PHILIPS A8.0A Training Manual

1

Colour television Chassis

A8.0A

Training Man ual

Contents

Introduction 2

Mechanical 3

Control 9

Power supply 24

Video processing 34

Synchronization 52

Audio processing 54

Horizontal deflection 60

Vertical deflection 80

Teletext + On-Screen Display 83

Published by TG9866 Television Service Department

Printed in The Netherlands

Copyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The Netherlands. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips

5

Widescreen view modes 89

4822 727 21613

©Copyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored ina retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise without the prior permission of Philips

Published by TG9866 Television Service DepartmentPrinted in The Netherlands 5 4822 727 21613

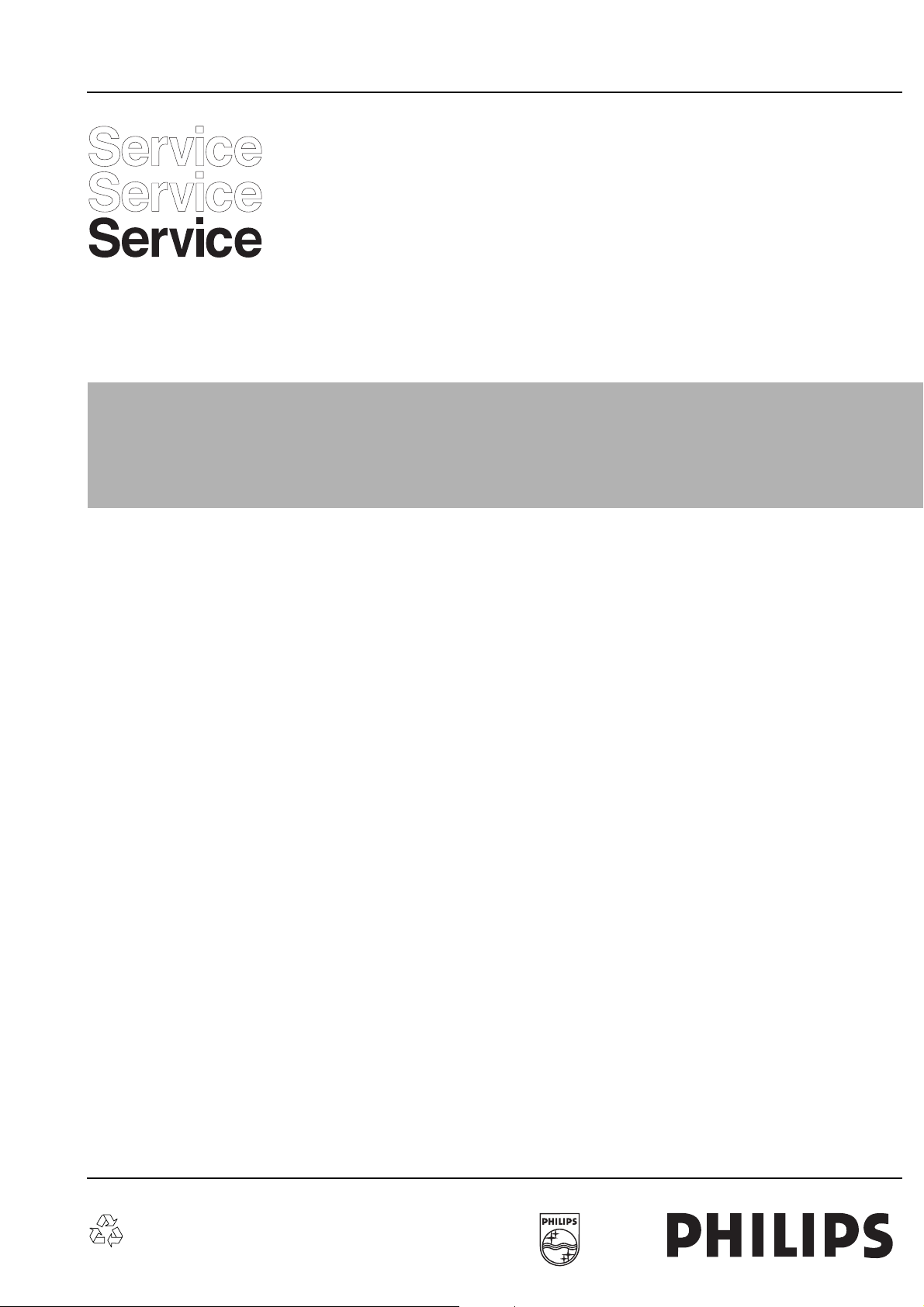

2 INTRODUCTION A8.0A

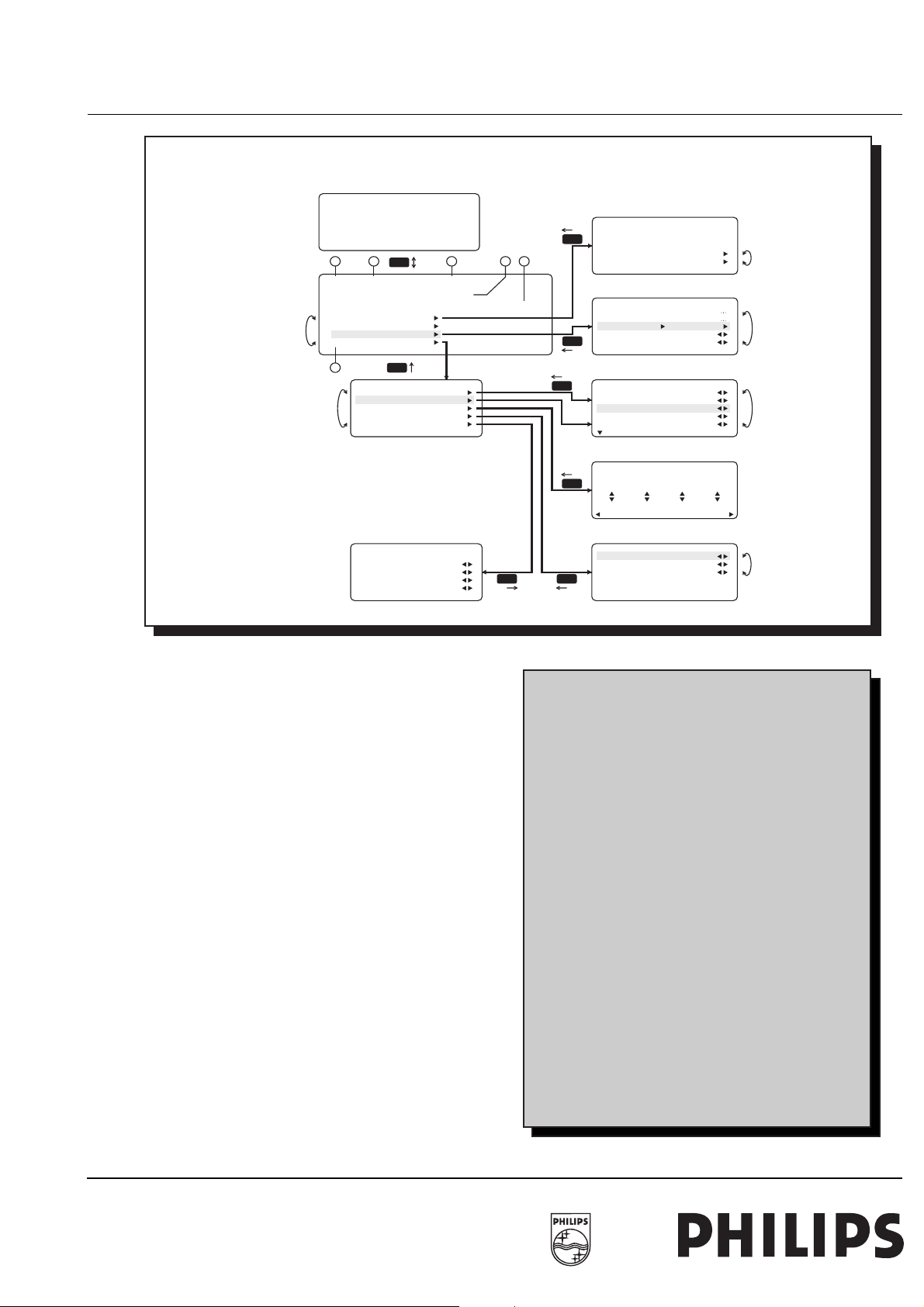

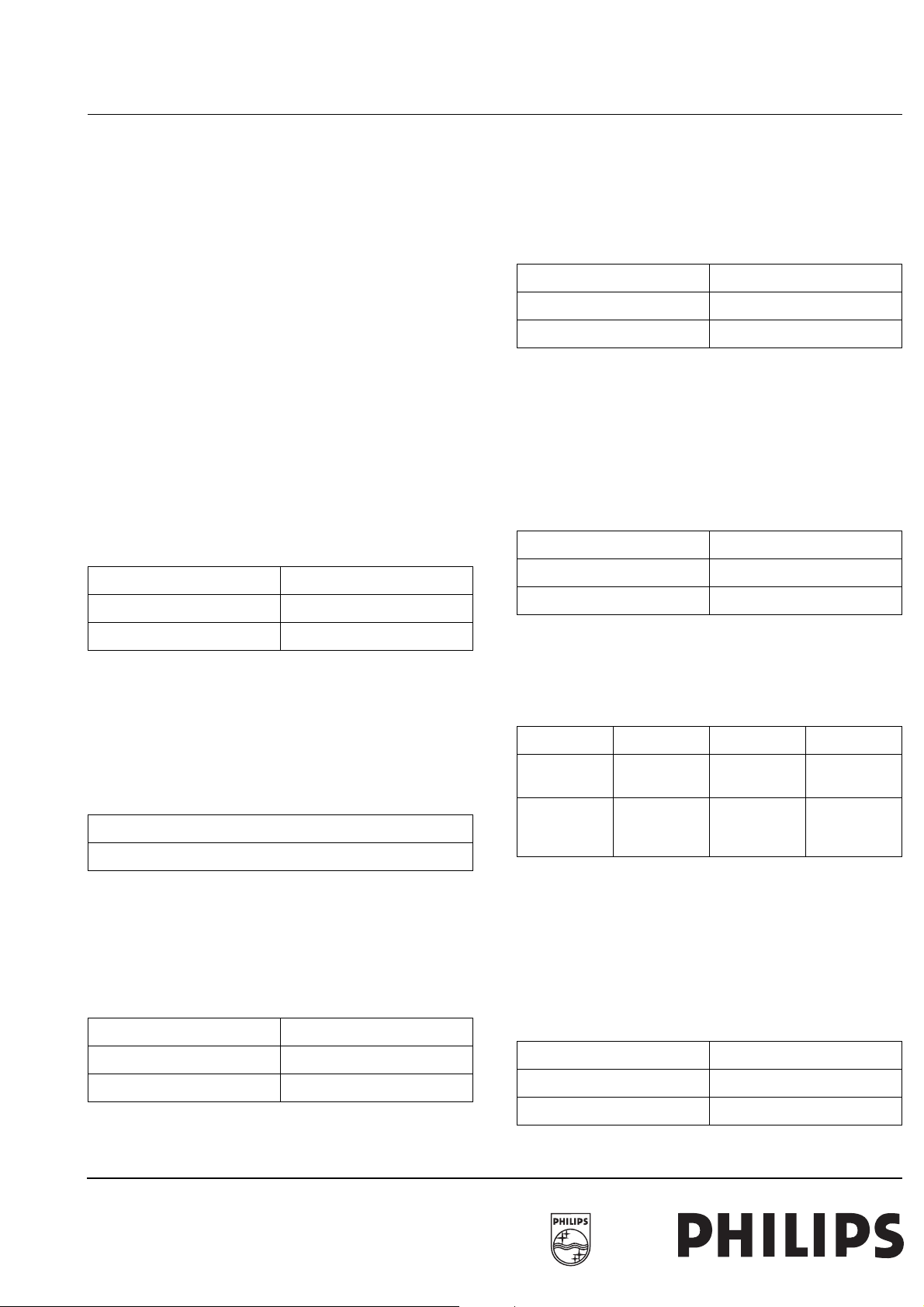

Block diagram

INTRODUCTIONBlock diagram

1125

TUNER

QSS

PANEL

7150-D

SYNC

7150-A

IF

YC PIP

PANEL

YCYC

Y/CVBS Y

IO

PANEL

SIF

SOUND

PROCES-

AM

SING

LINE

DRIVE

EW+

PANORAMA

PANEL

FRAME

AMPLIFIER

COMB

FILTER

CC

PANEL

AUDIO

AMPLIFIER

LOT

7150-0

VIDEO

PROCESSING

220V

YUV VYU

Y

U

V

R

G

B

DW PANEL

YUV

PANEL

TOP

CONTROL

PANEL

SUPPLY

SMPS

7150-C

RGB

PROCESSING

RGB

SWITCH

OSD/TXT

CONTROLS

+140

+33

+14

+8

+15

+5

+5 - STBY

RGB AMP

SCAVEM

I2C

CL 86532033_009.AI

160698

• The power is supplied by an SMPS (Switch Mode Power

Supply) creating the deflection power supply voltage (

+140V), the sound power supply voltage (+15V) and a

number of low voltages (+14V, +8v, +5v and

+5vSTANDBY).

• The controls located on the mono carrier are activated by

the keyboard and RC5 signals from the remote control receiver. The internal control is via I2C.

• TheTUNER transmits anIF video signalon 38.9 MHzto the

TDA884x (IC7150). In this IC the video processing

(PAL,NTSC and SECAM) and synchronization along with

the geometrical alignments are implemented.

• Sound decoding is performed in the sound processing part

which can be BTSC dedicated (TDA9855) ormulti standard

(MSP3410) (mono, stereo, nicam).

• In some stereo sets (mainly NICAM and FM DK) the QSS

panel (Quasi Split Sound) will be applied to improve the SIF

signal

• The CRT-panel contains integrated RGB amplifiers and

SCAVEMcircuitry. The RGB signalsare then transmitted to

the picture tube via the RGB amplifiers.

• The horizontal and vertical deflection signals (line and

frame) are amplified in the driver stages, which drive the deflection coils.

• In all sets except 21" E/W correction is needed which is accommodated on a separate panel. For 16:9 sets the panorama circuitry is also accommodated on this panel

Personal notes

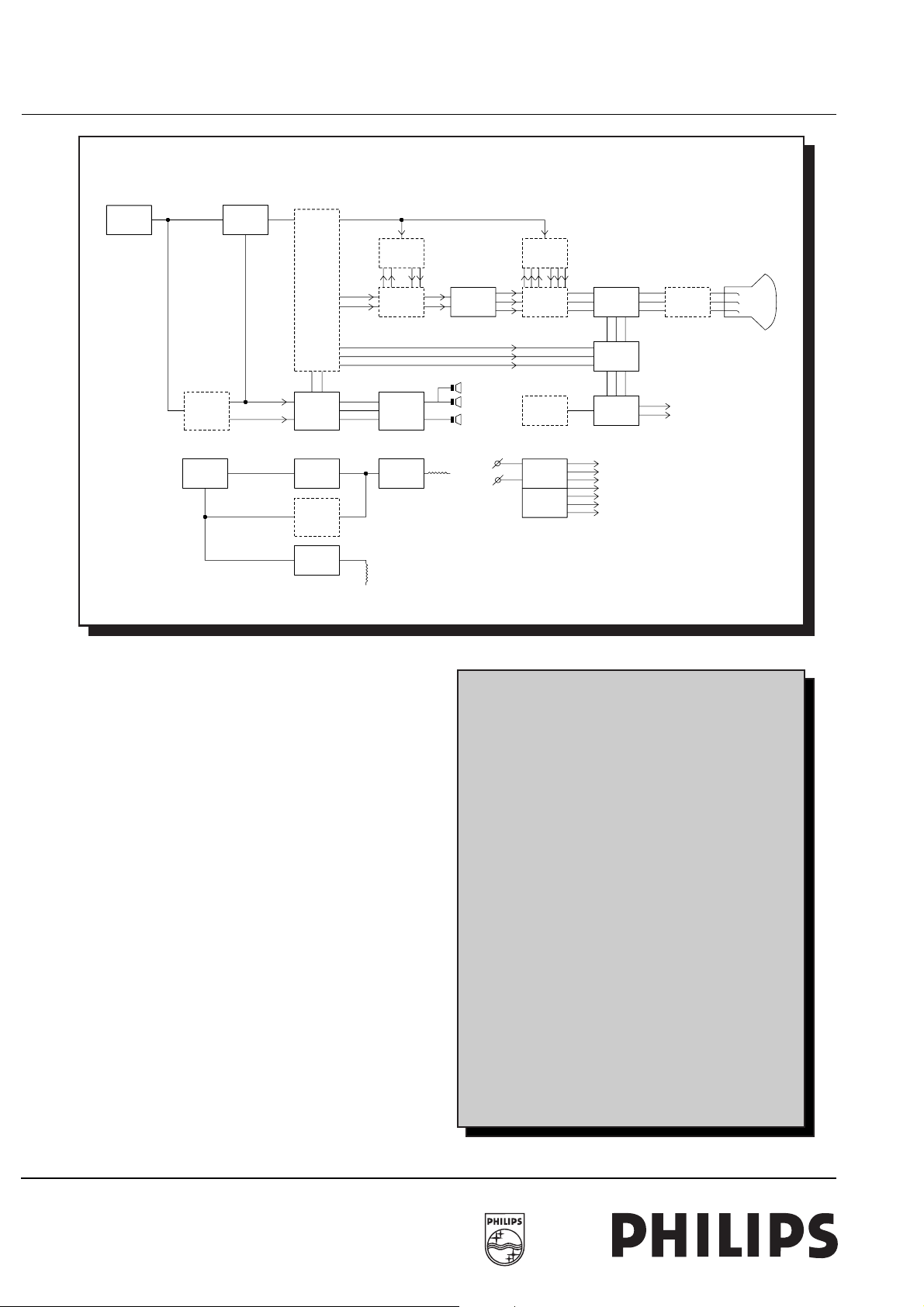

A8.0A Mechanical 3

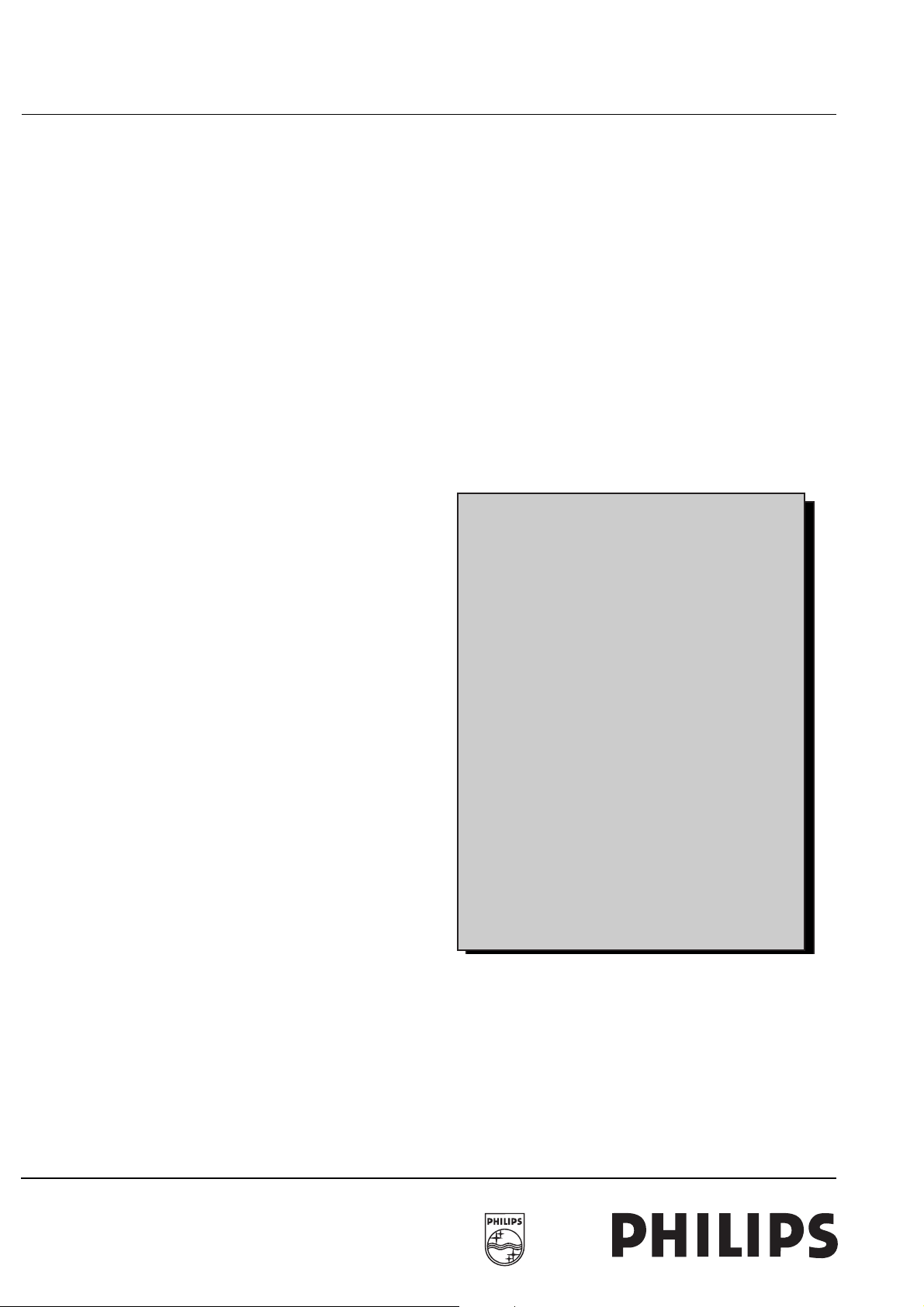

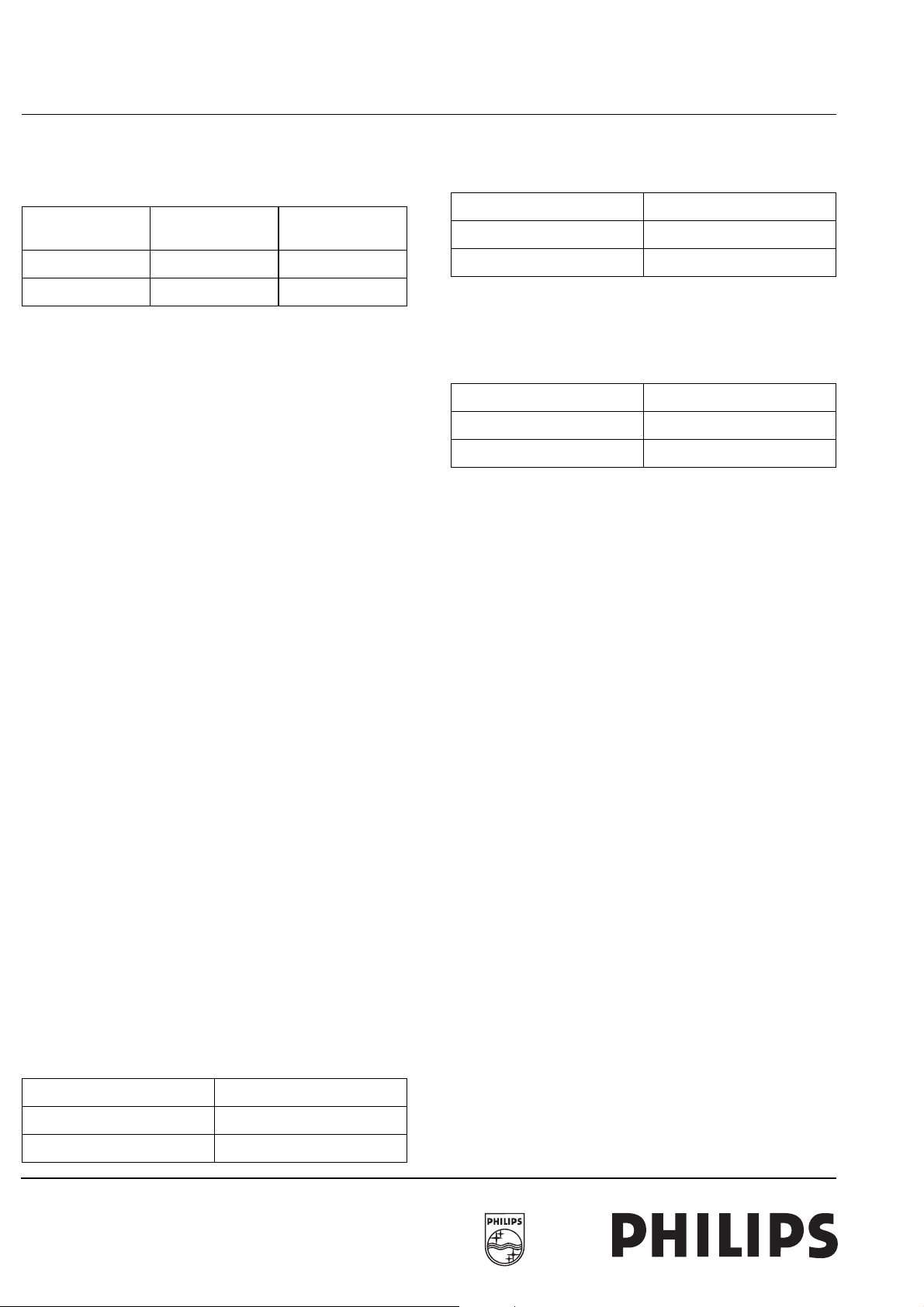

Chassis Set-up

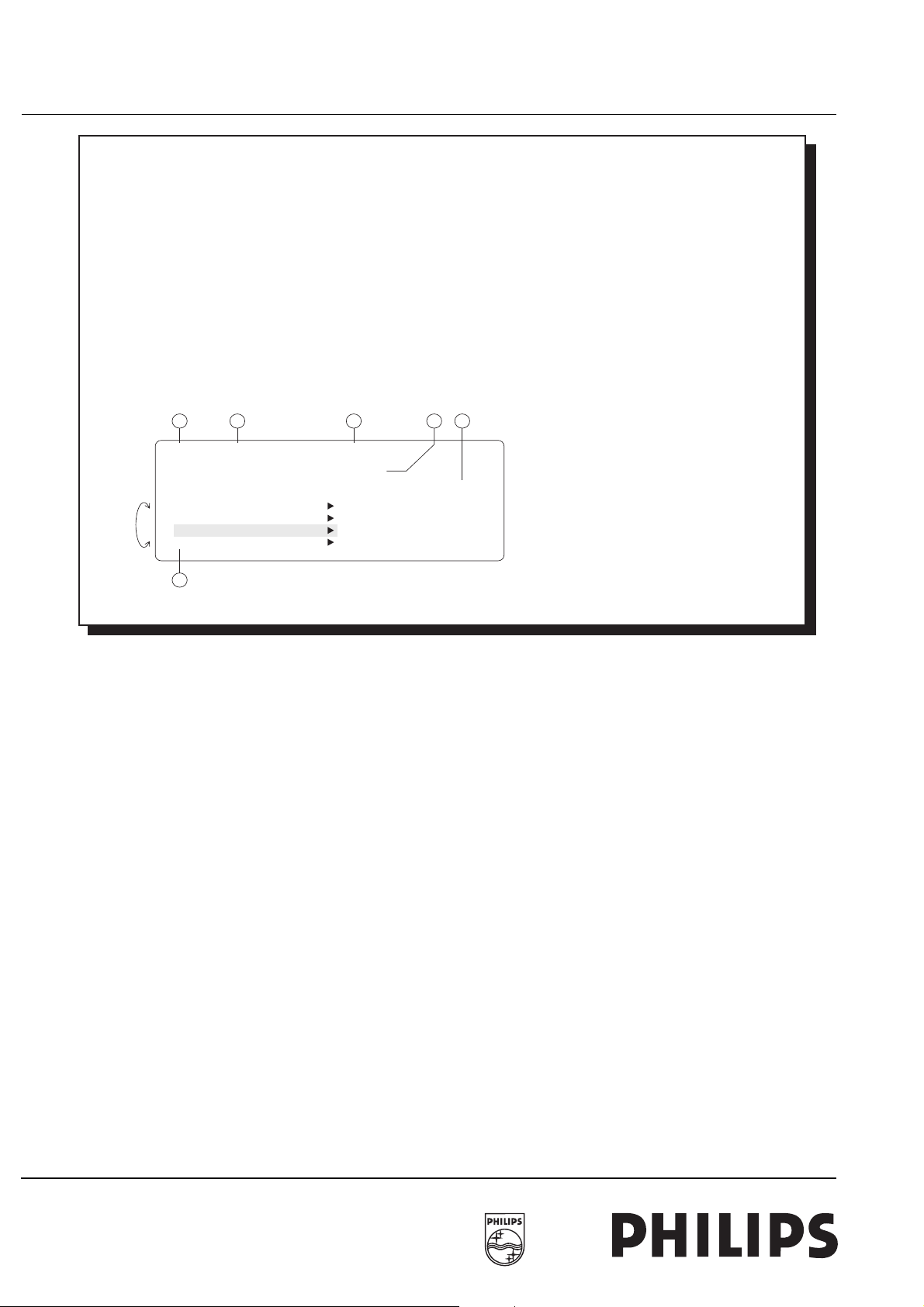

MechanicalChassis Set-up

TOP CONTROL PANEL

N

CRT PANEL

B

EAST WEST PANEL

C

OSD

S

SIDE AV PANEL

M

Q

INCREDIBLE SOUND PANEL

R

YUV PANEL

COMB. FILTER PANEL

G

QSS-DK PANEL

J

QSS (BGLI NICAM)

I

I/O CINCH PANEL

E

PIP PANEL

T

POWER SUPPLY

HOR. DEFLECTION + LINE OUTPUT

VERTICAL DEFLECTION

TUNER + VIF

VIDEO PROCESSING

SYNC

RGB PROCESSING

CONTROLS

AUDIO PROCESSING BTSC

AUDIO PROCESSING NICAM/2CS/FM/AM

AUDIO OUTPUT

IO SWITCHING

FRONT AV

FRONT CONTROL

MAINS FILTER PANEL

CL 86532033_055.AI

A1

A2

A3

A4

A5

A6

A7

A8

A10

A11

A12

A13

A14

A15

H

180698

(The A8 has a mono carrier and panels for East West, I/O

SCART/Cinch, Side AV, QSS, Teletext, Mains filter and Top

Control.

• The mono carrier is a double sided panel with SMDs at the

solder side. It accommodates:

• the control part

• video signal processing

• source select(front/rear)

•IF

• sound processing

• audio amplifier

• horizontal and vertical deflection

• power supply

• front control(IR, LED)

• teletext in the micro-processor.

• Different panels can be placed on the mono carrier:

• QSS panel

• YUV panel

• COMB. Filter panel

• E/W Panel

• OSD panel

• incredible sound panel

• Loose panels are

• Top Control panel

• Side AV panel

• Mains filter panel

• I/O panel.

• PIP panel/ DW panel

• The CRT panel (contains the RGB amplifier circuit and

SCAVEM)

4 Mechanical A8.0A

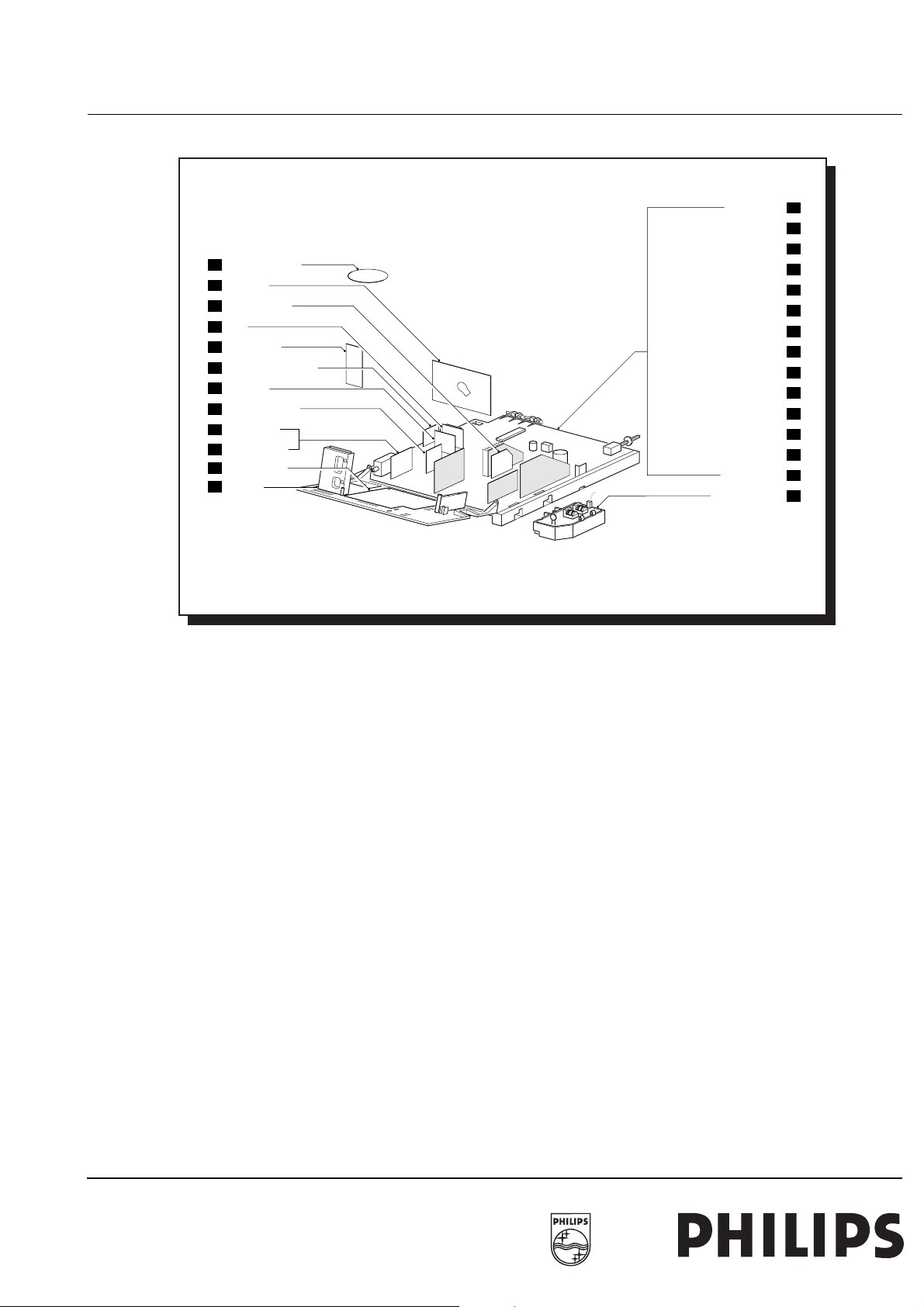

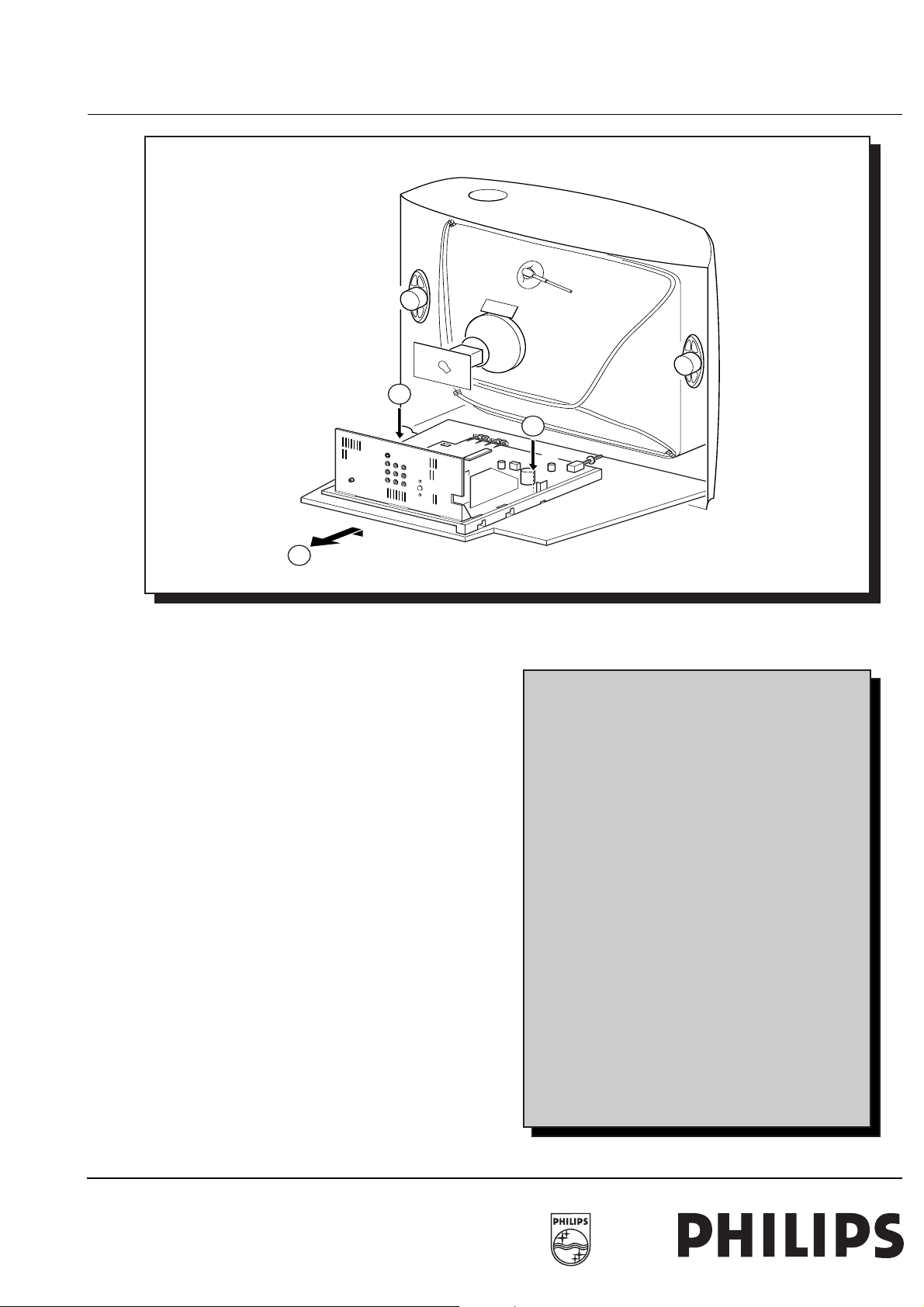

Removing the separate mains filter

Removing the separate mains filter

1

In order to remove the rear cover from the A8, all screws at the

side, the bottom and the top of the rear cover have to be removed. The screws near the I/O cinch connectors should NOT

be removed.

CAUTION!

Remember to disconnect the subwoofer connector !!

Unplug the mains cord before working on the separate mains

filter;the separate mains filter carries permanent mains voltage

(even when the mains knob is switched OFF).

Disconnect the separate mains filter panel

To disconnect the separate mains filter bracket from the chassis tray:

• firmly depress the click (with a screwdriver) in the chassis

tray (1)

• push the mains filter bracket in the direction of the CRT

2

• lift the panel from its bracket

CL 86532033_050.AI

180698

Remove the separate mains filter panel

To remove the separate mains filter panel from its bracket:

• push the 2 clips at the right hand side of the mains filter

bracket outside (2)

A8.0A Mechanical 5

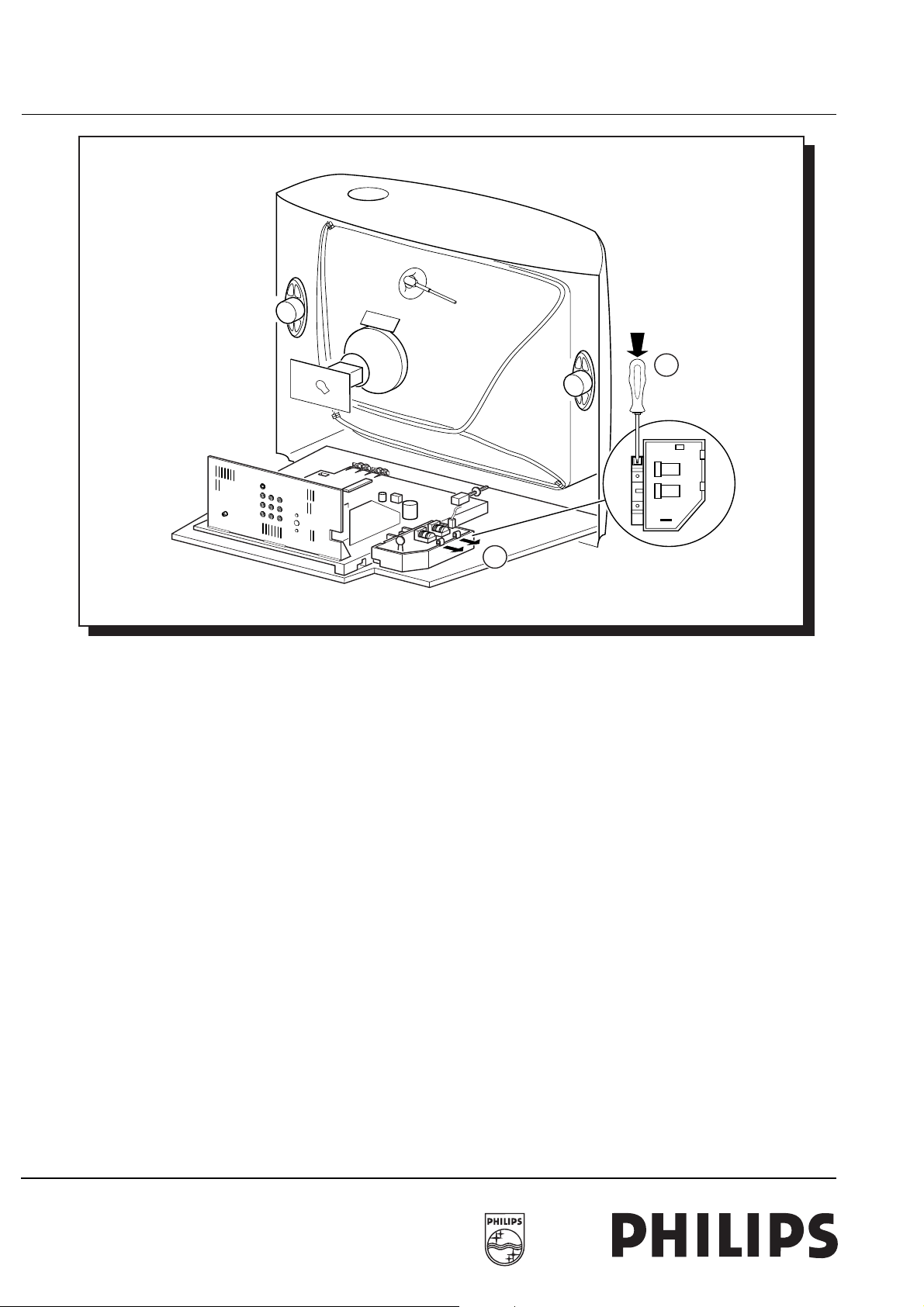

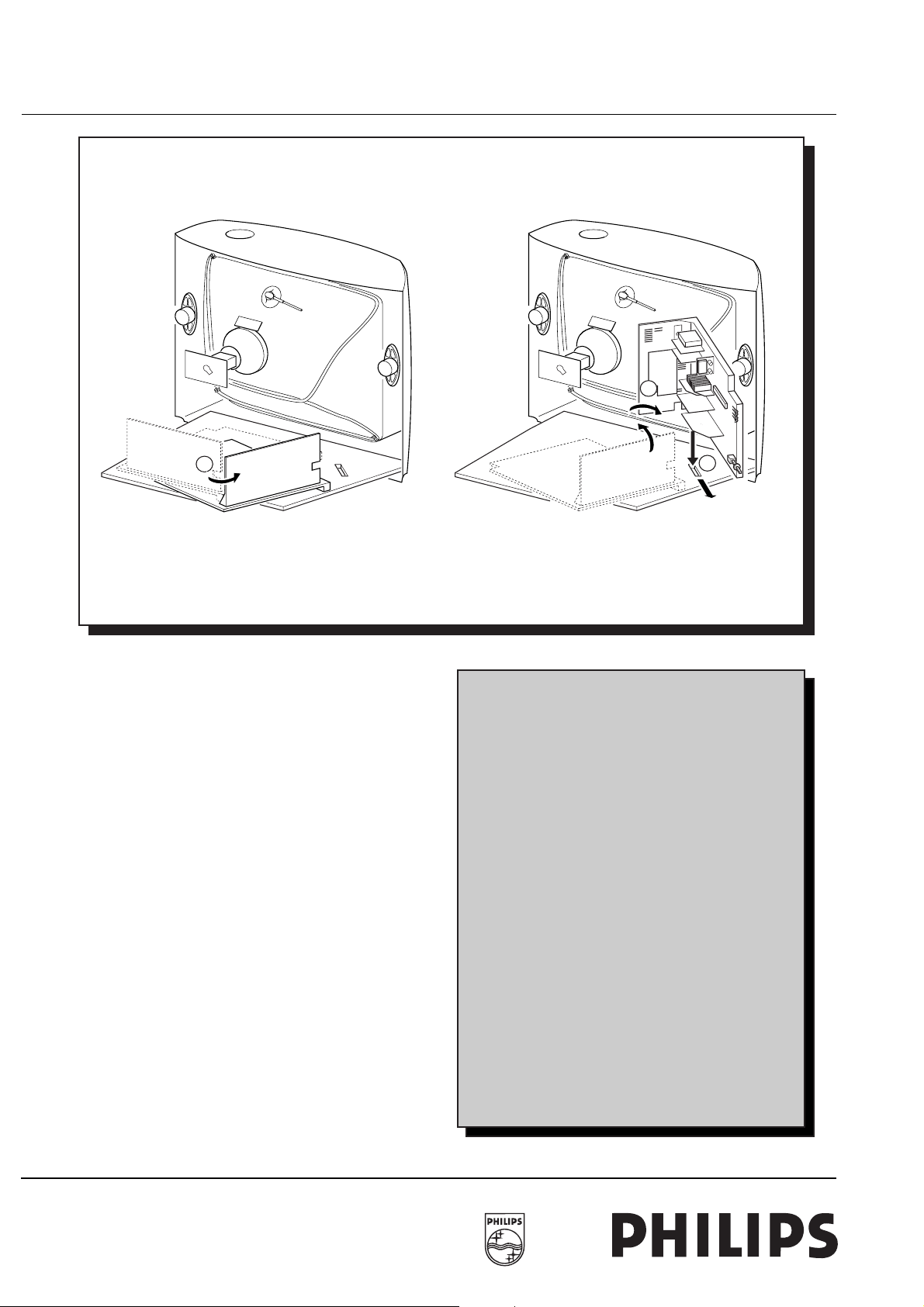

Removing the chassis

Removing the chassis

1

1

M16

2

Service position without the need for a largetable or workbench

To remove the chassis tray from the cabinet:

• disconnect the degaussing coil (connector M16 on the

mono carrier)

• pull the clips (1) backwards and pull the chassis tray as indicated (2)

The chassis tray should be turned 90 degrees counter clock

wise and flipped over to access the copper side of the mono

carrier.

Personal notes

CL 86532033_051.AI

180698

6 Mechanical A8.0A

Environment independent position

Environment independent position

2

1

A

For home repair the chassis tray with mono carrier can be fixed

in the cabinet.

• turn the chassis tray 90 degrees counter clock wise (1)

• flip the tray with the I/O panel towards the CRT (2)

• press (the hook of) the chassis tray firmly into the designated hole in the cabinet bottom (3) and pull the chassis tray

forward (the speaker cables may have to be disconnected)

B

Personal notes

IO PANEL

BRACKET

3

CL 86532033_052.AI

180698

A8.0A Mechanical 7

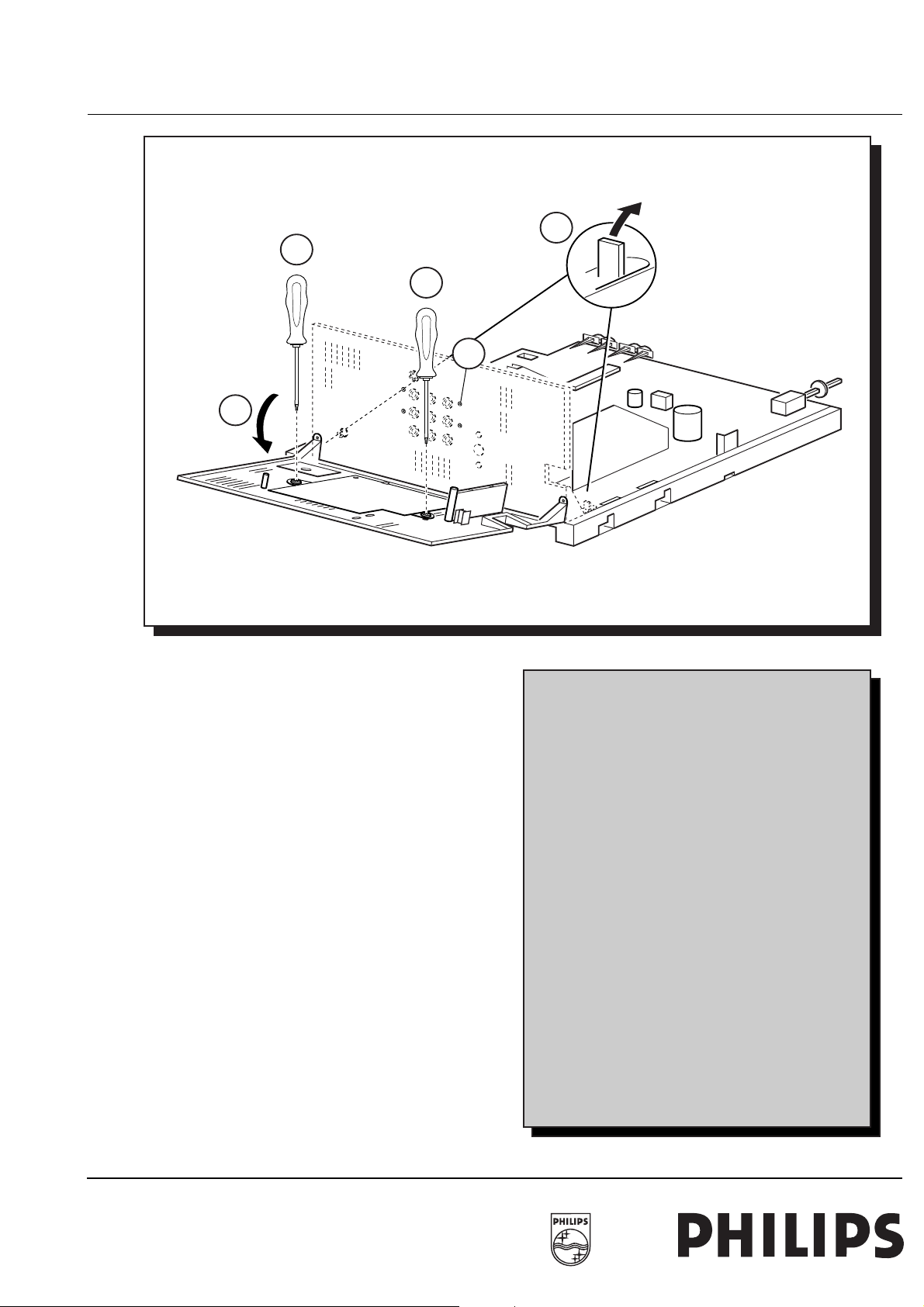

Accessing the I/O panel

Accessing the I/O panel

1

4

4

3

2

To access the copper side of the IO panel:

• push the clips (1) in the direction of the CRT (If the clips are

broken, the I/O panel can also be screwed to chassis tray)

• slide the I/O panel bracket (2) to its horizontal position

To remove the I/O panel from its bracket:

• remove the 2 screws on the connector side of the panel (3)

and (4).

(4X)

Personal notes

CL 86532033_053.AI

180698

8 Mechanical A8.0A

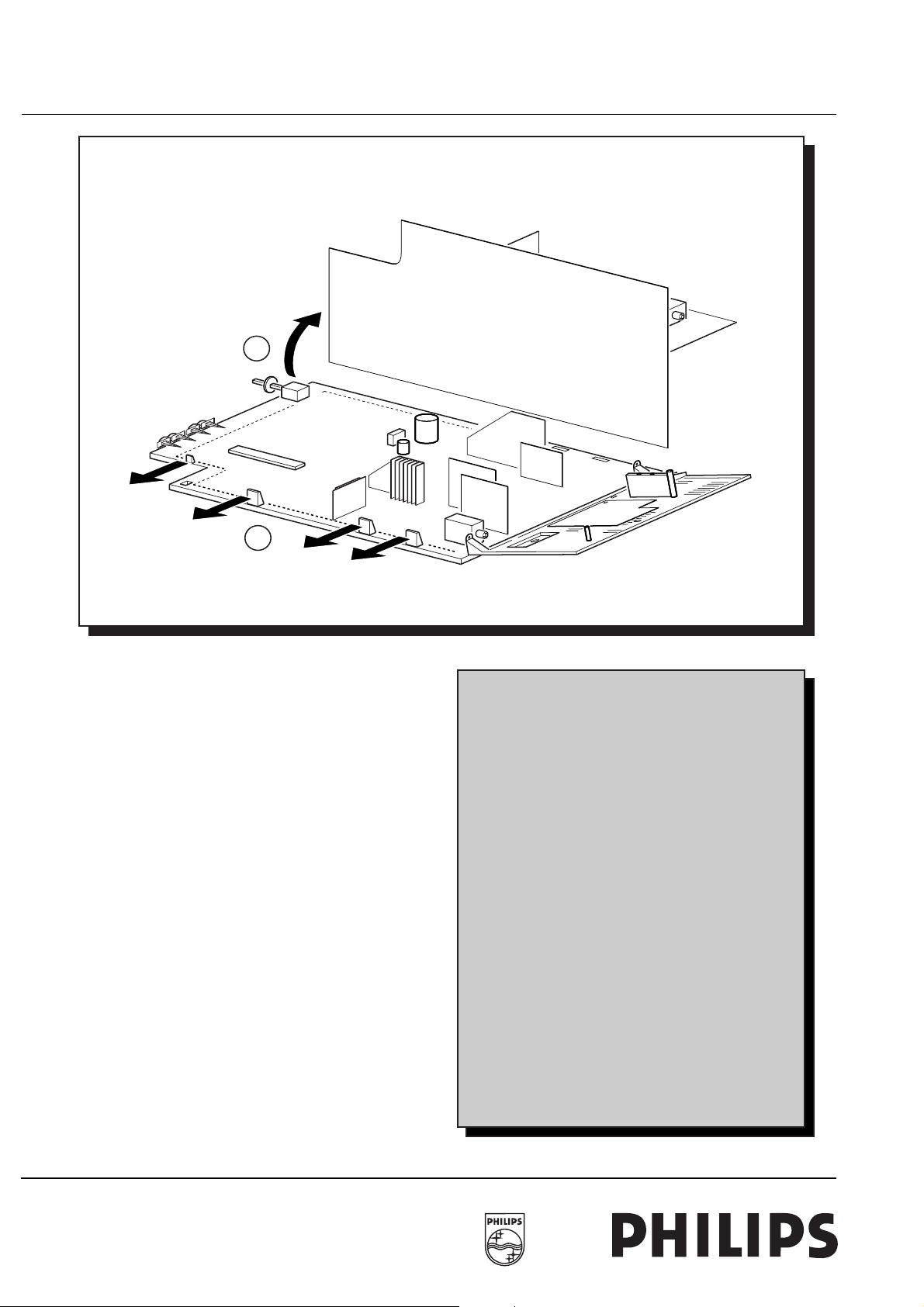

Repairing the mono carrier

Repairing the mono carrier

2

1

For full access to the component and copper side of the mono

carrier, it can be removed from the chassis tray.

• push the clicks of the chassis tray outwards (1)

• lift the mono carrier from the tray (2).

Personal notes

CL 86532033_054.AI

180698

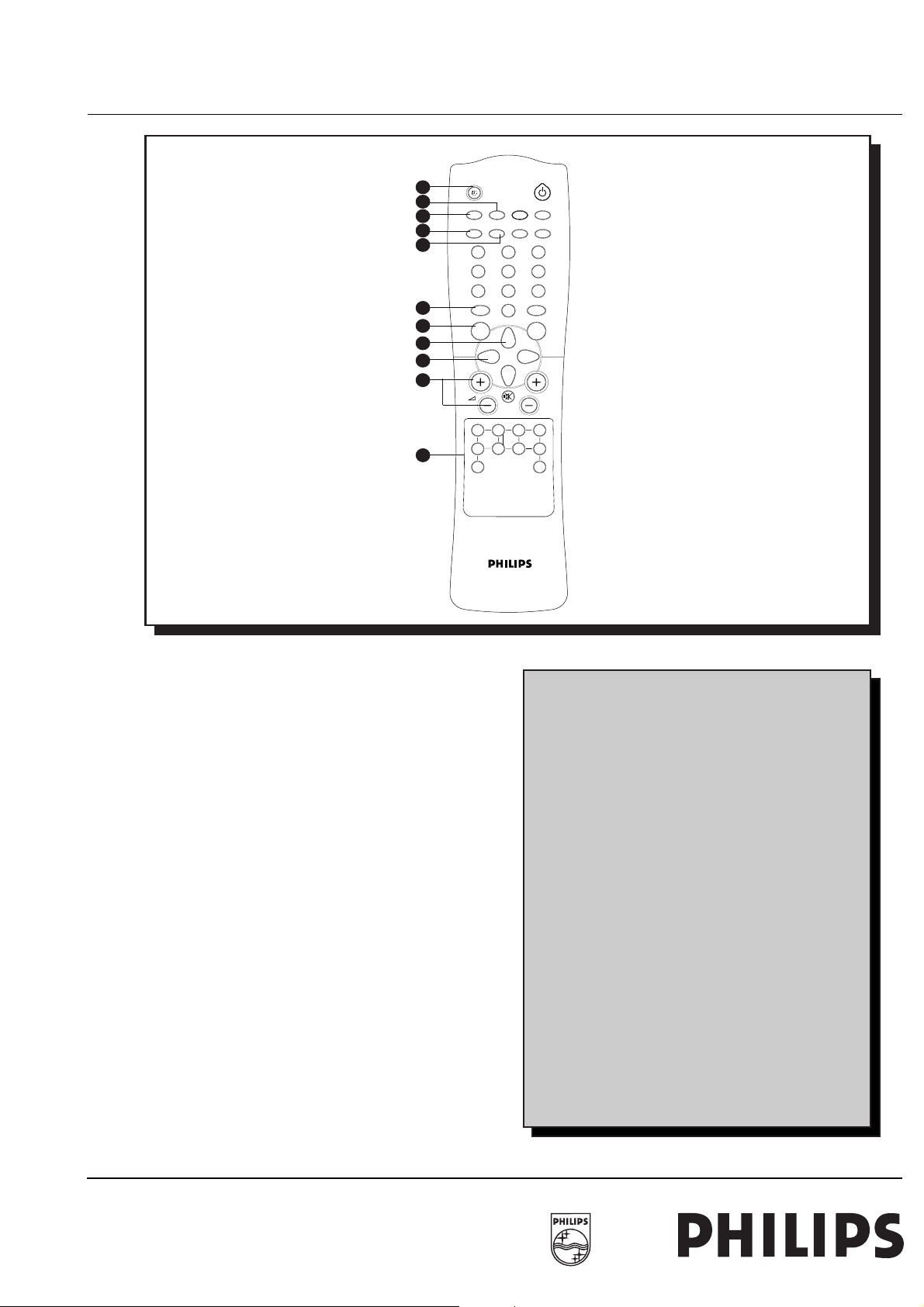

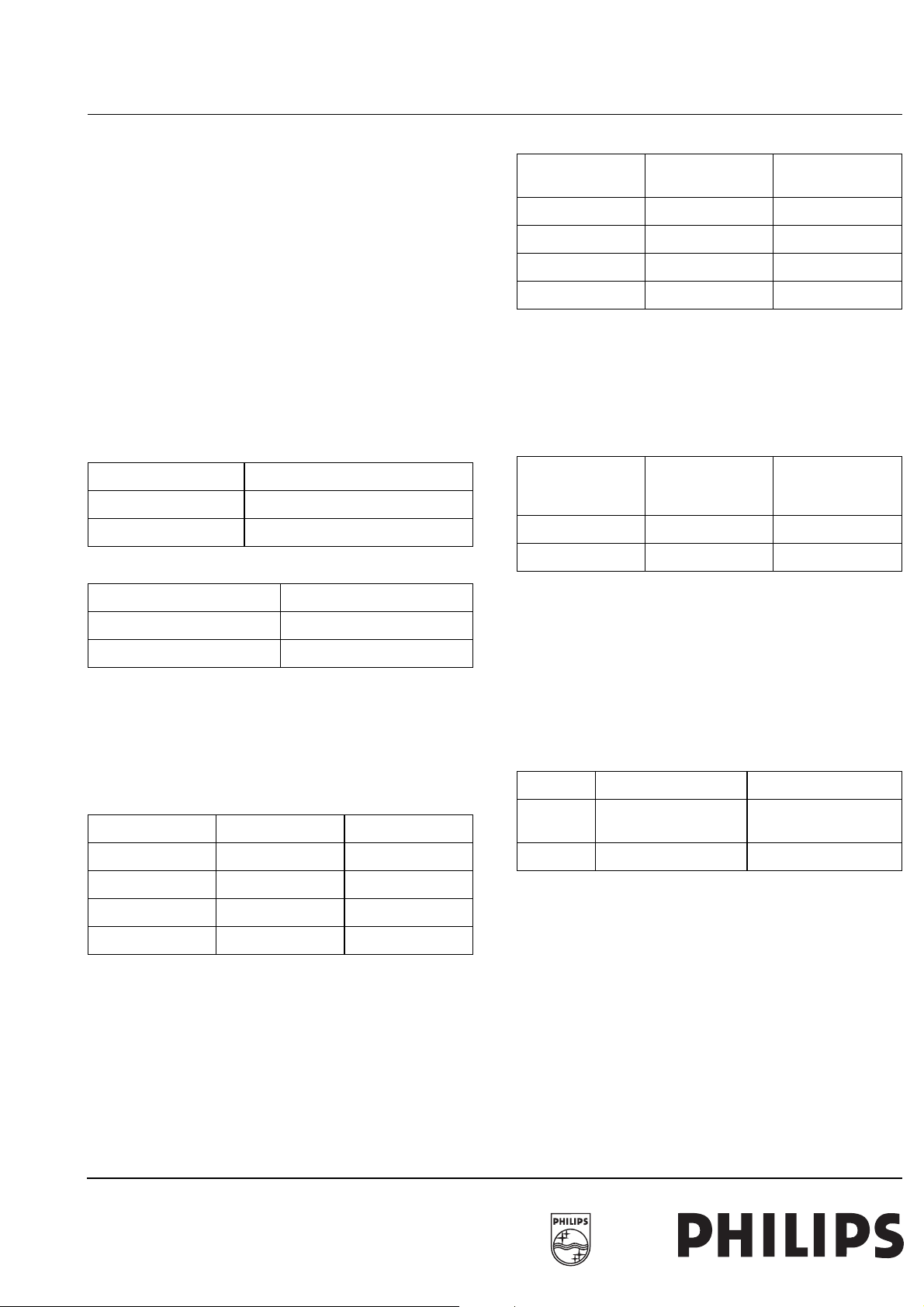

A8.0A CONTROLS 9

User Menu

CONTROLSUser Menu

1

2

3

4

5

6

7

8

9

10

11

AV

INCREDIBLE

INC. SURR.

1

2

4

5

8

7

0

MENU SURF

A/CH

GAME

3

6

9

SMARTSMART

CH

The complete control of TV sets with a A8 chassis is performed

via menus. Selections within the menus are made by the arrow

keys on the remote control (cursor control).

On the remote control the "smart controls" for picture and

sound are present. Pressing one of these buttons will give a

pre-programmed change of various audio or picture settings at

the same time.

Personal notes

CL 86532033_024.AI

160698

10 CONTROLS A8.0A

Installation

Installation

Installation

Automatic

Manually

DST (RC7150)

Installation of the A8 can be done via the installation menu or

via the Dealer Service Tool (DST);

1. With the Installation-menu the installation of the TV can be

performed in two ways:

• Automatic: The complete TV band is searched and all

transmitters are installed.

• Manually: The frequencies have to be given for all pro-

gram numbers.

2. With the RC7150 Dealer Service Tool (DST)

• The RC7150 can install a complete TV program table in

a single operation.

Personal notes

A8.0A CONTROLS 11

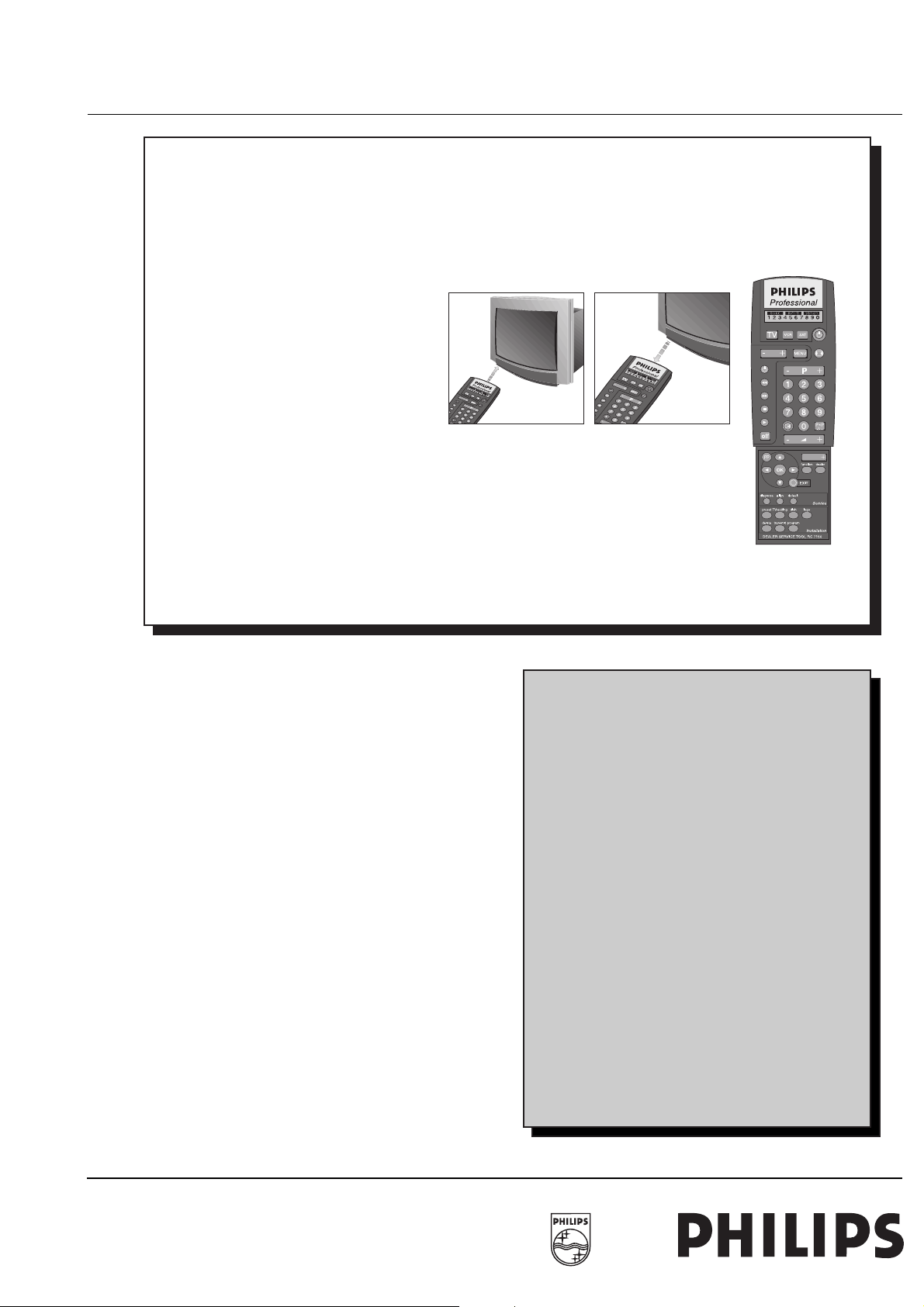

Dealer Service Tool (DST)

Dealer Service Tool (DST)

RC7150

Service Features

--Entering the Service Alignment Mode

Entering the Service Default Mode

Defined settings for tuning and control

The dealer service tool (DST, RC7150) is a remote control, especially developed for the dealer and service engineer.

• Dealer functions

– With the DST complete program tables can be transmit-

ted to the TV. 10 different tables can be stored in the

DST, e.g. for 10 different areas.

Programming tables into the DST can be performed in two

ways:

• From the TV (GFL only). If a GFL TV is installed with a complete table of program information the complete table can

betransmitted to the DST. Asuse is being made of the dealer link, the DST must be held at a short distance(within 10

cm) from the IR transmitter LED (next to the stand-by led).

• With a DST interface (22AV1376). This is a computer interface that can be used with the accompanying computer program to input tables in the computer and transmit these

tables to the DST.

• Service features of the DST for the A8

– Activating the Service Alignment Mode. By pressing the

"ALIGN" key on the DST the Service Alignment Mode

SAM) is activated.

– Activating Service Default Mode. By pressing the "DE-

FAULT" key on the DST the Service Default Mode

(SDM) is activated.

– Downloading program tables from DST into the TV.

Personal notes

CL 86532033_012.AI

160698

12 CONTROLS A8.0A

Service Default Mode (SDM)

Service Default Mode (SDM)

SERVICE DEFAULT MODE

--Shortcircuit 9040 & 9041 on the SSP

Press the "default" key on the RC7150

Tuner tuned to 475.25 MHz

All linear settings in "mid" position

Volume set to "low"

Entering the Service Default Mode (SDM):

– By transmitting the "DEFAULT" command with the RC7150

Dealer Service Tool.

– By shorting the jumpers 9040 & 9041 while switching onthe

set with mains switch.

Exiting the Service Default Mode (SDM):

– Switch the set to stand-by (the error buffer is also cleared)

Specification of the Service Default Mode (SDM)

Default values of the following must be set according;

• Tune to 475.25MHz. PAL/Secam sets

• Tune to channel 3 (61.25 MHz) for NTSC sets

• All linear setting at 50%, except volume at 25%

• Disable service unfriendly modes;

– Timer Off

– Sleeptimer Off

– Hospitality disabled

– No-ident timer disabled

– Parental lock disabled

Personal notes

CL 86532033_014.AI

160698

• The default system (for multi system sets) will be set according to the signal source input at the antenna.

A8.0A CONTROLS 13

Service Default Mode (SDM)

Service Default Mode (SDM)

SDM Menu

SDM

ERR nn nn nn nn nn nn

+

SDM

Others features of SDM

• Error codes OSD can be switched on and off with OSD button

• Switch to user menu by pressing MENU button

• LED blinks with info of the error in error buffer

• Start channel search by pressing "P+" button on the remote

control

PICTURE BRIGHTNESS

MENU

SOUND COLOUR

FEATURES CONTRAST

INSTALL SHARPNESS

Personal notes

SAM

COLOUR TEMP

CL 86532036_003.ai

260598

14 CONTROLS A8.0A

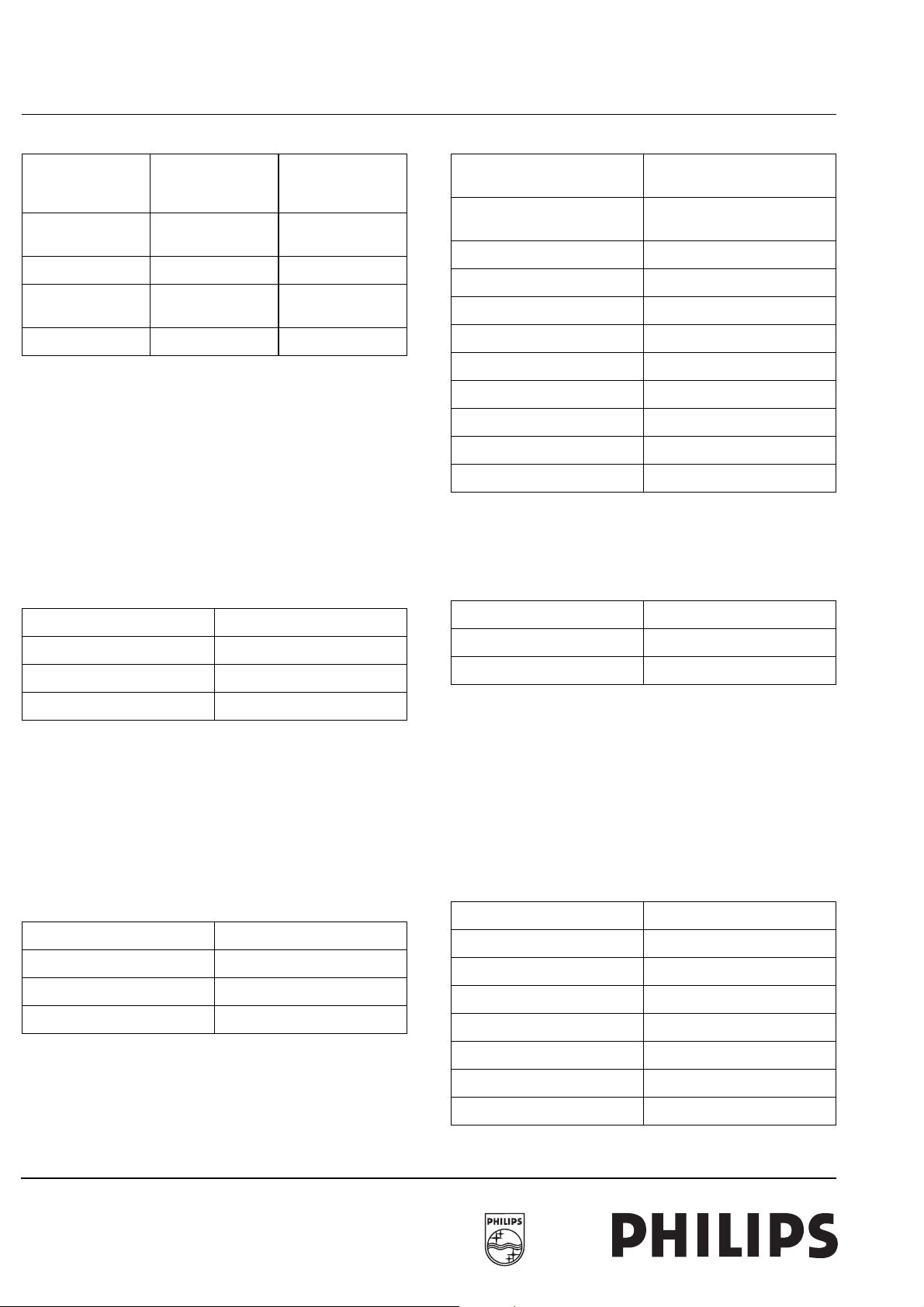

Service Alignment Mode (SAM)

Service Alignment Mode (SAM)

SERVICE ALIGNMENT MODE

- From SDM via "Vol +" & "Vol -"

Service Menu

1

nnnn A80EU1-1.0 5263-2-23

ERR nn nn nn nn nn nn

OP nnn nnn nnn nnn nnn nnn nnn

RELOAD DEFAULT

ERASE BUFFER

OPTIONS

ALIGNMENTS

6

2 3 4 5

Entering the Service Alignment Mode (SAM

• During normal operation and SDM by transmitting the

"ALIGN" command with the RC7150 Dealer Service Tool.

• By pressing and holding VOL+ & VOL- keys on the local

keyboard for 2 sec. while in SDM

Specification of the Service Alignment Mode

(SAM)

1. Operating hour counter ( in Hexadecimal)

2. Software version

3. Software of separate teletext controller; NOT implemented

for A/P.

4. Error code buffer (maximum the last 6 error codes

5. Option bytes (7 bytes possible

6. Sub menus

– Erase buffer

– Option codes

– Alignments and geometry information

– Reload default values

Errorcode Description ofpossible defective components 0 No

error detected - 1 EW and/or Vert protection active EW/Vertical circuit is defective 2 High beam protection active CRT

amplifier circuit or picture tube 3 Reserved 4 5V protection

active +5V supply line is low or short cuicuit 5 BiMOS s/w protectionactive or BiMOS register is corrupted IC7150 6 BiMOS

SAM

CL 86532033_039.AI

IIC error IC7150 7 General IIC bus error IICbus s/c or o/c 8

MainuP InternalRAM error IC7000 9 OSD generator IIC error

IC7101 on OSD panel 10 NVM addressing error IC7088 11

NVM IIC error IC7088 12 HistogramIIC error IC7770 on YUV

interface panel 13 Reserved 14 Sound processor IIC error

IC7430 (ITT) or IC7437 (BTSC) 15 Reserved 16 Main tuner

IIC error U1125 17 PIP processor IIC error IC7350 on PIP

panel 18 2nd tuner PIP IIC error U1126 or U1127 on PIP panel 19 EPG uProcessor/Guide Plus uProcessor IIC error

IC7007 on EPG panel

IC6 on guide plus panel 20 NV-clock IIC error IC7110 21 Reserve 22 EPG processor IIC internal RAM error IC7007 on

EPG error

160698

Exiting the Service Alignment Mode (SAM)

• The SAM will be left by the stand-by command. In case the

set is switched "off" and "on" again with the mains switch,

the set will start up in the SDM again.

Specification of the Service Alignment Mode

(SAM)

1. Operating hour counter (in hexadecimal)

2. Software version

3. Software of separate teletext controller

4. Error code buffer (maximum the last 6 error codes)

A8.0A CONTROLS 15

Service Alignment Mode (SAM)

5. Option bytes (7 bytes possible)

6. Sub menus

• Erase buffer

• Option codes

• Alignments and geometry information

• Reload default values

The error code buffer is written from left toright and contains all

errors detected since the last time the buffer is erased.

An example can be:

Error code buffer

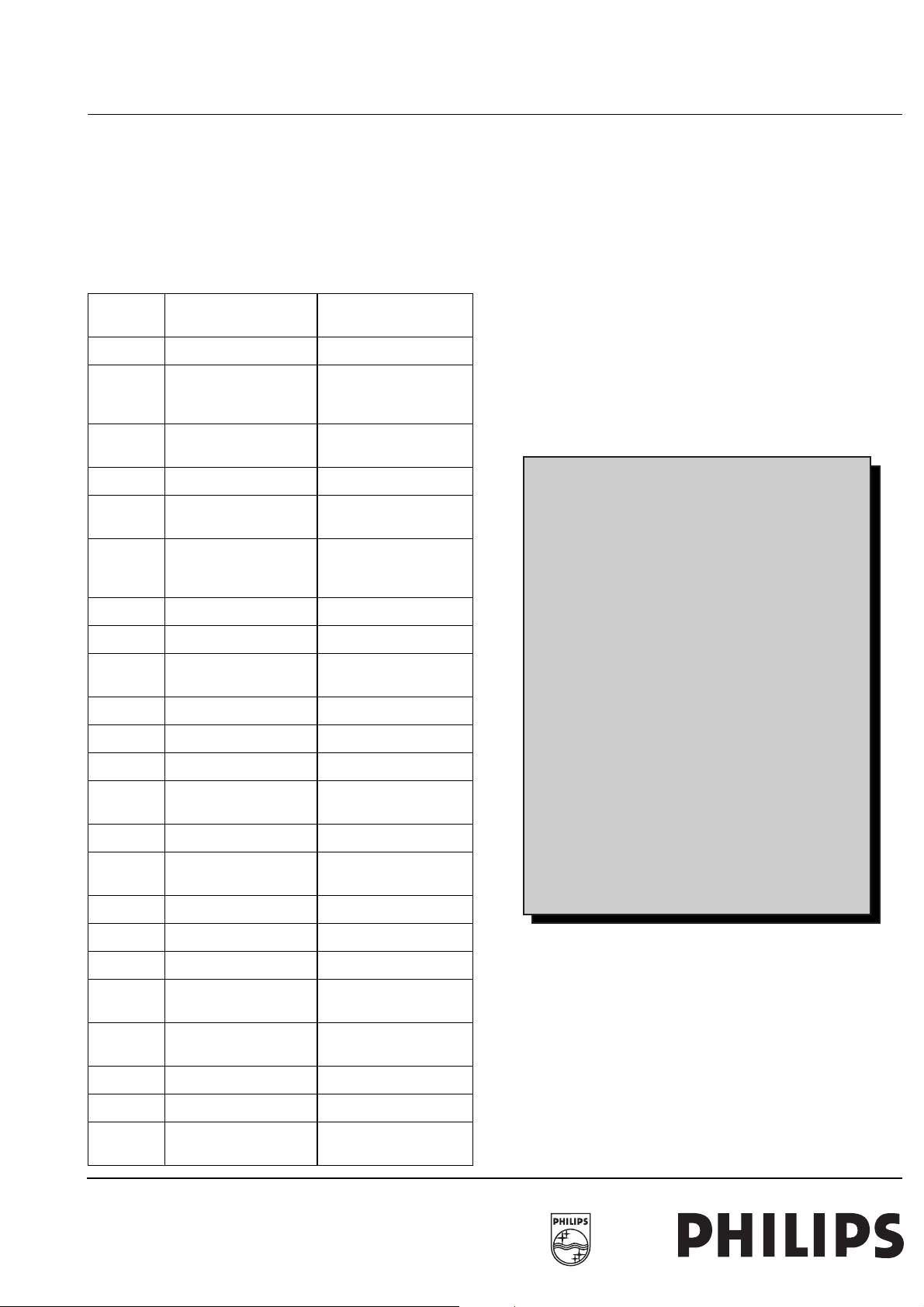

Error code Error description Possible defective com-

ponents

0 No error detected 1 E/W and/or Vert. protec-

tion active/X-ray protection.

2 High beam protection

active

3 Reserved 4 5V protection active +5V supply line is low or

5 BiMOS s/w protection

activeor BiMOS register

is corrupted

6 BiMOS IIC error IC7150

7 General IIC error IIC bus s/c or o/c

8 Main uP internal RAM

error

E/W Vertical circuit defective,line o/p stage.

CRT amplifier circuit or

picture tube

short circuit

IC7150, + 8V supply.

IC7000

ERROR:0 0 0 0 0 0:No error code detected

ERROR:6 0 0 0 0 0:Error code 6 is last and only detected

ERROR:5 6 0 0 0 0:Error code 6 is first detected, error code 5

last detected

• The last error detected (actual) is the error at the left side

• By leaving the SAM with the "standby" function or ERASE

BUFFER function the error buffer is reset.

Personal notes

9 OSD generator IIC error IC7101 on OSD panel

10 NVM addressing error IC7088

11 NVM IIC error IC7088

12 Histogram IICerror IC7770 or YUV interface

panel

13 Reserved 14 Sound processor IIC er-

ror

15 Reserved 16 Main tuner IIC error U1125

17 PIP processor IIC error IC7350 on PIP panel

18 2nd tuner PIP IIC error U1126 or U1127 on PIP

19 EPG uP/Guide Plus uP

IIC error

20 NV-clock IIC error IC7110

21 Reserved

22 EPG processor IIC inter-

nal RAM error

IC7430 or IC7437 (BTSC)

panel

IC7007 on EPG panel/

IC6 on Guide Plus panel

IC7007 on EPG panel

16 CONTROLS A8.0A

Service Alignment Mode (SAM)

Service Alignment Mode (SAM)

Service Alignment Mode

HORSHIFT: Horizontal shift

HORWIDTH:

SERV.BLANK: Service blanking

VERSHIFT: Vertical shift

VERHEIGHT: Vertical amplitude

VERSLOPE: Verti cal l inear i ty

EW PARABO: E-W parabola

EW TRAPEZ: E-W trapezium

EW CORNER: E-W corner

VER S-COR: Ver tical S-cor rection

VERZOOM: Vertical zoom

Alignments

• Selection of the desired alignment by the up/down cursor

• Change of the selected alignment by the left/right cursor

• The following alignments are possible (alignments for geometry are for the 4:3 picture format)

• A value between 0 and 63 can be given for all software

alignments

• Important! Any changed values will only be stored if the geometry menu is exit by pressing the MENU button.

Horizontal w i dth

Personal notes

Easy way to adjust vertical geometry (4 X 3)

1. Set vert. S-correction value to 13

2. Set vert. zoom value to 25

3. Set vert. blanking to “ON”

4. Adjust vert. slope till test pattern centre line touches the

centre edge

5. Adjust vert. shift and vert. height till best fix the screen.

A8.0A CONTROLS 17

Service Alignment Mode (SAM)

Service Alignment Mode (SAM)

SAM Menu

nn

nn

nn

nnn

SAM

MENU

PICTURE BRIGHTNESS

SOUND COLOUR

FEATURES CONTRAST

INSTALL SHARPNESS

1

nnnn A80EU1-1.0 5263-2-23

ERR nn nn nn nn nn nn

OP nnn nnn nnn nnn nnn nnn nnn

RELOAD DEFAULT

ERASE BUFFER

OPTIONS

ALIGNMENTS

6

COLOUR TEMP

2 3 4 5

MENU

MENU

GEOMETRY

GEOMETRY SW

WHITE TONE

TUNER

BTSC SOUND

Only when HW option is present

TDA9855

LA

SA

WA

AA

SAM

MENU

LOAD NOW

DON'T LOAD

OB6

OB7

STORE

AL

MENU

AK

MENU

HORSHIFT

HORWIDTH

SERV.BLANKING

VERSHIFT

VERWIDTH

MENU

COLD Rnnn Gnnn Bnnn

IF PLL

IF PLL

AGC

MENU

AFA

AFB

nnn

nnn

ON

OFF

nnn

nnn

nnn

nnn

nnn

nnn

nnn

n

n

CL 86532036_001.ai

260598

Options

• Setting of individual options.

– Selection of the desired "option to be changed" by the

up/down cursor.

– Changeof the selectedoption (ON/OFF) by the left/right

cursor or

• By keying the decimal values in the option bytes 1~7 item

– The options are activated immediately after they are

stored and powered up.

Reload Default

By selecting LOAD NOW, the current values stored in the non

volatile memory will be over written. Caution: It is used only

when the non volatile memory data is corrupted and no other

way to recover. Default values are activated when the set is restarted

Personal notes

18 CONTROLS A8.0A

Microprocessor

Microprocessor

Introduction

Hardware and software diversity.

Europe sets:

• Master micro processor 83C770 (64k ROM).

• Slave micro processor on TEXT/EPG panel, dedicated for

EPG (Electronic Programming Guide) and Teletext decoding.

Latam and USA standard sets:

• Single micro processor 83C770 (64k ROM). Complete controls including Closed Caption decoding.

Low end USA sets:

• Single micro processor 83C570 (48k ROM).

Asia/Pacific TXT sets:

• Single micro processor SAA5297(masked) or SAA5499

(OTP).Complete controls TXT decoding.

– PN3:Pal/Multi; NO teletext; English and Arabic

– PT1:Pal/Multi WITH teletext; English, Malay and Chi-

nese

– NG1:NTSC; 2CS sound; English and Korean

– NB1:NTSC; BTSC sound; English and Taiwanese

• X = (main version number)

• Y = (subversion number)

Software identification of a separate Teletext micro controller

(DDDD E FF) (not applicable for A8.0A)

NVM

TheNVM used forstoring the default settings is ST24W16 is16

KBand is interfaced with themain micro using the S/WI2C bus.

This is to avoid any data corruption in the NVM data by controlling the Write CLock of the NVM by the main micro.

Personal notes

Asia/Pacific NON-TXT sets:

• Single micro processor 83C770 (64K ROM)

Software diversity:

Version Region

EUROPE

A8EU1.1: Western Europe without EPG

A8EU1.2 : Eastern Europe

A8EU1.3 : Western Europe with EPG

USA

A8US1.1 : USA (all)

LATAM

A8LA1.1 : LATAM (all)

Software identification of the main micro controller (A80BBCX.Y)

• A80 is the chassis name for A8.0A

• BBC is 2 letter and 1 digit combination to indicate the software type and the supported languages:

– PN1:Pal/Multi; NO teletext; English, Malay and Chinese

– PN2:Pal/Multi; NO teletext; English and Hindi

A8.0A CONTROLS 19

Microprocessor

Microprocessor

Software control lines

SOFTWARE CONTROL LINES DESCRIPTION for the main

micro processor

Logic 0 is : 0 V

Logic 1 is : +5V

Pin 1: PAN_SWITCH/+5V_CNTRL

OUTPUT

Activates 16:9 feature (EUROPE only)

Activates+5V supply for the PIP board (USA only)

Pin 1: PAN_SWITCH Status

0 Default

1 Super Wide Selected in 16:9 sets

Pin 1: +5V CNTRL Status

Pin 4: SEL

_PIP_FRNT_RR

0 0 REAR1

0 1 REAR2

1 0 FRONT

1 1 INTERNAL

Pin 9:

SEL_PIP_R1R2

PIP Source Selection

Pin 5: SEL_IF_TRAP_MAIN or L/L'

OUTPUT

Select the MAIN IF TRAP and Sound Traps also.

Pin 5:

SEL_IF_TRAP_MA

IN

0 ON - for NTSC M ON - for othrs

1 OFF - for others OFF - SECAM L'

A/P Europe

Pin 6: POSNEG_QSS or SEL_INCRED

1 +5V OFF

0 +5V ON

Pin 2 & 3: SYS2 and SYS1

OUTPUT

Selects the XTALS and Combfilters.

Pin 2: SYS2 Pin 3: SYS1 System

0 0 PAL M

1 0 PAL B,G,H,I,D,K

0 1 NTSC M

1 1 PAL N

Pin 4 & 9: SEL_PIP_FRNT_RR & SEL_PIP_R1R2

(valid for PIP sets)

OUTPUTS

Selects the PIP video source from rear I/O, main or front.

OUTPUT

Selects the positive and negative demodulation mode for the

QSS IC during SECAM L reception (Europe only).

Selects the Incredible Stereo feature (USA only)

Pin 6: Status - POSNEG_QSS Status - INCRED

0 POSITIVE (SECAM L/

L')

1 NEGATIVE (Others) Incredible stereo is off

Incredible stereo is on

Pin 7: SDM

INPUT

Service Default Mode is activated by shorting this pin to GND.

Pin 8 & 14: SEL_MAIN_R1R2 &

SEL_MAIN_FRNT_RR

OUTPUTS

Selects the MAIN video source from INTERNAL, FRONT or

REAR.

20 CONTROLS A8.0A

Microprocessor

Pin 14:

SEL_MAIN_FRNT_

RR

0 0 REAR1 (AV2/

0 1 REAR2 (AV1)

1 0 FRONT (AV3/

1 1 INTERNAL

Pin 8:

SEL_MAIN_R1R2

MAIN Source Selection

SVHS)

SVHS)

Note: For Multimedia and Institutional TV Interface pin 8 will be

configured as TV CLK.

Pin 9: STAT2 or SEL_PIP_R1R2

(valid for non PIP sets)

ADC input.

Detects the presence of SCART2 Video source (CVBS) and

also whether it is 4:3 or 16:9 video source.

Pin 9: STAT2 ADC VALUES Status - SCART2 Video

0 - 4 Internal Video

5 - 10 External 16:9

Pin 10: Function AFC_TUNE

R2

Output of Analog tp Digital Converter

0 0 - 0.5

1 - 2 1

3 - 4 1.5

5 - 6 2

7 - 8 2.5

9 - 10 3

11 - 12 3.5

13 - 14 4

15 4.5

ADC

Input DC voltage

Input

Controls the Eco Double Window.

Pin 10: SYS_ECO_DW System Status

0 50 Hz

1 60 Hz

11 - 15 External 4:3

Pin 10: STAT_EXT 1/ AFC_TUNER2/

SYS_ECO_DW

ADC input

Comparatorto sense different DC levelsfrom I/O to indicate the

presenceof an EXTERNAL SCART video sources (CVBS), 4:3

or 16:9 SCART video.

Pin 10: STAT1 ADC VALUES Status - SCART1 Video

0 - 4 Internal Video

5 - 10 External 16:9

11 - 15 External 4:3

ADC input (Valid for NTSC-M)

Indicates for the 2nd tuner PIP application for Y/C PIP and

named AFC_TUNER2.

Pin 12: POR2

Note: For Multimedia and Institutional TV Interface this pin will

be configured as DATA IN.

Pin 11: FRNT_CNTRL

INPUT ADC

Connected to the keyboard and protection line PROT_E_W.

The keys are read by applying a unique voltage.

Input DC Voltage Function ketboard read

0 Protection

1V5 Program Up

2V1 Program Down

2V7 Menu (not forLatam)

3V4 Volume Up

4V Volume Down

5V No Key Pressed

OUTPUT

A8.0A CONTROLS 21

Microprocessor

Provides Power On Reset pulse during start-up for 2nd microp (both EPG and non-EPG boards used in Europe sets) and

GEMSTAR decoder boards used for USA sets.

For 2nd micro-p board the POR2 is high for at least 2 machine

cycles when the oscillator is running and then go back to LOW.

ForGemstar the POR2 mustgo from LOW toHIGH and remain

HIGH during start-up

Note: For Multimedia and Institutional TV Interface this pin will

be configured as DATA IN.

Pin 14: SEL_MAIN_FRNT_RR

See pin 8

Pin 15: SVHS_MODE

OUTPUT

Select/deselect the external SVHS or the CVBS inputs

Pin 15: SVHS_MODE Select

0 SVHS

Pin 18 : STAT_HP

INPUT.

To sense the presence of a Head Phone jack.

Pin 18: STAT_HP Status

0 Headphone NOT connected

1 Headphone connected

Pin 19: STBY

OUTPUT

To switch between standby and normal operation.

Pin 19: STBY TVStatus

1 In Stand-by Mode

0 in Normal Operation

1 CVBS

Pin 16: DEGAUS

OUTPUT

Controlsthe DEGAUS circuitin the Power Supply block. During

power ON this pin gives low going pulse for 2 seconds.

Pin 16: DEGAUS

'0' for 2 seconds and then goes to '1'

Pin 17: AMP_MUTE1

OUTPUT

Mutes the Audio Output Amplifier

Pin 17: AMP_MUTE1 Status

0 MUTE OFF

1 MUTE ON

Pin 20: LED

OUTPUT

Pin 20 Europe AP/Latam USA

0 LED brighter

= Standby

1 LED dimmer

= normal operation

LED lighted =

Standby

LED OFF =

normal operation

LED lighted =

normal

LED OFF =

Standby

Pin 21 SAA5297/P83C770: SEL_GAIN_SPLIT/

SEL_TUNER1_2

OUTPUT

Selects the gain of the antenna splitter of the 2nd tuner for PIP

(A/P and LATAM sets only).

Pin 21: SEL_GAIN_SPLIT Attenuation

0 OFF

1ON

OUTPUT

22 CONTROLS A8.0A

Microprocessor

Selects between the MAIN tuner 1 and MAIN tuner 2. (USA

and 2 Tuner PIP sets only).

Pin 21:

SEL_TUNER1-2

0 Not selected Selected

1 Selected Not selected

Tuner 1 Tuner 2

Pin 30 P83C770: RMT_LOC_DATA

OUTPUT

Signal: DATA to the REMOTE LOCATOR circuit (USA only),

others this pin is pulled to “high” via 3063.

Pin 46 for SAA5297 and P83C770 :

WRITE_CTRL

OUTPUT

Selects the global write protection control of the EEPROM

(IC7088).

Pin 52 of P83C770 : FFBL_EXT/4_NORMA_SEL

Pin 52: FFBL-EXT Status

0 RGB present on the SCART

1 No RGB on the SCART

ForLATAM setsthis pin isused toselect the respective crystals

4 or 2/3 Norma sets. This is configured by hardware as LOW or

HIGH depending on the crystals connected to the BiMOS.

Pin 52: 4 NORMA_SEL Status

0 Selects 4 Norma

1 Selects 2 or 3 Norma

OTHER PIN DETAILS

Pin 13: Ground

Ground line for digital circuits for SAA5297 and P83C770

Pin 47 SAA5297/P83C770 : SCL_EEPROM

Clock output EEPROM I2C bus.

Pin 48 SAA5297/P83C770 : SDA_EEPROM

Data in - output EEPROM I2C bus.

Pin 49 SAA5297/P83C770 : SCL

Clock output of master I2C bus.

For a survey of all connected ICs to this bus see the diagram

"I2C overview" in the service manual.

Pin 50 SAA5297/P83C770 : SDA

Data in - output of master I2C bus.

Pin 51: RGB_KILL

(Valid for SCART sets !)

Output

Pin 22: VSSA (For SAA5297 and P83C770 )

Ground line for analog circuits

Pin 23: Ground

Input

CVBS from which closed caption for USA/LATAM or TEXT

data for EUROPE/AP is to be extracted. A positive going 1V

(peak-to-peak) input is required.

Pin 24: STN For P83C770 and CVBS1 for SAA5297

For SAA5297 this data slicer decoupling capacitor input, connect to VSSA via a 100 nF capacitor (C2054).

Pin 25: BLACK & BLK (For SAA5297 and P83C770 )

CVBSsignal black level reference,connected to VSSA via100

nF capacitor (C2055).

Pin 26: IREF (For SAA5297 and P83C770 )

CVBS signal reference current input, connect to VSSA via a

27K resistor (R3058)

Pin 51: RGB_KILL Status

0 Default

1 Kill External RGB

Pin 27: TEST (For SAA5297 and P83C770 )

This pin is connected to +5V via 10 K Ohms resistor (R3060)

Pin 28: TEST (For SAA5297 and P83C770 )

A8.0A CONTROLS 23

Microprocessor

This pin is connected to Digital gnd for SAA5297. For P83C770

this pin is pulled to high via 3061.

Pin 29: TEST (For SAA5297 and P83C770 )

This pin is connected to +5V via 10 K Ohms resistor (R3062).

Pin 31: RGBREF & REFH (For SAA5297 and P83C770 )

For SAA5297 this is the DC input voltage to define the output

HIGH level on the RGB pins,

For P83C770 this is the data slicer reference high capacitor inputconnectedtoVSSAvia100nFcapacitor(C2070).

Pin 32 to 35 (For SAA5297 and P83C770 ): FBL, R, G and B

Outputs 'RED', 'GREEN' and 'BLUE' deliver the colour components for the OSD, while output 'Blanking' is used as a fast

blanking signal to insert R, G and B signals in the television picture. The output polarity of all four pins is active high.

Pin 36: HSYNC for OSD /TXT (For SAA5297 and P83C770 )

This signals is derived from the deflection part to get a stable

OSD picture on the television screen. The 'HSYNC' pins is

supplied with active low horizontal sync pulses (polarity is software programmable).

Pin 37: VSYNC for OSD/TXT (For SAA5297 and P83C770)

This signal is derived from the deflection part to get a stable

OSD picture on the television screen. The 'VSYNC' pin is supplied with active low vertical sync pulses (polarity is software

programmable).

Pin 38 for P83C770 & SAA5297 : VDDA

This pin is connected to +5VA

Pin 39: VDDT for SAA5297 & VDD_P P83C770

For SAA5297 this pin is connected to +5V Teletext power supply.

This is XTAL oscillator OUTPUT pin. All internal timing of the

micro-controller is derived from this oscillator The oscillator frequency has to be 12MHz.

Pin 43 for SAA5297 and P83C769 : POR

'POR' is used to reset the micro-controller after a power-on reset. This reset signal has to be HIGH until a stable 5V supply

voltage is available and then it goes LOW. Also when the supply voltage drops below the minimum required voltage the micro-controller has immediately to be reset via pin 'POR'.

Pin 44 for SAA5297 and P83C770: VDDM

For SAA5297 and P83C770 this pin is +5V micro-controller

power supply.

Pin 45 for SAA5297 and P83C770 : RC-5

This input pin is connected to an RC5 remote control receiver(TFMS5360). The input should be high when no remote control signal is received.

Pin 52 for SAA5297 and P83C770: N.C

For SAA5297 and P83C770 this pin can be used as an I/O port

and is not connected. Pulled to “high”.

Some hints on problem solving

No LED or IIC activity - Check for the +5V_STBY and the POR

pulse

Set always on standby - Check +8V of BiMOS

LED Blinking - The set may be on protection. Check pin 11

No LED blinking to RC5 - Check NVROM

No OSD/TXT - Check H sync on pin 36

No TXT- Check CVBS_TXT on pin 23 and +5V at pin 39.

For P83C770 this pin is the Digital periphery power supply.

Pin 40: OSCGND for SAA5297 & VSS_D for P83C770

For SAA5297 this pin is connected to crystal oscillator gnd.

For P83C770 this pin is the Digital Ground.

Pin 41 for SAA5297 and P83C770 : XTALIN

This is XTAL oscillator INPUT pin

Pin 42 for SAA5297 and P83C769 : XTALOUT

24 POWER SUPPLY A8.0A

Degaussing

POWER SUPPLYDegaussing

PTC

3908

*

+t

ZPB

2

3906

*

PTC

1

9950

*

1

3

2

M16

TO DEGAUSSING

COIL

}

0132

2

1

TO F15

OF MAINS

FILTER

2

{

1

M15

2M2

3950

4

3

9999

*

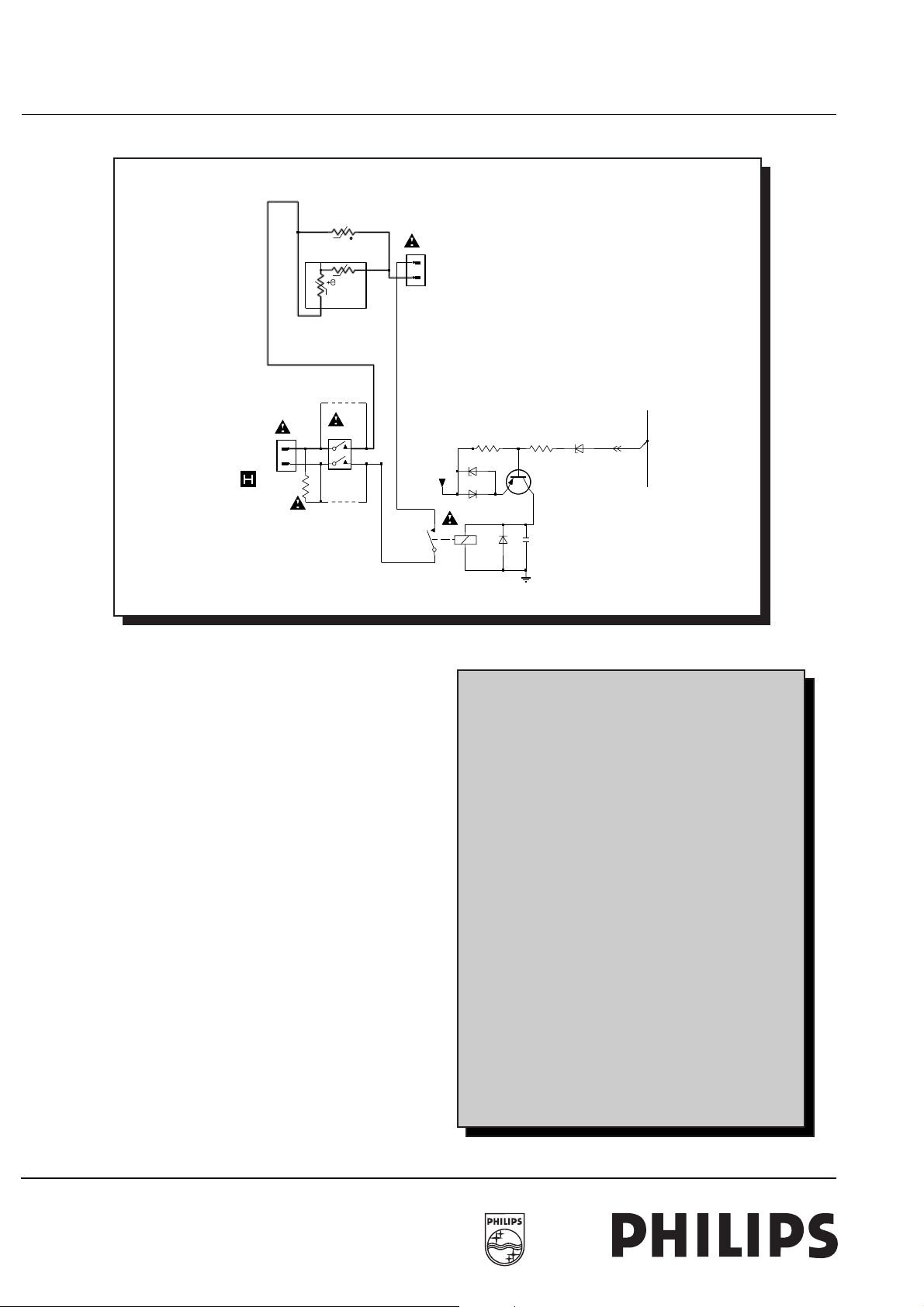

The degaussing circuit is activated whenever the TV set is

turned on. So from normal off to on and from stand-by to on the

degaussing circuit is activated. During start-up the signal degaus (A8-05) is high which blocks TS7900. After start-up of the

uPthe signal degaus (A8-05) becomeslow for 3 seconds which

forces TS7900 in conduction. Now the +13V is put on the coil

of the relay and switch G5P-1 is closed. The degaussing current passes through the degaussing coil. After three seconds,

DEGAUS goes high, 7900 turns off , 1901is de-energised and

no current passes through the degaussing coil at normal operation due to the fact that switch G5P-1 is opened. PTC 3906 is

present in 220V sets and PTC 3908 is present in 110V sets.

BZX79-C3V3

+13V

6920

1N4148

6935

G5P-1

14

23

6992

13V4

1N4148

6904

13V4

22n

3911

4K7

BC557B

7900

0V

2908

BZX79-C9V1

RELAY

SWITCHER

10K

3910

1901

Personal notes

DEGAUS

A8-05

CL 86532033_011.AI

160698

A8.0A POWER SUPPLY 25

General information

General information

CL 86532033_049.AI

160698

26 POWER SUPPLY A8.0A

General information

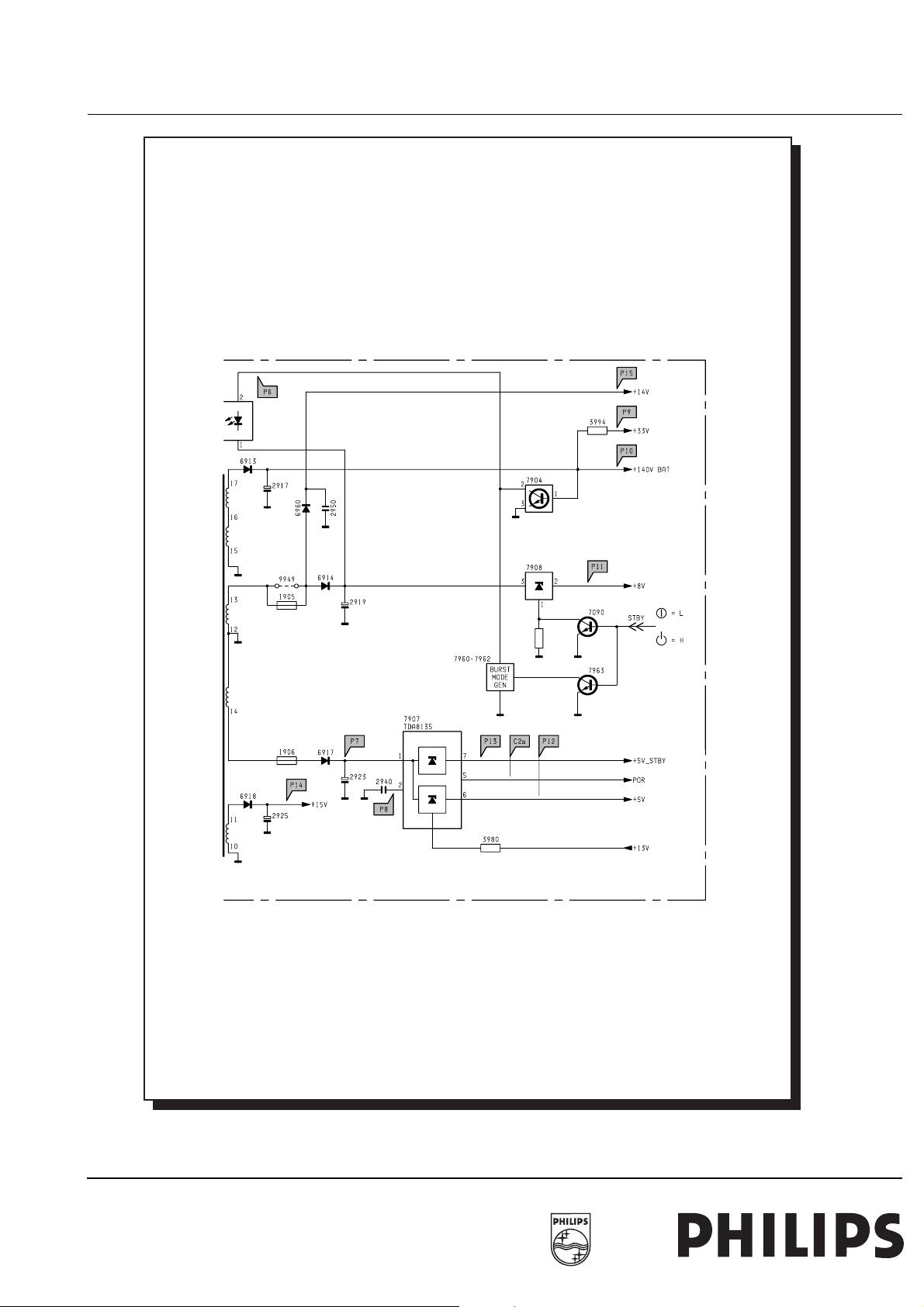

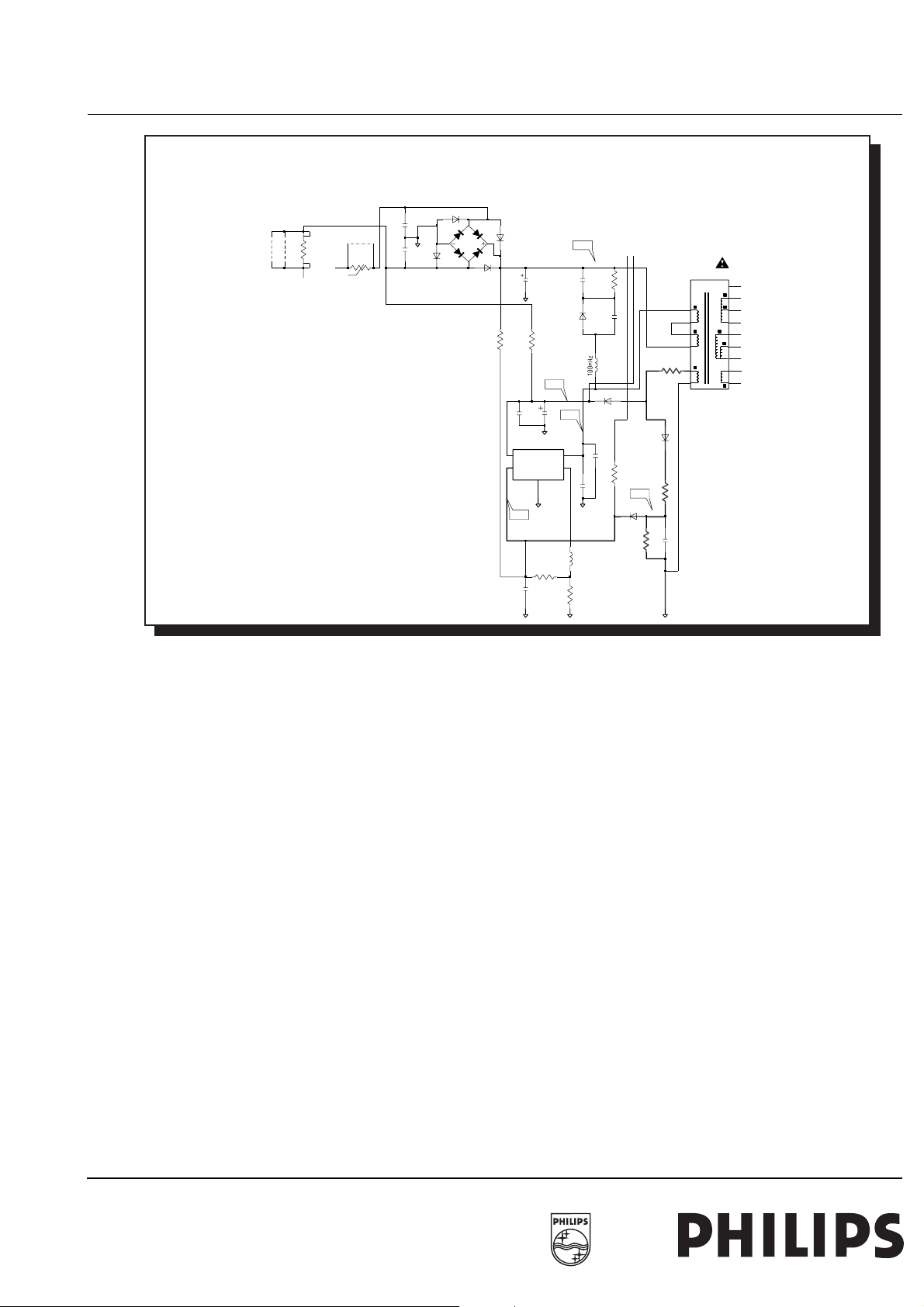

The A8 power supply is a Switch Mode Power Supply(SMPS)

with minimum voltage switch. The topology is a flyback converterwith primary current sensing, secondaryvoltage sensing and

mains input Voltage measuring. The power supply is built with

IC 7902 which has a built-in MOSFET and control circuit. The

frequency ranges for normal operation are 25kHz to 130kHz

(full range) and 40kHz to 130kHz (single range and 120V).

The SMPS works in discontinuous mode, so with a T-on, T-off

and a Tdead. The FET is switched on during T-dead when the

voltage at the drain of the built-in FET (IC7902 pin 3) is minimal

due to oscillation of C2913 and the primary inductance of

T5912. This is reducing the switching losses.

Output voltages

• +14V (For Line Circuit and input voltage for stabilizer 7908)

: +13.5V. If +14V and +8V are not present check 1905.

• +33V (For Tuner) : +33V. Created via R3994 and zenerdiode 6955

• Vbat (Battery Voltage for Line Output Stage) : +140V (9917

present) or +130V (9918 present).

• +8V (Bimos Supply ) : +8.3V. Output voltage from stabilizer

7908. This voltage is decreased in standby to 2V3. In standby TS7909 is conducting and switching R3933 parallel to

R3932. This will decrease the output voltage of 7908.

• +5Vstby (P Supply) : +5.1V. This voltage is also present

during standby. If this voltage and +5V are missing check

1906. If the voltage at pin 1 and 2 of IC7907 are present replace 7907.

• +5V (For Tuner, QSS, BTSC or ITT etc) : +5.1V. This voltage is disabled when the +13V is not present at pin 3 of

IC7907. +13V is generated by the line-output circuit. So

when the line-output circuit is working correctly the +5V is

enabled and the POR signal is generated to start the set.

• +15V ( Audio Supply) : +18V or +14V

Personal notes

A8.0A POWER SUPPLY 27

Control circuitry

Control circuitry

DEMAGNITIZING DETECTION CIRCUIT

6930

*

2

1N5062

2n2

9956

1R5

9952

9954

*

*

*

3902

3905

*

*

NTC

2904

41

2n2

2905

-t

1N5062

*

6933

6903

*

GBU4J

3

6932

*

1N5062

6931

*

3941

*

1N5062

(301V)

290V

2906

*

2M2

3917

*

10n

2920

*

17V6

(15V6)

7902

*

STR-F6626

4

VIN

1

OCFB2S

GND

1V6

(0V7)

P4

2915

470u

470p

100K

2912

5

3922

680R

P1

5912

*

TRANSFORMER

18

22n

3995

100K

2911

*

*

2971

6906

2913

5906

0R1

*

3n3

1n5

*

5911

*

6908

BYD33J

2966

*

3920

100P

3K3

P5

6911

BYD33J

BYD33M

P3

P2

47u

(301V)

290V

3

D

0V

(0V)

*

100mHz

3924

*

1

17

2

16

3

15

4

5

14

6

13

7

3959

*

3R3

6910

BYD33J

2K7

3962

*

1n5

1K5

3991

2914

*

*

12

8

11

9

10

CL 86532033_005.AI

030898

Mains input circuit

The mains voltage is rectified by bridge rectifier D6903 or

D6930 ,D6931 ,D6932, D6933 and filtered by C2906 . The DC

voltage across C2906 is the DC input voltage for the SMPS at

pin 6 of transformer T5912.

Start-up circuit

IC7902 is started when the voltage present at pin 4 is high

enough. When the set is switched on, C2912 is charged

through start-up resistor R3917. When the voltage across

C2912 reaches 16V (Typical), the control circuit of IC 7902

starts to operate.

After the control circuit starts itsoperation, power is supplied by

smoothing and rectifying the voltage of the supply winding ( 89 ) of T5912. The supply winding reaches the operation voltage

beforethe voltage of C2912 drops below theshutdown voltage.

Consequently, the control circuit can continue its operation.

Control circuit and oscillation phase

IC 7902 has two internal comparators . The thresholds of these

two comparators are 0.73V and 1.37V. During T-on , the MOSFET inside IC7902 is conducting . The voltage across R3924

increases due to the increase of the drain current. When the

voltage of pin 1 of IC7902 reaches the threshold voltage Vth(1)

=0.73V, the MOSFET turns off. The voltage of pin 8 of T5912

becomes now positive . Power supply flybacks at this moment

(so energy is released at the secondary side). Voltage applied

at pin1 of 7902 is determined by the turn ratio of the transformer T5912 and R3962, R3991 ( Typical voltage is 3.5V) . This

voltage is higher than threshold voltage Vth(2) (1.37V). Until

the transformer is demagnetized, this voltage remains high.

Once the energy stored in the transformer is fully transferred to

the secondary side, the voltage at pin1 of IC7902 drops below

the threshold voltage Vth1 after a certain delay time and a new

cycle starts.

Loading...

Loading...