Page 1

Colour Television Chassis

L01.2A

AB

(SMALL SCREEN)

Contents Page

1. Technical Specifications, Connections, and Chassis Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 8

6. Block Diagrams, Testpoints Overviews, and Waveforms

Block Diagram 15

Testpoint Overview 16

I2C and Supply Voltage Diagram 17

7. Circuit Diagrams and PWB Layouts Diagram PWB

Mono Carrier: Power Supply (A1)18 30-35

Mono Carrier: Line Deflection (A2) 19 30-35

Mono Carrier: Frame Deflection (A3) 20 30-35

Mono Carrier: Tuner IF (A4) 21 30-35

Mono Carrier: Video IF + Sound IF (A5) 22 30-35

Mono Carrier: Synchronisation (A6) 23 30-35

Mono Carrier: Control (A7) 24 30-35

Mono Carrier: Audio Amplifier (A8) 25 30-35

Mono Carrier: NICAM + 2CS + BTSC (A9)26 30-35

Mono Carrier: A/V Source Switching (A10) 27 30-35

Mono Carrier: Front I/O, Control + Headphone (A12) 28 30-35

Mono Carrier: Rear I/O CINCH (A13) 29 30-35

CRT Panel (B1) 36 37

Side AV Panel (E) 38 38

Side AV Panel + Headphone (E1) 39 39

8. Alignments 41

9. Circuit Descriptions, Abbreviation List, and IC Data Sheets 47

10. Spare Parts List 58

11. Revision List 61

CL 16532016_FSS.eps

050401

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JH 0561 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12751

Page 2

EN 2 L01.2A AB1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Introduction

1.2 Connections

1.3 Chassis Overview

Note:

• Below described specifications are not valid for one

product, but for the whole product range. See Product

Survey for specific models.

• Figures can deviate slightly from the actual situation, due

to different set executions.

1.1 Technical Specifications

1.1.1 Reception

Tuning system : PLL

Colour systems : NTSC

: PAL B/G, D/K, I

: SECAM B/G, D/K, K1

Sound systems : FM-mono

: FM-stereo

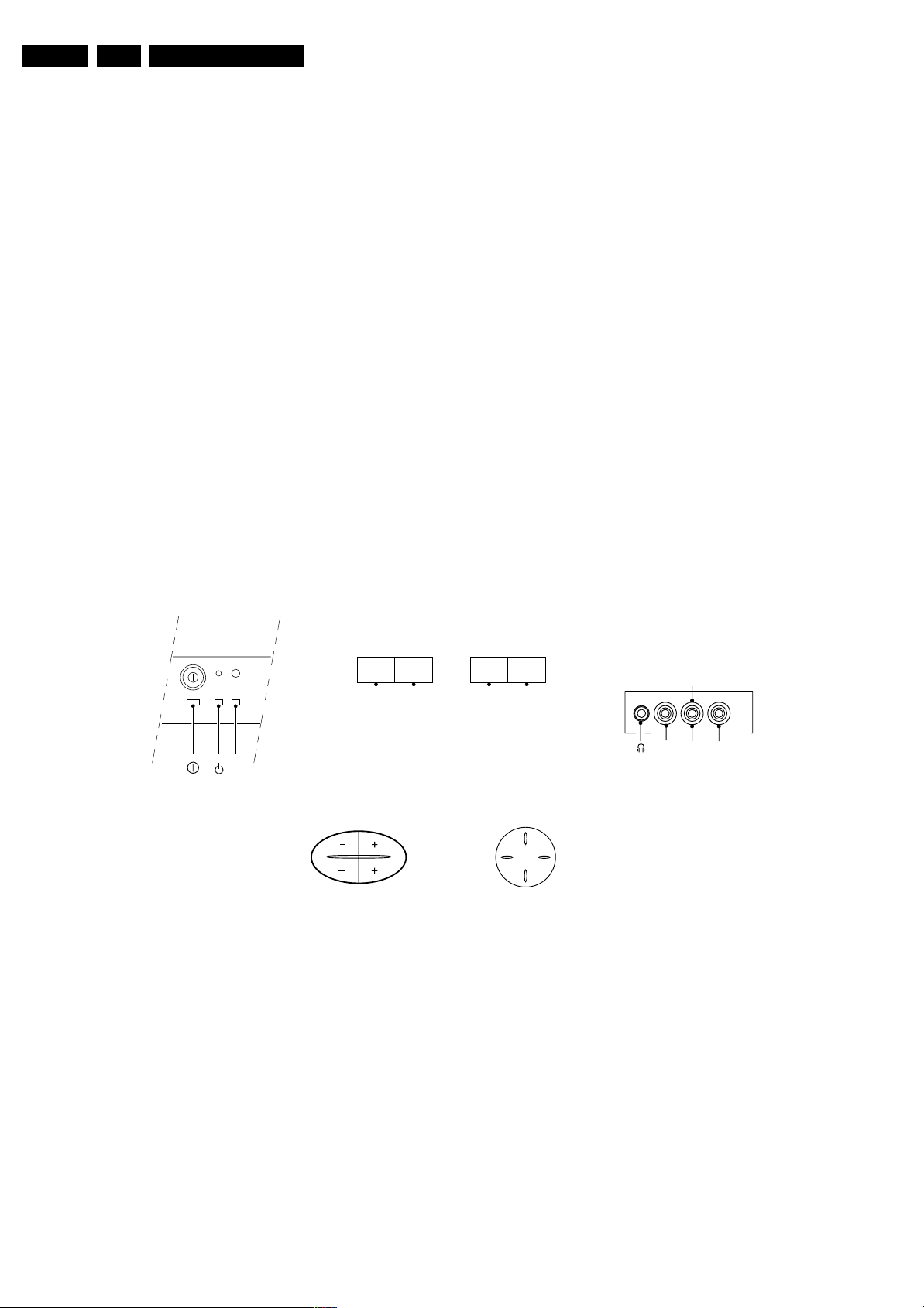

1.2 Connections

1.2.1 Front (or Side) Connections and Front (or Top) Control

A/V connections : NTSC 3.58, 4.43

: PAL 60

Channel selections : 100 channels

: U, V, S, H

Aerial input : 75 Ω, IEC-type

1.1.2 Miscellaneous

Audio output : 1 x 4 W or,

: 2 x 3 W or,

: 2 x 5 W + 10 W (sw) +

2 x 3 W

Mains voltage : 90 - 276 V or,

: 150 - 276 V

Mains frequency : 50 Hz or,

: 60 Hz

Ambient temperature : + 5 to + 45 °C

Maximum humidity : 90 %

Power consumption : 36 W (14”) to

: 52 W (21”)

Standby Power consumption : < 3 W

V- C+C-V+

IR

RED

- VOLUME +

- PROGRAM +

A/V In (if present)

1 -Video CVBS (1 Vpp / 75 Ω) jq

2 -Audio L (0.2 Vrms / 10 kΩ) jq

3 -Audio R (0.2 Vrms / 10 kΩ) jq

4 -Headphone (8 - 600 Ω / 4 mW) rt

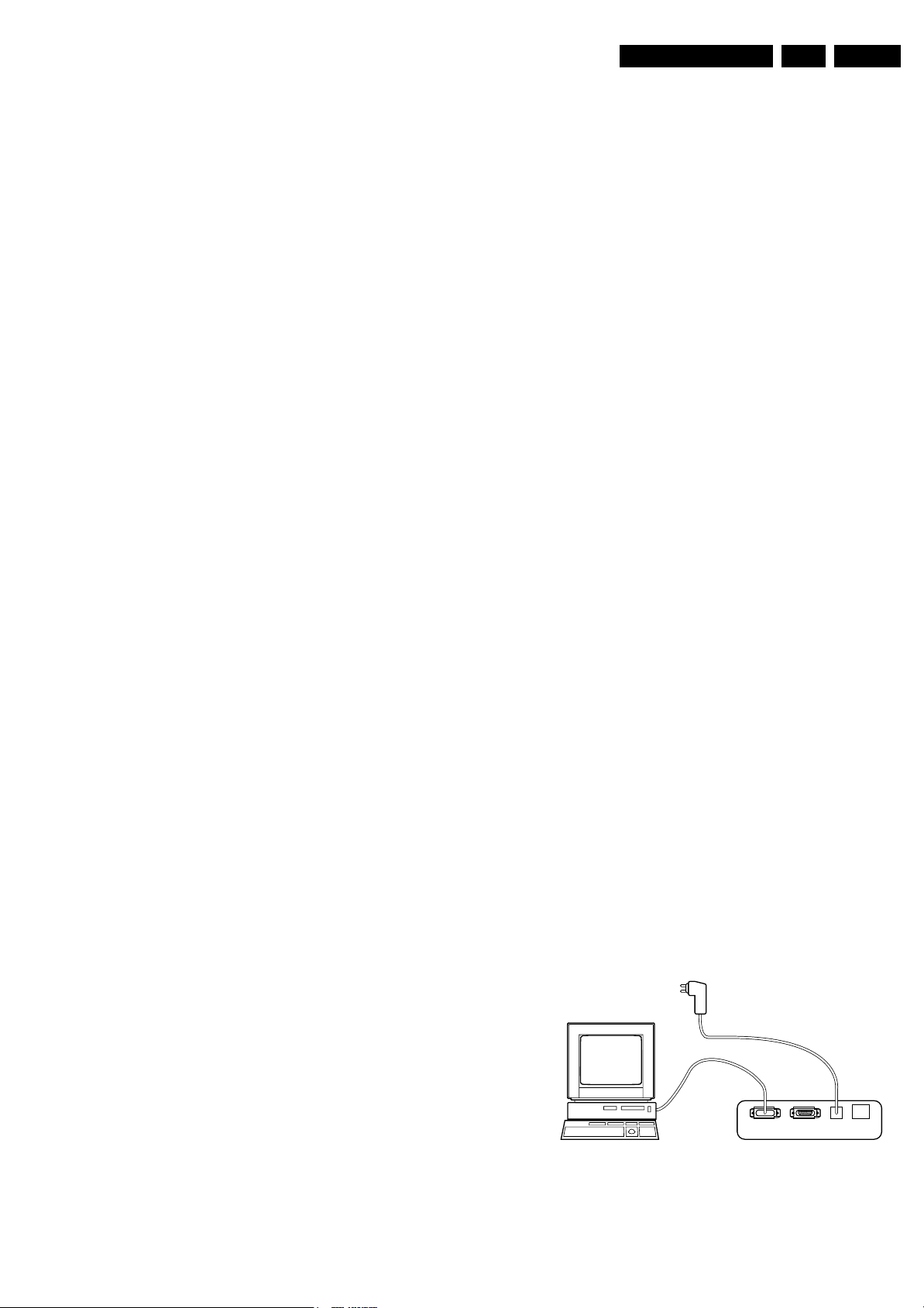

Figure 1-1

C+C-V+V-

P+

P-

Mono

R

L

Video

Audio

V+V-

CL 16532016_020.eps

220501

Page 3

Technical Specifications, Connections, and Chassis Overview

EN 3L01.2A AB 1.

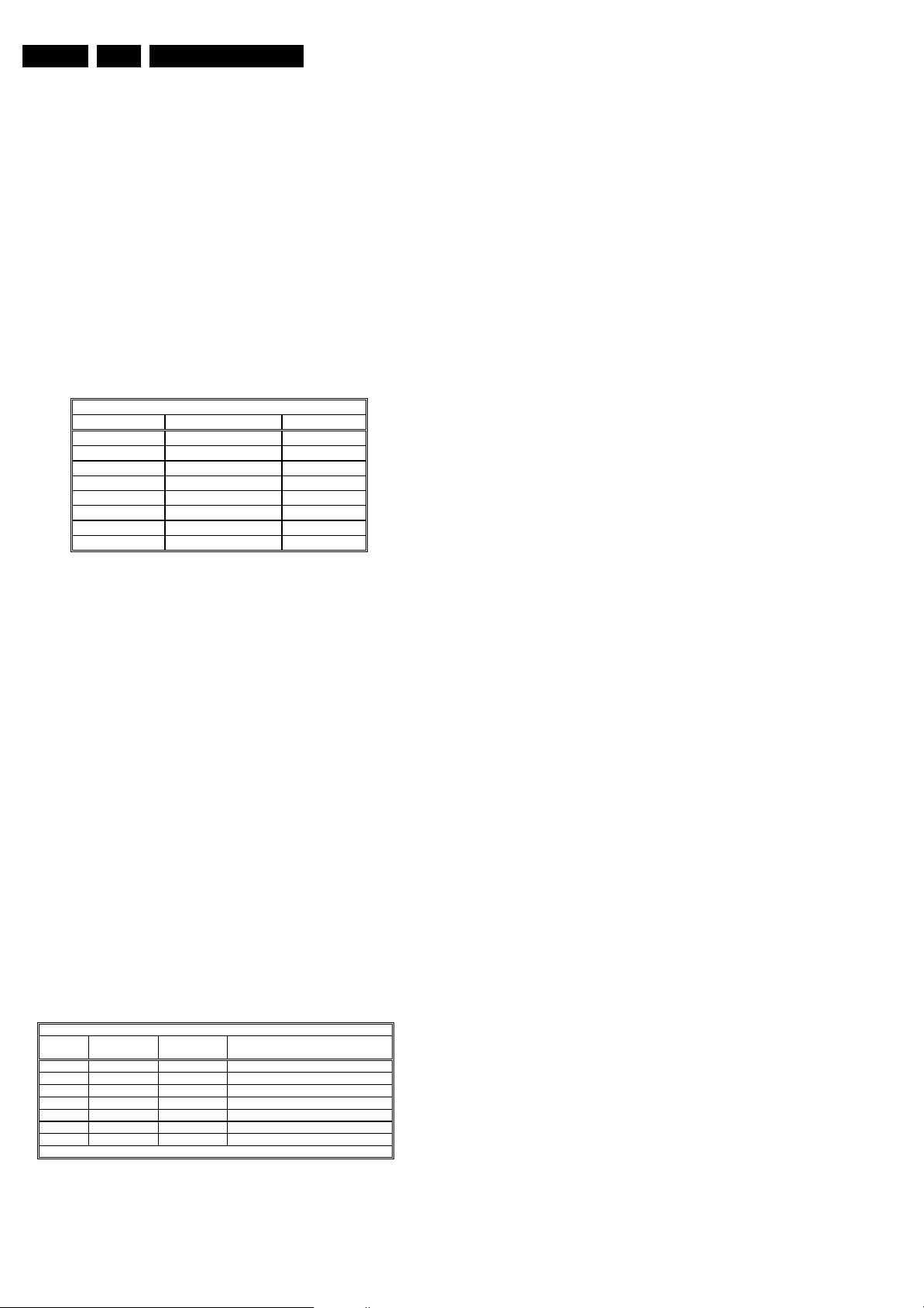

1.2.2 Rear Connections

75 Ohm

FM

MONITOR

OUT

V

L

R

AV1

IN

Y

U

V

V

L

R

AV2

V

L

R SVHS

Figure 1-2

Monitor Out

1 - Video CVBS (1 Vpp / 75 Ω) kq

2 - Audio L (0.5 Vrms / 1 kΩ) kq

3 - Audio R (0.5 Vrms / 1 kΩ) kq

1.3 Chassis Overview

IN

CL 16532008_005.eps

120601

YUV In (if present)

1 - Y 0.7 Vpp / 75 Ω jq

2 - U 0.7 Vpp / 75 Ω jq

3 - V 0.7 Vpp / 75 Ω jq

AV1 In

4 - Video CVBS (1 Vpp / 75 Ω) jq

5 - Audio L (0.5 Vrms / 10 kΩ) jq

6 - Audio R (0.5 Vrms / 10 kΩ) jq

AV2 In

1 - Video CVBS (1 Vpp / 75 Ω) jq

2 - Audio L (0.5 Vrms / 10 kΩ) jq

3 - Audio R (0.5 Vrms / 10 kΩ) jq

AV2 In (SVHS)

1 - gnd v

2 - gnd v

3 - Y 1 Vpp / 75 Ω j

4 - C 0.3 Vpp / 75 Ω j

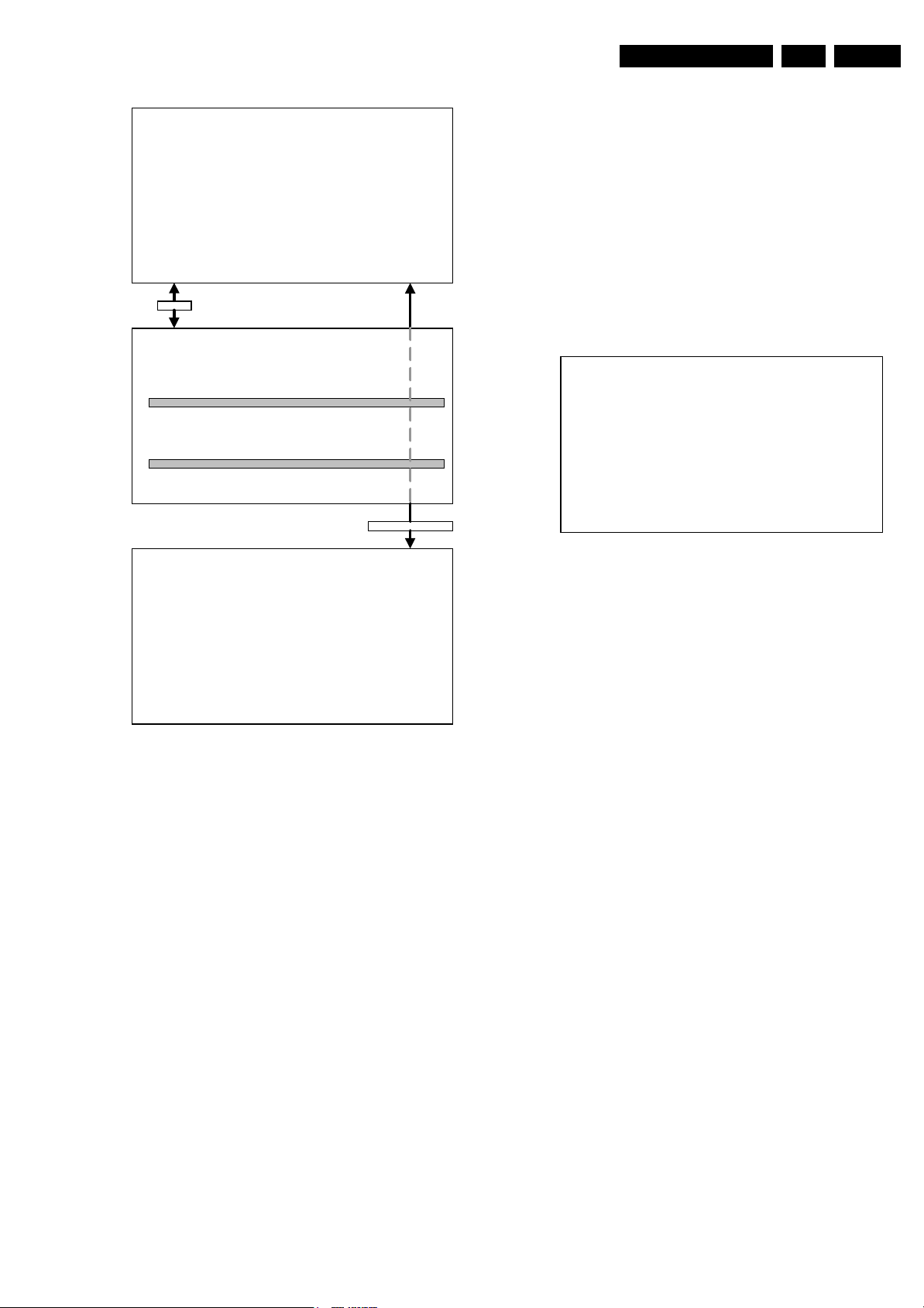

CRT PANEL

B

SIDE AV PANEL + HEADPHONE

E1

SIDE AV PANEL

E

(SMALL SCREEN)

Figure 1-3 Chassis overview

MAIN

CHASSIS

PA NE L

POWER SUPPLY

LINE DEFLECTION

FRAME DEFLECTION

TUNER IF

VIDEO + SOUND IF

SYNCHRONISATION

CONTROL (µP)

AUDIO AMPLIFIER

NICAM + 2CS +

BTSC DECODER

A/V SWITCHING

HEADPHONE + FR. CONTROL

REAR I/O CINCH

F_12751_005.eps

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A12

A13

120105

Page 4

EN 4 L01.2A AB2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions For Repairs

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions For Repairs

Safety regulations require that during a repair:

• Due to the ‘hot’ parts of this chassis, the set must be

connected to the AC power via an isolation transformer.

• Safety components, indicated by the symbol h, should be

replaced by components identical to the original ones.

• When replacing the CRT, safety goggles must be worn.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay particular attention to the

following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current is flowing, in particular:

– all pins of the line output transformer (LOT)

– fly-back capacitor(s)

– S-correction capacitor(s)

– line output transistor

– pins of the connector with wires to the deflection coil

– other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the AC power cord for external

damage.

• Check the strain relief of the AC power cord for proper

function, to prevent the cord from touching the CRT, hot

components, or heat sinks.

• Check the electrical DC resistance between the AC plug

and the secondary side (only for sets that have an isolated

power supply). Do this as follows:

1. Unplug the AC power cord and connect a wire between

the two pins of the AC plug.

2. Turn on the main power switch (keep the AC power

cord unplugged!).

3. Measure the resistance value between the pins of the

AC plug and the metal shielding of the tuner or the

aerial connection of the set. The reading should be

between 4.5 MΩ and 12 MΩ.

4. Switch the TV OFF and remove the wire between the

two pins of the AC plug.

• Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

2.2 Maintenance Instructions

It is recommended to have a maintenance inspection carried

out by qualified service personnel. The interval depends on the

usage conditions:

• When the set is used under normal circumstances, for

example in a living room, the recommended interval is

three to five years.

• When the set is used in an environment with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the 'general repair instruction' noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in Fig. 2-1, to

discharge the picture tube. Use a high voltage probe and a

multi-meter (position VDC). Discharge until the meter

reading is 0 V (after approx. 30 s).

V

CL 26532098/042

140792

Figure 2-1

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD) w. Careless handling

during repair can reduce life drastically. When repairing,

make sure that you are connected with the same potential

as the mass of the set by a wristband with resistance. Keep

components and tools also at this potential. Available ESD

protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable, and ground cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

• Together with the deflection unit and any multi-pole unit,

flat square picture tubes form an integrated unit. The

deflection and the multi-pole units are set optimally at the

factory. Adjustment of this unit during repair is therefore not

recommended.

• Be careful during measurements in the high voltage

section and on the picture tube.

• Never replace modules or other components while the unit

is switched ON.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.4 Notes

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

Page 5

Safety Instructions, Warnings, and Notes

EN 5L01.2A AB 2.

2.4.2 Schematic Notes

• All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device Removal

As is the case with any component that, it is essential when

removing an (LF)BGA, the board, tracks, solder lands, or

surrounding components are not damaged. To remove an

(LF)BGA, the board must be uniformly heated to a temperature

close to the reflow soldering temperature. A uniform

temperature reduces the chance of warping the PWB.

To do this, we recommend that the board is heated until it is

certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the

appropriate temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has shown to result in

problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

To reflow the solder, apply a temperature profile according to

the IC data sheet. So as not to damage neighbouring

components, it may be necessary to reduce some

temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Workshop Information”. Here you will find

Information on how to deal with BGA-ICs.

-9

), or pico-farads (p= x10

-12

2.4.4 Lead Free Solder

Philips CE is going to produce lead-free sets (PBF) from

1.1.2005 onwards.

-6

),

).

Figure 2-2 Lead-free logo

This sign normally has a diameter of 6 mm, but if there is less

space on a board also 3 mm is possible.

Regardless of this logo (is not always present), one must treat

all sets from this date onwards according to the following rules.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able

– To reach at least a solder-tip temperature of 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

- 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will rise drastically and flux-fluid will be destroyed. To

avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If not to avoid, clean carefully the

solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

short before it is used (soldered). Otherwise the body of the

IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam)pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution: For BGA-ICs, you must use the correct temperatureprofile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions)

P

b

Page 6

EN 6 L01.2A AB3.

Directions for Use

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repair help

desk.

2.4.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

3. Directions for Use

You can also download this information from the following

websites:

http://www.philips.com/support

http://www.p4c.philips.com

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

Page 7

4. Mechanical Instructions

Mechanical Instructions

EN 7L01.2A AB 4.

Index of this chapter:

4.1 Rear Cover Removal

4.2 Service Position Main Panel

4.3 Side I/O Panel Removal

4.4 Rear Cover Mounting

Note: Figures can deviate slightly from the actual situation, due

to different set executions.

4.1 Rear Cover Removal

1. Remove all fixation screws of the rear cover.

2. Now pull the rear cover backward and remove it.

4.2 Service Position Main Panel

1. Disconnect the strain relief of the AC power cord.

2. Remove the main panel, by pushing the two center clips

outward [1]. At the same time pull the panel away from the

CRT [2].

3. Disconnect the degaussing coil by removing the cable from

(red) connector 0201.

4. Move the panel somewhat to the left and flip it 90 degrees

[3], with the components towards the CRT.

4.3 Side I/O Panel Removal

1. Remove the complete Side I/O assembly after unscrewing

the 2 fixation screws [1].

2. Release the two fixation clamps [2] and lift the board out of

the bracket.

CL 06532012_004.eps

030200

Figure 4-2

4.4 Rear Cover Mounting

Before you mount the rear cover, perform the following checks:

1. Check whether the mains cord is mounted correctly in its

1

1

2

A

guiding brackets.

2. Replace the strain relief of the AC power cord into the

cabinet.

3. Check whether all cables are replaced in their original

position.

B

Figure 4-1

3

CL 16532016_006.eps

220501

Page 8

EN 8 L01.2A AB5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Problems and Solving Tips (Related to CSM)

5.4 ComPair

5.5 Error Buffer

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Repair Tips

5.1 Test Points

The chassis is equipped with test points printed on the circuit

board assemblies. These test points refer to the functional

blocks:

Test point Circuit Diagram

A1-A2-A3-…..

C1-C2-C3-…..

F1-F2-F3-…..

I1-I2-I3-…..

L1-L2-L3-….

P1-P2-P3-…..

S1-S2-S3-…..

V1-V2-V3-…..

TEST POINT OVERVIEW L01

Audio processing A8, A9 / A11

Control A7

Frame drive A3

Tuner & IF A4

Line drive A2

Power supply A1

Synchronisation A6

Video processing A5, B1

CL 16532008_044.eps

210501

5.2.1 Service Default Mode (SDM)

Purpose

• To create a predefined setting to get the same

measurement results as given in this manual.

• To override SW protections.

• To start the blinking LED procedure.

Specifications

• Tuning frequency:

– 475.25 MHz for PAL/SECAM (AP-PAL).

– 61.25 MHz (channel 3) for NTSC-sets (AP-NTSC).

• Colour system:

– PAL-BG for AP-PAL.

– NTSC for AP-NTSC.

• All picture settings at 50 % (brightness, colour contrast,

hue).

• Bass, treble and balance at 50 %; volume at 25 %.

• All service-unfriendly modes (if present) are disabled, like:

– (sleep) timer,

– child/parental lock,

– blue mute,

– hotel/hospitality mode

– auto switch-off (when no ‘IDENT’ video signal is

received for 15 minutes),

– skip / blank of non-favorite presets / channels,

– auto store of personal presets,

– auto user menu time-out.

Figure 5-1

The numbering is in a logical sequence for diagnostics. Always

start diagnosing within a functional block in the sequence of the

relevant test points for that block.

Perform measurements under the following conditions:

• Service Default Mode (when this mode is not present, set

all controls to 50%, set volume to 25% and select channel

3).

• Video: colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Menu (CSM) is used for communication

between dealer and customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements) and the TV chassis. It

offers the ability of structured trouble shooting, error code

reading and software version readout for all L01 chassis.

Minimum requirements: a 486 processor, Windows 3.1 and a

CD-ROM drive (see also paragraph 5.4).

SW

cluster

1AP1

1AP2

1AP3

1AP9

3AP1

3AP2

4AP1

Abbreviations: A= Asia Pacific, C= NTSC, N= no TXT, T= TXT

SOFTWARE VERSIONS (L01 AP SMALL SCREEN)

SW name UOC-type Diversity

L01AN1-x.y TDA9580/1 AP, non TXT, China/AP

L01AN2-x.y TDA9581/2 AP, non TXT, Thailand/Vietnam

L01AN3-x.y TDA9580/1 AP, non TXT, India

L01AN9-x.y TDA9581 AP, non TXT, Middle East

L01AT1-x.y TDA9561/7 AP, 10 page TXT, Sgp/Aus/NZ

L01AT2-x.y TDA9567 AP, 10 page TXT, Middle East

L01AC1-x.y TDA9580 AP, NTSC, Thailand/Philippines

CL 16532008_070.pdf

220801

How to enter SDM

Use one of the following methods:

• Use a standard customer RC-transmitter and key in the

code ‘062596’ directly followed by the MENU button or

• Short wires 9631 and 9641 on the mono carrier (see Fig. 8-

1) and apply AC power. Then press the power button

(remove the short after start-up).

Caution: Entering SDM by shorten wires 9631 and 9641

will override the +8V-protection. Do this only for a short

period. When doing this, the service-technician must know

exactly what he is doing, as it could lead to damaging the

set.

• Or via ComPair.

After entering SDM, the following screen is visible, with SDM at

the upper right side for recognition.

Figure 5-2

Page 9

Service Modes, Error Codes, and Fault Finding

/STA

AAABCDEE X . Y SDM

ERRXXXXXXXXXX

MENU

SDM

Ma i n ^

• Pic ture > Brightness

• Sound Col our

• Fea tu res Cont ras t

• I nsta l l Shar pness

Co l ou r Temp

Store

v

EN 9L01.2A AB 5.

Specifications

• Operation hours counter.

• Software version.

• Option settings.

• Error buffer reading and erasing.

• Software alignments.

How to enter

Use one of the following methods:

• Use a standard customer RC-transmitter and key in the

code ‘062596’ directly followed by the OSD / STATUS

button or

•Via ComPair.

The following screen is visible, with SAM at the upper right side

for recognition.

LLLL AAABCD X. Y SAM

ERR XX XX XX XX XX

XXX XXX XXX XXX XXX XXX XXX

CLEAR CL EAR ?

OPT I ONS >

AKB 0 / 1

TUNER >

WH I T E T ON E >

GEOMETRY >

AUD I O >

OSD

CL 16532020_060.pdf

Figure 5-3

How to navigate

Use one of the following methods:

• When you press the MENU button on the remote control,

the set will switch between the SDM and the normal user

menu (with the SDM mode still active in the background).

Return to the SDM screen with the OSD / STATUS button.

• When you press the OSD / STATUS button on the remote

control, the menu will show or hide the error buffer. This

feature is available to prevent interference during

waveform measurements.

• On the TV, press and hold the 'VOLUME down' and press

the 'CHANNEL down' for a few seconds, to switch from

SDM to SAM and reverse.

How to exit

Switch the set to STANDBY by pressing the power button on

the remote control transmitter (if you switch the set 'off' by

removing the AC power, the set will return in SDM when AC

power is re-applied). The error buffer is cleared.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform alignments.

• To change option settings.

• To display / clear the error code buffer.

SDM

220501

TUS

CL 16532020_061.eps

150401

Figure 5-4

1. LLLL This is the operation hours counter. It counts the

normal operation hours, not the standby hours.

2. AAABCD-X.Y This is the software identification of the main

micro controller:

• A = the project name (L01).

• B = the region: E= Europe, A= Asia Pacific, U= NAFTA,

L= LATAM.

• C = the software diversity: C= NTSC, D= DVD, N= no

TXT, T= TXT.

• D = the language cluster number.

• X = the main software version number.

• Y = the sub software version number.

3. SAM Indication of the actual mode.

4. Error buffer Five errors possible.

5. Option bytes Seven codes possible.

6. Clear Erase the contents of the error buffer. Select the

CLEAR menu item and press the CURSOR RIGHT key.

The content of the error buffer is cleared.

7. Options To set the Option Bytes. See chapter 8.3.1 for a

detailed description.

8. AKB Disable (0) or enable (1) the ‘black current loop’ (AKB

= Auto Kine Bias).

9. Tuner To align the Tuner. See chapter 8.3.2 for a detailed

description.

10. White Tone To align the White Tone. See chapter 8.3.3 for

a detailed description.

11. Geometry To align the Geometry. See chapter 8.3.4 for a

detailed description.

12. Audio To align the Audio. See chapter 8.3.5 for a detailed

description.

How to navigate

Use one of the following methods:

• In SAM, select menu items with the CURSOR UP/DOWN

key on the remote control transmitter. The selected item

will be highlighted. When not all menu items fit on the

screen, move the CURSOR UP/DOWN key to display the

next / previous menu items.

• With the CURSOR LEFT/RIGHT keys, it is possible to:

– (De)activate the selected menu item.

– Change the value of the selected menu item.

Page 10

EN 10 L01.2A AB5.

Service Modes, Error Codes, and Fault Finding

– Activate the selected submenu.

• When you press the MENU button twice, the set will switch

to the normal user menus (with the SAM mode still active

in the background). To return to the SAM menu press the

OSD / STATUS button [ i+ ].

• When you press the MENU key in a submenu, you will

return to the previous menu.

How to exit

Switch the set to STANDBY by pressing the power button on

the remote control (if you switch the set 'off' by removing the AC

power, the set will return in SAM when AC power is re-applied).

The error buffer is not cleared.

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer. The service technician can than ask the

customer to activate the CSM, in order to identify the status of

the set. Now, the service technician can judge the severness of

the complaint. In a lot of cases he can advise the customer how

to solve the problem, or he can decide if it is necessary to visit

the customer.

The CSM is a read only mode, therefore modifications in this

mode are not possible.

How to enter

The CSM will be turned on after pressing the MUTE key on the

remote control transmitter and any of the control buttons on the

TV for at least 4 seconds simultaneously. This activation only

works if there is no menu on the screen.

After switching ON the Customer Service Mode, the following

screen will appear:

10. Value indicates parameter levels at CSM entry (only for

stereo sets). TR= TREBLE, BS= BASS

How to exit

Use one of the following methods:

• After you press ‘any’ key of the remote control transmitter

with exception of the CHANNEL and VOLUME keys.

• After you switch-off the TV set with the AC power switch.

5.3 Problems and Solving Tips (Related to CSM)

5.3.1 Picture Problems

Note: Below described problems are all related to the TV

settings. The procedures to change the value (or status) of the

different settings are described.

No colours / noise in picture

Check CSM line 4. Wrong colour system installed. To change

the setting:

1. Press the MENU button on the remote control.

2. Select the INSTALL sub menu.

3. Select the MANUAL STORE sub menu.

4. Select and change the SYSTEM setting until picture and

sound are correct.

5. Select the STORE menu item.

Colours not correct / unstable picture

Check CSM line 4. Wrong colour system installed. To change

the setting:

1. Press the MENU button on the remote control.

2. Select the INSTALL sub menu.

3. Select the MANUAL STORE sub menu.

4. Select and change the SYSTEM setting until picture and

sound are correct.

5. Select the STORE menu item.

1AAABCD X.Y CSM

2 CODES XX XX XX XX XX

3 OP XXX XXX XXX XXX XXX XXX XXX

4 D ETECT ED SYST EM DET ECTED SOUND

5 NOT TUNED SKIPPED

6TIMER

7

8 CO XX CL XX BR XX HU XX SH XX

9VLXX BL XX AVL DVXX

10 TR XX BS XX

CL 16532008_046.eps

220501

Figure 5-5

1. Software identification of the main micro controller (see

paragraph 5.2.2 for an explanation).

2. Error code buffer (see paragraph 5.5 for more details).

Displays the last seven errors of the error code buffer.

3. In this line, the Option Bytes (OB) are visible. Each Option

Byte is displayed as a decimal number between 0 and 255.

The set may not work correctly when an incorrect option

code is set. See chapter 8.3.1 for more information on the

option settings.

4. Indicates which color and sound system is installed for the

selected pre-set.

5. Indicates if the set is not receiving an ‘IDENT’ signal on the

selected source. It will display ‘Not Tuned’.

6. Indicates if the sleep timer is enabled.

7. Indicates if the V-chip feature is enabled.

8. Value indicates parameter levels at CSM entry. CO=

CONTRAST, CL= COLOR, BR= BRIGHTNESS, HU=

HUE, SH= SHARPNESS

9. Value indicates parameter levels at CSM entry. VL=

VOLUME LEVEL, BL= BALANCE LEVEL, AVL= AUTO

VOLUME LEVEL LIMITER, DV= DELTA VOLUME

TV switches ‘off’ (or ‘on’) or changes the channel without any user action

(Sleep)timer switched the set ‘off’ or changed channel. To

change the setting:

1. Press the MENU button on the remote control.

2. Select the FEATURES sub menu.

3. Select the TIMER sub menu.

4. Select and change the SLEEP or TIME setting.

Picture too dark or too bright

Increase / decrease the BRIGHTNESS and / or the

CONTRAST value when:

• The picture improves after you have pressed the ‘Smart

Picture’ button on the remote control.

• The picture improves after you have switched on the

Customer Service Mode

The new ‘Personal’ preference value is automatically stored.

White line around picture elements and text

Decrease the SHARPNESS value when:

• The picture improves after you have pressed the ‘Smart

Picture’ button on the remote control.

• The picture improves after you have switched on the

Customer Service Mode

The new ‘Personal’ preference value is automatically stored.

Snowy picture

Check CSM line 5. If this line indicates ‘Not Tuned’, check the

following:

• No or bad antenna signal. Connect a proper antenna

signal.

• Antenna not connected. Connect the antenna.

• No channel / pre-set is stored at this program number. Go

to the INSTALL menu and store a proper channel at this

program number.

Page 11

Service Modes, Error Codes, and Fault Finding

EN 11L01.2A AB 5.

• The tuner is faulty (in this case the CODES line will contain

error number 10). Check the tuner and replace / repair if

necessary.

Snowy picture and/or unstable picture

• A scrambled or decoded signal is received.

Black and white picture

Increase the COLOR value when:

• The picture improves after you have pressed the ‘Smart

Picture’ button on the remote control.

• The picture improves after you have switched on the

Customer Service Mode

The new ‘Personal’ preference value is automatically stored.

Menu text not sharp enough

Decrease the CONTRAST value when:

• The picture improves after you have pressed the ‘Smart

Picture’ button on the remote control.

• The picture improves after you have switched on the

Customer Service Mode

The new ‘Personal’ preference value is automatically stored.

5.3.2 Sound Problems

No sound or sound too loud (after channel change / switching on)

Increase / decrease the VOLUME level when the volume is OK

after you switched on the CSM. The new ‘Personal’ preference

value is automatically stored.

5.4 ComPair

receive I

television. In this way, it is possible for ComPair to

communicate (read and write) to devices on the I

2

C commands to the micro controller of the

2

C busses

of the TV-set.

• Manually (by asking questions to you): Automatic

diagnosis is only possible if the micro controller of the

television is working correctly and only to a certain extend.

When this is not the case, ComPair will guide you through

the faultfinding tree by asking you questions (e.g. Does the

screen gives a picture? Click on the correct answer: YES /

NO) and showing you examples (e.g. Measure test-point I7

and click on the correct oscillogram you see on the

oscilloscope). You can answer by clicking on a link (e.g.

text or a waveform picture) that will bring you to the next

step in the faultfinding process.

By a combination of automatic diagnostics and an interactive

question / answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

Beside fault finding, ComPair provides some additional

features like:

• Up- or downloading of pre-sets.

• Managing of pre-set lists.

• Emulation of the (European) Dealer Service Tool (DST).

• If both ComPair and SearchMan (Electronic Service

Manual) are installed, all the schematics and the PWBs of

the set are available by clicking on the appropriate

hyperlink.

Example: Measure the DC-voltage on capacitor C2568

(Schematic/Panel) at the Monocarrier.Click on the ‘Panel’

hyperlink to automatically show the PWB with a highlighted

capacitor C2568. Click on the ‘Schematic’ hyperlink to

automatically show the position of the highlighted

capacitor.

5.4.1 Introduction

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

development on the European DST (service remote control),

which allows faster and more accurate diagnostics. ComPair

has three big advantages:

• ComPair helps you to quickly get an understanding on how

to repair the chassis in a short time by guiding you

systematically through the repair procedures.

• ComPair allows very detailed diagnostics (on I

is therefore capable of accurately indicating problem areas.

You do not have to know anything about I

yourself because ComPair takes care of this.

• ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the

microprocessor is working) and all repair information is

directly available. When ComPair is installed together with

the SearchMan electronic manual of the defective chassis,

schematics and PWBs are only a mouse click away.

5.4.2 Specifications

ComPair consists of a Windows based faultfinding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

or RS232 cable.

In case of the L01 chassis, the ComPair interface box and the

TV communicate via a bi-directional service cable via the

service connector (located on the Main panel, see also figure

8-1 suffix D).

The ComPair faultfinding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in two ways:

• Automatic (by communication with the television): ComPair

can automatically read out the contents of the entire error

buffer. Diagnosis is done on I

2

the I

C bus of the television. ComPair can send and

2

C level. ComPair can access

2

C level) and

2

C commands

5.4.3 How to Connect

1. First install the ComPair Browser software (see the Quick

Reference Card for installation instructions).

2. Connect the RS232 interface cable between a free serial

(COM) port of your PC and the PC connector (marked with

‘PC’) of the ComPair interface.

3. Connect the AC power adapter to the supply connector

(marked with ‘POWER 9V DC’) on the ComPair interface.

4. Switch the ComPair interface OFF.

5. Switch the television set OFF (remove the AC power).

6. Connect the ComPair interface cable between the

connector on the rear side of the ComPair interface

(marked with ‘I

2

C’) and the ComPair connector on the

mono carrier (see figure 8-1 suffix D).

7. Plug the AC power adapter in the AC power outlet and

switch on the interface. The green and red LEDs light up

together. The red LED extinguishes after approx. 1 second

while the green LED remains lit.

8. Start the ComPair program and read the ‘introduction’

chapter.

PC VCR I2CPower

Figure 5-6

9V DC

86532027_003.EPS

050898

Page 12

EN 12 L01.2A AB5.

Service Modes, Error Codes, and Fault Finding

5.4.4 How to Order

ComPair order codes:

• Starter kit ComPair + SearchMan software + ComPair

interface (excluding transformer): 4822 727 21629

• ComPair interface (excluding transformer): 4822 727

21631

• Starter kit ComPair software (registration version): 4822

727 21634

• Starter kit SearchMan software: 4822 727 21635

• ComPair CD (update): 4822 727 21637

• SearchMan CD (update): 4822 727 21638

• ComPair interface cable: 3122 785 90004

5.5 Error Buffer

The error code buffer contains all detected errors since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is written at the left side and all other errors shift one

position to the right.

5.5.1 How to Read the Error Buffer

Use one of the following methods:

• On screen via the SAM (only if you have a picture).

Examples:

– ERROR: 0 0 0 0 0: No errors detected

– ERROR: 6 0 0 0 0: Error code 6 is the last and only

detected error

–ERROR: 9 6 0 0 0: Error code 6 was first detected and

error code 9 is the last detected (newest) error

• Via the blinking LED procedure (when you have no

picture). See next paragraph.

•Via ComPair.

5.5.2 How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

• By activation of the CLEAR command in the SAM menu:

• When you exit SDM / SAM with the STANDBY command

on the remote control (when leaving SDM / SAM, by

disconnecting the set from AC power, the error buffer is not

reset).

• When you transmit the command DIAGNOSE-99-OK with

ComPair.

• If the content of the error buffer has not changed for 50

hours, it resets automatically.

5.5.3 Error Codes

In case of non-intermittent faults, clear the error buffer before

you begin the repair. These to ensure that old error codes are

no longer present.

If possible, check the entire contents of the error buffer. In

some situations, an error code is only the result of another error

code and not the actual cause (e.g., a fault in the protection

detection circuitry can also lead to a protection).

CL 16532008_047.pdf

Figure 5-7

210501

Page 13

Service Modes, Error Codes, and Fault Finding

EN 13L01.2A AB 5.

5.6 The Blinking LED Procedure

Via this procedure, you can make the contents of the error

buffer visible via the front LED. This is especially useful when

there is no picture.

When the SDM is entered, the LED will blink the contents of the

error-buffer.

Error-codes ≥ 10 are shown as follows:

– a long blink of 750 ms (which is an indication of the decimal

digit),

– a pause of 1.5 s,

– n short blinks (n = 1 - 9),

– when all the error-codes are displayed, the sequence

finishes with a LED blink of 3 s,

– the sequence starts again.

Example of error buffer: 12 9 6 0 0

After entering SDM:

– 1 long blink of 750 ms followed by a pause of 1.5 s,

– 2 short blinks followed by a pause of 3 s,

– 9 short blinks followed by a pause of 3 s,

– 6 short blinks followed by a pause of 3 s,

– 1 long blink of 3 s to finish the sequence,

– the sequence starts again.

5.7 Protections

time, measure the ‘+8V’. If this voltage is missing, check

transistor TS7480.

• Set is non-stop in hiccup mode Set is in over current

mode; check the secondary sensing (opto coupler 7515)

and the ‘MainSupply’ voltage. Signal ‘Stdby_con’ must be

logic low under normal operation conditions and goes to

high (3.3 V) under standby and fault conditions.

• Set turns on, but without picture and sound The screen

shows snow, but OSD and other menus are okay. Blinking

LED procedure indicates error 11, so problem is expected

in the tuner (pos. 1000). Check presence of supply

voltages. As ‘Vlotaux+5V’ at pin 5 and 7 are okay,

‘VT_supply’ at pin 9 is missing. Conclusion: resistor 3460

is defective.

• Set turns on, but with a half screen at the bottom.

Sound is okay Blinking LED (set in SDM mode) indicates

error 3. Check ‘Vlotaux+13V’ and ‘+50V’. If they are okay,

problem is expected in the vertical amplifier IC7471.

Measure with a scope the waveform on pin 17 of the UOC.

Measure also at pin 1 of IC7471. If here the signal is

missing, a defective resistor R3244 causes the problem.

If a fault situation is detected an error code will be generated

and if necessary, the set will be put in the protection mode.

Blinking of the red LED at a frequency of 3 Hz indicates the

protection mode. In some error cases, the microprocessor

does not put the set in the protection mode. The error codes of

the error buffer can be read via the service menu (SAM), the

blinking LED procedure or via ComPair. The DST diagnose

functionality will force the set into the Service-standby, which is

similar to the usual standby mode, however the microprocessor

has to remain in normal operation completely.

To get a quick diagnosis the chassis has three service modes

implemented:

• The Customer Service Mode (CSM).

• The Service Default Mode (SDM). Start-up of the set in a

predefined way.

• The Service Alignment Mode (SAM). Adjustment of the set

via a menu and with the help of test patterns.

See for a detailed description Chapter 9 paragraphs Deflection

and Power Supply.

5.8 Repair Tips

Below some failure symptoms are given, followed by a repair

tip.

• Set is dead and makes hiccuping sound ‘MainSupply’ is

available. Hiccuping stops when de-soldering L5561,

meaning that problem is in the ‘MainSupply’ line. No output

voltages at LOT, no horizontal deflection. Reason: line

transistor TS7460 is defective.

• Set is dead, and makes no sound Check power supply

IC7520. Result: voltage at pins 1, 3, 4, 5 and 6 are about

180 V and pin 8 is 0 V. The reason why the voltage on

these pins is so high is because the output driver (pin 6)

has an open load. That is why MOSFET TS7521 is not able

to switch. Reason: feedback resistor 3523 is defective.

Caution: be careful measuring on the gate of TS7521;

circuitry is very high ohmic and can easily be damaged!

(first connect measuring equipment to ground, then to the

gate).

• Set is in hiccup mode and shuts down after 8 s. Blinking

LED (set in SDM mode) indicates error 5. As it is unlikely

that µP ‘POR’ and ‘+8V protection’ happen at the same

Page 14

EN 14 L01.2A AB5.

Personal Notes:

Service Modes, Error Codes, and Fault Finding

E_06532_012.eps

131004

Page 15

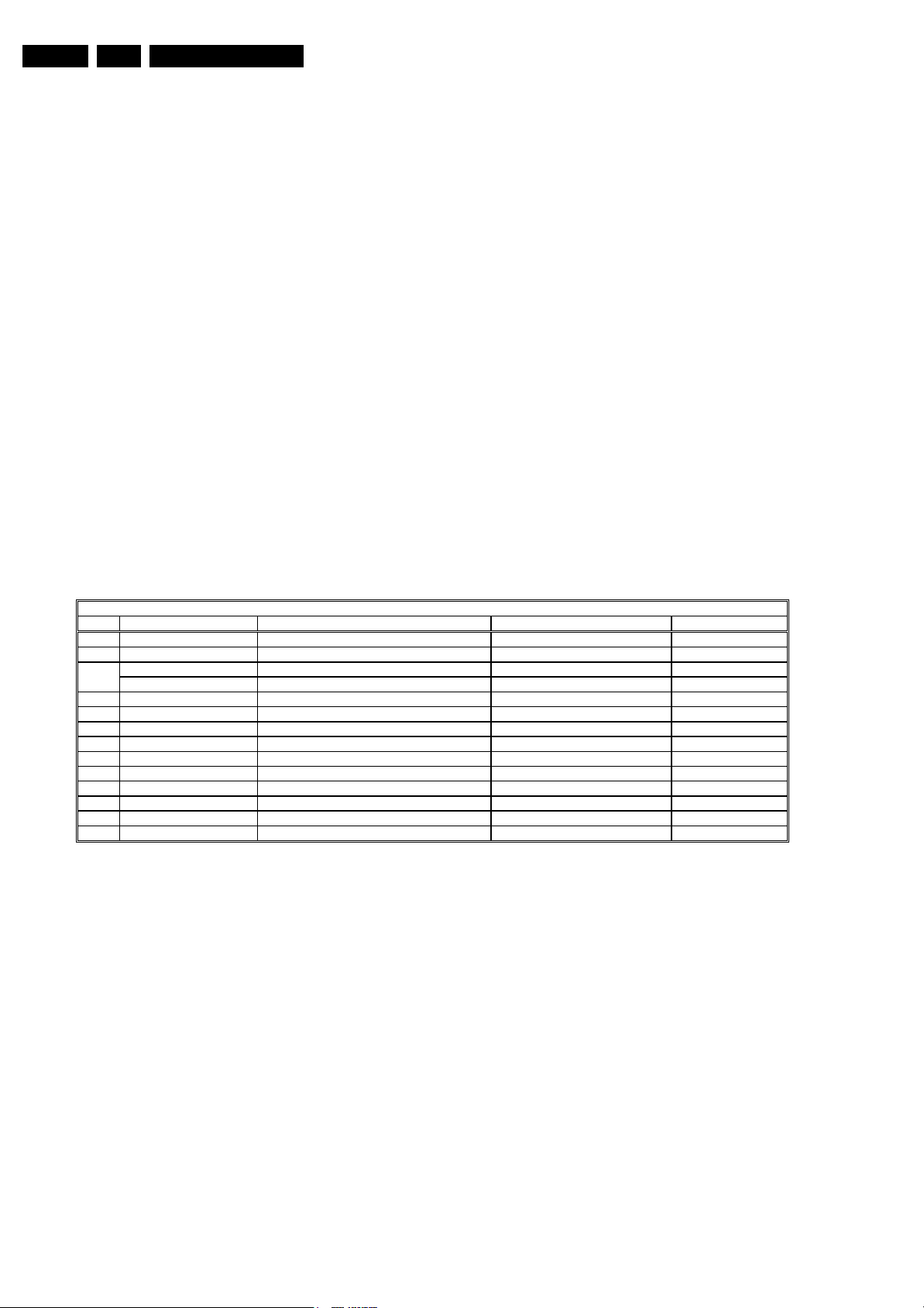

Block Diagrams, Testpoints Overviews, and Waveforms

6. Block Diagrams, Testpoints Overviews, and Waveforms

Block Diagram

EN 15L01.2A AB 6.

REAR I/O CINCH

A13

MONITOR

OUTPUT

YUV

INPUT

OR

SIDE AV

V

L

R

TUNER IF

A4

V

LOTAUX

FM

SDA

A7

SCL

A7

SEL-IF-LL-M-TRAP

A7

POWER SUPPLY

A1

150 - 250V

SINGLE RANGE

90 - 276V

FULL RANGE

AUDIO/VIDEO

A10

V

L

V-OUT

G-Y-IN

B-U-IN

R-V-IN

VT

FM

IF

AGC

1

0212

1

2

5500 :

5502

DRAIN

CTRL

CONTROL

IC

A5

A10

A10

A5

A5

A5

STEREO

V

L

R

6001

BZX79-C33

I3

10

I4

11

8

DRIVE R

SENSE

DEMAG

VCC

AV1

AV2

SVHS

6

5

4

1

3527

3523

3525

3522

3531

R

154

V

L

R

A

B

C

1002

1003

1004

1

R

P

+t

2

6500

AC

6502

P2

7101

V

L

R

Y

U

V

E1E

0253

3

0251

3

1

A2

+5V

0265

1

3001

3000

0231

0211

A12

0219

6

3

1

VT_SUPPLY

5001

1000 6, 7 9

2

ERR

10

TV

I1

I2

Degaussing

MAINS

SWITCH

SC1 L-OUT

SC1 R-OUT

FRONT I/O

A

B

C

FM-RADIO

TUNER

+

TV TUNER

5

4

7001

7002

FILTER

SELECTION

Coil

1

1500

T4E

MONO

V

L

7520

TEA1507

3

CVBS1-IN

9

11

10

6

Y-CVBS-IN

5

32

4

CVBS-FRONT-IN

L-FRONT-IN

R-FRONT-IN

FM

VIF_1

VIF_2

SIF1

SIF2

RF_AGC

3504

R

3

+t

3

+t

3503

6501

2503

6503

7521

STP7NB60FP

D

G

S

3526

6520

2521

3519

P3

HOT GROUND COLD GROUND

L1-IN

R1-IN

STATUS2

C-IN

L2-IN

R2-IN

A5

P1

1

2

3

5

6

7

N.C.

3

4

A5

A5

A10

A10

A7

A10

A5

A10

A10

A10

A5

A10

A10

VIDEO IF, SOUND IF

18

19

22

23

24

A13

A12

2

5520

SEL_MAIN_FRNT_RR

A7

A9

A12

A13

A13

A9

A12

A13

A13

A9

SEL_MAIN_FRNT_RR

A7

A12

A13

7209, 7210

FM RADIO

PRE-AMPLIFIER

7200-A

TDA95XX

VIDEO

IF

AGC

QSS

SOUND

IF + AGC

SOUND

FM-DEMOD.

DE-EMPH.

L1-IN

LF FRONT-IN

7580

1515

43

ENERGIZING

1

10

9

13

12

1

7515

TCET1103

2

SOURCE SWITCHING

SC2-CTRL

L-FRONT-IN

L1-IN

L2-IN

SC1-LOUT

R-FRONT-IN

R1-IN

R2-IN

SC1-R-OUT

CVBS-FRONT-IN

Y-CVBS-IN

CIRCUIT

7801

HEF4052BT

9

SWITCH

LOGIC

10

1

5

3

2

4

12

14

15

11

FMR

VIDEO

PLL

DEMOD.

QSS MIXER

AM DEMOD.

AUDIO

SWITCH

28 29

V

6562

6564

5562

6560

5560 5563 5561

6561

V

DEFL

7802

HEF4053BT

9

SWITCH

LOGIC

5

2

LOTAUX

7561, 7562

7564

POWER

DOWN

CIRCUIT

A2

7540, 6540

REFERENCE

CIRCUIT

7541, 7542

STANDBY

CIRCUIT

AMPLIFIER

+13V

3564

2564

13

4

VIDEO

SOUND

AMPL.

+ AVL

2561

SY-CVBS-IN

3558

7560

P5

3543

3544

7803

SC1-LIN

A13

SC1 L-OUT

7804

SC1-R IN

A13

SC1 R-OUT

A5

V10

38

+8V

33

48

+3.9V

P4

+3.3V

2567

M_AUX

3570

MAIN AUX

AUDIO SUPPLY GND

ERR

7

POWER DOWN

P6

95V

MAIN SUPPLY

STDBY_CON

A9

A9

7206

3230

MONO/AM_

MONO_SOUND

12V

A8 A9

A6

A7

AUDIO AMPLIFIER

A8

MONO SETS ONLY

MONO/AM-MONO-SOUND

A5

A7

TREBLE-BUZZER-HOSP-APP

A7

NICAM, 2CS BTSC DECODER

A9

QSS-AM-DEM-OUT

FMR

MONO/AM-MONO-SOUND

A11

A5

SC1-L IN

A10

SC1-R IN

A10

SDA

A7

SCL

A7

QSS_AM_DEM_OUT

AUDIO CARRIER

+8V

7201

3208

3211

SYNCHRONISATION

A6

EHT INFO

A2

SANDCASTLE

N.C.

H FLYBK

A2

POWER-DOWN

A7

EHT INFO

A2

EHT o

A2

ERROR CODE LIST

Error Description

0 No error

1 X-Ray / over voltage protection (USA only)

2 High beam (BCI) protection

3 Vertical guard protection

4 I2C error while communicating with the sound processor

5 Power ON reset (POR bit) 3.3V protection / +8V protection

6 General I2C error

7 Power Down (over current) protection

8 EW protection (Large Screen only)

9 I2C error EEPROM error

10 I2C error PLL tuner

11 Black current loop instability protection

BASS-PANORAMA

7834

7835

3834 2847

A7

3833

A6

3832

FILTERS

5201

1200

5.5MHz

1201

6MHz

7202

1202

4.5MHz

3259

3242

7241

3247

7831

MSP34X5G

47

DEMODULATOR

44

41

42

8

7

7203

2254

11

31

S1

34

7941:7943

NICAM, 2CS,

AM, FM

INPUT

SWITCHING

ERR

4

3213

3210

SEL-IF-LL-M-TRAP

7200-D

TDA95XX

VIDEO IDENT

H/V SYNC

SEPARATOR

H-OSC

+PLL

V9

A13

A10

A13

25

24

31

30

4

51

52

2203

C-IN

SY-CVBS-IN

CVBS1-IN

H

V

A10

MAIN-OUT-L

A9

MAIN-OUT-R

MONO/AM-MONO-SOUND

A8

SC1-L OUT

SC1-R OUT

SC2-CTRL

1831

18M432

40

45

44

42

A7

5241

9

H-DRIVE

2nd LOOP

H-SHIFT

TXT/OSD

DISPLAY

V-DRIVE

+

GEOMETRY

EW

+

GEOMETRY

MAIN-OUT-L

OR

A5

A10

A10

A10

7200-C

TDA95XX

I/O

SWITCHING

VIDEO

FILTERS

VIDEO

IDENT

DECODER

+8V

S2

3251

30 H DRIVE

S3

3244

17

S4

3249

16

S5

3250

15

OR

V4

Y-DELAY

PAL/NTSC

SECAM

V DRIVE+

V DRIVE-

N.C.

A7

47

R-Y

B-Y

VOLUME MUTE

MAINAUX

OR

R-

R+

L+

L-

7205

BASE

BAND

DELAY

A13

A13

A13

A2

A3

VDRIVE+

VDRIVE-

7901 AN7522N (STEREO)

7902 AN7523N (MONO)

62 L+

8

9

ERR

1

7

A12

L+

L-

R-

R+

E1

0254

0246

1

1

2

2

3

3

4

4

5

5

3222

3221

RGB

MATRIX

RGB

INSERT

Y

BLACK

STRETCH

U

WHITE

V

STRETCH

51 52 53 50 54

R-V-IN

G-Y-IN

B-U-IN

FBL-1N.C.

LINE DEFLECTION

V

+13V

LOTAUX

V

A1

DEF

7403

7404

7401

L1

FRAME DEFLECTION

F1

3474

3479

WITHOUT

SIDE AV

A1

A2

4L-

A3

10 R-

A4

12 R+

HEADPHONE

L+

L-

R-

R+

HEADPHONE

L+

L-

R-

R+

V-OUT

A13

+8V

OSD

RGB

R

CONTROL

G

OSD TEXT

B

INSERT

BLUE

STRETCH

WHITE-P.

ADJ

7204

EHT INFO

PROC.

M_AUX

6406

BAV70

3404

5444

DRIVER

STAGE

HFLYBK

A6

VLOT AUX +13V

7471

TDA9302H

7

1

F2

3475

+HP

0246

4

3

2

1

0255

4

3

2

1

6471

2

+

OP. AMP

-

56

R

57

G

B

58

55

MAIN SUPPLY

L3

7402

BUT11APX

L2

2473

6

FLYBACK

GENERATOR

THERMAL

PROTECTION

4

-13V

95V

L

R

L

R

3201

3202

3203

3204

3235

A12

6692

TSOP1836

V5

V6

V7

V9

BLK-IN

A2

EHT INFO

LINE

OUTPUT

CIRCUIT

FRONT CONTROL

+3.3V

LOCAL

KEYBOARD

0243 0245

1

2

3

4

5

BLK

6

A2

6409

F5

3

F3

5

F4

IR IR

6691

LED

KEYBOARDPROTN

B

1

2

3

4

5

6

+160V

3416

VIDEOSUPPLY

2

7

1

0221

1

2

HOR.

DEFL.

COIL

ERR

3

V_GUARD

0222

3471

1

2

3471

A7

CRT

V11

V13

BLKCURINFO

5445

A2

VERT.

DEFL.

COIL

CONTROL

STATUS1

STATUS2

A13

A1

POWER DOWN

LED

KEYBOARD-

_PROTN

7311:

-

7313

V12

3347

0244

0220

321

EHT

FOCUS VG 2

8

5

4

N.C.

3

10

9

6

ERR

5

67

N.C.

1

69

5

80

3316 3326

7321:

-

7323

FILAMENT

6402

6410

6405

6423

3411

6413

3421

7408

7200-B

TDA95XX

TRANSCEIVER

ROM

RAM

1/10

PAGES

MEMORY

TELE

TEXT

SYNC

CVBS

R

G

B

BL

COR

3317

7331:

7333

3423

3428 3427

+3.3V

66 61 59

I/O

IIC

BUS

I/O

PORTS

OSD

TELETEXT

DISPLAY

-

ERR

11

2417

2419

3336

R

5341

7407

L7

3413

3412

56035602

PWM-

G

B

VST

DAC

CPU

3317

3327

3337

3422

L8

7406, 7409

7405

5604

68 7

72

71

3

6

70

78

77

73

63

64

H

V

V15

V16

3349

V

LOTAUX

L4

L5

L6

PROT

CIRCUIT

PROT

CIRCUIT

+3.9V

C4

C5

C1

12MHz

C2

V14

7

5

3

3425

3431

2422

2410

+3.3V

7602

M24C08

EEPROM

8

(NVM)

6

ERR

5

9

36063607

3625

SDA

3624

SCL

ERR

6

SEL-IF-LL-M-TRAP

STANDBY-CON

SEL-MAIN-FRONT-RR

BASS PANORAMA

TREBLE-BUZZER-HOSP-APP

VOLUME/MUTE

SDM

9641

9631

1660

CONNECTION

SDA

SCL

+160V

R

G

B

3348

3350

2

G

V FOCUS

V

+13V

ERR

2

EHT INFO

A5 A6

V

+13V

LOTAUX

V

+5V

LOTAUX

+8V

FILAMENT

-13V

VT_SUPPLY

A4

V

A3

GUARD

BLK-IN

A5

EHT o

A6

ERR

2

CL 16532052_001.eps

3611

36033604

SDA

SCL

A4 A5

A1

A10

A8

A8

A8

SERVICE

COMPAIR

CRT

230801

EHT

A4

A7

A9

0217

25kV

1

2

3

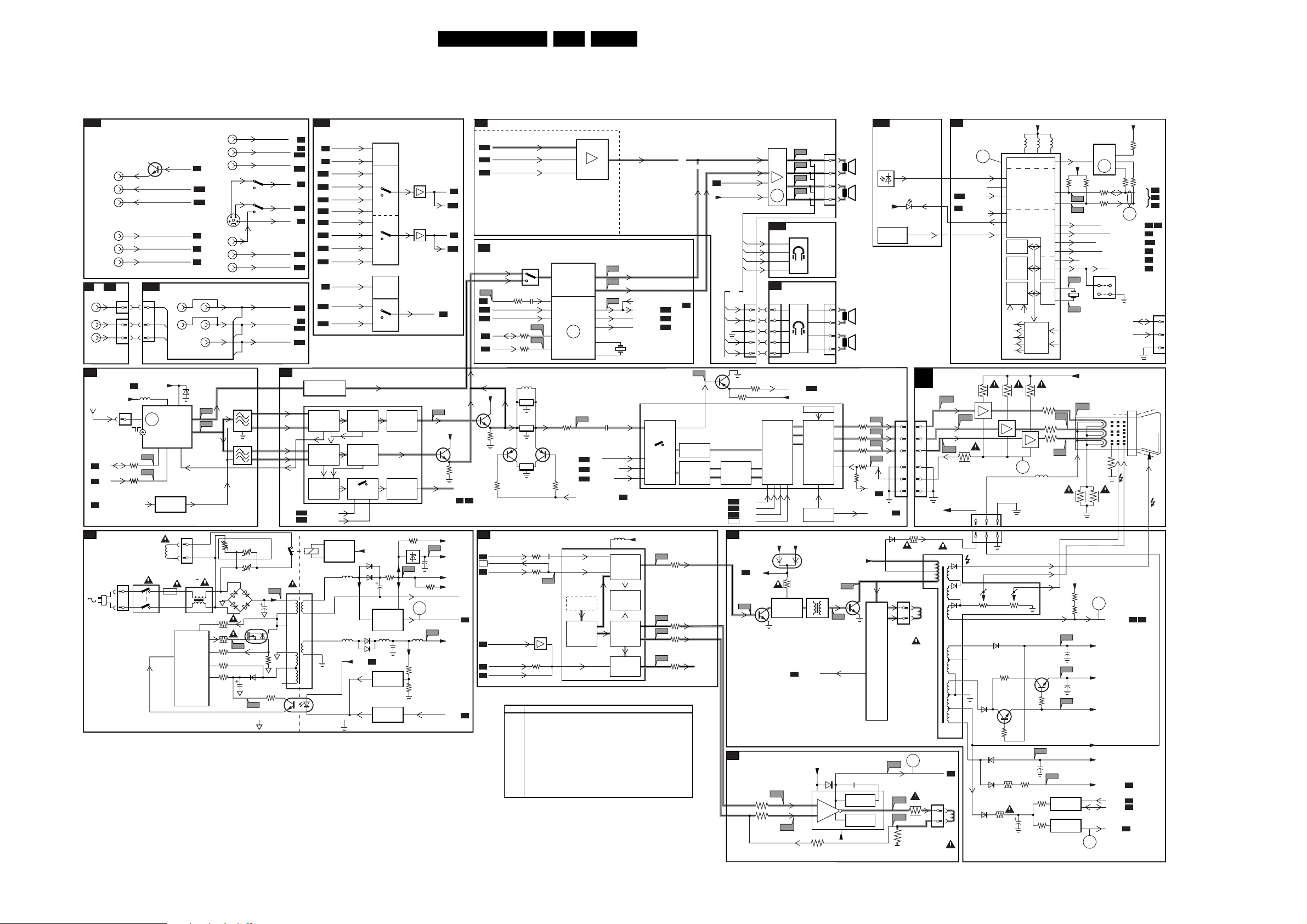

Page 16

Block Diagrams, Testpoints Overviews, and Waveforms

Testpoint Overview

Main Panel

Copper Track Side

NICAM + 2CS + BTSC

7831

CRT Panel Copper Track Side

5

4

3

2

12

11

6

7

8

9

10

5

6

7

8

9

HOT GROUND

HOT GROUND

AUDIO OUTPUT

7901 OR 7902

14

7520

85

SUPPLY

CONTROL

1

7521

D

SUPPLY

A1

A2

A3 - A4

S

G

2V / div DC

5us / div

2V / div DC

500us / div

2V / div DC

500us / div

7200

A6

2V / div DC

200us / div

A7

2V / div DC

200us / div

A11

1V / div DC

500us / div

TV-PROC.

7402

C

C1

C2

C4

EN 16L01.2A AB 6.

E

LINE

B

1V / div DC

500us / div

1V / div DC

500us / div

2V / div DC

200us / div

C5

2V / div DC

200us / div

F1

500mV / div DC

5ms / div

F2

500mV / div DC

5ms / div

7471

7

1

FRAME

F3

10V / div DC

5ms / div

F4

1V / div DC

5ms / div

F5

10V / div DC

5ms / div

A1 B3

A2 B3

A3 A3

A4 A3

A5 C1

A6 B1

A7 B1

A8 C2

A9 B2

A10 B3

A11 C2

A12 B2

A13 C3

C1 B4

C2 B4

C3 B5

C4 B5

C5 B5

C6 E1

F1 D6

F2 D6

F3 C6

F4 C6

I1 A6

I2 A6

I3 A6

I4 A6

L1 C4

L2 E5

L3 E5

L4 D5

L6 C5

L8 C6

L9 D5

P1 E3

P2 E3

P3 D3

P4 C4

P5 C4

P6 D5

S1 A4

S2 A4

S3 A5

S4 A5

S5 A4

V1 B6

V2 B6

V3 B5

V4 B4

V5 B4

V6 B4

V7 B4

V8 B4

V9 A4

V10 A4

I1

2V / div DC

200us / div

I2

2V / div DC

200us / div

I3

20mV / div DC

1ms / div

I4

500mV / div DC

250ns / div

L1

500mV / div DC

20us / div

L2

2V / div DC

20us / div

L4 = +13V

L5 = +5V

L6 = +8V

L7 = -13V

L8 = +34V

L10 = +176V

L9

2V / div DC

20us / div

P1

50V / div DC

20us / div

P3

5V / div DC

50ms / div

P2 = +308V (317V)

P4 = +3V3

P5 = +12V4 (+3V9)

P6 = +95V

S1

2V / div DC

20us / div

S2

500mV / div DC

20us / div

S3

500mV / div DC

5ms / div

S4

500mV / div DC

5ms / div

V4

100mV / div DC

20us / div

V5

1V / div DC

20us / div

V6

1V / div DC

20us / div

V7

1V / div DC

20us / div

V8

2V / div DC

5ms / div

V9

500mV / div DC

10us / div

V10

1V / div DC

500us / div

V11

1V / div DC

20us / div

V12

1V / div DC

20us / div

V13

1V / div DC

20us / div

V14

50V / div DC

20us / div

V15

50V / div DC

20us / div

V16

50V / div DC

20us / div

CL 16532008_033.eps

240801

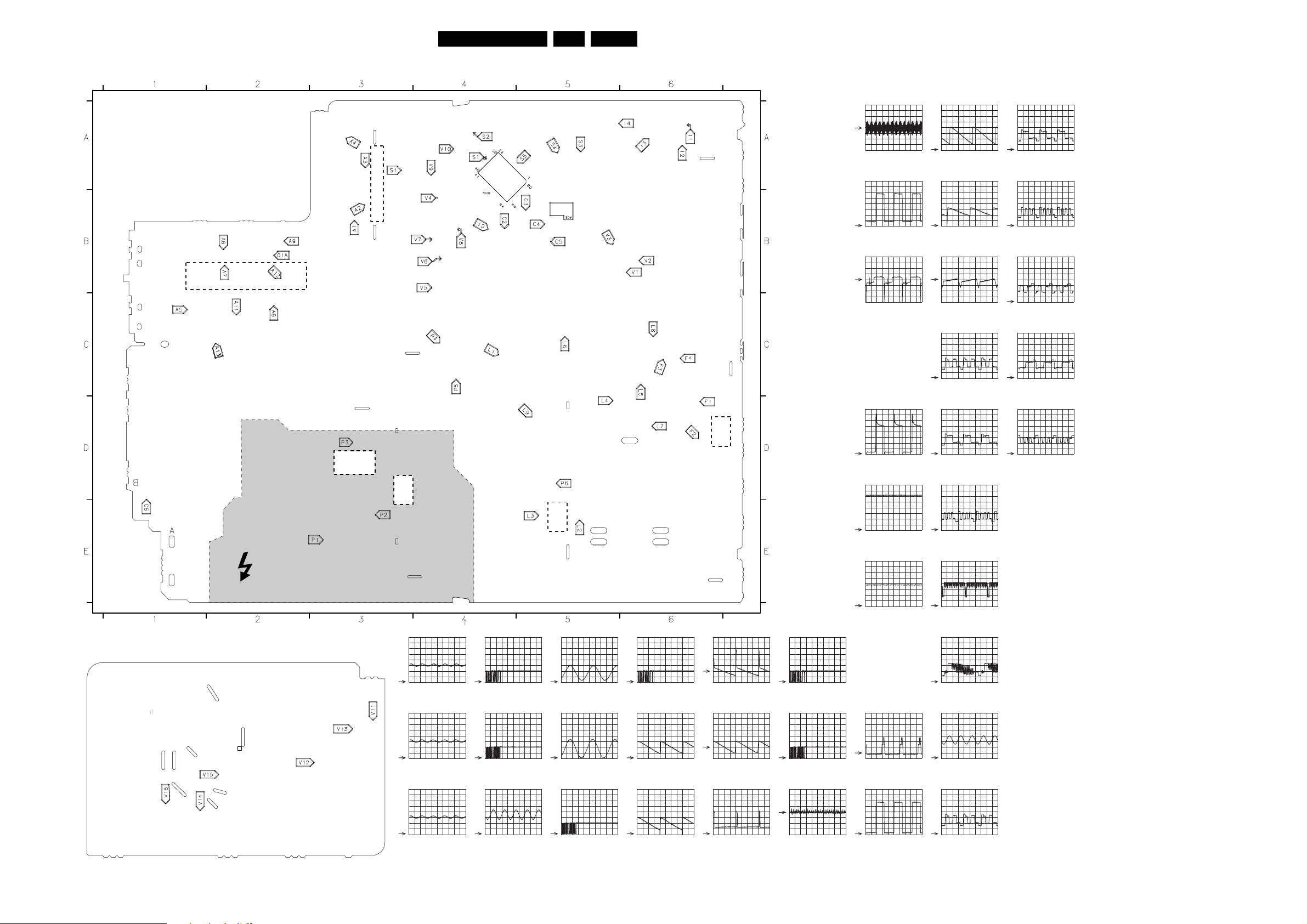

Page 17

Block Diagrams, Testpoints Overviews, and Waveforms

I2C and Supply Voltage Diagram

POWER SUPPLY

A1

0231

0211

150 - 250V

SINGLE RANGE

90 - 276V

FULL RANGE

MAINS

SWITCH

I2C BUS INTERCONNECTION DIAGRAM

CONTROL

A7

7200-B

SET

ERR

72

71

68

5

PROCESSOR

PART OF

VIDEO-

PROCESSOR

ERROR CODE LIST

Error Description

0 No error

1 X-Ray / over voltage protection

2 High beam (BCI) protection

3 Vertical guard protection

4 I2C error while communicating with the sound processor

5 Power ON reset (POR bit) 3.3V protection / +8V protection

6 General I2C error

7 Power Good (over current) protection

8 EW protection (Large Screen only)

9 I2C error EEPROM error

10 I2C error PLL tuner

11 Black current loop instability protection

C4

C5

SDA

SCL

+3.9V

3607 3606

1500

+3.9V

T4E

3

5500 :

5502

7520

TEA1507

DRAIN

CTRL

CONTROL

3625

3624

7

DRIVE R

SENSE

DEMAG

IC

3604

7602

M24C08

EEPROM

(NVM)

ERR

VCC

EN 17L01.2A AB 6.

B

LINE DEFLECTION

V DEF

A2

MAIN SUPPLY

M_AUX

VLOT AUX +13V

6467

H-DRIVE

3487

2450

3404

LINE

OUTPUT

5451

6406

5445

EHT

FOCUS

LOT

2

VG2

6409

73

9

6405

6

6410

8

6402

5

VLOT AUX +5V

NICAM 2CS -

A9

BTSC DECODER

VLOT AUX +5V

5833

AUDIO VIDEO

A10

SOURCE SWITCHING

+8V

3801

REAR I/O CINCH

A13

+8V (TO 7101-C)

7408

+8V

34116413

34286423

3421

34243423

+5VA

5832

to 2419

7407

+8V

SUPPLY

FILAMENT

3412

3413

6420

TO E-7406

46

33

VIDEO

3416

0220

2

1

-13V

3427

VT_SUPPLY

VLOT AUX +5V

C-6408

B-7409

3422

6419

+8V

VLOT AUX +5V

VLOT AUX +13V

3415

7831

BTSC

DECODER

+6V8

TO

6560

6561

5560 5563

6500

6501

AC

6502

3527

8

3523

6

3525

5

3522

4

3531

1

3603

65

9

7521

STP7NB60FP

G

P2

2521

ERR

6

0217

1

2

3

P1

5520

1

2503

6503

3526

6520

P3

SDA

SCL

FOR

COMPAIR

2

3

D

S

5

6

7

N.C.

3519

3

4

HOT GROUND COLD GROUND

TUNER IF

A4

I1 I2

3001

1000

TUNER

ERR

10

13

12

10

9

1

7515

TCET1103

2

3000

45

SDA

SCL

5562

7540, 6540

REFERENCE

CIRCUIT

7541, 7542

STANDBY

CIRCUIT

NICAM, 2CS,

A9

BTSC DECODER

3833

A7 A8

7831

MSP34X5G

SOUND

DECODER

ERR

4

6564

6562

3549

3832

78

2561

3564

2564

7561, 7562

7564

POWER

DOWN

CIRCUIT

A

3543

3544

P6

5561

A

P5

3537

AUDIO SUPPLY GND

7560

3557

3558

STDBY_CON

SDA

SCL

MAIN SUPPLY

12V

M_AUX

MAIN AUX

POWER DOWN

V DEFL.

P4

2567

A7

95V

+3.3V

+3.9V

CONTROL

A7

+3.3V

+3.9V

(TO 3606

3606,3633)

SYNCHRONISATION

A6

+3.3V (TO 3256)

FRONT CONTROL

A12

+3.3V

4693

A8

MAIN AUX

AUDIO SUPPLY

GND

+3.3V

5602

5603

5604

3611

+3V3A

AUDIO AMPL.

OR

OR

7200-B

66

61

uC

59

7602

8

EEPROM

(NVM)

7901

1

OUTPUT

STEREO

7902

1

OUTPUT

AUDIO

AUDIO

MONO

CRT

EHT

ANODE CRT

FOCUS

FOCUS CRT

VG2

VG2 CRT

0244

160V

3

5341

2

1

TUNER IF

A4

VT_SUPPLY 33V

VLOT AUX +5V

FRAME DEFLECTION

A3

VLOT AUX +13V

POWER SUPPLY

A1

VIDEO IF

A5

SYNCHRONISATION

A6

+8V

CONTROL

A7

AUDIO AMPLIFIER

A8

3349

3350

6001

BZX79

-/C33

5001

+8V (TO 3008)

-13V

VLOT AUX

VLOT AUX +13V

TO DEGAUSSING CIRCUIT

VLOT AUX +5V

(TO 2234)

+8V

5202

+8VA (TO 3248)

5241

+8V (TO 4-0217) NOT USED

VLOT AUX

+8V (TO 3948, 3950)

VLOT AUX

3336

3326

3316

+8VA

+5V (TO 3619)

+5V (TO 9921)

CL 16532052_002.eps

VIDEO

OUTPUTS

C-7332

C-7322

C-7312

TO CRT

FILAMENT

1000

9

TUNER

6

7

7471

4

FRAME

OUTPUT

3

7200-A

VIDEO

39

7200-D

SYNC

9

PROC.

IF

230801

Page 18

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Mono Carrier: Power Supply

123456

A1

POWER SUPPLY

A

B

C

D

E

F

ITEM NO

G

DEGAUSSING COIL

0212

1

2

*

0231

*

0211

MAINS

150 - 276 V SINGLE RANGE

90 - 276 V FULL RANGE

SDKV

2

1

24

13

MAINS SWITCH

3500

3501

P3

3531

0R

22u

2521

6520

BYD33D

22R

3521

*

SNDAMP1X4W-MN15RF-AP

2566 47uF/25V

3560 47R

3564 0R1

3567 2K2

3568

3570 -

BC857B

7562

BC857B

7564

"S" FOR MAINS 120V AC 170V (177V)

..V.. Normal Operation

(..V..) Standy Mode

SNDAMP2X3W-ST-

NA

47uF/25V

47R

0R1

2K2

8K2

8K2

BC857B

BC857B

HOT GROUND

COLD GROUND

220V AC 309V (317V)

9500

56

9501

*

3M3

3M3

2528

RES

6522

*

2505

16V8

(13V8)

RES

1V3

3520

2n2

T4E.250V

7520

TEA1507

1

Vcc

2

Gnd

3

Ctrl

1K2

2520

1500

470n

2500

3506

SUPPLY

MANAGEMENT

FREQUENCY

CONTROL

INPUT

CONTROL

CIRCUIT

BURST

DETECTOR

REGION NA

MAINS RANGE

AUDIO OUTPUT

100n

SET

1515 - LKS1AF

2503

2505 1KV 2N2

2516

2580 - 25V 47U

3503 PTC 120V 10R PTC 120V 10R

3504 - 3505 - 3508 - 1M5 1M5

3521

3523 RST FUSE 100R

3544

3545 82K 82K 82K

3552 4K7 4K7 4K7

3561 100R 100R 100R

3563 4K7 4K7 4K7

3580 - 47K 47K

1

1

5500

*

DMF-2820

2

14

*

5501

23

DMF-2405

5502

*

C914

220R

3507

DSP

VOLTAGE

CONTRLLED

OSCILLATOR

OVER

TEMPERATURE

PROTECTIOM

POWER-ON

RESET

13V S1W-19V S3W-19V

220V 220U 200V 220U

-

4R7 4R7

6K8

3

+t

Rs

Rp

4

3

46

31

LOGIC

CONTROL

CIRCUIT

MAXIMUM

ON-TIME

PROTECTION

LR

-

-

RST FUSE 100R

6K8 6K8

3504

*

2

3508

*

1M5

3505

*

V

3511

V

RST FUSE 100R

+t

3503

*

CURRENT SOURCE

VALLEY

CURRENT SOURCE

OUTPUT

DRIVER

LKS1AF

200V 220U

-

-

25V47U

PTC 120V 10R

-

-

22R

82K

10R - PTC

9502

*

3502

*

t

0213

*

2

1

START-UP

START-UP

CURRENT

SENSING

OVER

POWER

PROTECTION

PTC 200V 100R

2501

B57237

For ITV

ONLY

LA

FR

2X5W2X5W

201

-

400V 220U

1KV 2N2

-

-

-

-

-

4R7

RST FUSE 47R

6K8

82K

82K

4K7

220R

8K2

-

2502

Drain

HVS

Demag

Sense

Driver

EN 18L01.2A AB 7.

6500

2n2

1N5062 (COL)

6502

1N5062 (COL)

2n2

"$"

8

7

0V

4

3525

0V

5

1K

6

2V

REGION NA

MAINS RANGE

AUDIO OUTPUT

SET

3591

3595 180K 180K

3596

4411 SMD JUMPER SMD JUMPER SMD JUMPER

4562

5500 - 5501 - 5502 FL MAINS 5MH FIL MAINS 5MH

5520 SS28011-04B

5562 BEAD 100MHZ 50R

6561

6567

6570

6580

7515

7521

7580

6501

1N5062 (COL)

6503

1N5062 (COL)

47K

3529

6523

1N4148

0V

7522

4K7

3530

3522

BC847B

330K

2522

100n

3524

56K

13V S1W-19V S3W-19V

SMD JUMPER SMD JUMPER

180K 180K

SMD JUMPER SMD JUMPER

BEAD 100MHZ 50R

-

-

BZX384-C6V8-BZX384-C6V8

STP5NC50FP

-

0V

SS28011-04B

BYW76-RAS15/10

TCET1103TCET1103

STP5NC50FP

P1

2n2

2506

3527

2K2

2V5

7521

*

STP7NC80FP

2V5

G

3528

10K

2524

RES

2526

3523

100R

*

2525

470p

LR

2X5W

-

BAS816

BC857B

220u

2503

*

*

P2

D

S

0V

1n

3526

*

SMD JUMPER

180K

180K

SMD JUMPER

-

-

FIL MAINS 5MH

SS28011-04B

BEAD 100MHZ 50R

BYW76-RAS15/10

-

BZX384-C6V8

BAS816

TCET1103

STP5NC50FP

BC857B

7891011

VlotAux+13V

1515

2n2

2504

2507

9520

*

5521

"$"

2523

6521

0R15

TCET1103(G)

BEAD 100MHZ 80R

9503

*

"$"

RES

2508

1n5

2527

RES

3519

270R

7515

LA

FR

2X5W

201

SMD JUMPER

180K

180K

SMD JUMPER

SMD JUMPER

FIL MAINS 20MH

-

-

SS359B4-09

BYW76-RAS15/10

BZX384-C4V7

BZX384-C6V2

-

TCET1104

STP7NC80ZFP

-

*

G5PA

14

23

2516

*

330p

EAR

2515

1n5

5520

*

SS59B4

1

470p

3

5

6

7

470p

1V3

8V9

10V

16V4

*

*

132

12

11

10

9

8

3569

6570

7580

BC857B

5K6

1V8

6581

BAS216

*

12V4

5562

*

2569

470p

5560

2565

470p

3540

RES

470R

0R

3546

9V

7542

0V

BC857B

0V

3566

2K2

2568

BZX384-C6V8

1u

6580

BAS216

*

11V8

2562

1n

6562

EGP20DL

6564

SB340

3561

220R

6563

BAS216

BZX384-C4V7

BYW76

*

BYW76

3541

7541

PDTC114ET

2541

1n

3552

10K

6569

*

2560

6560

6561

6541

3565