Philips 200P6IS/00, 200P6EG/00, 200P6ES/00, 200P6EB/00, 200P6ES/27 Service Manual

...

Description Page

Important Safety Notice---- ------------------------------ 2

Technical Data----------------------------------------------3

Instalation/On Screen Display------------------------4~8

Lock/unlock,Aging,Factory mode-----------------------9

-----------------------------Mechanical Instructions ----------------------------11~12

Color adjustment -----------------------------------------13

Warning Message ----------------------------------------14

Troubleshooting ------------------------------------------15

Electrical instruction --------------------------------16~17

DDC Instructions-------------------------------------18~24

DDC DATA --------------------------------------------25~27

ISP Instructions --------------------------------------28~29

Philips Pixel Defect Policy 10

Horizontal frequencies

30-93kHz

Service

Service

Service

TABLE OF CONTENTS

Published by BCU Monitors Printed in Suzhou Copyright reserved Subject to modification K Mar. 31 2005

Description Page

Safety Test Requirments-------------------------------30

Wiring Diagram------------------------------------------31

Block Diagram--------------------------------------------32

Scaler Diagram&C.B.A. ---------------------------33~40

Audio Diagram&C.B.A. ----------------------------41~42

Control Diagram&C.B.A. --------------------------43~44

Power Diagram & C.B.A. --------------------------45~48

Exploded View -------------------------------------------49

Spare& parts list-----------------50~53

General product specification--------------------54~70

Repair tips--------------------------------------------71~72

Repair Flow chart-----------------------------------73~75

Different parts list-----------------------------------76~77

Recommended

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

SAFETY NOTICE

Chassis: UH6

GB

3138 106 10462

20 inch TFT UXGA LCD Colour Monitor

200P6IS/00

200P6EB/00

200P6EB/27

200P6EG/00

200P6ES/00

200P6ES/27

200P6IB/00

200P6IB/93

200P6IG/00

200P6IG/93

200P6IB/75

Important Safety Notice

2

200P6 LCD

Go to cover page

Proper service and repair isimportant to the safe, reliable

operation of all HPConsumer Electronics Company**

Equipment. The service procedures recommended by HP and

described in this service manual are effective methods of

performing service operations. Some ofthese service

operations require the use of tools specially designed for the

purpose. The special tools should be used when and as

recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. HP could not possibly know, evaluate and

advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, HP has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by HP must first satisfy himself thoroughly that

neither his safety nor the safe operation of the equipment will

be jeopardized by the service method selected.

* * Hereafter throughout this manual, HP Consumer

Electronics Company will bereferred to as HP.

Critical components having special safety characteristics are

identified with a bythe Ref. No. inthe parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability.

*BrokenLine

WARNING

Take care during handling the LCD module with backlight

unit

- Must mount the moduleusing mounting holes arranged infour

corners.

- Do not press onthe panel, edge of theframe strongly or electric

shock as this will result in damage to the screen.

- Do not scratch orpress on the panel withany sharp objects, such

as pencil or pen asthis may result in damage to the panel.

- Protect the module fromthe ESD as it maydamage the electronic

circuit (C-MOS).

- Make certain that treatment person s body are grounded through

wrist band.

- Do not leave themodule in high temperature andin areas of high

humidity for a long time.

- Avoid contact with water as it may ashort circuit within the module.

- If the surface ofpanel become dirty, please wipe it off with a soft

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

FOR PRODUCTS CONTAINING LASER :

DANGER- Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

CAUTION- Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

CAUTION- The use of optical instruments with this

product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART

NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

3

Technical Data

Go to cover page

200P6 LCD

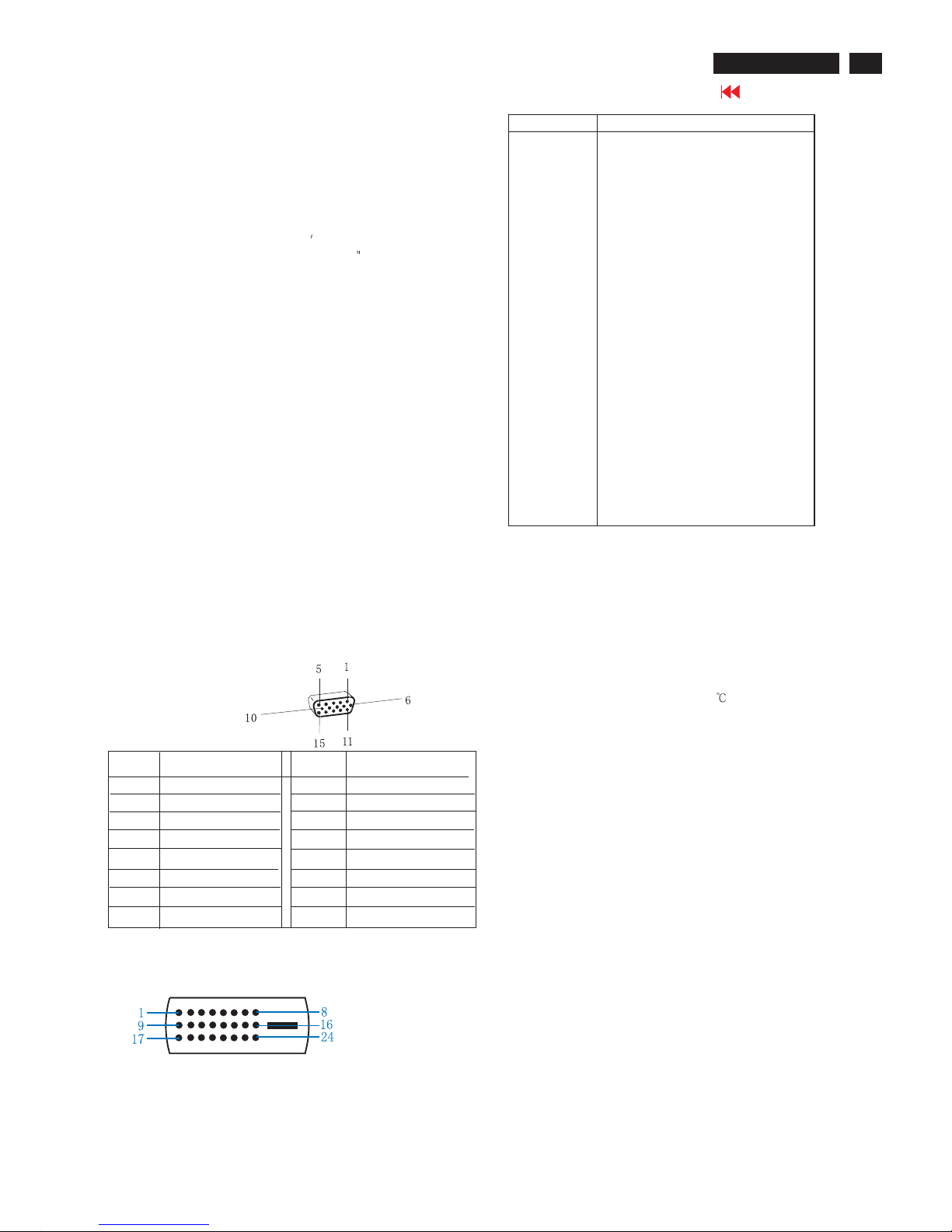

Pin Assignment

Input DVI-D connector pin

Red video input

Green video input

Blue video input

GND

Cable detect

Red video GND

Green video GND

Blue video GND

DDC +3.3V OR +5V

GND

GND

Serial data line (SDA)

H-sync

V-sync

Data clock line (SCL)

7

8

6

5

4

3

2

1

9

10

11

12

13

14

15

Pin No.

Pin No.

Assignment

Assignment

Pin No. Description

1

T.M.D.S. data2-

2

T.M.D.S. data2+

3

T.M.D.S. data2 shield

4

No Connect

5

No Connect

6

DDC clock

7

DDC data

8

No Connect

9

T.M.D.S. data1-

10

T.M.D.S. data1+

11

T.M.D.S. data1 shield

12

No Connect

13

No Connect

14

+5V Power

15

Ground (for +5V) - Cable detect

16

Hot plug detect

17

T.M.D.S. data0-

18

T.M.D.S. data0+

19

T.M.D.S. data0 shield

20

No Connect

21

No Connect

22

T.M.D.S clock shield

23

T.M.D.S. clock+

24

T.M.D.S. clock-

LCD panel

Type NR. : LM201U04 (LG.PHILIPS)

Outside dimensions : 432.0(w)*331.5(h)*25(d) (Typ) mm

Pitch ( mm ) : 0.255 (per one triad) x 0.-255mm

Color pixel arrangement : RGB vertical stripes

Display surface : low reflection, antiglare with hard coating

Color depth : 16777216 colors (8 bits)

Backlight : Six CCFL

s

Active area(WxH) : 408x306mm (20.1

diagonal)

View angle : Horizontal & Vertical 160 degree (CR>=10)

Contrast ratio : 400:1

White luminance : Panel original color >200nits (min), 250

nits (Typ.)

Main voltage : AC 90 - 135 Vrms and 170 - 264 Vrms,

50/60 ± 2Hz

Power cord length : 1.8M

Power cord type : 3 lead with earth plug

Power indicator : LED (ON: blue, Standby: amber, NEW

MODE: flashing blue twice per second

before user adjust and save it.).

Auto power saving : EPA, Nutek, VESA DPMS

Horizontal scan : 30 - 97 KHz

Vertical scan : 56 - 85 Hz

Horizontal scanning

Sync polarity :Positive or negative

Scanning frequency :30 - 93 K Hz

Vertical scanning

Sync polarity :Positive or negative

Scanning frequency :56 - 85 Hz

Mechanical

Pedestal : Detachable

Tilt angle : -5° to 35°

Swivel rotation : ±68°

Environmental conditions

Operating

-Temperature C : 0°cto35°c

-Humidity : 80 % max

-Altitude : 0-3658m

-Air pressure : 600-1100mBAR

Storage

-Temperature C : -30 to 60°

-Humidity : 85% max ( < 40

)

-Altitude : 0-12192m

-Air pressure : 300-1100mBAR

Note: recommend at 5°cto35°C, Humidity less than 60 %

4

Go to cover page

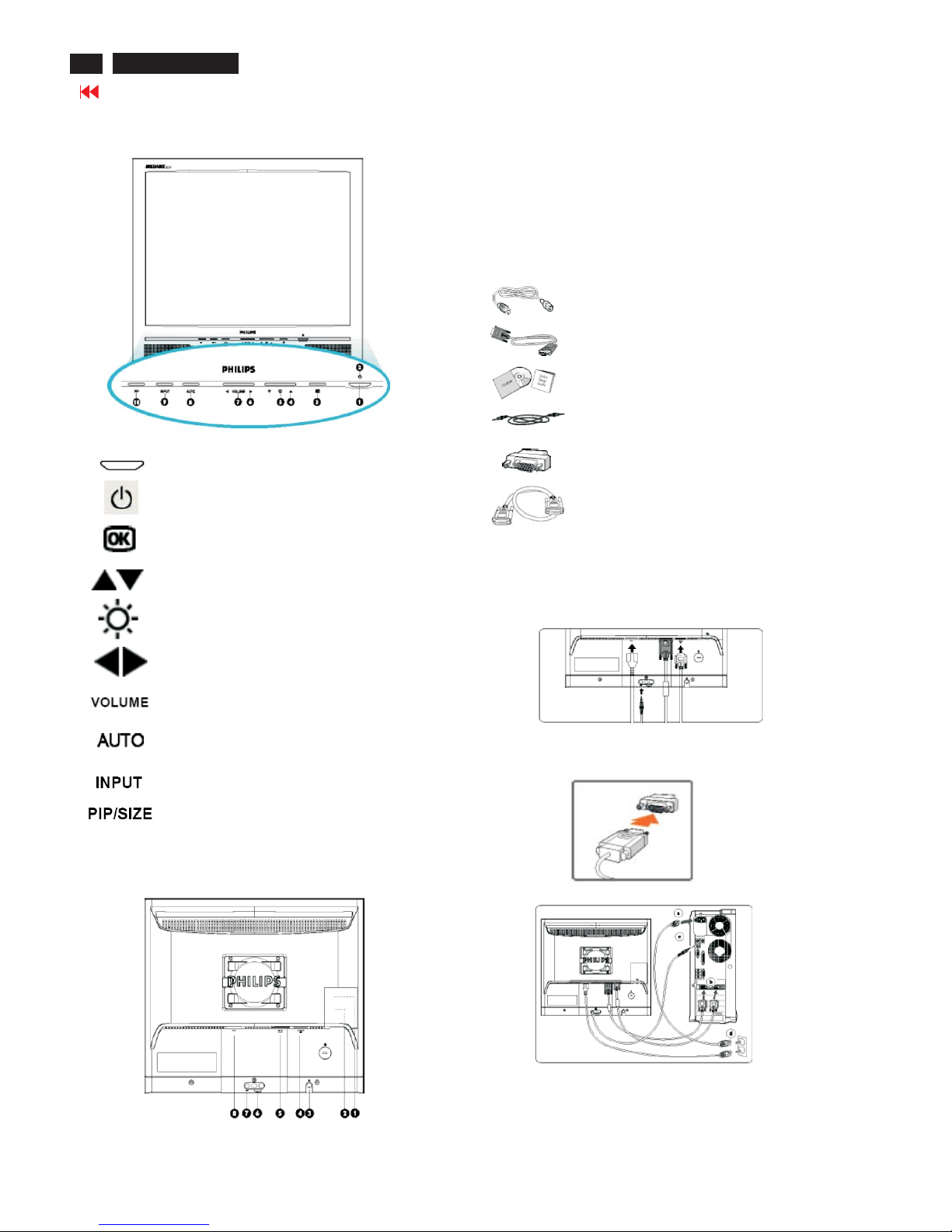

Installation

200P6 LCD

Front View

Rear View

Power cord

VGA signal cable

EDFU pack

PC audio cable (lime)

Mac adaptor (optional)

DVI-D cable

Accessory Pack

Item Description

Connecting to Your PC

1

2

3

4

5

6

7

8

9

10

To switch monitor's power On and Off

Power LED

To access OSD menu

To adjust the OSD

To adjust brightness of the display

To adjust the OSD

To adjust speaker volume

Automatically adjust the horizontal position,

vertical position, phase and clock setting

Signal input selection

Activate PIP (Picture in Picture) window (200P6I)

or adjust screen size (200P6E)

1 CVBS video input (for video model 200P6I- only )

2 S-Video input (for video model 200P6I- only )

3 Earphone jack

4 VGA input

5 DVI-I input

6 Audio R/L input

7 PC audio input

8 AC power input

Connect the power cord, DVI and audio cable to the back of the

monitor firmly. (Philips has pre-connected VGA cable for the first

installation.)

Notes:If you use an Apple Macintosh , you need to connect the

special Mac adapter to one end of the monitor signal cable.

TM

Connect the cables to the back of your computer by following these

steps:

(a) Turn off your computer and unplug its power cord.

(b) Connect the VGAor DVI cable to the video connector.

(c) Connect the audio cable.

5

Go to cover page

200P6 LCD

Installation

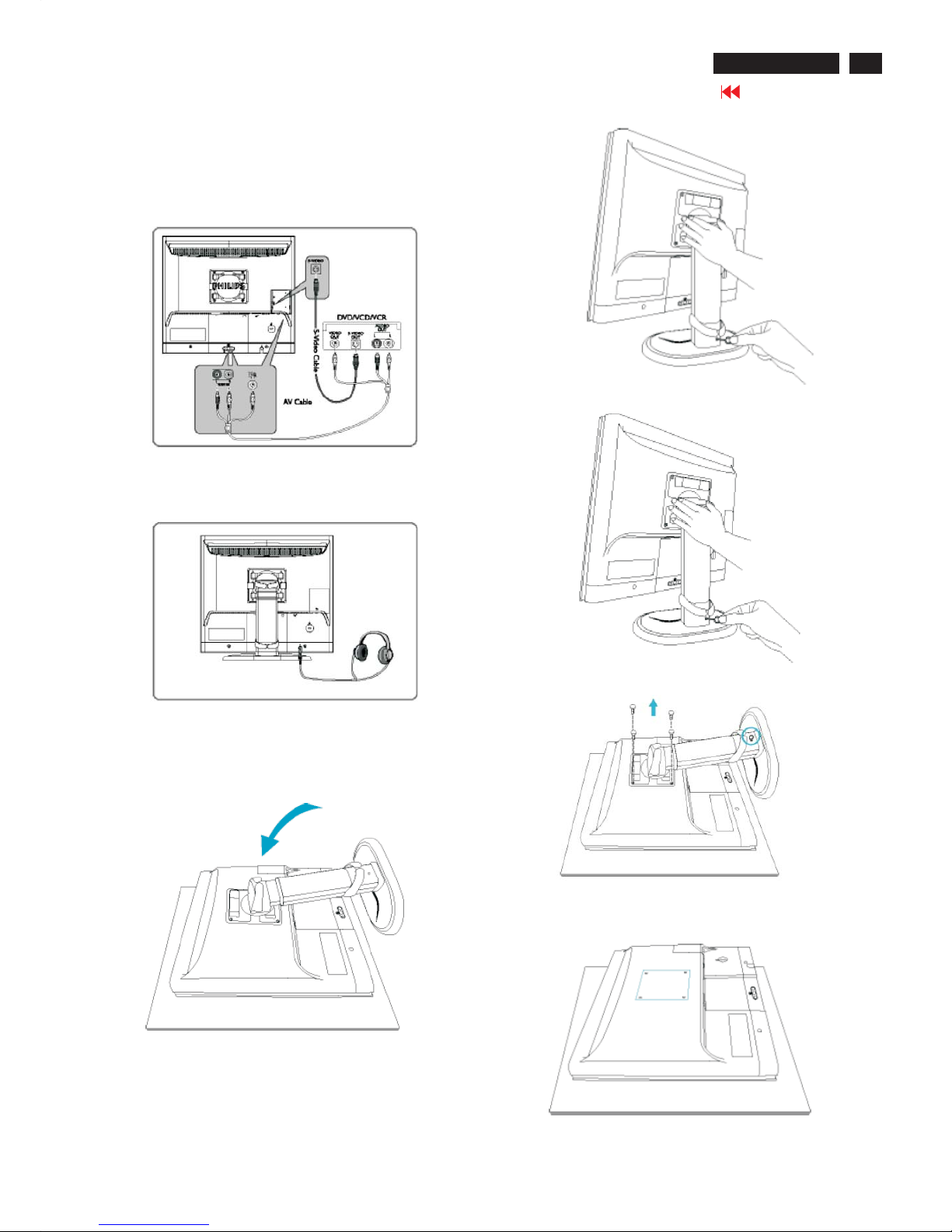

(d) Plug the power cord of the computer and the monitor into a

nearby outlet.

(e) Turn on your computer and monitor. If the monitor displays an

image, installation is complete.

Connect to DVD/VCR/VCD

Connect to Earphone

VESA Standard Mounting

1) Place monitor face down on a surface.

2) Remove the cable cover

3) Remove the base cover.

4) Unscrew the 5 screws at the base.

5) VESA mounting holes

6

Go to cover page

200P6 LCD

On Screen Display

Description of the On Screen Display

This is a feature in all Philips LCD monitors. It allows an end user to adjust screen performance of the monitors directly through an

on-screen instruction window. The user interface provides userfriendliness and ease-of-use when operating the monitor.

Basic and simple instruction on the control keys.

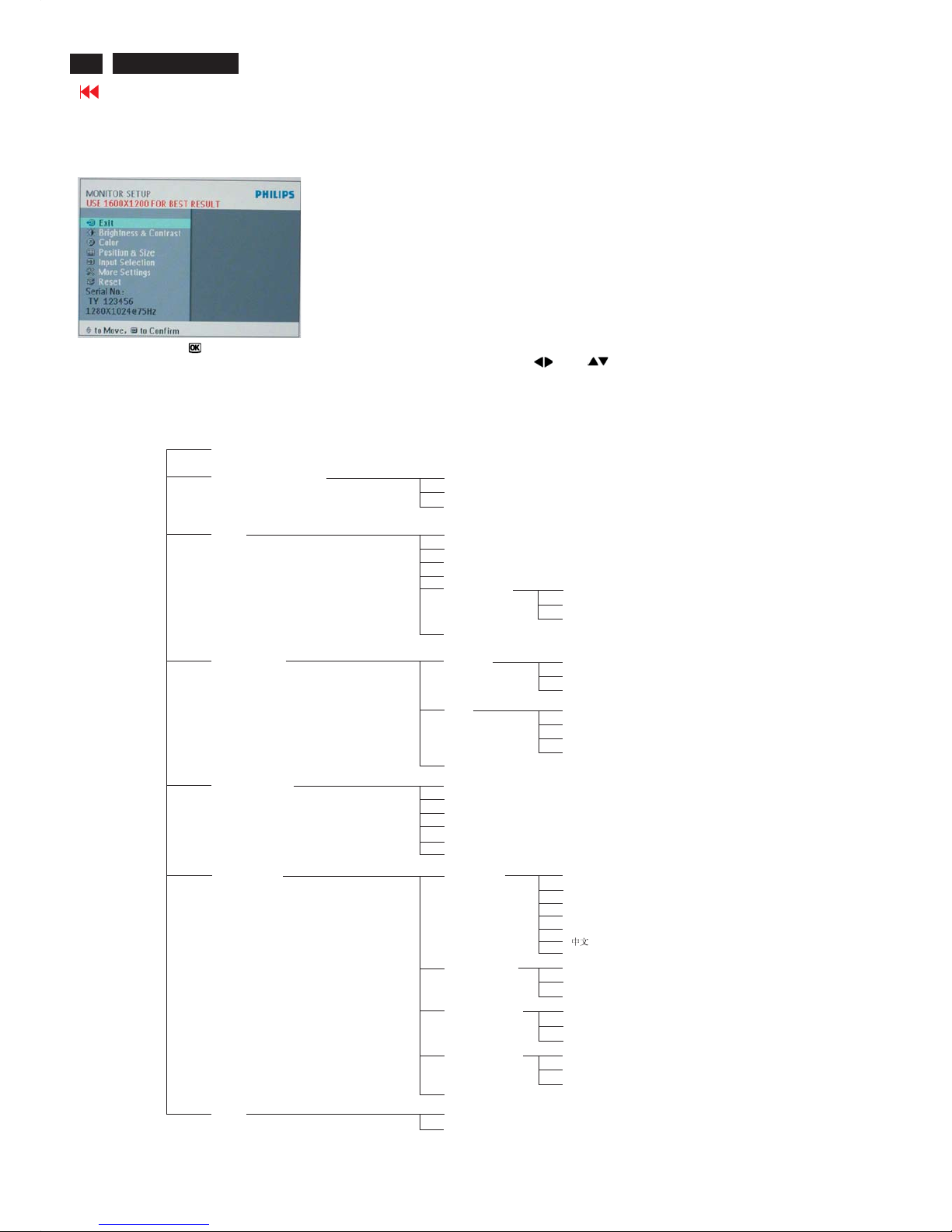

PC analog signal(VGA&DVI-A) input mode

Main Menu Sub Menu

When you press the button on the front control of your monitor, the On-Screen Display (OSD) Main Controls window will pop up and

you can then start making adjustments to your monitor's various features. Use the or the keys to make your adjustments.

Exit

Brightness&Contrast

Brightness

Contrast

Back

Color

Original Color

9300K

6500K

sRGB

User Define

Red

Green

Blue

Back

Position&Size

Position

Horizontal

Vertical

Back

Size

Full Screen

Native Mode

Fill With Aspect

Back

Back

Input Selection

Analog(D-Sub)

Analog(DVI-A)

Digital(DVI-D)

CVBS

S-Video

Back

More Setting

Language

ENGLISH

ESPANOL

FRANCALS

DEUTSCH

ITALIANO

Back

Phase/Clock

Phase

Clock

Back

OSD Settings

Horizontal

Vertial

Back

Audio Options

Stand-alone

Mute

Back

Back

Reset

No

Yes

7

Go to cover page

200P6 LCD

On Screen Display

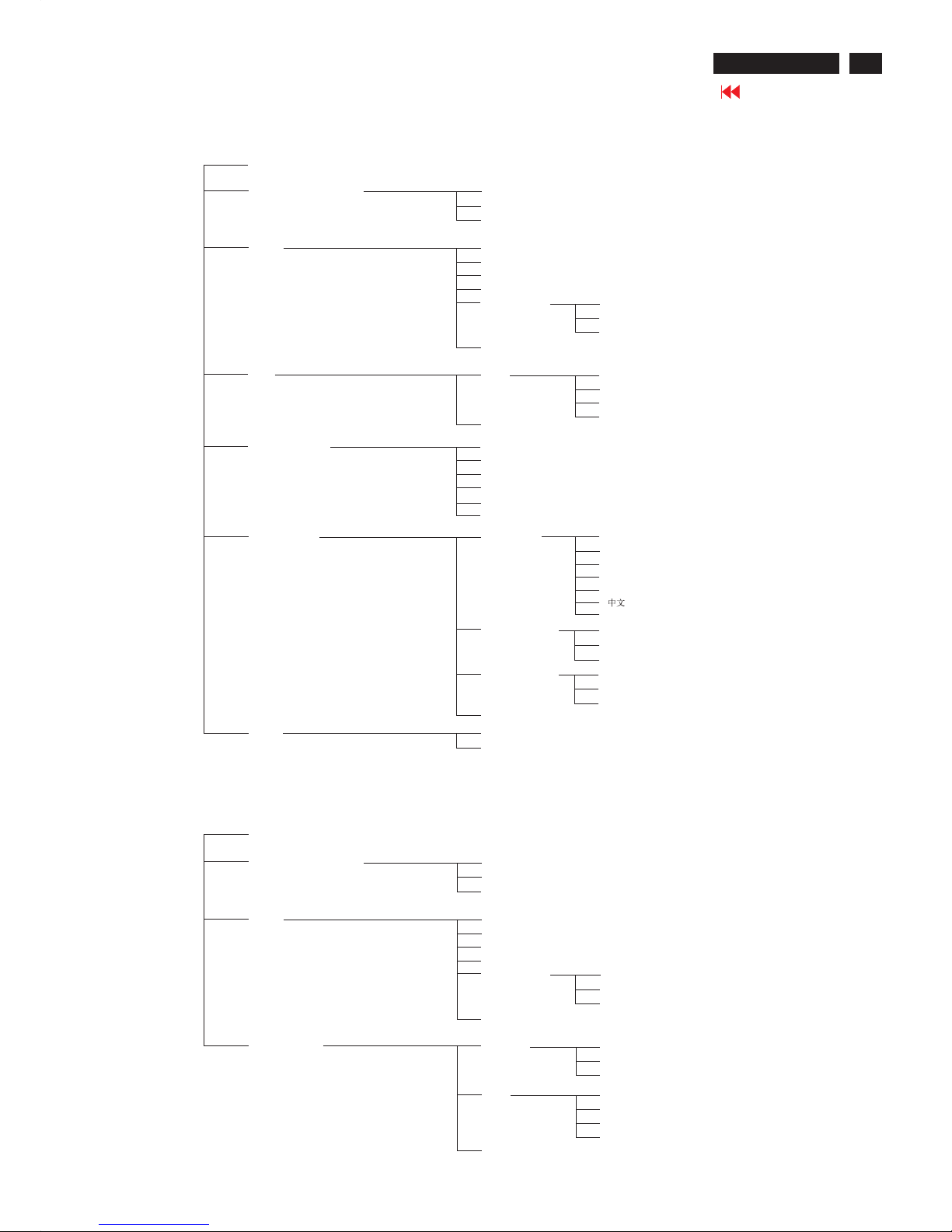

PC digital signal(DVI-D) input mode only

Main Menu Sub Menu

Exit

Brightness&Contrast

Brightness

Contrast

Back

Color

Original Color

9300K

6500K

sRGB

User Define

Red

Green

Blue

Back

Size

Size

Full Screen

Native Mode

Fill With Aspect

Back

Back

Input Selection

Analog(D-Sub)

Analog(DVI-A)

Digital(DVI-D)

CVBS

S-Video

Back

More Setting

Language

ENGLISH

ESPANOL

FRANCALS

DEUTSCH

ITALIANO

Back

OSD Settings

Horizontal

Vertial

Back

Audio Options

Stand-alone

Mute

Back

Back

Reset

No

Yes

PIP mode only

Main Menu Sub Menu

Exit

Brightness&Contrast

Brightness

Contrast

Back

Color

Original Color

9300K

6500K

sRGB

User Define

Red

Green

Blue

Back

Position&Size

Position

Horizontal

Vertical

Back

Size

Full Screen

Native Mode

Fill With Aspect

Back

Back

8

Go to cover page

200P6 LCD

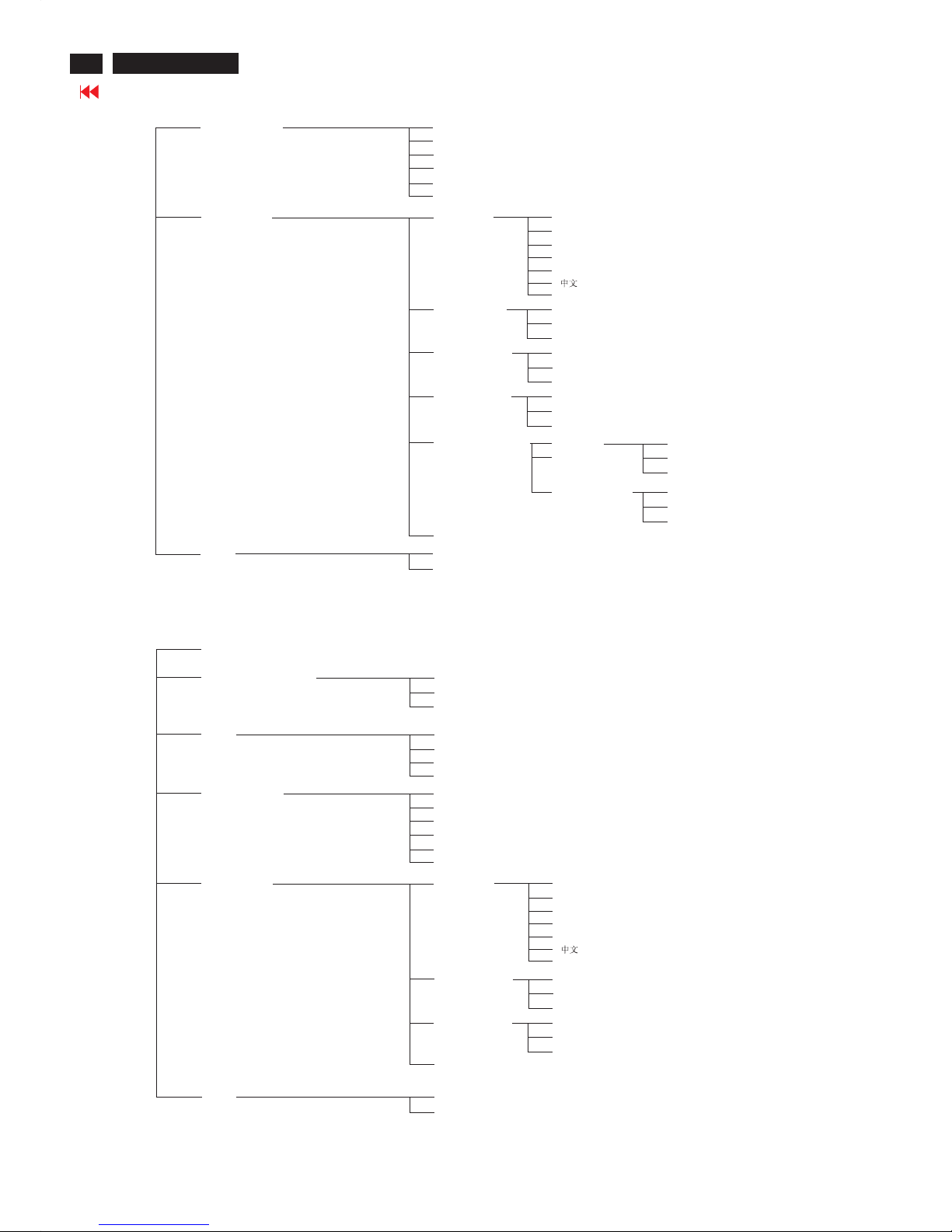

On Screen Display

Input Selection

Analog(D-Sub)

Analog(DVI-A)

Digital(DVI-D)

CVBS

S-Video

Back

More Setting

Language

ENGLISH

ESPANOL

FRANCALS

DEUTSCH

ITALIANO

Back

Phase/Clock

Phase

Clock

Back

OSD Settings

Horizontal

Vertial

Back

Audio Options

Stand-alone

Mute

Back

Back

Reset

No

Yes

Picture In Picture

Horizontal

Vertial

Back

Position

Audio Source

Audio 1(PC)

Audio 2(Video)

Back

Video Signal input mode only

Main Menu Sub Menu

Exit

Brightness&Contrast

Brightness

Contrast

Back

Color

Sharpness

Saturation

Tint

Back

Input Selection

Analog(D-Sub)

Analog(DVI-A)

Digital(DVI-D)

CVBS

S-Video

Back

More Setting

Language

ENGLISH

ESPANOL

FRANCALS

DEUTSCH

ITALIANO

Back

OSD Settings

Horizontal

Vertial

Back

Audio Options

Stand-alone

Mute

Back

Back

Reset

No

Yes

9

Go to cover page

200P6 LCD

Lock/Unlock,Aging,Factory Mode

Front Control

To Lock/Unlock OSD FUNCTION(User Mode)

The OSD function can be locked by pressing"OK"button(1) for more

than 10 seconds, the screen shows following windows for 4 seconds.

Everytime when you press"OK" button, this message

appears on the screen automatically.

ATTENTION SIGNAL

OSD MAIN CONTROLS

LOCKED

Unlock OSD function

Unlocked OSD function can be released by pressing "OK" button for

more than 10 seconds again.

ATTENTION SIGNAL

OSD MAIN CONTROLS

UNLOCKED

After 10 seconds,

bring up:

----------

---------repeatly

Connect Signal cable again=> go back to normal display

After 10 seconds,

bring up:

After 5 seconds,

bring up:

Access Aging Mode

Step1:D

Step 2 : [Push "AUTO"&"OK"buttons

at the same time and hold them]+[Press power " " button untill comes

out " AGING screen"] => then release all buttons.

Bring up:

isconnect Interface Cable between Monitor and PC.

Turn off LCD monitor.Then

Access Factory Mode

1). Turn off monitor.

2).

3).Press "OK" button, wait until the OSD menu with Characters

"HUDSON6 200P6 V0.02 050104 With VIDEO" (below OSD

menu) come on the Screen of the monitor.

[Push "AUTO" & "OK" buttons at the same time and hold them]

+[Press "power" button untill comes out "Windows screen" ]

=> then release all buttons

Factory Mode indicator

Factory Menu

Cursor can move on gray color area

Hot key function: by pressing " UP " and " DOWN " key

Simultaneously at User Mode (or Factory Mode)

(PS: The OffsetRGBfunction can be used on reduce or eliminate

snowy noise on the background when the resolution of video signal

is 1280*1024 vertical 60Hz. Slightly increase or decrease the value

until snowy noise completely disappear.

ATTENTION

AGING...

ATTENTION

AGING...

ATTENTION

AGING...

ATTENTION

AGING...

ATTENTION

AGING...

ATTENTION

AGING...

10

Go to cover page

200P6 LCD

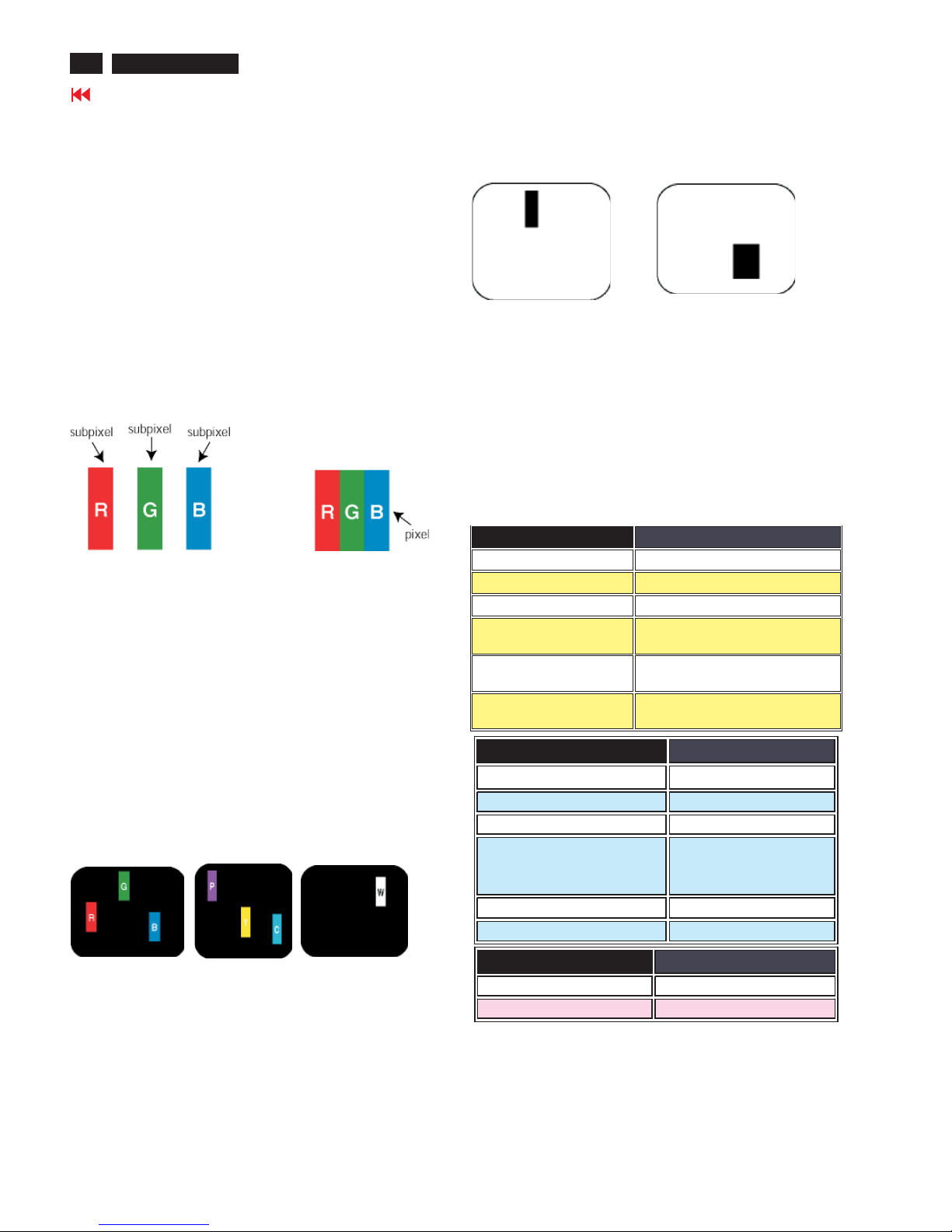

Philips Pixel Defect Policy

Philips' Flat Panel Monitors Pixel Defect Policy

Philips strives to deliver the highest quality products. We

use some of the industry's most advanced manufacturing

processes and practice stringent quality control. However,

pixel or sub pixel defects on the TFT LCD panels used in

flat panel monitors are sometimes unavoidable. No

manufacturer can guarantee that all panels will be free

from pixel defects, but Philips guarantees that any monitor

with an unacceptable number of defects will be repaired or

replaced under warranty. This notice explains the different

types of pixel defects and defines acceptable defect levels

for each type. In order to qualify for repair or replacement

under warranty, the number of pixel defects on a TFT LCD

panel must exceed these acceptable levels. For example,

no more than 0.0004% of the sub pixels on a 15" XGA

monitor may be defective. Furthermore, Philips sets even

higher quality standards for certain types or combinations

of pixel defects that are more noticeable than others. This

policy is valid worldwide.

Pixels and Sub pixels

A pixel, or picture element, is composed of three sub pixels

in the primary colors of red, green and blue. Many pixels

together form an image. When all sub pixels of a pixel are lit,

the three colored sub pixels together appear as a single

white pixel. When all are dark, the three colored sub pixels

together appear as a single black pixel. Other combinations

of lit and dark sub pixels appear as single pixels of other

colors.

Types of Pixel Defects

Pixel and sub pixel defects appear on the screen in different

ways. There are two categories of pixel defects and several

types of sub pixel defects within each category. Bright dot

defects appear as pixels or sub pixels that are always lit or

'on'. These are the types of bright dot defects:

One lit red,

green or

blue sub pixel

Two adjacent lit

sub pixels:

- Red+ Blue =Purple

- Red+ Green =Yellow

- Green+ Blue =Cyan

(Light Blue)

Three adjacent lit

sub pixels

(one white pixel)

Black Dot Defects Black dot defects appear as pixels or sub

pixels that are always dark or 'off'. These are the types of black

dot defects:

One dark sub pixel Two or three adjacent dark sub pixels

Proximity of Pixel Defects

Because pixel and sub pixels defects of the same type that are

near to one another may be more noticeable, Philips also specifies

tolerances for the proximity of pixel defects.

Pixel Defect Tolerances

In order to qualify for repair or replacement due to pixel defects

during the warranty period, a TFT LCD panel in a Philips flat panel

monitor must have pixel or sub pixel defects exceeding the

tolerances listed in the following tables.

Note:

* 1 or 2 adjacent sub pixel defects = 1 dot defect

All Philips monitors are ISO13406-2 Compliant

TOTAL DOT DEFECTS ACCEPTABLE LEVEL

MODEL 200P6

Total bright or black dot defects of all types 5 or fewer

BRIGHT DOT DEFECTS ACCEPTABLE LEVEL

MODEL

200P6

1 lit subpixel

4 or fewer

2 adjacent lit subpixels

2 or fewer

3 adjacent lit subpixels (one white

pixel)

0

Distance between two bright dot

defects*

Total bright dot defects of all types

BLACK DOT DEFECTS ACCEPTABLE LEVEL

MODEL

200P6

1 dark subpixel 4 or fewer

2 adjacent dark subpixels 2 or fewer

3 adjacent dark subpixels 0

Distance between two black dot defects* 15 mm or more

Total black dot defects of all types 4 or fewer

15mm or more

4 or fewer

11

Go to cover page

200P6 LCD

Mechanical Instruction

Front view

Back view

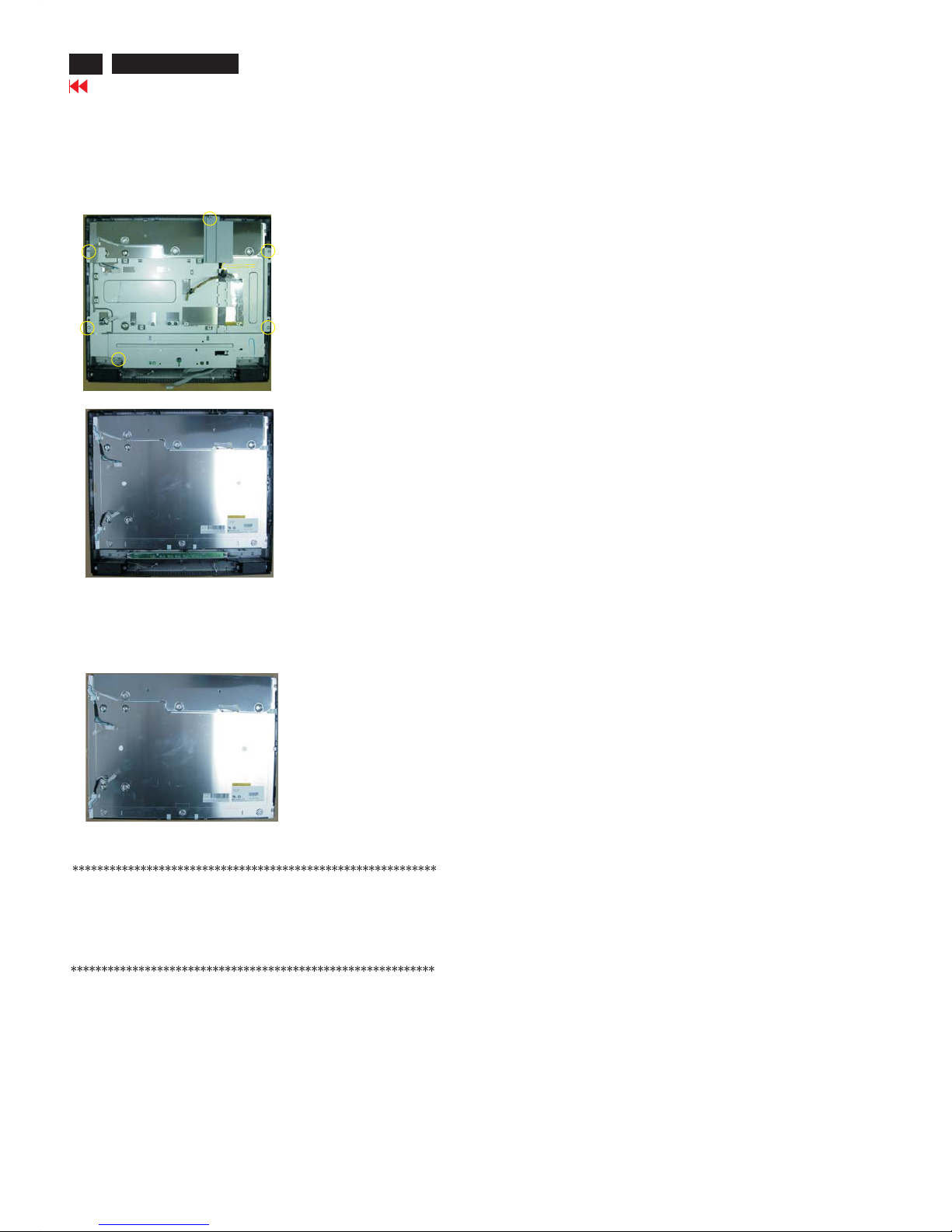

Step 1. Remove the stand.

Unscrew the 4 screws as Fig.3

Fig.3

Fig.2

Fig.1

Fig.7

Fig.8

Fig.4

Fig.5

Fig.6

Fig.9

Step 2: Remove the Back Cover Assy

a. Remove the COVER-VIDEO and COSMETIC BACK COVER in

Fig.4 .

b. Unscrew 4 screws as shown in Fig.5.

c. Open 3 clicks on right and left side as shown in Fig.6 and Fig.7.

d. Open 2 clicks on bottom side as shown in Fig.8.

e. Open 3 clicks on top side as shown in Fig.9.

f . Remove the CASE-AUDIO and BACK COVER ASSY in Fig.10.

Fig.10

Fig.11

Step 3. Remove the Scaler ,Audio and Power board.

a. Unscrew

b. Unscrew the 10 screws and disconnect the 10 cables as Fig. 11.

c.

the 12 screws to remove the METAL COVER ASSY

as Fig.10.

Remove as Fig. 12.the Scaler ,Audio and Power board

Fig.12

Mechanical Instruction

Go to cover page

12

200P6 LCD

In warranty, it is not allowed to disassembly the LCD panel, even the

backlight unit defect.

Out of warranty, the replacment of backlight unit is a correct way

when the defect is cused by backlight (CCFL,Lamp).

Fig. 13

Step 3. Remove the LCD panel.

a. Unscrew

b. Remove the BRACKET-HOLD DOWN and FRAME+WIRE

ASSY as Fig. 14.

c. Remove the LCD panel as Fig.15.

the 6 screws and disconnect the 1 cables as Fig. 13.

LCD Panel

1050 823827718031 TFT-LCD MOD LM201U04-A3KC(Fig.15).

Fig. 14

Fig. 15

13

Go to cover page

200P6 LCD

Color Adjustment

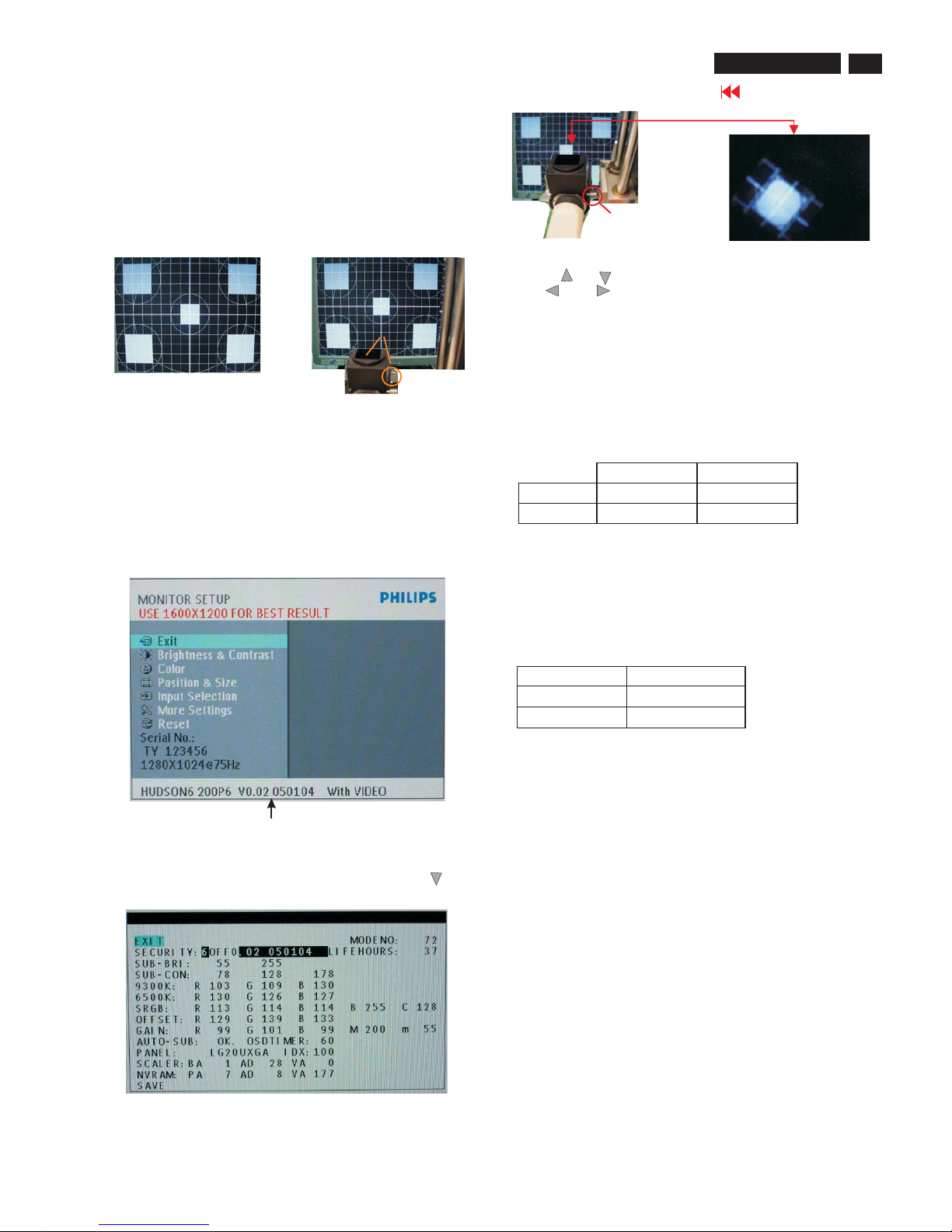

Alignment procedure

1. Turn on the LCD monitor.

2.Turn on the Timing/pattern generator. See Fig.1

3. Preset LCD color Analyzer CA-110

-Remove the lens protective cover of probe CA-A30.

-Set measuring/viewing selector to measuring position for reset

analyzer.(zero calibration) as Fig.2

- Turn on the color analyzer (CA-110)

-Press 0-CAL button to starting reset analyzer.

Fig. 1

Fig. 2

Clear imageClear image

Measurement/viewing selectorMeasurement/viewing selector

Fig. 3

4). Press button, then select factory mode indicator by"OK" " "

button .Press"OK" button to bring up submenu windows as below:

Fig.5

Cover (black)Cover (black)

Measurement viewing selectorMeasurement viewing selector

Fig. 4

Fig. 2

5.Display

Press " " or " " button to select . Change the value

by " " or " " key until the X,Y co-ordinates as below

4. Access Factory Mode

1). Turn off monitor.

2).

3).Press "OK" button, wait until the OSD menu with Characters

"HUDSON6 200P6 V0.02 050104 With VIDEO" (below OSD

menu) come on the Screen of the monitor. as shown in Fig3.

[Push "AUTO" & "OK" buttons at the same time and hold them]

+[Press "power" button untill comes out "Windows screen" ]

=> then release all buttons

Factory Mode indicator

5.1 Auto color adjustment (B)

Apply a 1280x1024/60Hz signal with 64-gray levels pattern, set

brightness control at 100%, and contrast control at 50%.

Adjust the R. G. B offset, and gain to calibrate the color smoothly

and 64-gray level distinguishable. Check all factory pre-setting modes.

5.2 Adjustment of WHITE-D (B)

Apply a 1280*1024 / 60Hz signal with white pattern, set brightness control

at 100%, and contrast control at 50%. Adjust the R, G, B Sub-Gain, for

he screen center, the 1931 CIE chromaticity (X, Y) co-ordinates shall be;

Use Minolta CA-110 for colour coordinates and luminance check.

Luminance is > 200 Nits in the center of the screen when brightness at

100% and contrast set to 100%.

5.3 Adjustment of sRGB

Apply a 1280*1024 / 60Hz signal with white pattern, set brightness control

at 100%, and contrast control at 50%. Adjust the R, G, B Sub-Gain, for

the screen center, the 1931 CIE chromaticity (X, Y) co-ordinates shall be;

sRGB

x(center) 0.313 ± 0.020

y(center) 0.329 ± 0.020

5.4 Factory Preset (B):

After finished all the adjustment, set:

OSD Default Setting:

Brightness : 100%

Contrast : 50%

Adjust size : Full screen

Language : English

Colour : 6500K for IMAGE MANAGEMENT

OSD position : middle of the LCD screen

Input Selection: Default as PC VGA (D-sub)

PIP position : bottom right corner

PIP audio source: PC Audio

PIP video source: CVBS

Volume: 50%

5.5 In Factory mode default setting :

SECURITY : OFF

SUB-BRI : 0 255 (Fix)

SUB-CON : 78 128 178 (Fix)

9300°K 6500°K

x (center) 0.283 ± 0.020 0.313 ± 0.020

y (center) 0.297 ± 0.020 0.329 ± 0.020

14

Go to cover page

200P6 LCD

Warning Message

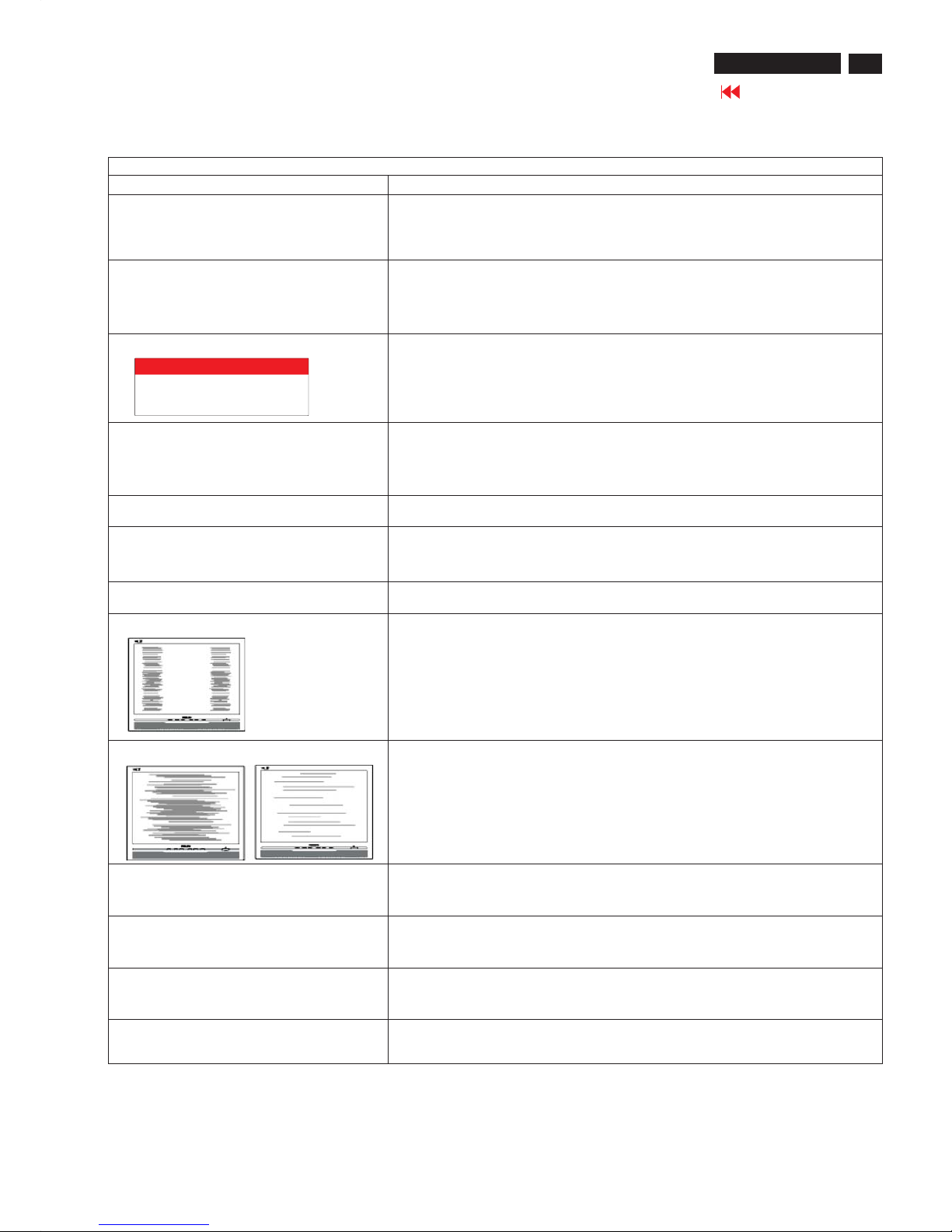

Item Attention Signals Display Time Condition

1 CANNOT DISPLAY THIS

VIDEO MODE, CHANGE

COMPUTER DISPLAY

INPUT TO 1600X1200@

60HZ

30 mins This warning appears when the input signal from your computer is not in a

standard video mode or is out of the monitor

s scanning range. After 30

mins, monitor enters sleeping mode.

2 NO VIDEO INPUT 30 mins This message appears when there is no signal input but with cable while AC

or DC power on. After 30 mins, monitor enters sleeping mode.

3 CHECK CABLE

CONNECTION

30 mins This message appears when a signal cable is disconnected while monitor is

working. After 30 mins, monitor enters sleeping mode.

4 ENTERING SLEEP

MODE

3 secs This message appears when monitor is about to enter power saving mode.

5 WAITING FOR

AUTOMATIC

ADJUSTMENT

till auto adjustment

finished

This message is displayed when the auto adjustment button is pressed. It

disappears when automatic adjustments are completed.

6 USE 1600X 14 FOR

BEST RESULT

On top of OSD main

menu

The message will show up at the top of the OSD main menu in red color

when the input resolution is not the 1280x1024.

7 OSD MAIN CONTROLS

LOCKED

3 secs / or Till "OSD

MAIN CONTROLS

UNLOCKED" appear

This message will appear 3 seconds to indicate the OSD MAIN CONTROLS

status when to lock or un-lock it by pressing "MENU(OK) " button for more

than 10 seconds while there is video input from PC. This function provides

the alternative that user can lock all the OSD main control in case user don

t want the FOS performance setting to be changed, for instance, during

commercial exhibition.

8 OSD MAIN CONTROLS

UNLOCKED

3 secs This message will appear 3 seconds to indicate the OSD MAIN CONTROLS

status when to un-lock it by pressing "MENU (OK) " button for more than 10

seconds while there is video input from PC.

9 the window of OSD

"MONITOR SETUP "

60 secs This message will appear when the "OK" button is pressed.

10 the window of

"BRIGHTNESS"

60 secs This message will appear when the BRIGHTNESS button is pressed.

11 the window of "VOLUME" 60 secs This message will appear when the VOLUME button is pressed.

12 "SELECTED INPUT NOT

AVAILABLE"

3 secs This message will appear 3 seconds to indicate the SIGNAL SOURCE status

when change the signal source but it is not found while there is video input

from PC.

Warning message table

15

Go to cover page

200P6 LCD

Troubleshooting

Common Problems

Having this problem

Check these items

No Picture

(Power LED not lit)

1.Make sure the power cord is plugged into the power outlet and into the back of the

monitor.

2.First, ensure that the power button on the front of the monitor is in the OFF position,

then press it to the ON position.

No Picture

(Power LED is amber or yellow)

1.Make sure the computer is turned on.

2. Make sure the signal cable is properly connected to your computer.

3.Check to see if the monitor cable has bent pins.

4.The Energy Saving feature may be activated

Screen says

1. Make sure the monitor cable is properly connected to your computer. (Also refer

to the Quick Set-Up Guide).

2.Check to see if the monitor cable has bent pins.

3. Make sure the computer is turned on.

AUTO button not working properly

1.The Auto Function is designed for use on standard Macintosh or IBM-compatible

PCs running Microsoft Windows.

2. It may not work properly if using nonstandard PC or video card.

Imaging Problems

Display position is incorrect

1.Press the Auto button.

2. Adjust the image position using the Horizontal Position and/or Vertical

Position in OSD Main Controls.

Image vibrates on the screen

Check that the signal cable is properly connected to the graphics board or PC.

Vertical flicker appears

1. Press the Auto button.

2. Eliminate the vertical bars using the More Settings of Phase/Clock in OSD Main

Controls.

Horizontal flicker appears

1. Press the Auto button.

2. Eliminate the vertical bars using the More Settings of Phase/Clock in OSD Main

Controls.

The screen is too bright or too dark

Adjust the contrast and brightness on OSD Main Controls. (The backlight of the

LCD monitor has a fixed life span. When the screen becomes dark or begins to

flicker, please contact your dealer).

An after-image appears

If an image remains on the screen for an extended period of time, it may be

imprinted in the screen and leave an afterimage. This usually disappears after a

few hours.

An after-image remains after the power

has been turned off.

This is characteristic of liquid crystal and is not caused by a malfunction or

deterioration of the liquid crystal. The after-image will disappear after a peroid

of time.

Green, red, blue, dark, and white dots

Remains

The remaining dots are normal characteristic of the liquid crystal used in

today's technology.

ATTENTION

NO VIDEO INPUT

16

Go to cover page

200P6 LCD

Electrical Instructions

1. General points

1.1 During the test and measuring, supply a distortion free AC mains voltage to the apparatus via an isolated transformer with low internal

resistance.

1.2 All measurements mentioned hereafter are carried out at a normal mains voltage (90 - 132 VAC for USA version, 195 -264 VAC for EUROPEAN

version, or 90 - 264 VAC for the model with full range power supply, unless otherwise stated.)

1.3 All voltages are to be measured or applied with respect to ground,unless otherwise stated.

Note: don't use heat-sink as ground.

1.4 The test has to be done on a complete set including LCD panel in a room with temperature of 25 +/- 5 degree C.

1.5 All values mentioned in these test instruction are only applicable of a well aligned apparatus, with correct signal.

1.6 The letters symbols (B) and (S) placed behind the test instruction denotes

(B): carried out 100% inspection at assembly line

(S): carried out test by sampling

1.7 The white balance (color temperature), has to be tested in subdued lighted room.

1.8 Repetitive power on/ off cycle are allowed. The image can be displayed after 8 sec.

1.9 All optical characteristics (including WHITE-D, Brightness, and so on) are determined according to panel specification after warming up

approximate 30 minutes that brightness stability is optimal, and follow strictly after panel specification.

2. Input signal

Signal type

2.1.1 Analogue Video: 0.7 Vp-p linear, positive polarity

Sync. : TTL level, separate, positive or negative polarity

Signal source: pattern generator format as attachment. Reference generator : QuantumData 802G/ 802R or Chroma 2237

2.1.2 Digital Video :600mVp-p TMDS Signal

2.1.3 CVBS Video :1Vp-p,75 Ohm

2.1.4 S-Video :Y-1Vp-p,75 Ohm C-0.3Vp-p,75 Ohm

2.1.5 Audio Signal : For S-terminal/ CVBS is L/R audio input PC line in

2.2 Input signal mode

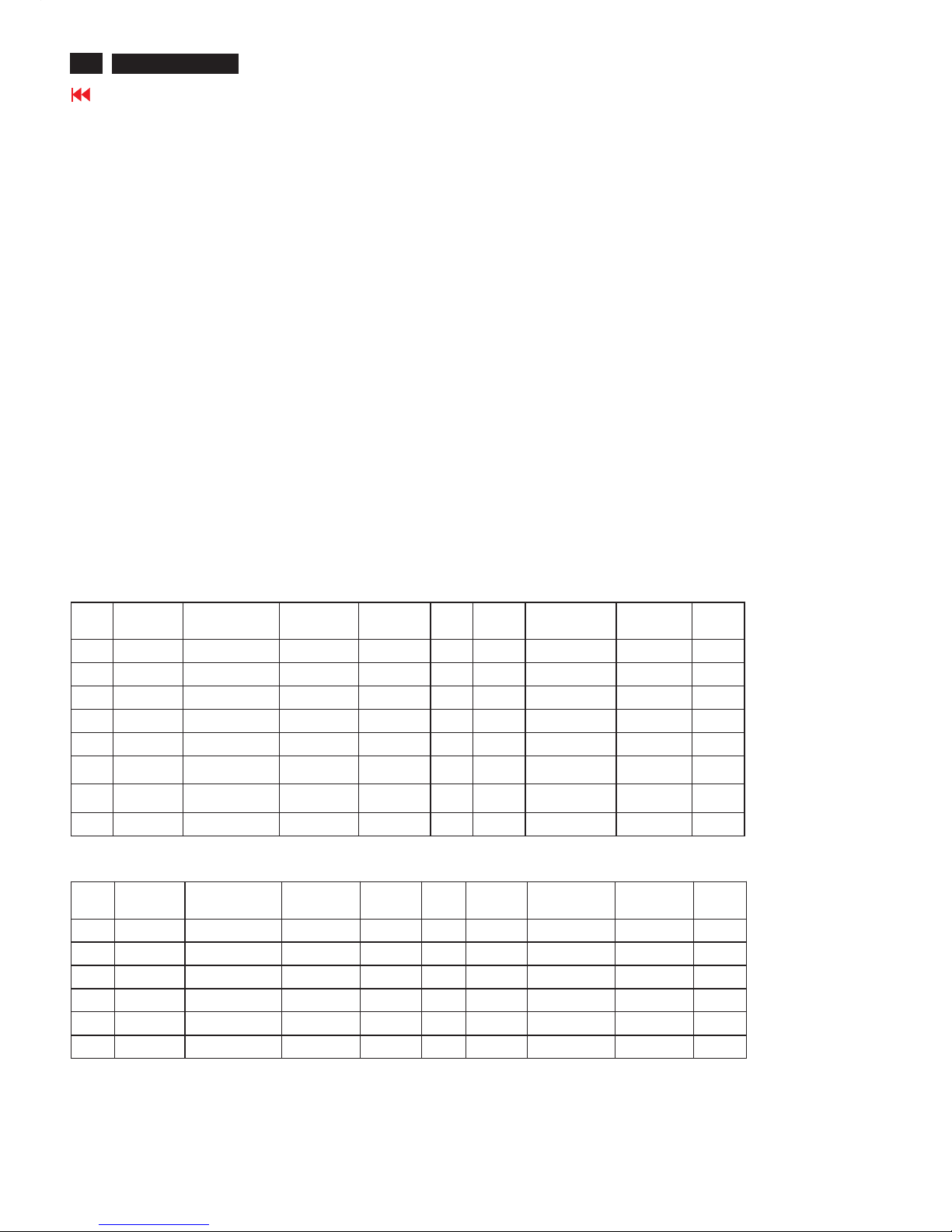

(1) Factory Preset Modes (15modes)

Item H.Freq.

(KHz)

Mode Resolution V.Freq.

(Hz)

Item H.Freq

.(KHz)

Mode Resolution V.Freq

.(Hz)

1 31.469 IBM VGA 10H 640x350 70.086 9 60.023 VESA 1024x768 75.029

2 31.469 IBM VGA 3H 720x400 70.087 10 68.700 MACINTOSH 1152x870 75.000

3 31.469 IBM VGA 12H 640x480 59.940 11 63.981 VESA 1280x1024 60.020

4 37.500 VESA 640x480 75.000 12 79.976 VESA 1280x1024 75.025

5 35.156 VESA 800x600 56.250 13 75.0 VESA 1600x1200 60

6 37.879 VESA 800x600 60.317 14 33.75 HDTV 1080i (D-

sub only)

60

7 46.875 VESA 800x600 75.000 15 45.0 HDTV 720p (D-

sub only)

60

8 48.363 VESA 1024x768 60.004

(2) Preset Modes (37modes)

Item H.Freq.

(KHz)

Mode Resolution V.Freq.

(Hz)

Item H.Freq.

(KHz)

Mode Resolution V.Freq

.(Hz)

1 31.469 IBM VGA 10H 640x350 70.086 21 67.500 VESA 1152x864 75.000

2 31.469 IBM VGA 3H 720x400 70.087 22 68.700 MACINTOSH 1152x870 75.000

3 31.469 IBM VGA 12H 640x480 59.940 23 61.845 SUN WS 1152x900 66.004

4 35.000 MACINTOSH 640x480 67.000 24 71.810 SUN WS 1152x900 76.150

5 37.861 VESA 640x480 72.809 25 60.000 VESA 1280x960 60.000

6 37.500 VESA 640x480 75.000 26 75.000 VESA 1280x960 75.000

17

Go to cover page

200P6 LCD

Electrical Instructions

7 43.269 VESA 640x480 85.008 27 85.939 VESA 1280x960 85.002

8 35.156 VESA 800x600 56.250 28 63.981 VESA 1280x1024 60.020

9 37.879 VESA 800x600 60.317 29 71.691 SUN WS 1280x1024 67.189

10 48.077 VESA 800x600 72.188 30 76.000 DOS/V 1280x1024 72.000

11 46.875 VESA 800x600 75.000 31 79.976 VESA 1280x1024 75.025

12 53.674 VESA 800x600 85.061 32 81.130 SUN WS 1280x1024 76.110

13 49.700 MACINTOSH 832x624 75.000 33 91.1 VESA 1280x1024 85

14 48.363 VESA 1024x768 60.004 34 75.0 VESA 1600x1200 60

15 56.476 VESA 1024x768 70.069 35 31.45 HDTV 480p (D-

sub only)

60

16 60.023 VESA 1024x768 75.029 36 33.75 HDTV 1080i (D-

sub only)

60

17 61.080 IBM XGA-2 1024x768 75.781 37 45.0 HDTV 720p (D-

sub only)

60

18 68.677 VESA 1024x768 84.997

19 54.1 1152x864 60

20 63.851 VESA 1152x864 70.012

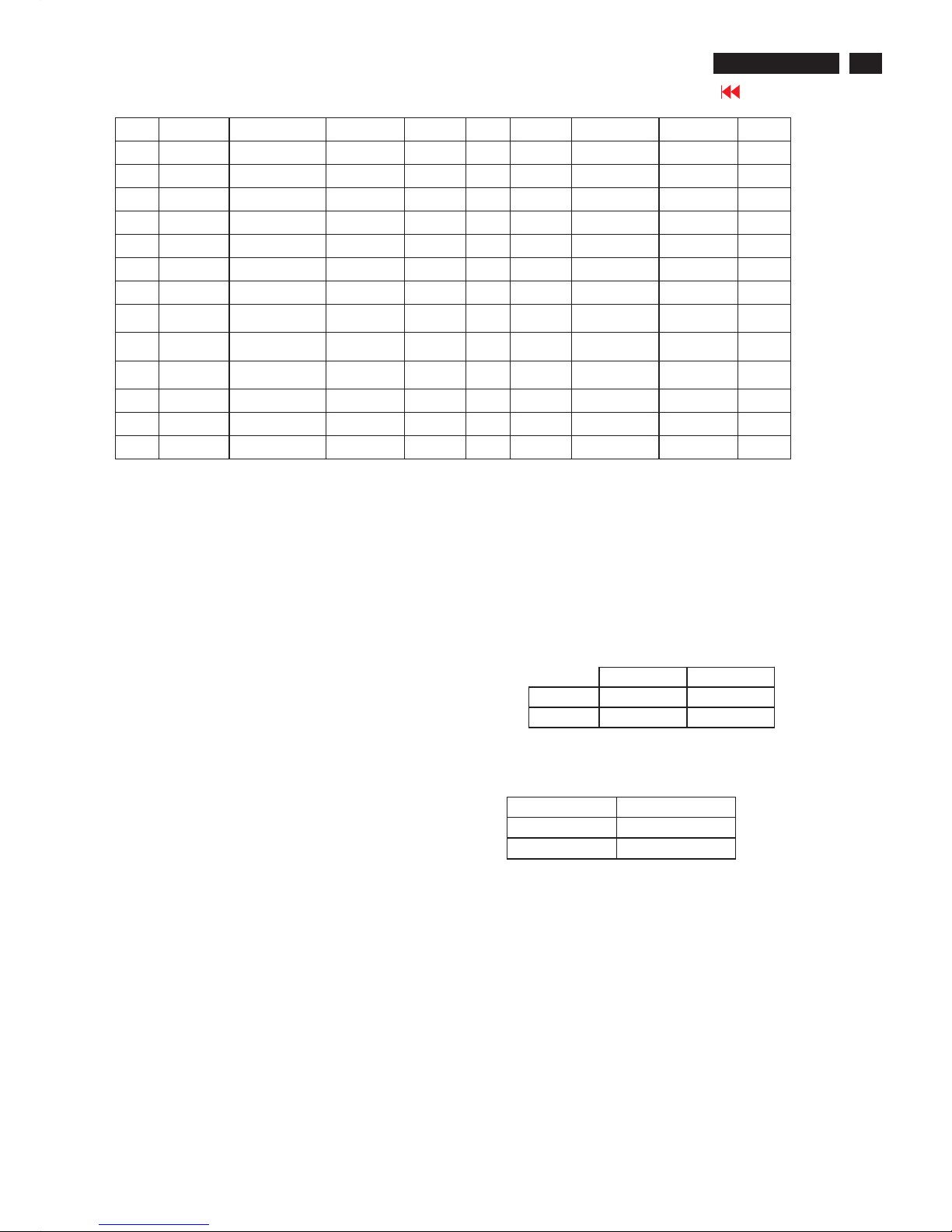

3. AC, DC power board

3.1 Setup the AC I/P at 90VAC, and 18V panel loading 0.25A, the voltage is 18V+/- 0.9V, inverter 18V loading 1.8A, the output voltage is

18V +/- 0.9V, 5V loading 1.2A, the DC output voltage is 5V +/-0.25VDC, 12V audio loading 0.6A, the output voltage is 12V + / - 0.6V. (B)

4. Display Adjustment

4.1 Access to factory mode (IIC) in auto-alignment system

The communication protocol switch to IIC .

4.2 Auto color adjustment (B)

Apply a 1280x1024/60Hz signal with 64-gray levels pattern, set brightness control at 100%, and contrast control at 50%.

Adjust the R. G. B offset, and gain to calibrate the color smoothly and 64-gray level distinguishable. Check all factory pre-setting modes.

4.3 Adjustment of WHITE-D (B)

Apply a 1280*1024 / 60Hz signal with white pattern, set brightness

control at 100%, and contrast control at 50%. Adjust the R, G, B

Sub-Gain, for the screen center, the 1931 CIE chromaticity (X, Y)

co-ordinates shall be;

Use Minolta CA-110 for colour coordinates and luminance check.

Luminance is > 200 Nits in the center of the screen when brightness at 100% and contrast set to 100%.

4.4 Adjustment of sRGB

Apply a 1280*1024 / 60Hz signal with white pattern, set brightness

control at 100%, and contrast control at 50%. Adjust the R, G, B

Sub-Gain, for the screen center, the 1931 CIE chromaticity (X, Y)

co-ordinates shall be;

4.5 Factory Preset (B):

After finished all the adjustment, set:

4.5.1 OSD Default Setting:

Brightness: 100% Input Selection: Default as PC VGA (D-sub)

Contrast: 50% PIP position: bottom right corner

Adjust size: Full screen PIP audio source: PC Audio

Language: English PIP video source: CVBS

Colour: 6500K for IMAGE MANAGEMENT Volume: 50%

OSD position: middle of the LCD screen

sRGB

x(center) 0.313 ± 0.020

y(center) 0.329 ± 0.020

9300°K 6500°K

x (center) 0.283 ± 0.020 0.313 ± 0.020

y (center) 0.297 ± 0.020 0.329 ± 0.020

4.5.2 In Factory mode default setting :

SECURITY : OFF

SUB-BRI : 0 255 (Fix)

SUB-CON : 78 128 178 (Fix)

18

Go to cover page

200P6 LCD

DDC Instructions

Pin No. Description

1 T.M.D.S. data2-

2 T.M.D.S. data2+

3 T.M.D.S. data2 shield

4 No Connect

5 No Connect

6 DDC clock

7 DDC data

8 No Connect

9 T.M.D.S. data1-

10 T.M.D.S. data1+

11 T.M.D.S. data1 shield

12 No Connect

13 No Connect

14 +5V Power

15 Ground (for +5V) - Cable detect

16 Hot plug detect

17 T.M.D.S. data0-

18 T.M.D.S. data0+

19 T.M.D.S. data0 shield

20 No Connect

21 No Connect

22 T.M.D.S clock shield

23 T.M.D.S. clock+

24 T.M.D.S. clock-

General

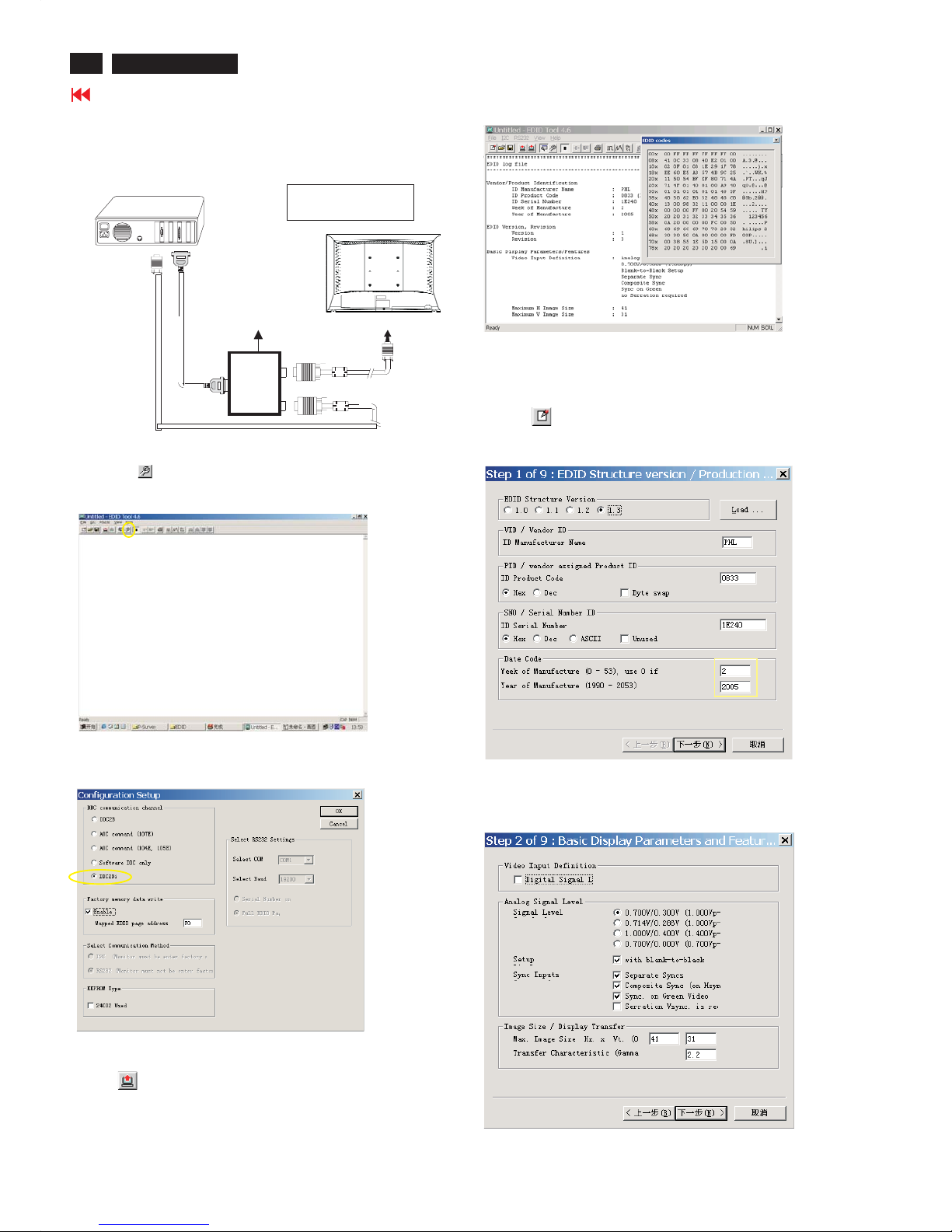

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed "Analog DDC IC, Digital DDC IC & EEPROM".

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this case

the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

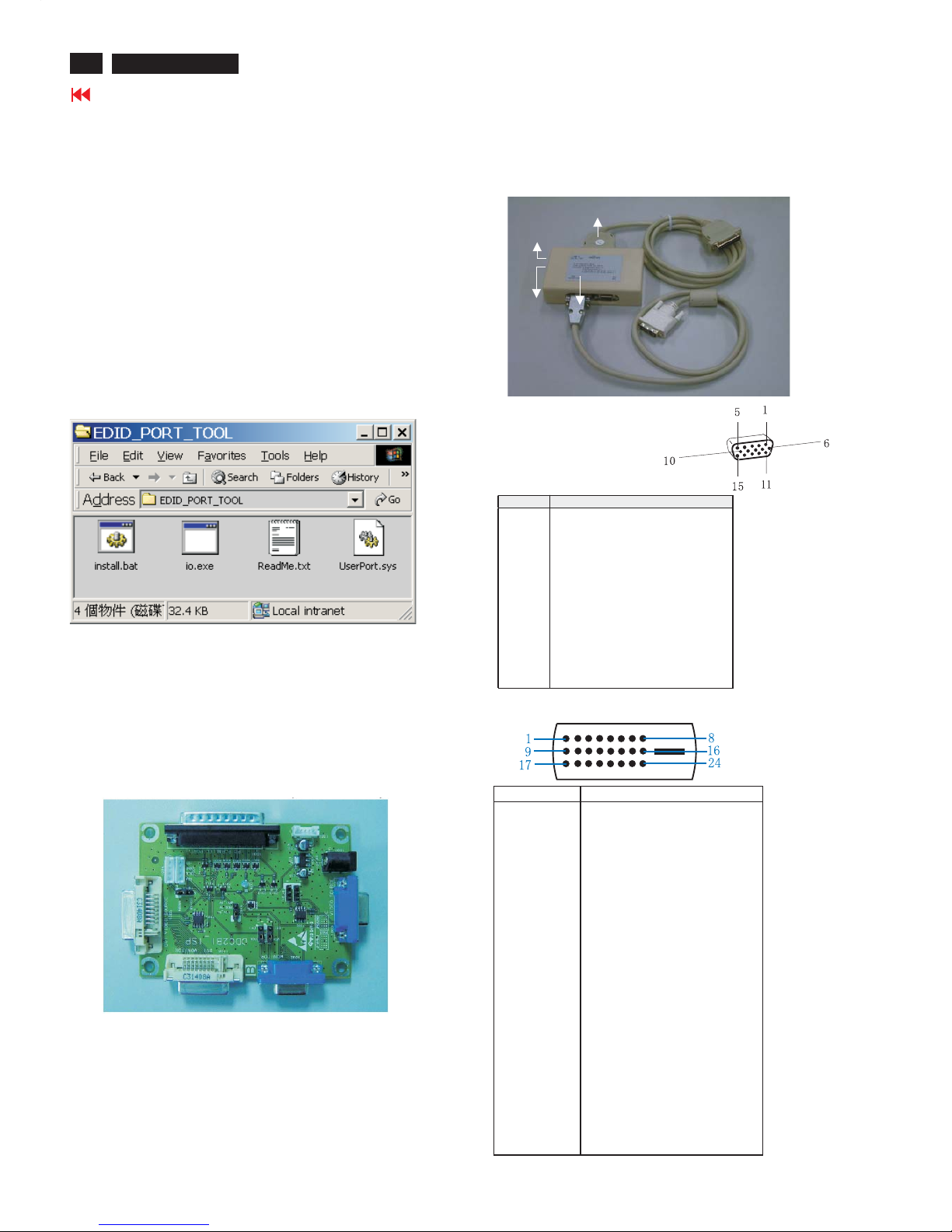

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98 .

Y o Install the EDID_PORT_Tool under Win2000/XP . As

Fig. 1 .

A. Cody the "UserPort.sys" to C:\WINNT\system32\drivers(win2000)

C:\WINDOWS\system32\drivers(winXP)

B. Running " io.exe" everytime, Before you start to programming

edid data .

4. A/D Alignment kits (12NC: 3138 106 10396):

inclusion : a. Alignment box x1 (Fig. 2)

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

D. (D-Sub) to (DVI) cable x1

System and equipment requirements

ou have t

3. EDID46.EXE program

Fig. 1

Fig. 1

Fig. 2

To Monitor

D-sub/DVI cable

DC 8~12V

To Printer port

Power

indicator

Note: The alignment box has already build-in a batteries socket for

using batteries (8~12V) as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

PIN No. SIGNAL

1 Red video input

2 Green video input / sync on green

3 Blue video input

4GND

5 GND - Cable detect

6RedvideoGND

7 Green video GND

8 Blue video GND

9DDC+3.3Vor+5V

10 Logic GND

11 GND

12 Serial data line (SDA)

13 H-sync / H+V

14 V-sync

15 Data clock line (SCL)

Pin assignment

A. 15-pin D-Sub Connector

B. Input DVI -D Connector pin

Fig. 3

19

Go to cover page

DDC Instructions

200P6 LCD

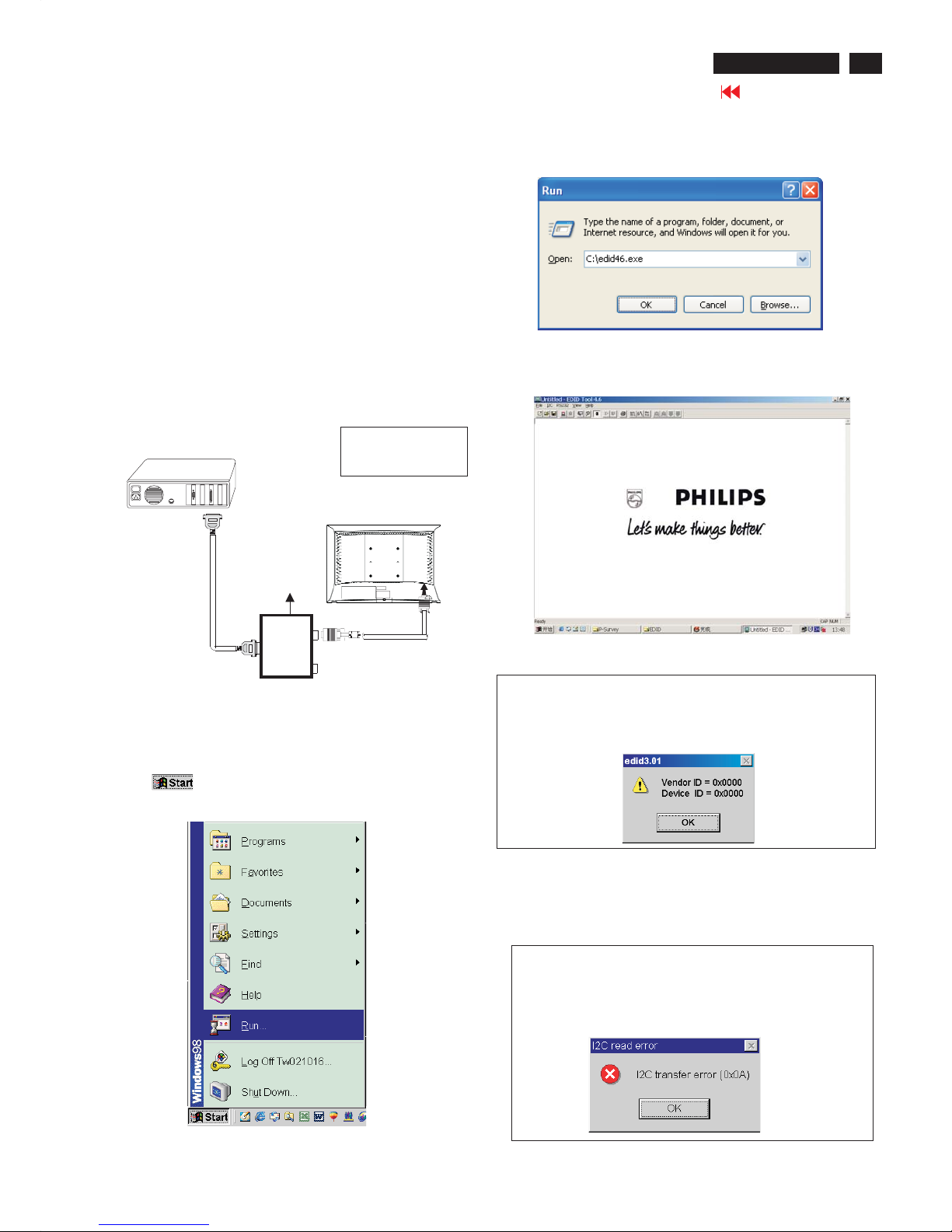

Step 3: Installation of EDID46.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. The Program"EDID46.EXE" in service manual cd-rom be copyed to C:\ .

2. Click , choose Run at start menu of Windows as shown

In Fig. 5.

Fig. 5

4. Click OK button. The main menu appears (as shown in Fig. 7).

This is for initialize alignment box.

Fig. 7

Fig. 6

3. At the submenu, type the letter of your computer's hard disk drive

followed by :EDID46 (for example, C:\EDID46, as shown in Fig. 6).

Note 2: During the loading, EDID46 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

1

Fig. 8

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 8) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this

time, please make sure all cables are connected correctly and

fixedly, and the procedure has been performed properly.

Fig. 9

Configuration and procedure

There is no Hardware DDC (DDC IC) anymore. Main EEPROM stores

all factory settings and DDC data (EDID code) which is also called

Software DDC. The following section describes the connection and

procedure for Software DDC application. The main EEPROM can be reprogrammed by enabling '' factory memory data write'' function on the

DDC program (EDID46.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due

to sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software

(EDID46.EXE). Following steps show you the procedures and

connection.

Step 1: Supply 8-12V DC power source to the Alignment box by

plugging a DC power cord .

Step 2: Connecting printer cable and D-Sub cable of monitor as Fig. 4

Fig. 4

PC

1= Power connector

2= D-SUB connector

To printer port (LTP1)

DC Power

8-12 V

Printer

Port

To

Monitor

To P C

1

2

----->

----->

20

Go to cover page

DDC Instructions

200P6 LCD

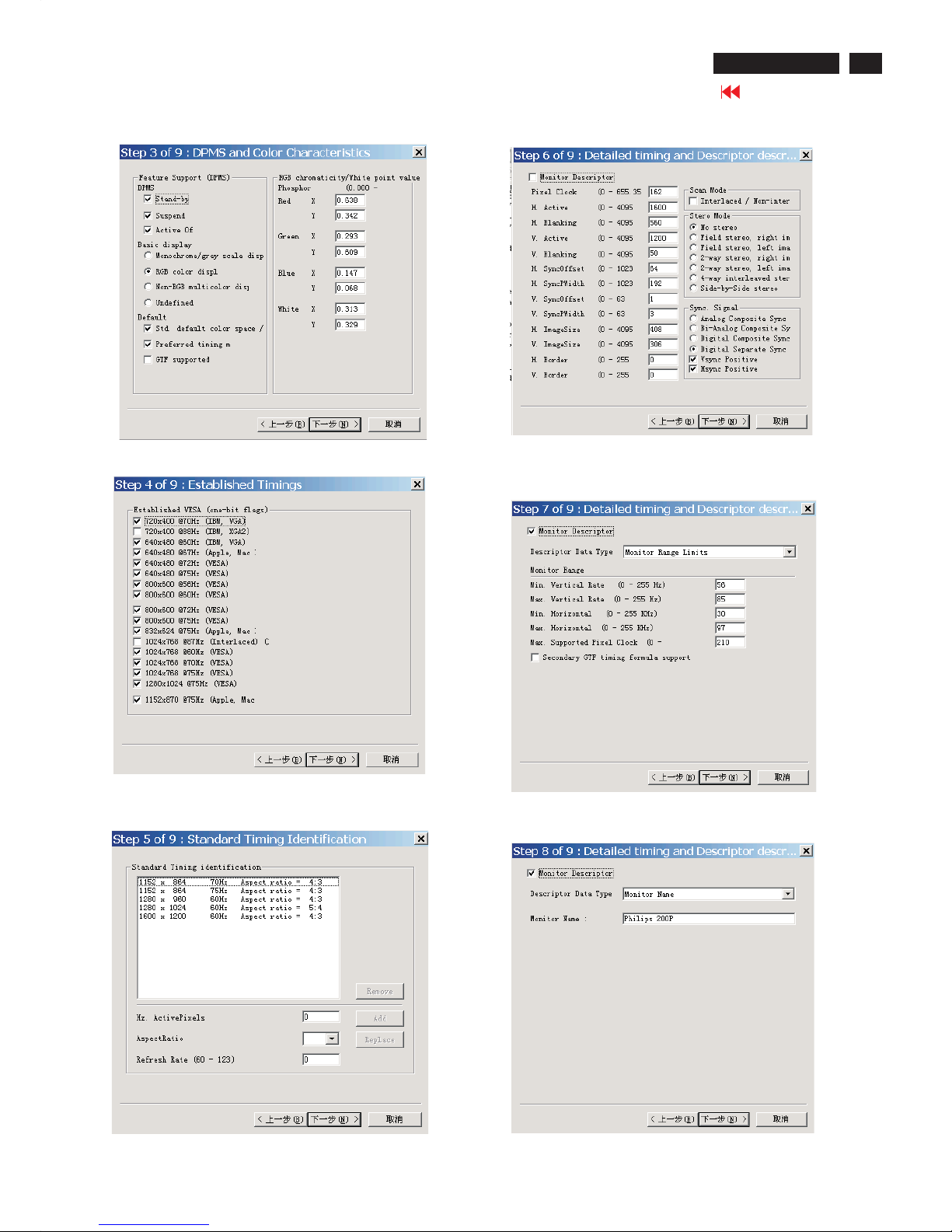

Step 3: Modify DDC data (verify EDID version, week,

year)

Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 14 .

EDID46 DDC application provides the function selection and

Step 4: Modify DDC data (Monitor Serial No.)

1. Click Next , bring up Fig. 15.

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 15

2. Select the DDC2Bi as the communication channel.

As shown in Fig. 12.

Fig. 12

Fig. 13

Fig. 14

Select and fill out,

If necessary.

Re-programming Analog DDC IC

Step 1: After initialize alignment box, connecting all

cables and box as shown in Fig. 10.

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 11 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 11.

Fig. 10

1= Power connector

2= D-S UB connector

PC

To printer port (LTP1)

DC Power

8-12V

Printer

Port

To

Monitor

To P C

1

2

----->

----->

To PC Video port (D-sub)

Click this button

=====>

Fig. 11

21

Go to cover page

DDC Instructions

200P6 LCD

Fig. 21

Fig. 18

Fig. 19

7. Click Next , bring up Fig. 21.

4. Click Next , bring up Fig.18.

5. Click Next , bring up Fig.19.

6. Click Next , bring up Fig. 20.

In this step, please confirm the Descriptor Data Type is

Monitor Range Limits, and all the items are same as below.

Fig. 20

2. Click Next , bring up Fig.16.

Fig. 16

Fig. 17

3. Click Next , bring up Fig.17.

22

Go to cover page

DDC Instructions

200P6 LCD

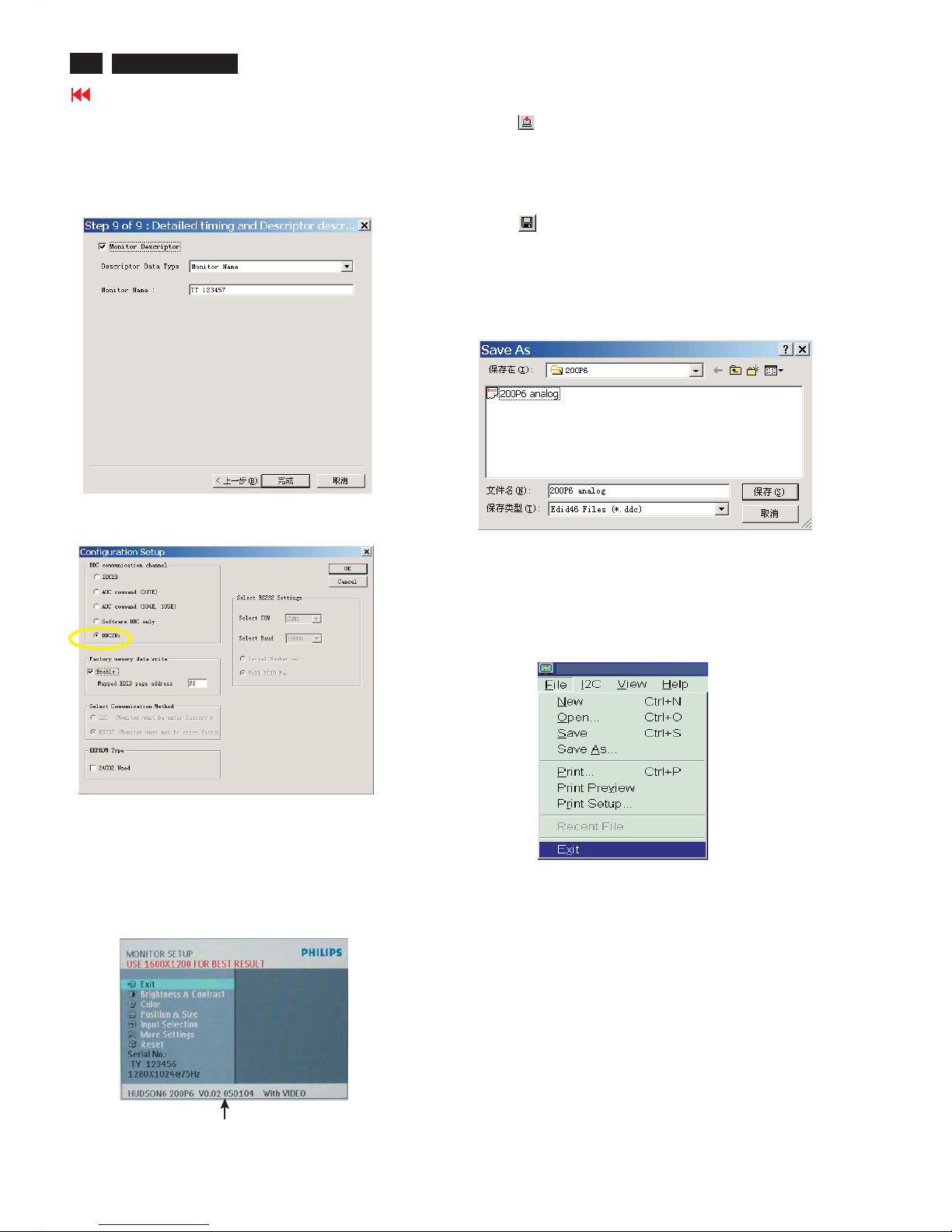

4). Click (Write EDID) icon from the tool bar to write DDC data. then

the EDID Tool will be closed automatically ,DDC data will be

finished Writing.

Fig. 24

3) Push Menu to exit OSD menu.""

Fig. 22

8. Click Next , bring up Fig. 22.

- Click Finish to exit the Step window.

- Serial number can be filled up at this moment (for example, TY

123457).

NOTE: You must modify the Serial NO. In step 9, otherwise the Serial NO.

In OSD Couldn't be modified correctly.

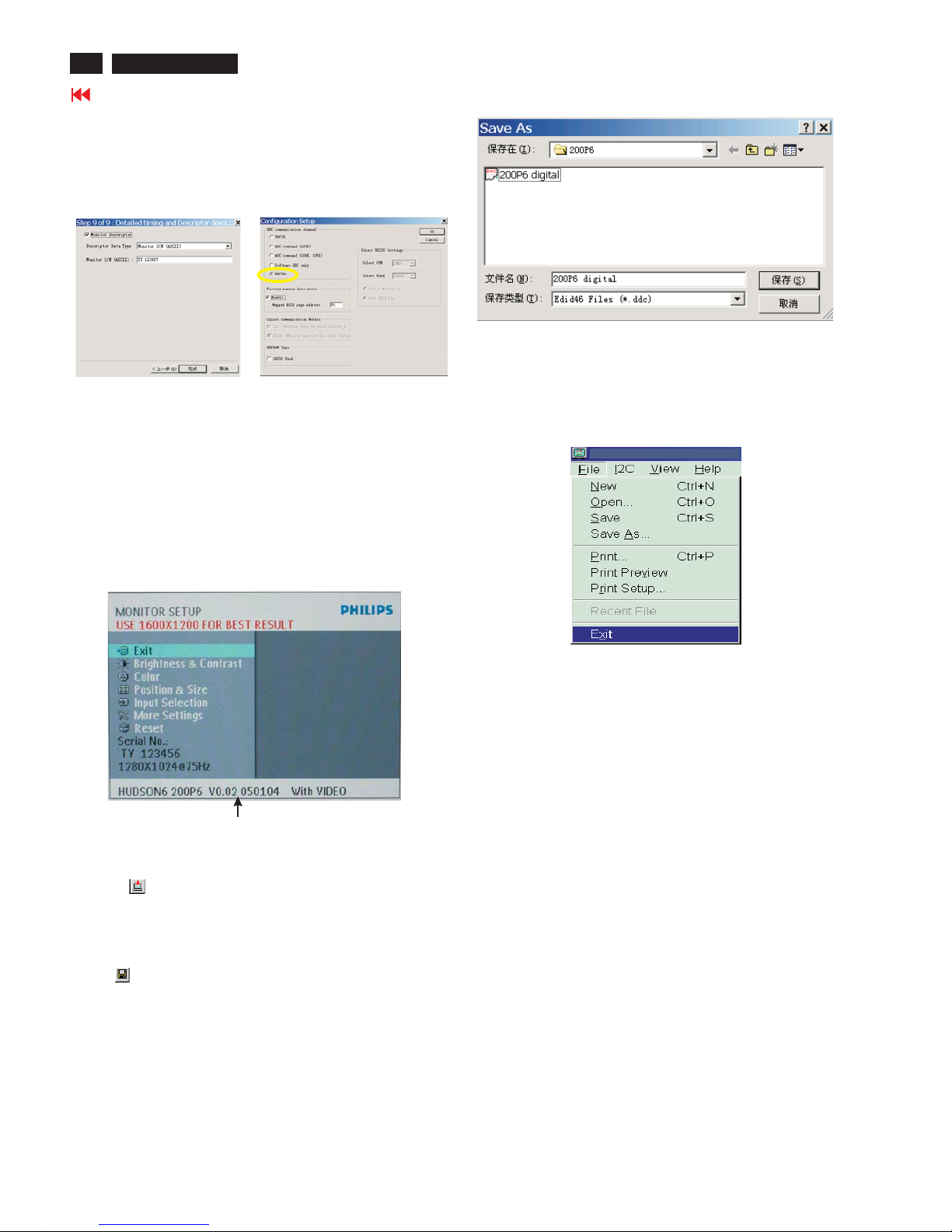

Step 5: Write DDC data

1. Configuration should be as Fig. 23. And press OK.

Fig. 23

2. Click Save.

Step 7: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 26.

Step 6: Save DDC data

Sometimes, you may need to save DDC data as a text file

for using in other IC chip. To save DDC data, follow the

steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool

bar and give a file name as shown in Fig. 25.

The file type is EDID46 file (*.ddc) which can be open in

WordPad. By using WordPad, the texts of DDC data & table

(128 bytes, hex code) can be modified. If DDC TEXTS &

HEX Table ar completely correct, it can be saved as .ddc flie

to re-load it into DDC IC for DDC Data application.

Fig. 26

Step 8: Turn off the monitor, exit the factory mode.

Fig. 25

2. Access Factory Mode

1). Turn off monitor.

2).

3).Press "OK" button, wait until the OSD menu with Characters

"HUDSON6 200P6 V0.02 050104 With VIDEO" (below OSD

menu) come on the Screen of the monitor. as shown in Fig24.

[Push "AUTO"&"OK" buttons at the same time and hold them]

+[Press "power" button untill comes out "Windows screen" ]

=> then release all buttons

Factory Mode indicator

23

Go to cover page

DDC Instructions

200P6 LCD

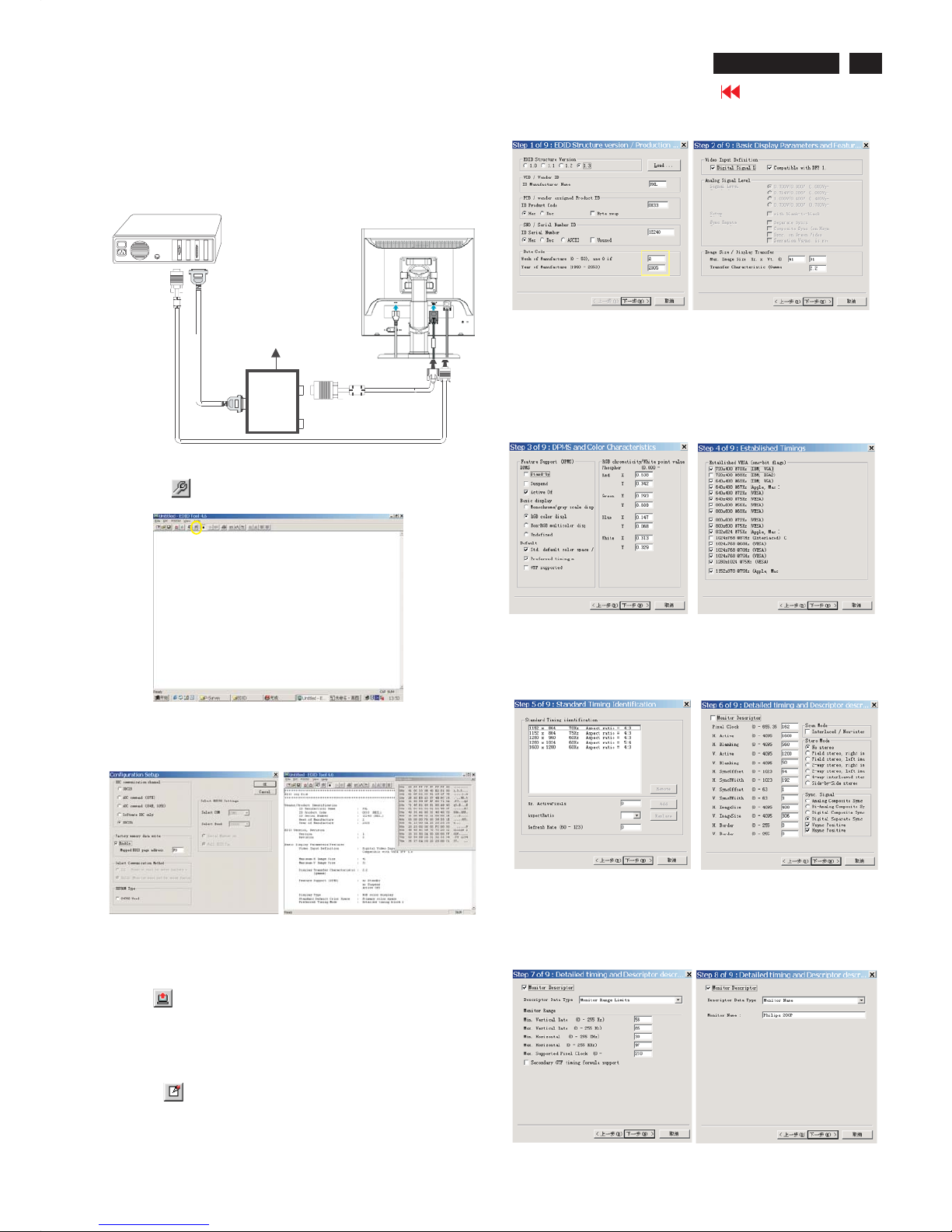

Step 3: Modify DDC data (verify EDID version, week,

year)

Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 31 .

EDID46 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Step 4: Modify DDC data (Monitor Serial No.)

1. Click Next , bring up Fig. 32.

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 30.

Fig. 32

2. Select the DDC2Bi as the communication channel.

As shown in Fig. 29.

Fig. 29

Fig. 30

Fig. 31

Select and fill out,

If necessary.

Re-programming Digital DDC IC

Step 1: After initialize alignment box, connecting all

cables and box as shown in Fig. 27.

Fig. 28

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 11 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 28.

Fig. 27

Click this button

=====>

D-sub to DVI-D cable

1=DVI-D connector

2=D-sub connector

3=Power Plug

2

1

3

D-sub cable

DC Power

8 12V

~

PC

To video card

To printer port (LTP1)

To

Monitor

Printer

Port

Fig. 38

Fig. 35

Fig. 36

7. Click Next , bring up Fig. 38.

4. Click Next , bring up Fig. 35.

5. Click Next , bring up Fig. 36.

6. Click Next , bring up Fig. 37.

In this step, please confirm the Descriptor Data Type is

Monitor Range Limits, and all the items are same as below.

Fig. 37

2. Click Next , bring up Fig. 33.

Fig. 33

Fig. 34

3. Click Next , bring up Fig. 34.

24

Go to cover page

DDC Instructions

200P6 LCD

3. Click (Write EDID) icon from the tool bar to write DDC data.

Then wait for 20-30 seconds ,DDC data will be finished Writing.

Fig. 41

Fig. 39

8. Click Next , bring up Fig. 39.

- Click Finish to exit the Step window.

- Serial number can be filled up at this moment (for example, TY

123457).

NOTE: You must modify the Serial NO. In step 9, otherwise the Serial

NO. In OSD Couldn't be modified correctly.

Step 5: Write DDC data

1. Configuration should be as Fig. 40. And press OK.

Fig. 40

2. Click Save.

Step 7: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 43.

Step 8: Turn off the monitor, exit the factory mode.

Fig. 43

3) Push Menu to exit OSD menu.""

Fig.42

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar and

give a file name as shown in Fig. 42.

The file type is EDID46 file (*.ddc) which can be open in WordPad. By

using WordPad, the texts of DDC data & table (128 bytes, hex

code) can be modified. If DDC TEXTS & HEX Table ar completely

correct, it can be saved as *.ddc flie to re-load it into DDC IC for DDC

Data application.

Step 6: Save DDC data

2. Access Factory Mode

1). Turn off monitor.

2).

3).Press "OK" button, wait until the OSD menu with Characters

"HUDSON6 200P6 V0.02 050104 With VIDEO" (below OSD

menu) come on the Screen of the monitor. as shown in Fig41.

[Push "AUTO" & "OK" buttons at the same time and hold them]

+[Press "power" button untill comes out "Windows screen" ]

=> then release all buttons

Factory Mode indicator

Loading...

Loading...