Installation Instructions

IMPORTANT :

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the owner.

Owner: Keep Installation Instructions for

future reference.

Save: Installation Instructions for local

electrical inspector’s use.

Part No. 8527389

www.personalvalet.com

™ Trademark of Whirlpool, U.S.A.

Tip Over Hazard

Do not use clothes vitalizer until completely

installed.

Install lag bolts securely into wall studs.

Use two or more people to move and install

clothes vitalizer.

Reapply tape or strap to secure doors

before moving clothes vitalizer.

Failure to follow these instructions can

result in death or serious injury.

WARNING

™

Clothes Vitalizing System

For model series:

PVWC600

PVWN600

PVWM600

PVWS600

PVBN600

PVBC600

PVBM600

PVBS600

PVFE600

Model shown:

PVWN600

Tools needed for

installation:

Electrical requirements

It is your

responsibility to:

ground

prong

PAGE 2

3-prong

ground-type

outlet

3-prong

ground plug

power supply

cord

Plug into a grounded 3-prong

outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these

instructions can result in death,

fire, or electrical shock.

Electrical Shock Hazard

Before y ou start...

Parts supplied for

installation:

Recommended ground method

The clothes vitalizer, when installed,

must be electrically grounded in

accordance with local codes, or in

the absence of local codes, with

National Electrical Code, ANSI/

NFPA 70*.

GROUNDING INSTRUCTIONS: This

clothes vitalizer must be grounded. In

the event of malfunction or

breakdown, grounding will reduce the

risk of electric shock by providing a

path of least resistance for electric

current.

We have provided many important

safety messages in this manual

and on your appliance. Always

read and obey all safety messages.

WARNING

This is the safety alert

symbol.

This symbol alerts you to

potential hazards that can kill or

hurt you and others.

All safety messages will follow the

safety alert symbol and either the

word “DANGER” or “WARNING”.

These words mean:

All safety messages will tell you

what the potential hazard is, tell you

how to reduce the chance of injury,

and tell you what can happen if the

instructions are not followed.

You can be killed or seriously

injured if you don’t immediately

follow instructions.

You can be killed or seriously

injured if you don’t follow

instructions.

DANGER

Your safety and the safety of

others are very important.

WARNING

Important: Observe all governing

codes and ordinances.

A 120-volt, 60-Hz, AC-only, 15- or

20-ampere fused electrical supply is

required. A Time-delay fuse or circuit

breaker is recommended.

It is recommended that a separate

circuit serving only this appliance be

provided.

If codes permit and a separate

ground wire is used, it is

recommended that a qualified

electrician determine that the

ground path is adequate.

3-prong ground-type outlet must

be located within 5 feet of lower

right corner of appliance.

Observe all governing codes and

ordinances.

Check code requirements: Some

codes limit or do not permit

installation of this product in garages,

closets, mobile homes or sleeping

quarters. Contact your local building

inspector.

Comply with the installation

specifications and dimensions.

Consider spacing requirements for

companion appliances.

Make sure you have everything

necessary for proper installation.

Properly install appliance.

Contact a qualified installer to insure

that the electrical installation meets

all national and local codes and

ordinances.

Copies of the standards listed above may be

obtained from:

* National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

• stud finder (optional)

• drill (electric recommended)

• 5/32" drill bit (pilot hole for lag bolt)

• tape measure

• pencil

• carpenter’s level

• 7/16" wrench (ratchet

recommended) for lag bolts

if installing on a concrete or concrete

block wall

• concrete drill bit for wall anchors

(refer to wall anchor for drill bit size)

• hammer

if installing on a metal studded wall

• 3/4" drill or as large as needed for

spring nut clearance

• magnetic stud finder

if changing the door on

Decor series only

• 11/32" wrench

• 1/4" nut driver or wrench

• Phillips screwdriver

(inside accessory box)

• 2, 1/4" x 2" lag bolts (for wood studs)

• 2, 1/4-20" nuts

• 1 mounting bracket cover (can be

painted or covered with wallpaper)

• separate metal mounting bracket

assembly

• 6, 1/8" thick adhesive backed cabinet

spacers

The power supply cord plug must be

plugged into an appropriate outlet

that is properly installed and

grounded in accordance with all local

codes and ordinances.

WARNING – Improper connection

of the equipment-grounding

conductor can result in a risk of

electric shock. Check with a

qualified electrician or serviceman

if you are in doubt as to whether

the appliance is properly

grounded. Do not modify the plug

provided with the appliance – if it

will not fit the outlet, have a proper

outlet installed by a qualified

electrician.

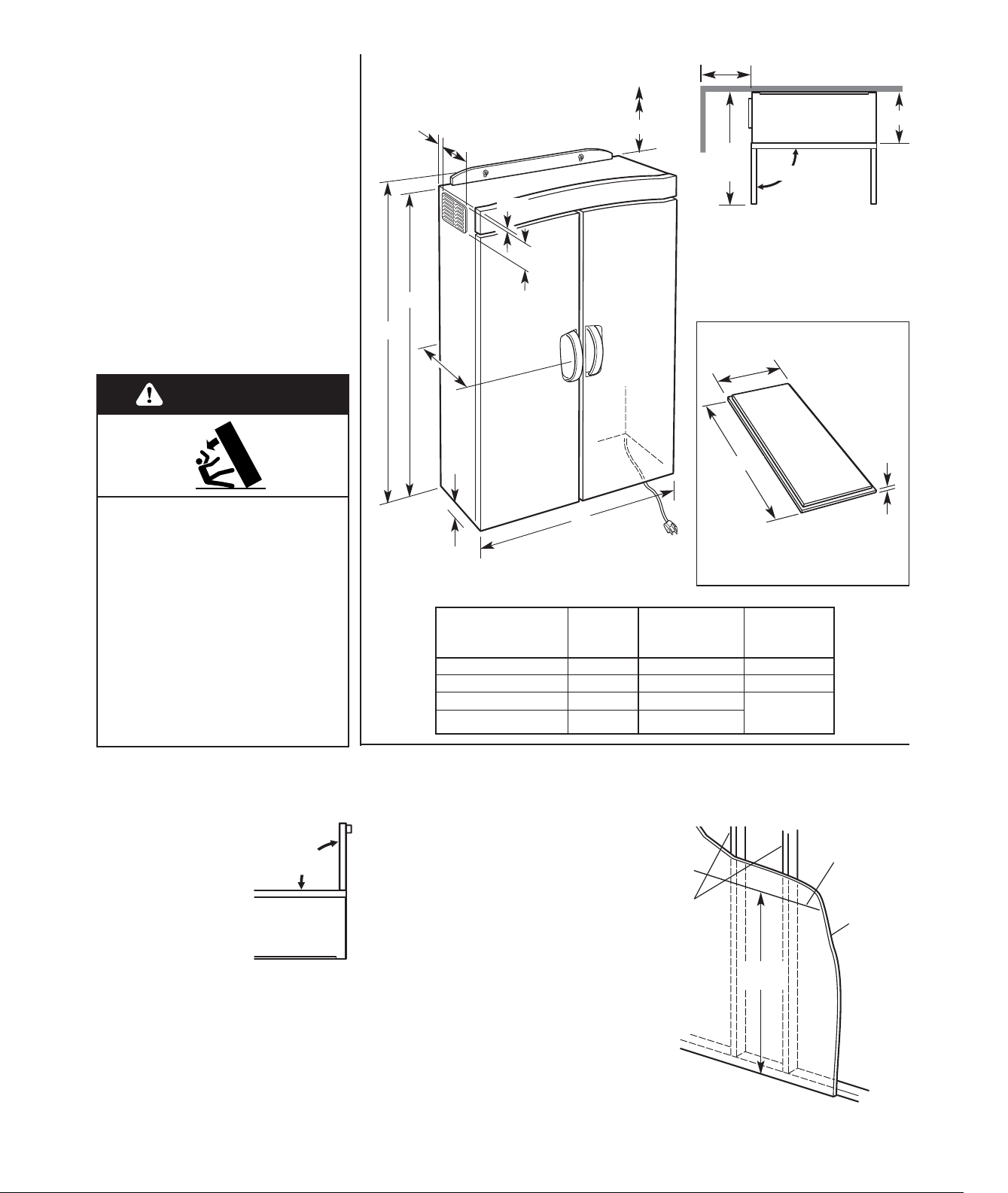

overall depth

for all models

(incl. handle)

panel

except PVFE600 weight A dimensions

white doors 117 lbs. 15-1/4" —

biscuit doors 117 lbs. 15-1/4" —

wood panel doors 137 lbs. 15-1/8" 17-1/16" x

mirrored doors 143 lbs. 15-1/8"

Product dimensions

Custom panels

PAGE 3

Parts not supplied

for installation:

• 2, 1/4"x1-1/4" lag bolts with wall

anchors for concrete or concrete

block wall installations.

Note: Lag bolt length is based on

mounting bracket thickness only.

Add thickness of any wall coverings

to length of lag bolts/wall anchors

used. These can be obtained from

local hardware store.

• 2, 1/4-20x3" toggle bolts and spring

nuts for metal studded walls. These

can be obtained from local

hardware store.

35"

6 ft. power supply cord.

3-prong ground-type outlet

must be located within 5

feet of lower right corner.

Cut door panel as shown. If the

desired panel is greater than 1/4"

thick, rout a 1/4" thick edge, in 1/4"

from all four edges.

1" minimum

clearance

required at

bottom of

vitalizer for

ventilation.

57"

7/16"

9/16"

5-7/8"

8-7/8"

59"

A

30-1/4"

both

doors

90°

12"

*

* 12" minimum clearance to side wall

on left side of appliance is required

for air venting.

** 24" minimum clearance to ceiling or

any non-removable object (cabinet,

soffit, shelf, etc.) above vitalizer is

required for serviceability.

1. With clothes

vitalizer in carton, lay

carton on back. Open

doors no more than

90° to avoid

damaging door hinges

and remove contents.

Important: Follow

removal instructions

printed on front of accessory box.

If installing model PVFE600, or if a

custom door panel is to be installed

on models PVWC600, PVWS600,

PVBC600, PVBS600, see "Product

dimensions" on this page for custom

panel size and then go to “Installing

custom door panels” on Page 5.

Note: It is not recommended to

customize mirrored models

PVWM600 or PVBM600.

Now start...

Installation steps

Tip Over Hazard

Do not use clothes vitalizer until

completely installed.

Install lag bolts securely into

wall studs.

Use two or more people to move

and install clothes vitalizer.

Reapply tape or strap to secure

doors before moving clothes

vitalizer.

Failure to follow these

instructions can result in death

or serious injury.

WARNING

90°

maximum

Model shown:

PVWN600

wood

studs

line

(must be level)

wall

70-3/4"

min.

24"**

11-1/4"

52-13/16" x

1/4" thick

2.Shut doors and reapply tape or

strap. Leave clothes vitalizer in box.

3.Remove the mounting bracket

assembly, nuts and lag bolts (if

installing in wall studs) from the

accessory box.

With washer sides of nuts facing

mounting bracket, start nuts onto the

bracket's threaded studs.

4.Mark a horizontal line at least

24 inches long, 70-3/4" minimum

from the floor. Important: The line

MUST be level.

For wood stud installations,

go to Step 5.

For metal studded wall

installations, go to Step 6.

For concrete of concrete block

installations, go to Step 7.

For models

PVFE600,

PVWC600,

PVWS600,

PVBC600,

PVBS600:

1/4"

52-13/16"

17-1/16"

toggle

bolt

spring

nut

toggle

bolt

bracket

assembly

Critical step:

For wood stud installations, each lag

bolt MUST be installed in a wood stud.

If there are not 2 studs in mounting

area, DO NOT install vitalizer.

DO NOT use toggle bolts through

dry wall to support the clothes

vitalizer.

5a. Locate and mark the centers

of each wall stud. Make these marks

about 72" from the floor.

align edge

with level line

1/4-20 nuts

5b. Align the lower edge of the

mounting bracket assembly with the

level horizontal line. Select and mark

a hole location on each side of the

bracket that is closest to the center of

each stud. Mark the holes to be used

on the bracket assembly also.

5c. Set bracket aside and drill

5/32" pilot holes.

5d. Fasten the mounting bracket

to wall. Check that the bracket is

level then securely tighten the lag

bolts.

Go to Step 8.

align edge

with level line

1/4-20 nuts

6b. Align the lower edge of the

mounting bracket assembly with the

level horizontal line. Select and mark

a hole location on each side of the

bracket that is closest to the center of

each stud. Mark the holes to be used

on the bracket assembly also.

6c. Set bracket aside and drill

5/32" pilot holes.

6d. Drill 3/4" holes for spring nuts

to slide through.

wood

stud

wood stud

center

wall

Critical step:

For metal studded wall installations,

each bolt MUST be installed in a metal

stud. If there are not 2 studs in

mounting area, DO NOT install

vitalizer.

DO NOT use toggle bolts through

dry wall to support the clothes

vitalizer.

6a. Use a magnetic stud finder to

locate and mark the centers of each

metal wall stud. Make these marks

about 72" from the floor.

6e. Insert 1/4-20 x 3" toggle bolts

through the selected holes in the

bracket assembly. Start a spring nut

on each toggle bolt. Leave enough

space for the spring nut to go

through the wall and stud and open

up behind the stud.

6g. Lightly tighten the toggle bolts.

Check that the mounting bracket

assembly is level. Securely tighten

the toggle bolts.

Go to Step 8.

6f. Position the mounting bracket

assembly on the wall and push the

toggle bolt and spring nut assemblies

through the wall and metal stud. Pull

the toggle bolt towards you and

finger tighten to insure that spring

nuts have opened fully against metal

stud.

metal

stud

metal stud

center

wall

5.Wood stud installations: 6.Metal studded wall

installations:

7.Concrete or concrete block

wall installations:

metal stud

mounting

bracket

assembly

7a. Align the lower edge of the

mounting bracket assembly with the

level horizontal line. Select and mark

a hole location on each side of the

bracket.

7b. Set bracket aside and drill

holes. Drive the wall anchors into

the holes with hammer.

7c. Fasten the mounting bracket

to wall. Check that the bracket is

level then securely tighten the lag

bolts.

8.Space the mounting bracket

nuts 1/2" to 3/8" away from mounting

bracket.

1/2" to

3/8"

mounting

bracket

nut

mounting

bracket

wood stud

shown

PAGE 4

9.Lift clothes vitalizer up and

slide keyhole slots over nuts. Lower

vitalizer down onto mounting bracket

studs and tighten nuts. Remove tape

or strap from doors.

10.Check tops of doors for

uniform vertical alignment. Wall

irregularities may require shimming

the back bottom corners of the

cabinet away from wall to align the

door tops.

If door tops are not aligned:

• Carefully pull a bottom cabinet

corner away from the wall and

observe the alignment shift.

• Separate adhesive backed spacers

(in accessory box) but do not

remove from the adhesive backing.

• Insert spacers at either or both

bottom corners to obtain door

alignment. The spacers may be

stacked for additional thickness if

needed.

• When alignment is obtained,

remove the spacers from the

adhesive backing and attach to

back of cabinet.

stud

mounting

flange

slot

adhesive

protective strips

flat side must

face up

drain openings

spacers as

needed

Model shown:

PVWN600

11. Remove mounting bracket

cover from accessory box. Peel off

adhesive protective strips. Align

cover with bracket and press cover

against bracket.

Note: Mounting bracket cover can be

painted or covered with wallpaper.

12. Remove collection basin

cover from accessory box. With flat

side facing up, place into depression

in bottom of inner liner.

13. Plug power supply cord into

grounded outlet.

14. If your clothes vitalizer

came with a storage drawer, follow

the instructions packed with the

drawer and install it now.

PAGE 5

Installing custom door panels

Door removal:

Custom panel installation:

1. Use 11/32” wrench and remove

acorn nuts on each end on of drip

tray. Use 1/4“ nut driver or wrench

and remove 4 hex head screws from

drip tray. Remove drip tray and set

aside along with acorn nuts and

screws.

1. Lay protective material such as

a blanket or cardboard that is slightly

larger than the door on floor or any

flat support surface.

2.Lay a door on protective

surface with door handle facing up.

2.Open door 90°. Support door in

this position and use Phillips

screwdriver to remove both screws

from lower door hinge. Set screws

and lower hinge aside.

3.Slide door out of upper hinge

and set aside. Remove plastic

shoulder washer from upper hinge

pin and set aside. Do not lose this

washer.

Remove other door.

3.Use Phillips screwdriver and

remove 3 screws from top end cap.

(This is same end cap from which

shoulder washer was removed.)

Remove end cap and set aside. Do

not lose the 3 plastic spacers on the

screws.

Important: If you are installing

models PVWC600, PVWS600,

PVBC600, PVBS600, remove and

discard the door panel that came

with your model. Model PVFE600

does NOT come with panels.

4.Slide custom door panel into

door channels until it fits snugly

under edge of door’s bottom end

cap.

5.Reassemble top door end cap.

Make sure that the 3 plastic spacers

are on screws.

Repeat to install custom panel in

other door.

acorn nut

hex head

screw

drip tray

lower

door

hinge

screws

screws

top

end cap

plastic spacers

Part No.8527389

©2002 Whirlpool Corporation Printed in U.S.A.

Benton Harbor, Michigan 49022

If clothes vitalizer

does not operate:

• Check that circuit breaker is not

tripped or house fuse blown.

• Check that power supply cord is

plugged into wall outlet.

• See Owner's Manual for

troubleshooting list.

If you need

assistance:

• Refer to Owner's Manual.

• Call the Consumer Interaction

Center. Check your Owner's

Manual for a toll-free number to call

or call the dealer from whom you

purchased the clothes vitalizer. The

dealer is listed in the Yellow Pages

of your phone directory under

“Appliances –Household – Major —

Service and Repair.”

Accessories:

The following storage drawer kits are

available from your dealer:

Kit No. 8527309 White

Kit No. 8527310 Biscuit

Kit No. 8527308 Signet Grey

If you need service:

Maintain the quality built into your

clothes vitalizer by calling an

authorized service company.

To obtain the name and number of

an authorized service company:

• Contact the dealer from whom you

purchased your clothes vitalizer, or

• Look in the Yellow Pages of your

phone directory under “Appliances

–Household – Major — Service and

Repair,” or

• Call the Consumer Interaction

Center. The toll-free number is

listed in your Owner's Manual.

When you call, y ou

will need:

• The clothes vitalizer model number.

• The clothes vitalizer serial number.

Both numbers are listed on the

model/serial number plate located on

the lower cabinet frame next to the

door magnet.

Reassemble doors to clothes

vitalizer:

1. Place plastic shoulder washer

on upper door hinge pin. Support

door in 90º open position and slide

door into upper hinge.

lower

door

hinge

screws

2.With door still in 90° open

position, reattach lower door hinge.

Use Phillips screwdriver to reinstall

both lower door hinge screws.

Securely tighten screws.

acorn nut

hex head

screw

drip tray

3.Reattach drip tray. Reinstall 4

hex head screws and 2 acorn nuts,

one on each end of drip tray.

Tighten securely.

Repeat to install other door.

4.Shut doors and reapply tape or

strap. Leave clothes vitalizer in

carton and go back to Step 2 of

"Installation steps" on Page 3 to

complete installation.

Important: Before vitalizer is

installed, do not open doors more

than 90° to avoid damaging door

hinges.

Loading...

Loading...