Page 1

Colour Television Chassis

A10PTV2.0

NTSC AA

Contents Page Contents Page

1. Technical Specifications, Connection Facilities

and Chassis Overview 2

2. Safety Instructions, Warnings and Notes 4

3. Directions For Use (Not Applicable) 5

4. Mechanical Instructions 5

5. Faultfinding and Repair Tips 7

6. Block Diagram, Wiring Diagram and Testpoints

Block Diagram 13

Testpoint Overview LSB Panel 14-15

Waveform Overviews 16

Testpoint Overview SSM Panel 17-18

Wiring Diagram 19

Supply Distribution Diagram 20

7. Electrical Diagram’s en PWB’s Diagram PWB

Large Signal Panel (Section 1) 21 24-29

Large Signal Panel (Section 2) 22 24-29

Large Signal Panel (Section 3) 23 24-29

CRT Red 30 33

CRT Blue 31 33

CRT Green 32 33

Small Signal Board (Section 1) 34 45-50

Small Signal Board (Section 2) 35 45-50

Small Signal Board (Section 3) 36 45-50

Small Signal Board (Section 4) 37 45-50

Small Signal Board (Section 5) 38 45-50

Small Signal Board (Section 6) 39 45-50

Small Signal Board (Section 7) 40 45-50

Small Signal Board (Section 8) 41 45-50

Small Signal Board (Section 9) 42 45-50

Small Signal Board (Section 10) 43 45-50

Small Signal Board (Section 11) 44 45-50

Side jack panel 51 52

Analog SSB:IF-Video-Sync-Chroma (Diagr. C1) 53 59-60

Analog SSB: Video Features (Diagram C2) 54 59-60

©

Copyright 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

Analog SSB: Micro Controller (Diagram C3) 55 59-60

Analog SSB: Memory (Diagram C4) 56 59-60

Analog SSB: Audio Processing (Diagram C5) 57 59-60

Analog SSB: Audio Processing (Diagram C6) 58 59-60

Analog SSB: SSB Connector (Diagram C7) 59 59-60

Double Window: PIP (Diagram F1) 61 66-67

Double Window: Tuner (Diagram F2) 62 66-67

Double Window: I/O Processing (Diagram F3) 63 66-67

Double Window: IF-Video-Sync (Diagram F4) 64 66-67

Double Window: V-Chip Processor(Diagram F5) 65 66-67

Double Window: NV-ROM (Diagram F6) 65 66-67

PFC Filter Panel 68 69

SVM Panel 70 71

Center Channel Switch (Diagram K) 72 72

AC Power Switch (Diagram L) 73 73

Local Control 74 75

IR-LED (Keyboard) 76 77

8. Alignments 79

9. Circuit Description and 83

List of Abbreviations 99

10 Spare Parts List 101

Published by TA 0167 Service PaCE Printed in the Netherlands Subject to modification

3122 785 11241

Page 2

GB 2 A10PTV2.0 NTSC1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

1.1 Technical Specifications

Mains Voltage : 90 V - 276 V

Power Consumption : 260 W max

Standby consumption : < 3 W

Mains Frequency : 50 / 60 Hz (+/- 5%)

Tuning System : PLL

Reception : NTSC M,

Sound System : BTSC DBX - / 97

Sound Output : 2 x 15W

(+/- 10%)

(3.58 - 4.5)

:FM / FM

(4.5 - 4.72) - / 61

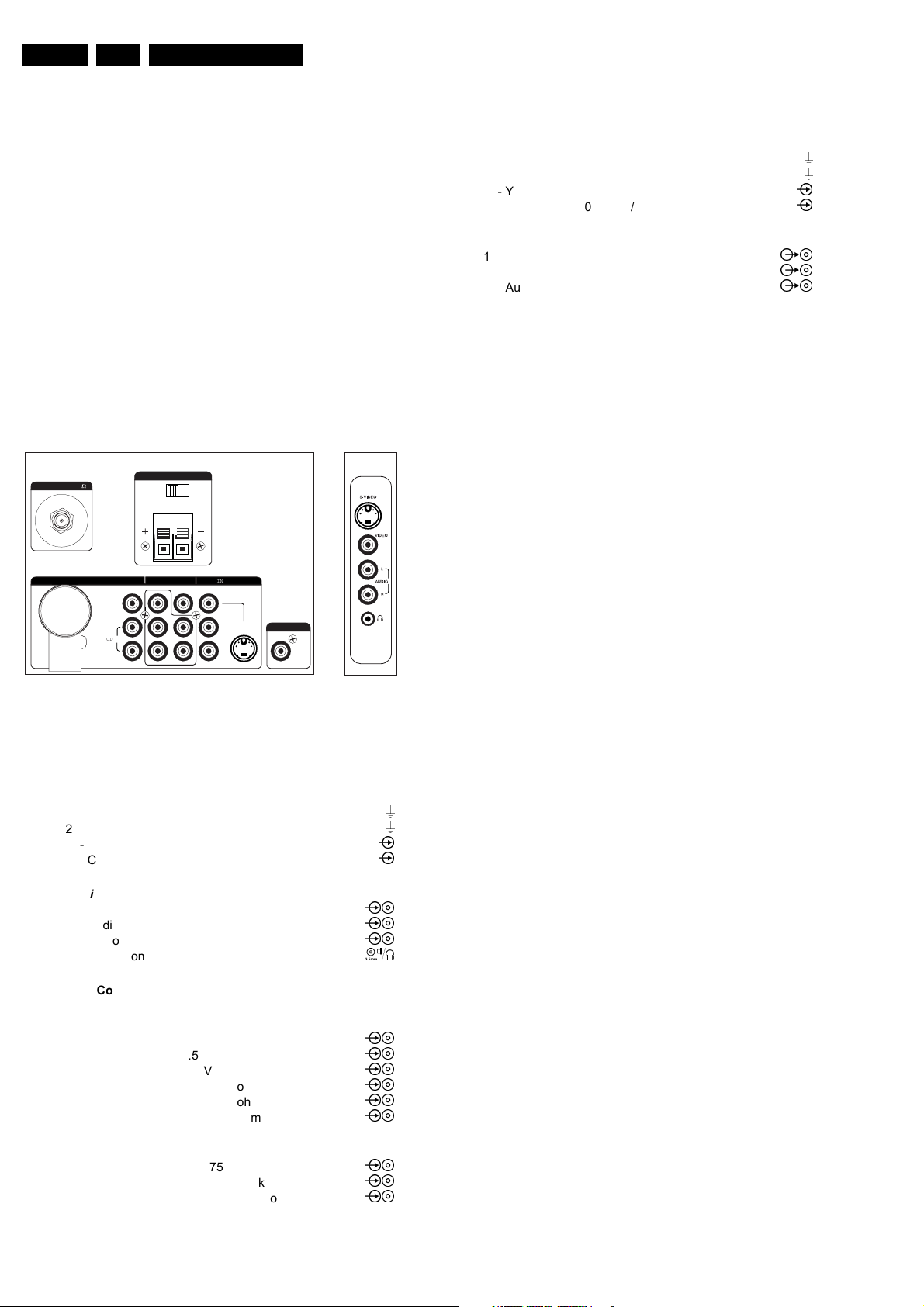

1.2 Connection Diagram

Audio/Video Jack Panels

Rear

ANTENNA IN 75

MONO/L

VIDEO

AUDIO

CENTER CHANNEL AMP INPUT

R

AMP SWITCH

EXT

Y

Pb

Pr

INT

AV2 INAV1 INMONITOR OUT

S-VIDEO

SUBWOOFER

V

Side

CL 06532143_001.eps

011100

AV2 In (SVHS)

1 - gnd

2 - gnd

3 - Y 1 Vpp / 75 ohm

4 - C 0.3 Vpp / 75 ohm

Monitor Out

1 - Video 1 Vpp / 75 ohm

2 - Audio L (0.5 Vrms / 10 k ohm)

3 - Audio R (0.5 Vrms / 10 k ohm)

Figure 1-1

1.2.1 Side Connections

SVHS

1 - gnd

2 - gnd

3 - Y 1 Vpp / 75 ohm

4 - C 0.3 Vpp / 75 ohm

Audio / Video

1 - Video 1 Vpp / 75 ohm

2 - Audio Left (0.2 Vrms / 10 k ohm)

3 - Audio Right (0.2 Vrms / 10 k ohm)

4 - Headphone 32 - 2000 ohm / 10 mW

1.2.2 Rear Connections

AV1 In

1 - Video 1 Vpp / 75 ohm

2 - Audio L (0.5 Vrms / 10 k ohm)

3 - Audio R (0.5 Vrms / 10 k ohm)

4 - Y 0.7 Vpp / 75 ohm

5 - Pb 0.7 Vpp / 75 ohm

6 - Pr 0.7 Vpp / 75 ohm

AV2 In

1 - Video 1 Vpp / 75 ohm

2 - Audio L (0.5 Vrms / 10 k ohm)

3 - Audio R (0.5 Vrms / 10 k ohm)

Page 3

Technical Specifications, Connections, and Chassis Overview

Side J

Blue CR

C P

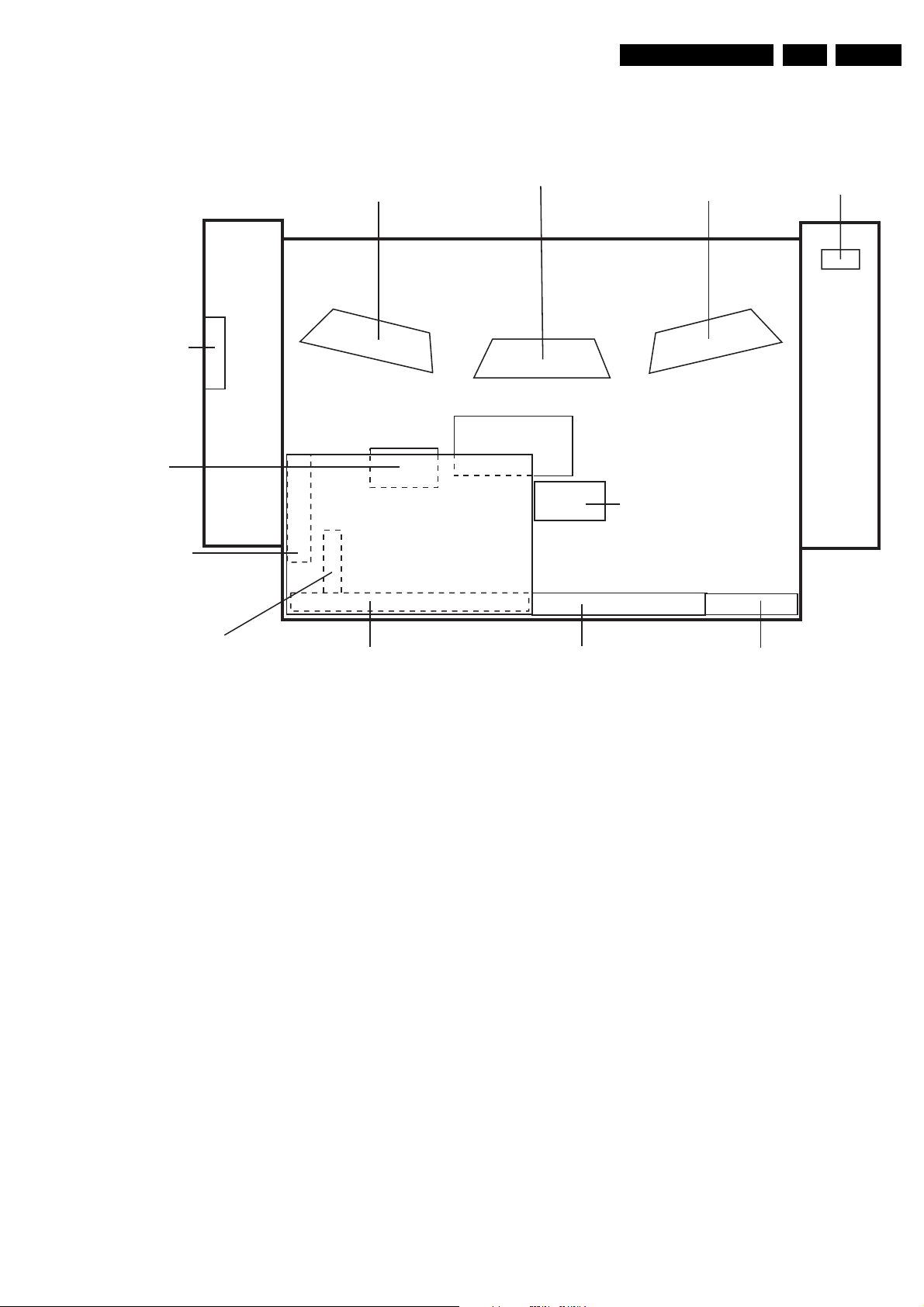

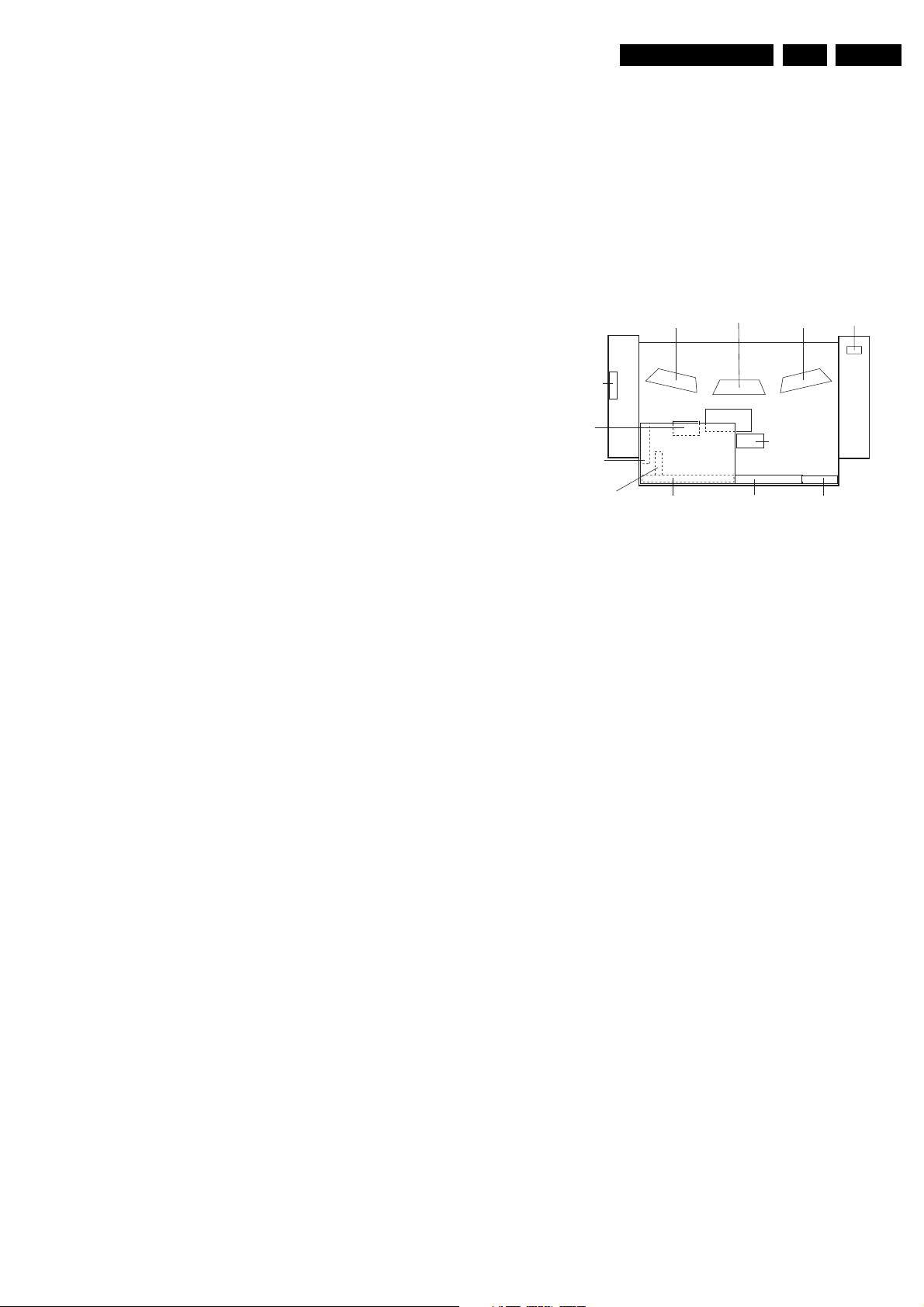

1.3 Chassis Overview

ack

Side J

Panel

Center

Channel

Switch

Red CRT

Green CRT

SVM Panel

Blue CR

Keyboard &

IR LED Panel

GB 3A10PTV2.0 NTSC 1.

AC P

ower

T

Switch Panel

PIP Panel

SSB Module

SSM Panel

LSB Panel

Figure 1-2

Filter Panel

CL 16532050_001.eps

090501

Page 4

GB 4 A10PTV2.0 NTSC2.

Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

2.1 Safety Instructions for Repairs

• Safety regulations require that during a repair:

– The set should be connected to the mains via an

isolating transformer;

– Safety components, indicated by the symbol

should be replaced by components identical to the

original ones;

– When replacing the CRT, safety goggles must be

worn.

• Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– General repair instruction: As a strict precaution, we

advise you to resolder the solder joints through which

the horizontal deflection current is flowing, in

particular

a. All pins of the line output transformer (LOT);

b. Fly-back capacitor(s);

c. S-correction capacitor(s);

d. Line output transistor;

e. Pins of the connector with wires to the deflection

coil;

f. Other components through which the deflection

current flows.

Note: This resoldering is advised to prevent bad

connections due to metal fatigue in solder joints

and is therefore only necessary for television

sets older than 2 years.

– The wire trees and EHT cable should be routed

correctly and fixed with the mounted cable clamps.

– The insulation of the mains lead should be checked

for external damage.

– The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets which have a mains isolated power supply). This

check can be done as follows:

1. Unplug the mains cord and connect a wire

between the two pins of the mains plug;

2. Set the mains switch to the "on" position (keep

the mains cord unplugged!);

3. Measure the resistance value between the pins

of the mains plug and the metal shielding of the

tuner or the aerial connection on the set. The

reading should be between 4.5 M9 and 12 M9

4. Switch off the TV and remove the wire between

the two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

2.2 Maintenance Instruction

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

,

• When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3

to 5 years.

• When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

• The maintenance inspection contains the following

actions:

– Execute the above mentioned 'general repair

instruction'.

– Clean the power supply and deflection circuitry on

the chassis.

– Clean the picture tube panel and the neck of the

picture tube.

2.3 Warnings

•ESD

• Available ESD protection equipment:

• Be careful during measurements in the high-voltage

• Never replace modules or other components while the

• When making settings, use plastic rather than metal

All ICs and many other semiconductors are susceptible

to electrostatic discharges (ESD). Careless handling

during repair can reduce life drastically. When repairing,

make sure that you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this same

potential.

– Complete kit ESD3 (small table mat, Wristband,

Connection box, Extension cable and Earth cable)

4822 310 10671

– Wristband tester 4822 344 13999

section and on the picture tubes.

unit is switched on.

tools. This will prevent any short circuits and the danger

of a circuit becoming unstable.

2.4 Notes

• The direct voltages and oscillograms should be

measured with regard to the tuner earth (

) as this is called.

(

• The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

• Where necessary, the oscillograms and direct voltages

are measured with (

Voltages in the power supply section are measured both

for normal operation (

values are indicated by means of the appropriate

symbols.

• The picture tubes PWB have printed spark gaps. Each

spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

• The semiconductors indicated in the circuit diagram and

in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

) and without aerial signal ().

) and in standby (). These

), or hot earth

Page 5

3. Directions for Use

PHILIPS

4. Mechanical Instructions

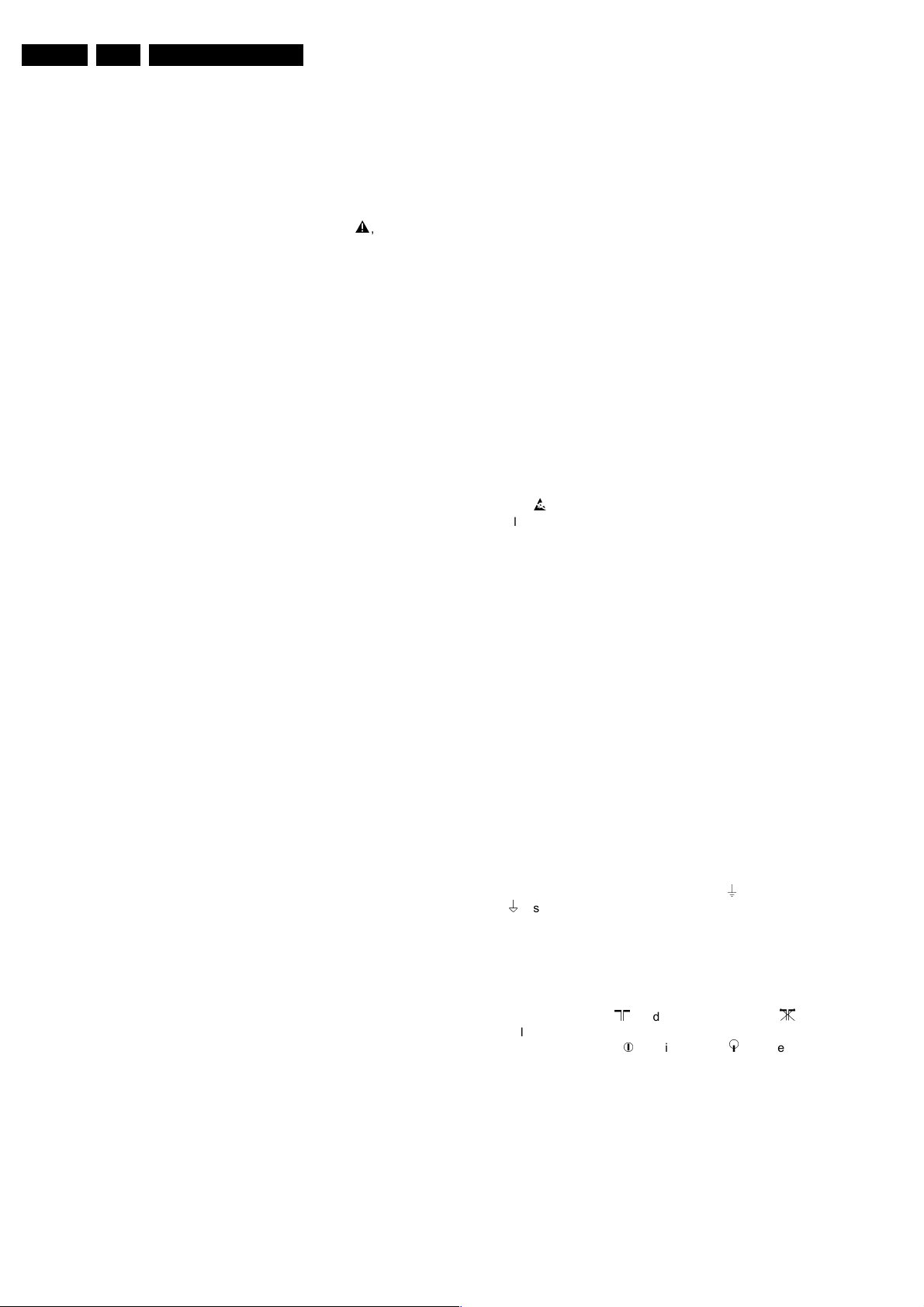

4.1 Disassembly Procedures

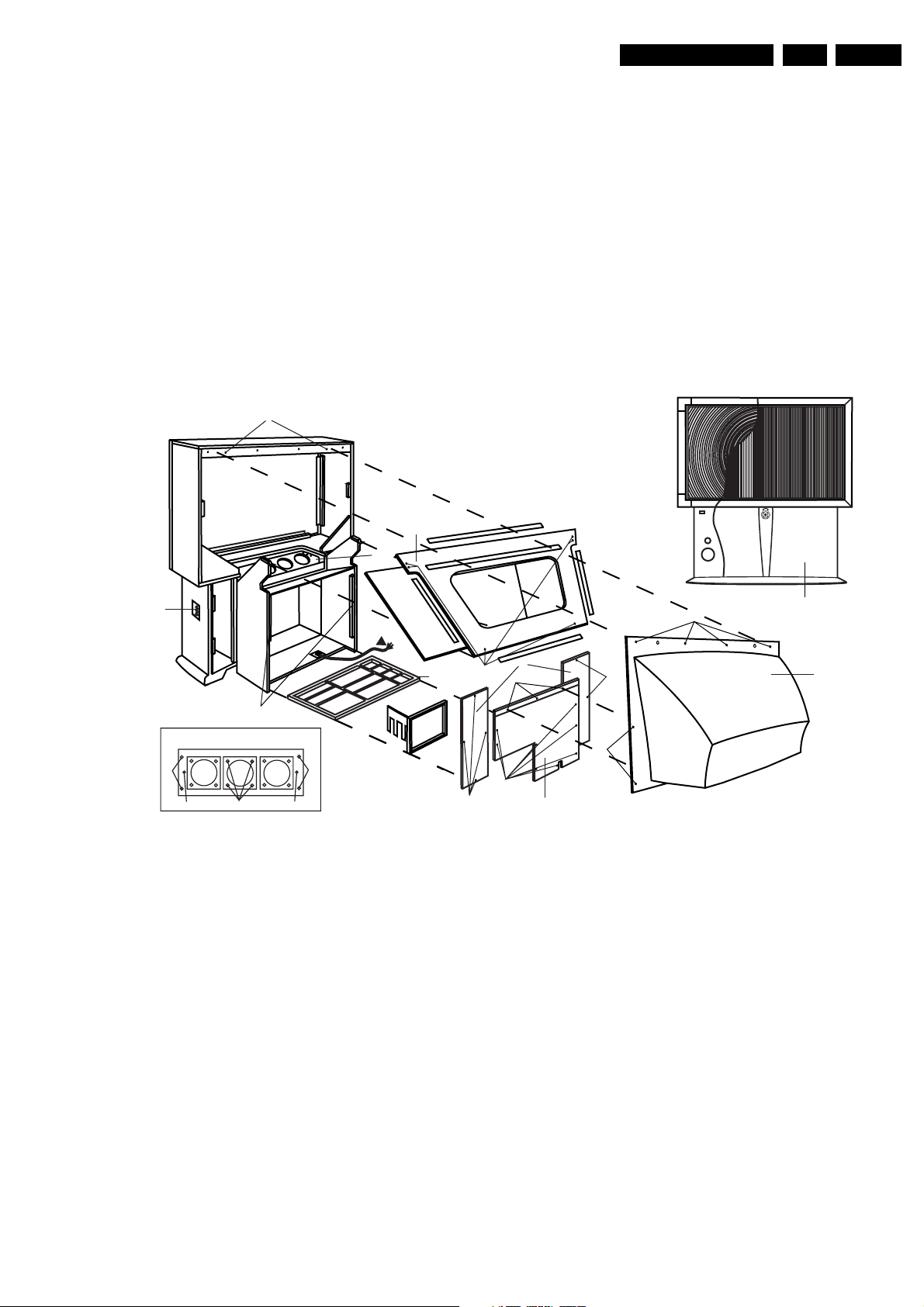

All numbers found in the following text refer to the

CABINET DISASSEMBLY EXPLODED VIEW drawing and

apply to all models.

NOTE: If you are only servicing a PCB or speaker, you do not

have to remove the plastic upper back cover.

CABINET DISASSEMBLY EXPLODED VIEW

J

Directions for Use

GB 5A10PTV2.0 NTSC 3.

PHILIPS

16

22

!

27

Optical Assembly

GG

E

H

E

4.1.1 Removal of Upper Back Cover (2)

1. Remove 8 screws (A).

2. Remove 3 screws (B).

3. Lift cover up to dislodge from pegs (J) and remove cover.

4.1.2 Removal of Lower Center Back Cover (1)

1. Remove 3 screws (B).

2. Remove 8 screws (C).

4.1.3 Removal of Mirror Mounting Board (18)

1. Remove 6 screws (D) located in the mirror mounting

board and remove the board.

NOTE: Care should be taken NOT to place fingerprints or

smudges on mirror.

4.1.4 Removal of Plastic Light Barrier (16)

1. Remove two screws (E) located at the sides of the Plastic

Light Barrier.

18

A

Right

3

Left

D

B

C

F

1

6

F

A

30

2

CL 06532143_003.eps

011100

Figure 4-1

4.1.5 Removal of Side Back Covers (3)

NOTE: To gain access to the Side Jack Panel (D) and two

Speakers, remove the Left Side Back Cover.

To gain access to the AC Power Switch Panel (L), remove

the Right Side Back Cover.

1. Remove 4 screws (F) from each of the Side Back Covers.

4.1.6 Removal of Large Signal Panel (A)

1. Pull 3 tabs on right of bracket and 2 tabs on left of

bracket.

2. Lift Large Signal Board up and out.

4.1.7 Removal of PFC Filter Panel (G)

1. Remove 4 screws from CBA.

2. Lift PFC Filter Panel up and out.

4.1.8 Removal of Small Signal Panel (C)

1. Remove 2 screws from the middle of the CBA.

2. Pull 3 tabs on right of bracket.

Page 6

GB 6 A10PTV2.0 NTSC4.

3. Lift Small Signal Board up, then to the right to remove.

4.1.9 Removal of Side Jack Panel (22) (D)

1. Remove Left Side Back Cover.

2. Pull tabs in; press Side Jack Panel out.

3. Remove two screws from panel.

4. Slide Side Jack Panel CBA out of bracket.

4.1.10 Removal of AC Power Switch Panel (L)

1. Remove Front Baffle (30) by gently pulling baffle frame

away from cabinet.

2. Remove Right Side Back Cover.

3. Remove 2 screws from panel.

4. Remove 2 plugs 1000 & 1002.

5. Pull panel out front of set.

4.1.11 Removal of Center Channel Switch Panel (K)

1. Remove 3 screws from panel.

4.1.12 Removal of Double Window PIP Panel (F)

1. Remove 3 screws from panel.

Mechanical Instructions

4.1.13 Removal of Analog SSB (E)

1. Pull frame up.

2. Pull board to right and then up.

4.1.14 Removal of Front Control

1. Remove front speaker baffle (30) by gently pulling baffle

frame away from cabinet.

2. Remove 3 screws from front control.

4.1.15 Removal of Euro SVM Panel (J)

1. Press 3 treelocks to remove Euro SVM board.

4.1.16 Removal of Complete Optical Assembly or Individual

Light Box Assemblies.

1. Remove the Plastic Light Barrier (16).

2. Separate CRT CBA's from assemblies to be removed.

3. To remove the complete Optical Assembly, loosen 4

screws (G) located in the assembly, and lift assembly up

and out.

4. To remove individual Light Box assemblies, loosen 4

screws (H) located in the assembly you wish to remove

and lift assembly up and out.

Page 7

Fault Finding and Repair Tips

5. Fault Finding and Repair Tips

GB 7A10PTV2.0 NTSC 5.

The lowing topics are covered:

• Test points

• Service Modes

• Error code buffer and error codes

• The “blinking LED” procedure

• Trouble shooting tips

• Customer Service Mode

5.1 Test Points

The A10 PTV chassis is equipped with test points shown on

the schematic diagrams.

Each test point has a reference number indicating the

schematic diagram on which it is located.

• A F106, A I126, etc.: Test points for the Large Signal

Panel [A1 - A3]

• C F001, C I001, etc.: Test points for the Small Signal

Panel [C1 - C11]

• G F114, G I001, etc.: Test points for the PFC Filter Panel

[G]

• J F004, J F006, etc: Testpoints for the SVM Panel [J]

• K I001, K I002: Test points for the Center Channel Switch

[K]

• M I004, M I005: Test points for the Local Control [M]

Measurements should be performed under the following

conditions:

Video: color bar signal

Audio: 3kHz left, 1kHz right

Note:The measurements at the following test points were

taken using a 100:1 probe:

• A I142

• A I220

5.2 Service Default Mode (SDM)

5.2.1 Introduction

The Service Default Mode (SDM) is a technical aid for the

service technician. The Service Default Mode (SDM)

establishes fixed, repeatable settings of customer controls,

which allow consistent measurements to be made. The SDM

also initiates the blinking LED procedure and, if necessary,

overrides the 5V protection. This mode also allows the

operating hours, the software version and error codes to be

read.

5.2.2 Entering Service Default Mode

To enter the Service Default Mode, press the following key

sequence on the remote control transmitter:

0-6-2-5-9-6-MENU

Do not allow the display to time out between entries while

keying the sequence.

Upon entry into the Service Default Mode, the letters “SDM”

will be displayed at the upper right corner of the screen.

Side Jack

Panel

Center

Channel

Switch

PIP Panel

SSB Module

Red CRT

SSM Panel

Green CRT

SVM Panel

LSB Panel

Blue CRT

Keyboard &

IR LED Panel

Figure 5-1

5.2.3 Special SDM Functions

Access to Normal User Menu

Pressing the “MENU” button on the remote control switches

between the SDM and the normal user menus (with the SDM

mode still active in the background)

Run Timer, Software Identification, and Error Buffer

Press the Index or status button on the remote control to

toggle the OSD (except “SDM”) ON and OFF to prevent the

OSD from interfering with measurements and oscilloscope

waveforms.

Access to SAM

To access the Service Alignment Mode while in the SDM

press the “VOLUME +” and “VOLUME -“ buttons on the local

keyboard simultaneously for at least 4 seconds.

5.2.4 Exiting Service Default Mode

Filter Panel

CL 16532050_001.eps

AC Power

Switch Panel

090501

The SDM Places the Set in the Following Pre-defined

Conditions:

• Tuning frequency set to channel 3.

• Volume level set to 25% (of the maximum volume level).

• Other picture and sound settings set to 50% (mid-range).

The Following Functions are Turned Off in SDM (and

After Leaving SDM):

•Timer

• Sleep timer

The Following Functions are Disabled During SDM (and

Enabled After Leaving SDM):

• Parental lock

All other controls operate normally.

To exit the Service Default Mode, press the Power button.

Page 8

GB 8 A10PTV2.0 NTSC5.

Fault Finding and Repair Tips

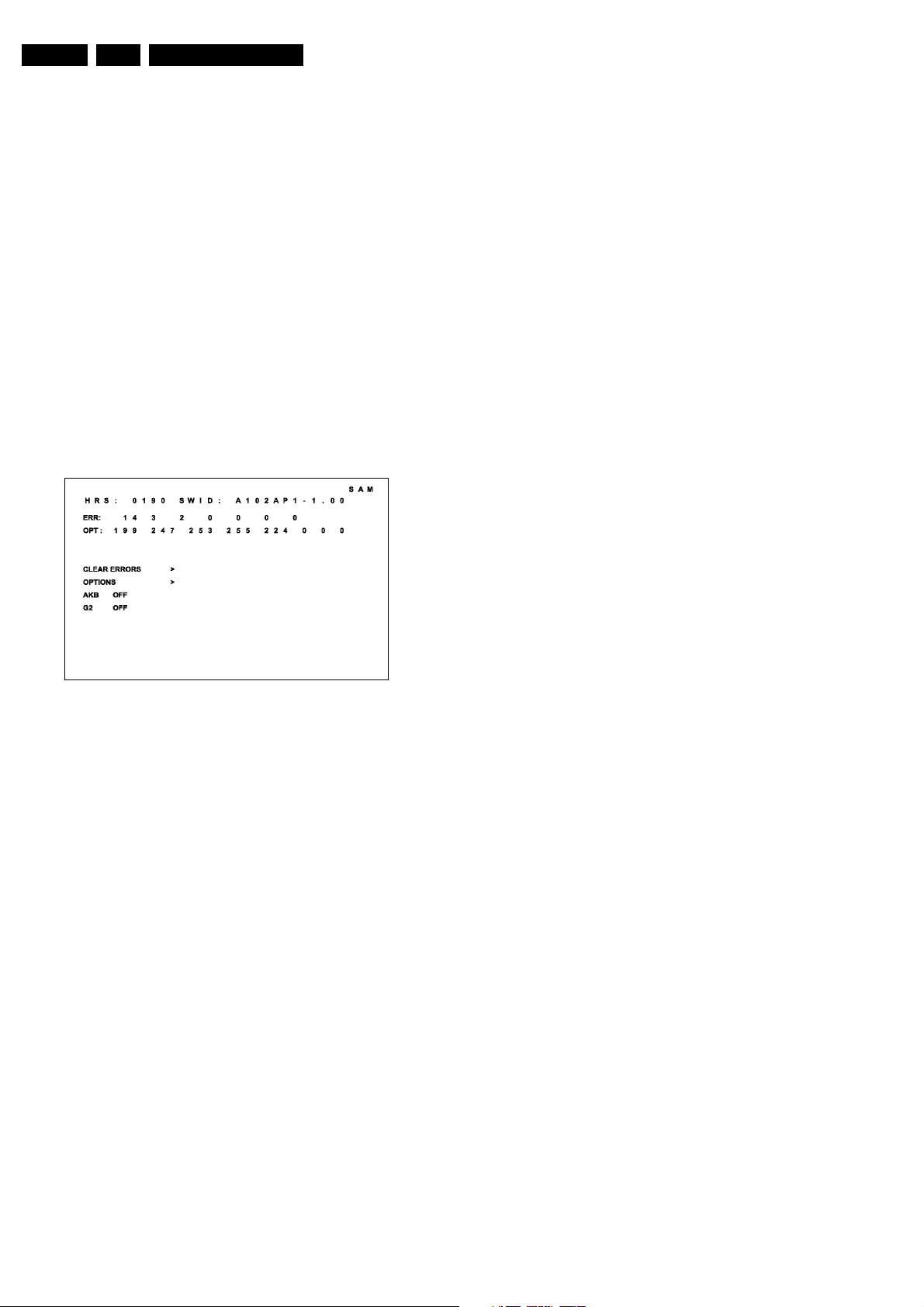

5.3 Service Alignment Mode (SAM)

5.3.1 Introduction

The Service Alignment Mode (SAM) is used to align the set

and/or adjust the option settings and to display/clear the error

code buffer values.

Entering Service Alignment Mode

To enter the Service Alignment Mode (SAM), press the

following key sequence on the remote control transmitter:

0-6-2-5-9-6-INDEX or status.

Do not allow the display to time out between entries while

keying the sequence

It is also possible to enter the Service Alignment Mode by

pressing the “VOLUME +” and “VOLUME -” key on the local

keyboard simultaneously for at least 4 seconds when the set

is in SDM.

5.3.2 Exit SAM:

To exit the Service Alignment Mode, press the Power button.

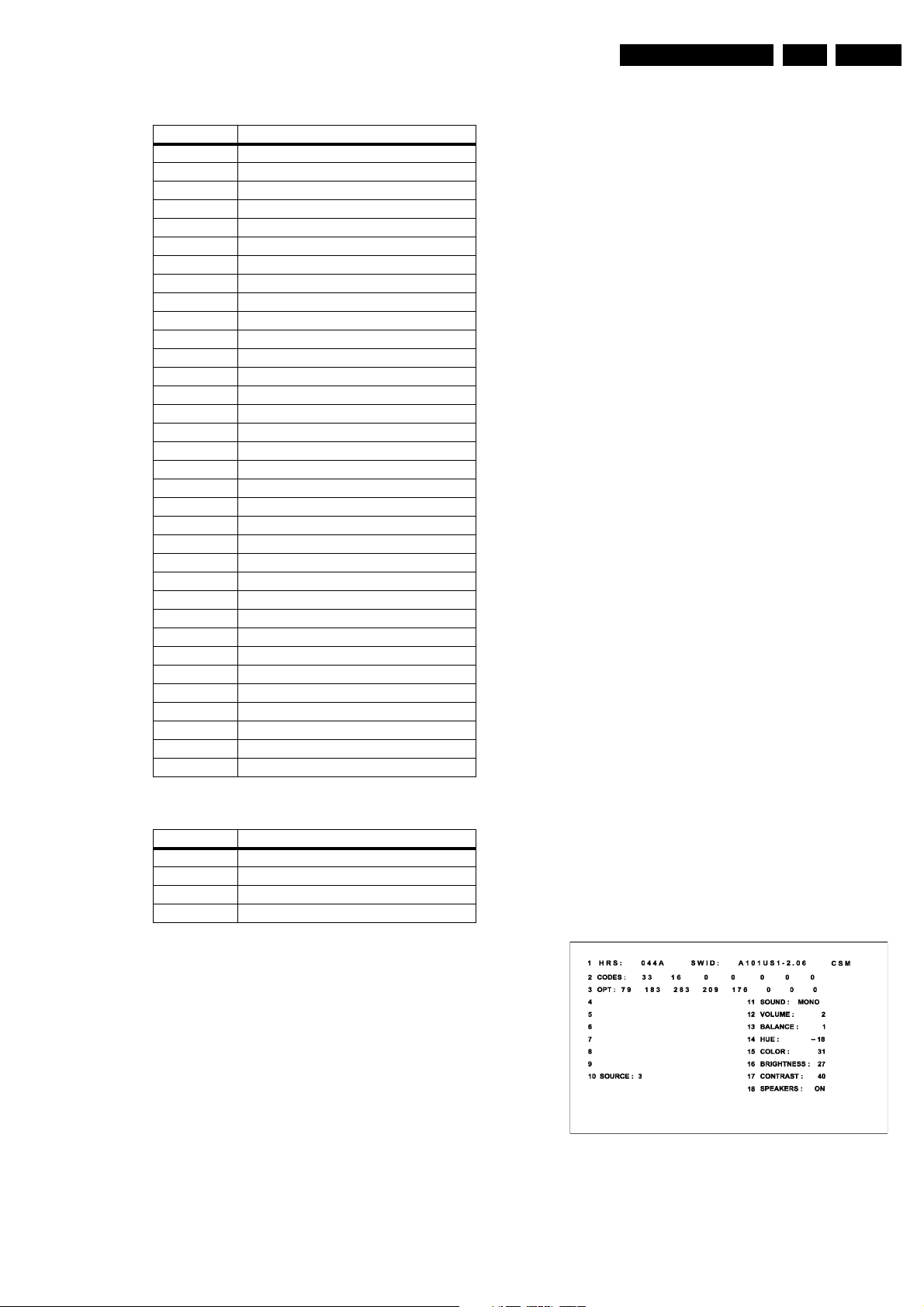

In SAM the following information is displayed on the screen:

Figure 5-2

5.3.3 Explanation Notes/References:

1. Operation Hours (Run Timer):

• This display indicates the accumulated total of

operational hours. (Shown in hexadecimal format)

2. Software identification of the main micro controller

(A101US1-2.06)

• A10 is the engineering chassis name for the A10

PTV chassis

• 1US1 is a character combination to indicate the

software type and the supported languages: 3AP1 or

3AP2 are also possible in the Asian Pacific Region.

• US = United States, AP = Asia Pacific

• 1 = Main Software language version number

• 2.06 = sub-version number

3. Error buffer (7 errors possible):

• Displays the 7 most recent errors. The most recent

error is displayed at the upper left.

4. Option bytes (8 codes possible):

• Summary of options is explained below.

5. Sub menus are listed in a scroll menu.

5.3.4 SAM Menu Control

Menu items may be selected using the cursor UP/DOWN

keys.

• The selected item will be highlighted.

• When not all menu items will fit on the screen, pressing

the cursor UP/DOWN keys on the remote transmitter will

display the next/previous menu items.

CL 16532052_003.eps

090501

With the cursor LEFT/RIGHT keys, it is possible to:

• (de)activate the selected menu item (e.g. GEOMETRY)

• change the value of the selected menu item ( e.g. VERSLOPE )

• activate the selected submenu (e.g. SERV-BLK)

Access to Normal User Menu

Pressing the “MENU” button on the remote control switches

between the SAM and the normal user menus (with the SAM

mode still active in the background). Pressing the “MENU”

key in a submenu will return the screen to the previous menu.

5.4 The Menus and Submenus

5.4.1 Clear Errors

Erases the contents of the error buffer. Select the CLEAR

ERRORS menu item and press the cursor LEFT or cursor

RIGHT key. The contents of the error buffer are cleared.

The functionality of the OPTIONS and ALIGNMENTS

(TUNER, WHITE TONE, GEOMETRY, SOUND, and

SMART SETTING) submenus are described in the service

adjustments.

5.4.2 Error Code Buffer and Error Codes

Explanation of the Error Code Buffer

The error code buffer contains all errors detected since the

last time the buffer was erased. The buffer is written from left

to right. When an error occurs that is not yet in the error code

buffer, the error code will appear at the left side and all other

errors shift one position to the right.

The error code buffer will be cleared in the following cases:

• by activating CLEAR ERRORS in SAM menu

• exiting SDM or SAM with the “Standby" command on the

remote control

• upon automatic reset when content has not changed for

50 consecutive hours

By leaving SDM or SAM via the power switch, the error buffer

will not be reset.

Examples:

ERROR: 0 0 0 0 0 0 0 :No errors detected

ERROR: 6 0 0 0 0 0 0 :Error code 6 is the last and only

detected error

ERROR: 9 6 0 0 0 0 0 :Error code 6 was first detected and

error code 9 is the last detected (newest) error

The contents of the error buffer can also be displayed by use

of the “blinking LED” procedure, if no picture is available. See

explanation of “The blinking LED procedure “below.

5.4.3 Error Code Definition

In case of non-intermittent faults, clear the error buffer before

starting the repair, to make sure “old” error codes are not

present. If possible check the entire content of the error

buffers. In some situations an error code is only the result of

another error code (and not the actual cause).

Note: a fault in the protection detection circuitry can also lead

to a protection.

Error codes 1,2, 3, and 4 are protection codes, and in this

case the supplies of some circuits will be switched off. Also

in protection, the LED will blink the number of times

equivalent to the most recent error code.

Page 9

Fault Finding and Repair Tips

GB 9A10PTV2.0 NTSC 5.

5.4.4 Error Code Table

Code Number Error Description

00 Not an Error

01 Too high I-beam or East/West protection

02 Vertical protection

03 X-Ray protection

04 5 volt protection

05 - not used

06 General IIC error

07 BC loop not stabilised

08 Bocma TDA888X IIC error

09 Bocma IC 8v failure

10 NVM IIC communication error

11 Wrong NVM type

12 Microp internal RAM error

13 Main tuner IIC failure

14 Sound IC failure

15 SRAM test failure

16 PIP Tuner IIC failure

17 ECO Pip IC or DW Pip IC failure

18 I/O expander I2C error

19 Gemstar Guide Plus board

20 V-chip located on the DW Pip

21 Non-Volatile clock

22 Incredible picture (YUV) CR

23 Bocma DoubleWindow TDA888X error

24 - not used

25 - not used

26 - not used

27 Virtual Dolby

28 - not used

29 - not used

30 CSP i2c error

31 CSP NVM i2c error

32 CSP NVM error - not valid data

33 CSP dac i2c error

5.4.5 A10 PTV Model Listing & Software

Model Software

43PP925/61 3AP2

43PP925/97 3AP1

55PP925/61 3AP2

55PP925/97 3AP1

Error buffer: 12 9 6 0 0

• After entering SDM:

• The sequence will begin with 1 long blink of 750

mSeconds, then pause 1500 mSeconds, then blink twice

(indicating error code 12), then the LED will pause for 3

seconds, then blink 9 times (indicating error code 9), then

the LED will pause for 3 seconds, then blink 6 times

(indicating error code 6), then pause 3 seconds and blink

for 3 seconds again, ending the blinking sequence.

NOTE: If errors 1, 2, 3, or 4 occur the LED ALWAYS

blinks indicating the last error which occurred, even if

the set is NOT in service mode.

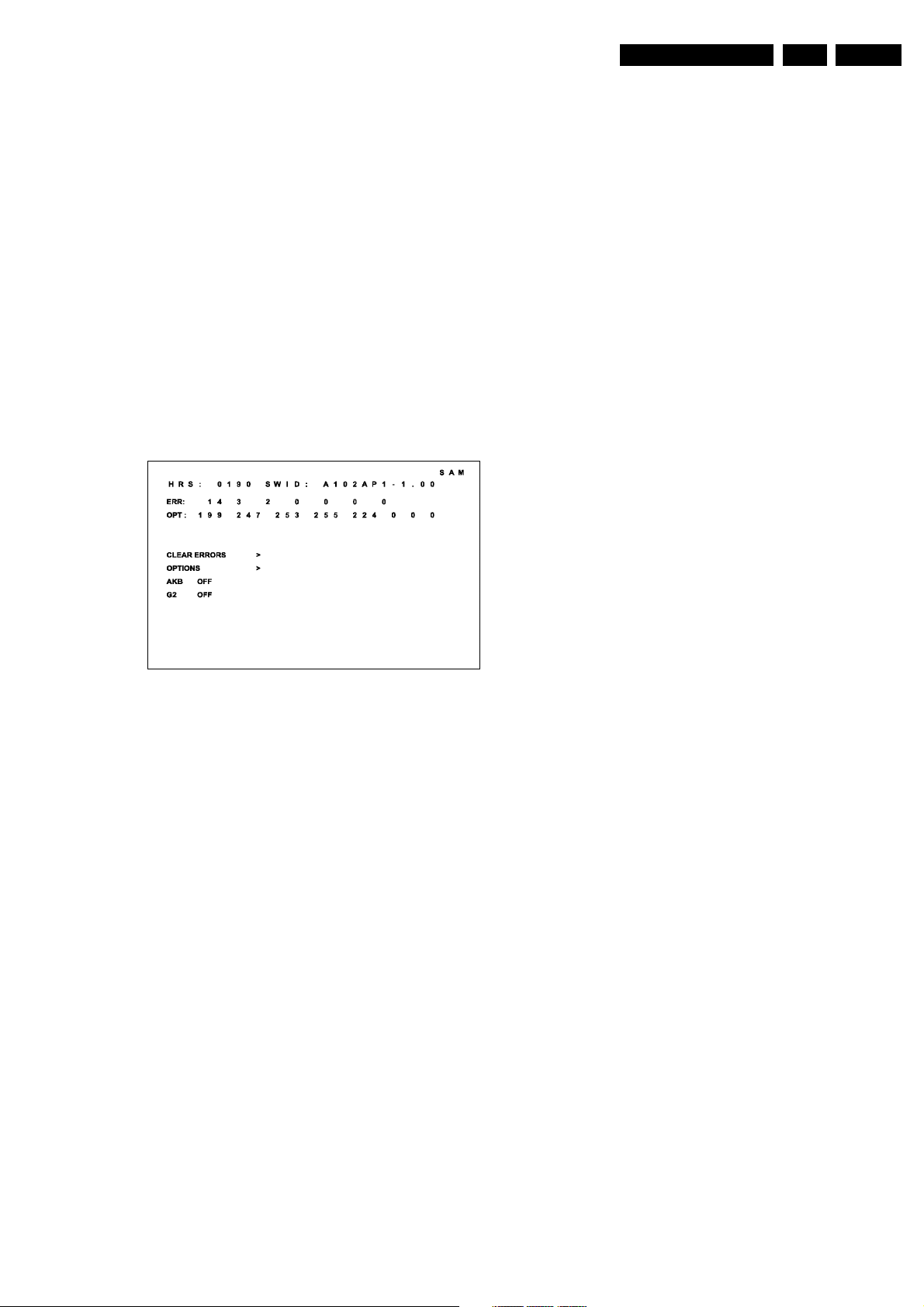

5.6 Customer Service Mode

All A10 PTV sets are equipped with the “Customer Service

Mode” (CSM). CSM is a special service mode that can be

activated and deactivated by the customer, by request of the

service technician/dealer in order to identify the status of the

set. This CSM is a 'read only' mode, therefore modifications

in this mode are not possible.

5.6.1 Entering the Customer Service Mode.

The Customer Service Mode can be switched on:

• By pressing the MUTE button on the remote control and

any key on the local keyboard (Channel Up, Channel

Down, VOL +, VOL -) on the TV simultaneously for at

least 4 seconds.

When the CSM is activated:

• picture and sound settings are set to nominal levels

• Modes that interfere with the behavior of the set are

switched off (sleep timer, auto standby, etc.)

5.6.2 Exit the Customer Service Mode.

The Customer Service Mode will be switched off after:

• Pressing any key on the remote control (except “Channel

Up” or “Channel Down”)

• Switching off the TV set by pressing the Power button on

the remote control or the local keyboard.

Exiting CSM resets the TV set back to its initial values.

5.6.3 The Customer Service Mode information screen

Upon entry into the Customer Service Mode the following

screen will appear.

5.5 The Blinking LED Procedure

The contents of the error buffer can also be made visible

through the “blinking LED” procedure. This is especially

useful when there is no picture.

• When the SDM is entered, the LED will blink the number

of times equal to the value of the error code. Upon entry

into the SDM, the LED will blink the contents of the errorbuffer. Error-codes greater than/equal to 10 are shown in

the following manner: A long blink of 750 mSeconds

indicating the decimal digit, followed by a pause of 1500

mSeconds. The LED will then blink the number equal to

the error code. When all error-codes are displayed, the

sequence is finished with an LED display of 3 seconds.

At this point the sequence will begin again.

Example:

Error code position 1 2 3 4 5

CL 16532052_002.eps

Figure 5-3

The Customer Service Menu shows the following

information:

090501

Page 10

GB 10 A10PTV2.0 NTSC5.

Fault Finding and Repair Tips

Line 1 : “HRS : nnnnn” and SWID : “A102BBC-X.YY”

HRS:

Indicates the accumulated total of operational hours. (Shown

in hexadecimal format.) (Standby hours are not counted as

operating hours).

SWID:

Software identification of the main micro controller (A10US1-

2.7)

A10 is the chassis name for the A10 PTV

• 1US1 is a character combination to indicate the software

type and the supported languages: 3AP1 or 3AP2 are

also possible for the Asian Pacific Region.

• US = USA/NAFTA, AP = Asia Pacific region

• 1 = Main Software language version number

• 2.7 = sub-version number

Line 2 : “CODES : xx xx xx xx xx xx xx ”

Error code buffer (see explanation of error codes above)

Displays the last 7 errors of the error code buffer.

Line 3 : “OPT xxx xxx xxx xxx xxx xxx xxx xxx”

Option bytes

Option bits control the software and hardware functionality of

the A10.0. An option byte or option number represents 8 of

those bits. Each option number is displayed as a number

between 0 and 255. The set may not work correctly when an

incorrect option code is set. See Service Adjustments for

more information on correct option settings

4. Set to “ADD” with the left/right cursor keys

Line 9 : “HOTELMODE ON”

Indicates that the Hotel mode has been activated.

Line 10 : “SOURCE :”

Indicates which SOURCE is installed for this preset.

EXT1, SVHS2, EXT2, Tuner

Line 11 : “SOUND”

Indicates which sound mode is installed for this preset.

Mono, NICAM, Stereo, L1, L2, SAP, Virtual or Digital

Line 12 : “VOLUME”

Value indicates level at CSM entry.

Line 13 : “BALANCE”

Value indicates level at CSM entry.

Line 14 : “HUE”

Value indicates level at CSM entry.

Line 15 : “COLOUR”

Value indicates level at CSM entry.

Line 16 : “BRIGHTNESS”

Value indicates level at CSM entry.

Line 17 : “CONTRAST”

Value indicates level at CSM entry.

Line 4: NOT USED

Line 5 : “NO SIGNAL”

Indicates that the set is not receiving an “ident” signal on the

selected source.

• no or bad antenna signal; connect a proper antenna

signal

• antenna not connected; connect the antenna

• no channel / preset is stored at this program number; go

to the INSTALL menu and store a proper channel at this

program number

• the tuner is faulty (in this case the CODES line will

contain number 13 or 16); check the tuner and replace/

repair if necessary

Note: On some models (if the BM option is ON), BLUE

MUTE is displayed when no signal is received.

Line 6 : “TIMER ON ”

Indicates that the on/off timer is running.

The following Complaints may be caused by the activation of

the sleep timer:

The set may turn on from standby or may switch to a different

channel without using either the remote control or the local

keyboard.

To switch off the activation timer:

Select “TIMER” in the “FEATURE” menu.

Select “ACTIVATE” in the “TIMER” menu.

Set to “OFF” with the left/right cursor keys.

Line 7 : NOT AVAILABLE

Line 8 : “NOT PREFERED”

Indicates that at least one channel is deleted as a preferred

channel (by default, all channels are skipped).

Note that “SKIPPED” will always be displayed in CSM

unless all the channels are not skipped.

To add a channel as a selected channel to the list of preferred

channels:

1. Select “INSTALL” menu

2. Select “CHANNEL EDIT”

3. Select “ADD/DELETE”

Line 18: “SPEAKERS”

Indicates the speakers are “ON” or “OFF”.

Page 11

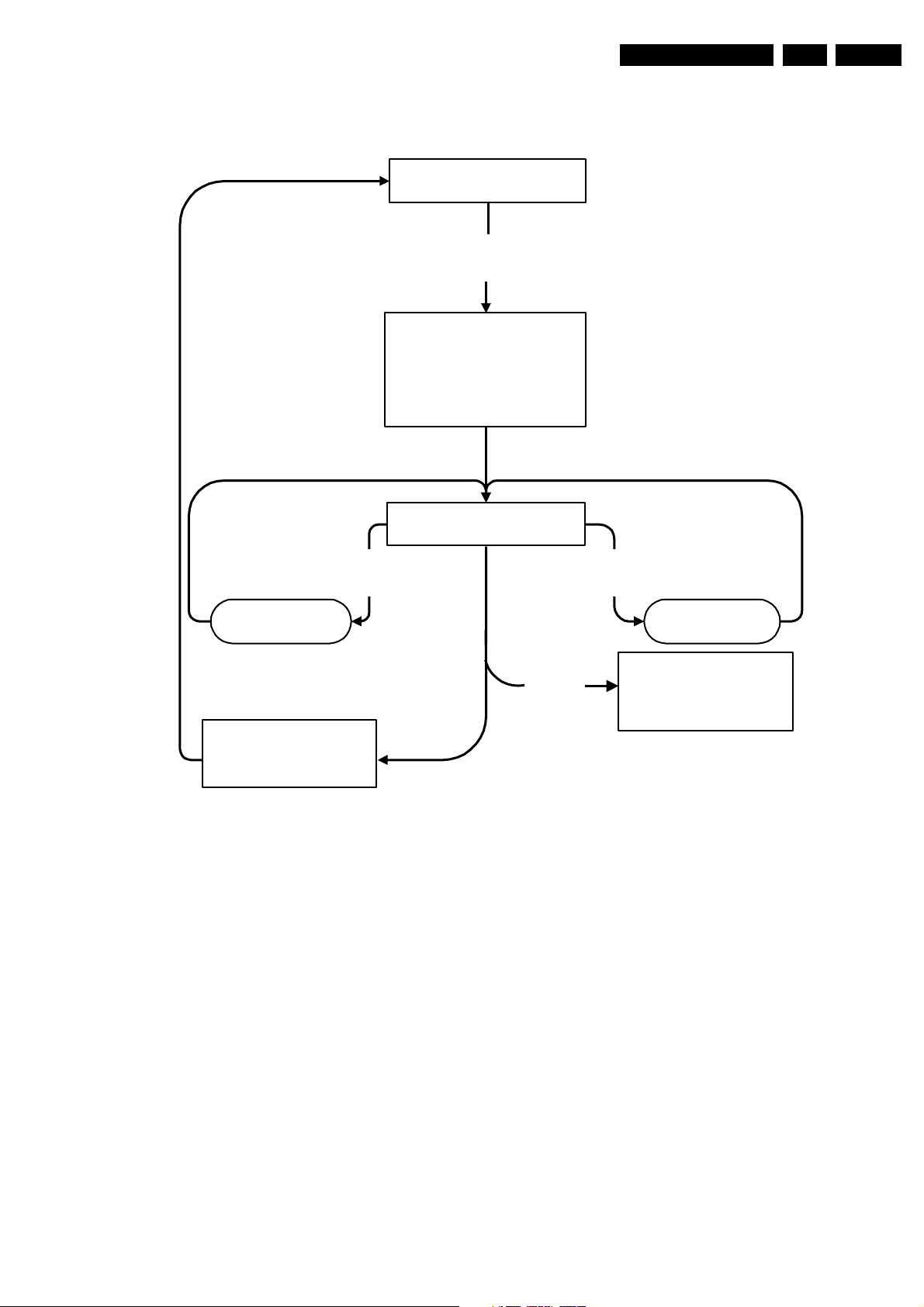

5.6.4 CSM Flow Chart

y

p

Fault Finding and Repair Tips

Normal operation mode

Press "MUTE" button (RC) and

key on the local keyboard

an

(except "POWER") for more than 4 seconds

Store current picture, sound and

feature settings (for later retrieval)

Set pre-defined picture, sound and

feature settings

Ignore service unfriendly options

GB 11A10PTV2.0 NTSC 5.

"Channel up"

(RC or local

keyboard)

Exit CSM

Restore picture, sound and

a

n

a

stored during entry)

Display CSM information screen

POWER

(RC or local

Other key

Figure 5-4

keyboard)

"Channel down"

(RC or local

keyboard)

Off (Exit CSM):

when the set is switched on,

icture, sound and feature

settings (that were stored

during entry) are restored

To next CSM pageTo previous CSM page

CL 06532143_007.eps

011100

Page 12

GB 12 A10PTV2.0 NTSC5.

Fault Finding and Repair Tips

5.7 Trouble Shooting Tips

5.7.1 The Power Supply Circuit:

When the set is turned On,the Main Switch Mode power

supply is turned On This supply produces the +130 volt,+32

volt,-32 volt,two +15 volt,and Audio supplies. When IC 7302

develops a normal steady state operation,the 130 volt supply

is sampled by resistors 3324,3323,and 3322.

This sample voltage is then sent to Shunt regulator 7303

which drives the feedback optoisolator 7303.The feedback

voltage on Pin 14 is then compared with an internal 2.5 volt

reference by comparator "C". Comparator "C"then sets the

reference voltage on the inverting side of comparator "B"to

control the On time of the drive at Pin 3.If the voltage on Pin

14 increases due to the 130 volt supply increasing,the On

time of the pulse on Pin 3 will be reduced.If the 130 volt

supply decreases,the voltage on Pin 14 would

decrease,causing the On time of the pulse on Pin 3 to

increase.This is used to keep the 130 volt supply at the

correct voltage.Variable resistor 3322 is used to adjust the

130 volt supply to the correct level.

The overvoltage protection circuit of the IC will shut the IC

down if the VCC level on Pin 1 exceeds 17 volts.

To troubleshoot this circuit,first check the On/Off line from the

Small Signal Panel to ensure that it is going Low.Then check

for the presence of startup voltage on Pin 1 of the regulator

IC 7302.If the IC is working correctly,this voltage will be

changing from 9.4 to 14.5 volts.If the startup voltage is not

present,check the startup resistor 3300 and the bridge

rectifier.If the voltage on Pin 1 is changing,check the drive

signal on Pin3.Then check for signal on the gate and drain of

7301.An excessive load on the secondary,a short on the 130

volt line for example,would cause the supply to pulse with

little or no voltage on the secondary.

Sound Problems

No sound or sound too loud (after channel change / switching

on)

– Enter the Customer Service Mode. If the volume is OK,

increase / decrease the volume level.

5.7.2 Picture Problems

Picture Too Dark or Too Bright

– Press “Smart Picture” button on the remote control. If this

improves the picture, increase / decrease the brightness

value or increase / decrease the contrast value.

– Enter the Customer Service Mode. If this improves the

picture, exit Customer Service Mode, then Increase /

decrease the brightness value or increase / decrease the

contrast value.

White Line Around Picture Elements and Text

– Press “Smart Picture” button on the remote control. If this

improves the picture, decrease the sharpness value.

– Enter the Customer Service Mode. If this improves the

picture. Decrease the sharpness value.

Snowy Picture

– Snow is an antenna or antenna connector problem.

Check tuner and AGC.

Black and White Picture

– Press the “Smart Picture” button on the remote control. If

this improves the picture, increase the color value.

– Enter the Customer Service Mode. If this improves the

picture. Increase the color value.

Menu Text Not Sharp Enough

– Press the “Smart Picture” button on the remote control. If

this improves the picture, decrease the contrast value.

– Enter the Customer Service Mode. If this improves the

picture. Decrease the contrast value.

Page 13

8. Alignments

Alignments

GB 79A10PTV2.0 NTSC 8.

General: The Service Default Mode (SDM) and Service

Alignment Mode (SAM) are described in Chapter 5.

8.1 Alignment Conditions

All electrical adjustments should be performed under the

following conditions:

• Supply voltage : 120V +/- ( 10%)

• Warm-up time: 10 minutes

• The voltages and oscilloscope waveforms are measured

in relation to the tuner ground.

• Test probe: Ri > 10Meg Ohm; Ci < 2.5 pF.

8.2 Software Alignments (Service Alignment

Mode)

With the software alignments of the Service Alignment Mode,

the geometry, white tone and tuner (IF) can be aligned.

CL 16532052_003.eps

Figure 8-1

8.2.1 Tuner Options - AFC Window and IF PLL Offset

AFC Window

Enter SAM (see Chapter 5 (Service Alignment Mode)). Press

Cursor Down button to highlight the TUNER menu item.

Press Cursor Right button to enter the TUNER submenu.

Press Cursor Down button to highlight the AFC submenu

item. Use the Cursor Left/Right buttons to toggle the value of

AFC between 100kHz (NORMAL) and 250kHz (ENLARGE).

090501

3. Connect an Oscilloscope to the Collector of each output

transistor on the Green CRT board. Set the probe to

times 10.

4. Adjust the Green G2 control until the Black Level is at

200V.

5. Repeat steps 3 and 4 for the Red and Blue CRTs.

Alternate Method

1. Connect a Black Level signal to the set.

2. Preset all G2 controls on the Focus/G2 Combo Block to

minimum (fully CCW).

3. Turn each G2 control clockwise until each CRT is barely

illuminated.

8.3.2 Gray Scale Setup

1. Connect a Gray Scale pattern to the set.

2. Preset the registers as shown below.

NORMAL RED 26

NORMAL GREEN 56

NORMAL BLUE 59

NORMAL BLACK LEVEL RED 10

NORMAL BLACK LEVEL GREEN 13

DELTA COOL RED -6

DELTA COOL GREEN -7

DELTA COOL BLUE 4

DELTA COOL BLACK LEVEL RED 2

DELTA COOL BLACK LEVEL GREEN 1

DELTA WARM RED 6

DELTA WARM GREEN 0

DELTA WARM BLUE -8

DELTA WARM BLACK LEVEL RED -2

DELTA WARM BLACK LEVEL GREEN -1

CATHODE DR 12

1. Set Brightness, Color, and Sharpness controls to 40 and

Picture control to maximum.

2. Adjust the NORMAL BLACK LEVEL controls to set the

correct gray scale in the dark areas of the picture.

3. Adjust the NORMAL RED AND BLUE controls to set the

correct gray scale in the light areas of the picture.

4. Use the Menu button on the Remote to back out to the

main service menu.

5. Turn the set Off using the Power Button on the Remote

or the front of the set.

8.4 Convergence Procedures

IF PLL Offset

NO ADJUSTMENT IS NECESSARY FOR THIS MENU

ITEM

The default value for these options is:

•IFPLLOFFSET:32

8.3 Gray Scale Alignment

Gray Scale alignment will be necessary after changing the

SSB (Small Signal Board) or the CRTs.

Enter the Service Alignment Mode by entering 0-6-2-5-9-6(Status or Index).

8.3.1 G2 Setup

Preferred Method

1. Connect a Black Level signal to the set.

2. Preset all G2 controls on the Focus/G2 Combo Block to

minimum (fully CCW)

The set should be warmed up for at least 20 minutes prior to

making any Geometry or Convergence adjustments.

A signal must be applied to the set while performing

Convergence or Geometry alignments. This is necessary to

provide the correct horizontal and vertical sync to the

Convergence panel. Failure to do so will result in an out of

convergence picture when signal is applied to the set.

The Serviced Technician should sit at least 5 to 10 feet from

the front of the screen while doing Convergence. Ensure

that you are eye level with the area of the screen you are

adjusting.

When performing Digital Convergence, the adjustments are

interactive. A change in one quadrant will affect adjacent

areas of the screen. Several passes through the

Convergence sequence may be necessary. When doing

Convergence, it is advised to follow the sequence pattern

when going fromon adjustment location to another. Pressing

the Right Cursor key will sequence the Icon through a

preloaded sequence.

Page 14

GB 80 A10PTV2.0 NTSC8.

When the Convergence error is small, a touch up

Convergence will be all that is necessary. Do not adjust

Green Geometry while in this mode. A compete in-depth

Convergence is required when the Small Signal Module

(SSM) or the Convergence Memory IC, has been replaced.

If the SSB (Small Signal Board) or the Large Signal Board

(LSB) has been replaced, a complete in-depth Geometry

should be completed before Convergence is adjusted. The

Geometry alignment should not be necessary if the SSB or

LSB have not been changed.

8.4.1 Screen Templates

When performing a complete in-depth Convergence

alignment, a Screen Template is necessary to obtain the

correct Geometry. The correct Templates are listed below:

43 INCH ST4168

50 INCH ST4169

55 INCH ST4170

60 INCH ST4171

64 INCH ST4172

Alignments

Complete In-Depth Convergence

8.4.3 Screen Centering

1. Make sure a signal is applied to the set.

2. Enter the Convergence mode by entering 0-6-2-5-9-7(Status or Index). Select an active channel or input. If

the Customer settings need to be adjusted, pressing the

Menu button will access the Customer menu.

3. Place a Template over the screen.

4. Select GREEN in the SELECTION menu.

5. Place a jumper across connector 1005 on the SSM to

defeat convergence drive.

6. Using the centering rings on the Green CRT, center the

convergence pattern onto the center point of the

Convergence Template.

7. Press the Menu button on the Remote to return to the

SELECTION menu.

8. Select RED TO GREEN in the menu.

9. Center the Red pattern onto the Green pattern.

10. Select BLUE TO GREEN in the SELECTION menu.

11. Center the Blue pattern onto the Green pattern.

12. Remove the Jumper on connector 1005.

8.4.2 Touch-up Convergence Adjustments

Enter the Digital Convergence Mode (DCM) by entering 0-62-5-9-7-(Status or Index) on the Remote control. The

following menu will appear:

Select an active channel or Aux Input. A signal must be

applied to the set when performing convergence. If any

Customer Adjustments need to be made, the Menu button

can be used to toggle between the Customer Menu and

DCM. The MPOSD ADJUST is used to center the Customer

Convergence grid. A highlighted cross will appear along with

the Convergence alignment grid. The highlighted cross

should be centered onto the center of the Convergence grid.

To perform a Touch Up Convergence, highlight SELECTION

and press the right cursor button on the remote. The

following menu will appear:

Selections STORE, RESTORE FACTORY, and RESTORE

DEFAULT are not shown after selecting SELECTION. Press

the cursor down button on the Remote for these selections to

appear. RESTORE FACTORY loads Convergence defaults

from the Factory Loaded section of the Convergence

Memory IC. RESTORE DEFAULT loads Convergence

defaults from the sets software.

To perform a Touch-up Convergence:

1. Enter the Convergence Mode and select RED TO

GREEN or BLUE TO GREEN. Do not select GREEN

(Green Geometry) without placing a Template over the

screen. To perform Green Geometry, refer to the

Complete in-depth Convergence.

2. Use the Cursor buttons on the Remote to Navigate from

one adjustment point to another. Press the Status or

Index button on the Remote to select ADJUST. Use the

cursor buttons on the Remote to adjust the Red to Green

or Blue to Green. Press the Status or Index button again

to navigate to the next adjustment location.

3. After Convergence alignments are complete, press the

Menu button on the Remote to return to the SELECTION

menu.

4. Highlight the STORE selection and press the right cursor

key on the Remote to save changes.

5. Use the GREEN TO RED or GREEN TO BLUE

selections to perform convergence when the Green CRT

has been replaced.

Note: If a CRT has been replaced, it is only necessary to

perform Screen Centering for the CRT being replaced.

8.4.4 Green Geometry

1. Make sure a signal is applied to the set.

2. Enter the Convergence mode by entering 0-6-2-5-9-7(Status or Index). Use the Menu button to toggle

between DCM and Customer Mode. Select an active

channel or input while in the Customer Mode.

3. Place a Template over the Screen.

4. Select GREEN in the SELECTION menu.

5. The Icon will appear in the center of the screen. Press

theRightCursorkeyontheremotetomovetheIconto

the next adjustment location. At each location press the

Status orIndex button to enter the ADJUST mode. Using

the Cursor keys, adjust the Icon onto the adjustment

point on the template. It is recommended that the two

outside vertical lines not be adjusted in the first two

passes.

6. Continue to follow the pattern and make corrections until

the Convergence Crosshatch pattern matches the

Template.

7. Press the Menu button to return to the SELECTION

menu.

8. Use the Cursor down key to highlight the STORE

selection.

9. Press the Right cursor key to save the alignments.

10. Remove the Template.

8.4.5 Red Convergence

1. Select RED TO GREEN in the SELECTION menu.

2. Adjust the Red crosshatch pattern onto the green pattern

in the same manner that Green was adjusted to the

Template.

3. Save the alignments.

8.4.6 Blue Convergence

1. Select BLUE TO GREEN in the SELECTION menu.

2. Adjust theBlue crosshatch pattern onto the greenpattern

in the same manner that Green was adjusted to the

Template.

3. Save the alignments.

Page 15

Alignments

GB 81A10PTV2.0 NTSC 8.

8.5 Complete In-Depth Geometry

To activate the Service Alignment Mode, enter 0-6-2-5-9-6(Status or Index) using the Remote Control.

Press Status or Index toggle to the Customer menu. Select

an active channel. Pressing the Status or Index button will

bring up the SAM mode.

Apply a Crosshatch pattern to the set and select that input.

Defeat Convergence by shorting the two pins of connector

1005 on the SSM.

Press the Cursor-down key on the remote and select

Geometry with the Right cursor key.

Adjust the Screen Geometry as necessary.

The following are default values:

VER.AMPL 30

VER.SLOPE 34

SERV.BLK OFF

HOR.SHIFT 32

HOR.BOW 20

HOR.PARALLEL 31

EW.WIDTH 22

EW.PARA 21

EW.TRAP 19

EW.UCORN 6

EW.LCORN 0

H60.WIDTH 2

H60.PARA 0

H60.SHIFT 7

V60.AMPL 0

VER.SCOR 18

VER.SHIFT 35

VER.ZOOM 32

VER.SCROLL 32

• Adjust Vertical height VER-ZOOMxx

• Adjust Vertical posistion VER-SCROLLxx

• Adjust Vertical linearity VER-SCORxx

• Not used H60-SHIFTxx

• Not used V60-AMPLxx

• Adjust Horizontal width EW-WIDTHxx

• Adjust Parabola EW-PARAxx

• Adjust Up corner EW-UCORNxx

• Adjust low corner EW-LCORNxx

• Adjust Trapezium EW-TRAPxx

• Adjust Horizontal parallelogram HOR-PARALLELxx

• Adjust Horizontal bow HOR-BOWxx

To save changes, use the Menu button on the Remote to

back out to the main menu. Then turn the set Off using the

power button on the Remote or the front of the set. This will

save any changes made.

8.6 Geometry Adjustment

The geometry alignments menu contains several items for

correct picture geometry alignment. In widescreen models,

the GEOMETRY SW is available for separate alignments of

the superwide (panorama) mode.

8.6.1 Initial Set-Up:

Press the PICTURE button on the remote control repeatedly

to change the Smart Picture setting to "NATURAL."

Enter SAM (see Chapter 5 (Service Alignment Mode)).

Press the Menu Down button to select the GEOMETRY

menu item.

Press the Cursor Right button to enter the GEOMETRY

submenu.

Press the Cursor Down button to highlight the VER-SCOR

submenu item.

Use the Cursor Right buttons to adjust VER-SCOR.

VER-SCOR aligns the vertical linearity, so that the vertical

intervals of the grid-patterns are the same over the entire

height of the screen.

Extra Alignment for 4:3 Sets

• Set Service blanking on SERV-BLK ON

• Adjust Vertical slope VER-SLOPExx

• Set Service blanking OFF SERV-BLKOFF

General Alignment (4:3 set)

• Adjust Vertical amplitude VER-AMPLxx

• Adjust Vertical shift VER-SHIFTxx

• Adjust Horizontal shift HOR-SHIFTxx

Page 16

GB 82 A10PTV2.0 NTSC8.

Alignments

8.7 Options

Options are used to control the presence / absence of certain

features and hardware. There are two ways to change the

option settings:

1. Changing asingle option: An option may be selected with

the MENU UP/DOWN keys and then changed with the

MENU LEFT/RIGHT keys.

2. Changing multiple options by changing option byte

values: Option bytes make it possible to set all options

quickly. An option byte represents a number of different

options. All options of the A10 PTV are controlled via 8

option bytes. Select the option byte (OB1, OB2, OB3,

OB4, OB5, OB6, OB7 or OB8) and enter the new value

by using the number keys on the remote control.

8.7.1 List of Options

The table below gives an overview of possible options. These

option bits can be set ON (1) or OFF (0). If an option is set

ON, it represents a certain value. (see Option bits/bytes).

Adding the value of 8 option bits gives the value of an option

byte (OB).

Option

abbreviation

ABSY AUTO STANDBY AFTER NO INTERAC-

SBNP AUTO STANDBY NO PICTURE ON

CVI COMPONENT VIDEO INPUT ON

C169 COMPRESS 16:9 MODE AVAILABLE OFF

E149 EXPAND 14:9 MODE AVAILABLE OFF

HWBMS HARDWARE BLUE MUTE STREAK ON

SMCK SMART CLOCK ON

AV3 SIDEAVSOURCE ON

AUSB AUTO STANDBY AUTO ON ON

CBFL COMB FILTER ON

IPIX INCREDIBLE PICTURE ON

IPMU INCREDIBLE PICTURE VIA MENU ITEM ON

VDBY VIRTUAL DOLBY ENABLED ON

PITN PHILIPS TUNER OFF

PLST PROGRAM LIST ON

SOSD SMART OSD ON

BLMU BLUE MUTE OFF

PIPC PIP CONTROL ON

PIPS PIP SURF ON

PIPT PIP TUNER ON

ISUR INCREDIBLE SURROUND ON

W4x3 DOUBLE WINDOW WITH 4:3 MAIN PIC-

W169 DOUBLE WINDOW TWO COM-

VSLC VERTICAL SLICING ON

SURF SURF FEATURE AVAILABLE ON

CCAP CLOSED CAPTION ON

DNRM DNR FUNCTION AVAILABLE ON

VMUT VIDEO BLANKING DURING CHANNELCHON

3AP1 & 3AP2 CODE DESCRIPTIONS D

TION

TURE AVAILABLE

PRESSED 16:9 AVAILABLE

OFF

ON

OFF

Option

abbreviation

NVM NVM CORRUPTION ON

HWBMS HARDWARE BLUE MUTE STREAK OFF

OB1 CAN BE USED TO ADJUST OPTION

OB2 246

OB3 251

OB4 253

OB5 112

OB6OB8

8.7.2 Option Bits / Bytes

An option byte value is calculated in the following way:

value “option bit 1” x1=

value “option bit 2” x2=

value “option bit 3” x4=

value “option bit 4” x8=

value “option bit 5” x16=

value “option bit 6” x32=

value “option bit 7” x64=

value “option bit 8” x 128 =

Total is value is “option byte” =

3AP1 & 3AP2 CODE DESCRIPTIONS D

BYTES AT ONCE

99

0

TIME TIMER FEATURE AVAILABLE ON

AAVL AVL AVAILABLE ON

CHLK CHILD LOCK FEATURE AVAILABLE ON

ROTI ROTATION/TILT OFF

SNIC SOUND BOARD PRESENT ON

TMWIN TIMEOUT FOR DIGIT ENTRY ON=5SEC

OFF=2SEC

INCF INTERNAL COMB FILTER PRESENT ON

OFF

Page 17

9. Circuit Description

Circuit Description

GB 83A10PTV2.0 NTSC 9.

The A10 PTV chassis is designed for release in the 20002001 model year. This product is scheduled for release in the

NAFTA and Asia Pacific regions. The set is built in three

screen sizes, 43 inch (109 cm), 50 inch (127 cm), and 55 inch

(140 cm). These sets are capable of receiving signals in the

PAL/D, PAL/I, PAL/BG, NTSC, or NTSC/M formats

depending on the package for a particular country. The set

is equipped with a two tuner PIP. The set has three

composite Video inputs, two on the Rear Jack Panel and one

on the Side Jack Panel. The set also has two SVHS inputs,

and one component input. A Center Channel Input on the set

allows the speakers in the set to be used as a centerchannel.

The MG99 Projection TV uses three single color tubes, Red,

Green, and Blue. The output of each tube is projected onto a

mirror where it is then reflected onto a viewing screen. The

Tubes are converged so the light from each tube strikes the

same spot on the Fresnel Lens. The Fresnel Lens equalizes

and Concentrates the light to provide equal light uniformity

across the screen. The Mirror is a first surface mirror type,

which has the reflective coating on the outside of the mirror.

To prevent scratching of this surface, always use a soft

cotton cloth to clean it.

The Lenticular Lens Screen calumniates the light from the

Fresnel Lens. The Lenticular Lens increases contrast by

reducing the ambient light by the use of Black Striping. The

Prismatic formation of the screen allows for nearly 3X light

output as compared to a flat screen. Caution should be used

when working with the screen. Damage can easily occur in

the form of scratching, or by using certain chemical screen

cleaners which can strip the black striping from the screen.

The clean the screen, use one drop of dish washing

detergent in a small bowl of water. (Approximately 2 liters)

Wipe the screen with a soft cotton cloth in the direction of the

stripes.

on if one is present. This circuit produces a +5 volt and a

+3.3 volt standby voltage. The +5 volt standby voltage

supplies power to the Full Power Supply Relay while the +3.3

volt standby voltage is applied to the Microprocessor

(Painter) located on the Small Signal Board.

When the Microprocessor pulls the Standby line Low, the

Startup Run Switch is turned On, switching the Neutral side

of the AC Mains to the Full Power Supply. This provides the

Startup voltage for the Full Power Supply. Once the Full

Power Supply is operating, a 14 volt supply is generated to

provide operating voltage. The Full Power Supply provides

a 130 volt supply for the Scan circuits, a plus and minus 32

volt supplies for the Convergence circuits, a +15 volt supply

for the Scan supply, a +15VSSB supply for the Signal

circuits, and a AMP_VCC supply for the Audio Amplifier

circuits.

9.1.2 AC Input circuit with Power Factor Correction.

The AC Mains are connected to 1108, pins 1 and 4. The ac

is fused by 1000 and then fed to two line chokes, 5000 and

5001. Spark gaps 1003, 1002, 1001, 1005, and 2004provide

lighting protection. AC is then routed through the AC Mains

Switch before being applied to the Power Factor Correction

circuit.

The Three CRT’s are driven by 30KV of high voltage and

15KV of focus voltage. The Tube produces a highly

concentrated light output of color. A liquid coolant of Glycol

is used to transfer heat from the face of the tube to the

surrounding mechanical assembly. The C-element lens

seals the Coupling fluid within the coupler. The C-element

lens and Coupling fluid are part of the light path and

contribute to the properties of the optical system.

9.1 Power Supply

9.1.1 Power Supply Block

AC Mains are fed to the PFC (Power Factor Correction) or

Line Conditioner. The output of this panel is fed to the

Standby and Full Power sections, which are located on the

Large Signal panel. The AC mains voltage is 230 volts for

sets with the Power Factor Correction circuit. The ac Mains

voltage can be either 115 or 230 volts for the multi-voltage

sets. There are two dc output voltages from this panel, which

are 160 to 325 volts dc to the Standby Power section on the

Large Signal panel and 160 to 380 volts dc to the Full Power

Section. The 160 volts dc is present is the AC Mains are 115

volts. The 325 volts dc is present if the AC Mains are 230

volts. If the Power Factor Correction circuit is present, 380

volts dc is present. If the Power Factor Corrections circuit is

present, the circuit is switched off when the set is in the

Standby mode. The Standby Line is switched low when the

set is turned on, switching the operating voltage from the

Standby Power Section to the Power Factor Correction

circuit.

CL 06532143_008.eps

Figure 9-1

9.1.3 AC Input circuit without Power Factor Correction.

The AC Mains are connected to 1108, Pins 1 and 4. The ac

is fused by 1000 and then fed to three line chokes, 5000,

5001, and 5005. The AC Mains voltage is applied to bridge

6000 and filtered by 2110 to produce the Main B+ voltage.

The AC Mains are also connected to bridge 6001 to produce

RAWSTBY voltage for the Standby Section of the power

supply. This circuit is fused by 1004. Startup voltage for the

Full Power Section is taken from the Neutral side of the AC

Mains and fed to the Full Power Section on the Large Signal

Panel through resistor 3300.

081100

The Standby Power Section begins operating as soon as

power is applied to the set and the AC Mains Switch is turned

Page 18

GB 84 A10PTV2.0 NTSC9.

Circuit Description

Figure 9-2

Figure 9-3

CL 06532143_009.eps

081100

CL 06532143_010.eps

081100

9.2 Power Factor Correction Circuit

The input to most switching power supplies consists of a

bridge rectifier and a large electrolytic capacitor when AC

power is applied, the Capacitor will charge to approximately

1.4 times the RMS value of the applied AC voltage. This type

of supply does not draw current from the AC power source

through out the entire AC cycle. When the capacitor charge

falls to point “A”, the instantaneous value of the AC voltage

exceeds the charge of the capacitor. The bridge diodes are

then forward biased, causing current to flow from the AC

source. Current will continue to flow from the AC line until the

AC sinusoidal voltage reaches its peak at Point “B”.Atthis

point, the charge on the capacitor will exceed the AC line

voltage reversing the bridge diodes. This results in an AC

current waveform that is narrow and distorted compared to

the AC voltage waveform. Non sinusoidal waveforms have a

high harmonic content, with excessive peaks, which results

in a low power factor of 0.5 to 0.6. Power Factor is a ratio of

real power divided by apparent power. Excessive harmonics

and peak currents reduce the efficiency of the power

distribution system. The A10 Projection TV without Power

Factor correction has a high harmonic content of 85 percent,

creating a Power Factor of 0.5. High current spikes will also

be created in the AC supply. With the Power Factor

correction circuit, the peak current is limited, with the

harmonic content being reduced. The Power Factor is

increased to 0.99. The ideal Power Factor is one, which

occurs when the current is sinusoidal and in phase with the

voltage. Many countries limit the current harmonic content

of equipment supplied by the AC Mains. The A10 Power

Factor correction circuit uses a Boost regulator to smooth out

the current draw from the ac line improving the Power Factor

to 0.99, which is accomplished by drawing current from the

AC source throughout the entire ac cycle making the current

waveform sinusoidal. Input to the module is connected to the

ac Mains. The output supplies are approximately 376 volts

dc to the Main and Standby Switched mode Power Supply

circuit. The Boost Regulator circuit produces a higher output

voltage than the input voltage. The regulator drive circuit

compares 6103’s output voltage, the input voltage from the

bridge, and the voltage across the current sensing resistors

to control the On time of 7104. This will maintain the output

voltage at 376 volts DC and limit the input current to

Page 19

Circuit Description

GB 85A10PTV2.0 NTSC 9.

acceptable levels. When 7104 is on, current flow through

5109 stores energy in the choke. When 7104 turns off, 5109

reverses polarity and charges 2109. Using this type of

regulation, current is drawn from the AC source throughout

the entire cycle, keeping the current waveform sinusoidal.

When the AC cycle is at its low point, 7104 is on for a longer

period of time. When the AC voltage is at its peak, 7104 is

on for a shorter time to store the same amount of energy in

5109 to maintain the output voltage at 376 volts dc. If the

Boost regulator circuit should become inoperative, due to a

loss of regulator drive, operating voltage is still applied to the

set. The supply voltage to the switching supplies will drop

from 350 volt to approximately 329 volts depending on the

Mains voltage. Since the customer would not detect a failure,

the operation of this circuit should be checked after any

repair of the set.

3131, 3132, and 3133. This sample is added to the error

signal from the Multiplier going into Pin 8. The error signal is

amplified and then compared to the oscillator ramp to

determine the reset point for the latch. When the oscillator

goes low, the latch is set making output “Q” High. With the

other inputs to the AND gate High, Pin 20 then goes High,

turning 7104 On. By comparing the input and output voltage,

the on time of 7104 is increased when the ac voltage is at its

low point to maintain the 376 volt dc output. When the acinput voltage is at its peak, 7104 is on for a shorter period.

The IPK circuit connected to Pin 2 is an overcurrent

protection circuit, which resets the latch if there is excessive

current through the return resistors. This will reduce the on

time of 7104. In a like manner, the OVP, Over Voltage

Protection, circuit will reset the latch removing drive to Pin 20

is the output voltage exceeds 392 volts.

To check the operation of this circuit when the set is

operating correctly, check the PFCOUT voltage. This

voltage should be approximately 376 volts. If the output

voltage is approximately 300 to 329 volts, this circuit is not

working. Check the operating voltage on Pin 19 of 7102.

Then check the output drive on Pin 20 and at the gate of

7104. There are three grounds on the hot side of the supply.

Ground HA is connected directly to the bridge 6000. Ground

“B” is the ground for the Power Factor Correction circuit. If

the current sensing resistors 3130 through 3133 should

open, this would remove the ground for all the switching

supplies and make the set inoperative. Ground “C” is the

ground for the switching supplies. When ground “B” passes

through the choke 5106, it becomes ground “C”.

Figure 9-4

Figure 9-5

9.3 Full Power Factor Correction Circuit

The Power Factor Correction circuit is a fixed-frequency

Pulse-Width modulated boost regulator power supply.

Operating frequency is approximately 60 kilohertz. Due to

the low power consumption of the set during the standby

mode, the Power Factor Correction circuit is turned off. The

operating voltage, PFC, on Pin 19 of 7102 is turned off.

When the set is turned on, the operating voltage is switched

to Pin 19 of 7102. Once the circuit is in operation, a 5.11-volt

internal reference voltage on Pin 11 is applied to Pin 6 of the

IC. Output of the bridge rectifier is fed to the IC on Pins 4 and

7. Feedback from the output circuit is fed to Pin 14 where it

is multiplied with the Bridge output. Inputs to the Gilberts

Multiplier produce an error signal that is fed to the current

amplifier. The Gilberts Multiplier multiplies the bridge output

voltage with the output voltage on D438. The 5.11-volt

reference is used to provide a clamping reference for the

other inputs. Input current is sampled by resistors 3130,

CL 06532143_011.eps

081100

CL 06532143_012.eps

081100

Startup up voltage for the Full Power supply is taken from the

neutral side of the AC mains via resistor 3300 and connector

1100 pin 1.

The AC Mains is also rectified by bridge 6001 to produce

RAWSTBY for the Standby Supply.

Page 20

GB 86 A10PTV2.0 NTSC9.

Circuit Description

9.4 Standby Power Supply

The Standby Power Supply provides 3.3 and 5-volt standby

voltages and operating voltage for the Power Factor

Correction circuit. When ac voltage is applied to the set and

the AC Mains Switch is turned On, RAWSTBY is developed

and applied to the Standby regulator 7211 through Pins 2

and 4 of the Standby transformer 5202 to Pin 5. The Startup

voltage is developed by charging capacitor 2283 through the

internal startup resistor Rs. When 2283 is charged to 5.7

volts, the IC switches to the internal supply. Power is now

supplied by the charge on 2283. The Pulse Width Modulator

will drive the internal switch to drive the Standby transformer

5202. The IC will continue to switch the transformer until the

charge on 2283 falls below 4.7 volts. Capacitor 2283 will

again be charged by the internal resistor and process will

repeat itself. Voltage is developed from the HOT secondary

winding on Pin 5. This voltage is rectified by 6207 to produce

operating voltage for the HOT secondary. Voltage from Pin

9 is rectified by 6231to produce the 3.3-volt Standby voltage.

When the 3.3-volt Standby voltage has reached the correct

level, it will turn the Shunt Regulator 6205 on. This drives the

Opto-isolator 7213, which switches the HOT secondary

operating voltage to Pin 4 of 7211 through resistor 3287. Pin

4 of 7211 will not stay at a constant 5.7 volts to provide the

operating voltage for the IC. Regulation is accomplished by

the Shunt Regulator 6025, Opto-isolator 7213, and the

internal current sensing resistor of 7211. This circuit also

produces a 5-volt standby voltage and Reset via 7209 and

7208.

Figure 9-6

CL 06532143_013.eps

081100

When the Set is turned on, the Standby line is switched low

by the Microprocessor on the SSB. Transistor 7214 is turned

off, which turns 7205 on, turning 7206 on. This turns

transistor 7204 on, switching operating voltage to the Power

Factor Correction panel via connector 1502, Pin 1.

Page 21

Circuit Description

GB 87A10PTV2.0 NTSC 9.

9.5 Full Power Supply

When the set is turned on, the Main Switch Mode power

supply is turned On This supply produces the +130 volt, +32

volt, -32 volt, two +15 volt, and Audio supplies. When the On/

Off line goes low, transistor 7309 is turned off, turning

transistor 7300 on. This switches relay 1305 on. Startup

voltage from the neutral side of the AC mains will charge

capacitor 2303 to 14.5 volts, which will overcome the

undervoltage lockout of IC 7302. After the Soft start

capacitor 2443 charges; the oscillator inside the IC will turn

on. Each cycle of the oscillator will set the flip-flop, which will

cause Pin 3to gohigh. This willturn the FET switch7301 on.

Voltage is applied to the Drain of 7301 through Pins 4 and 8

of 5300 from the Power Factor Correction circuit. Current

through sensing resistors 3308 and 3309 will develop a

voltage, which is applied to comparator “B” connected to Pin

7. When the voltage on Pin 7 reaches the reference voltage

on the inverting input, the flip-flop will be reset. The voltage

on the inverting side of comparator “B” is limited to 1 volt.

Therefore, the ramp voltage on Pin 7 will not exceed 1 volt.

The circuit will continue to operate until the charge on

capacitor 2303 falls below 9.4 volts shutting the IC Off. Each

time 7301 is turned on; energy is stored in transformer 5300.

Voltage from the hotsecondary onPin 10is rectifiedby 6301.

When the output of this circuit has sufficient energy to

maintain 2303 above 9.4 volts, the IC then operates in steady

state.

Figure 9-7

CL 06532143_014.eps

When IC 7302 develops a normal steady state operation, the

130-volt supply is sampled by resistors 3324, 3323, and

3322. This sample voltage is then sent to Shunt regulator

7303, which drives the feedback optoisolator 7303. The

feedback voltage on Pin 14 is then compared with an internal

2.5-volt reference by comparator “C”. Comparator “C” then

sets the reference voltage on the inverting side of comparator

“B” to control the On time of the drive at Pin 3. If the voltage

on Pin 14 increases due to the 130-volt supply increasing,

the On time of the pulse on Pin 3 will be reduced. If the 130volt supplydecreases, the voltage on Pin 14 would decrease,

causing the On time of the pulse on Pin 3 to increase. This

is used to keep the 130-volt supply at the correct voltage.

Variable resistor 3322 is used to adjust the 130-volt supply to

the correct level.

The overvoltage protection circuit of the IC will shut the IC

down if the VCC level on Pin 1 exceeds 17 volts.

To troubleshoot this circuit, first check the On/Off line from

the Small Signal Panel to ensure that it is going low. Then

check for the presence of startup voltage on Pin 1 of the

regulator IC 7302. If the IC is working correctly, this voltage

will be changing from 9.4 to 14.5 volts. If the startup voltage

is not present, check the startup resistor 3300 and the bridge

rectifier. If the voltage on Pin 1 is changing, check the drive

signal on Pin3. Then check for signal on the gate and drain

of 7301. An excessive load on the secondary, a short on the

130-volt line for example, would cause the supply to pulse

with little or no voltage on the secondary.

081100

Page 22

GB 88 A10PTV2.0 NTSC9.

Circuit Description

Voltage regulator 7611 produces an 8-volt supply for the

Audio Processor located on the SSB panel. Regulator 7612

produces a 12-volt source for the Video Output circuits

located on the SSM panel. Both of these regulators are

powered by the +15SSB source from the Full Power Section.

Figure 9-8

CL 06532143_015.eps

081100

Figure 9-9

9.6 5.2 Volt Regulator

A 5.2-volt source is developed by 7308 and 7307. The Pulse

Width modulator in 7307 drives transistor 7308 to produce

the source. Feedback for regulator is sampled by resistors

3339, 3340, and 3334 where it is fed to Pin 5 of 7307. This

circuit is powered by the 15 volt supply from the Full Power

Section. This source is fed to the SSB panel.

CL 06532143_016.eps

081100

Page 23

Circuit Description

GB 89A10PTV2.0 NTSC 9.

9.7 Video Signal Flow

Video input for the A10 PTV can be from either of two tuners,

three composite inputs, two SVHS inputs, or from a

component input. The Main Tuner is located on the SSM

panel and is controlled by a data line from the

Microprocessor located on the SSB Panel. IF from the Tuner

is fed to a switched Saw Filter circuit.

The Saw Filter circuit is made up of a PAL/SECAM Saw

Filter, 1455, and an NTSC Saw Filter, 1451.When the SELIF-LL line is Low, transistor 7413 is turned Off, switching

1451 On, turning transistor 7414 On which turns the PAL/

SECAM Saw Filter 1454 Off. When the SEL-IF-LL line is

High, 7413 is turned on, turning 7414 and the NTSC Saw

Filter 1451 off. A positive voltage will be applied to 1454, the

PAL/SECAM Saw Filter, turning it On. VSIF1 and VSIF2 is

output to the Audio processor from the Audio Saw Filter,

1455.

Video IF is fed to Pins 1 and 2 of 7301, which outputs

composite video on Pin 16. The composite video is buffered

by 7305, filtered by 1333, buffered by 7331, and fed to Pin 24

of 7301. This section of the Signal Processor selects

between composite video from the Main Tuner and External

Video or Luminance from7401. The selected Video or

Luminance is buffered by 7421 and fed to the Comb Filter

7405. If the input on Pin 12 is Composite Video, the Comb

Filter is switched on. If the input on Pin 12 is Y (Luminance)

and the input on Pin 1 is Chroma, the Comb Filter is switched

off. Luminance and Chroma is then fed to the Signal

Processor on Pins 20 and 21. YUV is then output on Pin 40,

45, and 46 to 7403, Video Enhancement circuit. IC 7403

provides Luminance processing, Colour vectors processing

and spectral processing. In the Luminance processor, the

luminance is processed in 5 discrete histogram sections. As

a result, the contrast ratio of the most important parts of the

scene will be improved. In the Colour Vector Processor, the

dynamic skin tone correction locally changes the hue of

colours that match skin tones to the correct hue. The Green

Enhancement circuit activates medium saturated green

towards to a more saturated green. The Blue Stretch circuit

can be activated which shifts colours near white towards

blue. The Spectral Processor provides luminance transient

improvement. YUV from 7403 is fed to the PIP/DW (Picture

in Picture/Double Window) panel.

Figure 9-10

CL 06532143_017.eps

YUV is fed to 7801, PIP/DW IC, and 7803, Switch IC, on the

PIP/DW panel. If the PIP/DW function has not been

selected, 7803 switches the YUV signal back to 7301 on the

SSB panel. Video for the PIP or Double Window is selected

by the user from the second tuner located on the PIP/DW

panel or from composite video from the SSM. IF from the

PIP/DW tuner is fed to a switchable Saw Filter 1352. The

Reset line switches the filter between NTSC and PAL/

SECAM. The output of the Saw filter is fed to the Signal

Processor 7301. This Saw Filter is located on the PIP/DW

panel. Composite video is then fed to Pin 24 of 7301, which

selects between the second tuner or selected Composite or

SVHS on Pins 29 and 20. YUV, labeled SY, SU, and SV is

then fed to the PIP/DW IC 7801. YUV from 7801 is fed to the

switch IC 7803.

On the Rear Jack panel, there are two Composite Video

inputs, one SVHS input, and one Component input. The Y or

Luminance signal from the Component input is fed to a YSharpness circuit and then fed to switching IC 7711 along

with the PB and PR signals. The YUV signal is then fed to

7301, Signal Processor located on the SSB panel. The Y

signal is also fed to 7712 where it is fed to 7401 and then to

7301. Since the Sync is on the Y signal in a Component

signal, the Y signal must be switched on this path for Sync

separation. If the set is in the Convergence adjustment

mode, 7711 selects Red, Green, and Blue drive from the

Convergence Circuit. Therefore, the inputs on Pins 41, 42,

and 43 of 7301 can be either YUV or RGB depending on the

selection made inside the IC. RGB and Fast Blanking for the

On Screen Display from the Microprocessor (Painter) is fed

to 7301 on Pins 35, 36, 37, and 38.

Brightness, Contrast, Colour, Colour Temperature, RGB

cutoffs and drives, and Tint (NTSC) are all controlled inside

7301. RGB is then output on Pins 33, 32, and 31 to the RGB

amplifiers, located on the SSM Panel.

081100

Page 24

GB 90 A10PTV2.0 NTSC9.

Circuit Description

Figure 9-11

Figure 9-12

CL 06532143_018.eps

081100

CL 06532143_019.eps

081100

Page 25

Circuit Description

GB 91A10PTV2.0 NTSC 9.

9.7.1 CRT Drive Circuit

Red, Green, and Blue drive from the SSB panel is fed to the

CRT drive circuit on the SSM PANEL. Red drive is fed to

transistors 7600 and 7602. Green drive is amplified by 7603

and 7605. An additional amplification circuit is added to the

Blue circuit to provide added gain. This is called the Blue

Stretch circuit. This circuit consists of transistors 7606, 7607,

and 7613.

Transistors 7601, 7604, 7609 provides CRT blanking. In the

event of a Sweep failure, the High on the CRT protection line

from the High Voltage Scan circuit will go low. Diodes 6602,