Philips 107P5 service manual

17" Auto scan Colour Monitor

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Chassis :V40

Service

Service

Service

TABLE OF CONTENTS

Description Page

V40 107P5

107P50

Horizontal frequencies

30-97kHz

Description Page

Important Safety Notice ------------------------------- 2

Technical Data ------------------------------------------ 3

Front control & OSD------------------------------------ 4

OSD menu tree------------------------------------------ 5

Lock/Unlock, Burn in,Service mode------------------6

Wiring Diagram-------------------------------------------7

Mechanical Instructions ----------------------------- 8~9

Warning and Notes ------------------------------------ 10

Electrical Adjustments --------------------------- 11~ 13

DDC Instructions -----------------------------------14~18

Hex Data of DDC2B--------------------------------19 ~20

Block Diagram ------------------------------------------21

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

Video Schematic Diagram & C.B.A.------------22~23

Main Schematic Diagram & C.B.A.------------24~27

Waveform of all Schematic ----------------------28~29

Key ControlPanel Schematic Diagram -------------30

Repair flow chart----------------------------------- 31~38

Repair Tips ----------------------------------------------39

Exploded View------------------------------------------40

Recommended

Spare parts list------------------------------------- 42~44

General Product Specification-------------------45~68

Safety test requirements (Hipot & Ground)------- 69

Different parts list---------------------------------------70

parts list------------------------------41

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Published by BCU Monitors Printed in Taiwan Copyright reserved Subject to modification Nov 21 2003

M

GB

3138 106 10334

2

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

9

Proper service and repair is important to the safe, reliable

operation of all PHILIPS Company** Equipment.

The service procedures recommended by PHILIPS and

described in this service manual are effective methods

of performing service operations. Some of these service

operations require the use of tools specially designed for

the purpose. The special tools should be used when and

as recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully

Read in order to minimize the risk of personal injury to

service personnel. The possibility exists that improper

Service methods may damage the equipment. It also is

important to understand that these CAUTIONS and

NOTICES ARE NOT EXHAUSTIVE. PHILIPS could not

possibly know, evaluate and advise the service trade of

all conceivable ways in which service might be done or of

the possible hazardous consequences of each way.

Consequently, PHILIPS has not undertaken any such broad

evaluation. Accordingly, a servicer who uses a service

procedure or tool which is not recommended by PHILIPS

must first satisfy himself thoroughly that

neither his safety nor the safe operation of the equipment

will be jeopardized by the service method selected.

V40 107P5

Go to cover page

IMPORTANT SAFETY NOTICE

FOR PRODUCTS CONTAINING LASER :

DANGER-

CAUTION-

CAUTION-

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR

PART NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

* * Hereafter throughout this manual, PHILIPS Company

Will be referred to as PHILIPS.

WARNING

Critical components having special safety characteristics

are identified with a by the Ref. No. in the parts list

and enclosed within a broken line* (where several critical

components are grouped in one area) along with the

safety symbol on the schematics or exploded views.

Use of substitute replacement parts which do not have

the same specified safety characteristics may create

shock, fire, or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from

PHILIPS. PHILIPS assumes no liability, express or

implied, arising out of any unauthorized modification

Of design.

Servicer assumes all liability.

* Broken Line

Technical Data

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

9

3

Technical Specification*

CRT

Size and deflection :17 inch/41cm, 90

Dot pitch : 0.21 mm with black matrix

Horizontal Dot pitch : 0.25 mm

Tube type : Shadow mask, real flat, high contrast,

Phosphor : P22

Recommended display area : 12.2" x 9.0"/310 x 230 mm

Maximum display area

Scanning

Horizontal scanning : 30 - 97 KHz

Vertical : 50 - 160 Hz

scanning

Video

Video dot rate : 203 Mhz

Input impedance

-Video : 75 Ohms

- Sync : 4.7K Ohms

Signal input level : 0.7Vpp

Sync input signal : Composite sync.

Sync polarities : Positive or negative

White Color Temperature

Chromaticity CIE coordinates:

Carton box

Size (with pedestal) : 399(W)x410(H)x419(D)

Net weight : 15.1 Kg

Power supply : 90 - 264 VAC, 50/60 Hz

Power consumption : 90 Watts Max.

Operating condition

Temperature : 0 C to 40 C

Relative Humidety : 10%-90%(W/O condensation)

Storage condition

Temperature : - 25 C to 65 C

Relative Humidity :5%to95%(W/O condensation)

o

at 9300 k x = 0.283 +/- 0.015 y = 0.297 +/- 0.015

o

at 6500 k x = 0.313 +/- 0.015 y = 0.329 +/- 0.015

o

at 5500 k x = 0.332 +/- 0.015 y = 0.347 +/- 0.015

at sRGB x = 0.313 +/- 0.015 y = 0.329 +/- 0.015

anti-glare, anti-static,anti reflection,

light transmission

: 12.8" x 9.6"/325 x 244 mm

Separate sync

00

OO

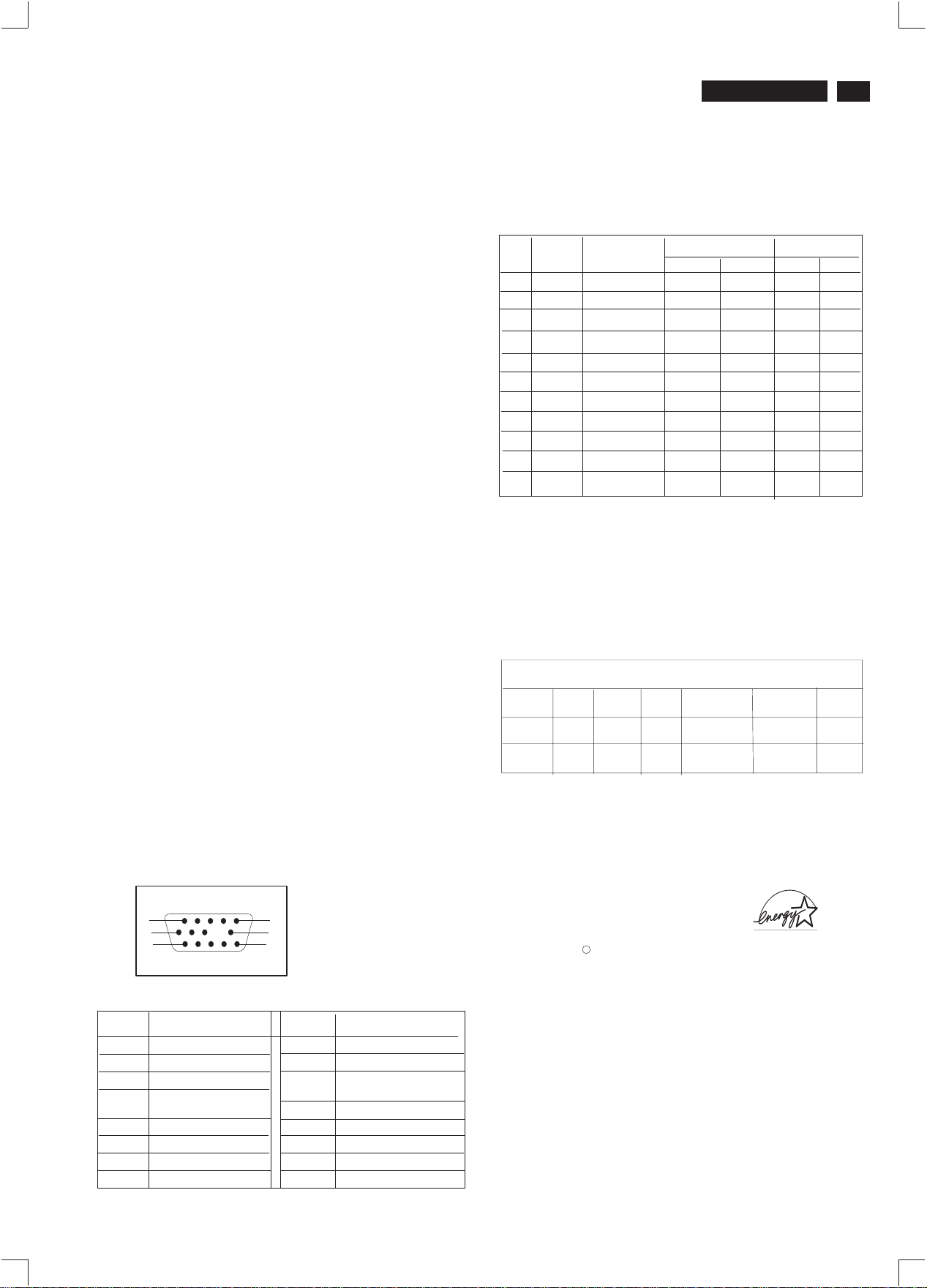

Pin assignment :

o

deflection angle

50%

Data Storage

Factory preset modes:

This monitor has 11 factory-preset modes as indicated in the

following table :

M01

M02

M03

M04

M05

M06

M07

M08

M09

M10

M11

Mode

VGA

VGA

VGA

VGA

VGA

SVGA

SVGA

EVGA

EVGA

Resolution

720 x 400

640 x 480

800 x 600

640 x 350

640 x 480

800 x 600

800 x 600

1080 x 960

1024 x 768

1280 x 1024

1280 x 1024

Frequen

H(KHz)

31.5

31.47

35.2

37.9

43.3

46.9

53.674

60.0

68.7

80.0

91.2

V(Hz)

70

60

56

85

85

75

85

60

85

75

85

Sync polarity

H

V

+

-

-

-

+

+

-

+

-

-

+

+

+

+

+

+

+

+

+

+

+

+

Automatic Power Saving

If you have VESA's DPMS compliance display card or software installed

in your PC, the monitor can automatically reduce power consumption

when power saving function active. And if an input from keyboard,

mouse or other input devices is detected, the monitor will automatically

"wake up". The following table shows the power consumption and

signaling of this automatic power saving feature :

Power Management Definition

POWER

SAVING( % )

97 %

Yes

No

POWER

USED

Tyical 70 w

<2 w

VESA's

mode

ON

OFF

This monitor is ENERGY STAR compliant.

As an ENERGY STAR Partner, PHILIPS has determined that

this product meets the ENERGY STAR guidelines for energy

efficiency

Blanked

VIDEO

Active

H-SYNC

Yes

No

V-SYNC

0%

LED

COLOR

Green

Flashing

Green

1

6

11

Pin No.

Assignment

1

Red video input

Green video input

2

Blue video input

3

Identical output-

4

connected to pin 10

fground

5

Red video ground

6

Green video ground

7

Blue video ground

8

5

10

15

Pin No.

9

10

11

12

13

14

15

Assignment

No pin

Logic. Ground

Identical outputconnected to pin 10

Serial data line(SDA)

H.Sync /H + V

V.Sync(VCLK for DDC)

Data clock line(SCL)

ENERGY STAR is a U.S. registered mark. AS AN ENERGY STAR

PARTNER, DELL Computer Corporation HAS DETERMINED THAT

THIS PRODUCT MEETS THE ENERGY STAR GUIDELINES FOR

:The 15-pin D-sub connector(male) of the signal cable

ENERGY EFFICIENCY.

R

4

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Go to cover page

9

V40 107P5

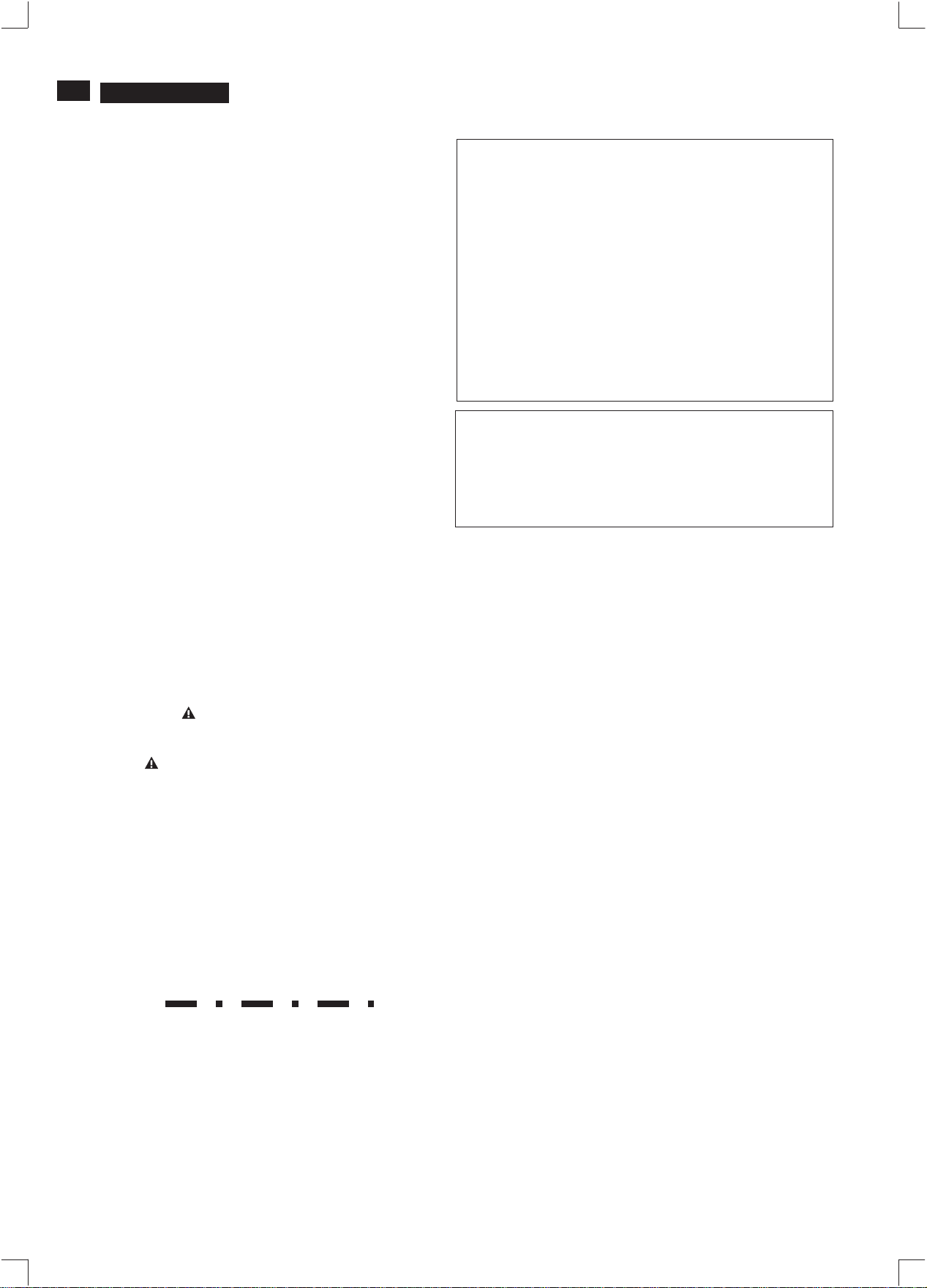

Front View

Front control & OSD

Rear view

Power button switches your monitor on.

OK button which when pressed will take you to the OSD

controls

Contrast hotkey. When the "-" button is pressed,

the adjustment controls for the CONTRAST will show up.

Brightness hotkey. When the "+" button is pressed,

the adjustment controls for BRIGHTNESS will show up.

"-" and "+" buttons, are used for adjusting the OSD of your

Monitor.

EXIT button which when pressed will close the OSD

controls.

1. Power in - attach power cable here.

2. Video In - this is a cable which is already attached to your monitor.

Connect the other end of the cable to your PC.

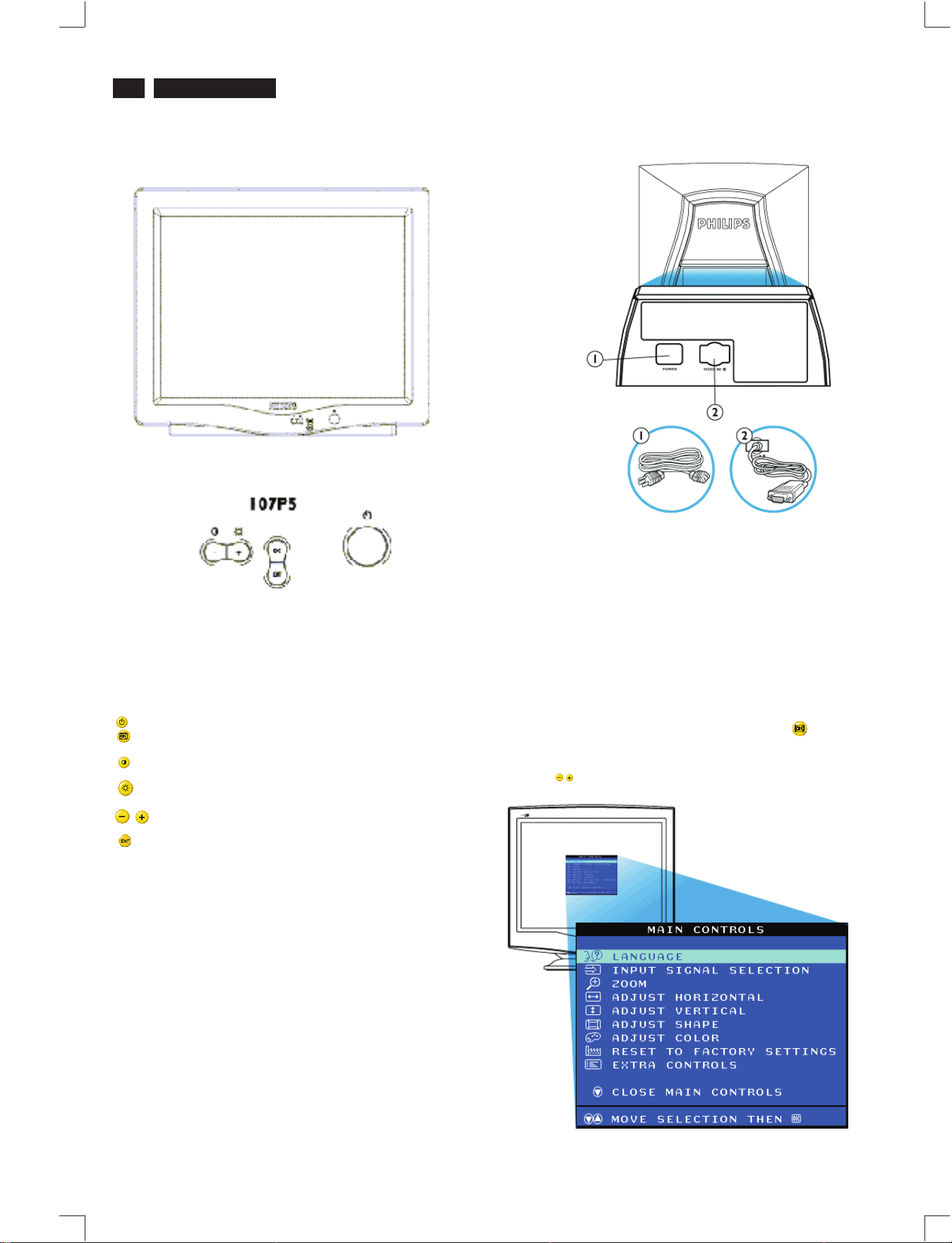

Description of the On Screen Display

What is the On-Screen Display?

This is a feature in all Philips monitors which allows an end-user to

adjust screen performance of monitors directly though an on-screen

instruction window. The user interface provides user-friendliness and

ease-of-use when operating the monitor.

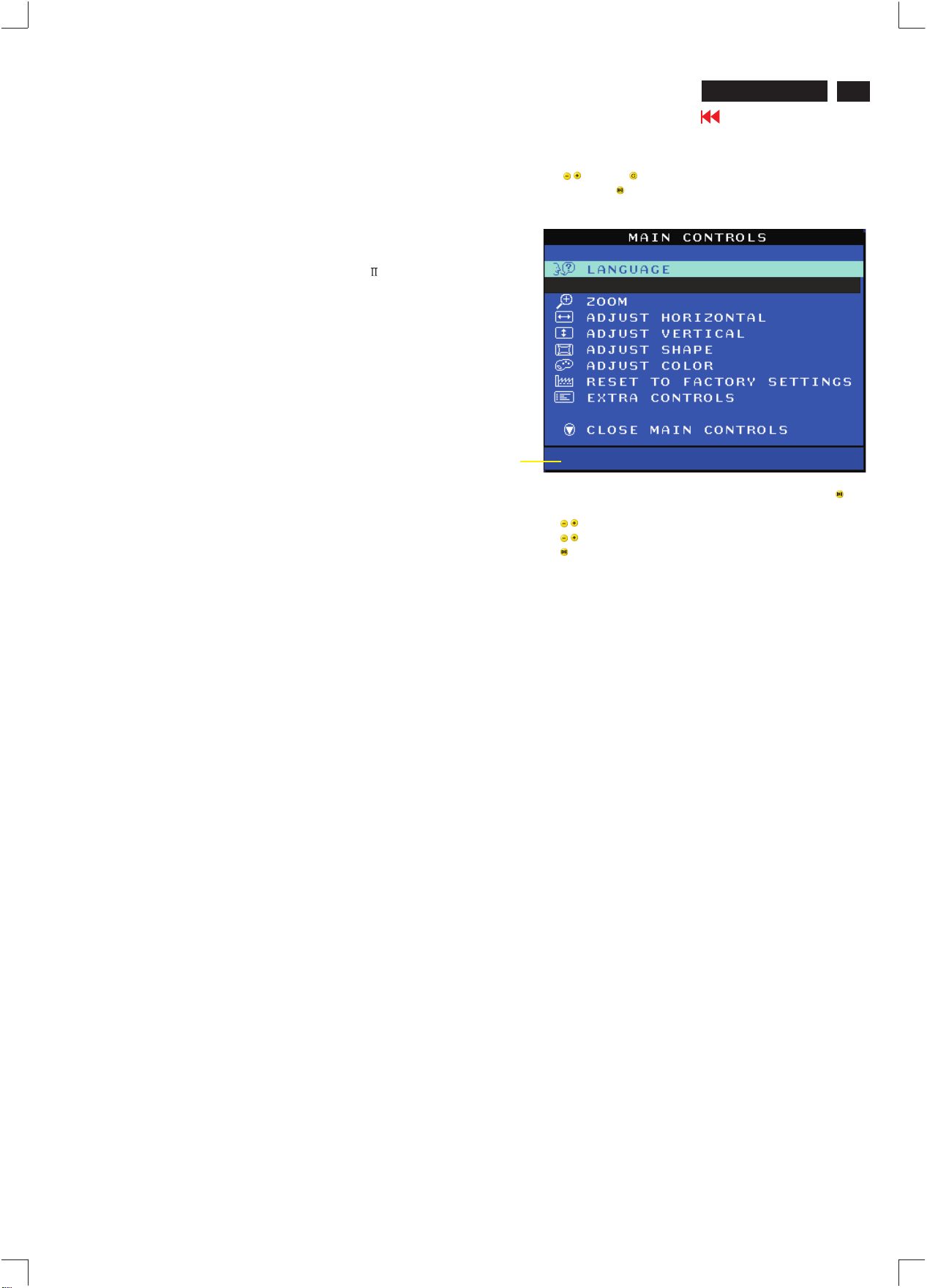

Basic and simple instruction on the control keys.

On the front controls of your monitor, once you press the button, the

On Screen Display (OSD) Main Controls window will pop up and you

can now start making adjustments to your monitor's various features.

Use the the keys to make your adjustments within.

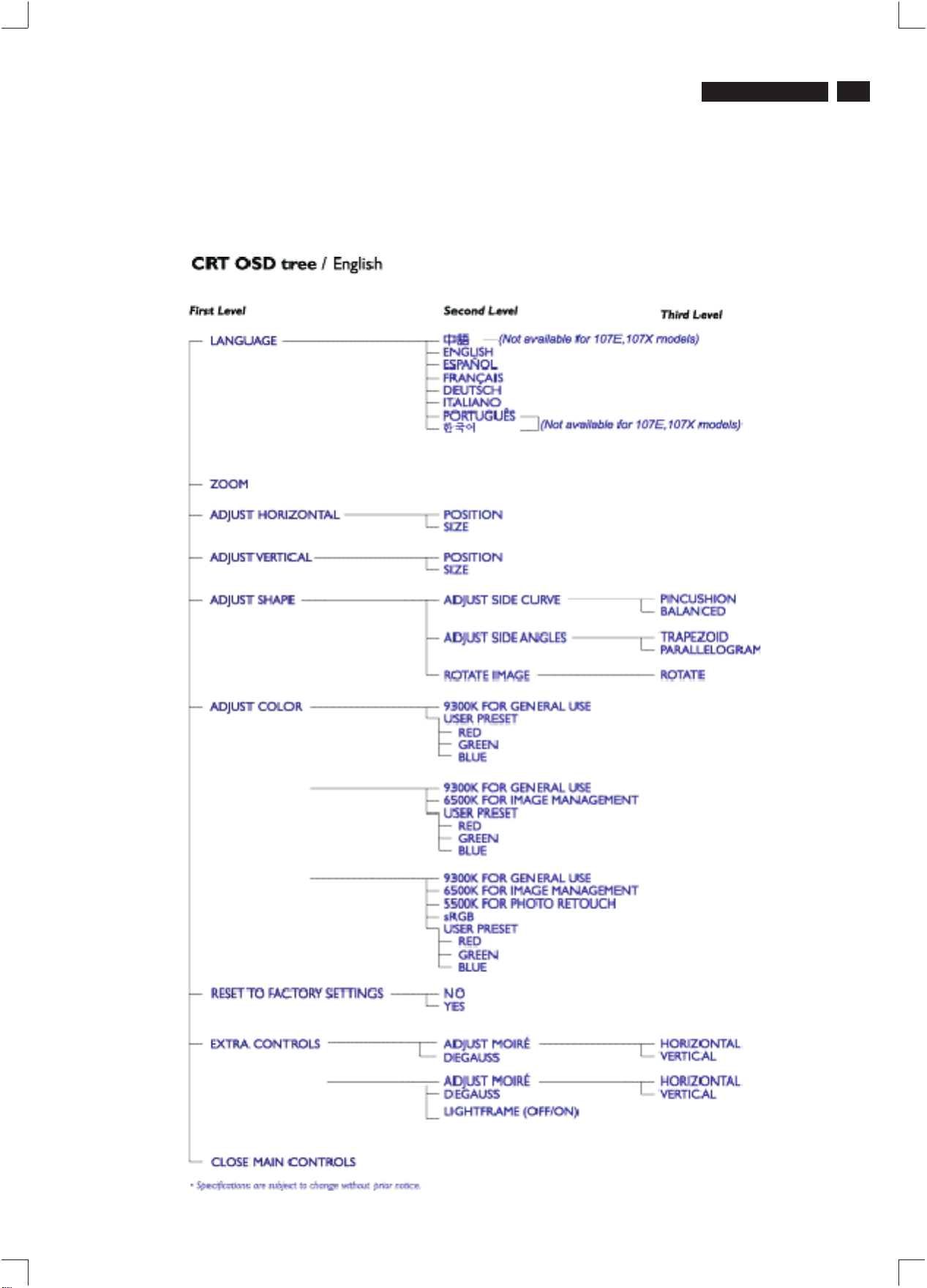

OSD menu tree

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

The OSD Tree

Below is an overall view of the structure of the On-Screen

Display. You can use this as reference when you want to

later on work your way around the different adjustments.

V40 107P5

Go to cover page

9

5

6

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

X

V40 107P5

Go to cover page

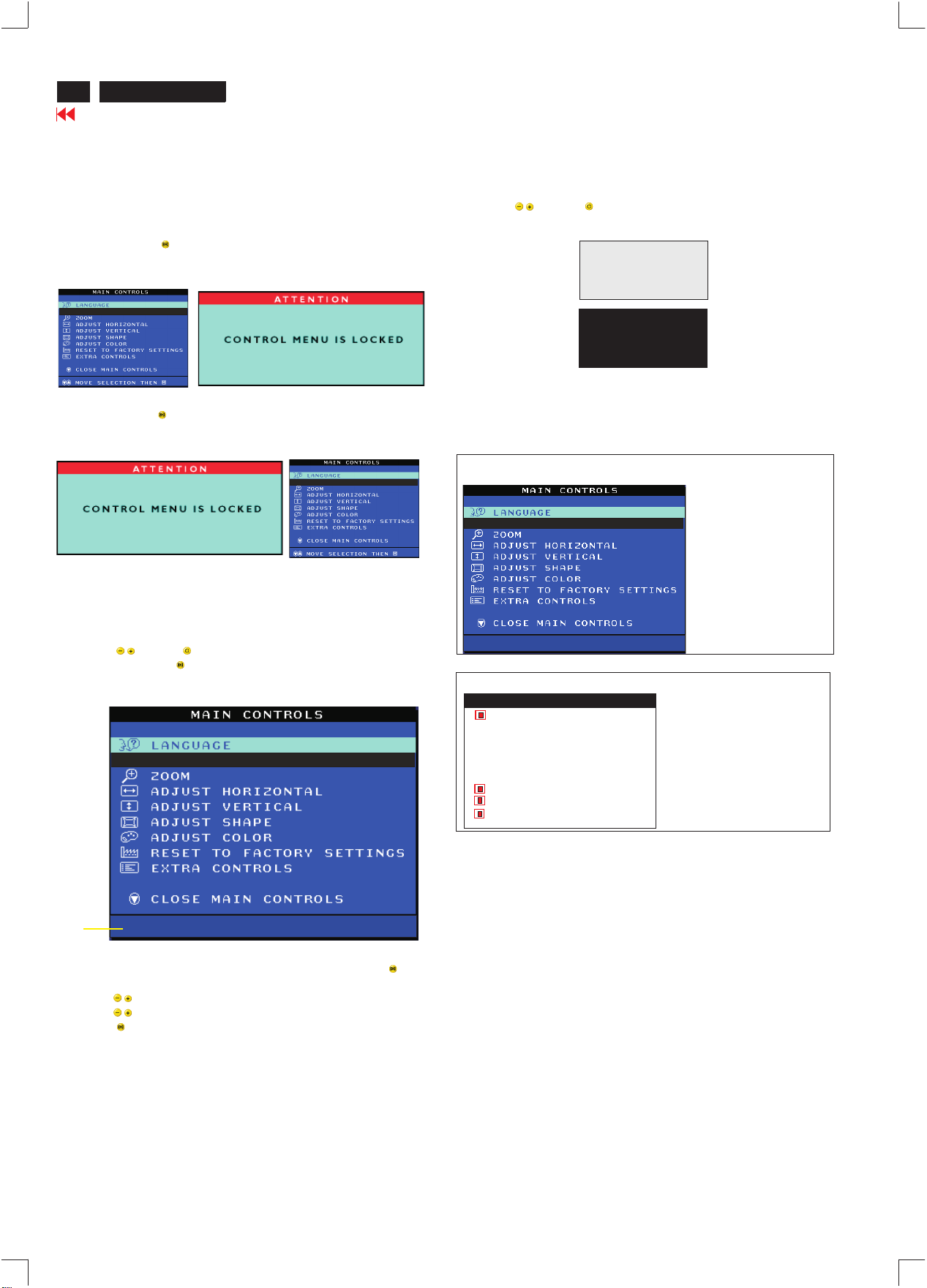

Lock/Unlock, Burn In, Service Mode

OSD Lock

OSD lock is a feature which disables the OSD controls. It can be used

when the monitor is set up for demonstration purposes or when

adjustment of the OSD is not desirable.

Switch on OSD lock feature:

Press and hold the button continuously for 15 seconds.

Release the button when the message

"CONTROL MENU IS LOCKED" appears.

Switch off OSD lock feature:

Press and hold the button continuously for 15 seconds or until the

message window "CONTROL MENU IS LOCKED" disappears, and

"MAIN CONTROLS" appears.

To access BURN IN mode

First of all, monitor displays an image.

1. Disconnect the video cable (interface cable).

2. Turn off monitor

3. Press '" " and " " simultaneously on the front control

panel,then the BURN IN mode comes on the screen of monitor

as below.

50 seconds around

5 seconds around

repeatly

Reconnect the video cable, then return to normal image.

4.

SERVICE MODE (Indication-Factory mode)

00010

------------------------>

00010: stands for

1. using 10 hours already.

2. turn on/off 10 times.

3. using several hours

+ turn on/off monitor.

To access factory mode

1. Turn off monitor (don't turn off PC)

2. Press '" " and " " simultaneously on the front control

panel,then press " ",wait till the OSD menu with characters

V40 107P5 V0.11 20030804 (below OSD menu)" come on the

screen of monitor.

Factory

Mode

Indicator

3. If OSD menu disappears on the screen of monitor, press " "

again (anytime), then the OSD menu comes on the screen again.

4. Using " " : to select OSD menu.

5. Using " " : to increase or decrease the setting.

6. Using " " to access/confirm the selection.

MODEL SELECT

V40 107P5 V0.11 20030804

MODEL SELECT

V40 107P5 V0.11 20030804

Default setting of MODEL SELECT (Do not change it.)

MODEL SELECT

107P5

RESERVE

RESERVE

RESERVE

RESERVE

RESERVE

SWDDC

LF 3 OSD

LF 3

To leave factory mode

7. After alignment of factory mode, turn off monitor (if you do not turn

off monitor, the OSD menu is always at the factory mode), then

turn on monitor again (at this moment, the OSD menu goes back

to user mode).

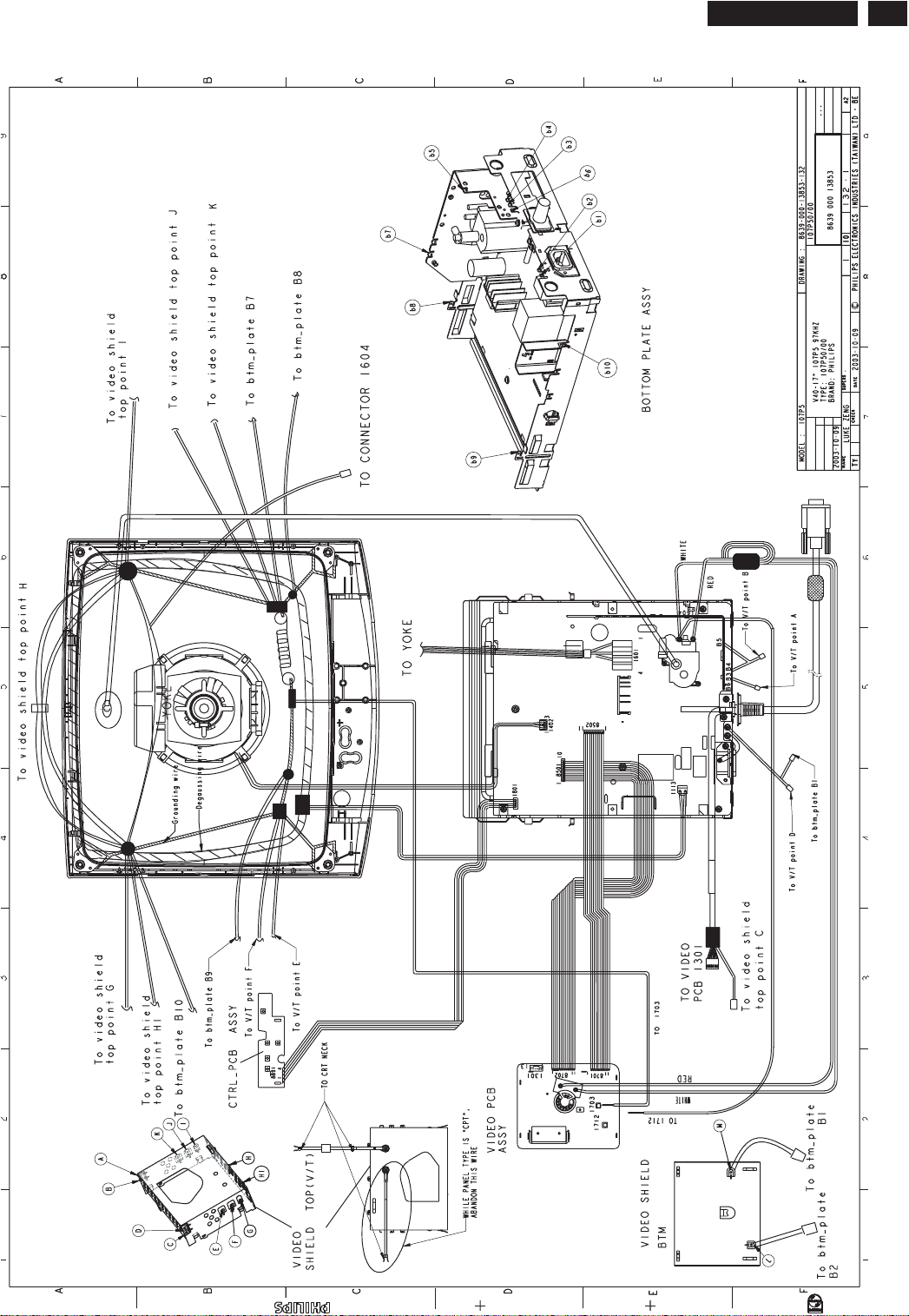

Wiring Diagram

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

9

Go to cover page

7

8

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

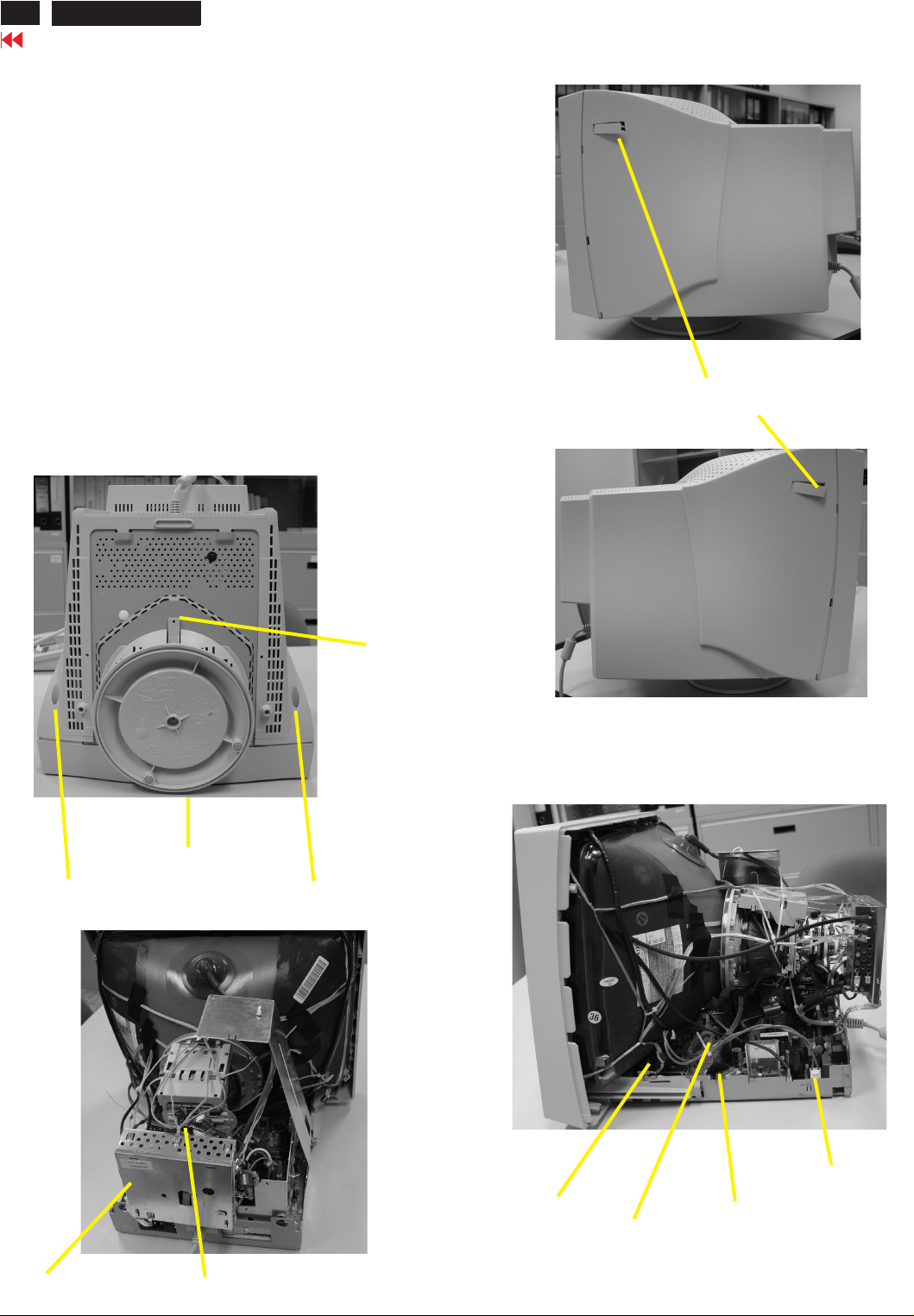

Mechanical Instructions

Go to cover page

0. General

To be able to perform measurements and repairs on the "circuit

boards", these unit should placed in the service position first.

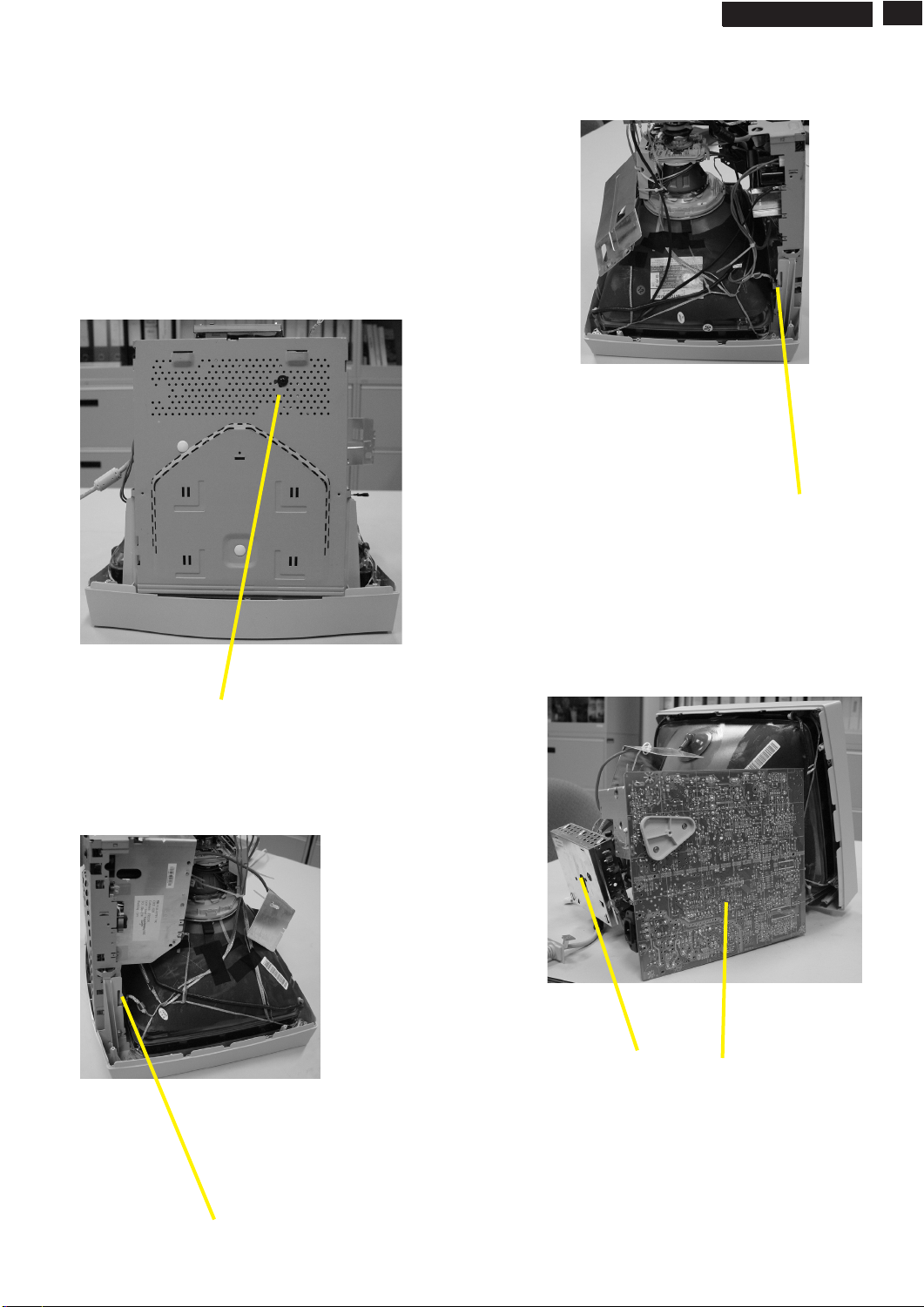

1.Remove the rear cover in Fig. 1.

-Remove 2 screws as shown

-Remove back cover as shown

-Remove pedestal as shown

-Remove cover clip at right and left side on the back cover in Fig2.

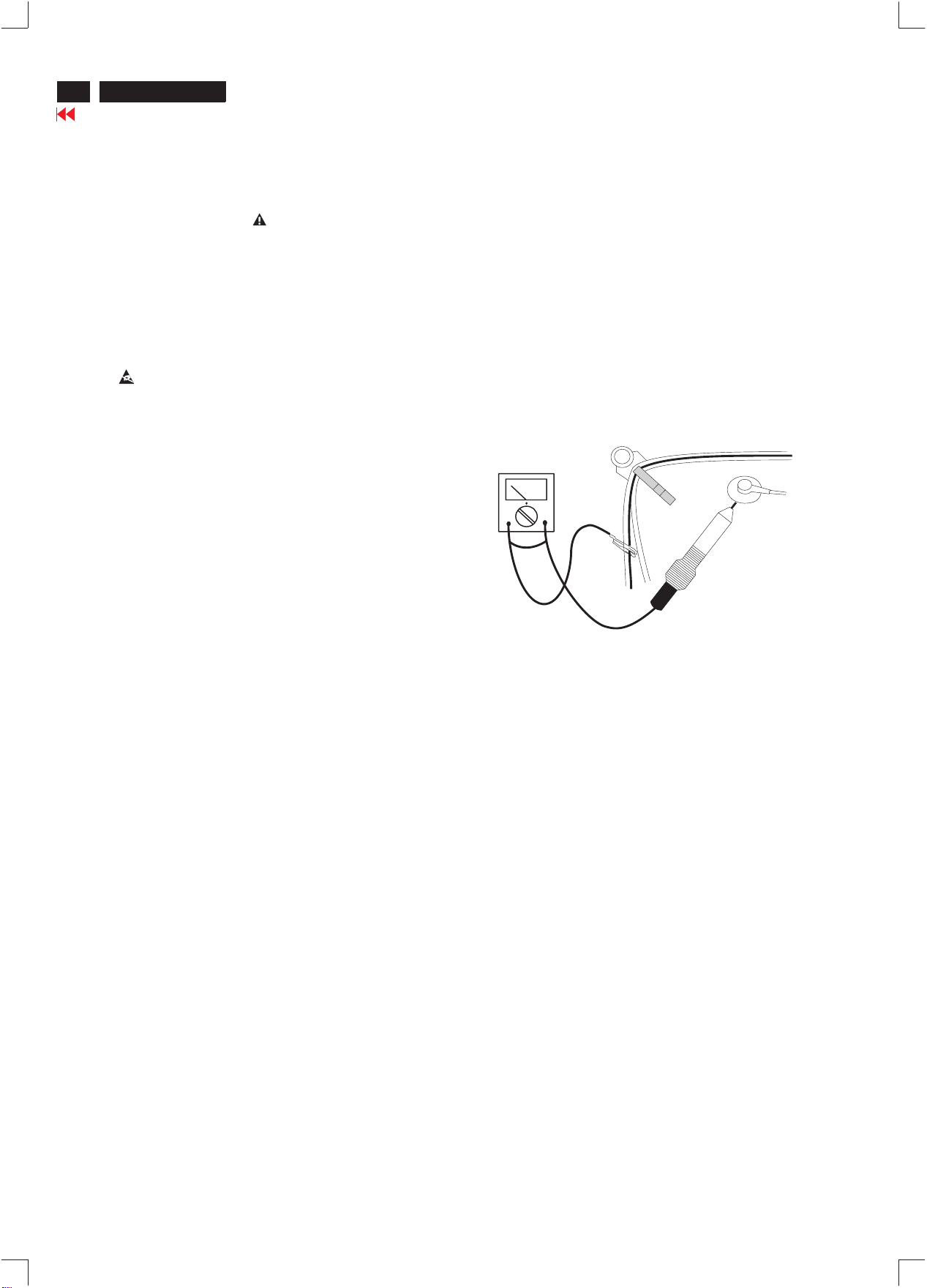

2. Video panel

- Disconnect the wire between metal shield of Video panel and

CRT neck as shown in Fig. 3.

- Disconnect the CRT ground from Video panel.

- Remove screw grounding and grounding wire in Fig. 3.

3.Main board connector in Fig. 4

-Disconnect york wire

-Disconnect rotation connector

-Disconnect control board connector

-Remove Screw for fixed I/F cable

Fig. 2

Cover clip

Screw

Pedestal ass'y

Fig. 1

Clip

Screw

Control connector

Rotation connector

Video Panel

CRT grouding wirel

Fig. 3

Signal connector

Degaussing wire connector

Fig. 4

Mechanical Instructions

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

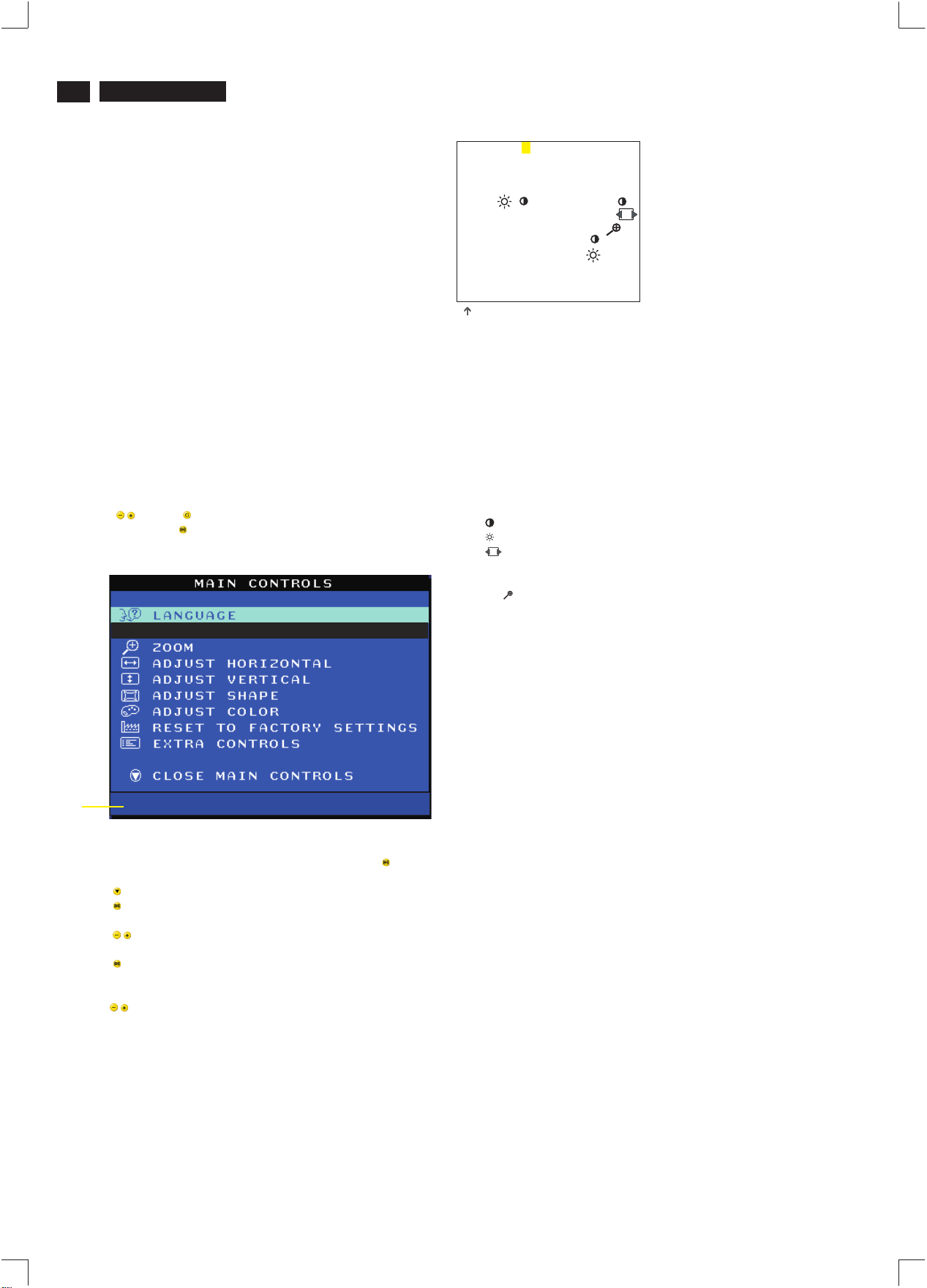

4. Main panel with Bottom Tray

-Remove 9 screws for disconnect the Bottom tray as Fig. 5.

-Pull the bottom tray from fig. 6 &

fig. 7.

Remove all screws between main board and bottom tray, then

transfer to service position.

5. SERVICE POSITION

Reconnect connectors, some wires and panels (chassis),

service position can be available for DC/AC measurement

as shown in Fig. 8.

on press right and left side clip

V40 107P5

9

Go to cover page

Press clip then Pull-up

9

=======>

Screw

Fig. 5

Video panel

Fig. 7

Main panel

Fig. 8 SERVICE POSITION

Press CLIP

Fig. 6

10

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

X

V40 107P5

Go to cover page

Warning and Notes

Warnings

. Safety regulations require that the unit should be returned

1

in its original condition and that components identical to

the original components are used. The safety components

are indicated by the symbol .

. In order to prevent damage to ICs and transistors, all

2

high-voltage flash-overs must be avoided. In order to

prevent damage to the picture tube, the method shown

in Fig. 1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DC-V).

Discharge until the meter reading is (after approximately

30 seconds).

.

3 ESD

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten their life. Make sure that

during repair you are connected by a pulse band with

resistance to the same potential as the ground of the unit.

Keep components and tools also at this same potential.

. When repairing a unit, always connect it to the AC Power

4

voltage via an isolating transformer.

. Be careful when taking measurements in the high-voltage

5

section and on the picture tube panel.

0V

Notes

The direct voltages and waveforms are average voltages.

1.

They have been measured using the Service test software

and under the following conditions :

- Mode : 640 * 480 (31.5kHz / 60Hz)

- Signal pattern : grey scale

- Adjust brightness and contrast control for the

mechanical mid-position (click position)

The picture tube panel has printed spark gaps.

2.

Each spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

The semiconductors indicated in the circuit diagram(s)

3.

and in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

V

. It is recommended that saferty goggles be worn when

6

replacing the picture tube.

. When making adjustments,use plastic rather than metal tools.

7

This will prevent any short-circuit or the danger of a

circuit becoming unstable.

. Never replace modules or other components while the

8

unit is switched on.

. Together with the defleciton unit, the picture tube is used

9

as an integrated unit. Adjustment of this unit during repair

is not recommended.

After repair, the wiring should be fastened in place with

10.

the cable clamps.

All units that are returned for service or repair must pass

11.

the original manufactures safety tests.

Fig.1

Electrical Adjustments

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

11

1. General

2.

Input signal mode

Resolution modes H. freq. V. freq. H. V.

1. 720 x 400 31.5 Khz 70Hz (VGA) - +

2. 640 x 480 31.5 Khz 60 Hz (VGA) - -

3. 800 x 600 35.2 Khz 56 Hz (Mac- ) + +

4. 640 x 350 37.9 Khz 85 Hz (VESA) + -

5. 640 x 480 43.3 Khz 85 Hz (VGA) - -

6. 800 x 600 46.9 Khz 75 HZ(VESA) + +

7. 800 x 600 53.7 Khz 85 HZ(VESA) + +

8. 1024 x 768 60.0 Khz 75 HZ(VESA) + +

9. 1024 x 768 68.7 Khz 85 HZ(VESA) + +

10. 1280 x 1024 80.0 Khz 75 Hz (VESA) + +

11. 1280 x 1024 91.2 Khz 85 Hz (VESA) + +

3.0 Main chassis alignment

3.1 Power supply adjustment

3.1.1 Set Vg2 manually (screen) to fully counterclockwise (zero

beam current).

3.1.2 Apply 80KHz/75Hz full black pattern.

3.1.3 Monitor the following auxiliary voltages.

+197.0V source across C2152 and gnd +197.0V +/- 3.0 VDC

+ 82.5V source across C2151 + 82.5V +/- 1.5 VDC

+ 6.2V source across C2155 + 6.2V +/- 0.2 VDC

+ 12.2V source across C2153 +12.2V +/- 0.7 VDC

- 12.2V source across C2154 - 12.2V +/- 0.7 VDC

3.2 H-Deflection supply voltage adjustment

3.2.1 Apply 80KHz /75Hz 1280 x 1024 full black pattern.

Adjust manually to obtain +/-0.3V for SDI CRT

3.3 Picture geometry and EHT regulation adjustment

3.3.1 EHT regulation adjustment

At 1280 x 1024 80KHz/75Hz mode full black pattern

Use DC voltage meter to measure socket 1681 Pin 1.

Adjust VR 3699

To get 4.7V +/- 0.05V at socket 1681 pin 1.

4. General conditions for alignment

4.1 During all alignments, supply a distortion free AC mains voltage

to set via an isolating transformer with low internal impedance.

4.2 Align in pre-warmed condition, at least 30 minutes warm-up with

nominal picture brightness.

4.3 Purity, geometry and subsequent alignments should be carried

out in magnetic cage with correct magnetic field.

Northern hemisphere : H=0, V=450 mG, Z=0

Southern hemisphere : H=0, V=-520 mG, Z=0

4.4 All voltages are to be measured or applied with respect to ground.

Note: Do not use heatsink as ground.

4.5 Adjust brightness controls to center position except for contrast

control which should be set to MAX.

4.6 Any external voltage sources should have a low internal

impedance.

4.7 Adjust function controls to center position unless otherwise

stated.

4.8 The white balance and purity has to be adjusted in dully lighted

room.

4.9 All alignments have to be done in a room with a temperature of

25+/- 10 C.

Factory preset modes : 11

R3561 48V

152V +/-0.3V for LG CRT

across C2600 at zero beam current.

0

5. To access factory mode

5.1 Turn off monitor (don't turn off PC)

5.2 Press '" " and " " simultaneously on the front control

panel,then press " ",wait till the OSD menu with characters

V40 109F5 V0.45 20030410 (below OSD menu)" come on the

screen of monitor.

Factory

Mode

Indicator

5.3 If OSD menu disappears on the screen of monitor, press " "

again (anytime), then the OSD menu comes on the screen again.

5.4 Using " " : to select OSD menu.

5.5 Using " " : to increase or decrease the setting.

5.6 Using " " to access/confirm the selection.

To leave factory mode

5.7 After alignment of factory mode, turn off monitor (if you do not

turn off monitor, the OSD menu is always at the factory mode),

then turn on monitor again (at this moment, the OSD menu goes

back to user mode).

6. Picture geometry setting

- Apply a video signal with cross-hatch pattern.

- Apply a video signal in the 1024 x 768 with 68.7 kHz/85 Hz mode.

- Set contrast control at Max. position, and brightness control in the

mid-point.

6.4 Alignment of horizontal geometry and vertical geometry

6.4.1 Adjust the H-width to 306 mm

6.4.2 Adjust the H-phase to center position.

6.4.3 Adjust V-size to 230mm.

6.4.4 Adjust V-Position to center.

Adjust/Trapezoid/pincushion/balance pincushion/paralleogram

6.4.5 Adjust picture tilt via I C BUS for correct top/bottom lines.

6.4.6 Adjust the top and bottom corner by I C to get optimum

corner geometry.

6.4.7 Adjust the parallelogram by I CBUS to get optimum vertical line.

6.4.8 Adjust the balance pincushion by I C BUS to get optimum

vertical line.

6.4.9 Adjust the trapezoid to get optimum vertical line.

6.5 Adjust size/centering/trapezium/pincushion/parallelogram

of all other preset modes via I C bus.

(to repeat from step 6.4.1 to step 6.4.9)

MODEL SELECT

V40 107P5 V0.45 20031013

2

2

2

2

2

12

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

9

V40 107P5

Go to cover page

Electrical Adjustments (Continued)

7. Alignment of Vg2 cut-off point, white tracking

Equipment : 1. Video Test Generator-801GC (Quantum Data)

VG2 [(screen), at the bottom of the L.O.T.].

7.1 Apply a video signal in the 1024 x 768 with 68.7 kHz/85 Hz mode,

select the "full white pattern" (sizes 306 x 230 mm).

* Use color-analyzer (Minolta CA-100) to adjust R/G/B cutoff and

gain.

OSD R/G/B cut-off and R/G/B gain can be accessed (for Philips

CRT), with initial data:

9300 K

R cutoff = 50%, R gain = 73% (I C)

G cutoff = 50%, G gain = 73% (I C)

B cutoff = 50%, B gain = 73% (I C)

6500 K

R cutoff = 50%, R gain = 71% (I C)

G cutoff = 50%, G gain = 71% (I C)

B cutoff = 50%, B gain = 71% (I C)

Brightness = 50%, Sub-Contrast = 86%, ABL = 63% (I C)

Step 1: To access factory mode

- Turn off monitor (don't turn off PC)

- Press " " and " " simultaneously on the front control

panel,then press " ",wait till the OSD menu with characters

V40 107P5 V0.11 20030804 (below OSD menu)" comes on the

screen of monitor as shown in Fig. 2.1.

2. Color-analyzer (Minolta CA-100)

o

2

2

2

o

2

2

2

2

9300 BIAS R G B GAINRGB

6500 BIAS R G B GAINRGB

5500 BIAS R G B GAINRGB

SRGB BIAS R G B GAINRGB

SRGB ( ) CUTOFF OSD

FOCUS(H V) VLINBAL USER

RASTER (H V) LIN(H V) SUB

V(OFFSET GAIN) SUB

CORNER(T B) ABL SUB

HEHT

LF(BRIGH SHARP)

EXIT

131

(for example: 131 is value of "BIAS R")

BIASRGB:R(red) G(green) B(blue) cutoff

GAINRGB:R(red) G(green) B(blue) gain

OSD contrast : OSD window contrast

V OFFSET : Vertical raster center

V GAIN : Vertical size center

VLIN BAL : Vertical Linearity Balance

V FOCUS : Vertical Focus adiustment

T CORNER: Corner Correctionof TOP

B CORNER: Corner Correctionof BOTTOM

EHT H : Horizontal Size compensation

ABL : Auto brightness Limitation

SUB : Sub Contrast allowance range

SUB : Sub Brigntness allowance range

SUB : Horizontal size range adjustment range

HLIN : Horizontal Linearity

V LIN : Vertical Linearity

RANGE : Zoom range

(for ref. 158,122,111,212,192,192)

(for ref. 159,123,110,238,186,144)

(for ref. 160,125,110,247,180,118)

(for ref. 165,129,115,162,114,81)

(for ref. 127,255,7,188)

(for ref. 0,143,98,50)

(for ref. 151,255,255,108,50)

(for ref. 153,255,161)

(for ref. 111,91,190,255)

(for ref. 0)

(for ref. 3,3)

Fig. 2.2

Factory

Mode

Indicator

- If OSD menu disappears on the screen of monitor, press " "

again (anytime), then the OSD menu comes on the screen again.

- Using " " to select .

- Press " " button to access/confirm the selection.

Bring up the "function adjustment" as shown in Fig. 2.2.

- Press '" " button for function selection as shown in

Fig. 2.2.

- Press " " button to access/confirm each item selection

(The cursor indicator will be changed from yellow colour to

red colour.)

- Using " " : to increase or decrease the value.

MODEL SELECT

V40 107P5 V0.11 20030804

Fig. 2.1

V40 107P5 V0.11 20030804

7.2 Connect the video input, set brightness control at center, and

contrast control at maximum

7.3

set R,G,B cut-off at 127 9300k and 6500K(EEPROM preload value)

R,G,B gain at 185 9300k and

180 6500K(EEPROM preload value)

ABL at 160 9300k (EEPROM preload value)

SUB-CON at 220 9300k (EEPROM preload value)

7.4 Adjust 9300K color:

With color analyzer CA 100,

set R,G,B cut-off x=0.283, y=0.297, Y=0.10

7.5 Set R,G,B gain Y= 41+/- 1FL, x=0.283, y=0.297

7.6 Repeat 7.4,7.5 until RGB three guns get x=0.283, y=0.297,

readings on low Y=0.10+/-0.05FL and high Y=41+/-1FL

brightness of 9300.

7.7 Adjust 6500K color:

With color analyzer CA 100,

set R,G,B cut-off x=0.313, y=0.329, Y=0.10

7.8 Set R,G,B gain Y= 36+/- 1FL, x=0.313, y=0.329

7.9 Repeat 7.7,7.8 until RGB three guns get x=0.313, y=0.329,

readings on low Y=0.10+/-0.05FL and high Y=36+/-1FL

brightness of 6500.

7.10 Adjust SUB-CON to get Y=41+/-1FL.

7.11 Apply full white pattern of 9300 mode, adjust ABL to reach

30 +/- 1FL(at 9300 high brightness of R/G/B gain,

contrast at 100%)

Electrical Adjustments (Continued)

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

8. Focus adjustment

9-blocks ME pattern 79.9KHz 1280 X 1024

With display at timing ,

each block is a square of . Set brightness at 50%

contrast at 100%

and at the center of the screen. and adjust focus

pot-meter which is located at fly-back transformer, until the haze

just disappears on 2/3 east and west, top and down of the screen.

90mm x 90mm

V40 107P5

Go to cover page

13

9. Loading DDC code

The DDC HEX data should be written into the EEPROM

(7802) by EDID301.EXE Program(3138 106 10103)

and software DDC Alignment kits (4822 310 11184).

10. Purity adjustment

- Make sure the monitor is not exposed to any

external magnetic field.

- Produce a full red pattern on the screen, adjust the

purity magnet rings on the PCM assy (on CRT) to

obtain a complete field of the color red. This is done

by moving the two tabs (2-pole) in such a manner

that they advance in an opposite direction but at

the same time to obtain the same angle between

the two tabs, which should be approximately 180

degree.

- Check by full green pattern and full blue pattern

again to observe their respective color purity.

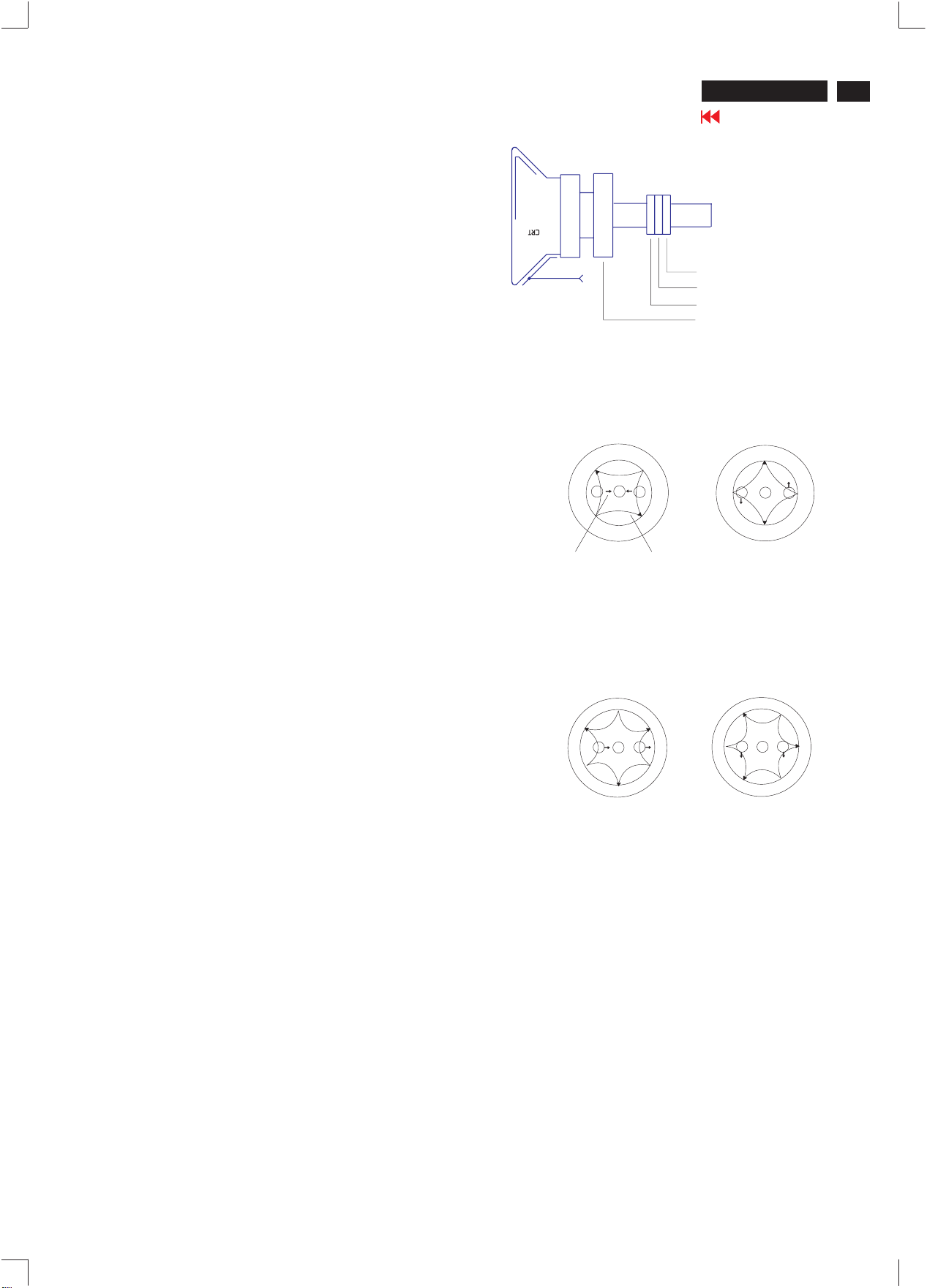

11. Static convergence

Introduction

Slight deviation in the static convergence can be

corrected by using two permanent pairs of magnets

which are fitted around the neck of the CRT. These

are the 4-pole magnet and the 6-pole magnet.

The 4-pole magnet move the outermost electron

beams (R and B) parallel in the opposite direction

from the other. The 6-pole magnet moves the

outermost electron beam (R, B and G) parallel in the

opposite direction from the other.

The magnetic field of the above magnets do not affect

the center of the CRT neck.

Setting

- Before the static convergence setting can be made,

the monitor must be switched on for 30 minutes.

- The focus setting must be made correctly.

- Signal: 640 * 480, 31.5 kHz/60 Hz mode.

- Set the tabs of the 4-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R and B electron beams.

- Set the tabs of the 6-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R, B, and G electron beams.

- First set the 4-pole magnet optimally.

- Then set the 6-pole magnet optimally.

- If the convergence is not now optimal, then adjust to

the optimal setting with the 4-pole magnet and then with

the 6- Pole magnet again.

- Set the tabs of the 6-pole magnet in the neutral

position. This is when the tabs are opposite one

another. In this position the magnets do not affect the

deflection of the R, B, and G electron beams.

- First set the 4-pole magnet optimally.

- Then set the 6-pole magnet optimally.

- If the convergence is not now optimal, then adjust to

the optimal setting with the 4-pole magnet and then

with the 6- pole magnet again.

2-pole purity magnet

6-pole convergence magnet

4-pole convergence magnet

Deflection Yoke

4-pole Beam motion producced by the

4-pole convergence magnet

S

B

N

Beam displacement

direction

6-pole

N

G

R

S

N

B

Magnetic flux

lines

Beam motion producced by the

6- pole convergence magnet

N

S

B

N

S

R

G

N

S

S

B

N

S

S

G R

S

G

N

N

S

R

N

14

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

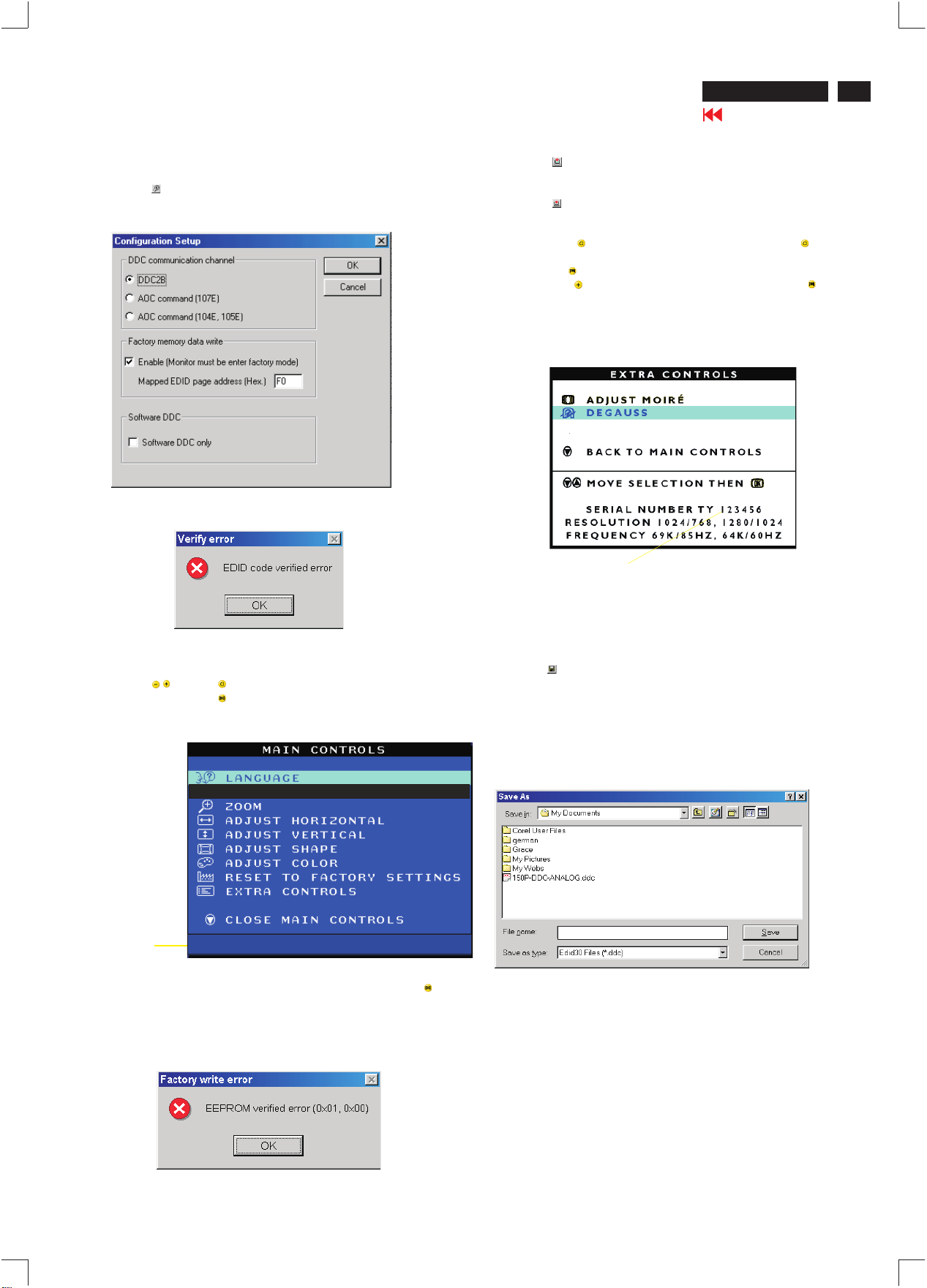

DDC Instructions

1. General

DDC Data Re-programming

In case the main EEPROM with Software DDC which store all factory

settings were replaced because a defect,repaired monitor the serial

numbers have to be re-programmed.

It is advised to re-soldered the main EEPROM with Software DDC from

the old board onto the new board if circuit board have been replaced, in

this case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

DDC EDID structure

For the monitor : Standard Version 3.0

Structure Version 1.2

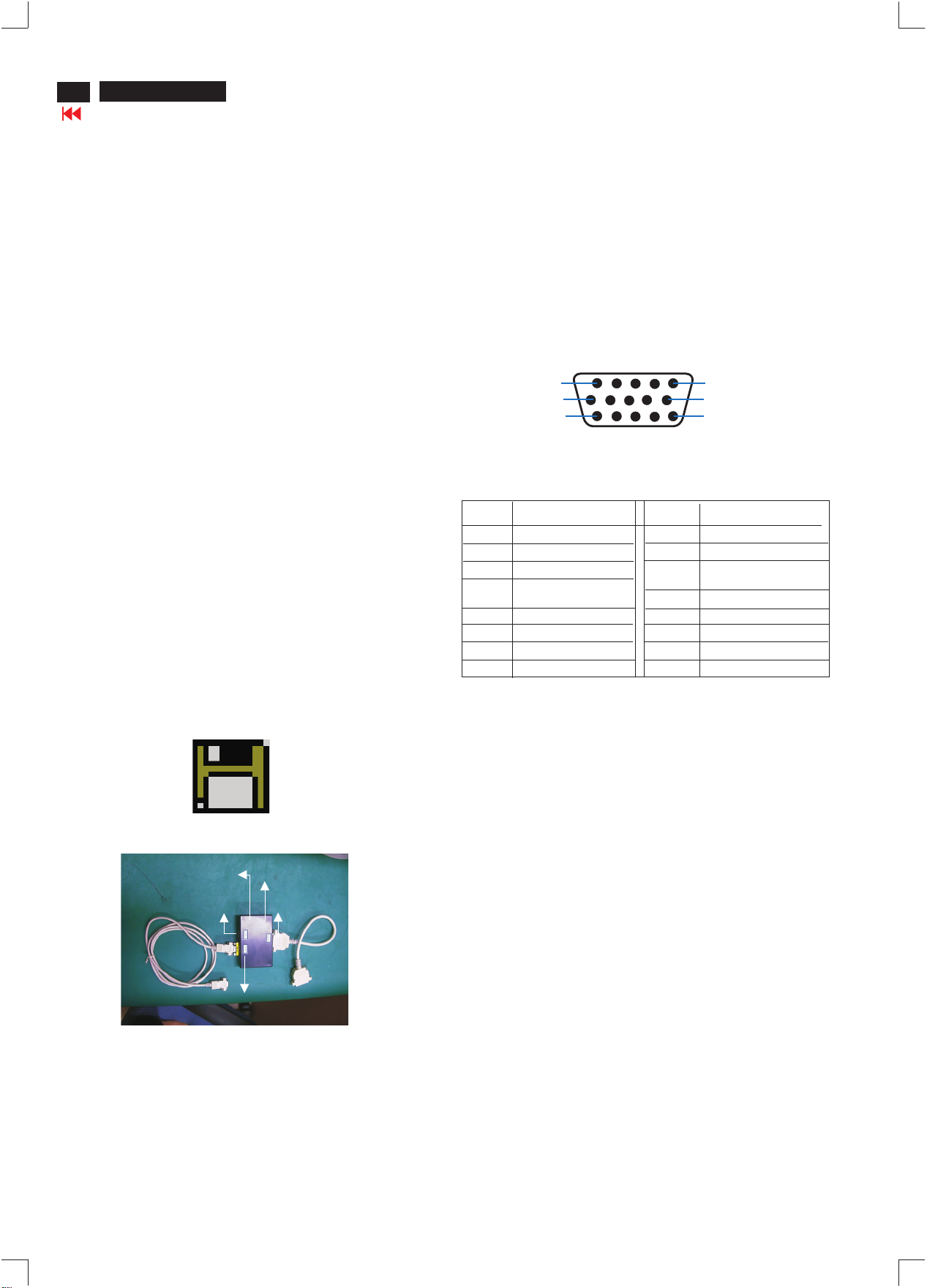

2. System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98.

3. EDID301.EXE program (3138 106 10103) shown as Fig. 1

4. Software DDC Alignment kits (4822 310 11184) shown as Fig. 2.

The kit contents: a. Alignment box x1

b. Printer cable x1

c. D-Sub cable x1

Note: The EDID301.EXE (Release Version 1.58, 20000818)is a

windows-based program, which cannot be run in MS-DOS.

3. Pin assignment

A. 15-pin D-Sub Connector

The 15-pin D-sub connector (male) of the signal cable

on the 3rd row for DDC feature :

Pin No.

1

2

3

4

5

6

7

8

1

6

11

Assignment

Red video input

Green video input

Blue video input

Ground

for selftest(PC ground)

Red video ground

Green video ground

Blue video ground

Pin No.

9

10

11

12

13

14

15

5

10

DDC 5V

Sync. Ground

Ground

Bi-directional data(SDA)

H.Sync

V.Sync(VCLK)

Data clock line(SCL)

15

Assignment

Figure 1

Diskette with EDID301.EXE

DC 8V~12V

To Monitor

Fig. 2 Alignment Kits

EDID301.EXE

Ver:1.58

Video CardVideo

Power

To Printer

Card

indicator

DDC Instructions (Continued)

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

15

X

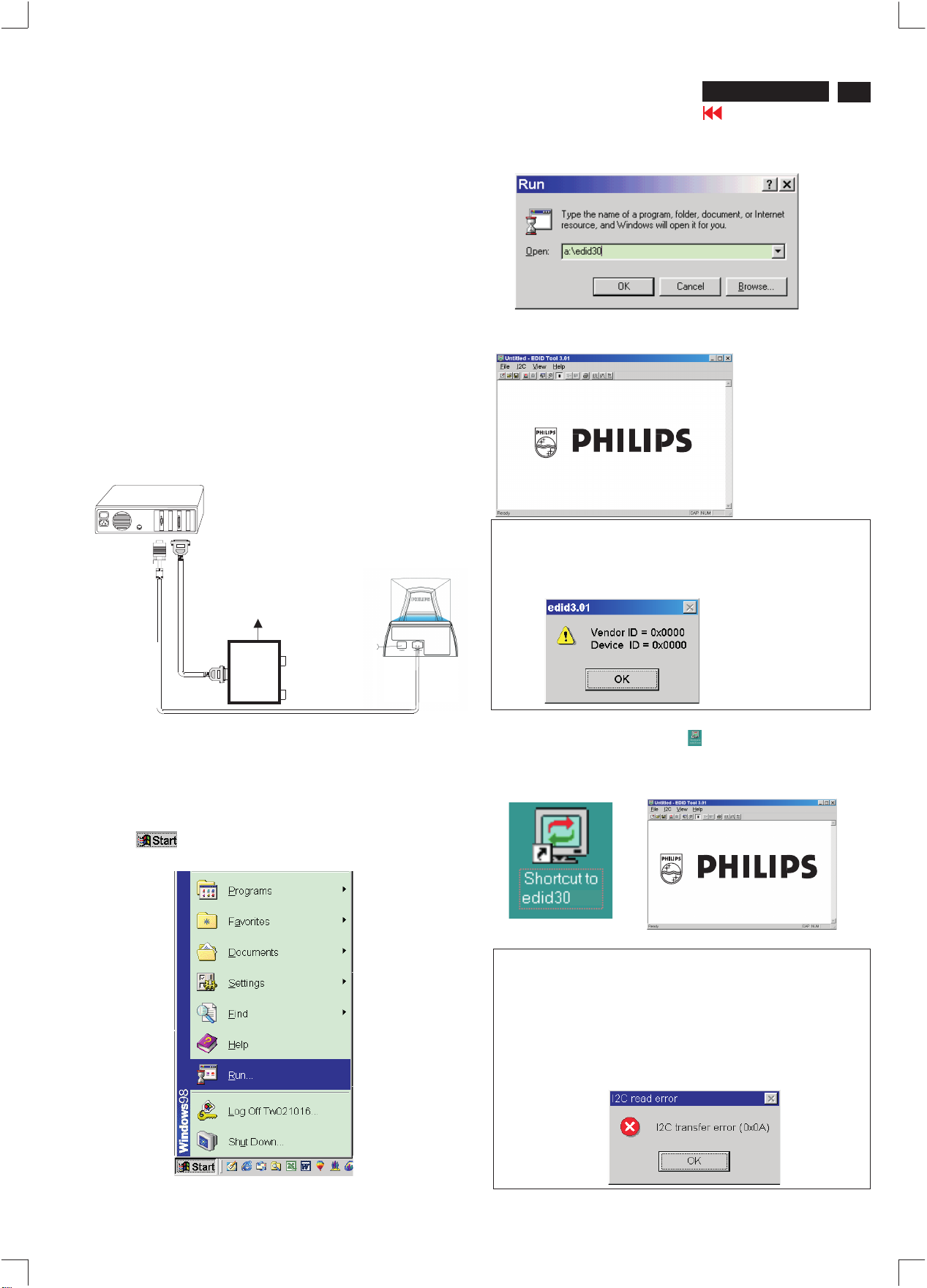

4. Configuration and procedure

There is no Hardware DDC (DDC IC) anymore. Main EEPROM stores

all factory settings and DDC data (EDID code) which is so called

Software DDC. The following section describes the connection and

procedure for Software DDC application. The main EEPROM can be reprobrammed by enabling "factory memory data write" function on the

DDC program (EDID301.EXE).

*** INITIALIZE ALIGNMENT BOX ***

In order to avoid that monitor entering power saving mode due to

sync will cut off by alignment box, it is necessary to initialize

alignment box before re-programming DDC Data. Following steps

show you the procedures and connection.

Step 1

: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

Step 2

: Connecting printer cable and video cable of monitor as

shown in Fig.3.

PC

Fig. 3

Rear view of the monitor

DC Power

8~12 V

~

~

3. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID301 (for example, A:\EDID301, as shown in Fig. 5).

Fig. 5

4. Click button. The main menu appears (as shown in Fig. 6).OK

This is for initialize alignment box.

Fig. 6

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 7) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this time,

please make sure all cables are connected correctly and fixedly,

and the procedure has been performed properly.

To video card

Step 3: Installation of EDID301.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID301.EXE program into floppy disk

drive.

2. Click , choose Run at start menu of Windows 95/98 as

shown in Fig. 4.

To printer port (LTP1)

Printer

Port

To

Monitor

To P C

Video cable

Fig. 4

Fig. 7

Method 2: After create a shortcut of EDID301.EXE

: Double click EDID301 icon (as shown in Fig. 8) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID301 as shown in Fig. 9.

This is for initialize alignment box.

1

Fig. 8

Note 2: During the loading, EDID301 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Fig. 9

16

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

DDC Instructions (Continued)

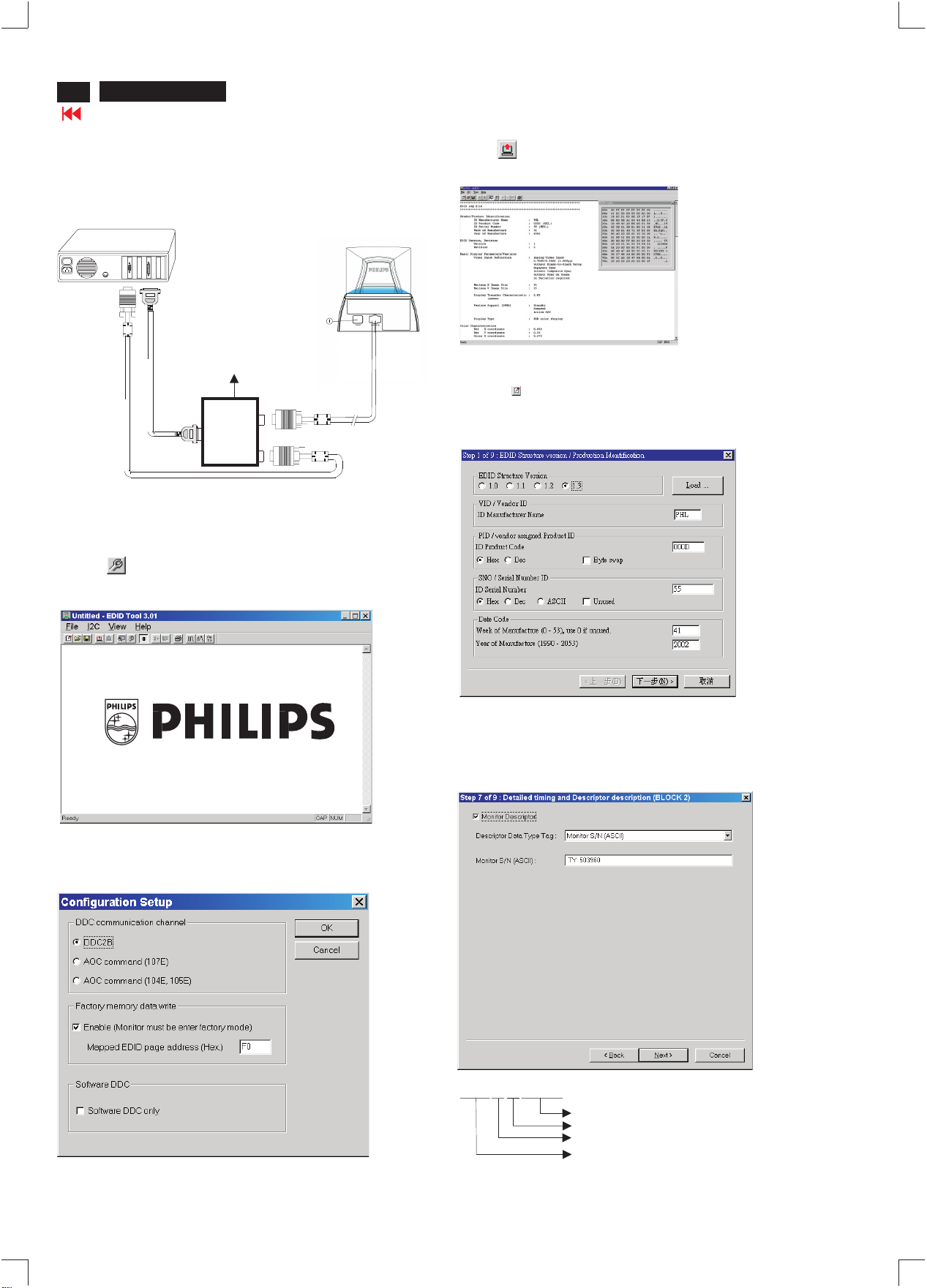

Re-programming EEPROM (Software DDC)

Step 1: After initialize alignment box, connecting all cables and

box as shown in Fig. 10

PC

Rear view of the monitor

Fig. 10

DC Power

8~12 V

~

~

To video card

Step 2: Read DDC data from monitor

1-1 Click the left key of Mouse, or hit any key on the keyboard,

then the characters disappear from the screen.

1-2 Click icon as shown if Fig. 11 from the tool bar to bring up

the "Configuration Setup" windows as shown in Fig. 12.

To printer port (LTP1)

Printer

Port

To

Monitor

To PC

Video cable

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 13

Step 3: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 14 .

EDID301 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Fig. 14

2. Select the DDC2B as the communication channel.

Select " " & fill out " " for Mapped EDID page address

Enable F0

as shown in Fig. 12.

3. Click OK button to confirm your selection.

Fig. 11

Fig. 12

Step 4: Modify DDC data (Monitor Serial No.)

1. Click till the Step 7 of 9 window appears as shown in Fig. 15.

2. Fill out the new Serial No. (for example, TY 503960, TY 123456).

3. Click till the last step window appears, then click to exit

Definition of Serial Number (barcode format)

TY00 03 15000001

Next

Next Finish

the Step window.

------>

two space

(for example: change it from TY 503960

to TY 123456)

Serial Number (U.S.A: 8 digit)

(Others regions: 6 digit)

Week

Year

TY Code

TY----Chungli

CX----Dong Guan

HD----Hungary

BZ----Suzhou

Fig. 15

DDC Instructions (Continued)

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

17

Step 5: **Configuration Setup & Enter Factory Mode **

for "write EDID data"

1. Click icon from the tool bar to bring up the Configuration Setup

windows again. Then, select "Software DDC only" as shown in

Fig. 16. Click "OK".

Fig. 16

If you do not select "Software DDC only", when you execute

"write EDID", it will bring up an error message as below.

Step 6: Write DDC data

1. Click (Write EDID) icon from the tool bar to write DDC data.

Bring up "Writing 0%~100%, ready" a progressing bar on the left

down corner.

2. Click (Read EDID) to confirm it.

Step 7: Confirm Serial Number in User Mode

1. Press the button to turn off the monitor. Press the button

again to turn on the monitor.

2. Press the button to bring up the OSD Main Menu.

3. Press the button to select Extra Controls, press the

button to confirm your selection.

4. Confirm the Serial Number "123456" is updated

as shown in Fig. 18.

To access factory mode

1. Turn off monitor (don't turn off PC)

2. Press " " and " " simultaneously on the front control

panel,then press " ",wait till the OSD menu with characters

V40 107P5 V0.11 20030804 (below OSD menu)" come on the

screen of monitor.

Fig. 17

MODEL SELECT

Factory

Mode

Indicator

If OSD menu disappears on the screen of monitor, press " "

again (anytime), then the OSD menu comes on the screen again.

V40 107P5 V0.11 20030804

Fig. 18

Step 8: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 19.

The file type is EDID301 file (*.ddc) which can be open in WordPad.

By using WordPad, the texts of DDC data & table (128 bytes, hex

code) can be modified. If DDC TEXTS & HEX Table are completely

correct, it can be saved as .ddc flie to re-load it into EEPROM for

DDC Data application.

Fig. 19

107P5 V40

2. Click .Save

If you do not access "Factory mode", when you execute

"write EDID", it will bring up an error message as below.

18

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

DDC Instructions (Continued)

Step 9: Load DDC data

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig. 20.

3. Click .

4. Access "Factory Mode" and enable "Software DDC only" as shown

5. Write EDID (click ).

Step 10: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 21.

(EDID Tool 3.01)

Open

in Fig. 17 & Fig. 16.

107P5 V40.DDC

107P5 V40.DDC

Fig. 20

Note2:InFactory Mode: Read/Write DDC data

Before Read/Write EDID code, please confirm that the

Software DDC only was enabled

as shown in Fig. 23.

Fig. 23

Fig. 21

Note1 : In User Mode: Read DDC data only

If you do not disable "Software DDC only", when you execute

"read EDID", it will bring up an error message as below.

Before read EDID code, please confirm that the

DDC only was disabled

as shown in Fig. 22.

Software

Fig. 22

Hex Data of DDC2B

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

19

**********************************************************************

EDID log file (LG tube)

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : E014 (HEX.)

ID Serial Number : 12345 (DEC.)

Week of Manufacture : 35

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.000V (0.70Vpp)

without Blank-to-Black Setup

Separate Sync

Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size : 31

Maximum V Image Size : 23

Display Transfer Characteristic : 2.87

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Color Characteristics

Red X coordinate : 0.625

Red Y coordinate : 0.336

Green X coordinate : 0.29

Green Y coordinate : 0.599

Blue X coordinate : 0.149

Blue Y coordinate : 0.073

White X coordinate : 0.283

White Y coordinate : 0.297

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

720 x 400 @88Hz (IBM,XGA2)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @67Hz (Apple ,Mac )

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple ,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings : 1152 x 870@75Hz(Apple,MacII)

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 85

Standard Timing Identification #5

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #6

Horizontal active pixels : 1920

Aspect Ratio : 4:3

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 202.5

H Active (pixels) : 1600

H Blanking (pixels) : 560

V Active (lines) : 1200

V Blanking (lines) : 50

H Sync Offset (F Porch) (pixels): 64

H Sync Pulse Width (pixels): 192

V Sync Offset (F Porch) (lines) : 1

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 310

V Image Size (mm) : 230

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : TY 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 107P5

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 50

Max. Vt rate Hz : 160

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 97

Max. Supported Pixel : 240

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : A3 (HEX.)

******************************************************************

EDID data (128 bytes LG)

******************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 14 11: e0 12: 39 13: 30 14: 00 15: 00

16: 23 17: 0d 18: 01 19: 03 20: 6c 21: 1f 22: 17 23: bb

24: e8 25: 05 26: 78 27: a0 28: 56 29: 4a 30: 99 31: 26

32: 12 33: 48 34: 4c 35: ff 36: ef 37: 80 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 81 45: 99 46: a9 47: 4f

48: d1 49: 40 50: 01 51: 01 52: 01 53: 01 54: 1a 55: 4f

56: 40 57: 30 58: 62 59: b0 60: 32 61: 40 62: 40 63: c0

64: 13 65: 00 66: 36 67: e6 68: 10 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 54 78: 59 79: 20

80: 31 81: 32 82: 33 83: 34 84: 35 85: 36 86: 0a 87: 20

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 30 105: 37 106: 50 107: 35 108: 00 109: 00 110: 00 111: fd

112: 00 113: 32 114: a0 115: 1e 116: 61 117: 18 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: a3

20

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

V40 107P5

Go to cover page

Hex Data of DDC2B

**********************************************************************

EDID log file (CPT tube)

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : E014 (HEX.)

ID Serial Number : 12345 (DEC.)

Week of Manufacture : 35

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.000V (0.70Vpp)

without Blank-to-Black Setup

Separate Sync

Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size : 31

Maximum V Image Size : 23

Display Transfer Characteristic : 2.86

(gamma)

Feature Support (DPMS): Standby

Suspend

Active Off

Display Type : RGB color display

Color Characteristics

Red X coordinate : 0.631

Red Y coordinate : 0.329

Green X coordinate : 0.276

Green Y coordinate : 0.600

Blue X coordinate : 0.143

Blue Y coordinate : 0.057

White X coordinate : 0.283

White Y coordinate : 0.297

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

720 x 400 @88Hz (IBM,XGA2)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @67Hz (Apple ,Mac )

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple ,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Manufacturer's timings : 1152 x 870 @75Hz (Apple ,Mac II)

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 85

Standard Timing Identification #5

Horizontal active pixels : 1600

Aspect Ratio : 4:3

Refresh Rate : 75

Standard Timing Identification #6

Horizontal active pixels : 1920

Aspect Ratio : 4:3

Refresh Rate : 60

Detailed Timing #1

Pixel Clock (MHz) : 202.5

H Active (pixels) : 1600

H Blanking (pixels) : 560

V Active (lines) : 1200

V Blanking (lines) : 50

H Sync Offset (F Porch) (pixels): 64

H Sync Pulse Width (pixels) : 192

V Sync Offset (F Porch) (lines) : 1

V Sync Pulse Width (lines) : 3

H Image Size (mm) : 310

V Image Size (mm) : 230

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Positive Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : TY 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 107P5

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 50

Max. Vt rate Hz : 160

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 97

Max. Supported Pixel : 240

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : E6 (HEX.)

**********************************************************************

EDID data (128 bytes CPT)

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 14 11: e0 12: 39 13: 30 14: 00 15: 00

16: 23 17: 0d 18: 01 19: 03 20: 6c 21: 1f 22: 17 23: ba

24: e8 25: 9e 26: a8 27: a1 28: 54 29: 46 30: 99 31: 24

32: 0e 33: 48 34: 4c 35: ff 36: ef 37: 80 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 81 45: 99 46: a9 47: 4f

48: d1 49: 40 50: 01 51: 01 52: 01 53: 01 54: 1a 55: 4f

56: 40 57: 30 58: 62 59: b0 60: 32 61: 40 62: 40 63: c0

64: 13 65: 00 66: 36 67: e6 68: 10 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 54 78: 59 79: 20

80: 31 81: 32 82: 33 83: 34 84: 35 85: 36 86: 0a 87: 20

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 30 105: 37 106: 50 107: 35 108: 00 109: 00 110: 00 111: fd

112: 00 113: 32 114: a0 115: 1e 116: 61 117: 18 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: e6

Flying cable

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

15 pin Dsub

HV

R

G

B

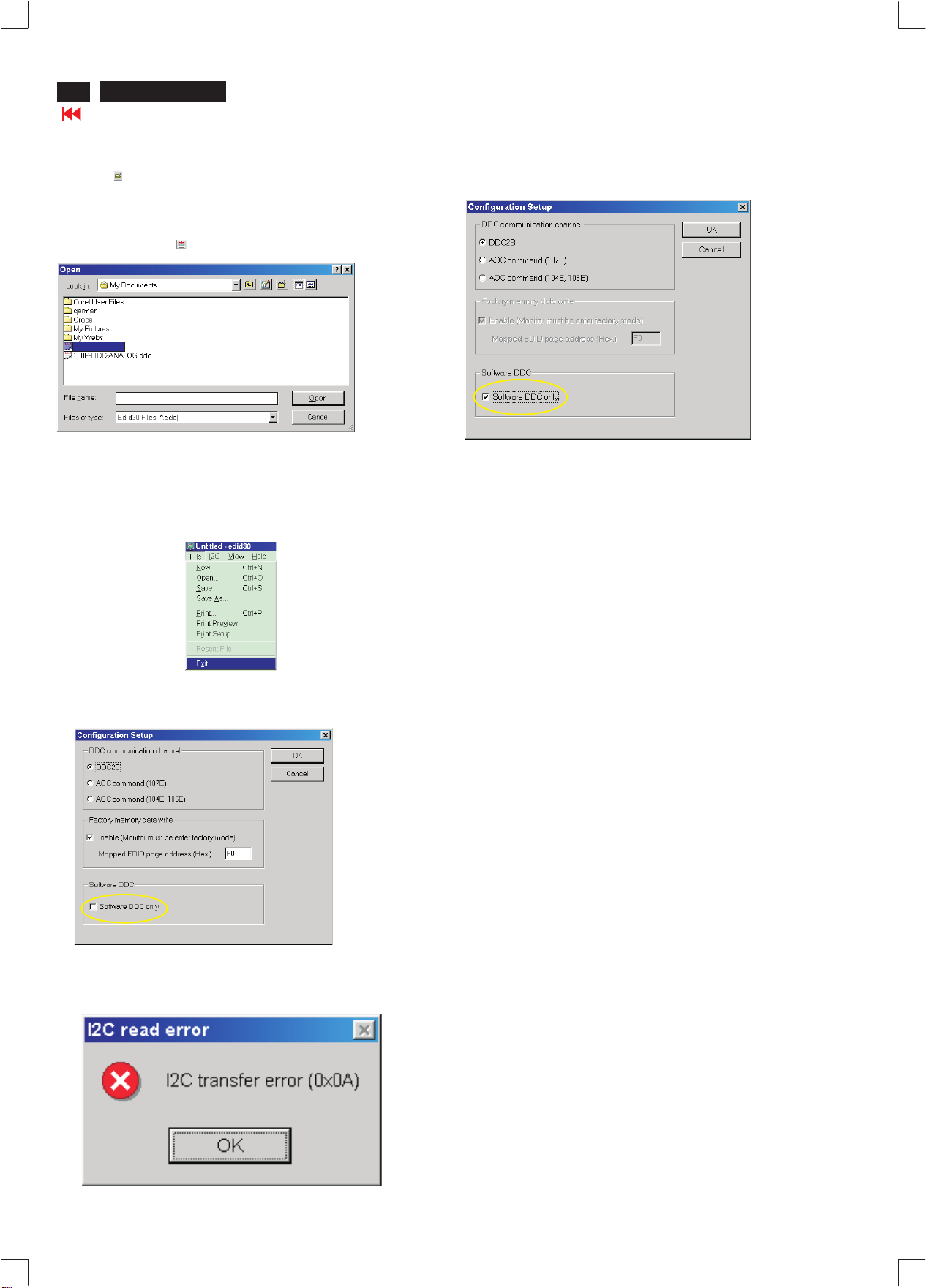

Block Diagram of V40 107P5

Video /B

Video-E

TDA4823

PS_V1

Pre -Amp

TDA4886

/V2

Post-Amp

LM2435T

V40 107P5

Go to cover page

9

CRT

21

Function

KeyContr

ol

Board &

LED

107P5

Main /B

VH

OSD NOV

Nt68275

Rotation

XXX

H

V

SDA/SCL

CPU

DA

DA

6148-K420PH-63

EEPROM

M24C16

SD

H. freq. : 30 - 92KHz

V. freq. : 50 - 160Hz S-Capacitor Switch

Switching power freq.: 30-80kHz

SC

EHT/UC3843A

X-RAY

Linearity Control

DAF/ SLA5094

S-Capacitor

CPU clock freq. : 12MHz

H

Sync Processor

V H/O

TDA 4841

+190

Power

90~264V +83

Supply

+13

TEA1507

47~63Hz +6

Degaussing

+

ckt

+12

-12

HUNLOCK

H/O

V/O

Horizontal

Deflection

Vertical

TDA8172

Muting CKT

22

http://jdwxzlw.5d6d.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

9

V40 107P5

Go to cover page

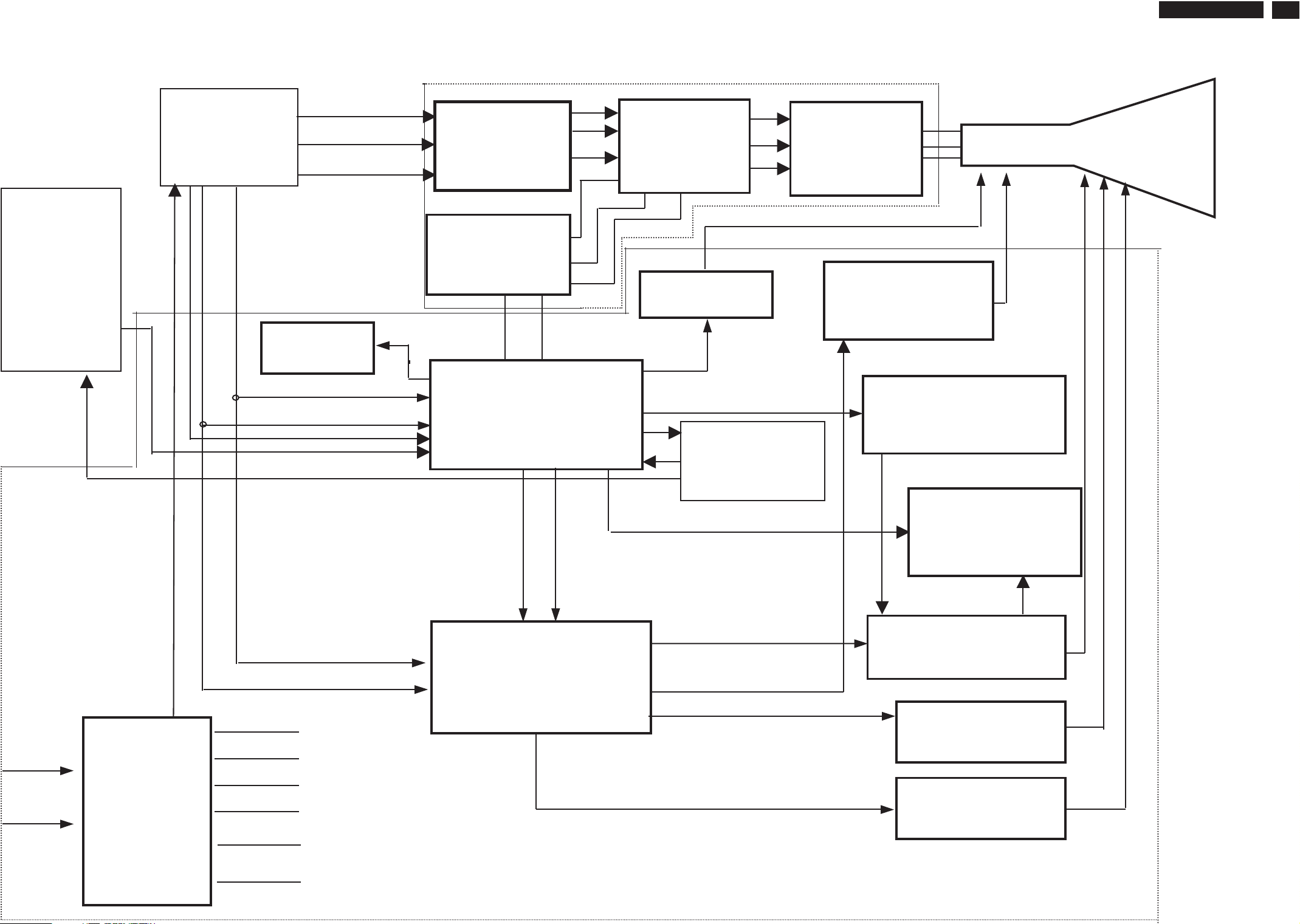

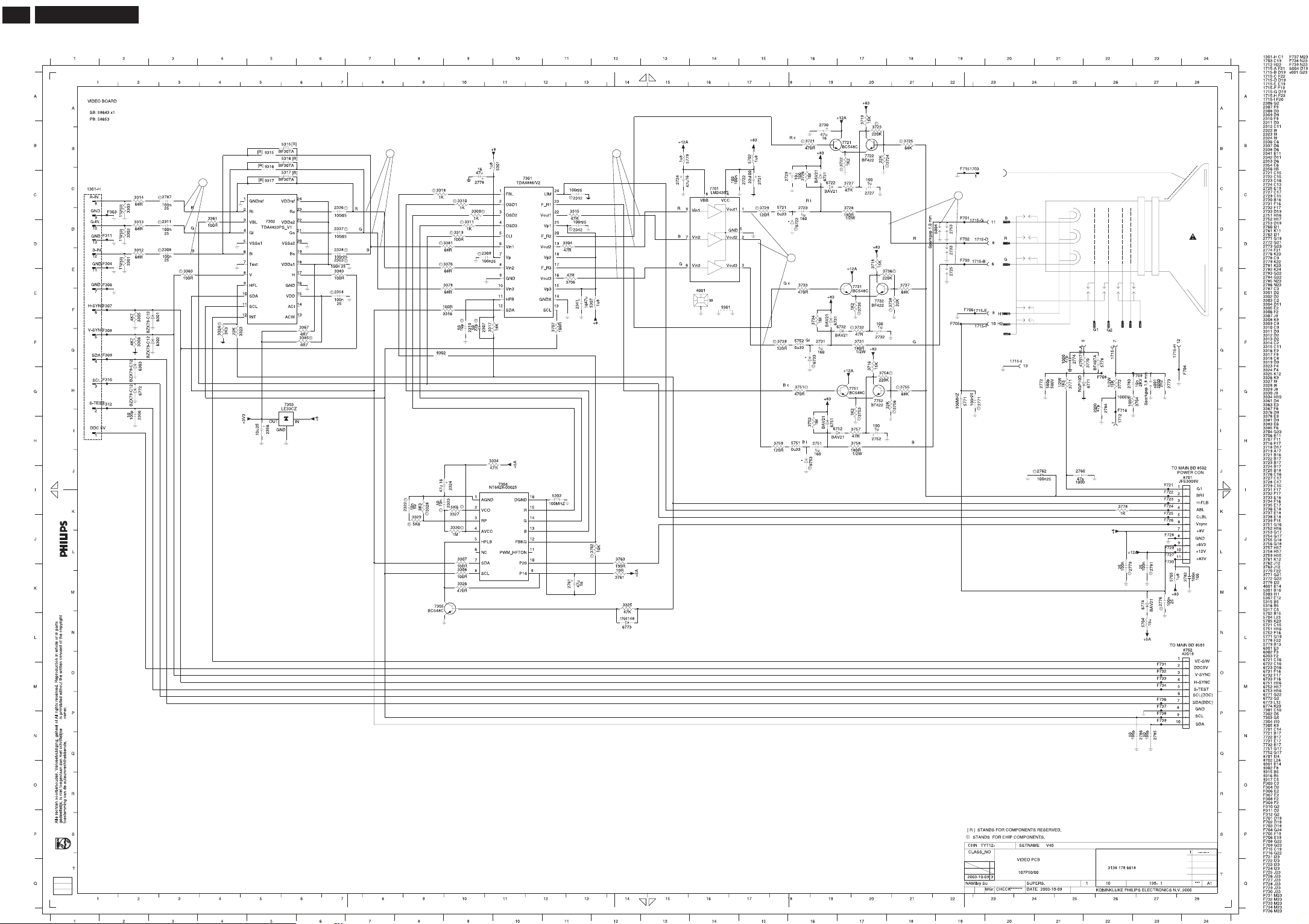

Video Panel Schematic diagram

49

48

50

52

51

Loading...

Loading...