Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

UTILITY COOLERS

MODEL NOS.

US4KP

US10KP

IMPORTANT INFORMATION

This manual has been prepared to assist you

in the installation of your Utility Cooler and to

acquaint you with its operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer

can provide you with a list of qualified service

agents. For your own protection, never return

merchandise for credit without our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction

IMPORTANT WARRANTY INFORMATION

To register your product, visit our web site at

(www.perlick.com). Click on “Commercial”, then

“Service”. You will see the link to “Warranty

Registration Form”. You must complete and submit

this form or the installation date will revert back to

the ship Date.

Table of Contents

Cabinet Specifications ......................................... 2

Preparing for Assembly

Tools Required .................................................... 3

Pre-Assembly ....................................................... 3

Placing the Utility Cooler ..................................... 3

Cam Lock Fastening Method ............................. 3

Assembling the Cooler

Preparing the Floor .............................................. 4

Assembly .............................................................. 4

Assembly Order-Four Keg Cooler ........................ 5

Assembly Order-Ten Keg Cooler ......................... 6

General Information

Electrical Requirements ....................................... 7

Starting the Cooler ............................................... 7

Temperature Control ............................................ 7

Ventilation Requirements ..................................... 7

Cleaning the Condensing Unit ............................. 7

Warranty Information ........................................... 7

Replacement Parts ............................................. 8

Wiring Diagrams

Four Keg Self-contained ...................................... 9

Ten Keg Self-contained ...................................... 10

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Form No. Z2026

Rev 01.28.09

Page 2

Installation and Operating Instructions

14”

14”

47”

4”

4”

4”

4”

4”

4”

4”

44”

21”

23 1/2”

14”

15”

14”

79”

67”

32 3/4”

12”

30”

7”

9” 8”

1”

REF

93”

11”

4”

7”

67”

77”

17”

51 1/4”

51 1/4”

47”

LIGHT BULB

W/GUARD

THERMOSTAT

REFRIGERATION

SLEEVE

REFRIGERATION

SLEEVE

TOP

VIEW

TOP

VIEW

FRONT

VIEW

FRONT

VIEW

END

VIEW

END

VIEW

39”

INSIDE

85” INSIDE

39”

INSIDE

39”

INSIDE

28”

INSIDE

DOOR

OPENING

28”

INSIDE

DOOR

OPENING

LIGHT BULB

W/GUARD

4 KEG COOLER 10 KEG COOLER

11”

23 1/2”

33 1/2”

32 3/4”

24 1/2”

9 1/2”

9 1/2”

C

L

C

L

C

L

JUNCTION

BOX

JUNCTION

BOX

C

L

4”

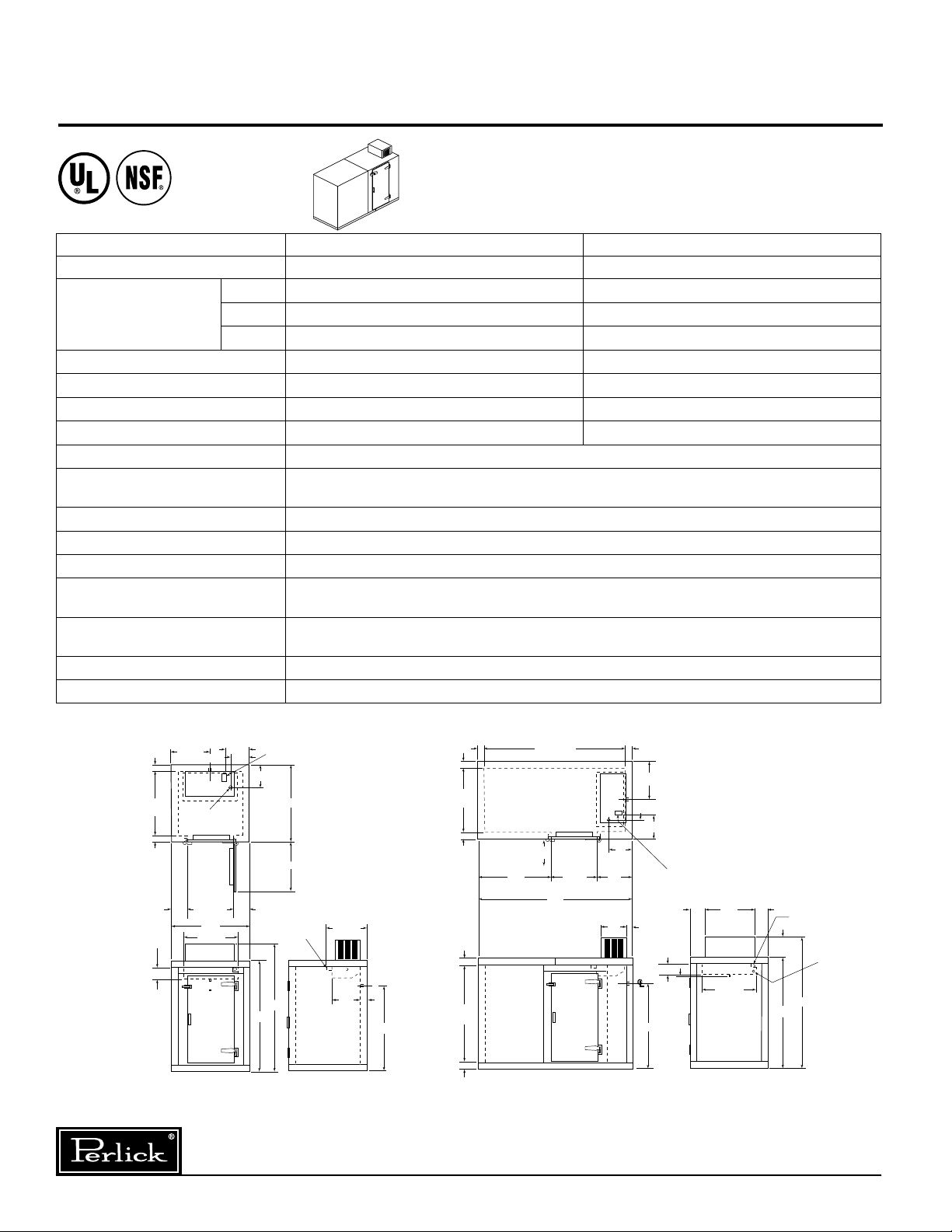

Sizes and Specifications, Utility Coolers - Self Contained

MODEL NOS. US4KP US10KP

KEG CAPACITY

DIMENSIONS

EXTERIOR

(mm)

Length 47" (1194) 93" (2362)

Depth 47" (1194) 47" (1194)

Height 77" (1956) 79" (2007)

CONDENSING UNIT

FULL LOAD AMPS

MAX. FUSE

SHIPPING WEIGHT

EXTERIOR

INTERIOR

lbs. (kg) 700 (318) 1150 (522)

Floor: Stucco galvanized steel. Roof, Walls & Doors: Stucco galvanized steel painted grey.

Floor: 16 gauge slip resistant stainless steell. Roof, Walls & Doors: 26 gauge stucco

galvanized steel.

ELECTRICAL 115 V, 60 Hz. 1ph AC. Junction box provided.

PLUMBING Evaporator condensate drains through access hole in wall. 20" x

REFRIGERATION

INSULATION

R134a refrigerant.

4" UL Class 1 urethane foam. Flame Spreading Rate: 25 or less.

Smoke Develop Rating: 450 or less.

DOORS Flush-mounted with cam-lift chrome hinges, automatic door closer, magnetic gaskets, chrome pull handle.

Standard right hinged. Door size: 30" W x 55" H.

FEATURES

Light “ON” indicator in door. Light switch and fixture installed on evaporator. Thermometer furnished loose.

OPTIONAL ACCESSORIES • Foor rack • Keg shelf kit

4 10

1

/

3

1

/

8.5 10.2

15 15

1

/2" I.D. drain line provided.

2

Form No. Z2026

Rev 01.28.09

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Page 3

Preparing the Cabinet for Use

CAM

CAM

HOLE

Tools Required

■

Tape Measure.

■

Chalk Line.

■

Caulking Gun.

■

Caulk (provided).

■

Clam Lock Wrench (provided).

■

Level.

■

Screw Driver.

■

Shims.

Pre-Assembly

Some panels have been protected with a strippable film to prevent surface damage. Remove this

film before assembly. It is very difficult to remove it

from the panel edges after panels have been joined

together. Note: Do not store panels with protective

film in sunlight or high temperature areas for an

extended period of time.

Placing the Utility Cooler

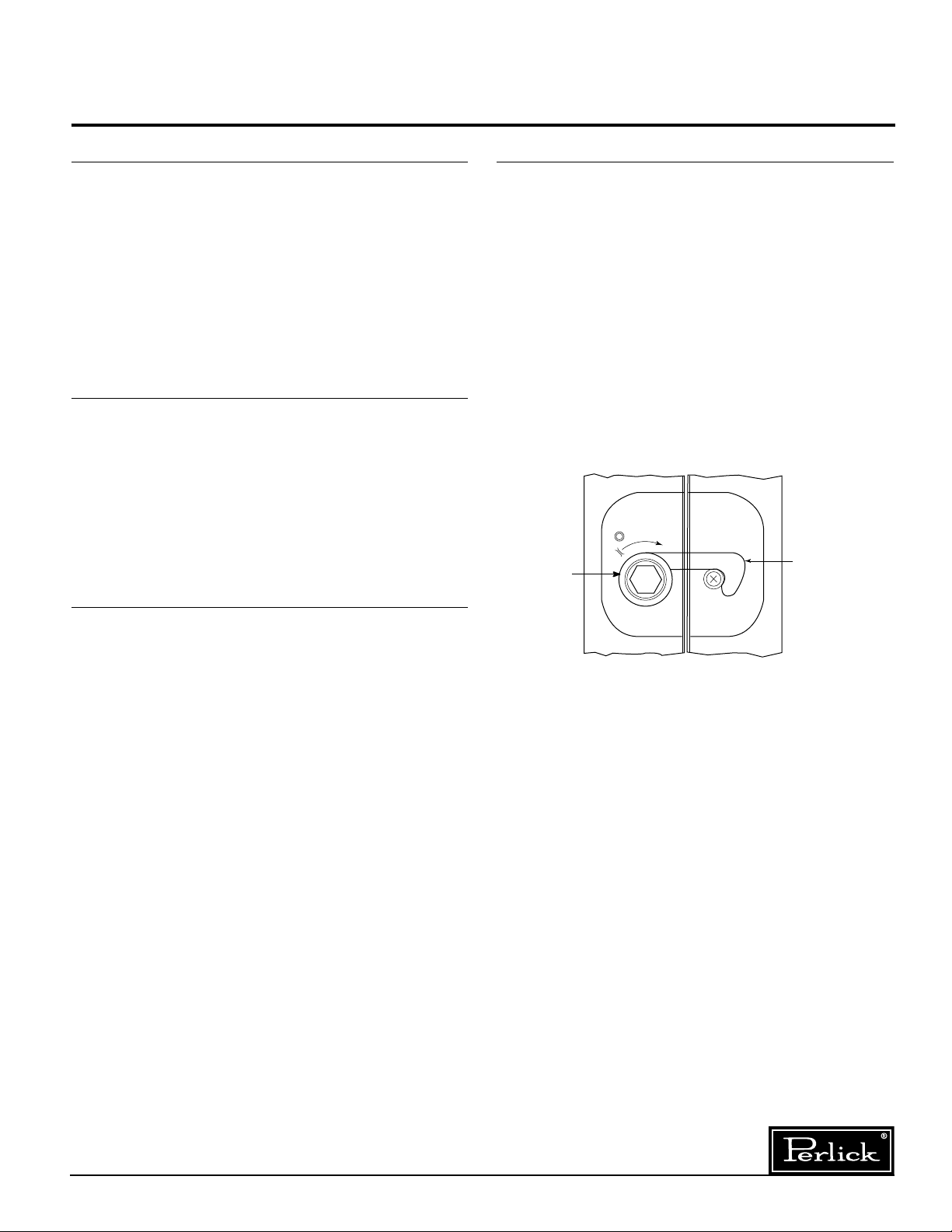

The Cam Lock Fastening Method

This utility cooler utilizes the cam-lock fastening

method. (See illustration on below.)

Insert the cam lock wrench into the lock before the

panels are pushed together. Turn the handle Cam

Hole counterclockwise as far as it will go to fully

cock the

cam. Note: The cam must be fully cocked to

assure proper locking. The panels should then be

pushed together tightly and locked by turning the

wrench clockwise.

Plugs are provided to insert in cam-lock holes after

final assembly.

This utility cooler should not be installed tight

against any building or adjacent cooler wall. A

minimum of two inches must be provided for air

circulation. Shims for leveling the floor must

also be incorporated into overall height and

clearance requirements.

Remote Units: A minimum four inch clearance is

required between the top of the utility cooler

and the ceiling of the building in which it is being

installed.

Self-contained Units: Sufficient clearance above the

cooler must be allowed for ceiling panel

and condensing unit installation. For ventilation

requirements, see page 7.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Form No. Z2026

Rev 01.28.09

Page 4

General Information

FLOOR PANEL

SEAL COOLER TO FLOOR

AFTER UNIT IS LEVEL AND

ASSEMBLED

CEILING

KEEP GASKETS

OUT OF GROOVE

FLOOR

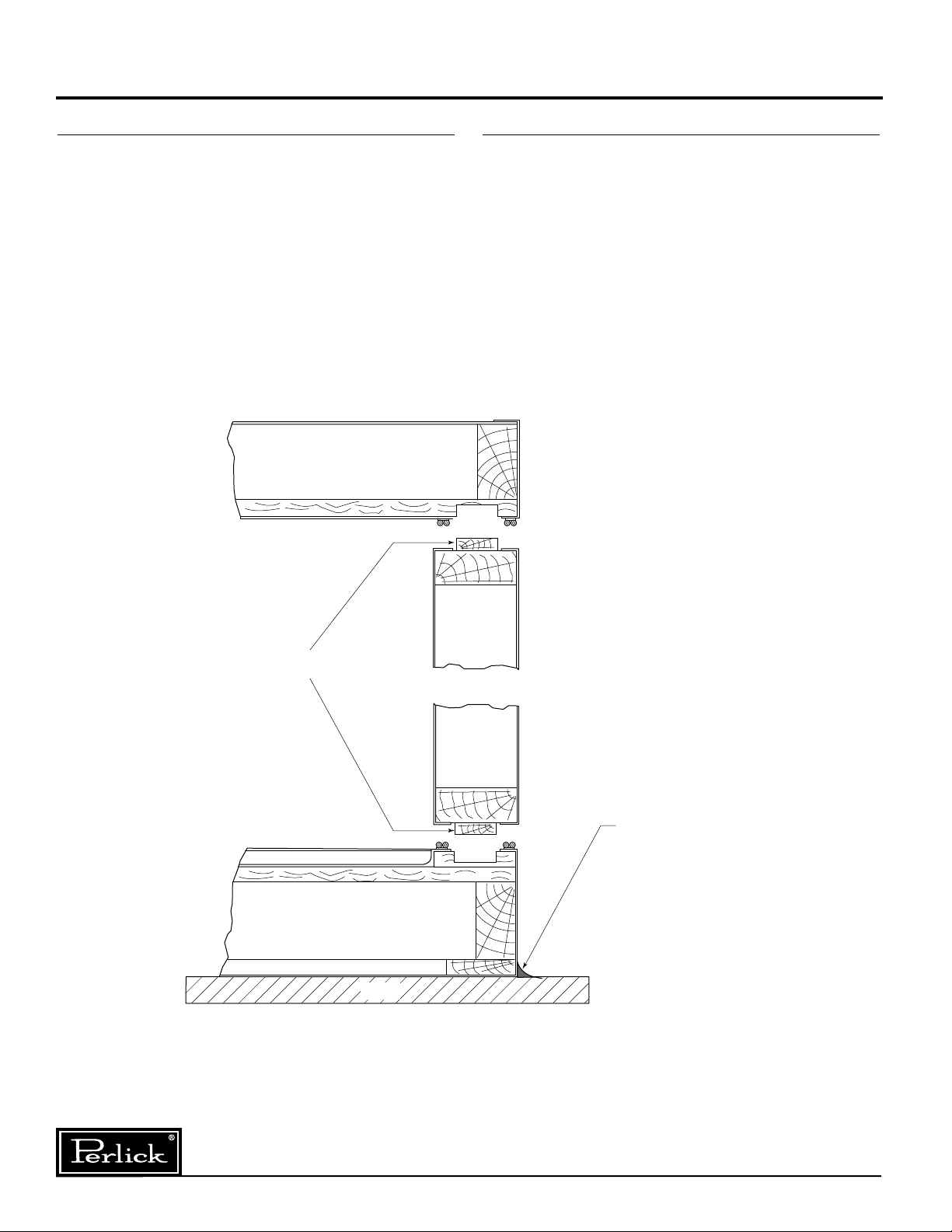

Preparing the Floor

Snap a chalk line on the building floor to establish

cooler location. Place floor panel(s) on the floor and

check for level. A level floor is essential to ensure

that vertical panels will be plumb. If shimming

is required to level the sections, the shims must

extend under the entire section, not just the edges.

Shims should be used at each end, at all wall

seams, and at each floor seam. They should not be

spaced further than 24 inches apart.

Assembly

1. Place (do not slide) all sections into position.

2. Each panel is numbered on the edge. For a four

keg cooler, follow the assembly order on page

5. For a ten keg cooler, the assembly order

appears on page 6.

Note: If ceiling height in building is restricted,

panel(s) can be carried through the door opening and placed into position from inside the

cooler.

3. Install cap plugs in all cam-lock holes.

4. Seal cooler to the floor.

Form No. Z2026

Rev 01.28.09

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

4

Page 5

Four Keg Cooler

FRONT VIEW

FLOOR

3

PANEL NO.#’S

UNIT

COOLER

4

6

1

5

7

2

Four Keg Cooler Assembly

Assemble panels as follows:

Section 1: .............. Floor

Section 2: .............. Left Wall

Section 3: .............. Left Back Wall

Section 4: .............. Right Back Wall

Section 6: .............. Front with Door

Section 5: .............. Right Wall

Section 7: .............. Ceiling

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

Form No. Z2026

Rev 01.28.09

Page 6

Ten Keg Cooler

FRONT VIEW

COOLER

UNIT

COOLER

PANEL NO.#’S

4

5

3

3A

9

2

1

6

8

10

10

7

9

Ten Keg Cooler Assembly

Assemble panels as follows:

Section 1 & 2: ........ Floor-Section

Section 3: .............. Left Wall

Section 4: .............. Left Back Wall

Section 5: .............. Right Back Wall

Section 3A: ............ Right Wall

Section 6: .............. Right Front Wall

Section 7: .............. Door Section

Section 8: .............. Left Front Panel

Section 9: .............. Celing Panel with

Evaporator Housiing

Section 10: ............ Celing Panel

Form No. Z2026

Rev 01.28.09

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Page 7

General Information

Electrical Requirements

The package unit must be installed so that the wiring conforms to, and is in accordance with National

and Local Electrical Codes. (See Condensing Unit

Data Plate for Electrical Specifications.

CAUTION: Do not attempt to operate the condensing unit on any other power source than that listed

on the unit data plate. See appropriate wiring diagram on pages 9, 10 or 11.

Starting The Cooler

Allow the empty utility cooler to operate 24 hours

for a settling-out period before use.

Temperature Control

The temperature control is located on the evaporator housing. It is factory adjusted to maintain a

temperature of approximately 34° F. cut out and

40° F. cut in. Cut out temperatures lower than 34°F.

are not advisable as excessive frost may accumulate on the evaporator.

If excessive frost does accumulate, the unit is

operating at too cold a temperature. To defrost the

evaporator, turn off the electrical power to the condensing unit or turn the control to a warmer position to allow the fan motor to defrost it. The control

should then be reset to a temperature that will not

ice up the evaporator. A plastic drain hose should

be attached to the drain pan of the evaporator and

routed through the wall panel. A receptacle should

be provided for accumulated condensing water or

connect to a building drain facility.

There should be nothing on or around the machinery compartment area which will restrict the flow of

room temperature air to the condenser or over the

compressor.

Natural

Compressor H.P.

1/3 to 1/2 600 220

Circulation Cu.

Ft. Room Volume

Needed

Forced Air

Circulation C.F.M.

Fresh Air Entering

Room

Cleaning the Condensing Unit

Inspect the machinery compartment every 60 days.

A heavy accumulation of dirt and/or grease on

the front of the condensing unit (radiator) must be

cleaned off with a stiff brush or vacuum cleaner. Be

careful not to bend the aluminum fins on the condensing unit.

Warranty

This Utility Cooler is fully warranted against defects

in both material and workmanship for a period

of one (1) year from date of sale. Defective parts

must be returned to Perlick freight prepaid. All

parts found to be defective upon inspection will be

replaced on a no-charge basis, F.O.B. our factory.

Perlick is not responsible for parts damaged by

alteration, unauthorized service, accident or abuse.

All costs incident to replacement, including labor,

refrigerant, and/or loss of sales are incidental to

this warranty and must be borne by the user.

Ventilation Requirements

Air-cooled units must be furnished with sufficent

ventilation to maintain their efficiency. The table

at right indicates the minimum room size/cubic

footage, only the space above the condensing

unit can be used. When the room size is below

minimum, some type of forced ventilation must

be provided.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2026

7

Rev 01.28.09

Page 8

Replacement Parts

How to Order Replacement Parts

Contact your local Perlick dealer to order

replacement parts.

SELF-CONTAINED UTILITY COOLERS

FOUR KEG TEN KEG

Description Part Number Description Part Number

Compressor Only 57499 Compressor Only 57860

Condensing Unit Fan Motor 57513 Condensing Unit Fan Motor C15250A2

Condensing Unit Fan Blade

Evaporator Coil Assembly 57861 Evaporator Coil Assembly 57872

E xpansion Valve 57877 E xpansion Valve 57877

Temp. Control (two-wired) 57891 Temp. Control (two-wired) 57891

ALL MODEL UTILITY COOLERS

Description Part Number Description Part Number

Switch 57878 Evaporator Fan Guard 57875

Light Bulb

Bulb Guard

Thermometer 57879 Door Closure 57884

Hinged Door Assy. 57880 Light Indicator 57858

Gasket-Door Assy. 57881 Hinge 57885

Evaporator Fan Motor 57873 Handle 57886

Evaporator Fan Blade

C3150-3 Condensing Unit Fan Blade C15250A3

C31358 Plug Button 57882

C25969-1 Door Sill 57883

57874 Door Wiper Gasket 57908

Be prepared to provide the model and serial num

ber of the cooler. The serial number is

printed on a label which is attached to the inside

wall, adjacent to the evaporator housing.

-

Form No. Z2026

Rev 01.28.09

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

8

Page 9

Wiring Diagram — Four Keg Self-Contained Cooler

OVERLOAD

RELAY

FAN

GREEN

BROWN

WHITE

WHITE

WHITE

WHITE

WHITE

BROWN

BROWN

LIGHT

SWITCH

BLACK

BLACK

BLACK

EVAPORATOR

FAN MOTORS

(ELECTRONIC)

THERMOSTAT

(4 MIN. “ON” DELAY)

(ALTERNATE)

THERMOSTAT

(STANDARD)

BLACK

GREEN

GREEN

COMPRESSOR

TERMINALS

CAPACITOR

L1

1

2

C

RS

L2

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

9

Form No. Z2026

Rev 01.28.09

Page 10

Wiring Diagram — Ten Keg Self-Contained Cooler

OVERLOAD

RELAY

1

L

3

1

C

R

S

5

M

2

GREEN

BROWN

GREEN

WHITE

EVAPORATOR

FAN MOTORS

BLACK

WHITE

WHITE

BLACK

LIGHT

SWITCH

BLACK

WHITE

FAN

CONDENSER

COMPRESSOR

TERMINALS

BROWN

GREEN

WHITE

RED

YELLOW

BLUE

CAPACITOR

(ELECTRONIC)

THERMOSTAT

(4 MIN. “ON” DELAY)

(ALTERNATE)

THERMOSTAT

(STANDARD)

BLACK

BROWN

Form No. Z2026

Rev 01.28.09

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

10

Page 11

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

11

Form No. Z2026

Rev 01.28.09

Page 12

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Form No. Z2026

Rev 01.28.09

Loading...

Loading...