Page 1

For Part Numbers: LU-142AP12, LU-143P12, LU-144P12, LU-149P12,

LU-162AP12, LU-165P12, LU-166AP12

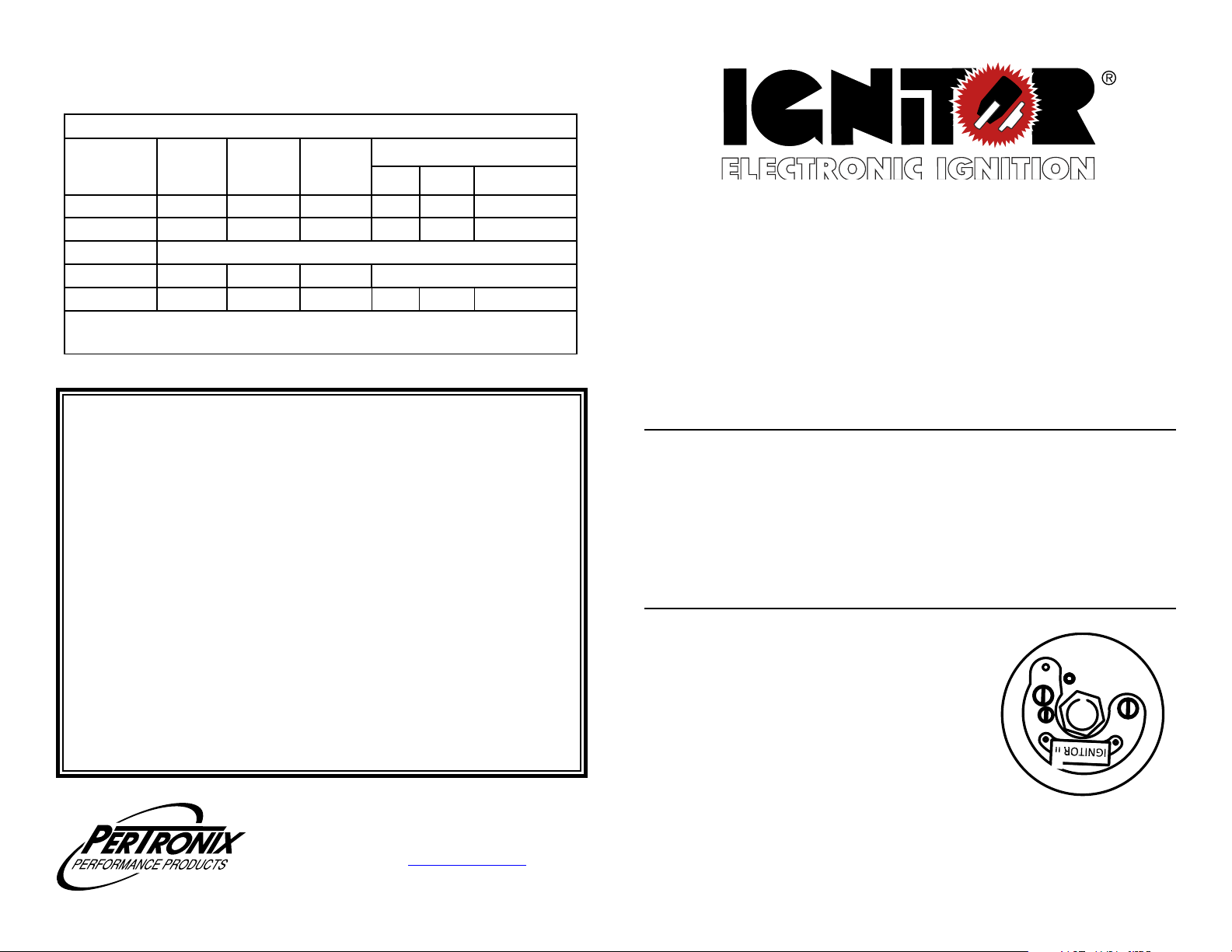

FLAME-THROWER COIL APPLICATIONS

Recommended Flamethrower Coils

Black Chrome Epoxy

Use with:

System

Voltage

Cylinders

Primary

Resistance

Ignitor Only 12V 8 1.5 ohms 40011 40001 40111

Ignitor Only 12V 4 & 6 3.0 ohms 40511 40501 40611

Agricultural & Industrial

Ignitor Only 12V 1,2,3,4, & 6 2.8 ohms 28010 or 40511, 40501, 40611

Ignitor Only 12V 8 1.5 ohms 40011 40001 40111

NOTE: REMOVE OR BYPASS EXTERNAL BALLAST RESISTOR OR RESISTANCE

WIRE WHEN INSTALLING THE RECOMMENDED FLAME-THROWER COIL.

LIMITED WARRANTY

Pertronix, Inc. Warrants to the original Purchaser of its solid-state ignition system

(product) that the Ignitor, magnet assembly and wiring (components) shall be free from

defects in material and workmanship for a period of (30) months from the date of purchase.

If within the period of the foregoing warranty Pertronix finds, after inspection, that

the product or any component thereof is defective, Pertronix will, at its option, repair such

products or component or replace them with identical or similar parts PROVIDED that within

such period Purchaser:

1. Promptly Notifies Pertonix, in writing, of such defects.

2. Delivers the defective products product or component to Pertronix (ATTN: Warranty)

with proof of purchase date; and

3. Has installed and used the product in a normal and Proper manner, consistent with

Pertronix printed instructions.

THE FORGOING LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED, INCLUDING AND IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PURPOSE.

THE FURNISHING OF A REPAIR OR REPLACEMENT COMPONENTS SHALL

CONSTITUTE THE SOLE REMEDY OF PURCHASER AND THE SOLE LIABILITY OF

PerTronix WHETHER ON WARRANTY, CONTRACT

EVENT WILL PerTronix BE LIABLE FOR MONEY DAMAGES WHETHER DIRECT OR

CONSEQUENTIAL.

440 E. Arrow Highway, San Dimas, CA. 91773

909-599-5955 www.pertronix.com

OR FOR NEGLIGENCE, AND IN NO

12-Volt Positive Ground Instructions

Before installing, please read the following important information....

1. The Ignitor is designed for 12-volt Positive ground systems.

2. See Chart on back page for coil recommendations.

3. The Ignitor is compatible only with a “resisted style” coil. Eight cylinder engines require a minimum

of 1.5 ohms of resistance. Six & four cylinder engines require a minimum of 3.0 ohms of resistance.

4. If your Ignition coil has the proper primary resistance, remove or bypass all external resistors. Note:

Do not remove resistors if the coil primary resistance is lower than specified.

5. The black wire from the Ignitor must be connected to the ignition switch wire.

6. The black/white wire must be connected to the negative (-) side of the coil.

7. Some magnet sleeves may have green tape, DO NOT REMOVE IT.

DISASSEMBLY

1. PRIOR TO INSTALLATION TURN IGNITION SWITCH OFF OR DISCONNECT THE BATTERY

2. Remove the distributor cap, and rotor. Do not disconnect spark plug wires. Examine cap and rotor

for wear or damage. Replace as needed.

3. Disconnect the point wire from the negative (-) terminal of the coil.

4. Remove the point wire, point, and condenser from the distributor. The Ignitor does not require

any modification to the distributor. Therefore the point, condenser and hardware can be used as

backup.

5. Clean all dirt and excess oil from the breaker plate and point cam.

IGNITOR INSTALLATION

1. Part Number LU-165P12, place Ignitor over eccentric screw,

rotate if necassary to line up holes on breaker plate. Note:

Ignitor mounts over condenser original location. Do not use

point pivot pin, it’s not used for Ignitor installation. See Figure

1. Secure Ignitor with screws provided.

2. Part numbers LU-143P12 & LU-144P12, Install Ignitor over

point guide pin, line up point screw hole and secure with screw

provided.

3. All Other kits, Install Ignitor adapter plate to the breaker plate

using the screws provided. NOTE: 25D and 22D distributors

will use both mounting screws, 23D distributors will use one

flat head mounting screw. Place the Ignitor module on the

adapter plate studs. Secure module to adapter plate with the nuts provided.

4. Install magnet sleeve over the distributor shaft, onto point cam. Rotate the sleeve until a slight

locating position is felt before applying pressure. Press down firmly insuring sleeve is fully seated.

5. Module and magnet sleeve air gap is not adjustable.

Figure 1

Page 2

6. Reinstall the rotor, and the distributor cap. Make sure all spark plug wires are securely attached.

7. See Wiring Instructions.

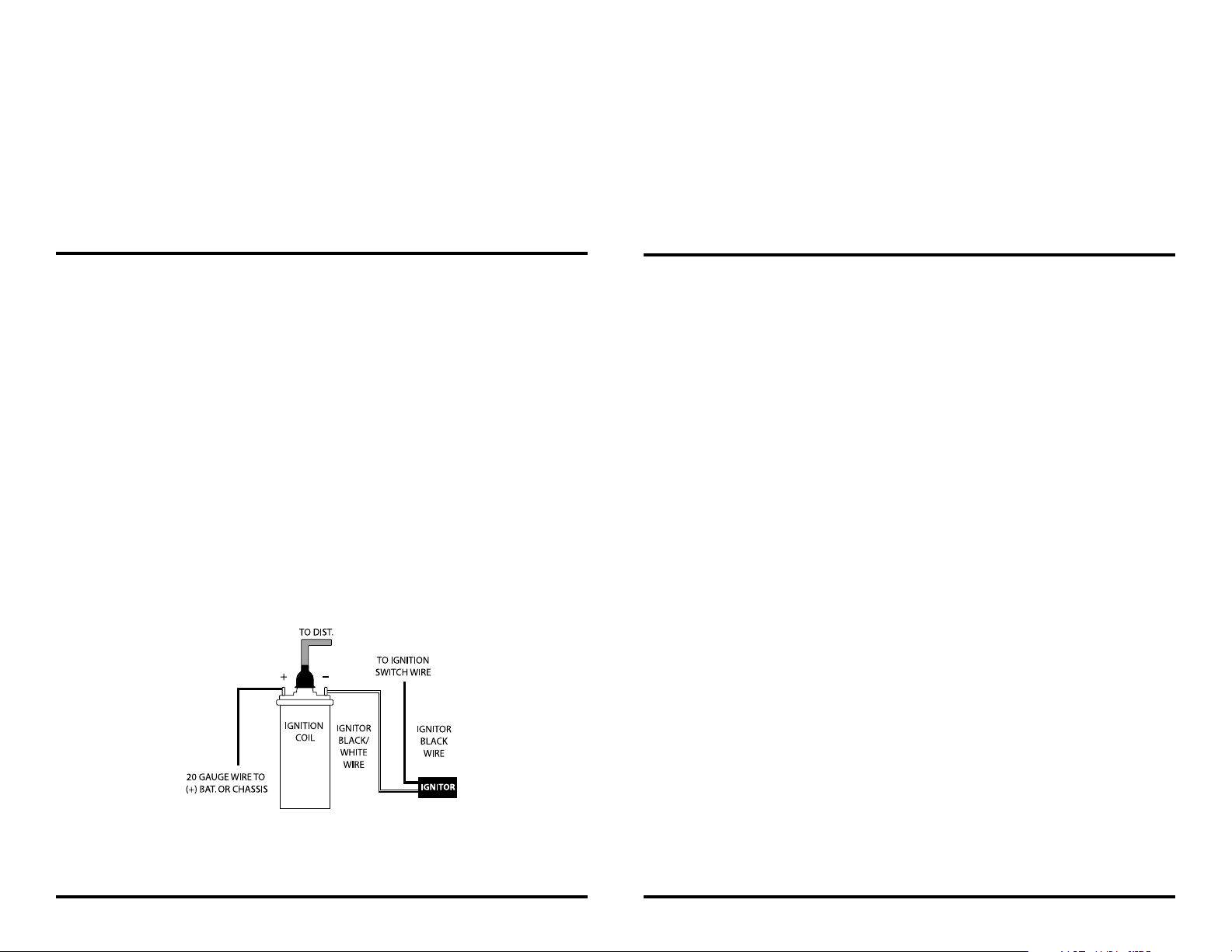

WIRING INSTRUCTIONS

1. NOTE: A BALLAST RESISTOR OR RESISTOR WIRE MAY OR MAY NOT BE

INCLUDED IN THE ORIGINAL EQUIPMENT.

2. Remove the ignition switch wire from the negative coil terminal. Connect the black Ignitor

wire directly to the ignition switch wire.

3. Connect the Ignitor black/white wire to negative (-) side of the ignition coil.

4. Connect an insulated, AWG 20 copper stranded wire from the positive coil terminal to the

positive battery or chassis.

5. The black/white Ignitor wire and the AWG 20 copper wire should be the only wires

connected to the coil.

6. Make sure all wires are connected correctly, and reconnect battery.

7. The engine can now be started. Let the engine run for a few minutes and then set the

timing in the conventional manner.

Ignitor COMMON QUESTIONS AND ANSWERS

Q. What is the first thing I should check if the engine would not start?

A. Make certain all wires are connected securely to the proper terminals.

Q. The engine will not start or runs rough. Are there any tests I can do?

A. Yes, remove the black wire from the ignition switch wire. Connect jumper wire from the negative (-) side of battery to

the Ignitor black wire. If the engine starts and runs well, you may have high resistance thru your Ignition switch. This is

just a test. Not intended for permanent installation.

Q. How can I fix a high resistance problem?

A. High resistance can be caused by an external ballast resistor, resistance wire or in some cases a resisted ignition

switch. If the proper coil is used, remove or bypass all external resistors.

Q. Should I remove the starter bypass wire?

A. No, the starter bypass wire is needed to provide voltage while starting (cranking).

Q. What type of coil do I need?

A. The ignitor is compatible only with a “points type” coil. Eight cylinder engines require a minimum of 1.5 Ohms of

resistance in the primary circuit. Four & six cylinder engines require a minimum of 3.0 Ohms of resistance (primary).

Q. How do I check my coil for resistance?

A. First you need an ohmmeter. Remove all the wires from the coil. Attach the ohmmeter to both the positive and

negative terminals. The reading should be 1.5 Ohms or greater for eight cylinder engines and 3.0 Ohms or greater for

four & six cylinder engines. (Your local auto parts store can do this for you if you don’t have an ohmmeter)

Q. What do I do if my coil does not have enough resistance?

A. You may purchase and install a ballast resistor from your local auto parts store. You may also choose to purchase a

Flamethrower 40,000-volt coil, which provides resistance internally. Note: Many vehicles come with resistor wire or a

ballast resistor. These applications do not need an additional resistor.

Q. What happens if you leave the ignition switch on when the engine is not running?

A. This can cause your coil to overheat, which may cause permanent damage to the coil and the ignitor.

Q. May I modify the length of the wires?

A. Yes, you can cut the wires to any length your application may require. You may also add length of wire if needed

(20-gauge wire). Please make sure all wire splice are clean and connections are secure.

Q. How can I get additional help?

A. Call our tech line (909-599-5955) for any further instructions or questions.

Loading...

Loading...