Page 1

LIMITED WARRANTY

PerTronix, Inc. warrants to the original purchaser of its products that the

Ignitor III shall be free from defects in material and workmanship for a period of

(30) months from the date of purchase.

If within the period of the foregoing warranty Pertronix finds, after inspection, that the product or any component thereof is defective, Pertronix will, at its

option, repair such products or component or replace them with identical or similar parts PROVIDED that within such period Purchaser:

Promptly Notifies Pertonix, in writing, of such defects.1.

Delivers the defective products product or component to Pertronix (ATTN: 2.

Warranty) with proof of purchase date; and

Has installed and used the product in a normal and Proper manner, consis-3.

tent with Pertronix printed instructions.

THE FORGOING LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED, INCLUDING

AND IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A

PURPOSE.

THE FURNISHING OF A REPAIR OR REPLACEMENT COMPONENTS SHALL

CONSTITUTE THE SOLE REMEDY OF PURCHASER AND THE SOLE LIABILITY

OF PerTronix WHETHER ON WARRANTY, CONTRACT

OR FOR NEGLIGENCE,

AND IN NO EVENT WILL PerTronix BE LIABLE FOR MONEY DAMAGES

WHETHER DIRECT OR CONSEQUENTIAL.

PRIOR TO INSTALLATION TURN IGNITION SWITCH OFF

OR DISCONNECT THE BATTERY

12-VOLT NEGATIVE GROUND INSTRUCTIONS

GENERAL INFORMATION

See our website (www.pertronix.com) for the latest product information. 1.

IMPORTANT: Read all instructions before starting installation.

WARNING!!! DO NOT USE WITH SOLID CORE IGNITION WIRES. 2.

The Ignitor III may not be compatible as a trigger for other electronic boxes.3.

The Ignitor III Rev-Limiter is preset at 5500 RPM’s. The Rev-Limiter can be user set 4.

to a minimum 4000 and a maximum 9000 RPM’s.

All external resistors must be removed to achieve optimum performance from the 5.

Ignitor III ignition system.

440 East Arrow Highway

San Dimas, CA 91773

909-599-5955

www.pertronix.com

IGNITOR III INSTALLATION

Note: A magnet sleeve is not required and the air gap between the face of the

module and the reluctor is not adjustable.

Remove cap and rotor from distributor. Do not disconnect spark plug wires from cap.1.

Examine cap and rotor for wear or damage. Replace as needed.2.

Disconnect the points wire from the (-) terminal of the Ignition coil.3.

Remove clip from vacuum advance arm. Remove vacuum advance screws and 4.

remove vacuum advance completely from distributor.

Remove breaker plate screws and lift out entire breaker plate assembly.5.

The Ignitor III does not require any modification to the distributor.6.

Clean all dirt and excess oil from the reluctor.7.

Ignitor III assembly Installation: 8.

Line up base plate assembly screw holes to distributor housing and secure with •

original screws.

Install vacuum advance onto distributor housing, secure vacuum advance arm with •

original or provided clip. Secure vacuum advance with original screws. TIP: Install

vacuum advance arm to Ignitor III adapter plate pin first before tightening

screws.

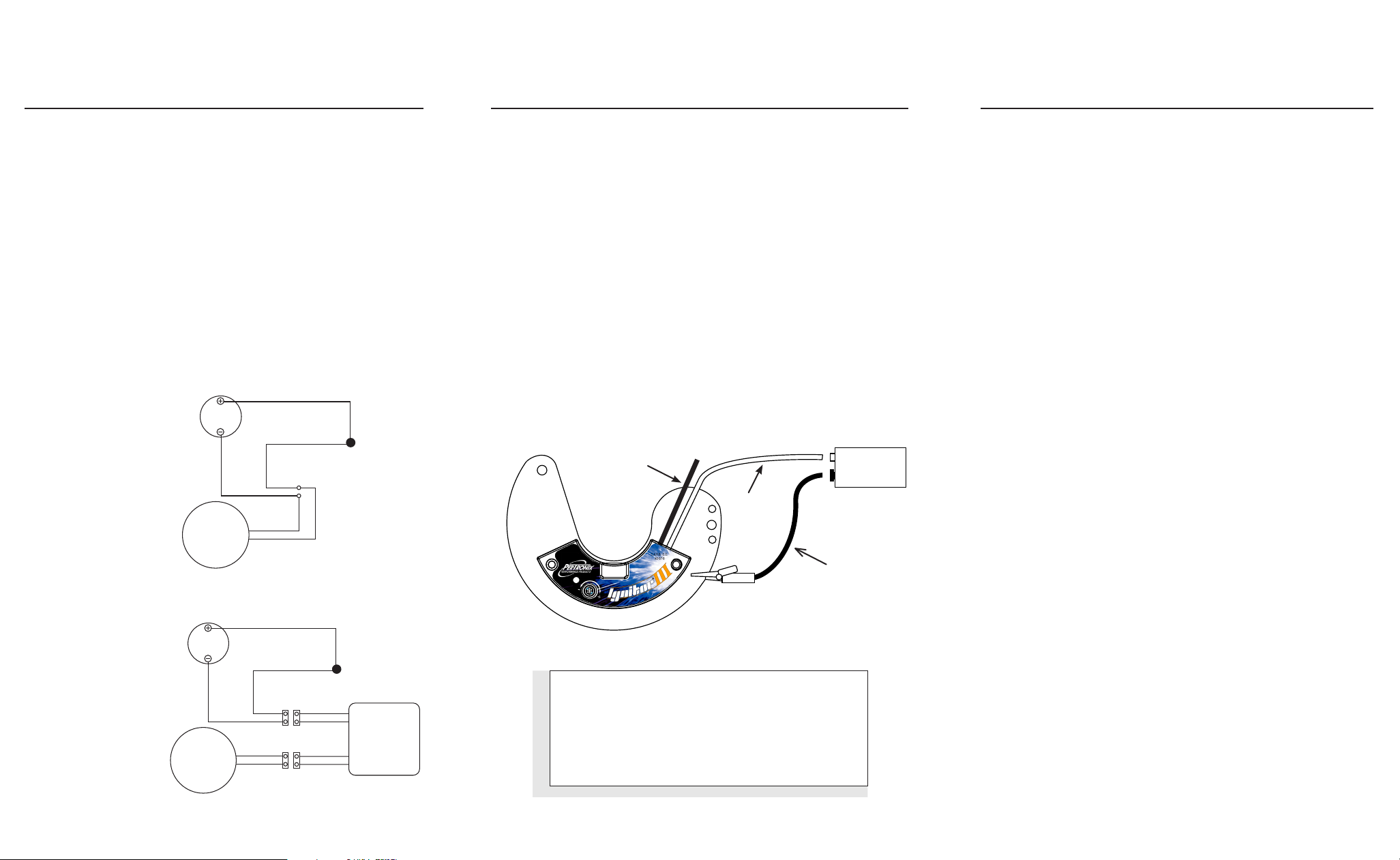

Insert Ignitor III wires into slot in the distributor housing. Remove the excess wire 9.

from inside the distributor housing by gently pulling the wire through the grommet.

Check to insure that the wire does not interfere with any moving parts.

Install the distributor cap and rotor. Check to insure that all spark plug wires are 10.

seated securely in the distributor cap.

See Wiring Instructions.11.

For Part Number: 7HO-181

08-09 0000-003005

Page 2

Red Wire

Jumper Wire

Black Wire (Open)

REV-LIMITER SPECIFICATIONS

Settings RPM’S

Minimum 4000

Maximum 9000

Factory Setting 5500

WIRING INSTRUCTIONS

The Ignitor III can be used in conjunction with most ignition coils rated at 0.32

ohms or greater. For optimum performance we recommend our Flame-Thrower

III canister style or HC e-core coil.

Many vehicles came equipped with ballast resistors or resistance wires. To

achieve optimum performance we recommend removal of these components.

Determine the proper wire length, and attach the provided terminals. (Use a

wire crimping tool to achieve an adequate connection).

To remove a ballast resistor, (normally white ceramic blocks 3 to 4 •

inches long), disconnect all wires on both ends of the ballast resistor.

Remove the resistor from the vehicle and splice the disconnected wires

together at a single point.

To remove a resistance wire, trace the coil power wire, which was previ-•

ously connected to the positive coil terminal, back to the fuse block.

Bypass this wire with a 12-gauge copper stranded wire.

REV-LIMITER SETTING PROCEDURE

Remove distributor cap and rotor. 1.

Turn the ignition key to the ‘ON’ position. Do not try star ting the engine.2.

Turn the Rev-Limit dial clockwise until it stops. Turn the dial counterclockwise until it 3.

stops. A slow blinking of the LED indicates that the setting procedure has been initialized and that the Rev-Limit can be set.

Turning the dial clockwise sets the Rev-Limit. After turning the dial, pause and watch 4.

the LED for verification of the Rev-Limit setting. Long flashes indicate 1000 RPM’s

and short flashes indicate 100 RPM’s. For example, 6 long flashes followed by 2 short

flashes means the Rev-Limit is 6200 RPM’s. Continue turning the Rev-Limit dial until

the desired Rev-Limit is reached.

NOTE: Leaving the Rev-Limit dial in the full counterclockwise position disables

the Rev-Limiter.

Let the LED sequence thru at least three complete cycles. This verifies the correct set-5.

ting and prepares the unit for permanent storage of the Rev-Limit.

Turn the ignition key off, this signifies to the Ignitor III that the Rev-Limit procedure is 6.

complete. Note: The Ignition key MUST be turned off or the engine will not start.

Your rev limit is now set and will not change until you go through this procedure again. 7.

Re-install cap and rotor.8.

NOTE: Setting the rev limit may be done effectively and easily on a bench or table.

Connect the module to a 9-volt battery as shown in figure 4. Then follow the setting

procedure outlined above.

9 Volt

Battery

+

-

Figure 4

COMMON QUESTIONS AND ANSWERS

Q. The engine will not star t or runs rough. What is the problem?

A. Check all connections to insure that they are tight, and in the proper location. Visually check

and measure all grounds. Remove paint and corrosion from around the distributor hold down

bracket. Make sure that the Ignitor III red and black wires are connected properly. The Ignitor III

will shut down if the wires are incorrectly attached. The Ignitor III is designed to sense high current

levels. Check all wires for shorts, correct polarity and that the ignition coil’s primary resistance

level is acceptable. For more detailed information log on to www.pertronix.com or contact the technical department at (909) 599-5955.

Q. The vehicle will start, but then dies. After waiting, it starts. What is wrong?

A. The Ignitor III may have a “Low Voltage Problem.” If the voltage supplied to the red distributor

wire is insufficient, the system may run for a period of time, and then shut down as the voltage

drops due to engine heat. The period may vary from minutes to hours depending on available voltage and wiring condition.

Q. How do I check for a “Low Voltage Problem” or determine if I am getting adequate voltage?

A. To quickly test for a “Low Voltage Problem” or for adequate voltage (Note: This is only a test

and is not intended as a permanent fix) attach a jumper wire from the positive battery terminal to the positive terminal of the coil. Try to start the vehicle. If the vehicle starts, low voltage is

present. Note: If the engine starts. The engine will not turn off unless the jumper wire is

removed from the positive battery terminal. Check connections and insure all external resistors

have being removed. For more detailed information on how to locate the source of the voltage

drop log on to www.pertronix.com or contact the technical department at (909) 599-5955.

Q. How do I check my coil for primary resistance?

A. Remove all wires from the coil. Set the ohmmeter to the lowest scale. Attach one lead of the

meter to the positive coil terminal. Attach the other lead to the negative coil terminal. The Ignitor III

is compatible with coils having a resistance of 0.32 ohms or greater.

Q. May I modify the length of the wires?

A. Yes, you may cut the wires to any length your application requires. You may also add lengths of

wire if needed (20-gauge). Make sure that all wire splices are clean and that the connections are

tight and insulated.

Q. Will the Ignitor III work with aftermarket capacitive discharge boxes?

A. We recommend the Ignitor or Ignitor II as a trigger source for a capacitive discharge box.

For more detailed information log on to www.pertronix.com or contact the technical department at

(909) 599-5955.

Q. How can I receive additional help?

A. Check our web site for current trouble shooting tips and up to date technical information. Log on

to www.pertronix.com. You may also contact our tech line at (909)599-5955.

Distributor

with Ignitor

Black

Red

Red

Brown

To Ignition Switch

Coil

Original Ignition

Control Module

Distributor

Ye llo w

Black

Ye llo w

Black

Red

Brown

Red

Brown

To Ignition Switch

Coil

Attach the black Ignitor 1.

III wire to the brown wire

previously connected

to the external control

module. The brown wire

should then connect to

the negative terminal of

the coil. (See Figure 1)

Attach the red Ignitor III 2.

wire to the original red

wire preciously connect-

ed to the external igni-

tion module. This original

red wire should provide

full 12 volts when the

key is turned on. (See

Figure 1)

Reconnect battery and 3.

make sure all wires are

connected.

The engine can now be 4.

started. Let the engine

run for a few minutes

and then set the timing

in the in the conventional

manner.

Figure 1 (IGNITOR WIRING)

Figure 2 (ORIGINAL FACTORY WIRING)

Loading...

Loading...