Philips 146498 User Manual

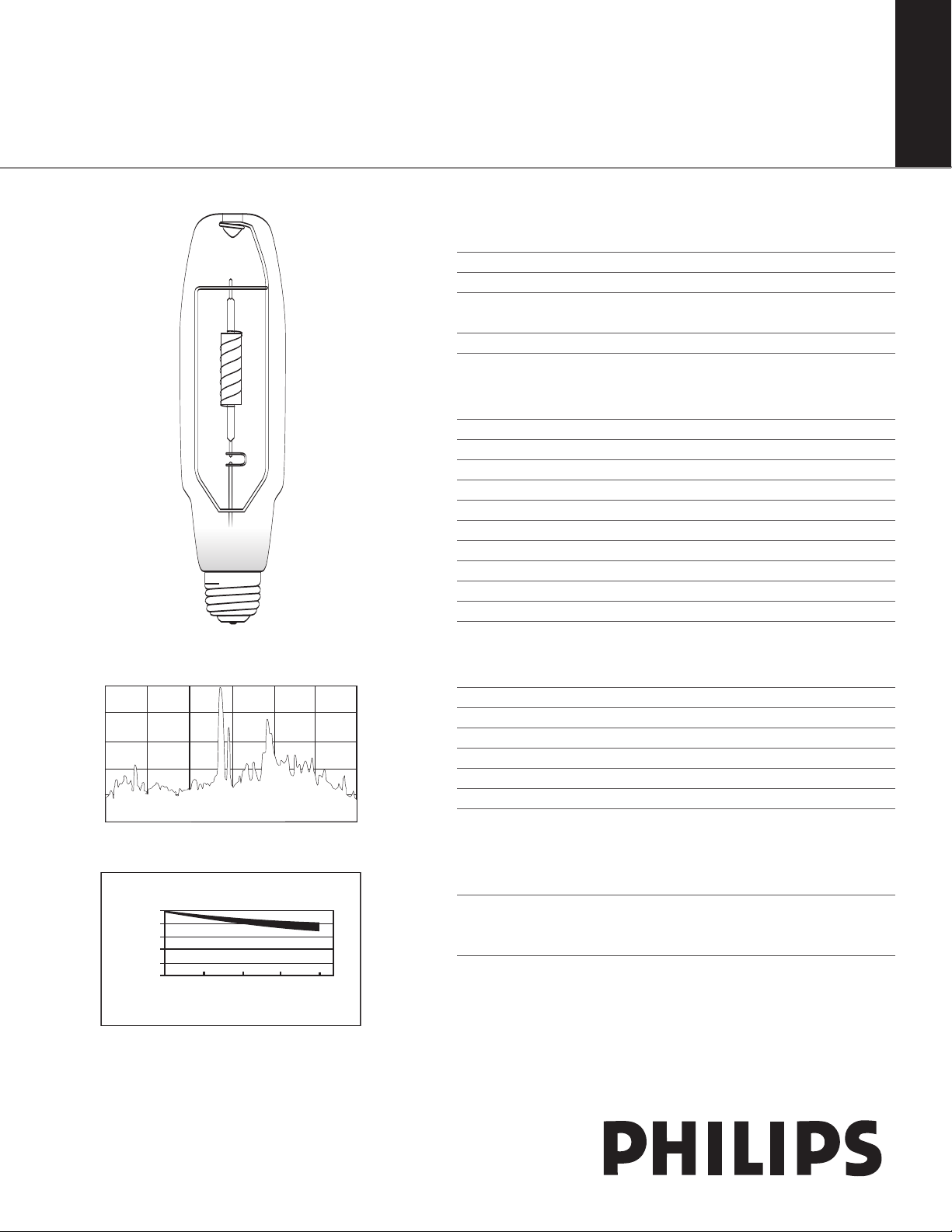

CDM 250 S50/V/HOR/4K Lumen Maintenance

Burning Hours, Rated Average Life 15,000 Hours

100%

80%

60%

40%

20%

0%

0 4000 8000 12000 15000

% Lumen Maintenance

MasterColor®Spectral Power Distribution — 4K Types

100

90

80

70

60

50

40

30

20

10

0

RELATIVE ENERGY

400 450 500 550 600 650 700

Wavelength (Nanometers)

MasterColor®Ceramic Metal Halide 250W

™

HPS-Retro White

Featuring ALTO®Lamp Technology

Horizontal Lamp

w Ordering Information

Ordering Code CDM250S50/HOR/4K/ALTO

ANSI Designation Operates on S50/M168/O

Product Number 14649-8

Description MasterColor Ceramic

Package Quantity 12

w Physical Characteristics

Bulb Size ED-18

Bulb Finish Clear

Base Mogul

Max. Overall Length (MOL) 9 3/4'' (248mm)

Light Center Length (LCL) 5 3/4'' (146mm)

Arc Length 1'' (25.4mm)

Ar

c Tube Material Poly Crystalline Alumina

Max. Permissible Bulb Temp. 400ºC (752ºF)

Max. Permissible Base Temp. 210ºC (410ºF)

Max. Bulb to Base Eccentricity 3º

Max.Arc Tube to Base Eccentricity 3º

Metal Halide

w Operating Characteristics (Photometric)

2

Approx. Initial Lumens

Approx. Mean Lumens

Rated Average Life, Hours

Correlated Color Temp. (CCT)

CIE Chr

omaticity Approx.

Color Rendering Index (CRI)

1,

2, 3

4

5

5

20,500

16,400 HOR

20,000 HOR

4000K

x-.378,

y-.370

85

Efficacy (lpw) 82

w Operating Position

Horizontal ± 15º–Open or Enclosed Luminaires. Do not operate in

tical position.

er

a v

Not for use in compact “wall pack” or “flood light” type fixtures.

Maximum temperature limit of outer bulb may be exceeded in these

applications and can lead to premature lamp failure

Luminare photometric distributions may be affected due to

erences in arc length vs. HPS lamp arc length.

diff

Philips Lighting Company

200 Franklin Square Drive

P.O. Box 6800

Somerset, NJ 08875-6800

1-800-555-0050

A Division of Philips Electronics North America Corporation

pdated 9/05 TDS-146498

U

www.philips.com

Philips Lighting

281 Hillmount Road

Markham, Ontario

Canada L6C 2S3

1-800-555-0050

Division of Philips Electronics Ltd.

A

MasterColor®Metal Halide 250 Watt HPS-Retro White™Horizontal Lamp

Electrical Data (Subject to change without notice)

Lamp Watts (Nominal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Lamp Operating Voltage (rms) (Nominal)

Initial Lamp Voltage Range (rms)6. . . . . . . . . . . . . . . . . . . . 90–120

Lamp Operating Current (Amps) (rms) (Nominal) . . . . . 3.0

Lamp Current Crest Factor (Maximum) . . . . . . . . . . . . . . 1.8

Warm-up Time to 80% of Output . . . . . . . . . . . . . . . . . . . 2 Minutes

Restrike Time for Hot Lamp. . . . . . . . . . . . . . . . . . . . . . . . . 15 Minutes (Average)

Ballast Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ANSI S50

Ballast Open Circuit Voltage (Minimum). . . . . . . . . . . . . . . 198 RMS Min.

Pulse Peak Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2500 Minimum, 4000 Maximum

Pulse Width @ 90% Peak . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Micro Second Minimum

Pulse Repetition Rate (Minimum) . . . . . . . . . . . . . . . . . . . . 1 per Half Cycle

inimum Operating Temperature . . . . . . . . . . . . . . . . . . . . -30º C

M

Footnotes:

1) Measured at 100 hours of life in horizontal position.

2) Approximate lumen values listed are for horizontal operation of lamp.

3) Approximate mean lumen output at 40% of lamp rated average life.

4) Rated average life is the life obtained, on the average, from large representative groups of lamps in laboratory tests under controlled conditions at 10 or more operating hours per start.

It is based on survival of at least 50% of the lamps and allows for individual lamps or groups of lamps to vary considerably from the average.

5) Measured at rated lamp watts on a linear reactor. LPW does not include ballast losses.

6) Measured with the lamp operating at rated watts.

5

. . . . . . . . . . . . 100

Warnings,

“WARNING:These lamps can cause serious skin burn and eye inflammation

from short wave ultraviolet radiation if outer envelope of the lamp is broken

or punctured. Do not use where people will remain for more than a few minutes

R

unless adequate shielding or other safety precautions are used. Certain lamps

that will automatically extinguish when the outer envelope is broken or punctured

are commercially available.” This lamp complies with FDA radiation performance

standard 21 CFR subchapter J. (USA:21CFR 1040.30 Canada:SOR/DORS/80-381)

If the outer bulb is broken or punctured, turn off at once and replace

the lamp to avoid possible injury from hazardous short wave ultraviolet

radiation. Do not scratch the outer bulb or subject it to pressure as this

could cause the outer bulb to crack or shatter

outer bulb may cause glass to fly if the envelope is struck.

WARNING:

pressure and at temperatures up to 1000ºC and can unexpectedly rupture due to

internal or external factors such as a ballast failure or misapplication. If the arc-tube

ruptures for any reason,the outer bulb may break and pieces of extremely hot glass

might be discharged into the sur

ha

URNS AND FIRE.

B

These lamps are designed to retain all the glass particles should an arc tube

rupture occur. The following operating instructions are recommended to

minimize these occurrences.

RELAMP FIXTURES

Allo

incr

This lamp contains an arc tube with a filling gas containing less than

25 nCi of Kr-85 and is distributed by Philips Lighting Company,a

division of Philips Electronics North America Corporation, Somerset,

New Jersey 08875-6800.

CA

AMA

D

FOLLOWING LAMP OPERATING INSTRUCTIONS MUST BE FOLLOWED.

Cautions and Operating Instructions

. A partial vacuum in the

The arc-tube of metal halide lamps is designed to operate under high

ounding en

ppen,

THERE IS

wing lamps to operate until the

ease the possibility of inner arc tube rupture.

UTION:

GE, BURNS AND FIRE RESULTING FROM AN ARC-TUBE RUPTURE THE

A RISK OF PERSONAL INJURY, PROPERTY DAMAGE,

O REDUCE

T

r

T OR BEFORE THE END OF RATED LIFE.

A

THE RISK OF PERSONAL INJURY, PROPERTY

vironment. If such a rupture were to

y fail is not advised and may

Lamp Operating Instructions:

1)RELAMP FIXTURES AT OR BEFORE THE END OF RATED LIFE.Allowing lamps

to operate until they fail is not advised and may increase the possibility

of inner arc tube rupture.

2)Before lamp installation/replacement, shut power off and allow lamp and fixture

to cool to avoid electrical shock and potential burn hazards.

3) Use only auxiliary equipment meeting Philips and/or ANSI standards.

Use within voltage limits recommended by ballast manufacturer.

A. Operate lamp only within specified limits of operation.

B. For total supply load refer to ballast manufacturers electrical data.

4) Periodically inspect the outer envelope.Replace any lamps that show scratches,

cracks or damage.

5) If a lamp bulb support is used, be sure to insulate the support electrically

to avoid possible decomposition of the bulb glass.

socket and wiring against moisture, corrosive atmospheres

otect lamp base

Pr

6)

and excessiv

Time should be allo

7)

first time

Lamp color is also subject to change under conditions of excess vibration

t.

star

or shock,

8) Lamps may require 10–20 minutes to re-light if there is a power interruption.

e in handling and disposing of lamps.

e car

ak

T

9)

contact with an

,

e heat.

or lamps to stabilize in color when turned on f

ed f

w

equir

y r

This ma

.

and color a

ppearance ma

y of the contents or fragments.

eral hours of operation, with more than one

v

e se

y var

een individual lamps.

y betw

If an ar

c tube is br

or the

oken, avoid skin

Loading...

Loading...