Operating Instructions

Ultra-Low Temperature Freezer

MDF-DU702VH

MDF-DU502VH

MDF-DU702VH

Please read the operating instructions carefully before using this product, and keep the operating

instructions for future use.

See page 58 for all model numbers.

CONTENTS

INTRODUCTION ········································································· 3

PRECAUTIONS FOR SAFE OPERATION ········································· 4

SYMBOLS ON UNIT ····································································· 9

ENVIRONMENTAL CONDITIONS ··················································· 9

FREEZER COMPONENTS

Main body ············································································ 10

LCD touch panel ··································································· 12

Remote alarm terminal ··························································· 14

Air intake port (Manual) ·························································· 14

INSTALLATION SITE ·································································· 15

INSTALLATION ········································································· 16

START-UP PROCEDURE ··························································· 18

DURING/AFTER POWER FAILURE

Operation during power failure ················································· 19

Operation after recovery from power failure ································· 19

BASIC OPERATION ON LCD TOUCH PANEL ································· 20

BASIC PARAMETERS

How to input numerical value and alphanumeric character ·············· 21

Setting Temperature, High Alarm and Low Alarm ························· 23

Setting operation control mode ················································· 24

Setting key lock ···································································· 25

Removing key lock ································································· 28

ALARM PARAMETERS ······························································ 29

OPERATION/ALARM LOG

Setting log interval ································································· 31

Displaying operation log ·························································· 32

Exporting operation log ·························································· 35

Displaying alarm log ······························································· 38

Exporting alarm log ································································ 40

OTHER PARAMETERS

Setting date and time······························································ 43

Setting brightness and sleep ···················································· 44

ALARMS AND SELF-DIAGNOSIS ················································· 46

ROUTINE MAINTENANCE

Cleaning the exterior, interior, and accessories ···························· 49

Cleaning of air intake port (Manual) ··········································· 49

Cleaning of condenser filter ····················································· 50

Defrosting of chamber ··························································· 51

CALIBRATION ·········································································· 51

REPLACEMENT OF WORN-OUT PARTS

Replacing the battery for power failure alarm ······························· 52

Replacing the battery for backup cooling kit ································ 52

TROUBLESHOOTING ································································ 53

DISPOSAL OF UNIT ·································································· 54

Recycle of battery ································································· 54

OPTIONAL COMPONENTS

Temperature recorder ···························································· 55

Small inner doors ·································································· 55

Inventory rack ······································································ 55

Back-up cooling kit ································································ 56

SPECIFICATIONS ····································································· 57

PERFORMANCE ······································································· 58

SAFETY CHECK SHEET····························································· 59

2

INTRODUCTION

■ Read the operating instructions carefully before using the product and follow the instructions for safe

operation.

■ PHC Corporation takes no responsibility for safety if the product is not used as intended or is used with

any procedures other than those given in the operating instructions.

■ Keep the operating instructions in a suitable place so that they can be referred to as necessary.

■ The operating instructions are subject to change without notice for improvement of performance or

function.

■ Contact our sales representative or agent if any page of the operating instructions is lost or the page

order is incorrect, or if the instructions are unclear or inaccurate.

■ No part of the operating instructions may be reproduced in any form without the express written

permission of PHC Corporation.

IMPORTANT NOTICE

PHC Corporation guarantees this product under certain warranty conditions. However, please note that

PHC Corporation shall not be responsible for any loss or damage to the contents of the product.

<Intended Use>

This equipment is designed for low temperature storage of biomedical samples.

3

PRECAUTIONS FOR SAFE OPERATION

It is imperative that the user complies with the operating instructions

as they contain important safety advice.

Items and procedures are described so that you can use this unit correctly and safely.

Following these precautions will prevent possible injury to the user and any other

person.

Precautions are illustrated in the following way:

WARNING

Warning indicates a potentially hazardous situation which, if not avoided,

could result in serious injury or death.

CAUTION

Failure to observe CAUTION signs could result in injury to personnel and

damage to the unit and associated property.

Symbols have the following meanings:

T

Be sure to keep the operating instructions in a place that is accessible to users of this

unit.

For the State of California, USA Only:

This product contains a CR Coin Cell Lithium Battery which contains Perchlorate Material – special

handling may apply.

his symbol means caution.

This symbol means an action is prohibited.

This symbol means an instruction must be followed.

See www.dtsc.ca.gov/hazardouswaste/perchlorate.

4

PRECAUTIONS FOR SAFE OPERATION

Do not use the unit outdoors. Exposure to rain may cause leakage and/or electric shock.

Only qualified engineers or service personnel should install the unit. Installation by unqualified

personnel may cause electric shock or fire.

Install the unit in a location capable of bearing the total combined weight (product + optional

accessories + stored items). After installing the unit, be absolutely sure to take precautions

to prevent the unit from falling over. If the unit is installed in a location which is not strong enough

or if the proper precautions are not taken, the unit may fall over and cause injuries.

Turn the leveling feet to separate the casters from the floor and secure the unit. If they are left

touching the floor, the unit may inadvertently move out of position when its door is opened or

closed. It may cause injury.

Do not install the unit where there are high levels of moisture or where it may be splashed with

water. Installing the unit where there are high levels of moisture or where it may be splashed with

water may cause the insulation to deteriorate and give rise to leakage and/or electric shock.

Do not install the unit in a location where flammable or volatile substances are present.

Installing the unit in a location where flammable or volatile substances are present may cause

explosions and/or a fire.

Do not install the unit in a location where corrosive gases such as acids are present. Installing

the unit in a location where corrosive substances are present may cause electrical components to

corrode, leading to leakage and/or electric shock due to the deterioration of insulation resulting from

corroded electrical components.

Do not place this unit in a location where it is difficult to disconnect the power supply plug.

Failure to disconnect the power supply plug may cause fire in the event of a problem or malfunction.

Be absolutely sure to earth (ground) the unit to prevent electric shock. Failure to earth the

product may give rise to electric shock. If necessary, ask a qualified contractor to do this work.

Do not connect the earth wire to a gas pipe, water pipe or lightning rod when earthing the

unit. Earthing the unit improperly may give rise to electric shock.

Connect the unit to a power source as indicated on the rating label attached to the unit. Use

of any other voltage or frequency other than that on the rating label may cause fire or electric shock.

Never store volatile or flammable substances in this unit except in a sealed container. Such

substances may cause explosion or fire if they leak.

Never insert metal objects such as pins and wires into any vent, gap, or outlet on the unit.

This may cause electric shock or injury by accidental contact with moving parts.

WARNING

5

PRECAUTIONS FOR SAFE OPERATION

When handling harmful samples (for example, those which consist of toxic, pathogenic or

radioactive substances), install the unit inside a designated isolation facility. If the unit is

installed in a location which is not an isolation facility, there may be detrimental effects on both people

and the natural environment.

Before proceeding with maintenance or checking the unit, set the power switch to OFF, and

disconnect the power supply plug. Performing the work while power is still flowing to the product

or while the power supply plug is still connected may give rise to electric shock and/or injury.

Do not touch any electrical parts (such as power supply plug) or operate switches with a wet

hand. This may cause electric shock.

Wear protective gloves and mask during maintenance. Touching or inhaling chemicals or

aerosols from around the unit may be detrimental to health.

Never splash water directly onto the unit as this may cause electric shock or short circuit.

Never put containers with liquid on top of the unit as this may cause electric shock or short circuit

if the liquid is spilled.

Never damage the power supply cord or power supply plug (by breaking, adapting, placing

near a source of heat, bending with force, twisting, pulling, adding weight, or binding). A

damaged power supply cord or power supply plug may cause electric shock, short circuit, or fire

Never disassemble, repair, or modify the unit yourself. A high-voltage area is located inside the

unit. Any work carried out by unauthorized personnel may result in electric shock. Contact our

sales representative or agent for maintenance or repair.

Make sure the power supply plug is pushed fully in. Faulty insertion of the power supply plug

may cause electric shock or fire due to generation of heat. Never use a damaged power supply plug

or loose power outlet

Disconnect the power supply plug if there is anything wrong with the unit. Continued abnormal

operation may cause electric shock or fire.

Grip the power supply plug when disconnecting the power supply cord from the outlet.

Pulling the power supply cord may cause electric shock or short circuit.

Remove dust from the power supply plug periodically. Dust on the power supply plug may

cause insulation failure due to moisture and thus cause a fire. Disconnect the power supply plug and

wipe it with a dry cloth

WARNING

6

PRECAUTIONS FOR SAFE OPERATION

Disconnect the power supply plug before moving the unit. Take care not to damage the power

supply cord. A damaged power supply cord may cause electric shock or fire.

Disconnect the power supply cord when the unit is not in use for long periods. Keeping the

unit connected may cause electric shock, leakage, or fire due to the deterioration of insulation.

If the unit is to be stored unused in an unsupervised area for a long period, ensure that children do

not have access and that doors cannot be closed completely.

Ask a qualified contractor to carry out disassembly and disposal of the unit. Leaving the unit in

a location that can be accessed by third parties may result in unexpected accidents (e.g. the unit may

be used for unintended purposes).

Do not leave the plastic bags used for packing in a place where they can be reached by small

children as this may result in unexpected accidents such as suffocation.

Never replace the battery for the power-failure alarm yourself. Only qualified engineers or

service personnel should replace the battery.

When moving the unit, be sure to take precautions to prevent it from falling over. Moving the

unit with too much force may cause it to fall over, possibly resulting in injury. A qualified individual

must be assigned to supervise the safe movement and relocation of the unit.

Install the unit in a well-ventilated (airy) location to prevent the accumulation of flammable

refrigerant. The flammable refrigerant may cause fire if it leaks.

Never damage the chamber wall or pipework in the chamber when removing frost. The

refrigerant is flammable and may cause a fire if it leaks.

Flammable and explosive product. The unit contains flammable refrigerant. When repairing or

recycling, only trained service personnel will repair and follow the procedure below.

Well ventilate the room to prevent refrigerant accumulation.

Keep fire away when the refrigerant is contained in the product.

Do not damage or break the pipework.

As with any equipment that uses CO

equipment. It is important that you assess the work site to ensure there is suitable and sufficient

ventilation. If lack of ventilation is suspected, then other methods of ensuring a safe environment

must be considered. These may include atmosphere monitoring systems and warning devices with

alarms.

Do not touch the condenser directly when the filter is removed for cleaning. Touching the

condenser may cause injury due to its hot surface.

WARNING

gas, there is a likelihood of oxygen depletion in the vicinity of the

2

7

PRECAUTIONS FOR SAFE OPERATION

Never install the unit in a location where corrosive materials such as sulphur compounds are

likely to be generated (e.g. near a drainage facility). Corrosion of the copper pipes may result in

the deterioration and consequently the failure of the cooling unit.

This unit must be plugged into a dedicated circuit protected by branch circuit breaker.

Use a dedicated power source as indicated on the rating label attached to the unit. A

multiple-tap may cause fire resulting from abnormal heating.

Do not climb on top of the unit or put any objects on the unit. Falling from the unit may cause

injury; falling objects may cause damage to the unit.

Never store corrosive substances such as acids or alkalis in this unit except in a sealed

container. These may be harmful to your health and may cause corrosion of internal components or

electrical parts.

Check the settings when restarting operation after a power failure or after turning the power off.

The settings may have changed as a result of stopping the unit. Stored items inside the unit may be

adversely affected when operation is resumed if the settings have changed.

To ensure the safety of the service engineer, submit a safety check sheet with the required

items filled out. This is provided as the photocopiable “Safety Check Sheet” at the end of these

operating instructions

Use designated parts for parts replacement. Using an incorrect part may cause fire.

Do not give strong shock or vibration during movement or use. The piping may be damaged,

causing a fire.

Flammable and explosive product. The unit contains flammable refrigerant. Consult repair

manual/owner’s guide before attempting to install or service this product. All safety precautions must

be followed.

Flammable and explosive product. Dispose of properly in accordance with federal or local

regulations. Flammable refrigerant used.

To prevent frostbite, wear protective gloves when handling frozen items in the chamber. To o

much frost may cause chamber temperature rise resulting from incomplete door close.

Clean the filter about every once a month. A dusty filter may cause poor cooling performance.

Please remove the frost on the air intake. When removing, please use the accessory's stick for air

intake port cleaning.

CAUTION

8

SYMBOLS ON UNIT

The following symbols are attached to the unit. The table describes the meaning of the symbols.

This symbol is attached to covers that access high-voltage electrical components to

prevent electric shock. Only a qualified engineer or service personnel should be

allowed to open these covers.

This symbol indicates that caution is required. Refer to product documentation for

details.

This symbol indicates Incorrect usage could lead to a fire hazard.

This symbol indicates an earth.

This symbol means “ON” for a power switch.

This symbol means “OFF” for a power switch.

ENVIRONMENTAL CONDITIONS

This equipment is designed to be safe at least under the following conditions (based on the IEC 61010-1):

■ Indoor use;

■ Altitude up to 2000 m;

■ Temperature 5

■ Maximum relative humidity 80 % for temperature up to 31

humidity at 40

■ Mains supply voltage fluctuations up to ±10 % of the nominal voltage;

■ Transient overvoltages up to the levels of OVERVOLTAGE CATEGORY II;

■ Temporary OVERVOLTAGES occurring on the mains supply;

■ Applicable pollution degree of the intended environment (POLUTION DEGREE 2 in most cases);

o

C to 40 oC;

o

C;

o

C decreasing linearly to 50 % relative

9

FREEZER COMPONENTS

Main body

The model below is the MDF-DU702VH. However, the MDF-DU502VH is also equivalent structures.

Door gasket

10

21

* When an optional backup cooling kit is installed.

10

9

8

7

16

17

20 (Inside the outer door)

5

6

18

19

20 (inside)

15* 14*

13

Outer door

1

2

3

4

11

*

12

10

FREEZER COMPONENTS

1. Inner door latch: Always lock the inner door latch when the inner door is closed.

2. Inner door: This prevents cold air from escaping when the outer door is opened. Always be sure to

close the inner door securely before closing the outer door. The inner door can be removed for cleaning

or defrosting [page 51].

3. Outer door latch: When closing the outer door push the latch until the latch is locked in place.

Provision has been made for use of an additional padlock (not included).

4. Keyhole: Turn clockwise to 180

5. Air intake vent (grille): Do not block this vent to keep the proper cooling performance.

6. Leveling feet: These are screw bolts used to install and fix the unit. Adjust the height of the leveling

feet by turning the screw bolts until 2 front casters are away from the floor.

7. Caster: 4 casters are provided to facilitate moving of the cabinet. For the installation, adjust the

leveling feet so that the front 2 casters cannot contact with the floor.

8. Condenser filter (behind the grille): This filter prevents the dust from accumulating on the

condenser. A dusty condenser filter may cause failure of refrigerating device. Clean the condenser

filter once a month [page 50].

9. Space for temperature recorder: A temperature recorder (optional) can be mounted here so that

the chamber temperature can be recorded automatically [page 55].

10. Access port (rear and bottom): These ports are used to pass the sensor or cable of measuring

equipment, the sensor of a temperature recorder (optional), or the nozzle of a back-up cooling kit

(optional) to the chamber.

11. Fixture (on back side): Use the fixtures and secure the unit to a wall with a strong rope or chain

[page 16].

12. Power switch: This is the power switch of the unit. (ON=“l”,OFF=“

13. Temperature setting knob (TEMP. SET)*: It is the knob which adjusts injection set temperature of

the backup cooling kit [page 56].

14. Backup power switch (BACK UP)*: Power switch of the backup cooling kit [page 56].

15. Backup test switch (TEST)*: It is the switch to confirm that the backup cooling kit can inject liquid

CO

[page 56].

2

16. Remote alarm terminal: A remote alarm device (separately available) can be connected to this

terminal. The remote alarm relays the alarm to an operator in a remote location if the unit is un attended

[page 14].

17. Battery switch: This is an ON-OFF switch for the battery for the power-failure alarm. Always turn

this switch on when the unit is operating to ensure that the power-failure alarm is working. Turn this

switch off when the unit is not used for a long period in order to protect the battery.

18. LCD touch panel: [pages 12 - 13]

19. USB port: Insert USB memory to export operations and alarms log [pages 35 - 42].

Note: It is impossible to use USB memory which is required password input.

20. Air intake port: This operates automatically when the outer door is closed. The outer door can be

opened easily because this port intake the outer air and the pressure difference between the chamber and

outside is deleted. During the operation of this port, the suction noise arises, but this is not a malfunction.

21. Air intake port (Manual): Adjust the pressure difference inside and outside the chamber manually to

open the outer door smoothly [page 14].

* When an optional backup cooling kit is installed.

o

with a key and the outer door is securely locked.

○”)

11

FREEZER COMPONENTS

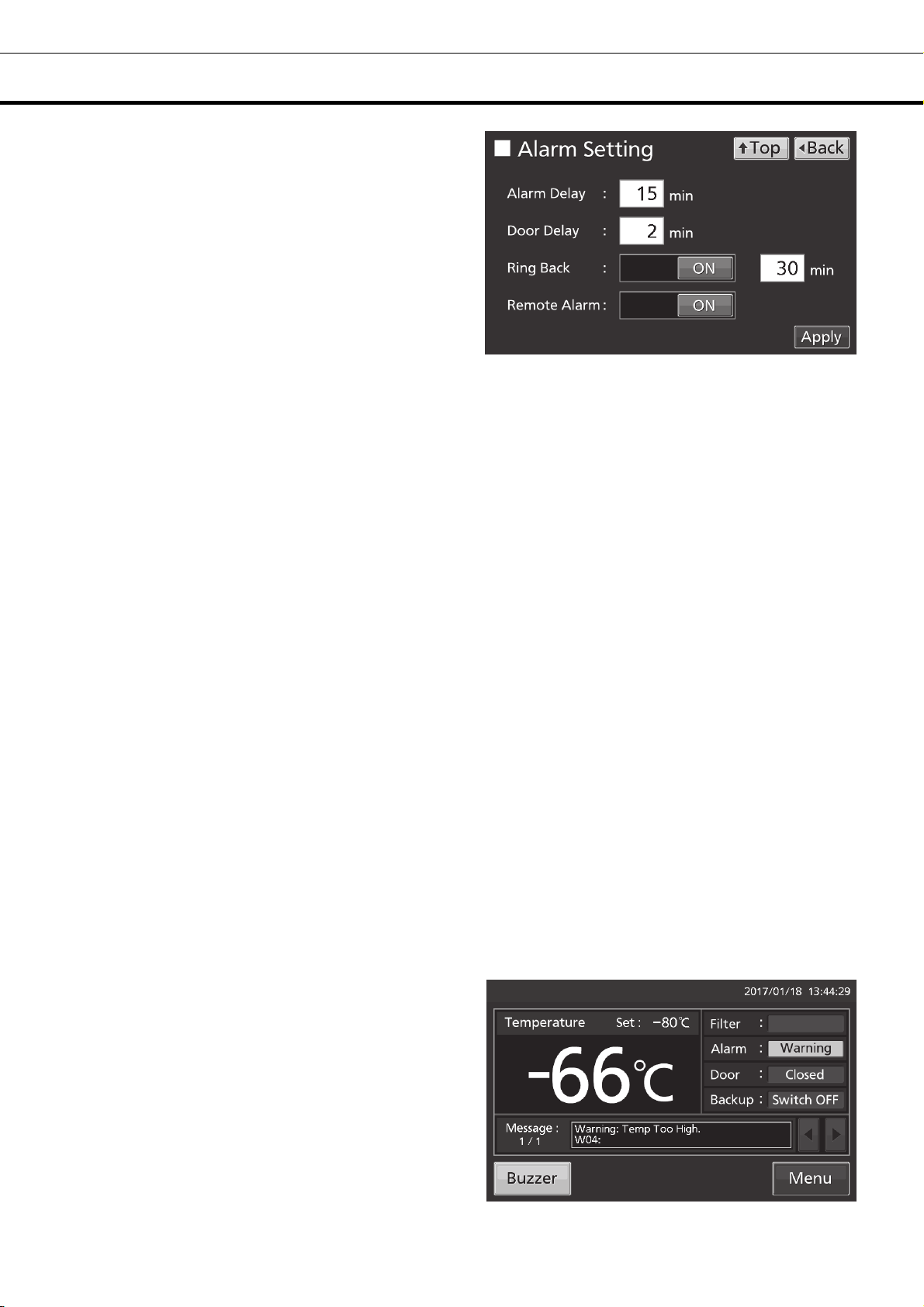

LCD touch panel

The following display (called the Top screen) will appear when the power switch is turned ON.

Note: It takes approximately 20 seconds until Top screen is displayed.

1. Present temperature display field: The current chamber temperature is displayed.

Note: An integer rounded off below a decimal point is displayed.

2. Set temperature value display field: The set value of chamber temperature is displayed. Default

setting: -80

3. Present date/time display field: Normally, this indicator shows date and time. The date and time is

simply set when the freezer is shipped from the factory [page 43].

4. Filter alarm indicator: This indicator is lit when the excessive dust is accumulated on the condenser

filter. When this indicator is lit, clean the condenser filter following the procedure [page 50].

5. Alarm display: [pages 46 - 47]

Normal condition: “Normal” is displayed.

Alarm-activated, buzzer-delayed: “Alarm” is displayed alternately in normal characters and reverse video.

Alarm-activated, buzzer-sounding: “Warning” is displayed alternately in normal characters and reverse video.

6. Door (opening/closing) display:

Open: “Open” is displayed alternately in normal characters and reverse video.

Close: “Closed” is displayed.

7. Backup display: (It is displayed only when an optional backup cooling kit is installed) ON/OFF of the

backup power switch is displayed [page 56].

ON: “Switch ON” is displayed.

OFF: “Switch OFF” is displayed.

o

C.

1 2 3

4

5

6

7

12

FREEZER COMPONENTS

8

11 10

8. Message display field: The information of the operation monitor system, alarms or status are

displayed when fault occurs [pages 46 -47].

9. Message select key: When there are a number of alarms, status or information of the operation

monitor system, the message on the screen is changeable.

10. Menu key: Press this key to lead the Menu screen. It is possible to set various setting on the Menu

screen [page 20].

11. Buzzer key: Press this key to silence the buzzer. However, when the ring back is ON, the buzzer will

sound again when the ring back passed and the alarm state still continues [pages 29 - 30 and 48].

9

13

FREEZER COMPONENTS

Remote alarm terminal

The alarm of this unit can be informed at a remote location from this unit by connecting the external alarm

device to the remote alarm terminals. For the type and behavior of remote alarm output [pages 46 - 47].

The terminal of the remote alarm is installed at the right side

of the unit (See the figure on the point). The alarm is outputted

from this terminal. Contact capacity is DC 30 V, 2 A.

When Buzzer key is pressed, the behavior of the remote

alarm is showed in Table.1.

Note:

• In the door alarm, the remote alarm does not work [page 47]

• It is recommended to use standard signal and interface cables

with a maximum length of 30 meters.

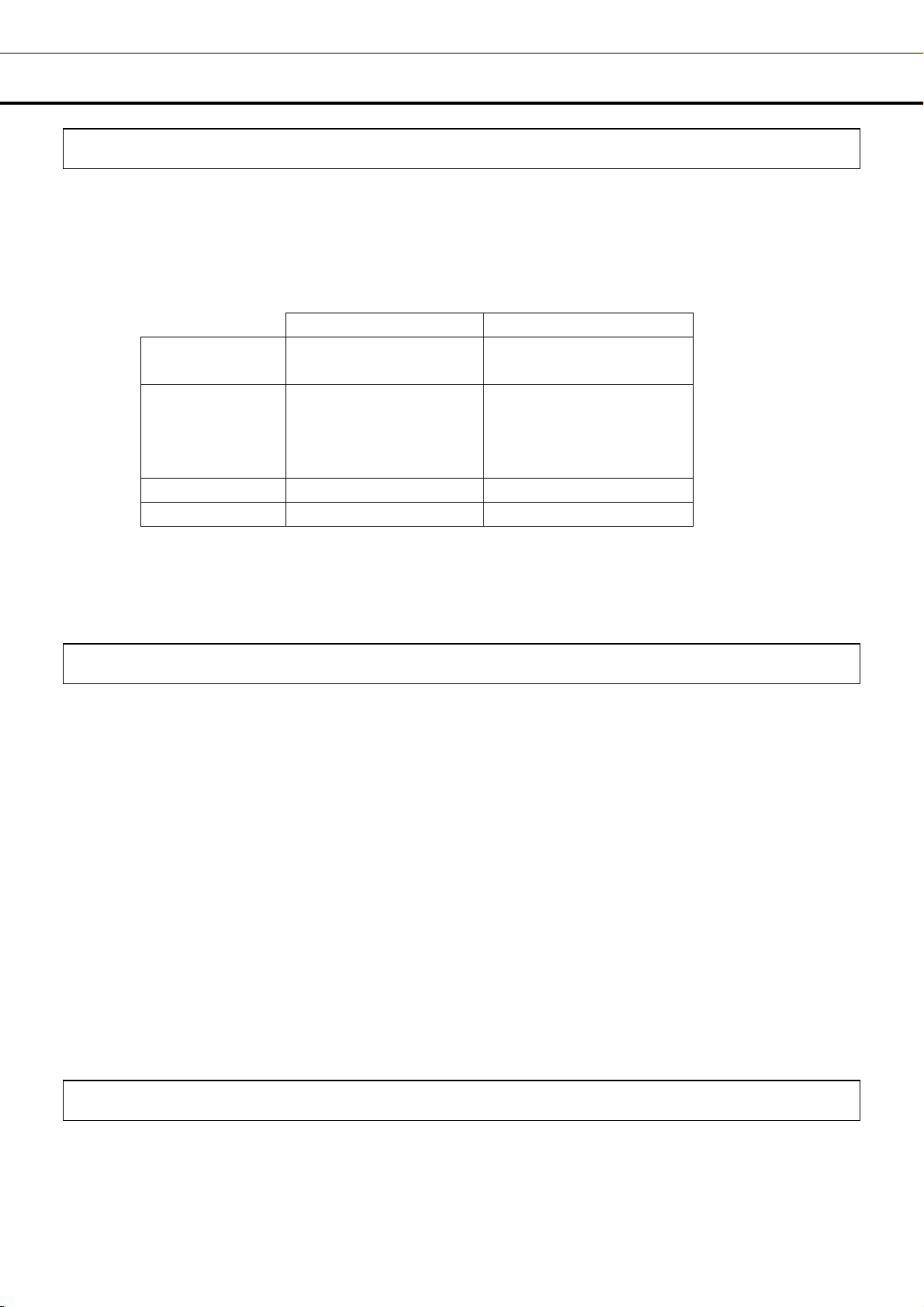

Table 1 The behavior of the remote alarm when pressing Buzzer key

Remote Alarm setting

[pages 29 – 30]

ON:

Non-interlock with Buzzer key

OFF:

Interlock with Buzzer key

Remote alarm terminal

Abnormal condition

Connecting

terminal

COM.-N.C. Close Open Open (Maintain in abnormality)

COM.-N.O. Open Close Close (Maintain in abnormality)

COM.-N.C. Close Open Close (Return to normal)

COM.-N.O. Open Close Open (Return to normal)

Normal

condition

(Including in the cases of power outage and

of where the power plug is pulled out.)

When pressing Buzzer key

Air intake port (Manual)

The difference in pressure inside and outside of the chamber is adjusted automatically to open the outer door

smoothly.

However, if the door becomes heavy and difficult to open, follow the procedure below.

1. Turn the cap on the left side counterclockwise about two laps.

(Or remove the cap.)

2. Allow about twenty seconds before open the outer door.

3. Close (or replace) the cap when the door operation is

completed.

Remove the cap on the air intake port and check for the frost inside

the air intake port.

If excessive frost has built up in the air intake port, remove with a

"Stick for air intake port cleaning" [page 49].

CAUTION

For removing the frost in the air intake port, do not use a tool with sharp edge such as a knife or a screw

driver.

About 2 laps

Cap

14

INSTALLATION SITE

This unit must be installed in a location which meets all the conditions described below.

If the unit is installed in a location which does not meet the conditions, its specified performance may

not be achieved or malfunctions and accidents may occur.

■ A location not exposed to direct sunlight

Avoid any location which is exposed to direct sunlight. Installing the unit in a location exposed to direct

sunlight may reduce its cooling performance.

■ A well-ventilated (airy) location

In order to ensure ventilation, leave clearances of at least 10 cm around the unit (at the left, right, top and

back). Blocking the ventilation may reduce the unit’s cooling performance or cause malfunctions.

■ A location away from sources of heat

Avoid any location which is close to a major source of heat (such as a heater or boiler). Installing the

unit near a major source of heat may reduce the unit’s cooling performance.

■ A location with minimal changes in temperature

Avoid any location where the ambient temperature is subject to sudden changes. If the unit is installed

in a location where the ambient temperature is subject to sudden changes, it will not be possible to

achieve a stable cooling performance.

■ A flat surface where the floor is also capable of bearing the total combined weight (product +

optional accessories + stored items)

Install the unit on a flat surface which is even and which is capable of bearing the total combined weight

(product + optional accessories + stored items). If the unit is installed where the surface is uneven or

where the unit will be inclined at an angle, the unit will be unstable, and accidents or injuries may occur

and/or unnecessary vibration or noise may be generated.

■ A location with minimal humidity

Install the unit in a location where the relative humidity is less than 80 %R.H. Installing the unit in a very

humid location may cause earth faults and/or electric shock.

■ A location free of flammable or corrosive gases

Avoid any location exposed to flammable or corrosive gases. Flammable or corrosive gases can cause

explosions and/or a fire. Furthermore, corrosion of the electrical parts may cause the insulation to be

reduced and result in earth faults and/or electric shock.

■ A location where nothing can fall onto the unit

Avoid locations where objects may fall onto the unit. Objects falling and hitting the unit may cause it to

break down or fail.

15

INSTALLATION

When installing the unit, follow the steps below to secure the unit properly, and also be absolutely sure to

earth the unit.

In addition, install an earth leakage circuit breaker (on the unit’s power supply side), which is mandatory

under the applicable laws and regulations.

1. Preparations after unpacking

Remove all the tape used to secure the doors and interior parts, and leave the doors open for a short

while for ventilation.

If any surfaces of the outer cabinet are dirty, wipe the surface using a cloth moistened with a diluted

neutral dish-washing detergent.

Using an undiluted solution of detergent may cause the unit’s plastic areas to crack. Follow the

directions on the detergent for details of dilution.

After wiping the unit using the diluted detergent, be absolutely sure to wipe the surfaces with a cloth

dipped in clean water to remove traces of the detergent. After this, be absolutely sure to wipe the

surfaces with a dry cloth, allowing the surfaces of the outer cabinet to dry out completely, and then

proceed with the installation.

Note:

Remove the cable tie that bands the power supply cord. Prolonged contact with the tie may cause

corrosion of the cord coating.

2. Securing and levelling the unit using the levelling feet

Rotate the front levelling feet clockwise until the casters

are raised 5 mm to 10 mm above the floor surface. (Fig. 1)

In addition, rotate the levelling feet slightly clockwise or

anticlockwise, and adjust them so that the unit is

completely level.

When the casters are raised from the floor surface, the

unit will be secured. If they are left touching the floor, the

unit may accidently move when its door is opened or

closed.

3. Securing the unit by using the fixtures

Use the fixtures on the rear panel of the unit, and secure

the unit to a wall with a strong rope or chain. (Fig. 2)

Fig.1

Levelling feet

Fixture

Fig. 2

16

INSTALLATION

4. Preventing electric shock by earthing the unit

When installing the unit, be absolutely sure to earth (ground) it. Earthing is necessary to prevent electric

shock resulting from deterioration of electrical insulations

This unit comes with a 3-pin plug having one earth pin. Earthing work is not required in the case of a

3-pin power outlet equipped with an earth contact.

If the power outlet is not a 3-pin outlet equipped with an earth contact, ask a qualified contractor to do

the earthing work.

5. Setting up the shelves

Three shelves are packaged at the bottom of the chamber.

Set the shelves firmly in place on the shelf stoppers at the

standard locations. (Fig. 3)

6. Installing an earth leakage circuit breaker

Install an earth leakage circuit breaker (on the unit’s power

supply side), which is mandatory under the applicable laws

and regulations.

Contact our sales representative or agent to arrange the

installation of an earth leakage circuit breaker.

Shelf stopper

Fig. 3

17

START-UP PROCEDURE

Follow this procedure for the initial operation of the unit and for consequent operations (after temporary

stoppage for cleaning, maintenance or moving).

After a power failure, the unit will restart operation automatically with the same settings as before the

power failure. [page 19],

1. Check that the following switches are turned off: [power switch, battery switch, switch of the optional

back-up cooling kit (if installed)].

2. Connect the power supply cord to the dedicated power source with the appropriate rating with the

chamber empty.

3. Turn ON the power switch to start operation of the unit.

4. Turn on the battery switch.

Note: When the battery switch for power failure alarm is OFF, “S20: Battery Inactive, SW may be OFF.” is

displayed in the message display field. By turning ON the battery switch for power failure alarm, this

message disappears.

5. Set the desired chamber temperature [pages 23 - 24].

The factory setting of chamber temperature is -80

6. Using the temperature display, check that the chamber temperature has cooled to the set

temperature.

Check that the chamber temperature falls to the set temperature when the start-up after cleaning,

maintenance or moving.

7. Turn on the switch of the optional back-up cooling kit (if installed).

8. Do the alarm test. Make sure that the buzzer sounds by pressing Buzzer key for 5 seconds. Press

Buzzer key again to stop the buzzer and the alarm test finishes.

9. Press the test switch of the optional back-up cooling kit (if installed) to check it is working.

10. Gradually place the material inside the chamber.

Putting a large amount of material into the chamber at one time causes the temperature to rise.

11. Set the alarm temperature [pages 23 – 24] and the buzzer suspended period [pages 29 - 30], lock

the menu setting [pages 25 - 27], and set the compressor delay [pages 24 - 25], and door alarm delay

[pages 29 - 30] as required.

Note:

• When closing the outer door push the latch until the latch is locked in place. Insufficient pushing can

lead to temperature rise in the chamber.

• In case some optional inventory racks are in the chamber, be careful not to drop inventory rack when

pulling out it.

o

C.

18

DURING/AFTER POWER FAILURE

Operation during power failure

When the battery switch for power failure is ON, during a power failure the behavior of this unit is as

follows.

●The power failure alarm is activated [page 46].

Press Buzzer key to silence the buzzer of the power failure alarm. In case the ring back is turned ON,

buzzer sounds again when a power failure still continues after ring back set time passed [page 30].

●LCD touch panel is turn OFF [page 46].

By touching the LCD touch panel, it lights in the set brightness for 5 seconds.

●The High/Low Alarm is ready to activate during a power failure [pages 23 - 24 and 46].

An alarm message is displayed on the message display field. Alarm display, the buzzer and the remote

alarm (although it is of the power failure alarm) are already activated.

●The clock function does not stop.

●Operation log data and alarm log data during a power failure is saved.

Note: When the capacity of the battery for power failure alarm is flat during a power failure, subsequent

operation log data and alarm log data is not saved.

Operation after recovery from power failure

The set value is memorized by nonvolatile memory. Accordingly, the chamber resumes the operation with

setting before power failure.

Note:

• It may take up to 1 minute until the LCD touch panel lights after recovery from power failure.

• All products start at the same time as the recovery from the power failure, so that, the temporary voltage

drop may have a bad influence on the starting of this unit. To prevent this situation, set the appropriate

compressor delay time of this unit [pages 24 - 25].

Although the power failure alarm is canceled at the

recovery of the power failure, in order to remind

that power failure had happened, buzzer is

sounding and “Alarm” is displayed alternately in

normal characters and reverse video in the alarm

display [page 48]. By pressing Buzzer key, the

alarm display returns to “Normal” and the buzzer

stops.

Note: It is possible to confirm the past alarms in

the “Displaying alarm log” [pages 38 - 39].

19

BASIC OPERATION ON LCD TOUCH PANEL

A

♦Message select key:

(Operate) Changing some messages

♦Buzzer key: (Operate) Silencing the buzzer

(Alarm is not canceled except for some alarms; page 48)

●Operation from Menu key

■Menu screen

♦Set →

♦Log →

♦Chart →

♦Actual Temp. (Display) Chamber temp. log graph (can be exported) 32~34

♦Door Opening (Display) Door opening log graph (can be exported) 32~34

♦Actual Temp. (Export) Chamber temperature log 35~37

♦Door Opening (Export) Door opening log 35~37

♦Setting (Setting) Log interval, Unique ID 31~32

♦Alarm (Display)

♦Alarm Export (Export) Alarm log 40~41

♦Key Lock →

♦Tools →

♦Operation Setting (Setting) Comp. delay time 24~25

♦Alarm Setting (Setting) Alarm delay, ring back, remote alarm etc. 29~30

♦DAQ Setting Do not press (It is not possible to set.)

♦Date & Time (Setting) Date, time 43

♦Brightness/Sleep (Setting) Brightness, sleep ON/OFF etc. 44~45

Page

■Temp. Setting screen

■Log screen

■Chart screen

Data

♦

Export

■Key Lock screen

■Tools screen

→

■Export screen

(Setting) Temp., High Alarm, Low Alarm 23~24

larm log (can be exported) 38~39

(Setting) Key lock ON/OFF, password 25~28

20

BASIC PARAMETERS

How to input numerical value and alphanumeric character

On each screen in the LCD touch panel, it may be necessary to input numerical value or alphanumeric

characters.

●When inputting numerical value

1. By pressing numeric input box, numeric input

window is displayed.

2. Press Numeric key or Up/Down key to input

numerical value, and press OK key.

●Key description

• Numeric key (0~9): Input numerical value.

• Up/Down key (▲/▼): Increases or decreases the numerical value displayed in the numeric input box.

• Clear key: Deletes the numerical value displayed on the numeric input box.

• Cancel key: Stops inputting on the numeric input box and closes the input window.

Note: Up/Down key may not be displayed.

Numeric input box

Numeric input window

21

BASIC PARAMETERS

●When inputting alphanumeric characters

1. By pressing alphanumeric input box, alphanumeric

input window is displayed.

2. Press alphabetic key and numeric key to input

alphanumeric characters, and press OK key.

●Key description

• Alphabetic key (A~Z, Space): Input alphabetic characters or spaces.

• Numeric key (0~9): Input numerical values.

• UC/LC key (A a): Change UC/LC of alphabetic key.

• Left/Right key ( / ): Move the cursor to left/right.

• Delete key: Delete an alphanumeric character on the left side of the cursor.

• Cancel key: Stops inputting on the alphanumeric input box and closes the alphanumeric input window.

Note: While the alphanumeric input window is open, it is not possible to operate Top key and Back key.

[Auto return function]

When there is no key operation for about 90 seconds on the screen excluding the top screen: Exit the

setting mode and return to the top screen.

<

When the sleep function is on >

When there is no key operation for about 90 seconds without alarm / error after sleep state: Exit the

setting mode and return to the top screen.

Alphanumeric input box

Alphanumeric input window

22

BASIC PARAMETERS

Setting Temperature, High Alarm and Low Alarm

Set the Temperature, High Alarm and Low Alarm for normal operation according to the following

procedure. The unit automatically starts operation using these settings after power-on.

1. Press Menu key to lead the Menu screen.

2. Press Set key to lead the Temp. Setting

screen.

3. Input each parameter. Press Apply key to

save the input value. The display returns to the

Menu screen.

●Each parameter setting

• Temperature: Set value of chamber temperature.

Settable range: -90

• High Alarm: When the chamber temperature exceeds the High Alarm set temperature (= the set

temperature + the set value of High Alarm)*, the High Alarm is activated.

Settable range: +5

• Low Alarm: When the chamber temperature falls below the Low Alarm set temperature (= the set

temperature - the set value of Low Alarm)*, the Low Alarm is activated.

Settable range: -40

o

C~-50 oC, Control range: -86 oC~-50 oC, factory setting: -80 oC.

o

C~+40 oC, factory setting: +10 oC.

o

C~-5 oC, factory setting: -10 oC.

23

BASIC PARAMETERS

* The current chamber temperature is the value rounded off below a decimal point, so the High/Low

Alarm may be activated when the value of the current chamber temperature is equal to the High/Low

Alarm set temperature.

4. On the Menu screen, press Back key to return to the Top screen.

Setting operation control mode

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Operation Setting key to lead the

Operation Setting screen.

24

BASIC PARAMETERS

4. Input each parameter. Press Apply key to

save the input value and setup. The display

returns to the Tools screen.

●Each setting

• Compressor Delay:

The time from turning ON this unit until starting its compressor. This unit is required a large electric power

at the moment its compressor starts. When some units are in a same room, set so as to be shifted to

each other the compressor delay times, to prevent the simultaneous start of all compressors after power

failure. Settable range: 3 minutes~15 minutes, factory setting: 3 minutes.

5. Press Top key to return to the Top screen.

Setting key lock

1. Press Menu key to lead the Menu screen.

2. Press Key Lock key to lead the Key Lock

screen.

25

BASIC PARAMETERS

3. On the Key Lock screen, it is possible to set

each setting of key lock.

• Key Lock: By holding Key Lock slide key and

sliding it to the right, Key Lock turns to ON.

• Password #1: The number (Max. 6 digits)

inputted here are registered the release password

of Key Lock.

• Confirm Password #1:

To prevent erroneous input, input the same

password as Password #1 input box. When

inputting different password, Notice dialog box is

displayed. Press OK key and input the correct

password.

• By pressing Apply key, Key Lock turns to ON,

password #1 is saved, and Confirm dialog box is

displayed.

Yes: On the Key Lock screen, it is possible to set

the release password #2.

No: The display returns to the Menu screen.

Select [No]when it is no need to set the password

#2.

Note: Two release passwords of Key Lock are

settable. To release it, you can unlock by entering

one of the passwords.

4. Set the password #2.

• Password #2: The number (Max. 6 digits)

inputted here are registered the release password

of Key Lock.

Confirm Password #2:

To prevent erroneous input, input the same

password as Password #2 input box. When

inputting different password, Notice dialog box is

displayed. Press OK key and input the correct

password.

• By pressing Apply key, the password #2 is saved

and Information dialog box is displayed.

26

BASIC PARAMETERS

5. On the Information screen, press OK key to

return to the Menu screen.

6. On the Menu screen, press Back key to return to the Top screen.

Note: Manage the release password of Key Lock properly.

●Operation for Keylock-ON

• When pressing Menu key, Password input box is

displayed, and input of the release password of

Key Lock is required. If two passwords are

registered, you can unlock by entering one of the

passwords

• When the inputted password is incorrect, Notice

dialog box is displayed. Press OK key, and then

input the correct password.

27

BASIC PARAMETERS

Removing key lock

1. By pressing Menu key, the Password input

window is displayed.

2. On Password input box, input the set release

password (#1 or #2) of Key Lock, and press OK

key to lead the Menu screen.

3. Press Key Lock key to lead the Key Lock

screen.

4. On the Key Lock screen, by holding Key Lock

slide key and sliding to the left, change to OFF.

Press Apply key to turn the key lock OFF. The

display returns to the Menu screen.

Note: The release password of key Lock is

deleted.

5. On the Menu screen, press Back key to return

to the Top screen.

28

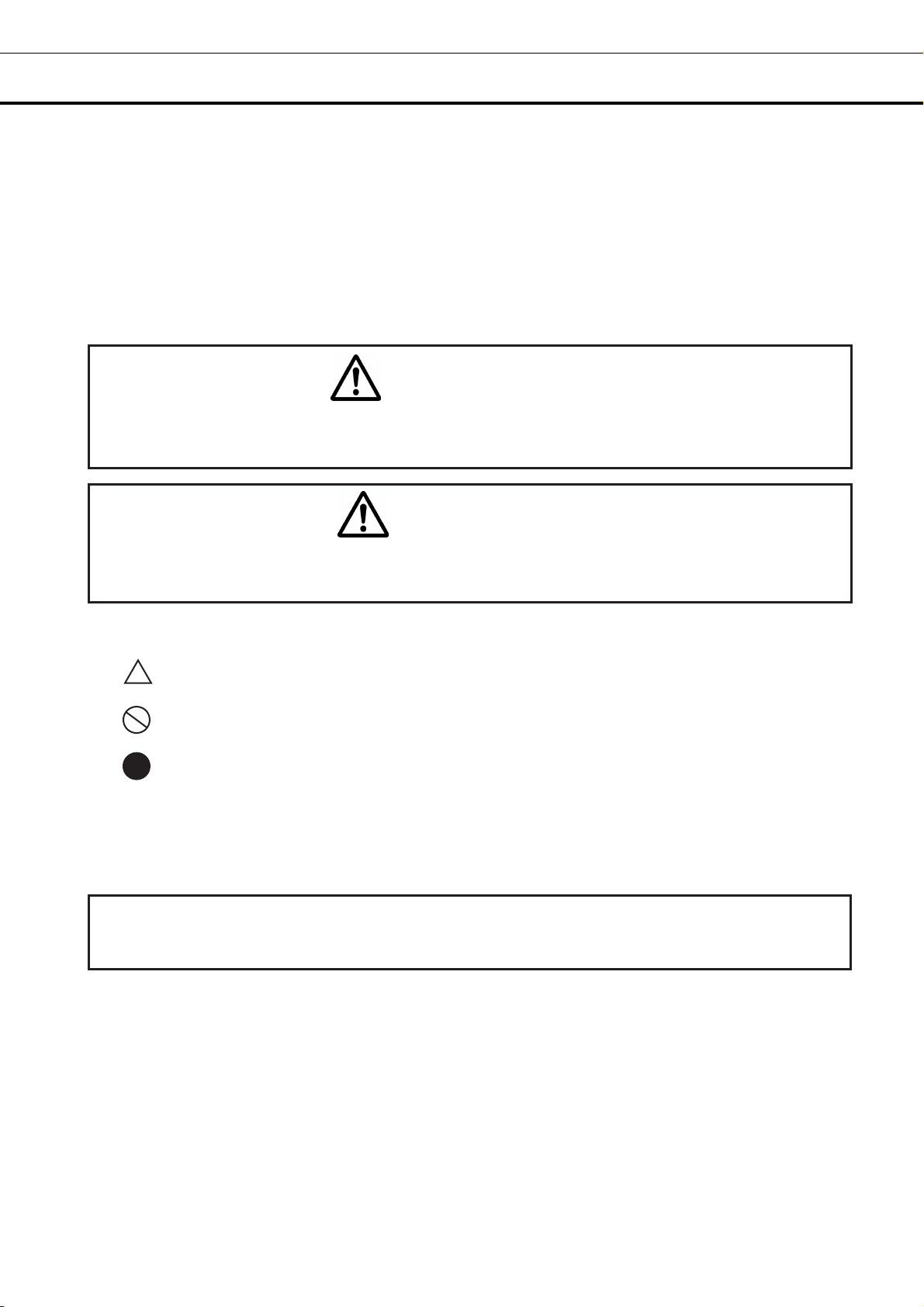

ALARM PARAMETERS

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Alarm Setting key to lead the Alarm

Setting screen.

29

ALARM PARAMETERS

4. On the Alarm Setting screen, it is possible to

set each setting. Press Apply key to save the

input value and setup. The display returns to the

Tools screen.

●Each setting

• Alarm Delay:

The function is that when the unit is in the alarm state of High Alarm or Low Alarm, the alarm buzzer will

sound after the alarm delay set time passed.

Settable range: 0 minute~15 minutes, factory setting: 15 minutes.

Note: When the unit is recovered from the alarm state within the alarm delay time, the buzzer does not

sound after the elapse of the alarm delay.

• Door Delay:

The function is that when the unit is in the alarm state of door, the alarm buzzer will sound after the alarm

delay set time passed. Settable range: 0 minute~15 minutes, factory setting: 2 minutes.

Note: When the unit is recovered from the alarm state within the door alarm delay time, the buzzer does

not sound after the elapse of the door alarm delay.

• Ring Back:

The function is that the alarm buzzer sounds again when the alarm state still continues after the ring back

set time passed even though the alarm buzzer was stopped by pressing Buzzer key. By holding and

sliding Ring Back slide key to the right, the Ring Back is turned to ON.

Settable range: 1 minute~99 minutes, factory setting: 30 minutes.

Note: At Door alarm, the alarm is not re-activated because the alarm itself is deactivated by pressing

Buzzer key [page 48].

• Remote Alarm:

The function is that the remote alarm is continued even though the buzzer is stopped by pressing Buzzer

key. By holding and sliding Remote Alarm slide key to the right, the Remote Alarm is turned to ON (not in

conjunction with Buzzer key). Factory setting: ON.

5. Press Top key to return to the Top screen.

●

At the alarm state

• While the unit’s alarm is being activated and the

buzzer is being sounding, the buzzer is silenced by

pressing Buzzer key. For the behavior at the time

of pressing Buzzer key and the re-activation of

alarm, under each setting condition, refer to Table

2-3 on page 48.

Resolve the cause of the alarm in reference to

pages 46 - 48 because the alarm itself is not

deactivated by pressing Buzzer key except for

some alarms.

30

OPERATION/ALARM LOG

Setting log interval

The unit is equipped with a function of saving operation log data (chamber temperature and open/close

state of door).

Note: When the battery switch for power failure alarm is ON, operation log is saved during a power

failure.

Use the following procedure to set the log interval (interval of acquiring the operation log).

1. Press Menu key to lead the Menu screen.

2. Press Log key to lead the Log screen.

3. Press Setting key to lead the Setting screen.

31

OPERATION/ALARM LOG

4. On the Setting screen, input Log Interval. Press

Apply key to save the input value. The display

returns to the Log screen.

Settable range: 2 minutes~30 minutes.

Factory setting: 6 minutes.

Note: Only an even number can be inputted.

When inputting an odd number and when pressing

OK key in the numeric input window, it changes to

an even number which is 1 smaller than that.

Note: It is possible to register 8-digit alphanumeric

characters as the Unique ID [page 37].

Note: Relation between log interval and the estimated amount of data that can be saved

Log interval=2 minutes: Approx. 46 days

Log interval=6 minutes: Approx. 135 days

Log interval=30 minutes: Approx. 664 days

When saving data more than the above, and the data is overwritten and the old data is delated.

5. Press Top key to return to the Top screen.

Displaying operation log

Operation log saved in the freezer can be displayed graphically on the LCD touch panel.

1. Press Menu key to lead the Menu screen.

2. Press Log key to lead the Log screen.

32

OPERATION/ALARM LOG

3. Press Chart key to lead the Chart screen.

4. On the Chart screen, input the date (year /

month / day) of the operation log you want to

display graphically.

5. On the Chart screen, by pressing Show key

after pressing the item you want to display

graphically, the graph of each operation log is

displayed.

• Actual Temp.:

Chamber temperature log graph

(Go to procedure 6)

• Door Opening:

Open/close state of door log graph

(Go to procedure 7)

6. Actual Temp. log graph is displayed.

• Press Back key to return to the Chart screen.

• Press Top key to return to the Top screen.

To previous day To next day

To Door Opening log

33

OPERATION/ALARM LOG

To Actual Temp. log

7. Door Opening log graph is displayed.

• Press Back key to return to the Chart screen.

• Press Top key to return to the Top screen.

●On the Chart screen of procedure 6 or 7 log data can be exported in CSV format to the USB memory

inserted into the USB port.

To previous day

To next day

8. Insert the USB memory into the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

9. Press Export key.

10. When the export is complete, Information

dialog box is displayed. Press OK key. Refer to

pages 36 and 37 for the details about abnormal

export or exported file name.

11. Press Top key to return to the Top screen.

34

OPERATION/ALARM LOG

Exporting operation log

Operation log data saved in the freezer can be exported in CSV format to the USB memory inserted into

the USB port.

1. Insert the USB memory into the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

2. Press Menu key to lead the Menu screen.

3. Press Log key to lead the Log screen.

4. Press Data Export key to lead the Export

screen.

35

OPERATION/ALARM LOG

5. On the Export screen, select the time period

you want to export.

• To export the saved operation log data over the

entire period, press All radio button.

• To export the operation log data of a specified

date, press 1 Day radio button and input the date

(year / month / day) of the operation log data you

want to export.

Note: The error of about 1 minute may be

observed during a month. Refer to page 43 for the

procedure of setting time.

6. On the Export screen, select the type of

operation log data you want to export.

• To export all types of operation log data, press All

Ch key.

• To export only operation log data you want to

export, select operation log data you want to export,

and then press Selected Ch key.

• Actual Temp.: Chamber temperature log data

• Door Opening: Open/close state of outer door log

data

Note: When no USB memory is inserted into

the USB port, Notice dialog box is displayed.

Press OK key, and then insert a USB memory

into the USB port.

36

OPERATION/ALARM LOG

Note: When the specified operation log data

does not exist, Notice dialog box is displayed.

Press OK key, and then re-specified according

to procedure 5 and 6.

7. When the export is complete, Information

dialog box is displayed. Press OK key.

Note: Even after the export of operation log

data is complete, operation log data saved in

the unit are not deleted.

8. Remove the USB memory from the USB port.

Note:

• The log folder is created in the USB memory, and the exported file is saved in it in CSV format. The

exported file name is in date (8 digits) - type of data format.

(e.g.) When exporting all types of data using All (from Jan. 1st, 2017 to Oct. 1st, 2017):

20170101-20171001_AllCh.csv

20170101-20171001_Door.csv

(e.g.) When exporting Actual Temp. using 1 Day (Jan. 1st, 2017):

20170101_Temp.csv

If the file name is duplicated, A sequential number such as "-1" is added to the end of the file name to

be output later.

• On the beginning of the exported file, product name (“MDF-DU502VH” or “MDF-DU702VH”) is written.

However when the Unique ID is registered [page 32], product name and Unique ID (8-digit) are written.

(e.g.) When “RoomA001” is set as the Unique ID of MDF-DU702VH:

MDF-DU702VH, RoomA001

9. Press Top key to return to the Top screen.

37

OPERATION/ALARM LOG

Displaying alarm log

The unit is equipped with a function of saving alarm log data (Max. 256 logs).

Note:

• When saving alarm logs more than 257, the oldest alarm log is deleted, and then overwritten.

• When the battery switch for power failure alarm is ON, operation log is saved during a power failure.

Alarm log saved in the freezer can be displayed graphically on the LCD touch panel.

1. Press Menu key to lead the Menu screen.

2. Press Log key to lead the Log screen.

3. Press Alarm key to lead the Alarm screen.

38

OPERATION/ALARM LOG

4. On the Alarm screen, the newest 7 days’ alarm

logs (containing that day) are displayed.

Note: When the number of applicable alarm log is

6 or more, by pressing the top (▲) or the bottom

(▼) log, the log table currently displayed scrolls

and hidden alarm logs can be seen.

• Press Back key to return to the Log screen.

• Press Top key to return to the Top screen.

5. On the Alarm screen, by inputting days into the

Last XX Days input box, alarm logs for specified

days (containing that day) are displayed.

Settable range: 1 day~45 days.

Note: The error of about 1 minute may be

observed during 1 month. Refer to page 43 for the

procedure of setting time.

• Press Back key to return to the Log screen.

• Press Top key to return to the Top screen.

●On the Alarm screen of procedure 4 or 5, alarm log data can be exported in CSV format to the USB

memory inserted into the USB port.

6. Insert the USB memory into the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

7. Press Export key.

8. When the export is complete, Information

dialog box is displayed. Press OK key. Refer to

pages 41 and 42 for the details about abnormal

export or exported file name.

9. Press Top key to return to the Top screen.

39

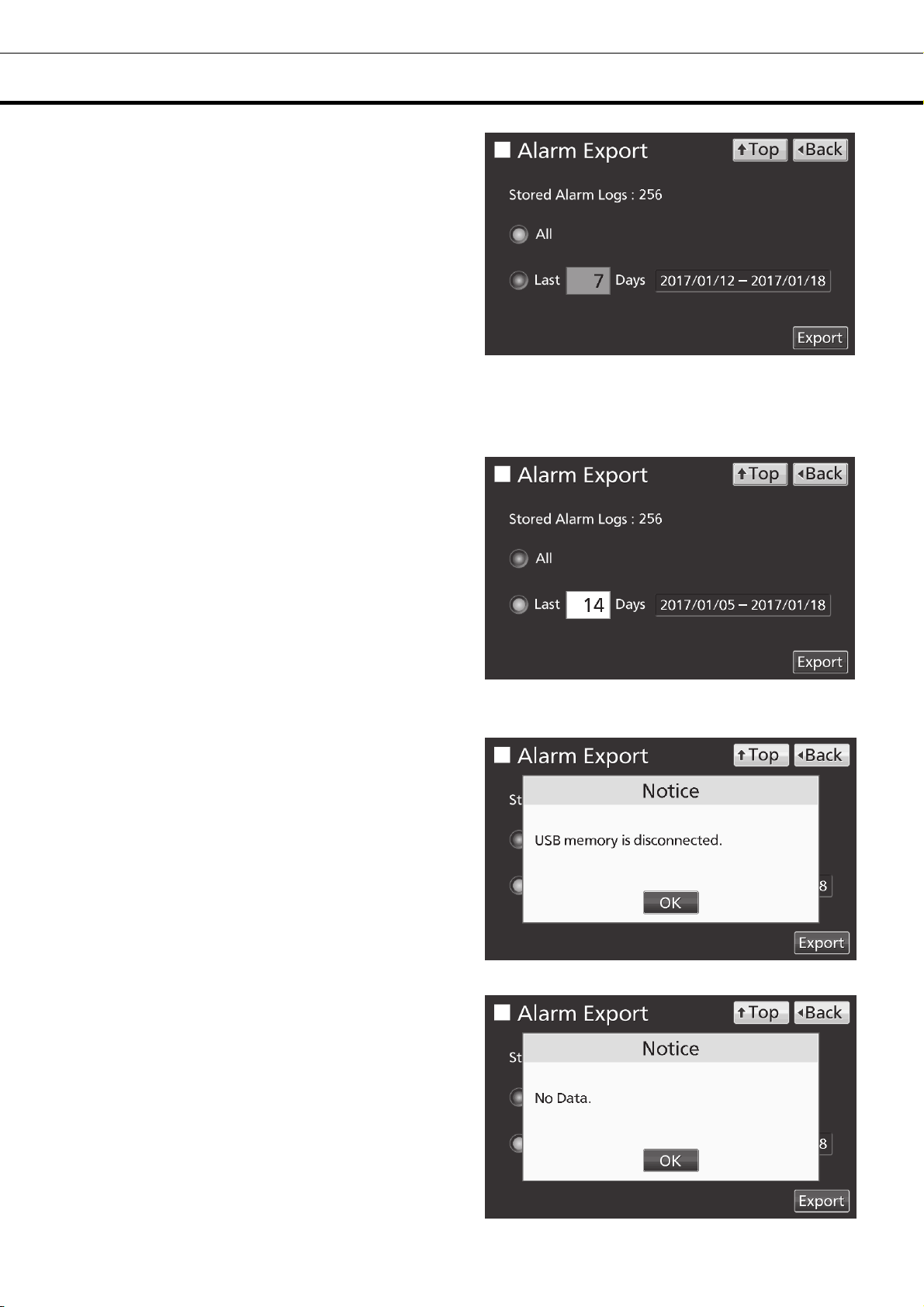

OPERATION/ALARM LOG

Exporting alarm log

It is possible to export saved alarm log data to a USB memory inserted in the USB port by CSV format.

1. Insert a USB memory in the USB port.

Note: It is not possible to use a USB memory with security functions that requires entering password.

2. Press Menu key to lead the Menu screen.

3. Press Log key to lead the Log screen.

4. Press Alarm Export key to lead Alarm Export

screen.

40

OPERATION/ALARM LOG

5. On the Alarm Export screen, select the period

to export.

• To export the saved alarm log data over the

entire period, press All radio button.

• To export the alarm log data for the specified

days (The newest period containing that day),

press Last XX Days radio button and input days.

Settable range: 1 day~45 days.

Note: The error of about 1 minute may be

observed during 1 month. Refer to page 43 for

the procedure of setting time.

6. Press Export key.

Note:

• When USB memory is not inserted in the USB

port, Notice dialog box is displayed. Press OK

key and insert an USB memory into the USB

port.

• When alarm log data does not exist in the

specified days, Notice dialog box is displayed.

Press OK key and specify days again as shown

in the procedure 5.

41

OPERATION/ALARM LOG

7. Even after completion the export of alarm log

data, Information dialog box is displayed. Press

OK key.

Note: After completing the export of alarm log

data, alarm log data saved at unit is not deleted.

8. Remove a USB memory from the USB port.

Note: A log folder is created in a USB memory, and an exported data file is saved in the log folder by

CSV format.

Exported file name; The first date during exported period (8 digits) + the last date (8 digits) + AlarmLog

Example) When exporting alarm log data for 7 days on January 7, 2017;

20170101-20170107_AlarmLog.csv

If the file name is duplicated, A sequential number such as "-1" is added to the end of the file name to

be output later.

9. Press Top key to return to the Top screen.

42

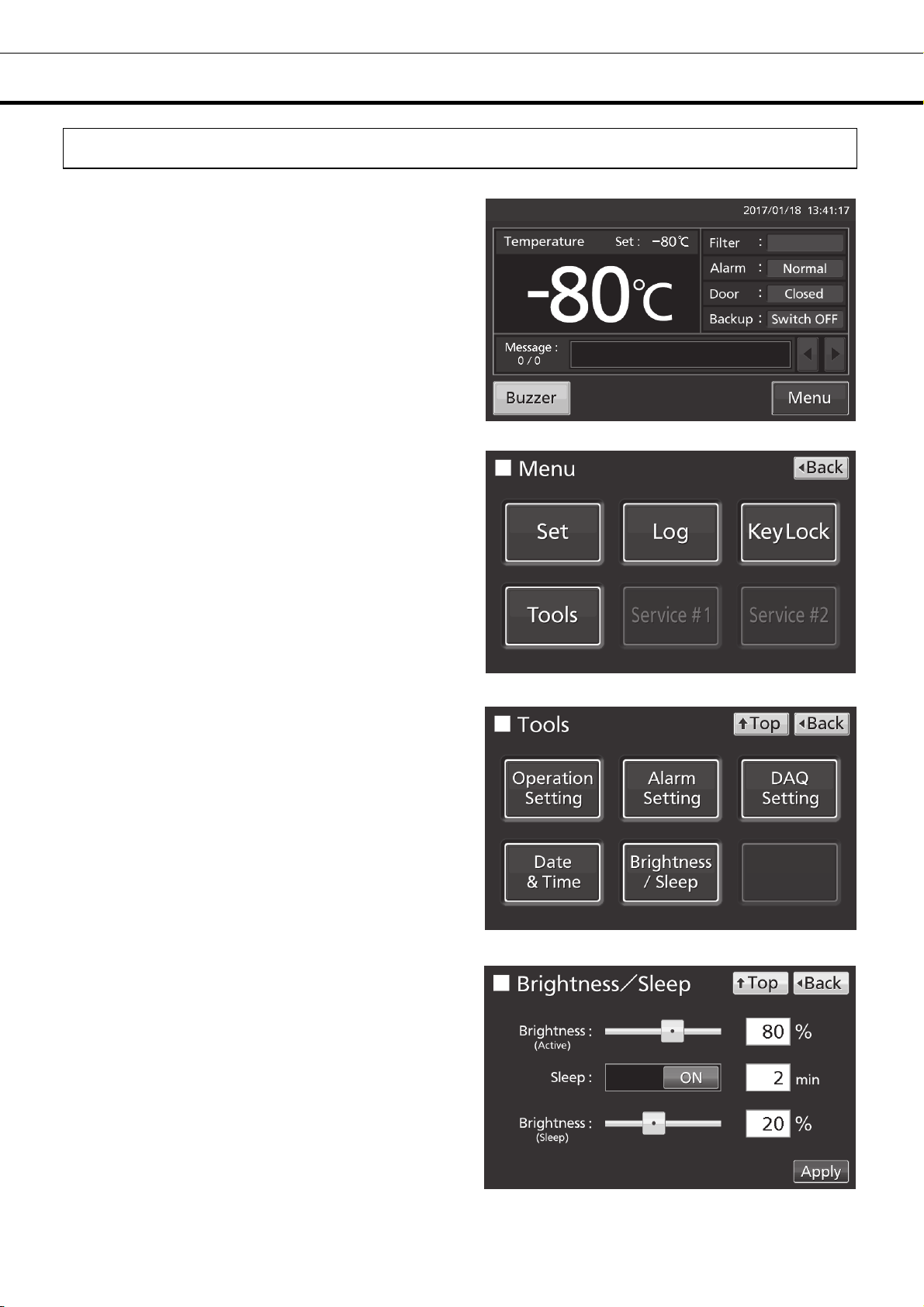

OTHER PARAMETERS

Setting date and time

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Date & Time key to lead the Date &

Time screen.

4. On the Date & Time screen, input the present

date and time. Press Apply key to save the input

value. The display returns to the Tools screen.

Note:

• 24-hour clock.

• It is recommended to set the time periodically

since the error of about 1 minute may be observed

during a month.

5. Press Top key to return to the Top screen.

43

OTHER PARAMETERS

Setting brightness and sleep

1. Press Menu key to lead the Menu screen.

2. Press Tools key to lead the Tools screen.

3. Press Brightness/Sleep key to lead the

Brightness/Sleep screen.

4. On the Brightness/Sleep screen, each setting of

brightness and sleep is available. Press Apply key

to save the input value and setup. The display

returns to the Tools screen.

44

OTHER PARAMETERS

●Each setting

• Brightness(Active):

Brightness of LCD touch panel of the usual state. Adjust Brightness(Active) slide bar or input set value

into the Brightness(Active) input box. Settable range: 50~100, factory setting: 80.

• Sleep:

The function is that the brightness of LCD touch panel is lowered to save electricity, when there is no key

operation during set time.

By holding the Sleep slide key and sliding it right, the Sleep function is turned to ON. Input the set value

of time to change the Sleep state. Settable range: 1 minute~5 minutes, factory setting: 2 minutes.

Note: It is not possible to operate any key in the Sleep state. By touching the LCD touch panel, the Sleep

state is released and the LCD touch panel returns to the usual state. Under this condition, key operations

are available.

• Brightness(Sleep):

Brightness of LCD touch panel of the Sleep state. Adjust Brightness(Sleep) slide bar or input set value

into the Brightness(Sleep) input box. Settable range: 0~50, factory setting: 20.

5. Press Top key to return to the Top screen.

45

ALARMS AND SELF-DIAGNOSIS

Warning: The cooling performance is significantly reduced. The chamber temperature may get higher

considerably. Take some precautions for the storage items immediately (transferring the storage items

to another freezer or placing of dry ice wrapped in newspaper in the chamber) except when the cause is

clear and the chamber temperature can be recovered soon.

Contact our sales representative or agent after turning off the power switch.

LCD touch panel

Message display field

Warning: Temp Control Failure.

W01: Power Failure.

Warning: Temp Control Failure. *1

W02: Compressor Temp Abnormal.

Warning: Temp Too High.

W04

Warning: Temp Too Low.

W05

Warning: Temp Control Failure.

W06: Compressor 'H' Control Failure.

Warning: Temp Control Failure.

W07: Compressor 'L' Control Failure.

Warning: Temp Control Failure. *3

W08: Temperature Controller Failure.

Warning: Temp Control Failure. *2

W09: Temperature Sensor Error.

Warning: Temp Control Failure. *2

W10: Temperature Sensor Error.

Situation Buzzer

The battery switch for power failure alarm is

ON, and under any of the following

conditions.

•During a power failure

•Power switch is OFF

•Power supply cord is disconnected.

Compressor Temp Abnormality.

If the chamber temperature exceeds the

set temp. + the set value of High Alarm.

If the chamber temperature falls below the

set temp. - the set value of Low Alarm.

Compressor control failure due to

communication failure of H side inverter

Compressor control failure due to

communication failure of L side inverter

When communication between LCD touch

panel and control substrate is died out or

unstable.

If the thermal sensor is disconnected.

If the thermal sensor is short-circuited.

Intermittent

tone

― ― Communication error

Intermittent

tone

Remote

alarm

Alarm

mode

Alarm

mode

Alarm & safety

Power failure

alarm

Compressor Temp

Abnormality *1

High Alarm

Low Alarm

Communication error

Communication error

Temperature Sensor

disconnected *2

Temperature Sensor

short-circuited *2

*1:The compressor stops in the case of W02.

*2:The compressor runs continuously in the case of W09 or W10.

The compressor stop has a priority over the continuous running if the above two errors come up at one time.

*3:The chamber temperature is not displayed in the case of W08

Alarm: Cooling performance may decline and the temperature of the chamber may rise. Wait for the

recovery of chamber temperature if the temperature change is temporary resulting from user operation.

For other cases, failure or chamber temperature rise may cause if this status continues.

Take some precautions for the storage items (transferring the storage items to another freezer or placing

of dry ice wrapped in newspaper in the chamber).

Contact our sales representative or agent.

LCD touch panel

Message display field

Alarm: Temp Too High.

A04

Alarm: Temp Too Low.

A05

Situation Buzzer

If the chamber temperature exceeds the

set temp. + the set value of High Alarm.

If the chamber temperature falls below the

set temp. - the set value of Low Alarm.

― ―

Remote

alarm

Alarm & safety

High Alarm

Low Alarm

46

ALARMS AND SELF-DIAGNOSIS

Status: There is a possibility of failure other than the cooling performance. The chamber temperature is

under control. The alarm may not be triggered in the case of any failure if this status continues

Contact our sales representative or agent.

LCD touch panel

Situation Buzzer

Message display field

Remote

alarm

Alarm & safety

Status: Temp Control Risk. *4

S01: Cooling Circuits Overload.

Status: Temp Under Control. *5

S02: Ambient Temp Abnormal.

Status: Temp Under Control.

S03: Air Intake Port Heater Failure.

Status: Temp Under Control.

S10: Cascade Sensor Error.

Status: Temp Under Control.

S11: Cascade Sensor Error.

Status: Temp Under Control.

S12: Filter Sensor Error.

Status: Temp Under Control.

S13: Filter Sensor Error.

Status: Temp Under Control.

S14: Ambient Temp Sensor Error.

Status: Temp Under Control.

S15: Ambient Temp Sensor Error.

Status: Temp Under Control.

S16: Main Battery Charging Failure.

Status: Temp Under Control.

S17: Backup Battery Charging Failure.

Status: Temp Under Control.

S18: Exchange a Main Battery.

Status: Temp Under Control.

S19: Exchange a Backup Battery.

Status: Temp Under Control.

S20: Battery Inactive, SW may be OFF.

When the chamber temp. does not reach

the set temp. for approx. 5 days or more.

When the ambient temp. is over 35 oC or

o

lower than 0

Heater failure.

When the cascade sensor disconnected.

When the cascade sensor short-circuited.

When the filter sensor disconnected.

When the filter sensor short-circuited.

When the ambient temp. sensor

disconnected.

When the ambient temp. sensor

short-circuited.

When the battery voltage does not

increase after certain period.

When the cumulative operating time

exceeds about 3 years.

When about 3 years passed after installing

backup cooling kit.

When the battery switch for power failure

alarm is OFF.

C.

―

Intermittent

tone

―

―

Overload operation

*4

Abnormal ambient

temperature *5

Air Intake Port

Heater Failure

Cascade Sensor

disconnected

Cascade Sensor

short-circuited

Filter Sensor

disconnected

Filter Sensor

short-circuited

Ambient Temp Sensor

disconnected

Ambient Temp Sensor

short-circuited

Main Battery

Charging Failure

Backup Battery

Charging Failure

Battery for power

failure alarm

replacement

Battery for backup

cooling kit

replacement

Battery switch check

Door Open. When door is open.

*4: In the case of S01, check the following:

(1) There are too many items stored inside the chamber at a time.

(2) The door is frequently opened. The door seal is damaged.

(3) The set chamber temperature is higher than -80

*5: Check the air conditioning at the installation site in the case of S02.

o

The ambient temperature should be 5

C~30 oC.

o

C.

Intermittent tone

(After door delay

time has

elapsed.)

Door alarm

47

ALARMS AND SELF-DIAGNOSIS

●Table 2

Table 2 In the cases of other than the door alarm.

Remote Alarm setting

ON: Non-interlock

with Buzzer key

OFF: Interlock

Note: Resolve the cause of the alarm in reference to pages 46 - 47 because the alarm itself is not

deactivated by pressing Buzzer key.

Table 3 In the cases of the door alarm.

Remote Alarm setting

ON: Non-interlock

with Buzzer key

OFF: Interlock

●Table 4 shows the situation after being canceled the High/Low Alarm and recovery from a power failure

with no operation.

Table 4 The situation after being canceled the High/Low Alarm and recovery from a power failure with

no operation

Canceled alarm

~3 show the behavior of the alarm (buzzer) and Ring Back function when pressing Buzzer key.

Buzzer from unit Remote Alarm

OFF

Buzzer from unit

OFF

LCD touch panel

with Buzzer key

with Buzzer key

Message display field Alarm display

Ring Back

setting

ON

OFF OFF

ON ON

OFF OFF OFF

Ring Back

setting

ON

OFF

ON

OFF

When pressing

Buzzer key

(Alarm is not

canceled)

When pressing

Buzzer key

(Alarm is

canceled)

When the Ring Back

set time passes

ON

When the Ring Back

set time passes

OFF

(Alarm is already

canceled)

When pressing

Buzzer key

ON

OFF (Alarm is

not canceled)

Remote Alarm setting

Buzzer

When the Ring Back

set time passes

ON

(Under continuation)

ON

OFF

Remote

alarm

Safety

operation

High Alarm

Low Alarm

Power failure

alarm

Note: By pressing Buzzer key, the alarm display returns to “Normal” and buzzer stops.

―

―

“Alarm” is displayed alternately in

normal characters and reverse video

“Alarm” is displayed alternately in

normal characters and reverse video

Intermittent

Intermittent

tone

tone

― ―

― ―

48

ROUTINE MAINTENANCE

Cleaning the exterior, interior, and accessories

Use a dry cloth to wipe down the outside and inside of the unit and all accessories. If the outside panels

are dirty, clean them with a diluted neutral dish-washing detergent.

Wipe off condensation from the exterior of the cabinet with a dry, soft cloth.

Using an undiluted solution of detergent may cause the unit’s plastic areas to crack. Follow the

directions on the detergent for details of dilution.

After the wiping the cabinet or accessories with a diluted detergent, be absolutely sure to wipe the

surfaces with a cloth dipped in clean water to remove traces of the detergent. After this, be absolutely

sure to wipe the surfaces with a dry cloth.

<Important>

■ Do not use a brush, an acid, a thinner, laundry soap, a powder detergent, or boiling water for cleaning.

These may cause damage to painted surfaces or cause perishing of plastic and rubber components.

Moreover, do not wipe plastic and rubber components with a volatile material.

■ In order to maintain the unit’s intended level of performance, always replace accessories that have

been removed for cleaning.

Cleaning of air intake port (Manual)

Using the cap for air vent is likely to build a frost in/around the air intake port. Clean it in the case shown

below.

Condition Check / Remedy

When frost and ice can be

seen in the air intake port.

The outer door does not

open even if the cap of the

air intake port is opened.

Frost and ice can be seen in

the chamber.

WARNING

For removing the frost in the air intake port, do not use a tool with sharp edge such as a knife or a screw

driver.

The pipe of the air intake port is thrust with a stick for air intake port

cleaning of the accessories, and frost is taken.

The pipe of the air intake port is thrust with a stick for air intake port

cleaning of the accessories, and frost is taken.

Frost and ice inside the chamber are taken with scraper of the

accessories.

49

ROUTINE MAINTENANCE

Cleaning of condenser filter

This unit is provided with the filter alarm indicator on the LCD touch panel. Clean the condenser filter

when this indicator is lit. Clean the condenser filter once a month even if the filter alarm indicator is not

on. A dusty condenser filter may cause shorter compressor life as well as the poor cooling.

Clean the condenser filter by the procedure below.

1. Open the grille by pulling it to you as shown in the

figure.

2. Take out the condenser filter.

3. Wash the condenser filter with water.

4. Replace the condenser filter and the grille. (Set the

handle of the condenser filter at the front.)

5.

Check that the filter alarm indicator is off in the event

the filter alarm indicator was ON.

Condenser

filter

Grille

WARNING

Do not touch the condenser directly when the filter is removed for cleaning. This may cause injury by

hot surface.

50

ROUTINE MAINTENANCE

Defrosting of chamber

Frost may accumulate near the top of the chamber, near the door in the chamber, or near the air intake

port (Auto). Excessive accumulation of frost is likely to create gaps between the door and the door

gasket, which can reduce the cooling performance. Remove the frost from the chamber and the inner

door with the scraper enclosed with the unit. Use the following procedure for defrosting when excessive

frost builds up in the chamber.

Note:

Do not use tool with a sharp edge (such as a knife or screw-driver) to remove the frost.

1. Turn off the switch for the back-up cooling kit (if installed).

2. Take out all contents from the freezer and transfer them

to another freezer or a container which is refrigerated by

liquid carbon dioxide or dry ice.

3. Turn off the power switch and battery switch of the

freezer.

4. Open the outer door and inner door. Remove the

inner door by lifting up as shown in the figure.

5. Leave the freezer in this state until the frost in the

chamber melts.

6. Wipe up the water that accumulates at the bottom of the

chamber with a dry cloth.

7. After cleaning the chamber, replace the inner door and

start up the unit according to the procedure on page 18.

8. Check that the chamber temperature reaches the set temperature and then replace the contents.

9. Turn on the switch for the back-up cooling kit (if installed).

WARNING

Always wear gloves when mounting and/or removing the inner door to prevent injury.

CALIBRATION

During continuous operation, the following service tasks must be performed:

• Perform a temperature calibration at least once a year.

For temperature calibration, contact our sales representative or agent.

51

REPLACEMENT OF WORN-OUT PARTS

Replacing the battery for power failure alarm

Replace the battery for power failure alarm about every 3 years. Contact our sales representative or agent

for the replacement of battery when “S18: Exchange a Main Battery.” is displayed in the message display

field.

The replacement of the battery for power failure alarm is a paid service.

The alarm function (message display, sound of buzzer and remote alarm) will not operate when the battery for

power failure alarm is flat.

“W01: Power Failure.” is displayed and the buzzer sounds by the battery for power failure alarm.

WARNING

«Important» The used battery is a recyclable resource. Do not dispose of the battery.

Always follow the procedure for recycling.

The replacement of the battery for power failure alarm

should be executed by a qualified engineer or service

personnel only.

alarm involves the risk of electric shock.

The replacement of the battery for power failure

Replacing the battery for backup cooling kit

Replace the battery for backup cooling kit about every 3 years. Contact our sales representative or agent for

the replacement of battery when “S19: Exchange a Backup Battery.” is displayed in the message display

field.

The replacement of the battery for backup cooling kit is a paid service.

The backup cooling kit will not operate when the battery for backup cooling kit is flat.