Page 1

Installation Manual for

For Right and Left Hinged Doors

Durable. Reliable. Attractive.

For door openings up to 36” (914 mm) wide

and 80 9/16” (2,047 mm) high

Quick

and

Easy

to

Size

and

Install

Page 2

Congratulations and

thank you for purchasing

Viewpoint!

The Viewpoint Screen is designed and manufactured by Seiki Screen

Systems, the world’s largest manufacturer of retractable screens.

Phantom Screens, North America’s leading brand of retractable

solutions, is proud to bring you these innovative products. Thanks to

rigorous design and product testing, the Viewpoint Screen will provide

years of dependable operation. Plus, it comes with a factory-supplied

limited lifetime warranty on all parts against manufacturer’s defects.

Viewpoint was designed for easy sizing and installation. This

Installation Manual provides a step by step guide through the

entire process.

Any questions? Contact

our Help Line, Toll Free at

1-877-446-7180.

Page 3

Getting to Know the Viewpoint Screen ................

Parts and Tools ......................................................

Measuring the Door Opening ...............................

Cutting the Horizontal

and Vertical Parts ..................................................

Installing the Bottom Rail and

Preparing the Screen Housing Assembly ..............

Installing the Mounting Bracket ..........................

Installing the Top Rail

and Catch Frame .................................................

Adjusting the Latch

and Tension Wires ...............................................

Attaching the Fixing Strip

and Installing the Clips .......................................

Service and Maintenance Hints ..........................

Index

For installation on a double hinged door (French Doors), you

will need: two Viewpoint Screens and one Double Door Kit.

Please refer to the Installation Manual within the “Double

Door Kit” prior to starting.

The Viewpoint Screen is not intended for installation on a

Sliding Patio Door.

4

5

6

7

8

9

10

11

12

13

Page 4

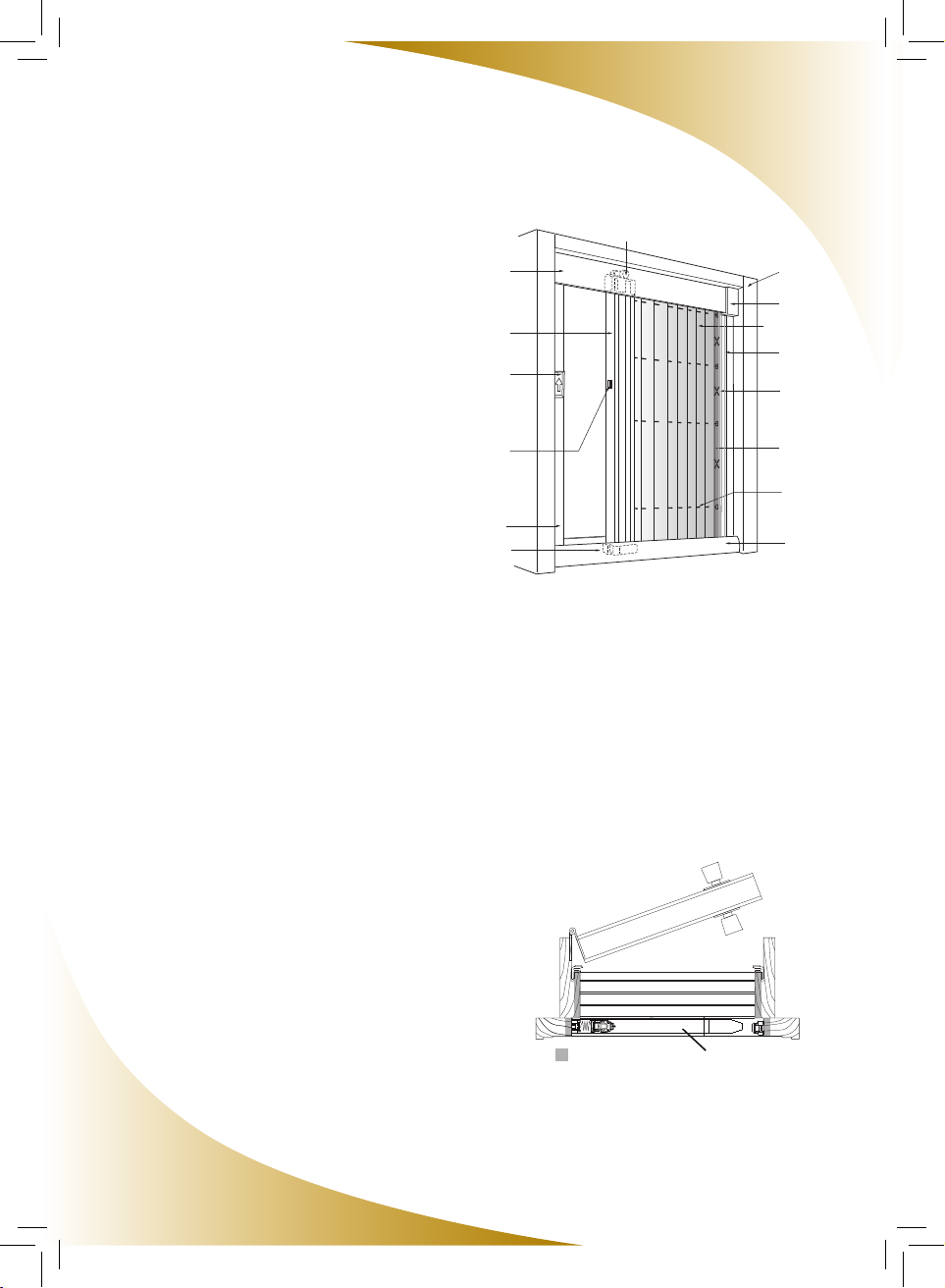

Getting to Know the Viewpoint Screen

Before beginning, become familiar with the

Viewpoint Screen and the door on which it

will be installed.

The Viewpoint Screen accommodates both

in-swing and out-swing doors. In-swing

doors open to the inside of the home and

require the Viewpoint Screen to be

installed on the outside of the home.

Out-swing doors open to the outside of the

home and require the Viewpoint Screen

to be installed on the inside of the home.

Does the Viewpoint Screen t the

Door Opening?

Make sure that the Viewpoint Screen

will t the door. This application

will accommodate an opening of

up to 36” (914 mm) wide, and between

76 9/16” (1,947 mm) and 80 9/16”

(2,047 mm) high. If the door opening is

larger than that, the Viewpoint Screen can

still be installed by attaching a ller strip

under the door frame to reduce the height of

the door opening. Refer to page 6 for details.

NOTE: The Viewpoint Screen can only be

shortened by 4” (100 mm) to a minimum

height of 76 9/16” (1,947 mm). If the door

opening is smaller than this, the Viewpoint

Screen will not accomodate the door.

4

Is the Door Opening Square?

For the Viewpoint Screen to operate

effectively, the door opening must be

perfectly square. Using a Carpenter

Square, check to ensure that the door

frame is square. If not, use shims to

bring the door frame to square before

beginning installation.

Is there enough Mounting Surface?

The Viewpoint Screen is a recess

mount screen that installs on the

inside surface of the door frame.

A minimum Mounting Surface of

1 3/4” (45 mm) is required. This

Mounting Surface must be at and

ush, and at a right angle (90˚)

to the door.

Door Frame

Corner Cover

Mesh

Mounting Bracket

Clip

Fixing Strip

Tension Wire

Bottom Rail

Sliding Bar Bottom Cap

Catch Frame

Latch Hole

Latch

Sliding Bar

Top Rail

Rollers

Mounting Surface

Viewpoint Screen

Page 5

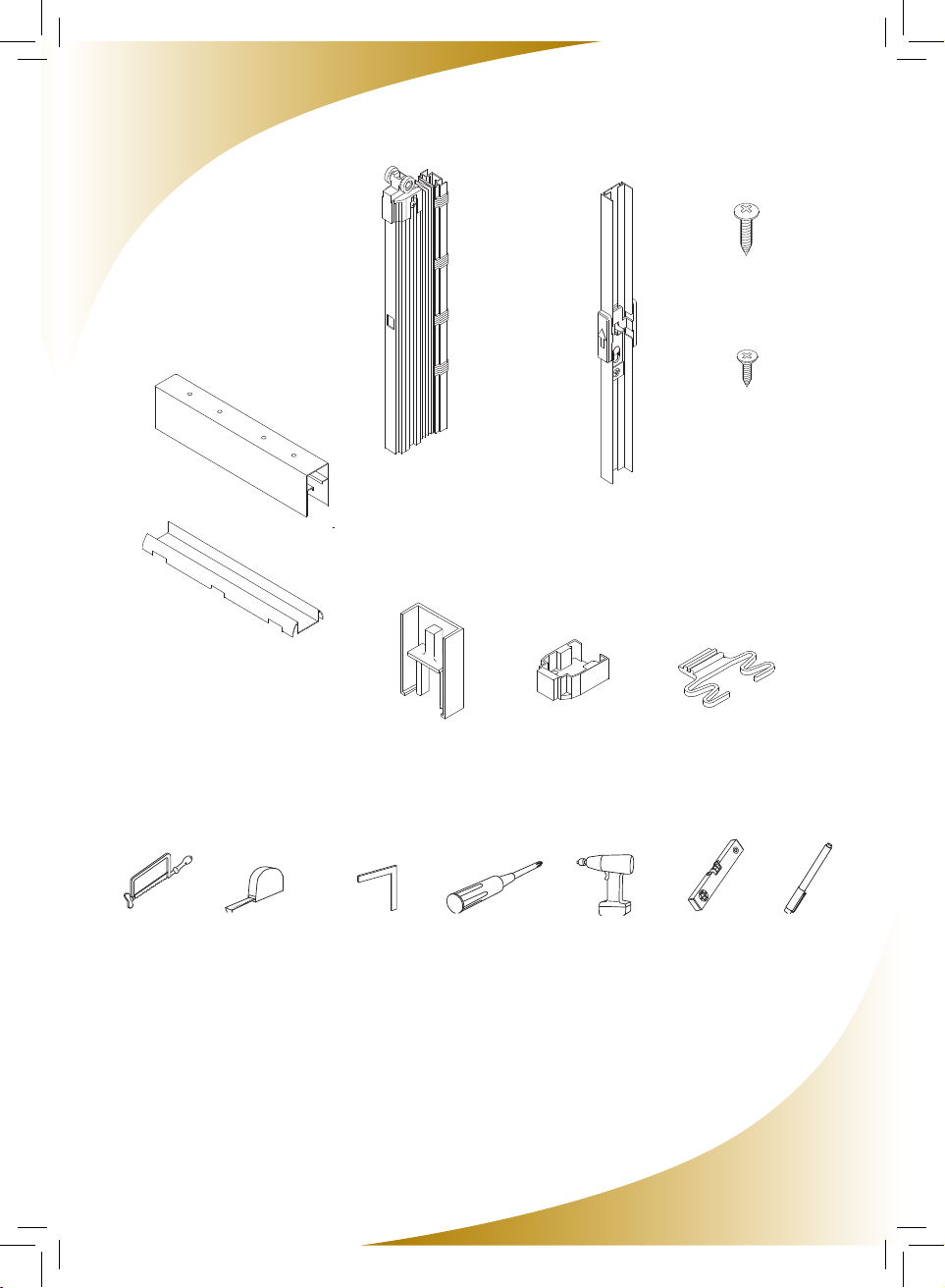

Parts and Tools

Before beginning,

make sure that all these

parts are included with

the Viewpoint Screen

package.

Required Tools

Viewpoint Screens can be sized and installed using common household

tools. Make sure all necessary tools are available before beginning.

NOTE: A chop saw can be used in place of a hacksaw provided that a

bi-metal blade has been properly installed

5

Top Rail

Bottom Rail

Screen Housing

Assembly

Catch Frame

(not required for a

double door application)

5/8” (16 mm)

Pan Head Screws

(12 pcs

.)

1/2” (12 mm)

Flat Head Screws

(2 pcs.)

Hack saw Philips

screwdriver

Electric drillMeasuring tape LevelCarpenter

square

Pen

Corner Cover

Sliding Bar

Bottom Cap

Clips (5 pcs.)

Page 6

Measuring the Door Opening

H

W

The Viewpoint Screen requires a minimum

Mounting Surface of 1 3/4" (45 mm). This

mounting surface must be at and ush, and at

a right angle (90º) to the door.

For the Width - Measure the width of the

opening between the right and left surfaces of

the door frame, record this dimension in the box

below labeled “W”.

For the Height – Measure the height of the

opening between the underside of the top of

the door frame (or ller strip), and the top of

the door sill at a point 1 3/4" (45 mm) from the

front surface of the frame. Record this

dimension in the box below labeled “H”.

NOTE: If the height of the door opening is

greater than the maximum height requirement,

it is still possible to install the Viewpoint

Screen. Simply attach a ller strip under the

top of door frame to reduce the height of the

opening to at least 80 9/16" (2,047 mm). Be

sure to attach the ller strip before taking the

height measurement.

=

=

6

W

H

A

1 3/4”

(45 mm)

mounting

surface

Door Sill

Page 7

-

Cutting the Horizontal and

Vertical Parts

Cutting the Horizontal Parts

Calculate the correct cut off Lengths.

Cut from each part the cut off length provided by the calculation performed above.

Maximum Opening

Width

Subtract inside door

frame width “W”

Enter Cut off Length

Below

36” (914 mm)

=

After cutting any part of the

Viewpoint Screen, use a le

to remove any burrs from the

surfaces.

Cutting the Vertical Parts

Calculate the correct cut off Lengths.

NOTE: Cutting of the Screen Housing Assembly must take place from the

bottom of the unit, note the “Cut” / “No Cut” labels. No more than 4” (100 mm)

can be cut from the Screen Housing Assembly.

-

Maximum Opening

Height

Subtract inside door

frame height “H”

Enter Cut off Length

Below

80 9/16” (2,047 mm)

=

Cut from each part the cut off length provided by the calculation performed above.

Do NOT remove the tape that keeps the components of the Screen Housing

Assembly secure until all cutting is complete.

After cutting any part of the

Viewpoint Screen, use a le to

remove any burrs from the

surfaces.

NOTE: Safety glasses should

be worn at all times during the

cutting process.

7

Top Rail

Bottom Rail

Cut O Length

Cut O Length

Cut o Length

Screen Housing Assembly

Cut o Length

Catch Frame

Page 8

Installing the Bottom Rail and

Preparing the Screen Housing Assembly

Remove the backing from the

double sided tape on the bottom

of the Bottom Rail. Attach the

Bottom Rail onto the door sill,

placing the front edge of the

Bottom Rail even with the face

or front edge of the door frame

on both sides of the opening.

Installing the Bottom Rail

Preparing the Screen Housing Assembly

1. Before installing the Screen

Housing Assembly,

rotate the Mounting Bracket so

that the Tension Wires are

no longer wound around it.

Failing to do so prior to

installing the Mounting Bracket

will restrict the motion of the

Tension Wires and prevent the

screen from operating.

2. Attach the Sliding Bar

Bottom Cap to the bottom of

the Sliding Bar using the two

screws provided.

3. Insert the Corner Cover onto

the top of the Mounting Bracket.

8

Bottom Rail

Corner

Cover

Mounting

Bracket

Sliding

Bar

Sliding Bar

Sliding Bar

Bottom Cap

Page 9

Installing the Mounting Bracket

1. Remove the backing of the adhesive strip on the back of the

Mounting Bracket.

2. Insert the bottom of the Mounting Bracket into the track of the Bottom

Rail on the hinge side of the door.

3. Push the Mounting Bracket upwards, ensuring that the top of the Corner

Cover is tight against the upper portion of the door frame.

4. Using a level, ensure that the Mounting Bracket is positioned plumb.

Then press the Mounting Bracket rmly against the door frame, allowing

the adhesive tape to temporarily hold it in place.

5. Move the Sliding Bar and Mesh off to the side as indicated in

the illustration.

6. Using the provided screws, secure the Mounting Bracket to the

door frame.

7. Return the Sliding Bar and Mesh back to its original position, in front of

the Mounting Bracket.

9

Door Frame

(Top)

Sliding Bar

Mounting Bracket

Door Frame

Page 10

Installing the Top Rail and Catch Frame

Installing the Top Rail

1. Remove the backing of the adhesive tape on the

top of the Top Rail.

2. Insert the Rollers at the top of the Sliding Bar

into the Top Rail, then push the Top Rail into the

Corner Cover on the top of the

Mounting Bracket.

3. Position the Top Rail along the top of the door

frame at a 90º angle to the side

mounting surfaces.

4. Making sure that the Top Rail is tight against the

side of the door frame opposite the

Mounting Bracket, press rmly in place,

allowing the adhesive tape to temporarily hold

it in place.

5. Using the 5/8” (16mm) screws provided, secure

the Top Rail to the door frame.

Installing the Catch Frame

1. Insert the bottom of the Catch Frame inside the

Bottom Rail and the top of the Catch frame into the

Top Rail. Position it against the door frame on

the opposite side of the Screen Housing Assembly.

2. Lift the Catch Frame upward into the Top Rail

as far as it will go, and secure to the door frame

using the provided wood screws.

Top Rail

Catch Frame

Latch

Door Frame

Push up the top of the

Catch Frame all the way

into the Top Rail

10

Push into the

Corner Cover

Corner Cover

Mounting Bracket

Insert Rollers

as shown

Page 11

Adjusting the Latch and

Tension Wires

Adjusting the Latch

Pull the Sliding Bar over to the Catch Frame and

ensure that the Latch can be engaged. If the Latch

cannot be engaged, adjust it by following the

procedure shown in the diagram. Loosen the

screw, adjust the height of the Latch until it

engages with the Sliding Bar. Tighten the screw,

careful not to over tighten.

Adjusting the Tension Wires

1. Slide the Sliding Bar to the opposite end to

engage the Latch. Push the entire mesh over

to the Sliding Bar so that only the Tension

Wires are visible in the opening of the door.

Loosen the screw of the top most Tension Wire

Adjuster. Slide it up or down until snug, without

any sag in the Tension Wire. Tighten the screw

to secure it.

NOTE: do not over tighten the tension on the

Tension Wire.

2. If any of the other Tension Wires are sagging,

perform the same procedure with each adjuster.

If any of the situations below occur, follow the

appropriate procedure to correct the situation.

After adjusting the tension, move the Sliding Bar

two or three times to check the operation of the

Viewpoint Screen.

Loosen the screw

to move up and down.

Tension Wire

Tension Wire

Adjuster

Screw

Keep the topmost Tension

Wire Adjuster xed, loosen

the remaining Adjusters.

Starting from the bottom

Adjuster, adjust the tension of

each wire to remove the gap

as well as any sag in the

Tension Wires.

To correct this situation,

reverse the steps in

Situation #1 starting from

the top Adjuster.

Tighten the tension of the

loose Tension Wire to the

same tension as the other

Tension Wires.

Solution #3

Situation #1

Situation #2 Situation #3

Solution #2Solution #1

Gap

Gap Loose Tension Wire

11

Page 12

Attaching the Fixing Strip

and Installing the Clips

Attach the Fixing Strip

Insert one edge of the Fixing Strip into the

Mounting Bracket on an angle, beginning at

the top, and working toward the bottom. Again

from the top, press the other edge of the Fixing

Strip into the Mounting Bracket, working it into

position all the way to the bottom so that it is

now fully inserted into the Mounting Bracket.

Installing the Clips

Install the Clips into the Mounting Bracket

evenly between the Tension Wires keeping the

ribbed face of the Clip facing outward.

(Refer to the diagram.)

The Viewpoint Screen Installation

is Now Complete!

Mounting Bracket

Fixing Strip

Sliding Bar

Fixing Strip

Clip

12

Page 13

The Viewpoint Screen is designed and engineered

to be maintenance free. The following are some

helpful hints to ensure the smooth operation of the

Viewpoint Screen for years to come.

• All moving components used in the Viewpoint

Screen are manufactured from a mixture of nylon

and other materials. This combination of

compounds is strong, impact resistant, and

self-lubricating. Do not use oil, grease, oil based

sprays or lubricants on any of the components on

the Viewpoint Screen. These products attract

dirt and debris, and may cause the Viewpoint

Screen to react abnormally. However, the periodic

application of a dry silicon lubricant to the moving

parts is permissible.

• We recommend that while not in use, the Viewpoint

Screen be kept in the retracted position. This

will help extend the life of the screen mesh.

In the retracted position, the mesh is protected

and kept clean.

• The Screen Mesh and Bottom Rail should be kept

free of dirt and debris. Lightly vacuum to remove

any obstructions from the Screen Mesh and

Bottom Rail.

* Before installing the Viewpoint Screen, please

take the time to read the installation

instructions thoroughly.

Service and Maintenance Hints

13

Page 14

Help Hotline

The Viewpoint Screen was designed for easy sizing and

installation. This Installation Manual provides a step by step

guide through the entire process.

If there are any questions during the installation of the Viewpoint

Screen, please call toll free:

1-877-446-7180

14

Page 15

Viewpoint Screen

Limited Lifetime/Non-transferable

Manufacturer’s Warranty

The Viewpoint Screen is warranted by Seiki Screen Systems to be free of manufacturer’s defects in

materials or workmanship, for as long as the original purchaser owns and or resides at that residence and

that the product remains at its original point of installation. Seiki Screen Systems will repair or replace at

its discretion any component, within the terms and conditions of this warranty, which is deemed as being

defective from the manufacturing process upon proof of purchase. This warranty excludes the screen mesh.

Furthermore this warranty does not cover components damaged through improper use or installation, or if

components have been altered from their original state in a manner not otherwise prescribed in the

Viewpoint Screen Installation Instructions. This warranty is strictly limited to defective

components only. This non-transferable, limited warranty excludes labor, breakage or damage due to

normal wear and tear, lack of maintenance (as illustrated in our Installation Instructions), or use for other

than residential applications, accidents and “acts of god”. Replacements or repairs made subject to this limited warranty are otherwise warranted for the balance of the original warranty period. Seiki Screen Systems’

liability under this limited warranty is restricted to the corrective actions as set forth herein and contrarily

repudiates all incidental and consequential damage. It is the responsibility of the consumer to notify Seiki

Screen Systems of missing components, within 30 days of the purchase of the Viewpoint Screen.

The Viewpoint Screen is designed to assist in keeping unwanted insects from the home; it is in no way

intended as a safety or security device to prevent access by individuals, animals or small children. Liability

for any damages, including but not limited to general, special, indirect, incidental, consequential,

aggravated, punitive or exemplary damages, and economic loss, as well as for breach of any expressed or

implied warranties, including but not limited to implied warranties of merchantability, quality and tness for

any purpose other than as prescribed herein, is disavowed and omitted here from, to the extent that such a

disclaimer and preclusions are permitted by the laws of any particular jurisdiction.

Maintenance: Keep Bottom Rail clean and free of debris. Periodic use of silicone spray to the rollers on the

top of the Sliding Bar is recommended, do not use petroleum based lubricants.

Viewpoint Screen

Designed and Manufactured by

Seiki Screen Systems

INSTALLATION INSTRUCTION MANUAL

For warranty claims

Call 1-877-446-7180

Or email: info@seikiscreensystems.com

15

Page 16

Designed & Manufactured by Seiki Screen Systems ™

Marketed and Distributed by Phantom Screens ®

Seiki Screen Systems

Call 1-877-446-7180

Or email: info@seikiscreensystems.com

www.seikiscreensystems.com

Phantom Mfg. (Int’l) Ltd.

Call 1-888-PHANTOM

Or email: phantom@phantomscreens.com

www.phantomscreens.com

© 2008 Phantom Mfg. (Int’l) Ltd. & Seiki Screen Systems

VI0508

Loading...

Loading...