Operating Instructions

Ultra-Low Temperature Freezer

MDF-DU900V

Please read the operating instructions carefully before using this product, and keep the operating

instructions for future use.

See page 64 for model number.

CONTENTS

INTRODUCTION ········································································· 2

PRECAUTIONS FOR SAFE OPERATION ········································· 3

LABELS ON UNIT ········································································ 7

SYMBOLS ON UNIT ····································································· 7

ENVIRONMENTAL CONDITIONS ··················································· 8

INTENDED USE AND PRECAUTIONS ············································· 8

FREEZER COMPONENTS

Unit ······················································································ 9

LCD touch panel ··································································· 11

Remote alarm terminal ··························································· 13

AIR INTAKE PORT ····································································· 14

INSTALLATION SITE ·································································· 14

INSTALLATION ········································································· 16

START-UP OF UNIT ·································································· 17

Operation during power failure ················································· 18

Operation after recovery from power failure ································· 18

BASIC OPERATION ON LCD TOUCH PANEL ································· 19

BASIC PARAMETERS

How to input numerical value and alphanumeric character ·············· 20

Setting Temperature, High Alarm and Low Alarm ························· 22

Setting operation control mode ················································· 23

Setting key lock ···································································· 25

Removing key lock ································································· 27

ALARM PARAMETERS ······························································ 28

OPERATION/ALARM LOG

Setting log interval ································································· 31

Displaying operation log ·························································· 32

Exporting operation log ·························································· 35

Displaying alarm log ······························································· 38

Exporting alarm log ································································ 40

OTHER PARAMETERS

Setting date and time······························································ 43

Setting brightness and sleep ···················································· 44

OPERATION MONITOR SYSTEM ················································ 46

ALARMS, SAFETY, AND SELF-DIAGNOSIS ··································· 47

ROUTINE MAINTENANCE ·························································· 50

Cleaning of cabinet ································································ 50

Cleaning of condenser filter ···················································· 50

Defrosting of chamber ··························································· 51

Cleaning of air intake port ······················································ 52

CALIBRATION ·········································································· 52

REPLACEMENT OF WEAR-OUT PARTS

Replacing the battery for power failure alarm ······························· 53

Replacing the battery for backup cooling kit ································ 53

TROUBLESHOOTING ································································ 54

DISPOSAL OF UNIT ·································································· 55

Recycle of battery ································································· 55

TEMPERATURE RECORDER (OPTION) ········································ 60

SMALL INNER DOOR (OPTION) ·················································· 60

INVENTORY RACK (OPTION) ······················································ 61

BACKUP COOLING KIT (OPTION) ················································ 62

SPECIFICATIONS ····································································· 63

PERFORMANCE ······································································· 64

SAFETY CHECK SHEET····························································· 65

1

INTRODUCTION

■ Read the operating instructions carefully before using the product and follow the instructions for safe

operation.

■ PHC Corporation takes no responsibility for safety if the product is not used as intended or is used with

any procedures other than those given in the operating instructions.

■ Keep the operating instructions in a suitable place so that they can be referred to as necessary.

■ The operating instructions are subject to change without notice for improvement of performance or

function.

■ Contact our sales representative or agent if any page of the operating instructions is lost or the page

order is incorrect, or if the instructions are unclear or inaccurate.

■ No part of the operating instructions may be reproduced in any form without the express written

permission of PHC Corporation.

IMPORTANT NOTICE

PHC Corporation guarantees this product under certain warranty conditions. However, please note that

PHC Corporation shall not be responsible for any loss or damage to the contents of the product.

2

PRECAUTIONS FOR SAFE OPERATION

It is imperative that the user complies with the operating instructions

as it contains important safety advice.

Items and procedures are described so that you can use this unit correctly and safely.

If the precautions advised are followed, this will prevent possible injury to the user and

any other person.

Precautions are illustrated in the following way:

WARNING

Failure to observe WARNING signs could result in a hazard to personnel

possibly resulting in serious injury or death.

CAUTION

Failure to observe CAUTION signs could result in injury to personnel and

damage to the unit and associated property.

Symbol shows;

T

Be sure to keep the operating instructions in a place accessible to users of this unit.

his symbol means caution.

This symbol means an action is prohibited.

This symbol means an instruction must be followed.

WARNING

As with any equipment that uses CO

of the equipment. It is important that you assess the work site to endure there is suitable and

sufficient ventilation. If restricted ventilation is suspected, then other methods of ensuring a safe

environment must be considered. These may include atmosphere monitoring and warning

devices.

gas, there is a likelihood of oxygen depletion in the vicinity

2

3

PRECAUTIONS FOR SAFE OPERATION

Do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to

rain water.

Only qualified engineers or service personnel should install the unit. The installation by

unqualified personnel may cause electric shock or fire.

Install the unit on a sturdy floor and take an adequate precaution to prevent the unit from

turning over. If the floor is not strong enough or the installation site is not adequate, this may result

in injury from the unit falling or tipping over.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

Never install the unit in a flammable or volatile location. This may cause explosion or fire.

Never install the unit where acid or corrosive gases are present as current leakage or electric

shock may result due to corrosion.

Always ground (earth) the unit to prevent electric shock. If the power supply outlet is not

grounded, it will be necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod. Such

grounding may cause electric shock in the case of an incomplete circuit.

Connect the unit to a power source as indicated on the rating label attached to the unit. Use

of any other voltage or frequency other than that on the rating label may cause fire or electric shock.

Never store volatile or flammable substances in this unit if the cylinder cannot be sealed. These

may cause explosion or fire.

Do not insert metal objects such as a pin or a wire into any vent, gap or any outlet on the unit.

This may cause electric shock or injury by accidental contact with moving parts.

Use this unit in safe area when treating the poison, harmful or radiate articles. Improper use

may cause bad effect on your health or environment.

Turn off the power switch (if provided) and disconnect the power supply to the unit prior to any

repair or maintenance of the unit in order to prevent electric shock or injury.

Do not touch any electrical parts (such as power supply plug) or operate switches with a wet

hand. This may cause electric shock.

WARNING

4

WARNING

Ensure you do not inhale or consume medication or aerosols from around the unit at the time of

maintenance. These may be harmful to your health.

Never splash water directly onto the unit as this may cause electric shock or short circuit.

Never put cylinders with liquid on the unit as this may cause electric shock or short circuit when

the liquid is spilled.

Never bind, process, or step on the power supply cord, or never damage or break the power

supply plug. A broken supply cord or plug may cause fire or electric shock.

Do not use the supply cord if its plug is loose. Such supply cord may cause fire or electric shock.

Never disassemble, repair, or modify the unit yourself. Any such work carried out by an

unauthorized person may result in fire, or electric shock or injury due to a malfunction.

Disconnect the power supply plug if there is something wrong with the unit. Continued

abnormal operation may cause electric shock or fire.

Do not position this unit and the other unit so that it is difficult to operate the disconnection of

the power supply plug. Failure to disconnect the power supply plug may cause fire if there is

something wrong with the unit.

When removing the plug from the power supply outlet, grip the power supply plug, not the cord.

Pulling the cord may result in electric shock or fire by short circuit.

Disconnect the power supply plug before moving the unit. Take care not to damage the power

cord. A damaged cord may cause electric shock or fire.

Disconnect the power supply plug when the unit is not used for long periods. Keeping the

connection may cause electric shock, current leakage, or fire due to the deterioration of insulation.

If the unit is to be stored unused in an unsupervised area for an extended period, ensure that

children do not have access and that doors cannot be closed completely with a key.

The disposal of the unit should be accomplished by appropriate personnel. Remove doors to

prevent accidents such as suffocation.

Do not put the packing plastic bag within reach of children as suffocation may result.

Connect the power supply plug to the power source firmly after removing the dust on the plug.

A dusty plug or improper insertion may cause a heat or ignition.

Do not touch the condenser directly when the filter is removed for cleaning. This may cause injury

by hot surface.

5

PRECAUTIONS FOR SAFE OPERATION

This unit must be plugged into a dedicated circuit protected by branch circuit breaker.

Use a dedicated power source as indicated on the rating label attached to the unit. A

multiple-tap may cause fire resulting from abnormal heating.

Never store corrosive substances such as acid or alkali in this unit if the container cannot be

sealed. These may cause corrosion of inner components or electric parts.

Check the setting when starting up of operation after power failure or turning off of power

switch. The stored items may be damaged due to the change of setting.

Be careful not to tip over the unit during movement to prevent damage or injury.

Prepare a safety check sheet (copy the last page) when you request any repair or maintenance for

the safety of service personnel.

Never touch the storage items with wet hands. Touching with the wet hands may cause frostbite.

CAUTION

6

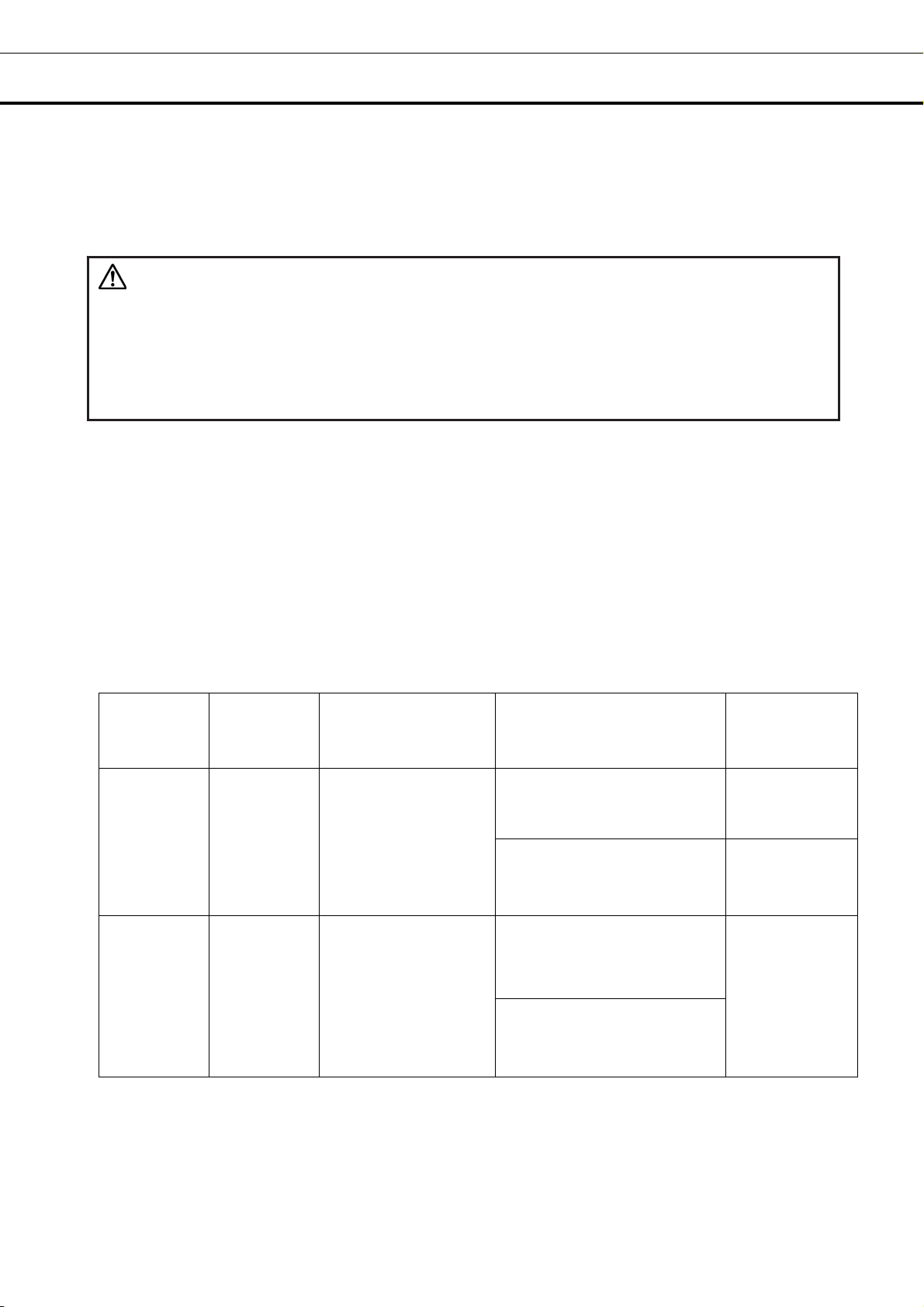

LABELS ON UNIT

Warning safety labels applied to the ultra-low temperature freezer

Users are advised to avoid accidents by carefully reading the warnings and cautions contained on

warning labels at key locations on the interior and exterior of the ultra-low temperature freezer.

Possible

Danger

Personal

injury

Warning/Caution Type

Location of Danger

Frostbite and frost

Interior

Warning/Caution Label Description of Danger

Frostbite and frost caution label.

Sample

damage

Sample

damage

Personal

injury

SYMBOLS ON UNIT

The symbols are attached to the ultra-low temperature freezer. The following table describes the

symbols.

Chamber temperature

Interior

Chamber temperature

Interior

Negative pressure

release

Interior

This symbol is attached to covers that access high-voltage electrical components to

prevent electric shock. Only a qualified engineer or service personnel should be

allowed to open these covers.

Forgets to close a door and latch.

Rise in temperature is prevented.

Door cannot open.

This symbol indicates that caution is required. Refer to product documentation for

details.

This symbol indicates an earth.

This symbol means “ON” for a power switch.

This symbol means “OFF” for a power switch.

7

ENVIRONMENTAL CONDITIONS

This equipment is designed to be safe at least under the following conditions (based on the IEC 61010-1):

■ Indoor use;

■ Altitude up to 2000 m;

■ Ambient temperature 5

■ Maximum relative humidity 80% for temperature up to 31

o

at 40

C;

■ Mains supply voltage fluctuations up to ±10% of the nominal voltage;

■ Transient overvoltages up to the levels of OVERVOLTAGE CATEGORY II;

■ Temporary OVERVOLTAGES occurring on the mains supply;

■ Applicable pollution degree of the intended environment (POLUTION DEGREE 2 in most cases);

o

C to 40oC;

o

C decreasing linearly to 50% relative humidity

INTENDED USE AND PRECAUTIONS

This equipment is designed for low temperature storage of human cells, organs, plasma and DNAs.

■ The effective storage period depends on the sample condition and storage temperature. It is

necessary to determine the storage temperature and period suitable for the purpose.

■ For the live cells, the lower storage temperature should be required for long term storage. It is

recommended to store the live cells at -130

o

C or lower.

8

FREEZER COMPONENTS

Unit

13

12 (inside)

Front side

11

12

10 (inside)

18

19

17

9

7

8

16 15

1

2

3

4

5

6

14

Rear side

9

FREEZER COMPONENTS

1. Outer door: To open the outer door, grip the outer door latch. When closing, lock the outer door

latch completely.

2. Inner door: The operation of the inner door should be quick to minimize the temperature rise in

chamber. Lock the inner door latch completely when the inner door is closed. The inner door is

removable for cleaning or defrosting. See page 51.

3. Outer door latch: Always lock the outer door latch when the outer door is closed. A padlock is also

available.

4. Keyhole: Turn clockwise to 180

5. Inner door latch: Always lock the inner door latch when the inner door is closed.

6. Magnetic door gasket: This provides a tight door seal and prevents cold air leak. Keep clean.

7. Air intake vent (grille): Do not block this vent to keep the proper cooling performance.

8. Leveling feet: These are screw bolts used to install and fix the unit. Adjust the height of the leveling

feet by turning the screw bolts until 2 front casters are away from the floor.

9. Caster: 4 casters are provided to facilitate moving of the cabinet. For the installation, adjust the

leveling foot so that the front 2 casters cannot contact with the floor.

10. Condenser filter (behind the grille): This filter prevents the dust from accumulating on the

condenser. The dusty condenser filter may cause failure of refrigerating device. Clean the condenser

filter once a month. See page 50.

11. Space for temperature recorder: A temperature recorder (optional component) can be attached

here. See page 60.

12. Access port (rear and bottom): This is used for leading a cable and sensor of a measuring

equipment, or nozzle of backup cooling kit to chamber.

Replace the cap and insulation after using the access port. Improper replacement may cause poor

cooling or condensation around the outside of access port.

13. Air intake port: Used for open the outer door immediately after closing the outer door. See page 14.

14. Fixture (on back side): 2 fixtures are provided as spacers between the cabinet and wall and also

serve as hooks to fix the unit. See page 16.

15. Battery switch: This is a switch for a battery for power failure alarm. Normally, turn on this switch.

Be sure to turn off this switch if the freezer is not in operating for the long period (over one month).

16. Remote alarm terminal: This is used to notice an alarm condition of the unit to remote location.

See page 13.

17. Power switch: This is for turning ON/OFF the power to the unit.

18. LCD touch panel: See page 11~12.

19. USB port: Insert USB memory to export operations and alarms log. See page 35~42.

Note: It is impossible to use USB memory which is required password input.

Note:

3 shelves are packaged at the bottom of the chamber. Set the shelves on the shelf stoppers at the

standard location firmly. The upward edge should be upside.

Refer to page 61 for the attachment of shelf stopper when changing the location of shelf stopper.

o

with a key and the outer door is securely locked.

10

LCD touch panel

The following display (called the Top screen) will appear when the power switch is turned ON.

Note: It takes approximately 20 seconds until Top screen is displayed.

1 2 3

1. Present temperature display field: The current chamber temperature is displayed.

Note: An integer rounded off below a decimal point is displayed.

2. Set temperature value display field: The set value of chamber temperature is displayed. Default

setting: -80

3. Present date/time display field: Normally, this indicator shows date and time. The date and time is

simply set when the freezer is shipped from the factory. Refer to page 43 for details.

4. Filter alarm indicator: This indicator is lit when the excessive dust is accumulated on the condenser filter.

When this indicator is lit, clean the condenser filter following the procedure on page 50.

5. Alarm display: Refer to page 47~48 for details of alarms.

Normal condition: “Normal” is displayed.

Alarm-activated, buzzer-delayed: “Alarm” is displayed alternately in normal characters and reverse video.

Alarm-activated, buzzer-sounding: “Warning” is displayed alternately in normal characters and reverse video.

6. Door (opening/closing) display: Refer to page 47

Open: “Open” is displayed alternately in normal characters and reverse video.

Close: “Closed” is displayed.

7. Backup display: (It is displayed only when an optional backup cooling kit MDF-UB6B is installed)

ON/OFF of the backup power switch is displayed (refer to page 62).

ON: “Switch ON” is displayed.

OFF: “Switch OFF” is displayed.

o

C.

4

5

6

7

11

FREEZER COMPONENTS

8

11 10

8. Message display field: The information of the operation monitor system, alarms or errors are

displayed when fault occurs. Refer to page 46~48.

9. Message select key: When there are a number of alarm, errors or information of the operation monitor

system, the message on the screen is changeable.

10. Menu key: Press this key to lead the Menu screen. It is possible to set various setting on the Menu

screen. Refer to page 19.

11. Buzzer key: Press this key to silence the buzzer. However, when the ring back is ON, the buzzer will

sound again when the ring back passed and the alarm state still continues. Refer to page 29 and 49.

9

12

Remote alarm terminal

The alarm of this unit can be informed at a remote location from this unit by connecting the external alarm

device to the remote alarm terminals. For the type and behavior of remote alarm output, refer to page

47~48.

The terminal of the remote alarm is installed at the

right side of the unit (See the figure on the point).

The alarm is outputted from this terminal. Contact

capacity is DC 30 V, 2 A.

When Buzzer key is pressed, the behavior of the

remote alarm is showed in Table.1.

Note: In the door alarm, the remote alarm does not

work. Refer to page 47.

Table 1 The behavior of the remote alarm when pressing Buzzer key

Remote Alarm setting

(Refer to page 28~30)

ON:

Non-interlock with Buzzer key

OFF:

Interlock with Buzzer key

Use a twisted sealed wire for the connection.

Type; UL 2343, UL 2448, UL 2464, UL2552, UL2623.

Length: 30 m max.

Connecting

terminal

COM.-N.C. Close Open Open (Maintain in abnormality)

COM.-N.O. Open Close Close (Maintain in abnormality)

COM.-N.C. Close Open Close (Return to normal)

COM.-N.O. Open Close Open (Return to normal)

Normal

condition

(Including in the cases of power outage and

Remote alarm terminal

Abnormal condition

of where the power plug is pulled out.)

When pressing Buzzer key

13

AIR INTAKE PORT

Opening the outer door immediatery after closing it, may make

feel heavy. The cause is the pressure difference between inside

and outside the unit that caused by contraction of the chamber air

which cooled down rapidly. When the outer door is closed and

opened soon, the outer door is easy to open with the following

process.

1. Turn the cap on the left side counterclockwise about two laps.

(Or remove the cap.)

2. Allow about twenty seconds before open the outer door.

3. Close (or replace) the cap when the door operation is

completed.

The outer door may not open in the above method when there are frost and ice in the air intake port. In

that case, remove the cap and check the frost inside the air intake port. Remove the frost inside the air

intake port with the enclosed "stick for air intake port cleaning" when the excessive frost is built in the air

intake port. Clean the air intake port every month even when there is no frost in the air intake port.

Refer to page 52 for the cleaning.

Two laps

Cap

INSTALLATION SITE

CAUTION

For removing the frost in the air intake port, do not use a tool with sharp edge such as a knife or a screw

driver.

Replace the cap when the air intake port is not used. Improper replacement may cause rise of chamber

temperature or condensation around the air intake port.

To operate this unit properly and to obtain maximum performance, install the unit in a location with the

following conditions:

■ A location not subjected to direct sunlight

Do not install the unit under direct sunlight. Installation in a location subjected to direct sunlight cannot

obtain the intended performance.

■ A location with adequate ventilation

Leave at least 10 cm around the unit for ventilation. Poor ventilation will result in a reduction of the

performance and consequently the failure.

■ A location away from heat generating sources

Avoid installing the unit near heat-emitting appliances such as a heater or a boiler etc. Heat can decrease

the intended performance of the unit.

14

■ A location with little temperature change

Install the unit under stable ambient temperature. The allowable ambient temperature is between +5

and +30

■ A location with a sturdy and level floor

Always install the unit on a sturdy and level floor. The uneven floor or tilted installation may cause failure

or injury. Install the unit in stable condition to avoid the vibration or noise. Unstable condition may cause

vibration or noise.

o

C.

WARNING

Install the unit on a sturdy floor. If the floor is not strong enough or the installation site is not

adequate, this may result in injury from the unit falling or tipping over.

Select a level and sturdy floor for installation. This precaution will prevent the unit from tipping.

Improper installation may result in water spillage or injury from the unit tipping over.

■ A location not prone to high humidity

Install the unit in the ambient of 80 %R.H. or less humidity. Installation under high humidity may cause

current leakage or electric shock.

o

C

WARNING

Do not use the unit outdoors. Current leakage or electric shock may result if the unit is exposed to

rain water.

Never install the unit in a humid place or a place where it is likely to be splashed by water.

Deterioration of the insulation may result which could cause current leakage or electric shock.

■ A location without flammable or corrosive gas

Never install the unit in a location where it will be exposed to inflammable or corrosive gas. This may

cause explosion or fire or may result in the current leakage or electric shock by the corrosion of the

electrical components.

■ A location without corrosive substance

Never install the unit in a location where corrosive substance such as sulfur-contained compound may

generate (ex. near a sink). The corrosion of copper pipe of the cooling circuit may result in the failure of

the unit.

■ A location without the possibility of anything fall

Avoid installing the unit in the location where anything can fall down onto the unit. This may cause the

breakdown or failure of the unit.

15

INSTALLATION

1. Remove the packaging materials and tapes

Remove all transportation packaging materials and tapes. Open the doors and ventilate the unit. If the

outside panels are dirty, clean them with a diluted neutral dishwashing detergent (Undiluted detergent can

damage the plastic components. For the dilution, refer to the instruction of the detergent). After the

cleaning with the diluted detergent, always wipe it off with a wet cloth. Then wipe off the panels with a dry

cloth.

Note: Remove the cable tie banding the power supply cord. Prolonged banding may cause the corrosion

of the cord coating.

2. Adjust the leveling feet

Stretch the leveling feet by rotating them as shown in Fig. 1 to contact them to the floor. Ensure the unit

is installed horizontally.

3. Fix the unit

Two fixtures are attached to the rear of the frame. Fix the frame to the wall with these fixtures and rope

or chain. (Fig. 2)

Shrink

Stretch

4. Setting the shelves

3 shelves are packaged at the bottom of the chamber. Set the shelves on the shelf stoppers at the

standard location firmly. The upward edge should be upside.

5. Ground (earth)

The ground (earth) is for preventing the electric shock in the case of unexpected deterioration of the

electrical insulation. Always ground the unit at the time of installation.

6. Installation branch circuit breaker

This unit is to be connected to a dedicated circuit protected by branch circuit breaker.

Contact our sales representative or agent.

Leveling feet

Fig.1

Fixture

Fig. 2

WARNING

Use a power supply outlet with ground (earth) to prevent electric shock. If the power supply outlet is

not grounded, it is necessary to install a ground by qualified engineers.

Never ground the unit through a gas pipe, water main, telephone line or lightning rod. Such

grounding may cause electric shock in the case of an incomplete circuit.

16

START-UP OF UNIT

Use the following procedure to start trial operation or actual operation of the unit.

1. Make sure that both of the power switch and the battery switch for power failure alarm are OFF (factory

setting is OFF).

Note: When the power switch is ON and the battery switch for power failure alarm is ON, the power

failure alarm is activated (refer to page 47).

2. (When an optional backup cooling kit MDF-UB6B is installed) Turn OFF the backup power switch.

3. Before putting some contents to cryopreserve into the chamber, connect the power supply cord to the

outlet.

4. Turn ON the power switch to start operation of the unit.

5. Turn ON the battery switch for power failure alarm.

Note: When the battery switch for power failure alarm is OFF, “Err09: Battery Switch is OFF.” is displayed

in the message display field. By turning ON the battery switch for power failure alarm, this message

disappears.

6. Set the chamber temperature and the high/low alarm (refer to page 22~23).

Note: Keep the ambient temperature between 5

set temperature when the ambient temperature is higher than 30

7. Make sure that chamber temperature is cooled to the set temperature.

8. Do the alarm test. Make sure that the buzzer sounds by pressing Buzzer key for 5 seconds. Press

Buzzer key again to stop the buzzer and the alarm test finishes.

9. (When an optional backup cooling kit MDF-UB6B is installed) After the chamber temperature reaches

the set temperature, turn ON the backup power switch.

Note: When operating this unit for the first time or after not using it for an extended period of time, it is

required 3 days (72 hours) operation of unit before using the backup cooling kit. The capacity of internal

battery for backup cooling kit may be less or flat by electric discharge.

10. (When an optional backup cooling kit MDF-UB6B is installed) Set the injection set temperature of the

backup cooling kit by adjusting the temperature setting knob.

11. Put the contents to cryopreserve into the chamber.

Note:

• Do not put a large amount of contents to cryopreserve at a time. Put little by little to prevent rapid rise of

the chamber temperature.

• Do not put a large amount of warm contents to cryopreserve. The rise of the chamber temperature may

have a bad influence on the contents in the unit.

• In case some optional inventory racks are in the chamber, be careful not to drop inventory rack when

pulling out it.

o

C to 30 oC. The chamber temperature may not reach

o

C.

17

START-UP OF UNIT

Operation during power failure

When the battery switch for power failure is ON, during a power failure the behavior of this unit is as

follows.

●The power failure alarm is activated (refer to page 47).

Press Buzzer key to silence the buzzer of the power failure alarm. In case the ring back is turned ON,

buzzer sounds again when a power failure still continues after ring back set time passed (refer to page

29).

●LCD touch panel is turn OFF (refer to page 47).

By touching the LCD touch panel, it lights in the set brightness for 5 seconds.

●The High/Low Alarm is ready to activate during a power failure (refer to page 22~23 and 47).

(While the LCD touch panel is lighting after touching) The message of the High/Low Alarm is displayed in

the message display field, and “Alarm” (or “Warning”) is displayed alternately in normal characters and

reverse video in the alarm display. The buzzer and the remote alarm (although it is of the power failure

alarm) are already activated.

●The clock function does not stop.

●Operation log data and alarm log data during a power failure is saved.

Note: When the capacity of the battery for power failure alarm is flat during a power failure, subsequent

operation log data and alarm log data is not saved.

Operation after recovery from power failure

The set value is memorized by nonvolatile memory. Accordingly, the chamber resumes the operation with

setting before power failure.

Note:

• It may take up to 1 minute until the LCD touch panel lights after recovery from power failure.

• All products start at the same time as the recovery from the power failure, so that, the temporary voltage

drop may have a bad influence on the starting of this unit. To prevent this situation, set the appropriate

compressor delay time of this unit (refer to page 24).

Although the power failure alarm is canceled at the

recovery of the power failure, in order to remind

that power failure had happened, buzzer is

sounding and “Alarm” is displayed alternately in

normal characters and reverse video in the alarm

display (refer to page 49). By pressing Buzzer key,

the alarm display returns to “Normal” and the

buzzer stops.

Note: It is possible to confirm the past alarms in

the “Displaying alarm log” (refer to page 38~39).

18

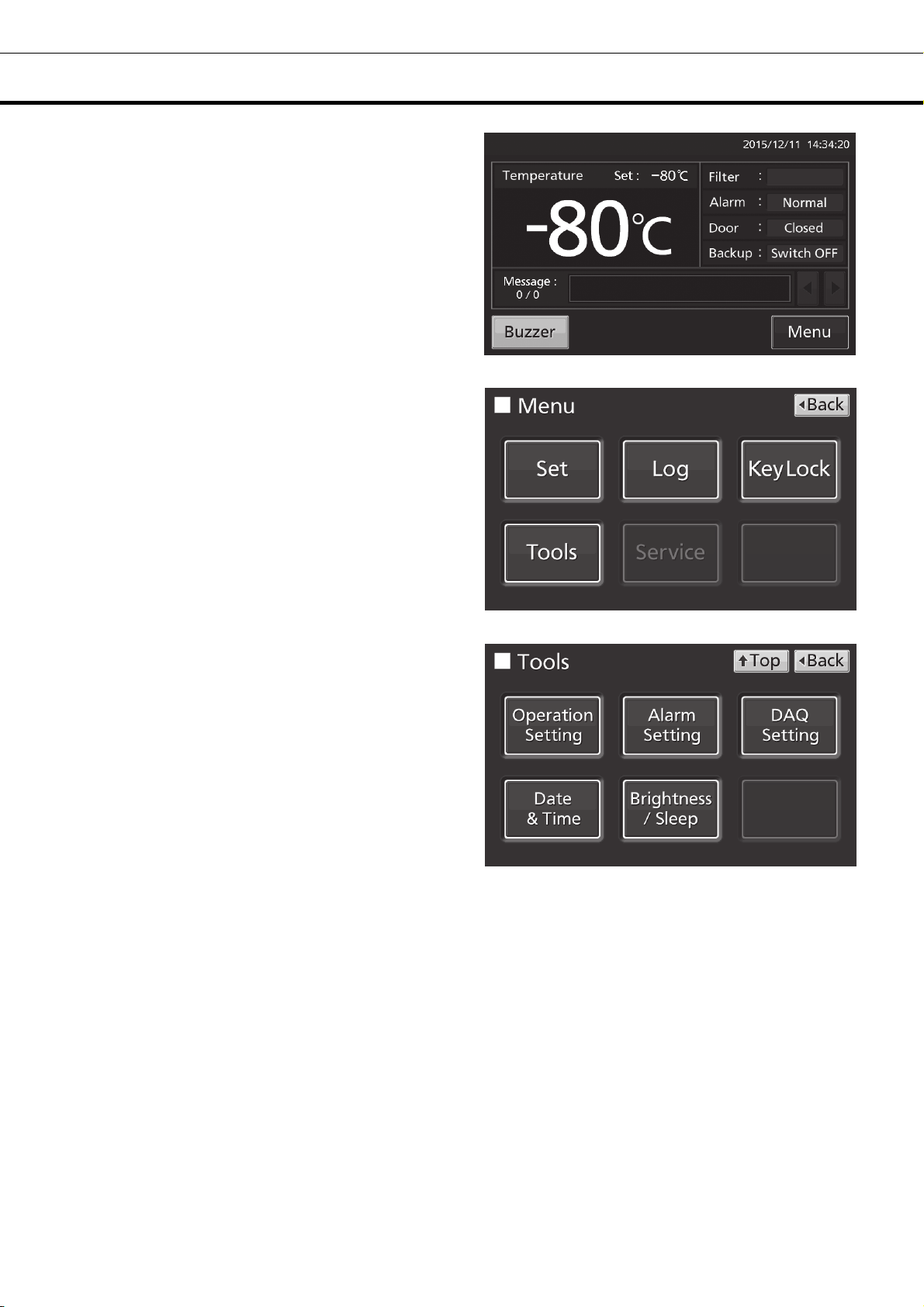

BASIC OPERATION ON LCD TOUCH PANEL

A

♦Message select key:

(Operate) Changing some messages

♦Buzzer key: (Operate) Silencing the buzzer

(Alarm is not canceled except for some alarms; page 49)

●Operation from Menu key

■Menu screen

♦Set →

♦Log →

♦Chart →

♦Actual Temp. (Display) Chamber temp. log graph (can be exported)

♦Door Opening (Display) Door opening log graph (can be exported)

♦Actual Temp. (Export) Chamber temperature log

♦Door Opening (Export) Door opening log

♦Setting (Setting) Log interval, Unique ID

♦Alarm (Display)

♦Alarm Export (Export) Alarm log

♦Key Lock →

♦Tools →

♦Operation Setting (Setting) Comp. delay time

♦Alarm Setting (Setting) Alarm delay, ring back, remote alarm etc.

♦DAQ Setting Do not press (It is not possible to set.)

♦Date & Time (Setting) Date, time

♦Brightness/Sleep (Setting) Brightness, sleep ON/OFF etc.

■Temp. Setting screen

■Log screen

■Chart screen

Data

♦

Export

■Key Lock screen

■Tools screen

→

■Export screen

(Setting) Temp., High Alarm, Low Alarm

larm log (can be exported)

(Setting) Key lock ON/OFF, password

Page

22

32

32

35

35

31

38

40

25

23

28

43

44

~23

~34

~34

~37

~37

~32

~39

~42

~27

~24

~30

~45

19

BASIC PARAMETERS

How to input numerical value and alphanumeric character

On each screen in the LCD touch panel, it may be necessary to input numerical value or alphanumeric

characters.

●When inputting numerical value

1. By pressing numeric input box, numeric input

window is displayed.

2. Press Numeric key or Up/Down key to input

numerical value, and press OK key.

●Key description

• Numeric key (0~9): Input numerical value.

• Up/Down key (▲/▼): Increases or decreases the numerical value displayed in the numeric input box.

• Clear key: Deletes the numerical value displayed on the numeric input box.

• Cancel key: Stops inputting on the numeric input box and closes the input window.

Note: Up/Down key may not be displayed.

Numeric input box

Numeric input window

20

●When inputting alphanumeric characters

1. By pressing alphanumeric input box,

alphanumeric input window is displayed.

2. Press alphabetic key and numeric key to input

alphanumeric characters, and press OK key.

●Key description

• Alphabetic key (A~Z, Space): Input alphabetic characters or spaces.

• Numeric key (0~9): Input numerical values.

• UC/LC key (A a): Change UC/LC of alphabetic key.

• Left/Right key ( / ): Move the cursor to left/right.

• Delete key: Delete an alphanumeric character on the left side of the cursor.

• Cancel key: Stops inputting on the alphanumeric input box and closes the alphanumeric input window.

Note: While the alphanumeric input window is open, it is not possible to operate Top key and Back key.

Alphanumeric input box

Alphanumeric input window

21

BASIC PARAMETERS

Setting Temperature, High Alarm and Low Alarm

Set the Temperature, High Alarm and Low Alarm for normal operation according to the following

procedure. The unit automatically starts operation using these settings after power-on.

1. Press Menu key to lead the Menu screen.

2. Press Set key to lead the Temp. Setting

screen.

3. Input each parameter. Press Apply key to save

the input value. The display returns to the Menu

screen.

●Each parameter setting

• Temperature: Set value of chamber temperature.

Settable range: -90

• High Alarm: When the chamber temperature exceeds the High Alarm set temperature (= the set

temperature + the set value of High Alarm)*, the High Alarm is activated.

Settable range: +5

• Low Alarm: When the chamber temperature falls below the Low Alarm set temperature (= the set

temperature - the set value of Low Alarm)*, the Low Alarm is activated.

Settable range: -40

o

C~-50 oC, Control range: -86 oC~-50 oC, factory setting: -80 oC.

o

C~+40 oC, factory setting: +10 oC.

o

C~-5 oC, factory setting: -10 oC.

22

* The current chamber temperature is the value rounded off below a decimal point, so the High/Low

Alarm may be activated when the value of the current chamber temperature is equal to the High/Low

Alarm set temperature.

4. On the Menu screen, press Back key to return to the Top screen.

Setting operation control mode

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Operation Setting key to lead the

Operation Setting screen.

23

BASIC PARAMETERS

4. Input each parameter. Press Apply key to save

the input value and setup. The display returns to

the Tools screen.

●Each setting

• Compressor Delay:

The time from turning ON this unit until starting its compressor. This unit is required a large electric power

at the moment its compressor starts. When some units are in a same room, set so as to be shifted to

each other the compressor delay times, to prevent the simultaneous start of all compressors after power

failure. Settable range: 3 minutes~15 minutes, factory setting: 3 minutes.

5. Press Top key to return to the Top screen.

24

Setting key lock

1. Press Menu key to lead the Menu screen.

2. Press Key Lock key to lead the Key Lock

screen.

3. On the Key Lock screen, it is possible to set

each setting of key lock (refer to next page).

Press Apply key to change key lock ON and to

save the password. The display returns to the

Menu screen.

25

BASIC PARAMETERS

●Each setting of key lock

• Key Lock: By holding Key Lock slide key and sliding it to the right, Key Lock turns to ON.

• Password: The number (Max. 6 digits) inputted here are registered the release password of Key Lock.

• Confirm Password:

To prevent erroneous input, input the same

password as Password input box. When inputting

different password, Notice dialog box is displayed.

Press OK key and input the correct password.

Note: Manage the release password of Key Lock properly.

4. On the Menu screen, press Back key to return to the Top screen.

●Operation for Keylock-ON

• When pressing Menu key, Password input box is

displayed, and input of the release password of

Key Lock is required.

• When the inputted password is incorrect, Notice

dialog box is displayed. Press OK key, and then

input the correct password.

26

Removing key lock

1. By pressing Menu key, the Password input

window is displayed.

2. On Password input box, input the set release

password of Key Lock, and press OK key to lead

the Menu screen.

3. Press Key Lock key to lead the Key Lock

screen.

4. On the Key Lock screen, by holding Key Lock

slide key and sliding to the left, change to OFF.

Press Apply key to turn the key lock OFF. The

display returns to the Menu screen.

Note: The release password of key Lock is

deleted.

5. On the Menu screen, press Back key to return to the Top screen.

27

ALARM PARAMETERS

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Alarm Setting key to lead the Alarm

Setting screen.

28

4. On the Alarm Setting screen, it is possible to

set each setting. Press Apply key to save the

input value and setup. The display returns to the

Tools screen.

●Each setting

• Alarm Delay:

The function is that when the unit is in the alarm state of High Alarm or Low Alarm, the alarm buzzer will

sound after the alarm delay set time passed.

Settable range: 0 minute~15 minutes, factory setting: 15 minutes.

Note: When the unit is recovered from the alarm state within the alarm delay time, the buzzer does not

sound after the elapse of the alarm delay.

• Door Delay:

The function is that when the unit is in the alarm state of door, the alarm buzzer will sound after the alarm

delay set time passed. Settable range: 0 minute~15 minutes, factory setting: 2 minutes.

Note: When the unit is recovered from the alarm state within the door alarm delay time, the buzzer does

not sound after the elapse of the door alarm delay.

• Ring Back:

The function is that the alarm buzzer sounds again when the alarm state still continues after the ring back

set time passed even though the alarm buzzer was stopped by pressing Buzzer key. By holding and

sliding Ring Back slide key to the right, the Ring Back is turned to ON.

Settable range: 1 minute~99 minutes, factory setting: 30 minutes.

Note: At Door alarm, the alarm is not re-activated because the alarm itself is deactivated by pressing

Buzzer key (refer to page 49).

• Remote Alarm:

The function is that the remote alarm is continued even though the buzzer is stopped by pressing Buzzer

key. By holding and sliding Remote Alarm slide key to the right, the Ring Back is turned to ON (not in

conjunction with Buzzer key). Factory setting: ON.

5. Press Top key to return to the Top screen.

29

ALARM PARAMETERS

●

At the alarm state

• While the unit’s alarm is being activated and the

buzzer is being sounding, the buzzer is silenced by

pressing Buzzer key. For the behavior at the time

of pressing Buzzer key and the re-activation of

alarm, under each setting condition, refer to Table

4-5 on page 49.

Resolve the cause of the alarm in reference to

page 47~48 because the alarm itself is not

deactivated by pressing Buzzer key except for

some alarms.

30

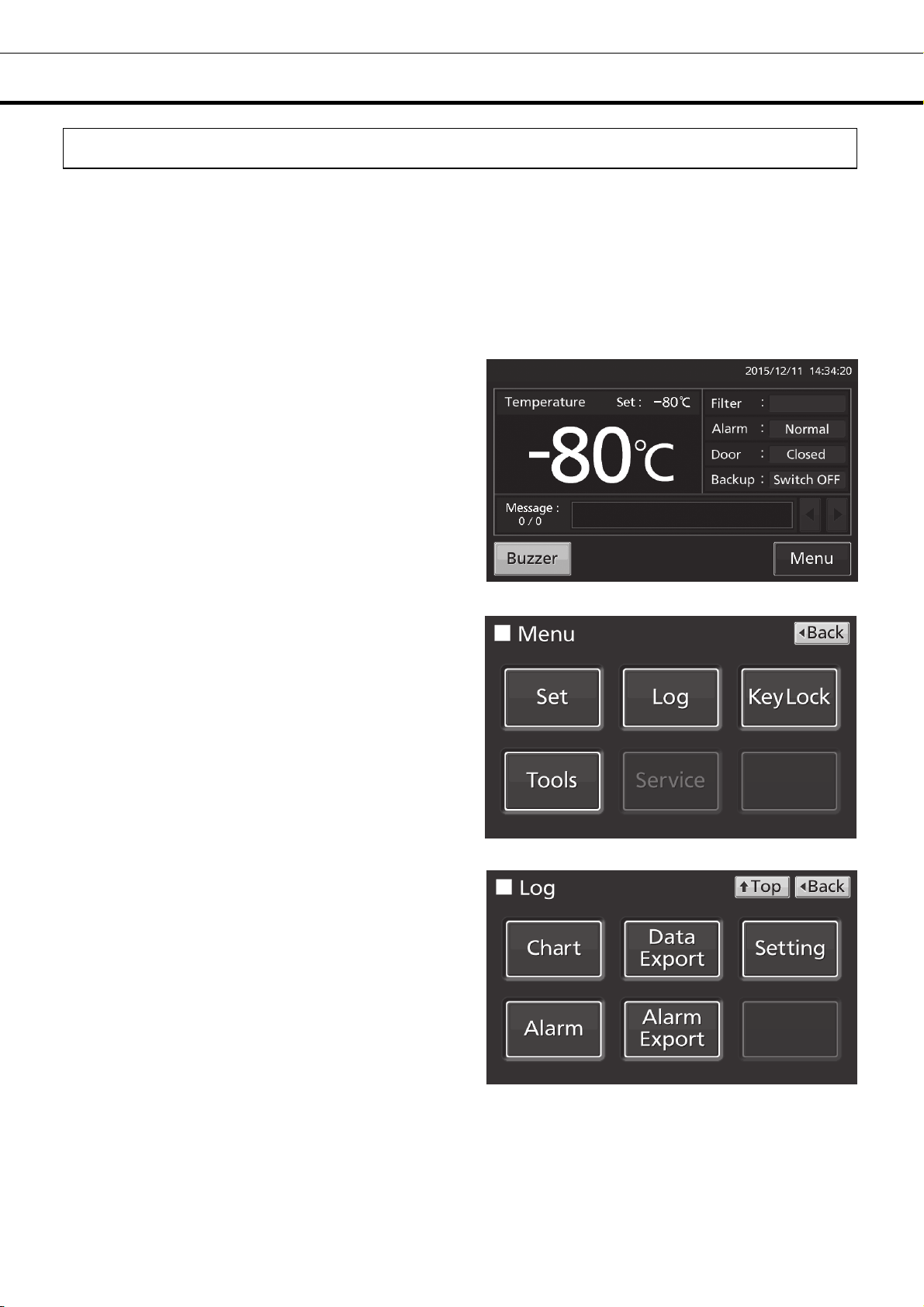

OPERATION/ALARM LOG

Setting log interval

The unit is equipped with a function of saving operation log data (chamber temperature and open/close

state of door).

Note: When the battery switch for power failure alarm is ON, operation log is saved during a power

failure.

Use the following procedure to set the log interval (interval of acquiring the operation log).

1. Press Menu key to lead the Menu screen.

2. Press Log key to lead the Log screen.

3. Press Setting key to lead the Setting screen.

31

OPERATION/ALARM LOG

4. On the Setting screen, input Log Interval. Press

Apply key to save the input value. The display

returns to the Log screen.

Settable range: 2 minutes~30 minutes.

Factory setting: 6 minutes.

Note: Only an even number can be inputted.

When inputting an odd number and when pressing

OK key in the numeric input window, it changes to

an even number which is 1 smaller than that.

Note: It is possible to register 8-digit alphanumeric

characters as the Unique ID. Refer to page 37.

Note: Relation between log interval and the estimated amount of data that can be saved

Log interval=2 minutes: Approx. 46 days

Log interval=6 minutes: Approx. 135 days

Log interval=30 minutes: Approx. 664 days

When saving data more than the above, and the data is overwritten and the old data is delated.

5. Press Top key to return to the Top screen.

Displaying operation log

Operation log saved in the freezer can be displayed graphically on the LCD touch panel.

1. Press Menu key to lead the Menu screen.

2. Press Log key to lead the Log screen.

32

3. Press Chart key to lead the Chart screen.

4. On the Chart screen, input the date (year /

month / day) of the operation log you want to

display graphically.

5. On the Chart screen, by pressing Show key after

pressing the item you want to display graphically,

the graph of each operation log is displayed.

• Actual Temp.:

Chamber temperature log graph

(Go to procedure 6)

• Door Opening:

Open/close state of door log graph

(Go to procedure 7)

33

OPERATION/ALARM LOG

6. Actual Temp. log graph is displayed.

• Press Back key to return to the Chart screen.

• Press Top key to return to the Top screen.

7. Door Opening log graph is displayed.

• Press Back key to return to the Chart screen.

• Press Top key to return to the Top screen.

*When exporting operation log data, without pressing the Export key, follow the procedure on page 35~37.

When pressing Export key by mistake, press the Back key to return to the previous screen.

Note: The error of about 1 minute may be observed during a month. Refer to page 43 for the procedure

of setting time.

To previous day To next day

To previous day

To next day

Export key*

To Door Opening log

To Actual Temp. log

Export key*

34

Exporting operation log

Operation log data saved in the freezer can be exported in CSV format to the USB memory inserted into

the USB port.

1. Insert the USB memory into the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

2. Press Menu key to lead the Menu screen.

3. Press Log key to lead the Log screen.

4. Press Data Export key to lead the Export

screen.

35

OPERATION/ALARM LOG

5. On the Export screen, select the time period you

want to export.

• To export the saved operation log data over the

entire period, press All radio button.

• To export the operation log data of a specified

date, press 1 Day radio button and input the date

(year / month / day) of the operation log data you

want to export.

Note: The error of about 1 minute may be

observed during a month. Refer to page 43 for the

procedure of setting time.

6. On the Export screen, select the type of

operation log data you want to export.

• To export all types of operation log data, press All

Ch key.

• To export only operation log data you want to

export, select operation log data you want to export,

and then press Selected Ch key.

• Actual Temp.: Chamber temperature log data

• Door Opening: Open/close state of outer door log

data

Note: When no USB memory is inserted into

the USB port, Notice dialog box is displayed.

Press OK key, and then insert a USB memory

into the USB port.

36

Note: When the specified operation log data

does not exist, Notice dialog box is displayed.

Press OK key, and then re-specified according

to procedure 4 and 5.

7. When the export is complete, Information

dialog box is displayed. Press OK key.

Note: Even after the export of operation log

data is complete, operation log data saved in

the unit are not deleted.

8. Remove the USB memory from the USB port.

Note:

• The log folder is created in the USB memory, and the exported file is saved in it in CSV format. The

exported file name is in date (8 digits) - type of data format.

(e.g.) When exporting all types of data using All (from Oct. 1st, 2015 to Jan. 1st, 2016):

20151001-20160101_AllCh.csv

20151001-20160101_Door.csv

(e.g.) When exporting Actual Temp. using 1 Day (Jan. 1st, 2016):

20160101_Temp.csv

• On the beginning of the exported file, product name (“MDF-DU900V”) is written. However when the

Unique ID is registered (refer to page 32), product name and Unique ID (8-digit) are written.

(e.g.) When “RoomA001” is set as the Unique ID of MDF-DU900V:

MDF-DU900V, RoomA001

9. Press Top key to return to the Top screen.

37

OPERATION/ALARM LOG

Displaying alarm log

The unit is equipped with a function of saving alarm log data (Max. 256 logs).

Note:

• When saving alarm logs more than 257, the oldest alarm log is deleted, and then overwritten.

• When the battery switch for power failure alarm is ON, operation log is saved during a power failure.

Alarm log saved in the freezer can be displayed graphically on the LCD touch panel.

1. Press Menu key to lead the Menu screen.

2. Press Log key to lead the Log screen.

3. Press Alarm key to lead the Alarm screen.

38

4. On the Alarm screen, the newest 7 days’ alarm

logs (containing that day) are displayed.

Note: When the number of applicable alarm log is

6 or more, by pressing the top (▲) or the bottom

(▼) log, the log table currently displayed scrolls

and hidden alarm logs can be seen.

• Press Back key to return to the Log screen.

• Press Top key to return to the Top screen.

5. On the Alarm screen, by inputting days into the

Last XX Days input box, alarm logs for specified

days (containing that day) are displayed.

Settable range: 1 day~45 days.

Note: The error of about 1 minute may be

observed during 1 month. Refer to page 43 for the

procedure of setting time.

• Press Back key to return to the Log screen.

• Press Top key to return to the Top screen.

●On the Alarm screen of procedure 4 or 5, alarm log data can be exported in CSV format to the USB

memory inserted into the USB port.

6. Insert the USB memory into the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

7. Press Export key.

8. When the export is complete, Information dialog

box is displayed. Press OK key. Refer to page 41

and 42 for the details about abnormal export or

exported file name.

9. Press Top key to return to the Top screen.

39

OPERATION/ALARM LOG

Exporting alarm log

It is possible to export saved alarm log data to a USB memory inserted in the USB port by CSV format.

1. Insert a USB memory in the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

2. Press Menu key to lead the Menu screen.

3. Press Log key to lead the Log screen.

4. Press Alarm Export key to lead Alarm Export

screen.

40

5. On the Alarm Export screen, select the period to

export.

• To export the saved alarm log data over the

entire period, press All radio button.

• To export the alarm log data for the specified

days (The newest period containing that day),

press Last XX Days radio button and input days.

Settable range: 1 day~45 days.

Note: The error of about 1 minute may be

observed during 1 month. Refer to page 43 for

the procedure of setting time.

6. Press Export key.

Note:

• When USB memory is not inserted in the USB

port, Notice dialog box is displayed. Press OK

key and insert an USB memory into the USB

port.

• When alarm log data does not exist in the

specified days, Notice dialog box is displayed.

Press OK key and specify days again as shown

in the procedure 5.

41

OPERATION/ALARM LOG

7. Even after completion the export of alarm log

data, Information dialog box is displayed. Press

OK key.

Note: After completing the export of alarm log

data, alarm log data saved at unit is not deleted.

8. Remove a USB memory from the USB port.

Note: A log folder is created in a USB memory, and an exported data file is saved in the log folder by

CSV format.

Exported file name; The first date during exported period (8 digits) + the last date (8 digits) + AlarmLog

Example) When exporting alarm log data for 7 days on January 7, 2016;

20160101-20160107_AlarmLog.csv

9. Press Top key to return to the Top screen.

42

OTHER PARAMETERS

Setting date and time

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Date & Time key to lead the Date &

Time screen.

4. On the Date & Time screen, input the present

date and time. Press Apply key to save the input

value. The display returns to the Tools screen.

Note:

• 24-hour clock.

• It is recommended to set the time periodically

since the error of about 1 minute may be observed

during a month.

5. Press Top key to return to the Top screen.

43

OTHER PARAMETERS

Setting brightness and sleep

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Brightness/Sleep key to lead the

Brightness/Sleep screen.

4. On the Brightness/Sleep screen, each setting of

brightness and sleep is available. Press Apply key

to save the input value and setup. The display

returns to the Tools screen.

44

●Each setting

• Brightness(Active):

Brightness of LCD touch panel of the usual state. Adjust Brightness(Active) slide bar or input set value

into the Brightness(Active) input box. Settable range: 50~100, factory setting: 80.

• Sleep:

The function is that the brightness of LCD touch panel is lowered to save electricity, when there is no key

operation during set time.

By holding the Sleep slide key and sliding it right, the Sleep function is turned to ON. Input the set value

of time to change the Sleep state. Settable range: 1 minute~5 minutes, factory setting: 2 minutes.

Note: It is not possible to operate any key in the Sleep state. By touching the LCD touch panel, the Sleep

state is released and the LCD touch panel returns to the usual state. Under this condition, key operations

are available.

• Brightness(Sleep):

Brightness of LCD touch panel of the Sleep state. Adjust Brightness(Sleep) slide bar or input set value

into the Brightness(Sleep) input box. Settable range: 0~50, factory setting: 20.

5. Press Top key to return to the Top screen.

45

OPERATION MONITOR SYSTEM

This unit has the operation monitor system. It is the function to detect and inform some hard operating

conditions that leaving the unit operating may cause a failure. The table 2 shows the information of the

operation monitor system.

Table 2 Information of the operation monitor system

Information Status

Abnormal

ambient

temperature

Overload

operation

When the ambient

temp. is over approx.

o

35

C or lower than

approx. 0

When the chamber

temp. does not reach

the set temp. for

approx. 5 days or

more.

o

C.

Status1:

Ambient Temp Abnormal.

Status3:

Cooling Circuits

Overload.

Message

display field

Note:

• The operation monitor system is not the alarm function. Buzzer, remote alarm and safety operation are

not activated.

• “Status 2” does not exist.

• When the above remedy results in the following situations, contact our sales representative or agent.

The message does not disappear.

The message is displayed repeatedly.

Other situations.

If this status

continues

The cooling

performance and/or the

durability of the

refrigerating circuit may

get worse.

Recheck air-conditioning of

installed site.

* The message disappears

when the ambient temp.

returns to within allowable

range. (approx. 0

(1) Do not put a large amount

of contents to cryopreserve at

a time.

(2) Reduce the opening

frequency of the door.

(3) Make sure that there is no

leak around the door or the

inner lid.

(4) Set the chamber temp. to

o

-80

C or higher.

* The message disappears

when the chamber temp.

reaches the set temp. after

resolving the overload

operation by the above

remedy.

Remedy

o

C~35 oC)

46

ALARMS, SAFETY, AND SELF-DIAGNOSIS

This unit has the alarms, safety functions, and self-diagnostic functions of the table 3.

Table 3 Alarms and safety function list

LCD touch panel

Alarm & safety Situation

Message

display field

Warning:

High Temp.

(After alarm delay

time has elapsed.)

Warning:

Low Temp.

(After alarm delay

time has elapsed.)

Warning:

Power Failure

High Alarm

Low Alarm

Power failure

alarm

If the chamber temperature exceeds

the set temp. + the set value of High

Alarm.

(Settable range: +5

If the chamber temperature falls

below the set temp. - the set value of

Low Alarm.

(Settable range: +5

The battery switch for power failure

alarm is ON, and under any of the

following conditions.

o

C~+40 oC)

o

C~+40 oC)

• During a power failure

• Power switch is OFF

• Power supply cord is disconnected.

Door alarm When door is open. ―

Other

• Alarm display

(During alarm delay)

“Alarm” is displayed

alternately in normal

characters and reverse video

(After alarm delay)

“Warning” is displayed

alternately in normal

characters and reverse video

• Present temperature

display field

Present temperature blinks.

• LCD touch panel

Turned OFF. By touching the

LCD touch panel, it lights in

the set brightness for 5

seconds.

• Door display

“Open” is displayed

alternately in normal

characters and reverse video

Buzzer

Intermittent tone

(After alarm

delay time has

elapsed.)

Intermittent tone ON

Intermittent tone

(After door delay

time has

elapsed.)

Remote

alarm

ON

(After

alarm

delay time

has

elapsed.)

―

Filter alarm

Auto-return

Battery for power

failure alarm

replacement

Battery for backup

cooling kit

replacement

When the excessive dust is

accumulated on the condenser filter.

On screens other than the Top

screen, there is no key operation for

approx. 90 s.

(When the sleep function is ON)

After sleep function is turned ON,

there is no alarm/error and key

operation for approx. 90 s.

When the cumulative operating time

exceeds 3 years.

When 3 years passed after installing

backup cooling kit.

―

― (Return to the “Top screen”.) ― ―

Warning:

Exchange

a Main Battery.

Warning:

Exchange

a Backup Battery.

• Filter alarm indicator

Indicator is lit (orange).

― ― ―

― ― ―

Intermittent tone

Note:

• Settable range of the alarm delay time: 0 minute~15 minutes (refer to page 29).

• After turning ON the unit to start operation, only the first time, alarm delay is activated until the chamber

temperature is cooled to the High Alarm set temperature or less (Namely, the alarm display does not

change to “Warning”, buzzer does not sound and remote alarm is not activated).

• Settable range of the door delay time: 0 minute~15 minutes (refer to page 29).

• The battery for power failure alarm and for backup cooling kit are articles for consumption. It is

recommended that both batteries will be replaced about every 3 years. Contact our sales representative

or agent at the time of replacement of the battery.

―

47

ALARMS, SAFETY, AND SELF-DIAGNOSIS

Table 3 Alarms & safety function list

LCD touch panel

Alarm & safety Situation

If the thermal sensor is

disconnected.

If the thermal sensor is

short-circuited.

If the cascade sensor is

disconnected.

If the cascade sensor is

Sensor abnormality

Battery switch check

Condenser temp

abnormality

Communication

error

short circuited.

If the filter sensor is

disconnected.

If the filter sensor is

short-circuited.

If the ambient tem. sensor

is disconnected.

If the ambient tem. sensor

is short-circuited.

When the battery switch

for power failure alarm is

OFF.

When the fan motor for

cooling the compressor

fails.

(If the temperature of the

filter sensor is 52

higher.)

When communication

between LCD touch

panel and control

substrate is died out or

unstable.

o

C or

●When “disconnecting/short-circuit of the thermal sensor” and “condenser temp. abnormality” are

activated at the same time, safety operation of compressor OFF is prioritized.

Message display field Alarm display

Err01:

Temperature Sensor Open.

Err02:

Temperature Sensor Short.

Err03:

Cascade Sensor Open.

Err04:

Cascade Sensor Short.

Err05:

Filter Sensor Open.

Err06:

Filter Sensor Short.

Err07:

Ambient Temp Sensor Open.

Err08:

Ambient Temp Sensor Short.

Err09:

Battery Switch is OFF.

Err10:

Condenser Temp Abnormal.

Err56:

Communication Failure.

“Warning” is

displayed

alternately in

normal

characters and

reverse video.

― ― ― ―

“Warning” is

displayed

alternately in

normal

characters and

reverse video

― ― ― ―

Buzzer

Intermittent

tone

Intermittent

tone

Remote

alarm

ON

ON

Safety

operation

Unit is

continuous

running.

―

―

―

Compressor

OFF

48

●Table 4~5 show the behavior of the alarm (buzzer) and Ring Back function when pressing Buzzer key.

Table 4 In the cases of other than the door alarm.

Remote Alarm setting

ON: Non-interlock

with Buzzer key

OFF: Interlock

with Buzzer key

Note: Resolve the cause of the alarm in reference to page 47~48 because the alarm itself is not

deactivated by pressing Buzzer key.

Table 5 In the cases of the door alarm.

Remote Alarm setting

ON: Non-interlock

with Buzzer key

OFF: Interlock

with Buzzer key

●Table 6 shows the situation after being canceled the High/Low Alarm and recovery from a power failure

with no operation.

Table 6 The situation after being canceled the High/Low Alarm and recovery from a power failure with

no operation

Canceled alarm

Ring Back

setting

ON

OFF OFF

ON ON

OFF OFF OFF

Ring Back

setting

ON

OFF

ON

OFF

Message display field Alarm display

When pressing

Buzzer key

(Alarm is not

canceled)

When pressing

Buzzer key

(Alarm is

canceled)

Buzzer from unit Remote Alarm

When the Ring Back

set time passes

OFF

Buzzer from unit

When the Ring Back

set time passes

OFF

(Alarm is already

LCD touch panel

ON

OFF

canceled)

When pressing

Buzzer key

ON

OFF (Alarm is

not canceled)

Remote Alarm setting

Buzzer

When the Ring Back

set time passes

(Under continuation)

OFF

Remote

alarm

ON

ON

Safety

operation

High Alarm

Low Alarm

Power failure

alarm

Note: By pressing Buzzer key, the alarm display returns to “Normal” and buzzer stops.

―

―

“Alarm” is displayed alternately in

normal characters and reverse video

“Alarm” is displayed alternately in

normal characters and reverse video

Intermittent

Intermittent

tone

tone

― ―

― ―

49

ROUTINE MAINTENANCE

WARNING

Always disconnect the power supply to the unit prior to any repair or maintenance of the unit in

order to prevent electric shock or injury.

Ensure you do not inhale or consume medication or aerosols from around the unit at the time of

maintenance. These may be harmful to your health.

Cleaning of cabinet

• Clean the unit once a month. Regular cleaning keeps the unit looking new.

• Use a dry cloth to wipe off small amounts of dirt on the outside and inside of the unit and all accessories.

If the outside panels are dirty, clean them with a diluted neutral dishwashing detergent (Undiluted

detergent can damage the plastic components. For the dilution, refer to the instruction of the detergent).

After the cleaning with the diluted detergent, always wipe it off with a wet cloth. Then wipe off the cabinet

or accessories with a dry cloth.

• Never pour water onto or into the unit. Doing so can damage the electric insulation and cause failure.

• The compressor and other mechanical parts are completely sealed. This unit requires absolutely no

lubrication.

Note: Always replace the inner accessories removed for the cleaning to keep the intended performance.

Cleaning of condenser filter

This unit is provided with the filter alarm indicator on the LCD touch panel. Clean the condenser filter

when this indicator is lit. Clean the condenser filter once a month even if the filter alarm indicator is not

on. A dusty condenser filter may cause shorter compressor life as well as the poor cooling.

Clean the condenser filter by the procedure below.

1. Open the grille by pulling it to you as shown in the

figure.

2. Take out the condenser filter.

3. Wash the condenser filter with water.

4. Replace the condenser filter and the grille. (Set the

handle of the condenser filter at the front.)

5. Check that the filter alarm indicator is off in the event

the filter alarm indicator was ON.

Condenser

filter

Grille

WARNING

Do not touch the condenser directly when the filter is removed for cleaning. This may cause injury by

hot surface.

50

Defrosting of chamber

The frost is built at the upper portion of the chamber and inner door. The excessive frost possibly make

some gap between the cabinet and the magnetic door gasket, which may cause poor cooling. Remove

the frost on the inner door with a scraper enclosed with the unit. Following shows the procedure for

removing the chamber frost.

Note: For removing the frost, do not use a tool with sharp edge such as a knife or a screw driver.

1. Turn off the backup cooling kit if it is installed.

2. Take out and transfer all the contents to another freezer or a container which is refrigerated by liquid

carbon dioxide or dry ice.

3. Turn off the power switch and battery switch of the

freezer.

4. Open the outer door and inner door. Remove the

inner door by lifting up as shown in the figure.

5. Leave the freezer as it is.

6. The water accumulated on the bottom of the

chamber should be wiped up with a dry cloth.

7. After cleaning the chamber and inner door, replace

the inner door and start up the unit according to the

procedure on page 17.

8. Put back the articles into the sufficiently cooled

freezer compartment.

9. Turn on the backup cooling kit if it is installed.

WARNING

Always mount and/or remove the inner door by two people. The work by oneself may cause injury

from falling.

Always wear gloves when mounting and/or removing the inner door to prevent injury.

51

ROUTINE MAINTENANCE

Cleaning of air intake port

To open the outer door, the cap on the left side is turned counterclockwise to take the air. Therefore, the

frost is easy to be settled around the air intake port or in it. Clean the air intake port depending on the

conditions below:

Condition Remedy

When the frost and ice can

be seen in the air intake port.

The outer door cannot be

opened even if the cap on

the air intake port is

removed.

The frost and ice are built in

the chamber.

Remove the frost and ice with the stick for air intake port cleaning.

Remove the frost and ice with the stick for air intake port cleaning.

Remove the frost and ice with the enclosed scraper.

Stick for air intake port cleaning (Accessory)

CAUTION

For removing the frost in the air intake port, do not use a tool with sharp edge such as a knife or a screw

driver.

CALIBRATION

During running operation, the following service works must be performed;

• Perform temperature calibration at least once a year.

For the temperature calibration, contact our sales representative or agent.

52

REPLACEMENT OF WEAR-OUT PARTS

Replacing the battery for power failure alarm

Replace the battery for power failure alarm every 3 years. Contact our sales representative or agent for the

replacement of battery when “Warning: Exchange a Main Battery.” is displayed in the message display

field.

The replacement of the battery for power failure alarm is a paid service.

The alarm function (message display, sound of buzzer and remote alarm) will not operate when the battery for

power failure alarm is flat.

“Warning: Power Failure.” is displayed and the buzzer sounds by the battery for power failure alarm. The

regular replacement of the battery for power failure alarm is important to prevent the rise of chamber

temperature in the case of unexpected situation.

WARNING

«Important» The used battery is a recyclable precious resource. Do not dispose of the

battery. Always follow the procedure for recycling.

The replacement of the battery for power failure alarm

should be executed by a qualified engineer or service

personnel only.

alarm involves the risk of electric shock.

The replacement of the battery for power failure

Replacing the battery for backup cooling kit

Replace the battery for backup cooling kit every 3 years. Contact our sales representative or agent for the

replacement of battery when “Warning: Exchange a Backup Battery.” is displayed in the message display

field.

The replacement of the battery for backup cooling kit is a paid service.

The backup cooling kit will not operate when the battery for backup cooling kit is flat.

When the chamber temperature rises, the backup cooling kit is activated by the battery for backup cooling kit

even during a power failure. The regular replacement of the battery for backup cooling kit is important to

prevent the rise of chamber temperature in the case of unexpected situation.

WARNING

«Important» The used battery is a recyclable precious resource. Do not dispose of the

battery. Always follow the procedure for recycling.

The replacement of the battery for backup cooling kit should

be executed by a qualified engineer or service personnel

only.

involves the risk of electric shock.

The replacement of the battery for backup cooling kit

53

TROUBLESHOOTING

If the unit malfunctions, check out the following before calling for service.

Malfunction Check/Remedy

The unit does not operate

at all when turning ON the

power switch.

The compressor does not

operate at all when turning

ON the power switch.

(LCD touch panel is turned

ON)

An alarm is activated. □ A little before, the value of the chamber temperature has been

The cooling is poor. □ A large amount of warm contents are put into the chamber.

The outside of the unit is

wet with dew.

Noisy in motor sound or

flowing liquid.

Note:

• If the malfunction is not eliminated after checking the above items, or the malfunction is not shown in the

above table, contact our sales representative or agent.

• Keep an electric product which emits an electromagnetic wave away from this unit. A noise from an

electromagnetic wave may cause malfunction to this unit.

□ The unit is not connected to the power supply.

□ During a power failure.

□ The circuit breaker is activated.

□ The capacity of power supply is not sufficient. When the capacity of

power supply is not sufficient to start the compressor, compressor may

not start.

changed significantly.

□ The door had been left open for a long time.

□ Some warm contents are put into the chamber.

*In the above cases, the alarm is canceled with no operation.

□ A large amount of frost is built on the inside wall of the chamber.

□ The door is often opened.

□ The set value of the chamber temperature is lower than -86

temperature settable range is between -50

temperature control range is between -50

□ The ambient temperature is higher than 30

temperature is between 5

□ The unit is in the direct sunlight.

□ There is no more than 10 cm clearance around the unit.

□ The grille or the exhaust air bent is blocked by something.

□ The unit is not installed horizontally.

In case of sultriness or bad location, the exterior of the unit may be wet

with dew. Under a high humidity environment, the cold exterior of the

unit condenses the moisture in the air, so that it is not malfunction. Wipe

the dew with a dry cloth.

On the characteristics of the cooling circuit, the sound of motor or

flowing refrigerant may be heard during operation. Especially a few

hours after starting operation, the sound of compressor or flowing

refrigerant may be loud, however it is a normal operation.

o

C~30 oC.

o

C~-90 oC. However, the

o

C~-86 oC.

o

C. The allowable ambient

o

C. The

54

DISPOSAL OF UNIT

請回收

Before disposing the unit with biohazardous danger, decontaminate the unit to the extent possible by the

user.

WARNING

If the unit is to be stored unused in an unsupervised area for an extended period ensure that children

do not have access and doors cannot be closed completely.

The disposal of the unit should be accomplished by appropriate personnel. Always remove

doors to prevent accidents such as suffocation.

Recycle of battery

■ Label indication is obliged to comply with Japanese battery regulation.

廢電池

■ Label indication is obliged to comply with Taiwanese battery regulation.

55

DISPOSAL OF UNIT

(English)

Disposal of Old Equipment and Batteries

Only for European Union and countries with recycling systems