Page 1

Color Television Chassis

TC7.1U

CA

H_17090_000.eps

150307

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 5

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 9

6. Block Diagrams, Test Point Overview, and

Waveforms

Block Diagram Mono Carrier 13

Block Diagram ATSC Module 14

7. Circuit Diagrams and PWB Layouts

Mono Carrier (A) 15 16-17

CRT Panel (B) 18 16-17

ATSC: Power Reset (C1) 19 26-27

ATSC: Tuner Link (C2) 20 26-27

ATSC: Audio Video (C3) 21 26-27

ATSC: Embedded (C4) 22 26-27

ATSC: DDR Memory (C5) 23 26-27

ATSC: Flash Memory (C6) 24 26-27

ATSC: Power GND (C7) 25 26-27

Side AV & Control Panel (D) 28 28

Front Control Panel (E) 29 29

8. Alignments 31

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 35

Abbreviation List 38

10. Spare Parts List 39

11. Revision List 42

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JY 0772 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17091

Page 2

EN 2 TC7.1U CA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Side and Rear Connections

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : CRT, Real Flat

Screen size : 27” (69 cm), 4:3

Tuning system : PLL

Presets/channels : 181

Tuner bands : Full-Cable

TV color systems : ATSC

Video playback : NTSC

Aerial input : 75 ohm, F-type

Cable : Unscrambled Digital

1.1.2 Sound

Sound systems : Stereo BTSC

Maximum power (W

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50 / 60

Ambient conditions:

- Temperature range (°C) : +5 to +40

- Maximum humidity : 90% R.H.

Power consumption (values are indicative)

- Normal operation (W) : ≈ 120

- Stand-by (W) : < 1

):2 x 2

RMS

) : 108-132

AC

:NTSC

Cable -QAM

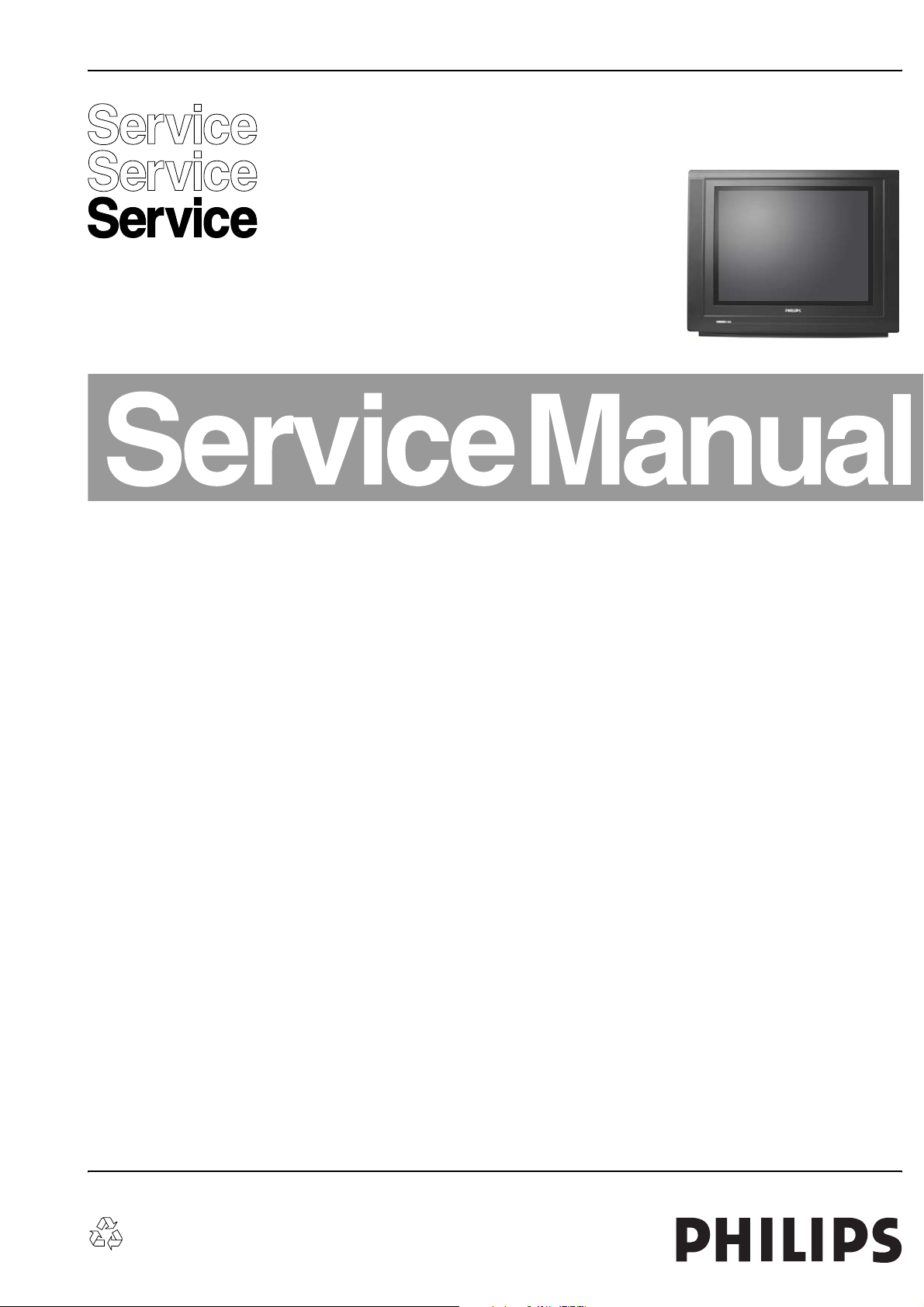

1.2 Side and Rear Connections

Figure 1-1 Side and rear I/O connections

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Side Connections

Audio / Video In

Ye - Video (CVBS) 1 V_pp / 75 ohm jq

Wh - Audio - L 0.2 V_rms / 10 kohm jq

Rd - Audio - R 0.2 V_rms / 10 kohm jq

S-Video

1 -Ground GND H

2 -Ground GND H

3 -Y 1 V_pp / 75 ohm jq

4 -C 0.3 V_pp / 75 ohm jq

1.2.2 Rear Connections

CVI (YPbPr In)

Gn - Y 0.7 V_pp / 75 ohm jq

Bu - Pb 0.7 V_pp / 75 ohm jq

Rd - Pr 0.7 V_pp / 75 ohm jq

Wh - Audio - L 0.5 V_rms / 10 kohm jq

Rd - Audio - R 0.5 V_rms / 10 kohm jq

H_17090_007.eps

160307

Dimensions (WxHxD inch) : 29.2 x 23 x 19.1

Weight (lb) : 94.8

AV In

Ye - Video (CVBS) 1 V_pp / 75 ohm jq

Wh - Audio - L 0.5 V_rms / 10 kohm jq

Rd - Audio - R 0.5 V_rms / 10 kohm jq

AV Out

Ye - Video (CVBS) 1 V_pp / 75 ohm kq

Wh - Audio - L 0.5 V_rms / 10 kohm kq

Rd - Audio - R 0.5 V_rms / 10 kohm kq

Aerial In

- F-type Coax, 75 ohm D

Page 3

Technical Specifications, Connections, and Chassis Overview

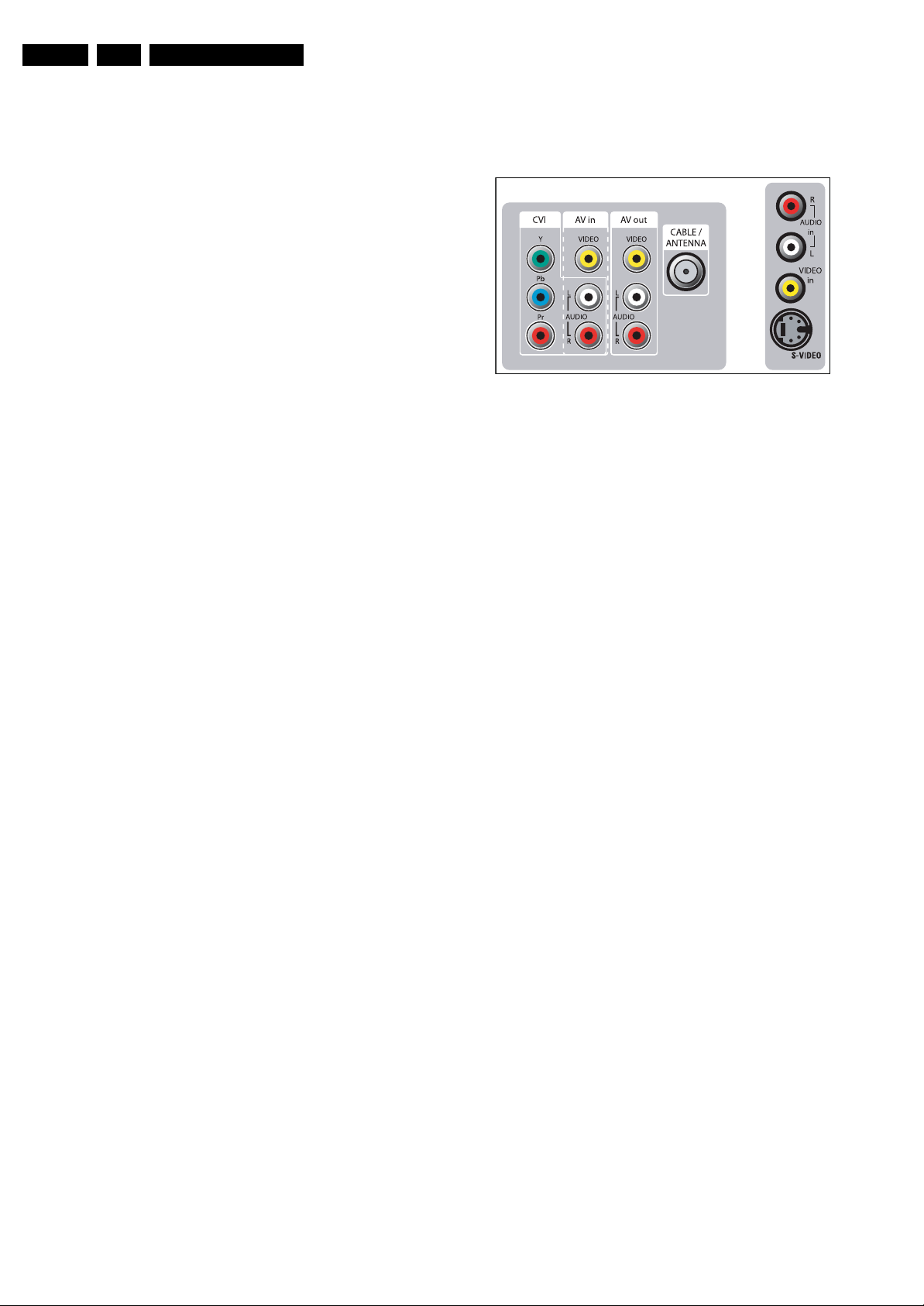

1.3 Chassis Overview

CRT PANEL

B

SIDE AV PANEL +

D

HEADPHONE

EN 3TC7.1U CA 1.

C1

C2

C3

C4

C5

C6

C7

POWER RESET

TUNER LINK

AUDIO VIDEO

EMBEDDED

DDR MEMORY

FLASH MEMORY

POWER GROUND

ATSC PANEL

Figure 1-2 PWB/CBA locations

FRONT CONTROL PANEL

MONO CARRIER

H_17090_057.eps

E

A

300307

Page 4

EN 4 TC7.1U CA2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current flows. In particular this is valid

for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function, to prevent the cord from touching the CRT,

hot components, or heat sinks.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the “general repair instruction” noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

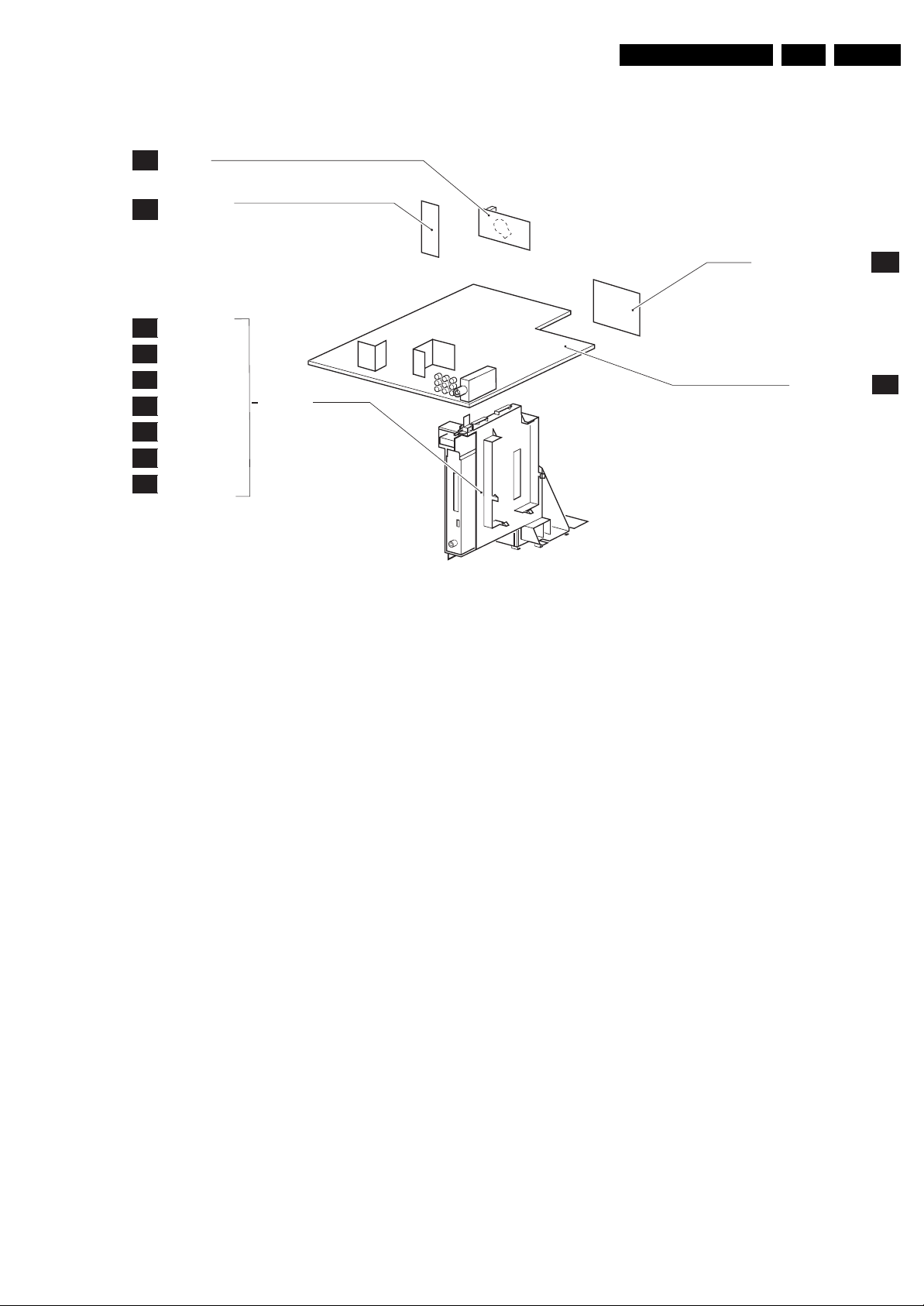

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in figure “Discharge

picture tube”, to discharge the picture tube. Use a high

voltage probe and a multi-meter (position V

until the meter reading is 0 V (after approx. 30 s).

V

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and prevents circuits

from becoming unstable.

2.4 Notes

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

). Discharge

DC

E_06532_007.eps

250304

Page 5

Directions for Use

EN 5TC7.1U CA 3.

2.4.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= x10

nano-farads (n= x10

-9

), or pico-farads (p= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.4.4 Alternative BOM identification

The third digit in the serial number (example:

BF2A0635000001) indicates the number of the alternative

-12

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

-6

),

).

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: BF1A063500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: BF2A0635000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

BJ3.0E LA

S

128W

E_06532_024.eps

130606

Figure 2-2 Serial number (example)

2.4.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 6

EN 6 TC7.1U CA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Set Disassembly

4.2 Assy / Board Removal

4.3 Service Positions

4.4 Set Re-assembly

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

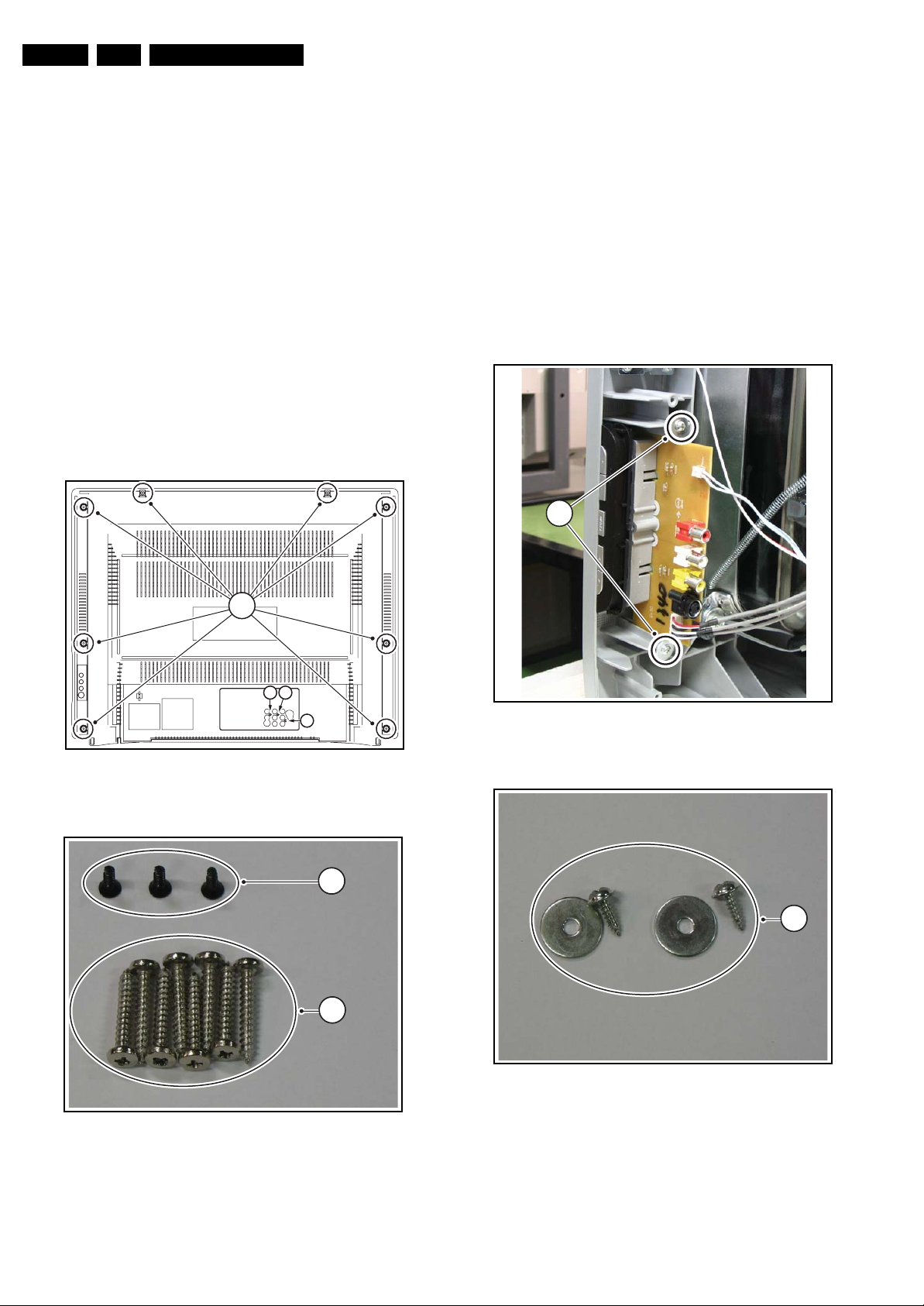

4.1 Set Disassembly

Follow the disassemble instructions in described order.

4.1.1 Rear Cover Removal

Warning: disconnect the mains power cord before you remove

the rear cover.

1. Remove all the fixation screws of the rear cover [1] and [2].

2. Now, pull the rear cover backwards and remove it.

4.2 Assy / Board Removal

Sometimes, it can be necessary to swap a complete assy or

Printed Wiring Board (PWB). How that can be done is

explained below.

4.2.1 Side IO/Keyboard Panel Removal

1. Remove the fixation screws [3].

2. Remove the module from the TV.

3. If necessary, release the two fixation clamps [4] at the

underside of the panel, and lift the button frame from the

panel.

3

1

222

Figure 4-1 Rear Cover removal

H_17090_034.eps

290307

2

1

H_17090_024.eps

Figure 4-3 Side-IO/Keyboard panel removal

280307

3

Figure 4-2 Rear Cover fixation screws

H_17090_023.eps

280307

H_17090_025.eps

Figure 4-4 Side-IO/Keyboard module fixation screws

280307

Page 7

4

Figure 4-5 Button frame removal

4.2.2 ATSC Panel Removal

1. Pull the fixation clamp upwards [5].

2. At the same time, slide the module backwards [6], away

from the CRT.

3. To remove the panel from its bracket, remove fixation

screw [7] and pull away fixation brackets [8]. Lift the panel

from the bracket, it hinges at the underside.

When defective, replace the whole module.

6

Mechanical Instructions

H_17090_026.eps

280307

5

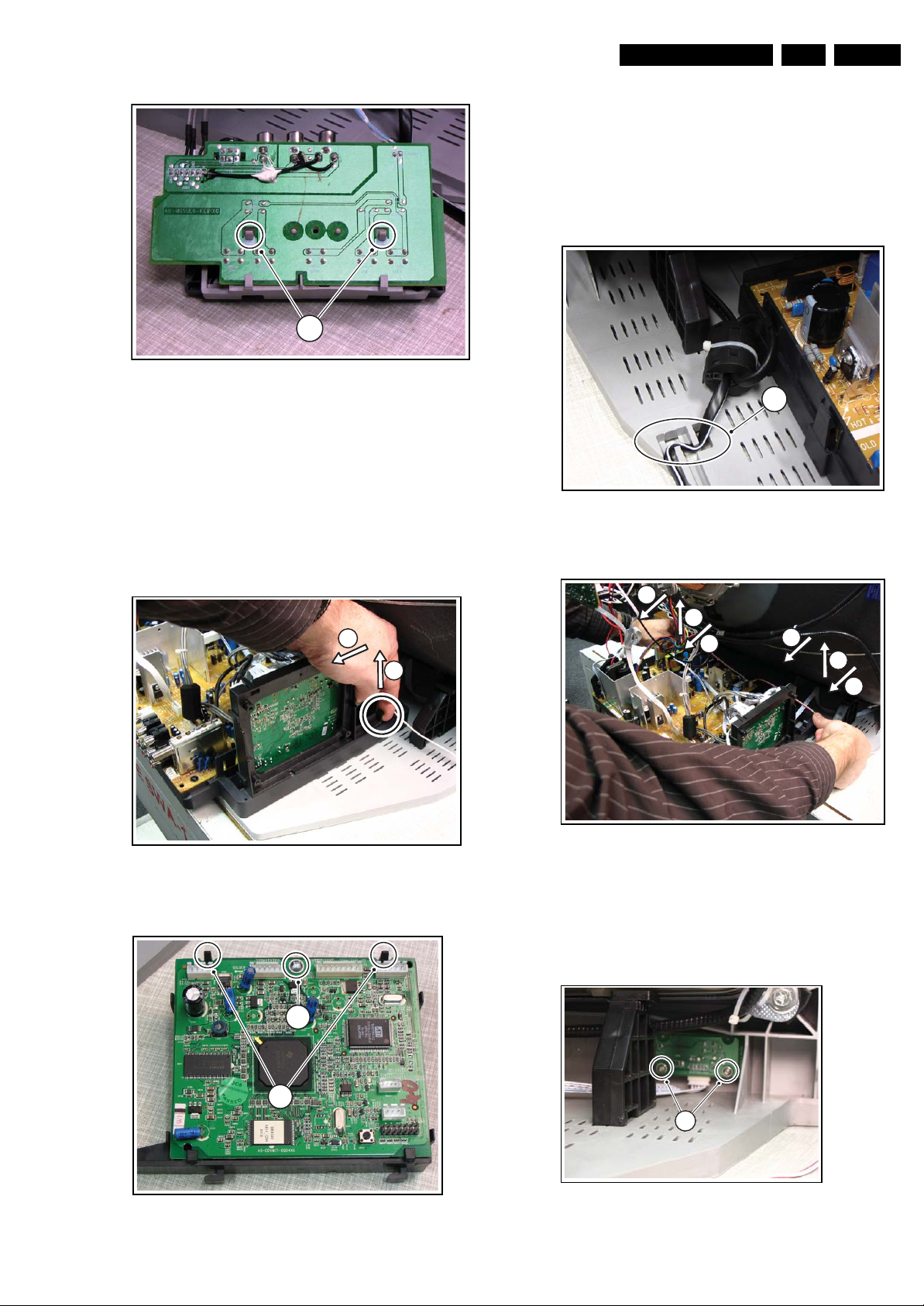

4.2.3 Mono Carrier Removal

1. First, disconnect the strain relief of the AC power cord [9].

2. Disconnect all the necessary cables.

3. To remove the Mono Carrier; slide the whole panel

backwards [10] (= away from the front). When stopped, pull

it upwards [11] at the front corners of the bracket (towards

the CRT), and at the same time, move it away from the

CRT [12].

9

Figure 4-8 Mono carrier removal [1/2]

12

11

10

12

EN 7TC7.1U CA 4.

H_17090_029.eps

290307

11

10

Figure 4-6 ATSC panel removal [1/2]

7

8

H_17090_027.eps

Figure 4-7 ATSC panel removal [2/2]

H_17090_028.eps

280307

290307

Figure 4-9 Mono carrier removal [2/2]

4.2.4 IR/LED Panel Removal

1. Remove the fixation screws [13].

2. Remove the module from the TV.

13

Figure 4-10 IR/LED panel removal

H_17090_032.eps

290307

H_17090_031.eps

290307

Page 8

EN 8 TC7.1U CA4.

4.3 Service Positions

For easy measurements, you can use the following service

position.

4.3.1 Service Position Mono Carrier

Removing cables and repostioning the panel

For better accessibility of the Mono Carrier, do the following

(see Figure “Service position”):

1. If necessary, disconnect some cables, and move the panel

somewhat to the left. Then flip it 90 degrees with its

components towards the CRT [14].

Mechanical Instructions

Figure 4-11 Service position

4.4 Set Re-assembly

To re-assemble the whole set, do all processes in reverse

order.

Be sure that, before the rear cover is mounted:

• The mains cord is postioned correctly in its guiding

brackets (make sure that the strain relief is replaced in its

correct position and that it will function correctly!).

• All wires/cables are returned in their original positions.

14

H_17090_033.eps

290307

Page 9

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

EN 9TC7.1U CA 5.

Index of this chapter:

5.1 Service Modes

5.2 Error Codes

5.3 Fault Finding

5.1 Service Modes

For an explanation of the Factory Mode, see chapter 8

“Alignments”.

5.2 Error Codes

Not applicable for this chassis.

5.3 Fault Finding

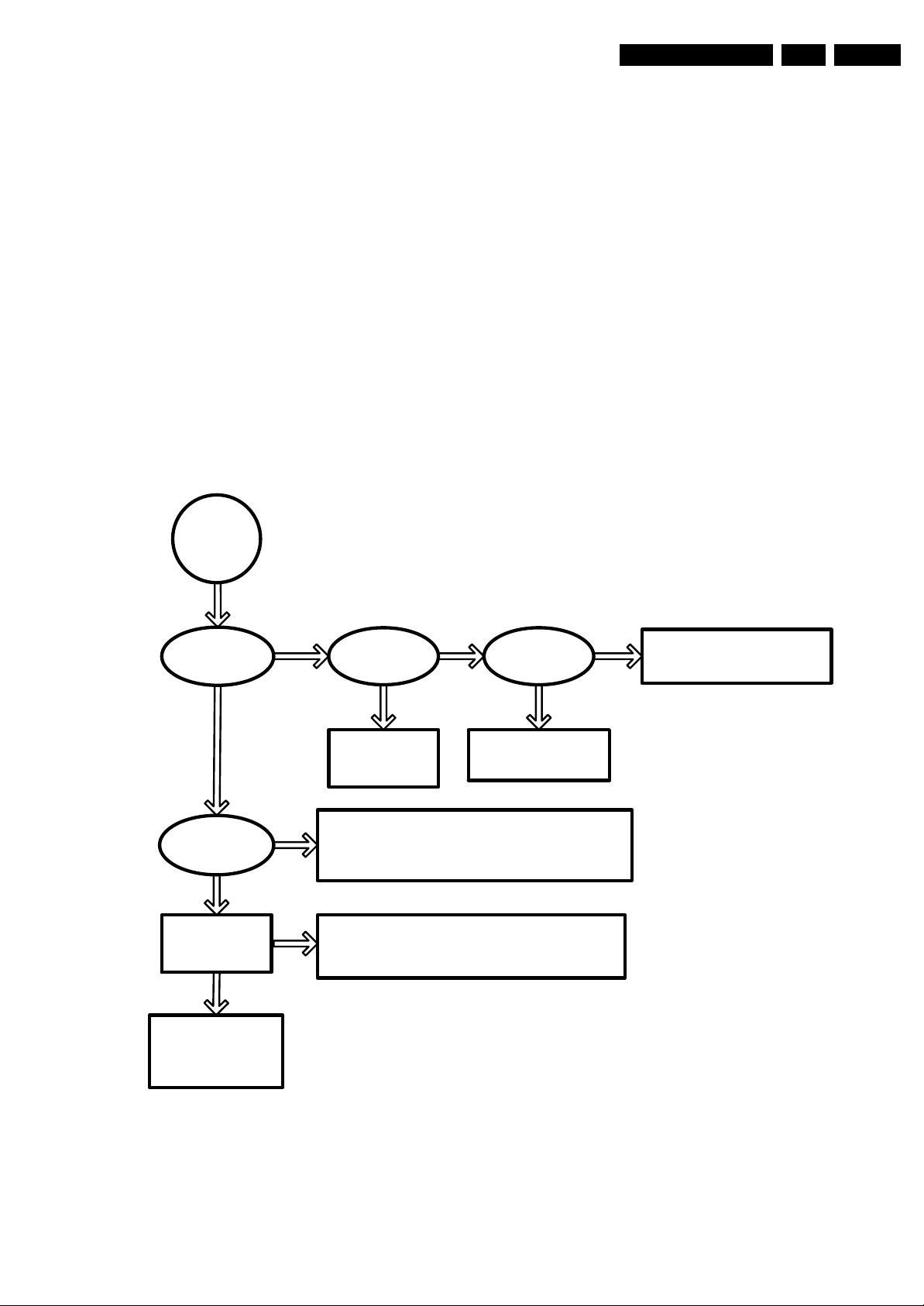

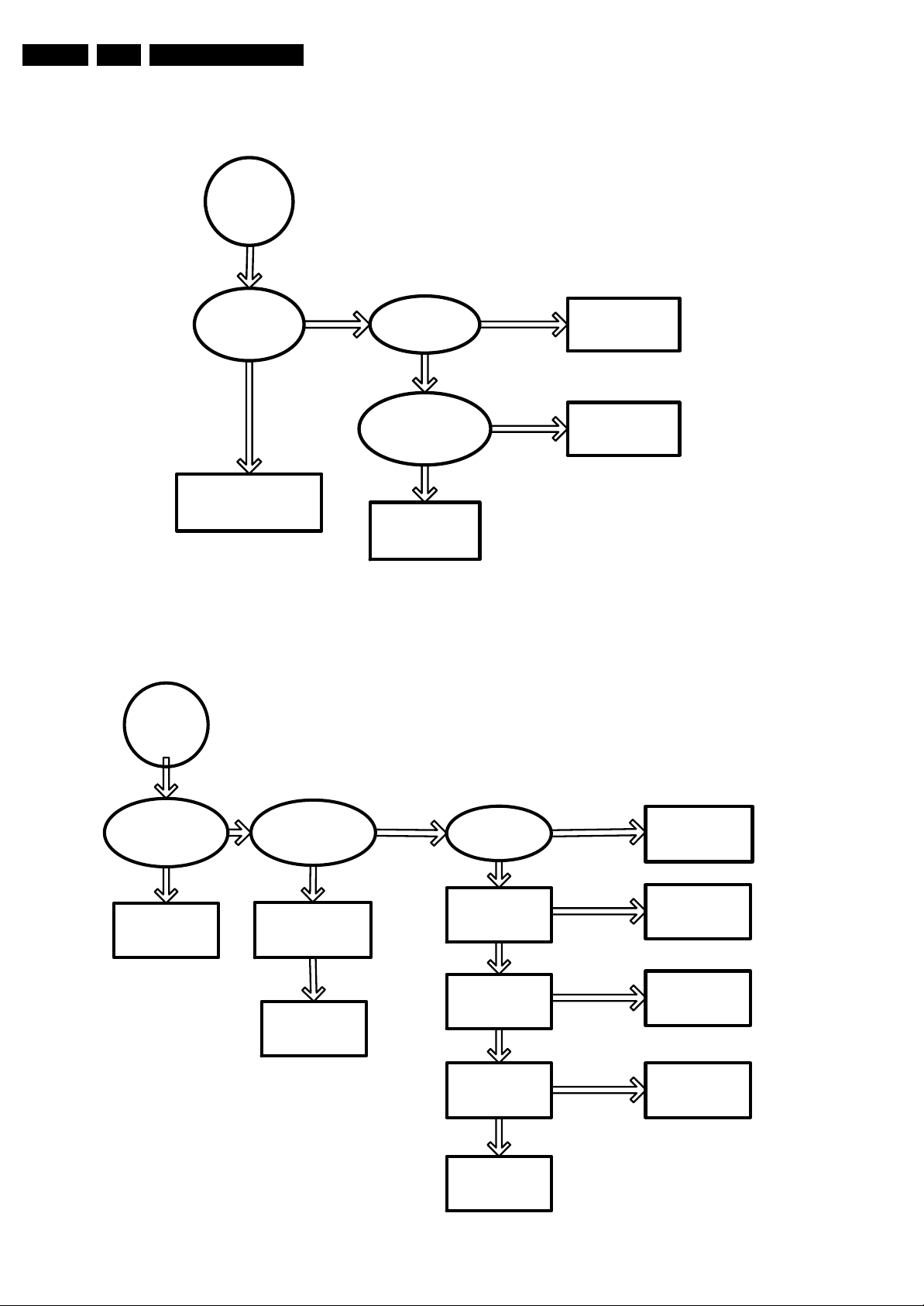

5.3.1 Can Not Power “On”

Can not Power

On

Fuse OK?

Y

N

Check B+ Ok?

Y

Check the

+5VSTand +12V

Check Horizontal Scan

circuit: Check H-Vcc

and H-out of IC200

Check Q401, T401 and

Q411

Is it IC801 Pin 1

shorted to earth?

N

Y

Check/Replace

IC801

(1) Check if B+ shorted to earth.

(2) To check whether D820 are turnoff. And whether C823

shorted.

N

(3) To check whether Q823 and Q822 are working normally.

1.check the power supply of IC200 is ok?

2.Is Q080,Q081 are working normally?

3. Q821, Q825, IC090 IC201/IC202 are working ok?

Is DB801 OK?

N

Y

Replace DB801

Check the components such as

N

C801, C802, C806, C807

H_17090_035.eps

300307

Figure 5-1 Flow chart “Can not power on”.

Page 10

EN 10 TC7.1U CA5.

5.3.2 No Raster, Sound OK

Service Modes, Error Codes, and Fault Finding

No Raster

Sound OK

Is the power supply

of Q403 ok?

N

To check whether R404,

C405, D409ˈT401, Q403,

R422 /R421 are ok?

Figure 5-2 Flow chart “No Raster, Sound OK”.

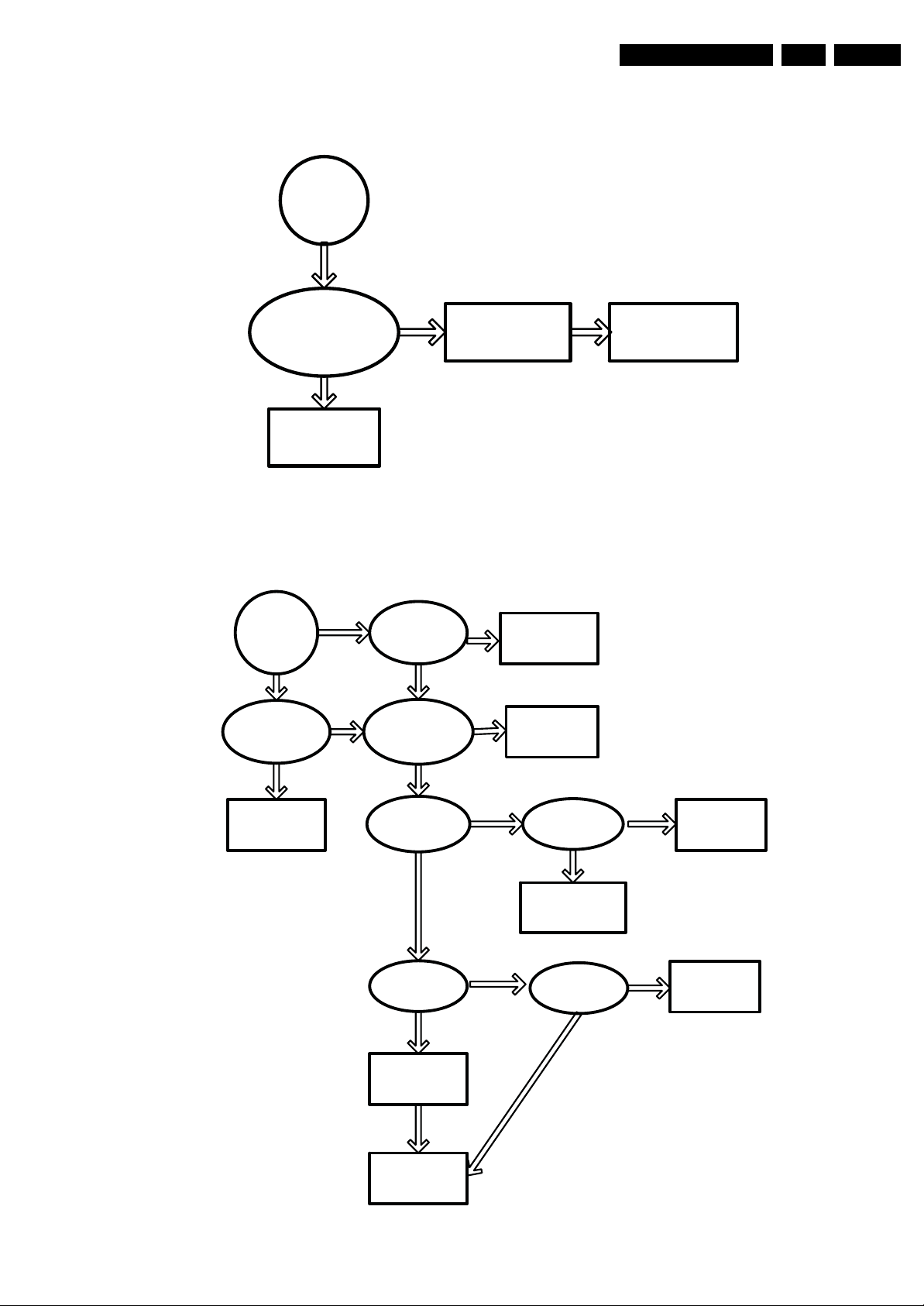

5.3.3 No TV (NTSC) Picture, No Sound, Raster OK

Raster OK, No

Sound , No TV

picture (NTSC)

Check Pin 67 (H-

Y

OUT) voltage ok?

Is there any shorted

in the scan part of the

Change IC200

circuit?

Check each output

Y

voltage of FBT

N

Change the shorted

Y

part.

N

H_17090_036.eps

300307

Is the antenna feed line

or the adapter broken?

Y

Handing the antenna

fault

Check the wave of

pin24/pin25 on IC200 is

N

ok?

Check the power

supply pin15 and RFAGC on IC200 is ok?

Change IC200

Y

N

Check Z100,Q101

ok?

Y

Check tuner power-

supply 33v/5v is ok?

Y

Check tuner RF-

AGC/SCL/SDA is

ok?

N

Check Q105,

Q103/Q102 ,Q104

is ok?

Y

Change the failing

components

Y

Y

Y

Figure 5-3 Flow chart “No TV (NTSC) Picture, No Sound, Raster OK”.

Change the failing

components

Check the power

supply circuit

Change the tuner

Change IC200

H_17090_037.eps

300307

Page 11

Service Modes, Error Codes, and Fault Finding

5.3.4 No AV Picture, Sound OK, Raster OK

Raster OK,

Sound OK, No

AV picture

EN 11TC7.1U CA 5.

Is the signal waveform at

Pin55 and Pin58 of IC200

right?

Y

Replace the fail

component.

Figure 5-4 Flow chart “No AV Picture, Sound OK, Raster OK”.

5.3.5 No TV (ATSC) Picture, No Sound, Raster OK

Raster OK, No

Sound , No TV

picture (ATSC)

Is the antenna feed

line or the adapter

broken?

N

Is the power supply

N

N

Check the power

supply of digital

board is ok?

Y

+5V,+33V of

tuner is ok

To check whether

D901, C918, C915 and

D906,C231are ok?

Check the power

circuit or replace

another digital BD

N

Check the power

circuit or replace

the tuner

N

Change the failing

component

H_17090_038.eps

290307

Handing the antenna

fault

YY

Check SCL/SDA of

the tuner is ok?

N

Check

Q102/Q103/Q104 is

ok?

N

Check the IC200

pin106/ok?

N

Check or change

IC200

Y

Y

N

Is the signal at

pin20,pin21 ,pin18

of tuner ok?

N

Check Q105 or

replace the tuner

Check pin98 of

IC200

Check or replace a

Y

Check or replace a

digital board

Y

digital board

H_17090_039.eps

300307

Figure 5-5 Flow chart “No TV (ATSC) Picture, No Sound, Raster OK”.

Page 12

EN 12 TC7.1U CA5.

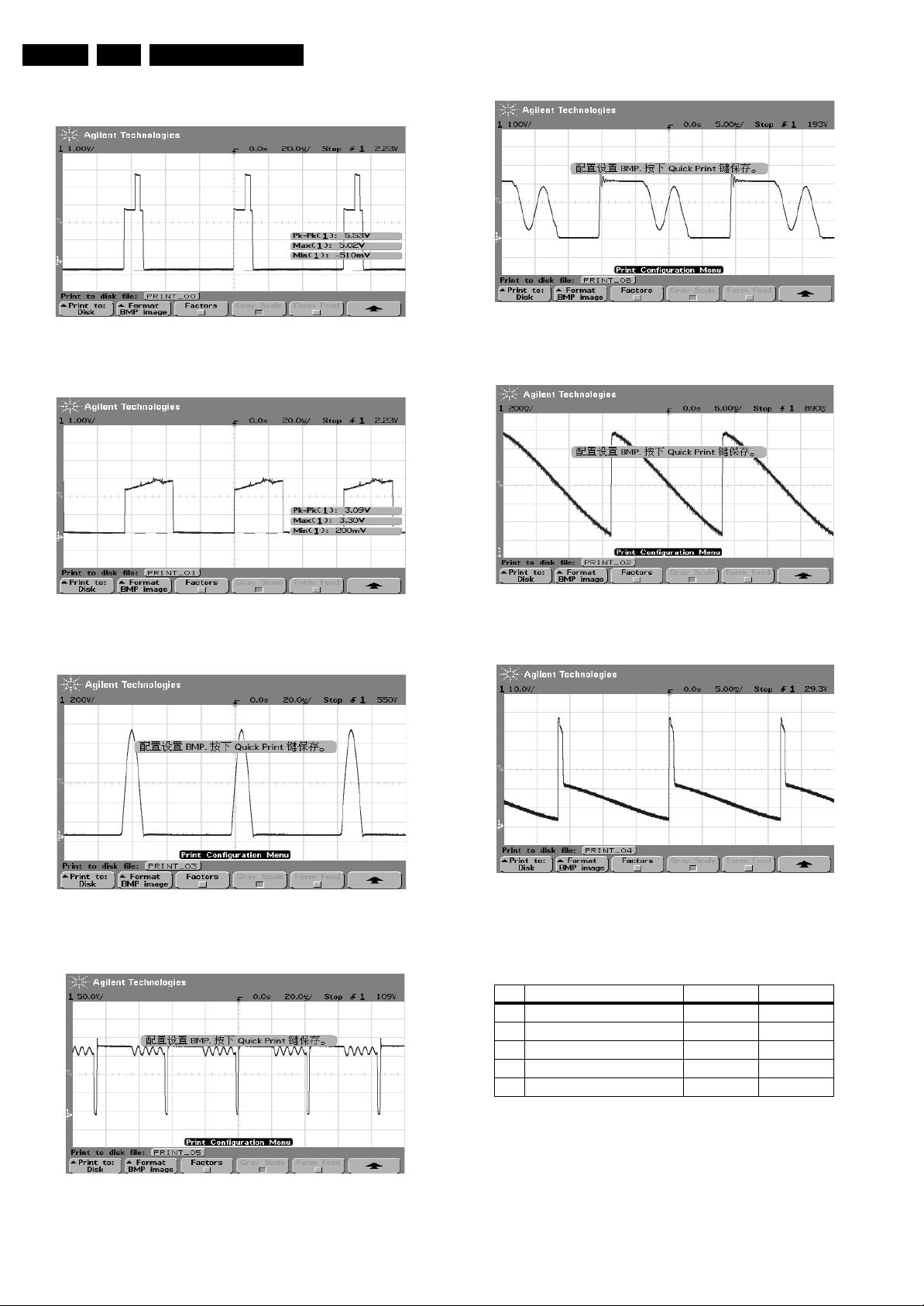

5.3.6 Some Waveforms:

Figure 5-6 Pin 66 of IC200

Service Modes, Error Codes, and Fault Finding

H_17090_050.eps

300307

Figure 5-10 Pin 1 of IC801

H_17090_054.eps

300307

Figure 5-7 H_out pin 67 of IC200

Figure 5-8 Q405 C

H_17090_051.eps

300307

H_17090_052.eps

300307

Figure 5-11 V_out pin 23 of IC200

Figure 5-12 V_out pin 5 of IC301

5.3.7 Important Voltages Overview

P/N Position Normal (V) Standby (V)

1 B+ Joint of L801 and R826A 130.9 9.3

2 Joint of C834 and D831 12.8 0.8

3 Joint of L212 and C090 5 1.2

4 Pin99 of IC200 3.6 0.1

5 Joint of D281 and R284 24.5 0

H_17090_055.eps

300307

H_17090_056.eps

300307

Figure 5-9 Pin 1 of IC801 when stand-by

H_17090_053.eps

300307

Page 13

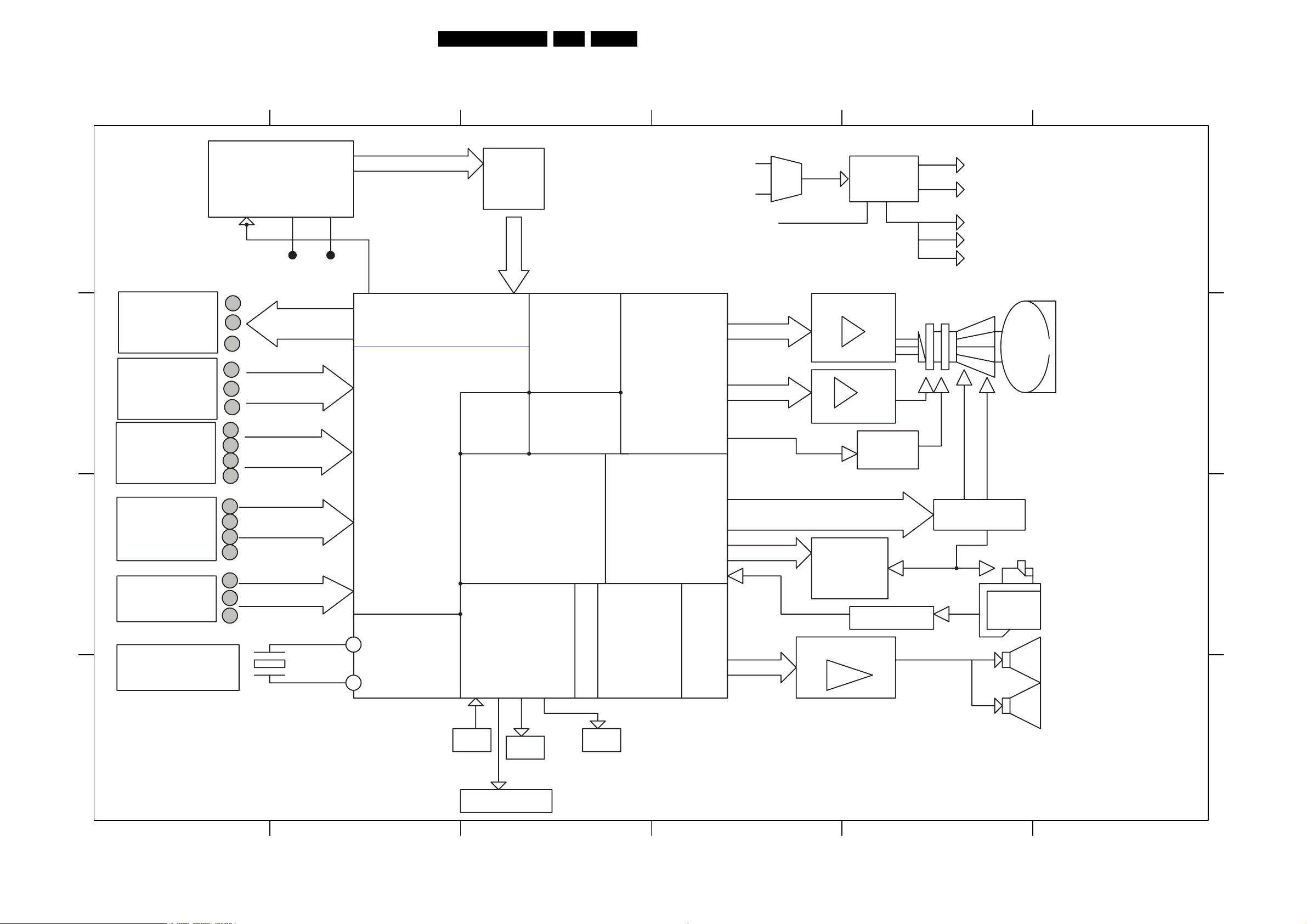

Block Diagrams, Test Point Overview, and Waveforms

6. Block Diagrams, Test Point Overview, and Waveforms

Block Diagram Mono Carrier

13TC7.1U CA 6.

54321

6

FSS TUNER

VIF/SIF

Ac in

SAW

D

AGC IN

Stb P1.1 99

MAIN

Power

Suply

12V

+B (130V)

13V(Audio)

D

5V

5V (ST)

3.3V(ST)

5V 33V

P900 REAR

AV OUTPUT

P902

C

REAR AV IN

P901/P903

REAR AV IN

S-SHS IN

P960/P905

SIDE AV IN

SIDE SVHS IN

B

31 AGC OUT

36 A-OUTSL

37 A-OUTSR

48 SVO

VIF & SIF

53 AUDIO INL

54 AUDIO INR

55 CVBS2/Y2

49 AUDIO INL

50 AUDIO INR

51 CVBS4/Y4

52 C4

56 AUDIO INL

57 AUDIO INR

58 CVBS3/Y3

59 C2/C3

IO PORT

Color

Decoder

Micro

CC V-CHIP

POWER

YUV

Procrssor

RGB

RGB OUT 85,86,87

ROTATION 113

SVM 65

Jungle

VDRA 23

VDRB 22

E-W 21

RGB

PWM

V+ V-

EW, HD

78 R/PrIN3

P904 REAR

Y Pb Pr IN

24.576MHZ

79 G/YIN3

80 B/PbIN3

PLL

10 XTALIN

11 XTALOUT

I/O Port

120 KEYB

97 IR P0.5

103 LED P0.3

A

DSP

D

Stereo

C

BTSC

109 SDA P1.7

108 SCL P1.6

AUDIO

OUT

RGB Amp

Rot Amp

VM

Pin out

H-drive

H-out

Feedback

AUDIO AMP

C

H,V-out

B

Hout

FBT

L

R

A

IR

Key buttons

1234 65

LED

NVM

H_17090_008.eps

160307

A

Page 14

Block Diagrams, Test Point Overview, and Waveforms

Block Diagram ATSC Module

14TC7.1U CA 6.

$WL

7KHDWHU

/LQNB,45

/LQNB5HVHW

03(* 76

6<6B, &

''5

0%

793

+RVW,&

6:

+RVWB,& ,&B6:

,&6:

+RVW, &

$QDORJ5)$*&

)/$6+

0%

<3E3U

UG/3)

&2(PLWWHU

'9070RGXOH

0+]

&/2&.

,6

$XG

3&0

'$&

&2(PLWWHU

$8'B/5

Personal Notes:

/'

7XQHU

7XQHUVHFW

/'

6KDUS

6$:

7KRPVRQ

'77

/09 $&0

3%66

03

VKDUS

&KDVVLVERDUG

9

9

1&3

7RWDO

H_17090_009.eps

160307

E_06532_012.eps

131004

Page 15

Circuit Diagrams and PWB Layouts

Y

C

15TC7.1U CA 7.

7. Circuit Diagrams and PWB Layouts

Mono Carrier

21

R516

470

C512

Q512

1n

CRT500

GND

TUBE

G2G3

D

< H1 >

< H2 >

< H3 >

+200V

C503

22uF/250V

+

R505

C504

33

33n

+200V

4

NC

L501

3

22uH*

Heat

2

GND

1

G1

C505

1000p/2KV

R541

1.5K

R540

R542

470

2.2M

+

C540

10U/250V

D540

8

1N4004

8

R519

KR

R529

KG

1K

R539

KB

1234567

1234567

P502

BC422

Q513

1K

1K

P500

R518

470

BC423

R528

470

R538

470

Q522

BC422

BC423

BC422

Q533

BC423

R517

560

R526

470

C522

1n

Q523

R527

560

R536

470

C532

Q532

1n

R537

560

CRT BOARD

1K

C265

2.2uF

C266

2.2uF

+

+

L

1

GND

R251

R250

1K

2

R

47K

3

R252

P209

R253

47K

+5V

68K

R200

C

P900

REAR AV OUT

D908

5.6V

P902

REAR AV Input

D914

5.6V

B

D911

4.7V

P904

REAR YUV INPUT

REAR AV I/O

P951

SIDE RUDIO INPUT

A

P960

SIDE AV I/O

R912

1K

5V

Q900

BC847A

R910

75

D910

5.6V

R904

330

R902

R905

330

R903

D901

5.6V

R917

D912

5.6V

47K

R914

D913

4.7V

47K

R913

Cb

D903

R921

5.6V

Cr

D904

R922

5.6V

Y

D905

R923

5.6V

P961

P200

1

1

2

2

3

3

4

4

5

5

6

6

7

7

D906

5.6V

D907

5.6V

Q901

BC857A

R908

1K

C904

C902

10uF

100pF

+

100K

Q903

BC847A

C903

C905

100pF

+

10uF

100K

Q902

BC847A

C918

1uF

R919

100

+

C915

75

100pF

C919

2.2uF

R916

1K

+

C912

100pF

C917

2.2uF

R915

1K

+

C914

100pF

R927

75

C921

100P

R928

75

C922

10P

R926

75

C923

10P

R924

R925

Cb

100

C926

100pF

R3

V3/Y3

Cr

100

C928

100pF

Y

100

C927

100pF

C960

R962

100pF

L3

1K

47K

R960

R963

R3

1K

47K

C961

R961

100pF

R929

V3/Y3

100

C930

82

100pF

R932

C3

100

C929

82

100pF

CUP & SIGNAL PROCESS

1 2 3 4 5 6 87

R204

1K

C204

2.2nF

R201

39K

C203

2.2uF

33

AVL

+

34

A.IN5L

35

A.IN5R

R203

36

1K

A.OUTSL

R202

37

A.OUTSR

1K

C201

C200

220nF

10uF

+5V

C235

100nF

L3

C3

38

DECSDEM

C202

+

3n3

39

AUDEEM

40

C229

100nF

C230

4.7nF

L204

10uH

L205

10uH

+

C235A

10U

C236

2.2uF

C237

2.2uF

C231

0.1uF

C232

22nF

GND2

R241

41

390

PLLIF

C234

42

SIFAGC

+

1uF

43

IFVEDIO OUT

44

DVB/FM OUT

C230A

45

10U

VCC8V

+

C228

2.2u

46

AGC2SIF

+

47

VP2

R225

48

1K

SVO

49

A.IN4L

50

A.IN4R

51

CVBS4/Y4

52

C4

53

A.IN2L

54

A.IN2R

55

CVBS2/Y2

56

A.IN3L

+

57

A.IN3R

+

58

CVBS3/Y3

+

59

C2/C3

60

A.OUTL

61

A.OUTR

C239

1uF

62

A.OUTHL

+

63

A.OUTHR

+

C238

64

1uF

CVBSO

5V

R218

39

+

C240

47uF

Q211

BC847A

P201

3

12V

12V

GND

2

1

VM

220

R219

R236

AOUTL

AOUTR

1k

D226

1N4148

R525

15K

C205

22nF

R535

15K

D531

4148

32

EHT

65

R2201KR221

47k

R235

56k

R234

D511

4148

270

D521

4148

R533

RF AGC

AV-MUTE

680

R205

31

AGCOUT

FBISO66SVM

10K

SANDCAST

270

100

R515

15K

270

R523

67

H OUT

C4544

1K

R222

+200V

Q511

C4544

R513

Q521

10

10

R534

RF AGC

3

SIF230SIF1

R223

L206

10uH

C241

10uF

Pb

6

1M

R226

Bin

Gin

Rin

150nF

R501

1K

75

P503

72

5

4

3

2

1

21

C207

1nF

24

VIFIN225VIFIN1

YSYNC

YIN

73

C267

0.1uF

C245

0.1u

R260

R261

R262

S006A

VDRA

100

R207

R208

C209

1nF

23

22

VDRA

YOUT

75

74

R227

470K

ABL

R511

47

R512

10K

10

R514

C511

330P

R521

47

GND

10K

R522

AKB

R524

C521

330P

Q531

4544

R531

47

10K

R532

C531

330P

4

C206

39K

R206

26

28

27

29

VSC

IREF

GNDIF

PrIN70PbIN

+5V comb69GND comb68HOUT

71

C242

0.1uF

C244

0.1u

C243

0.1u

+

75

75

Pr

Y

12345

P203

3

P+

TUNER IF

VDRB

100

C213

1nF

VDRB

UOUT

VOL+

TU101 T

R010B

3K9

R209

100

C208

10uF

21

E-W

76

R237

2.2K

Q204

BC857A

C252

2N2

R240

390K

E-W

R027A

3.9K

+5V

R101

R100

S004A

+

20

77

R238

P-

10K

68K

DECBG

INSSW3

C246

0.1uF

4.7K

10uH

VOL-

MENU

S002A

R026A

470

S003A

R025A

390

S001A

R024A

330

R023A

220

P001D

KEY

P001B

1

2

DQU2 ALPS

NC15V2NC3NC4RF-AGC533V11GND12SCL14SDA15GND16IFA17IF-AGC18GND19IFD120IFD2

SCL-T

SDA-T

C101

D102

R105 alt

10K

R106 alt

10K

12

D.GND

100P

R104

100

Z200

24.576MHz

11

XTALOUT

C114

100P

R109

100

R120

22

R121

22

TUN_SDA

TUN_SCL

R245

470K

R244

3.3K

22n

C264

C223

100nF

100uF

+

9

10

XTALIN

vrefP_Sdac

100uF

RFAGC-T

5V-T

C117

C103

+

L101

C102

10n

BSH103

Q105

R103

39K

D100

IN4148

SDA

4

SCL

3

GND

2

1

VIDEO

P130

TO R917

C217

C212

100nF

100uF

+

C210

C215

22nF

2.2uF

+

12K

R210

C214

C211

6n8

220nF

17

18

19

GND1

SECPLL

33V-T

+33V

C105

10n

47uF/50V

+

BYV79C33

C106

0.01uF

3.3V

+

10uF

C100

R130

100

R131

100

C130

C131

100P*

100P*

L200

10uH

+5V

C216

10nF

14

15

13

VP1

PH2LF16PH1LF

VG/LED

DECDIG

+3.3V analog88BO87GO86RO85BLKIN84BCLIN83LPF82GND381B/PbIN380G/YIN379R/PrIN378VOUT

C255

220nF

100

100

100

R232

R231

L208

10uH

33K

R270

220

R228

Cr Y

C248

100nF

C249

100nF

C251

+

4.7K

R230

R229

0.1uF

C250

+

10uF

C253

33uF

L207

10uH

R271

5V

18K

C270

Cb

D204

BCL

5.6V

2200P

STANDBY

S008

R010B

3K9

KEY

GND

12345

IFAGC-T

R107

IFA

IF-AGC

5V

Q102

3 4

6

UM6KIN

C115

100n

ABL

+3.3V-STB

C222

L201

1uH

7

6

8

VrefP_Sdac

VrefN_Sdac

VREFAD_NEG

VREFAD_POS

C256

220n

91

L209

10uH

C258

100nF

D001B

LED

VCC

100

C111

10n

R112

10K

5

2

VrefN_Sdac

C257

47uF

4

LED

R009B

470

R008B47

IR

IFD1-T

R108

2.2

alt

alt

C112

100n

IFD1

1

1

L202

1uH

4

5

3.3VA3

VrefP_Sdac

IC200

TDA12000H

TDA12001H

VDDA1

GNDA92VREFAD

93

+

C260

220nF

L210

10uH

IR001

+

C001B

47u

IR BOARDKEY BOARD

IFD2-T

alt

21

R110

2.2

alt

C113

100n

IFD2

R119 alt

10K

5

2

C116 alt

100n

C225

C224

100nF

10uF

+

2

3

GAME L P1.5

1.8VC4

GAME R P1.4

MUTE P2.4

KEYB P3.3

X-RAY P3.2

DECV1V8

SCART1 P3.1

SCART2 P3.0

ROTATION P2.2

TUNING P2.0

SDA2 P1.3

SCL2 P0.0

IBO D/A P0.1

IBO STB P0.2

TV STB P1.1

VDDA2

94

95

C108

0 .01

C107

10nF

R113

8

34

6

Q103

UM6KIN

Q104

BC847

IFD2

12345

P100

GND1GND

P1.2

GND

1.8V

P2.5

GND

1.8V

P2.3

P2.1

3.3V

SDA P1.7

SCL P1.6

LED P0.3

P0.4

VSSC2

VDDC2

IRQ P1.0

IR P0.5

VDD96VSS

C261

220nF

312

IFD1

3.3V

R114

GND

R116

R117

51

C226

100nF

GND

IF-AGC

C262

47uF

WP

n.c.

A2

Vss

E2PROM I/O

L102

1UH

680

R118

150

22

R122

4.7K

C227

L203

10uF

10uH

+

128

127

126

125

C017

100nF

124

123

122

C018

121

0.01uF

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

L211

1uH

+

Q208

BC857A

J214

0

IC001

24C32

C004

R010

10nF

100

Vdd

R092 NC

PTC

0

R009

100

SCL

C003

22pF

R011

100

SDA

C005

22pF

150

+9V

R115

R111

560

Z100

M3953M

C109

10nF

Q101

C3779

C110

10nF

SW

SDA

54321

Z101

M9370M

54321

SCL

+5VSTB

R093

R094

10K

100

C019

100uF

+

R018

10K

R033

2K2

R256

Q206

BC857A

D006

1N4148

D005

R030

1N4148

2.2K

R023

5.6K

R032

5.6K

R027

3.3K

R029

3.3K

R045

10K

R050

22K

R051

3.3K

R047

2.2K

C029

100u

R048

3.3K

D002

D004

220

220

R255

R024

100

R031

100

D010

3V9

R039

1K

L002

10uH

C023

220nF

100

R025

100

R026

R035

100

R036

100

R034

100

5V1

D001

220

R257

Q207

BC857A

P003

123

4

+5VSTB

PTC

SCL

0

SDA

1

2

C084

10n

5VSTB

3

4

P001

C086

IR

5

LED

4

+5VSTB

3

KEY

2

GND

1

1V8A

PTC

L001

10uH

MUTE

3.3V

KEYB

X-RAY

SDA

1

SCL

2

IIC SW

3

RESET

4

5

6

TUN_SDA

7

TUN_SCL

8

P008

1K

ROTATION

R022

RELAY

+3.3V

SDA

SCL

RESET

LED

AV-MUTE

10K

R052

Q205

BC857A

D008

1N4148

+

STB

47K

R049

IIC SW

IR IN

C277

1V8D

1000u

+5V

+

C278

0.1

B OUT

5

G OUT

4

R OUT

3

GND

2

AKB

1

P202

Q081

C085

D667

100uF

+

R087

680

D081

10n

5V1

D082

1N4148

C219

C218

0.1u

100u

1V8A

+

C218A

C219A

0.1u

100u

1V8D

+

VDRB

VDRA

H-OUT

E-W

X-RAY

ABL

SANDCASE

BCL

LINE&FRAME DEFLECTION

AOUTL

AOUTR

MUTE

2K7

AUDIO AMPL

ROTATION

AC 120V 60H z

C083

C088

100uF

10n

C087

10n

R086

10

P801

3

2

1

Q080

D667

+

R090

120

D080

3.9V

D852

1N4001

+

C829

4700U/16V

STBY

IC201

5VSTB

R606

IC202

1117D

0

1N4148

Q601

BC847A

1117D

100uF/50V

J309

D414

C090

L212

220U/16V

InOut

+

0.6μH

Gnd

+5V

InOut

Gnd

C350

1500P

R314

1K

R350

2K2

D300

C307

C300

47UF/25V

1N4148

+

+

R300

1K2

D411

1N4001

+14V

12V

D412

1N4001

C405

D409

R412

0.1uF

1N4148

10K

R430

0

D282

1N4148

+12V

D283

1N4148

Q281

BC847A

22uF/16V

D623

Q602

4148

BC857A

R607

+

C609

2K7

R608

1uF/50V

2K7

CRT

Conversion table

A68QFN893X002 37-050120-5020T 6800PF

P802

C801

AC275V/22 0n

3

2

1

F800

FUSE T5AL 125V

RELAY

+5VSTB3.3V

Q820

2CS2688

Q824

BF422

6.8K 5W

D823

9V1

Q823

R829A

C1815

4.7K

R829

47K

InOut

1.5 3W

Gnd

C091

0.1u

IC090

7805

220U/16V

R316

1K

C334

2200P

-14V

+14V

D307

D306

3V9

4148

D308

4148

C406

C402

1000u/25V

+

+

R413

820

Q403

BC846B

C404

R406

Q402

470

C639

R282

68

D281

1N4148

Q280

BC857A

R286

R285

0

470

D280

R283

24V

430*

+

C600

22uF/16V

R603

C604

4K7

+

R604

3K3

D624

4148

R609

1K

R610

1K

T402 C410 C414 L400

T801

36-LIF007-XX0

1

R801

1M 1/2W

+12V

R03

1K

+

C02

100uF/16V

D851

1N4001

R820

4.7 1W

R821

R822

D822

33K 2W

5V1

Q822

R828

C1815

6.8K

10n

220U/16V

C832

R012

C833

+

D832

8V2

C835

+

R834

1K

INPUT

C351

2200P

C308

+

+

D309

1N4001

56 1/2W

36-HDR029-XX1*

D4151N4148 R437

VCC

T401

Q409

BC857A

C360

100uF

R833

1K

+

C407

0.01uF

0.01u

POMP UP

+

C323

100uF/35V

15k

R438

36k

BZX79C5V6

D408

C093

220uF/25V

C313

50V/4.7uF

R410

R409

R411

120 2W

22n

P402

R284

100K

+12Va

C602

4700p/63V

R600

0.22uF/63V

4K7

C601

R601

3K3

4700p/63V

C605

C606

C607

0.22uF/63V

100uF/16V

Q603

BC847A

Q604

BC847A

C408 C41 3 C411

3300PF

6200PF

C01

100uF/25V

D02

1N4148

+33V

+130V

R826

2.2K

C828

220UF16V

Q821

D667

Q825

STV8172A

GND

+

220uF/25V

Q405

2SD2638*

C424

1nF

R439

36k

R612

0.12/2W

+

C603

100uF/16V

+

Q605

BC857A

D625

4148

27n

+

R01

4K7

R02

27K

R826A

22K 2W

C423

220uF/160V

R827

750

D667

C325

0.33uF

C324

R418

68K

1N4148

D305

C611

470uF/16V

R602

470

R605

470

C608

100uF/16V

390n 600 UH

RT802

3D210

IC802

615A

D821

1N4148

+

R831

1.5 3W

1K 1/4W

OUT

R313

1

1W

3300P/1.6KV

Q407

630MFP

BC857A

10

11

7

6

8

+

+

+

220u/160V

R832

C408

R420

3.9/2W

Q404

+

C610

100uF/16V

R611

33K

L403

D01

1N4001

Q01

C2236

C851

1000uF/25V

+12Va

L801

100uH

+

C823

R825

33K

R824A

3K9

IC803

TL431

D831

C834

1N4001

10nF

+12V

L803

123

6V GND

VP

130V

D401

RS3FS*

D402

FR104

C412

4.7uF/50V

C612

10n

16

IC601

TEA2025B

9

13

12

D626

12V

4148

31 UH 5.6OHM

THE CIRCUIT CONTAINS AND ITSELF ARE SUBJECT TO CHANGE WITHOUT NOTICE

K802

C852

0.01uF

+

C850

470P/1KV

10n/500V

C824

R823

C826

100K 1/2W

1000P

C825

0.1 50V

R824

3K9

C830

220P/500V

C831

1000u

+

C841

1000uF/16V

L804

4

P807

IC301

VREF

R419

68 2W

6200P/1.6KV*

C410

C413 6200P/1.6KV*

L403

600UH*

C411

0.022uF/400V*

R443

120K

14

15

C613

100uF/16V

3

2

C615

100uF/16V

5

4

R421

5.6OHM

220n/250VAC

D850

RU3YX

D820

RU3AM

C820

470P 2KV

D830

RU3YX

+

RU3YX

C842

10nF

L404

4.7mh

C414*

390n/400V

470uF/16V

+

+

470uF/16V

R422

765

P803

X800

2

1

1

2

C802

R850

FUS 3A 250V

L802

C844

10u/50V

F802 2A 250V

D840

F801 2A 250V

C840

220P/500V

100K

R442

+

C614

C616

+

47n

C617

R428

5.6K

8

C803

400V/100n

RT801

MZ75-9RM

T803

BCK-4201-XX

16

15

9

11

+

12

13

14

C840A

2200P AC400V

R840A

8.2M 1/2W

36-LIF007-XX0

L806/J804

1

L803/J805

5

R813

22 1/4W

8

D811

FR104

R814

2K2 1/4W

C812

3300P

7

T802

C804A

470P AC400V

DB801

D3SB60*

C805A

R817

120K 2W

D814

1H8

470P AC400V

D810

FR104

C814

10u/35V

D812

FR104

C808

0.01U 1KV

C809

220P 1KV

10n 500v

R811

D813

6V2

+

C813

100n

C807

1K

C804

250V AC 4n7

R810

47K 3W

C806

470u/200V

R812

1K

D815

+

33V

6

R818

47K

1uF 50V

4

5

C811

C805

250V AC 4n7

STR-W6735

+

R815

100

IC801

1

37

C810

220P

R816A

0.22 2W

D

C815

680P 1KV

R816

NC

C

POWER SUPPLY

R315

2K2

C342

330n

C337

1000P

C401

220P500V

R433

1/2W 10K

D285

1N4148

+

D400

FR104MF

R425

R427

0.47

1/2W FUS

R426

0.47

1/2W FUS

R407

1 1/2W

+12V

R424

3.9K

+14V

Q282

1

10

2

7

11

8

4

5

37-FCAT02-EAA0A*

R428

5.6K*

R440

150K*

1N4148

D284

BC857A

R1301

10 2W

R1304

1K

R1307

1.2K

+200V

C400

22uF/250V

130V

C420

2200P

D413

5V1

C419

220P 500V

-14V

D405

+

FR104MF

C416

1000uF/35V

D404

FR105

+14V

+

C418

220P 500V

C415

1000uF/35V

+

D406

FR104

C417

4u7/50V

100

R287

P601

P600

C618

47n

NC

R440

150K

D311

R324

180

1W

R321

1

1W

TRL242 31uH

EHT

FOCUS

SCREEN

9

T402

R421

R422

10 1/2W *

R429

Q408

1K

BC847A

+

R1302

C1301

1K

100u/25V

R1303

470

Q1302

BC847A

C1302

1uF/50V

R1306

10K

R1305

470

+

Q1301

BC847A

C1303

1uF/50V

H_17091_003.eps

L400

R401 680

C421

100n

+

Q1306

A1015

< H1 >

< H3 >

< H2 >

* R435

200V

HERTER

GND

Q1303

C1815

Q1304

A1015

Q1305

C1815

P400

1

2

3

4

P403

4

3

2

1

+

C1304

2.2u/50V

071207

P1301

V+

VH-

H+

B

1

2

A

Page 16

Circuit Diagrams and PWB Layouts

Layout Mono Carrier (Top Side)

16TC7.1U CA 7.

40-9007PH-MAD1XG

H_17091_001.eps

051207

Page 17

Circuit Diagrams and PWB Layouts

Layout Mono Carrier (Bottom Side)

17TC7.1U CA 7.

40-9007PH-MAD1XG

H_17091_002.eps

051207

Page 18

CRT Panel

Circuit Diagrams and PWB Layouts

18TC7.1U CA 7.

D

C

B

5

B

CRT BD

< H1 >

< H2 >

< H3 >

+200V

C503

22uF/250V

C504

33n

+200V

4

NC

3

Heat

2

GND

1

P502

CRT

+

R505

33

L501

22uH*

R542

470

GND

G2

G3

R540

2.2M

+

C540

10U/250V

4

CRT500

TUBE

G1

R541

1.5K

D540

1N4004

C505

1000p/2KV

3

2

1

D

R516

D511

4148

270

D521

4148

270

R533

R515

15K

270

Q521

C4544

R523

+200V

Q511

C4544

10

R513

C511

330P

10

R524

C521

330P

Q531

4544

10

R534

C531

330P

R514

10K

R511

R512

10K

R521

47

R522

10K

R532

47

R531

47

470

R526

470

Q522

BC422

Q523

BC423

R536

470

Q532

BC422

Q533

BC423

C512

1n

R517

560

C522

1n

R527

560

C532

1n

R537

560

R525

15K

R535

15K

D531

4148

Q512

BC422

KR

KG

KB

4

5

6

7

8

4

5

6

7

8

R519

1K

R529

1K

R539

1K

1

2

3

P500

1

2

3

Q513

BC423

R518

470

R528

470

R538

470

B

P503

Bin

5

Gin

4

Rin

GND

AKB

H_17090_004.eps

3

2

1

R501

1K

140307

C

B

A

5

4

3

2

A

1

Page 19

ATSC: Power Reset

Circuit Diagrams and PWB Layouts

19TC7.1U CA 7.

C1 C1

LP103

LP103

1000R

1000R

500mA

500mA

12

CP113

CP113

100N

100N

IP103

IP103

LD1117-3.3V

LD1117-3.3V

3

IN

CP115

CP115

10U

10U

AAA

10V

10V

IP104

IP104

LD1117-2.5V

LD1117-2.5V

3

IN

CP119

CP119

10U

10U

A

10V

10V

+5VR

RP1241KRP124

1K

1

IN

CP139

+

+

CP140

CP140

A

A

CP139

10U

10U

6.3V

6.3V

A

4.7U

4.7U

6.3V

6.3V

CP142

CP142

100U

100U

16V

16V

A

2

RP126

RP126

4.7K

4.7K

EN

2

OUT

GND

1

2

OUT

GND

1

AAA

IP105

IP105

PQ010GNA1ZPH

PQ010GNA1ZPH

3

OUT

4

NC

GND

5

AA

YP112YP112

BP101

BP101

1

+6V

+6V

2

+6V

+6V

3

GND

GND

4

GND

GND

POWER_CONNECTOR

POWER_CONNECTOR

CP101

CP101

100P

100P

A

YP113YP113

A

V0.4 to V0.5 updated note

1 Added RP107 27K 1%

2 Changed RP105 to 15K 1%

3 Changed RP106 22K 1%

4 Changed Cp128 to 100N

5 Changed CP107 to 1000UF

If RP114 and DP104 are used: RP102

510ohm, RP127 2K, RP105 8.2K, RP106

10K.

+3.3VR

RP1121KRP112

1K

12

SP101

SP101

ALT

ALT

CP134

CP134

100N

100N

+6VIN

CP102

CP102

100N

100N

DP103

DP103

SS1P4

SS1P4

LP101

LP101

200R

200R

2A

2A

12

IP106

IP106

3

VCC

PT7M7803ST

PT7M7803ST

RST_

GND

CP103

CP103

100N

100N

2

1

+6VR

CP104

CP104

10U

10U

AA

10V

10V

RP114

RP114

20K

20K

ALT

ALT

+6VR

RP106

RP106

22K

22K

1

A

RP111

RP111

100R

100R

RP1131KRP113

1K

A

12

CP107

CP107

+

+

CP106

15K

15K

1

CP127

CP127

100N

100N

RP115

RP115

10K

10K

CP1371NCP137

1N

A

CP106

10U

10U

A

10V

10V

DP104

DP104

SS1P4

SS1P4

ALT

ALT

9

10

CP128

CP128

100N

100N

YP108YP108

YP109YP109

IP101

IP101

RP107

RP107

27K

27K

1

1000U

1000U

10V

10V

AAA

2

BS

EN

SS

GND

1

6

AA

Reset# pull up on +5V on

Chassis Board

NC1

CP105

CP105

10U

10U

10V

10V

RP105

RP105

A A

+3.3VR

LP102

LP102

200R

200R

2A

2A

CP122

CP122

10N

10N

4

IN

SW

FB

NC2

COPM

3

8

MP1411

MP1411

CP129

CP129

100P

100P

ALT

ALT

A

RESET#

DELAY_HW_RST#

CP108

CP108

0.33U

0.33U

A

10V

10V

DP105

DP105

4148

4148

RP102

RP102

2.7K

2.7K

5

7

RP108

RP108

10K

10K

CP130

CP130

4.7N

4.7N

A

RP101

RP101

10K

10K

ALT

ALT

RP127

RP127

10K

10K 10V

LP107

LP107

10uH

10uH

DP102

DP102

SS32

SS32

A

1

2

CP109

CP109

100N

100N

IN

EN

IP102

IP102

PQ050DNA1ZPH

PQ050DNA1ZPH

OUT

NC

GND

5

A

RP109

RP109

10K

10K

1%

1%

RP110

RP110

10K

10K

1%

1%

A

3

4

CP131

CP131

10U

10U

A

10V

10V

CP138

CP138

10N

10N

A

RP117

RP117

1K

1K

1%

1%

RP1031RRP103

1R

A

A

RP1160RP116

0

CP110

CP110

10U

10U

10V

CP132

CP132

10U

10U

10V

10V

4

2

+

+

A

+

+

A

35

TP101

TP101

TLV431CDBVR

TLV431CDBVR

Vr=1.24V

A

CP111

CP111

100U

100U

10V

10V

CP133

CP133

100U

100U

16V

16V

LP104

LP104

1000R

1000R

500mA

500mA

12

LP105

LP105

1000R

1000R

500mA

500mA

12

+5VR

RP118

RP118

332R

332R

RP119

RP119

4.7K

4.7K

ALT

ALT

A

RP120

RP120

240R

240R

1%

1%

RP121

RP121

10R

10R

CP141

CP141

10N

10N

6.3V

6.3V

A

CP112

CP112

10U

10U

AA

10V

10V

CP114

CP114

100N

100N

CP118

CP118

100N

100N

A

12

LP123

LP123

200R

200R

2A

2A

12

LP109

LP109

200R

200R

2A

2A

23

1

TP102

TP102

PBSS4540

PBSS4540

RP1221RRP122

1R

CP143

CP143

10U

10U

A

6.3V

6.3V

CP116

CP116

10U

10U

10V

10V

CP120

CP120

10U

10U

10V

10V

YP104YP104

YP105YP105

YP106YP106

YP101YP101

YP102YP102

+

+

+

+

RP1251RRP125

1R

CP144

CP144

10U

10U

6.3V

6.3V

CP117

CP117

100U

100U

16V

16V

AA

YP103YP103

CP121

CP121

100U

100U

16V

16V

+5VR

+3.3VR

+2.5VR

+1.8VR

+1.0VR

CP145

CP145

+

+

100U

100U

16V

16V

A

+1.5VR

POWER RESET

A

A

H_17090_011.eps

160307

Page 20

Circuit Diagrams and PWB Layouts

20TC7.1U CA 7.

ATSC: Tuner Link

A

CH106

CH106

47P

47P

ALT

ALT

+3.3V_LINK

RI119

RI119

20K

20K

RI136

RI136

100

100

RH105

RH105

100R

100R

RH106

RH106

2R2

2R2

RH107

RH107

2R2

2R2

RI129

RI129

20K

20K

RI128 33RRI128 33R

CI1421NCI142

1N

A

+3.3V_LINK

CI1551NCI155

1N

A

RI110

RI110

10K

10K

+1.0V_LINK

A

CI174

CI174

10U

10U

6.3V

6.3V

+3.3V_LINK

RI127

RI127

20K

20K

+1.8_LINK

LI107

LI107

2200R

2200R

CI141

CI141

4.7U

4.7U

6.3V

6.3V

A

RI122

RI122

33R

33R

CI154

CI154

4.7U

4.7U

A

6.3V

6.3V

A

A

AA

CI175

CI175

10U

10U

6.3V

6.3V

12

LI106

LI106

1000R

1000R

LI105

LI105

200R

200R

CI140

CI140

4.7U

4.7U

A

12

+1.8VR

CI139

CI139

100P

100P

A

LINK_INT#

+3.3VR

CI153

CI153

4.7U

4.7U

A

6.3V

6.3V

LINK_RESET#

SDA_SYS

SCL_SYS

LINK_SYNC

12

CI125

CI125

4.7U

4.7U

6.3V

6.3V

H_17090_011.eps

CI152

CI152

100P

100P

A

+1.0VR

CI124

CI124

100P

100P

A

160307

RI130 33RRI130 33R

CI143

CI143

10N

10N

A

+3.3V_LINK

RI123

RI123

10K

10K

ALT

ALT

RI1240RI124

0

A

CI157

CI157

10N

10N

A

+3.3V_LINK

RI151

RI151

10K

10K

A

CI1271NCI127

1N

RI150

RI150

10K

10K

+3.3V_LINK

RI121

RI121

4K7

4K7

CI156

CI156

10N

10N

A

CI126

CI126

4.7U

4.7U

6.3V

6.3V

RI102

30P

30P

2%

2%

2

A

2

A

CI148

CI148

10N

10N

A

CI135

CI135

10N

10N

A

CI163

CI163

10N

10N

A

+3.3VR

23

QI101

QI101

25M14Hz

25M14Hz

CI102

30P

30P

A

2%

2%

CI107

CI107

10U

10U

6.3V

6.3V

CI112

CI112

4.7U

4.7U

6.3V

6.3V

CI115

CI115

100N

100N

A

CI149

CI149

10N

10N

A

CI164

CI164

10N

10N

A

RI146

RI146

51R

51R

RI1471KRI147

1K

1

CI170

CI170

100N

100N

A

RI102

10R

10R

CI136

CI136

10N

10N

A

CI165

CI165

10N

10N

A

A

A

A

A

CI108

10N

10N

CI1131NCI113

1N

CI116

CI116

100P

100P

CI150

CI150

10N

10N

A

CI137

CI137

10N

10N

A

CI1691UCI169

1U

RI145

RI145

33K

33K

TI101

TI101

BC847B

BC847B

RI101

RI101

100K ALT

100K ALT

CI166

CI166

10N

10N

A

CI109

CI109

100N

100N

CI151

CI151

10N

10N

A

CI138

CI138

10N

10N

A

CI114

CI114

100N

100N

ALT

ALT

CI167

CI167

10N

10N

A

+1.8_LINK

TH102

TH102

2

UM6K1N

UM6K1N

6

1

3

4

CI110

2

1

LINK_DATA

LINK_VALID

1

CH10RCH1

0R

RI155

RI155

3.3P

3.3P

2

LINK_CLK

CI110

100N

100N

5

CH102

CH102

<>

100N

100N

<>

IF_AFC

A

CI106

CI106

100N

100N

ALT

ALT

CI105

CI105

100N

100N

LI112

LI112

220nH

220nH

CI173

CI173

5.6P

5.6P

ALT

ALT

LI110

LI110

220nH

220nH

ALT

ALT

LI111

LI111

220nH

220nH

ALT

ALT

CI172

CI172

5.6P

5.6P

ALT

ALT

12

LI101

LI101

2200R

2200R

RI154

RI154

470R

470R

ALT

ALT

2

CH20RCH2

0R

RI153

RI153

3.3P

3.3P

1

CI101

A

1

LI102

LI102

2200R

2200R

1

LI103

LI103

2200R

2200R

12

LI104

LI104

2200R

2200R

CI134

CI134

10N

10N

A

CI162

CI162

10N

10N

A

RI148

RI148

100R

100R

DI101

DI101

LED

LED

RI149

RI149

1

2.2K

2.2K

CI101

CI104

CI104

CI103

CI103

100N

100N

100P

100P CI102

A

A

6.3V

6.3V

CI111

CI111

100N

100N

1

LI113

LI113

2220nH

2220nH

2

RI112

RI112

33R

33R

RI113

RI113

33R

33R

RI114

RI114

33R

33R

TI102

TI102

BC847B

BC847B

+1.8_LINK

+1.8_LINK

+1.8_LINK

23

A

II101

II101

1

VDD_3P3_1

2

DGND_1

3

VDD_1P0_1

4

DGND_2

5

VDD_1P8_1

6

OSC_XTAL_OUT

7

OSC_XTAL_IN

8

AGND_1

9

AVDD_OSC

10

FAT_INP

11

FAT_INN

12

AVDD_FAT_1

13

AGND_2

14

FAT_VREF_P

15

AVDD_FAT_2

16

AGND_3

17

FAT_VREF_N

18

FDC_INP

19

FDC_INN

20

AVDD_FDC_1

21

AGND_4

22

FDC_VREF_P

23

AVDD_FDC_2

24

AGND_5

25

FDC_VREF_N

26

DGND_3

27

AVDD_FS_1

28

AVDD_FS_2

29

AGND_6

30

AGND_7

31

FS_OUTP

32

FS_OUTN

33

VDD_1P8_2

34

DGND_4

35

VDD_1P0_2

36

DGND_5

37

VDD_3P3_2

38

VDD_3P3_3

39

PDD_CRX

40

PDD_DRX

41

MPEG_DATA_0

42

MPEG_DATA_1

43

VDD_3P3_4

44

VDD_1P8_3

45

VDD_1P0_3

46

DGND_6

47

MPEG_DATA_2

48

MPEG_DATA_3

49

DGND_7

50

MPEG_DATA_4

51

MPEG_CLK

52

VDD_1P0_4

53

DGND_8

54

MPEG_DATA_5

55

VDD_3P3_5

56

VDD_1P8_4

57

MPEG_DATA_6

58

DGND_9

59

MPEG_DATA_7/SER_DATA

60

DGND_10

61

VDD_1P0_5

62

DGND_11

63

MPEG_DATA_EN

64

VDD_3P3_6

ATI312

ATI312

A

AVDD_PLL

AGND_8

DGND_23

VDD_1P0_11

DGND_22

VDD_3P3_13

IF_AGC

FDC_AGC

AUX_AGC

VDD_1P8_9

VDD_3P3_12

RF_AGC

DGND_21

VDD_1P0_10

PDET_REF_OUT

VREF

DGND_20

DGND_19

VDD_1P0_9

VDD_1P8_8

VDD_3P3_11

GPIO_0

GPIO_1

VDD_3P3_10

DGND_18

GPIO_2/PDET_C

GPIO_3

GPIO_4

DGND_17

DGND_16

I2C_ADDR1

I2C_ADDR0

GPIO_5

VDD_1P0_8

VDD_1P8_7

VDD_3P3_9

GPIO_6

GPIO_7

GPIO_8

DGND_15

DGND_14

GPIO_9

GPIO_10

VDD_1P0_7

VDD_1P8_6

VDD_3P3_8

TRST

DGND_13

DGND_12

POWER_RESET#

I2C_DATA

VDD_1P0_6

VDD_1P8_5

VDD_3P3_7

I2C_SCL

MPEG_PKT_SYNC

MPEG_ERR

NC3

NC2

NC1

TDO

TCK

TMS

CI122

CI122

A

10N

10N

+3.3V_LINK

RI135

RI135

33R

33R

LINK_TDO

CI133

CI133

10N

10N

+1.8_LINK

LI108

LI108

2200R

2200R

12

A

RI1321KRI132

1K

CI161

CI161

10N

10N

A

TCK

TMS

TRST#

LINK_TDI

A

CI123

CI123

100P

100P

CI132

CI132

10N

10N

RI1341KRI134

CI121

CI121

1K

100N

100N

A

CI147

CI147

CI146

CI146

CI145

CI145

10N

10N

10N

A

RI1311KRI131

1K

CI119

CI119

100P

100P

A

KI101

KI101

PAD

PAD

CI160

CI160

10N

10N

A

RI111

RI111

10K

10K

RI118 33RRI118 33R

RI117 33RRI117 33R

RI116 33RRI116 33R

RI115 33RRI115 33R

AA

CI131

CI131

10N

10N

10N

10N

10N

A

A

+3.3V_LINK

RI125

RI125

10K

10K

ALT

ALT

RI1260RI126

0

A

CI158

CI158

10N

10N

A

+3.3V_LINK

A A

CI129

CI129

CI128

CI128

10N

10N

10N

10N

A

+3.3V_LINK

CI159

CI159

10N

10N

A

+3.3V_LINK

CI130

CI130

10N

10N

CI144

CI144

10N

10N

A

RI152

RI152

10K

10K

A

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

TDI

72

71

70

69

68

67

66

65

C2 C2

TUNER LINK

RH101

RH101

100R

100R

CH107

CH107

CH108

CH108

47P

47P

47P

47P

A

A

ALT

ALT

ALT

ALT

DH101

DH101

SS1P4

SS1P4

ALT CI108

ALT

LH104

LH104

2

1

220R

220R

CH117

CH117

CH116

CH116

10N

10N

100P

100P

A

A

BI101

BI101

HEADER5

HEADER5

RH103

RH103

100R

TUN_SDA

TUN_SCL

TUN_SW

Updated note:

100R

CH109

CH109

47P

47P

A

ALT

ALT

1 Added RI119 20K

2 Added RI1136 100 ALT

3 Added CH102 20K

4 Added TH102 UM6K1

5 Added DH101 SS1P4 ALT

6 change RI127 and RI129(3.3K) to 20K

5

4

3

2

1

A

Page 21

Circuit Diagrams and PWB Layouts

21TC7.1U CA 7.

ATSC: Audio Video

BV101

BV101

1

R/Pr

C3 C3

AUDIO VIDEO

CV1111UCV111

1U

A

A

CV126

CV126

470p

470p

A

A

CV123

CV123

82p

82p

LV110

LV110

3u9

3u9

+5_VID

RV105

RV105

470R

470R

TV101

TV101

BC857B

BC857B

A

RV131

RV131

100R

100R

RV140

RV140

100R

100R

1%

1%

A

A

IA103

IA103

5

VIN

3

CKO

6

X1

ICS726

ICS726

IA101

IA101

1

X1

6

CKO

3

VIN

4

GND

A

PI6CX100-272WEX

PI6CX100-272WEX

ALT

ALT

IA102

IA102

1

BCK

2

DATA

3

LRCK

16

SCK

13

MD

14

MC

15

ML

5

NC

PCM1754

PCM1754

CV127

CV127

82p

82p

VOUTL

VOUTR

VDD

GND

QA101

QA101

27MHz

27MHz

VDD

NC2

NC1

VCC

Vcom

AGND

DGND

LV102

LV102

200R

A

200R

LV103

LV103

200R

200R

LV104

LV104

200R

200R

LA102

LA102

2200R

2200R

CA113

CA113

4.7U

4.7U

CA1061NCA106

1N

A

RA107 1KRA107 1K

RA108 1KRA108 1K

+5_VID

RV106

RV106

470R

470R

TV102

TV102

BC857B

BC857B

A

RV133

RV133

100R

100R

RV139

RV139

100R

100R

1%

1%

A

4

2

1

X2

8

X2

5

7

2

6

11

ZR

12

ZL

7

8

10

9

4

A

CA111

CA111

6.8P

6.8P

A

2%

2%

AAA

A

CA116

CA116

+5_VID

RV107

RV107

TV103

TV103

BC857B

BC857B

A

CA112

CA112

100P

100P

CA107

CA107

100N

100N

A

10U

10U

470R

470R

+3.3VR

AUD_MD

AUD_ML

LINK_DATA

LINK_CLK

LINK_SYNC

LINK_VALID

RM5010RM501

0

RM503

RM503

0

0

ALT

ALT

A

+3.3VR

A

RM5020RM502

0

RM504

RM504

0

0

ALT

ALT

A

KV502

KV502

RM5050RM505

0

A

A

A

A

PAD

PAD

A

RA112 1K

RA112 1K

RA113 1K ALTRA113 1K ALT

RM5070RM507

0

A

RM5060RM506

0

A

ALT

ALT

A

D25

D26

C26

C25

A25

A24

B24

D22

A22

A21

C21

B20

C20

D20

C19

B19

D24

B22

B21

A19

D17

A12

D15

C10

D10

R25

P25

N25

M25

U23

U24

R24

P24

U26

T26

T25

U25

W26

Y25

Y24

AE23

AC24

AB23

AD23

AE5

AD5

AE24

IM101A

IM101A