PHILIPS 27G7, 29G7, 32G7, 26G7 Service Manual

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all Philips

Consumer Electronics Company** Equipment. The service procedures recommended by

Philips and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed

for the purpose. The special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES

which should be carefully read in order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service methods may damage the

equipment. It also is important to understand that these CAUTIONS and NOTICES

ARE NOT EXHAUSTIVE. Philips could not possibly know, evaluate and advise the

service trade of all conceivable ways in which service might be done, or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such

broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is

not recommended by Philips must first satisfy himself thoroughly that neither his safety

nor the safe operation of the equipment will be jeopardized by the service method

selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company will be

referred to as Philips.

WARNING

Critical components having special safety characteristics are identified with a or

"S" by the Ref. No. in the parts list and enclosed within a broken line* (where

several critical components are grouped in one area) along with the safety symbol

on the schematics or exploded views. Use of substitute replacement parts which

do not have the same specified safety characteristics may create shock, fire, or other

hazards. Under no circumstances should the original design be modified or altered

without written permission from Philips. Philips assumes no liability, express or

implied, arising out of any unauthorized modification of design. Servicer assumes all

liability.

* Broken Line ____ _ ____ _ ____ _ ____

FIRE AND SHOCK HAZARD

1. Be sure all components are positioned in such a way as to avoid the possibility of adjacent component

shorts. This is especially important on those chassis which are transported to and from the service shop.

2. Never release a repaired unit unless all protective devices such as insulators, barriers, covers, strain

reliefs, and other hardware have been installed in accordance with the original design.

3. Soldering and wiring must be inspected to locate possible cold solder joints, solder splashes, sharp solder

points, frayed leads, pinched leads, or damaged insulation (including the ac cord). Be certain to remove

loose solder balls and all other loose foreign particles.

4. Check across-the-line components and other components for physical evidence of damage or

deterioration and replace if necessary. Follow original layout, lead length, and dress.

5. No lead or component should touch a receiving tube or a resistor rated at 1 watt or more. Lead tension

around protruding metal surfaces or edges must be avoided.

6. Critical components having special safety characteristics are identified with an 'S' by the Ref. No. in the

parts list and enclosed within a broken line* (where several critical components are grouped in one area)

along with the safety symbol on the schematic diagrams and /or exploded views.

7. When servicing any unit, always use a separate isolation transformer for the chassis. Failure to use a

separate isolation transformer may expose you to possible shock hazard, and may cause damage to

servicing instruments.

8. Many electronic products use a polarized ac line cord (one wide pin on the plug). Defeating this safety

feature may create a potential hazard to the servicer and the user. Extension cords which do not

incorporate the polarizing feature should never be used.

9. After reassembly of the unit, always perform an ac leakage test or resistance test from the line cord to all

exposed metal parts of the cabinet. Also, check all metal control shafts (with knobs removed), antenna

terminals, handles, screws, etc., to be sure the unit may be safely operated without danger of electrical

shock.

* Broken line ____ _ ____ _ ____ _ ____

LEAKAGE CURRENT COLD CHECK

1. Unplug the ac line cord and connect a jumper between the two prongs of the plug.

2. Turn on the power switch.

3. Measure the resistance value between the jumpered ac plug and all exposed cabinet parts of the receiver,

such as screw heads, antennas, and control shafts. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 megohm and 5.2 megohms. When the exposed metal does not

have a return path to the chassis, the reading must be infinity. Remove the jumper from the ac line cord.

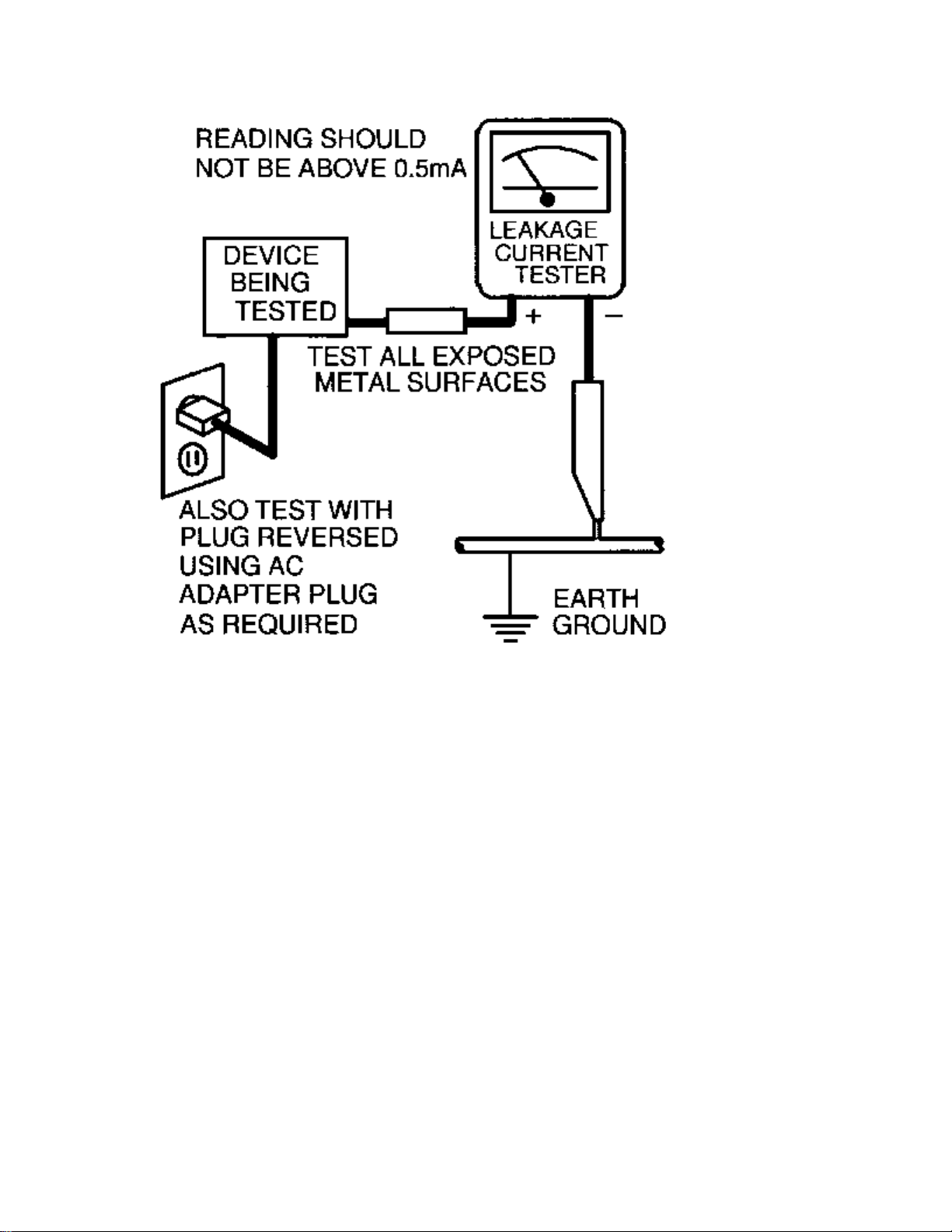

LEAKAGE CURRENT HOT CHECK

1. Do not use an isolation transformer for this test. Plug the completely reassembled receiver directly into

the ac outlet.

2. Connect a 1.5k, 10W resistor paralleled by a 0.15uF. capacitor between each exposed metallic cabinet

part and a good earth ground such as a water pipe, as shown below.

3. Use an ac voltmeter with at least 5000 ohms/volt sensitivity to measure the potential across the resistor.

4. The potential at any point should not exceed 0.75 volts. A leakage current tester may be used to make

this test; leakage current must not exceed 0.5mA. If a measurement is outside of the specified limits,

there is a possibility of shock hazard. The receiver should be repaired and rechecked before returning it

to the customer.

5. Repeat the above procedure with the ac plug reversed. (Note: An ac adapter is necessary when a

polarized plug is used. Do not defeat the polarizing feature of the plug.)

OR

With the instrument completely reassembled, plug the ac line cord directly into a 120Vac outlet. (Do not

use an isolation transformer during this test.) Use a leakage current tester or a metering system that

complies with American National Standards Institute (ANSI) C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7). With the instrument ac switch first in the on position and

then in the off position, measure from a known earth ground (metal water pipe, conduit, etc.) to all exposed

metal parts of the instrument (antennas, handle brackets, metal cabinet, screw heads, metallic overlays,

control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5mA. Reverse the instrument power cord plug in the outlet and

repeat the test. See the graphic below.

TV SAFETY NOTES

SAFETY CHECKS

After the original service problem has been corrected, a complete safety check should be made. Be sure to

check over the entire set, not just the areas where you have worked. Some previous servicer may have left

an unsafe condition, which could be unknowingly passed on to your customer. Be sure to check all of the

following:

Fire and Shock Hazard

Implosion

X-Radiation

Leakage Current Cold Check

Leakage Current Hot Check

Picture Tube Replacement

Parts Replacement

WARNING: Before removing the CRT anode cap, turn the unit OFF and short the HIGH VOLTAGE to

the CRT DAG ground.

SERVICE NOTE: The CRT DAG is not at chassis ground.

IMPLOSION

1. All picture tubes used in current model receivers are equipped with an integral implosion system.

Care should always be used, and safety glasses worn, whenever handling any picture tube. Avoid

scratching or otherwise damaging the picture tube during installation.

2. Use only replacement tubes specified by the manufacturer.

X-RADIATION

1. Be sure procedures and instructions to all your service personnel cover the subject of X-radiation.

Potential sources of X-rays in TV receivers are the picture tube and the high voltage circuits. The

basic precaution which must be exercised is to keep the high voltage at the factory recommended

level.

2. To avoid possible exposure to X-radiation and electrical shock, only the manufacturer's specified

anode connectors must be used.

3. It is essential that the service technician has an accurate HV meter available at all times. The

calibration of this meter should be checked periodically against a reference standard.

4. When the HV circuitry is operating properly there is no possibility of an X-radiation problem. High

voltage should always be kept at the manufacturer's rated value - no higher - for optimum

performance. Every time a color set is serviced, the brightness should be run up and down while

monitoring the HV with a meter to be certain that the HV is regulated correctly and does not exceed

the specified value. We suggest that you and your technicians review test procedures so that HV and

HV regulation are always checked as a standard servicing procedure, and the reason for this prudent

routine is clearly understood by everyone. It is important to use an accurate and reliable HV meter. It

is recommended that the HV reading be recorded on each customer's invoice, which will

demonstrate a proper concern for the customer's safety.

5. When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, reduce the line voltage by means of a Variac to bring the HV into acceptable limits while

troubleshooting. Do not operate the chassis longer than necessary to locate the cause of the excessive

HV.

6. New picture tubes are specifically designed to withstand higher operating voltages without creating

undesirable X-radiation. It is strongly recommended that any shop test fixture which is to be used

with the new higher voltage chassis be equipped with one of the new type tubes designed for this

service. Addition of a permanently connected HV meter to the shop test fixture is advisable. The

CRT types used in these new sets should never be replaced with any other types, as this may result in

excessive X-radiation.

7. It is essential to use the specified picture tube to avoid a possible X-radiation problem.

8. Most TV receivers contain some type of emergency "Hold Down" circuit to prevent HV from rising

to excessive levels in the presence of a failure mode. These various circuits should be understood by

all technicians servicing them, especially since many hold down circuits are inoperative as long as

the receiver performs normally.

PICTURE TUBE REPLACEMENT

The primary source of X-radiation in this television receiver is the picture tube. The picture tube

utilized in this chassis is specially constructed to limit X-radiation emissions. For continued Xradiation protection, the replacement tube must be the same type as the original, including suffix letter,

or a Philips approved type.

PARTS REPLACEMENT

Many electrical and mechanical parts in Philips television sets have special safety related

characteristics. These characteristics are often not evident from visual inspection nor can the protection

afforded by them necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. The use of a substitute part which does not have the same safety characteristics as the

Philips recommended replacement part shown in this service manual may create shock, fire, or other

hazards.

PRODUCT SAFETY GUIDELINES FOR ALL PRODUCTS

CAUTION: Do not modify any circuit. Service work should be performed only after you are thoroughly

familiar with all of the following safety checks. Risk of potential hazards and injury to the user increases if

safety checks are not adhered to.

USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

Some semiconductor solid state devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES) Devices, Examples of typical ES devices are

integrated circuits and some field-effect transistors and semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of component damage caused by electrostatic

discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging ESD wrist strap, which should be removed for potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "antistatic

(ESD protected)" can generate an electrical charge sufficient to damage ES devices.

5. Do not use Freon propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it (most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your feet from a carpeted

floor can generate static electricity (ESD) sufficient to damage an ES device.)

NOTE to CATV system Installer:

This reminder is provided to call the CATV system installer's attention to article 820-22 of the NEC that

provides guidelines for proper grounding and, in particular, specifies that the cable ground shall be

connected to the grounding system of the building, as close to the point of cable entry as practical.

PRACTICAL SERVICE PRECAUTIONS

IT MAKES SENSE TO AVOID EXPOSURE TO ELECTRICAL SHOCK. While some sources are

expected to have a possible dangerous impact, others of quite high potential are of limited current and are

sometimes held in less regard.

ALWAYS RESPECT VOLTAGES. While some may not be dangerous in themselves, they can cause

unexpected reactions – reactions that are best avoided. Before reaching into the powered color TV set, it is

best to test the high voltage insulation. It is easy to do, and is just a good service precaution.

BEFORE POWERING UP THE TV WITH THE BACK OFF (or on a test fixture), attach a clip lead to

the CRT DAG ground and to a screwdriver blade that has a well insulated handle. After the TV is powered

on and high voltage has developed, probe the anode lead with the blade, starting at the bottom of the High

Voltage Transformer (flyback – IFT). Move the blade to within two inches of the connector of the CRT. IF

THERE IS AN ARC, YOU FOUND IT THE EASY WAY, WITHOUT GETTING A SHOCK! If

there is an arc to the screwdriver blade, replace the High Voltage Transformer or the lead, (if removable)

whichever is causing the problem.

PICTURE TUBE REPLACEMENT PROCEDURE

Note: a. Two (2) people are required to handle this picture tube.

b. Safety Glasses must be worn during this procedure or whenever directly handling a picture tube.

c. Take care in each step not to damage the CRT or the cabinet.

1. Remove the Chassis and the CRT Socket Board Module from the cabinet.

2. A furniture pad or blanket should be positioned on the floor to support only the CRT Face. This pad or

blanket should be high enough to keep the CRT Face approximately 12 to 14 inches off the floor.

3. Using two people, place the cabinet in a front down position with the CRT Face on the pad or blanket.

4. Place padded blocks under each corner of the cabinet to keep it from rocking.

5. Remove the four screws, at the corners of the CRT.

6. With two people lowering the cabinet to the floor, leave the CRT elevated by the pad or blanket.

Note: Take care not to grasp the neck of the CRT during this procedure, as it is extremely fragile.

7. Two (2) people may then lift the CRT from the cabinet.

8. Remove the degaussing coil from the defective CRT and mount on the replacement. Take care to

maintain the exact shape and fit.

To install the new CRT, reverse steps 1 to 7.

GENERAL INFORMATION

CHASSIS SPECIFICATIONS

Channel Tuning:

Antenna: Channels 2 through 69

Cable: Channels 1 through 125

Allowable cable offset ± 2.0 MHz

Operating and Storage Temperatures:

Operating Temperature: 0ºC to +50ºC

Storage Temperature: -40ºC to +60ºC

Audio In/Out:

½ VRMS

System:

NTSC-M only

IF Frequencies:

45.75 Mhz picture, 41.25 MHz sound (intercarrier),

4.5 MHz sound IF

Sound Performance:

At 360 mv RMS/1 kHz to Audio input;

Output 8 Watt per channel with <10% Total Harmonic Distortion (THD).

At 1 Watt RMS, both channels driven, response is within ± 2dB from 20Hz to 20kHz.

Power Supply Voltages:

NAME VALUE TOLERANCE AT COMPONENT

VlotAux 1 18.8 volts +/- 3.5% 2663 (27“ and 32“ models)

VlotAux 1 12.5 volts +/- 3.5% 2663 (36“ models)

VlotAux 2 -14 volts +/- 3.5% 2664 (27“ and 32“ models)

VlotAux 2 -12.5 volts +/- 3.5% 2664 (36“ models)

VlotAux 3 210 volts +/- 5.5% 2656 (27“ and 32“ models)

VlotAux 3 200 volts +/- 5% 2656 (36“ models)

Vbat 130 volts +/- 1 volt 2917+

Vsound 13.5 volts +/- 1 volt 2925+

Vstby 5.1 volts +/- 0.1 volts 2938+

V+5v 5 volts +/- 0.2 volts 2937+

V+8v 8.3 volts +/- 0.2 volts 2931+

33V 33 volts +/- 2 volts 6955 cathode

200V 205 volts +5 volts/-35 volts Pin 2 of connector M60

These voltages are taken with a dummy load from Vbat to ground of 165 ohms.

Mains (AC Power):

60 Hz, 120 volts AC nominal:

Allowed 105 to 132 volts AC

For Auto-Multi-Voltage Only:

60 Hz, 120 to 247 volts AC

Power consumption, worst control setting:

1.6 Amps, 192 Watts

Standby power consumption:

<3 Watts +/-10%

High Voltage (EHT):

(At minimum brightness)

Screen Size: 27" 32" 36“

Voltage: 30.0kV +/- 1kV 30.0kV +/- 1kV 31.5kV +/- 1kV (for reference only)

Color Temperature:

NORMAL WARM COOL

10,500 +/- 10% 8,200 +/- 20% 14,000 +/- 20%

Note: Nominal specifications represent the design specifications. All units

should be able to approximate these. Some will exceed and some may

drop slightly below these specifications. Limit specifications represent

the absolute worst condition that still might be considered acceptable. In

no case should a unit fail to meet limit specifications.

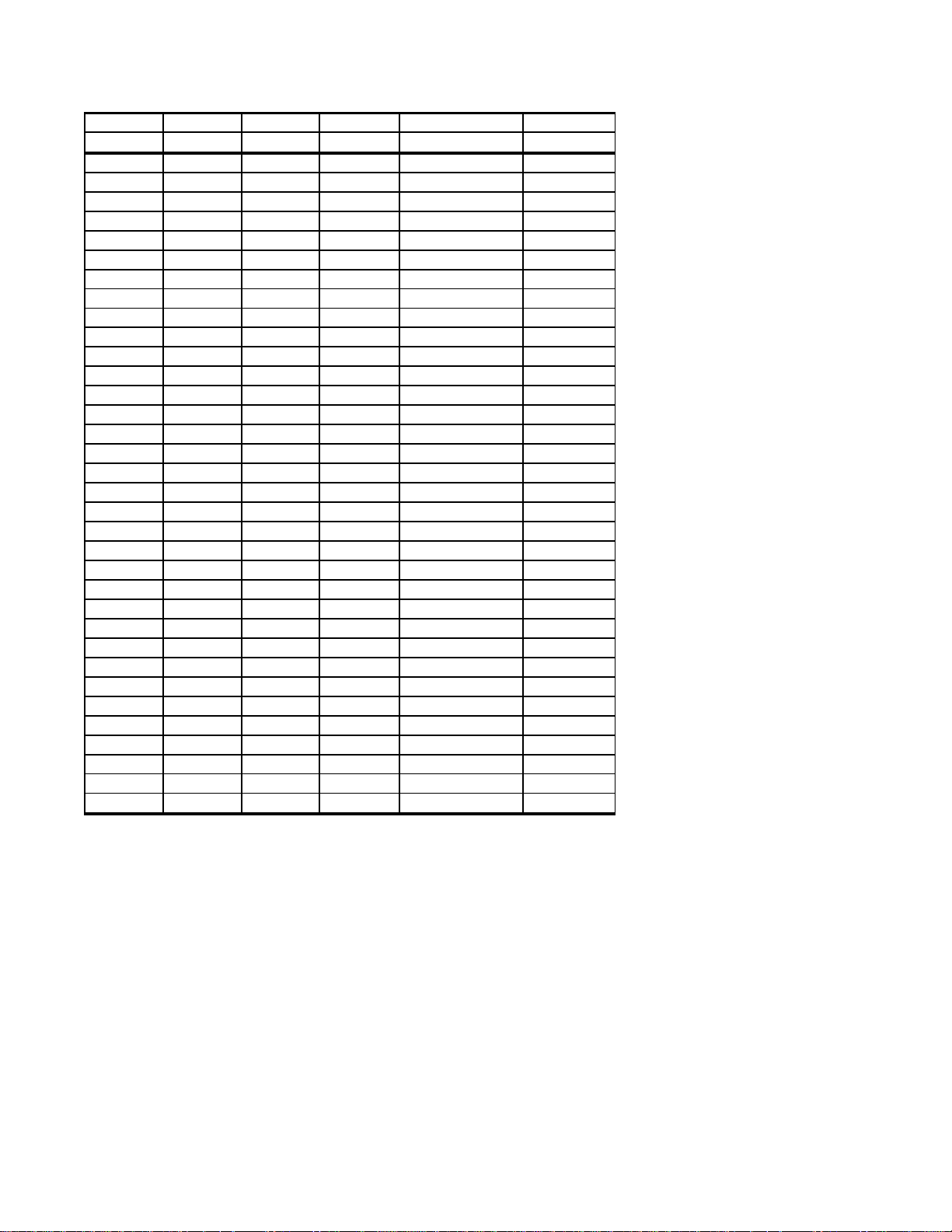

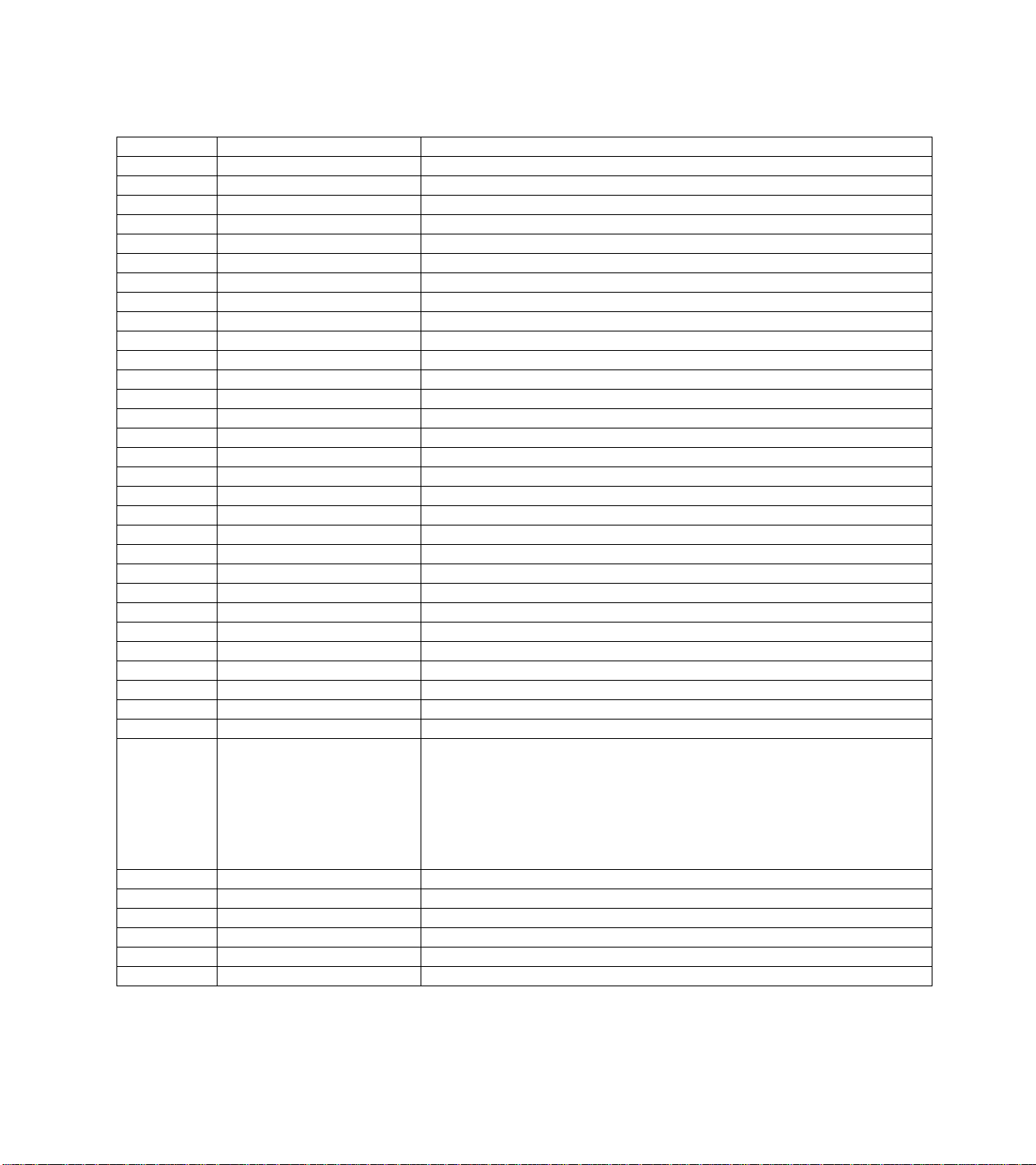

MODEL TO MODULE LIST

The model to Module list shown below identifies all electrical panels, modules and assemblies used in each

model produced with the G7 chassis. This information was current at time of printing.

Information concerning cabinet parts and cabinet mounted parts (CRT/Yoke/etc.) is shown in the Cabinet

Replacement Parts List.

If you are attempting to service a model equipped with the G7 chassis, the necessary electrical information

should be covered in this service manual, even if the corresponding model number is not listed.

Model Size

Panel Number Description

Sub Panel Description

PHILIPS – MAGNAVOX MODELS

00TP2784-C1 27“

00AVJ245 Jack Panel (I/O Cinch Panel) (JP9110)

00A10783 Single PIP Panel

00EMG770 Main Chassis

00A10784 Comb Filter Panel

00TP2797-B1 27“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG772 Main Chassis

00A10773 YUV Panel (Histogram)

00A10784 Comb Filter Panel

00TP3284-C1 32“

00AVJ245 Jack Panel (I/O Cinch Panel) (JP9110)

00A10783 Single PIP Panel

00EMG782 Main Chassis

00A10780 East West Panel (Diode Modulator)

00A10784 Comb Filter Panel

00TP3297-B1 32“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG784 Main Chassis

00A10773 YUV Panel (Histogram)

00A10780 East West Panel (Diode Modulator)

00A10784 Comb Filter Panel

00TP3684-C1 36“

00AVJ245 Jack Panel (I/O Cinch Panel) (JP9110)

00A10783 Single PIP Panel

00EMG792 Main Chassis

00A10781 East West Panel (Diode Modulator)

00A10784 Comb Filter Panel

00TP3697-B1 36“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG794 Main Chassis

00A10773 YUV Panel (Histogram)

00A10781 East West Panel (Diode Modulator)

00A10784 Comb Filter Panel

00TS3259-C1 32“

00AVJ244 Jack Panel (I/O Cinch Panel) (JP9110)

00EMG780 Main Chassis

00A10780 East West Panel (Diode Modulator)

00TS3659-C1 36“

00AVJ244 Jack Panel (I/O Cinch Panel) (JP9110)

00EMG790 Main Chassis

00A10781 East West Panel (Diode Modulator)

00A10785 Comb Filter Panel

PHILIPS GUIDE PLUS MODELS

0027PT40-B1 27“

00AVJ247 Jack Panel (I/O Cinch Panel) (JP9420)

00A10775 Virtual Dolby Panel

00A10776 Guide Plus Panel

00A10786 Double Window PIP Panel

00EMG774 Main Chassis

00A10774 YUV Panel (Histogram)

00A10785 Comb Filter Panel

0032PT70-B1 32“

00AVJ247 Jack Panel (I/O Cinch Panel) (JP9420)

00AVJ249 Side AV Panel

00A10775 Virtual Dolby Panel

00A10776 Guide Plus Panel

00A10786 Double Window PIP Panel

00EMG786 Main Chassis

00A10774 YUV Panel (Histogram)

00A10780 East West Panel (Diode Modulator)

00A10785 Comb Filter Panel

PHILIPS – MAGNAVOX CANADIAN MODELS

00XP2784-C1 36“

00AVJ245 Jack Panel (I/O Cinch Panel) (JP9110)

00A10783 Single PIP Panel

00EMG770 Main Chassis

00A10784 Comb Filter Panel

00XS3259-C1 32“

00AVJ244 Jack Panel (I/O Cinch Panel) (JP9110)

00EMG780 Main Chassis

00A10780 East West Panel (Diode Modulator)

00XS3659-C1 36“

00AVJ244 Jack Panel (I/O Cinch Panel) (JP9110)

00EMG790 Main Chassis

00A10781 East West Panel (Diode Modulator)

00A10785 Comb Filter Panel

PHILIPS - LATIN AMERICA MODELS

0033LL89-11 32“

00AVJ244 Jack Panel (I/O Cinch Panel) (JP9110)

00EMG783 Main Chassis

00A10780 East West Panel (Diode Modulator)

0037LP99-22 36“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG791 Main Chassis

00A10773 YUV Panel (Histogram)

00A10781 East West Panel (Diode Modulator)

00A10784 Comb Filter Panel

PHILIPS - LATIN AMERICA - AMV MODELS

0029LP69-22 27“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG771 Main Chassis

00A10773 YUV Panel (Histogram)

00A10784 Comb Filter Panel

0029LP69-32 27“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG773 Main Chassis

00A10773 YUV Panel (Histogram)

00A10784 Comb Filter Panel

0033LP89-32 32“

00AVJ246 Jack Panel (I/O Cinch Panel) (JP9115)

00A10782 2 Tuner Single PIP Panel

00EMG781 Main Chassis

00A10773 YUV Panel (Histogram)

00A10780 East West Panel (Diode Modulator)

00A10784 Comb Filter Panel

Model to Remote Transmitter and Jack Panel Listing

Model

Number

0027PT40-B1

0029LP69-22

0029LP69-32

0032PT70-B1

0033LL89-11

0033LP89-32

0037LP99-22

00TP2784-C1

00TP2797-B1

00TP3284-C1

00TP3297-B1

00TP3684-C1

00TP3697-B1

00TS3259-C1

00TS3659-C1

00XP2784-C1 36“ RCU81B JP9110

00XS3259-C1 32“ RCU81BX JP9110

00XS3659-C1 36“ RCU81BX JP9110

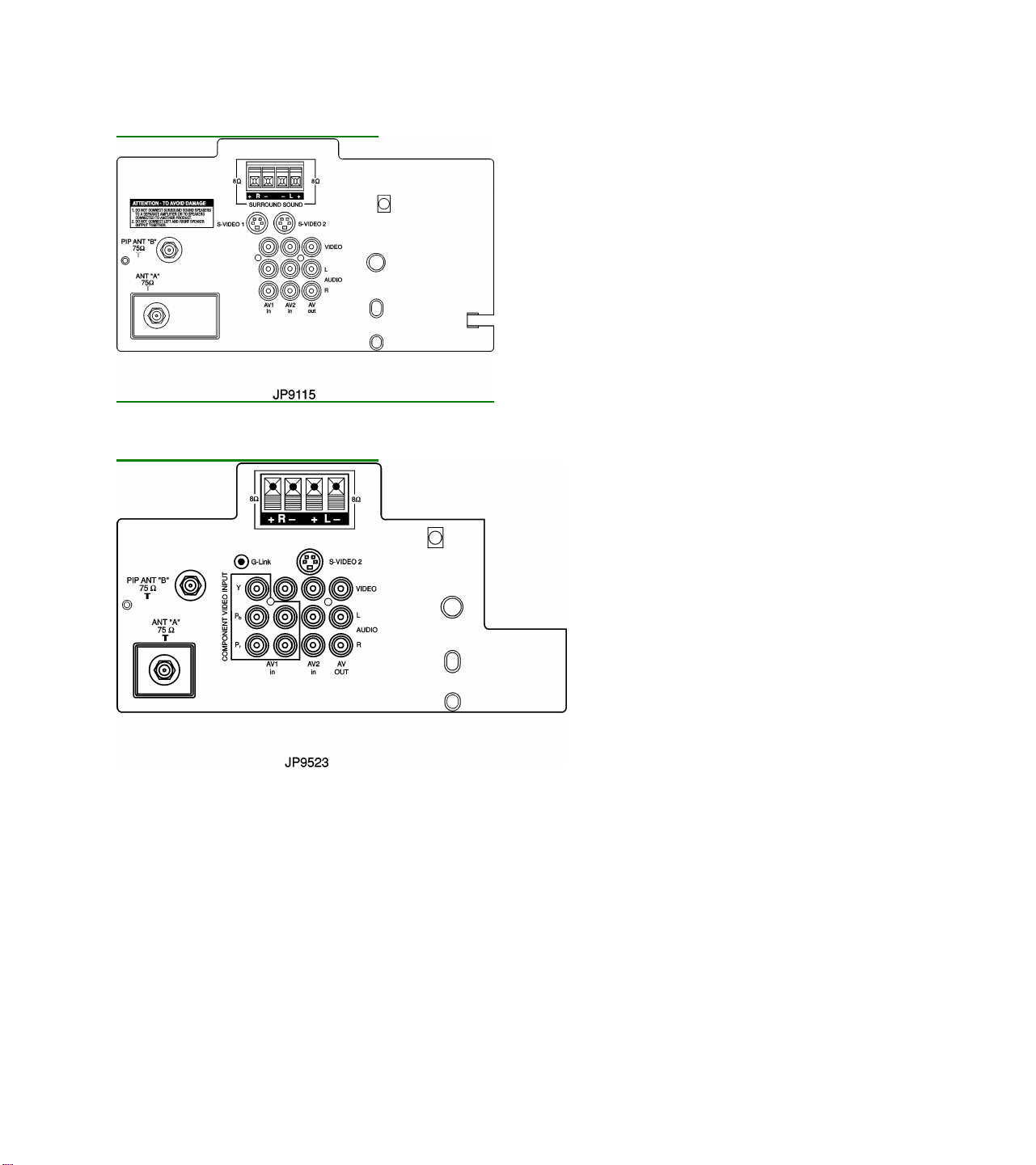

Rear Connections of JP9110

Screen

Size

27“ RC2010/01 JP9420

27“ RCU81AX JP9115

27“ RCU81AX JP9115

32“ RC2010/01 JP9523

32“ RCU81BX/01 JP9110

32“ RCU81AX JP9115

36“ RCU81AX JP9115

27“ RCU81B JP9110

27“ RCU81E JP9115

32“ RCU81B JP9110

32“ RCU81E JP9115

36“ RCU81B JP9110

36“ RCU81E JP9115

32“ RCU81BX JP9110

36“ RCU81BX JP9110

Remote

Transmitter

Jack Panel

Rear Connections of JP9115

Rear Connections of JP9523

GLOSSARY OF TERMS, ACRONYMS, AND ABBREVIATIONS

2CS Two Channel Stereo

AFC Automatic Frequency Control

AFT Automatic Fine Tuning

AP Asia Pacific

ATS Automatic Tuning System

AV External Audio/Video

AVL Automatic Volume Level control

BTSC Broadcast Television Standard Committee (TV stereo)

CBA Circuit Board Assembly (PCB)

CC Closed Captioning

CSM Customer Service Mode

CVBS Color Video Blanking Sync

DNR Dynamic Noise Reduction

EEPROM Electrical Erasable Programmable Read-Only Memory

Error Buffer Register that keeps track of errors that occur and stores error codes

Error Code A numerical value used to indicate a failure in the television

EU Europe

EXT External audio/video input

FM Frequency Modulation

I²C Inter IC bus, 2-wire bi-directional (SCL/SDA)

ID Identification

IDENT Horizontal coincidence signal, transmitter identification

IF Intermediate Frequency

IN ITT sound IC with NICAM function

IT ITT sound IC without NICAM function

LATAM Latin America

LED Light Emit ting Diode

Local Keyboard The buttons (usually volume up, volume down, channel up, and channel down) located on

the front of the television set

MA Mono All; single mono carrier receiver

NICAM Near Instantaneous Companding Audio Multiplex; Digital Sound System

NR Noise Reduction

NTSC National Television Systems Committee (video)

NVM Non Volatile Memory

OB Option Byte (Feature Byte)

OSD On Screen Display

PCB Printed Circuit Board (CBA)

PIP Picture In Picture

PLL Phase Locked Loop

PP Personal Preference

RAM Random Access Memory

RC Remote Control

RC-5 Remote Control System 5

RGB Red Green Blue

ROM Read Only Memory

SAM Service Alignment Mode

SAP Second Audio Program

SCL Serial Clock

SDA Serial Data

SDM Service Default Mode

SVHS Super Video Home System

Top Level Menu This refers to the main menu (as opposed to sub menus) in SAM

V-Chip Violence-Chip

VCR Video Cassette Recorder

Y/C Luminance/Chrominance (video)

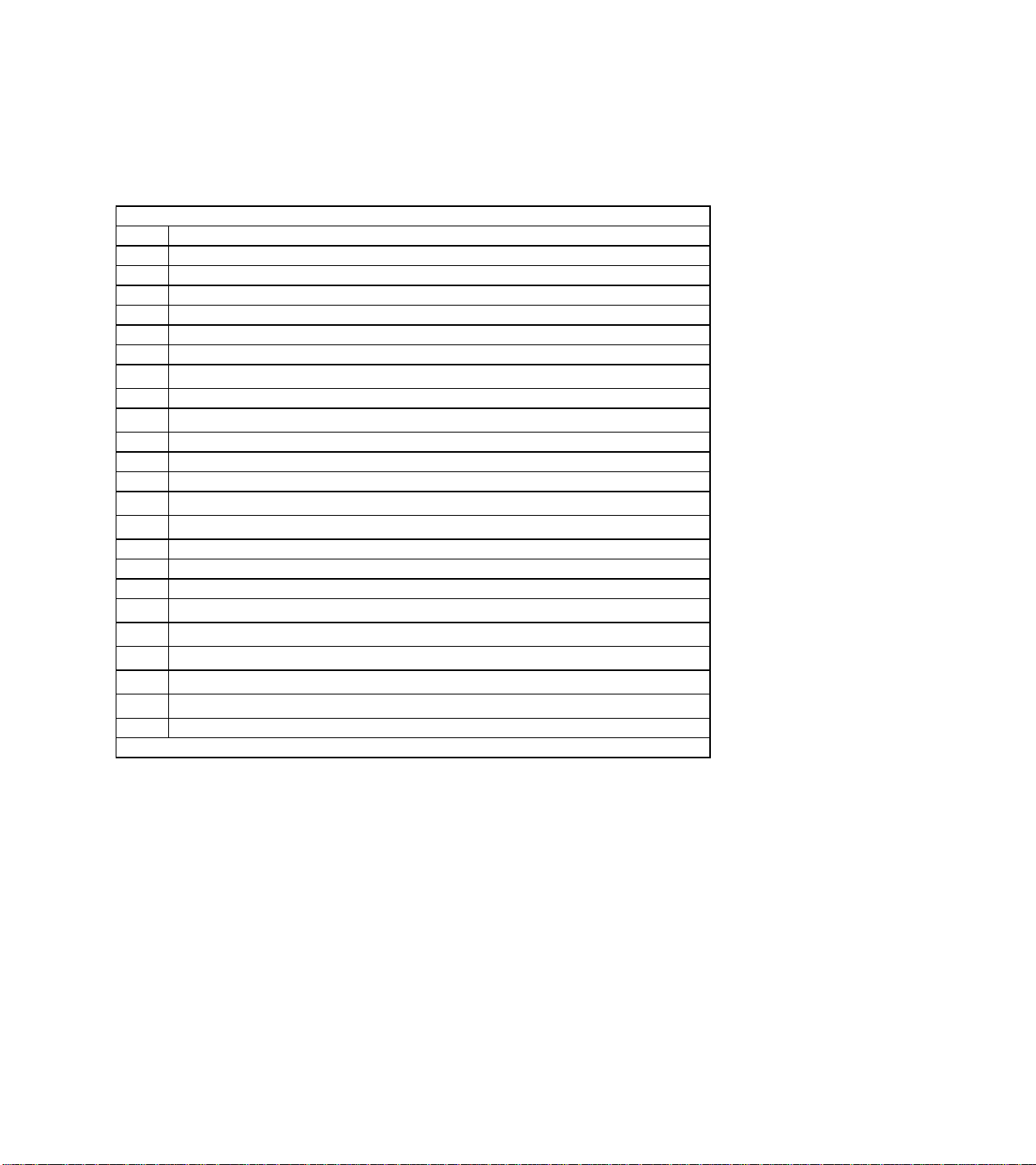

G7 CHASSIS FEATURE WORDS

Instrument

Assembly

mitter

A/B

Control

Standby

Volume L

No Picture

Inputs

16 x 9

Service Mode

Reduction

14 x 9

Str A/V

Tuning

Mode

Picture

Control

Lock

Un-Rated

No Rating

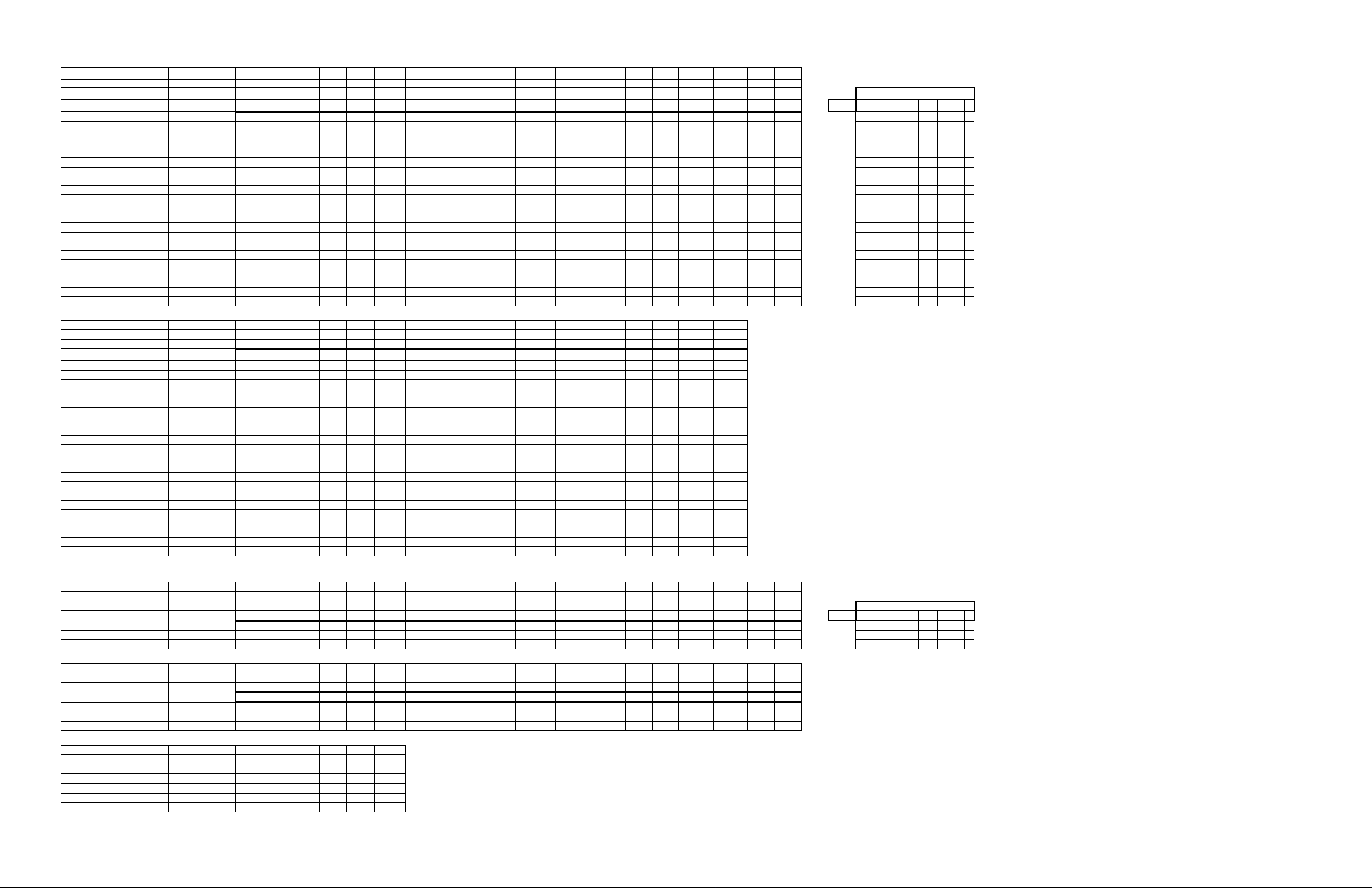

Chart No. Final Chassis Trans- Antenna Audio Auto Auto Auto Standby Muliple A/V Compress Customer Dynamic Noise Expand Mono Fine Hospitality Incredible PIP Parental

AB AD AK AL AN AV CM CS DN EX FM FT HO IP PI PL Feature Byte Values

27A950/37R TP2784C1 EMG770 RCU81B 0 1 0 1 0 1 0 1 1 0 0 1 0 0 1 1 85 147 47 188 0 0 0

27A950/35R XP2784C1 EMG770 RCU81B 0 1 0 1 0 1 0 1 1 0 0 1 0 0 1 1 85 147 47 188 0 0 0

27A985/37R TP2797B1 EMG772 RCU81E 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 239 188 0 0 0

27A975/85R 29LP6922 EMG771 RCU81AX 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 141 160 0 0 0

27A976/87R 29LP6932 EMG773 RCU81AX 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 141 160 0 0 0

32A940/37R TS3259C1 EMG780 or EMG785 RCU81BX 0 1 0 1 0 1 0 1 1 0 0 1 0 0 0 1 85 145 46 188 0 0 0

32A940/35R XS3259C1 EMG780 or EMG785 RCU81BX 0 1 0 1 0 1 0 1 1 0 0 1 0 0 0 1 85 145 46 188 0 0 0

32A950/37R TP3284C1 EMG782 or EMG787 RCU81B 0 1 0 1 0 1 0 1 1 0 0 1 0 0 1 1 85 147 47 188 0 0 0

32A985/37R TP3297B1 EMG784 or EMG788 RCU81E 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 239 188 0 0 0

32A960/85R 33LL8911 EMG783 or EMG710 RCU81BX 0 1 0 1 0 1 0 1 1 0 0 1 0 0 0 1 85 145 12 160 0 0 0

32A976/87R 33LP8932 EMG781 or EMG789 RCU81AX 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 141 160 0 0 0

36A940/37R TS3659C1 EMG790 or EMG796 RCU81BX 0 1 0 1 0 1 0 1 1 0 0 1 0 0 0 1 85 145 47 188 0 0 0

36A940/35R XS3659C1 EMG790 or EMG796 RCU81BX 0 1 0 1 0 1 0 1 1 0 0 1 0 0 0 1 85 145 47 188 0 0 0

36A950/37R TP3684C1 EMG792 or EMG798 RCU81B 0 1 0 1 0 1 0 1 1 0 0 1 0 0 1 1 85 147 47 188 0 0 0

36A985/37R TP3697B1 EMG794 or EMG799 RCU81E 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 239 188 0 0 0

36A975/85R 37LP9922 EMG791 or EMG797 RCU81AX 1 1 0 1 0 1 0 1 1 0 0 1 0 1 1 1 213 151 141 160 0 0 0

EEPROM ADR 3 b7 3 b6 3 b5 3 b4 3 b3 3 b2 3 b1 3 b0 4 b7 4 b6 4 b5 4 b4 4 b3 4 b2 4 b1 4 b0 Byte # 3 4 5 6 7 8 9

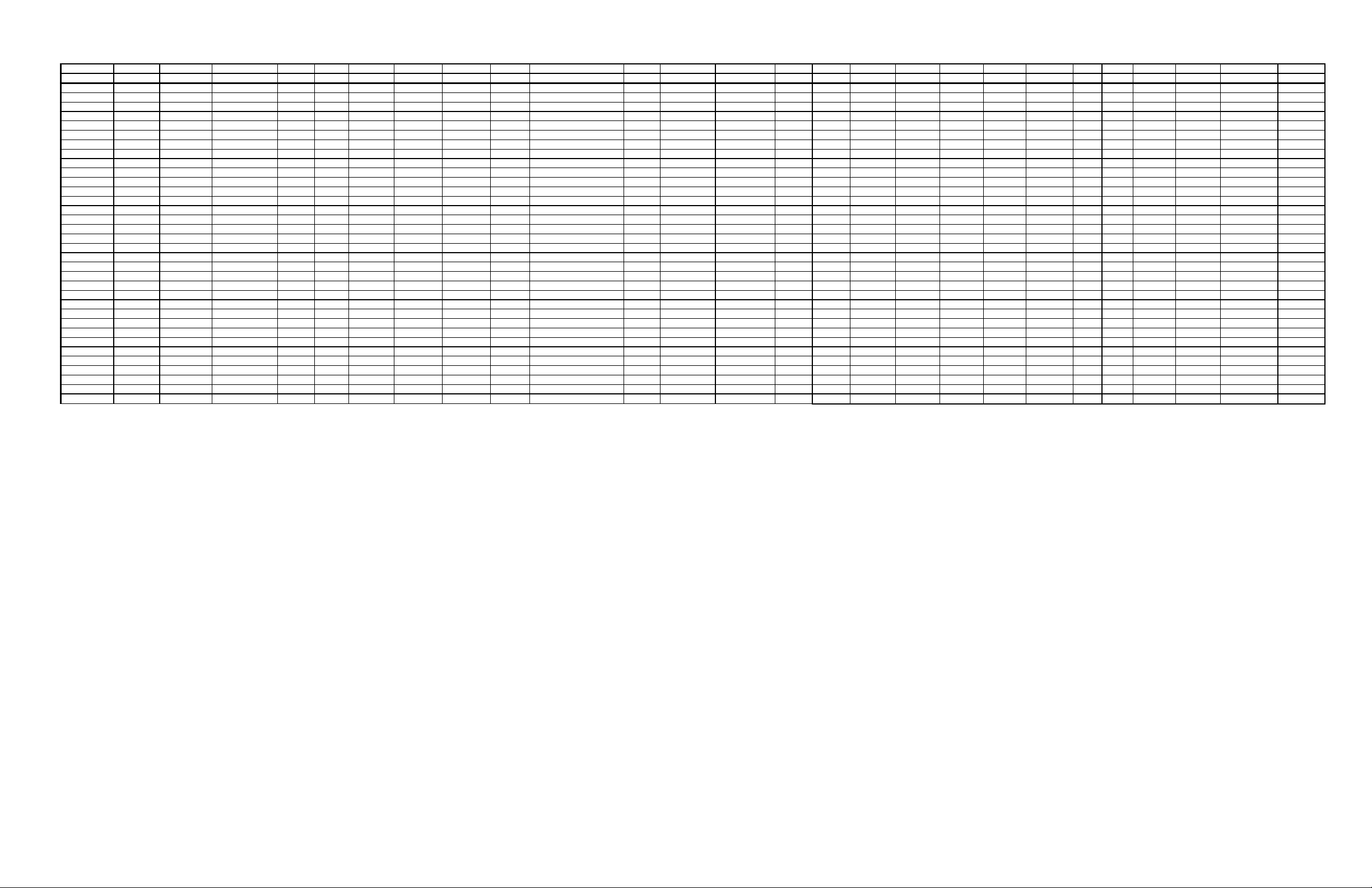

Chart No. Final Chassis Trans- PIP Remote Smart Number Speaker Auto Stby First Time Comb Incred. Pix Sync Timer V-Chip V-Chip V-Chip

Instrument Assembly mitter Tuner Locator Clock of A/Vs On/Off Auto On Setup Filter Via Menu Slice L. On/Off Un-Rated No Rating

PT RL SC SO SP ST SU CF IM VS TM VC VU VN

27A950/37R TP2784C1 EMG770 RCU81B 0 0 1 0 1 1 1 1 1 0 1 1 1 1

EEPROM ADR 5 b7 5 b6 5 b5 5 b4 5 b3 5 b2 5 b1 5 b0 6 b7 6 b6 6 b5 6 b4 6 b3 6 b2

27A950/35R XP2784C1 EMG770 RCU81B 0 0 1 0 1 1 1 1 1 0 1 1 1 1

27A985/37R TP2797B1 EMG772 RCU81E 1 1 1 0 1 1 1 1 1 0 1 1 1 1

27A975/85R 29LP6922 EMG771 RCU81AX 1 0 0 0 1 1 0 1 1 0 1 0 0 0

27A976/87R 29LP6932 EMG773 RCU81AX 1 0 0 0 1 1 0 1 1 0 1 0 0 0

32A940/37R TS3259C1 EMG780 or EMG785 RCU81BX 0 0 1 0 1 1 1 0 1 0 1 1 1 1

32A940/35R XS3259C1 EMG780 or EMG785 RCU81BX 0 0 1 0 1 1 1 0 1 0 1 1 1 1

32A950/37R TP3284C1 EMG782 or EMG787 RCU81B 0 0 1 0 1 1 1 1 1 0 1 1 1 1

32A985/37R TP3297B1 EMG784 or EMG788 RCU81E 1 1 1 0 1 1 1 1 1 0 1 1 1 1

32A960/85R 33LL8911 EMG783 or EMG710 RCU81BX 0 0 0 0 1 1 0 0 1 0 1 0 0 0

32A976/87R 33LP8932 EMG781 or EMG789 RCU81AX 1 0 0 0 1 1 0 1 1 0 1 0 0 0

36A940/37R TS3659C1 EMG790 or EMG796 RCU81BX 0 0 1 0 1 1 1 1 1 0 1 1 1 1

36A940/35R XS3659C1 EMG790 or EMG796 RCU81BX 0 0 1 0 1 1 1 1 1 0 1 1 1 1

36A950/37R TP3684C1 EMG792 or EMG798 RCU81B 0 0 1 0 1 1 1 1 1 0 1 1 1 1

36A985/37R TP3697B1 EMG794 or EMG799 RCU81E 1 1 1 0 1 1 1 1 1 0 1 1 1 1

36A975/85R 37LP9922 EMG791 or EMG797 RCU81AX 1 0 0 0 1 1 0 1 1 0 1 0 0 0

Chart No. Final Chassis Trans- Antenna Audio Auto Auto Auto Standby Muliple A/V Compress Customer Dynamic Noise Expand Mono Fine Hospitality Incredible PIP Parental

Instrument Assembly mitter A/B Control Standby Volume L No Picture Inputs 16 x 9 Service Mode Reduction 14 x 9 Str A/V Tuning Mode Picture Control Lock

AB AD AK AL AN AV CM CS DN EX FM FT HO IP PI PL Feature Byte Values

27FSQ985/37R 27PT40B1 EMG774 RC2010 1 1 0 1 0 1 0 1 1 0 0 0 0 1 1 1 213 135 175 222 224 0 0

EEPROM ADR 3 b7 3 b6 3 b5 3 b4 3 b3 3 b2 3 b1 3 b0 4 b7 4 b6 4 b5 4 b4 4 b3 4 b2 4 b1 4 b0 Byte # 3 4 5 6 7 8 9

32FSQ985/37R 32PT70B1 EMG786 RC2010 1 1 0 1 0 1 0 1 1 0 0 0 0 1 1 1 213 135 191 222 224 0 0

Chart No. Final Chassis Trans- PIP Remote Smart Number Speaker Auto Stby First Time Comb Incred. Pix Virtual Sync Timer D Window D Window Guide Go to

Instrument Assembly mitter Tuner Locator Clock of A/Vs On/Off Auto On Setup Filter Via Menu Dolby Slice L. 4:3 16:9 Plus Guide+

PT RL SC SO SP ST SU CF IM VD VS TM W1 W2 GP GG

27FSQ985/37R 27PT40B1 EMG774 RC2010 1 0 1 0 1 1 1 1 1 1 0 1 1 1 1 0

EEPROM ADR 5 b7 5 b6 5 b5 5 b4 5 b3 5 b2 5 b1 5 b0 6 b7 6 b6 6 b5 6 b4 6 b3 6 b2 6 b1 6 b0

32FSQ985/37R 32PT70B1 EMG786 RC2010 1 0 1 1 1 1 1 1 1 1 0 1 1 1 1 0

Chart No. Final Chassis Trans- V-Chip V-Chip V-Chip Expand

Instrument Assembly mitter On/Off

4:3

VC VU VN EP

27FSQ985/37R 27PT40B1 EMG774 RC2010 1 1 1 0

EEPROM ADR 7 b7 7 b6 7 b5 7 b4

32FSQ985/37R 32PT70B1 EMG786 RC2010 1 1 1 0

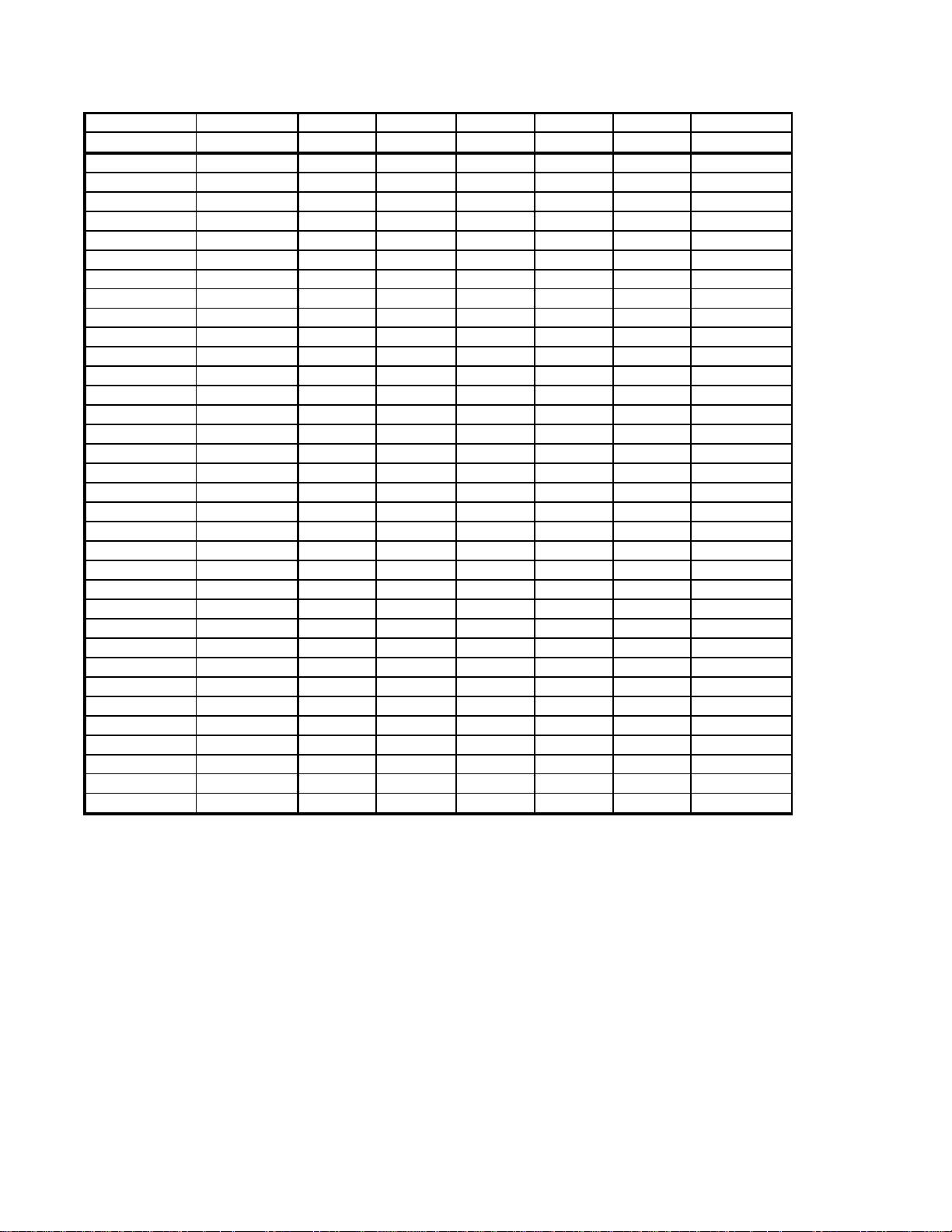

G7 Chassis Feature Listing

Model

Chassis

Trans-

Rear

Side

Head

Top

AMV

Diode

Guide +

PIP

Clock

Histogram/

Color

Blue

Comb

Var/Fix

Tone

Virtual

Surround

Incredible

AVL

Surf

Remote

Sub-

Audio

Bimos

Number

Assembly

mitter

Jacks

A/V

phone

Control

Modulator

Gold

LTI

Temperature

Stretch

Filter

A-Out

Control

Dolby

Jacks

Surround

Locator

Woofer

27PT40B101

EMG774

RC20-STIK

JP9420 -AVJ247

front A10776

D Window PIP- A10786

SMT

A10774

XXA10785

XXA10775

XXX

SMT 2x8W DBX Str

TDA8847

TP2784C101

EMG770

RCU81B

JP9110 -AVJ245

S-PIP - A10783

SMTXX

A10784

XXXXSMT

2x5W DBX Str

TDA8846

TP2797B101

EMG772

RCU81E

JP9115 -AVJ246

S-PIP 2 Tuner - A10782

SMT

A10773

XXA10784

XXXXX

SMTX2x5W DBX Str

TDA8847

XP2784C101

EMG770

RCU81B

JP9110 -AVJ245

S-PIP - A10783

SMTXX

A10784

XXXXSMT

2x5W DBX Str

TDA8846

29LP692201

EMG771

RCU81AX

JP9115 -AVJ246

S-PIP 2 Tuner - A10782

X

A10773

XXA10784

XX X XSMT 2x5W DBX Str

TDA8847

29LP693201

EMG773

RCU81AX

JP9115 -AVJ246

X

S-PIP 2 Tuner - A10782

X

A10773

XXA10784

XX X XSMT 2x5W DBX Str

TDA8847

32PT70B101

EMG786

RC20-STIK

JP9523 -AVJ247

AVJ249

sideXA10780

A10776

D Window PIP- A10786

SMT

A10774

XXA10785

XXA10775

XXX

SMT 5W

2x5W DBX Str

TDA8847

TP3284C101

EMG782

RCU81B

JP9110 -AVJ245

A10780

S-PIP - A10783

SMTXX

A10784

XX XX

SMT 2x5W DBX Str

TDA8847

TP3284C102

EMG787

RCU81B

JP9110 -AVJ245

A10780

S-PIP - A10783

SMTXX

A10784

XX XX

SMT 2x5W DBX Str

TDA8847

TP3297B101

EMG784

RCU81E

JP9115 -AVJ246

A10780

S-PIP 2 Tuner - A10782

SMT

A10773

XXA10784

XX XXXSMTX2x5W DBX Str

TDA8847

TP3297B102

EMG788

RCU81E

JP9115 -AVJ246

A10780

S-PIP 2 Tuner - A10782

SMT

A10773

XXA10784

XX XXXSMTX2x5W DBX Str

TDA8847

TS3259C101

EMG780

RCU81BX

JP9110 -AVJ244

A10780

SMTXX

PAL-DL

XX XX

SMT

2x5W DBX Str

TDA8843

TS3259C102

EMG785

RCU81BX

JP9110 -AVJ244

A10780

SMTXX

PAL-DL

XX XX

SMT

2x5W DBX Str

TDA8843

XS3259C101

EMG780

RCU81BX

JP9110 -AVJ244

A10780

SMTXX

PAL-DL

XX XX

SMT

2x5W DBX Str

TDA8843

XS3259C102

EMG785

RCU81BX

JP9110 -AVJ244

A10780

SMTXX

PAL-DL

XX XX

SMT

2x5W DBX Str

TDA8843

33LL891101

EMG783

RCU81BX/01

JP9110 -AVJ244

X

A10780

XXXPAL-DL

XX XX

SMT

2x5W DBX Str

TDA8843

33LL891102

EMG710

RCU81BX/01

JP9110 -AVJ244

X

A10780

XXXPAL-DL

XX XX

SMT

2x5W DBX Str

TDA8843

33LP893201

EMG781

RCU81AX

JP9115 -AVJ246

X

A10780

S-PIP 2 Tuner - A10782

X

A10773

XXA10784

XX XXXSMT 2x5W DBX Str

TDA8847

33LP893202

EMG789

RCU81AX

JP9115 -AVJ246

X

A10780

S-PIP 2 Tuner - A10782

X

A10773

XXA10784

XX XXXSMT 2x5W DBX Str

TDA8847

37LP992201

EMG791

RCU81AX

JP9115 -AVJ246

A10781

S-PIP 2 Tuner - A10782

X

A10773

XXA10784

XX XXXSMT 2x5W DBX Str

TDA8847

37LP992202

EMG797

RCU81AX

JP9115 -AVJ246

A10781

S-PIP 2 Tuner - A10782

X

A10773

XXA10784

XX XXXSMT 2x5W DBX Str

TDA8847

TP3684C101

EMG792

RCU81B

JP9110 -AVJ245

A10781

S-PIP - A10783

SMTXX

A10784

XX XX

SMT 2x5W DBX Str

TDA8847

TP3684C102

EMG798

RCU81B

JP9110 -AVJ245

A10781

S-PIP - A10783

SMTXX

A10784

XX XX

SMT 2x5W DBX Str

TDA8847

TP3697B101

EMG794

RCU81E

JP9115 -AVJ246

A10781

S-PIP 2 Tuner - A10782

SMT

A10773

XXA10784

XX XXXSMTX2x5W DBX Str

TDA8847

TP3697B102

EMG799

RCU81E

JP9115 -AVJ246

A10781

S-PIP 2 Tuner - A10782

SMT

A10773

XXA10784

XX XXXSMTX2x5W DBX Str

TDA8847

TS3659C101

EMG790

RCU81BX

JP9110 -AVJ244

A10781

SMTXX

A10785

XX XX

SMT

2x5W DBX Str

TDA8847

TS3659C102

EMG796

RCU81BX

JP9110 -AVJ244

A10781

SMTXX

A10785

XX XX

SMT

2x5W DBX Str

TDA8847

XS3659C101

EMG790

RCU81BX

JP9110 -AVJ244

A10781

SMTXX

A10785

XX XX

SMT

2x5W DBX Str

TDA8847

XS3659C102

EMG796

RCU81BX

JP9110 -AVJ244

A10781

SMTXX

A10785

XX XX

SMT

2x5W DBX Str

TDA8847

Model

Chassis

Comb

Var/Fix

Tone

Virtual

Surround

Incredible

Number

Assembly

Filter

A-Out

Control

Dolby

Jacks

Surround

27PT40B101 EMG774 A10785 X X A10775 X X

XS3659C102

EMG796

A10785

XX

X

TP2784C101 EMG770 A10784 X X X

TP2797B101 EMG772 A10784 X X X X

XP2784C101 EMG770 A10784 X X X

29LP692201 EMG771 A10784 X X X

29LP693201 EMG773 A10784 X X X

32PT70B101 EMG786 A10785 X X A10775 X X

TP3284C101 EMG782 A10784 X X X

TP3284C102 EMG787 A10784 X X X

TP3297B101 EMG784 A10784 X X X X

TP3297B102 EMG788 A10784 X X X X

TS3259C101 EMG780 PAL-DL X X X

TS3259C102 EMG785 PAL-DL X X X

XS3259C101 EMG780 PAL-DL X X X

XS3259C102 EMG785 PAL-DL X X X

33LL891101 EMG783 PAL-DL X X X

33LL891102 EMG710 PAL-DL X X X

33LP893201 EMG781 A10784 X X X X

33LP893202 EMG789 A10784 X X X X

37LP992201 EMG791 A10784 X X X X

37LP992202 EMG797 A10784 X X X X

TP3684C101 EMG792 A10784 X X X

TP3684C102 EMG798 A10784 X X X

TP3697B101 EMG794 A10784 X X X X

TP3697B102 EMG799 A10784 X X X X

TS3659C101 EMG790 A10785 X X X

TS3659C102 EMG796 A10785 X X X

XS3659C101 EMG790 A10785 X X X

AVL

Surf

Remote

Sub-

Audio

Bimos

Locator

Woofer

X SMT 2x8W DBX Str TDA8847

X

SMT

2x5W DBX Str

TDA8847

X SMT 2x5W DBX Str TDA8846

X SMT X 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8846

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 5W 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT X 2x5W DBX Str TDA8847

X SMT X 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8843

X SMT 2x5W DBX Str TDA8843

X SMT 2x5W DBX Str TDA8843

X SMT 2x5W DBX Str TDA8843

X SMT 2x5W DBX Str TDA8843

X SMT 2x5W DBX Str TDA8843

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT X 2x5W DBX Str TDA8847

X SMT X 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

X SMT 2x5W DBX Str TDA8847

G7 CHASSIS SERVICE ADJUSTMENTS

REQUIRED TOOLS FOR SERVICING

Isolation Transformer

Multimeter

Oscilloscope

High Voltage (100:1) Oscilloscope Probe

Sencore VG91 Universal Video Generator

Caution: The G7 chassis incorporates a ”hot“ ground system. Always use a separate isolation

transformer when applying power to the exposed chassis.

Service Adjustment Notes:

Unless Otherwise Specified:

1. All service adjustments are ”hot“ voltagewise. For maximum safety, ensure the use of properly insulated

tools.

2. Refer to the G7 Main Chassis Printed Circuit Board for location of test points and adjustable components.

3. Grid Locations (Ex.: D-2) next to the reference numbers for components refer to the Main Chassis Printed

Circuit Board.

Focus Adjustment

1. Tune the set to a local or cable station.

2. Adjust the Focus Control (located on the upper part of the flyback transformer) for best picture details at

high light conditions.

Degaussing the Television

1. Position the television so that the screen faces the direction it will be facing when in use.

2. Ensure the television is turned off.

3. Move a degaussing coil in a circular motion slowly around the sides and front of the television.

4. Withdraw the degaussing coil at least six feet from the television before disconnecting it from its power

source.

G7 SERVICE MODES

Introduction

1. There are three service modes used in the G7 chassis. They are:

a. SAM - Service Alignment Mode

b. SDM - Service Default Mode

c. CSM - Customer Service Mode

2. The Service Alignment Mode corresponds to the older "Service Mode". The SAM allows

adjustments/alignments, setting of options, writing defaults to the memory IC, and erasing error codes.

This mode also displays the Run Timer, the Software Version, and current option settings.

3. The Service Default Mode is a technical aid for the service technician. It establishes a fixed, repeatable

setting of controls to allow measurements to be made. On screen display is kept at a minimum to reduce

the cluttering of wave forms with unwanted information.

4. The Customer Service Mode shows error codes and information on the TV operation settings. The servicer

can instruct the customer to enter CSM by telephone and read off the information displayed. This helps the

servicer to diagnose problems and failures in the TV set before making a service call.

5. Each of these Service Modes displays their acronym (SAM, SDM, or CSM) in the upper right hand corner

of the screen when they are active.

6. It will be memorized in the NVM that the TV set is in SDM or SAM. This is necessary because the TV must

show up in SDM or SAM again after an ac power interrupt.

7. When the television is in SAM or SDM, all normal features (such as volume control and direct channel

access) are available.

Service unfriendly modes

In the service modes, a number of modes/features are ignored since they interfere with diagnosing or repairing

a set. These are ”service unfriendly modes.“

”Ignoring“ means that the event that is triggered is not executed; the setting remains unchanged (Example:

Timer OFF: 8:00 PM; the set will not switch OFF in service mode at 8:00PM, but the setting will remain).

The service unfriendly modes are:

• Timer

• Sleep timer

• Hospitality mode

• Auto switch off (when there is no video signal identified)

• Smart lock or blocking by V-chip

• Skipped Channels

• Closed Captioning

SERVICE ALIGNMENT MODE (SAM)

S A M

0

0

0

0

1. The Service Alignment Mode (SAM) is used to set the option codes and bytes of the set, and display the

error codes (the Power LED begins blinking procedure for error code display, if errors are detected). SAM

also overrides software protections.

2. To enter the Service Alignment Mode, press the following key sequence on the remote control transmitter:

0-6-2-5-9-6-Status

Do not allow the display to time out between entries while keying the sequence.

SAM can also be entered by pressing the Channel Down and Volume Down keys on the local keyboard

simultaneously while in SDM mode.

When Service Alignment Mode is entered, the text "SAM" will be displayed in the upper right corner of the

screen.

3. When Service Alignment Mode is entered, the Power LED will begin blinking to display any detected error

codes, and service unfriendly modes are disabled. All customer controls are set to predetermined values.

4. When the unit is operating in Service Alignment Mode, all normal on-screen displays are suppressed and

replaced by a special service display. The first screen seen upon entering SAM is the ”top level SAM

menu.“ The service technician must return to the top level SAM menu before exiting with a power-off

command.

A sample top level SAM menu display is shown below.

0019 A81US1–1. 2

ERR 14 0

OPT 85 139 47 222 224 0 0

GUIDE PLUS TEST

ERASE BUFFER

OPTIONS

5. To select a sub-menu from the top level SAM menu, use the Menu Up or Menu Down keys on the remote

control to highlight the sub-menu.

6. To enter the selected sub-menu, use the Menu Left/Right keys on the remote control.

7. When the Menu button is pressed in a lower level Menu (or sub-menu), the software will switch back to the

next higher level menu.

8. Press the Status button on the remote control to toggle the OSD ON and OFF.

9. From the top level SAM menu, press the Menu button on the remote control to switch the software to a

Virtual Customer Mode; the text "SAM" will still be displayed in the upper right corner of the screen. In this

mode, all customer menu adjustments to the set can be made. From the Virtual Customer Mode, press the

Menu button to return to the top level SAM menu display.

10. To exit the Service Alignment Mode and erase the error codes, turn the unit off with the Power button on

the remote control or the local keyboard, then unplug the ac cord.

11. To exit the Service Alignment Mode and save the error codes, unplug the ac cord to turn off the set. When

the set is turned on again, the Service Alignment Mode will still be active.

Explanation of Display:

Run Timer

The first set of characters (0019 in the example) is a run timer. The run timer counts the normal operation hours,

but does not count standby hours. The run timer displays hours in hexadecimal format. The value of the run

timer is displayed in SAM and CSM. This display will increment based on the amount of time the set has been

on. The display will also be incremented one hour each time the set is turned on.

Software Identification, Cluster, and Version

The software identification, cluster, and version will be shown in the top level SAM menu, and in CSM.

The following format will be used: ”AAABBC-X.Y“. (Example: A81US1 1.2)

− AAA is the engineering project name (Ex: A81 = A8.1).

− BB is additional specification indicating specific functionality or a region (Ex: US). Processors with the same

engineering project name and function name are interchangeable, except for the languages they support.

− C is the language cluster number within the ”BB“ software version (Ex: 1 = English/Spanish/French)

− X is the main version number (Ex: 1)

− Y is the sub version number (Ex: 2)

− the main version number is updated with a major change of specification (incompatible with the previous

software version)

− the sub version number is updated with a minor change (backwards compatible with the previous versions)

− Note: A new micro controller is considered to be compatible if it works instead of the old software and the

functionality is not significantly changed.

Error Buffer

The six most recent errors are encoded on the following line of the display. The most recent error will be

displayed in the register nearest the text ”ERR.“ The error codes and their meanings are shown below.

Error Code Table

0 = No error

1 = X-ray protection, E/W protection and/or Vertical protection active

2 = High beam current protection active

3 = Reserved

4 = +5V protection active

5 = Signal Processor (IC 7150) register corrupted

6 = Signal Processor (IC 7150) error

7

8 = Internal RAM error (Microprocessor IC 7000)

9

10 = NV memory (IC 7088) addressing error

11 = NV memory (IC 7088) identification error

12 = Histogram (YUV) (IC 7330) error (TDA9178)

14

15

16 = ALPS Tuner I²C error (IC 1125)

17 = PIP Processor I²C error (IC 7350)

18 = PIP Tuner I²C error (IC 1127)

19

20

21

22

23

Note: I²C = (SCL/SDA)

The error buffer will automatically be erased if its contents haven't changed in the last 50 hours of use (run timer

count). This is to prevent an error buffer full of codes which are not valid.

Manual erasure of the buffer is possible through:

To save error codes, remove ac power. When ac power is reapplied, the chassis will be on, in SAM or SDM,

and the error codes may be viewed again.

A blinking LED may indicate a current error. The error code can be determined by counting the "off" blinks.

= General I2C error

= OSD generator I2C error (PCA 8516 )

= Sound processor I2C error (IC 7430) (MSP3430)

= I/O expander I2C error (PCF8674 for DW)

= EPG I2C error or Guide Plus I2C error

= Non Volatile Clock I2C error

= I/O Expander I2C error (PCF8574 for I/O panel)

= Virtual Dolby I2C error (DPL3518)

= Reserved (for 2nd Painter)

l ERASE BUFFER (SAM mode only) command from the remote control

l exiting SDM or SAM by pressing the Power button on the remote control or the television set

Reading Error Codes

Error codes are displayed in the following ways:

1. By SAM, SDM, or CSM display

2. By blinking Power LED

1. If the on screen display is working, enter SAM, SDM or CSM and read the error buffer display.

2. If the on screen display is not working, read the error code from the Power LED:

a. The number of blinks represents the number of the most recent error (the error in the ”left“ position)

b. The error code can be determined by counting the "off" blinks

Note: Some indications take 30 seconds or longer to appear on the LED.

3. Displayed error codes are saved by removing the ac power. Displayed error codes are erased by pressing

the power button on the remote control or local keyboard.

Option Bytes

The next line of the display (OPT 85 139 47 222 224 0 0) shows the option byte values for the

particular model. These values can be changed by changing feature bits or entering new option byte values in

the Options sub-menu of SAM.

Refer to the Chassis Feature Listing to see the values for Option Bytes 1 through 7. These values can be used

to set the feature package for a particular model.

Sub-menus

The bottom three lines of the top level SAM menu represent the SAM sub-menus. All sub-menus cannot be

displayed on the screen at once. Other sub-menu items can be displayed by pressing the Menu Down and

Menu Up keys on the remote control.

Note: All sub-menu items may not be available in all models. The presence of a particular sub-menu item may

depend on the hardware and software features of the model.

Erase Buffer Sub-Menu

Allows manual erasure of the error buffer.

1. Enter the Service Alignment Mode (SAM) by pressing the following key sequence on the remote control

transmitter:

0-6-2-5-9-6-Status

Do not allow the display to time out between entries while keying the sequence.

2. From the top level SAM menu, use the Menu Up/Down keys to highlight the ERASE BUFFER sub menu.

3. To erase the error buffer, press the Menu Left or Menu Right key. The error buffer will display all zeros.

The error buffer is now cleared.

Options Sub-menu

Allows the servicer to change the chassis feature bits listed in the Options List. This sub-menu also allows the

servicer to change the feature bytes of the set; these are OB1, OB2, OB3, OB4, OB5, OB6, and OB7. The

feature byte values will also change when the feature bits are changed.

When accessing feature bits, refer to the Options List to determine what particular feature is controlled by each

bit.

When accessing feature bytes, refer to the Feature Byte Values table to see the factory preset feature word.

This allows the servicer to set the feature package of the unit.

1. Enter the Service Alignment Mode (SAM) by pressing the following key sequence on the remote control

transmitter:

0-6-2-5-9-6-Status

Do not allow the display to time out between entries while keying the sequence.

2. From the top level SAM menu, use the Menu Up/Down keys to highlight the OPTIONS sub-menu.

3. To enter the OPTIONS sub-menu, press the Menu Left or Menu Right key.

4. To select an option code or option byte, use the Menu Up or Menu Down keys on the remote control.

5. Use the Menu Up/Down keys to highlight a feature bit, then use the Menu Left/Right keys to toggle the

feature bit ON or OFF. (Remember that when feature BIT values are changed, the feature BYTE values

will automatically change.)

6. To change a feature byte, use a 3 digit entry on the remote control. (Remember that when feature BYTE

values are changed, the feature BIT values will automatically change.)

Note: Option byte values must be entered in three-digit form.

Example 1: ”87“ would be entered as ”0-8-7“

Example 2: ”4“ would be entered as ”0-0-4“

7. Any changes made to either the feature bits or feature bytes must be stored to take effect. To store the

values:

a. Use the Menu Up/Down keys to highlight STORE.

b. Press the Menu Right key to store the new option settings. The STORE text will briefly

change to STORED.

c. When the text changes back to STORE, press the Menu button to return to the top level SAM

menu. The changes are now stored in NVM.

d. To return to the top level SAM menu without storing changes, simply press the Menu button

without performing the STORE procedure.

8. If no changes to the feature bits or feature bytes are required, press Menu to exit the OPTIONS sub-menu

and return to the top level SAM menu.

Options Table

ptions simultaneously with

one byte (when the option byte is highlighted, the value can be keyed

Refer to the Chassis Feature Listing to see the values for Option Bytes

se values can be used to set the option package for a

Option Code Option Name Value Range

AB Antenna A/B Control OFF/ON

AD Audio Control OFF/ON

AK Auto Standby OFF/ON

AL Auto Volume Limiter OFF/ON

AN Auto Standby No Picture OFF/ON

AV Muliple A/V Inputs OFF/ON

CM Compress 16 x 9 OFF/ON

CS Customer Service Mode OFF/ON

DN Dynamic Noise Reduction OFF/ON

EX Expand 14 x 9 OFF/ON

FM Mono/Stereo A/V OFF/ON

FT Fine Tuning OFF/ON

HO Hospitality Mode OFF/ON

IP Incredible Picture OFF/ON

PI PIP Control OFF/ON

PL Parental Lock OFF/ON

PT PIP Tuner OFF/ON

RL Remote Locator OFF/ON

SC Smart Clock OFF/ON

SO Number of A/Vs OFF/ON

SP Speaker On/Off OFF/ON

ST Auto Standby/Auto On OFF/ON

SU First Time Setup OFF/ON

CF Comb Filter OFF/ON

IM Incredible Picture Via Menu OFF/ON

VS Sync Slice Limiter OFF/ON

TM Timer OFF/ON

VC V-Chip On/Off OFF/ON

VU V-Chip Un-Rated OFF/ON

VN V-Chip No Rating OFF/ON

OB1 Option Byte 1 Option Bytes 1 through 7 are used to set 8 o

in with the numerical buttons on the remote control).

Values = 0 – 255

1 through 7. The

particular model.

OB2 Option Byte 2

OB3 Option Byte 3

OB4 Option Byte 4

OB5 Option Byte 5

OB6 Option Byte 6

OB7 Option Byte 7

Loading...

Loading...