Philips 241P4QPYKES/00, 241P4QPYKEB/00(AP), 241P4QPYKES/93, 241P4QPYKES/00(AP), 241P4QPYKEB/00 Service Manual

inch FHD

24

LCD Colour Monitor

TFT

241P4QPYKES/00

241P4QPYKES/00(AP)

241P4QPYKES/93

241P4QPYKEB/00

241P4QPYKEB/00(AP)

Chassis:

MERIDIAN 4

TABLE OF CONTENTS

Description Page

Important Safety Notice--------------------------------------2

Technical Data--------------------------------------------- ----3

Installation----------------------------------------------------4~5

Troubleshooting---------------------------------------------6~7

On Screen Display------------------------------------------8~9

Lock/unlock, Aging,Factory mode-------------------------10

Philips Pixel Defect Policy

Mechanical Instructions ------------------------------12~14

Color adjustment --------------------------------------------15

FAQs (Frequently Asked Questions)---------------16~17

Electrical instruction ----------------------------------18~19

Service Tool-----------------------------------------------20~21

DDC Instructions & Serial Number -----------------22~28

DDC DATA -----------------------------------------------29~30

Firmware Upgrade for CPU-

Failure Mode Of Panel -

Wiring

Diagram----------------------------------------------34

ANY PERSON

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

EQUIPMENT CONTAINING

---------------------------------11

------------------------31~32

-----------------------------------33

SAFETY NOTICE

ATTEMPTING TOSERVICE THIS CHASSIS

HIGH VOLTAGES.

Horizontal frequencies

Description Page

Block Diagram------------------------------------------------35

Scaler Diagram & C.B.A. ------------------------------36~41

Power

Diagram

Control Diagram & C.B.A. -----------------------------45~46

LED

Diagram & C.B.A.--------- -------------------------47~48

IR

Diagram & C.B.A.--------- -------------------------49~50

Jack

Diagram & C.B.A.--------- -------------------------51~52

Tx

Diagram & C.B.A.--------- -------------------------53~54

USB

Diagram & C.B.A.--------- -------------------------55~56

General product specification------------------------57~74

Exploded V iew -----------------------------------------------75

Spare/ arts List-------------------------76

Recommended P

PCBA photos---------------------------------------------------77

Repair tips-------------------------------------------------78~79

Repair Flow chart----------------------------------------80~81

Safety Test Requirments------------------------------------82

BZL&CTRL BD Replace ---------------------------------------83

Auto Color & User reset

MUST FAMILIARIZE

TO BE USED WHEN

& C.B.A.

HIMSELF

------------------------------42~44

--------------------------------84~85

WITH THE

SERVICING ELECTRONIC

30-83kHz

CHASSIS

A SEPARATE

CAUTION:

Published by Philips Consumer Lifestyle Copyright reserved Subject to modification JFeb 24 2012

USE

REFERTO BACK COVER FOR

ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

IMPORTANT SAFETY GUIDELINES

GB

2 241P4QPYK LCD

Important Safety Notice

Proper service

operation of all Philips Consumer Electronics Co

equipment. The service procedures

described in this service manual a

performing service ope

operations require the useof tools speciall y designed

purpose. The spe

recomm ended.

It is im portant to note t hat this m anual c ontains various

CAUTI ON

order to m inimize the risk of personal injury to servic

personnel . The possibility exists th

methods may damage the equipment

underst and that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. Phil

advise the servic etrade of all conceivable ways i n w

service might be done or of the possible hazardous

consequences of each way. Consequently,Philips has not

undertaken any suc

who uses a servi ce procedure or tool which is not

recommended by Philipsmust f

neither his saf ety nor the safeoperation of the equipment will

be jeopardized by the servi

* * Hereafter throughout this manu

Electronics Co mpany will be referred to as Philips

and repair is important

rations

cial tools should be used w

S and NOTICES which should be

ips

could not poss ibly know, evaluate and

h broad evalua

ce method sel

to the sa

commended by

re

re eff

.Someof

at im

. It is also important t

ti

on. Accordingly

irst sati

al,

PhilipsConsumer

fe,

reliable

mpany

Phil

ect

ive met hod

these servic

hen and as

carefully read in

proper

sfy

himself thoroughly that

ect ed.

servi

.

,

**

e

e

ce

hic

sof

for the

h

ips and

o

FOR PRODUCTS CONTAINING LASER :

DANGER - Invisible laser radiation when open.

MANUF

O BEAM.

in

OF THIS

ACTURER'S

THIS

AVOID DIRECT EXPOSURE T

CAUTION - Use of controls or adjustments or

performance of procedures other than

those specified herein may result

hazardous radiation exposure.

CAUTION - The use of optical instruments with this

product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY

PRODUCT, USE ONLYORIGINAL

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR P

NUMBERS IN THE PAR

SERVICE MANUAL.

TS LIST SECTION OF

ART

WARNING

Critical components havingspecial safety characteristics are

identified with a by the Ref. No. in the parts list and

enclosed within a broken line

(where several critical co

along with t

exploded vie

Use of substitute replacement parts w hic h do no

same speci fied safety characteristics may create

or other hazards .

Under no cir cumstances should th

modified or altered without written permission from Philip

Philips assumes no liabilit

any unauthorized modification of design.

Servicer assumes all liability.

he saf e

ws.

mponents are grouped in

mbol on the schematics

y

ty s

e original

y, express or implied, arising

one area)

or

t have the

shock,

design be

fire,

out of

Take care during handling the LCD module with backlight

unit

- Must mount the module using mounting holes arranged in four

corners.

- Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

- Do not scratch or press on the panel with any sharp objects, such

as pencil or pen as this may result in damage to the panel.

- Protect the module from the ESD as it may damage the electronic

circuit (C -MOS).

Make certain that treatment body are grounded through

-

wrist band.

- Do not leave the module in high temperature and

humidity for a long time.

s.

- Avoid contact with water as it may as hort circuit within the module.

If the surface of panel become dirty

-

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

, please wi

in areas of high

pe it off with a soft

Technical Data

q

AUO

Type NR. : AUO M240HW02 V6

Resolution : 1920 x 1080 (FHD)

Outside dimensions

Pitch (mm) : 0.27675mm x 0.27675mm

Color pixel arrangement

Display surface

Color depth

Backlight : WLED

Active area (W x H) : 531.36mm (H) ×298.89 (V) mm

View angle (CR=10) :>=178/178 for H/V

Contrast ratio

White luminance : 250 (center,Typ)

Color gamut

Scanning frequencies

Hor.: 30 – 83 K Hz

Ver.: 50 - 76 Hz

Analog:

RTD 2486RD Integrated 8-bit triple-channel 210MHz ADC/PLL

(over 2048x1152@60hz input), High resolution true 64 phase

ADC PLL, YPbPr support up to HDTV 1080p resolution.

Digital:

DVI Single link on-chip TMDS receiver up to 165MHz; DP

Support 4 lanes digital input, each lanes speed up to 1.62Gbps

Hz and 2.7Gbps Hz

Power range: FULL RANGE POWER SUPPLY 90 – 264 VAC

Ambient temperature: 0 q

Power input connection

Power cord length : 1.8 M

Power cord type : 3 leads power cord with protective earth plug.

Power management

Mode HS

VSYNCVideo Pwr-cons.Indication Rec.

YN

C

Power-On On On Active

Standby Off Off Blanked

DC Power

Off

ġġ N/A < 0.2 W LED Off ġ

: 556.0(H) x 323.2(V) x 11.5(D) mm

: 1920 horiz. by 1080 vert. Pixels. RGB

stripe arrangement

: Hard coating (3H), Anti-glare treatment

of the front polarizer

: 16.7 M colors 8-bit with A-FRC, 16.7M

colors

: 5000:1(Typ.)

:72%(Typ.)

C-40qC

time

<52W(ma

x.)

EPA5.0 <

33.97W

< 0.2W

White LED

Blinking white

LED

Period 1sec on

3sec off

--

<3s

241P4QPYK LCD 3

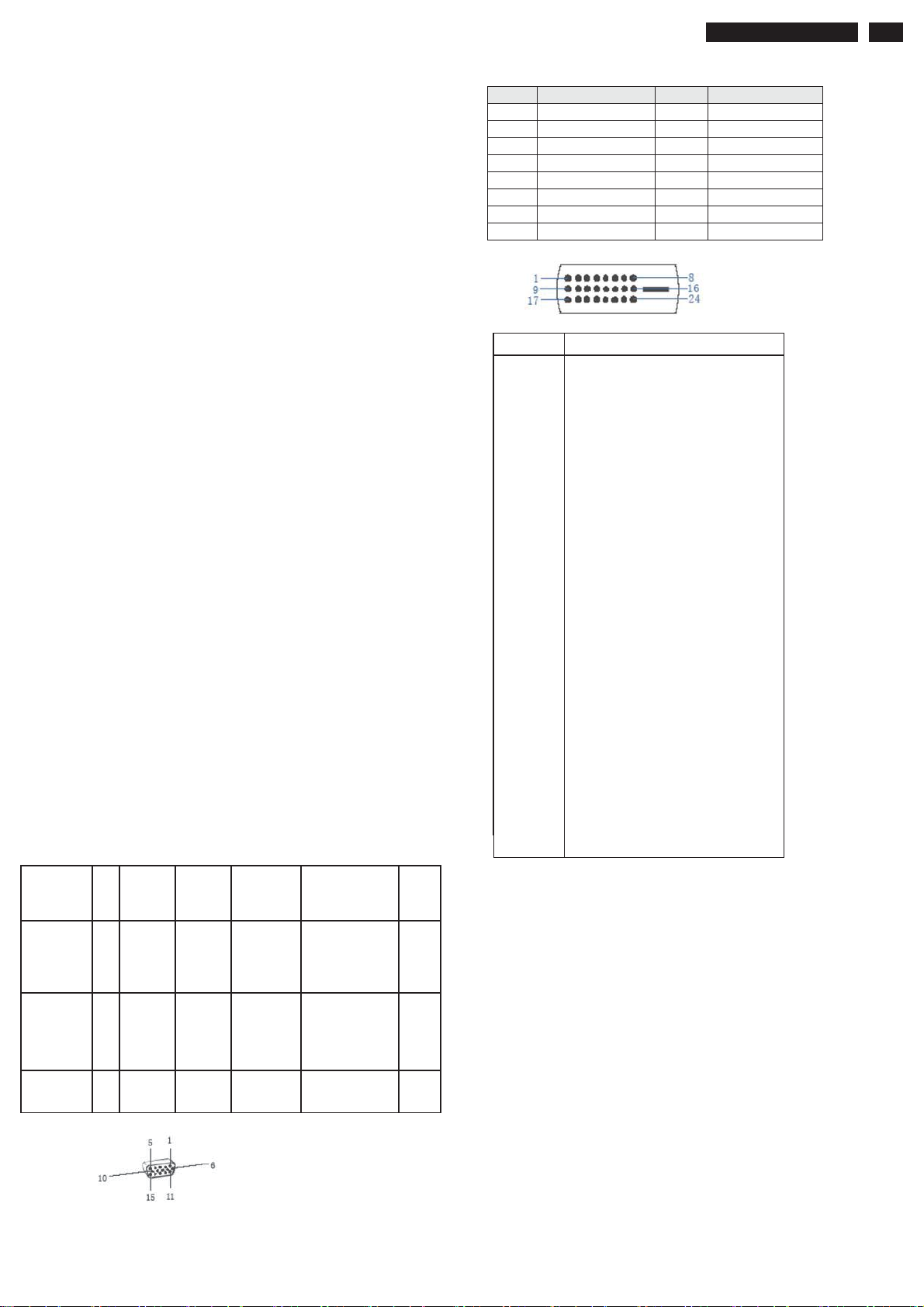

PIN No. SIGNAL PIN No. SIGNAL

1 Red 9 DDC +3.3V or +5V

2 Green/ SOG 10 Logic GND

3 Blue 11 Sense (GND)

4 Sense (GND) 12 Bi-directi onal data

5 Cable Detect (GND) 13 H/H+V sync

6 Red GND 14 V-sync

7 Green GND 15 Data clock

8Blue GND

Pin No. Description

1 T.M.D.S. data22 T.M.D.S. data2+

3 T.M.D.S. data2 shield

4 No Connect

5 No Connect

6 DDC clock

7 DDC data

8 No Connect

9 T.M.D.S. data110 T.M.D.S. data1+

11 T.M.D.S. data1 shield

12 No Connect

13 No Connect

14 +5V Power

15 Ground (for +5V)

16 Hot plug detect

17 T.M.D.S. data018 T.M.D.S. data0+

19 T.M.D.S. data0 shield

20 No Connect

21 No Connect

22 T.M.D.S clock shield

23 T.M.D.S. clock+

24 T.M.D.S. clock-

ġġ

Susceptibility of display to external environment

Operating

- Temperature : 0 to 40 degree C

- Humidity : 80% max

- Altitude :

- Air pressure : 600-1100 mBAR

Storage

- Temperature : -20 to 60 degree C

- Humidity : 95% max

-Altitude :0-12192m

- Air pressure : 300-1100 mBAR

Note: recommend at 5 to 35qC, Humidity less than 60 %

0-3658m

4 241P4QPYK LCD

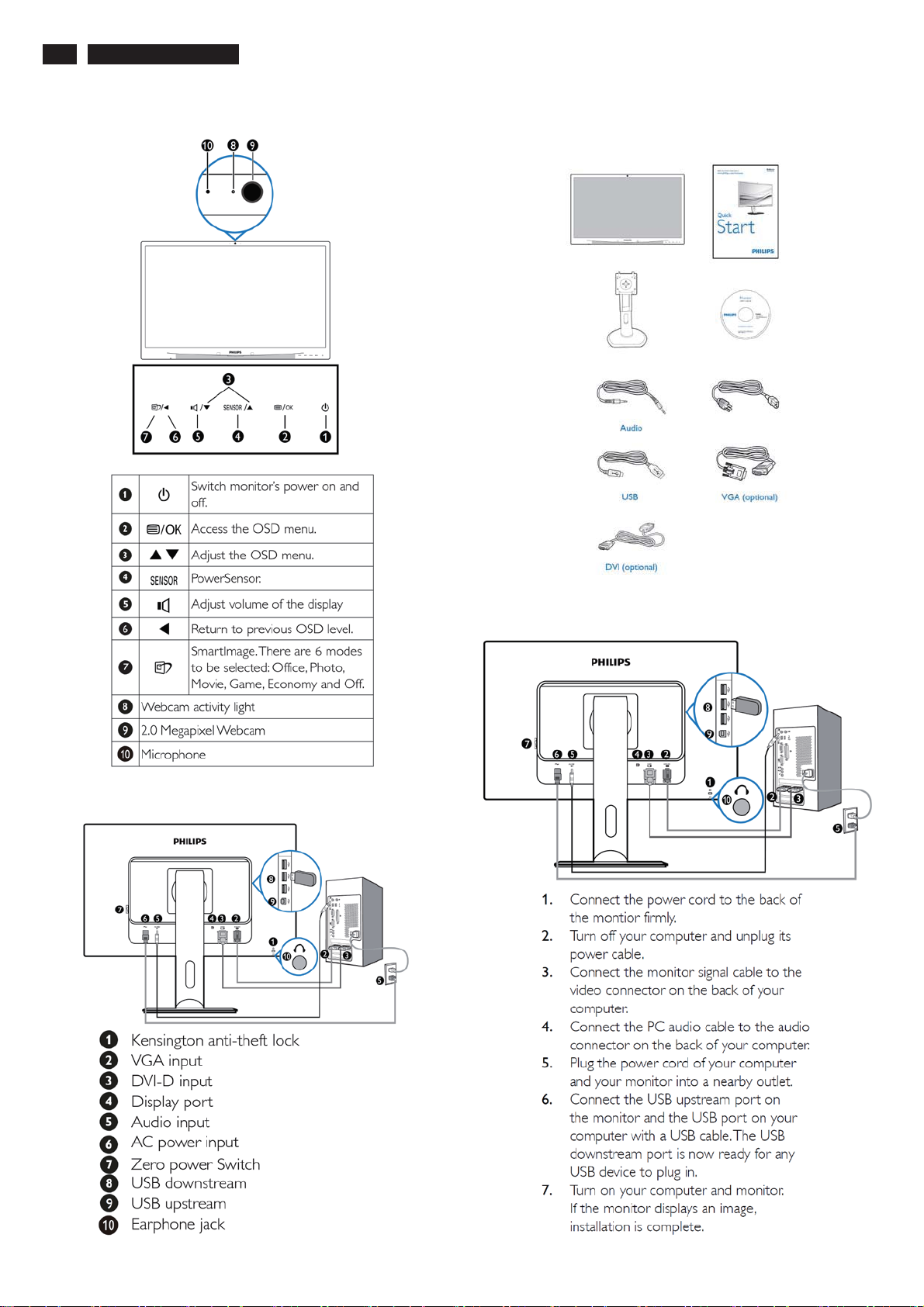

Installation

Front View Product Description

Accessory Pack

Unpack all the parts

Rear View

Connecting to Your PC

1) Connect the power cord to the back of the monitor firmly.

(Philips has pre-connected VGA cable for the first installation.

ġ

241P4QPYK LCD 5

ġ

Troubleshootingġ

6 241P4QPYK LCD

Troubleshooting

On-Screen Display

ġ

ġ

ġ

241P4QPYK LCD 7

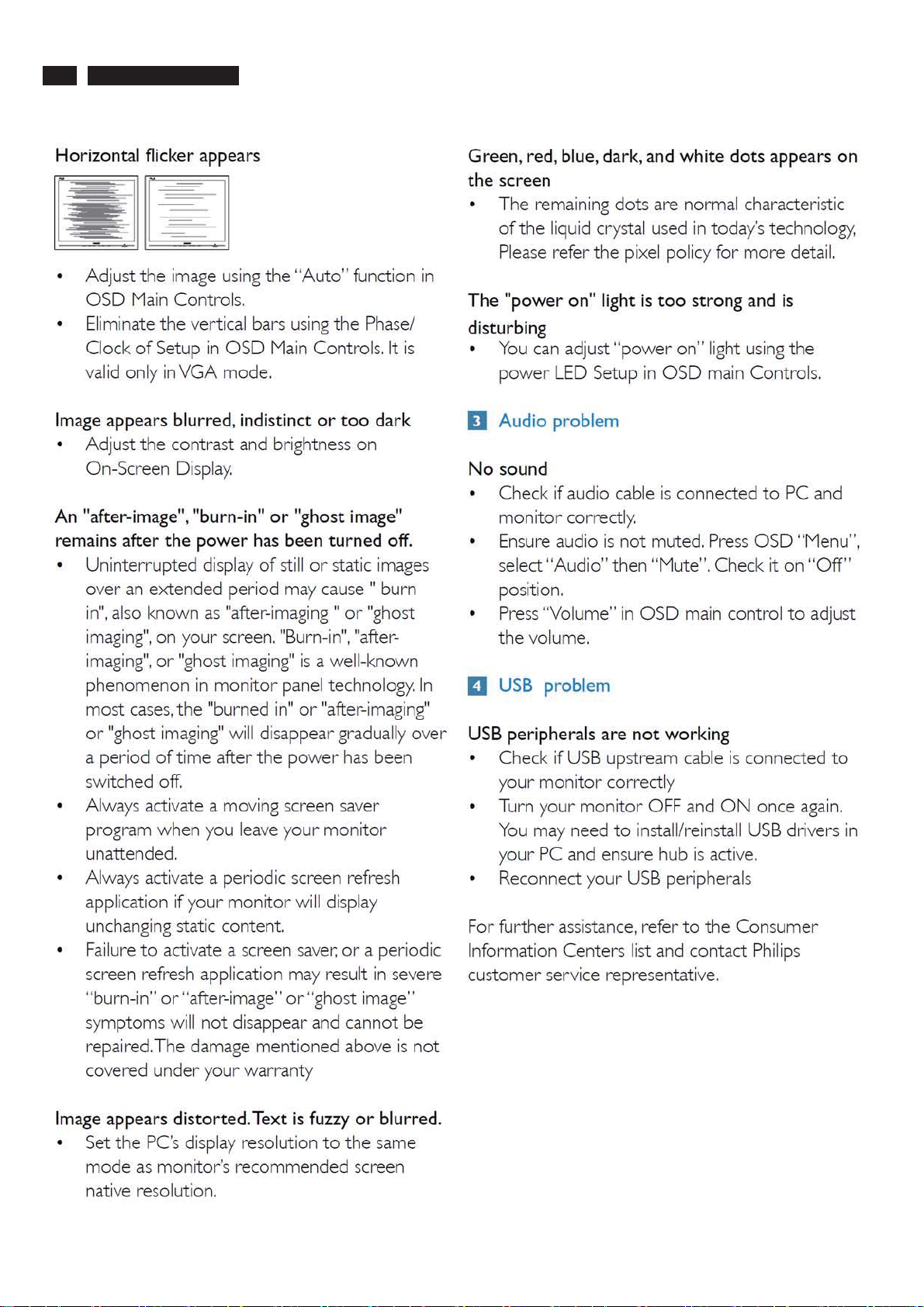

Description of the On Screen Displayġ

What is the On-Screen Display?

On-Screen Display (OSD) is a feature in all Philips LCD monitors. It allows an end user to adjust screen performance or

select functions of the monitors directly through an on-screen instruction window. A user friendly on screen display

interface is shown as below :

ġ

Basic and simple instruction on the control keys.

In the OSD shown above users can press buttons at the front bezel of the monitor to move the cursor, to

confirm the choice or change.

ġ

ġġ

8 241P4QPYK LCD

ġ

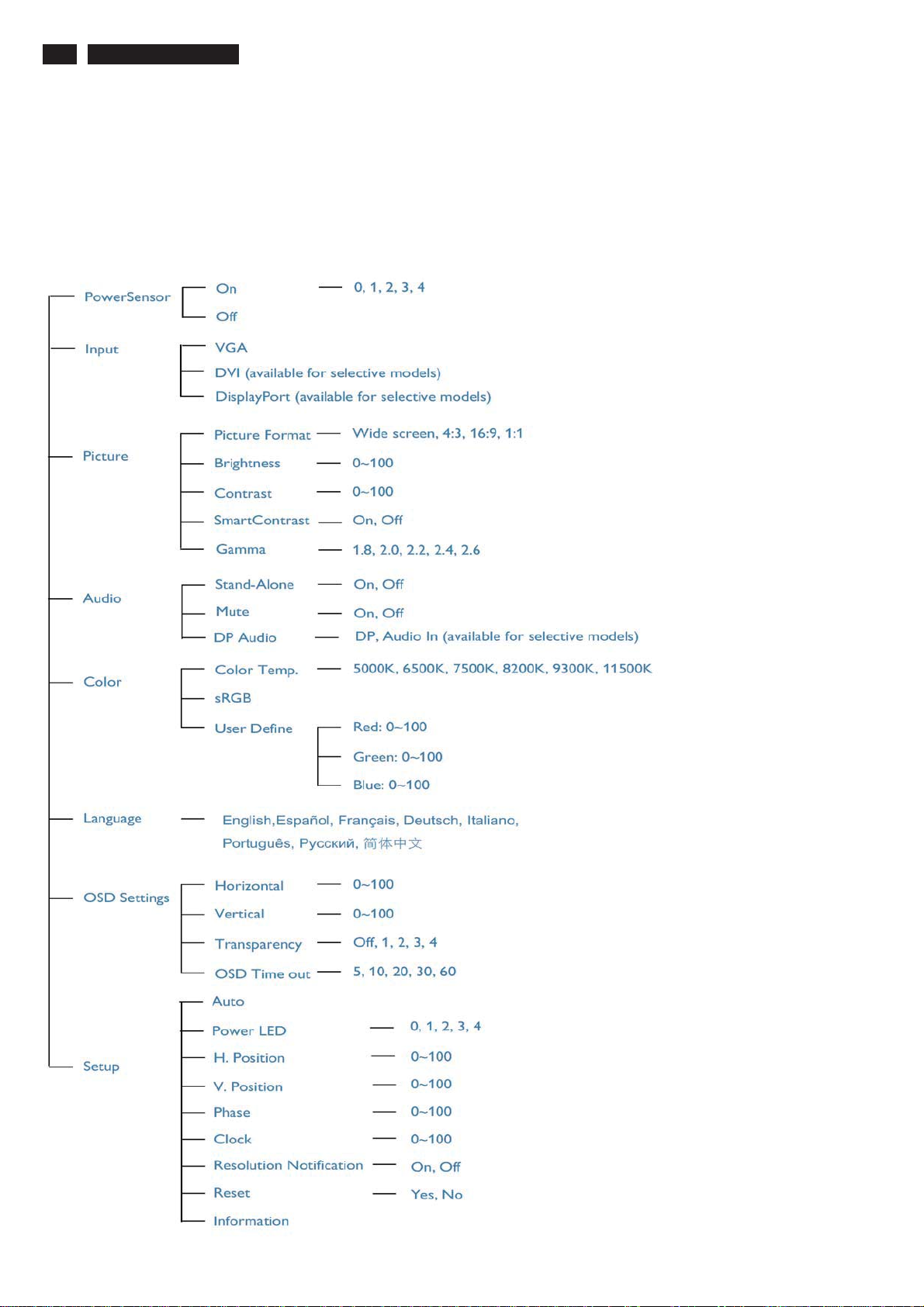

On-Screen Display

The OSD Treeġ

Below is an overall view of the structure of the On-Screen Display. You can use this as a reference when you want to work

your way around the different adjustments later on.

ġ

ġ

/

/RFN8QORFN$JLQJ)DFWRU\0RGH

241P4QPYK LCD 9

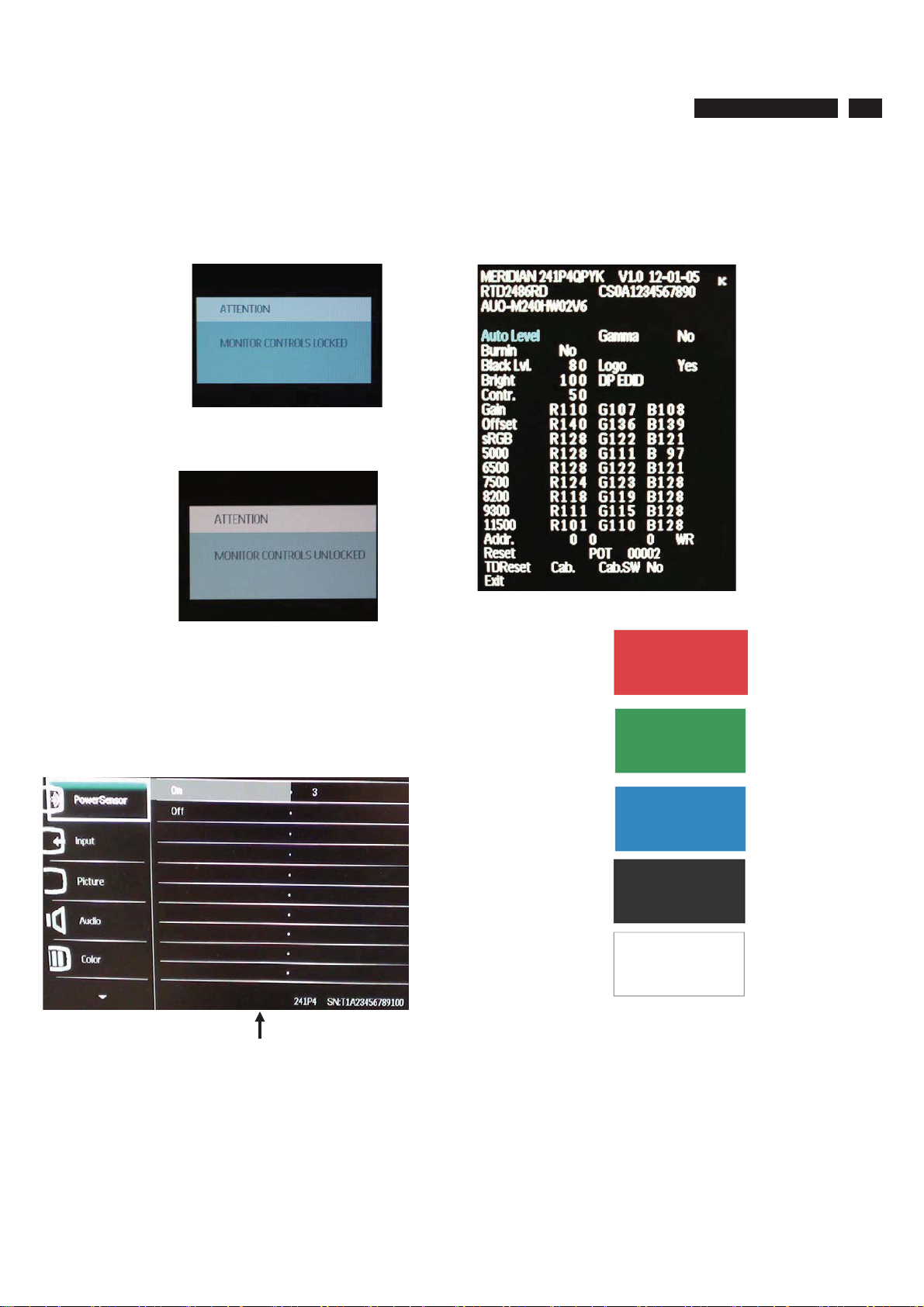

To lock/unlock OSD FUNCTION(User Mode)

The OSD function can be locked by pressing"OK"button(1) for more than 10

seconds, the screen shows following windows for 4 seconds. Every time

when you press"OK" button, this message appears on the screen

automatically .

Unlock OSD function

Unlocked OSD function can be released by pressing "OK" button for more

than 10 seconds again.

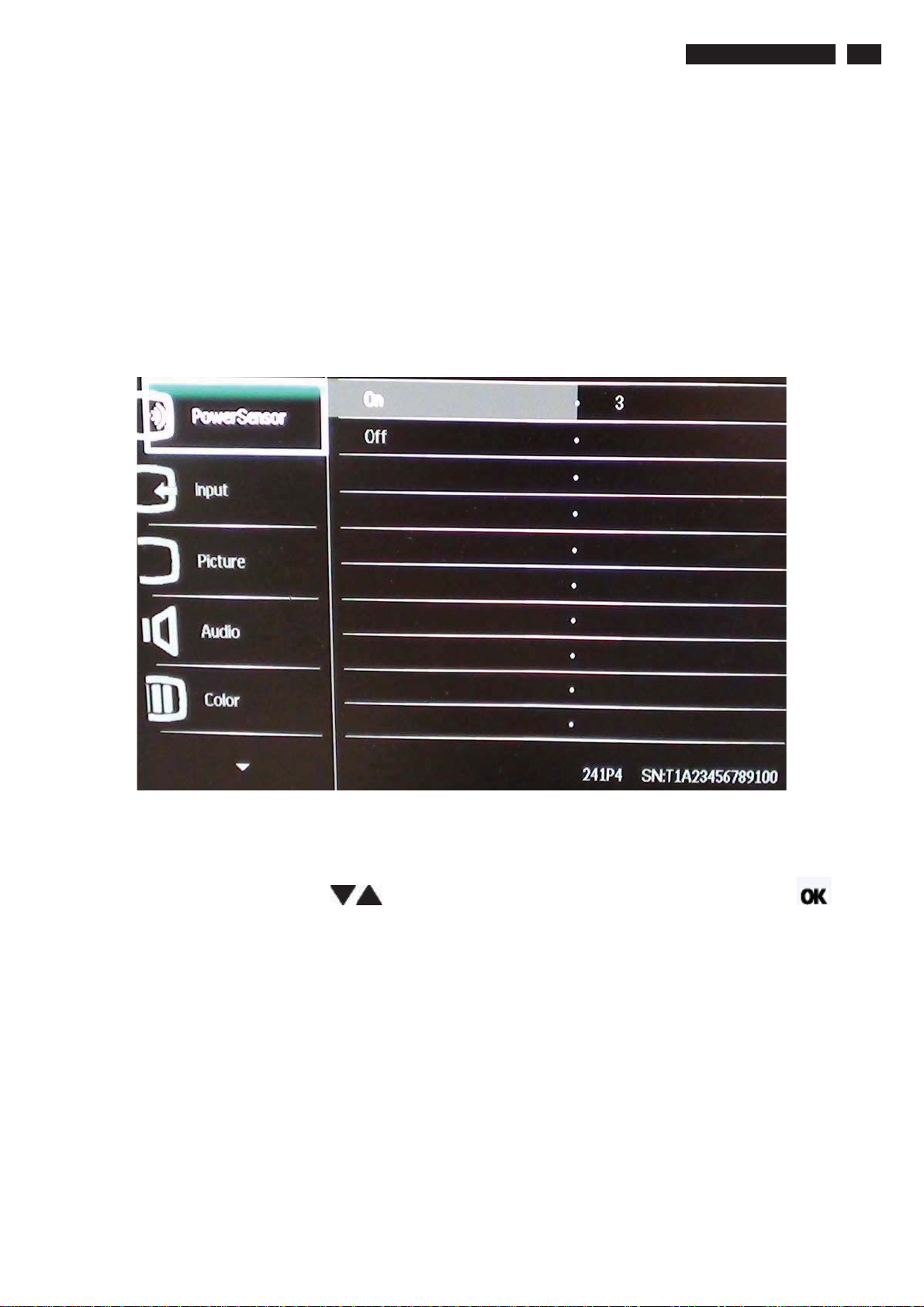

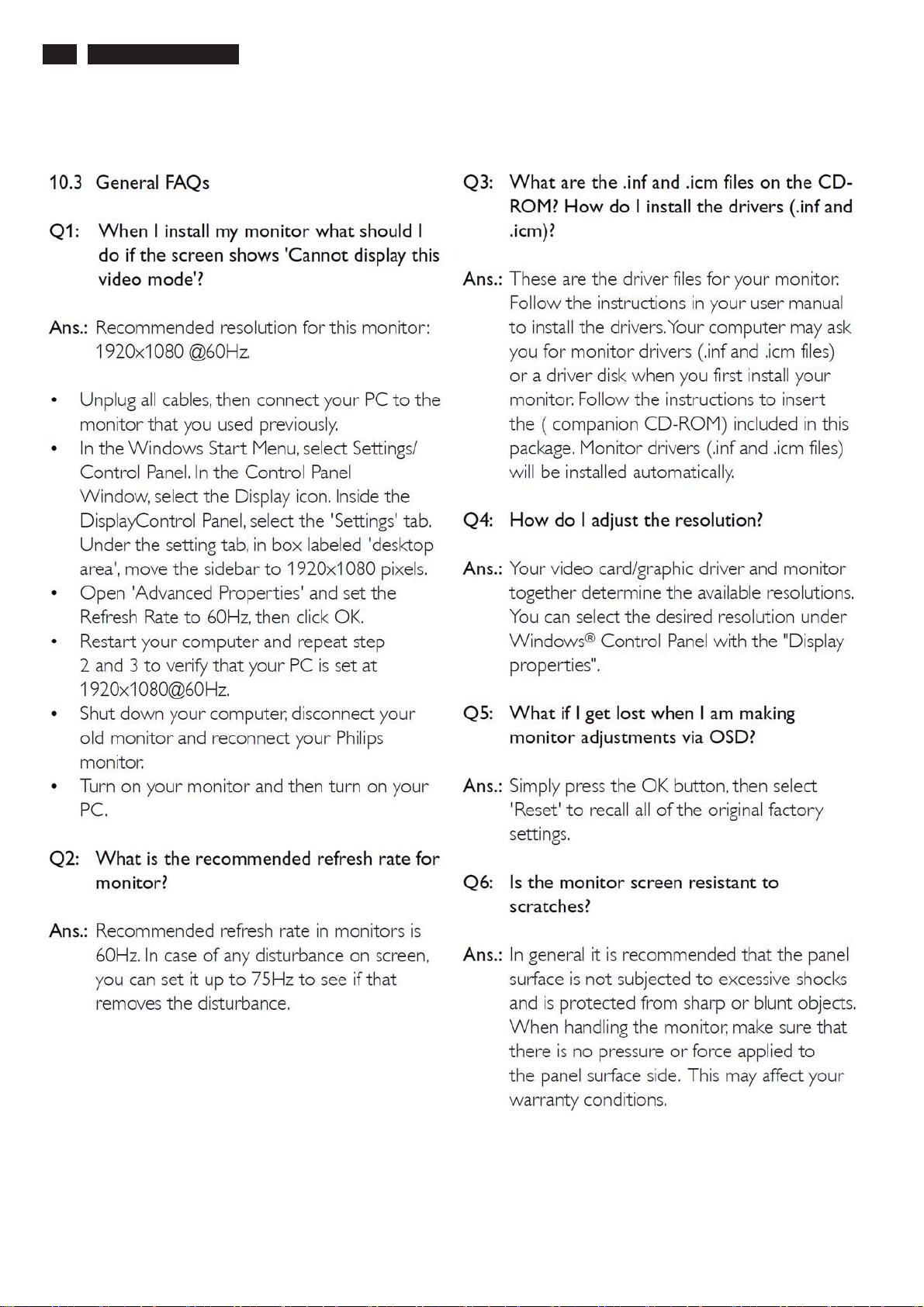

$FFHVV)DFWRU\0RGH

1). Turn off monitor.

2).[Push "EXIT" & "MENU" buttons at the same time and hold them]+[Press

"power" button until comes out "Windows screen" ]=> then release all

buttons

3).Press "MENU" button, wait until the OSD menu with Characters

"MERIDIAN 241P4QPYK V1.0 2012-01-05” (below OSD menu) come on

the Screen of the monitor.

$FFHVV$JLQJ0RGH

Step 1 : Access Factory Mode then enter Factory Menu.

Step 2 : By pressing " UP" and " DOWN " key to Burni ng Icon. Press

"MENU then press " UP" and "DOWN " key to turn on Aging Mode.

Step 3 : Disconnect interface cable between Monitor and PC.

After 3 seconds,

bring up:

Factory Mode indicator

Factory Menu

Cursor can move on gray color area

Hot key function: by pressing " UP " and " DOWN " key Simultaneously at

User Mode (or Factory Mode) (PS: The Of fset R G B function can be used

on reduce or eliminate snowy noise on the background when the resolut i on

of video signal is 1280*1024vertical 75Hz. Slight l y increase or decreas e the

value until snowy noise completely disappear .

repeatly

Connect Signal cable again=> go back to normal display

10 241P4QPYK LCD

ġ

ġ

ġ

ġ

ġ

ġ

ġ

ġ

Philips Pixel Defect Policyġ

Philips' Flat Panel Monitors Pixel Defect Policy

Philips strives to deliver the highest quality products. We use some of the

industry's most advanced manufacturing process es and practice stringent

quality control. However, pixel or sub pixel defects on the TFT LCD panels

used in flat panel monitors are sometimes unavoidable. No manufacturer

can guarantee that all panels will be free from pixel defects, but Philips

guarantees that any monitor with an unacceptable number of defects will be

repaired or replaced under warranty. This notice explains the different types

of pixel defects and defines acceptable defect levels for each type. In order

to qualify for repair or replacement under warranty, the number of pixel

defects on a TFT LCD panel must exceed these acceptable levels. For

example, no more than 0.0004% of the sub pixels on a 19" XGA monitor may

be defective. Furthermore, Philips sets even higher quality standards for

certain types or combinations of pixel defects that are more noticeable than

others. This policy is valid worldwide.

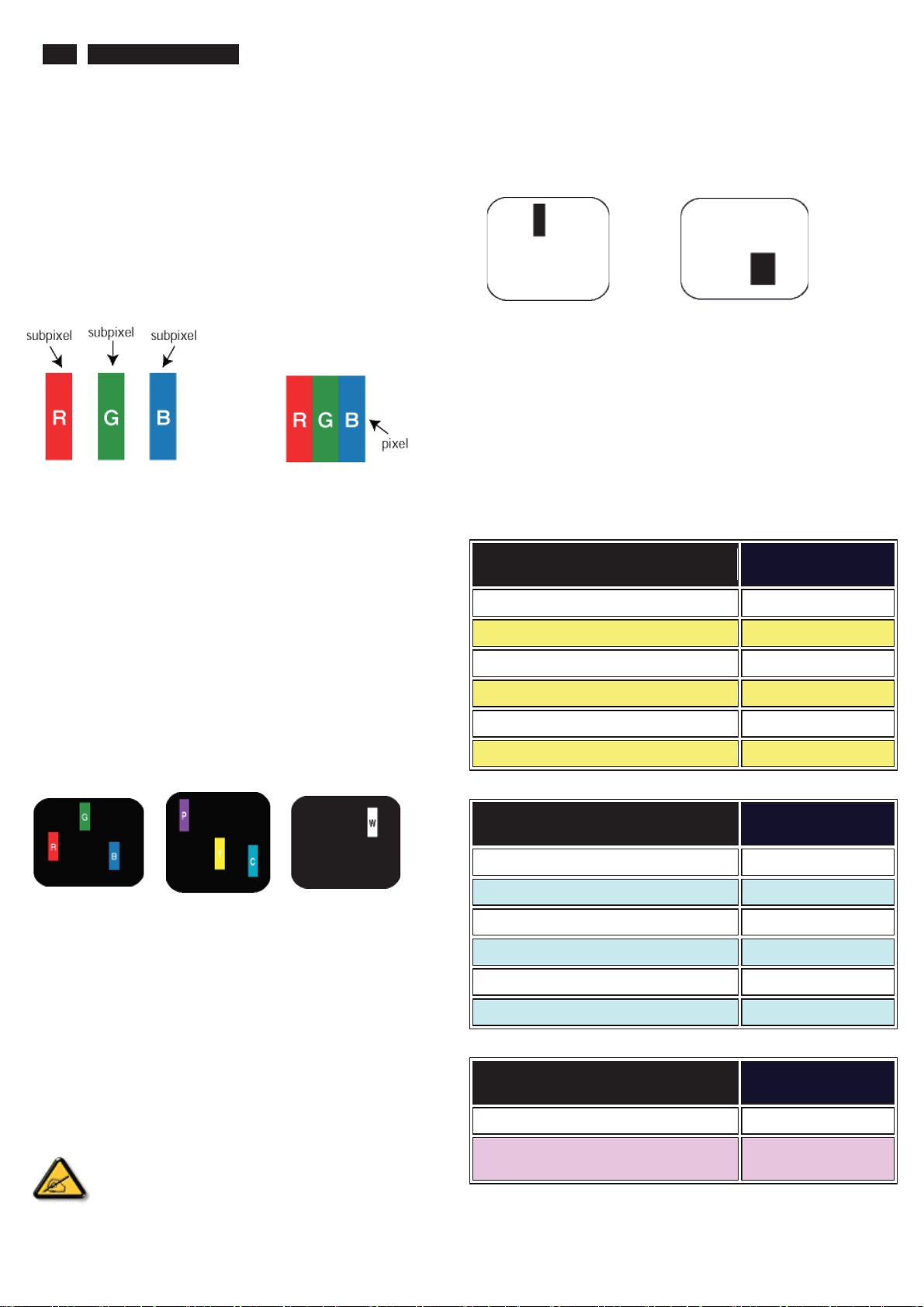

Pixels and Sub pixels

A pixel, or picture element, is composed of three sub pixels in the primary

colors of red, green and blue. Many pixels together form an image. When all

sub pixels of a pixel are lit, the three colored sub pixels together appear as a

single white pixel. When all are dark, the three colored sub pixels together

appear as a single black pixel. Other combinations of lit and dark sub pixels

appear as single pixels of other colors.

ġTypes of Pixel Defects

Pixel and sub pixel defects appear on the screen in different ways. There are

two categories of pixel defects and several types of sub pixel defects within

each category. ġ

Bright Dot Defects Bright dot defects appear as pixels or sub pixels that are

always lit or 'on'. That is, a bright dot is a sub-pixel that stands out on the

screen when the monitor displays a dark pattern. There are the types of

bright dot defects:ġ

Black Dot Defects Black dot defects appear as pi xels or sub pi xels that are

always dark or 'off'. That is, a dark dot is a sub-pixel that stands out on the

screen when the monitor displays a light pattern. These are the types of

black dot defects:ġ

ġ

One dark sub pixelġ Two or three adjacent dark sub pixelsġ

Proximity of Pixel Defects

Because pixel and sub pixels defects of the same type that are near to one

another may be more noticeable, Philips also specifies tolerances for the

proximity of pixel defects.

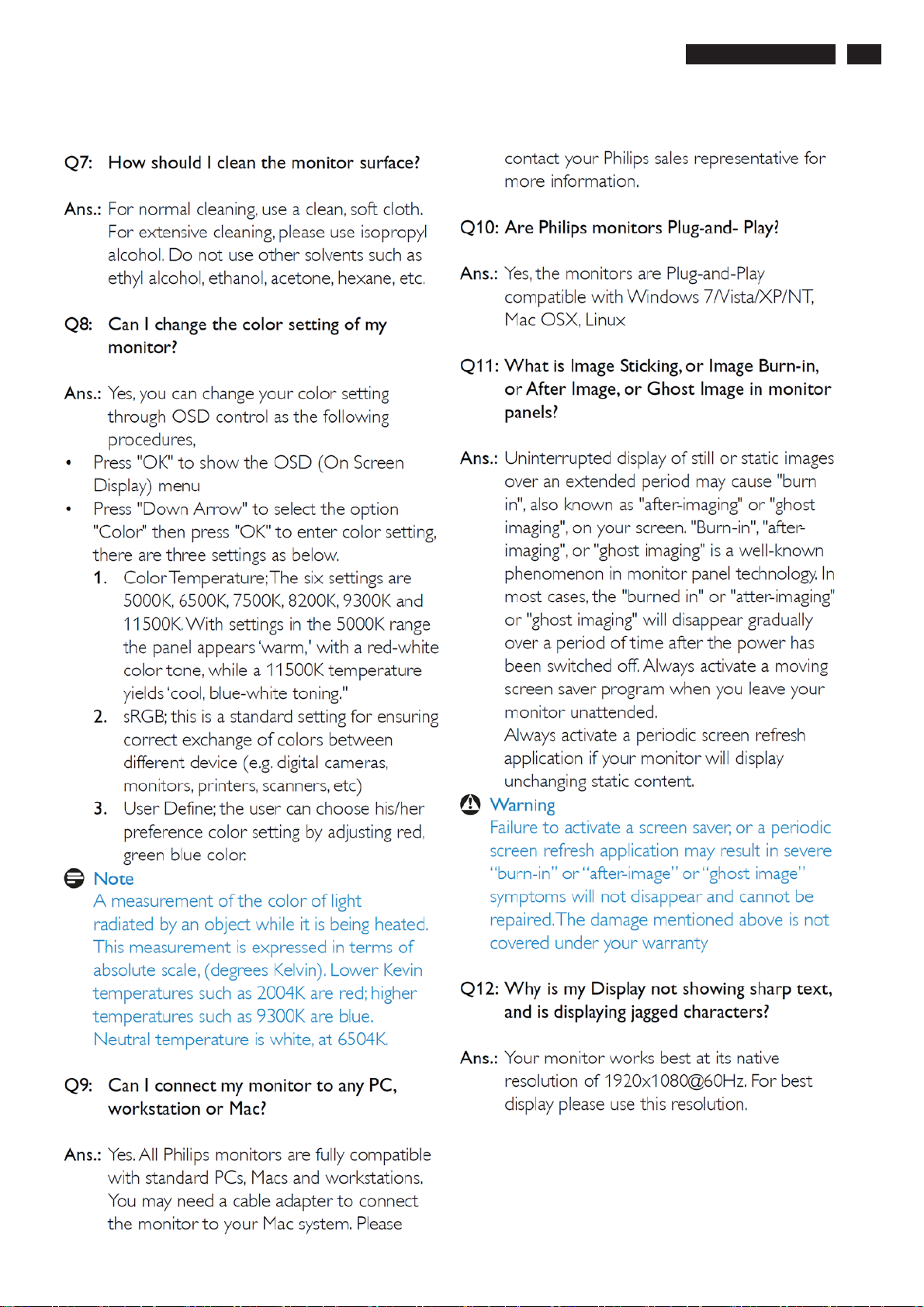

Pixel Defect Tolerances

In order to qualify for repair or replacement due to pixel defects during the

warranty period, a TFT LCD panel in a Philips flat panel monitor must have

pixel or sub pixel defects exceeding the tolerances listed in the following

tables.ġ

BRIGHT DOT DEFECTSġ

MODELġ

1 lit subpixelġ 3ġ

2 adjacent lit subpixelsġ 1ġ

3 adjacent lit subpixels (one white pixel)ġ 0ġ

Distance between two bright dot defects*ġ >15mmġ

Total bright dot defects of all typesġ 3ġ

ġ

ACCEPTABLE

LEVEL ġ

241P4QPYKġ

One lit red, green or

blue sub pixelġ

A red or blue bright dot must be more than 50 percent bright er

than neighboring dots while a green bright dot is 30 percent

ġ

brighter than neighboring dots.ġ

ġ

Two adjacent lit sub

pixels:

- Red + Blue =

Purple

- Red + Green =

Yellow

- Green + Blue =

Cyan (Light Blue)!

ġ

Three adjacent lit sub

pixels (one white

pixel)ġ

BLACK DOT DEFECTSġ

MODELġ

ġ

1 dark subpixelġ 5or fewerġ

ACCEPTABLE

LEVEL ġ

241P4QPYKġ

2 adjacent dark subpixelsġ 2or fewerġ

3 adjacent dark subpixelsġ 0 ġ

Distance between two black dot defects*ġ >15mmġ

Total black dot defects of all typesġ 5or fewerġ

TOTAL DOT DEFECTSġ

MODELġ

Total bright or black dot defects of all

typesġ

Note:

* 1 or 2 adjacent sub pixel defects = 1 dot defect

ACCEPTABLE

LEVEL ġ

241P4QPYKġ

5or fewerġ

241P4QPYK LCD

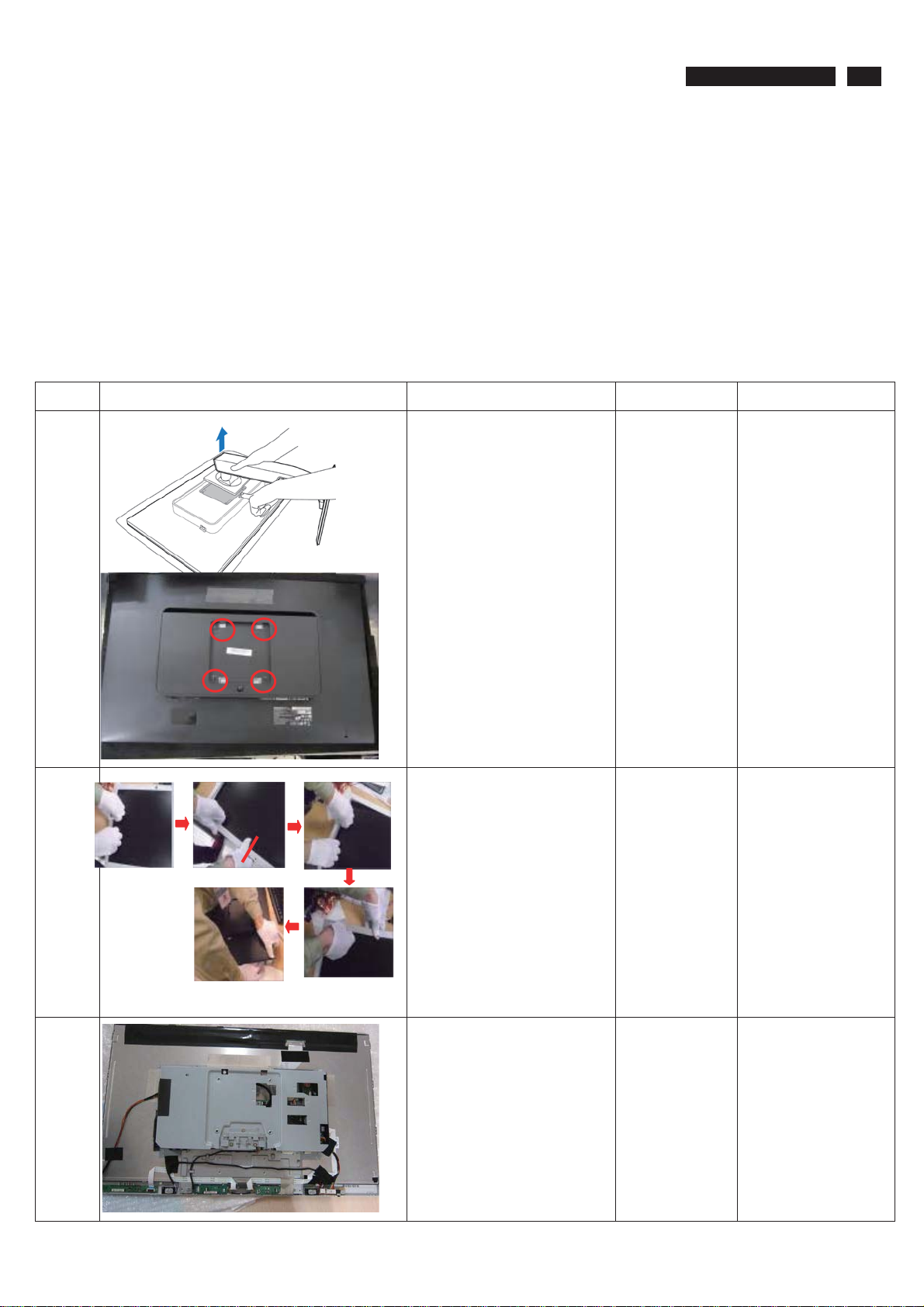

Mechanical Instruction

Preparation before disassemble

1.Clean the room for disassemble

2.Identify the area for monitor

3.Check the position that the monitors be placed and the quantity of the monitor ;prepare the area for material flow;

according to the actual condition plan the disassemble layout

4.Prepare the implement, equipments, materials as bellow:

1) Press-fixture

2) working table

3) Screw-driver

4) knife*1

5) glove

6) cleaning cloth

7) ESD protection

item picture Operation Tool Notes

11

1

2 Turn over the monitor ,

Disassemble the Stand.

While keeping the release

button pressed, tilt the base

and slide it out.

Disassembly 4 screws, Take

off the stand.

Bring the Bezel from the

monitor in sequence as left

picture

Screw-driver

When disassembly the

bezel ,

man must wear glove

The purpose is loose

3 Remove the RC cover

the BZL

12

g

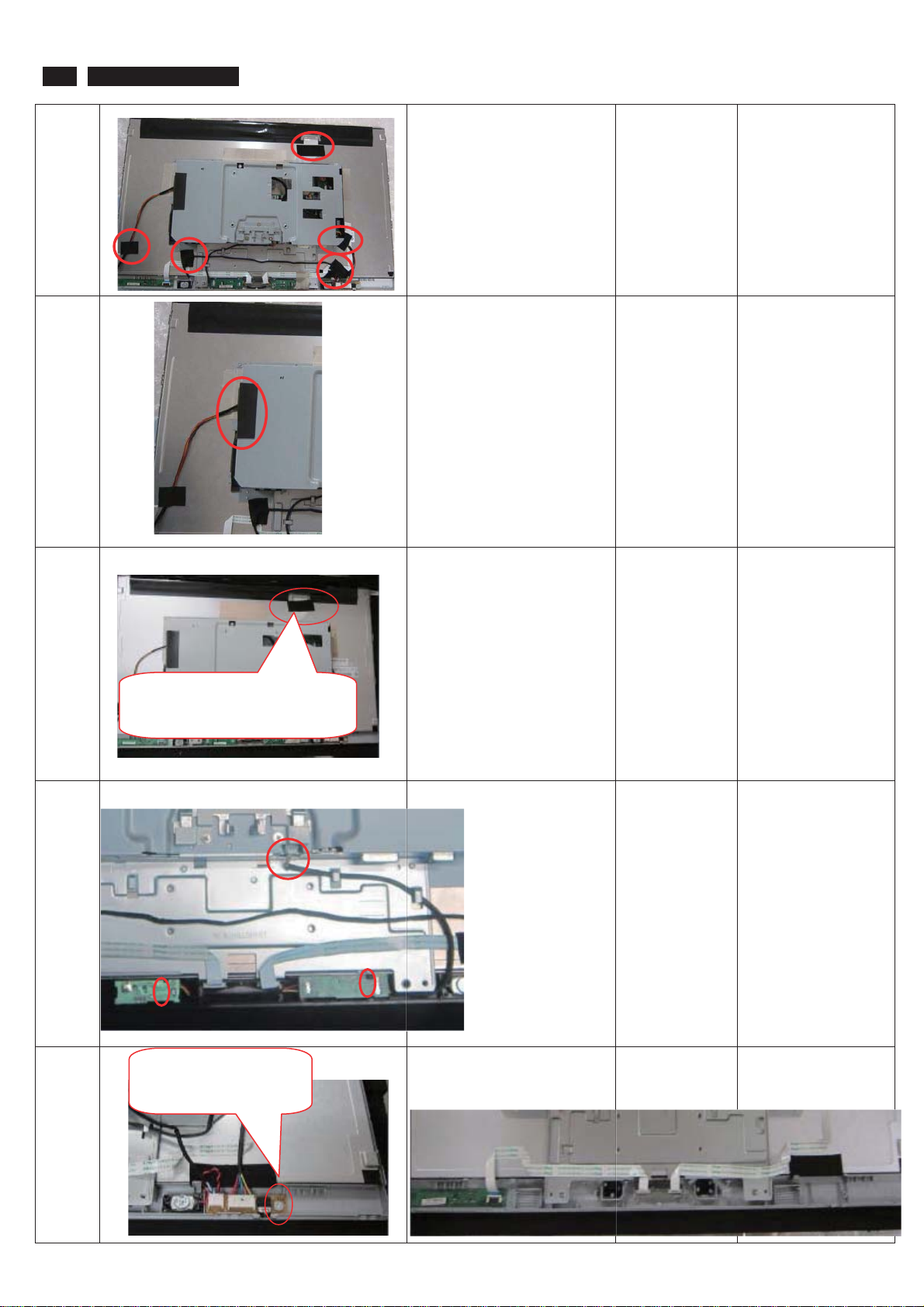

241B4QPYK LCD

4 Remove all the Tapes on each

cable

5 Disassembly the Mylar on

lamp cables and draw the lamp

cables

6 Unlock the FFC by using two

hands(see note).

The locking-latch of FFC

cable’s housin

7 Remove TX bd and IR bd

Please carefully use

two hands(one hand

presses the lockinglatch of FFC cable’s

housing, and at the

same time another

hand pulls out the FFC

cable.) for this step to

avoid from deforming

the terminals of

positive-locking type

FFC cable.

8 Remove speaker and remove

Disassembly the

Audio bd screw*1

the Audio BD

Screw-driver

9 Disassemble the Control bd

and LED bd out from the Bezel

10 Remove all the Tape on SHD

and the tape on Camera cable

241P4QPYK LCD

13

11 Disassemble the D-SUB DVI

and DP screws

12 Take the Main-BKT out from

the Bezel

13 Disassemble the Camera BD

screws*2 and then

Remove the Camera BD on

Bezel loose the Cable at the

Screw-driver

Screw-driver

same time

Remove tape on BKT

14 Turn over the Main-BKT and

Disassemble all the PCBA bd

screws*9

Screw-driver

14

241B4QPYK LCD

15 Remove the USB bd USB

cable and Camera cable

&DPHUDFDEOH

86%FDEOH

16 Remove the IF BD and Cables

on it

))&FDEOH

3RZHUEGFDEOH

3LQFDEOH

17 Remove the AC-Switch and all

cables on Power bd

18 Remove the AC-Switch cover

on Main-BKT

19 Take the PCBA out from

Screw-knife

Main-BKT and then put it on

the cushion

Color Adjustment

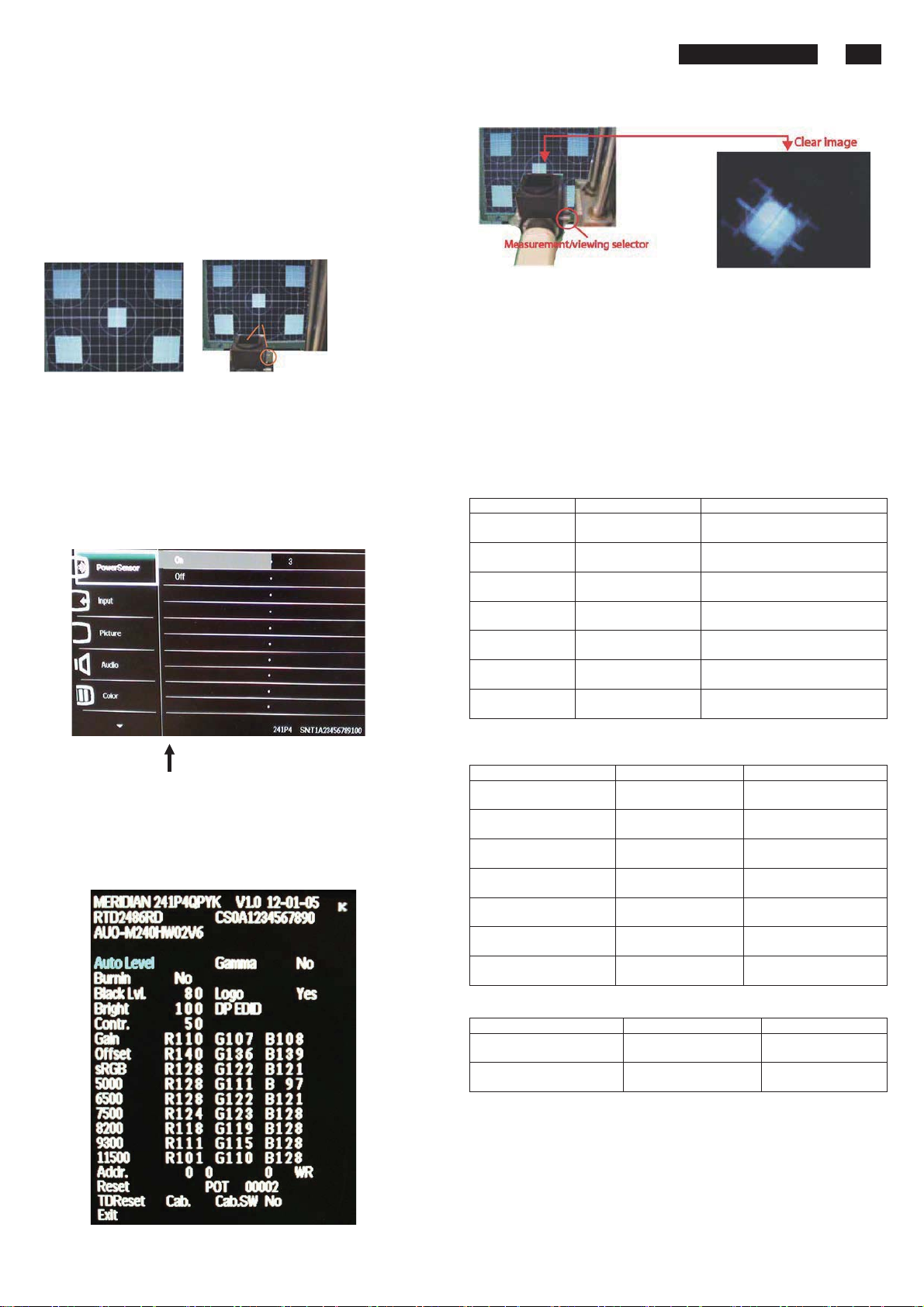

Alignment procedure

1. Turn on the LCD monitor

2. Turn on the Timing/pattern generator. S ee Fig. 1

3. Preset LCD color Analyzer CA-1 10

-Remove the lens protective cover of probe CA-A30.

-Set measuring/viewing selector to measuring position for reset

analyzer .(zero calibration) as Fig.2

- Turn on the color analyzer (CA-1 10)

-Press 0-CAL button to starting reset analyzer .

Fig. 1 Fig.2

4. Access Factory Mode

1). Turn off monitor.

2). [Push "AUTO" & "MENU" butt ons at the same time and hold them]

+[Press "power" button untill comes out "Windows screen" ]

=> then release all buttons

3).Press "MENU button, wait until the OSD menu with

Characters " MERIDIAN 241P4QPYK V1.0 2012-01-05” (below OSD

menu) come on the Screen of the monitor as shown in Fig3.

241P4QPYK LCD 15

Fig.5

5.Display

Press "UP" or "DOWN" button to select . Change the value

by "UP" or "DOWN" key until the X, Y co-ordinates as below

5.1

Color temperature adjustment

There are six factory pres et white color 11500K, 9300K, 8200K, 7500K,

6500K, sRGB, 5000K

Align by Philips PerfecTune (also called FGA) function.

Apply full white pattern, with brightness in 100 % position and the contrast

control at 50 % position.

The 1931 CIE Chromaticity (color triangle) diagram (x , y) coordinate for

the screen center should be:

Product specification

CIE coordinates (x,y)

11500K x = 0.270 ± 0.02

y = 0.281 ± 0.02

9300K x = 0.283 ± 0.02

y = 0.297 ± 0.02

8200K x = 0.291 ± 0.02

y = 0.306 ± 0.02

7500K x = 0.298 ± 0.02

y = 0.314 ± 0.02

6500K/sRGB x = 0.313 ± 0.02

y = 0.329 ± 0.02

sRGB x = 0.313 ± 0.02

y = 0.329 ± 0.02

5000K x = 0.345 ± 0.02

y = 0.357 ± 0.02

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

Factory Mode indicator

)LJ

4). Press button, then select factory mode indicator by "MENU" "LEFT"

or "RIGHT" button .Press"MENU" button to bring up submenu

windows as below:

Production alignment spec

CIE coordinates (x,y)

11500K x = 0.270 ± 0.006

y = 0.281 ± 0.006

9300K x = 0.283 ± 0.006

y = 0.297 ± 0.006

8200K x = 0.291 ± 0.006

y = 0.306 ± 0.006

7500K x = 0.298 ± 0.006

y = 0.314 ± 0.006

6500K/sRGB x = 0.313 ± 0.006

y = 0.329 ± 0.006

sRGB x = 0.313 ± 0.006

y = 0.329 ± 0.006

5000K x = 0.345 ± 0.006

y = 0.357 ± 0.006

Quality Inspection specification

CIE coordinates (x,y)

9300K x = 0.283 ± 0.015

y = 0.297 ± 0.015

6500K/sRGB x = 0.313 ± 0.015

y = 0.329 ± 0.015

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

)LJ

16 241P4QPYK LCD

FAQs (Frequently Asked Questions)

FAQs (Frequently Asked Questions)

241P4QPYK LCD 17

18 241P4QPYK LCD

Electrical Instructions

Electrical characteristics

1. Interface signals

1.1 D-Sub Analog

Input signal: Video, Hsync., Vsync

Video: 0.7 Vp-p, input impedance , 75 ohm @DC

Sync.: Separate sync TTL level , input impedance 2.2k ohm terminate

Hsync Positive/Negative

Vsync Positive/Negative

Composite sync TTL level, input impedance 2.2k ohm terminate

Sync on green video 0.3 Vp-p Negativ e (Video 0.7 Vp -p Posi tive)

1.2 1.2 DVI-D Digital (241P4QPY)

Input signal: Single TMDS link (Three channels: RX0-/+, RX1-/+, RX2-/+)

1.3 Display port (241P4QPY)

2. Interface

2.1 D-Sub Cable

Length : 1.8 M +/- 50 mm

Fix with monitor when packing, with transplant pin protective cover.

Connector type : D-Sub male with DDC2B pin assignments.

Blue connector thumb-operated jack screws

2.2 DVI Cable

The input signals are applied to the display through DVI-D cable.

Length : 1.8 M +/- 50 mm

Connector type : DVI-D male with DDC-2B pin assignments

White connector thumb-operated jackscrews

With transplant pin protective cover.

2.3 Display port cable

Length : Please refer to cable bundle summary file

Connector type : DP1.4

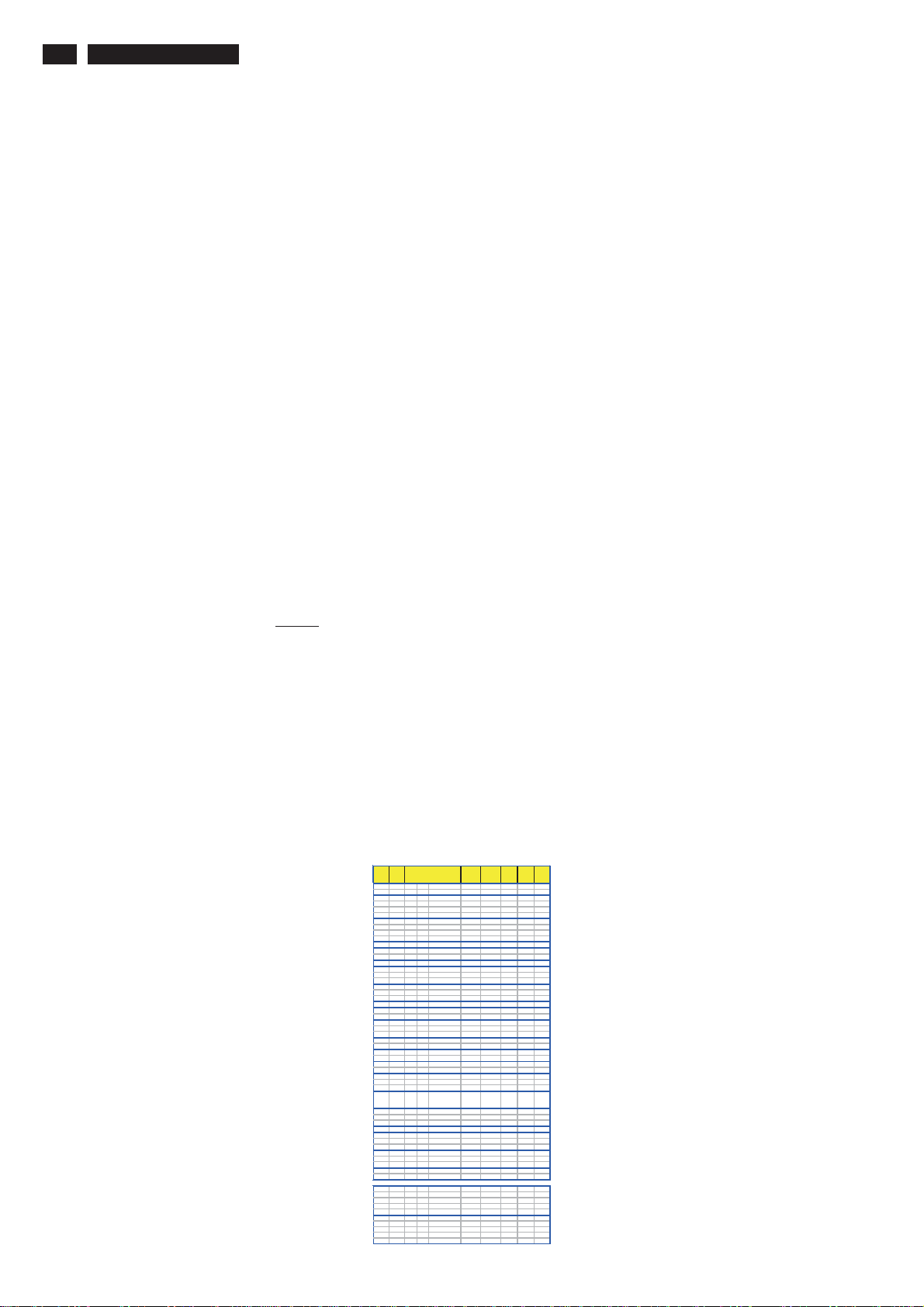

3. Timing requirement

3.1 Factory Preset mode definitions:

3.1.1 Perfect FOS while presenting those timings.

3.1.2 Will specify those timing in User's Manual

3.2 Preset mode definition:

3.2.1 Need to support those timings.

3.2.2 Perfect FOS after auto adjustment.

3.3 User mode

3.3.1 Can save those timing that not in Preset mode and can be showed

(not over scalar or Panel spec.)

3.3.2 It needs to reserve the 10 timings space in memory size.

3.3.3 Factory modes and preset modes are defined in the enclosed timing table file

type A cable-connector

241SB4 support

Support

Auto

Timing

DOS

1

DOS

2

DMT

3

MAC

4

DMT

5

DMT

6

DMT

7

DMT

8

DMT

9

DMT

10

MAC

11

CVT 960x720/60 55.750 44.671 59.721 748

12

CVT

13

14

DMT

15

DMT

16

DMT

17

CVT 1152x864/60 81.750 53.783 59.959 897

18

19

DMT

20

MAC

21

SUN 1152x900/66 94.500 61.846 66.004 937

22

23 SUN 1152x900/76 108.000 71.809 76.149 943 p / p

CVT

24

CVT

25

CVT

26

DMT 1280x768/60 79.500 47.776 59.870 798

27

DMT

28

CVT 1280x800/60 83.500 49.702 59.810 831

29

CVT

30

DMT

31

CVT

32

DMT

33

DOS

34

DMT

35

DMT

36

CVT

37

DMT

38

DMT 1440x900/60_RB 88.750 55.469 59.901 926

39

DMT

40

DMT

41

DMT

42

DMT

43

DMT

44

DMT

45

CVT

46

DMT

47

CVT

48

DMT

49

DMT

50

Extra Supported Video Timing ( Video Timing Don’t Care Picture Quality )

51

576P 720x576/50

52

576i

53

720P

54

1080i 1920x1080/50 74.250 28.125 50.000 1125

55

1080P

56

480P

57

480i

58

720P 1280x720/60 74.250 45.000 60.000 750

59

1080i

60

1080P

Pixel Rate

Resolution

( MHz )

640x350/70 25.175 31.469 70.086 449

720x400/70 28.322 31.469 70.087 449

640x480/60 25.175 31.469 59.940 525

4:3

640x480/67 30.240 28.571 66.667 525

640x480/72 31.500 37.861 72.809 520

4:3

640x480/75 31.500 37.500 75.000 500

4:3

800x600/56 36.000 35.156 56.250 625

4:3

800x600/60 40.000 37.879 60.317 628

4:3

800x600/72 50.000 48.077 72.188 666

4:3

800x600/75 49.500 46.875 75.000 625

4:3

832x624/75 57.280 49.722 74.546 667

960x720/75 71.250 56.369 74.660 755

1024x600/60

1024x768/60 65.000 48.363 60.004 806

4:3

1024x768/70 75.000 56.476 70.069 806

4:3

1024x768/75 78.750 60.023 75.029 800

4:3

1152x864/70

1152x864/75 108.000 67.500 75.000 900

1152x870/75 100.001 68.682 74.980 916

1280x720/60 74.250 45.000 60.000 750

16:9

1280x720/70 89.040 52.500 70.000 750

16:9

1280x720/75 95.750 56.456 74.777 755

16:9

1280x768/75 102.250 60.289 74.893 805

1280x800/75 106.500 62.795 74.934 838

1280x960/60 108.000 60.000 60.000 1000

4:3

1280x960/75 130.000 75.231 74.857 1005

4:3

1280x1024/60 108.000 63.981 60.020 1066

5:4

1280x1024/72 130.223 76.020 71.447 1064

5:4

1280x1024/75 135.000 79.976 75.025 1066

5:4

1360x768/60 85.500 47.712 60.015 795

16:9

1360x768/75 109.000 60.288 74.891 805

16:9

1366x768/60 85.500 47.712 59.790 798

16:9

1440x900/60 106.500 55.935 59.887 934

1440x900/75 136.750 70.635 74.984 942

1600x1200/60 162.000 75.000 60.000 1250

4:3

1680x1050/60_RB 119.000 64.674 59.883 1080

16:10

1680x1050/60 146.250 65.290 59.954 1089

16:10

1680x1050/75 187.000 82.306 74.892 1099

16:10

1920x1080/60_RB 138.500 66.587 59.934 1111

16:9

1920x1080/60 148.500 67.500 60.000 1125

16:9

1920x1080/60 173.000 67.158 59.963 1120

16:9

1920x1200/60_RB 154.000 74.038 59.950 1235

16:10

1920x1200/60 193.250 74.556 59.885 1245

16:10

720x576/50

1280x720/50 74.250 37.500 50.000 750

1920x1080/50 148.500 56.250 50.000 1125

720x480/60 27.000 31.468 60.000 525

720x480/60 13.500 15.734 60.000 525

1920x1080/60 74.250 33.750 60.000 1125

1920x1080/60 148.500

Horizontal

( KHz )

48.964 37.320 60.000 622

94.499 63.851 70.012 912

27.000 31.250

13.500 15.625

67.500 60.000 1125

Vertical

V_Total

Polarity

( Hz )

( Line )

( H / V )

p / n

n / p

n / n

n / n

n / n

n / n

p / p

p / p

p / p

p / p

P / p

n / p

n / p

n / p

n / n

n / n

p / p

n / p

p / p

p / p

n / n

p / p

p / p

n / p

n / p

n / p

n / p

n / p

n / p

p / p

n / p

p / p

p / p

p / p

p / p

n / p

p / p

p / n

n / p

n / p

p / p

p / n

n / p

n / p

p / n

p / p

n / p

p / n

n / p

625

50.000

625

50.000

241P4QPYK LCD 19

Electrical Instructions

White color adjustment

There are three factory preset white color 9300K, 6500K, sRGB.

Apply full gray64 pattern, with brightness in 100 % position and the contrast control at 50 % position.The 1931 CIE

Chromaticity (color triangle) diagram (x ,y) coordinate for the screencenter should be:

Product specification

CIE coordinates (x,y)

11500K x = 0.270 ± 0.02

y = 0.281 ± 0.02

9300K x = 0.283 ± 0.02

y = 0.297 ± 0.02

8200K x = 0.291 ± 0.02

y = 0.306 ± 0.02

7500K x = 0.298 ± 0.02

y = 0.314 ± 0.02

6500K/sRGB x = 0.313 ± 0.02

y = 0.329 ± 0.02

sRGB x = 0.313 ± 0.02

y = 0.329 ± 0.02

5000K x = 0.345 ± 0.02

y = 0.357 ± 0.02

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

Production alignment spec.

CIE coordinates (x,y)

11500K x = 0.270 ± 0.006

y = 0.281 ± 0.006

9300K x = 0.283 ± 0.006

y = 0.297 ± 0.006

8200K x = 0.291 ± 0.006

y = 0.306 ± 0.006

7500K x = 0.298 ± 0.006

y = 0.314 ± 0.006

6500K/sRGB x = 0.313 ± 0.006

y = 0.329 ± 0.006

sRGB x = 0.313 ± 0.006

y = 0.329 ± 0.006

5000K x = 0.345 ± 0.006

y = 0.357 ± 0.006

Quality Inspection specification:

CIE coordinates (x,y)

9300K x = 0.283 ± 0.015

y = 0.297 ± 0.015

6500K/sRGB x = 0.313 ± 0.015

y = 0.329 ± 0.015

sRGB x = 0.313 ± 0.015

y = 0.329 ± 0.015

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

PerfecTune II

20 241P4QPYK LCD

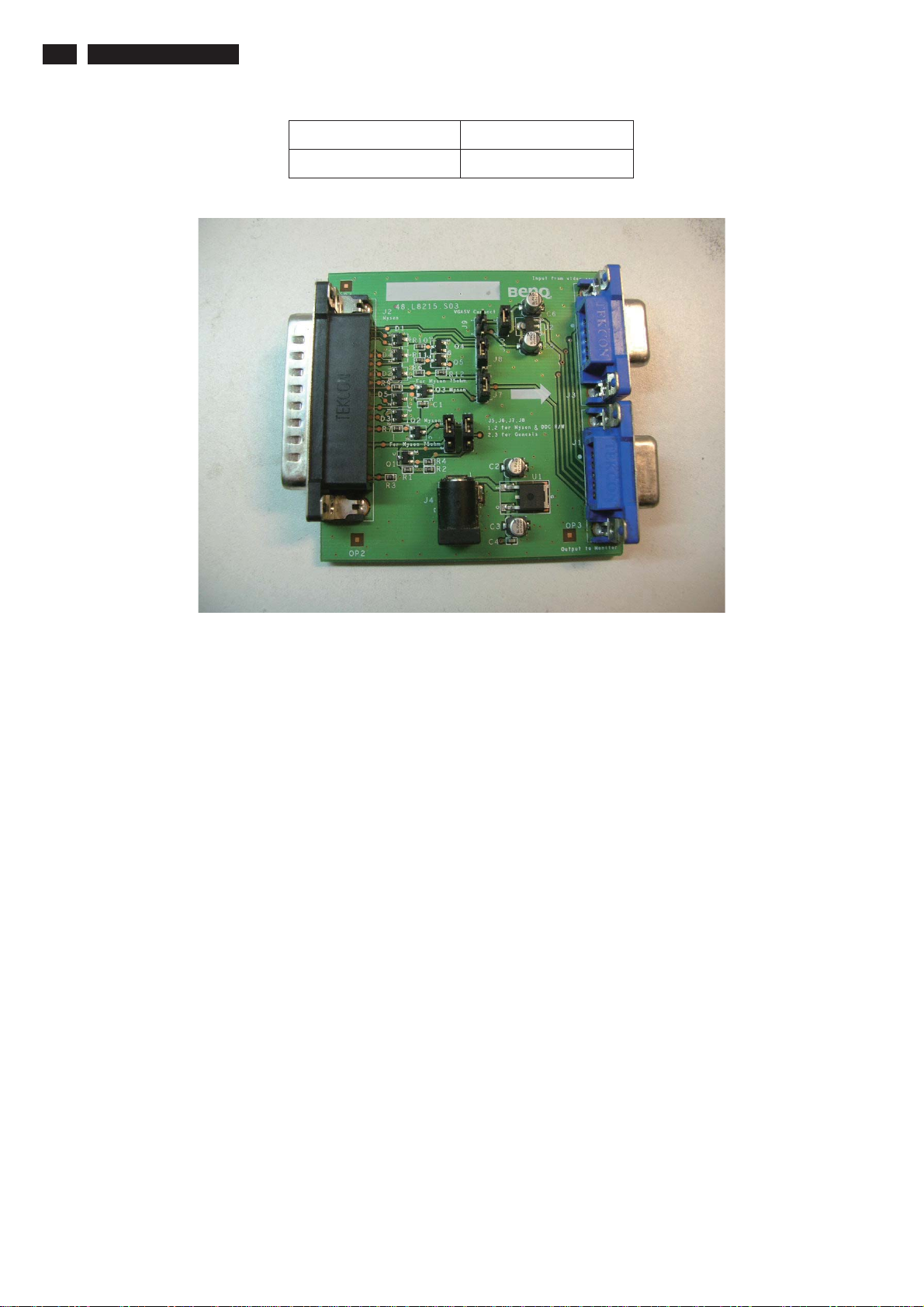

Service tool-Hardware

PCM code 12NC

5E.L8215.001 996510019769

Service tool-Software

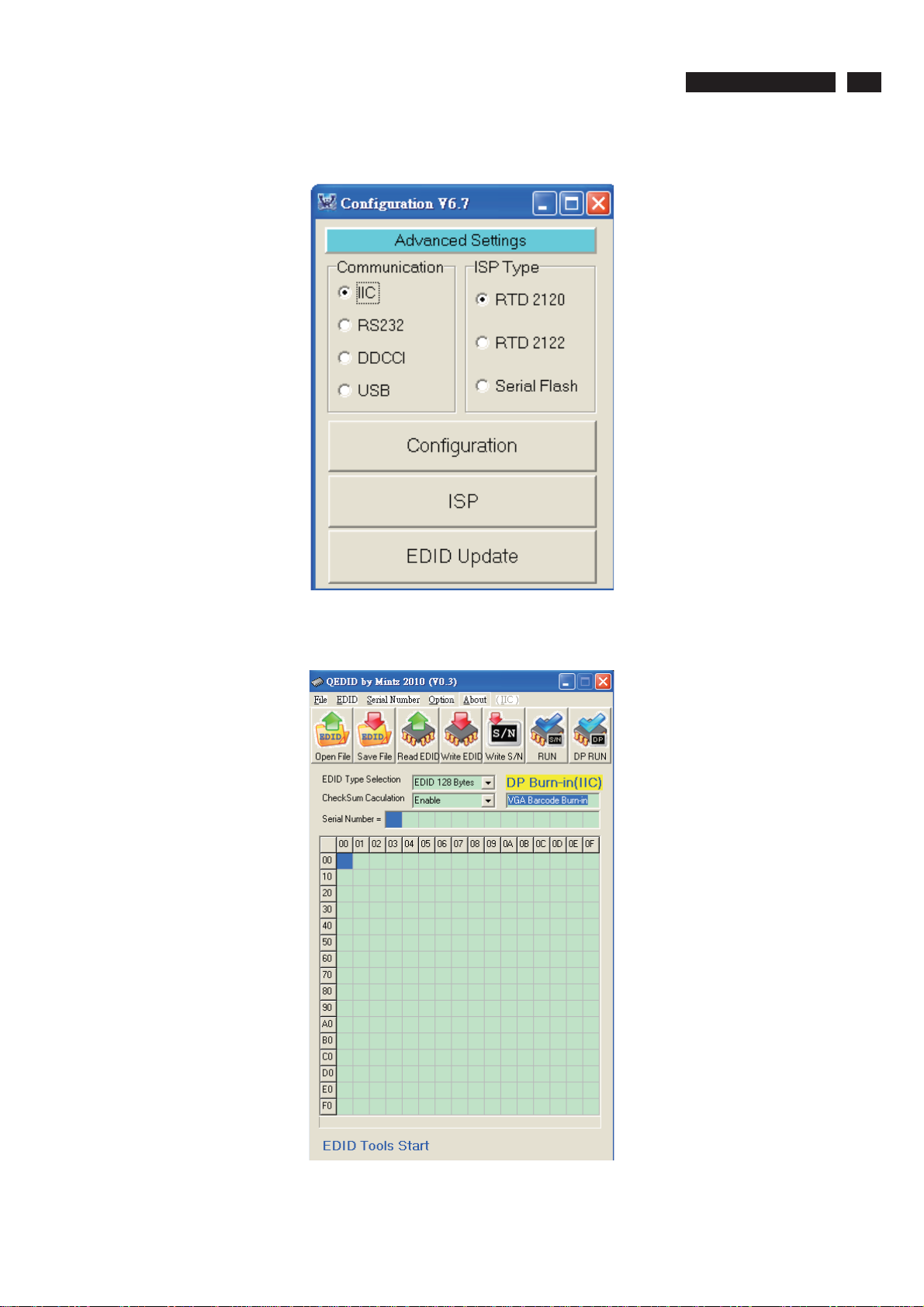

FW writing tool: RTD tool V6.7

241P4QPYK LCD 21

DDC writing tool: Q-EDID-V30

22 241P4QPYK LCD

DDC Instructions

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all factory settings were

replaced due to a defect, the serial numbers have to be re-programmed "Analog

DDC IC, Digital DDC IC & EEPROM".

It is advised to re-soldered DDC IC and main EEPROM from the old board onto the new

board if circuit board have been replaced, in this case the DDC data does not need to be

re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be obtained from Video

Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also obtained from

VESA.

Configuration and procedur e

"PI-EDID" The software is provided by IMS to upgrade the firmware of CPU.

PI-EDID Tools is for the interface between "Parallel Port of PC" and "15 pin-D-SUB

connector of Monitor".

It is a windows-based program, which cannot be run in MS-DOS.

System and equipment requirements

1. An Pentium (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98/2000/XP and Port95NT.exe.

3. EDID Software "QEDID.exe"

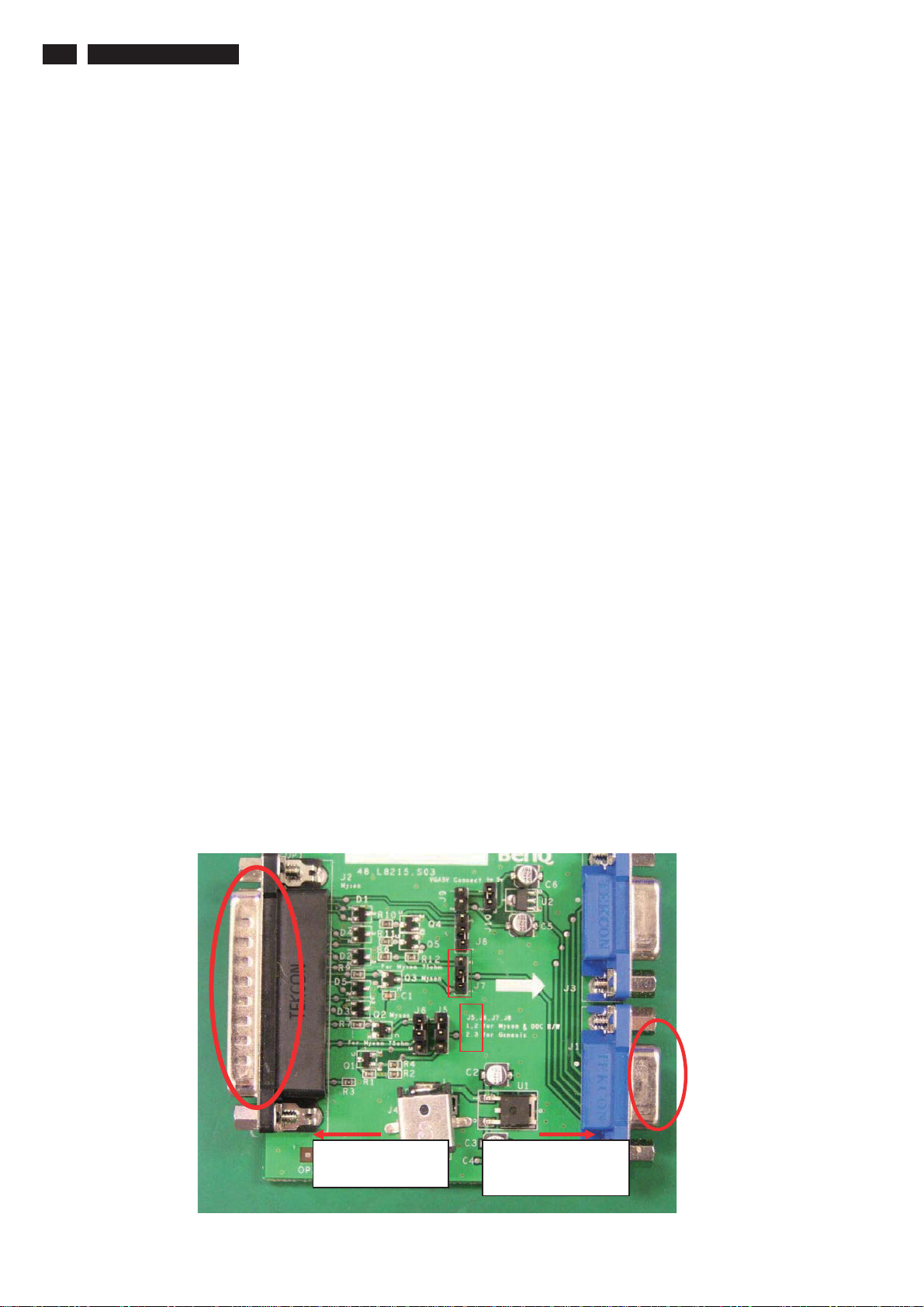

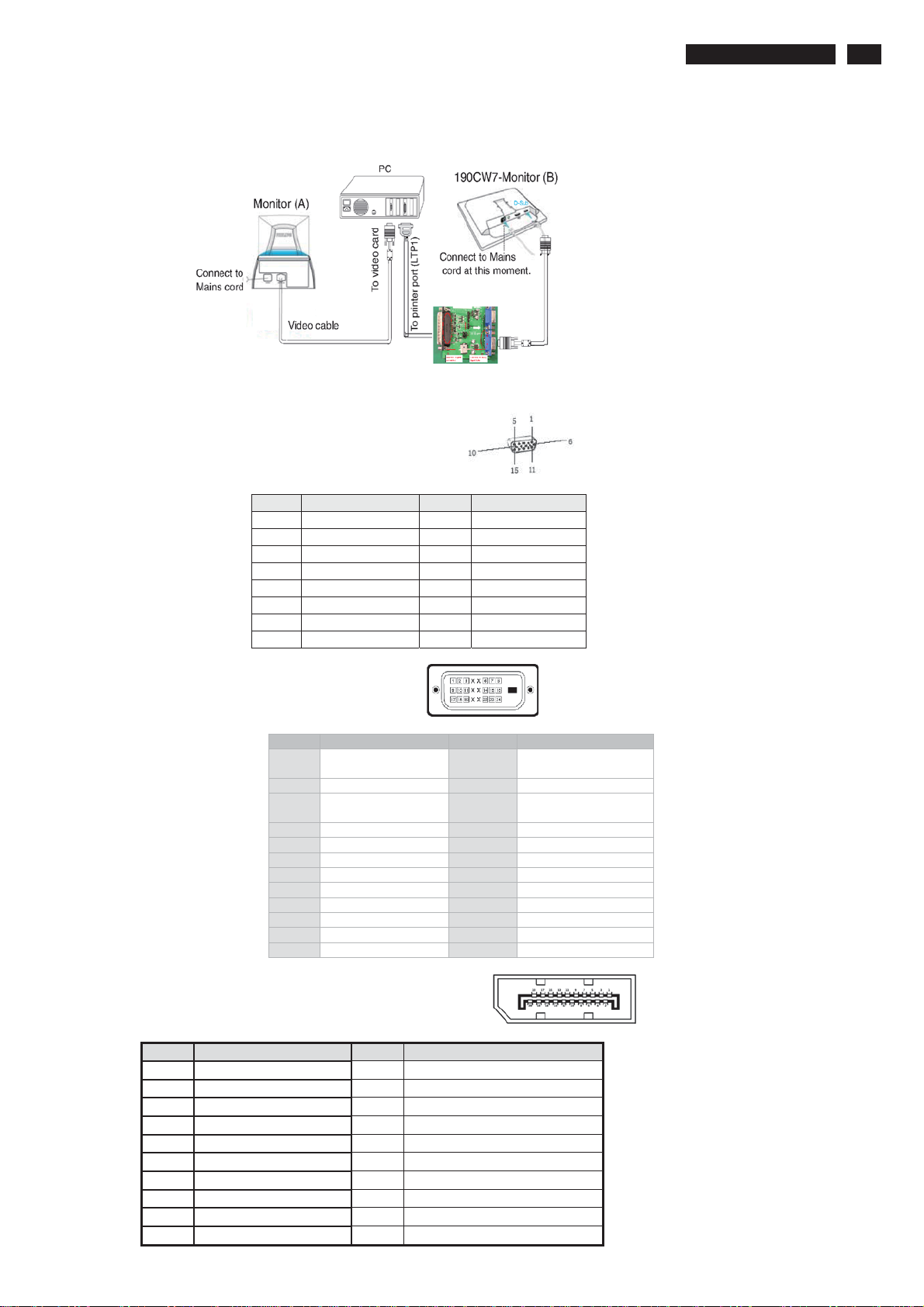

4. ISP boardas shown in Fig. 1

And I2C Board Jump wire should follow J10 (short), J9 (open), J5/J6/ (1and 2 pin short)

J7/J8 (1 and 2 pin short)

3

2

Connected to print

cord and PC

Fig.1

1

2

Connected to Display

Signal Cable

DDC Instructions

g

_

5. Connect and Mains cord to Monitor as shown in Fig.2.

Fig.2

Pin assignments:

A. 15-pin D-Sub Connecto r

PIN No. SIGNAL PIN No. SIGNAL

1 Red 9 DDC +3.3V or +5V

2 Green/ SOG 10 Logic GND

3 Blue 11 Sense (GND)

4 Sense (GND) 12 Bi-directi onal dat a

5 Cable Detect (GND) 13 H/H+V sync

6 Red GND 14 V-sync

7 Green GND 15 Data clock

8Blue GND

ġġ

241P4QPYK LCD 23

B. Input DVI Connector pin

Pin Signal Assignment Pin Signal assignment

1

TMDS RX22TMDS RX2+ 14 +5V Power

3 TMDS Ground 15

4 Floating 16 Hot Plug Detect

5 Floating 17 TMDS RX06 DDC Clock 18 TMDS RX0+

7 DDC Data 19 TMDS Ground

8 Floating 20 Floating

9TMDS RX1- 21 Floating

10 TMDS RX1+ 22 TMDS Ground

11 TMDS Ground 23 TMDS Clock+

12 Floating 24 TMDS Clock-

13 Floating

Self-test (Cable

detector)

C. Input Display Port Connector pin

Pin Signal Assignment Pin Signal Assignment

20

Ground

Lane3 N

Hot Plu

Return

DP

PWR

Detect

1 Lane0 P 11

2 Ground 12

3 Lane0 N 13 Ground

4 Lane1 P 14 EDID WP

5 Ground 15 AUX_CH P

6 Lane1 N 16 Ground

7 Lane2 P 17 AUX_CH N

8 Ground 18

9 Lane2 N 19

Lane3 P

10

24 241P4QPYK LCD

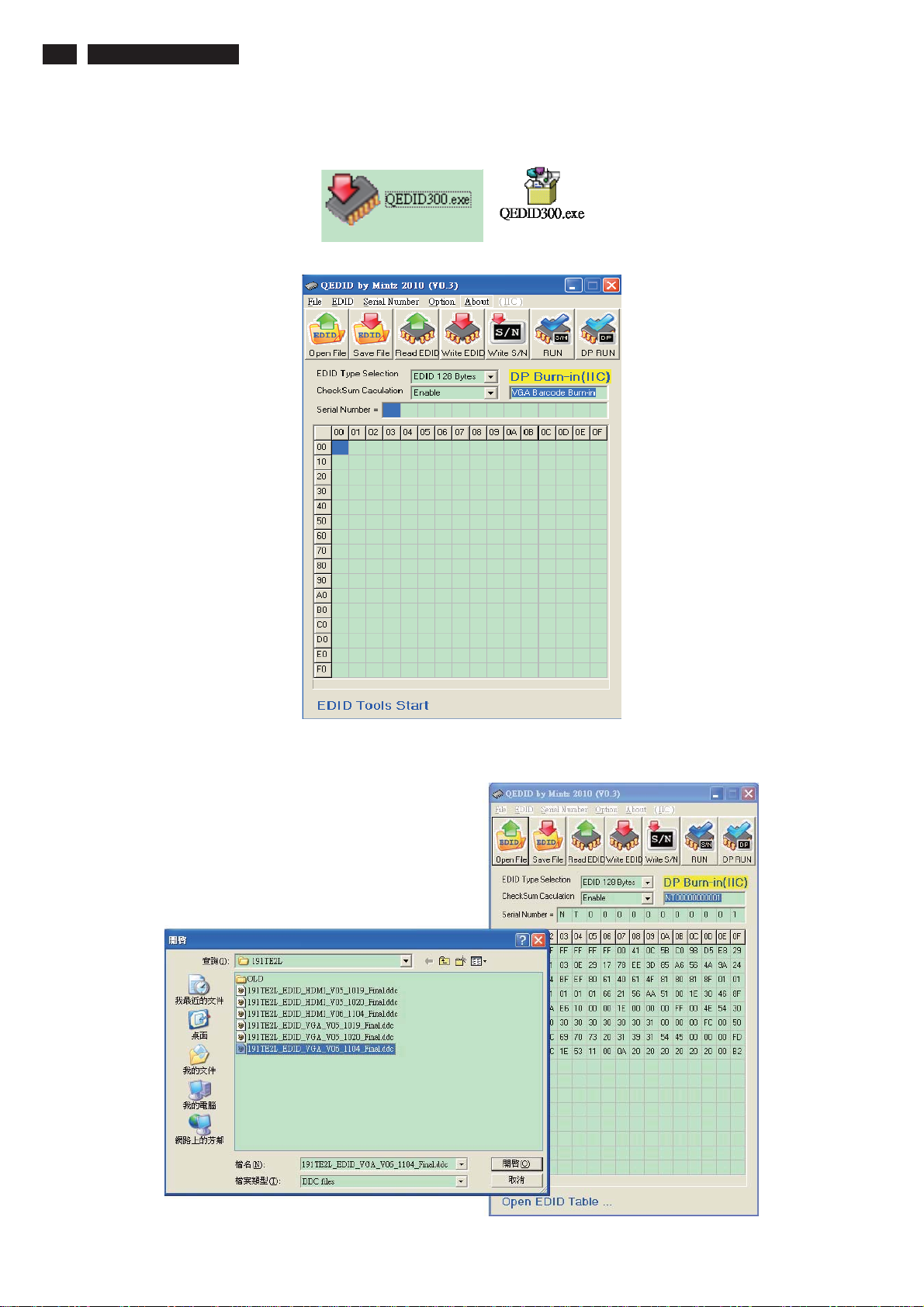

6. Setup the Philips-IMS EDID Tools program

Step 1: Open Q-EDID V030 Software into your folder as shown in Fig.3. and Fig.4.

DDC Instructions

Fig.3

Fig.4

Step 2: Press “Open File” then chooses 241P4QPYK DDC FILE

Fig.5

DDC Instructions

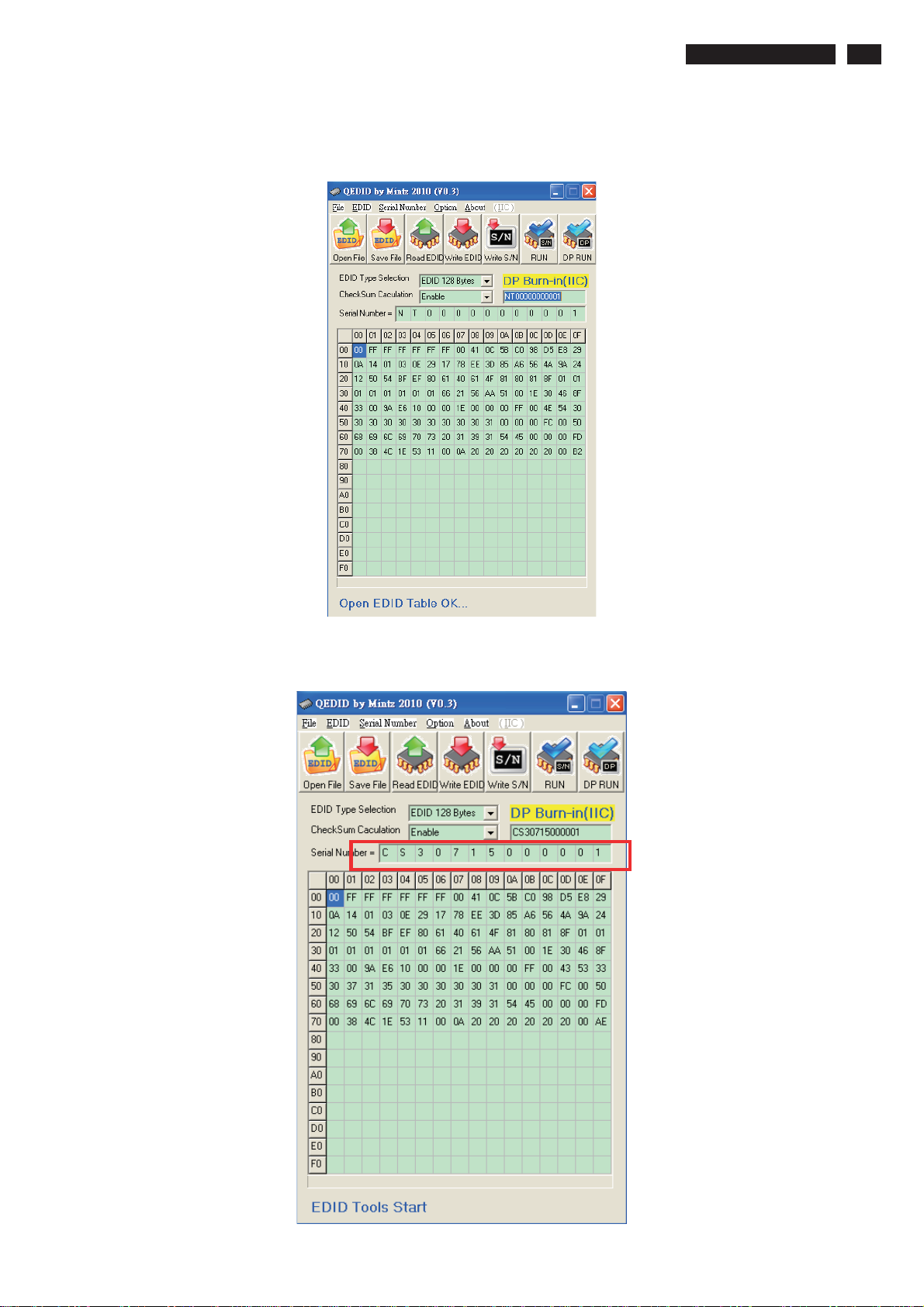

Step 3 : Load DDC file success as shown in Fig. 6 .

241P4QPYK LCD 25

Fig.Step 4 : update Serial number and press enter to correct S/N number

shown as Fig.7 .

Fig.7

26 241P4QPYK LCD

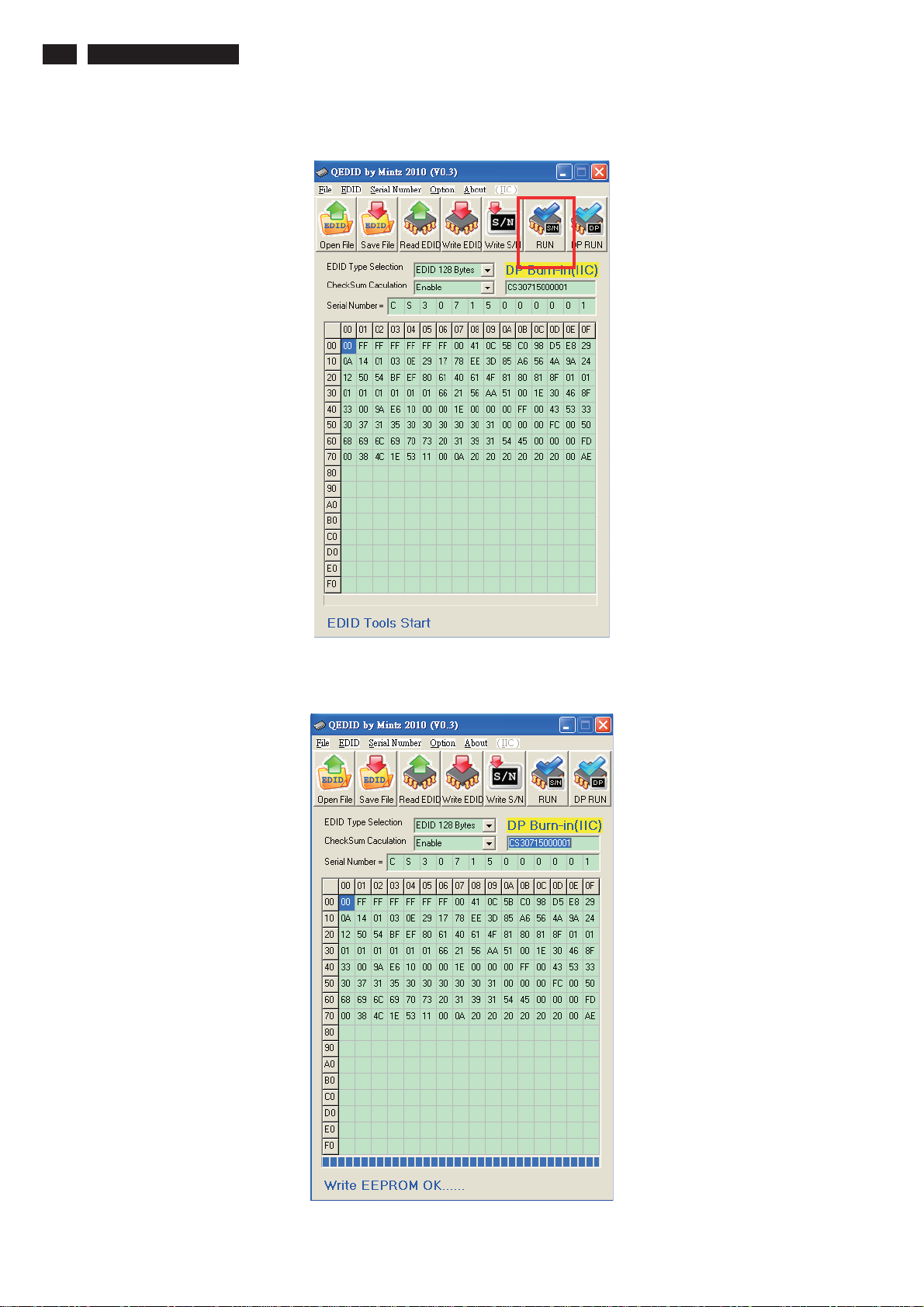

Step 5 : Press “RUN” to write EDID and serial number shown as Fig.8 .

DDC Instructions

Fig.8

Step 6 : EDID and serial number update success shown as Fig.9

Fig.9

Loading...

Loading...