electronic

Quality is our Drive.

Assembly- and Commissioning Instructions

Safety Standstill Monitor

VersiSafe

Ver si Safe 1

as per 09/18 17800.10001

Table of Contents Page

1. Safety remarks 3

2. Conformity 3

3. EC Declaration of Conformity 4

4. Function 5

5. General description 6

5.1 Applications 6

5.2 Features 6

5.3 Funtion 6

5.4 Functional diagram 8

5.5 Functional description 8

6. Technical data 9

6.1 Input (L1 - L2 - L3) 9

6.2 Output 10

6.3 General data 10

6.4 Dimensions 14

6.5 Characteristics 15

7. Commissioning 15

7.1 Terminal connections 15

7.2 Setup and setting 16

7.3 Special applications and operation notes 17

8. Failure monitoring 19

8.1 Types of error 19

8.2 Failure indication 20

8.3 Failure treatment 21

9. Connection diagramm 24

9.1 with 3-phase motor 24

9.2 with single-phase motor 24

9.3 Typical connection combination with E-Stop 25

9.4 Typical connection combination with star delta timer, 2-channel connection of the

measuring inputs 26

9.5 Typical connection combination with star delta timer, 3-channel connection of the

measuring inputs 27

2VersiSafe

These commissioning instructions were prepared with great care. Nevertheless, PETER

electronic GmbH & Co. KG does not assume liability for damage resulting from mistakes

possibly contained in this manual. Technical changes that serve to improve the product are

subject to change without notice.

Disposal Instructions

Equipment containing electrical components may not be disposed of

together with domestic waste. It must be collected separately as electrical

and electronic waste according to local and currently valid legislation.

Notes and symbols used in these instructions

Note: Notes explain the advantages of certain adjustments or settings and help

you to make use of the device in the best possible way.

Warning notices: Read them carefully and follow them strictly!

Warning notices are indicated in order to protect you against danger or to

help you to prevent the device from being damaged.

Caution: Danger to life through electric shock!

When you see this sign, always make sure that the device is de-energized

and secured against unintentional energizing.

Ver si Safe 3

1. Safety remarks

Installation and setup of the VersiSafe must only be carried out by well trained staff,

with knowledge about all relevant standards for safety, accident avoidance and

control circuits. This manual must be read and understood before installation and

setup.

The VersiSafe is suitable to operate as a part in safety circuits of a plant or machine. Usually also

other components are part of these circuits. It is the liability of the builder of the plant or machine

to guarantee the complete safety function by selecting the correct components, wiring and

operation.

Also the correct tripping point and time delay setting of VersiSafe suitable for the application is in

the liability of the user.

When stocking, transporting and operating the VersiSafe the conditionsstated in the technical

data must be observed. Defective units must not be operated. Opening a device or making

unauthorised changes can influence the safety function and finish warranty.

When switching capacitive or inductive load over the output contacts appropriate protection

should be provided in order not to overload the contacts. In addition a fuse must be provided to

protect the contacts against welding (see technical data).

The unit should be panel mounted in an enclosure rated at IP 54 or superior. Dust and dampness

may lead to malfunction

be heeded. The permissible ambient conditions must be observed. In particular, the current limit

curve must be heeded.

Risk of fire or other thermal hazards!

The device may only be used for the applications described in the mutually applicable

operating instructions / data sheet. The notes in the respective documentation must

2. Conformity

In industrial linguistic usage the Safety Standstill Monitor of the type series VersiSafe are called

"devices", however, in the sense of the "device-safety-law", the "EMC-law" or the "EC machinery

directive" they are not devices or machines ready for use or connection but they are components.

It is only possible to define their final function, when these components are integrated into the

design and construction of the user.

To be able to use the devices to their intended purpose, it requires power supply networks

according to DIN EN 50160 (IEC38).

The user takes the responsibility that the user’s design and construction comply with the applicable legal provision.

The commissioning is strictly forbidden as long as the conformity of the final product with the

guideline 2006/42/EC (Machinery directive) is not proved.

4VersiSafe

3. EC Declaration of Conformity

EC Declaration of Conformity

The manufacturer / company placing the product on the market

(authorized representatives of the manufacturer / companies placing the product on the market

that are established within the Community)

Name / Address: PETER electronic GmbH & Co. KG

Bruckäcker 9

92348 Berg

hereby declares that the following product (device, component, unit) in the version as supplied

Product designation: Standstill monitor

Series / type designation: VersiSafe

Article number: 278...

Year of manufacture: 2007

complies with the provisions of the following EU-directives:

2014/30/EU

2006/42/EG

2011/65/EU

The following harmonized standards have been applied:

Basis of Testing

This EC Declaration of Conformity is no longer valid, if the product is modified or changed

without our agreement.

This declaration is issued under the sole responsibility of the signatory.

Berg, 29.06.2018 Dr. Thomas Stiller, Managing director

(place, date) (signatory and function of the signatory) (signature)

Electromagnetic compatibility

Machinery Directive

RoHS-Directive

EN ISO 13849-1:2015

IEC 61800-5-1:2016

IEC 61508 Parts 1-7:2010

EN 61000-6-1:2007

EN 61000-6-3:2007 + A1:2011

EN 61000-6-7:2015

IEC 62061:2005 + A1:2012 + A2:2015

IEC 61800-5-2:2016

EN 61000-6-2:2005

EN 61000-6-4:2007 + A1:2011

Ver si Safe 5

4. Function

The VersiSafe is connected to the motor terminals and measures the induced back emf voltage of

a freewheeling motor. 2 redundant measuring channels are used (L2-L1 and L3 L1). If the back

emf voltage drops to 0 simultaneously in both channels this indicates standstill and the output

relay is energised.

To adopt the unit to all different types of motors and applications the voltage threshold indicating

standstill on VersiSafe is adjustable. Also the time delay between detection and energisation of

the relay is adjustable (standstill time t

In addition the unit detects broken wire on the measuring inputs L1 / L2 / L3. If broken wire is

detected the output relays goes into safe state (as with running motor). This state is stored and

can be reset by bridging terminals X3-X2.

The input signals of both channels are permanently compared. If the signals are different for more

then 2.5 sec a simultaneity failure isdetected. This failure resets when both input channels

receive simultaneous signals with the same level.

To the terminals X1-X2 the feedback circuit of external contactors (used for contact

reinforcement) is connected (NC contact). If no feedback circuit is required, these terminals must

be linked. Open terminals will cause a failure message.

Circuit diagram

54

53

X3 33

X1

X2

11 23 33 43 53 A3+

K1

K2

A3

ON

A4

+

ERR

).

s

L1

11

12

L3

L2

23

43

54

ON ERR24 34 44

A412

44

34

24

A1

A2

M9163_d

Warning:

The terminals X1 - X2 - X3 has no galvanic separation to the measuring ciruit

L1 - L2 - L3. They must be controlled with volt free contacts.

6VersiSafe

Indicators

green-red LED „UH“: green on, when operation red on, with internal error

yellow-green LED „OUT“: yellow on, at EMK > U

flashes green at time progression of t

permanent on, when output contacts are enable

an

s

red LED „ERR“: flashes at error in measuring and

feedback circuit and low auxiliary

voltage UH (see flashing codes)

5. General description

5.1 Applications

Safe standstill detection on 3- and single-phase motors, e.g. to enable gate interlocks on machine

tools or to activate hold in brakes.

5.2 Features

• According to

- Performance Level (PL) e and category 4 to EN ISO 13849-1

- SIL-Claimed Level (SIL CL) 3 to IEC/EN 62061

- Safety Integrity Level (SIL) 3 to IEC/EN 61508 and IEC/EN 61511

• Safe standstill detection on 3- and single-phase motors

• No external sensors necessary

• Independent of direction

• Broken wire detection

• Forcibly guided safety contacts: 3 NO contacts, 1 NC contact for AC 250 V

• 2 semiconductor monitoring outputs

• 1 monitoring output (NO contact)

• Adjustable voltage setting

• LED indicators for standstill, event of line breakage and operation voltage

• Suitable for operation with inverters

• Width 45 mm

5.3 Funtion

The VersiSafe can be used for standstill detection on all 3-phase, single phase and DC motors,

that generate a voltage caused by remanence when freewheeling. As the voltage level Uan for

standstill monitoring and the time delay t

switched on, are adjustable, the function can be adopted to different motors and applications.

, after detection of standstill until the safety relays are

s

Ver si Safe 7

Terminals and settings

L1 - L2 - L3: connection to monitored motor

11 - 12: safety contacts (NO)

23 - 24, 33 - 34, 43 - 44: safety contacts (NC)

53 - 54: monitoring contact (C/O)

X1 - X2: connection of feedback circuit

(for external contactors)

X2 - X3: manual reset for external faults

A1 - A2: auxiliary supply (UH)

A3(+) - A4: supply for semiconductor outputs

ON: semiconductor output indicates state of safety contacts

ERR: semiconductor output indicates failures

Poti „Uan“: adjustment of voltage level for standstill detection

Poti „ts“: adjustment of time delay before activation of safety contacts

Attention:

The outputs 53-54, ON and ERR are only monitoring outputs and must not be used in

safety circuits!

8VersiSafe

5.4 Functional diagram

U

H

A1/A2

motor speed /

voltage

L1/L2/L3

line breakage

L1/L2/L3

23-24

33-34

43-44

53-54

A3-ON

11-12

A3-ERR

eon

auxiliary voltag

own

stop

motor on

start up delay time U

standstill detected

motor runs d

t

E

standstill delay time t

motor runs down

2

reset X3-X

M9647_a

voltage level

U

an

eakage

X3-X2

line br

reset

line breakage

Motor Ein

t

E

s

t =2...2,5s

H

E

5.5 Functional description

The auxiliary voltage is connected to the terminals A1-A2; the LED „UH“ lights up green. On

undervoltage or missing auxiliary supply the safety outputs are disabled.

If semiconductor monitoring outputs are used, their supply voltage must be connected to A3(+)A4.

A motor connected to the terminals L1-L2-L3 of the VersiSafe generates a voltage when running

down (motor is switched off). The voltage is proportional to the speed and caused by residual

magnetism (remanence).

This voltage is measured redundant on 2 input channels via the terminals L2 and L3 with L1 as

common reference.

If the voltage drops on both channels below the adjusted value Uan, the unit detects standstill.

When the terminals X1-X2 of the feedback circuit are bridged and the time delay ts is finished, the

safety contacts 23-24, 33-34 and 43-44 close while contact 11-12 opens. All 4 contact paths have

2 positive guided contacts of 2 safety relays wired in series.

Ver si Safe 9

At the same time the monitoring relay energises (53-54 closes), the semiconductor output „ON“ is

switched on and the LED „OUT“ lights green. During time delay ts this LED flashes.

If the voltage measured on terminals L1-L2-L3 of VersiSafe rises over the adjusted value plus

hysteresis in at least one channel (the motor is switched on or the shaft turns mechanically), the

positive guided output contacts are switched off immediately (contacts 23-24, 33-34 and 43-44

open while contact 11-12 closes). The monitoring relay de-energises (53-54 opens), the semicon

ductor output „ON“ goes off and the LED OUT“ lights yellow (= U

Feedback circuit X1 - X2

If the safety contacts control external contactors/components (e.g. to re-enforce or multiply the

contacts) the safety function of them must be monitored.

This is done with the feed back circuit (terminals X1-X2) to which the NC contacts of the

contactors/components must be connected. (see also wiring diagrams).

The VersiSafe will only enable its safety output if the feedback loop X1-X2 is closed while standstill is detected, i.e. the external contactors/components are in initial state (NC contacts are

closed).

The feedback circuit X1-X2 must be closed as long as the safety outputs because of running

motor or external failure) are not enabled. If not the failure „feedback circuit“ is indicated.

If the feedback circuit is not used, the terminals X1-X2 must be bridged.

6. Technical data

6.1 Input (L1 - L2 - L3)

Measuring-/Motor voltage: max. AC 690 V

Input resistance: 500 kOhm

Response value Uan: 20 mV ... 400 mV, adjustable

Response value dependent on frequency

special variant 0,2 ... 4V

over adjusted value).

an

-

Input frequency (Hz): 50 100 200 400 600 1k 1,5k 2k

Multiplication factor for Uan: 1,0 1,1 1,2 1,5 2,0 2,8 5 8

Hysteresis (for detection

of running motor): 100 %

Release delay for detection

of running motor: < 100 ms

Standstill time delay ts: 0,2 ... 6s adjustable

Auxiliary voltage U

(A1 - A2): AC 230 V, AC 400 V, DC 24 V

H

Recommended fusing: 2 A

Voltage range

AC: 0,8 ... 1,1 U

DC: 0,9 ... 1,2 U

N

N

Nominal consumption: 5 VA, 3 W

10 VersiSafe

Nominal frequency (AC): 50 / 60 Hz

Frequency range (AC): 45 ... 65 Hz

max. residual ripple (DC): 10 %

Start up delay when

connecting U

6.2 Output

Contacts

(saftey contacts)

VersiSafe 230VAC: 3 NO contacts, 1 NC contact

The NC contacts 11-12 can only be used for monitoring.

Contact type: relay, positive guide

Nominal output voltage: AC 250 V

Thermal current Ith: 5 A (bis 40°C)

Quadratic total current: see derating curve

Switching capacity

to AC 15

NO contact: AC 3 A / 230 V IEC/EN 60 947-5-1

NC contact: AC 1 A / 230 V IEC/EN 60 947-5-1

to DC 13: DC 1 A / 24 V IEC/EN 60 947-5-1

Electrical contact life

to 5 A, AC 230 V cos phi = 1: 2 x 105 switching cycles

Fusing of the

safety contacts: max. fuse rating 4AgL

Max. operating frequency: 1200 / h

Mechanical life: => 50 x 10

Semiconductor monitoring

output: 100 mA DC 24 V, plus switching,

NO monitoring contact: 3 A AC 250 V (closed when enabled)

at standstill: 0,4 ... 0,8 s + adjustable t

H

line circuit breaker C6A

6

switching cycles

galvanic separation; supply via

A3+ / A4 for output; „ON“ and „ERR“

s

6.3 General data

Nominal operating mode: continuous operation

Temperature range

operation: - 25 ... + 60°C

(+ 40°C with max. contact current, see Derating)

storage: - 40 ... + 75°C

Clearance and creepage distance

rated impuls voltage/pollution degree: IEC 60 664-1

Contacts 11/12, 23/24,

33/34, 43/44 against all others: 6 kV / 2

Ver si Safe 11

Contacts 11/12, 23/24,

33/34, 43/44 against each others: 4 kV / 2

Indicator contact 53/54

against all others: 4 kV / 2

Semiconductor outputs A3+/

ON / ERR / A4 against all others: 6 kV / 2

Auxiliary voltage A1 / A2

against all others

at auxiliary voltage AC: 6 kV / 2

at auxiliary voltage DC: 4 kV / 2

Control terminal X1 / X2 / X3: no galvanic separation to L1 / L2 / L3

EMC IEC/EN 62 061

Interference suppression

Auxiliary voltage AC: limit value class B EN 55 011

Auxiliary voltage DC: limit value class A*) EN 55 011

*) The device is designed for the usage under industrial conditions (Class A, EN 55011). When

connected to a low voltage public system (Class B, EN 55011) radio interference can be

generated. To avoid this, appropriate measures have to be taken.

Degree of protection

Housing: IP 40 IEC/EN 60 529

Terminals: IP 20 IEC/EN 60 529

Enclosure: thermoplastic with VO behaviour

Vibration resistance: amplitude 0,35 mm

Climate resistance: 25 / 060 / 04 IEC/EN 60 068-1

Terminal designation: EN 50 005

Wire connection: DIN 46 228-1/-2/-3/-4

Screw terminals (integrated): 1 x 4 mm

Insulation of wires

or sleeve length: 8 mm

Wire fixing: Plus-minus terminal screws M 3,5

Mounting DIN rail IEC/EN 60 715

Weight: approx. 400 g

according to UL subject 94

frequency 10 ... 55 Hz IEC/EN 60 068-2-6

2

1 x 2,5 mm2 stranded ferruled or

2 x 1,5 mm

solid or

2

stranded ferruled or

2 x 2,5 mm2 solid

box terminal with wire protection or

cage clamp terminals

12 VersiSafe

Safety related data

Values according to EN ISO 13849-1:

Category: 4

PL: e

MTTFd: 93 a

DC

: 99,0 %

avg

dop: 365 d/a (days/year)

hop: 24 h/d (hours/day)

t

: 28,8E+03 s/Zyklus

Zyklus

Values according to IEC EN 62061 / IEC EN 61508 / IEC EN 61511:

SIL CL: 3 IEC EN 62061

SIL: 3 IEC EN 61508 / IEC EN 61511

HFT*: 1

DC: 99,0 %

PFHD : 4,10E-10 h

T1: 20 a (years)

*)HFT = Hardware-Failure Toleranz

= 1 /8 h (hours)

-1

Demand to our device based on the evaluated

Intervall for cyclic test of the safety function

neccessary safety level of the application

acc. to EN ISO 13849-1 PL e with

once per month

Cat. 3

PL d with

once per year

Cat. 3

acc. to

IEC/EN 62061,

IEC/EN 61508

SIL CL 3,

SIL 3

with HFT = 1

SIL CL 2,

once per month

once per year

SIL 2

with HFT = 1

acc. to EN 61511 SIL 3 once per year

Info: The values stated above are valid for the standard type.

Safety data for other variations are available on request.

The safety relevant data of the complete system has to be determined by the

manufacturer of the system.

Ver si Safe 13

UL -Data

The safety functions were not evaluated by UL. Listing is accomplished according to

requirements of Standard UL 508, „general use apllications“.

Measuring-/Motor voltage: max. AC 600V

Ambient temperature: -25 ... +60°C, (+40°C with max. contact current,

Switching capacity

safety contacts

(11/12, 23/24, 33/34, 43/44)

Ambient temperature 40°C: Pilot duty B300

Ambient temperature 60°C: Pilot duty B300

Switching capacity

indicator contact (53/54): 3A 250VAC G.P.

Wire connection: 60°C / 75°C copper conductors only

Fixed screw terminal: 1x AWG 20 - 12 Sol/Str Torque 0.8 Nm or

Device with auxiliary

voltage Uh 24V DC: Device must be supplied with a Class 2 or a Voltage /

Info: Technical data that is not stated in the UL-Data, can be found in the

technical data section.

see Derating)

5A 250VAC G.P.

5A 24VDC G.P.

2A 250VAC G.P.

2A 24VDC G.P.

2x AWG 20 - 14 Sol/Str Torque 0.8 Nm

Current limeted Power Supply.

14 VersiSafe

6.4 Dimensions

90

45

121

All dimensions in mm.

Standard type

VersiSafe AC 230 V 50/60 Hz

Article number: 27800.69000

• Safety output: 3 NO contacts, 1 NC contact

• Auxiliary voltage U

• Response value U

• Standstill time t

: AC 230 V

H

: 20 ... 400 mV

an

: 0,2 ... 6 s

s

• 1 semiconductor and 1 NO contacs for indicator output

• 1 semiconductor for fault indicator output

• Width: 45 mm

Ver si Safe 15

6.5 Characteristics

2

2

(A)

I

80

70

60

50

40

30

20

10

T( C)

0

10 20 30 40 6050

Quadratic total current

=I2+I2+I

I,I,I

123

2

1

23

- current in contact paths

max. permitted current up to 40˚Con 3 contact paths = 5A

222 2

(5 5 +5 = 75A )

+

max. permitted current up to 60˚Con 3 contact paths = 2A

222 2

(2 +2 = 12A )

+2

Derating curve for contact currents of safety contacts

M9658

°

7. Commissioning

7.1 Terminal connections

The VersiSafe has to be connected according to connection examples or in a similar way. The

connection of DC- motors is made as with single phase AC-motors.

L1 - L2 - L3

The measuring wires L1-L2-L3 have to be connected directly to the windings of the monitored

motor (not via transformers) in order to provide a correct broken wire detection for the connection

wires and motor windings.

The motor windings must not be disconnected from the measuring wires by motor contactors,

because broken wire detection is activated and standstill monitoring is disabled.

Interference to the measuring wires should be avoided as no standstill may be detected by the

VersiSafe. If possible the measuring wires should be run separately from the motor wires or

screened wires should be used. In this case the screen can be connected at the

motor side.

16 VersiSafe

A 1 - A2

Connection of the auxiliary supply, recommended fuse : 2A.

A3+ / A4

DC 24 V supply (12 … 30 V) for the semiconductor monitoring outputs „ON“ and „ERR“, if these

are used.

11-12, 23-24, 33-34, 43-44

Safety output contacts, connection according to the connection examples or similar.

Recommended fuse: 5 A fast acting, to avoid welding of the contacts in the case of external

wiring or component failures. See also technical data.

53 - 54

Monitoring contact to indicate the state of the safety output (non safety contact).

X1 - X2 (feedback circuit)

Connection of NC contacts of external components or contactors for contact re-enforcement,

must be linked if not used.

X2 - X3

Connection for manual or auto reset, connection is made according to he required application.

When monitoring DC motors or in the case of DC-braking the broken wire / offset failure will be

shown during operation.

In this case the terminals must be linked because if storing the failure would not allow activation of

the safety contacts at standstill.

Attention:

The terminals X1-X2-X3 have electrical connections to the measuring inputs L1-L2-L3. Volt

free contacts must be used for bridging. If terminal 3 should be controlled by a PLC via an

interface relay this must have the necessary insulation between the motor voltage (mea

suring input) and PLC potential.

-

7.2 Setup and setting

Preparation

• Motor on standstill

• Terminals L1-L2-L3 connected to the motor windings

• Provide link on terminals X1-X2

• Provide also link on X2-X3 on DC motors or DC braking

• Adjust U

• Adjust t

to minimum (20 mV)

an

to minimum (0,2 s)

s

Ver si Safe 17

Connect correct auxiliary voltage to terminals A-A2

==>After 1 sec the LEDs „UH“ and „OUT“ light up green and the safety contacts are switched on.

Also the monitoring relay and the semiconductor output „ON“ must be activated.

If standstill is not detected (LED „OUT“ lights yellow), possibly interference is coupled on the

measuring circuit. Adjust U

Start of motor

==>LED „OUT“ changes colour to yellow. The output relays and the semiconductor output „ON“

switch off. On DC motors the LED „ERR“ starts to flash after 2 s with flash code 2 and the output

„ERR“ comes on.

Stop of motor - run down or DC braking

The speed at which standstill is detected (yellow LED „OUT“ changes to green/green flashing)

can be adjusted on Potentiometer „U

delay must possibly be increased to avoid switching on and off of the output relays. Possibly this

effect can also be avoided by slightly increasing U

green.

If standstill detection shall only take place at very low speed of the motor, U

minimum. By increasing the delay time t

A longer time delay will also guarantee standstill detection only when the motor has already

stopped turning. (especially on motors that generate only a small remanence voltage).

On slow decrease of motor speed it is possible that a simultaneity failure occurs (see failure

monitoring) when the measuring channels reach the tripping values slowly and not within 2.5 sec.

To avoid this failure a single phase connection could be the solution (to make sure that both

inputs get the same signal) or the increase of the setting value U

If the run down time of the motor is short ts can be set to a minimum (0.2 s). This is suitable in

production systems to shorten machine cycles.

higher or screen the measuring wires.

an

“. When the run down is very slow or irregular the time

an

. During time delay ts the LED „OUT“ flashes

an

a possible pulsing of the output relays can be avoided.

s

is set normally to

an

.

an

Warning:

It is the responsibility of the user to adjust Uan and ts in a way that standstill

detection and enabling of the safety contacts in the application is only

possible when danger to men and material by the rotating can be excluded.

7.3 Special applications and operation notes

Motors with switched windings

(e.g. star delta starters, reversing circuits, multi speed motors)

With these applications please make sure, that the measuring inputs must be linked via the motor

windings. An open connection will result in broken wire indication and disable the safety contacts.

When connecting the VersiSafe to a 3-phase motor with star delta starter the star contactor must

be energised while the motor is switched off, in order to achieve closed circuits between L1-L2-L3

via the motor windings.

18 VersiSafe

If it is not possible to switch in the star contactor after the motor is switched off, the measuring

inputs of the VersiSafe have to be connected like a single phase connection. L2-L3 are bridged

and connected to one end of a motor winding and L1 to the other end of the same winding.

For reversing circuits and multi speed motors please follow the same procedure.

If in a 3-phase connection of VersiSafe windings are switched over, and the interruptions of the

measuring circuits are longer then 2 s, the standstill monitor detects broken wire. In order not to

store this failure, the unit should work with auto reset.

Operation with DE motors

The VersiSafe can be used on DC motors if these generate a remanence voltage during run

down.

The connection is made similar as with a single phase motor.

As the remanence voltage in this case is normally a DC voltage the unit will detect a broken wire /

offset failure and indicate it on LED „ERR“ and semiconductor output „ERR“. Taking this in mind

and operating the unit with auto reset for these failures the unit can be used for safety standstill

monitoring.

Operation with electronic motor controller

(inverters, DC-brakes)

The operation of VersiSafe to detect standstill on motors with electronic motor control is possible

if the control units do not generate any voltage n standstill. (NO position control on inverters, no

DC voltage on brakes after standstill).

If the inverter produces a DC offset or a DC brake is active, an offset or broken wire failure is

indicated on LED „ERR“ and semiconductor output „ERR“. This error resets automatically if on

terminals X2-X3 automatic reset is selected.

When there are inverters in the installation it is recommended to use screened measuring wires

to the motor. The screen can be connected to the motor.

Attention

If the motor current is run down by inverters or softstop modules in a slow

way the motor may be de-magnetised. It is necessary to check if the

remaining remanence voltage is sufficient to guarantee a correct and safe

standstill monitoring. At high frequencies an increasing damping of the

measuring inputs has to be taken into account (see technical data

Measuring input „response value dependant on frequency“).

Ver si Safe 19

8. Failure monitoring

8.1 Types of error

The VersiSafe includes a number of facilities to to detect failures that could influence the safety

function of the module. The failure check is carried out on power up of the unit and in cycles

during normal operation.

If a failure occurs the output relays switch off. The failure state is indicated with the LEDs „ERR“

and „UH“ and the semiconductor output „ERR“ switches on.

With safety relevant failures the unit differentiates between external failures (broken wire / offset,

simultaneity failure, feedback circuit failure) and internal failures.

Broken wire / offset failures and feedback circuit failures can be stored or automatic reset after

removing the fault. (see chapter failure storing).

Broken wire / offset

The connection wires between VersiSafe and motor are continuously monitored for broken wire

and on a DC-voltage offset higher then U

In the case of a broken wire or offset failure the output relays are switched off immediately and the

LED „OUT“ lights yellow.

In addition a failure signal comes up with delay (on broken wire after 2s on offset failure after 8 s):

the semiconductor output „ERR“ switches on and the LED „ERR“ flashes with failure code 2 or 3

depending on the failure located either between L1-L2 or L1-L3.

Simultaneity of the measuring signals

As additional safety feature the 2 input signals (L2 and L3) are compared continuously. This

allows to detect also internal failures in one measuring channel.

If the signals are different for at least 2.5 s (one channel >U

is detected. The semiconductor output „ERR“ is switched on and the LED „ERR“ flashes with

failure code 5.

If the measured signals return to the same level <Uan the error remains stored and the outputs are

disabled.

The simultaneity failure is only reset when both channels return to > Uan. If after that both

channels drop below the setting value, get < U

Failure in feedback circuit X1-X2

As already mentioned the failure code „feedback circuit“ occurs when the outputs are disabled

and there is no connection between terminal X1-X2. The semiconductor output „ERR“ is switched

on and the LED ERR“ flashes with failure code 4.

Also when both input signals drop now to <U

failures are present the feedback circuit failure remains active and the outputs remain disabled.

If the feedback circuit is now closed and the unit is on auto reset for external failures (see failure

storing) the output relays are enable and switch on.

.

an

the other <U

an

the out relays will switch on.

an

) simultaneity failure

an

and besides the open feedback loop no other

an

20 VersiSafe

Potentiometer error

To achieve the required safety when adjusting the voltage threshold for standstill detection, ech

setting function is realised with 2 potentiometers having one common setting knob. If on 2 corres

ponding potentiometers a different setting is detected the potentiometer error Uan or ts is

displayed.

To remove the failure please try to readjust the potentipometer. Please make sure that you feel

the detent.

Internal device failure

Internal failures are always stored, independent of the reset input X3 and cause the output relays

immediately to switch off, the semiconductor output „ERR“ to switch on and the LED „UH“ to

change it’s colour from reen to red.

Examples for internal failures:

• Failure on safety relays e.g. welded output contacts

• Internal failures on measuring channels and measuring circuits

• Internal failures on control circuits for the safety relays

• failures on setting potentiometers for U

• Undervoltage failure (LED „ERR“ flashes with failure code 1)

8.2 Failure indication

Failure indication with flash code of LED „ERR“

The flash codes indicate failures caused externally (see diagram on first page).

A series of flash pulses 1-5 followed by a slightly longer space is displayed. The flash code

indicates the type of failure. If several failures are present at the same time only the failure with

the highest priority (lowest flash code) is shown. When this failure is removed the other existing

failures are displayed in the same way according to their priority.

an

and t

s

-

Failure storing / reset (terminals X2-X3)

With the external failures broken wire/offset and feedback circuit the operator can choose

between manual and automatic reset after the failure is removed.

X2-X3 open: manual reset

X2-X3 closed: automatic reset

Attention:

The a.m. storing function of the external failures broken wire /offset, and feedback circuit

is not a safety function. I.e. in respect to safety aspects it can not be regarded as

guaranteed. The reset for these failures must be therefore regarded as auto reset after

removing the faults.

Internal device failures that could occur in seldom cases (e.g. caused by temporary interference) can be reset by switching the supply voltage off and on. If a reset is not possible

also if the voltage is applied correctly, the device could be defective and should be sent

back to the manufacturer for examination or repair.

Ver si Safe 21

undervoltage

at U

H

wire-break/offset

on L2

wire-break/offset

on L3

failure in feedback

circuit X1-X2

simultaneity failure

signal L2/L3

potentiometer error

U

an

potentiometer error

t

s

t

8.3 Failure treatment

Failure:

The unit enables the safety outputs while the motor is still turning (LED OUT“ lights green).

Solution:

Reduce setting of Uan if necessary to minimum. If the outputs are still enabled a wiring problem

on the measuring wires could be the reason (short circuit on terminals L2/L3 to L1) or the motor

generates only a very low remanence voltage. Please check connection of measuring inputs to

motor winding according to the connection examples.

M9648_c

Failure:

The output contacts are enabled to early (motor has not finally stopped):

Solution:

Adjust setting value Uan to lower level. Additionally the delay time ts could be increased.

Failure:

Output contacts remain disabled while the motor is already on standstill

Solution:

Observe status of indicator LEDs:

22 VersiSafe

1. LED „UH“ lights green?

If yes, go to 2.

has undervoltage or the unit has an internal device failure.

If no, U

H

(Internal failures can occur in the case of undervoltage, welded safety output contacts or

seldom because of interference)

==> switch supply voltage off and on. If the failure still exists in spite of correct auxiliary

supply UH the unit could be defective and has to be sent to manufacturer for test or

repair.

2. 2. LED „ERR“ (red) flashes with code 1?

If no, go to 3.

If yes, the unit has detected undervoltage

==> Apply correct auxiliary voltage

3. LED „OUT“ flashes green?

If no, go to 4.

If yes, standstill is detected, but the time ts till enabling of the outputs is not elapsed.

==> wait till time ts is finished.

If after 6 s the outputs are not enabled, the measuring input L1-L2-L3 receives intermittent

voltage peaks that are higher then U

This should normally be indicated by intermittent yellow flashes on the LED).

==> Adjust U

cables).

to a higher value, clear interference on measuring wires (use screened

an

4. 4. LED „OUT“ lights yellow?

If yes, the voltage on the measuring input is higher then the adjusted value U

If no, LED is off

Standstill is detected (voltage on measuring input is <U

because

a) Feedback circuit X1-X2 is not closed or

b) a simultaneity failure occurred (see failure monitoring) or

c) a previous failure ( broken wire / offset, feedback circuit) is still

stored (terminals x2-x3 are not linked.

The type of failure is indicated by flash code on the red LED „ERR“:

a) flash code 4 (feedback circuit not closed)

b) flash code 5 (simultaneity fault of the measuring signals on L2 L3)

c) code 2, 3 or 4 depending on priority and failure.

==> - close feedback circuit

- Bridge terminals X2-X3 (manual reset)

If now still the simultaneity failure (flash code 5 on LED „ERR“) is indicated it can be

reset by switching the auxiliary supply off and on. The reset also takes place, when

both input signals rise above Uan e.g. when starting the motor. If the simultaneity

failure remains active after start of the motor (e.g. because of short circuit between

L2-L1 or L3-L1) the wiring of the measuring circuit has to be checked according to

the connection example.

If the simultaneity failure occurs often e. g. on slow decease of the motor speed,

the problem can be solved by increasing the tripping value Uan or/and by making

a single phase instead of a 3-phase connection of the measuring circuit to the motor.

.

an

; go to 5.

an

) but the outputs are not enabled

an

Ver si Safe 23

5. LED „OUT“ lights yellow while the motor is on standstill

If the yellow LED „OUT“ is on this indicates that the measuring inputs

still receive an input signal higher then the adjusted value U

Observe in addition the LED „ERR“:

a) if it stays off after a time of 8 s the problem could be a interference

or residual voltage (induced AC voltage) on the measuring inputs

==> Increase the setting of U

an

If this shows no result, or if an increase is not wished, the interference to the

measuring lines must be reduced e.g. by creening, shortening or separating the

wires, Test: Disconnect motor and short circuit terminals L1-L2-L3 on the unit, the

yellow LED must change to green or green flashing.

b) if the red LED flashes code 2 the unit has detected broken wire or DC voltage offset

between the measuring inputs L1 and L2 (or between L1 and L2 and L1 and L3).

c) if the red LED flashes code 3 the unit has detected broken wire or DC voltage offset on

measuring input L3

In the 2 last cases the wiring between VersiSafe terminals L1-L2-L3 and the motor

terminals has to be checked on interruption. Possibly the interruption comes from disregarding the operating remarks for motors with switchable windings (see remarks).

If failures by interruption of the input circuits can be excluded the failure can result from a DC

voltage offset > Uan. This can come from motor ontrollers like inverters or DC brakes that are not

completely switched off and supply a DC-voltage to the measuring circuit (check with Voltmeter).

If the DC content is only minor, the failure can be removed by increasing the setting value Uan

The yellow LED „OUT“ must change to green or green flashing. If not the motor controllers must

be switched off in a way that standstill can be detected correctly.

an

Failure:

While motor is on operation a failure is indicated.

If the LED „UH“ lights red, an internal failure occurred.

Solution:

Switch auxiliary supply off and on again (see 1.)

If the LED „ERR“ indicates a failure the flash code shows the type of fault and how to remove it.

Flash code 2 or 3 are normal during operation of DC motors. If the terminals X2-X3 are bridged,

The failure is reset automatically at standstill and the output relays are enabled. The same is valid

for operation with electronic controllers, if these produce a DC voltage e.g. during braking of a

DC-brake.

24 VersiSafe

PE L1 L2 L3

K4 K5

L1

L2

L3

X1

X2

X3

LH5946

M

3~

M9649_b

N

L

23 33 4311A1 A3+ A4

24 34 4412 ON ERRA2

K4

K5

motor contactor

53

54

LPE N

K4 K5

L1

L2

L3

X1

X2

X3

LH5946

M

1~

M9650_b

N

L

23 33 4311A1 A3+ A4

24 34 4412 ON ERRA2

K4

K5

motor contactor

53

54

9. Connection diagramm

9.1 with 3-phase motor

suitable up to SIL3, Performance Level e, Cat. 4

9.2 with single-phase motor

suitable up to SIL3, Performance Level e, Cat. 4

Ver si Safe 25

A1

On

K4

K4

F2

S11 S12 S22

13 23 33 41

S21 S33 S34 14 24 34 42 A2

Entriegelung

Unlock

F1

Off

Not-Aus

E-Stop

Open

Auf

Stillstandswächter

Stand-Still-Monitor

Détecteur de vitesse zéro

LH5946

L1

K4

L2

L3

N

Not-Aus-Modul

E-Stop-Modul

Module d'arrêt d'urgence

LG5925

M9165_f

A1

11

53

54

23

24

43

A3 ON

ERR A4

12

+

44

X1

X2

A2

33

34

L1 L2 L3

Meldelampe

Signal lamp

*

*

Lampe de signalisation

Meldung an

Steuerung

übergeordnete

Signal to SPS

Signalisation à la

* optional

commande supérieure

M

3

+24V

E0

E1

...

SPS / PLC / API

Déverrouillage

Ouvert

Arrêt d'urgence

9.3 Typical connection combination with E-Stop

suitable up to SIL3, Performance Level e, Cat. 4

26 VersiSafe

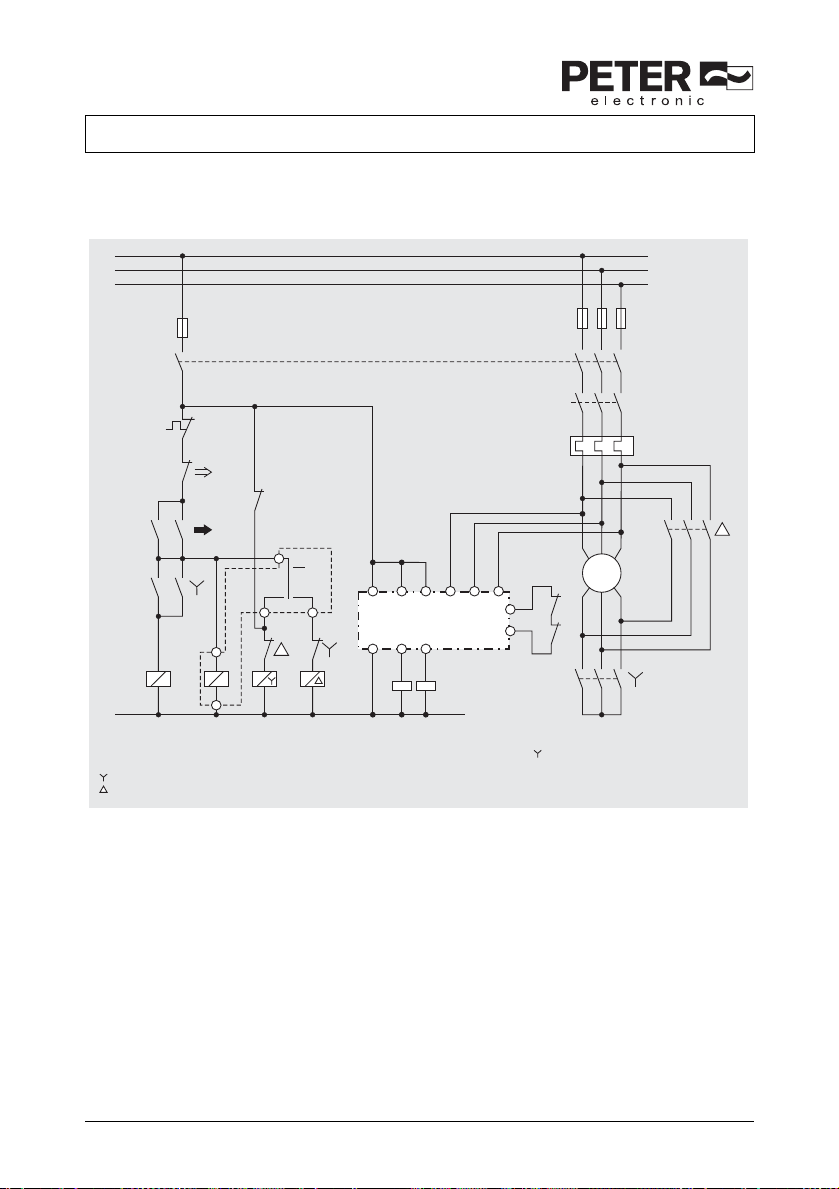

9.4 Typical connection combination with star delta timer, 2-channel connection of the measuring inputs

suitable up to SIL3, Performance Level e, Cat. 4

L1

L2

L3

fuse

main switch

N

F

off

F

N

N

N

d = star delta timer

N = mains contactor

= star-contactor

= triangle contactor

on

A1

dN

A2

BC7936N

U1

17

27

d

18

28

A1 23 33 L1 L2 L3

LH5946

24 34A2

K4 K5

X1

X2

V1U2W1

M

3~

W2

K4

K5

V2

M9967_a

Ver si Safe 27

9.5 Typical connection combination with star delta timer, 3-channel connection of the measuring inputs

suitable up to SIL3, Performance Level e, Cat. 4

L1

L2

L3

fuse

main switch

N

F

N

N

N

d = star delta timer

N = mains contactor

= star-contactor

= triangle contactor

off

on

A1

dN

A2

N

17

27

d

18

28

BC7936N

With “3-phase” connection of LH5946 the star contactor ( )

has to be closed after the motor is switched off to detect standstill.

If this is not the case the failure signal “broken wire” blocks

the output contacts in off posisition.

A1 23 33 L1 L2 L3

LH5946

24 34A2

K4 K5

F

U1

V1U2W1

M

3~

W2

X1

K4

X2

K5

V2

M9969_a

28 VersiSafe

Loading...

Loading...