board

Switch on the set

Set will go into protection or in stanby

exchange window

Click the "On" button.

In the titlel bar the module type will appear

8.

9.

Use the "Save" button to save the information to a file

10.

11.

Click button "copy from original"

Click the "Off" button

Switch off the set and replace the Logic board

1. Unscrew the SCAVIO panel to be able to reach the cable

going to connector CN1 on the Logic Board

2. Disconnect the cable from the SCAVIO panel at connector

0301. Leave the rest connected!

Note: In the diagram the cable at 0301 is still connected,

but at this moment in the process that should not be.

3. Connect the ComPair I2C cable as given in this diagram.

4. Switch on the set. It will go to stand by or protection mode.

5. Click the link in ComPair to open the Logic Board exchange

window.

6. Click the 'On' button. In the title bar the module type will

appear: 37H1.11, 42H2, or something similar.

Figure 5-18

7. Click button 'Copy from original'

8. The data is read from the EEPROM on the logic board and

displayed in the list.

9. Use the 'Save' button to save the information to a file. This

is optional, but better to be safe.

Note: If you close the window without saving, all settings

will be lost. If you intend to close this window before

replacing the board you should save the settings so you

can load them later.

10. Click the 'Off' button.

11. Switch off the set and replace the Logic Board with another

one.

Page 27

Repair Process and Fault Finding

Logic Board Exchange (2)

2. Write NVM Data to the new Logic Board

EN 27ALIS-PDP Suppl. 5.

1.

Switch off the set and replace the Logic board

And connect the service cable to the SCAVIO (CN0301)

2.

Switch the set on with the RC and bring the set in CSM

using code 123654

3.

4.

5.

Click the "On" button

Load the saved values

Click button paste to replacement

6.

7.

When ready you can switch off the set, and disconnect

Click button "Ship Out" (1)

ComPair

8.

Exchange back the original LVDS cable to the

original with ferrits

1. Switch off the set and replace the Logic Board with another

one. Now also connect the cable to connector 0301 as

depicted in the diagram above.

2. Restart the set with the new board. Switch the set on with

the remote control and activate CSM (123654). This is to

prevent the set to switch off because no input devices are

connected.

3. Click the 'On' button.

4. The module type will again appear in the title bar. This may

be different now from step 7 because another Logic Board

is used. If you closed the window after step 9 and did save

the settings you should load them now. Use the Load

button to do so.

Figure 5-19

(1) The PDP screen will be blanked for about 15s,

then 15s later, the ’Ship out’ process will end

E_14580_022.eps

250304

5. Click button 'Paste to replacement'. The settings copied

from the old board previously are now being written to the

new board. If successful the button 'Ship out' will be

enabled.

6. Click button 'Ship out'.

7. Now a process of voltage feedback initialization and self-

adjustment starts. This will take a few seconds. When

ready you can switch off the set, disconnect ComPair and

restart the set again to test.

8. Exchange the service LVDS cable with the original LVDS

cable.

Page 28

EN 28 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

No Fault contents Suspected fault

Fault status

location

X-SUS, Y-SUS

PSU

Panel chassis

LOGIC

ABUSL

ABUSR

1

Entire screen

After momentarily

going on, the screen

becomes black

immediately or after a

few seconds. Main

power is turned off.

does not light.

Screen lights dimly

LOGIC Replace LOGIC

even on the back

2

3

Vertical Line

screen

Single vertical line (of

different color)

Vertical line from the

Panel chassis

LOGIC

Panel chassis Replace panel

middle of effective scan

4

area (Vertical line of

different color)

Analysis

procedure and

measure

Refer to the entire

screen does not

light.

board and folow

Logic Board

echange

procedure

Refer to vertical

Line / bar..

chassis

5

Vertical bar

6

7

Horizontal line

8

Bar width of 1/7 0f

horizontal size or in

multiples of 1/7, is

displayed. Abnormal

display.

Bar width of 3/7 or 4/7

of the screen width, is

displayed. Abnornial

display. (Vertical line of

different color)

Single horizontal line

(No light) or single

horizontal does not

light among the

effective scanning

area. Single horizontal

line does not light

Every other line(No

light) Entire screen

Panel chassis

ABUSL ABUSR

Refer to vertical

Line / bar..

LOGIC Above

boards are

connected

Panel chassis

ABUSL ABUSR

Refer to vertical

Line / bar..

LOGIC Above

boards are

connected

Panel chassis Replace panel

chassis

X-SUS

Y-SUS

Replace X-SUS

Y-SUS board

Figure 5-20

E_14580_005.eps

260304

Page 29

Repair Process and Fault Finding

EN 29ALIS-PDP Suppl. 5.

No Fault contents Suspected fault

Fault status

location

Bar width of 1/8 or

Panel chassis Replace panel

multiples of 1/8 of the

screen height, is

9

displayed Abnormal

(Screen does light)

Horizontal bar

Panel chassis Y-

SUS, X-SUS

Above boards

are connected

Panel chassis Perform all white

10

Image sticking.

Burn in?

Bar width of 1/2 of the

screen height.

Abnormal display

(Screen does not light)

Fixed display contents

are always displayed.

burn in?

11

Analysis

procedure and

measure

chassis

Refer to horizontal

bar.

heat run. After

judgment, replace

panel chassis if

needed.

Stains Oval-shaped points

having abnormal

luminance are

12

scattered in the upper

or lower part of screen.

Twinkle The entire screen

momentarily becomes

13

brighter or darker.

Flicker The entire screen

flickers continuously

14

Luminance is

abnormal

15

Screen is too dark or

too bright. (Out of

specifications)

Chrominance is

abnormal

16

Sync is

17

disturbed

Colors cannot be

displayed orrectly.

Panel chassis Perform all white

heat run. After

judgment, replace

panel chassis.

Poor connector

contact. Panel

chassis

Poor connector

contact. FFC

(Flat Foil

Connector / cable

reconnection or

Cable Exchange

connector Cable)

LOGIC

Replace LOGIC

board and folow

Logic Board

LOGIC

echange

procedure

Figure 5-21

E_14580_006.eps

260304

Page 30

EN 30 ALIS-PDP Suppl.5.

Repair Process and Fault Finding

No Fault contents Suspected fault

Fault status

location

Picture

18

distorted

Steps of

19

gradations are

Luminance linearity is

poor.

LOGIC

LOGIC

skipped

PSU, X-SUS

Y-SUS

(Core is broken,

Abnormal

20

sound

Control on

external

21

communication

Contrast, color

temperature

adjustment and Y

cannot be changed.

or transformer is

abnormal)

LOGIC Replace LOGIC

is abnormal

Analysis

procedure and

measure

Replace LOGIC

board and folow

Logic Board

echange

procedure

Locate cause of

abnormality from

listening and

viewing. Replace

the cause of

problem

board and folow

Logic Board

echange

procedure

E_14580_007.eps

260304

Figure 5-22

Page 31

Block Diagrams, Testpoint Overview, and Waveforms

6. Block Diagrams, Testpoint Overview, and Waveforms

Supplement on FM23, FM24, FM33 (3122 785 13891) service

manuals.

EN 31ALIS-PDP Suppl. 6.

Figure 6-1

E_14580_003.eps

250304

Page 32

EN 32 ALIS-PDP Suppl.6.

Block Diagrams, Testpoint Overview, and Waveforms

Figure 6-2

E_14580_004.eps

250304

Page 33

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Supplement on FM23, FM24, FM33 (3122 785 13891) service

manuals.

8. Alignments

8.1 Voltage Setting Procedure

The Voltage Setting label, at the top left of the back of the PDP,

shows the following messages:

Table 8-1

Item Adjustment items Measurement point Adjustment value (conditions)

1 Vs voltage adjustment PSU board F241or CN392 test points Voltage setting label indication value* I% (all black)

2 Va voltage adjustment PSU board F240 or CN392 test points Voltage setting label indication value* I% (all black)

3 Vw voltage adjustment X-SUS board connecter CN26 6-pin Voltage setting label indication value* 1% (all black)

4 Vx voltage adjustment X-SUS board connecter CN26 1-pin Voltage setting label indication value* (all black)

If the voltage adjustments Vs and Va on the Power Supply Unit,

must be performed, depends on the version of Power Supply

Unit (see table 2).

EN 33ALIS-PDP Suppl. 7.

Table 8-2

PSU version 3 PSU v3 with precision R's PSU version 4

PDP with Vs feedback (-52 PDP) Feedback loop 'OFF', alignment is necessary Feedback loop 'ON', alignment (check) is

PDP with Vs/Va feedback

(with 'B' in serial number)

Feedback loop 'OFF', alignment is necessary Feedback loop 'ON', no alignment (check)

necessary (see voltage setting label)

necessary

This table also shows if the Vs and Va control loop must be

switched ON or OFF.

The voltage adjustments Vw and Vx are done automatically via

ComPair. After exchange of the Logic Board, click on ship out.

The settings from the old Logic Board will be restored in the

new Logic Board

Feedback loop 'ON', no alignment necessary

Feedback loop 'ON', no alignment necessary

Page 34

EN 34 ALIS-PDP Suppl.9.

Circuit Descriptions and Abbreviation List

9. Circuit Descriptions and Abbreviation List

9.1 Board Function Description

9.1.1 Logic board Function

Data Processor

• ( γ adjustment ( 1 / 2 . 2/ 2 . 4 / 2 . 6 / 2 8)

• NTSC/EBU format (Color matrix) Switch

• RGB gain Control (White balance adjustment, Amplitude

1imitation)

• Error Diffusion Technology (Greyscale adjustment)

• Dither (Greyscale adjustment)

• Burn-in Pattern generation

Data Converter

• Quasi out-line adjustment (luminous Pattern control)

Scan Controller

• Address driver control signal generator (ADM)

• Scan driver control signal generator (SDM)

• X/Y sustain control signal generator

Waveform ROM

• Waveform Pattern for drive / Timing memory

MPU

• Synchronous détection

• System control

• Driving voltage (Va, Vs, Vr, Vw) Minute adjustment

• Abnormal watch (breakdown detection)/abnormal

processing

• Ls (sustain) current control (sustain pulse control)

• La (address) current control (sub-field control)

• External communication control

• Flash memory (firmware)

9.1.3 Function of Y-SUS Board

DC/DC power supply block

• Vcc (+5V) -> Y Fvcc (+5V, floating)/Y Fve (+ 18V, floating)/

Ve (+ 17V)

Switching block

• Switching during address period

• Switching during sustain period

• Switching during reset period

Current detector block

• Isy (sustain) current detection

• Isp (SDM) current detection

9.1.4 Function of PSU Board

Standby power supply block

• AC100-240 +5V & +3V3 Standby

PFC block (AD/DC power supply block)

• AC100-240 +390V

AD/DC power supply block

• +380V - Vcc (+5V) / Vs (+80V)/Va (+60V)

Current detection block

• la (address) current detection

Abnormal voltage monitoring

• Vs excess voltage monitoring

• Va excess voltage monitoring

EEPROM

• Control parameter memory

• The accumulation energizing time (Every hour)

• Abnormal status memory (16 careers)

9.1.2 Function of X-SUS Board

DC/DC power supply block

• Vs (+60V) Vw (+185V)/Vx (+45V)

• Vcc (+5V) XFvcc (+5V, floating)/XFve (+ 18V,

floating)/Ve (+ 17v)/Vb(-5)

X switching block

• Switching during address period

• Switching during sustain period

• Switching during reset period

Current detector block

• Isx (sustain) current detection

Page 35

Circuit Descriptions and Abbreviation List

EN 35ALIS-PDP Suppl. 9.

9.2 List of abbreviations

ADM Address module

Burn-in rack Test equipment of the shelf test in

which the PDP unit is left to stand in

drive condition

CPU The unit for controlling the circuit

operation

DOXE The control voltage for even-

numbered lines in the X direction

DOYSD Used in the drive voltage in the Y

direction (down)

DOYSU Used in the drive voltage in the Y

direction (up)

DOXO The control voltage for odd-numbered

lines in the X direction

External power ON Running the external powers (Vcc, Va,

Vs) on the designated voltage. Unless

otherwise specified

External power OFF Making the external powers (Vcc, Va,

Vs) to stop their operation completely.

Unless otherwise specified

Flexible cable The cable to connect the electric

circuit to the panel

Flicker Continuous switching between bright

and dark views by the PDP itself

Gradation Shading of the display colour

OPUMP The name of a circuit where the

current from X/YSUS is returned

Oscilloscope A device that allows the flow and

strength of the running current to be

visually checked and measured

Panel The indication part of the plasma

display panel (PDP)

Panel voltage The voltage required operating the

PDP normally

Parts Each PC board and parts mounted in

the PC boards

PDP Plasma display panel abbreviated

Probe A cable with contact finger that can

transfer the status of the electric circuit

to be measured to an oscilloscope

Protection cover A cover made by aluminium to protect

the PDP entirely during test

ROM Memory that stores the drive

sequence and other data

SDM Scan module

SUS XSUS or YSUS

Tapping Light impact

Unit of COM The unit of circuits connected to the

panel with flexible cable. (YCOM UP/

DOWN, XBUS UP/DOWN, address

sections, the unit of PC boards in

ACOM 1 to 5)

Va The power supply at 60 V. which is

used to write data on the panel

Vcc The power supply at 5 V, which is used

to operate the logic section mainly

Vs The power supply ranging from 127 V

to 180 V, which is used to maintain

display data. In addition, this can

serve as the primary side for the

secondary voltage (Vw, -Vy, Vsc)

White solid A condition when the screen display is

entirely white

XSUS The name of the circuit that controls

the panel operation in the X direction

YCOM The circuit used to output a panel Y

line selection signal and the voltage of

a display data keep signal

YCOMDV The name of the panel drives voltage

signal output from YCOM UP/DOWN

section

YSUS The name of the circuit that controls

the panel operation in the Y directio

Page 36

EN 36 ALIS-PDP Suppl.10.

10. Spare Parts List

For spare parts list see chapter 5.2

11. Revision List

Supplement on FM23, FM24, FM33 (3122 785 13891) service

manuals.

Spare Parts List

Loading...

Loading...