Colour Television Chassis

QFU1.1E

LA

Contents Page

1. Revision List 2

2. Technical Specs, Diversity, and Connections 2

3. Precautions, Notes, and Abbreviation List 5

4. Mechanical Instructions 9

5. Service Modes, Error Codes, and Fault Finding 20

6. Alignments 39

7. Circuit Descriptions 43

9. Block Diagrams

Wiring diagram 7000 series 40" 55

Wiring diagram 8000 series 40" 56

Wiring diagram 7000 series 46" 58

Wiring diagram 8000 series 46" 59

Wiring diagram 7000 series 55" 62

Wiring diagram 8000 series 55" 63

10. Circuit Diagrams and PWB Layouts Drawing PWB

B 310431365554

B 310431365664 125 177-178

E 272217190673 - 272217190698 Keyboard 179

J 272217190536 Sensor board 183 184

AL 310431365771 16 LED AmbiLight 203

AL 310431365781 15 LED AmbiLight 206

AL 310431365804 12 LED AmbiLight 209

AL 310431365813 10 LED AmbiLight 211

AL 310431365823 9 LED AmbiLight 214

AL 310431365833 7 LED AmbiLight 216

11. Styling Sheets

7000 series 40" 218

8000 series 40" 219

7000 series 46" 221

8000 series 46" 222

7000 series 55" 225

8000 series 55" 226

70 123-124

Published by ER/EL 1269 Quality Printed in the Netherlands Subject to modification EN 3122 785 19212

2012-Sep-14

2012 ©

TP Vision Netherlands B.V.

All rights reserved. Specifications are subject to change without notice. Trademarks are the

property of Koninklijke Philips Electronics N.V. or their respective owners.

TP Vision Netherlands B.V. reserves the right to change products at any time without being obliged to adjust

earlier supplies accordingly.

PHILIPS and the PHILIPS’ Shield Emblem are used under license from Koninklijke Phili ps Electronics N.V.

EN 2 QFU1.1E LA1.

1. Revision List

Manual xxxx xxx xxxx.0

• First release.

Revision List

• Chapter 5: added white tone alignment values; see section

.

6.3.1

Manual xxxx xxx xxxx.1

• Chapter 4: added additional LVDS cable handling info; see

section 4.3.2

.

Manual xxxx xxx xxxx.2

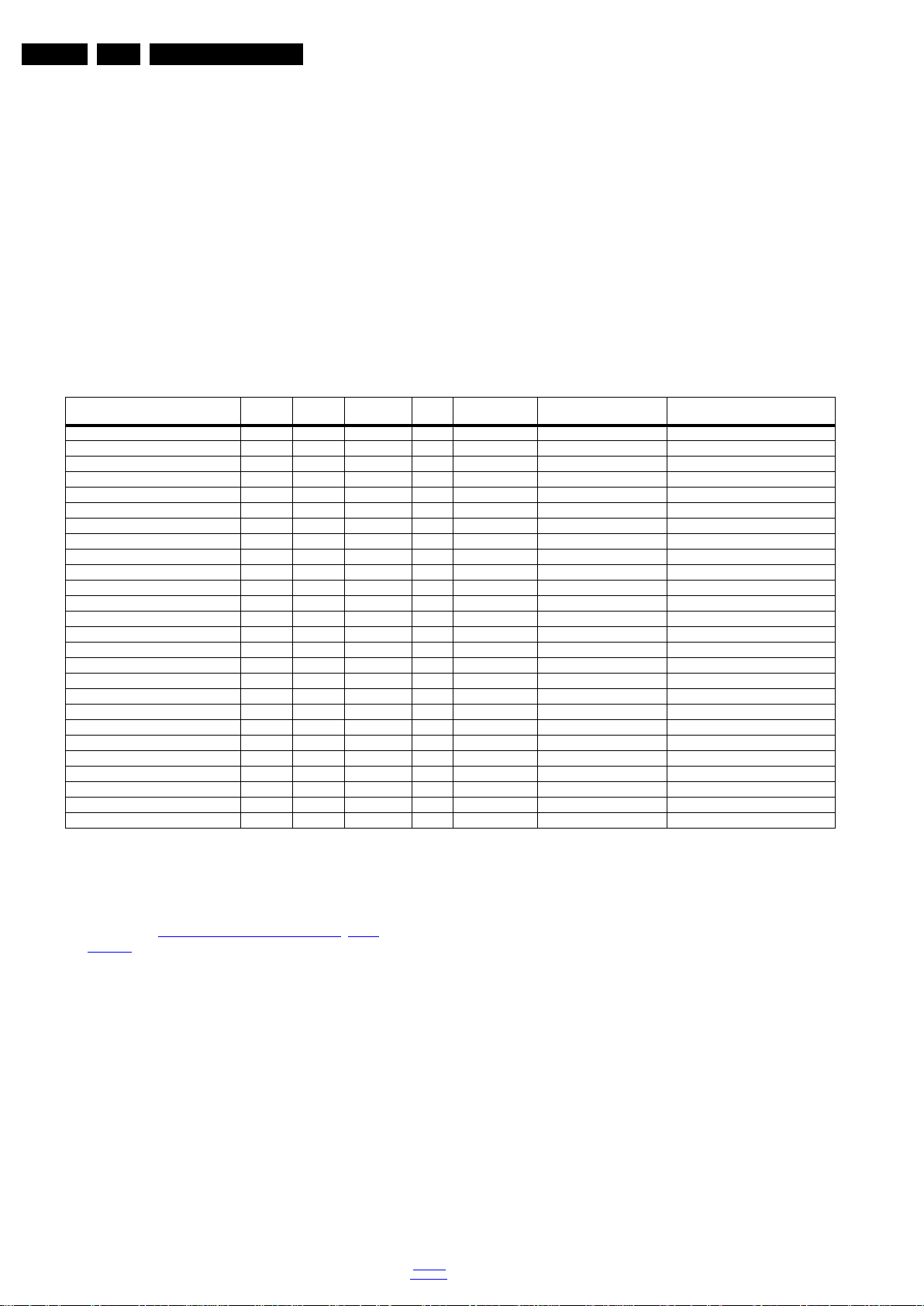

• Chapter 2: Table 2-1

2. Technical Specs, Diversity, and Connections

Index of this chapter:

2.1 Technical Specifications

2.2 Directions for Use

2.3 Connections

2.4 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

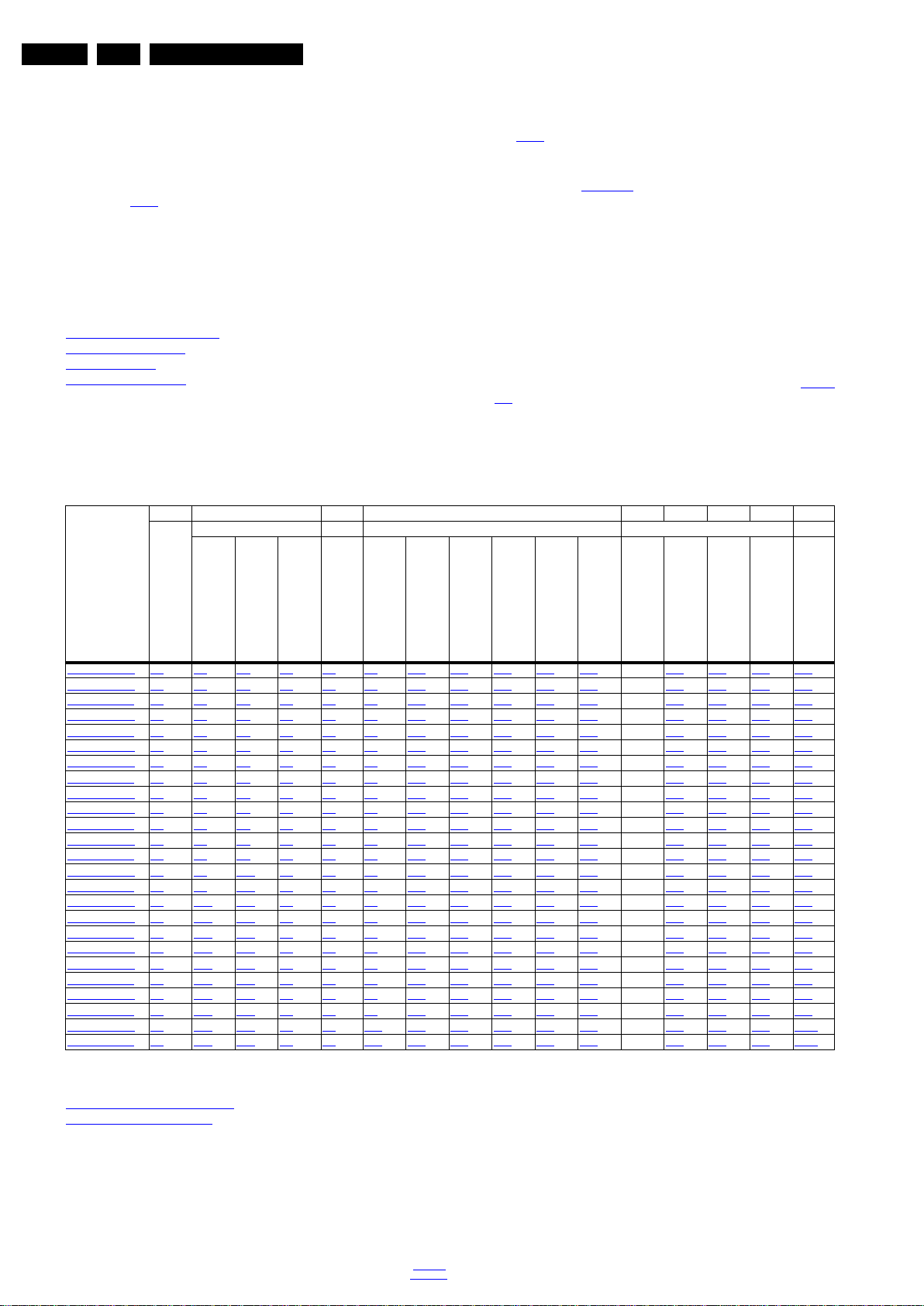

Table 2-1 Described Model Numbers and Diversity

2 4 7 9 10 11

Mechanics Descr. Block Diagrams Schematics Styling

2.1 Technical Specifications

For on-line product support please use the CTN links in Table

2-1. Here is product information available, as well as getting

started, user manuals, frequently asked questions and

software & drivers.

updated (added CTNs).

CTN

40PFL7007H/12 2.3 4-1 4-2 4.3 7.2 9.1 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.1

40PFL7007K/12 2.3 4-1 4-2 4.3 7.2 9.1 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.1

40PFL7007T/12 2.3 4-1 4-2 4.3 7.2 9.1 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.1

40PFL8007K/12 2.3 4-1 4-3 4.3 7.2 9.2 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.2

40PFL8007T/12 2.3 4-1 4-3 4.3 7.2 9.2 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.2

42PFL6907H/12 2.3 4-4 4-5 4.3 7.2 9.3 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.4 11.3

42PFL6907K/12 2.3 4-4 4-5 4.3 7.2 9.3 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.4 11.3

42PFL6907T/12 2.3 4-4 4-5 4.3 7.2 9.3 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.4 11.3

46PFL7007H/12 2.3 4-6 4-7 4.3 7.2 9.4 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.4

46PFL7007K/12 2.3 4-6 4-7 4.3 7.2 9.4 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.4

46PFL7007T/12 2.3 4-6 4-7 4.3 7.2 9.4 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.4

46PFL8007K/12 2.3 4-6 4-8 4.3 7.2 9.5 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.5

46PFL8007T/12 2.3 4-6 4-8 4.3 7.2 9.5 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.5

46PFL9707S/12 2.3 4-9 4-10 4.3 7.2 9.7 9.11 9.12 9.13 9.14 9.15 - 10.2 10.7 10.4 11.6

46PFL9707T/12 2.3 4-9 4-10 4.3 7.2 9.7 9.11 9.12 9.13 9.14 9.15 - 10.2 10.7 10.4 11.6

47PFL6907H/12 2.3 4-11 4-12 4.3 7.2 9.7 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.4 11.7

47PFL6907K/12 2.3 4-11 4-12 4.3 7.2 9.7 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.4 11.7

47PFL6907T/12 2.3 4-11 4-12 4.3 7.2 9.7 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.4 11.7

55PFL7007H/12 2.3 4-13 4-14 4.3 7.2 9.8 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.8

55PFL7007K/12 2.3 4-13 4-14 4.3 7.2 9.8 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.8

55PFL7007T/12 2.3 4-13 4-14 4.3 7.2 9.8 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.8

55PFL8007K/12 2.3 4-13 4-15 4.3 7.2 9.9 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.9

55PFL8007T/12 2.3 4-13 4-15 4.3 7.2 9.9 9.11 9.12 9.13 9.14 9.15 - 10.1 10.7 10.3 11.9

60PFL9607S/12 2.3 4-16 4-17 4.3 7.2 9.10 9.11 9.12 9.13 9.14 9.15 - 10.2 10.7 10.4 11.10

60PFL9607T/12 2.3 4-16 4-17 4.3 7.2 9.10 9.11 9.12 9.13 9.14 9.15 - 10.2 10.7 10.4 11.10

Connection Overview

Wire Dressing

Wire Dressing rear cover

Assembly Removal

Power Supply

Wiring Diagram

Video

Audio

Control & Clock

I2C

Supply lines

Power Supply

SSB

2.2 Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

J (Sensor Board)

E (Keyboard/Leading Edge)

Sheet

2012-Sep-14

back to

div. table

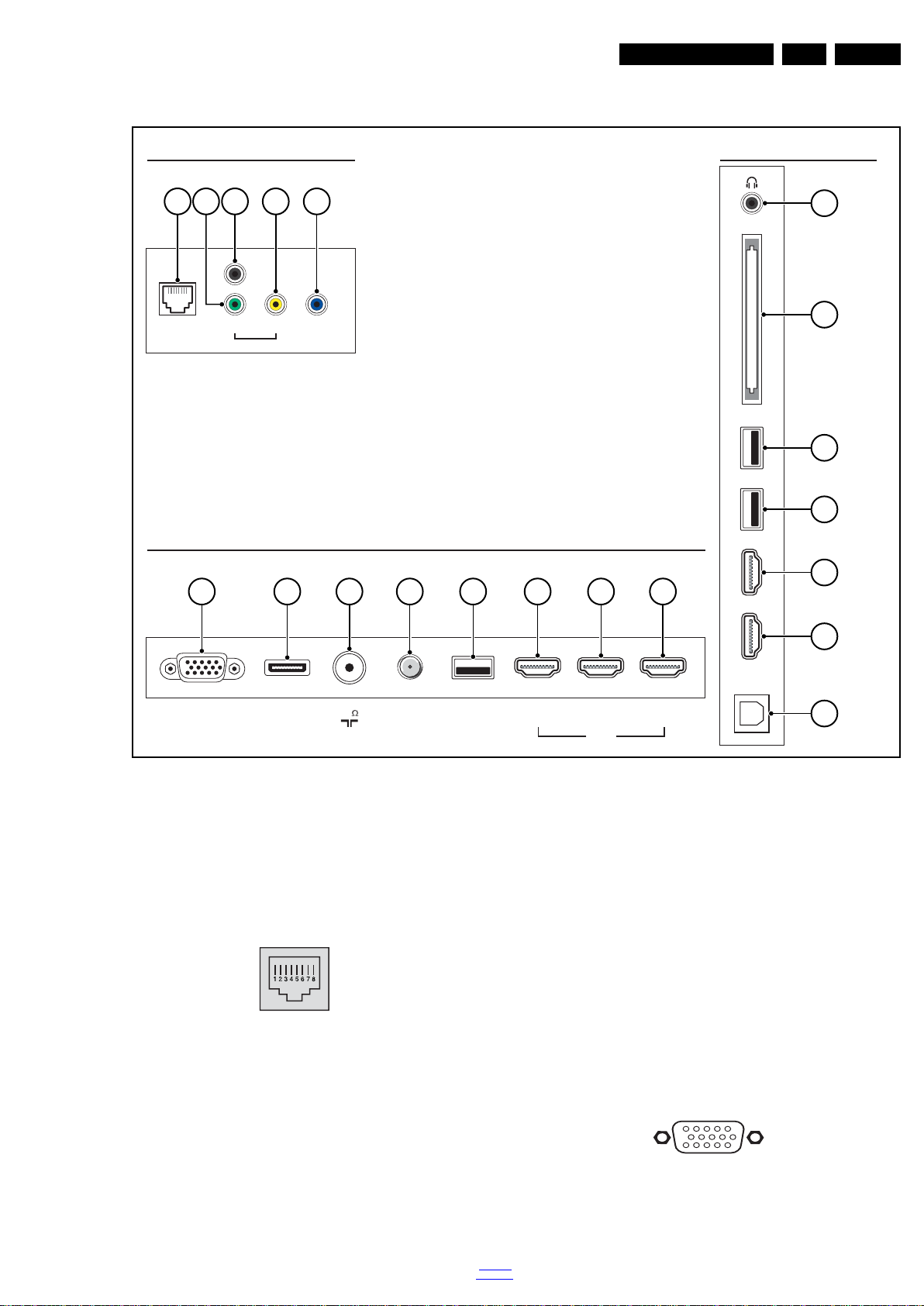

2.3 Connections

REAR CONNECTORS

BOTTOM REAR CONNECTORS

SIDE CONNECTORS

HDMI 4

HDMI 5

DIGITAL

AUDIO OUT

(OPTICAL)

USB 3

USB 2

CI

NETWORK L/RY/Pb/Pr

SERV.U

AUDIO IN

DVI/VGA

VGA SCART 75

(RGB/CVBS)

USB 1 (1) (2) (3)

HDMI

TV ANTENNA

SATELLITE

19210_062_120504.eps

120504

6 7 8 9 10 11 11 11

3 51 4

2

12

13

10

10

11

11

14

1

6

10

11

5

15

10000_002_090121.eps

090127

Technical Specs, Diversity, and Connections

EN 3QFU1.1E LA 2.

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, Ye= Yellow.

2.3.1 Connections

1 - RJ45: Ethernet

Figure 2-2 Ethernet connector

1 -TD+ Transmit signal k

2 -TD- Transmit signal k

3 -RD+ Receive signal j

4 -CT Centre Tap: DC level fixation

5 -CT Centre Tap: DC level fixation

6 -RD- Receive signal j

7 -GND Gnd H

8 -GND Gnd H

Figure 2-1 Connection overview (SATELLITE and HDMI5 are optional)

10000_025_090121.eps

120320

back to

div. table

2,4 - Cinch: Video YPbPr - In, Audio - In (via break-out cable)

Gn -Video Y 1 V

Bu -Video Pb 0.7 V

Rd - Video Pr 0.7 V

Rd - Audio - R 0.5 V

Wh -Audio - L 0.5 V

3 - Service Connector (UART)

1 -Ground Gnd H

2 -UART_TX Transmit k

3 -UART_RX Receive j

5 - Cinch: Audio - In (VGA/DVI)

Rd - Audio R 0.5 V

Wh -Audio L 0.5 V

6 - VGA: Video RGB - In

Figure 2-3 VGA Connector

1 -Video Red 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm j

PP

2012-Sep-14

EN 4 QFU1.1E LA2.

21

20

1

2

10000_001_090121.eps

090121

1 2 3 4

10000_022_090121.eps

090121

10000_017_090121.eps

090428

19

1

18 2

Technical Specs, Diversity, and Connections

2 -Video Green 0.7 VPP / 75 ohm j

3 -Video Blue 0.7 V

/ 75 ohm j

PP

4-n.c.

5 -Ground Gnd H

6 -Ground Red Gnd H

7 -Ground Green Gnd H

8 -Ground Blue Gnd H

9-+5V

+5 V j

DC

10 - Ground Sync Gnd H

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

7 - Video RGB - In, CVBS - In/Out, Audio - In/Out (via breakout cable)

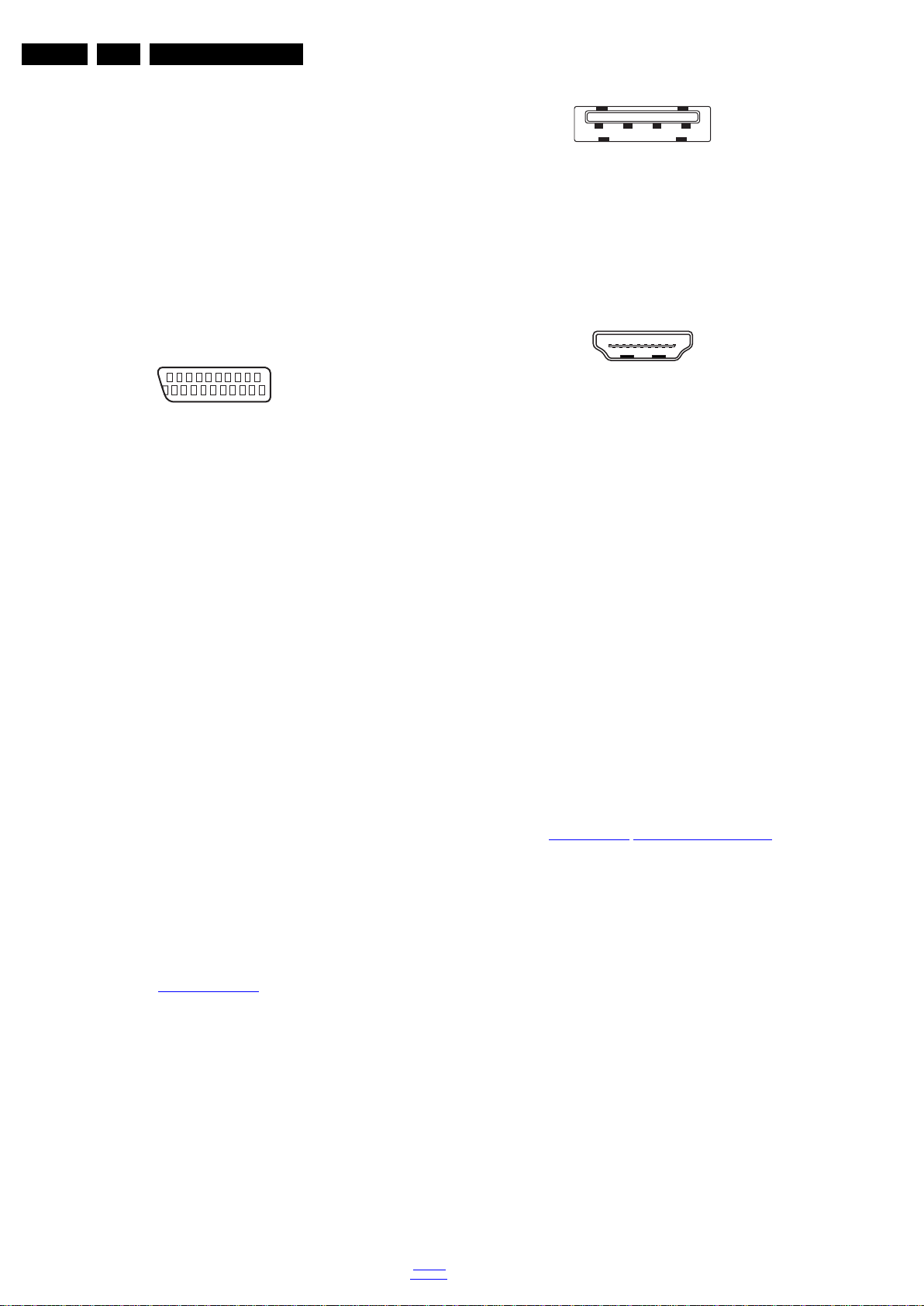

Figure 2-4 SCART connector

1 -Audio R 0.5 V

2 -Audio R 0.5 V

3 -Audio L 0.5 V

4 -Ground Audio Gnd H

/ 1 kohm k

RMS

/ 10 kohm j

RMS

/ 1 kohm k

RMS

5 -Ground Blue Gnd H

6 -Audio L 0.5 V

7 -Video Blue 0.7 V

/ 10 kohm j

RMS

/ 75 ohm jk

PP

8 -Function Select 0 - 2 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9 -Ground Green Gnd H

10 - n.c.

11 - Video Green 0.7 V

/ 75 ohm j

PP

12 - n.c.

13 - Ground Red Gnd H

14 - Ground P50 Gnd H

15 - Video Red 0.7 V

16 - Status/FBL 0 - 0.4 V: INT

/ 75 ohm j

PP

1 - 3 V: EXT / 75 ohm j

17 - Ground Video Gnd H

18 - Ground FBL Gnd H

19 - Video CVBS/Y 1 V

20 - Video CVBS 1 V

21 - Shield Gnd H

/ 75 ohm k

PP

/ 75 ohm j

PP

10 - USB2.0

Figure 2-5 USB (type A)

1-+5V k

2 -Data (-) jk

3 -Data (+) jk

4 -Ground Gnd H

11 - HDMI 1, 2, 3, 4, 5 (optional): Digital Video - In, Digital Audio with ARC - In/Out

Figure 2-6 HDMI (type A) connector

1 -D2+ Data channel j

2 -Shield Gnd H

3 -D2- Data channel j

4 -D1+ Data channel j

5 -Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8 -Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - Easylink/CEC Control channel jk

14 - ARC Audio Return Channel k

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

12 - Head phone (Output)

Bk -Head phone 32 - 600 ohm / 10 mW ot

13 - Common Interface

68p- See Figure 10-1-48

B07D, Common interface jk

8 - Aerial - In

- -IEC-type (EU) Coax, 75 ohm D

9 - SAT - In (optional)

- -F-type Coax, 75 ohm D

2.4 Chassis Overview

Refer to chapter 9. Block Diagrams for PWB/CBA locations.

2012-Sep-14

back to

div. table

14 - Cinch: S/PDIF - Out

Bk -Coaxial 0.4 - 0.6V

/ 75 ohm kq

PP

Precautions, Notes, and Abbreviation List

3. Precautions, Notes, and Abbreviation List

Index of this chapter:

3.1 Safety Instructions

3.2 Warnings

3.3 Notes

3.4 Abbreviation List

3.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 M and 12 M.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

3.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

3.3 Notes

3.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode with a colour bar signal and stereo

sound (L: 3 kHz, R: 1 kHz unless stated otherwise) and

picture carrier at 475.25 MHz for PAL, or 61.25 MHz for

NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

3.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 k).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220 ).

• All capacitor values are given in micro-farads (10

nano-farads (n 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed on the Philips

Spare Parts Web Portal.

3.3.3 Spare Parts

For the latest spare part overview, consult your Philips Spare

Part web portal.

3.3.4 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: http://www.atyourservice-magazine.com

“Magazine”, then go to “Repair downloads”. Here you will find

Information on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile.

Where applicable and available, this profile is added to the IC

Data Sheet information section in this manual.

3.3.5 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin. If lead-free solder paste is

required, please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

3.3.6 Alternative BOM identification

It should be noted that on the European Service website,

“Alternative BOM” is referred to as “Design variant”.

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

back to

div. table

-9

), or pico-farads (p 10

. Select

EN 5QFU1.1E LA 3.

-6

),

-12

).

2012-Sep-14

EN 6 QFU1.1E LA3.

10000_053_110228.eps

110228

Precautions, Notes, and Abbreviation List

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

SN is Lysomice, RJ is Kobierzyce), digit 3 refers to the B.O.M.

code, digit 4 refers to the Service version change code, digits 5

and 6 refer to the production year, and digits 7 and 8 refer to

production week (in example below it is 2010 week 10 / 2010

week 17). The 6 last digits contain the serial number.

Figure 3-1 Serial number (example)

3.3.7 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

3.3.8 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3.4 Abbreviation List

0/6/12 SCART switch control signal on A/V

board. 0 = loop through (AUX to TV),

6 = play 16 : 9 format, 12 = play 4 : 3

format

AARA Automatic Aspect Ratio Adaptation:

algorithm that adapts aspect ratio to

remove horizontal black bars; keeps

the original aspect ratio

ACI Automatic Channel Installation:

algorithm that installs TV channels

directly from a cable network by

means of a predefined TXT page

ADC Analogue to Digital Converter

AFC Automatic Frequency Control: control

signal used to tune to the correct

frequency

AGC Automatic Gain Control: algorithm that

controls the video input of the feature

box

AM Amplitude Modulation

AP Asia Pacific

AR Aspect Ratio: 4 by 3 or 16 by 9

ASF Auto Screen Fit: algorithm that adapts

aspect ratio to remove horizontal black

bars without discarding video

information

ATSC Advanced Television Systems

Committee, the digital TV standard in

the USA

ATV See Auto TV

Auto TV A hardware and software control

system that measures picture content,

and adapts image parameters in a

dynamic way

AV External Audio Video

AVC Audio Video Controller

AVIP Audio Video Input Processor

B/G Monochrome TV system. Sound

carrier distance is 5.5 MHz

BDS Business Display Solutions (iTV)

BLR Board-Level Repair

BTSC Broadcast Television Standard

Committee. Multiplex FM stereo sound

system, originating from the USA and

used e.g. in LATAM and AP-NTSC

countries

B-TXT Blue TeleteXT

C Centre channel (audio)

CEC Consumer Electronics Control bus:

remote control bus on HDMI

connections

CL Constant Level: audio output to

connect with an external amplifier

CLR Component Level Repair

ComPair Computer aided rePair

CP Connected Planet / Copy Protection

CSM Customer Service Mode

CTI Color Transient Improvement:

manipulates steepness of chroma

transients

CVBS Composite Video Blanking and

Synchronization

DAC Digital to Analogue Converter

DBE Dynamic Bass Enhancement: extra

low frequency amplification

DCM Data Communication Module. Also

referred to as System Card or

Smartcard (for iTV).

DDC See “E-DDC”

D/K Monochrome TV system. Sound

carrier distance is 6.5 MHz

DFI Dynamic Frame Insertion

DFU Directions For Use: owner's manual

DMR Digital Media Reader: card reader

DMSD Digital Multi Standard Decoding

DNM Digital Natural Motion

2012-Sep-14

back to

div. table

Precautions, Notes, and Abbreviation List

EN 7QFU1.1E LA 3.

DNR Digital Noise Reduction: noise

reduction feature of the set

DRAM Dynamic RAM

DRM Digital Rights Management

DSP Digital Signal Processing

DST Dealer Service Tool: special remote

control designed for service

technicians

DTCP Digital Transmission Content

Protection; A protocol for protecting

digital audio/video content that is

traversing a high speed serial bus,

such as IEEE-1394

DVB-C Digital Video Broadcast - Cable

DVB-T Digital Video Broadcast - Terrestrial

DVD Digital Versatile Disc

DVI(-d) Digital Visual Interface (d= digital only)

E-DDC Enhanced Display Data Channel

(VESA standard for communication

channel and display). Using E-DDC,

the video source can read the EDID

information form the display.

EDID Extended Display Identification Data

(VESA standard)

EEPROM Electrically Erasable and

Programmable Read Only Memory

EMI Electro Magnetic Interference

EPG Electronic Program Guide

EPLD Erasable Programmable Logic Device

EU Europe

EXT EXTernal (source), entering the set by

SCART or by cinches (jacks)

FDS Full Dual Screen (same as FDW)

FDW Full Dual Window (same as FDS)

FLASH FLASH memory

FM Field Memory or Frequency

Modulation

FPGA Field-Programmable Gate Array

FTV Flat TeleVision

Gb/s Giga bits per second

G-TXT Green TeleteXT

H H_sync to the module

HD High Definition

HDD Hard Disk Drive

HDCP High-bandwidth Digital Content

Protection: A “key” encoded into the

HDMI/DVI signal that prevents video

data piracy. If a source is HDCP coded

and connected via HDMI/DVI without

the proper HDCP decoding, the

picture is put into a “snow vision” mode

or changed to a low resolution. For

normal content distribution the source

and the display device must be

enabled for HDCP “software key”

decoding.

HDMI High Definition Multimedia Interface

HP HeadPhone

I Monochrome TV system. Sound

2

C Inter IC bus

I

2

I

D Inter IC Data bus

2

S Inter IC Sound bus

I

carrier distance is 6.0 MHz

IF Intermediate Frequency

IR Infra Red

IRQ Interrupt Request

ITU-656 The ITU Radio communication Sector

(ITU-R) is a standards body

subcommittee of the International

Telecommunication Union relating to

radio communication. ITU-656 (a.k.a.

SDI), is a digitized video format used

for broadcast grade video.

Uncompressed digital component or

digital composite signals can be used.

back to

div. table

The SDI signal is self-synchronizing,

uses 8 bit or 10 bit data words, and has

a maximum data rate of 270 Mbit/s,

with a minimum bandwidth of 135

MHz.

iTV Institutional TeleVision; TV sets for

hotels, hospitals etc.

LS Last Status; The settings last chosen

by the customer and read and stored

in RAM or in the NVM. They are called

at start-up of the set to configure it

according to the customer's

preferences

LATAM Latin America

LCD Liquid Crystal Display

LED Light Emitting Diode

L/L' Monochrome TV system. Sound

carrier distance is 6.5 MHz. L' is Band

I, L is all bands except for Band I

LPL LG.Philips LCD (supplier)

LS Loudspeaker

LVDS Low Voltage Differential Signalling

Mbps Mega bits per second

M/N Monochrome TV system. Sound

carrier distance is 4.5 MHz

MHEG Part of a set of international standards

related to the presentation of

multimedia information, standardised

by the Multimedia and Hypermedia

Experts Group. It is commonly used as

a language to describe interactive

television services

MIPS Microprocessor without Interlocked

Pipeline-Stages; A RISC-based

microprocessor

MOP Matrix Output Processor

MOSFET Metal Oxide Silicon Field Effect

Transistor, switching device

MPEG Motion Pictures Experts Group

MPIF Multi Platform InterFace

MUTE MUTE Line

MTV Mainstream TV: TV-mode with

Consumer TV features enabled (iTV)

NC Not Connected

NICAM Near Instantaneous Compounded

Audio Multiplexing. This is a digital

sound system, mainly used in Europe.

NTC Negative Temperature Coefficient,

non-linear resistor

NTSC National Television Standard

Committee. Color system mainly used

in North America and Japan. Color

carrier NTSC M/N= 3.579545 MHz,

NTSC 4.43= 4.433619 MHz (this is a

VCR norm, it is not transmitted off-air)

NVM Non-Volatile Memory: IC containing

TV related data such as alignments

O/C Open Circuit

OSD On Screen Display

OAD Over the Air Download. Method of

software upgrade via RF transmission.

Upgrade software is broadcasted in

TS with TV channels.

OTC On screen display Teletext and

Control; also called Artistic (SAA5800)

P50 Project 50: communication protocol

between TV and peripherals

PAL Phase Alternating Line. Color system

mainly used in West Europe (colour

carrier = 4.433619 MHz) and South

America (colour carrier

PAL M = 3.575612 MHz and

PAL N = 3.582056 MHz)

PCB Printed Circuit Board (same as “PWB”)

PCM Pulse Code Modulation

2012-Sep-14

EN 8 QFU1.1E LA3.

Precautions, Notes, and Abbreviation List

PDP Plasma Display Panel

PFC Power Factor Corrector (or Pre-

conditioner)

PIP Picture In Picture

PLL Phase Locked Loop. Used for e.g.

FST tuning systems. The customer

can give directly the desired frequency

POD Point Of Deployment: a removable

CAM module, implementing the CA

system for a host (e.g. a TV-set)

POR Power On Reset, signal to reset the uP

PSDL Power Supply for Direct view LED

backlight with 2D-dimming

PSL Power Supply with integrated LED

drivers

PSLS Power Supply with integrated LED

drivers with added Scanning

functionality

PTC Positive Temperature Coefficient,

non-linear resistor

PWB Printed Wiring Board (same as “PCB”)

PWM Pulse Width Modulation

QRC Quasi Resonant Converter

QTNR Quality Temporal Noise Reduction

QVCP Quality Video Composition Processor

RAM Random Access Memory

RGB Red, Green, and Blue. The primary

color signals for TV. By mixing levels

of R, G, and B, all colors (Y/C) are

reproduced.

RC Remote Control

RC5 / RC6 Signal protocol from the remote

control receiver

RESET RESET signal

ROM Read Only Memory

RSDS Reduced Swing Differential Signalling

data interface

R-TXT Red TeleteXT

SAM Service Alignment Mode

S/C Short Circuit

SCART Syndicat des Constructeurs

d'Appareils Radiorécepteurs et

SCL Serial Clock I

Téléviseurs

SCL-F CLock Signal on Fast I

SD Standard Definition

SDA Serial Data I

SDA-F DAta Signal on Fast I

2

C

2

C bus

2

C

2

C bus

SDI Serial Digital Interface, see “ITU-656”

SDRAM Synchronous DRAM

SECAM SEequence Couleur Avec Mémoire.

Colour system mainly used in France

and East Europe. Colour

carriers = 4.406250 MHz and

4.250000 MHz

SIF S ound Intermediate Frequency

SMPS Switched Mode Power Supply

SoC System on Chip

SOG Sync On Green

SOPS Self Oscillating Power Supply

SPI Serial Peripheral Interface bus; a 4-

wire synchronous serial data link

standard

S/PDIF Sony Philips Digital InterFace

SRAM Static RAM

SRP Service Reference Protocol

SSB Small Signal Board

SSC Spread Spectrum Clocking, used to

reduce the effects of EMI

STB Set Top Box

STBY STand-BY

SVGA 800 × 600 (4:3)

SVHS Super Video Home System

SW Software

SWAN Spatial temporal Weighted Averaging

Noise reduction

SXGA 1280 × 1024

TFT Thin Film Transistor

THD Total Harmonic Distortion

TMDS Transmission Minimized Differential

Signalling

TS Transport Stream

TXT TeleteXT

TXT-DW Dual Window with TeleteXT

UI User Interface

uP Microprocessor

UXGA 1600 × 1200 (4:3)

V V-sync to the module

VESA Video Electronics Standards

Association

VGA 640 × 480 (4:3)

VL Variable Level out: processed audio

output toward external amplifier

VSB Vestigial Side Band; modulation

method

WYSIWYR What You See Is What You Record:

record selection that follows main

picture and sound

WXGA 1280 × 768 (15:9)

XTAL Quartz crystal

XGA 1024 × 768 (4:3)

Y Luminance signal

Y/C Luminance (Y) and Chrominance (C)

signal

YPbPr Component video. Luminance and

scaled color difference signals (B-Y

and R-Y)

YUV Component video

2012-Sep-14

back to

div. table

4. Mechanical Instructions

19210_069_120504.eps

120504

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

4.1 Cable Dressing

Mechanical Instructions

EN 9QFU1.1E LA 4.

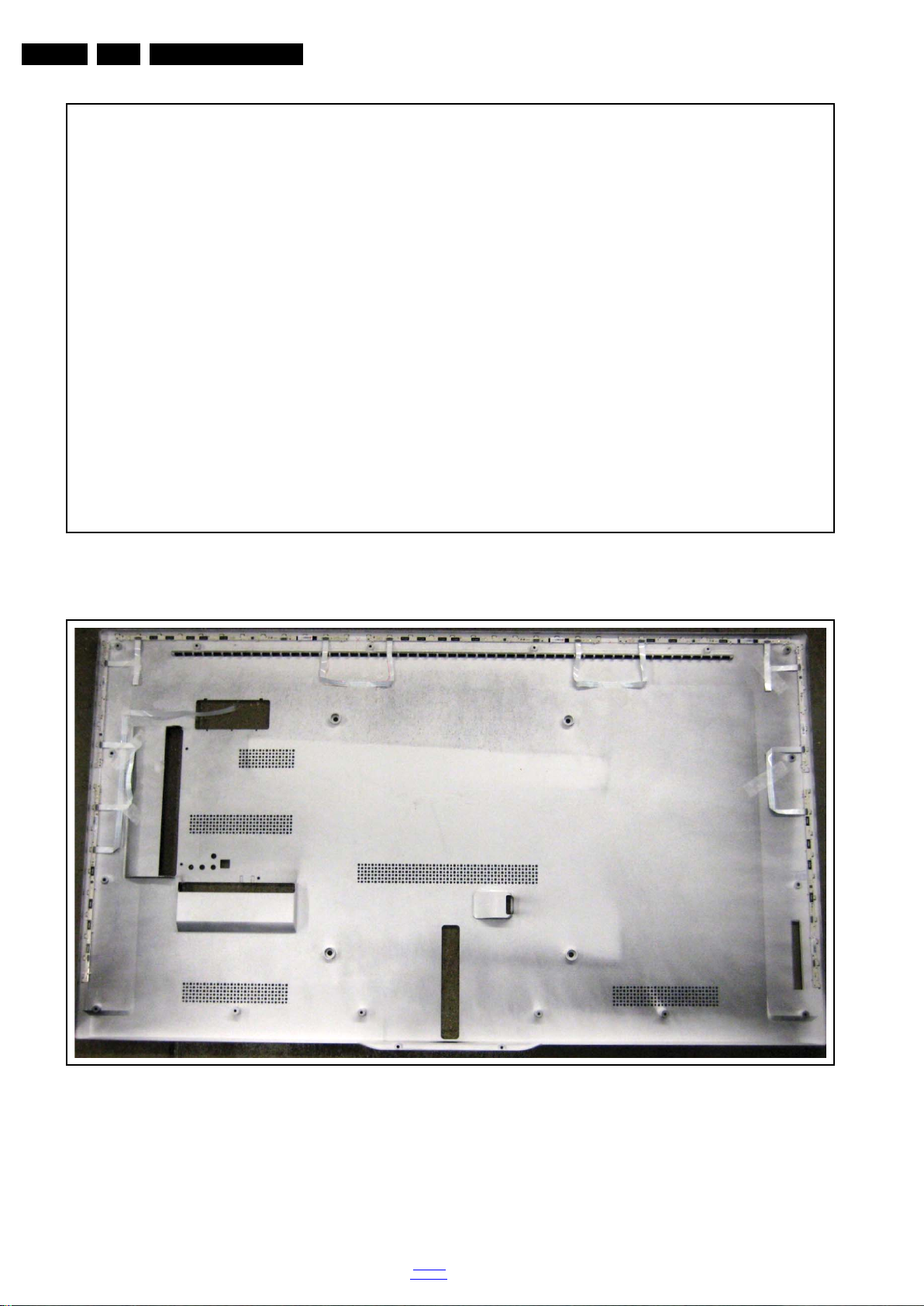

Figure 4-1 Cable dressing 40" 7000/8000 series

back to

div. table

2012-Sep-14

EN 10 QFU1.1E LA4.

19210_070_120504.eps

120504

19210_071_120504.eps

120504

Mechanical Instructions

Figure 4-2 Cable dressing 40" rear cover 7000 series

2012-Sep-14

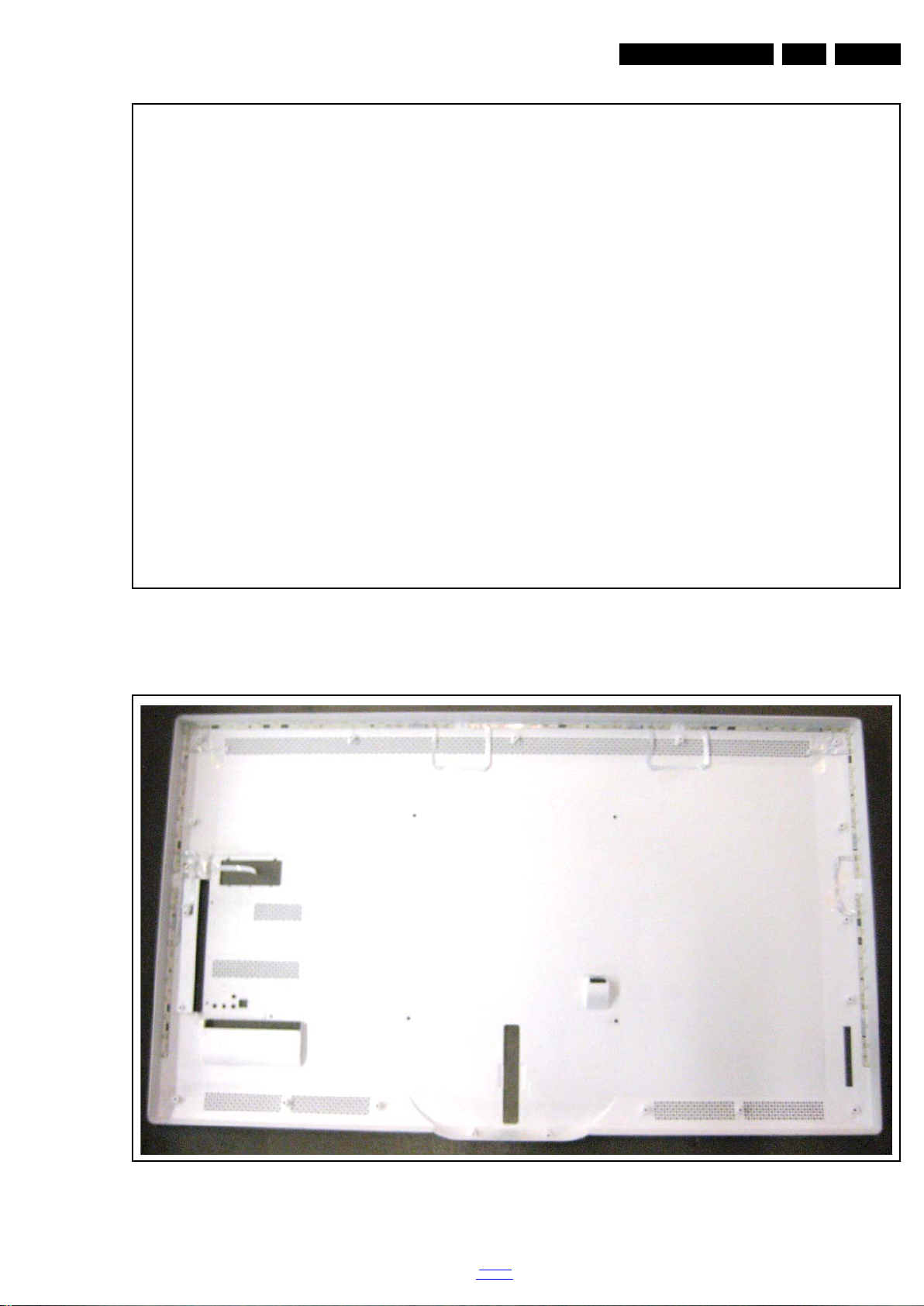

Figure 4-3 Cable dressing 40" rear cover 8000 series

back to

div. table

Mechanical Instructions

19212_001_120912.eps

120912

19212_002_120912.eps

120912

EN 11QFU1.1E LA 4.

Figure 4-4 Cable dressing 42" 6900 series

Figure 4-5 Cable dressing 42" rear cover 6900 series

back to

div. table

2012-Sep-14

EN 12 QFU1.1E LA4.

19210_072_120504.eps

120504

19210_073_120504.eps

120504

Mechanical Instructions

Figure 4-6 Cable dressing 46" 7000/8000 series

2012-Sep-14

Figure 4-7 Cable dressing 46" rear cover 7000 series

back to

div. table

Mechanical Instructions

19210_074_120504.eps

120504

19212_003_120912.eps

120912

EN 13QFU1.1E LA 4.

Figure 4-8 Cable dressing 46" rear cover 8000 series

Figure 4-9 Cable dressing 46" 9707 series

back to

div. table

2012-Sep-14

EN 14 QFU1.1E LA4.

19212_004_120912.eps

120912

19212_005_120912.eps

120912

Mechanical Instructions

Figure 4-10 Cable dressing 46" rear cover 9707 series

2012-Sep-14

Figure 4-11 Cable dressing 47" 6900 series

back to

div. table

Mechanical Instructions

19212_006_120912.eps

120912

19210_103_120516.eps

120516

EN 15QFU1.1E LA 4.

Figure 4-12 Cable dressing 47" rear cover 6900 series

Figure 4-13 Cable dressing 55" 7000/8000 series

back to

div. table

2012-Sep-14

EN 16 QFU1.1E LA4.

19210_104_120516.eps

120516

Not available

19210_105_120516.eps

120516

Mechanical Instructions

Figure 4-14 Cable dressing 55" rear cover 7000 series

2012-Sep-14

Figure 4-15 Cable dressing 55" rear cover 8000 series

back to

div. table

Mechanical Instructions

19212_007_120912.eps

120912

19212_008_120912.eps

120912

EN 17QFU1.1E LA 4.

Figure 4-16 Cable dressing 60" 9607 series

Figure 4-17 Cable dressing 60" rear cover 9607 series

back to

div. table

2012-Sep-14

EN 18 QFU1.1E LA4.

19300_054_120418.eps

120418

3

3

4

4

4

3

19054_001_111010.eps

111010

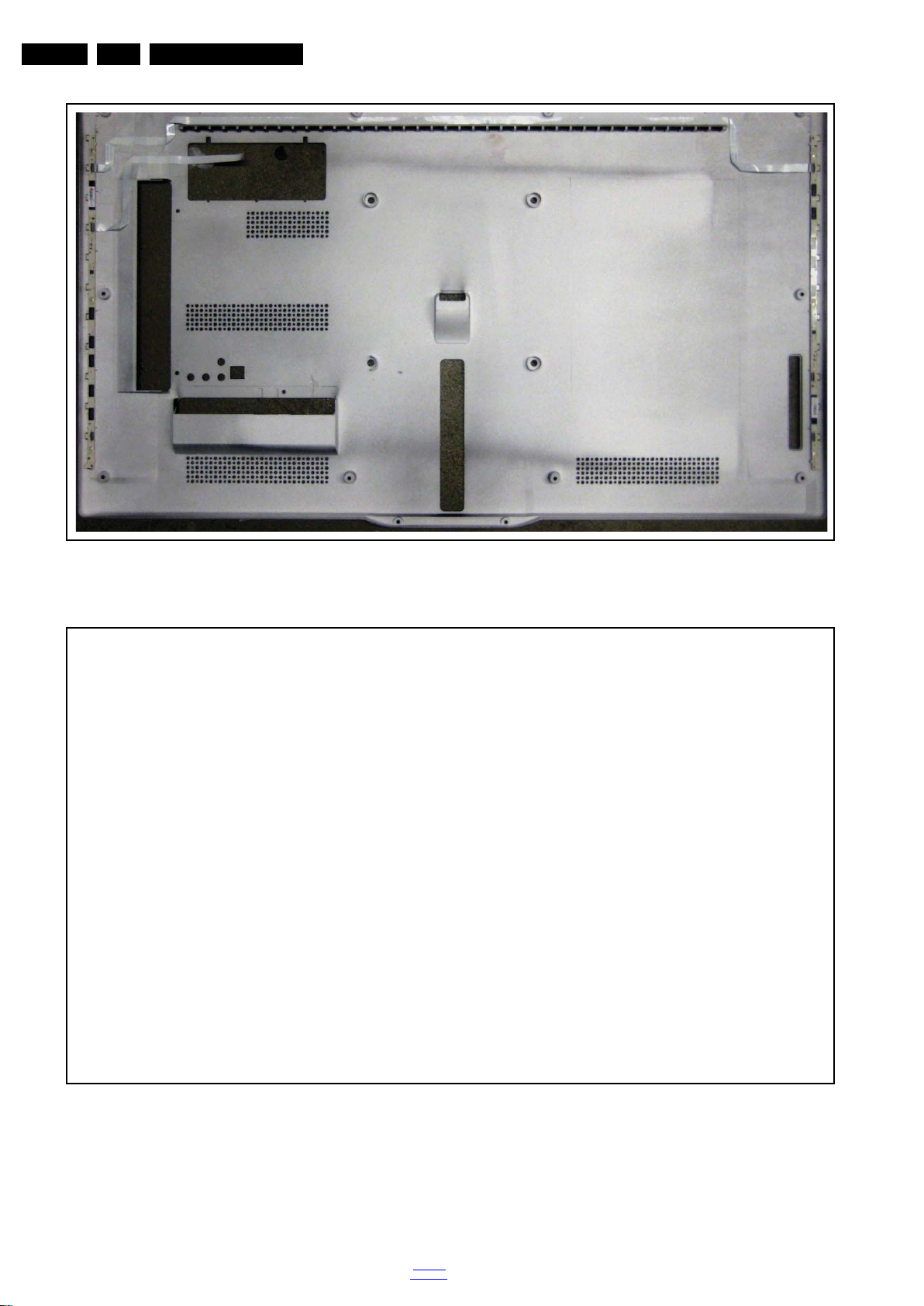

4.2 Se rvice Positions

For easy servicing of a TV set, the set should be put face down

on a soft flat surface, foam buffers or other specific workshop

tools. Ensure that a stable situation is created to perform

measurements and alignments. When using foam bars take

care that these always support the cabinet and never only the

display. Caution: Failure to follow these guidelines can

seriously damage the display!

Ensure that ESD safe measures are taken.

4.3.1 Rear Cover

Warning: Disconnect the mains power cord before removing

the rear cover.

Attention: All sets are equipped with a hatch to disconnect the

keyboard control panel. Ambilight sets are in addition equipped

with a hatch to disconnect the Ambilight units.

These hatches are indicated on the rear cover with

SERVICE h.

It is mandatory to open the hatches and disconnect the

cables prior to removal of the rear cover!

See Figure 4-18

1. For sets equipped with Ambilight: open the hatch that

covers the Ambilight connector and unplug the connector

[1].

2. Remove the hatch that covers the keyboard control panel

connector by removing the screws [3].

3. For sets equipped with Ambilight: remove the stand and

swivel block [4].

4. Unplug the keyboard control panel connector located

underneath the keyboard control hatch.

5. Remove remaining fixation screws.

6. Lift the rear cover from the TV. Make sure that wires and

flat foils are not damaged while lifting the rear cover from

the set.

and Figure 4-19 for details.

Mechanical Instructions

4.3 Assy/Panel Removal

Figure 4-19 Rear cover removal -all models -2-

4.3.2 SSB

19300_053_120418.eps

Figure 4-18 Rear cover removal -all models -1-

1

120418

Refer to Figure 4-20

and Figure 4-21 for details.

Some SSBs have a dedicated LVDS connector, requiring

pressing two catches as indicated in the figure, before

removing the LVDS cable.

Figure 4-20 SSB LVDS connector catches (optional) -1-

Upon re-connecting the LVDS cable, ensure the catches are

locked after having inserted the LVDS cable.

2012-Sep-14

back to

div. table

Figure 4-21 SSB LVDS connector catches (optional) -2-

19222_001_120626.eps

120626

Click!

LVDS flat foil

Click!

19210_089_120509.eps

120509

Mechanical Instructions

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position.

• Pay special attention not to damage the EMC foams in the

set. Ensure that EMC foams are mounted correctly.

EN 19QFU1.1E LA 4.

Underneath the SSB an adhesive heat path is located.

Refer to Figure 4-22

for details.

After board swap, it should be located at the correct position.

Figure 4-22 SSB adhesive heath path

back to

div. table

2012-Sep-14

EN 20 QFU1.1E LA5.

19210_082_120507.eps

120507

SDM

19210_083_120507.eps

120507

SDM

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Start-up

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Fault Finding and Repair Tips

5.9 Software Upgrading

5.1 Test Points

As most signals are digital, it will be difficult to measure

waveforms with a standard oscilloscope. However, several key

ICs are capable of generating test patterns, which can be

controlled via ComPair. In this way it is possible to determine

which part is defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default mode (SDM) and Service Alignment Mode

(SAM) offers several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between the call centre and the customer.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it “off”, push the “MENU” (or

"HOME") button again.

Analogue SDM can also be activated by grounding the

solder path on the SSB, with the indication “SDM” (see

figures Service mode pad - front

back.

• Digital SDM: use the RC-transmitter and key in the code

“062593”, directly followed by the “MENU” (or "HOME")

button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it “off”, push the “MENU” (or

"HOME") button again.

) and Service mode pad -

This chassis also offers the option of using ComPair, a

hardware interface between a computer and the TV chassis. It

offers the abilities of structured troubleshooting, error code

reading, and software version read-out for all chassis.

(see also section “5.4.1 ComPair

”).

Note: For the new model range, a new remote control (RC) is

used with some renamed buttons. This has an impact on the

activation of the Service modes. For instance the old “MENU”

button is now called “HOME” (or is indicated by a “house” icon).

5.2.1 Service Default Mode (SDM)

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections detected by the standby

processor and make the TV start up to the step just before

protection. See section “5.3 Start-up

”.

• To start the blinking LED procedure where only LAYER 2

errors are displayed. (see also section “5.5 Error Codes

Specifications

Table 5-1 SDM default settings

Region Freq. (MHz) Default system

Europe, AP(PAL/Multi) 475.25 PAL B/G

Europe, AP DVB-T 546.00 PID Video: 0B

06 PID PCR: 0B 06 PID

Audio: 0B 07

• All picture settings at 50% (brightness, colour, contrast).

• Sound volume at 25%.

How to Activate SDM

For this chassis there are two kinds of SDM: an analogue SDM

and a digital SDM. Tuning will happen according Table 5-1

• Analogue SDM: use the RC-transmitter and key in the

code “062596”, directly followed by the “MENU” (or

“HOME”) button.

2012-Sep-14

DVB-T

”).

.

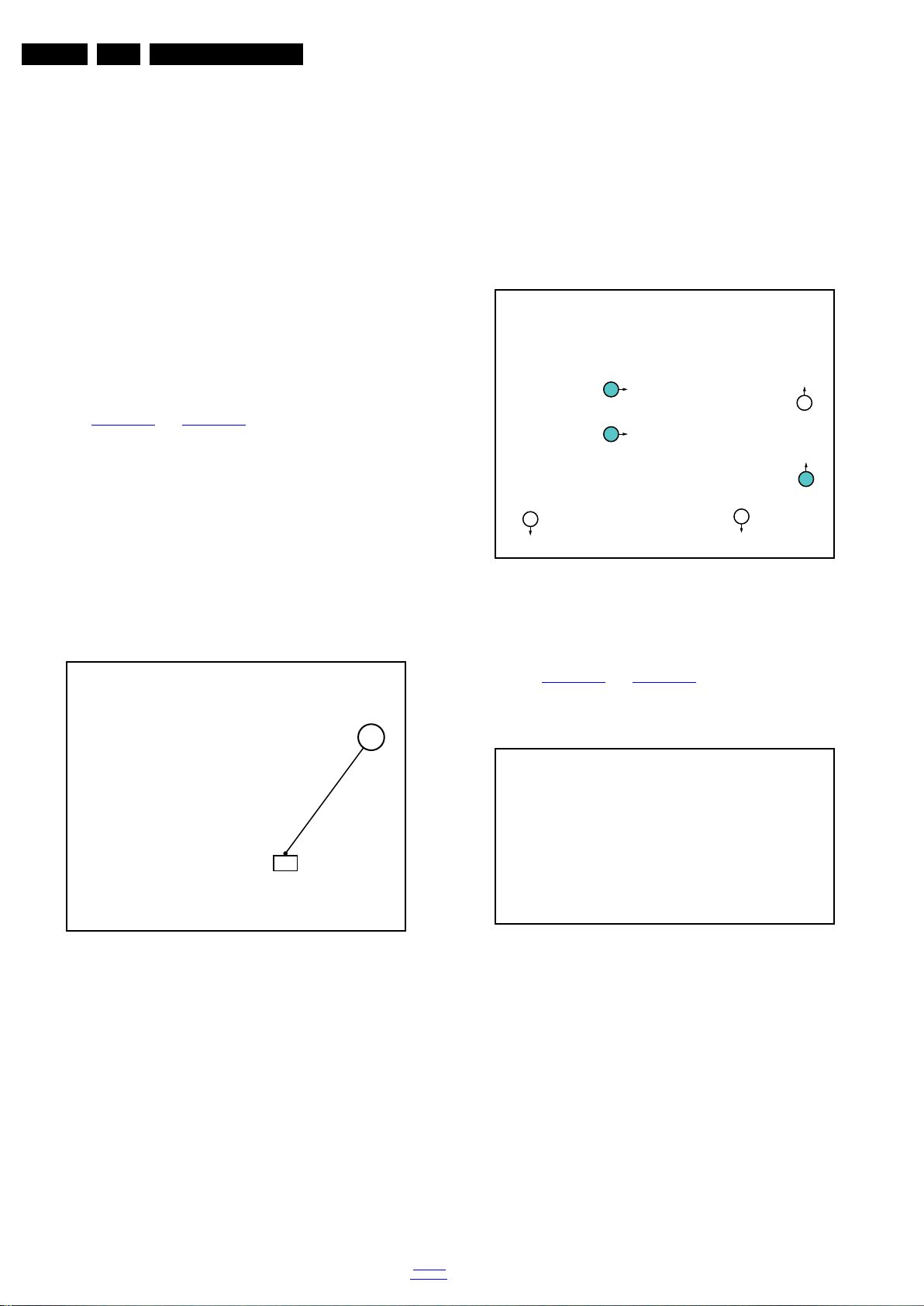

Figure 5-1 Service mode pad - front

Figure 5-2 Service mode pad - back

After activating this mode, “SDM” will appear in the upper right

corner of the screen (when a picture is available).

How to Exit SDM

Use one of the following methods:

• Switch the set to STANDBY via the RC-transmitter.

• Via a standard customer RC-transmitter: key in “00”sequence.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

back to

div. table

10000_038_090121.eps

090819

PHILIPS

MODEL:

32PF9968/10

PROD.SERIAL NO:

AG 1A0620 000001

040

39mm

27mm

(CTN Sticker)

Display Option

Code

Service Modes, Error Codes, and Fault Finding

EN 21QFU1.1E LA 5.

How to Activate SAM

Via a standard RC transmitter: Key in the code “062596”

directly followed by the “INFO” or “OK” button. After activating

SAM with this method a service warning will appear on the

screen, continue by pressing the “OK” button on the RC.

Contents of SAM

• Hardware Info.

– A. SW Version. Displays the software version of the

main software (example: QF1XX-1.2.3.4 =

AAABB_X.Y.W.Z).

• AAA= the chassis name.

• BB= Product ID.

• X.Y.W.Z= the software version, where X is the

main version number (different numbers are not

compatible with one another) and Y.W.Z is the sub

version number (a higher number is always

Figure 5-3 Location of Display Option Code sticker

compatible with a lower number).

– B. Standby processor version. Displays the software

version of the standby processor.

– C. Production Code. Displays the production code of

the TV, this is the serial number as printed on the back

of the TV set. Note that if an NVM is replaced or is

initialized after corruption, this production code has to

be re-written to NVM. The update can be done via the

NVM editor available in SAM.

• Operation hours. Displays the accumulated total of

operation hours (not the standby hours). Every time the TV

is switched “on/off”, 0.5 hours is added to this number.

• Errors (followed by maximum 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see section “5.5 Error Codes

”).

• Reset Error Buffer. When “cursor right” (or “OK” button)

pressed here, followed by the “OK” button, the error buffer

is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu. See Chapter 6. Alignments

.

• Options numbers. Extra features for Service. For more

info regarding option codes, see chapter 6. Alignments

.

Note that if the option code numbers are changed, these

have to be confirmed with pressing the “OK” button before

the options are stored, otherwise changes will be lost.

• Initialise NVM. The moment the processor recognizes a

corrupted NVM, the “initialise NVM” line will be highlighted.

Now, two things can be done (dependent of the service

instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initializing. This will give

the Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialise the NVM.

• Store - go right. All options and alignments are stored

when pressing “cursor right” or the “OK” button.

• Software maintenance.

– SW Events. In case of specific software problems, the

development department can ask for this info.

– HW Events. In case of specific software problems, the

development department can ask for this info :

- Event 26: refers to a power dip, this is logged after

the TV set reboots due to a power dip.

- Event 17: refers to the power OK status, sensed even

before the 3 x retry to generate the error code.

• Test settings. For development purposes only.

• RF4CE pairing tables. Clear paired remote control. Repairing (coldboot of platform possibly needed) can be done

by pressing the red/blue hot keys simultaneously for a few

seconds.(be sure the distance between the remote control

and TV set RF4CE receiver is less then 30cm). Message

like “Pairing successful”, confirms the match-make.

• Development 1 file versions. Not useful for Service

purposes, this information is mainly used by the

development department.

• Development 2 file versions. Not useful for Service

purposes, this information is mainly used by the

development department.

• Upload to USB. To upload several settings from the TV to

an USB stick, which is connected to the SSB. The items are

“Personal settings”, “Option codes”, “Alignments”,

“Identification data” (includes the set type and prod code +

all 12NC like SSB, display, boards), “History list”. The “All”

item supports the upload of all several items at once.

A directory “repair\” will be created in the root of the

USB stick.

To upload the settings, select each item separately, press

“cursor right” (or the “OK” button), confirm with “OK” and

Note: When the NVM is corrupted, or replaced, there is a high

possibility that no picture appears because the display code is

not correct. So, before initializing the NVM via the SAM, a

picture is necessary and therefore the correct display option

has to be entered. Refer to Chapter 6. Alignments

for details.

To adapt this option, it’s advised to use ComPair (the correct

values for the options can be found in Chapter 6. Alignments

)

or a method via a standard RC (described below).

Changing the display option via a standard RC: Key in the

code “062598” directly followed by the “MENU” (or "HOME")

button and “XXX” (where XXX is the 3 digit decimal display

code as mentioned on the sticker in the set). Make sure to key

in all three digits, also the leading zero’s. If the above action is

successful, the front LED will go out (Standby) as an indication

that the RC sequence was correct. After the display option is

changed in the NVM, the TV will go to the Standby mode. If the

NVM was corrupted or empty before this action, it will be

initialized first (loaded with default values). This initializing can

take up to 20 seconds.

wait until the message “Done” appears. In case the

download to the USB stick was not successful, “Failure” will

be displayed. In this case, check if the USB stick is

connected properly and if the directory “repair” is present in

the root of the USB stick. Now the settings are stored onto

the USB stick and can be used to download into another TV

or other SSB. Uploading is of course only possible if the

software is running and preferably a picture is available.

This method is created to be able to save the customer’s

TV settings and to store them into another SSB.

Important remark : to upload the “channel list”, select

“Home” => “Setup” => “TV settings” => “General settings”

=> “Channel list copy” => “Copy to USB”.The procedure is

also described in the (electronic) user manual.

• Download from USB. To download several settings from

the USB stick to the TV, same way of working needs to be

followed as described in “Upload to USB”. The “All” item

supports to download all several items at once.

Important remark : to download the “channel list”, select

“Home” => “Setup” => “TV settings” => “General settings”

=> “Channel list copy” => “Copy to TV”. The procedure is

also described in the (electronic) user manual.

• NVM editor. For Smart TV the set “Type number” must be

back to

div. table

2012-Sep-14

EN 22 QFU1.1E LA5.

Service Modes, Error Codes, and Fault Finding

entered correctly.

Also the “Production code” (factory location code), “12NC

SSB”, “12NC display” and “12NC supply” can be entered

here via the RC-transmitter.Be sure the cursor is put fully

to the left (use back key) of the dialog box before enter the

new data.

Correct data can be found on the side/rear sticker.

How to Navigate

• In SAM, the menu items can be selected with the

“CURSOR UP/DOWN” key on the RC-transmitter. The

selected item will be highlighted. When not all menu items

fit on the screen, move the “CURSOR UP/DOWN” key to

display the next/previous menu items.

• With the “CURSOR LEFT/RIGHT” keys, it is possible to:

– (De) activate the selected menu item.

– (De) activate the selected sub menu.

• With the “OK” key, it is possible to activate the selected

action.

How to Exit SAM

Use one of the following methods:

• Switch the TV set to STAND-BY via the RC-transmitter.

• Via a standard RC-transmitter, key in “00” sequence, or

select the “BACK” key.

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Helpdesk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

Provided CSM is activated, every menu from CSM can be used

as check for the back end chain video.So for all CSM content

displayed, it could be determined that the back end video chain

is working.

When CSM is activated and there is a USB stick connected to

the TV set, the software will dump the CSM content to the USB

stick. The file (CSM_model number_serial number.txt) will be

saved in the root of the USB stick. This info can be handy if no

information is displayed.

Additional in CSM mode (with USB stick connected), pressing

“OK” will create an extended CSM dump file on the USB stick.

This file (Extended_CSM_model number_serial number.txt)

contains:

• The normal CSM dump information,

• All items (from SAM “load to USB”, but in readable format),

• Operating hours,

• Error codes,

• SW/HW event logs.

To have fast feedback from the field, a flashdump can be

requested by development. When in CSM, push the “red”

button and key in serial digits ‘2679’ (same keys to form the

word ‘COPY’ with a cellphone). A file “Dump_model

number_serial number.bin” will be written on the connected

USB device. This can take 1/2 minute, depending on the

quantity of data that needs to be dumped.

Also when CSM is activated, the LAYER 1 error is displayed via

blinking LED.(see also section 5.5 Error Codes

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

2012-Sep-14

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to Navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter, can be navigated through the menus.

Contents of CSM

The contents are reduced to 3 pages: General, Software

versions and Quality items. The group names itself are not

shown anywhere in the CSM menu.

General

• Set type. This information is very helpful for a helpdesk/

workshop as reference for further diagnosis. In this way, it

is not necessary for the customer to look at the rear of the

TV set. Note that if an NVM is replaced or is initialized after

corruption, the set type content has to be re-written to

NVM.The update can be done via the NVM editor available

in SAM.

• Production code. Displays the production code (the serial

number) of the TV. Note that if an NVM is replaced or is

initialized after corruption, the production code content has

to be re-written to NVM. The update can be done via the

NVM editor available in SAM.

• Installed date. Indicates the date of the first installation of

the TV. This date is acquired by time extraction.

• Options 1. Displays the option codes numbers of option

group 1 as set in SAM (Service Alignment Mode).

• Options 2. Displays the option codes numbers of option

group 2 as set in SAM (Service Alignment Mode).

• 12NC SSB. Gives an identification of the SSB as stored in

NVM. Note that if an NVM is replaced or is initialized after

corruption, this identification number has to be re-written to

NVM. The update can be done via the NVM editor available

in SAM. This identification number is the 12nc number of

the SSB.

• 12NC display. Shows the 12NC of the display. Note that if

an NVM is replaced or is initialized after corruption, this

identification number has to be re-written to NVM. The

update can be done via the NVM editor available in SAM.

• 12NC supply. Shows the 12NC of the power supply. Note

that if an NVM is replaced or is initialized after corruption,

this identification number has to be re-written to NVM. The

update can be done via the NVM editor available in SAM.

• 12NC RF4CE board. Shows the 12NC of the RF4CE

board.

Software versions

• Current main software. Displays the build-in main

software version. In case of field problems related to

software, software can be upgraded. As this software is

consumer upgradeable, it will also be published on the

Internet.

Example: QF1xx-1.2.3.4

• Standby software. Displays the build-in standby

processor software version. Upgrading this software will be

possible via USB (see section 5.9 Software Upgrading

).

Example: STDBY_61.0.0.7

• e-UM version. Displays the electronic user manual SWversion (12NC version number). Most significant number

here is the last digit.

• Strings database version. Reflects the latest embedded

string database version .

• FPGA video version.Displays the Scan/backlight FPGA

software version.Device processes the backlight + boost

pwm control, scanning, 3D drive and ambilight buffering.

• 3D dongle software version.Not applicable.

• FRC-V software.Not applicable.

).

• RF4CE software.Embedded software version located on

the RF4CE board.

• FPGA lattice backlight software.

• FPGA HDR software.

back to

div. table

Service Modes, Error Codes, and Fault Finding

19210_076_120504.eps

120504

Active

Off

On

Semi

St by

St by

Mains

on

Mains

off

GoToProtection

-WakeUp requested

-Acquisition needed

- stby requested and

no data Acquisition

required

St by

requested

WakeUp

requested

Protection

WakeUp

requested

(SDM)

GoToProtection

GoToProtection

(triggered during startup

by standby µP)

EN 23QFU1.1E LA 5.

Quality items

• Signal quality. Bad / average /good (not for DVB-S).

• Ethernet MAC address. Displays the MAC address

present in the SSB.

• Wireless MAC address. Displays the wireless MAC

address to support the Wi-Fi functionality.

• BDS key. Indicates if the set is in the BDS status.

• CI module. Displays status if the common interface

module is detected.

• CI + protected service. Yes/No.

• Event counter :

S : 000X 0000(number of software recoveries : SW

EVENT-LOG #(reboots)

S : 0000 000X (number of software events : SW EVENTLOG #(events)

H : 000X 0000(number of hardware errors)

H : 0000 000X (number of hardware events : SW EVENTLOG #(events).

• Coldboot counter. Neglect “BDS mode settings”

• Fastcoldboot counter. Neglect “BDS mode settings”

• Hotboot counter. Neglect “BDS mode settings”

• Application hotboot counter. Neglect “BDS mode

settings”

How to Exit CSM

Press “MENU” (or "HOME") / “Back” key on the RC-transmitter.

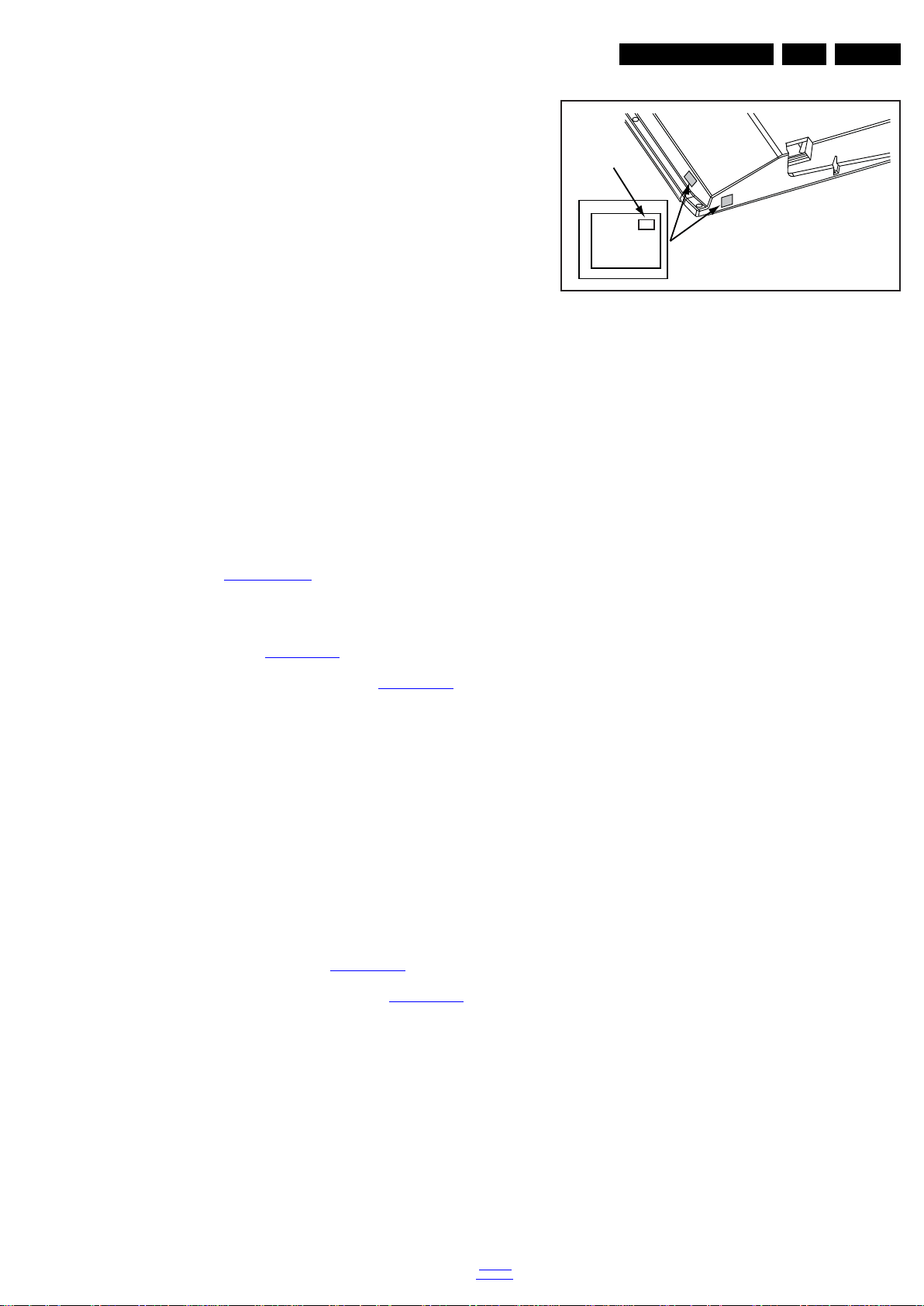

5.3 Start-up

As described, the start-up diagrams below, documents which

supplies are present at any certain moment.

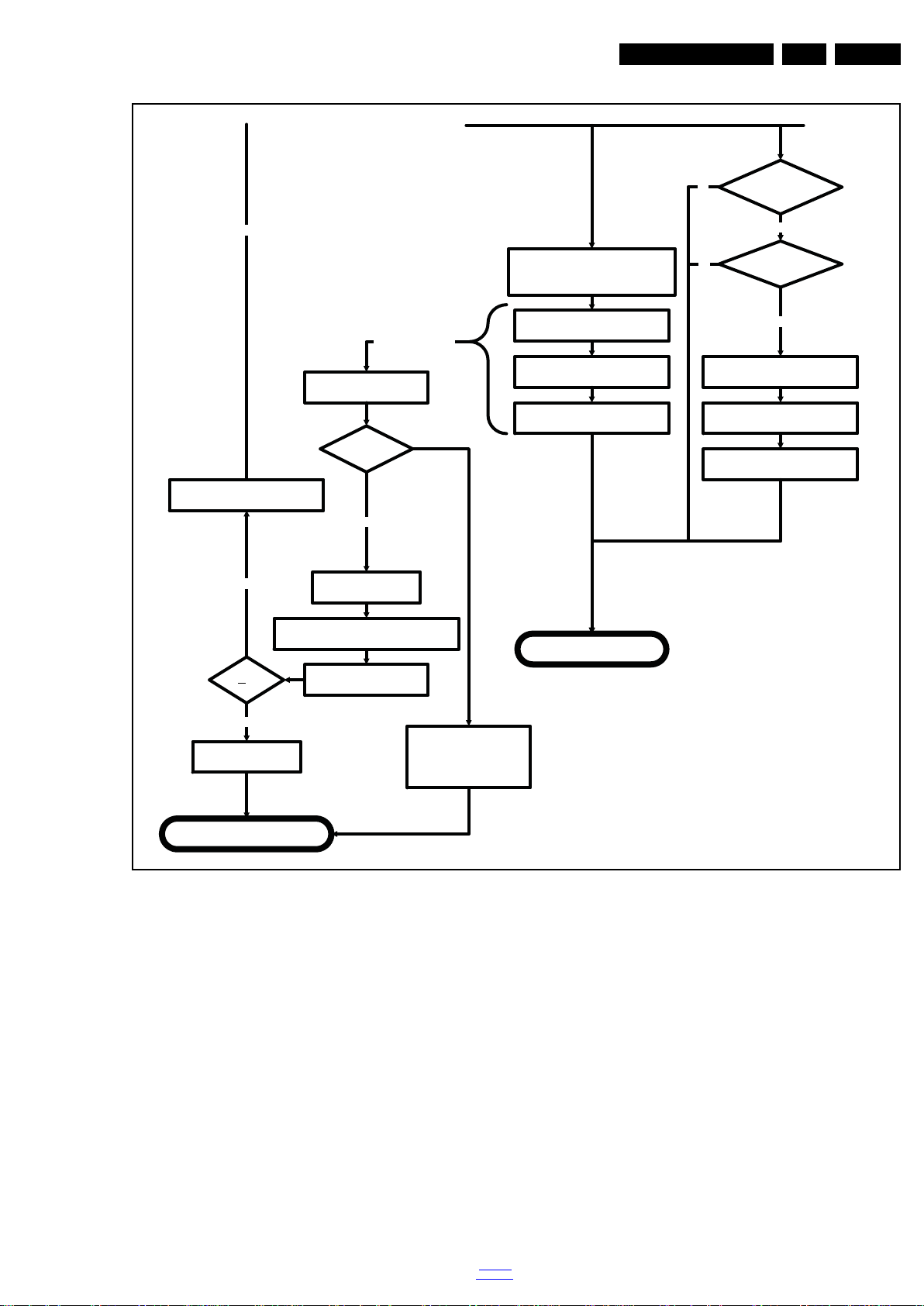

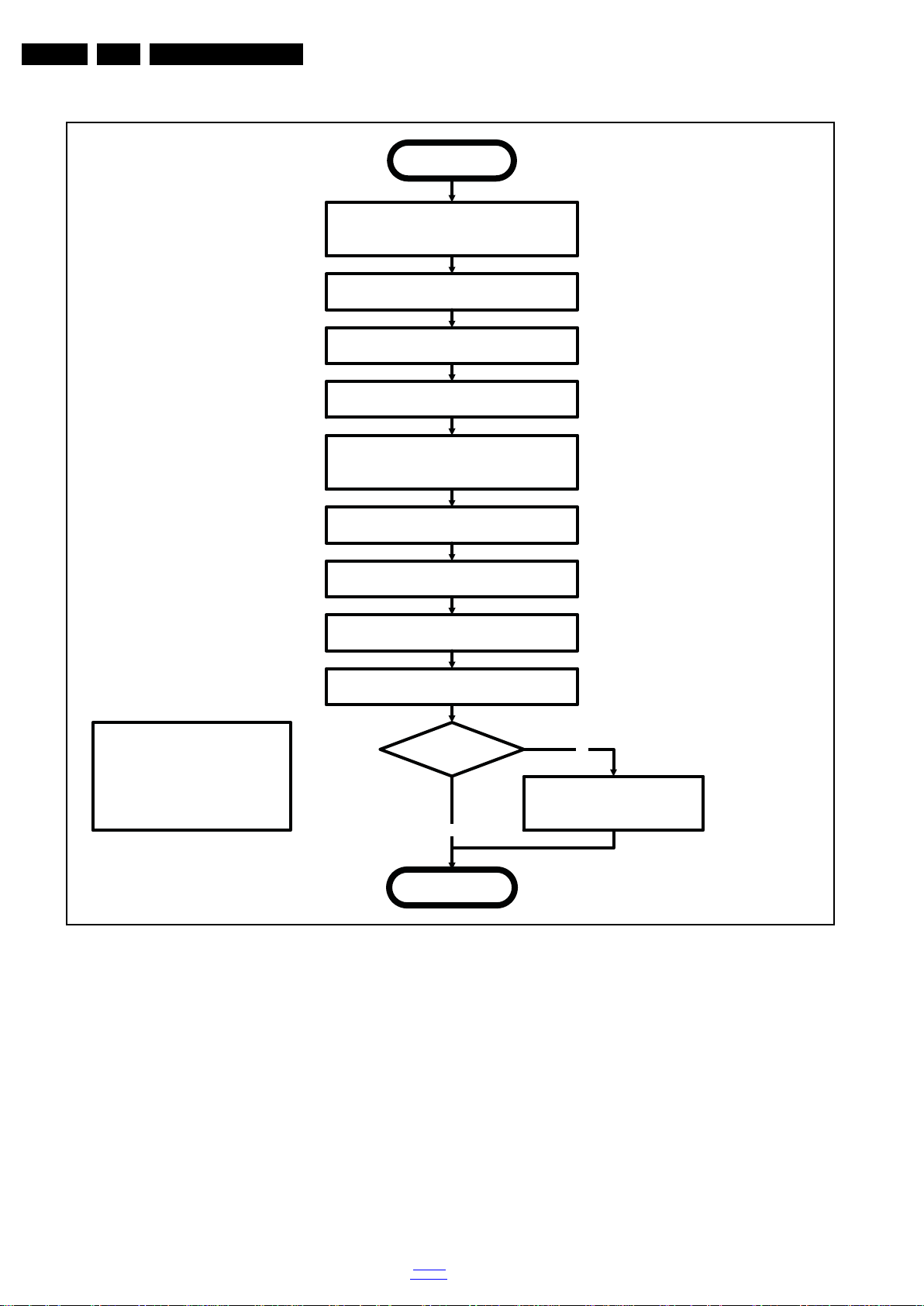

Figure 5-4 Transition diagram

back to

div. table

2012-Sep-14

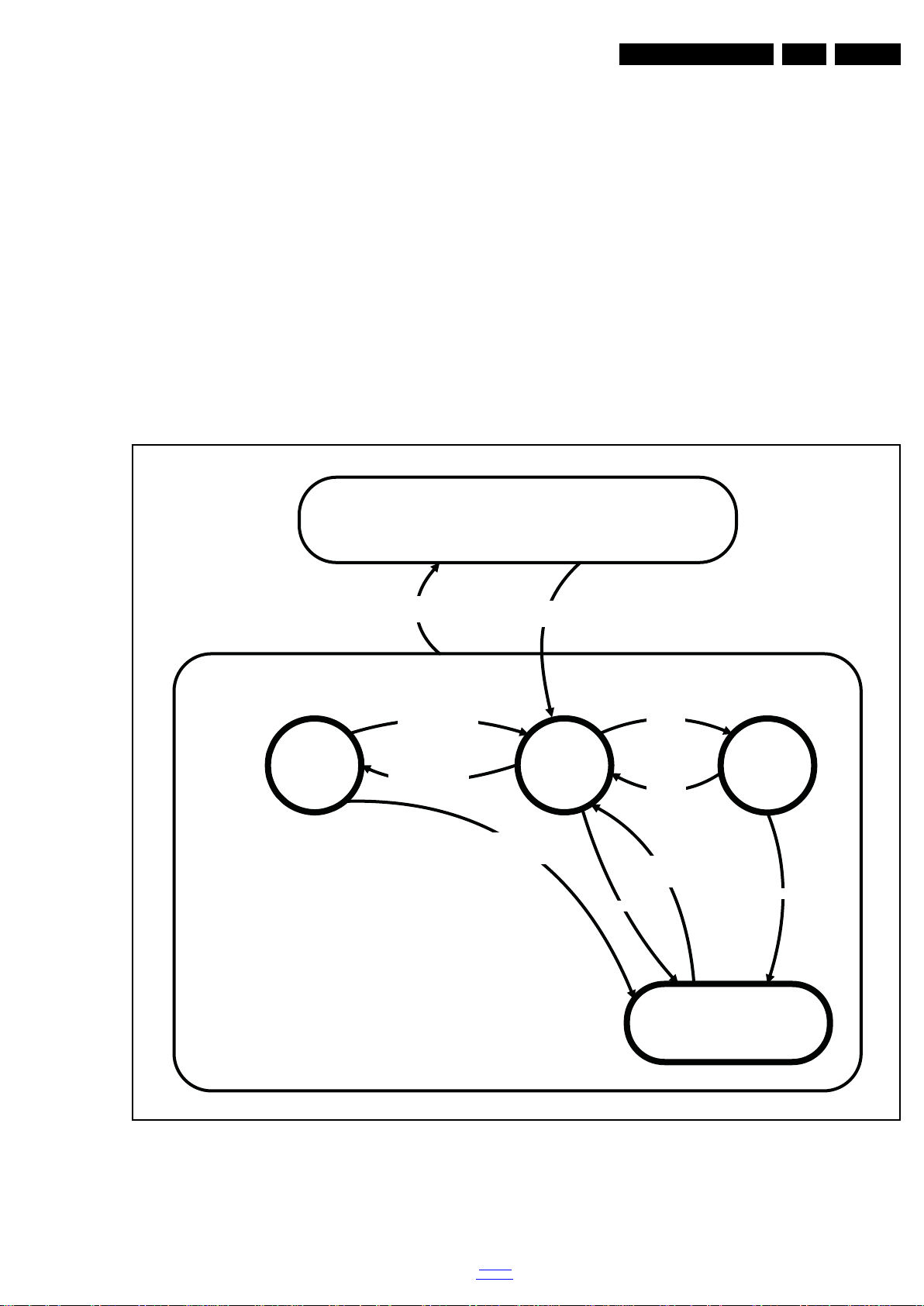

EN 24 QFU1.1E LA5.

19210_080_120504.eps

120504

No

Start AVC system

Off

Standby Supply starts running.

All standby supply voltages become available.

st-by µP resets, resulting in a high impedant output

stage of the I/O ports.

Stand by or

Protection

AC~ Mains is applied

start keyboard scanning, RC detection.

Wake up reasons are off.

If the protection state was left by short circuiting the

SDM pins, detection of a protection condition during

startup shall stall the startup. Protection conditions

occuring in a playing set shall be ignored. The

protection mode shall not be entered.

12V platform is turned on, automatically enabling the

low voltage DCDC converter outputs

Enable the supply detect io n algorithm

Switch ON Platform supply by switching High the

STANDBYn line.

Initialise I/O pins of th e st-by µP

- Keep AVC system in reset (internal signal)

- Switch RESET-FUSION-OUTn LOW

- Switch RESET-HDMI-MUXn LOW

- Switch RESET-ETHERNETn LOW

- Switch AUDIO-MUTEn LOW

- Switch SPLASH-ON LOW

- Switch LCD-PWR-ONn High

No

Detect2 high received

within 2 seconds?

12V error:

Layer1: 3

Layer2: 16

Enter protection

Yes

Wait 300ms

Switch followin g lines asap:(part of preBOOT)

(GPIO2): LOW

CTRL-DISP2 (GPIO3): LOW

CTRL-DISP3 (GPIO8): LOW

CTRL-DISP4 (BKLGON): LOW

3D-LR (PWM0): LOW

BL-SPI-CS_BL-I-CTRL (PWM1): LOW

BL-DIM (BOOST): LOW

All display related I/O lines should be

LOW as long as the Tcon is not

powered to avoid leakage current and

tcon startup problems.

These lines will furtheron be

dynamically controll e d by the mainSW.

Wait 10ms

Switch RESET-FUSION-OUTn, RESET-

HDMI-MUXn , RESET-ETHERNETn High

Small delay between AVC boot and

other platform ICs is preferred to limi t

rush-in current on Platform.

Switch ENABLE-WOLAN high to power Ethernet PHY

and Wifi dongle

Switch ENABLE-WOLANn high to power Ethernet

PHY and internal Wifi dongle if Networked Standby

was Off in the Standby mode.

Startup shall continue from the

moment a valid detection is received.

Service Modes, Error Codes, and Fault Finding

2012-Sep-14

Figure 5-5 “Off” to “Semi Stand-by” flowchart (part 1)

back to

div. table

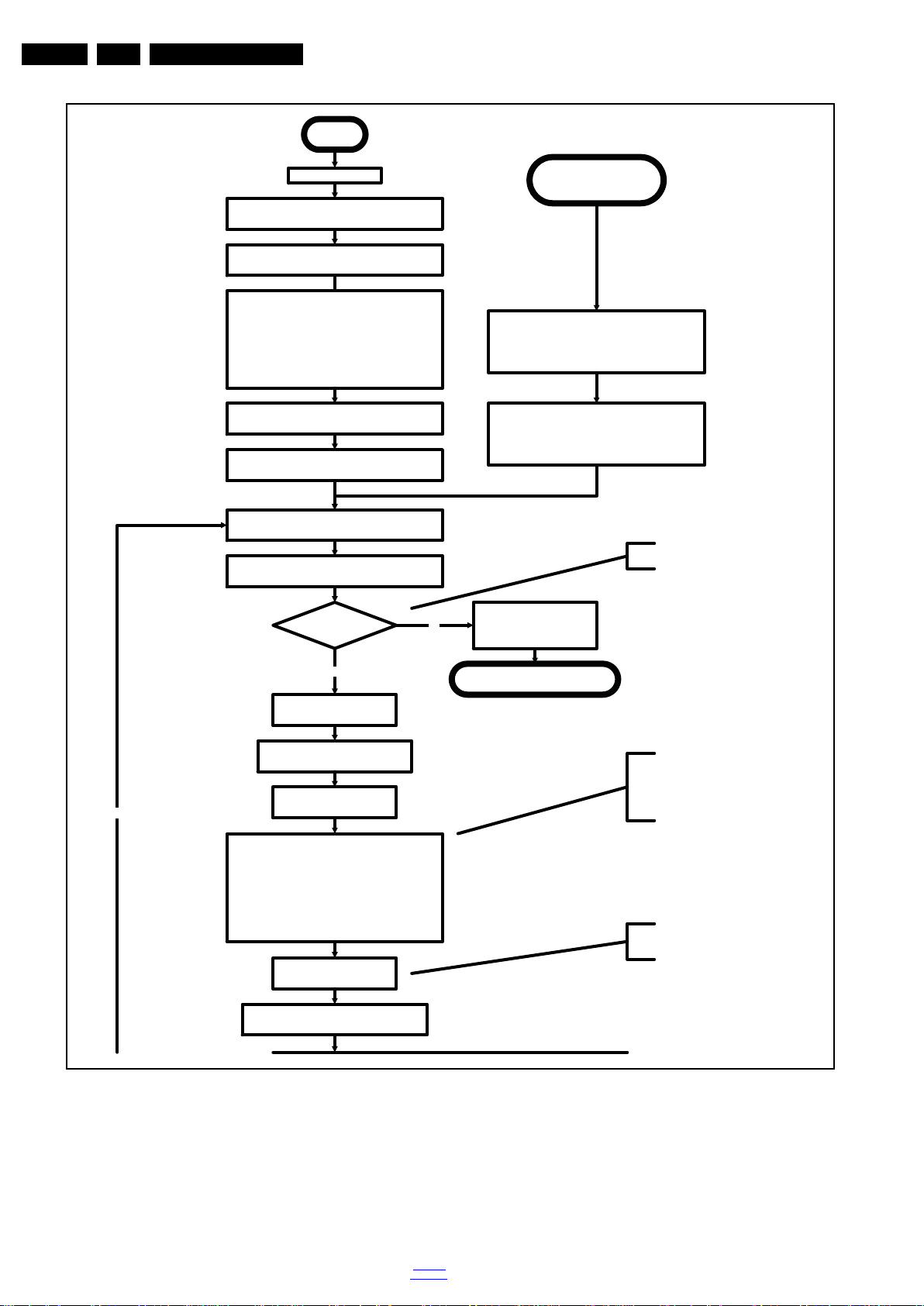

Service Modes, Error Codes, and Fault Finding

19210_081_120504.eps

120504

Yes

Semi-Standby

3-th try?NoSwitch Standby I/O l ine LOW

Switch AVC in reset

Enter protection

Wake up reason

coldboot to Active mode?

Startup screen cfg file

present?

yes

No

No

yes

AUDIO-MUTEn is switched by MIPS code

later on in the startup process when audio

needs to be released

Switch RESET-FUSION-OUTn, RESET-

HDMI-MUXn , RESET-ETHERNETn Low

Boot is failing

Reset-lines are switched

MIPS boots

Standby µP monitors

boot process and will

init a restart if Boot

process hampers

TV application starts

Set was

started with

SDM pin?

Yes

Ignore boot failure:

Stall the startup process.

Blink Layer2 error 53.

Enter protection without

turning off the supplies

No

Wait 4 seconds before restarting

No

Blink error code

Layer 1 error 2

MIPS sends out startup screen

MIPS starts up the display.

Startup screen visible

EN 25QFU1.1E LA 5.

Figure 5-6 “Off” to “Semi Stand-by” flowchart (part 2)

back to

div. table

2012-Sep-14

EN 26 QFU1.1E LA5.

19210_079_120504.eps

120504

Active

Semi Standby

Initialize audio and video

processing IC's and functions

according needed use case.

Assert RGB video blanking

and audio mute

Wait until previous on-state is left more than2

secondsago. (to prevent LCD display problems)

The assumption here is that a fast toggle (<2s) can

only happen during ON->SEMI ->ON. In these states,

the AVC is still active and can provide the 2s delay. A

transition ON->SEMI->STB Y->SEMI->ON cannot be

made in less than 2s, because the standby state will

be maintained for at least 4s.

unblank the video

Wait until valid and stable audio and video, corresponding to the

requested output is delivered

AND

the backlight has been switched on for at least the time which is

indicated in the display file as preheat time

Release audio mute

Set the Ambilight functionality according the last status

settings

No

Start POWER-OK line

detection algorithm as defined

in the CHS service.

return

Display already on?

(cold boot with splash

screen)

Yes

Startup display

(see separate tab)

Display cfg file present

and up to date, according

correct display option?

No

Prepare Start screen Display config

file and copy to Flash

Yes

Service Modes, Error Codes, and Fault Finding

2012-Sep-14

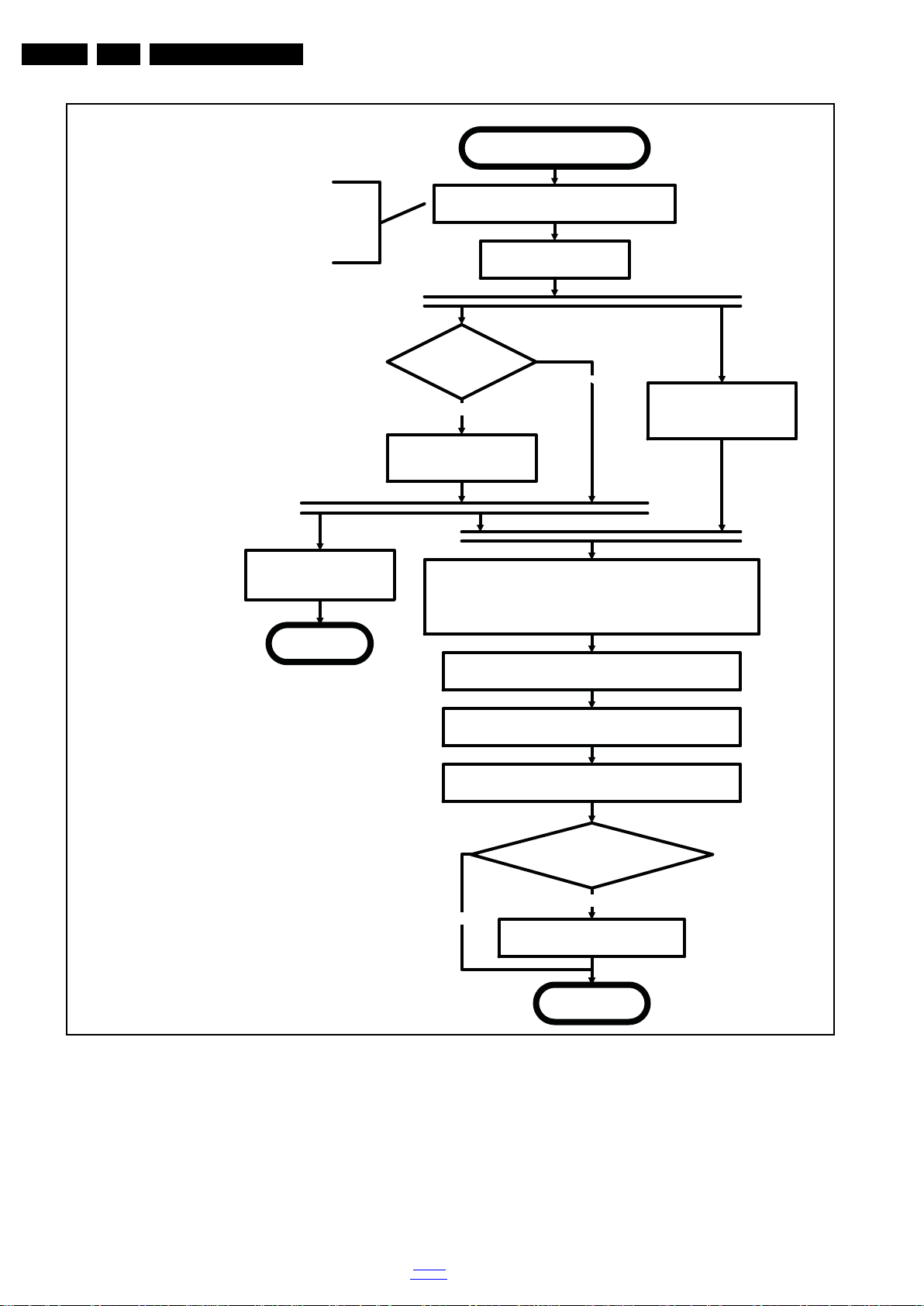

Figure 5-7 “Semi Stand-by” to “Active” flowchart

back to

div. table

Service Modes, Error Codes, and Fault Finding

19210_077_120504.eps

120504

Semi Standby

Active

Mute all sound outputsaccording

information in the FMS AUDIO

Mute all video outputs switch off Ambilight (see CHS ambilight)

Wait 100ms

Wait until Ambilight has faded out:

Output power Observer should be zero

Switch off POK line detection

algorithm (see CHS service)

Shut down the display

(see separate sheet)

Switch Off LCD backlight

EN 27QFU1.1E LA 5.

Figure 5-8 “Active” to “Semi Stand-by” flowchart

back to

div. table

2012-Sep-14

EN 28 QFU1.1E LA5.

19210_078_120504.eps

120504

transfer Wake up reasons to the Stand by µP.

Stand by

Semi Stand by

Disable all supply related protections and switch off

the DC/DC converters (ENABLE-3V3n)

No

Switch OFF all supplies by switching HIGH the

Standby I/O line

Switch AVC system in reset state

Switch reset-USB, Reset-Ethernet and Reset-DVBs

LOW

Important remarks:

release reset audio 10 sec after entering

standby to save power

Also here, the standby state has to be

maintained for at least 4s before starting

another state transition.

Wait 10ms

Delay transition until ramping down of ambient light is

finished. *)

If ambientlight functionality was used in semi-standby

(lampadaire mode), switch off ambient light (see CHS

ambilight)

*) If this is not performed and the set is

switched to standby when the switch off of

the ambilights is still ongoing, the lights will

switch off abruptly when the supply is cut.

Switch RESET-FUSION-OUTn, RESET-HDMI-MUXn ,

RESET-ETHERNETn Low

Switch ENABLE-WOLAN Low to

power off the Ethernet PHY and

Internal Wifi dongle.

Networked Standby

required?

Yes

transfer specific Firmware and Wake up reasons to the

Wifi dongle to allow networked standby

Service Modes, Error Codes, and Fault Finding

2012-Sep-14

Figure 5-9 “Semi Stand-by” to “Stand-by” flowchart

back to

div. table

Service Modes, Error Codes, and Fault Finding

10000_036_090121.eps

091118

TO

UART SERVICE

CONNECTOR

TO

UART SERVICE

CONNECTOR

TO

I2C SERVICE

CONNECTOR

TO TV

PC

HDMI

I

2

C only

Optional power

5V DC

ComPair II Developed by Philips Brugge

RC out

RC in

Optional

Switch

Power ModeLink/

Activity

I

2

C

ComPair II

Multi

function

RS232 /UART

EN 29QFU1.1E LA 5.

5.4 Service Tools

5.4.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products and offers the following:

1. ComPair helps to quickly get an understanding on how to

2. ComPair allows very detailed diagnostics and is therefore

3. ComPair speeds up the repair time since it can

4. ComPair features TV software up possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The ComPair II interface box is connected to the PC via an

USB cable. For the TV chassis, the ComPair interface box and

the TV communicate via a bi-directional cable via the service

connector(s).

The ComPair fault finding program is able to determine the

problem of the defective television, by a combination of

automatic diagnostics and an interactive question/answer

procedure.

How to Connect

This is described in the chassis fault finding database in

ComPair.

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs can be

blown!

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• Software is available via the Philips Service web portal.

• ComPair UART interface cable for QF1x.x.

Note: When you encounter problems, contact your local

support desk.

repair the chassis in a short and effective way.

capable of accurately indicating problem areas. No

knowledge on I

2

C or UART commands is necessary,

because ComPair takes care of this.

automatically communicate with the chassis (when the µP

is working) and all repair information is directly available.

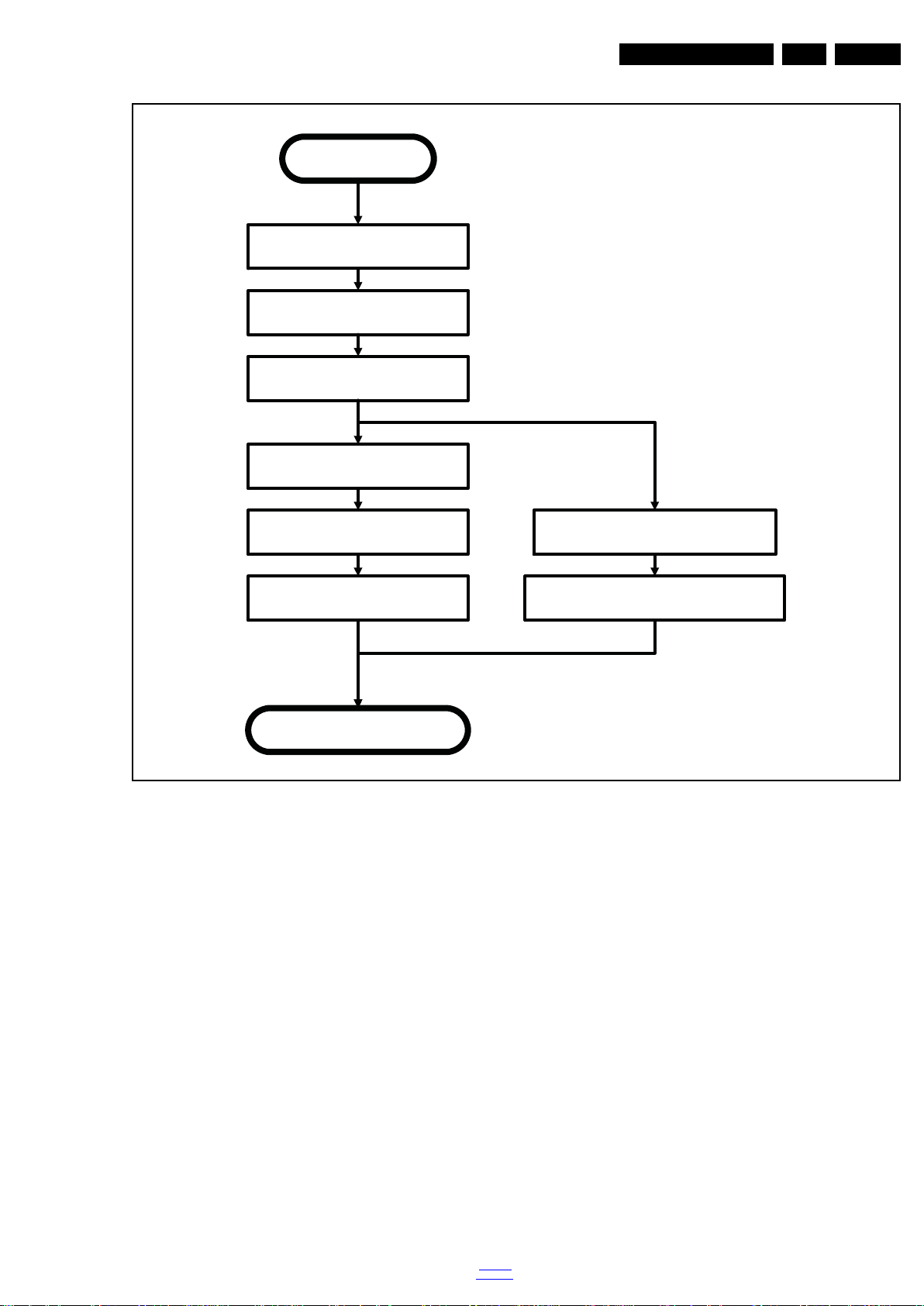

Figure 5-10 ComPair II interface connection

(using 3.5 mm Mini Jack connector): 3138 188 75051.

5.5 Error Codes

5.5.1 Introduction

The error code buffer contains all detected errors since the last

time the buffer was erased. The buffer is written from left to

right, new errors are logged at the left side, and all other errors

shift one position to the right.

When an error occurs, it is added to the list of errors, provided

the list is not full. When an error occurs and the error buffer is

full, then the new error is not added, and the error buffer stays

intact (history is maintained).

To prevent that an occasional error stays in the list forever, the

error is removed from the list after more than 50 hrs. of

operation.

When multiple errors occur (errors occurred within a short time

span), there is a high probability that there is some relation

between them.

• If no errors are there, the LED should not blink at all in

CSM or SDM. No spacer must be displayed as well.

• There is a simple blinking LED procedure for board

level repair (home repair) so called LAYER 1 errors

next to the existing errors which are LAYER 2 errors (see

Table 5-2

– LAYER 1 errors are one digit errors.

– LAYER 2 errors are 2 digit errors.

• In protection mode.

– From consumer mode: LAYER 1.

– From SDM mode: LAYER 2.

• Fatal errors, if I2C bus is blocked and the set reboots,

CSM and SAM are not selectable.

– From consumer mode: LAYER 1.

– From SDM mode: LAYER 2.

• In CSM mode.

– When entering CSM: error LAYER 1 will be displayed

• In SDM mode.

– When SDM is entered via Remote Control code or the

• Error display on screen.

– In CSM no error codes are displayed on screen.

– In SAM the complete error list is shown.

Basically there are three kinds of errors:

• Errors detected by the Standby software which lead to

protection. These errors will always lead to protection and

an automatic start of the blinking LED LAYER 1 error.

(see section “5.6 The Blinking LED Procedure

• Errors detected by the Standby software which not

lead to protection. In this case the front LED should blink

the involved error. See also section “5.5 Error Codes

Error Buffer”. Note that it can take up several minutes

before the TV starts blinking the error (e.g. LAYER 1

error = 2, LAYER 2 error = 15 or 53).

• Errors detected by main software (MIPS). In this case

the error will be logged into the error buffer and can be read

out via ComPair, via blinking LED method LAYER 1-2

error, or in case picture is visible, via SAM.

5.5.2 How to Read the Error Buffer

Use one of the following methods:

• On screen via the SAM (only when a picture is visible).

E.g.:

– 00 00 00 00 00: No errors detected

– 23 00 00 00 00: Error code 23 is the last and only

– 37 23 00 00 00: Error code 23 was first detected and

– Note that no protection errors can be logged in the

• Via the blinking LED procedure. See section 5.5.3 How to

Clear the Error Buffer.

back to

div. table

).

by blinking LED.

hardware pins, LAYER 2 is displayed via blinking LED.

detected error.

error code 37 is the last detected error.

error buffer.

”).

, 5.5.4

2012-Sep-14

EN 30 QFU1.1E LA5.

Service Modes, Error Codes, and Fault Finding

•Via ComPair.

5.5.3 How to Clear the Error Buffer

Use one of the following methods:

• By activation of the “RESET ERROR BUFFER” command

in the SAM menu.

• If the content of the error buffer has not changed for 50+

hours, it resets automatically.

5.5.4 Error Buffer

In case of non-intermittent faults, clear the error buffer before

starting to repair (before clearing the buffer, write down the

content, as this history can give significant information). This to

ensure that old error codes are no longer present.

Table 5-2 Error code overview

Description Layer 1 Layer 2

I2CM3 (SSB + SRF bus) 2 13 MIPS E BL / EB SSB SSB

I2CM2 (BE bus) 2 14 MIPS E BL / EB SSB SSB

I2CM1(FE bus) 2 18 MIPS E BL / EB SSB SSB

Fusion doesn’t boot (HW cause) 2 15 Stby µP P BL Fusion SSB

12V 3 16 Stby µP P BL / Supply

Display supply (POK) 3 17 MIPS E EB / Supply

HDMI mux 2 23 MIPS E EB SII9387 SSB

I2C switch 2 24 MIPS E EB PCA9540 SSB

Channel dec DVB-T2 2 27 MIPS E EB CXD2834 SSB

Channel dec DVB-S2 2 28 MIPS E EB STV0903 SSB

Lnb controller 2 31 MIPS E EB LNBH25 SSB

Hybrid Tuner 2 34 MIPS E EB SUT-RE214Z SSB

Main NVM 2 35 MIPS E EB STM24C64 SSB

Tuner DVB-S2 2 36 MIPS E EB STV6110 SSB

Class-D 2 37 MIPS E EB TAS 5731 PHP SSB

FPGAScanBacklight 2 38 MIPS E EB XC6SLX4 SSB

T° sensor SSB/Display 2 42 MIPS E EB LM 75 T° sensor on SSB/Display

Light sensor 6 43 MIPS E EB TSL2571 Set

µP touch control 6 44 MIPS E EB / Set

RF4CE 6 46 MIPS E EB / Set

MIPS doesn’t boot (SW cause) 2 53 Stby µP P BL FUSION SSB

FPGA HDR 5 61 MIPS E BL Xilinx Spartan Display

FPGA Lattice Backlight 5 62 MIPS E BL Lattice Display

TCON µP (SHARP) 7 54 MIPS E BL / Display

TCON ASIC (SHARP) 7 55 MIPS E BL / Display

VCON cal (SHARP) 7 56 MIPS E BL / Display

Monitored

by

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

code and not the actual cause.(e.g. a fault in the protection

detection circuitry can also lead to a protection)

There are several mechanisms of error detection:

• Via error bits in the status registers of ICs.

• Via polling on I/O pins going to the standby processor.

• Via sensing of analog values on the standby processor or

the Mips.

• Via a “not acknowledge” of an I

Take notice that some errors need several minutes before they

start blinking or before they will be logged. So in case of

problems wait 2 minutes from start-up onwards, and then

check if the front LED is blinking or if an error is logged.

Error/

Error Buffer/

Prot

Blinking LED Device Defective Board

2

C communication.

Extra Info

• Rebooting. When a TV is constantly rebooting due to

internal problems, most of the time no errors will be logged

or blinked. This rebooting can be recognized via a ComPair

interface and Hyperterminal (for Hyperterminal settings,

see section “5.8 Fault Finding and Repair Tips

Logging). It’s shown that the loggings which are generated

by the main software keep continuing.

• Error 13 (I

2

C bus M3, SSB + SRF bus blocked). Current

situation: when this error occurs, the TV can reboot due to

the blocked bus. The best way for further diagnosis here, is

to check the logging output.

• Error 14 (I

2

C bus M2, BE bus blocked). Current situation:

when this error occurs. The best way for further diagnosis

here, is to check the logging output.

• Error 18 (I

2

C bus M1, FE bus blocked). Current situation:

when this error occurs. The best way for further diagnosis

here, is to check the logging output.

• Error 15 (Fusion doesn’t boot). Indicates that the main

processor was not able to read his bootscript. This error will

point to a hardware problem around the Fusion (supplies

not OK, Fusion device completely dead, link between Mips

and Stand-by Processor broken, etc...)

Other root causes for this error can be due to hardware

problems regarding the DDR’s and the bootscript reading

from the Fusion device.

2012-Sep-14

, 5.8.6

back to

div. table

• Error 16 (12V). This voltage is made in the power supply

and results in protection (LAYER 1 error = 3) in case of

absence. When SDM (maintain grounding continuously) is

activated we see blinking LED LAYER 2 error = 16.

• Error 17 (Display Supply). Here the status of the “Power

OK” is checked by software, no protection will occur during

failure of the display supply, only error logging. LED

blinking of LAYER 1 error = 3 in CSM, in SDM this gives

LAYER 2 error = 17.

• Error 23 (HDMI mux). When there is no I

2

C

communication towards the HDMI mux after start-up,

LAYER 2 error = 23 will be logged and displayed via the

blinking LED procedure if SDM is switched on.

• Error 24 (I2C switch). When there is no I

communication towards the I

2

C switch, LAYER 2

2

C

error = 24 will be logged and displayed via the blinking LED

procedure when SDM is switched on.