Page 1

Troubleshooting

Problem: Beer flow is slower with Universal Empty Keg Sensor

than with standard Perlick coupler.

INSTALLATION AND OPERA TING INSTRUCTIONS

UNIVERSAL EMPTY KEG SENSOR

Probable Cause: Beer Flow Control Handle is in CLEAN position.

Solution: Slowly turn Beer Flow Control Handle to ON position.

Problem: Beer does not flow after keg is tapped.

Probable Cause: Universal Empty Keg Sensor has locked up.

Solution: Turn Beer Flow Control Handle to OFF position.

Wait two or three seconds than slowly turn Beer Flow

Control Handle to ON position.

Probable Cause: Beer Flow Control Handle is OFF.

Solution: Slowly turn Beer Flow Control Handle to ON position.

Probable Cause: Universal Empty Keg Sensor is dirty.

Solution: Clean Universal Empty Keg Sensor.

Probable Cause: Out of gas.

Solution: Reestablish gas flow.

Problem: Excessive foam.

Probable Cause: Beer temperature too high. Excessive beer flow rate. Beer

is over-carbonated

Solution: These problems are not caused by the Universal Empty

Keg Sensor. Follow established procedures to correct

the problem.

Part No.

■■ 43739

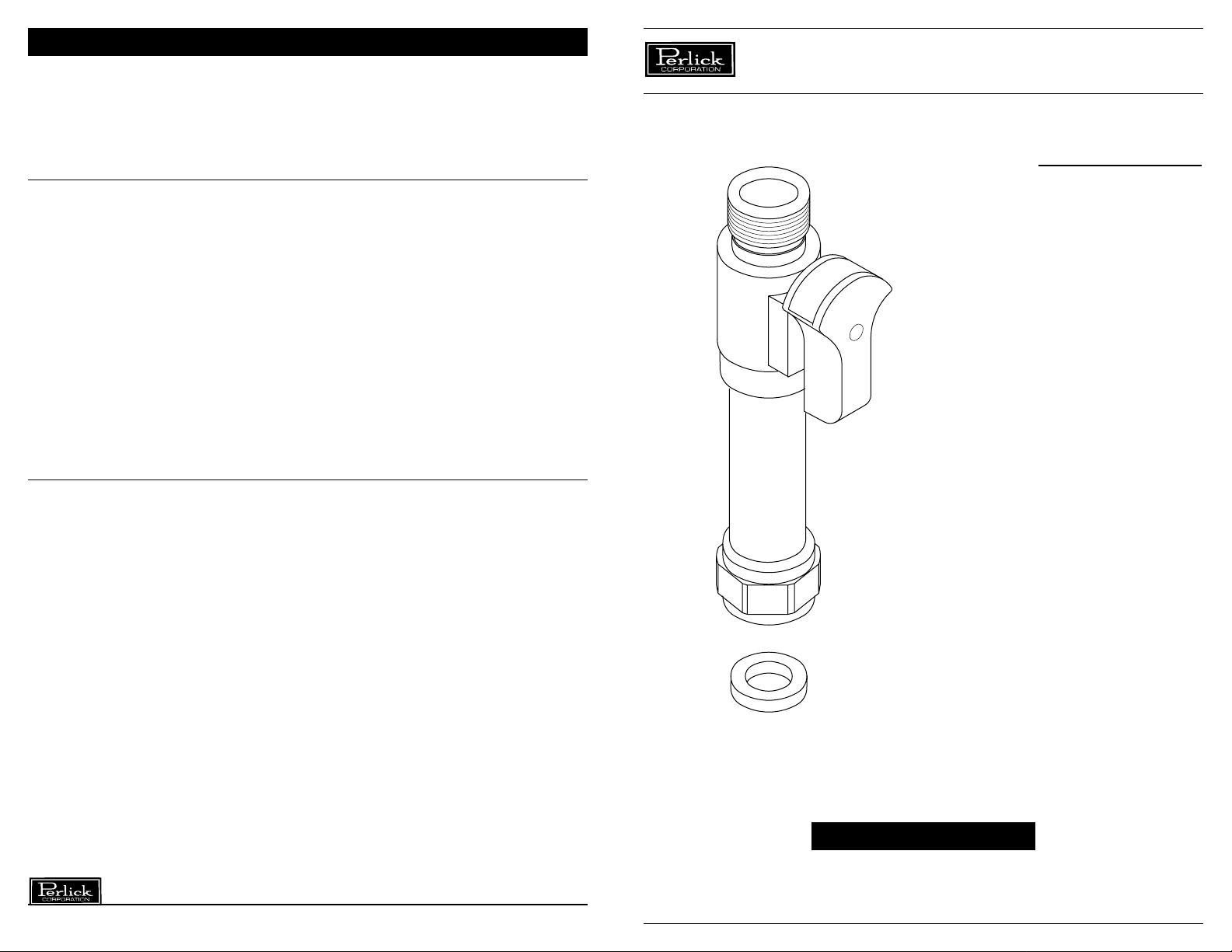

The Perlick Universal Empty

Keg Sensor shuts off the flow

of beer when the keg empties.

With the line full of beer, the

foaming and resulting beer

waste from changing kegs is

eliminated.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060

Fax 414-353-7069 • Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www .Perlick.com

Form Z2148EMU

08.20.04

No. 43739

Universal Empty

Keg Sensor

IMPORTANT!

To ensure your complete satisfaction, please read these instructions

before using Perlick’s Universal Empty Keg Sensor.

* U.S. Patent #5,630,411

Page 2

INSTALLATION INSTRUCTIONS TAPPING AND CLEANING PROCEDURES

1. Disconnect keg coupler from keg.

2. Open faucet to relieve line pressure and

close when flow ceases.

3. Disconnect beer line including seal washer

EXISTING

BEER LINE

AND SEAL

WASHER

from keg coupler.

4. Connect beer line including seal washer to

external thread of Universal Empty Keg

Sensor and turn Beer Flow Control Handle

to OFF position.

(See Fig. 1)

. In this

position the Universal Empty Keg Sensor

acts as a shut-off valve.

5. Where fitted, remove retaining clip/spring

and check ball from keg coupler center

probe.

6. Insert seal washer supplied into coupling

nut on Universal Empty Keg Sensor and

couple to the keg coupler.

P/N 43739

UNIVERSAL

EMPTY KEG

SENSOR AND

SEALING

WASHER

REMOVE

CLIP/SPRING

AND CHECK

BALL FROM

COUPLER

7. Connect keg coupler to keg and tap keg.

8. Turn Beer Flow Control Handle to CLEAN.

(See Fig. 3)

.

9. Open beer faucet. When solid beer

appears, close the faucet.

10. Turn Beer Flow Control Handle ON.

(See Fig. 2)

. The line is full and ready

for service.

Warranty

Perlick Products are fully guaranteed against defects in both material and

workmanship for a period of one year from date of sale. Defective parts will be

replaced on a no-charge basis, F.O.B. our factory, subject to our inspection. We

are not responsible for parts damaged by alteration, unauthorized service,

accident or abuse. All costs incident to replacement to include freight, labor and/or

loss of sales are incidental to this warranty and must be borne by the user.

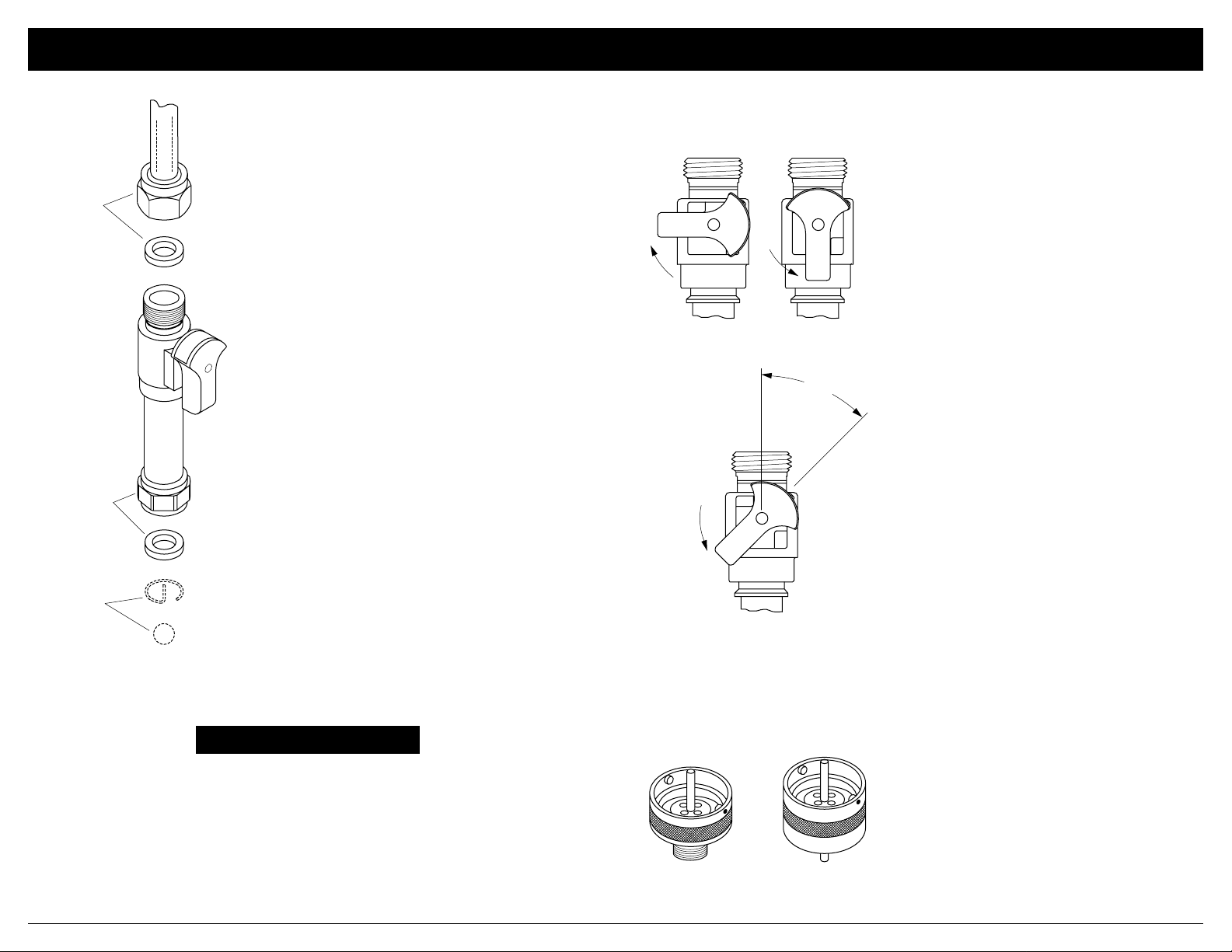

Beer Flow Control

Handle Operating

Positions

Fig. 1

OFF

Fig. 3

CLEAN

Cleaning Adapters

No. 43657 No. 43681

Single Adapter Dual Adapter

Fig. 2

ON

45°

Filling the Lines the First Time

1. Turn Beer Flow Control Handle OFF.

(See Fig. 1).

2. Tap fresh keg.

3. Turn Beer Flow Control Handle to CLEAN.

(See Fig. 3).

4. Open the beer faucet. When solid beer

appears, close the faucet. The line is full.

5. Turn Beer Flow Control Handle ON.

. The line is full and ready for service.

Fig.2)

(See

When Tapping Fresh Kegs

1. Remove coupler from empty keg.

2. Turn Beer Flow Control Handle OFF.

(See Fig. 1).

2. Tap fresh keg in normal manner.

3. Turn Beer Flow Control Handle to CLEAN.

position.

then turn to ON position.

(See Fig. 3).

Wait for five seconds

(See Fig. 2).

To Restart System

If beer does not flow, first turn the Flow Control

Handle to OFF.

the CLEAN position.

seconds then turn the Handle to ON position.

(See Fig. 1).

(See Fig. 3).

Then turn Handle to

Wait for five

(See Fig. 2).

To Clean

1. Untap Keg in usual manner.

2. Turn Beer Flow Control Handle OFF.

(See Fig. 1).

3. Attach cleaning adapter. Use Perlick’s

single cleaning adapter, No. 43657, if

cleaning from faucet to keg. If two or

more lines are cleaned, use Perlick’s

dual cleaning adapter, No. 43681.

4. Turn Beer Flow Control Handle to

CLEAN and clean as usual.

5. After flushing, turn Beer Flow Control

Handle OFF and retap keg.

6. To restore service, see above instructions.

(See Fig. 3).

(See Fig. 1).

Loading...

Loading...