Page 1

TK Series frameless motors installation and application

manual

Rel 2.6 doc MA0012.6 ENG

Phase Motion Control

Via Adamoli 461, 16141 Genova Italy

Ph: +39 010 83 51 61

Fax: +39 010 420 67 36

e-mail:

info@phase.eu

http://www.phase.eu

Page 2

2 Phase Motion Control

TABLE OF CONTENTS

TABLE OF CONTENTS ............................................................................................................ 2

Introduction ......................................................................................................................... 3

Safety ................................................................................................................................. 3

General safety instructions .................................................................................................. 3

Electrical risk ..................................................................................................................... 4

Transport and storage conditions............................................................................................. 5

Transport and packaging ..................................................................................................... 5

Unpacking and mounting ..................................................................................................... 5

Storage ............................................................................................................................ 5

Transportation ................................................................................................................... 6

General technical information on TK frameless motors ................................................................ 7

Thin ring, large diameter motors for high torque, low speed (torque motors) ............................ 8

Spindle motors for mills and lathes .................................................................................... 9

Tube motors, small diameter, for multiple spindle units ......................................................... 9

Selection guidelines ............................................................................................................. 10

How to choose the optimal TK motor? ................................................................................. 10

Motor morphology and protections......................................................................................... 13

TKST Stator..................................................................................................................... 13

Type and manufacture of TK motors ................................................................................... 16

Insulation voltage .......................................................................................................... 17

Over temperature protection ........................................................................................... 17

Ground connection......................................................................................................... 18

Standard type and size of output power leads .................................................................... 19

Anti-resonance filter (snubber) ........................................................................................ 19

Motor integration ................................................................................................................ 21

Stator ............................................................................................................................. 21

Rotor .............................................................................................................................. 22

Mounting of the rotor inside the stator ................................................................................. 22

Radial force vs. mounting eccentricity ................................................................................. 24

Check list after integration ................................................................................................. 24

Page 3

3 Phase Motion Control

Introduction

The present document detail the installation, integration and initial mechanical set-up of PHASE

MOTION CONTROL series TK frameless torque motors (henceforth named TK motors). It provides the

customer with the necessary information on how to integrate and operate with TK in his application.

Remark: The liability of PHASE MOTION CONTROL is in all events limited to the functionality of the

motor alone and is limited to its repair or replacement according to the rules agreed in the documente

Condizioni Generali di vendita Phase Motion Control ,

www.phase.eu, which are implicitly accepted

when the motor is purchased.

Frameless motors are just components, however important, of complex systems of which Phase

Motion Control is not aware and not responsible. The Customer or whoever owns or operates the

system must take the responsibility to assess all safety or economical concerns relevant to the

complete system, over and beyond motor replacement, which may stem from any type of motor

failure, and of which Phase Motion Control is unaware and is not and cannot be responsible.

Safety

The user must have read and understood this documentation before carrying out any activity. In case

of unclear information, please contact PHASE MOTION CONTROL.

Handling, installation and maintenance must be done by competent and trained technical personnell

according to IEC 364. Non-compliance with the safety instructions, statutory and technical regulations

may lead to injuries to persons, damage to property and the environment.

General safety instructions

Anyone having active implants (pacemakers) or having any other ferromagnetic

prosthesis is not qualified to work with these kinds of devices, or to approach them.

Keep at safe distance from the motor!

Electronic devices and measuring equipment may be affected or destroyed by strong

magnetic fields. Avoid placing devices with magnetic parts close to computers,

monitors and all magnetic data carriers (e.g. disk, credit cards, audio and videotape,

etc). Because of strong attraction forces, special caution is required in the direct

proximity of the rotor (i.e. under 100 mm). Therefore heavy or wide objects made of

steel of iron must never be brought close to the rotor by free hand. As magnetic forces

are invisible, their effects are generally overlooked close to the rotor.

To cope with any event of an accident while handling the motor, always have at

hand at least two wedges of solid, non-magnetic material (i.e. aluminium) as well as a

non-magnetic hammer (approx. 2-3 Kg). In emergency cases, these tools are for

separating parts magnetically attached to the rotor in order to free caught limbs

(finger, hand, foot).

Page 4

4 Phase Motion Control

Electrical risk

Before installation verify the motor about any damage due transportation and handling, that may

impair electrical safety.

Drive start-up may produce sudden uncontrolled movement. Keep away from all moving parts to

avoid injury!

Do not connect motor to power supply other that specified by PHASE MOTION CONTROL.

A defective power supply may damage the TK assembly.

It is dangerous to interrupt earth or grounding connections. In no way must an earth wire be

disconnected!

Before servicing, make sure that the TK is not powered.

TK motors may have hot surfaces also when the motor is not powered. Normal operating temperature

could be over 100°C.

Slow turning motors have high back-EMF. For example, a TK-xxx-xxx-100 would develop 300 Vac at

its terminals when manually rotated at 5 rpm. Beware of manual or gravitational rotation, dangerous

voltage can be present at the motor terminals even if the machine is not connected.

WARNING: Deep deflux motors (constant power range > 1:2) may deploy higher than mains voltage

between motor and series inductor. Verify maximum interconnection voltage while siziong the plant.

Page 5

5 Phase Motion Control

Transport and storage conditions

Transport and packaging

The PHASE MOTION CONTROL standard package is designed to avoid transport damage.

If any transport damage is observed upon reception of the goods, please inform immediately Phase

Motion Control so that transport damages can be timely claimed or corrected.

Unpacking and mounting

To unpack the TK, please adopt all general safety instructions, reported on the paragraph 3.1.

After opening the package, never pull the motor cable, nor lift the motor by its cables.

Check for cable damage during transport or unpacking

For handling of heavy motors (i.e. >15Kg) the use of lifting tools is recommended, using threaded

lifting bolts, when possible, or using a lift belt.

When storing the motor outside the original packaging put a non-magnetic spacer (i.e. wood) with

40-mm minimum thickness between stator and rotor.

After unpacking the rotor, keep the original rotor wrapping or wrap the magnetic part of the rotor

with paper tape, to keep the magnetic surface clean. The tape must be removed just before mounting

the rotor into the stator.

Take care with the rotors banded with carbon fibre ring: an accidental contact with metallic parts

attracted by the magnetic field can cause damages to the carbon ring, if this happens please contact

PHASE MOTION CONTROL.

Do not leave the rotor outside of its package longer than necessary for assembly to prevent pollution

of the magnet surface and accidents

After mounting verify that the rotation of the rotor inside the stator is free, without contact for the

whole revolution.

Storage

The storage area of TK motors must be strictly restricted and indicated with “Caution, powerful

magnets”.

Motors and motors parts, whenever possible, should be stored in the original packaging.

The storage air humidity should be between 5 and 80% and the temperature between 5 and 45°C.

Should components be stored outside their original packaging, wrapping with oiled paper to prevent

corrosion is recommended.

Magnetic parts should be separated and wrapped in non-magnetic protection. These protections

should be at least 40 mm thick.

Page 6

6 Phase Motion Control

Transportation

By land

The motor must be shipped with original packaging; if it is not possible use IP54 protection

packaging. The parts must be packaged firmly to avoid any movement in case of shocks.

By sea

Use only sea standard packaging (IP55).

By air

CAUTION: if the rotor must be shipped unassembled, i.e. not inside the stator, airline authorisation is

required because of the stray field of the rotor. The use of the original iron box in which the rotor was

supplied is recommended. As required, enquire with Phase Motion Control for the supply of a shielding

box.

Page 7

7 Phase Motion Control

General technical information on TK frameless motors

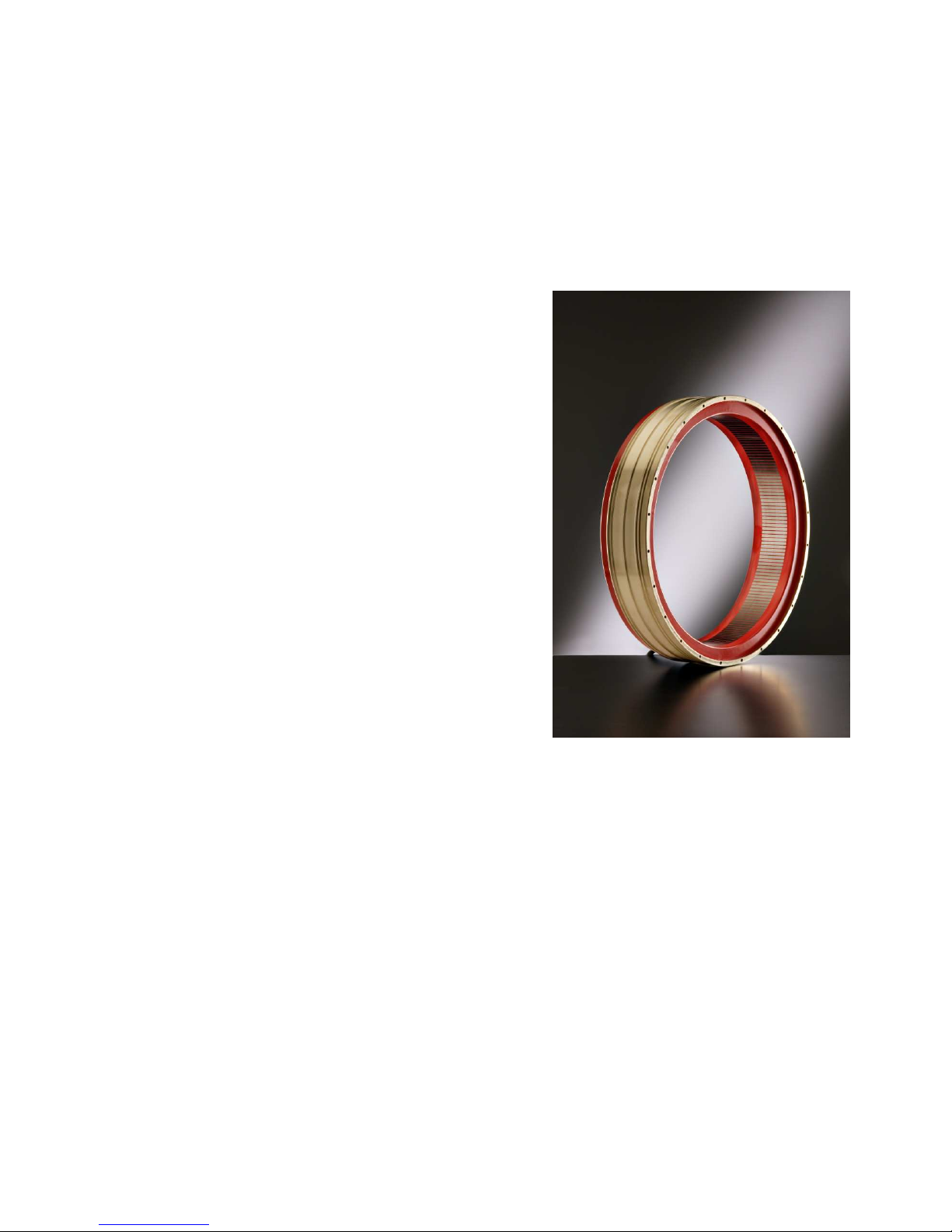

The TK series of frameless brushless motors provide the

highest torque density available today for direct drive,

high performance applications. Unlike traditional torque

motors, TK units have both high torque and high speed

capability and thus operate seamlessly both as spindle

and table motors.

TK motors consist of separately supplied stator and rotor

units suitable for direct assembly inside the structure of

the machine. TK motors are three phase, rare earth (Iron

Neodymium Boron) permanent magnet units and reach

the highest continuous and peak torque density available

today, together with high speed and flux control ability

over a constant power range up to 10:1.

The rotors use special manufactured magnets with

minimized loss factor allowing high speed operation with

a thin isotropic rotor. All rotors are rigid units with

mechanical, glue free magnet retention, preloaded carbon

fiber sleeve for safe operation even at very high speed.

Rotor are often semi custom units to allow direct coupling

to bearings, encoders, brakes.

All TK motors are designed for fluid (water) cooling on the outside of the stator for maximum

performance. Conduction/convection cooling is also possible. Constant power operation (flux control)

always requires water cooling.

Customized frames with integral cooling or even partial machine subassemblies with bearings and

encoders are manufactured on request based on the standard frameless magnetic designs available.

The torque range spans from 10 to 40,000 Nm with maximum diameter 1150mm; above that size,

segmented semi custom units are available, currently up to 18 m diameter.

Page 8

8 Phase Motion Control

Typical applications:

Metal cutting DD rotary tables with both contouring and turning ability;

DD spindles for mills and lathes;

Tubular spindle motors for multi spindle machines;

Rotary table indexing for transfer machines;

Metal forming DD flywheels for press;

Cold rolling machines;

DD Capstans for hot and cold rolling/drawing;

Plastic DD extruders;

Injection and mixing stages for plastic injection molding machines;

Gearbox suppression in mixer, grinders, shredders;

Energy PM generators for small steam or gas turbine, cogeneration;

Micro Hydro-generators;

Wind turbines;

Depending on their geometry and magnetic circuit, TK motors can be divided into three main

branches:

Thin ring, large diameter motors for high torque, low speed

(torque motors)

Typical applications:

• Rotary tables for NC machine tools, often with turning capacity

• Indexers for transfer machines

• NC machine head orientation

• Large rotary tables (glass, packaging, assembly)

•

Carbon fiber deposition machinery

•

Direct drive of mills (concrete, ceramics, rubber

•

Large low speed generators (mini hydro, wind power)

•

Metal forming: electric press and bending

•

Direct drive plastic injection machines

In all these applications, direct drive eliminates play and removes the

need of an accurate mechanical gearbox, which in turn would limit the accuracy and the dynamic

performance of the system. Mechanical brakes-dividers are unnecessary. The table accuracy is the

accuracy of the encoder system. The system is thus extremely simple, flexible and reprogrammable.

The removal of the transmission system and of its backlash and elasticity results in control bandwidth

up to 250 Hz, so that a positioning cycle can be completed with great accuracy within a few msec with

advantage on the machine cycle time.

To ensure adequate servo performance in direct drive high accuracy, high stiffness applications such

as indexing and rotary tables in NC machine tools, the sensor must be sinusoidal so that the drive

Page 9

9 Phase Motion Control

may interpolate the actual position with a resolution at least ten times greater than the required

accuracy. Additionally, the sensor fastening or spring mount must have intrinsic resonance frequency

above 2000 Hz not to limit the overall system performance.

Spindle motors for mills and lathes

long and thin motors, brushless with flux control ability, medium to high speed, high power density, suitable

for heavy machining or control of large inertia loads for spool winding/unwinding. The TK motors have

currently the highest power density and allow the manufacture of electrospindles with torque rating hiterto

unattainable, in the range of several thousand Nm while reaching high speeds in the thousands of rpm.

Spindle type motors are anyway high performance servo motors so another emerging application area is

very short cycle actuation. Recent application are in direct drive of the ram of high speed turret punching

press with stroke rates in excess of 300 strokes/min, or fast, heavy indexing in wire frame welding

machines.

Typical applications:

• Power lathes for automotive,

• Spindle motors for mills and high speed machining centers

•

Wire grid manufacturing

Tube motors, small diameter, for multiple spindle units

Typical applications:

• High speed/power motors where lateral (pitch) space is limited

• Multiple drilling heads

• Swiss type lathes

Page 10

10 Phase Motion Control

Selection guidelines

How to choose the optimal TK motor?

First, define the technical feasibility of the application. In general, all motors share the same physical

limitation, that is, the ability to generate “airgap thrust”, i.e. a sideways thrust between stator and

rotor which is linear thrust in linear motor, and becomes a torque when the motor is round. The

amount of thrust per unit area depends on motor technology but is fundamentally limited by the

properties of the materials (magnets, copper, steel) used in the motors. PM technology offers the

highest specific thrust available today, and this value is gradually increased as the technology

improves. Many factors (cooling conditions, size, air-gap thickness, linear speed etc.) affect this value

which should only be used as a rough guideline. TK rotary motors are characterised by a peak thrust

around 90000 N/m2, continuous thrust with water cooling ~ 55000 N/m2.

The thrust limitation explains why it is always appropriate to use the maximum diameter available to

maximize output torque. In general if a motor

is scaled in diameter, torque is scaled with

the square of diameter, while it scales only

linearly in length. Consequently, to verify

whether a new application is feasible at all, if

the torque availability is expected to be a

limitation, the maximum diameter available

should be determined compatibly with

physical limitation and maximum peripheral

speed (values below 150 m/sec pose no

problem) and the air-gap surface can then be

evaluated. This would give a rough estimate

of motor length and therefore indicate

whether the application is feasible or not.

A typical power and torque curve versus

speed is shown in side figure for a combined

torque/spindle motor with 570 mm diameter,

100 mm axial length; in Fig. 2, the motor

temperature at no load and full loads are

displayed. It can be observed that above the

“knee speed” i.e. the speed of transition

between constant torque and constant power

operation, the motor temperature becomes

progressively independent of motor load.

Page 11

11 Phase Motion Control

Large rings with very limited axial length are the most efficient solution for high torque low speed

applications

, and they have the additional advantage of not needing separate bearings as they can

be generally carried by the same bearings of the load. However, inertia scales with the cube of

diameter, so

where the inertia is the dominant load, long and thin motors are more

appropriate.

A typical example is the direct drive of the ram of high speed punch presses, in which

motion is reversed over 300 times/min, or in high speed flying shears; in this case, tubular, water

cooled TK motors provide the highest performance solution.

Spindle drives

generally demand both high torque and high speed but the diameter is generally

restricted, so they tend to be long and thin. Air-gap hole diameter to length ratios up to 1:3 are

routinely manufactured. In this case, the Phase PM magnet technology allows the manufacture of

extremely

thin stators and rotors which are particularly useful in multispindle applications.

Spindle PM motors

manufactured with the high frequency Phase magnetic technology can operate

both in constant torque and constant power mode. The constant power range, depending on the type,

can exceed 10:1 although this is generally limited by the ability of the drive selected to control a deep

deflux range. When compared to AC Induction spindle motors, the PM motor design offers:

• Rated torque approximately double in

the same size

• Larger shaft compared to the outer

diameter

• Loss only limited to stator, rotor is

“cool” so that bearings can operate

more accurately and reliably

• Solid, “mechanical” rotor (non

laminated) which guarantees

balancing stability

• Wide constant power control range (up

to 10:1) without tap change

• Free from radial flux which may

generate currents in the bearings

In the Phase TK technology, there is no fundamental physical difference between torque motors and

spindle motors; they have the same smoothness and high bandwidth necessary for direct drive

indexing and contouring operation, so that

milling and turning operations on the same motor

are now possible.

There is, however, a fundamental difference between PM and induction spindle drives. In the

induction technology, power is used to magnetize the motor (at low speed, high torque) thus

resulting in limited output torque available; flux reduction is easily obtained by just reducing the

Page 12

12 Phase Motion Control

magnetizing current. Thus the motor is “hot” at max load, and “cool” at no load. PM motors,

conversely, derive the field from high energy permanent magnets, so that no power is required to

build the motor field and more power can be devoted to torque generation. When the flux must be

reduced, however, power must be applied just to lower the field so that PM motors at high speed

need some current even at no load.

Another useful feature of PM technology is the ability to operate with a

wide air-gap, up to several

millimetres in the larger motors. This feature can be useful in machines with important deformations,

such as plastic injection press or impact hammers. As a standard the air-gap is in the order of 1 mm,

radial, and this generally enables designs in which the motor rides on the machine supports without

need of separate bearings.

Page 13

13 Phase Motion Control

Motor morphology and protections

PHASE MOTION CONTROL TK brushless motors are the technical solution with the highest torque

density currently available and are designed for high performance motion control.

Tk motors are frameless and are supplied as separate stator and rotor units for integration into the

final equipment. The motors are all three phases brushless and rotors are based on rare earth, high

energy FeNdB magnets.

TK Motors codification

TK motors consist of two main components one stator (TKST) and one rotor (TKRT). When ordering a

TK motor, the two parts have different codes. The general codification system of TK parts is a s

follows:

Stator TKST.XXX.YYY.ZZZ.K

where:

XXX = Stator outer diameter

YYY = Active part length

ZZZ = Approximate Torque Constant

K = Version

Rotor TKRT.XXX.YYY.K

where:

XXX = Stator outer diameter

YYY = Active part length

K = Version

TKST stator description

A three phase stator, wound and vacuum encapsulated in super high

thermal conductivity compound (for low surface temperature

operation) or impregnated (3 dips, preferred solution for high thermal

cycling), which is either built into a metallic frame carrying the cooling

chambers and coupling O-Rings on the outside and a set of tapped

holes on one side (SQUID type), or into a thin steel microframe,

cylindrical.

The standard SQUID frame is much simpler to use and only requires a

cylindrical cavity, while motor assembly and fastening s just through a

set of screws. The cooling circuit channels are designed by Phase

Motion Control in order to maximize heat exchange and simplify

integration in customer machine.

Page 14

14 Phase Motion Control

Alternatively, the microframe units are ground to h7 tolerance on the

outside diameter and are machined parallel on the two stack sides.

This construction is intended for interference fit or axial pressure

locking. The microframe technology maximizes the usage of space in

the assembly and requires the machine body to carry the cooling

cavities on the inside. It requires some care in the design of the

application.

The insulation system of the motors is rated Class H (magnet wire: Class C) with reinforced insulation

specifically designed for the high DV/dt typical of 600 Vdc servo drive application; the windings are

equipped with thermal sensors and thermal protectors as detailed later in this document.

The star point of the winding is also generally available for filtering purposes.

Page 15

15 Phase Motion Control

TKRT rotor description

A Permanent Magnet Rotor

, with

tubular, isotropic base shape, which

carries the magnets on the outside

periphery, protected by a preloaded

carbon fiber (up to 150 m/sec) ring.

The magnets are generally high

temperature, high energy FeNdB

sintered magnets, Phase Motion

Control manufactured with a special

patented technology. They are

designed for the maximum class

temperature and are virtually impossible to demagnetise except in case of drive failure or improper

operation. If continuous exposure to oil is forecast, special oil resistant magnets can be specified.

The rotor may be fastened on the shaft

either by interference fit or by an array of

axial bolts. The latter construction is

preferred for high torque, low speed

applications such as rotary tables. In

general, the rotor inside profile is

customised to fit with the needs of the

machine provided the required profile is

compatible with the maximum hole required

by the magnetic field, and specified in the

accompanying technical sheets. For proper

operation, the motors need a position

sensor on the shaft (not supplied) both for

field orientation and for position/speed control. The rotor is permanent magnet type and has no

primary losses, so that no rotor cooling is needed in principle. However, the inverter chopper

frequency must be set high enough to ensure that the ripple current, pk-pk is less than 20% of the

nominal rms current to avoid the insurgency of unacceptable, and dangerous, stray rotor loss.

For TK motor until and included size TK1340, we apply phosphating treatment on rotor iron part

and stator steel frame.

This will be done by default and included in the supply unless different requests

Customized frames with integral cooling or even partial machine subassemblies with bearings and

encoders are manufactured on request based on the standard frameless magnetic designs available.

Page 16

16 Phase Motion Control

Type and manufacture of TK motors

TK motors can be supplied in the following types:

Stato

r Standard SQUID

(water cooling jacket)

The stator is inserted into a frame, designed

on customer specification, for liquid cooling

using internal chambers or using the

external surface. The frame carries fixing

holes for interfacing with the driven

machine. O-Ring sealing can be included in

motor supply according to customer

request.

Closed SQUID frame

(Optional)

Same as standard SQUID design, but the

external cooling circuit is closed with a

special water proof carbon fibre sleeve. This

option is available in pre-defined motor

diameters.

Microframe

(Optional)

Inserted on thin steel sleeve machined to h7

tolerance, suitable for hot assembly on the

operating equipment

Rotor

Carbon fibre

(standard)

Tubular ring with magnets, with carbon fibre

sleeve for peripheral rotation speed from 50

to 150m/s. Shaft assembly is performed on

the internal tube diameter generally ground

to H6 tolerance. Shaft interface can be

selected between:

• screw mounting (standard);

• interference mounting w/ or w/o oil

pressure chamber (opt.);

• locking rings seats (opt.);

Standard TK motor rotors are not pre

balanced; final balancing, if necessary, must

take place after rotor assembly on the shaft.

Pre-balancing is available on request

(optional).

Page 17

17 Phase Motion Control

PHASE MOTION CONTROL, together with the Customer, often achieve higher level of efficiency and

performance by designing and supplying semi-custom variants of the TK motors with special winding,

rotor and frame designs.

TK motors express their maximum performance in liquid cooled version. Nevertheless they can be

calculated also for conduction/convection cooling where the performance is defined together with the

customer depending on the available external cooling surface.

For high speed and filed weakening operation liquid cooling is necessary

All the stators windings of TK motors are encapsulated under vacuum with high thermal conductivity

epoxy resin to provide the best mechanical characteristics, protection, insulation and thermal

transfer.

For special application (extra-low weight, very aggressive chemical agents…) the stator can be

provided with impregnation varnish instead of encapsulation

All standard TK motors are supplied with power and sensor wire length 1000mm, different length on

request.

With custom frames also power and signal.connectors can also be supplied.

TK motors are supplied without position sensors

Insulation voltage

All TK PHASE MOTION CONTROL motors are tested with following parameters:

Insulation voltage between Phases-GND 4,5KVDC 60s

Insulation voltage between Phases - Thermal Sensors 3,5KVDC 60s

Insulation voltage between Thermal Sensors - GND 3,5KVDC 60s

Over temperature protection

All TK PHASE MOTION CONTROL motors are supplied with two types of sensors: two PT1000 and

three PTC 130 or PTC 155.

The PTC130 sensors (blue/blue wires) or PTC155 sensors (blue/black

wires) are localized one on each phase, so can react very fast when

the temperature rise of the winding exceeds the tripping threshold in

any one phase. PTC sensors MUST be used for protection. The PTC

sensors are highly non linear, so they are sensed via a threshold

circuit. The sensors guarantee <750 Ohm resistance for Tw <125 C,

and >4000 Ohm resistance for Tw>145 C.

Page 18

18 Phase Motion Control

PT1000 sensors have double insulation to the winding.

All TK stators have two PT1000 sensors. The customer can use either one of them indifferently.

Should a KTY probe fail for any reason, the other one can be used without need for repair.

The PT1000 sensor (white/red wires) is a linear temperature

sensor and provides a reading of actual stator winding

temperature (see figure), which must be used for monitoring

and verification of the motor temperature during the cycle. It

is NOT a protection, because it is localized on only one point

and cannot guarantee true information, when a localized

overcurrent occurs on a zone far from the PT1000.

PT1000sensors are polarized, be sure to respect the +/- wires

assignment at installation.

KTY84-130 sensors (out of production) are available on request in

place of PT100 sensors. The behaviour is similar just with a different

R/T characteristics.

Ground connection

Rotor and stator must be connected to the ground. Do not energize before connecting the grounding

terminals.

0 20 40 60 80 100 120 140 160

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

Temperature, C

KTY 84 resistance value (Ohm)

Page 19

19 Phase Motion Control

Standard type and size of output power leads

Standard TK motors power leads have Radox 155 insulation for best mechanical and thermal

resistance. Cablex exiting from the stator must be kept as short as possible in order to limit the risk

of damage during handling and transportation.

Typical output cable cross-sections are as follows:

Nominal current

Wire size Cable diameter

In < 15 Arms 1.5 mm2 2.85

15 Arms <= In< 21 Arms 2.5 mm2 3.5

21 Arms <= In< 30 Arms 4 mm2 4.2

30 Arms <= In< 40 Arms 6 mm2 5

40 Arms <= In< 60 Arms 10 mm2 6.4

60 Arms <= In< 90 Arms 16 mm2 7.6

90 Arms<=In<110 Arms 25 mm2 9.2

110 Arms<=In<150 Arms 35 mm2 10.6

150 Arms<=In<200 Arms 50 mm2 12.4

Anti-resonance filter (snubber)

In some conditions of the power supply chain, electrical resonance phenomena may occur in motor

windings. These phenomena can multiply several times the instantaneous voltage of winding versus

ground, leading to excessive stress of the motor insulation system resulting in quick degeneration and

total insulation failure after a short time of operation.

Picture below shows the star point voltage versus ground waveform acquired in a system with

significant resonance. The DC-Bus setting of the power amplifier is only 600 Vdc but the

instantaneous voltage can reach a value as high as 1600 V. The insulation system cannot withstand

this high voltage in long term operation.

Page 20

20

To limit such voltage transients

, P

resonance filter (snubber) which

star terminal (white wire) and m

failure by insulator puncturing.

Ph

NOTE: larger snubbers

in norma

200W) and need to be mounted o

Also PMC suggest , in the first

exceed 90°C.

On request Phase can supply spe

IMPORTANT NOT

configuration. The

PWM modulation m

and/or filter insta

Consequently it is s

type or significant

power amplifier typ

snubber connected

b

tional condition

can dissipate a not negli

installation, to check the temperature of the sn

: the values of snubber filter are calculate

supply cables, type

modification of the power supply components

The peak value must be <= +/-

1200

Phase Motion Control

-

er

(such as different

Page 21

21 Phase Motion Control

Motor integration

During mounting always refer to the assembly drawing in your hand.

Mounting and installation of TK motor are always operation strictly linked to the architecture of the

machine where it must be installed, the following information are only general basic information for

the correct handling of motor.

Stator

The stator installation does not have any particular critical item.

Checklist:

Wiring Protect the wiring from being caught between metallic parts during assembly

and bending in the conduits. Contact PHASE MOTION CONTROL if wiring

appears damaged.

Winding heads generally, if not covered by protection flanges, the winding heads are

vulnerable during the motor integration. avoid all accidental impact with

metallic parts to protect the insulation. Contact PHASE MOTION CONTROL if

damaged.

Liquid cooling When the liquid cooling circuit is assembled and sealed, pay attention to

avoid any loss of liquid from input/output nipples and prevent the cooling

liquid from wetting with the windings. Contact PHASE MOTION CONTROL in

case if loss of liquid on the winding.

Safety distance If there are flanges or metallic parts in proximity of the winding heads, check

that the minimum safety distance between the unprotected winding head

and any grounded metallic part is kept, A value >=6 mm must be ensured to

guarantee correct dielectric rigidity Should a shorter distance be

unavoidable, supplementary insulation may be necessary. In this case

contact PHASE MOTION CONTROL to obtain detailed instructions

Special warnings for liquid cooling systems:

1) With SQUID type frames, or anyway whenever the cooling cavity is made with adjacent rings

and cuts according to Phase Motion technique, carefully check that the inlet and outlet bores

are placed exactly opposite with respect to the nearest cooling ring cut, and are centered on

the first and last ring respectively. Frames with an even number of rings must have inlet and

outlet on the same side; with an odd ring number, input and output are 180

o

opposite.

2) Make sure that under no circumstance the static pressure in the cooling chamber could

exceed 500,000 Pa to prevent motor deformation leading to O-Ring sealing failure (expecially

for motor diameter > 400 mm)

3) Should a mix of water and glycole be used in the cooling circuit, be advised that glycole tends

to dissolve most seals with the except of VITON rubber. All O-rings supplied by Phase are

made of VITON,

Page 22

22 Phase Motion Control

4) It is anyway better to mix the water with an appropriate ion neutralizer (such as ELF Chip

Supra, Total 60L, Eurotherm Eurocold 131, Dowtherm SR-1) instead of Glycole with the

additional benefit of limiting corrosion and clogging risk

5) Do not cool the motor or parts thereof below room temperature to prevent condensation on

the motor, which would quickly degenerate the winding.

6) As far as possible, water must be prevented from leaking on the winding even in case of O-

Ring failure, by means of small drain holes and channels in the appropriate positions.

7) Always make sure that all air bubbles and pockets are removed from the circuit before

performing a full power test and commissioning.

Rotor

The procedure for rotor assembly is determined by the type of coupling with the shaft

Checklist

Insertion of rotor to the shaft All TK rotors have permanent magnets, so avoid mounting

procedure using hot insertion, because there is a risk of rotor

demagnetising if the temperature exceeds 80°C. Contact PHASE

MOTION CONTROL in case of demagnetization

Shaft-Rotor coupling Always respect interference value between shaft and rotor as

indicated by PHASE MOTION CONTROL.

Carbon fiver sleeve On this type of rotors check carefully the integrity of the sleeve.

This preloaded unidirectional composite structure displays

exceptional strength for high speed rotors, but can be damaged by

shocks. Contact PHASE MOTION CONTROL if rotor is damaged.

On request, rotors can be supplied with dual diameter and connection hole for hydraulic disassembly

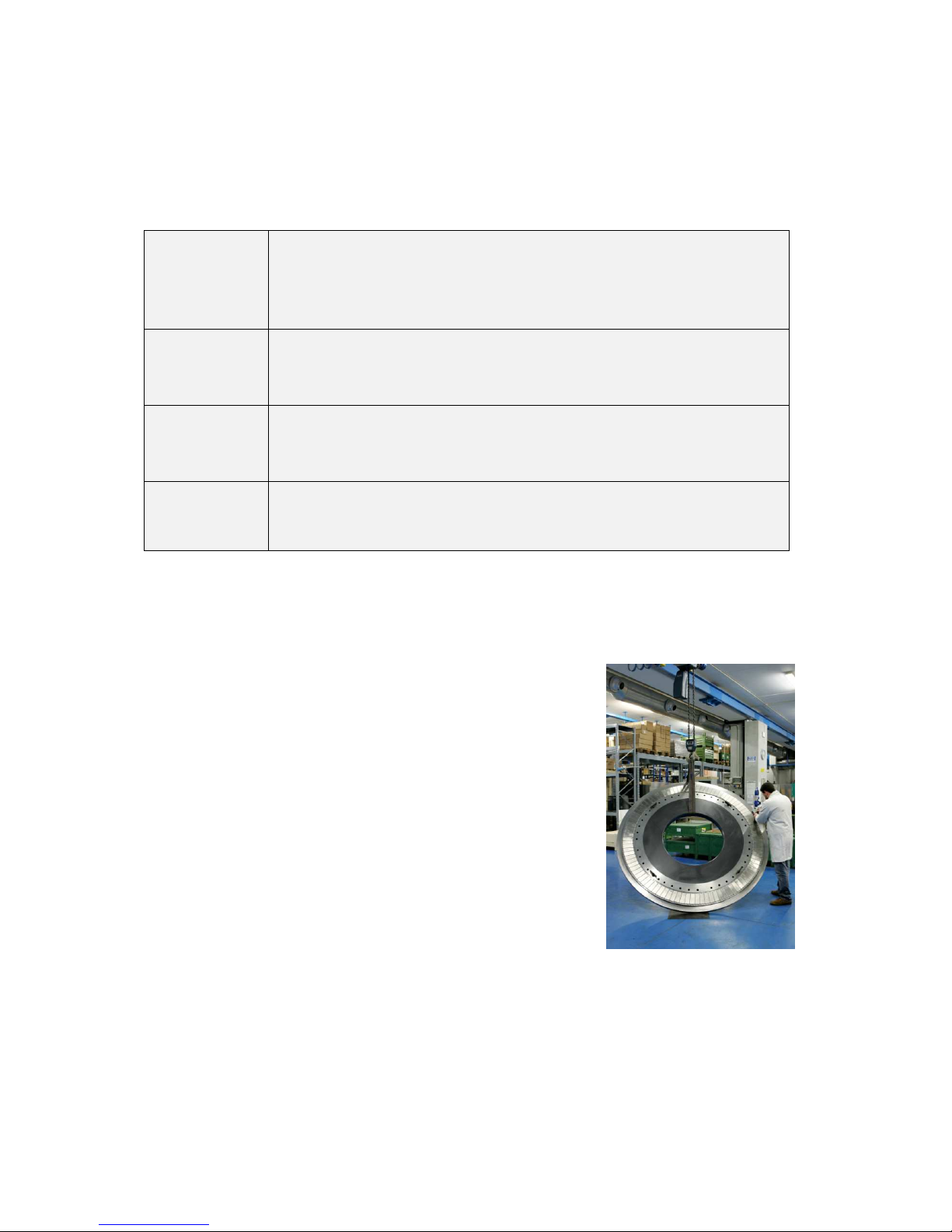

Mounting of the rotor inside the stator

Important warning: Avoid contact or close proximity of the bearings or parts thereof with the rotor

magnets. Magnetized bearings, or magnetized cages, wear rapidly and catastrophycally expecially at

high speed.

If special assembly tools or jigs have not been designed with the application, (i.e. special long shafts

on which the rotor may slide, or positioning pins), then the rotor introduction is performed according

to the following procedure:

1) Make ready a few (at least four) “shims”, (flexible spacers made of non magnetic, not

scratching, material, e.g. brass, copper, lexan or mylar) to interpose between rotor and

stator. The shims should be at least 4 and are placed in the stator hole, equispaced on

the internal circumference of the stator. The shims are best made with thickness

approximately half of the theoretical mechanical air gap. This to guarantee a right

Page 23

23 Phase Motion Control

cantering and to achieve the extraction after rotor mounting. (Remark: on request Phase

can supply mylar shims together with the motor).

2) Immediately prior to rotor instertion in the stator, peel the protective tape from the

surface of the sleeve, check for cleanliness of the rotor surface; if any metallic part is

attracted by the rotor, clean the surface peeling with a adhesive tape.

3) Position the rotor in front of the stator, well centered, making sure that the “shims” are

in the correct positions, and that they can be removed after rotor insertion.

4) Insert the rotor; pay attention to the attraction force of the magnets that tend to “suck”

the rotor inside the stator. This force is about 15 N/mm of rotor diameter and starts to be

felt when the rotor is at some centimetres from the stator stack.

5) If a crane is used to move the rotor check for metallic parts in the rotor trajectory which

could be attracted to the rotor causing damage

6) After rotor insertion the shaft/bearings can be locked, and te shims removed;

7) If the rotor interface is based on bearings on both sides of the rotor, the shims are

extracted when only one bearing is in the correct position. Generally, assembly of the

second bearing is possible and the rotor will be re-centered if the last bearing seat is

machined with a proper conical chamfer.

The photograph shows a mounting example.

Page 24

24 Phase Motion Control

Radial force vs. mounting eccentricity

The magnetic flux in the rotor generates radial

attraction forces. These are perfectly balanced only if

the rotor sits in the center of the stator, and increase

with eccentricity. In practice, this is equivalent to a

“negative stiffness” which must be compensated by a

much higher positive stiffness in the bearing system.

The attraction data can be supplied on demand, the

order of magnitude is shown in the graph in Fig. 3,

for a 1000 Nm, 370 mm diameter, 105 mm long

torque motor with a 1 mm radial airgap.

Check list after integration

1) After rotor installation, if possible, check that the rotation is free and there is no

interference between rotor and stator;

2) Immediately perform a back-EMF testing and compare with the spec; if the back EMF is

within +/- 8% of specified voltage and balance between the 3 phases is better than 5%

the assembly is electricaly and magnetically correct. Note the measured EMF value and

the temperature of the measurement for possible, future diagnostics and rotor

temperature measurement.

3) Repeat the motor insulation test (according to table in paragraph 6.1) to verify the

proper connection and integrity of cables and to be sure that no damage occurred to the

windings during installation. The “Spike Suppressor Unit” (if present) must be

disconnected for this test. It is recommended to execute the test with a DC voltage (AC

insulation test may be disruptive and test results can be affected by errors due to motor

and cables capacitance to ground). Max. leakage current acceptable is 100 uA stable or

reducing in time..

4) Connect the the “Spike Suppressor Unit” between the star point terminal of the motor

and ground.

5) Check the proper sealing of the water cooling circuit (if present) by applying a pressure

of 1.5 bar and verify that the same pressure is maintained;

6) Proceed with the electrical installation.

7) After machine completion proceed with insulation voltage testing according to the

relevant local regulation (CE or UL-CSA).

IMPORTANT NOTE: in case of first installation of a new motor type execute the measure of winding

voltage to ground as reported in previous chapter “Precautions”.

Loading...

Loading...