Page 1

Colour Television Chassis

A10PTV 2.0 Pal

AA 01.01

Touch-up Convergence adjustments

Ensure that a signal is connected to the set for the Mode being

Convergence Alignment

The set should be warmed up for at least 20 minutes prior to making

any Geometry or Convergence adjustments.

adjusted. Enter the Digital Convergence Mode (DCM) by entering 06-2-5-9-7-(Status or Index) on the Remote control. The following

menu will appear:

A signal must be applied to the set, for the Mode being adjusted,

while performing Convergence or Geometry alignments. This is

necessary to provide the correct Line and Frame sync to the

Convergence panel. Failure to do so will result in an out of

convergence picture when signal is applied to the set. The set must

be convergenced twice, once forPAL or SECAM and once forNTSC.

Since the Line and Frame rate is the same for PAL and SECAM, it is

not necessary to adjust for both.

The Serviced Technician should sit at least 5 to 10 feet from the front

of thescreen while doing Convergence. Ensurethat you are eyelevel

with the area of the screen you are adjusting.

When performing Digital Convergence, the adjustments are

interactive. A change in one quadrant will affect adjacent areas of the

screen. Several passes through the Convergence sequence may be

necessary. When doing Convergence, it is advised to follow the

sequence patternwhen goingfrom on adjustment location to another.

Pressing the Right Cursor key will sequence the Icon through a

preloaded sequence.

When the Convergence error is small, a touch up Convergence will

be all that is necessary. Do not adjust Green Geometry while in this

mode. A compete in-depth Convergence is required when the Small

Signal Module (SSM) or the Convergence Memory IC, has been

replaced. If the SSB (Small Signal Board) or the Large Signal Board

(LSB) has been replaced, a complete in-depth Geometry should be

completed beforeConvergence isadjusted. The Geometry alignment

should not be necessary if the SSB or LSB have not been changed.

CL 16532049_001.eps

Figure 1

Select an active channel or Aux Input. A signal must be applied to the

set when performing convergence. If any Customer Adjustments

need to be made, the Menubutton can be usedto toggle between the

Customer Menu and DCM. The MPOSD ADJUST is used to center

the Customer Convergence grid. A highlighted cross will appear

along with the Convergence alignment grid. The highlighted cross

should be centered onto the center of the Convergence grid.

110501

When performing a complete in-depth Convergence alignment, a

Screen Template is necessary to obtain the correct Geometry. The

correct Templates are listed below:

43 INCHST4168

50 INCHST4169

55 INCHST4170

©

Copyright 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

photocopying, or otherwise without the prior permission of Philips.

Published by TA 0165 Service PaCE Printed in the Netherlands Subject to modification

3122 785 40380

Page 2

GB 2 A10PTV2.0 01.01

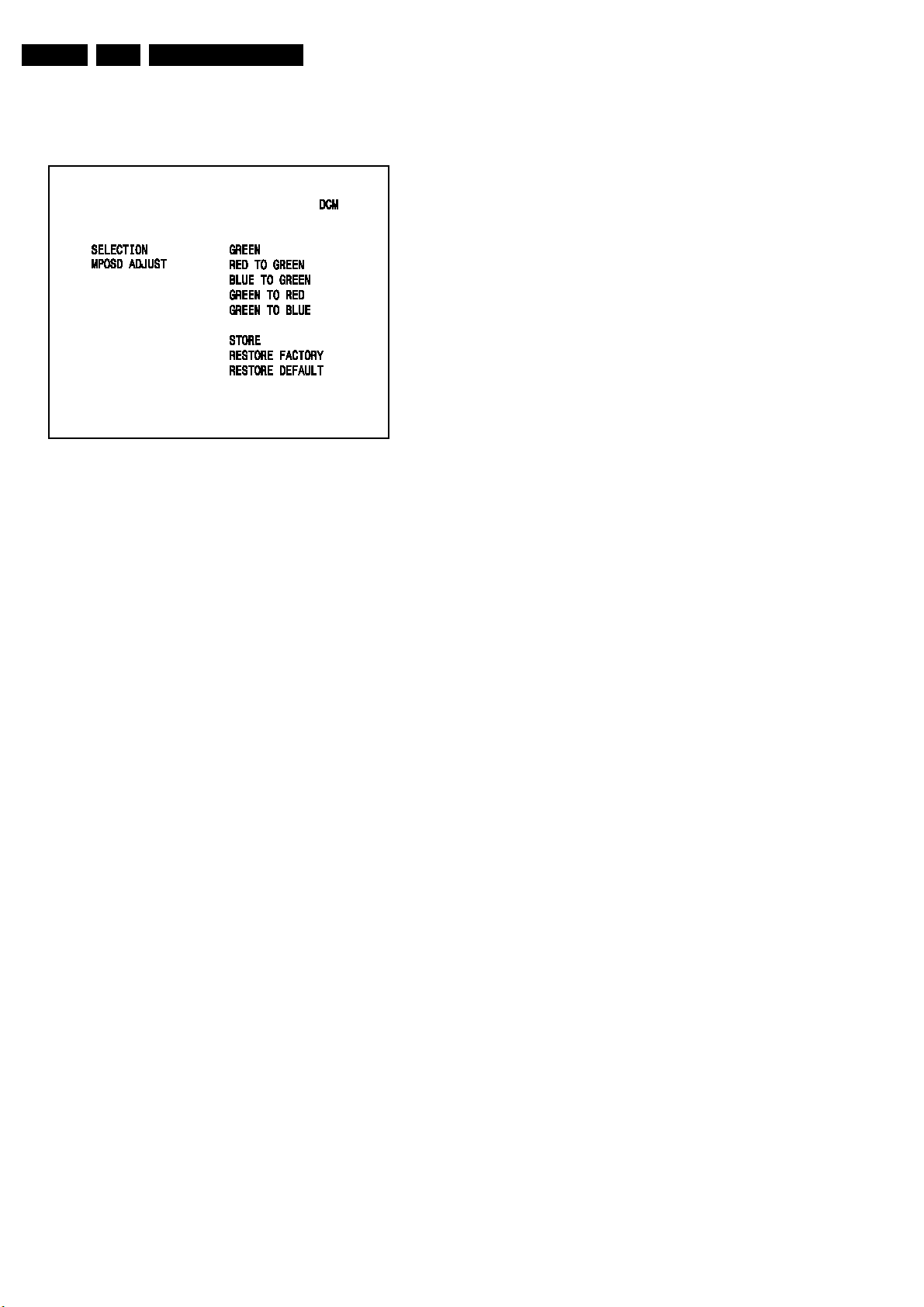

To perform a Touch Up Convergence, highlight SELECTION and

press the right cursor button on the remote. The following menu will

appear:

CL 16532049_002.eps

Figure 2

110501

12. Remove the Jumper on connector 1005.

Note: If a CRT has been replaced, it is only necessary to perform

Screen Centering for the CRT being replaced.

GREEN GEOMETRY

1. Make sure a signal is applied to the set.

2. Enter the Convergence mode by entering 0-6-2-5-9-7-(Status or

Index). Use the Menu button to toggle between DCM and

Customer Mode. Select an active channel or input while in the

Customer Mode.

3. Place a Template over the Screen.

4. Select GREEN in the SELECTION menu.

5. The Icon will appear in the center of the screen. Press the Right

Cursor keyon the remote tomove the Icon to thenext adjustment

location. At each location press the Status or Index button to

enter the ADJUST mode. Using the Cursor keys, adjust the Icon

onto the adjustment point on the template. It is recommended

that the two outside vertical lines not be adjusted in the first two

passes.

6. Continue to follow the pattern and make corrections until the

Convergence Crosshatch pattern matches the Template.

7. Press the Menu button to return to the SELECTION menu.

8. Use the Cursor down key to highlight the STORE selection.

9. Press the Right cursor key to save the alignments.

10. Remove the Template.

Selections STORE, RESTORE FACTORY, and RESTORE

DEFAULT are not shown after selecting SELECTION. Press the

cursor down button on the Remote for these selections to appear.

RESTORE FACTORY loads Convergence defaults from the Factory

Loaded section of the Convergence Memory IC. RESTORE

DEFAULT loads Convergence defaults from the sets software.

To perform a Touch-up Convergence:

1. Enter the Convergence Mode and select RED TO GREEN or

BLUE TO GREEN. Do not select GREEN (Green Geometry)

without placing a Template over the screen. To perform Green

Geometry, refer to the Complete in-depth Convergence.

2. Use the Cursor buttons on the Remote to Navigate from one

adjustment point to another. Press the Status or Index button on

the Remote to select ADJUST. Use the cursor buttons on the

Remote to adjust the Red to Green or Blue to Green. Press the

Status or Index button again to navigate to the next adjustment

location.

3. After Convergence alignments are complete, press the Menu

button on the Remote to return to the SELECTION menu.

4. Highlight the STORE selection and press the right cursor key on

the Remote to save changes.

5. Use the GREEN TO RED or GREEN TO BLUE selections to

perform convergence when the Green CRT has been replaced.

Complete in-depth Convergence

SCREEN CENTERING

1. Make sure a signal is applied to the set for the mode being

adjusted.

2. Enter the Convergence mode by entering 0-6-2-5-9-7-(Status or

Index). Selectan active channel orinput. If the Customer settings

need to be adjusted, pressing the Menu button will access the

Customer menu.

3. Place a Template over the screen.

4. Select GREEN in the SELECTION menu.

5. Place a jumper across connector 1005 on the SSM to defeat

convergence drive.

6. Using the centering rings on the Green CRT, center the

convergence pattern onto the center point of the Convergence

Template.

7. Press the Menu button on the Remote to return to the

SELECTION menu.

8. Select RED TO GREEN in the menu.

9. Center the Red pattern onto the Green pattern.

10. Select BLUE TO GREEN in the SELECTION menu.

11. Center the Blue pattern onto the Green pattern.

RED CONVERGENCE

1. Select RED TO GREEN in the SELECTION menu.

2. Adjust the Red crosshatch pattern onto the green pattern in the

same manner that Green was adjusted to the Template.

3. Save the alignments.

BLUE CONVERGENCE

1. Select BLUE TO GREEN in the SELECTION menu.

2. Adjust the Blue crosshatch pattern onto the green pattern in the

same manner that Green was adjusted to the Template.

3. Save the alignments.

Page 3

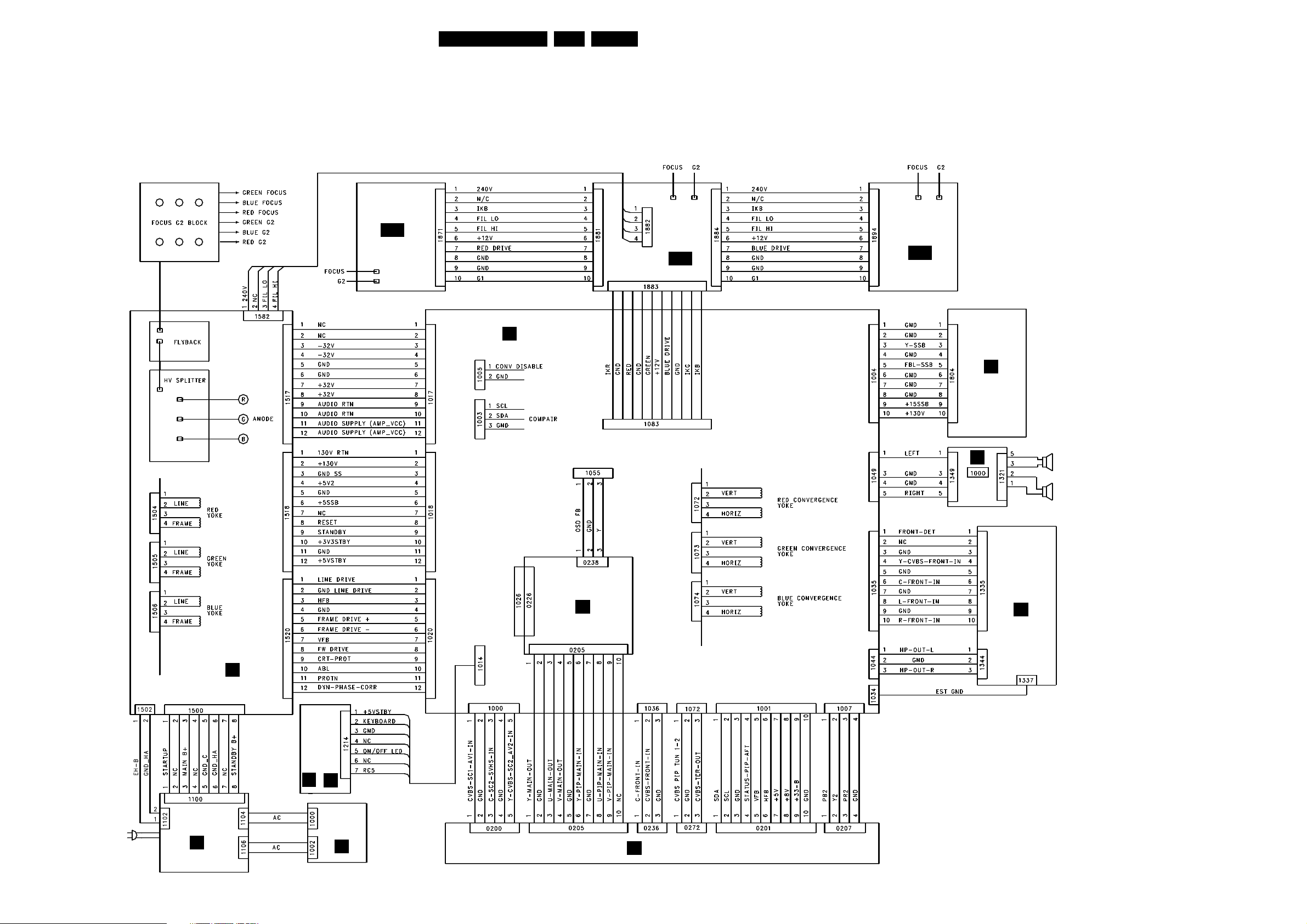

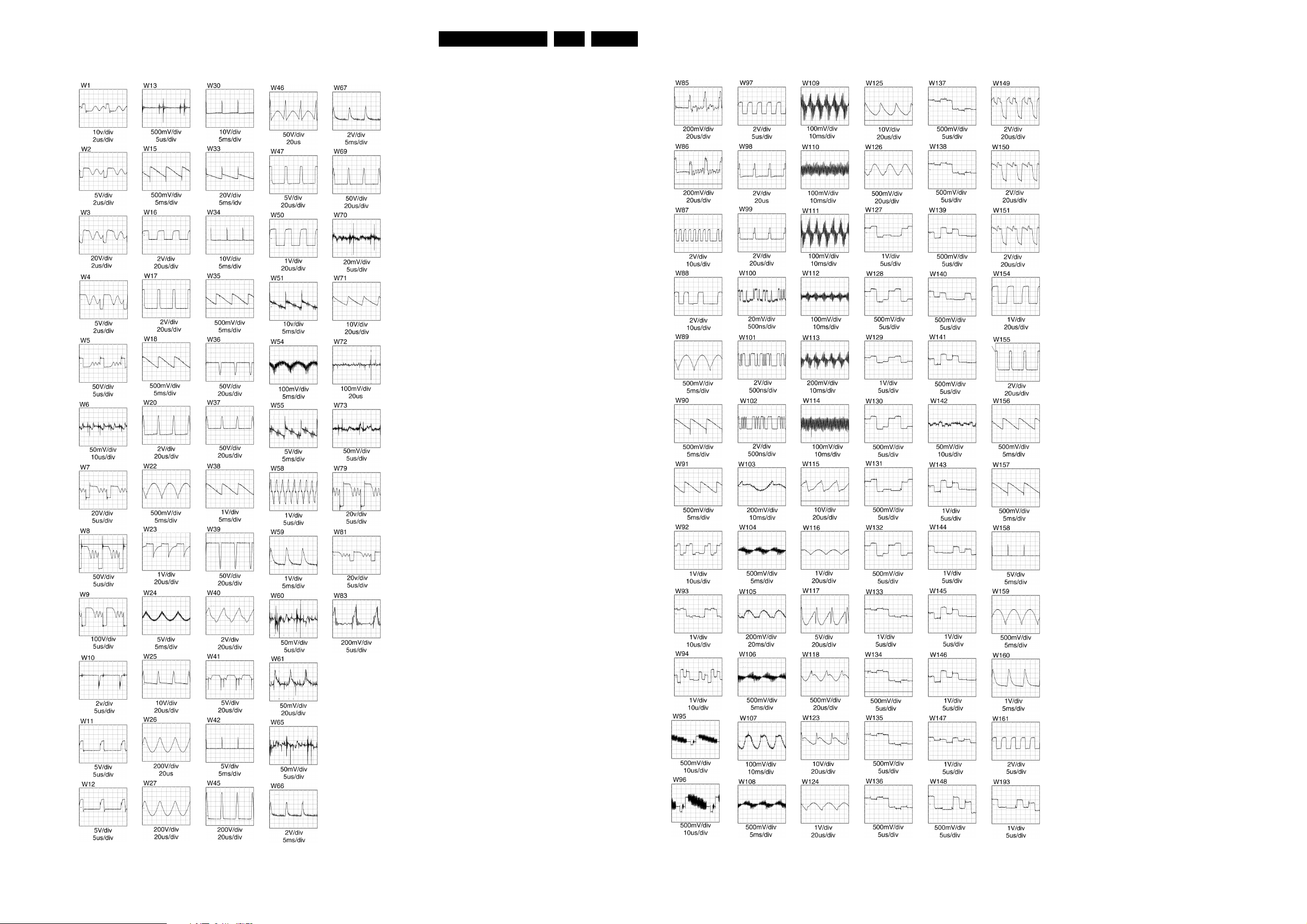

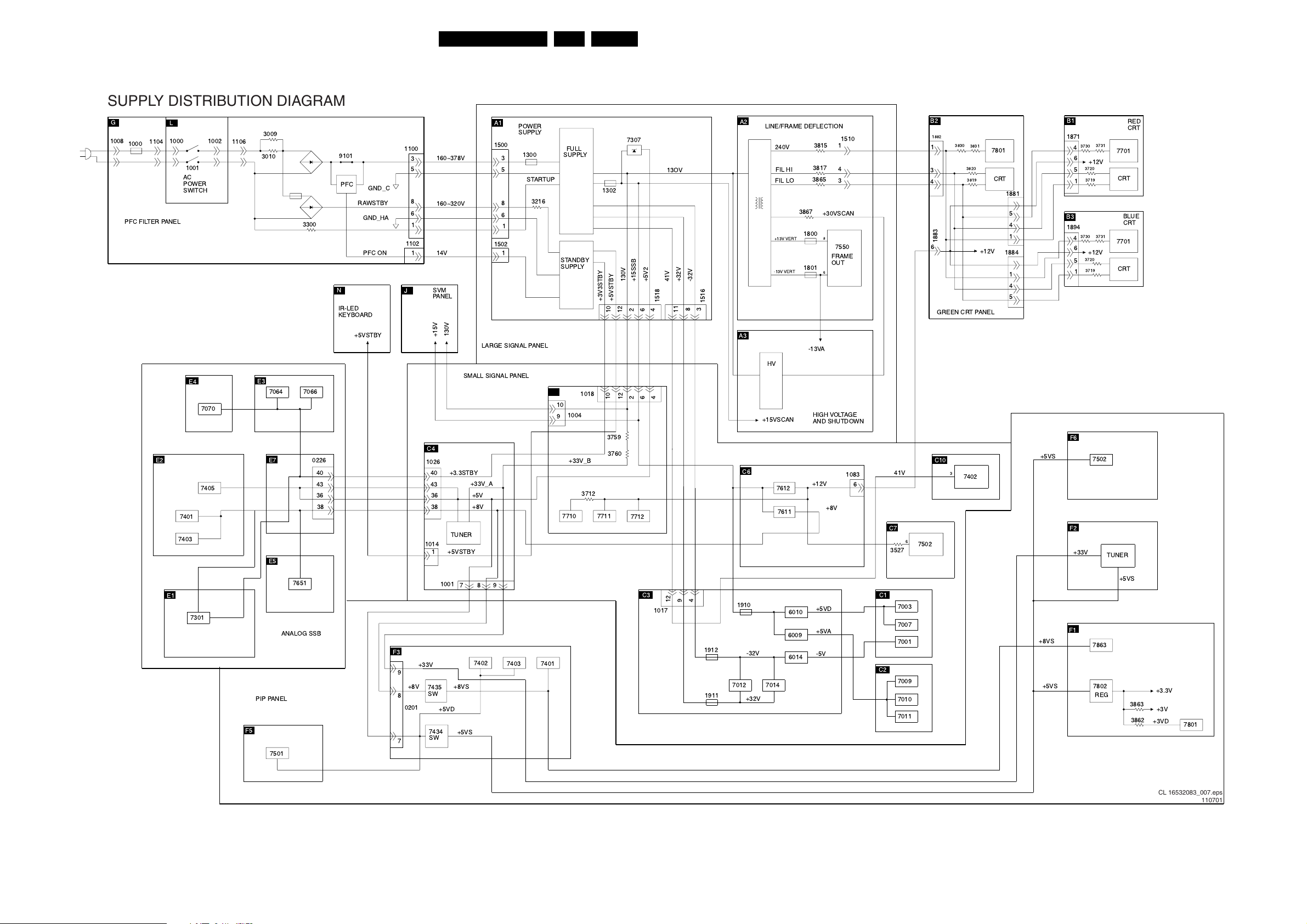

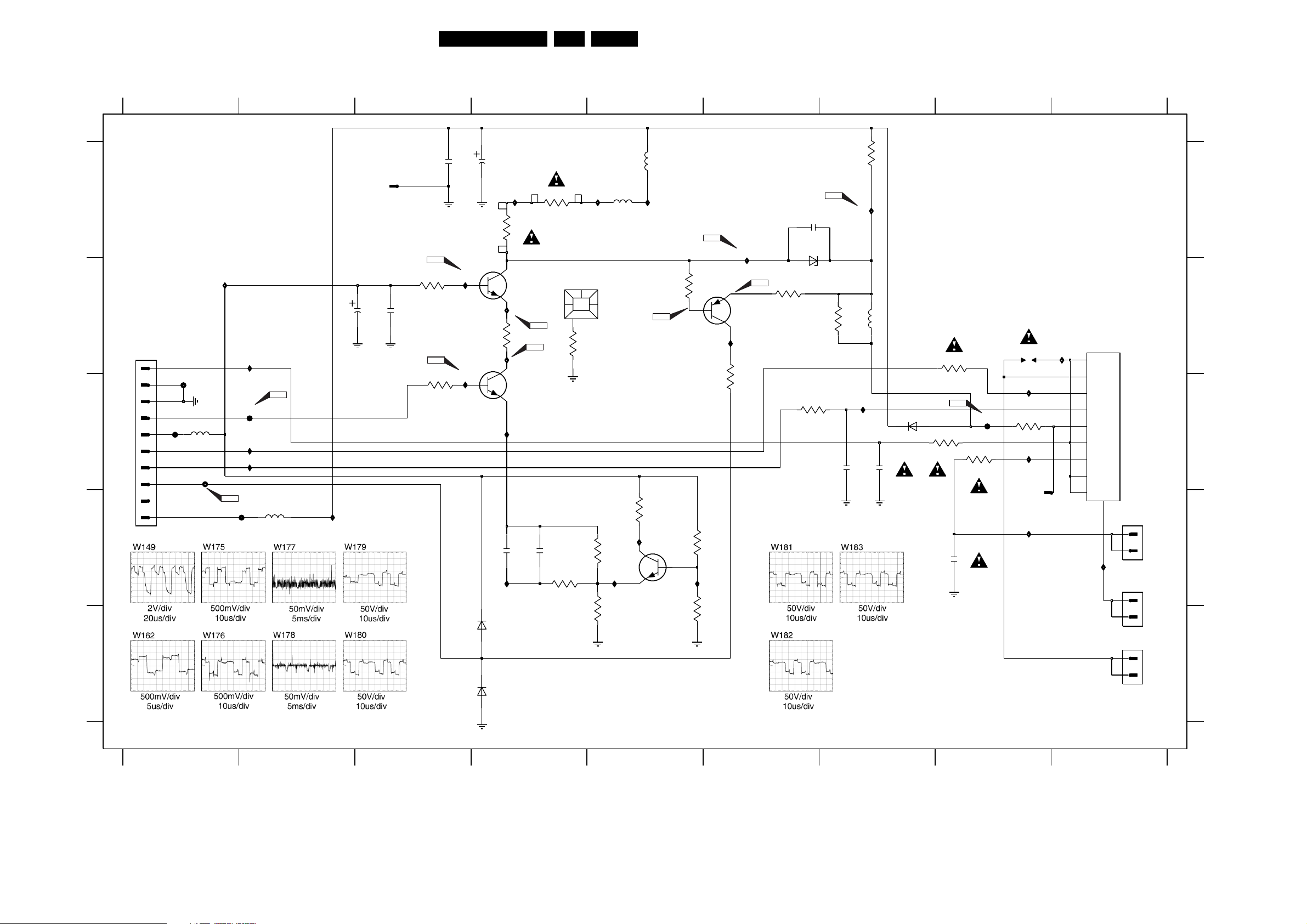

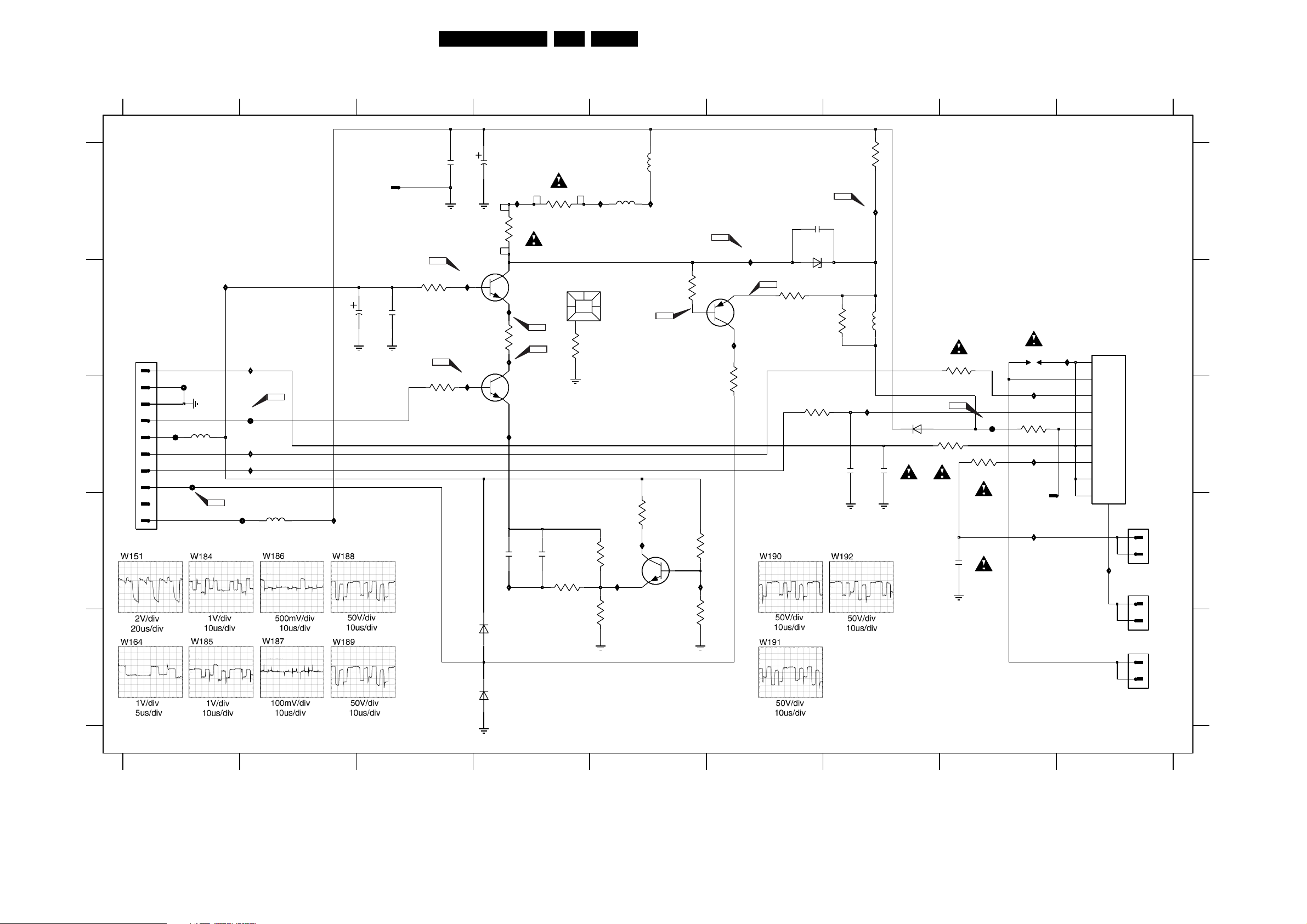

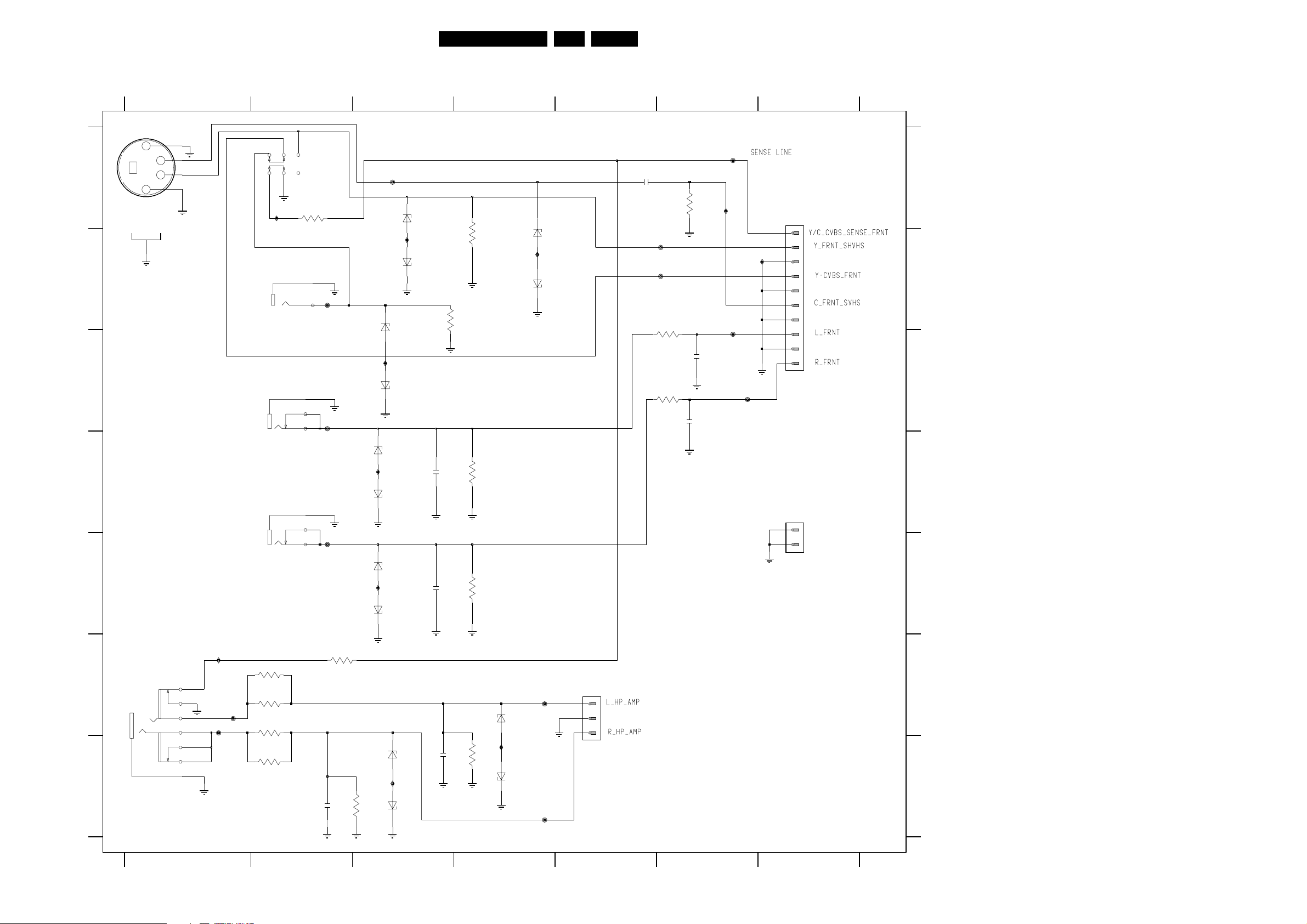

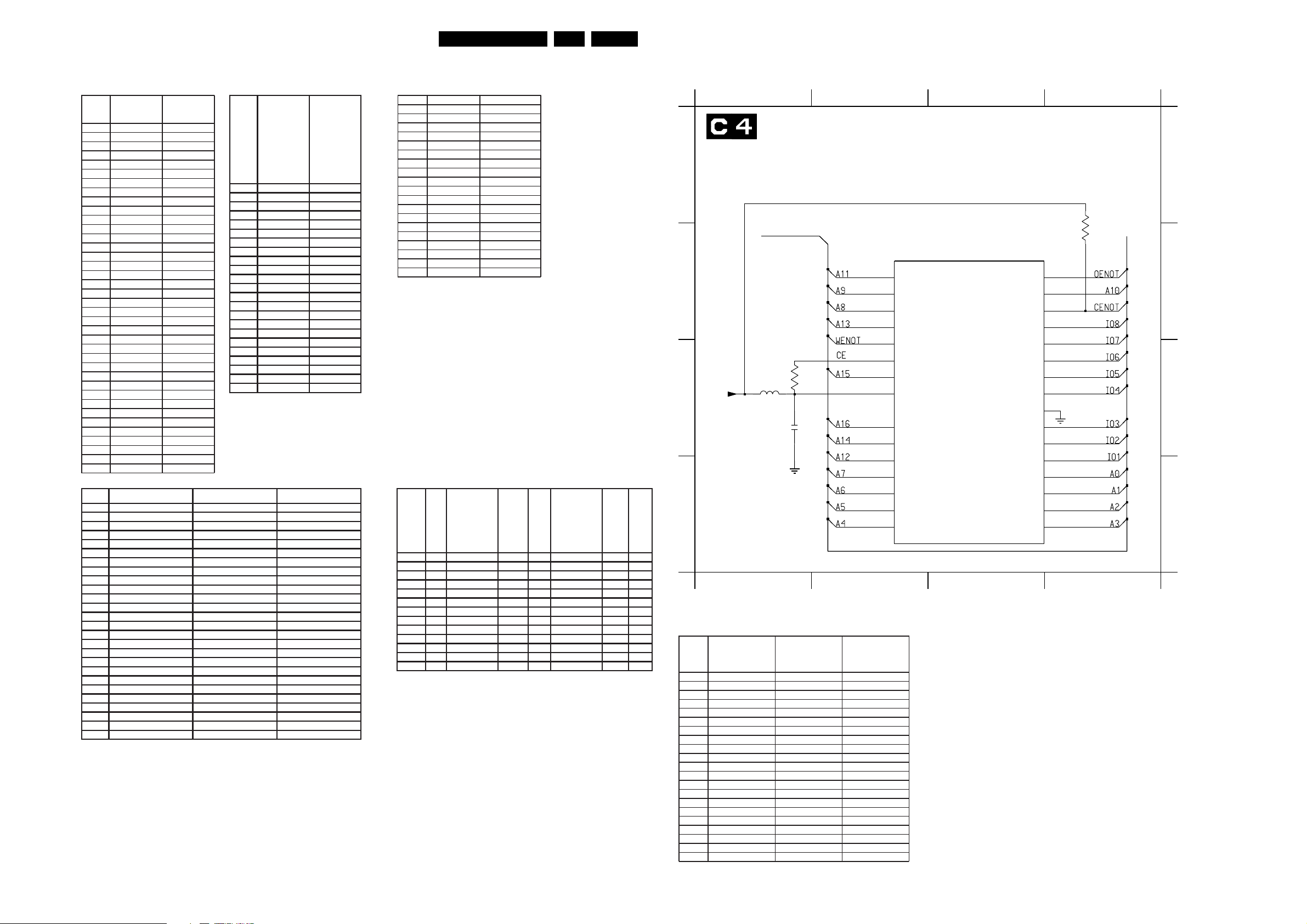

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

13A10PTV2.0 NTSC 6.

6. Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

Block Diagram

BLOCK DIAGRAM

RED CRT

PANEL

B 1

SMALL SIGNAL PANEL

C

GREEN CRT

PANEL

B 2

BLUE CRT

PANEL

B 3

SVM PANEL

J

LARGE SIGNAL PANEL

A

or

LOCAL CONTROL

IR/LED KEYBOARD

M

N

ANALOG SSB

E

K

CENTER

CHANNEL

SWITCH

SIDE

JACK

PAN EL

D

PFC PANEL

G

AC POWER

SWITCH

PANEL

L

PIP PANEL

F

CL 06532143_031.eps

091100

Page 4

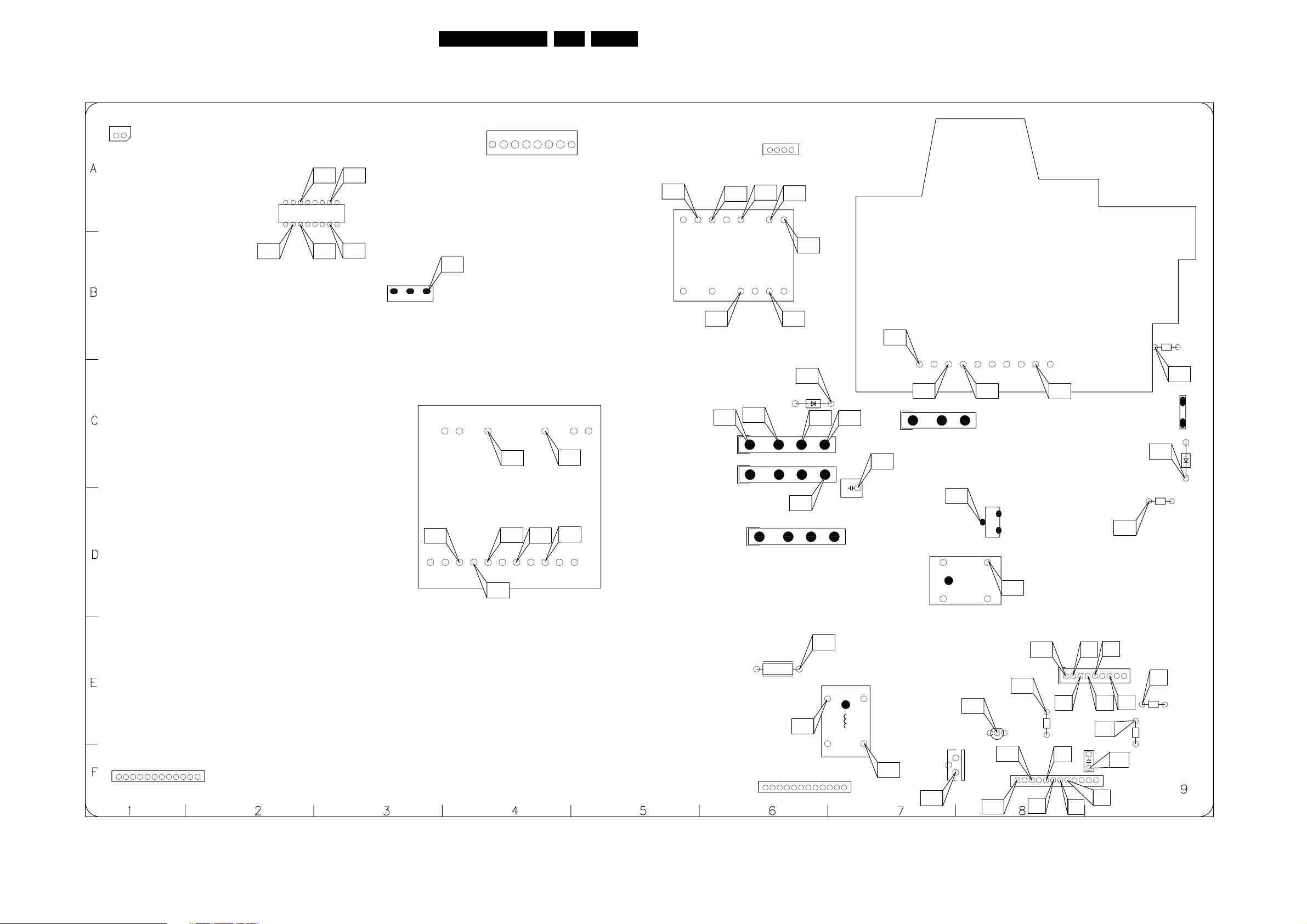

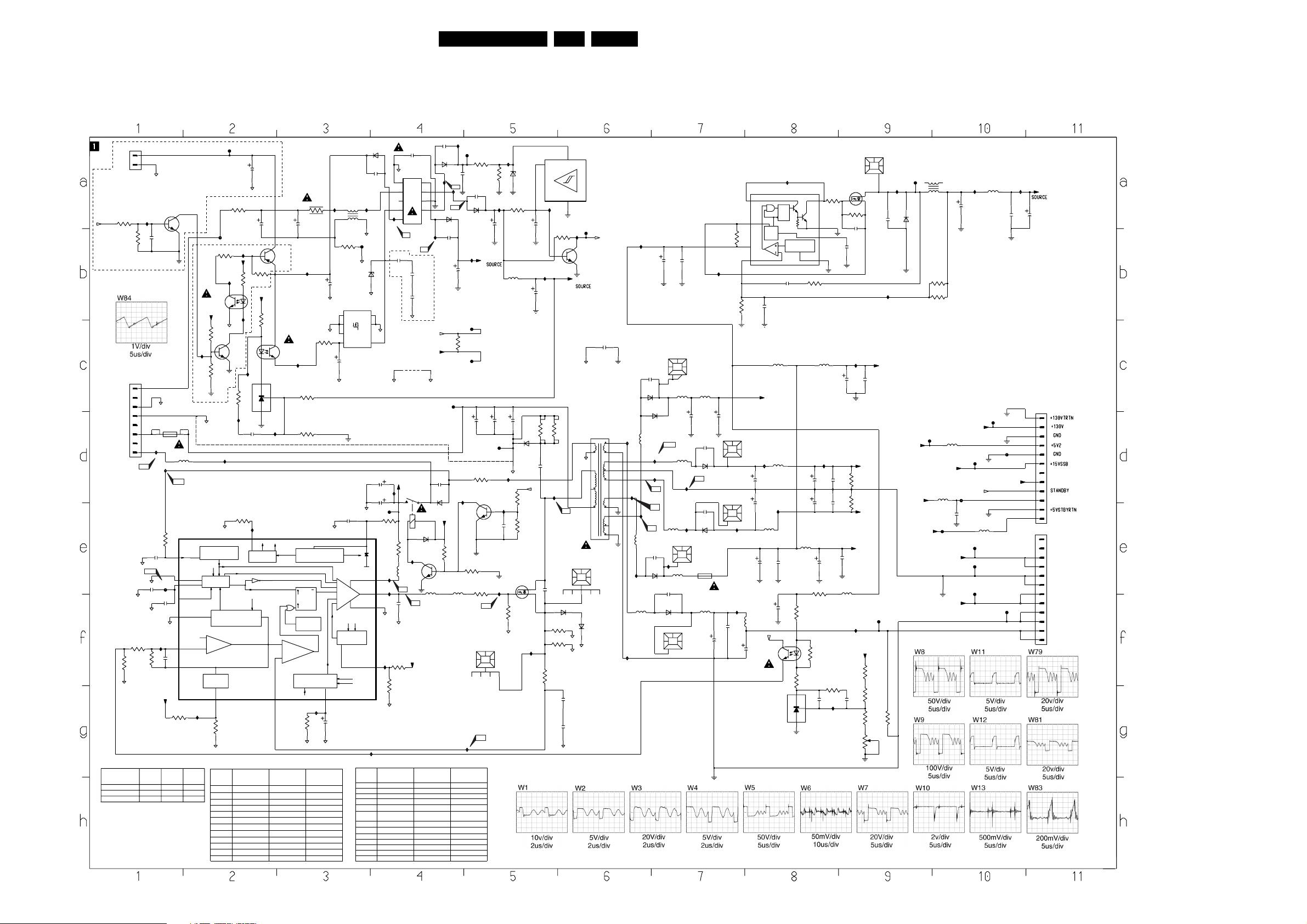

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

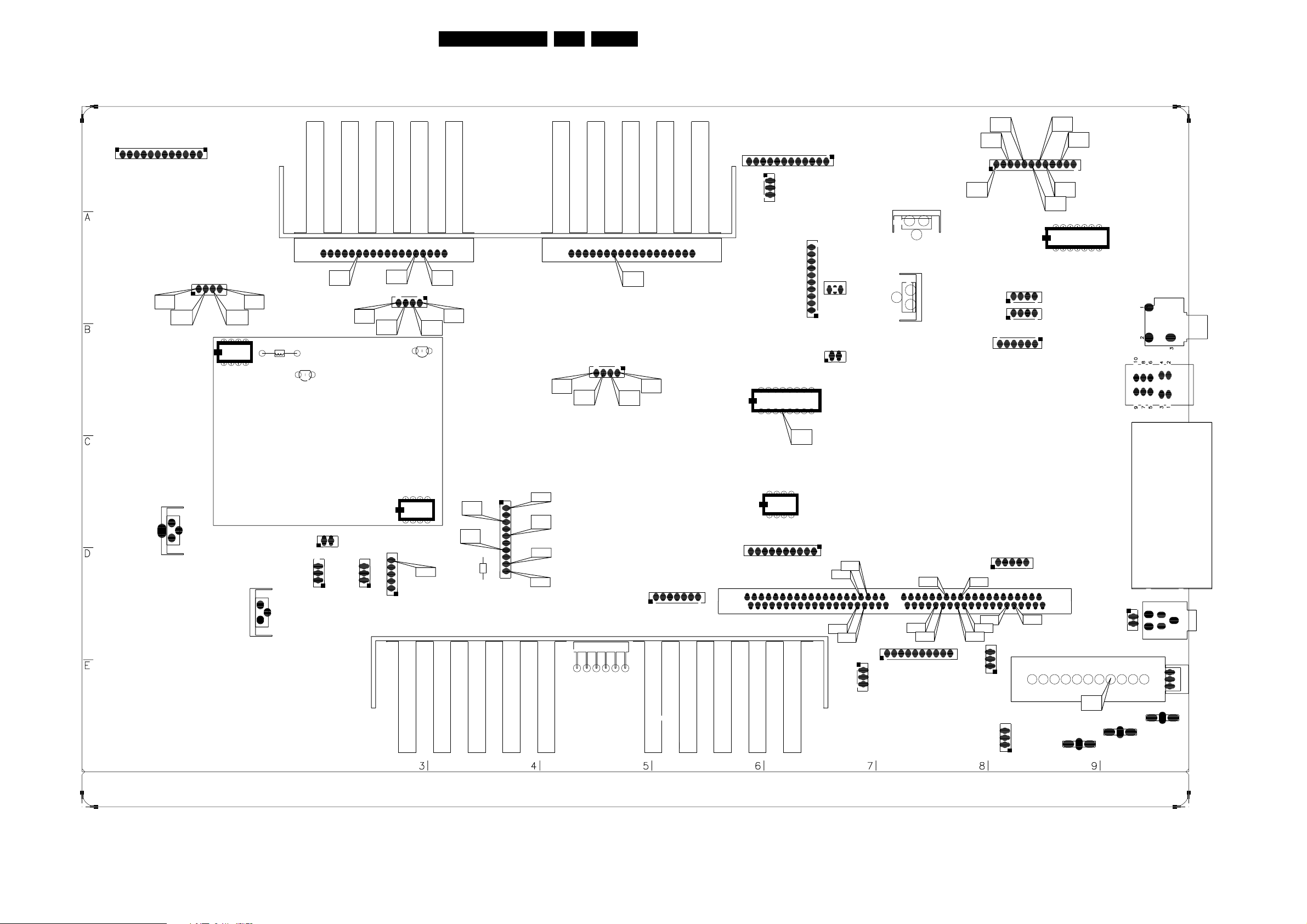

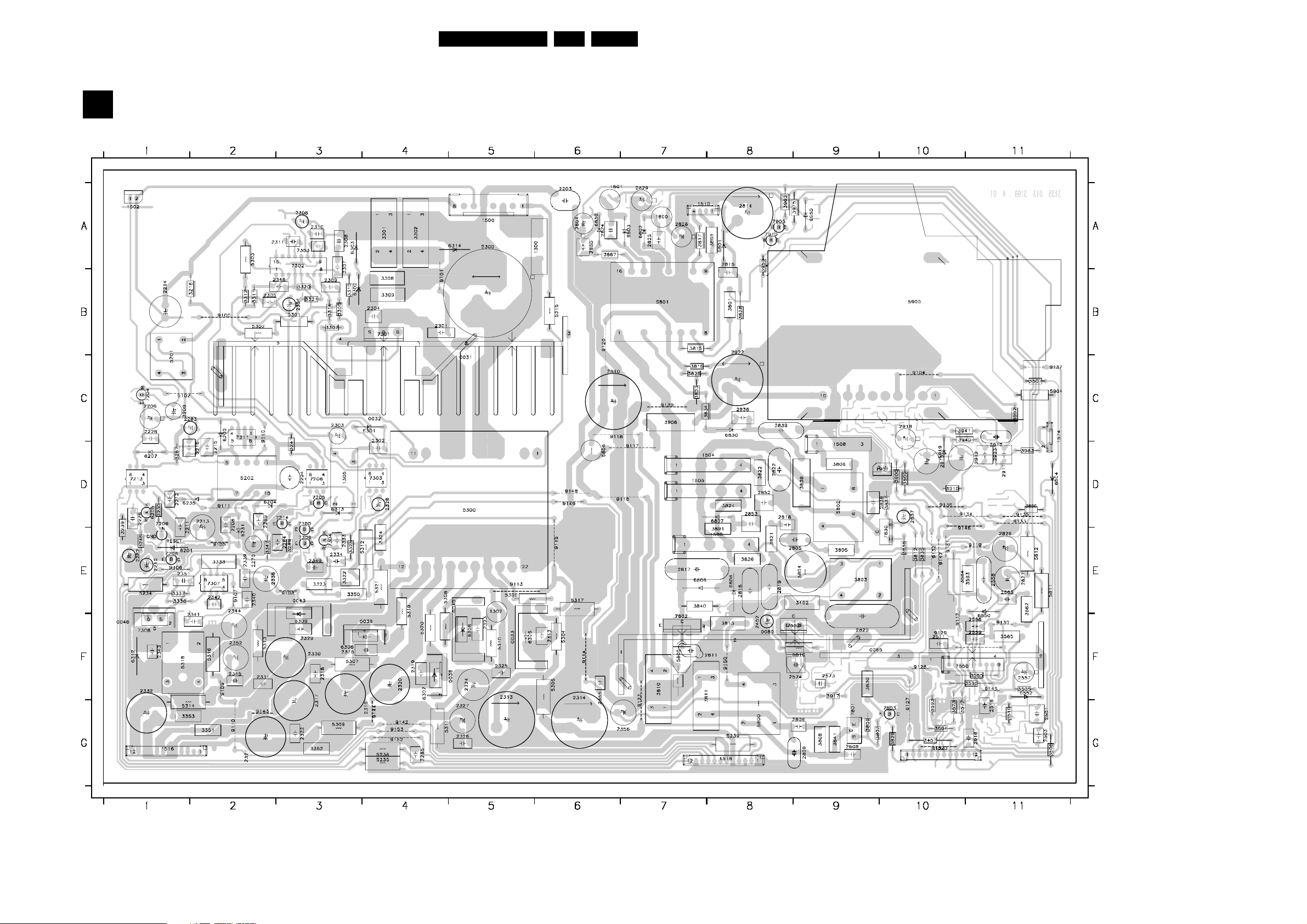

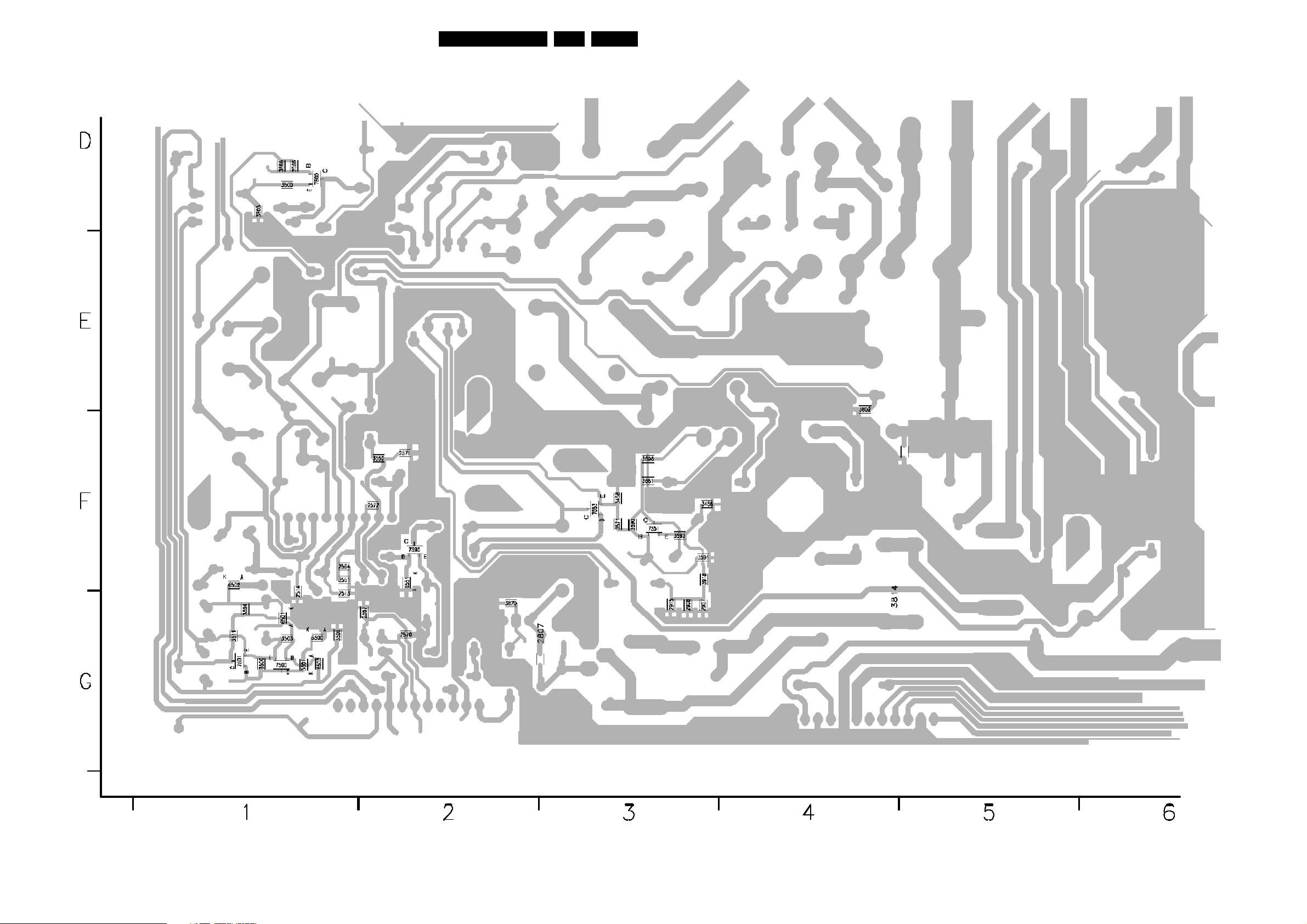

Large Signal Panel testpoint overview (top side)

LSB Panel Component Location Diagram (Top Side)

14A10PTV2.0 NTSC 6.

1502

1 2

7302

I154

W10

16914

I159

W82

I155

W11

10

1 2 3 7 8

F106

W84

I165

W83

7301

1510

3

4

8

1

1

1500

I214

W39

3

I201

W29

5801

I220

W45

I156

W12

S

D

G

11

84

1

18

I212

W37

567

I221

W46

I210

W36

I205

W32

916

1012131415

F209

W20

5900

F305

W78

F217

W25

6830

I224

W49

I227

W51

I300

W57

10

F301

W65

8

7

I301

W58

2

1

F302

W66

1508

1

3

3507

F305

W69

1

1574

2

1504

I140

W7

F111

W14

1

1505

1

I145

W9

20

22

1506

1

3840

12

I231

W55

I216

W41

1518

I223

W48

4

2

4

4

4

5800

2852

1

I218

W43

3

1

I215

W40

5803

F215

W23

3

4

7801

C

F218

W26

B

C

2

E

F202

W16

1

B

1520

E

I229

W53

7803

F203

W17

C

I232

W56

1

I204

W31

3

F201

W15

7550

5

I208

W35

3593

F204

W18

6

I200

W28

3

2

1

2916

8

7

I217

W42

7830

I225

W50

E

B

I228

W52

I206

W33

4

7

5

I207

I203

W34

W30

F314

W77

I302

W58

12

F214

W22

I142

W8

5300

I171

W79

15

12

14

12

1

1516

I137

W5

16

18

I138

W6

F307

W71

3890

F304

9

W68

3505

3510

CL 16532085_001.eps

6504

110701

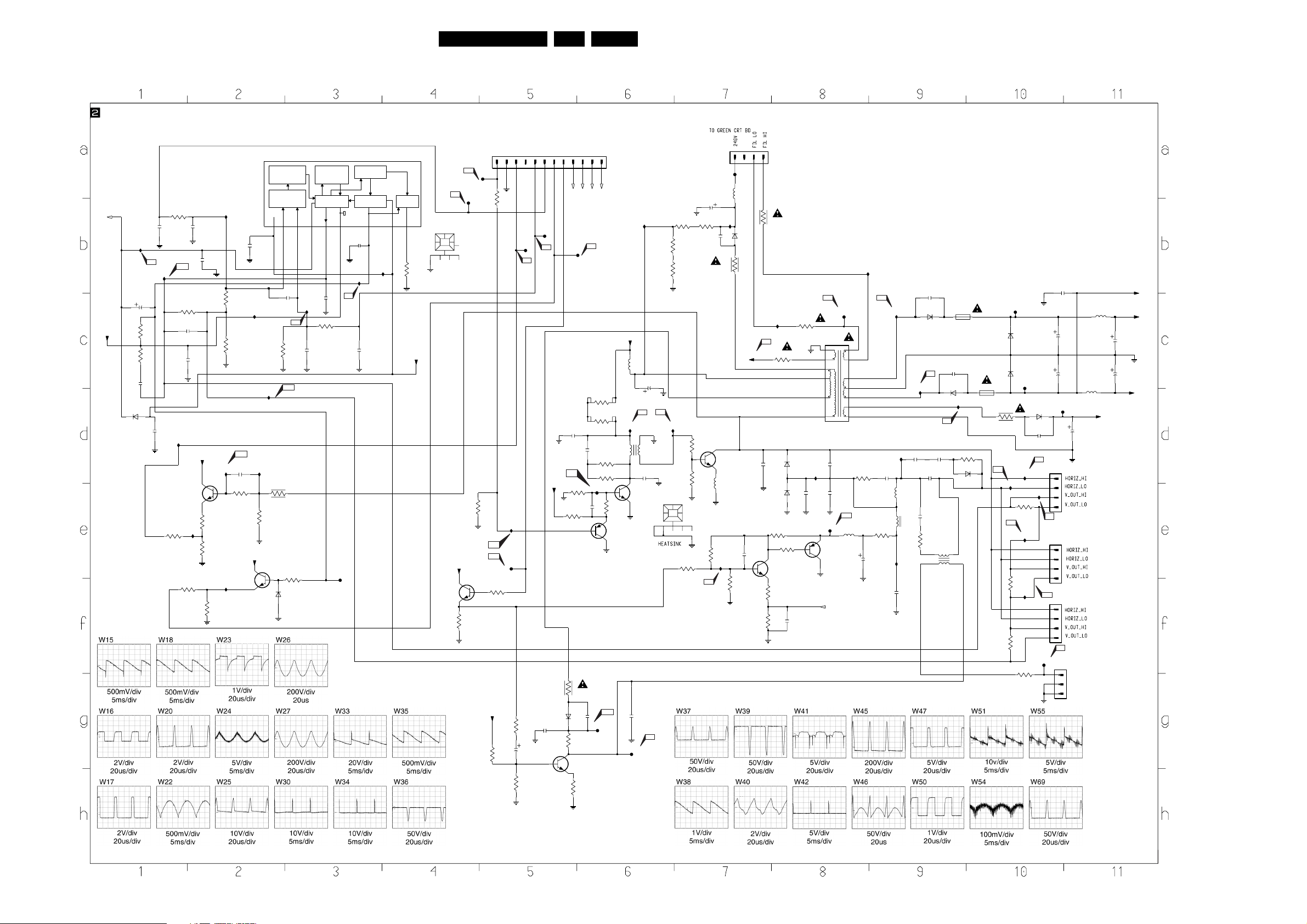

Page 5

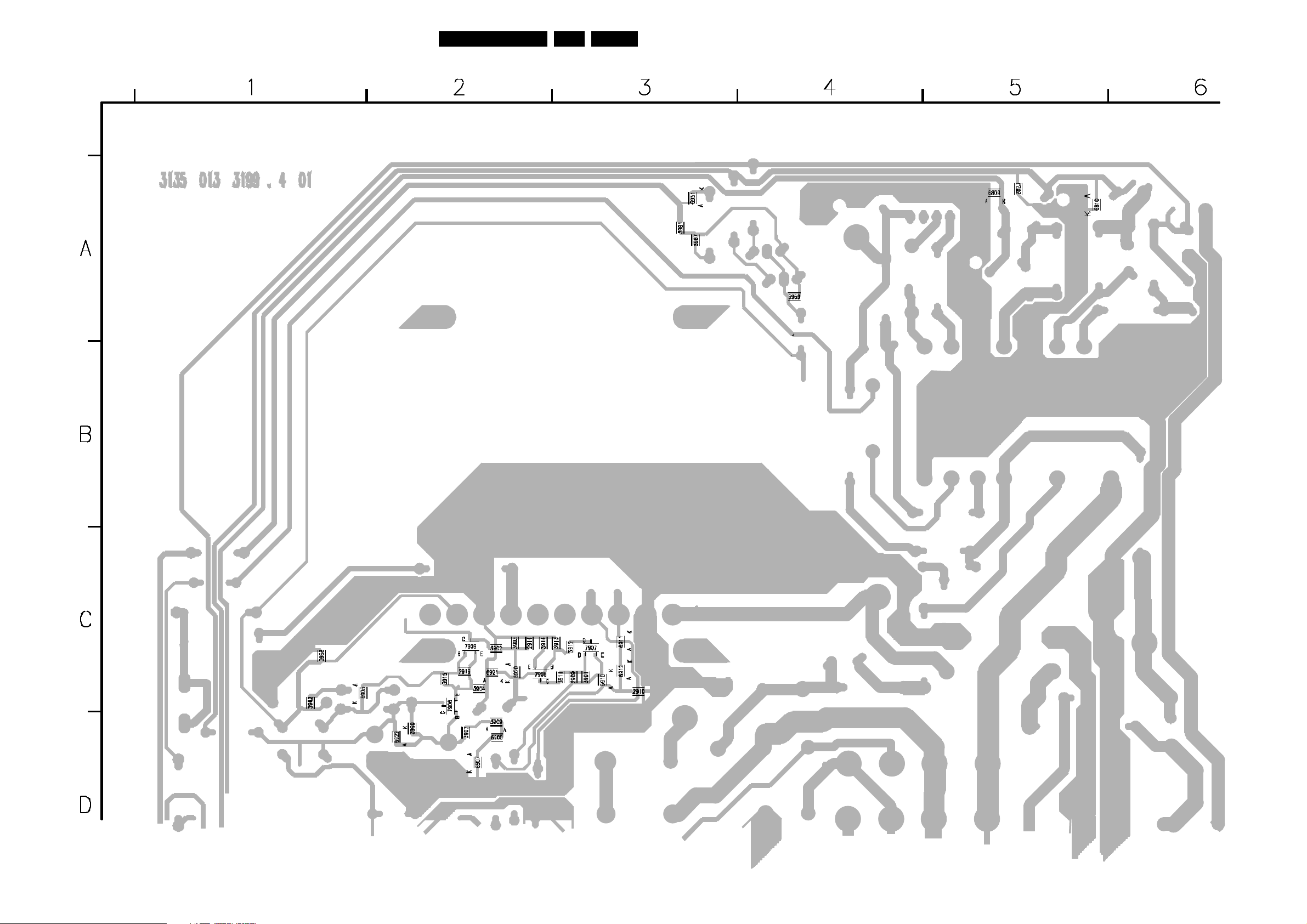

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

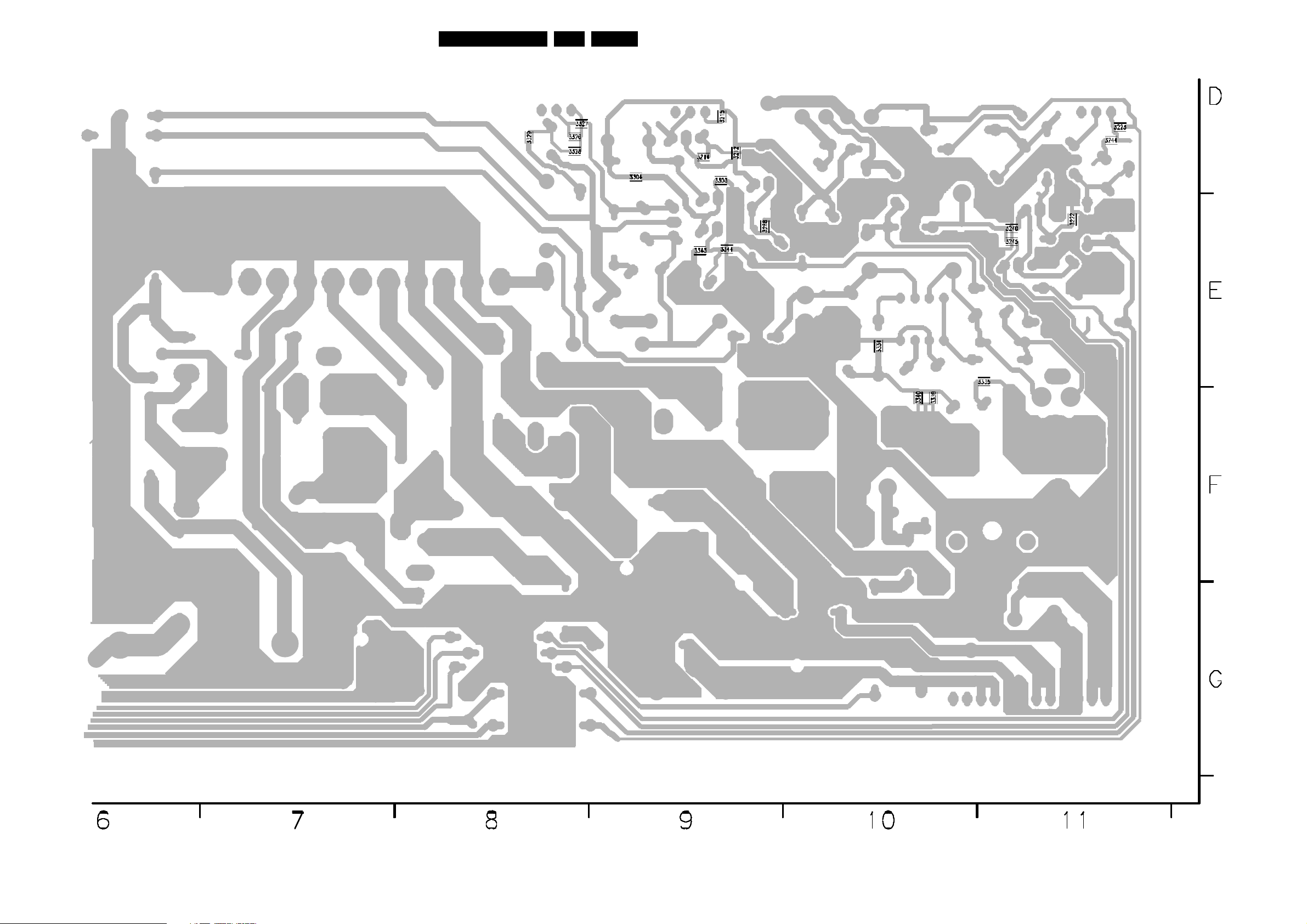

Large Signal Panel testpoint overview (bottom side)

LSB Panel Component Location Diagram (Bottom Side)

1510

3

1

15A10PTV2.0 NTSC 6.

1502

4

1

8

2 1

1574

6504

F305

W69

1

2

3507

F307

W71

3890

I228

W52

1500

1

I214

W39

I156

W12

S

D

G

F111

W14

4

1

I142

W8

8

11

7301

5300

22

I145

W9

I140

W7

20

I137

W5

18

I138

W6

I171

W79

15

16

12

14

I210

I205

W32

916

F209

W20

I212

W36

W37

10 12 13 14 15

5801

5900

8

F305

I224

W49

4

4

F217

W25

6830

W78

I231

W55

I221

W46

1

1

1

7

C

E

F218

W26

I309

W64

F301

I300

W65

W57

8

10

F310

W74

3

I218

W43

I227

W51

2852

4

5803

4

F302

W66

2

1

F311

W75

I306

W62

I222

W47

B

C

7800

E

C

7909

E

B

E

B

C

7906

F312

W76

I229

W53

I308

W63

B

E

E

I301

W58

7908

C

1

2

B

C

7830

7907

B

567

1506

I220

W45

1504

1505

I201

W29

3

F106

W84

I165

W83

I159

W82

10

78

I155

W11

14

16

7302

3

1

2

I154

W10

9

F309

W73

I223

W48

7553

7801

B E

C

F215

W23

C

7551

B E

I230

W54

I215

W40

3840

3

5800

1

4

I216

W41

2

1

12

1

12

1516

1518

CL 16532085_002.eps

110701

C

7590

B E

I232

I305

W56

W61

E

7501

B E

7500

C

F308

W72

B

C

7803

C

B

C

I225

W50

E

E

B

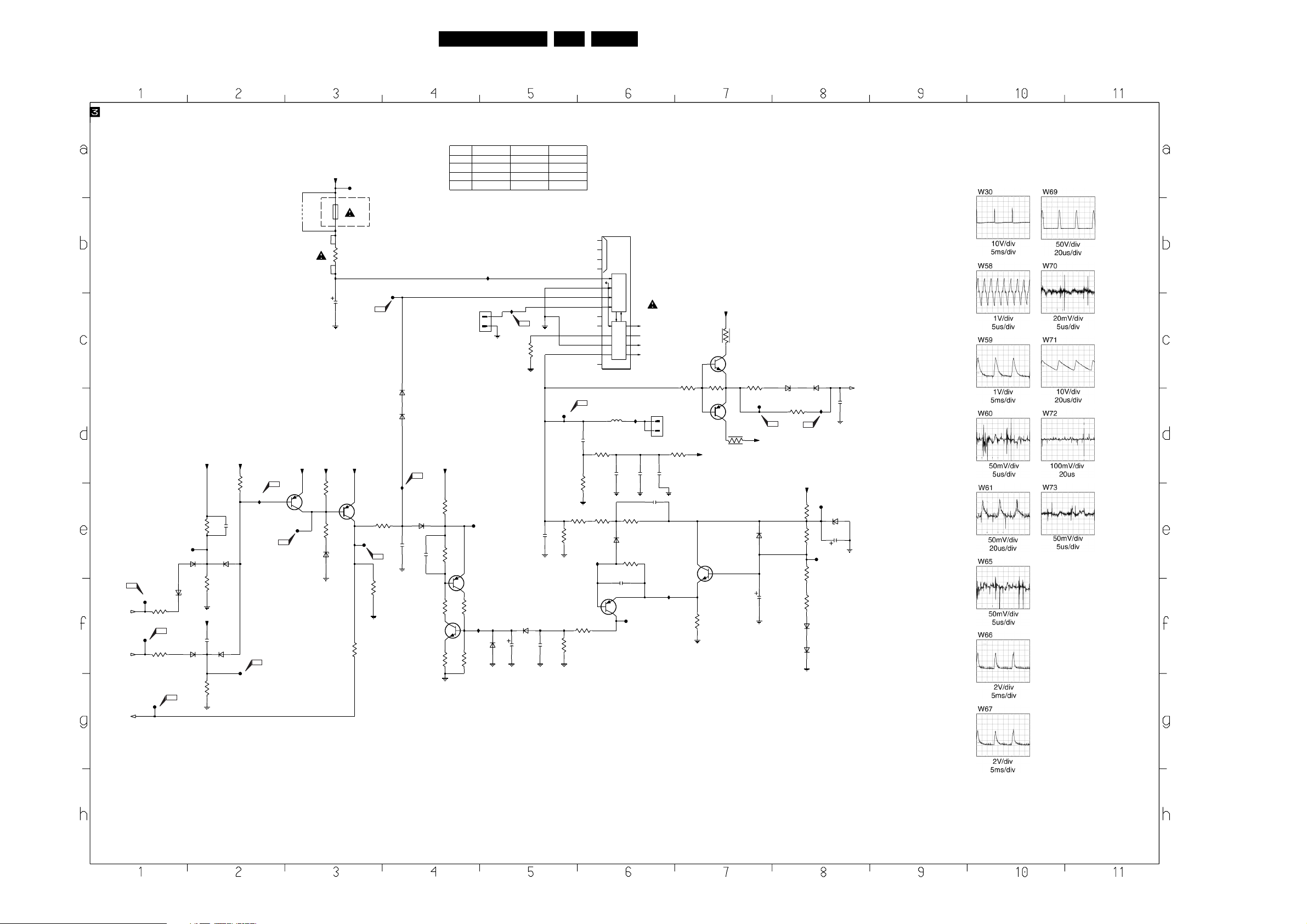

Page 6

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

16A10PTV2.0 NTSC 6.

Large Signal Panel Waveform Overview

Small Signal Panel waveform overview

CL 16532085_005.eps

110701

CL 16532085_006.eps

110701

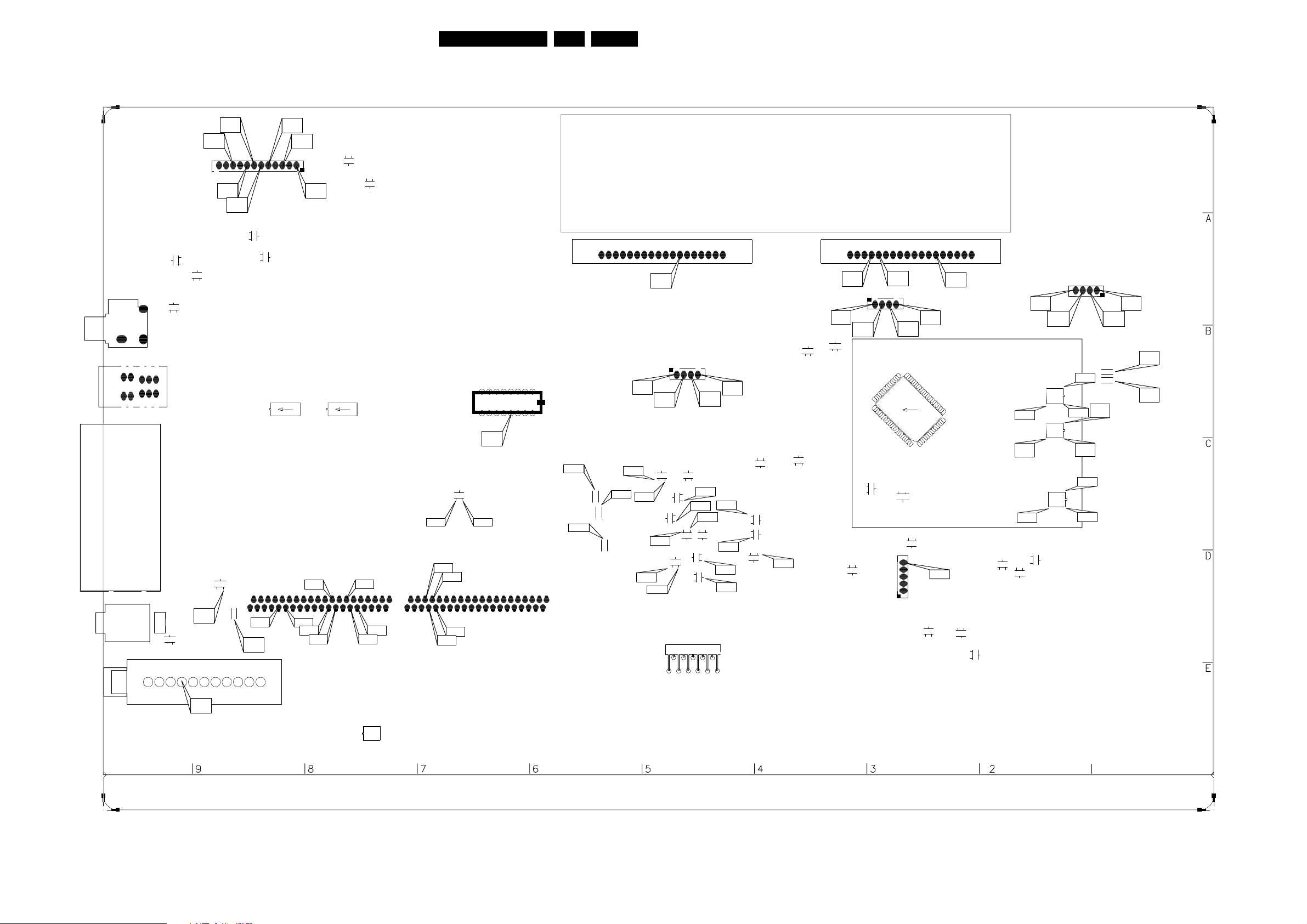

Page 7

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

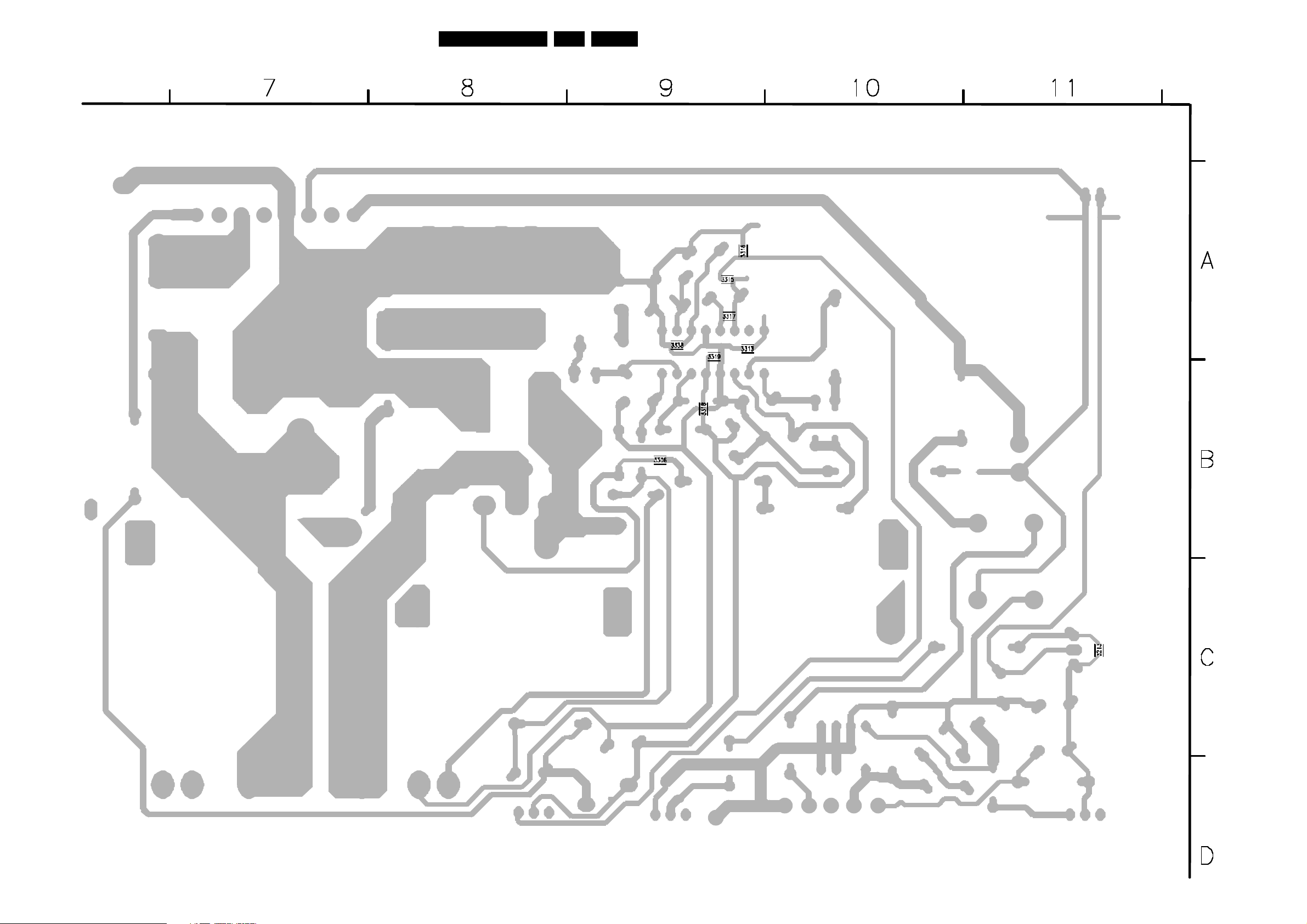

Small Signal Panel testpoint overview (top side)

SSM Panel Component Location Guide (Top Side)

17A10PTV2.0 NTSC 6.

6

5

F708

W158

8

10

7

I058

W159

I057

W157

14

1 7

F716

W160

12

7502

8

1266

1264

1

2

3

I056

W156

1020

F706

W154

F707

W155

1

1007

1008

6 1

3

1 4

1 4

1016

12

1017

F048

W115

RED

F049

W116

1

F059

W126

1

F058

W125

1074

4 1

F014

W112

BLUE

F057

W124

7014

F056

W123

1

1913

1

4

F040

W118

F050

W117

8

5

7001

1

5022

4

7000

B

C

E

F011

W109

6

F055

W122

7012

F054

W121

F028

W110

1073

4 1

14

7015

E

15

F053

W120

B

F029

W111

GREEN

C

18

F052

W119

186

12

16

1006

1

1018

1 3

7710

4

1004

F741

W161

1

IN

GND

10

1055

7612

3 1

1

1056

1 2

9

8

GND

OUT

2

OUT

7611

IN

1

2

7007

W158

1 5

5

F604

W132

4

F605

W148

1

1083

W149

I091

W138

W150

3661

10

W151

1014

1 7

1039

1 3

8

1

2

OUT

1

GND

6009

IN

2

6010

OUT

1

GND

IN

1010

1005

1 2

1 3

1002

7402

1

11

10

1

2

8 5

7308

1 4

1084

1262

1

1000

W86

W85

W88

W87

33

34

32

3 1

1026

35

39

40

W91

41

42

50

525356

W89

W90

1

1001

1036

W93

57

58

W92

10

1 5

70

72

W95

W94

1072

1 3

1044

W96

1 3

24

79

80

23

22

1

5

2

1013

2

3

8

1263

1

11

1301

F301

W97

1 2

1015

4

1 2

1

1023

CL 16532085_003.eps

1003

3

1 2

1037

110701

Page 8

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

Small Signal Panel Testpoint Overview (Bottom Side)

SSM Panel Component Location Guide (Bottom Side)

18A10PTV2.0 NTSC 6.

22

1003

F708

W158

F716

W160

8

10

12

I058

W159

I057

W157

B

E

E

C

7501

B

C

7500

E

B

C

7415

1

B

E

1266

2

3

2

4

6810

1264

579

3

1

1

2

3

1262

24

23

1013

1263

1

C

7229

B

E

1

4

F041

W153

1301

C

7224

B

E

79

80

3225

F222

W152

7504

W96

11

I056

W156

F707

W155

1

567

3

F706

W154

C

B

C

7503

E

7711

1

W93

70

72

W95

W94

1020

W92

E

B

7300

C

B

E

7303

C

18

6

1

7014

F014

W112

C

7016

B

7615

B

E

C

E

1074

1

E

C

C

7602

C

7606

B

E

B

C

7604

B

7605

E

7600

E

E

B

4

E

W130

B

E

7601

C

C

B

E

F058

W125

W136

W128

C

E

7607

B

7613

F059

W126

B

E

7614

C

W144

B

W141

C

W145

E

7610

B

C

7608

E

B

C

7609

E

B

C

W146

W143

BLUE

7710

9

7712

1

8

F741

W161

16

4

1

W133

C

7301

B

E

W98

W88

W91

57

53

58

52

56

50

1026

35

33

39

41

42

40

34

32

W89

W90

W87

W99

W86

1

2

W85

3615

W193

3600

3621

W127

W134

F056

W123

W135

W139

F057

W124

7603

B

W129

W140

C

7402

10

11

2

1

C

7005

B

F052

W119

E

18

F029

W111

GREEN

E

7018

F053

W120

B

C

14

15

F028

W110

1073

4

1

F054

W121

25

7012

24

F055

W122

6

40

7003

41

64

65

B

C

B

E

7002

E

7004

C

E

B

7017

C

W158

1039

1 5

C

7410

B

E

F011

W109

1

80

E

7405

1

RED

1913

W107

I013

W104

W105

W106

I012

W103

1

F049

W116

3058

3059

F048

W115

F019

W113

F020

W114

4

F040

W118

F050

W117

5

1

7011

6

10

5

6

7009

5

7010

6

W108

1

10

1

10

W102

I017

W100

W101

B

E

7020

C

7019

E

B

C

C

7021

B

E

B

C

B

C

7401

E

3

F301

W97

85

7403

4

1

1

CL 16532085_004.eps

110701

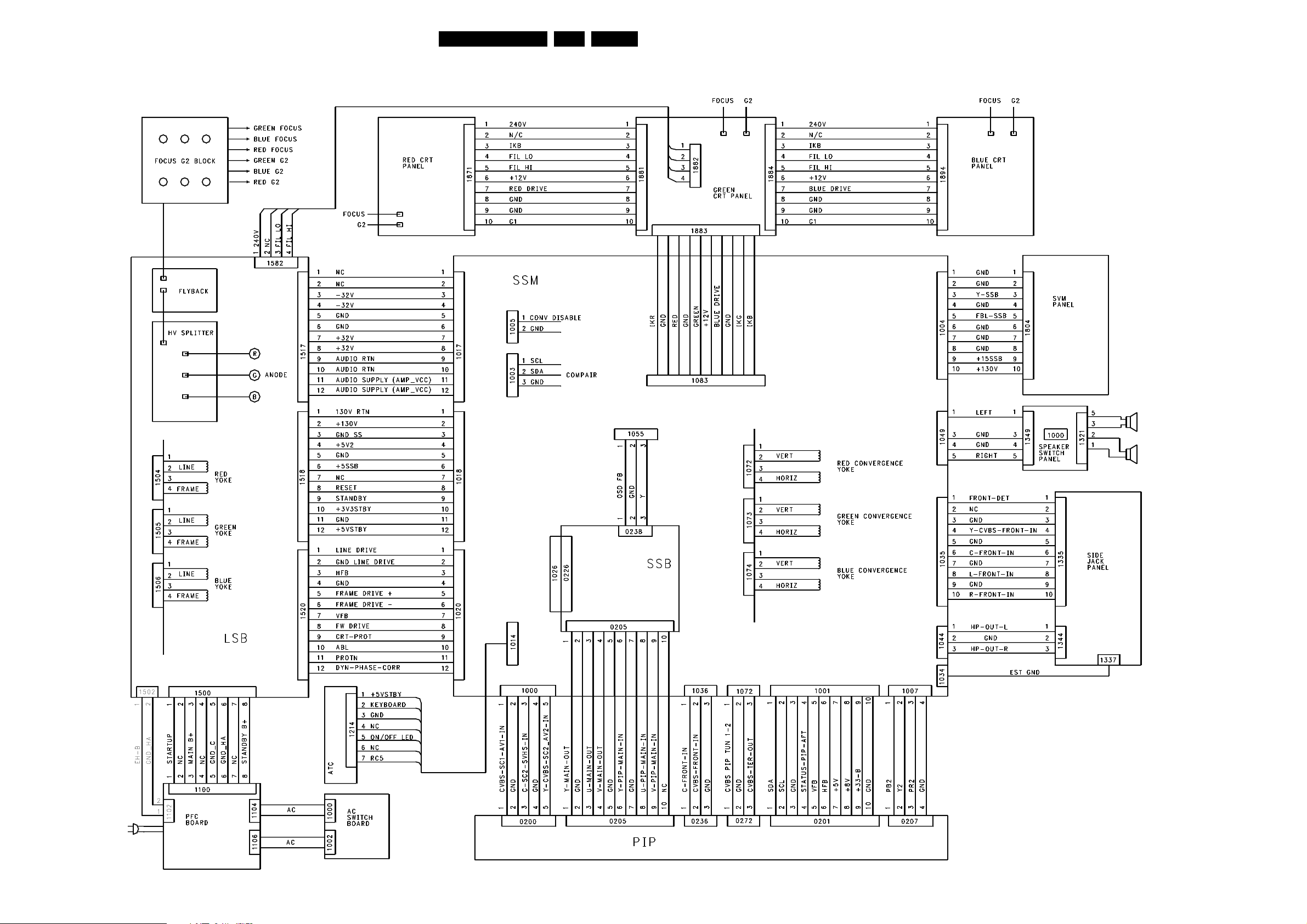

Page 9

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

Wiring diagram

19A10PTV2.0 NTSC 6.

CL 06532143_034.eps

091100

Page 10

Block- and Wiring Diagram, Testpoint Overview and Oscillogramms

Supply Distribution Diagram

SUPPLY DISTRIBUTION DIAGRAM

G

1008

1000

PFC FILTER PANEL

1104

L

1000

1001

AC

POWER

SWITCH

1002

1106

3009

3010

3300

9101

PFC

GND_C

RAWSTBY

GND_HA

1100

3

5

8

6

1

1102

N

IR-LED

KEYBOARD

PFC ON

11

J

+5VSTBY

E4

E3

7064

7066

7070

E2

0226

40

7405

43

36

38

7401

7403

E5

7651

E1

7301

ANALOG SSB

F3

+33V

9

+8V

PIP PANEL

8

0201

F5

7

7501

C4

1026

1014

7435

SW

7434

SW

SVM

PANEL

40

43

36

38

1

160~378V

160~320V

14V

130V

+15V

SMALL SIGNAL PANEL

+3.3STBY

TUNER

+5VSTBY

1001

78

+8VS

+5VD

+5VS

A1

1500

3

5

8

6

1

1502

LARGE SIGNAL PANEL

+33V_A

+5V

+8V

9

7402

7403 7401

POWER

SUPPLY

1300

STARTUP

3216

C9

10

9

FULL

SUPPLY

STANDBY

SUPPLY

1004

+33V_B

7710

1018

3712

20A10PTV2.0 NTSC 6.

1302

+3V3STBY

+5VSTBY

10

12

1012264

3759

3760

7711

7307

130V

264

7712

+15SSB

+5V2

C3

1017

1518

13OV

41V

12

+32V

11

A2

LINE/FRAME DEFLECTION

240V

FIL HI

FIL LO

3815

3817

3865

1

4

3

1510

B2

1882

3830

3820

3819

3831

7801

CRT

1

3

4

B1

1871

RED

CRT

3731

3730

4

6

5

1

3720

3719

7701

+12V

CRT

1881

3867

8

-32V

3

1516

+13V VERT

-13V VERT

1800

1801

+30VSCAN

8

7550

FRAME

OUT

6

1883

6

GREEN CRT PANEL

+12V

5

4

1

1884

1

4

5

B3

1894

BLUE

CRT

3731

3730

4

6

5

1

3720

3719

7701

+12V

CRT

A3

-13VA

HV

+15VSCAN

HIGH VOLTAGE

AND SHUTDOWN

F6

C10E7

C6

7612

+12V

7611

1083

6

+8V

41V

3

7402

+5VS

C7

6

7502

3527

F2

+33V

7502

TUNER

+5VS

4

9

1912

1910

-32V

6010

6009

6014

+5VD

+5VA

-5V

C1

7003

7007

7001

+8VS

F1

7863

C2

7009

7010

7011

+5VS

7802

REG

3863

3862

+3.3V

+3V

+3VD

7801

1911

7012

7014

+32V

CL 16532083_007.eps

110701

Page 11

Circuit Diagrams and PWB’s

7. Circuit Diagrams and PWB’s

Large Signal Panel

1502

EH-B

1

2

GND_HA

*

SEE TABLE

3289

11.7V

I108

10K

10n

10K

2284

3288

154V

8

7

GND_HA

6

5

4

1300

3

5A0

5HT

I169

2

1

VH

1500

W13

I135

100MHZ

STANDBY

1-D5,1-C4,

1-D10

RAWSTDBY

RAWSTDBYRTN

RAWMAINRTN

W81

82K

3314

2309

W84

2310

680p

3317

CHINA

X3135_017_05241

82p

GND_ C

I159

15K

F106

220p

2353

2311

VCC

AMV

.28V

2.6V

12

14

2.5V

1n

13

3.2V

X

8

9

10

15

3318

150K

GND_ C

GND_C

GND_ C

GND_C

3315

15K

1K

3316

GND_ C

3135_013_31995_02

3135_017_05261

3135_017_05281

NOTES

1. CAPACITANCE VALUES ARE IN FARADS:

m=MILI u=MICRO n=NANO p=PICO f=FEMTO

2. RESISTANCE VALUES ARE IN OHMS:

R=OHM K=KILO M=MEGA G=GIGA T=TERA

3. SAFETY TRIANGE REPRESENTS PCEC

REPLACEMENT PART ONLY.

4. COMPONENT USAGE VARIES.

REFER TO PARTS LIST / COMPONENT

*

TABLES FOR VERIFICATION.

+18VHOT

7214

BC547B

5315

7302

MC44603A

Vdem in

Sync

C

T

R standby

F

6.3V

R standby

P

2.5V

VOLTAGE

FEEDBACK

E/A OUT

FOLDBACK INPUT

USA

Fighter

X

F114

100u

2209

GND_HB

3231

22R

10u

F113

*

SEE

3241

TABLE

6K8

7206

CQY80N G

+5VSTBY

GND_HB

10K

3212

I116

3214

100K

*

SEE

TABLE

GND_ C

I170

GND_ C

DEMAGNETICATION

MANAGEMENT

Vdem out

Iref

OSCILLATOR

(REDUCED FREQUENCY)

ERROR

AM P

FOLDBAC K

5

I164

15K

3319

GND_ C

Ref Des

0031 NOT USED NOT USED

0032

1502 YES NOT USED NOT USED

2209 YES

2214 YES YES

2218 NOT USED NOT USED YES

2284 YES

2300 YES NOT USED NOT USED

2335

2336 NOT USED YES

3212

3213 YES

2218

I110

+5VSTBY

I114

3215

42

I115

7205

BC547B

3244

I123

3313

10K

Rref

Vosc prot

Vosc

Iref

STANDBY

CURRENT SENSE INPUT

3135_017_05241

CHINA

YES YES

NOT USED NOT USED YES

YES NOT USED NOT USED

1K

15

I118

33K

22n

2226

REFERENCE

3213

10K

+5VSTBY

3223

5V

1

3.9V

I146

2.6V

16

Vref

BLOCK

7204

BC636

47R

1

6205

TL431

3

2.4V

2

I124

Iref

3135_017_05261

AMV

NOT USED NOT USED

NOT USED NOT USED

NOT USED NOT USED

2214

18.3V

5

7213

CQY80N G

I117

8.3V

42

3246

820R

Vref

enable

INITIALIZATION BLOCK

Latch

Reset

THERMAL

SHUTDOW N

CURRENT

SENSE

Dmax & SOFT-START

Iref

7

.13V

GND_ C

3216

10R

10u

I113

GND_HB

3239

2K4

SUPPLY &

QSet

CONTROL

I163

3338

reserved

3135_017_05281

USA_FIGHTER

YES

NOT USED

NOT USED

NOT USED

I105

220u

2206

GND_HB

3287

5.8V

470R

2283

GND_ C

Vovp out

Vref

Soft Start & Dmax

11

2.4V

1u

2306

GND_ C

6207

BYD33D

100p

2228

12

W8051

I103

43

5201

GND_HB

F112

3232

22R

GND_HA

6200

GND_HB

7211

TOP221P

1

8

S1

SH3

2

3

4

GND_HB

BUFFER

OVERVOLTAGE

MANAGEMENT

7

S2

SH2

S36SH1

CTRL5D

47u

GND_ C

2346

100n

11.5V

1

Vcc

18V

UVLO1

Vc

OUTPUT

GND

Vcc

OVERVOLTAGE

PROTECTION

UVLO1

Vref

I133

Ref Des

3214 YES

3215 YES NOT USED NOT USED

3241 YES NOT USED NOT USED

3288

3289 YES

5300

6305 YES YES NOT USED

6310 NOT USED

6314 NOT USED NOT USED NOT USED

7204 YES

7205 YES NOT USED NOT USED

7206 YES NOT USED

7214 YES NOT USED NOT USED

2204

470p

GND_HB

110

2

154V

S229B3

5202

3

153V

4

5

2.7V

I107

W3

W4

100p

2215

2216

3321

reserved

3320

GND_ C

GND_ C

VCC

4

3312

5303

W10

2305

reserved

100p

NOT

USED

100p

2217

GND_HB

+5VSTBY

9100

LKS1AF

12

1305

6313

1N4148

75R

I151

.08V (5.2V)

BC547B

7300

100MHZ

W11

470p

GND_ C

VCC

3135_017_05261

AMV

NOT USED

NOT USED NOT USED

242253102425

S549C1

NOT USED YES

NOT USED

P4KE550

GND_HB

153V

2354

220u

I139

2303

100u

F107

3311

4R7

I154

2

11.2V

I155

3

2V

4

GND_ C

I162

6

1.7V

3135_017_05241

CHINA

YES NOT USED NOT USED

242253102425

S549C1

2212

100p

6235

BYD33D

I102

9

8

7

6204

BYV10-40

100p

I109

2269

1-D5,1-A1,1-D10

STANDBY

GND_HA

F111

2302

470p

6301

3

BYD33J

+5VSTBY

1K

3304

.8V (.06V)

5302

100MHZ

100MHZ

I100

F102

2211

W1

I104

W2

BYV10-40

I112

100u

2270

F117

4K7

3347

F118

I141

.8V (.06V)

7309

BC547B

3303

100K

5301

I165

3135_017_05281

USA_FIGHTER

NOT USED

242253102439

S549C1

NOT USED

NOT USED

8.5V

3230

1K5

100n

2208

100p

6231

2213

+5VSTBY

**

2336

470u

2335

3307

4R7

3306

15R

W12

0031

*

HEATSINK

1234

W83

I101

3222

reserved

6201

I106

3240

39K

1m

5234

10u

*

470u

2300

F108

GND_ C

I136

1-A1,1-C4,1-D10

3344

I143

.02V (.6V)

10n

2349

3343

I156

2V

1

10K

3305

GND_ C

BZX79-C8V2

470u

BYD33M

STANDBY

*

7301

*

6314

10K

10K

I160

.1V

2210

2282

2

3

7209

MC34064P

1

.7V

I122

33R

2301

127V

330p

I120

22u

1u

3310

RESET_

33R

3301

1n5

I142

21

2304

390R

.7V

1N5062

3308

0R1

3309

0R33

7.3V

2

IN

GND

3

F103

I121

3245

0V

1K

7208

BC547B

+3V3STBY

3302

11

10

GND_ C

8

4

W8

22021

1

0032

*

MECHPART

12345

6302

6303

GND_ C

GND_ C

GND_ C

4n7

2307

4n7

2308

GND_ C

21A10PTV2.0 NTSC 7.

LSB PANEL SCHEMATIC

(Section 1 of 3)

1-D11

GND_ C

5300

*

S549C1

1N5062

RESET

2203

2n2

I149

1m

2338

2339

100n

0033

534265

2312

N/U

12

470p

6305

*

100MHZ

I171

I137

I145

W9

220p

2323

6308

6310

W79

W5

W7

5320

100MHZ

I152

220p

2329

6309

BY229X-600

0043

100MHZ

5319

100MHZ

0040

5310

100MHZ

12

5304

1

2313

BY229X-600

I138

I147

BY229X-600

534265

2

534265

*

MUR8100E

BY229X-600

I168

12

5306

13

14

15

16

17

I140

18

19

22

5308

100MHZ

I153

BY229X-600

5321

3u3

I161

5305

10u

470u

220p

2315

6306

W6

220p

2319

6307

1302

T4A

MRT

5313

100MHZ

2330

I130

2314

470u

0036

12

HEATSINK

0038

12

2331

1m

3333

I148

I157

100n

8.7V

13.9V

0R1

13.9V

1.2V

3334

HEATSINK

5314

2332

7307

MC34063A

8 DCOL

7IS

6

VCC

5 CIN-

1K

2340

I172

1m

2316

1m

2320

2324

10u

1-G1,1-F4,1-D4

VCC

1m

CQY80N G

IPK

OSC

+130V

5309

10u

2m 2

7303

TL431

10n

5322

10u

5307

10u

I144

2325

2328

11.7V

1.8V

7304

I126

QRS

REFERENCE

REGULATOR

2341

100n

5311

10u

100n

1u

3328

100R

13V

15

3326

42

12V

3327

100R

11.9V (.03V)

1

3

2.4V

2

3335

100K

2317

2321

2327

3329

330R

4K7

2333

1SWC

8.7V

2SWE

3TIMC

.7V

4GND

5317

10u

I134

1m

1m

(.5V)

2m 2

2n2

3336

100R

3325

I173

100n

2322

10K

IRF9Z24N

9.8V

1

2342

2356

2318

100n

+15VSSB

2326

5312

10u

2334

3351

3352

100n

7308

3337

390R

22n

2351

I132

I158

470p

470u

33n

+32V

4K7

4K7

+130V

3322

2

1

2355

2

-32V

3324

3350

2K7

0046

5.8V

13.9V

47K

3323

12

470p

F125

100K

470R

HEATSINK

I127

1n

2343

I131

+15VSCAN

4K7

3353

F101

6312

+5V2

+3V3STBY

32VRTN

UC15006

SB360

+5VSTBY

5318

F116

3339

3K3

3340

220K

+15VSSB

5235

10u

F123

5239

10u

2344

F121

10n

-32V

+32V

I128

1m

+130V

F119

1-D5,1-A1,1-C4

STANDBY

2285

5238

10u

F126

F124

F127

5316

10u

F115

F110

F122

2345

RESET

I129

10n

2352

+5V2

1m

1518

EH-B

1

2

3

4

5

6

7

8

9

10

11

12

1516

EH-B

1

2

3

4

5

6

7

8

9

10

11

12

RESET

+3.6v

+3V3STBY

+5VSTBY

-31.3V

-31.3V

GND

GND

31.1V

31.1V

GND

GND

37.8V

37.8V

CL 16532050_005.eps

150501

Page 12

Large Signal Panel

W30

220R

4R7

100n

2586

2570

I206

100n

470p

3890

100R

3573

100R

F205

W33

2571

3563

220R

2558

68n

2559

+15VSCAN

7800

BC847B

I228

3594

100R

1n

470p

100n

3800

2K2

VPUL

-13V

3-F1

I203

2557

100u

3565

3562

2565

6550

BYV27-200

Circuit Diagrams and PWB’s

LSB PANEL SCHEMATIC

(Section 2 of 3)

7550

TDA4861

THERMAL

AND SOAR

PROTECTION

VERTICAL

INP2

V-OUT

VP2

3

5

4

13V 12V -13V -10V 13V .3V

.8V

150p

I208

3572

W35

100R

1n

2K

2564

3595

33K

14V

2.5V

3593

2513

1K

3803

2K2

I200

2511

2K

3550

I209

1R

3584

W47

I222 I223

2556

10n

3866

.9V

47K

+15VSCAN

7590

BC847B

I232

VERTICAL

DRIVER

DIFFERENTIAL

INPUT

AMPLIFIER OUTPUT

VP1

INP1

1

2

13V

.8V

100n

2572

2n2

3551

W38

I213

*

3840

1M

47K

3802

14V

-.2V

.26V

6551

BAS216

FLYBACK

DRIVER

FLYBACK

GENERATOR CIRCUIT

SUB

6

2514

470p

I207

W34

2516

2567

F213

FLB

470p

22A10PTV2.0 NTSC 7.

DY_PHASE CORR.

ABL

E/W DR.

CRT_PROT

W23

3834

6830

3839

9

3-G1

CRT_PROT

I217

2809

100n

3809

330R

3830

470R

BYD33M

330K

212V

7830

2SC3675

1.4V

3838

101112

3-D8

ABL

W42

2806

2807

1.5V

1R

2836

1K5

PROTN

PROTN

DY_PHASE_CORR

3810

1K5

3811

1K5

470p

3808

4K7

3841

4K7

F215

.15V

3807

100n

2V

0V

W25

1n

F217

330R

7803

BC557B

70V

0V

+130V

I215

5806

12

C925

1n

F218

47u

7801

BF819

I201

470u

2810

W40

34

5800

680p

2608

2838

W26

3816

68K

68K

3825

68K

3823

W41

I216

-.39V

0080

1234

3571

12K

3813

3814

1510

2

3

22u

BYD33J

0R27

+170V_PULSE

3817

EH-B

4

0R27

I211

3865

W69

0R47

3801

0R47

3828

68K

2814

68u

2815

F208

I202

1n

1

5807

6801

3815

130V

131V

1R

131V

7802

BU4515

0V

33R

5805

5

3590

150K

I230

W54

3591

330p

2811

6806

BY228

I219

18n

2816

6808

BYW95C

3581

2K2

12V

2573

470p

7551

.6V

BC847B

.05V

2K2

22R

3592

3456

100R

3596

47R

2574

12V

11.7V

680n

VFB

FRAMEDRIVE +

FRAMEDRIVE -

LINE DR GND

HFB

LINE DR

EH-B

1520

W16

1

2345678

F202

W15

HEATSINK

1234

F201

3829

100R

F204

N/C

2K7

3820

I225

F203

W18

W17

+15VSCAN

PULSE

PCO

VP3

9

8

7

I204

3585

0065

10K

+13V

W50

W22

3.8V

+15VSCAN

3812

3457

2K2

F214

2839

2K7

3835

18n

10u

2837

68K

3837

1.9V

12K

+15VSCAN

7553

BC847B

3458

14V

3.2v

2K2

NOTES

1. CAPACITANCE VALUES ARE IN FARADS:

m=MILI u=MICRO n=NANO p=PICO f=FEMTO

2. RESISTANCE VALUES ARE IN OHMS:

R=OHM K=KILO M=MEGA G=GIGA T=TERA

3. SAFETY TRIANGE REPRESENTS PCEC REPLACEMENT PART ONLY.

4. COMPONENT USAGE VARIES.

REFER TO PARTS LIST / COMPONENT TABLES FOR VERIFICATION.

*

I205

I210

5804

2820

I218

I229

40u

5803

4u7

BYV27-200

I212

2852

1u

2805

3805

2825

470p

6802

2822

430n

W37

100n

100R

BYV27-200

W39

2853

1u

5802

W8073

W20

F209

5801

S409C3

89

7

10

6

5

12

13

14

3

15

16

1

11n

2817

3821

470R

18n

2819

W24

F216

5810

100MHZ

TIP42C

7552

3-D7

2452

SCAN-1

W36

2818

470p

3452

1R5

2u2

2824

470p

6803

I214

14

68

1800

T1A

MRT

3891

6K8

6807

BYD33M

1801

T1A

MRT

W46

3867

2823

6850

BYD33J

2850

470p

W45

I224

W55

F219

2828

2829

1100VP-P

1504

1

2

3

4

W33

1505

1

2

3

4

1506

1

2

3

4

1508

1

2

3

100n

100u

100u

5811

10u

F212

100u

2851

LV

LV

LV

W27 600V P-P

LV

242202514409|con-b03p-lv-ta

5812

10u

+30VSCAN

F210

6809

BAS216

6810

BAS216

F211

1R

I220

I221

3822

220R

W51

I227

3824

220R

I231

3826

220R

3806

1K

2827

2826

-13V

+13V

1m

1m

-13V

CL 16532005_006.eps

150501

Page 13

Large Signal Panel

+15VSCAN

470K

F314

6502

BAS216

VPUL

+170V_PULSE

CRT_PROT

W30

F304

3505

2-B1

220R

W69

F305

3507

2-C7

47K

W70

F306

2-A5

6552

BZX55-C4V7

+15VSCAN

6504

BYD33D

120K

680p

120K

Circuit Diagrams and PWB’s

LSB PANEL SCHEMATIC

(Section 3 of 3)

+130V

F300

T2A

MRT

1900

4R7

3906

330u

2922

+15VSCAN+15VSCAN

+15VSCAN +15VSCAN

4K7

3500

13.8V

13.2V

13.8V

10K

3501

6500

BZX284-C10

3510

6501

BAS216

3504

2503

BAS216

6503

3506

470n

+15VSCAN

3503

2501

F307

120K

W71

I305

W61

13.7V

W72

13.8V

13.2V

F308

9901

7500

BC807-25

NOT

USED

7501

BC807-25

F309

3K9

3508

23A10PTV2.0 NTSC 7.

W58

6920

3992

470K

2917

2914

3135_017_05281

USA_FIGHTER

NOT USED

NOT USED

F302

3968

100n

100n

3903

129V

7.4V

2.1V

4.4V

12.5V

W66

1u

2911

3917

15K

3910

NOT USED

3941

3942

1K2

220K

I306

#

3902

39K

12K

# = Do Not Measure

12 13 14

11023456789 11

68K

10K

.003V

NC

NC

NC

5904

100MHZ

19.4V

MT

OFF

TEST

100n

BAS216

VB+

GND

ON /

OVP

DRIVER & CONTROL

GND

Vaux

TRANSFORMER

ABL RETURN Vaux

I303

2907

3940

3K3

6905

NOT USED

3915

1K5

2919

4n7

7909

BC807-25

F311

HVG-PTV

5900

BLUEGREENRED

EHT EHT

EHT

Vfoc

PCB-TAB4.8x0.5

1574

1

2

100n

2908

100n

2923

1u

NOT USED

NOTES

1. CAPACITANCE VALUES ARE IN FARADS:

m=MILI u=MICRO n=NANO p=PICO f=FEMTO

2. RESISTANCE VALUES ARE IN OHMS:

R=OHM K=KILO M=MEGA G=GIGA T=TERA

3. SAFETY TRIANGE REPRESENTS PCEC REPLACEMENT PART ONLY.

4. COMPONENT USAGE VARIES.

REFER TO PARTS LIST / COMPONENT TABLES FOR VERIFICATION.

*

+30VSCAN

3960

100R

11.2V

(20.5V)

SCAN-1

3969

47K

(20.2V)

30V

7905

BC547B

11V

(20.2V)

11V

7910

BC557B

-13.2V

100R

3975

3967

270R

F303

6922

W67

-13VA

BAS216

6950

BZX55-C4V7

3991

100K

+30VSCAN

2915

3918

10K

3959

1K

10.8V

(20.2V)

27.9V

19.9V

7906

BC817-25

10K

19.4V

3904

2913

220u

I308

W59W

3983

3990

3907

2K7

6900

6907

6951

BAS216

F313

220R

2K

F312

2K

3909

BAS216

BAS216

I302

BZX79-B27

6919

2912

220u

2916

ABL

2-A6

10n

3135_017_05241Ref Des

CHINA

1900 NOT USED NOT USED

NOT USED NOT USED

2923

NOT USED

3910 NOT USED NOT USED

3915

NOT USED

3135_017_05261

AMV

NOT USED NOT USED

I300

F301

W65

6911

6912

BAS216

BAS216

EH-B

1901

1

2

I301

W60

I304

10K

3900

2910

BAS216

10n

6910

4n7

13.8V

7908

BC817-25

2909

3509

10K

W73

10K

3511

3901

3911

3914

10K

13.8V

.003V

100R

13.8V

0V

10R

F310

7907

BC807-25

3912

.003V

3913

100R

1K5

I309

6921

2918

BAS216

BAS216

47u

CL 16532050_007.eps

150501

Page 14

Circuit Diagrams and PWB’s

Layout Large Signal Panel (Top View)

Large Signal Panel CBA (Top View)

A

24A10PTV2.0 NTSC 7.

3826 E8

2565 E11

CL 06532143_071.eps

091100

0031 C4

0032 C4

0033 F5

0036 F4

0038 F4

0040 F5

0043 F3

0046 F1

0065 F10

0080 F8

1300 A6

1302 E5

1305 D3

1500 A5

1502 A1

1504 D8

1505 D8

1506 E8

1508 D9

1510 A7

1516 G1

1518 G8

1520 G10

1574 C11

1800 A7

1801 A6

1901 D10

2203 A6

2204 D3

2206 C1

2208 D2

2209 C1

2210 E1

2211 D1

2212 D1

2213 D2

2214 B1

2215 D2

2216 D1

2226 D1

2228 C1

2269 D2

2270 E2

2282 E1

2283 C2

2284 E3

2285 G4

2300 B5

2301 B4

2302 D4

2303 C3

2304 B4

2305 B2

2306 A3

2307 A3

2308 A3

2309 B3

2310 A3

2311 A3

2312 F6

2313 G5

2314 G6

2315 F4

2316 F3

2317 G3

2318 F3

2319 F4

2320 F4

2321 G2

2322 G3

2323 F5

2324 F5

2325 F5

2326 G5

2327 G5

2328 D4

2329 F3

2330 F3

2331 F2

2332 G1

2333 E3

2334 E3

2338 E2

2339 E2

2340 E2

2341 F2

2342 E2

2343 F1

2344 F2

2345 F2

2346 B3

2349 E3

2351 E1

2352 F2

2353 A3

2354 B3

2355 F6

2356 G7

2452 F8

2501 G11

2503 G11

2511 F10

2516 G11

2557 F11

2558 E11

2559 F11

2573 F9

2574 F9

2586 F11

2608 G9

2805 E9

2806 G9

2809 G9

2810 C6

2811 F7

2814 A8

2815 B8

2816 E8

2817 E7

2818 D8

2819 E8

2820 F9

2822 D8

2824 A6

2825 A7

2826 E11

2827 E11

2828 A7

2829 A7

2836 C8

2837 D10

2838 D9

2839 C8

2850 A6

2851 A6

2852 D8

2853 D8

2911 D11

2912 D10

2913 D10

2916 G11

2917 C11

2918 C10

2922 C8

2923 D11

3216 B2

3230 D1

3239 E1

3241 D3

3246 E1

3287 D1

3289 E3

3301 A4

3302 A4

3305 B3

3307 B3

3308 B4

3309 B4

3310 B3

3311 B2

3312 B2

3314 B3

3320 B3

3321 B3

3322 E3

3323 E3

3324 E4

3325 E3

3333 E2

3336 E1

3337 E1

3347 E2

3350 E3

3351 G2

3352 G3

3353 G1

3452 E9

3457 G10

3505 F11

3507 C11

3508 G11

3509 D10

3510 G11

3562 E11

3563 E11

3565 F11

3572 G10

3573 G10

3584 E10

3585 F11

3593 G10

3594 G10

3595 F11

3801 B8

3805 E9

3806 D9

3807 G9

3808 G9

3809 G9

3810 F7

3811 F7

3812 E10

3813 F8

3815 B7

3816 C7

3817 A7

3821 E8

3822 D8

3823 C7

3824 D8

3825 C7

3828 B8

3829 G10

3830 F9

3834 C7

3835 E10

3837 D10

3838 E10

3839 D9

3840 E7

3841 G9

3865 A8

3867 A6

3890 D11

3891 E8

3900 D10

3906 C7

3910 D10

3917 F9

3940 C10

3941 C10

3959 A8

3960 A8

3975 A9

3983 D11

3992 C11

5201 C1

5202 D2

5234 E1

5235 G4

5238 G4

5239 G8

5300 D5

5301 B3

5302 B2

5303 A2

5304 F6

5305 F6

5306 E5

5307 F3

5308 F4

5309 G3

5310 F5

5311 G4

5312 E4

5313 F2

5314 G1

5315 B6

5316 F2

5317 E6

5318 F1

5319 E4

5320 F4

5321 E4

5800 G8

5801 B7

5802 D9

5803 E9

5804 E9

5805 F7

5806 D6

5810 F9

5811 E11

5812 E11

5900 B10

5904 C11

6200 C2

6201 E1

6204 D2

6205 D1

6207 D1

6231 E2

6235 D2

6301 C4

6302 B3

6303 A3

6305 F5

6306 F4

6307 F4

6308 F5

6309 E3

6312 F1

6313 D3

6314 A5

6504 D11

6550 E11

6552 F11

6801 A8

6802 A7

6803 A7

6806 E7

6807 D8

6808 E8

6830 C8

6850 A6

6919 D10

6950 A9

7204 C1

7205 D3

7206 D3

7208 E1

7209 E1

7211 C2

7213 D1

7214 D3

7300 E3

7301 B4

7302 A3

7303 D4

7304 E3

7307 E2

7308 F1

7309 E3

7550 F11

7552 F9

7801 G9

7802 F7

7803 G10

7830 E10

7905 A8

7910 A8

9100 B2

9101 B4

9102 C1

9104 C10

9105 E2

9106 E1

9107 E2

9108 E3

9109 F2

9110 G2

9111 D2

9112 F10

9113 E5

9114 F6

9115 E6

9116 D7

9117 D7

9118 C6

9119 E11

9120 B6

9123 G7

9124 G10

9127 G10

9128 F10

9129 F11

9130 F11

9131 E10

9132 E10

9133 D11

9134 D11

9135 D11

9136 D10

9137 C11

9139 C7

9140 C2

9142 G4

9143 G2

9144 G4

9145 F11

9146 D10

9147 E10

9148 D6

9149 D6

9150 F8

9152 G4

9153 G4

Page 15

Circuit Diagrams and PWB’s

Layout Large Signal Panel Overview (Bottom View)

Large Signal Panel CBA (Bottom overview)

A

Part 1

CL 06532143_92a.eps

Part 3

CL 06532143_92c .eps

25A10PTV2.0 NTSC 7.

Part 2

CL 06532143_92b.eps

Part 4

CL 06532143_92d.eps

CL 06532143_092.eps

230201

2513 G1

2514 G1

2556 D1

2564 F1

2567 G2

2570 G2

2571 F2

2572 F2

2807 G3

2823 A5

2907 G3

2908 G3

2909 C3

2910 C3

2914 C2

2915 G3

2919 C2

3212 D9

3213 C11

3214 D9

3215 D9

3222 E11

3223 D11

3240 E11

3244 D11

3245 E11

3288 E9

3303 D9

3304 D9

3306 B9

3313 A9

3315 A9

3316 A9

3317 A9

3318 B9

3319 A9

3326 D8

3327 D8

3328 D8

3329 D8

3334 E10

3335 E11

3338 A9

3339 F10

3340 F10

3343 E9

3344 E9

3456 F3

3458 F3

3500 G1

3501 G1

3503 G1

3504 G1

3506 G1

3511 G1

3550 F2

3551 F1

3571 F3

3581 F3

3590 F3

3591 F3

3592 F3

3596 F3

3800 D1

3802 E4

3803 D1

3814 F5

3820 G2

3866 D1

3901 C3

3902 C2

3903 C2

3904 C2

3907 D2

3909 D2

3911 C3

3912 C3

3913 C3

3914 C2

3915 C2

3918 F3

3942 C1

3967 A3

3968 C1

3969 A4

3990 D2

3991 A3

6500 G1

6501 G1

6502 F1

6503 G1

6551 F2

6809 A5

6810 A5

6900 D2

6905 C1

6907 D2

6910 C3

6911 C3

6912 C3

6920 C2

6921 C2

6922 D2

6951 A3

7500 G1

7501 G1

7551 F3

7553 F3

7590 F2

7800 D1

7906 C2

7907 C3

7908 C2

7909 C2

Page 16

Circuit Diagrams and PWB’s

Layout Large Signal Panel Part 1 (Bottom View)

26A10PTV2.0 NTSC 7.

Page 17

Circuit Diagrams and PWB’s

Layout Large Signal Panel Part 2 (Bottom View)

27A10PTV2.0 NTSC 7.

Page 18

Circuit Diagrams and PWB’s

Layout Large Signal Panel Part 3 (Bottom View)

28A10PTV2.0 NTSC 7.

Page 19

Circuit Diagrams and PWB’s

Layout Large Signal Panel Part 4 (Bottom View)

29A10PTV2.0 NTSC 7.

Page 20

CRT Panel Red

A

B

G1

GND

GND

RED

C

+12V

FIL HI

FIL LO

IKR

NC

240V

D

E

1871

Circuit Diagrams and PWB’s

30A10PTV2.0 NTSC 7.

123456789

10M

3752

2752

I020

22K

I021

1n

3733

5705

2702

22u

6705

BYD33J

10n

RED CRT PANEL

SCHEMATIC

3720

5R6

W183

F007

3716

2705

3718

22K

RT-01T 1

1n

100R

1702

DSP

I023

3710

1K5

I025

1001

I026

I022

231V

1701

HPS0521

4

5

6

7

8

9

10

11

12

I027

11.5V

8.7V (20.7)

Fil Hi

Fil Lo

169V (189V)

11.5v

230V

11.5V

11.5V

1

1875

1

2

PCB-TAB4.8x0.5

1872

1

2

1873

1

2

SCRN

VH

TO DAG

VH

TO DAG

EH-B

11.5V

10

F005

9

8

2.6V (2.0V)

7

F003

6

5

4

7.1V (5.4V)

3

F004

2

1

5701

100u

I001

W149

I002

F002

I003

I004

F001

W162

5702

15u

I005

2720

1000

10u

1

RT-01T

2721

100n

W178

3735

100R

W175

3703

100R

2701

10n

I006

11.4

I007

2.6V

(2.0V)

2717

(11.1V)

(10.8V)

6701

10u

170V

(192V)

10.9V

10.4V

2.0V

(1.7V)

I008

3K3

3731

7701

2SC3790

I011

68R

3756

I012

7702

BC337-25

I013

220p

2750

I014

BYD33J

W177

W176

2751

3730

3K3

1n

3751

15R

0079

12

3738

I009

HEATSINK

100K

3745

3753

5704

47u

75R

I016

27R

5703

3755

I015

9.4V

1.4V

2SC2383-O

47u

I010

W180

47R

7703

2.0V

3750

170V

(193V)

3742

3743

W179

(172V)

100R

8.7V

(5.7V)

1K

I017

220R

166V

7705

BF421

3740

I019

I018

1K

W181

W182

2722

560p

6702

BZX79-B6V2

3737

3K3

3719

5R6

A

B

C

D

E

12

6706

BYD33J

CL 16532050_008.eps

150501

3456789

Page 21

CRT Panel Blue

A

B

G1

GND

GND

BLUE

C

+12V

FIL HI

FIL LO

IKB

NC

240V

D

E

1871

Circuit Diagrams and PWB’s

31A10PTV2.0 NTSC 7.

123456789

10M

22K

2752

I020

I021

1n

3733

5705

2702

22u

6705

BYD33J

10n

BLUE CRT PANEL

SCHEMATIC

3720

5R6

W192

3716

100R

2705

F007

3718

22K

1n

1702

DSP

I023

3710

1K5

I025

1001

RT-01T 1

I026

I022

1701

HPS0521

4

5

6

7

8

9

10

11

12

266V

I027

11.5V

8.7V (20.7V)

Fil Hi

Fil Lo

192V (212V)

11.5V

266V

11.5V

11.5V

1

1875

1

2

PCB-TAB4.8x0.5

1

2

1

2

SCRN

1872

VH

TO DAG

1873

VH

TO DAG

EH-B

11.5V

10

F005

9

8

2.6V (2.0V)

7

F003

6

5

4

(5.4V)

7.1V

3

2

1

5701

100u

F004

W151

I001

I002

F002

I003

I004

F001

W164

5702

15u

I005

2720

1000

10u

1

RT-01T

2721

100n

W187

3735

100R

W184

3703

100R

2701

10n

I006

11.4V

I007

2.6V

(2.0V)

2717

10.9V

(11.1V)

(10.8V)

6701

10u

188V

(208V)

10.4V

2.0V

(1.7V)

I008

3K3

3731

7701

2SC3790

I011

68R

3756

I012

7702

BC337-25

I013

220p

2750

I014

BYD33J

W186

W185

2751

3730

3K3

1n

3751

15R

0079

12

3738

I009

HEATSINK

100K

3745

3753

5704

47u

75R

I016

27R

5703

3755

I015

9.4V

1.4V

2SC2383-O

47u

I010

W189

47R

7703

2.0V

3750

188V

(209V)

3742

3743

W188

100R

7.5V

(5.6V)

1K

I017

220R

191.5V

(195.6V)

7705

BF421

I018

3740

I019

1K

W190

W191

2722

560p

6702

BZX79-B6V2

3737

3K3

3752

3719

5R6

A

B

C

D

E

12

6706

BYD33J

CL 16532050_009.eps

150501

3456789

Page 22

CRT Panel Green

1 23456789

Circuit Diagrams and PWB’s

32A10PTV2.0 NTSC 7.

A

B

C

D

E

240V

NC

FIL LO

FIL HI

1882

1

2

3

4

EH-B

10

+240V

NC

IKB

FIL LO

FIL HI

+12V CRT

BLUE

GND

GND

G1

IKR

GND

RED

GND

GREEN

+12V

BLUE

GND

IKG

IKB

1

2

3

4

5

6

7

8

9

1881

1884

1883

EH-B

IKR

8.4V (5.7V)

+12V CRT

RED

2.8V (2.5V)

GND

GND

11.5V

G1

EH-B

1

2

3

7.8V

(5.5V)

4

5

6

7

(2.0V)

2.5V

8

9

10

11.5V

F003

EH-B

1

(5.7V)

8.4V

2

3

(2.5V)

2.8V

4

5

(2.6V)

2.9V

6

7

2.5V (2.0V)

F005

8

9

7.9V (5.5V)

10

7.8V (5.7V)

F001

5801

100u

I001

I002

I003

I004

W151

W149

W164

I005

F002

F004

W162

W163

W150

+240V

5802

15u

2820

10u

2821

3857

100n

10K

W165

3835

100R

W167

3803

100R

2801

6806

10n

2817

I010

11.5V

W166

I015

2.9V

(2.6V)

I016

I017

6801

BYD33J

10u

3831

162.5V

10.9V

I011

3856

I012

10.2V

2.4V (2.1V)

2850

BYD33J

I006

I007

3K3

(185.0V)

7801

2SC3790

68R

W168

(10.4V)

7802

BC337-25

220p

I020

I013

2851

3830

3K3

I019

1n

3851

15R

0089

12

3838

I008

100K

5804

47u

HEATSINK

3819

5R6

I018

I023

9.5V

75R

3845

1.5V

2SC2383-O

27R

3853

+240V

3825

3855

7803

5803

I014

3826

100K

47u

I009

W170

220K

47R

W169

3850

162.6V

(185.6V)

3842

2.0V

3843

100R

1K

220R

160.0V

(165.0V)

7805

BF421

8.2V

(5.6V)

3840

1K

W171

2852

BZX79-B6V2

3837

3K3

1n

2822

560p

6802

3852

I027

I024

22K

3833

5805

10M

W172

22u

2807

6805

BYD33J

10n

2805

GREEN CRT PANEL

SCHEMATIC

I025

1802

DSP

W174

3810

1K5

1002

RT-01T 1

1000

1

F006

RT-01T

3818

1n

22K

3820

5R6

I026

W173

F007

3816

100R

I028

I029

1886

1

2

3

4

1801

HPS0521

4

5

6

7

8

9

10

11

12

I030

VH

TO DAG

11.5V

9.6V (20.6V)

Fil Hi

Fil Lo

162V (186V)

11.5V

232.7V

11.5V

11.5V

1

1001

1

2

PCB-TAB4.8x0.5

1885

1

2

VH

CL 16532050_010.eps

232.9V

SCRN

TO DAG

150501

A

B

C

D

E

1 23456789

Page 23

Circuit Diagrams and PWB’s

33A10PTV2.0 NTSC 7.

Layout CRT Panel Red and Blue

Layout CRT Panel Green

CL 06532143_073.eps

091100

CL 06532143_074.eps

091100

Page 24

SmallSignalBoard

100n

2005

CONV_RED

9-C2

CONV_GRN

9-B2

CONV_BLU

9-C2

FB

9-D2

SDA-2

4-C2

SCL-2

4-C2

SDA-2

SCL-2

+5VD

3112

5V

2004

220p

4.1V

7000

BF450

1.7V

3015

220R

3104

5010

5u6

1002

1

2

3

1010 EH-B

1

2

3

SCL-2

47K

4.7V

7017

BC847B

4.8V

3113

+5VD

5002

3007

330R

3105

330R

EH-B

F044

3-C8

100K

9591

F045

5u6

100R

2002

220p

F002

9590

2020

3106

330R

6018

+5VD

3.3V

27p

BAS216

I034

5000

3004

3014

5u6

2021

I032

1K5

2K7

27p

3-C8

F043

6019

3114

2000

I010

6022

6008

BAS216

6020

BAS216

2023

SDA-2

4.8V

BAS216

BC847B

100K

100n

BAS216

6021

BAS216

27p

4.7V

7018

6023

BC847B

+5VD

0V

3038

100R

Circuit Diagrams and PWB’s

+5VD

5u6

5001

2001

100n

BB148

3010

4K7

330p

F001

3024

100R

BAS216

.02V

5

+5VD

SDA

2003

3034

+5VD

VSS

4

3016

3030

1K5

3032

1K5

3033

1K5

8

VCC

10p

4K7

10K

3020

10K

2017

M24C32

7007

SCL

WC_

-5V

3115

I011

BAS216

+5VD

7005

+5VD

47K

I033

3036

I039

2026

6000

5022

2009

330R

330R

3103

330R

.4V

6u8

6024

3101

3102

3K3

100p

SSM PANEL SCHEMATIC

(Section 1 of 11)

+5VD

2010

100n

5007

5u6

5009

5u6

E0

E1

E2

5005

5u6

1

2

3

6

7

3023

3011

33K

10n

2012

2n2

GND_C

2018

+5VD

4K7

+5VD

4u7

3042

4K7

3019

2.5V

2.5V

-.01V

4K7

3

2

5

6

3037

2082

1n

2025

100n

3K3

4.6V

8

4

4.6V

8

4

-4.6V

7016

BC847B

3111

2027

7001-A

LM833N

-4.6V

7001-B

LM833N

+5VD

3107

3110

220R

I040

100p

.5V

.5V

1

7

-.4V

4K7

220R

+5VD

3017

.38V

3039

+5VD

3108

3109

100R

1.2V

100R

2K2

4K7

100R

+5VD

5003

2007

4u7

2014

100n

BC547B

3041

3K3

3013

2013

10K

3009

+5VD

7015

5u6

100n

5u6

100n

+5VD

3018

5006

2019

.02V

+5VD

3003

10K

+5VD

3081

.5V

10K

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

4K7

GND1

VDD1

GND2

H50

PE

HPHI

GND3

CLK

GND4

FID

TST_

NC1

NC2

NC3

NC4

NC5

NC6

NC7

NC8

NC9

NC10

GND5

VDD2

NC11

34A10PTV2.0 NTSC 7.

3000

2.5V

2.5V

1.7V

2.2V

+5VD

5u6

100n

470R

CLGR

5V

5V

5V

.02V

PBL

25

5008

2022

3001

79

GND17

INT

26

470R

78

CLRD

GND6

27

3002

77

7680

CLBL

GND16

5V

VDD3

RP

28

29

470R

75

GND15

GP

30

72

71

73

74

GRN

GND14

RED

GND13

70

BLUE

uPD65654GF

7003

BP

31

SDA

32

GND7

33

NC1235NC1336NC14

34

SCL

CONVERGENCE

69

GND12

68

NC31

37 38

67

GND11

5V

NC15

65

66

NC30

VDD6

VDD5

GND10

HBLN

GND9

VUPR

SW1

VLWR

SW2

VBLN

NC29

NC28

NC27

NC26

NC25

NC24

NC23

NC22

NC21

NC20

NC19

GND8

5V

VDD4

NC18

NC1639NC17

40

WS

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

GND_C

GND_C

F042

F047

3006

3008

100R

100R

2008

100p

2K2

3005

3012

I036

I035

3021

100R

100R

2011

100p

+5VD

+5VD

5u6

5004

2016

100n

+5VD

7002

BC847B

.9V

3025

6001

I037

BAS216

2015

100p

2K2

7004

BC847B

+5VD

3031

3027

.12V

2K2

.8V

6K8

.13V

+5VD

BAS216

BAS216

6005

6007

I038

6004

2029

2028

BAS216

100p

100p

+5VD

5011

2024

5u6

100n

0001

TOP SHIELD

1234

NOTES

1. CAPACITANCE VALUES ARE IN FARADS:

m=MILI u=MICRO n=NANO p=PICO f=FEMTO

2. RESISTANCE VALUES ARE IN OHMS:

R=OHM K=KILO M=MEGA G=GIGA T=TERA

3. SAFETY TRIANGE REPRESENTS PCEC REPLACEMENT PART ONLY.

4. FOR VALUE SEE TABLE.

*

2-D4

GCLK

RCLK

2-A4

BCLK

2-B4

1005

EH-B

1

CONV.

2

DISABLE

GDATA

2-D4

RDATA

2-A4

2006

100p

BDATA

2-C4

WS

2-D3

3026

1K

3028

1K

CL 16532050_011.eps

9-D7,4-D8

9-D7,4-D8

150501

HFB

VFB

Page 25

SmallSignalBoard

Circuit Diagrams and PWB’s

35A10PTV2.0 NTSC 7.

+5VA

5018

5u6

2037

2032

47u

2036

2031

100n

100n

RCLK

1-A8

W100

RDATA

1-A8

BCLK

BDATA

1-A8

1-B8

W101

I017

I018

2.2V

2.5V

1.7V

2.2V

2.5V

2.3V

LC78817M

BCLK4

5 LACK

DATA6

NC2

LC78817M

BCLK4

5 LACK

DATA6

NC2

TIMING CONTROL

16

CH1

LATCH

16

SIPO

16

CH1

LATCH

16

TIMING CONTROL

16

CH1

LATCH

16

SIPO

16

CH1

LATCH

16

7009

AND TEST

484

LS DACLS DAC

REG.

484

7010

AND TEST

484

LS DACLS DAC

REG.

484

RS DACRS DAC

RS DACRS DAC

PWM DAC PWM DAC

NC1

PWM DAC PWM DAC

NC1

4.9V

2

VDD

REFH 9

CH2O

GND

38

4.9V

2

VDD

REFH 9

CH2O

GND

38

SSM PANEL SCHEMATIC

(Section 2 of 11)

W103

W105

I012

I013

W106

W104

3-B1

3-A1

3-E1

3-E1

RED_HORIZ

RED_VERT

BLU_HORIZ

BLU_VERT

1CH1O

2.1V

2030

3.5V

10u

10

2V

7

1CH1O

1.8V

2035

3.5V

10u

10

2V

7

2042

47u 47u

2041

100n

WS

1-B8

GCLK

1-A8

2.2V

2.5V

W102

GDATA

1-A8

2V

CONVERGENCE

BCLK4

5 LACK

DATA6

NC2

TIMING CONTROL

16

CH1

LATCH

16

SIPO

16

CH1

LATCH

16

AND TEST

484

LS DACLS DAC

REG.

484

RS DACRS DAC

PWM DAC PWM DAC

NC1

4.9V

27011LC78817M

VDD

REFH 9

CH2O

GND

38

1CH1O

2V

2040

3.5V

10u

10

2V

W107

W108

3-D1

3-C1

GRN_HORIZ

GRN_VERT

7

CL 16532050_012.eps

150501

Page 26

SmallSignalBoard

3048

3K3

2046

RED_VERT

RED_HORIZ

GRN_VERT

GRN_HORIZ

BLU_VERT

BLU_HORIZ

2-D6

2-B6

2-A6

2-E6

2-C6

2-C6

3098

100p

3099

3084

560R

3082

820R

3087

2K2

560R

560R

3083

270R

3088

2K2

3100

560R

2074

I045

3055

3057

-5V

3047

3022

1K

27K

3090

2K2

W114

I007

3117

1K

3086

2K2

1n

2061

6K8

27K

4u7

1n

3051

-5V

F020

2043

4u7

3035

2078

1n

3085

2K2

6K8

1n

1K

BC547B

3089

2K2

2077

6006

BAS216

I006

-31V

2073

2076

6016

BAS216

3054

27K

-31V

3056

3K3

2062

100p

W113

F019

3059

-5V

Circuit Diagrams and PWB’s

-32V

+32V

3046

27K

1n

3118, 1K

3120, 1K

3050

-5V

3052

3K3

2049

100p

6K8

-30V

3049

6K8

-32V

3122

2075

1K

BC547B

-5V

W110

W111

F017

7013

-30V

3043

3126

6K8

1n

1K

F021

7008

3116

1K

I008

W112

1K

+32V

3124

3058

-5V

2052

F022

F011

W109

F028

F029

1K

3121

F014

3123

1K

I042

1K

6K8

3125

3045

3

6I+1

7 I-1

14 I+2

13 I-2

15 I+3

16 I-3

3119

1K

F018

I041

100n

7012

STK392

MUTE

GND_C

2068

14 I+2

13 I-2

15 I+3

16 I-3

I043

1K

1K

2053

SGND

1

100n

7014

STK392

3

MUTE

6I+1

7 I-1

3127

1K

GND

2

SGND

1

3062

3K3

2072

100p

2054

2069

100u

-VCCP

4