Page 1

17 inch TFT LCD Colour Monitor

Service

Chassis: SH6

Service

Service

TABLE OF CONTENTS

Description Page

Important Safety Notice ------------------------------2

Technical Data ------------------------------------- 3~4

Front Control & Connections---------------------- 5~6

On-screen Display(OSD)------------------------------7

Factory Mode ----------------------------------------- 8

Aging Mode ------------------------------------------- 9

Pixel Defect Policy------------------------------------10

Smart management --------------------------------- 11

Display Adjustments ------------------------------- 12

Mechanical Instructions-------------------------13~14

Safety Test Requirement ---------------------------- 15

Wiring Message----- ---------------------------------16

Block Diagram----------------------------------------17

Scaler Schematic Diagram & C.B.A ---- -----18~23

170C6FS/00

170C6FS/78

170C6FS/93

Horizontal frequencies

30 - 83KHz

Description Page

Control Schematic Diagram & C.B.A. -------------- 24

«

Power Schematic Diagram & C.B.A ------------25~31

Exploded View--------------------------------------- 32

Spare parts list --------------------------------- -----33

Recommended parts list --------------------------- 34

Warning Message ----------------------------------- 35

Trouble Shooting ------------------------------- 36~37

Repair Tips -------------------------------------- 38~39

Repair Flow Chart ------------------------------ 40~42

ISP Instruction --------------------------------- 43~44

DDC Instructions & Data ---------------------- 45~49

Panel Defect Policy --------------------------------- 50

General Product Specification -----------------51~76

Different Parts List ---------------------------------- 77

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Published by BCU Monitors Printed in Suzhou Copyright reserved Subject to modification S Jun. 16 2005

GB

3138 106 10474

Page 2

2

Proper service and repair is important to the safe,

reliable operation of all Philips Consumer Electronics

Company** Equipment. The service procedures

recommended by Philips and described in this service

manual are effective methods of performing service

operations. Some of these service operations require

theuseoftoolsspeciallydesignedforthepurpose.The

specialtoolsshouldbeusedwhenandas

recommended.

Itisimportanttonotethatthismanualcontains

various CAUTIONS and NOTICES which should be

carefully read in order to minimize the risk of personal

injury to service personnel. The possibility exists that

improper service methods may damage the equipment.

It is also important to understand that these

CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

Philips could not possibly know, evaluate and advise

theservicetradeofallconceivablewaysinwhich

service might be done or of the possible hazardous

consequences of each way. Consequently, Philips has

not undertaken any such broad evaluation. Accordingly,

aservicerwhousesaserviceprocedureortoolwhich

is not recommended by Philips must first satisfy

himself thoroughly that neither his safety nor the safe

operationoftheequipmentwillbejeopardizedbythe

service method selected.

Important Safety Notice

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH

THEIR PART NUMBERS IN THE PARTS LIST SECTION

OF THIS SERVICE MANUAL.

Take care during handling the LCD module with

Backlight unit

- Must mount the module using mounting holes

arranged in four corners.

-Donotpressonthepanel,edgeoftheframe

stronglyorelectricshockasthiswillresultin

damage to the screen.

-Donotscratchorpressonthepanelwithanysharp

objects,suchaspencilorpenasthismayresultin

damage to the panel.

- Protect the module from the ESD as it may damage

the electronic circuit (C-MOS).

- Make certain that treatment person s body are

grounded through wrist band.

-Donotleavethemoduleinhightemperatureandin

areasofhighhumidityforalongtime.

-Avoidcontactwithwaterasitmayashortcircuit

within the module.

- If the surface of panel become dirty, please wipe it

offwithasoftmaterial.(Cleaningwithadirtyor

rough cloth may damage the panel.)

* *Hereafter throughout this manual, Philips Consumer

Electronics Company will be referred to as Philips.

WARNING

Critical components having special safety

characteristics are identified with a by the Ref. No.

in the parts list and enclosed within a broken line*

(where several critical components are grouped in one

area)alongwiththesafetysymbol onthe

schematics or exploded views.

Use of substitute replacement parts which do not have

the same specified safety characteristics may create

shock, fire, or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from

Philips. Philips assumes no liability, express or implied,

arising out of any unauthorized modification of design.

Servicer assumes all liability.

*BrokenLine

FOR PRODUCTS CONTAINING LASER :

DANGER-

CAUTION-

CAUTION-

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

Page 3

Technical Data - 170C6

3

Technical Sp ecifications*

LCD PANEL

• Type TFT LCD

•Screen size 17"/43.2cmdiagonal

•Pixel Pitch 0.264x0.264mm

•LCD Panel type

•Effective viewing area 337.9 x 270.3 mm

• Display Colors 16.2 M colors

SCANNING

Vertical refresh rate 56 Hz-76 Hz

Horizontal Frequency 30kHz-83 kHz

VIDEO

•Videodot rate 140 MHz

•Inputimpedance

- Video 75ohm

- Sync 2.2K ohm

•Input signal levels 700mVpp

•Sync input signal

•Sync polarities Positiveand negative

•Video interface D-Sub (analog)

1280 x 1024 pixels

R.G.B. vertical stripe

Anti-glare polarizer, hard coated

Separate sync

Composite sync

Sync on green

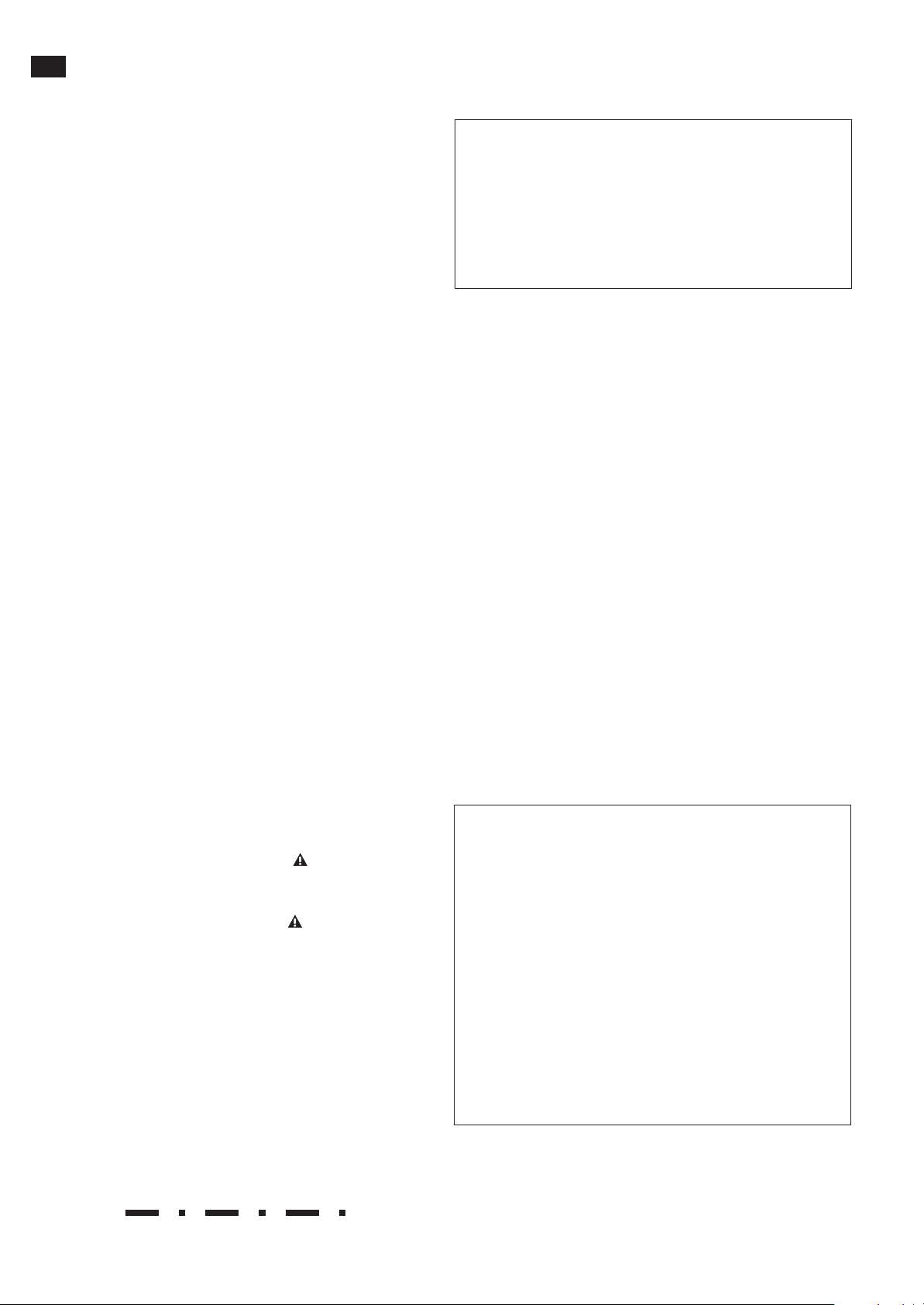

Pin Assignment

The 15-pin D-sub connector (male)ofthe signal cable:

Pin

Assignment

No.

1 Redvideo input 9 +5V

2 Green video input/SOG 10 Logic ground

3 Blue video input 11 Ground

4 Sense (GND) 12 Serial data line (SDA)

5 Hot Plug Detect 13 H. Sync /H+V

6 Redvideoground 14 V. Sync (VCLK for DDC)

7 Green videoground 15 Data clock line (SCL)

8 Blue videoground

Resolution &Preset Modes

•Maximum 1280 x 1024 at 75Hz

•Recommended 1280 x 1024 at 60 Hz

50 userdefinable modes

15fact ory preset modes:

H. freq (kHz) Resolution V. freq(Hz)

Pin

No.

Assignment

Optical charac teri stics

• Contrast ratio 500:1 (typ.)

•Brightness 250cd/m2(typ.)

•Peak contrastangle 6 o'clock

•White Chromaticity

•ViewingAngle (C/R>5)

•Responsetime < 8ms(typ.)

Physical Specification s

• Dimension (WxHxD)* 403 x 392 x 171 mm (incl.Pedestal)

•Weight 4.5 kg

• Tilt -5° ~ 20°

•Power supply 100 —240 VAC, 60 - 50 Hz

•Power consumption 30 W* (typ.)

• Temperature

•Relativehumidity 20% to80%

x: 0.283 y: 0.297 (at 9300°K)

x: 0.313y:0.329 (at 6500°K)

x: 0.313y:0.329 (at sRGB)

Upper>75° (typ.)

Lower>70°(typ.)

Left >80°(typ.)

Right >80°(typ.)

5° Cto40° C (operating)

-20° Cto 60° C (storage)

31.5 640*350 70

31.5 720*400 70

31.5 640*480 60

35.0 640*480 67

37.5 640*480 75

35.2 800*600 56

37.9 800*600 60

46.9 800*600 75

49.7 832*624 75

48.4 1024*768 60

60.0 1024*768 75

69.0 1152*870 75

71.8 1152*900 76

63.9 1280*1024 60

80.0 1280*1024 75

•SystemMTBF 50K hours (including CCFL 40K hours)

Page 4

4

Automat ic PowerSaving

If you have VESA DPMS compliance display card or software

installed in your PC, the monitor can automaticallyreduce itspower

consumption when notinuse.Ifan input from a keyboard, mouse or

other input device isdetected, the monitor will 'wake up'

automat

ically. The following table shows the power consumptionand

signalingofthis automatic powersavingfeature:

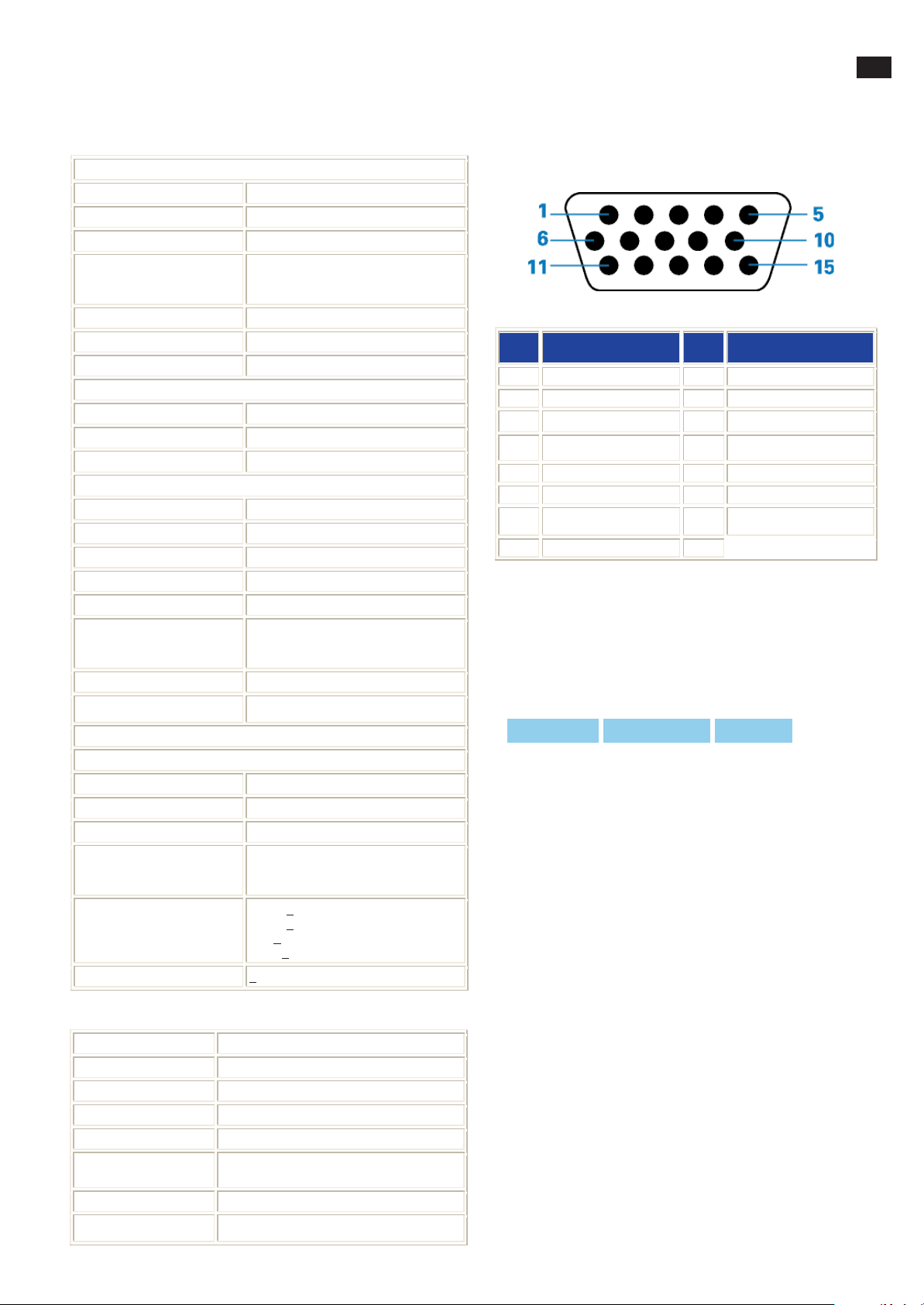

PowerManagement Definition

Technical Data - 170C6

VESA

Mode

Active ON YesYes<30 WGreen

Sleep OFF No No < 1 WAmber

Switch Off OFF --< 1WOff

Thismonitor isENERGYSTAR compliant.Asan ENERGY

STAR Partner, PHILIPS hasdetermined that thisproduct meets

the ENERGY STAR guidelinesforenergy efficiency.

VideoH-sync V-sync PowerUsedLEDcolor

R

R

R

Page 5

Connection to PC

g

S

c

5

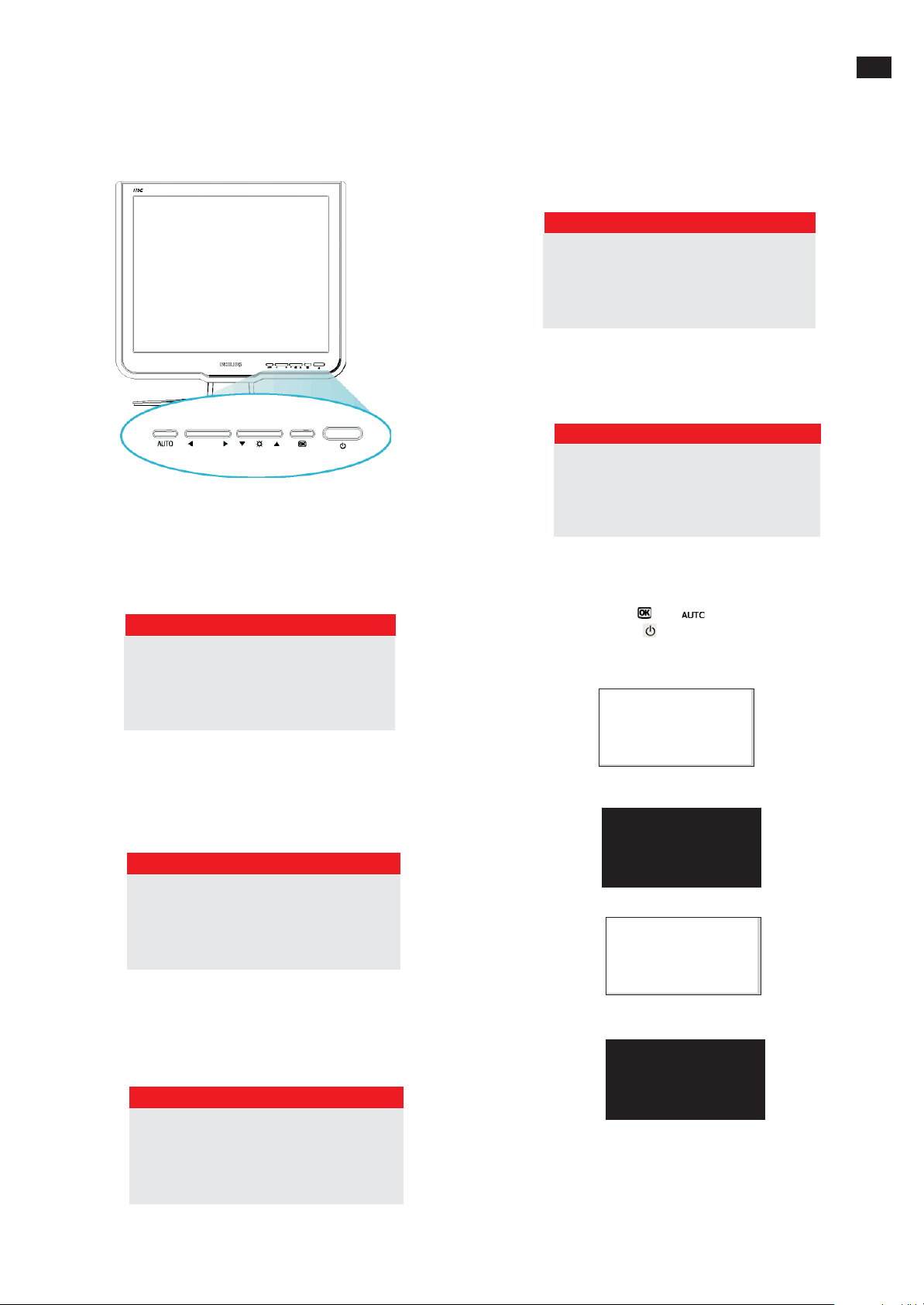

Installing Your LCD Monitor

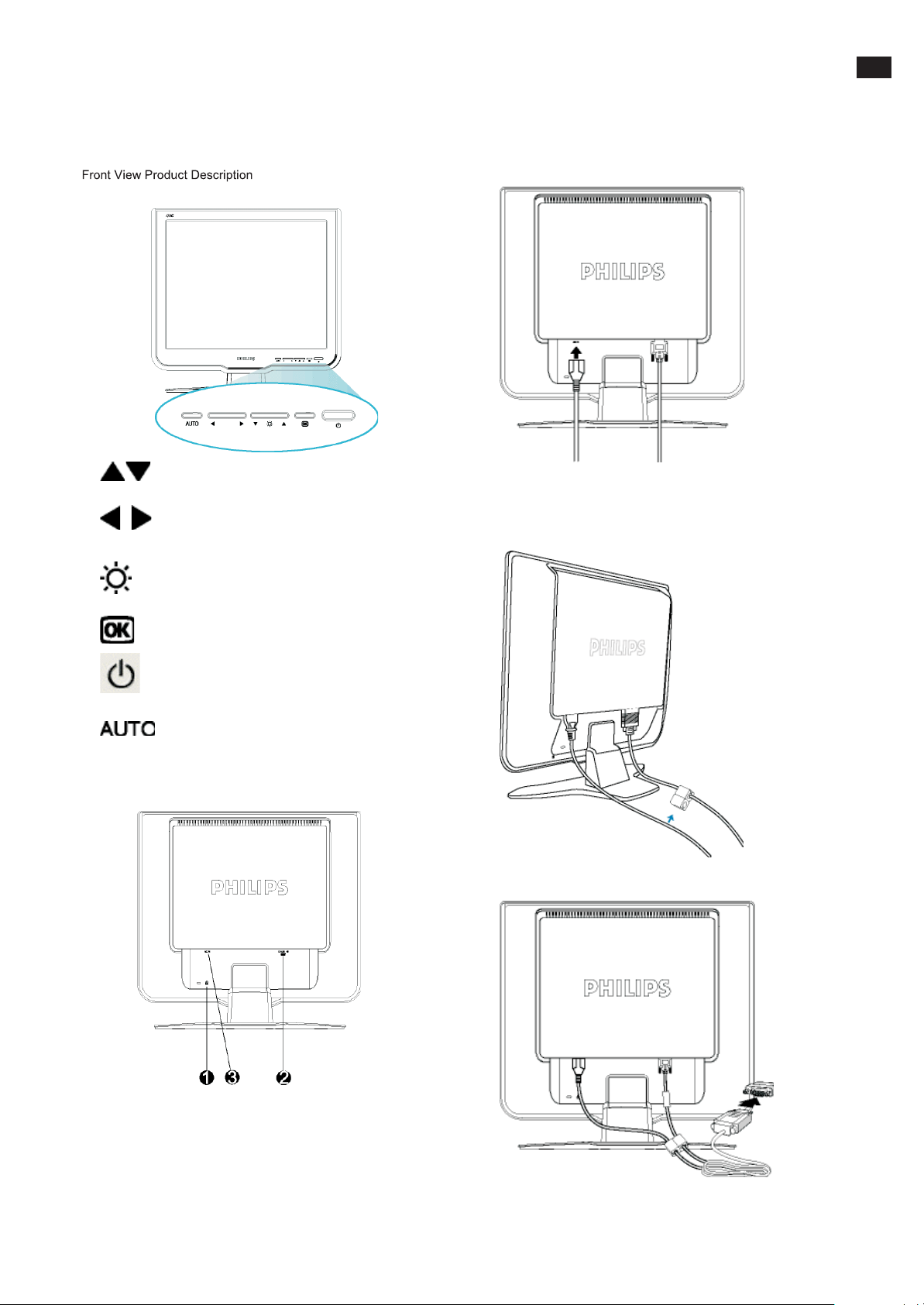

UP andDOWNbuttonsare usedwhen

adjusting the OSD ofyour monitor.

LEFT andRIGHTbuttons, likethe UP an

DOWN buttons, are also used in adjustin

the OSD ofyour monitor.

BRIGHTNESS hotkey. When the UP and

DOWN arrowbuttonsare pressed, the

adjustment controls for the BRIGHTNES

will showup.

OK button whichwhen pressedwill take

you to the OSD controls.

Connecting to Your PC

1) Plug the power cord into mo

nitorfirmly.

Rear View

POWER button switchesyour monitor on

Automatically adjustthe horizontal

position,vertical position, phase and clo

setting.

2) Clip the power cord andsignal cabletogetherfor cable

management.

1Kensington anti-thieflock

2VGAinput

3AC power input

Note:Ifyouuse an Apple Macintosh, you need to connect the

special Mac adapter to one end of the monitorsignal cable.

Page 6

6

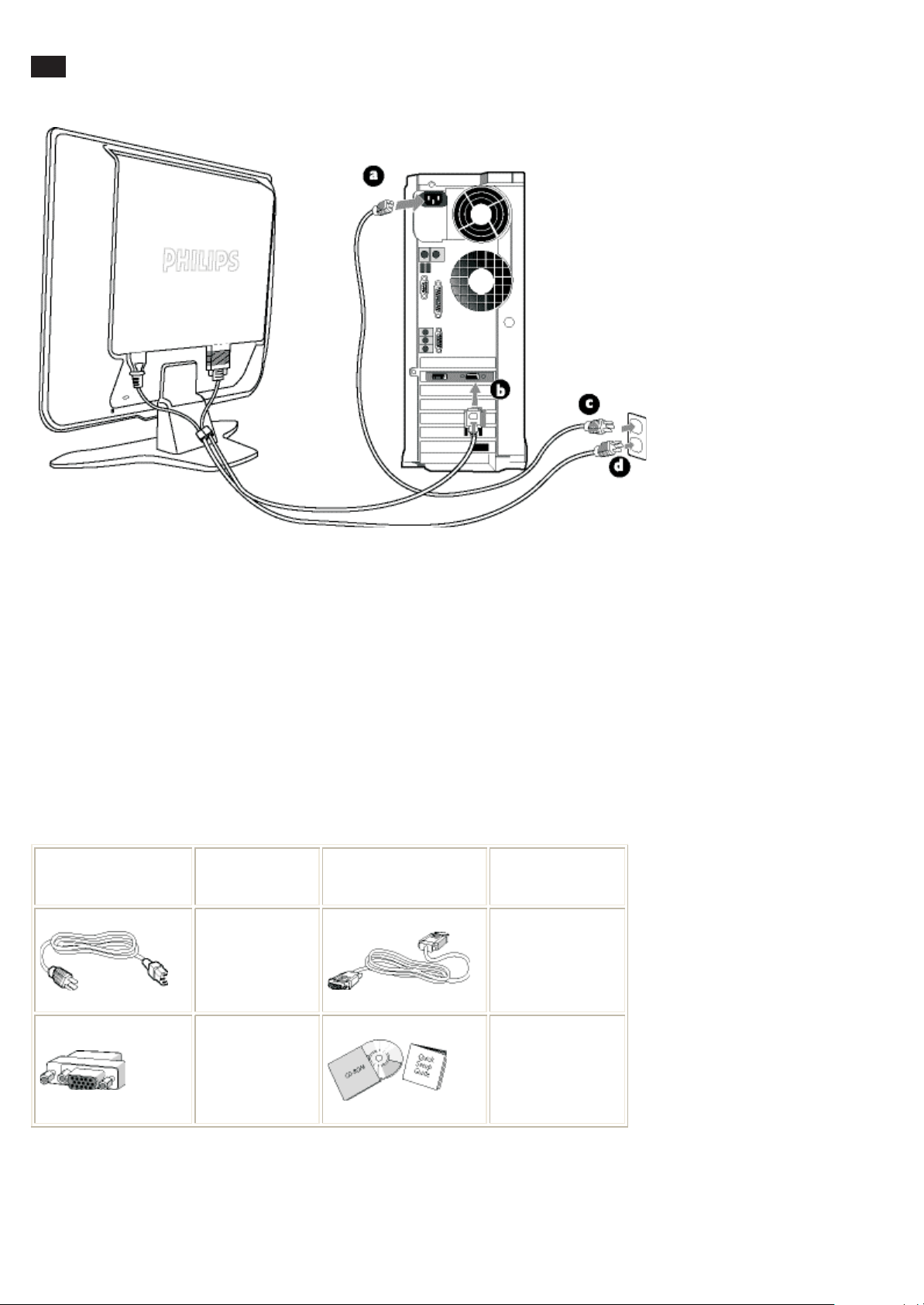

Connection to PC

2) Connect to PC

(a) Turnoff your computerandunplug itspower cable.

(b) Connect the monitorsignal cabletothe video connector on the back ofyour computer.

(c) Plug the power cord ofyour computerandyour monitor into a nearby outlet.

(d) Turnonyour comp

uterandmonitor. If the monitordisplays animage, installation is complete.

Acc essory Pack

Unpackallthe parts.

ItemDescri ption Item

1) Power Cable

(socket may differ

fordifferent

countries)

3) VGA Signal Cable

Descri ption

2) Macintosh

Adapter(optional)

4) E-DFU package

withQuickSetup

Guide and CD-ROM.

Page 7

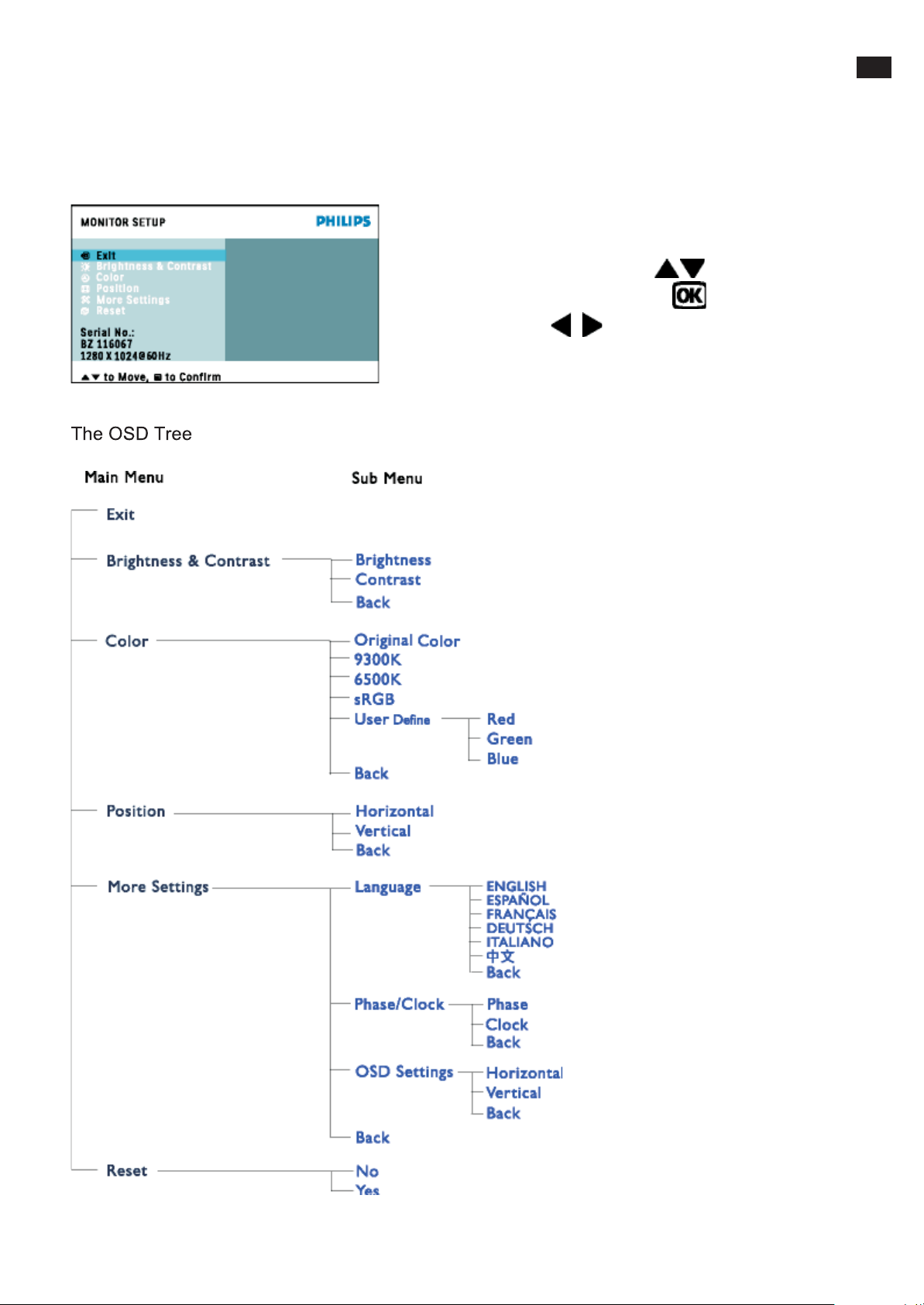

On Screen Display

Description of the On Screen Display

On-Screen Display (OSD) is a feature in all Philips LCD monitors.Itallowsanenduser to adjust screen performance orselectfunctions

of the moni tors directly through an on-screen instruction window. A user friendly onscreendisplay interface is shownasbelow :

Basic and simple instruc t ion on thecontrol key s.

In theOSDshownabove users can press buttons atthe

7

frontbezel of the monitor to move thecursor,

choice orchange, and

to adjust/selectthechange.

to confirmthe

Page 8

8

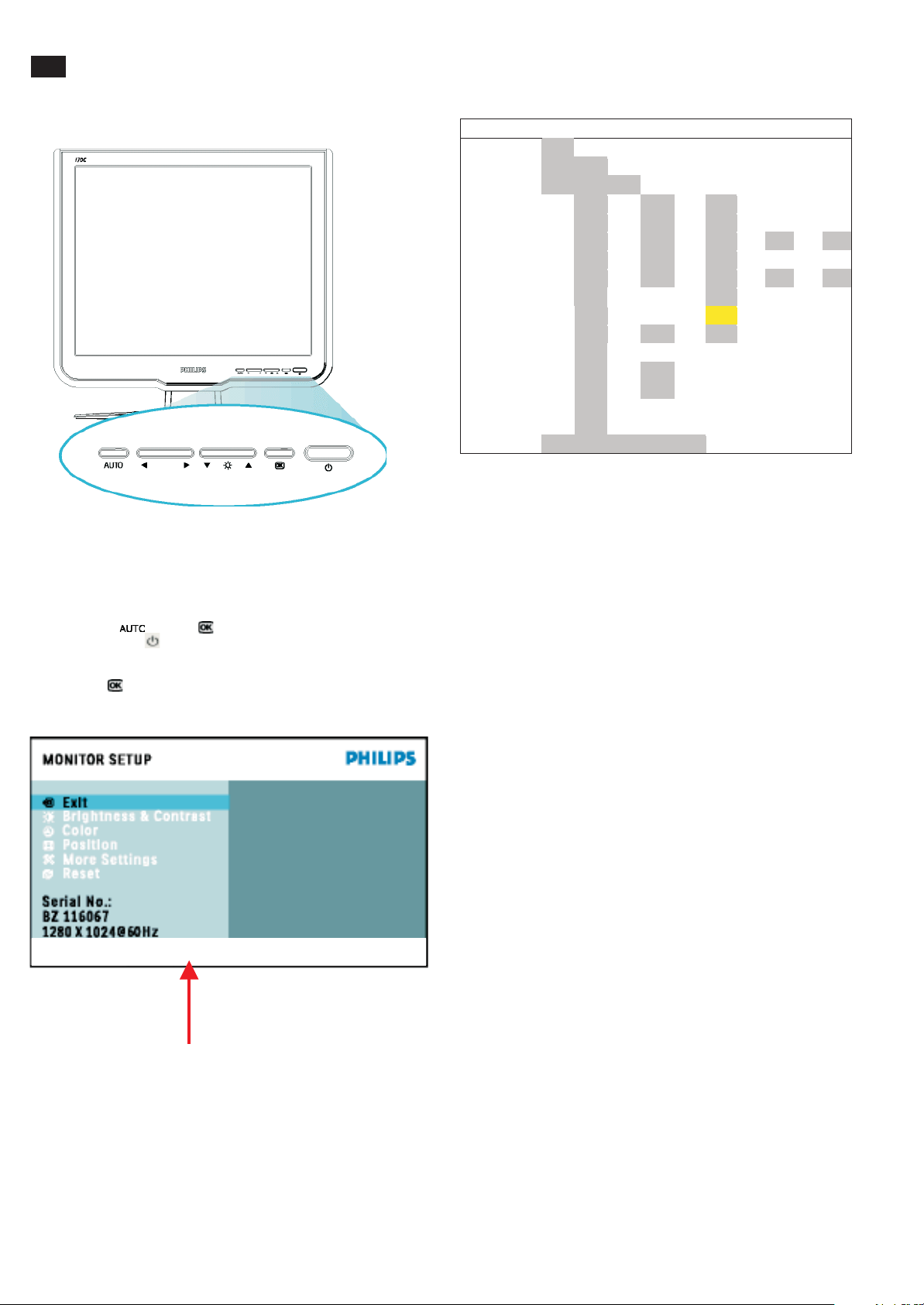

Factory Mode

Front control panel

Access Factory Mode

How to get into Factory Mode Menu

Step1:

Turn off monitor.

Step2:

[Push AUTO " " & OK " " buttons at the same time and hold it]

+[Press power " " button untill comes out "Windows screen" ]

=> then release all buttons

Step3:

Press OK " " button, bring up Factory mode indication as shown

in Fig2.

Hudson 170C6 V004 2005/03/21

BL :

SUB - BRI:

SUB - CON: 78 128 178

9300K R Xxx G xxx B xxx

6500K R Xxx G xxx B xxx

SRGB R Xxx G xxx B xxx B 255 C 128

OFFSET2 R Xxx G xxx B xxx

GAIN R Xxx G xxx B xxx M 255 m 0

AUTO-SUB OK! OSDTIMER 60

OFFSET1 R Xxx G xxx B xxx

SCALER:ADD:

NVRAM:ADD:

PANEL:

0

0 255

IDX : 40

VAL: READ

VAL: READ

LG

17

1024x768 48.3KHz @60Hz

WRITE

WRITE

BL blacklevel value

SUB-BRI : Brightness value range(Min Max)

SUB-C ONContrast value range(Min Mid Max)

SRGB-B : Brightness of sRGB

SRGB-C : Contrast of sRGB

Gain-m : Minimum value of User Gain

Gain-M: Maximum value of User Gain

AUTO-SUB: To do Auto color function when push

Menu key in white pattern

OSDTIMER :OSD time out control(sec)

IDX : Limit current of inverter

SCALER : Read/Write scaler register

Panel : HS (Hannstar panel)

CPT (CPT panel)

LG

(LG.Philips panel)

AU

QDI (Quanta Display Inc.)

DEFAULT

HUDSON 170C6 V004 2005/03/21

Factory mode indicaor

Factory Menu

Cursor can move on gray color area

Hot key function: by pressing " up " and " DOWN " key

(PS: The Offset RGBfunction can be used on reduce or eliminate

snowy noise on the background when the resolution of video signal

is 1280*1024 vertical 60Hz. Slightly increase or decrease the value

until snowy noise completely disappear

Simultaneously at User Mode (or Factory Mode)

Page 9

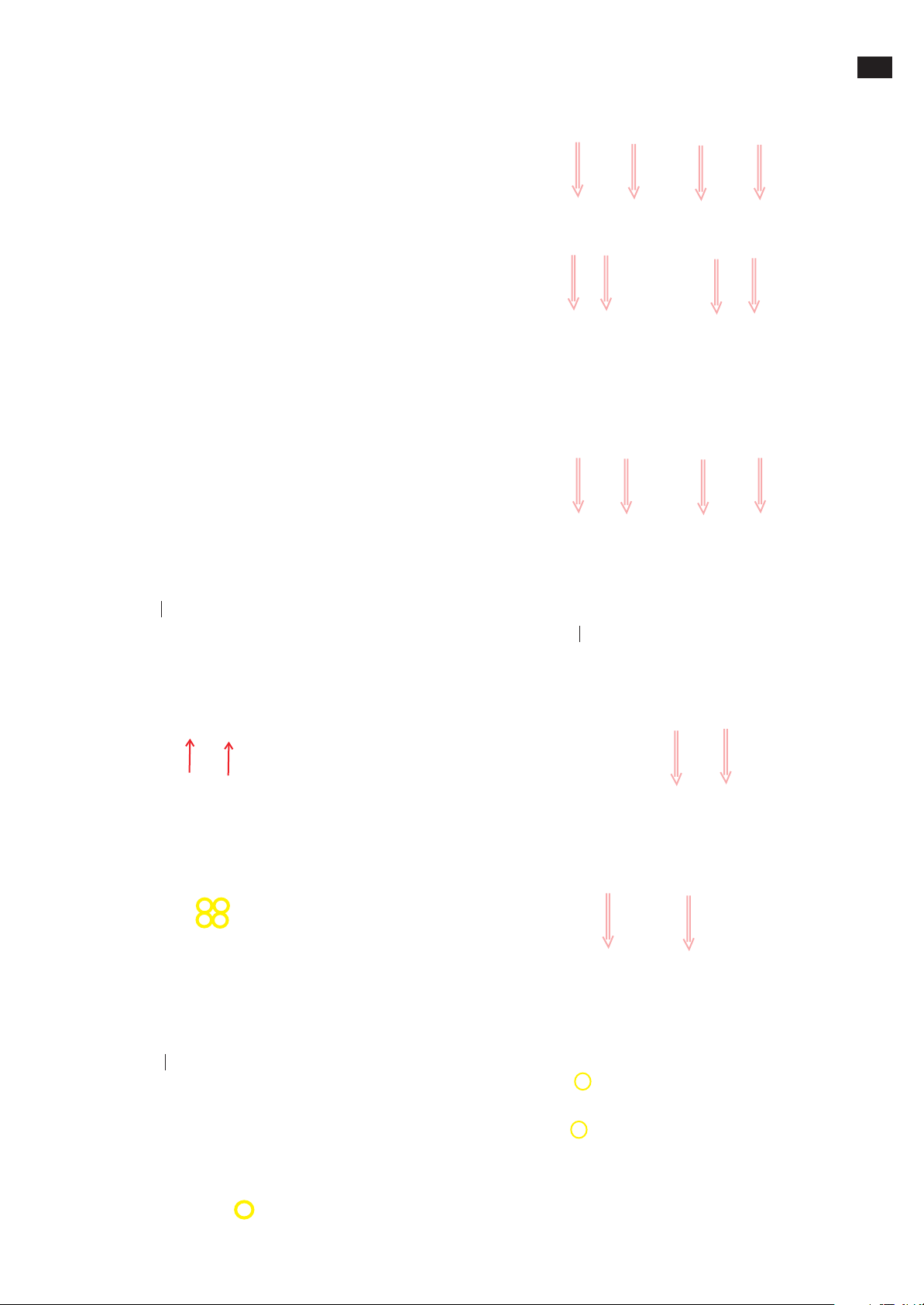

OSD Lock/Unlock, Aging Mode 9

Front Control Panel

To Lock/Unlock OSD FUNCTION(User Mode)

The OSD function can be locked by pressing"OK"button(1) for more

than 10 seconds, the screen shows following windows for 3 seconds.

Everytime when you press"AUTO" or "OK" button, this message appears on the screen automatically.

ATTENTION SIGNAL

CANNOT DISPLAY THIS VIDEO MODE..

This screen warns when the input frequency from the computer is not

a standard video mode or out of the monitor's scanning range.

Please change the display mode of the operating software in the computer(i.e.windows) to 1280*1024@60HZ for best display results.

ATTENTION SIGNAL

CANNOT DISPLAY THIS VIDEO

MODE,CHANGE COMPUTER DISPLAY

INPUT TO 1280*1024@60HZ

I

WAIT FOR AUTOMATIC ADJUSTMENT

This screen appears when you press the "AUTO" buttons at the same

time. It will disappear when the monitor is properly adjusted

ATTENTION SIGNAL

WAITING FOR AUTOMATIC ADJUSTMENT

Access Aging.. Mode

Step1:TurnoffLCDmonitor, and disconnect Interface Cable

between Monitor and PC.

Step 2 : [Push AUTO " " & " " buttons at the same time and

hold it]+[Press power " " button until comes out " AGING screen"

] => then release all buttons.

OSD MAIN CONTROLS LOCKED

Unlock OSD function

Locked OSD function can be released by pressing "OK" button for more

than 10 seconds again

ATTENTION SIGNAL

OSD MAIN CONTROLS UNLOCKED

NO VIDEO INPUT

This screen appears if there is no video signal input. Please check that

the signal is properly connected to the video card of PC and make sure

PC is on

ATTENTION SIGNAL

Bring up:

AGING...

After 15 seconds, bring up:

After 15 seconds, bring up:

AGING...

After 15 seconds, bring up:

CHECK CABLE CONNECTION

----------

---------repeatly

Connect Signal cable again=> go back to normal display

Page 10

10

Pixel Defect Policy

Philips' Flat Panel Monitors Pixel Defect Policy

Philips strives to deliver the highest quality products. We use some of

the industry's most advanced manufacturing processes and practice

stringent quality control. However, pixel or subpixel defects on the TFT

LCD panels used in flat panel monitors are sometimes unavoidable.

No manufacturer can guarantee that all panels will be free from pixel

defects, but Philips guarantees that any monitor with an unacceptable

number of defects will be repaired or replaced under warranty.

This notice explains the different types of pixel defects and defines

acceptable defect levels for each type. In order to qualify for repair or

replacement under warranty, the number of pixel defects on a TFT LCD

panel must exceed these acceptable levels.

For example, no more than 0.0004% of the subpixels on a 15" XGA

monitor may be defective. Furthermore, Philips sets even higher quality

standards for certain types or combinations of pixel defects that are

more noticeable than others. This policy is valid worldwide .

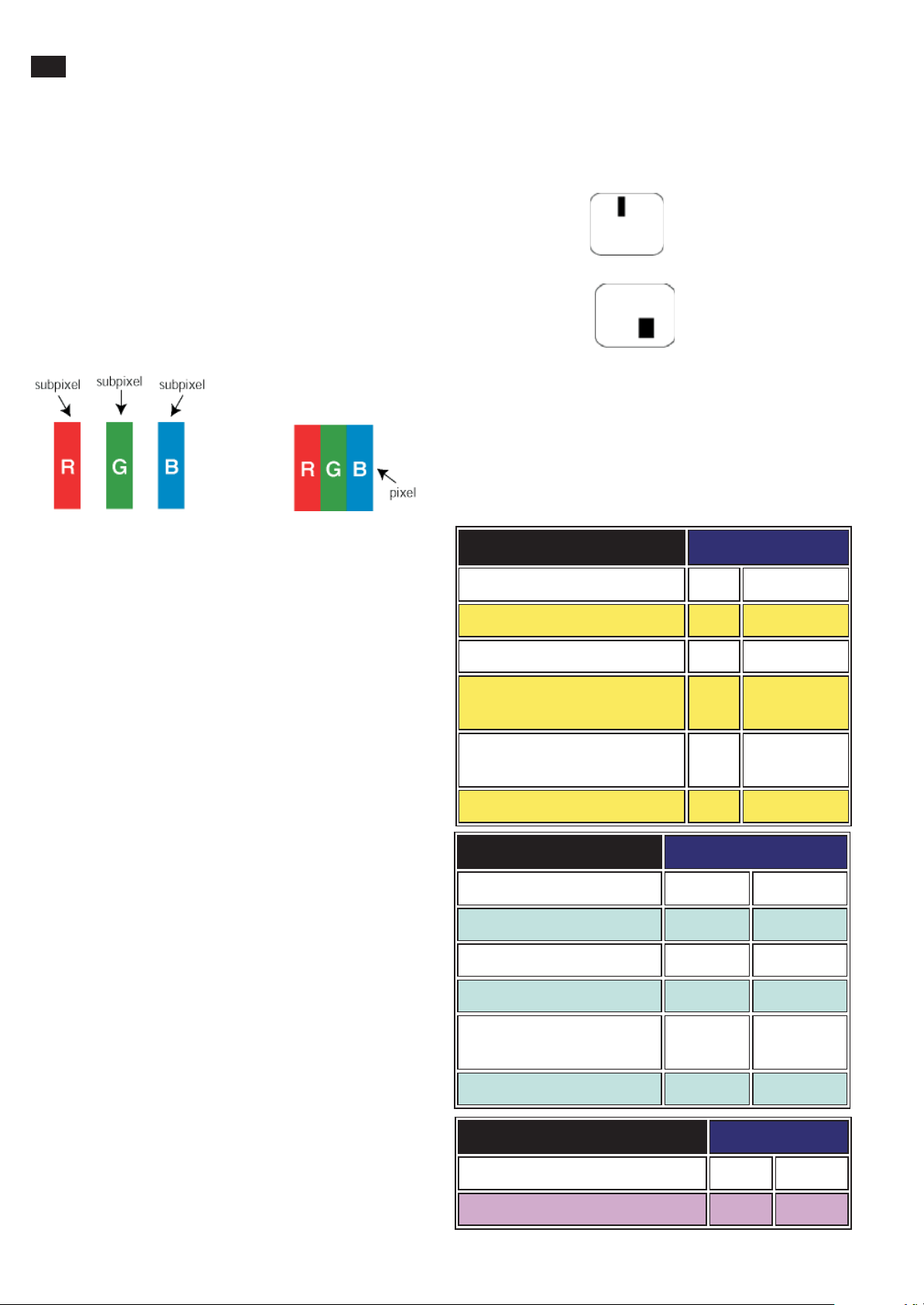

Pixels and Subpixels

A pixel, or picture element, is composed of three subpixels in the

primary colors of red, green and blue. Many pixels together form an

image. When all subpixels of a pixel are lit, the three colored subpixels

together appear as a single white pixel. When all are dark, the three

colored subpixels together appear as a single black pixel.

Other combinations of lit and dark subpixels appear as single pixels of

other colors.

Types of Pixel Defects

Pixel and subpixel defects appear on the screen in different ways.

There are two categories of pixel defects and several types of subpixel

defects within each category.

Bright Dot Defects Bright dot defects appear as pixels or subpixels that

are always lit or "on".

These are the types of bright dot defects:

Black Dot Defects

Black dot defects appear as pixels or subpixels that are always dark or

"off".

These are the types of black dot defects:

One dark subpixel

Two or three adjacent dark subpixels

Proximity of Pixel Defects

Because pixel and subpixels defects of the same type that are nearby

one another may be more noticeable, Philips also specifies tolerances

for the proximity of pixel defects.

Pixel Defect Tolerances

In order to qualify for repair or replacement due to pixel defects during

the warranty period, a TFT LCD panel in a Philips flat panel monitor

must have pixel or subpixel defects exceeding the tolerances listed in

the following tables.

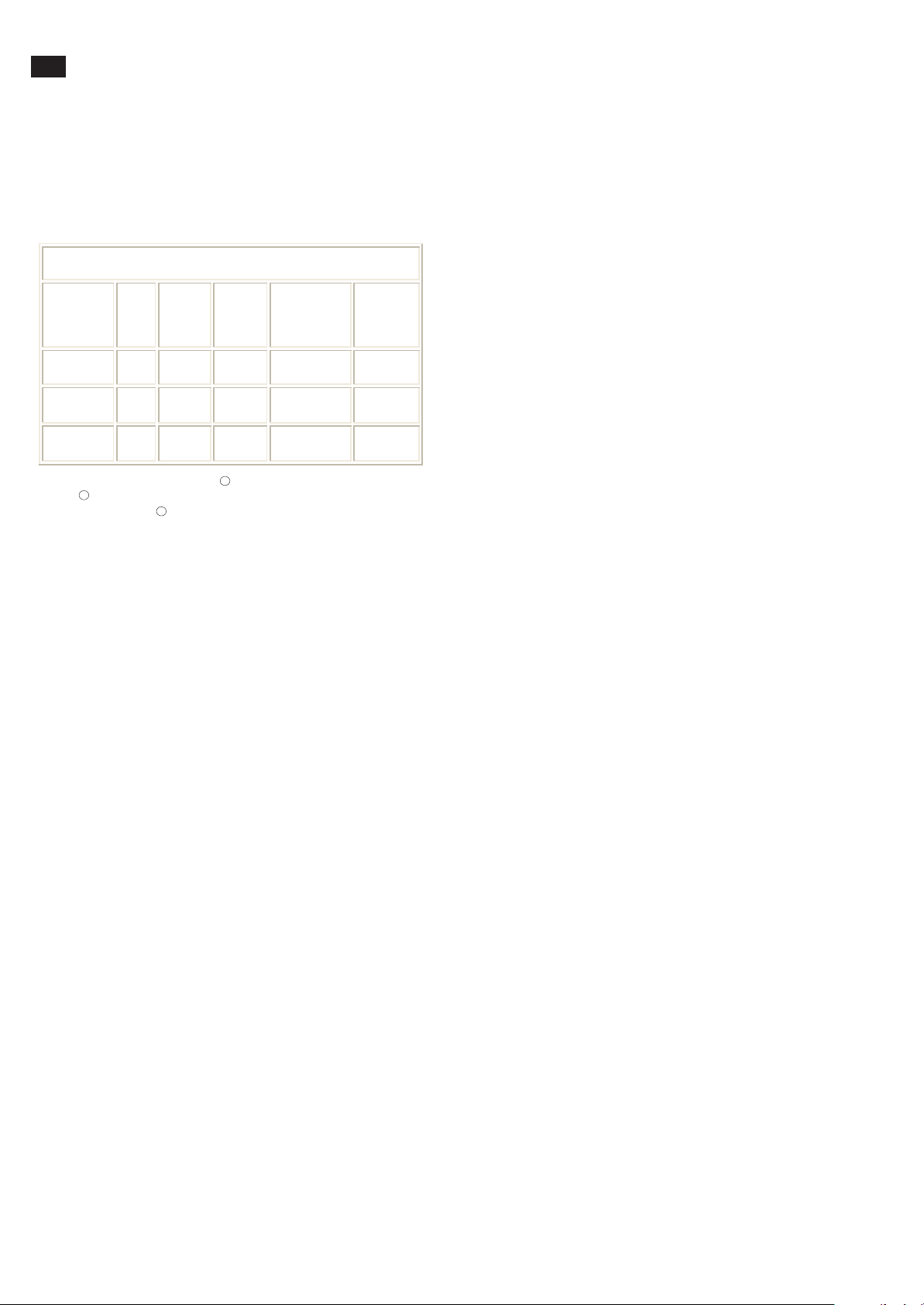

BRIGHT DOT DEFECTS ACCEPTABLE LEVEL

MODEL 190C6 170C6

1 lit subpixel 0 4 or fewer

2 adjacent lit subpixels 0 2 or fewer

3 adjacent lit subpixels (one white

pixel)

Distance between two bright dot

defects*

0 0

015mmormore

One lit red, green or blue subpixel

Two adjacent lit subpixels:

- Red + Blue = Purple

-Red+Green=Yellow

- Green + Blue = Cyan (Light Blue)

Three adjacent lit subpixels

(one white pixel)

Total bright dot defects of all types 0 4or fewer

BLACK DOT DEFECTS ACCEPTABLE LEVEL

MODEL 190C6 170C6

1 dark subpixel 0 4orfewer

2 adjacent dark subpixels 0 2 or fewer

3 adjacent dark subpixels 0 0

Distance between two black dot

defects*

Total blackdot defects of all types 0 4orfewer

TOTAL DOT DEFECTS ACCEPTABLE LEVEL

MODEL 190C6 170C6

Total bright or black dot defects of all types 0 5orfewer

0

15 mm or

more

Page 11

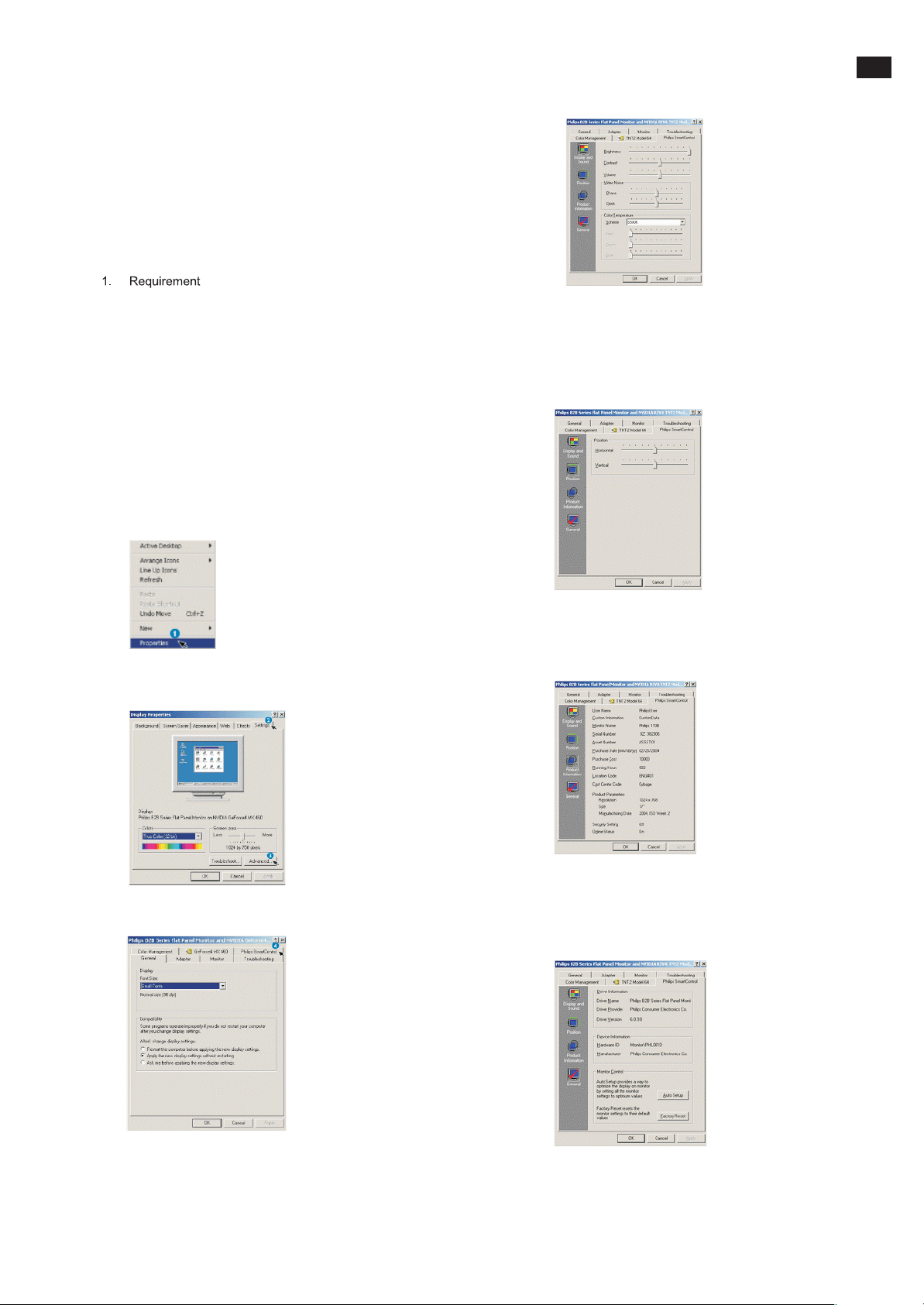

Smart Management

SmartControl

It's a convenient alternative for adjusting monitor performances and

settings through a software interface.

SmartControl displays a properties control panel to adjust the

brightness, contrast, color temperature, position and other settings.

SmartControl also displays hardware information including the

model, serial number, run hours from the interface.

The SmartControl is deployed and installed in computers using

Philips monitors. So the monitors and PC can interact with the

Administrator's inquiries.

11

· All graphic cards with n VIDIA and ATI graphic chipsets

which support DDC/CI interface

· Microsoft Windows 2000 and XP operation systems.

· All Philips monitors supporting DDC/CI interface

2. Installation

How to download "SmartControl Installation " file:

Please follow the guidance in the SmartControl installation program.

3. Accessing SmartControl

· Right click on the desktop of your PC, and select

Pro pert ies from the shortcut menu pops up.

· Click on Setting s tab, and click on Ad vanc ed button.

· Position

Users can adjust the horizontal and vertical position of

the screen by moving the sliding bar left and right.

This function is disabled when using DVI-D (digit)

input.

· Product Information

Click Product Information in the left pane to view the

product information stored in the monitor's memory.

Click Philips SmartControl tab.

4. SmartControl Options

Display and Sound

By moving the sliding bar toward left or right, users will be able to

adjust brightness, contrast, volume (if applicable), video noise (not

applicable when using DVI-D input), and color temperatures.

· General

Click on general, users will be able to know some

general information such as driver information, device

information and monitor control.

Within monitor control, users can click on Auto Setup to achieve

optimum performance or click on factory reset to reset the

parameters of the monitor. Su ch choices are disabled when

using DVI-D (digit) input.

Page 12

12

Display Adjustment

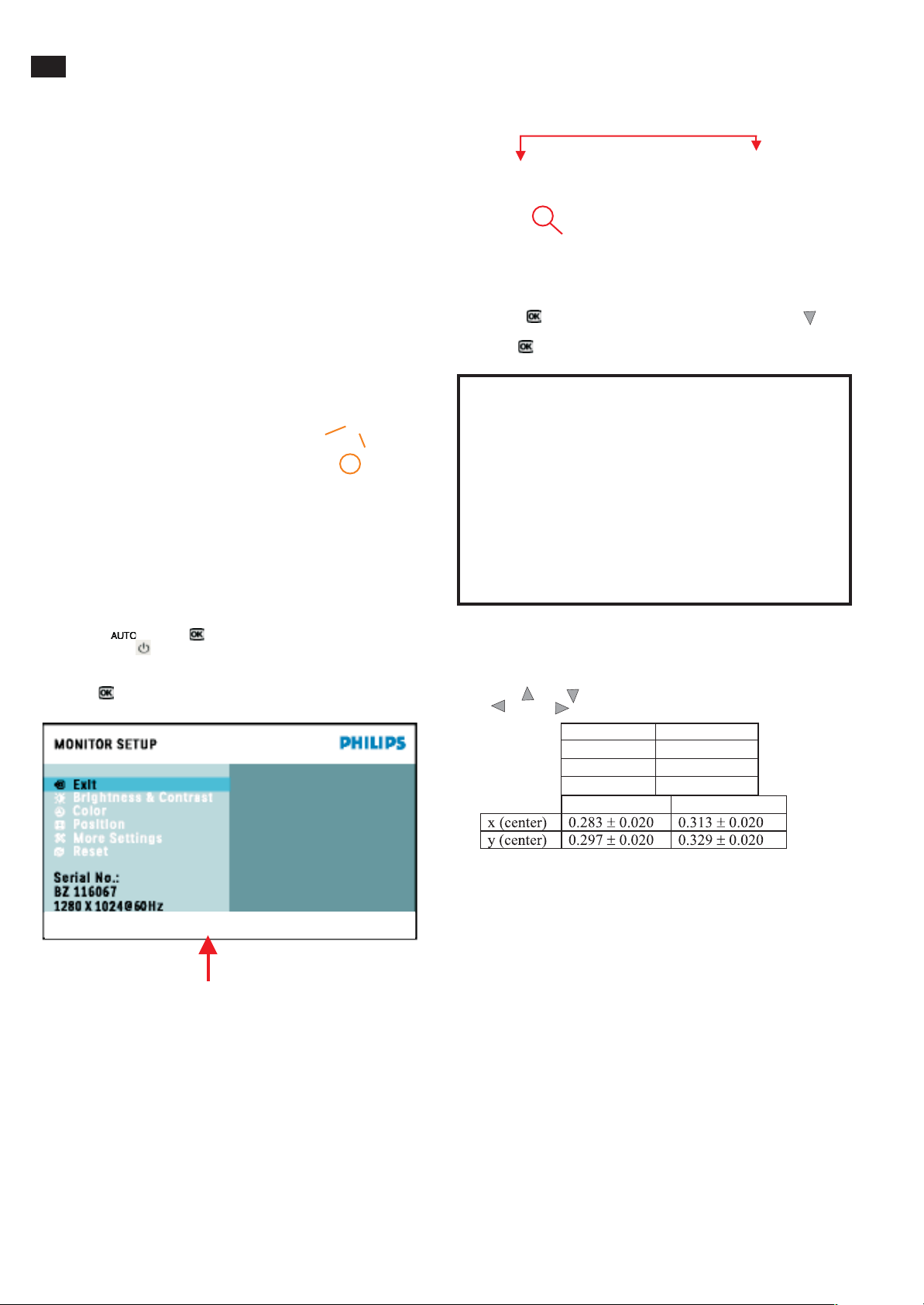

Alignment procedure

1. Turn on the LCD monitor.

2.Turn on the Timing/pattern generator. See Fig.1

Resolution :1280x1024(Use the best resolution)

Timing : H= 31.47KHz V=60Hz

3. Preset LCD color Analyzer CA-110

-Remove the lens protective cover of probe CA-A30.

-Set measuring/viewing selector to measuring position for reset

analyzer.(zero calibration) as Fig.2

- Turn on the color analyzer (CA-110)

-Press 0-CAL button to starting reset analyzer. See Fig.3

Cover (black)Cover (black)

Measurement viewing selectorMeasurement

Fig. 1

viewing selector

Fig. 2

4. Access Factory Mode

How to get into Factory Mode Menu

Step1:

Turn off monitor.

Step2:

[Push AUTO" "& OK ""buttons at the same time and hold it]

+[Press power ""button untill comes out "Windows screen" ]

=> then release all buttons

Step3:

Press OK ""button, bring up Factory mode indication as shown

in Fig3.

Clear imageClear image

Measurement/viewing selectorMeasurement/viewing selector

Fig.4

10. Setting pattern to full white picture

11. Press button, then select factory mode indicator by"" ""

button

12. Press""button to bring up submenu windows as below:

13. Press ""or ""button to select R GB. Change the value by

""or ""key until the X,Y co-ordinates as below

sRGB

x(center) 0.313 ± 0.008

y(center) 0.329 ± 0.008

Ynits 180 ± 10

9300°K 6500°K

HUDSON 170C6 V004 2005/03/21

Factory mode indicaor

Note: after alignment, please reset OSD to user s mode for normal

operation. Otherwise, the monitor won t entering power saving mode

and showing full white picture all the time as no video signal supplied.

To leave factory mode by restart the monitor.

5.Adjust OSD menu to lower position of screen (i.g. adjust V-position to

value " 0 " at submenu of OSD Setting.

6. Setting Brightness and Contrast

-Adjust Brightness to value "90".

-Adjust Contrast to value " 80" .

7. Switch light probe to Viewing position.

8. Move the Lens barrel forward or backward to get clear image as

showninFig.4

9. Switch light probe to Measuring position. It should be able to indicate

Fig. 3

Alignment hits: 1. R for x value,Gfor y value,Bfor Y value on the

15. EEPROMpresetting(B)

After finishing all the adjustment, set:

Brightness control to 100%

Contrast control to 50%

OSD position at middle of screen

COLORadjusts to 6500K color.

colour analyzer.

2. If the colour analyzer has been calibrated and preset

colour temperature in it. Please switch to correct

setting in accordance with colour settings.

Page 13

Front View

Back View

Mechanical Instructions

Fig.1

13

Fig.6

Fig.7

Fig.8

Step1. Remove the base

-Use two

thin " " screw drivers to drive upon the cover simultaneously

as shown in Fig.3

-Remove the screws as shown in Fig.4, then remove the base

Step2. Remove the Front Bezel

-Remove the one screw as shown in Fig.5

-Use the thin " " screw driver to open the clicks as shown

in Fig.6-8

Fig.2

Fig.3

Fig.4

Step3.Remove the Back cover

- Remove the two screws as shown in Fig.9 ,then remove the Control

board

-Use the thin " " type screw driver to open the clicks as shown in Fig.10

Fig.9

Fig.10

Step4. Remove the Matel frame

- Remove the two screws as shown in Fig.11

- Remove the matel frame as shown in Fig.12

Fig.5

Fig.11

Page 14

14

Mechanical Instruction

Step 5. Remove the sclar and power board.

- Remove the ten screws as shown in Fig.13

- Disconnect the 1501,1512,1451 and 4 backlight cables

as shown in Fig.13

- Remove the scaler and power board as shown in Fig.14

Fig.12

Fig.15

**************************************************************************************

In warranty, it is not allowed to disassembly the LCD panel, even the

backlight unit defect.

Out of warranty, the replacement of backlight units is a correct way

when the defect is caused by backlight (CCFL, Lamp).

***************************************************************************************

Panel

Fig.13

Fig.14

Page 15

Safety test requirements

15

All units that are returned for service or repair must pass the

original manufactures safety tests. Safety testing requires both

and testing.Hipot Ground Continuity

HI-POT TEST INSTRUCTION

1.Application requirements

1.1 All mains operated products must pass the Hi-Pot test as

described in this instruction.

1.2 This test must be performed again after the covers have

been refitted following the repair, inspection or modification

of the product.

2.

Test method

2.1 Connecting conditions

2.1.1 The test specified must be applied between the parallel-

blade plug of the mainscord and all accessible metal

parts of the product.

2.1.2 Before carrying out the test, reliable conductive

connections must be ensured and thereafter be

maintained throughout the test period.

2.1.3 The mains switch(es) must be in the "ON" position.

2.2 Test Requirements

All products should be HiPot and Ground Continuity tested as

follows:

3. Equipments and Connection

3.1. Equipments

For example :

- ChenHwa 9032 PROGRAMMABLE AUTO SAFETY

TESTER

- ChenHwa 510B Digital Grounding Continuity Tester

- ChenHwa 901 (AC Hi-pot test), 902 (AC, DC Hi-pot test)

Withstanding Tester

3.2. Connection

* Turn on the power switch of monitor before Hipot and

Ground Continuity testing.

Clip

Clip

Condition HiPot Test for HiPot Test for Ground Continuity

products where products where Test requirement

the mains input the mains input is

range is Full 110V AC(USA

range(or 220V type)

AC)

Test 2820VDC 1700VDC Test current:

voltage (2000VAC) (1200VAC) 25A,AC

Test time:

Test time 3 seconds 1 second 3 seconds(min.)

(min.) Resistance

required:

Trip set at 100 uA 5 mA <=0.09+Rohm,

current for Max. R is the

(Tester) limitation; set resistance of

at 0.1 uA for the mains cord.

Min. Limitation

Ramp set at 2

time seconds

(Tester)

2.2.1 The minimum test duration for Quality Control Inspector

must be 1 minute.

2.2.2 The test voltage must be maintained within the specified

voltage + 5%.

(ChenHwa 9032 tester)

Video cable

Connect the "video cable"

or "grounding screw"

to the CLIP on your tester.

Grounding screw

Connect the power cord

to the monitor.

2.2.3 There must be no breakdown during the test.

2.2.4 The grounding blade or pin of mains plug must be

conducted with accessible metal parts.

Power outlet

4. Recording

(Rear view of monitor)

Hipot and Ground Continuity testing records have to be kept

for a period of 10 years.

Page 16

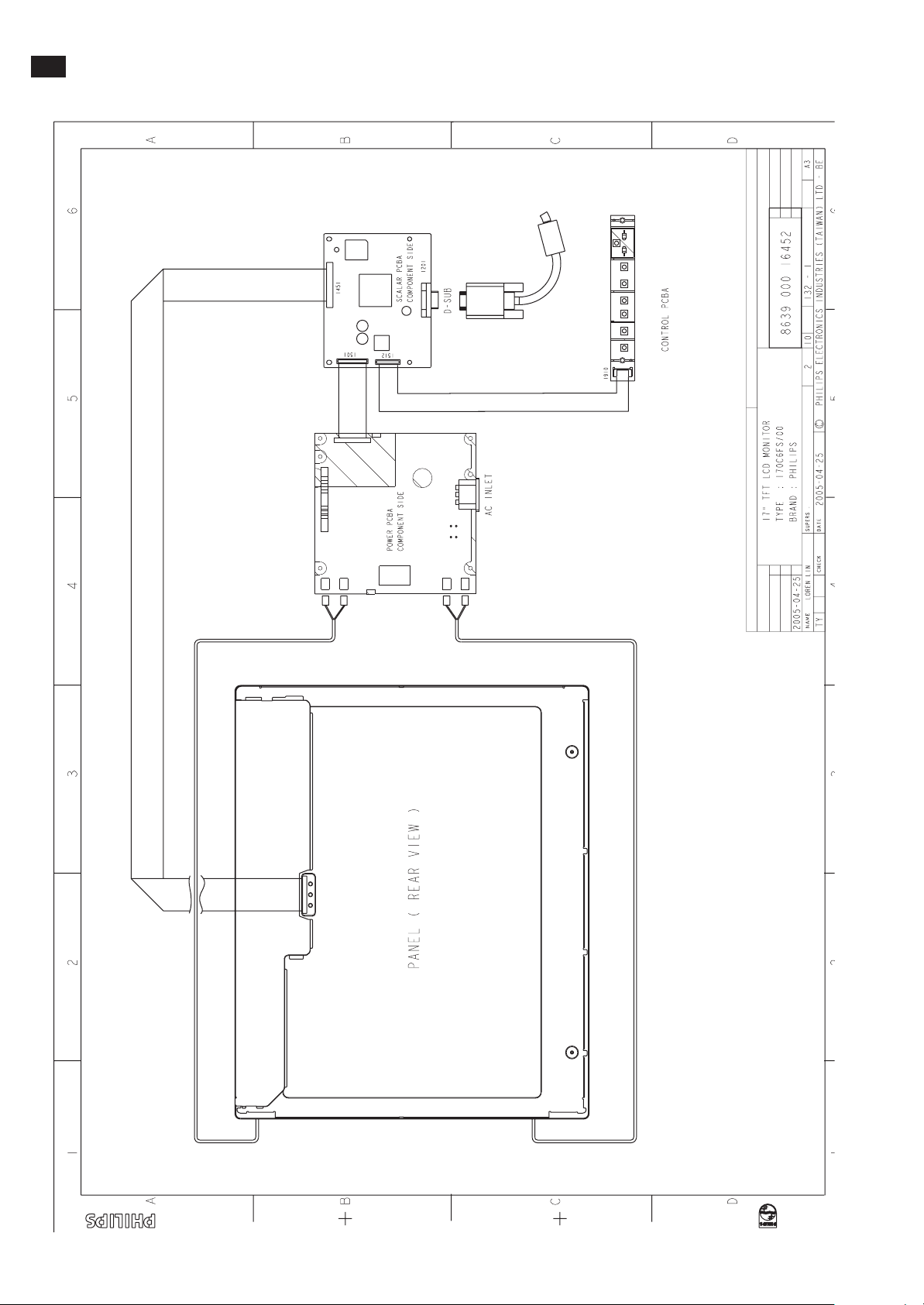

16

Wiring Diagram

17

Page 17

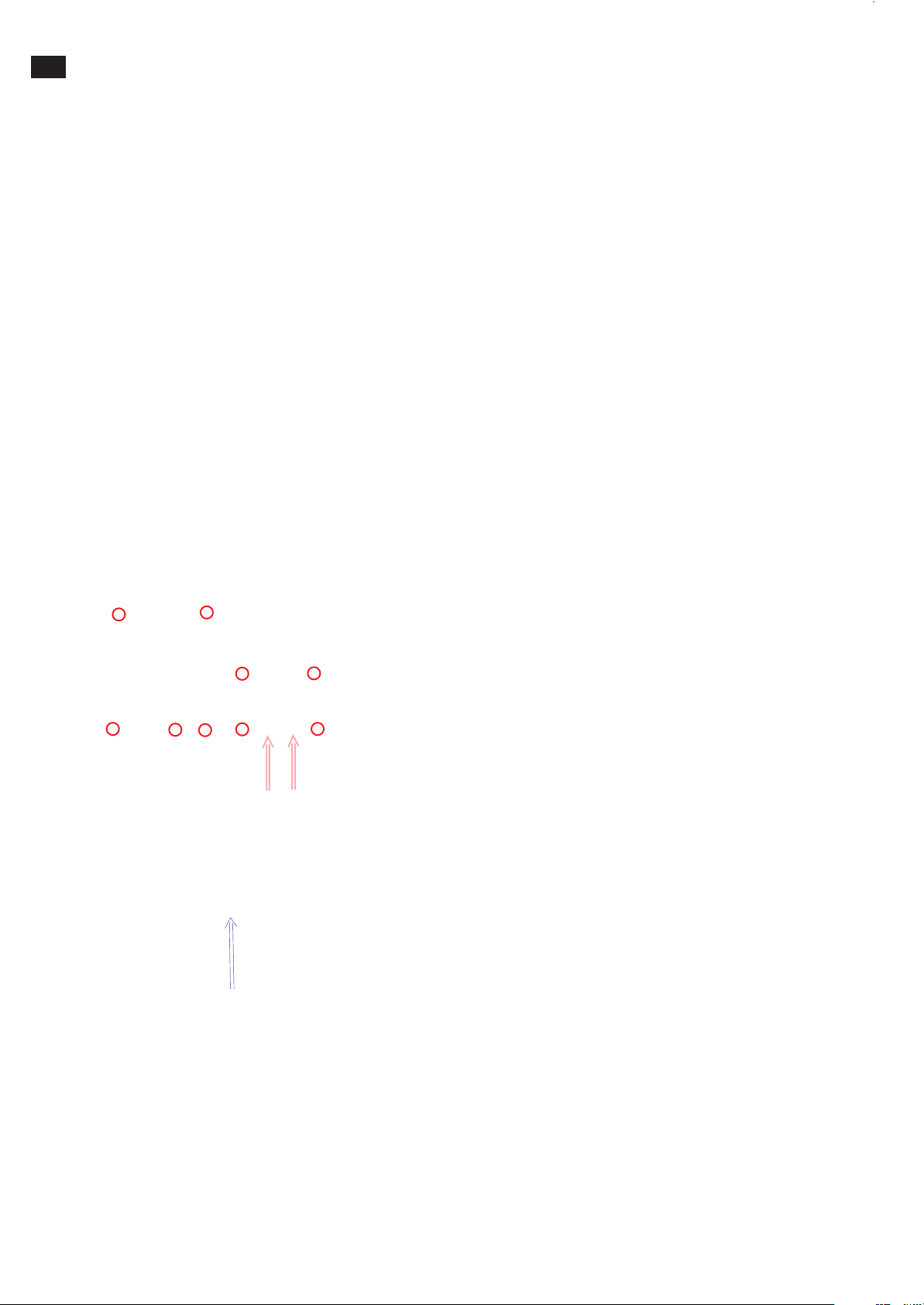

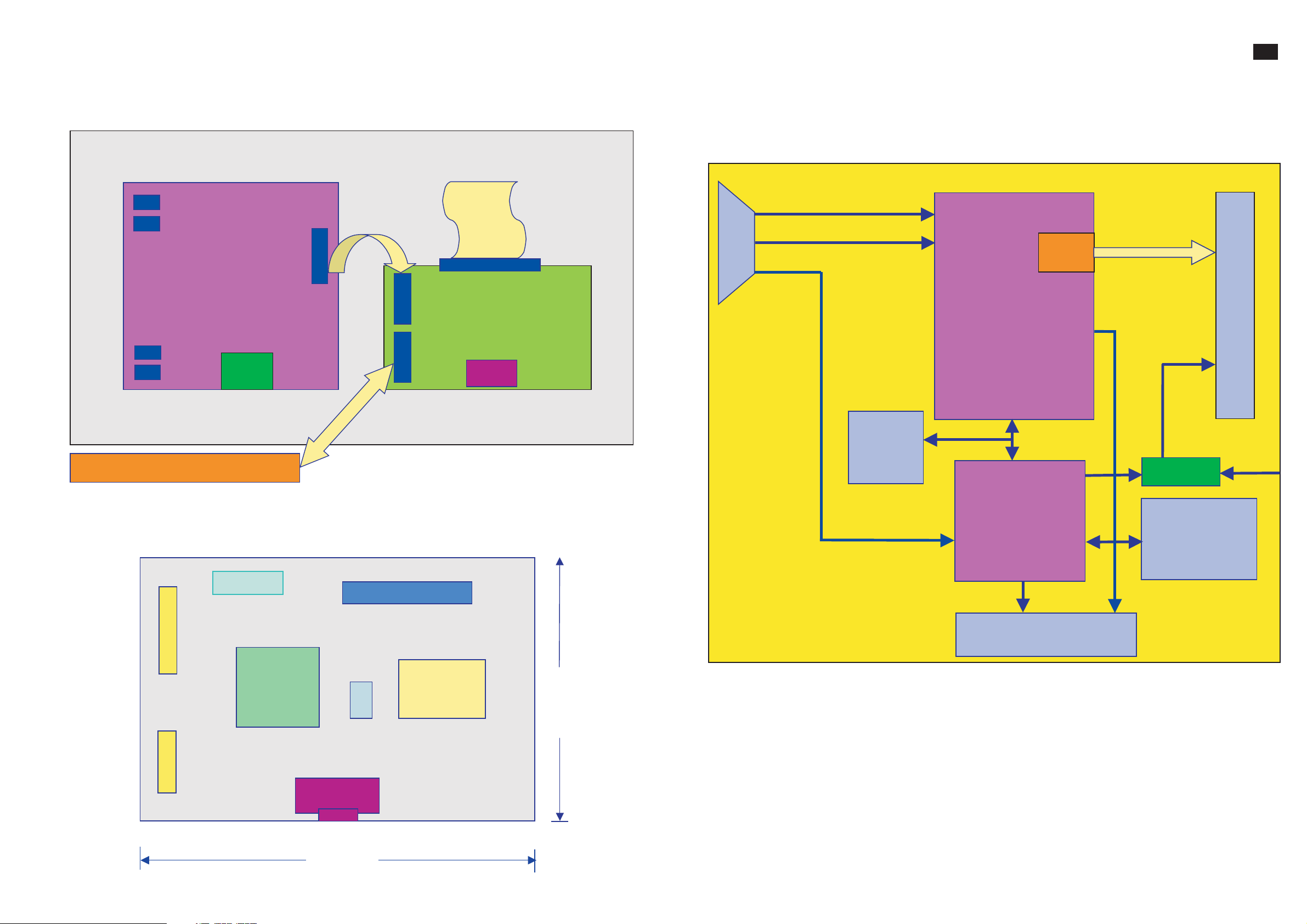

System Block Diagram

System Block Diagram

Blodk Diagram-170C6

17

Connector

Connector

Buy--InIn

Buy

ACAC--DC Power supply

Inverter and

Inverter and

DCDC--DC converter

(150mm x 135mm)

(150mm x 135mm)

Connector

Connector

CONTROL BD

DC Power supply

DC converter

AC

input

Connector

30 Pin FFC Cable

11P-Connector

7P-Connector

30 pin wafer

Scalar(LVDS interface)

Scalar(LVDS interface)

Analog Input

Analog Input

(94mm x 74mm)

(94mm x 74mm)

D_SUB

VIDEO

Input

D-SUB

HS/VS

R/G/B

Scaler

Scaler

DDCSDA

DDCSCL

EEPROM

M24C16

Board Block Diagram

Board Block Diagram

CLK and R/G/B

DATA

(LVDS interface)

LVDS

Tx

SCALER

NT68521A

Brightness

IICSDA

IICSCL

Panel_PWR

Connector to Panel

5V/12V

11-Pin

Power Input

connector

7-Pin Control

Output

Connector

Scaler

Scaler

EEPROM

MCU

NT68F633L

Board Layout

Board Layout

LVDS Interface Connector

ScalerIC

12MHz

XTAL

D_SUB

(NT68521A)

74mm

MCU (64K)

NT68F633

BL_CTRL

Connector to

Inverter

Connector to

Control

Board

94 mm

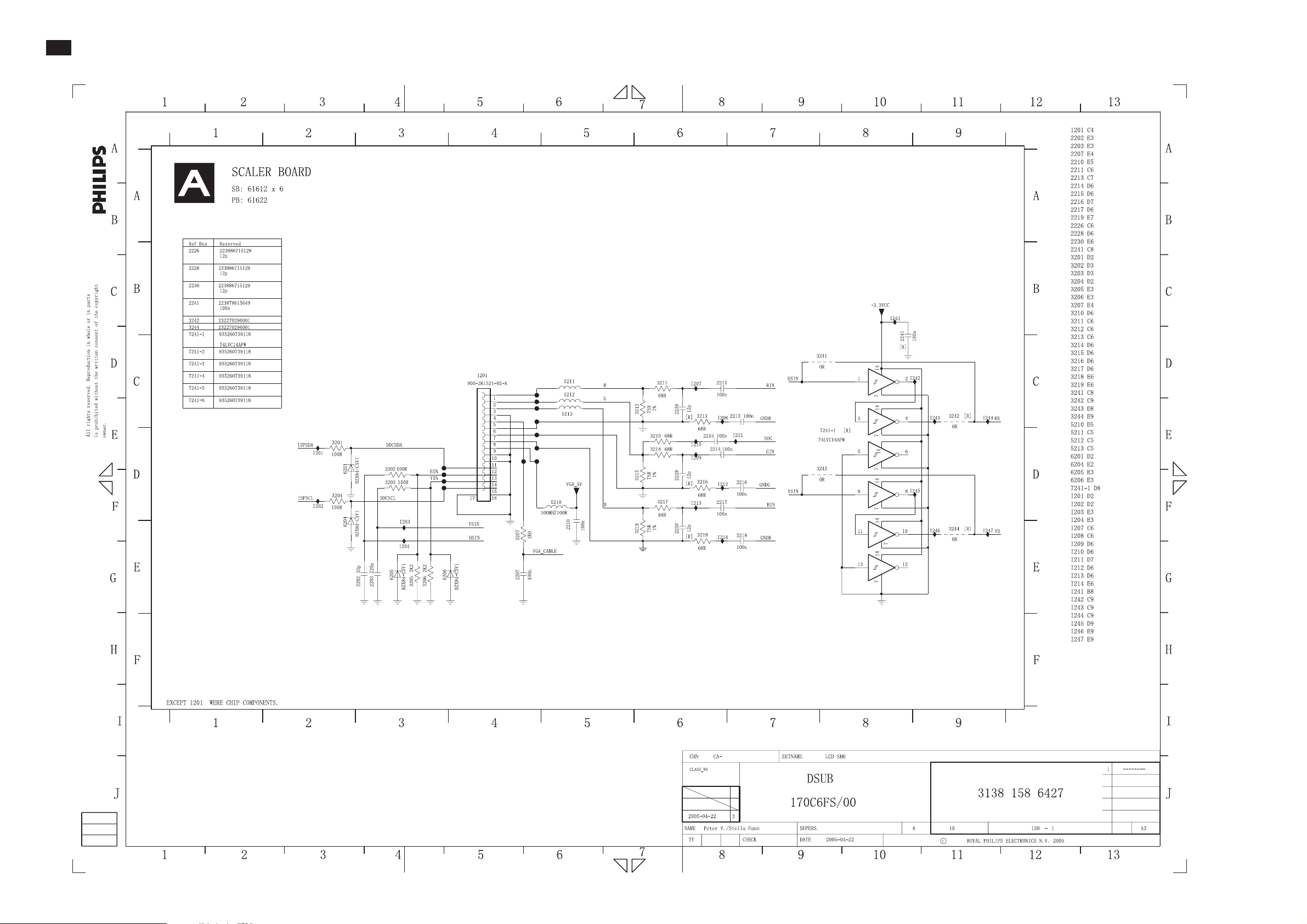

Page 18

18

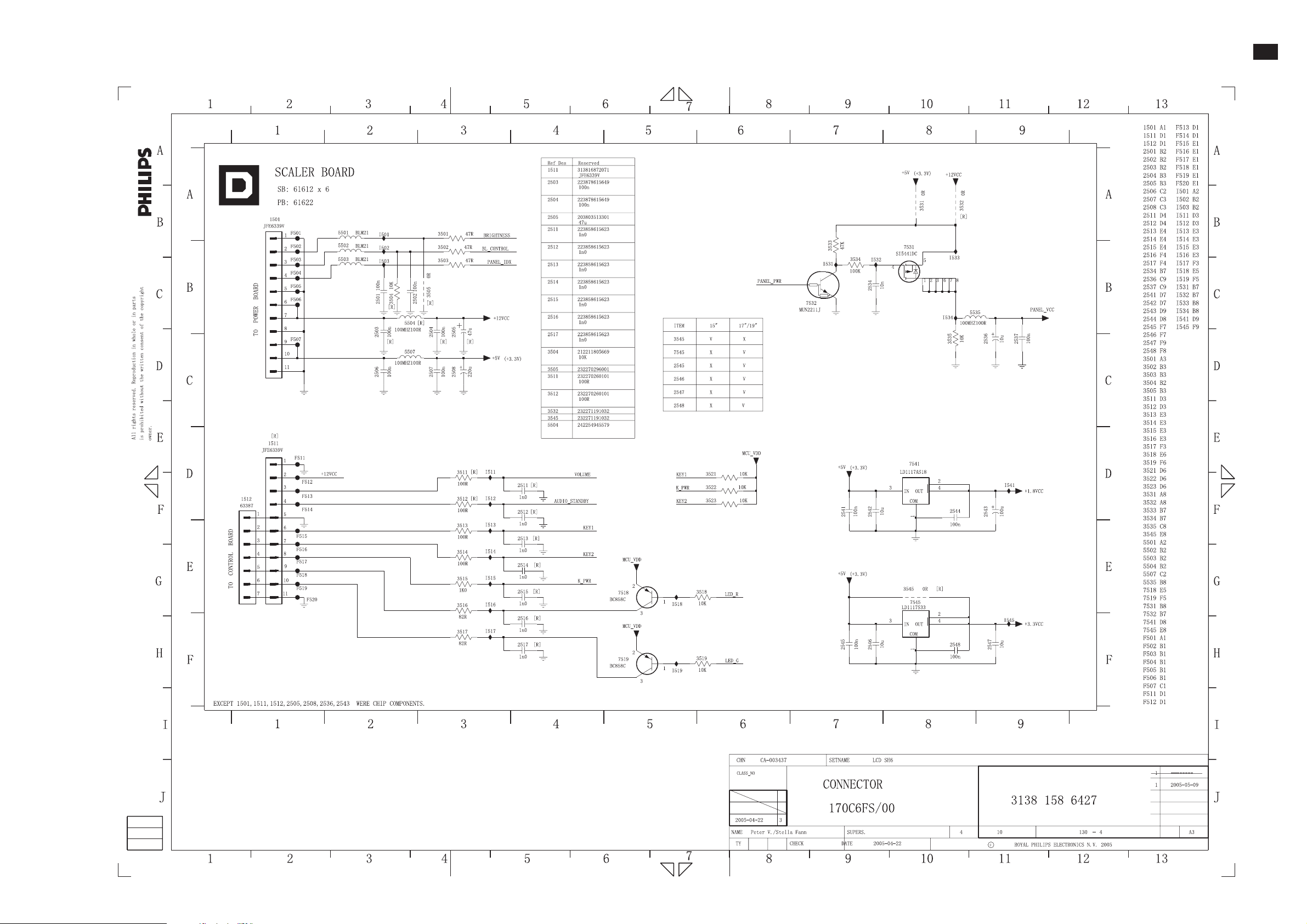

Scaler Schematic Diagram - 1

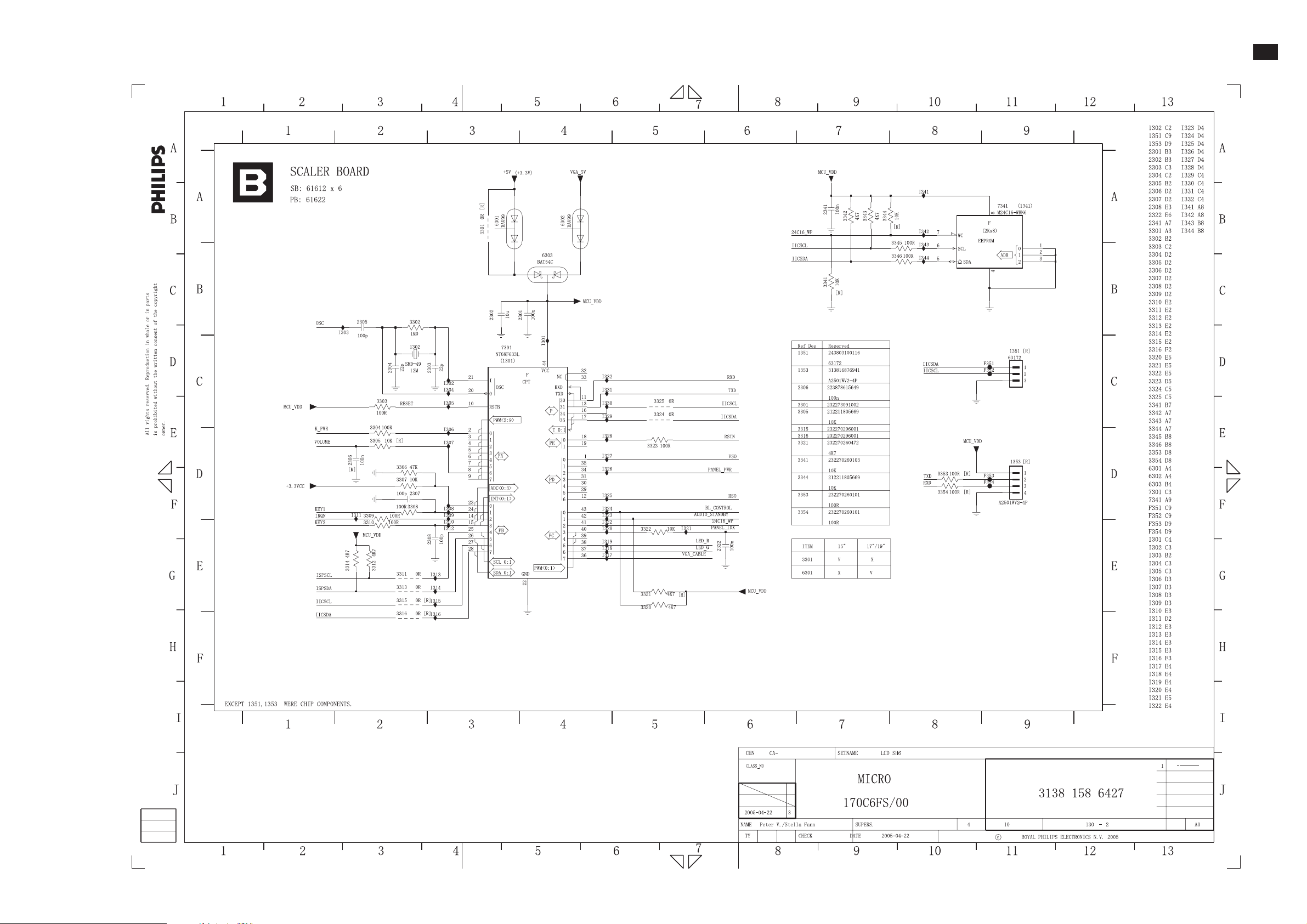

Page 19

Scaler Schematic Diagram - 2

19

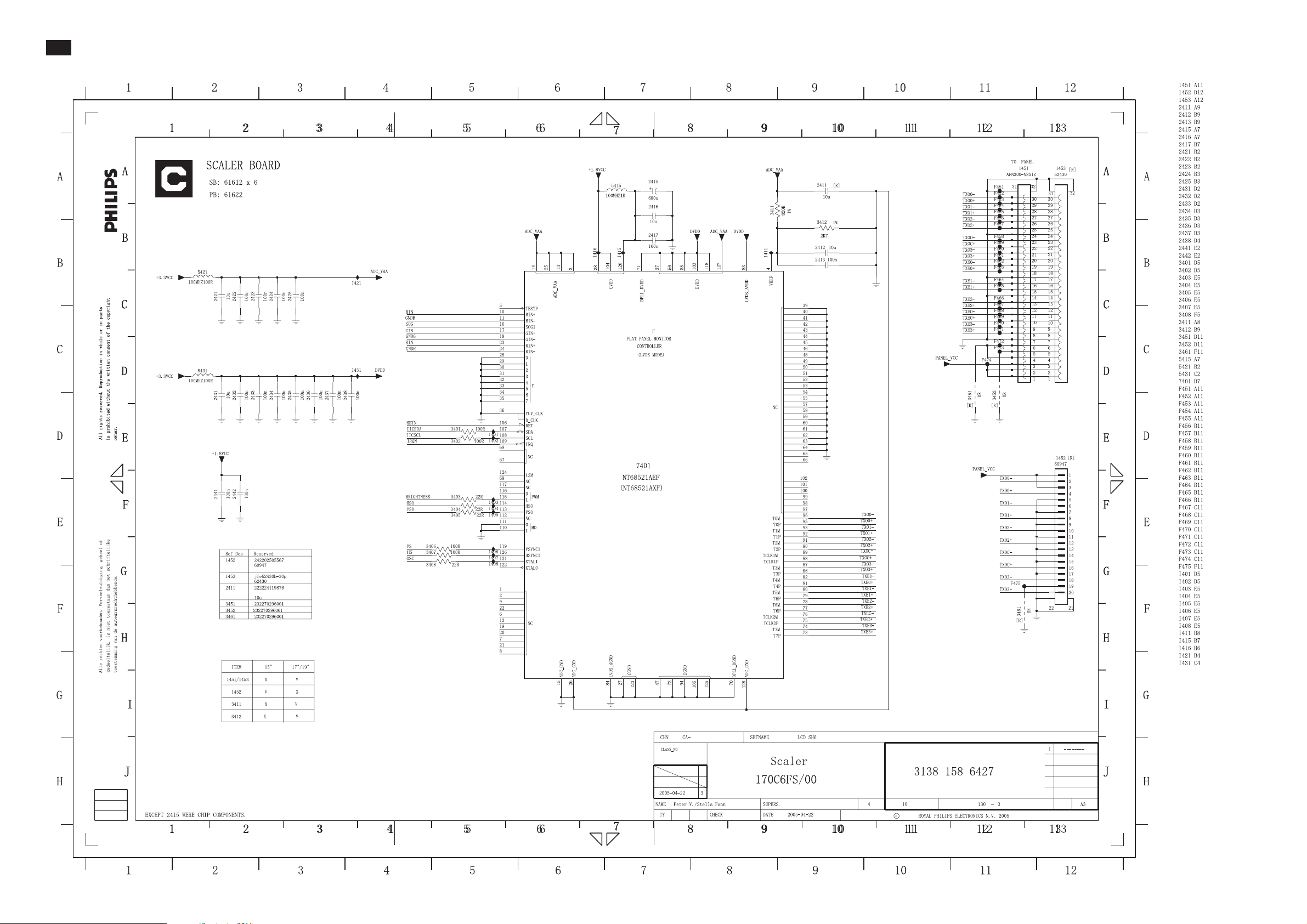

Page 20

20

Scaler Schematic Diagram - 3

Page 21

Scaler Schematic Diagram - 4

21

Page 22

22

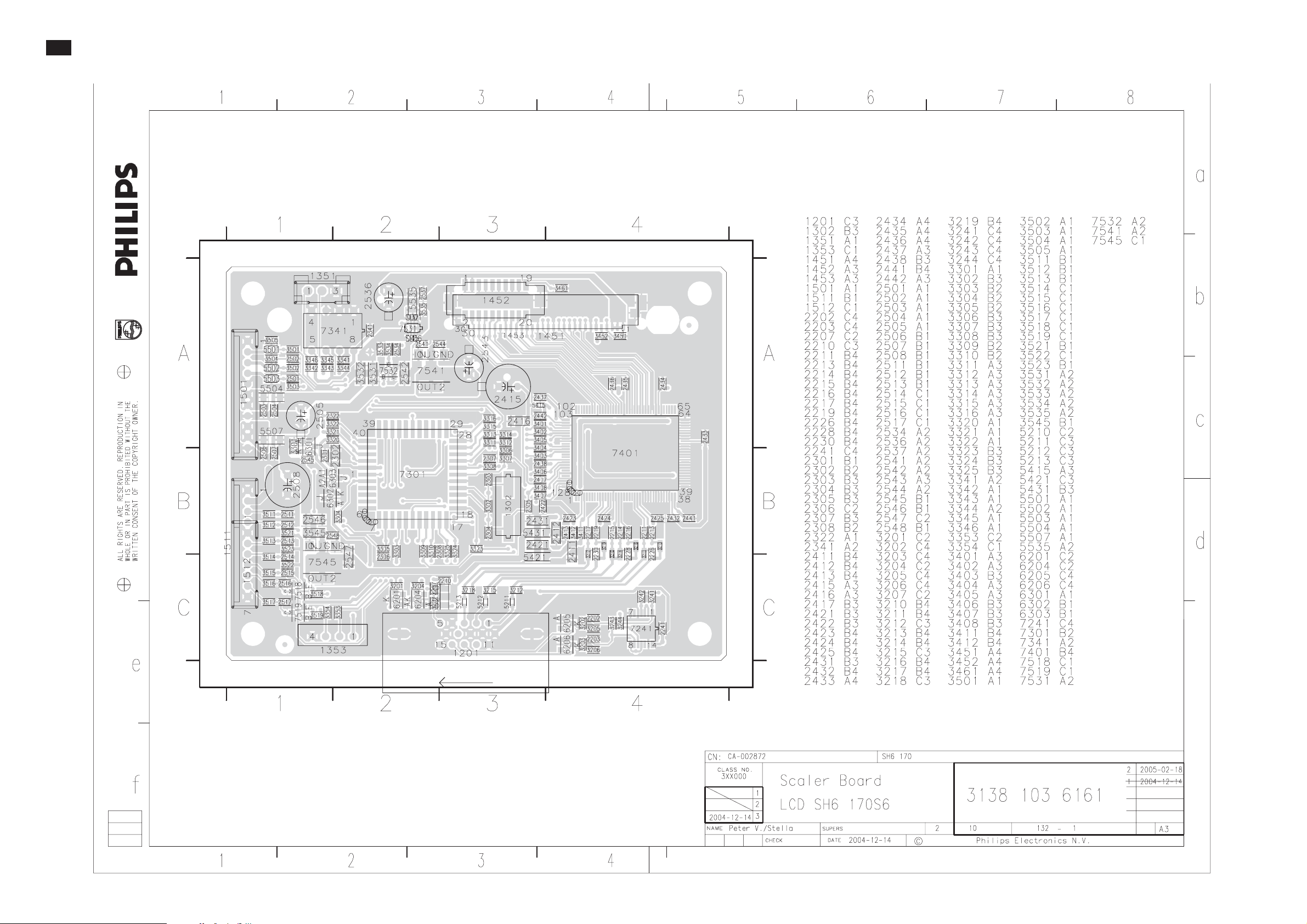

Scaler Board C.B.A - 1

Page 23

Scaler Board C.B.A - 2

23

Page 24

24

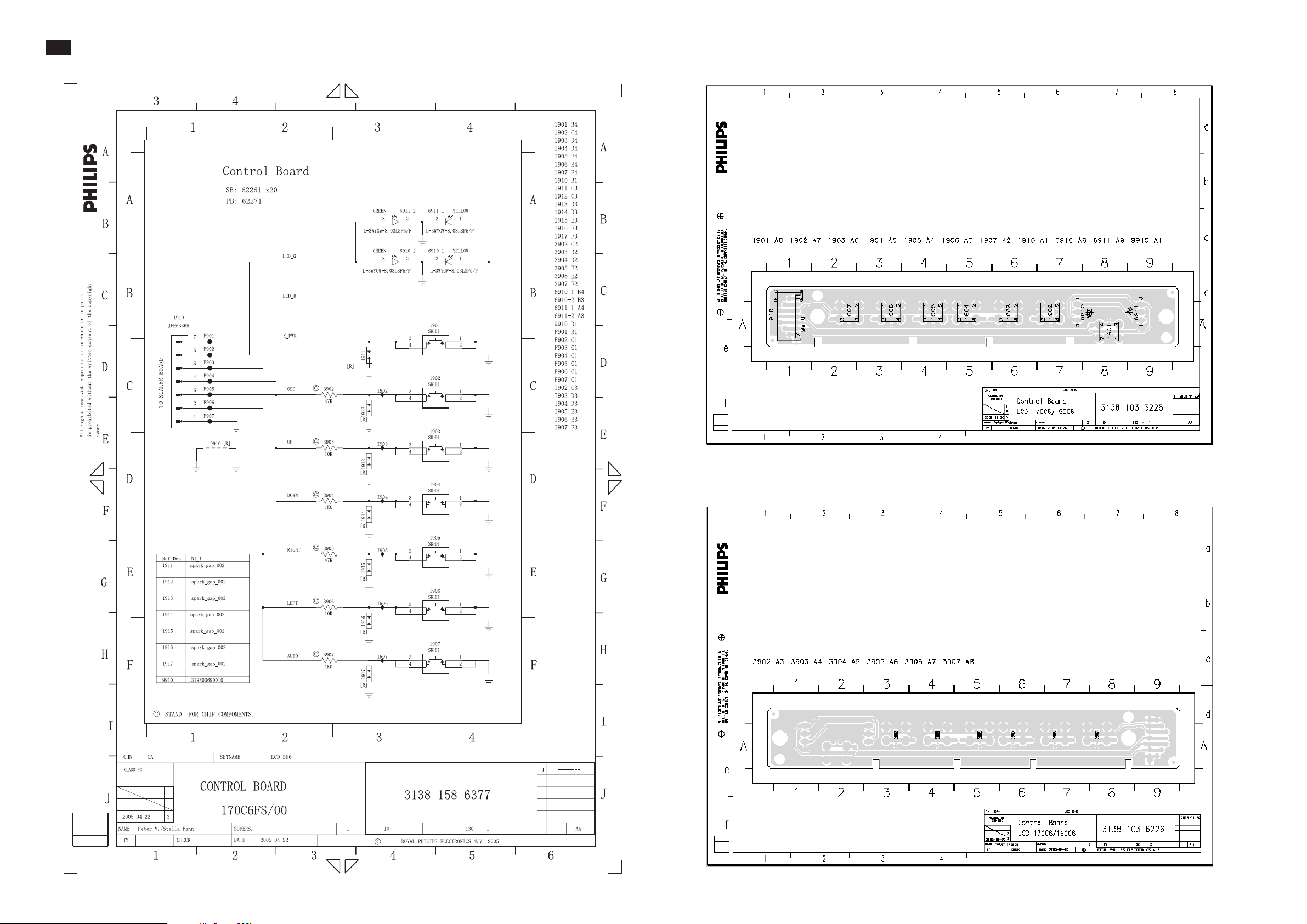

Control Schematic Diagram & C.B.A

Page 25

PowerBoardBlockDiagram-Delta

25

Page 26

26

Power Board Schematic Diagram - Delta

Page 27

Power Board Schematic Diagram - Delta

27

Page 28

28

Power Board C.B.A - Delta

Page 29

PowerBoardSchematicDiagram-LienChang

29

Page 30

30

Power Schematic Diagram - Lien Chang

Page 31

AIP-0093

Power Board C.B.A - Lien Cheng

31

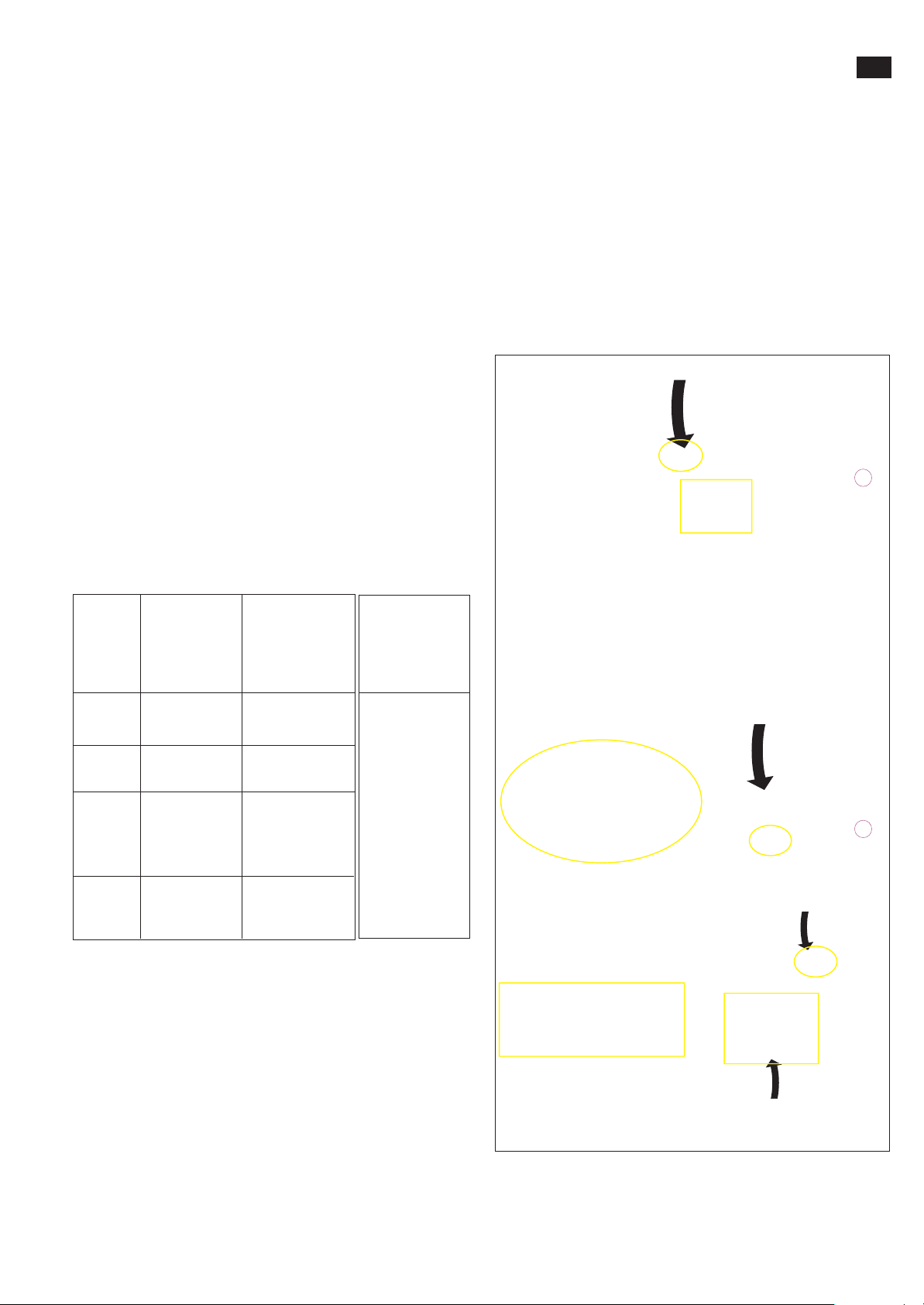

Page 32

32

Exploded View

50

313815760101

FOLDABLE BASE(B)

1050

8238277117631

TFT-LCD QD170EL07 REV.09

823827718251

LCD LM170E01-TLA8

313815864281

SCALER ASSY

313815864271

SCALER ASSY

1051

1052

823827717131

LIPS(EADP-43AF A)POWER BOARD

100

1160

40

313815136741

SHIELDING-LPL

313815865021

METAL FRAME+WIRE ASSY

313815760121

BACK COVER ASSY(B)

30

313815760111

BEZEL ASSY(S)

1053

313815863771

CONTROL ASSY

Page 33

Spare Parts Lists

33

Type:170C6FS/00(LCD: QDI/ 12NC:823827717631)

Mechani cal Parts

0030 313815760111 BEZEL ASSY(S)

0031 313815416531 BEZEL(S)

0032 313815416481 POWER BUTTON

0033 313815416471 CONTROL BUTTON

0034 313815416491 POWER LENS

0040 313815760121 BACK COVER ASSY(B)

0041 313815416541 BACK COVER(B)

0042 313815137561 HINGE-PLATE

0050 313815760101 FOLDABLEBASE(B)

0090 313810440571 HOUSING COVER

0101 313815416501 HINGE COVER

0104 313815135311 DSUB PLATE

0301 313815136971 METAL FRAME

0450 313815640441 CARTON

0451 313815640451 CUSHION-R

0452 313815640461 CUSHION-L

0453 313815640881 P.E. BAG

Access ories

0602 313811708561 E-D.F.U.

1157 313812874931 MAINSCORD

1158 313819871252 CORD SUB-D 15/1M8/SUB-D 15 BK

LCD

1050 823827717631 TFT-LCD QD170EL07 REV.09

PCB ASSY

1051 313815864281 SCALER

1052 823827717131 LIPS(EADP-43AF A)POWER BOARD

1053 313815863771 CONTROL ASSY

Miscellan eous

0291 313815567361 LABEL-CPU

0295 313815567381 LABEL-EEPROM(Q)

0615 313811708511 HEX CODE OF F/W(NO MATL REQ)

1160 313815865021 METAL FRAME+WIRE ASSY

1201 242202518432 SOC SUBDH15P F SBFR Y

1302 243854300079 RES XTLSM 12MHZ 32PSMD-49 R

1341 243803100435 SOC IC V 8P F 2.54 DILL

1451 242202519002 CON H 30P F 1.00 SM FFC 0.3 R

1501 242202518824 CON V 11P M 2.00 63391 B

1512 242202518999 CON V 7P M 2.00 61387 B

1901 242212803007 SWI TACT 1P 1POS 12V V 5MM B

1902 242212803007 SWI TACT 1P 1POS 12V V 5MM B

1903 242212803007 SWI

1904 242212803007 SWI TACT 1P 1POS 12V V 5MM B

1905 242212803007 SWI TACT 1P 1POS 12V V 5MM B

1906 242212803007 SWI TACT 1P 1POS 12V V 5MM B

1907 242212803007 SWI TACT 1P 1POS 12V V 5MM B

4444 313810610473 CD ROM - SERVICE MANUAL

4444 313810610474 SERVICE MANUAL

8161 313819875901 CBLE-267 7/165/7-267A AWG28

8163 313819874611 FFC 30/185/30 PITCH 1.0MM

1051 313815864281 SCAL ER ASSY

2202 223886715339 CER1 0603 NP0 50V 33PPM5 R

2203 223886715221 CER1 0603 NP0 50V 220PPM5 R

2207 223878615649 CER2 0603 X7R 16V 100N PM10 R

2210 223878615649 CER2 0603 X7R 16V 100N PM10 R

2211 223878615649 CER2 0603 X7R 16V 100N PM10 R

2213 223878615649 CER2 0603 X7R 16V 100N PM10 R

2214 223878615649 CER2 0603 X7R 16V 100N PM10 R

2215 223878615649 CER2 0603 X7R 16V 100N PM10 R

2216 223878615649 CER2 0603 X7R 16V 100N PM10 R

2217 223878615649 CER2 0603 X7R 16V 100N PM10 R

2219 223878615649 CER2 0603 X7R 16V 100N PM10

2301 223878615649 CER2 0603 X7R 16V 100N PM10 R

2302 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2303 223886715229 CER1 0603 NP0 50V 22PPM5 R

2304 223886715229 CER1 0603 NP0 50V 22PPM5 R

2305 223886715101 CER1 0603 NP0 50V 100PPM5 R

2307 223886715101 CER1 0603 NP0 50V 100PPM5 R

2308 223886715101 CER1 0603 NP0 50V 100PPM5 R

2322 223878615649 CER2 0603 X7R 16V 100N PM10 R

2341 223878615649 CER2 0603 X7R 16V 100N PM10 R

2412 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2413 223878615649 CER2 0603 X7R 16V 100N PM10 R

2415 202203100422 ELCAPPF6V3S 680U PM20 B

2416 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2417 223878615649 CER2 0603 X7R 16V 100N PM10 R

2421 222224119876 CER2 1206 Y5V 10V 10U P8020 R

ASSY

TACT 1P 1POS 12V V 5MM B

2422 223878615649 CER2 0603 X7R 16V 100N PM10 R

2423 223878615649 CER2 0603 X7R 16V 100N PM10 R

2424 223878615649 CER2 0603 X7R 16V 100N PM10 R

2425 223878615649 CER2 0603 X7R 16V 100N PM10 R

2431 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2432 223878615649 CER2 0603 X7R 16V 100N PM10 R

2433 223878615649 CER2 0603 X7R 16V 100N PM10 R

2434 223878615649 CER2 0603 X7R 16V 100N PM10 R

2435 223878615649 CER2 0603 X7R 16V 100N PM10 R

2436 223878615649 CER2 0603 X7R 16V 100N PM10 R

2437 223878615649 CER2 0603 X7R 16V 100N PM10 R

2438 223878615649 CER2 0603 X7R 16V 100N PM10 R

2441 223878615649 CER2 0603 X7R 16V 100N PM10 R

2442 223878615649 CER2 0603 X7R 16V 100N PM10 R

2501 223878615649 CER2 0603 X7R 16V 100N PM10 R

2502 223878615649 CER2 0603 X7R 16V 100N PM10 R

2506 223878615649 CER2 0603 X7R 16V 100N PM10 R

2507 223878615649 CER2 0603 X7R 16V 100N PM10 R

2508 202203100414 ELCAP RGA 16V S 220U PM20 B

2534 223858615636 CER2 0603 X7R 50V 10N PM10 R

2536 202203100413 ELCAP RGA 50V S 10U PM20 B

2537 223878615649 CER2 0603 X7R 16V 100N PM10 R

2541 223878615649 CER2 0603 X7R 16V 100N PM10 R

2542 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2543 202202001017 ELCAPSM 10V S 100U PM20 B

2544 223878615649 CER2 0603 X7R 16V 100N PM10 R

2545 223878615649 CER2 0603 X7R 16V 100N PM10 R

2546 222224119876 CER2 1206 Y5V 10V 10U P

222224119876 CER2 1206 Y5V 10V 10U P8020 R

2547

2548 223878615649 CER2 0603 X7R 16V 100N PM10 R

3201 232270260101 RST SM 0603 RC21 100R PM5 R

3202 232270260101 RST SM 0603 RC21 100R PM5 R

3203 232270260101 RST SM 0603 RC21 100R PM5 R

3204 232270260101 RST SM 0603 RC21 100R PM5 R

3205 232270260222 RST SM 0603 RC21 2K2 PM5 R

3206 232270260222 RST SM 0603 RC21 2K2 PM5 R

3207 232270260102 RST SM 0603 RC21 1K PM5 R

3210 232270260689 RST SM 0603 RC21 68R PM5 R

3211 232270260689 RST SM 0603 RC21 68R PM5 R

3212 232270467509 RST SM 0603 RC22H 75R PM1 R

3213 232270260689 RST SM 0603 RC21 68R PM5 R

3214 232270260689 RST SM 0603 RC21 68R PM5 R

3215 232270467509 RST SM 0603 RC22H 75R PM1 R

3216 232270260689 RST SM

3217 232270260689 RST SM 0603 RC21 68R PM5 R

3218 232270467509 RST SM 0603 RC22H 75R PM1 R

3219 232270260689 RST SM 0603 RC21 68R PM5 R

3241 212211805631 RST SM 0603 JUMP. MAX 0R05 R

3243 212211805631 RST SM 0603 JUMP. MAX 0R05 R

3302 232270260105 RST SM 0603 RC21 1M PM5 R

3303 232270260101 RST SM 0603 RC21 100R PM5 R

3304 232270260101 RST SM 0603 RC21 100R PM5 R

3306 232270260473 RST SM 0603 RC21 47K PM5 R

3307 212211805669 RST SM 0603 RC0603 10K PM5 R

3308 232270260101 RST SM 0603 RC21 100R PM5 R

3309 232270260101 RST SM 0603 RC21 100R PM5 R

3310 232270260101 RST SM 0603 RC21 100R PM5 R

3311 212211805631 RST SM 0603 JUMP. MAX 0R05 R

3312

232270260472 RST SM 0603 RC21 4K7 PM5 R

3313 212211805631 RST SM 0603 JUMP. MAX 0R05 R

3314 232270260472 RST SM 0603 RC21 4K7 PM5 R

3320 232270260472 RST SM 0603 RC21 4K7 PM5 R

3322 212211805669 RST SM 0603 RC0603 10K PM5 R

3323 232270260101 RST SM 0603 RC21 100R PM5 R

3324 212211805631 RST SM 0603 JUMP. MAX 0R05 R

3325 212211805631 RST SM 0603 JUMP. MAX 0R05 R

3342 232270260472 RST SM 0603 RC21 4K7 PM5 R

3343 232270260472 RST SM 0603 RC21 4K7 PM5 R

R

3345 232270260101 RST SM 0603 RC21 100R PM5 R

3346 232270260101 RST SM 0603 RC21 100R PM5 R

3401 232270260101 RST SM 0603 RC21 100R PM5 R

3402 232270260101 RST SM 0603 RC21 100R PM5 R

3403 212211805637 RST SM

3404 212211805637 RST SM 0603 RC0603 22R PM5 R

3405 212211805637 RST SM 0603 RC0603 22R PM5 R

3406 232270260101 RST SM 0603 RC21 100R PM5 R

3407 232270260101 RST SM 0603 RC21 100R PM5 R

3408 212211805637 RST SM 0603 RC0603 22R PM5 R

3411 232270468201 RST SM 0603 RC22H 820R PM1 R

3412 232270462702 RST SM 0603 RC22H 2K7 PM1 R

3501 212211805639 RST SM 0603 RC0603 47R PM5 R

3502 212211805639 RST SM 0603 RC0603 47R PM5 R

3503 212211805639 RST SM 0603 RC0603 47R PM5 R

3513 232270260101 RST SM 0603 RC21 100R PM5 R

0603 RC21 68R PM5 R

0603 RC0603 22R PM5 R

3514 232270260101 RST SM0603RC21 100RPM5 R

3515 232270260102 RST SM0603RC21 1KPM5 R

3516 232270260101 RST SM0603RC21 100RPM5 R

3517 232270260101 RST SM0603RC21 100RPM5 R

3518 212211805669 RST SM 0603 RC0603 10K PM5 R

3519 212211805669 RST SM 0603 RC0603 10K PM5 R

3521 212211805669 RST SM 0603 RC0603 10K PM5 R

3522 212211805669 RST SM 0603 RC0603 10K PM5 R

3523 212211805669 RST SM 0603 RC0603 10K PM5 R

3531 212211805972 RST SM1206JUMP. MAX 0R05 R

3533 232270260473 RST SM0603RC21 47KPM5 R

3534 232270260104 RST SM0603RC21 100KPM5 R

3535 212211805669 RST SM 0603 RC0603 10K PM5 R

5210 242254945579 IND FXD 1206 EMI 100MHZ 100R R

5211 242254943769 IND FXD 0603 EMI 100MHZ 30R R

5212 242254943769 IND FXD 0603 EMI 100MHZ 30R R

5213 242254943769 IND FXD 0603 EMI 100MHZ 30R R

5415 242254900113 IND FXD 0603 EMI 100MHZ 1K R

5421 242254945579 IND FXD 1206 EMI 100MHZ 100R R

5431 242254945579 IND FXD 1206 EMI 100MHZ 100R R

5501 242254944196 IND FXD 0805 EMI 100MHZ 120R R

5502 242254944196 IND FXD 0805 EMI 100MHZ 120R R

5503 242254944196 IND FXD 0805 EMI 100MHZ 120R R

5507 242254945579 IND FXD 1206 EMI 100MHZ 100R R

5535 242254945579 IND FXD 1206 EMI 100MHZ 100R R

8020 R

6201 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6204 933137390215 DIO REG SM

6205 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6206 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6301 932209863685 DIO SIG SM BAV99 (VISH) R

6302 932209863685 DIO SIG SM BAV99 (VISH) R

6303 933976370215 DIO SIG SM BAT54C (PHSE) R

7301 313815864291 CPUICASSY

7301 932220582682 IC SM NT68F633L (NOVA) L

7341 313815865011 EEPROM ASSY-QDI

7341 932218650682 IC AT24C16A-10PU-2.7 (ATME) L

7401 823827716531 NT68521AEF ANALAG SXGA SCALER

7518 932217439685 TRA SIG SM BC857C (KEC0) R

7519 932217439685 TRA SIG SM BC857C (KEC0) R

7531 932216638668 FET POW SM SI5441DC-E3 (VISH)R

7532 932209265685 TRA SIG SM MUN2211JG (ONSE) R

7541 932222077668 IC SM AME1117ECGTZ (AME0) R

7545 932222076668 IC SM

1053 313815863771 CONTROL ASSY

3902 232270260473 RST SM0603RC21 47KPM5 R

3903 212211805669 RST SM 0603 RC0603 10K PM5 R

3904 232270260102 RST SM0603RC21 1KPM5 R

3905 232270260473 RST SM0603RC21 47KPM5 R

3906 212211805669 RST SM 0603 RC0603 10K PM5 R

3907 232270260102 RST SM0603RC21 1KPM5 R

6910 932222562682 LED VSL-115WSYKCGKW* (KIEL)B

6911 932222562682 LED VSL-115WSYKCGKW* (KIEL)B

Diversity of 170C6FS/00(LPL)comparedwith 170C6FS/00(QDI)

Item 12NC Description

1050 823827718251 LCD LM170E01-TLA8

1051 313815864271 SCALER ASSY

7341 313815864301 EEPROM ASSY-LPL

0295 313815567371 LABEL-EEPROM(L)

BZX84-C5V1 (PHSE) R

AME1117CCGTZ (AME0) R

Page 34

34

Recommended Parts List

Typ e:170C6FS/00

0031 313815416531 BEZEL(S)

0032 313815416481 POWER BUTTON

0033 313815416471 CONTROL BUTTON

0034 313815416491 POWER LENS

0041 313815416541 BACK COVER(B)

0042 313815137561 HINGE-PLATE

0050 313815760101 FOLDABLE BASE(B)

0090 313810440571 HOUSING COVER

0101 313815416501 HINGE COVER

0104 313815135311 DSUB PLATE

0301 313815136971 METAL FRAME

1052 823827717131 LIPS(EADP-43AF A)POWER BOARD

6201 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6204 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6205 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6206 933137390215 DIO REG SM BZX84-C5V1 (PHSE) R

6301 932209863685 DIO SIG SM BAV99 (VISH) R

6302 932209863685 DIO SIG SM BAV99 (VISH) R

6303 933976370215 DIO SIG SM BAT54C (PHSE) R

7301 313815864291 CPU IC ASSY

7301 932220582682 IC SM NT68F633L (NOVA) L

7341 313815865011 EEPROM ASSY-QDI

7341 932218650682 IC AT24C16A-10PU-2.7 (ATME) L

7401 823827716531 NT68521AEF ANALAG SXGA SCALER

7518 932217439685 TRA SIG SM BC857C (KEC0) R

7519 932217439685 TRA SIG SM BC857C (KEC0) R

7531 932216638668 FET POW SM SI5441DC-E3 (VISH)R

7532 932209265685 TRA SIG SM MUN2211JG (ONSE) R

7541 932222077668 IC SM AME1117ECGTZ (AME0) R

7545 932222076668 IC SM AME1117CCGTZ (AME0) R

8161 313819875901 CBLE-267 7/165/7-267A AWG28

8163 313819874611 FFC 30/185/30 PITCH 1.0MM

Page 35

Warning Message Table

Warning message table

Item Attention Signals Display Time Condition Attention off

35

1 CANNOT DISPLAY

THIS VIDEO MODE,

CHANGE COMPUTER

DISPLAY

INPUTTO 1024X768

@ 60HZ

2 NO VIDEO INPUT 30 mins This message appears when there is no signal inputbut with

3 CHECK CABLE

CONNECTION

4 ENTERING SLEEP

MODE

5 WAITING FOR

AUTOMATIC

ADJUSTMENT

6 USE 1024 X 768 FOR

BEST RESULT

7 OSD MAIN

CONTROLS LOCKED

8 OSD MAIN

CONTROLS

UNLOCKED

9 ATTENTION SIGNAL

ON

30 mins This warning appears when theinput signal from your

30 mins This message appears when a signal cable is disconnected

3 secs This message appears when monitorisaboutto enter power

till auto

adjustment

finished

Ontop of OSD

main menu

3 secs /or Till

OSD MAIN

CONTROLS

UNLOCKED

appear

3 secs This message will appear 3 secondsto indicate the OSD

3 secs

computer is notinastandardvideo mode orisout of the

monitor’sscanning range.After 30 mins, monitor enters

sleeping mode.

cable while AC or DC while power on.After 30 mins, monitor

enters sleeping mode.

while monitorisworking.After 30 mins, monitor enters

sleeping mode.

saving mode.

This message is displayedwhen theauto adjustment button

is pressed. It disappears when automatic adjustments are

completed.

The message will show up at thetop of the OSD main menu

in redcolor when theinputresolutionisnotthe 1024x768.

This message will appear 3 secondsto indicate the OSD

MAIN CONTROLS status when to lock or un-lock it by

pressing MENU(OK) button formore than 10 seconds while

there is video input from PC. This function provides the

alternativethat user can lock all the OSD main controlin

case user don’t want the FOS performance setting to be

changed, forinstance,during commercial exhibition.

MAIN CONTROLS status when toun-lock it bypressing

MENU(OK) button formore than 10 seconds while there is

video input from PC.

This message will appear 3 secondsto indicate the attention

signals in ON or OFF status when to switch this function on

or off bypressing the AUTO button formore than 10 seconds

while at novideo input from PC.

No

Yes

Show floating

menu

ATTENTION

SIGNAL OFF

Yes

Show floating

menu

ATTENTION

SIGNAL OFF

No

No

Yes

No function when

push10secs (If

OSD lock then

attention off, not

any message and

only attention on)

No function when

push10secs

Yes

ATTENTION SIGNAL

OFF

10 THISIS85HZ

OVERSCAN, CHANGE

COMPUTER DISPLAY

INPUTTO

1024X768@60HZ

11 the window of OSD

MAIN CONTROLS

3 secs

10 mins This message will appear 5 secondsinevery60seconds for

10 minutes when theinput of PC video timing is at 85Hz

mode.

Remark: AUTO is still functional in this mode

60 secs This message will appear when the OK buttonispressed. Yes

No

Page 36

36

Trouble Shooting

Common Problems

Having this problem Check these items

· Make sure the power cord is plugged into

the power outlet and into the back of the

No Picture

(Power LED not lit)

No Picture

(Power LED is amber or yellow)

monitor.

· First, ensure that the power button on the

front of the monitor is in the OFF position,

then press it to the ON position.

· Make sure the computer is turned on.

· Make sure the signal cable is properly

connected to your computer.

· Check to see if the monitor cable has bent

pins.

· The Energy Saving feature may be

activated

Screen says

Screen says

AUTO button not working

properly

· Make sure the monitor cable is properly

connected to your computer. (Also refer to

the Quick Set-Up Guide).

· Check to see if the monitor cable has bent

pins.

· Make sure the computer is turned on.

· Make sure the vertical sync of input signal

is within the range of 56 ~ 75 Hz.

· Change the refresh rate to 56~75Hz within

10 minutes.

· Re-power on monitor to start over again if

youfailedtochangetherefreshratewithin

10 minutes.

· The Auto Function is designed for use on

standard Macintosh or IBM-compatible

PCs running Microsoft Windows.

· It may not work properly if using

nonstandard PC or video card.

Imaging Problems

Display position is incorrect

Image vibrates on the screen

· Press the Auto button.

· Adjust the image position using the

Horizontal Position and/or Vertical Position

in OSD Main Controls.

· Check that the signal cable is properly

connected to the graphics board or PC.

Page 37

Trouble Shooting

Vertical flicker appears

Horizontal flicker appears

The screen is too bright or too dark

37

· Press the Auto button.

· Eliminate the verticalbars using the

More Settings ofPhase/Clock in OSD

Main Controls.

· Press the Auto button.

· Eliminate the verticalbars using the

More Settings ofPhase/Clock in OSD

Main Controls.

· Adjustthecontrast and brightness on

OSDMain Controls. (The backlight of

the LCD monitor has a fixed life span.

When the screen becomesdark or

begins to flicker,please contact your

dealer).

An after-image appears

An after-image remainsafter the

power has been turned off.

Green, red, blue,dark, andwhite

dots remains

· If animage remains on the screen for

anextendedperiod of time, it may be

imprinted in the screen and leave an

after-image. This usuallydisappears

after afew hours

· This ischaracteristic of liquidcrystal

and is not caused byamalfunction or

deterioration of the liquidcrystal . The

after-image will disappear after aperoid

of time.

· The remaining dotsare normal

characteristic of the liquidcrystalused

in today’s technology

Page 38

38

Repair Tips

0. Warning

All ICsand many other semi-conductors are susceptible to

electrostaticdischarges (ESD). Careless handling during

repair can reduce life drastically. When repairing, makesure

that you are connectedwith thesamepotential as the mass

of the unitvia

and toolsalso atthesamepotential!

a wristwrap with resistance.Keep components

1. Servicing of SMDs (Surface MountedDevices)

1.1 Generalcautions on handling and storage

-Oxidation on the terminals of SMDsresultsin poorsoldering.

Do not handle SMDs with bare hands.

-Avoidusing storageplaces that are sensitive to oxidation

such as places with sulphur or chlorine gas,direct sunlight,

high

temperatures orahigh degree of humidity. The

capacitance or resistance value of the SMDs maybe

affectedbythis.

- Rough handling of circuitboards containing SMDs may

cause damage to the componentsaswell as the circuit

boards.Circuitb

bent or flexed. Different circuitboardmaterialsexpand and

contract atdifferent rates whenheatedor cooled and the

componentsand/orsolder connections maybe damaged

due to

thestress.Never rub orscrape chip componentsas

this maycause the value of the component to change.

Similarly,donotslide the circuitboard across any surface.

1.2 RemovalofSMDs

-Heatthesolder (for 2-3 seconds) at each terminalofthe

chip.Bymeans of litz wire and aslight horizontalforce,

small components canberemovedwith thesoldering iron.

Theycan alsoberemovedwith asolder sucker (see Fig.

1A)

oards containing SMDsshould never be

preferably beequippedwith a thermal control (soldering

temperature: 225 to 250 C).

- The chip, onceremoved, mustnever bereused.

1.4 Attachment of SMDs

- Locate the SMD on thesolder lands by means of tweezers

and solder the component on oneside.Ensure thatthe

component is positionedcorrectly on thesolder lands (see Fig.2A).

-Next complete thesoldering of the terminals of the

component (see Fiq.

2B).

2. Caution when attaching SMDs

-When soldering the SMD terminals, do not touch them

directly with thesoldering iron. Thesoldering should be

doneasquickly as possible,care mustbe takentoavoid

damage to the terminals of the SMDs themselves.

-Keep the SMD's body in contact with

soldering.

- Thesoldering iron to be used(approx. 30 W ) should

preferably beequippedwith a thermal control (soldering

temperature: 225 to 250 C).

- Soldering should not be done outside thesolder land.

- Soldering flux (of rosin) maybe used, but should not be

acidic.

-

After soldering, letthe SMD cool down gradually at room

temperature.

- The quantity of solder mustbeproportionaltothesize of the

solder land. If the quantity is too great, the SMD might

crack or thesolder lands might be torn loose from the

printedb

oard(see Fig. 3).

the printedboardwhen

While holding the SMD with a pair of tweezers,takeitoffgently using the

soldering iron's heat appliedtoeach terminal(see Fig. 1 B).

- Remove theexcess solder on thesolder lands by means of

litz wire orasolder sucker (see Fig. 1C).

1.3 Caution on removal

-Whenhandling thesoldering.iron. use suitable pressure a nd be careful.

-When removing the chip, do not use undue force with the pair of tweezers.

- Thesoldering iron to be used(approx. 30 W) should

Right

Fig.3 Examples

Page 39

Repair Tips

3. Lead-f ree product i dentifi cation

You can identify lead-free product by Philips-lead-free logo on PCB.

P

b

4. Lead-free product repair instruction

4.1 Use only lead-free Solder Alloy 0622 149 00106(1.2mm SAC305) or 0622 149

00108(1.0mm SAC305).

Remark: For lead free soldering material, please visit www.alphametals.com website for

details. This is recommended by Philips.

4.2 Use only adequate solder tools applicable for lead-free soldering-tin. The solder tool must be able to reach at least a

solder-temperature of 400

applications.

Small Passives/Actives to be removed with thermal tweezers

Automated system for IC and BGA repair (Microscope, Camera, Beam split optics, Computer, Programmer, Heat

controllers, Vacuum system, Laser pointer)

Solder Hand-Tool (Adjustable in temperature height, Temperature shall be held constant,

Flexible tips)

, to stabilize the adjusted temperature at the solder-tip and to exchange solder-tips for different

39

4.3 Adjust your solder tool so that a temperature around 360

Heating-time of the solder-joint should not exceed ~ 4 sec. Avoid temperatures above 400

rise drastically and flux-fluid will be destroyed.

Corrosion of Tool-Spikes can be avoided when using SAC305 and a temperature of less than 400

4.4 Mix of lead-free solder-tin/parts with leaded soldering-tin/parts is possible but not recommended. If not to avoid clean

carefully the solder-joint from old tin and re-solder with new tin.

4.5 Use only original spare-parts listed in the Service-Manuals. Standard-material

(consumables) can also be purchased at external companies.

4.6 Special information for lead-free BGA-ICs: this ICs will be delivered in so-called

dry-packaging to protect the IC against moisture and with lead-free logo on it. This

packaging may only be opened shortly before it is used (soldered). Otherwise the

body of the IC gets wet inside and during the heating time the structure of the IC

will be destroyed due to high (steam-)pressure. If the packaging was opened before

usage the IC has to be heated up for some hours (around 90

attention for ESD-protection!)

5. Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are deformed drastically so the removed (LF)BGA has to be

discarded.

Devi ce Removal

As is the case with any component that, it i s essential when removing an (LF)BGA, the board, tracks, solder lands, or

surrounding components are not damaged. To remove an (LF)BGA, the board must be uniformly heated to a temperature

close to the reflow soldering temperature. A uniform temperature reduces the chance of warping the PWB.

To do this, we recommend that the board is heated until it is certain that all the joints are molten. Then carefully pull the

component off the board with a vacuum nozzle. For the appropriate temperature profiles, see the IC data sheet.

Area Preparati on

When the component has been removed, the vacant IC area must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be removed with a brush and cleaning agent. After the board

is properly cleaned and inspected, apply flux on the solder lands and on the connection balls of the(LF)BGA

Note: Do not apply solder paste, as this has shown to result in problems during re-soldering.

Devi ce Replacem ent

The last step in the repair process is to solder the new component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not possible, try to align the (LF)BGA with any board markers.

To reflow the solder, apply a temperature profile according to the IC data sheet. So as not to damage neighbouring

components, it may be necessary to reduce some temperatures and times.

More Information

For more in formation on how to handle BGA devices, visit this URL: http://www.atyourservice.ce.philips.com (needs

subscription). After login, select Magazine , then go to Workshop Information . Here you will find Information on how

.to deal with BGA-ICs.

-380 is reached and stabilized at the solder joint.

otherwise wear-out of tips will

.

) for drying (Take

Page 40

40

Repair Flow Chart

Page 41

Repair Flow Chart

41

Page 42

42

Repair Flow Chart

Page 43

Configuration and procedure

Firmware Upgrade for CPU

43

"Easywriter " The software

is provided by Novatek to upgrade the

firmware of CPU.

It is a windows-based program, which cannot be run in MS-DOS.

DDC2BI_ISP TOOL (3138 106 10396)

is for the interface between

"Parallel Port of PC" and "15 pin-D-SUB connector of Monitor".

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98/2000/XP.

3. ISP Software " Easywrite "

4. as shown in Fig. 1

DDC2BI_ISP TOOL (3138 106 10396)

ParallelPorttoPrintPortinPC

D-SUB to monitor

Fig. 1

5 Connect and Mains cord to Monitor as shown

. DDC2BI_ISP TOOL

in Fig. 2.

PC

170C6(B)

Fig. 4

Step 5 :Copy the hex file to C:\170C6 as shown in Fig. 5 .

170C6

170C6

H170C6_V200

_8A18.hex

Fig. 5

Update the firmware

1. DoubleclicktheEasywriter.exeiconindesktopthenappears

window as shown in Fig.7 .

Monitor (A)

------------------------------->

Connect to

Mains cord

Connect to Mains

cord at this moment.

To video card

ISP box

Video cable

To printer port (LTP1)

Fig.2

6. Install and setup the Easywriter program

Step 1 : Make a folder in your PC as shown in Fig. 3.

For example : C:\170C6

Step 2 : Copy the Software Easywriter into your folder

.zip

as shown in Fig.3.

Step 3 : Unzip Easywriter.zip into your folder as shown in Fig. 3.

Step 4 : Double click the EasywriterV2.09a_user.exe icon to install the

Application as Fig. 4.

170C66

Fig. 6

Fig. 3

Fig. 7

Page 44

44

2. Press the Load hex then select the hex file as shown

in Fig. 8.

4 Select NT68F633 then press the AUTO to running program ,

the firmware be updated as shown in Fig. 9~10.

Firmware Upgrade for CPU

Fig. 8

Fig. 11

4 Pressthe file-->exit toend program ,asshown inFig.12.

Fig. 9

Fig.

Fig. 12

If there is a warring message coming as shown in Fig 13. , you

havetochecktheACpower,Videocable,orNovatekMCU.

2.09

Fig. 13

Page 45

DDC Instructions

45

General

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed" ".

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA). Extended

Display Identification Data(EDID) information may be also obtained from

VESA.

Analog DDC IC, & EEPROM

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98 .

Y o Install the EDID_PORT_Tool under Win2000/XP . As

ou have t

Fig. 1 .

Fig. 1Fig.

1

PIN No. SIGNAL

1Red

2 Green/SOG

3Blue

4 Sense (GND)

5 Test (GND)

DC 8~12V

Power

indicator

6RedGND

7 Green GND

8BlueGND

To Monitor

D-sub cable

9+5V

10 Sync GND

11 Sense (GND)

12 Serial data (SDA)

13 H/H+V sync

14 V -sync

15 Data clock (SCL)

Re-programming Analog DDC IC

There are 2 chips contained OSD string, serial number..etc

on the circuit board, main EEPROM which storage all factory settings,

OSD string. DDC IC which storage 128 byte EDID data(serial number

..etc.). Following descirptions are the connection and procedure for

Analog and main EEPROM can be re-programmed along with

Analog/Digital IC by enable factory memory data write function on

The DDC program (EDID45.1.EXE).

A. Cody the "UserPort.sys" to C:\WINNT\system32\drivers(win2000)

C:\WINDOWS\system32\drivers(winXP)

B. Running " io.exe" everytime, Before you start to programming

edid data .

3. EDID45.1.EXE program .

4. DDC 2BI-ISP TOOL:

inclusion : a. DDC2BI-ISP TOOL(3138 106 10396) x1 (as Fig. 2)

B. Printer cable x1

c. (D-Sub) to (D-Sub) cable x2

Note: The EDID45.EXE is a windows-based program, which cannot

be run in MS-DOS.

Pin assignment

A. 15-pin D-Sub Connector

Fig. 2Fig. 2

Following steps show you the procedures and connection.

Step 1: Connecting printer cable and D-Sub cable of monitor as Fig. 4

PC

Printer

Port

To P C

To Monitor

Fig. 4

To printer port (LTP1)

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 8) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this

time,please make sure all cables are connected correctly and

fixedly,

To Printer port

Fig. 3Fig. 3

Fig. 8

Page 46

46

DDC Instructions

Step 2: Installation of EDID45.1.EXE

Start Microsoft Windows.

1.The Program"EDID45.1.EXE" in service manual cd-rom be copyed

to C:\ .

2.Click" " choose Run at start menu of Windows as shown

In Fig. 5.

Fig. 5

3. At the submenu, type the letter of your computer's hard disk drive

followed by :EDID45

(for example, C:\EDID45, as shown in Fig. 6).

Step 3: Read DDC data from monitor

1. Click icon as shown in Fig. 7 from the tool bar to bring up

The Channels "Configuration Setup" windows as shown in Fig. 8

Select the DDC2Bi as the communication channel.

2.

As shown in Fig. 8.

Fig. 8

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig.9

EDID45

Fig. 6

4. Click button. The main menu appears (as shown in Fig. 7).OK

Fig. 7

Note 2: During the loading, EDID45 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

Confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Don't close this screen. --->

Fig. 9

Step 4: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 10-18 .

EDID45 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Select and fill out,

If necessary.

Fig. 8

1

Fig. 10

Page 47

DDC Instructions

47

Step 5: Modify DDC data (Monitor Serial No.)

Next1. Click , bring up Fig. 11.

2. Click , bring up Fig. 12.Next

Fig. 11

5. Click , bring up Fig. 15.Next

Fig. 15

6. Click , bring up Fig. 16.Next

- Serial number can be filled up or be changed at this moment.

3. Click , bring up Fig. 13.Next

4. Click , bring up Fig. 14.Next

Fig. 12

Fig. 13

7. Click , bring up Fig. 17.Next

8. Click , bring up Fig. 18. Then click finish to exit the step

Next

window

Fig. 16

Fig. 17

Fig. 14

Fig. 18

Page 48

48

DDC Instructions

Step 5: Write DDC data

1. Configuration should be as Fig. 19. And press OK.

Fig. 19

2. Access Factory Mode

- Turn off monitor.

-

[PushAUTO" "&OK" "buttonsatthesametimeand

holdit]+[Presspower" "buttonuntillcomesout"Windows

screen"] => then release all button

3. Click (Write EDID) icon from the tool bar to write DDC data.

Step6:

-1. Disconnect the monitor power cord and connect it again.

-2. Press the OK button to bring up the OSD main manu.

-3. Re-confirm the serial Number is updated as shown in Fig.20.

2. Click .Save

Step 8: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 22.

Edid45.1

Fig. 22

Fig.20

Step 7: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

And give a file name as shown in Fig. 21.

The file type is EDID45 file (*.ddc) which can be open in WordPad.

By using WordPad, the texts of DDC data & table (128 bytes, hex

code) can be modified. If DDC TEXTS & HEX Table are completely

correct, it can be saved as .ddc flie to re-load it into DDC IC for DDC

Data application.

Fig. 21

Page 49

DDC Data

49

THE DISPLAY DATA CHA NNEL (DDC_2B ) CONTENT

**********************************************************************

EDID log file

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID ProductCode : C011 (HEX.)

ID Serial Number : 12345(HEX.)

Week of Manufacture : 13

YearofManufacture : 2005

EDID Version, Revision

Version : 1

Revision : 3

Basic DisplayParameters/Features

Video InputDefinit ion : Analog Video Input

0.700V/0.300V (1.00Vpp)

Blank-to-Black Se

Se

parateSync

CompositeSync

Sync on Green

Serration required

Maximum H Image Size : 34

Maximum V Image Size : 27

DisplayTransfer Characteristic : 2.2(gamma)

Feature Support (DPMS) : Standby

Display Type : RGB color display

Standard DefaultColor Space : Primary color space

Preferred Timing Mode : Detailed timing block 1

olor Characteristics

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

Red X coordinate:0.641

Red

Y coordinate:0.341

Green X coordinate:0.28

Green Y coordinate : 0.616

Blue X coordinate:0.144

Blue Y coordinate : 0.077

White X coordinate : 0.313

White Y coordinate : 0.329

640x480 @60Hz (IBM,VGA)

640x480 @67Hz (Apple,MacII)

640x480 @72Hz (VESA)

640x480 @75Hz (VESA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

tup

Suspend

Active Off

Standard Timing Identification #1

Detailed Timing #1

Monitor Descriptor #2

Monitor Descriptor #3

Monitor Descriptor #4

Extension Flag:0

Check sum : 94 (HEX.)

**********************************************************************

EDID data (128 bytes)

**********************

0: 00 1: ff 2: ff 3: ff 4:ff 5:ff 6:ff 7:00

8: 41 9: 0c 10: 11 11: c0 12: 45 13: 23 14: 01 15: 00

16: 0d 17: 0f 18: 01 19: 03 20: 1f 21: 22 22: 1b 23: 78

24: ee 25: 1f 26: f5 27: a4 28: 57 29: 47 30: 9d 31: 24

32: 13 33: 50 34:54 35: bf 36: ef 37: 80 38: 81 39:80

40: 01 41: 01 42: 01 43: 01 44:01 45: 01 46: 01 47: 01

48: 01 49: 01 50: 01 51: 01 52: 01 53: 01 54: 30 55: 2a

56: 00 57: 98 58: 51 59: 00 60: 2a 61: 40 62: 30 63: 70

64: 13 65: 00 66: 52 67: 0e 68: 11 69: 00 70: 00 71: 1e

72: 00 73: 00 74: 00 75: ff 76: 00 77: 20 78: 54 79:59

80: 20 81: 20 82: 31 83: 32 84: 33 85: 34 86: 35 87: 36

88: 0a 89:20 90: 00 91: 00 92: 00 93: fc 94:00 95:

96: 68 97: 6998: 6c 99:69 100: 70 101: 73 102: 20 103: 31

104: 37 105: 30 106: 43 107: 0a 108: 00 109: 00 110: 00 111: fd

112: 00 113: 38 114: 4c 115: 1e 116: 53 117: 0e 118: 00 119:0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 94

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate:60

Pixel Clock (MHz) : 108

HActive (pixels) : 1280

HBlanking (pixels) : 408

VActive (lines) : 1024

VBlanking (lines) : 42

H Sync Offset (F Porch) (pixels) : 48

H Sync Pulse Width (pixels) : 112

V Sync Offset (F Porch) (lines) : 1

V Sync Pulse Width (lines) : 3

HImage Size (mm) : 338

VImage Size (mm) : 270

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

Serial Number : TY 123456

Monitor Name : Philips 170C

Monitor Range Limits

Min. Vt rateHz : 56

Max. Vt rateHz : 76

Min. Horiz. ratekHz : 30

Max. Horiz. ratekHz : 83

Max. Supported Pixel : 140

No secondary GTF timing formula supported.

************************************************

:Normal Display, No stereo

: DigitalSeparatesync.

:Positive VerticalS

:Positive HorizontalSync.

ync.

50

Established Timings II : 800 x 600 @72Hz (VESA)

Manufacturer's timings : 1152 x 870 @75Hz (Apple,Mac II)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,MacII)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

1280 x 1024 @75Hz (VESA)

Page 50

Failure Mode of Panel

Quick reference for failure mode of LCD panel

this page presents problems that could be made by LCD panel.

It is not necessary to repair circuit board. Simply follow the mechanical

instruction on this manual to eliminate failure by replace LCD panel.

Polarizer has bubbles

Failure description

Vertical block defect

Vertical dim lines

Vertical lines defect

(Always bright or dark)

Horizontal block defect

Phenomenon

Polarizer has bubbles

Foreign material inside

polarizer. It shows liner or

dot shape.

Concentric circle formed

Horizontal dim lines

Horizontal lines defect

(Always bright or dark)

Has bright or dark pixel

Bottom back light of LCD is

brighter than normal

Back light un-uniformity

Backlight has foreign material.

Black or white color, liner or

circular type

Page 51

General Product Specification

HUDSON-6 170C6

GENERAL PRODUCT

SPECIFICATION

. ANALOG INPUT

. AUTO PICTURE ADJUSTMENT

. 15 FACTORY PRESET MODES AND 34 PRESET MODES WHICH

CAN BE RECOVERED TO PRESET MODES

. NEWOSD STYLING DISPLAY FORMODE IDENTIFICATION

/ADJUSTMENT

. DDC 2B & DDC/CI COMMUNICATION CAPABILITY

. MAX. RESOLUTION1280*1024 NON-INTERLACED AT 76 HZ

51

. 17” COLOR TFT LCD FLAT PANEL

. EASY TILT & FOLDABLE BASE

. FULL RANGEPOWER SUPPLY 90 – 264 VAC

. CE

ENVIRONMENTAL POLICY

. LEAD-FREE PRODUCT POLICY

. ANTI-GLARE TO REDUCE LIGHT REFLECTION

. POWER MANAGEMENT CAPABILITY

. SOG SUPPORT

. TCO’99

. PROTECTIVECOVER (OPTION)

2005-04-25

Peter.V

17 inch TFT-LCD Monitor

TYPE : 170C6FS/00

BRAND : PHILIPS

2005-04-25

26

8639 000 16452

590

1

Page 52

52

General Product Specification

CONTENTS

1.0Foreword

2.0Product profile

2.1LCD

2.2Scanningfrequencies

2.3 Video dot rate

2.4Powerinput

2.5Powerconsumption

2.6Dimensions

2.7 Weight

2.8 Functions

2.9Ambient temperature

2.10 Regulatory compliance

3.0Electr

3.1Interfacesignals

3.2Interface

3.2.1D-Sub cable

3.2.2 OSD function control

3.3 Timing requirement

3.3.1Mode storing capacity

3.3.2Factory/ presettimings

3.3.3 Horizontal scanning

3.3.4 Vertical sc anning

3.4Powerinput

3.5Power management

3.6Display identification

3.6.1Analog DDC

4.0 Visual characteristics

4.1Testconditions

4.2Resolution

4.3 Brightness

4.4Image size

4.4.1Actual display size

4.4.2Max scan size

4.5Brightness uniformity

4.6C

4.7 White color adjustment

ical characteristics

connection

heck cross talk

202P Gs3 CM25

2005-04-25

Peter.V

5.0Mechanical characteristics

5.1 Controls

5.2 Unit dimension / weight

5.3 Tilt and base

5.4Transportation pac kages

17 inch TFT-LCD Monitor

TYPE : 170C6FS/00

BRAND : PHILIPS

2005-04-25

26

8639 000 16452

590

2

Page 53

General Product Specification

5.4.1Shippingdimension / weight

5.4.2Blockunit / palletization

6.0Environmental characteristics

6.1Susceptibility ofdisplay to external environment

6.2Transportation tests

6.3Display disturbances fromexternal

6.4Display disturbances to external environment

6.4.1EMI

7.0Reliability

7.1Meantime between failures

8.0 Quality assurance requirements

8.1Acceptance test

9.0Serviceability

environment

53

10.0Philips Flat panel

monitorspixel defect policy

2005-04-25

Peter.V

17 inch TFT-LCD Monitor

TYPE : 170C6FS/00

BRAND : PHILIPS

2005-04-25

26

8639 000 16452

590

3

Page 54

54

General Product Specification

1.0FOREWORD

2.0PRODUCT PROFILE

2.1LCD

2.1.1Type NR. : LM170E01-TL

2.1.2Typ

Thisspecification describes a 17" SXGA multi-scancolor TFT-LCD monitor with maximum resolution

up to 1280*1024 /76 Hz non-interlaced.

Thisdisplay monitor unit isacolor display monitor enclosed in PHILIPS global styling

cabinet,which has a foldable base wit