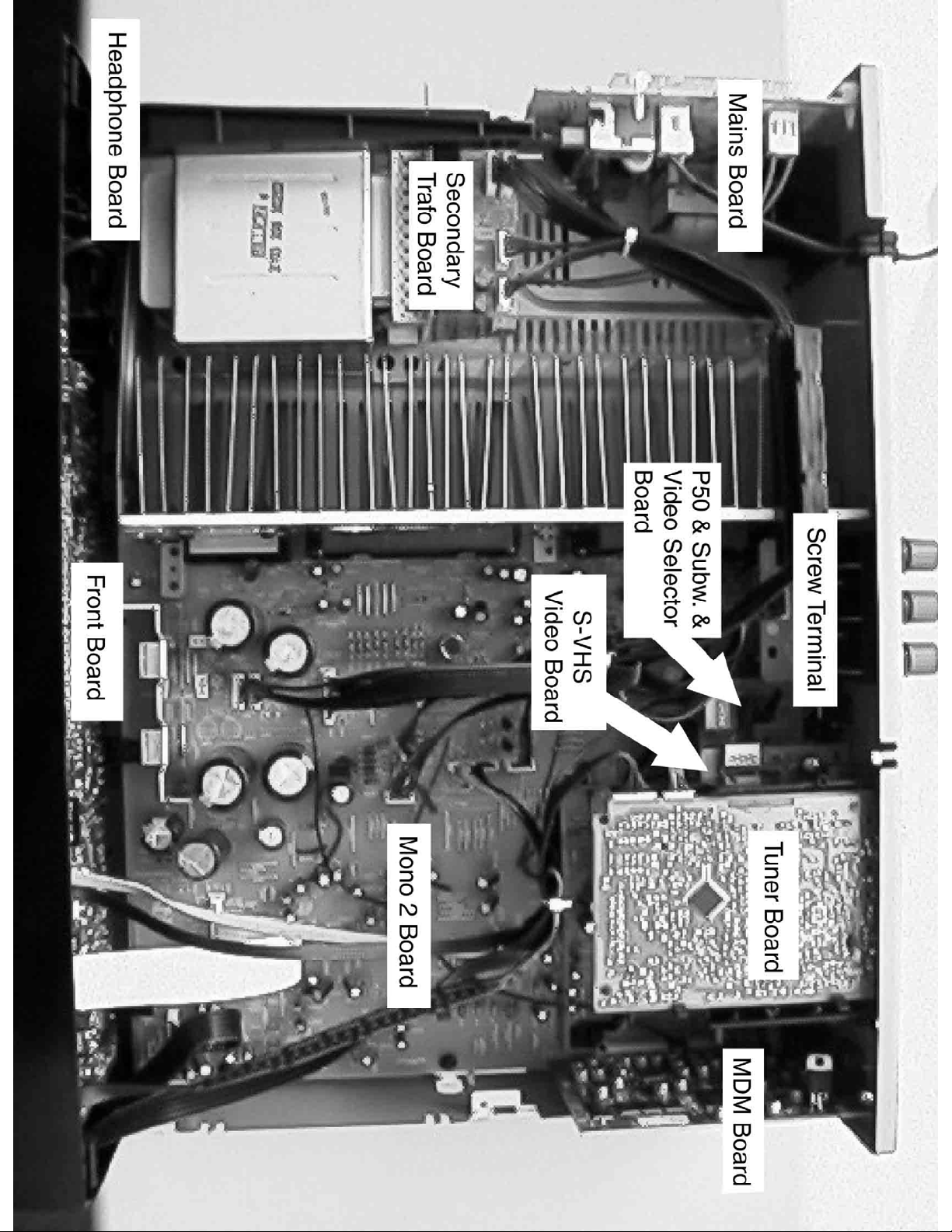

Philips 1980 Service Manual

Color Television Chassis

Service

Service

1980

Service

ServiceManual

Contents Contents

4. Mechanical Instructions 00

5. Service Modes, Error Codes and Faultfinding 00

6. Block Diagrams and Testpoints 00

7. Electrical Diagrams and PWB's Diagram PWB

OVERALL WIRING DIAGRAM 1 0

FRONT BOARD SCHEMATIC DIAGRAM 2 10

EC05 TUNER SCHEMATIC DIAGRAM 3 101

MAINS BOARD SCHEMATIC DIAGRAM 4 12

MONO 2 BOARD SCHEMATIC DIAGRAM 1 5 14

MONO 2 BOARD SCHEMATIC DIAGRAM 2 6 14

MONO 2 BOARD SCHEMATIC DIAGRAM 3 7 14

MONO 2 BOARD SCHEMATIC DIAGRAM 4 8 14

S-VHS VIDEO SELECT OR SCHEMATIC DIAGRAM 9 16

FRONT AND HEADPHONE CBA (CO MPONENT SIDE) 10 0

FRONT AND HEADPHONE CBA (CO PPER SIDE) 11 0

MAINS CBA (COMPONENT SIDE) 12

MAINS CBA (COPPER SIDE) 13

MONO 2 CBA (COMPONENT SIDE) 14

MONO 2 CBA (COPPER SIDE) 15

S-VHS VIDEO SELECT OR CBA (COMPONENT SIDE) 16

S-VHS VIDEO SELECT OR CBA (COPPER SIDE) 17

OVERALL BLOCK DIAGRAM 18

EC05 TUNER BLOCK DIAGRAM 19

MDM MODULE BLOCK DIAGRAM 20

MDM MODULE TOP VIEW 21

8. Adjustments 00

10. Spare Parts List 00

©

Copyrig ht 2001 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. N o part of thi s publication may be reproduced , stored in a

retrieval system or transmi tted, in any for m or by means, electr onic, mechanical,

photographic, or otherwis e without the p rior p ermi ssion of Philips.

Published by Philips Consumer Electronics Subject to modification 2005 Nov 03

GENERAL SAFETY NOTES

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all Philips Consumer Electronics

Company** equipment. The service procedures recommended by Philips and described in this service

manual are effective methods of performing service operations. Some of these service operations require

the use of tools specially designed for the purpose. The special tools should be used when and as

recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be

carefully read in order to minimize the risk of personal injury to service personnel. The possibility exists

that improper service methods may damage the equipment. It also is important to understand that

these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Philips could not possibly know, evaluate

and advise the service trade of all conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Philips has not undertaken any such broad

evaluation. Accordingly, a servicer who uses a service procedure or tool which is not recommended by

Philips must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company will be referred to as

Philips.

WARNING

Critical components having special safety characteristics are identified with a or "S" by the Ref. No.

in the parts list and enclosed within a broken line* (where several critical components are grouped in

one area) along with the safety symbol on the schematics or exploded views. Use of substitute

replacement parts which do not have the same specified safety characteristics may create shock, fire, or

other hazards. Under no circumstances should the original design be modified or altered without written

permission from Philips. Philips assumes no liability, express or implied, arising out of any unauthorized

modification of design. Servicer assumes all liability.

• Broken Line ____ _ ____ _ ____ _ ____

SAFETY CHECKS

After the original service problem has been corrected, a complete safety check should be made. Be sure

to check over the entire set, not just the areas where you have worked. Some previous servicer may

have left an unsafe condition, which could be unknowingly passed on to Your customer. Be sure to

check all of the following:

FIRE AND SHOCK HAZARD

IMPLOSION

X-RADIATION

LEAKAGE CURRENT COLD CHECK

LEAKAGE CURRENT HOT CHECK

PICTURE T UBE REPLACEMENT

PARTS REPLACEMENT

FIRE AND SHOCK HAZARD

1. Be sure all components are positioned in such a way as to avoid the possibility of adjacent

component shorts. This is especially important on those chassis which are transported to and from the

service shop.

2. Never release a repaired unit unless all protective devices such as insulators, barriers, covers, strain

reliefs, and other hardware have been installed in accordance with the original design.

3. Soldering and wiring must be inspected to locate possible cold solder joints, solder splashes, sharp

solder points, frayed leads, pinched leads, or damaged insulation (including the ac cord). Be certain to

remove loose solder balls and all other loose foreign particles.

4. Check across-the-line components and other components for physical evidence of damage or

deterioration and replace if necessary. Follow original layout, lead length, and dress.

5. No lead or component should touch a receiving tube or a resistor rated at 1 watt or more. Lead

tension around protruding metal surfaces or edges must be avoided.

6. Critical components having special safety characteristics are identified with an 'S' by the Ref. No. in

the parts list and enclosed within a broken line* (where several critical components are grouped in one

area) along with the safety symbol on the schematic diagrams and /or exploded views.

7. When servicing any unit, always use a separate isolation transformer for the chassis. Failure to use

a separate isolation transformer may expose you to possible shock hazard, and may cause damage to

servicing instruments.

8. Many electronic products use a polarized ac line cord (one wide pin on the plug). Defeating this

safety feature may create a potential hazard to the servicer and the user. Extension cords which do not

incorporate the polarizing feature should never be used.

9. After reassembly of the unit, always perform an

all exposed metal parts of the cabinet. Also, check all metal control shafts (with knobs removed),

antenna terminals, handles, screws, etc., to be sure the unit may be safely operated without danger of

electrical shock.

* Broken line ____ _ ____ _ ____ _ ____

ac leakage test or resistance test from the line cord to

IMPLOSION

1. All picture tubes used in current model receivers are equipped with an integral implosion system.

Care should always be used, and safety glasses worn, whenever handling any picture tube. Avoid

scratching or otherwise damaging the picture tube during installation.

2. Use only replacement tubes specified by the manufacturer.

X-RADIATION

1. Be sure procedures and instructions to all your service personnel cover the subject of X-radiation.

Potential sources of X-rays in TV receivers are the picture tube and the high voltage circuits. The basic

precaution which must be exercised is to keep the high voltage at the factory recommended level.

2. To avoid possible exposure to X-radiation and electrical shock, only the manufacturer's specified

anode connectors must be used.

3. It is essential that the service technician has an accurate HV meter available at all times. The

calibration of this meter should be checked periodically against a reference standard.

4. When the HV circuitry is operating properly there is no possibility of an X-radiation problem. High

voltage should always be kept at the manufacturer's rated value - no higher - for optimum performance.

Every time a color set is serviced, the brightness should be run up and down while monitoring the HV

with a meter to be certain that the HV is regulated correctly and does not exceed the specified value.

We suggest that you and your technicians review test procedures so that HV and HV regulation are

always checked as a standard servicing procedure, and the reason for this prudent routine is clearly

understood by everyone. It is important to use an accurate and reliable HV meter. It is recommended

that the HV reading be recorded on each customer's invoice, which will demonstrate a proper concern for

the customer's safety.

5. When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, reduce the line voltage by means of a Variac to bring the HV into acceptable limits while

troubleshooting. Do not operate the chassis longer than necessary to locate the cause of the excessive

HV.

6. New picture tubes are specifically designed to withstand higher operating voltages without creating

undesirable X-radiation. It is strongly recommended that any shop test fixture which is to be used with

the new higher voltage chassis be equipped with one of the new type tubes designed for this service.

Addition of a permanently connected HV meter to the shop test fixture is advisable. The CRT types used

in these new sets should never be replaced with any other types, as this may result in excessive

X-radiation.

7. It is essential to use the specified picture tube to avoid a possible X-radiation problem.

8. Most TV receivers contain some type of emergency "Hold Down" circuit to prevent HV from rising to

excessive levels in the presence of a failure mode. These various circuits should be understood by all

technicians servicing them, especially since many hold down circuits are inoperative as long as the

receiver performs normally.

LEAKAGE CURRENT COLD CHECK

1. Unplug the ac line cord and connect a jumper between the two prongs of the plug.

2. Turn on the power switch.

3. Measure the resistance value between the jumpered ac plug and all exposed cabinet parts of the

receiver, such as screw heads, antennas, and control shafts. When the exposed metallic part has a

return path to the chassis, the reading should be between 1 megohm and 5.2 megohms. When the

exposed metal does not have a return path to the chassis, the reading must be infinity. Remove the

j

umper from the ac line cord.

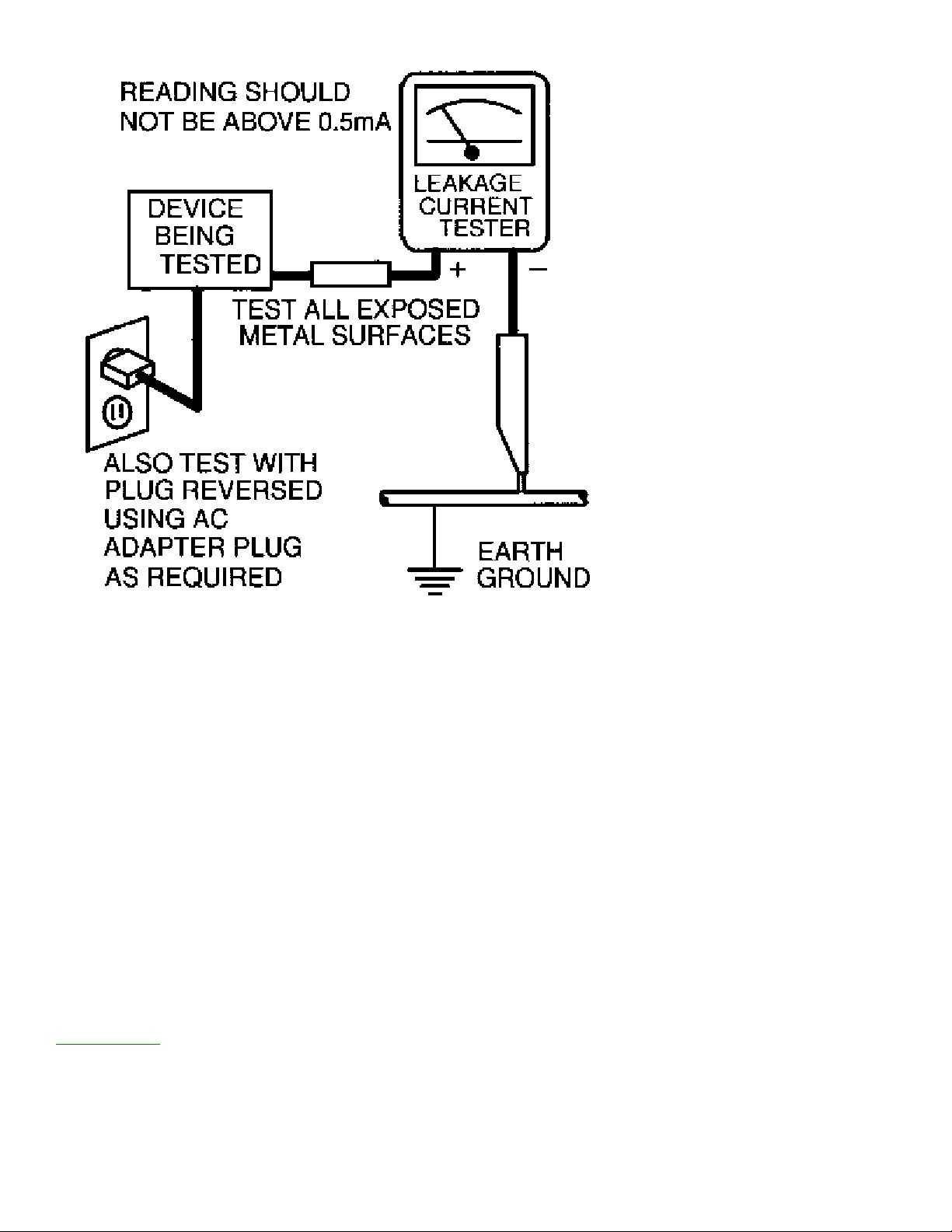

LEAKAGE CURRENT HOT CHECK

1. Do not use an isolation transformer for this test. Plug the completely reassembled receiver directly

into the ac outlet.

2. Connect a

metallic cabinet part and a

3. Use an ac voltmeter with at least 5000 ohms/volt sensitivity to measure the potential across the

resistor.

The potential at any point should not exceed 0.75 volts. A leakage current tester may be

4.

used to make this test; leakage current must not exceed 0.5milliamp. If a measurement is outside of the

specified limits, there is a possibility of shock hazard. The receiver should be repaired and rechecked

before returning it to the customer.

. Repeat the above procedure with the ac plug reversed. (Note: An ac adapter is

5

necessary when a polarized plug is used. Do not defeat the polarizing feature of the plug.)

1.5k, 1OW resistor paralleled by a 0.15uF. capacitor between each exposed

good earth ground such as a water pipe, as shown below.

OR

With the instrument completely reassembled, plug the AC line cord directly into a 120V AC outlet. (Do

not use an isolation transformer during this test.) Use a leakage current tester or a

metering system that complies with American National Standards Institute (ANSI) C101.1 Leakage

Current for Appliances and Underwriters Laboratories (UL) 1410, (50.7).

AC switch first in the on position and then in the off position, measure from a

known earth ground (metal water pipe, conduit, etc.) to all exposed metal

parts of the instrument (antennas, handle brackets, metal cabinet, screw

heads, metallic overlays, control shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the chassis. Any current

measured must not exceed 0.5 milliamp. Reverse the instrument power cord

plug in the outlet and repeat the test. See graphic below.

With the instrument

T

T

T

PICTURE TUBE REPLACEMENT

he primary source of X-radiation in this television receiver is the picture tube. The picture tube utilized

in this chassis is specially constructed to limit X-radiation emissions. For continued X-radiation

protection, the replacement tube must be the same type as the original, including suffix letter, or a

Philips approved type.

PARTS REPLACEMENT

Many electrical and mechanical parts in Philips television sets have special safety related characteristics.

hese characteristics are often not evident from visual inspection nor can the protection afforded by

them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

he use of a substitute part which does not have the same safety characteristics as the Philips

recommended replacement part shown in this service manual may create shock, fire, or other hazards

TV SAFETY NOTES

SAFETY CHECKS

IMPLOSION

X-RADIATION

PICTURE T UBE REPLACEMENT

PARTS REPLACEMENT

WARNING

Before removing the CRT anode cap, turn the unit OFF and short the HIGH VOLTAGE to the CRT DAG

ground.

SERVICE NOTE:

The CRT DAG is not at chassis ground.

TV-VCR COMBI SAFETY NOTES

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and

electrical codes of the countries in which they are to be sold. However, in order to maintain such

compliance, it is equally important to implement the following precautions when a set is being serviced.

SAFETY PRECAUTIONS FOR TV CIRCUITS

1. Before returning an instrument to the customer, always make a safety check of the entire instrument,

including, but not limited to, the following items:

a. Be sure that no built-in protective devices are defective or have been defeated during servicing.

(1) Protective shields are provided on this chassis to protect both the technician and the customer.

Correctly replace all missing protective shields, including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place all

protective devices, including but not limited to, nonmetallic control knobs, insulating fishpapers,

adjustment and compartment covers/shields, and isolation resistor/capacitor networks. Do not

operate this instrument or permit it to be operated without all protective devices correctly installed

and functioning. Servicers who defeat safety features or fail to perform safety checks may be liable

for any resulting damage.

b. Be sure that there are no cabinet openings through which an adult or child might be able to insert

their fingers and contact a hazardous voltage. Such openings include, but are not limited to, (1)

spacing between the picture tube and the cabinet mask, (2) excessively wide cabinet ventilation slots,

and (3) an improperly fitted and/or incorrectly secured cabinet back cover.

c. Do a

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK

HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE INSTRUMENT TO THE CUSTOMER

LEAKAGE CURRENT CHECK

OR BEFORE CONNECTING THE ANTENNA OR ACCESSORIES.

d. X-Radiation and High Voltage Limits - Because the picture tube is the primary potential

source of X-radiation in solid-state TV receivers, it is specially constructed to prohibit X-radiation

emissions. For continued X-radiation protection, the replacement picture tube must be the same type

as the original. Also, because the picture tube shields and mounting hardware perform an X-radiation

protection function, they must be correctly in place. High voltage must be measured each time

servicing is performed that involves B+, horizontal deflection or high voltage. Correct operation of

the X-radiation protection circuits also must be reconfirmed each time they are serviced. (X-radiation

protection circuits also may be called "horizontal disable" or "hold down.") Read and apply the high

voltage limits and, if the chassis is so equipped, the X-radiation protection circuit specifications given

on instrument labels and in the Product Safety & X-Radiation Warning note on the service data

chassis schematic. High voltage is maintained within specified limits by close tolerance safety-related

components/adjustments in the high-voltage circuit. If high voltage exceeds specified limits, check

each component specified on the chassis schematic and take corrective action.

2. Read and comply with all caution and safety-related notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning - Do not alter or add to the mechanical or electrical design of this TV

receiver. Design alterations and additions, including, but not limited to circuit modifications and the

addition of items such as auxiliary audio and/or video output connections, might alter the safety

characteristics of this receiver and create a hazard to the user. Any design alterations or additions will

void the manufacturer's warranty and may make you, the servicer, responsible for personal injury or

property damage resulting therefrom.

4. Picture Tube Implosion Protection Warning - The picture tube in this receiver employs integral

implosion protection. For continued implosion protection, replace the picture tube only with one of the

same type number. Do not remove, install, or otherwise handle the picture tube in any manner without

first putting on shatterproof goggles equipped with side shields. People not so equipped must be kept

safely away while picture tubes are handled. Keep the picture tube away from your body. Do not

handle the picture tube by its neck. Some "in-line" picture tubes are equipped with a permanently

attached deflection yoke; because of potential hazard, do not try to remove such "permanently attached"

yokes from the picture tube.

5. Hot Chassis Warning

a. Some TV receiver chassis are electrically connected directly to one conductor of the ac power

cord and may be serviced safely without an isolation transformer only if the ac power plug is inserted

so that the chassis is connected to the ground side of the ac power source. To confirm that the ac

power plug is inserted correctly, with an ac voltmeter, measure between the chassis and a known

earth ground. If a voltage reading in excess of 1.OV is obtained, remove and reinsert the ac power

plug in the opposite polarity and again measure the voltage potential between the chassis and a

known earth ground.

b. Some TV receiver chassis normally have 85Vac (RMS) between chassis and earth ground

regardless of the ac plug polarity. This chassis can be safety-serviced only with an isolation

transformer inserted in the power line between the receiver and the ac power source, for both

personnel and test equipment protection. Some TV receiver chassis have a secondary ground

system in addition to the main chassis ground. This secondary ground system is not isolated from

the ac power line. The two ground systems are electrically separated by insulation material that

must not be defeated or altered.

6. Observe original lead dress. Take extra care to assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts - be sure that leads and components do not touch

thermally hot parts, c. the ac supply, d. high voltage, and e. antenna wiring. Always inspect in all areas

for pinched, out of place, or frayed wiring. Check ac power cord for damage.

7. Components, parts, and/or wiring that appear to have overheated or are otherwise damaged should

be replaced with components, parts, or wiring that meet original specifications. Additionally, determine

the cause of overheating and/or damage and, if necessary, take corrective action to remove any

potential safety hazard.

PRECAUTIONS DURING SERVICE

A. Parts identified by the symbol are critical for safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies are specified for conformance with regulations

applying to spurious radiation. These must also be replaced only with specified replacements.

Examples: RF converters, RF cables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing ac primary side components (transformers, power cord, etc.), wrap ends of wires

securely about the terminals before soldering.

F. Observe that the wires do not contact heat producing parts (heatsinks, oxide metal film resistors,

fusible resistors, etc.)

G. Check that replaced wires do not contact sharp edged or pointed parts.

H. When a power cord has been replaced, check that 10-15 kg of force in any direction will not

loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

When replacing the power transformer in sets where the connections between the power cord and power

transformer primary lead wires are performed using crimp type connectors, in order to prevent shock

hazards, perform carefully and precisely the following steps.

Replacement procedure

1) Remove the old connector by cutting the wires at a point close to the connector. Important: Do

not re-use a connector (discard it).

2) Strip about 15 mm of the insulation from the ends of the wires. If the wires are stranded, twist

the strands to avoid frayed conductors.

3) Align the lengths of the wires to be connected. Insert the wires fully into the connector.

4) Use the crimping tool to crimp the metal sleeve at the center position. Be sure to crimp fully to

the complete closure of the tool.

L. When connecting or disconnecting the VCR connectors, first, disconnect the ac plug from the ac

supply socket.

SAFETY CHECK AFTER SERVICING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws,

parts and wires have been returned to original positions. Afterwards, perform the following tests and

confirm the specified values in order to verify compliance with safety standards.

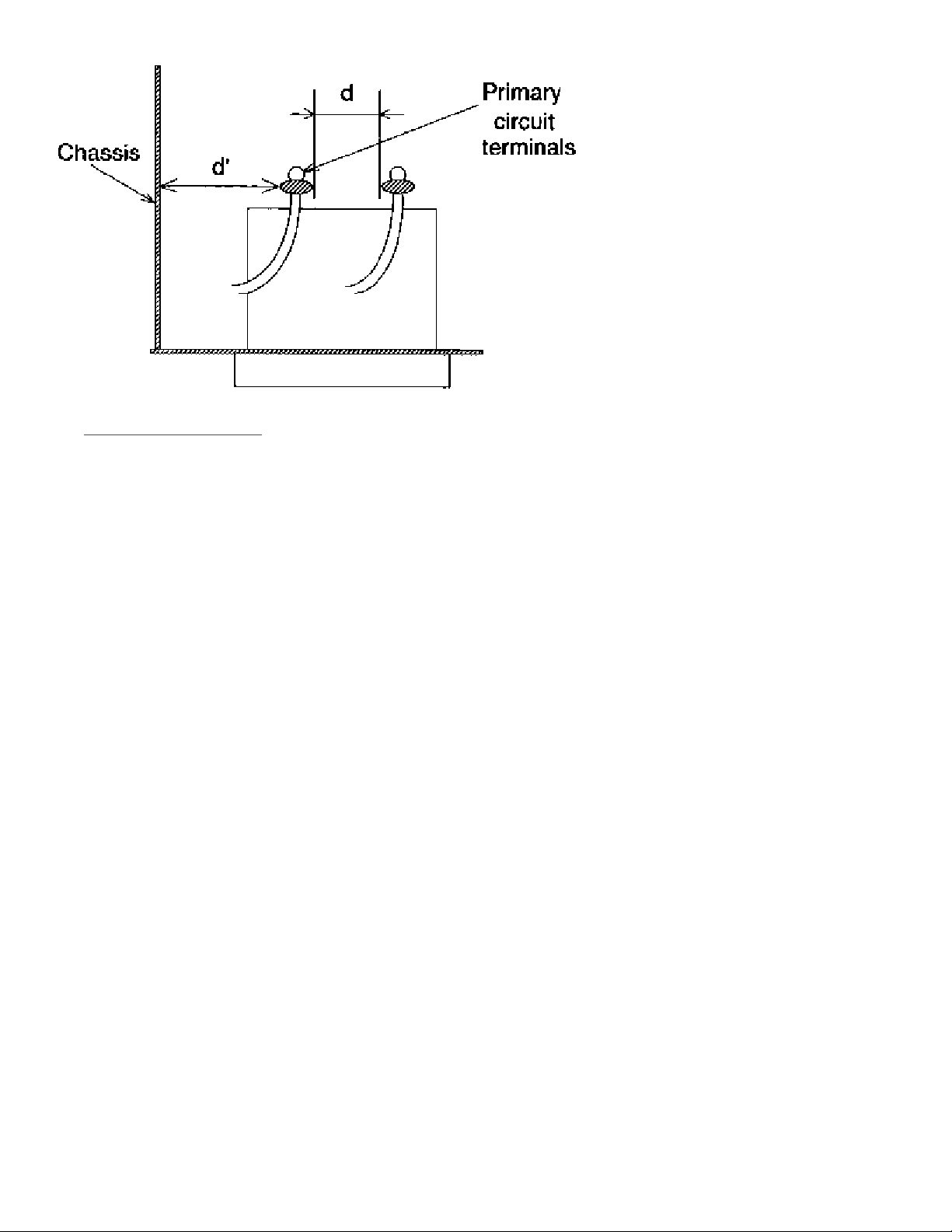

1. Clearance Distance

When replacing primary circuit components, confirm specified clearance distance (d) and (d') between

soldered terminals, and between terminals and surrounding metallic parts. (See graphic bllow)

Table 1 : Ratings for selected area

AC Line Voltage Region Clearance Distance

(d) (d')

USA or > 3.2 mm

110 to 130 V CANADA (0.126 inches)

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

2. LEAKAGE CURRENT CHECKS

VCR SAFETY NOTES

FIRE & SHOCK HAZARD (VCR)

1. Be sure that all components are positioned in such a way to avoid possibility of shorts to adjacent

components. This is especially important on those chassis which are transported to and from the repair

shop.

2. Always replace all protective devices such as insulators and barriers after working on a set.

3. Check for damaged insulation on wires including the ac cord.

4. Check across-the-line components for damage and replace if necessary.

5. After re-assembly of the unit, always perform an ac leakage test on the exposed metallic parts of the

cabinet such as the knobs, antenna terminals, etc. to be sure the set is safe to operate without danger of

electrical shock. Do not use a line isolation transformer during this test. Use an ac voltmeter

having 5000 ohms per volt or more sensitivity in the following manner: Connect a 1500 ohm 10 wan

resistor, paralleled by 0.15 MFD ac type capacitor, between a known good earth ground (water pipe,

conduit, etc.) and the exposed metallic parts, one at a time. Measure the ac voltage across the

combination 1500 ohm resistor and 0.15 MFD capacitor. Reverse the ac plug on the set and repeat ac

voltage measurements again for each exposed metallic part. Voltage measured must not exceed O.6

volts R.M.S. This corresponds to 0.4 milliamp ac. Any value exceeding this limit constitutes a potential

shock hazard and must be corrected immediately.

GENERAL

Power Supply-This receiver is designed for operation on 120 Volts, 6OHz alternating current (ac) only.

T

Never connect to a supply having a different frequency or voltage.

IMPORTANT NOTICE

his device employs many circuits, components, and mechanical parts designed for protection against

fire, shock and RF interference. For continued safety any servicing should be performed by qualified

personnel and exact replacement parts should be used. Under no circumstances should the original

design be altered.

PRODUCT SAFETY GUIDELINES FOR ALL PRODUCTS

CAUTION: Do not modify any circuit. Service work should be performed only after you are thoroughly

familiar with all of the following safety checks. Risk of potential hazards and injury to the user increases

if safety checks are not adhered to.

USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

Some semiconductor solid state devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES) Devices, Examples of typical ES devices are

integrated circuits and some field-effect transistors and semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of component damage caused by electrostatic

discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly,

drain off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging ESD wrist strap, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "antistatic

(ESD protected)" can generate an electrical charge sufficient to damage ES devices.

5. Do not use freon·propelled chemicals. These can generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are

ready to install it (Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch

T

the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION : Be sure no power is applied to the chassis or circuit and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your feet from a carpeted

floor can generate static electricity (ESD) sufficient to damage an ES device.)

NOTE to CATV system Installer:

his reminder is provided to call the CATV system installer's attention to article 820-22 of the NEC that

provides guidelines for proper grounding and, in particular, specifies that the cable ground shall be

connected to the grounding system of the building, as close to the point of cable entry as practical.

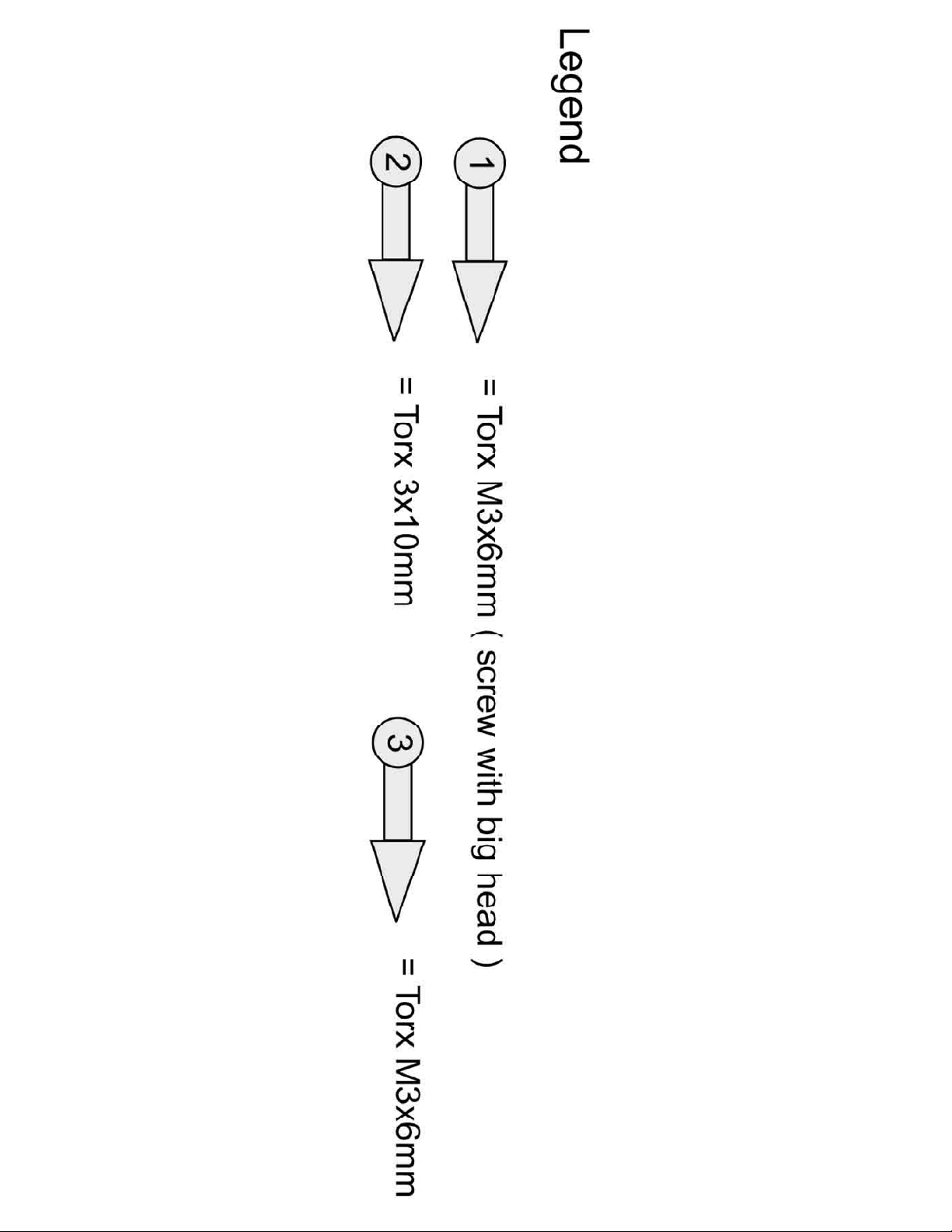

Disassembly Procedures

Disassembly Legend

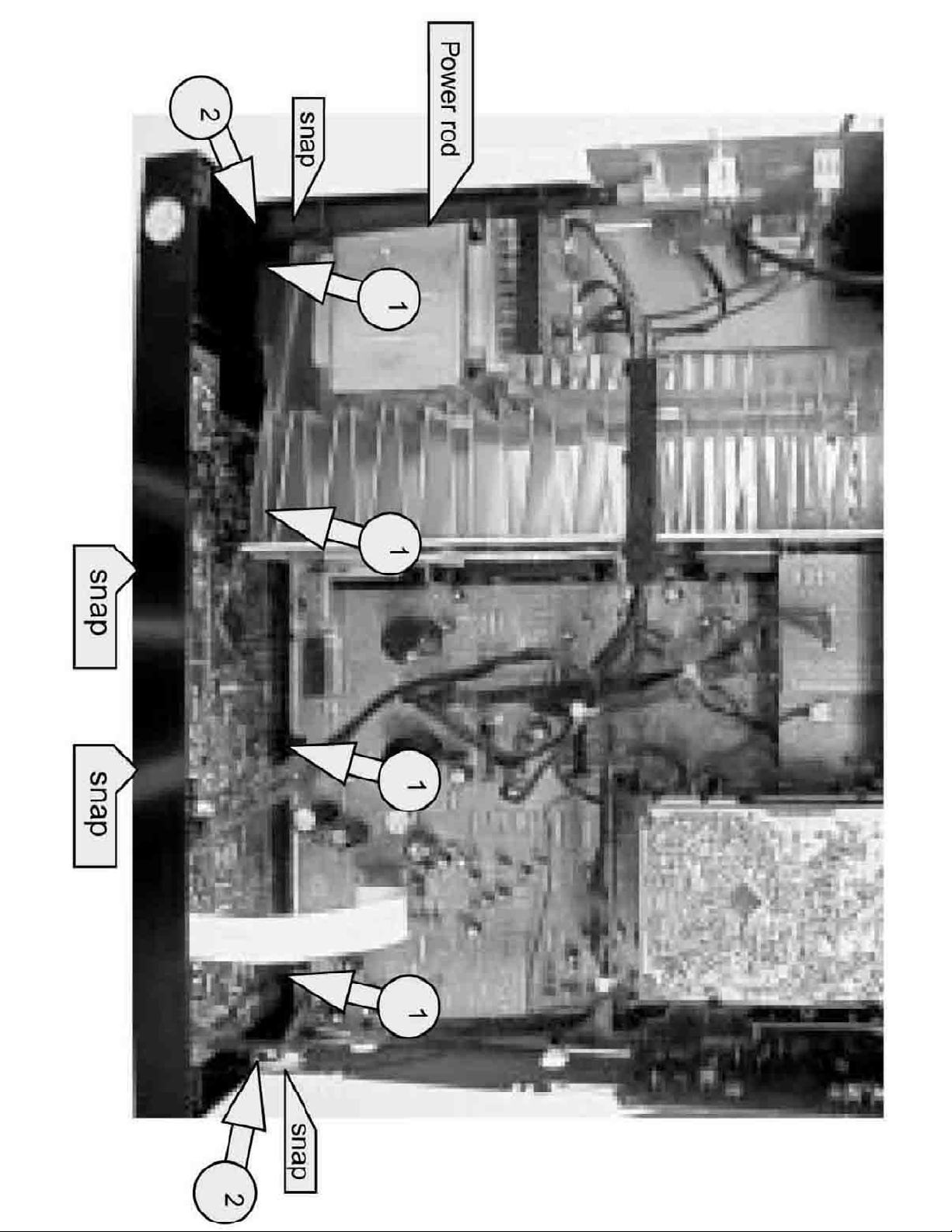

Cabinet Front Disassembly

1) Remove the top cover.

2) Remove the power rod.

3) Remove six screws as shown in picture 1.

4) Release two snaps (left and right side of the cabinet front).

5) Release two snaps on the bottom side of the cabinet front.

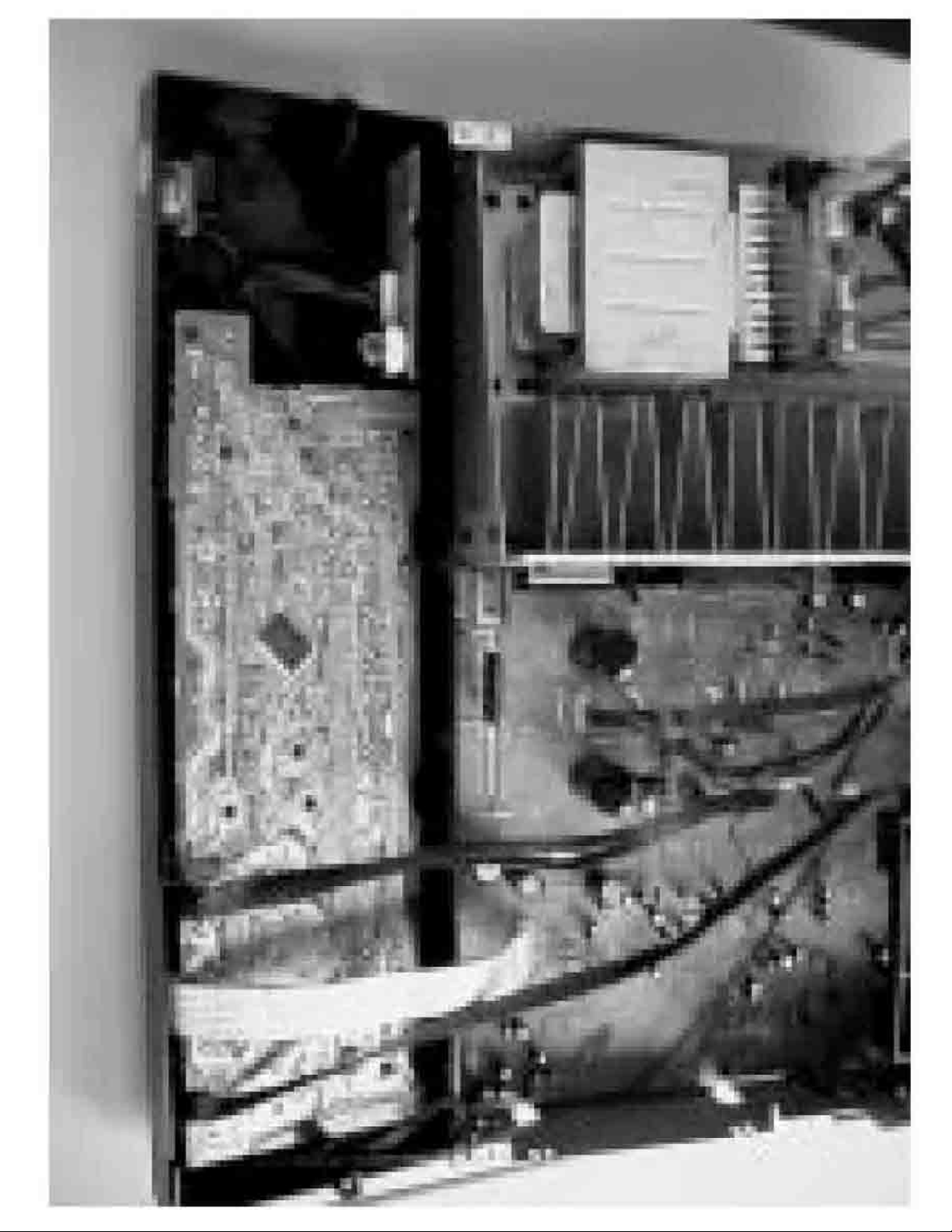

6) Lower the cabinet front as shown in picture 2.

Disassembly Picture 1

Disassembly Picture 2

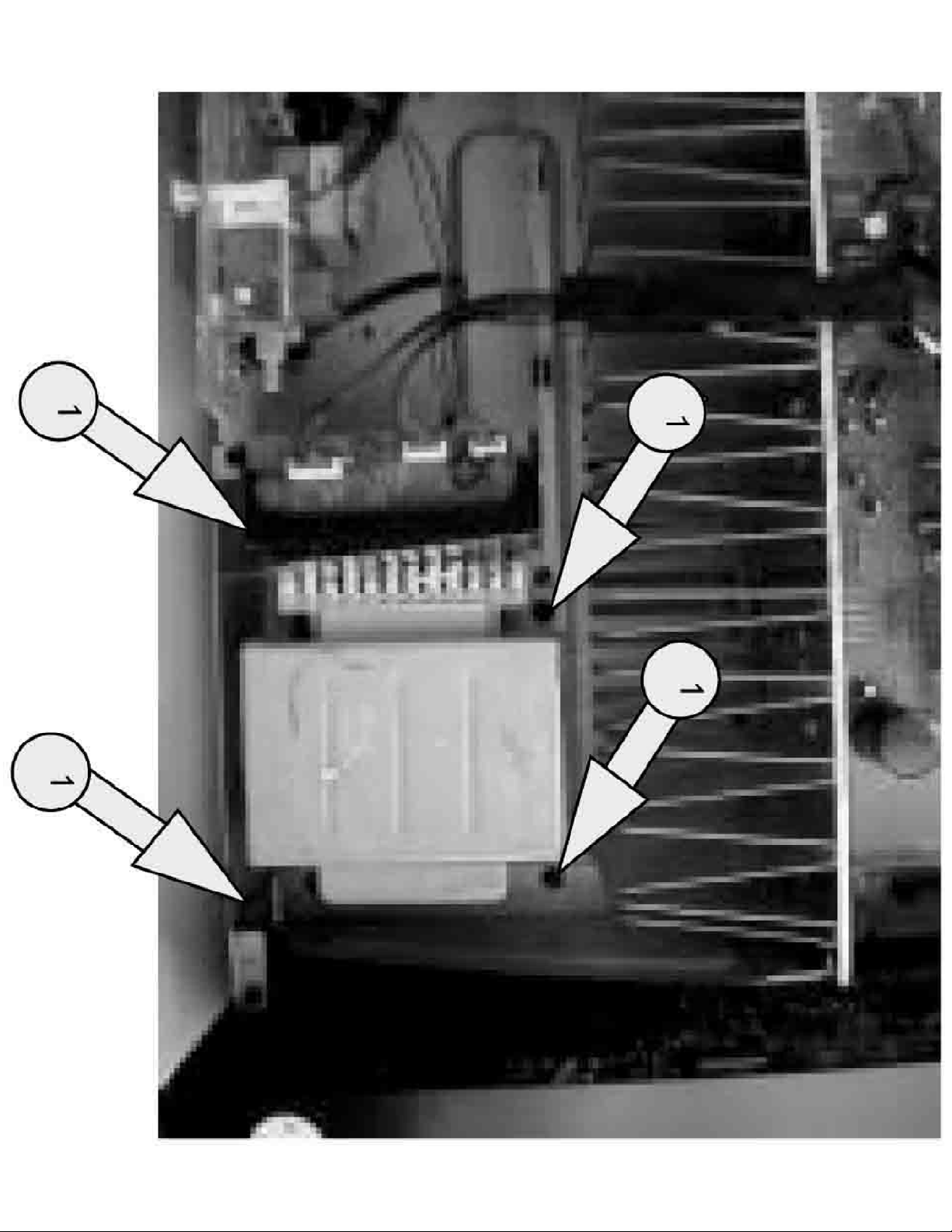

Mains Transformer Disassembly

1) Remove the power rod.

2) Remove four screws as shown in picture 3.

Disassembly Picture 3

Mono Board Disassembly

1) Lower the cabinet front (refer to picture 1).

2) Remove the entire cabinet front (disconnect the wires on the mono board

coming from the front).

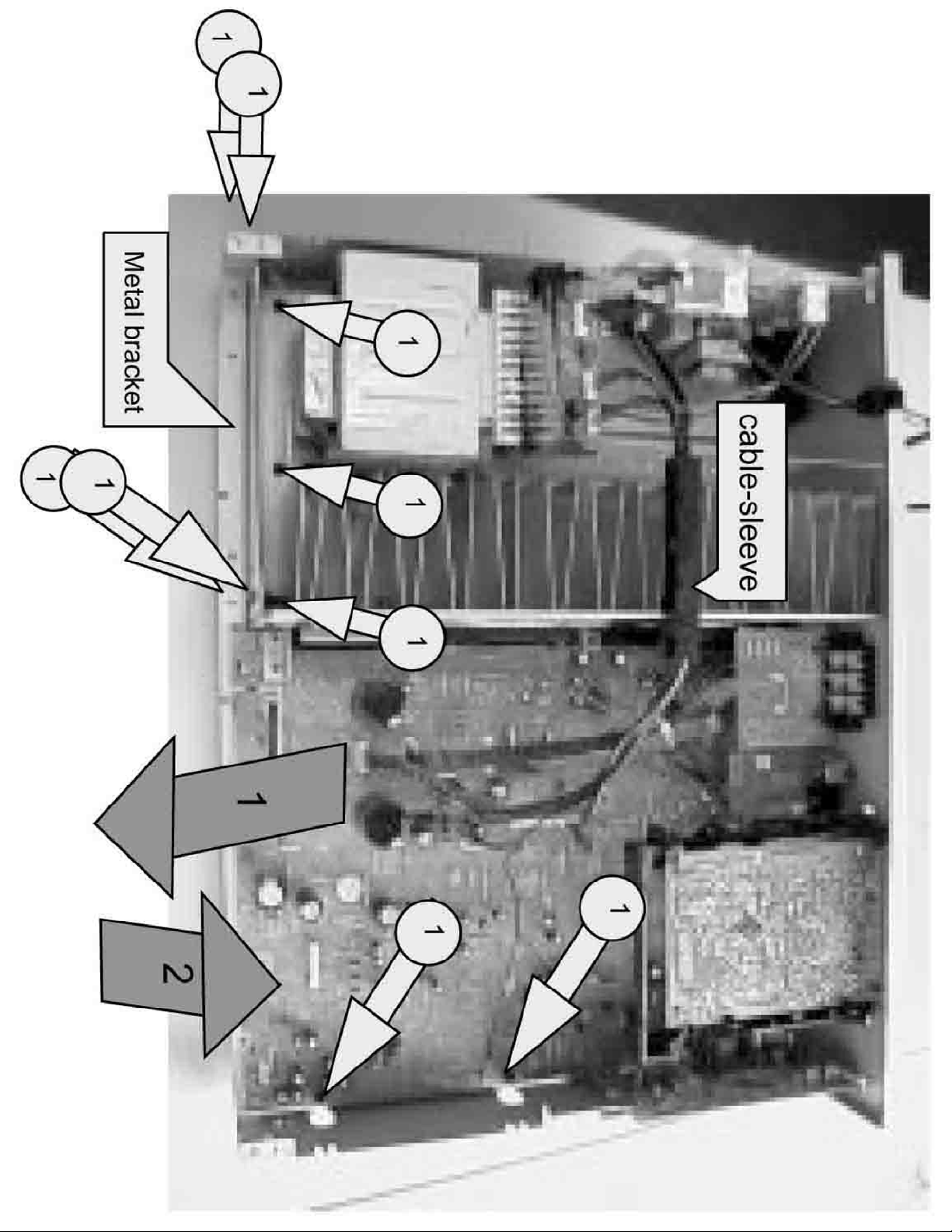

3) Remove 14 screws as shown in picture 4.

Disassembly Picture 4

4) Remove the wires from the cable sleeve.

5) Remove seven screws and take out the metal bracket.

6) Remove two screws from the mono board (refer to picture 5).

7) Move the mono board as shown by arrows 1 and 2 in picture 5.

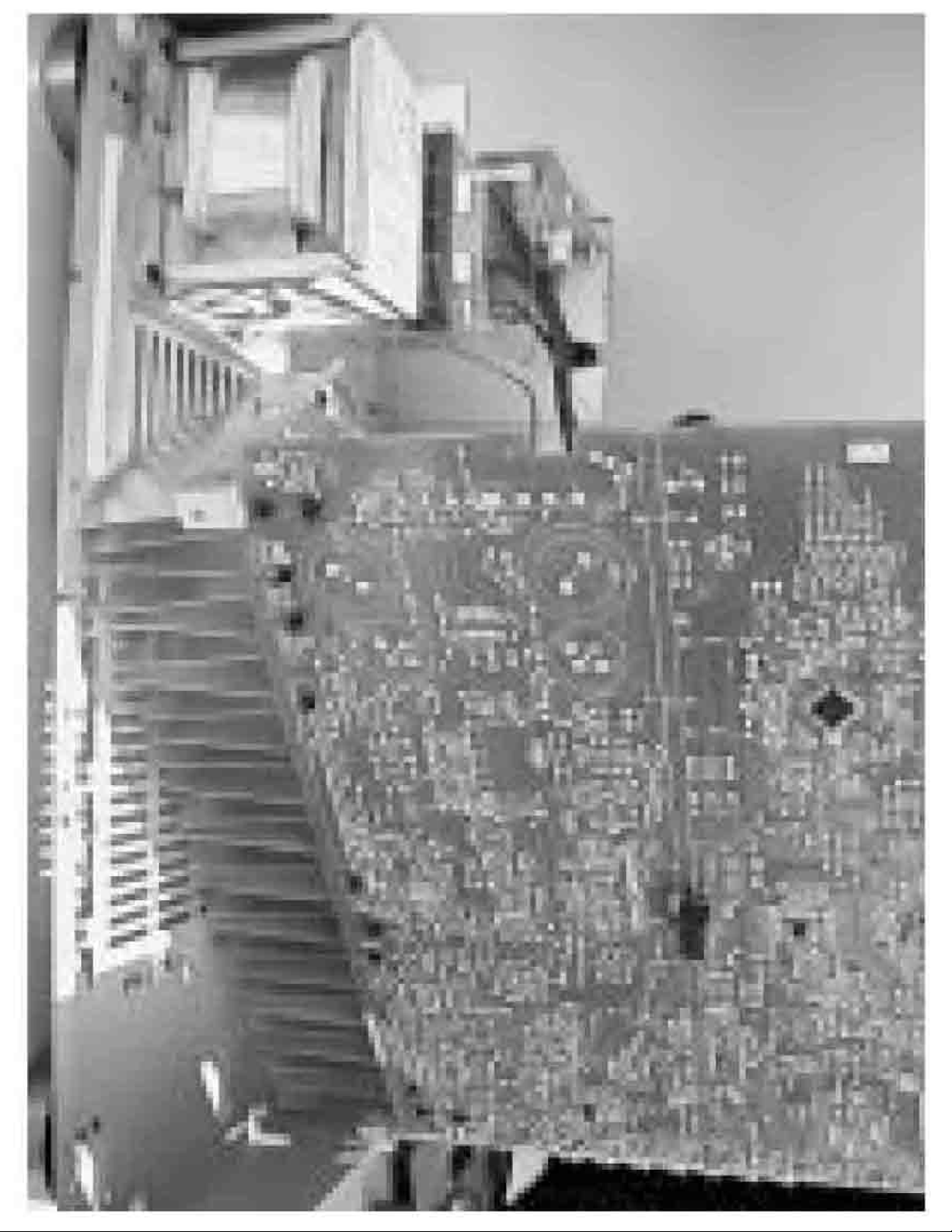

8) Place the mono board into the service position shown in picture 6.

Disassembly Picture 5

Disassembly Picture 6

Mono Board Service Position

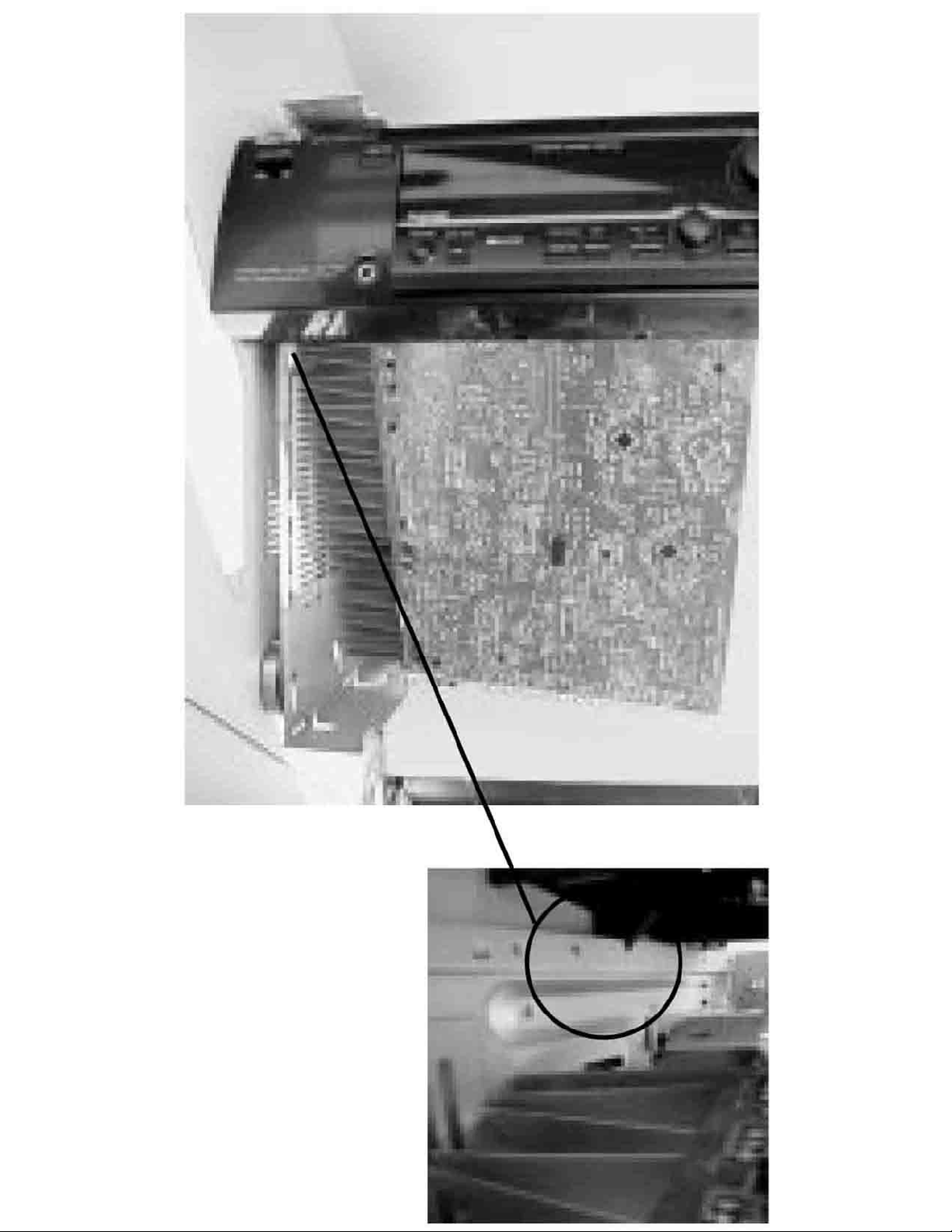

1) Place the cabinet front into the position shown in picture 7.

2) Snap the retaining clips of the cabinet front into the bottom to stabilize

the cabinet front as shown in picture 8.

3) Connect the front panel wiring back to the mono board.

Disassembly Pictures 7 and 8

Note that it is not necessary to connect the tuner module, because a

different source (e.g., CD) may be used.

Mains Transformer Service Position

1) Place the mains transformer into the position shown in picture 9.

Disassembly Picture 9

Handling Service Cover

1) To open the service cover, cut 14 lugs between the cover and the

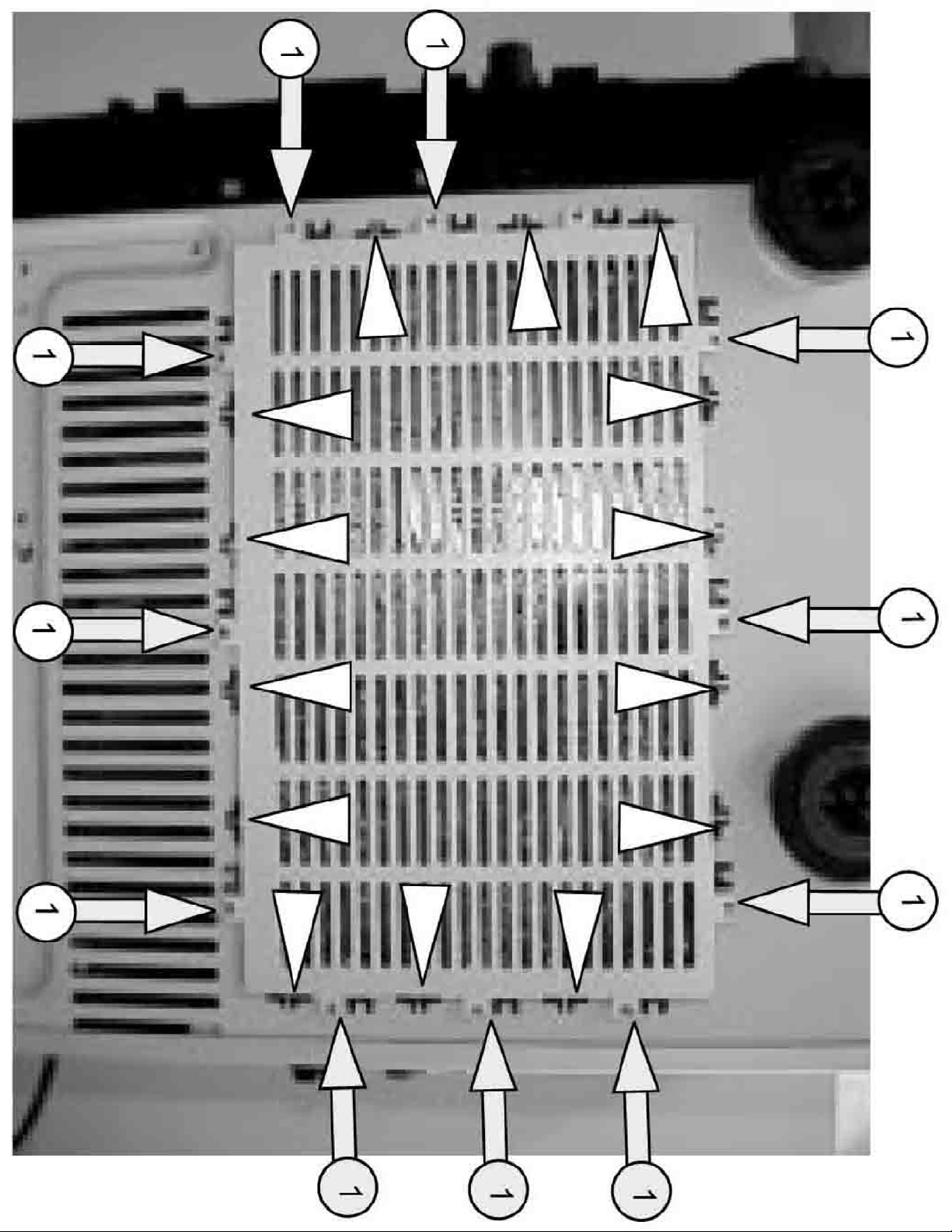

bottom (refer to picture 10).

Disassembly Picture 10

2) To close the service cover, put 11 screws in the holes shown in picture 10.

The service code number for 12x Torx M3x6mm screws is 4822 502 14659.

MDM Module Disassembly

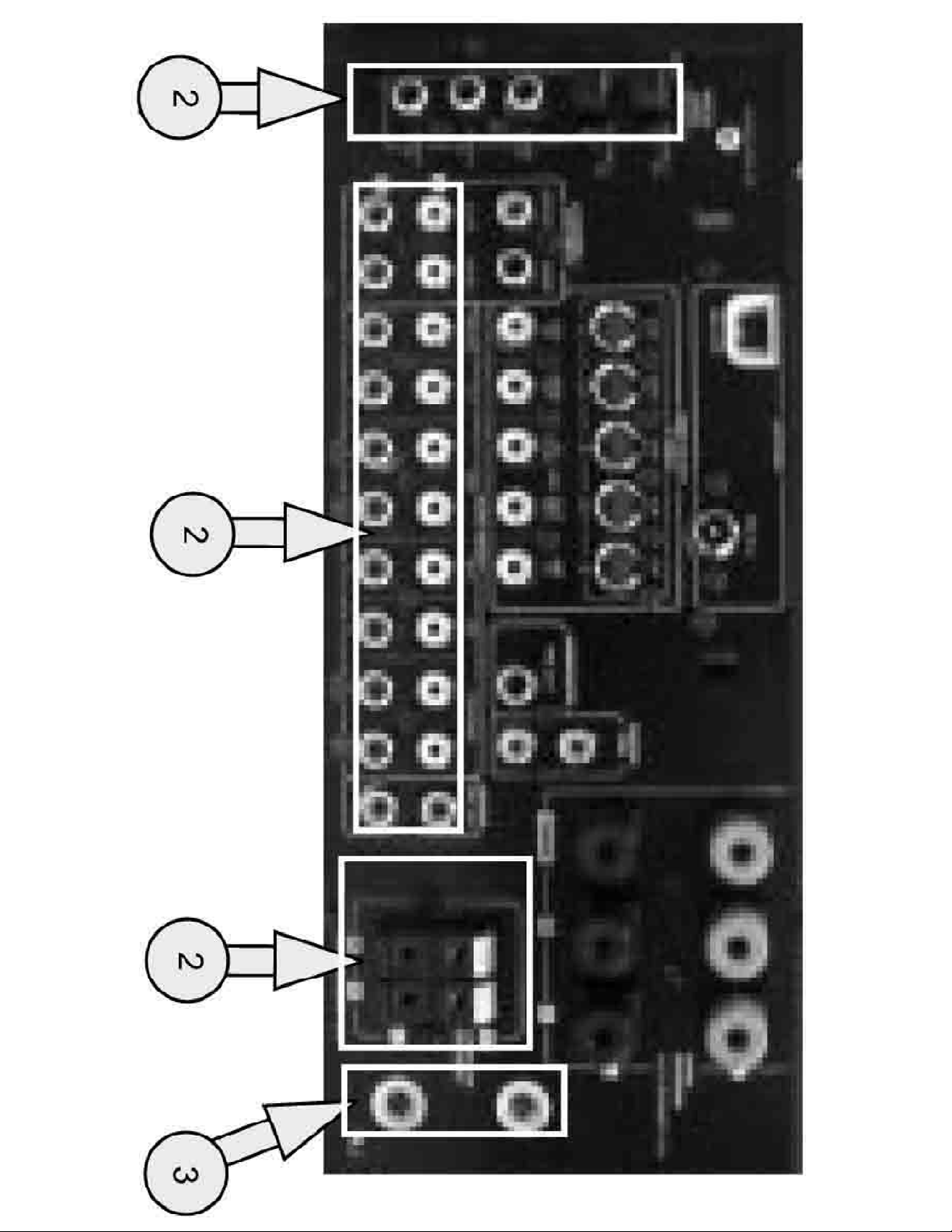

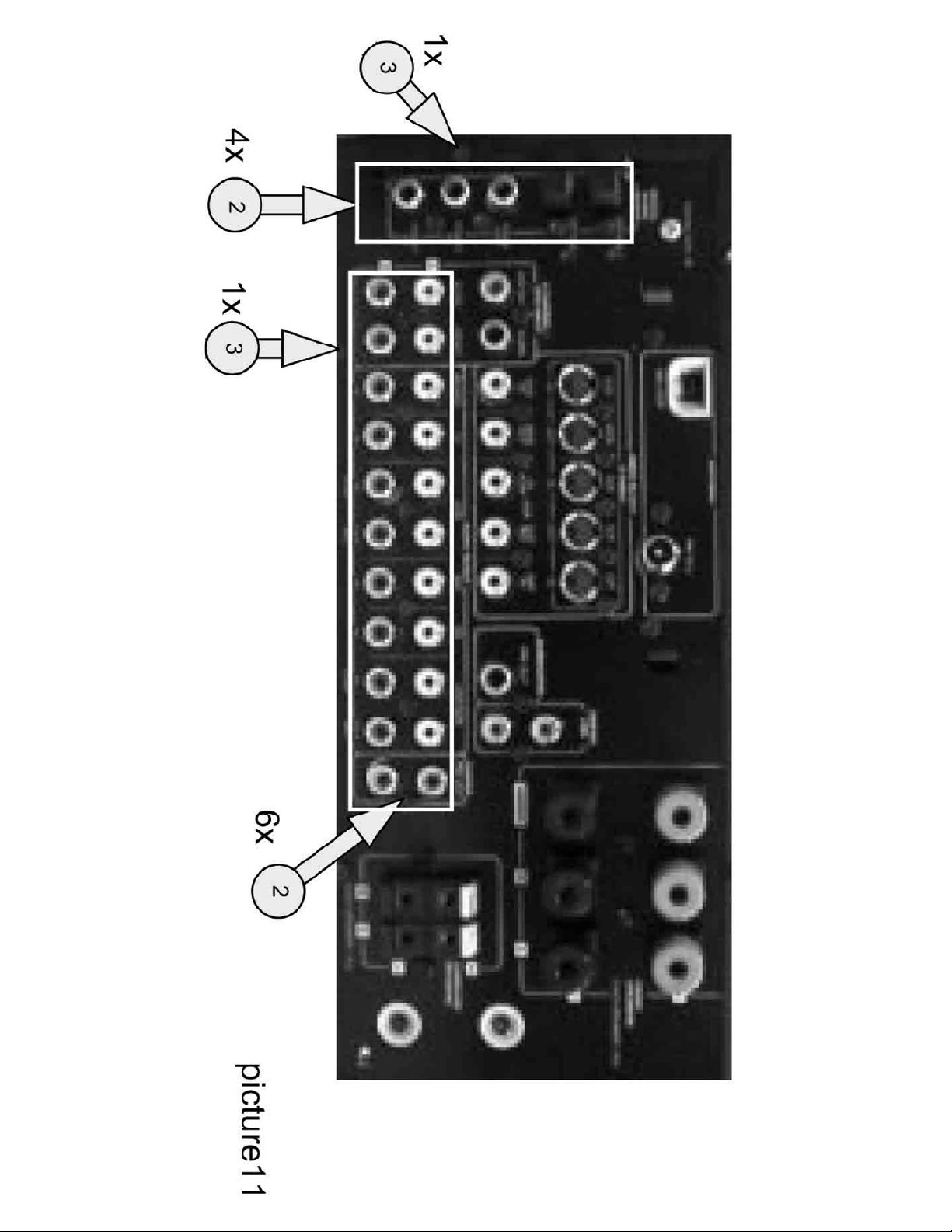

1) Remove all the screws noted in picture 11.

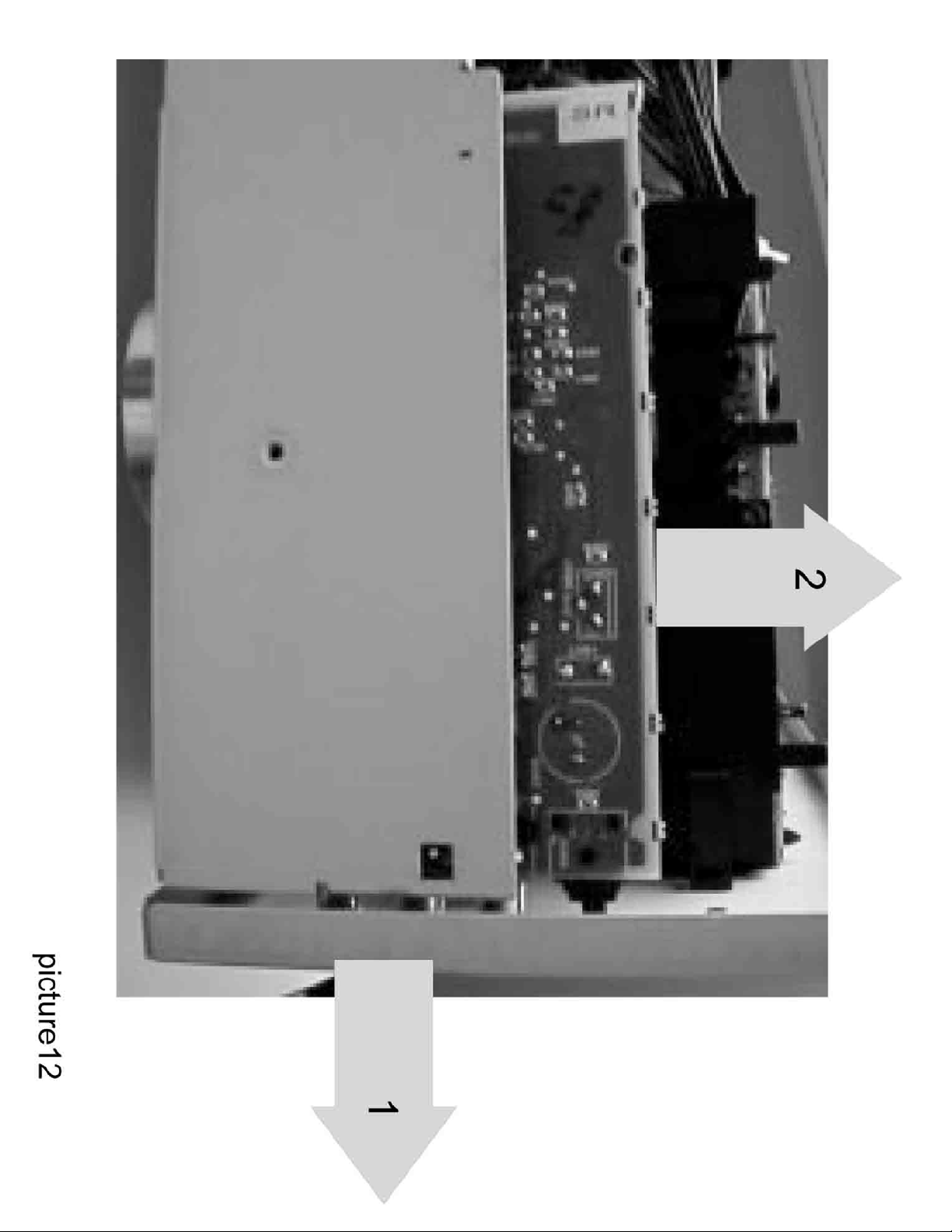

2) Pull the backplate out slightly as shown by arrow 1 in picture 12.

3) Pull the MDM Module out of the unit as shown in picture 12.

Disassembly Picture 11

Disassembly Picture 12

Loading...

Loading...