17” TFT LCD Colour Monitor

DVI-D & D-SUB Dual Input/Plug & Play

Auto Picture Adjustment/Wide Viewing Angle

TABLE OF CONTENTS

Description

Important Safety Notice..................................2

Technical Data & Power Management ............3~4

Connection to PC...........................................5

Installation & Accessories...............................6

Description of Controls...................................7

Advanced Control of OSD...............................8

Clock & Phase Adjustments............................9

OSD Menu Control Level Structure.................10~11

OSD Attention Signal.....................................12

Troubleshooting............................................13

Failure Mode of LCD Panel.............................14

USB Connection & USB Hub Installation.........15

Flat Panel Adjust (FP Adjust)......................... 16

Definition Of Pixel Defects..............................17

Wiring Diagram..............................................18

Mechanical Instructions..................................19~21

Electrical Instructions.....................................22~23

Factory Adjustment........................................24

Safety test Requirements...............................25

DDC Instructions............................................26~29

DDC Data.......................................................30~31

Page

170B1A/00(ADT panel)

Horizontal frequencies

30 - 82 kHz

Description

Repair Flow Chart...........................................32~34

Repair tips .....................................................35

Colour Adjustment..........................................36~42

PCBA Architecture..........................................43

Power Distribution Flow...................................44

Block Diagram & Control Panel C.B.A...............45

AC Adapter Schematic Diagram and C.B.A.......46

DC Converter & Video in Schematic Diagram....47

RGB Digitizer Diagram and Waveforms.............48

Scaling Schematic Diagram and Waveforms......49

MCU Schematic Diagram and Waveforms..........50

Frame buffer and Power Saving Diagram...........51

Inverter & Control Panel Schematic Diagram.....52

TMDS Receiver and Main Panel C.B.A ..............53

TTL to LVDS Schematic Diagram.......................54

Exploded View..................................................55

Recommended Parts List..................................56

Spare Parts List................................................57~62

General Product Specification...........................63~85

Inverter Panel C.B.A.........................................86

Spare Parts List for Inverter...............................87

Page

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Published by BCU Monitor Printed in Taiwan Copyright reserved Subject to modification August 4, 2000

©

3138 106 10106

Technical Data

170B LCD

Go to cover page

3

Technical Specifications

LCD Panel

Screen type : ADT Active matrix - TFT LCD

Screen dimensions : 17 inches (diagnoal)

Preset display area

Horizontal : 337 mm

Vertical : 270 mm

Pixel pitch : 0.26 x 0.26 mm

Viewing angle : 135 (vertical)

: 160 (horizontal)

Luminance output : 250 CD/m

Contrast ratio : 400 typical

Faceplate coating : Anti-glare with hard coating 3H

Backlight : CCFL edge light system

Resolution

Horizontal scan range : 30 kHz to 82 kHz (automatic)

Vertical scan range : 56 Hz to 76 Hz (automatic)

Optimal preset resolution : 1280 x 1024 at 60 Hz

Highest preset resolution : 1280 x 1024 at 75 Hz

Electrical

Video input signals : Analog,0.7Vpp, positive at 75 ohms

Synchronization input signals : Separate horizontal and vertical /

composite ;TTL level, positive or

negative, Sync On Green

AC input voltage / frequency : 90 to 264 VAC / 50 or 60 Hz 3 Hz

2

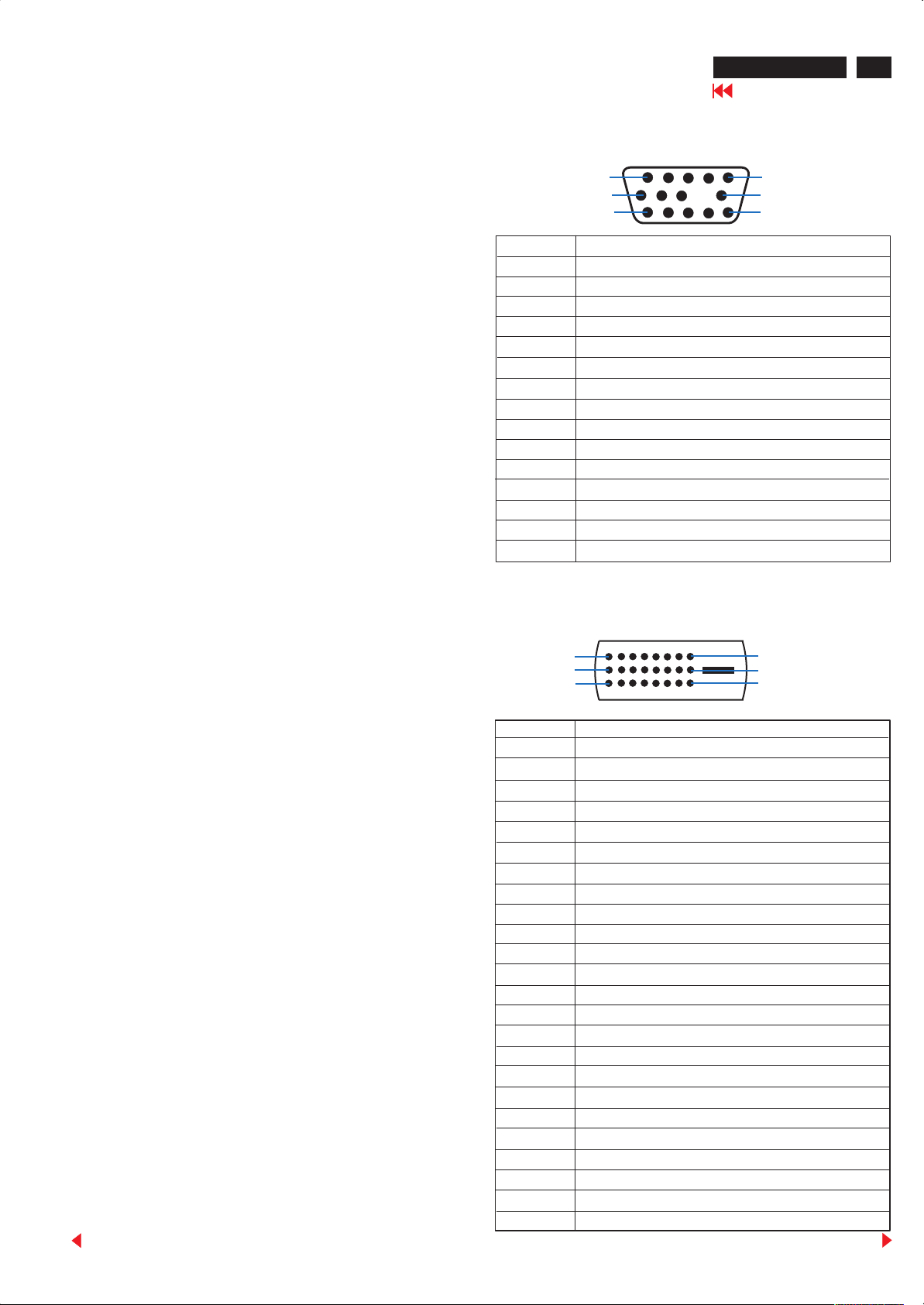

Pin Assignment

D-Sub connector

1

6

11

Pin No. Assignment

1 Red video input

2 Green video input / Sync On Green

3 Blue video input

4 Sense (ground)

5

6 Red video ground

7

8 Blue video ground

9 Not connected

10 Logic (Sync) ground

11 Sense (ground)

12 Bi-directional data (SDA of DDC)

13 H / H+V Sync

14 V. Sync (VCLK of DDC)

15 Data clock (SCL of DDC)

No connected

Green video ground

5

10

15

Physical Characteristics

Connector type : DVI-D, 15-pin D-subminiature

Signal cable type : Detachable

Tilt and swivel angle of pedestal

Tilt angle of forward : 0 degree

Tilt angle of backward : 30 degree

Swivel angle of left : 40 degree

Swivel angle of right : 40 degree

Dimensions

Height : 452 mm

Depth : 180 mm

Width : 454 mm

Weight (monitor only) : 7.2 kg

Temperature

Operating : 5 C to 35 C (41 F to 95 F)

Non-operating : -20 C to 60 C (-43 F to 140 F)

Humidity

Operating : 80% max. (non-condensing)

Non-operating : 95% max. (non-dondensing)

Altitude

Operating : 3,658 m

Non-operating : 12,192 m

Back

DVI-D connector

(Digital Visual Interface - Digital)

1

9

17

Pin No. 24-Pin Side of the Signal Cable

1 TMDS Data 2-

2 TMDS Data 2+

3 TMDS Data 2/4 Shield

4 TMDS Data 4-

5

6 DDC Clock

7

8 No connection

9 TMDS Data 1-

10 TMDS Data 1+

11 TMDS Data 1/3 Shield

12 TMDS Data 3-

13 TMDS Data 3+

14 +5V Power

15 Ground (+5)

16 Hot Plug Detect

17 TMDS Data 0-

18 TMDS Data 0+

19 TMDS Data 0/5 Shield

20 TMDS Data 5-

21 TMDS Data 5+

22 TMDS Clock Shield

23 TMDS Clock+

24 TMDS Clock-

TMDS Data 4+

DDC Data

8

16

24

Forward

4

170B LCD

Go to cover page

Technical Data

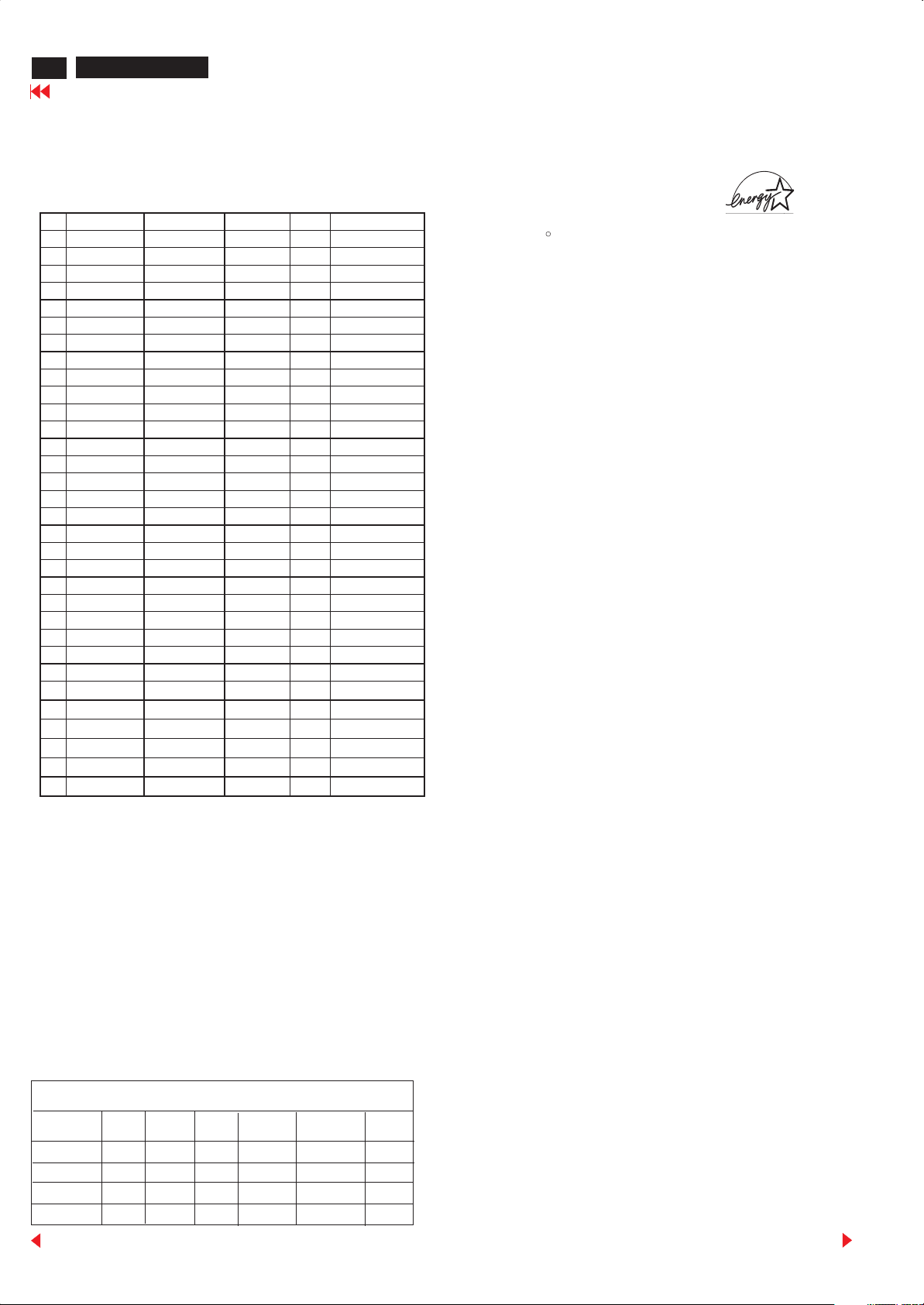

Data Storage

Factory preset mode:

This monitor has 16 factory-preset modes as indicated in the

following table :

# Resolution Frequency Pixel rate Sync Comment

1 640X350 31.5K/70HZ 25.175 (+/-) IBM VGA 10h

2 720X400 31.5K/70HZ 28.322 (-/+) IBM VGA 3h

3 640X480 37.5K/75HZ 31.501 (-/-)

4 640X480 43.3K/85HZ 36 (-/-)

5 640X480 37.9K/72HZ 31.5 (-/-)

6 640X480 35.0K/67HZ 30.24 (-/-)

7 640X480 31.5K/60HZ 25.175 (-/-)

8 800X600 35.2K/56HZ 36 (+/+)

9 800X600 46.9K/75HZ 49.498 (+/+)

10 800X600 37.9K/60HZ 40 (+/+)

11 800X600 53.7K/85HZ 56.251 (+/+)

12 832X624 49.7K/75HZ 57.28 (+/+) MAC

13 800X600 48.1K/72HZ 50 (+/+)

14 1024X768 60.0K/75HZ 78.75 (+/+)

15 1024X768 48.4K/60HZ 65 (-/-)

16 1024X768 56.5K/70HZ 75 (-/-)

17 1024X768 61.1K/76HZ 83.096 (+/+) IBM XGA-2

18 1024X768 68.7K/85HZ 94.5 (+/+)

19 1152X864 67.5K/75HZ 108 (+/+)

20 1152X864 63.9K/70HZ 94.5 (+/+) non-VESA

21 1152X864 54.0K/60HZ 79.9 (+/+) non-VESA

22 1152X870 68.7K/75HZ 100 (-/-) MAC

23 1152X900 61.8K/66HZ 92.94 serr- SUN Mode IV

24 1152X900 71.8K/76HZ 108 (+/+) SUN Mode II

25 1280X960 60.0K/60HZ 108 (+/+)

26 1280X960 75.0K/75HZ 129.895 (+/+) non-VESA

27 1280X1024 76.0K/72HZ 130.223 (+/+) DOS/V

28 1280X1024 64.0K/60HZ 108 (+/+)

29 1280X1024 80.0K/75HZ 135 (+/+)

30 1280X1024 81.1K/76HZ 135.008 (-/-) SUN Mode I

31 1280X1024 71.7K/67HZ 117 (+/+) SUN Mode V

32 688X556 31.3K/50HZ 27 (-/+) TV-PAL

This monitor is Environmental Protection Agency (EPA) Energy Star

compliant and TCO'99 power management compatible.

*Zero power consumption in OFF mode can only be achieved by

disconnecting the mains cable from the monitor.

ENERGY STAR is a U.S. registered mark. AS AN ENERGY STAR

R

PARTNER, PHILIPS HAS DETERMINED THAT THIS PRODUCT

MEETS THE ENERGY STAR GUIDELINES FOR ENERGY

EFFICIENCY.

Meanwhile, it also reverse 16 sets data space available for user

storage new timings data.

Automatic Power Saving

If you have VESA's DPMS compliance display card or software

installed in your PC, the monitor can automatically reduce power

consumption when power saving function active. And if an input

from keyboard, mouse or other input devices is detected, the

monitor will automatically "wake up". The following table shows

the power consumption and signaling of this automatic power

saving feature :

Power Management Definition

VESA's mode

ON

Stand-by

Suspend

OFF

Back

VIDEO

Active

Blanked

Blanked

Blanked

H-SYNC

Yes

No

Yes

No

V-SYNC

Yes

Yes

No

No

POWER

USED

< 42 W

< 3 W

< 3 W

< 3 W

POWER

SAVING( % )

0 %

83.3 %

83.3 %

90 %

LED

COLOR

Green

Amber

Amber

Amber

Forward

10

170B LCD

Go to cover page

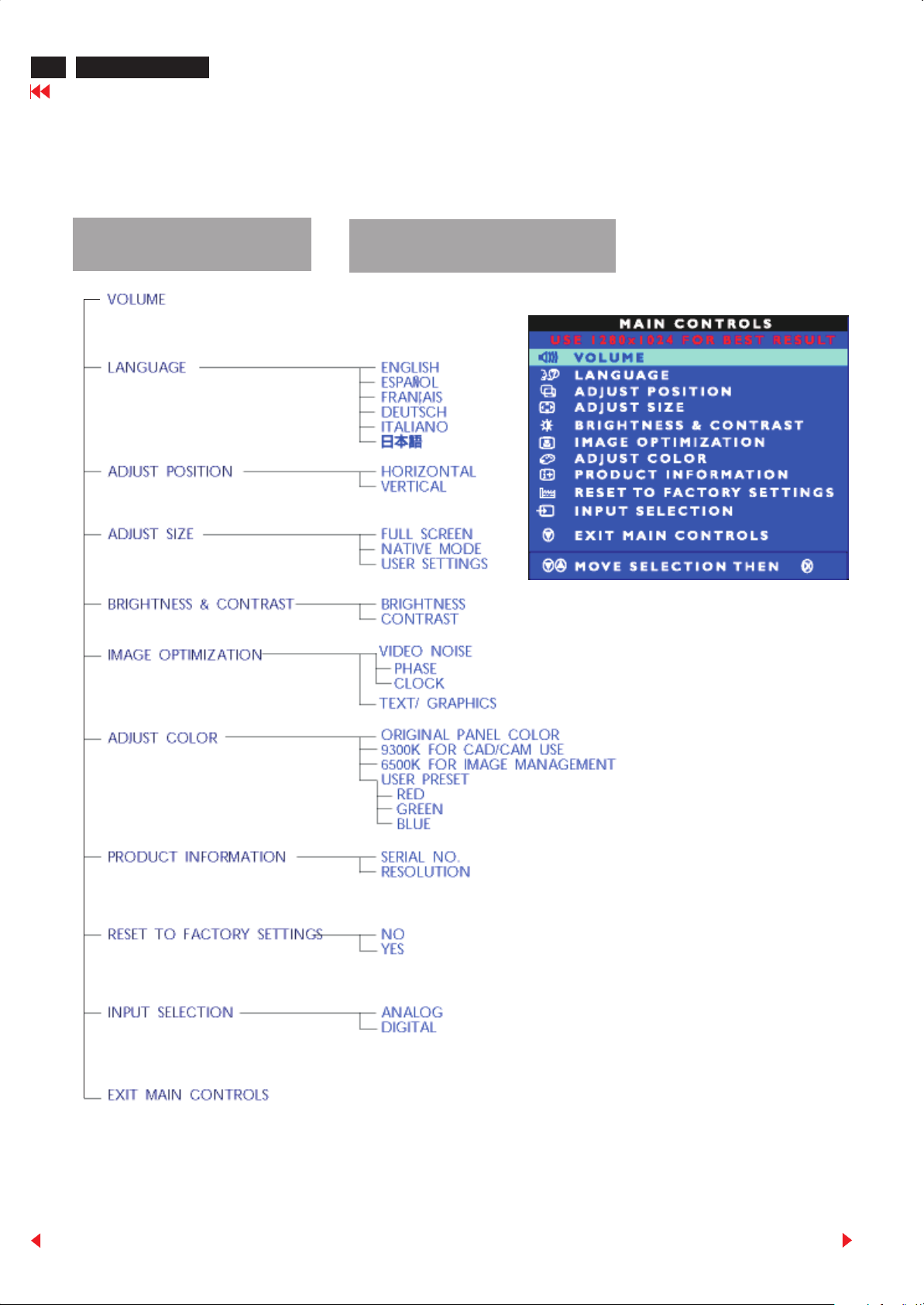

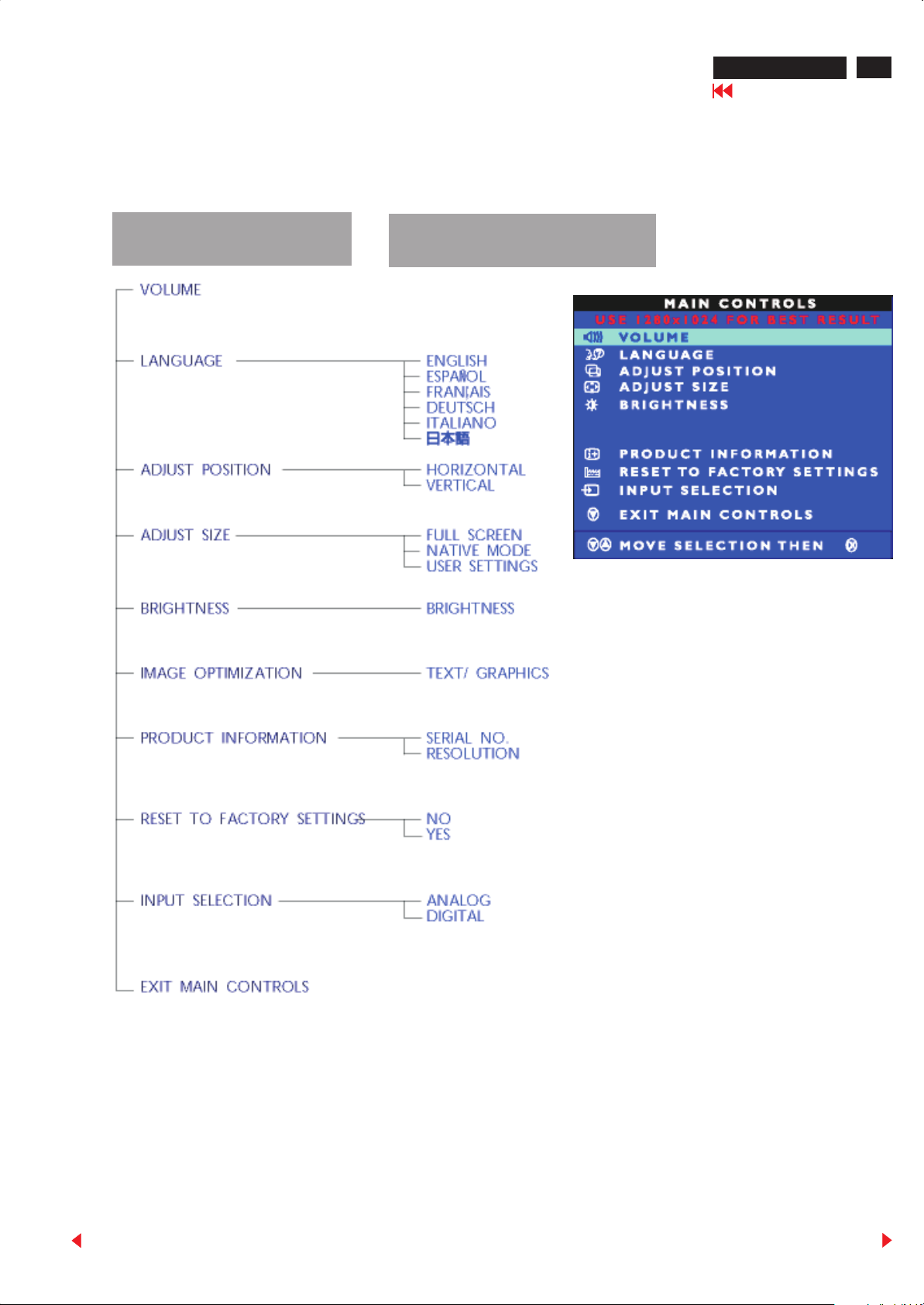

OSD Control Structure for Analog

The OSD Tree for analog video signal

Below is an overall view of the structure of the On-Screen Display. You can use this as reference when you want to later on work your way around the

different adjustments.

First Level

Second Level

OSD Menu (Analog)

Back

Forward

OSD Control Structure for Digital

170B LCD

Go to cover page

11

The OSD Tree for digital video signal (DVI-D)

This OSD structure is different from analog menu, there are three functions will be disable on digital OSD menu: Contrast, Image Optimization, and

Adjust Color.

First Level

Second Level

OSD Menu (Digital)

Back

Forward

12

170B LCD

Go to cover page

OSD Attention signals

The monitor will detect various display situation automatically. When

the monitor detects the problems, the screen will show the different

warning signals to remind you what is happen to your monitor.

NO VIDEO INPUT

This screen appears if there is no video signal input. Please check

that the signal cable is properly connected to the video card of PC.

ATTENTION

NO VIDEO INPUT

VIDEO INPUT SELECTED

This windows appears 3 seconds that show you which video input

has selected by monitor when every time you turn on the monitor.

ATTENTION

ANALOG VIDEO INPUT SELECTED

USE OSD MENU TO CHANGE

DEFAULT INPUT SELECTION

ENTERING SLEEP MODE

This screen appears when the monitor is about to enter the sleep

mode. Please press any key on the keyboard or click the mouse to

wake up the monitor and computer.

ATTENTION

ENTERING SLEEP MODE

THIS IS BEST PICTURE SHARP

When you expand picture size by using OSD menu “ADJUST

SIZE/USER SETTINGS”, during the adjustment, Once the pixels

number of horizontal size has reached 1280 pixels, following

window will appear on the screen that remind you the resolution of

video signal was expanded exactly can match the LCD panel

(1280X1024).

ATTENTION

THIS IS BEST PICTURE SHAPE

CANNOT DISPLAY THIS VIDEO MODE..

This screen warns when the input frequency from the computer is not

a standard video mode or out of the monitor's scanning range.

Please change the display mode of the operating software in the

computer(i.e. Windows) to 1280 x 1024@ 60Hz for best display

results.

ATTENTION

CANNOT DISPLAY THIS VIDEO

MODE, CHANGE COMPUTER DISPLAY

INPUT TO 1280 X1024@60HZ

91.1 KHz 85.0Hz

In this case, the picture will still showing on the screen about 60

seconds then shut down by monitor. Attention message will

disappear as well after 30 minutes remaining then enter power

saving state. (No picture, power indicator showing amber.)

USE 1280 X 1024 FOR BEST RESULT

This message appears at the top of the OSD window when the video

mode input is not the recommended 1280x1024. Other modes may

result in some picture distortion. Please adjust the video mode to

1280x1024 at 60Hz for best display quality.

WAIT FOR AUTOMATIC ADJUSTMENT

This screen appears when you touch the button. It will

disappear when the monitor is properly adjusted.

ATTENTION

WAITING FOR AUTOMATIC

ADJUSTMENT

SECOND VODEO IS NOT AVAILABLE

When you select video input between Analog or Digital signal via

INPUT SELECTION function of OSD menu, if the one you are

selecting is not available, following message will appear on the

screen then switching back to the previous setting automatically.

ATTENTION

SECOND VIDEO

NOT AVAILABLE

USE 1280 x 1024 FOR BEST RESULT

Back

Forward

Trouble Shooting

170B LCD

Go to cover page

13

TROUBLESHOOTING

This page presents problems that can be corrected by the user. If the

problem still exists after these possible solutions, a further action has

to be take by authorized technicians.

No Picture

(Power LED not lit)

No Picture

(Power LED is

Amber or Yellow in

color)

Screen says

AUTO button not

working

properly

Make sure the Power cable is plugged to the

wall and back of the monitor.

Make sure the DC power cord has been

attached to the DC jack.

First, power button in front of the monitor

should be in the OFF position, then press it to

ON position again.

Make sure the computer is turned on.

Make sure the signal cable is properly

connected to your computer.

Check to see if the monitor cable has bent pins.

The Energy Saving Feature may be activated.

Make sure the monitor cable is properly

connected to your computer.

Check to see if the monitor cable has bent pins.

Make sure the computer is turned on.

The Auto Function is designed for

use on standard Macintosh or

IBM-compatible PC running Microsoft

Windows.

It may not work properly if using

non-standard PCs or video card.

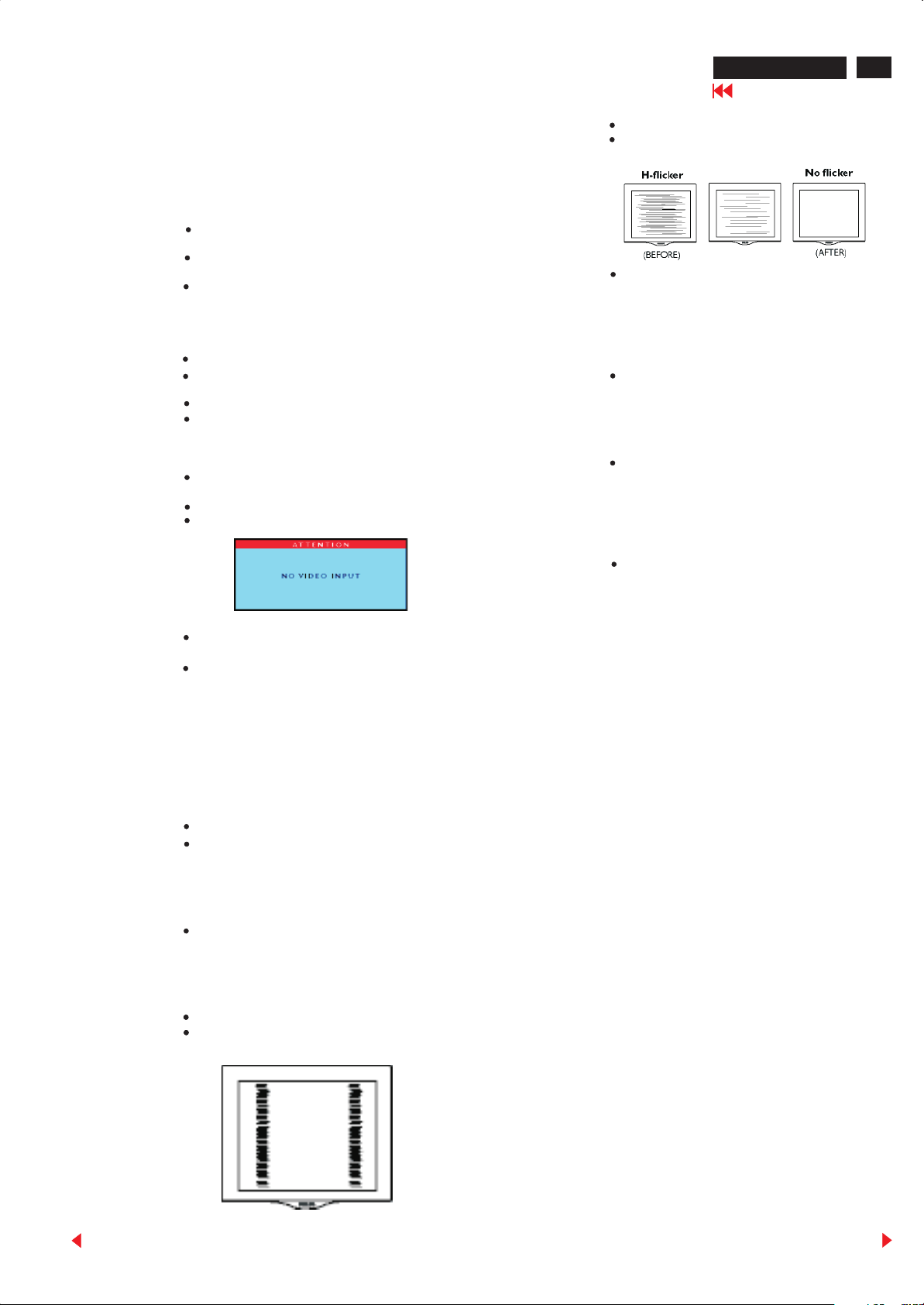

Horizontal flicker

appears

The screen is too

bright or too dark

An after-image

appears

An after-image

remains after the

power has been

turned off

Green, red,

blue, dark and

white dots

remain on the

screen

Push the Auto button.

Eliminate the horizontal bars using the Phase

Adjustment in the First Window.

Adjust the contrast and brightness using the

First Window.

(The backlight of the LCD monitor has a fixed

life span. When the screen becomes dark or

begins to flicker,please contact your dealer.)

If an image remains in the screen for an

extended period of time,it may be imprinted in

the screen and leave an after-image. This

usually disappears after a few hours.

This is characteristic of liquid crystal and is

not caused by a malfunction or deterioration

of the liquid crystal. The after-image will

disappear after a set amount of time.

The remaining dots are normal

charactericstic of the liquid crystal used in

today's technology.

Imaging

Problems

Display position

is incorrect

Image vibrates

on the screen

Vertical flicker

appears

Push the AUTO button.

Adjust the image position using the Horizontal

Position & / or Vertical Position in the Second

Window.

Check that the signal cable is properly

connected to the graphics board or PC.

Push the AUTO button.

Eliminate the vertical bars using the Clock

Adjustment in the FIRST Window.

Back

Forward

14

Quick reference for failure mode of LCD panel

This page presents problems that could be made by LCD panel. It is

not necessary to repair circuit board. Simply follow the “Mechanical

instruction” on this manual to eliminate failure by replace LCD panel

or backlight tubes.

170B LCD

Go to cover page

Failure description Phenomenon

Failure Mode of LCD panel

Polarizer has bubbles

..

Vertical block defect

Vertical dim lines

Vertical lines defect

(Always bright or dark)

Horizontal block defect

Polarizer has bubbles

. .. .

Foreign material inside

polarizer. It shows linear or

dot shape.

Concentric circle formed

Horizontal dim lines

Horizontal lines defect

(Always bright or dark)

Has bright or dark pixel

Bright pixel

.

.

..

..

Dark pixel

.

.

.

.

.

.

Bottom back light of LCD is

brighter than normal

Backlight un-uniformity

Backlight has foreign

material. Black or white

color, linear or circular type

. .. .

Back

Forward

16

170B LCD

Flat Panel Adjust (FP Adjust)

Go to cover page

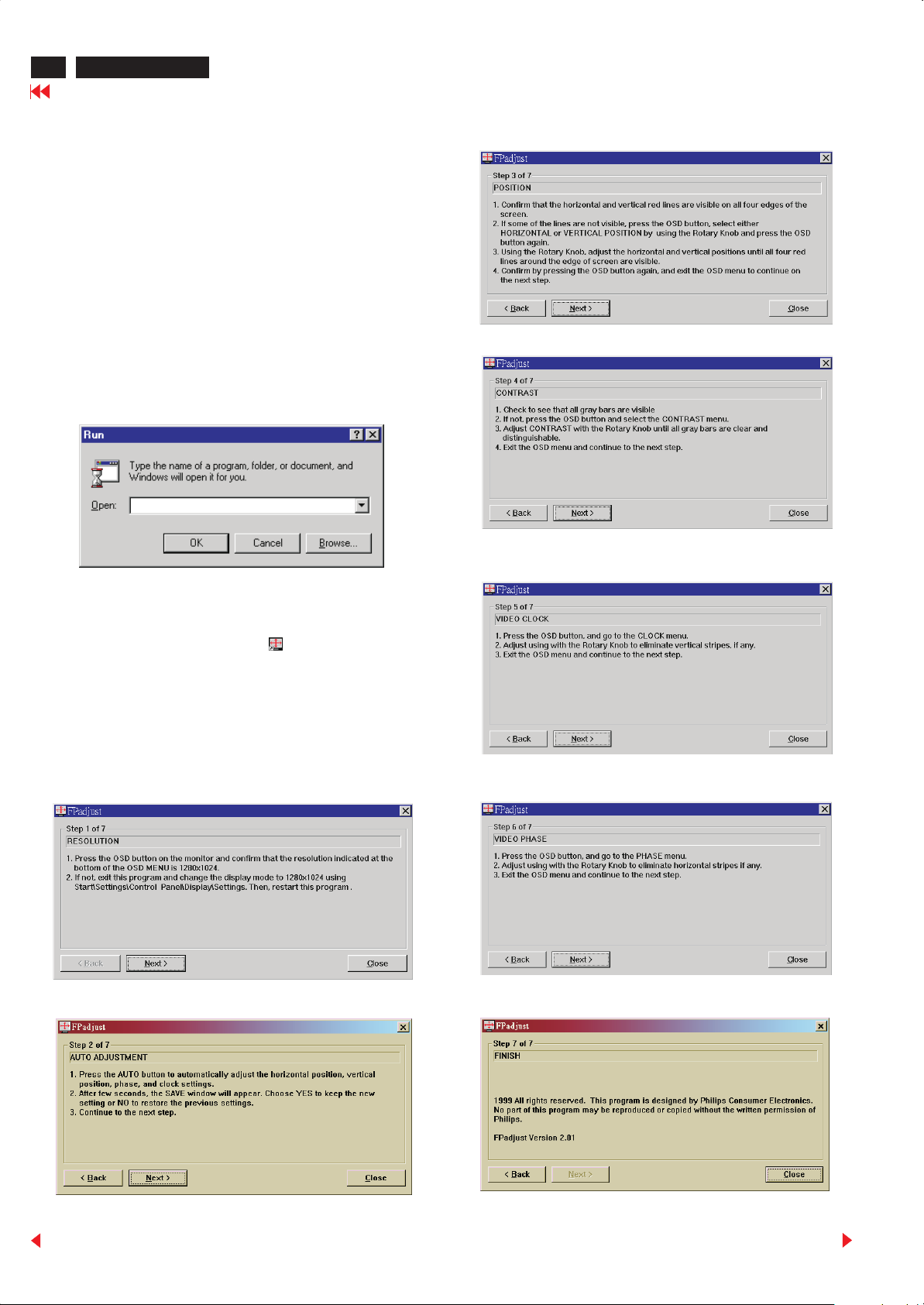

Fpadjust program

The Flat Panel Adjust (FPadjust) software helps you to find the best

setting for your Philips LCD monitor. It allows you to adjust the image

performance of LCD monitor, such as RESOLUTION,

AUTO ADJUSTMENT, POSITION, CONTRAST, IMAGE OPTIMIZATION.

Note: Image optimization function is only available for analog video

signals.

Install and Run FPadjust

In "MS Windows 95/98" environment : For example

1. Insert CD-DFU(3138 117 01953) to your CD-ROM driver.

2. Run "E:\PC\FPADJUST\SETUP.EXE" as Fig. 1. (Replace E by the

letter of your CD-ROM driver)

E:\PC\FPADJUST\SETUP.EXE

Fig. 1

3. Then follow the instructions to install the FPadjust program.

When finish, double click FPadjust icon " ", then the

description (can be moved by mouse) and background pattern

come on the screen for image adjustment.

FPadjust program is working as a pattern generator to provide the

pattern display on the screen for the adjustment of CONTRAST,

CLOCK, PHASE ...etc. Please follow the steps below to adjust your

PHILIPS Flat Panel Monitor for best display quality.

FPadjust.lnk

Back

Forward

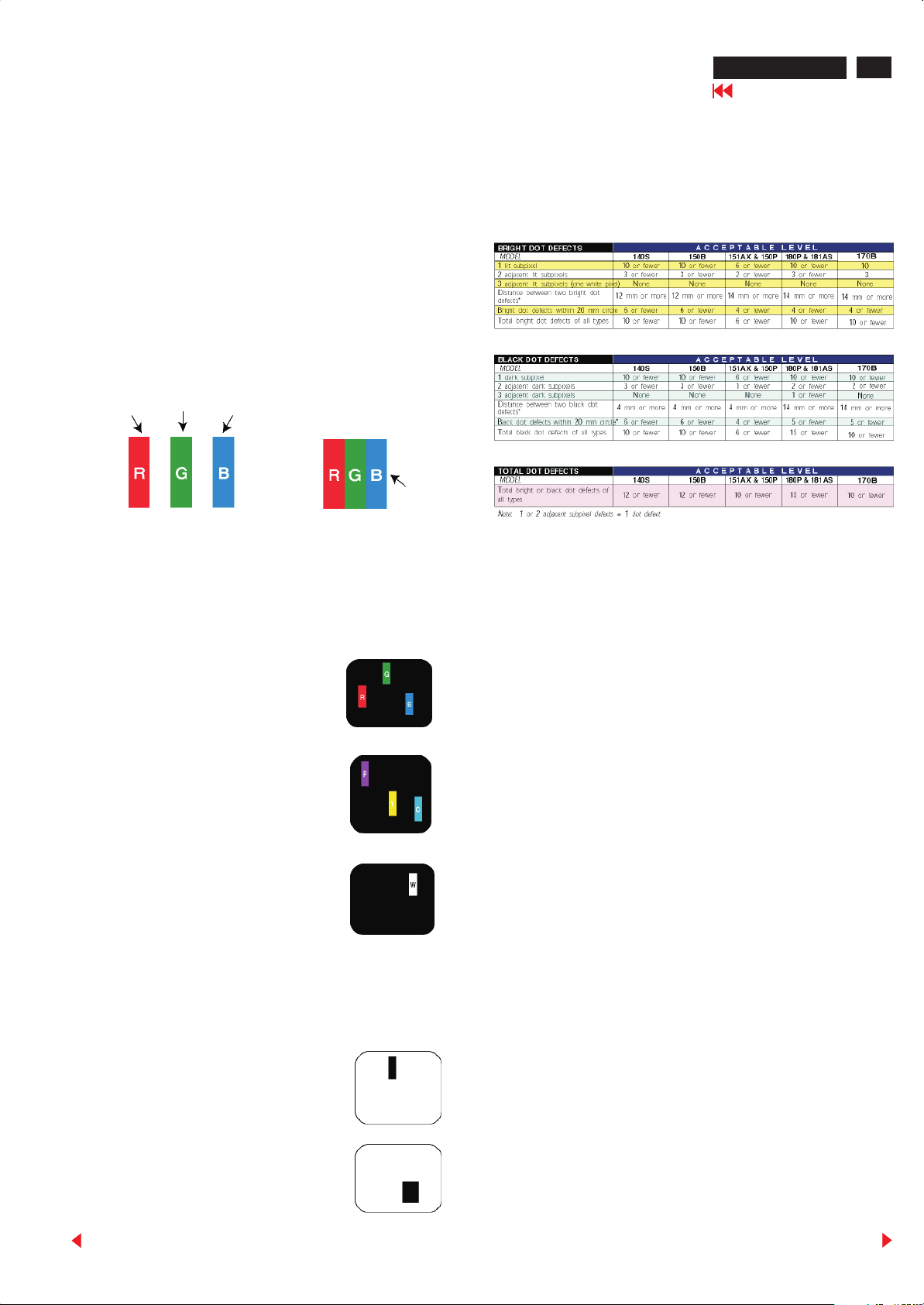

Definition of Pixel Defects

170B LCD

Go to cover page

17

0. General

This section explains the different types of pixel defects and

defines acceptable defect levels of each type. In order to qualify

for repair or replacement under warranty, the number of pixel

defects on a TFT LCD panel must exceed these acceptable levels.

1. Definition of Pixels and Subpixels

A pixel, or picture element , is composed of three subpixels in the

primary colors of red, green and blue. Many pixels together from

an image. When all subpixels of a pixel are lit, the three colored

subpixels together appear as a single white pixel. When all are

dark, the three colored subpixels together appear as a single black

pixel. Other combinations of lit and dark subpixels appear as

single pixels of other colors.

Subpixel

Subpixel

Subpixel

Pixel

2. Types of Pixel Defects

Pixel and subpixel defects appear on the screen in different ways.

3. Pixel Defect Tolerances

In order to qualify for repair or replacement due to pixel defects

during the warranty period, a TFT LCD panel in a PHILIPS flat

panel monitor must have pixel or subpixel defects exceeding the

tolerances listed in the following tables.

Bright dot defects

Bright dot defects appear as pixels or subpixels that are always lit

or “On”. These are the types of bright dot defects:.

One lit red, green or blue subpixel

Two adjacent lit subpixels:

- Red + Blue = Purple

- Red + Green = Yellow

- Green + Blue = Cyan (Light Blue)

Three adjacent lit subpixels

(One white pixel)

Black dot defects

Black dot defects appear as pixels or subpixels that are always

dark or “off”. These are the types of black dot defects:

One dark subpixel

Two or three adjacent dark subpixels

Back

Forward

18

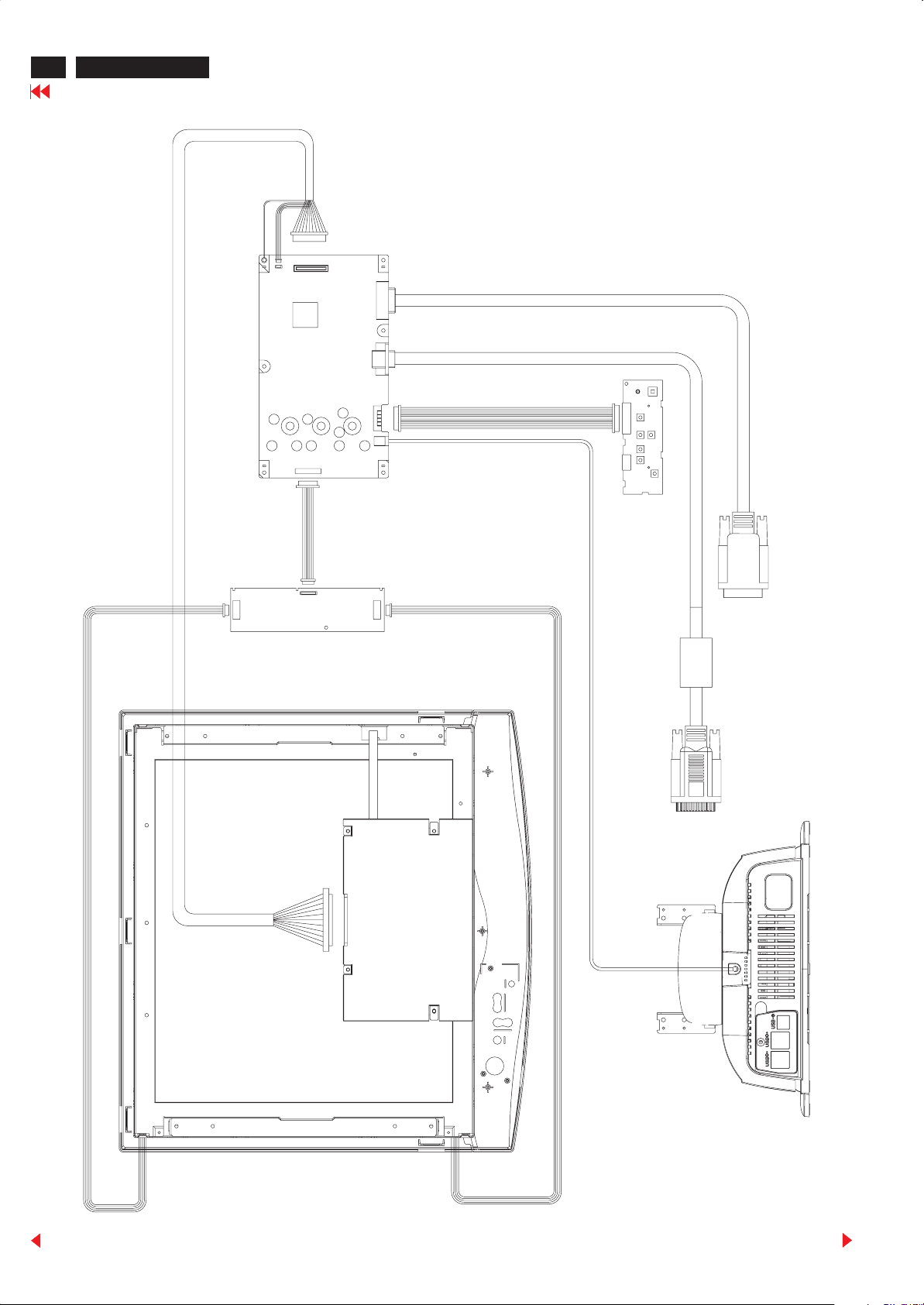

170B LCD

Go to cover page

1013

MAIN BOARD

Wiring Diagram

1012

1302

1301

1201

1261

1910

1909

CONTROL BOARD

LCD PANEL

INVERTER BOARD

Back

Forward

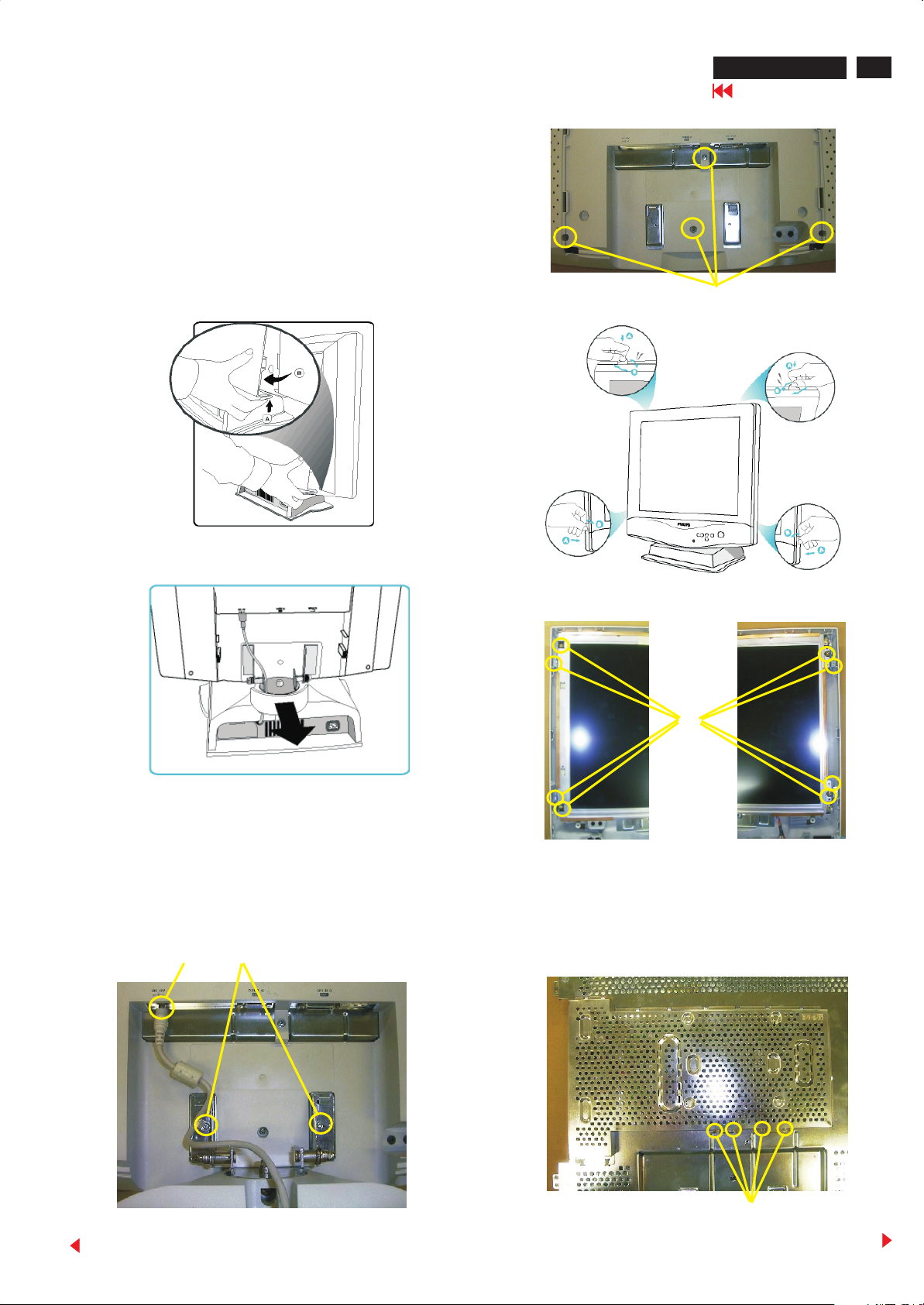

Mechanical instructions

General

To be able to perform measurements and repairs on the circuit

boards, Spread a soft mat underneath to avoid damaging the LCD

surface.

1. Rear cover removal

170B LCD

Go to cover page

19

Step 1 : To remove the back cover, press up to disengage the clips

on each side, then pull and lift as shown in Fig.1

Step 2 : Remove plastic ring from the hinge. See Fig. 2

Fig. 1

(C)

Fig. 4

Fig. 5

Fig. 2

2. LCD panel removal and Fluorescent lamp

replacement

Step 1 : Remove two screws (A) and unplug 18VDC power

connector (B). See Fig. 3

Step 2 : Remove four screws (C). See Fig. 4

Step 3 : Remove protective cover. See Fig. 5

Step 4 : Remove eight screws (D). See Fig. 6

(A)(B)

(D)

Fig. 6

Step 5 : Remove four screws (E). See Fig.7

Step 6 : Disconnect five connectors (F). See Fig. 8

Step 7 : Remove two screws (G). Draw out upper and lower lamp

set. See Fig. 9

Back

Fig. 3

Fig.7

(E)

Forward

20

170B LCD

Go to cover page

Mechnical instructions

4. Inverter PCB removal

(F)

Fig. 8

Note: The fluorescent lamps

are consumable. When replace

the lamps, both upper and lower

fluorescent lamps should be

replaced in all cases. If only one

lamp is replaced on either side,

there can be unevenness in the

brightness.

(G)

Step 1 : Disconnect three connectors (A) and remove screw (B).

See Fig. 12

(A)

(B)

Fig. 12

5. Disassemble the pedestal

Step 1 : Remove two screws ( C). See Fig. 2

Step 2 : Disconnect one connector (E), remove two screws (D),

release three clips (F). See Fig. 3

(C)

Fig. 9

3. Main panel and inverter panel removal

Step 1 : Disconnect three connectors (H). See Fig. 10

Step 2 : Remove seven screws (I). See Fig. 10

(H)

Fig. 10

(I)

Fig. 2

Back

Forward

(F)

Mechanical instructions

170B LCD

Go to cover page

21

(E)

Recommended service position

(D)

Fig. 3

Back

Forward

22

170B LCD

Go to cover page

Electrical instructions

0. General

When carry-out the electrical settings in many cases a video

signal must be applied to the monitor. A computer with :

- ATI VGA 1024 V6-1.04/PH BETA4 interface card

- PGA 1024 (4822 212 30916), Mach 8.

- PGA 1280 (4822 212 30917), Mach 32.

- ATI GPT-1600 (4822 397 10065), Mach 64 (up to 107kHz)

are used as the video signal source. The signal patterns are

selected from the "service test software" package, see user

guide 4822 727

19896 (ATI1024), or 4822 727 20273 (PGA 1280), or

4822 727 21046 (GPT-1600).

0.1 With normal VGA card:

If not using the ATI card during repair or alignment, The service

engineer also can use this service test software adapting with

normal standard VGA adaptor and using standard VGA mode

640 x 480, 31.5 kHz/60 Hz (only) as signal source.

0.2 AC/DC Measurement:

The measurements for AC waveform and DC figure is based on

640 x 480 31.5 kHz/60 Hz resolution mode with test pattern "gray

scale".

1.General points

1.1 During the test and measuring, supply a distortion free AC mains

voltage to the apparatus via an isolated transformer with low

internal resistance.

1.2 All measurements mentioned hereafter are carried out at a

normal mains voltage (90 - 132 VAC for USA version, 195 -264

VAC for EUROPEAN version, or 90 - 264 VAC for the model with

full range power supply, unless otherwise stated.)

1.3 All voltages are to be measurement or applied with respect to

ground, unless otherwise stated. Note: don't use heat-sink as

ground.

1.4 The test has to be done on a complete set including LCD panel in

a room with temperature of 25 +/- 5 degree C.

1.5 All values mentioned in these test instruction are only applicable

of a well aligned apparatus, with correct signal.

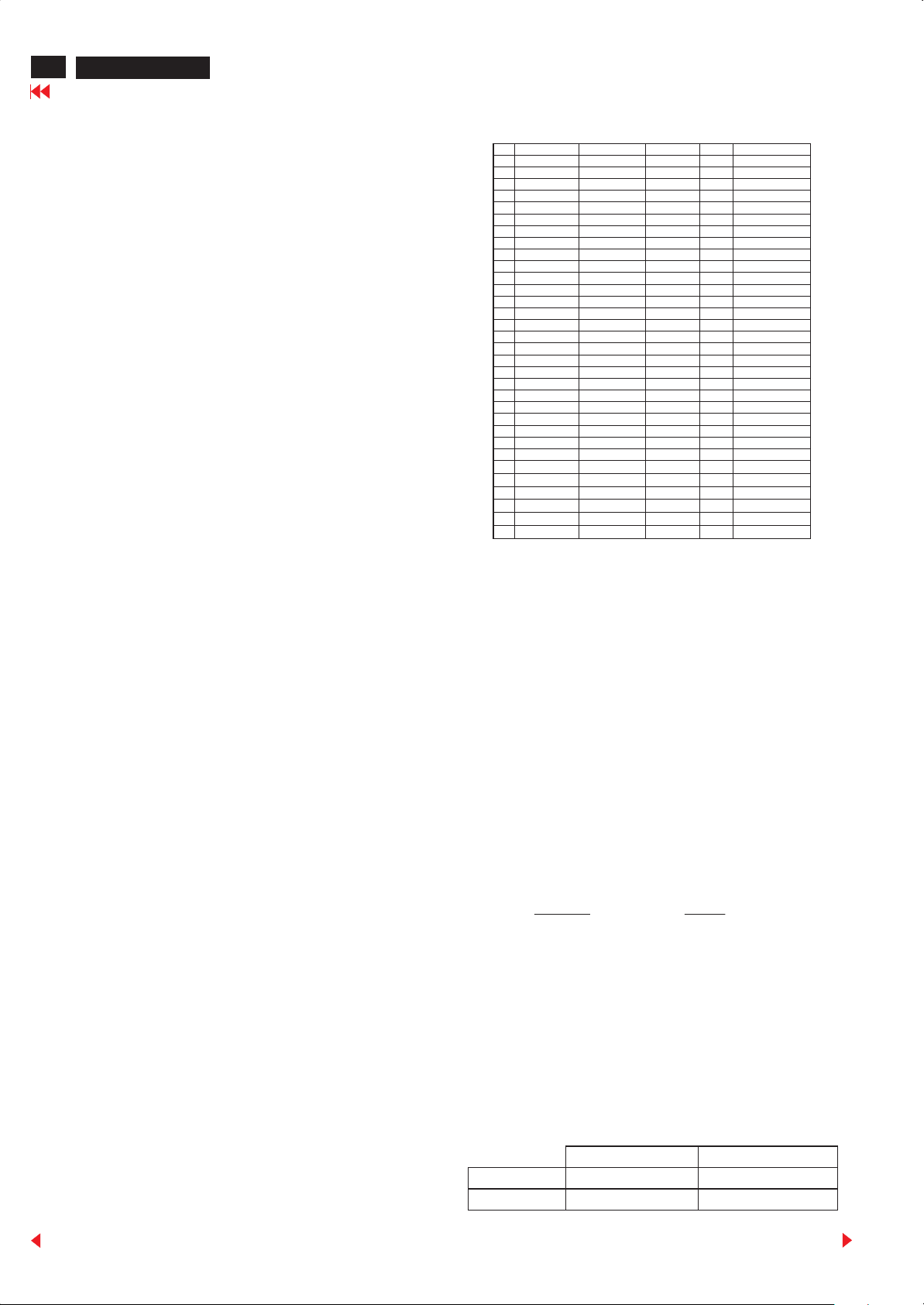

PRESET VIDEO RESOLUTION

Factory preset video resolution

# Resolution Frequency Pixel rate Sync Comment

1 640X350 31.5K/70HZ 25.175 (+/-) IBM VGA 10h

2 720X400 31.5K/70HZ 28.322 (-/+) IBM VGA 3h

3 640X480 37.5K/75HZ 31.501 (-/-)

4 640X480 43.3K/85HZ 36 (-/-)

5 640X480 37.9K/72HZ 31.5 (-/-)

6 640X480 35.0K/67HZ 30.24 (-/-)

7 640X480 31.5K/60HZ 25.175 (-/-)

8 800X600 35.2K/56HZ 36 (+/+)

9 800X600 46.9K/75HZ 49.498 (+/+)

10 800X600 37.9K/60HZ 40 (+/+)

11 800X600 53.7K/85HZ 56.251 (+/+)

12 832X624 49.7K/75HZ 57.28 (+/+) MAC

13 800X600 48.1K/72HZ 50 (+/+)

14 1024X768 60.0K/75HZ 78.75 (+/+)

15 1024X768 48.4K/60HZ 65 (-/-)

16 1024X768 56.5K/70HZ 75 (-/-)

17 1024X768 61.1K/76HZ 83.096 (+/+) IBM XGA-2

18 1024X768 68.7K/85HZ 94.5 (+/+)

19 1152X864 67.5K/75HZ 108 (+/+)

20 1152X864 63.9K/70HZ 94.5 (+/+) non-VESA

21 1152X864 54.0K/60HZ 79.9 (+/+) non-VESA

22 1152X870 68.7K/75HZ 100 (-/-) MAC

23 1152X900 61.8K/66HZ 92.94 serr- SUN Mode IV

24 1152X900 71.8K/76HZ 108 (+/+) SUN Mode II

25 1280X960 60.0K/60HZ 108 (+/+)

26 1280X960 75.0K/75HZ 129.895 (+/+) non-VESA

27 1280X1024 76.0K/72HZ 130.223 (+/+) DOS/V

28 1280X1024 64.0K/60HZ 108 (+/+)

29 1280X1024 80.0K/75HZ 135 (+/+)

30 1280X1024 81.1K/76HZ 135.008 (-/-) SUN Mode I

31 1280X1024 71.7K/67HZ 117 (+/+) SUN Mode V

32 688X556 31.3K/50HZ 27 (-/+) TV-PAL

3. AC Adaptor

3.1Setup the AC I/P at 90VAC, and Output DC loading at 4 Amp,

The DC output voltage is 18 1 V DC

3.2 DC setting

1003: all on (connect 3.3V,5V DC power to main board)

1005: all on (connect 12V DC power to main board)

4. Display Adjustment

4.1Input signals check

In factory mode, use 64 gray level and set the R,G,B sub gain to

100%.

4.2 Display quality test

Use timing mode as described in 2.2, and use the POPO (pixel on

pixel off) pattern to adjust the clock until no stripe and adjust the

phase until clear picture. Check all pre-setting 32 modes.

4.2.1 SOG mode test : Use following timing for SOG test

1.6 The letters symbols (B) and (S) placed behind the test instruction

denotes

(B): carried out 100% inspection at assembly line

(S): carried out test by sampling

1.7 The white balance (color temperature), has to be tested in

subdued lighted room.

1.8 Repetitive power on/off cycle are allowed except it should be

avoided within 6 sec.

2. Input signal

2.1 Signal type

Video : 0.7 Vp-p linear, positive polarity

Sync. : TTL level, separate, positive or negative polarity

Signal source: pattern generator format as attachment.

(table 1 to 16) Reference generator : CHROMA 2200 or 2250

2.2 Input signal mode

Pre-set 32 modes

Back

64 KHz/60Hz, 1280 X 1024, pixel=108 MHz

Horizontal Vertical

Frame border = 0 Frame border = 0

Total size = 15.620 us Total size = 16.670 ms

Display size = 11.852 us Display size = 16.000 ms

Rear porch = 2.000 us Rear porch = 0.580 ms

Sync width = 1.000 us Sync width = 0.080 ms

Sync polarity = - Sync polarity = Sync on green

4.3 Check of WHITE-D (B)

Apply a 80kHz/75Hz signal with white pattern, set brightness

control at 70%, and contrast control at 50%. Adjust the R, G, B

sub_gain, for the screen center, the 1931 CIE chromaticity (X,

Y) co-ordinates shall be;

9300 K 6500 K

x (center) 0.281 0.005 0.312

y (center) 0.311 0.338

0.005 0.005

0.005

Forward

Electrical instructions

Use Minolta CA-110 for color coordinates and luminance check.

Luminance; 200 Nits (ADT panel) in the center of the screen.

4.4 Check the digital interface

Set the delay time to be 6 nsec.

Check the 64 gray level color poor & noise condition.

170B LCD

Go to cover page

23

Back

Forward

24

POGO2 V0.17 2000-05-09

AUTO SUB

9300K R G B

6500K R G B

OFFSET R G B

SUB CON

OK

POGO2 V0.17 2000-05-09

9300K R G B

6500K R G B

OFFSET R G B

SUB CON

GAIN R G B

GAIN R G B

170B LCD

Go to cover page

Factory Adjustment

Factory Mode Adjustment

Entering Factory Adjustment Menu

Push & buttons then power on the monitor, release them

after picture display normally. Press button to bring up OSD

menu of factory mode as shown below.

POGO2 V0.17 2000-05-09

Use button to select factory adjustment indication (for example:

POGO2 V0.17 2000-05-09), which is the entrance of the factory

adjustment menu, press button to access it. The window shows

as below.

POGO2 V0.17 2000-05-09

(PS: The “Offset R G B” function can be used on reduce or eliminate

snowy noise on the background when the resolution of video signal is

1024 X 768 vertical 60Hz. Slightly increase or decrease the value

until snowy noise completely disappear.)

PRESET VIDEO RESOLUTION

AUTO SUB

-

9300K R G B

6500K R G B

OFFSET R G B

GAIN R G B

Use or buttons to select SUB-CON, 9300K R G B,..etc.

Use or buttons to decrease/increase the value of each item

: adjust Sub-brightness & Sub-contrast automatically.

AUTO

AUTO SUB

9300K R G B

6500K R G B

OFFSET R G B

GAIN R G B

Contrast adjustment (Sub-Contrast). Use this menu item to

9 3 0 0 K R G B

6 5 0 0 K R G B

Color temperature gain adjustment. Use these menu items to

adjust the contrast gain of pre-amp ranges from 0 to 255.

adjust the RGB gains of pre-amp for different color

temperatures, ranges from 0 to 255.

POGO2 V0.17 2000-05-09

-

205

255

22

OK

SUB CON

OK

SUB CON

233

255

20

-

-

166

255

149

20

OFFSET R G B

Sub-Brightness adjustment. Use this menu item to adjust

the brightness level (DC-level) of pre-amp range from 0 to

255.

Back

Forward

26

170B LCD

Go to cover page

DDC Instructions

1. General

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed.

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

DDC EDID structure

For Analog interface: Standard Version 3.0

Structure Version 1.3

For Digital inferface: Standard Version 3.0

Structure Version 1.3

2. System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98.

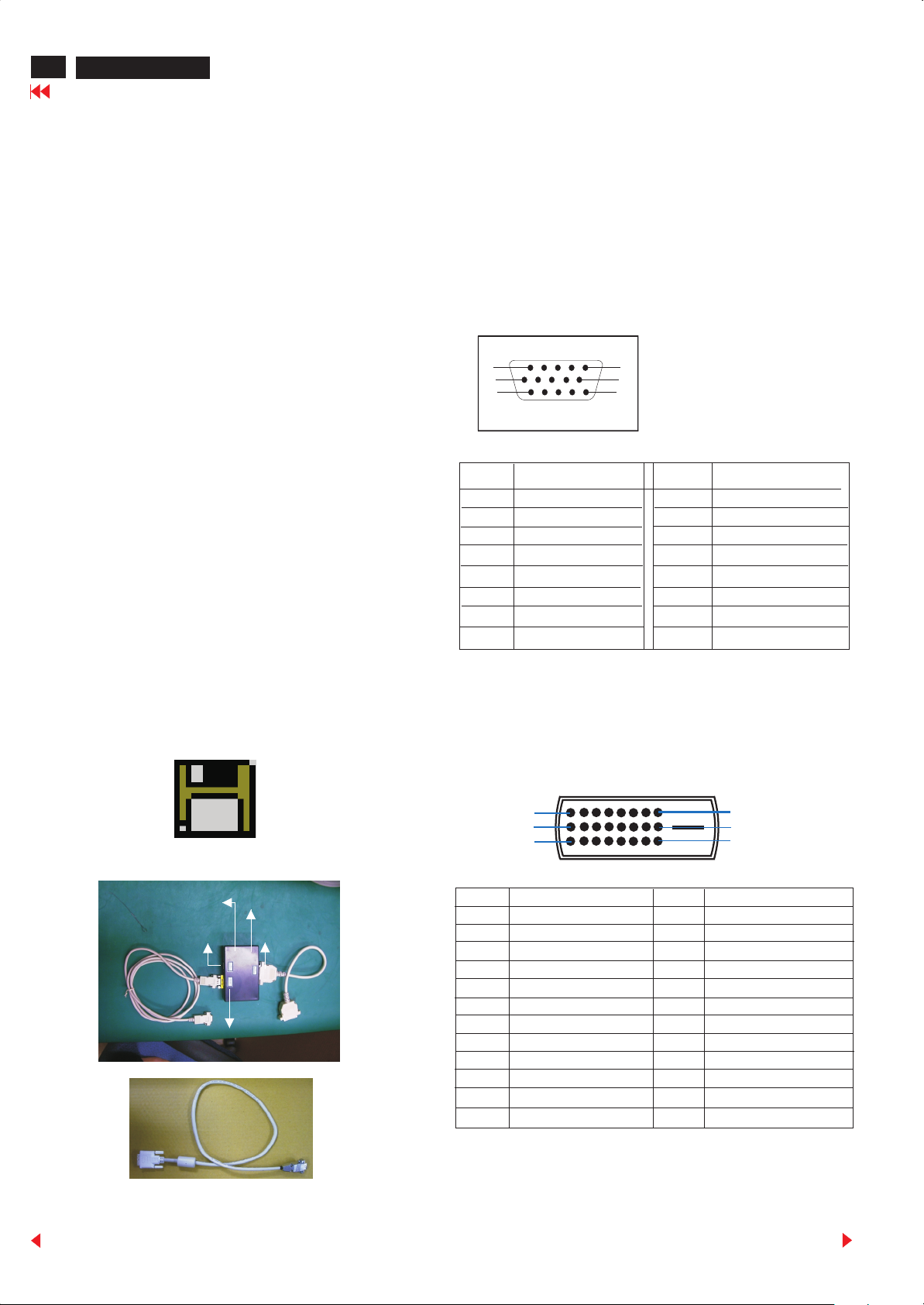

3. EDID30.EXE program (3138 106 10075) shown as Fig. 1

4. A/D Alignment kits (3138 106 10079) shown as Fig. 2. This kit

contents: a. Alignment box x1

b. Printer cable x1

c. D-Sub cable x1

d. (DVI-D) to (D-Sub) cable x1

Note: The alignment box has already build-in a batteries socket for

using batteries (9V) as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

3. Pin assignment

A. 15-pin D-Sub Connector

1

6

11

Pin No.

Assignment

1

Red video input

Green video input

2

Blue video input

3

Ground

4

No Connected

5

Red video ground

6

Green video ground

7

8

Blue video ground

PRESET VIDEO RESOLUTION

5

10

15

Pin No.

9

10

11

12

13

14

15

Assignment

+5V

Ground

Ground

Serial data line(SDA)

H.Sync

V.Sync(VCLK for DDC)

Data clock line(SCL)

Note: The EDID30.EXE (Release Version 1.5 1999.11.17)is a

windows-based program, which cannot be run in MS-DOS.

Meanwhile, it is also fully compatible with previous programs

DDCV2X.EXE series(MS-DOS based).

EDID30.EXE

Ver:1.5

Figure 1

Diskette with EDID30.EXE

DC 8V~12V

To Monitor

Power indicator

To Printer

Video Card

B. DVI-D Connector

1

9

17

Pin No. Assignment Pin No. Assignment

1 TMDS Data 2- 13 TMDS Data 3+

2 TMDS Data 2+ 14 +5V Power

3 TMDS Data 2/4 Shield 15 Ground (+5V)

4 TMDS Data 4- 16 Hot Plug Detect

5 TMDS Data 4+ 17 TMDS Data 06 DDC Clock 18 TMDS Data 0+

7 DDC Data 19 TMDS Data 0/5 Shield

8 No connect 20 TMDS Data 5-

9 TMDS Data 1- 21 TMDS Data 5+

10 TMDS Data 1+ 22 TMDS Clock Shield

11 TMDS Data 1/3 Shield 23 TMDS Clock+

12 TMDS Data 3- 24 TMDS Clock-

8

16

24

Back

(DVI-D) to (D-Sub) cable

Fig. 2 A/D Alignment Kits

Forward

DDC Instructions

170B LCD

Go to cover page

27

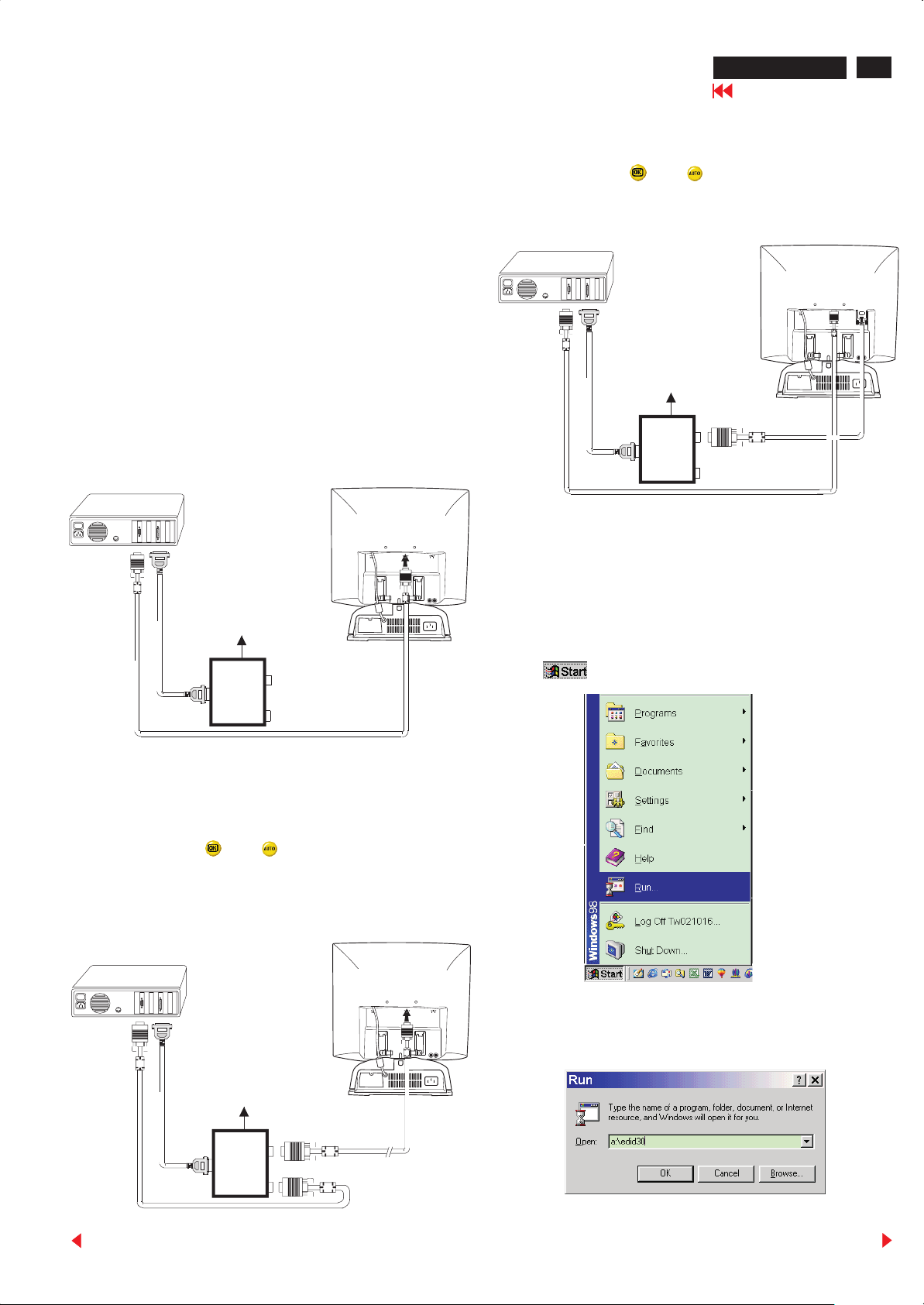

4. Configuration and procedure

There are three chips contained serial number on the circuit board,

Analog DDC IC (7301), Digital DDC IC (7302) and main EEPROM

(7204) which storage all factory settings. Following descriptions are the

connection and procedure for Analog DDC IC and Digital DDC IC, the

main EEPROM can be re-programmed along with Analog IC by enable

“factory memory data write” function on the DDC program

(EDID30.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due to

sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software (EDID30.EXE).

Following steps show you the procedures and connection.

Step 1: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

Step 2: Connecting printer cable and video cable of monitor as Fig. A

Step 3: Run the EDID30.EXE program until the main menu appears.

This is for initialize alignment box.

PC

Rear view of 170B

DVI-DD-Sub

Re-programming Digital DDC IC

Connecting all cables and alignment box as shown on Fig. 4

Step 1:

Step 2: Press and hold “ “ and “ “ buttons then power on the

monitor.

Step 3: Follow the steps on DDC re-programing instructions to starting

re-programming.

PC

Rear view of 170B

DVI-DD-Sub

DC Power

8~12 V

~

~

To video card

To printer port (LTP1)

Printer

Port

DVI-D to D-Sub cable

To

Monitor

To PC

Fig. 4

DC Power

8~12 V

~

~

To video card

To printer port (LTP1)

Printer

Port

To

Monitor

To PC

Fig. A

Re-programming Analog DDC IC

Step 1: After initialize alignment box, connecting all cables and box as

Fig. 3

Step 2: Press and hold “ “ and “ “ buttons then power on the

monitor.

Step 3: Follow the steps on DDC re-programming instructions to staring

re-programming.

Rear view of 170B

PC

DVI-DD-Sub

5. DDC re-programming instructions

Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID30.EXE program into floppy disk drive.

2. Click , choose Run at start menu of Windows 95/98.

3. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID30 (for example, A:\EDID30, as shown in Fig. 5).

Back

To video card

To printer port (LTP1)

DC Power

8~12 V

~

~

To

Monitor

Printer

Port

To PC

Fig. 3

Fig. 5

Forward

28

170B LCD

DDC Instructions

Go to cover page

4. Click button. The main menu appears (as shown on Fig. 6).

Command bar

Tools bar

Status bar

Fig. 6

Note: If the connection is improper, you will see the following error

message before entering the main menu. Meanwhile, the

(read EDID) function will be disable. At this time, please make

sure all cables are connected correctly and fixedly, and the

procedure has been performed properly.

Note: During the loading, EDID30 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen (Fig. 8). Please confirm

following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Loading DDC data from monitor

1. Click icon on the tools bar to bring up the Configuration Setup

windows as Fig.7

2. Select the DDC2B as the communication channel.

3. Enable Factory memory data write function and fill in page address

“F0” to the block.

4.. Click button to confirm your selection.

Note: The Factory memory data write function will allow EDID30 to

rewrite serial numbers both Analog DDC IC and main EEPROM to

make sure both S/N are exactly the same. You may confirm the

function by checking the S/N at Product information of the OSD

menu after restarting the monitor.

Fig. 7

Fig. 8

Modify DDC data (Serial No.)

1. Click icon on the tools bar.

2. Click till the Step 7 of 9 window appears.

3. Type the new Serial No. (for example, Tw9928000001).

4. Click till the last step window appears, then click to

exit the Step window.

Tw9928000001

5. Click icon to read DDC EDID data from monitor. The EDID

codes will display on screen as following. (The EDID codes are

depend on the model.) Meanwhile, The status bar will indicate 00%

to 100% when reading.

Back

Forward

DDC Instructions

170B LCD

Go to cover page

29

Write DDC data to monitor

1. Click icon from the tools bar to starting rewrite DDC data.

2. Click for confirmation.

Save DDC data as a file

Sometimes, you maybe need to save DDC data as a text file for using

on other DDC chip. To save DDC data, follow the steps below:

1. Click icon on the tools bar and type a file name you like. The

file format is ddc type which can be open by Microsoft WordPad.

2. Click button.

Load DDC data from file

1. Click from the tools bar.

2. Select the file you want to open.

3. Click . Button.

Definition of Serial Number

T Y 0 0 9 9 2 8 0 0 0 0 0 1

Serial Number (U.S.A: 8 digit)

Week

Year

TY Code

TY----Chungli

CX----Dong Guan

HD----Hungary

BZ----Suzhou

(Other regions: 6 digit)

4. Now you can re-programming DDC data which you just loaded

from a file, please be confirmed that model and serial number are

correct and match with the monitor you are trying to re-write.

Exit DDC program

1. Click file command on the command bar then select Exit.

Back

Forward

30

170B LCD

Go to cover page

DDC data of Analog

THE DISPLAY DATA CHANNEL ( DDC ) 1/2B CONTENT INCLUDING

(FOR ADT ANALOG)

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : 170B (HEX.)

ID Serial Number : 123456 (DEC.)

Week of Manufacture : 29

Year of Manufacture : 2000

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.300V (1.00Vpp)

Without Blank-to-Black Setup

Separate Sync

Composite Sync

Sync on Green

No Serration required

Maximum H Image Size : 34

Maximum V Image Size : 27

Display Transfer Characteristic : 2.1

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Preferred Timing mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.63

Red Y coordinate : 0.33

Green X coordinate : 0.30

Green Y coordinate : 0.60

Blue X coordinate : 0.15

Blue Y coordinate : 0.10

White X coordinate : 0.31

White Y coordinate : 0.33

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @67Hz (Apple,Mac II)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings : 1152 x 870 @75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Back

Standard Timing Identification #4

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #5

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 70

Standard Timing Identification #6

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #7

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 135

H Active (pixels) : 1280

H Blanking (pixels) : 408

V Active (lines) : 1024

V Blanking (lines) : 42

H Sync Offset (F Porch) (pixels) : 248

H Sync Pulse Width (pixels) : 144

V Sync Offset (F Porch) (lines) : 38

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 337

V Image Size (mm) : 270

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : TY 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 170B

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 56

Max. Vt rate Hz : 75

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 82

Max. Supported Pixel : 140

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : 0E (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 0b 11: 17 12: 56 13: 34 14: 12 15: 00

16: 1d 17: 0a 18: 01 19: 03 20: 0f 21: 22 22: 1b 23: 6e

24: ea 25: 6e 26: a6 27: a1 28: 54 29: 4c 30: 99 31: 26

32: 19 33: 4f 34: 54 35: bf 36: ef 37: 80 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 61 45: 4f 46: 71 47: 4a

48: 71 49: 4f 50: 81 51: 80 52: 01 53: 01 54: bc 55: 34

56: 00 57: 98 58: 51 59: 00 60: 2a 61: 40 62: f8 63: 90

64: 63 65: 08 66: 51 67: 0e 68: 11 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 54 78: 59 79: 20

80: 20 81: 31 82: 32 83: 33 84: 34 85: 35 86: 36 87: 0a

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 37 105: 30 106: 42 107: 0a 108: 00 109: 00 110: 00 111: fd

112: 00 113: 38 114: 4b 115: 1e 116: 52 117: 0e 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 0e

Forward

DDC data of Digital

170B LCD

Go to cover page

31

THE DISPLAY DATA CHANNEL ( DDC ) 1/2B CONTENT INCLUDING

(FOR ADT DIGITAL)

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : 170B (HEX.)

ID Serial Number : 123456 (DEC.)

Week of Manufacture : 29

Year of Manufacture : 2000

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Digital Video Input

Compatible with VESA DFP 1.x

Maximum H Image Size : 34

Maximum V Image Size : 27

Display Transfer Characteristic : 2.1(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Preferred Timing mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.63

Red Y coordinate : 0.33

Green X coordinate : 0.30

Green Y coordinate : 0.60

Blue X coordinate : 0.15

Blue Y coordinate : 0.10

White X coordinate : 0.31

White Y coordinate : 0.33

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @67Hz (Apple,Mac II)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings : 1152 x 870 @75Hz (Apple,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Back

Standard Timing Identification #4

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #5

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 70

Standard Timing Identification #6

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #7

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 135

H Active (pixels) : 1280

H Blanking (pixels) : 408

V Active (lines) : 1024

V Blanking (lines) : 42

H Sync Offset (F Porch) (pixels) : 248

H Sync Pulse Width (pixels) : 144

V Sync Offset (F Porch) (lines) : 38

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 337

V Image Size (mm) : 270

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : TY 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 170B

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 56

Max. Vt rate Hz : 75

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 82

Max. Supported Pixel : 140

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : 9C (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 0b 11: 17 12: 56 13: 34 14: 12 15: 00

16: 1d 17: 0a 18: 01 19: 03 20: 81 21: 22 22: 1b 23: 6e

24: ea 25: 6e 26: a6 27: a1 28: 54 29: 4c 30: 99 31: 26

32: 19 33: 4f 34: 54 35: bf 36: ef 37: 80 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 61 45: 4f 46: 71 47: 4a

48: 71 49: 4f 50: 81 51: 80 52: 01 53: 01 54: bc 55: 34

56: 00 57: 98 58: 51 59: 00 60: 2a 61: 40 62: f8 63: 90

64: 63 65: 08 66: 51 67: 0e 68: 11 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 54 78: 59 79: 20

80: 20 81: 31 82: 32 83: 33 84: 34 85: 35 86: 36 87: 0a

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 37 105: 30 106: 42 107: 0a 108: 00 109: 00 110: 00 111: fd

112: 00 113: 38 114: 4b 115: 1e 116: 52 117: 0e 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 9c

Forward

32

170B LCD

Go to cover page

Repair Flow Chart

Block Diagram

AC IN

AC adapter

18V DC

Inverter panel

AC

Fluorescent

Lamp

18VCC

Main panel

LCD panel

No power

(power indicator off)

18V DC

Front control

panel

Back

Check

AC adapter output

18V DC

Yes

Check

Front control panel

(power SW)

OK

Replace Main panel

No

Bad AC adapter Bad AC adapter

Adapter fixed

still no good

Forward

Repair Flow Chart

No Raster

170B LCD

Go to cover page

33

Check

AC adapter output

18V DC

Yes

Check

video signals input

interface

Yes

Check

Inverter panel

No

Replace inverter

panel

No

No

OK

No

Bad AC adapter Bad AC adapter

Video source

Replace fluorescent

lamp

Replace main panel

Back

Front control key

does not work

Check

Front control panel

(Key & SW)

Yes

Check

Signal connectors

1910

Yes

Replace main panel

Forward

34

170B LCD

Go to cover page

Repair Flow Chart

Bad brightness

Check

Inverter panel output

Yes

Replace fluorescent

lamp

No

Replace LCD panel

Bad image

No

Bad Inverter

panel

Check

Video,fh/fv,DVI-D

signals

Yes

Replace main panel

No

Check

all connectors

No

Replace LCD panel

Back

Forward

Repair Tips

170B LCD

Go to cover page

35

0. Warning

All ICs and many other semi-conductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically. When repairing, make sure

that you are connected with the same potential as the mass

of the unit via a wrist wrap with resistance. Keep components

and tools also at the same potential !

1. Servicing of SMDs (Surface Mounted Devices)

1.1 General cautions on handling and storage

- Oxidation on the terminals of SMDs results in poor

soldering. Do not handle SMDs with bare hands.

- Avoid using storage places that are sensitive to oxidation

such as places with sulphur or chlorine gas, direct sunlight,

high temperatures or a high degree of humidity. The

capacitance or resistance value of the SMDs may be

affected by this.

- Rough handling of circuit boards containing SMDs may

cause damage to the components as well as the circuit

boards. Circuit boards containing SMDs should never be

bent or flexed. Different circuit board materials expand and

contract at different rates when heated or cooled and the

components and/or solder connections may be damaged

due to the stress. Never rub or scrape chip components as

this may cause the value of the component to change.

Similarly, do not slide the circuit board across any surface.

preferably be equipped with a thermal control (soldering

temperature: 225 to 250 C).

o

- The chip, once removed, must never be reused.

1.4 Attachment of SMDs

- Locate the SMD on the solder lands by means of tweezers

and solder the component on one side. Ensure that the

component is positioned correctly on the solder lands (see

Fig.2A).

- Next complete the soldering of the terminals of the

component (see Fiq. 2B).

Fig. 2

SOLDERING

IRON

SOLDERING TIME

< 3 sec/side

MOUNTING

e.g. A PAIR OF TWEEZERS

SOLDER

0.5 - 0.8 mm

PRESURE

PRESURE

SOLDER

0.5 - 0.8 mm

SOLDERING

IRON

A

B

2. Caution when attaching SMDs

1.2 Removal of SMDs

- Heat the solder (for 2-3 seconds) at each terminal of the

chip. By means of litz wire and a slight horizontal force,

small components can be removed with the soldering iron.

They can also be removed with a solder sucker (see Fig.

1A)

Fig. 1

DISMOUNTING

VACUUM PISTON

SOLDERING

IRON

e.g. WELLER

SOLDER TIP PT -H7

SOLDERING

IRON

SOLDER WICK

4822 321 40042

HEATING

4822 395 10159

A

e.g. A PAIR OF TWEEZERS

HEATING

B

SOLDERING

IRON

SOLDER WICK

C

- While holding the SMD with a pair of tweezers, take it off

gently using the soldering iron's heat applied to each

terminal (see Fig. 1 B).

- Remove the excess solder on the solder lands by means of

litz wire or a solder sucker (see Fig. 1C).

- When soldering the SMD terminals, do not touch them

directly with the soldering iron. The soldering should be

done as quickly as possible, care must be taken to avoid

damage to the terminals of the SMDs themselves.

- Keep the SMD's body in contact with the printed board when

soldering.

- The soldering iron to be used (approx. 30 W ) should

preferably be equipped with a thermal control (soldering

temperature: 225 to 250 C).

o

- Soldering should not be done outside the solder land.

- Soldering flux (of rosin) may be used, but should not be

acidic.

- After soldering, let the SMD cool down gradually at room

temperature.

- The quantity of solder must be proportional to the size of the

solder land. If the quantity is too great, the SMD might

crack or the solder lands might be torn loose from the

printed board (see Fig. 3).

Examples

Fig. 3

RIGHT

1.3 Caution on removal

- When handling the soldering.iron. use suitable pressure and

be careful.

- When removing the chip, do not use undue force with the

pair of tweezers.

- The soldering iron to be used (approx. 30 W) should

Back

SOLDERING

IRON

Forward

44

170B LCD

Go to cover page

Power Distribution Flow

+3.3V_PLL

5401

+3.3V_ADC

(for ADC chip)

(for ADC chip)

5402

+5V

(for MCU chip)

+5VD

(for OSD chip)

5632

+5VD

7902

+5V

+5V

1003

1003

+5VA

+5VA

Jumper

Jumper

+3.3V_A

7401

ADT LCD panel

5640

+12VL

1005

Power saving

Power saving

control (from CPU)

control (from CPU)

+12VA

Jumper

Jumper

5502

5501

+3.3V

5503

+3.3VM

(for SDRAM chip)

5651

(for Sil161 chip)

+3.3VD

7901

+3.3V

1003

Jumper

+3V3A

+3.3VS

(for SAA6721 chip)

5603

Power saving

control (from CPU)

Back

AC IN

90V~264VAC

DC to DC converter

AC adapter

18VCC

18VCC

1004

Chopper

Chopper

7001

Fuse

Filter

18V DC

DC Power jack

7003

7003

Chopper

Chopper

7002

18V On

Power switch

7006

+18VCC

(for Inverter panel)

Chopper

7033

Forward

TMDS

Block Diagram

Frame Buffer

(1Mx16 SDRAM x3)

Control Panel C.B.A.

Copper side

170B LCD

Go to cover page

45

DVI

DDC1

24LC21

D-Sub (R,G,B)

H/V (D-sub)

DDC1/2B

24LC21

EEPRO

24C16

receiver

SiI161A

H/V(TMDS)

M

SyncSlicer

(Discrete)

D-sub/DVI select

DDC

Sync pre-

processor

R/A

G/A

B/A

ADC

ADC

ADC

PLL Clock

Generator

AD9884A

R/D

G/D

B/D

CLK

R(A

G(A

FORMAT

SCALER CONVERSION

SAA6721

B(A

HSYNC

SI_DE

HS_ADC

0~7,B0~7

0~7,B0~7

0~7,B0~7

)

)

OSD

)

LSC

(reserved)

LVD

S

3863DW

TFT LCD MODULE

Component side

BACK LIGHT

Back

Front

panel

Control

MCU

ST72774

I2C (SDA,SCL)

Glue Logic

I/O

Expansion

DC-DC

Converter(+12V,

+5V, +3.3V)

AC ADAPTER (+18V)

USB Hub

AC 90 ~ 260V

Repeater

DC-AC INVERTER

2901 A1

3901 A2

3902 A2

3903 A3

3904 A3

3905 A3

3906 A2

3910 A1

6902 A2

1910 A2

6901 A1

9901 A3

9902 A1

9903 A1

9904 A2

9905 A1

9906 A1

1901 A2

1902 A2

1903 A3

1904 A3

1905 A4

1906 A2

1908 A1

1909 A3

Forward

46

170B LCD

Go to cover page

Schematic Diagram (AC adapter)

C.B.A for AC adapter

Component side

Copper side

6111 E1 6112 D1 6113 C1 6117 C1

6118 B1 6151 C3 7102 C1 7121 B1

7150 B2 7151 B2 7152 B2 8101 C3

8102 B3 9102 D1 9121 C1 9151 B2

9152 B1 9154 B3 1171 D3 2101 D2

2102 E2 2103 D2 2104 E3 2105 D1

2108 C1 2109 E2 2113 C1 2115 C1

2116 D1 2122 C1 2125 C1 2150 B2

2151 C3 2152 B2

2121 B1 2123 B1 2124 B1 2126 B1

2127 B1 2156 B2 2157 B2 3105 C1

3106 C1 3120 B1 3121 B1 3122 B1

3123 B1 3124 B1 3125 B1 3126 B1

3128 B1 3129 B1 3155 B2 3157 B2

3158 B2 3161 B2 5111 C1 5113 C2

5114 C1 6153 B2 6158 B2 1101 E3

1102 D3 1103 A2 1151 A1 1161 A1

2153 A3 2154 B2 2155 B2 3101 E2

3102 E1 3103 E1 3104 E1 3107 C1

3108 D1 3109 C1 3110 D1 3111 E1

3112 C1 3113 C1 3115 B1 3116 E1

3117 C1 3127 B1 3150 B2 3151 C3

3152 B2 3156 B2 4102 C1 4151 C3

5101 E2 5102 E2 5103 E2 5112 C1

5150 D2 5151 B2 5155 B3 6101 E1

Back

Forward

1

1

1

1

1302

DVI

11

12

13

14

15

DHSL-15UKL4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

C1

C2

C3

C4

C5

C6

3

1 2

6302BAV99

3

1 2

6303BAV99

1301

1

1

6

2

1

7

3

1

8

1

4

9

5

1

10

1

1

1

1

1

1

1

1

1

1

1

1

100N/0805

1 2

+5V_DSUB

+5V_DSUB

6301BAV99

3

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

+5V_DSUB

1 2

1 2

1 2

1 2

1 2

6311BAV99

3

3

6312BAV99

6313BAV99

3

3

6314BAV99

6315BAV99

3

3

6316BAV99

6317BAV99

3

3

6318BAV99

Schematic Diagram (Video in)

3303

10R/PM5/0805

3305

3306

1 2

100R/PM5/0805

330775R/PM5/0805

1 2

100R/PM5/0805

330875R/PM5/0805

1 2

100R/PM5/0805

330975R/PM5/0805

(FROM SiI161)

(TO SiI161)

RXB+

RXB+

RXB-

RXB-

RXG+

RXG+

RXG-

RXG-

+5VPD

RXR+

RXR+

RXR-

RXR-

RXC+

RXC+

RXC-

RXC-

(TO SiI161)

330410K/PM5/0805

3312

3313

3314

SI_VS

1 2

1 2

100R/PM5/0805

100R/PM5/0805

3

6304BAV99

3

6305BAV99

3

6306BAV99

3

6307BAV99

3

6308BAV99

+5VPD

+5VPD

+5VPD

+5VPD

+5VPD

+5VPD

+5VPD

+5VPD

3301

3302

100P/0805

100P/0805

+5V_DSUB

+5V_DSUB

3326 0R/PM5/0805

+5V_DSUB

3327 0R/PM5/0805

+5V_DSUB

3328 0R/PM5/0805

+5V_DSUB

10R/PM5/ARV241

1 8

2 7

3 6

4 5

2310 100N/0805

1 2

1 8

2 7

3 6

4 5

10R/PM5/ARV241

6309

BAS32L

2302

2303

2K2/PM5/0805

2K2/PM5/0805

3315

12

6319BAV99

3

3316

33172K2/PM5/0805

DDCSCL_DSUB

DDCSDA_DSUB

DDCSCL_DSUB

DDCSDA_DSUB

3310330R/PM5/0805

3311330R/PM5/0805

A2

A3

+5V

6321BAV99

3

3

6322BAV99

+5V

6310

BAS32L

230510P/0805

230610P/0805

A1

6324

BAS32L

3319

100R/PM5/0805

+5VPD

+5VPD

6320

BAS32L

2304

100N/0805

24FC21/SO8

8

VCC

7

VCLK

6

SCL

A5

VIN_DSUB

(TO Multiplexer)

R

G

3325

470R/PM5/0805

B

3335

10K/PM5/0805

3318

10R/PM5/0805

3323

10K/PM5/0805

3324

10K/PM5/0805

+5V_DSUB

7301

2333

100N/0805

1 2

8

7

6

332210K/PM5/0805

2314

100N/0805

3331

5K6/PM5/0805

7331

1

VCC+

2

IN+

3

IN-

4 5

VCC- LE

TL3016CD

3332

5K6/PM5/0805

100N/0805

2313

7302

24FC21/SO8

GNDSDA

7303

BC848C

NC

NC

NC

332910K/PM5/0805

333010K/PM5/0805

VCC

VCLK

SCL

1

NC

2

NC

3

NC

45

GNDSDA

A4 A6

VIN_DSUB

G_SOG

3320100R/PM5/08051 2

2311100P/0805

1 2

3321100R/PM5/08051 2

1 2

2312100P/0805

+5V

1 2

BLM31P500S

8

OUT-

7

OUT

6

GND

1

2

3

45

/DVI_5V_ON

5331

+5V

1 2

2331

100N/0805

3333

47R/PM5/0805

NI

3334

22R/PM5/0805

2332

10U/1206

HIN_DSUB

HIN_DSUB

+5VA

1

12

1

2011

470U/25V/DIP

+3V3A

1

12

1

2031

470U/25V/DIP

1002

1

2

3

DC-PWR-JACK

10UH/C10-K4L

1

TP61-63

DCINGND

5004

5034

10UH/C10-K4L

1

1

2005

100N/1206

DCINGND

2012

12

470U/25V/DIP

2032

12

470U/25V/DIP

1

ACM0706-102-2P-T

12

43

1

TP74-75

5001

5002

68UH

5032

68UH

12

6003

SFPJ-73

6033

SFPJ-73

12

2016

470U/25V/DIP

2015 100N/0805

1 2

2036

470U/25V/DIP

2035 100N/0805

1 2

1 2

2006

100N/1206

12

1

1

TP70-71

12

1

1

TP70-71

1004

SSQ4

18V_ON

Schematic Diagram (DC to DC converter)

18VCC

12

2022 470U/25V/DIP

A23

7003

1

VIN

2

SW

3

GROUND

4

FB

5

SHDN

LM2596S-5.0

A21

7033

1

VIN

2

SW

3

GROUND

4

FB

5

SHDN

LM2596S-3.3

18V_ON

GND

M1

GND

10K/PM5/0805

M1

M1

DC-DC CONV. SIDE

(SHDN pin, 2.4V--5V --> ON; SHDN<2.4V --> OFF)

3030

3001

120K/PM5/0805

3002

18K/PM5/0805

7006

VIN

SW

GROUND

GND

FB

SHDN

LM2596S-12

/PANEL_12V_ON

Normal Low

3028

10K/PM5/0805

1

2002

100N/0805

1

2

1

3

1

TP72-73

4

5

1

+12VA

+3V3A

+5VA

8

7

3

2 6

51

7001

SI4835/P-MOS

4

Normal Low

7002

BSR14

2 3

2021

100N/0805

(1000U/25V)

A22

6004

SFPJ-73

1 2

1

1

1

1

1

18VCC

5003

68UH

1005

HEAD-2.54-2x2

1003

HEAD-2.54-5X2

+18V

18VCC

170B LCD

47

Go to cover page

5005

12

12

10UH/C10-K4L

+12VL

+3.3V

+5V

1

TP76-77

2025

470U/25V/DIP

( 1000U/ 25V)

12

34

910

78

56

34

12

1

1

1

1

1

+12VA

1

2026

470U/25V/DIP

DC SWITCH

Back

Forward

48

170B LCD

Go to cover page

Schematic Diagram (RGB Digitizer)

Waveforms

Waveforms

+5VD

7401

PQ3DZ13

1

VIN

2

2401

10U/1206

/SHDN

iic address: 99h read

iic address: 98h write

(level of HS, COAST cannot exceed 3.3V)

set CLAMP Low at power saving mode

& 5V tolarence?

+3.3V_A

3

Vo

2402

4

NC

GND

5

1 2

5402

BEAD/1206

2423

100N/0805

+

47U/16V/RV2-6X5

10U/1206

2424

2403

100N/0805

+3.3V_PLL

1 2

5401

BEAD/1206

2425

100N/0805

A3

HS-MCU

VS-MCU

B

A2

G

A1

R

HS-MCU

VS-MCU

243147N/0805

243247N/0805

243347N/0805

(FROM MCU)

+3.3V_ADC

2404

10U/1206

2427

100N/0805

(FROM MCU)

Normal Low

Active High

(FROM MCU)

IICSDA

IICSDA

IICSCL

IICSCL

A7

2405

100N/0805

2428

100N/0805

100N/0805

ADC_PDN

3403 150R/PM5/0805

1 2

1 2

3404

150R/PM5/0805

2429

2406

100N/0805

+3.3V_PLL

2407

100N/0805

Decoupling for ADC; all supply pins must be decoupled

with a 0.1uF capacitor located very close to the pin.

1 2

1

7405

MMUN2211

CLAMP

(680R recommended)

2 3

+3.3V_PLL

39N/0805 2438

2408

100N/0805

3402

10K/PM5/0805

3405

1 2

1K/PM5/0805

3N9/0805

2409

100N/0805

/ADC_PDN

2436

100N/0805

3409 10K/PM5/0805

2437

3410

3K3/PM5/0805

2410

100N/0805

+3.3V_ADC

124

128

125

127

126

118

1

2

3

4

8

10

11

16

18

19

23

25

27

28

29

30

31

32

7

15

22

36

37

38

40

41

44

45

5

6

9

12

13

14

17

20

21

24

26

46

2411

100N/0805

+3.3V_PLL

NC

NC

NC

VD

VD

VD

VD

VD

VD

VD

VD

VD

VD

VD

/PWRDWN

CKINV

CLAMP

SDA

SCL

A0

A1

RAIN

GAIN

BAIN

REFIN

REFOUT

NC

NC

NC

HSYNC

COAST

CKEXT

FILT

GND

GND

GND

GND

GND

SOGIN

GND

GND

GND

GND

GND

NC

SOGOUT

GND

GND

35

39

33

34

43

PVD

PVD

PVD

GND

GND

GND

42

47484950515253

2412

100N/0805

PVD

PVD

AD9884AKS-140

GND

GND

GND

GND

122

54

GND

123

2413

100N/0805

VDD

GND VDD

GND VDD

63 64

73 74

83 84

Waveforms for RGB Digitizer

2416

100N/0805

A1 3312

0.2 V/div AC

5403

BEAD/1206

+3.3V_9884

2439

100N/0805

112

DRA0

111

DRA1

110

DRA2

109

DRA3

108

DRA4

107

DRA5

106

DRA6

105

DRA7

102

DRB0

101

DRB1

100

DRB2

99

DRB3

98

DRB4

97

DRB5

96

DRB6

95

DRB7

92

DGA0

91

DGA1

90

DGA2

89

DGA3

88

DGA4

87

DGA5

86

DGA6

85

DGA7

82

DGB0

81

DGB1

80

DGB2

79

DGB3

78

DGB4

77

DGB5

76

DGB6

75

DGB7

72

DBA0

71

DBA1

70

DBA2

69

DBA3

68

DBA4

67

DBA5

66

DBA6

65

DBA7

62

DBB0

61

DBB1

60

DBB2

59

DBB3

58

DBB4

57

DBB5

56

DBB6

55

DBB7

115

DATACK

HSOUT

GND

121

7403

116

117

/DATACK

GND VDD

GND VDD

GND VDD

GND VDD

GND VDD

93 94

103 104

113 114

119 120

2440

100N/0805

3412

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

3413

100R/PM5/ARV241

3416 100R/PM5/ARV241

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

3417

3420 100R/PM5/ARV241

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

3421 100R/PM5/ARV241

A11

3427

33R/PM5/0805

2441

100N/0805

100R/PM5/ARV241

100R/PM5/ARV241

3425 33R/PM5/0805

BIN_A0

BIN_A1

BIN_A2

BIN_A3

BIN_A4

BIN_A5

BIN_A6

BIN_A7

RIN_A0

RIN_A1

RIN_A2

RIN_A3

RIN_A4

RIN_A5

RIN_A6

RIN_A7

A9

2442

100N/0805

GIN_A0

GIN_A1

GIN_A2

GIN_A3

GIN_A4

GIN_A5

GIN_A6

GIN_A7

2443

100N/0805

BIN_A[0..7]

GIN_A[0..7]

RIN_A[0..7]

12

2624

100N/0805

7602

1

/OE

2

A

3 4

GND Y

74AHC1G125DCK

2444

100N/0805

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

3415

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

3419

1 8

2 7

3 6

4 5

1 8

2 7

3 6

4 5

VCC

2445

100N/0805

100R/PM5/ARV241

3414

100R/PM5/ARV241

100R/PM5/ARV241

3418

100R/PM5/ARV241

100R/PM5/ARV241

3422

3423 100R/PM5/ARV241

5

2446

100N/0805

RIN_B0

RIN_B1

RIN_B2

RIN_B3

RIN_B4

RIN_B5

RIN_B6

RIN_B7

+3.3V_9884

22R/PM5/0805

2447

100N/0805

BIN_B0

BIN_B1

BIN_B2

BIN_B3

BIN_B4

BIN_B5

BIN_B6

BIN_B7

GIN_B0

GIN_B1

GIN_B2

GIN_B3

GIN_B4

GIN_B5

GIN_B6

GIN_B7

(TO MUX.-->SAA6721)

3623

1 2

2448

+

47U/16V/RV2-6X5

BIN_B[0..7]

GIN_B[0..7]

RIN_B[0..7]

DATACK_ADC

HS_ADC

+3.3VD

5 uS/div

A9 7602-2

2 V/div AC

5 uS/div

Waveforms for Video in and DC to DC converter

A1 3312

0.2 V/div AC

5 uS/div

A6 7331-7

2 V/div AC

5 uS/div

A2 3313

0.2 V/div AC

5 uS/div

A10 7602-4

2 V/div AC

5 uS/div

A2 3313

0.2 V/div AC

5 uS/div

A3 3314

0.2 V/div AC

5 uS/div

A11 7403-115

2 V/div AC

50 nS/div

A3 3314

0.2 V/div AC

5 uS/div

A7 7403-40

2 V/div AC

2 V/div AC

5 uS/div

5 uS/div

A4 7331-2 A5 3311

2 V/div AC

5 uS/div

A8 7403-41

2 V/div AC

2 V/div AC

2 uS/div

5 uS/div

2 V/div AC

2 uS/div

A10

Back

Forward

Schematic Diagram (Scaling)

OV2

BLUE

MEM_A0

MEM_A1

MEM_A2

MEM_A3

3619 22R/PM5/ARV241

18

27

36

45

MA0

MA1

MA2

MA3

MA[0..10]

Waveforms

170B LCD

Go to cover page

49

+3.3VD

12

2601

100N/0805

PAG0

PAG1

PAG2

PAG3

PAG4

PAG5

PAG6

PAG7

PBR0

PBR1

PBR2

PBR3

PBR4

PBR5

PBR6

PBR7

PBB0

PBB1

PBB2

PBB3

PBB4

PBB5

PBB6

PBB7

(TO PANEL INTERFACE)

1 2

5601

BLM31P500S

12

2603

100N/0805

1 2

5603

BLM31P500S

+3.3VD

12

2602

10U/1206

2609

100N/0805

Back

4

1

PAR0

PAR1

PAR2

PAR3

PAR4

PAR5

PAR6

PAR7

PAB0

PAB1

PAB2

PAB3

PAB4

PAB5

PAB6

PAB7

PBG0

PBG1

PBG2

PBG3

PBG4

PBG5

PBG6

PBG7

VCC

NC

A29

GND OUT

2 3

+3.3VD

12

100R/PM5/0805

1601

27MHZ/OSC/SMD

+3.3VS

10U/1206

BIN_B[0..7]

GIN_B[0..7]

RIN_B[0..7]

BIN_A[0..7]

GIN_A[0..7]

RIN_A[0..7]

22R/PM5/ARV241

22R/PM5/ARV241

22R/PM5/ARV241

22R/PM5/ARV241

22R/PM5/ARV241

22R/PM5/ARV241

1 2

5602

BLM31P500S

2604

100N/0805

3641

2610

470P/0805

/RST_6721

2611

4 5

3 6

2 7

1 8

2 7

3 6

4 5

2 7

3 6

4 5

2 7

3 6

4 5

4 5

3 6

2 7