Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 1 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

BOHEMIA X 40 INSET STOVE

SUITABLE FOR INSTALLATION IN A STANDARD UK 16” X 22” OPENING

CE AND EN13229 APPROVED

APPROVED FOR USE IN SMOKE CONTROL AREAS WHEN

BURNING DRY WOOD LOGS OR AUTHORISED FUELS

Pevex Enterprises Ltd

Unit 16 Seven Acres Business Park, Waldringfield, Ipswich, IP12 4PS.

Tel: 01473 736399 Fax: 01473 736406

Congratulations on the purchase of your new Bohemia stove. Your new purchase will provide you with a level of

pleasure and comfort not previously experienced in your home.

Please read and follow the advice and instructions on the safe and efficient operation of your stove to ensure it has

a long trouble free life and also read and follow the installation instructions before installing the stove.

PART 1 OPERATING INSTRUCTIONS

A stove compared with an open fire is a very efficient heating appliance and must be installed and used safely and wisely,

it is important to understand the working of such an appliance and to understand the process of converting the fuel into

heat and its efficient transfer from the firebox to the room in order to gain the most from the stove.

A stove creates an almost perfect environment to burn wood in. The firebox will run at a very high temperature ideal to

burn the volatiles given off in the burning process and the concise air controls allow minimal heat loss into the flue. The

Bohemia X 40 inset stove operates at an efficiency of 71 % on a Gross CV basis (78% Net) and is very much more

efficient than an open fire avoiding the wasteful draughts normally associated with that type of appliance

Burning wood is the natural way to store the sun‟s energy to then be released in a carbon neutral process to heat your

house when the need is most. On a cold winters night there is nothing to beat the release of heat and flame in a stove to

raise the spirit.

The preparation and burning of wood as a fuel in stoves can be traced back many centuries, however it is a forgotten or

maybe never fully discovered activity in the United Kingdom, we have much to learn from our European and

Scandinavian neighbours whose colder winters have instinctively led them into a natural wood burning culture.

Wood for fuel is probably one of the most environmentally friendly energy sources, it is carbon neutral, trees used for

fuel production regenerate very quickly and it is a pleasant and satisfying job preparing the firewood for the coming

winters.

WARNING NOTE

Properly installed, operated and maintained this stove will not emit fumes into the dwelling. Occasional fumes from deashing and refueling may occur. However, persistent fume emission is potentially dangerous and must not be tolerated.

If fume emission persists, then the following immediate action should be taken:

a) Open doors and windows to ventilate room

b) Let the fire out or eject and safely dispose of fuel from the appliance

c) Check for flue or chimney blockage and clean if required

d) Do not attempt to relight the fire until the cause of the fume emission has been identified and corrected. If

necessary seek expert advice

The most common cause of fume emission is flue way or chimney blockage. For your own safety these must be kept

clean at all times. Any permanent air vent provided for combustion air must not be blocked off. There must not be

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 2 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

Wood length

an extractor fan fitted in the same room as the stove as this can cause the stove to emit dangerous fumes into the

room.

CHIMNEY CLEANING

The chimney should be swept at least once a year for smokeless fuels and a minimum of twice a year for wood and other

fuels. It is important that the flue connection and chimney are swept prior to lighting up after a prolonged shutdown

period. If the stove is fitted in place of an open fire then the chimney should be swept one month after installation to

clear any soot falls which may have occurred due to the difference in combustion between the stove and the open fire.

In situations where it is not possible to sweep through the stove the installer will have provided alternative means such as

a soot door. After sweeping the chimney, the stove flue outlet and the flue pipe connecting the stove to the chimney must

be cleaned with a flue brush.

The connecting flue pipe and stove baffle should be checked monthly to clear any fly ash or soot deposits.

USE OF A FIREGUARD

When using the stove in situations where children, aged and/or infirm persons are present a fireguard must be used to

prevent accidental contact with the stove. The fireguard should be manufactured in accordance with BS6539.

INSTRUCTIONS FOR USE:

First Firing

The stove has been treated with a heat-resistant coating, which hardens at a temperature of approximately 2500 C. This

hardening process causes the production of smoke and malodorous fumes, so the room must be very well ventilated.

During the first firing, which should be carried out using approximately 1 kg of wood, the stoking door must be left

slightly open and must not be closed until the stove is cold. This is to prevent the sealing rope sticking to the stove.

RECOMMENDED FUELS

The recommended fuels that can be burnt on these stoves are dry/seasoned wood logs and fuel that are Authorised for use in

Smoke Control Areas (eg., ancit).

Correct firing provides optimal heat output and maximum economy. At the same time, correct firing prevents

environmental damage in the form of smoke and malodorous fumes and also reduces the risk of chimney fires.

Well seasoned wood fuel is essential for correct use. Make sure your fuel is kept dry. If the fuel is wet, a large

proportion of the heat will be used to vaporize the water, and this energy will disappear up the chimney. It is clearly not

only uneconomical to fire with wet fuel but also, as mentioned above, increases the risk of producing soot, smoke and

other environmentally damaging by-products. When wood is used as a fuel it is important that it is dry, i.e. wood with

moisture content less than 20%. Ideally firewood needs seasoning for at least 2 summers, logs should be stacked in a well

ventilated situation, and logs over 100mm diameter should be split. The stack should be protected from rain but remain

well ventilated.

APPLIANCE

MAXIMUM

WOOD LENGTH

Bohemia X 40 Inset

26cm

FUELS USED IN SMOKE CONTROL AREAS

In a building in a smoke control area you are legally only allowed to use this appliance to burn dry/seasoned wood logs of

the maximum length given above or authorised fuels. If you are unsure if your property is located in a smoke control

area or need further guidance on fuels you should contact your Local Authority. Please see Appendix A for further

information

MIXED FUEL USE

Use of brown coal and smokeless fuel

Uni-logs (brown coal brickettes) may be burned on the stove. Good performance will be obtained using these brickettes.

Approved smokeless solid fuels may also be used such as Ancit. Avoid over firing. A mixture of seasoned wood and

smokeless fuel will provide extended burn times with a good flame picture.

USE OF BROWN COAL OR OTHER NON-AUTHORISED FUELS SHOULD NOT BE USED ON THE

APPLIANCE IF LOCATED IN A SMOKE CONTROL AREA UNLESS IT IS PART OF A MANUFACTURED

AUTHORISED FUEL.

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 3 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

It is essential when burning smokeless solid fuels that the ash pan is emptied on a daily basis. Ash must not be allowed

to build up below the grate. Note brown coal and smokeless fuel should also be stored dry and ventilated.

Use of Petroleum coke and liquid fuels will invalidate the guarantee and must not be used as this will cause the stove

to “over fire”. Operating at temperatures in excess of 500ºC will cause irreparable damage which is not covered by the

guarantee.

FUEL CONSUMPTION AT NOMINAL HEAT OUTPUT

Nominal Output KW

Wood kg/hr

Smokeless Fuel (Ancit) kg/hr

Bohemia X 40 Inset

4.5

1.3

0.71

Tested according to the requirements of EN13229 and are fully assessed and considered to meet UK smoke control

requirements. Note that different fuel consumption results may be achieved due to other factors which include the fuel,

chimney draught and atmospheric conditions etc.

LIGHTING AND COMBUSTION

The primary air is drawn into the stove through the airslide on the lower part of the door. The secondary air is regulated

with the aid of a slider above the door. The heated secondary air flows down the viewing window and then feeds the fire;

it is this secondary combustion that completes the burning cycle by turning unburned volatiles into flame. Finally, any

remaining unburnt volatiles are burnt when preheated tertiary air enters the firebox through the tertiary air diffuser at the

rear of the firebox.

As much as half of the heat obtainable from wood is achieved from secondary and tertiary combustion. It is important

that the firebox temperature is maintained at a high level as this also aids complete combustion. For example, when first

lighting a stove it is important to get it really hot before closing the burning rate down. The firebox temperature should

reach 400°C which equates to approximately 250 °C at the flue pipe

The Bohemia X 40 inset stove is designed and has been tested to burn extremely cleanly with very little smoke discharge

even when the airsliders are in the fully shut off position. This is because the airsliders allow a permanent and preset

bleed of air into the firebox to fuel the fire eliminating smoke and unburnt hydrocarbons. Permanent stops are fitted to

the appliance to ensure that the primary and tertiary air controls cannot be closed beyond 0.5cm open and 2cm open

positions. The appliance will only be considered as exempt appliances if these stops are in place.

When both sliders are in the off position (fully positioned to the left) the stove burns at approximately 30% of its rated

nominal output. Adjusting the secondary airslider to 50% of its travel to the right will ensure that the stove operates at its

nominal optimum cleanburning combustion producing negligible levels of smoke.

The nominal output is the output to which the stove has been tested. In practice, the stove burns with a heat output range

between its minimum and maximum ratings.

LIGHTING THE STOVE

1. Put 2 small logs on a bed of ash spaced

about 10-12cm apart. Place some scrunched

up newspaper/paper with 1-2 firelighters in

between .

2. Neatly stack dry kindling on top of the

logs into approx 3 layers and light the

bottom fire lighters.

3.Fully open the top (secondary) and bottom

(primary) airsliders and leave the door

slightly ajar to allow air to enter and the fire

to establish.

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 4 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

Note:

If the fire dies down completely or embers are smoldering then it will be necessary to place some screwed up paper or

firelighters onto the grate with some kindling or small pieces of wood to reestablish the fire once again. Leave the

airsliders fully open and allow the fire to build before refueling with larger pieces of wood and then adjust the sliders for

optimum combustion.

Do not overload the firebox by loading above the tertiary air diffuser at the back of the firebox and ensure that

the wood is retained by the log guard. Always ensure that the wood is not tightly stacked so that air can circulate

freely.

Do not leave door left open: Operation with the door open can cause excess smoke. The appliance must not be

operated with the appliance door left open except as directed in the instructions.

Do not leave the airsliders completely open: Operation with the airsliders permanently open can cause excess

smoke. The appliance must not be operated with air controls or dampers door left open except as directed in the

instructions.

SAFETY PRECAUTIONS

A risk of blowback can arise if too much dry wood is placed in the stove and burnt with insufficient combustion air. This

may result in the production of gaseous compounds which can ignite if the intake of primary and secondary air is

insufficient and the firebox temperature too low.

To achieve optimal firing and the best possible heat output, the primary and secondary air intakes must be correctly

adjusted. As a general rule, the fire should be regulated using secondary air supply, with which smoke and gases are

ignited. This produces a high level of efficiency and also keeps the viewing window clean because the secondary air

„washes over‟ the glass.

For woodburning it is an advantage always to leave some ash lying in the bottom of the combustion chamber.

Take care when emptying the ash pan, as cinders can continue to burn in the ash for long periods of time. Only dispose

of ashes when cold.

NOTE: It is always advisable to leave the top air control open to allow the stove to operate to optimum combustion.

MAINTENANCE OF MATT BLACK PAINT FINISH

The surface of the stove has been treated with heat-resistant paint. The stove should be cleaned with a soft brush. Any

damage to the surface in the form of chips or scratches can be repaired using touch-up paint, which is available in spray

cans. If the stove has become grey in colour due to overheating, touch-up paint of this kind can be used to repaint the

stove entirely. Alternatively the stove can be maintained with a traditional type of stove polish of which there are several

proprietary makes available. Do not use an aerosol spray when the stove is alight or when the surfaces are hot.

CLEANING THE GLASS

Incorrect firing, for example using wet wood, or slow burning can result in the viewing window becoming covered in

soot. This soot can be easily and effectively removed by using a damp cloth or when necessary a proprietary stove glass

cleaner or an ordinary scouring liquid, when the glass is cold

4. With the door slightly open the fire will

quickly build warming the stove and chimney.

After about 5/10 minutes the door can be shut

and the stove can be controlled by the

airsliders. Shut the primary airslider and

control the burning rate with the secondary air

to give optimal combustion.

5. After about 40/50 minutes and when

the last flames go out a red hot ember

bed will be left and further wood can be

added.

6. Place 2/3 logs on the ash bed ensuring

that the wood is not stacked too closely

and with the airsliders fully open. The

wood will ignite in 2/3 minutes. Shut the

primary air and adjust the secondary air

for optimum combustion.

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 5 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

OPERATIONAL PROBLEMS

In the event of smoke or malodorous fumes being produced, you must first check to see whether the chimney is blocked.

The chimney must, of course, always provide the minimum draught necessary to ensure that it is possible to regulate the

fire. However, the chimney draught may also be affected by weather conditions. Both wind and temperature can affect

the performance of a chimney.

In cases where the wood burns too quickly, this may be due to excessive chimney draught. You should also check to

make sure that the door seal is intact. If the stove produces too little heat, this may be due to the fact that you are firing

with wet wood. A large proportion of the heat output will be used to dry the wood, resulting in both uneconomical

heating and an increased risk of soot and tar deposits forming in the chimney.

STANDING DOWN AT THE END OF THE SEASON

At the end of the burning season the stove should be prepared for the stand down period, this is to prevent corrosion both

in the stove and flue system.

The stove should be cleared of all ash, the baffle and flue ways cleared of soot and fly ash and the chimney swept.

All air vents should be in the open position and it is recommended that the door is left ajar to ventilate the chimney.

This is the ideal time to check for parts that may need replacing and to lubricate door hinges and catches. Also it is

recommended that all screws holding the glass in place are removed and replaced with a high temperature lubricant. Any

repainting should be done when the stove is cold and only with a suitable high temperature paint.

PART II INSTALLATION INSTRUCTIONS (for UK excluding Scotland where local Building

regulations must be conformed to).

It is essential that the installation is carried out by an experienced and competent installer who is HETAS registered (see

www.hetas.co.uk). Under England & Wales Building Regulations it is a legal requirement that the stove is either

installed by a competent person, which is an installer who is HETAS Registered, OR that the installation is carried out

under Local authority building control approval and inspection.

See the Building Regulations 2002 Approved document J

RECOMMENDED READING

Fireplaces Chimneys and Stoves by Michael Waumsley.

Published by the Crowood Press. ISBN1 86126 746 0

Health and Safety Precautions

Special care must be taken when installing the stove such that the requirements of the Health and Safety at Work Act are

met.

Handling

Adequate facilities must be available for loading, unloading and site handling.

Fire Cement

Some types of fire cement are caustic and should not be allowed to come into contact with the skin. In cases of contact

wash immediately with plenty of water.

Asbestos

This stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course of the installation then

please seek specialist guidance and use appropriate protective equipment.

Metal Parts

When installing or servicing this stove care should be taken to avoid the possibility of personal injury

ASSESSING THE REQUIREMENTS FOR THE INSTALLATION OF A STOVE

Your supplier or Hetas registered installer will be able to advise you on the individual requirements that are needed to

install a stove safely.

It is most important that the stove is the correct size. This means that the output should match the heat requirements of

the room. Also to be considered is the fuel choice and the provision of suitable and convenient storage with easy access

to the stove.

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 6 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

There must not be an extractor fan fitted in the same room as the stove as this can cause the stove to emit fumes

into the room.

Having decided on the ideal appliance then the installation should be fully assessed. The Bohemia X 40 inset is designed

to function as a built in unit, please note that high thermal build up in the chamber will be experienced it is therefore

essential that the fireplace and recess have been built using suitable materials that will accommodate the operating of

such an appliance. COMBUSTIBLE MATERIALS MUST NOT BE USED IN THE CONSTRUCTION. The

chimney requirements should be carefully assessed. Hearth requirements should be carefully specified, remember the

building regulations lay out the minimum requirements. The chances of damaging a floor or carpet will be much reduced

if the depth of a hearth is extended beyond the minimum. Any combustible materials should be at least 500mm distant

from the sides, 300mm from the back, 600mm above and 800mm clear of the front of the door and should never be

allowed to exceed 80 °C. For further advice on chimney and hearth also see details below.

Assess also the fireplace surround if any is to be used, it is essential that combustible materials are not used close to the

stove and flue pipe of a stove. This requirement may vary depending on the construction of a stove but is advised to keep

combustible materials at least 500mm or preferably 1metre away from the stove or flue pipe.

THE FOLLOWING ITEMS ARE INCLUDED WITH THE STOVE

A pair of leather gloves for operation of door handle and air sliders, flue collar and door handle and catch assembly,

ashpan and ashpan handle.

DOOR HANDLE AND CATCH ASSEMBLY

Handle Bush Door & Bush Catch Washer Screw

HEARTH

The fireplace and hearth should conform to at least the minimum requirements laid out in the Building Regulations

Approved Document J. The hearth should be able to accommodate the weight of the stove and its chimney if the chimney

is not independently supported

Stoves must stand on a non-combustible hearth that must extend at least 300mm in front and 150mm to either.

DIMENSIONS AND CLEARANCES

No Combustible materials should be used in the construction of a fireplace or within the chimney or used in the

installation of a stove, flue or chimney.

Care should also be taken in the construction of hearths or fireplaces to ensure that suitable provision is taken to allow for

expansion and contraction of the construction materials.

CLEARANCES FROM COMBUSTIBLES when installing in a freestanding situation

Recommended minimum clearance from sides to combustible material 500mm

Recommended minimum clearance from rear to combustible material 300mm

Recommended minimum clearance from front to combustible material 800mm

NOTES

uninsulated flue pipe must be installed to local building regulations (we recommend that not more than a 1 metre

length of plain uninsulated pipe is used before connection to a chimney system and that no combustible materials

are within 500mm of the flue pipe).

if the stove is to be installed in front of combustible materials nearer than 500mm a heat shield must be fitted

(not supplied).

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 7 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

ALL CHIMNEYS SHOULD BE SWEPT AND INSPECTED BEFORE INSTALLATION OF ANY APPLIANCE

For relining existing chimneys 316 or 904 grade stainless steel liners or pumice cement liners in accordance with

Building Regulations Approved Document J should be used. Liners should be suitably insulated. We recommended that

any chimney relining is carried out by an experienced and competent installer who is HETAS registered (see

www.hetas.co.uk). The HETAS Guide to Approved Products and Services lists Chimneys and lining systems suitable for

use with solid fuel.

CHIMNEY IMPORTANT WARNING

This stove must not be installed into a chimney that serves any other heating appliance.

The chimney must be a minimum height of 4.5 metres overall height and be in accordance with Building Regulations

Approved Document J.

Any chimney, either masonry or a prefabricated stainless steel system must be constructed and installed according to

building regulations. It is recommended that the minimum diameter of the flue liner be 125mm.

For new masonry chimneys we recommend pumice cement liners. A chimney draught of at least .06” (1.5mm) is

recommended.

BOHEMIA FLUE COLLAR

The flue collar is a 5” (125mm) outlet and is supplied pre-assembled on the stove in the vertical position however,

depending on the installation it may be more appropriate to remove the collar by removing the two M6 nuts and bolts,

rotating it 180 degrees and reattaching the nuts and bolts which will angle it at 30 degrees off the stove. This will help in

some installations where for example clearance is required to clear a lintel.

Additionally we are able to supply an offset flue extension which will position the collar 115mm behind the stove

allowing for installations where the collar needs to be further back.

Bohemia offset flue extension

INSTALLING THE STOVE.

The flue outlet can be attached to a suitable flue pipe and liner, when required, and left suspended in the chimney for

connection to the firebox after installation of the firebox.

The Bohemia inset is designed to fit against the chairbrick with a small gap that should be filled either with a rockwool

blanket or a weak cement/vermiculite fill. Air should not be allowed to pass around the outside of the body of the stove

into the chimney void. This fill should also act as an expansion joint. If an existing chimney is to be used it must be

checked for suitability. If suitable then a connection into the existing throat may be made by using a weak vermiculite fill

around the flue outlet and throating formed with a sand lime cement mix. It is important that the top of the firebox is

insulated to protect the lintel above the fire opening and also (if applicable) the fire surround top slip. This can be done

with rockwool or Skamolex Blue (calcium silicate insulating board) which is cut to fit. The stove must be secured into

position with fixing screws (not supplied) through the predrilled holes in the body of the stove. Removal of the internal

side and rear bricks will allow access to the predrilled holes.

The installation must be airtight so that room air is not drawn around the appliance into the chimney.

BAFFLE PLATE REMOVAL

The Bohemia X 40 inset stove is fitted with a twin baffle system to improve efficiency and reduce CO with the lower one

made from skamolex vermiculite and the upper one made from steel. Both baffles are easily removed to allow

installation of the stove and for gaining access for cleaning the flue pipe.

The lower skamolex baffle is supported on the two side bricks and the rear tertiary air diffuser. Removal is achieved by

gently lifting the baffle and easing one of the side bricks out of the stove. The baffle can now be tilted and guided out of

the stove.

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 8 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

The upper steel baffle rests on two rear support pegs and has slots at the front of the baffle that hook over two M13 bolt

heads. Removal is achieved by undoing the two locking bolts (M13 spanner) by 1-2 turns then drawing it forward off the

rear pegs allowing the bolt heads to pass through the slots. Reassembly is the reverse by hooking the front of the baffle

over the bolt heads and sliding it backwards until it engages onto the rear pegs.

Removal of the steel baffle allows immediate access into the flue system for sweeping and maintenance.

VENTILATION

Adequate ventilation in the form of a permanent air vent must be provided in accordance with building regulations.

COMMISSIONING

The installer should carry out the following checks and ensure that the stove is fully functional. We strongly recommend

that a first firing is included in the commissioning process

1. Check all flue pipe connections

2. Check door latch mechanism

3. Check door and glass seals are all intact and secure

4. Warm chimney and check draught.

5. Check that the stove burns controllably and does not emit fumes into the room.

6. Instruct customer in use of stove.

7. Leave instructions for customer

8. Check that after initial firing the door seals are not stuck to the body of the stove

Appendix A

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a smoke

control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any fixed boiler if

located in a designated smoke control area. It is also an offence to acquire an "unauthorised fuel" for use within a smoke

control area unless it is used in an "exempt" appliance ("exempted" from the controls which generally apply in the smoke

control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise smokeless fuels or

exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests with Ministers in

the devolved administrations for those countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981,

applies in Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for use in smoke control areas have

been "authorised" in Regulations and that appliances used to burn solid fuel in those areas (other than "authorised" fuels)

have been exempted by an Order made and signed by the Secretary of State or Minister in the devolved administrations.

The Bohemia X 40 Inset Stove has been recommended as suitable for use in smoke control areas when burning wood

fuel.

Further information on the requirements of the Clean Air Act can be found here : http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision of

smoke control areas and you can contact them for details of Clean Air Act requirements.

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 9 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

Appendix B

TECHNICAL DETAILS

TECHNICAL DATA

Nominal output kW

4.5

Range rating kW

4-5

Heating area square metres

10-90

Wood

Ancit

Average combustion gas temp C

272

262

Efficiency Net

78.2%

78.9%

CO% @ 13% O2

0.77%

0.2%

Fuel consumption kg/hr

1.3

0.71

Weight kg

55

Installation and Operating Instructions for Bohemia X 40 Inset Multi Fuel Stoves Page 10 of 10

Reference: Pevex10004/AH/ver2 Date: June 2011

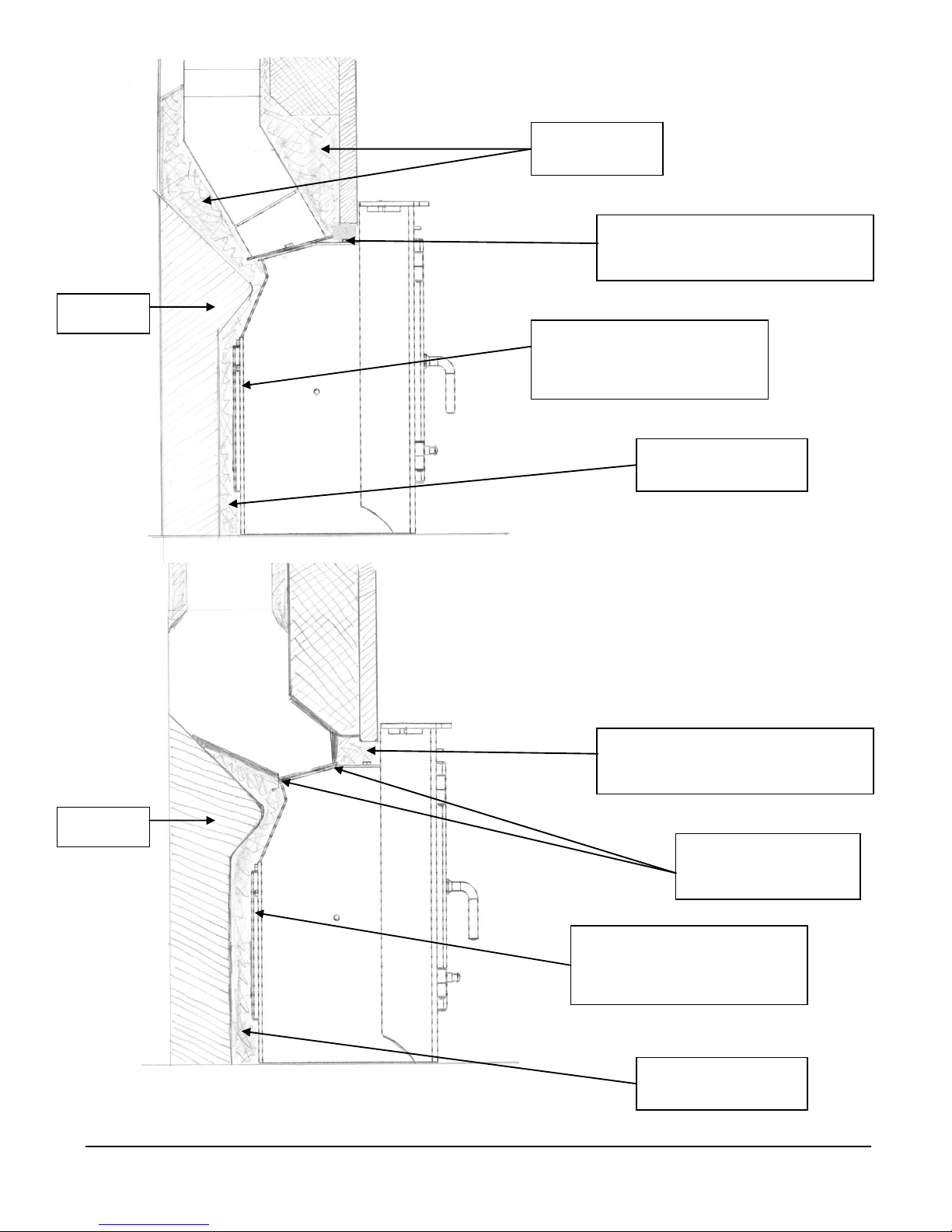

Weak mix vermiculite

infill or rockwool

Weak mix

vermiculite infill

Skamolex Blue (calcium silicate board

cut and shaped to form heat insulator)

or rockwool insulation.

Refractory mortar or

plaster sealing fillet

Appendix C

Illustrative guide to installing in standard fireplace showing Inset

with flue pipe connection

Showing Inset with flue flaunched into flue

gather connection

Fix firmly to chair brick with fixing

bolts (not supplied). Remove

side and rear bricks in stove to

access predrilled holes

Chair brick

Skamolex Blue (calcium silicate board

cut and shaped to form heat insulator)

or rockwool insulation.

Weak mix vermiculite

infill or rockwool

Fix firmly to chair brick with fixing

bolts (not supplied). Remove

side and rear bricks in stove to

access predrilled holes.

Chair brick

Loading...

Loading...