OPERATING INSTRUCTIONS

ACP 15

Dry compact Multi-stage Roots pump

EN

Translation of the original instructions

Table of contents

Table of contents

1 About this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Transport and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1.1 Applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.3 Instructions/Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.4 Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Product identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.1 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.2 Differences between the pump versions . . . . . . . . . . . . . . . . . . . . 12

4.2 Man/machine interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Connection to the pumping line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.1 Connection at pump inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.2 Connection at pump exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.3 Connecting the purge circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Leak test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4.1 Customer electrical installation protection. . . . . . . . . . . . . . . . . . . 17

5.4.2 Connection to the mains power supply . . . . . . . . . . . . . . . . . . . . . 18

5.5 Remote connector wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5.1 Wiring of digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.5.2 Setting of the rotation speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.5.3 Wiring of the digital outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 RS-485 serial link wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.6.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.6.2 Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.6.3 Command list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Prerequisites to use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Matrix gas/applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Different control modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3.1 Local mode operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3.2 Remote mode operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.3 RS-485 serial link operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.4 Operation monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Gas ballast operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 Purge operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 Safety and maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1.1 How to contact us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.2 Maintenance frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.3 Maintenance on the customer’s site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.4 Standard repair exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2

Table of contents

7.4.1 Disconnecting the pump from the installation . . . . . . . . . . . . . . . . 33

7.4.2 Conditioning the pump for shipping. . . . . . . . . . . . . . . . . . . . . . . . 33

8 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.1 Shutting down for longer periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2 Re-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9 Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.1 Trouble at pump start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.2 The pump runs incorrectly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

12 Technical data and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

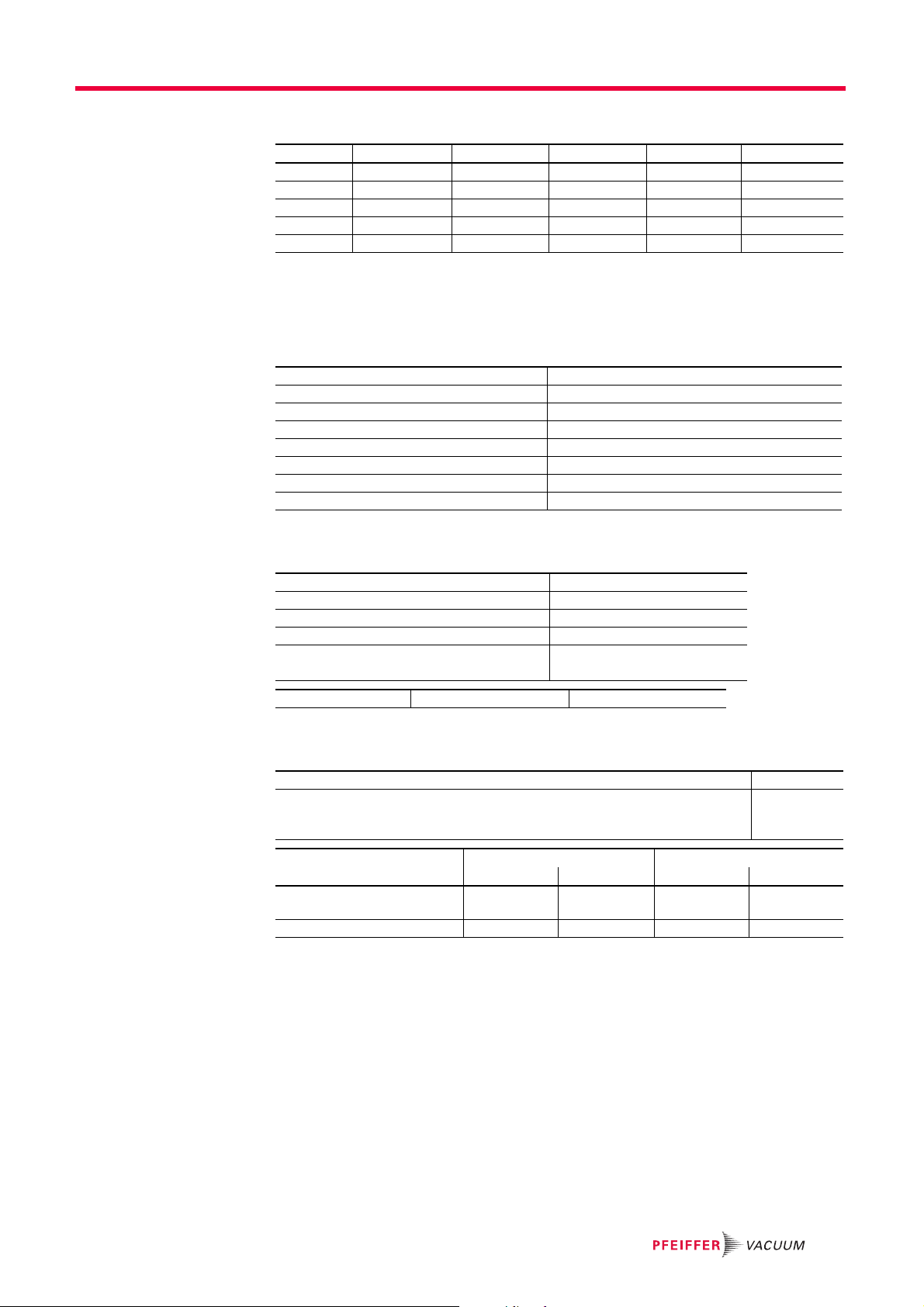

12.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12.2 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

12.3 Facilities characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12.3.1 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12.3.2 Nitrogen characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12.3.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

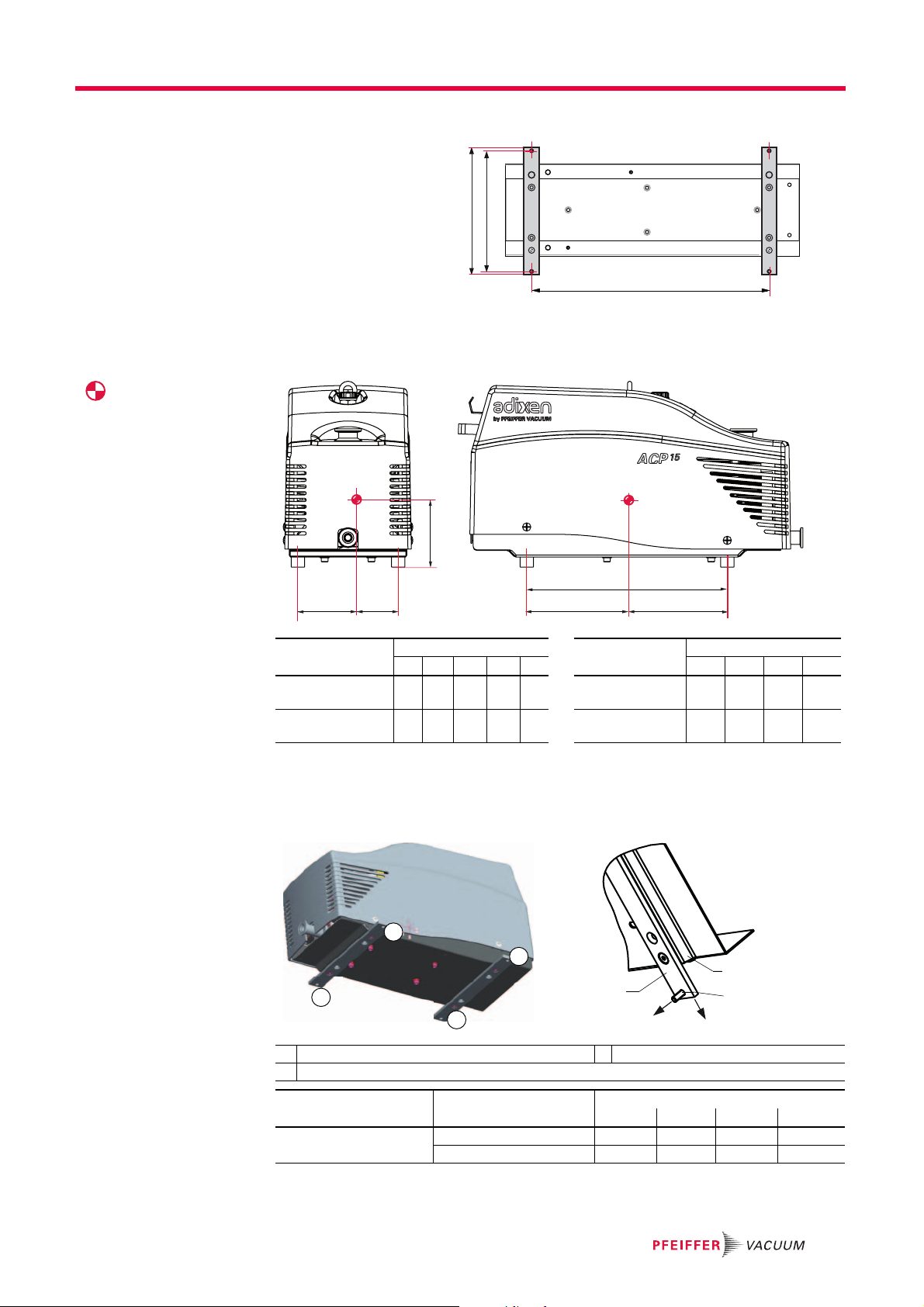

12.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12.5 Weight distribution and seismic brackets . . . . . . . . . . . . . . . . . . . . . . . . . 41

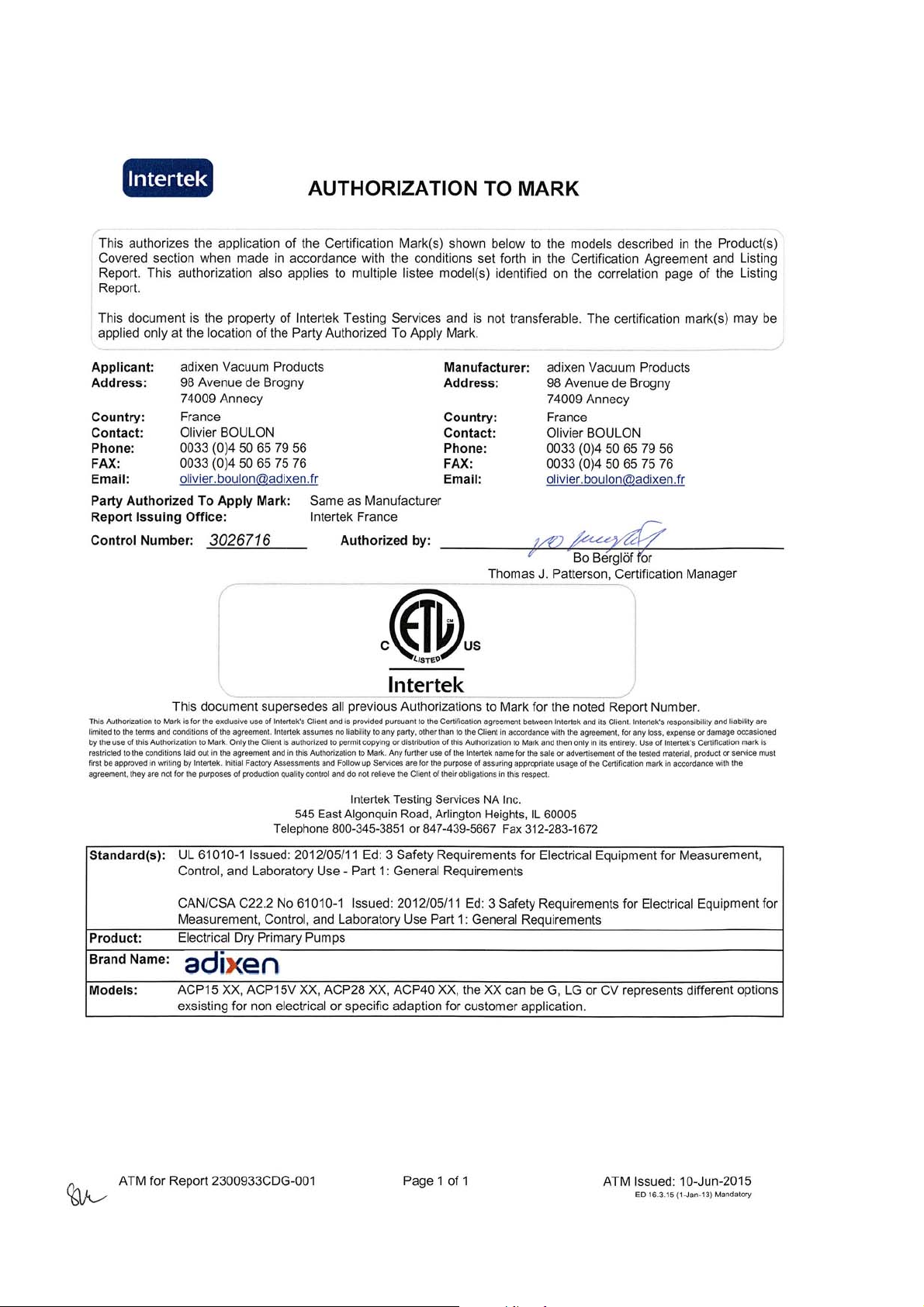

ETL Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3

About this manual

1 About this manual

1.1 Validity

This operating manual is for customers of Pfeiffer Vacuum. It describes the functioning

of the designated product and provides the most important information for safe use of

the unit. The description follows applicable EU guidelines. All information provided in this

operating manual refers to the current state of the product's development. The documentation remains valid as long as the customer does not make any changes to the product.

Up-to-date operating instructions can also be downloaded from

www.pfeiffer-vacuum.com.

This document is a translation of the original French instructions.

This manual covers products with the following references:

Part number Model Description

V5SAXXXXXX

V5VSXXXXXX

V5GAXXXXXX

V5VGXXXXXX

ACP 15 Models for standard applications

ACP 15 G Models for applications with traces of corrosive gases

1.1.1 Applicable documents

Declaration of conformity included with this manual

UL/CSA compliant use (ETL mark) included with this manual

1.2 Conventions

1.2.1 Safety instructions

The safety instructions in Pfeiffer Vacuum operating instructions are the result of risk

evaluations and hazard analyses and are oriented on international certification standards as specified by UL, CSA, ANSI Z-535, SEMI S2, ISO 3864 and DIN 4844. In this

document, the following hazard levels and information are considered:

Imminent danger

Indicates an imminent hazardous situation that will result in death or serious injury.

Possibly imminent danger

Indicates an imminent hazardous situation that can result in death or serious injury.

DANGER

WARNING

CAUTION

Possibly imminent danger

Indicates an imminent hazardous situation that can result in minor or moderate injury.

NOTICE

Command or note

Command to perform an action or information about properties, the disregarding of

which may result in damage to the product.

4

1.2.2 Pictographs

P0385E4

AC Rating 110-230V 50/60Hz 15-10A

Frequency inverter serial n°

Référence

SEISMIC TIE DOWN

A 329 962 - 5

Prohibition of an action or activity in connection with a source of danger,

the disregarding of which may result in serious accidents

Warning of a displayed source of danger in connection with operation of

the unit or equipment

Command to perform an action or task associated with a source of danger, the disregarding of which may result in serious accidents

Important information about the product or this document

1.2.3 Instructions/Abbreviations used

About this manual

1.2.4 Labels

or Work instruction: you must perform an operation here.

I/O Pump Start/Stop

INLET Pump inlet connection

PUMP EXHAUST Pump exhaust connection

This label warns the user against possible risk of injury due to any hand contact with

hot surfaces.

It states that protective gloves should be used before performing any intervention.

This label informs the user, that moving parts present inside the pump could cause personal injury, like crushing or cutting.

The user must keep all body parts away from moving parts.

This label indicates that due to its heavy weight, the product should not be handled

manually,

but always through appropriate handling devices.

This label indicates that some of the internal parts are energized and could cause electrical shocks in case of contact.

It advises to disconnect the pump before any intervention or to properly lock-out and

tag-out the equipment breaker before any intervention on the pump.

This label indicates the voltage of the equipment in which the pump is to be connected.

This label indicates the location of the holes for seismic bracket installation.

5

About this manual

CAUTION

Use suitable power supply cord

for required voltage

Hot surface

Do not touch

See user’s manual

ATTENTION

Utiliser le câble d’alimentation

adapté pour la tension requise

Surface chaude

Ne pas toucher

Consulter les documents joints

1

2

3

4

5

6

7

7

6

6

1Weight Label

2 Heavy object label

3 Hot surface label

4 Hazardous voltage label

5 Presence of moving part label

6 Seismic down label

7 Mains voltage Label

This label indicates that the power supply must be switched off before connecting and/

or disconnecting the pump. Any person responsible for installation or operation of the

product must first refer to the operating manual.

This label warns the user against potential risks associated with the use of this product.

Any person responsible for installation or operation of the product must first refer to the

operating manual.

The installer must glue the following labels to the most appropriate and visible

place on the pump to warn the operator about potential hazards:

6

2Safety

2.1 Safety precautions

Obligation to inform

Any person responsible for installing, using or maintaining the product must first read

the security instructions in this operating manual and comply with them.

It is the operating customer’s responsibility to protect all operators against the dan-

gers associated with the product, with the media pumped and with the entire installation.

Installation and use of the accessories

The products can be fitted with special accessories. The installation, use and refurbishment of the connected accessories are described in detail in the respective manuals.

Only use original accessories.

Accessory part numbers: see Accessories.

Hazard associated with non-compliant electrical installation

Safe operation after installation is the operator’s responsibility.

Connect the product to an installation that is compliant with local safety standards.

Do not carry out any alterations or modifications to the product on your own initiative.

For specific questions, contact your service center.

Safety

WARNING

WARNING

Electric shock hazard in case of contact

When the product's mains switch is set at O, some internal components still have an

electrical charge.

Make sure that the mains connection is always visible and accessible so that it can

be unplugged at any time.

Disconnect the power cable from all power sources before starting any work on the

product.

WARNING

Danger due to lack of lock out/tag out (LO/TO) electrical device.

In order to properly secure the pump for installation and/or maintenance, it is required

to lock out/tag out the pump properly in accordance with OSHA requirement

29 CFR.1910.147.

WARNING

Other located hazardous energies

Electrical circuit and other pressurized circuits as nitrogen are potential hazards:

Always lock out these energy sources before working on the product.

7

Safety

WARNING

Risk associated with process gases

The user and/or integrator of the product is/are fully responsible for the operational safety conditions of the equipment. The manufacturer has no control over the types of gases

this pump is exposed to. Frequently process gases are toxic, flammable, corrosive, explosive and/or otherwise reactive. It is the user and/or the integrator's responsibility to

follow the necessary safety requirements. Toxic gases can cause serious injury or

death. Operators and users must:

Take the appropriate safety recommendations to prevent injury. Consult the respon-

sible department for instructions and safety information.

Hazardous gases from the pump can cause serious injury or death. Regula-

tions require to connect the pump’s exhaust to a facility hazardous gas exhaust system which incorporates appropriate filters, scrubbers, etc. This system

must meet all air and water regulations.

Check that the pump is correctly connected to the equipment (see Installation).

Contact the service center for further information.

The potential risks with an air cooled, dry multi-stage Roots pump involve electricity, the

chemical processes, hot surfaces, the pressurized nitrogen device.

● Only qualified personnel trained in safety rules (EMC, electrical safety, chemical pollution) may carry out the installation and maintenance described in this manual. Our

service centers can provide the necessary training.

● Do not remove the blanking plates sealing the inlet and exhaust ports if the product is

not connected to the pumping line.

● Do not operate the product unless the inlet and exhaust are connected to a vacuum

and exhaust pumping line.

● Do not expose any part of the human body to the vacuum.

● Comply with all safety and risk prevention instructions in accordance with local safety

standards.

● Regularly check compliance with all precautionary measures.

● Do not turn on the product if the covers are not in place.

2.2 Protective equipment

In some situations, personal protective equipment must be worn when handling the vacuum pump and its components. The owner must provide operators with the necessary

equipment. This equipment must be checked regularly and used in accordance with the

supplier's recommendations.

Health risk relating to contact with toxic materials

The vacuum pump, pumping line components, and operating media may be contaminated with toxic, corrosive, reactive, or radioactive materials, depending on the process.

Wear appropriated safety equipment when pump is disconnected for maintenance,

or re-installed, and also for oil filling and draining.

Risk of injury due to hot surfaces

For the operator's safety, the products are designed to avoid thermal risk. However, specific operating conditions may exist that require extra caution from users due to the high

temperatures (external surfaces > 70°C on the exhaust pipe).

Let the part cool before working on the product.

If necessary wear protective gloves according to directive EN 420.

DANGER

WARNING

8

2.3 Proper use

kg

Safety

WARNING

Risk of injury due to falling objects

When transporting parts/items by hand, there is a danger of loads slipping and falling

down.

Carry small and medium-size parts/items with two hands.

Carry parts/items > 20 kg with a suitable lifting device.

Wear safety shoes with steel toe according to directive EN 347.

NOTICE

EC conformity

The manufacturer's declaration of conformity becomes invalid if the operator modifies

the original product or installs additional components.

Following installation into a plant and before commissioning, the operator must check

the entire system for compliance with the valid EU directives and reassess it accordingly.

● The vacuum pump may only be used to generate a vacuum while pumping gases.

● The product may be used in an industrial environment.

● The product may be used in a laboratory environment.

● The G version pump is compatible with traces of corrosive gases.

2.4 Improper use

Improper use will cause all claims for liability and warranties to be forfeited. Improper use

is defined as usage for purposes deviating from those mentioned above, especially:

● pumping of flammable and explosive mixtures

● pumping of corrosive gases (exception: pumps in G version)

● pumping of liquids

● pumping of dusts

● use of the vacuum pump to generate pressure

● operation in potentially explosive areas

● use of accessories or spare parts, which are not named in this manual

The product is not designed to carry people or loads and is not for use as a seat, stepladder or any other similar purpose.

9

Transport and storage

3 Transport and storage

Upon delivery, check that the product has not been damaged during transport. If the

product is damaged, contact the carrier and notify the manufacturer. In all situations we

recommend:

Keeping the product in its original packaging so it stays as clean as it was when dis-

patched by us. Only unpack the product once it has arrived at the location where it will

be used.

Keeping the packaging (recyclable materials) in case the product needs to be trans-

ported or stored.

Keeping the blanking plates in place on the inlet, exhaust and purge ports while the

product is not connected to the pumping line.

3.1 Transport

Risk of injury associated with heavy loads

Given the weight of the product, it should be removed from its packaging only by personnel qualified and trained in handling heavy materials.

Use the lifting rings and devices provided with the product.

The manufacturer cannot be held liable for the consequences of using lifting devices

other than those provided.

WARNING

WARNING

Risk of tilting

Even though compliance with EEC safety rules is guaranteed, all necessary precautions

should be taken when moving, installing and operating the product.

Do not place the product on an inclined plane.

Place it on a flat, hard floor.

Do not push the product sideways.

To lift the product:

Use a lifting device suitable for the product's weight.

Use a lifting sling with a single arm that can withstand a

load > 23 kg.

A wheel kit is available as accessory: fitted over the frame,

it facilitates the displacement of the pump over short distanc-

es (see 11) and (see 12.4).

10

3.2 Storage

Storage of a new pump If the new pump is going to be put into storage:

Keep the pump wrapped in its protective film.

It is absolutely necessary to leave the inlet, the exhaust and purge blanking plates

in place.

Store the pump according to storage temperatures (see 12.3.1).

Store the pump in a clean and dry area, for a maximum period of 1 year.

For longer storage, we recommend operating the pump regularly at least once a year:

factors such as temperature, degree of humidity, salt air, ... may cause the deterioration

of the pump components. Proceed as follows:

Let the pump to run:

– for 30 minutes with gas ballast opened or by injecting a dry inert gas into the pump

(G version),

– then, for 30 minutes at ultimate pressure (inlet, gas ballast and purge ports closed).

Stop the pump.

Seal the pump inlet, exhaust and purge ports with included accessories.

Repeat this at least once a year.

For a storage period of over 4 years, the pump must be revised before any start up. Re-

turn it to a service center according to the product return Service procedure (see 10).

Storage after use Stop the pump according to pump shut-down procedure (see 6.3.1), (see 6.3.2) or

(see 6.3.3).

Disconnect the pump from the installation (see 7.4.1).

Seal the pump inlet, exhaust and purge ports with included accessories.

Store the pump in a clean, dry, non-polluted area for a maximum of 6 months accord-

ing to the storage temperatures (see 12.3.1).

Transport and storage

For longer storage, we recommend operating the pump every 6 months. Proceed as fol-

lows:

Let the pump to run:

– for 30 minutes with gas ballast opened or by injecting a dry inert gas into the pump

(G version),

– then, for 30 minutes at ultimate pressure (inlet, gas ballast and purge ports closed).

Stop the pump.

Seal the pump inlet, exhaust and purge ports with included accessories.

Repeat this every 6 months.

For a storage period of over 2 years, the pump must be revised before any start up. Re-

turn it to a service center according to the product return Service procedure (see 10).

11

Product description

4 Product description

4.1 Product identification

To correctly identify the product when communicating with Pfeiffer Vacuum, always have

the information from the rating plate available.

V6SATSFEMF

2015

AC668838

Max. pres:1013 mBar

Fig. 1: Product identification on the rating plate

4.1.1 Scope of delivery

● 1 vacuum pump

● 1 remote cover plug for remote connector (connected to the pump)

● 1 operating instructions

● 1 sheet of multilingual labels

and depending on the ordering guide, the following components are present:

1 main power cable

4.1.2 Differences between the pump versions

The multi-stage Roots pump technology of the ACP series meets the requirements of

applications where clean and dry vacuum is needed.

Standard version The SD version is designed for applications that require pumping of clean (dust-free)

and non-corrosive gases. Standard pumps are equipped with a gas ballast device to improve pumping of light gases and avoid vapor condensation inside the pump.

G version The G version pump is compatible with traces of corrosive gases. Three purge gas jets

protect low and high pressure bearings and dilute trace amounts of corrosive gases.

Please contact Pfeiffer Vacuum to obtain more detailed information according to the applications.

4800 rpm

12

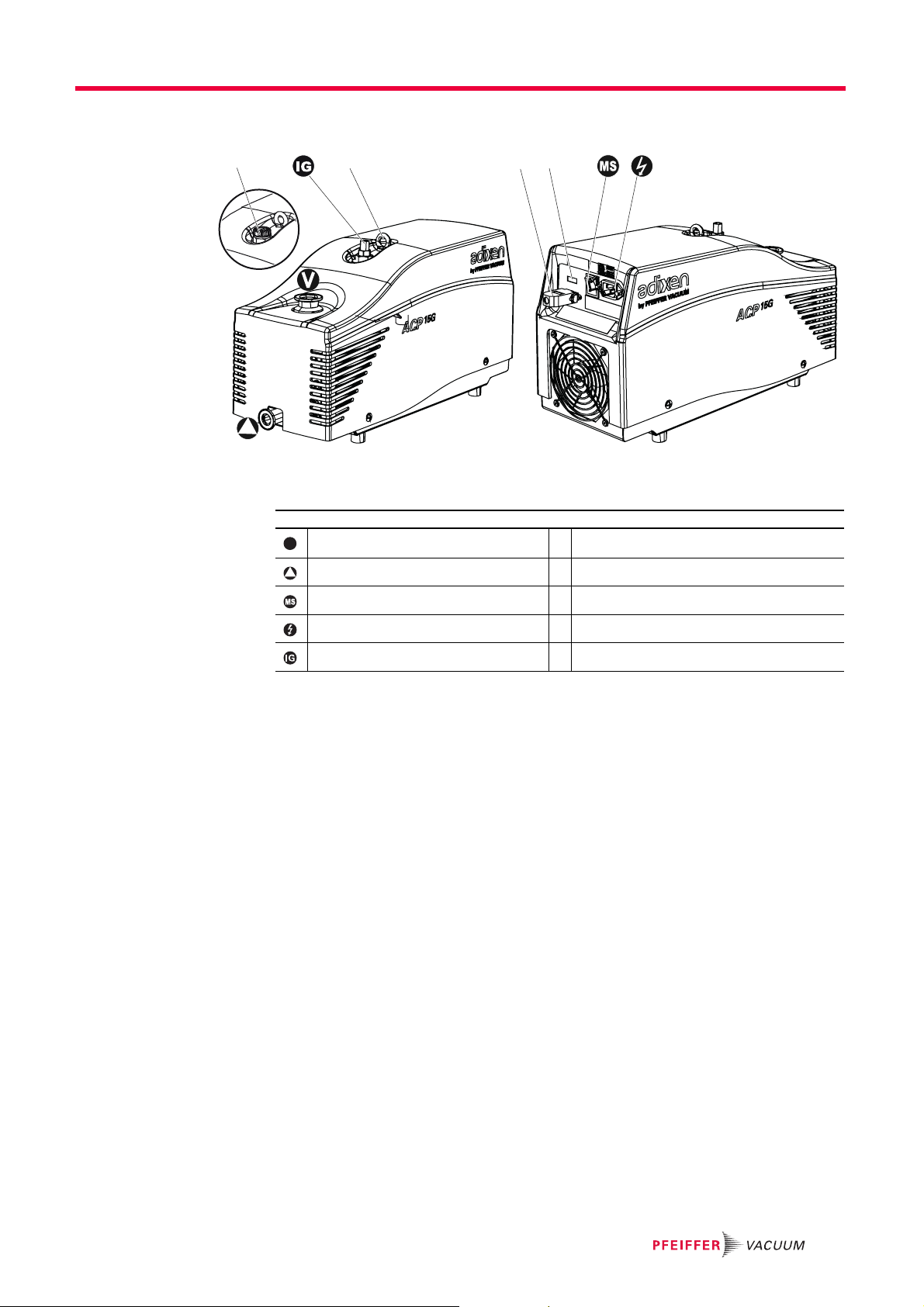

4.2 Man/machine interfaces

1342

V

Fig. 2: ACP 15 with single-phase frequency converter

Pump inlet 1 Gas ballast (SD version)

Product description

Pump exhaust 2 Hoisting ring

I/O mains switch 3 Remote connector and RS-485 connector

Power supply 4 Hour meter

Inert gas purge connection (G version)

13

Installation

80 mm

mini

80 mm

mini

80 mm

mini

80 mm

mini

80 mm

mini

5 Installation

5.1 Set-up

Ventilation To guarantee the characteristics and performances of the pump within the boundaries of

The pump must be operated in the horizontal position in support on its feet, with the

pumping axis vertical and the inlet opening upwards.

Determine where the pump will be placed.

Use the handling devices to position the pump in the desired location, lift the pump

using hoisting rings (see 3.1).

Install the pump so that the I/O mains switch is accessible by the operator.

the operating conditions:

Check that the air circulation grids are not blocked.

Take away the pump of the fixed walls, at least the value indicated on the diagram be-

low.

5.2 Connection to the pumping line

Risk of crushing or cutting related to the rotating parts

Do not expose any part of the human body to the vacuum. The product is supplied with

the inlet and exhaust sealed.

Remove these blanking plates when you are ready to connect the product to your

vacuum system.

Do not operate the product unless the inlet and exhaust are connected to a vacuum

and exhaust pumping line.

Use accessories on the inlet and exhaust lines whose materials and sealing proper-

ties are compatible with gases being used.

Provide in the pumping line, accessories to isolate the pump from the vacuum and ex-

haust line, to make the maintenance easier (inlet and exhaust isolation valves, purges,…).

Remove the blanking plates blocking the inlet and exhaust ports.

Keep the blanking plates, screws and washers for reuse when transporting the pump.

Ensure that no screws, washers or other objects are dropped into the pump inlet.

Fit flexible flanged bellows in the pumping line to reduce the transmission of vibra-

tions.

14

WARNING

The O-rings located under the blanking plates are compatible with standard applications.

Other types of connection accessories are available in the product catalogue. The inlet

and exhaust connections must not cause stress that could lead to leaks in the pumping

line.

5.2.1 Connection at pump inlet

Limit of operation

Make sure that the parts or chambers connected to the inlet of our products withstand

a negative pressure of 1·10

When the pump stops, the pressure rises at the inlet. This rise depends on the

inlet volume.

If necessary, install an isolation valve on the inlet which closes when the pump stops.

The product is not designed to withstand loads on its inlet flange which may compromise

stability.

NOTICE

3

hPa in relation to atmospheric pressure.

NOTICE

Installation

Mechanically attach the vacuum chamber separately from the pump.

It may be necessary to install a filter on the inlet (particulate filter or (see 11) condens-

ables filter).

To improve pumping speed, the pumping line must be as short as possible and its internal diameter must not be less than the pump inlet flange.

Use only dry parts and clean, grease-free, dust-free pipelines.

5.2.2 Connection at pump exhaust

Limit of operation

Ensure that all components in the exhaust pipeline have maximum pressure rating

which is greater than the highest pressure that can be generated in your system.

G version

Health risk in case of contact with toxic substances

Exhaust of corrosive, reactive, flammable, pyrophoric or oxidizing process gases may

result in severe injury or death.

Always connect the pump exhaust to an exhaust extraction system.

NOTICE

DANGER

5.2.3 Connecting the purge circuit

The gas purge consists of injecting an inert gas into the pump.

In this manual, the inert gas will be called 'nitrogen', as it is the most commonly used gas.

For more information about the type of purge gas, contact your service center Pfeiffer

Vacuum.

15

Installation

DANGER

Risk of explosion

If pyrophoric materials above the LEL (lower explosive limit) are sent to the pump, the

nitrogen supply must make it possible to dilute this concentration.

Ensure there is a sufficient flow of nitrogen to lower the concentration below the LEL.

Provide in addition an interlock to ensure that gas flow towards the pump is stopped

when nitrogen is lost.

NOTICE

Risk of nitrogen supply failure

If loss of purge flow creates a significant risk for the process:

Control the nitrogen supply using an external system able to take over in case of fail-

ure.

G version A gas purge circuit protects the low and high pressure bearings and dilutes trace

amounts of corrosive gases.

Connect the inert gas pipe to the 1/4 BSPT connector provided for this purpose (flex-

ible or rigid pipe supplied by the customer).

Install as close as possible from pump gas port, an isolation valve on the inert gas

pipe, to allow pump performance recovering when the gas supply is not used (see

12.2).

Inject inert gas purge with maximum relative pressure of 300 hPa (see 12.2).

A filtered dry nitrogen supply with the characteristics defined is required for opti-

mum performance (see 12.3.2).

5.3 Leak test

Leak-tightness of the equipment

It is the user's responsibility to ensure this level of leak tightness is maintained, especially when dangerous gases are pumped. The operator must maintain this level of tightness, particularly when pumping dangerous gases. Proceed as follows:

Perform a leak test on the entire pumping line after installation.

Carry out regular checks to ensure that there are no traces of the gases pumped in

the surrounding environment and that no air is entering the pumping line while the

pump is running.

For more information concerning leak tests, please contact your service center.

5.4 Electrical connection

Electric shock hazard in case of contact

When the product's mains switch is set at O, some internal components still have an

electrical charge.

Make sure that the mains connection is always visible and accessible so that it can

be unplugged at any time.

Disconnect the power cable from all power sources before starting any work on the

product.

WARNING

WARNING

16

Installation

WARNING

Risk of electromagnetic disturbance

The product’s EMC behavior is guaranteed only if the relevant EMC standards are followed during installation.

Use shielded cables and connections for the interfaces in interference-prone environ-

ments.

WARNING

Hazard associated with non-compliant electrical installation

Safe operation after installation is the operator’s responsibility.

Connect the product to an installation that is compliant with local safety standards.

Do not carry out any alterations or modifications to the product on your own initiative.

For specific questions, contact your service center.

Electrical safety The pump is equipped with an I/O mains switch that isolates the product from power line

when it is on O position.

The pump is equipped with a frequency converter in compliance with EC standards that

allows pump running in high and low voltages (see 5.4.1). The frequency converter is

protected against short-circuits from power line. Once this safety activated, power is

switched off and the pump is put in a safe condition. To restart the pump, you must:

switch power off, mains switch to O position,

delete the origin of the fault, then,

wait for about 15 seconds,

then, switch power on , to I position.

The pump is equipped with thermal sensors that prevent pump start-up at certain tem-

peratures (see 6.1).

5.4.1 Customer electrical installation protection

The pump is connected to the mains with the delivered mains power cable. The earth

connection (frequency converter, cover, pump) is made via the power cable connected

to a compliant electrical installation.

When the mains power cable is provided by the customer:

Use an EEC cable in compliance with IEC 60227 and IEC 60245 standards with the

following characteristics:

– heatproof (because it can come into contact with hot surfaces),

– with conducting wire section suitable with the voltage (see 12.3.3),

– and which one of the wire ensures grounding of the pump.

Installation protection with circuit breaker

The user must supply the pump from facilities equipped with main circuit breaker, curve

D (IEC 60947-2), in accordance with local regulations and with at least a 10 kA short circuit cut-off capacity. This protection device should be in close proximity to the pump (no

further than 7 m) within line of sight of the pump.

This circuit breaker supply and wiring is a customer’s responsibility: main circuit breaker

rating (see 12.3.3).

WARNING

Absence of emergency off

This pump is not equipped with an emergency off device EMO or a lock-out device. It is

designed to be integrated with the host tool equipment equipped with an emergency device. This EMO device must de-energize the pump when it is activated.

17

Installation

1567234

91015 14 13 12 11

8

S1

S3S4S5

Operation in local mode

There is no device to warn that the pump is operating in local mode.

Provide a device to warn about local mode operation when the pump is not integrat-

ed with equipment/host tool.

5.4.2 Connection to the mains power supply

Connect the mains power cable to the connector .

5.5 Remote connector wiring

Connection made via the Remote connector (Male 15-pin D-Sub) (see 4.2), allows:

– remote control of following functions: start, stop of the pump,

– setting of pump rotational speed (see 5.5.2).

The remote control connector wiring is the customer's responsibility.

5.5.1 Wiring of digital inputs

NOTICE

Fig. 3: Digital input wiring

There are dry contact inputs. Do not add more connections than those provided : S1, S3,

S4 and S5.

Contact Function

S1 (7-8) Pump Start/Stop Contact open, S1=0 : pump stopped

S3 (9-10) Rotational speed

S4 (11-12)

S5 (13-14)

setting

Contact closed, S1 =1 : pump start-up

Depending on the contact status (open or closed), the rotation

speed changes.

18

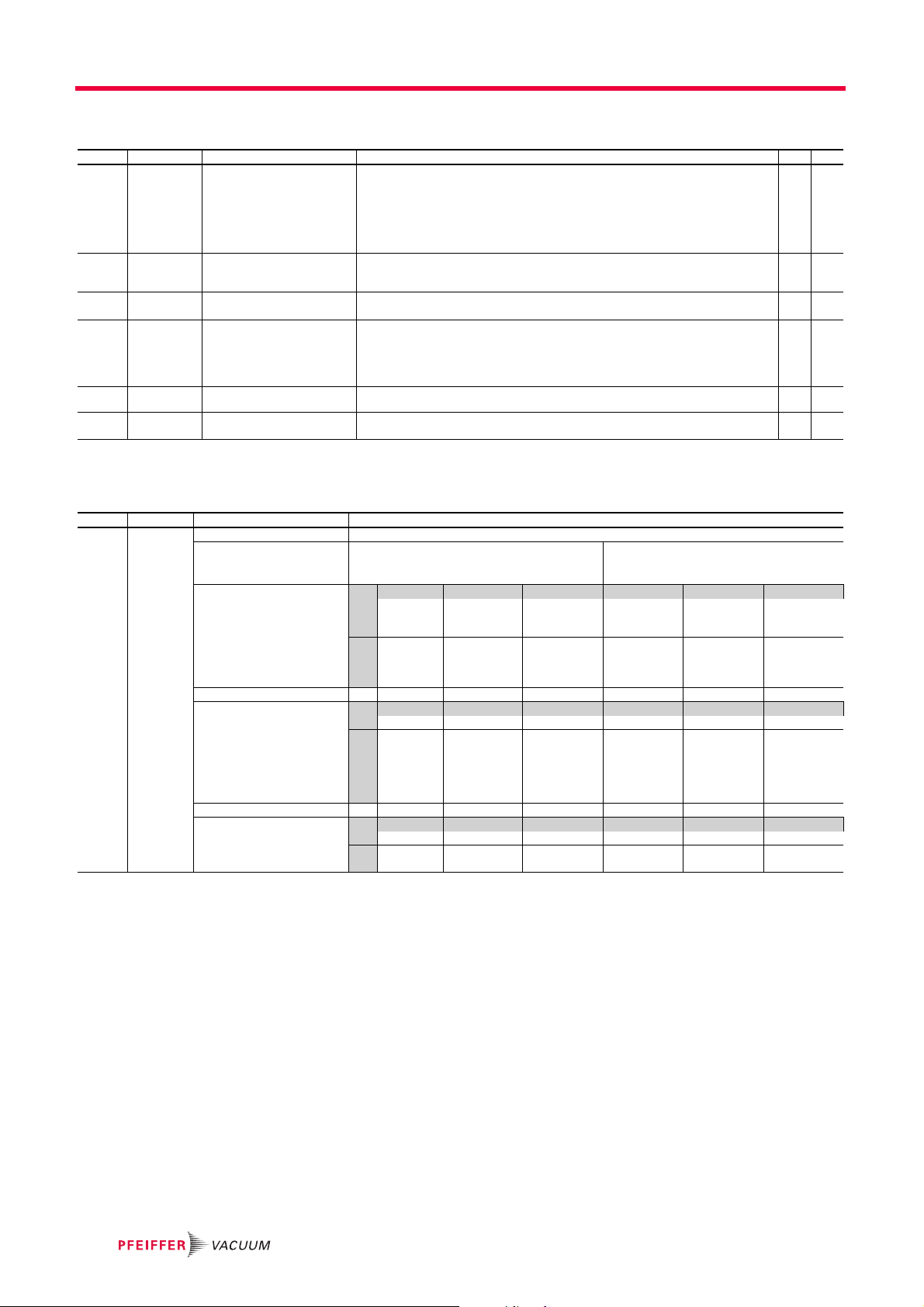

5.5.2 Setting of the rotation speed

Vcc

5

6

C

I

R

Vout

ACP 15 model

Contact Contact Contact Rotation speed

S3 S4 S5 Hz min

S3 = 1 S4 = 0 S5 = 1 60 3600

S3 = 1 S4 = 0 S5 = 0 70 4200

S3 = 0 S4 = 1 S5 = 1 80 4800

S3 = 0 S4 = 1 S5 = 0 90 5400

S3 = 0 S4 = 0 S5 = 1 95 5700

S3 = 0 S4 = 0 S5 = 0 100* 6000*

* Corresponds to the speed set on the cover plug delivered with the pump.

Rotation speed

Pump performances are guaranteed for a nominal speed of 100 Hz. Changing the rota-

tion speed affects the pumping speed and the ultimate pressure of the pump. In low

speed, it is the customer's responsibility to find the correct settings according to the

pump and the process.

For the safety of the pump, do not exceed the maximum frequency.

Do not run the pump continuously at speeds ≤ 60 Hz.

Installation

-1

NOTICE

5.5.3 Wiring of the digital outputs

Contact Function

S2 (5-6) Status of the rotation speed Contact closed: nominal speed reached

S2 output wiring precautions

Do not connect a relay between contacts 5 and 6: the relay coil could create an in-

duced current which may damage the frequency converter.

Do not apply to S2 output a current greater than 35 mA: a greater current would dam-

age the frequency converter.

Use the open collector output S2 according to the wiring below.

* supply and wiring are the customer’s responsibility.

NOTICE

Vcc : direct voltage delivered by the installation *(between 7 and 30 VDC)

R : resistance value *

Vout : output voltage

The values of Vcc and R must be calculated so that the current I is less than 35 mA.

When the setpoint speed is reached, the transistor becomes conductive ’on-state’ and

Vout = 0 V.

As long as the setpoint speed is not reached, the transistor is blocked (’off-state’) and

Vout = Vcc.

This assembly does not make pass of power, add an amplifier stage to control the power.

The S2 output can be used as a relay (dry contact) using the accessory socket interface

(see 11).

19

Installation

5.6 RS-485 serial link wiring

Risk of electromagnetic disturbance

The product’s EMC behavior is guaranteed only if the relevant EMC standards are followed during installation.

Use shielded cables and connections for the interfaces in interference-prone environ-

ments.

Electric shock hazard in case of contact

When the product's mains switch is set at O, some internal components still have an

electrical charge.

Make sure that the mains connection is always visible and accessible so that it can

be unplugged at any time.

Disconnect the power cable from all power sources before starting any work on the

product.

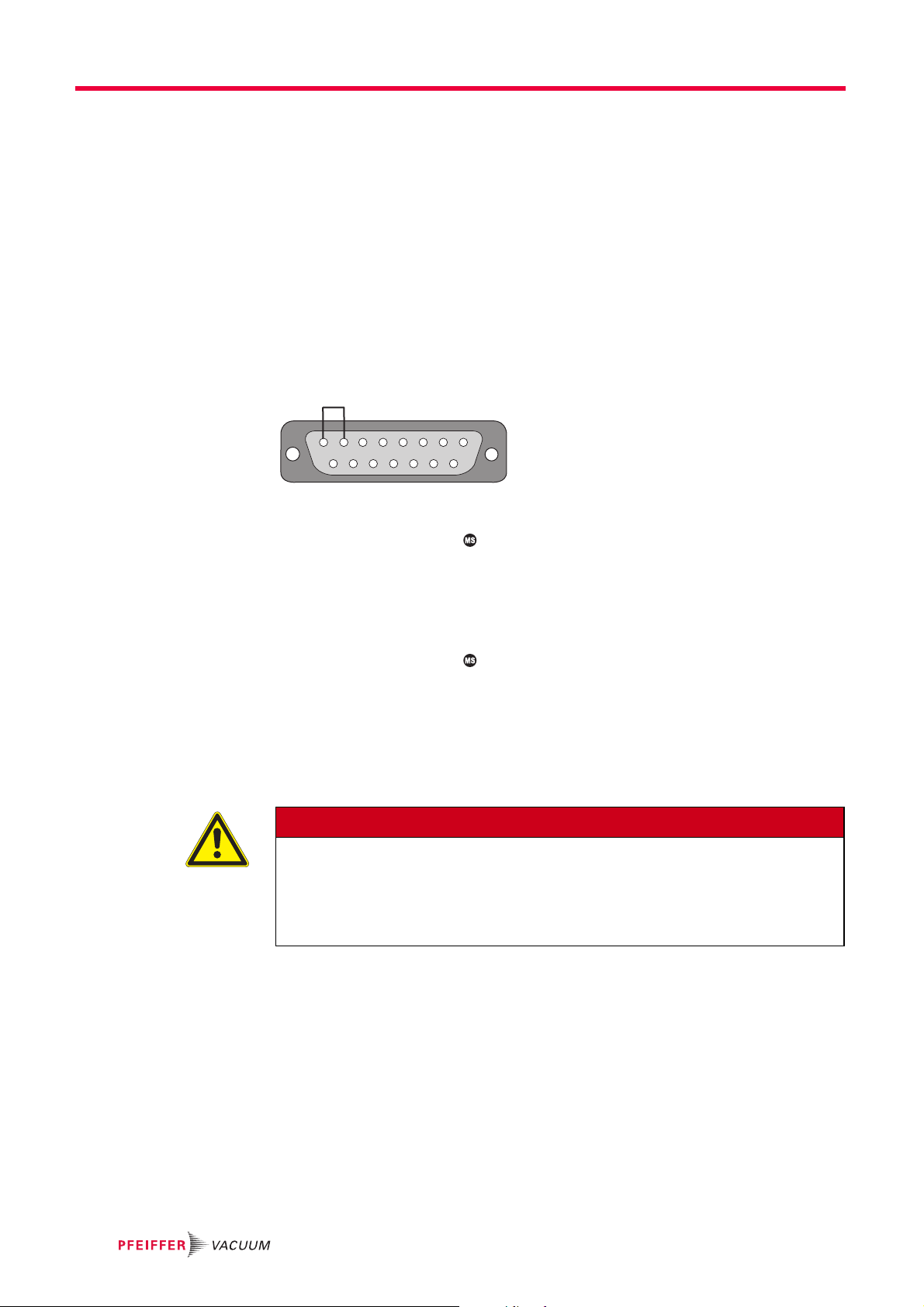

5.6.1 Connections

The male D-Sub 15 pin connector (see 4.2) is used to control and monitor the pump us-

ing a computer. It allows also the installation of several pumps in a network. The default

serial link setting can be modified from the connected computer, according to the com-

mand list (see 5.6.3).

WARNING

WARNING

Description Default setting

Serial link RS-485

Transmission speed 9600 bauds

Date word length 8 bits

Parity none (no parity)

Stop bit 1

Echo no

Pin Assignment

8GND

3 RS-485 : V2 RS-485 : V+

1 +5 VDC -10 mA max (only for RS-485)

It is the operator's responsibility to use shielded links and connections in compliance with

EMC and electrical safety standards.

V+(A)V-(B)

(RS 485)(RS 485)GND

+5 V-10 mA max.

8

1567234

91015 14 13 12 11

RS-485 connection

A computer manages several pumps (P1, P2, Pn, ...) using an RS-485 serial link via RS485 connector. This parallel wiring allows communication between the pumps even if a

pump is disconnected.

The wiring of the product at the end of line Pn* and the wiring of a single product on the

network is specific (see figure below).

20

Installation

5.6.2 Setting

The control commands

8

15

1,5 kΩ / 1/4 W1,5 kΩ / 1/4 W

4

3

2

1

9

Pn*

RS-485

communication

box

8

15

4

3

2

9

1

P1 P2

8

15

4

3

2

9

1

When the wiring is done, to allow pump control via serial link, proceed as follows:

Position the mains switch to I position.

Send an order via the serial link: this order has no priority on remote control mode via

dry contacts (see 5.5.1).

Header character The default setting is the decimal code 035 of the character #

Address Number given to the pump, 3 characters

Order Command sent on serial link, 3 characters

Parameter The number of characters depends on the command

End character This is the message end character. Default setting: ASCII code 13 <CR>.

Example:

The responses

Header character Pump address Order Parameter End character

# ADR ODR XXXX <CR>

Header character Pump address Order Parameter En d ch a r a cter

# ADR yyyxxxabc <CR>

Interpretation of the responses

OK OK or specific response to the order.

ERR0 Setting fault.

ERR1 Context fault.

ERR2 Parameter fault.

ERR3 Order fault.

Example of dialog

Order: #005ACPON<CR>

Response: #005,OK<CR>

21

Installation

5.6.3 Command list

Setting Parameter Description Functions Min Max

ADR xxx Number given to the pump in

IDN none Identification of the connected

NSP none Switches from set point speed

RPM nnnn* Set point speed setting Example: #adrRPMnnnn<CR>

SBY none Switches from stand-by speed

ACP ON or OFF Start/Stop the pump The pump rotation starts with ACPON, pump stops with ACPOFF.

the serial link

product

to the nominal speed

to the default setting

Can be used only when the pump is stopped.

adr = pump address before change

aaa = new pump address

When the address of the product is unknown, it is possible to recover pump address only

if this pump is connected in the link. For this, send the order:

#???ADR<CR>

??? chain of three ASCII characters.

Example: #adr,ACP 15- VB.05<CR>

Returns the type of pump connected with the computer (12345), the software of the

pump (V) followed by the software release (zz).

Example: #adrNSP<CR>

Nominal speed = 100 Hz

Set point speed can be set in steps of 10 min

ACP 15, maximum speed : 100 Hz

Before changing the set point speed with RPM order, it is mandatory to send the

SBY order.

Stand-by speed is reset at 35 Hz.

-1

: minimum speed : 35 Hz

000 255

35 100

Hz

* Note: Only speeds recommended in the rotational speed setting table are allowed

(see 5.5.2).

Order Parameter Description Functions

STA none Pump status Example: #adr,xxxxxx yyyyyy,zzzzzz,sssss,iiii,www,ppp,vvv,ttttt<CR>

sssss = pump rotation speed (min

iiii = motor power (W)

xxxxxx: status bits

www = reserved (by default 000 )

Bit 5 4 3 2 1 0

00 0 0 0

1- - 1

-1

)

pump running1set nominal

ppp = frequency converter temperature (°C)

vvv = reserver (by default 000)

tttt = pump operating time (from first start-up) (h)

set speed set

point

speed

00

1

stand-by

speed

reached

-

yyyyyy : fault bits

zzzzzz: alert bits

Bit 5 4 3 2 1 0

0-00000

11

power transistor not

powered

(red LED

copy = 1)

Bit 5 4 3 2 1 0

000000OFF

1------

1

motor temperature too

high

1

motor current

too high

---

22

6Operation

6.1 Prerequisites to use

Risk associated with process gases

The user and/or integrator of the product is/are fully responsible for the operational safety conditions of the equipment. The manufacturer has no control over the types of gases

this pump is exposed to. Frequently process gases are toxic, flammable, corrosive, explosive and/or otherwise reactive. It is the user and/or the integrator's responsibility to

follow the necessary safety requirements. Toxic gases can cause serious injury or

death. Operators and users must:

Take the appropriate safety recommendations to prevent injury. Consult the respon-

sible department for instructions and safety information.

Hazardous gases from the pump can cause serious injury or death. Regula-

tions require to connect the pump’s exhaust to a facility hazardous gas exhaust system which incorporates appropriate filters, scrubbers, etc. This system

must meet all air and water regulations.

Check that the pump is correctly connected to the equipment (see Installation).

Contact the service center for further information.

Operation

WARNING

WARNING

Electric shock hazard

Some components have capacitors charged to over 60VDC. When power is switched

off, they maintain this charge for some time. Residual voltages from the filter capacitors

can cause electric shocks all the way back to the mains plug.

Wait 5 minutes after power-off before commencing any work on the product.

DANGER

Risk due to auto-restart

When the pump has been stopped following a temperature rise, the pump automati-

cally restarts when the ambient temperature returns to within the permissible

range.

Provide a device integrated with the host tool equipment to warn or avoid this auto-

restart.

Take all the measures required to prevent risks resulting from this type of operation.

WARNING

Increased noise emission

At the beginning of the chamber’s pumping and at high pressure operation, the pump

noise level may temporarily exceed 70 dB (A).

Connect the exhaust port to a chimney or to an exhaust pipe.

Install an external silencer on the pump exhaust (see Accessories chapter).

Wear hearing protection.

NOTICE

Operating fluids

The pump is delivered with filled oil charge. The oil safety data sheet concerning the lubricant (MSDS) are available on our website.

Do not modify the lubricant level.

Do not drain the pump: the draining will be done during pump overhaul in our repair

service center.

23

Operation

NOTICE

Thermal safety

The pump is fitted with temperature sensors which prevent operation or start-up when

the temperature of the pump body is < 12 °C or > 40 °C. In order for the pump to operate:

Operate the pump within the required temperature range (see 12.3.1).

Avoid sudden changes of ambient temperature when the pump is running.

The pump automatically restarts when the thermal safety fault disappears.

Before each switching on:

Check that the pump inlet is connected to the pumping line.

Check that exhaust pipe line is not clogged and that all the valves in the exhaust sys-

tem are open.

Connect the pump to the mains supply.

Check that the inlet pressure is not higher than atmospheric pressure. A too high pres-

sure can damage the product.

Check that the ambient temperature is well within the permitted operating range (see

12.3.1).

Check the exhaust line during pumping to prevent the risks related to excess over-

pressure.

24

6.2 Matrix gas/applications

You are advised to use the appropriate pump version according to the applications and

the nature of the gases pumped and apply the usual precautions to guarantee the reliability and safety of the procedure.

Ensure that the gases pumped are compatible with the various materials (see 8.3).

Type of gas or vapor pumped Recommended equip-

ment

Neutral or inert gas Air, nitrogen, CO2, noble gas

or permanently non-reactive

gas

Gas containing condensable vapor

Reactive and/or corrosive

gas excluding halogens

(F

, CL2, Fr2, I2)

2

Inflammable or explosive

gas

● Cyclic pumping of volume

● Pumping large volumes

● Presence of degassing ma-

terial: plastic, elastomer,

polymer, etc.

● Drying

Pumping reactive gas:

● Oxidising

● Base

● Acid

1. Reference in USA NFPA 69-2002, chap. 6.3.1 Combustible concentration threshold;

LEL = Lower Explosion Limit

2. MOC = Minimum Oxygen Concentration

None See use of gas ballast for

Avoid condensation which

reduces the performance

and reliability of the pump

Dilute the corrosive gas to

reduce its activity.

Avoid the presence of humidity which increases the

reactivity of acids and bases.

Work outside the flammability range of the product.

(ideal = 25 to 50 % of the

1

LEL

and/or below the

2

MOC)

Actions/Monitoring to be

done

purging (see 6.4).

Before and after pumping on

the installation, allow the pump

to run for 1 hour at ultimate

pressure with the gas ballast

open (inlet closed).

Dilute the gas to lower its con-

centration and avoid any condensation.

Use the purge.

Avoid excess pressure at the

exhaust.

Check that the pump materials

and their sealing are compatible with the pumped vapors.

Dilute the pumped gas up-

stream or in the pump to lower

its concentration below the

lower flammability limit via

purge and/or the neutral gas

ballast.

Dilute the gas discharged by

the pump to lower its concentration to 25% of the LEL via

purge and/or the inert gas ballast.

Avoid any build-up of gas in

the pumping line.

Avoid air or humidity back-

streaming by maintaining a

gas speed > 0.1 m/s in the exhaust line.

Check the tightness of the in-

stallation.

Operation

Minimum configuration

ACP ACPG

Gas ballast

open

Gas ballast

closed

Purge

open

25

Operation

1567234

91015 14 13 12 11

8

6.3 Different control modes

3 control modes are available:

LOCAL The pump is controlled with I/O mains switch. The pump is running as a stand-alone part

of the equipment on which it has been integrated.

REMOTE The pump is remote controlled. The pump rotational speed is set by the opening and

closing dry contacts on the remote control connector (see 6.3.2).

SERIAL LINK The pump is remote-controlled by the commands transmitted via the serial link RS-

485(see 6.3.3).

6.3.1 Local mode operation

In local mode, the pump can run only if the cover plug is fitted on the remote control

connector. This cover plug is delivered with the pump.

Fig. 4: 15-pin plug with strap for operation in local mode

Pump start-up Position the mains switch to I position: pump starts automatically.

An hour counter displays the pump model and running time in hours.

G version: allow the purge to run (see 6.5).

Pump shut-down Isolate the pump in the pumping line (isolation valve at pump inlet, closed) and let it

to run for 1 hour with gas ballast or purge open (see 6.4).

Position the mains switch to O position, and/or activate the mains circuit breaker:

pump stops.

Prolonged stop

If the pump has to be stopped for a prolonged period, apply the Decommissioning pro-

cedure (see 8).

Restart

DANGER

Risk due to auto-start

In local mode, the pump starts automatically when the mains switch is switch to I.

Install an interlock safety device in the equipment/tool to warn the operator or to avoid

this type of operation.

Take all the measures required to prevent risks resulting from this type of operation.

Restart after emergency stop (from the equipment)

The equipment/tool emergency off manages the pump stop. To restart the pump after an

emergency stop, it is necessary to:

fix the problem,

unlock the emergency button from the equipment/tool: the pump restarts automatical-

ly.

Restart after power failure

After a power failure, the pumps restarts automatically when the power comes back.

26

6.3.2 Remote mode operation

Wire and connect the remote connector located at the rear of the pump (see 5.5).

Pump start-up Position the mains switch to I position: the pump is powered.

Send a ’Start’ pump order via S1 contact :

– the pump starts up and runs at the speed set on the contacts of the remote con-

nector.

G version: allow the purge to run (see 6.5).

Note: when S1 is closed, sending of ACPON or ACPOFF via the serial link doesn’t disturb the operation (’context error’ response).

Rotation speed

Pump performances are guaranteed for a nominal speed of 100 Hz. Changing the rota-

tion speed affects the pumping speed and the ultimate pressure of the pump. In low

speed, it is the customer's responsibility to find the correct settings according to the

pump and the process.

For the safety of the pump, do not exceed the maximum frequency.

Do not run the pump continuously at speeds ≤ 60 Hz.

Operation

NOTICE

Pump shut-down Isolate the pump in the pumping line (isolation valve at pump inlet, closed) and let it

to run for 1 hour with gas ballast or purge open (see 6.4).

Send a ’Stop’ pump order via S1: the pump stops.

Switching off

Position the mains switch to O position.

Prolonged stop

If the pump has to be stopped for a prolonged period, apply the Decommissioning pro-

cedure (see 8).

Restart

DANGER

Risk due to auto-start

In local mode, the pump starts automatically when the mains switch is switch to I.

Install an interlock safety device in the equipment/tool to warn the operator or to avoid

this type of operation.

Take all the measures required to prevent risks resulting from this type of operation.

Restart after emergency stop (from the equipment)

The equipment/tool emergency off manages the pump stop. To restart the pump after an

emergency stop, it is necessary to:

fix the problem,

unlock the emergency button from the equipment/tool: the pump restarts automatical-

ly.

Restart after power failure

After a power failure, the pumps restarts automatically when the power comes back.

27

Operation

6.3.3 RS-485 serial link operation

Wire and connect the serial link pins from the remote connector (see 5.6.1)

Pump start-up Position the mains switch to I position: the pump is powered.

Send an ’ACPON’ order via the serial link (see 5.6.3) :

– the pump starts and runs at the speed set on the serial link parameters.

G version: allow the purge to run (see 6.5).

Note : when ACPON is activate, if S1 contact on remote connector is closed then open,

then the pump stops.

Rotation speed

Pump performances are guaranteed for a nominal speed of 100 Hz. Changing the rota-

tion speed affects the pumping speed and the ultimate pressure of the pump. In low

speed, it is the customer's responsibility to find the correct settings according to the

pump and the process.

For the safety of the pump, do not exceed the maximum frequency.

Do not run the pump continuously at speeds ≤ 60 Hz.

NOTICE

Pump shut-down Isolate the pump in the pumping line (isolation valve at pump inlet, closed) and let it

to run for 1 hour with gas ballast or purge open (see 6.4).

Send an ’ACPOFF’ order via the serial link: the pump stops. (see 5.6.3).

Restart after emergency stop (from the equipment)

The equipment/tool emergency off manages the pump stop. To restart the pump after an

emergency stop, it is necessary to:

fix the problem,

unlock the emergency button form the equipment/tool,

send an ’ACPON’ order via the serial link.

Restart after power failure

After a power failure, send ’ACPON’ order via the serial link to restart the pump.

Switching off

Position the mains switch to O position.

Prolonged stop

If the pump has to be stopped for a prolonged period, apply the Decommissioning pro-

cedure (see 8).

28

6.3.4 Operation monitoring

The pump equipped with a three-phase frequency converter has two LED at the rear that

indicate the pump operating status.

LED LED status Display Description

Green Off No power supply

On, constant light The pump is powered.

Red Off No default

On, constant light ● During pump start-up, LED is On when the selected

On, flashing The thermal safety indicates that the pump temperature

Fig. 5: LED meaning on a pump equipped with a three phase frequency converter

6.4 Gas ballast operation

Principle The user must take the appropriate measures in case of condensable vapors pumping

or when gas ballast use is required (see 6.2).

When condensable vapors or moist air are being pumped, gas is compressed beyond its

saturated vapor pressure in the compression phase. It can condense, impairing pump

performance.

The gas ballast can be used to inject a certain quantity of air (neutral or dry gas) into the

pump during the ‘compression’ phase so that the partial pressure of the pumped gas is

less than its saturated vapor pressure at the temperature of the pump. Condensation is

therefore impossible if this limit is not reached.

The saturated vapor pressure of a body is higher when the system is hot than when it is

cold; therefore, the pump must reach operating temperature before pumping condensable vapors.

Using the gas ballast increases the ultimate pressure of the pump as well as the

temperature.

Commissioning To better pump with condensable vapors or moist air, it is necessary to operate with a hot

pump. Proceed as follows:

Operation

The pump has reached the selected speed.

speed is not reached.

● Presence of a default which prevents the pump running.

is too low, or too high (imminent shutdown or starting

impossible).

Isolate the pump from the system (inlet isolation valve closed) and allow it to operate

for 1 hour with the gas ballast open.

Then, open the isolation valve: the pump operates in the best conditions by reducing

the risk of condensation inside the pump.

Recommendations To ensure the proper discharge by the exhaust of condensable vapors, avoid to connect

an ES25S type silencer.

The gas ballast can be automated. It is an accessory available upon request (see 11).

Besides, the gas ballast could be supplied with filtered dry air. Contact us.

Gas ballast with permanent

filter

Fig. 6: The various gas ballast models

Gas ballast closed with a

plug

ON/OFF manual gas ballast

29

Operation

6.5 Purge operation

Principle A gas purge circuit protects the low and high pressure bearings and dilutes trace

amounts of corrosive gases.

Commissioning When the inert gas pipe is connected on purge connection (see 5.2.3):

Inject inert gas purge according to the flow rate values (see 12.2).

Recommendations To ensure the proper discharge by the exhaust of corrosive gases, avoid to connect an

ES25S type silencer.

Inert gas connection (see 4.2).

30

7 Maintenance

In case of presence of corrosive gases, users are advised to observe the following precautions before working on the product.

7.1 Safety and maintenance information

Duty to inform

Every person who is involved in maintenance and servicing work on the pump must read

and follow the safety-relevant parts of all associated documents.

Exclusion of liability

Pfeiffer Vacuum accepts no responsibility concerning equipment damage, disrupted

service or physical injury resulting from maintenance carried out by technicians who

have not been trained in safety rules (EMC, electrical hazards, chemical pollution). Liability and warranty claims shall be inadmissible in this case.

Risk to the health in the event of contact with toxic substances

The vacuum pump, pumping line components, and operating media may be contaminated with toxic, corrosive, reactive, or radioactive materials, depending on the process.

Wear appropriate safety equipment when pump is disconnected for maintenance, or

reinstalled, and also for oil filling and draining.

Ventilate the premises well.

Do not eliminate maintenance waste via standard disposal channels. Have it de-

stroyed by a qualified company if necessary.

Install the inlet and exhaust blanking plates, accessories delivered with the pump or

available as accessories (see chapter Accessories).

Maintenance

NOTICE

DANGER

WARNING

Electric shock hazard in case of contact

When the product's mains switch is set at O, some internal components still have an

electrical charge.

Make sure that the mains connection is always visible and accessible so that it can

be unplugged at any time.

Disconnect the power cable from all power sources before starting any work on the

product.

WARNING

Tightness after maintenance

Insufficient tightness after servicing could result in chemical hazards.

Always perform a leak test after maintenance.

WARNING

Risk of injury through hot surfaces

The exhaust temperature remains high even after the pump has stopped.

Wait for the product to cool completely before carrying out any operations on it.

31

Maintenance

7.1.1 How to contact us

WARNING

Other localised hazardous energies

Electrical circuits and other pressurized circuits, such as nitrogen and water are potential hazards.

Always lock out these energy sources before working on the product.

● Ensure that the maintenance technician is trained in the safety rules concerning

pumped gases.

● Disconnect the mains cable on the product from all sources of power before carrying

out any work on the product.

● Wait 5 minutes after switching off the electricity supply before carrying out any operations on the electrical components.

● Collect the residues from the processes and call in a competent organisation to destroy them.

● Always protect the inlet and exhaust surfaces.

Personnel trained by the manufacturer must perform the overhaul. Contact your nearest

service center at the following e-mail address: support.service@adixen.fr

7.2 Maintenance frequency

Description Frequency ACP 15 ACP 15 G

Pump overhaul by Pfeiffer Vacuum service center.

Maintenance frequencies are typical values for non corrosive applications. For applications using G version pump, these values can be reduced. Contact the service center

(see 10).

In general no maintenance is required before product overhaul in your service

center(see 10).

Life-time Under normal operating conditions (at ambient temperature, low humidity and neutral

pumped gas), in a non-polluted environment, a new pump which is regularly maintained

according to the instructions in this manual (subject to the components becoming obsolete) has a life-time greater than 10 years.

7.3 Maintenance on the customer’s site

The pump does not require any maintenance on the customer’s site apart from that described in this manual. All other maintenance must be carried out by your service center

(see 10).

Clean the outer surfaces of the product using a clean, lint-free cloth and a product that

will not damage the screen-printed surfaces and adhesive labels.

20,000 h or 4 years

32

Cleaning of the air ventilation grids with a cloth to remove dust. Do not use com-

pressed air blower.

7.4 Standard repair exchange

To proceed with a standard exchange, key steps must be followed in sequential order:

– Disconnecting the pump from the installation (see 7.4.1)

– Conditioning the pump for shipping (see 7.4.2)

– Declaration of contamination (see 10)

– Handling the new pump (see 3)

– Installing the new pump (see 5)

When returning a product to our service center, please consult the Service procedure

(see 10) and fill in the contamination declaration available on our website.

7.4.1 Disconnecting the pump from the installation

Risk to the health in the event of contact with toxic substances

During pump disconnection, operator could be in contact with process residues on the

exhaust that could cause severe injury or death.

Take the appropriate safety recommendations to prevent injury. Consult the depart-

ment manager for instructions and safety information.

Maintenance

DANGER

Position the mains switch to O position.

Switch off your main circuit breaker.

Disconnect the main plug (see 5.4.2).

Disconnect the nitrogen purge connector.

Disconnect the pump from the inlet piping and fit a blanking plate on the inlet (see 1 1).

Disconnect the pump from the exhaust and fit a blanking plate on the exhaust port

(see 11).

Remove the pump from the installation.

7.4.2 Conditioning the pump for shipping

After use in clean appli-

cations

After use with traces of

corrosive gases

Product transport and

shipping

Install the connecting accessories provided with the pump when it was first delivered.

Contact the service center to order accessories if necessary (see 11).

Join the cover plug (delivered with the pump) connected to the remote connector.

Respect safety instructions before working on the product (see 2.1) and (see 7.1).

Install the connecting accessories allowing to seal the pump (see 11).

Join the cover plug (delivered with the pump) connected to the remote connector.

For product transport and shipping, pack it in the original packing and apply the instruc-

tions from the Service procedure (see 10).

33

Decommissioning

8 Decommissioning

8.1 Shutting down for longer periods

Stop the pump according to pump shut-down procedure (see 6.3.1), (see 6.3.2) or

(see 6.3.3).

Disconnect the pump from the installation (see 7.4.1).

Store the pump (see 3.2).

8.2 Re-starting

To restart the pump after a prolonged storage, refer to the installation instructions (see 5).

8.3 Disposal

According to the regulations 2012/19/EC about Waste of electrical and electronic equipment, and 2011/65/EC about Restriction of Hazardous substances, the manufacturer

provides a paid recycling service for the end of life of the equipment.

Any obligation of the manufacturer to take back such equipment shall apply only to complete not amended or modified equipment, using Pfeiffer Vacuum SAS original spare

parts, delivered byPfeiffer Vacuum, containing e.g. all its components and subassemblies.

This obligation will not cover the shipping cost to a Pfeiffer Vacuum reclamation facility.

Before returning the product, please consult the Service procedure (see 10). Fill in the

declaration of contamination form available on our website. Attach it to the product before shipping to the closest service-repair office.

WARNING

Environmental protection

The product or its components must be disposed of in accordance with the applicable

regulations relating to environmental protection and human health, with a view to reducing natural resource waste and preventing pollution.

The materials Our products contain different materials which must be recycled:

Description SD version G version

Jet - Brass

Purge line - Stainless steel

Val ves FP M

O-rings, lip seals FPM / NBR / PTFE

Shaft, spring, inlet filter Stainless steel

Stators, lobes Aluminum, aluminum alloy

Screws, worked pins, deflectors Stainless steel

Ball barings Steel, PFPE grease

Inlet and exhaust flanges Aluminum

Take particular precautions for:

● fluoroelastomers which may breakdown if they are subjected to high temperatures.

● components in contact with the products resulting from the processes which may have

been contaminated.

+ Al

2O3

coating

34

This list of materials corresponds to the products listed in the chapter (see 1.1). Contact

us for products with specific features.

Malfunctions

9 Malfunctions

Read the safety instructions for maintenance (see 7.1).

9.1 Trouble at pump start-up

Symptom Cause Remedy

The pump does not start and the

fan does not run

The pump does not start but the fan

runs

9.2 The pump runs incorrectly

Symptom Cause Remedy

Pump runs intermittently Temperature Check the pump ventilation conditions (see 5.1).

Pump noisy Gas ballast Check if the gas ballast is open.

Bad vacuum Gas ballast Check if the gas ballast is open.

Mains switch Check the mains switch position to I.

The pump supply voltage is not compatible with

the equipment's power configuration

Main cable not correctly connected or damaged Check / replace the main power cable.

Other problem Contact your service center.

Temperature Check the pump ventilation conditions (see 5.1)

Remote control connector wiring Check that the cover plug is properly connected to

Other problem Contact your service center.

The pump supply voltage is not compatible with

the equipment's power configuration

Other problem Contact your service center.

The pressure does not go down - leak in the installation

Vibration Check that the pump is properly attached to the

Other problem Contact your service center.

Purge (G and CV versions) if the purge is used: check the purge connection

Rotation speed If remote controlled via RS-485: check the value of

Pumping of condensable vapors If the application allows it, let the pump to run for

Defective gauge Check the accuracy of the measurement means.

Leak in the installation Perform a leak test on the pumping line.

Other problem Contact your service center.

Check the equipment’s voltage corresponds to re-

quired power voltage (see 1.2.4).

Wait for 1 hour at ambient temperature between

12 °C et 40 °C. The pump must start automatically

(see 6.1).

the remote connector at the rear of the pump.

Check the equipment’s voltage corresponds to re-

quired power voltage (see 1.2.4).

Warning: if the application requires it, the gas ballast must remain open despite the noise!

Check the pressure at the pump inlet

(see 6.1).

frame.

Warning: if the application requires it, the gas ballast must remain open despite the noise!

between pump and installation.

If the purge is not used: check the tightness of the

plug installed on the purge port.

the speed set point (see 5.6.3).

If remote controlled via dry contacts: check the

contact setting (see 5.5.2).

30 min to 1 hour with gas ballast open; this evacuates the condensable vapors.

35

Service

10 Service

Pfeiffer Vacuum offers first-class customer service!

● On-Site maintenance for many products

● Overhaul/repair at the nearby Service Location

● Fast replacement with refurbished exchange products in mint condition

● Advice on the most cost-efficient and quickest solution

Detailed information, addresses and forms at: www.pfeiffer-vacuum.com (Service).

Overhaul and repair at the Pfeiffer Vacuum Service Center

The following general recommendations will ensure a fast, smooth servicing process:

Fill out the "Service Request/Product Return" form and send it to your local Pfeiffer

Vacuum Service contact.

Include the confirmation on the service request from Pfeiffer Vacuum with your ship-

ment.

Fill out the declaration of contamination and include it in the shipment (mandatory!).

The Declaration of contamination is valid for any product/device including a part exposed to vacuum.

Dismantle all accessories and keep them.

Close all the flange opening ports by using the original protective covers or metallic

airtight blank flanges for contaminated devices.

If possible, send the pump or unit in its original packaging.

Sending contaminated pumps or devices

No devices will be accepted if they are contaminated with micro-biological, explosive, or

radioactive substances. "Hazardous substances" are substances and compounds in accordance with the hazardous goods regulations (current version).

Neutralize the pump by flushing it with nitrogen or dry air.

Close all openings airtight.

Seal the pump or device in suitable protective film.

Return the pump/device only in a suitable and sturdy transport container and send it

in while following applicable transport conditions.

Pump or device returned without declaration of contamination form fully completed and/

or not secured in suitable packaging will be decontaminated and/or returned at the shipper’s expense.

Exchange or repair

The factory operating parameters are always pre-set with exchange or repaired devices.

If you use specific parameters for your application, you have to set these again.

Service orders

All service orders are carried out exclusively according to our general terms and conditions for the repair and maintenance, available on our website.

36

Accessories

11 Accessories

Accessory Description Dimension Model P/N

Inlet filter Installed on the pump inlet, it allows to collect particles

Exhaust silencer It allows to reduce noise level at the exhaust when the

Noise reduction cover In order to reduce significantly noise level.

Sound enclosure kit In order to reduce significantly noise level.

Frequency converter interface

plug

Pump fastening kit It allows to fasten the pump in the equipment with

Wheel kit It allows to install 4 wheels on the frame to move eas-

Automatic gas ballast It ensures tightness when the pump stops or it can be

Isolation valve Installed upstream of the pump, it enables the pump to

Connecting accessories Centering ring with FPM o-ring DN 25 ISO-KF

with a diameter greater than 25 microns (in clean applications such as vacuum packing, metallurgy, lamp

manufacture, evaporation, etc...).

pump operates at high pressures, on clean applications.

Noise level reduction at atmospheric pressure (12 dBA).

Noise level reduction (-5 dBA) at 35 °C. max. ambient

temperature

Noise level reduction (-10 dBA) at 32 °C. max. ambient temperature.

and to manage a power supply up to 24 VDC - 1 A. 112851

plates (M6 screws for frame assembly not supplied)

(compatible with all pump models).

ier the pump (compatible with all pump models).

used to remote control cyclical air inlets (compatible

with all pump models).

be reset to the atmospheric pressure by isolating it

from the pumping line.

Blanking plate in stainless steel DN 25 ISO-KF

Quick-connect clamp DN 25 ISO-KF

Table 1: Refer to the accessory operating instructions to install the accessory.

DN 25 ISO-KF IPF 25 111649

DN 25 ISO-KF ES25S 109873

NRC 15 111968

SEK 15 122480

112846

111138S

230 V 50/60Hz

200 V 50/60 Hz

110 V 60 Hz

100 V 50/60 Hz

24VDC

ISV 25 - 240 V 50/60 Hz

ISV 25 - 220 V 50/60 Hz

ISV 25 - 200 V 50/60 Hz

ISV 25- 110 V 50/60 Hz

ISV 25 -100 V 50/60 Hz

ISV 25 - 24VDC

ISV 40 - 240 V 50/60 Hz

ISV 40 - 220 V 50/60 Hz

ISV 40 - 200 V 50/60 Hz

ISV 40- 110 V 50/60 Hz

ISV 40 - 100V 50/60 Hz

ISV 40 - 24VDC

DN 16 ISO-KF

DN 16 ISO-KF

DN 16 ISO-KF

114812

114815

114813

114814