Page 1

>

d

ARTS

HITS THE BULLS-EYE

arrive in Jacksonville, Florida, only to be

surprised on two counts: the first being

that what I took to be a small village

I

turned out to be a sprawling city bustling

with life; the other being that if I don’t find the

United Speaker Systems building soon, the humidity is going to do me in. Fortunately, Ken

Hecht, president of the company, is there to

usher me into the building and the blessed

A/C. What’s interesting is that I’m in a working

factory for speakers – it’s not just a place where

engineers toss ideas around and then call someone overseas to take care of. United Speaker

Systems has been producing speakers for wellknown manufacturers for more than 50 years.

Ken conducts a tour of the facilities, noting

that they produce the entire product from beginning to end. And through a rapid turnaround and a number of innovations, they can

turn on a dime (as it were) and change the

procedures to handle just about anything those

having speakers made can ask for.

Normally we’d have a lot of questions, but

since we’re interviewing Ken later (Industry

Giants, p. 68), we can dive right in.

The process of making a speaker distilled

down to its basics – and ignoring the obvious

fact that it has to be designed in the first place

– is simple enough: you build a box, take

speaker drivers and put them into that box, wire

the speaker drivers up, close and finish the box,

stick it in a package and wave goodbye. But

as Ken takes us through the 60,000-squarefoot plant, we can see there’s a lot more to each

of these steps. For instance, in a corner is a thin

wire (that will be used for voice coils) being

stretched from one end of the plant to the other

and coated with a thermosetting adhesive. After

the wire is wound on the voice coils, it is baked

at 500 degrees to thermoset it. This insures it

will not soften due to heat from the electric current flowing through it when in operation. In

passing by some of the testing cubicles, we’re

told that they match each speaker to +-1 1/2dB

of the reference speakers for an exacting sound.

In the room where the speaker boxes are

being cut to size – by people actually using machines, not machines being watched by people – a vacuum system keeps all the wood chips

and sawdust moving away so it doesn’t settle

down on the speaker enclosures, which are being cut with a near-fanatical precision (the CNC

router weighs around 1,700 pounds!). In the

paint room, slightly more air is being pumped

into it than being evacuated out, so as to keep

the paint from being sucked out before it has

time to evenly spread on the cabinet. And of

course, computer workstations are used in conjunction with human testers to make sure the

various speaker drivers are tested for frequency

response and accurate motion, in order to accurately reproduce and handle the type of musical power for which they are intended (i.e.,

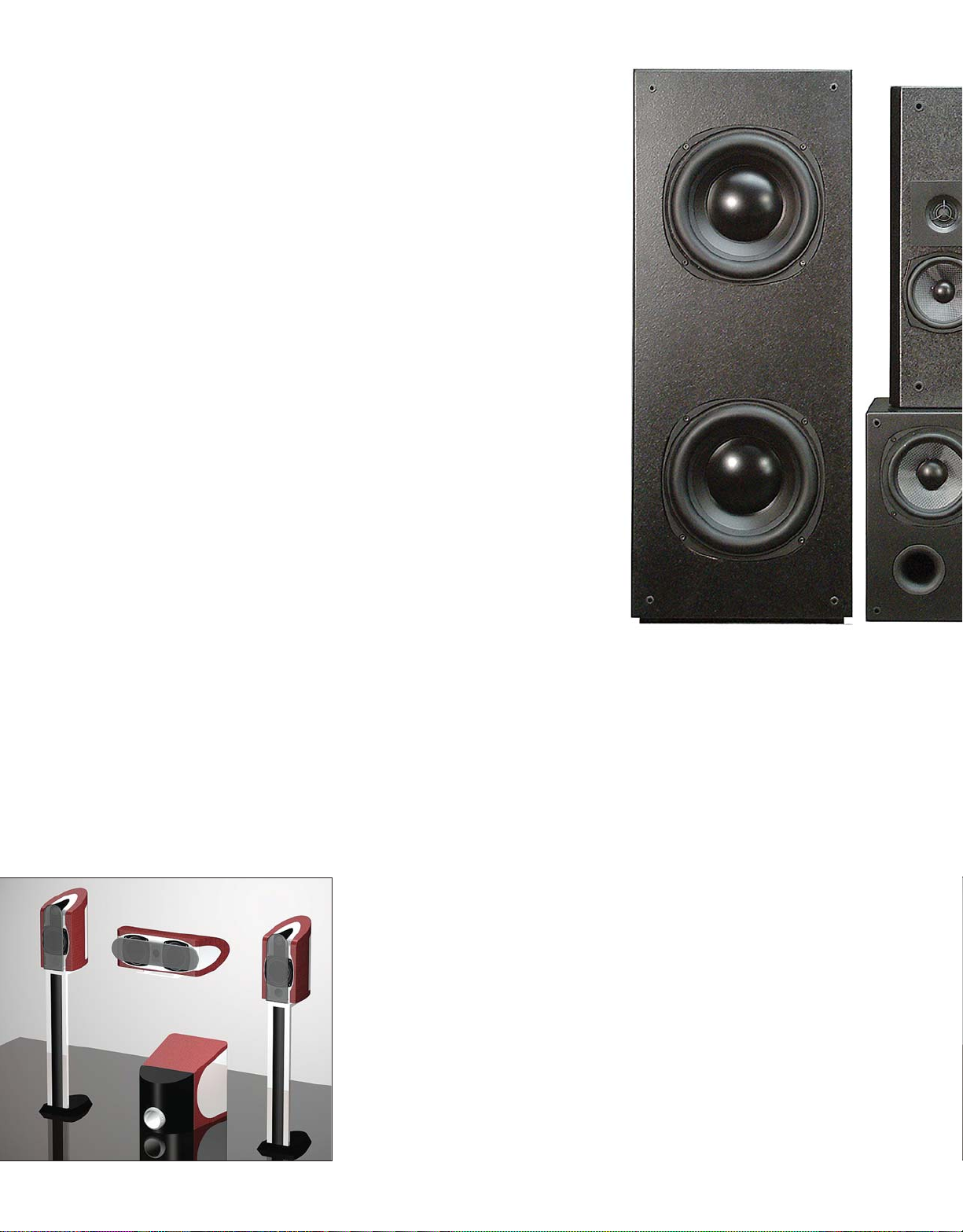

There are three versions of the dARTS speaker system:

free-standing, wall-mountable (on or flush) and in-wall.

at one station, a worker delivers a spike of 100W

to a tweeter driver, then analyzes the response

to verify the driver hasn’t given up the ghost

and can handle such demands in the future).

Ken also points out that the word “tolerance”

is treated like unto a god here: voice coils (basically wire wrapped around a metal core that

is then magnetized) are of such a tight tolerance that it seems a wonder that they can fit so

perfectly snugly into their intended speaker

drivers’ magnets. This, by the way, is just one

of the reasons that work done here is so exacting. While overseas expertise is quite good,

tolerance factors such as this are not followed,

as a wider tolerance is considered good enough.

Maybe for others, but not for Ken, which is also

why every speaker is checked twice on the assembly line before being boxed. Additionally,

samples of each group of boxes are pulled out

to be rechecked once again before a production run is released for shipment.

The result is a near 0.1% failure rate, which

not only makes United Speaker Systems’ clients

(you’d know their names because you probably have one of these speakers) and the consumers happy, but also ties into the Phase

Technology line, giving it excellent quality right

out of the starting gate.

52 HDTV ETC•December/January 2006 www.hdtvetc.com

Page 2

The dARTS speaker system is designed to remove your

listening room’s anomalies from the sound equation.

But there’s more to that – which is one of

the reasons we came over. While Phase

Technology was created originally as a “showcase,” Ken says that they expect to strengthen

the line and give it more prominence in the future. The dARTS system is one heck of a way

to get it going through an evolutionary leap into

their second half-century.

dARTS stands for Digital Audio Reference

System and basically consists of four distinct

parts. First, you have the speakers themselves,

the best dynamic products Phase Technology

makes, consisting of free-standing speakers that

are aesthetically pleasing and deliver superior

sound, a complete set of speakers that can be

either mounted on or flush in the wall, and a

series of in-wall speakers that include their own

dedicated, damped, in-wall enclosure, utilizing

a patented Positive Clamping System to assure

optimal performance regardless of the wall’s

construction. In the factory’s demo room in

which the system is set up, we have a pair of

left/rights, each featuring a one-inch variable

axis soft-dome tweeter (United Speaker Systems

invented the soft-dome tweeter in 1962!) and

two six-inch glass/honeycomb woofers that are

able to synch together so as to form one sound

output. Each of these is sitting upon a powered 500-watt subwoofer. For the center channel there’s a one-inch variable axis soft-dome

tweeter and two six-inch glass/honeycomb

woofers. The side surrounds consist of two

5.25-inch glass/honeycomb woofers and two

one-inch variable axis soft-dome tweeters,

which are bipole/dipole switchable. All the

woofers and tweets are powered by their own

250-watt digital amplifier channel. The digital

electronics in the amplifier control all aspects

of the speakers, including crossovers, phase

and frequency response. Because this is done

in the digital domain, they are able to keep the

speakers’ tolerance to an incredible +-1/2dB to

their reference standard.

Of course, there is a matching powered subwoofer featuring two of Phase Technology’s 10inch long-throw drivers, coupled to one

250-watt amplifier each, for a total of 500 watts

per cabinet. The subwoofer’s cabinet is the

same width as the front speaker, so it can be

used as a stand for a speaker.

All models are designed using the same drivers, and voiced identically so they can be used

interchangeably in any position in the system,

no matter if that system is stereo, 5.1-, 6.1-, 7.1channel or any other future format. If more

bass impact is needed, multiple subwoofers can

be used. Systems can be stacked to provide

adequate volume levels in even very large

spaces. Phase Technology will even work with

clients and their A/V installer to design custom

systems with larger speakers and custom designed software to match. Add to that the magic

of the digital processing power of the amplifier’s setup modes and the optional Audyssey

MultEQ XT room calibration package, and stunning realism, involving effects and dynamic

power are assured in any listening environment.

Rooted to them all is a 4,000-watt digital amplifier able to put out 250 watts per each of its

sixteen channels. Barely over 20 pounds in

all, the digital amp runs extremely cool and

the fan inside barely purrs. The amplifier also

contains powerful DSP configuration tools for

each channel, allowing Phase Tech to individually tweak each speaker (and the entire system) to match each other and the target

response curves, within +/-1/2dB. By setting

the crossover point, frequency response and

time alignment, a perfectly-matched system can

be provided to each consumer.

The amp also has a front-mounted USB con-

HDTV ETC•December/January 2006 www.hdtvetc.com 53

Page 3

>

d

ART S HITS THE BULLS-EYE

nector that is designed to accept input from the

additional system component – the software.

Using a PC rather than a chip in the digital

processor enables greater abilities in the digital

measuring and room correction applications that

are needed. This is opposed to those processors on the market that do this through a builtin chip – functional to a point, but limited in

scope and unable to match the power of a PC

devoted to this task through software.

The final component, used in conjunction

with the software, is a microphone on a stand

and a digital audio mixer. These will be used to

measure the audio response of the room in several locations to let the software work its magic.

The dARTS speakers may be perfectly

matched to each other and to a chosen target

curve, but that’s not enough in the real world.

As I understand it, the real problem with sound

is that no matter how well a speaker has been

designed, it can’t take into effect the room in

which it will be placed, and therefore the

acoustic impact that will occur. Sound bounces

multiple times off the floor, walls and ceiling,

and is also affected by such things as carpeting

or whether there are glass windows or a fireplace, etc. So the idea is to correct for this – or

to be more accurate, the hope is to take the room

out of the equation of the resultant sound.

To date, the process has been to place a microphone in the “sweet spot” of a single listener,

play and analyze tones and then calculate an

equalization curve. Obviously this doesn’t bode

well for those not seated in the sweet spot, and

so additional techniques have been added to

average in reading from those in other positions

as well. But the end result is still averaging –

person A who is seated in chair #4 will not gain

the benefit of hearing what person B might,

since B is in the best position for listening. Ken

adds that when different positions are averaged,

if one seat has a peak at, say, 200 Hz, and another has a dip at the same frequency, the resulting average will yield NO correction at all.

Where dARTS is different is that the software

(from Audyssey Laboratories) isn’t doing an averaging – it’s actually able to compare and

weigh the responses from the different seats

over and over, and then modify the sound so

that people in various positions hear it the same.

This is possible due to the speed and power of

the digital processor – something that Ken notes

wasn’t possible earlier on. He places the microphone in the first position – which is for one

seated in the center of a couch – and provides

the processor with its delay and channel level

settings. Readings 2 and 3 are for those seated

at the sides, while 4 and 5 are for hypothetical

people standing behind those seated, and 8, 9

and 10 are for a second row of seats. After the

software does its thing (a process taking a few

minutes, at most), I can see a graphical display

of the sound for each channel, and then how

each position has now been evened out with

the other so that no matter where you are, you’ll

hear the same sound without the room getting

in the way. Ken says that up to 32 positions

can be enacted, though realistically there is a

sensibility that needs to be applied. But this

works regardless of small or large space, as the

correction filters which are derived compensate for the room’s anomalies, making the

speakers sound the same regardless of the

room, and again, at every seat.

A key press now sends this information into

the amplifier’s EPROM for permanent storage.

This process can be repeated at any time to increase/decrease/change the number of people

who will be in the specific listening space, or

to correct for new room furnishings.

So, let’s watch some movies and listen to

some music. Ken keeps the software running

so I can toggle the digital technology on and

off (as dARTS is sold through a dealer/installer

bringing his/her own PC as well as the other

needed installation equipment, the system is

left “on” without this toggling available to the

end user). He puts on “House of Flying

Daggers,” which features an amazing sequence

of drums sounding off as they’re struck by both

pebbles and coiled cloth. I focus on the echoes

of the drum strikes, which fade rapidly and indistinctly. Toggled “on” however, I can now

hear a gradual fading of the echoes around me,

creating a much more distinct surround that is

as realistic as it is impressive.

For gunshots, it’s The League of Extraordinary

Gentlemen and the sequence in which Dorian

Gray’s library is shot to pieces by machine guns.

Again, the echoes of the bullets are much more

realistic and well defined with the DSP enacted,

without it they sound teeny and hard. But U571’s

scene in which the men in the submarine wait

as depth charges go off all around them really

drives the value of the system home. Here, it’s

big explosions that literally rattle your teeth.

But the realism now attained is quite astounding: one hears the rippling of the water as the

shock waves dissipate from the explosions, and

the creaking of the sub’s metal has an immediate intimacy that is nearly painful. Of course

this was in there all along, having been put in

place by the sound editor and heard in the theaters. But it’s taken dARTS to unlock it from the

DVD so that it can now be revealed.

Perhaps the most telling example comes

from a more than 25-year-old Telarc CD,

Tchaikovsky’s 1812 Overture. Digitally remastered, it sounds quite good, but the ending –

where digital cannons mix with church bells

and the orchestra crescendos – becomes truly

muddy and even mushy. Toggling the DSP

back on, the replay displays none of these negative characteristics: the bells are distinct and

their “tink” sharp and clear, the cannon shots

are properly weighted in their bass and solid

response, and the orchestration swells as a

merger of joyous sound in which all are participating without timidity.

Nice as this is, an in-room version is also in

the works. The in-rooms will consist of the

same drivers as the custom box version except

for the front left and right speakers, which have

only one woofer each. The cabinets are made

of a molded polymer and wood blend that

makes them very rigid and acoustically inert.

They are also highly stylized.

Now probably the hardest thing is to sum

up describing the results: after all, this is all about

listening, not reading about listening. So

imagine first covering your ears and listening

to music for an hour or so. Your brain will become accustomed and will attempt to compensate. Upon taking your hands away,

suddenly everything sounds brighter, clearer

and with greater clarity and more definition. Or

how about this – imagine a spinning wheel with

jagged edges: the sound as it spins is harsh

and biting and grrrr.... Now replace that with a

smooth wheel to find a gentler, even swooshing sound that is not just more pleasant, but

more even and considerate to the ear. This is

what dARTS is doing by building perfectlymatched speakers and removing the room from

the equation so the sound you hear in your

home is now as near to what the creators had

intended as is humanly possible. Did I momentarily envision backing up a truck to load

it all on and drive off into the Floridian sunset?

You bet I did!

•

– By Marshal M. Rosenthal

54 HDTV ETC•December/January 2006 www.hdtvetc.com

Loading...

Loading...