Page 1

0

AxN

CONFIGURABLE MOTION

CONTROL PLATFORM

Installation Manual

Support Model:

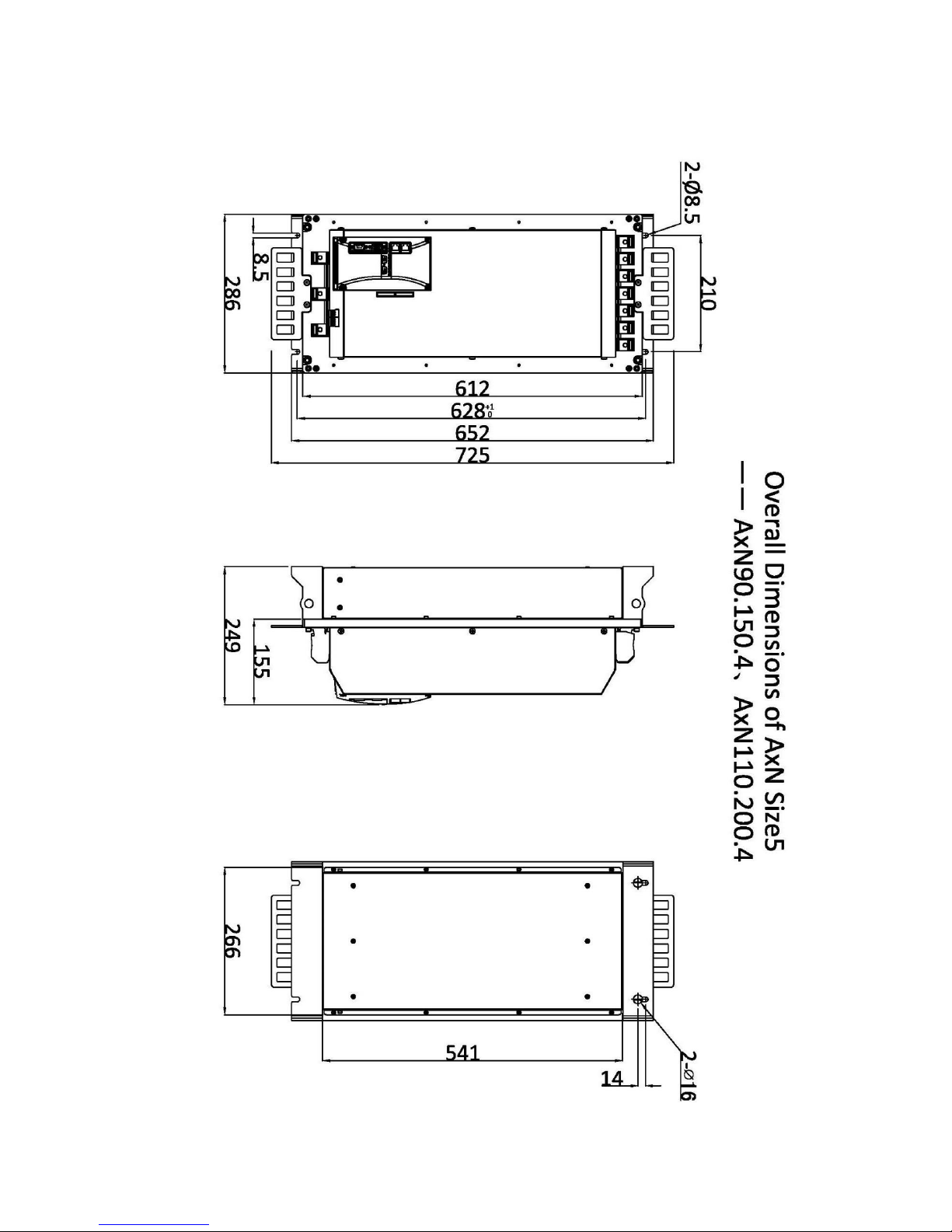

AxN Size5: AxN 90.150.4, AxN 110.200.4

Version:V1.0(E)

Page 2

Page 3

1

Summary

1 Mechanical Installation .............................................................................................................. 3

1.1 Notes for Operation ...................................................................................................... 3

1.2 Installation Environment ............................................................................................... 4

1.3 Overall Dimensions ....................................................................................................... 5

1.4 Installation Orientation ................................................................................................. 6

1.5 Installation Spacing ....................................................................................................... 7

2 Main Circuit Wiring .................................................................................................................... 8

2.1 AC Power Supply Input .................................................................................................. 8

2.1.1 AC Power Supply Requirement .......................................................................... 8

2.1.2 AC Power Supply Cable Fabrication ................................................................... 8

2.1.3 AC Power Supply Input Installation .................................................................. 11

2.2 DC Power Supply Input ................................................................................................ 14

2.2.1 DC Power Supply Requirement ........................................................................ 14

2.2.2 DC Power Supply Cable Fabrication ................................................................. 14

2.2.3 DC Power Supply Input Installation .................................................................. 17

2.3 Brake Resistor .............................................................................................................. 20

2.3.1 Internal Brake Resistor ..................................................................................... 20

2.3.2 Internal Brake Resistor Installation .................................................................. 20

2.3.3 External Brake Resistor .................................................................................... 21

2.3.4 External Brake Resistor Installation .................................................................. 22

2.4 Motor Power Output ................................................................................................... 25

2.4.1 Motor Power Output Cable Fabrication ........................................................... 25

2.4.2 Motor Power Output Installation ..................................................................... 28

3 Control Circuit Wiring .............................................................................................................. 31

3.1 Auxiliary Power Supply (AUX_Power) ......................................................................... 31

3.1.1 Auxiliary Power Supply Requirement ............................................................... 31

3.1.2 Auxiliary Power Supply Cable Fabrication ........................................................ 31

3.1.3 Auxiliary Power Supply Installation .................................................................. 32

3.2 System Relay (R1) ........................................................................................................ 34

4 Communication Port ................................................................................................................ 36

4.1 Overview of Communication Port Panel ..................................................................... 36

4.2 E1 —— Main Encoder Port ......................................................................................... 37

4.2.1 Sincos Encoder ................................................................................................. 38

4.2.2 Endat Encoder ................................................................................................. 39

4.2.3 Digital Incremental Encoder with Hall .............................................................. 40

4.2.4 Resolver ........................................................................................................... 41

4.2.5 Hiperface Encoder ........................................................................................... 42

4.3 S1 —— Serial Bus Port ................................................................................................ 43

4.3.1 RS-232 ............................................................................................................. 43

4.3.2 RS422/485 ....................................................................................................... 46

4.3.3 Auxiliary CAN ................................................................................................... 47

4.4 C1 —— Main CAN Port ............................................................................................... 49

Page 4

2

4.4.1 Main CAN ......................................................................................................... 49

4.4.2 Auxiliary Encoder ............................................................................................. 51

4.5 EtherCAT IN/OUT——EtherCAT Port ........................................................................... 52

4.6 U1/U2 —— User Connectors ...................................................................................... 53

4.7 U3/U4 —— Insulated User Connectors ...................................................................... 55

Page 5

3

1 Mechanical Installation

1.1 Notes for Operation

Avoid

Please be sure to avoid:

1. penetration of damp into the device;

2. aggressive or conductive substances in the immediate vicinity;

3. explosive and flammable substances in the immediate vicinity;

4. drill chippings, screws or foreign bodies dropping into the device;

5. ventilation openings being covered over, as otherwise the device may be damaged

Note

Note the following points:

1. Make sure every part of the drive is anchored before moving the drive. Failure to comply may

result in minor or moderate injury from the drive parts falling.

2. Observe proper electrostatic discharge (ESD) procedures when handling the drive. Failure to

comply could result in ESD damage to the drive circuitry;

3. Prevent foreign matter such as metal shavings or wire clippings from falling into the drive

during installation and project construction. Failure to comply could result in damage to the

drive. Place a temporary cover over the top of the drive during installation. Remove the

temporary cover before start-up, as the cover will reduce ventilation and cause the drive to

overheat.

Install proper cooling to ensure the temperature in the enclosure does not exceed 40 °C.

Page 6

4

1.2 Installation Environment

To help prolong the optimum performance life of the drive, install the drive in the proper

environment. The table below provides description of the appropriate environment for the drive.

Environment

Condition

Installation Area

Indoor

Ambient

Temperature

0℃ to 40℃, up to 50℃ with power reduction (2%/℃)

Drive reliability improves in environments without wide temperature

fluctuations.

When using an enclosure panel, install a cooling fan or air conditioner in the

area to ensure that the air temperature inside the enclosure does not exceed

the specified levels.

Do not allow ice to develop on the drive.

Humidity

5 to 90% without condensation

Surrounding Area

Install the drive in an area free from:

1. oil mist and dust

2. metal shavings, oil, water or other foreign materials

3. radioactive materials

4. combustible materials (e.g., wood)

5. harmful gases and liquids

6. excessive vibration

7. chlorides

Altitude

Up to 1000m above MSL, over 1000 m above MSL with power reduction ( 3%

per 100m)

Vibration

Amplitude up to 0.3mm at 2 to 9 Hz

Acceleration up to 1m/s2 at 9 to 200 Hz

Orientation

Install the drive vertically to maintain maximum cooling effects.

Page 7

5

1.3 Overall Dimensions

Page 8

6

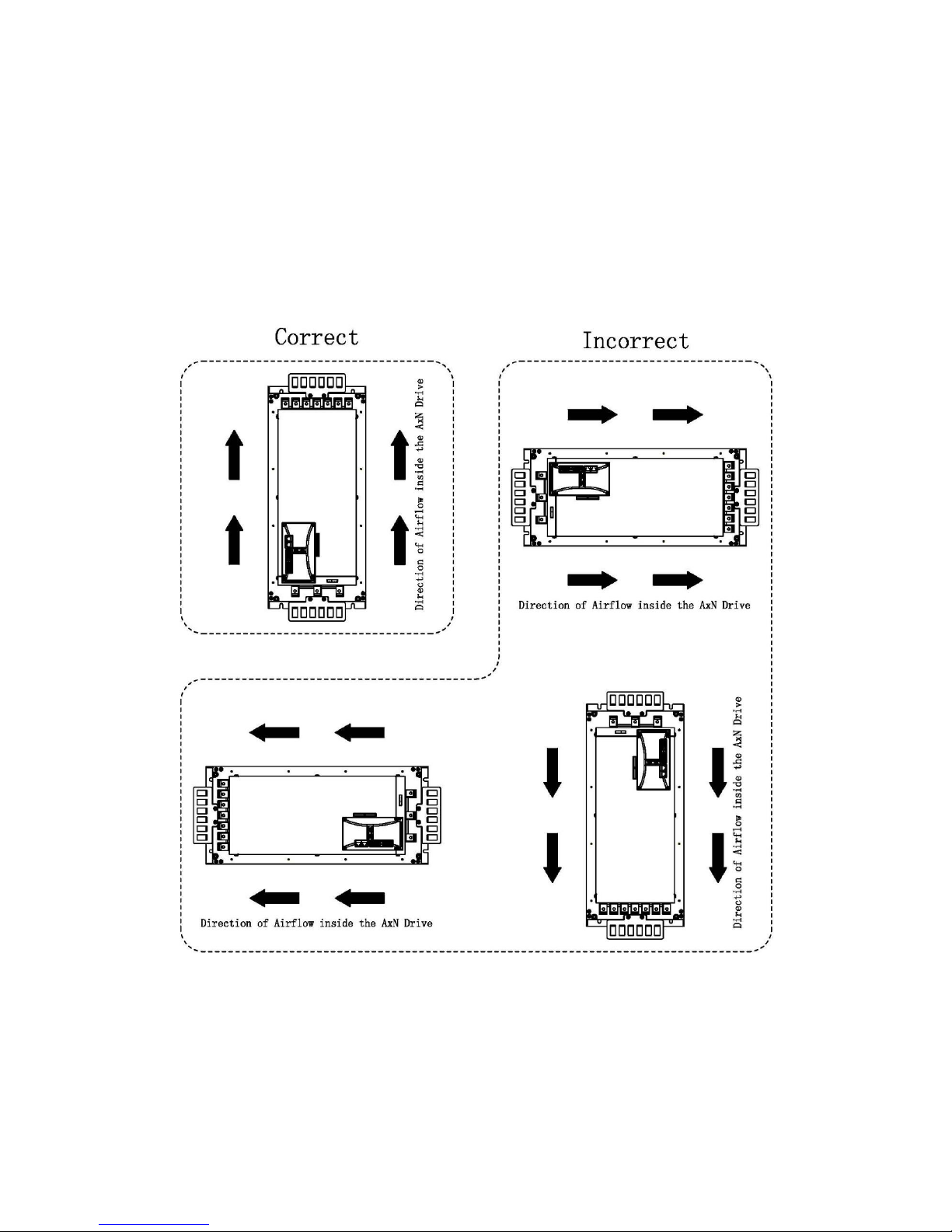

1.4 Installation Orientation

To maintain proper cooling, install the AxN drive upright inside the switch cabinet as illustrated

below:

WARNING: The airflow inside the drive must be upright after installation as illustrated below. If

other form of installation must be taken, CONNECT PMC ENGINEER BEFORE INSTALLATION.

Installation Orientation of AxN Size5

Page 9

7

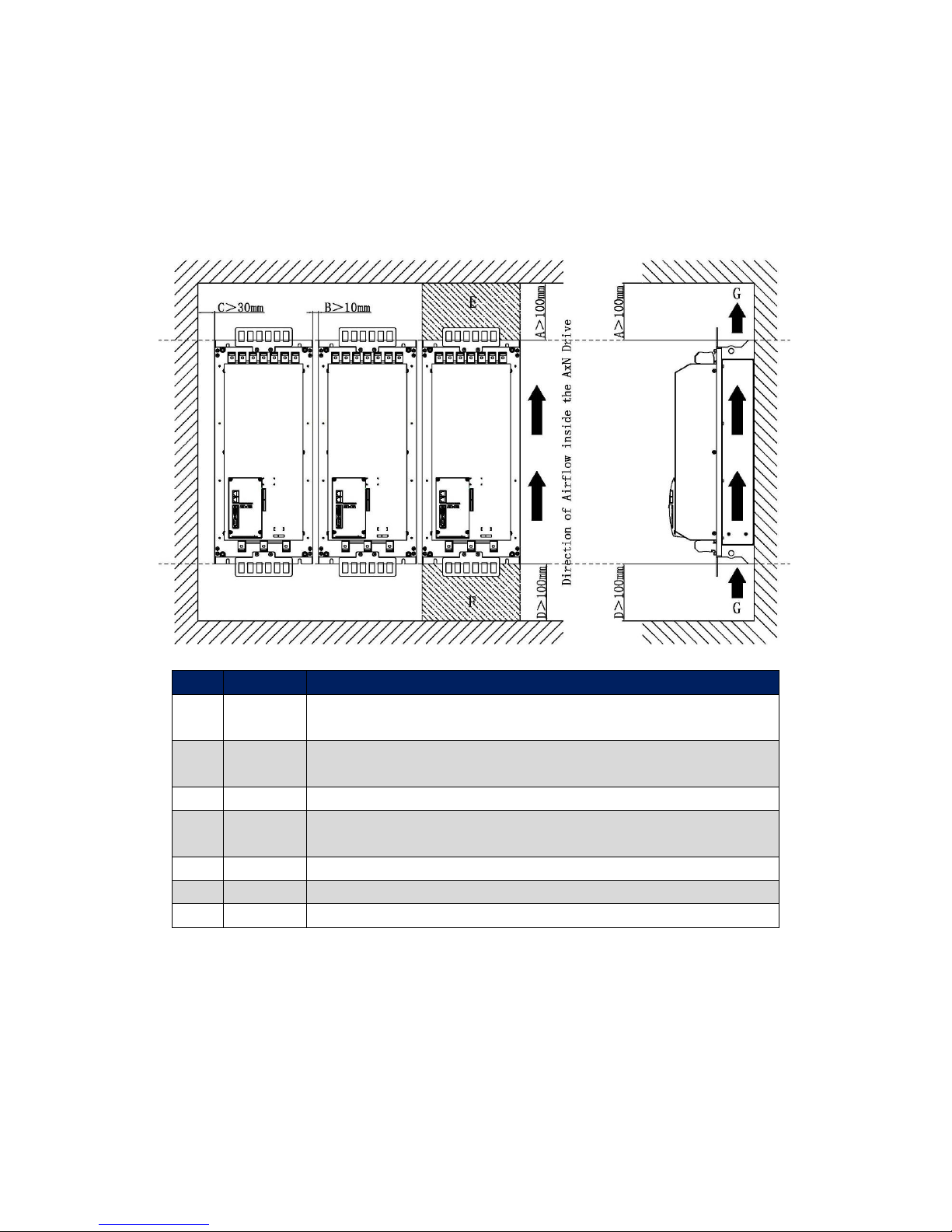

1.5 Installation Spacing

To maintain sufficient space for airflow and wiring, the space between AxN drive and other device

(including other AxN drives) must comply the requirement below.

Correct Installation Spacing of AxN Series Drive

No.

Distance

Description

A

>100mm

The distance between the top of the switch cabinet, to ensure enough

space for air-out.

B

>10mm

The distance between other device (including other AxN drives and

peripheral devices)

C

>30mm

The distance between the inside wall of the switch cabinet.

D

>100mm

The distance between the bottom of the switch cabinet, to ensure enough

space for air-in.

E

>100mm

Air-out area, do not place any other device in this area

F

>100mm

Air-in area, do not place any other device in this area

G Airflow Direction

NOTE: The switch cabinet must have air outlets and inlets to ensure the thermal exchange between

the cold air outside and the hot air inside.

Page 10

8

2 Main Circuit Wiring

2.1 AC Power Supply Input

2.1.1 AC Power Supply Requirement

Mains Supply

AxN Series

Voltage

150 ~ 500Vac

Type

Three-phase AC power

Frequency

50/60Hz

Fluctuation of Frequency

±10% (45 ~ 66Hz)

Asymmetry

±3%

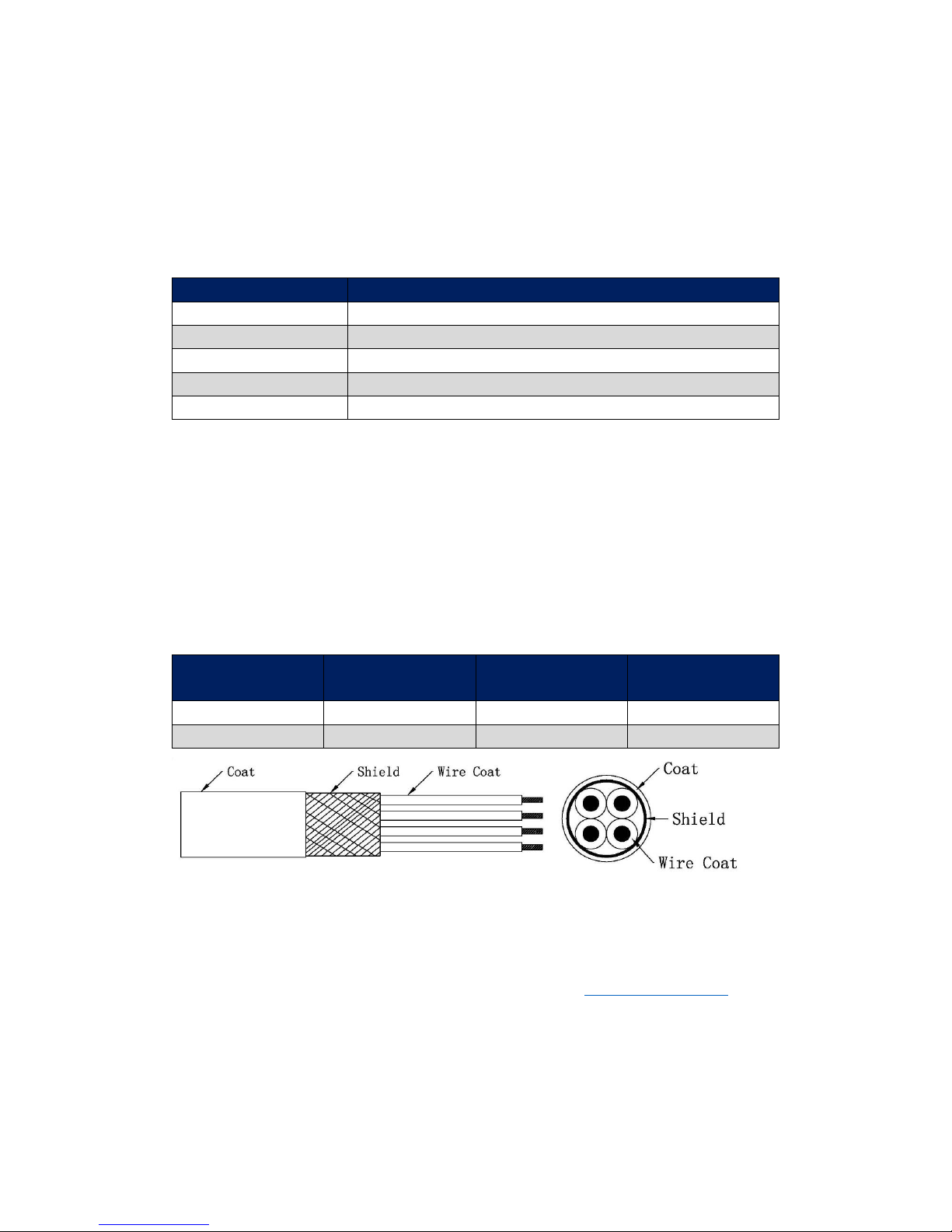

2.1.2 AC Power Supply Cable Fabrication

AC power supply cable is the cable which connect the AxN Size5 Drive with the filter. The

connection between AC power supply and the filter is not mentioned in this manual, and should

be connected properly based on the real application.

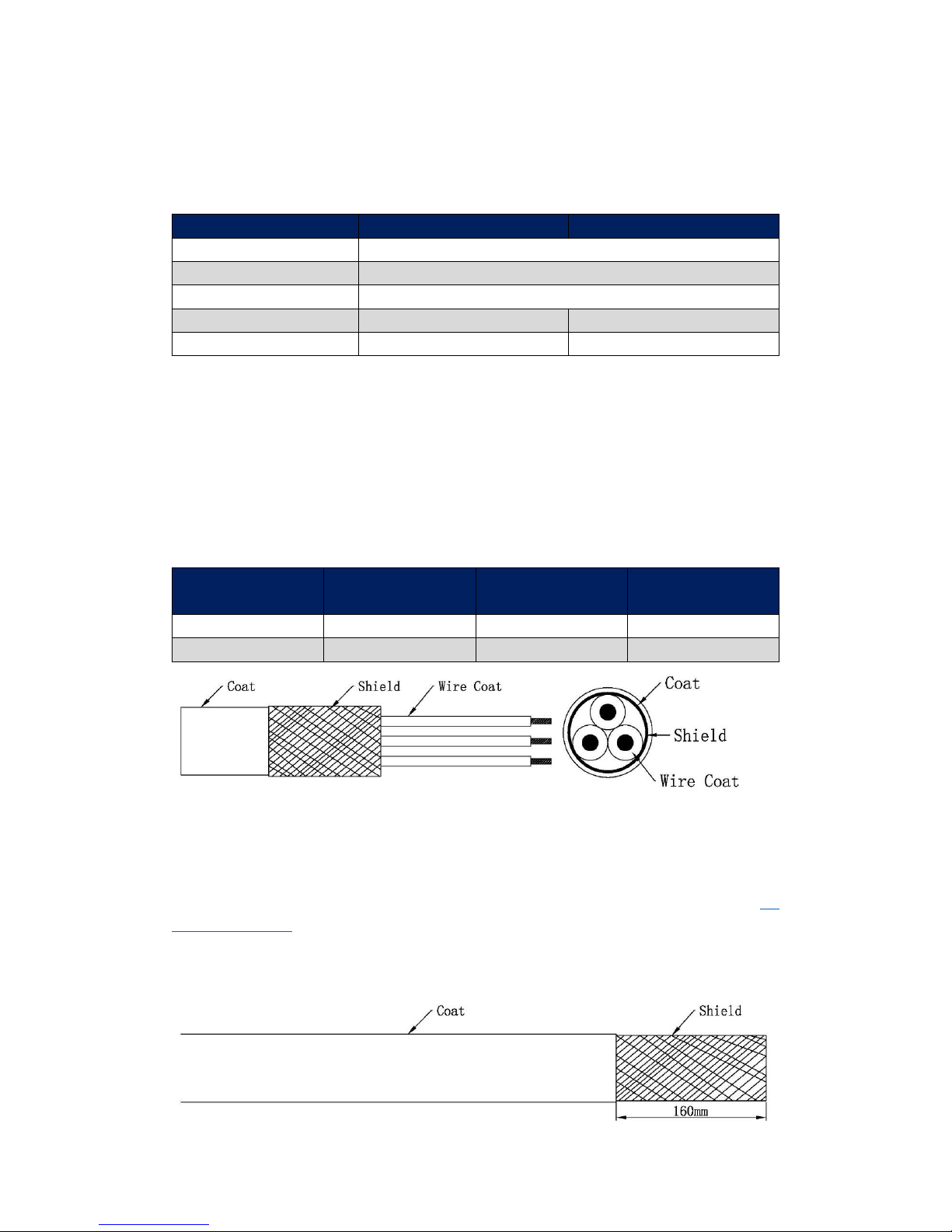

Step 1: Cable Selection

AxN Size5 drive must use a 4 wire cable with shield as its AC power supply cable. Refer to the

table below to select the appropriate cable:

AxN Size5

Current (A rms)

Recommended

Gauge (mm2)

Recommended

Gauge (AWG)

AxN 90.150.4

90

21.15

4

AxN 110.200.4

110

26.67

3

Step 2: Cable Length Measurement

The AC power supply cable is used to connect the output of the filter with the Power Input Port

(P1) of AxN Size5 Drive. To minimize the interference, the filter must be installed in close proximity

to AxN Size5 Drive as much as possible. But, the distance between two devices should also comply

with the Installation Space Regulation of AxN Size5 Drive (Refer to 1.5 Installation Spacing).

NOTE: The length of AC power supply cable should NOT exceed 0.5m.

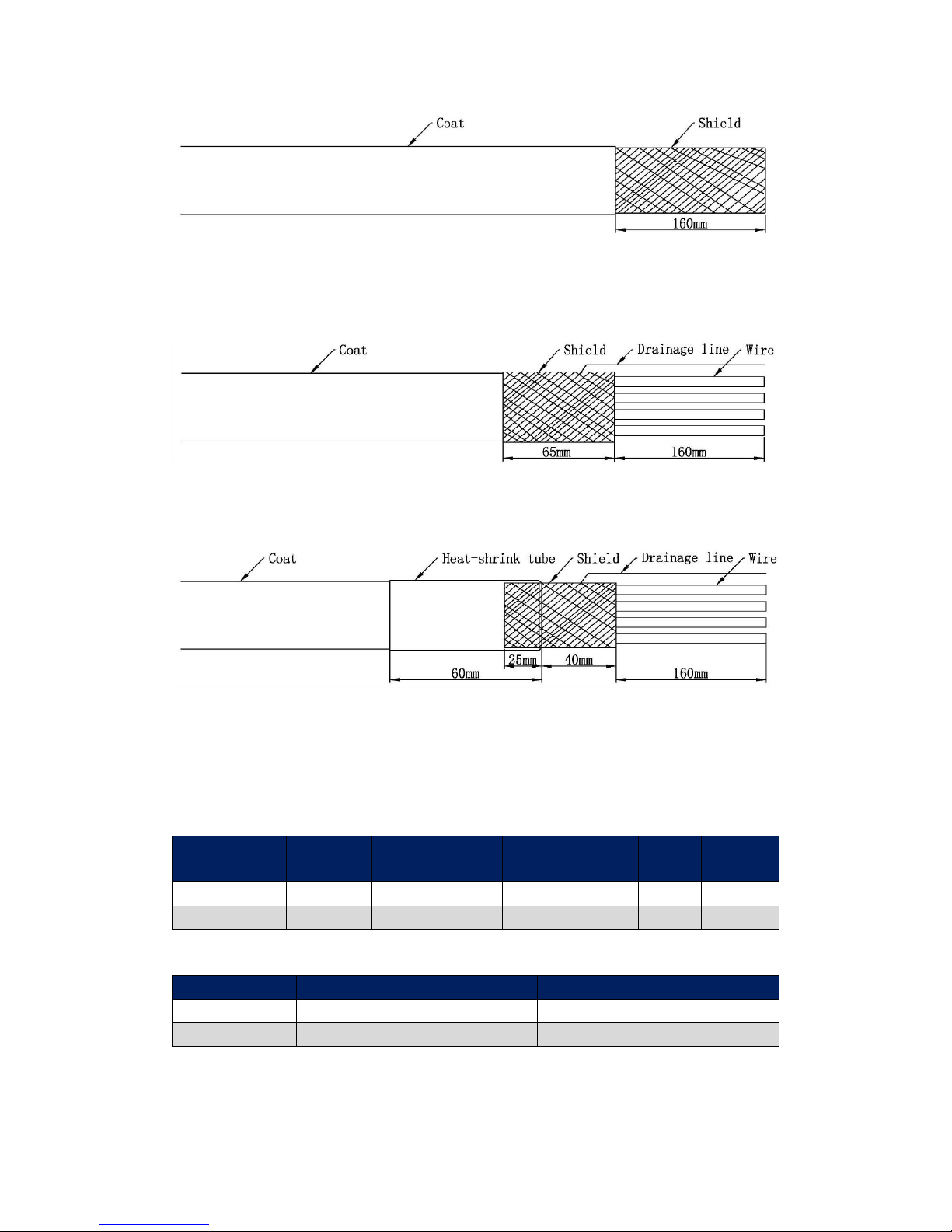

Step 3: Strip the Cable Coat

Strip the outside coat of the AC power supply cable for 160mm and reveal the inside shield.

Page 11

9

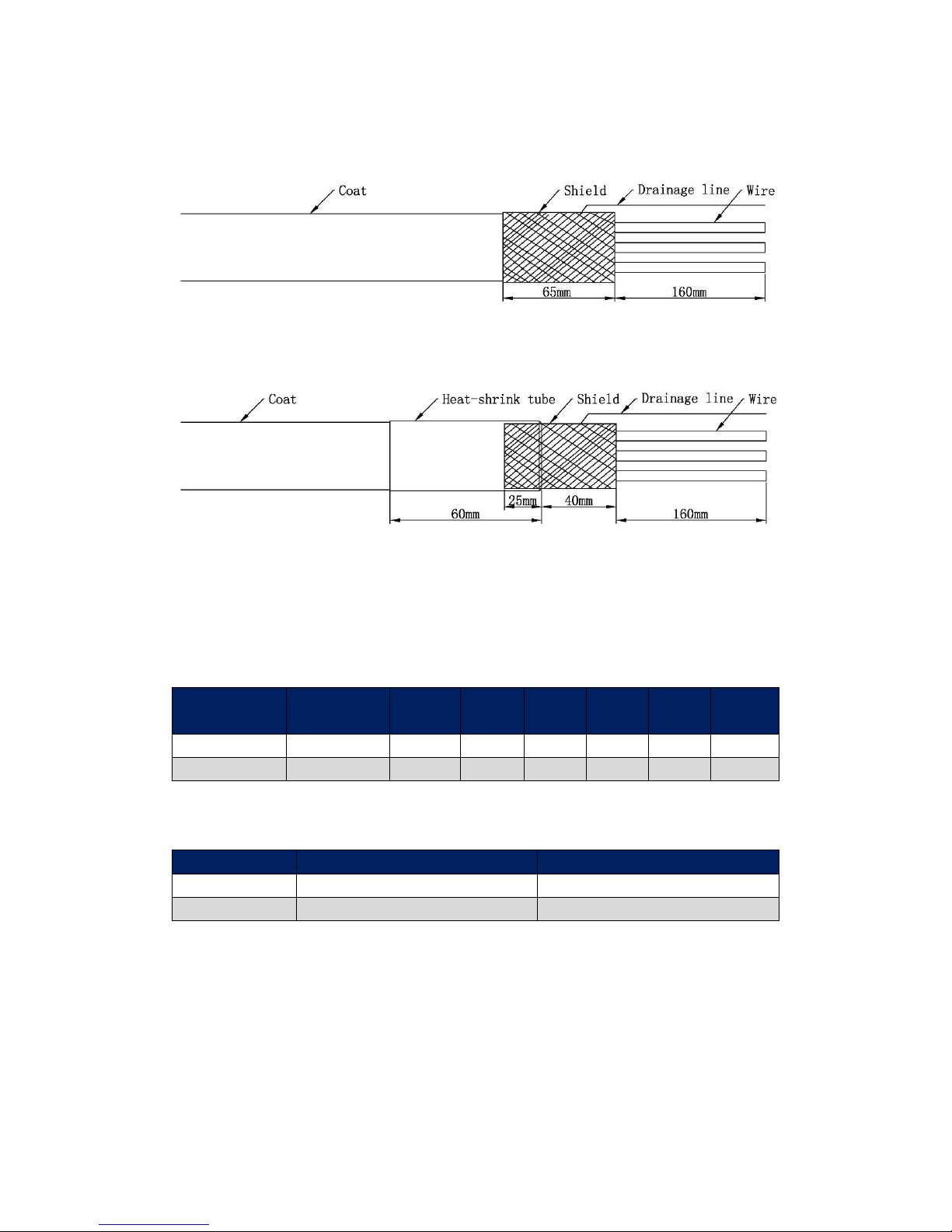

Step 4: Make the Grounding Shield

Leave 65mm Shield as the grounding shield and turn it to the outside of the coat. Then, weld a wire

on the shield as the drainage line.

Step 5: Fix the Grounding Shield

Use a 60mm heat-shrink tube to fix the grounding shield and leave 40mm shield outside.

Step 6: Make the Phase Wires

Choose 3 wires of the cable as the phase wires (R, S and T). Crimping pre-insulated Terminals on

the wires will enhance the connection stability and simplicity between the cable and drive. AxN

Size5 series drives are recommended to use the RNY Series Ring Terminals manufactured by KST.

Refer to the following table to select the appropriate terminal:

AxN Size5

Ring

Terminals

d2(mm)

W(mm)

F(mm)

E(mm)

D(mm)

d1(mm)

AxN 90.150.4

RNYB22-8

8.4

16.5

13.5

24

13

7.7

AxN 110.200.4

RNYB22-8

8.4

16.5

13.5

24

13

7.7

Strip the wires for L mm (1 ≤ L ≤ E), the recommend strip length is E/2 mm, refer to the following

table to select an appropriate length:

AxN Size5

Strip Length (mm)

Recommended Strip Length (mm)

AxN 90.150.4

1 ~ 24

12

AxN 110.200.4

1 ~ 24

12

Page 12

10

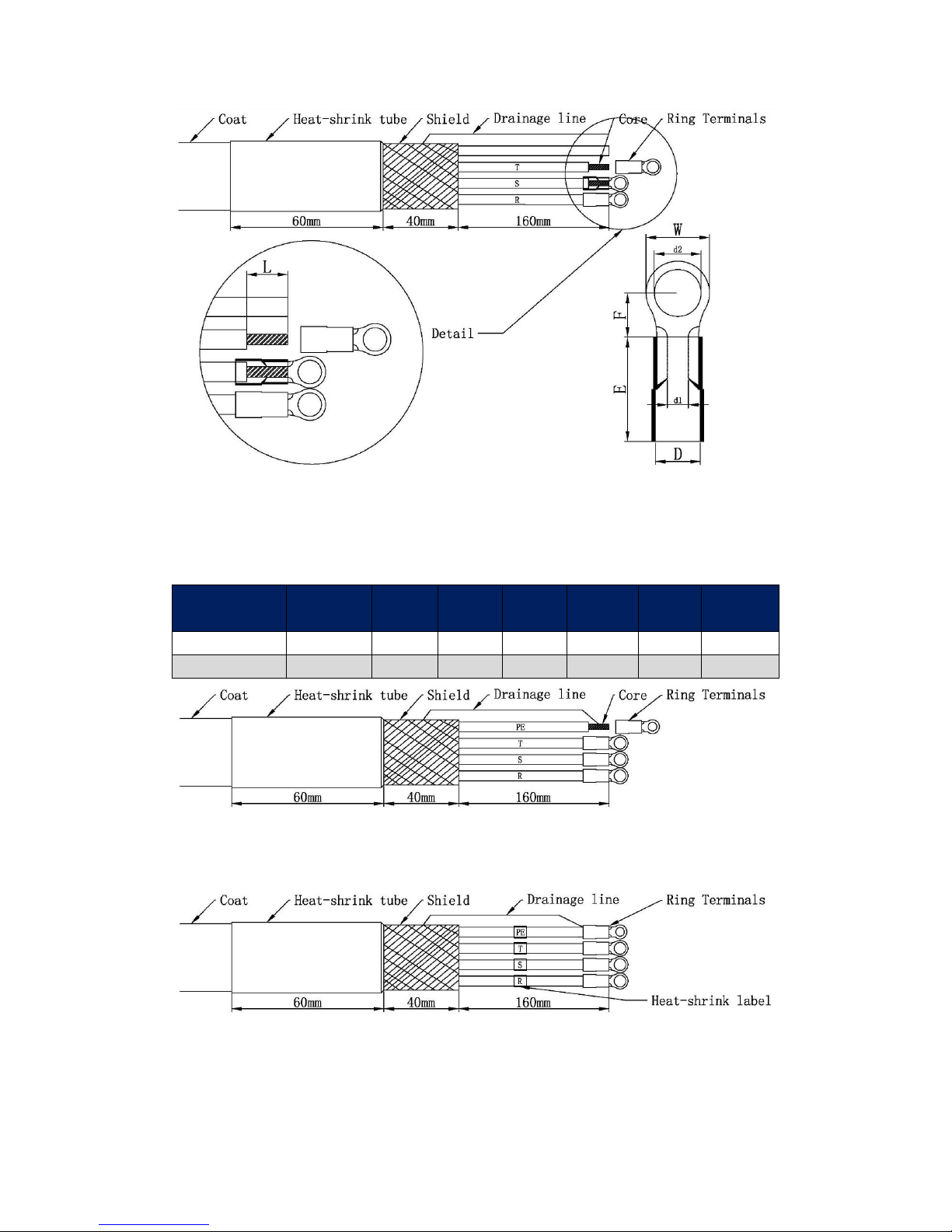

Step 7: Connect the PE wire with Shield

Use the same method to make the remaining wire as the PE wire. Then crimp the PE wire into the

Ring Terminal along with the drainage line. Refer to the following table to select the appropriate

terminal:

AxN Size5

Ring

Terminals

d2(mm)

W(mm)

F(mm)

E(mm)

D(mm)

d1(mm)

AxN 90.150.4

RNYBS22-6

6.4

12.2

15.1

24

13

7.7

AxN 110.200.4

RNYBS22-6

6.4

12.2

15.1

24

13

7.7

Step 8: Check and Mark

Check every wire and the connection between shield and PE wire, then label each wire.

Page 13

11

2.1.3 AC Power Supply Input Installation

Step 1: Check the Power Supply Type and Voltage

Make sure that the mains power supply is a 3 phase AC power supply, and its voltage is 150 ~ 500

Vac.

Step 2: Install the Filter

Connect the filter to the AC power supply. Then, connect one end of the AC power supply cable to

the filter. Fuses or Breaker can be installed before the filter based on the real application.

NOTE: To minimize the interference, the filter must be installed in close proximity to AxN Size5

Drive as much as possible. But, the distance between two devices should also comply with the

Installation Space Regulation of AxN Size5 Drive (Refer to 1.5 Installation Spacing). The length of

AC power supply cable should NOT exceed 0.5m.

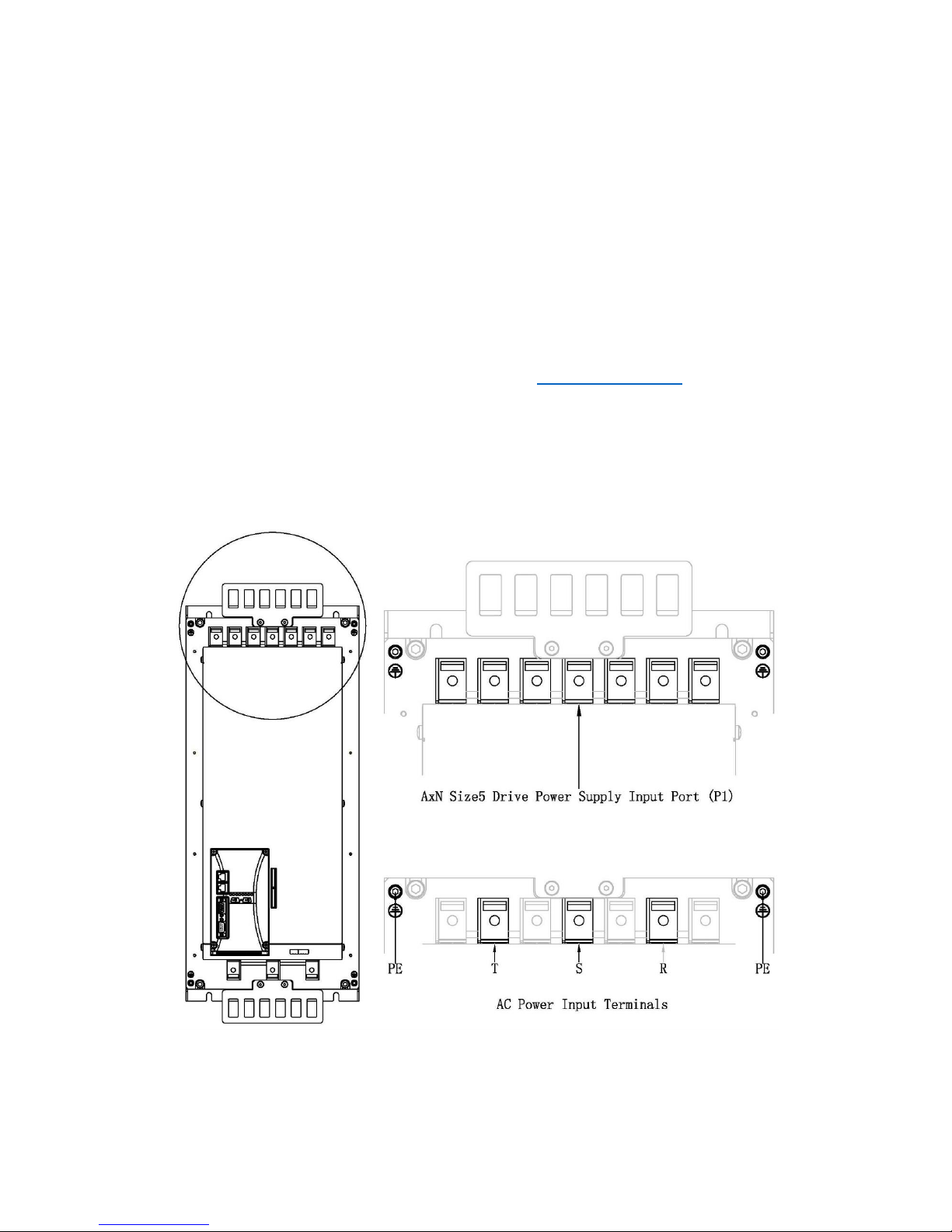

Step 3: Find out the AC Power Input Terminals

PE, T, S and R, these are the four terminals called AC Power Input Terminals. AxN Size5 Drive’s AC

Power Input Terminals are in the Power Supply Input Port (P1) which is on the top of the drive.

Refer to the following figures for exact locations and terminal Assignment.

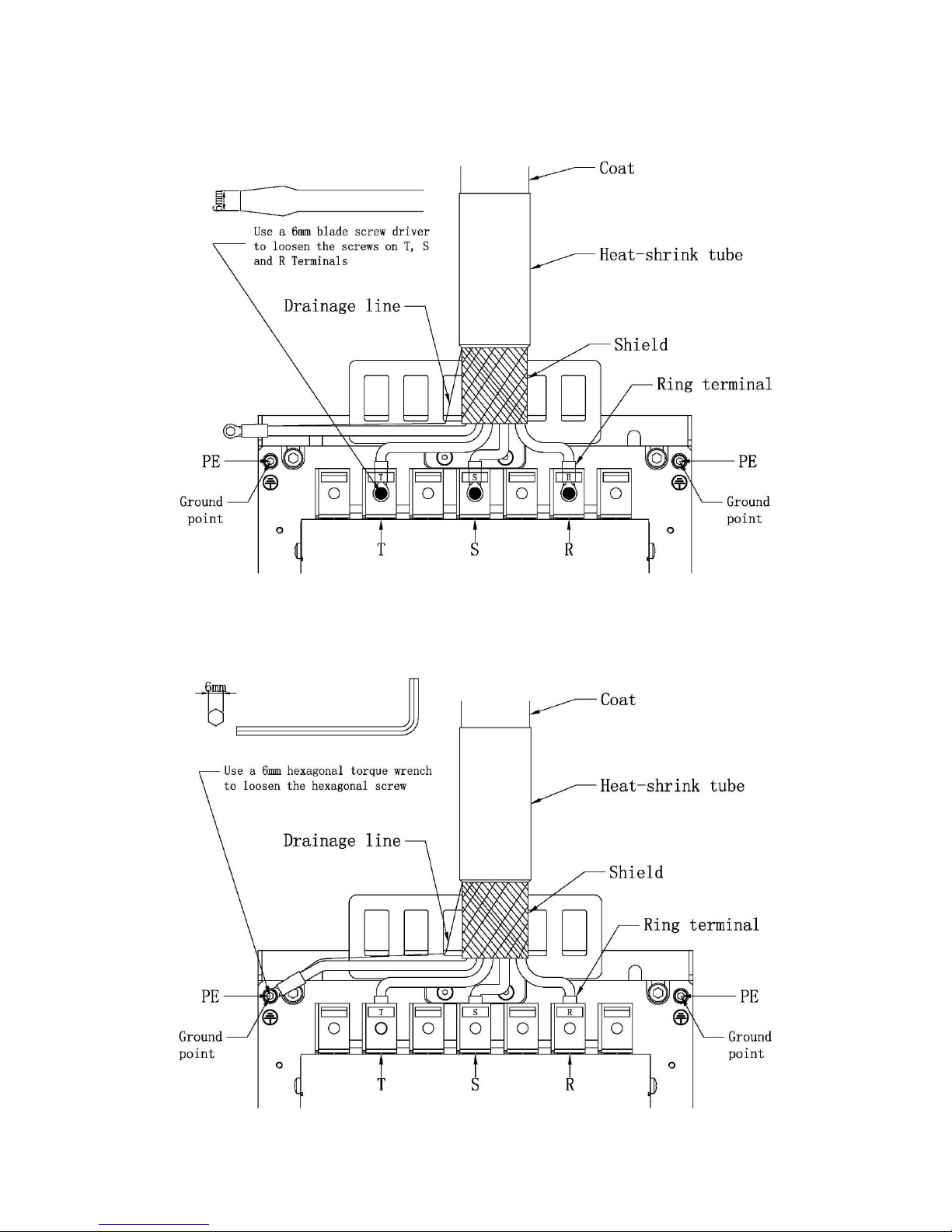

Step 4: Install Phase Wires (T, S and R)

Use a 6mm blade screw driver to loosen the screws on T, S and R Terminals which are in the drive’s

Power Supply Input Port (P1). Insert the AC power supply cable’s phase wires into the

Page 14

12

corresponding terminals: T to T, S to S and R to R. Then use a 6mm blade screw driver to tight the

screws.

Step 5: Install Grounding Wire

Use a 6mm hexagonal torque wrench to loosen the hexagonal screw on either PE Terminal which

is on the drive’s body. Fix the grounding wire on the PE terminal.

Page 15

13

Step 6: Cable Fixing

Use a hose clamp to fix the cable on the cable support. Make sure that the cable shield has a large-

area contact against the cable support, so that they can together be grounded through drive

housing.

Page 16

14

2.2 DC Power Supply Input

2.2.1 DC Power Supply Requirement

Main Supply

AxN 90.150.4

AxN 110.200.4

Voltage

565V

Type

DC power

Fluctuation of Voltage

0 ~ 800V

Nominal Power

62.4KW

76.2 KW

Peak Power

103.9KW

138.6 KW

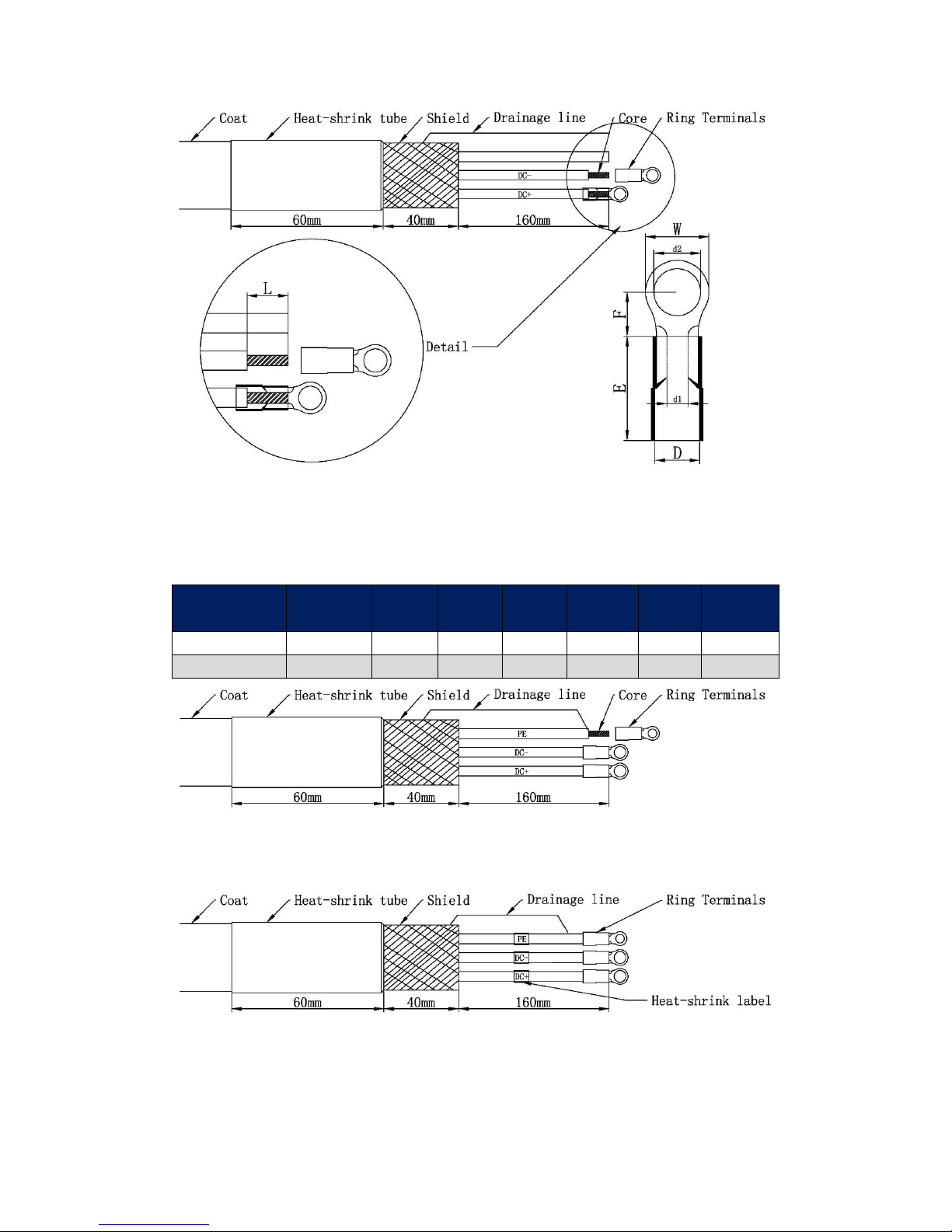

2.2.2 DC Power Supply Cable Fabrication

DC power supply cable is the cable which connect the AxN Size5 Drive with the DC power supply.

This manual only mention the cable fabrication of AxN drive side. The power supply side should be

fabricated based on the requirement of the DC power supply

Step 1: Cable Selection

AxN Size5 drive must use a 3 wire cable with shield as its DC power supply cable. Refer to the

table below to select the appropriate cable:

AxN Size5

Current (A rms)

Recommended

Gauge (mm2)

Recommended

Gauge (AWG)

AxN 90.150.4

110.4

26.67

3

AxN 110.200.4

134.9

33.62

2

Step 2: Cable Length Measurement

The AC power supply cable is used to connect the output of the DC power supply with the Power

Input Port (P1) of AxN Size5 Drive. To minimize the interference, the DC power supply must be

installed in close proximity to AxN Size5 Drive as much as possible. But, the distance between two

devices should also comply with the Installation Space Regulation of AxN Size5 Drive (Refer to 1.5

Installation Spacing).

Step 3: Strip the Cable Coat

Strip the outside coat of the DC power supply cable for 160mm and reveal the inside shield.

Page 17

15

Step 4: Make the Grounding Shield

Leave 65mm Shield as the grounding shield and turn it to the outside of the coat. Then, weld a wire

on the shield as the drainage line.

Step 5: Fix the Grounding Shield

Use a 60mm heat-shrink tube to fix the grounding shield and leave 40mm shield outside.

Step 6: Make the Phase Wires

Choose 2 wires of the cable as DC+ and DC-. Crimping pre-insulated Terminals on the wires will

enhance the connection stability and simplicity between the cable and drive. AxN Size5 series

drives are recommended to use the RNY series Ring Terminals manufactured by KST. Refer to the

following table to select the appropriate terminal:

AxN Size5

Ring

Terminals

d2(mm)

W(mm)

F(mm)

E(mm)

D(mm)

d1(mm)

AxN 90.150.4

RNYB22-8

8.4

16.5

13.5

24

13

7.7

AxN 110.200.4

RNYB22-8

8.4

16.5

13.5

24

13

7.7

Strip the wires for L mm (1 ≤ L ≤ E), the recommend strip length is E/2 mm, refer to the following

table to select an appropriate length:

AxN Size5

Strip Length (mm)

Recommended Strip Length (mm)

AxN 90.150.4

1 ~ 24

12

AxN 110.200.4

1 ~ 24

12

Page 18

16

Step 7: Connect the PE wire with Shield

Use the same method to make the remaining wire as the PE wire. Then crimp the PE wire into the

Ring Terminal along with the drainage line. Refer to the following table to select the appropriate

terminal:

AxN Size5

Ring

Terminals

d2(mm)

W(mm)

F(mm)

E(mm)

D(mm)

d1(mm)

AxN 90.150.4

RNYBS22-6

6.4

12.2

15.1

24

13

7.7

AxN 110.200.4

RNYBS22-6

6.4

12.2

15.1

24

13

7.7

Step 8: Check and Mark

Check every wire and the connection between shield and PE wire, then label each wire.

Page 19

17

2.2.3 DC Power Supply Input Installation

Step 1: Check the Power Supply Type and Voltage

Make sure that the mains power supply is a DC power supply, and its voltage is 0 ~ 800 Vdc.

Step 2: Find out the DC Power Input Terminals

PE, DC+ and DC-, these are the three terminals called DC Power Input Terminals. AxN Size5 Drive’s

DC Power Input Terminals are in the Power Supply Input Port (P1) which is on the top of the drive.

Refer to the following figures for exact locations and terminal Assignment.

Step 3: Install DC Power Wires (DC+ and DC-)

Use a 6mm blade screw driver to loosen the screws on DC+ and DC- Terminals which are in the

drive’s Power Supply Input Port (P1). Insert the DC power supply cable’s power wires into the

corresponding terminals: DC+ to DC+ and DC- to DC-. Then use a 6mm blade screw driver to tight

the screws.

Page 20

18

Step 4: Install Grounding Wire

Use a 6mm hexagonal torque wrench to loosen the hexagonal screw on either PE Terminal which

is on the drive’s body. Fix the grounding wire on the PE terminal.

Step 6: Cable Fixing

Use a hose clamp to fix the cable on the cable support. Make sure that the cable shield has a large-

Page 21

19

area contact against the cable support, so that they can together be grounded through drive

housing.

Page 22

20

2.3 Brake Resistor

Dynamic braking (DB) helps bring the motor to a smooth and rapid stop when working with high

inertia loads. As the drive lowers the frequency of a motor with high inertia connected,

regeneration occurs. This can cause an overvoltage situation when the regenerative energy flows

back into the DC bus capacitors. A brake resistor prevents these overvoltage faults.

AxN Series Drive has an internal brake resistor inside the drive. And it can also connect an external

brake resistor (Recommended).

WARNING: Do not operate AxN Drive without any brake resistor. Failure to comply may result in

damage to braking circuit or drive.

2.3.1 Internal Brake Resistor

Every AxN Series Drive has an internal brake resistor. Regard to its properties, using internal brake

resistor in real applications is NOT recommended. Refer to the following table for more details:

AxN Size5

Resistance (Ω)

Power (W)

AxN 90.150.4

3.5

150

AxN 110.200.4 3 150

2.3.2 Internal Brake Resistor Installation

Step 1: Fabricate Shortcut Wire

In order to activate the internal brake resistor, a shortcut wire is needed to shortcut terminal Brk+

and DC+. Select a 25mm2 wire which is longer than 110mm, clamp two RNYB 22-8 ring terminals

on both sides. The recommended strip length is 14mm. Refer to following figure and table for more

detail.

Ring Terminal

d2 (mm)

W (mm)

F (mm)

E (mm)

D (mm)

d1 (mm)

RNYB 22-8

8.4

16.5

13.5

24

13

7.7

Step 2: Find out the Internal Brake Resistor Terminals

DC+ and Brk+, these are the two terminals called Internal Brake Resistor Terminals. AxN Size5

Drive’s Internal Brake Resistor Terminals are in the Power Supply Input Port (P1) which is on the

top of the drive. Refer to the following figure for exact locations and terminal Assignment.

Page 23

21

Step 3: Shortcut DC+ and Brk+

Use a 6mm blade screw driver to loosen the screws on DC+ and Brk+ Terminals which are in the

drive’s Power Supply Input Port (P1). Then, use the shortcut wire to shortcut DC+ and Brk+.

2.3.3 External Brake Resistor

The External Brake Resistor must be sized properly in order to dissipate the required power to

decelerate the load in desired time. There are three important factors: Resistance, Maximum

Absorb Energy and Maximum Power.

Page 24

22

Resistance

The selection of the external brake resistor resistance must be proper. If the resistance is smaller

than Minimum Resistance, the IGBT might be damaged by the overload brake current. And if the

resistance is bigger than Maximum Resistance, the brake procedure might be abort because of the

high DC-Bus Voltage (over 900V).

Refer to following table to check the Minimum and Maximum Resistance of external brake resistor

which is suitable for a particular drive:

AxN Size5

Minimum Resistance (Ω)

Maximum Resistance (Ω)

AxN 90.150.4 2 3.7

AxN 110.200.4 2 2.7

Maximum Absorb Energy and Maximum Power

Maximum Absorb Energy and Maximum Power are two important factors to evaluate the energy

absorption ability of the brake resistor. The values of these two factors may differ from one

application to another, but the basic idea is always the same, to dissipate the required power to

decelerate the load in desired time.

NOTE: Brake resistor wires’ insulation grade must be higher than 1000Vac and 3000Vdc.

2.3.4 External Brake Resistor Installation

Step 1: Check the Brake Resistor

Check the external brake resistor’s resistance, maximum absorb energy and maximum power.

Make sure that the brake resistor is suitable for AxN Size5 Drive and real application.

Step 2: Fabricate Brake Resistor Wires

In order to install the brake resistor to AxN Size5 Drive, the brake’s wire should be clamped ring

terminals to fit the terminals on drive. AxN Size5 series drives are recommended to use the RNY

series Ring Terminals manufactured by KST. And the recommended strip length is 14mm. Refer to

following figure and table for more detail.

Ring Terminal

d2 (mm)

W (mm)

F (mm)

E (mm)

D (mm)

d1 (mm)

RNYB 22-8

8.4

16.5

13.5

24

13

7.7

Step 3: Find out the External Brake Resistor Terminals

DC+ and Brk-, these are the two terminals called External Brake Resistor Terminals. AxN Size5

Drive’s Internal Brake Resistor Terminals are in the Power Supply Input Port (P1) which is on the

Page 25

23

top of the drive. Refer to the following figures for exact locations and terminal Assignment.

Step 4: Insert Wires into Corresponding Terminals

Use a 6mm blade screw driver to loosen the screws on DC+ and Brk- Terminals which are in the

drive’s Power Supply Input Port (P1). Insert the two wires of the external brake resistor separately

into these two terminals. Then tight the screws.

Step 5:Wire Fixing

Use a cable tie to fix the wires on the cable support of AxN Size5 drive.

Page 26

24

Step 6: Resistance Measurement

Use an avometer to measure the resistance between DC+ and Brk-. Compare it with the resistance

of the external resistor, if they are the same, then the external resistor has been correctly installed.

WARNING: DO NOT BYPASS THIS STEP! This step can prevent malfunctions like wires shortcut,

brake resistor fault and so on.

Page 27

25

2.4 Motor Power Output

2.4.1 Motor Power Output Cable Fabrication

Motor Power Output Cable has two sides: drive side and motor side. This manual only mention the

fabrication of drive side. And the motor side fabrication differs from different motors. If the motor

is manufactured by Phase Motion Control, our Prefabricated Motor Power Output Cables are

recommended. Refer to: Appendix: Prefabricated Cable——5.1 Motor Power Output cable for

more details.

Step 1: Cable Selection

AxN Size5 drive must use a 4 wire cable with shield as its motor power output cable. Refer to the

table below to select the appropriate cable:

AxN Size5

Current (A rms)

Recommended

Gauge (mm2)

Recommended

Gauge (AWG)

AxN 90.150.4

90

21.15

4

AxN 110.200.4

110

26.67

3

Step 2: Cable Length Measurement

Measure the distance between drive and motor then determine the suitable cable length.

Step 3: Strip the Cable Coat

Strip the outside coat of the DC power supply cable for 160mm and reveal the inside shield.

Step 4: Make the Grounding Shield

Leave 65mm Shield as the grounding shield and turn it to the outside of the coat. Then, weld a wire

on the shield as the drainage line.

Page 28

26

Step 5: Fix the Grounding Shield

Use a 60mm heat-shrink tube to fix the grounding shield and leave 40mm shield outside.

Step 6: Make the Phase Wires

Choose 3 wires of the cable as phase wires: U, V, W. Crimping pre-insulated Terminals on the

wires will enhance the connection stability and simplicity between the cable and drive. AxN Size5

series drives are recommended to use the RNY Series Ring Terminals manufactured by KST. Refer

to the following table to select the appropriate terminal:

AxN Size5

Ring Terminal

d2(mm)

W(mm)

F(mm)

E(mm)

D(mm)

d1(mm)

AxN 90.150.4

RNYB 22-8

8.4

16.5

13.5

24

13

7.7

AxN 110.200.4

RNYB 22-8

8.4

16.5

13.5

24

13

7.7

Strip the wires for L mm (F ≤ L ≤ F+B), the recommend strip length is F+2 mm, refer to the

following table to select an appropriate length:

AxN Size5

Strip Length (mm)

Recommended Strip Length (mm)

AxN 90.150.4

1 ~ 24

12

AxN 110.200.4

1 ~ 24

12

Step 7: Connect the PE wire with Shield

Use the same method to make the remaining wire as the PE wire. Then crimp the PE wire into the

Ring Terminal along with the drainage line. Refer to the following table to select the appropriate

Page 29

27

terminal:

AxN Size5

Ring

Terminals

d2(mm)

W(mm)

F(mm)

E(mm)

D(mm)

d1(mm)

AxN 90.150.4

RNYBS22-6

6.4

12.2

15.1

24

13

7.7

AxN 110.200.4

RNYBS22-6

6.4

12.2

15.1

24

13

7.7

Step 8: Check and Mark

Check every wire and the connection between shield and PE wire, then label each wire.

Page 30

28

2.4.2 Motor Power Output Installation

Step 1: Find out the Motor Power Output Terminals

PE, A, B and C, these are the four terminals called Motor Power Output Terminals. AxN Size5 Drive’s

Motor Power Output Terminals are in the Motor Power Output Port (P2) which is on the bottom

of the drive. Refer to the following figures for exact locations and terminal Assignment.

Step 2:Install Phase Wires (U, V and W)

Use a 6mm blade screw driver to loosen the screws on U, V and W Terminals which are in the

drive’s Motor Power Output Port (P2). Insert the motor power output cable’s phase wires into the

corresponding terminals: U to A, V to B and W to C. Then use a 6mm blade screw driver to tight

the screws.

WARNING: The correspondence between the Motor Power Output wires and terminals should

be adhered! Otherwise the motor cannot work properly!

Page 31

29

Step 3: Install Grounding Wire

Use a 6mm hexagonal torque wrench to loosen the hexagonal screw on either PE Terminal which

is on the drive’s body. Fix the grounding wire on the PE terminal.

Step 4: Cable Fixing

Use a hose clamp to fix the cable on the cable support. Make sure that the cable shield has a large-

area contact against the cable support, so that they can together be grounded through drive

housing.

Page 32

30

Page 33

31

3 Control Circuit Wiring

3.1 Auxiliary Power Supply (AUX_Power)

3.1.1 Auxiliary Power Supply Requirement

Main Supply

AxN Size5

Voltage

24V

Type

DC power

Fluctuation of Voltage

±15% (22.8 ~ 25.2V)

Nominal Power

192W

Nominal Current

8A

3.1.2 Auxiliary Power Supply Cable Fabrication

This manual only mention the fabrication of auxiliary power supply port on AxN drive side.

Step 1: Cable Selection

Select a 2 mm2 (14 AWG) two wires cable as drive’s auxiliary power supply cable.

Step 2: Cable Length Measurement

Measure the distance between drive and power supply then determine the suitable cable length.

NOTE: the distance between two devices should comply with the Installation Space Regulation of

AxN Size5 Drive (Refer to 1.5 Installation Spacing).

Step 3: Strip the Cable Coat

Strip the outside coat of the auxiliary power supply cable for 15mm and reveal the wires.

Step 4: Make DC+ Wire and DC- Wire

Mark one wire as DC+ and another as DC-, then strip wires’ coat for 5mm.

Step 5: Check and Label

Check every wire’s conductivity and then label them.

Page 34

32

3.1.3 Auxiliary Power Supply Installation

Step 1: Check Power Supply Voltage and Power

Make sure that the auxiliary power supply’s voltage is 22.8 ~ 25.2Vdc, and it can provide 6A, 140W

power.

Step 2: Find out the Auxiliary Power Supply Port (AUX_Power)

AxN Series Drive’s Auxiliary Power Supply Port (Female Plug, 4Pin) is on the right bottom of the

drive. And a corresponding Auxiliary Power Supply Terminal (Male Plug, 4Pin) is provided in the

accessories. Refer to the following figure for exact location.

Terminal Configuration

Pin

Name

Function

Description

1

24V_AUX

Control circuit power supply

24Vdc Positive

2

24V_SAF_H

STO high-side power bridge power supply

24Vdc Positive

3

24V_SAF_L

STO low-side power bridge power supply

24Vdc Positive

4

GND_AUX

Reference ground

24Vdc Negative

Page 35

33

STO Function

Normal version AxN Series Drive does not have the STO function. If you want to use the STO

function, you must order a STO version AxN Series Drive. There are 2 pins which are related to the

STO function, 24V_SAF_H and 24V_SAF_L. If you cut either of these pins’ power, STO will be

activated and the motor will stop. Normal version AxN Series Drive has already internally short cut

Pin 24V_AUX, 24_SAF_H and 24V_SAF_L, so that STO function is disabled.

Step 3: Connect the Cable to Terminal

Insert DC+ wire into terminal 24V_AUX and insert DC- wire into PE_AUX, then use a screwdriver to

tight the screws on the terminals.

Step 4: Insert Terminal into Port

Insert the terminal along with the cable into Auxiliary Power Supply Port (AUX_Power).

Page 36

34

3.2 System Relay (R1)

Port Location

AxN Size5 Drive’s System Relay Port (Female Plug, 3Pin) is on the right bottom of the drive. And a

corresponding System Relay Terminal (Male Plug, 3Pin) is provided in the accessories. Refer to the

following figures for exact location.

Terminal Configuration

Pin

Name

Function

Description

1

Com

Common relay contact

To be used as drive system OK signal

2

N.O.

Relay normally open contact

3

N.C.

Relay normally closed contact

Diagram

AxN Series Drive use a relay to indicate the status. When Drive is power off or system is not ready,

the circuit is connected between N.C. (Normally Closed) and Com. In the meantime, the circuit is

disconnect between N.O. (Normally Open) and Com, illustrated as below.

Page 37

35

When the drive is ready, N.O. connects Com and N.C. disconnects Com, illustrated as below.

Page 38

36

4 Communication Port

4.1 Overview of Communication Port Panel

Name

Function

Description

E1

Encoder Connector

SinCos, Endat, Digital Incremental with Hall,

Resolver and Hiperface

U1/U2

User Connectors

4 Analog Inputs, 2 Analog Outputs;

8 Digital Inputs, 4 Digital Outputs

S1

Serial Bus Connector

RS232, RS422 and RS485 / Secondary CAN

C1

CAN Connector

Main CAN / Auxiliary Encoder

EtherCAT IN/OUT

EtherCAT Connector

RJ45 100Base-TX

U3/U4

Insolated User

Connectors (Optional)

Insolated: 3 Analog Inputs, 2 Analog Outputs;

8 Digital Inputs, 2 Digital Outputs. Optional

Page 39

37

4.2 E1 —— Main Encoder Port

AxN Series Drive’s Main Encoder Port is used to connect motor‘s position sensor (encoder). AxN

Series Drive can support 5 different kinds of position sensor: Sincos Encoder, Endat Encoder,

Digital incremental Encoder with Hall, Resolver and Hiperface Encoder. Different position sensor

has different pin assignment, refer to correspond section for more details.

If the motor is manufactured by Phase Motion Control, our Prefabricated Encoder Cables are

recommended. Refer to: Appendix: Prefabricated Cable——5.2 Encoder Cable for more details.

Location

AxN Series Drive’s Main Encoder Port (Female Plug, 15 Pin D-Sub) is on the right bottom of the

Communication Port Panel. Refer to the following figures for exact location.

Page 40

38

4.2.1 Sincos Encoder

Pin Assignment

Pin

Name

Function

Signal Description

1

GND

Supply ground

Encoder ground

2

SIN+

Encoder absolute channel

1 Vpp differential

3

COS+

Encoder absolute channel

1 Vpp differential

4

COS-

Encoder absolute channel

1 Vpp differential

5

SIN-

Encoder absolute channel

1 Vpp differential

6

+Vcc

Encoder supply, 5Vdc

Positive supply voltage

7

A+

Encoder incremental channel

1 Vpp differential

8

KTY+

Thermal sensor positive

9 I-

Encoder index

1 Vpp differential

10

——

——

——

11

——

——

——

12

A-

Encoder incremental channel

1 Vpp differential

13

B-

Encoder incremental channel

1 Vpp differential

14

I+

Encoder index

1 Vpp differential

15

B+

Encoder Incremental channel

1 Vpp differential

Connection Table (with Ultract Series Motors)

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Page 41

39

4.2.2 Endat Encoder

Pin Assignment

Pin

Name

Function

Signal Description

1

GND

Supply ground

Encoder ground

2

——

——

——

3

CLOCK+

Endat clock

TTL 4 CLOCK-

Endat clock

TTL

5

——

——

——

6

+Vcc

Encoder supply, 8Vdc

Positive supply voltage

7

——

——

——

8

KTY+

Thermal sensor positive

9 DATA-

Endat data

TTL

10

——

——

——

11

——

——

——

12

——

——

——

13

——

——

——

14

DATA+

Endat data

TTL

15

——

——

——

Connection Table (with Ultract Series Motors)

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Page 42

40

4.2.3 Digital Incremental Encoder with Hall

Pin Assignment

Pin

Name

Function

Signal Description

1

GND

Supply ground

Encoder ground

2

——

——

——

3

H1

Hall sensor

TTL 4 H2

Hall sensor

TTL 5 H3

Hall sensor

TTL

6

+Vcc

Encoder supply, 8Vdc

Positive supply voltage

7

B+

Encoder incremental channel

TTL

8

KTY+

Thermal sensor positive

9 I-

Encoder index

TTL

10

——

——

——

11

——

——

——

12

B-

Encoder incremental channel

TTL

13

A-

Encoder incremental channel

TTL

14

I+

Encoder index

TTL

15

A+

Encoder incremental channel

TTL

Connection Table (with Ultract Series Motors)

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Page 43

41

4.2.4 Resolver

Pin Assignment

Pin

Name

Function

Signal Description

1

——

——

——

2

SIN+

Absolute channel

Differential signal

3

COS+

Absolute channel

Differential signal

4

COS-

Absolute channel

Differential signal

5

SIN-

Absolute channel

Differential signal

6

——

——

——

7

——

——

——

8

KTY+

Thermal sensor positive

9

——

——

——

10

RESEX+

Resolver energising +

8kHz sinusoidal wave

11

RESEX-

Resolver energising -

8kHz sinusoidal wave

12

——

——

——

13

——

——

——

14

——

——

——

15

——

——

——

Connection Table (with Ultract Series Motors)

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Page 44

42

4.2.5 Hiperface Encoder

Pin Assignment

Pin

Name

Function

Signal Description

1

GND

Supply ground

Encoder ground

2

——

——

——

3

——

——

——

4

——

——

——

5

——

——

——

6

+Vcc

Encoder supply, 8Vdc

Positive supply voltage

7

COS+

Process data channel

TTL

8

KTY+

Thermal sensor positive

9 DATA-

RS-485 parameter channel

TTL

10

——

——

——

11

——

——

——

12

COS-

Process data channel

TTL

13

SIN-

Process data channel

TTL

14

DATA+

RS-485 parameter channel

TTL

15

SIN+

Process data channel

TTL

Connection Table (with Ultract Series Motors)

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Page 45

43

4.3 S1 —— Serial Bus Port

AxN Series Drive’s Serial Bus Port (S1) supports RS-232, RS-422, RS-485 and CAN protocol. But only

one communication interface can be used at a time.

Location

AxN Series Drive’s Serial Bus Port (Male Plug, 9 Pin D-Sub) is on the downside of drive‘s

communication port panel. Refer to the following figures for exact location.

4.3.1 RS-232

Pin Assignment

Pin

Standard RS-232

AxN RS-232

Function

1

DCD

---

Data Carrier Detect

2

RXD

RXD

Received Data

3

TXD

TXD

Transmitted Data

4

DTR

DTR

Data Terminal Ready

5

GND

GND

Common Ground

6

DSR

DSR

Data Set Ready

7

RTS

RTS

Request To Send

8

CTS

CTS

Clear To Send

9

RI

---

Ring Indicator

Notes:

1. RS-232 devices may be classified as Data Terminal Equipment (DTE) or Data Communication

Equipment (DCE); this defines at each device which wires will be sending and receiving each

signal. AxN Series Drive is a Data Communication Equipment (DCE), and a controller or a

Page 46

44

computer is a Data Terminal Equipment (DTE).

2. The signal voltage is ±12V, and the max current of DTR (Pin4) is 100mA.

Minimal "3-wire" Connection

A minimal "3-wire" RS-232 connection consisting only of transmit data, receive data, and ground,

is commonly used when the full facilities of RS-232 are not required. And it also the minimal

connection requirement of Cockpit communication with AxN Series Drive.

Connection table

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Connection diagram

Page 47

45

Maximal "7-wire" Connection

When the controller has a full facilities of RS-232, "7-wire" connection is the maximal connection

which AxN series drive can support.

NOTE: Do NOT use "9-wire" connection, AxN series drive do not support DCD and RI function.

Connection table

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Connection diagram

Page 48

46

4.3.2 RS422/485

Pin Assignment

Pin

RS-422

RS-485

Function

1

---

---

---

2

RX-

RX-(LN-)

Receive Data -

3

TX+

TX+(LN+)

Transmit Data +

4

---

---

--- 5 GND

GND

Ground connection

6

---

---

---

7

TX-

TX-(LN-)

Transmit Data -

8

RX+

RX+(LN+)

Receive Data +

9

---

---

---

RS-422 Connection Table

RS-485 Connection Table

Page 49

47

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

4.3.3 Auxiliary CAN

AxN Series Drive supports CANOpen protocol and has two independent CAN controller. The

auxiliary CAN controller links to the S1 connector.

Pin Assignment

Pin

CANOpen

Function

1

CAN_H

CAN_H bus line (dominant high)

2

---

---

3

---

---

4

---

---

5

GND

Ground connection

6

---

--- 7 ---

--- 8 ---

--- 9 CAN_L

CAN_L bus line (dominant low)

Note: CANOpen pin assignment on S1 connector does NOT meet CiA 102 Standard.

Connection Table

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Page 50

48

Connection diagram

Note: Only the first and the last CAN node device should use a 120Ω terminal resistor.

Page 51

49

4.4 C1 —— Main CAN Port

AxN Series Drive’s Main CAN Port (C1) connects to the main CAN controller inside the AxN drive. It

the default CAN network port of AxN drive. Moreover, C1 port can also be used as Auxiliary Encoder

Port.

Location

AxN Series Drive’s Main CAN Port (Female Plug, 9 Pin D-Sub) is on the middle side of drive‘s

communication port panel. Refer to the following figures for exact location.

4.4.1 Main CAN

AxN Series Drive supports CANOpen protocol and has two independent CAN controller. The main

CAN controller links to the C1 connector.

Pin Assignment

Pin

CANOpen

Function

1

---

--- 2 CAN_L

CAN_L bus line (dominant low)

3

GND

Ground connection

4

---

--- 5 ---

--- 6 ---

--- 7 CAN_H

CAN_H bus line (dominant high)

8

---

---

9

---

---

Page 52

50

Connection Table

1) N/C——No Connection;

2) Connector back shell shielded 360°(Both ends);

3) ● means that the shield or cable should connect to connectors.

Connection diagram

Note: Only the first and the last CAN node device should use a 120Ω terminal resistor.

Page 53

51

4.4.2 Auxiliary Encoder

C1 port is also the Auxiliary Encoder Port. It supports Endat Encoder IN, Incremental Encoder IN

and Simulated Incremental Encoder OUT. The output voltage of Simulated Incremental Encoder is

0 ~ 3.3V.

Endat Encoder (IN)

Pin

Name

Function

1

DATA+

Endat Data

2

---

--- 3 GND

Ground connection

4

CLOCK-

Endat Clock

5

---

---

6

DATA-

Endat Data

7

---

---

8

CLOCK+

Endat Clock

9

---

---

Incremental Encoder (IN/OUT)

Pin

Name

Function

1

B+

Encoder incremental channel

2

---

--- 3 GND

Ground connection

4

A-

Encoder incremental channel

5

I-

Encoder index

6

B-

Encoder incremental channel

7

---

--- 8 A+

Encoder incremental channel

9

I-

Encoder index

Page 54

52

4.5 EtherCAT IN/OUT——EtherCAT Port

AxN Series Drive supports EtherCAT fieldbus protocol. And can be connected to a EtherCAT network

through two connectors: EtherCAT IN and EtherCAT OUT.

Port Location

AxN Series Drive’s EtherCAT Port is on the upside of drive‘s communication port panel, formed by

two RJ45 100Base-TX female plug. Refer to the following figure for exact location.

Pin Assignment

Pin

Name

Function

1

TX +

Transmit Data +

2

TX -

Transmit Data -

3

RX +

Receive Data +

4

---

--- 5 ---

--- 6 RX -

Receive Data -

7

---

--- 8 ---

---

Page 55

53

4.6 U1/U2 —— User Connectors

Port Location

AxN Series Drive’s User Connectors (Male Plug, 2 × 12 pin) are on the left bottom of the

Communication Port Panel. Refer to the following figure for exact location.

Pin Assignment

User Connector U1

Pin

Name

Function

Signal Description

1

R0P

Differential analog input

+/-10V, Zin=10KΩ

2

R0N

Differential analog input

+/-10V, Zin=10KΩ

3

AO0

Programmable analog output

+/-10V f.s., 30 mA

4

GND

Analog reference ground

Analog signals reference

5

DI0

Programmable digital input

6.6 kΩ to ground, 20-30 V

6

DI1

Programmable digital input

6.6 kΩ to ground, 20-30 V

7

DI2

Programmable digital input

6.6 kΩ to ground, 20-30 V

8

DI3

Programmable digital input

6.6 kΩ to ground, 20-30 V

9

DO0

Programmable digital output

PNP open collector, 24 V, 100mA max

10

DO1

Programmable digital output

PNP open collector, 24 V, 100mA max

11

24V

Auxiliary supply of control circuits

22 ~ 30Vdc to Pin 12 (0V), 500mA

12

0V

Auxiliary supply negative

Digital signal reference

Page 56

54

User Connector U2

Pin

Name

Function

Signal Description

13

GND

Analog reference ground

Analog signals reference

14

R1P

Differential analog input

+/-10V, Zin=10KΩ

15

R1N

Differential analog input

+/-10V, Zin=10KΩ

16

AO1

Programmable analog output

+/-10V f.s., 30 mA

17

GND

Analog reference ground

Analog signals reference

18

DI4

Programmable digital input

6.6 kΩ to ground, 20-30 V

19

DI5

Programmable digital input

6.6 kΩ to ground, 20-30 V

20

DI6

Programmable digital input

6.6 kΩ to ground, 20-30 V

21

DI7

Programmable digital input

6.6 kΩ to ground, 20-30 V

22

DO2

Programmable digital output

PNP open collector, 24 V, 100mA max

23

DO3

Programmable digital output

PNP open collector, 24 V, 100mA max

24

0V

Auxiliary supply negative

Digital signal reference

Notes:

1. Pin 4, 13 and 17 are the same analog reference ground;

2. Pin 1 and 2, 14 and 15 are two pairs of differential analog input. If not using differential signal,

connect pin 1, 2, 4 and 15 separately to analog reference ground (pin 4, 13 and 17), you will

have 4 channels of programmable analog input;

3. Pin 12 and 24 are the same digital signal reference.

Page 57

55

4.7 U3/U4 —— Insulated User Connectors

Port Location

AxN Series Drive’s Insulated User Connectors (Male Plug, 2× 12 pin) are on the right of the

Communication Port Panel. Refer to the following figure for exact location.

Page 58

56

Pin Assignment

Insulated User Connector U3

Pin

Name

Function

Signal Description

1

IS_AO0P

Programmable analog output

Insulated analog output channel No.0:

±10V f.s., 30 mA

2

IS_AO0G

Analog reference ground

Insulated analog output channel No.0:

Insulated reference ground

3

IS_AO1P

Programmable analog output

Insulated analog output channel No.1:

±10V f.s., 30 mA

4

IS_AO1G

Analog reference ground

Insulated analog output channel No.1:

Insulated reference ground

5

IS_AI0G

Analog reference ground

Insulated analog input channel No.0:

Insulated reference ground

6

IS_AI0P

Programmable analog input

Insulated analog input channel No.0: ±10V

7

IS_AI1G

Analog reference ground

Insulated analog input channel No.1:

Insulated reference ground

8

IS_AI1P

Programmable analog input

Insulated analog input channel No.1: ±10V

9

IS_AI2G

Analog reference ground

Insulated analog input channel No.2:

Insulated reference ground

10

IS_AI2P

Programmable analog input

Insulated analog input channel No.2: ±10V

11

IS_DO0P

Programmable digital output

Insulated digital output channel No.0:

On/Off switch, 9V ~ 28Vdc/2A

12

IS_DO0N

Programmable digital output

Insulated User Connector U4

Pin

Name

Function

Signal Description

13

DI_COM

Digital reference ground

Insulated reference ground for digital input

14

IS_DO1P

Programmable digital output

Insulated digital output channel No.1:

On/Off switch, 9V ~ 28Vdc/2A

15

IS_DO1N

Programmable digital output

16

IS_DI0

Programmable digital input

5mA, 24Vdc max

17

IS_DI1

Programmable digital input

5mA, 24Vdc max

18

IS_DI2

Programmable digital input

5mA, 24Vdc max

19

IS_DI3

Programmable digital input

5mA, 24Vdc max

20

IS_DI4

Programmable digital input

5mA, 24Vdc max

21

IS_DI5

Programmable digital input

5mA, 24Vdc max

22

IS_DI6

Programmable digital input

5mA, 24Vdc max

23

IS_DI7

Programmable digital input

5mA, 24Vdc max

24

DI_COM

Digital reference ground

Insulated reference ground for digital input

Notes: Pin 13 and 24 are the same digital reference ground.

Loading...

Loading...