Temperature probes

type T/TW

Contents

Content

1 General

1 Preface

1.1 Introduction

2 General instructions

1.2 Scope

2.1 Operating range

1.3 Continuous glass monitoring

2.2 Warnings contained in the operating

2 Safety instructions

instructions (OI)

2.1 General safety notes

2.3 Notes on deliveries

2.2 Product-specific safety notes

2.4 Transport and storage

2.3 Safety instructions for accessing reactors

2.5 Warranty notes

2.4 Avoiding damages to the glass

2.6 Notes on return deliveries

3 Storage

3 Safety

4 Transport

3.1 Proper use

5 Product description

3.2 Qualified personnel

4 Glass-lined temperature probes

4.1 Probe types

4.2 Joint features and properties

4.3 General information

4.4 Avoiding damages to peripheral devices

Contents

5 Temperature probe type T

5.1 Measuring principle

5.2 Construction of the T probe

1 General

5.3 Transmitter TTH300 Ex

1.1 Introduction

5.4 Technical data of T probe

1.2 Scope

5.5 Installation of the T probe

1.3 Continuous glass monitoring

5.6 Connection of the T probe

5.7 Start-up and maintenance of the T probe

2 Safety instructions

5.8 Calibration of the T probe

2.1 General safety notes

5.9 Explosion protection

2.2 Product-specific safety notes

6 Temperature probe type TW

2.3 Safety instructions for accessing

6.1 Measuring principle

reactors

6.2 Construction of the TW probe

6.3 Transmitter TTH300 Ex

2.4 Avoiding damages to the glass

6.4 Technical data of TW probe

3 Storage

6.5 Installation of the TW probe

4 Transport

6.6 Connection of the TW probe

5 Product description

6.7 Start-up and maintenance of the TW probe

6.8 Calibrating the TW probe

6.9 Explosion protection

Operating Instructions

302-10 e

Annex 1

PTB 03 ATEX 2132 X

Annex 2

Declaration of conformity

Annex 3

A 3.1 Potentially hazardous

atmospheres

A 3.2 Atmospheric conditions

A 3.3 Equipotential bonding

A 3.4 Lightning protection

A 3.5 Quatro-Pipe

Temperature probes type T/TW

Temperature probes type T/TW

1 Preface

The present operating instructions are

designed to familiarize users with the

construction of the glass-lined temperature probes and their use.

The operating instructions should be

accessible to the operating and maintenance personnel in order to ensure that

all necessary information is available for

any assembly and maintenance work.

By knowing these operating instructions

(OI), you can avoid damage to the measuring equipment and ensure trouble-free

operation. The information contained

in these operating instructions corresponds to the state of the art at the time

it is printed and is provided to the best

of our knowledge. We reserve the right to

include any improvements, amendments

and new developments in the operating

instructions without prior notice. The

actual design of products may differ from

the information provided in the catalog

if warranted by technical modifications

resulting from product improvements.

The proposal submitted by Pfaudler for

a concrete application will be binding in

this case. The latest edition will always

supersede all previous ones.

The present operating instructions are

made available to our customers and

interested parties free of charge. Reprints

and copies as well as transformation into

electronic forms, in whole or in part, shall

require our written approval.

2.2 Warnings contained in the operating instructions (OI)

In the operating instructions, the

danger symbol m is used to draw

your attention to especially important safety instructions. Compliance

with these instructions is mandatory, because adherence to the

instructions can avoid severe damage to people and/or equipment.

2.3 Notes on deliveries

The respective scope of delivery is specified on the shipping documents attached

to the shipment and corresponds to the

valid purchase agreement.

Check that the items delivered are complete and intact.

If possible, keep the packing material for

re-use for possible return shipments.

2.4 Transport and storage

The probes should only be transported

and stored in their closed original packaging. Where it is no longer available, the

probes must be protected against shock

and impacts. In order to guarantee an

as-new condition of the probes, maintain

the following storage conditions:

n dry and dust-free

n steady temperature and ventilation

The probes do not need any preservatives, they are resistant to normal environmental influences.

2.6 Notes on return deliveries

Before sending used probes to Pfaudler

Werke GmbH or third parties for repair

or other purposes, all parts must be

cleaned and decontaminated.

To protect our staff and for insurance

reasons, your return shipment must be

accompanied by a clearance certificate

(refer to publication 332) on which you

confirm that the probe was properly

cleaned and decontaminated. You may

obtain a form sheet for this purpose

from us on request.

3 Safety

For detailed safety instructions and information concerning explosion protection,

please refer to the end of the operating

instructions.

3.1 Proper use

Any use of the probe for purposes other

than described in the present operating instructions will adversely affect the

safety and functioning of the measuring

device and is therefore not allowed.

It is important to note the safety instructions applicable to the electrical systems

and equipment and all explosion protection provisions, if any.

m Do not practice any working

me th od s wh ic h ma y en d a n ge r sa fe ty.

All rights reserved.

2 General instructions

2.1 Operating range

Glass-lined temperature probes are used

to measure the product temperature in

reactors and storage vessels as well as

in pipelines.

For the resistance of the probes, please

refer to our publication no. 614.

Never operate this measuring device

outside its permissible operating conditions.

2

2.5 Warranty notes

Any warranty claims shall not be extended

or limited by the information contained in

the present operating instructions.

For the exact warranty conditions, please

refer to the Terms of Sale of Pfaudler

Werke GmbH as amended.

3.2 Qualified personnel

The probe may only be installed, started

up and serviced by authorized personnel

with special skills in measuring technolog y and in strict compliance with the present Operating Instructions as well as the

valid provisions.

The failure to observe these instructions

– no matter whether intentionally or negligently – releases Pfaudler Werke GmbH

from all liability and warranty claims.

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 2

4 Glass-lined temperature

probes

t [%]

Temperature probes type T/TW

Temperature probes type T/TW

4.1 Probe types

Pfaudler offers two different types of

100

probes for temperature measurement

which operate according to different

physical measuring principles.

These probe types are:

n Temperature probe type T

E T/TW Ta

With this probe, a thermocouple performs the sensing function. Thermocouples are based on the physical

50

effect of a charge shift in an electrical

conductor (wire) along a temperature

gradient. The free electrons move

from the hot end of the wire to the

cold end of the wire.

n Temperature probe type TW

This probe is equipped with a resistance thermometer as the sensor.

Resistance thermometers are based

on the physical effect that the electrical resistance of conductors and

semiconductors changes subject to

the temperature.

4.2 Joint features and properties

Both probe types have a sensor that is

fused into the glass. Thus, the sensor

is excellently protected against aggressive media, and its placed directly in the

product. This arrangement offers users

the following advantages:

n The probes have very short response

times. The response behavior of the

measuring probes type T and TW

is shown in Fig. 1 in comparison to

0 10 20 30 40 50 [s]

Measured in inside the reactor (100 l) with water at 120 rpm

T/TW measuring probe type T/TW on

thermometer well, D = 40 mm

Ta thermocouple with tantalum sensor in

thermometer well, D = 40 mm

E Reference measurement with unprotected

pallaplat element (cannot be used in glass-lined reactor)

Fig. 1 Time response

MT_05_00001

probes with plugged-in sensors.

n The sensors of the probes have not

been simply screwed-in, producing

error-prone sealing surfaces in the

product.

n Due to the quick and precise tem-

perature measurement, the production process can be controlled safely

and economically. In many cases, the

product quality is also improved.

n The sensors are not subject to ageing

because they are made of extremely

pure and highly resistant noble metals and have been fused into the glass

layer in a chemically inert process.

Glass is absolutely diffusion-tight,

therefore, reaction with hydrogen is

also excluded.

© Pfaudler GmbH ·

OI 302-8 e

© Pfaudler GmbH 3

3

Temperature probes type T/TW

Temperature probes type T/TW

4.3 General information

During a spark test, inflammable sparks

may occur at the pores in the form of an

electric arc. Therefore, spark testing may

only be carried out outside of potentially

explosive atmospheres.

4.4 Avoiding damages to peripheral devices

When performing a spark test, please

note the following information; otherwise, the components and/or the electronic transmitter may get damaged.

n The measuring transducers for tem-

perature, glass monitoring, capacitive

sensors and other electronic/electric

components that have been attached

to the valve or the baffle must be disconnected prior to the spark test.

n Suitable equipment must be employed

for the test (impulse voltage). We recommend using the GlaSparker®, our

high-voltage tester

n For glass lined measuring probes, the

max. test voltage must not exceed

7 k V .

n The contact window around the meas-

uring probe site (e. g. P) must not be

tested.

In general, however, we recommend calling our technical service for performing

the test.

5 Temperature probe type T

5.1 Measuring principle

The temperature probe Ty p e T will also

be referred to as the T probe in the

present Operating Instructions.

As already mentioned, a thermocouple

serves as the sensor of the T probe. A

thermocouple consists of two electrical

conductors made of different materials

(wires) that are connected (in contact) to

each other at one end. The contact point

is the measuring location of the thermocouple. The two free wire ends constitute

the reference location of the thermocouple. If the thermocouple is heated in the

measuring location, a thermal voltage is

present in the reference location. This

thermal voltage depends on the temperature difference between the mea suring

location and the reference location (temperature gradient along the thermocouple), and on the material combination

of the two metal wires. For temperature

measurements, the temperature of the

reference location must be kept constant at 0 °C, or it must be precisely measured in order to perform an appropriate

adjustment in mV. To evaluate the thermal voltage, the free wire ends of the

thermocouple (the reference location)

are connected to a suitable transmitter.

m The T probe is not identical to

thermocouple type T.

The standardized thermocouple types

are not suitable for the T probe for reasons of glassing technology. The positive

branch of the T probe is made of a platinum-rhodium alloy (PtRh), the negative

branch is made of a gold-palladium-platinum alloy (AuPdPt). This material combination is known as “pallaplat”. Table 1

shows the values of the basic characteristic of pallaplat. However, these values

may only serve as reference values. The

exact characteristic depends on the

manufacturing batch of the pallaplat.

For programming the transmitter (refer

to Section 5.3), the characteristic that

was determined for the specific pallaplat

batch after production will be used. The

values entered during programming will

be indicated in the test report that is

attached to each probe supplied.

Only the Pfaudler-approved pallaplat

compensating line (part no. 029034)

may be used as an extension for the

thermocouple.

Standard EN 60584 defines the various

material combinations for the production of thermocouples. These standardized material combinations are referred

to as “thermocouple types” and marked

by different capital letters. One of them

is the letter “T“.

4

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 4

Temperature probes type T/TW

Temperature probes type T/TW

5.2 Construction of the T probe

5.2.1 Probe carrier

The T probe can be installed in various

probe carriers:

n Baffles, thermometer well, Quatro-

Pipe and C baffle (the term tubular

probe will be used below for this type

of probe carriers)

n Ring

probe

n Valve shaft of outlet valves

5.2.2 Tubular probe

The thermocouple of tubular probes consists of very thin, narrow bands made of

the pallaplat material combination. The

pallaplat bands are fused into the glass

layer.

The measuring location, where the two

pallaplat bands are in contact is normally

at the end of the tube in order to measure the product temperature even at

low liquid levels inside the reactor. When

using tubular probes, several measuring

locations may be fitted at the same or at

different levels. The maximum possible

number of measuring locations depends

on the size of the tubular probe. For

more details, please contact the Pfaudler

Instrumentation department.

In order to provide electrical connection

to the thermocouple, the pallaplat bands

fused into the glass are routed close to

the terminal box and connected to the

compensating line. In turn, the compensating line is introduced into the terminal

box where it is connected to the transmitter.

Tubular probes equipped with T probes

can optionally be combined with the

following measuring probes made by

Pfaudler:

n Typ P Measuring probe for glass

monitoring

n Typ FT Measuring probe for capaci-

tive detection of filling limits

or interfaces between liquids

n Typ FS Measuring probe continuous,

capacitive detection of filling

levels

n Typ TW Measuring probe for tem-

perature measurement using a resistance thermometer

For more details about possible combinations, please contact the Pfaudler

Instrumentation department.

5.2.3 Ring probe

The thermocouple of ring probes consists of very thin, narrow bands made of

the pallaplat material combination. The

pallaplat bands are fused into the glass

layer.

The measuring location is in the middle

of the cylindrical inside area. Ring probes

can be produced with a maximum of 4

measuring locations.

In order to provide electrical connection to the thermocouples, the pallaplat

bands fused into the glass are routed

close to the terminal box and connected

to the compensating line. In turn, the

compensating line is introduced into the

terminal box where it is connected to the

transmitter.

Ring probes equipped with T probes can

optionally be combined with the following

measuring probes made by Pfaudler:

n Typ P Measuring probe for glass

monitoring

n Typ FT Measuring probe for capaci-

tive detection of filling limits

or interfaces between liquids

For more details about possible combinations, please contact the Pfaudler

Instrumentation department.

5.2.4 Valve shaft

The measuring location of a probe

mounted on a valve shaft is in the middle of the valve shaft on the product side.

Power supply to the thermocouple is by

means of pallaplat wires that are insulated and routed through the inside bore

of the valve shaft. The wire ends are connected to the compensating line which in

turn is introduced into the terminal box

where it is connected to the transmitter

type TTH300 (or terminals).

With nominal sizes DN 80/50 or more,

the T probe can be installed in a valve

shaf t. A maximum of 2 T measuring locations are possible. Optionally, a T probe

can be combined with the a measuring

probe Type P (for glass monitoring). For

more details about this possible combination, please contact the Pfaudler

Instrumentation department.

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 5

5

Temperature probes type T/TW

Temperature probes type T/TW

5.3 Transmitter

A transmitter of the type TTH300 made

by ABB is used as a standard for evaluating the signal measured by the T probe

(the thermal voltage). The transmitter is

a freely programmable unit that converts

the measured signals of thermocouples

and of resistance thermo meters into a

standard potential-free 4-20 mA signal.

The transmitter is integrated into the terminal box on the probe carrier already in

the factory where it is also connected to

the sensor lines.

Based on product-dependent tolerances

in the manufacture of pallaplat, the values of the characteristic may slightly

deviate between batches. Therefore, the

batch-specific characteristic is measured

after the production of each batch. During the internal acceptance test in the

factory, the TTH300 is parameterized

with this batch-specific characteristic.

The characteristic has a total of 32 intermediate points. The values of the characteristic are indicated in the test report

that is attached to each probe supplied.

The transmitter is programmed using the

“Smart Vision” firmware. The TTH300

is also equipped with a HART interface

which allows for programming of the

transmitter on location.

As a rule, it is possible to use other types

or makes instead of the TTH300. However, the following conditions must be

observed in this case:

n The transmitter must be freely pro-

grammable and must be programmed

with the batch-specific pallaplat characteristic. Third-party transmitters

cannot be programmed by Pfaudler

because we do not have the hardware

and software necessary for that purpose. However, Pfaudler will support

you with the programming of thirdparty transmitters.

n The transmitter must have a reference

location.

n Pfaudler cannot provide any binding

information concerning the accuracy

of the measuring system as a whole if

third-party transmitters are used.

If the ambient temperature in the surroundings of the transmitter is excessively high on location (refer to Sect. 5.4),

the transmitter must be installed next to

the probe carrier in an area in which the

temperature is lower. A pallaplat compensation line must be used to connect

the terminal box on the probe carrier

to the transmitter. Suitable compensating lines are available from Pfaudler

(part no. 029034).

For more details concerning the transmitter, please refer to the documentation

that is attached to each probe supplied.

6

m The T probe must in all cases

be operated in conjunction with a

freely programmable transmitter,

otherwise, the temperature measurement will not be correct.

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 6

5.4 Technical data of T probe

Sensor material: Pallaplat

pos. branch made of platinum-rhodium

neg. branch made of gold-palladium-platinum

Resistance of pallaplat: 30 Ω /m

Resistance of the compensating line: 0,33 Ω /m

min/max temperature in

the terminal box: – 40/+80 °C

min/max operating temperature: – 25/+200 °C

Measuring variance: max. ± 1,5 °C

Temperature probes type T/TW

Temperature probes type T/TW

Electrical data if used in potentially explosive atmospheres:

Please note the details in the type examination certificate

PTB 03 ATEX 2132 X in annex 1.

© Pfaudler GmbH ·

OI 302-8 e

© Pfaudler GmbH 7

7

Temperature probes type T/TW

Temperature probes type T/TW

5.5 Installation of the probe carriers

5.5.1 Installation of tubular probe

The term tubular probe is used for the

following probe carriers in this context:

n Baffles

n Thermometer well

n Quatro-Pipe

n C baffles

Before installing a tubular probe in a

reactor or a pipeline, you should verify

whether there is sufficient distance to

the agitator and the reactor wall. If necessary, suitable spacers or reducing

flanges must be used.

Assembly process:

t Place flange gasket on nozzle.

t Protect the nozzle and the probe

against damage by inserting a piece

of cloth or a PTFE sleeve into the nozzle. Slowly introduce the tubular probe

into the reactor through the nozzle.

Avoid pendulum motion.

t Tighten flange screws evenly cross-

wise with the prescribed tightening

torque; (cf. Tab. 3).

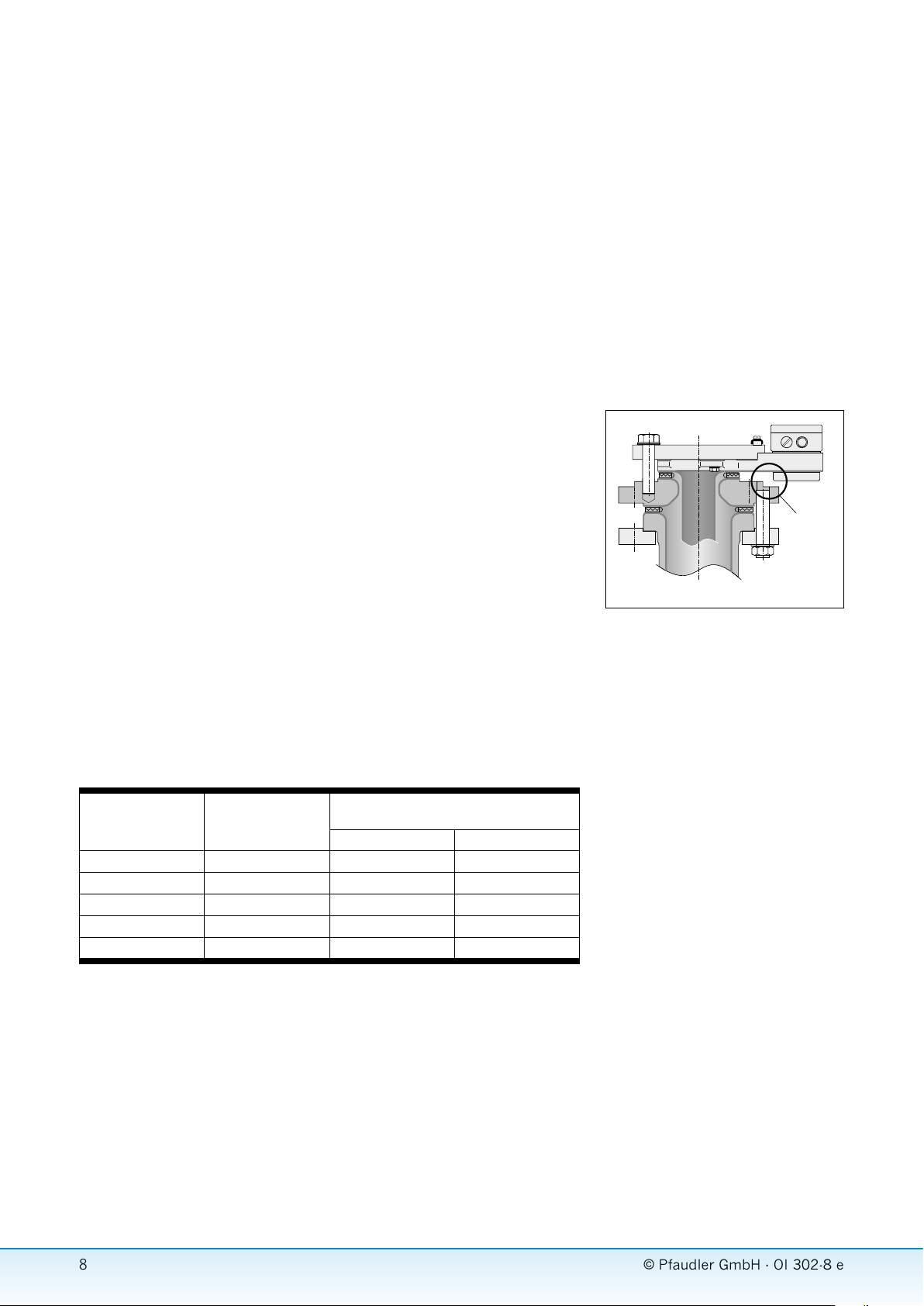

m When using your own reduc-

ing flanges, please make sure that

the element covering the contact

area below the terminal box does

not sit on the reducing flange (cf.

Fig. 2). In the event of non-compliance, the glass may be damaged at

the bottom side of the flange, and

the fused-in metal strips may be

interrupted.

5.5.2 Installation of ring probe

The ring probe may generally be installed

in any position inside the pipeline. However, it must be noted that the T probe

does not work unless the measuring location is sufficiently covered with product. In

radial direction, the measuring location is

in the same place as the terminal box.

The ring probe is be installed in the pipeline between 2 flanges using gaskets.

Tighten flange screws evenly crosswise

with the prescribed tightening torque;

(cf. Tab. 3).

5.5.3 Installation of outlet valve

For details concerning the installation,

please refer to our Operating Instructions 322.

These Operating Instructions are attached

to each valve supplied. They are available

from Pfaudler on request.

collision

area

MT0010_1E

Fig. 2 Installation example with reducing flange

Table 3 Tightening torques of glass-lined flange connections

Flange Screws Max. tightening torques in Nm with admis-

DN50 4 x M16 30 30

DN80 8 x M16 35 35

DN100 8 x M16 35 35

DN150 8 x M20 40 40

DN200 8 x M20 55

sible operating pressures of:

–1 to +10 bar –1 to +16 bar

8

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 8

Temperature probes type T/TW

Temperature probes type T/TW

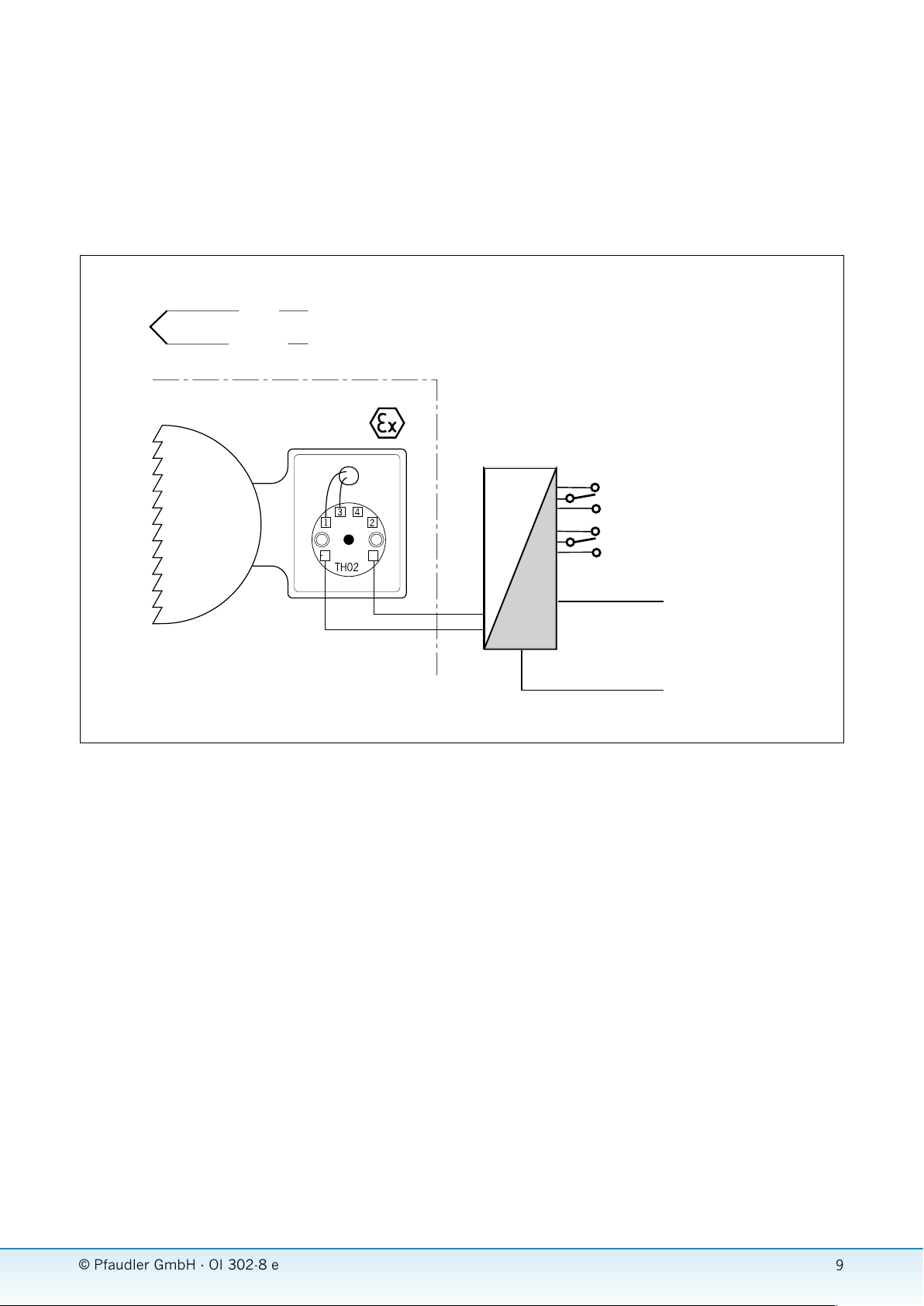

+ red

– violett

T probe

Fi

g. 3 Connection diagram of the T probe

3

1

power supply unit with electrical

isolation Ex ia/ib

max. 30 V DC 100 mA

optional floating

change-over

contacts

}

+5

6

current output

4 -2 0 m A

power Supply 24 V DC/AC

(230 V AC)

MT_05_003_1e

5.6 Connection of the T probe

The following information only applies to

T probes in c

onnection with the TH02-Ex

transmitter.

A power supply unit with the following

specifications is necessary for power

supply:

n Supply current: I

n Supply voltage: U

n in potentially explosive

= 0 - 20 mA

S

= 8,5 ... 30 V DC

S

atmospheres: Ui = 8,5 ... 29,4 V DC

For applications in potentially explosive

atmospheres, power supply units in

intrinsically safe design must be used.

The power supply unit must be installed

outside the potentially explosive area.

The installation instructions of the manufacturer are mandatory in this respect.

The connection between the power supply unit and the transmitter can be made

using standard signal cables.

The probe carriers must be grounded

using copper or stainless steel wires with

a minimum conductor area of 10 mm2.

The electrical connection is made in

compliance with the connection diagram

shown in Fig. 3. Connection is identical

for all probe carriers.

5.7 Start-up and maintenance of the T probe

No start-up procedure is necessary for T

probes supplied together with the standard transmitter. When the transmitter

has been connected to the power supply

unit, the T probe is ready for use. However, we recommend verifying whether

the transmitter’s measuring range as set

by Pfaudler complies with your requirements. The measuring range setting is

indicated on a rating plate each on the

transmitter and in the terminal box as

well as in the test report.

If necessary, the measuring range can

be changed. Upon final acceptance in

the factory, a functional test and a single-point calibration will be performed.

A test report will be prepared which is

attached to each probe.

If the T probe is ordered and delivered

without a transmitter, it is the operator’s

responsibility to ensure that a suitable

transmitter is used and configured (refer

to Sect. 5.3). The values comprised in

the characteristic of the thermocouple

are provided in the attached test report.

Due to its special construction (thermocouple fused into glass layer) and noncritical operating conditions, the probes

are not subject to ageing. Therefore,

inspections (calibration) of the thermocouple are not necessary for measuring

reasons. As a result, the T probe is maintenance-free.

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 9

9

Temperature probes type T/TW

Temperature probes type T/TW

If it is used for processes, however, which

are associated with the risk of product

deposits, it must be verified whether

or not product has accumulated on the

probe carrier. Deposits must be removed

using suitable means and methods.

5.8 Calibration of the T probe

5.8.1 General instructions

As mentioned before, the thermocouple

has been fused into the glass layer, thus

forming an integral part of the probe carrier. Calibrating the thermocouple separately is not possible for this reason. It is

most practical to calibrate the T probe

with the probe carrier installed because

stable, reproducible temperature conditions at the T probe are most conveniently achieved. Calibration outside the

reactor or pipeline is very problematic

because there is considerable heat dissipation, which results in instable temperature conditions at the thermocouple,

due to the shape and size of the probe

carriers. For calibration, the reactor or

the pipeline must be filled either with

product or with water. A steady temperature at the transmitter must be ensured

during calibration. For this reason, the

terminal box should be closed.

For calibrating tubular probes, the reactor must be filled until the immersion

depth of the measuring location is at

least five times the tube diameter. When

calibrating inside a reactor, the agitator

must turn slowly in order to ensure an

even temperature distribution inside the

liquid.

For ring probes, the pipeline must be

fully filled. Ring probes may also be calibrated outside the pipeline due to their

compact dimensions. For this purpose,

the probe must then be immersed into a

suitable vessel. Caution! Do not immerse

the terminal box.

When calibrating outlet valves, the valve

cone must be sufficiently covered with

product so as to ensure a stable temperature condition in the measuring

location. Furthermore, the agitator must

be slowly turned during calibration.

5.8.2 Calibrating the measuring

chain

In order to calibrate the entire measuring

chain including the sensor, transmitter

and display unit, immerse a calibrated

reference thermometer into the liquid

and compare its measured value (reference value) with the value measured by

the T probe (actual value). If it is necessary to calibrate the T probe at different

temperatures, we recommend calibrating it in icy water at 0 °C and in boiling

water at 100 °C.

The result will be reliable information

concerning the accuracy of the entire

measuring chain and the actual temperature conditions in the subsequent production process.

If an excessive, inadmissible measuring

deviation is detected during calibration,

the individual elements of the measuring

chain must be verified or calibrated.

5.8.3 Calibrating the sensor

Actually, it is not necessary to calibrate

the sensor (thermocouple) for technical

reasons because the sensor is not subject to ageing (refer to Sect. 5.7).

However, in some cases the sensor has

to be calibrated to comply with internal

or process-related requirements. The

Pfaudler T-Calibrator (part no. 256572-)

and the Smart Vision firmware must be

available in order to calibrate the thermocouple. For more information and a

detailed description of the calibration

process, please refer to the Operating

Instructions of the T-Calibrator.

5.8.4 Calibrating the transmitter

In order to calibrate the transmitter, a

process calibrator is connected to the

transmitter input that serves to simulate

the thermocouple‘s characteristic. Then,

the voltage values of the characteristic

are entered one by one at the process

calibrator. In parallel, the actual values

of the transmitter (input and output signal) are compared to the programmed

values (values of the characteristic). The

values of the characteristic are indicated

in the test report that is attached to each

probe supplied. It is important to deactivate the internal reference point of the

transmitter during calibration. Please

refer to the Operating Instructions of the

TH02-Ex unit for a description of how to

deactivate the reference point.

5.8.5 Calibrating the display unit

In order to calibrate the display unit,

an additional, calibrated display unit

is looped into the transmitter’s output

circuit, and the two values displayed as

actual and programmed values must be

compared.

5.9 Explosion protection

The tubular and ring probes with an

integrated T probe have been approved

for use in potentially hazardous atmospheres of zone 0 in accordance with the

EC type examination certificate No. PTB

03 ATEX 2132 X. For outlet valves with

an integrated T probe, an EC type examination certificate has been applied for.

10

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 10

Temperature probes type T/TW

Temperature probes type T/TW

6 Temperature probe type TW The resistance values of resistance ther-

mometers made of platinum have been

6.1 Measuring principle

The temperature probe Type TW w

also be referred as the TW probe in the

present Operating Instructions.

standardized and are referred to as Pt 100,

Pt 500 and PT 1000. The number speci-

ill

fies the nominal resistance in Ohm at a

temperature of 0 °C. Therefore, a Pt 100

has a nominal resistance of R0 = 100 Ω .

As already mentioned, a resistance thermometer serves as the sensor of the TW

probe. The measuring principle of resistance thermometers is based on the fact

that the electrical resistance of all conductors and semiconductors changes

For these standardized measuring resist-

ances, basic value series (characteris-

tics) have been specified in EN 60 751.

The measured signal is evaluated by the

transmitter based on this characteristic

in order to determine the temperature.

with the temperature. The amount of

change in referred to as varies depending

on the material used. The relative change

of the electrical resistance as a function

of the temperature, ∆R/∆t, is referred to

as the temperature coefficient. This value

is not constant over the whole temperature range. Rather, it is a function of the

temperature. The relationship between

resistance and temperature is subject

to higher-order mathematical polynomials for calculating the characteristic of a

For the TW probe, no Pt 100 to the EN

standard was used as resistance ther-

mometer. For technical reasons, the

TW probe cannot be produced with an

exact resistance value of 100 Ω . The re-

sistance of the TW probe is 100 ± 3 Ω .

Therefore, it is absolutely necessary to

use a programmable transmitter (refer

to Sect. 6.3) that compensates the de-

viation from the 100 Ω characteristic in

order to evaluate the measured signal.

resistance thermometer.

The special properties of platinum, such

as high measuring accuracy, high temperature resistance, chemical resistance,

an approximately linear characteristic as

well as an excellent reproducibility of the

thermo-electrical properties, were reason

enough to produce most resistance thermometers from this metal today. Since

platinum can also be easily glassed, it is

also used for the TW probe.

6.2 Construction of the TW probe

The TW probe can be installed in the

following probe carriers:

n Paddle-type baffles

n Thermometer well

n Quatro-Pipe

It is not possible to install the TW probe in

a ring probe, a C baffle or a valve shaft.

The resistance thermometer consists of

a very thin platinum band that is spirally

wound around the end of the probe carrier tube. The platinum band is fused into

the glass layer. The maximum possible

number of measuring locations on a

tubular probe depends on the size of the

probe carrier. For more details, please

contact the Pfaudler Instrumentation

department. The measuring locations are

always at the same level. Measuring locations at different levels can only be provided using the T probe (refer to Sect. 5)

The supply wires of the resistance thermometers are also made of platinum.

The supply wires fused into the glass are

routed close to the terminal box where

they are connected to terminal wires. In

turn, the terminal wires are introduced

into the terminal box where they are connected to the transmitter type TH02-Ex

(or terminals).

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 11

11

Temperature probes type T/TW

Temperature probes type T/TW

The TW probe is designed in four-wire

technology (2 parallel supply bands

each). Therefore, TW probes can be connected in a four-wire circuit. With this

measuring method, a constant measuring current flows through 2 wires, whereas the temperature-dependent voltage

drop at the measuring resistor is measured via the remaining 2 wires. In a fourwire circuit, the influence of the supply

conductor resistance on the measured

result is totally neutralized.

Probe carriers equipped with TW probes

can optionally be combined with the

following measuring probes made by

Pfaudler:

n Typ P Measuring probe for glass

monitoring

n Typ FT Measuring probe for capaci-

tive detection of filling limits

or interfaces between liquids

n Typ FS Measuring probe continuous,

capacitive detection of filling

levels

n Typ T Measuring probe for tem-

perature measurement using

a thermocouple

For more details about possible combinations, please contact the Pfaudler

Instrumentation department.

6.3 Transmitter TTH300

A transmitter of the type TTH300 made

by ABB is used as a standard for evaluat-

ing the signal measured by the TW probe.

The transmitter is a freely programmable

unit that converts the measured signals

of resistance thermometers and thermo-

couples into a standard potential-free

4-20 mA signal. The transmitter is inte-

grated into the terminal box already in

the factory where it is also connected to

the sensor lines.

As already mentioned in Sect. 6.1, the

resistance thermometer for the TW probe

cannot be produced to have a resistance

of exactly 100 Ω at 0 °C. For this reason,

the exact resistance in Ω of the resist-

ance thermometer is measured upon

completion of the TW probe. During the

internal acceptance test in the factory,

the transmitter is parameterized with the

characteristic of this Ω value. The char-

acteristic has a total of 32 intermediate

points. The values of the characteristic

are indicated in the test report that is

attached to each probe supplied.

The transmitter is programmed using the

“Smart Vision” firmware. The TTH300

is also equipped with a HART interface

which allows for programming of the

transmitter on location.

For more details concerning the trans-

mitter, please refer to the documentation

that is attached to each probe supplied.

As a rule, it is possible to use other types

or makes instead of the TTH300. However, the following conditions must be

observed in this case:

n The transmitter must be freely pro-

grammable and must be programmed

with the probe-specific characteristic.

Third-party transmitters cannot be

programmed by Pfaudler because

we do not have the hardware and

software necessary for that purpose.

However, Pfaudler will support you

with the programming of third-party

transmitters.

n Pfaudler cannot provide any binding

information concerning the accuracy

of the measuring system as a whole in

this case.

If the ambient temperature in the surroundings of the terminal box is excessively high on location (refer to Sect. 6.4),

the transmitter must be installed next to

the probe carrier in an area in which the

ambient temperature is lower. The 4-wire

signal lead may be used to connect the

terminal box on the probe carrier to the

transmitter.

m The TW probe must in all

cases be operated in conjunction

with a programmable transmitter,

otherwise, the temperature measurement will not be correct.

Table 3 Tightening torques of glass-lined flange connections

Reactor type AE AE/BE/CE E BE/CE

Nominal reactor size 63

baffle with stuffing box 1 2 2 2 2

baffle/thermowell with

flange

Quatro Pipe – 2 2 2 2

to

400

2 2 2 – 2

630

to

1000

1600

to

6300

1200

to

20000

8000

40000

12

to

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 12

6.4 Technical data of TW probe

Sensor material: Platin

Resistance of the sensor material: ca. 40 Ω/m

Resistance of the feed conductors: ca. 10 Ω/m

min/max temperature in

the terminal box: – 40/+80 °C

min/max operating temperature: – 25/+200 °C

Measuring variance: max. ± 1 °C

Electrical data if used in potentially explosive atmospheres::

Please note the details in the type examination certificate

PTB 03 ATEX 2132 X in the appendix

Temperature probes type T/TW

Temperature probes type T/TW

© Pfaudler GmbH ·

OI 302-8 e

© Pfaudler GmbH 13

13

6

+5

MT_05_0004_1d TW-Sonde.fh11

Temperature probes type T/TW

Temperature probes type T/TW

Pt

100

TW-Sonde

Fig. 4 Connection diagram of the TW probe

white

red

green

black

1

4

2

3

power supply unit with electrical

isolation Ex ia/ib

max. 30 V DC 100 mA

-

optional floating

change-over

contacts

}

current output

4 - 20 m A

power supply 24 V DC/AC

(230 V AC)

MT_05_0004_1e

6.5 Installation of the TW probe

As already mentioned, the TW probe can

be installed in the following probe carriers: Paddle-type baffles, thermometer

wells, Quatro Pipe These probe carriers

are generally also referred to as tubular

probes.

Before installing a tubular probe in a

reactor or a pipeline, you should verify

whether there is sufficient distance to

the agitator and the reactor or pipeline

wall. If necessary, suitable spacers or

reducing flanges must be used.

Assembly process:

t Place flange gasket on nozzle.

t Protect the nozzle and the probe

against damage by inserting a piece

of cloth or a PTFE sleeve into the nozzle. Slowly introduce the tubular probe

into the reactor through the nozzle.

Avoid pendulum motion.

t Tighten flange screws evenly cross-

wise with the prescribed tightening

torque; (cf. Tab. 3).

m When using your own reduc-

ing flanges, please make sure that

the element covering the contact

area below the terminal box does

not sit on the reducing flange (cf.

Fig. 2). In the event of non-compli-

ance, the glass may be damaged at

the bottom side of the flange, and

the fused-in metal strips may be

interrupted.

6.6 Connection of the TW probe

The following information only applies

to TW probes in connection with the

transmitter.

A supply unit with the following specifica-

tions is necessary for power supply:

n Supply current: I

n Supply voltage: U

n in potentially explosive

atmospheres: Ui = 8,5 .. . 29,4 V DC

For applications in potentially explosive

atmospheres, supply units in intrinsically

safe design must be used.

= 0 - 20 mA

S

= 8,5 ... 30 V DC

S

The power supply unit must be installed

outside the potentially explosive area.

The installation instructions of the manufacturer are mandatory in this respect.

The connection between the power supply unit and the transmitter can be made

using standard signal cables.

The probe carriers must be grounded

using copper or stainless steel wires with

a minimum conductor area of 10 mm2.

The electrical connection is made in

compliance with the connection diagram

shown in Fig. 4.

14

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 14

Temperature probes type T/TW

Temperature probes type T/TW

6.7 Start-up and maintenance of

the TW probe

No start-up procedure is necessary for

TW probes supplied together with the

standard transmitter. When the electrical connection of the transmitter to the

power supply unit has been made, the

TW probe is ready for use. However,

we recommend verifying whether the

transmitter’s measuring range as set

by Pfaudler complies with your requirements. The measuring range setting is

indicated on a rating place each on the

transmitter and in the terminal box as

well as in the test report. If necessary,

the measuring range can be changed.

Upon final acceptance in the factory, a

functional test and a single-point calibrati

on will be performed. A test report will

be prepared which is attached to each

probe.

If the TW probe is ordered and delivered

without a transmitter, it is the operator’s

responsibility to ensure that a suitable

transmitter is used and configured (refer

to Sect. 5.3). The values comprised in

the characteristic of the resistance thermometer are provided in the attached

test report.

Due to its special construction (resistance thermometer fused into glass layer)

and non-critical operating conditions, the

probes are not subject to ageing. Therefore, inspections (calibration) of the

resistance are not necessary for measuring reasons. As a result, the TW probe is

maintenance-free.

If it is used for processes, however, which

are associated with the risk of product

deposits, it must be verified whether

or not product has accumulated on the

probe carrier. Deposits must be removed

using suitable means and methods.

6.8 Calibrating the TW probe

6.8.1 General instructions

As me ntioned before, the resistance thermometer has been fused into the glass

layer, thus forming an integral part of the

probe carrier. Calibrating the resistance

thermometer separately is not possible

for this reason. It is most practical to

calibrate the TW probe with the probe

carrier installed because stable, reproducible temperature conditions at the T

probe are most conveniently achieved.

Calibration outside the reactor or pipeline is very problematic because there

is considerable heat dissipation, which

results in instable temperature conditions at the resistance thermometer, due

to the shape and size of the probe carriers. For calibration, the reactor or the

pipeline must be filled either with product or with water. A steady temperature

at the transmitter must be ensured during calibration. For this reason, the terminal box should be closed.

For calibrating tubular probes, the reactor must be filled until the immersion

depth of the measuring location is at

least five times the tube diameter. When

calibrating inside a reactor, the agitator

must turn slowly in order to ensure an

even temperature distribution inside the

liquid.

6.8.2 Calibrating the measuring

chain

In order to calibrate the entire measuring

chain including the sensor, transmitter

and display unit, immerse a calibrated

reference thermometer into the liquid

and compare its measured value (reference value) with the value measured

by the TW probe (actual value). If it is

necessary to calibrate the TW probe at

different temperatures, we recommend

calibrating it in icy water at 0 °C and in

boiling water at 100 °C.

The result will be reliable information

concerning the accuracy of the entire

measuring chain and the actual temperature conditions in the subsequent production process.

If an excessive, inadmissible measuring

deviation is detected during calibration,

the individual elements of the measuring

chain must be verified or calibrated.

6.8.3 Calibrating the sensor

Actually, it is not necessary to calibrate

the sensor (resistance thermometer) for

technical reasons because the sensor is

not subject to ageing (refer to Sect. 5.7).

However, in some cases the sensor has

to be calibrated to comply with internal

or process-related requirements. For

calibrating the probe, a process calibrator capable of measuring the resistance

of the resistance thermometer and the

product temperature in a four-wire circuit must be used. The measured values

(actual values) must then be compared

to the programmed values (values taken

from the characteristic).

6.8.4 Calibrating the transmitter

To calibrate the transmitter, an adjustable precision resistor must be connected

to the transmitter input. Then, the resistance values from the characteristic are

input one by one, and the related temperature (programmed value) is compared

to the output value of the transmitter

(actual value). The values of the characteristic are indicated in the test report

that is attached to each probe supplied.

6.8.5 Calibrating the display unit

In order to calibrate the display unit,

an additional, calibrated display unit

is looped into the transmitter’s output

circuit, and the two values displayed as

actual and programmed values must be

compared.

6.9 Explosion protection

The tubular with an integrated TW probe

have been approved for use in potentially

hazardous atmospheres of zone 0 in

accordance with the EC type examination

certificate No. PTB 03 ATEX 2132 X.

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 15

15

Annex 1

PTB 03 ATEX 2132 X

Annex 1

PTB 03 ATEX 2132 X

16

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 16

Annex 1

Annex 1

PTB 03 ATEX 2132 X

PTB 03 ATEX 2132 X

© Pfaudler GmbH ·

OI 302-8 e

© Pfaudler GmbH 17

17

Annex 1

PTB 03 ATEX 2132 X

Annex 1

PTB 03 ATEX 2132 X

18

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 18

Annex 1

Annex 1

PTB 03 ATEX 2132 X

PTB 03 ATEX 2132 X

© Pfaudler GmbH ·

OI 302-8 e

© Pfaudler GmbH 19

19

Annex 2

Annex 2

Declaration of conformity

Declaration of conformity

20

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 20

nex 2

An

Declaration of conformity

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 21

21

Annex 3

Safety instructions and explosion protection

A 3.1 Potentially hazardous atmospheres

Please note the details in the type examination certificate PTB 03 ATEX 2132 X, Issue: 1 in the annex.

A 3.2 Atmospheric conditions

Please note the details in the type examination certificate PTB 03 ATEX 2132 X, Issue: 1 in the annex.

A 3.3 Equipotential bonding

Please note the details in the type examination certificate PTB 03 ATEX 2132 X, Issue: 1 in the annex.

A 3.4 Lightning protection

If the temperature probe is installed in systems that must be protected against ignition hazards

due to lightning, the redox probe must be included in the lightning protection.

The lightning protection must comply with the requirements of VDE 0165.

A 3.5 Quatro Pipe

When using a Quatro Pipe with T / TW probe, please observe the

information in the type examination certificate

PTB 03 ATEX 2132 X,

Issue: 1.

Annex 3

22

© Pfaudler GmbH · OI 302-8 e

© Pfaudler GmbH 22

Notes

Notes

© Pfaudler GmbH

23

The information provided in this documentation corresponds

to the state of the art at the time of printing. It is published

in good faith. However, we will accept no warranty claims

based on the information provided in this documentation. We

reserve the right to include improvements, amendments and

new findings in this documentation without prior notice. The

actual design of products may deviate from the information

contained in the calatoge if technical alterations and product

improvements so require. The proposal made by Pfaudler for

a concrete application will be binding in such cases.

The present documentation is made available free of charge

to our customers and other interested parties. The right to

print or copy this documentation, or any parts there of, or to

convert the same into electronic form shall be subject to our

written permission.

All rights reserved by us.

Pfaudler GmbH

P.O. Box 1780 D-68721 Schwetzingen

Pfaudlerstraße D-68723 Schwetzingen

Phone +49 6202 85-233

Telefax +49 6202 85-273

E-mail info@pfaudler-instrumentation.com

www.pfaudler-instrumentation.com

Loading...

Loading...