Philips 200WS8FS/00, 200WS8FB/00, 200WS8FB/69, 200WS8FB/75, 200WS8FB/93 Service Manual

20” TFT LCD COLOR MONITOR

ServiceService

ServiceService

ServiceService

Service Manual

TABLE OF CONTENTS

Description

Important Safety Notice .............................................

Technical Data & Power Management .......................

Connection to PC .......................................................

OSD Menu Control Level Structure ...........................

Advanced OSD Adjustment .......................................

OSD Attention Signal .................................................

Safety and troubleshooting information ....................

Definition of Pixel Defects ..........................................

...........

Wiring Diagram ..........................................................

Mechanical Instructions .............................................

F/W Upload Instructions ............................................

DDC Instructions ........................................................

DDC DATA .................................................................

Safety Instructions, Warnings and Notes ........

Page

2

3~4

5

6

7

8

9

10~11

12

13~15

16~17

17~20

21~22

23

Description

Block Diagram ...........................................................

Scaler Board Schematic Diagram ..............................

Power Board Schematic Diagram ..............................

Button Board Schematic Diagram .............................

Scaler Board Layout Side View .................................

Power Board Layout Side View .................................

Button Board Layout Side View .................................

Exploded View ...........................................................

Recommended Parts List ..........................................

Spare Parts List .........................................................

Different Parts List .....................................................

General Trouble Shooting Guide ...............................

General Product Specification ...................................

Safety Check Process ...............................................

Page

24

25~29

30~31

32

33~34

35~36

37

38

39~47

48~49

50

51~65

66~79

80

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINE.

Subject to modification

Oct. 23th 2007

EN :

200WS8FS/00

200WS8FB/00

200WS8FB/69

200WS8FB/75

200WS8FB/93

2

200WS8 LCD

Proper service and repair is important to the safe, reliable

operation of all Philips Consumer Electronics Company**

Equipment. The service procedures recommended by Philips

and described in this service manual are effective methods of

performing service operations. Some of these service

operations require the use of tools specially designed for the

purpose. The special tools should be used when and as

recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. Philips could not possibly know, evaluate and

advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, Philips has not

undertaken any such broad evaluation. Accordingly , a

servicer who uses a service procedure or tool which is not

recommended by Philips must first satisfy himself thoroughly

that neither his safety nor the safe operation of the equipment

will be jeopardized by the service method selected.

* * Hereafter throughout this manual, Philips Consumer

Electronics Company will be referred to as Philips.

WARNING

Critical components having special safety characteristics are

identified with a by the Ref. No.in the parts list and

enclosed within a broken line*

(where several critical components are grouped in one

area) along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability , express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability .

* Broken Line

Important Safety Notice

FOR PRODUCTS CONTAINING LASER :

DANGER - In visible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

CAUTION - Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

CAUTION - The use of optical instruments with this

Product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH

THEIR PART NUMBERS IN THE PARTS LIST SECTION

OF THIS SERVICE MANUAL.

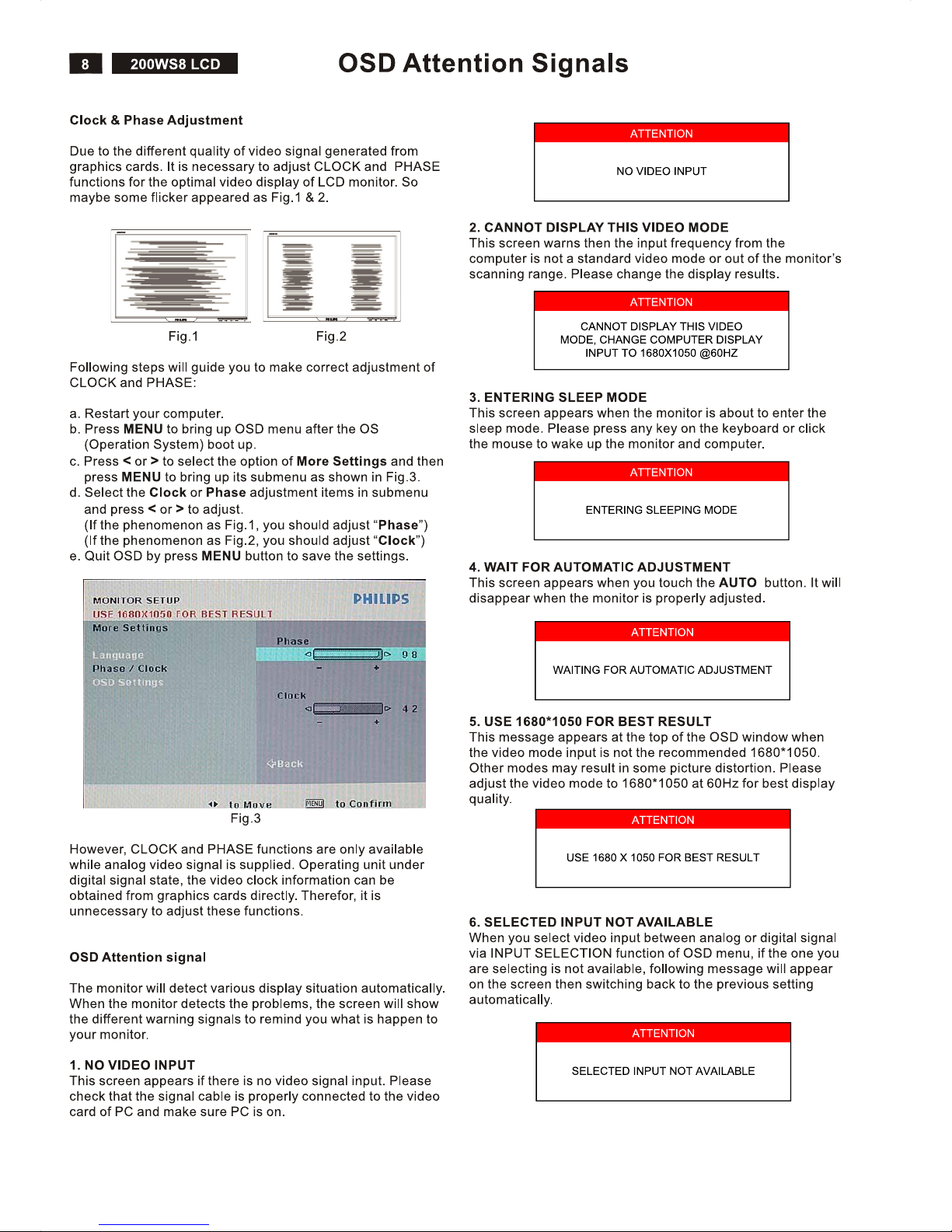

Take care during handling the LCD module with backlight

unit

- Must mount the module using mounting holes

four corners.

- Do not press on the panel, edge of the frame

electric shock as this will result in damage to the screen.

- Do not scratch or press on the panel with any sharp

such as pencil or pen as this may result in

panel.

- Protect the module from the ESD as it may damage

electronic circuit (C-MOS).

- Make certain that treatment persons body are

through wrist band.

- Do not leave the module in high temperature and in

of high humidity for a long time.

- Avoid contact with water as it may a short circuit

the module.

- If the surface of panel become dirty, please wipe it

a soft material.( Cleaning with a dirty or

damage the panel.)

arranged in

strongly or

objects,

damage to the

the

grounded

areas

within

off with

rough cloth may

200WS8 LCD

Technical Data

3

1. General Specification

AUO M201EW02 V1/V8

1.1 Panel characteristic

Panel source

Screen type

Screen dimensions

Resolution

Outside dimensions

Pixel pitch (mm)

Color pixel arrangement

Display surface

Color depth

Backlight

View angle (CR>10)

Contrast ratio

White luminance

Color gamut

Response time

Active area (mm)

Resolution

Outside dimensions

Pixel pitch (mm)

Color pixel arrangement

Display surface

Color depth

Backlight

Active area (mm)

View angle (CR>10)

Contrast ratio

White luminance

Color gamut

Response time

Resolution

Outside dimensions

Pixel pitch (mm)

Color pixel arrangement

Display surface

Color depth

Backlight

Active area (mm)

View angle (CR>10)

Contrast ratio

White luminance

Color gamut

Response time

1.2 Scanning frequencies

Horizontal scan range

Vertical scan range

1.3 Video

Video dot rate

Input impedance

(Analog signal input)

- video

- Sync

CPT CLAA201WA04

LPL

LM201WE3-TLH2

: AUO

:

: CPT CLAA201WA04

: LPL

: TN+film

: 20 inches (diagonal) 16:10

: 1680 x 1050 (WXGA+)

: 459.4 (W) x 296.4 (H) x 16.6 (D)

: 0.258 x 0.258

: R. G. B. Vertical Stripe

: Hard-coating (3H), Non-glare type

: 16.7M colors

: 4 lamps

: >= 160 for H/V (typical)

:>=1000:1

: >= 300 nits (7.0mA)

:>=72%

:5ms

M201EW02_V8

LM201WE3-TLH2

M201EW02_V1

AUO

: 433.44 (H) x 270.90(V)

: 1680 x 1050 (WXGA+)

: 459.4 (W) x 296.4 (H) x 16.6 (D)

: 0.258 x 0.258

: R. G. B. Vertical Stripe

: Hard-coating (3H), Non-glare type

: 16.7M colors

: 4 lamps

: 433.44 (H) x 270.90(V)

: >= 160 for H/V (typical)

:>=1000:1

: >= 300 nits (7.0mA)

:>=72%

:5ms

: 1680 X 1050 (WXGA+)

: 459.4 (W) X 296.4 (H) X 16.5 (D)

: 0.258 x 0.258

: R. G. B. Vertical Stripe

: Hard-coating (3H), Non-glare type

: 16.7M colors

: 4 lamps

: 433.44 (H) x 270.90(V)

: >= 160 for H/V (typical)

:>=1000:1

: >= 300 nits (7.0mA)

:>=72%

:5ms

: 30 - 93 K Hz (automatic)

: 56 - 76 Hz (automatic)

: < 165 M Hz (Over 165MHz,

Warning message will show up)

:75ohm

: 2.2K ohm

: 700 mVpp

: Analog R/G/B separate inputs

Separate horizontal and vertical /

Composite (H+V) TTL level,

Sync On Green (SOG) sync

0.3Vp-p Negative

: Signal TMDS link

(3 channels : Rx0 & Rx1 & RX2-/+)

: Both Analog and Digital input.

It can be switching via OSD option.

: 472.9 mm

: 400.4 mm

: 213.6 mm

: 525 mm

: 174 mm

: 452 mm

: 5.3 Kg (Including I/F cable 240g)

:-5°+2/-0°(forward )

+25°+0/-3°(backward )

: nil

: nil

: nil

:AC90-264V,

:50/60 2Hz

: < 50W maximum, 43W (typ)

:40

: 5 to 35 degree C

: 10% to 85% (max.)

: 0 - 3658 m

: 600 - 1000 mBAR

(Recommend at 5 to 35 degree C,

Humidity less then 60%)

: -20 to 60 degree C

: 95% max

: 0 - 12192 m

: 300 - 1100 mBAR

: 50,000 Hrs

+

: 555 mm

: 190 mm

: 472 mm

0 to degree C

Input signal levels

Sync. input signals

Input impedance (Digital)

Video interface

1.4 Physical characteristics

Unit dimensions

- Width

- Height

- Depth

Packed unit dimensions

Weight (monitor only)

Title angel

Swivel angel

Height adjustment

Portrait display

AC input: - voltage

- frequency

Power consumption

Ambient temperature

Operating

- Temperature

- Humidity

- Altitude

- Air pressure

Storage

System MTBF

- Width

- Height

- Depth

Packed unit dimensions

(China only)

- Width

- Height

- Depth

- Temperature

- Humidity

- Altitude

- Air pressure

4

200WS8 LCD

Automatic Power Saving

If you have VESA / DPMS compliance display card or software

installed in your PC, the monitor can automatically reduce

power consumption when power saving function active. And if

an input from keyboard, mouse or other devices is detected,

the monitor will automatically wake up. The following table

shows the power consumption and signaling of this automatic

power saving feature:

This monitor must comply with the Microsoft On Now

specification, with two power management states, as defined

by the VESA DPMS document. And must appropriately display

the DPMS states. Also comply with Environmental Protection

Agency (EPA) Energy Star and TCO03 power management

standard strictly.

ENERGY STAR is a U.S. Registered mark. AS AN ENERGY

STAR PARTNER, PHILIPS HAS DETERMINED THAT THIS

PRODUCT MEETS THE ENERGY STAR GUIDELINES OF

ENERGY EFFICIENCY.

Data Storage

Factory preset mode:

This monitor has 18 factory-preset modes as indicated in the

following table:

Technical Data

2. Pin Assignment

2.1 PC analog video input with D - sub connector.

Connector type of analog signal cable :

D - Sub male with DDC2B pin assignment.

Blue connector with thumb-operated jackscrews.

Pin assignment :

2.2 PC digital video input with DVI-D connector.

Connector type of DVI-D signal cable :

DVI-D male with DDC2B pin assignment.

White connector with thumb-operated jackscrews.

Pin assignment :

Mode HSYNC VSYNC Video Pwr-cons. Indication Rec. time

Power-On On On active < 50W (<54W : for audio model) Green LED --

Off Off Off blanked < 1 W Amber LED < 5 s

DC Power Off N/A < 1 W LED Off

PIN

No.

Signal

Assignment

PIN

No.

Signal

Assignment

PIN

No.

Signal

Assignment

1 Red 6 Red GND 11 Sense (GND)

2 Green/ SOG 7 Green GND 12 Bi-directional

data

3 Blue 8 Blue GND 13 H/H+V sync

4 Sense (GND) 9 DDC +3.3V or

+5V

14 V-sync

5 N/A 10 Logic GND 15 Data clock

PIN

No.

Signal

Assignment

PIN

No.

Signal

Assignment

PIN

No.

Signal

Assignment

1 T.M.D.S.

data2-

9 T.M.D.S.

data1-

17 T.M.D.S.

data0-

2 T.M.D.S.

data2+

10 T.M.D.S.

data1+

18 T.M.D.S.

data0+

3 T.M.D.S.

data2 shield

11 T.M.D.S.

data1 shield

19 T.M.D.S.

data0 shield

4 No Connect 12 No Connect 20 No Connect

5 No Connect 13 No Connect 21 No Connect

6 DDC clock 14 +5V Power 22 T.M.D.S clock

shield

7 DDC data 15 Ground (for

+5V)

23 T.M.D.S.

clock+

8 No Connect 16 Hot plug

detect

24 T.M.D.S. clock-

Item Resolution H. freq/ V. freq Standard

1 640*350 31.469 KHz/70.086 Hz

IBM VGA 10H

2 720*400 31.469 KHz/70.087 Hz

IBM VGA 3H

3 640*480 31.469 KHz/59.94 Hz

IBM VGA 12H

4 640*480 35 KHz/67 Hz

MACINTOSH

5 640*480 37.5 KHz/75 Hz

VESA

6 800*600 35.0156 KHz/56.25 Hz

VESA

7 800*600 37.879 KHz/60.317 Hz

VESA

8 800*600 46.875 KHz/75 Hz

VESA

9 1024*768 48.363 KHz/60.004 Hz

VESA

10 1024*768 60.023 KHz/75.029

VESA

11 1280*1024 63.981 KHz/60.02 Hz

VESA

12 1280*1024 79.976 KHz/75.025 Hz

VESA

13 1440*900 55.469 KHz/59.901 Hz

VESA

14 1440*900 55.935 KHz/59.887

VESA

15 1440*900 70.635 KHz/74.984 Hz

VESA

16 1920*1080 66.587 KHz/60 Hz

CVT 2.3 MA-R

17 1680*1050 65.29 KHz/60 Hz

CVT 1.76 MW

18 1680*1050 65.29 KHz/60 Hz

CVT 1.76 MW -R

200WS8 LCD

Connection to PC

5

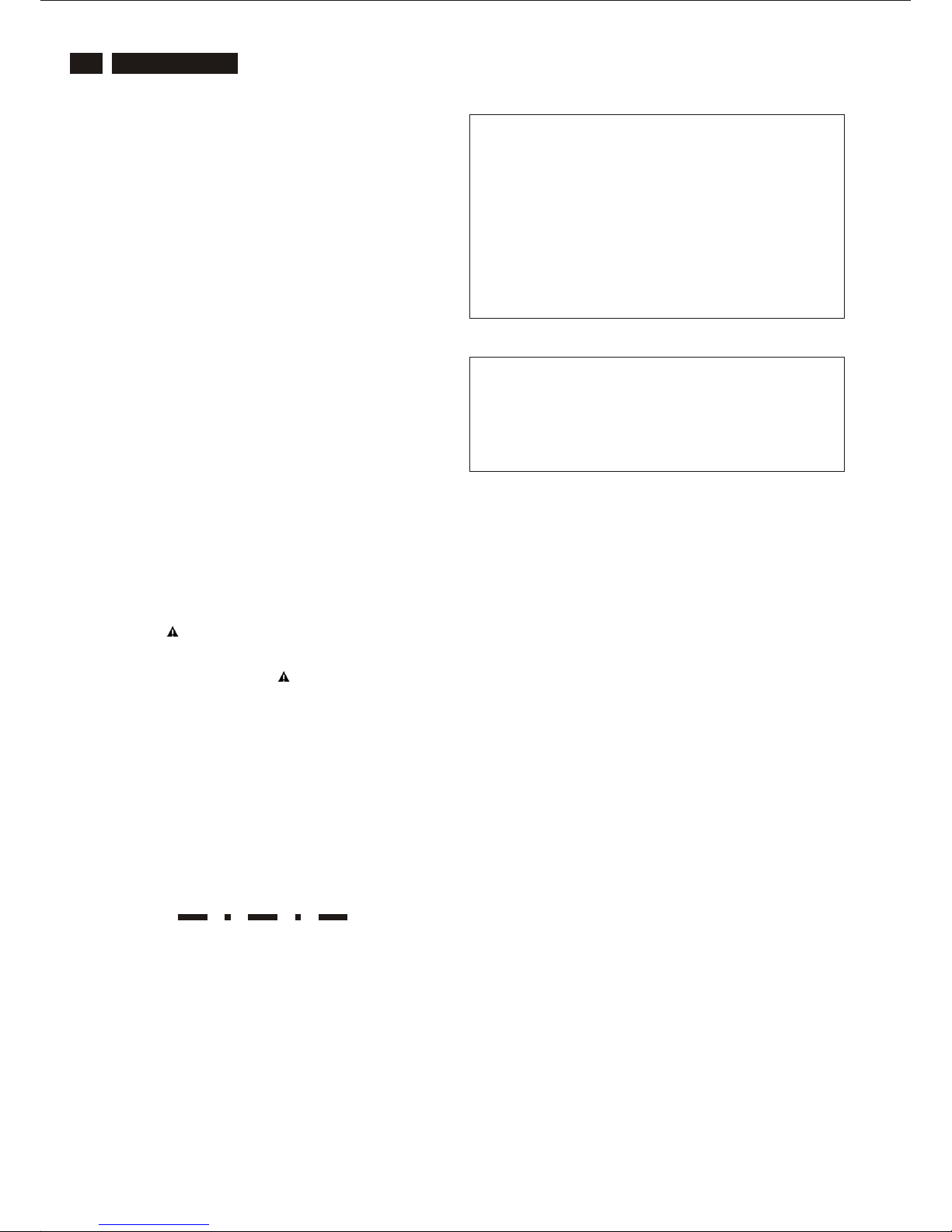

1. Connection to PC

c. Accessory Pack

Please follow the steps to connect your LCD Monitor to PC.

a. Assembly LCD Monitor with base

b. Connect to PC

1). Turn off your computer and unplug its power cable.

2). Connect the monitor signal cable to the video connector

on the back of your computer.

3). Plug the power cord of your computer and your monitor

Into a nearby outlet.

4). Turn on your computer and monitor. If the monitor

displays an image, installation is complete.

Port definition:

(1) AC power input

(2) DVI-D input

(3) VGA input

(4) Kensington anti-thief lock

Set your Monitor at 1680*1050@60Hz for best performance.

It is also strongly recommended to use DVI input(may require

the optional DVI cable) for the ture digital enjoyment.

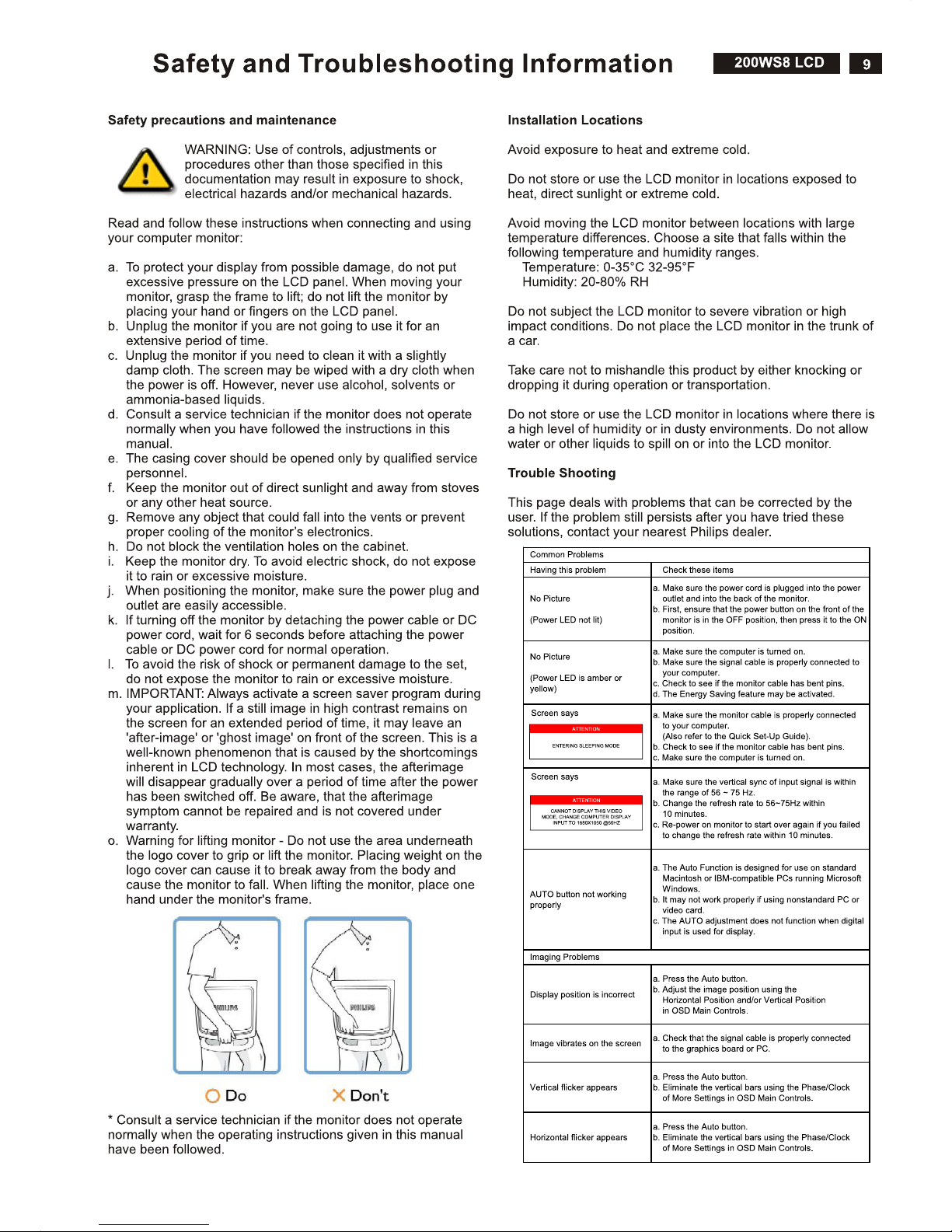

2. Function key definition

3. Description of the On Screen Display

<>

MENU

(1) To switch monitor’s power on and off

(2) To access OSD menu

(3) Hot key of contrast adjustment and to adjust OSD

value up when OSD menu is active

(4) Hot key of brightness adjustment and to adjust OSD

Value down when OSD menu is active

(5) Automatically adjust the horizontal position, vertical

position, phase and clock settings

On-Screen Display(OSD) is a feature in all Philips LCD

monitors. It allows and end user to adjust screen performance

or select functions of the monitors directly through an on-screen

instruction window. A user friendly on screen display interface is

shown as below:

Basic and simple instruction on the control keys.

According to the above OSD structure, users can :

press or buttons to move the cursor,

press button to confirm the choice or change,

press button to adjust the value,<>

MENU

AUTO

or

press button to save the changes.

press button to automatically adjust the horizontal

position, vertical position, phase and clock setting.

1

1

2

3

4

2

3

Power cord VGA cable EDFU CD

DVI cable (Optional)

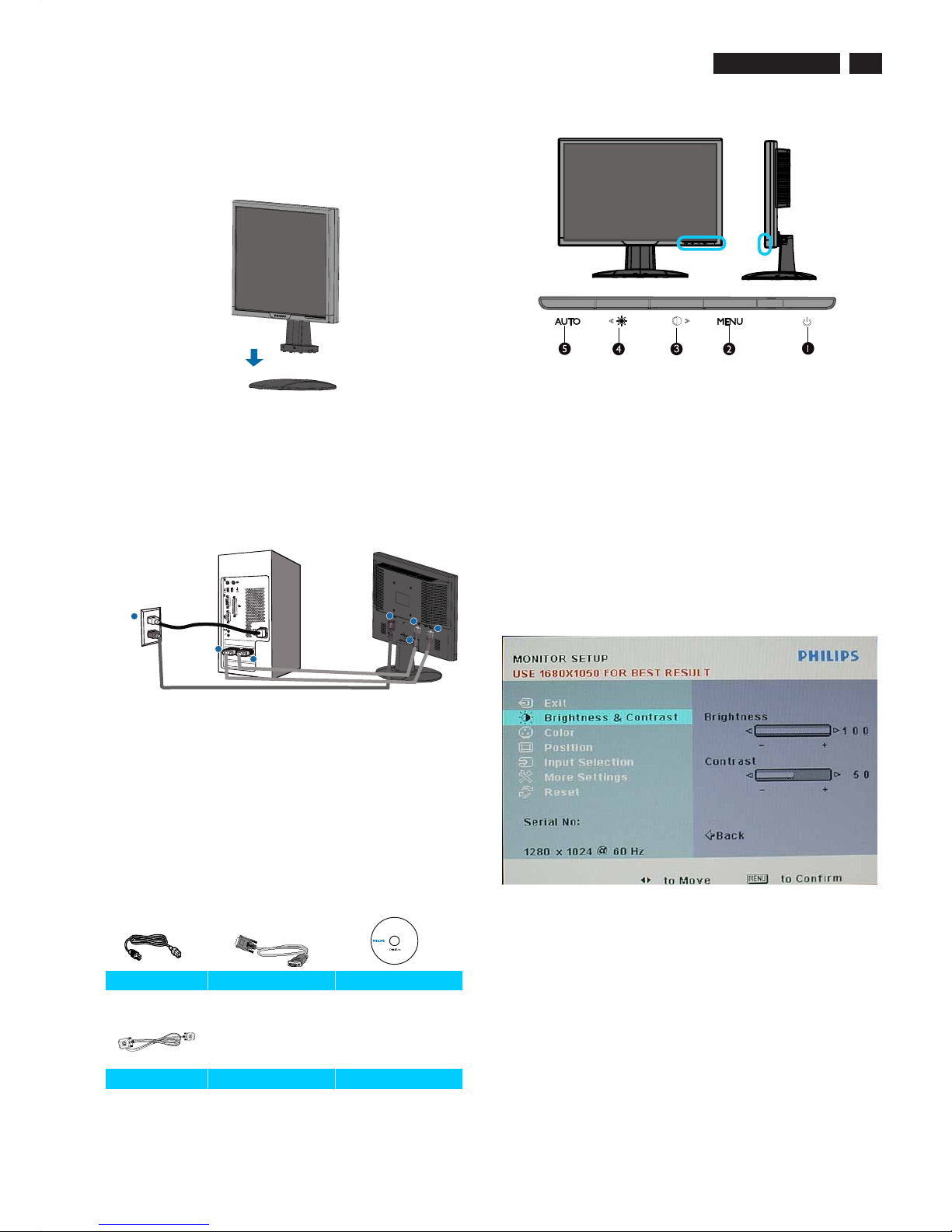

Brightness & Contrast Brightness

Color

Position

Input selection

More Settings

Main Menu (1st Level)

Sub Menu (2nd Level)

Contrast

Back

9300K

Original Color

6500K

User Define

Back

Red

Green

Blue

Exit

Horizontal

Vertical

Back

Analog

Digital

Back

Language English

Français

Deutsch

Italiano

Back

Phase/Clock Phase

Clock

Back

OSD Settings Horizontal

Vertical

Back

Back

oNteseR

Yes

Español

Русский

Brightness & Contrast Brightness

Color

Position

Input selection

More Settings

Main Menu (1st Level)

Sub Menu (2nd Level)

Contrast

Back

9300K

Original Color

6500K

User Define

Back

Red

Green

Blue

Exit

Horizontal

Vertical

Back

Analog

Digital

Back

Language English

Français

Portugues

Back

Phase/Clock Phase

Clock

Back

OSD Settings Horizontal

Vertical

Back

Back

oNteseR

Yes

Español

中文

Brightness & Contrast Br ightness

Color

Position

Input selection

More Settings

Main Menu (1st Level)

Sub Menu (2nd Level)

Contrast

Back

9300K

Original Color

6500K

User Define

Back

Red

Green

Blue

Exit

Horizontal

Vertical

Back

Analog

Digital

Back

Language English

Français

Deutsch

Italiano

Phase/Clock Phase

Clock

Back

OSD Settings Horizontal

Vertical

Back

Back

oNteseR

Yes

Español

中文

Back

200AW8 LCD

60

4.

200WS8 LCD

200WS8 LCD

Advanced OSD Adjustment

7

Advanced OSD Adjustment

MENU

MENU

MENU

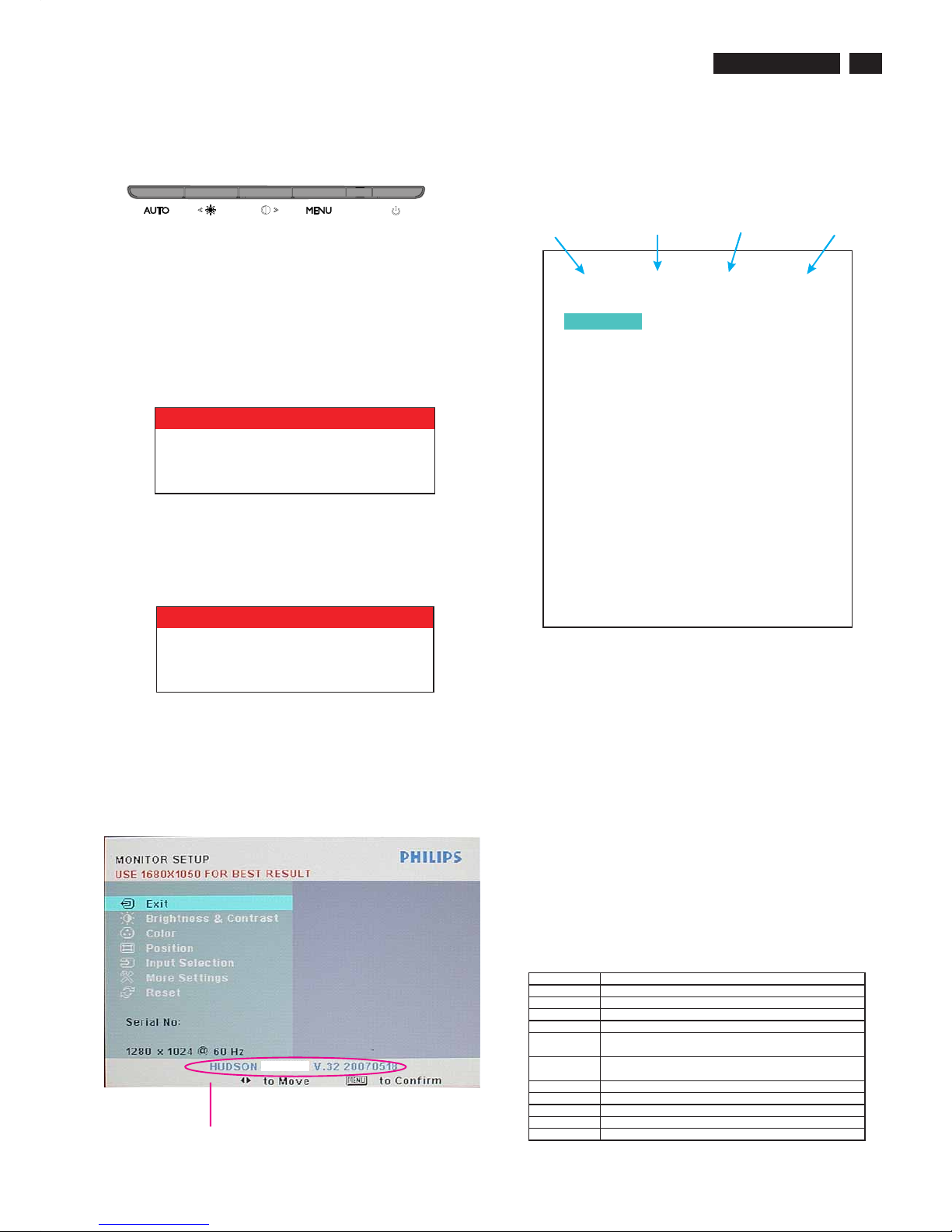

1. Front control panel

2. To Lock/Unlock OSD function

The OSD function can be locked by pressing button

for more than 10 seconds, the screen shows following

windows for 3 seconds.

Every time when you press any button, this message

appears on the screen automatically.

Locked OSD function can be released by pressing

button for more than 10 seconds. While press button

for OSD unlocked purpose, the screen will keep showing

OSD MAIN MENU LOCKED until OSD function unlocked and

screen automatically shows following window for 3 seconds.

3. Access Factory Mode

To hold and buttons, you can saw the LED

light flashing at this time. Then release the button and

Keep pressing the button. The monitor will power on

and LED light give out orange light. Press to bring up

OSD menu for confirmation as below:

If this message appeared, means monitor already entered

the factory mode.

AUTO POWER

AUTO

POWER

MENU

4. Entering Burn-in mode and others

If you access into factory mode, press or button to move

the cursor on the message bar of “ HUSDON 220WS8 V.34..”.

Then press to confirm, OSD menu will convert into

another format as below:

Move the cursor by button, and press the

to change the burn-in mode from Off to ON.

Leave factory mode by simply power off the monitor.

* If you only want to enter burn in mode, please don’t change

any other setting items as above listed.

* Unfortunately, if some settings has been changed by

unknown reasons or wrong operation. Please refer to the

chapter of “W/B Adjustment” to guide the operator how to

restore the default settings or do adjustment.

Appendix:

Explanation of above listed selections.

<>

MENU

MENU

Warning

or

button

<>

BIOS Revision Scaler IC Type Panel Type BIOS issued date

ATTENTION

OSD MAIN CONTROLS LOCKED

ATTENTION

OSD MAIN CONTROLS UNLOCKED

Selection Description

Burn in On/Off Enter Aging Mode

Auto Color Auto Color Adjustment

Con Contrast Adjustment

Bri Brightness Adjustment

Gain

ADC Gain Value Adjustment

(Auto adjustment by H/W when implement Auto Color function)

Offset

ADC Offset Value Adjustment

(Auto adjustment by H/W when implement Auto Color function)

sRGB sRGB Color Temperature Gain Value Adjustment

9300K 9300K Color Temperature Gain Value Adjustment

6500K 6500K Color Temperature Gain Value Adjustment

Color Update Save All of Color Temperature Gain Value

Factory Reset Memory Recall to Factory Default Settings

V8 07/03/03

Off

Con 50

Bri 100

Gain R 88 G 91 B 88

Offset R 121 G 131 B 131

sRGB R 97 G 98 B 82

9300K R 91 G 94 B 95

6500K R 97 G 98 B 82

AU M201EW02TSUMU58WHJ

Fatory Reset

Color Update

AutoColor

Burn in

200WS8

200WS8 LCD

Definition of pixel defects

11

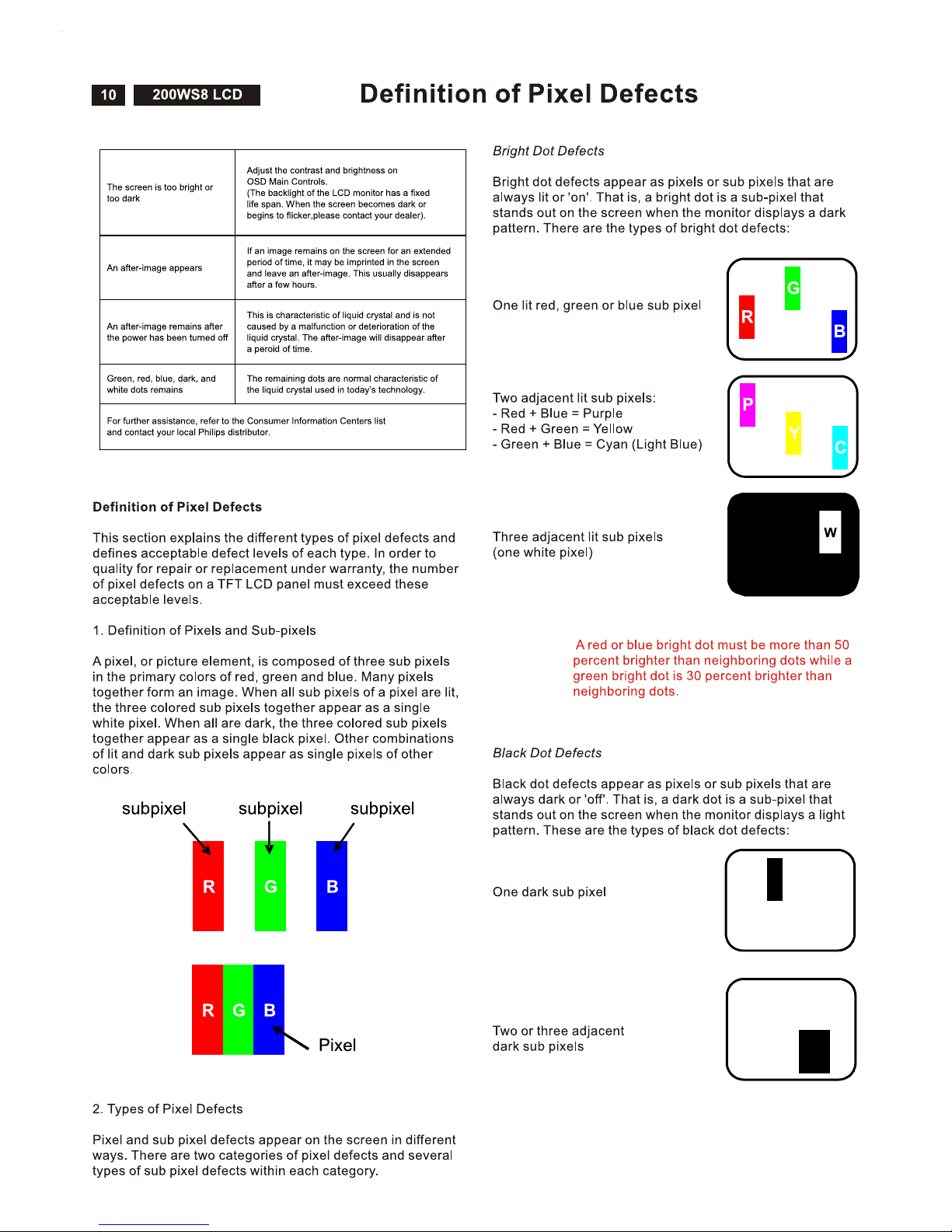

3. Proximity of Pixel Defects

Because pixel and sub pixels defects of the same type that

are near to one another may be more noticeable, Philips also

specifies tolerances for the proximity of pixel defects.

Perfect Panel - ISO 13406-2 Class II compliant do-defectfree-display.

BRIGHT DOT DEFECTS ACCEPTABLE LEVEL

MODEL 200WS8

1 lit subpixel 3

2 adjacent lit subpixels 1

3 adjacent lit subpixels (one white pixel) 0

Distance between two bright dot defects* 15 mm

Total bright dot defects of all types 3

BLACK DOT DEFECTS ACCEPTABLE LEVEL

MODEL 200WS8

1 dark subpixel 5

2 adjacent dark subpixels 2

3 adjacent dark subpixels 0

Distance between two black dot defects* 15 mm

Total black dot defects of all types 5

TOTAL DOT DEFECTS ACCEPTABLE LEVEL

MODEL 200WS8

Total bright or black dot defects of all types 5

Note:

* 1 or 2 adjacent sub pixel defects = 1 dot defect

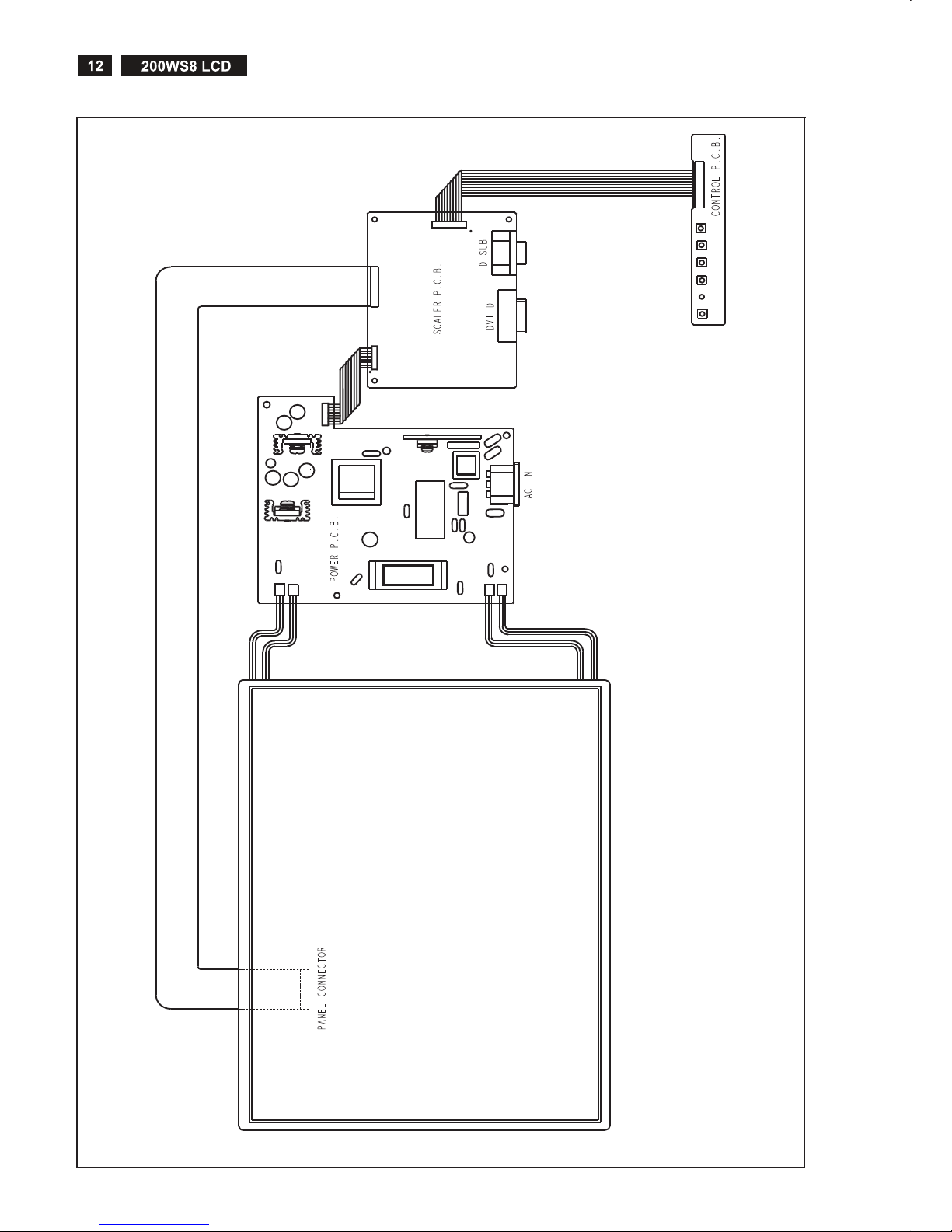

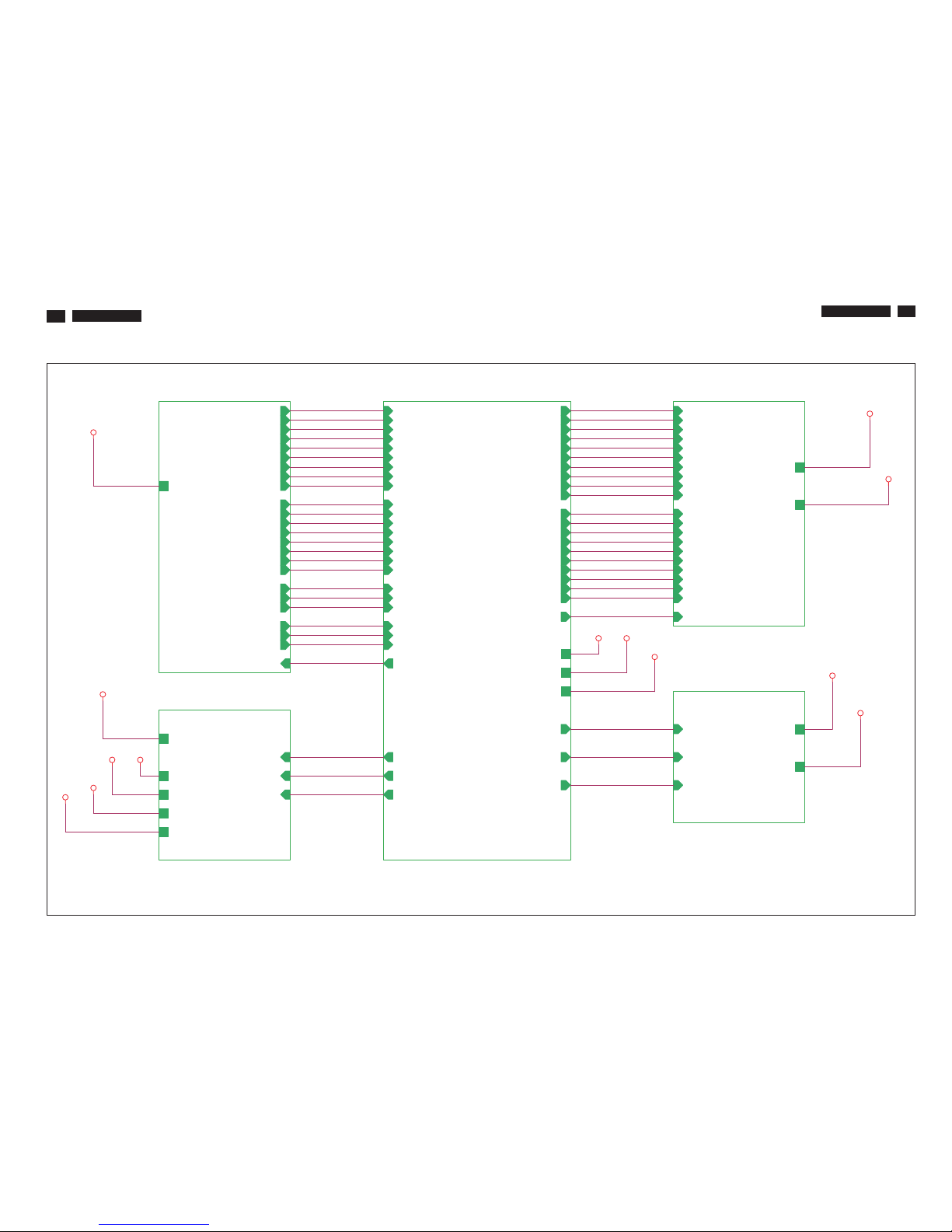

Wiring Diagram

CN2

1

2

29

30

CN78 1

CN3

CN4

CN1

7

8

1

2

CN101

CN1

CN2

CN3

CN4

CON1

1

8

200WS8 LCD

Mechnical instructions

13

Fig. 1

1. Lay down the monitor on the electrostatic cushion, then

wear your gloves, all tools (screwdriver, both with small and

big one) prepared.

Fig. 2

2. Put down the monitor softly and take out the base from

it.(note: care of the panel without scraped.)

Fig. 3

3. Release the six screws and take out the plastic parts

between the rear cover and stand neck.

Fig. 4

4. Release the two screws as below photo show, then take

out the metal parts between rear cover and stand neck, then

take off rear cover.

Fig. 5

Fig. 6

5. Release the three screws on the left side of bezel, then

release the other three screws on the right of bezel.

14

200WS8 LCD

Mechnical instructions

Fig. 7

6. Tear off the adhesive tape and take out the cable from the

sink of main board(note: don’t do it forcibly).

Fig. 8

Fig. 9

7. Release the two screws on the left side of shielding, then

release the other two screws on the right side of shielding.

Fig. 10

Fig. 11

8. Take out the lamp cable shielding and undo the lamp cable.

Fig. 12

9. Tear off the adhesive tape and undo the LVDS cable.

Fig. 13

10. Separate the panel and shielding

200WS8 LCD

Mechnical instructions

15

Fig. 14

11. The shielding with boards.

Fig. 15

12. Release the four hexagonal screws.

Fig. 16

Fig. 17

Fig. 18

14. Separate the connect cable between main board and

power board, then take out the connect cable from main

board.(note: be careful of the jack, don’t do it forcibly.)

13. Take out the protect film and release the four screws from

power board, then release the three screws from the main

board.

Fig. 4

5. If the hex file opened correctly, a message will be showed in

the dialog box to notice the operator. At this moment, please

verify the checksum of the hex file with the firmware control

table to make sure the suitable file will be used. Mentioned

firmware control table will be provided by supplier(Fig.5)

Fig. 5

6. Press the config icon to setting up:

Port type : LPT1

Base Addr : 0X0378

E2PROM device setting : 50 (default value)

7. Press connect icon to create a linkage between PC and

monitor. If the linkage was steady, a dialog box will shown

as Fig. 6. At this moment, LED of monitor will be black out.

16

200WS8 LCD

F/W upload instruction

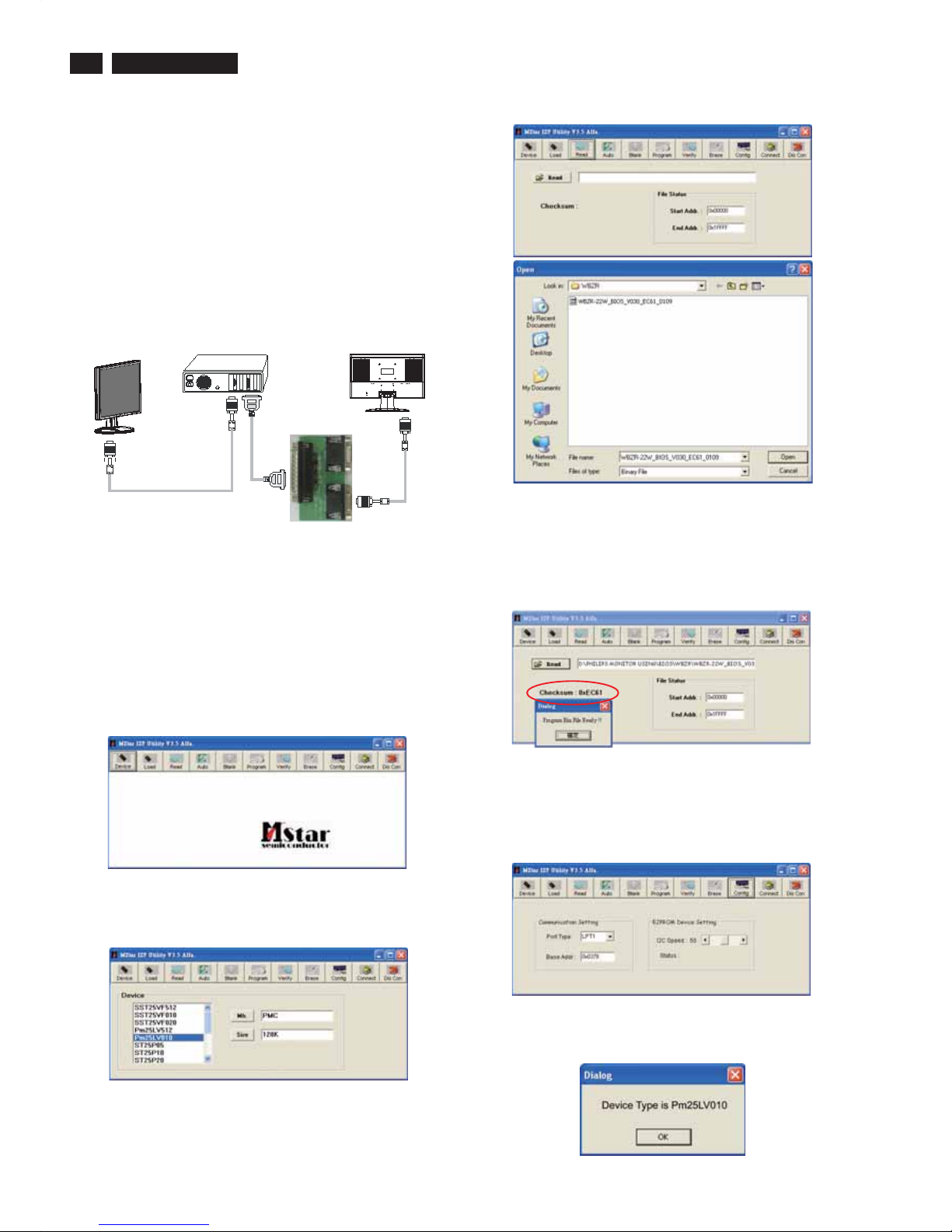

Configuration and procedure (ISP Tool)

"ISP Tool " software is provided by Mstar to upgrade the

firmware of Scaler IC. It is a windows-based program, which

cannot be run in MS-DOS.

System and equipment requirements:

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 98/2000/XP.

3. ISP software " ISP Tool ".

(No need to install, it can be performed directly)

4. Firmware uploading tool, as shown in Fig1.

* Connect the firmware uploading tool as Fig.1 shown.

* Before the servicer perform the ISP Toll program, the

Communicating connection must be well done.

* When the connection fixed, power on the monitor.

Setup and perform the ISP Tool program

1. Save the software in your PC, and create a shortcut

on the desktop.

2. Double click the ISP Tool. exe icon at the desktop then

appears window as shown in Fig. 2.

Fig. 2

3. Press the device icon then select the matching IC type and

double click it as shown in Fig. 3.

Fig. 3

4. Press the read icon, file status will shown the start address

as 0X00000 and end address as 0X1FFFF. Then open the

destination hex files as shown in Fig.4.

Electronic Instructions

Fig. 1

PC

Monitor(A)

Monitor (B)

To graphics card

To LPT1 port

To monitor

ISP TOOL

200WS8 LCD

Electronic Instruction

17

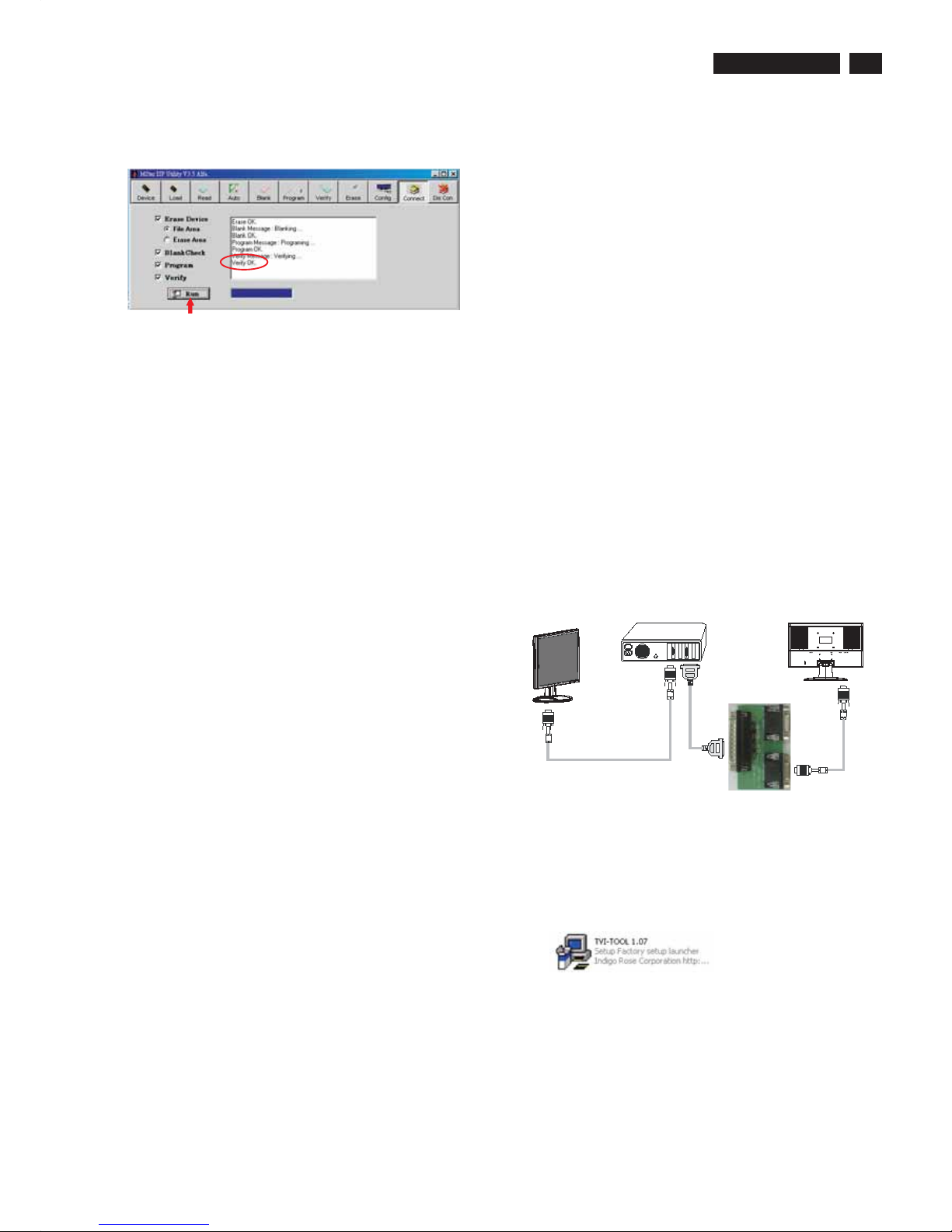

7. Press icon of the toolbox and make sure all of the

setting are fixed, then press the icon. Program will

perform the loading process automatically.

8. When the loading process completed, and the dialog box

appeared the message of verify ok. Press the icon

to disconnect the linkage, LED of monitor will light up.

AUTO

RUN

DIS-CON

DDC instructions

General

DDC Data Re-programming

Additional information

System and equipment requirements

In case the DDC data memory ICwhich storage all factory

settings were replaced due to a defect, the serial numbers

have to be re-programmed.

It is advised to re-soldered DDC IC from the old board onto the

new board if circuit board have been replaced, in this case the

DDC data does not need to be re-programmed.

* According to the design concept of this product, DDC data

will be divided into two parts to deposit in different place:

DDC data of VGA interface are saved in scaler IC.

Additional information about DDC (Display Data Channel) may

be obtained from Video Electronics Standards Association

(VESA). Extended Display Identification Data(EDID)

information may be also obtained from VESA.

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 98/2000/XP.

3. Installation software of " TVI Tool ".

4. Executive program " TVI Tool. exe ".

5. ISP tool kit, as shown in Fig1.

Including: a. Alignment fixture x 1

b. Printer cable (LPT type) x 1

c. D-sub to D-sub cable x 1

Install and setup programTVI-TOOL

Step 1: Create a folder in your PC, for example : D:\TVI-TOOL.

Step 2: Copy the installation file into the folder.

Step 3: Double click the INSTALL icon as shown in the Fig.2.

Step 4: Following the installation wizard, complete the whole

installing progress.

Step 5: Restart your PC to

(More details are shown in the next page)

Fig. 1

PC

Monitor(A)

Monitor (B)

To graphics card

To LPT1 port

To monitor

ISP TOOL

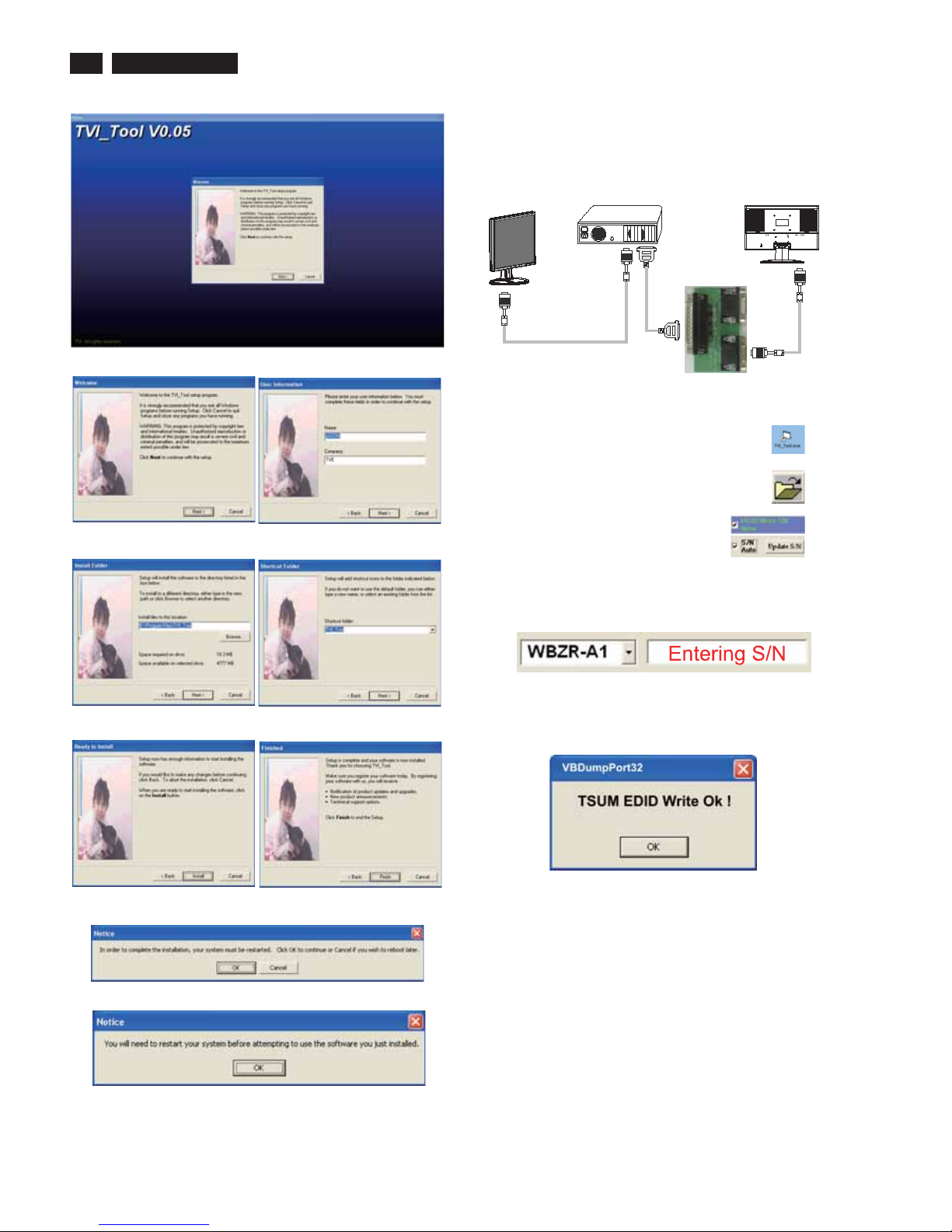

Re-programming Analog DDC

TVI_TOOL

OPEN

Step 1: After initialize the alignment fixture, connecting all

cables as shown in Fig.10.

Step 2: Connect the power code of monitor and power on it.

Step 3: Double check the icon

to run the TV_TOOL.exe.

Step 4: Click the icon at the main menu

to open the DDC files.

Step 5: Select the icon of DDC IC type and

serial number write-in method.

Step 6: Entering the monitor’s serial number into the block

as shown in following photos, program will running

Automatically.

Step 7: When the DDC data download into the DDC IC, a

dialog box will be appeared automatically as shown

in below photos.

Step 8: Press the OK button, waiting for several seconds

and then power off the monitor.

18

200WS8 LCD

Fig.1 (Installation interface)

Fig.2 Fig.3

Fig.4 5

Fig.6 7

Fig.8

Fig.9

Fig.

Fig.

Fig. 10

PC

Monitor(A)

Monitor (B)

To graphics card

To LPT1 port

To monitor

ISP TOOL

Electronic Instruction

200WS8 LCD

19

User Interface of DDC programming

Toolbar function introduction

Open a DDC file

Save DDC file

Write to IC

Read from IC

Get a exsample

DDC report

Exit the program

Model name option S/N coding rule S/N entering option

a. If the DDC programing under

VGA mode, this dialog box

will show “ TSUM ”.

B. If the DDC programing under

DVI mode, this dialog box

will show “ 24C02 ”.

Dialog box of DDC data download progress.

Re-programming Digital DDC IC

TVI_TOOL

OPEN

WRITE TO IC

READ TO IC

Step 1: After initialize the alignment fixture, connecting all

cables as shown in Fig.11.

Step 2: Connect the power code of monitor and power on it.

Step 3: Double check the icon

to run the TV_TOOL.exe.

Step 4: Click the icon at the main menu

to open the DDC files.

Step 5: Select the icon of DDC IC type and

serial number write-in method.

Step 6: Entering the monitor’s serial number into the block

as shown in following photos, program will running

Automatically.

Step 7: When the DDC data download into the DDC IC,

dialog window of main menu will show the message

as below.

Step 8: Press the OK button, waiting for several seconds

and then power off the monitor.

* If the operator don’t want to key in

the serial number, he or she can

Keep the option as blank.

Press the icon to execute the download

by program itself.

And select the icon to check the

EDID contents.

Fig. 11

PC

Monitor(A)

Monitor (B)

To graphics card

To LPT1 port

To monitor

ISP TOOL

Electronic Instructions

20

200WS8 LCD

Re-programming of writing HDCP KEY

Step 1: Please install the software of isp HDCP key Version1.13

,the tool is the same with isping EDID.

Step 2: Opening the software.

Step 3: Pressing the button of “OPEN FILE”, as follows:

Step 4: Choosing the HDCP KEY that you save:

button of ”ISP HDCP”.

Step 5: If the Flash Rom of monitor is 2MB, please

choose”3F000”,but if it is 1MB please choose 1F000(if you

choose amiss ,the monitor maybe shut down) ,then press

the

Step 6: The software will write HDCP KEY into monitor.

Step 7: If the software write HDCP KEY into monitor

successfully ,the message will be display ,as follow , if the

software write HDCP KEY into monitor unsuccessfully

,please check the cable ,and restart from step5 .

Electronic Instruction

200WS8 LCD

DDC Data

21

DDC DATA

THE DISPLAY DATA CHANNEL (DDC_2B) CONTENT INCLUDING:

(Digital mode)

------------------------------------------------------------------------------------EDID data ( 128 bytes )

------------------------------------------------------------------------------------01 2345 678 9

-------------------------------------------------------------------

0|00FFFFFFFFFFFF00410C

10|50080101 010108 110103

20|802F1E78 2E9345 A3554A

30|98271550 54BFEF 00B300

40|A940950F 950081 C08140

50|714F8180 7C2E90 A0601A

60|1E403020 3600B20E1100

70|001C0000 00FF00434A31

80|30373038 313233343536

90|000000FC 005068696C69

100|70732032 3030 57530000

110 | 00 FD 00 38 4C 1E 5D 11 70 0A

120|20323030 57 5300FB

__________________________________________________

(08-09) ID Manufacturer Name = PHL

(10-11) Product ID Code (Non-Alphanumerical) = 0850 - (2128)

(12-15) Last 5 Digits of Serial Number = NOT SPECIFIED

(16) Week of Manufacture = 08

(17) Year of Manufacture = 2007

(10-17) Complete Serial Number = NOT SPECIFIED

(18) EDID Structure Version Number = 1

(19) EDID Structure Revision Number = 3

(20) VIDEO INPUT DEFINITION : = Digital signal,

0.700V/0.300V (1.000 Vp-p)

(21) Maximum Horizontal Image Size = 470mm

(22) Maximum Vertical Image Size = 300mm

(23) Display Gamma = 2.20

(24) DPMS Supported Feature: = Active Off.

Display type = RGB color display

(25-34) CHROMA INFO:

Red x = 0.639 Green x = 0.289

Blue x = 0.153 White x = 0.313

Red y = 0.333 Green y = 0.597

Blue y = 0.082 White y = 0.329

(35) ESTABLISHED TIMING I:

720 x 400 @ 70Hz (VGA, IBM)

640 x 480 @ 60Hz (VESA)

640 x 480 @ 67Hz (MAC II, Apple)

640 x 480 @ 72Hz (VESA)

640 x 480 @ 75Hz (VESA)

800 x 600 @ 56Hz (VESA)

800 x 600 @ 60Hz (VESA)

(36) ESTABLISHED TIMING II:

800 x 600 @ 72Hz (VESA)

800 x 600 @ 75Hz (VESA)

832 x 624 @ 75Hz (MAC II, Apple)

1024 x 768 @ 60Hz (VESA)

1024 x 768 @ 70Hz (VESA)

1024 x 768 @ 75Hz (VESA)

1280 x 1024 @ 75Hz (VESA)

(37) Manufacturer's Reserved Timing: None specified.

(38-53) Standard Timing Identification:

#1: 1680 x 1050 @ 60Hz

#2: 1600 x 1200 @ 60Hz

#3: 1440 x 900 @ 75Hz

#4: 1440 x 900 @ 60Hz

#5: 1280 x 720 @ 60Hz

#6: 1280 x 960 @ 60Hz

#7: 1152 x 864 @ 75Hz

#8: 1280 x 1024 @ 60Hz

(54-71) Detail Timing Description #1:

1680x1050 Pixel Clock=119.0MHz

-------------------------------------------------------------------------------Horizontal Image Size=434mm

Vertical Image Size=270mm

Refresh Mode:

Non-Interlaced Normal display, no stereo

HORIZONTAL:

Active Time = 1680 pixels

Blanking Time = 160 pixels

Sync Offset = 48 pixels

Sync Pulse Width = 32 pixels

Border = 0 pixels

Frequency = 64.7 kHz

VERTICAL:

Active Time = 1050 lines

Blanking Time = 30 lines

Sync Offset = 3 lines

Sync Pulse Width = 6 lines

Border = 0 lines

Frequency = 59.9 Hz

Sync configuration: Digital separate, V(+), H(-)

(72-89) Monitor Description:

-------------------------------------------------------------------------------

Monitor S/N: CJ10708123456

(90-107) Monitor Description:

--------------------------------------------------------------------------------

Monitor Name: Philips 200WS

(108-125) Monitor Description:

--------------------------------------------------------------------------------

Monitor Range Limits:

Vertical Frequency (min) = 56Hz

Vertical Frequency (max) = 76Hz

Horizontal Frequency (min) = 30KHz

Horizontal Frequency (max) = 93KHz

Maximum Supported Pixel Clock = 170MHz

(127) Checksum OK.

22

200WS8 LCD

DDC DATA

THE DISPLAY DATA CHANNEL (DDC_2B) CONTENT INCLUDING:

(Analog mode)

------------------------------------------------------------------------------------EDID data ( 128 bytes )

------------------------------------------------------------------------------------01 2 345 6789

---------------------------------------------------------------------

0|00FFFFFFFFFFFF00410C

10|500801 0101 010811 0103

20|082F1E782E 9345A3554A

30|982715 5054BFEF00B300

40|A940950F 950081 C08140

50|714F8180 213990 30621A

60|274068B036 00DA281100

70|001C000000FF 00 434A31

80|30373038 3132 33343536

90|000000FC0050 68696C69

100|70732032 3030 57530000

110 | 00 FD 00 38 4C 1E 5D 11 70 0A

120|203230 305753 001E

__________________________________________________

(08-09) ID Manufacturer Name = PHL

(10-11) Product ID Code (Non-Alphanumerical) = 0850 - (2128)

(12-15) Last 5 Digits of Serial Number = NOT SPECIFIED

(16) Week of Manufacture = 08

(17) Year of Manufacture = 2007

(10-17) Complete Serial Number = NOT SPECIFIED

(18) EDID Structure Version Number = 1

(19) EDID Structure Revision Number = 3

(20) VIDEO INPUT DEFINITION :

= Separate Sync, Analog signal, 0.700V/0.300V (1.000

Vp-p)

(21) Maximum Horizontal Image Size = 470mm

(22) Maximum Vertical Image Size = 300mm

(23) Display Gamma = 2.20

(24) DPMS Supported Feature:

= Active Off. Display type = RGB color display

(25-34) CHROMA INFO:

Red x = 0.639 Green x = 0.289

Blue x = 0.153 White x = 0.313

Red y = 0.333 Green y = 0.597

Blue y = 0.082 White y = 0.329

(35) ESTABLISHED TIMING I:

720 x 400 @ 70Hz (VGA, IBM)

640 x 480 @ 60Hz (VESA)

640 x 480 @ 67Hz (MAC II, Apple)

640 x 480 @ 72Hz (VESA)

640 x 480 @ 75Hz (VESA)

800 x 600 @ 56Hz (VESA)

800 x 600 @ 60Hz (VESA)

(36) ESTABLISHED TIMING II:

800 x 600 @ 72Hz (VESA)

800 x 600 @ 75Hz (VESA)

832 x 624 @ 75Hz (MAC II, Apple)

1024 x 768 @ 60Hz (VESA)

1024 x 768 @ 70Hz (VESA)

1024 x 768 @ 75Hz (VESA)

1280 x 1024 @ 75Hz (VESA)

(37) Manufacturer's Reserved Timing: None specified.

DDC Data

(38-53)Standard Timing Identification:

#1: 1680 x 1050 @ 60Hz

#2: 1600 x 1200 @ 60Hz

#3: 1440 x 900 @ 75Hz

#4: 1440 x 900 @ 60Hz

#5: 1280 x 720 @ 60Hz

#6: 1280 x 960 @ 60Hz

#7: 1152 x 864 @ 75Hz

#8: 1280 x 1024 @ 60Hz

(54-71) Detail Timing Description #1:

1680x1050 Pixel Clock=146.2MHz

-------------------------------------------------------------------------------Horizontal Image Size=474mm

Vertical Image Size=296mm

Refresh Mode:

Non-Interlaced Normal display, no stereo

HORIZONTAL:

Active Time = 1680 pixels

Blanking Time = 560 pixels

Sync Offset = 104 pixels

Sync Pulse Width = 176 pixels

Border = 0 pixels

Frequency = 65.3 kHz

VERTICAL:

Active Time = 1050 lines

Blanking Time = 39 lines

Sync Offset = 3 lines

Sync Pulse Width = 6 lines

Border = 0 lines

Frequency = 60.0 Hz

Sync configuration: Digital separate, V(+), H(-)

(72-89) Monitor Description:

-------------------------------------------------------------------------------Monitor S/N: CJ10708123456

(90-107)Monitor Description:

--------------------------------------------------------------------------------

Monitor Name: Philips 200WS

(108-125) Monitor Description:

--------------------------------------------------------------------------------

Monitor Range Limits:

Vertical Frequency (min) = 56Hz

Vertical Frequency (max) = 76Hz

Horizontal Frequency (min) = 30KHz

Horizontal Frequency (max) = 93KHz

Maximum Supported Pixel Clock = 170MHz

(127) Checksum OK.

200WS8 LCD

Safety Instruction, Warnings and Notes

23

Safety instruction, warnings and notes

index of this chapter:

1 Safety Instructions

2 Warnings

3 Notes

1 Safety Instructions

Safety regulations require that during a repair:

a. Connect the set to the AC Power via an isolation transformer

(> 800 VA).

b. Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any other

component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

a. Route the wire trees correctly and fix them with the mounted

cable clamps.

b. Check the insulation of the AC Power lead for external

damage.

c. Check the strain relief of the AC Power cord for proper

function.

d. Check the electrical DC resistance between the AC Power

plug and the secondary side (only for sets which have a AC

Power isolated power supply):

* Unplug the AC Power cord and connect a wire between the

two pins of the AC Power plug.

* Set the AC Power switch to the "on" position (keep the AC

Power cord unplugged!).

* Measure the resistance value between the pins of the AC

Power plug and the metal shielding of the tuner or the aerial

connection on the set. The reading should be between 4.5

Mohm and 12 Mohm.

* Switch "off" the set, and remove the wire between the two

Pins of the AC Power plug.

e. Check the cabinet for defects, to avoid touching of any inner

parts by the customer.

2 Warnings

a. All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD ). Careless handling during

repair can reduce life drastically. Make sure that, during

repair,

you are connected with the same potential as the mass of the

set by a wristband with resistance. Keep components and

tools also at this same potential.

b. Be careful during measurements in the high voltage section.

c. Never replace modules or other components while the unit

is switched "on".

d. When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a circuit

becoming unstable.

3 Notes

3.1 General

Measure the voltages and waveforms with regard to the

chassis ground or hot ground, depending on the tested area of

circuitry. The voltages and waveforms shown in the diagrams

are indicative.

The semiconductors indicated in the circuit diagram and in the

parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type indication on

3.2 Schematic Notes

All resistor values are in ohms and the value multiplier is often

used to indicate the decimal point location (e.g. 2K2 indicates

2.2 Kohm).

Resistor values with no multiplier may be indicated with either

an "E" or an "R" (e.g. 220E or 220R indicates 220 ohm).

All capacitor values are given in micro-farads ( X10 ),

nano-farads (n= X10 ), or pico-farads (p= X10 ).

Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

An "asterisk" (*) indicates component usage varies. Refer to the

diversity tables for the correct values.

The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list when

there is any doubt.

3.3 Lead Free Solder

Philips CE is going to produce lead-free sets (PBF) from

1.1.2005 onwards.

Lead-free sets will be indicated by the PHILIPS-lead-free logo

on the Printed Wiring Boards (PWB):

This sign normally has a diameter of 6 mm, but if there is less

space on a board also 3 mm is possible.

In case of doubt wether the board is lead-free or not (or with

mixed technologies), you can use the following method:

* Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

* De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

: For BGA-ICs, you must use the correct temperature

profile, which is coupled to the 12NC. For an overview of these

profiles, visit the website

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repair desk.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

Use only lead-free soldering tin Philips SAC305 with order code

0622 149 00106. If lead-free solder paste is required, please

contact the manufacturer of your soldering equipment.

In general, use of solder paste within workshops should be

avoided because paste is not easy to store and to handle.

Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able

- To reach at least a solder-tip temperature of 400 degree C.

- To stabilise the adjusted temperature at the solder-tip.

- To exchange solder-tips for different applications.

-6

-9 -12

Caution

http://www.atyourservice.ce.philips.com/

200VW8 LCD

Block Diagram

24

S-A3

200WS8 LCD

24

A2

2.POWER

on_BACKLIGHT

Adj_BACKLIGHT

VCC1.8

VCC3.3

+5V

VCC12

VCTRL

PC5V

A4

4.SCALER

DDCD_SDA

CLK-

DDCA_SDA

VSYNC

HSYNC

LVACKP

DDCD_SCL

DET_VGA

on_PANEL

DDCA_SCL

LVA3M

+5V

VCC3.3

VCC1.8

RIN

GNDG

GIN

BIN

GNDB

SOG

GNDR

R+

R-

G-

B+

B-

G+

CLK+

on_BACKLIGHT

Adj_BACKLIGHT

LVA3P

LVA2M

LVACKM

LVA2P

LVA1P

LVA1M

LVA0M

LVA0P

LVBCKP

LVB1P

LVB0P

LVBCKM

LBA2M

LVB3P

LVB0M

LVB2P

LVB1M

LVB3M

HPD_CTRL

DET_DVI

VCTRL

MUTE

VOLUME

STBY

A5

5.PANEL

LVB1M

LVB0M

LVB2P

LVA1 M

LVB2M

LVB3M

LVA3 P

LVBCKP

LVB3P

LVA1P

LVB1P

LVA0 M

LVBCKM

LVA3 M

LVA0 P

LVB0P

LVACKP

LVA2 P

LVACKM

LVA2 M

on_PANEL

+5V

VCC12

A3

3.INPUT

RIN

GIN

BIN

VSYNC

GNDR

GNDG

GNDB

DET_VGA

HSYNC

SOG

DDCA_SDA

DDCA_SCL

B-

G+

G-

R-

CLK-

R+

CLK+

B+

DDCD_SDA

DDCD_SCL

PC5V

DET_DVI

HPD_CTRL

A6

6.AUDIO

VOLUME

STBY

MUTE

VCC12

VCC3.3

+5V

VCC12

+5V VCC1.8

VCC3.3

PC5V

PC5V

VCC12+5V

VCC3.3

VCC1.8

VCC12

VCC3.3

Loading...

Loading...