Philips 107S7 Schematic

17” CDT Color Monitor 107S7

Service

Service

Service

Horizontal Frequency

30-71 kHz

Table of contents

Description Page Description Page

Table Of Contents...................................................1

Revision List...........................……………...........................2

Important Safety Notice...................……………….............3

1. Specifications..........………………................................4

2. Precaution and notices..………………............................7

2-1.Safety precautions....…........……......…..............7

2-2 Product safety notice ……….........................................7

2-3. Service Notices........………………..........…………......7

2-4. High voltage warning..........................................…8

3. Operating Instructions.....................…………….........9

4. Adjustment .............................………………….....10

4-1. Adjustment conditions and precautions ...……........10

4-2. Main adjustments.........................…………………....10

4-3.Adjustment methods.….......................................13

4-4. DDC Instructions………….……………………..……..16

5.Circuit description ..………………………............20

5-1.Micro controller and deflection circuit ..........20

5-2.Transistor & diode circuit..............…………................22

6.Mechanical Instructions…………………...….……23

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING

ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFOMER FOR THIS UNIT WHEN SERVICING

7. Trouble shooting chart..………...................................26

7-1.No raster,CRT relative circuit problems……..................26

7-2. Abnormal displays................…………………….….......28

7-3. No blanking……………...…...........................................29

7-4. Hor./OSC/DEF/HV circuit fault.....….........................29

7-5. Abnormal horizontal deflection...................................30

7-6. Abnormal vertical scanning........……..…......................31

7-7. Side-pin cushion distortion…………………...................31

7-8. Poor focus.……........……............……..........................31

7-9. Power supply trouble shooting chart..……….............32

8. Block diagram................……………..........................33

9. IC block diagrams.......….………...................................34

10. PCB layout............…………………..............................38

10-1 Main Board PCB layout...…..........……........................38

10-2 CRPC board layout.....…………..................................39

11. Schematic diagram.…………........................................40

12. Mechanical of cabinet front Dis-assembly…….……......44

13. Spare parts list................……………….......................45

14. Different Parts List…………………………………..……..59

15. General Product Specification……………...…..………72

GB

1

3138 106 10534

17” CDT Color Monitor 107S7

Revision List

Version Date Revision History

A00 May.20. 2006

A01 Jun.13. 2006

A02 Sep-15-2006

A03 Oct-25-2006

A04 Nov-10-2006 Revise the DDC Kit 12NC

A05 Jan-18-2007

Add CTV model 107S71/75, 107S71/77, 107S76/75 in

Item 10.

Add CTV model 107S77/00 in Item 10

Change CPU P/N , R134 and R607 P/N

Add To Lock/Unlock OSD function in Page 11

Initial Release

Add service kit in page 45

2

17” CDT Color Monitor 107S7

Important Safety Notice

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINGS

Proper service and repair is important to the safe, reliable operation of all PHILIPS Company Equipment. The service

procedures recommended by PHILIPS and described in this service manual are effective methods of performing

service operations. Some of these service operations require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service personnel. The possibility exists that improper service methods

may damage the equipment. It is also important to understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. PHILIPS could not possibly know, evaluate and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each way. Consequently, PHILIPS has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not

recommended by PHILIPS must first satisfy himself thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

Hereafter throughout this manual, PHILIPS Company will be referred to as PHILIPS.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create shock,

fire, or other hazards.

Under no circumstances should the original design be modified or altered without written permission from PHILIPS.

PHILIPS assumes no liability, express or implied, arising out of any unauthorized modification of design. Servicer

assumes all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER - Invisible laser radiation when open. AVOID DIRECT EXPOSURE TO BEAM.

CAUTION - Use of controls or adjustments or performance of procedures other than those

CAUTION - The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY

ORIGINAL MANUFACTURER'S REPLACEMENT PARTS, WHICH ARE LISTED WITH

THEIR PART NUMBERS IN THE PARTS LIST SECTION OF THIS SERVICE MANUAL.

specified herein may result in hazardous radiation exposure.

3

17” CDT Color Monitor 107S7

1. Monitor Specifications

1. CRT : 43.2CM(17") F&S high contrast CRT, 90 Deflection, 29mm Neck, 0.25mm phosphor dot pitch, NonGlare Screen

2. Viewable image Size: 40.6CM (16") diagonal

3. Display Color: Unlimited Colors

4. External Controls:

Power On/Off, OSD key, OSD Function: Contrast, Brightness, H-Center, H-Size, H-Center, V-Size, Zoom,

Pincushion, Trapezoid, Pin-Balance, Parallelogram, Rotation, 6500 Color Temperature, User Color, 9300 Color

Temperature, Degauss, Moire Reduce, Recall, Exit, Language.

5. Input Video Signal

6. Display Size

Horizontal: 306mm ± 4mm

Vertical: 230mm ± 4mm

7. Scanning Frequencies

Horizontal: 30KHz ~ 71KHz

Vertical: 50 Hz ~ 160 Hz

8. Factory Preset Timings: 8

User Timings: 6

GTF supported

9. Misconvergence

10. Video Bandwidth: 110 MHz

11. Power Source:

Switching Mode Power Supply

AC 90 ~264V, 50/60

,anti-static

Timing 1. 2. 3.

Resolution 640 x 480 640 x 480 720 x 400

H. Frequency 31.469 kHz 43.269 kHz 31.468 kHz

V. Frequency 59.941 Hz 85.008 Hz 70.084 Hz

H/V sync polarity

Timing 4. 5. 6.

Resolution 800 x 600 800 x 600 1024 x 768

H. Frequency 46.875 kHz 53.674 kHz 60.023 kHz

V. Frequency 75.000 Hz 85.061 Hz 75.029 Hz

H/V sync polarity

Timing 7. 8.

Resolution 1024 x 768 1280 x 1024

H. Frequency 68.677 kHz 63.981 kHz

V. Frequency 84.997 Hz 60.020 Hz

H/V sync polarity

Zone A < 0.25 mm

Zone B < 0.35 mm

- / - - / - - / +

+ / + + / + + / +

+ / + + / +

0.4mm (for modes < 50kHz).

<

± 3 Hz Universal Type.

4

17” CDT Color Monitor 107S7

12. Operating Temperature: 0°C to 40°C Ambient

13. Humidity: 5% to 90% Relative, Non-Condensing

14. Weight: Net weight - 13.5 kg

Gross weight - 15.8 kg (for China, India)

15.4 kg (for other regions)

15. Dimensions Monitor:

Unit dimension (with stand) - 397mm (W) x 382mm (H) x 423.5mm (D)

Packed unit dimension (carton) - 460mm (W) x 450mm (H) x 526mm (D) for China, India

446mm (W) x 420mm (H) x 475mm (D) for other regions

16. External Connection:

15 Pin D-type Connector

AC Power Cord

17. Power Consumption Modes :

Power on - < 75w.

DPMS off state - < 2w at 240Vac.

Power off (by switch) - < 1w at 120Vac, <2w at 240Vac.

18.Regulations:

International Regulatory Specification

Country Domain Safety / EMC / Ergonomics / Standards Documents

IEC60950-1: 2001. Group -and national

INTERNATIONAL Sa

Sa

EUROPE

E

Sa EN60950-1: 2001 TUV certificate

O

GERMANY

O GS-Mark / EK1-ITB 2000 TUV-GS certificate

differences of all countries listed in CB

Bulletin No. 107A

European Low Voltage Directives

73/23/EEC and 93/68/EEC

European Electromagnetic Compatibility

Directive 89/336/EEC amended by the

directive 93/68/EEC. EN 55022:1998

Class B

EN 55024: 1998

EN 61000-3-2: 2000

IEC 61000-3-3: 1994/EN61000-3-3:

1995

CISPR 22:1997 Class B International

EMC standard

ISO 9241-3-7-8 (CRT) & 13406-2 (LCD),

prEN 50279:1998

CB Report and CB certificate

Declaration of Conformity

Declaration of Conformity and Full EMC/CE

TUV-ERG certificate

test report

X Decree ROV 08.01.87 (CRT) PTB

5

17” CDT Color Monitor 107S7

Sa EN60950-1: 2001 SEMKO certificate

SWEDEN

RUSSIA Sa GOST R 50377-1992 GOST certificate

SOUTH AFRICA

USA

CANADA

MEXICO Sa NOM-019-SCFI-1994 NOM certificate

KOREA

SINGAPORE Sa IEC60950 PSB certificate

O TCO 99 (TCO03) (to TCO models) TCO99 (TCO03) report + certificate

O

Sa SABS IEC 60950 and IEC 60950-1 Certificate of Conformity

E EN55022 or Cisper 22 Certificate of Conformity

Sa UL 60950-1: 2003 UL certificate

E FCC Part 15 Class B FCC ID grant or DOC

O Energy Star EPA registration

X 21CFR 1002.10 to 13 (CRT) DHHS report

Sa CSA C22.2 No 60950 CSA certificate

E ICES-003 issue 3 Statement on label

E RED (CRT) DNHW

Sa Korean Safety Control law IEC 60950 eK certificate

E

MPR 1990: 8 / MPR 1990:10 (to MPR

models)

Regulations laws: EMI 1996-78, 80. EMS

1996-79,81

Meet requirement

MIC certificate

Sa GB4943-2001

CHINA

TAIWAN

AUSTRALIA/

NEW-ZEALAND

ISRAEL

Saudi Arabia

Japan

Argentina Sa EN60950-1: 2001

Sa = Safety

E = Electromagnetic Compatibility

O = Other which including recycling, energy saving, ergonomics

X = X-ray

For detailed regulatory items please refer to the international regulatory specification provided by Philips.

E GB9254-1998; 17625.1-2003

O CSC/G1205-2004 CECP certificate

Sa CNS-14336 (IEC 60950-1)

E CNS-13438 (CISPR22) Class B

O Criteria 18 (Monitor) (LCD) Green Mark / certificate

E AS/NZS3548: 1995 Declaration of Conformity

S IS 1121, IEC60950/IEC60950-1 Certificate of Conformity

E EN or Cisper 22 Certificate of Conformity

S IEC standard SASO

E IEC standard SASO

Sa EN60950-1:001 (AC adapter only) PSE

E

VCCI class B (CISPR 22) VCCI Certificate

CCC certificate

BSMI certificate

IRAM

6

17” CDT Color Monitor 107S7

2. Precautions and notices

2-1.Safety precautions

1. Observe all caution and safety related notes located inside the display cabinet.

2. Operation of the display with the cover removed, may cause a serious shock hazard from the display power

supply. Work on the display should not be attempted by anyone who is not thoroughly familiar with

precautions necessary when working on high voltage equipment.

3. Do not install, remove or handle the picture tube in any manner unless shatter-proof goggles are worn.

People who are not so equipped should be kept away while handling picture tube. Keep picture tube away

from the body while handling.

4. The picture tube is constructed to limit X-RAY radiation to 0.5 mR/HR. For continued protection, use the

designated replacement tube only, and adjust the voltages so that the designated maximum rating at the

anode will not be exceeded.

5. Symbol“

the same characteristics as specified in the parts list may create shock, fire or explode etc.

6. Symbol“ ” means X-ray relative parts. Before replacing any of these components please read the parts

list in this manual carefully to avoid creating higher anode voltage or x-ray. Especially for sealed controls,

such as VR902, VR903, VR701 and FBT screen VR etc, which were sealed by the manufacturer once their

optimum position has been set, please don’t dismantle them as your likes, otherwise you will break or

damage the component. If you need replace the parts with sealed control, please adjust the relative VR to

make sure the B+ voltage under 59V and well seal it with A+B glue or equivalent, which you can not move

away with one screw driver

7. Before returning a serviced display to the customer, a thorough safety test must be performed to verify that

the display is safe to operate without danger or shock. Always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as screw heads.

Test method for current leakage is described as follow.

(a) Plug the AC line cord directly into rated AC outlet (do not use a line isolation transformer during this

(b) Use an AC voltmeter having 5000 ohms per volt or with more sensitivity in the following manner:

(c) Reverse the AC plug at the AC outlet and repeat AC voltage measurements for each exposed metallic

(d) Voltage measured must not exceed 0.5 volts RMS. This corresponds to 0.35 milliamp AC. Any value

2-2 Product safety notice

Many electrical and mechanical parts in this chassis have special safety visual inspections and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for higher voltage,

wattage, etc. Before replacing any of these components read the parts list in this manual carefully. The use of

substitute replacement parts which do not have the same safety characteristics as specified in the parts list may

create shock, fire, X-RAY radiation or other hazards.

2-3 Service notes

1. When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

2. When replacing a high wattage resistor (more than 1/2W of metal oxide film resistor) in circuit board, keep

the resistor about 10mm (1/2 in) away from circuit board.

3. Keep wires away from high voltage or high temperature components.

4. Keep wires in their original position so as to reduce interference.

!

“ means safety relative parts. The use of substitute replacement parts which do not have

check).

Connect a 1500 ohms 10 Watt resistor, paralleled by a 0.15UF, AC type capacitor between a known

good earth ground (water pipe, conduit, etc.) and the exposed metallic parts simultaneously. Measure

the AC voltage across the combination of 1500 ohms resistor and 0.15UF capacitor.

part.

exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

7

17” CDT Color Monitor 107S7

2-4 High voltage warning

Operation of monitor outside of cabinet or with back removed may cause a serious shock hazard. Work on this

model should only be performed by those who are thoroughly familiar with precautions necessary when working

on high voltage equipment.

Exercise care when servicing this chassis with power applied. Many B plus and high voltage terminals are

exposed which, if carelessly contacted, can cause serious shock or result in damage to the chassis. Maintain

interconnecting ground lead connections between chassis and picture tube dag when operating chassis.

Certain HV failures can increase X-ray radiation. Monitor should not be operated with HV levels exceeding the

specified rating for the chassis type. The maximum operating HV specified for the chassis used in this monitor is

25KV ±0.8KV

with a line voltage of 120/240 VAC. Higher voltage may also increase possibility of failure in HV supply.

It is important to maintain specified values of all components in the horizontal and high voltage circuits and

anywhere else in the monitor that could cause a rise in high voltage or operating supply voltages. No changes

should be made to the original design of the monitor. Components shown in the shaded areas on the schematic

should be replaced with exact factory replacement parts. The use of unauthorized substitute parts may create a

shock, fire or other hazard.

To determine the presence of high voltage, use accurate, high impedance, HV meter connected between second

anode lead and CRT dag grounding device. When servicing the High Voltage System, remove static charge from

it by connecting a 10K ohm resistor in series with an insulated wire (such as a test probe) between picture tube

dag and 2nd anode lead.(AC line cord disconnected from AC power outlet.)

The picture tube used in this monitor employs integral implosion protection. Replace with tube of the same type

number for continue safety. Do not lift picture tube by the neck. Handle the picture tube only after discharging the

high voltage completely.

8

17” CDT Color Monitor 107S7

3. Operating instructions

This procedure gives you instructions for installing and using the Color display.

1. Position the display on the desired operation and plug the power cord into a convenient AC outlet. Threewire power cord must be shielded and is provided as a safety precaution as it connects the chassis and

cabinet to the electrical conduit ground. If the AC outlet in your location does not have provisions for the

grounded type plug, the installer should attach the proper adapter to ensure a safe ground potential.

2. Connect the 15-pin color display shielded signal cable to your signal system device and lock both screws on

the connector to ensure firm grounding. The connector information is as follow:

Pin No.

Description Pin No. Description

1. Red video 9. +5V (Supply from PC for DDC circuit)

2. Green video 10. Sync GND

3. Blue video 11. GND

4. Self test 12. DDC serial data

5. DDC return 13. H-sync

6. Red GND 14. V-sync

7. Green GND 15. DDC serial clock

8. Blue GND

3. Apply power to the display by turning the power switch to the "ON" position and allow about thirty seconds

for display tube warm-up. The Power-On indicator lights when the display is on.

4. With proper signals feed to the display, a pattern or data should appear on the screen, adjust the brightness

and contrast to the most pleasing display.

5. This monitor has power saving function following the VESA DPMS. Be sure to connect the signal cable to

the PC.

6. If your color display requires service, it must be returned with the power cord.

1

6

11 15

5

10

15 - Pin Color Display Signal Cable

9

17” CDT Color Monitor 107S7

4. Adjustment

4-1. Adjustment conditions and precautions

1. Approximately 30 minutes should be allowed for warm up before proceeding.

2. Adjustments should be undertaken only on those necessary elements since most of them have been carefully

preset at the factory.

4-2. Main adjustments

10

17” CDT Color Monitor 107S7

Description of the On Screen Display

What is the On-Screen Display?

This is a feature in all Philips monitors which allows an end-user to adjust screen performance of

monitors directly through an on-screen instruction window. The user interface provides userfriendliness

and ease-of-use when operating the monitor.

Basic and simple instruction on the control keys.

On the front controls of your monitor, once you press the MENU button, the On Screen Display

(OSD) Main Controls window will pop up and you can now start making adjustments to your

monitor's various features. Use the (-) (+) to make your adjustments within.

To Lock/Unlock OSD function (User Mode)

The OSD function can be locked by pressing “MENU” button for more than 10 seconds.

Locked OSD function can be released by pressing “MENU” button for more than 10 seconds again.

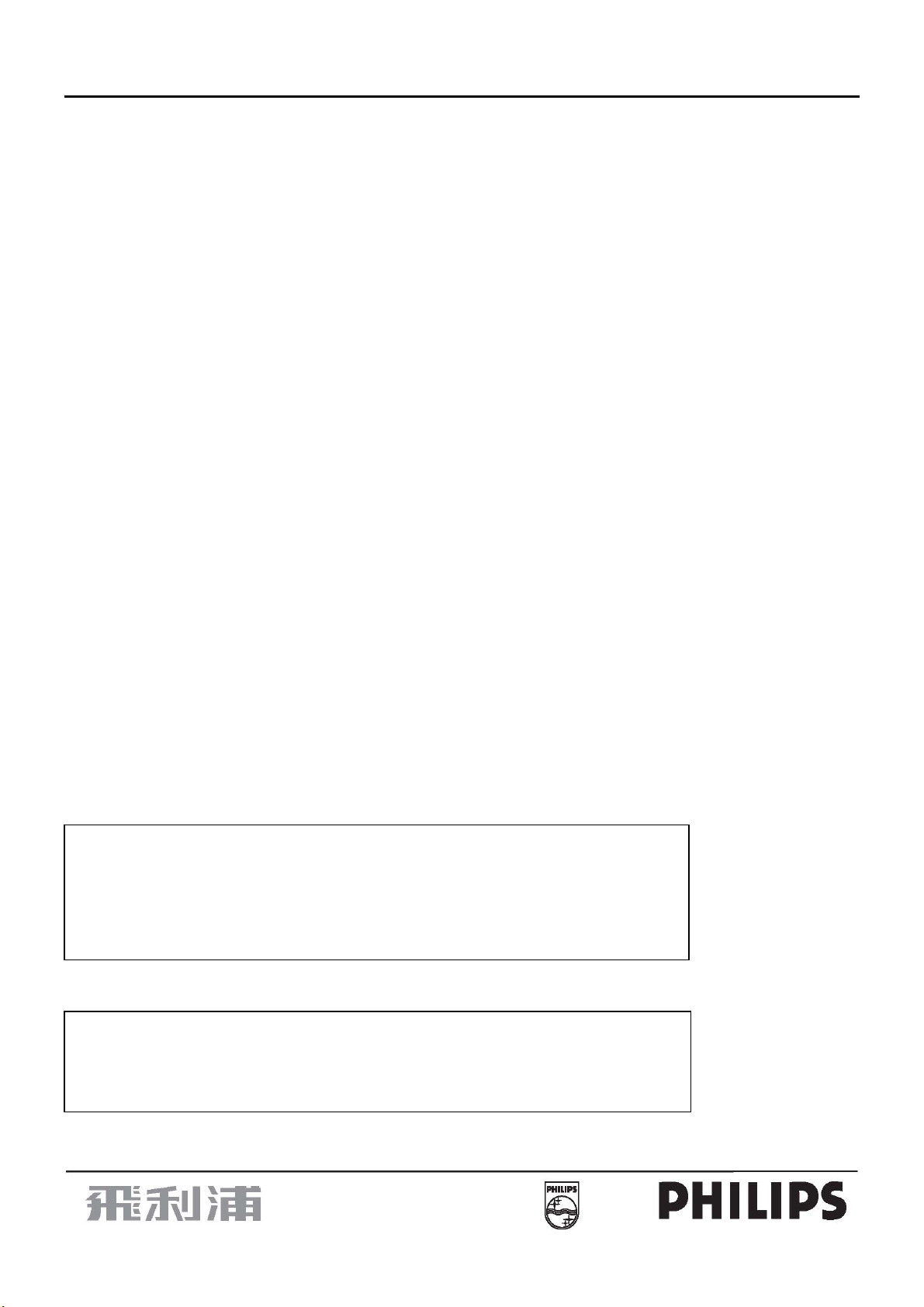

The OSD Tree

Below is an overall view of the structure of the On-Screen Display. You can use this as reference

when you want to later on work your way around the different adjustments.

Your monitor may not include all the items in the OSD tree shown below.

11

17” CDT Color Monitor 107S7

12

17” CDT Color Monitor 107S7

4-3. Adjustm ent method

1. B + ,G2 voltage adjustment:

A. Chroma-2135 Signal generator or PC equivalent set mode 6, UVGA 640X480 pattern 101 .

B. Connect a DC Volt meter between TP902 and ground, then adjust VR902 to be 57±0.2 VDC for CPT and

LPDCRT.

C. Set the contrast and brightness max,and then adjust G2=600V for CPT CRT and G2=560V for LG CRT.

2. Factory preset Timings Adjustment:

A. Press MENU Key to show OSD window press Up or Down Key to switch the functional controls.

B. Press the Up Key to select the "ZOOM" function, then press the MENU Key. While do not release the

MENU Key until the OSD window changed to the Factory preset window.

C. The Factory preset window contains the following functional controls. Select one of the control. Then press

the Up/Down Key to adjust its value for the optimum picture.

SR

55

OS

LH

SB

BI

SW Set H/Freq Max 85~72K HBRIOSD VC

DC

AB

OV

OH

EA

Save SRGB color

Save 5500C color

User OSD size

Brightness

SBQ

Set Burn/in Off & On

DCOffset ADJ

ABL

User OSD VC

User OSD HC

EHT Auto Adjustment

VO

VG

HM

HR

HS

HG

V Offset

V Gain

H size Max

H Size Range

HSUB Size Range

H Gain

HBRIOSD HC

User adjustment

Save and Exit

Degauss

B-Bias

HE

VE

EO

HEHT Gain

VEHT Gain

EHT Offset

13

G-Bias

R-Bias

G-Gain

17” CDT Color Monitor 107S7

EU

BP

BB

TB

HB

HS

TM

65

93

VF

VB

VI

HL

BC

EHT Current

B Plus

Bottom Balance

Top Balance

HS Wave Balance

HSWAVE

User Timr:00273hours

Save 6500C color

Save 9300C color

V-Focus

VLIN Balance

V Linearity

H Linearity

Bottom Corner

B-Gain

R-Gain

Brightness

Contrast

V-Moire Reduce

H-Moire Reduce

PIN-Balance

Parallelogram

Trapezoid

Pincushion

Rotation

V- Center

V-size

H-Center

TC

TOP Corner

H -size

D. To switches the input signal to the other Timing Mode. Please follow step A ~ C to get the optimum picture.

E. Select the "

" RETURN function and press the MENU Key, then the Factor Preset window will be

returned to the original OSD window.(user's operating condition)

F. The setting data of the CONTRAST, BRIGHTNESS, COLOR TEMPERATURE are common mode saved

in the memory. Don't needed adjust it individual at every timing Mode and save in the memory.

3. White Balance, Luminance adjustment:

A. Press MENU Key to show OSD menu ,and press the down Key to select the "zoom" function, then press

the menu Key to enter second menu, press the down key to select “

“above 10S,then enter into factory

setting area for modulation.

B. Brightness & contrast ratio MAX.

C. Raster Max modulation: Raster Pattern, adjust R or B bias and G2, make x=270±10, y=290±10, Y=2.0±0.2

2

cd/m

D. Raster cut off modulation: Raster Pattern, adjust brightness to make Cut off: 0.08±0.02 cd/m

2

9300K & 6500K into it.

E.Small white screen appears,

(1).Choose 4 for LH ,set R or G or B gain, make x=283±15, y=297±15,Y=350±15 cd/m

Raster cut off, make SB to select 4

2

,then save it into

9300K color temperature, set R or G or B gain, make x=313±15, y=329±15,Y=300±15, then save it into

6500K color temperature, then exit the factory setting area.

(2). Choose 3 for LH,set R or G or B gain, make x=283±15, y=297±15,Y=270±15,then save it into 9300K

color temperature; set R or G or B gain, make x=313±15, y=329±15,Y=250±15,then save it into 6500K color

temperature, then exit the factory setting area.

(3). Choose 2 for LH,set R or G or B gain, make x=283±15, y=297±15,Y=210±15,then save it into 9300K

color temperature, set R or G or B gain, make x=313±15, y=329±15,Y=200±15,then save it into 6500K color

temperature, then exit the factory setting area.

,and then put

14

17” CDT Color Monitor 107S7

(4). Choose 1 for LH,set R or G or B gain, make x=283±15, y=297±15,Y=140±15

cd/m

2

,then save it into

9300K color temperature, set R or G or B gain, make x=313±15, y=329±15,Y=130±15,then save it into 6500K

color temperature.

F. White screen appears, brightness cut off, set “SB” as 4,adjust AB value, make 9300K color temperature

Y=98±1 cd/m

temperature Y=96±1 cd/m

temperature Y=94±1 cd/m

temperature Y=92±1 cd/m

2

,then save it into 9300K color temperature; set “SB” as 3,adjust AB value, make 9300K color

2

,then save it into 9300K color temperature; set “SB” as 2, make 9300K color

2

,then save it into 9300K color temperature; set “SB” as 1, make 9300K color

2

,then save it into 9300K color temperature.

G. After modulation, it’s necessary to check if the white balance accords with the normal specification. If not,

needs reset. then exit factory setting area.

4.Focus Adjustment:

A. Set mode7 1024×768@85Hz with character full page.

B.Under the RECALL state.

C.Then adjust focus VR1 to a fine vertical line.

D.Adjust focus VR2 to a fine horizontal line.

E. Repeat step C & D,after that ,set the Focus VR,G2 VR with the white lacquer.

5. Purity Adjustment

A. Be sure that the display is not being exposed to any external magnetic fields.

B.Ensure that the spacing between the Purity, Convergence, Magnet, (PCM), assembly and the CRT stem is

29mm. (See below diagram)

C.Produce a complete, red pattern on the display. Adjust the purity magnet rings on the PCM assembly to

obtain a complete field of the color red. This is done by moving the two tabs in such a manner that they

advance in an opposite direction but at the same time to obtain the same angle between the two tabs, which

should be approximately 180'.

D.Check the complete blue and complete green patterns to observe their respective color purity. Make minor

adjustments if needed.

Relative placement of typical components

6. Convergence adjustment

A. Produce a magenta crosshatch on the display.

B. Adjust the focus for the best overall focus on the display.

Also adjust the brightness to the desired condition.

C. Vertical red and blue lines are converged by varying the angle between the two tabs of the 4 pole magnets

on the PCM assembly. (See above diagrams)

D. Horizontal red and blue lines are converged by varying the two tabs together, keeping the angle between

them constant.

E. Produce a white crosshatch pattern on the display.

F. Vertical green and magenta lines are converged by varying the angle between the two tabs of the 6-pole

magnets.

G. Horizontal green and magenta lines are converged by varying the two tabs together, keeping the angle

between them constant.

Purity Magnets

6-pole Convergence Magnets

4-pole Convergence Magnets

Deflection Yoke

15

17” CDT Color Monitor 107S7

4-4. DDC Instructions

128 bytes EDID Data (Hex):

00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

0 00 FF FF FF FF FF FF 00 41 0C 1C 00 01 00 00 00

16 01 0F 01 03 68 20 18 78 2B 9E A8 A1 54 46 99 24

32 0E 48 4C A5 6E 00 31 59 31 68 45 59 45 68 61 59

48 71 4F 81 40 81 80 EA 24 00 60 41 00 28 30 30 60

64 13 00 36 E6 10 00 00 1E 00 00 00 FF 00 41 55 30

80 35 30 31 30 30 30 30 30 31 0A 00 00 00 FD 00 32

96 A0 1E 47 0B 00 0A 20 20 20 20 20 20 00 00 00 FC

112 00 50 48 31 30 37 45 2F 53 2F 54 37 0A 20 00 2E

Take 105G7 DDC writer for example:

1.General

DDC Data Re-programming

In case the main EEPROM with Software DDC which store all factory settings were replaced because a defect,

repaired monitor’ the serial numbers have to be re-programmed.

It is advised to re- soldered the main EEPROM with Software DDC from the old board onto the new board if circuit

board have been replaced, in this case the DDC data does not need to be re-programmed.

Additional information:

Additional information about DDC (Display Data Channel) may be obtained from Video Electronics Standards

Association (VESA). Extended Display Identification Data (EDID) information may be also obtained from VESA.

2.System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98,etc.

3. Newphl.exe program

4. (105G7 )S554BPHL.ddc EDID program.

5. Software DDC Alignment kits shown as fig 1.

The kit contents:

a. DDC board x1

b. Printer cablex1

c. D-Sub cable x1

d. 12V DC input

Note: The Newphl.exe is a MS-DOS -based program, which cannot be run in windows.

Printer connector

DC 12V input

D-SUB connector

Fig 1

16

17” CDT Color Monitor 107S7

Step 1: Put the “Newphl.exe” and “(105G7) S554BPHL.ddc” to a special folder, such as 105G7. And rename the

“(105G7) S554BPHL.ddc” as “W.ddc”

Step 2: Access to MS-DOS program, Input the command as shown fig 2

Note: g: is the disk position for 105G7

Fig 2

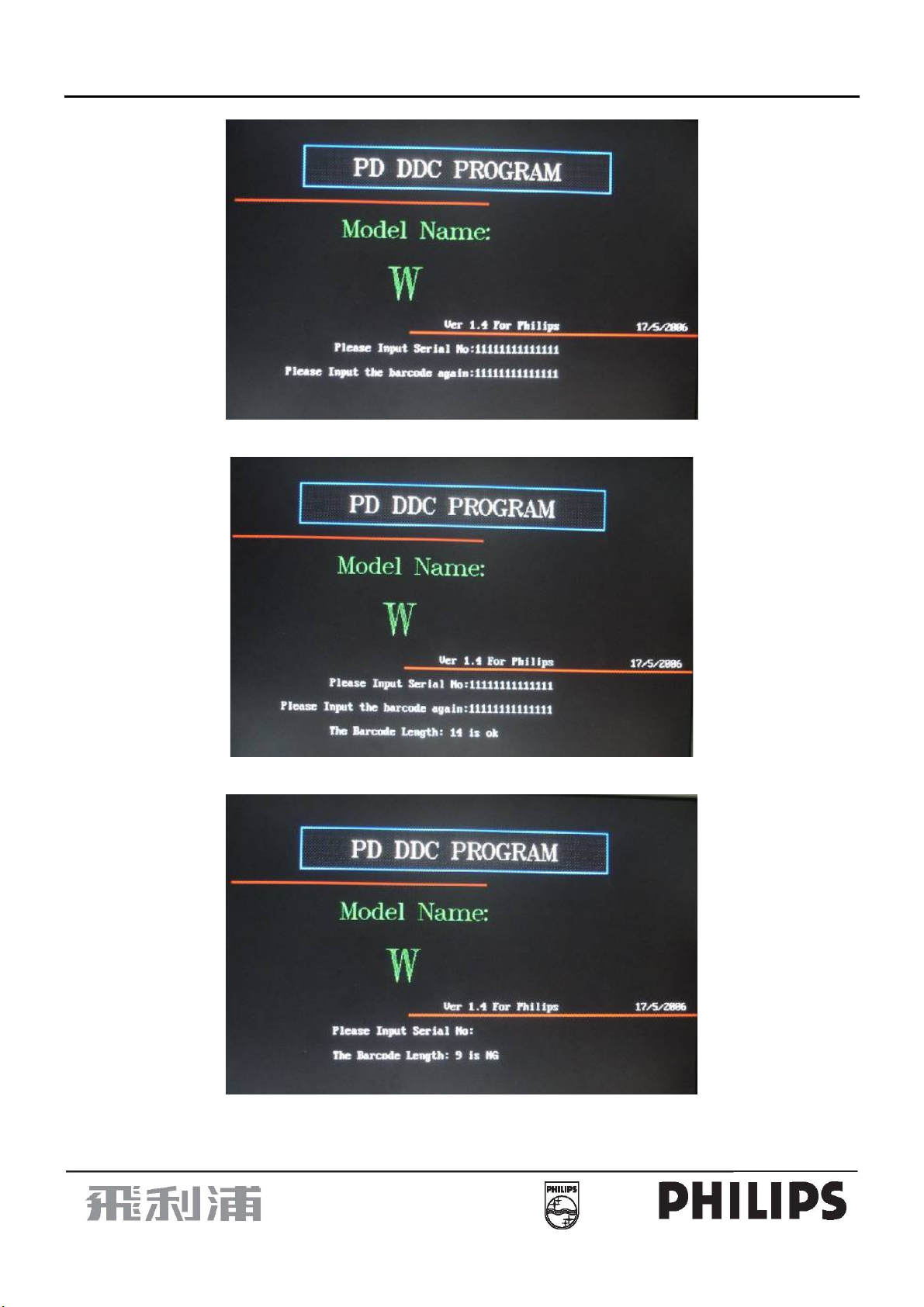

Step 3: Press Enter into the next screen as shown Fig 3.

a. Input 14 byte digital Serial No. such as “11111111111111” as shown Fig 3.

b. Enter and press “F3” key to input Serial No. again as shown Fig 4. Enter

The Serial No. length is”14” as shown Fig 4.

c. If you correctly input, there will appear” The Barcode length: 14 is OK” as shown Fig 5.

d. And if you incorrectly input, there will appear “The Barcode length: 9 is NG” as shown Fig 6.

You have to input again.

Fig 3

17

17” CDT Color Monitor 107S7

Fig 4

Fig 5

Fig 6

18

17” CDT Color Monitor 107S7

Step 4: Enter, go into the next screen as shown Fig 7.

Step 5: Enter into Fig 8.

Fig 7

Step 6: Enter into Fig 9.

Fig 8

Fig 9

19

17” CDT Color Monitor 107S7

5. Circuit description

5-1. Micro controller and deflection circuit

Micro Controller

The micro controller(IC101) core is a 80C51 type. The micro clock frequency of 12 Mhz is derived from the

Xtal oscillator, which is running at 48MHz. The DDC interface is suitable to handle DDC2 by a modified hardware

2

C-bus interface .Standard high current ports,3 ADC pouts with voltage inputs and 4 static standard 8 bit DAC

I

outputs (low interference) and one PWM output for digital control application are implemented. The central

processing unit (CPU) manipulates operands in two memory spaces. These are the 1024byte internal data

memory(consisting of 256 bytes standard RAM and 768 bytes AUX-RAM) and 48K-byte internal program memory .

The programmemory of the SAA4849 consists of 48K bytes ROM.

The SAA4849P provides sync. Processing with full auto sync. Capability, a flexible SMPS block and an

extensive set of geometry control facilities. Further the IC generates the drive waveforms for DC coupled vertical

boosters to the TDA4863A.

H/V sync signals processor

The functions of the sync processor include polarity detection, H-SYNC & V-SYNC signals counting,

Programmable SYNC signals output, free running signal generator. Pin52/Pin53 are for the H-SYNC and V-SYNC

input. and the polarity are setting in the positive. When no signal input, the Pin49 will output a 75Hz V-SYNC free

run signal. The Pin18/20will output a 60KHz H-SYNC free run signal. for the monitor testing use.

Reset Circuit(pin23)

There are three ways possible to invoke a reset and initialize the SAA4849P micro controller part:

Via power-on reset circuit

Via watchdog timer overflow(only micro controller reset)

Via deflection reset after start up(only micro controller reset)

The reset pin(pin23) is connected to a Schmitt trigger for nose reduction. A reset is accomplished by holding the

Reset pin HIGH.

C145

22U

5V

x-ray protection

The x-ray ptotection(pin22) input XRAY provides a voltage detector with a precise voltage input for X-ray

protection .If the input voltage at XRAY exceeds the upper threshold for 150us to 300us,the system is forced to

shut down by switching off vertical,H-and B-drive signals. There are two different ways to handle the system in

case of XRAY occurrence:

1.If the xray latch enable bit UCXRAY[2] was set to “0” during startup the system will shut down without any

interference of the uC.The deflection controller is set to ldle mode.Restart of the system only possible due to

seitching power off/power on.

+

R153

2.7K

C102

0.1UF

RST Pin23

20

17” CDT Color Monitor 107S7

2.If register bit UCXRAY[2] was set to “1”,micro controller interaction is allowed .If the micro controller doesn’t

interrupt the system, the system will shut down to ldle mode.For any interaction of the micro controller the XRAY

occurrence has to be acknowledged by the micro controller by clearing the bit SY-STATUS[2].The micro controller

take over the control of the handling via software.The actual xray pin status can be read through bit SYSTATUS[1].

Quartz Oscillator(pin45,pin46)

The quartz oscillator circuit is available on pins XTAL1(input) and XTAL2(output) and works together with an

external 48MHz 3

crystal frequencies than 48 MHz cannot be used.External capacitors on XTAL1 and XTAL2 are not allowed.

B+ Control Function Block

The B+control block of the SAA4849P has the same behaviour as the TDA4856 with adapted threshol voltages.

The circuit allows the user to choose the trigger edge of the HDRV signal and the polarity of the output stage via

2

I

C-Bus.

The B+ control function block of the SAA4849P consists of an Operational Tran conductance Amplifier(OTA), a

voltage comparator, a flip-flop and a discharge circuit. This configuration allows easy application for different B+

control concepts.

HPLL

The horizontal part contains a PLL,which works over the full frequency range from 25kHz to 140 kHz. This range

can be reduced by a ower and an upper frequency limit(Write Once Registers HPMAX and HPMIN).Via I

number of 48MHz clock cycles is sent through the register. The slewing speed during mode change is also

programmable in a write once register (HSLEW)

After the clocks for the HPLL are switched on, the HPLL starts with a fixed freerunning frequency of 60 kHz. The

H-drive pulses are not active and the start up procedure is inhibited. The default setting of register bit HCONTROL [0]

will cause the HPLL to slew ,not switch. to the freerunning frequency defined in the I

value is also 60 kHz).Independent on H-syncs which are possibly present. the HPLL will slew to that freerunning

frequency. To achieve an always defined starting point for the startup procedure, this procedure cannot be interrupted.

rd

overtone quartz. As a result the quartz oscillator is always running on 48MHz.Other quartz

2

C bus the

2

C register HPFREE( the default

21

17” CDT Color Monitor 107S7

5-2. Transistor & diode circuit

Location Description Function

IC101 SAA4849PS CPU

IC601 TDA4863A Vertical Output IC

IC801 NT6812KG-20019 Video PreAmplifier/OSD IC

IC802 LM2476 Video Output IC

IC901 STR-G5643D PWM Combi power MOS IC

IC902 L7805CV DC to DC IC

C907 220UF/400V Filter capacitance

Q911 IRF634B B+ Transistor

Q403 2SC5929 Horizontal Output Transistor

Q406 IRF630M/S.T Horizontal Size Transistor

Q410 2SC2120-Y Horizontal linearity Transistor

D901~D904 1N5408 PEC Crtical Safety Component

Q426/Q420/Q427 IRF630M/S.T CS adjust Transistor

D919 31DF4/I.R Rectifier DIODE

D922 RG-4S Rectifier DIODE

D923 RG-4S Rectifier DIODE

D925 UF4004 Rectifier DIODE

D408 DMV1500MFD Rectifier DIODE

C961 3300PF 250VAC/400VAC Crtical Safety Component

C962/C963/ C964 3300PF 250VAC/400VAC Crtical Safety Component

22

17” CDT Color Monitor 107S7

6. Mechanical Instructions

0. General

To be able to perform measurements and repairs on the "circuit boards", these unit should be placed

in the service position first.

1. Remove the rear cover

Remove 3 screws as shown in Fig. 1 and Fig. 2

Fig. 1

Fig. 2

2. Video board

Cut the tip on the front frame as show in Fig. 3

Disconnect the adhesive tape and ground pins

between metal shield of Video board and main

board as shown in Fig. 4 to Fig. 7

Cut the tie between the CRT neck and the video

board as shown in Fig. 8

Fig. 3

Fig. 4

Fig. 5

Fig. 6

23

17” CDT Color Monitor 107S7

g

Fi

. 7

Fig. 8

3. Main panel

Disconnect the rotation coil from Main

board as shown in Fig. 9

Disconnect the degaussing coil and ground-screw

from Main board as shown in Fig. 10.

Disconnect the BY coil from Main board

as shown in Fig. 11.

Disconnect the key board connector P102 from

Main board as shown in Fig. 12

Disconnect the ground pins from Main board

as shown in Fig. 13

Disconnect the Hi-Pot cap between the CRT and

Main board as show in Fig. 14.

Fig. 9

Fig. 10

Fig. 11

Fig. 12

24

17” CDT Color Monitor 107S7

Fig. 13

Fig. 14

4. Remove Main board

Fig. 15

5. Remove Front frame

Remove four screws as show in Fig. 16

Fig. 16

25

17” CDT Color Monitor 107S7

7.Trouble Shooting Chart

7-1 No Raster

1.CRT Relative Circuit Problems

CHECK MAIN PCB POWER SUPPLY

56V, 14V, 80V, 7V(80V FROM FBT)

NG

OK

CHECK THE HIGE VOLTAGE

OF CRT ABOUT 21.0~ 22.8KV

OK

CHECK THE VOLTAGE OF CRT

HEATER ABOUT 6.3V

OK

CHECK SCREEN VOLTAGE ABOUT

400V TO 600V

NG

NG

CHECK POWER SAVING CIRCUIT,

H-SYNC, V-SYNC SIGNAL

Q907, Q908, Q909, Q910

REFER ITEM S.M.P.S.

CHECK IC101 PIN18 OUTPUT

CHECK CRT'S HEATER RELATIVE

CIRCUIT Q907, Q908

OK

LESS THAN 300V

OK

BRIGHTNESS SET TO MAX. THEN

CHECK CRT G1 VOLTAGE

NG

OK

CHECK VOLTAGE OF THE CRT

CATHODE ABOUT 56V TO 65V

NG

CHECK FBT

CHECK BRIGHTNESS CIRCUIT

Q705 RELATIVE CIRCUIT

REFER ITEM 6-2

"ABNORMAL DISPLAY"

26

17” CDT Color Monitor 107S7

A

2.Abnormal Video Level On Screen

CHECK THE VOLTAGE OF IC801

PIN 10, 18 ABOUT 5V

OK

CHECK THE SIGNAL INPUT OF R.G.B.

BOUT 0.7Vpp

NG

CHECK 5V RELATIVE CIRCUIT

OK

CHECK IC801 PIN 23 CLAMP PULSE

OK

CHECK THE VIDEO OUTPUT OF IC801

PIN 19, 20, 21 ABOUT 4Vpp,

CONTRAST SET MAX.

OK

R.G.B. APPROACH STANDARD

3. Abnormal DDC (Plug & Play)

CHECK IC101 PIN 5 VOLTAGE ABOUT 5V

NG

NG

CHECK SIGNAL CABLE OR

INTERFACE CARD.

CHECK THE IC801 PIN 23

RELATIVE CIRCUIT

CHECK IC801 PIN19/PIN20/PIN21

RELATIVE CIRCUIT

NG

OK

CHECK SIGNAL CABLE

OR H802 PIN 2, 4 DATA OUTPUT

CHECK IC902 GOOD OR FAIL

27

17” CDT Color Monitor 107S7

N

K

A

T

7-2. Abnormal Display

7-2-1.No Signal On Screen

CHECK VIDEO IC801 VCC ABOUT 5V

NG

OK

CHECK THE 5V PIN

OF P802 CONNECTOR

CHECK THE OUTPUT VOLTAGE

OF IC801 PIN 19, 20, 21 ABOUT 3Vpp

OK

CHECK THE VOLTAGE OF

VIDEO AMP ABOUT 80V

O

CHECK THE VOLTAGE OF CRT

CATHODE ABOUT 40Vpp

OK

CHECK THE VOLTAGE OF FBT SCREEN

BOUT 400V TO 700V

LESS THAN 400V

NG

NG

G

CHECK THE RELATIVE CIRCUIT

OF IC801 PIN 10/PIN 18 Vcc CIRCUI

CHECK THE 80V RELATIVE CIRCUIT

ON MAIN PCB

CHECK THE IC802

RELATIVE CIRCUIT

CHECK FBT RELATIVE CIRCUIT

EXCEED 700V

CHECK FBT & CRT RELATIVE

CIRCUIT OR REFER ITEM 6-1

28

Loading...

Loading...