Philips 5-DTC-Module-MP-3 Service Manual

10-1 10-1

TABLE OF CONTENTS

Service hints ...............................................................................10-1

Location of Printed Circuit Boards..............................................10-3

Wiring ..........................................................................................10-3

Emergency opening....................................................................10-4

Location of switches....................................................................10-4

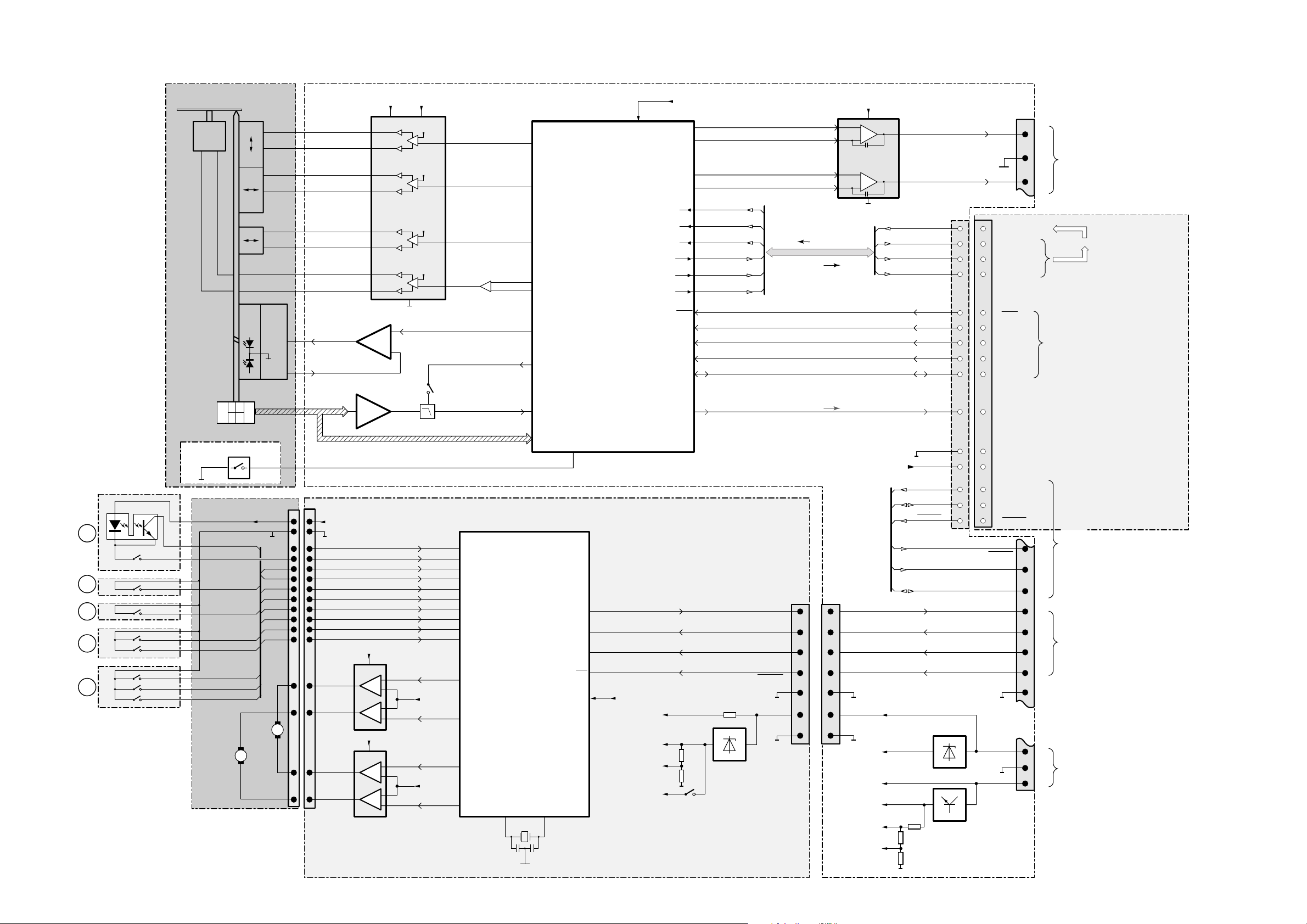

Blockdiagram..............................................................................10-5

CD BOARD

Circuit Diagram .......................................................................10-6

Component Layout side A.......................................................10-7

Component Layout side B.......................................................10-8

CONTROL BOARD

Circuit Diagram .......................................................................10-9

Component Layout .................................................................10-9

MP3 BOARD (for orientation only)

Circuit Diagram .....................................................................10-10

Component Layout ...............................................................10-11

Exploded view loader ...............................................................10-12

Partslist.....................................................................................10-13

5DTC Module

(MP3 version)

Layout stage CD .5/ Control .4

In case of symptom „skipping tracks“ perform following actions:

1. VERIFY THE COMPLAINT

PLAYABILITY CHECK

Use CDDA SBC 444A: . . . . . . . . . . . . .4822 397 30245

TR 14 (600µ black dot) maximum at 01:15

TR 19 (fingerprint)

TR 10 (1000µ wedge)

Use CD-RW Printed Audio Disk . . . . . .7104 099 96611

TR 3 (Fingerprint)

TR 8 (600µ black dot) maximum at 01:00

• playback of all these tracks without audible disturbance

• jump forward/backward within a reasonable time

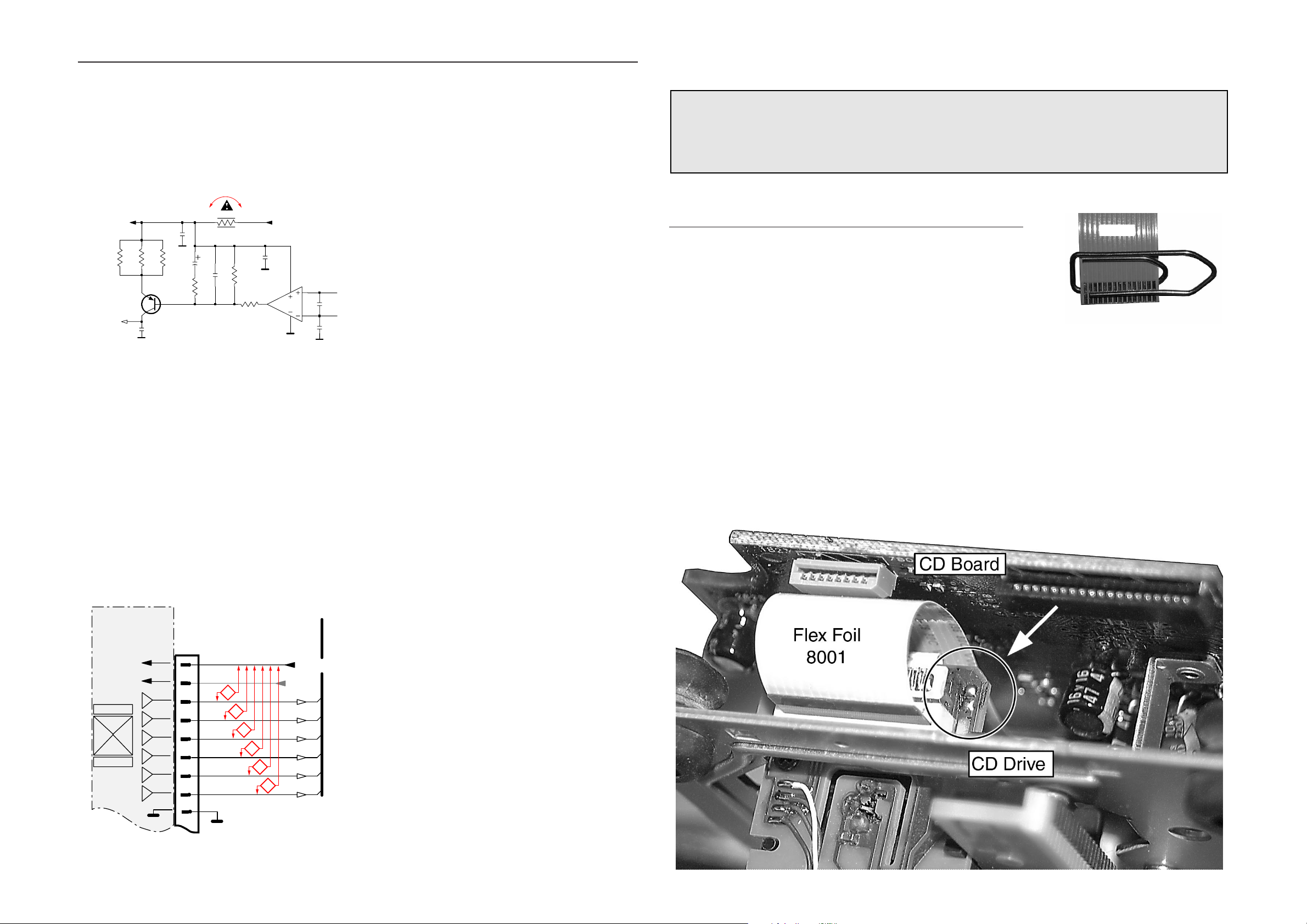

2. CLEAN THE LENS

CD DRIVE – LENS CLEANING

Because the material of the lens is synthetic and coated

with a special anti-reflectivity layer, cleaning must be

done with a non-aggressive cleaning fluid.It is advised to

use “KODAK LENS CLEANER CAT 176 71 36”, available

in normal photo shops.

The actuator is a very precise mechanical component

and may not be damaged in order to guarantee its full

function. It is advised to clean the lens gently (don’t press

too hard) with a soft and clean cotton bud moistened with

the special lens cleaner.

The direction of cleaning must be in the way as indicated

in the picture below.

3. MEASURE THE EYE-PATTERN SIGNAL

EYE-PATTERN SIGNAL – JITTER MEASUREMENT

Measure the signal direct on resistor 3898 using an oscilloscope (see also chapter 10-9).

See below examples of the signal.Amplitude should read at

least 700mVpp using SBC444A.

good

bad

If the oscilloscope shows a signal like the ‘bad’ one, and/or

the amplitude decreases within 1minute - the CD drive has

to be replaced.

Sanyo

DA12T3

HF-Amplifier

D3

D2

D1

Drive detection

680R

3905

3903

3K3

BC847B

7877

47n

2818

1K5

3902

5

7

4

2

1

6

3

64

8

9

10

11

470R

3893

+3.3V

2K2

3908

10K

3923

BC847B

7878

BC847B

7876

4n7

2813

3896

100R

220u

2885

2881

560p

47n

2887

560R

3901

2883

470n

2817

4u7

3n3

2814

3898

220R

3895

27K

470n

2884

+3.3V

3909

820R

3907

100R

3920

33K

3897

2882

82p

3K3

3904

2K7

3899

3906

470R

+5V_HF

HFIN

VrefCD10

100p

28152816

22n

LDON

to 3826,3827

VREF GEN.

VDDA1

VRIN

VSSA1

ISLICE

LDON

D1

D2

D3

D4

HFIN

HFREF

IREF

CD_DA: 0V / CD_RW: 3V

Σ (A-D)

800mVpp

TB = 0.5µs/div

EYE-PATTERN

1,8V

1,2V

2,4V

2,6V

0,65V

Before touching the lens it is advised to clean

the surface of the lens by blowing clean air over

it in order to avoid that little particles make

scratches on the lens.

Service Hints

10-2 10-2

4. MEASURE THE LASER CURRENT

CD DRIVE – LASER CURRENT MEASUREMENT

The laser current can be measured as a voltage drop on

resistor 3820.Typical value 170 - 190mV for CD-DA respectively 200 - 220mV for CD-RW.

5. MEASURE THE OFFSETS OF THE CD-DRIVE

CD DRIVE – OFFSET MEASUREMENT

Each photodiode of the CD-drive may have an offset.

This offset has to be compensated by the signal processor.A high offset of the CD-dr ive leads to poor playability

of some CDs (skipping tracks).

Start the Service Test Program - section „Focus Test“

without a CD.Focus sensitivity = CD-RW.

Use a DC Millivoltmeter for measurement.The offsets

can be measured direct on the connector.See drawing

below.

The values from diode A-D should read

0±10mV. Diodes E and F are less critical.

If one of the offsets is higher than ±10mV the CD drive

has to be replaced.

Sanyo DA12T3

CD Drive

A

A

F

C

B

E

C

D

E

VCC

B

VREF

F

D

9

10

11

12

13

14

15

16

1800

+5V_HF

VrefCD10

A

D

E

B

C

F

GND

8

E

D

A

B

C

F

Laser power control

(example for DA2x drive)

100n

2878

470n

2876

3821

1R

1K

3823

2880

33p

+5V

BC807-40

7879

3817

47R

3820

4R7

47R

3819

1n

2879

2877

47u

1

8

4

7811-A

LM358D

3

2

10K

3822

47R

3818

2841

100n

47n

2869

+5V_HF

LASER DIODE

U >250mV

->Laser damaged !

4,6V

3V

3,3V

3,9V

2V

0,17V

0,17V

Service Hints

The CD drive forms a compact building block with the CD Board.

The following steps have to be done when replacing the CD mechanism:

1. Desolder disc and slide motor

2. Loosen 2x screw

1. Disconnect flexfoil from old CD drive

2. Put a paperclip over contacts of flexfoil to short-circuit the contacts (fig.1)

3. Remove old CD drive

4. Mount new CD drive to CD board

5. Solder disc and slide motor after fixing the drive to the board

5. Move slide outside

6. Remove paperclip from flexfoil

7. Connect flexfoil to new CD drive

8. Remove ESD-protection (solder joint) from laserunit (see picture below)

CHARGED CAPACITORS ON THE SERVO BOARD MAY DAMAGE THE CD DRIVE ELECTRONICS WHEN

CONNECTING A NEW CDM MECHANISM.THAT´S WHY, BESIDES THE SAFETY MEASURES LIKE

• SWITCH OFF POWER SUPPLY

• ESD PROTECTION

ADDITIONAL ACTIONS MUST BE TAKEN BY THE REPAIR TECHNICIAN.

WARNING

fig.1

Attention: The laser diode of this CD dr ive is protected against ESD by a solder joint which shortcircuits the

laserdiode to ground.

For proper functionality of the CD drive this solder joint must be removed after connection the drive to

the set.

10-3 10-3

Location of Printed Circuit Boards

5DTC Location of PCBs 2002 08 29

CD Board

Control

Board

Motor

Board

MP3 Board

8051

8052

8021

Wiring Diagram 5DTC Module

5DTC Wiring Diagram 2002 08 30

8001

8052

dig.out (optional)

8051

to / from

AF Board

to / from

CD-drive

1825

1820

1800

1824

1802

1801

1451

1823

Control Board

Motor Board

MP3 Board

CD Board

8021

The FFC-Cables are available as sparepart.

8001 3103 308 93090 FFC CABLE 16Pin 80mm BD Connection from CD Board to CD Drive

8051 3103 308 93100 FFC-CABLE 19Pin 90mm AD Connection from CD Board to MP3 Board

8052 3103 308 93120 FFC CABLE 8Pin 80mm BD Connection from CD Board to Control Board

8021 3103 308 93110 FFC-CABLE 16Pin 60mm AD Connection from Control Board to Motor Board

10-4 10-4

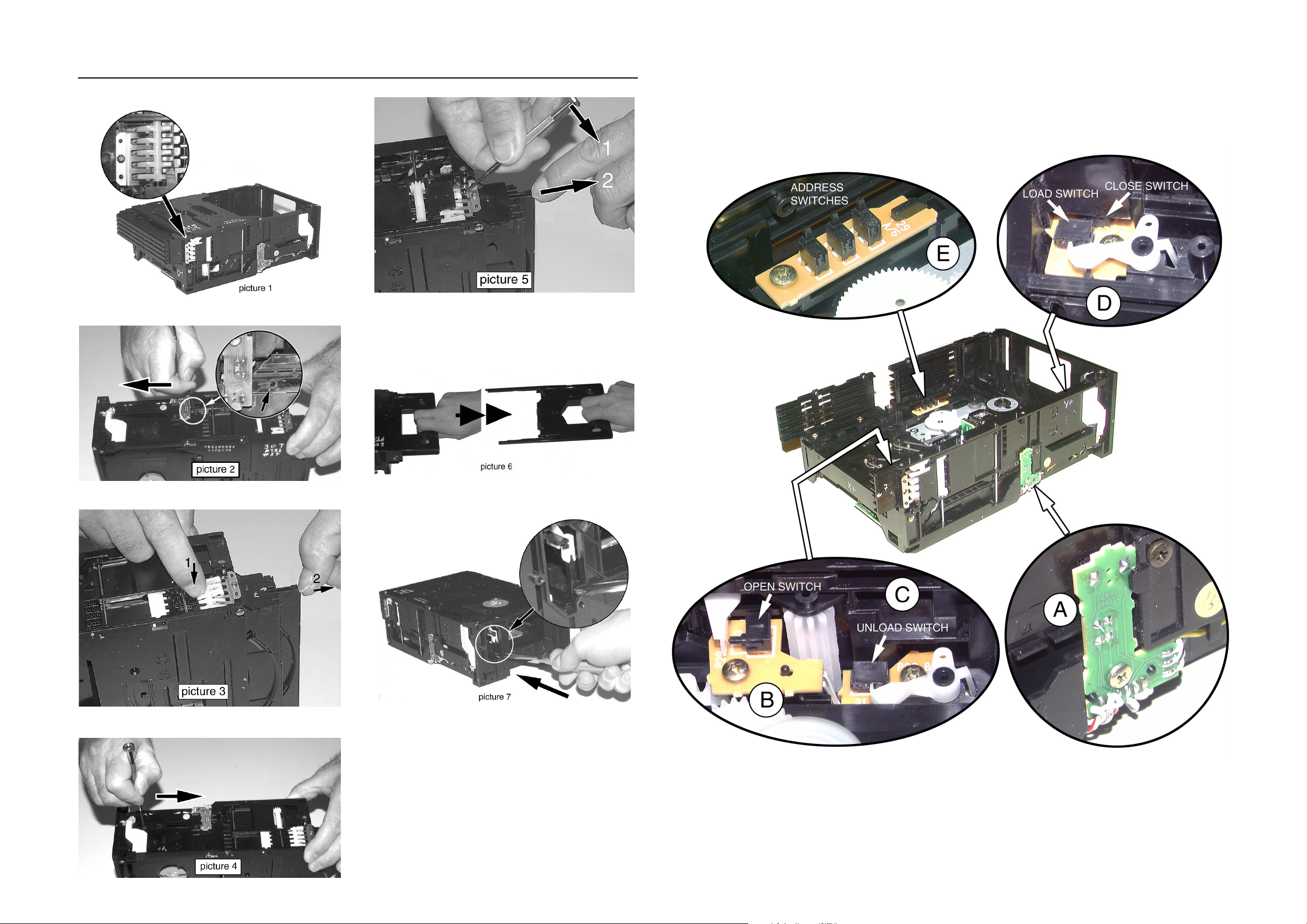

The trays of the 5DTC are mechanically

locked.

To open tray 1, 2 and 3 move lever (pos 29) backwards

(e.g. with a screwdriver - see picture 2) to its endposition.

Release the locking mechanism and pull out the tray (see

picture 3).

To open tray 4 and 5 move lever (pos 29) forward to its

endposition (see picture 4).

Release snap as shown in picture 5 and pull tray out.

To remove a CD from Play Position perform following

steps:

1. Open tray 1 as described before.

2. Tear the tray out with speed (see picture 6).The tray can

be inserted aftewards without any alignment.

3. Move lever (pos 29) forward to its endposition (see picture 4).

4. Push lever (pos 31) forward (see picture 7).

5. Remove CD.

Emergency opening of the trays Location of switches

10-5 10-5

MP3 Version

MP3 Version

1820

15

17

13

16

1824

1824

8

7

10

9

11

CD_IIS_DATA

IIS_WCLK

IIS_SCLK

MP3-Decoder

Communication

Front-µP and MP3 module

RAB

41

RESET

SDA

µP_DATA

12

µP_CLK

11

14

µP_FRAME

SICL

3

2

4

µP_CLK

µP_FRAME

µP_DATA

µP_CLK

µP_FRAME

µP_DATA

SILD

6

SPDIF

Control Logic

Communication

DSP ↔ Signal Processor

WCLI

35

WCLK

28

SCLI

37

SCLK

29

SDI

36

DATA

27

CD_IIS_DATA

AU_IIS_DATA

AU_IIS_DATA

IIS_WCLK

IIS_SCLK

AU_IIS_DATA

IIS_WCLK

IIS_SCLK

1,5,12,14,18

19

CD_IIS_DATA

IIS_SCLK

IIS_WCLK

22

23

RN

RP

DIGITAL AUDIO

MP3 coded

Digital out

CD-DA coded

38

42

40

39

GND

+5V

GND

+5V

For DIGITAL OUT versions only

MP3 BOARD

DOBM

51

10

VCC

7803

7801

TCA0372

TMP87CA409A

V1

D1

D2

D3

D4

R1,R2

Micro Controller

SIGNAL PROCESSOR

CD10

SAA7324 (SAA7325)

TRAY

MOTOR

VDD

DIODES

PHOTO

INNER SWITCH

not on all versions

LASER &

MONITOR

DIODE

TURNTABLE

MOTOR

DISC

CD MECHANISM CD MAINBOARD

CONTROL BOARDMOTOR BOARD

TRAY_IRQ

I2C_SCL

ADDRESS3 SW

ADDRESS3 SW

CLOSE SW

CLOSE SW

ADDRESS2 SW

ADDRESS2 SW

LOAD SW

LOAD SW

ADDRESS1 SW

ADDRESS1 SW

UNLOAD SW

UNLOAD SW

HOLDER HEIGHT COLLECTOR

HOLDER HEIGHT COLLECTOR

OPEN SW

OPEN SW

HOME SW

HOME SW

I2C_SDA

OSC.

DISC SENSOR COLLECTOR

+5V

SWITCH

GND

GND

+5V

GND

GND

GND

7800

5,17,21,52,57

+5V22Vref

Vref

23

7811

63

8,13,15,16,28,29,30

4

19

16

17

RST

27

12

13

16

23

24

8

5

6

7

3

1

+3,3V

Blockdiagram 5DTC 2002-09-05

+5V

+5V

ST

+3,3V

+A (+12V)

7815

+5V

Vref

+3servo

+8V

7801

+12V

BLOCK DIAGRAM 5DTC

+5V

ST

28

V

REF

V

REF

+A

OPAMP

V

REF

+5V

SWITCH

FOCUS

MOTOR

RADIAL

MOTOR

SLEDGE

MOTOR

MOTOR

TURNTABLE

MOT1

SL

RA

FO

55

54

56

59

25

19

26

27

2

1

11

12

18

17

3

7802

MM1469PH

TTM-

TTM+

SLEDGEB-

SLEDGEB+

RADB-

RADB+

FOCB-

FOCB+

MOT2

60

10

LD ON

HF IN

64

V4

61

2

CD RW= 3V

CD DA= 0V

EQ-Selection

7876,7877

7811,7879

7878

LD

MON

A-D

A-C

FE

BA

CD

+A

OPAMP

+A

OPAMP

2

1801

TCA0372

15

14

21

26

5

8

7

6

1

3

2

7805

LIFT

MOTOR

Vref

Vref

Vref

7800

8M

1800

CST

4

6

5

9

7

8

13,15

Tray_IRQ

Tray_I2C_SCL

Tray_I2C_SDA

5

2,3

4

Tray_IRQ

µC_RESET

Tray_I2C_SCL

Tray_I2C_SDA

1

7

8

6

+A

7

9,10

8

Tray_IRQ

Pin 1..3 not used!

µC_RESET

Tray_I2C_SCL

Tray_I2C_SDA

11

5

4

6

7806

+5V

SWITCH

OPEN SW

UNLOAD SW

HOME SW

LOAD SW

CLOSE SW

ADDRESS3 SW

ADDRESS1 SW

ADDRESS2 SW

A

B

C

D

E

12

11

10

9

8

7

6

5

4

13

4

12

5

11

6

10

7

9

1

8

2

3

1802

Active low pass

Filter

LM358

7887

1

2

3

6

5

7

+5V

8

+

-

+

-

1824

3

2

1

CD LEFT

CD RIGHT

18

19

LN

LP

Analog Audio

+5V

+A

GND

Supply

1823

RAB

SDA

SCL

SILD

RESET

µC_RESET

Loading...

Loading...