IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all Philips

Consumer Electronics Company** Equipment. The service procedures recommended by

Philips and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed

for the purpose. The special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES

which should be carefully read in order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service methods may damage the

equipment. It also is important to understand that these CAUTIONS and NOTICES

ARE NOT EXHAUSTIVE. Philips could not possibly know, evaluate and advise the

service trade of all conceivable ways in which service might be done, or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such

broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is

not recommended by Philips must first satisfy himself thoroughly that neither his safety

nor the safe operation of the equipment will be jeopardized by the service method

selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company will be

referred to as Philips.

WARNING

Critical components having special safety characteristics are identified with a or

"S" by the Ref. No. in the parts list and enclosed within a broken line* (where

several critical components are grouped in one area) along with the safety symbol

on the schematics or exploded views. Use of substitute replacement parts which

do not have the same specified safety characteristics may create shock, fire, or other

hazards. Under no circumstances should the original design be modified or altered

without written permission from Philips. Philips assumes no liability, express or

implied, arising out of any unauthorized modification of design. Servicer assumes all

liability.

* Broken Line ____ _ ____ _ ____ _ ____

FIRE AND SHOCK HAZARD

1. Be sure all components are positioned in such a way as to avoid the possibility of adjacent component

shorts. This is especially important on those chassis which are transported to and from the service shop.

2. Never release a repaired unit unless all protective devices such as insulators, barriers, covers, strain

reliefs, and other hardware have been installed in accordance with the original design.

3. Soldering and wiring must be inspected to locate possible cold solder joints, solder splashes, sharp solder

points, frayed leads, pinched leads, or damaged insulation (including the ac cord). Be certain to remove

loose solder balls and all other loose foreign particles.

4. Check across-the-line components and other components for physical evidence of damage or

deterioration and replace if necessary. Follow original layout, lead length, and dress.

5. No lead or component should touch a receiving tube or a resistor rated at 1 watt or more. Lead tension

around protruding metal surfaces or edges must be avoided.

6. Critical components having special safety characteristics are identified with an 'S' by the Ref. No. in the

parts list and enclosed within a broken line* (where several critical components are grouped in one area)

along with the safety symbol on the schematic diagrams and /or exploded views.

7. When servicing any unit, always use a separate isolation transformer for the chassis. Failure to use a

separate isolation transformer may expose you to possible shock hazard, and may cause damage to

servicing instruments.

8. Many electronic products use a polarized ac line cord (one wide pin on the plug). Defeating this safety

feature may create a potential hazard to the servicer and the user. Extension cords which do not

incorporate the polarizing feature should never be used.

9. After reassembly of the unit, always perform an ac leakage test or resistance test from the line cord to all

exposed metal parts of the cabinet. Also, check all metal control shafts (with knobs removed), antenna

terminals, handles, screws, etc., to be sure the unit may be safely operated without danger of electrical

shock.

* Broken line ____ _ ____ _ ____ _ ____

LEAKAGE CURRENT COLD CHECK

1. Unplug the ac line cord and connect a jumper between the two prongs of the plug.

2. Turn on the power switch.

3. Measure the resistance value between the jumpered ac plug and all exposed cabinet parts of the receiver,

such as screw heads, antennas, and control shafts. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 megohm and 5.2 megohms. When the exposed metal does not

have a return path to the chassis, the reading must be infinity. Remove the jumper from the ac line cord.

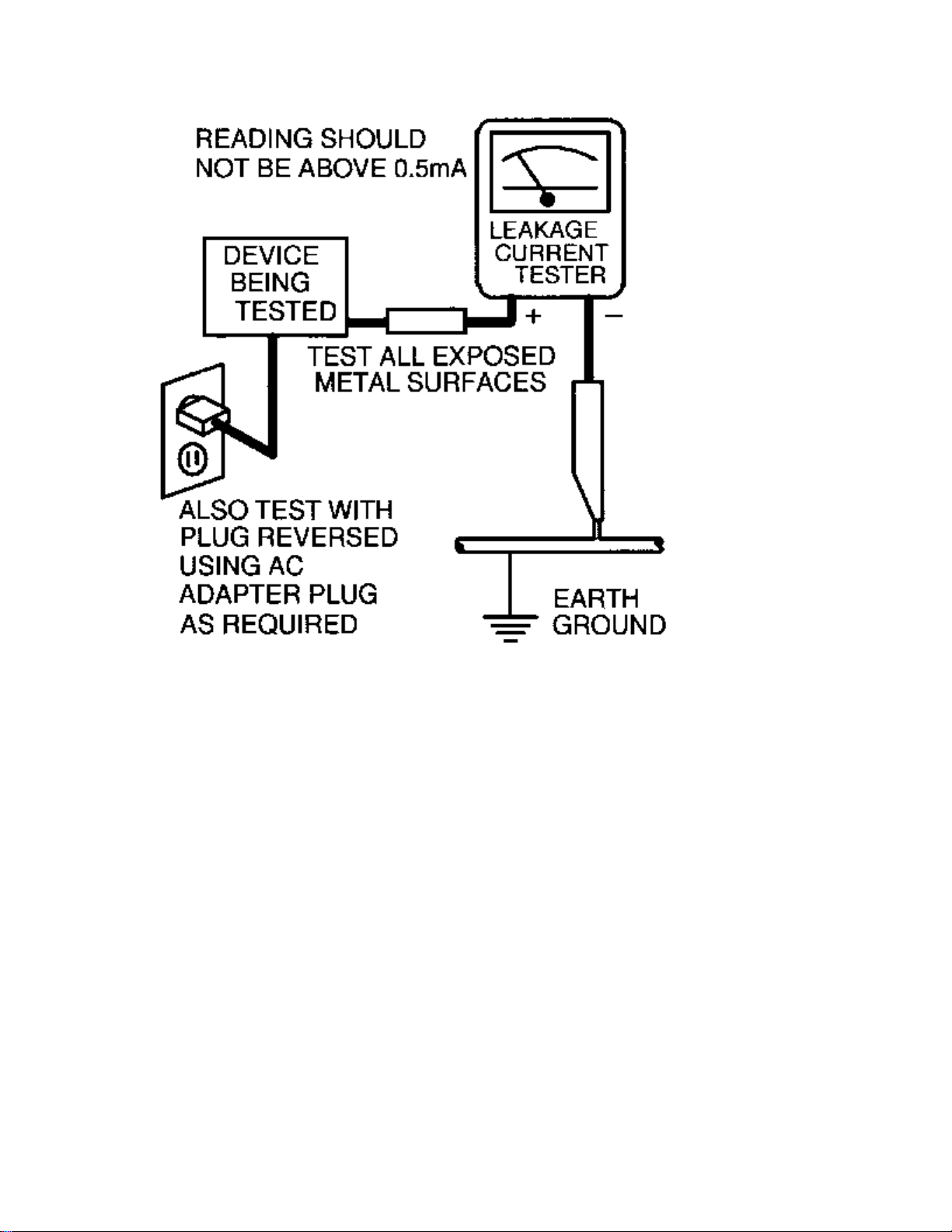

LEAKAGE CURRENT HOT CHECK

1. Do not use an isolation transformer for this test. Plug the completely reassembled receiver directly into

the ac outlet.

2. Connect a 1.5k, 10W resistor paralleled by a 0.15uF. capacitor between each exposed metallic cabinet

part and a good earth ground such as a water pipe, as shown below.

3. Use an ac voltmeter with at least 5000 ohms/volt sensitivity to measure the potential across the resistor.

4. The potential at any point should not exceed 0.75 volts. A leakage current tester may be used to make

this test; leakage current must not exceed 0.5mA. If a measurement is outside of the specified limits,

there is a possibility of shock hazard. The receiver should be repaired and rechecked before returning it

to the customer.

5. Repeat the above procedure with the ac plug reversed. (Note: An ac adapter is necessary when a

polarized plug is used. Do not defeat the polarizing feature of the plug.)

OR

With the instrument completely reassembled, plug the ac line cord directly into a 120Vac outlet. (Do not

use an isolation transformer during this test.) Use a leakage current tester or a metering system that

complies with American National Standards Institute (ANSI) C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7). With the instrument ac switch first in the on position and

then in the off position, measure from a known earth ground (metal water pipe, conduit, etc.) to all exposed

metal parts of the instrument (antennas, handle brackets, metal cabinet, screw heads, metallic overlays,

control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5mA. Reverse the instrument power cord plug in the outlet and

repeat the test. See the graphic below.

TV SAFETY NOTES

SAFETY CHECKS

After the original service problem has been corrected, a complete safety check should be made. Be sure to

check over the entire set, not just the areas where you have worked. Some previous servicer may have left

an unsafe condition, which could be unknowingly passed on to your customer. Be sure to check all of the

following:

Fire and Shock Hazard

Implosion

X-Radiation

Leakage Current Cold Check

Leakage Current Hot Check

Picture Tube Replacement

Parts Replacement

WARNING: Before removing the CRT anode cap, turn the unit OFF and short the HIGH VOLTAGE to

the CRT DAG ground.

SERVICE NOTE: The CRT DAG is not at chassis ground.

IMPLOSION

1. All picture tubes used in current model receivers are equipped with an integral implosion system.

Care should always be used, and safety glasses worn, whenever handling any picture tube. Avoid

scratching or otherwise damaging the picture tube during installation.

2. Use only replacement tubes specified by the manufacturer.

X-RADIATION

1. Be sure procedures and instructions to all your service personnel cover the subject of X-radiation.

Potential sources of X-rays in TV receivers are the picture tube and the high voltage circuits. The

basic precaution which must be exercised is to keep the high voltage at the factory recommended

level.

2. To avoid possible exposure to X-radiation and electrical shock, only the manufacturer's specified

anode connectors must be used.

3. It is essential that the service technician has an accurate HV meter available at all times. The

calibration of this meter should be checked periodically against a reference standard.

4. When the HV circuitry is operating properly there is no possibility of an X-radiation problem. High

voltage should always be kept at the manufacturer's rated value - no higher - for optimum

performance. Every time a color set is serviced, the brightness should be run up and down while

monitoring the HV with a meter to be certain that the HV is regulated correctly and does not exceed

the specified value. We suggest that you and your technicians review test procedures so that HV and

HV regulation are always checked as a standard servicing procedure, and the reason for this prudent

routine is clearly understood by everyone. It is important to use an accurate and reliable HV meter. It

is recommended that the HV reading be recorded on each customer's invoice, which will

demonstrate a proper concern for the customer's safety.

5. When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, reduce the line voltage by means of a Variac to bring the HV into acceptable limits while

troubleshooting. Do not operate the chassis longer than necessary to locate the cause of the excessive

HV.

6. New picture tubes are specifically designed to withstand higher operating voltages without creating

undesirable X-radiation. It is strongly recommended that any shop test fixture which is to be used

with the new higher voltage chassis be equipped with one of the new type tubes designed for this

service. Addition of a permanently connected HV meter to the shop test fixture is advisable. The

CRT types used in these new sets should never be replaced with any other types, as this may result in

excessive X-radiation.

7. It is essential to use the specified picture tube to avoid a possible X-radiation problem.

8. Most TV receivers contain some type of emergency "Hold Down" circuit to prevent HV from rising

to excessive levels in the presence of a failure mode. These various circuits should be understood by

all technicians servicing them, especially since many hold down circuits are inoperative as long as

the receiver performs normally.

PICTURE TUBE REPLACEMENT

The primary source of X-radiation in this television receiver is the picture tube. The picture tube

utilized in this chassis is specially constructed to limit X-radiation emissions. For continued Xradiation protection, the replacement tube must be the same type as the original, including suffix letter,

or a Philips approved type.

PARTS REPLACEMENT

Many electrical and mechanical parts in Philips television sets have special safety related

characteristics. These characteristics are often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. The use of a substitute part which does not have the same safety characteristics as the

Philips recommended replacement part shown in this service manual may create shock, fire, or other

hazards.

PRODUCT SAFETY GUIDELINES FOR ALL PRODUCTS

CAUTION: Do not modify any circuit. Service work should be performed only after you are thoroughly

familiar with all of the following safety checks. Risk of potential hazards and injury to the user increases if

safety checks are not adhered to.

USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

Some semiconductor solid state devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES) Devices, Examples of typical ES devices are

integrated circuits and some field-effect transistors and semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of component damage caused by electrostatic

discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging ESD wrist strap, which should be removed for potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "antistatic

(ESD protected)" can generate an electrical charge sufficient to damage ES devices.

5. Do not use Freon propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it (most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your feet from a carpeted

floor can generate static electricity (ESD) sufficient to damage an ES device.)

NOTE to CATV system Installer:

This reminder is provided to call the CATV system installer's attention to article 820-22 of the NEC that

provides guidelines for proper grounding and, in particular, specifies that the cable ground shall be

connected to the grounding system of the building, as close to the point of cable entry as practical.

PRACTICAL SERVICE PRECAUTIONS

IT MAKES SENSE TO AVOID EXPOSURE TO ELECTRICAL SHOCK. While some sources are

expected to have a possible dangerous impact, others of quite high potential are of limited current and are

sometimes held in less regard.

ALWAYS RESPECT VOLTAGES. While some may not be dangerous in themselves, they can cause

unexpected reactions – reactions that are best avoided. Before reaching into the powered color TV set, it is

best to test the high voltage insulation. It is easy to do, and is just a good service precaution.

BEFORE POWERING UP THE TV WITH THE BACK OFF (or on a test fixture), attach a clip lead to

the CRT DAG ground and to a screwdriver blade that has a well insulated handle. After the TV is powered

on and high voltage has developed, probe the anode lead with the blade, starting at the bottom of the High

Voltage Transformer (flyback – IFT). Move the blade to within two inches of the connector of the CRT. IF

THERE IS AN ARC, YOU FOUND IT THE EASY WAY, WITHOUT GETTING A SHOCK! If

there is an arc to the screwdriver blade, replace the High Voltage Transformer or the lead, (if removable)

whichever is causing the problem.

PICTURE TUBE REPLACEMENT PROCEDURE

Note: a. Two (2) people are required to handle this picture tube.

b. Safety Glasses must be worn during this procedure or whenever directly handling a picture tube.

c. Take care in each step not to damage the CRT or the cabinet.

1. Remove the Chassis and the CRT Socket Board Module from the cabinet.

2. A furniture pad or blanket should be positioned on the floor to support only the CRT Face. This pad or

blanket should be high enough to keep the CRT Face approximately 12 to 14 inches off the floor.

3. Using two people, place the cabinet in a front down position with the CRT Face on the pad or blanket.

4. Place padded blocks under each corner of the cabinet to keep it from rocking.

5. Remove the four screws, at the corners of the CRT.

6. With two people lowering the cabinet to the floor, leave the CRT elevated by the pad or blanket.

Note: Take care not to grasp the neck of the CRT during this procedure, as it is extremely fragile.

7. Two (2) people may then lift the CRT from the cabinet.

8. Remove the degaussing coil from the defective CRT and mount on the replacement. Take care to

maintain the exact shape and fit.

To install the new CRT, reverse steps 1 to 7.

GENERAL INFORMATION Typical Models

Standard Screen - Model: 27PT71

Flat Screen - Model: 27PT91

Technical Specifications

Supply

Supply Voltage : 90 – 140Vac

Power Consumption : 90 W max.

Stand By consumption : 7 – 8W

Supply Frequency : 50 - 60 Hz ? 5 %

Tuning System : PLL

Reception : NTSC-M

Sound System : BTSC DBX

Sound Output : 2 x 5 W – 27”/32”/36” FSQ

: 2 x 5 W + 10W – 27” /32” RF

Reception : Off air - 45.75Mhz

Aerial input : coaxial 75 Ohm

Remote Control : Type - RCA10U81 - 27”/32”/36” FSQ

: Type - RCA10U20 - 27”/32” RF

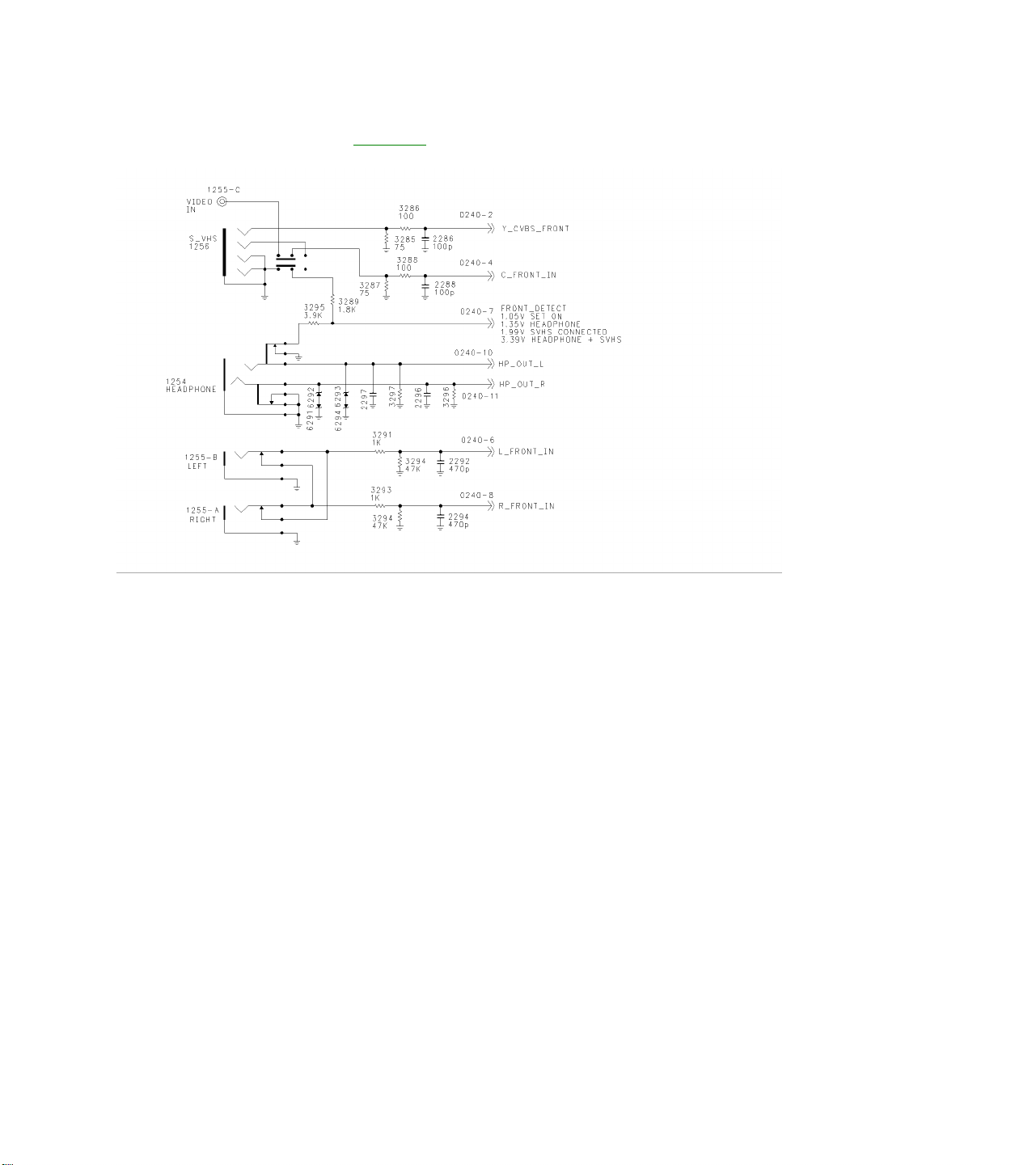

Connection Facilities

EXT1: CVBS (in) + YUV (in)

Cinch - CVBS (yellow) (1 V)

Cinch - Audio L (red) (0.2 - 2 V-RMS / 10 k ohm)

- Audio R (white) (0.2 - 2 V-RMS / 10 k ohm)

EXT2: CVBS (in) + YC (in)

Cinch CVBS (yellow) (1 V)

Cinch Audio L (red) (0.2 - 2 V-RMS / 10 k ohm)

Audio R (white) (0.2 - 2 V-RMS / 10 k ohm)

MON: CVBS (out) + L/R (out)

Cinch CVBS (yellow) (1 V)

Cinch Audio L (red) (0.2 - 2 V-RMS / 10 k ohm)

Audio R (white) (0.2 - 2 V-RMS / 10 k ohm)

YUV (in)

Cinch Y (0.7Vpp/ 75 ohm)

Cinch U (0.7Vpp/ 75 ohm)

Cinch V (0.7Vpp / 75 ohm)

Cinch Front - audio/video in

Cinch CVBS (yellow) 1(1 V)

Cinch Audio L (red) (0.2 - 2 V-RMS / 10 k ohm)

Audio R (white) (0.2 - 2 V-RMS / 10 k ohm)

Headphone

Jack 32 - 2000 ohm (10 mW)

SVHS

1 - gnd

2 - gnd

3 – Y (1 V-PP / 75 ohm)

4 – C (0.3 V-PP / 75 ohm)

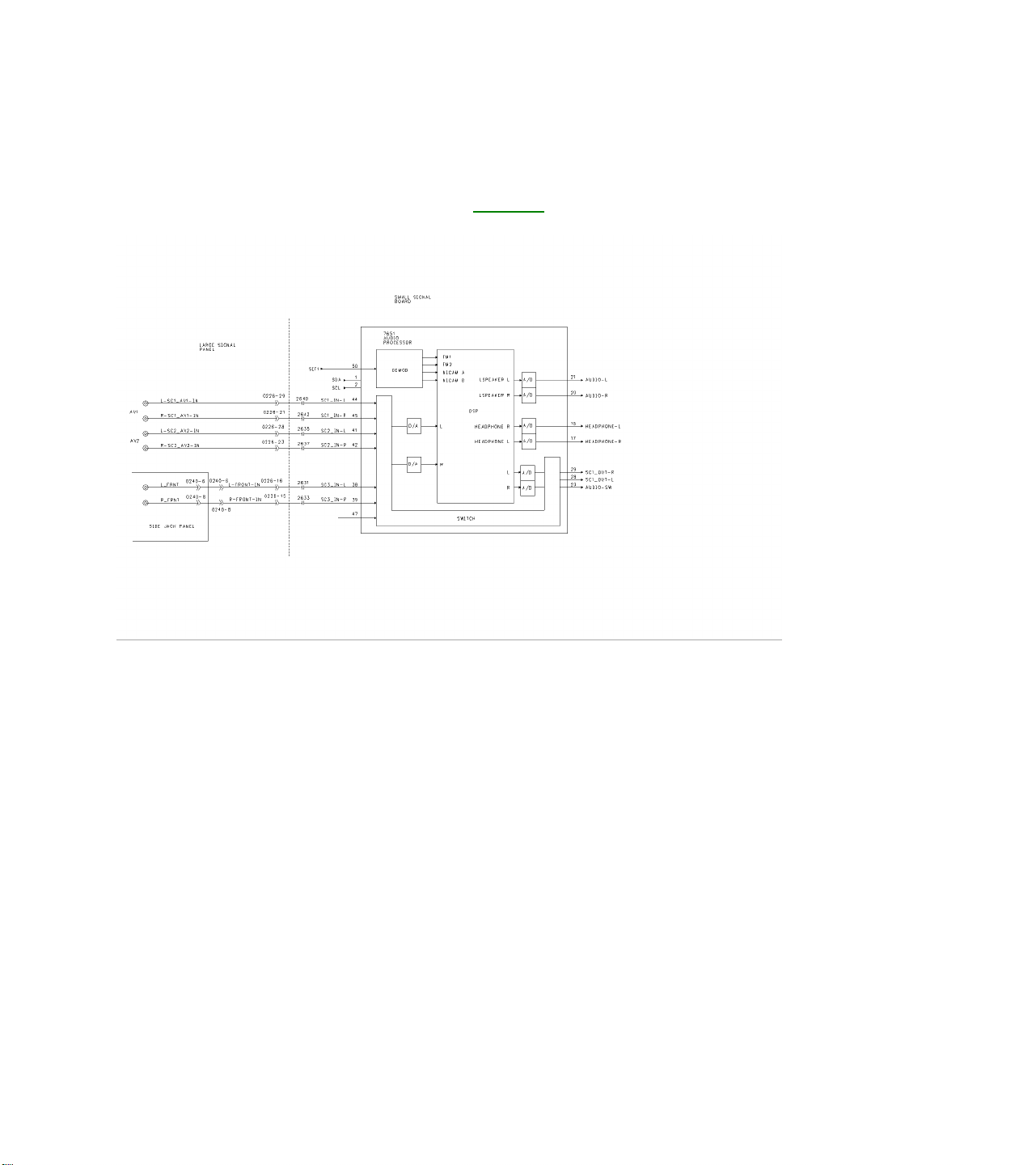

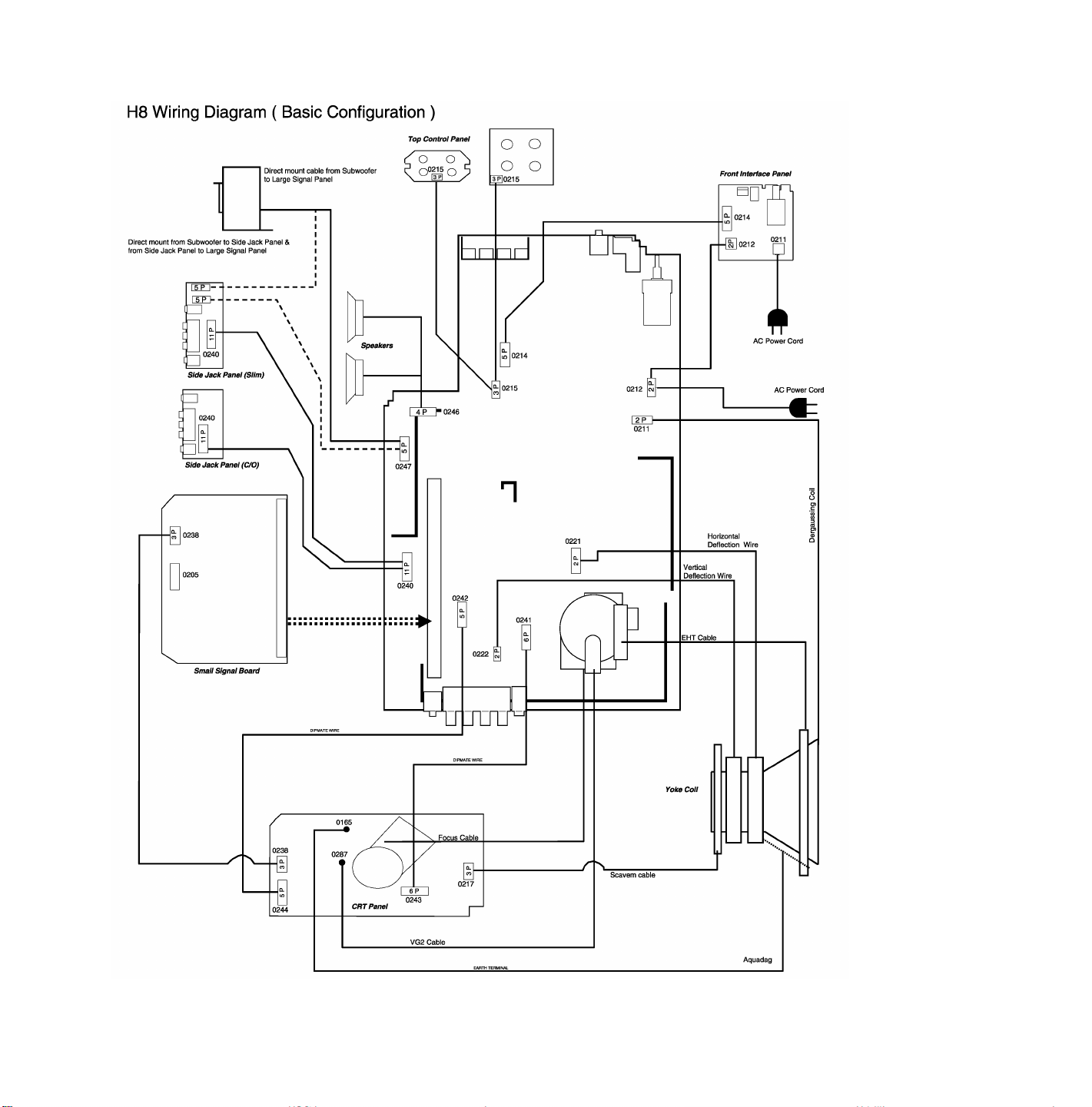

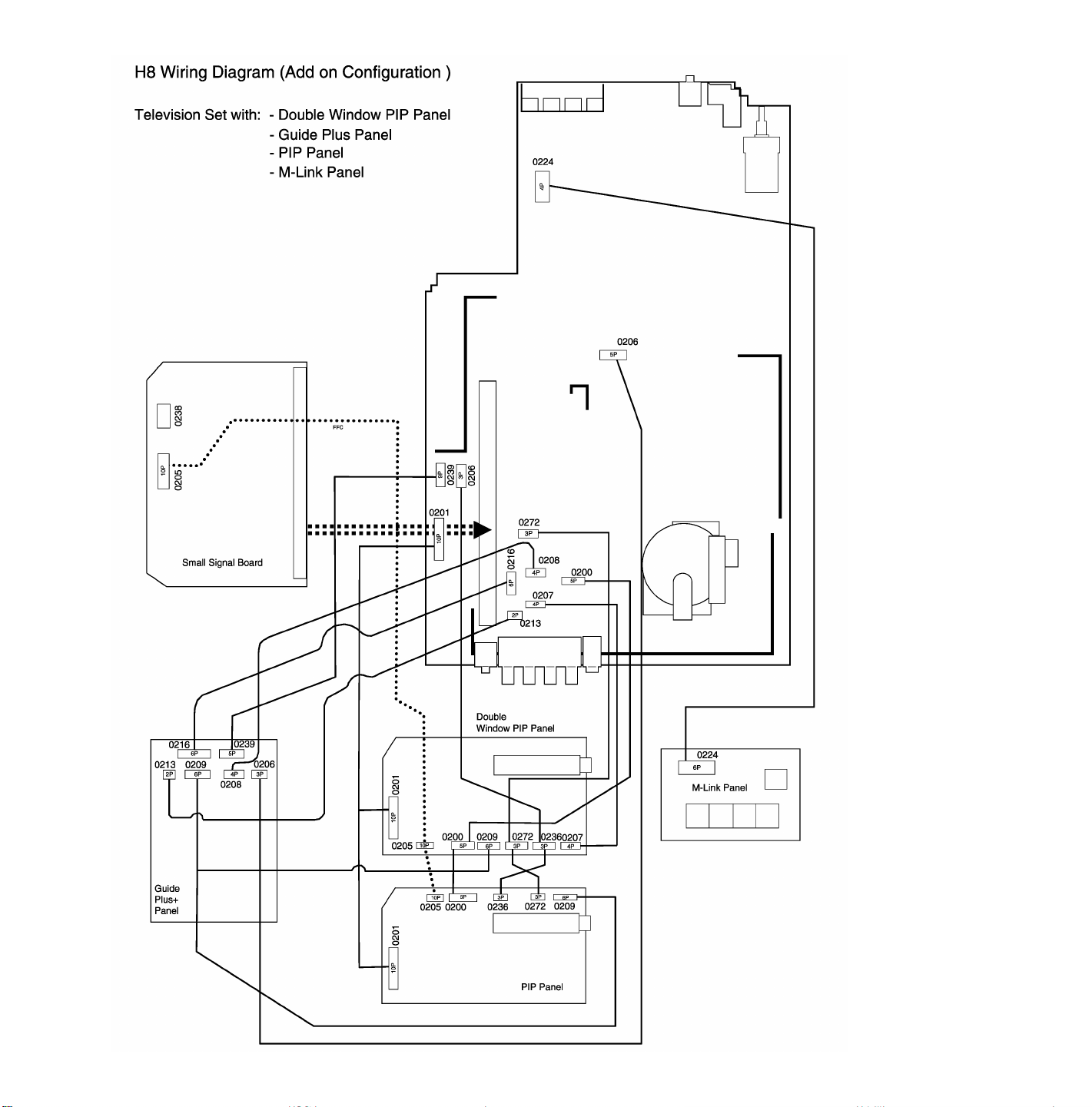

CBA Location Guide

Model to Module Listings

MODEL PANEL

27PT31B/121

313917867841 Large Signal Panel

313917883531 Small Signal Panel

313917880521 M-Link Assembly (W/O M-Link)

AVJ400A/001 Side Jack Panel

27PT41B/121

313917867851 Large Signal Panel

313917865621 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10904A/001 PIP Panel

27PT71B/121

EMH802A/001 Large Signal Panel

313917863191 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10901A/001 PIP Panel

310420710191 Receiver Assembly IR Board

27PT81S/125

313917888281 Large Signal Panel

313917863191 Small Signal Panel

313917867911 Side Jack Panel

313917860611 M-Link Assembly (With Matrix)

313917882271 Top Control Assembly

313917865661 Front Interface Assembly

313917859401 PIP Panel (2 Tuner)

310420710191 Receiver Assembly IR Board

27PT91S/125

313917867901 Large Signal Panel

313917865601 Small Signal Panel

313917882271 Top Control Assembly

313917867911 Side Jack Panel

A10902A/001 M-Link Assembly

313917865661 Front Interface Panel

312123751431 Double Window PIP Assembly

313917863791 * Guide Plus Panel

313917857061 * Double Window PIP Panel

* These panels are subassemblies of the Double Window PIP assembly.

32PT41B/121

313917868651 Large Signal Panel

313917865621 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10904A/001 PIP Panel

32PT71B/121

313917867861 Large Signal Panel

313917863191 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10901A/001 PIP Panel

310420710191 Receiver Assembly IR Board

32PT81S/128

313917888271 Large Signal Panel

313917863191 Small Signal Panel

313917867911 Side Jack Panel

313917860611 M-Link Assembly (With Matrix)

313917882271 Top Control Assembly

313917865661 Front Interface Panel

313917859401 PIP Panel

310420710191 Receiver Assembly IR Board

32PT91B/128

313917865591 Large Signal Panel

313917865601 Small Signal Panel

312123751431 Double Window PIP Assembly

313917857061 * Double Window PIP Panel

313917863791 * Guide Plus Panel

A10901A/001 PIP Panel (2 Tuner)

A10902A/001 M-Link Assembly

A10904A/001 PIP Panel

313917865661 Front Interface Panel

313917864271 Top Control Assembly

313917867911 Side Jack Panel

* These panels are subassemblies of the Double Window PIP assembly.

32PT91S/121

313917865591 Large Signal Panel

313917865601 Small Signal Panel

A10901A/001 PIP Panel (2 Tuner)

A10902A/001 M-Link Assembly

A10904A/001 PIP Panel

313917865661 Front Interface Panel

313917864271 Top Control Assembly

313917867911 Side Jack Panel

310420710191 Receiver Assembly IR Board

312123751431 Double Window PIP Assembly

313917857061 * Double Window PIP Panel

313917863791 * Guide Plus Panel

* These panels are subassemblies of the Double Window PIP assembly.

36PT41B/129

EMH860A/001 Large Signal Panel

313917865621 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10904A/001 PIP Panel

310420710191 Receiver Assembly IR Board

36PT71B/129

313917867871 Large Signal Panel

313917863191 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10901A/001 PIP Panel

310420710191 Receiver Assembly IR Board

29LP602/221

EMH802A/001 Large Signal Panel

313917863191 Small Signal Panel

310420710191 Receiver Assembly IR Board

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10901A/001 PIP Panel (2 Tuner)

32PT71B/129

313917885031 Large Signal Panel

313917863191 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10901A/001 PIP Panel (2 Tuner)

310420710191 Receiver Assembly IR Board

33LP803/221

313917867861 Large Signal Panel

313917863191 Small Signal Panel

AVJ400A/001 Side Jack Panel

A10902A/001 M-Link Assembly

A10901A/001 PIP Panel (2 Tuner)

310420710191 Receiver Assembly IR Board

Model To Remote Transmitter Listing

Model Part Ref. Part No. Transmitter Type

27PT91S/125 AC19 3128 147 12101 RC2037/01 Remote Transmitter

32PT91S/121 AC19 3129 147 12101 RC2037/01 Remote Transmitter

27PT41B/121 AC19 3139 128 75961 RCA10U81E Remote Transmitter

32PT41B/121 AC19 3140 128 75961 RCA10U81E Remote Transmitter

36PT41B/129 AC19 3141 128 75961 RCA10U81E Remote Transmitter

27PT71B/121 AC19 3139 128 75991 RCA10U81FX Remote Transmitter

27PT81S/125 AC19 3140 128 75991 RCA10U81FX Remote Transmitter

29LP602/221 AC19 3141 128 75991 RCA10U81FX Remote Transmitter

32PT71B/121 AC19 3142 128 75991 RCA10U81FX Remote Transmitter

32PT71B/129 AC19 3143 128 75991 RCA10U81FX Remote Transmitter

32PT81S/128 AC19 3144 128 75991 RCA10U81FX Remote Transmitter

33LP803/221 AC19 3145 128 75991 RCA10U81FX Remote Transmitter

36PT71B/129 AC19 3146 128 75991 RCA10U81FX Remote Transmitter

27PT31B/121 AC19 3139 128 76001 RCA10U81BX/01 Remote Transmitter

Mechanical Disassembly

Rear Cover Removal & Replacement

Removal of the Rear Cover

1. Remove all screws from the rear cover.

2. Remove the rear cover.

Replacement of the Rear Cover

Before replacing the Rear Cover, perform the following inspection:

• Ensure that AC Cord is placed correctly in the guide brackets.

• Ensure that all cables are placed in their original position.

Service Positions

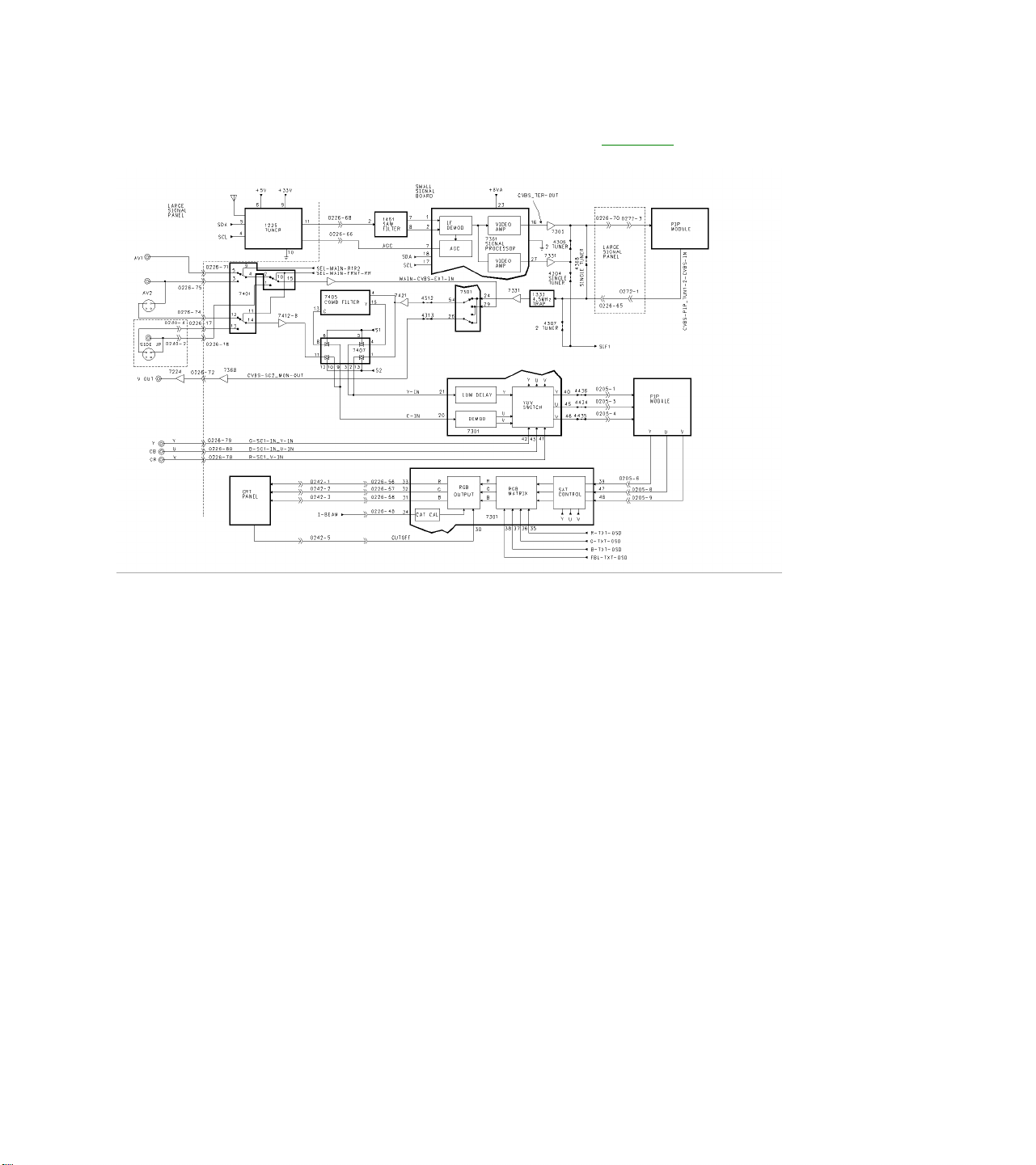

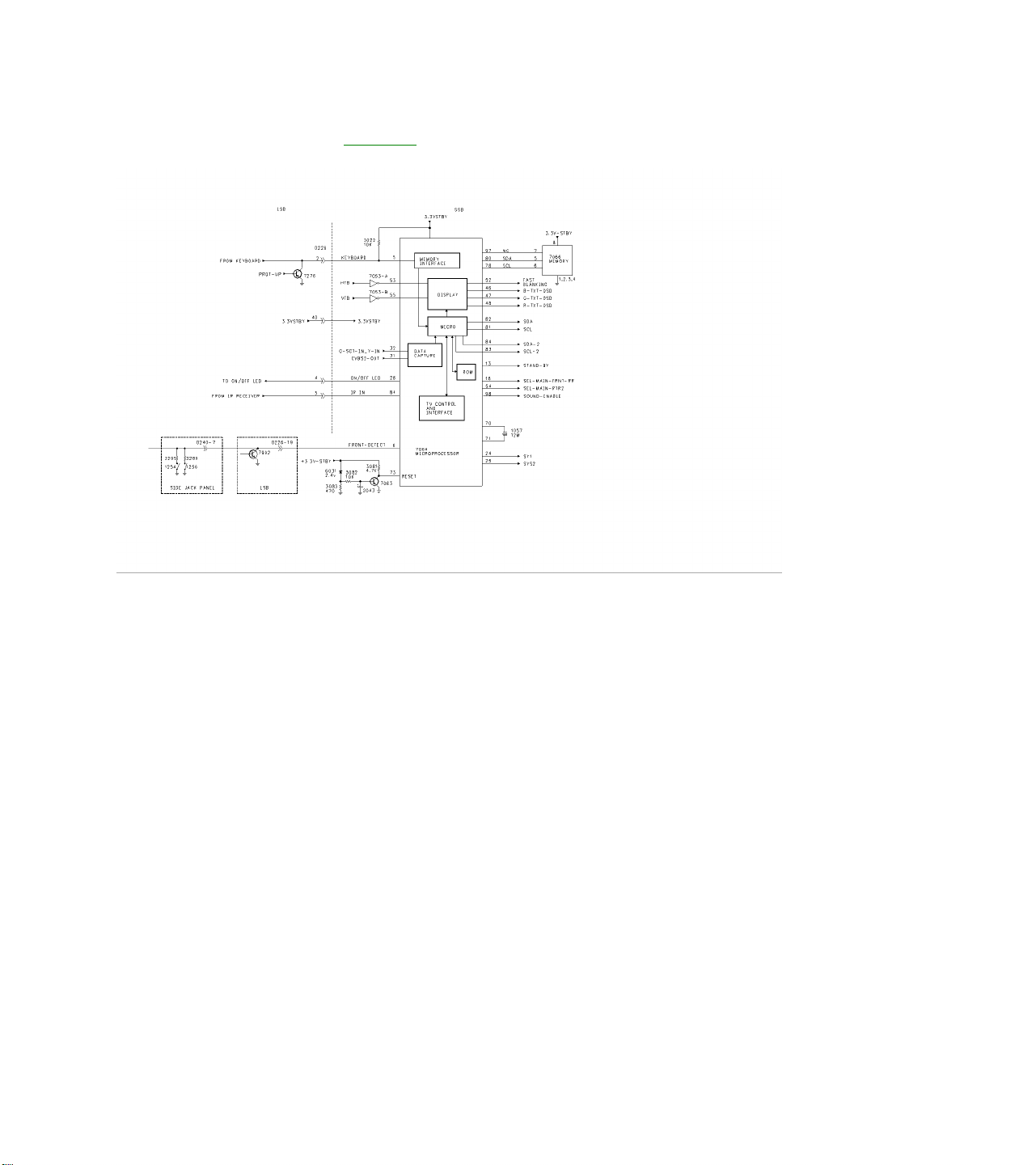

The following CBA's are present in this chassis (see also 'Chassis overview', CBA Location Diagram):

1. Large Signal Panel (LSP)

2. Small Signal Board (SSB)

3. Top Control panel

4. CRT panel (or PTP)

5. Side I/O panel

6. Mains Switch/LED panel

7. M-Link

8. PIP-panel

9. Guide+ panel

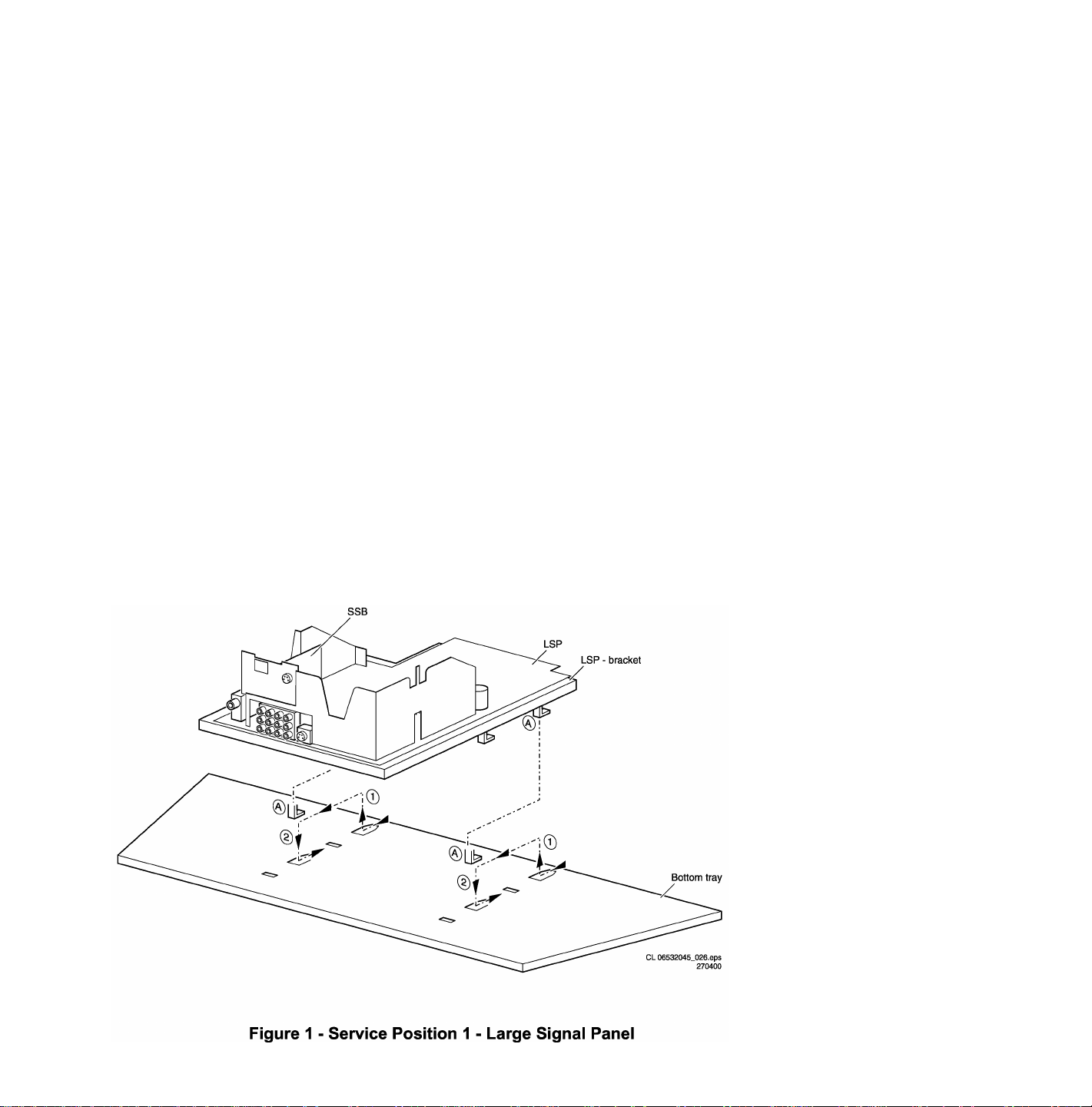

Service Position 1 for the Large Signal Panel (LSP)

Position 1: The following service position will provide the best accessibility to the Top Side of the Large Signal Panel:

1. Remove the LSP-bracket from the bottom tray by sliding the bracket backward and then pull the bracket up and out of the

bottom tray.

2. Place the Hooks (A) of the bracket in the first row of fixation holes of the cabinet bottom. In other words reposition the

bracket hooks from position (1) to position (2).

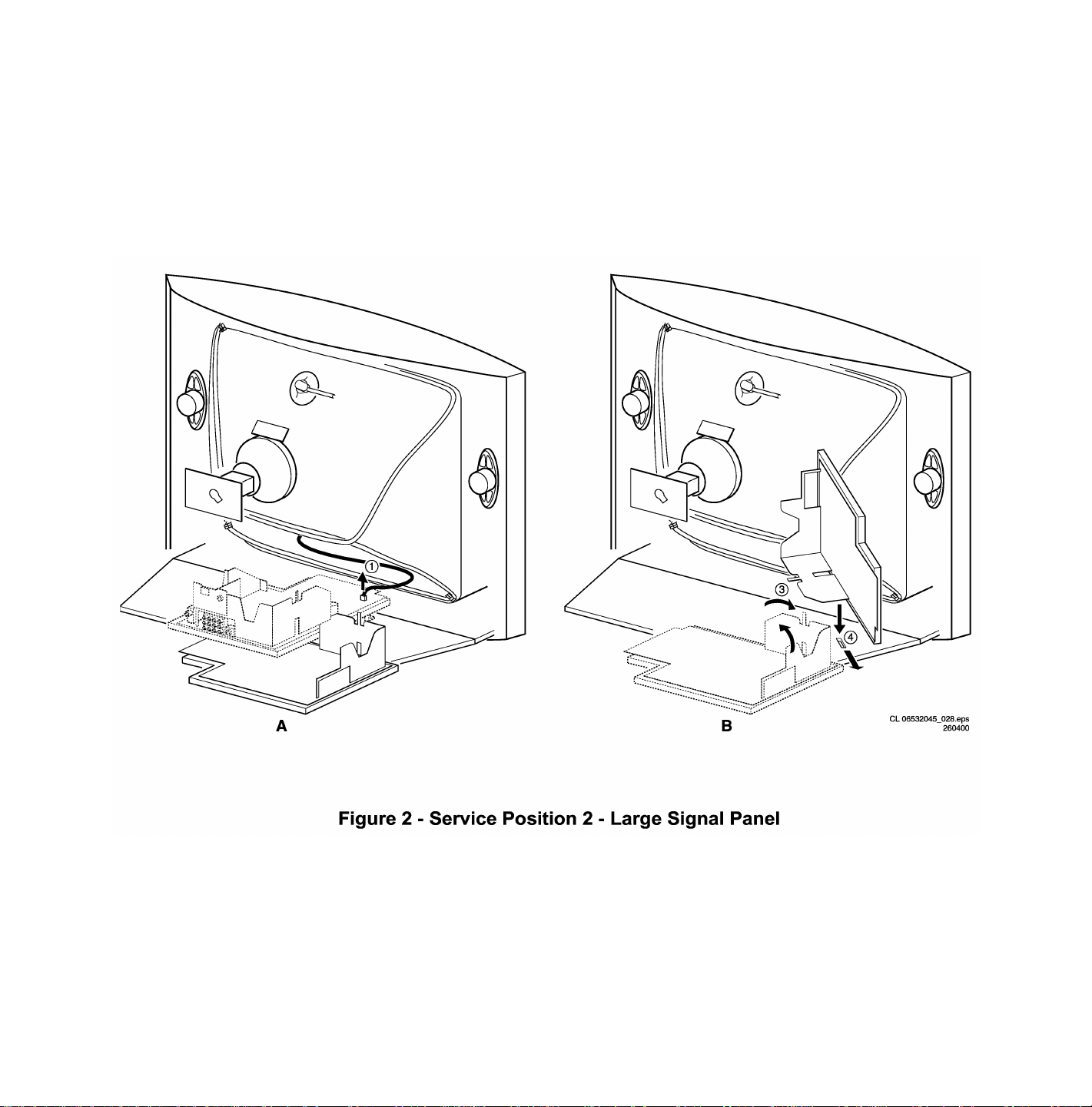

Service Position 2 for the Large Signal Panel (LSP)

Position 2: The following service position will provide the best accessibility to the bottom side (solder side) of the Large Signal

Panel:

1. Disconnect the degaussing coil from the LSP by removing the cable from connector 0211 (1).

2. Release the wiring from their clamps, to enable for repositioning the LSP.

3. Turn the chassis tray 90 degrees counter clockwise (2).

4. Flip the tray with the rear I/O panel toward the CRT (3).

5. Place the hook of the tray into the slot (4) at the right side of the cabinet bottom (4) and slide the chassis tray forward.

Service position for the Small Signal Board (SSB)

There is not a predefined service position for the bottom (B-) side of the SSB. All relevant test points can be accessed in both

LSB service positions.

If IC's must be replaced: take the complete panel out of the SIMM-connector.

1. Put the Large Signal Panel in service position 1 (as described above).

2. Release the 2 metal clamps at both sides of the SIMM-connector and the complete SSB can be taken out. It 'hinges' in the

SIMM-connector.

Access to the Top Control Panel

1. Remove the two screws that hold the panel to the cabinet back.

2. Slide the board backward (release it from the front hinge).

3. The board can easily be lifted out of the bracket after releasing the two clamps on the connector side.

Access to the Side I/O Panel

1. Remove the two screws.

2. Remove the complete Side I/O-assembly.

3. Release the two clamps then lift the board out of the bracket.

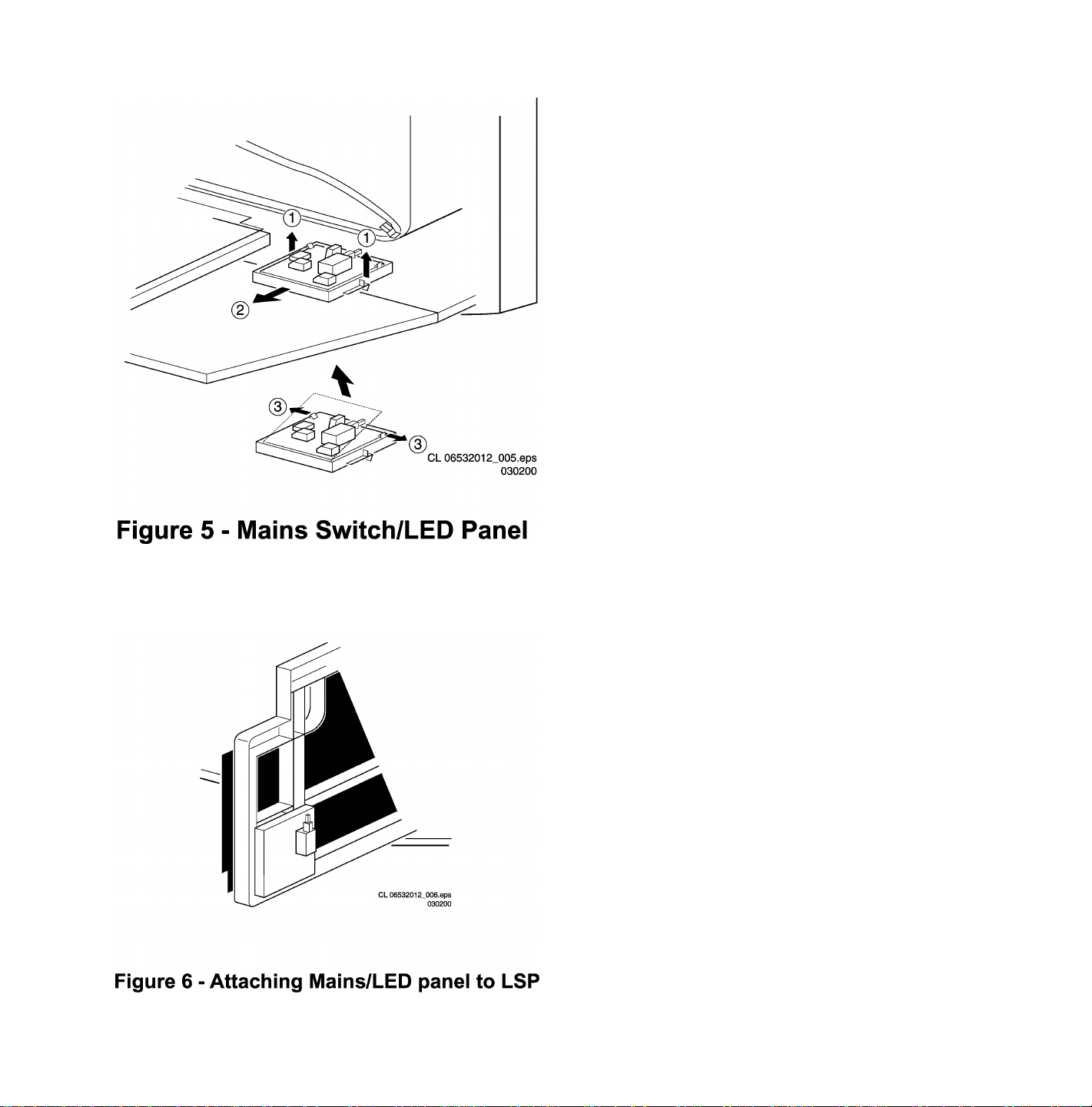

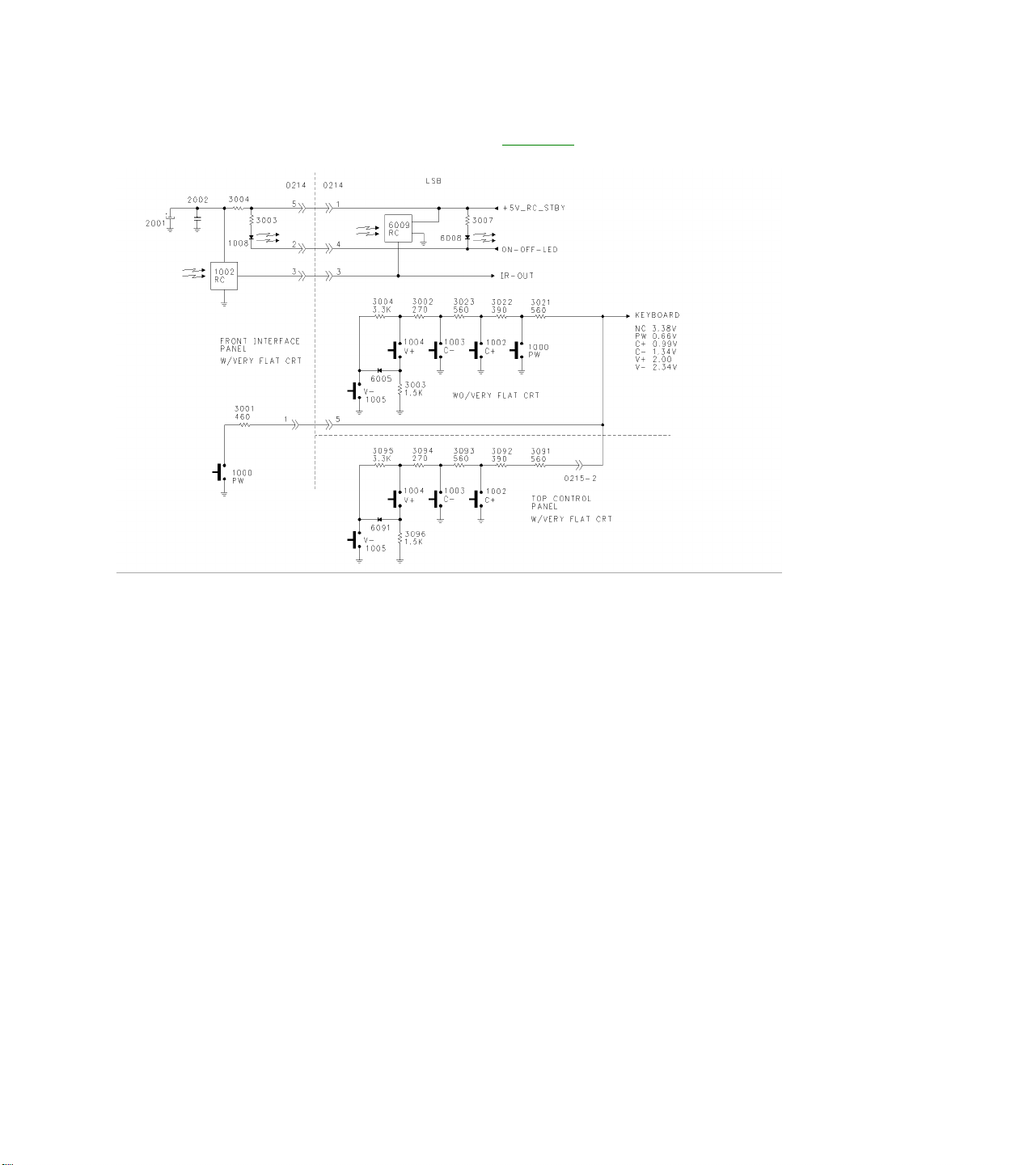

Access to the Mains Switch/LED Panel

1. Release the two clamps (1) by pulling them upward.

2. While pulling upward on the clamps, slide the complete assembly backward (2).

3. If it is necessary to remove the board, release the two clamps at the sides of the bracket and lift the board out (3).

1. To perform measurements, the panel may be attached to the LSP bracket (4).

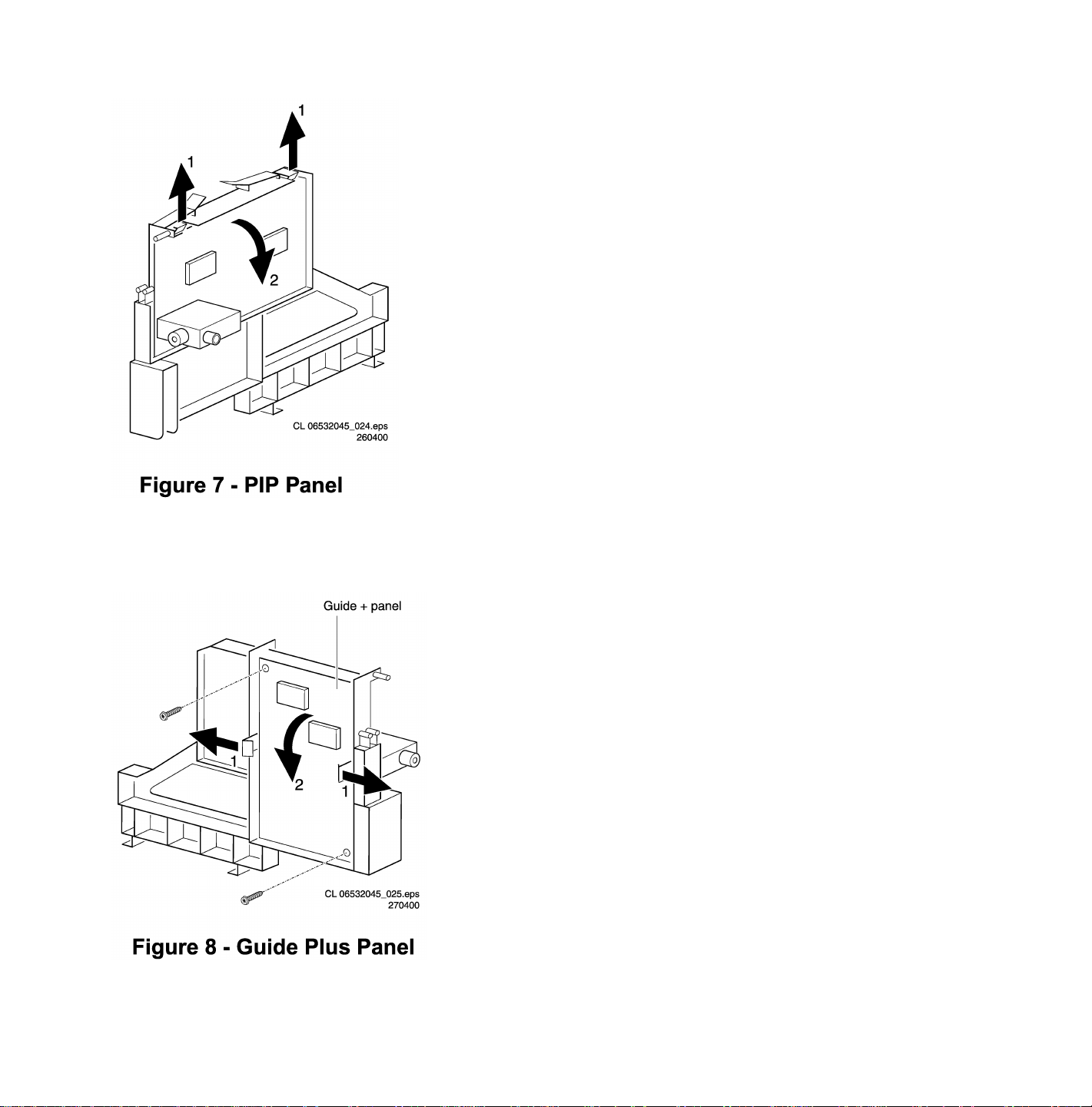

Access to the PIP Panel

1. Release the two clamps (1) and remove the PIP CBA from the bracket.

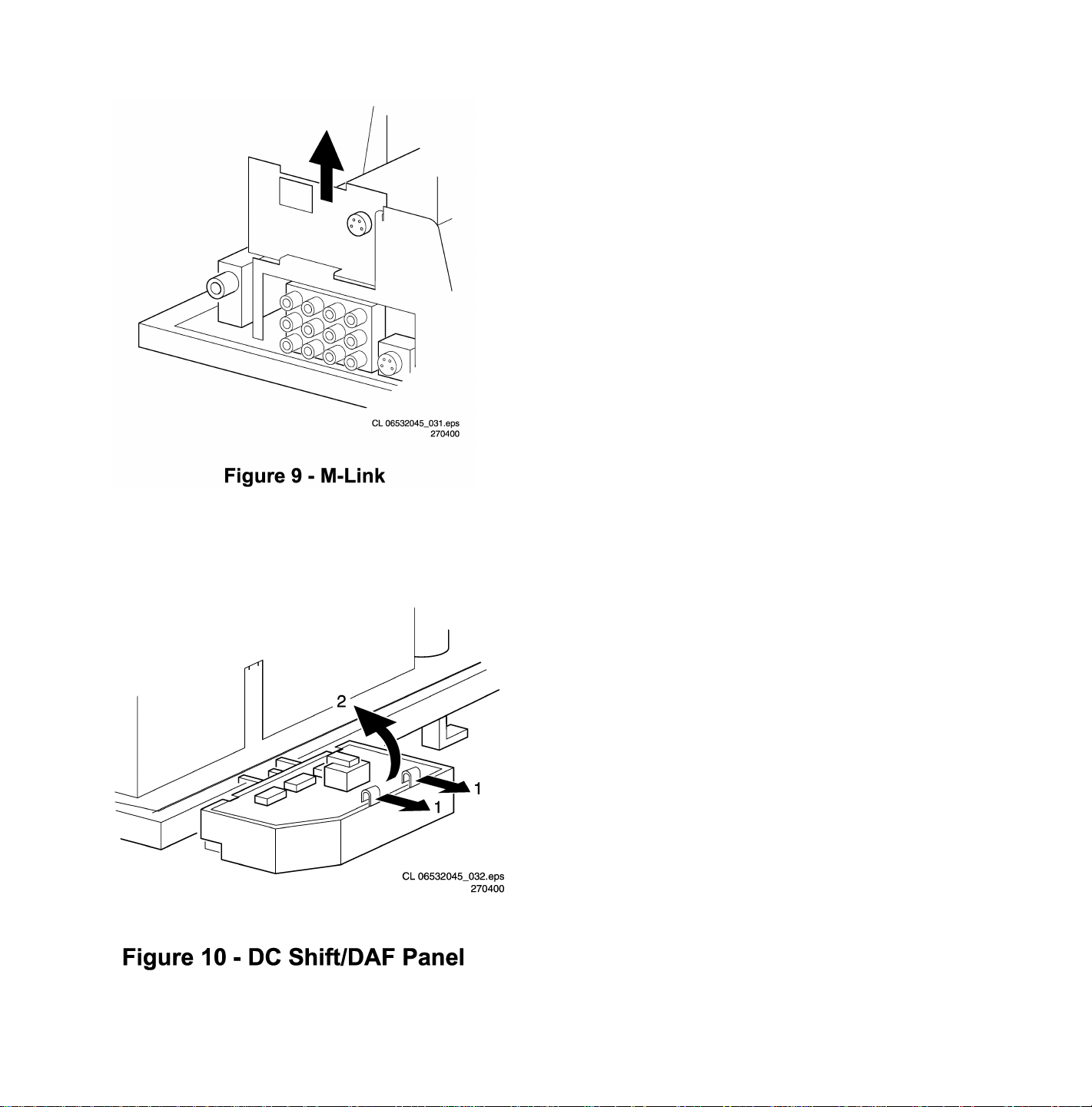

Access to the Guide+ Panel

1. Remove the two screws that secure the Guide+ assembly in place. This will release the complete Guide+ assembly.

2. Pull the two clamps (1) outward and remove the board (2) from the bracket.

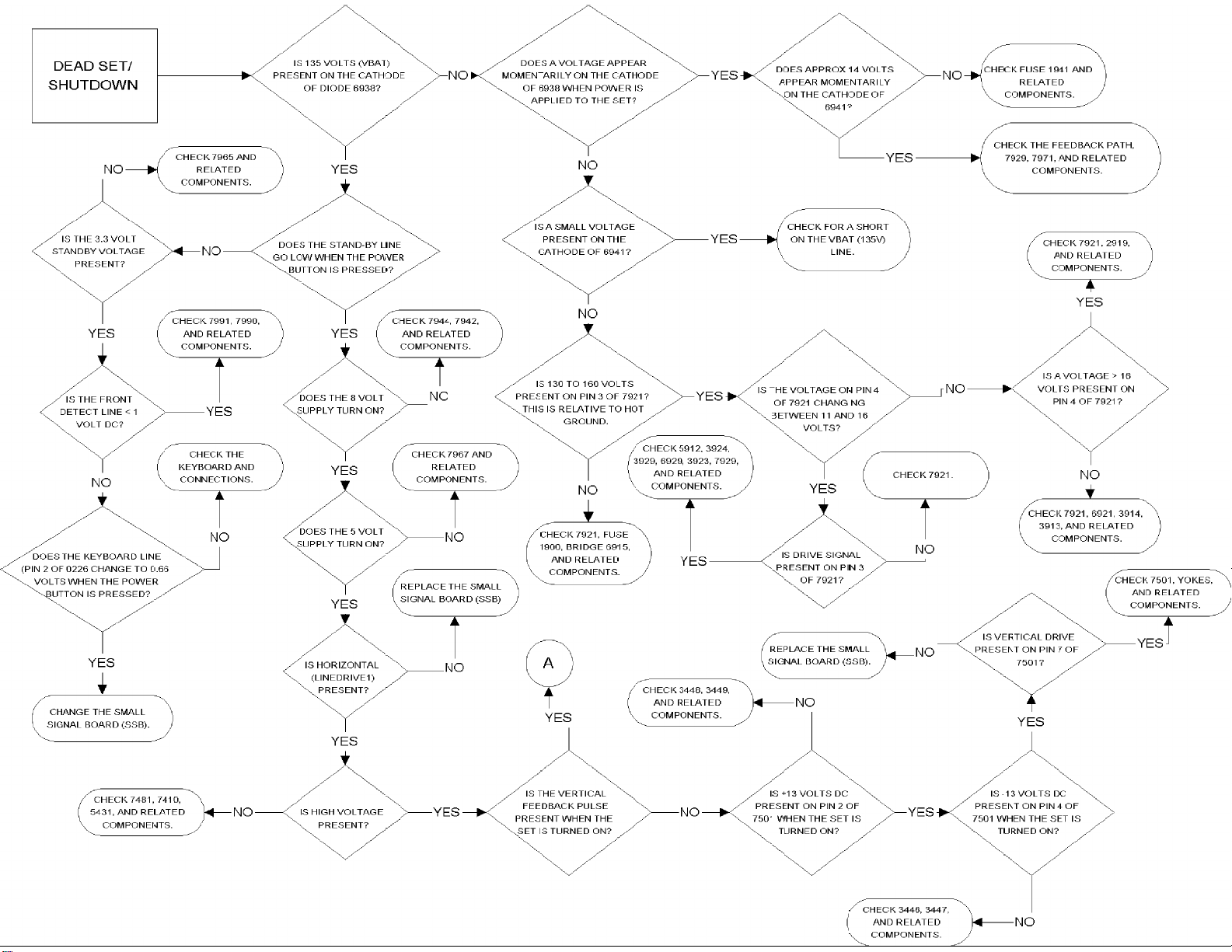

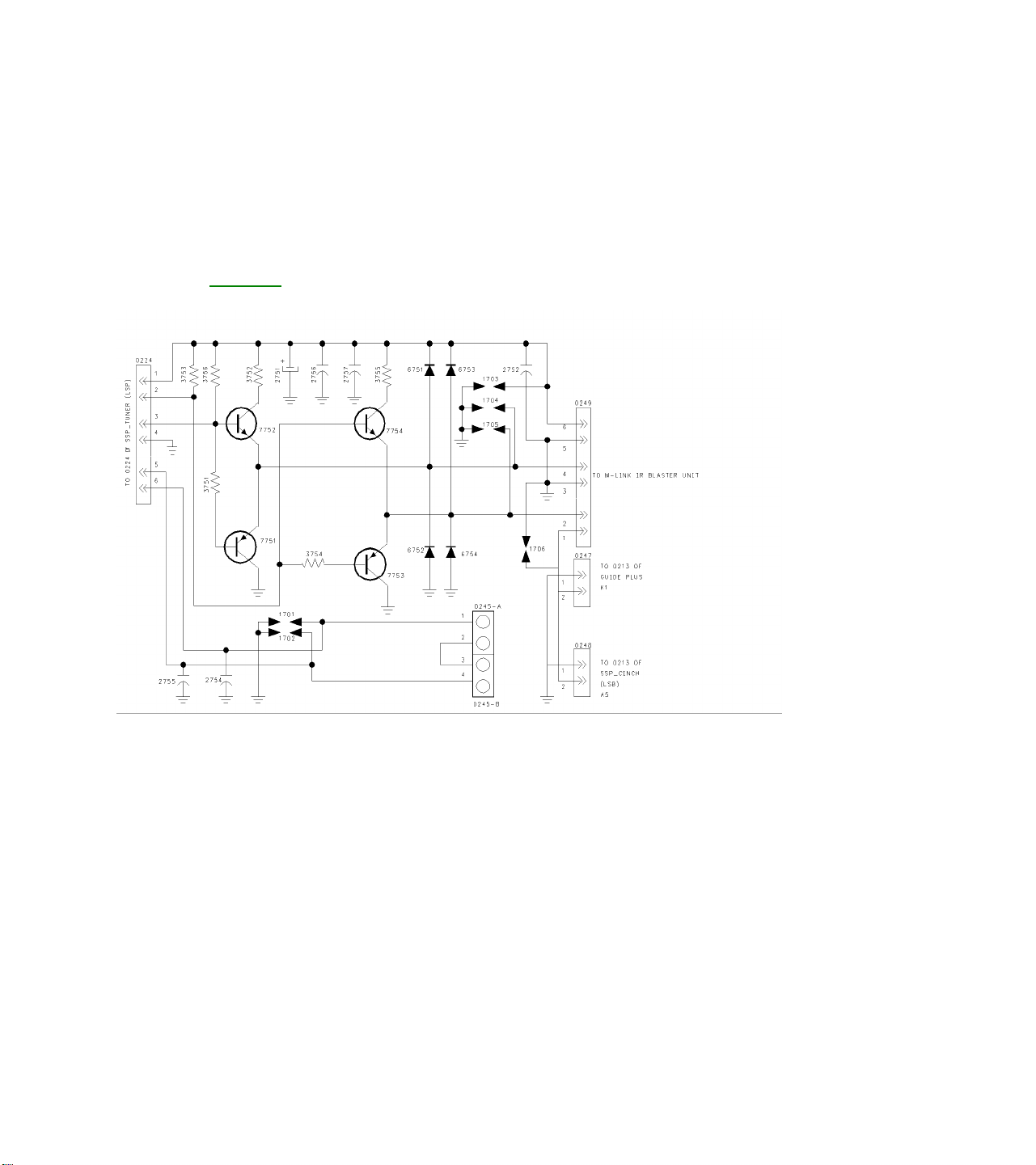

Access to the M-Link

1. Release the two clamps at both sides and remove the board from the bracket.

Access to the DC-shift/DAF panel

1. Release the clamps (1) and remove the board (2) from the bracket.

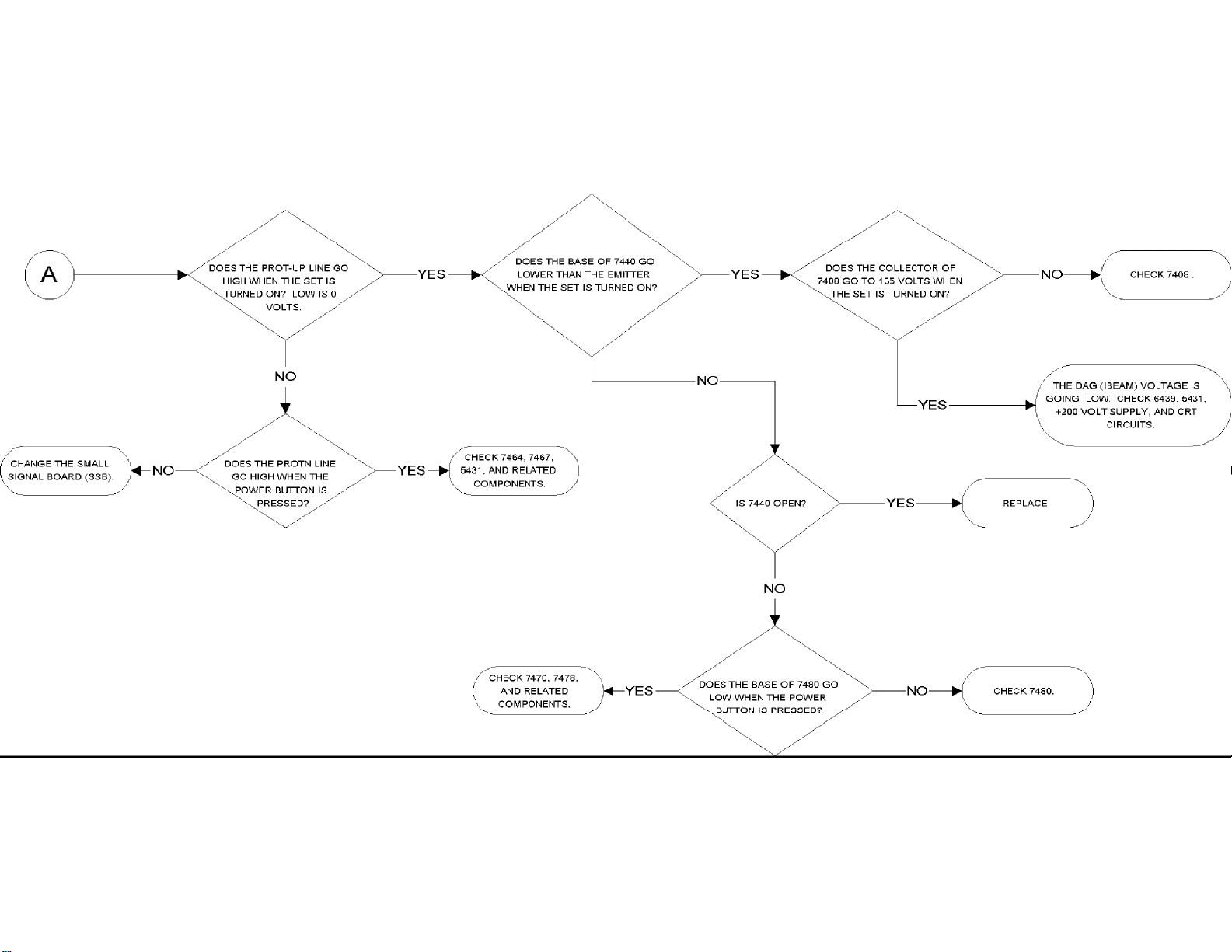

Troubleshooting Tips

Troubleshooting tips for the deflection and power supply circuitry.

The Deflection Circuit:

• Measure for VBAT (140V) across 2939/2940 (Section - A1 POWER SUPPLY). If the voltage is not present, disconnect

jumper 9936 and 9937 (see A1 Power Supply) The complete Line Deflection stage is now disconnected. If the voltage is

present then the deflection circuit may be the cause of the problem.

Possibilities include:

• Defective Transistor 7410

• Faulty driver circuit around transistor 7481

• No horizontal drive signal coming from the BOCMA (signal processor) IC 7301 pin 56 on the SSB

Note: If the Collector and Emitter of 7410 are shorted, a “hiccup” noise may be heard from the power supply circuit.

To determine whether the fault is present in the line deflection circuit (Section - A2 LINE DEFLECTION) or in the EW

circuit/panel (screen size above 21”), insert jumper into position numbers 9409 (in this case the EW protection is disabled). If

the basic deflection is working (picture is parabolic distorted), then the fault is located in the EW circuit/panel. If there is no

horizontal deflection, the fault is present in the basic deflection circuitry.

Also take note of protection circuits in the line output stage. If any of these circuits are activated, the set will shut down.

Depending upon protections, the LED will blink according to the fault defined. In order to determine which protection circuit is

active, isolation of circuits is necessary. These protection circuits are:

• High beam protection. See error 1 - High Beam Protection.

• X-ray protection : See error 1

If the high beam protection or the X-ray protection is active, it will switch the set to protection and the SDM will be automatically

activated. The service LED blinks repeatedly 1 time. If this happens, isolate each circuit to determine the cause

The Power Supply Circuit:

Trouble-shooting the H8 Switch Mode Power Supply (SMPS)

• First check the +5V_STBY voltage on IC 7968, pin 3/4.

• If this voltage is not present, check fuse 1961 and D6961.

• If there is not an open circuit at 1906 or D6917, the problem may be caused on the primary side of the switching supply.

Check the output of the bridge diodes on the cathode side of D6912/D6913 or D6915 - pin 1 for approximately 150V DC.

• If this voltage is not present, check the bridge diodes and the fuse.

• If fuse F1900 is open, check IC7921 (circuit A1) between pins 2 and 3 to insure that there is no short circuit present.

• If the 150V DC is present on pin 3 of IC7902, check for a startup voltage of 16V on pin 4 of IC7921.

• If the startup voltage is not present, check R3914 for an open circuit; a short circuit between pins 4 and 5 may also be the

cause of this problem.

• It is necessary to have a feedback signal from the hot secondary side of switch mode transformer T5912 at pin 8 and pin 9

for the power supply to oscillate.

• If this startup voltage is present on pin 4 of IC7902 and the supply is not oscillating, check R3929 and D6929.

• The H8 power supply has been designed with Over Voltage Protection (OVP).

• To determine whether OVP is active, check whether VBAT – 141V is present at IC7971 pin 1. If not, check the components

D6938, C2939 and C2940 and L5941.

• If these components are O.K., then check voltage at pin 3 of IC 7942.

• If this voltage is not present check fuse 1941 and fuse 1942. Replace if necessary.

• If dc-voltage is present at pin 3, replace opto-coupler 7929.

• Another way to confirm whether OVP is active is to measure the voltage with an oscilloscope at IC7902 pin 4. If the voltage

is fluctuating between 11-14V, then check the components described above.

Solving other problems

TV switched off or changes channel without any user action

Set switches off after “TV SWITCHING OFF” was displayed

Auto standby switched the set off because:

• there was no ident signal for more than 15 minutes

• there was no remote control signal received or local key pressed for > 2 hours

See Service Adjustments for a description of options to enable/disable auto standby.

Picture problems

Picture too dark or too bright

- Press “Smart Picture” button on the remote control. If this improves the picture, increase / decrease the brightness value or

increase / decrease the contrast value.

- Enter the Customer Service Mode. If this improves the picture, exit Customer Service Mode, then Increase / decrease the

brightness value or increase / decrease the contrast value.

White line around picture elements and text

- Press “Smart Picture” button on the remote control. If this improves the picture, decrease the sharpness value.

- Enter the Customer Service Mode. If this improves the picture. Decrease the sharpness value.

Snowy picture

- Snow is an antenna or antenna connector problem. Check tuner and AGC.

Black and white picture

- Press the “Smart Picture” button on the remote control. If this improves the picture, increase the color value.

- Enter the Customer Service Mode. If this improves the picture. Increase the color value.

Menu text not sharp enough

- Press the “Smart Picture” button on the remote control. If this improves the picture, decrease the contrast value.

- Enter the Customer Service Mode. If this improves the picture. Decrease the contrast value.

Sound problems

No sound or sound too loud (after channel change / switching on)

- Enter the Customer Service Mode. If the volume is OK. Increase / decrease the volume level.

H8 CHASSIS (A10) ADJUSTMENTS

Electrical Adjustments

Conditions

All electrical adjustments should be performed under the following conditions:

• Supply voltage: 120V +/- (10%)

• Warm-up time: 10 minutes

• The voltages and oscilloscope waveforms are measured in relation to the tuner ground.

• Test probe: Ri > 10Meg Ohm; Ci < 2.5 pF.

VG2 Adjustment

Rough alignment

Using a pattern generator displaying a circle pattern, adjust the VG2 potentiometer of LOT L5630 to obtain a normal picture.

Fine adjustment

1. Enter Service Alignment Mode (SAM) (see Software alignments (Service Alignment Mode)). Press the Cursor Down button

to Highlight the WHITE TONE menu item. Use the Cursor Right button to enter the WHITE TONE submenu. The NORMAL

RED submenu item appears.

- Use the Cursor Up/Down buttons to select NORMAL RED, NORMAL GREEN, and NORMAL BLUE submenu items.

- Using the Cursor Right button, increase the value of RED, GREEN and BLUE to 40

- Adjust the value of RED, GREEN and BLUE to 42 for 29” Models.

2. Press the MENU button to leave the SAM-menu and go to the customer menu. When the customer menu appears, the

PICTURE menu item is highlighted. Press Cursor Right button to enter the PICTURE submenu. Press the Cursor Down

button to highlight PICTURE submenu item. Press the Cursor Right/Left buttons to set register value to 0.

3. Press the MENU button to return to the main customer menu. Press MENU again to return to the SAM Main Menu. Press

the Cursor Down button to highlight the AKB menu item. Press Cursor Right button to turn AKB OFF.

4. Connect RF output of the pattern generator to input antenna. Test pattern: blank pattern (blank screen on CRT). Set the

time base of the oscilloscope to 0.5ms with external triggering of the vertical pulse. Measure the black level pulse during the

vertical flyback at the RGB cathodes of the CRT.

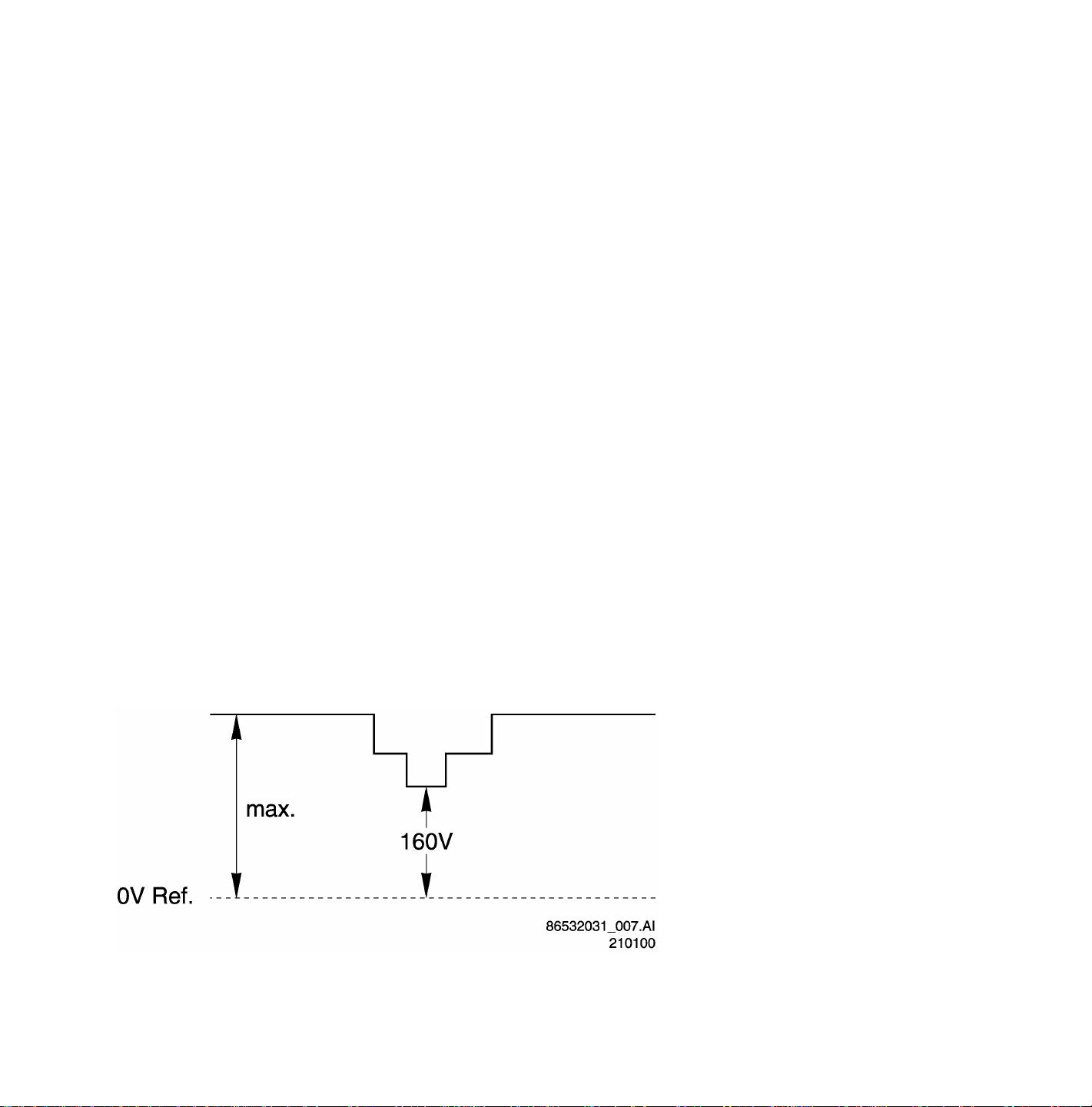

Black Level Pulse

Adjust the highest of the three guns with the VG2 potentiometer of the LOT to 160Vdc for 27FSQ-sets, while the minimum black

level voltage 165Vdc is for 32” / 36” FSQ-sets and 29” / 34” RF picture tubes.

Focus Adjustment

Using a pattern generator displaying a crosshatch pattern, adjust the focus potentiometer of LOT L5431 in such a way that the

haze on the vertical lines at 2/3 from the left and right edges of the screen (just) disappears.

PIP AGC Adjustment

The Automatic Gain Correction adjustment prevents overdriving of the PIP-tuner if the input signal is too strong. Overdriving is

visible as a loss of color and synchronization in the PIP picture. Amplification has to be adjusted to minimum level, but the PIPpicture should be as free of noise as possible.

Adjustment

• Connect the pattern generator to the tuner.

• Select color bar without sound and apply a strong input signal of 4mV (72dBµV) and set frequency to 61.25MHz. (Channel

3).

• Connect an oscilloscope to the output of the tuner (pin 11).

• Adjust potentiometer R3942 so that the oscilloscope indicates 0.5Vpp.

• If an input signal is not available, adjust R3942 to 1/3 maximum (maximum is completely counterclockwise).

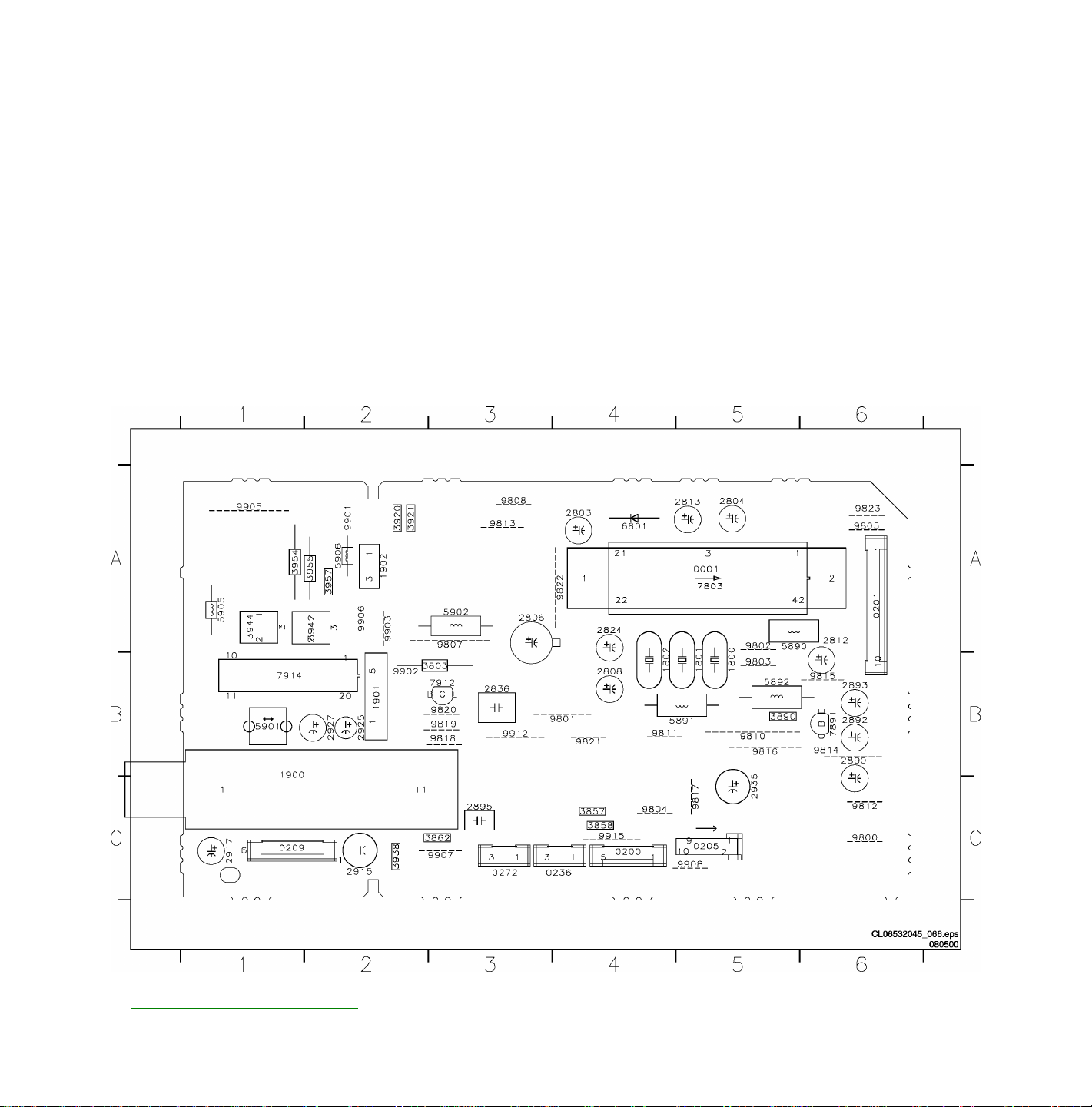

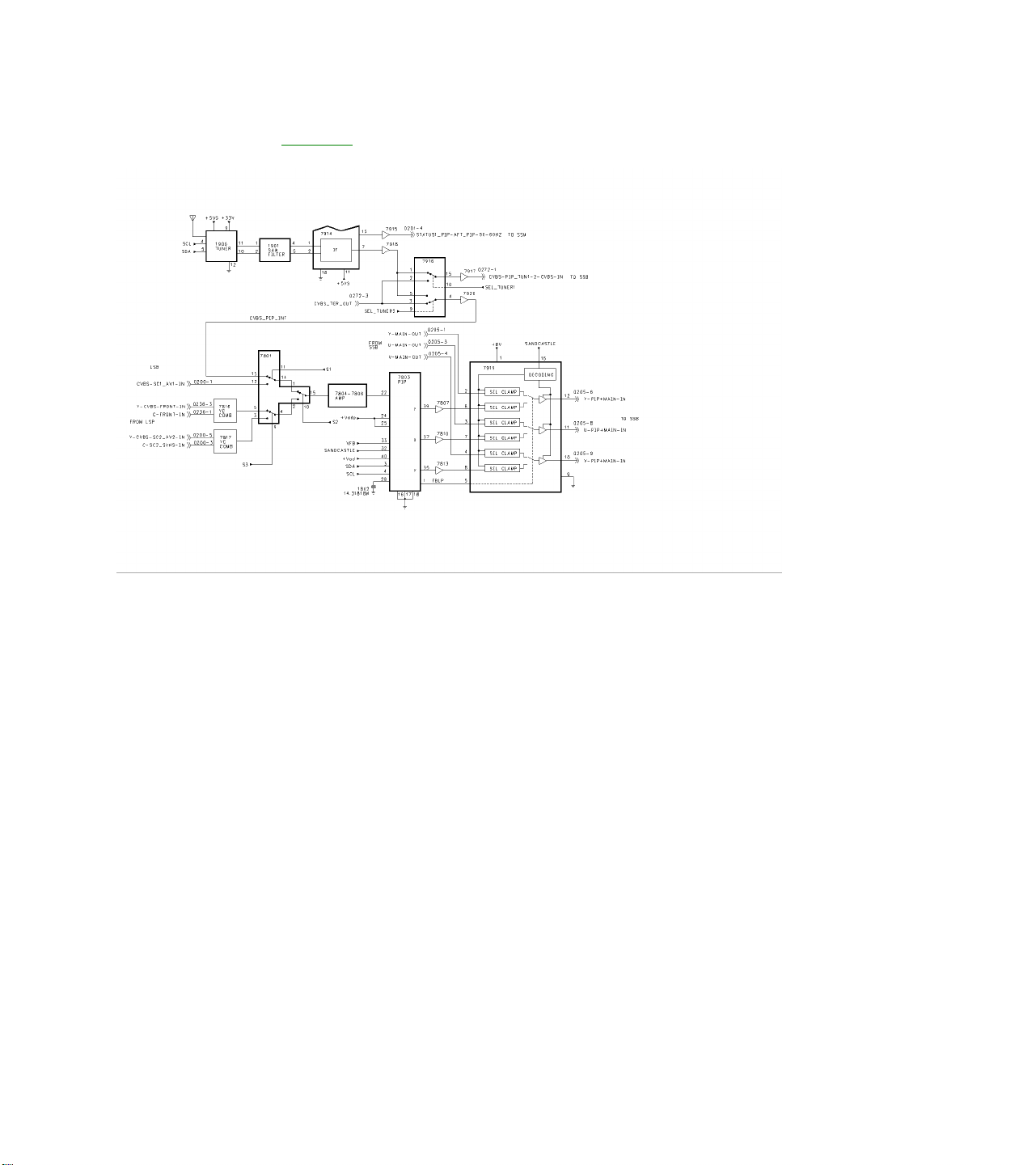

PIP Panel PCB (Top View)

PIP AFC Adjustment

• Connect a video generator with a color bar and a frequency of 61.25 MHz to the tuner.

• Connect a multimeter to the AFC output on pin 15 of IC 7914 – TDA9801

• Use potentiometer R3944 to adjust the AFC output to 2.6 Volts.

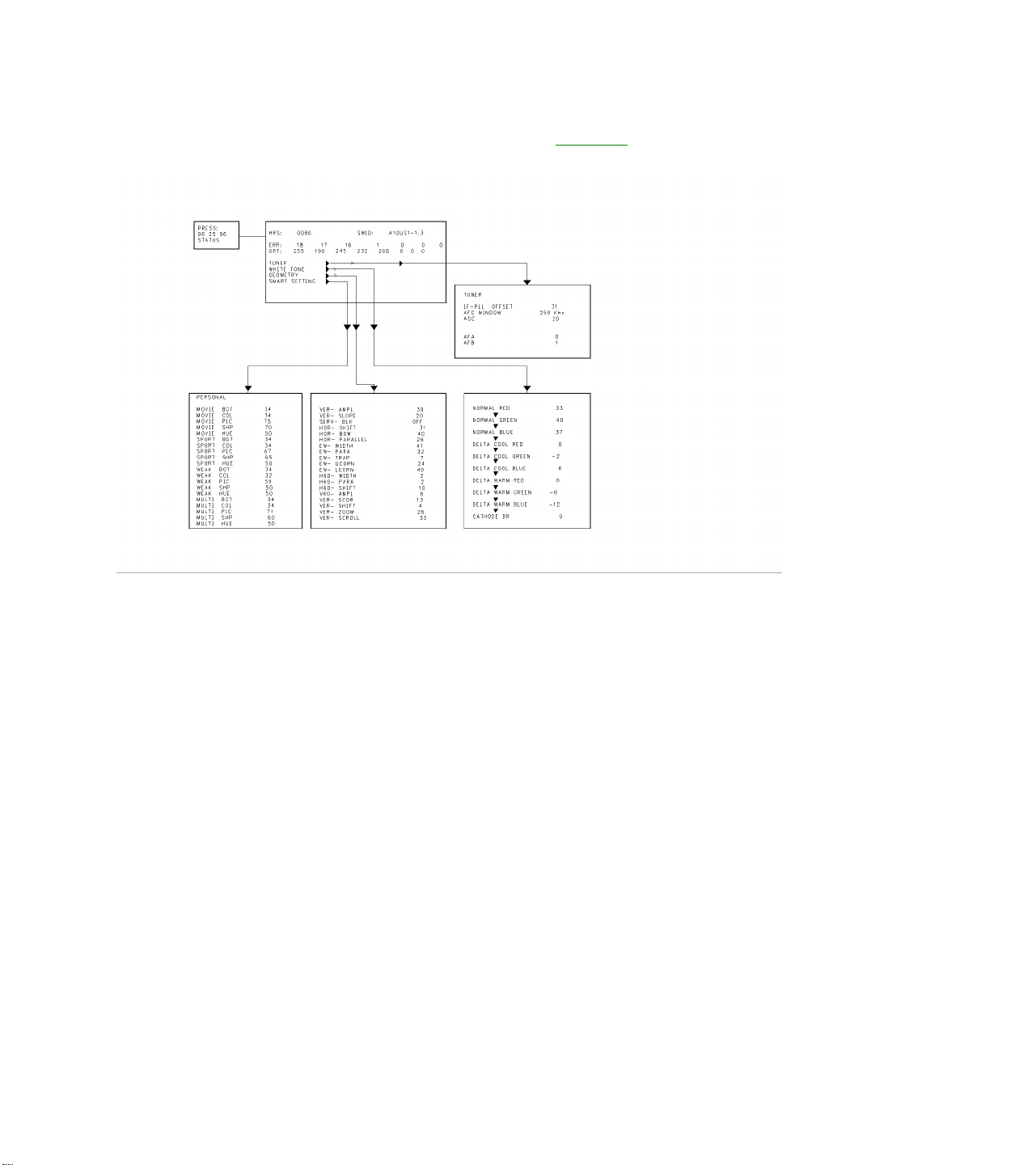

Software alignments (Service Alignment Mode)

With the software alignments of the Service Alignment Mode, the geometry, white tone and tuner (IF) can be aligned.

Service Alignments Mode screens and structure

Tuner (Large Signal Panel and Double Window)

AGC Adjustment

Set pattern generator with gray scale video signal and connect to antenna input with RF signal amplitude - 10mV and set

frequency to 63.25 MHz.

• Enter SAM (see Software alignments (Service Alignment Mode)). Press Cursor Down button to highlight the TUNER menu

item. Press Cursor Right button to enter the TUNER submenu. Press Cursor Down button to highlight the AFC submenu

item. Use the Cursor Left/Right buttons to set the value of AFC to 100kHz.

• Press the Cursor Down button to highlight AGC submenu item.

• Connect a DC multi-meter to pin 1 of the tuner IC 1225 ( Large Signal Panel ) or IC 1900 ( Double Window PIP Panel ).

• Press the Cursor Right/Left buttons to adjust the AGC register value until the voltage at pin 1 of the tuner is within 2.5 V

AGC takeover voltage of 3.8 V.

• Press the power button on the local keyboard or the remote control to turn the power off and save the settings.

Tuner options - IF PLL OFFSET and AFC WINDOW

NO ADJUSTMENT IS NECESSARY FOR THESE MENU ITEMS

The default values for these options are:

• IF PLL OFFSET : 32

• AFC WINDOW : 100kHz

White Tone Adjustment

Enter SAM (see Software alignments (Service Alignment Mode)). Press the Cursor Down button to highlight the WHITE TONE

menu item. Press the Cursor Right button to enter the WHITE TONE submenu. In the white tone submenu the values for the

color temperature values can be adjusted.

The color can be selected with the Cursor Up/Down buttons. The value can be changed with the Cursor Left/Right buttons.

First the values for the NORMAL color temperature should be selected. Then the offset values for the DELTA COOL and

DELTA WARM mode can be selected. Note that the alignment values are non-linear

0 represents the middle value (no offset difference).

Submenu: WHITE TONE

NORMAL

NORMAL RED 0..63

NORMAL GREEN 0..63

NORMAL BLUE 0..63

DELTA

COOL

DELTA COOL

DELTA COOL

DELTA COOL

DELTA

WARM

DELTA WARM

DELTA WARM

DELTA WARM

RED

BLUE

GREEN

RED

BLUE

GREEN

Values Remarks

-63..0..+63 The displayed values will satisfy the following

equation: 0 <= (NORMAL RED + DELTA

COOL RED) <= 63

EXAMPLE: If NORMAL RED = 40, then

DELTA COOL RED will range from –40 to 23.

-63..0..+63 Similar rule to DELTA COOL RED applies.

-63..0..+63 Similar rule to DELTA COOL RED applies.

-63..0..+63 Similar rule to DELTA COOL RED applies.

-63..0..+63 Similar rule to DELTA COOL RED applies.

-63..0..+63 Similar rule to DELTA COOL RED applies.

Geometry Adjustment

The geometry alignments menu contains 13 items for correct picture geometry alignment. In widescreen models, the

GEOMETRY SW is available for separate alignments of the superwide (panorama) mode. The geometry alignments are:

Initial set-up:

• Press the PICTURE button on the remote control repeatedly to change the Smart Picture setting to "SPORTS."

• Enter SAM (see Software alignments (Service Alignment Mode)).

• Press the Menu Down button to select the GEOMETRY menu item.

• Press the Cursor Right button to enter the GEOMETRY submenu.

• Press the Cursor Down button to highlight the VER-SCOR submenu item.

• Use the Cursor Right buttons to adjust VER-SCOR to 13 for 27”, 28”, 32” and 34” picture tubes.

• Use the Cursor Right buttons to adjust VER-SCOR to 23 for 29” RF- sets

• Vertical zoom should be set at a default value of 35.

• Vertical scroll should be set at a default value of 32.

VER-SCOR aligns the vertical linearity, so that the vertical intervals of the grid-patterns are the same over the entire height of

the screen.

Extra Alignment for 4:3 sets

• Set Service blanking on SERV-BLK ON

• Adjust Vertical slope VER-SLOPE xx

• Set Service blanking OFF SERV-BLK OFF

General Alignment (4:3 set)

• Adjust Vertical amplitude VER-AMPL xx

• Adjust Vertical shift VER-SHIFT xx

• Adjust Horizontal shift HOR-SHIFT xx

• Adjust Vertical height VER-ZOOM xx

• Adjust Vertical position VER-SCROLL xx

• Adjust Vertical linearity VER-SCOR xx

• Not used H60-SHIFT xx

• Not used V60-AMPL xx

• Adjust Horizontal width EW-WIDTH xx

• Adjust Parabola EW-PARA xx

• Adjust Up corner EW-UCORN xx

• Adjust low corner EW-LCORN xx

• Adjust Trapezium EW-TRAP xx

• Adjust Horizontal parallelogram HOR-PARALLEL xx

• Adjust Horizontal bow HOR-BOW xx

Geometry Submenu Item Descriptions

SERV-BLK: - To turn on/off the blanking of the lower half of the screen (To be used in combination with the vertical slope

alignment)

VER-SLOPE - To adjust the picture so the proportions are the same at the top and bottom of the screen. (This alignment

must be performed first, before all other vertical alignments)

VER-AMPL - To align the picture height (other vertical alignments are NOT compensated)

VERSHIFT - To align the vertical center of the picture to the vertical center of the CRT

HORSHIFT - To align the horizontal center of the picture to the horizontal center of the CRT

VER-ZOOM - To adjust picture height

VER-SCROLL - To vertically align the raster

VER-SCOR - To adjust the vertical linearity of the picture

H60-SHIFT - Not used

V60-AMPL - Not used

EW-WIDTH - To align the picture width (*)

EW PARA - To align straight vertical lines at the sides of the screen (*)

EW-UCORN - To align straight vertical lines in the upper corners of the screen (*)

EW-LCORN - To align straight vertical lines in the lower corners of the screen (*)

EW TRAP - To align straight vertical lines at the middle of the screen (*)

HOR-PARALLEL - To align straight vertical lines at the top and at the bottom of the screen; vertical rotation around the center

(*)

HOR-BOW - To align straight horizontal lines at the top and the bottom of the screen; horizontal rotation around the center

Alignments indicated with (*) are not applicable for sets without East/West circuitry

Options/Features

Options are used to control the presence / absence of certain features and hardware. There are two ways to change the option

settings, see Figure 2: Service Alignments Mode screens and structure.

Changing a single option

An option may be selected with the MENU UP/DOWN keys and then changed with the MENU LEFT/RIGHT keys.

Changing multiple options by changing option byte values

Option bytes make it possible to set all options quickly. An option byte represents a number of different options. All options of

the H8 are controlled via 8 option bytes. Select the option byte (OB1, OB2, OB3, OB4, OB5, OB6, OB7 or OB8) and enter the

new value.

List of options

Unless otherwise stated ON means the option is turned on or present, OFF means the option is turned off or not present.

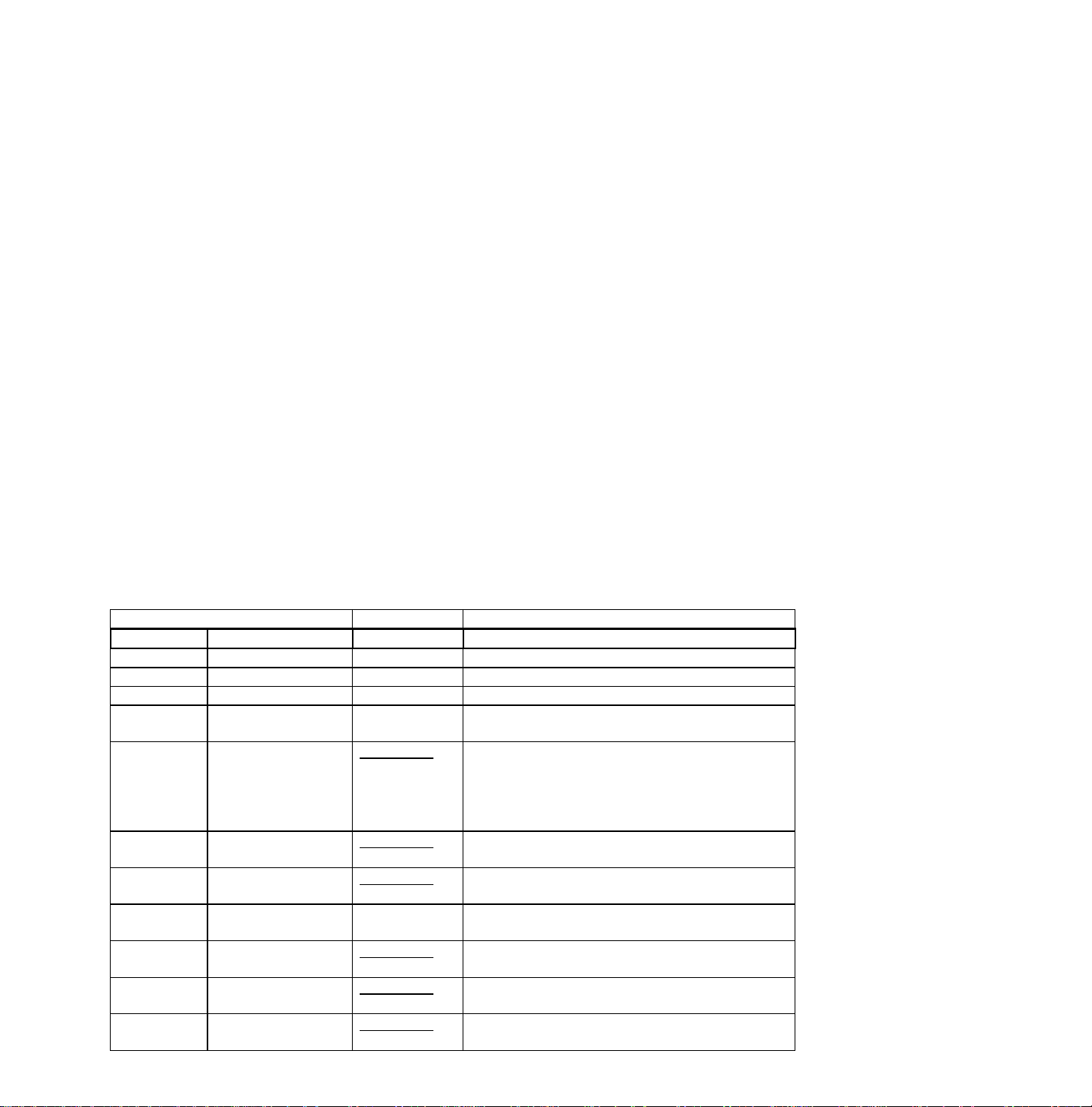

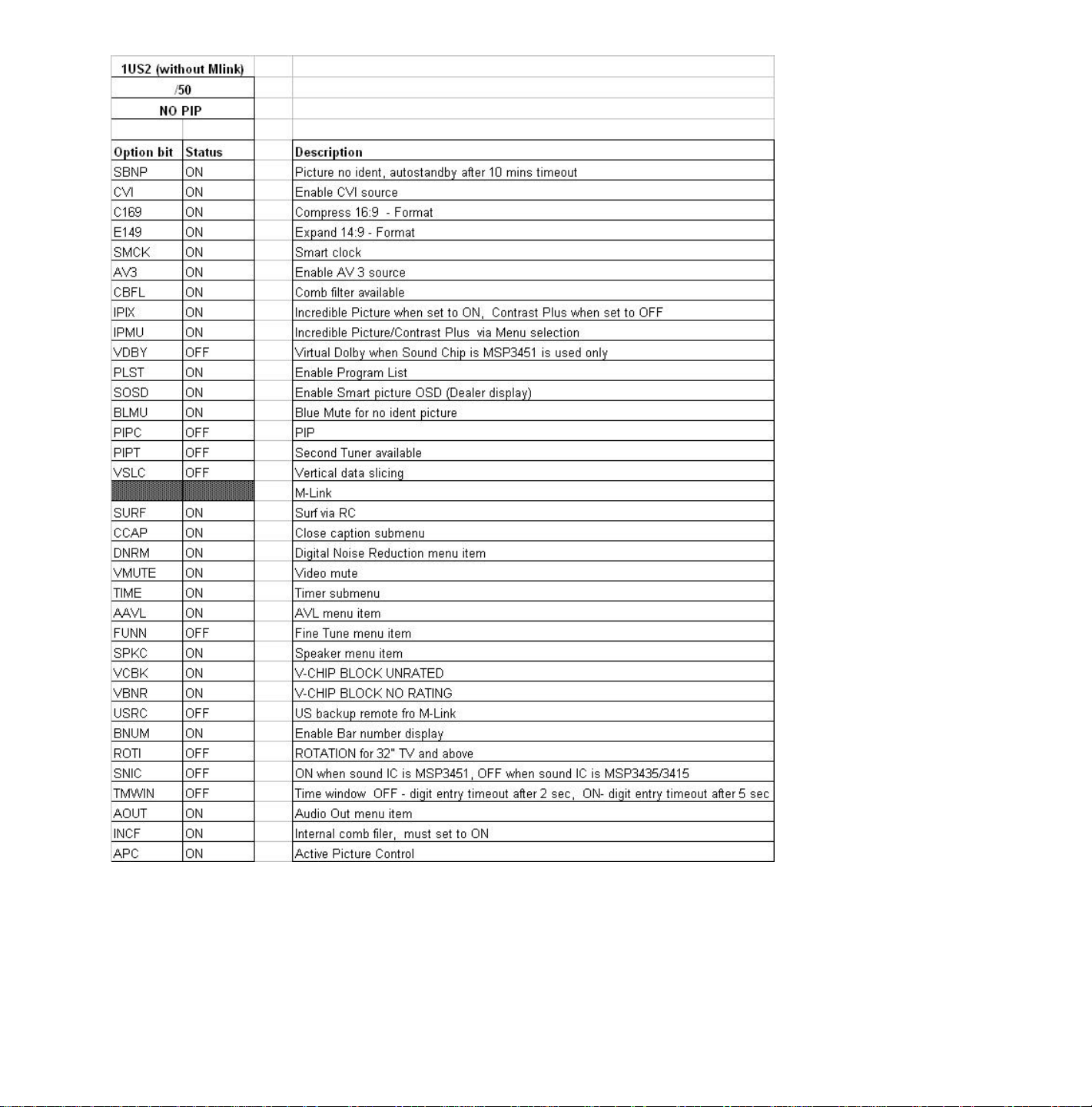

Option Codes for Single Tuner PIP, and 2 Tuner PIP

Option Codes for Models Without PIP

Option Codes for Double Window

Option bits/bytes

Option bytes for NAFTA models (4:3 Standard Screen) with software named: A10_1US1.

OB1 bits 8, 7, ..., 1: SBNP, CVI, C169, E149, SMCK, AV3, CBFL, and IPIX

OB2 bits 8, 7, ..., 1: IPMU, VDBY, PLST, SOSD, BLMU, PIPC, PIPT, VSLC

OB3 bits 8, 7, ..., 1: MLNK, SURF, CCAP, DNRM, VMUT, TIME, AAVL, FUNN

OB4 bits 8, 7, ..., 1: SPKC, VCBK, VBNR, USRC, BNUM, ROTI, SNIC, TMWIN

OB5 bits 8, 7, ..., 1: AOUT, INCF, APC, NVM, (res), (res), (res), (res)

OB6 bits 8, 7, ..., 1: (RESERVED)

OB7 bits 8, 7, ..., 1: (RESERVED)

OB8 bits 8, 7, ..., 1: (RESERVED)

Option bytes for NAFTA models (Flat Screen 16:9 Screen) with software named : A10_1US1.

OB1 bits 8, 7, ..., 1: SBNP, CVI, C169, E149, SMCK, AV3, CBFL, IPIX

OB2 bits 8, 7, ..., 1: IPMU, VDBY, PLST, SOSD, BLMU, PIPC, PIPT, W4X3

OB3 bits 8, 7, ..., 1: W169, VSLC, MLNK, SURF, CCAP, DNRM, VMUT, TIME

OB4 bits 8, 7, ..., 1: AAVL, FUNN, SPKC, GPLS, VCBK, VBNR, USRC, BNUM

OB5 bits 8, 7, ..., 1: SNIC, TMWIN, STOR, AOUT, INCF, APC, (res), (res)

OB6 bits 8, 7, ..., 1: (RESERVED)

OB7 bits 8, 7, ..., 1: (RESERVED)

OB8 bits 8, 7, ..., 1: (RESERVED)

An option byte value is calculated in the following way:

value “option bit 1” x 1 =

value “option bit 2” x 2 =

value “option bit 3” x 4 =

value “option bit 4” x 8 =

value “option bit 5” x 16 =

value “option bit 6” x 32 =

value “option bit 7” x 64 =

value “option bit 8” x 128 =

Total value is “option byte” =

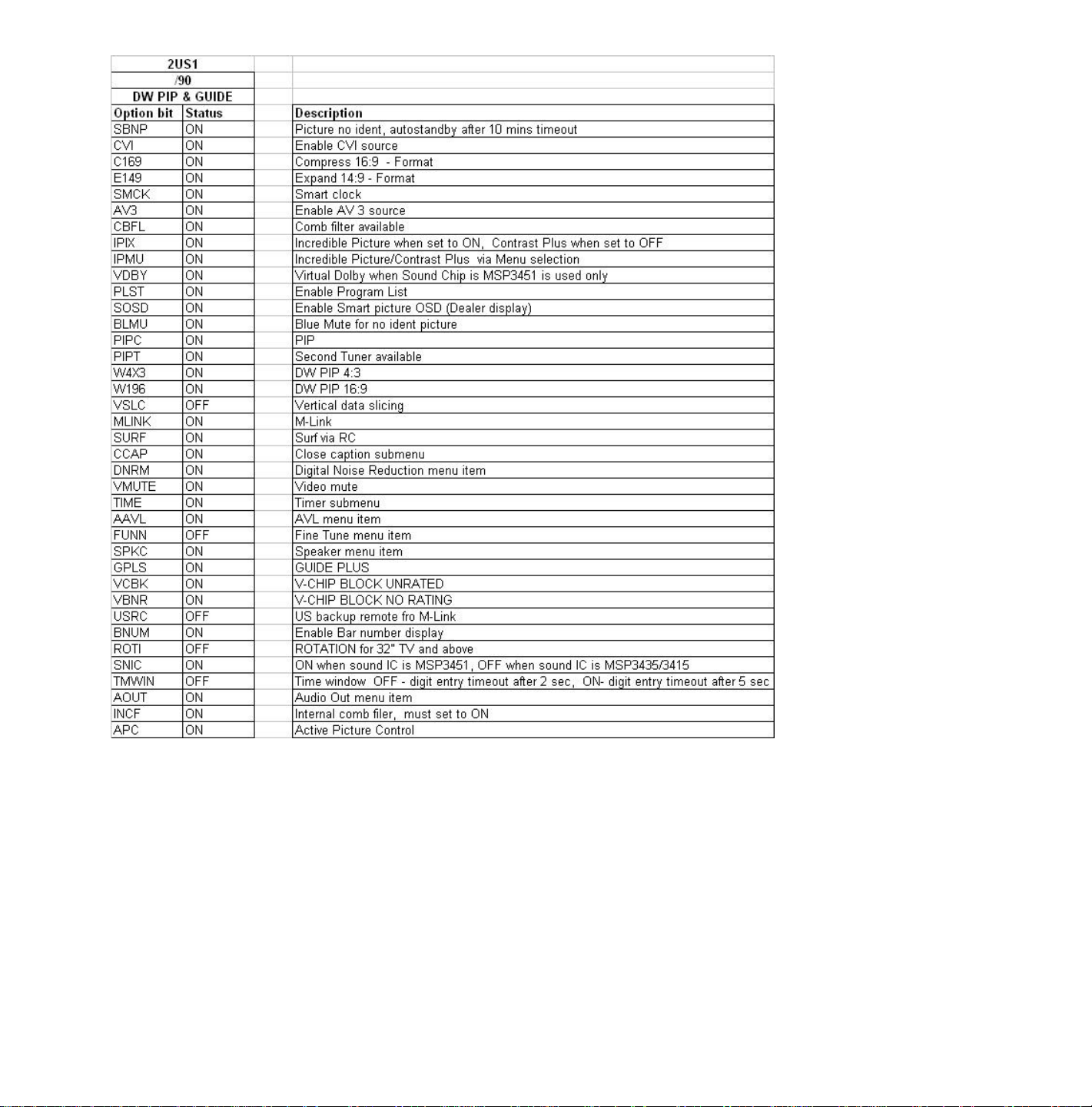

Option Code Bytes

MODEL OPTION BYTES

1 2 3 4 5 6 7 8

27PT31B121

27PT41B121

27PT71B121

27PT81S125

27PT91S125

32PT41B121/9

32PT71B121/9

32PT81S121/7

36PT41B129

36PT71B129

27RF70S125

32RF50S121/7

27DV60S125

32DV60S127

29PD802

255 184 126 232 208 0 0 0

255 188 254 232 208 0 0 0

255 190 254 232 208 0 0 0

255 190 254 232 208 0 0 0

127 255 127 245 122 0 0 0

255 188 254 232 208 0 0 0

255 190 254 232 208 0 0 0

255 190 254 236 208 0 0 0

255 188 254 232 208 0 0 0

255 190 254 232 208 0 0 0

255 188 254 232 208 0 0 0

255 184 126 236 208 0 0 0

251 223 186 056 0 0 0 0

251 223 187 056 0 0 0 0

251 223 250 056 0 0 0 0

(EXPORT)

Service Modes & Error Messages

The following topics are covered:

• Test points

• Service Modes and Dealer Service Tool (DST)

• Error code buffer and error codes

• The “blinking LED” procedure

• Trouble shooting tips

• Customer Service Mode

Test points

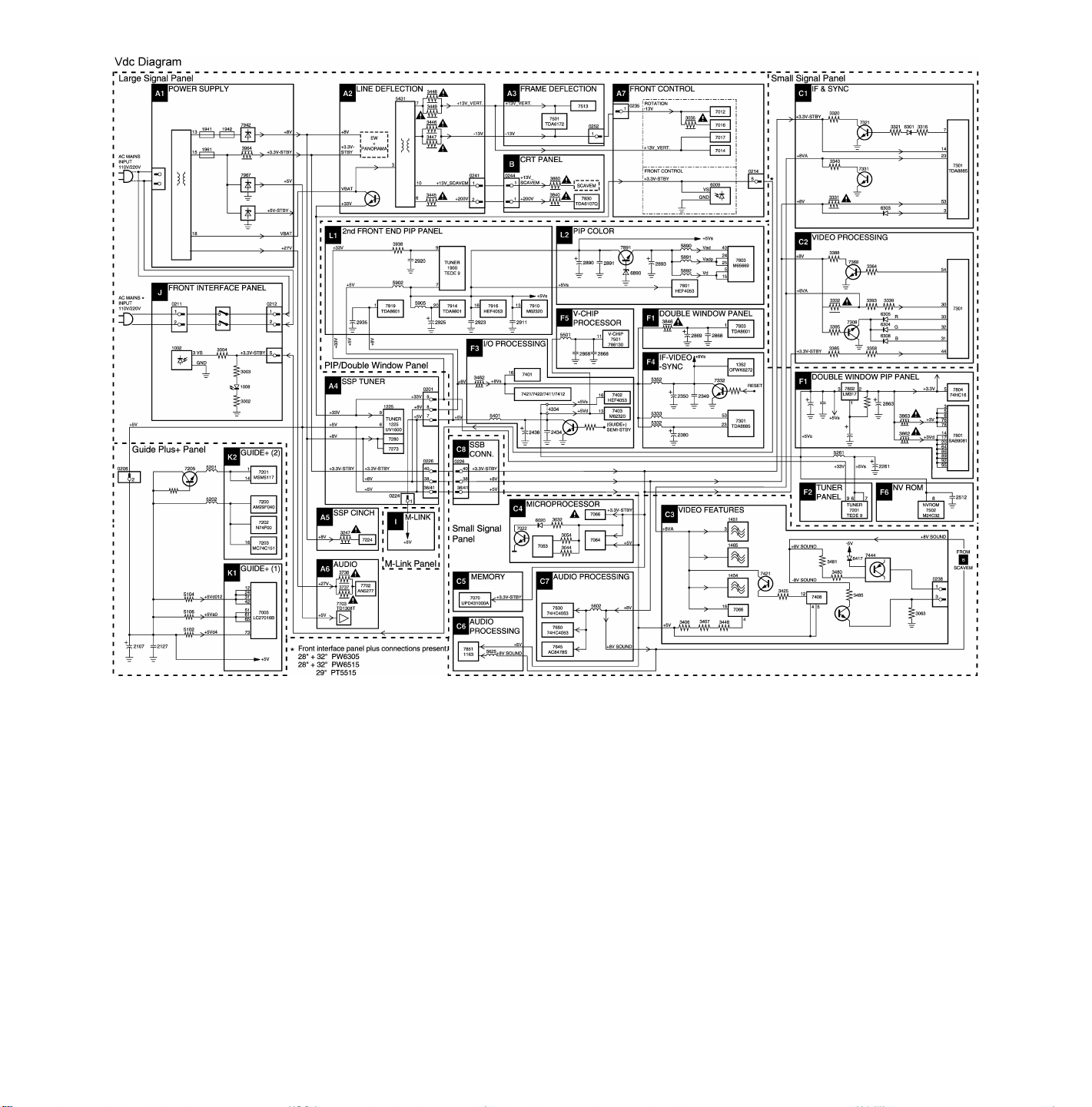

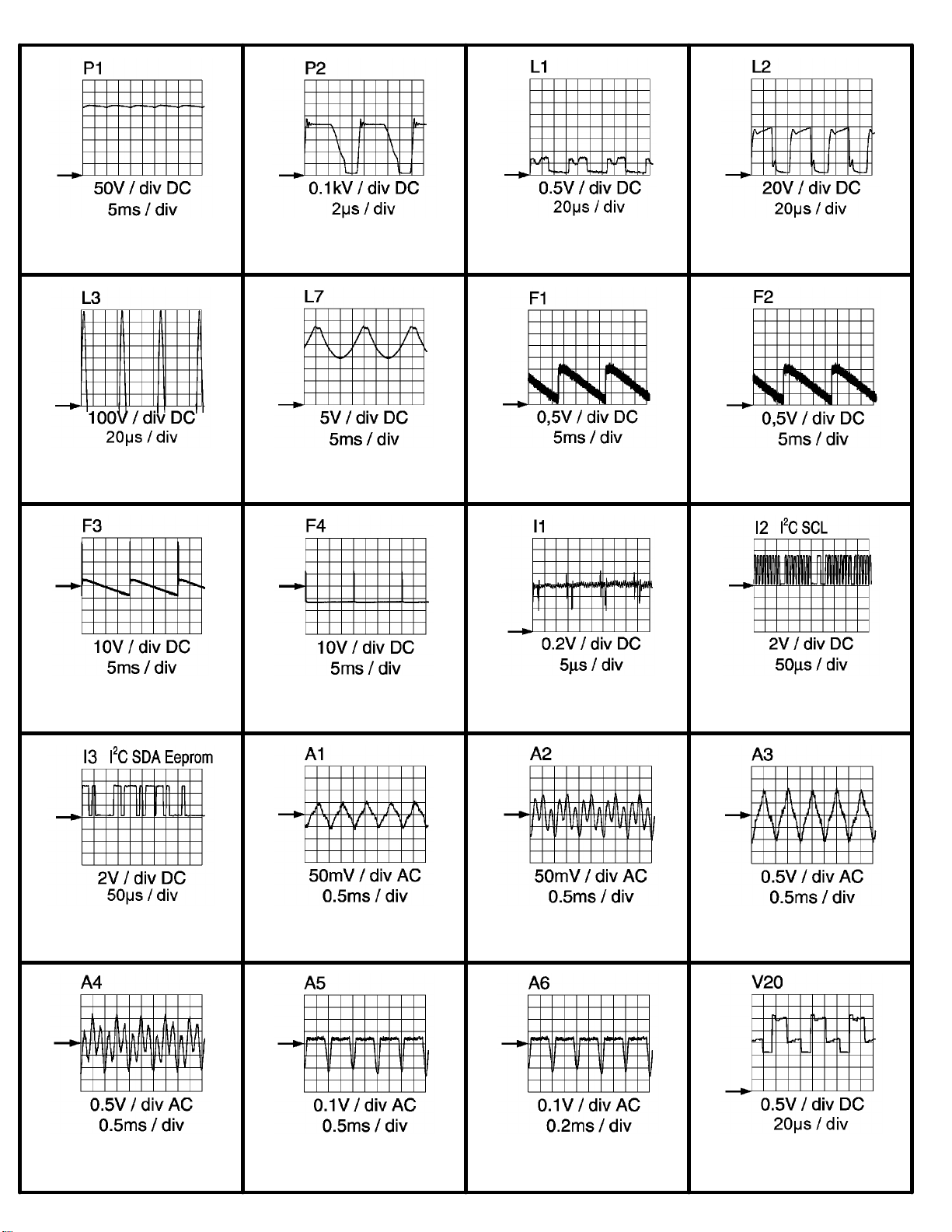

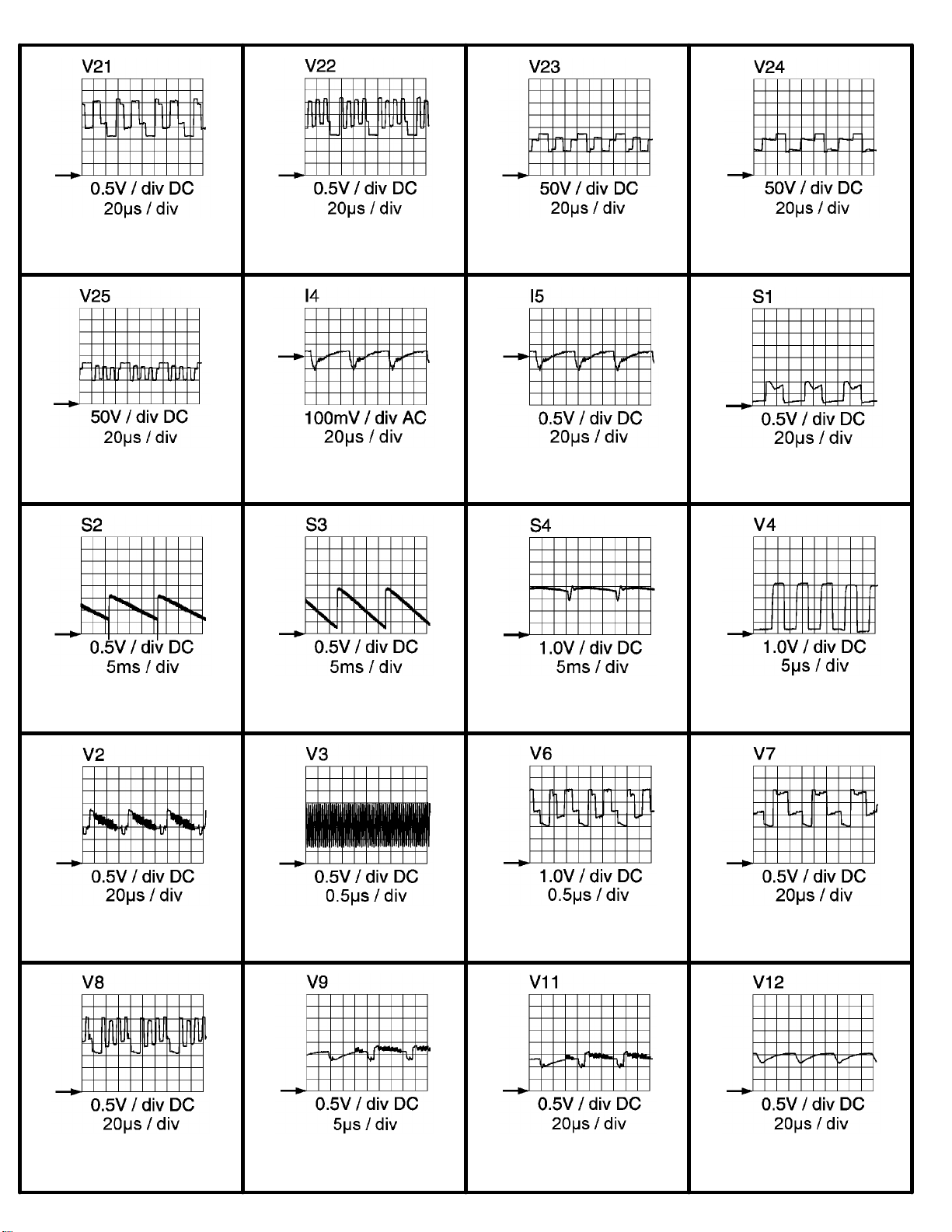

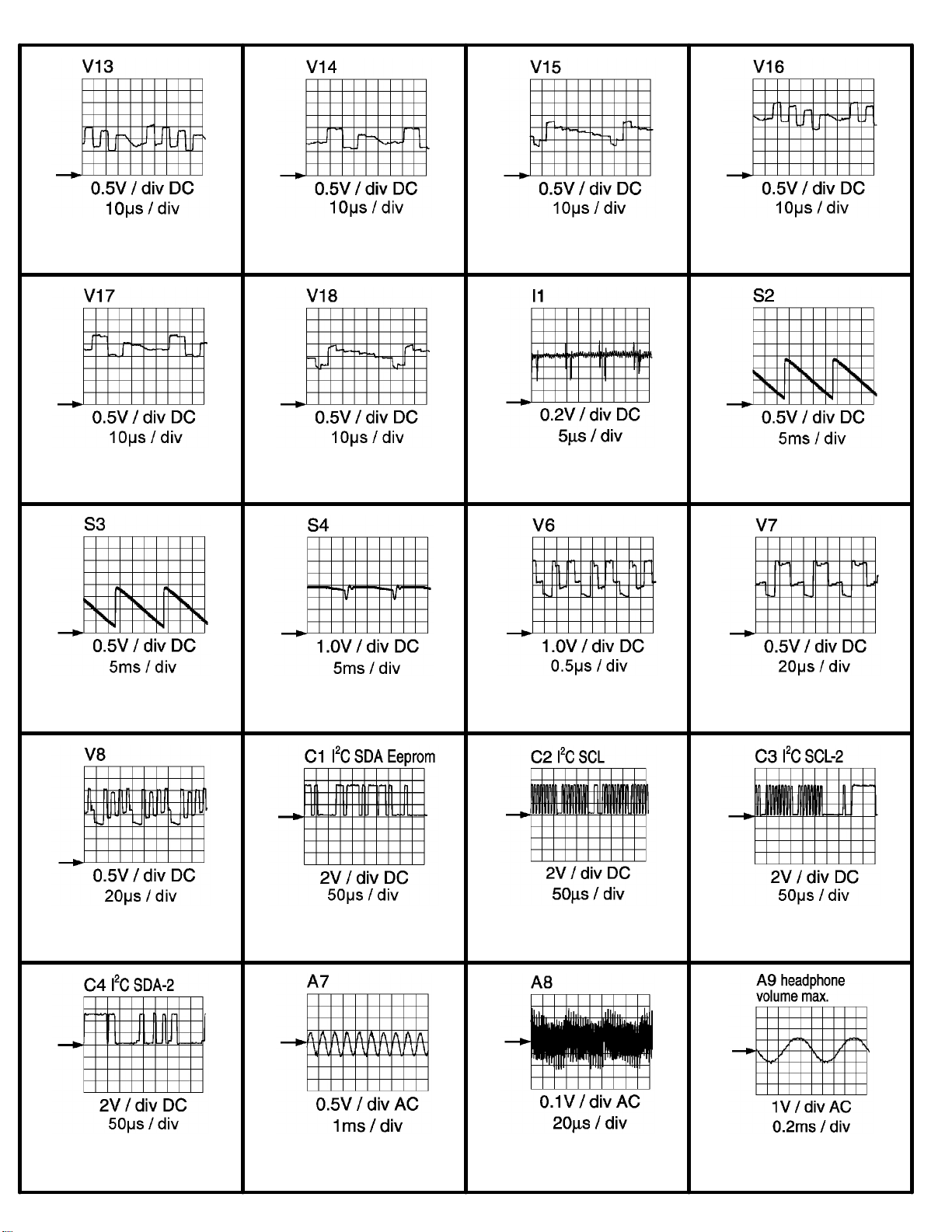

The H8 chassis is equipped with test points shown on the CBA and the schematic diagrams.

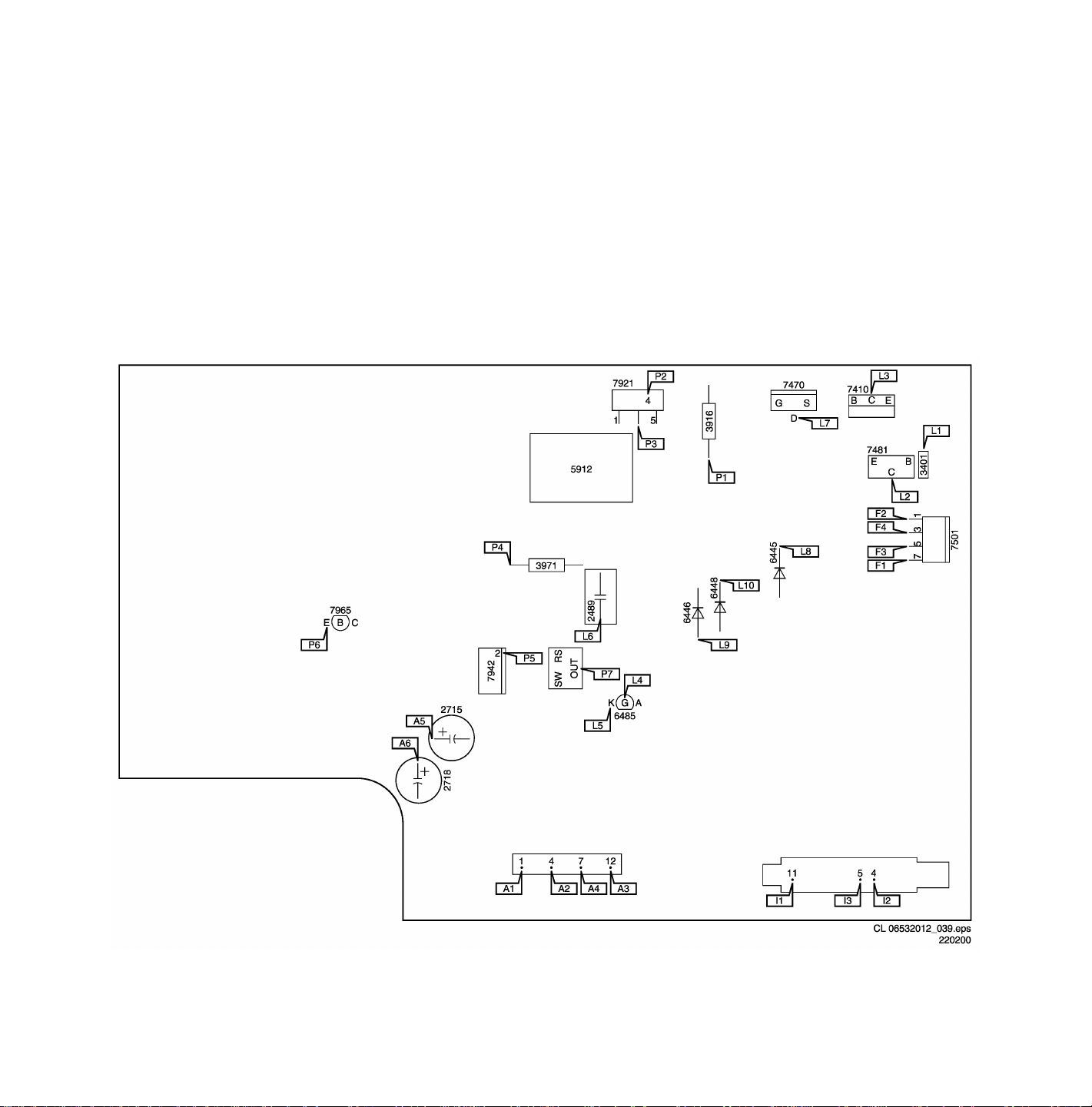

Large Signal Panel PCB Test Point Guide

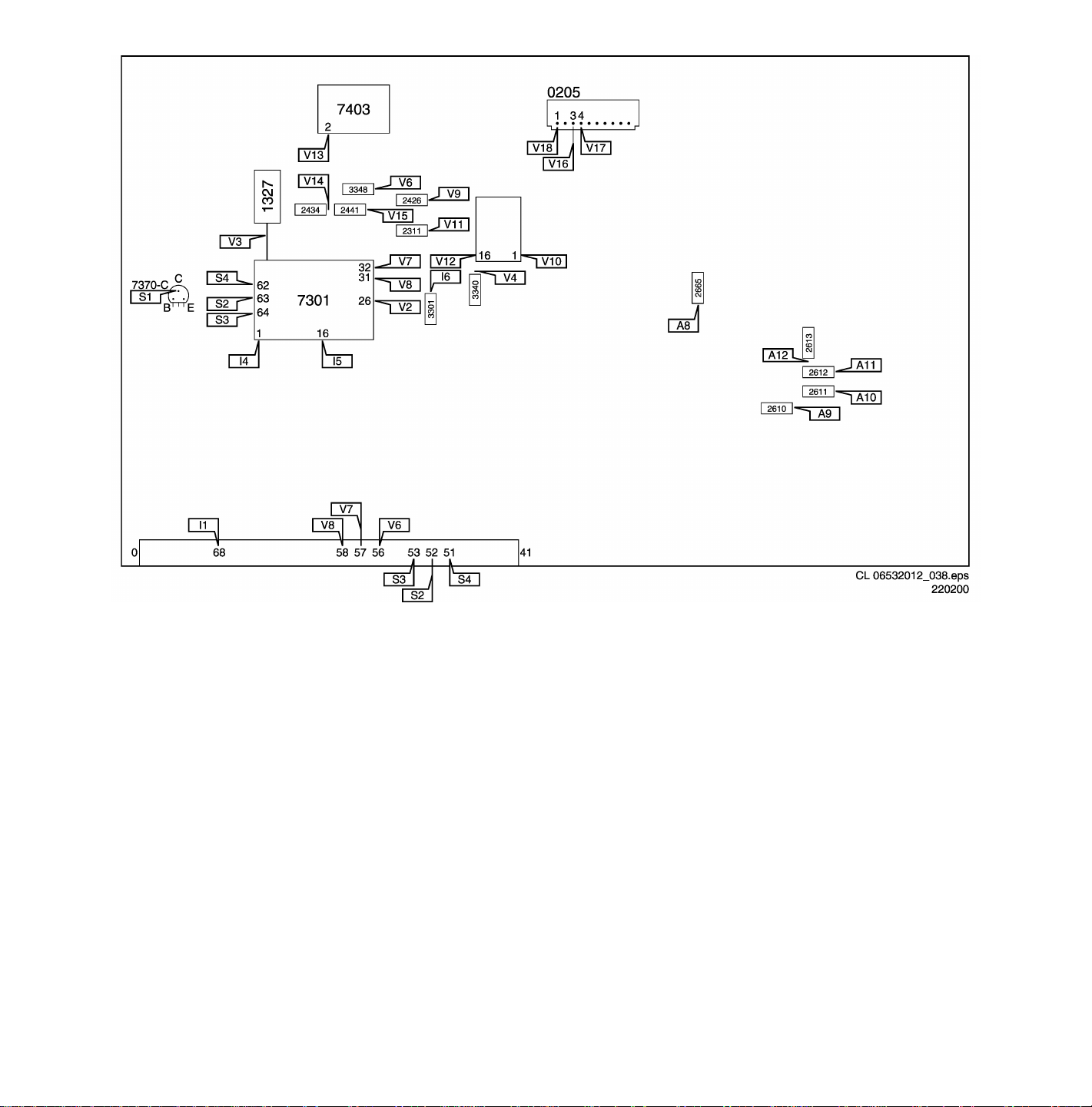

Small Signal Panel PCB Test Point Guide

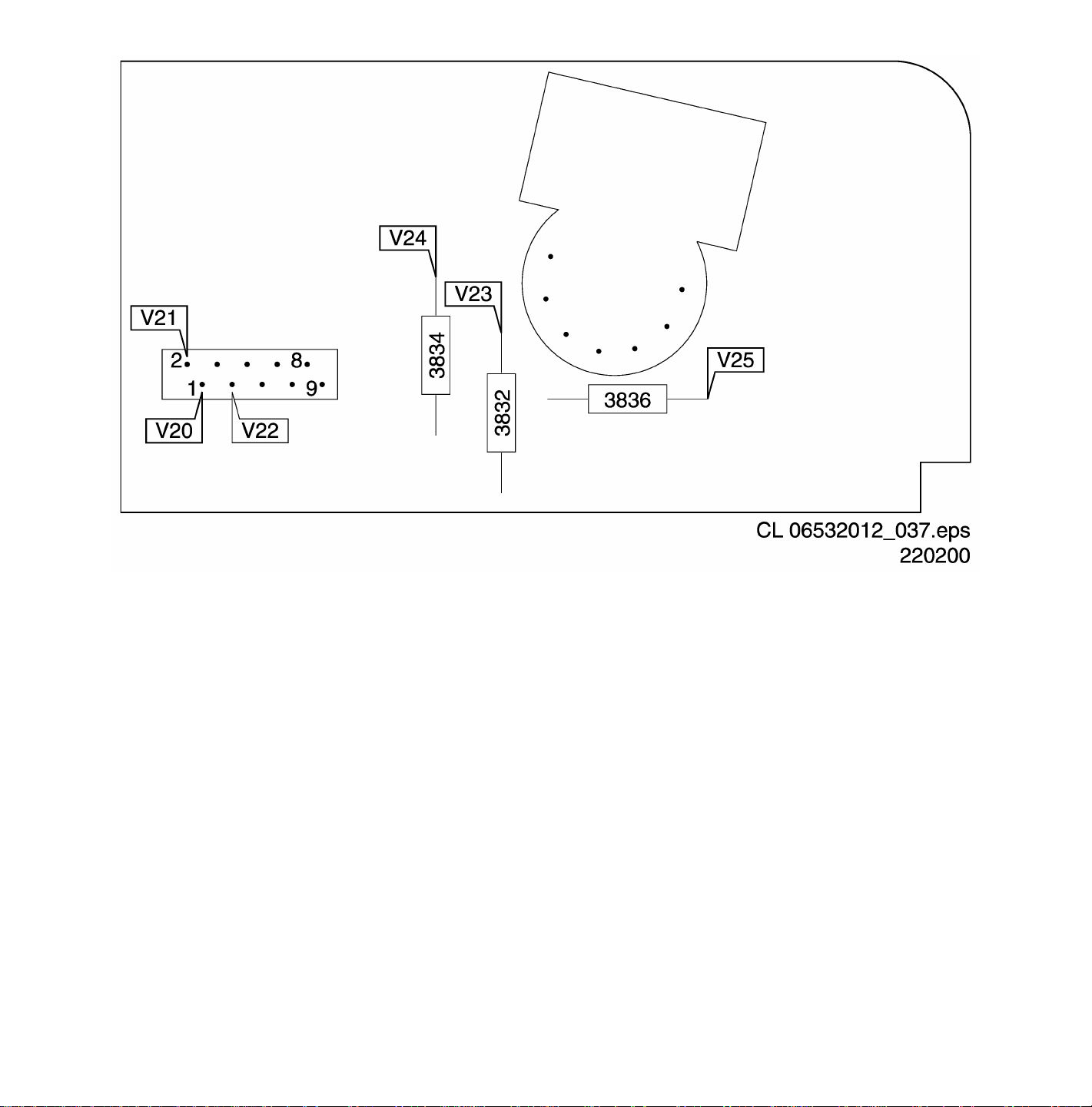

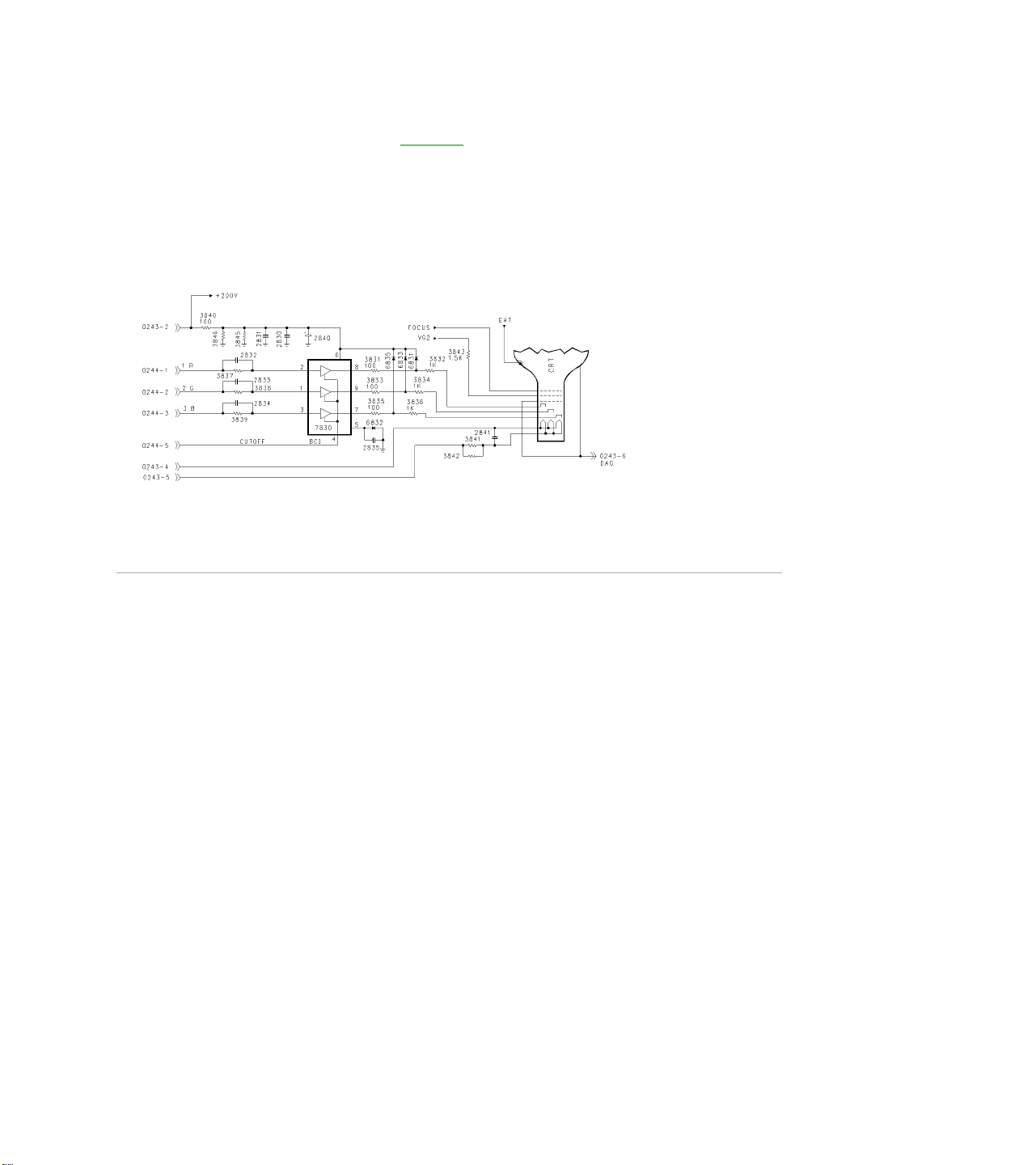

CRT Panel PCB Test Point Guide

Each test point has a reference number indicating the functional block in which it is located.

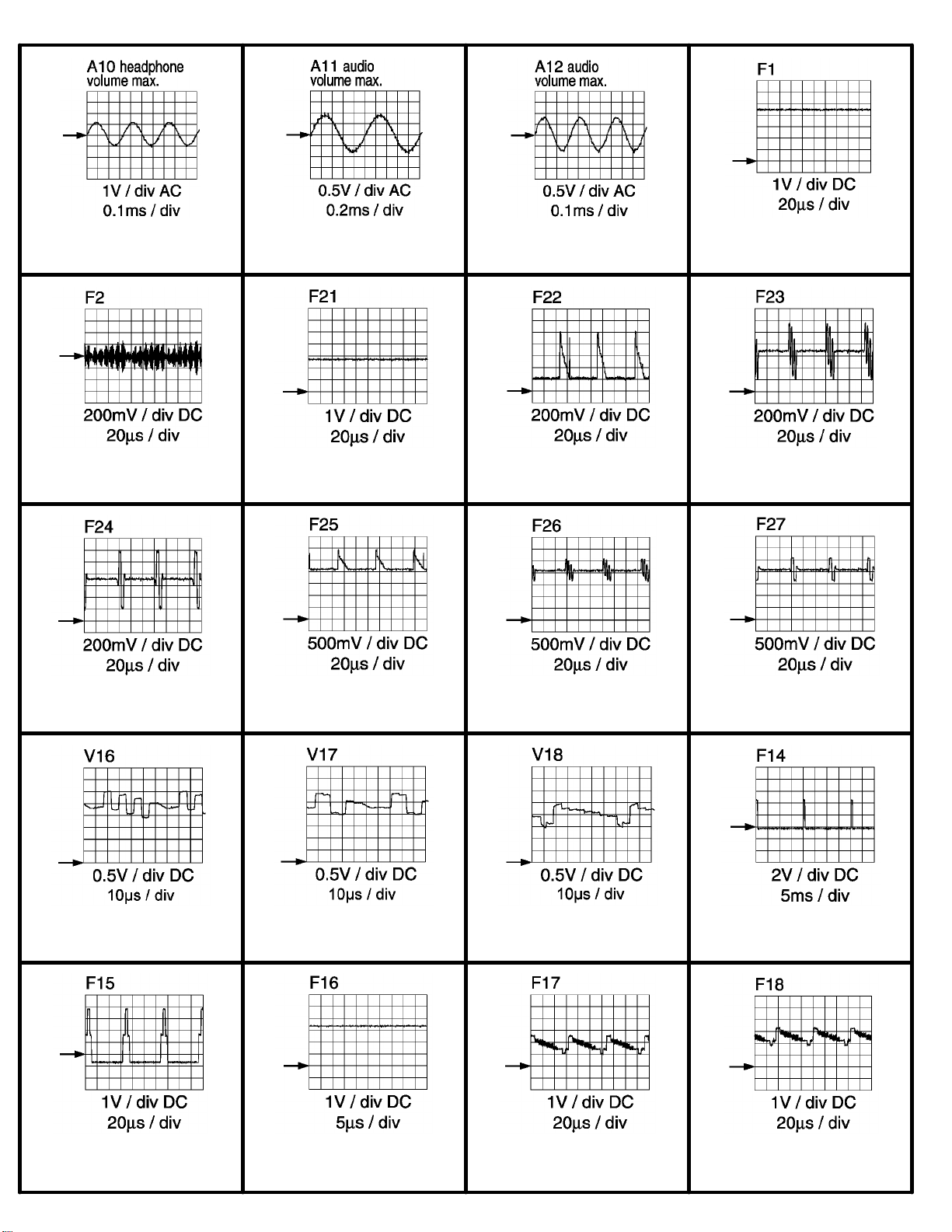

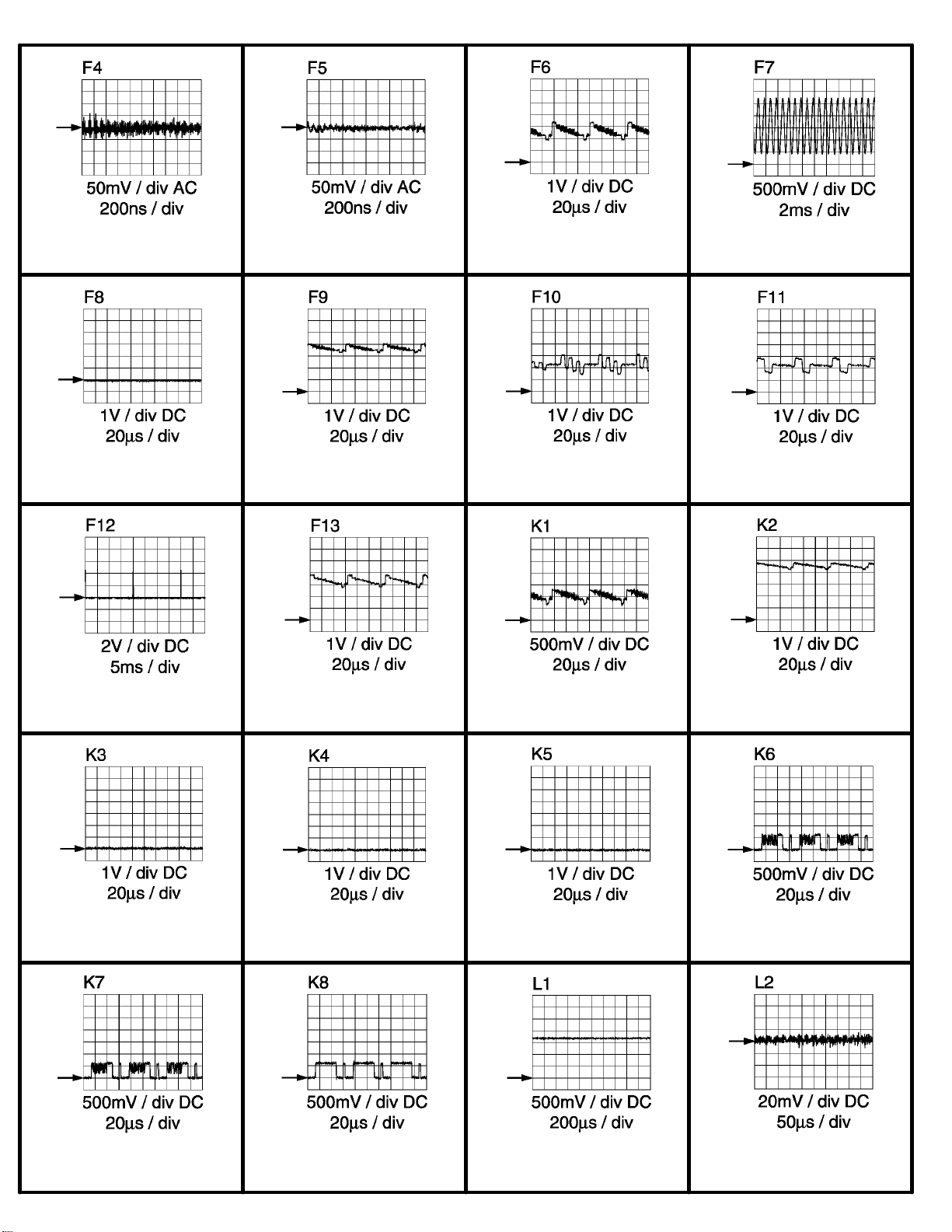

• A1-A2-A3, etc.: Test points for the audio processing circuitry [A6, C6]

• C1-C2-C3, etc.: Test points for the control circuitry [C8]

• F1-F2-F3, etc.: Test points for the frame drive and frame output circuitry [A3]

• I1-I2-I3, etc.: Test points for the Intermediate Frequency Circuitry [A4, C1]

• K1-K2-K3, etc: Test points for the Guide+ panel

• L1-L2-L3, etc.: Test points for the line drive and line output circuitry [A2] and PIP-panel

• P1-P2-P3, etc.: Test points for the power supply [A1]

• S1, S2, S3, etc.: Test points for the synchronization circuitry [C1]

• V1-V2-V3, etc.: Test points for the video processing circuitry [B, C2, C3]

Measurements should be performed under the following conditions:

Video: NTSC color bar signal

Audio: 3kHz left, 1kHz right

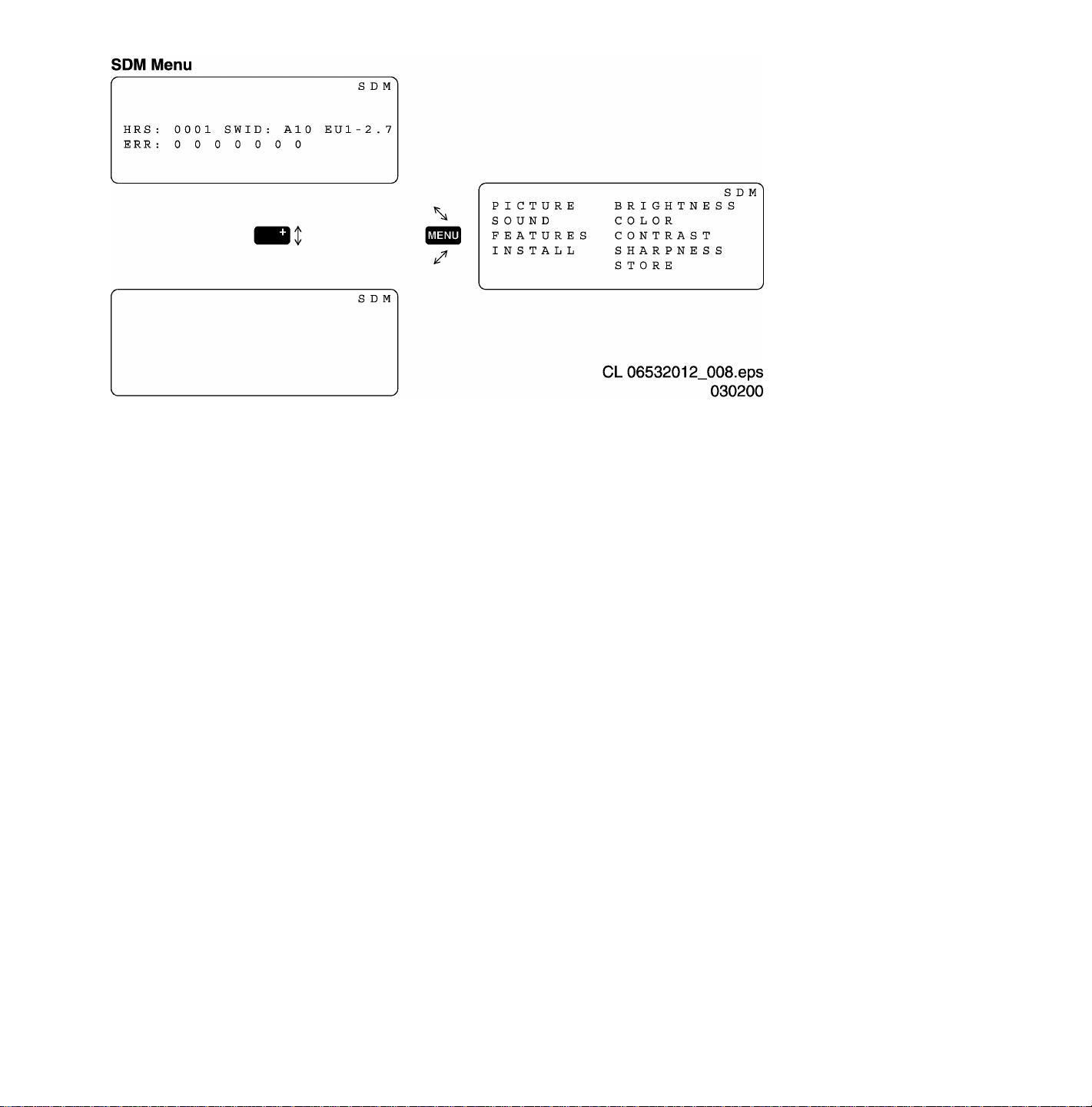

Service Default Mode (SDM)

Introduction

The Service Default Mode (SDM) is a technical aid for the service technician. The Service Default Mode (SDM) establishes

fixed, repeatable settings of customer controls, which allow consistent measurements to be made. The SDM also initiates the

blinking LED procedure and, if necessary, overrides the 5V protection.

The SDM places the set in the following pre-defined conditions:

• Tuning frequency set to 61.25 MHz (channel 3).

• Volume level set to 25% (of the maximum volume level).

• Other picture and sound settings set to 50% (mid-range)

The following functions are turned off in SDM (and after leaving SDM):

• Timer

• Sleep timer

The following functions are disabled during SDM (and enabled after leaving SDM):

• Parental lock

• Blue mute

• Hospitality Mode

• No-ident Timer (normally the set is automatically switched off when no video signal (IDENT) was received for 15 minutes).

All other controls operate normally.

Entering Service Default Mode

To enter the Service Default Mode, press the following key sequence on the remote control transmitter:

0-6-2-5-9-6-Menu

Do not allow the display to time out between entries while keying the sequence.

It is also possible to enter the Service Default Mode by temporarily short-circuiting jumpers 9261 and 9262 while turning the set

on By shorting jumpers 9261 and 9262 while turning the set on.

Note: Entry into SDM by temporarily shorting jumper 9261 and 9262 while turning the set on, the 5V protection will be

disabled.

CAUTION! Overriding the 5V protection should only be used for a short period of time. In case of S/W protections

(error 1-4) the set will shutdown after 15 sec.

Upon entry into the Service Default Mode, the letters “SDM” will be displayed at the upper right corner of the screen.

Service Default Mode (SDM) Screen

Special SDM functions

Access to normal user menu

Pressing the “MENU” button on the remote control switches between the SDM and the normal user menus (with the SDM

mode still active in the background)

Auto Program

Press the Cursor Down button and highlight the "Install" menu item. Press the Cursor Right button to highlight the "Language

" menu item. Press the Cursor Down button until the "Auto Program" menu item is highlighted. Press the Cursor Right button

to activate Auto Program.

Auto programming is indicated by a blinking LED; the LED will discontinue blinking when a transmitter is located.

Error buffer

To show/hide the error buffer press the “Status/Exit” button on the remote control. The error buffer information can be hidden

to prevent interference with oscilloscope measurements.

Access to SAM

To access the Service Alignment Mode while in the SDM press the “VOLUME +” and “VOLUME –“ buttons on the local

keyboard simultaneously.

Exiting Service Default Mode

To exit the Service Default Mode, press the Power button.

Note: To save the error codes, unplug the AC power cord without turning off the set. When the power is turned back

on, the Service Default Mode will still be active.

Service Alignment Mode (SAM)

Introduction

The Service Alignment Mode (SAM) is used to align the set and/or adjust the option settings and to display/clear the error code

buffer values.

Entering Service Alignment Mode

To enter the Service Alignment Mode (SAM), press the following key sequence on the remote control transmitter:

0-6-2-5-9-6-STATUS

Do not allow the display to time out between entries while keying the sequence

It is also possible to enter the Service Alignment Mode by pressing the “VOLUME +” and “VOLUME -” key on the local keyboard

simultaneously when the set is in SDM

Exiting the Service Alignment Mode (SAM)

To Save Changes and Exit:

Press the Menu button on the Remote Control until you have backed-up to the upper level SAM Menu.

Upon returning to the upper level SAM Menu, pressing the power button on the Remote Control or the set's own front control

will cause current register settings to be saved. The set will pause for a few seconds (while saving this data), and then both exit

the SAM Mode and shut down.

Note: Pressing the power button, while in a sub-menu, will exit the SAM Mode and cause the set to shut down, but changes

will not be saved.

Note: To save the error codes, unplug the AC power cord without turning off the set. When the power is turned back

on, the Service Alignment Mode will still be active.

In the SAM the following information is displayed on the screen:

SAM Screen and Menu Structure

Explanation notes/references:

1 Operation Hours (Run Timer):

This display indicates the accumulated total of operational hours. (Shown in hexadecimal

format)

2 Software identification of the main micro controller (A10US1-2.7)

A10 is the engineering chassis name for the H8 chassis

• US1 is 2 letter and 1 digit combination to indicate the software type and the supported

languages:

• US = USA

• 1 = Main Software language version number

• 2.7 = sub-version number

3 Error buffer (7 errors possible) Displays the 7 most recent errors. The most recent

error is displayed at the upper left.

4 Option bytes (8 codes possible), summary of options are explained below.

5 Sub menus are listed in a scroll-menu.

SAM Menu Control

Menu items may be selected using the cursor UP/DOWN key.

• The selected item will be highlighted.

• When not all menu items will fit on the screen, pressing the cursor UP/DOWN key on the remote transmitter will display the

next/previous menu items.

With the cursor LEFT/RIGHT keys, it is possible to:

• (de)activate the selected menu item (e.g. GEOMETRY)

• change the value of the selected menu item ( e.g. VER-SLOPE )

• activate the selected submenu (e.g. SERV-BLK)

Access to normal user menu

Pressing the “MENU” button on the remote control switches between the SDM and the normal user menus (with the SAM

mode still active in the background). Pressing the “MENU” key in a submenu will return the screen to the previous menu.

The Menus and Submenus

CLEAR ERRORS

Erasing the contents of the error buffer. Select the CLEAR ERRORS menu item and press the MENU RIGHT key. The

content of the error buffer is cleared.

The functionality of the OPTIONS and ALIGNMENTS (TUNER, WHITE TONE, GEOMETRY and SMART SETTING) sub

menus is described in the service adjustments.

Error code buffer and error codes

Explanation of the Error code buffer

The error code buffer contains all errors detected since the last time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code buffer, the error code will appear at the left side and all other

errors shift one position to the right.

The error code buffer will be cleared in the following cases:

• by activating CLEAR ERRORS in SAM menu

• exiting SDM or SAM with the “Standby" command on the remote control

• upon automatic reset when content has not changed for 50 consecutive hours

By leaving SDM or SAM via the power switch, the error buffer will not be reset.

Examples:

ERROR: 0 0 0 0 0 0 0 : No errors detected

ERROR: 6 0 0 0 0 0 0 : Error code 6 is the last and only detected error

ERROR: 9 6 0 0 0 0 0 : Error code 6 was first detected and error code 9 is the last detected (newest) error

The contents of the error buffer can also be displayed by use of the “blinking LED” procedure, if no picture is available. See

explanation of “The blinking LED procedure “below.

Error code definition

In case of non-intermittent faults, clear the error buffer before starting the repair, to make sure “old” error codes are not present.

If possible check the entire content of the error buffers. In some situations an error code is only the result of another error code

(and not the actual cause).

Note: a fault in the protection detection circuitry can also lead to a protection.

Error 0 = No error

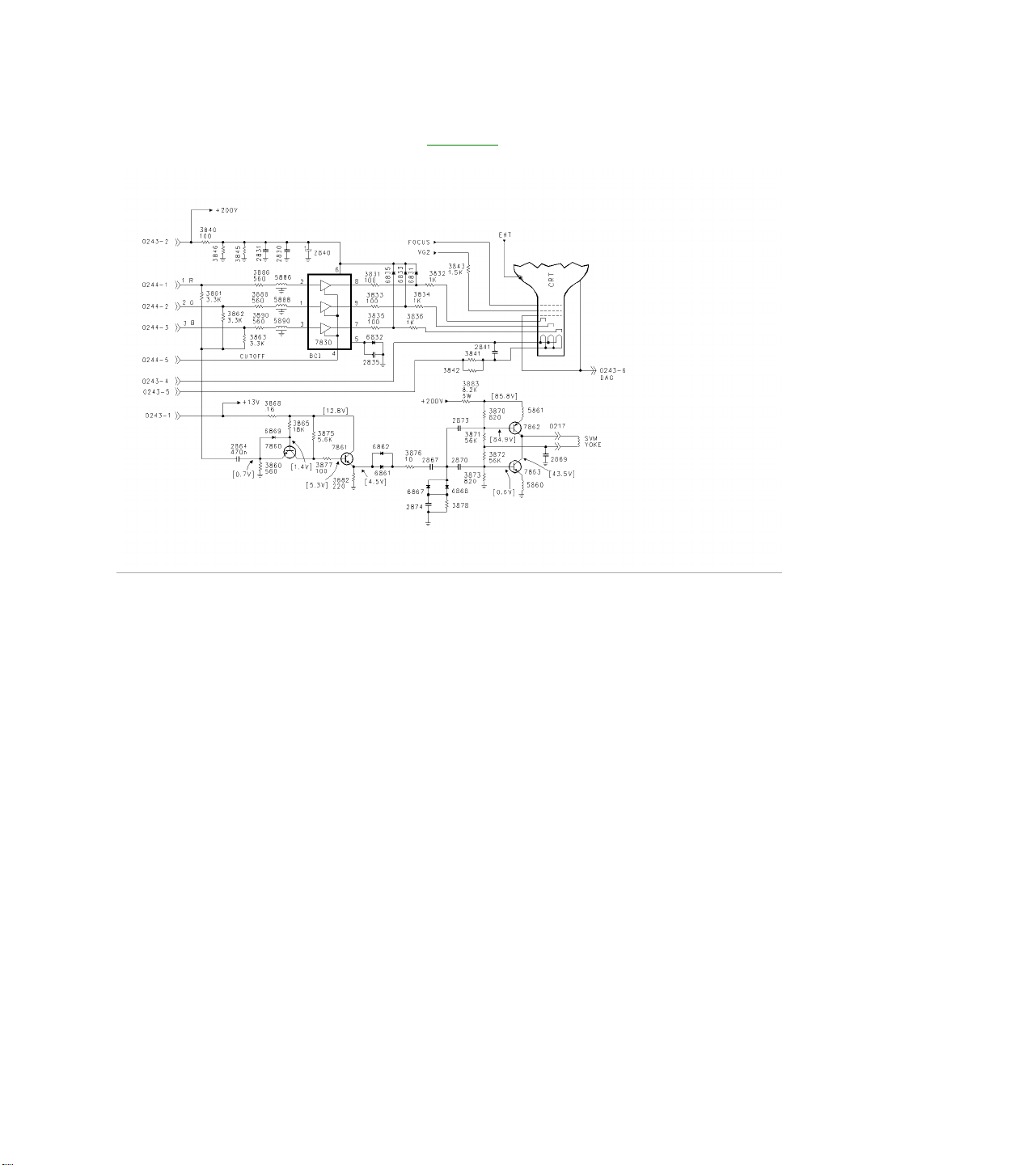

Error 1 = X-ray protection, E/W protection and/or Beam

X-ray protection, E/W protection and/or Beam; set is switched to protection; error code 1 is placed in the error buffer; the LED

will blink 1 time (repeatedly). If this happens, isolate each circuit to determine the cause. These circuits are:

• x-ray protection – PROTN

If this protection is active, the most likely cause is the LOT. Detection via pin 3 of the signal processor – item 7301.

• EW protection – PROT-UP

If this protection is active, the causes could be one of the following:

• bad contacts of:

- horizontal deflection coil

- linearity coil 5417

- S-correction capacitor 2418/2419

- flyback capacitor 2414/2416

- line output stage

• short circuit of:

- flyback diode 6414

- EW transformer (bridge coil) 5478/5479 or 5474/5475/5476 (item number depends upon the model version)

- EW driver 7470

• High beam current protection - Beam

As the name implies, what causes this protection is a high beam current (bright screen with flyback lines) which is too high.

Check for the presence of the +200V supply to the CRT panel. If the voltage is present, the most likely cause is the CRT

panel or the picture tube. Disconnect the CRT panel to determine the cause. If the +200V voltage is not present, check

R3840 at CRT-panel and R3445 & D6445 on the main chassis.

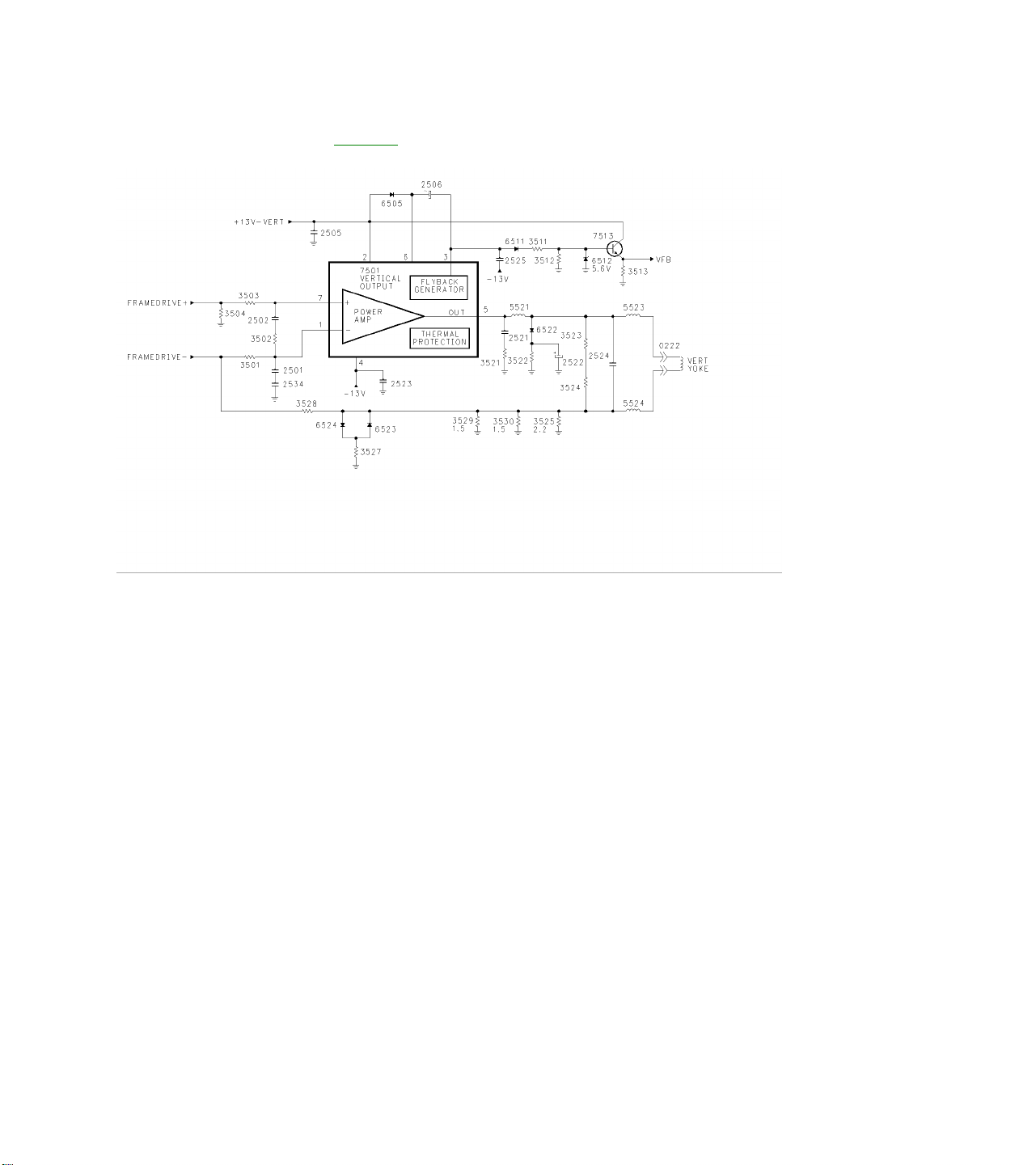

Error 2 = Vertical protection - VFB

If this protection is active, the cause could be one of the following (most likely in the vertical output stage):

- 7501 is faulty

- poor contact or open circuit of deflection coil

- +13V-VERT and/or -13V not present

Error 3 = Reserved

Error 4 = +5V protection

5V protection active; set is switched to protection; error code 4 is placed in the error buffer; the LED will blink 4 times

(repeatedly). A 5V failure can cause a drop in the 5V-supply output, resulting in an undefined behavior of the set. Therefore, all

I2C devices connected to the 5V supply are constantly monitored. When none of these devices responds to the micro controller

for a prolonged time, the micro controller assumes that there is a failure in the 5V supply.

By starting up the set with the service jumpers shorted, the 5V protection is disabled and it is easier to determine the cause.

+5V protection will be activated when these I2C devices fail (no I2C communication):

• Main Tuner – 1125 on main panel

• ITT sound processor – MSP34xx (7064) on the SSB

The following tips are useful to isolate the problem area after overriding the +5V protection. Determine whether:

• The +5V source is working properly; isolate coil 5430 and jumper 9044 and measure the +5V

• ITT sound processor circuit is loading the +5V; isolate coil 5430

• The tuner is loading the +5V source; isolate jumper 9044

• Main tuner circuit is loading the +5V source; isolate coil 5261

Caution! Overriding the 5V protection when there is a 5V failure can increase the temperature in the set and may cause

permanent damage to components. Do not override the 5V protection for a prolonged period of time.

Error 5 = Reserved

Error 6 = General I2C error. This error code will be displayed in the following cases:

• SCL or SDA is shorted to ground

• SCL is shorted to SDA

• SDA or SCL connection at the micro controller is open circuit.

Error 7 = BC-loop not stabilized (BCF = 1) Black current loop instability protection. The possible cause could be a defect in

one or more of the RGB amplifiers, RGB guns or RGB driving signals.

Error 8 = BOCMA (signal processor) IC – TDA888xx I2C communication failure. BOCMA (item 7301 on SSB) is corrupted or

the I2C line to the BOCMA is low or no supply voltage present at pin 14 and/or pin 60 (3V3)

Error 9 = BOCMA (signal processor) IC – TDA888xx 8V failure (SUP bit). No supply voltage at pin 53. Check NFR 3331 and

coil 5333.

Error 10 = Non Volatile Memory I2C error. NV memory (EEPROM – item 7066) does not respond to the micro controller.

Error 11 = Micro controller / NV Memory identification error. During the last start-up the NVM and the micro controller did not

recognize each other (e.g. one of them was replaced or the NVM memory has been changed/adapted or lost),

therefore the NVM was loaded with default values.

Error 12 = Microprocessor (Painter – item 7064) internal RAM test failure.

Error 13 = Main Tuner I2C failure UV13xx. Tuner (item 1225) is corrupted or the I2C line to the Tuner is low or not supplying

voltage at pin 9, pin 6 or pin 7 of the tuner.

Error 14 = Sound processor I2C error (MSP34xx -). Sound controller MSP3400 or MSP3410 does not respond to the micro

controller.

Error 15 = SRAM (Static Random Access Memory) IC uPD431000A-B test failure (item – 7070).

Error 16 = PIP/DW Tuner I2C error. The Tuner (TEDE9 – item 1900) on the PIP-panel does not respond to the micro

controller.

Error 17 = PIP IC – M65669SP I2C failure (item 7803) or Double Window IC SAB9081 I2C failure.

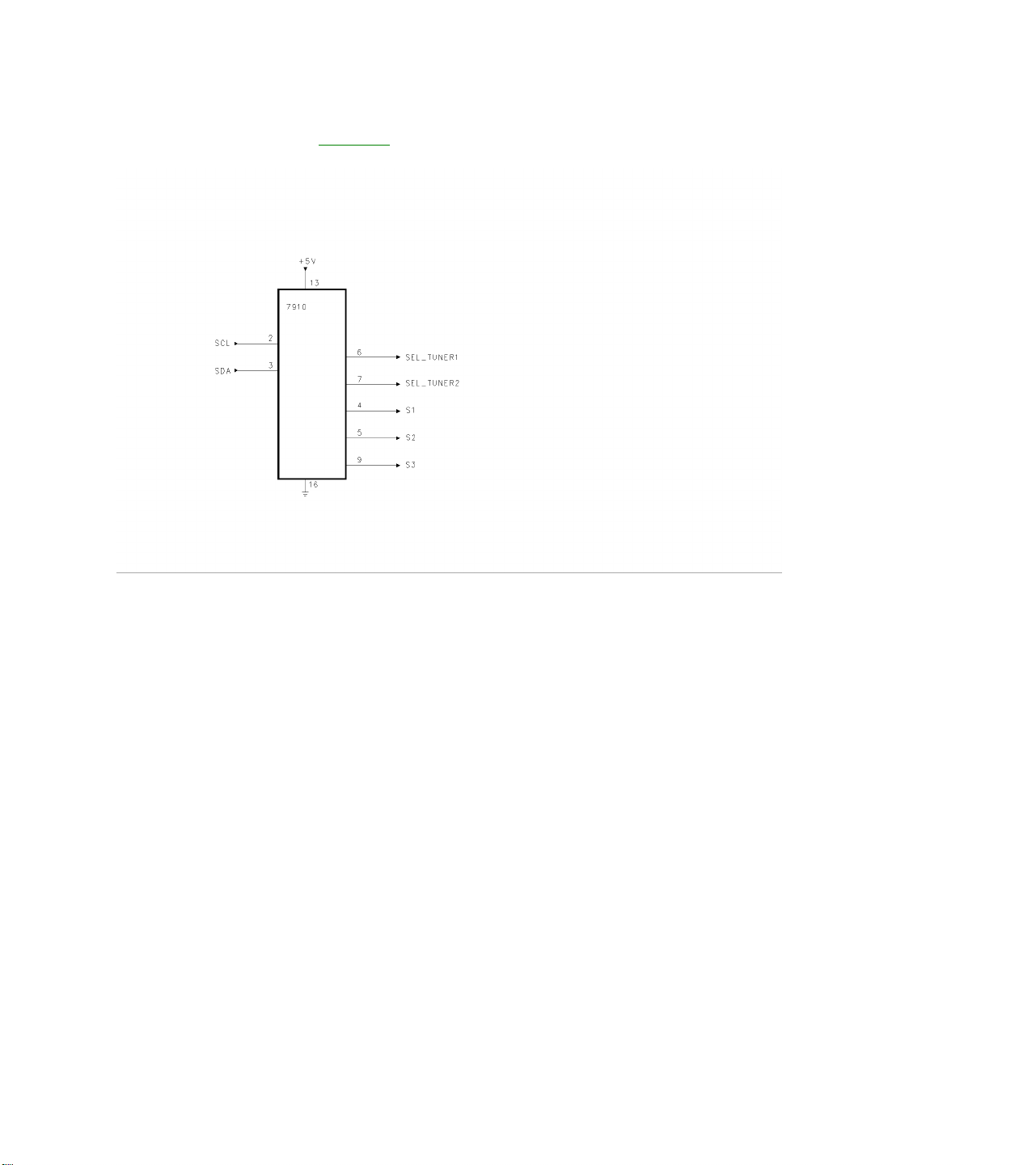

Error18 = I/O expander IC – 62320P I2C failure (item 7910 on PIP panel).

Error 19 = Guide+ I2C failure (LC27016B – item 7005).

Error 20 = V-chip for PIP, IC ZILOG 86130 I2C failure.

Error 21 = NV clock IC MK41T56 I2C failure at mono board – Item 7011 at A7. (Latam only)

Error 22 = Reserved.

Error 23 = Second BOCMA IC – TDA888xx (item 7301on Double Window PIP panel) I2C communication failure.

Error codes 1,2, and 4 are protection codes, and in this case the supplies of some circuits will be switched off. Also in

protection, the LED will blink the number of times equivalent to the most recent error code.

Error code table

Error code Error description Possible defective components

0 No error detected —

1 X-ray protection/ EW and/or High

beam protection active

2 Vertical protection Vertical circuit is defective

3 Reserved

4 5V protection active +5V supply line is low or short circuit

5 Reserved

6 General I2C bus error

7 BC-loop not stabilized RGB amplifiers, RGB guns or RGB

8

BOCMA (signal processor) I2C error

9 BOCMA (signal processor) 8V

supply failure

10

NVM I2C error

11 NVM identification failure IC 7066

12 µProcessor internal RAM test failure IC 7064

13

Main Tuner I2C error

14 Sound processor I2C error IC 7 (2CS/Nicam)

15 SRAM I2C error IC 7070

16

17

PIP tuner I2C error

PIP IC I2C error or DW IC I2C error

18 I/O expander IC 62320P I2C error IC 62230P – item 7910

19

20

21

Guide+ I2C error

V-chip for PIP – I2C error

NV clock – I2C error

22 Reserved

23 Second BOCMA (signal processor)

IC (on Double Window PIP panel) –

I2C error

LOT, Line deflection circuit, EW-circuit

or CRT amplifier circuit, picture tube or

+200V missing

I2C bus s/c or o/c on µP

driving signals of BOCMA

IC 7301on SSB

IC 7301 and R3331on SSB

IC 7066

IC 1225 – UV13xx

IC 1900 – TEDE9

IC LC27016B – item 7005

IC ZILOG 86130 -

IC MK41T56 – item 7011

IC TDA888xx – item 7301on Double

Window PIP Panel

The Blinking LED Procedure

The contents of the error buffer can also be made visible through the “blinking LED” procedure. This is especially useful when

there is no picture.

• When the SDM is entered, the LED will blink the number of times, equal to the value of the error code.

Upon entry into the SDM, the LED will blink the contents of the error-buffer.

Error-codes greater than/equal to 10 are shown in the following manner:

A long blink of 750 mSeconds Indicating the decimal digit, followed by a pause of 1500 mSeconds. The LED will then blink

the number equal to the error code. When all error-codes are displayed, the sequence is finished with an LED display of 3

seconds. At this point the sequence will begin again.

Example:

Error code position 1 2 3 4 5

Error buffer: 12 9 6 0 0

• After entering SDM:

• The sequence will begin with 1 long blink of 750 mSeconds, then pause 1500 mSeconds, then blink twice (indicating error

code 12), then the LED will pause for 3 seconds, then blink 9 times (indicating error code 9), then the LED will pause for 3

seconds, then blink 6 times (indicating error code 6), then pause 3 seconds and blink for 3 seconds again, ending the

blinking sequence.

NOTE: If errors 1, 2 or 4 occur the LED ALWAYS blinks indicating the last error which occurred, even if the set is NOT in

service mode.

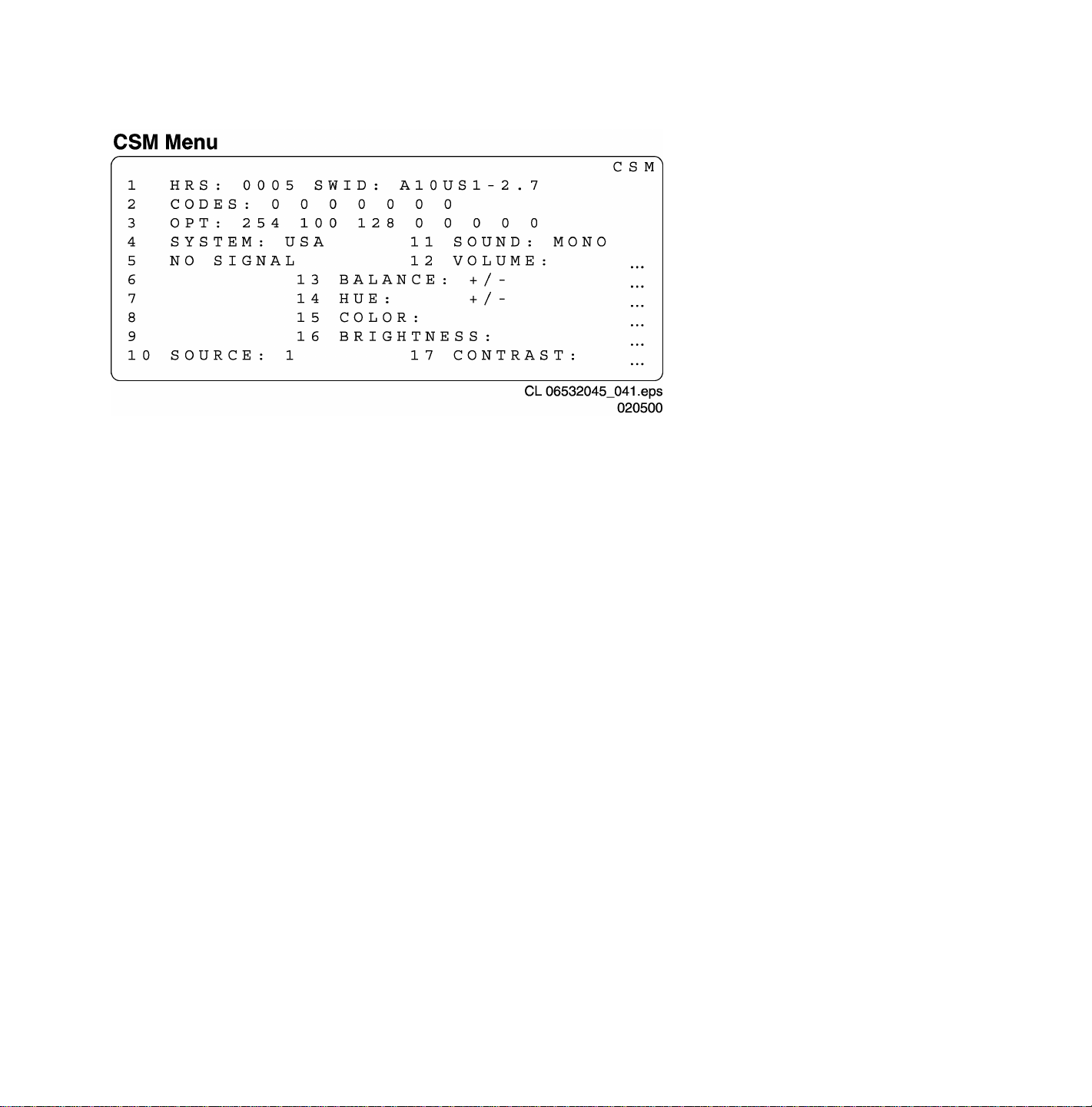

Customer Service Mode (CSM)

All H8 sets are equipped with the “Customer Service Mode” (CSM). CSM is a special service mode that can be activated and

deactivated by the customer, by request of the service technician/dealer in order to identify the status of the set. This CSM is a

'read only' mode, therefore modifications in this mode are not possible.

Entering the Customer Service Mode.

The Customer Service Mode can be switched on:

• By pressing the MUTE button on the remote control and any key on the local keyboard (Channel Up, Channel Down, VOL

+, VOL -) on the TV simultaneously for at least 4 seconds.

When the CSM is activated:

• picture and sound settings are set to nominal levels

• Modes that interfere with the behavior of the set are switched off (sleep timer, auto standby, etc.)

Exit the Customer Service Mode.

The Customer Service Mode will be switched off after:

• Pressing any key on the remote control (except “Channel Up” or “Channel Down”)

• Switching off the TV set by pressing the Power button on the remote control or the local keyboard.

Exiting CSM resets the TV set back to its initial values.

The Customer Service Mode information screen

Upon entry into the Customer Service Mode the following screen will appear.

CSM Menu Screen

The Customer Service Menu shows the following information:

- Line 1 : “HRS : nnnnn” and SWID : “A10BBC-X.Y”

HRS:

Indicates the accumulated total of operational hours. (Shown in hexadecimal format.) (Standby hours are not counted as

operating hours).

SWID:

Software identification of the main micro controller (example: A10US1-2.7)

A10 is the engineering chassis name for the H8 chassis

• US1 is 2 letter and 1 digit combination to indicate the software type and the supported languages:

• US = USA

• 1 = Main Software language version number

• 2.7 = sub-version number

- Line 2 : “CODES : xx xx xx xx xx xx xx ”

Error code buffer (see explanation of error codes above) Displays the last 7 errors of the error code buffer.

- Line 3 : “OPT xxx xxx xxx xxx xxx xxx xxx xxx”

Option bytes

Option bits control the software and hardware functionality of the A10.0. An option byte or option number represents 8 of those

bits. Each option number is displayed as a number between 0 and 255. The set may not work correctly when an incorrect option

code is set. See Service Adjustments for more information on correct option settings

- Line 4: “SYSTEM : USA”

Indicates this set is equipped to receive an NTSC broadcast signal.

- Line 5 : “NO SIGNAL”

Indicates that the set is not receiving an “ident” signal on the selected source.

• no or bad antenna signal; connect a proper antenna signal

• antenna not connected; connect the antenna

• no channel / preset is stored at this program number; go to the INSTALL menu and store a proper channel at this program

number

• the tuner is faulty (in this case the CODES line will contain number 13 or 16); check the tuner and replace/repair if

necessary

Note: On some models, (if the BM option is ON), BLUE MUTE is displayed when no signal is received.

- Line 6 : “TIMER ON ”

Indicates that the on/off timer is running.

The following Complaints may be caused by the activation of the sleep timer:

The set may turn on from standby or may switch to a different channel without using either the remote control or the local

keyboard.

To switch off the activation timer:

Select “TIMER” in the “FEATURE” menu.

Select “ACTIVATE’ in the “TIMER” menu.

Set to “OFF” with the left/right cursor keys.

- Line 7 : NOT AVAILABLE

- Line 8 : “NOT PREFERED”

Indicates that at least one channel is deleted as a preferred channel (by default, all channels are skipped.

Note that “SKIPPED” will always be displayed in CSM unless all the channels are not skipped.

To add a channel as a selected channel to the list of preferred channels:

Select “INSTALL” menu

Select “CHANNEL EDIT”

Select “ADD/DELETE”

Set to “ADD” with the left/right cursor keys

- Line 9 : “HOTEL MODE ON”

Indicates that the Hotel mode has been activated.

- Line 10 : “SOURCE :”

Indicates which SOURCE is installed for this preset.

EXT1, SVHS2, EXT2, Tuner.

- Line 11 : “SOUND”

Indicates which sound mode is installed for this preset.

Mono, NICAM, Stereo, L1, L2, SAP, Virtual or Digital

- Line 12 : “VOLUME”

Value indicates level at entry CSM.

- Line 13 : “BALANCE”

Value indicates level at entry CSM.

- Line 14 : “HUE”

Value indicates level at entry CSM.

- Line 15 : “COLOR”

Value indicates level at entry CSM.

- Line 16 : “BRIGHTNESS”

Value indicates level at entry CSM.

- Line 17 : “CONTRAST”

Value indicates level at entry CSM.

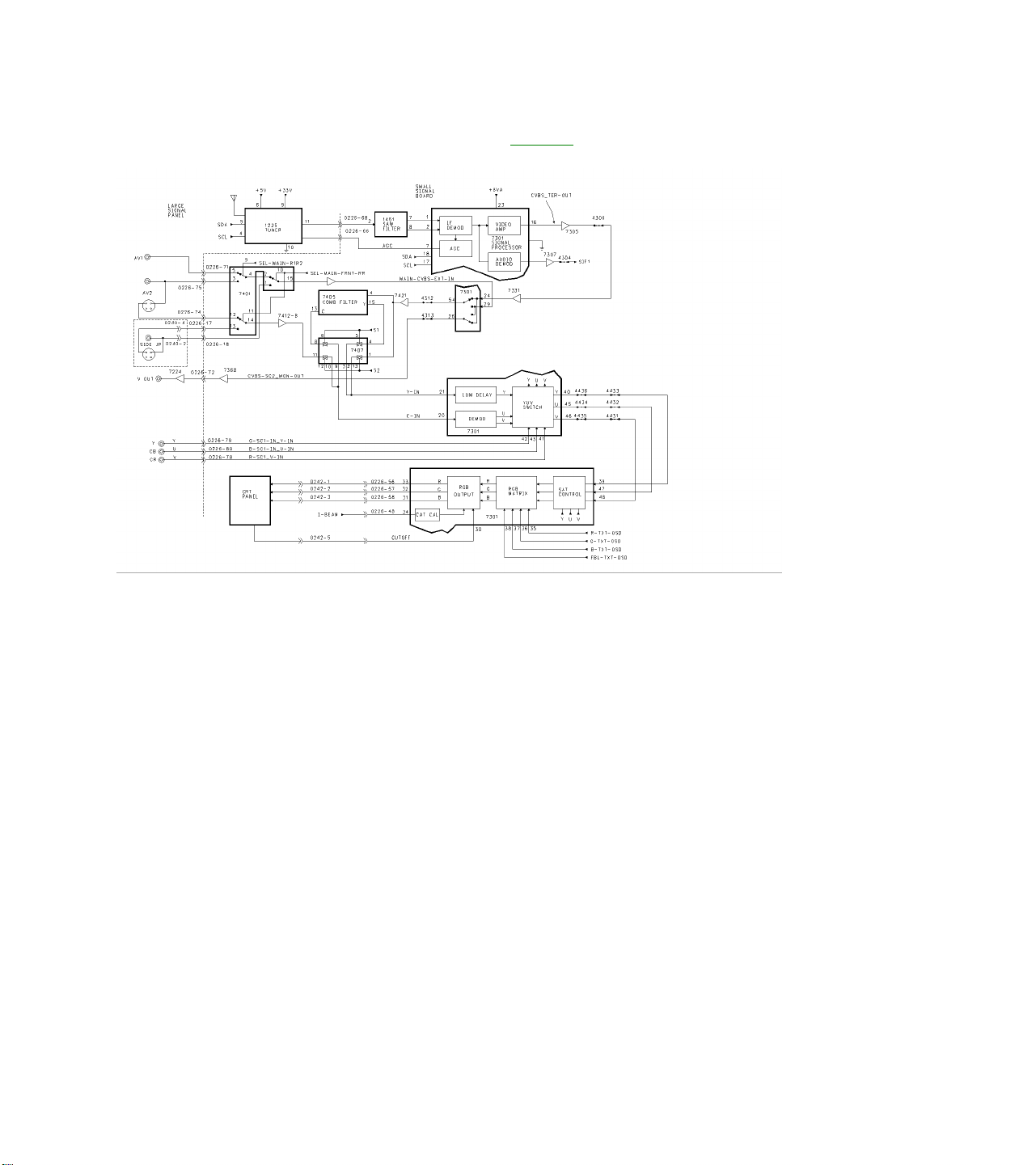

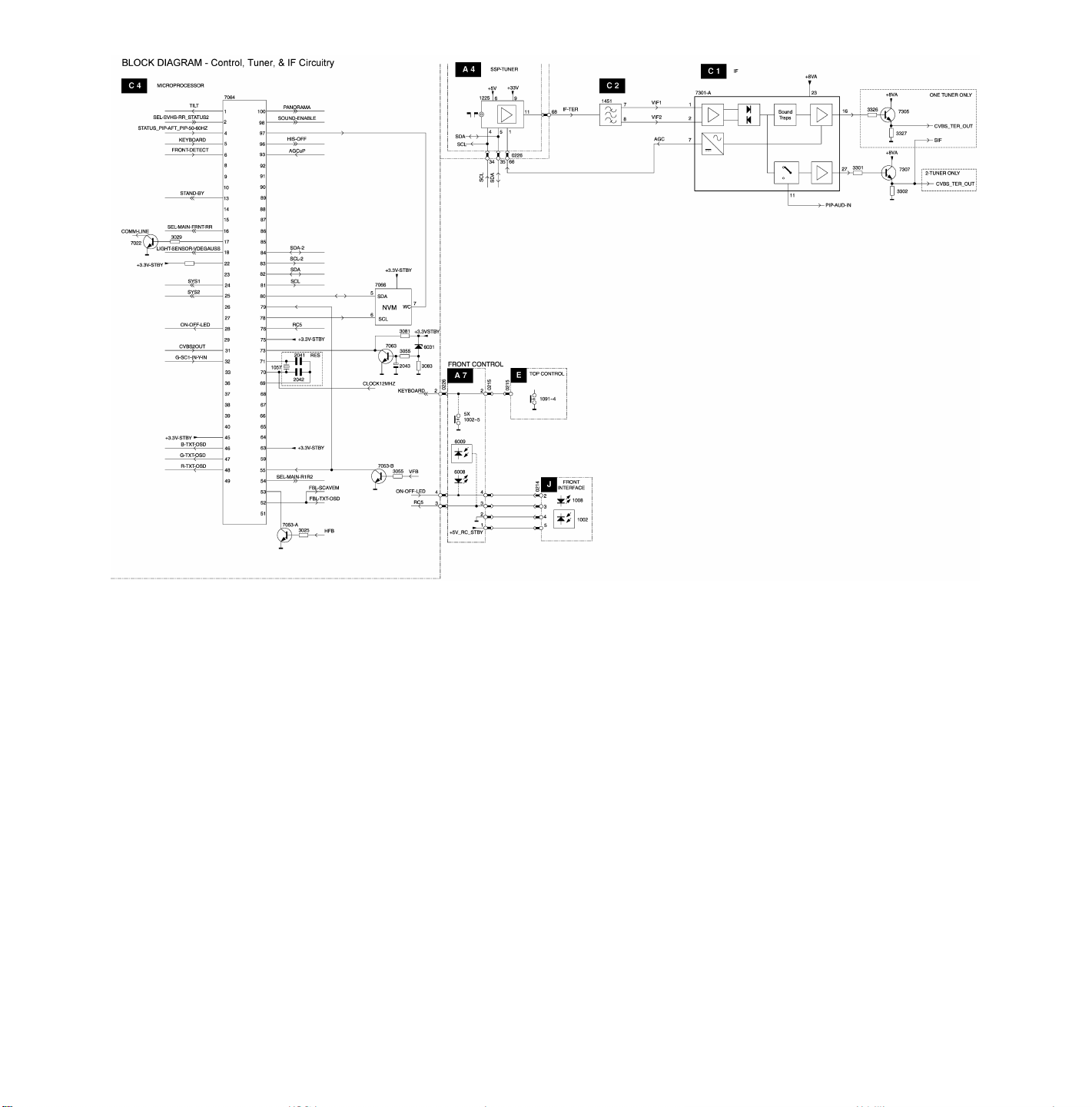

H8 Technical Training

INTRODUCTION

The H8 TV Chassis is designed for the 2000-2001 model years. It comes in three screen sizes, which are 27,

32, and 36 inch. All Chassis versions have a Side Jack Panel, a Component Input, and Surround Speaker

Jacks. The Rear Jack and Side Jack Panels are equipped with Composite, Component, and SVHS inputs.

The sets are equipped with either a Standard Dark Glass picture tube or a Very Flat Square Invar picture tube.

The H8 Chassis comes in Non-PIP (Picture in Picture), Single Tuner PIP, two Tuners PIP, or Double Window

versions. Each time the User selects the PIP window, the PIP window appears, changes size, then disappears.

In the Double Window version when the PIP On/Off button on the Remote is pressed, a PIP window appears.

When the button is pressed again, the window changes size. Press it again and the picture goes to a double

window (split screen). Pressing the button again, the picture returns to normal. The XXPT41 and larger

models are equipped with the M-Link feature. The M-Link feature allows VCRs, DVD, etc to be controlled

through the TV. Up to five devices can be controlled. Refer to the Model to Module listing in the Service

Manual to determine which modules are in a given model. Other features include an Audio Volume Leveler

(AVL) to compensate for changes in volume level. AutoLock, which allows certain channels, or programs with

certain ratings to be blocked. Each time the set is turned Off and back On, the Access Code must be reentered

to view the blocked channels. If the Customer forgets the Access Code, entry into the Menu to change the code

can by obtained by entering Access Code 0711. To gain entry, the code must be entered twice. A Format

selection in the menu allows the user to select between 4x3, Zoom, or 16x9 aspect ratio for the picture. This is

accomplished by changing the Height and Width settings in the set.

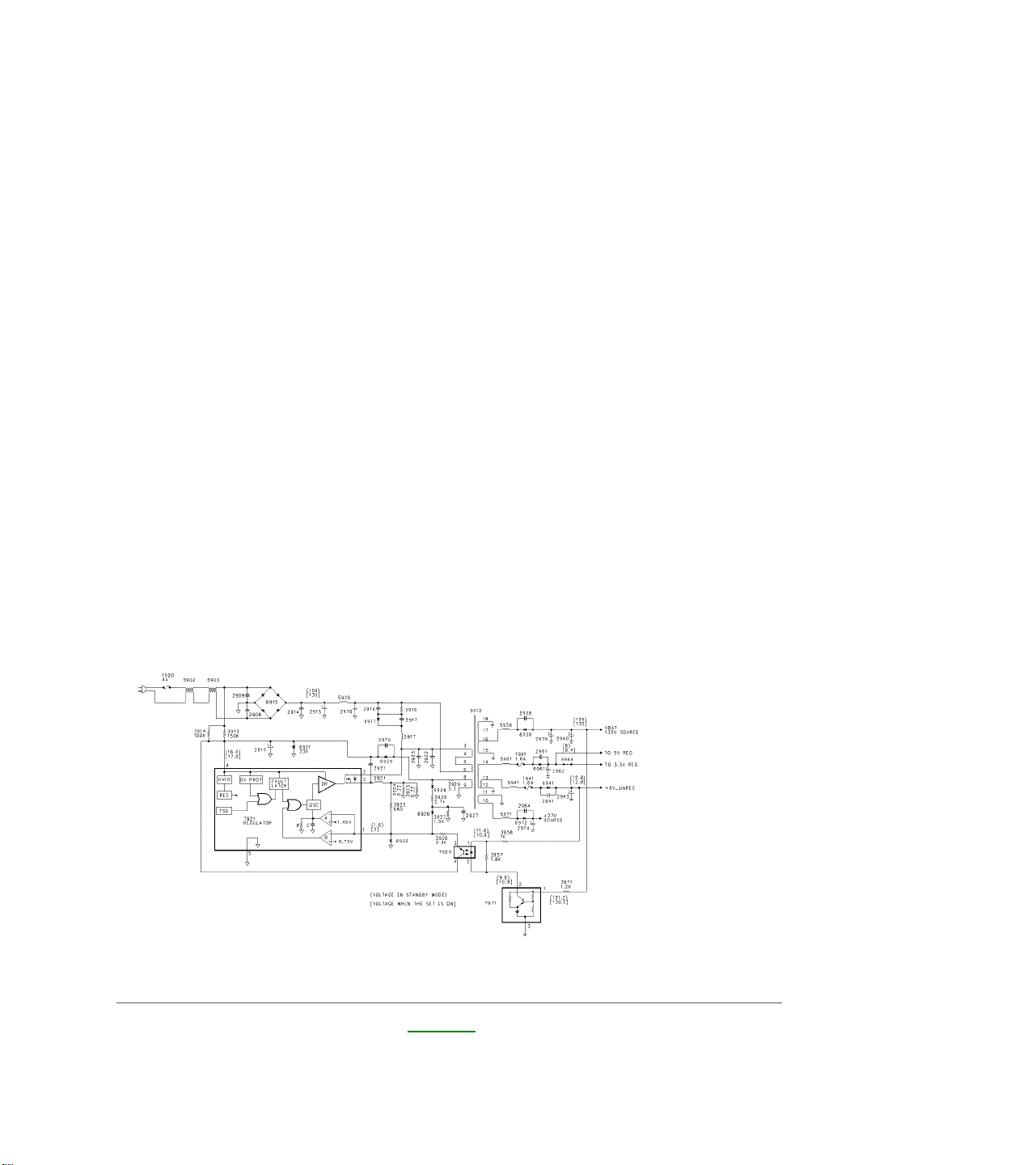

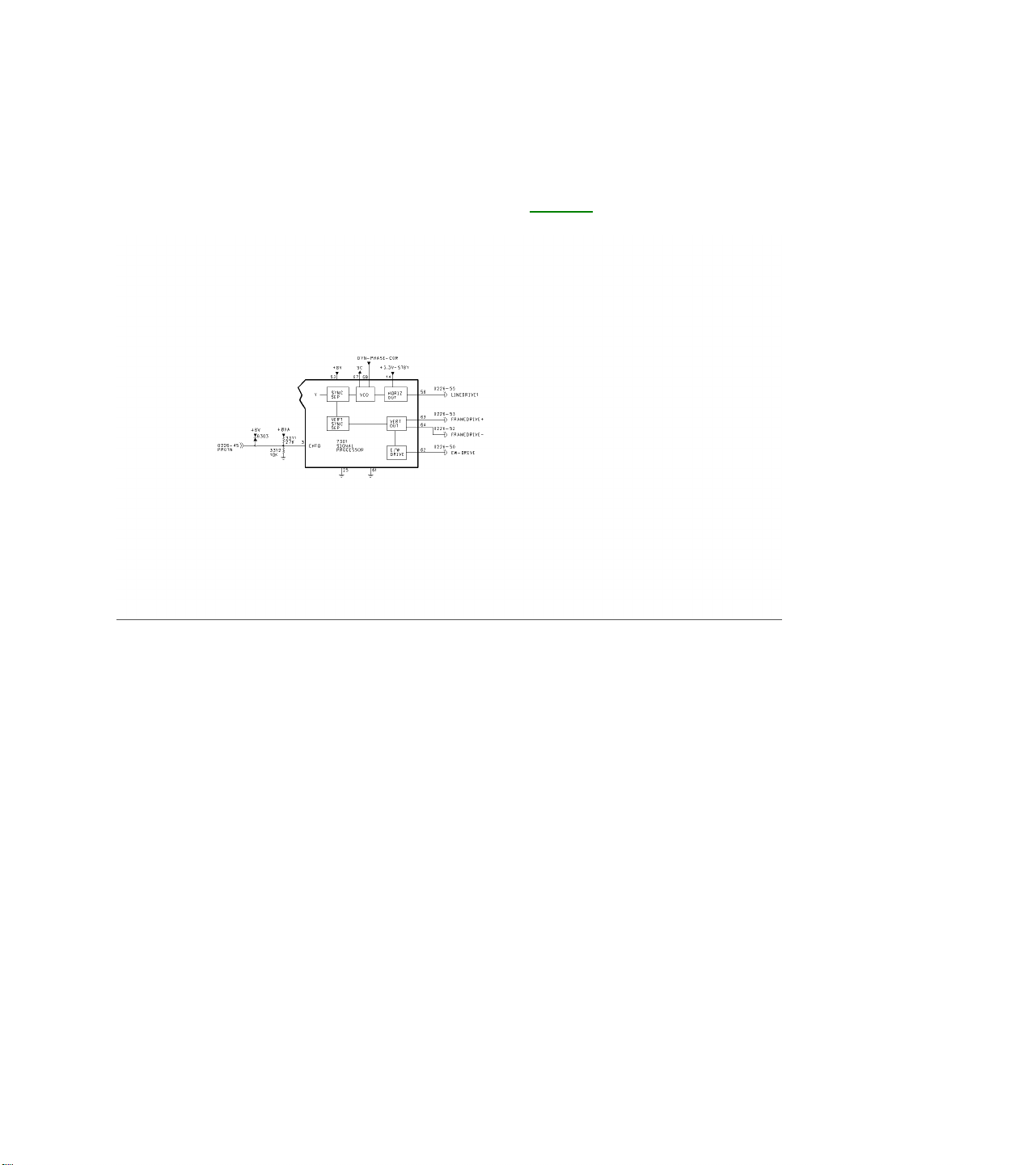

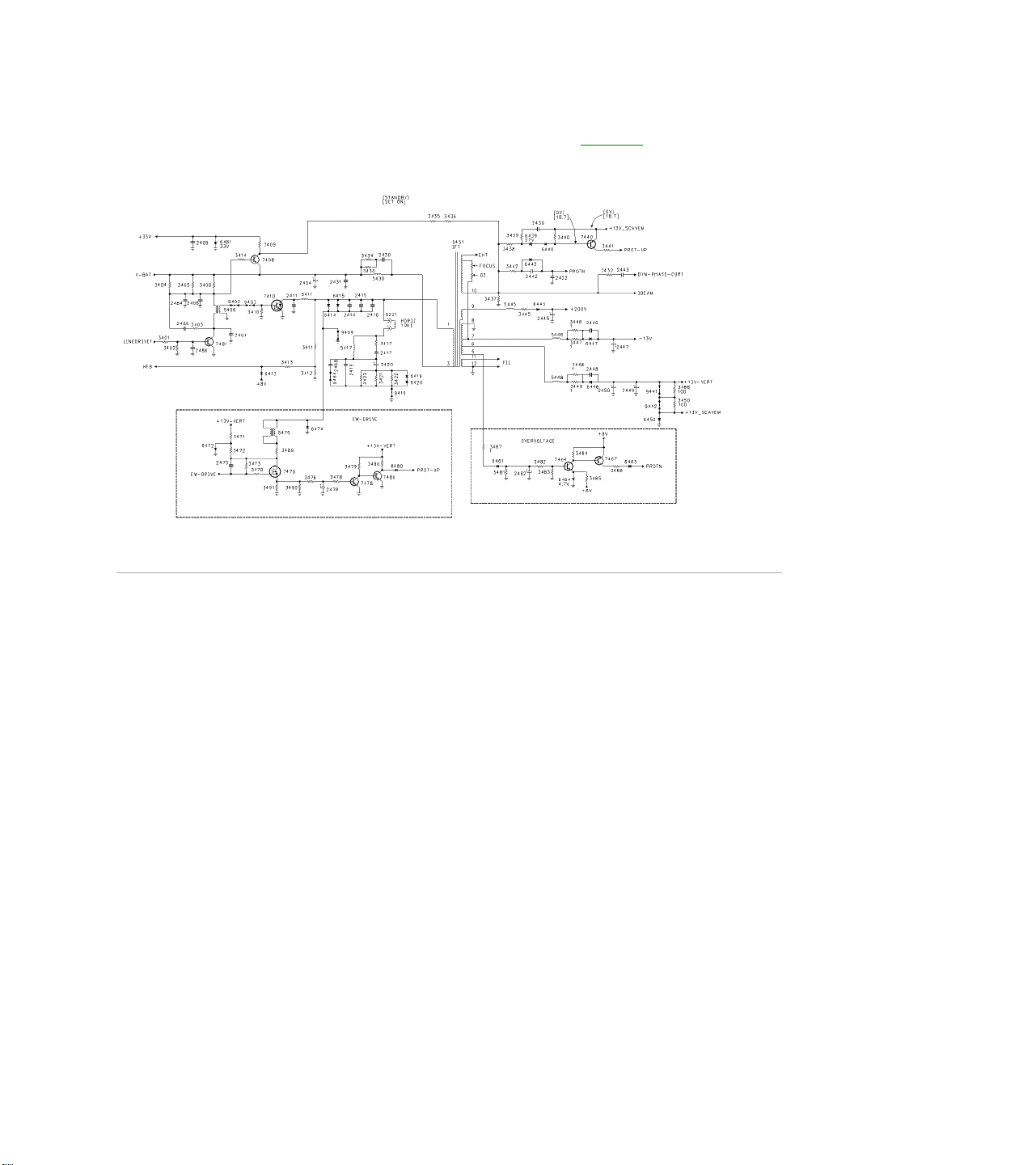

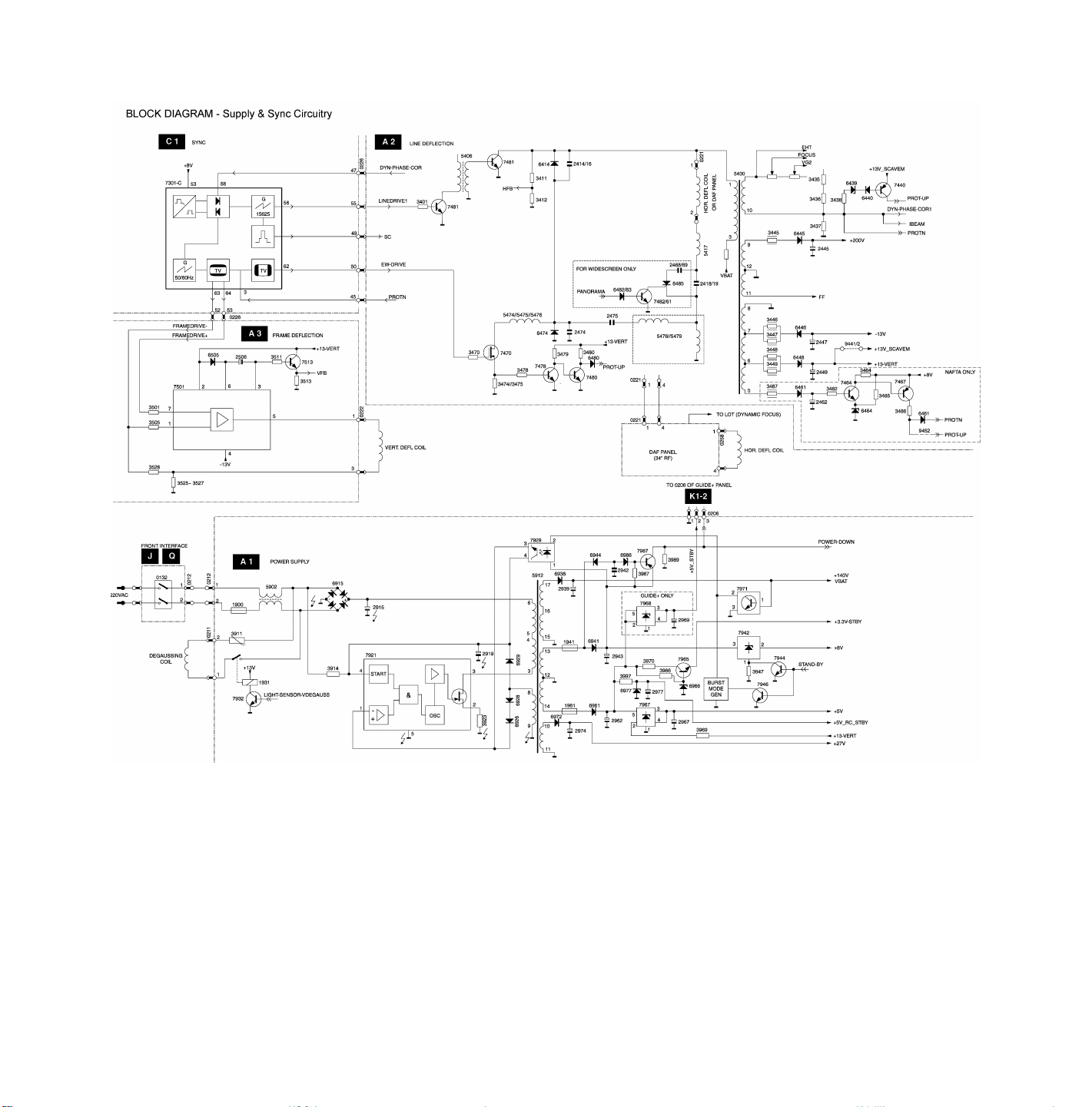

POWER SUPPLY

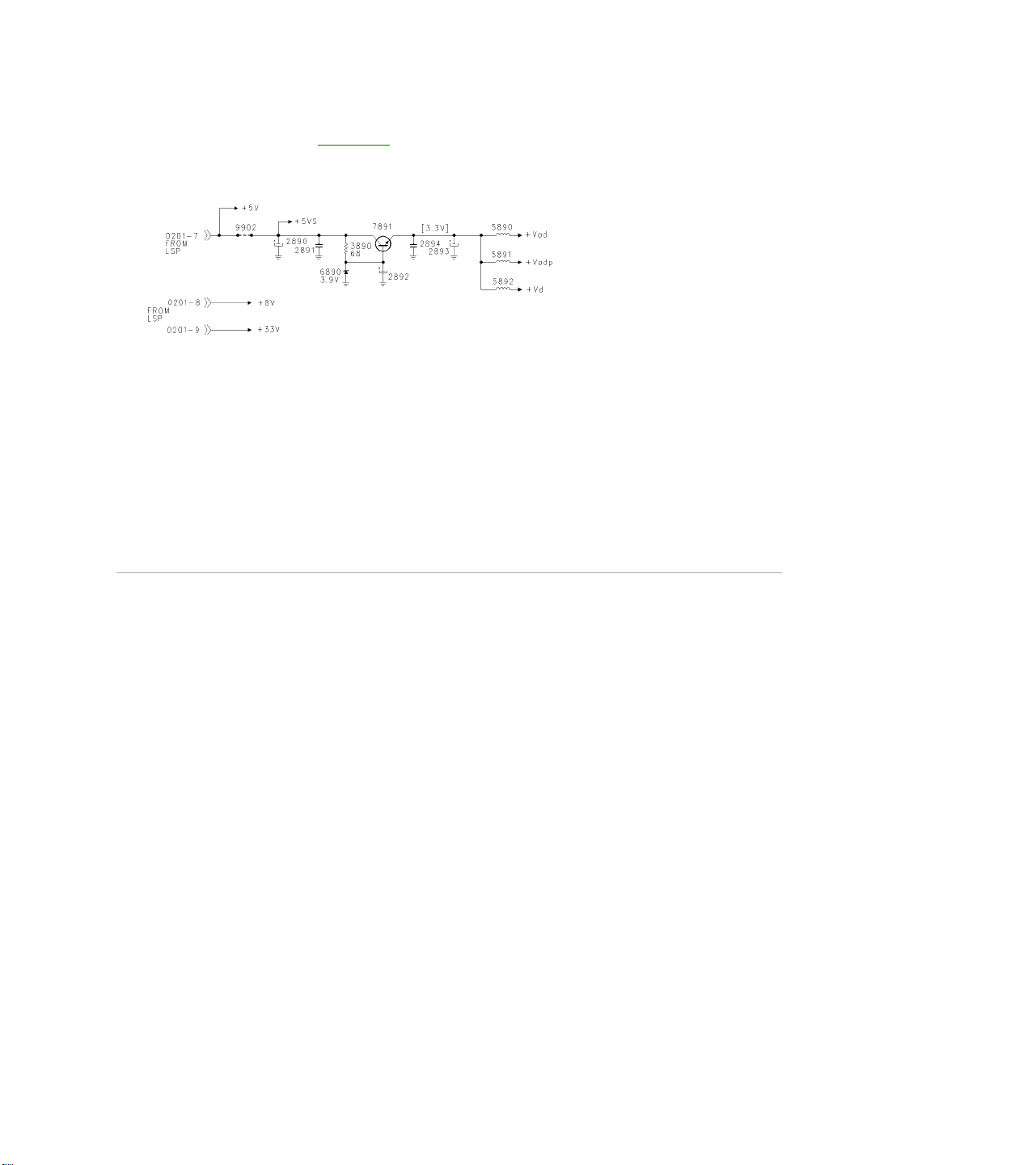

Switch Mode Supply Figure 1

The Power Supply is a Switching type supply. The Power Supply begins operating as soon as AC power is

applied to the set. AC power is applied to the Large Signal Board through Fuse 1900 and applied to the Bridge

Rectifier 6915. The rectified B+ voltage is applied to the regulator switching IC, 7921, through Pins 6 and 3 of

transformer 5912. Startup voltage for the supply is applied to Pin 4 through resistors 3914 and 3913. The Zener

Diode 6921 prevents the voltage on Pin 4 from exceeding 33 volts in case the Regulator IC is not working.

When the voltage on Pin 4 reaches 16 volts, the Oscillator inside the IC begins operating. Once the Supply is in

full operation, the operating voltage for the supply is supplied by Pin 8 of 5912 and is rectified by 6929. The

Oscillator drives the internal switching FET. When the FET is On, energy is stored in 5912. When the FET is

Off, energy is transferred to the secondary of 5912. The Frequency and On time of the internal switching FET is

determined by the Internal Comparator, the internal RC network, and the Magnetizing Inductance of the

Transformer. The Internal RC network also determines the Off time of the FET switch. The ramping voltage

determines the On Time across 3924, 3923, the feedback voltage from Pin 8 of the transformer, and the voltage

from the feedback opto-isolator. The Reference Voltage for the supply is the VBAT (135-volt source). This

source is sampled by 7971, which drives the feedback opto-isolator 7929 to set the switch time of comparator B.

This controls the On time of the internal switching FET to maintain the VBAT voltage at the correct level. There

are four output voltages from the transformer which are the VBAT voltage, 8 volts to the 5 and 3.3 volt

regulators, 8 volts unregulated, and 27 volts for the Audio Output circuit. To troubleshoot the Power Supply, first

check the VBAT (135-volt source). If this voltage is missing, check for a short on the VBAT line. The most likely

cause would be a shorted Horizontal Output Transistor. If the voltage is pulsing or is Low, check the feedback

circuit, 7971 and 7929. Also check Fuse 1941 on the 8 volt unregulated supply. This line supplies the operating

voltage for the feedback circuit. Next, check the B+ voltage for 7921 on Pin 3. If the drive signal is pulsing On

and Off on Pin 3, there may be a problem with the feedback circuit. If there is no drive signal on Pin 3, check for

the operating voltage on Pin 4. This voltage must ramp to 16 volts to start the supply. If it is missing or is not

ramping to 16 volts, check 3913, 3914, and 2919. Resistors 3923 or 3924 changing value could cause

regulation problems. If 7921 should fail, these resistors should be changed by using original parts only.

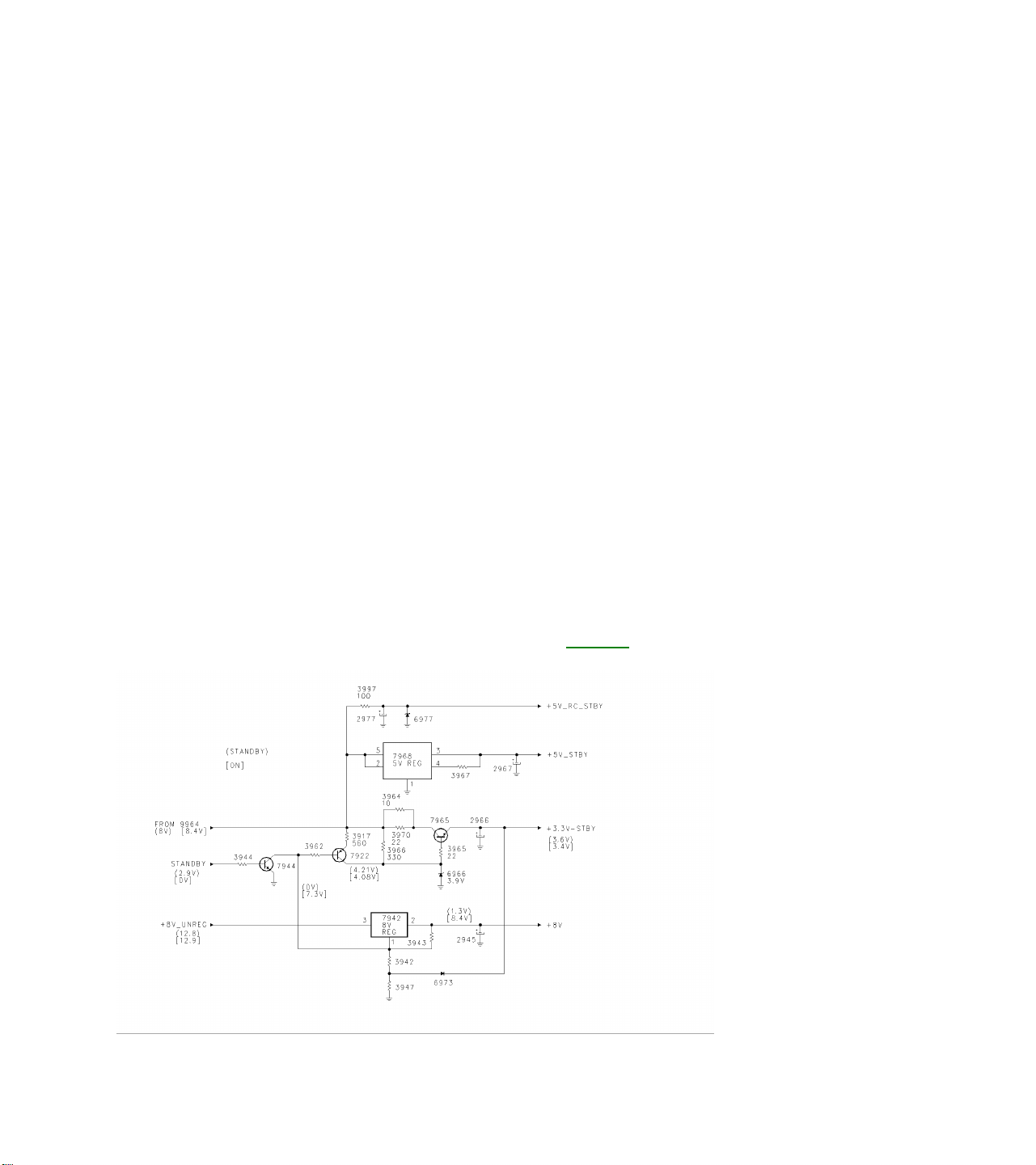

Standby Regulators and On/Off Figure 2

The voltage from jumper 9964 (approximately 8 volts) is used to produce the 3.3 volt standby, 5 volt standby, 5

volt remote control, and switched 8 volt supplies. The voltage is applied to transistor 7965 to produce the 3.3volt Standby supply. When the set is in the Standby mode, transistor 7944 is turned On, turning 7922 On,

providing a extra current drive for the 3.3 volt regulator. The 8 volt unregulated supply is applied to 7942, which

is a switched 8-volt regulator. The Standby line goes Low when the set is turned On, turning transistor 7944

Off, switching 7942 On. The switched 8-volt supplies the Horizontal Oscillator in the Signal Processor IC

located on the SSB.

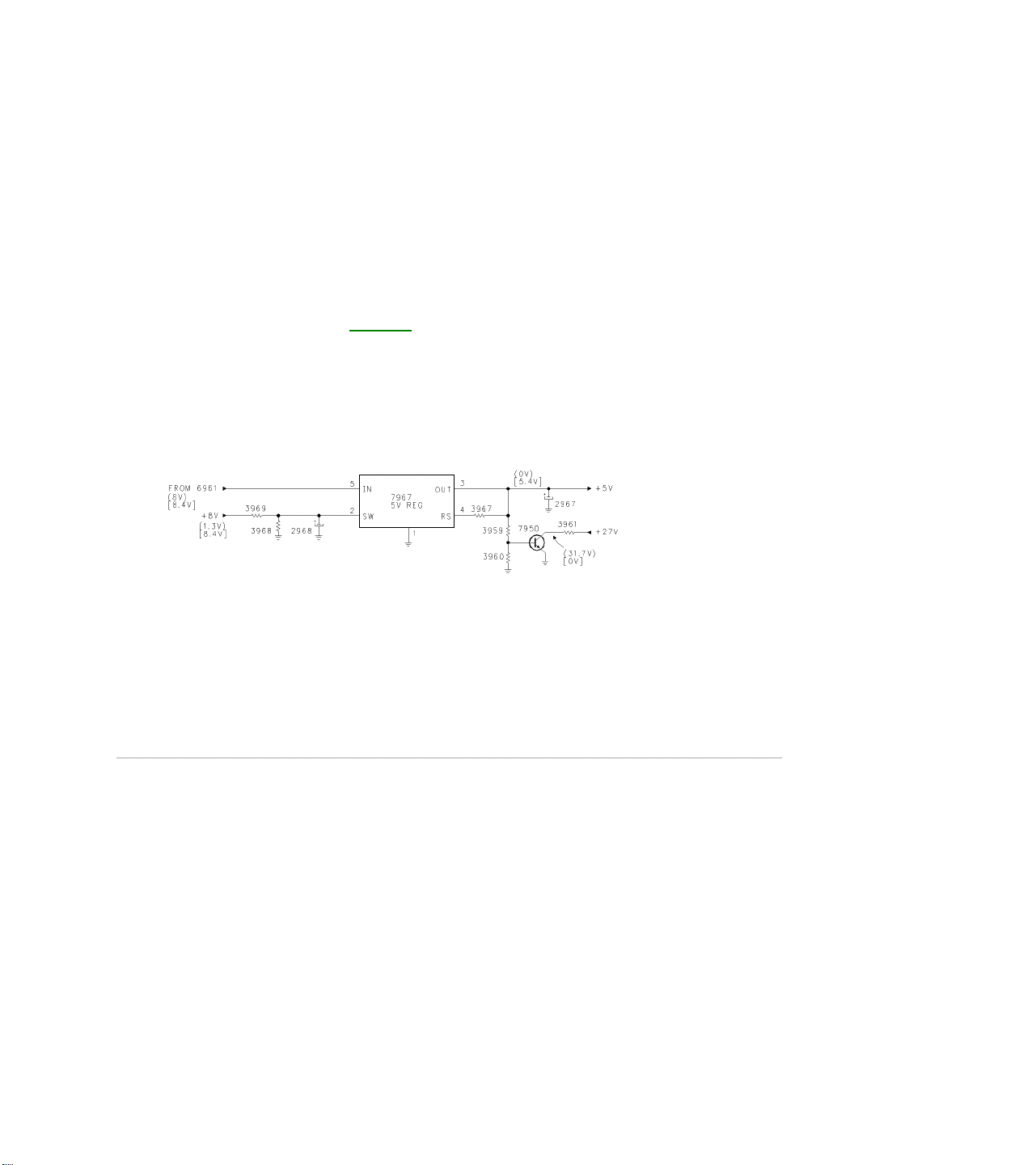

Five Volt Switch Figure 3

The Switched 8-volt supply also turns On the 5 volt regulator, 7967, to produce a switched 5 volt supply. The

Switched 5-volt supply turns transistor 7950 On. This provides a load on the 27-volt Audio Supply line to

discharge any remaining voltage on the line in the event that power is removed from the set while it is being

turned On. This is necessary to prevent a POP in the speaker while the set is powering down.

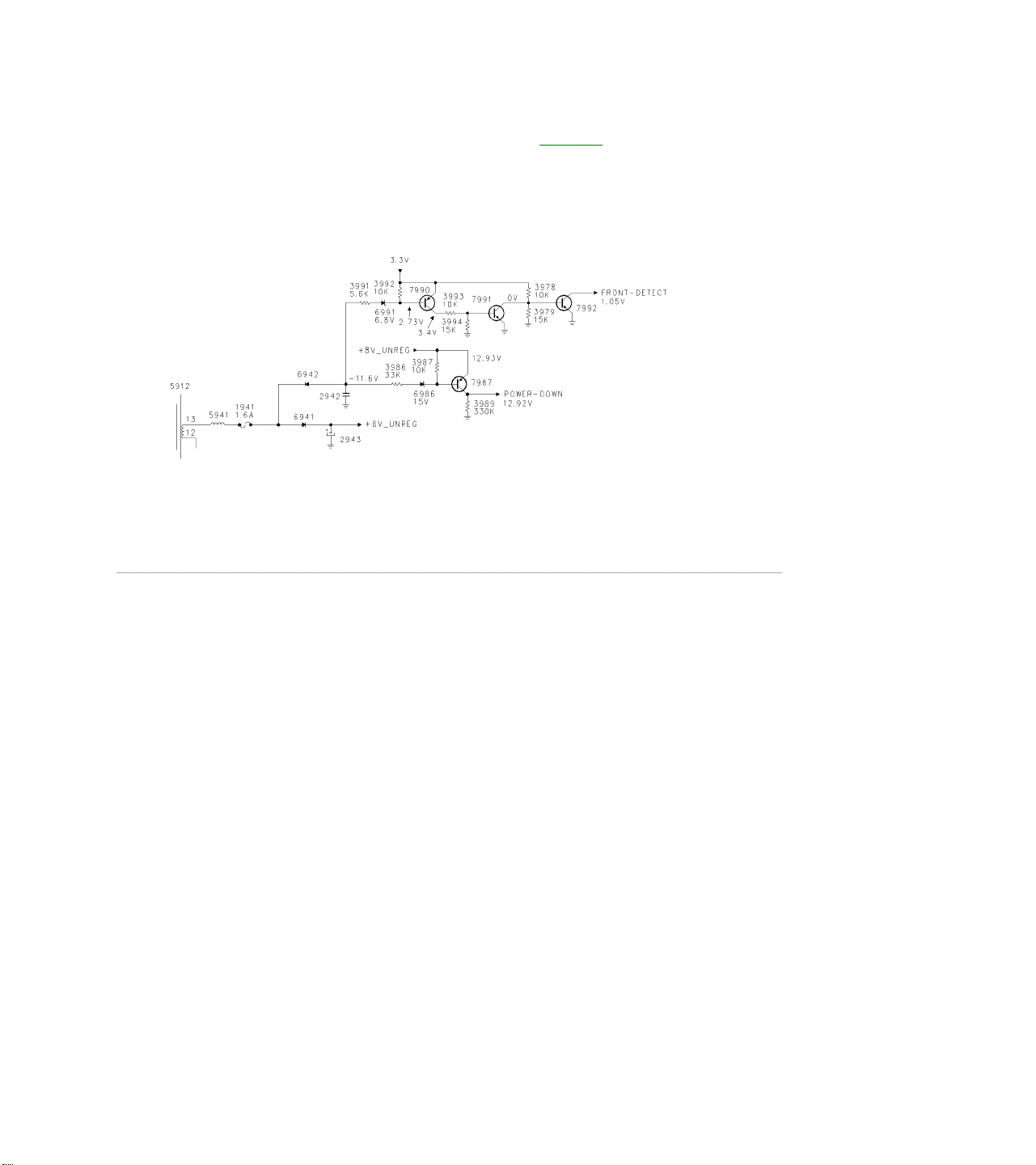

Power Down and Front Detect Figure 4

The Power-Down and Front Detect circuits signal the Microprocessor in case power is removed from the set.

The Microprocessor will store the customer settings before shutting the set down. Diode 6942 produces a

negative voltage to turn transistor 7987 On, keeping the Power-Down line High. This keeps transistor 7277

turned Off. If power is removed from the set, the negative voltage will discharge before the operating voltage for

the set falls. Transistor 7987 will turn Off. 7277 will then turn On, placing a High on the RGB CRT drive lines,

blanking the CRT. Transistor 7277 will continue to conduct until Capacitor 2284 has discharged. In the same

manner, 7990 will be turned Off, turning 7991 Off, which will turn 7992 On, causing the Front-Detect line to go

Low. This will prevent the Microprocessor from receiving any commands while the set is being shut down. If