Page 1

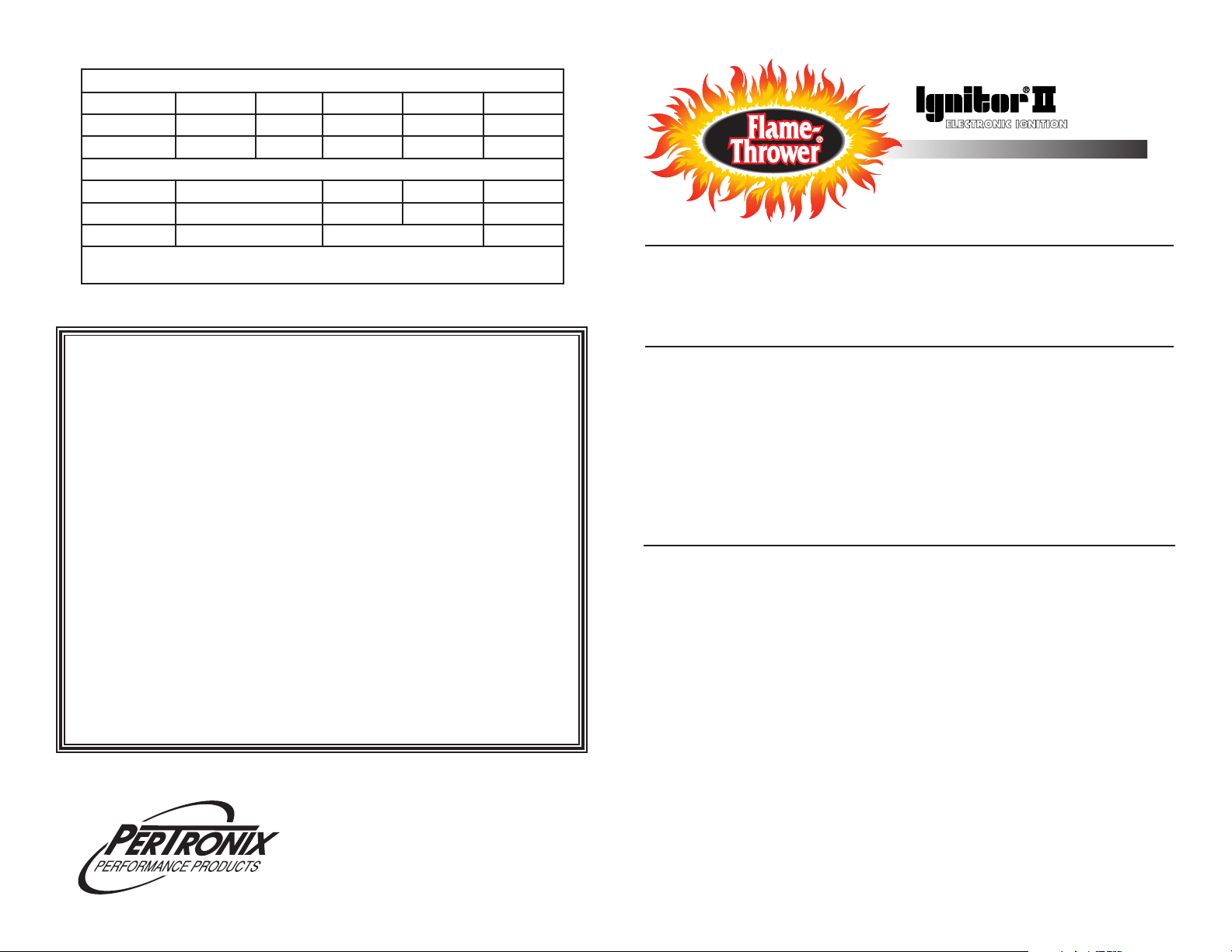

For Part Numbers:

D190500 D190509 D190600 D190609

Recommended Flame-Thrower II & HV Coils

Application Primary resistance Chrome Black Epoxy

Ignitor II Only 0.6 ohm 45001 45011 45111

Ignitor II Only 0.45 ohm E-Core HV Coil 60104

NOTE: REMOVE OR BYPASS EXTERNAL BALLAST RESISTOR OR RESISTANCE WIRE WHEN

INSTALLING THE RECOMMENDED FLAME-THROWER II OR HV E-CORE COIL.

LIMITED WARRANTY

PerTronix, Inc. warrants to the original Purchaser of its Flame-Thrower billet distributor that the product shall be free from defects in material and workmanship (normal wear and tear excluded) for a period of 12 months from the date of

purchase.

If within the period of the foregoing warranty PerTronix finds, after inspection, that

the product or any component thereof is defective, PerTronix will, at its option, repair

such products or component or replace them with identical or similar parts PROVIDED

that within such period Purchaser:

1. Promptly notifies PerTronix, in writing, of such defects.

2. Delivers the defective product or component to

PerTronix (Attn: Warranty) with proof of purchase date; and

3. Has installed and used the product in a normal and proper

manner, consistent with PerTronix printed instructions

THE FOREGOING LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

THE FURNISHING OF A REPAIR OR REPLACEMENT COMPONENT

OR COMPONENTS SHALL CONSTITUTE THE SOLE REMEDY OF PURCHASER

AND THE SOLE LIABILITY OF PerTronix WHETHER ON WARRANTY, CONTRACT

OR FOR NEGLIGENCE, AND IN NO EVENT WILL PerTronix BE LIABLE FOR

MONEY DAMAGES WHETHER DIRECT OR CONSEQUENTIAL.

440 East Arrow Highway

San Dimas, CA 91773

909-599-5955

www.pertronix.com

DISTRIBUTOR INSTALLATION

INSTRUCTIONS FOR:

FORD-OHC, X-FLOW, TWIN CAM

GENERAL INFORMATION

1. IMPORTANT: Read all instructions before starting installation.

2. For 12-volt negative ground systems only.

3. New spark plug wires may be required.

4. Solid core spark plug wires MUST NOT be used.

DISTRIBUTOR REMOVAL

1. Crank the engine until the first cylinder in the firing order is at TDC "Top Dead

Center" on its compression stroke. The timing indicator should point to TDC or 0.

2. Remove the distributor cap, and make sure that the rotor is pointing towards the

contact on the distributor cap for the first cylinder in the firing order.

3. Disconnect the battery negative (-) cable.

4. Disconnect all wires and hoses attached to the distributor.

5. Remove the distributor hold down bolt.

6. Remove the distributor by lifting up on the distributor housing while slightly

turning the rotor.

7. Check the distributor gear for signs of excess wear, or potential problems.

DISTRIBUTOR INSTALLATION

Note: Original hold down clamp must be used with new Flame-Thrower

distributor. Hold down bracket must be free of paint and corrosion, this will insure

that a proper ground is made to the engine block.

1. Remove the Flame-Thrower distributor cap.

2. Lubricate the distributor gear and distributor shaft with clean engine oil.

3. Turn the shaft so that when the distributor is placed into the engine, the rotor

position matches that of the original distributor. As the distributor drops down,

the rotor will turn slightly as it engages with the camshaft gear. Adjust for this

rotation by turning the rotor a few degrees prior to the gear engagement. Several

attempts may be necessary to achieve the proper rotor position. Note: The

distributor flange will be flush with the engine block if the installation is done

properly.

4. Place the distributor cap onto the housing.

5. Turn the housing so that the terminal, that represents the first cylinder in the

firing order, lines up with the rotor.

6. Install the distributor hold down bolt and tighten completely. Once the ignition

timing is adjusted the hold down clamp should be tightened completely.

7. Tighten the cap into place and install the spark plug wires in the proper firing

order.

10-13

0017-004425

Page 2

8. For Vacuum advance distributors:

Locate the vacuum hose that was previously attached to the vacuum advance

canister. This hose should originate at a ported vacuum source. Some applications have vacuum advance hoses attached to a manifold vacuum source, due

to the performance advance curve, we recommend that you relocate this hose

to a ported vacuum source. After setting initial timing the hose will be unplugged

and attached to the vacuum advance on the distributor.

For Non-vacuum advance distributors:

Locate the vacuum hose that was previously attached to the vacuum advance

canister. Remove the vacuum hose and plug the vacuum port.

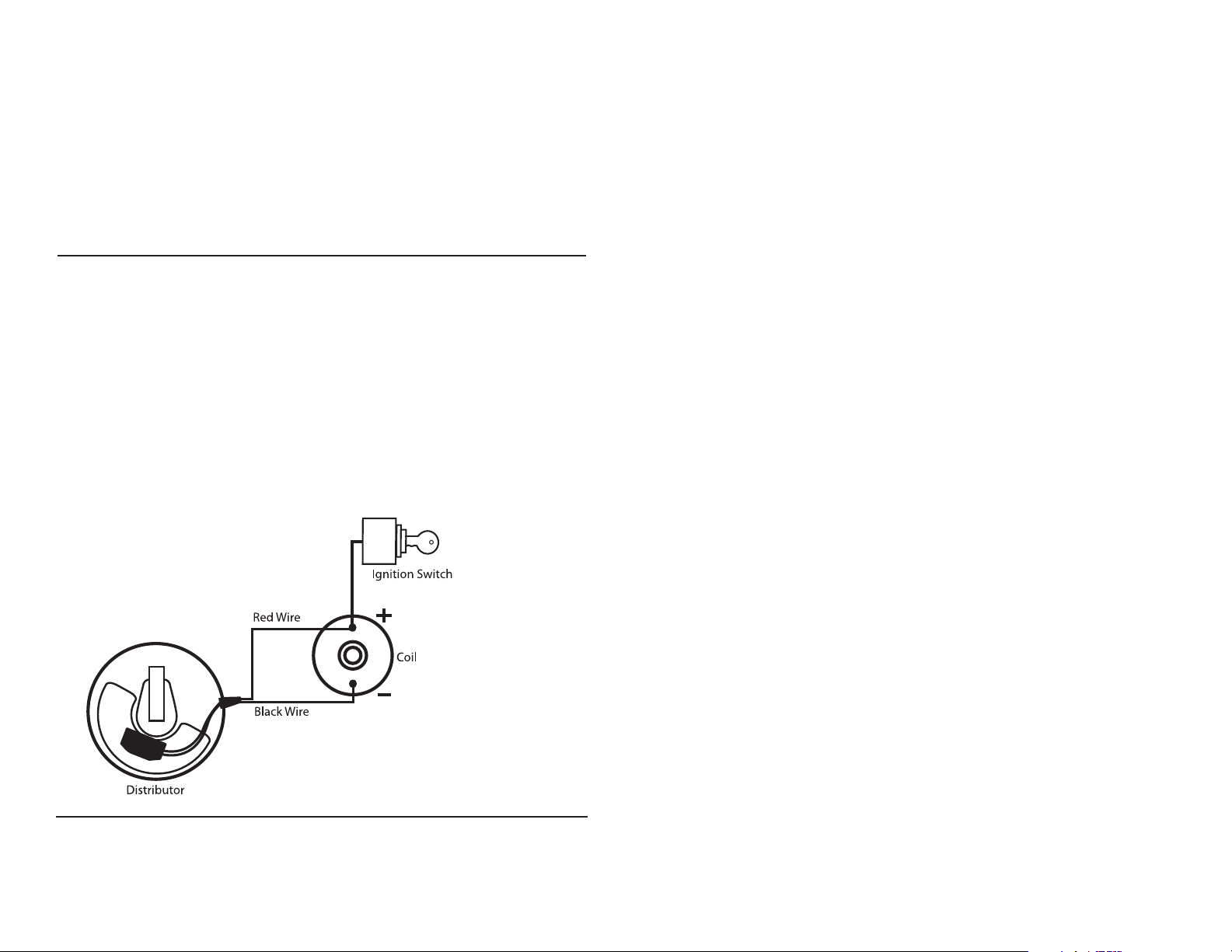

WIRING

The Flame-Thrower distributor can be used in conjunction with most

Ignition coils rated at 0.45 ohms or greater. For optimum performance purchase

and install a 0.6 ohm Flame-Thrower II or 0.45 ohm HV high performance coil.

1. Many vehicles came equipped with ballast resistors or resistance wires. To

achieve optimum performance we recommended removal of these

components.

2. Determine the proper wire length, and attach the provided terminals. (Use a

designated wire crimping tool to achieve an adequate connection)

3. Attach the Red wire to the coil positive terminal or a 12-volt ignition source.

Note: Original ignition wire must be connected to the (+) positive side of the

Ignition coil.

4. Attach the Black wire to the coil negative terminal.

5. Check to insure correct polarity and that all connections are tight.

6. Reconnect the battery negative cable.

COMMON QUESTIONS AND ANSWERS

Q. The engine will not start or runs rough. What is the problem?

A. Check all connections to insure that they are tight, and in the proper location.

Make sure that the red wire from the Flamethrower distributor is supplied with a

full 12 volts. The Flame-Thrower distributor uses Ignitor II technology and is designed

to sense high current levels, and shut off before damage occurs. Check all wires

for shorts, correct polarity and that the ignition coil’s primary resistance level is

acceptable.

Q. The vehicle will start, but then die. After waiting it will start again. What is wrong?

A. Check for a “Low Voltage Problem.” If the voltage supplied to the Flame-Thrower

distributor red wire is insufficient, the system may run for a period of time, and

then shut down as the voltage drops due to engine heat. The period may vary

from minutes to hours depending on available voltage and wiring condition.

Q. How do I check for a “Low Voltage Problem” or determine if I am getting ade-

quate voltage?

A. To quickly test for a “Low Voltage Problem” or for adequate voltage, remove the

Flame-Thrower distributor red wire from the coil positive terminal. Attach a jumper

wire from the battery positive terminal to the distributor red wire. Try to start the

vehicle. If the vehicle starts, low voltage is the problem.

Q. How do I check my coil for primary resistance?

A. Remove all wires from the coil. Set the ohmmeter to the lowest scale. Attach one

lead of the meter to the positive coil terminal. Attach the other lead to the negative

coil terminal. The Flame-Thrower distributor is compatible with coils having a resis-

tance of 0.45 ohms or greater. See chart for compatible Flame-Thrower coils.

FINAL ADJUSTMENTS

1. Start the engine and set the initial timing.

2. Tighten the distributor hold down clamp.

3. For vacuum advance distributors, connect the vacuum hose to the vacuum

advance canister.

Q. May I modify the length of the wires?

A. Yes, you may cut the wires to any length your application requires. You may also

add lengths of wire if needed (20-gauge). Make sure that all wire splices are clean

and the connections are tight.

Q. Will the Flame-Thrower distributor work with aftermarket capacitive discharge boxes?

A. Yes, the Flame-Thrower distributor is compatible with most CD boxes in the same

respect as points. Use the CD box wiring instructions for point systems and treat

the Ignitor II black wire as a point wire. The Flame-Thrower red wire should be

attached to the 12-volt power source.

Q. How can I receive additional help?

A. Check our web site for current trouble shooting tips and up to date technical

information. Log on to www.pertronix.com. You may also contact our tech line at

(909-547-9058)

Loading...

Loading...