Page 1

14” Auto scan Colour Monitor

Chassis

Service

Service

Service

DDC/Power saving/TCO

User-friendliness Control

Contents Page

104S CM23 GSIII

104S11/00(COCA)

Horizontal frequencies

30-54kHz

TABLE OF CONTENTS

Description Page

Important Safety Notice ------------------------------- 2

Technical Data ------------------------------------------ 3

Installation and Control-------------------------------- 4

Warning and Notes ------------------------------------ 5

Mechanical Instructions ------------------------------ 6

Wiring Diagram----------------------------------------- 7

Electrical Instructions -----------------------------8 ~15

DDC Instructions------DDC Data---------Safety test requirements (Hipot & Ground)--------22

Block Diagram &C.B.A(A)-----------------------------23

Video Panel (A) Schematic Diagram ---------------24

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

--------------------------- 16~19

--------------------------------- 20~21

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

SAFETY NOTICE

Description Page

Main Panel (B1) Schematic Diagram---------------25

U-control Schematic Diagram & Waveforms for

Diagram B2----------------------------------------------26

Main Panel C.B.A. ------- ------------------------------27

Power supply Schematic Diagram & Waveforms

for Diagram C ------------------------------------------28

Repair Tips ----------------------------------------------29

Exploded View ----------------------------------------- 30

Recommanded parts List ---------------------------- 31

Spare parts list--------------------------------------32~38

Repair flow chart----------------------------------- 39~46

General product specification------------------- 47~71

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

Published by BCU Monitors Printed in Taiwan Copyright reserved Subject to modification MAY 26 2000

©

GB

3138 106 10099

Page 2

2

104S CM23 GSIII

IMPORTANT SAFETY NOTICE

Go to cover page

Proper service and repair is important to the safe, reliable

operation of all Philips Consumer Electronics Company**

Equipment. The service procedures recommended by

Philips and described in this service manual are effective

methods of performing service operations. Some of these

service operations require the use of tools specially designed

for the purpose. The special tools should be used when and

as recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper

service methods may damage the equipment. It also is

important to understand that these CAUTIONS and NOTICES

ARE NOT EXHAUSTIVE. Philips could not

possibly know, evaluate and advise the service trade of all

conceivable ways in which service might be done or of the

possible hazardous consequences of each way.

Consequently, Philips has not undertaken any such broad

evaluation. Accordingly, a servicer who uses a service

procedure or tool which is not recommended by Philips must

first satisfy himself thoroughly that neither his safety nor the

safe operation of the equipment will be jeopardized by the

service method selected.

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL

MANUFACTURER'S REPLACEMENT PARTS, WHICH ARE

LISTED WITH THEIR PART

NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

* * Hereafter throughout this manual, Philips Consumer

Electronics Company will be referred to as Philips.

WARNING

Critical components having special safety characteristics are

identified with a by the Ref. No. in the parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability.

* Broken Line

Page 3

Technical Data

Technical Specification*

CRT

Size and deflection :14 inch/35.5cm,90 defection angle

Dot pitch/Grille pitch : 0.28mm

Horizontal pitch : 0.24mm

Tube type : Shadow mask, anti-glare, anti-static,

anti-reflection, light transmission

57%

Phosphor : P22

O

White Color Temperature

Chromaticity CIE coordinates:

at 9300 k x = 0.281 y = 0.311

o

104S CM23 GSIII

Go to cover page

3

Recommended display

area : 9.8" x 7.4" / 250 x 188 mm

Maximum display area :10.8" x 7.9" / 274 x 201 mm

Scanning

Horizontal scanning : 30 - 54 KHz

Vertical : 50 - 120 Hz

scanning

Video

Video dot rate : 65 Mhz

Input impedance

-Video : 75 Ohm

- Sync : 2.2 kOhm

Input signal levels : 0.7Vpp

Separate sync

Sync input signal

: Composite sync

Sync polarities : Positive and negative

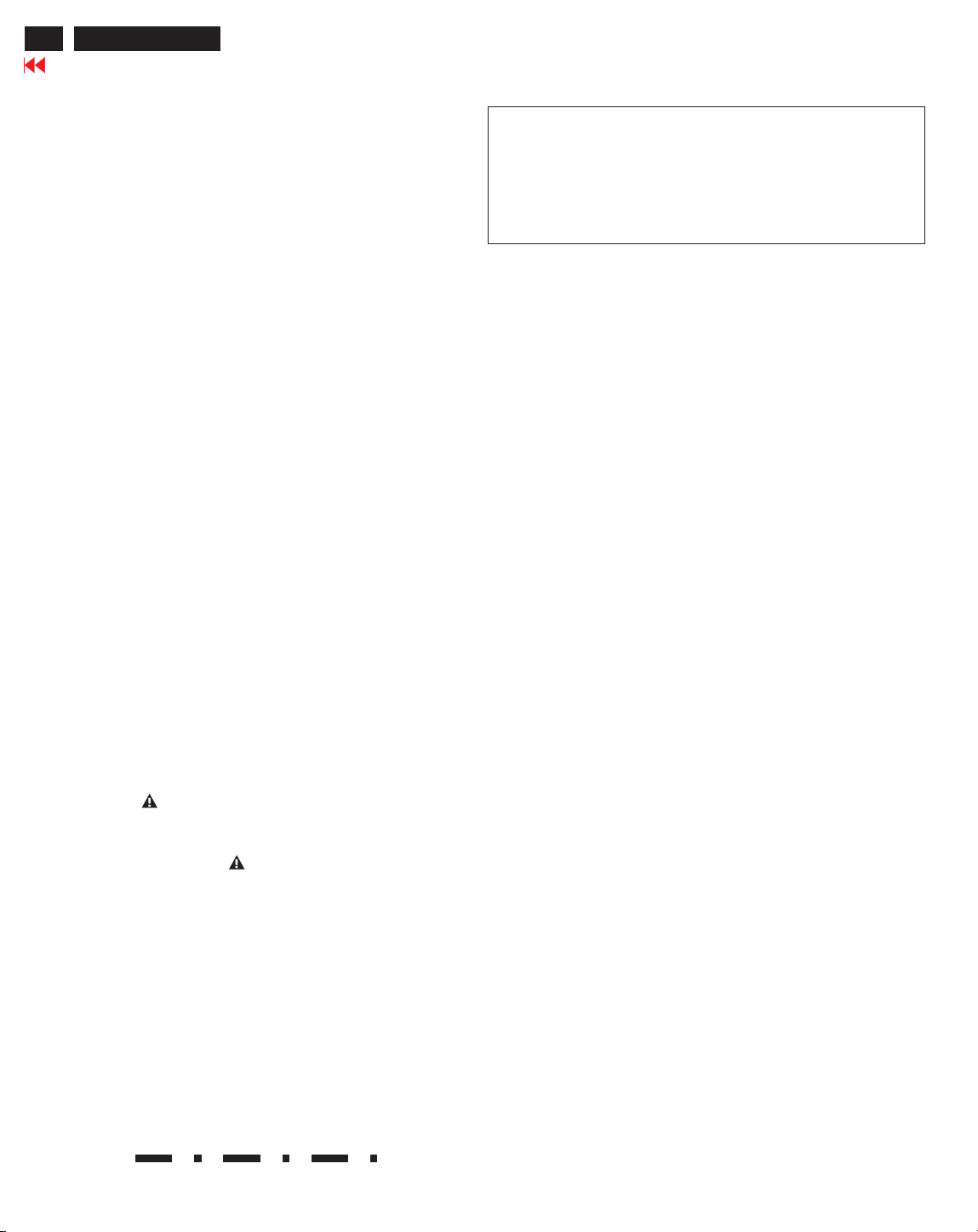

Pin assignment :

The 15-pin D-sub connector(male) of the signal cable

(IBM systems) :

1

6

11

Pin No.

1

2

3

4

5

6

7

8

Assignment

Red video input

Green video input

Blue video input

Identification output Connected to pin 10

Ground

Red video ground

Green video ground

Blue video ground

5

10

15

Pin No.

9

10

11

Assignment

No pin

Logic ground

Identification output Connected to pin 10

12

13

14

15

Serial data line(SDA)

H.Sync

V.Sync(VCLK for DDC)

Data clock line(SCL)

Physical Specifications

Dimensions : 347x367x360mm(including base)

347x367x310mm(excluding base)

weight : 9.5 Kg

Power supply : 90 - 264 VAC, 50/60HZ

Power consumption : <= 72 Watt

Operating condition

Temperature : 0 C - 40 C

OO

Relative Humidety : 20%-80%(W/O condensation)

Storage condition

Temperature : - 25 C - 65 C

OO

Relative Humidity : 20%-90%(W/O condensation)

Automatic Power Saving

If you have VESA's DPMS compliance display card or

software installed in your PC,the monitor can automaticlly

reduce its power consumption when not in use. And if an

input from a keyboard, mouse or other input devices is

detected, the monitor will automatically "wake up". The

following table shows the power consumption and

signalling of this automatic power saving features :

Power Management Definition

VESA's mode

ON

Stand-by

Suspend

OFF

VIDEO

Active

Blanked

Blanked

Blanked

H-SYNC

Yes

No

Yes

No

V-SYNC

Yes

Yes

No

No

POWER

USED

<75W

<15W

<15W

<8W

POWER

SAVING( % )

80 %

80 %

94 %

0%

LED

COLOR

Green

Yellow

Yellow

Amber

For Tne monitor is pre-set with 6 modes for optimal display size and centering as indicated in the

following table:

Mode Resolution

VGA 640 X 400 31.5 70 Non-interlaced

VGA 640 X 480 31.5 60 Non-interlaced

VESA / 75 640 X 480 37.5 75 Non-interlaced

VESA / 75 800 X 600 46.9 75 Non-interlaced

VESA / 85 800 X 600 53.7 85 Non-interlaced

VESA 1024 X 768 48.3 60 Non-interlaced

(dots x lines)

Horizontal

Freq. (KHz)

Vertical

Freq. (KHz)

Remark

This monitor is Energy Star compliant .As an ENERGY STAR

Partner, PHILIPS has determined that this product meets the

ENERGY STAR guidelines for energy efficiency.

Page 4

104S CM23 GSIII

4

Go to cover page

Front View

For detailed information about the knobs and keys,

please refer to controls

Rear View

Installation and Control

Front Controls

For an optimized adjustment of the picture following controls are

available at the front.

Power

1.Press this knob, the green LED lights and the power is ON.

2.Press this knob again, the green LED disappears and

the power is OFF.

Hotkeys

Contrast

Rotate to adjust the picture contrast level.

Brightness

Rotate to adjust the overall screen brightness as a

compensation for ambient light.

Digital Controls

Press to adjust (increase) the function selected.

Press to adjust (decrease) the function selected.

To select the level of function.

"SHIFT" LED off - control is on first level.

"SHIFT" LED on - control is on second level.

1.Power in - attach power cable here.

2.Video In - this is a cable which is already attached to your

monitor.Connect the other end of the cable to your PC.

The function pads:

H-Shift: to adjust the horizontal position of the image.

H-Size: to adjust the horizontal amplitude of the image.

V-Shift: to adjust the vertical position of the image.

V-Size: to adjust the vertical amplitude of the image.

Select level of the function pads:

Trapezoid:to correct the trapezoid distortion of the image.

Pincushion:to correct the barrel distortion of the image.

Recall: to recall original factory preset mode.

Remarks:

1.When pressing any function pad, the "Shift" LED will flash

once to indicate the function has been selected.

2.Once the limit of the adjustable range has been reached,

the shift LED will flash continuously.

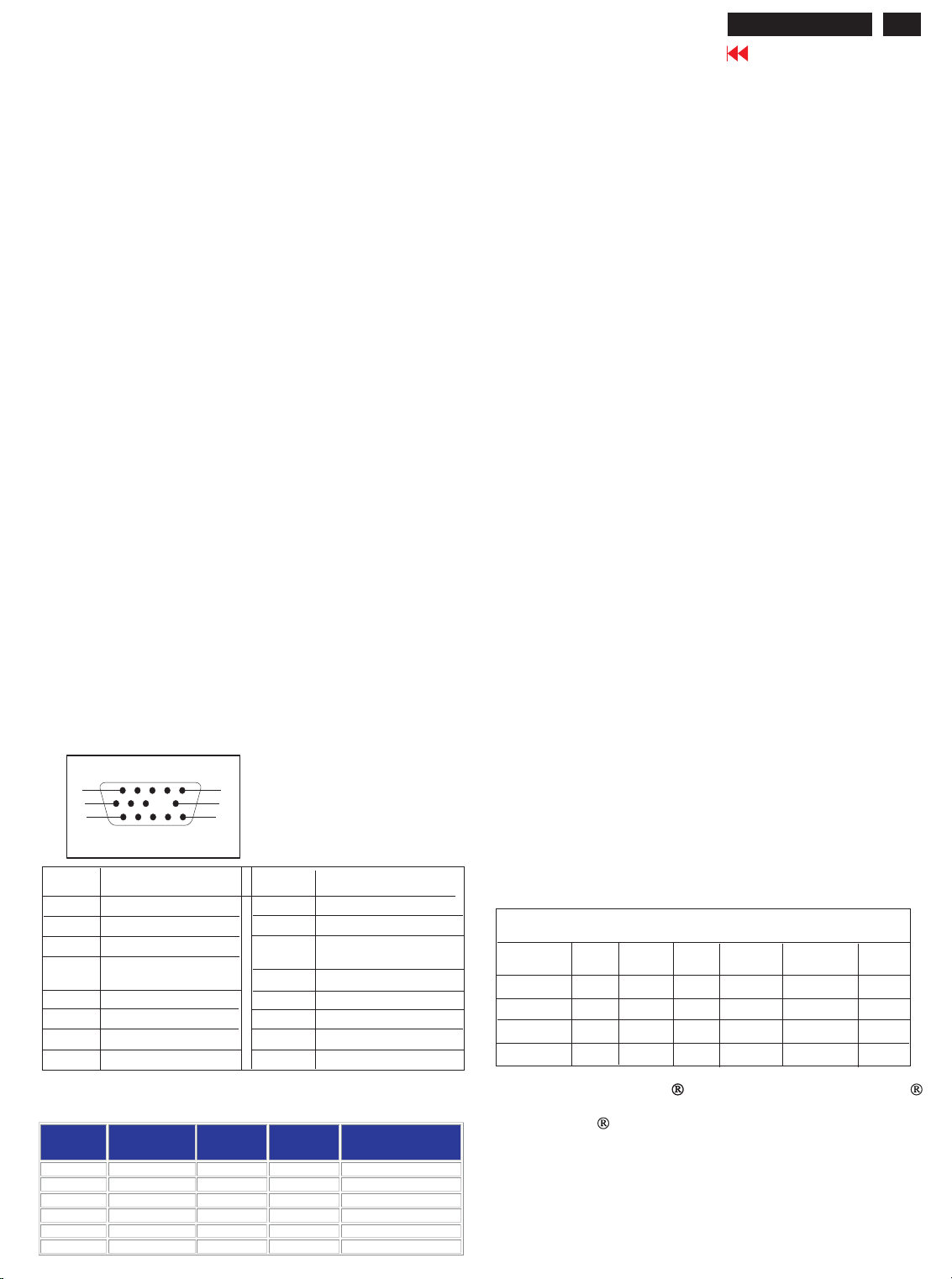

Adjustment

For the monitor is pre-set with 6 modes for optimal display size

and centering as indicated in the following table:

Mode

VGA

M01

VGA

M02

M03

VGA

M04

SVGA

M05

SVGA

M06

EVGA

The set will save the user's setting parameters automatically.

After 10 seconds of key-pad inactivity, the LED will flash twice to

indicaate the parameters being saved.

Press to recall factory preset mode. (at second level)

Resolution

640 x 400

640 x 480

640 x 480

800 x 600

800 x 600

1024 x 768

Frequency

H(KHz)

31.5

31.5

37.5

46.9

53.7

48.3

V(Hz)

70

60

75

75

85

60

Remark

Non-interlaced

Non-interlaced

Non-interlaced

Non-interlaced

Non-interlaced

Non-interlaced

Page 5

Warning and Notes

104S CM23 GSIII

Go to cover page

5

Warnings

1

. Safety regulations require that the unit should be returned

in its original condition and that components identical to

the original components are used. The safety components

are indicated by the symbol .

2

. In order to prevent damage to ICs and transistors, all

high-voltage flash-overs must be avoided. In order to

prevent damage to the picture tube, the method shown

in Fig. 1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DC-V).

Discharge until the meter reading is (after approximately

30 seconds).

3 ESD

.

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten their life. Make sure that

during repair you are connected by a pulse band with

resistance to the same potential as the ground of the unit.

Keep components and tools also at this same potential.

4

. When repairing a unit, always connect it to the AC Power

voltage via an isolating transformer.

5

. Be careful when taking measurements in the high-voltage

section and on the picture tube panel.

6

. It is recommended that saferty goggles be worn when

replacing the picture tube.

0V

Notes

. The direct voltages and waveforms are average voltages.

1

They have been measured using the Service test software

and under the following conditions :

- Mode : 640 * 480 (31.5kHz / 60Hz)

- Signal pattern : grey scale

- Adjust brightness and contrast control for the

mechanical mid-position (click position)

. The picture tube panel has printed spark gaps.

2

Each spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

. The semiconductors indicated in the circuit diagram(s)

3

and in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

V

7

. When making adjustments,use plastic rather than metal tools.

This will prevent any short-circuit or the danger of a

circuit becoming unstable.

8

. Never replace modules or other components while the

unit is switched on.

9

. Together with the defleciton unit, the picture tube is used

as an integrated unit. Adjustment of this unit during repair

is not recommended.

10.

After repair, the wiring should be fastened in place with

the cable clamps.

11.

All units that are returned for service or repair must pass

the original manufactures safety tests.

Fig.1

Page 6

104S CM23 GSIII

6

Mechanical Instructions

Go to cover page

0. General

To be able to perform measurements and repairs on the "circuit

boards", these unit should placed in the service position first.

1. Remove the rear cover

- Open two lids with "-" type screwdriver. Refer to fig2 and fig3.

- Remove 4 screws with "+" type screwdriver.

2. Video panel

- Remove the metal shielding on rear side of Video panel by

desolder lags of metal shielding.

3. Main panel

- Disconnect the degaussing coil from Main panel.

- Remove the video panel from CRT.

- Remove the "screw" of I/F cable from Main panel.

- Disconnect the CRT ground "1701" from Video panel.

- Disconnect the Hi-Pot cap from CRT.

- Disconnect the yoke wire connector "1601" from Main panel.

- Slide the main panel out of bottom tray.

- Place Main panel in service position as shown in Fig.1.

- Mount Video panel again on CRT.

- To connect Hi-Pot cap again.

- To connect "1701" again.

- To connect the yoke wire "1601" again.

lids

lid

screws

Fig.2

screws

Fig. 1

Fig.3

Page 7

B1

120K

Deflection

104S CM23 GSIII

25

Go to cover page

B1 7503 -B

B1

43K

B3

B13

20 mV/div AC

10 mS/div

B2

B11

B12

B6

B4

B5

B7

B8

B14

B15

B16

B38

B37

B19

B17

B40

4k3

B39

750n

B43

820n

B44

B2 7503-C

0.2 V/div AC

5 mS/div

B3 7502-B

B9

B10

B20

B18

B41

B42

50 mV/div AC

5 mS/div

B21

B4 7504-C

B24

B23

B25

B26

270R

10 V/div AC

5 mS/div

B5 7504-B

B28

B27

B47

B49

0.2 V/div AC

5 mS/div

B6 7501-14

B31

B29

B30

B34

Back

B32

B33

B36

B35

B48

B50

B51

2 V/div AC

5 mS/div

B7 7501-16

1 V/div AC

10 uS/div

Forward

Page 8

104S CM23 GSIII

26

Go to cover page

B2

U-CONTROL

B8 7501 -19

B15 7501-12

B22 7501-2

B29 7508-C

B36 7401-6

B43 7615-D

B52 7801-2

B59 7801-27

B53

B52

B57

B58

B56

B60

B59

B61

B62

50 mV/div AC

10 uS/div

B9 7501-18

50 mV/div AC

10 uS/div

B10 7501-15

1 V/div AC

5 uS/div

B11 7501-24

0.2 V/div AC

5 mS/div

B16 7501-13

0.5 V/div AC

5 mS/div

B17 7501-20

0.1 V/div AC

5 mS/div

B18 7501-6

0.1 V/div AC

5 mS/div

0.2 V/div AC

5 mS/div

1 V/div AC

5 mS/div

50 V/div AC

5 uS/div

B23 7501-1 B30 7508-B B37 7605-G B44 7616-C

1 V/div AC

5 uS/div

B24 7501-29

0.5 V/div AC

5 uS/div

B25 7505-B

0.1 V/div AC

5 mS/div

B31 7401-1

1 V/div AC

5 mS/div

2 V/div AC

5 uS/div

B38 7605-D

50 V/div AC

5 uS/div

B32 7401-2 B39 7606-C

10 V/div AC

10 uS/div

B47 7623-D

50 V/div AC

5 uS/div

B48 7621-E

2 V/div AC

5 uS/div

B53 7801-11

50 mV/div AC

10 uS/div

B54 7804-C

50 V/div AC

5 mS/div

B55 7801-15

1 V/div AC

5 uS/div

B60 7801-28

1 V/div AC

5 mS/div

B61 7811-E

1 V/div AC

10 uS/div

B62 7811-B

B54

B55

1 V/div AC

5 mS/div

B12 7501-22

20 mV/div AC

5 mS/div

B13 7501-21

20 mV/div AC

10 uS/div

B14 7501-11

5 V/div AC

5 uS/div

B19 7501-4

0.2 V/div AC

5 uS/div

B20 7501-5

20 mV/div AC

5 uS/div

B21 7501-8

0.2 V/div AC

5 uS/div

B26 7505-C

2 V/div AC

5 uS/div

B27 7507-B

5 mV/div AC

5 uS/div

B28 7507-E

0.2 V/div AC

5 mS/div

B33 7401-4

1 V/div AC

5 mS/div

100 V/div AC

5 uS/div

B40 7611-E

0.1 V/div AC

10 uS/div

B34 7401-8 B41 7611-C

5 V/div AC

5 mS/div

B35 7401-5

0.5 V/div AC

5 uS/div

B42 7610-C

5 V/div AC

2 uS/div

B49 5611-3

20 V/div AC

5 uS/div

B50 5611-10

50 V/div AC

5 uS/div

B51 7631-B

20 mV/div AC

5 uS/div

B56 7801-21

2 V/div AC

5 uS/div

B57 7801-20

20 mV/div AC

5 uS/div

B58 7801-26

1 V/div AC

10 uS/div

Back

0.1 V/div AC

5 mS/div

2 V/div AC

5 uS/div

10 mV/div AC

5 mS/div

10 V/div AC

5 mS/div

2 V/div AC

5 uS/div

2 V/div AC

5 mS/div

50 mV/div AC

10 uS/div

Forward

Page 9

28

C

104S CM23 GSIII

Go to cover page

POWER SUPPLY SCHEMATIC DIAGRAM

C1 7103-4

C8 5110-1

1 V/div AC

5 uS/div

C2 7103-6

5 V/div AC

5 uS/div

C3 7103-3

0.2 V/div AC

5 uS/div

C4 7102-G

100 V/div AC

5 uS/div

C9 5110-2

100 V/div AC

5 uS/div

C10 5110-6

10 V/div AC

5 uS/div

C11 5110-8

5 V/div AC

5 uS/div

C5 7102-D

100 V/div AC

5 uS/div

C6 7102-S

0.2 V/div AC

5 uS/div

C7 5110-11

10 V/div AC

5 uS/div

C12 5110-5

5 V/div AC

5 uS/div

Back

10 V/div AC

5 uS/div

Forward

Loading...

Loading...