Three Ventilation Stage Control

TVS user manual

Limited warranty

This warranty applies only to the Automatic Environment Control (TVS). If you need warranty

service, return the product and original proof of purchase to your dealer.

Phason Inc. (Phason) warrants this product subject to the following terms and conditions.

This warranty is valid only to the original purchaser of the TVS, for two years from the manufacturing

date. The manufacturing date is stated in the first eight digits of the serial number in the form yearmonth-day.

Phason hereby warrants that should the TVS fail because of improper workmanship, Phason will

repair the TVS, effecting all necessary parts replacements without charge for either parts or labor.

Conditions

Installation must be done according to our enclosed installation instructions.

The TVS must not have been previously altered, modified, or repaired by anyone other than

Phason.

The TVS must not have been involved in an accident, misused, abused, or operated or installed

contrary to the instructions in our user and/or installation manuals. Phason's opinion about these

items is final.

The person requesting warranty service must be the original purchaser of the TVS, and provide

proof of purchase upon request.

All transportation charges for products submitted for warranty must be paid by the purchaser.

Except to the extent prohibited by applicable law, no other warranties, whether expressed or implied,

including warranties of merchantability and fitness for a particular purpose, shall apply to the TVS.

Any implied warranties are excluded.

Phason is not liable for consequential damages caused by the TVS.

Phason does not assume or authorize any representatives, or other people, to assume any obligations or

liabilities, other than those specifically stated in this warranty.

Phason reserves the right to improve or alter the TVS without notice.

©2009 Phason Inc.

All rights reserved.

Printed in Canada.

10245506

2009-09-14

i

Service and technical support

Your dealer will be happy to answer all technical questions that will help you use the TVS

Before contacting your dealer or Phason, check the following:

Read this manual for information about the feature with which you are having trouble.

If you still have a problem with the TVS, collect the following information:

− Model/serial number

− A description of the problem

My dealer’s name:

How to contact my dealer:

Street/PO Box

City

State/Province

Zip/Postal

Phone

Fax

E-mail

Web site

2 Terracon Place

Winnipeg, Manitoba

Canada

R2J 4G7

Phone

Fax

E-mail

Web site

204-233-1400

204-233-3252

support@phason.ca

www.phason.ca

ii

Table of contents

Features of the TVS ....................................................................................................................1

Getting started.............................................................................................................................2

TVS electrical ratings..................................................................................................................4

Equipment list .............................................................................................................................5

Getting to know the TVS.............................................................................................................6

Definition of terms.................................................................................................................................. 7

Adjusting the TVS.......................................................................................................................8

Selecting a new operating program....................................................................................................... 8

Changing parameter settings................................................................................................................. 9

Setup parameters................................................................................................................................. 11

Programming tips................................................................................................................................. 11

Reloading the factory programs........................................................................................................... 13

TVS operation............................................................................................................................14

Parameter descriptions........................................................................................................................ 16

Parameter ranges ................................................................................................................................19

Factory programs................................................................................................................................. 20

Methods of use..................................................................................................................................... 21

Alarm messages........................................................................................................................22

Care and maintenance..............................................................................................................24

Power factor correction............................................................................................................25

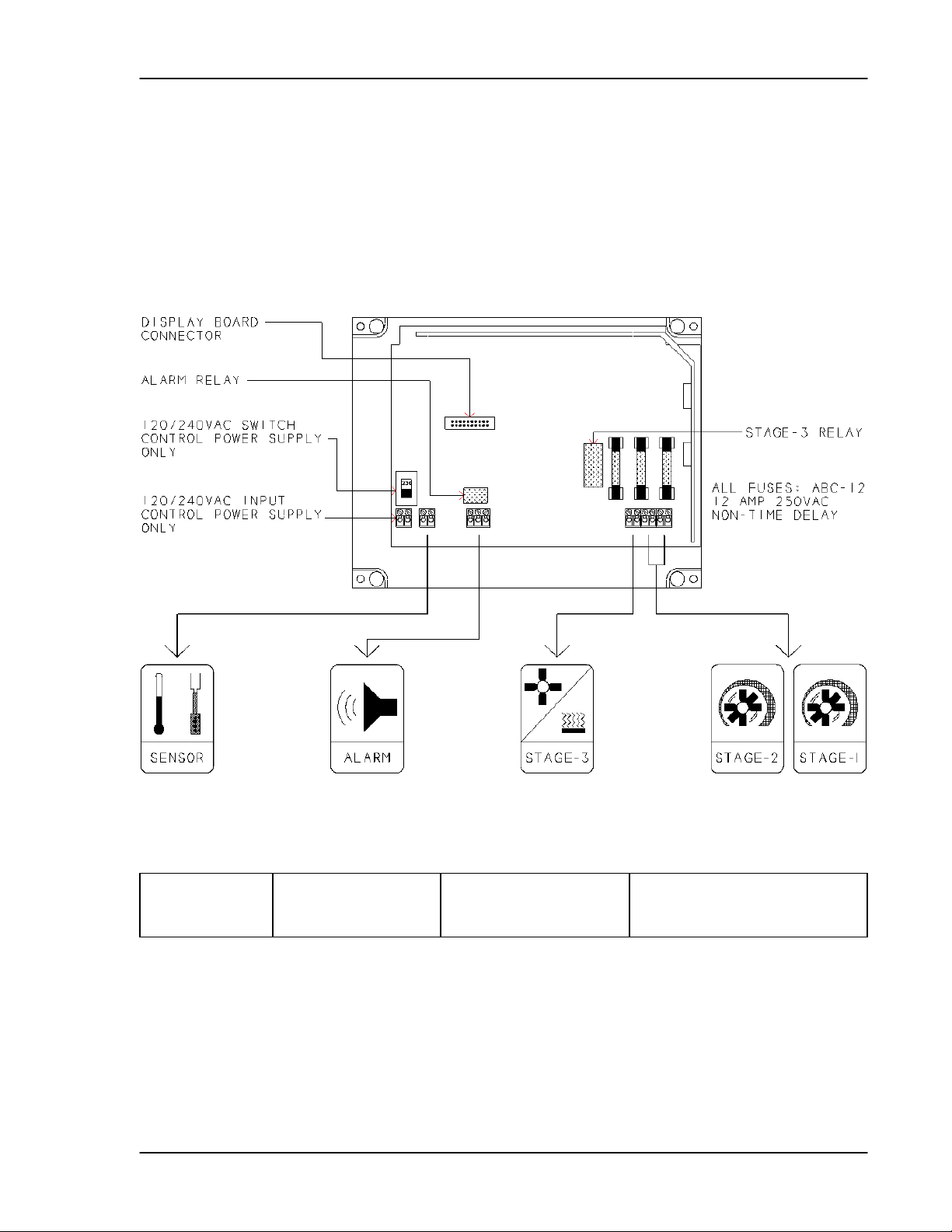

Appendix A - Wiring diagrams.................................................................................................27

115 VAC control power........................................................................................................................ 30

Temperature sensor............................................................................................................................. 31

4-zone averaging ................................................................................................................................. 31

Manually extending sensor.................................................................................................................. 32

Alarm siren installation......................................................................................................................... 33

Alarm panel installation........................................................................................................................ 33

230 VAC heat/cool stage..................................................................................................................... 34

115 VAC heat/cool stage..................................................................................................................... 34

Heat/cool stage furnace-power............................................................................................................ 35

Heat/cool stage furnace-thermostat..................................................................................................... 35

230 VAC variable speed fan................................................................................................................ 36

115 VAC variable speed fan................................................................................................................ 36

Correct 3-phase wiring......................................................................................................................... 37

Incorrect 3-phase wiring....................................................................................................................... 37

Heat/cool bypass switch....................................................................................................................... 38

Variable stage bypass switch............................................................................................................... 38

Appendix B - Test procedure...................................................................................................39

Appendix C – Troubleshooting guide.....................................................................................42

Appendix D – Blank program tables .......................................................................................44

iii

iv

Phason TVS user manual

Features of the TVS

The Three Ventilation Stage Control (TVS) is a microprocessor-based product designed to efficiently

control the environment in livestock buildings. It connects to two variable speed fans, a secondary fan or

heater and an alarm system. When operating, the TVS measures and displays the room temperature.

While monitoring the temperature, it controls the connected ventilation and heating equipment according

to the programmed settings to keep the temperature at the desired point. The program settings may be

adjusted to change the turn on points and other parameters of the stages. This is a list of the standard

features of the TVS.

•

Digital display of temperature, alarms and settings

•

7 programs with pre-programmed factory settings that can be easily changed

A built-in keyboard to allow easy adjustment of settings

•

1 stage with a user definable relay contact to control secondary fans or heaters

•

A relay to signal high or low temperature, power interruptions or low line voltage conditions

•

Internal memory is retained during power failures

•

120/230 VAC operation @ 7.5 amps output for each variable speed fan (with RFI noise

•

suppressors to eliminate radio and T.V. interference)

3 second full power turn on for variable speed outputs to minimize fan freeze-up

•

Transient protected

•

Compact design, 18cm/7" (H) x 23cm/9" (W) x 9.5cm/3.75" (D)

•

Non-corrosive, fire retardant enclosure

•

2-year warranty

•

Extendable sensor

•

10245506 1

TVS user manual Phason

Getting started

Congratulations on the purchase of your new TVS environment control! This manual has been prepared

to help you get the utmost in satisfaction from your TVS. It contains detailed information regarding the

installation and operation of the control. The Getting Started section will step you through the installation

and configuration of your TVS. The following steps refer to other sections of this user's guide for

additional information. Therefore, it is not necessary to read the entire document from front to back, but

rather in the order that the information is needed.

STEP

1

STEP

STEP

CHECKING RATINGS OF EQUIPMENT

• • Read the TVS ELECTRICAL RATINGS on page 4.

Fill in the EQUIPMENT LIST on page 5.

WARNING: The equipment to be connected to the TVS control must

not draw more current than the TVS stages are rated for. Use of

equipment that is rated higher than the TVS will result in damage

to the control and will void the warranty.

INSTALLATION

• Follow the instructions in Appendix A for installing and wiring the

2

3

TVS and equipment. Be sure to read the General Warnings section

in Appendix A before installation.

TESTING

• Follow the instructions in Appendix B for testing the operation of

the equipment installed to ensure that it is connected properly.

2 2009-09-15

Phason TVS user manual

STEP

4

STEP

5

STEP

6

SETTING UP

•

Read through the GETTING TO KNOW THE TVS section on page

6 and get familiar with the programming procedures.

•

Read the SETUP section on page 11.

•

Configure the TVS according to the type of equipment connected.

Mark the changes in the Blank Program Tables in Appendix D.

•

PUTTING CONTROL INTO SERVICE

•

Read the TVS OPERATION section on page 15.

•

Select the most useful factory program; see page 20.

Make changes to the program as desired; see page 9.

•

•

Mark the changes in the Blank Program Tables in Appendix D.

METHODS OF USE

• Read the METHODS OF USE section on page 21.

10245506 3

TVS user manual Phason

TVS electrical ratings

Variable stage

Variable stage fuse

Relays

Relay fuses

Alarm relay

7.5 A at 120/230 VAC, general-purpose (resistive)

5 FLA at 120/230 VAC, PSC motor

1/3 HP at 120 VAC, 1/2 HP at 230 VAC, PSC motor

12 A, 250 VAC ABC-type ceramic

6 A at 120/230 VAC, general-purpose (resistive)

1/3 HP at 120 VAC, 1/2 HP at 230 VAC

360 W tungsten at 120 VAC

12 A, 250 VAC ABC-type ceramic

0.4 A at 125 VAC; 2 A at 30 VDC, resistive load

0.2 A at 125 VAC; 1 A at 30 VDC, inductive load

NOTE: This is not a wiring diagram. All wiring diagrams are located in Appendix A.

4 2009-09-15

Phason TVS user manual

Equipment list

Make and Model # of fan(s):

Variable

Speed

Stage 1

Variable

Speed

Stage 2

Cool/Heat

Stage 3

Alarm

Max. Total Current Draw of fan(s):

Must not be greater than 7.5 amps.

Operating Voltage:

Make and Model # of fan(s):

Max. Total Current Draw of fan(s):

Must not be greater than 7.5 amps.

Operating Voltage:

Make and Model # of fan/heater:

Max. Total Current Draw: *

Operating Voltage:

Alarm relay connected to:

* A power contactor must be used if the maximum total current draw is greater than the maximum ratings

of the relay. See the maximum ratings on page 4.

10245506 5

TVS user manual Phason

Getting to know the TVS

1) PROGRAM button - used to select the desired

operating program.

6) UP button - used to adjust a parameter.

2) STORE button - used to save selected

programs and parameter settings in memory.

7) STAGE 1 indicator light.

3) PARAMETER button - used to scroll through

the parameter list.

8) STAGE 2 indicator light.

4) RETURN button - used to bring the control

back to normal operation.

9) STAGE 3 indicator light.

5) DOWN button - used to adjust a parameter.

6 2009-09-15

10) Complete parameter list.

Phason TVS user manual

Definition of terms

NORMAL OPERATION The TVS is in normal operation when it is displaying room temperature.

When alarms occur, the display will alternately flash the alarm signal and

room temperature.

PROGRAMS Programs consist of the Main, Differential, General and Setup parameters.

The TVS has seven programs that can be selected and reprogrammed by the

user.

OPERATING PROGRAM The TVS operates according to the parameters in the operating program. Any

one of the seven programs may be selected as the operating program.

PARAMETER LIST The parameter list is shown on page 19, and is printed on the front of the

TVS control. It is a list of all the parameters that may be programmed by the

user.

PARAMETERS Parameters are the individual settings that may be programmed. Read the

PARAMETER DESCRIPTIONS section on page 16 for an explanation of

each parameter. There are four categories of parameters:

1)

Main: Main parameters control the main operation of the control.

2)

Differential: These parameters are programmable differentials. They

are the number of degrees above or below the temperature set point

the particular stage starts or turns on.

3)

General: General parameters are common to all programs. These

parameters can have only one setting which is the same in all

programs.

4)

Setup: Setup parameters control the overall operation of the unit.

These parameters can have only one setting which is the same in all

programs.

10245506 7

TVS user manual Phason

Adjusting the TVS

Selecting a new operating program

As livestock mature, often the room climate needs to be changed. The TVS has seven different programs

in memory for seven different climate settings. Any one of these programs can be the operating program.

In order to change the operating program of the TVS, follow the instructions below. For a list of the

factory settings see Table 2 on page 20.

1) Press the PROG button once.

The TVS will display the current operating program

(one of A, b, C, d, E, F or g). The display will flash the

program name and Pr.

2) Press the PROG button several times until the desired

program is displayed.

By pressing the PROG button, the program names are

displayed one after another. To change to a different

operating program, press the PROG button until the

proper program is displayed.

3) Press the STORE button to enter the desired program

into memory.

When the correct program is displayed, pressing the

STORE button will tell the TVS to use the selected

program as the operating program. After Stor is

displayed, the TVS returns to normal operation.

8 2009-09-15

Phason TVS user manual

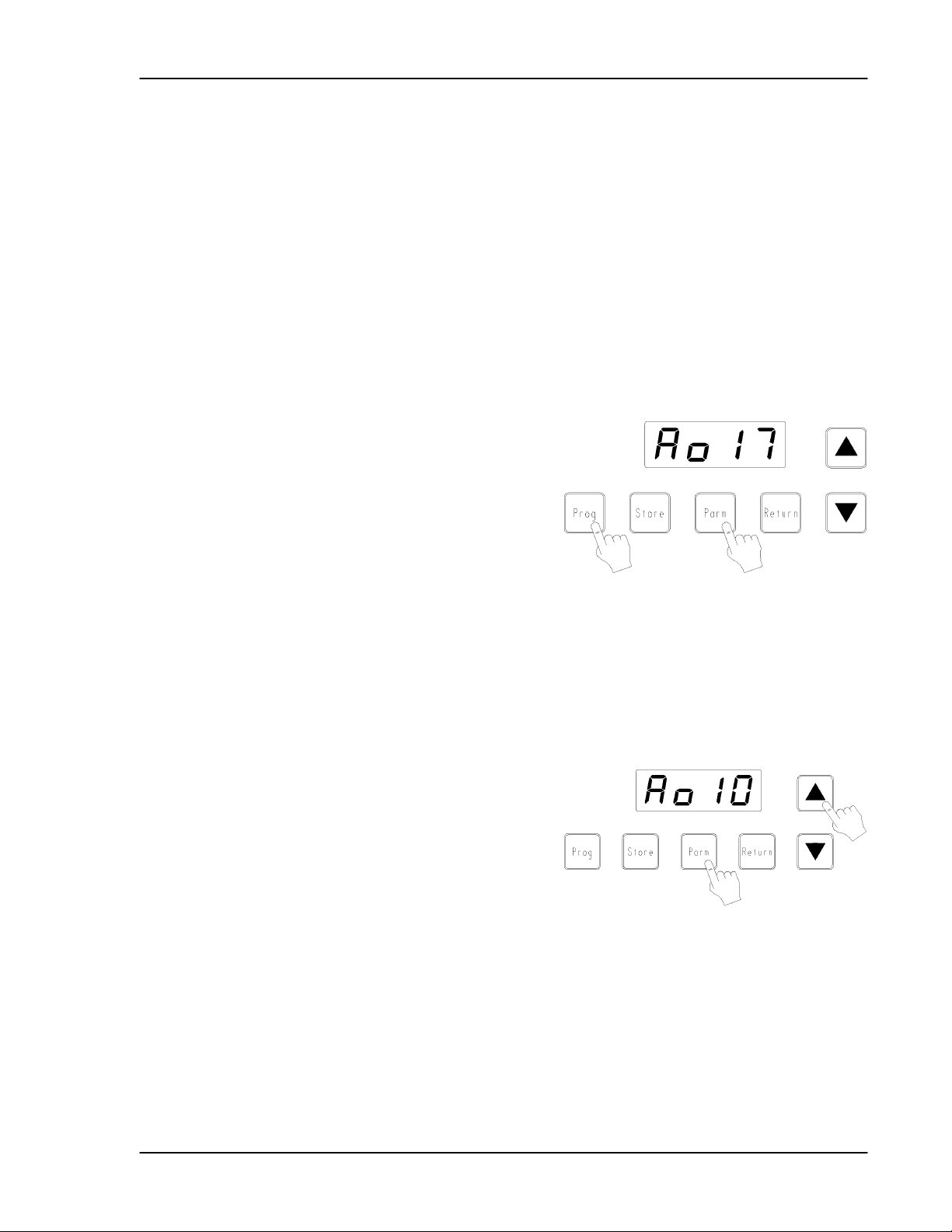

Changing parameter settings

Follow the steps below to view and/or edit the parameters in any program. After editing the parameters,

mark the changes in the Blank Program Tables in Appendix D for future reference.

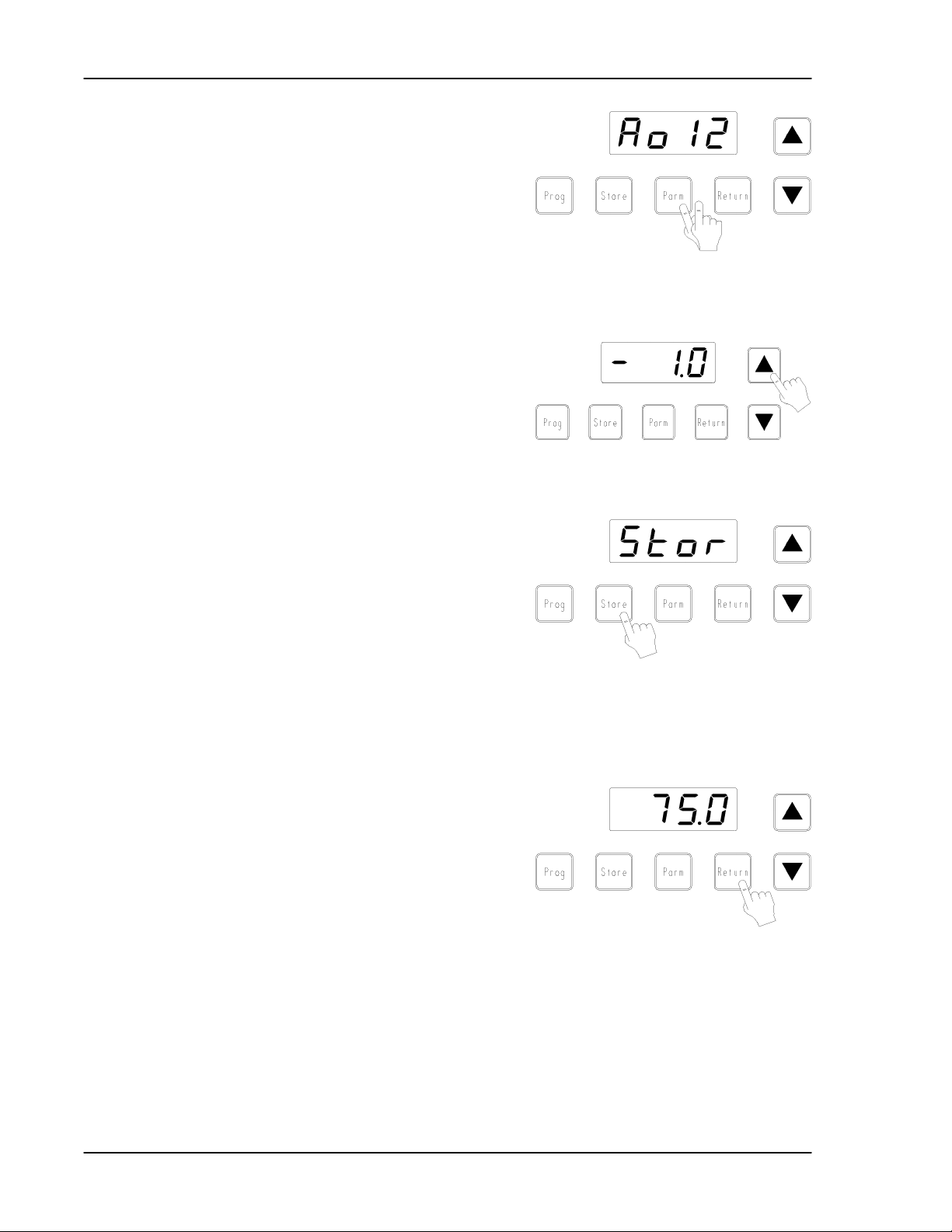

1) Press the PROG button until the program that you want to

edit is displayed.

The display will flash the program letter (A to g) and Pr.

2) Press the PARM button once.

The first (left-most) digit shows the program letter that is

being edited.

The second digit indicates if the program is the operating

program. An o means the program is the operating

program, a blank means it is not the operating program.

The two right-most digits show the parameter number to be

edited.

3) Press the UP or DOWN key to turn memory protect off.

The display will show Ao 0 and then oFF, indicating

memory protect has been turned off. The parameters can

now be adjusted. If memory protect is not turned off, the

parameters can only be viewed. Attempting to adjust the

parameters while memory protect is on will result in an Err

message being displayed.

10245506 9

TVS user manual Phason

4) Press the PARM button to step through the parameter list

until the desired parameter is reached.

Refer to the front cover of the TVS control or see Table 2

on page 20 for the parameter list.

5) Use the UP / DOWN buttons to adjust the setting.

The parameter can be adjusted to any value with in the

parameter's range. The ranges can be found on page 19.

6) Press STORE to save the setting in memory.

The display will show Stor for 1 second indicating the new

setting has been stored in memory. If the PARM button is

pressed before pressing STORE the next parameter will

appear and the previous one will change back to its

previous

setting.

Continue through the parameter list by pressing the PARM

button and making changes to the settings where

needed.

Follow the same procedure shown in steps 4 to 6 above.

7) To return to normal operation (displaying of room

temperature) at any time, press the RETURN button.

When RETURN is pressed, memory protect is

automatically turned back on. If a parameter has been

changed but the value has not been stored, pressing

RETURN will change the parameter's setting to the last

stored setting and return the control to normal operation.

NOTE: If the TVS is left displaying a parameter it will revert back to normal operation in 1 minute

automatically. If STORE was not pressed the displayed parameter will change back to its previous value.

10 2009-09-15

Phason TVS user manual

Setup parameters

The setup parameters should be programmed when the installation has been completed to configure the

TVS, and then generally the parameters do not need to be reprogrammed. These parameters are different

from the other parameters because they do not have a different setting for each program and cannot be

edited in the normal way. Each setup parameter setting is common to all programs. Follow the

instructions below to change the setup parameters.

When the setup parameters have been programmed, the blank program table in Appendix D should be

filled in with the new settings for future reference.

To edit the setup parameters

Press the PARM button once to enter the edit mode. If you

wish to edit the setup parameters, you must turn off the

memory protect now. See page 9 to turn off the memory

protection.

Next, press the PROG and PARM buttons simultaneously

to get to the setup parameters. The Setup parameters can be

adjusted as needed and stored in the same way the normal

parameters can. After the setup parameters have been

changed and stored, press the RETURN button to return to normal operation.

Programming tips

Scrolling backwards

When viewing or editing the parameters, sometimes it is

helpful to scroll backwards through the parameter list. To

do this, press the PARM and UP buttons simultaneously.

Instead of the TVS displaying the next parameter on the

list, it will display the previous parameter.

10245506 11

TVS user manual Phason

Selecting a parameter to edit

The parameters are stored in a table in memory that is similar to the Factory Program Table on page 20.

Any parameter in any program can be edited when memory protection has been turned off. Follow these

procedures when editing parameters to become more efficient.

To move down to the next parameter press the PARM button.

To move up or backwards to the previous parameter, press the PARM and UP buttons simultaneously.

To move right, press the PROG button until the desired program is displayed, then press the PARM

button once to edit the same parameter number that was being edited before.

To Move Button(s)

PARM

PARM and UP

PROG

An example of where this method of programming is useful is a situation where the temperature set point

of each program needs to be changed. This can done by turning off memory protection and changing the

temperature set point in the operating program (the operating program is displayed with an o and the

program name). Then press the PROG button twice to edit the next program. Press the PARM button and

edit the parameter. To continue to the next program press the PROG button twice again. Remember that

STORE must be pressed after each change to save the new setting in memory.

Fast editing

When editing the setting of a parameter by adjusting it up

or down, hold down either button and then press the other

one. This will change the setting ten times faster. If you

want to increase the setting, hold down the UP button and

then press the DOWN button. The setting will increase ten

times faster. To decrease the setting ten times faster, ho

down the DOWN button and then press the UP

button.

ld

12 2009-09-15

Phason TVS user manual

Reloading the factory programs

The factory programs can be reloaded, if so desired, to replace the existing program. If the existing

programs are not operating properly or need to be changed back to the original factory programs, follow

the steps below to reload the factory programs.

When reloading the factory programs, the existing programs including the setup parameters are

replaced. The TVS will begin with program A as the operating program. The parameters in all

programs and most importantly the setup parameters will need to be reprogrammed for the

equipment that is connected. Pay close attention to the setup parameter for stage 3

1) Turn off the power to the TVS.

2) Hold down the PROG and STORE buttons.

3) While holding the buttons down, turn the power back on.

The display will flash Stor for two seconds and then the

TVS will be in the normal operating mode, displaying the

room temperature and a power failure al

arm.

.

10245506 13

TVS user manual Phason

TVS operation

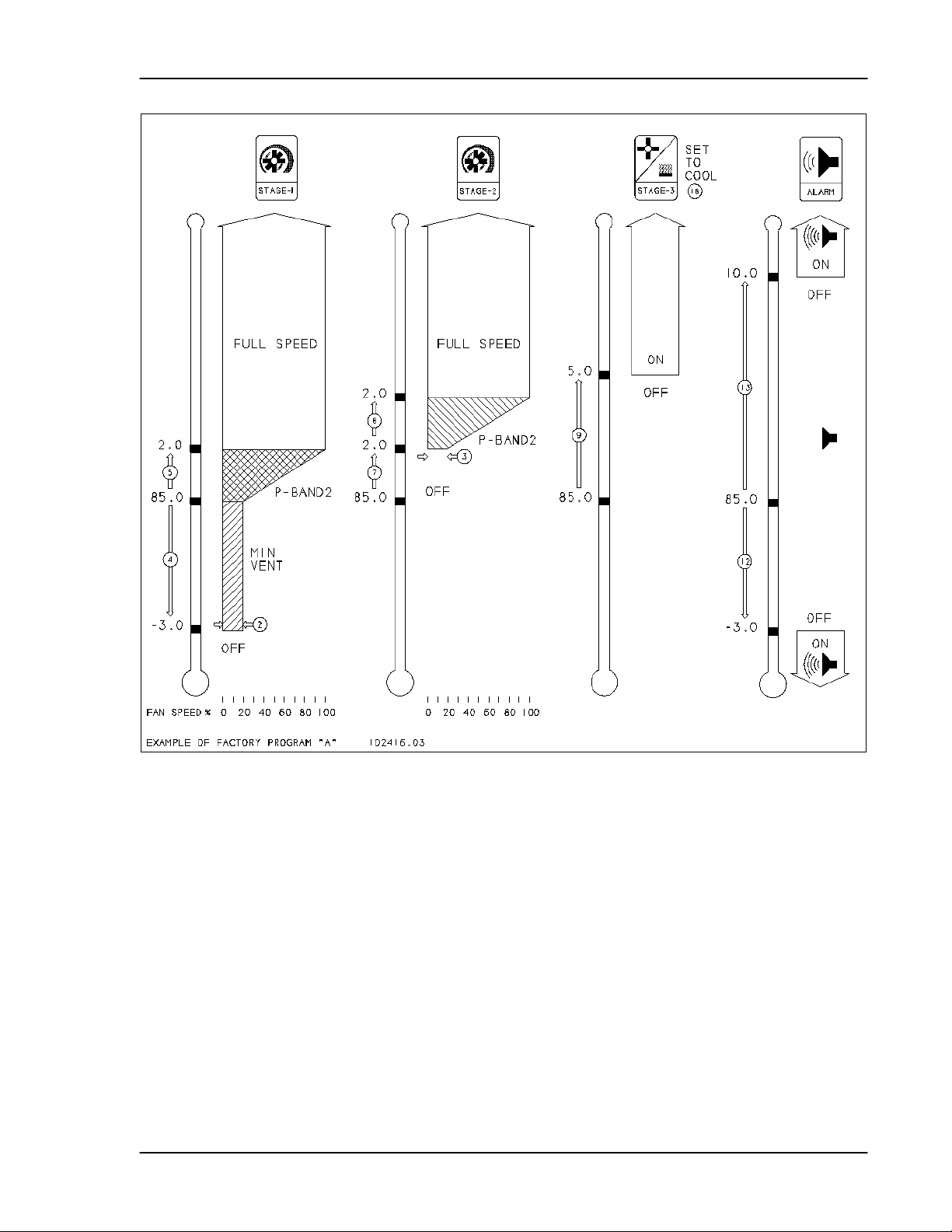

Figure 2 shows the operation of each stage of the TVS. This particular diagram shows the temperatures at

which the stages would turn on and off if the TVS was operating according to the factory settings in

program A. Some settings are listed here but the entire factory program table can be found on page 20.

The circled numbers in the diagram correspond to the parameter numbers. Use these numbers to cross

reference the parameters in the diagram to their descriptions. All stages except the low temperature and

high temperature alarms have a programmable hysteresis, parameter # 23.

PARAMETER SETTINGS

1 Temp Set 85.0

2 Stage 1 Min Vent 20%

3 Stage 2 Min Vent 20%

4 Stage 1 OSB -3.0

5 Stage 1 P-Band1 2.0

6 Stage 2 OSB 0.0

7 Stage 2 Start P-Band2 2.0

8 Stage 2 P-Band 2.0

9 Stage 3 Turn On 5.0

12 Low Temp Alarm -3.0

13 High Temp Alarm 10.0

NOTE: When the variable speed stages turn on, they will run full speed for three seconds and then

decrease to the required speed.

EXAMPLE

As an example, say the temperature is 75

When the temperature rises to 82

The Stage 1 fan will run at full speed for three seconds and then slow down to the Minimum Ventilation

setting.

o

At 85

F the Stage 1 P-Band begins. While the temperature rises in the P-Band, the Stage 1 fan will

increase in speed. At 87

When the temperature rises to 88

now, it will run full speed for three seconds and then slow down to the required speed. As the temperature

rises, the Stage 2 fan will increase in speed proportionally to the temperature. At 90

be at full speed.

o

At 90

F Stage 3 (cool) will turn on.

When the temperature rises to 95

o

F

o

o

F, the Low Temp Alarm will turn off and the Stage 1 fan will turn on.

o

F Stage 1 will be at full speed.

o

F the Stage 2 P-Band begins. Since the Stage 2 fan has been off until

o

F the High Temp Alarm will turn on.

F and rising. At this point the Low Temp Alarm will be on.

o

F the Stage 2 fan will

14 2009-09-15

Phason TVS user manual

Figure 2 : TVS Operation diagram. Circled numbers correspond to the parameter numbers.

10245506 15

TVS user manual Phason

Parameter descriptions

MAIN PARAMETERS

0 MEMORY PROTECT [On/Off] - ensures parameters are not changed by accident. Memory protect

must be turned off every time the parameters are edited. The memory protect parameter can not be

stored and is turned on automatically when the control is returned to normal operation.

1 TEMPERATURE SET (Start P-Band 1) [32.0 - 110.0

temperature. All differentials and alarms are referenced to this setting. It is the starting point of the

Stage 1 P-Band1 (parameter #5).

2 STAGE 1 MINIMUM VENTILATION [Minimum Idle (#21) - 99] - is the idle speed in % of full

power at which the Stage 1 fan will idle. It cannot be adjusted below the setting of the Minimum Idle

(#21) parameter.

3 STAGE 2 MINIMUM VENTILATION [Minimum Idle (#22) - 99] - is the idle speed in % of full

power at which the Stage 2 fan will idle. It cannot be adjusted below the setting of the Minimum Idle

(#22) parameter.

DIFFERENTIALS

4 STAGE 1 OFF-SET-BACK [IDLE, -20.0 - 0.0

o

F, -11.1 - 0.0o C] - is a range of degrees below the

temp set where the Stage 1 fan will be at idle speed, and below this range the fan will be off. Idle

means the fan will run at the Min Vent setting at all temperatures below the temp set. If Temp Set

(#1) is set to 80° F and Stage 1 Off-Set-Back (#4) is set at -8° F the fan will idle when the

temperature is between 80° F and 72° F, and will be off below 72°F.

5 STAGE 1 P-BAND1 [0.0 - 16.0

o

F, 0.0 - 8.9o C] - The proportional band is a range of degrees above

the Temp Set where the Stage 1 fan increases in speed proportionally to the temperature. If Temp Set

(#1) is set to 80° F and Stage 1 P-Band1 (#5) is set at 5° F the variable speed fan will start to increase

speed at 80° F and will be at full speed at 85° F.

6 STAGE 2 OFF-SET-BACK [IDLE, -20.0 - 0.0

o

F, -11.1 - 0.0o C] - is a range of degrees below the

Stage 2 Start P-Band2 (#7) where the Stage 2 fan will be at idle speed, and below this range the fan

will be off. Idle means the fan will run at the Min Vent setting at all temperatures below Stage 2 Start

P-Band2 (#7). If Temp Set (#1) is set to 80° F, Stage 2 Start P-Band2 (#7) is set to 10° F and Stage 2

Off-Set-Back (#6) is set at –3° F, the Stage 2 fan will idle between 90° F and 87° F and will be off

below 87° F.

7 STAGE 2 START P-BAND2 [-10.0 - 15.0

o

F, -5.5 - 8.4o C, OFF] - is the number of degrees above or

below the Temp Set at which the Stage 2 proportional band starts. All Stage 2 differentials are with

respect to this setting. If the Temp Set (#1) is 80° F and this parameter (#7) is set to 10° F, the Stage 2

fan will turn on at 90° F.

o

F, 0.0 - 43.3oC] - is the target room

16 2009-09-15

Phason TVS user manual

8 STAGE 2 P-BAND2 [0.0 - 16.0o F, 0.0 - 8.9o C] - The proportional band is a range of degrees above

the Stage 2 Start P-Band2 where the Stage 2 fan will increase in speed proportionally to the

temperature. If Temp Set (#1) is set to 80° F, Stage 2 Start P-Band2 (#7) is set to 10° F and Stage 2 PBand2 (#8) is set at 5° F, the Stage 2 variable speed fan will start to increase speed at 90° F and will

be at full speed at 95° F.

9 STAGE 3 TURN ON [-10.0 - 15.0

o

F, -5.5 - 8.4o C, OFF] - The number of degrees above or below

the Temp Set at which Stage 3 will turn on. If the Temp Set (#1) is set to 80° F and On Stage 3 (#9) is

set to 5° F, Stage 3 will turn on at 85° F. The Stage 3 Operation (#18) parameter regulates what mode

Stage 3 operates as (heat or cool).

10 Not Applicable

11 Not Applicable

12 LOW TEMPERATURE ALARM [OFF, -36.0 - 0.0

o

F, -20.0 - 0.0o C] - The number of degrees

below the Temp Set that a low temperature alarm will be generated (A Lt). This alarm may be

disabled by adjusting it to OFF.

13 HIGH TEMPERATURE ALARM [0.0 - 36.0

o

F, 0.0 - 20.0o C, OFF] - The number of degrees

above the Temp Set that a high temperature alarm will be generated (A Ht). This alarm may be

disabled by adjusting it to OFF.

GENERAL PARAMETERS

General parameters have one setting common to all programs. When they are changed in one program,

they change in all programs.

14 LOW POWER ALARM [ON - OFF] - When the line voltage drops below the proper operating level

a low power alarm will be displayed (A LP). This alarm may be disabled by adjusting it to OFF.

When disabled, the display will still flash A LP but the alarm relay will not activate.

15 LATCHING ALARMS [ON - OFF] - When this parameter is turned ON, all alarms will be

displayed on the TVS and will continue to flash after the alarm condition is gone. They can be reset

by pressing the RETURN button. This feature is useful to keep track of the alarms that occur during

times when the control is not being supervised. For example; in the morning, the TVS could be

checked for alarms that occurred during the night and then the alarms could be cleared. If this

parameter is turned OFF, the display will only show the alarm when the condition is present. When

the alarm condition is gone, the alarm will no longer be displayed.

16 VENTILATION [ON - OFF] - When this parameter is turned OFF, the variable speed outputs and

cooling stages are turned off completely and all alarms will not be displayed. The heating stages are

not affected. Ventilation may be turned OFF when a room is vacant to conserve energy. When it is

turned OFF the TVS will display VoFF. DO NOT use this to shut down fans to work on the wiring ensure the breakers are turned off.

10245506 17

TVS user manual Phason

SETUP

The setup parameters are common to all programs and can only have one setting. They can not be

accessed by the same procedure as the normal parameters. This has been done to protect these parameters

from accidentally being changed. Follow the instructions on page 11 to reprogram these parameters.

17 TEMPERATURE UNITS [

o

F - oC] - This parameter programs the TVS to display the temperature in

Fahrenheit or Celsius.

18 STAGE 3 OPERATION [HEAT - COOL] - This parameter programs the Stage 3 output to operate

as a heating stage or a cooling stage. When it is set to HEAT, the stage will be on below the Stage 3

Turn On (parameter #9). If it is set to COOL, the stage will be on above the Stage 3 Turn On (#9).

19 Not Applicable

20 Not Applicable

21 STAGE 1 MINIMUM IDLE [0 - 99] - This is the minimum idle preset in per cent of full speed. The

Stage 1 Min Vent (#2) cannot be adjusted below this setting. If it is programmed to 20 the Stage 1

Min Vent (#2) parameter cannot be adjusted below 20. It is recommended that this parameter be

programmed to correspond to the lowest speed at which the motor can safely operate.

22 STAGE 2 MINIMUM IDLE [0 - 99] - This is the minimum idle preset in per cent of full speed. The

Stage 2 Min Vent (#3) cannot be adjusted below this setting. If it is programmed to 20 the Stage 2

Min Vent (#3) parameter cannot be adjusted below 20. It is recommended that this parameter be

programmed to correspond to the lowest speed at which the motor can safely operate.

23 HYSTERESIS [0.5 - 2.5

o

F, 0.3 - 1.4oC] - This is the number of degrees of difference between the

turn-on point and turn-off point for all stages. It is the number of degrees above the turn-on point that

a heating stage will turn off, and the number of degrees below the turn-on point that a cooling stage

will turn off.

24 STAGE 1 POWER FACTOR COMPENSATION [0.5 - 2.5 ] - This is set at the factory to 1.0 and

should only be adjusted if the Stage 1 variable speed fan does not operate properly with the TVS.

25 STAGE 2 POWER FACTOR COMPENSATION [0.5 - 2.5] - This is set at the factory to 1.0 and

should only be adjusted if the Stage 2 variable speed fan does not operate properly with the TVS.

18 2009-09-15

Phason TVS user manual

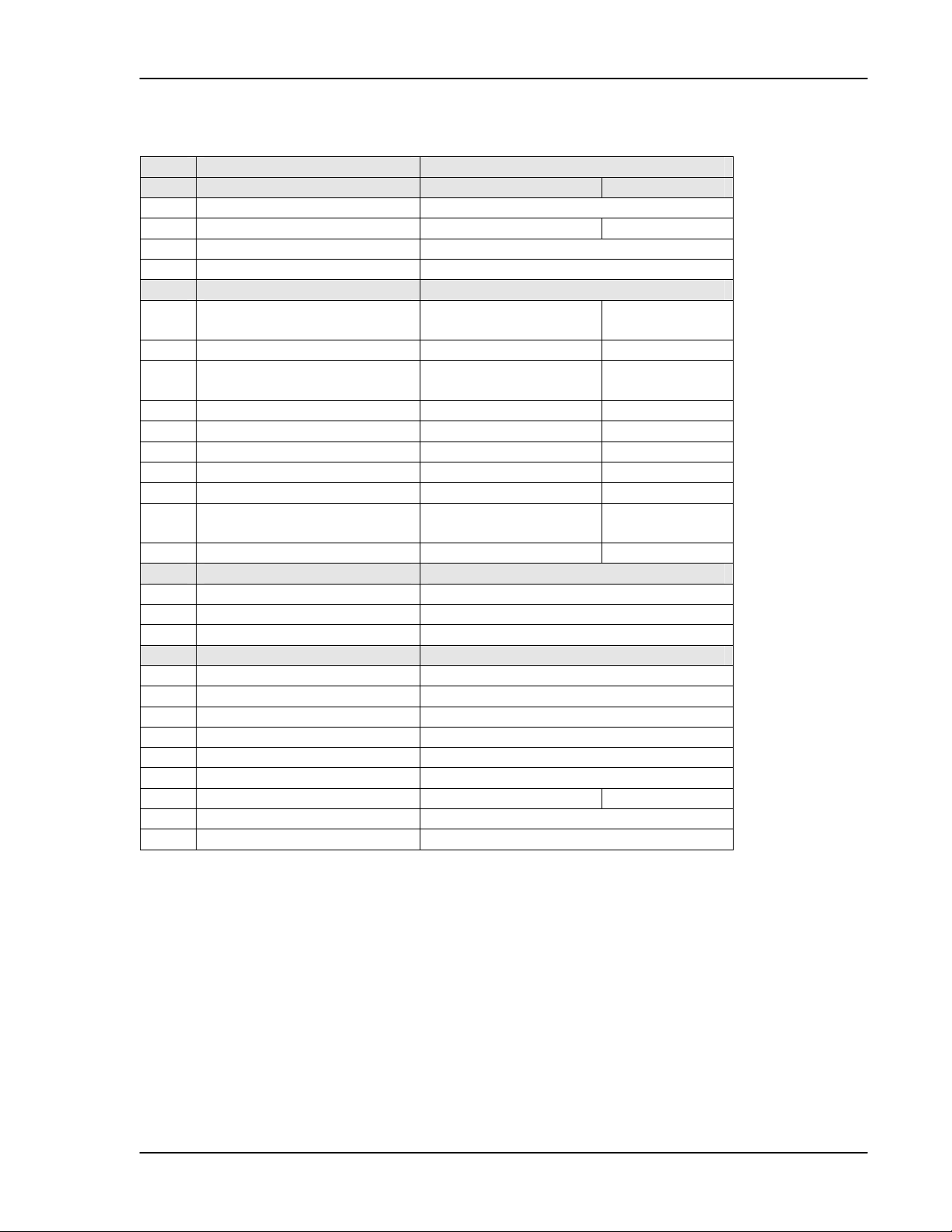

Parameter ranges

# PARAMETERS RANGE

MAIN

0 Memory Protect ON / OFF

1 Temp Set (Start P-Band1) 32.0 to 110.0 0.0 to 43.3

2 Stage 1 Min Vent Min Idle (parm #21) – 99

3 Stage 2 Min Vent Min Idle (parm #22) – 99

DIFFERENTIAL

4 Stage 1 Off-Set-Back IDLE, -20.0 to 0.0

5 Stage 1 P-Band1 0.0 to 16.0 0.0 to 8.9

6 Stage 2 Off-Set-Back IDLE, -20.0 to 0.0

7 Stage 2 Start P-Band2 -10.0 to 15.0, OFF -5.5 to 8.4, OFF

8 Stage 2 P-Band2 0.0 to 16.0 0.0 to 8.9

9 Stage 3 Turn On -10.0 to 15.0, OFF -5.5 to 8.4, OFF

10 Not Applicable

11 Not Applicable

12 Low Temp Alarm OFF, -36.0 to 0.0

13 High Temp Alarm 0.0 to 36.0, OFF 0.0 to 20.0, OFF

GENERAL

14 Low Power Alarm ON / OFF

15 Alarm Display Latching ON / OFF

16 Ventilation ON / OFF

SETUP

17 Units oF or oC

18 Stage 3 Operation HEAT / COOL

19 Not Applicable

20 Not Applicable

21 Stage 1 Minimum Idle 0 to 99

22 Stage 2 Minimum Idle 0 to 99

23 Hysteresis 0.5 to 2.5 0.3 to 1.4

24 Stage 1 P.F. Compensation 0.5 to 2.5

25 Stage 2 P.F. Compensation 0.5 to 2.5

Table 1: Adjustable ranges of parameters

o

F

o

C

IDLE, -11.1 to

0.0

IDLE, -11.1 to

0.0

OFF, -20.0 to

0.0

o

F / oC

10245506 19

TVS user manual Phason

Factory programs

The TVS is programmed with the factory settings as shown below. See the ADJUSTING THE TVS

section for instructions to change the operating program. Select the most useful program and make

changes where necessary.

# PARAMETERS

MAIN

Temp Set (Start P-

1

Band1)

A b C d E F G

85.0 80.0 75.0 70.0 65.0 65.0 65.0

2 Stage 1 Min Vent 20 20 20 20 20 20 20

3 Stage 2 Min Vent 20 20 20 20 20 20 20

DIFFERENTIAL

4 Stage 1 Off-Set-Back -3.0 -3.0 -4.0 -5.0 -5.0 -5.0 -5.0

5 Stage 1 P-Band1 2.0 2.0 2.5 3.0 3.0 3.0 3.0

6 Stage 2 Off-Set-Back 0.0 0.0 0.0 0.0 0.0 0.0 0.0

7 Stage 2 Start P-Band2 2.0 2.0 2.5 3.0 3.0 3.0 3.0

8 Stage 2 P-Band2 2.0 2.0 2.5 3.0 3.0 3.0 3.0

Stage 3 Turn On

9

(Cool)

5.0 5.0 6.0 7.0 7.0 7.0 7.0

10 Not Applicable

11 Not Applicable

12 Low Temp Alarm -3.0 -4.0 -5.0 -5.0 -5.0 -5.0 -5.0

13 High Temp Alarm 10.0 10.0 12.0 15.0 15.0 15.0 15.0

GENERAL

14 Low Power Alarm ON

Alarm Display

15

Latching

16 Ventilation ON

SETUP

17 Units oF or oC

18 Stage 3 Operation COOL

19 Not Applicable

20 Not Applicable

21 Stage 1 Minimum Idle 20

22 Stage 2 Minimum Idle 20

23 Hysteresis 0.5

Stage 1 P.F.

24

Compensation

Stage 2 P.F.

25

Compensation

Table 2: Factory programs

PROGRAM NAMES (A - g)

ON

o

F

1.0

1.0

20 2009-09-15

Phason TVS user manual

Methods of use

The TVS has seven programs which can be selected as the operating program. To take advantage of the

programs, adjust them for different climate settings. They can be used for different kinds of livestock or

used at different stages of maturity of the particular livestock. Time is saved by simply changing the

program, instead of adjusting every parameter. Remember to mark all changes to the programs in the

Blank Program Tables in Appendix D to keep track of the settings.

10245506 21

TVS user manual Phason

Alarm messages

Alarm

Description

Error - an incorrect key has been pressed

Alarm High Temperature - temperature is above the high temp

alarm setting

Alarm Low Temperature - temperature is below the low temp

alarm setting

Alarm Low Power - the line voltage is low

Alarm Probe Disconnect - the temperature sensor is

disconnected

Alarm Probe Short - The temperature sensor is short circuited

Alarm Power Failure - the power has been interrupted

Alarm Internal Error - indicates an internal error has occurred

Ventilation Off - ventilation has been turned off in the program

Reasons for alarms to activate

The Err message appears when an incorrect key has been pressed or if an attempt has

been made to change a parameter while memory protect is on. The Err message will

22 2009-09-15

appear for 2 seconds and then disappear.

The high temperature alarm appears when the room temperature is above the high

temperature alarm setting (parameter #13). Check if the fans are operating properly. This

alarm may occur on very hot days when the desired room temperature can not be

maintained.

The low temperature alarm appears when the room temperature is below the low

temperature alarm setting (parameter #12). Check if the heater is operating properly.

Phason TVS user manual

The low power alarm turns on when the line voltage drops below 190 for 230

VAC operation or below 95 for 120 VAC operation. This indicates a problem

with the electrical service of the building. The control may operate erratically if

the voltage drops below these levels.

This indicates the temperature sensor is disconnected. The sensor wire may be

broken or damaged somewhere.

This alarm indicates the temperature sensor is short circuited. The sensor or wire

may be damaged somewhere.

NOTE: When a A Pd or a A PS alarm occurs, the heating and cooling stages will turn off

and the variable stages will run at idle speed.

The Power Failure alarm appears when there has been an interruption in the

power. The control will continue to operate normally and the alarm can be

cleared by pressing the RETURN button.

When this alarm appears it indicates an internal error has occurred. To clear this

alarm check through the parameters; adjust and store the ones that are incorrect.

Next, turn the power off and then back on and the alarm will be cleared.

NOTE: A parameter must be changed and stored and the power turned off and on before

the alarm will be cleared. Another way to clear the alarm is downloading the

factory programs. This will reset all the parameters to the factory settings and

then they must be programmed to the desired settings again. Consult your dealer

or Phason for information to prevent this problem from happening again.

VoFF is displayed when VENTILATION (parameter #16), is turned OFF. When

this is displayed, the variable speed stages and the cooling stages will be turned

off. The heating stage(s) will operate normally.

10245506 23

TVS user manual Phason

Care and maintenance

Moisture will not cause a problem with the control if the proper care is taken in installation. The control's

enclosure is made of fire retardant plastic and is sealed with a rubber gasket. The sensor entry is sealed

with a liquid tight cable connector.

Caution should be taken when washing the room with a high pressure washer. DO NOT direct a high

pressure washer at the control. In order to clean the control, wipe it with a damp cloth.

Be sure power is off before cleaning to avoid electrical shock.

MAINTENANCE

1) To prevent damage to the control, after the first two weeks of operation remove the cover from the

unit and check for moisture inside. Be sure to turn off the power to the control before opening the

cover.

2) If moisture is present, wipe it out with a dry cloth and check the cable entry points and rubber gasket

for proper sealing.

3) If the cable connectors are not sealing, apply RTV or Silicon II sealant around the cable.

WARNING: If a sealant is used, be aware that some silicone sealants release acetic acid while

curing. This can cause corrosion damage to the control. Let silicone cure completely (1 to 3 days),

before closing the control or the control may be damaged and the warranty will be VOID.

4) Check the control again after two weeks to verify that it is properly sealed.

The control should be opened and inspected once a year for moisture. Proper care and maintenance will

extend the life of the control.

24 2009-09-15

Phason TVS user manual

Power factor correction

Adjusting the P-Band to correct for a particular power factor may improve your ventilation system's

performance. Power factor correction is generally unnecessary and there is no danger of damage being

done to the control or motor if it is not done. As a result of different power factors between the many

makes and models of fan motors, the actual P-Band may be less then the P-Band setting displayed by the

control.

If the power factor of the motor is available, use the chart of correction numbers (listed in table 4 below)

and CALC 1 below to calculate the P-Band setting required in order to get the desired P-Band. A power

factor of 0.8 or greater will cause an insignificant change to the P-Band and does not need to be corrected.

POWER

FACTOR

1.0 1.00

0.9 1.05

0.8 1.10

0.7 1.25

0.6 1.33

0.5 1.60

Table 4: Power Factor Correction Numbers

CALC 1: P-BAND SETTING = DESIRED P-BAND x CORRECTION NUMBER

Example 1: To have a 6oF P-Band with a motor which has a power factor of 0.7, set the P-Band to 7.5oF

o

(ie. 6

F x 1.25 = 7.5oF).

CORRECTION

NUMBERS

10245506 25

TVS user manual Phason

If the power factor is not known the correction number may be measured. Follow the steps below.

1) Set the Minimum Ventilation parameters (# 2 and 3) to the desired value.

2) Set the P-Band(s) to 10

o

F (parameters # 5 and 8).

3) Observe the ROOM TEMPERATURE.

4) Adjust the TEMP SET (parameter # 1) to equal the ROOM TEMPERATURE and Stage 2 Start PBand2 (parameter # 7) to 0. The Stage 1 and Stage 2 fans will now be running just above minimum

ventilation.

5) Slowly decrease the TEMP SET (parameter # 1) and listen to the fans increase in speed.

6) Observe the TEMP SET (FULL SPEED TEMP SET) at which the motors reach full speed.

7) Use CALC 2 to calculate the Correction number for the motors as follows:

CALC 2:

10oF = Correction number

FULL SPEED TEMP SET - ROOM TEMPERATURE

Example 2: ROOM TEMP = 75

o

F and FULL SPEED TEMP SET = 82oF

Correction Number =

10oF = 1.43

o

82

F - 75oF

Now use CALC 1 to find the P-Band setting.

26 2009-09-15

Phason TVS user manual

Appendix A - Wiring diagrams

Installation overview

TEMP SENSOR

See pages A-6 and

A-7 for diagrams.

ALARM RELAY

See page A-8 for wiring

an alarm system.

HEAT / COOL STAGE

See pages A-9 and A-10 for

wiring diagrams.

VARIABLE SPEED STAGES

See page A-11 for wiring diagrams

of the variable speed stages.

Wiring diagrams and instructions for the different stages are located on the pages listed above. First read

the General Warnings and Mounting Instructions sections, then follow the diagrams for each stage.

10245506 27

TVS user manual Phason

General warnings

BE SURE POWER IS OFF BEFORE DOING ANY WIRING.

The TVS should be installed by a qualified electrician.

Install all equipment according to the applicable local electrical codes.

Most variable speed fan motors draw more current at fractional speeds than at full speed. Fan motor

specifications show current draw at full speed. The increase in current draw may be as much as two times

the rated current. Current over 7.5 Amps will cause overheating and eventual failure of the TVS. Please

check current requirements for the fan motor by either measuring current draw at all speeds from idle to

full speed or consult the dealer for information on the particular fan.

CAUTION: Stages 1 and 2 are for control of shaded pole, permanent split capacitor or universal

motors only.

ATTENTION: Destine uniquement a la commande de moteurs universels, a bague de dephasage ou a

condensateur permanent.

DO NOT mount power contactors inside the TVS enclosure. Power contactors create electrical noise,

which may cause the TVS to work improperly.

Warning: Phason controls are designed and manufactured to provide reliable performance, but they are

not guaranteed to be 100% free of defects. Even reliable products may experience occasional failures, and

this possibility should be recognized by the user. If Phason products are used in a life support ventilation

system where failure could result in loss or injury, the user should provide adequate back-up ventilation,

supplementary natural ventilation or an independent failure alarm system. The user's lack of such

precautions acknowledges their willingness to accept the risk of such loss or injury.

Electrical noise varies according to the type of equipment installed, the wiring layout and many other

factors. It's effects are not apparent in most installations but over time it can cause degradation of

electronic circuits, relays and power contactors. These transients can cause unreliable operation of your

equipment if they are not properly controlled. A false 'A PF' alarm is due to electrical noise caused by

high voltage transients in certain installations. Therefore, snubbing filters must be installed on all

inductive loads for installations of this type. The filters must be connected in parallel with the load so the

snubbing filter may absorb

28 2009-09-15

Phason TVS user manual

Mounting instructions

To mount the TVS, remove the four screws in the front cover and lift off the cover. The cover can be

unplugged from the bottom to make wiring easier. Mount the box to the wall with the four wood screws

provided with the control. Insert the screws into the large holes in each corner of the box and tighten.

Use the knockouts provided at the bottom of the enclosure for mounting cable connectors. DO NOT make

additional holes in the enclosure - this will void the warranty! All wires should enter the enclosure

through the electrical-knockout holes provided and all grounds should be connected to the ground plate.

When installing a control route the wires inside away from the control's electronics so that they are not

draped across the components. This may result in a part being broken or damaged, which will affect the

reliability of your control.

DO NOT mount the bottom enclosure with the electrical-knockouts located at the top of the enclosure.

This may cause moisture to enter the control along the wiring and corrode the electronic circuitry, which

voids the warranty.

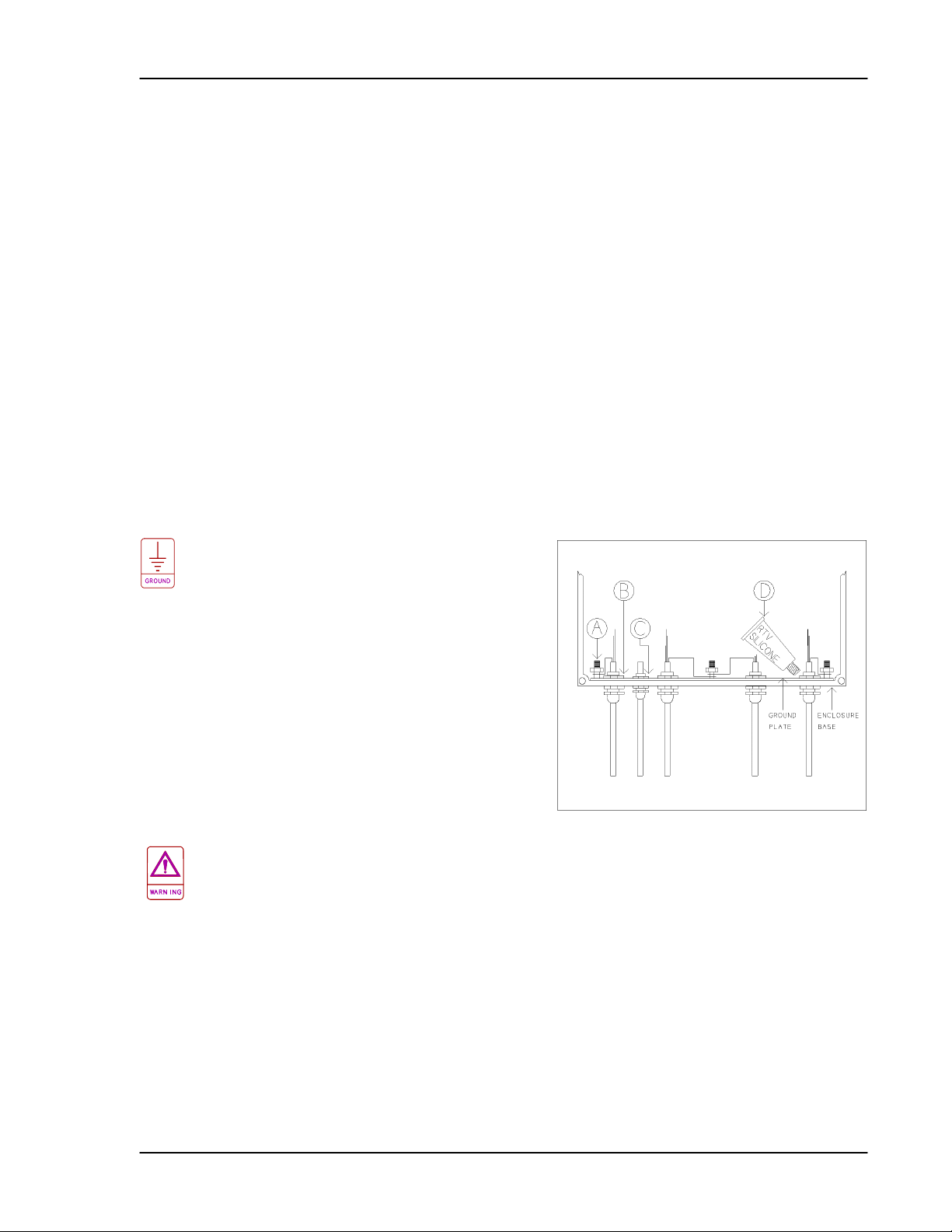

Grounding and sealing

A - Connect all ground wires to ground studs.

B - Use 3/4" liquid tight wire connectors for large holes.

C - Use 1/2" liquid tight wire connectors for small holes.

D - Use RTV silicone or Silicon II sealant to seal cable

entry points if liquid tight wire connectors are not used.

If silicone is used, be aware that some silicone sealants release acetic acid while curing. This can

cause corrosion damage to the control. Let the silicone cure completely (1 to 3 days) before

closing the control or the control may be damaged and the warranty VOID.

10245506 29

TVS user manual Phason

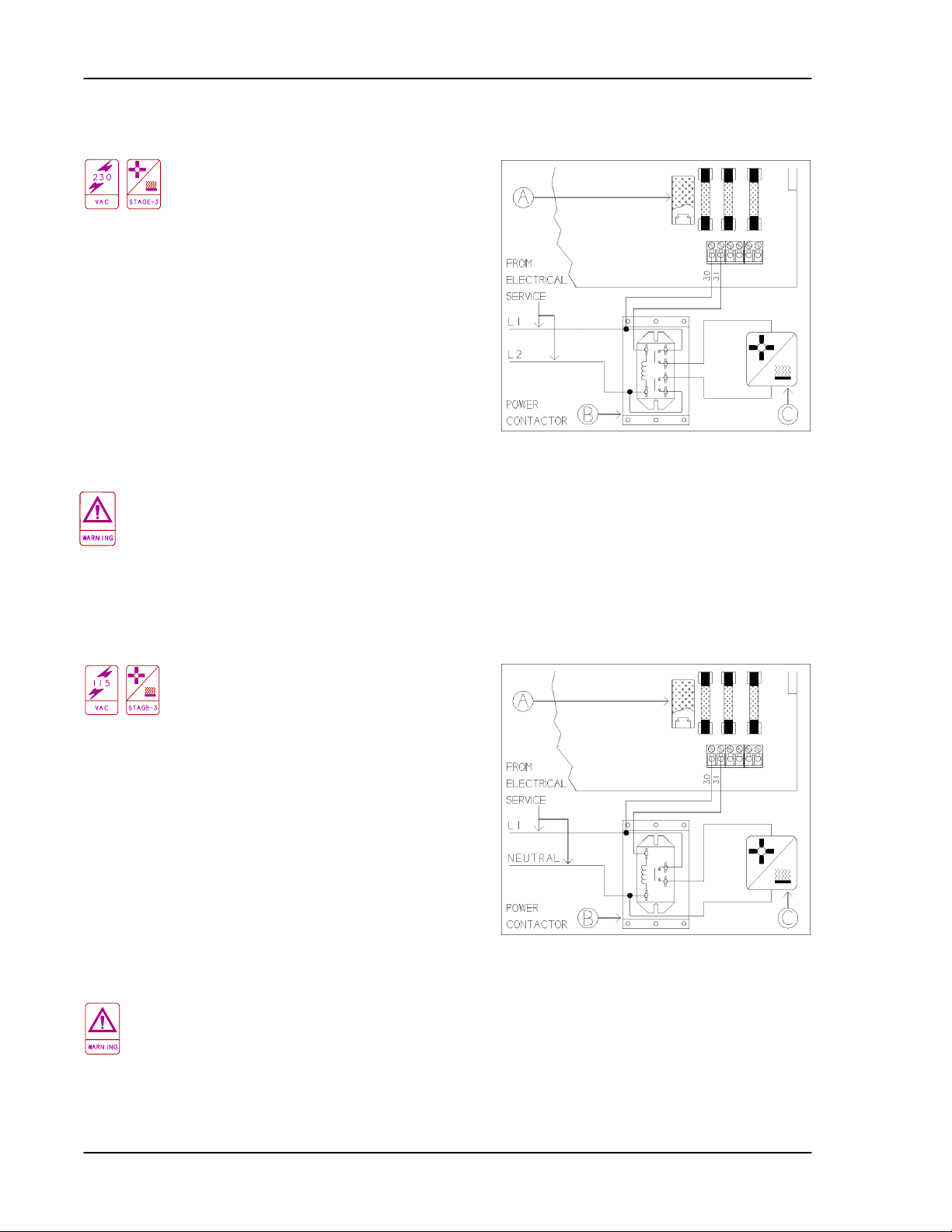

230 VAC control power

Connect power to terminals 1 and 2.

A - Set switch to 230 VAC position.

See page A-12 for instructions on connecting the

TVS to three-phase power.

120 VAC control power

Connect power to terminals 1 and 2.

A - Set switch to 115 VAC position.

30 2009-09-15

Phason TVS user manual

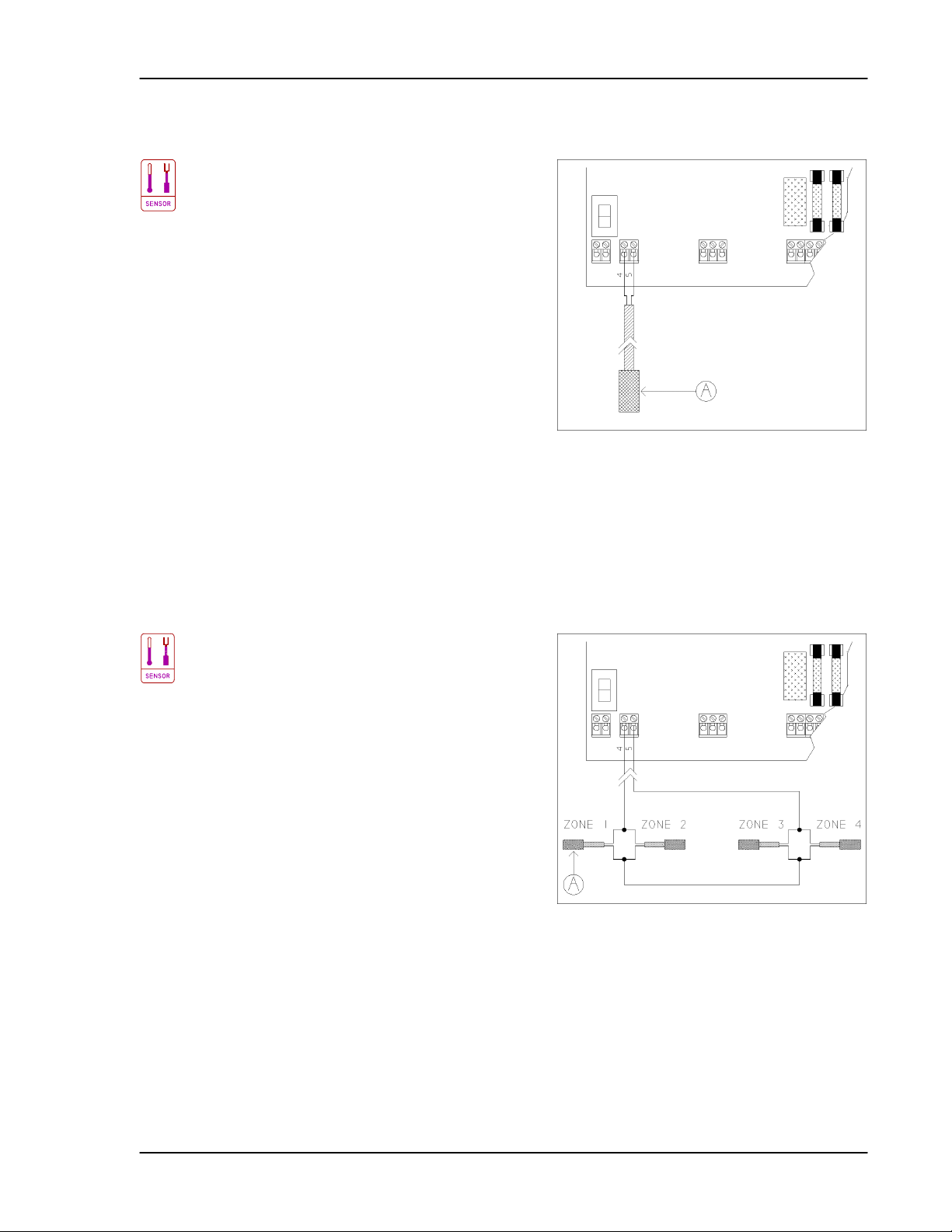

Temperature sensor

Connect sensor to terminals 4 and 5.

The temperature sensor can be extended if so desired. An

extended sensor can be ordered from PHASON. To

manually extend the sensor, follow the instructions

page 32

.

on

Do not run the probe cable in the same conduit as AC

power cables.

Do not run the sensor cable beside AC power cables or

near electrical equipment.

When crossing other cables or power lines, cross them at a

90 degree angle.

4-zone averaging

Connect sensor to terminals 4 and 5.

The TVS is capable of monitoring the temperature in four

areas and operating accordingly to the average. To take

advantage of this option, you must connect four

temperature sensors to the unit.

A - The TVS can operate with one or four probes

connected.

10245506 31

TVS user manual Phason

Manually extending sensor

To extend the sensor, use 2-wire 18 or 20 AWG jacketed

cable. To splice two wires together follow the steps below

and refer to the diagram.

A - Slide pieces of heat shrink tubing on the wire ends as

shown.

B - Strip the ends of wire and twist together.

C - Using a soldering iron and solder, connect the twisted

wire ends together.

D - Slide the heat shrink tubing over the soldered

connection.

E - Heat tubing with a hot air gun (paint stripper).

F - When finished, the splice should be completely

sealed.

NOTE: If the unit operates erratically with the extended

sensor, try running the extended sensor on a different path

or shortening it. Follow the guidelines on the previous

page when extending temperature probes.

32 2009-09-15

Phason TVS user manual

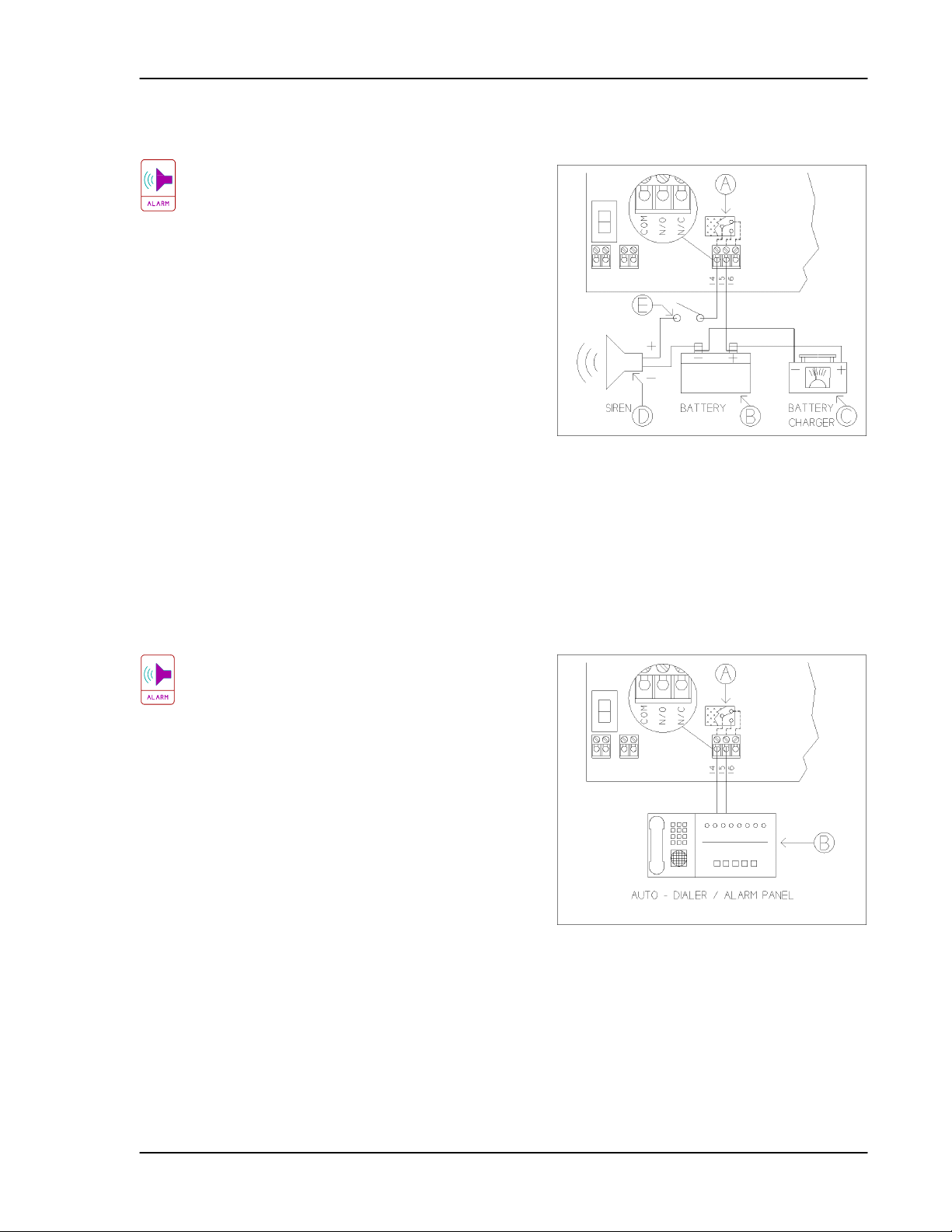

Alarm siren installation

Connect alarm to terminals 14, 15 and 16.

14 - COMMON

15 - NORMALLY OPEN

16 - NORMALLY CLOSED

A - See the TVS Electrical Ratings section for the alarm

relay ratings.

B & C - Use a backup battery and an appropriate charging

system.

D - The siren ratings must not be greater than the alarm

relay ratings.

E - Alarm disable switch.

Alarm panel installation

Connect the alarm panel / auto-dialer to terminals 14, 15

and 16.

14 - COMMON

15 - NORMALLY OPEN

16 - NORMALLY CLOSED

A - See the TVS Electrical Ratings section for the alarm

relay ratings.

B - Consult the Alarm Panel / Auto-dialer owner's manual

for proper installation guidelines.

10245506 33

TVS user manual Phason

230 VAC heat/cool stage

Connect Stage 3 to terminals 30 and 31.

A - Normally Open Relay Contact

Rating: 6 A at 120/230 VAC, general-purpose

(resistive)

1/3 HP at 120 VAC, 1/2 HP at 230 VAC

360 W tungsten at 120 VAC

Fuse 12 A, 250 VAC ABC-type ceramic

B - 230 VAC power contactor (if required).

C - Load type: fan or heater.

Install according to applicable local electrical codes.

120 VAC heat/cool stage

Connect Stage 3 to terminals 30 and 31.

A - Normally Open Relay Contact

Rating: 6 A at 120/230 VAC, general-purpose

(resistive)

1/3 HP at 120 VAC, 1/2 HP at 230 VAC

360 W tungsten at 120 VAC

Fuse 12 A, 250 VAC ABC-type ceramic

B - 120 VAC power contactor (if required).

C - Load type: fan or heater.

Install according to applicable local electrical codes.

34 2009-09-15

Phason TVS user manual

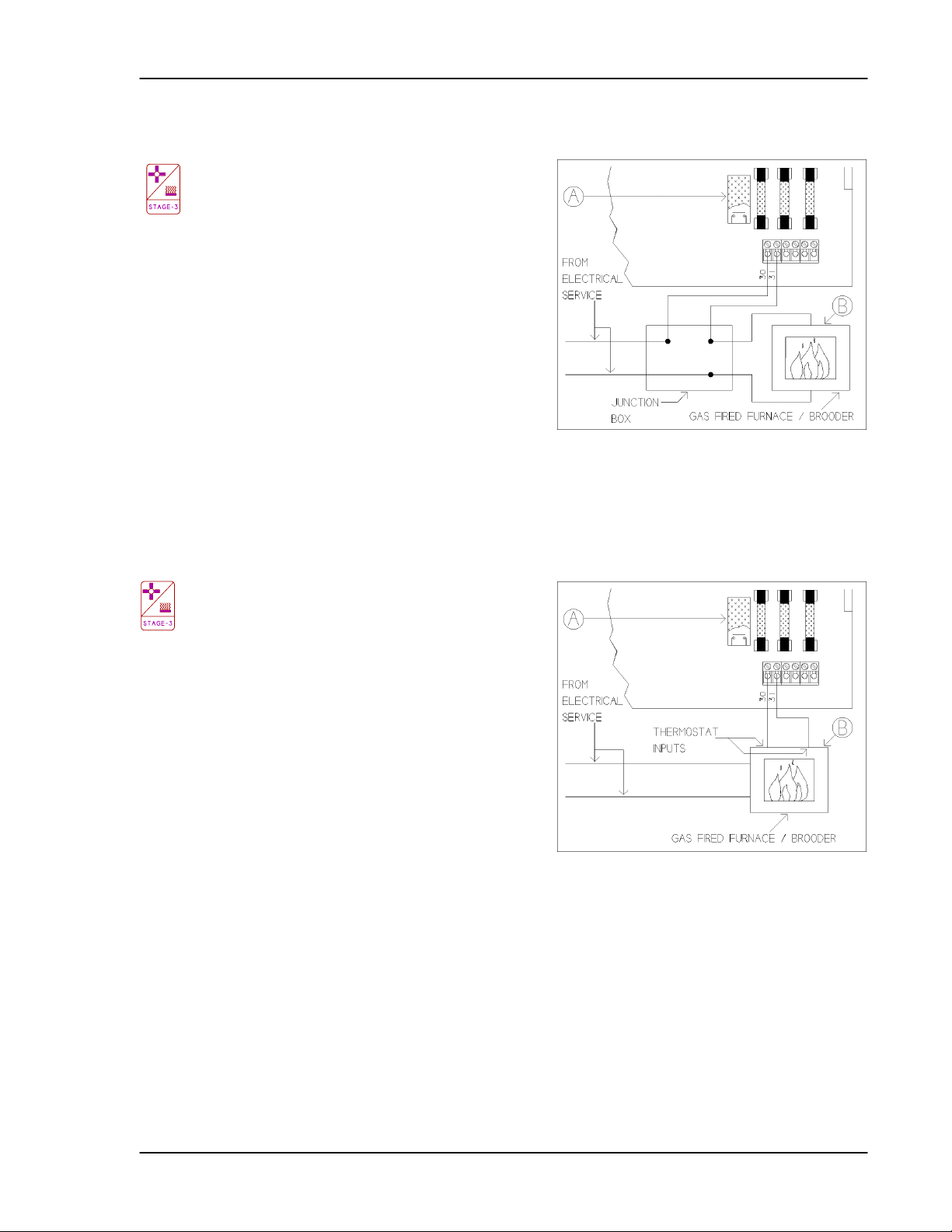

Heat/cool stage furnace-power

Connect Stage 3 to terminals 30 and 31.

A - Relay Ratings: 6 A at 120/230 VAC, general-purpose

(resistive)

1/3 HP at 120 VAC, 1/2 HP at 230 VAC

360 W tungsten at 120 VAC

Fuse 12 A, 250 VAC ABC-type ceramic

B - This configuration shows the TVS connected to the

power connections for a gas fired furnace or brooder.

Heat/cool stage furnace-thermostat

Connect Stage 3 to terminals 30 and 31.

A - Relay Ratings: 6 A at 120/230 VAC, general-purpose

(resistive)

1/3 HP at 120 VAC, 1/2 HP at 230 VAC

360 W tungsten at 120 VAC

Fuse 12 A, 250 VAC ABC-type ceramic

B - In this configuration the TVS is connected to the

thermostat inputs for a gas fired furnace or brooder.

10245506 35

TVS user manual Phason

230 VAC variable speed fan

Connect Stage 1 to terminals 34 and 35.

Connect Stage 2 to terminals 32 and 33.

A - Stage 1 and 2 fuse type:

ceramic

12 A, 250 VAC ABC-type

B - Variable speed fan.

Wire according to applicable local electrical codes.

For 3-phase wiring instructions, see page A-12.

120 VAC variable speed fan

Connect Stage 1 to terminals 34 and 35.

Connect Stage 2 to terminals 32 and 33.

A - Stage 1 and 2 fuse type:

ceramic

12 A, 250 VAC ABC-type

B - Variable speed fan.

Wire according to applicable local electrical codes.

36 2009-09-15

Phason TVS user manual

Correct 3-phase wiring

When connecting the TVS to a 3 phase power system, the

control power and Stage 1 and 2 must be connected to the

same circuit. If this is not done the variable speed fans will

run erratically.

DO NOT connect 120 VAC power to terminals 1 and 2 on

the TVS and power the fans with 230 VAC.

Incorrect 3-phase wiring

If the control power and the variable speed stages are

wired to different phases the fans will operate erratically.

This will also happen if the TVS is powered with 120

VAC and the variable speed fans are powered with 230

VAC.

10245506 37

TVS user manual Phason

Heat/cool bypass switch

A - A bypass switch may be installed so the stage can be

operated manually, turned off, or controlled

automatically by the TVS. When the switch is in the

right position the stage will be controlled

automatically. When the switch is in the center

position the stage will be off, and when the switch is

in the left position (manual position) the stage will

be fully on.

Connect a "SPDT center off" switch. This switch is

included with Phason power contactor units but can

also be ordered separately. Note: This switch is NOT a

disconnect switch.

Variable stage bypass switch

A - A bypass switch may be installed so the fan can be

operated manually, turned off, or controlled

automatically by the TVS. When the switch is in

the upper position the fan will be controlled

automatically. When the switch is in the center

position the fan will be off, and when the switch is

in the lower position (manual position) the fan will

be on full speed.

Connect a "SPDT center off" switch. Note: This switch

is NOT a disconnect switch.

38 2009-09-15

Phason TVS user manual

Appendix B - Test procedure

The TVS has a built in test procedure. The test should be performed after the control has been installed

and may be used at any time to check the operation of the control. The test procedure tests the circuitry in

the control and tests each stage individually. Follow the instructions below to step through the test

procedure.

If an alarm system is connected, be aware that it is normal for the alarm be activated during most

of the test procedure.

In order to start the test procedure, the power to the TVS

must be off. Then, while holding the UP and DOWN

buttons in, turn on the power. The TVS will start up in the

test mode.

1. Input test

Press the PROG button once. The TVS will display a

number. This number should be between 80.0 and 130.0.

Press the PROG button again. The TVS will display the

temperature. If the temperature displayed is not correct,

make sure that the sensor is installed properly.

2. Memory test

Press the STORE button. The TVS will display PASS if

the factory programs are in the memory. It will display

FAIL if the programs have been changed in any way from

the factory settings. See Reloading the Factory Programs

under the Adjusting The TVS section in this user's guide to

reload the factory programs.

10245506 39

TVS user manual Phason

3. Display test

Press the PARM button to perform the display test. The

TVS will display 8888 and then will count from 0 to 9 on

each digit. After the display test is done the TVS will

display "t ds" which stands for "test display".

4. Variable stage test

Press the UP button once. This will start the variable speed

fan test. The display should be flashing tSP1 and oFF

("tSP1" means "test variable speed stage 1"). Press the UP

button again. Now the display will flash tSP1 and FuLL,

and the Stage 1 fan will be running full speed. Press UP

again and the fan will be running at half speed, and the

display will flash tSP1 and HALF. Press UP again and the

fan will run at low speed.

The display will flash tSP1 and Lo (some fans can not operate at this low speed).

Pressing the UP button four more times will cycle through

the Stage 2 fan test. The display will flash tSP2 and the speed

("tSP2" means "test variable speed stage 2"). The Stage 2

variable speed fan will run at oFF, FuLL, HALF and Lo

speeds (like the Stage 1 test). Pressing the UP button again

will restart the Stage 1 fan test.

40 2009-09-15

Phason TVS user manual

5. Relay test

Press the DOWN button to start the relay test. The display will

flash t rL and ALAr ("t rL" stands for "test relay"), and the alarm

should be on. Press the DOWN button again and the display will

flash t rL and St 3. Now Stage 3 should be on and the alarm will

be off. Pressing DOWN again will restart the relay test cycle.

If the stage does not function properly when activated, refer to

the troubleshooting guide in Appendix C.

6. Reset test

Press the RETURN button. This will return the TVS to normal

operation. The display will flash t SA for one second and then reset

("t SA" stands for "test sanity circuit"). When the control is in

normal operation the display will be flashing the room temperature

and a power failure alarm (A PF). Press the RETURN button to

clear the alarm. Other alarms might be displayed if the TVS has not

yet been programmed.

This completes the built-in test procedure in the TVS. If at any point during this test the TVS or

equipment did not function properly, refer to the troubleshooting guide in Appendix C.

10245506 41

TVS user manual Phason

Appendix C – Troubleshooting guide

PROBLEM

No Power/Display

Stage 1/Stage 2 fan(s)

not running

CAUSE SOLUTION

Circuit breaker at service panel off

or tripped

Wiring incorrect

Display board inter-connect cable

unplugged from power supply

board

115/230 VAC switch in the wrong

p

osition

Wiring incorrect

12 A, 250 VAC ABC-type ceramic

fuse

open

Display board inter-connect cable

is not plugged into the power

supply board properly

Minimum ventilation settings too

low (Parameters 2/3)

Stage 1/Stage 2 Minimum Idle

setting too low (Parameters 21/22)

Temperature Set setting above

room temperature (Parameter 1)

Room temperature below range of

Stage 1 / Stage 2 Off-Set-Back

(Parameters 4/6)

Ventilation is turned off (V off)

(Parameter 16)

Fan is faulty

Reset circuit breaker

Correct wiring

Plug in display board cable

Set switch to the correct setting

Correct wiring

Replace fuse(s)

Be sure the inter-connect cable is

firmly plugged in

Increase minimum ventilation

settings

Increase minimum idle setting

Adjust Temperature Set to desired

temperature

Adjust Off-Set-Back to cover

required range

Change Ventilation to on

Replace fan

42 2009-09-15

Phason TVS user manual

PROBLEM CAUSE SOLUTION

Stage 1/Stage 2 fan(s)

run full speed

Stage 1/Stage 2 fan(s)

run erratically

Stage 3 Relay is not

operating loads

Alarm relay not

operating alarm system

Alarm message on

display

Wiring incorrect

Minimum ventilation settings

too high (Parameters 2/3)

Stage 1/Stage 2 P-Band set to 0

(Parameters 5/8)

Room temperature above

Temperature Set (Parameter 1)

P.F. Compensation is not set

correctly

Wiring incorrect

12 Amp, ABC12 Fuse open

Display board inter-connect

cable is not plugged into the

power supply board properly

Turn-on setting for stage is

incorrect (Parameter 9)

Wrong Setup parameter

selected (Parameter 18)

Ventilation is turned off (V off)

(Parameter 16)

Note: This is only applicable to

a stage in cooling mode

Fan/Heater is faulty

Wiring incorrect

Alarm condition present

Correct wiring

Decrease minimum ventilation

settings

Increase Stage 1/Stage 2 P-Band

Adjust Temperature Set to desired

temperature

Adjust P.F. Compensation

(Parameters 24/25)

Correct wiring

Replace fuse with 12Amp, 250VAC

Be sure the inter-connect cable is

firmly plugged in

Adjust Turn-on setting

Correct Setup Parameter setting

Change Ventilation to ON

Replace Fan/Heater

Correct wiring

See Alarm section. Clear alarm

condition by pressing RETURN

10245506 43

TVS user manual Phason

Appendix D – Blank program tables

When changes to the programs are made the changes should be marked in table 1 below. This will

provide a quick reference chart to refer to when reprogramming the TVS in the future.

# PARAMETERS

MAIN

A b C d E F G

1 Temp Set (Start P-Band1)

2 Stage 1 Min Vent

3 Stage 2 Min Vent

DIFFERENTIAL

4 Stage 1 Off-Set-Back

5 Stage 1 P-Band1

6 Stage 2 Off-Set-Back

7 Stage 2 Start P-Band2

8 Stage 2 P-Band2

9 Stage 3 Turn On (Cool)

10 Not Applicable

11 Not Applicable

12 Low Temp Alarm

13 High Temp Alarm

GENERAL

14 Low Power Alarm

15 Alarm Display Latching

16 Ventilation

SETUP

17 Units oF or oC

18 Stage 3 Operation

19 Not Applicable

20 Not Applicable

21 Stage 1 Minimum Idle

22 Stage 2 Minimum Idle

23 Hysteresis

24 Stage 1 P.F. Compensation

25 Stage 2 P.F. Compensation

Table 1: Blank Parameter Chart

PROGRAM NAMES (A - g)

44 2009-09-15

Phason Inc.

2 Terracon Place

Winnipeg, Manitoba, Canada

R2J 4G7

Phone: 204-233-1400

Fax: 204-233-3252

E-mail: support@phason.ca

Web site: www.phason.ca

Loading...

Loading...