Inhaltsverzeichnis

2017-08-07

Operating Manual

PFT SCREW MIXER HM 24

Part 2, EC Declaration of Conformity

Overview – Operation – Spare Parts Lists

Article number of operating instructions:

00 01 20 81

HM 24, 400V, 3 phases 60Hz item number 00211876

HM 24, 400 V, 3 phases 60 Hz with AV 1000 and rubber mixing tube item number 00508157

HM 24, 400 V, 3 phases 50 Hz item number 00007874

HM 24, 230 V, 3 phases 60 Hz with rubber mixing tube item number 00265323

HM 24, 400 V, 3 phases 50 Hz with rubber mixing tube item number 00020357

HM 24, 400V with separate mortar outlet flange and dosing shaft 35 l/min item number 00008783

HM 24, 400V, 3 phase, 50Hz with control box for level probe and vibrators item number 00036940

HM 24, 400V, rubber mixing tube / control box / water pressure booster pump item number 00070219

HM 24, 400V, rubber mixing tube, control box, water pressure booster pump item number 00463945

Please read the operating instructions before starting work!

© Knauf PFT GmbH & Co. KG

Postfach 60 97343 Iphofen

Einersheimer Straße 53 97346 Iphofen

Deutschland

Telefon +49 9323 31-760

Telefax +49 9323 31-770

Technische Hotline +49 9323 31-1818

info@pft-iphofen.de

www.pft.eu

2

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Table of Contents

1 EC Declaration of Conformity ..................... 5

2 Testing .......................................................... 6

2.1 Testing by machine operator ............... 6

2.2 Periodic inspection .............................. 6

3 General notes ............................................... 7

3.1 Information about operating

instructions........................................... 7

3.2 Please retain the instructions for

later use ............................................... 7

3.3 Division ................................................ 7

4 Technical data .............................................. 8

4.1 General specifications ......................... 8

4.2 Electrical 400V ..................................... 8

4.3 Operating conditions ............................ 8

4.4 Noise level ........................................... 8

4.5 Vibrations ............................................. 8

5 Overview HM 24 ........................................... 9

5.1 Water Manifold................................... 10

5.2 Water Manifold with Water pressure

booster pump ..................................... 10

6 Type plate ................................................... 11

7 Quality control sticker ............................... 11

8 Connections ............................................... 11

8.1 Connection without control box 400V 11

8.2 Connection with control box 400V ..... 11

8.3 Connection without control box 230V 12

8.4 Connection HM 24 with control box ... 12

9 Description of Functions .......................... 13

10 Basic Saftey Instructions .......................... 14

11 Safety rules ................................................. 15

12 Transport, packing and storage ............... 15

12.1 Safety instructions for transport ......... 15

12.2 Transport inspection .......................... 16

13 Packaging ................................................... 16

14 Operation ..................................................... 17

14.1 Safety ................................................. 17

15 Preparing the machine ............................... 18

16 Connecting the power supply ................... 19

16.1 Power connection without control

cabinet ................................................ 19

16.2 Power connection with control

cabinet ................................................ 19

16.3 Check the individual connectors ........ 19

17 Check the direction of rotation ................. 20

17.1 Main switch on the control cabinet ..... 20

17.2 On/Off switch with phase inverter ...... 20

17.3 Connecting the power supply 230 V .. 21

18 Setting Up the Machine .............................. 21

18.1 Water from a water barrel .................. 23

19 Putting the machine into operation .......... 23

19.1 Hazardous dust .................................. 23

20 Cleaning ...................................................... 24

21 Measures against danger of frost ............. 25

22 Measures during power failure ................. 25

23 Measures for Water Supply Failure .......... 25

24 Maintenance ................................................ 25

24.1 Safety ................................................. 25

24.2 Cleaning ............................................. 26

24.3 Maintenance schedule ....................... 27

24.4 Dirt trapping sieve .............................. 27

25 Dismantling ................................................. 28

25.1 Safety ................................................. 28

25.2 Dismantling......................................... 29

25.3 Disposal.............................................. 29

26 Spare parts drawing ................................... 30

26.1 Hopper with Frame Unit ..................... 30

26.2 Spare parts list Hopper with Frame

Unit ..................................................... 31

2017-08-07

3

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Inhaltsverzeichnis

26.3 Drive Unit Art.No. 00211876 .............. 32

26.4 Spare parts list Drive Unit Art.No.

00211876 ........................................... 33

26.5 Drive Unit 60Hz Art.No. 00265323 .... 34

26.6 Spare parts list Drive Unit Art.No.

00265323 ........................................... 35

26.7 Drive Unit ........................................... 36

26.8 Spare parts list Drive Unit .................. 37

26.9 Mixing Tube Unit Art.No. 00012594 ... 38

26.10 Spare parts list Mixing Tube Unit

Art.No. 00012594 ............................... 39

26.11 Mixing Tube Unit HM22/24 Art.No.

00002116 ........................................... 40

26.12 Spare parts list Mixing Tube Unit

Art.No. 00002116 ............................... 41

26.13 Mixing Tube Unit Art.No. 20548520 ... 42

26.14 Spare parts list Mixing Tube Unit

Art.No. 20548520 ............................... 43

26.15 Electrical Unit 400V 60Hz .................. 44

26.16 Spare parts list Electrical Unit 400V

60Hz ................................................... 44

26.17 Electrical Unit 230V 60Hz .................. 45

26.18 Cable set HM 24 Art.No. 00002127 ... 46

26.19 Support for mounted plug HM

22/24/2002 ......................................... 46

26.20 Control box HM 24 Art.No.

00008735 ........................................... 48

26.21 Water Manifold Unit Art.No.

00002119 / 00211923 ....................... 50

26.22 Spare parts list Water Manifold Unit

Art.No. 00002119 / 00211923 ........... 51

26.23 Water pressure booster pump HM

24 cpl. Art. No. 00070238 .................. 52

26.24 Spare parts list water pressure

booster pump HM 24 cpl. Art.No.

00070238 ........................................... 53

26.25 Water pressure booster pump

AV1000 HM 24 Art. No. 00466201 .... 54

26.26 Spare parts list water pressure

booster pump HM 24 cpl. Art.No.

00070238 ........................................... 55

26.27 Spare parts list AV1000/1 400V

60Hz Art.No. 00491839 ..................... 56

26.28 Spare parts list AV1000/1 400V

60Hz Art.No. 00492679 ..................... 57

27 Circuit Diagramm 60Hz ............................. 58

28 Circuit Diagramm Cable set 00002127 ..... 59

29 Circuit Diagramm HM 24 S163754C ......... 60

30 Circuit Diagramm HM 24, 230 V, 3

phases 60 Hz .............................................. 61

4

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation and serviceOverview – Operation – Spare Parts

1 EC Declaration of Conformity

Lists

EC Declaration of Conformity

Company:

Knauf PFT GmbH & Co. KG

Einersheimer Straße 53

97346 Iphofen

Germany

declares under our sole responsibility that the product:

Type of machine: HM 24

Type of equipment: SCREW MIXER

Serial number:

Guaranteed sound power level: 78 dB

is in conformity with the following CE directives:

• Outdoor directive (2000/14/EC),

• Machine directive (2006/42/EC),

• Electromagnetic Compatibility Directive (2014/30/EC).

Operative Conformity Assessment according to Outdoor Directive 2000/14/EC:

Internal production control as per article 14 paragraph 2 in connection with annex V.

This declaration only refers to the machine in the state in which it has been placed on the market. Parts

subsequently added by the user and/or subsequent interventions are not covered. This declaration ceases

to be valid if the product is converted or changed without consent.

Person authorised to compile the relevant technical documentation:

Diploma in industrial engineering (FH) Michael Duelli, Einersheimer Straße 53, 97346 Iphofen.

The technical documentation is available from:

Knauf PFT GmbH & Co.KG, Technical Department, Einersheimer Straße 53, 97346 Iphofen.

Iphofen Dr. York Falkenberg

Managing director

Place, date of issue Name and signature Details of signatory

2017-08-07

5

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Testing

2 Testing

2.1 Testing by machine operator

Before the start of each work shift, the machine operator must test

the effectiveness of the control and safety devices as well as check

the proper attachment of all protective devices.

During operation, construction machines must be tested by the

machine operator for their operational safety.

If defects are found in the safety devices or any other area that

could impair safe operation, the supervisor must be notified

immediately.

For defects posing a hazard to persons, the operation of the

construction machine must be halted until the defect is eliminated.

2.2 Periodic inspection

Construction machines must be tested for safe operation by

a specialist as the usage conditions and operating circumstances

require, but at least once a year.

Pressure vessels must undergo the prescribed inspections by

authorised experts.

The inspection results are to be documented and must be stored at

least until the next inspection.

6

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

3 General notes

3.1 Information about operating instructions

This operating instructions document provides important

instructions about handling the device. Compliance with all

specified safety instructions and operational directions is a

precondition for safe working.

Furthermore, the local accident prevention rules and general safety

provisions applicable to the use area of the device must also be

observed.

Please go through the operating instructions manual carefully

before starting work It is an integral part of the product and must be

kept in the immediate vicinity of the device so that it can be

accessed easily by the personnel.

If the device is handed over to a third party, please hand over the

operating instructions document too.

The figures in this operating instructions document are not

necessarily made to scale for better display and may deviate

marginally from the actual design of the device.

General notes

3.2 Please retain the instructions for later use

The operating instructions must be available during the entire life

span of the product.

3.3 Division

The operating instructions consist of two books:

Part 1 Safety

General safety instructions of mixing/delivery pumps

Article No. 00 14 63 78

Part 2 Overview, operation, service and spare part lists (this

book).

Both sections must be read and observed for safe operation of the

device. They are to be treated as one operating instructions

document.

2017-08-07

7

piece

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Technical data

4 Technical data

4.1 General specifications

Item number Specification Value Unit

00211876 Weight 127 kg

00007874 Weight 100 kg

00020357 Weight 107 kg

00008783 Weight 117,5 kg

00036940 Weight 107 kg

00070219 Weight 135 kg

00463945 Weight 134 kg

00265323 Weight 123 kg

Overall length 1870 mm

Overall width 670 mm

Overall height 970 mm

Container volumev 110 Ltr.

4.2 Electrical 400V

Data Value Unit

Voltage, AC 60 Hz 400 V

Voltage, AC 50 Hz 400 V

Current intake, maximum 16 A:

Fuse Min. 3 x 16 A:

4.3 Operating conditions

Environment

Duration

Data Value Unit

temperature range 2-45 °C

Relative humidity, maximum 80 %

Data Value Unit

Maximum operating duration on

8 Hours

4.4 Noise level

Guaranteed noise level LWA 95dB (A)

4.5 Vibrations

Weighted effective value of acceleration to which the upper body parts are exposed <2,5 m/s²

8

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Overview HM 24

5 Overview HM 24

1 2 3

12 11 10 9 8 7 6 5 4

Fig. 1: Overview HM 24

1. ON / OFF switch

2. Protection grille

3. Mixer Motor

4. Material hopper

5. Water input, water connection

6. Water Manifold Unit

7. Frame

8. Water flow meter 100-1000 l/h

9. Mixing tube

10. Rubber mixing tube

11. Mortar outlet flange

12. Bearing

2017-08-07

9

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Overview HM 24

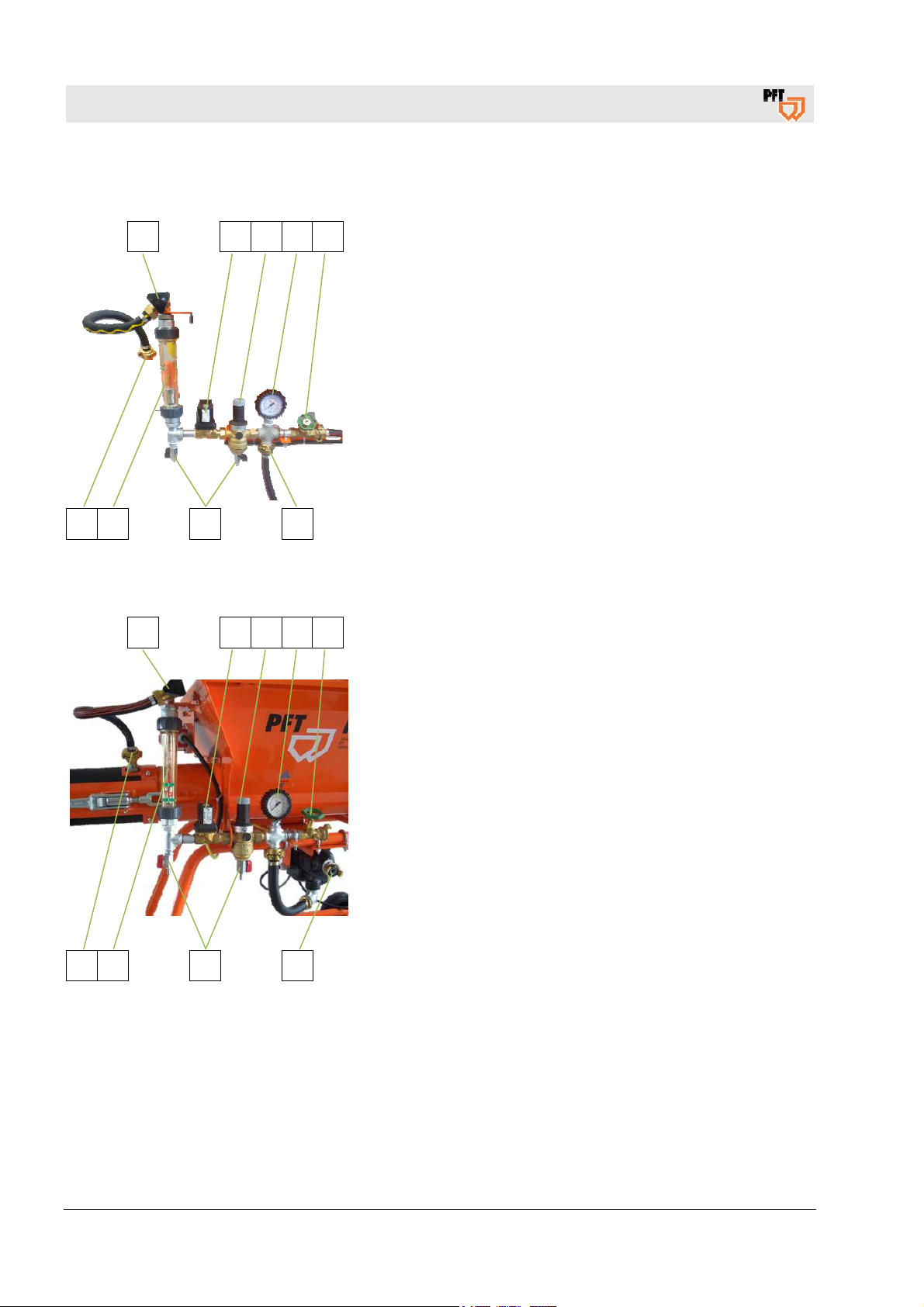

5.1 Water Manifold

1 2 3 4 5

1. Needle Valve.

2. Soleniod Valve.

3. Pressure Reducer.

4. Water Pressure Gauge.

5. Water Extraction Valve.

6. Water Mains.

7. Outlet Tap.

8. Water Flow Meter 100-1000 l/h.

9. Water to Mixing Tube.

9 8 7 6

Fig. 2: Water Manifold

5.2 Water Manifold with Water pressure booster pump

1 2 3 4 5

1. Needle Valve.

2. Soleniod Valve l.

3. Pressure reducer.

4. Water Pressure Gauge.

5. Water Extraction Valve.

6. Water Mains.

7. Outlet Tap.

8. Water Flow Meter 100-1000 l/h.

9. Water to Mixing Tube.

9 8 7 6

Fig. 3: Water Manifold with Water pressure

booster pump

10

2017-08-07

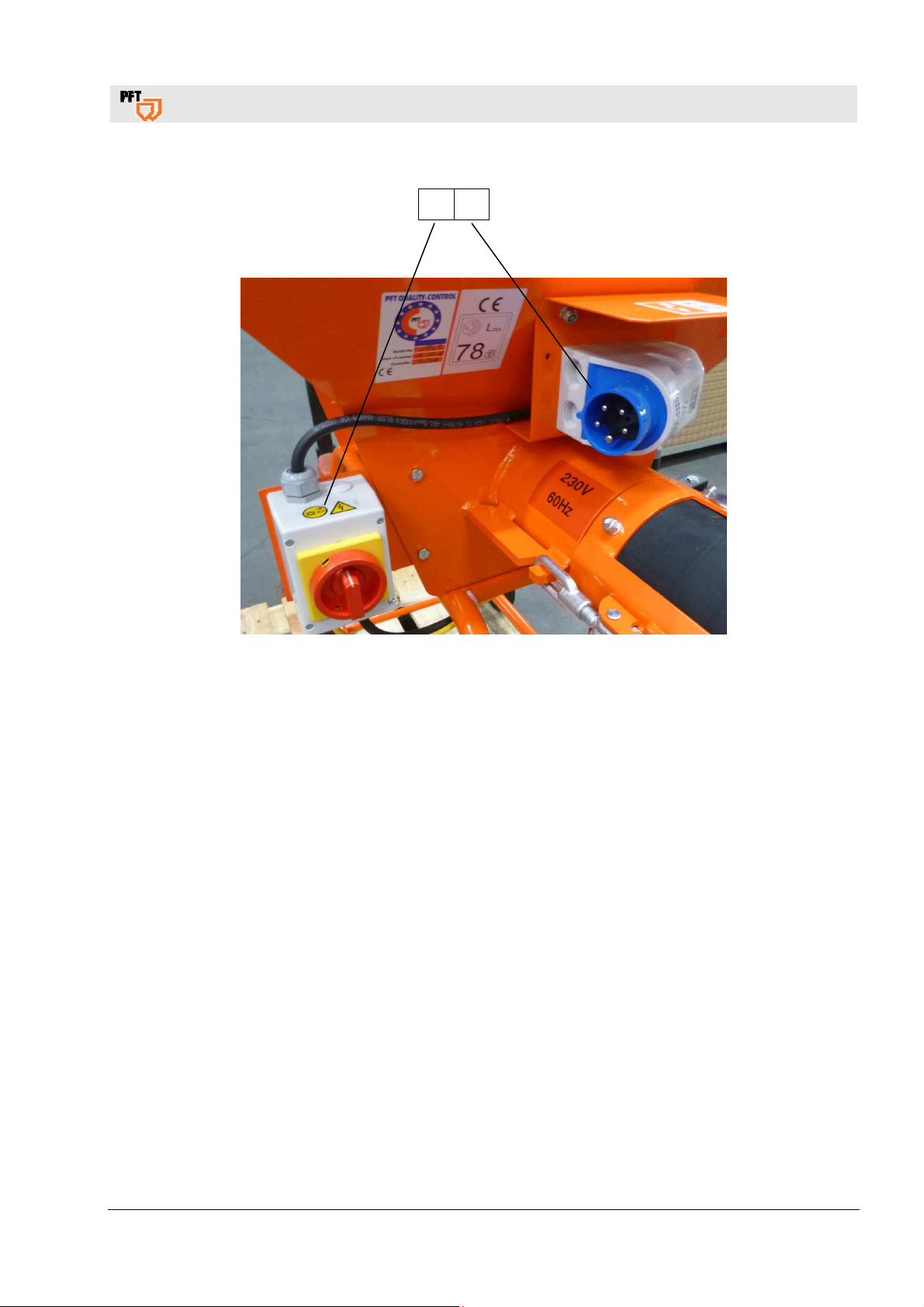

6 Type plate

The type plate contains the following information:

Fig. 4: Type plate

7 Quality control sticker

The quality control sticker contains the following information:

Fig. 5: Quality control sticker

8 Connections

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Type plate

Manufacturer

Type

Year built

Machine number

CE confirmed in compliance with EU directives

Serial no. / serial number

Controlled by / signature

Date of control

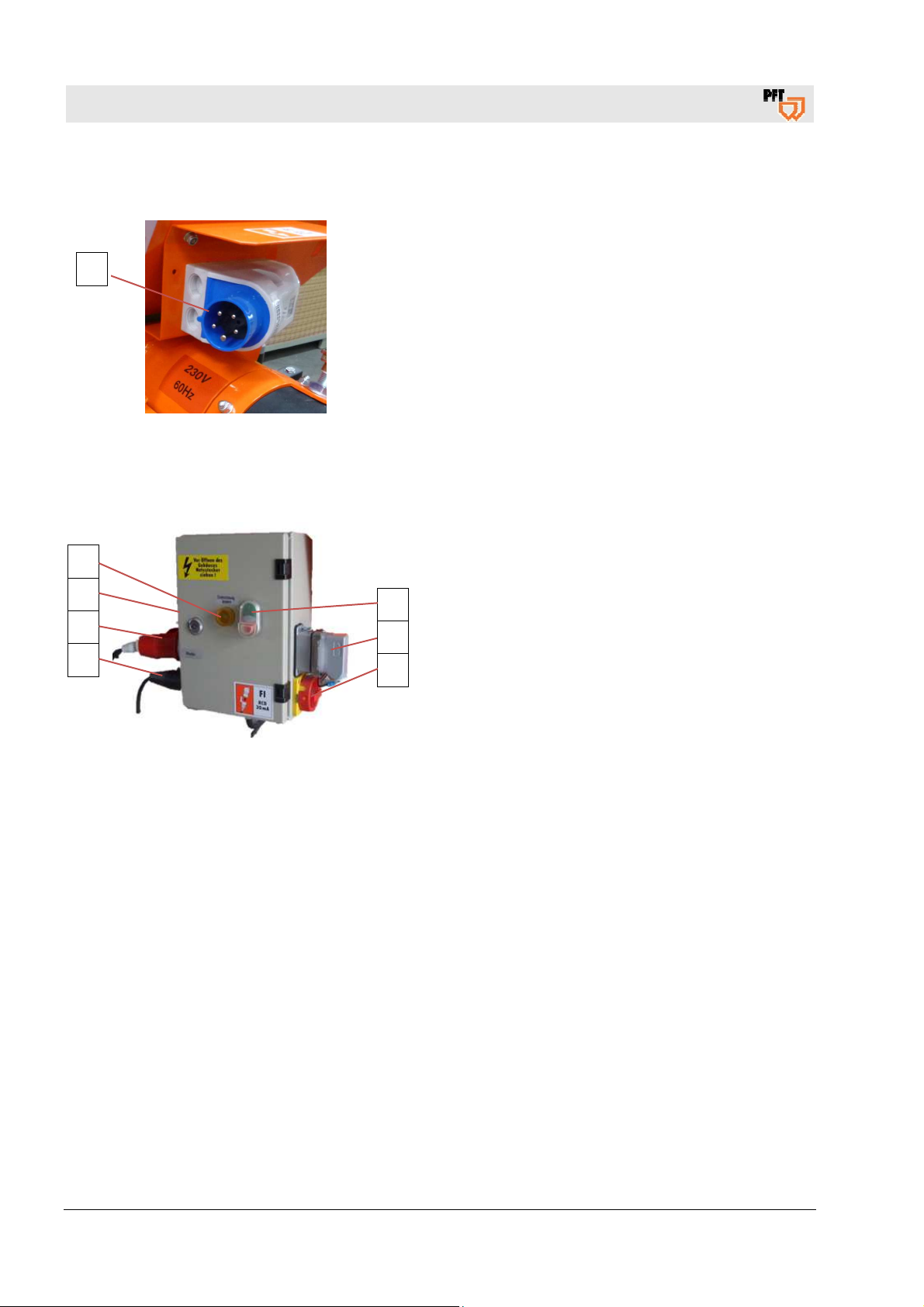

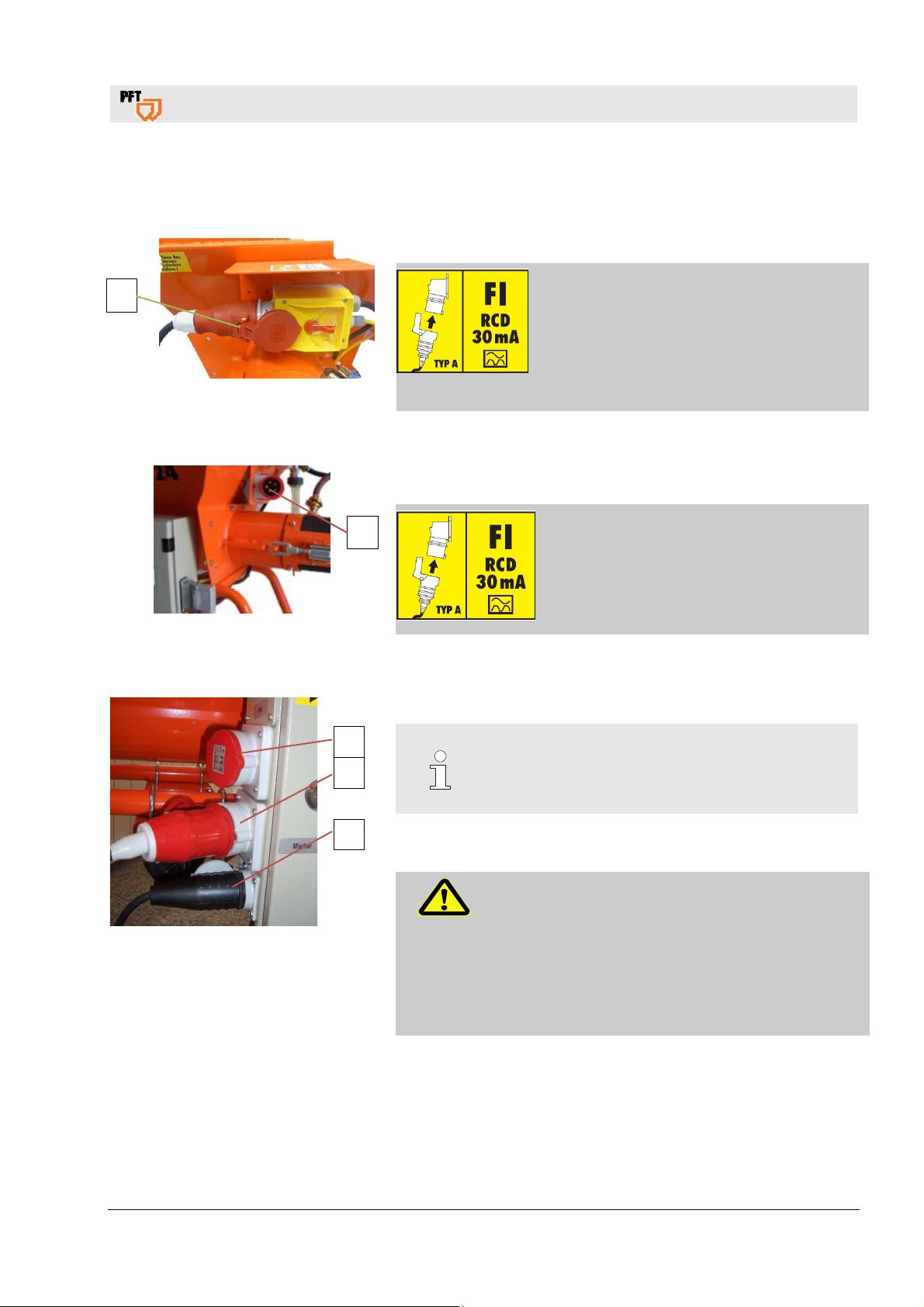

8.1 Connection without control box 400V

1

1. Three-phase current connection (1), 400 V.

Fig. 6: Electrical connection

8.2 Connection with control box 400V

1

Fig. 7: Electrical connection

1. Three-phase current connection (1), 400 V.

2017-08-07

11

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Connections

8.3 Connection without control box 230V

1

2. Three-phase current connection (1), 230 V.

Fig. 8: Electrical connection

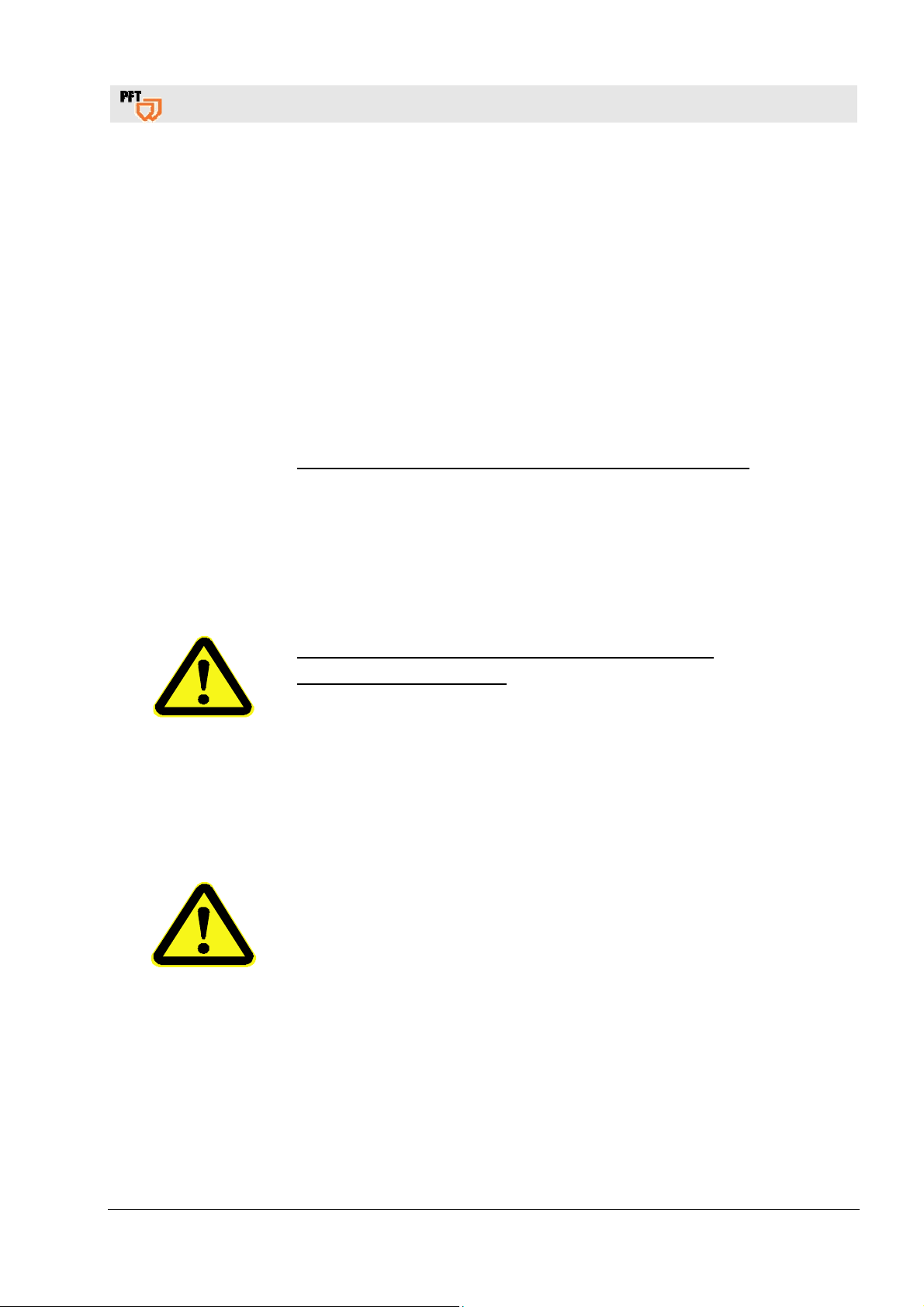

8.4 Connection HM 24 with control box

1. Operation press button ON - OFF.

7

6

5

4

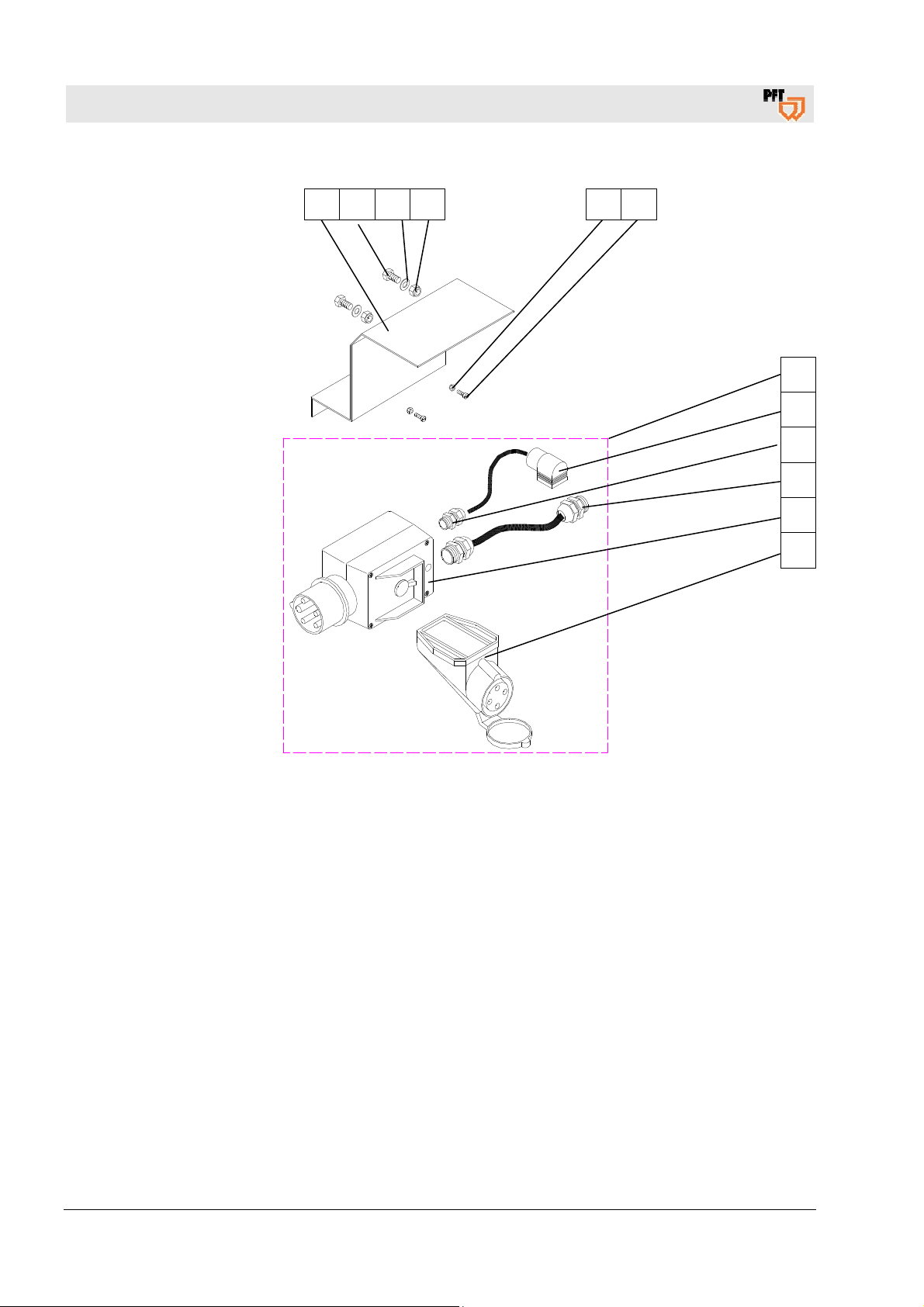

Fig. 9: Connection control box

2. Blind plug / connector KPS1 probe.

3. Master switch is also emergency-stop switch.

1

4. Connection water pressure booster pump.

2

5. Connection geared motor.

3

6. Connection for vibrating unit.

7. Yellow pilot lamp, for wrong direction of rotation.

12

2017-08-07

blended dry

can be filled either by means of bags, a delivery hood or an

The machine consists of individual portable components whose handy

The PFT HM 24 is a new generation machine based on a modular concept. Use

The machine should only be operated in perfect working conditions. Comply with

all safety instructions in this manual! Rectify all defects and faults immediately.

ce with all operating instructions,

service from the

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

9 Description of Functions

PFT's HM 24 is a horizontal continuous screw mixer for factorymortars e.g.

masonry mortar

•

outdoor cement plasters (for rendering)

•

scratch coat

•

The PFT HM 24

injection hood.

dimensions and low weight allow for quick and easy transportation.

NOTE THE FOLLOWING CONNECTIONS WHILE OPERATING:

1. Electrical Panel - Main Switch

2. Water Mains - Water Manifold

3. Water Manifold - Mixing Tube

Description of Functions

the snaps to remove or fit on various dosing shafts and mixing tubes easily.

FOLLOW ALL MATERIAL MIXING INSTRUCTIONS FROM

MORTAR MANUFACTURER!

The following terms and symbols are used in this manual to highlight important

information:

NOTE:

Information for running the Machine efficiently.

WARNING!

Precautionary information for the prevention of accidents.

WARNING!

Proper machine operation includes full complian

carrying out specified inspections, and complying with maintenance instructions.

The most important safety instructions follow. Please read them thoroughly.

Comply with these instructions in order to get reliable quality

machine.

2017-08-07

13

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Basic Saftey Instructions

10 Basic Saftey Instructions

1. Follow all safety instructions on the machine. Ensure that all instructions are legible

2. Inspect the machine once every shift for visible damages and defects. Stop operating

the machine immediately if you notice any changes in safety or operating behavior.

Notify a supervisor immediately.

3. Do not make any changes to the machine that can jeopardize its safety. Always

consult the machine dealer first. Do not tamper with the machine by equipping it with

extra "safety devices."

4. All spare parts must conform to our technical specifications. Only use spare parts

manufactured by PFT.

5. Only trained personnel should operate the machine. Clearly designate all lines of

responsibility for operation, equipping maintenance and repairs.

6. Technicians undergoing training in the operation of the machine should be

supervised by experienced personnel.

7. Only qualified personnel should work on the machine's electrical system. All

electrical work should only take place under the supervision of a qualified electrician

and should comply with electro-technical safety regulations.

8. Observe all instructions for switching the machine on and off. Watch display lamps

for signals.

9. When the machine is completely switched off for maintenance and repair work,

ensure that it cannot switch back on accidentaly. Do this by switching off the main

switch,

removing the key or by attaching a warning sign to the main switch.

10. Before cleaning the machine with a water jet, seal all openings that can be damaged

through water, e.g. electrical motors and control boxes, thoroughly. After cleaning

remove all seals and covers.

11. Use only original fuses with prescribed amps.

12. If work has to be carried out on a voltage-conducting component, a second technician

should stand by to switch off mains in case of an emergency.

13. Disconnect the machine from the mains before you move it, even if you are only

moving it a short distance. Reconnect the machine to the mains properly before

starting up again.

14. Set up the machine on stable ground. Secure it from rolling away or moving during

operation.

15. Depressure all conveying systems before dismantling them.

16. Have the machine inspected at once a year by a qualified person. The machine

should also be inspected otherwise as required.

14

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

11 Safety rules

Caution!

Please observe the regional safety rules for mortar

pumping while performing all jobs!

12 Transport, packing and storage

12.1 Safety instructions for transport

Improper transport

Suspended loads

ATTENTION!

Damage from improper transport!

Improper transport may cause substantial property

damage.

When unloading the packages on delivery as

Use only the specified anchorage points.

Remove packaging only shortly before the

WARNING!

Danger to life from suspended loads!

When lifting heavy loads there is danger to life from

falling parts or uncontrolled swinging parts.

Therefore:

Never step under suspended loads.

Observe the instructions regarding the

Do not fix to projecting machine parts or

Ensure safe fit of the sling gear.

Use only approved lifting gear and sling gear

Safety rules

well as transport within the company pay

attention and observe the symbols and

instruction on the package.

assembly.

provided anchorage points.

eyelets of attached components.

with sufficient lifting capacity.

2017-08-07

15

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Packaging

12.2 Transport inspection

Immediately after receipt, check to ensure that the delivery is

complete and free of transport damages.

Proceed as follows if there are externally identifiable transportation

damages:

Do not accept delivery or accept delivery only under

reservation.

Mention the scope of damage on the transport documents or on

the delivery receipt of the transport agency.

NOTE:

Complain about each defect as soon as it is

detected. Damage claims can be filed only within

the valid complaint periods.

Transportation of machine already

in operation

DANGER!

Danger of injury through mortar discharge!

Face and eyes can be damaged.

Perform the following steps before transportation:

1. Pull out the main power cable first.

2. Detach all other cable connections.

3. Remove water supply line.

4. Start transportation.

13 Packaging

On packaging The individual units are packaged in accordance with the expected

transport conditions. Environment-friendly materials were used for

packaging.

The packaging should protect the individual components from

transport damages, corrosion and other damages up to installation.

Hence, do not destroy the packaging and remove it only just before

installation.

16

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Operation

Handling packaging materials If no return agreement was signed for the packaging, separate the

materials according to type and size and channelize them for

further use or reuse.

CAUTION!

Environment damages due to incorrect

disposal!

Packaging materials are valuable raw materials

and can be used further or processed meaningfully

and reused in many cases.

Hence:

– Dispose of packaging material in an

environment-friendly manner.

– Observe the locally applicable disposal

specifications. If necessary, commission a

specialized company to perform the disposal.

14 Operation

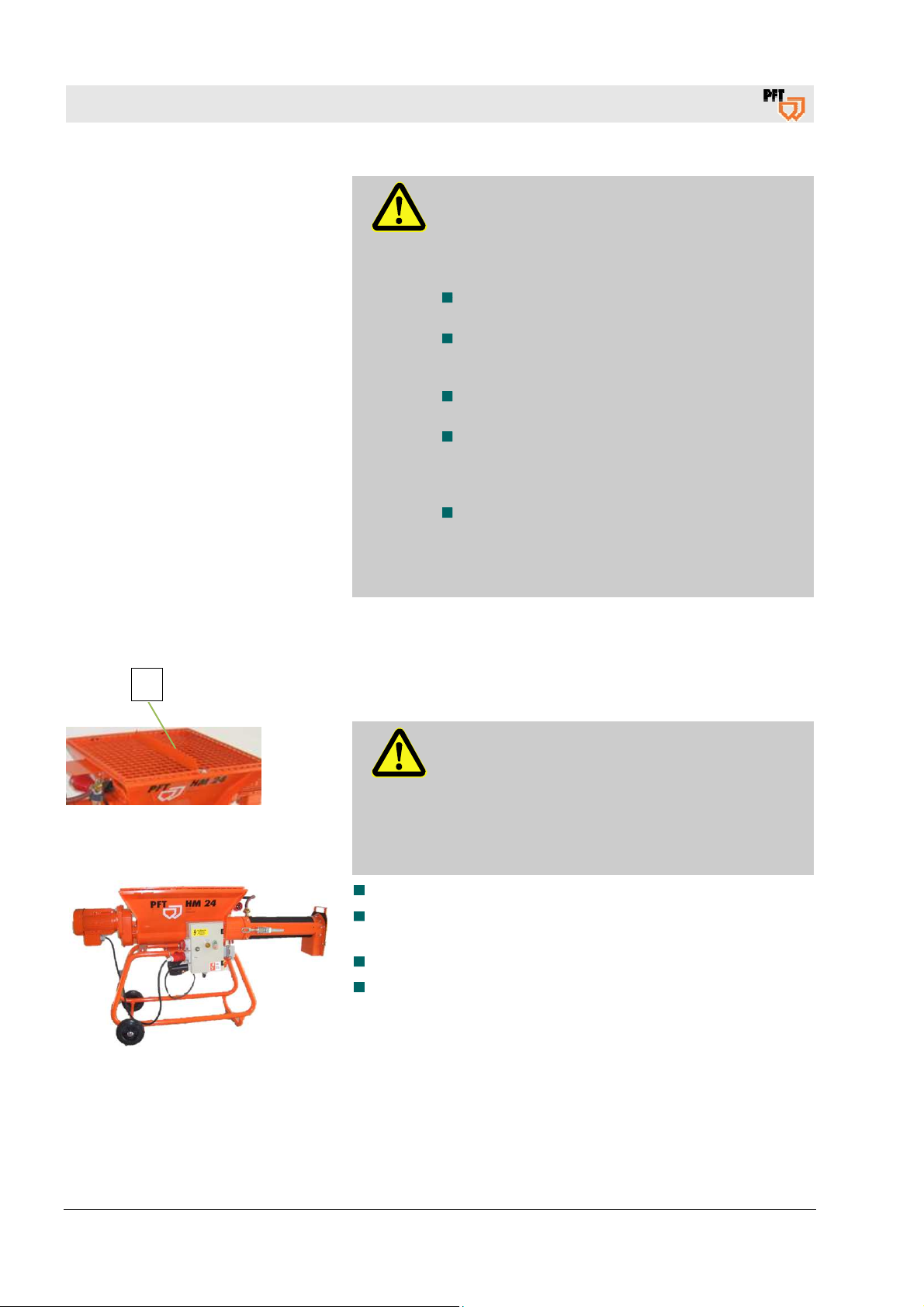

14.1 Safety

Personal protection equipment

The following protective equipment must be worn while performing

all jobs:

Work safety clothing

Safety glasses

Safety gloves

Safety shoes

Hearing protection

NOTE:

Further protective equipment that is to be worn

when effective particular jobs will be pointed out

separately in the warning instructions of this

chapter.

2017-08-07

17

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Preparing the machine

Basic information

WARNING!

Danger of injury due to incorrect operation!

Improper operation may lead to serious damage to

persons or property.

Therefore:

Carry out all operating steps according to the

instructions in this user manual.

Prior to starting your work, ensure that all covers

and protection devices are installed and work as

intended.

Never deactivate protection devices during

operation.

Ensure order and cleanliness in the work area!

Loose components and tools on top of one

another or lying about pose potential accident

risks.

Increased noise level may cause permanent

hearing deficiencies. At close range of the

machine 78 dB(A) can be exceeded due to

operational conditions. Close range is a distance

of less than 5 metres to the machine.

15 Preparing the machine

1

Fig. 10: Grille cover

Fig. 11: Set-up

Prior to operating the machine carry out the following steps for

preparing the machine:

DANGER!

Rotating dosing shaft!

Risk of injury when reaching into the material

container.

– During machine preparation and operation, the

grille cover (1) must not be removed.

– Never reach into the running machine.

The operating elements have to be freely accessible.

Put up the machine on a stable, even surface and secure

against unwanted movements:

Neither tilt nor roll off the machine.

Put up the machine in such a way that it cannot be hit by falling

objects.

18

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

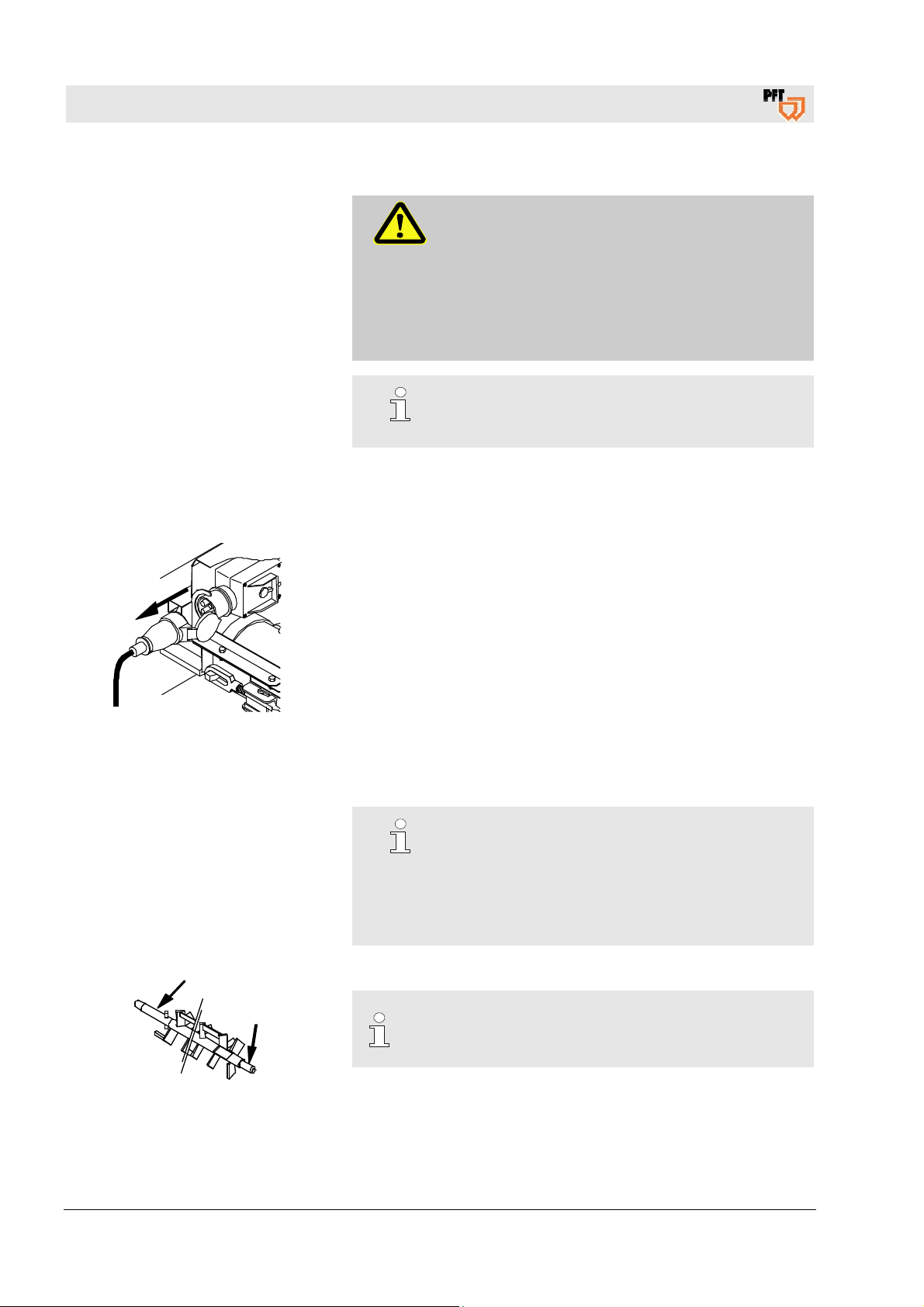

16 Connecting the power supply

16.1 Power connection without control cabinet

1. Connect machine (1) to three-phase network 400V.

Connecting the power supply

1

Fig. 12: Power supply 400 V

16.2 Power connection with control cabinet

1. Connect machine (1) to three-phase network 400V.

1

Fig. 13: Power supply 400 V

16.3 Check the individual connectors

Connect water pump (1).

DANGER!

Danger of death from electric current!

The connection line has to be fused

properly:

Connect the machine only to a power source

with permissible RCCB (30 mA) RCD

(residual current operated device) type A.

DANGER!

Danger of death from electric current!

The connection line has to be fused properly:

Connect the machine only to a power source

with permissible RCCB (30 mA) RCD

(residual current operated device) type A.

Fig. 14: Power connections

3

2

1

Check connection of mixing motor (2).

NOTE!

The booster pump is necessary should the water

pressure be less than 2.5 bar when the machine is

running.

Check connection of Vibrator (3).

WARNING!

Danger to life from rotating parts!

Improper operation may lead to serious damage to

persons or property.

The respective drive (motors) must be operated

only with the control cabinet of the machine.

Using other or external power sources is forbidden

for safety reasons.

2017-08-07

19

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Check the direction of rotation

17 Check the direction of rotation

17.1 Main switch on the control cabinet

Switch on the main selector switch (1).

2

1

Fig. 15: M

ain switch

17.2 On/Off switch with phase inverter

Fig. 16: On/Off switch with phase inverter

Rotating field control:

All three phases are present and the rotating field is OK: LED

green lights up.

1

One phase is missing: LED flashes red.

L1 is missing: LED red flashes 1x (fast).

L2 is missing: LED red flashes 2x (fast).

L3 missing: LED red flashes 3x (fast).

Wrong rotating field: LED red is always lit.

The PFT HM 24 is equipped with a phase display that will light up if

the direction of rotation is wrong. With the right phase order, the

mixing shaft should rotate clockwise.

The PFT HM 24 is equipped with a contact reversing switch that

enables the user to change the direction of rotation.

To do this, disconnect the power cable and alter the contacts with

a screw driver (1).

HINWEIS!

Check the direction of rotation.

If the direction of rotation is incorrect, the yellow

direction indicator (2) lights up and the following

steps must be carried out:

The main selector switch (1) is locked in the neutral

position by sliding the selector plate to the left or

right in a preset position, thus selecting the direction

of rotation. If the switch is on the left, the switch can

be switched back to zero, but is disabled for the right

position.

20

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

17.3 Connecting the power supply 230 V

1. Connect machine (1) only to a 230V AC network.

1

Fig. 17: Power connection

2. Interrupt the control circuit by removing the plugs (2) from the

control cabinet.

3. Remove connector Air compressor (3) from control cabinet.

Setting Up the Machine

DANGER!

Danger of death from electric current!

The connection line has to be fused

properly:

Connect the machine only to a power

source with permissible 30 mA FI

protection switch RCD (residual current

operated device) of type “B” that is

sensitive to all currents that are required

for the operation of frequency

converters.

18 Setting Up the Machine

Assemble the machine as follows:

Set up the hopper straight

•

Insert the mixing shaft into the dosing shaft.

•

Mount mixing tube and secure it on the hopper with snaps.

•

Attach protection grill.

•

Water Supply

Connect a 3/4“ hose to water mains. Open water discharge

•

valve slightly. Let water run through the hose to deaerate and

clean it. Wait till water comes out of the hose.

Shut off water discharge valve.

•

Connect water hose to water inlet on the machine (dirt filter).

•

Open the water mains. If water pressure is under 2,5 bar, attach

•

water boosterpump AV 3 ( Item no. 00 00 11 40 ) to the mains.

WARNING!

Danger to life from rotating parts!

Improper operation may lead to serious damage to

persons or property.

The respective drive (motors) must be operated

only with the control cabinet of the machine.

2017-08-07

21

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Setting Up the Machine

Caution!

While using stored water from a tank, connect the

suction inlet with a filter.

(Item no. 20 47 50 00) ( deaerate water pump )

Connect the water hose of the needle valve to the mixing tube.

When the PFT HM 24 has been completely assembled and

connected, follow these steps:

Fill hopper.

•

Switch on the HM 24 at main switch.

•

Regulate the amount of water at the needle valve.

Mortar Consistency

Adjust the needle valve in such a way that the machine emits

trowel-suited mortar at the mortar outlet.

NOTE:

Follow all material mixing instructions of the mortar

manufacturer!

NOTE:

Interrupting Work!

The length of a break during operation will depend on

the material and on the

conditions at the construction site (e.g. temperature,

humidity etc.)

22

NOTE:

Follow all material mixing instructions of the mortar

manufacturer!

2017-08-07

18.1 Water from a water barrel

Booster pump AV3000/1 (1) item number 00493686

1

The booster pump which is connected ensures the required water

pressure of minimum 2.5 bar.

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Putting the machine into operation

NOTE!

When working with water from the barrel,

the inlet strainer must be fitted with a filter strainer

(item no. 00136619) (bleed booster pump).

19 Putting the machine into operation

19.1 Hazardous dust

WARNING!

Danger of health problems due to dust!

Inhaled dust can lead to long-term lung damage

or other health problems.

NOTE!

The machine operator or the person working in the

dusty area must always wear a dust mask when

filling the machine.

The decisions of the Committee for Hazardous

Materials (AGS) can be read in the Technical Rules

for Hazardous Substances (TRGS 559).

2017-08-07

23

While assembling cleaned parts, make sure they are

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Cleaning

20 Cleaning

Locking to prevent reactivation

Connect 1/2" water hose with Geka coupling (Item no. 20 21 11 00)

DANGER!

Danger to life from unauthorized reactivation!

While working at the machine one is exposed to

the danger that the power supply may be activated

without authorization. This exposes the persons in

the danger zone to the risk of death.

– Before starting work, switch off all power

supplies and lock them against reactivation.

NOTE:

The machine must be cleaned daily after work and

after long pauses.

and spray nozzle (Item no. 20 21 57 00) to water mains.

Cleaning should take place in the following 5 steps:

When the hopper is 1/3 full, reduce the water entry at the needle

•

valve by a quarter. Switch off the PFT HM 24 as soon as highly

diluted mortar is discharged.

Remove the coupling of the power cable before disconnecting

•

the mixing tube, or else the safety hook on the machine will block

the coupling.

Open the snaps on the mixing tube and remove it. Release the

•

mixing shaft and clean it along with the mixing tube. Use a trowel

and water for this purpose.

Clean the hopper on the outside with a brush or dry mop. Use

•

water to clean the hopper only when it is empty.

NOTE:

No water should enter the bearings or electrical

parts ( plug, main switch, motor connections box).

24

really dry and clean. Connect mixing shaft to dosing

shaft.

NOTE:

Keep all snaps and seals clean.

Grease bearing tang and connectors regularly.

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

21 Measures against danger of frost

1. Remove hose (1) from water connecting piece on the mixing

zone.

1

2. Remove water hose (2) from water inlet.

3. Open the two release cocks (3) on the fittings block.

4. Drain out water and shut the cocks again.

3

3

2

CAUTION!

Damage due to frost!

Water that expands inside the machine during

frosting can damage it seriously.

– Perform the following steps if the machine is out

of operation due to the danger of frost.

Measures against danger of frost

22 Measures during power failure

The PFT HM 24 is equipped with a restart lock. After a power

failures switch on the machine at the main switch for operation.

23 Measures for Water Supply Failure

In case of a water supply failure, the PFT HM 24 will keep on

running without mixing the material. As soon as the fault is

rectified, the HM 24 will mix material quite

normally again.

24 Maintenance

24.1 Safety

Personal

Some maintenance jobs may be performed only by specially

trained mechanics or exclusively by the manufacturer.

Jobs on the electrical system may in principle be performed

only by electricians.

2017-08-07

25

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Maintenance

Basic

Electrical system

WARNING!

Danger of injury from improperly performed

maintenance jobs!

Improper maintenance can lead to serious personal

injuries and material damages.

Hence:

– Ensure sufficient installation space before

starting work.

– Pay attention to cleanliness and order at the

installation site! Components and tools lying

loosely on each other or lying scattered are

accident sources.

– Ensure correct installation if components are

removed, reinstall all fastening elements and

screw torques.

DANGER!

Danger to life from electric current!

Contact with electrically live components poses

danger to life. Activated electrical components can

execute uncontrolled movements and lead to

serious injuries.

Hence:

– Before starting work, switch off the power

supply and lock the switch against reactivation.

Environment protection

24.2 Cleaning

The material container can be cleaned internally with a water hose after being emptied fully.

Observe the following instructions on environment protection while

performing maintenance jobs:

Remove discharged, used up or excess grease from all

lubrication points that are lubricated manually, and dispose it in

accordance with the valid local provisions.

Collect the replaced oil in suitable containers and dispose

according to the valid local provisions.

CAUTION!

Water can penetrate into sensitive machine

components!

– Before cleaning the machine, cover all openings

into which water should not enter for safety and

functional reasons (for example: electric motors

and control cabinets).

– Remove the covers fully after the cleaning.

26

2017-08-07

24.3 Maintenance schedule

24.4 Dirt trapping sieve

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Maintenance

If increased wear and tear is detected during the regular checks,

shorten the required maintenance intervals according to the actual

wear and tear.

After every operation, check the following parts for defects:

bearings, hauling bracket, all connectors, hose connections and

power cable connections.

Check dirt trapping sieve in the water inlet daily:

1. Take out dirt trapping sieve from the Geka coupling.

2. Clean dirt trapping sieve.

3. Replace sieve if there are thick dirt deposits.

4. Reinsert dirt trapping sieve

Dirt trapping sieve Geka coupling: Article No. 20152000

.

Remove and clean the dirt filter in the water inlet and in the

pressure reducer at least once every two weeks. Replace them, if

necessary. Open filter holder with special spanner ( Item

no. 20 10 24 00 ).

2017-08-07

27

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Dismantling

25 Dismantling

On reaching the end of its life span, the device must be dismantled

25.1 Safety

Personal The device is to be dismantled only by specially trained

Basics

Electrical system

and disposed in an environment-friendly manner.

technicians.

Jobs on the electrical system may be performed only by

electricians.

WARNING!

Risk of injury from improper dismantling!

Stored residual energies, sharp-edged

components, tips and corners on or in the device or

on the required tools can cause injuries.

Hence:

– Ensure sufficient free space before starting

work.

– Handle open sharp-edged components

carefully.

– Pay attention to cleanliness and order at the

workplace! Components and tools lying loosely

on each other or lying scattered are accident

sources.

– Dismantle components properly. Consider the

partially high dead weight of the components.

Use lifting tools if necessary.

– Lock components so that they do not fall down

or topple over.

– Contact the manufacturer in case of doubt.

DANGER!

Danger to life from electric current!

Contact with electrically live components poses

danger to life. Activated electrical components can

execute uncontrolled movements and lead to

serious injuries.

Hence:

– Switch off and cut the power supply

permanently before starting the dismantling

operation.

28

2017-08-07

25.2 Dismantling

25.3 Disposal

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Dismantling

For selection, clean the device and take it apart according to the

valid work safety and environment protection specifications.

Before start of dismantling:

Switch off device and lock it against reactivation.

Cut total power supply from device physically, discharge stored

residual energies.

Remove operating and auxiliary substances as well as

remaining processing materials and dispose of them in an

environment-friendly manner.

Recycle the dismantled components if no return- or disposal

agreement was signed:

Scrap metals.

Recycle plastic elements.

Dispose of the remaining components sorted by material

quality.

CAUTION!

Environmental damages due to incorrect

disposal!

Electrical scrap, electronic components, lubricants

and other auxiliary substances are subject to

special waste treatment, and may be disposed only

by certified specialized companies!

The local municipal authorities or specialized disposal companies

provide information about environment-friendly disposal.

2017-08-07

29

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26 Spare parts drawing

26.1 Hopper with Frame Unit

26

25

24

23

22

21

20

19

18

17

16

1

2

3

4

5

6

7

8

9

10

11

12

13

10

14

15

30

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.2 Spare parts list Hopper with Frame Unit

Item Qty. Art.No. Description

1 1 00 00 21 13 Protection grill with rounded frame

2

3 1 00 00 25 69 Dosing shaft HM 22/24 35l at 280rpm

4 1 00 00 21 12 Material hopper HM 22/24 RAL2004

1 00 02 05 81 Material hopper HM 22/24 removable motor flange 2004

5 4 20 20 72 00 Safety nut M 8 galv.

6 1 20 54 57 02 Sealing ring for drive D 107x40x5

7 1 00 25 15 80 Seal ring for gear sealing D160x110x4

8 1 20 54 57 05 Clamping flange for rubber seal HM

9 4 20 20 78 01 Hex. screw M8 x 35 galv.

10 4 20 20 86 04 Quick fastener with cap 16s x N 2 7 (packing unit = 10 pcs)

1 00 21 45 19 Securing disk and saucer head screw M8x25 cpl.

11 2 20 70 58 02 Bolt A16 H11 x 50

12 2 20 20 99 21 Collar nut M16

13 2 20 20 85 00 Eye screw M16 x 80, galvanised

14 2 20 54 83 10 Wheel 180 x 50 x 90

15 2 20 20 86 03 Fastener with cap 20s x N 2 7

16 1 00 00 78 76 Frame HM 22/24 (1") RAL2004

17 1 20 20 72 00 Safety nut M 8 galv.

18 4 20 20 93 13 Washer B 8,4 galv.

19 4 20 20 87 01 Hex. screw M8 x 16 galv.

20 4 20 20 96 11 Screw with inner thread. M4 x 12 galv.

21 1 20 54 95 15 Clamping flange for mixing tube seal HM 2/200/2002

22 1 20 54 80 10 Rubber seal D154 X D107 X 5

23 1 20 54 71 03 Dosing wear-tube HM 200/2002 D102 x 151

24 2 20 20 72 00 Safety nut M 8 galv.

25 2 20 20 78 10 Hex. screw M8 x 25 galv.

26 1 00 04 07 21 Dosing shaft HM 104 35l at 280 rpm

For spare parts orders only with specification of the type plate!

2017-08-07

31

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.3 Drive Unit Art.No. 00211876

32

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.4 Spare parts list Drive Unit Art.No. 00211876

Item Qty. Art.No. Description

1 1 00 42 92 99 Geared motor ZF21 3kw 274rpm RAL2004

2 1 00 01 01 61 Protection bail for motor adjustable for HM 202/204 RAL2004

3 1 20 42 41 10 Motor connection cable 0,85m CEE plug 4x 16A 6h red loop 4mm

4 1 20 42 79 00 Plug CEE 4 x 16A 6h red

5 4 20 20 72 00 Safety nut M 8 galv.

6 4 20 20 78 10 Hex. screw M8 x 25 galv.

7 1 00 01 01 60 Motor flange without protection bail HM 202/204 RAL2004

8 1 20 54 80 20 Gasket 200 x 190 x 10 D160

9 1 20 10 29 11 Hauling bracket with round funnel 25 mm boring HM 2/HM 200

10 1 20 20 96 03 Threaded pin hex. M8 x 20 galv.

For spare parts orders only with specification of the type plate!

2017-08-07

33

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.5 Drive Unit 60Hz Art.No. 00265323

1 2 3

8

7 6 5 4

34

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.6 Spare parts list Drive Unit Art.No. 00265323

Item Qty. Art.No. Description

1 1 20 42 79 01 Plug CEE 4 x 16A 9h blue

1 00 06 62 83 Motor connection cable CEE 4 x 16A - 1.2 m cpl.

2 1 00 42 92 99 Geared motor ZF21 3kw 274rpm RAL2004

3 1 00 01 01 61 Protection bail for motor adjustable for HM 202/204 RAL2004

4 1 00 02 20 86 CEE-Panel mounted socket 4 x 16A 9h blue

5 1 20 54 80 20 Gasket 200 x 190 x 10 D160

6 1 20 10 29 11 Hauling bracket with round funnel 25 mm boring HM 2/HM 200

7 1 20 20 96 03 Threaded pin hex. M8 x 20 galv.

8 1 00 01 01 60 Motor flange without protection bail HM 24 RAL2004

For spare parts orders only with specification of the type plate!

2017-08-07

35

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.7 Drive Unit

8

7

6

5

4

1

2

3

36

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.8 Spare parts list Drive Unit

Item Qty. Art.No. Description

1

2

3

4

5

6

7

8

For spare parts orders only with specification of the type plate!

1 00 42 92 99 Geared motor ZF21 3kw 274rpm RAL2004

1 20 42 41 10 Motor connection cable 0,85m CEE plug 4x 16A 6h red loop 4mm

1 20 42 79 00 Plug CEE 4 x 16A 6h red

1 00 00 21 10 Cover with flap HM 22/24

1 20 20 91 10 Spring washer B 12 galv.

1 00 00 81 49

Hex. screw M12 X 60 modified stainless

1 20 20 96 03 Threaded pin hex. socket. M8 x 20 galv.

1 00 13 98 10 Hauling bracket Hm 22 / 24 galv. cpl.

2017-08-07

37

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.9 Mixing Tube Unit Art.No. 00012594

1 2 3 4 5 6 7 8 9 10 11 12 13

33

32

31

30

29

28

27

26

25 24 23 22 21 20 19 18 17 16 15 14

38

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.10 Spare parts list Mixing Tube Unit Art.No. 00012594

Item Qty. Art.No. Description

1 1 00 01 25 94

2 2 20 20 87 01 Hex. screw M8 x 16 galv.

3 10 20 20 66 03 Safety nut M8 galv.

4 1 20 20 63 23 Saucer-head screw M8 x 25 galv.

5 1 00 01 25 93 Rubber mixing tube HM 104/204 620mm long coped

6 4 20 20 63 23 Saucer-head screw M8 x 25 galv.

7 2 20 20 85 22 Pin 8 H11 x 58 x 54 with washer and spline galv.

8 2 20 10 08 01 Snap lock with safety device M14

9 1 00 01 25 91 Flange for rubber mixing tube HM 2 with fixed mortar output

10 1 00 00 22 29 Water inlet for ruber mixing tube HM 2

11 1 20 20 93 15 Washer

12 1 00 00 28 11 Nut 1/2" int. thread

13 1 20 20 13 00 Geka coupling 1/2" int. thread

14

1 00 43 11 98 Sprocket mixing shaft HM 104 4 rows RAL2004 (Art.Nr. 00070219)

15 1 00 00 25 69 Dosing shaft HM 22/24 35l at 280rpm

16 1 00 02 14 95 Mixing shaft HM 2002 (3 levels)

17 1 20 54 76 00 Dowel pin 10 x 40

18 1 20 54 76 03 Dowel pin 6 x 40

19 1 00 01 25 92 Mortar output flange fixed to rubber mixing tube HM 2 RAL2004

20 1 00 01 94 21 Rubber front plate for mortar output flange

21 1 20 20 78 00 Hex. screw M8 x 30 galv.

22 1 20 20 79 50 Ring nut M8 galv.

23 1 00 01 94 20 Front plate for mortar output flange RAL2004

24 1 20 54 55 01 Bearing with square bore and housing

25 2 20 20 99 63 Hex. screw M12 x 25 galv.

26 1 00 02 04 09 Cylindrical screw M8 x 25

27 1 20 20 93 14 Washer A 8,4 galv.

28 1 20 54 54 09 Locking disc for HM galv.

29 1 20 54 55 06 Bearing with square bore

30 1 00 04 13 96 Housing for bearing Y-P 80

31 2 20 20 89 00 Safety nut M12 galv.

32 1 20 20 97 11 Hex. socket head screw M8 x 20 galv.

33 1 20 20 64 00 Hex. nut M8 galv.

Mixing tube HM 2 with rubber mixing zone and fixed mortar output flange

RAL2004

For spare parts orders only with specification of the type plate!

2017-08-07

39

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.11 Mixing Tube Unit HM22/24 Art.No. 00002116

1 2 3 4 5 6 7

18

17

16

15

14

13

8

9

10

11

12

40

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

26.12 Spare parts list Mixing Tube Unit Art.No. 00002116

Item Qty. Art.No. Description

Spare parts drawing

1

2

3

4

5

6

7

1 00 00 21 16 Mixing tube HM 22/24 cpl.

1 00 00 21 17 Mixing tube HM 22/24

2 20 20 09 00 Geka coupling 1/2" ext. thread (packing unit = 10 pcs)

3 20 20 17 00 Gasket Geka-coupling (packing unit = 50 pieces)

1 20 20 16 50 Geka coupling dummy cover

2 20 10 08 01 Snap lock with safety device M14

2 20 20 85 22 Pin 8 H11 x 58 x 54 with washer and spline galv.

8 2 20 20 99 92 Threaded pin hex.socket M6 x 6 galv.

9

10

11

12

13

14

15

16

17

18

1 20 02 60 01 Glide bearing with insert

1 20 02 60 02 Bearing bushing Thermoplast D60 x 40

1 20 54 82 10 Bearing bush HM 2/2000/2002 with bushing

1 00 01 99 67 Mixing shaft HM 2/22/24/2002 with scraper

1 20 54 76 00 Dowel pin 10 x 40

1 20 54 76 03 Dowel pin 6 x 40

2 20 20 72 00 Safety nut M 8 galv.

2 20 20 93 13 Washer B 8,4 galv.

2 00 00 86 14 Security-screw, buttonhead with socket and flat M8 x 16 A2

1 00 00 71 52 Safety hook for CEE plug RAL2004

For spare parts orders only with specification of the type plate!

2017-08-07

41

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.13 Mixing Tube Unit Art.No. 20548520

1 2 3 4 5 6

15

14

13

12

11

10

7

8

9

42

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

26.14 Spare parts list Mixing Tube Unit Art.No. 20548520

Item Qty. Art.No. Description

Spare parts drawing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1 20 54 85 20 Mixing tube HM 2/200/2002 cpl.

2 20 20 85 22 Pin 8 H11 x 58 x 54 with washer and spline galv.

2 20 10 08 01 Snap lock with safety device M14

2 20 20 09 00 Geka coupling 1/2" ext. thread (packing unit = 10 pcs)

1 20 20 17 00 Gasket Geka-coupling (packing unit = 50 pieces)

1 20 20 16 50 Geka coupling dummy cover

1 20 54 81 05 Mixing tube HM 2/200/2002 RAL2004

1 20 55 29 10 Safety chain 2mm 250mm long K20

1 20 10 10 10 Splint D 4,5 with ring

1 20 54 55 01 Bearing with square bore and housing

2 20 20 68 01 Hex. screw M12 x 30 galv.

1 20 54 55 06 Bearing with square bore

1 00 04 13 96 Housing for bearing Y-P 80

2 20 20 89 00 Safety nut M12 galv.

1 20 54 81 03 Mortar outlet flange removable HM 2/200/2002 RAL2004

For spare parts orders only with specification of the type plate!

2017-08-07

43

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.15 Electrical Unit 400V 60Hz

1 2 3 4 5 6

7

8

9

10

26.16 Spare parts list Electrical Unit 400V 60Hz

Item Qty. Art.No. Description

1 1 00 00 71 53 Support for mounted plug HM 22/24/2002

2 2 20 20 61 00 Hex. screw M8 x 20 galv.

3 2 20 20 93 13 U disc B 8,4 galv.

4 2 20 20 72 00 Nut M8 galv.

5 2 20 20 62 03 Nut M4 galv.

6 2 20 20 63 05 Cylindrical screw M4 x 12 galv.

7 1 00 21 24 19 Cable set HM24 400V 60Hz

8 1 00 45 64 61 Plug solenoid valve 400V 50/60Hz

9 1 00 04 11 41 Skintop screwed joint M16 x 1,5

10 2 00 04 11 42 Skintop screwed joint M25 x 1,5

11 1 00 21 18 78 On/Off switch with phase changing device 6.5-10A 60Hz

12 1 00 02 20 73 CEE-Socket 4 x 16A 6h red

11

12

44

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.17 Electrical Unit 230V 60Hz

1 2

Item Qty. Art.No. Description

1 1 20 45 69 46 On/Off switch with motor protection 10-16 A, 230 V, 60 Hz

2 1 00 02 20 80 CEE connection plug, phase inverter 5 x 16A 9h, blue

For spare parts orders only with specification of the type plate!

2017-08-07

45

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

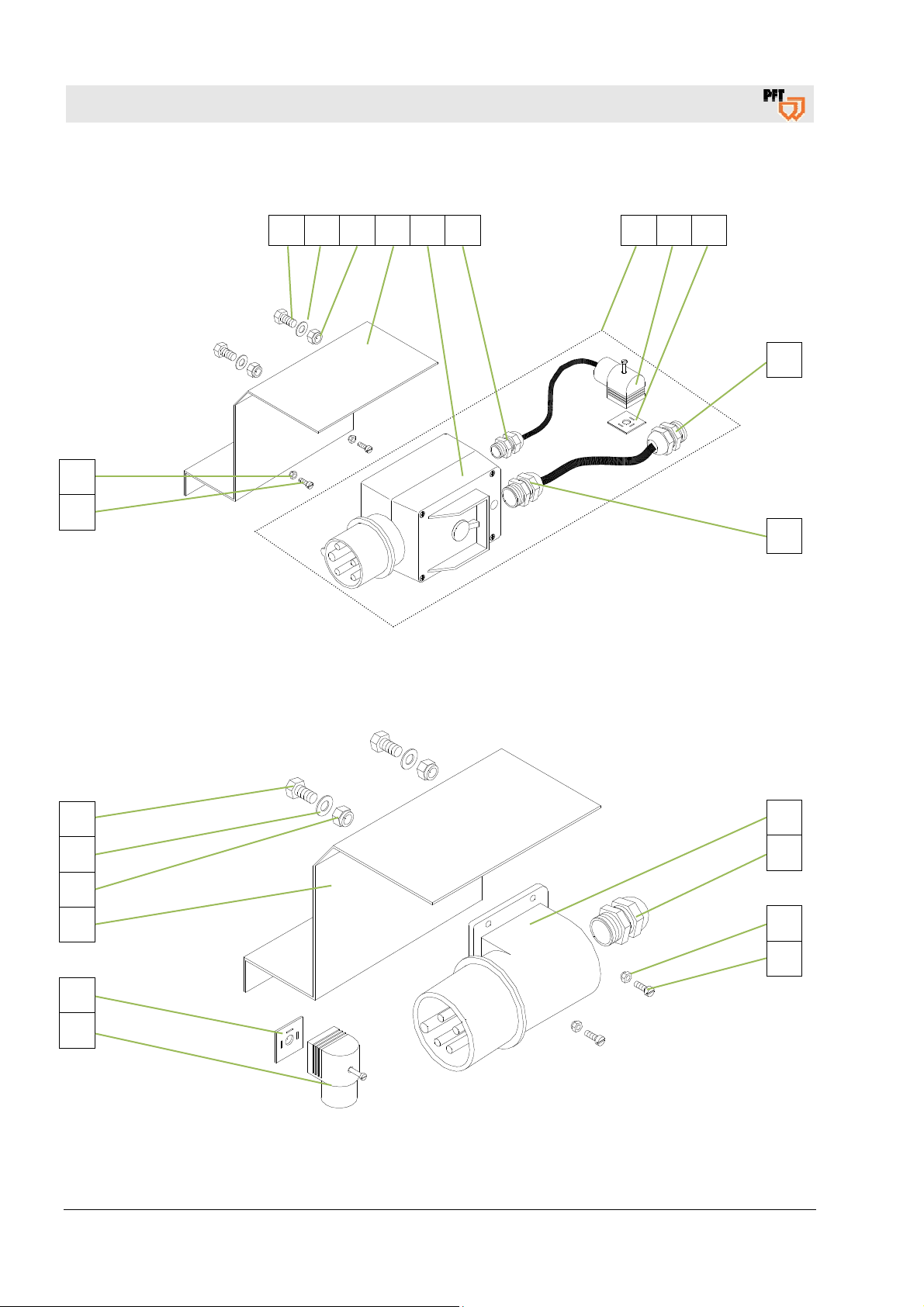

26.18 Cable set HM 24 Art.No. 00002127

1 2 3 4 5 6 7 8 9

12

13

26.19 Support for mounted plug HM 22/24/2002

10

10

1

2

3

4

9

8

11

10

12

13

46

2017-08-07

Item Qty. Art.No. Description

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

1

2

3

4

5

6

7

8

9

10

11

12

13

4 20 20 61 00 Hex. screw M8 x 20 galv.

4 20 20 93 13 Washer B 8,4 125 galv.

4 20 20 72 00 Safety nut M 8 985 galv.

2 00 00 71 53 Support for mounted plug HM 22/24/2002

1 00 00 12 28 On/Off switch with phase changing device 6.5-10A

1 00 04 11 41 Connector skintop with nut M16 x 1.5

1 00 00 21 27 Cable set HM 24

2 00 02 20 63 Plug solenoid valve

2 20 15 26 12 Gasket solenoid coil type 280

3 00 04 11 42 Skintop screwing M 25 x 1.5

1 00 02 20 75 CEE-plug 5 x 16A 6h

4 20 20 62 03 Safety nut M4 galv.

4 20 20 63 05 Cheese-head screw M4 x 12

For spare parts orders only with specification of the type plate!

2017-08-07

47

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

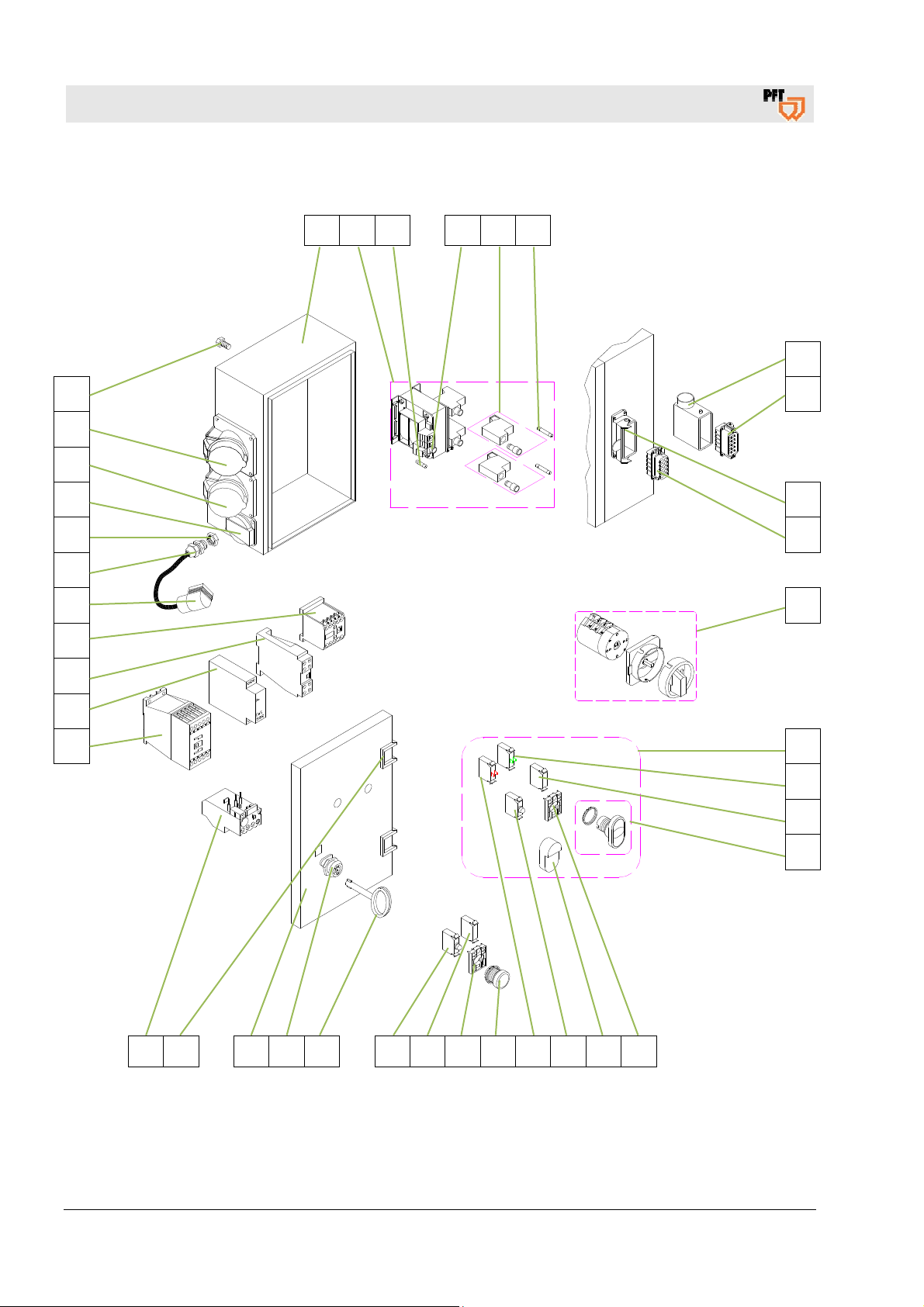

26.20 Control box HM 24 Art.No. 00008735

1 2 3 4 5 6

35

34

34

33

32

31

30

29

28

27

26

7

8

9

10

11

12

25 24 23 22 21 18 14 16 20 19 18 17 16

48

2017-08-07

13

14

15

Item Qty. Art.No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

1 00 02 21 13 Empty housing HM 104 RAL 7032/structure

1 00 02 21 38 Transformer 400 V - 42 V 70 VA

1 20 41 90 21 Fuse 5 x 20, 2.0 A

1 00 01 24 75 Fuse cap round/black bayonet socket

2 20 41 92 50 Fuse link TRKS 4/1-SI (5x30)

1 00 08 72 53 Fuse 5 x 30, 0,63A

1 20 42 98 23 Socket housing HAN 10A 10 pins angled

1 20 42 98 22 Male insert small 10 pins HAN 10A

1 20 42 98 21 Socket housing 10 poles, HAN 10A

1 20 42 98 24 Female insert 10 pins, HAN 10A

1 20 45 52 00 Main reversing switch, cpl.

1 00 05 59 54 Luminous push-button key on/off cpl. M22

1 00 05 38 35 Contact-element 1 make contact M 22

2 00 05 38 86 LED - resistor - additional series resistor 42 V

1 00 05 38 32 Luminous push-button key on/off M 22

2 00 05 38 34 Fastening adapter M 22

1 00 05 38 31 Membranes angular for double pressure switch M22-TDD

1 00 05 38 81 Luminous element white 12-30V

1 00 05 38 36 Contact-element 1 break contact M 22

1 00 05 38 74 Front cap for the signal lamp yellow M 22

1 20 44 45 00 Key for control box

1 00 03 62 49 Lock for control box

1 00 04 31 13 Door HM 104 RAL7032

2 00 05 37 67 Hinge 180° cpl. for control box

1 00 08 53 76 Motor protection relay 6-10A type ZB12, construction size I

1 00 08 42 24 Air-break control DIL M15-10 42V

1 20 45 27 51 Phase sequence relay 200-500 V type FPF 2

1 20 45 27 00 Time lag relay 42V, 1,5-30 sec.

1 20 44 72 00 Contactor DIL ER 22, 42V

1 00 02 20 63 Plug solenoid valve

2 00 04 11 41 Connector skintop with nut M16 x 1.5

2 00 04 11 43 Counternut Skintop M 16 x 1.5

1 20 42 72 10 Panel mounted socket Schuko 16A grey

2 20 42 66 10 Panel mounted socket CEE 4 x 16A 6h red

4 20 20 87 01 Hex. screw M8 x 16 galv.

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

For spare parts orders only with specification of the type plate!

2017-08-07

49

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.21 Water Manifold Unit Art.No. 00002119 / 00211923

1 2 3 4 5 6 7 8 9 10 11 12

34

33

32

31

13

30

29

28

13

14

15

16

7

17

18

19

27

26

25

24

5

22 11 16 23 21

50

2017-08-07

20

21

22

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.22 Spare parts list Water Manifold Unit Art.No. 00002119 / 00211923

Item Qty. Art.No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

1 00 00 21 19 Wasserarmatur HM 24

1 20 15 77 00 Needle valve 1/2" type 6701

1 20 15 78 00 Hand knob for needle valve 1/2"

1 20 20 36 12 Curved section 1/2" ext. thread galv.

2 20 20 54 00 Reducing nipple 1" ext. thread 1/2" int. thread galv.

1 00 00 22 92 Bracket for water flow meter HM 24 100-1000 l/h 200mm

5 20 20 72 00 Safety nut M 8 galv.

1 20 20 93 13 Washer B 8,4 galv.

1 20 20 87 01 Hex. screw M8 x 16 galv.

1 20 21 60 00 Gauge 0-10 bar 1/4" at bottom, D = 63mm

1 20 20 52 00 Reduction piece 1/2" ext. thread - 1/4" int. thread galv.

1 20 20 47 00 Angled distributor 1/2" int. thread, 4-way

3 20 20 17 00 Seal for Geka coupling (50 pieces)

2 20 20 09 00 Geka coupling 1/2" ext. thread with gasket

1 20 21 52 00 Tap 1/2" without drainer

2 20 20 34 01 Double nipple 1/2" X 60mm galv.

3 20 20 99 86 Steel bow M8 X 1"

1 00 00 21 21 Support for water manifold HM 22/24

1 20 15 20 00 Water inlet filter for Geka coupling

1 00 00 15 58 Pressure reducer D 06F 1/2"

2 20 20 31 07 Nipple 1/2" ext. thread flat with nut 3/4"

2 20 21 53 00 Tap 1/4" ext. thread with socket 10mm

1 00 45 64 51 Solenoid valve 1/2", 400V, 50/60Hz, type 6213 A

1 00 00 22 13 Water flow meter 100-1000l/h 250mm

2 20 18 45 10 Connection nut 1 1/2" for water flow meter 20184000

1 20 18 42 00 Cone for water flow meter type 1600/2500

2 20 18 43 00 O-ring D 34 x 3,5

2 20 18 46 00 Insertion piece 1"

2 20 18 47 00 Stop for part. no. 20 18 40 00, 20 18 49 00, 20 18 50 00

1 20 18 40 12 Plastic tube 100-1.000 l/h 200mm

1 20 20 15 00 Geka coupling 1/2"

2 00 05 91 96 Hose clamp 19-21

1 20 21 36 02 Water-/air hose 1/2" x 400mm

1 20 20 37 80 Hose socket 1/2" conical with nut 3/4" int. thread

For spare parts orders only with specification of the type plate!

2017-08-07

51

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.23 Water pressure booster pump HM 24 cpl. Art. No. 00070238

1 2 3 4 5 4 6 7

19

18

17

16

15

8

9

10

11

14 13 12

52

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.24 Spare parts list water pressure booster pump HM 24 cpl. Art.No.

00070238

Item Qty. Art.No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1 00 07 02 38 Water pressure booster pump HM 24 cpl.

1 20 20 17 00 Seal for Geka coupling (50 pieces)

1 20 20 16 00 Geka coupling 3/4" socket (packing unit = 10 pcs)

1 00 00 21 98 Water-/air hose 3/4" x 290mm

2 00 05 91 96 Hose clamp 19-21

1 20 19 04 43 Hose screw joint 1" ext. thread socket 3/4"

1 20 20 36 20 Curved section 1" int. thread-ext.thread galv.

1 00 23 13 67

Water pressure booster pump SL-AV3 PK a 37kW 230V

4 20 20 71 03 Hex. screw M6 x 20 galv.

4 20 20 93 00 Washer B 6,4 galv.

4 20 20 62 00 Safety nut M6 galv.

4 20 20 99 86 Steel bow M8 X 1"

2 20 20 72 00 Safety nut M8 galv.

1 00 00 97 69 Support for AV 3 at HM 22/24

1 20 15 20 00 Water inlet filter for Geka coupling

2 20 20 17 00 Gasket Geka-coupling (packing unit = 50 pieces)

1 20 20 09 10 Geka coupling 3/4" ext. thread

1 20 20 50 00 Reducing nipple 1" ext. thread-3/4" int. thread galv.

1 20 42 41 43 Motor connection cable 0,8m Schuko plug and cable lug

For spare parts orders only with specification of the type plate!

2017-08-07

53

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.25 Water pressure booster pump AV1000 HM 24 Art. No. 00466201

1 2 3

12

11

10

4

9 8 7 6 5

14 13

54

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.26 Spare parts list water pressure booster pump HM 24 cpl. Art.No.

00070238

Item Qty. Art.No. Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

4 20 20 99 86 Steel bow M8 X 1"

1 20 19 04 43 Hose screw joint 1" ext. thread socket 3/4"

1 20 20 36 20 Curved section 1" int. thread-ext. thread galv.

1 20 20 16 81 High pressure coupling 3/4" ext. Thread with seal

1 00 27 19 87 Ball tap 1/8" Internal thread/external thread, one-side lever

1 20 56 53 27 Copper gasket D=10.5

1 00 49 30 84 Water pressure booster pump AV1000/1 230V 1Phase 50Hz

1 00 46 62 03 Support AV1000/1 HM 22/24 RAL2004

1 20 42 41 43 Motor connection cable 0,8m Schuko plug and cable lug

1 20 21 36 08 Water-/air hose 3/4" x 750mm

2 20 20 29 00 Hose clip 28-31 packing unit=10ST

1 20 20 16 80 High pressure coupling 3/4" socket with seal

8 20 20 72 00 Safety nut M8 galv.

2 20 20 63 23 Saucer-head screw M8 x 25 galv.

For spare parts orders only with specification of the type plate!

2017-08-07

55

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.27 Spare parts list AV1000/1 400V 60Hz Art.No. 00491839

1 2 3 4 5 6 7 8 9

10

11

12

27 26 25 24 23 22

13

14

15

16

17

18

19

20

21

56

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Spare parts drawing

26.28 Spare parts list AV1000/1 400V 60Hz Art.No. 00492679

Item Qty. Art.No. Description

1 1 On request Nozzle

2 4 On request Screw

3 1 On request Cover

4 4 On request Screw

5 1 On request Terminal board

6 1 On request Bearing cap rear

7 4 On request Screw

8 1 On request Fan

9 1 On request Fan hood

10 1 On request Compensating spring

11 1 On request Grooved ball bearing

12 1 On request Shaft with rotor

13 1 On request Grooved ball bearing

14 1 On request Arrester

15 1 On request Motor housing with winding (230/400V)

16 1 On request Support foot

17 1 On request Bearing cover front

18 3 On request Screw

19 1 On request Cover pump body

20 1 On request O-ring for pump body

21 1 00467107 Face seal for AV 1000

22 1 On request Wheel- und Diffuser set

23 1 On request O-ring for pump body

24 1 On request Washer

25 1 On request Nut for wheel

26 4 On request Screw for pump body

27 1 On request Screw with O-ring

For spare parts orders only with specification of the type plate!

2017-08-07

57

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Circuit Diagramm 60Hz

27 Circuit Diagramm 60Hz

58

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Circuit Diagramm Cable set 00002127

28 Circuit Diagramm Cable set 00002127

2017-08-07

59

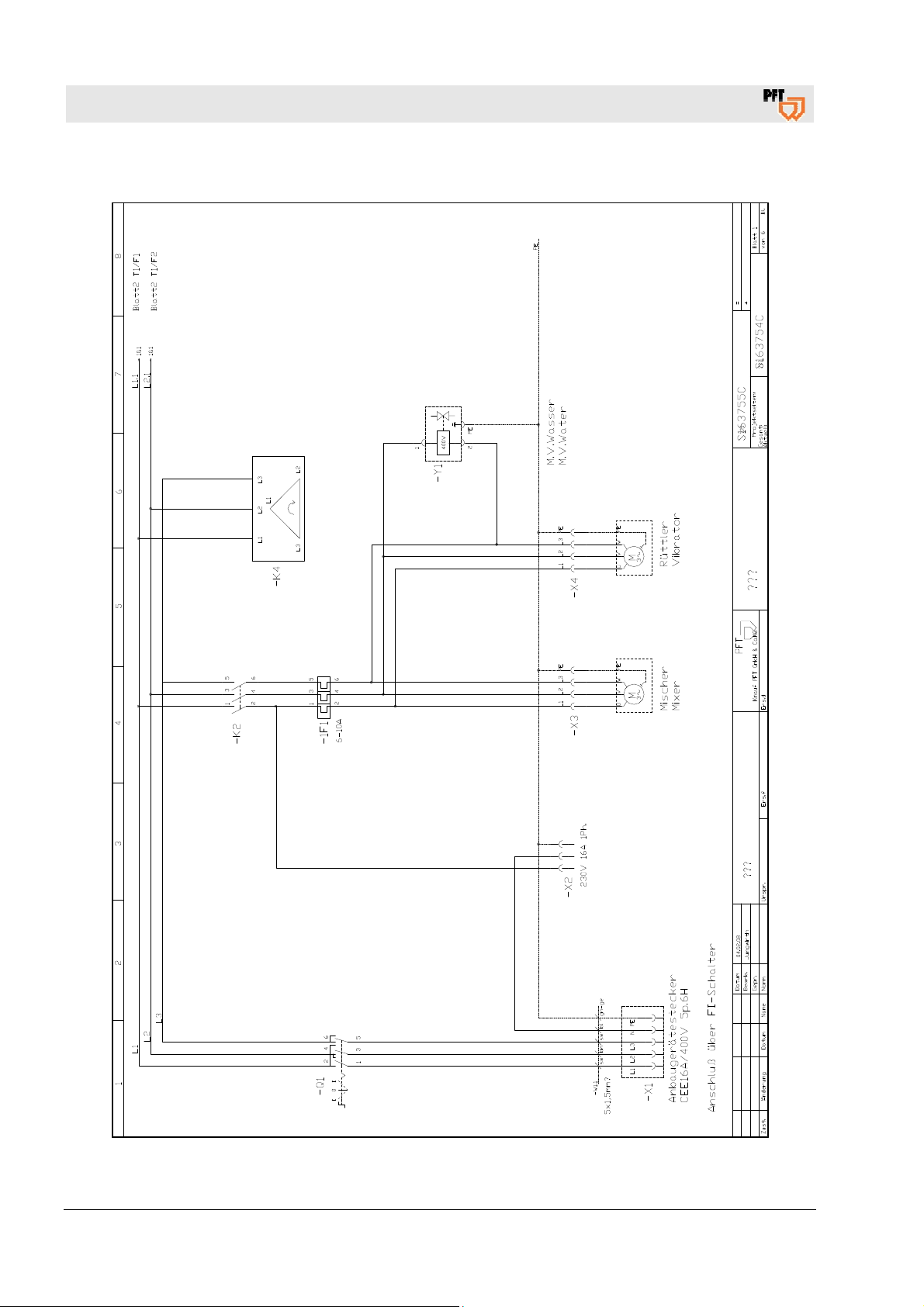

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Circuit Diagramm HM 24 S163754C

29 Circuit Diagramm HM 24 S163754C

60

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Circuit Diagramm HM 24, 230 V, 3 phases 60 Hz

30 Circuit Diagramm HM 24, 230 V, 3 phases 60 Hz

2017-08-07

61

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

62

2017-08-07

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

2017-08-07

63

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

PFT – THE FLOW OF PRODUCTIVITY

Knauf PFT GmbH & Co. KG

Postfach 60 97343 Iphofen

Einersheimer Straße 53 97346 Iphofen

Deutschland

Telefon +49 9323 31-760

Telefax +49 9323 31-770

Technische Hotline +49 9323 31-1818

info@pft-iphofen.de

www.pft.eu

64

2017-08-07

Loading...

Loading...