Philips 2moa3 DATASHEETS

TM

HT2 MOA3 S20

HITAG

Revision 1.1

2 Chip Module

August 1997Preliminary Specification

Specifications of the HT2 MOA3 S20 Rev. 1.1 1997-08-19

Table of Contents

1 Definitions.............................................................................................................................. 3

1.1 Objective of the Specifications..................................................................................................................... 3

1.2 Definition of the Chip Module..................................................................................................................... 3

1.3 Use of the Modules......................................................................................................................................3

2 Specifications.........................................................................................................................4

2.1 Mechanical Properties ................................................................................................................................. 4

2.2 Materials .....................................................................................................................................................4

2.3 Temperature Range .....................................................................................................................................4

2.4 Storage Conditions ...................................................................................................................................... 5

2.5 Delivery Conditions.....................................................................................................................................5

2.6 Electrical Specifications............................................................................................................................... 6

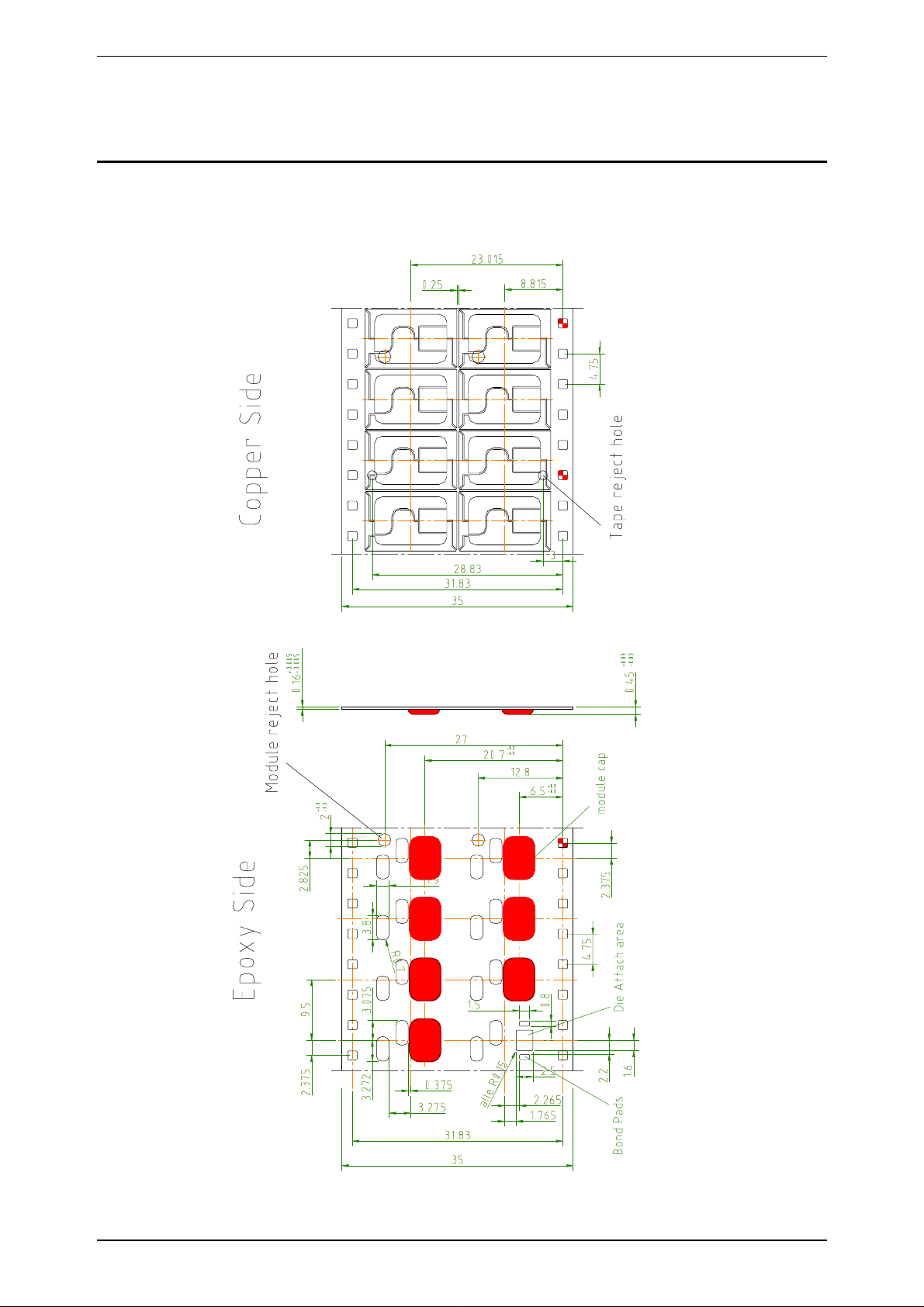

3 Drawing of the Chip Module HT2 MOA3 S20 ..................................................................... 7

3.1 Drawing of the Reel.....................................................................................................................................7

3.2 Module outline suggestion........................................................................................................................... 8

3.3 Splicing Specification..................................................................................................................................9

4 Coil Specifications................................................................................................................ 10

5 Functional Description of HITAG 2 ................................................................................... 12

5.1 Memory Organization........................................................................................................ ........................ 12

5.2 Operation Modes and Configuration.......................................................................................................... 13

5.2.1 Modes of Operation............................................................................................................................13

5.2.2 Status Flow ........................................................................................................................................14

5.2.3 Configuration.....................................................................................................................................15

5.3 Configuration of Delivered HITAG 2 Transponders................................................................................... 16

5.4 Definition of Passwords and Keys..............................................................................................................17

6 Quality Inspection ............................................................................................................... 18

7 Characterisation and Test of the Final Transponder.........................................................19

7.1 Characterisation of the Transponder.......................................................................................................... 19

7.2 Final Test of the Transponder.................................................................................................................... 19

8 Ordering Information..........................................................................................................20

HITAGTM is a trademark of Philips Electronics N.V.

Ht2moa3.doc/HS Page 2 of 22

Specifications of the HT2 MOA3 S20 Rev. 1.1 1997-08-19

1 Definitions

1.1 Objective of the Specifications

This specification lists the parameters to be fulfilled by the HITAG 2 chip module

HT2 MOA3 S20 for contactless smart cards or similar transponders (as e.g. discs).

1.2 Definition of the Chip Module

A chip module is an electronically packaged chip covered with a globe top cap. The

HT2 MOA3 S20 is above all used as card module, i.e. for further lamination into contactless

smart cards according to ISO 10536.1.

So the HIT AG 2 chip module HT2 MOA3 S20 is best suited for customers that do not want t o

spend time with micro assembly and therefore start - e.g. ISO card production - with the

HITAG 2 chip module.

1.3 Use of the Modules

The HITAG 2 modules are designed to be connected to a coil and then to be further processed by

packaging into a transponder (e.g. lamination into an ISO smart card). Specific processing

information for the coil-module connection and packaging is given in the specification.

For production of contactless chip cards it is recommended to prepunch card foils to create a

recess for the chip module in the card body.

Ht2moa3.doc/HS Page 3 of 22

Specifications of the HT2 MOA3 S20 Rev. 1.1 1997-08-19

2 Specifications

2.1 Mechanical Properties

Width

(Proposed Punching Outline)

Length

(Proposed Punching Outline)

Overall Thickness 0.45 mm ± 0.03 mm

Film Thickness 0.16 mm ± 0.005 mm

Bondpad Size for

Transponder Coil / Module

Interconnection

7.55 mm

11.75 mm see also drawing in chapter 3

1.9 x 3.5 mm Suitable for Welding/Soldering/

Conductive Gluing

2.2 Materials

Tape 110 µm Glass epoxy

Copper Plating 35 µm ED copper

Bond Plating Ni / Au Suitable for Al and Au wire

bonding

Backside Plating Ni / Au

Glob Top Filled Epoxy Thermal curing

2.3 Temperature Range

Operating -25°C to +85°C For packed transponder,

depending on type of package

Processing 150°C for 30 minutes at a standard lamination

pressure for contactless smart

card plastic materials (e.g. PVC,

PET, ...)

Welding Parameters max. 25 ms @ 500 °C on bond pads

Soldering Parameters max. 3 s @ 390 °C on bond pads

Ht2moa3.doc/HS Page 4 of 22

Specifications of the HT2 MOA3 S20 Rev. 1.1 1997-08-19

2.4 Storage Conditions

Temperature 15 - 30 °C

Relative Humidity 40 - 70 %

Duration 1 year

2.5 Delivery Conditions

Delivery Identification Date of ready for shipment, reel numbers, total quantity of good

modules with the detail of good modules per reel, order number,

product type, no supplier identification on reels, bags and boxes.

Types of Delivery Chip modules on reel

approx. 15.000 to 20.000

pcs. per reel,

tape width super 35 mm,

pitch 9,5 mm, 2 rows

single chip modules (bulk goods)

Packing and Transport According to documentation

"Packing Method Modules (reel)"

"Packing Method Modules (singulated)"

Bad Module Marking All bad modules (mechanical and

electrical faults) must be punched by

reject hole for customer

Bad positions (reel): <20%

Splicing Specifications Tape material: adhes. tape 15,5 +/- 0,7

mm, thermal resistance at

<190°C by < 100 cN tractive power and

< 30 sec. duration.

Labeling Identification label on the reel and on

carton bag:

- Product type

- Number of the reel

- Total number of positions

- Number of good positions

- Date of sealing (to be checked)

- Two batches per reel only

- Batch number indication (only coded,

to be checked)

500 pcs . per bag

Order-No. 3322 845 04881

see drawings chapter 3

see drawings chapter 3

Ht2moa3.doc/HS Page 5 of 22

Specifications of the HT2 MOA3 S20 Rev. 1.1 1997-08-19

2.6 Electrical Specifications

Symbol min typ max Comment / Conditions

Absolute Maximum Ratings

Junction Temperature T

Input Peak Current I

J

INpeak

-55°C 140°C

30 mA

Latch up Current 100 mA MIL-STD 883D, Method 3023

ESD 2 kV MIL-STD 883D, Method 3015.7,

Human Body

Operating Range

Temperature T

Input Read Only Threshold

Voltage

Input Threshold Voltage

Input Read Voltage

Input Write Voltage

1)

3)

1)

3)

1)

3)

1)

3)

V

V

V

V

A

IN,RO

IN,TH

IN,RD

IN,WR

-40°C 85°C

2,8 Vp3,9 Vpstart modulation in read only

3,1 Vp4,2 Vpstart modulation after SETCC

3,5 Vp4,5 Vpread E²PROM

3,7 Vp4,7 Vpwrite E²PROM

R

ThJunctionAmbient

= 30 mA

I

INpeak

modes

≤ 30 K/W @

Demodulator

Range

3)

V

DEM_R

2,0 V

p

4,0 VpV

- V

INHigh

T0=8 µs, T

INLow

MOD

@ V

=6*T

INHigh

0

= 5,0 V

2)

Modulator

R_MOD linear

R_MOD nonlinear

3)

3)

Resonance Capacitor

3)

R

MODL

R

MODNL

4,5 kΩV

3,6 kΩV

INLow

INLow

≤ 2,0 V

≥ 2,0 V

p

p

p

C

ResInit

189 pF 210 pF 231 pF VIN = 4,0 V

EEPROM

Write Current

Read Current

4)

4)

I

W

I

R

25 µA VDD = 2,8 V

9 µA VDD = 2,8 V

Data Retention Years 10 @ 55°C

Write Endurance Cycles 100.000

1)

2)

3)

4)

tested on silicon level

V

IN

INHigh

INLow

MOD

= V

V

V

T

@ Ri = 10

IN1

− V

... voltage between connection pads

IN2

input voltage before modulation

input voltage during modulation

duration of the modulation

resistance of measurement equipment

Ω

k

p

Ht2moa3.doc/HS Page 6 of 22

Specifications of the HT2 MOA3 S20 Rev. 1.1 1997-08-19

3 Drawing of the Chip Module HT2 MOA3 S20

3.1 Drawing of the Reel

Ht2moa3.doc/HS Page 7 of 22

Loading...

Loading...