19” CDT Color Monitor 109B7

Service

Service

Service

30-92 kHz

Horizontal F re q ue ncy

Table of contents

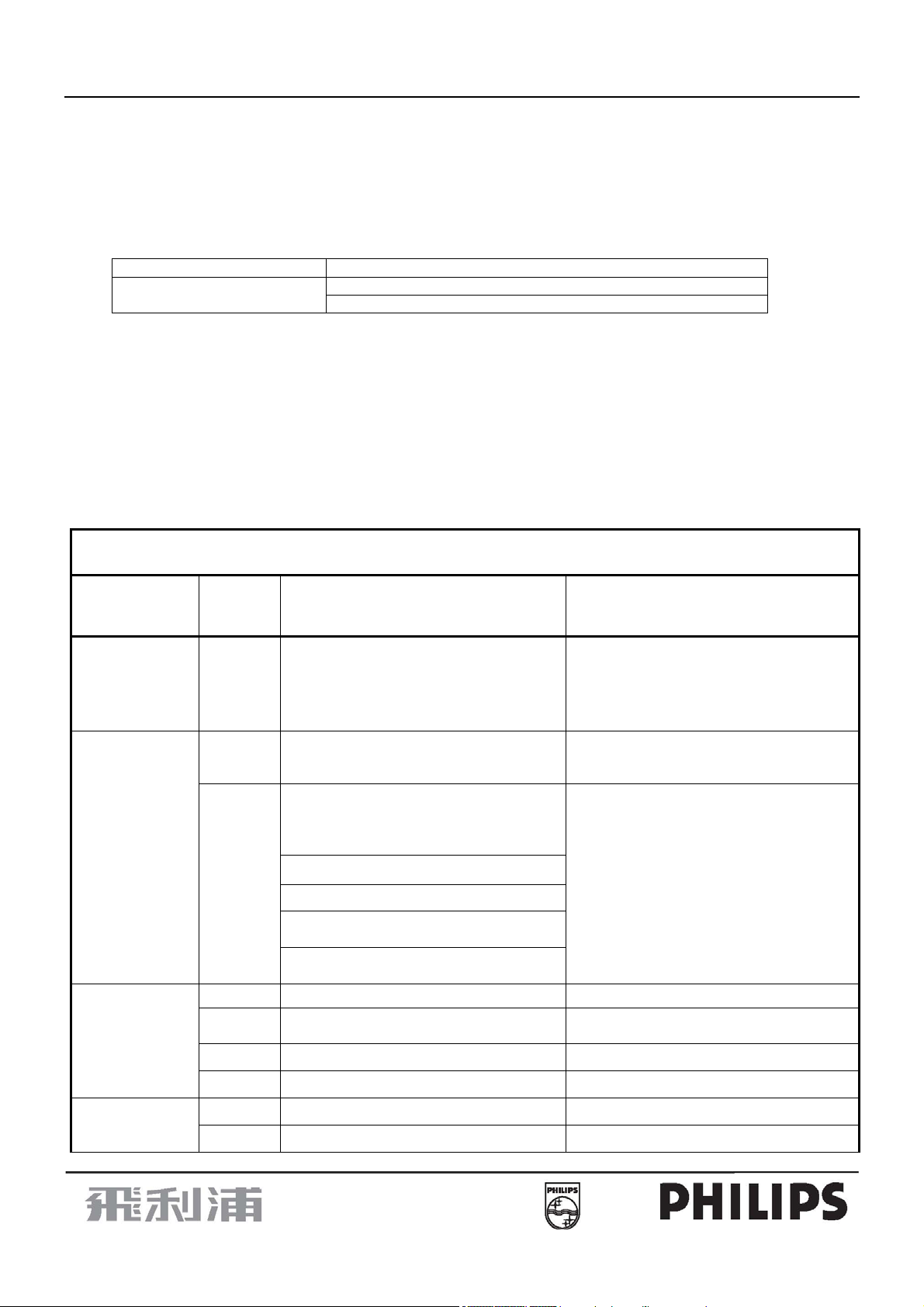

Description Page Description Page

Table Of Contents...............................................1

Revision List.......................................................2

Important Safety Notice.................................3

1. Specifications..........................................4

2. Precaution and Notices................................7

2-1Safety Precautions....…...............…..............7

2-2 Product Safety Notice .......................................8

2-3 Service Notices....................…………......8

2-4 High Voltage Warning......................................8

3. Operating Instructions.................………............9

4. Adjustment ............................…………………....10

4 -1. Adjustment Conditions and Precautions .......10

4-2. Main Adjustments..............................10

4-3 Adjustment Methods........................................12

4-4 DDC Instructions....................…………...............17

5.Circuit Description ..………………………............22

5-1.Micro Controller and Deflection Circuit ..........22

5-2.Transistor & Diode Circuit...............................24

6.Mechanical Instructions…………………...….……25

7. Trouble Shooting Chart........................…...........28

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS AND BE AWARE OF THE

NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

SAFETY NOTICE

7-1. No Power (No voltage)......………………….........28

7-2. No Picture(The Relative Scan Circuit )……...29

7-3 No Raster(CRT Relative Circuit Problem)......30

7-4 Abnormal Display(The Relative Video Amplifying

Circuit)……………………………………………………31

7-5. No Horizontal Blanking.................................32

7-6. A Horizontal Bright Trace…........................32

7-7. Abnormal Horizontal Size Function……….........33

7-8. Abnormal Vertical Size....…………..................34

7-9. Focus Failure......…………………………...........34

8. Mechanical of Cabinet Front Dis-Assembly..........35

9. Spare Parts List...........………….............................36

10. Differen parts list...................................................50

11. Block Diagram..................……..........................58

12. IC Block Diagrams..........…..................................59

13. PCB Layout............…………................................64

13-1 Main Board PCB Layout.....................................64

13-2 CRPC Board Layout.........................................65

14. Schematic Diagram.........................................66

15. General Product Specification…………………70

GB

1

3138 106 10540

19” CDT Color Monitor 109B7

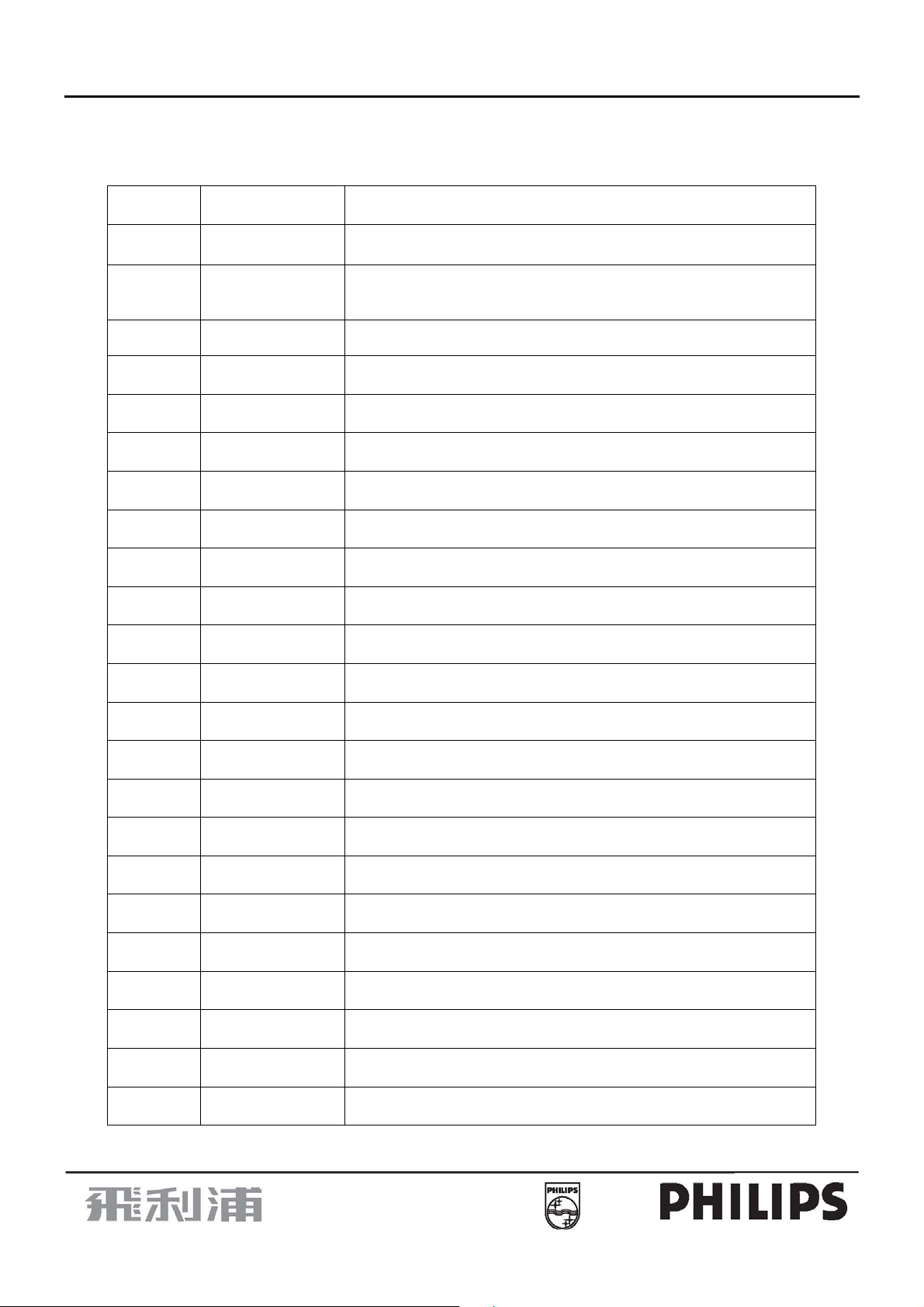

Revision List

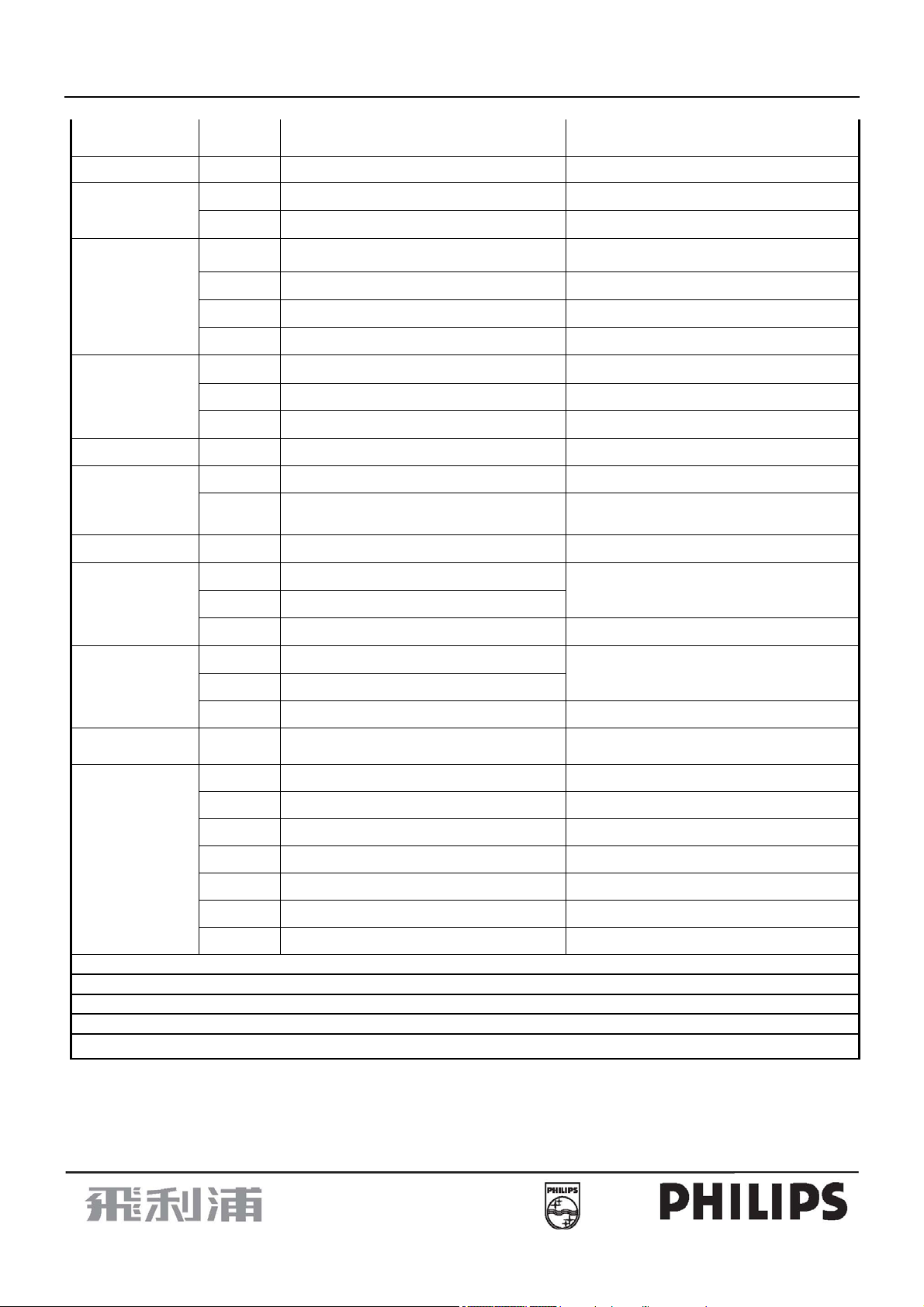

Version Date Revision History

A00 May-28-2006

A01 Jun-13-2006

A02 Jul-14-2006 Add CTV model 109B75/00 in Item 10

Add CTV model 109B70/05, 109B75/05, 109B75/27, 109B76/93 in

Item 10.

Initial Release

2

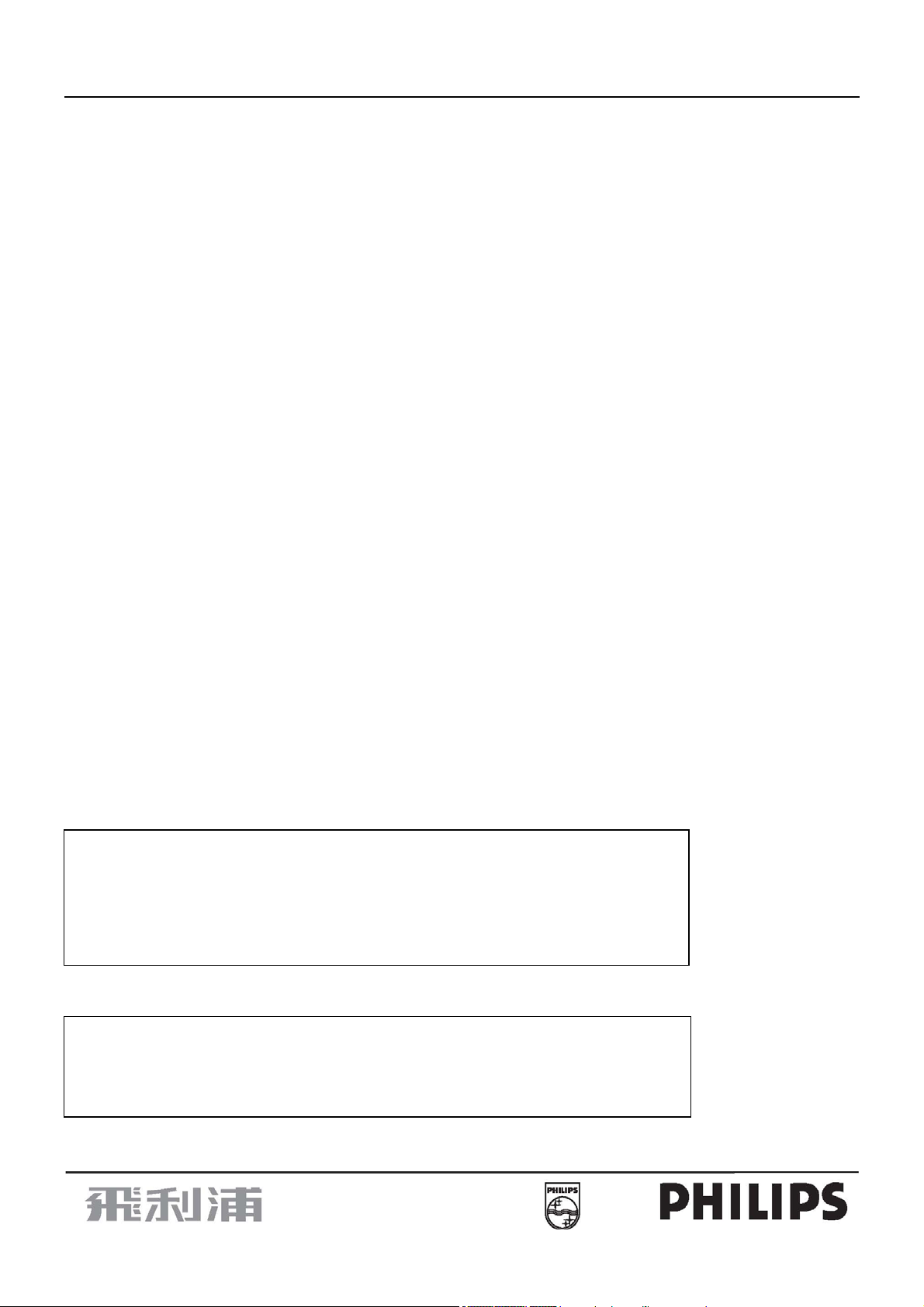

19” CDT Color Monitor 109B7

A

Important Safety Notice

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINGS

Proper service and repair is important to the safe, reliable operation of all PHILIPS Company Equipment. The service

procedures recommended by PHILIPS and described in this service manual are effective methods of performing

service operations. Some of these service operations require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service personnel. The possibility exists that improper service methods

may damage the equipment. It is also important to understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. PHILIPS could not possibly know, evaluate and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each way. Consequently, PHILIPS has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by PHILIPS must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

Hereafter throughout this manual, PHILIPS Company will be referred to as PHILIPS.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create shock,

fire, or other hazards.

Under no circumstances should the original design be modified or altered without written permission from PHILIPS.

PHILIPS assumes no liability, express or implied, arising out of any unauthorized modification of design. Servicer

assumes all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER - Invisible laser radiation when open. AVOID DIRECT EXPOSURE TO BEAM.

UTION - Use of controls or adjustments or performance of procedures other than those

CAUTION - The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY

ORIGINAL MANUFACTURER'S REPLACEMENT PARTS, WHICH ARE LISTED WITH

THEIR PART NUMBERS IN THE PARTS LIST SECTION OF THIS SERVICE MANUAL.

specified herein may result in hazardous radiation exposure.

3

19” CDT Color Monitor 109B7

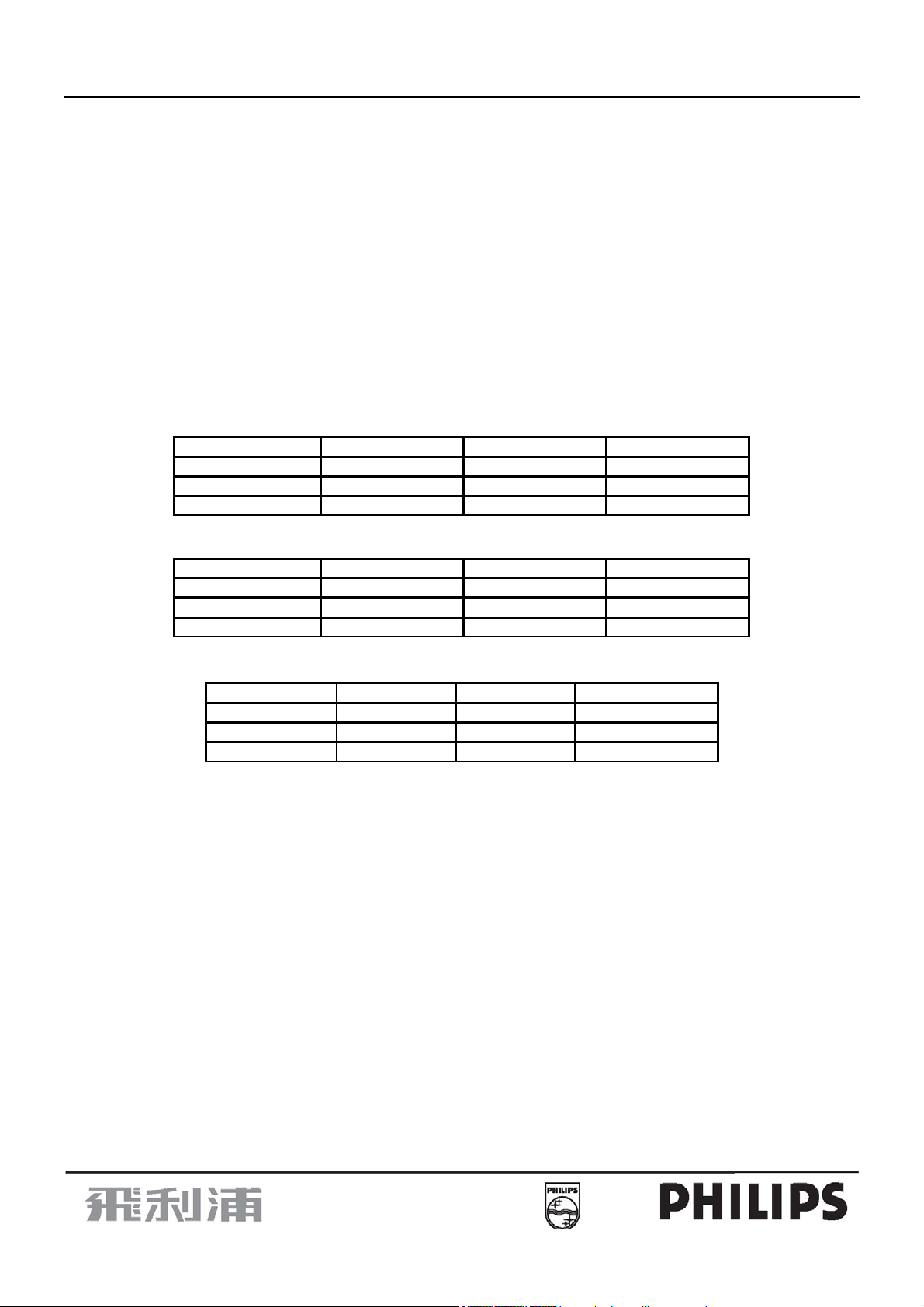

1. Monitor Specifications

1. CRT : 46CM(19") 90 Deflection,

Glare Screen

2. Viewable image Size: 45.7CM (18") diagonal

3. Display Color: Unlimited Colors

4. External Controls:

Power On/Off, OSD key, Function knob: Contrast, Brightness, H-Size, H-Center, V-Size, V-Center, ZOOM,

Pincushion, Trapezoid, Pin-Balance, Parallelogram, Rotation, Moire Reduce, Recall, Degaussing,

Color Temperature, 6500K Color Temperature, 5500K Color Temperature, sRGB Color Temperature, User

Color.

5. Input Video Signal

6. Display Size

355mm x 265mm ± 4mm for all preset modes.

355mm x 265mm ± 10mm for preload modes.

7. Scanning Frequencies

Horizontal: 30KHz ~ 92KHz

Vertical: 50 Hz ~ 160 Hz

8. Factory Preset Modes: 8

User Modes: 6

9. Mis-convergence

Zone A < 0.25mm, Zone B < 0.35mm.

Zone B < 0.4mm (for modes < 50kHz).

10. Video Dot Rate: 180 MHz

11. Power Source:

Switching Mode Power Supply

AC 90 ~264V, 50±3/60±3Hz Universal Type

Resolution 640 x 480 720 x 400 800 x 600

H. Frequency 31.469 kHz 31.468 kHz 46.875 kHz

V. Frequency 59.941 Hz 70.084 Hz 75.000 Hz

Resolution 800 x 600 1024 x 768 1024 x 768

H. Frequency 53.674 kHz 60.023 kHz 68.677 kHz

V. Frequency 85.061 Hz 75.029 Hz 84.997 Hz

Timing 1. 2. 3.

Timing 4. 5. 6.

Timing 7. 8.

Resolution 1280 x 1024 1280 x 1024

H. Frequency 79.976 kHz 91.146 kHz

V. Frequency 75.024 Hz 85.024 Hz

Shadow mask ,29mm Neck, flat high contrast CRT, 0.25mm dot pitch, Non-

9300K

4

19” CDT Color Monitor 109B7

12. Operating Temperature: 0°C to 40°C Ambient

13. Operating Humidity : 5% to 90% Relative, Non-Condensing

14. Weight: 19.9 Kg (Net), 22.9kg (for China, India)

22.9kg (for other regions) (Gross)

15. Dimensions Monitor:

Monitor(with stand): 439mm(W) × 422.5mm(H) ×457mm(D)

Carton:

16. External Connection :

15 Pin D-type Connector AC Power Cord

17. Power Consumption

Power on - < 75W. (Test requirements refer to EN61000-3-2)

Active off - < 2W at 120Vac / 240Vac.

Switch off - < 2W at 120Vac / 240Vac.

18. Regulations:

495mm(W) × 466mm(H) × 520mm(D) for China,India

494mm(W) × 434mm(H) × 534mm(D)for other regions

International Regulatory Specification

Country Domain Safety / EMC / Ergonomics / Standards Documents

IEC60950-1: 2001. Group -and national

INTERNATIONAL Sa

Sa

EUROPE

E

Sa EN60950-1: 2001 TUV certificate

O

GERMANY

O GS-Mark / EK1-ITB 2000 TUV-GS certificate

differences of all countries listed in CB

Bulletin No. 107A

European Low Voltage Directives

73/23/EEC and 93/68/EEC

European Electromagnetic Compatibility

Directive 89/336/EEC amended by the

directive 93/68/EEC. EN 55022:1998

Class B

EN 55024: 1998

EN 61000-3-2: 2000

IEC 61000-3-3: 1994/EN61000-3-3:

1995

CISPR 22:1997 Class B International

EMC standard

ISO 9241-3-7-8 (CRT) & 13406-2 (LCD),

prEN 50279:1998

CB Report and CB certificate

Declaration of Conformity

Declaration of Conformity and Full EMC/CE

test report

TUV-ERG certificate

SWEDEN

X Decree ROV 08.01.87 (CRT) PTB

Sa EN60950-1: 2001 SEMKO certificate

O TCO 99 (TCO03) (to TCO models) TCO99 (TCO03) report + certificate

5

19” CDT Color Monitor 109B7

RUSSIA Sa GOST R 50377-1992 GOST certificate

SOUTH AFRICA

USA

CANADA

MEXICO Sa NOM-019-SCFI-1994 NOM certificate

KOREA

SINGAPORE Sa IEC60950 PSB certificate

CHINA

O

Sa SABS IEC 60950 and IEC 60950-1 Certificate of Conformity

E EN55022 or Cisper 22 Certificate of Conformity

Sa UL 60950-1: 2003 UL certificate

E FCC Part 15 Class B FCC ID grant or DOC

O Energy Star EPA registration

X 21CFR 1002.10 to 13 (CRT) DHHS report

Sa CSA C22.2 No 60950 CSA certificate

E ICES-003 issue 3 Statement on label

E RED (CRT) DNHW

Sa Korean Safety Control law IEC 60950 eK certificate

E

Sa GB4943-2001

E GB9254-1998; 17625.1-2003

MPR 1990: 8 / MPR 1990:10 (to MPR

models)

Regulations laws: EMI 1996-78, 80. EMS

1996-79,81

Meet requirement

MIC certificate

CCC certificate

O CSC/G1205-2004 CECP certificate

Sa CNS-14336 (IEC 60950-1)

TAIWAN

AUSTRALIA/

NEW-ZEALAND

ISRAEL

Saudi Arabia

Japan

Argentina Sa EN60950-1: 2001

Sa = Safety

E = Electromagnetic Compatibility

O = Other which including recycling, energy saving, ergonomics

X = X-ray

For detailed regulatory items please refer to the international regulatory specification provided by Philips.

E CNS-13438 (CISPR22) Class B

O Criteria 18 (Monitor) (LCD) Green Mark / certificate

E AS/NZS3548: 1995 Declaration of Conformity

S IS 1121, IEC60950/IEC60950-1 Certificate of Conformity

E EN or Cisper 22 Certificate of Conformity

S IEC standard SASO

E IEC standard SASO

Sa EN60950-1:001 (AC adapter only) PSE

E

VCCI class B (CISPR 22) VCCI Certificate

BSMI certificate

IRAM

6

19” CDT Color Monitor 109B7

2. Precautions and Notices

2-1 Safety Precautions

1. Observe all caution and safety related notes located inside the display cabinet.

2. Operation of the display with the cover removed, may cause a serious shock hazard from the display power

supply. Work on the display should not be attempted by anyone who is not thoroughly familiar with

precautions necessary when working on high voltage equipment.

3. Do not install, remove or handle the picture tube in any manner unless shatter-proof goggles are worn.

People who are not so equipped should be kept away while handling picture tube. Keep picture tube away

from the body while handling.

4. The picture tube is constructed to limit X-RAY radiation to 0.5 mR/HR. For continued protection, use the

designated replacement tube only, and adjust the voltages so that the designated maximum rating at the

anode will not be exceeded.

!

5. Symbol“

the same characteristics as specified in the parts list may create shock, fire or explode etc.

6. Symbol“ ” means X-ray relative parts. Before replacing any of these components please read the parts

“ means safety relative parts. The use of substitute replacement parts which do not have

list in this manual carefully to avoid creating higher anode voltage or x-ray. Especially for sealed controls,

such as VR902, VR903, VR701 and FBT screen VR etc, which were sealed by the manufacturer once their

optimum position has been set, please don’t dismantle them as your likes, otherwise you will break or

damage the component. If you need replace the parts with sealed control, please adjust the relative VR to

make sure the B+ voltage under 59V and well seal it with A+B glue or equivalent, which you can not move

away with one screw driver

7. Before returning a serviced display to the customer, a thorough safety test must be performed to verify that

the display is safe to operate without danger or shock. Always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as screw heads.

Test method for current leakage is described as follow.

(a) Plug the AC line cord directly into rated AC outlet (do not use a line isolation transformer during this

check).

(b) Use an AC voltmeter having 5000 ohms per volt or with more sensitivity in the following manner:

Connect a 1500 ohms 10 Watt resistor, paralleled by a 0.15UF, AC type capacitor between a known

good earth ground (water pipe, conduit, etc.) and the exposed metallic parts simultaneously. Measure

the AC voltage across the combination of 1500 ohms resistor and 0.15UF capacitor.

(c) Reverse the AC plug at the AC outlet and repeat AC voltage measurements for each exposed metallic

part.

(d) Voltage measured must not exceed 0.5 volts RMS. This corresponds to 0.35 milliamp AC. Any value

exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

7

19” CDT Color Monitor 109B7

2-2 Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety visual inspections and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Before replacing any of these components read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same safety characteristics as specified in the parts list may

create shock, fire, X-RAY radiation or other hazards.

2-3 Service Notes

1. When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

2. When replacing a high wattage resistor (more than 1/2W of metal oxide film resistor) in circuit board, keep

the resistor about 10mm (1/2 in) away from circuit board.

3. Keep wires away from high voltage or high temperature components.

4. Keep wires in their original position so as to reduce interference.

2-4 High Voltage Warning

Operation of monitor outside of cabinet or with back removed may cause a serious shock hazard. Work on this

model should only be performed by those who are thoroughly familiar with precautions necessary when working

on high voltage equipment.

Exercise care when servicing this chassis with power applied. Many B plus and high voltage terminals are

exposed which, if carelessly contacted, can cause serious shock or result in damage to the chassis. Maintain

interconnecting ground lead connections between chassis and picture tube dag when operating chassis.

Certain HV failures can increase X-ray radiation. Monitor should not be operated with HV levels exceeding the

specified rating for the chassis type. The maximum operating HV specified for the chassis used in this monitor is

26.5KV ± 1KV

with a line voltage of 120/240 VAC. Higher voltage may also increase possibility of failure in HV supply.

It is important to maintain specified values of all components in the horizontal and high voltage circuits and

anywhere else in the monitor that could cause a rise in high voltage or operating supply voltages. No changes

should be made to the original design of the monitor. Components shown in the shaded areas on the schematic

should be replaced with exact factory replacement parts. The use of unauthorized substitute parts may create a

shock, fire or other hazard.

To determine the presence of high voltage, use accurate, high impedance, HV meter connected between second

anode lead and CRT dag grounding device. When servicing the High Voltage System, remove static charge from

it by connecting a 10K ohm resistor in series with an insulated wire (such as a test probe) between picture tube

dag and 2nd anode lead.(AC line cord disconnected from AC power outlet.)

The picture tube used in this monitor employs integral implosion protection. Replace with tube of the same type

number for continue safety. Do not lift picture tube by the neck. Handle the picture tube only after discharging the

high voltage completely.

8

19” CDT Color Monitor 109B7

3. Operating Instructions

This procedure gives you instructions for installing and using the Color display.

1. Position the display on the desired operation and plug the power cord into a convenient AC outlet. Three-

wire power cord must be shielded and is provided as a safety precaution as it connects the chassis and

cabinet to the electrical conduit ground. If the AC outlet in your location does not have provisions for the

grounded type plug, the installer should attach the proper adapter to ensure a safe ground potential.

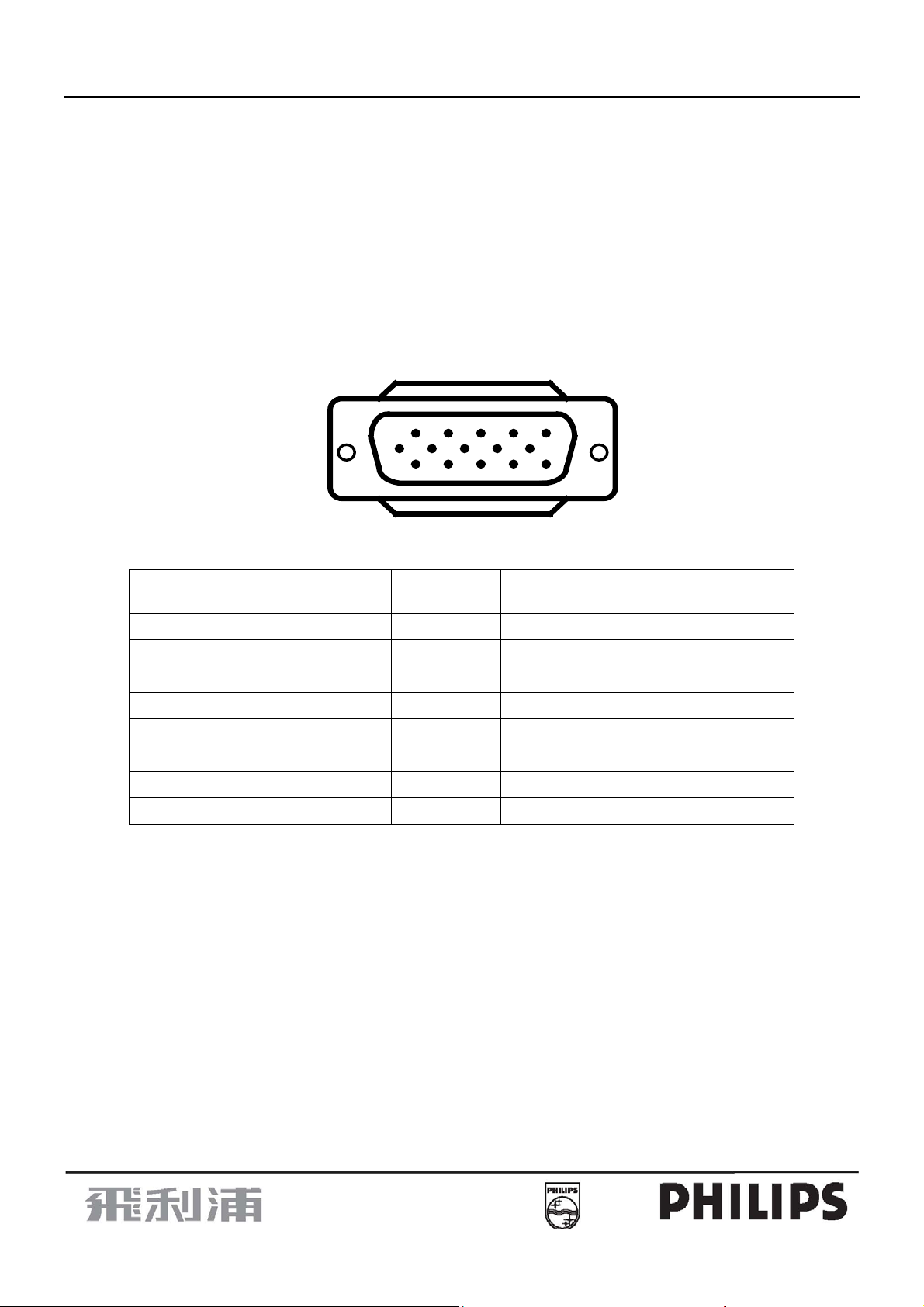

2. Connect the 15-pin color display shielded signal cable to your signal system device and lock both screws on

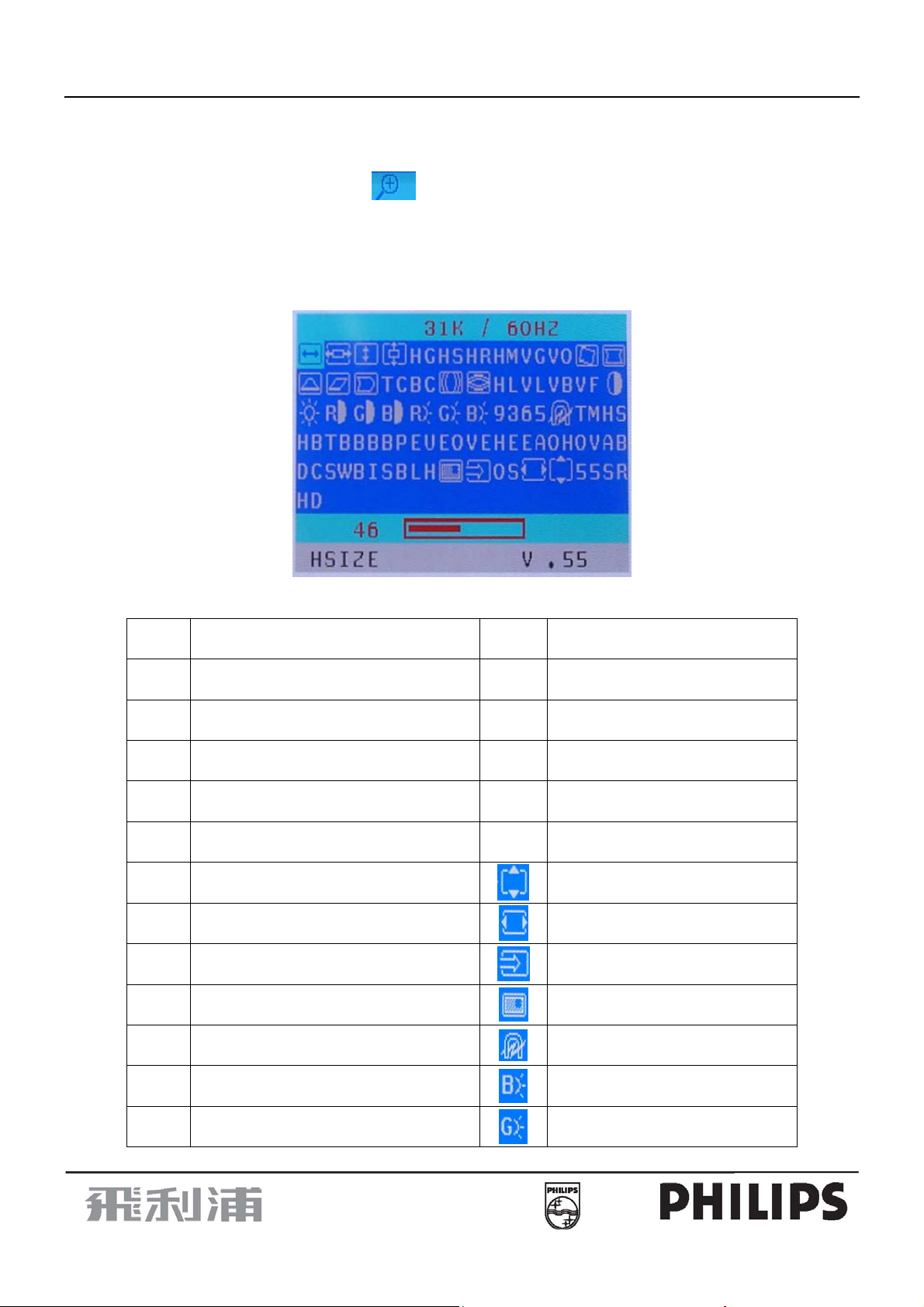

the connector to ensure firm grounding. The connector information is as follow:

1

6

11 15

5

10

15 - Pin Color Display Signal Cable

Pin No. Description Pin No. Description

1.

2.

3.

4.

5.

6.

7.

8.

Red video

Green video

Blue video

GND

Self test

Red GND

Green GND

9.

10.

11.

12.

13.

14.

15.

Blue GND

+5V (Supply from PC for DDC circuit)

Sync GND

GND

DDC serial data

H-sync

V-sync

DDC serial clock

3. Apply power to the display by turning the power switch to the "ON" position and allow about thirty seconds

for display tube warm-up. The Power-On indicator lights when the display is on.

4. With proper signals feed to the display, a pattern or data should appear on the screen, adjust the brightness

and contrast to the most pleasing display.

5. This monitor has power saving function following the VESA DPMS. Be sure to connect the signal cable to

the PC.

6. If your color display requires service, it must be returned with the power cord.

9

19” CDT Color Monitor 109B7

4. Adjustment

4-1 Adjustment Conditions and Precautions

1. Approximately 30 minutes should be allowed for warm up before proceeding.

2. Adjustments should be undertaken only on those necessary elements since most of them have been carefully

preset at the factory.

4-2 Main Adjustments

10

19” CDT Color Monitor 109B7

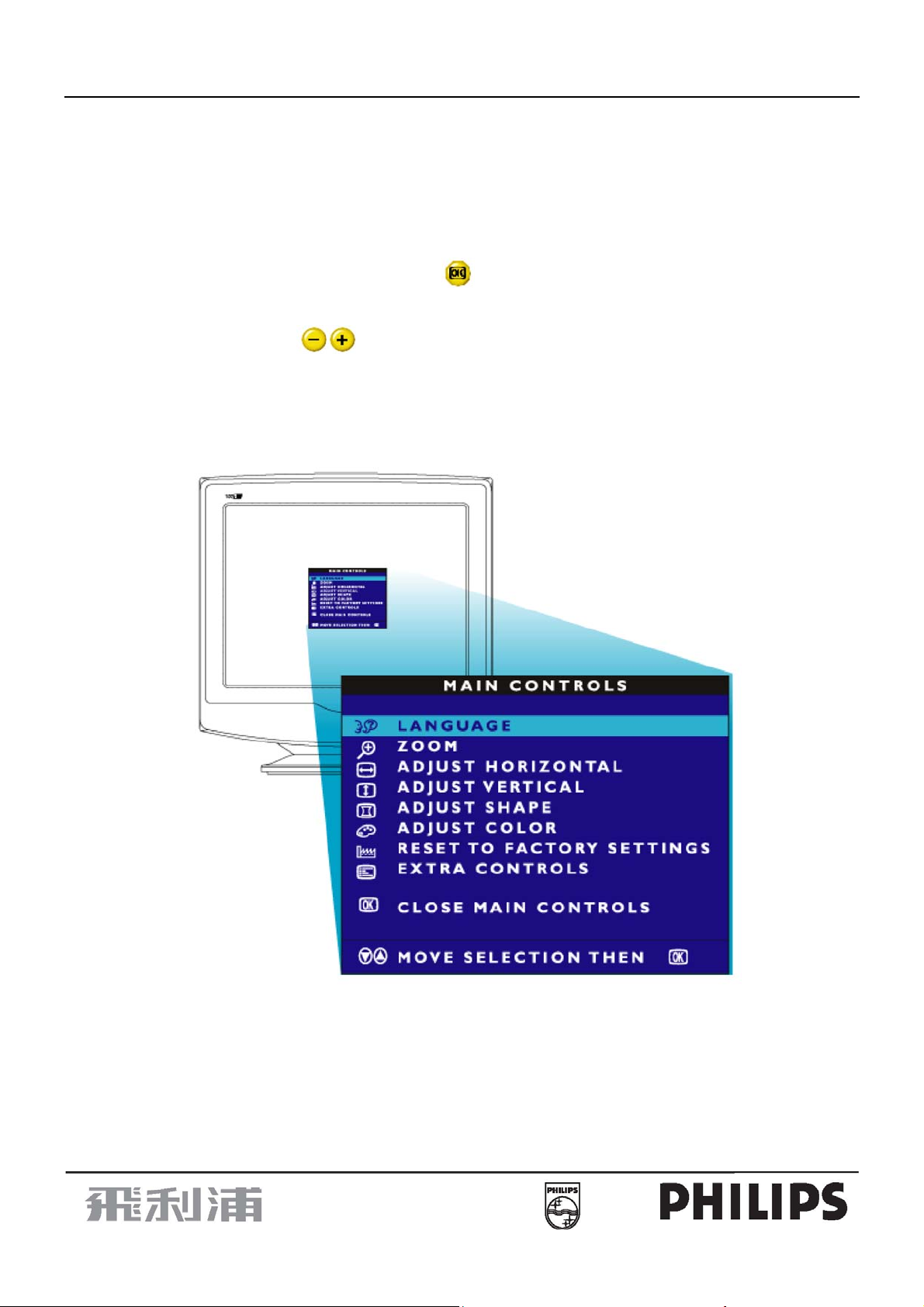

Description of the On S creen Display

What is the On-Screen Display?

This is a feature in all Philips monitors which allows an end-user to adjust screen performance of

monitors directly through an on-screen instruction window. The user interface provides user friendliness

and ease-of-use when operating the monitor.

Basic and simple instruction on the control keys.

On the front controls of your monitor, once you press the

(OSD) Main Controls window will pop up and you can now start making adjustments to your

monitor's various features. Use the

to make your adjustments within.

button, the On Screen Display

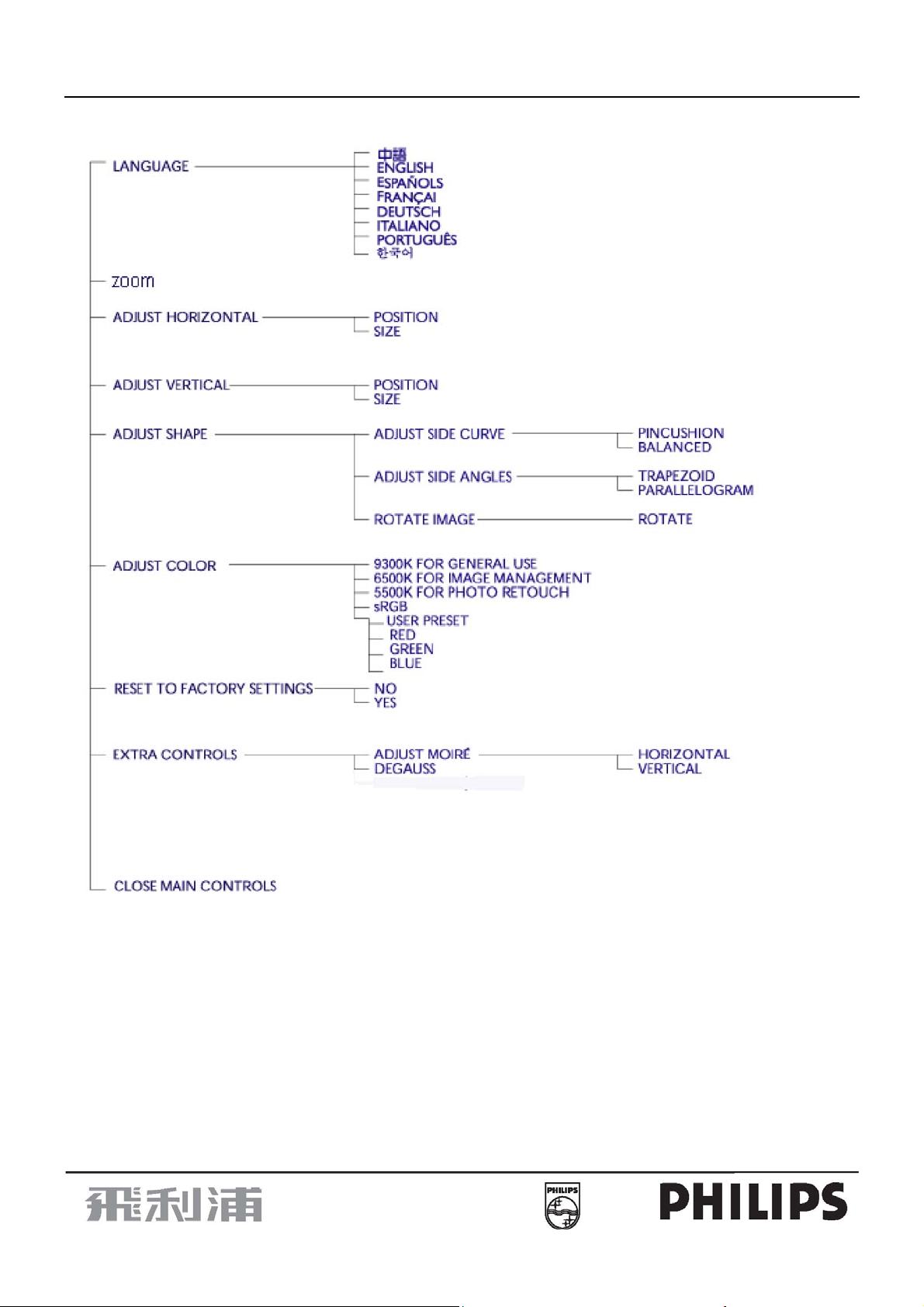

The OSD Tree

Below is an overall view of the structure of the On-Screen Display. You can use this as reference

when you want to later on work your way around the different adjustments.

Your monitor may not include all the items in the OSD tree shown below.

11

19” CDT Color Monitor 109B7

4-3 Adjustment Method

1. TP403, B+ voltage adjustment:

A. Chroma-2135 Signal generator or PC equivalent set timing 140, pattern 101.

B. Connect a DC Volt meter between TP403 and ground, then adjust VR902 to be 125 VDC for CPT CRT and

125 VDC for LPD CRT,set G2 for 560VDC.

C. Set the contrast and brightness max,and then adjust focus and make the screen clear.

12

19” CDT Color Monitor 109B7

2. Factory preset Timings Adjustment:

A. Press MENU Key to show OSD window press Up or Down Key to switch the functional controls.

B. Press the Up Key to select the "

MENU Key until the OSD window changed to the Factory preset window.

C. The Factory preset window contains the following functional controls. Select one of the control. Then press

the Up/Down Key to adjust its value for the optimum picture.

" function, then press the MENU Key. While do not release the

SR

Save SRGB color

VO

V Offset

55

OS

LH

SB

BI

SW

DC

AB

OV

OH

EA

HE

Save 5500C color

User OSD size

Brightness

SBQ

Set Burn/in Off & On

Set H/Freq Max 85~72K

DCOffset ADJ

ABL

User OSD VC

User OSD HC

EHT Auto ADJ

HEHT Gain

VG

HM

HR

HS

HG

V Gain

H size Max

H Size Range

HSUB Size Range

H Gain

HBRIOSD VC

HBRIOSD HC

User adjustment

Save and Exit

Degauss

B-Bias

G-Bias

13

19” CDT Color Monitor 109B7

VE

EO

EU

BP

BB

TB

HB

HS

TM

65

93

VF

VEHT Gain

EHT Offset

EHT Current

B Plus

Bottom Balance

Top Balance

HS Wave Balance

HSWAVE

User Timr:00273hours

Save 6500C color

Save 9300C color

V-Focus

R-Bias

G-Gain

B-Gain

R-Gain

Brightness

Contrast

V-Moire Reduce

H-Moire Reduce

PIN-Balance

Parallelogram

Trapezoid

Pincushion

VB

VI

HL

BC

TC

HD

D. To switches the input signal to the other Timing Mode. Please follow step A ~ C to get the optimum picture.

E. Select the "

returned to the original OSD window.(user's operating condition)

F. The setting data of the CONTRAST, BRIGHTNESS, COLOR TEMPERATURE are common mode saved

in the memory. Don't needed adjust it individual at every timing Mode and save in the memory.

3. White Balance, Luminance adjustment:

VLIN Balance

V Linearity

H Linearity

Bottom Corner

TOP Corner

" RETURN function and press the MENU Key, then the Factor Preset window will be

H Driver

Rotation

V- Center

V-size

H-Center

H -size

A. Press MENU Key to show OSD menu, and press the down Key to select the "

14

" function, then press

19” CDT Color Monitor 109B7

the menu Key to enter second menu, press the menu key about 10S,then enter into factory setting area for

modulation.

B. Set brightness and contrast ratio max.

C. Raster max modulate, Raster Pattern, adjust R-bias or B-bias and G-bias, make x= 270,y=290,Y=1.8±0.2

2

cd/m

.

2

D. Raster cut off modulate: Raster Pattern, adjust brightness and cut off: 0.08 cd/m

6500K and 5500K color temperature.

E. Small white screen appears (9300 color temperature). Raster cut off, SB select four, Contrast =100,adjust

R or G or B gain, make x=283,y=297,Y=340,and save it into 9300K color temperature; LH select 3,adjust

Contrast, and make Y=270,save it into 9300 color temperature, LH select 2,adjust contrast, make Y=200

and save it into 9300 color temperature; LH select 1,adjust contrast, make Y=140 and save it into 9300

color temperature; then exit factory setting area.

F. Small white screen appears (6500 color temperature). LH select 4,contrast –100,adjust R or G or B gain,

make x=313,y=329,Y=300 and save it into 6500 color temperature; then exit factory setting area.

G. Small white screen appears (5500K color temperature). LH select 4,contrast –100,adjust R or G or B gain,

make x=332,y=347,Y=280 and save it into 5500 color temperature; then exit factory setting area.

H. ABL modulates. Full white screen appears (9300K color temperature), brightness cut off, adjust AB value:

1) LH select 4,adjust AB value and make 9300 color temperature Y=99 cd/m

2

value and make 9300 color temperature Y=99 cd/m

temperature Y=99 cd/m

2

.4) LH select 1,adjust AB value and make 9300 color temperature Y=99 cd/m2.

.3) LH select 2,adjust AB value and make 9300 color

I. SRGB color temperature. Full white screen appears, adjust R or G or B gain, make x=313,y=329,Y=80

2

, then save it into SRGB color temperature.

cd/m

J. After modulation, it’s necessary to check if the white balance accords with the normal specification. If not,

which needs reset.

4. Focus Adjustment:

A. Set mode5 1024×768@85Hz with character full page.

B. Under the “recall” state.

C. Then adjust focus VR1 of the FBT to a fine vertical line.

D. Adjust focus VR2 to a fine horizontal line.

E. Repeat step C & D.then rivet the focus VR, G2 VR.

5. Purity Adjustment

A. Be sure that the display is not being exposed to any external magnetic fields.

B. Ensure that the spacing between the Purity, Convergence, Magnet, (PCM), assembly and the CRT stem is

29mm. (See below diagram)

C. Produce a complete, red pattern on the display. Adjust the purity magnet rings on the PCM assembly to

obtain a complete field of the color red. This is done by moving the two tabs in such a manner that they

advance in an opposite direction but at the same time to obtain the same angle between the two tabs,

, and save it into 9300K,

2

.2) LH select 3,adjust AB

15

19” CDT Color Monitor 109B7

which should be approximately 180'.

D. Check the complete blue and complete green patterns to observe their respective color purity. Make minor

adjustments if needed.

Relative placement of typical components

Purity Magnets

6-pole Convergence Magnets

4-pole Convergence Magnets

Deflection Yoke

6.Convergence adjustment

A. Produce a magenta crosshatch on the display.

B. Adjust the focus for the best overall focus on the display.

Also adjust the brightness to the desired condition.

C. Vertical red and blue lines are converged by varying the angle between the two tabs of the 4 pole magnets

on the PCM assembly. (See above diagrams)

D. Horizontal red and blue lines are converged by varying the two tabs together, keeping the angle between

them constant.

E. Produce a white crosshatch pattern on the display.

F. Vertical green and magenta lines are converged by varying the angle between the two tabs of the 6-pole

magnets.

G. Horizontal green and magenta lines are converged by varying the two tabs together, keeping the angle

between them constant.

16

19” CDT Color Monitor 109B7

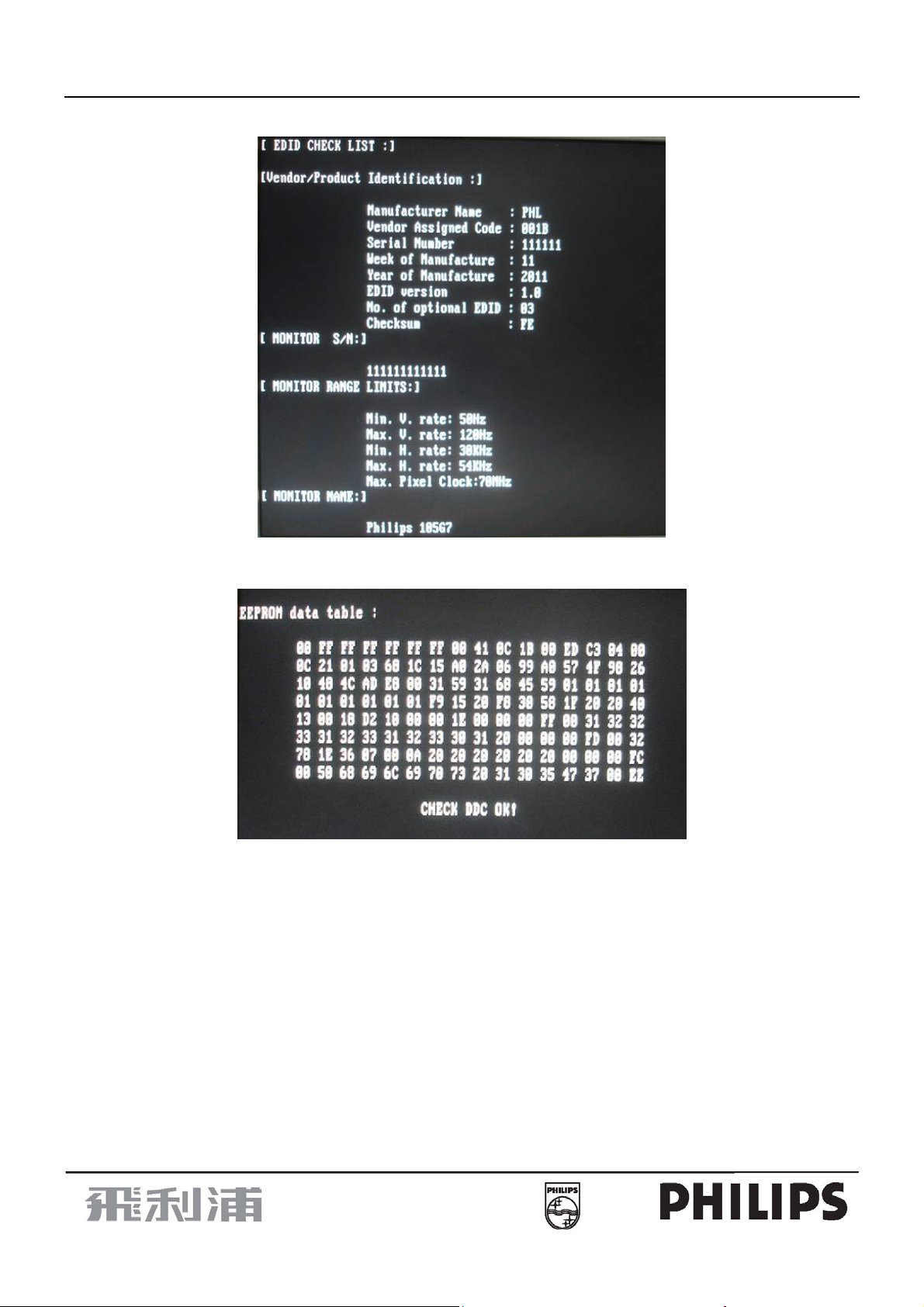

4-4 DDC Instructions

128 bytes EDID Data (Hex):

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

0: 00 FF FF FF FF FF FF 00 41 0C 1E 00 01 00 00 00

16: 01 10 01 03 68 24 1B 78 2B 06 99 A0 57 4F 98 26

32: 10 48 4C A5 EF 00 31 59 45 59 61 59 71 4F 81 59

48: 81 99 A9 40 A9 45 EA 24 00 60 41 00 28 30 30 60

64; 13 00 63 09 11 00 00 1E 00 00 00 FF 00 41 55 30

80: 35 30 31 30 30 30 30 30 31 0A 00 00 00 FD 00 32

96: A0 1E 5C 12 00 0A 20 20 20 20 20 20 00 00 00 FC

112: 00 50 48 31 30 39 42 37 0A 20 20 20 20 20 00 B3

Take 105G7 DDC writer for example

1.General

DDC Data Re-programming

In case the main EEPROM with Software DDC which store all factory settings were replaced because a defect,

repaired monitor’ the serial numbers have to be re-programmed.

It is advised to re- soldered the main EEPROM with Software DDC from the old board onto the new board if circuit

board have been replaced, in this case the DDC data does not need to be re-programmed.

Additional information:

Additional information about DDC (Display Data Channel) may be obtained from Video Electronics Standards

Association (VESA). Extended Display Identification Data (EDID) information may be also obtained from VESA.

2.System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98,etc.

3. Newphl.exe program

4. (105G7)S554BPHL.ddc EDID program.

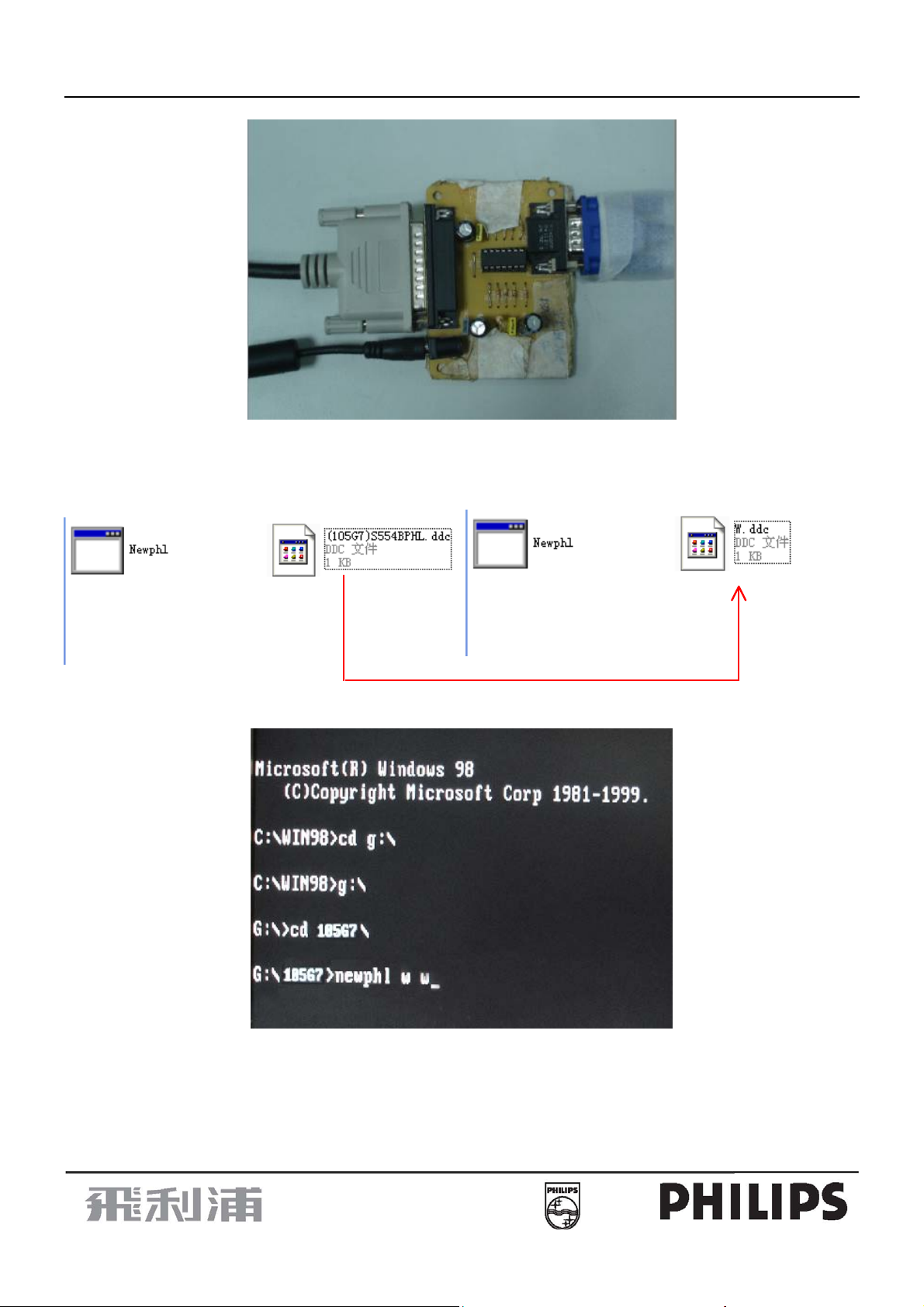

5. Software DDC Alignment kits shown as fig 1.

The kit contents:

a. DDC board x1

b. Printer cablex1

c. D-Sub cable x1

d. 12V DC input

Note: The Newphl.exe is a MS-DOS -based program, which cannot be run in windows.

17

19” CDT Color Monitor 109B7

D-SUB connector

Printer connector

DC 12V input

Fig 1

Step 1: Put the “Newphl.exe” and “(105G7) S554BPHL.ddc” to a special folder, such as 105G7. And rename the

“(105G7) S554BPHL.ddc” as “W.ddc”

Step 2: Access to MS-DOS program, Input the command as shown fig 2

Note: g: is the disk position for 105G7

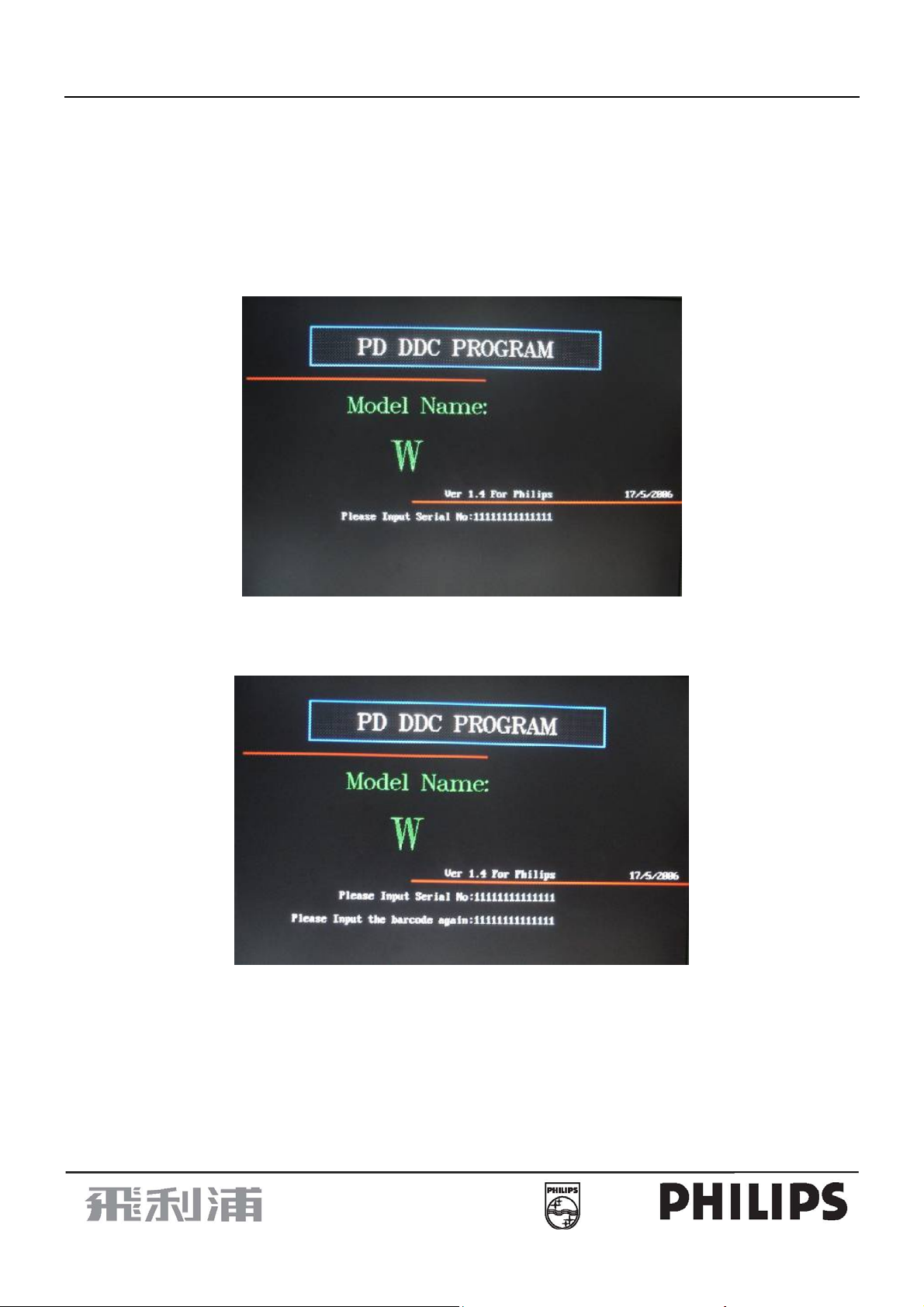

Step 3: Press Enter into the next screen as shown Fig 3.

Fig 2

18

19” CDT Color Monitor 109B7

a. Input 14 byte digital Serial No. such as “11111111111111” as shown Fig 3.

b. Enter and press “F3” key to input Serial No. again as shown Fig 4. Enter

The Serial No. length is”14” as shown Fig 4.

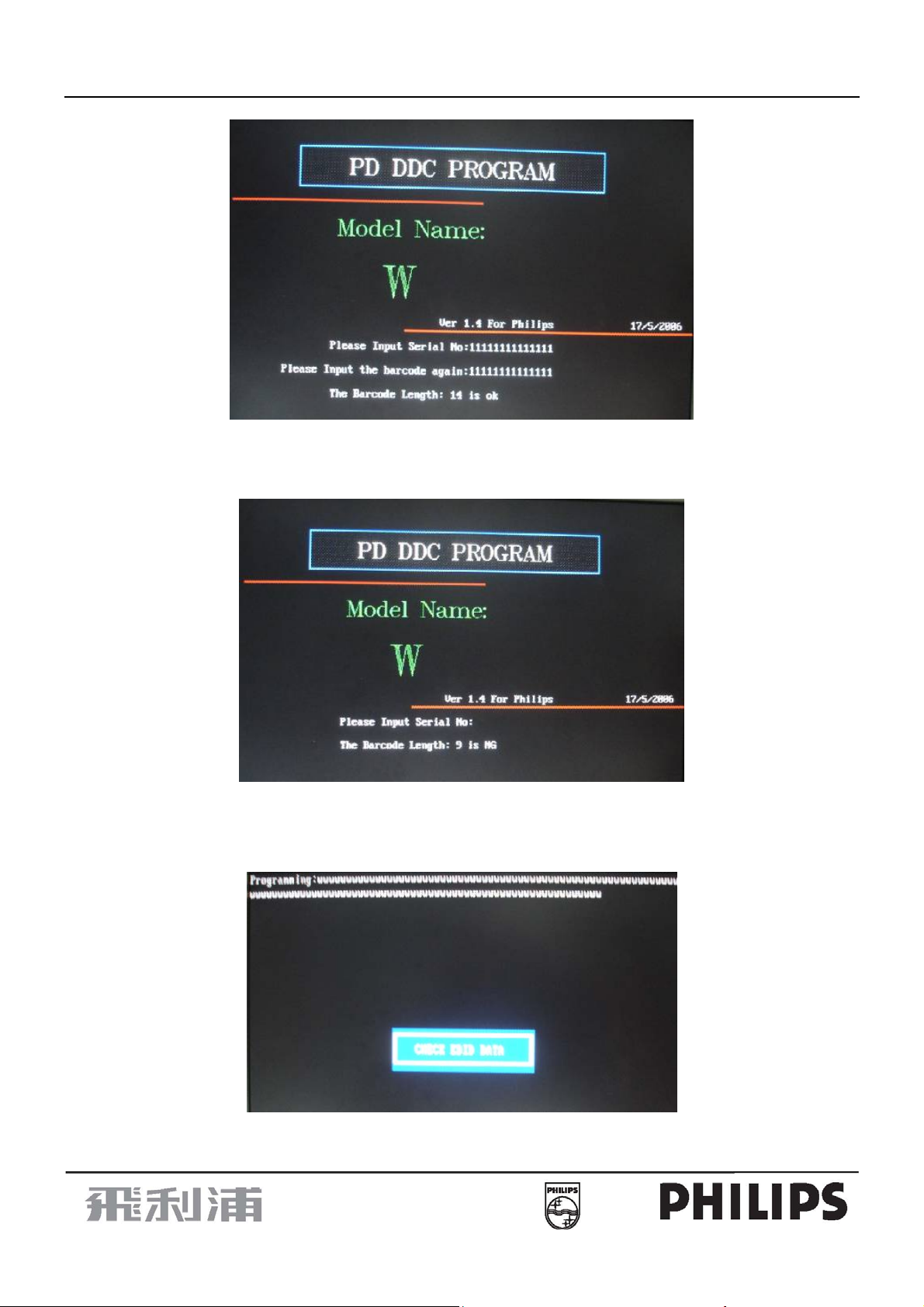

c. If you correctly input, there will appear” The Barcode length: 14 is OK” as shown Fig 5.

d. And if you incorrectly input, there will appear “The Barcode length: 9 is NG” as shown Fig 6.

You have to input again.

Fig 3

Fig 4

19

19” CDT Color Monitor 109B7

Step 4: Enter, go into the next screen as shown Fig 7.

Fig 5

Fig 6

Fig 7

20

19” CDT Color Monitor 109B7

Step 5: Enter into Fig 8.

Step 6: Enter into Fig 9.

Fig 8

Fig 9

21

19” CDT Color Monitor 109B7

5. Circuit description

5-1 Micro controller and deflection circuit

MICRO Controller

The micro controller(IC101) core is a 80C51 type. The micro clock frequency of 12 Mhz is derived from the

Xtal oscillator, which is running at 48MHz. The DDC interface is suitable to handle DDC2 by a modified hardware

2

C-bus interface .Standard high current ports,3 ADC pouts with voltage inputs and 4 static standard 8 bit DAC

I

outputs (low interference) and one PWM output for digital control application are implemented. The central

processing unit (CPU) manipulates operands in two memory spaces. These are the 1024byte internal data

memory(consisting of 256 bytes standard RAM and 768 bytes AUX-RAM) and 48K-byte internal program memory .

The programmemory of the SAA4849 consists of 48K bytes ROM.

The SAA4849P provides sync. Processing with full auto sync. Capability, a flexible SMPS block and an

extensive set of geometry control facilities. Further the IC generates the drive waveforms for DC coupled vertical

boosters to the TDA4863A.

H/V sync signals processor

The functions of the sync processor include polarity detection, H-SYNC & V-SYNC signals counting,

Programmable SYNC signals output, free running signal generator. Pin52/Pin53 are for the H-SYNC and V-SYNC

input. and the polarity are setting in the positive. When no signal input, the Pin49 will output a 75Hz V-SYNC free

run signal. The Pin18/20will output a 60KHz H-SYNC free run signal. for the monitor testing use.

Reset Circuit(pin23)

There are three ways possible to invoke a reset and initialize the SAA4849 micro controller part:

Via power-on reset circuit

Via watchdog timer overflow(only micro controller reset)

Via deflection reset after start up(only micro controller reset)

The reset pin(pin23) is connected to a Schmitt trigger for nose reduction. A reset is accomplished by holding the

Reset pin HIGH.

C145

22U

5V

+

R153

2.7K

22

C102

0.1UF

RST Pin23

19” CDT Color Monitor 109B7

x-ray protection

The x-ray ptotection(pin22) input XRAY provides a voltage detector with a precise voltage input for X-ray

protection .If the input voltage at XRAY exceeds the upper threshold for 150us to 300us,the system is forced to

shut down by switching off vertical,H-and B-drive signals. There are two different ways to handle the system in

case of XRAY occurrence:

1. If the x-ray latch enable bit UCXRAY[2] was set to “0” during startup the system will shut down without any

interference of the uC.The deflection controller is set to ldle mode. Restart of the system only possible due to

seitching power off/power on.

2. If register bit UCXRAY[2] was set to “1”,micro controller interaction is allowed .If the micro controller doesn’t

interrupt the system, the system will shut down to ldle mode. For any interaction of the micro controller the XRAY

occurrence has to be acknowledged by the micro controller by clearing the bit SY-STATUS[2].The micro controller

take over the control of the handling via software. The actual x-ray pin status can be read through bit SY-

STATUS[1].

Quartz Oscillator(pin45,pin46)

The quartz oscillator circuit is available on pins XTAL1(input) and XTAL2(output) and works together with an

external 48MHz 3

crystal frequencies than 48 MHz cannot be used. External capacitors on XTAL1 and XTAL2 are not allowed.

rd

overtone quartz. As a result the quartz oscillator is always running on 48MHz.Other quartz

B+ Control Function Block

The B+control block of the SAA4849 has the same behaviour as the TDA4856 with adapted threshol voltages.

The circuit allows the user to choose the trigger edge of the HDRV signal and the polarity of the output stage via

2

C-Bus.

I

The B+ control function block of the SAA4849 consists of an Operational Transconductance Amplifier(OTA), a

voltage comparator, a flip-flop and a discharge circuit. This configuration allows easy application for different B+

control concepts.

HPLL

The horizontal part contains a PLL,which works over the full frequency range from 25kHz to 140 kHz. This range

2

can be reduced by a ower and an upper frequency limit(Write Once Registers HPMAX and HPMIN).Via I

C bus the

number of 48MHz clock cycles is sent through the register. The slewing speed during mode change is also

programmable in a write once register (HSLEW)

After the clocks for the HPLL are switched on, the HPLL starts with a fixed freerunning frequency of 60 kHz. The

H-drive pulses are not active and the start up procedure is inhibited. The default setting of register bit HCONTROL [0]

2

will cause the HPLL to slew ,not switch. to the freerunning frequency defined in the I

C register HPFREE( the default

value is also 60 kHz).Independent on H-syncs which are possibly present. the HPLL will slew to that freerunning

frequency. To achieve an always defined starting point for the startup procedure, this procedure cannot be interrupted.

23

19” CDT Color Monitor 109B7

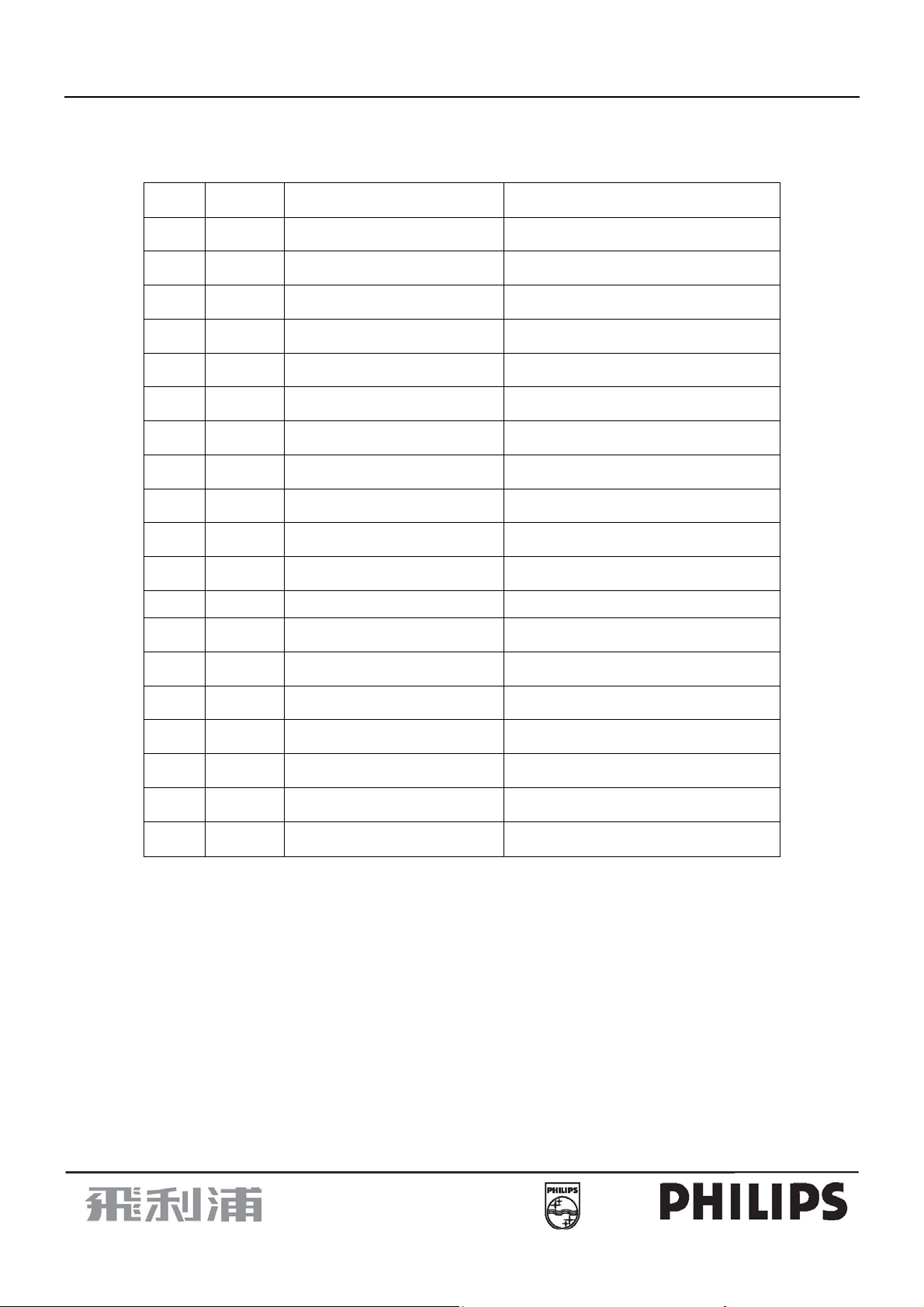

5-2 Transistor & diode circuit

Item Location Description Function

1 IC101 SAA4849PS CPU

2 IC601 TDA4863A Vertical Output IC

3 IC801 NT6812KG-20019 Video Preamplifier/OSD IC

4 IC802 LM2476 Video Output IC

5 Q911 2SJ584LS B+ Transistor

6 IC901 TEA1507P PWM Combi power MOS IC

7 Q901 STP9NK70Z MOS FET for Switching Power Control

8 C907 150UF/450V Filter Capacitance

9 Q403 PHILIPS 1500V/12A BU2527 Horizontal Output Transistor

10 BD901 U4KB80R Bridge Rectifier for AC Source

11 Q417 MOSFET CS Transistor

12 Q418 IRF630B CS Transistor

13 D918 31DF4-FC Rectifier for Output Voltage

14 D919 BYV26C/TFK Rectifier for Output Voltage

15 D922 BYV27-200 PHILIPS Rectifier for Output Voltage

16 D923 SB240 Rectifier for Output Voltage

17 D930 BYV27-200 PHILIPS Rectifier for Output Voltage

18 D408 DMV1500MFD Rectifier DIODE

19 Q705 Transistor Brightness Control CKT

24

19” CDT Color Monitor 109B7

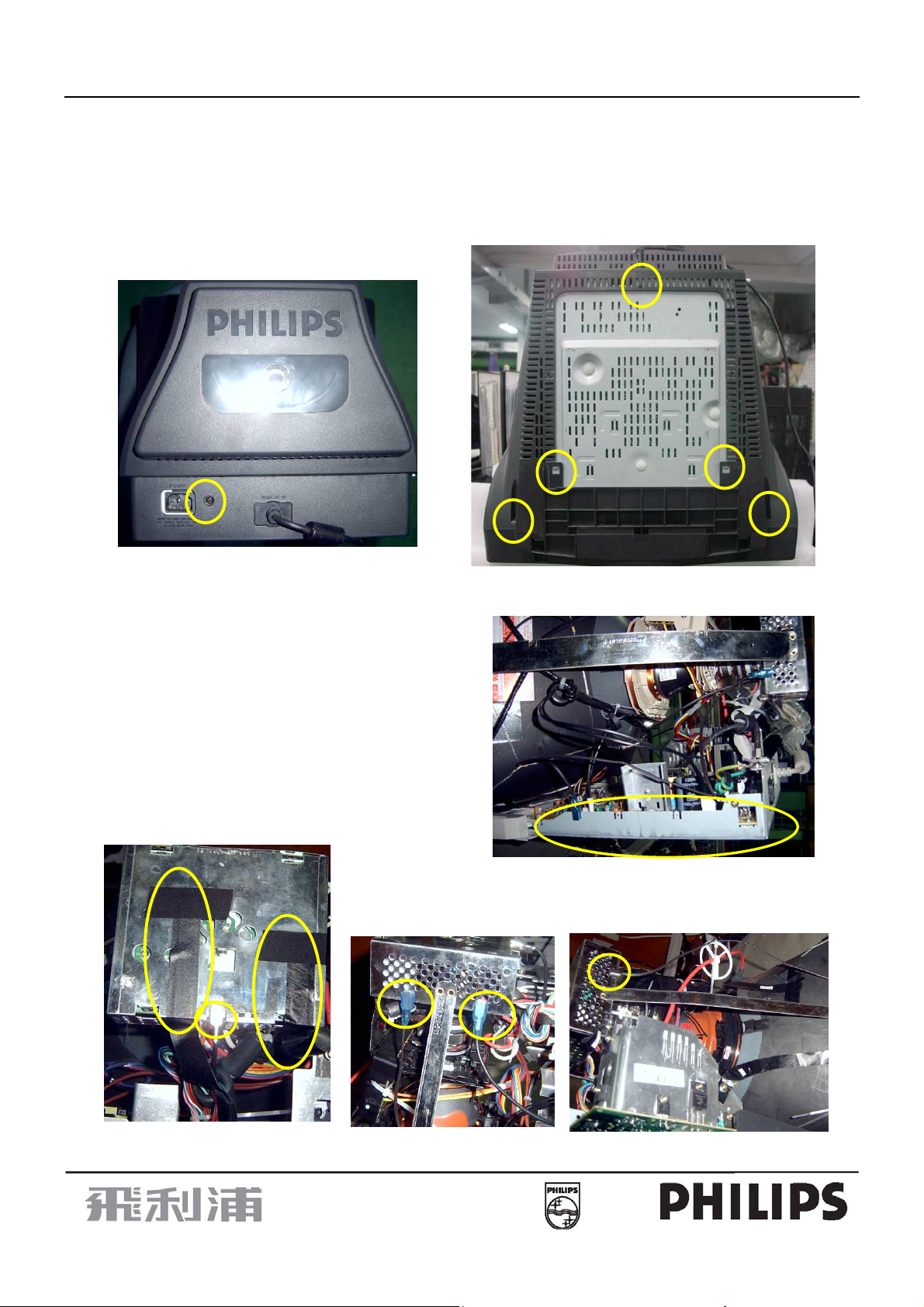

6. Mechanical Instructions

0. General

To be able to perform measurements and repairs on the "circuit boards", these unit should be placed

in the service position first.

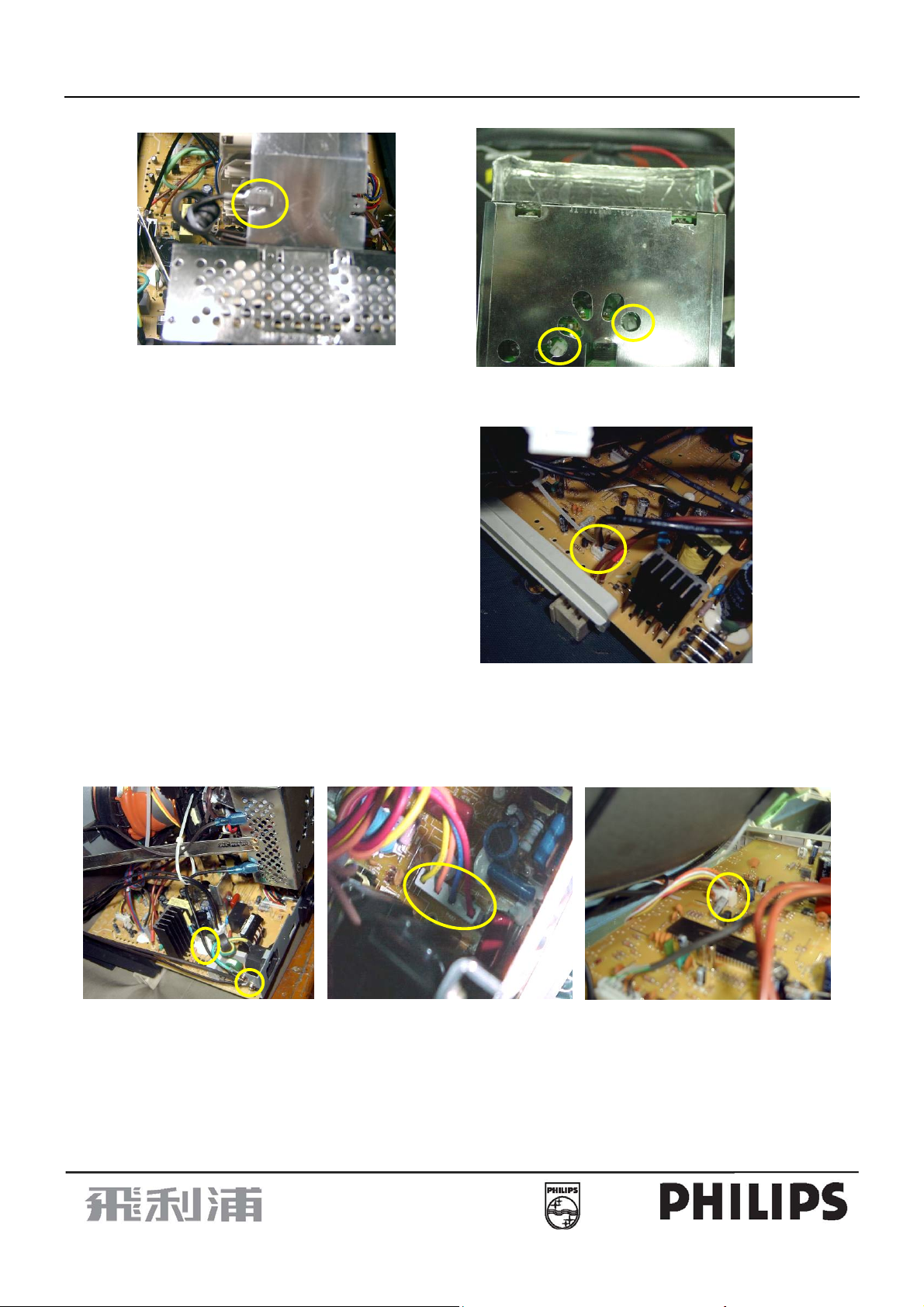

1. Remove the rear cover

Remove 6 screws as shown in Fig. 1 and Fig. 2

Fig. 1

Fig. 2

2. Video board

Remove the main frame as show in Fig. 3

Disconnect the adhesive tape and ground pins

between metal shield of Video board and main

board as shown in Fig. 4 to Fig. 7

Cut the tie between the CRT neck and the video

board as shown in Fig. 8

Fig. 3

Fig. 4

Fig. 5

Fig. 6

25

19” CDT Color Monitor 109B7

g

Fi

. 7

Fig. 8

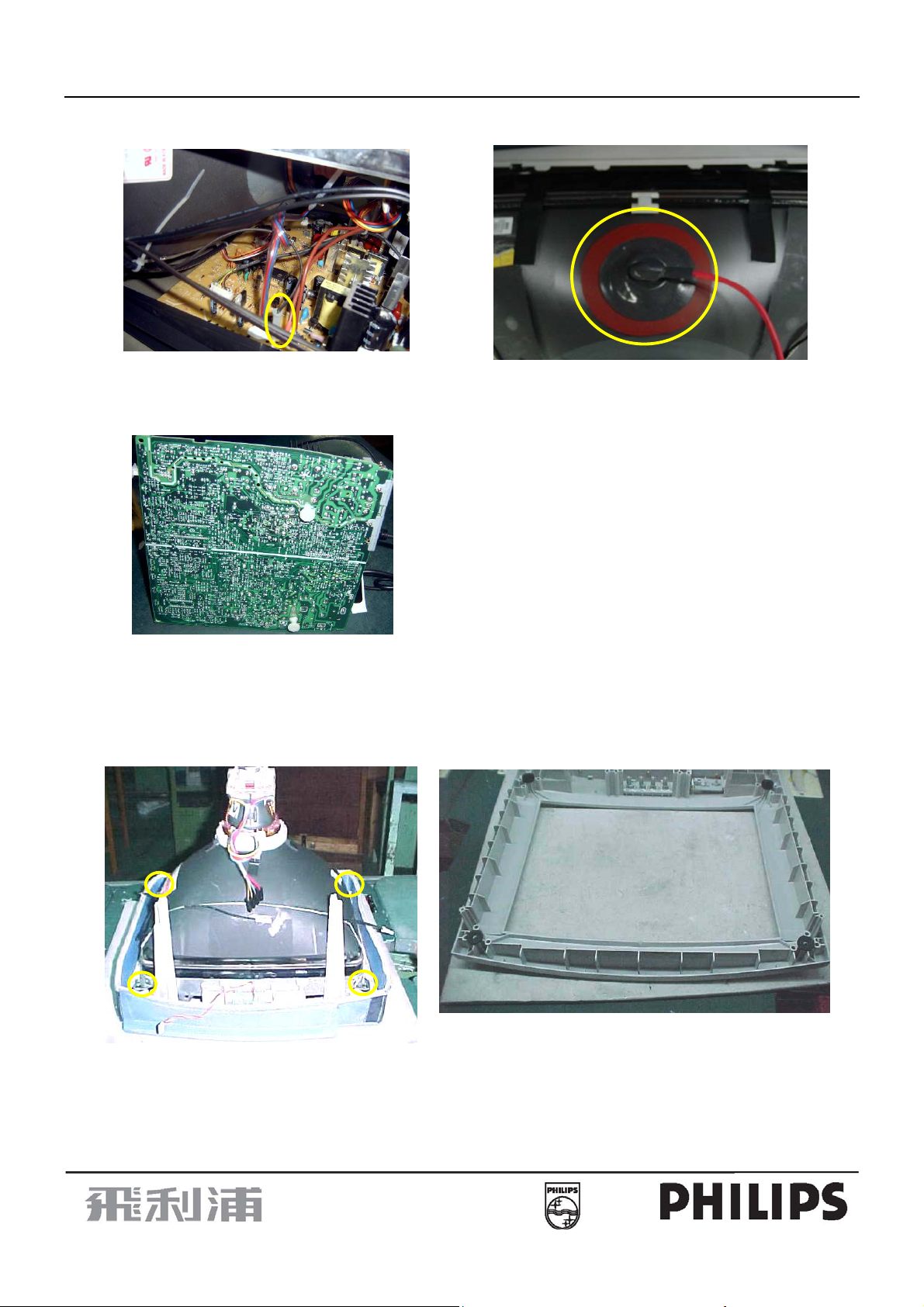

3. Main panel

Disconnect the rotation coil from Main

board as shown in Fig. 9

Disconnect the degaussing coil and ground-screw

from Main board as shown in Fig. 10.

Disconnect the BY coil from Main board

as shown in Fig. 11.

Disconnect the key board connector P102 from

Main board as shown in Fig. 12

Disconnect the ground pins from Main board

as shown in Fig. 13

Disconnect the Hi-Pot cap between the CRT and

Main board as show in Fig. 14.

Fig. 9

Fig. 10

Fig. 11

Fig. 12

26

19” CDT Color Monitor 109B7

Fig. 13

Fig. 14

4. Remove Main board

Fig. 15

5. Remove Front frame

Remove four screws as show in Fig. 16

Fig. 16

27

19” CDT Color Monitor 109B7

7. Trouble Shooting Chart

7-1 No Power (No Voltage)

Source part unconventionality

Check AC correlative loop voltage

OK

Check the two-side voltage of C907 Check the VCC of IC901

OK

Check IC901 VCC

OK

Check the voltage of secondary side of T901

NG

NG

Check full bridge rectifier and C907

Check F901

NG

Check startup circuit

NG

Check IC901 and feedback circuit, T901

OK

Replace T901

28

19” CDT Color Monitor 109B7

7-2. No Picture(The Relative Scan Circuit)

Check IC101 (Pin 16) VCC

about 5V

NG

Check the relative circuit of VCC

OK

Check IC101 Pin52、53

synchro signal

OK

Check IC101 Pin18 B+ driving

signal

NG

Check the relative circuit of

IC101Pin52、53.

OK

Check IC101 Pin20 horizontal

driving signal

OK

NG

Check the relative circuit of

Q901、Q911

NG

Check the relative circuit of the

Q403、T401

Check the waveform horizontal

prompting transistor Q403 collector

OK

NG

Check the relative circuit of Q401、

T401、IC101 Pin39、Pin40、Pin41.

Check the antidromic pulse of

Q403 collector about 1000V

OK

NG

Reference Item3

Check the high voltage about

25KV

NG

Check the relative circuit of main

source.

29

19” CDT Color Monitor 109B7

7-3. No Raster(CRT Relative Circuit Problem)

Check IC801,IC802 VCC about

80V,12V

OK

NG

Check the circuit of Power saving

and main source circuit

Check CRT high voltage about 25KV

OK

Check the CRT filament voltage

about 6.3V

NG

Check Q403、FBT

NG

OK

Check the CRT G2 voltage

about 570V

NG

OK

Check the relative circuit of 6.3V

Check the FBT

Set the brightness DAC for 100,and

then check G1 voltage

OK

about –30V

NG

Check the relative circuit of G1

Check the waveform of R, G, B

cathode and the voltage about 65V

NG

Check the relative circuit of 12V(P802)

30

19” CDT Color Monitor 109B7

7-4. Abnormal Display (The Relative Video Amplifying Circuit)

Check IC801 Pin9 VCC about 12V

NG

Check the relative circuit of 12V

OK

Check IC801 Pin5、6、7

(R,G,B)input signal

OK

NG

Check signal source and

video card

Check IC801 Pin23 vice pulse

and Pin24 blanking signal

OK

NG

Check IC101 Pin8 and horizontal blanking

relative circuit.(references Item5)

Check IC801 Pin19, 20,21

three gun output signal

OK

NG

Check IC801 and IC802

Check IC801 Pin1, 3,4(R, G,

B) zoom circuit output

waveform

NG

Check the relative circuit

of IC803

OK

NG

Check the voltage of CRT tube

socket R, G, B cathode about

65V and the waveform

References Item3

31

19” CDT Color Monitor 109B7

7-5 . No Horizontal Blanking

Check Q403 collector antidromic

pulse about 1000V

OK

NG

Check D701、C412、C410、D705、

D707 and relative component

Check H802 Pin8 waveform

OK

NG

Check P802

Check IC801 Pin24 input waveform

NG

Check relative circuit of IC101

7-6 . A Horizontal Bright Trace

Check the vertical toothed waveform voltage of

IC101 Pin33, 34

Check the inputting vertical toothed waveform

voltage of IC601 Pin6, 7

OK

NG

Check C105、R135、R154

OK NG

Check R603、R604、C601、R601

Check IC601 Pin1,4 VCC about 12V,-12V

OK

Check DY、IC601 and relative component

NG

Check IC601 Pin5 vertical output

NG

Check IC601, DY and relative

32

19” CDT Color Monitor 109B7

7-7 . Abnormal Horizontal Size Function

Adjust H-size function and then

test the variety of IC101 Pin35

OK

NG

Check IC101 B+ adjustment circuit

Check the waveform of IC101 Pin18

OK

Check the variety rang Vcp of Q403

collector antidromic pulse

waveform

Check the relative circuit of IC101 B+

NG

OK

Check high voltage about 25KV

Check the relative circuit of Q401, Q402

NG

References Item4

33

19” CDT Color Monitor 109B7

7-8. Abnormal Vertical Size

Adjust V-size function and then test the

voltage variety of IC101 Pin33, 34

Check the vertical output waveform v of

IC601 Pin5

OK

OK

NG

Check IC601 、R606 and relative circuit

NG

Check IC601, R606

Check the inner setting of IC102

NG

Reinstall IC102(EEPROM)

7-9 . Focus Failure

Adjust the FBT Focus VR and

then check the screen

OK

NG

Check CRT G1

G2 voltage

、

OK

CRT failure

NG

Check FBT Pin13 dynamic

focus waveform

Readjust voltage

NG

OK

Check IC101 Pin24

output waveform

NG

IC101

Check it is horizontal focus

waveform or vertical focus

waveform?

Vertical NG

Horizontal NG

Check Q742、R741、D740 related circuit

Check T403、

C720、C489 related

circuit

34

19” CDT Color Monitor 109B7

8. Mechanical of Cabinet Front Dis-Assembly

35

19” CDT Color Monitor 109B7

9.Spare Parts List

109B70/00

PCB

Part No. for TPV Description Philips P/N (12NC)

CMB995D1NPHP CHASSIS FOR B995D-1PHP 9965 000 36335

CKB985DPHP KEY BOARD 9965 000 36349

CRB985D1NPHP CRT BOARD 9965 000 36398

Panel

Part No. for TPV Description Philips P/N (12NC)

750C55565AV LPD 19" EZ WB CRT 9965 000 36334

750C5Z453AV CPT 19" RF TCO P2 HB CRT 9965 000 36400

Accessory and Mechanical

Part No. for TPV Description Philips P/N (12NC)

071C100504T CORE 9965 000 36326

085C6027604 SHIELD CASE 9965 000 35407

089C404E18NIS POWER CORD 9965 000 37531

705A985DP0003A 19" CRT BEZEL COVER ASS'Y 9965 000 37532

750A169777BKG DEGAUSSING COIL 9965 000 36333

750C55565AV LPD 19" EZ WB CRT 9965 000 36334

750C5Z453AV CPT 19" RF TCO P2 HB CRT 9965 000 36400

CMB995D1NPHP CHASSIS FOR B995D-1PHP 9965 000 36335

Q34C6352BVCT FRONT PANEL 9965 000 37533

Q34C6353VCT BACK COVER 9965 000 37534

Q34C6354VCB SWIVEL 9965 000 37535

Q34C6355VCB BASE 9965 000 37536

Q40C90B8133A RATING LABEL 9965 000 37537

089C73F8TYGG4 SINGEL CABLE 9965 000 37538

9965 000 37532

033C64001 POWER LENS 9965 000 36345

Q33C0002VCTW BEZEL COVER 9965 000 37539

CKB985DPHP KEY BOARD 9965 000 36349

Key Board

Location Part No. for TPV Description Philips P/N (12NC)

SW102 077C6001GCJ TACT SWITCH TSPB-2-NP 9965 000 35740

SW103 077C6001GCJ TACT SWITCH TSPB-2-NP 9965 000 35740

CKB985DPHP KEY BOARD 9965 000 36349

36

19” CDT Color Monitor 109B7

SW104 077C6001GCJ TACT SWITCH TSPB-2-NP 9965 000 35740

SW105 077C6001GCJ TACT SWITCH TSPB-2-NP 9965 000 35740

SW106 077C6001GCJ TACT SWITCH TSPB-2-NP 9965 000 35740

LED1 081C232P LED 9965 000 35741

AKB985DPHP KEY BOARD 9965 000 36350

Main Board

Location Part No. for TPV Description Philips P/N (12NC)

IC902 056C1335ST L7805CV 9965 000 35460

IC903 056C1395A TCET 1103G 9965 000 36352

IC901 056C625500S TEA1507P 9965 000 36353

IC101 056C1125575X SAA4849PS 9965 000 35461

Q416 057C60028 IRF630B 9965 000 36354

PR901 061C52274J PTCR 9965 000 35465

R401 061C20810964 MOFR 1 OHM -5% 1W 9965 000 35466

R907 061C20868164 MOFR 680 OHM -5% 1W 9965 000 35469

R607 061C152M10964 MOFR 1 OHM -5% 2W 9965 000 36355

R455 061C152M22064 22 OHM -5% 2W 9965 000 35474

R723 061C152M22064 22 OHM -5% 2W 9965 000 35474

R424 061C152M39364 MOFR 39KOHM -5% 2W 9965 000 36356

R426 061C152M68164 MOFR 680 OHM -5% 2W 9965 000 36357

R927 061C152M82364 MOFR 82K -5% 2W 9965 000 36358

R456 061C153M15159 MOFR 150 OHM -5% 3W 9965 000 36359

R428 061C153M51859 MOFR 0.51 OHM -5% 3W 9965 000 36360

SG408 062C1016J SPARK GAP 1KV 500-100V JINTAN 9965 000 36361

C472 063C210J1227CC MPP 1.2NF/1.6KV. -5% 9965 000 36362

C419 063C210J1827CC 1800P 1600V 9965 000 36363

C426 063C210J2725CC 2700PF/1KV 9965 000 36364

C422 064C100J22559 2.2UF -5% 100V 9965 000 35485

C410 065C2K4706A692 47PF 2KV 9965 000 36365

C489 065C2K4706A692 47PF 2KV 9965 000 36365

C919 065C2M1033A692 10000PF 2KV 9965 000 36366

C961 065C305M2222BH 2.2NF,400VAC, Y2, M 9965 000 36367

C962 065C305M3322B2 3.3NF,400VAC, Y2, M 9965 000 35489

C963 065C305M3322B2 3.3NF,400VAC, Y2, M 9965 000 35489

C931 067C21522012P LOW E.SD 22UF 250V 9965 000 36368

C930 067C21547010 47UF -20% 160V 9965 000 36369

C481 067C21547012J 47UF -20% 250V JAMICON 9965 000 36370

C936 067C3051019 100UF -20% 100V 9965 000 36371

C606 067C3051023 1000 UF -20% 16V 9965 000 35492

CMB995D1NPHP CHASSIS FOR B995D-1PHP 9965 000 36335

37

19” CDT Color Monitor 109B7

C939 067C3051023 1000 UF -20% 16V 9965 000 35492

C944 067C3051024 1000UF -20% 25V 9965 000 35493

C918 067C3052724 CAP EC 2700UF 25V 12.5X30 LRF 9965 000 36372

C945 067C3054714 470UF -20% 25V 9965 000 36373

C937 067C3054714 470UF -20% 25V 9965 000 36373

C603 067C3054714 470UF -20% 25V 9965 000 36373

C907 067C40D15115P 150UF -20% 450V 9965 000 35497

FB903 071C5524 FERRITE BEAD 10*6.0*0.6 9965 000 36374

FB401 071C55503 FERRITE BEAD 9965 000 35501

FB404 071C55503 FERRITE BEAD 9965 000 35501

FBTF 071C1009 FERRIRE CORE 28.5*17.5*9.5 9965 000 35725

FBTG2 071C100501S CORD 9965 000 36375

L901 073A1747TG LINE FILTER 25MH MIN 9965 000 36376

L401 073C147542H LINEARITY COIL 9965 000 36377

L405 073C25369T CHOKE COIL 150UH -10% 9965 000 35504

L906 073C253513H CHOKE COIL 9965 000 36378

L903 073C25810110T 100UH 9965 000 36379

L904 073C25810110T 100UH 9965 000 36379

L902 073C25818110H 180UH 9965 000 36380

L905 073C25818110H 180UH 9965 000 36380

VR902 075A335222 CFVR 2.2K OHM -20% 9965 000 36381

RY401 077C26054 RELAY 9965 000 35507

RY901 077C26054 RELAY 9965 000 35507

T401 079C167118LC DRIVE TRANSFORMER 9965 000 36382

T403 079C167124HB DRIVER TRANS 9965 000 36383

T402 079C793504LB FBT/BAILI 9965 000 36384

T901 080C995D1N5 TRANSFORMER 9965 000 36385

BD901 093C5046016 U4KB80R 9965 000 36386

D918 093C6073F 31DF4-FC 9965 000 36387

IC601 056C5841A TDA4863A/PHILIPS 9965 000 35520

Q911 057C7514 2SJ584LS 9965 000 36391

005C711 TRANSISTOR HOUSING 9965 000 35735

Q901 057C724502 STP9NK70Z 9965 000 36392

705A995DC5704A D408/Q403 ASS'Y 9965 000 36393

NR901 061C588NL NTCR 16OHM -20%2.5A NANWUNO.11 9965 000 35526

NR901 061C588TL NTCR 15OHM -15%2.5A THINKING 9965 000 35732

F901 084C3310 FUSE CLIP 9965 000 35535

F901 084C7H400SL FUSE 4A 250V LF-618 004 9965 000 35536

087C50166425 AC SOCKET 9965 000 36394

X101 093C2248H 48MHZ 9965 000 35527

E750A 750A5Z459953AK 19" TCO CPT ASS'Y 9965 000 36396

C910 067C3054703T 47UF -20% 16V 9965 000 35584

38

19” CDT Color Monitor 109B7

C929 067C3054704T 47UF -20% 25V 9965 000 36409

C605 067C3054707T 47UF -20% 50V 9965 000 35861

C115 067C3054787T 0.47UF -20% 50V 9965 000 35862

C714 067C3054793T 4U7 16V 9965 000 35586

C434 067C3054797T 4.7UF -20% 50V 9965 000 35863

C436 067C30547910T 4.7UF 160V 9965 000 36410

C119 067C3091003T 10UF -20% 16V 9965 000 35864

C743 067C3091007T 10UF -20% 50V 9965 000 35865

C113 067C3091013T 100UF -20% 16V 9965 000 35866

C118 067C3091097T 1.0UF -20% 50V 9965 000 35867

C145 067C3092204T 22UF -20% 25V 9965 000 35868

C433 067C3092207T 22UF -20% 50V 9965 000 36411

FB902 071C5519T FERRITE BEAD 9X3.5X0.8 9965 000 35812

FB901 071C5519T FERRITE BEAD 9X3.5X0.8 9965 000 35812

FB402 071C5529 FERRITE BEAD 9965 000 35500

FB910 073C5333910T 3.3UH -10% 9965 000 36412

ZD702 093C397352T HZ6B1-E 9965 000 35815

ZD904 093C397752T HZ5C1-E 9965 000 36413

D705 093C3950452T HZ3B2-E 9965 000 36418

ZD101 093C3950752T ZENER DIODE 9965 000 36414

ZD102 093C3951352T HZ6C2-E 9965 000 36415

ZD103 093C3951352T HZ6C2-E 9965 000 36415

ZD104 093C3951352T HZ6C2-E 9965 000 36415

ZD105 093C3951352T HZ6C2-E 9965 000 36415

ZD108 093C3951352T HZ6C2-E 9965 000 36415

ZD726 093C3951652T TZX5V1B 9965 000 36416

ZD701 093C3951652T TZX5V1B 9965 000 36416

ZD107 093C3951652T TZX5V1B 9965 000 36416

ZD901 093C3951852T TZX8V2A 9965 000 36417

ZD106 093C3953052T TZX5V6D 9965 000 35814

ZD902 093C3953052T TZX5V6D 9965 000 35814

D920 093C3956252T P4KE440A 9965 000 36419

D923 093C521ZJ26T SB240 9965 000 36420

D601 093C5247T52T 1N4004 9965 000 35819

D474 093C6026T52T RECTIFIER DIODE FR107 9965 000 35820

D470 093C6026T52T RECTIFIER DIODE FR107 9965 000 35820

D463 093C6026T52T RECTIFIER DIODE FR107 9965 000 35820

D706 093C6044T52T RECTIFIER DIODE FR157S 9965 000 35821

D940 093C641152T 1N4148 4822 130 30621

D939 093C641152T 1N4148 4822 130 30621

D937 093C641152T 1N4148 4822 130 30621

D936 093C641152T 1N4148 4822 130 30621

39

19” CDT Color Monitor 109B7

D707 093C641152T 1N4148 4822 130 30621

D476 093C641152T 1N4148 4822 130 30621

D450 093C641152T 1N4148 4822 130 30621

D409 093C641152T 1N4148 4822 130 30621

D104 093C641152T 1N4148 4822 130 30621

D701 093C6431T52T BAV20 9965 000 36421

D914 093C6431T52T BAV20 9965 000 36421

D912 093C6431T52T BAV20 9965 000 36421

D917 093C6450152T BAV21 4822 130 30842

D915 093C6450752T BAV21 4822 130 30842

D460 093C6450752T BAV21 4822 130 30842

D103 093C10021P52T 1N5817 9965 000 36422

D405 093C10021P52T 1N5817 9965 000 36422

D913 093C10021P52T 1N5817 9965 000 36422

D942 093C10021P52T 1N5817 9965 000 36422

D909 093C102050152T RGP10D 9965 000 36423

D911 093C102050152T RGP10D 9965 000 36423

D740 093C1040252T UF4004 9965 000 35824

D929 093C1040252T UF4004 9965 000 35824

D406 093C10606P52T ER106/PANJIT 9965 000 36424

D407 093C10606Z52T TBYV26C 9965 000 36425

D938 093C106050652T DIODE 9965 000 35825

D910 093C11001C52T BYV26EGP 9965 000 36426

D922 093C2020552T ER202 9965 000 35826

D916 093C20401A ER204 2A 400V 9965 000 36427

R901 061A212Y10552T MGFR 1M OHM -5% 1/2W 9965 000 36428

R921 061A212Y10552T MGFR 1M OHM -5% 1/2W 9965 000 36428

R900 061A212Y10652T 10MOHM -5% 1/2W 9965 000 36429

R741 061A212Y11452T 110K 1/2W 9965 000 36430

R725 061A212Y18452T MGFR 180K OHM -5% 1/2W 9965 000 35528

R480 061A212Y47152T 470 OHM 1/2W 9965 000 36431

R459 061A212Y47252T MGFR 4.7KOHM -5% 1/2W 9965 000 36432

R973 061A212Y82352T MGFR 82K OHM -5% 1/2W 9965 000 36433

R936 061A214Y10252T MGFR 1K 1/4W 9965 000 36434

NR601 061C58450UT NTCR 45OHM -15%3100K UPPERMOST 9965 000 35752

R413 061C17210052T CFR 10OHM -5% 1/4W 9965 000 35753

R989 061C17210052T CFR 10OHM -5% 1/4W 9965 000 35753

R965 061C17210052T CFR 10OHM -5% 1/4W 9965 000 35753

R934 061C17210052T CFR 10OHM -5% 1/4W 9965 000 35753

R475 061C17210052T CFR 10OHM -5% 1/4W 9965 000 35753

R421 061C17210052T CFR 10OHM -5% 1/4W 9965 000 35753

R170 061C17210152T CFR 100OHM -5% 1/4W 9965 000 35754

40

19” CDT Color Monitor 109B7

R909 061C17210152T CFR 100OHM -5% 1/4W 9965 000 35754

R982 061C17210352T CFR 10KOHM -5% 1/4W 9965 000 35756

R983 061C17210352T CFR 10KOHM -5% 1/4W 9965 000 35756

R415 061C17210452T CFR100K OHM -5% 1/4W 9965 000 35757

R471 061C17210452T CFR100K OHM -5% 1/4W 9965 000 35757

R435 061C17210452T CFR100K OHM -5% 1/4W 9965 000 35757

R414 061C17211252T CFR 1.1K OHM -5% 1/4W 9965 000 36435

R418 061C17211352T CFR 11K OHM -5% 1/4W 9965 000 36436

R611 061C17212052T CFR 12 OHM -5%1/4W 9965 000 36437

R150 061C17212452T CFR 120K OHM -5% 1/4W 9965 000 35759

R161 061C17212452T CFR 120K OHM -5% 1/4W 9965 000 35759

R416 061C17212452T CFR 120K OHM -5% 1/4W 9965 000 35759

R950 061C17215452T CFR 150K OHM -5% 1/4W 9965 000 36438

R916 061C17218052T CFR 18 OHM -5% 1/4W 9965 000 36439

R138 061C17218452T CFR 180KOHM -5% 1/4W 9965 000 36440

R972 061C17220252T CFR 2KOHM -5% 1/4W 9965 000 36441

R463 061C17220552T CFR 2MOHM -5% 1/4W 9965 000 35762

R980 061C17222152T CFR 220OHM -5% 1/4W 9965 000 35746

R477 061C17222252T CFR 2.2KOHM -5% 1/4W 9965 000 36442

R442 061C17222252T CFR 2.2KOHM -5% 1/4W 9965 000 36442

R437 061C17222252T CFR 2.2KOHM -5% 1/4W 9965 000 36442

R939 061C17222352T CFR 22KOHM -5% 1/4W 9965 000 35763

R420 061C17222452T CFR 220KOHM -5% 1/4W 9965 000 36443

R476 061C17222452T CFR 220KOHM -5% 1/4W 9965 000 36443

R479 061C17222452T CFR 220KOHM -5% 1/4W 9965 000 36443

R478 061C17222452T CFR 220KOHM -5% 1/4W 9965 000 36443

R904 061C17227252T CFR 2.7KOHM -5% 1/4W 9965 000 36444

R707 061C17230352T CFR 30KOHM -5% 1/4W 9965 000 35764

R715 061C17236352T CFR 36K OHM -5% 1/4W 9965 000 36445

R417 061C17236352T CFR 36K OHM -5% 1/4W 9965 000 36445

R402 061C17236952T 3.6OHM -5% 1/4W 9965 000 36446

R969 061C17239352T CFR 39K OHM -5% 1/4W 9965 000 36447

J080 061C17247052T CFR 47 OHM -5% 1/4W 9965 000 35767

R906 061C17247052T CFR 47 OHM -5% 1/4W 9965 000 35767

R962 061C17247052T CFR 47 OHM -5% 1/4W 9965 000 35767

R912 061C17247152T CFR 470OHM -5% 1/4W 9965 000 35768

R481 061C17247252T CFR 4.7K OHM -5% 1/4W 9965 000 35769

R473 061C17247252T CFR 4.7K OHM -5% 1/4W 9965 000 35769

R460 061C17247252T CFR 4.7K OHM -5% 1/4W 9965 000 35769

R412 061C17247352T CFR 47K OHM -5% 1/4W 9965 000 35770

R967 061C17247352T CFR 47K OHM -5% 1/4W 9965 000 35770

R920 061C17247852T 0.47OHM 1/4 W 9965 000 36448

41

19” CDT Color Monitor 109B7

R923 061C17247852T 0.47OHM 1/4 W 9965 000 36448

R924 061C17247852T 0.47OHM 1/4 W 9965 000 36448

R925 061C17247852T 0.47OHM 1/4 W 9965 000 36448

R147 061C17256352T CFR 56K OHM -5% 1/4W 9965 000 35774

R133 061C17275252T CFR 7.5K OHM -5% 1/4W 9965 000 36449

R726 061C17275252T CFR 7.5K OHM -5% 1/4W 9965 000 36449

R749 061C17275352T CFR 75K OHM -5% 1/4W 9965 000 35780

R918 061C20733252T 3.3K 1/2W 9965 000 36450

R602 061C21020252T MFR 2KOHM -1% 1/6W 9965 000 36451

R604 061C21020252T MFR 2KOHM -1% 1/6W 9965 000 36451

R429 061C30110052T 1/2W 10 OHM FUSIBIE RES 9965 000 36452

R605 061C60210052T CFR 10 OHM -5% 1/6W 9965 000 35781

R111 061C60210052T CFR 10 OHM -5% 1/6W 9965 000 35781

R110 061C60210052T CFR 10 OHM -5% 1/6W 9965 000 35781

R172 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R165 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R159 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R145 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R143 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R140 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R132 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R122 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R117 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R105 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R104 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R103 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R101 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R951 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R933 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R152 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R124 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R126 061C60210352T CFR 10K OHM -5% 1/6W 9965 000 35551

R130 061C60210352T CFR 10K OHM -5% 1/6W 9965 000 35551

R144 061C60210352T CFR 10K OHM -5% 1/6W 9965 000 35551

R149 061C60210352T CFR 10K OHM -5% 1/6W 9965 000 35551

R118 061C60212252T CFR 1.2K OHM -5% 1/6W 9965 000 36453

R938 061C60215052T CFR 15 OHM -5% 1/6W 9965 000 36454

R167 061C60215252T CFR 1.5K OHM -5% 1/6W 9965 000 36455

R106 061C60215352T CFR 15K OHM -5% 1/6W 9965 000 35784

R113 061C60218252T CFR 1.8K OHM -5% 1/6W 9965 000 35785

R114 061C60218252T CFR 1.8K OHM -5% 1/6W 9965 000 35785

R142 061C60218352T CFR 18K OHM -5% 1/6W 9965 000 36456

42

19” CDT Color Monitor 109B7

R162 061C60220352T CFR 20K OHM -5% 1/6W 9965 000 35786

R423 061C60220352T CFR 20K OHM -5% 1/6W 9965 000 35786

R131 061C60222252T CFR 2.2K OHM -5% 1/6W 9965 000 35787

R109 061C60222252T CFR 2.2K OHM -5% 1/6W 9965 000 35787

R108 061C60222252T CFR 2.2K OHM -5% 1/6W 9965 000 35787

R102 061C60224252T CFR 2.4K OHM -5% 1/6W 9965 000 35742

R153 061C60227252T CFR 2.7K OHM -5% 1/6W 9965 000 35788

R932 061C60227352T CFR 27K OHM -5% 1/6W 9965 000 36457

R751 061C60230152T 300OHM 1/6W 9965 000 36458

R931 061C60233152T CFR 330 OHM -5% 1/6W 9965 000 36459

R168 061C60233252T CFR 3.3K OHM -5% 1/6W 9965 000 35553

D991 061C60233252T CFR 3.3K OHM -5% 1/6W 9965 000 35553

R141 061C60233352T CFR 33K OHM -5% 1/6W 9965 000 36460

R440 061C60233352T CFR 33K OHM -5% 1/6W 9965 000 36460

R489 061C60233352T CFR 33K OHM -5% 1/6W 9965 000 36460

R156 061C60236252T CFR 3.6K OHM -5% 1/6W 9965 000 36461

R157 061C60236252T CFR 3.6K OHM -5% 1/6W 9965 000 36461

R928 061C60239152T CFR 390 OHM -5% 1/6W 9965 000 36462

R134 061C60239252T CFR 3.9K OHM -5% 1/6W 9965 000 35789

R116 061C60239252T CFR 3.9K OHM -5% 1/6W 9965 000 35789

R112 061C60247052T CFR 47 OHM -5% 1/6W 9965 000 35790

R119 061C60247052T CFR 47 OHM -5% 1/6W 9965 000 35790

R914 061C60247052T CFR 47 OHM -5% 1/6W 9965 000 35790

R115 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R603 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R601 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R433 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R154 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R151 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R135 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R129 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R125 061C60247152T CFR 470 OHM -5% 1/6W 9965 000 35791

R446 061C60247252T CFR 4.7K OHM -5% 1/6W 9965 000 35554

R158 061C60247252T CFR 4.7K OHM -5% 1/6W 9965 000 35554

R148 061C60247252T CFR 4.7K OHM -5% 1/6W 9965 000 35554

R123 061C60247252T CFR 4.7K OHM -5% 1/6W 9965 000 35554

R107 061C60247252T CFR 4.7K OHM -5% 1/6W 9965 000 35554

R905 061C60262252T CFR 6.2K OHM -5% 1/6W 9965 000 35793

R127 061C60268152T CFR 680 OHM -5% 1/6W 9965 000 36463

R748 061C60268252T CFR 6.8K OHM -5% 1/6W 9965 000 35794

R146 061C60275252T CFR 7.5K OHM -5% 1/6W 9965 000 36464

R902 061C60275252T CFR 7.5K OHM -5% 1/6W 9965 000 36464

43

19” CDT Color Monitor 109B7

R137 061C60275352T CFR 75K OHM -5% 1/6W 9965 000 36465

R910 061C60291352T CFR 91K OHM -5% 1/6W 9965 000 35796

R721 061C175L10252T CFR 1K OHM -5% 1/2W 9965 000 35801

R610 061C175L10952T CFR 1 OHM -5% 1/2W 9965 000 36466

R606 061C175L12152T CFR 120 OHM -5% 1/2W 9965 000 35803

R908 061C175L15052T CFR 15 OHM -5% 1/2W 9965 000 36467

R977 061C175L20452T CFR 200K OHM -5% 1/2W 9965 000 36468

R427 061C175L22052T CFR 22 OHM -5% 1/2W 9965 000 36469

R970 061C175L22452T CFR 220K OHM -5% 1/2W 9965 000 36470

R609 061C175L27152T CFR 270 OHM -5% 1/2W 9965 000 36471

R903 061C175L43152T CFR 430 OHM -5% 1/2W 9965 000 36472

R740 061C175L56352T CFR 56K OHM -5% 1/2W 9965 000 35807

R403 061C175L68352T CFR 68K OHM -5% 1/2W 9965 000 36473

R917 061C203S10452T 100KOHM 1/2W 9965 000 36474

R913 061C203S12452T 120KOHM 1/2W 9965 000 36475

R935 061C203S24452T 240K 1/2W 9965 000 36476

R915 061C203S27252T 2.7K 1/2W 9965 000 36477

R937 061C203S33452T 330K 1/2W 9965 000 36478

R953 061C203S56252T 5.6K OHM 1/2W 9965 000 36479

IC904 056C1584T H431-B 9965 000 36480

Q401 057C417503T 2N3904 9965 000 35827

Q910 057C417503T 2N3904 9965 000 35827

Q913 057C419503T 2SC945P 9965 000 35829

Q912 057C419503T 2SC945P 9965 000 35829

Q903 057C419503T 2SC945P 9965 000 35829

Q422 057C419503T 2SC945P 9965 000 35829

Q412 057C419503T 2SC945P 9965 000 35829

Q408 057C419503T 2SC945P 9965 000 35829

Q407 057C419503T 2SC945P 9965 000 35829

Q907 057C4197APT BC547B 9965 000 36481

Q905 057C420502T 2SA733P 9965 000 35830

Q920 057C420502T 2SA733P 9965 000 35830

Q902 057C4461T 2SC1213ACTZ-E 9965 000 36482

Q906 057C4461T 2SC1213ACTZ-E 9965 000 36482

Q404 057C4463T 2SC2120-Y 9965 000 36483

Q743 057C446500T 2SC1213C 9965 000 35831

Q742 057C49312T BF420 9965 000 35833

Q705 057C4981T BF423 9965 000 36484

Q410 057C5211T 2SD667ACTZ-E 9965 000 36485

Q935 057C5661PH BT169B 9965 000 36486

Q402 057C7341 BSN254A 9965 000 36487

C946 063C212J1042AT MPE 0.1UF/250V -5% 9965 000 36488

44

19” CDT Color Monitor 109B7

C116 064C45G2221AT .0022UF -2% 100V 9965 000 35837

C610 064C176J1041T 0.1UF 5% 100V 9965 000 35838

C601 064C178J1020T 1000PF -5% 63V 9965 000 35841

C401 064C178J1031T CL21X 0.01UF 100V -5% 9965 000 35842

C702 064C178J1031T CL21X 0.01UF 100V -5% 9965 000 35842

C710 064C178J1032T MPE 0.01UF 250V -5% 9965 000 36489

C925 064C178J1032T MPE 0.01UF 250V -5% 9965 000 36489

C941 064C178J1032T MPE 0.01UF 250V -5% 9965 000 36489

C494 064C178J1040T CL21X0.1UF 63V -5% 9965 000 35568

C117 064C178J1521T 1500PF 100V -5% 9965 000 36490

C412 064C178J1521T 1500PF 100V -5% 9965 000 36490

C906 064C178J2231T CL21X 0.022UF 100V -5% 9965 000 36491

C414 064C178J2242T 0.22UF 250V 9965 000 36492

C417 064C178J4740T CL21X. 0.47UF 63V -5% 9965 000 36493

C920 065C1K2215T692 220PF/1KV Y5P -10% 9965 000 36404

C706 065C1K3315T692 330PF/1KV Y5P -10% 9965 000 36494

C928 065C1K4705T692 47P/1KV 9965 000 36495

C720 065C1K5615T692 560PF 10% Y5P 1KV 9965 000 36496

C927 065C2K2215T692 220PF 2000V 9965 000 35846

C947 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C122 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C121 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C110 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C107 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C131 065C44233013T 33PF -5% NPO 50V 9965 000 35847

C127 065C4424719T 470PF 50V 9965 000 36497

C130 065C4441025T 1000 PF 10% 50V Y5P 9965 000 35848

C106 065C4441025T 1000 PF 10% 50V Y5P 9965 000 35848

C105 065C4441025T 1000 PF 10% 50V Y5P 9965 000 35848

C934 065C4442215T 220PF/50V 9965 000 36498

C109 065C4442225T 2200PF 10% Y5P 50V 9965 000 35849

C114 065C4442225T 2200PF 10% Y5P 50V 9965 000 35849

C124 065C4442225T 2200PF 10% Y5P 50V 9965 000 35849

C933 065C4443325T 3300PF 10% 50V Y5P 9965 000 35850

C123 065C4501037T 10000PF/50V Y5V 80% -20% 9965 000 35853

C101 065C4501043T 0.1UF 50V Y5V 9965 000 35854

C102 065C4501043T 0.1UF 50V Y5V 9965 000 35854

C103 065C4501043T 0.1UF 50V Y5V 9965 000 35854

C120 065C4501043T 0.1UF 50V Y5V 9965 000 35854

C411 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C911 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C908 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

45

19” CDT Color Monitor 109B7

C429 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C402 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C128 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C111 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C932 065C4504734T 47000PF -20 80% 50V Z5V 9965 000 36499

C940 065C517K1025T6 1000PF 500V -10% Y5P 9965 000 35580

C914 065C517K1025T6 1000PF 500V -10% Y5P 9965 000 35580

C430 065C517K2225T6 2200PF 10% 500V 9965 000 36500

C740 065C517M1033T6 10NF 500V 9965 000 35857

C935 067C701097T 1UF -20% 50V 9965 000 36501

C967 067C3051007T 10UF -20% 50V 9965 000 36502

C104 067C3051013T 100UF -20% 16V 9965 000 36503

C909 067C3051013T 100UF -20% 16V 9965 000 36503

C483 067C3052213T 220UF -20% 16V 9965 000 36504

C713 067C30522912T 2.2UF -20% 250V 9965 000 35860

C100 067C3054703T 47UF -20% 16V 9965 000 35584

ZR160 093C3953052T TZX5V6D 9965 000 35814

CRB985D1NPHP CRT BOARD 9965 000 36398

9965 000 36393

005C711 TRANSISTOR HOUSING 9965 000 35735

Q417 057C60014 MOSFET 9965 000 36406

Q418 057C60014 MOSFET 9965 000 36406

Q406 057C60021 IRF630M/S.T 9965 000 35518

Q403 057C7057 PHILIPS 1500V/12A BU2527AX 9965 000 36407

D408 093C220512 DMV1500MFD 9965 000 35522

9965 000 36396

750C5Z453AV CPT 19" RF TCO P2 HB CRT 9965 000 36400

C420 063C210J1242CC 0.12UF 250V 9965 000 35718

C425 063C210J2243CC .22U 400V 9965 000 36401

C427 063C210J3342CC .33UF -5% 250V FOR CAMEL 9965 000 36402

C418 063C210J4327CC .0043UF 1600V 9965 000 36403

C428 063C210J7542CC 0.75UF 250V 9965 000 35722

C450 065C1K2215T692 220PF/1KV Y5P -10% 9965 000 36404

TP405 095C201F50182 18" PULSE 9965 000 36405

CRT Board

Location Part No. for TPV Description Philips P/N (12NC)

IC801 056C366521 NT6812KG-20019 9965 000 35539

R846 061C152M15864 0.15 OHM -5% 2W 9965 000 36505

R804 061C175L10152T CFR 100 OHM -5% 1/2W 9965 000 35559

CRB985D1NPHP CRT BOARD 9965 000 36398

46

19” CDT Color Monitor 109B7

C806 065C2M1033FB69 10000PF -20%~ 18% 2KV 9965 000 35488

C844 065C44210013T 10PF -5% NPO 50V 9965 000 35572

C848 067C3051099T 1UF -20% 100V 9965 000 35540

C805 067C3054709 47UF -20% 100V 9965 000 35541

C811 067C3054709 47UF -20% 100V 9965 000 35541

RF804 071C552A FERRITE BEAD 3*5*1.5 9965 000 35499

J818 071C559T CORE RF BEAD RH 3.5X6X0.76TP 9965 000 35562

FB809 071C5521 FERRITE BEAD 10*6.0*0.8 9965 000 35542

IC802 056C551525 LM2476 9965 000 35543

ARB985D1NPHP CRT BOARD 9965 000 36506

R815 061C17215152T CFR 150 OHM -5% 1/4W 9965 000 35544

R819 061C17233452T CFR 330K OHM -5% 1/4W 9965 000 35546

R837 061C17233452T CFR 330K OHM -5% 1/4W 9965 000 35546

R844 061C17233452T CFR 330K OHM -5% 1/4W 9965 000 35546

R806 061C21019252T MFR 1.9KOHM - 1% 1/6W 9965 000 35547

R810 061C21033352T MFR 33K OHM - 1% 1/6W 9965 000 35548

R802 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R805 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R820 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R832 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R835 061C60210152T CFR 100 OHM -5% 1/6W 9965 000 35549

R816 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R813 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R812 061C60210252T CFR 1K OHM -5% 1/6W 9965 000 35550

R814 061C60210352T CFR 10K OHM -5% 1/6W 9965 000 35551

R818 061C60233052T CFR 33 OHM -5% 1/6W 9965 000 35552

R821 061C60233052T CFR 33 OHM -5% 1/6W 9965 000 35552

R836 061C60233052T CFR 33 OHM -5% 1/6W 9965 000 35552

R845 061C60233252T CFR 3.3K OHM -5% 1/6W 9965 000 35553

R830 061C60247052T CFR 47 OHM -5% 1/6W 9965 000 35790

R817 061C60247052T CFR 47 OHM -5% 1/6W 9965 000 35790

R809 061C60247052T CFR 47 OHM -5% 1/6W 9965 000 35790

R822 061C60247252T CFR 4.7K OHM -5% 1/6W 9965 000 35554

R811 061C60256252T CFR 5.6KOHM -5% 1/6W 9965 000 35555

R824 061C60275052T CFR 75 OHM -5% 1/6W 9965 000 35556

R826 061C60275052T CFR 75 OHM -5% 1/6W 9965 000 35556

R834 061C60275052T CFR 75 OHM -5% 1/6W 9965 000 35556

FB804 061C175L56452T CFR 560K OHM -5% 1/2W 9965 000 35561

L809 061C175S10152T CFR 100 OHM -5% 1/2W 9965 000 36508

L808 061C175S10152T CFR 100 OHM -5% 1/2W 9965 000 36508

L807 061C175S10152T CFR 100 OHM -5% 1/2W 9965 000 36508

R828 061C175S33052T CFR 33OHM -5% 1/2W 9965 000 36509

47

19” CDT Color Monitor 109B7

R829 061C175S33052T CFR 33OHM -5% 1/2W 9965 000 36509

R840 061C175S33052T CFR 33OHM -5% 1/2W 9965 000 36509

C815 064C178J1040T CL21X0.1UF 63V -5% 9965 000 35568

C823 064C178J1040T CL21X0.1UF 63V -5% 9965 000 35568

C824 064C178J1040T CL21X0.1UF 63V -5% 9965 000 35568

C830 064C700J3330AT 0.033UF 63V -5% 9965 000 35569

C841 065C1K1025T692 1NF/1KV Y5P -10% 9965 000 36510

C835 065C2K1015T692 100PF/2KV 9965 000 35571

C836 065C2K1015T692 100PF/2KV 9965 000 35571

C842 065C44210013T 10PF -5% NPO 50V 9965 000 35572

C843 065C44210013T 10PF -5% NPO 50V 9965 000 35572

C812 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C809 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C803 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C802 065C44210113T 100PF -5% NPO 50V 9965 000 35573

C839 065C44268013T 68PF -5% NPO 50V 9965 000 36511

C816 065C4441015T 100 PF 10% 50V Y5P 9965 000 35575

C817 065C4441015T 100 PF 10% 50V Y5P 9965 000 35575

C818 065C4441015T 100 PF 10% 50V Y5P 9965 000 35575

C833 065C4441525T 1500PF 10% Y5P 50V 9965 000 35576

C837 065C44447113T 470PF -10% Z5P 50V 9965 000 35577

C814 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C804 065C4501047T 0.1UF 80-20% 50V Y5V 9965 000 35578

C813 065C251K1042T 0.1UF 250V 9965 000 35579

C827 065C251K1042T 0.1UF 250V 9965 000 35579

C829 065C251K1042T 0.1UF 250V 9965 000 35579

C831 065C251K1042T 0.1UF 250V 9965 000 35579

C832 065C251K1042T 0.1UF 250V 9965 000 35579

C849 065C517K1025T6 1000PF 500V -10% Y5P 9965 000 35580

C847 065C517K1025T6 1000PF 500V -10% Y5P 9965 000 35580

C846 065C517K1025T6 1000PF 500V -10% Y5P 9965 000 35580

C834 065C517K1025T6 1000PF 500V -10% Y5P 9965 000 35580

C801 065C517K5612T6 560PF 500V Z5P -10% 9965 000 35581

C820 067C701099T 1UF -20% 100V 9965 000 35582

C821 067C701099T 1UF -20% 100V 9965 000 35582

C822 067C701099T 1UF -20% 100V 9965 000 35582

C808 067C3051003T 10UF -20% 16V 9965 000 36512

C810 067C3052203T 22UF -20% 16V 9965 000 35583

C807 067C3054703T 47UF -20% 16V 9965 000 35584

C819 067C3054703T 47UF -20% 16V 9965 000 35584

C828 067C3054703T 47UF -20% 16V 9965 000 35584

C826 067C3054713T 470UF -20% 16V 9965 000 35585

48

19” CDT Color Monitor 109B7

L805 071C5523 FERRITE BEAD 7.5*3.5*0.8 9965 000 35563

L804 071C5523 FERRITE BEAD 7.5*3.5*0.8 9965 000 35563

J808 071C5523 FERRITE BEAD 7.5*3.5*0.8 9965 000 35563

FB806 071C5523 FERRITE BEAD 7.5*3.5*0.8 9965 000 35563

FB805 071C5523 FERRITE BEAD 7.5*3.5*0.8 9965 000 35563

R841 073C5447810T 0.47UH -10% PEAKING COIL 9965 000 36513

R842 073C5447810T 0.47UH -10% PEAKING COIL 9965 000 36513

R843 073C5447810T 0.47UH -10% PEAKING COIL 9965 000 36513

ZD804 093C3951952T TZX8V2B 9965 000 35588

D809 093C6021P52T PS156R 9965 000 35566

D814 093C641152T 1N4148 4822 130 30621

D813 093C641152T 1N4148 4822 130 30621

D812 093C641152T 1N4148 4822 130 30621

D811 093C641152T 1N4148 4822 130 30621

D805 093C641152T 1N4148 4822 130 30621

D803 093C641152T 1N4148 4822 130 30621

D810 093C6450152T BAV21 4822 130 30842

D808 093C6450152T BAV21 4822 130 30842

D807 093C6450152T BAV21 4822 130 30842

D806 093C6450152T BAV21 4822 130 30842

D804 093C6450152T BAV21 4822 130 30842

D802 093C6450152T BAV21 4822 130 30842

49

19” CDT Color Monitor 109B7

10.Differen parts list

Diversity of 109B72-93 compared with 109B70/00

Location Part No. for TPV Description Philips P/N (12NC)

E089A 089C414A18NIS POWER CORD 9965 000 36327

705A985DP0006A 19" CRT BEZEL COVER ASS'Y 9965 000 38386

Q34C6352BVDF FRONT PANEL 9965 000 38387

Q34C6353VBF BACK COVER 9965 000 38388

Q34C6354VBL SWIVEL 9965 000 38389

Q34C6355VBL BASE 9965 000 38390

Q33C0002VDFW BEZEL COVER 9965 000 38391

Q33C6422VEF KEY PAD 9965 000 38392

R191 061C60224252T CFR 2.4K OHM -5% 1/6W 9965 000 35742

R194 061C60224252T CFR 2.4K OHM -5% 1/6W 9965 000 35742

R192 061C60256252T CFR 5.6KOHM -5% 1/6W 9965 000 35555

R193 061C60256252T CFR 5.6KOHM -5% 1/6W 9965 000 35555

IC102 056C11332PH M24C16-WBN6/P 9965 000 35462

Diversity of 109B73/93 compared with 109B70/00

Location Part No. for TPV Description Philips P/N (12NC)

V000 012C3851 RUBBER FOOT 9965 000 35354

023C31558131A LOGO 9965 000 36315

V000 040C152509 RECYCLE LABEL 9965 000 35703

V000 040C152512 RECYCLE LABEL 9965 000 35704

040C58162435A MANUAL P/N LABEL 9965 000 35400

040C5818131A CARTON LABEL 9965 000 35401

044C600012A CARTON 9965 000 36316

044C60027868A PAPER BOARD 9965 000 36317

044C69341 EPS CUSHION 9965 000 36318

044C69342 EPS CUSHION 9965 000 36319

044C9003194 CORNER PAPER 9965 000 36320

045C7620RN PE BAG FOR MONITOR 9965 000 36321

045C7628RN PE BAG FOR MANUAL 9965 000 35404

V000 045C7634RN PE BAG FOR BASE 9965 000 36322

045C88539 OUT PE BAG 9965 000 36323

045C88601C EPE COVER 9965 000 36324

070CD9188131B CD MANUAL 9965 000 36325

E089A 089C414A18NIS POWER CORD 9965 000 36327

095C91205813 WIRE HARNESS 9965 000 36328

095C2070600 BRAID WIRE 9965 000 36329

0D1C10306128 SCREW 9965 000 36330

50

19” CDT Color Monitor 109B7

0D1C1030847 SCREW 9965 000 36331

0Q1C3401647 SCREW 9965 000 35435

705A985DP0005A 19" CRT BEZEL COVER ASS'Y 9965 000 36332

Q34C6352BVDT FRONT PANEL 9965 000 36336

Q34C6353VBT BACK COVER 9965 000 36337

Q34C6354VBB SWIVEL 9965 000 36338

Q34C6355VBB BASE 9965 000 36339

Q40C90B8134A RATING LABEL 9965 000 36340

Q41C688139B WARRANTY CARD 9965 000 36341

Q41C6881316A QSG 9965 000 36342

Q44C69348132A CARTON 9965 000 36343

E089B 089C73B8TYGG4 SIGNAL CABLE D-SUB GREATLAND 9965 000 36344

0Q1C3406128 SCREW FOR KEPC 9965 000 36346

Q33C0002VDTW BEZEL COVER 9965 000 36347

Q33C6422VET KEY PAD 9965 000 36348

H102 095C80135633 WIRE HARNESS 9965 000 36351

040C5816242B CHASSIS LABEL 9965 000 35459